Toro 41440, 41441, 41442, 41443 Operator Instructions Manual

FORM NO. 95-9093

Model No. 41443-80001 & UP

Model No. 41442-80001 & UP

Model No. 41441-80001 & UP

Model No. 41440-80001 & UP

OPERATORS

INSTRUCTIONS

SKID SPRAYER

CONTENTS

GENERAL .............................................................................. 2 - 9

SAFETY INSTRUCTIONS ............................................................................................ 2 - 3

PRODUCT IDENTIFICATION ........................................................................................... 4

DECALS ............................................................................................................................ 5

BEFORE SPRAYING ......................................................................................................... 6

NOZZLE SELECTION CHARTS ................................................................................... 7 - 8

STORAGE.......................................................................................................................... 9

ENGINE.............................................................................. 10 - 13

BEFORE OPERATING .................................................................................................... 10

OPERATING INSTRUCTIONS ........................................................................................ 11

MAINTENANCE ....................................................................................................... 12 - 13

STORAGE........................................................................................................................ 13

41441 CENTRIFUGAL PUMP ............................................ 14 - 19

CONTROLS ..................................................................................................................... 14

BEFORE SPRAYING ....................................................................................................... 15

OPERATION .................................................................................................................... 16

PREVENTIVE MAINTENANCE ....................................................................................... 17

MAINTENANCE ....................................................................................................... 18 - 19

41443 DIAPHRAGM PUMP ............................................... 20 - 24

SAFETY INSTRUCTIONS ............................................................................................... 20

CONTROLS ..................................................................................................................... 21

BEFORE SPRAYING ................................................................................................ 22 - 23

AFTER SPRAYING .......................................................................................................... 23

MAINTENANCE .............................................................................................................. 24

41442 PTO CENTRIFUGAL PUMP........................................... 25

CONTROLS ..................................................................................................................... 25

BEFORE SPRAYING ....................................................................................................... 26

PREVENTIVE MAINTENANCE ....................................................................................... 27

MAINTENANCE ....................................................................................................... 28 - 29

©The TORO Company - 1998

All Rights Reserved

To assure maximum safety, optimum

performance, and to gain knowledge of the

product, it is essential that you or any other

operator of this Vehicle read and understand

the contents of this manual before the engine

is ever started. Pay particular attention to the

SAFETY INSTRUCTIONS highlighted by the

triangular safety alert symbol.

personal safety instruction. Failure to comply

with the instruction may result in personal

injury.

The safety alert symbol means

CAUTION, WARNING or DANGER -

SAFETY INSTRUCTIONS

Keep this Operators Manual and the Engine Manual in the plastic tube on the side of the Tank Frame.

It is very important that all persons operating this equipment have easy access to these instructions at all

times!

Carefully read and follow the set-up instructions that are provided with this equipment . The installation

of accessories on the TORO Skid Frame, other than those designated and sold for that express purpose

by TORO, may adversely affect the performance and safety characteristics of this equipment.

RECOGNIZE SAFETY INFORMATION

This safety-alert symbol is used to call

attention to a dangerous situation, which

could result in serious injury or death to the

operator or a bystander.

Safety, mechanical and some general information

in this manual are emphasized. DANGER,

WARNING and CAUTION identify safety

messages. Whenever the triangular safety symbol

appears, it is followed by a safety message that

must be read and understood. For more details

concerning safety, read the Safety Instructions on

this page and page 2. IMPORTANT identifies

special mechanical information and NOTE

identifies general information worthy of special

attention.

These instructions are provided as a guide for the

safe operation and maintenance of this equipment.

However, the operators personal safety, as well

as those persons in the work area, will depend on

the careful actions and good judgement of the

operator. To reduce the potential for injury or

death, comply with the following safety

instructions.

BEFORE OPERATING:

1. Operate this machine only after reading and

understanding the contents of this manual. A

replacement manual is available by sending

complete model and serial number to: Hahn

Equipment Co., a subsidiary of The Toro Company,

1625 N. Garvin, Evansville, IN 47711.

2. Learn how to operate the Sprayer and how to

use the controls properly. DO NOT let anyone

operate this equipment without first receiving

thorough instructions.

2

3. Keep all shields, safety devices and decals in

place. If a shield, safety device or decal is

malfunctioning, illegible or damaged, repair or

replace it before operating the machine.

4. Chemicals can injure persons, animals, plants,

soils or other property. To eliminate environmental

damage and personal injury:

A. Obtain proper training before using or

handling chemicals.

B. Select the proper chemical for the job.

C. Follow manufacturers instructions on

chemical container labels. Apply and handle

chemicals as recommended.

D. Handle and apply chemicals with care.

Wear goggles and other necessary protective

equipment. Handle chemicals in well

ventilated areas. Never smoke while handling

chemicals.

E. Properly dispose of chemical container and

unused chemicals.

4. To be sure of optimum performance and safety,

always purchase genuine TORO replacement

parts and accessories. Replacement parts and

accessories made by other manufacturers could

be dangerous. Altering the Skid Sprayer in any

manner may affect the Skid Sprayer's operation,

performance, durability or its use may result in

injury or death. Such use could void the product

warranty of the Toro Company.

5. This equipment should not be modified without

The Toro Companys authorization. Direct any

inquiries to:

Hahn Equipment Co.

1625 N. Garvin

Evansville, IN 47711

SAFETY INSTRUCTIONS

6. Since gasoline is highly flammable, handle it

carefully.

A. Use an approved gasoline container.

B. Do not remove cap from fuel tank when

engine is hot or running.

C. Do not smoke while handling gasoline.

D. Fill fuel tank outdoors and to about 1/2

below top of tank, (bottom of filler neck). Do

not overfill.

E. Wipe up any spilled gasoline.

WHILE OPERATING:

Drive the transport vehicle safely.

WARNING

Attaching the trailer sprayer to a vehicle

changes the weight and handling of the

vehicle, and could cause loss of control

resulting in serious injury or death.

Refer to the vehicles operators manual

for tow bar and braking capacities and

do not exceed those recommendations.

Consider the terrain that the trailer

sprayer will be used on when evaluating

the capacities of the tow vehicle. Hills

and slopes will require more braking

power and stopping distance than flat

areas.

1. DO NOT make sudden or sharp turns. DO

NOT suddenly change direction of travel on an

incline, ramp, grade, slope or similar surface.

2. Make certain everyone is clear of the machine

before starting the engine to move the transport

vehicle or to engage the Sprayer Pump drive.

3. Do not touch engine, muffler or muffler shield

while engine is running or soon after it has

stopped. These areas may be hot enough to cause

burns.

4. If equipment begins to vibrate abnormally, stop

immediately. Shut off the Skid Sprayer engine

and disengage all power. Repair all damage

before commencing operation.

MAINTENANCE:

WARNING

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects, or

other reproductive harm.

WARNING: Engine exhaust contains carbon

monoxide which is an odorless, deadly poison.

Do not run engine indoors or in an enclosed

area.

1. Before servicing or making any adjustments

to the Skid Sprayer:

Do not use the fully loaded sprayer in

areas where stopping and vehicle

handling is questionable. The following

chart should be used to adjust the weight

of the sprayer to fit the tow vehicle and

its conditions.

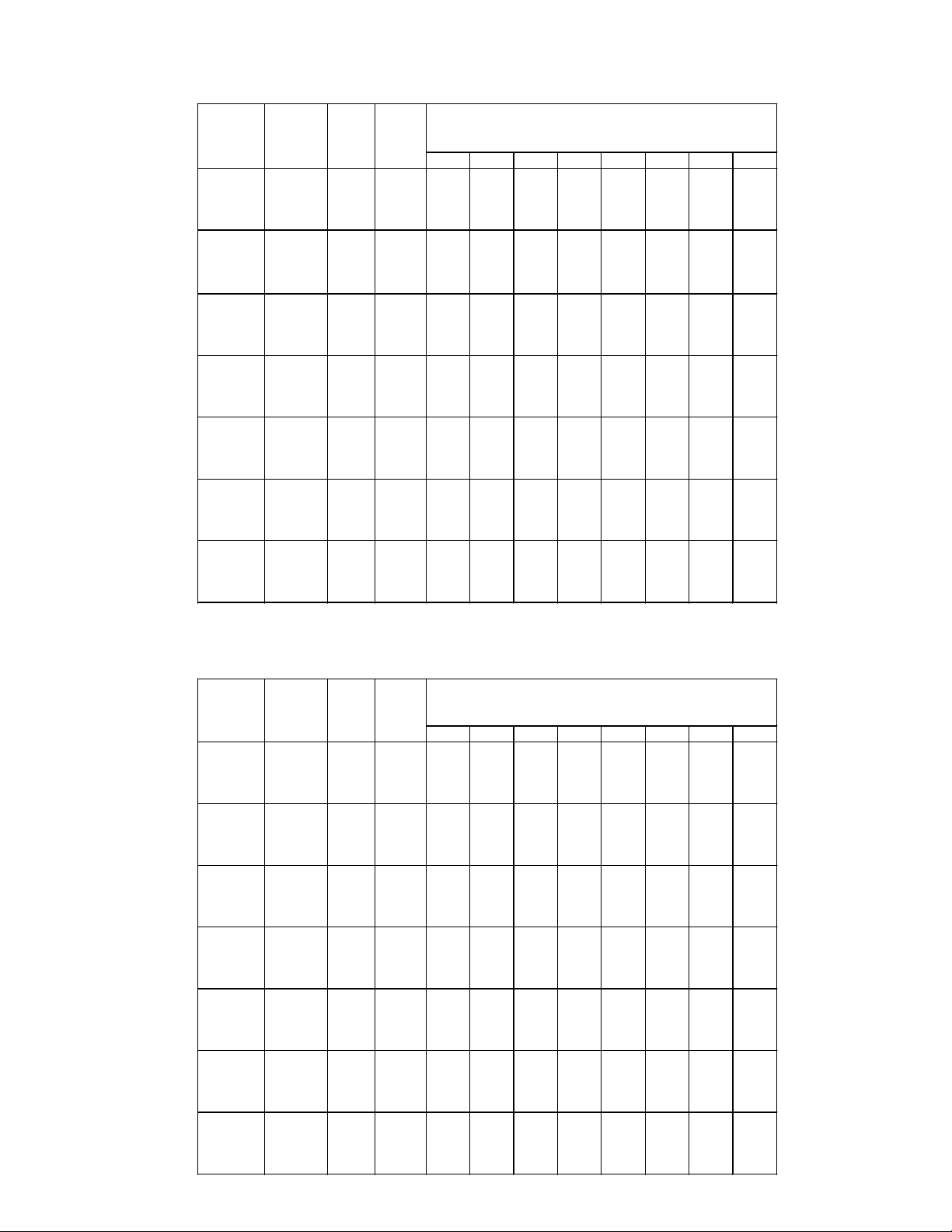

TANK VOL. TRAILER WT. SKID WT.

(GAL) (LBS) (LBS)

110 1620 1385

100 1535 1300

90 1455 1220

80 1370 1135

70 1285 1050

60 1200 965

50 1120 885

Based on the weight of water.

A. Stop the transport vehicle on level surface

and set the parking brake.

B. Disengage all power and wait until all

moving parts have stopped.

C. Shut off the Skid Sprayers engine and

remove wire from spark plug. Make sure wire

cannot contact plug accidentally.

D. Keep hands, feet and clothing away from

all power driven parts.

2. Keep all nuts, bolts and other fasteners

tightened securely. Replace any shields removed

during servicing or adjustments.

3. To reduce potential fire hazard, keep the

engine area free of excessive grass, leaves and

accumulation of dirt.

3

PRODUCT IDENTIFICATION

Skid Sprayer

Model No. 41440

Serial No. ____________

Record the serial numbers on your equipment in the space above as soon as possible, as it is necessary

to include this information when ordering service parts or requesting information. Please fill out the

Product Registration Card and return it to:

The TORO Company

8111 Lyndale Ave. South Date Purchased ___________

Minneapolis, MN 55420

SPARK ARRESTOR

When the machine is used or operated on any California forest, brush or grass covered land, a properly

operating spark arrestor must be attached to the muffler. The operator is violating state law, Section 442

Public Resources Code if a spark arrestor is not used.

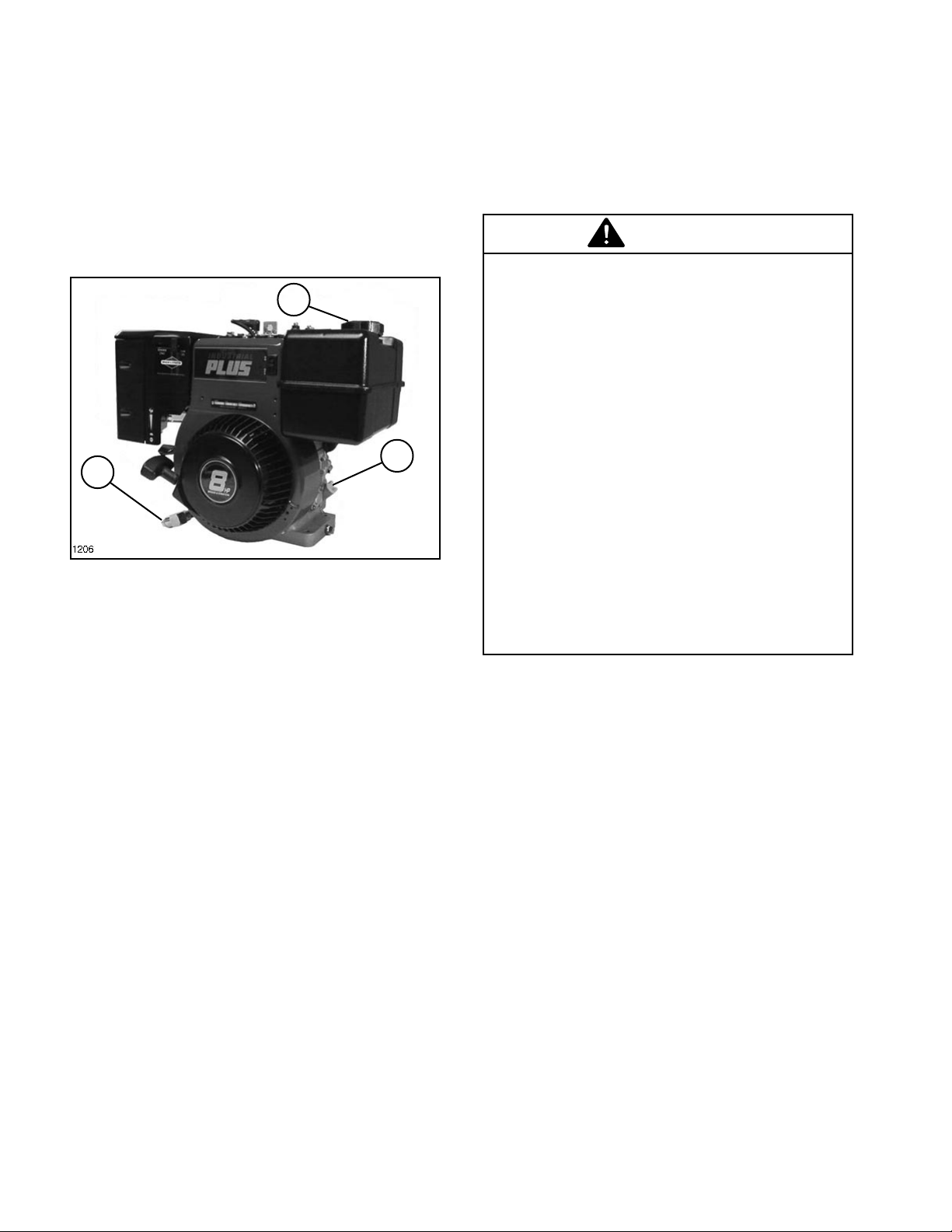

Briggs & Stratton Engine

Model No. 196432

Type No. 1063 E2

Code No. ____________

All information, illustrations and specifications in this manual are based on the latest product information available at the time

of publication. The right is reserved to make changes at any time without notice.

4

SAFETY INSTRUCTIONS

READ YOUR OPERATOR’S MANUAL FOR OPERATING AND

SAFETY INSTRUCTIONS. TO GET A REPLACEMENT MANUAL,

SEND MODEL AND SERIAL NUMBERS TO : THE TORO CO., 8111

LYNDALE AVE. S., MPLS., MN 55420

65-3090

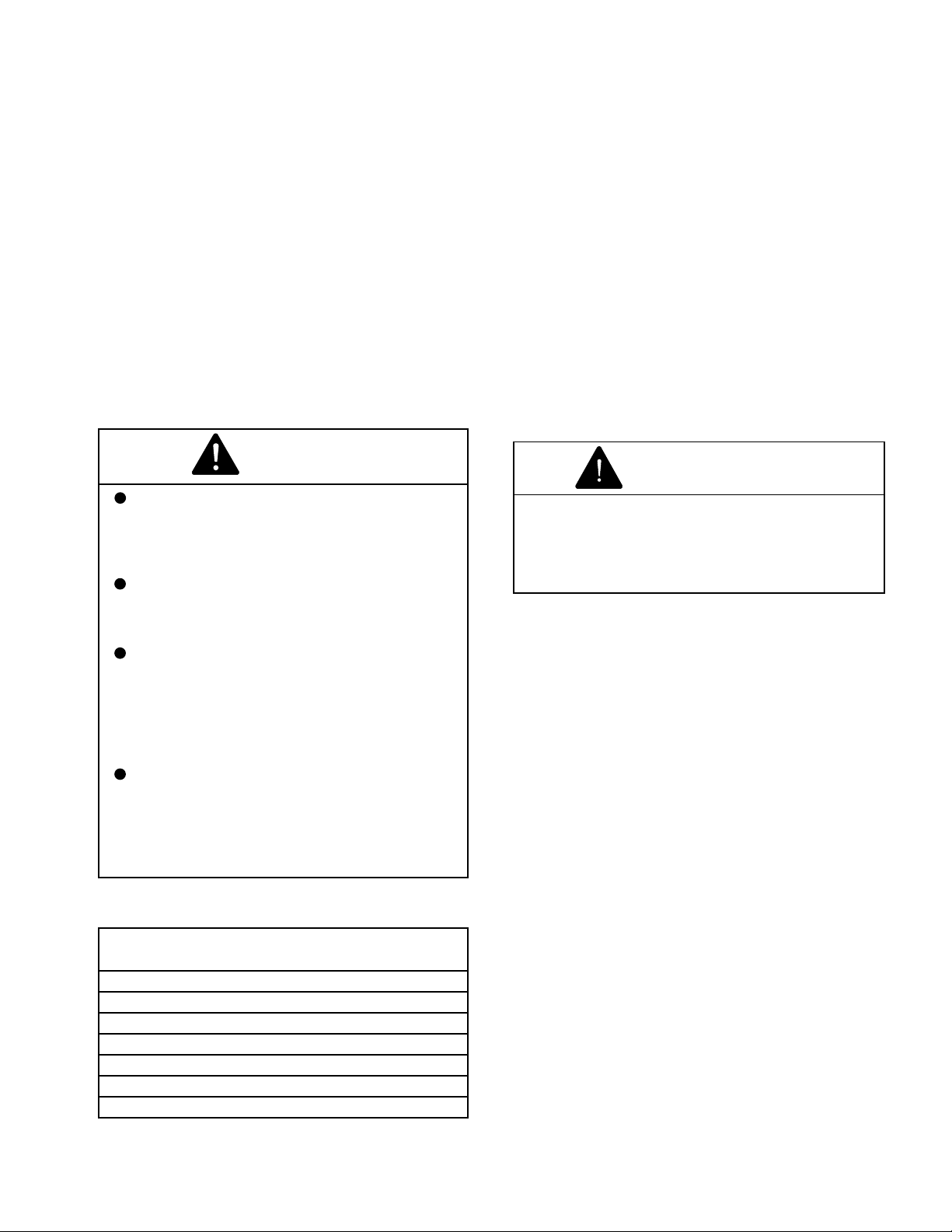

The following safety and instruction decals are installed on the Skid Sprayer. If any become damaged

or illegible, replace them. Decals and part numbers are listed below and in the parts catalog.

Order replacements from your Authorized Toro Distributor.

Part No. 92-3518: Located on front of Tank.

CAUTION

TO AVOID PER SONAL INJURY KEEP

ALL SHIELDS IN PLACE.

DISENGAGE AND SHUT OFF

ENGINE BEFORE SERVICING OR

UNCLOGGING MACHINE.

KEEP HANDS, FEET AND CLOTHI NG

AWAY FROM POWER-DRIVEN PARTS.

Part No. 87-0450: Located on top of Belt Guard.

ON

OFF

Part No. 41174: Located on

Belt Cover.

WARNING

87-0450

Part No. 65-3090: Located on top of Engine Cover.

WARNING

Shut engine off and release pressure at pump before

disconnecting any high pressure components. To release

pressure, lift relief valve at pump.

See operat or’s manual for complete safety and operating

procedures.

Part No. 92-3709: Located on top of Engine Air Cleaner.

(41443 Diaphragm Pump only)

92-3709

EXCEEDING THE TOWING OR HAULING VEHICLE’S

CAPACITY CAN RESULT IN SERIOUS INJURY OR

DEATH.

ALWAYS REFER TO TOWING OR HAULING VEHICLE’S

OPERATOR MANUAL AND THE FOLLOWING CHART

TO DETERMINE MAXIMUM CAPACITY.

TANK VOLUME

(GAL)

110

100

90

80

70

60

50

TRAILER WEIGHT

(LBS)

1620

1535

1455

1370

1285

1200

1120

BASED ON WEIGHT OF WATER

SKID WEIGHT

(LBS)

1385

1300

1220

1135

1050

965

885

Part No. 95-9320: Located on front of Tank.

Part No. 80-9350: Located on Belt Cover.

95-9320

5

BEFORE SPRAYING

NOZZLE SELECTION:

See the nozzle charts on page 7 or 8 to be sure

that your spray nozzles have the capacity

necessary to achieve the application rate selected.

To select the proper nozzle, you need to know:

1. Recommended chemical application rate in

gallons per acre, gallons per 1000 sq. ft. or liters

per hectare.

2. Average Vehicle speed in Miles per hour or

kilometers per hour.

3. Nozzle spacing (20 inches or 50 centimeters.)

With this information you can calculate the volume

per minute per nozzle, using the formulas below.

US FORMULA:

G.P.M. =

(Per Nozzle) 5940

TU (Turf) FORMULA:

G.P.M. =

(Per Nozzle) 137

SI (METRIC) FORMULA:

lit/min =

(Per Nozzle) 60,000

Use G.P.M. (lit/min) and Pressure to select

appropriate nozzle from chart on page 7 or 8.

EXAMPLE (US FORMULA):

Application Rate = 75 Gallons/Acre

Vehicle Speed = 4 M.P.H.

Nozzle Spacing = 20 inches

G.P.A. x M.P.H. X 20 ins.

G.P.K. x M.P.H. x 20 ins.

lit/ha x km/h x 50 cm

SYMBOL DEFINITIONS:

GPM - Gallons per minute

lit/min - Liters per minute

dl/min - Deciliter per minute

PSI - Pounds per square inch

kPa - Kilopascal

GPA - Gallons per acre

lit/ha - Liter per hectare

ml/ha - Milliliter per hectare

GPK - Gallons per 1,000 sq. ft.

mm - Millimeters

cm - Centimeters

dm - Decimeters

m - Meter

MPH - Miles per hour

km - Kilometers

km/h - Kilometers per hour

US - Volume per ACRE

SI - Volume per HECTARE

TU - Volume per 1,000 sq. ft.

LIQUID CONVERSIONS

U.S. Gallons x 128 = Fluid Ounces

U.S. Gallons x 3.785 = Liters

U.S. Gallons x 0.83267 = Imperial Gallons

U.S. Gallons x 8.34 = Pounds (Water)

LENGTH

1 millimeter (mm) = 0.039 inch

1 centimeter (cm) = 0.393 inch

1 meter (m) = 3.281 feet

1 kilometer (km) = 0.621 mile

1 inch = 25.4 millimeters; 2.54 centimeters

1 mile = 1.609 kilometers

75 G.P.A. x 4 M.P.H. x 20 = 1.00 G.P.M.

5940 (per nozzle)

With 1.00 G.P.M. and a pressure of 40 P.S.I. you

would select Nozzle No. 95-9188.

EXAMPLE (TU FORMULA):

Application Rate = 1.70 Gal./1000 sq. ft.

Vehicle Speed = 4 M.P.H.

Nozzle Spacing = 20 inches

1.70 G.P.K. x 4 M.P.H. x 20 = 1.00 G.P.M.

137 (per nozzle)

EXAMPLE (SI FORMULA):

Application Rate = 907 lit/hectare

Vehicle Speed = 5 km/h

Nozzle Spacing = 50 cm

907 lit/ha x 5 km/h x 50 = 3.78 lit/min.

60,000 (per nozzle)

With 3.78 lit/min and a pressure at 275 kPa you

would select nozzle No. 95-9188

6

PRESSURE

1 psi = 6.89 kPa

AREA

1 square meter = 10.764 sq. feet

1 hectare (ha) = 2.471 acres; 10,000 sq.meters

1 acre = 0.405 hectare; 43,560 sq. ft.

1 sq. mile = 640 acres; 258.9 hectares

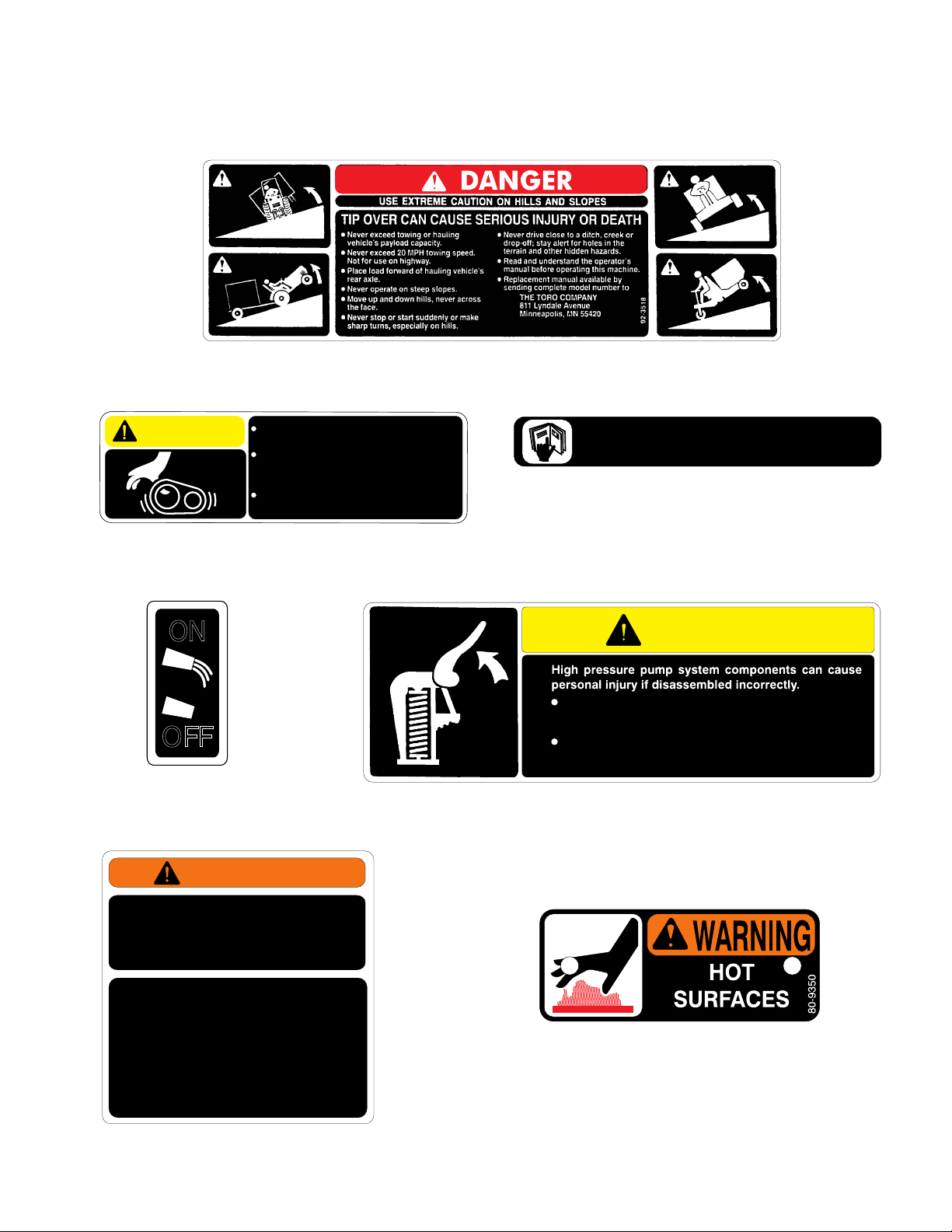

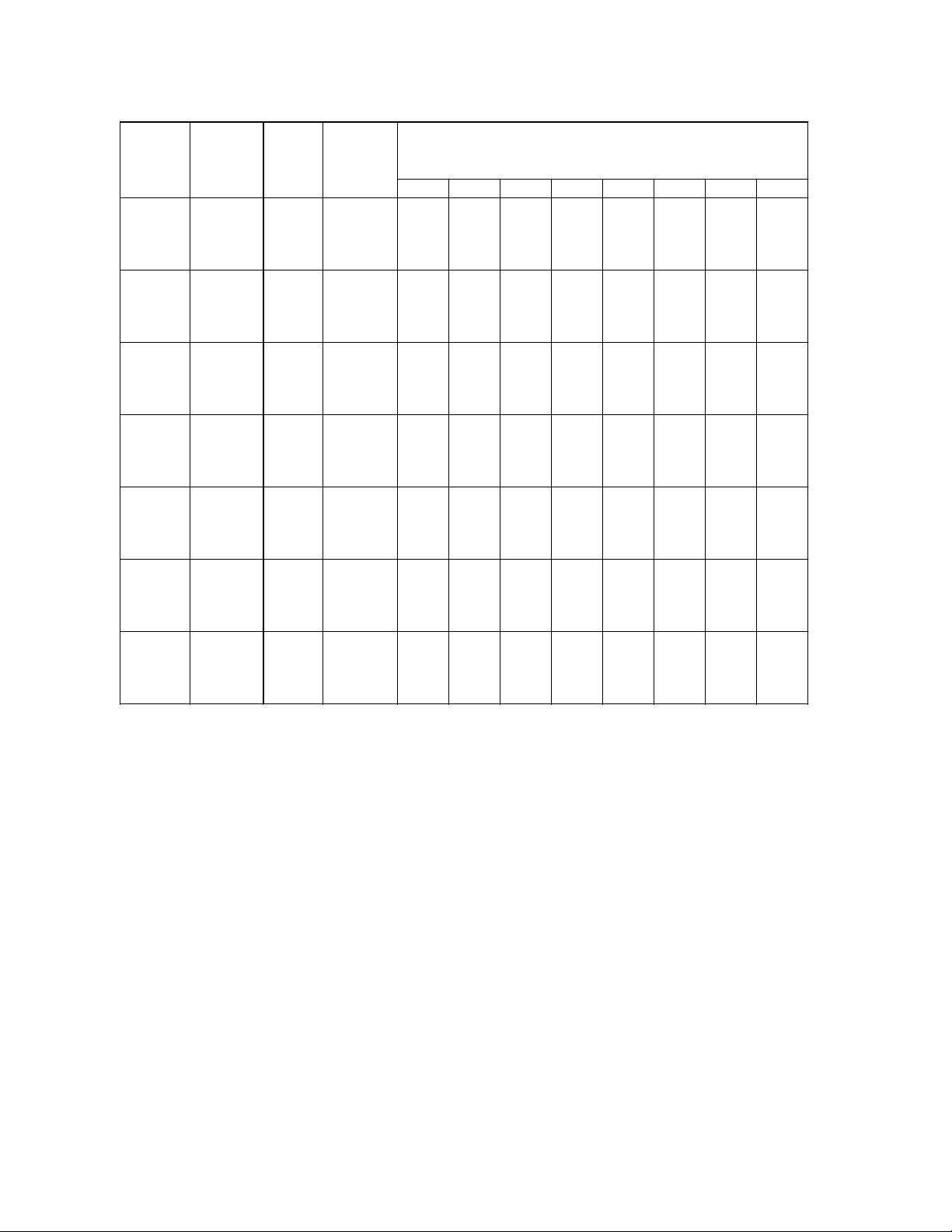

TORO TURF-JET NOZZLES

Gallons Per Acre Application Rates

TORO Nozzle Press ure Capac ity

Part No. Number (PSIG) 1 Nozzle

(GPM)

Color Co de 2.5 MPH 3 MPH 3.5 MP H 4 MPH 4.5 MPH 5 MPH 5. 5 MPH 6 MPH

20 0.14 16.6 13.9 11.9 10.4 9.2 8.3 7.6 6.9

95-9221 Yellow 30 0.17 20.2 16.8 14.4 12.6 11.2 10.1 9.2 8.4

40 0.20 23.8 19.8 17.0 14.9 13.2 11.9 10.8 9.9

50 0.22 26.1 21.8 18.7 16.3 14.5 13.1 11.9 10.9

20 0.28 33 28 24 21 18 17 15 14

95-9222 Red 300.354235302623211917

40 0.40 48 40 34 30 26 24 22 20

50 0.45 53 45 38 33 30 27 24 22

20 0.35 42 35 30 26 23 21 19 17

95-9223Brown300.435143363228262321

40 0.50 59 50 42 37 33 30 27 25

50 0.56 67 55 48 42 37 33 30 28

20 0.42 50 42 36 31 28 25 23 21

95-9224 Gray 30 0.52 62 51 44 39 34 31 28 26

40 0.60 71 59 51 45 40 36 32 30

50 0.67 80 66 57 50 44 40 36 33

20 0.57 68 56 48 42 38 34 31 28

95-9225White 300.698268595146413734

40 0.80 95 79 68 59 53 48 43 40

500.8910688766659534844

20 0.71 84 70 60 53 47 42 38 35

95-9188 Light Blue 30 0.87 103 86 74 65 57 52 47 43

401.0011999857466595450

50 1.12 133 111 95 83 74 67 60 55

20 1.06 126 105 90 79 70 63 57 52

95-9226 Light Green 30 1.30 154 129 110 97 86 77 70 64

40 1.50 178 149 127 111 99 89 81 74

50 1.68 200 166 143 125 111 100 91 83

Gallons per Acre at 20" Spacings

Gallons Per 1000 Sq. Ft. Application Rates

TORO Nozzle Press ure Capac ity

Part No. Number (PSIG) 1 Nozzle

(GPM)

Color Co de 2.5 MPH 3 MPH 3.5 MP H 4 MPH 4.5 MPH 5 MPH 5. 5 MPH 6 MPH

20 0.14 0.38 0.32 0.27 0.24 0.21 0.19 0.17 0.16

95-9221 Yellow 30 0.17 0.46 0.39 0.33 0.29 0.26 0.23 0.21 0.19

40 0.20 0.54 0.45 0.39 0.34 0.30 0.27 0.25 0.23

50 0.22 0.60 0.50 0.43 0.37 0.33 0.30 0.27 0.25

20 0.28 0.76 0.63 0.54 0.48 0.42 0.38 0.35 0.32

95-9222 Red 30 0.35 0.95 0.79 0.68 0.60 0.53 0.48 0.43 0.40

40 0.40 1.09 0.91 0.78 0.68 0.60 0.54 0.49 0.45

50 0.45 1.22 1.02 0.87 0.77 0.68 0.61 0.56 0.51

20 0.35 0.95 0.79 0.68 0.60 0.53 0.48 0.43 0.40

95-9223 Brow n 30 0.43 1.17 0 .97 0.84 0.73 0.65 0.58 0.53 0.49

40 0.50 1.36 1.13 0.97 0.85 0.76 0.68 0.62 0.57

50 0.56 1.52 1.27 1.09 0.95 0.85 0.76 0.69 0.63

20 0.42 1.14 0.95 0.82 0.71 0.63 0.57 0.52 0.48

95-9224 Gray 30 0.52 1.41 1.18 1.01 0.88 0.79 0.71 0.64 0.59

40 0.60 1.63 1.36 1.17 1.02 0.91 0.82 0.74 0.68

50 0.67 1.82 1.52 1.30 1.14 1.01 0.91 0.83 0.76

20 0.57 1.55 1.29 1.11 0.97 0.86 0.78 0.70 0.65

95-9225 White 30 0.69 1.88 1.56 1.34 1.17 1.04 0.94 0.85 0.78

40 0.80 2.18 1.81 1.55 1.36 1.21 1.09 0.99 0.91

50 0.89 2.42 2.02 1.73 1.51 1.34 1.21 1.10 1.01

20 0.71 1.93 1.61 1.38 1.21 1.07 0.97 0.88 0.80

95-9188 Light Blue 30 0.87 2.37 1.97 1.69 1.48 1.31 1.18 1.08 0.99

40 1.00 2.72 2.27 1.94 1.70 1.51 1.36 1.24 1.13

50 1.12 3.05 2.54 2.18 1.90 1.69 1.52 1.38 1.27

20 1.06 2.88 2.40 2.06 1.80 1.60 1.44 1.31 1.20

95-9226 Light Green 30 1.30 3.54 2 .95 2.53 2.21 1.96 1 .77 1.61 1.47

40 1.50 4.08 3.40 2.91 2.55 2.27 2.04 1.85 1.70

50 1.68 4.57 3.81 3.26 2.86 2.54 2.28 2.08 1.90

Gallons per 1000 Sq. Ft. at 20" S pacings

7

TORO TURF-JET NOZZLES

Liters Per Hectare Application Rates

TORO Nozzle Pressure Capacity

Part No. Number (kPa) 1 Nozzle

(L/min)

C ol or Code 4 km /h 5 km/h 6 km/h 7 km/h 8 km / h 9 km/h 10 km/h 11 km/h

150 0.53 159 127 106 91 80 71 64 58

95-9221 Yellow 200 0.64 192 154 128 110 96 85 77 70

275 0.76 228 182 152 130 114 101 91 83

350 0.83 249 199 166 142 125 111 100 91

150 1.06 318 254 212 182 159 141 127 116

95-9222 Red 200 1.32 396 317 264 226 198 176 158 144

275 1.51 453 362 302 259 227 201 181 165

350 1.70 510 408 340 291 255 227 204 185

150 1.40 420 336 280 240 210 187 168 153

95-9223 Brow n 200 1.61 483 386 322 276 242 215 193 176

275 1.89 567 454 378 324 284 252 227 206

350 2.13 639 511 426 365 320 284 256 232

150 1.67 501 401 334 286 251 223 200 182

95-9224 Grey 200 1. 93 579 463 386 331 290 257 232 211

275 2.27 681 545 454 389 341 303 272 248

350 2.56 768 614 512 439 384 341 307 279

150 2.23 669 535 446 382 335 297 268 243

95-9225 White 200 2.58 774 619 516 442 387 344 310 281

275 3.02 906 725 604 518 453 403 362 329

350 3.41 1023 818 682 585 512 455 409 372

150 2.79 837 670 558 478 419 372 335 304

95-9188 Light Blue 200 3.22 966 773 644 552 483 429 386 351

275 3.78 1134 907 756 648 567 504 454 412

350 4.28 1284 1027 856 734 642 571 514 467

150 4.18 1254 1003 836 717 627 557 502 456

95-9226 Light Green 200 4.84 1452 1162 968 830 726 645 581 528

275 5.67 1701 1361 1134 972 851 756 680 619

350 6.40 1920 1536 1280 1097 960 853 768 698

Li ters per Hectare a t 50 cm Spacin gs

8

STORAGE

FLUSH PUMP AFTER USE

One of the most common causes for faulty pump

performance is gumming or corrosion inside the

pump. Flush the pump and entire system with a

solution that will chemically neutralize the liquid

pumped. Mix according to chemical

manufacturers directions. This will dissolve most

residue remaining in the pump, leaving the inside

of the pump clean for the next use.

TO PREVENT CORROSION

IMPORTANT: FREEZING TEMPERATURES

MAY DAMAGE THE PUMP & CONTROL VALVE

IF THE WATER IS NOT DRAINED

COMPLETELY!

SERVICING AFTER STORAGE:

Flush the entire spraying system with clean, clear

water and detergent.

Flush the entire spraying system again with clean,

clear water to rinse.

After cleaning the pump as directed above, flush

it with a permanent type automobile antifreeze

(Prestone, Zerex, etc.) containing a rust inhibitor.

Use a 50% solution - that is, half antifreeze and

half water, or fill pump with FLUID FILM and then

drain it. A protective coating of FLUID FILM will

remain on the inner pump surfaces. Save the

excess FLUID FILM for the next application. Plug

the ports to keep out air during storage. For short

periods of idleness, noncorrosive liquids may be

left in the pump, BUT AIR MUST BE KEPT OUT.

Plug ports or seal port connections.

Drain entire spraying system.

STORAGE AND DISPOSAL OF

CHEMICALS:

Follow chemical manufacturers recommendations

for storage and disposal of chemicals.

9

BEFORE OPERATING

ENGINE

FILL ENGINE CRANKCASE WITH OIL:

IMPORTANT! The Skid Sprayer is shipped from

the factory without oil in the engines crankcase.

1. Position the Skid Sprayer on a level surface.

2. Clean the area around the oil fill/check plug

and remove it.

2

1

3

FIG. 1

1. Oil Fill/Check Plug 2. Fuel Tank Cap

3. Oil Drain

3. Insert a funnel into the oil fill tube and slowly

pour engine oil into the crankcase. The engine

uses any high-quality oil having the American

Petroleum Institute-API - service classification

SE, SF or SG. See viscosity on page 12 chart for

recommended weight to use. The capacity of the

crankcase is approximately 44 ounces (1.3 L).

4. The level should be up to, but not over, the

point of overflowing the filler neck.

FILL FUEL TANK WITH GASOLINE:

Fuel tank capacity is approximately 4 U.S. quarts

(3.8 L).

WARNING

Because gasoline is flammable, caution

must be used when storing or handling it.

Do not fill fuel tank while engine is running,

hot or when machine is in an enclosed area.

Vapors may build up and be ignited by a

spark or flame source many feet away. DO

NOT SMOKE while filling the fuel tank to

prevent the possibility of an explosion.

Always fill fuel tank outside and wipe up any

spilled gasoline before starting engine. Use

a funnel or spout to prevent spilling gasoline,

and fill tank to about 1/2 inch (13 mm) below

the filler neck. Store gasoline in a cool, well-

ventilated place; never in an enclosed area

such as a hot storage shed. To ensure

volatility, do not buy more than a 30 day

supply of gasoline. Gasoline is a fuel for

internal combustion engines; therefore, do

not use it for any other purpose. Since many

children like the smell of gas, keep it out of

their reach because the fumes are explosive

and dangerous to inhale.

1. Clean area around fuel tank cap so foreign

matter cannot enter tank when cap is removed.

See FIG. 1.

2. Remove cap from fuel tank and fill tank with

unleaded gasoline to within 1/2" (13 mm) from top

of tank. Then reinstall fuel tank cap.

5. Reinstall the oil fill/check plug and tighten

securely. Make sure it is tightened to 13 ft. lbs.

(17.6 N m) torque.

IMPORTANT! Check the oil level every five (5)

operating hours or each time the engine is

started. For a new engine, drain the oil and

replace it after the first five (5) hours of

operation: thereafter, under normal conditions,

change oil after every 25 hours of operation.

Change the oil more frequently when the engine

is operated in dusty or dirty conditions.

10

3. Wipe up any gasoline that may have spilled.

Loading...

Loading...