Toro 41593, Multi-Pro 5800, 41593N Operator's Manual

FormNo.3384-937RevA

g018932

Multi-Pro5800TurfSprayer

ModelNo.41593—SerialNo.312000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3384-937*A

TheMulti-Pro

G013755

1

®

turfsprayerisadedicatedturfspray

applicationvehicleandisintendedtobeusedbyprofessional,

hiredoperatorsincommercialapplications.Itisprimarily

designedforsprayingonwell-maintainedlawnsinparks,golf

courses,sportselds,andoncommercialgrounds.

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Figure1

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Engine Owner's Man ual

issuppliedfor

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Introduction

Readthismanualcarefullytolearnhowtooperateand

maintainyourproductproperly.Theinformationinthis

manualcanhelpyouandothersavoidinjuryandproduct

damage.AlthoughTorodesignsandproducessafeproducts,

youareresponsibleforoperatingtheproductproperlyand

safely.YoumaycontactTorodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndingadealer,or

toregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.

modelandserialnumbersontheproduct.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1illustratesthelocationofthe

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ChemicalSafety.......................................................4

BeforeOperating....................................................5

WhileOperating......................................................5

Maintenance...........................................................6

SoundPower..........................................................7

SoundPressure.......................................................7

Hand-ArmVibration...............................................7

WholeBodyVibration.............................................7

SafetyandInstructionalDecals.................................8

Setup...........................................................................12

1CheckingtheBoomHingeSprings.........................13

ProductOverview.........................................................14

Controls...............................................................15

Specications........................................................19

Operation....................................................................20

ThinkSafetyFirst...................................................20

PreparingtoDrivetheSprayerfortheFirst

Time.................................................................20

PerformingPre-StartingChecks...............................21

DrivingtheSprayer.................................................22

BreakinginaNewSprayer.......................................22

OperatingtheSprayer.............................................22

FillingtheFreshWaterTank....................................23

FillingtheSprayTank..............................................23

OperatingtheBooms..............................................24

Spraying................................................................24

TurfCarePrecautionswhileOperatingin

StationaryModes................................................24

SprayingTips.........................................................25

UncloggingaNozzle..............................................25

SelectingaNozzle..................................................25

CleaningtheSprayer...............................................25

CalibratingtheBoomBypassValves..........................26

CalibratingtheAgitationBypassValve.......................27

Pump....................................................................27

TransportingtheSprayer.........................................28

TowingtheSprayer.................................................28

Maintenance.................................................................30

RecommendedMaintenanceSchedule(s)......................30

DailyMaintenanceChecklist....................................32

NotationforAreasofConcern.................................32

PremaintenanceProcedures........................................33

JackingtheSprayer.................................................33

Lubrication...............................................................33

GreasingtheSprayer...............................................33

GreasingtheBoomHinges......................................34

GreasingtheActuatorRodBearings..........................34

EngineMaintenance..................................................35

ServicingtheAirCleaner.........................................35

ServicingtheEngineOil..........................................36

FuelSystemMaintenance...........................................38

CheckingtheFuelLineandConnections...................38

BleedingtheFuelSystem.........................................38

BleedingAirfromtheInjectors................................39

DrainingtheFuelTank...........................................39

ServicingtheFuelFilters.........................................39

ElectricalSystemMaintenance....................................40

ReplacingtheFuses................................................40

ServicingtheBattery...............................................40

DriveSystemMaintenance.........................................42

CheckingtheTirePressure......................................42

InspectingtheWheels/Tires....................................42

ChangingthePlanetaryGearboxFluid.......................42

AdjustingtheFrontWheelToe-in.............................43

CoolingSystemMaintenance......................................43

CheckingtheCoolantLevel.....................................43

ServicingtheCoolingSystem...................................44

BrakeMaintenance....................................................45

CheckingtheBrakes...............................................45

AdjustingtheBrakes...............................................45

BeltMaintenance......................................................46

ServicingtheDriveBelts.........................................46

HydraulicSystemMaintenance....................................47

HydraulicFluidSpecication...................................47

CheckingtheHydraulicFluid...................................47

ServicingtheHydraulicOil......................................48

SpraySystemMaintenance..........................................50

InspectingtheHoses..............................................50

PumpMaintenance.................................................50

AdjustingtheActuators...........................................50

InspectingtheNylonPivotBushings.........................51

InspectingtheTankStraps.......................................52

FlowDiagram...........................................................53

Cleaning...................................................................53

CleaningtheSuctionStrainer...................................53

Storage........................................................................54

Troubleshooting...........................................................56

3

Safety

ChemicalSafety

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCAUTION,WARNING,or

DANGER-“personalsafetyinstruction."Failuretocomply

withtheinstructionmayresultinpersonalinjuryordeath.

Supervisors,operators,andservicepersonsshouldbefamiliar

withthefollowingstandardsandpublications:(Thematerial

maybeobtainedfromtheaddressshown).

•FlammableandCombustibleLiquidsCode:

ANSI/NFPA30

•NationalFireProtectionAssociation:

ANSI/NFPA#505;PoweredIndustrialTrucks

NationalFirePreventionAssociation

BarrymarchPark

Quincy,Massachusetts02269U.S.A.

•SAEJ2258LightUtilityVehicle

SAEInternational

400CommonwealthDrive,Warrendale,PA

15096-0001,U.S.A.

•ANSI/UL558;InternalCombustionEnginePowered

IndustrialTrucks

AmericanNationalStandardsInstitute,Inc.

1430BroadwayNewYork,NewYork10018U.S.A.

or

UnderwritersLaboratories

333PngstenRoad

Northbrook,Illinois60062U.S.A.

WARNING

Chemicalsubstancesusedinthespraysystemmay

behazardousandtoxictoyou,bystanders,animals,

plants,soilsorotherproperty.

•Carefullyreadandfollowthechemical

warninglabelsandMaterialSafetyData

Sheets(MSDS)forallchemicalsused,and

protectyourselfaccordingtothechemical

manufacturer'srecommendations.Forexample,

useappropriatePersonalProtectiveEquipment

(PPE)includingfaceandeyeprotection,gloves,

orotherequipmenttoguardagainstpersonal

contactwiththechemical.

•Keepinmindthattheremaybemorethan1

chemicalused,andinformationoneachshould

beassessed.

R efuse to operate or w or k on the spray er if this

•

inf or mation is not a v aila ble!

•Beforeworkingonaspraysystem,makesure

thatthesystemhasbeentriplerinsedand

neutralizedaccordingtotherecommendations

ofthechemicalmanufacturer(s)andthatallof

thevalveshavebeencycled3times.

•Verifythatthereisanadequatesupplyofclean

waterandsoapnearby,andimmediatelywash

offanychemicalsthatcontactyou.

•Obtainpropertrainingbeforeusingorhandling

chemicals.

SafeOperatingPractices

WARNING

Thesprayerisanoff-highwayvehicleonlyandis

notdesigned,equipped,ormanufacturedforuseon

publicstreets,roads,orhighways.

Supervisor'sResponsibilities

•Makesurethatoperatorsarethoroughlytrainedand

familiarwiththeOperator'sManual,engineowner’smanual,

andalllabelsonthesprayer.

•Establishyourownspecialproceduresandworkrules

forunusualoperatingconditions(e.g.slopestoosteep

forsprayeroperation).

•Usethecorrectchemicalforthejob.

•Followthechemicalmanufacturer'sinstructionsforthe

safeapplicationofthechemical.

•Handlechemicalsinawellventilatedarea.

•Weargogglesandotherprotectiveequipmentas

instructedbythechemicalmanufacturer.Ensurethatas

littleskinaspossibleisexposedwhileusingchemicals.

•Havecleanwateravailableespeciallywhenllingthe

spraytank.

•Donoteat,drink,orsmokewhileworkingwithchemicals.

•Alwayswashyourhandsandotherexposedareasassoon

aspossibleafternishingthework.

•Properlydisposeofunusedchemicalsandchemical

containersasinstructedbythechemicalmanufacturer

andyourlocalcodes.

•Chemicalsandfumesinthetanksaredangerous;never

enterthetankorplaceyourheadoverorintheopening.

4

BeforeOperating

•Operatethemachineonlyafterreadingandunderstanding

thecontentsofthismanual.

•Neverallowchildrentooperatethesprayer.

•Neverallowotheradultstooperatethesprayerwithout

rstreadingandunderstandingtheOperator'sManual.

Onlytrainedandauthorizedpersonsshouldoperatethis

sprayer.Makesurethatalloperatorsarephysicallyand

mentallycapableofoperatingthesprayer.

•Thissprayerisdesignedtocarryonlyyou,theoperator

andonepassengerintheseatprovidedbythe

manufacturer.Nevercarryanypassengersonthesprayer.

•Neveroperatethesprayerwhenundertheinuence

ofdrugsoralcohol.Evenprescriptiondrugsandcold

medicinescancausedrowsiness.

•Donotdrivethesprayerwhenyouaretired.Besureto

takeoccasionalbreaks.Itisveryimportantthatyoustay

alertatalltimes.

•Becomefamiliarwiththecontrolsandknowhowtostop

theenginequickly.

•Keepallshields,safetydevices,anddecalsinplace.Ifa

shield,safetydevice,ordecalismalfunctioning,illegible,

ordamaged,repairorreplaceitbeforeoperatingthe

machine.

•Alwayswearsubstantialshoes.Donotoperatethe

machinewhilewearingsandals,tennisshoes,orsneakers.

Donotwearloosettingclothingorjewelrywhichcould

getcaughtinmovingpartsandcausepersonalinjury.

•Wearingsafetyglasses,safetyshoes,longpants,anda

helmetisadvisableandrequiredbysomelocalsafetyand

insuranceregulations.

•Avoiddrivingwhenitisdark,especiallyinunfamiliar

areas.Ifyoumustdrivewhenitisdark,besuretodrive

cautiously,usetheheadlights,andevenconsideradding

additionallights.

•Beextremelycarefulwhenoperatingaroundpeople.

Alwaysbeawareofwherebystandersmightbeandkeep

themawayfromtheworkarea.

•Beforeoperatingthesprayer,alwayscheckthedesignated

areasofthesprayerthatarestatedinthePre-Starting

ChecksintheOperationsection.Ifthemachinedoes

notfunctioncorrectlyorisdamagedinanyway ,donot

usethesprayer.Makesurethattheproblemiscorrected

beforethesprayerorattachmentisoperated.

•Ensurethatalluidlineconnectorsaretightandallhoses

areingoodconditionbeforeapplyingpressuretothe

system.

•Sincegasolineishighlyammable,handleitcarefully.

–Useanapprovedgasolinecontainer.

–Donotremovethecapfromthefueltankwhenthe

engineishotorrunning.

–Donotsmokewhilehandlinggasoline.

–Fillthefueltankoutdoors,andllittoabout25mm

(1inch)belowthetopofthetank(thebottomofthe

llerneck).Donotoverllit.

–Wipeupanyspilledgasoline.

WhileOperating

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

•Theoperatorshouldremainseatedwheneverthesprayer

isinmotion.Theoperatorshouldkeepbothhandson

thesteeringwheelwheneverpossible.Keepyourarms

andlegswithinthesprayerbodyatalltimes.

•Alwayswatchoutforandavoidlowoverhangssuchas

treelimbs,doorjambs,andoverheadwalkways.Make

surethereisenoughroomoverheadtoeasilyclearthe

sprayerandyourhead.

•Failuretooperatethesprayersafelymayresultinan

accident,tipoverofthesprayer,andseriousinjuryor

death.Drivecarefully .Topreventtippingorlossof

control:

–Useextremecaution,reducespeed,andmaintain

asafedistancearoundsandtraps,ditches,creeks,

ramps,unfamiliarareas,oranyareasthathaveabrupt

changesingroundconditionsorelevation.

–Watchforholesorotherhiddenhazards.

–Useextracautionwhenoperatingthesprayeronwet

surfaces,inadverseweatherconditions,athigher

speeds,orwithafullload.Stoppingtimeanddistance

willincreasewithafullload.

–Avoidsuddenstopsandstarts.Donotgofrom

reversetoforwardorforwardtoreversewithoutrst

comingtoacompletestop.

–Slowdownbeforeturning.Donotattemptsharp

turnsorabruptmaneuversorotherunsafedriving

actionsthatmaycausealossofsprayercontrol.

–Beforebackingup,looktotherearandensurethat

nooneisbehindyou.Backupslowly.

–Watchoutfortrafcwhenyouarenearorcrossing

roads.Alwaysyieldtherightofwaytopedestrians

andothervehicles.Thissprayerisnotdesignedfor

useonstreetsorhighways.Alwayssignalyourturns

orstopearlyenoughsothatotherpeopleknowwhat

youplantodo.Obeyalltrafcrulesandregulations.

–Theelectricalandexhaustsystemsofthesprayercan

producesparkscapableofignitingexplosivematerials.

Neveroperatethesprayerinornearanareawhere

thereisdustorfumesintheairwhichareexplosive.

5

–Ifyouareeverunsureaboutsafeoperation,stop

workandaskyoursupervisor.

•Donottouchtheengineormuferwhiletheengineis

runningorsoonafterithasstopped.Theseareasmaybe

hotenoughtocauseburns.

•Ifthemachineevervibratesabnormally,stopimmediately ,

waitforallmotiontostop,andinspectthesprayerfor

damage.Repairalldamagebeforeresumingoperation.

•Beforegettingoffoftheseat:

1.Stopthemovementofthemachine.

2.Removeyourfootfromthetractionpedalandset

theparkingbrake.

3.TurntheignitionkeytoOff.

4.Removetheignitionkey .

Important:Donotparkthemachineonan

incline.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Heavyloadsaffectstability.Reducetheweightoftheload

andyourspeedwhenoperatingonhills.

•Avoidstoppingonhills,especiallywithaload.Stopping

whilegoingdownahillwilltakelongerthanstopping

onlevelground.Ifthesprayermustbestopped,avoid

suddenspeedchanges,whichmayinitiatetippingor

rollingofthesprayer.Donotslamonthebrakes

whenrollingbackward,asthismaycausethesprayerto

overturn.

•Usetheseatbeltwhenoperatingthemachineandbe

certainthatitcanbereleasedquicklyintheeventofan

emergency.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•Donotremovetherolloverprotectionsystem(ROPS).

•Reducespeedandloadwhenoperatingonroughterrain,

unevenground,andnearcurbs,holes,andothersudden

changesinterrain.Loadsmayshift,causingthesprayer

tobecomeunstable.

Braking

•Slowdownbeforeyouapproachanobstacle.Thisgives

youextratimetostoporturnaway.Hittinganobstacle

candamagethesprayeranditscontents.Moreimportant,

itcaninjureyou.

•GrossVehicleWeight(GVW)hasamajorimpactonyour

abilitytostopand/orturn.Heavyloadsandattachments

makeasprayerhardertostoporturn.Theheavierthe

load,thelongerittakestostop.

•Turfandpavementaremuchmoreslipperywhenthey

arewet.Itcantake2to4timesaslongtostoponwet

surfacesasondrysurfaces.Ifyoudrivethroughstanding

waterdeepenoughtogetthebrakeswet,theywillnot

workwelluntiltheyaredry.Afterdrivingthroughwater,

youshouldtestthebrakestomakesuretheywork

properly.Iftheydonot,driveslowlywhileputtinglight

pressureonthebrakepedal.Thiswilldrythebrakesout.

OperatingonHillsandRoughTerrain

Operatingthesprayeronahillmaycausetippingorrolling

ofthesprayer,ortheenginemaystallandyoucouldlose

headwayonthehill.Thiscouldresultinpersonalinjury.

•Donotacceleratequicklyorslamonthebrakeswhen

backingdownahill,especiallywithaload.

•Neverdriveacrossasteephill;alwaysdrivestraightupor

downorgoaroundthehill.

•Iftheenginestallsoryoubegintoloseheadwaywhile

climbingahill,graduallyapplythebrakesandslowlyback

straightdownthehill.

•Turningwhiletravelingupordownhillscanbe

dangerous.Ifyouhavetoturnwhileonahill,doitslowly

andcautiously.Nevermakesharporfastturns.

Loading

Theweightofthecargocanchangethesprayercenterof

gravityandsprayerhandling.Toavoidlossofcontroland

personalinjury,followtheseguidelines:

•Reducetheweightoftheloadwhenoperatingonhills

androughterraintoavoidtippingoroverturningofthe

sprayer.

•Liquidloadscanshift.Thisshiftinghappensmostoften

whileturning,goingupordownhills,suddenlychanging

speeds,orwhiledrivingoverroughsurfaces.Shifting

loadscancausethesprayertotipover.

•Whenoperatingwithaheavyload,reduceyourspeedand

allowforsufcientbrakingdistance.Donotsuddenly

applythebrakes.Useextracautiononslopes.

•Beawarethatheavyloadsincreaseyourstoppingdistance

andreduceyourabilitytoturnquicklywithouttipping

over.

Maintenance

•Onlypermitqualiedandauthorizedpersonnelto

maintain,repair,adjust,orinspectthesprayer.

•Beforeperforminganymaintenance,ensurethatthe

systemhasbeenthoroughlyrinsedandcleaned.

•Beforeservicingormakingadjustmentstothemachine,

stoptheengine,settheparkingbrake,andremovethekey

fromtheignitiontopreventsomeonefromaccidentally

startingtheengine.

•Tomakesurethattheentiremachineisingoodcondition,

keepallnuts,bolts,andscrewsproperlytightened.

•Toreducethepotentialforre,keeptheengineareafree

ofexcessivegrease,grass,leaves,andaccumulationofdirt.

6

•Neveruseanopenametocheckthelevelorleakageof

fuelorbatteryelectrolyte.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keepyourhands,feet,clothing,andanyparts

ofyourbodyawayfromtheengineandanymovingparts.

Keepeveryoneaway.

•Donotuseopenpansoffuelorammablecleaning

uidswhencleaningparts.

•Donotadjustthetractioncontrolspeed.Toensure

safetyandaccuracy ,haveanAuthorizedToroDistributor

checkthegroundspeed.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthighpressureuid.Usecardboardor

papertondleaks.Fluidescapingunderpressurecan

penetrateskinandcauseinjuryrequiringsurgerywithina

fewhoursbyaqualiedsurgeonorgangrenemayresult.

•Ifmajorrepairsareeverneededorassistanceisrequired,

contactanAuthorizedToroDistributor.

•Tobesureofoptimumperformanceandsafety ,

alwayspurchasegenuineTororeplacementpartsand

accessories.Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous.Alteringthis

sprayerinanymannerthatmayaffectsprayeroperation,

performance,durability ,oritsuse,mayresultininjuryor

death.Suchusecouldvoidtheproductwarranty.

WholeBodyVibration

Measuredvibrationlevel=0.3m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

2

2

SoundPower

Thisunithasaguaranteedsoundpowerlevelof99dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressure

Thisunithasasoundpressurelevelattheoperator’ searof85

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

Hand-ArmVibration

Measuredvibrationlevelforrighthand=0.22m/s

Measuredvibrationlevelforlefthand=0.26m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

2

2

2

7

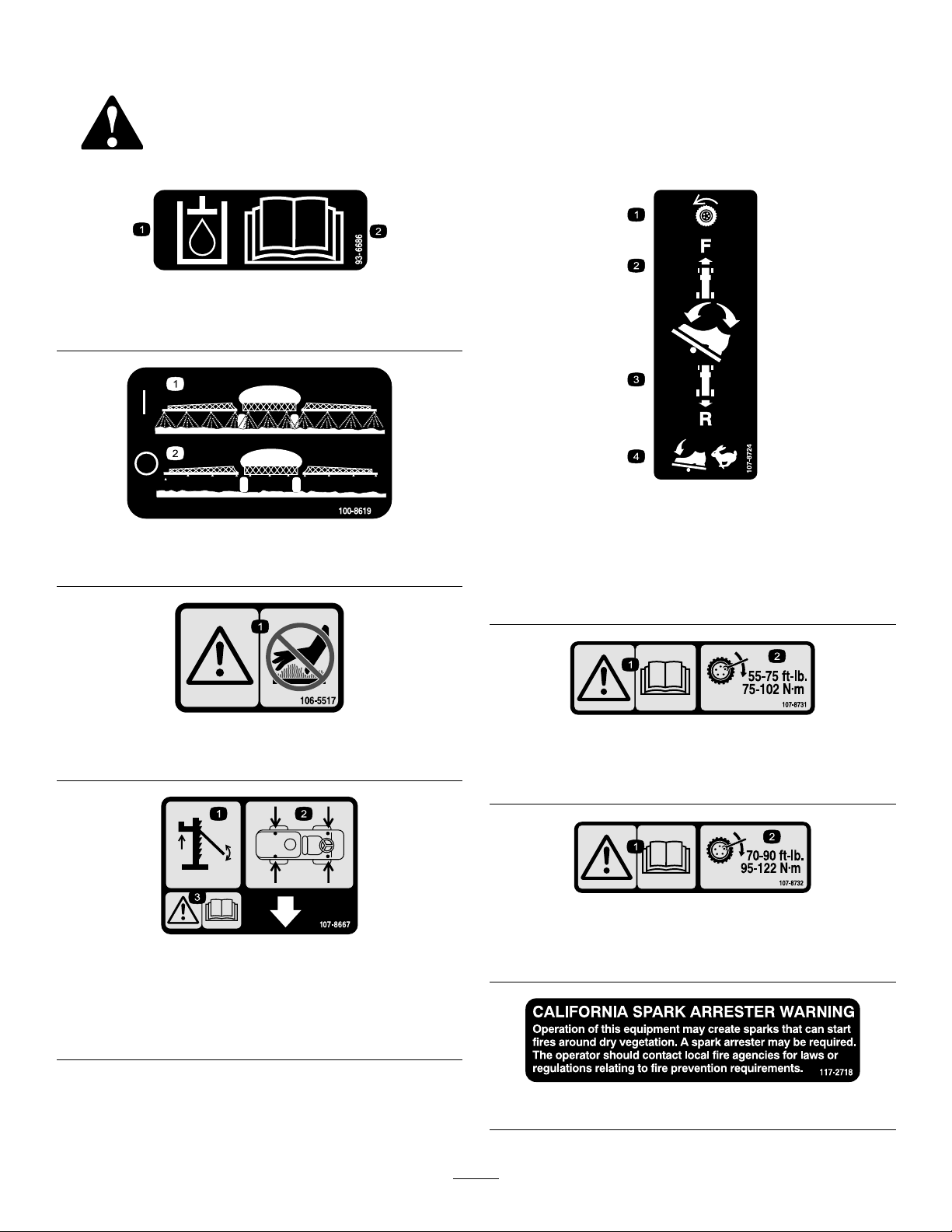

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93–6686

1.Hydraulicoil

2.ReadtheOperator's

Manual.

100-8619

1.Sprayon2.Sprayoff

106-5517

1.Warning—donottouchthehotsurface.

107-8724

1.Tractiondrive3.Todriveinreverse,press

2.Todriveforward,pressthe

topofthetractionpedal

forwardanddown.

thebottomofthepedal

rearwardanddown.

4.Vehiclespeedincreases

withmorepedalpressure.

107-8731

1.Warning—readtheOperator'sManual.

2.Torquelugnutsto75to102N-m(55to75ft-lb).

107-8667

1.Jacking

2.Jackpointlocations

3.Warning—ReadtheOperator'sManualformoreinformation

onjackingthevehicle

107-8732

1.Warning—readtheOperator'sManual.

2.Torquelugnutsto95to122N-m(75to90ft-lb).

117–2718

8

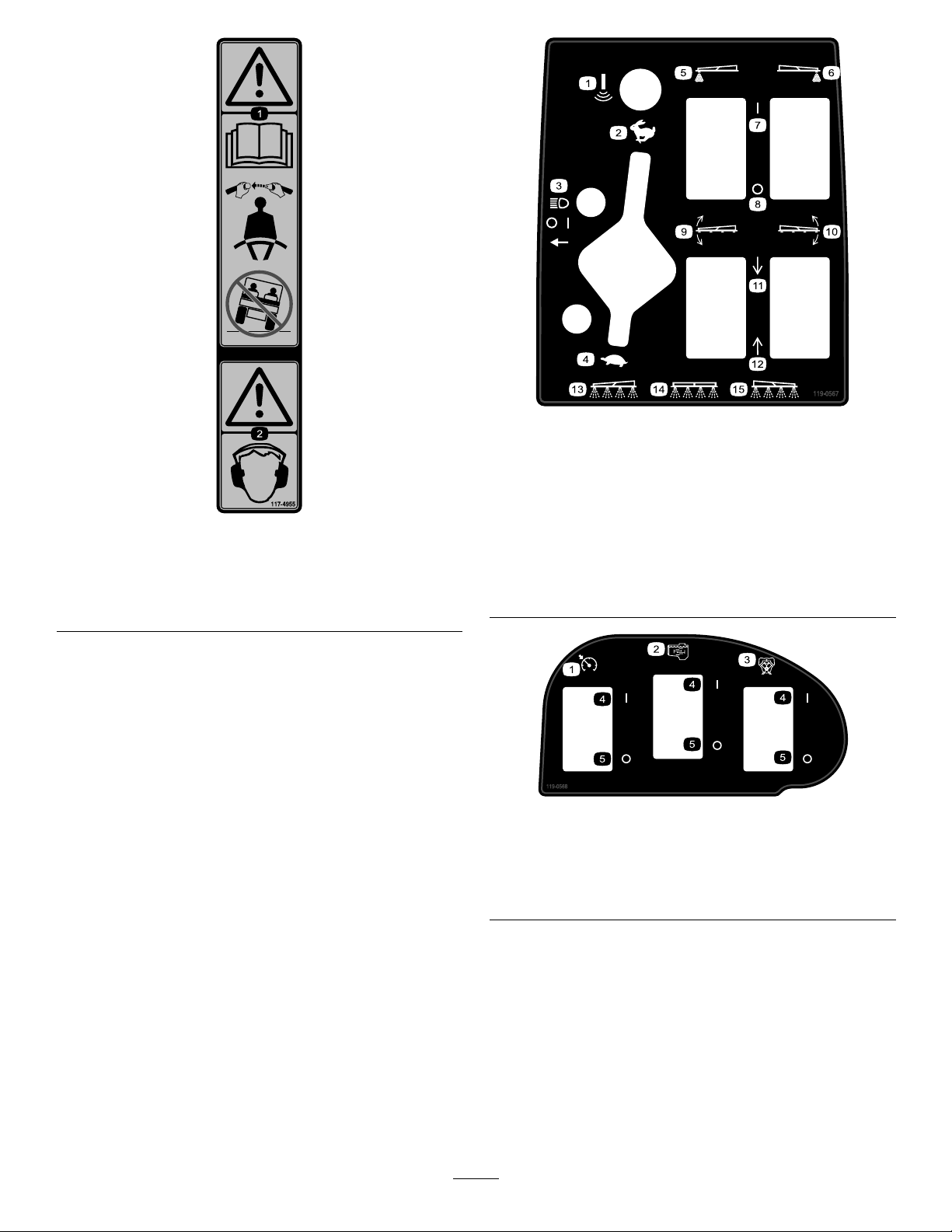

117-4955

1.Warning—readtheOperator'sManual;weartheseatbelt

whenseatedintheoperator'sposition;avoidtippingthe

machine.

2.Warning—wearhearingprotection.

119-0567

1.Sonicboom9.Boomlift,leftboom

2.Throttle—fast10.Boomlift,rightboom

3.Headlights11.Raise

4.Throttle—slow12.Lower

5.Foammarker,leftboom13.Leftboomsprayswitch

6.Foammarker,rightboom

7.On

8.Off

14.Centerboomsprayswitch

15.Rightboomsprayswitch

119-0568

1.Tractionpedallocking

2.Agitation

3.Pump

9

switch

4.On

5.Off

120-0759

1.Decrease

2.Continuousvariable

setting,spraypressure

3.Increase

4.Rinsefromcleanwater

tank

5.Off

6.On

7.Mixeductor

8.Sonicboom

9.Hazardlights

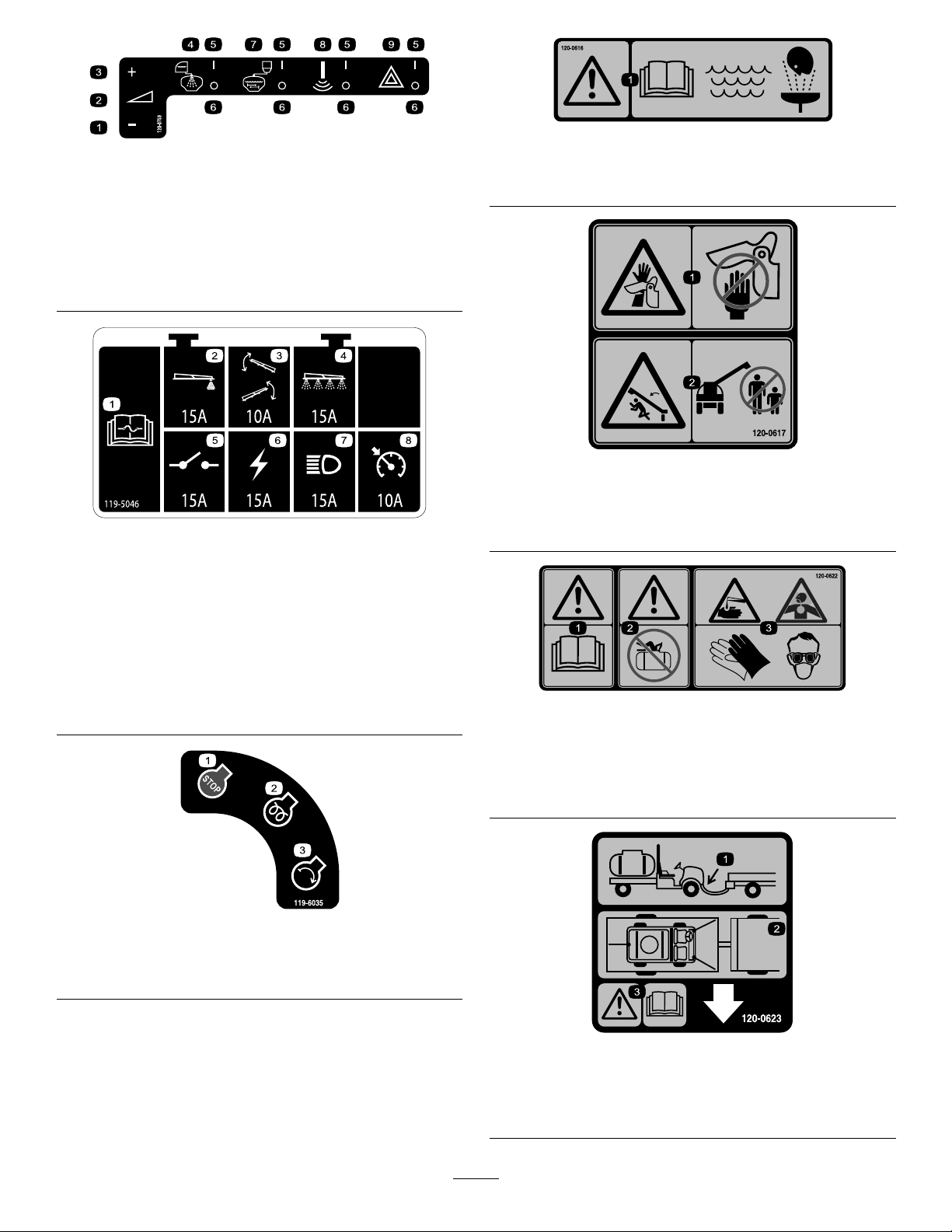

119-5046

1.ReadtheOperator'sManualforinformationonfuses.

2.Foammarker—15amp

3.Boomlift—10amp

4.Spraysystem—15amp

5.Breakerswitch—15amp

6.Ignition—15amp

7.Headlights—15amp

8.Tractionpedallockingswitch—10amp

120–0616

1.Warning—readtheOperator'sManual;usefresh,clean

waterforrst-aidwashing.

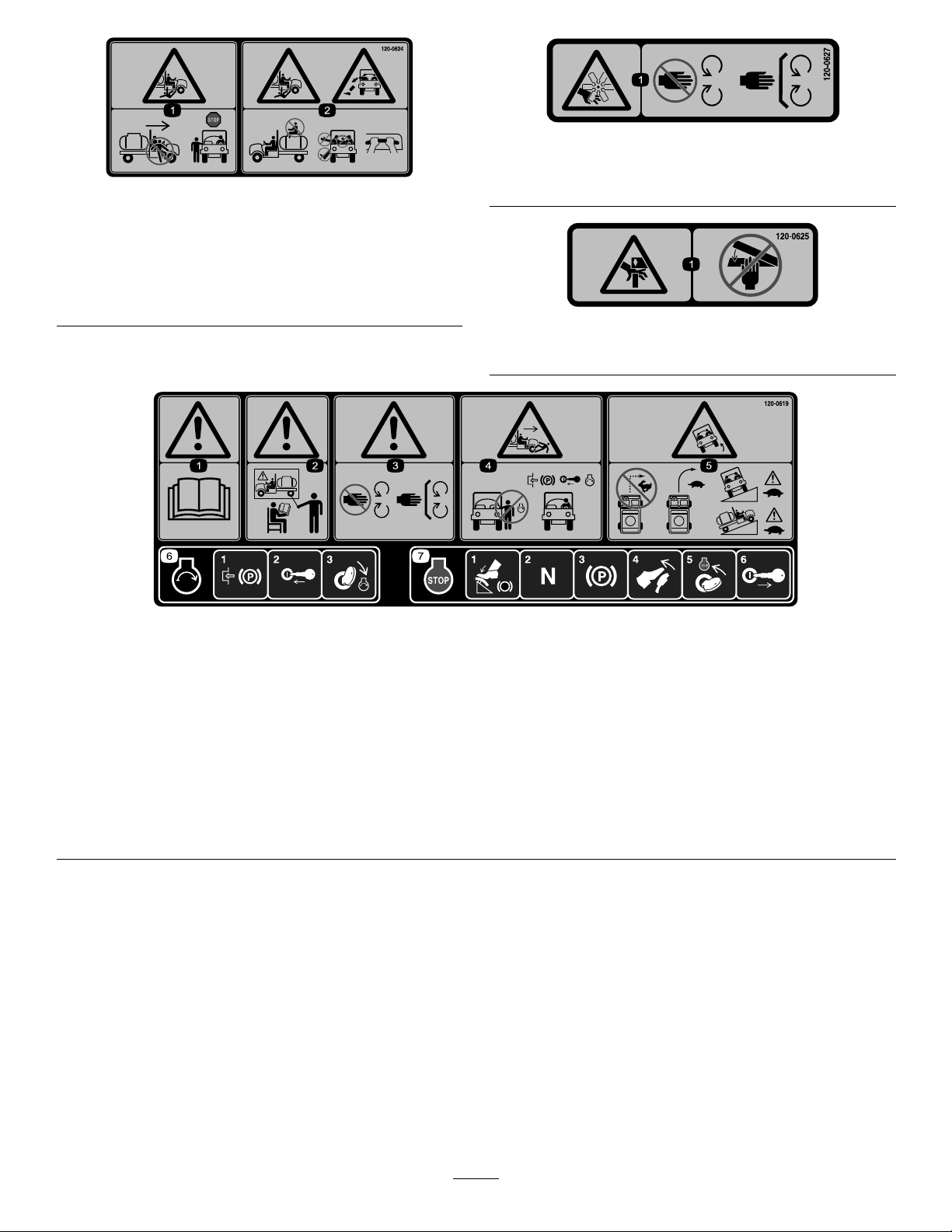

120-0617

1.Pinchpoint,hand—keephandsawayfromhinge.

2.Crushinghazard,boom—keepbystandersasafedistance

fromthemachine.

120-0622

1.Warning—readtheOperator'sManual.

2.Warning—donotenterthetank.

3.Causticliquid/chemicalburnandtoxicgasinhalation

hazards—wearhand,skin,eye,andrespiratoryprotection.

1.Engine—stop3.Engine—start

2.Engine—run,preheat

119-6035

120-0623

1.Towhitchlocation

2.Tiedownlocations

3.Warning—ReadtheOperator'sManual.

10

120-0624

1.Crushing/dismembermenthazardofbystanders—donot

exitorenterthemachinewhileitismoving;stopthe

machinebeforeenteringorexiting.

2.Falling,crushinghazard—noridersontank;keeparms

andlegsinsideofthevehicleatalltimes,usepassenger

handholds.

120-0627

1.Cutting/dismembermenthazard,fan—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

120-0625

1.Pinchpoint,hand—keephandsaway.

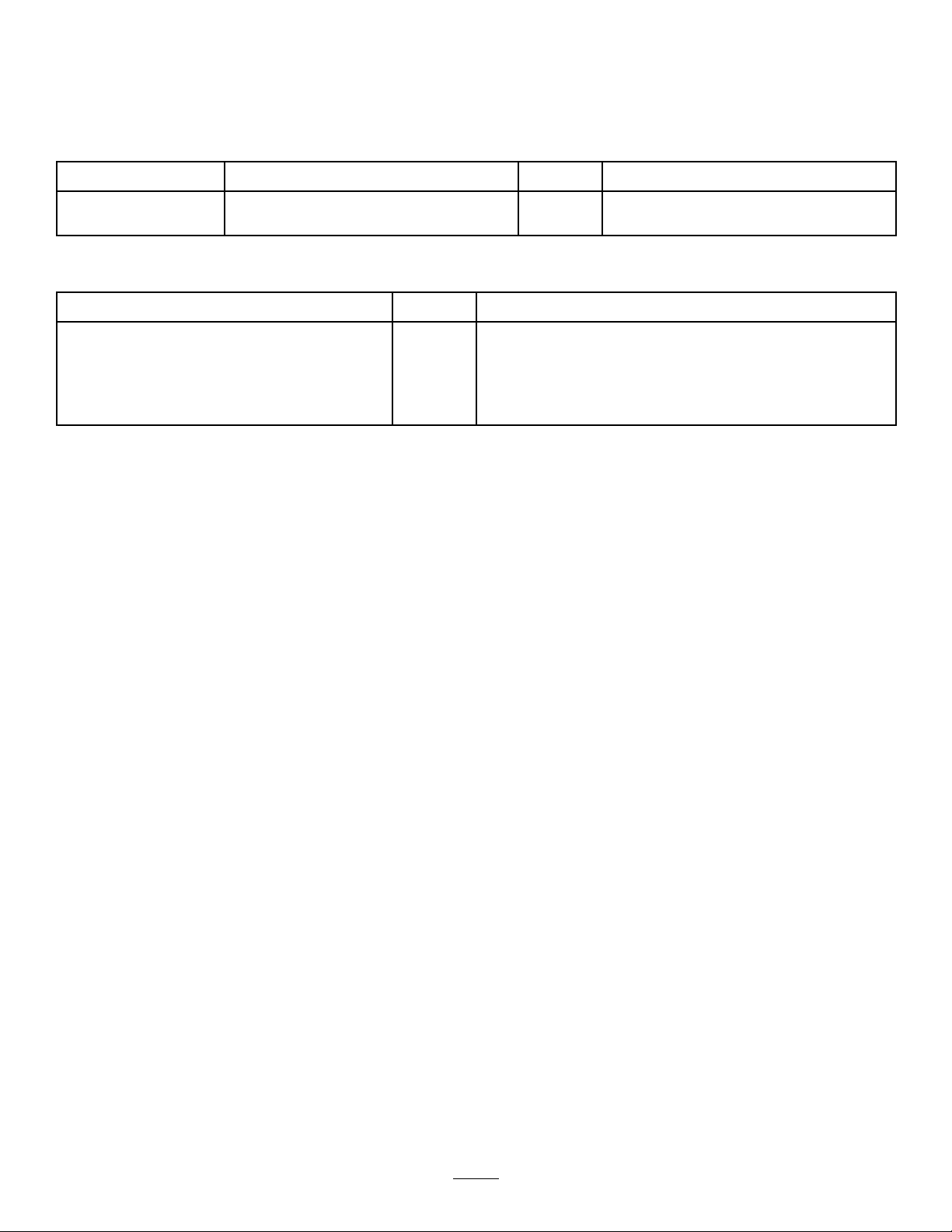

120-0619

1.Warning—readtheOperator'sManual.5.Tippinghazard—donotturnsharplywhiletravelingfast,drive

2.Warning—donotoperatethismachineunlessyouaretrained.6.T ostarttheengine,engagetheparkingbrake,insertthe

3.Warning—stayawayfrommovingparts,keepallguardsand

shieldsinplace.

4.Crushing/dismembermenthazardofbystanders—donotstart

theenginewhileenteringorexitingthevehicle;engagethe

parkingbrake,insertthekey,andstarttheenginewhile

seatedinthedriver’sseat.

slowlywhenturning;usecautionanddriveslowlywhen

travelingacrossorupanddownslopes.

ignitionkeyandturnittothestartposition.

7.Tostoptheengine,pressthebrake,putthegearselectorin

neutral,settheparkingbrake,releasethebrake,stopthe

engine,andremovethekey.

11

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

Qty.

Nopartsrequired

–

Checktheboomhingesprings.

Use

MediaandAdditionalParts

Description

Ignitionkey2

Operator'sManual

Engineowner'sManual1

PartsCatalog

OperatorTrainingMaterials

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Note:Ifyouhavequestionsorneedadditionalinformationregardingthespraycontrolsystem,refertotheOperator’sManual

suppliedwiththesystem.

Important:Thissprayerissoldwithoutnozzlesandacontroller.Eithera

Pr oContr ol

Tousethesprayer,

ontheavailableboomkitandaccessories.

Afteryouinstallyournozzlesandbeforeusingthesprayerforthersttime(ifyou

System),adjusttheboombypassvalvessothatthepressureandapplicationrateremainsthesameforallbooms

whenyouturnoneormoreboomsoff.RefertoCalibratingtheBoomBypassV alvessectionintheOperationsection.

™

™ ™

XPKit

isnecessaryfortheproperfunctionofthemachine.

y ou must obtain and install nozzles

Qty.

1

1

1

Readthemanualsandwatchthetrainingmaterialsbefore

operatingthemachine.

Man ual Spray Operation Kit

.ContactyourAuthorizedToroDistributorforinformation

Use

do not

useProControl™ ™™XPSpray

or

12

1

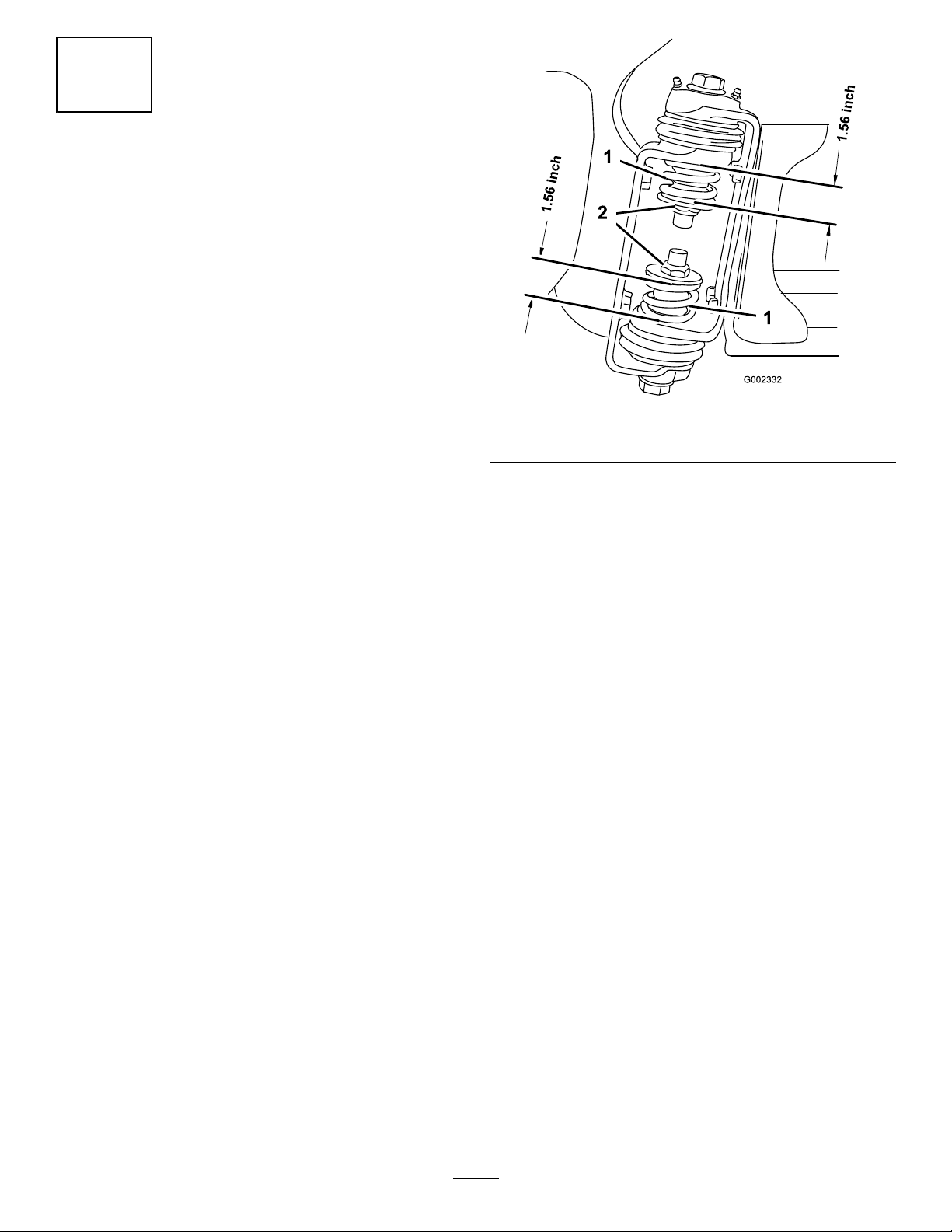

CheckingtheBoomHinge Springs

NoPartsRequired

Procedure

Important:Operatingthespraysystemwiththeboom

hingespringsundertheincorrectcompressioncould

damagetheboomassembly.Measurethespringsand

usethejamnuttocompressthespringsto3.96cm(1.56

inches),ifnecessary.

Thesprayerisshippedwiththeboomextensionsswung

forwardtofacilitatepackagingofthemachine.Thesprings

arenotfullytightenedatthetimeofmanufacturetoallowthe

boomstobeinthispositionfortransit.Beforeoperatingthe

machine,adjustthespringstothecorrectcompression.

1.Ifnecessary,removethepackingcomponentsthat

securetherightandleftextensionboomsduring

shipping.

2.Supporttheboomswhiletheyareextendedtothe

sprayposition.

3.Attheboomhinge,measurethecompressionofthe

upperandlowerspringswhiletheboomsareintheir

extendedposition(Figure1).

A.Compressallspringsuntiltheymeasure3.96cm

(1.56inches).

B.Usethejamnuttocompressanyspringthat

measuregreaterthan3.96cm(1.56inches).

Figure3

1.Boomhingespring2.Jamnut

4.Repeattheprocedureforeachspringonbothboom

hinges.

5.Movetheboomsintothetransport“X”position.Refer

toOperatingtheBooms(page24).

13

ProductOverview

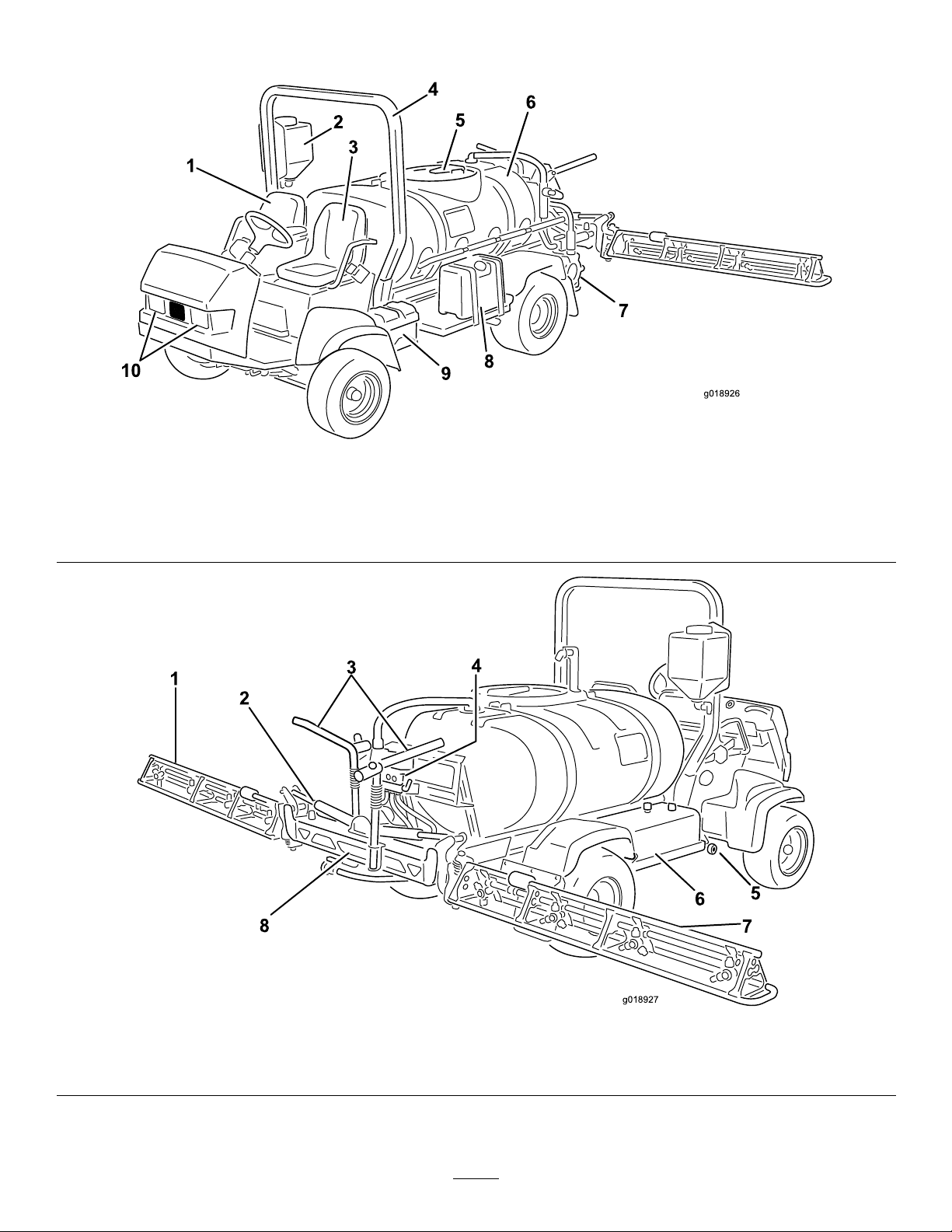

1

2

3

4

5

6

8

9

7

10

g018926

1

2

3

4

6

7

5

8

g018927

Figure4

1.Passengerseat

2.Freshwatertank5.Tanklid8.Fueltank

3.Operator’sseat6.Chemicaltank

4.RollOverProtection

System(ROPS)

7.Pump10.Headlight

9.Battery

Figure5

1.Leftboom

2.Boomcontrolcylinder4.Valvecluster6.Hydraulictank

3.Boomtransportcradle5.Tankdrain7.Rightboom

14

8.Centerboom

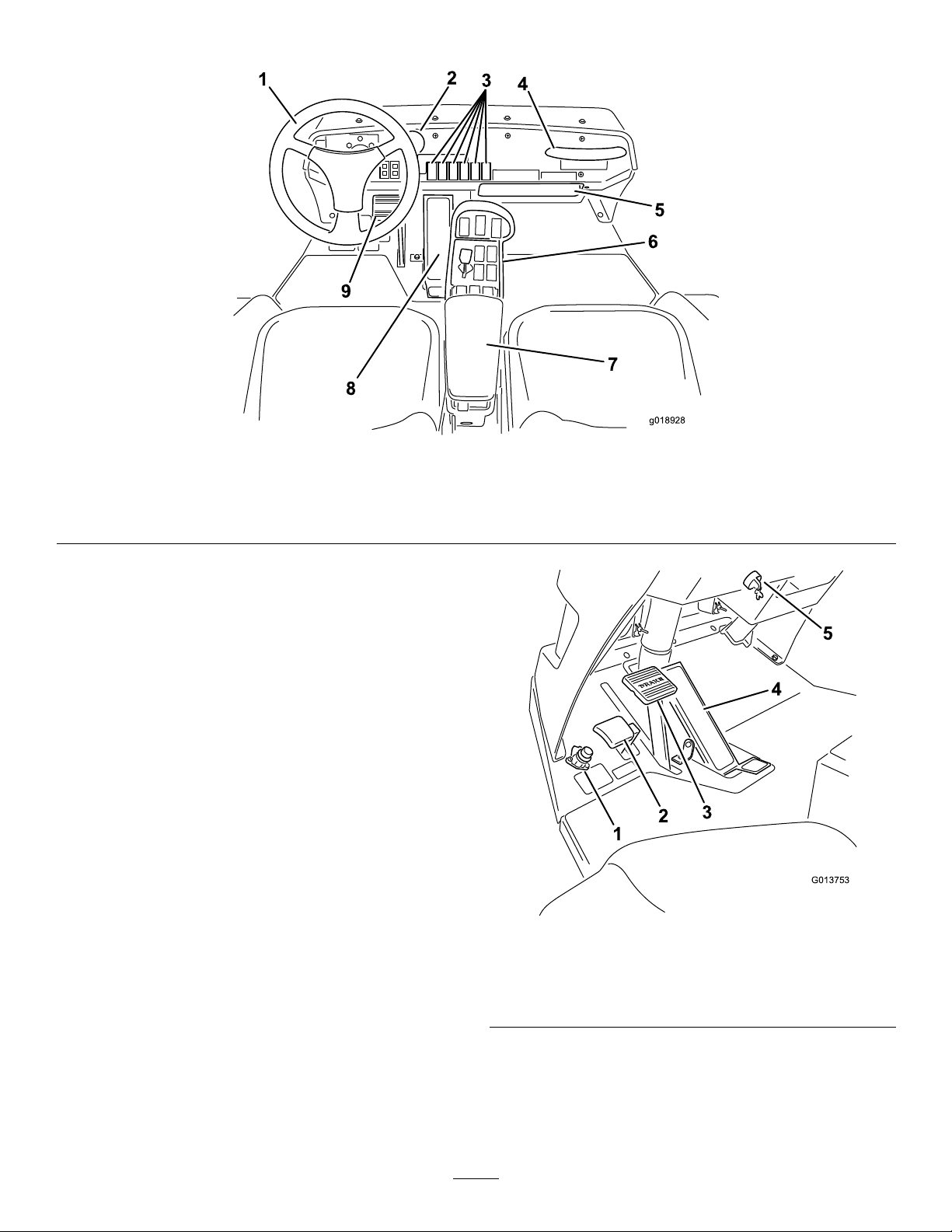

Controls

g018928

G013753

1

2

3

4

5

Figure6

1.Steeringwheel

2.Pressuregauge

3.Dashcontrols

4.Passengerhandhold7.Armrest

5.Storagecompartment

6.Centerconsole

VehicleControls

TractionPedal

Thetractionpedal(Figure7)controlsthemovementofthe

machine,bothforwardandreverse.Usingtheheelandtoe

oftherightfoot,pressthetopofthepedaltomoveforward

orthebottomofthepedaltomoveinreverse.Releasethe

pedaltoslowandstop.

Important:Ensurethatyouallowthesprayertocome

toastopbeforeswitchingbetweentheForwardandthe

Reversepositions.

Note:Thefartheryoupressthepedalineitherdirection,the

fasterthesprayerwilltravel.Toobtainmaximumforward

speed,setthethrottlelevertotheFastpositionandpressthe

tractionpedalallthewayforward.

Note:Togetmaximumpowerunderheavyloadorwhen

ascendingahill,havethethrottleintheFastpositionwhile

pressingtractionpedalslightlytokeeptheenginespeedhigh.

Whentheenginespeedbeginstodecrease,releasethetraction

pedalslightlytoallowtheenginespeedtoincrease.

8.Tractionpedal

9.Brake

Figure7

1.Master-boomswitch4.Tractionpedal

2.Parking-brakepedal5.Ignitionswitchandkey

3.Brakepedal

15

BrakePedal

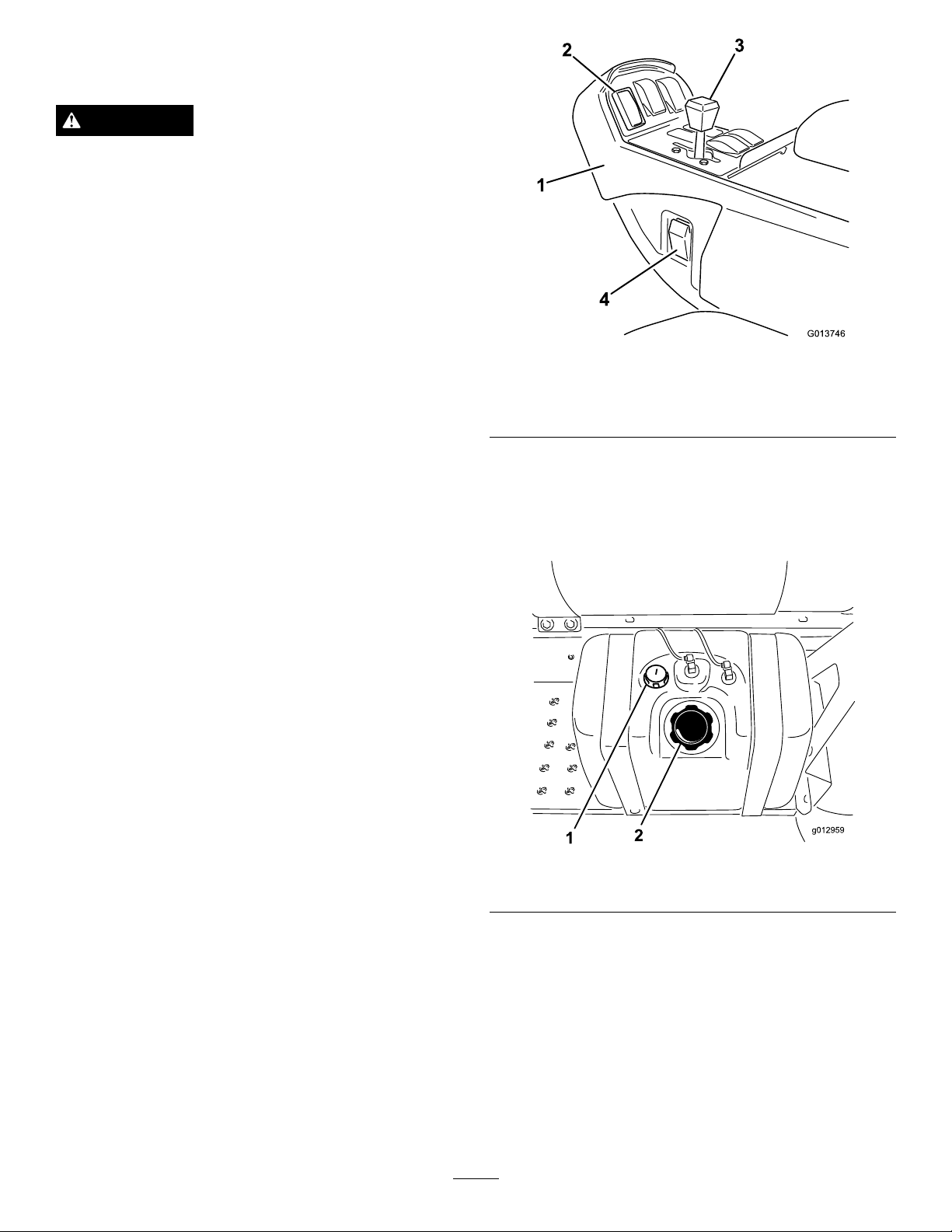

G013746

1

2

3

4

Usethebrakepedaltostoporslowthesprayer(Figure7).

CAUTION

Ifyouoperatethesprayerwithpoorlyadjusted

orwornbrakes,youcouldlosecontrolofthe

sprayer,resultinginseriousinjuryordeathtoyou

orbystanders.

Alwayscheckthebrakesbeforeoperatingthe

sprayerandkeepthemproperlyadjustedand

repaired.

ParkingBrake

Theparkingbrakeisapedaltotheleftofthebrake(Figure

7).Engagetheparkingbrakewheneveryouplanonleaving

theseattopreventthesprayerfromaccidentlymoving.

Toengagetheparkingbrake,pressthebrakepedaland,

whileholdingthebrake,presstheparkingbrakepedal.T o

disengage,pressandreleasethebrakepedal.Ifthesprayeris

parkedonasteepgrade,applytheparkingbrakeandplace

blocksonthedownhillsideofthewheels.

IgnitionSwitch

Theignitionswitch(Figure7),usedtostartandstopthe

engine,has3positions:Off,On/PreheatandStart.

Figure8

1.Centerconsole

2.Traction-pedallocking

switch

FuelGauge

3.Throttlelever

4.Headlightswitch

Thefuelgaugeislocatedontopofthefueltank(Figure9),

ontheleftsideofthemachineandshowstheamountof

fuelinthetank.

ThrottleLever

Thethrottlelever,locatedonthecontrolpanelbetweenthe

seats(Figure8),controlsthespeedoftheengine.Pushthe

leverforwardtoincreasetheenginespeedandpullitrearward

todecreasetheenginespeed.

Traction-PedalLockingSwitch

Thetraction-pedallockingswitchlocksthepositionofthe

tractionpedalatthetimetheswitchisengaged(Figure8).

Thisensuresthesprayerstaysataconstantspeedwhile

drivingonlevelground.

HeadlightSwitch

Toggletheswitchtooperatetheheadlights(Figure8).Pushit

forwardtoturnthelightsonandrearwardtoturnthemoff.

Figure9

1.Fuelgauge2.Fueltankcap

HourMeter

Thehourmeter(Figure10)indicatesthetotalnumberof

hourstheenginehasrun.Thehourmeterstartstofunction

wheneverthekeyisturnedtotheRunposition.

16

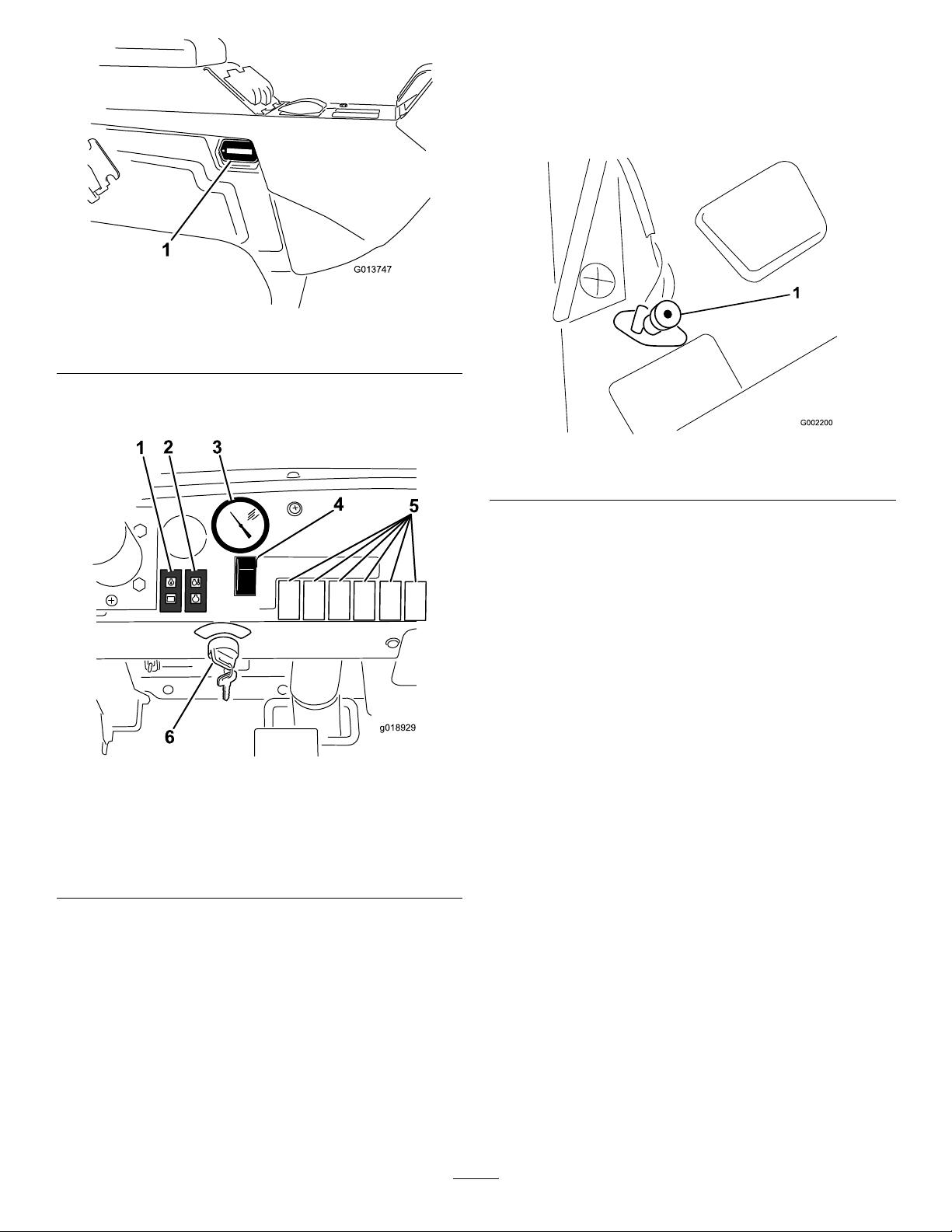

G013747

1

1.HourMeterlocation

g018929

SprayerControls

MasterBoomSwitch

Themasterboomswitchislocatedontheoorboardofthe

machinecabandtotheleftoftheoperator.Itallowsyouto

startorstopthesprayoperation.Presstheswitchwithyour

foottoenableordisablethespraysystem(Figure12).

Figure10

Figure12

1.Masterboomswitch

Figure11

1.Oilpressureandbattery

light

2.Watertemperatureand

glowpluglight

3.Pressuregauge6.Ignitionswitchandkey

ApplicationRateSwitch

4.Applicationrateswitch

5.Dashcontrolsforoptional

kits

Theapplicationrateswitchislocatedonthedashtotheright

ofthesteeringwheel(Figure13).Pressandholdtheswitch

forwardtoincreasethespraysystempressure,orpressand

holditrearwardtodecreasepressure.

BoomSwitches

Theboomswitchesarelocatedonthecontrolpaneltothe

rightoftheseat(Figure13).Toggleeachswitchforwardto

turnthecorrespondingboomsectiononandrearwardto

turnthemoff.Whentheswitchisturnedon,alightonthe

switchilluminates.Theseswitcheswillonlyaffectthespray

systemwhenthemasterboomswitchison.

PumpSwitch

Thepumpswitchislocatedonthecontrolpaneltotheright

oftheseat(Figure13).Togglethisswitchforwardtorun

thepumporrearwardtostopthepump.Whentheswitchis

turnedon,alightontheswitchilluminates.

Important:Onlyengagethepumpswitchwhenthe

engineisatlowidletoavoiddamagingthepumpdrive.

BoomLift

Theboomliftswitchesarelocatedonthecontrolpaneltothe

rightoftheseatandusedtoraisetheleftandrightbooms

respectively(Figure13).

PressureGauge

Thepressuregauge(Figure11)islocatedonthedash.This

gaugeshowsthepressureoftheuidinthesysteminpsi

andkPa.

17

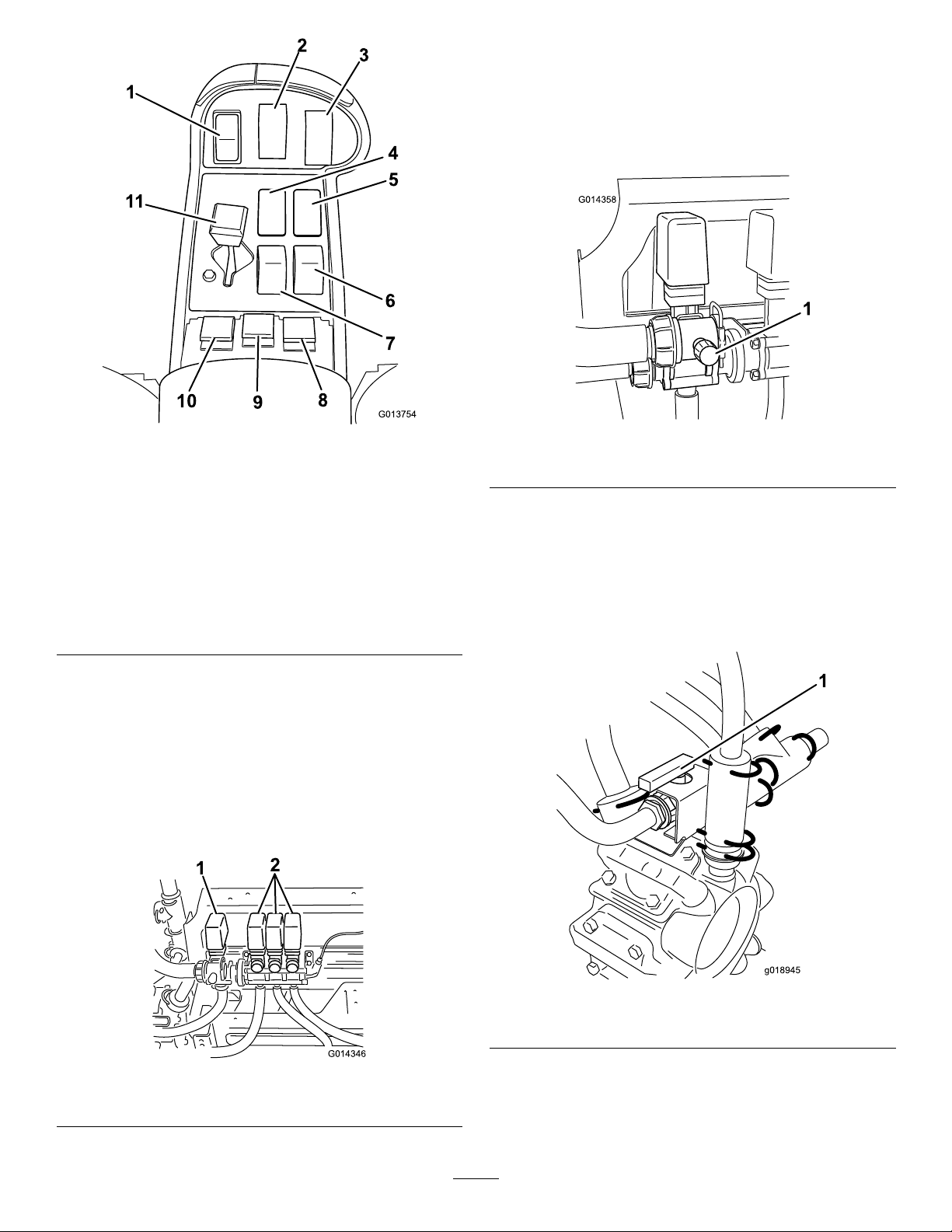

G013754

1

2

3

4

5

6

7

8

9

10

11

G014346

1

2

AgitationBypassValve

G014358

1

1

g018945

Theagitationbypassvalveredirectstheuidowtothe

pumpwhenyouturnoffagitation(Figure15).Itislocatedat

thebackoftheagitationvalve.Youcanadjustthisvalveto

ensurethatpressureremainsconstantduringagitation.Refer

toCalibratingtheAgitationBypassValve(page27).

Figure13

1.Tractionpedallocking

switch

2.Agitation8.Boomswitch,rightboom

3.Pumpswitch9.Boomswitch,centerboom

4.Foammarkerswitch,left

boom(optional)

5.Foammarkerswitch,right

boom(optional)

6.Boomliftswitch,right

boom

AgitationSwitch

7.Boomliftswitch,leftboom

10.Boomswitch,leftboom

11.Throttlelever

Theagitationswitchislocatedonthecontrolpaneltothe

rightoftheseat(

Figure13).T ogglethisswitchforwardto

turnontheagitationinthetankorrearwardtostopthe

agitation.Whentheswitchisturnedon,alightontheswitch

illuminates.Foragitationtowork,thepumpmustbeonand

theenginemustberunningaboveanidle.Theagitationvalve

Figure14)

islocatedbehindthetank(

Figure15

1.Agitationbypassvalve

AgitationControlValve

Theagitationcontrolvalveisamanualballvalvethatcontrols

owtotheagitationnozzlesinthemaintank(Figure

16).Usingthisvalveallowstheuserfurthercontrolover

pressureattheagitationnozzlesofthemaintankwhenlarger

applicationratesarerequired.

1.Agitationvalve2.Boomvalves

Figure14

Figure16

1.Agitationcontrolvalve,open

BoomValves

Thesevalvesturnthe3boomsonoroff(Figure14).Ifyou

everneedtomanuallyturnoffaboom,rotatetheknobon

18

Loading...

Loading...