Toro 4130, greensmaster 500 Operator's Manual

FORM NO. 3319-870 GB Rev A

© The T oro Company—1998

®

MODEL NO. 04130—80001 & UP

GREENSMASTER

OPERATOR’S

MANUAL

®

500

To assure maximum safety, optimum performance,

and to gain knowledge of the product, it is essential

that you or any other operator of the mower read and

understand the contents of this manual before the

engine is ever started. Pay particular attention to the

SAFETY INSTRUCTIONS highlighted by this symbol:

The safety alert symbol means CAUTION, WARNING or DANGER—personal safety instruction.

Failure to comply with the instruction may result in

personal injury.

FOREWORD

The GREENSMASTER 500 was developed to satisfy the demand for a maneuverable, intermediate size,

turf maintenance rotary mower. The machine has

advanced concepts in engineering, design and safety;

and if maintained properly, it will give excellent service.

Since the GREENSMASTER 500 is a high quality

product, Toro is concerned about the future use of

the machine and the safety of the user. Read this

manual to familiarize yourself with the proper set up,

operation, and maintenance instructions.

Certain information in this manual is emphasized.

DANGER, WARNING and CAUTION identify personal safety related information. IMPORTANT identifies mechanical information demanding special

attention. Be sure to read the directive because it

deals with the possibility of damaging a part or parts

of the machine. NOTE identifies general information

worthy of special attention.

If help concerning set up, operation, maintenance or

safety is ever needed, contact a local Authorized

Toro Distributor. In addition to genuine Toro replacement parts, the distributor also has optional equipment form the complete line of Toro turf care equipment. Keep your Toro all Toro – buy genuine Toro

replacement parts and accessories.

Whenever you have questions or need service, contact your local authorized Toro Distributor. In addition to having a complete line of accessories and

professional turf care service technicians, the distributor has a complete line of genuine TORO replacement parts to keep your machine operating properly.

Keep your TORO all TORO. Buy genuine TORO

parts and accessories.

TABLE OF CONTENTS

SAFETY INSTRUCTIONS 3

SPECIFICATIONS 8

BEFORE OPERATING 9

CONTROLS 14

OPERATING INSTRUCTIONS 15

MAINTENANCE 17

PRODUCT IDENTIFICATION 21

2

3

Safety

Before Operating

1. Read the instructions carefully. Be familiar

with the controls and the proper use of the

equipment.

2. Never allow children or people unfamiliar with

these instructions to use the machine. Keep

everyone, especially children and pets away

from the area of operation

3. Become familiar with the controls and know

how to stop the machine quickly

4. Keep all shields, safety devices and decals in

place. If a shield, safety device or decal is

defective or damaged, repair or replace it before

operating the machine.

5. Always wear substantial shoes. Do not operate

the machine while wearing sandals, tennis shoes

or sneakers. Do not wear loose fitting clothing

that could get caught in moving parts and cause

personal injury.

6. Wearing safety glasses, safety shoes, long pants

and a helmet is advisable and required by some

local safety and insurance regulations.

7. Be sure the work area is clear of objects that

might be picked up and thrown by the reel.

8. keep everyone, especially children and pets,

away from the areas of operation.

9. Since gasoline is highly flammable, handle it

carefully.

A. Use an approved gasoline container.

B. Do not remove the cap from the fuel tank

when the engine is hot or running.

C. Do not smoke while handling gasoline.

D. Fill the fuel tank outdoors and not over one

inch (25 mm) from the top of the tank, not

the filler neck. Do not overfill.

E. Wipe up any spilled gasoline.

While Operating

10. Do not run the engine in a confined area with-

out adequate ventilation. Exhaust fumes are

hazardous and could be deadly.

11. Always stand behind the handle when starting

and operating the machine.

12. Do not touch the engine, muffler or exhaust pip

while the engine is running or soon after it is

stopped because these areas could be hot

enough to cause burns.

13. If you leave the machine unattended, be sure to

stop the engine so the cutting reel is not spinning.

Maintenance

14. Before servicing or making adjustments to the

machine, stop the engine and pull the wire from

the spark plug to prevent accidental starting.

15. To reduce potential fire hazard, keep the engine

area free of excessive grease, grass, leaves and

dirt.

16. If the engine must be running to perform a

maintenance adjustment, keep hands, feet,

clothing and any part of the body away from the

cutting unit and any moving parts. Keep everyone away.

17. Do not overspeed the engine by changing the

governor settings. Maximum engine speed is

3000 rpm. To assure safety and accuracy, have

an authorized Toro distributor check engine

speed with a tachometer.

18. Shut off the engine before checking or adding

oil.

19. Check the performance of the clutch system

daily. Do not defeat this system, it is for your

own protection.

Safety

4

Sound & Vibration Levels

Sound Levels

This unit has an equivalent continuous A-weighted

sound pressure at the operator ear of: 82.5 dB(A),

based on measurements of identical machines per

91/386/EEC.

This unit has a sound power level of 94.5 LWA,

based on measurements of identical machines per

procedures outlined in Directive 84/538/EEC and

amendments

Vibration Levels

This unit has a vibration level of 10.05 m/s2at the

hands/arms, based on measurements of identical

machines per ISO 5349 procedures.

5

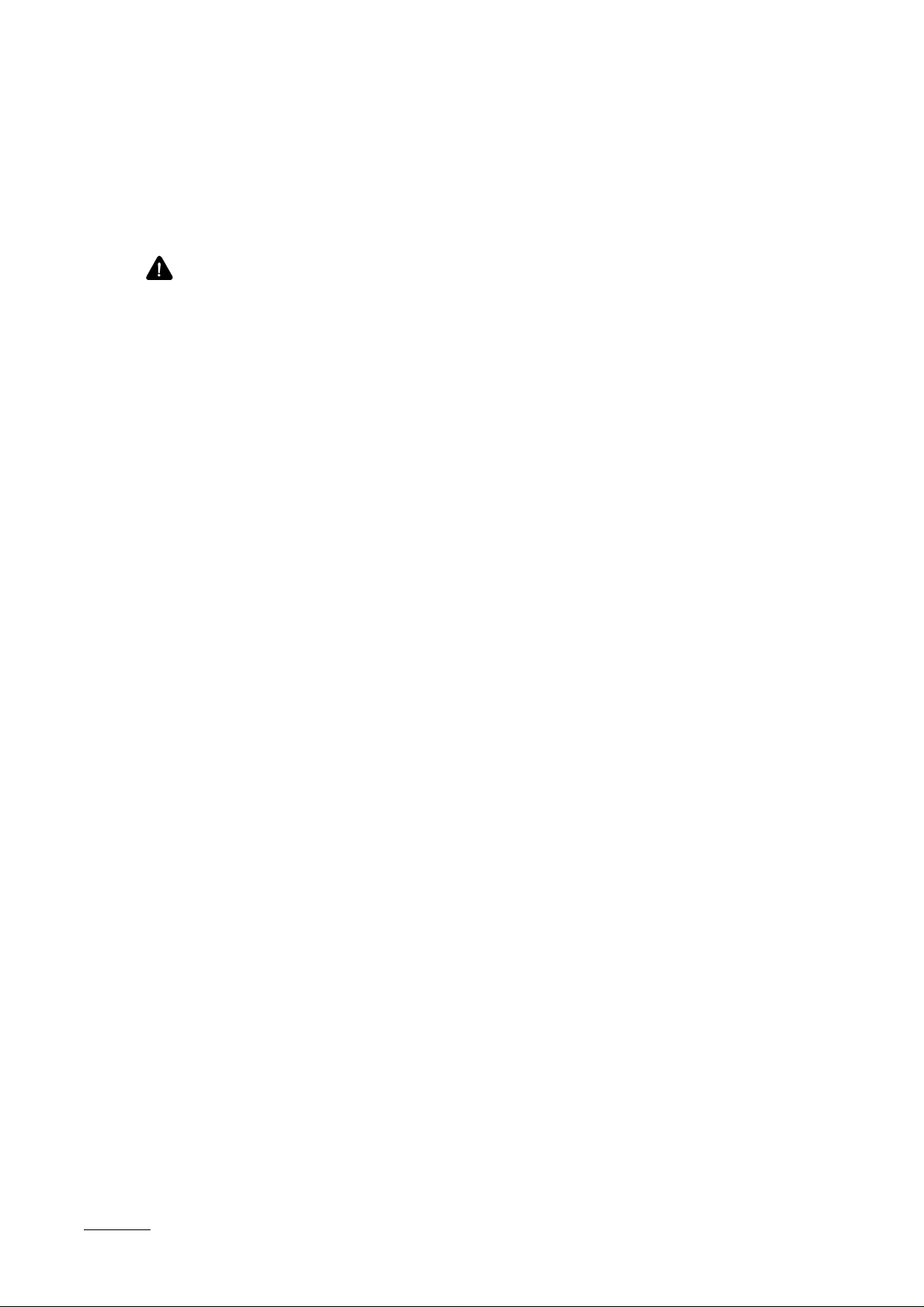

Symbol Glossary

Caustic liquids,

chemical burns to

fingers or hand

Poisonous

fumes or toxic

gases, asphyxiation

Electrical shock,

electrocution

High pressure

fluid, injection

into body

High pressure

spray, erosion of

flesh

High pressure

spray, erosion of

flesh

Crushing of

fingers

or hand,

force

applied from

above

Crushing of

toes or foot, force

applied from above

Crushing of

whole body,

applied from

above

Crushing of

torso, force

applied from side

Crushing of fingers

or hand/, force

applied from side

Crushing of

whole body

Crushing of

head, torso and

arms

Cutting of

fingers or hand

Cutting of footCrushing of leg,

force applied

from side

Cutting or

entanglement of

foot, rotating auger

Severing of

foot, rotating

knives

Severing of

fingers or hand,

impeller blade

Wait until all

machine

components have

completely stopped

before touching them

Severing of

fingers or hand,

engine fan

Whole body entanglement,

implement input drive line

Fingers or

hand entanglement, chain drive

Runover/backover, (relevant

machine to appear

in dashed box)

Machine tipping,

riding mower

Machine rollover,

ROPS (relevant

machine to appear

in dashed box)

Stored energy

hazard, kickback

or upward motion

Hot surfaces,

burns to fingers

or hands

Hand & arm

entanglement,

belt drive

Thrown or flying objects, whole

body exposure

Thrown or

flying objects,

face exposure

Explosion Fire or open

flame

Secure lifting

cylinder with locking

device before getting

in hazardous area

Stay a safe

distance from

the machine

Stay clear of

articulation area

while engine is

running

Do not open

or remove safety

shields while

engine is

running

Do not step on

loading platform if

PTO is connected to tractor

& engine is running

Do not step

Shut off engine

& remove key before

performing maintenance or repair work

Riding on this

machine is allowed

only on a passenger seat & only if the

driver’s view is not

Consult

technical manual

for proper service

procedures

Fasten seat belts Safety alert

triangle

outline safety

alert symbol

Read operator’s

manual

Safety

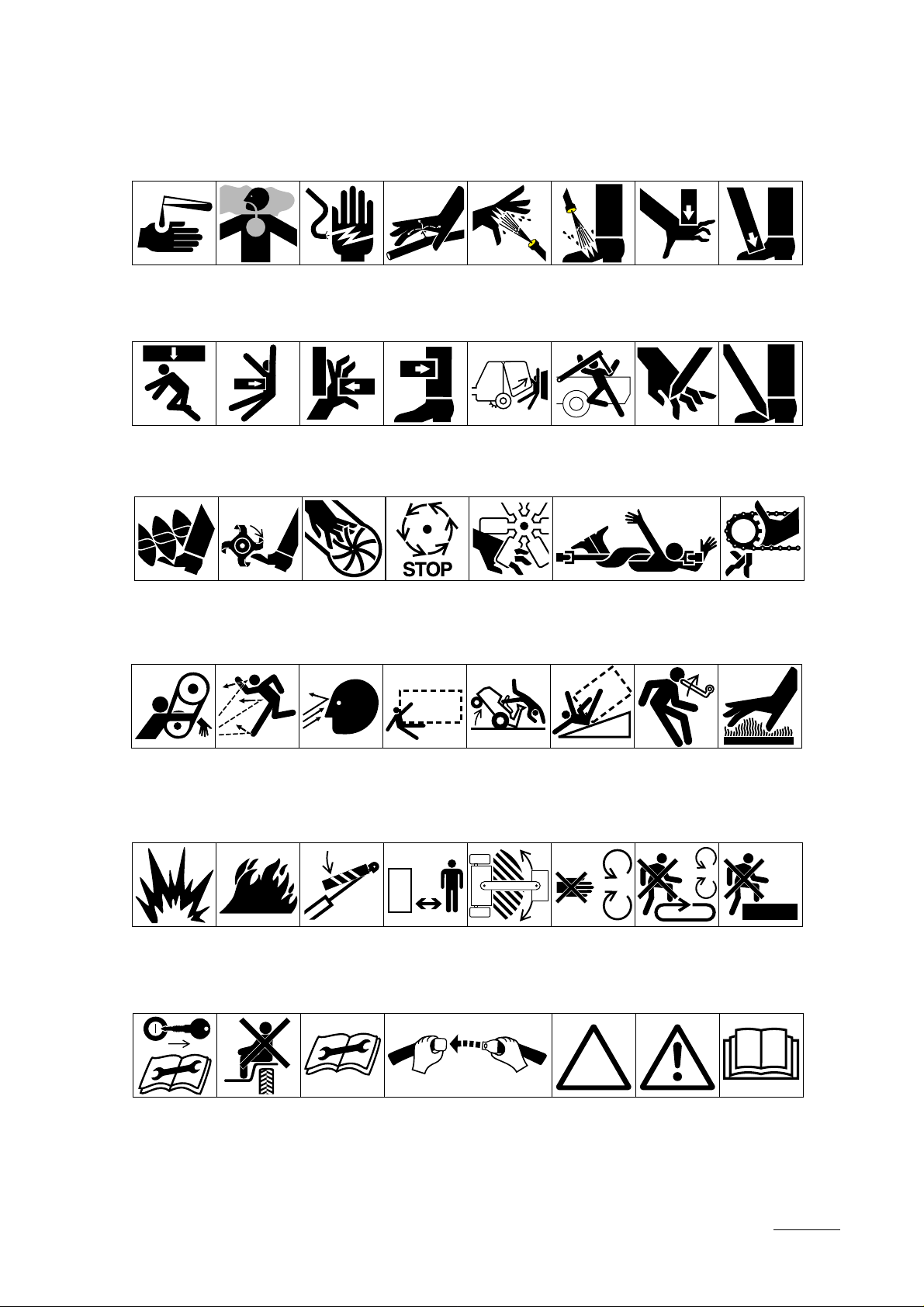

6

Eye protection

must be worn

Fire, open light

& smoking

prohibited

Level

indicator

Head protection

must be worn

Hydraulic

system

Liquid level Filter Temperature Failure/

Hearing

protection must

be worn

Brake system

Caution, toxic

risk

Oil Coolant (water) Intake air Exhaust gas Pressure

First aid

Malfunction

Flush with water Engine Transmission

Start switch/

mechanism

On/start Off/stop

Engage Disengage

Horn Battery charging

Machine travel

direction,

forward/rearward

Jack or

support point

condition

Control lever

operating

direction, dual

direction

Draining/

emptying

Attachment

lower

Hourmeter/elapsed

operating hours

Control lever

operating

direction, multiple

direction

Engine lubricating oil

Attachment

raise

Fast Slow Continuous

Clockwise

rotation

Engine lubricating

oil pressure

Spacing distance Snow thrower,

Counter-clockwise rotation

Engine lubricating

oil level

collector auger

variable, linear

Grease

lubrication

point

Engine lubricating

oil filter

Plus/increase/

positive polarity

Volume empty Volume full

Oil lubrication

point

Engine

lubricating oil

temperature

Minus/decrease/

negative polarity

Lift point

Engine coolant

7

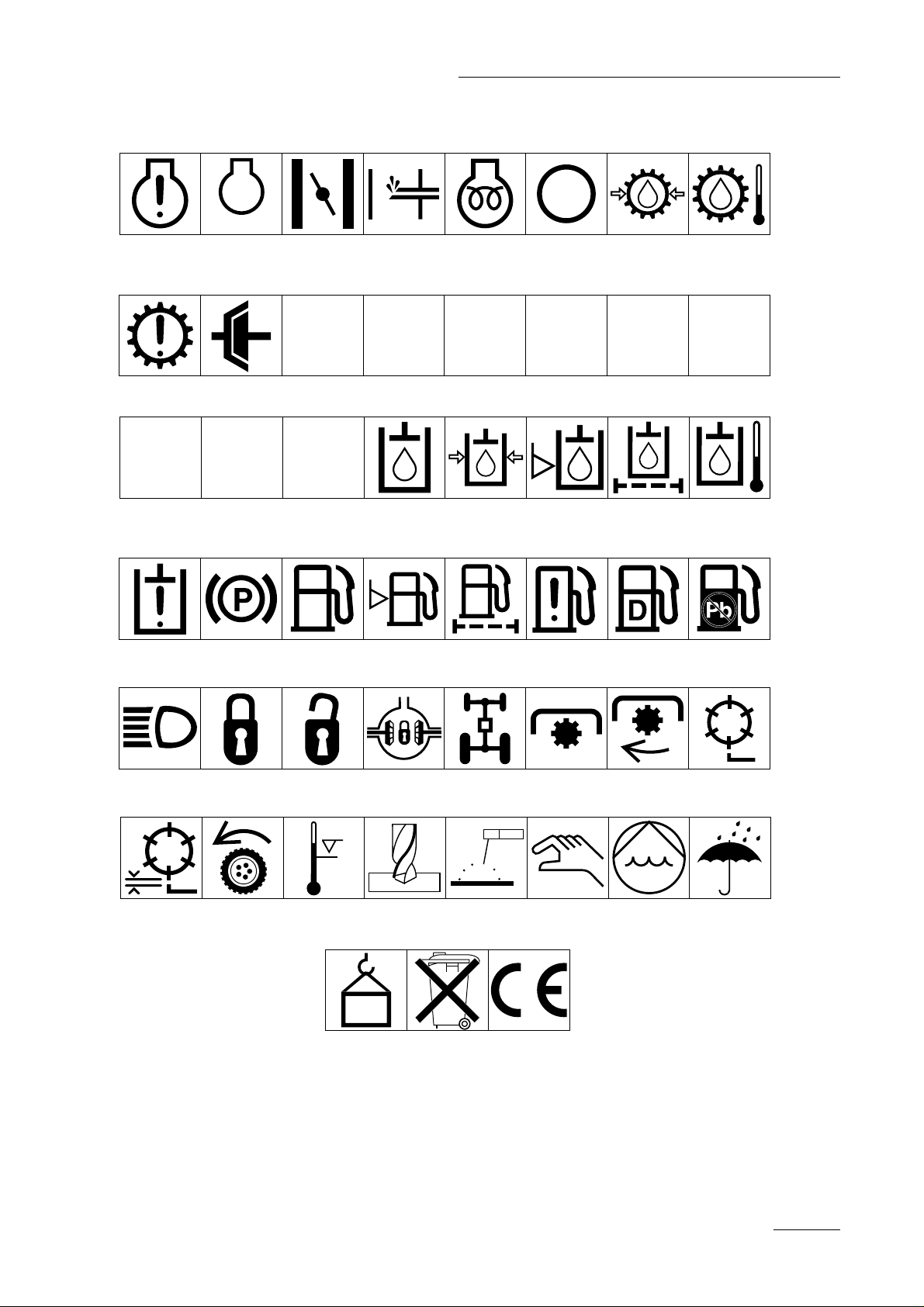

Safety

Transmission

failure/malfunction

Clutch Neutral High Low Forward Reverse Park

N H L F R P

First gear Second gear

Third gear (other #'s

may be used until

the maximum # of forward gears is reached.)

Hydraulic oil Hydraulic oil

temperature

2 31

Hydraulic oil

pressure

Hydraulic oil level Hydraulic oil filter

Hydraulic oil

failure/malfunction

Parking brake Fuel Fuel level Fuel filter Fuel system

failure/malfunction

Diesel fuel Unleaded fuel

Headlights Lock Unlock Differential lock 4-Wheel drive Power Take-Off Power Take-Off,

rotational speed

Reel cutting

element

Reel cutting

element, height

adjustment

Traction Above working

temperature range

Drilling Manual metal arc

welding

Manual 0356 Water pump

0626 Keep dry

0430 weight Do not dispose

in the garbage

CE logo

Engine failure/

malfunction

Engine rotational

speed/frequency

Choke Primer (start aid) Electrical preheat

(low temperature

start aid)

Transmission oil Transmission oil

pressure

n/min

Transmission oil

temperature

Engine: 3.7 horsepower (2.7 kw) engine with 2.64

quarts (2.5 l) capacity gas tank.

Handle: 7/8 in.(22 cm) diameter, 17-gauge welded

steel tubing with formed steel reinforcement panel.

Traction Unit: Cast aluminum housing.

Reel Unit: Cast aluminum and zinc side plates, alu-

minum extrusion back plate. Reel unit independent

of traction unit and catcher.

Front Rollers: 2 in. (51 mm) O.D. Steel tube with

ball bearings, moisture excluding oil seals and

replaceable wear sleeves.

Height Of Cut: 1/8 to 11/16 in. (3 to 17 mm).

(Optional micro-cut bedknife 6mm to 24)

Width Of Cut: 21 in. (0.53 m).

Clip: 0.197 in. (5.0 mm).

Ground Speed: 2.1 mph (3.4 Km/hr) at 1600 RPM

and 4.0 mph (6.4 Km/hr.) at 3100 RPM.

Traction Drive: "A” section "V" belt on 2.0 pitch

diameter and 3.70 pitch diameter. to countershaft (1.

85:1) 18T and 48T gear 2.67:1 and 20T and 56T

gear (2. 8:1). All gears 16 pitch, 20° involute full

depth, 1/2 in. (13 mm) wide. Gears running in oil.

Reduction, Engine to Traction Drum: 13.86:1.

Traction Drum: 6 in. (15.2 cm) diameter solid rub-

ber on 16 gauge (1.5 mm) steel rims. Two sections

running on ball bearings.

Traction Drive Clutch: Friction Disk type—Hand

operated latch and bail at handle.

Differential: Enclosed spur gears.

Reel Drive: “A” section V-belt on 2.0 RD. and 3.70

RD. to countershaft (1. 85:1) 3/8 in. pitch x 3/16 in.

wide chain on 20T and 14T sprockets from counter-

shaft. Reduction Engine to Reel—1.30:1.

Reel Clutch: Engaging jaw type—hand operated at

the transaxle.

Reel: 3-1/2 in. (89 mm) diameter 9-blade, welded

tubular construction. Reel blades, high carbon heat

treated steel. Reel bearings, taper roller with adjustment.

Bedknife and Bar: Single-edge high carbon steel

knife, extra hard for long life, screwed to extruded

aluminum one-piece bed bar and back plate.

Dimensions:

Width: 27 in. (0.69 m)

Height: 44-3/4 in. (1.1 m) with handle

Length: 60 in. (1.5 m) including handle and catcher

Weight: 69 kilograms with catcher and cutting unit.

Optional Equipment:

Cutting Unit Model 04216

Brush Kit Part No. 2-2949

Skid Kit, Part No. 4-7299

Sectional Roller Kit Part No. 4-7319

Urethane Comb Kit Part No. 8-2560

Full Roller Kit Part No. 4-7309

Micro-cut Bedknife Part No. 95-3147

8

Specifications

Loading...

Loading...