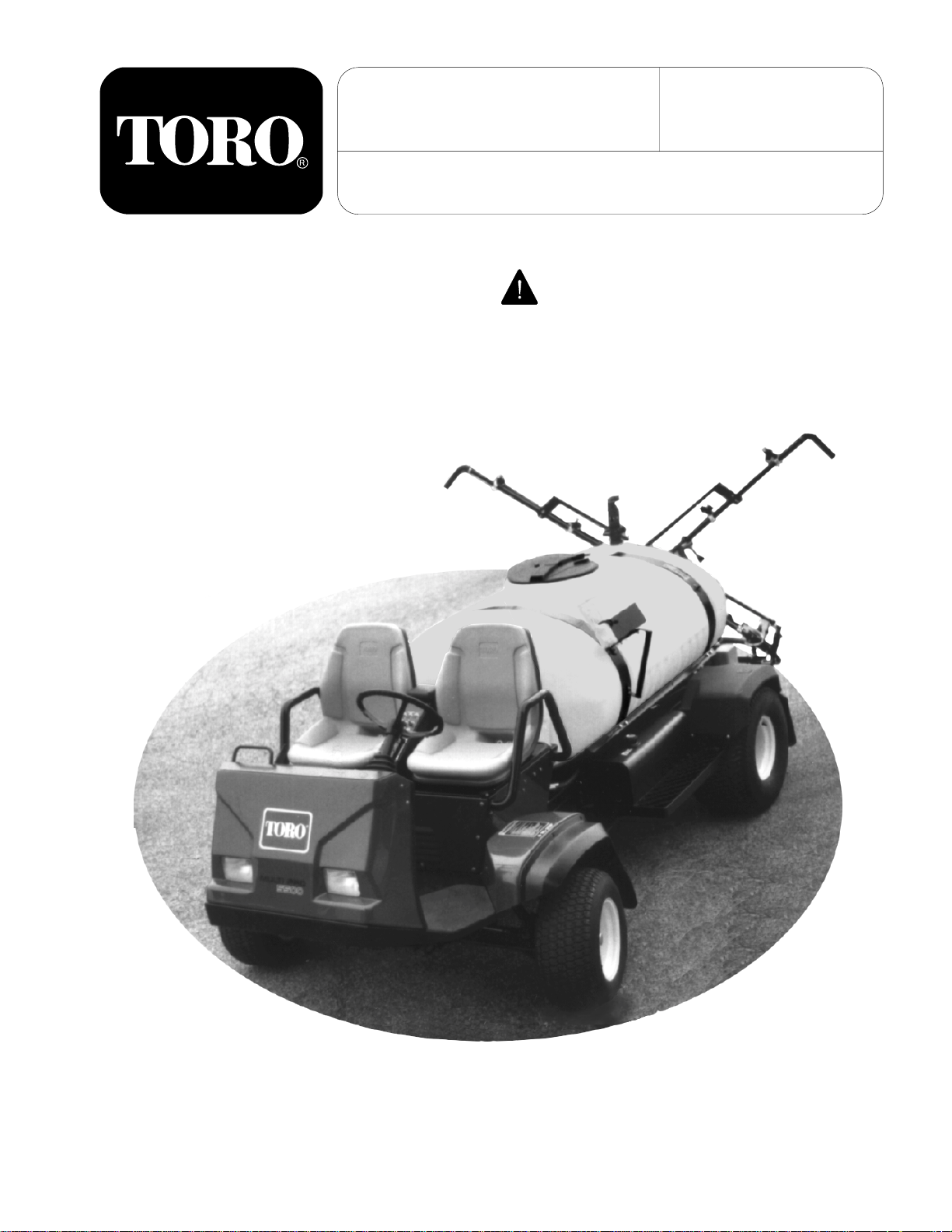

Toro 41564, 41020, Multi Pro 5500, 41021 Operator's Manual

FORM NO. 95-9309 Rev A

MODEL NO. 41020-70224 and UP

MODEL NO. 41021-70224 and UP

MODEL NO. 41564-70224 and UP

To assure maximum safety, optimum

performance, and to gain knowledge of the

product, it is essential that you or any other

operator of this vehicle read and understand

the contents of this manual before the engine

is ever started. Pay particular attention to the

SAFETY INSTRUCTIONS highlighted by the

triangular safety alert symbol.

OPERATOR'S &

SET-UP

MANUAL

MULTI PRO® 5500

TURF SPRAYER

The safety alert symbol means CAUTION,

WARNING, or DANGER - personal safety

instruction. Failure to comply with the

instruction may result in personal injury.

©The TORO Company - 1998

All Rights Reserved

1

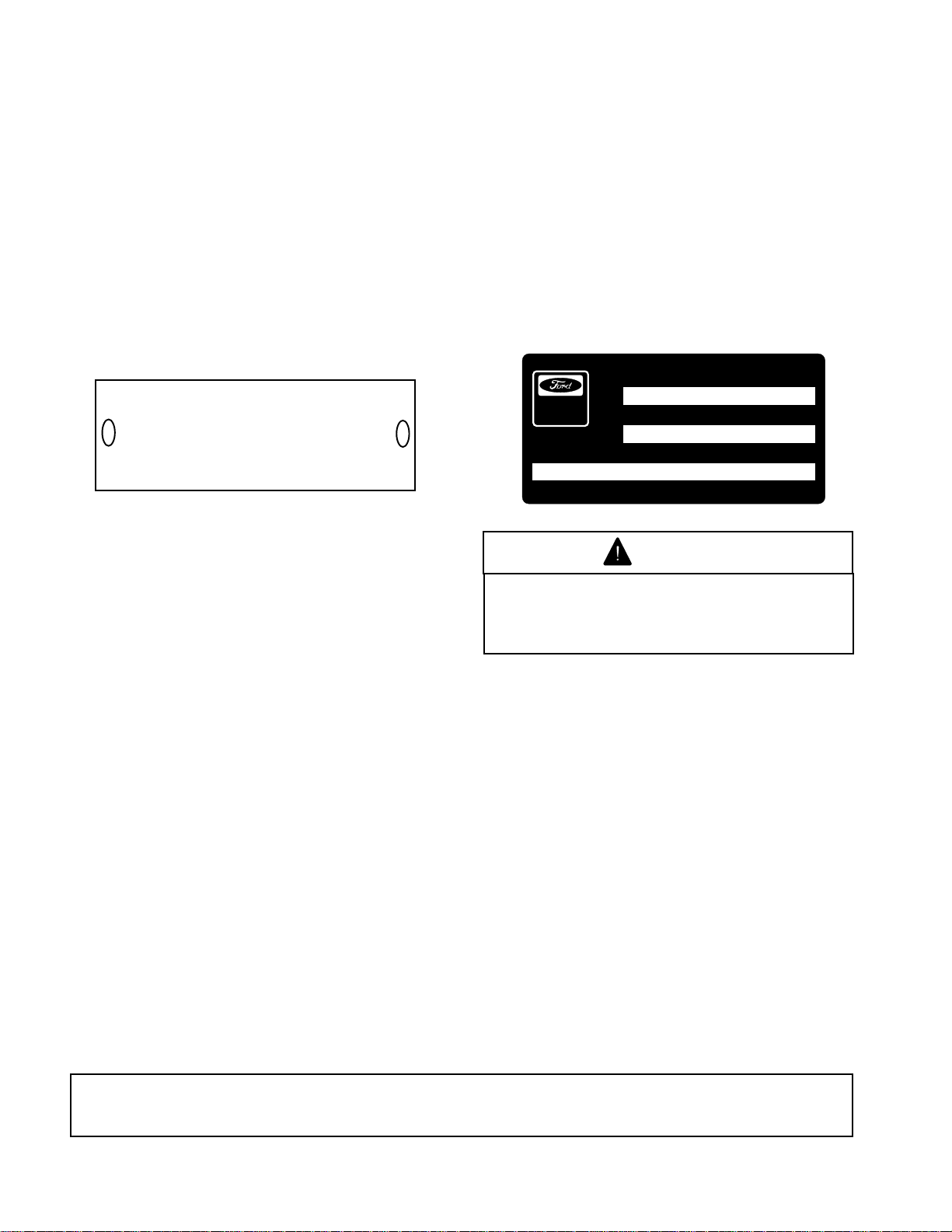

IDENTIFICATION AND ORDERING

VEHICLE:

The MULTI PRO

®

5500 has two identification

numbers: a model number and a serial number.

These numbers are stamped into a plate located

behind the left front fender of the vehicle. In any

correspondence concerning the unit, supply the

model number and serial numbers to ensure

correct information and replacement parts are

obtained. Record your Vehicle Identification

numbers on the illustration below for future

reference.

MOD.

SER.

THE TORO CO.

MINNEAPOLIS, MN. 55420

DATE PURCHASED: _______________________

This vehicle is not a motor vehicle as defined by

the National Traffic Motor Vehicle Safety Act. It is

not designed or manufactured for use on roads,

streets, or highways, and is not to be licensed

as a motor vehicle.

ENGINE:

An Identification Decal is affixed to the right side

of the engine. The decal contains the engine serial

number which identifies this unit from all others.

The model number and S.O.. or special options

determine the parts or components required on

this unit. When ordering parts or in any

communication involving the engine, it will be

necessary to supply the engine manufacturer with

these numbers, to ensure correct information and

replacement parts are obtained. Record the

engine identification numbers on the illustration

below for future reference.

SERIAL NUMBER

Power

Produ c ts

MODEL NUMBER

MODEL CODES.O./OPTIONS

WARNING

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects, or other reproductive harm.

FOREWORD

You have purchased a vehicle from the industry leader in maintenance excellence. Its future performance

and dependability are of prime importance. TORO is also concerned about future use of the vehicle and

of safety to the user. Therefore, this manual must be read by you and those involved with the MULTI

®

PRO

5500 to assure that safety, proper set-up, operation, and maintenance procedures are followed at

all times. The major sections of the manual are:

1. SAFETY INSTRUCTIONS

4. OPERATING INSTRUCTIONS

Safety, mechanical, and some general information in this manual are emphasized. DANGER, WARNING,

and CAUTION identify safety messages. Whenever the triangle safety symbol appears, it is followed by

a safety message that must be read and understood. For more details concerning safety, read the safety

instructions on pages 4 through 6. IMPORTANT identifies special mechanical information and NOTE

identifies general information worthy of special attention.

OPTIONAL SPARK ARRESTER

In some places a Spark Arrester muffler must be used because of local, state, or federal regulations. The

Spark Arrester available from your local TORO Distributor is approved by the United States Department

of Agriculture and the United States Forest Service.

When the machine is used or operated on any California forest, brush, or grass covered land,

a properly operating Spark Arrester must be obtained and installed to the Muffler. The operator

is violating state law, Section 442 Public Resources Code if a Spark Arrester is not used.

2. SET-UP INSTRUCTIONS

5. MAINTENANCE

3. BEFORE OPERATING

6. SPRAY SYSTEM SECTION

All information, illustrations and specifications in this manual are based on the latest product information available at the time of

publication. The right is reserved to make any changes at any time without notice.

2

TABLE OF CONTENTS

SAFETY INSTRUCTIONS .................................................................................................... 4-6

SPECIFICATIONS ...................................................................................................................7

SAFETY AND INSTRUCTION DECALS ............................................................................... 8,9

SET-UP INSTRUCTIONS

BATTERY SERVICE ........................................................................................................ 10

SPRAY SYSTEM......................................................................................................... 11-14

FRESH WATER TANK ..................................................................................................... 14

BEFORE OPERATING ...................................................................................................... 15-19

VEHICLE CONTROLS ......................................................................................................20,21

OPERATING INSTRUCTIONS.......................................................................................... 22-26

MAINTENANCE ................................................................................................................26-44

DAILY MAINTENANCE SCHEDULE................................................................................ 27

MAINTENANCE SCHEDULE .......................................................................................... 28

JACKING VEHICLE ......................................................................................................... 29

LUBRICATION ................................................................................................................. 30

AIR CLEANER MAINTENANCE ...................................................................................... 31

ENGINE MAINTENANCE ........................................................................................... 32-33

COOLING SYSTEM MAINTENANCE.............................................................................. 34

BELT MAINTENANCE ..................................................................................................... 35

HYDRAULIC SYSTEM MAINTENANCE .......................................................................... 36

HYDRAULIC SYSTEM DIAGRAM ................................................................................... 37

HYDRAULIC SYSTEM ..................................................................................................... 38

BRAKE MAINTENANCE .................................................................................................. 39

THROTTLE LEVER TENSION ......................................................................................... 39

AXLE MAINTENANCE ..................................................................................................... 40

ELECTRICAL MAINTENANCE ........................................................................................ 41

VEHICLE ELECTRICAL DIAGRAM ................................................................................. 42

TRACTION DRIVE MAINTENANCE ........................................................................... 43-44

SPRAY SYSTEM

SPRAYING SYSTEM ..............................................................................................................45

CONTROLS AND OPERATION ............................................................................................. 46

BEFORE SPRAYING

NOZZLE SELECTION GPA/GAL/1000 FT2................................................................ 46,47

NOZZLE SELECTION LIT/HA ......................................................................................... 48

DEFINITIONS/CONVERSIONS ....................................................................................... 49

FRESH WATER WASH TANK ......................................................................................... 50

SYSTEM SET-UP............................................................................................................. 51

FILLING SOLUTION TANK.............................................................................................. 51

OPERATION

USING THE SPRAYER............................................................................................... 51,52

AFTER SPRAYING .......................................................................................................... 52

PREVENTATIVE MAINTENANCE ......................................................................................... 52

PUMP MAINTENANCE......................................................................................................... 53

MAINTENANCE

TROUBLESHOOTING SOLENOID VALVE...................................................................... 54

SOLENOID VALVE MAINTENANCE .......................................................................... 55,56

FLOW DIAGRAM .................................................................................................................. 57

SPRAY SYSTEM ELECTRICAL DIAGRAM .......................................................................... 58

STORAGE ............................................................................................................................. 59

PERFORMANCE VERIFICATION................................................................................... 60, 61

TORO PROMISE................................................................................................................... 64

3

SAFETY INSTRUCTIONS

The MULTI PRO

®

5500 Turf Sprayer was

designed and tested to offer safe service when

operated and maintained properly. Although

hazard control and accident prevention partially

are dependent upon the design and

configuration of the vehicle, these factors are

also dependent upon the awareness, concern,

and proper training of the personnel involved

in the operation, maintenance, and storage of

the vehicle. Improper use or maintenance of

the vehicle can result in injury or death.

This is a specialized Turf Sprayer designed for

off road use. Its ride and handling will have a

different feel than what drivers experience with

passenger cars or trucks. So take time to

become familiar with your MULTI PRO

®

5500.

The attachments that adapt to the MULTI PRO

5500 are not covered in this manual. See the

specific Operator's Manual provided with the

attachment for additional safety instructions.

READ THESE MANUALS.

TO REDUCE THE POTENTIAL FOR INJURY OR

DEATH, COMPLY WITH THE FOLLOWING

SAFETY INSTRUCTIONS:

SUPERVISOR'S RESPONSIBILITIES

1. Make sure operators are thoroughly trained

and familiar with the Operator's Manual and all

labels on the vehicle.

2. Be sure to establish your own special

procedures and work rules for unusual operating

conditions (e.g. slopes too steep for vehicle

operation).

BEFORE OPERATING

3. Operate the vehicle only after reading and

understanding the contents of this manual. A

replacement manual is available by sending

complete model and serial number to: Hahn

Equipment Co., A subsidiary of The Toro

Company, 1625 N. Garvin, Evansville, Indiana

47711-4596.

5. This vehicle is designed to carry One

Operator, and One Passenger. Never carry more

than one passenger on the vehicle.

6. Never operate the vehicle when under the

influence of drugs or alcohol.

7. Become familiar with the controls and know

how to stop the engine quickly.

8. Keep all shields, safety devices, and decals

in place. If a shield, safety device, or decal is

malfunctioning, illegible, or damaged, repair or

replace it before operating the vehicle.

9. Always wear substantial shoes. Do not

operate vehicle while wearing sandals, tennis

®

shoes, or sneakers. Do not wear loose fitting

clothing or jewelry which could get caught in

moving parts and cause personal injury.

10. Wearing safety glasses, safety shoes, long

pants, and a helmet is advisable and required by

some local safety and insurance regulations.

11. Keep everyone, especially children and pets,

away from the areas of operation.

12. Before operating the vehicle, always check

all parts of the vehicle and any attachments. If

something is wrong, stop using the vehicle.

Make sure the problem is corrected before vehicle

or attachment is operated again.

13. Since gasoline is highly flammable, handle it

carefully.

A. Use an approved gasoline container.

B. Do not remove cap from fuel tank when

engine is hot or running.

C. Do not smoke while handling gasoline.

D. Fill fuel tank outdoors and to

approximately one inch below top of tank,

(bottom of filler neck). Do not overfill.

Read and understand the Engine Manufacturer's

Operator's Manual. Follow the safety alert

messages.

4. Never allow children to operate the vehicle

or adults to operate it without proper instructions.

Only trained and authorized persons should

operate this vehicle. Anyone who operates the

vehicle should have a motor vehicle license.

4

E. Wipe up any spilled gasoline.

14. The MULTI PRO

®

5500 is equipped with a

Neutral Lock-Out Switch. The purpose of this

switch is to insure that the vehicle will not start

unless the Traction Pedal is in the NEUTRAL

position. Should the vehicle start when the

Traction Pedal is not in the NEUTRAL position,

shut off the engine and refer to the Traction Drive

Maintenance instructions on pages 43 and 44.

SAFETY INSTRUCTIONS

WHILE OPERATING

WARNING: Do not run engine in a confined

area without adequate ventilation. Exhaust

fumes are hazardous and could possibly be

deadly.

15. Operator and passenger should remain

seated whenever the vehicle is in motion. Operator

should keep both hands on steering wheel

whenever possible, and passenger should use

hand holds provided. Keep arms and legs within

the vehicle body at all times. Remember your

passenger may not be expecting you to brake or

turn and may not be ready.

16. Sit on seat when starting and operating the

vehicle.

17. When starting the engine:

A. Engage the Parking Brake.

B. Make sure Traction Pedal is in

NEUTRAL. Move the Throttle Lever to 1/4

to 1/3 throttle.

whenever possible. Reduce speed when

making sharp turns or when turning on

hillsides.

D. If engine stalls or loses power and

cannot make it to the top of a slope, do not

turn vehicle around. Always back slowly

straight down the slope.

E. Use extra caution when operating

vehicle on wet surfaces, at higher speeds

or with a full load. Stopping time will

increase with a full load.

F. Operate vehicle with extra caution

when handling off-center loads that cannot

be centered.

G. Avoid sudden starts and stops. Do not

go from reverse to forward or forward to

reverse without first coming to a complete

stop.

H. Do not attempt sharp turns or abrupt

maneuvers or other unsafe driving actions

that may cause a loss of vehicle control.

C. After engine is started, release parking

brake and keep foot off traction pedal. The

vehicle must not move. If movement is

evident, the neutral return mechanism is

adjusted incorrectly. Shut engine off and

refer to the Traction Drive Maintenance

section on pages 43 and 44.

18. Operator and passenger must be skilled and

trained in how to drive on hillsides. Failure to use

caution on slopes or hills may cause loss of control

and vehicle to tip or roll, possibly resulting in

personal injury or death.

19. Using the vehicle demands attention. Failure

to operate vehicle safely may result in an accident,

tip over of vehicle and serious injury or death.

Drive carefully. To prevent tipping or loss of

control:

A. Use extreme caution, reduce speed

and maintain a safe distance around sand

traps, ditches, creeks, ramps, and any

unfamiliar areas, or other hazards.

B. Watch for holes or other hidden

hazards.

I. Before backing up, be sure no one is

behind the vehicle. Back up slowly.

J. Watch out for traffic when near or

crossing roads. Always yield the right of

way to pedestrians and other vehicles. This

vehicle is not designed for use on streets

or highways. Always signal your turns and

stop early enough to let other people know

what you plan to do. Obey all traffic rules

and regulations.

K. Never operate vehicle in or near an

area where dust or fumes which are

explosive, are in the air. The electrical and

exhaust systems of the vehicle can produce

sparks capable of igniting explosive

materials.

L. Watch out for and avoid low overhangs

such as tree limbs, door jambs, overhead

walkways, etc. Make sure there is enough

room overhead to easily clear the vehicle

and your head.

M. If ever unsure about safe operation,

STOP WORK and ask your supervisor.

C. Always reduce speed before starting

up or down a hill. Do not start or stop

suddenly when traveling uphill or downhill.

Use caution when operating vehicle on a

steep slope. Normally travel straight up and

down slopes. Avoid turning on hillsides

5

SAFETY AND INSTRUCTIONS

20. Do not touch Engine, Muffler, or Muffler Shield

while engine is running or soon after it has stopped

because these areas may be hot enough to cause

burns.

21. If the vehicle ever vibrates abnormally, stop

immediately, turn off engine, wait for all motion to

stop, and inspect for damage. Repair all damage

before commencing operation.

22. Before getting off the seat:

A. Remove foot from Traction Pedal,

stopping movement of the vehicle.

B. Set Parking Brake.

C. Shut engine off.

D. Remove Key from Ignition Switch.

E. Do not park on slopes unless wheels

are chocked or blocked.

MAINTENANCE

23. Before servicing, lubricating or making

adjustments to the vehicle, stop engine, set

Parking Brake and remove Key from Ignition

Switch to prevent accidental starting of the engine.

24. Make sure the vehicle is in safe operating

condition, keeping all nuts, bolts, and screws tight.

25. To reduce potential fire hazard, keep the

engine area free of excessive grease, grass,

leaves, and accumulation of dirt. Do not wash a

warm engine or electrical components.

26. Make sure all hydraulic line connectors are

tight, and all hydraulic hoses and lines are in good

condition before applying pressure to the system.

27. Keep body and hands away from pin hole

leaks in hydraulic lines that eject high pressure

hydraulic fluid. Use cardboard or paper to find

hydraulic leaks. Hydraulic fluid escaping under

pressure can penetrate skin and cause injury.

Fluid accidentally injected into the skin must be

surgically removed within a few hours by a doctor

familiar with this form of injury, or gangrene may

result.

28. Before disconnecting or performing any work

on the hydraulic system, all pressure in the system

must be relieved by stopping the engine.

29. If major repairs are ever needed or assistance

is required, contact an Authorized TORO

Distributor.

30. Disconnect battery before servicing the

vehicle. If battery voltage is required for

troubleshooting, temporarily connect the battery.

31. If the engine must be running to perform

maintenance, or an adjustment, keep hands, feet,

clothing, and any parts of the body away from the

engine and any moving parts. Keep everyone

away.

32. Do not over-speed engine by changing

Governor settings. Maximum engine speed is

3200 no-load rpm. To assure safety and accuracy,

have an Authorized TORO Distributor check

maximum engine speed with a tachometer.

33. Shut engine off before checking or adding oil

to the crankcase.

34. To assure optimum performance and

continued safety of the vehicle, always use

genuine TORO replacement parts and

accessories. Replacement parts and accessories

made by other manufacturers could be

dangerous. Altering this vehicle in any manner

may affect the vehicle's operation, performance,

durability, or its use may result in injury or death.

Such use could also void the product warranty of

the TORO Company.

35. This vehicle should not be modified without

The Toro Company's authorization. Direct any

inquiries to:

Hahn Equipment Co.

A subsidiary of The Toro Company

1625 N. Garvin Street

Evansville, IN 47711-4596

6

SPECIFICATIONS

Vehicle: Four-wheel step through, out front

operator style, two person vehicle.

Engine: Ford, 4 cycle, 4 cylinder, overhead valve,

liquid cooled gas engine with centrifugal water

pump. Ford rates engine at 45 HP. Mechanically

governed to a maximum speed of 3200

79 cu. in. (1300 cc) displacement. Distributorless

electronic ignition. 3.5 quart (3.25 liter) oil

capacity; replacement oil filter. Forged connecting

rods, cast iron cylinder head and block.

Mechanical fuel pump.

Air Cleaner: Heavy duty, 2 stage, remote

mounted.

Battery: 12 volt with 420 cold cranking amps at

0° F.

Cooling System: Mid mounted radiator with oil

cooler mounted in front of radiator. Cooling

system capacity is 12 quarts (11.5 liters) of 50/50

mixture of ethylene glycol anti-freeze.

Fuel System: Capacity is approximately 10.6

gallon (40 liters) of lead-free gasoline.

+ 100 rpm.

Controls: Foot operated traction pedal, brake,

brake lock pedals, and remote boom on/off switch.

Hand operated throttle, speed control, choke

control, ignition switch, light switch, pressure

increase/decrease, master boom on/off, hydraulic

spray pump, agitator, and individual boom on/off

switches.

Gauges: Sprayer pressure gauge, engine oil

pressure warning light, temperature gauge,

voltmeter, and hour meter.

Lights: Twin halogen headlights.

Ground Speed: Working 2 - 6 mph

Transporting 0 - 11.5 mph

Reverse 0 - 4 mph

Sprayer Tank: 300 gallon capacity.

Spray Pump: Closed impeller hydraulic driven

centrifugal. Adjustable hydraulic drive. 120 gpm

(454 lpm), 100 psi (690 kpa) maximums.

Boom Assembly: Three section, 18.5 foot (5.6

meter) working width.

Traction System: Servo-controlled hydrostatic

system driving double planetary gear reduction

rear wheel drives. Foot pedal control of forward/

reverse ground speed.

Frame: Welded, high strength steel tubing.

Front Suspension: Straight axle with twin

independent leaf springs, dual shock absorbers.

Rear Suspension: Rigid frame.

Tires: Front: 23 x 10.5 x 12, 4-ply rating, turf tread.

Rear: 26.5 x 14 x 12, 4-ply rating, turf tread.

Brakes: Individual totally enclosed, multi-disc, wet

brakes and parking brakes on rear traction wheels.

Hydrostatic braking through traction drive.

Steering: Full hydraulic power with dedicated

power source.

Seats: Twin molded cushions and back rests, with

hip restraints.

Electrical Features: 12 volt, 420 cold cranking

amperes at 0° F, maintenance free battery. 51 amp

alternator with I/C regulator. Automotive type

electrical system. Traction interlock switch.

Nozzles: Drift reduction, quick disconnect with

diaphragm check valves.

General Specifications (approx.):

Base Weight: Base unit 1,750 lbs.

With standard spray sys.

and operator: dry 2,540 lbs.

full 5,040 lbs.

Maximum Gross Vehicle Weight: 6,040 lbs.

Measurements with spray system:

Overall Width: 72"

Overall Length: 136"

Height: 57-1/2"

Ground Clearance: 6-1/2"

Wheel Base: 78"

7

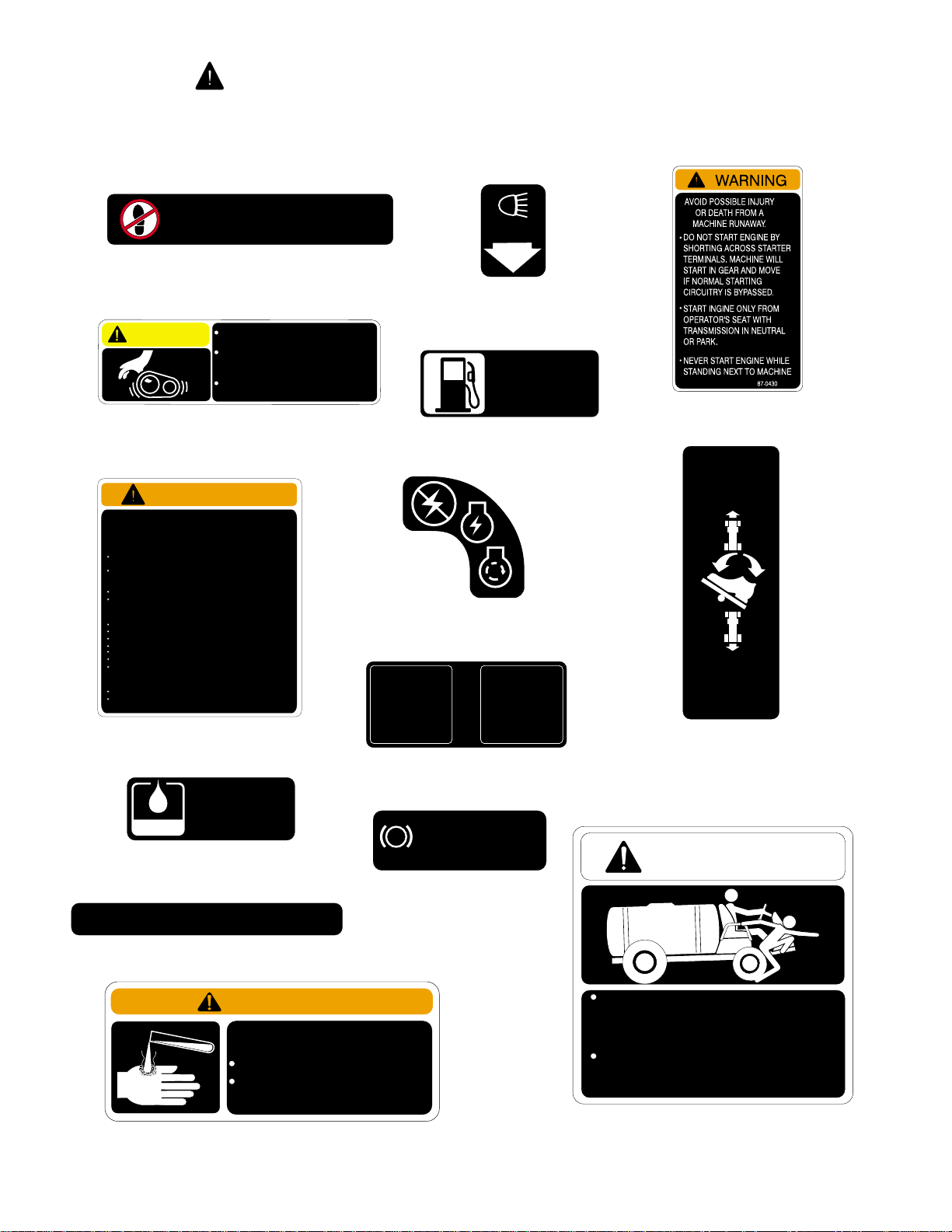

SAFETY AND INSTRUCTION DECALS

The following safety and instruction decals are installed on the vehicle. If any become damaged

or illegible, replace them. Decal part numbers are listed below and in the parts catalog. Order

replacements from your Authorized TORO Distributor.

94-7171

NO STEP

Part No. 36-3400: One Located on

right Front Fender, One on left Front

Fender.

CAUTION

Part No. 87-0450: Located on left side

WARNING

FAILURETO OBEY THE SAFETY WARNINGS MAY RESULT IN

INJURY TO YOU OR OTHERS.

THIS VEHICLE IS OF SUFFICIENT SIZE AND WEIGHT TO CAUSE

SERIOUS INJURY IN CASE OF UPSET OR COLLISION.

BEFORE OPERATING VEHICLE:

READ AND UNDERSTAND OPERATOR’S MANUAL LOCATED

BEHIND SEAT.

DO NOT EXCEED PAYLOAD CAPACITY OF VEHICLE AND/OR

TORO ACCESSORIES OR PERMIT PASSEGER ANY PLACE ON

VEHICLE EXCEPTSEAT.

USE HAND HOLDS WHERE APPLICABLE.

PLACE HEAVYLOADS FORWARD OF REAR AXLE.UNBALANCED

OR TOP HEAVYLOADS CAN CAUSE UPSET.

BEFORE OPERATING VEHICLE:

REMAIN SEATED AND USE BOTHHANDS FOR STEERING.

KEEP ARMS AND LEGS WITHIN VEHICLE BODY.

AVOID SUDDEN STARTS AND STOPS

SUDDEN SHARP TURNS CAN CAUSE UPSET.

REGULATE SPEED TO MEET ROAD AND WEATHER CONDITIONS.

DO NOT OPERATE IN OR NEAR AN EXPLOSIVE ENVIRONMENT.

IF A MALFUNCTION OCCURS, CEASE OPERATION. DO NOT

OPERATE VEHICLE UNTIL CONDITION IS CORRECTED.

BEFORE LEAVINGVEHICLE:

TURN IGNITION TO "OFF" POSITION, REMOVEKEY.

APPLY PARKING BRAKE; PARKING BRAKE IS NOT

AUTOMATICALLY APPLIED.

Part No. 87-0580: Located on Left

Front Fender.

Part No. 85-4730: Located on top of

Hydraulic Tank.

BOOM SECTION

BOOM 1 BOOM 2 BOOM 3

Part No. 94-7173: Located on Dash

Panel, above Indicator Lights.

TO AVOID PERSONAL INJURY KEEP

ALL SHIELDS IN PLACE.

DISENGAGE AND SHUT OFF

ENGINE BEFORE SERVICING OR

UNCLOGGING MACHINE.

KEEP HANDS, FEET AND CLOTHING

AWAY FROM POWER-DRIVEN PARTS.

of Center Console.

87-0580

HYDRAULIC

OIL ONLY

USE MOBIL 424

85-4730

94-7173

36-3400

87-0450

Part No. 71-3730: Located on

Part No. 87-0500: Located on Dash

Panel, above Key Switch.

MASTER

BOOM

ON/OFF

Part No. 94-7132: Located on Floor

Board, left of Brake Lock Pedal.

PARKING BRAKE

1. DEPRESS BRAKE PEDAL

P

2. DEPRESS PARKING

BRAKE LOCK

Part No. 94-7172: Located

on left side of Dash Panel,

under Steering Wheel.

LIGHTS

Part No. 94-7171:

Located on Dash Panel,

right of Light Switch.

GAS

ONLY

top of Gasoline Tank.

PARKING

BRAKE

94-7132

LOCK

94-7172

71-3730

Part No. 87-0430: Located behind Left

Front Fender.

TRACTION

PEDAL

FORWARD

92-0479

REVERSE

VEHICLE SPEED

INCREASES

WITH MORE PEDAL

PRESSURE

Part No. 92-0479: Located on

Floorboard, right of Traction Pedal.

WARNING

LEAVING SEAT WHILE VEHICLE IS

IN MOTION COULD RESULT IN SERIOUS

INJURY OR DEATH.

ALWAYS ALLOW VEHICLE TO COME

TO A COMPLETE STOP BEFORE

EXITING OR BOARDING VEHICLE.

Part No. 95-2136: Located on

the right end of the Dash.

95-2136

93-0688

WARNING

CHEMICALS CAN BE HAZARDOUS

TO REDUCE THE RISK OF ENVIRONMENTAL

DAMAGE AND PERSONAL INJURY

SELECT THE CORRECT CHEMICAL FOR THE

APPLICATION.

HANDLE AND APPLY CHEMICALS AS

INSTRUCTED BY THE CHEMICL

MANUFACTURER’S LABELS. ALWAYS

WEAR PROTECTIVE CLOTHING AND MASK.

Part No. 93-0688: Located on

Spray Tank Lid.

8

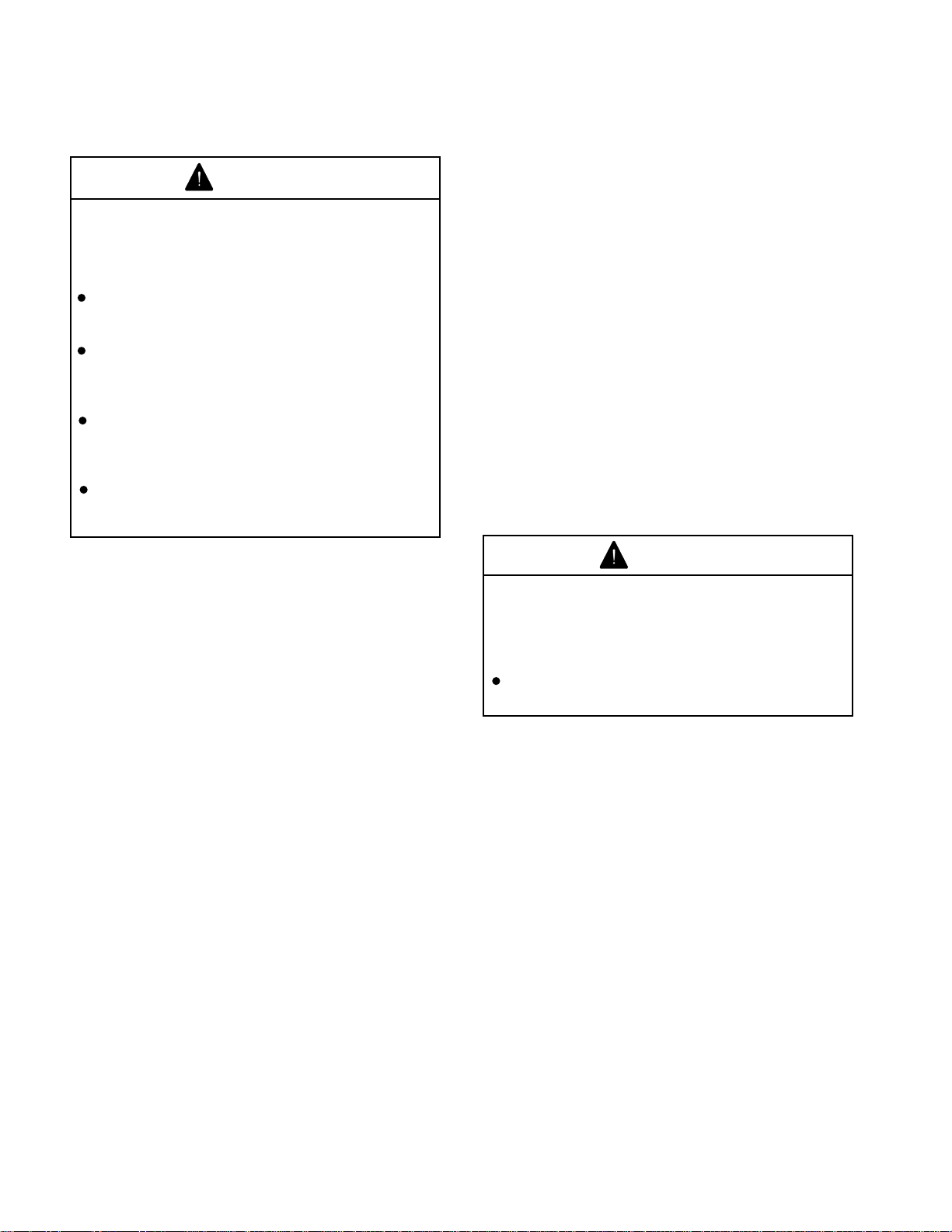

SAFETY AND INSTRUCTION DECALS

The following safety and instruction decals are installed on the vehicle. If any become damaged

or illegible, replace them. Decal part numbers are listed below and in the parts catalog. Order

replacements from your Authorized TORO Distributor.

Part No. 62-5550: Located on Front of

Front Console.

READ YOUR OPERATOR’S MANUAL FOR OPERATING AND

SAFETY INSTRUCTIONS. TO GET A REPLACEMENT MANUAL,

SEND MODEL AND SERIAL NUMBERS TO : THE TORO CO., 8111

LYNDALE AVE. S., MPLS., MN 55420

Part No. 65-3090: Located on left side

of Dash Panel.

SPEED CONTROL

WARNING

IMPROPER USE OF

SPEED CONTROL

COULD RESULT IN

PERSONAL INJURY.

SEE OPERATOR’S

MANUAL PRIOR TO

OPERATION.

ON

OFF

94-7175

VEHICLE LOAD AND TURF

CONDITIONS AFFECT BRAKE

PERFORMANCE. FAILURE TO

OPERATE VEHICLE PROPERLY

COULD RESULT IN PERSONAL

INJURY.

AVOID HIGH SPEEDS OR ABRUPT

STOPS ON SLOPES AND WET

TURF.

SEE OPERATOR’S MANUAL

FOR ADDITIONAL INFORMATION.

65-3090

WARNING

94-7176

ON

L

T

H

OFF

FOAM MARKER

R

O

T

T

L

E

ON

OFF

MASTER

BOOM

ON

OFF

BOOM 1 BOOM 2 BOOM 3

ON

DOWN DOWN

L

UP UP

BOOM LIFT

LOWER

RAISE

PRESSURE

(DUMP BED)

ON

OFF

PUMP

ON

OFF

ON

ON

R

OFF

R

AUTO

OFF

(SET)

MAN

SONIC

BOOM

ON

OFF

AGITATOR

ON

OFF

ON

SET

Part No. 94-7175: Located on Dash

Panel, right of Steering Wheel.

CAUTION

Part No. 42958: Located on

left radiator brace.

CAUTION

Part No. 87-0570: Located on Rear

Tank Band.

TO AVOID ELECTRIC SHOCK

AND PERSONAL INJURY TO

INSPECT AREA OVERHEAD FOR

WIRES BFORE RAISING BOOMS.

KEEP BYSTANDERS AWAY WHILE

RAISING AND LOWERING BOOMS.

Part No. 94-7176: Located

on Dash panel, under grab bar.

BYSTANDERS

87-0570

OFF

AGITATOR

CHEM 1

OFF

RINSE

PUMP

InJector Pro™

OFF

AGITATOR

CHEM 2

94-7134

Part No. 94-7134: Located on the Center

Console.

Part No. 94-7133: Located on

Front of Front Console.

9

SET-UP INSTRUCTIONS

BATTERY SERVICE:

CAUTION

Electrolyte gases are explosive and can

cause serious injury to eyes, lungs, and

skin. Nausea may result if the gases are

inhaled.

Wear safety goggles and rubber gloves

when working with electrolyte or battery.

Charge the Battery in a well ventilated

place so gases produced while charging

can dissipate.

Unplug charger from electrical outlet

before connecting to or disconnecting

charger leads from battery posts.

Since the gases are explosive, keep open

flames and electrical spark away from the

battery; DO NOT SMOKE!

The Battery has been filled with electrolyte and

charged at the factory. However, prior to actual

operation, it may be necessary to bring the Battery

to a full charge as follows:

1. First disconnect the black negative (-) cable,

then disconnect the red positive (+) cable.

2. Connect a 3 to 4 amp battery charger to the

Battery Posts. Charge the Battery at a rate of 3 to

4 amperes for 4 to 8 hours.

3. When Battery is charged, disconnect the

charger from electrical outlet and battery posts.

IMPORTANT! If optional electric powered

equipment is to be installed on the MULTI PRO

5500, DO NOT connect the battery cables until

all wiring harness connections for the optional

equipment have been completed. If

accidentally grounded, the lead to the battery

terminal will burn the accessory's wiring

harness. After the accessory's wiring harness

has been connected, proceed as follows:

4. Connect the red positive (+) cable to the

positive (+) post on the battery first, then connect

the black negative (-) cable to the negative (-)

post on the battery. Secure with cap screws and

nuts. Slide the rubber boot over the positive

terminal to prevent short-out from occurring.

WARNING

Connecting cables to the wrong post

could cause the battery to explode,

resulting in personal injury and damage

to the electrical system.

Make sure Battery Cables do not interfere

or rub on any moving or hot parts.

®

10

SET-UP INSTRUCTIONS

CAUTION

Chemicals are hazardous and can cause

personal injury!

Securely tighten all sprayer hose clamp

connections during initial set-up to

prevent leaks and hose blow-offs while

spraying system is in operation.

SPRAY SYSTEM:

NOTE: In the following instructions, "sealer"

refers to the Teflon Thread Tape.

1. Apply a heavy coating of grease to the tubes

of the two Boom Mount Assemblies and insert

them into the Vehicle Frame until Stop Pin bottoms

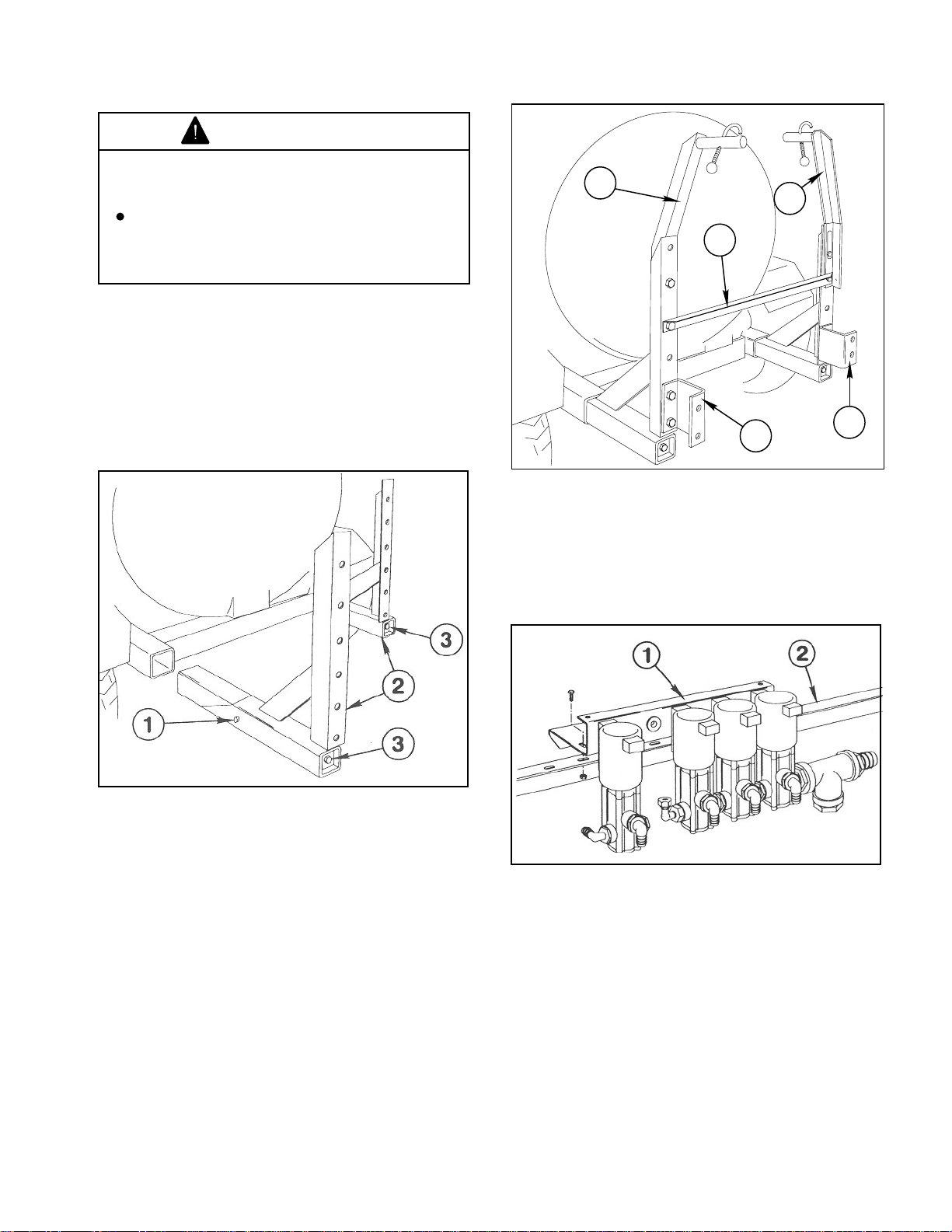

out against Vehicle Frame. (See FIG. 1.)

1

1

2

3

3

1140

Figure 2

1. Boom Hold-In Ass'y. 3. Boom Mounting

2. Angle Crossmember Bracket

1139-1

Figure 1

1. Stop Pin 3. 1/2" x 18" screws

2. Boom Mount Ass'y.

2. Using a torque wrench, tighten the 1/2" x 18"

screws that join the Wedges to the Boom Mounts.

Tighten to 50 ft. lbs.

NOTE: If installing the "Enclosed Boom" option

in place of the Standard Boom, DO NOT install

the (2) Boom Hold-In Assemblies in Step 3 or

the (2) Boom Mounting Brackets in Step 4.

.

3. Install the two (2) Boom Hold-In Assemblies

and the Angle Crossmember to the top of the

Boom Mount uprights as shown in FIG. 2, using

four (4) 1/2" x 1-1/4" cap screws, flat washers and

lock nuts.

5. Attach the Solenoid Assembly to the Angle

Crossmember with four (4) 5/16" hex head cap

screws and hex nuts. (See FIG. 3.)

1015

Figure 3

1. Solenoid Ass'y 2. Angle Crossmember

NOTE: If installing the "Enclosed Boom" option

in place of the Standard Boom, skip steps 6-19.

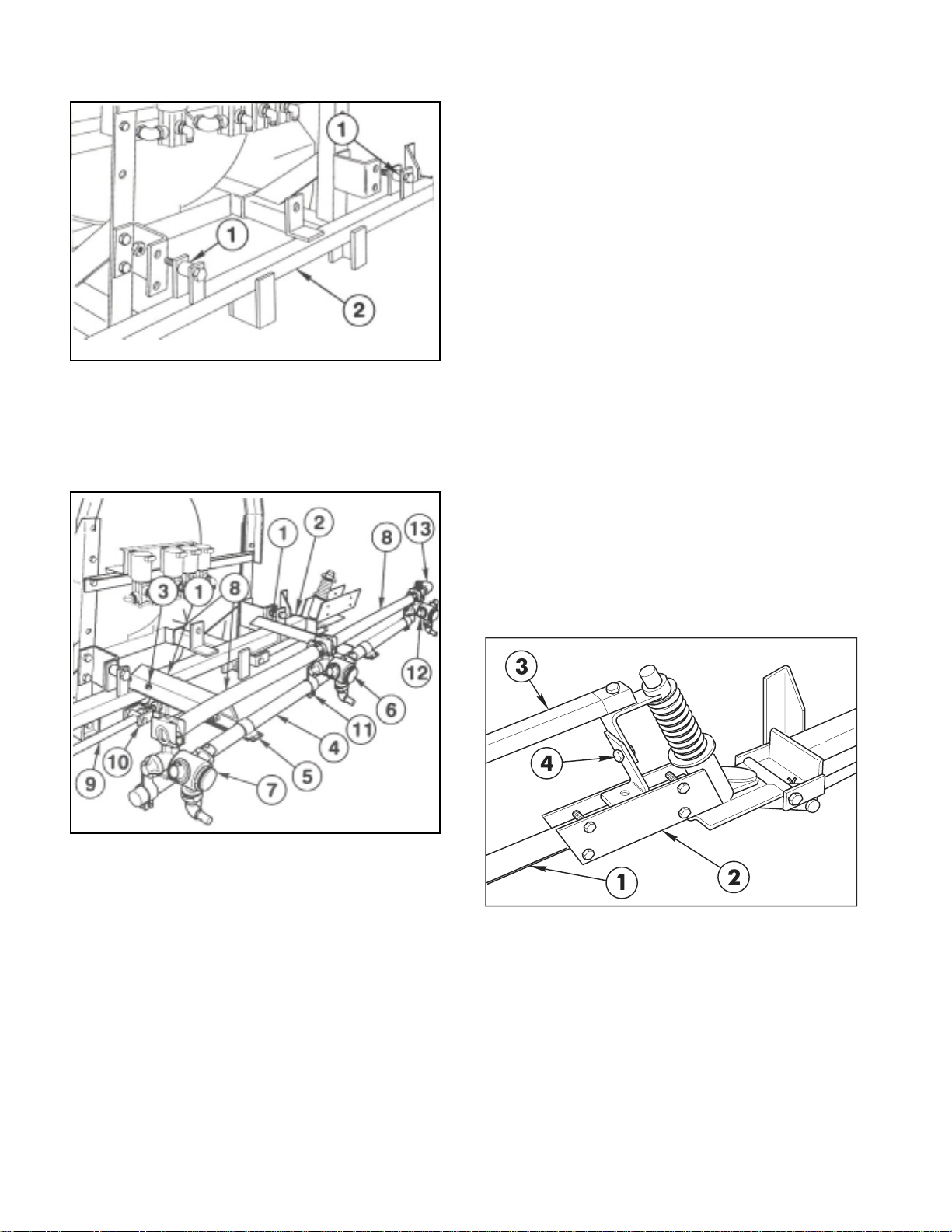

6. Position a Spacer Tube between the lugs on

each side of the Main Frame tube. Insert a 1/2" x

2-1/2" cap screw through the lugs and spacers.

Secure the Main Frame to the Boom Mounting

Brackets with lock nuts. (See FIG. 4.)

4. Attach the two "U"-shaped Boom Mounting

Brackets to the bottom of the Boom Mount

uprights with four (4) 1/2" x 1-1/4" cap screws, and

lock nuts. (See FIG. 2.)

11

SET-UP INSTRUCTIONS

1141

Figure 4

1. Spacer Tube 2. Main Frame

10. Loosely attach a Single Barb Turret Body with

the Turret Body Clamp to LH end of the Center

Boom Pipe. Loosely attach a threaded Turret Body

with the Turret Body Clamp to RH end of the Center

Boom Pipe.

11. Place two Hose Clamps on two 3/4" x 19"

Jumper Hoses and connect the two "end" Turret

Bodies to the Double Barb Turret Body. Space

nozzles 20" apart and tighten fasteners securely.

Apply thread sealer and install the 90° 3/4" Hose

Barb on the Threaded Turret Body. (See FIG. 5.)

12. Attach the two Strut Assemblies to the two

adjustable clevis' found on each side of the Main

Frame tube with two (2) 1/2" x 2" clevis pins and

two (2) 1/8" x 1" cotter pins. (See FIG. 5)

7. Position the two (2) Center Boom angles on

the Main Frame and secure them to the Main

Frame tube with two (2) square U-bolts, four (4)

flat washers and hex nuts. (See FIG. 5.)

1016

Figure 5

1. Center Boom Angle 8. Jumper Hose

2. Main Frame 9. Strut Assembly

3. U-bolt 10. Adjustable Clevis

4. Center Boom Pipe 11. Turret Body Clamp

5. Boom Clamp 12. Threaded Barb Turret

6. Double Barb Turret 13. 90° Hose Barb

7. Single Barb Turret

8. Center and attach the Center Boom Pipe to

the two Center Boom Angles with two (2) clamps,

(2) 3/8" x 1" cap screws, flat washers and lock nuts.

Once mounted the Center Boom Pipe should be

approx. 20" from ground.

9. Loosely attach the Double Barb Turret Body

with the Turret Body Clamp in the approximate

center of the Center Boom Pipe. For the most

uniform spray coverage, position all Nozzles level

as shown in FIG. 5.

NOTE: If the optional "Foam Marker Kit" is to

be installed, refer to the instructions furnished

with that kit before proceeding to step 13.

IMPORTANT! DO NOT over-tighten the nuts in

steps 13 and 15. The clamping action could

crush the Boom Pipe.

13. Insert the plugged end of an Extension Boom

Pipe into the Pivot Assembly and secure with four

(4) 1/4" x 1-1/4" cap screws and lock nuts. (See

FIG. 6) Repeat on the opposite side to assemble

the other Extension Boom.

Figure 6

1. Extension Boom Pipe 3. Boom Support

2. Pivot Assembly Assembly

4. Height Adjustment

14. Attach the LH Boom Support Assembly to the

Pivot Assembly, using a 5/16" x 1-1/2" cap screw

and lock nut. (See FIG. 6 & 7.)

15. Secure the two plates of the Boom Support

Assembly to the Extension Boom Pipe, using two

(2) 1/4" U-bolts, four (4) lock nuts and flat washers.

(See FIG. 7.)

12

SET-UP INSTRUCTIONS

2

1

TO CONTROL

VALVE

WHITE

WHITE

BROWN

BLUE

BLACK

1017

Figure 7

1. Boom Support Ass'y 5. Single Barb Turret

2. Extension Boom Pipe 6. Jumper Hose 3/4 x 19"

3. U-bolt 7. Boom Cap

4. Double Barb Turret 8. Jumper Hose 3/4 x 21"

16. Assemble the RH Boom Support Assembly to

the other Extension Boom Pipe.

17. Adjust the Booms to a level position by

adjusting the jam nuts on the adjustable clevis

assemblies (See FIG. 5) to the desired position,

then tighten the end nuts against the Main Frame

plate.

18. Attach three Double Barb Turret Bodies and

one Single Barb Turret Body with Clamp

Assemblies on each Extension Boom Pipe as

shown in FIG. 7.

19. Level Nozzles and space 20" apart. Connect

the Turret Body Assemblies with 3/4" x 19" Jumper

Hoses and a 3/4" x 21" Jumper Hose. Secure with

hose clamps. (See FIG. 7.)

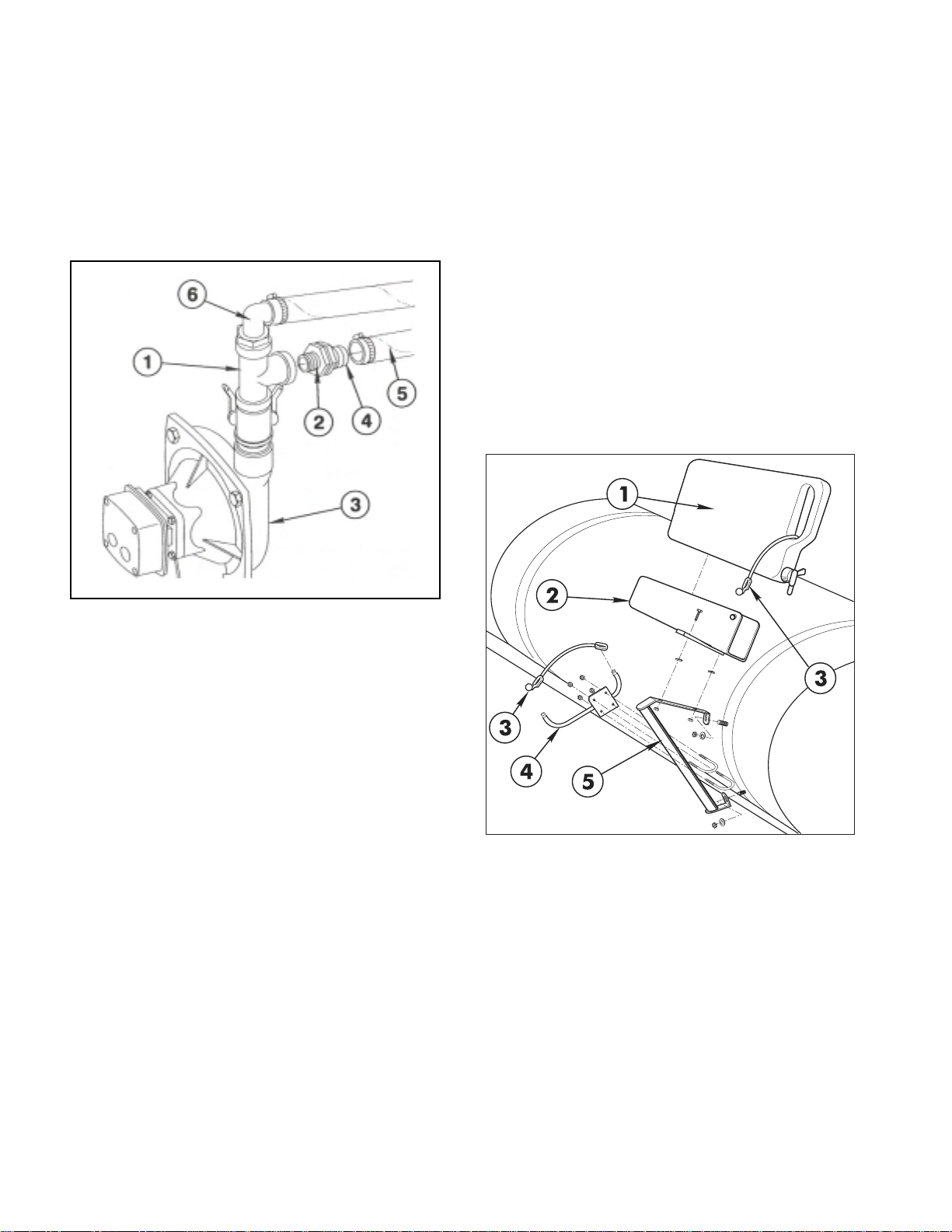

20. Apply thread sealer and install a 90° hose barb

into the top of the Tee at the pump for Boom supply.

Attach one end of the 1-1/4" x 52" Supply Hose to

the 90° hose barb, and secure with a hose clamp.

(See FIG. 10)

21. Attach the other end of the Supply Hose to the

hose barb in Tee at the Solenoid Assembly. Secure

with two hose clamps, one clamp at 1/4" and the

other clamp at 1-1/4" from the hose barb hex. (See

FIG. 8 & 9)

22. Secure the Supply Hose to the Solenoid

Assembly using a large "R" clamp. (See FIG. 8)

Figure 8

1. Supply Hose 4. Small "R" Clamp

2. Large "R" Clamp 5. Solenoid Valve Shield

3. Wiring Harness 6. Hyd. Control Valve Plug

24. Connect the plug on the wiring harness to the

mating plug from the Hydraulic Control Valve. Then

make connections to the four solenoid valves as

shown in FIG. 8 & 9.

Figure 9

1. 90° Hose Barb 3. Supply Hose

2. Gauge Tube

25. Install Gauge Tube into the 90° street elbow at

through port of Solenoid Assembly and secure

with Compression Adapter. (See FIG. 9)

26. Install Solenoid Valve Shield to top of Solenoid

Mounting Bracket using two (2) 1/4 x 3/8" flange

screws. (See FIG. 8)

23. Route wiring harness across rear of vehicle and

secure to Solenoid Assembly with a small

"R" clamp. (See FIG. 8)

13

SET-UP INSTRUCTIONS

27. Apply thread sealer and install Reducing

Bushing into side of Tee on top of Pump. Install 1"

MPT x 3/4" hose barb into Reducing Bushing, and

attach one end of the Agitator Solenoid Feed

Hose. (See FIG. 10) Secure with a hose clamp.

Attach other end of hose to the 90° hose barb at

the side of the Agitator Solenoid. (See FIG. 9)

Secure with a hose clamp.

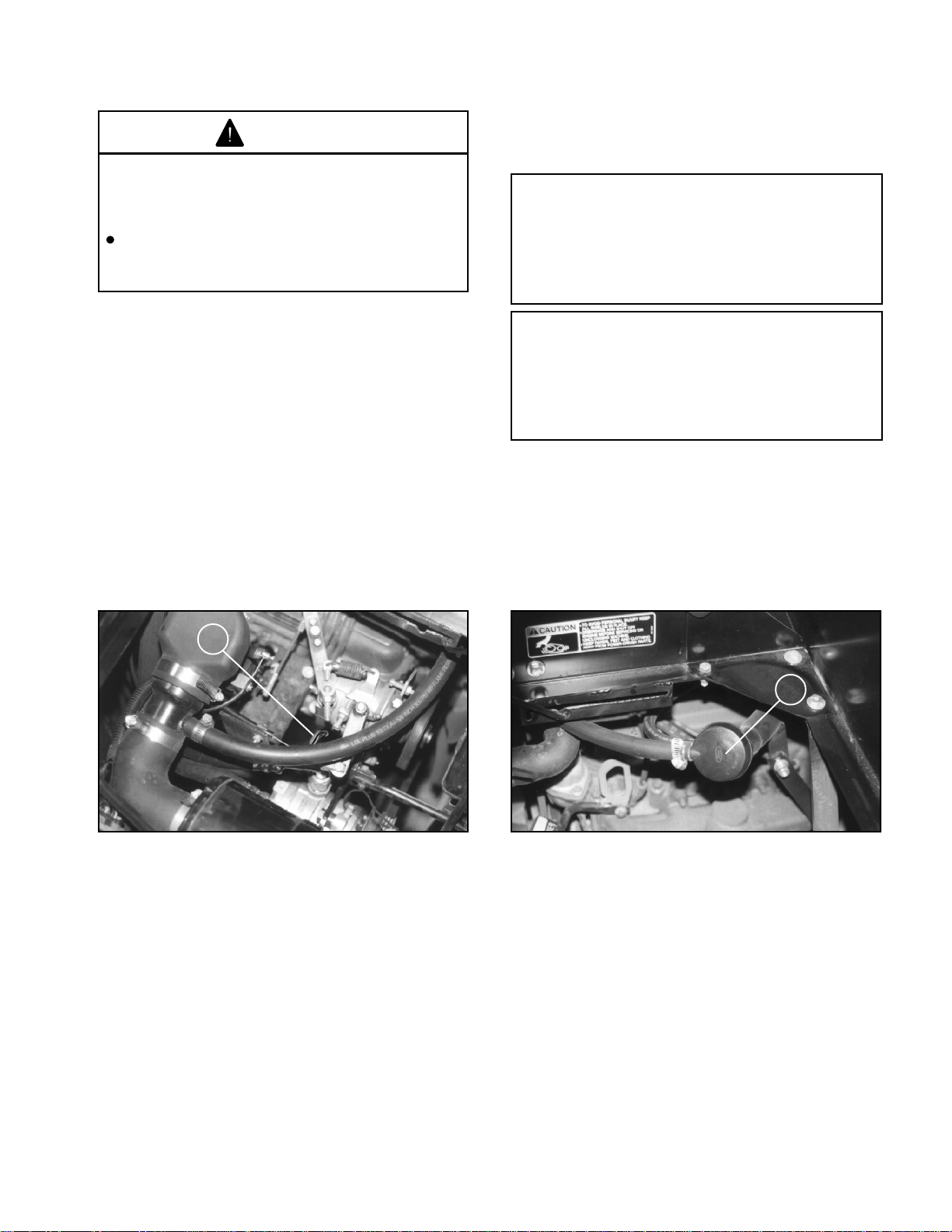

FRESH WATER TANK (Fig. 11)

1. Mount Brace assembly to the two (2) 5/16"

carriage bolts in the right side front Tank Band

using two (2) 5/16" flat washers and hex nuts.

Tighten securely.

NOTE: Left hold-in assembly and hardware will

not be used.

2. Mount Wash Tank Bracket (open end forward)

to right-hand Hold-In Brace assembly using two

(2) 5/16" x 1" hex hd. cap screws, flat washers,

and hex nuts. Place Clean Water Wash Tank into

Wash Tank Bracket and secure with Rubber HoldDown, as shown in FIG. 11.

NOTE: Tighten all fasteners and hose clamps

securely before using the spray system.

1142

Figure 10

1. Tee 4. Hose Barb

2. Reducing Bushing 5. Agitator Feed Hose

3. Pump 6. 90° Hose Barb

NOTE: If installing the "Enclosed Boom" option

in place of the Standard Boom, skip Steps 2830 and refer to the instructions furnished with

that kit before continuing with Step 31.

28. Attach the Boom Feeder Hoses to the barbs

in the Solenoids with hose clamps.

29. Place a hose clamp on the center Boom

Feeder Hose and attach it to the 90° Hose Barb at

the RH end of Center Boom Pipe.

30. Place a hose clamp on the right and left Boom

Feeder Hoses and attach them to the double barb

nozzles on the right and left Boom Pipes.

31. Install the "Anti-Siphon Kit". Instructions and

parts are included with your MULTI PRO

®

5500

Turf Sprayer.

Figure 11

1. Clean Water Wash Tank 4. Boom Hold-In Ass'y

2. Wash Tank Bracket 5. Hold-In Brace Ass'y

3. Rubber Hold-Down

NOTE: If installing the optional "Foam Marker

Kit", refer to the instructions furnished with

that kit for remaining set-up procedures.

14

BEFORE OPERATING

CAUTION

Servicing the vehicle while the engine is

running or vehicle is not properly secured

could result in personal injury or death.

Before servicing or making adjustments

to the vehicle, stop engine, set parking

brake, and remove key from the switch.

IMPORTANT! Check level of oil BEFORE EACH

USE, while engine is cool so the oil has had

some time to drain into the sump.

SINGLE VISCOSITY OILS

Outside Temperature

- 10°F to +60°F SAE 10W

+10°F to +90°F SAE 20W-20

Above +32°F SAE 30

Above +50°F SAE 40

CHECK ENGINE OIL (Fig. 12 a, b)

The engine is shipped with approximately 3.5

quarts (3.25 liter) of oil in the crankcase; however,

level of oil must be checked before and after

the engine is first started.

1. Position vehicle on a level surface. Tilt right

seat forward to gain access to the engine

compartment.

2. Remove dipstick from oil tube, wipe clean,

and reinstall into the tube. Pull it out again and

check oil level on dipstick. Oil level must be

maintained between the minimum and maximum

marks on the dipstick.

MULTI-VISCOSITY OILS

Outside Temperature

Below +60°F SAE 5W-30

- 10°F to +90°F SAE 10W-20

Above -10°F SAE 10W-40 or 10W50

Above +50°F SAE 20W-40 or 20W50

Change oil and filter after the first 50 hours of

operation. Thereafter, change oil and filter after

every 100 hours of operation. Change oil more

frequently when engine is operated in extremely

dusty or dirty conditions. See page 32.

Figure 12 a

1. Oil Dipstick

3. If oil level is low, tilt drivers side seat forward,

remove oil fill cap, and add Ford or Motorcraft oil

or equivalent that meets Ford Specification ESEM2C153-E and API categories SG, SG/CC or

SG/CD until level is between the "MIN" and "MAX"

marks on the dipstick. DO NOT OVERFILL. See

viscosity chart for recommended weight to use.

4. Install the dipstick firmly in place.

5. Install oil fill cap.

6. Close access door and secure handle.

7. Lower seat to original seating position.

Figure 12 b

1. Filler Cap

15

BEFORE OPERATING

CAUTION

If engine has been running, pressurized

hot coolant can escape and cause burns

if cap is removed.

Before removing cap, allow engine to

cool for at least 15 minutes or until the

cap is not hot to the touch.

CHECK COOLING SYSTEM (Fig. 13)

Capacity of system is 12 quarts (11.5 liters). The

cooling system is filled with a 50/50 solution of

water and permanent ethylene glycol anti-freeze.

Check level of coolant at beginning of each day

before starting the engine.

1. Park machine on level surface and fold seats

forward.

1143

Figure 13

1. Coolant level 2. Radiator cap.

(3/4 to 1-1/2 inches

below cap seal.)

2. When engine is cool remove radiator cap

and check coolant level. Coolant level should be

approximately 3/4 to 1-1/2 inches below the filler

neck seat when the coolant is cold.

3. If coolant is low, add a 50/50 mixture of water

and antifreeze. DO NOT USE WATER ONLY OR

ALCOHOL/METHANOL BASE COOLANTS.

4. Replace radiator cap securely.

16

BEFORE OPERATING

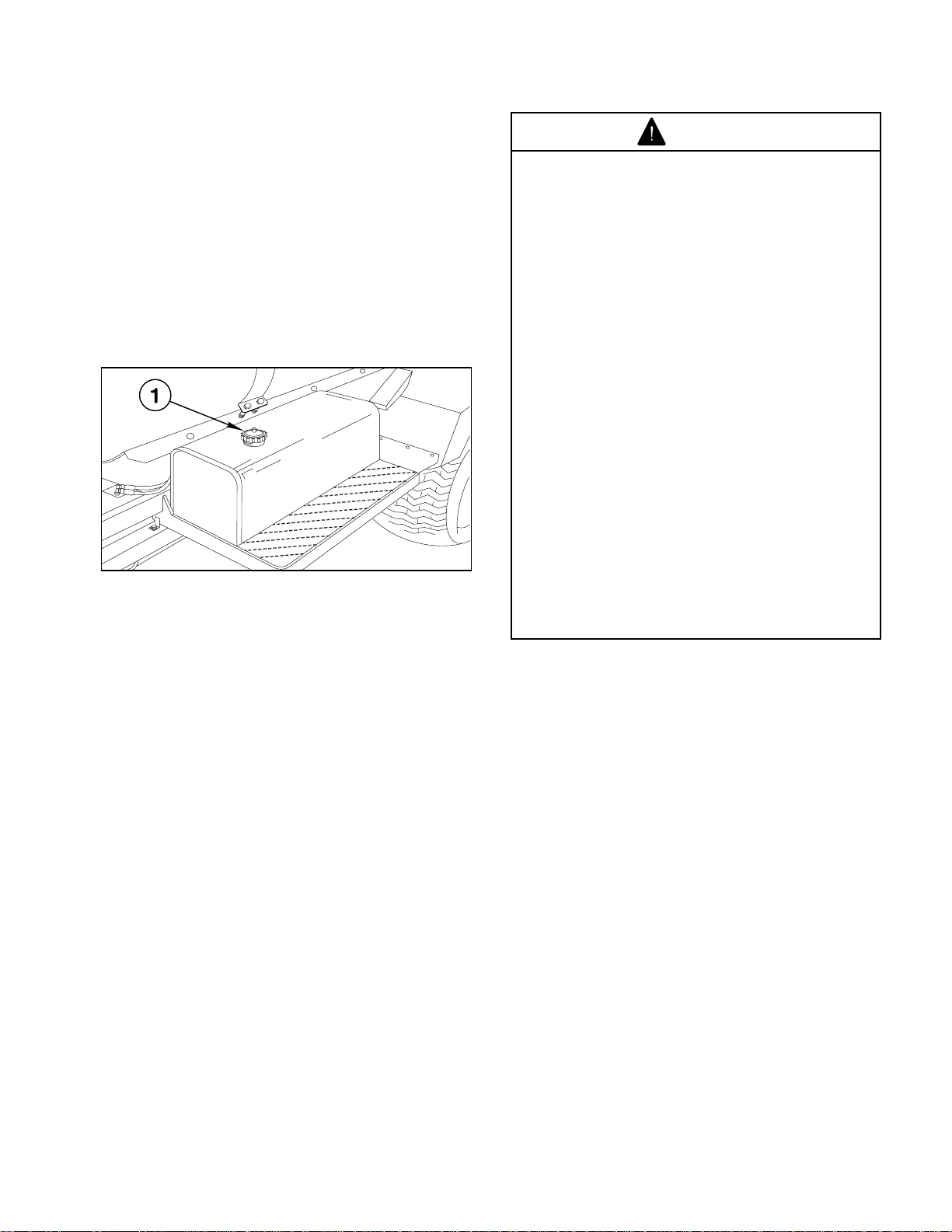

FILL FUEL TANK (Fig. 14)

Fuel tank capacity is 10.6 gallons (40 liters).

THE TORO COMPANY STRONGLY

RECOMMENDS THE USE OF FRESH, CLEAN

UNLEADED REGULAR GRADE GASOLINE IN

TORO GASOLINE POWERED PRODUCTS.

UNLEADED GASOLINE BURNS CLEANER,

EXTENDS ENGINE LIFE, AND PROMOTES

GOOD STARTING BY REDUCING THE BUILDUP

OF COMBUSTION CHAMBER DEPOSITS.

MINIMUM OCTANE RATING OF 87.

1144

Figure 14

1. Fuel tank cap.

DANGER

Because gasoline is flammable, caution

must be used when storing or handling

it. Do not fill fuel tank while engine is

running, hot, or when vehicle is in an

enclosed area. Vapors may build up and

be ignited by a spark or flame source

many feet away. DO NOT SMOKE while

filling the fuel tank to prevent the

possibility of an explosion. Always fill fuel

tank outside and wipe up any spilled

gasoline before starting the engine. Use

a funnel or spout to prevent spilling

gasoline, and fill tank no higher than one

inch below top of tank, (bottom of filler

neck). DO NOT OVER FILL. Store

gasoline in a clean safety approved

container and keep the cap on the

container. Keep gasoline in a cool, well

ventilated place; never in an enclosed

area such as a hot storage shed. To

assure volatility, do not buy more than a

30 day supply of gasoline. Gasoline is a

fuel for internal combustion engines;

therefore do not use it for any other

purpose. Since many children like the

smell of gas, keep it out of their reach

because the fumes are explosive and

dangerous to inhale.

IMPORTANT! NEVER USE METHANOL,

GASOLINE CONTAINING METHANOL,

GASOLINE CONTAINING MORE THAN 10%

ETHANOL, GASOLINE ADDITIVES, OR WHITE

GAS. ENGINE FUEL SYSTEM DAMAGE COULD

RESULT.

1. Clean area around fuel tank cap.

2. Remove fuel tank cap.

3. Fill tank to about one inch below top of tank

(bottom of filler neck). DO NOT OVERFILL. Then

install cap.

4. Wipe up any fuel that may have spilled to

prevent a fire hazard.

FUEL GAUGE: The Fuel Tank Cap shows amount

of fuel in tank.

17

BEFORE OPERATING

1145

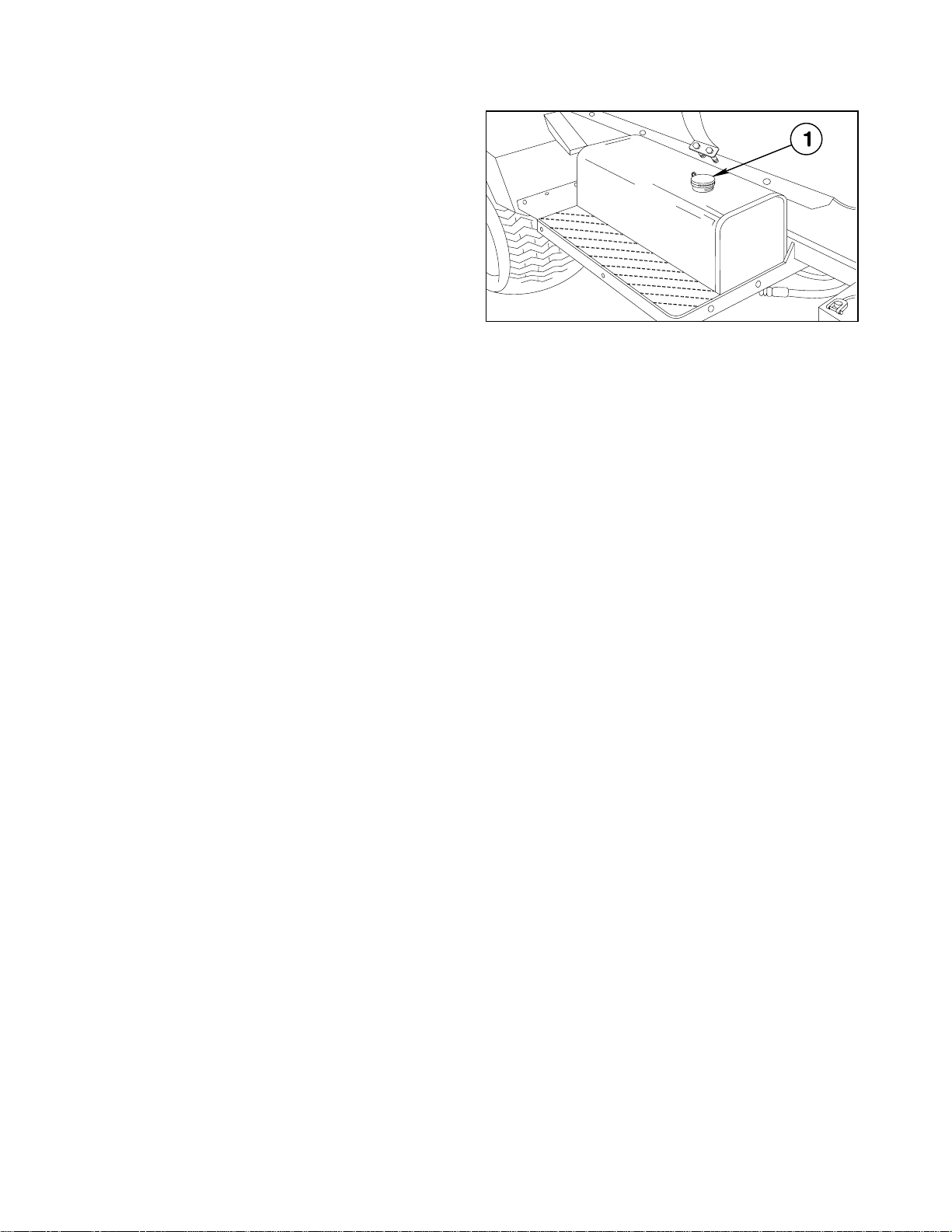

CHECK HYDRAULIC FLUID (Fig. 15)

IMPORTANT! ALWAYS USE EXTREME

CAUTION WHEN FILLING THE RESERVOIR OR

CHECKING THE LEVEL OF THE HYDRAULIC

FLUID. KEEP THE SYSTEM FREE OF

CONTAMINANTS.

1. Position vehicle on a level surface, set parking

brake, and stop the engine

2. Clean area around filler neck and cap of

hydraulic tank. Remove cap from filler neck.

Figure 15

3. If level is low, add appropriate fluid to raise

level to two inches from top of the tank (bottom of

strainer) DO NOT OVERFILL.

4. Install cap onto filler neck.

5. Start engine.

6. Turn the steering wheel completely to the left,

then completely to the right.

7. Turn off the engine and recheck level of

hydraulic fluid. Replenish as required.

1. Hydraulic fluid tank cap.

The vehicle's reservoir is filled at the factory with

approximately 12 gallons (45.42 liters) of Mobil

424 hydraulic fluid. Check level of hydraulic fluid

before engine is first started and daily

thereafter.

18

BEFORE OPERATING

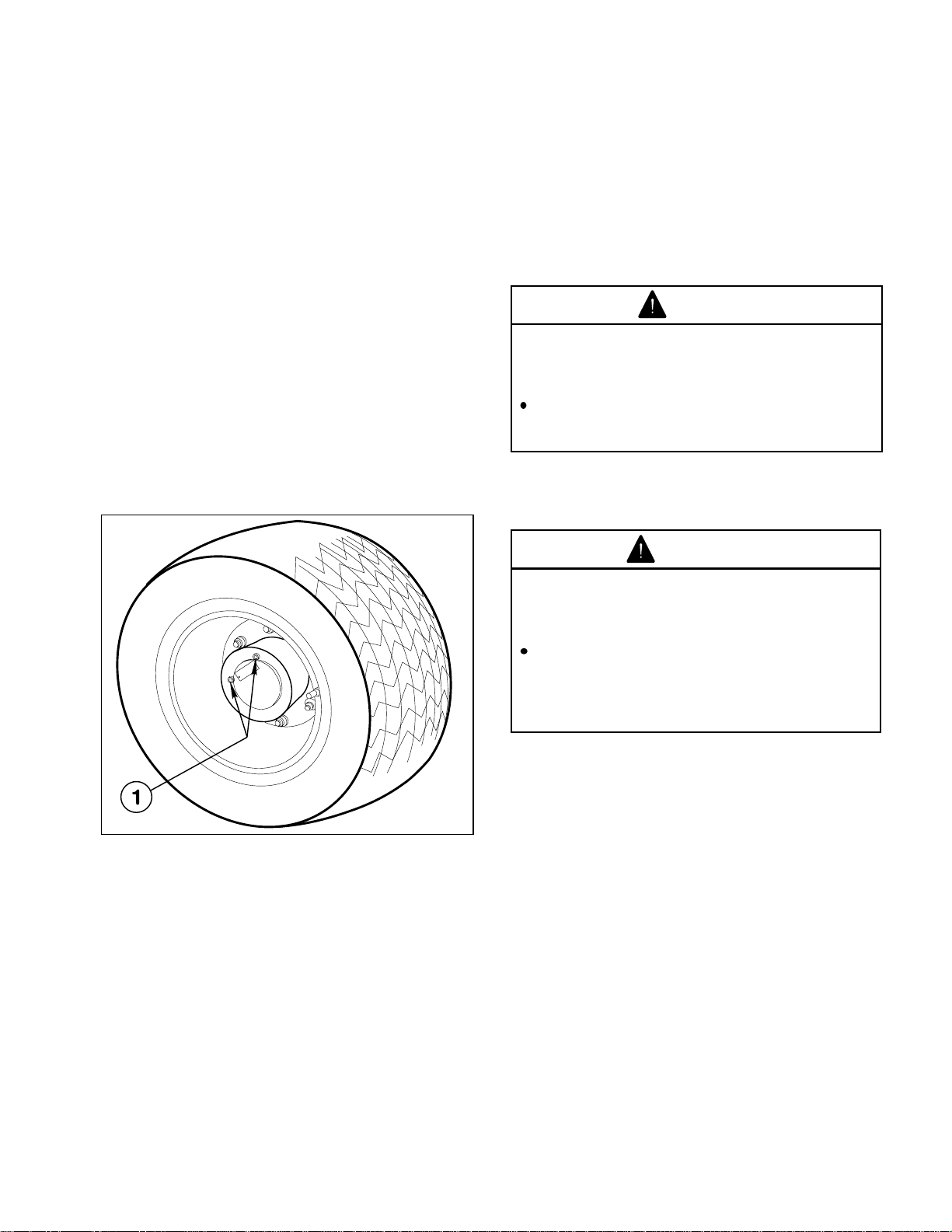

CHECK PLANETARY GEAR OIL

(Fig. 16)

Check oil if external leakage is noted. Use high

quality SAE 85W-140 wt. gear lube replacement.

Capacity of system is 16 oz.

1. With machine on level surface, position wheel

so check/drain plugs are at the 9 and 12 o'clock

position.

2. Remove the 9 o'clock positioned plug. Oil

should be to bottom of the hole.

3. If necessary add gear oil to the 12 o'clock hole

until oil begins to flow from the 9 o'clock hole.

4. Wipe surface clean and reinstall plugs.

5. Repeat steps 1 through 4 on opposite gear

assembly.

CHECK EMERGENCY/PARK BRAKE

Adjust the Emergency/Park Brake when there is

more than 1 inch of "free travel" of the Brake Pedal,

or if the Brake does not work effectively. "Free

travel" is the distance the Brake Pedal moves

before braking resistance is felt. To reduce "free

travel" of brake pedal see the MAINTENANCE

section on "ADJUSTING BRAKES".

DANGER

Operating the vehicle with worn or poorly

adjusted brakes can result in serious

injury or death.

If Brake Pedal travels to within 1 inch of

the Vehicle floor board, the brakes must

be adjusted or repaired.

CHECK TORQUE OF WHEEL NUTS

WARNING

1146

Figure 16

1. Check/Drain Plugs

Failure to maintain proper torque could

result in failure or loss of wheel and may

result in personal injury.

Torque front wheel nuts to 55-65 ft-lb (7588N-m) and rear wheel nuts or bolts to

85-100 ft-lb (116-136 N-m) after 1-4 hours

of operation and every 200 hours

thereafter.

IMPORTANT! After the "initial run-in"

(approximately one to two hours) check all the

MULTI PRO

tightness.

®

5500 wheel fasteners for

CHECK TIRE PRESSURE

Check tire pressure every 8 hours or daily to assure

proper levels. Maximum air pressure in both front

and rear tires is 18 p.s.i.

The air pressure needed is determined by the

payload carried. Once the desired pressure has

been ascertained, it is to be used and maintained

to insure the accuracy of the spraying system.

INSPECT TIRES

Check tire condition for wear or damage.

Operating accidents, such as hitting curbs, can

damage a tire or rim and also disrupt wheel

alignment, so inspect tire condition after any

accident.

19

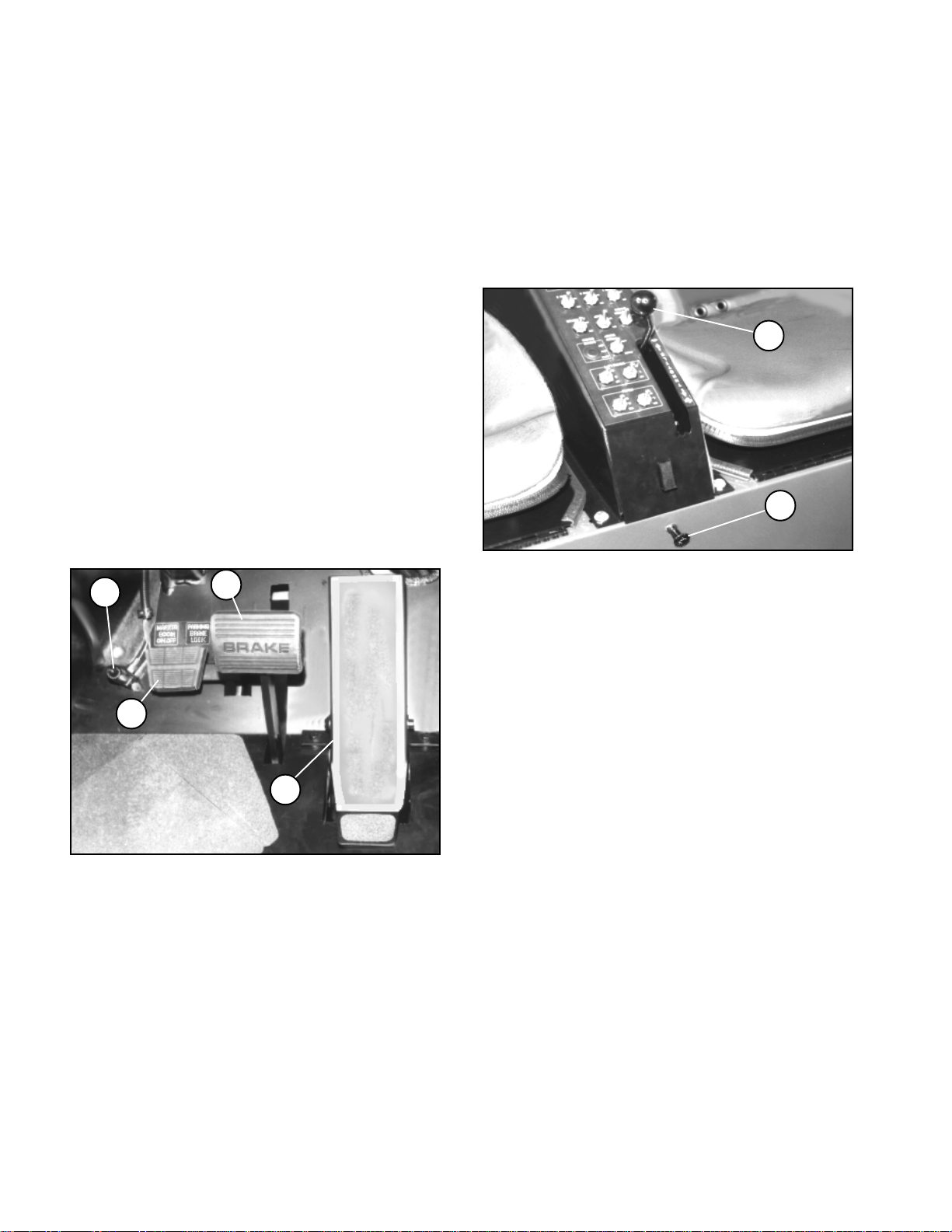

VEHICLE CONTROLS

Familiarize yourself with the controls and

recommended operating procedures before

operating the MULTI PRO

TRACTION PEDAL: (Fig. 17) Controls forward

and reverse operation. Depress top of pedal to

move forward and bottom of pedal to move

backward. Ground speed depends on how far

pedal is depressed. For maximum ground speed,

fully depress pedal while throttle is in FAST.

To stop, reduce foot pressure on traction pedal

and allow it to return to center position.

EMERGENCY/PARKING BRAKE PEDAL:

(Fig. 17) Functions as a parking brake and an

emergency brake in situations demanding an

immediate stop.

BRAKE LOCK: (Fig. 17) The small pedal to the

left side of the brake pedal actuates the parking

brake lock. To engage parking brake, fully depress

brake pedal and depress brake lock which locks

brake pedal. To release parking brake, fully

depress brake pedal to release brake lock.

"

®

5500.

THROTTLE CONTROL: (Fig. 18) Move control

forward, toward "FAST", to increase engine speed,

rearward, toward "SLOW", to decrease engine

speed. Set at 1/4 to 1/3 throttle when starting

engine.

MANUAL CHOKE: (Fig. 18) Pull OUT when

starting cold engine, gradually push IN after

successfully starting engine.

Figure 18

1. Throttle control 2. Manual Choke

!

Figure 17

1. Traction Pedal 3. Brake Lock

2. Brake Pedal 4. Remote Master Switch

REMOTE BOOM ON/OFF SWITCH: (Fig. 17) Is

in series with the MASTER BOOM ON/OFF switch;

The operator must first turn on the Master Boom

ON/OFF switch on the center console; then click

on the Remote Boom ON/OFF Switch on the floor

board.

20

Loading...

Loading...