FormNo.3409-695RevE

MultiPro

ModelNo.41240—SerialNo.400000000andUp

®

WMTurfSprayer

Registeratwww.T oro.com.

OriginalInstructions(EN)

Note:

TheinstallationoftheMultiProWMrequirestheinstallation

ofoneormoreinterdependentkits.ContactyourAuthorized

ToroDistributorformoreinformation.

*3409-695*E

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Readthismanualcarefullytolearnhowtooperate

andmaintainyourproductproperly.Theinformationin

thismanualcanhelpyouandothersavoidinjuryand

productdamage.AlthoughTorodesignsandproduces

safeproducts,youareresponsibleforoperatingthe

productproperlyandsafely .YoumaycontactT oro

directlyatwww.Exmark.comforproductsafetyand

operationaltrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

illustratesthelocationofthemodelandserialnumbers

ontheproduct.

Figure1

1.Locationofthemodelandserialnumbers

g022350

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

©2019—TheToro®Company

8111L yndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafeOperatingPractices....................................4

Training..............................................................4

BeforeOperating................................................5

ChemicalSafety.................................................6

WhileOperating..................................................6

Maintenance.......................................................8

SafetyandInstructionalDecals..........................9

Setup......................................................................14

1RemovingtheExistingBed............................16

2PreparingtoInstalltheTankSkid...................17

3InstallingtheHold-DownBracketsforthe

TankSkid......................................................18

4InstallingtheTankSkid..................................18

5AssemblingtheDrainValve...........................20

6DisconnectingtheBattery..............................21

7ConnectingtheSpeedSensor

Harness........................................................22

8CouplingtheSprayerPump...........................23

9InstallingtheControlConsoletothe

Machine........................................................23

10InstallingtheElectricalHarnessesforthe

Sprayer.........................................................24

11InstallingtheSprayerFuseBlock.................25

12ConnectingtheSprayerHarnesstothe

Battery..........................................................27

13LoweringtheTankSkid................................30

14InstallingtheCenterBoomSection...............31

15InstallingtheLeftandRightBoom

Section..........................................................32

16InstallingtheBoomHoses............................34

17InstallingtheNozzles...................................36

18InstallingtheFreshwaterTank......................36

19InstallingtheAnti-SiphonFill

Receptacle....................................................38

20CheckingtheBoomHingeSprings...............39

21StoringtheJackStands(Optional)...............39

22LearningMoreaboutY ourProduct...............40

ProductOverview...................................................41

Controls...........................................................41

Specications..................................................44

Operation................................................................44

ThinkSafetyFirst..............................................44

UsingtheInfoCenter.........................................44

PreparingtoUsetheSprayer............................54

OperatingtheSprayer......................................55

FillingtheFreshwaterTank...............................56

FillingtheSprayT ank........................................56

OperatingtheBooms........................................57

Spraying...........................................................58

TurfCarePrecautionswhileOperatingin

StationaryModes..........................................58

SprayingTips....................................................59

UncloggingaNozzle.........................................59

SelectingaNozzle............................................59

CleaningtheSprayer........................................59

CalibratingtheSprayer.....................................60

SprayFilterRecommendations........................64

Maintenance...........................................................67

RecommendedMaintenanceSchedule(s)...........67

DailyMaintenanceChecklist.............................68

NotationforAreasofConcern...........................68

Pre-MaintenanceProcedures..............................69

AccessingtheMachine.....................................69

Lubrication..........................................................70

GreasingtheSprayerSystem...........................70

GreasingtheSprayerPump.............................70

GreasingtheBoomHinges...............................71

SpraySystemMaintenance.................................71

InspectingtheHoses........................................72

ChangingtheSuctionFilter...............................72

ChangingthePressureFilter............................72

ChangingtheNozzleFilter................................73

InspectingtheSprayerPump............................73

AdjustingtheBoomstoLevel............................74

InspectingtheNylonPivotBushings.................75

Cleaning..............................................................75

CleaningtheFlowmeter...................................75

CleaningtheSprayerValves.............................76

Storage...................................................................86

RemovingtheSprayerandT ankSkid...............87

Troubleshooting......................................................90

Schematics.............................................................91

3

Safety

Important:Readandunderstandtheinformation

inthesafetysectionoftheOperator’sManual

foryourWorkmanvehiclebeforeoperatingthe

machine.

GeneralSafety

Thisproductiscapableofcausingpersonalinjury .

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Useappropriatepersonalprotectiveequipment

(PPE)toguardagainstcontactwithchemicals.

Chemicalsubstancesusedinthesprayersystem

maybehazardousandtoxic.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeareaofthesprayer

nozzlesandspraydrift.Keepbystandersand

childrenoutoftheoperatingarea.

•Neverallowchildrentooperatethemachine.

•Shutofftheengine,removethekey(ifequipped),

andwaitforallmovementtostopbeforeyouleave

theoperator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

Improperlyusingormaintainingthismachinecan

resultininjury .T oreducethepotentialforinjury ,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Notalltheattachmentsthatadapttothismachine

arecoveredinthismanual.Refertotheoperator’s

manualprovidedwitheachattachmentforadditional

safetyinstructions.

SafeOperatingPractices

Important:Themachineisdesignedprimarily

asanoff-roadvehicleandisnotintendedfor

extensiveuseonpublicroads.

,which

Whenusingthemachineonpublicroads,follow

alltrafcregulationsanduseanyadditional

accessoriesthatmayberequiredbylaw,suchas

lights,turnsignals,slow-movingvehicle(SMV)

sign,andothersasrequired.

TheWorkmanwasdesignedandtestedtooffer

safeservicewhenoperatedandmaintained

properly.Althoughhazardcontrolandaccident

preventiondependuponthedesignand

congurationofthemachine,thesefactors

alsodependontheawareness,concern,and

propertrainingofthepersonnelinvolvedin

theoperation,maintenance,andstorageofthe

machine.Improperlyusingormaintainingthe

machinecanresultininjuryordeath.

TheWorkmanisaspecializedutilityvehicledesigned

foroff-roaduseonly.Therideandhandlingofthe

machinehasadifferentfeelthanthatofpassenger

carsortrucks.T aketimetobecomefamiliarwithyour

machine.

NotalltheattachmentsthatadapttotheWorkman

arecoveredinthismanual.SeetheInstallation

Instructionsprovidedwithattachmentforadditional

safetyinstructions.

Toreducethepotentialforinjuryordeath,complywith

thefollowingsafetyinstructions:

Supervisor'sResponsibilities

•Makesurethatoperatorsarethoroughlytrained

andfamiliarwiththeOperator’sManual,the

Operator’sManualoftheWorkmanmachine,

trainingmaterial,enginemanual,andalllabelson

theWorkmanmachine.

•Establishyourownspecialproceduresandwork

rulesforunusualoperatingconditions(e.g.,slopes

toosteepformachineoperation).Usethethird

highlockoutswitchifhighspeedcouldresultina

safetyormachineabusesituation.

Training

•ReadtheOperator'sManualandothertraining

materialbeforeoperatingthemachine.

Note:Iftheoperator(s)ormechanic(s)cannot

readthemanuallanguage,itistheowner's

responsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverallowuntrainedpeopletooperateorservice

theequipment.

4

Note:Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeople,ordamagetoproperty.

BeforeOperating

•Operatethemachineonlyafterreadingand

understandingthecontentsofthismanual.

•Neverallowchildrentooperatethemachine.

•Neverallowotheradultstooperatethemachine

withoutrstreadingandunderstandingthe

Operator'sManual.Onlytrainedandauthorized

personsshouldoperatethismachine.Makesure

thatalloperatorsarephysicallyandmentally

capableofoperatingthemachine.

•Thismachineisdesignedtocarrytheoperator

and1passengerintheseatprovidedbythe

manufacturer.Nevercarryanyadditional

passengersonthemachine.

•Neveroperatethemachinewhileyouareill,tired,

orundertheinuenceofalcoholordrugs.

•Usetheseatbeltwhenoperatingthemachineand

becertainthatitcanbereleasedquicklyinthe

eventofanemergency .

•Becomefamiliarwiththecontrolsandknowhow

toshutofftheenginequickly.

•Keepallshields,safetydevices,anddecals

inplace.Ifashield,safetydevice,ordecalis

malfunctioning,illegible,ordamaged,repairor

replaceitbeforeoperatingthemachine.

•Wearappropriateclothing;includingsafety

glasses,longpants,substantialslip-resistant

footwearorrubberboots,andgloves.Donotwear

jewelryorlooseclothing.Tiebacklonghair.

•Keepbystandersawayfromtheareasofoperation.

•Avoiddrivingwhenitisdark,especiallyin

unfamiliarareas.Ifyoumustdrivewhenitisdark,

besuretodrivecautiouslyandusetheheadlights.

•Beforeoperatingthemachine,alwayscheckall

partsofthemachineandanyattachments.If

somethingiswrong,stopusingthemachine.

Makesurethattheproblemiscorrectedbeforethe

machineorattachmentisoperatedagain.

•Makesuretheoperatorandpassengerareais

cleanandfreefromchemicalresidueanddebris

buildup.

•Ensurethatalluidlineconnectorsaretightand

allhosesareingoodconditionbeforeapplying

pressuretothesystem.

Note:Donotusethemachineifitisleakingor

damaged.

•Sincefuelishighlyammable,handleitcarefully.

–Useanapprovedfuelcontainer.

–Donotremovethecapfromthefueltankwhen

theengineishotorrunning.Allowtheengine

tocoolbeforefuelingthemachine.

–Donotsmokewhilehandlingfuel.

–Fillthefueltankofthemachineoutdoors.

5

–Fillthefueltankofthemachinetoabout25mm

(1inch)belowthetopofthetank(thebottom

ofthellerneck).Donotoverllthefueltank.

–Wipeupanyspilledfuel.

ChemicalSafety

WARNING

Chemicalsubstancesusedinthe

spreader-sprayersystemmaybehazardous

andtoxictoyou,bystanders,animals,plants,

soilsorotherproperty .

•Carefullyreadandfollowthechemical

warninglabelsandmaterialsafetydata

sheets(MSDS)forallchemicalsusedand

protectyourselfaccordingtothechemical

manufacturer'srecommendations.Ensure

thataslittleskinaspossibleisexposed

whileusingchemicals.Useappropriate

personalprotectiveequipment(PPE)

toguardagainstpersonalcontactwith

chemicals;personalprotectiveequipment

includes:

–safetyglasses,goggles,and/orface

shield

–respiratororltermask

–chemical-resistantgloves

–rubberbootsorothersubstantial

footwear

–hearingprotection

–cleanchangeofclothes,soap,and

disposabletowels,tobekepton-hand,

intheeventofachemicalspill.

•Keepinmindthattheremaybemorethan

1chemicalused,andinformationoneach

chemicalshouldbeassessed.

•Refusetooperateorworkonthesprayerif

thisinformationisnotavailable!

•Beforeworkingonasprayersystem,

makesurethatthesystemhasbeen

triplerinsedandneutralizedaccording

totherecommendationsofthechemical

manufacturer(s)andthatallthevalves

havebeencycled3times.

•Verifythereisanadequatesupplyofclean

waterandsoapnearby ,andimmediately

washoffanychemicalsthatcontactyou.

•Obtainpropertrainingbeforeusingorhandling

chemicals.

•Usethecorrectchemicalforthejob.

•Followthechemicalmanufacturer'sinstructionsfor

thesafeapplicationofthechemical.Donotexceed

recommendedsystemapplicationpressure.

•Donotll,calibrate,orcleantheunitwhenpeople,

especiallychildren,orpetsareinthearea.

•Handlechemicalsinawell-ventilatedarea.

•Havecleanwateravailableespeciallywhenlling

thespraytank.

•Donoteat,drink,orsmokewhileworkingwith

chemicals.

•Donotcleanspraynozzlesbyblowingthrough

themorplacinginmouth.

•Alwayswashyourhandsandotherexposedareas

assoonaspossibleafteryounishworkingwith

chemicals.

•Keepchemicalsintheiroriginalpackagesand

storedinasafelocation.

•Properlydisposeofunusedchemicalsand

chemicalcontainersasinstructedbythechemical

manufacturerandyourlocalcodes.

•Chemicalsandfumesaredangerous;neverenter

thetankorplaceyourheadoverorintheopening

ofatank.

•Followalllocal,state,andfederalregulationsfor

spreadingorsprayingchemicals.

WhileOperating

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorless,deadlypoisonthatcan

befatal.

Donotrunengineindoorsorinanenclosed

area.

•Theoperatorandpassengershouldremain

seatedwheneverthemachineisinmotion.The

operatorshouldkeepbothhandsonsteering

wheelwheneverpossibleandthepassenger

shouldusetheprovidedhandholds.Keeparms

andlegswithinthevehiclebodyatalltimes.Never

carrypassengersintheboxoronattachments.

Rememberthatyourpassengermaynotbe

expectingyoutobrakeorturn.

•Alwayswatchoutforandavoidlowoverhangs

suchastreelimbs,doorjambs,andoverhead

walkways.Makesurethatthereisenoughroom

overheadtoeasilyclearthemachine,sprayer

boomsectionsandyourhead.

•Whenstartingtheengine:

6

–Sitontheoperator’sseatandensurethatthe

parkingbrakeisengaged.

–IfyourmachineisequippedwithaPTOor

handthrottlelever,disengagethePTOand

returnhandthrottlelevertotheOFFposition.

–Movetheshiftlevertoneutralanddepress

clutchpedal.

–Keepyourfootoffacceleratorpedal.

–TurnthekeyforthestarterswitchtoSTART

position.

•Usingthemachinedemandsattention.Failure

tooperatethemachinesafelymayresultinan

accident,tipoverofthemachine,andserious

injuryordeath.Drivecarefully.T opreventtipping

orlossofcontrol:

–Useextremecaution,reducespeed,and

maintainasafedistancearoundsandtraps,

ditches,creeks,ramps,andanyunfamiliar

areasorotherhazards.

–Watchforholesorotherhiddenhazards.

–Usecautionwhenoperatingthemachineona

steepslope.Normallytravelstraightupand

downslopes.Reducespeedwhenmaking

sharpturnsorwhenturningonhillsides.Avoid

turningonhillsideswheneverpossible.

–Useextracautionwhenoperatingthemachine

onwetsurfaces,athigherspeeds,orwitha

fullload.Stoppingtimeanddistanceincreases

withafullload.Shiftintoalowergearbefore

startingupordownahill.

–Avoidsuddenstopsandstarts.Donotgo

fromreversetoforwardorforwardtoreverse

withoutrstcomingtoacompletestop.

–Slowdownbeforeturning.Donotattempt

sharpturns,abruptmaneuvers,orotherunsafe

drivingactionsthatmaycausealossofvehicle

control.

–Beforebackingup,looktotherearandensure

thatnooneisbehindyou.Backupslowly.

–Watchoutfortrafcwhenyouarenearor

crossingroads.Alwaysyieldtherightofwayto

pedestriansandothervehicles.Thismachine

isnotdesignedforuseonstreetsorhighways.

Alwayssignalyourturnsorstopearlyenough

sothatotherpeopleknowwhatyouplantodo.

Obeyalltrafcrulesandregulations.

–Theelectricalandexhaustsystemsofthe

machinecanproducesparkscapableof

ignitingexplosivematerials.Neveroperatethe

machineinornearanareawherethereisdust

orfumesintheairthatareexplosive.

–Whendrainingthetank,donotletanyone

standbehindthemachineanddonotdrain

liquidonanyone’sfeet.

–Ifyouareeverunsureaboutsafeoperation,

stopworkandaskyoursupervisor.

•Donottouchtheengineormuferwhiletheengine

isrunningorsoonafterithasshutoff.These

areasmaybehotenoughtocauseburns.

•Ifthemachineevervibratesabnormally,stop

immediately,waitforallmotiontostop,andinspect

themachinefordamage.Repairalldamage

beforeresumingoperation.

•Beforegettingofftheseat:

1.Stopthemachine.

2.Removeyourfootfromthetractionpedal

andengagetheparkingbrake.

3.TurnthekeyforthestarterswitchtotheOFF

position.

4.Removethekeyfromthestarterswitch.

Important:Donotparkthemachineon

anincline.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

Braking

•Slowdownbeforeyouapproachanobstacle.This

givesyouextratimetostoporturnaway.Hitting

anobstaclecandamagethemachineandits

contents.Moreimportant,itcaninjureyouand

yourpassenger.

•Grossvehicleweight(GVW)hasamajorimpact

onyourabilitytostopand/orturn.Heavyloads

andattachmentsmakeamachinehardertostop

orturn.Theheaviertheload,thelongerittakes

tostop.

•Turfandpavementareslickwhentheyarewet.

Itcantake2to4timesaslongtostoponwet

surfacesasondrysurfaces.Ifyoudrivethrough

standingwaterdeepenoughtogetthebrakes

wet,theywillnotworkwelluntiltheyaredry.After

drivingthroughwater,youshouldtestthebrakes

tomakesurethattheyworkproperly .Iftheydo

not,driveslowlywhileputtinglightpressureonthe

brakepedal.Thisdriesthebrakesout.

7

OperatingonHillsandRough

Loading

Terrain

WARNING

Suddenchangesinterrainmaycauseabrupt

steeringwheelmovement,possiblyresulting

inhandandarminjuries.

•Reduceyourspeedwhenoperatingon

roughterrainandnearcurbs.

•Gripthesteeringwheellooselyaroundthe

perimeter.Keepyourhandsclearofthe

steeringwheelspokes.

Operatingthemachineonahillmaycausetippingor

rollingofthemachine,ortheenginemaystallandyou

couldloseheadwayonthehill.Thiscouldresultin

personalinjury.

•Donotacceleratequicklyorsuddenlyapplythe

brakeswhenbackingdownahill,especiallywitha

load.

•Neverdriveacrossasteephill;alwaysdrive

straightupordownorgoaroundthehill.

•Iftheenginestallsoryoubegintoloseheadway

whileclimbingahill,graduallyapplythebrakes

andslowlybackstraightdownthehill.

•Turningwhiletravelingupordownhillscanbe

dangerous.Ifyouhavetoturnwhileonahill,doit

slowlyandcautiously.Nevermakesharporfast

turns.

•Heavyloadsaffectstability.Reducetheweightof

theloadandyourspeedwhenoperatingonhills.

•Avoidstoppingonhills,especiallywithaload.

Stoppingwhilegoingdownahilltakeslongerthan

stoppingonlevelground.Ifthemachinemustbe

stopped,avoidsuddenspeedchanges,whichmay

initiatetippingorrollingofthemachine.Donot

suddenlyapplythebrakeswhenrollingbackward,

asthismaycausethemachinetooverturn.

TheweightofthecargocanchangetheWorkman

centerofgravityandhandling.T oavoidlossofcontrol

andpersonalinjury ,followtheseguidelines:

•Reducetheweightoftheloadwhenoperating

onhillsandroughterraintoavoidtippingor

overturningofthevehicle.

•Liquidloadscanshift.Thisshiftinghappens

mostoftenwhileturning,goingupordownhills,

suddenlychangingspeeds,orwhiledrivingover

roughsurfaces.Shiftingloadscancausethe

vehicletotipover.

•Whenoperatingwithaheavyload,reduceyour

speedandallowforsufcientbrakingdistance.Do

notsuddenlyapplythebrakes.Useextracaution

onslopes.

•Beawarethatheavyloadsincreaseyourstopping

distanceandreduceyourabilitytoturnquickly

withouttippingover.

Maintenance

•Onlypermitqualiedandauthorizedpersonnelto

maintain,repair,adjust,orinspectthemachine.

•Beforeservicingormakingadjustmentstothe

machine,parkthemachineonalevelsurface,

engagetheparkingbrake,shutofftheengine,

andremovethekeytopreventsomeonefrom

accidentallystartingtheengine.

•Emptythetankbeforetiltingorremovingthe

sprayerfrommachineandbeforestorage.

•Neverworkunderthemachinewithoutusingthe

tanksupportproprod.

•Ensurethatallhydrauliclineconnectorsaretight,

andthatallhydraulichosesandlinesareingood

conditionbeforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksthatcanejecthydraulicuidunderhigh

pressure.Usepaperorcardboard,notyourhands,

tosearchforleaks.

•Checkcarefullyforoverheadclearances(i.e.,

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontactthem.

•Donotremovetherolloverprotectionsystem

(ROPS).

•Reducespeedandloadwhenoperatingonrough

terrain,unevenground,andnearcurbs,holes,and

othersuddenchangesinterrain.Loadsmayshift,

causingthesprayertobecomeunstable.

DANGER

Hydraulicuidescapingunderpressure

canhavesufcientforcetopenetrateskin

anddoseriousdamage.

Ifuidisinjectedintotheskinitmustbe

surgicallyremovedwithinafewhoursby

adoctorfamiliarwiththisformofinjuryor

gangrenemayresult.

•Beforedisconnectingorperforminganywork

onthehydraulicsystem,relieveallpressurein

systembystoppingtheengine,cyclingthedump

valvefromraisetolower,and/orloweringthetank

8

andattachments.Ifthetankmustbeintheraised

position,secureitwiththesafetysupport.

•Tomakesurethattheentiremachineisingood

condition,keepallnuts,bolts,andscrewsproperly

tightened.

3,650rpm.T oassuresafetyandaccuracy,have

anAuthorizedT oroDistributorcheckthemaximum

enginespeedwithatachometer.

•Ifmajorrepairsareeverneededorassistanceis

required,contactanAuthorizedT oroDistributor.

•Toreducepotentialrehazard,keeptheengine

areafreeofexcessivegrease,grass,leavesand

accumulationofdirt.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,

clothing,andanypartsofthebodyawayfromthe

engineandanymovingparts.Keepeveryone

away.

•Donotoverspeedtheenginebychangingthe

governorsettings.Themaximumenginespeedis

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineTororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

•RefertoyourWorkmanmachineOperator’s

Manualforadditionalmaintenanceinformation.

131-5808

1.Automatic—closed

loop-ratecontrol

1.Warning—readtheOperator’sManual;usefresh,clean

waterforrst-aidwashing.

2.Manual—openloop-rate

control

120–0616

decal131-5808

1.Warning—readthe

Operator’sManual.

2.Warning—donotenterthe

sprayertank.

decal120-0616

120–0622

3.Chemicalburnhazard;

toxicgasinhalation

hazard—wearhandand

skinprotection;weareye

andrespiratoryprotection.

decal120-0622

9

decal120-0617

120–0617

1.Tankcontents

1.Grasptheboomhere.

1.Severinghazardofhand,

pinchingpoint—keep

awayfromactuatedjoints.

decal119-9434

2.Crushinghazard—keep

bystandersawayfromthe

machine.

119-9434

decal125-4052

125–4052

decal104-8904

104-8904

1.Raiseleftboom

2.Lowerleftboom5.Toggletankrinseon/off

3.Raiserightboom

4.Lowerrightboom

6.Togglesonicboomon/off

127-6976

1.Decrease2.Increase

decal127-6976

decal125-8139

125–8139

1.Toggleboomsprayerson/off

10

decal127-3966

127–3966

1.ReadtheOperator’s

Manualforinformationon

4.7.5A—TECcontroller

output

fuses.

2.30A—T ankrinse5.10A—Ignition

3.2A—TECcontrollerlogic6.15A—Sprayerboom

127–3936

1.Backwardtipping

hazard—donotraise

afulltank;donotmove

themachinewitharaised

tank;onlyraiseand

emptytank;onlymovethe

machinewithalowered

tank.

2.Electricalshockhazard,

overheadpower

lines—checkthearea

foroverheadpowerlines

beforeoperatingthe

machineinthearea.

3.Crushinghazard—keep

bystandersawaywhen

loweringthetank.

decal127-3937

127–3937

1.Warning—donotstep.3.Entanglementhazard,

belt—keepawayfrom

movingparts;keepall

guardsandshieldsin

place.

2.Warning—keepawayfrom

hotsurfaces.

decal127-3936

decal127-6979

127-6979

1.Bypass-returnow3.Agitationow

2.Flow

11

decal127-6981

127-6981

1.Bypass-returnow

2.Flow

1.Bypass-returnow

3.Boomspray

decal127-6982

127-6982

2.Boomspray

decal127-6984

127-6984

1.Flow

2.Tank-returnow

12

decal130-8294

130-8294

1.Leftboom5.Centerboomsprayon9.Rightboomsprayoff

2.Leftboomsprayon6.Centerboomsprayoff10.Speed

3.Leftboomsprayoff

4.Centerboom

7.Rightboom11.Increasespeed

8.Rightboomsprayon12.Decreasespeed

13.Agitation

14.Agitationon

15.Agitationoff

13

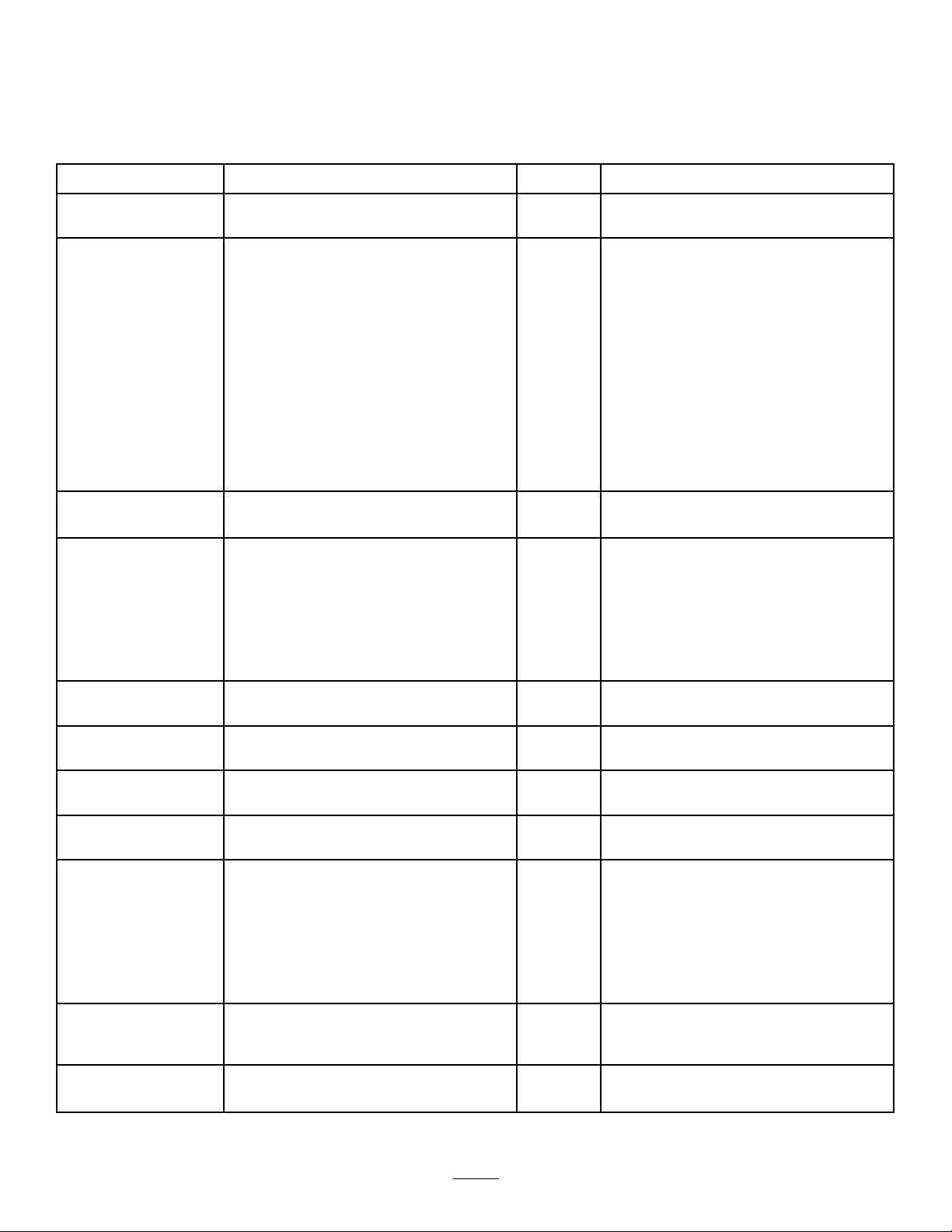

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Nopartsrequired

RearPTOKit,Heavy-DutyWorkman

Vehicle(HD-SeriesModelswitha

ManualTransmission)

MultiProWMTurfSprayerFinishing

Kit,ManualWorkmanUtilityVehicle

(HD-SeriesModelswithaManual

Transmission)

MultiProWMTurfSprayerFinishing

Kit,ManualWorkmanUtilityVehicle

(HD-SeriesModelswithaManual

Transmission)

MultiProWMTurfSprayerFinishing

Kit,AutomaticWorkmanUtilityVehicle

(HDX-AutoModel)

Hold-downbrackets2

Tankandskidassembly1

Clevispins

Taperedclevispin2

Hairpins2

Lynchpins4

Bolt(1/2x1-1/2inches)

Nuts(1/2inch)

Qty.

Use

–

1

1

1

1

2

2

2

Removetheexistingbed.

Preparetoinstallthecenterboom

section.

Installtheattachmenthold-down

brackets.

Installthetankskid.

5

6

7

8

9

10

11

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Consolemountingbracket

Flangelocknut(5/16inch)

Flange-headbolt(5/16inch)

Plasticbushing2

Controlconsole

Spring-clippin

Handknob1

J-clips3

Bolt(1/4x3/4inch)

Flangenut(1/4inch)

Fusedecal(127–3966)

–

–

–

–

1

3

3

1

1

1

1

1

Assemblethedrainvalve.

Disconnectthebattery.

Connectthespeedsensorharness.

Couplethesprayerpump.

Installthecontrolconsoletothe

machine.

Installthecontrolconsoleontothe

machine.

Installthecontrolconsoleandthe

electricalharness.

14

ProcedureDescription

12

13

14

15

16

18

19

Batteryterminalbolt2

Clampnut

Cover—wide(batteryterminal—red)

Bolt(1/2x1-1/2inch

Locknut(1/2inch)

Center-boomassembly

Bolt(3/8x1inch)

Flangelocknut(3/8inch)

Boom-transportcradle2

Bolt(1/2x1-1/4inches)

Flangenut(1/2inch)

Leftboomsection

Rightboomsection1

Flange-headbolts(3/8x1-1/4inch)

Backingplates8

Flangelocknuts(3/8inch)

Clevispin

Hairpin2

Hoseclamps3

R-clamp2

Shoulderbolt

Washer2

Nut2

Freshwatertank1

90°elbow(3/4inchNPT)

90°spigot

Freshwater-tankmount1

Mountstrap4

Flange-headbolt(5/16x5/8inch)

Flangelocknut(5/16inch)

Supporttube(freshwatertank)

Jamnut(5/16inch)

Bolt(5/16x1inch)

Shoulderbolt(1/2x1-15/16inches)

Bolt(5/16x2-1/4inch)

Washer(5/16inch)

Fillreceptacleassembly1

Flange-headbolt(5/16x3/4inch)

Qty.

10

10

10

Use

2

1

2

2

1

4

4

1

8

8

2

2

1

1

4

1

1

1

2

2

2

1

Connectthesprayerharnesstothe

battery.

Lowerthetankskid.

Installtheboomsection.

Installtheleftandrightboomsections.

Installtheboomhoses.

Installthefreshwatertank.

Installtheanti-siphonllreceptacle.

20

21

22

Nopartsrequired

Frontjackstand2

Rearjackstand2

Cotterpin

Clevispin(4-1/2inch)

Clevispin(3inch)

Knob2

Operator'sManual

Operatortrainingmaterial

Registrationcard1

Selectionguide

Pre-deliveryinspectionsheet1

15

–

4

2

2

1

1

1

Checktheboomhingesprings.

Storethejackstands(optional).

Readthemanualandviewthetraining

materialbeforeoperatingthemachine.

Important:TheMulti-ProWMturfsprayerrequiresa4-postROPSorcabinstalledwiththeWorkman

vehicle.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

1

RemovingtheExistingBed

NoPartsRequired

Procedure

CAUTION

Thefullbedweighsapproximately95kg(210

lb).Youcaninjureyourselfifyouremovethe

bedwithoutaid.

•Donottrytoinstallorremovethebedby

yourself.

•Getthehelpof2or3otherpeopleoruse

anoverheadcrane.

1.Cylinderrodend

2.Bedmountingplate

3.Clevispin6.Frontslots(2/3bed)

Figure3

4.Lynchpin

5.Rearslots(fullbed)

g002368

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andstarttheengine.

2.Movethehydraulicliftleverforwardandlower

thebeduntiltheclevispinsforthecylinderrod

endliftcylindersarelooseinthemountingslots

ofthebedmountingplates.

3.Releasethehydraulicliftlever,setthehydraulic

liftlocklever,andshutofftheengine;refertothe

Operator’sManualofyourmachine.

4.Removethelynchpinsfromtheouterendsof

thecylinderrodclevispins(Figure3).

5.Removetheclevispinssecuringthecylinder

rodendstothebedmountingplatesbypushing

thepinstowardthecenterlineofthemachine

(Figure3).

6.Removethelynchpinsandclevispinssecuring

thepivotbracketsofthebedtotheframe

channelsofthemachine(Figure4).

16

Figure4

1.Left,rearcornerofbed4.Clevispin

2.Vehicleframechannel

3.Pivotplate

7.Liftthebedoffthevehicle.

8.Stowtheliftcylindersinstorageclips.

5.Lynchpin

InstallationInstructionsfortheRearPTOKitforHeavy

DutyWorkmanVehicles.

High-FlowHydraulicsKit,

WorkmanHDX-AutoUtilityVehicle

(Non-TC—HDX-AutoModel)

FullyinstalltheHigh-FlowHydraulicsKitforWorkman

HDX-AutoUtilityVehicles;refertotheInstallation

InstructionsfortheHigh-FlowHydraulicsKit,

WorkmanHDX-AutoUtilityVehicle.

LiftingtheSprayerSkid

Usingliftingequipmentwitha408kg(900lb)lift

g002369

capacity,liftthetankskidfromtheshippingcrateat

the2frontand2rearliftpoints(Figure5).

Note:Ensurethatthetankskidisraisedhighenough

toinstallthejackstands.

2

PreparingtoInstallthe

TankSkid

Partsneededforthisprocedure:

RearPTOKit,Heavy-DutyWorkmanVehicle

1

(HD-SeriesModelswithaManualTransmission)

MultiProWMTurfSprayerFinishingKit,Manual

1

WorkmanUtilityV ehicle(HD-SeriesModelswitha

ManualTransmission)

MultiProWMTurfSprayerFinishingKit,Manual

1

WorkmanUtilityV ehicle(HD-SeriesModelswitha

ManualTransmission)

MultiProWMTurfSprayerFinishingKit,Automatic

1

WorkmanUtilityVehicle(HDX-AutoModel)

InstallingtheRearPTOKitfor

HeavyDutyWorkmanVehicles

(HD-SeriesModelswithaManual

Transmission)

ForHD-andHDX-SeriesWorkmanmodelswith

amanualtransmission,fullyinstalltheRearPTO

KitforHeavy-DutyWorkmanVehicles;refertothe

g023738

Figure5

1.Rearliftpoint2.Frontliftpoint

MultiProWorkmanTurfSprayer

FinishingKit(HD-SeriesModels

withaManualTransmission)

ForHD-andHDX-SeriesWorkmanmodelswith

amanualtransmission,completethestepsinthe

MultiProWMTurfSprayerFinishingKitforManual

WorkmanUtilityVehicles;refertotheInstallation

InstructionsfortheMultiProWMTurfSprayer

FinishingKit,ManualWorkmanUtilityVehicle.

MultiProWorkmanTurfSprayer

FinishingKit(HDX-AutoModel)

HDX-AutomaticSeriesWorkmanmodels,complete

thestepsintheMultiProWMTurfSprayerFinishing

17

KitforAutomaticWorkmanUtilityVehicles;referto

theInstallationInstructionsfortheMultiProWMTurf

SprayerFinishingKit,AutomaticWorkmanUtility

Vehicle.

3

InstallingtheHold-Down

BracketsfortheTankSkid

Partsneededforthisprocedure:

2Hold-downbrackets

Procedure

1.Supportbracket(engine

tube)

2.Hold-downbracket(tank

skid)

g028421

Figure7

3.Flanged-headbolts

4.Liftcylinder

1.Removethe2rearange-headboltsand2

angelocknutsthatsecurethesupportbracket

fortheenginetubetotheframeofthemachine

(Figure6).

Note:Retainthefastenersforlateruse.

Figure6

4.Torquetheboltsandnutsto91to113N∙m(67

to83ft-lb).

5.Repeatsteps1to4attheoppositesideofthe

machine.

g028410

1.Rearhole—support

bracket(enginetube)

2.Flangelocknut

3.Flange-headbolt

2.Rotatetheliftcylindertoprovideclearanceto

installthehold-downbracketforthetankskid

(Figure6).

3.Assemblethehold-downbracketstosupport

bracketandframetheusingthe2ange-head

boltsandangelocknutsremovedinstep1

(Figure7).

4.Enginesupporttube

5.Liftcylinder

18

4

InstallingtheTankSkid

Partsneededforthisprocedure:

1Tankandskidassembly

2

Clevispins

2Taperedclevispin

2Hairpins

4Lynchpins

2

Bolt(1/2x1-1/2inches)

2

Nuts(1/2inch)

2.Slowlylowerthetankskidontotheframeofthe

machine.

3.Extendtheliftcylinderstothebracketsonthe

tankskid,andalignthecylinderttingswiththe

holesinthetankskidbrackets(Figure9).

g022353

Figure9

Procedure

DANGER

Thesprayertankassemblyrepresentsa

storedenergyhazard.Ifnotproperlyretained

wheninstallingorremovingtheassembly,

itcanmoveorfallandinjureyouorother

bystanders.

Usestrapsandanoverheadlifttosupport

thesprayertankassemblyduringinstallation,

removal,oranymaintenancewheneveryou

removeretainingfasteners.

1.Usingalift,raisethetankskidassembly(Figure

8)andpositionitoverthevehicleframewiththe

pumpandvalveassembliesfacingrearward.

Note:Haveanotherpersonhelpyouperform

thefollowingsteps.

1.Hairpin

2.Clevispin

4.Securethetankskidtotheliftcylinderswith

theclevispinsandhairpinsatbothsidesofthe

machine.

5.Lineuptheholesinthepivotlugsattherear

ofthetankskidassemblywiththeholesinthe

bedpivottubeattheendofthevehicleframe

(Figure10).

3.Liftcylinders

Figure8

1.Rearliftpoint2.Frontliftpoint

g022354

Figure10

1.Taperedclevispin2.Lynchpin

6.Installataperedclevispinand2lynchpinsto

thepivotlugtosecurethetankassemblytothe

frame(Figure10).

7.Extendtheliftcylinderstoraisethetankand

supportitsweight.

g023738

19

Note:Disconnectthetankassemblyfromthe

liftingequipment.

8.Removethebedsupportfromthestorage

bracketsonbackoftheROPSpanel(Figure11).

5

AssemblingtheDrainValve

NoPartsRequired

Procedure

Figure11

1.Bedsupport

9.Pushthebedsupportontothecylinderrod,

makingsurethatthesupportendtabsreston

theendofcylinderbarrelandonthecylinderrod

end(Figure12).

g002397

1.Removethecabletiethatsecuresthedrain

valveandhoseforthesprayertanktotheskid

channel(Figure13).

Figure13

1.Drainvalve

2.Cabletie

3.Skidchannel

g213728

g009164

Figure12

1.Bedsupport

2.Liftcylinder

3.Skidframe

2.Movethedrainvalveandhoseoutboardofthe

skidchannel(Figure14A).

20

Figure14

1.Drainvalve3.Drain-valvebracket

2.Flange-headbolt(5/16x

5/8inch)

3.Removethe2ange-headbolt(5/16x5/8inch)

fromthecaseofthedrainvalve(Figure14).

6

DisconnectingtheBattery

NoPartsRequired

Procedure

WARNING

Incorrectbatterycableroutingcoulddamage

thesprayerandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalsprayercomponentscausing

sparks.Sparkscancausethebatterygasses

g213726

toexplode,resultinginpersonalinjury .

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthesprayer.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsof

thesprayer.

4.Assemblethedrainvalvetothedrain-valve

bracket(Figure14B)withthe2ange-headbolts

(5/16x5/8inch)thatyouremovedinstep3.

5.Tighten2anged-headboltsbyhand(Figure

14B).

1.Squeezethesidesofthebatterycovertorelease

thetabsfromtheslotsinthebatterybase,and

removethebatterycoverfromthebatterybase

(Figure15).

21

Figure15

1.Slot(batterybase)3.T ab(batterycover)

2.Cover(positivebattery

terminal)

2.Slidethecoverbackandremovethenegative

batteryterminalfromthebattery(Figure15).

3.Removethepositivebatteryterminalfromthe

battery(Figure15).

4.Terminal(negativebattery

cable)

7

ConnectingtheSpeed

SensorHarness

NoPartsRequired

g024088

g028456

1.Existingspeedsensorplugs

3.Connectthe3-pinconnectorforthevehicle

circuitofthewireharnessofthesprayerintothe

3-pinsocketforthevehiclecircuitofthewire

harnessforthemachine.

Figure16

ConnectingtheSpeedSensor

Harness(HDX-AutoModel)

1.Atthewireharnessforthesprayer,locatethe

3-socketconnectorforthespeedsensorcircuit

(Figure17).

ConnectingtheSpeedSensor

Harness(HD-SeriesModelswitha

ManualTransmission)

1.Atthewireharnessforthesprayer,locatethe

3-socketconnectorforthespeedsensorcircuit

andthe3-pinconnectorforthevehiclecircuit.

2.Atthetransaxleofthemachine,connectthe

3-pinconnectorofthewireharnessofthe

machineforspeedsensorintothe3-socket

connectorofthesprayerharnessforthespeed

sensor(Figure16).

22

1.3-pinconnector(machine

wireharness—speed

sensor)

2.3-socketconnector

(sprayerwire

harness—speedsensor)

3.Hydraulictank

g028436

Figure17

4.Rearframetube

5.Backofthemachine

6.Rightsideofthemachine

2.Connectthe3-pinconnectorofthewireharness

ofthemachineforspeedsensorintothe

3-socketconnectorofthesprayerharnessfor

thespeedsensor(Figure17).

ofthecontrolmountplate.RefertotheHandThrottle

KitInstallationInstructionsfordirectionsonremoving

andinstallingthehandthrottleassembly.

1.Removethe3boltsand3nutsthatsecurethe

lower-centerportionofthedashpaneltothe

dashsupportbracket(Figure18).

8

CouplingtheSprayerPump

NoPartsRequired

Procedure

•ForHD-seriesmodelswithamanualtransmission,

couplethePTOshafttothetransaxlePTO;refer

totheInstallationInstructionsfortheMultiProWM

TurfSprayerFinishingKit,ManualWorkmanUtility

Vehicle.

•ForHDX-Automodel—connectthehydraulic

motorhosestothequick-disconnectttingsatthe

high-owhydraulicpanel;refertotheInstallation

InstructionsfortheMultiProWMTurfSprayer

FinishingKit,AutomaticWorkmanUtilityVehicle.

9

Note:SomeolderWorkmanmachinesmayuse

4boltsandangenuts.

Note:Discardtheboltsandnuts.

InstallingtheControl

ConsoletotheMachine

Partsneededforthisprocedure:

1

Consolemountingbracket

3

Flangelocknut(5/16inch)

3

Flange-headbolt(5/16inch)

2Plasticbushing

1

Controlconsole

1

Spring-clippin

1Handknob

InstallingtheConsoleMounting

Bracket

Note:OnsomeWorkmanvehicles,thecontrolmount

plateisattachedtothedashboardatthesamelocation

wherethebracketfortheoptionalhandthrottlekitis

mounted.Ifthehandthrottlekitisinstalled,youneed

toremovethebracketofthehandthrottleassembly

fromthedashboard,alignthecontrolmountplateto

thedash,andinstallthehandthrottlebracketontop

Figure18

1.Bolt

2.Nut

3.Cashpanel(lowercenter

area)

4.Mountingbracket(control

console)

2.Aligntheholesinthemountingbracketforthe

controlconsolewiththeholesinthedashand

supportbracket(Figure18).

3.Assemblethemountingbracketdashpaneland

supportbracketwiththe3ange-headbolts

(5/16x1inch)and3angelocknuts(5/16inch).

4.Torquethenutsandboltsto(Figure18).

5.Bushing(plastic)

6.Flange-headbolts(5/16x

1inch)

7.Flangelocknuts(5/16

inch)

g028408

23

5.Insertthe2plasticbushingsintothemounting

bracket(Figure18).

InstallingtheControlConsoleto

theMachine

10

InstallingtheElectrical

1.Removethehairpinsecuringthepivotpinofthe

controlconsoletothestoragebracketonthe

sprayertank.

2.Installthecontrolconsoleontothecontrol

mountingbracketandsecurethecontrolconsole

withthespring-clippin(Figure19).

Note:Ensurethatthespringclipisrotatedover

thepivotpintopositivelysecurethespring-clip

pin.

HarnessesfortheSprayer

Partsneededforthisprocedure:

3J-clips

1

Bolt(1/4x3/4inch)

1

Flangenut(1/4inch)

RoutingtheRearElectrical

HarnessfortheSprayertothe

ControlConsole

1.Install2J-clipsinthecenterconsoleatthe

pointslocatedinFigure20orFigure21using

theexistingscrews.

Figure19

1.Spring-clippin3.Controlmountingbracket

2.Pivotpin(controlconsole)

3.Installthehandknobandtightenittopreventthe

consolefromrotatingduringoperation(Figure

19).

4.Handknob

g002507

Figure20

HD-Seriesmodelswithanmanualtransmission

g033521

1.J-clip

2.Existingscrews

24

3.Control-boxharness

4.Centerconsole

HDX-AutoModel

ConnectingtheRearElectrical

HarnesstotheFrontElectrical

HarnessattheControlConsole

1.Alignthe2keysofthe38-pinconnectorofthe

rearwireharnessforthesprayerwiththe2

keywaysofthe38-socketconnectorofthefront

wireharnessconnectedtothecontrolconsole

(Figure23).

g028443

Figure21

1.Centerconsole

2.J-clip

3.Existingscrews

4.Control-boxharness

2.InstallaJ-clipbehindthepassengerseat(Figure

22)usingabolt(1/4x1/2inch)andaanged

nut(1/4inch).

Figure22

1.J-clip

g033524

Figure23

1.38-socketconnector(front

wireharness—control

console)

2.Alignmentkeys

g024089

2.Plugtherearwire-harnessconnectorintothe

3.38-pinconnector(rear

wireharness—sprayer)

frontwireharnessconnectoruntilthelatchesof

theconnectorssnaptogethersecurely(Figure

23).

3.Securethecontrolconsoleharnesstothe

consoleandROPScoverusingtheJ-clips

(Figure22).

25

11

InstallingtheSprayerFuse

Block

Partsneededforthisprocedure:

1

Fusedecal(127–3966)

Procedure

1.Atthecontrolconsoleforthesprayer,routethe

branchofthefrontwireharnesswiththefuse

blocksbetweenthebottomofthedashpanel

andthecrosstubeofthemachinechassisand

downtowardtheforwardsideofthefuseblock

ofthemachine(Figure24).

Figure25

1.Uninsulatedreceptacle

terminal(yellow,

optional-power

wire—sprayerfuseblock)

2.Insulatedbladeterminal

(yellow,optional-power

wire—sprayerfuseblock)

3.Backofthemachine6.Fuseblock(machine

4.Fuseblock(sprayer

wiring)

5.Uninsulatedreceptacle

terminal(yellowpower

wire—machinefuseblock)

wiring)

g033529

1.Fuseblocks(frontwire

harness—controlconsole)

3.Connecttheuninsulatedreceptacleterminalof

thefuseblockforthemachinetotheinsulated

bladeterminalofthefuseblockofthesprayer

(Figure25).

4.AligntheT-ttingsontheofthefuseblockof

thesprayertotheT-slotsofthefuseblockfor

themachineandslidethesprayerfuseblock

intotheslotsuntilthefuseblockisfullyseated

(Figure26).

g033528

Figure24

2.Crosstube(machine

chassis)

2.Locatetheuninsulatedreceptacleterminalat

theendoftheopen,yellowpowerwireofthe

fuseblockforthemachineandtheinsulated

bladeterminalattheendoftheyellow,optional

powerwireofthefuseblockofthesprayer

wiring(Figure25).

26

Figure26

1.Backofthemachine4.T-slots(fuseblockforthe

2.T-ttings(fuseblockfor

thesprayer)

3.Fuseblockforthesprayer

machine)

5.Fuseblockofthemachine

12

ConnectingtheSprayer

HarnesstotheBattery

Partsneededforthisprocedure:

2Batteryterminalbolt

2

Clampnut

1

Cover—wide(batteryterminal—red)

PreparingthePositiveBattery

Terminal

WARNING

Incorrectbatterycableroutingcoulddamage

thesprayerandcables,causingsparks.

Sparkscancausethebatterygassesto

g028445

explode,resultinginpersonalinjury.

Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative(black)

cable.

1.RemovethenutsandT-boltsattheclampsofthe

positiveandnegativebatterycables(Figure27).

5.Attachthefusedecalonasurfacenearthefuse

blockforthesprayer.

Note:YounolongerneedthenutsandT-bolts.

27

Figure27

g033559

1.T-bolt3.Positivebatterycable

(machine)

2.Nut4.Negativebatterycable

(machine)

2.Removethecover(narrow)fromthepositive

batterycable(Figure28).

Note:Y ounolongerneedthenarrowbattery

cover.

Figure28

1.Cover–narrow(battery

terminal—red)

2.Positivebatterycable

(machine)

3.Cover–wide(battery

terminal—red)

3.Installthewidebatterycoveroverthepositive

batterycableasshowninFigure28.

Note:Slidethecoverfarenoughoverthe

cablestoallowaccesstothepostclamp.

4.Aligntheringterminalofthefusiblelink(sprayer

wireharness)thoughthewidebatterycoveras

showninFigure29.

g033568

28

Figure29

1.Cover–wide(battery

terminal—red)

2.Terminal(fusible-link

harness—sprayer

harness)

5.Looselyassembleaterminalboltandaclamp

nuttothepositiveandnegativebattery-cable

clamps(Figure30).

g033560

1.Ringterminal(fusible-link

harness—sprayer

harness)

2.Positivebatterycable

(machine)

3.Negativebatterycable

(machine)

Figure31

4.Clampnut

5.Terminalbolt

6.Ringterminal(negative

batterywire—sprayerwire

harness)

g033561

7.Securetheringterminalofthenegativewire

(black—sprayerwireharness)tothepostofthe

terminalboltthatyouassembledtothenegative

batterycablewithaclampnut(Figure31).

8.Assemblethepositivebatterycableontothe

positivebatterypostandtightentheclampnut

byhand(Figure32).

Figure30

1.Terminalbolt3.Positivebattery-cable

2.Clampnut

clamp

4.Negativebattery-cable

clamp

6.Securetheringterminalofthefusiblelink

(sprayerwireharness)tothepostoftheterminal

boltthatyouassembledtothepositivebattery

cablewithaclampnut(Figure31).

g033558

g033567

Figure32

1.Cover–new(battery

terminal—red)

2.Positivebatterypost

3.Negativebatterypost

9.Assemblethenegativebatterycableontothe

negativebatterypostandtightentheclampnut

byhand.

29

10.Squeezethesidesofthebatterycover,alignthe

tabsofthecoverwiththeslotsinthebattery

base,andreleasethebatterycover(Figure33).

g002397

Figure35

1.Bedsupport

Figure33

1.Slot(batterybase)2.T ab(batterycover)

13

LoweringtheTankSkid

Partsneededforthisprocedure:

2

Bolt(1/2x1-1/2inch

2

Locknut(1/2inch)

Procedure

1.Startthemachineandraisethetankskidslightly

withtheliftcylinders.

2.Removethebedsupportfromtheliftcylinder

andstowthesupportinthestoragebrackets

atthebackoftheROPSpanel(Figure34and

Figure35).

g033557

3.Useliftcylinderstoslowlylowerthetanktothe

frame.

Note:Haveanotherpersonobservethetank

skidasitlowers.Lookforhosesandwiringthat

mightbecomepinchedorbent.

4.Checkthealignmentofthetankskidtothe

frameofthemachine.

5.Removetheaccesspanelsatbothsidesofthe

skidframe(Figure36).

g022355

Figure36

1.Accesspaneldoor

2.Bolt(1/2x1-1/2inch

3.Locknut(1/2inch)

Figure34

6.Checkthehosesorwiringthatyoucansee

throughtheopeningintheskidframeforsigns

ofpinchingorbending.

Important:Ifanyhosesorwiringonthe

tankskidassemblyarepinchedorbent,

raisetheassemblyup,adjustitspositioning,

andtietheitemsback.

7.Alignthefrontmountingbracketswiththe

hold-downbracketsinstalledin3Installingthe

g033569

30

Hold-DownBracketsfortheTankSkid(page18).

8.Securetheholddownbracketofthetankskid

assemblytothebedbracketontheframeat

eachsideofthemachinewithabolt(1/2x1-1/2

inches)andalocknut(1/2inch)asshownin

Figure36.

9.Torquetheboltandlocknutto91to113N∙m(67

to83ft-lb).

10.Repeatsteps7through9attheothersideofthe

tankskidandmachine.

14

InstallingtheCenterBoom

Section

Partsneededforthisprocedure:

1

Center-boomassembly

10

Bolt(3/8x1inch)

10

Flangelocknut(3/8inch)

2Boom-transportcradle

4

Bolt(1/2x1-1/4inches)

4

Flangenut(1/2inch)

AssemblingtheBoom-Transport

Cradles

1.Attachliftingequipmenttothecenterboom

sectionandremoveitfromtheshipping

container.

2.Aligntheboomtransportcradlestothecenter

boomsection(Figure37).

Figure37

1.Boom-transportcradle

2.Bolts(3/8x1inch)5.Flangedlocknut(3/8inch)

3.Verticalholes(boom

centersection)

3.Assemblethecradlestotheboomsection

(Figure37andFigure38)with6bolts(3/8x1

inch)and6angedlocknuts(3/8inch).

1.Locknuts(3/8inch)

4.Horizontalhole(boom

centersection)

Figure38

g028458

g028459

4.Torquetheboltsandnutsto37to45N∙m(27

to33ft-lb).

InstallingtheCenterBoomSection

totheTankSkid

1.Startthemachine,removethebedsupportfrom

theliftcylinderandstowthesupport,lowerthe

tankskid,shutoffthemachine,andremovethe

keyfromthestarterswitch.

2.Alignthebottomholeinthesectionmounting

bracketsofthecenterboomassemblywiththe

31

thirdholefromthebottomintheboomsupports

onthesprayskidframe,asshowninFigure39.

Note:Ifnecessary,loosentheboomsupports

andadjustedthemtothecenterboomsection

forbetterholealignment.T orquetheboltsand

nutsto67to83N∙m(91to113ft-lb).

Figure39

1.Locknut(1/2inch)4.Sectionmountingbracket

2.Hole3—fromthebottom

(boomsupport)

3.Sectionmountingbracket

(left)

3.Assemblethecenterboomassemblytothe

sprayskidframewith4bolts(1/2x1-1/4inches)

and4locknuts(1/2inch).

4.Torquetheboltsandnutsto67to83N∙m(91

to113ft-lb).

(right)

5.Bolt(1/2x1-1/4inches)

15

InstallingtheLeftandRight

BoomSection

Partsneededforthisprocedure:

1

Leftboomsection

1Rightboomsection

8

Flange-headbolts(3/8x1-1/4inch)

8Backingplates

8

Flangelocknuts(3/8inch)

2

Clevispin

2Hairpin

g028460

Procedure

Eachboomsectionweighsapproximately14kg(30

lb).

1.Removethe4ange-headbolts(3/8x1-1/4

inch),4backingplates,and4angelocknuts

(3/8inch)fromthehingebracketofthe

center-boomsection.

2.Rotateeachpivotbracketattheendofthe

centerboomsectionsothatthebracketsalign

vertically(Figure40).

ConnectingtheHosesandWiring

fortheBoomLiftValve

•ForHD-SeriesModelswithaManualTransmission,

refertotheinstallationinstructionsfortheMultiPro

WMTurfSprayerFinishingKit,ManualWorkman

UtilityVehicle.

•ForHDX-AutoModel,refertotheinstallation

instructionsfortheMultiProWMTurfSprayer

FinishingKit,AutomaticWorkmanUtilityVehicle.

Figure40

1.Centerboomsection

2.Boomextension6.Backingplates

3.Hingeplate

4.Flange-headbolts(3/8x

1-1/4inch)

3.Lifttheouterboomsectionandalignholesinthe

triangularmountingplateattheendoftheouter

boomsectionwiththeholesinthepivotbracket.

32

5.Triangularmountingplate

7.Flangelocknuts(3/8inch)

g028737

Note:Ensurethattheturretsforthesprayer

nozzlesarefacingrearward.

4.Assemblehingeplatetothetriangularplate

using4ange-headbolts,4backingplates,and

4angelocknuts(Figure40),thatyouremoved

instep1.

5.Torquethenutsboltsandnutsto37to45N∙m

(27to33ft-lb).

6.Aligntherodendoftheboomliftcylinderwith

theholesinthehornofthepivotbracket(Figure

40).

Figure41

1.Rodend(boomlift

cylinder)

2.Horn(pivotbracket)

3.Clevispin(5/8x4-3/4

inch)

4.Hairpin

7.Securetherodendtothepivotbracketwitha

clevispinandahairpin(Figure40).

8.Repeatstep1through5ontheothersideofthe

center-boomassemblywiththeopposingboom

section.

Note:Beforeyounishthisprocedure,ensure

thatallofturretsforthespraynozzlesarefacing

rearward.

g028738

33

16

InstallingtheBoomHoses

Partsneededforthisprocedure:

3Hoseclamps

2R-clamp

2

Shoulderbolt

2Washer

2Nut

InstallingtheLeftandRightBoom

SectionHoses

1.Routetheboom-sectionhosesasshownin

Figure42andFigure43.

1.Nut

2.Washer

3.R-clamp6.Hoseclamp

4.Shoulderbolt7.Left-boomhose

5.T-tting8.Left-sectionvalve

g028468

Figure42

Hose—LeftBoomSection

34

Figure43

Hose—RightBoomSection

g213727

1.Nut

2.Washer

3.R-clamp6.Hoseclamp

4.Shoulderbolt

5.T-tting

2.Securetheboomhosestothefrontsideofthe

centerboomsection(Figure42andFigure43)

with1R-clamp,1shoulderbolt(5/16x1inch),1

locknut(5/16inch),and1washer(5/16inch).

3.Installtheboomsectionhoseoverthebarbed

T-ttingattheboomsectionandsecurethehose

withahoseclamp(Figure42andFigure43).

Note:Applyacoatofliquidsoaptothehose

barboftheteettingtoeaseinstallationofthe

hose.

4.Repeatsteps1through3onthehosetothe

boomsectionontheothersideofthesprayer.

7.Right-boomhose

8.Right-sectionvalve

35

InstallingtheCenterBoom-Section

Hose

1.Routethecenterboom-sectionhoseasshown

inFigure44.

Figure44

1.Up

2.T-tting5.Center-sectionvalve

3.Hoseclamp

2.Installtheboomsectionhoseoverthebarbed

T-ttingatthecenterboomsectionandsecure

thehosewithahoseclamp(Figure44).

4.Center-boomhose

6.Frontofthemachine

Note:Applyacoatofliquidsoaptothehose

barboftheteettingtoeaseinstallationofthe

hose.

17

InstallingtheNozzles

3.Turnthenozzleclockwisetolockthecamson

thereceptacleinplace.

4.Verifythefanportionofthenozzle.

SeetheInstallationInstructionsaccompanyingthe

nozzlesformoreinformation.

18

InstallingtheFreshwater

Tank

g028471

Partsneededforthisprocedure:

1Freshwatertank

1

90°elbow(3/4inchNPT)

1

90°spigot

1Freshwater-tankmount

4Mountstrap

4

Flange-headbolt(5/16x5/8inch)

10

Flangelocknut(5/16inch)

1

Supporttube(freshwatertank)

1

Jamnut(5/16inch)

1

Bolt(5/16x1inch)

2

Shoulderbolt(1/2x1-15/16inches)

2

Bolt(5/16x2-1/4inch)

2

Washer(5/16inch)

NoPartsRequired

Procedure

Thenozzlesthatyouusetoapplyyourchemicals

varydependingontherateofapplicationthatyou

need;therefore,nozzlesarenotsuppliedwiththekit.

Toobtainthecorrectnozzlesforyourneeds,contact

yourAuthorizedT oroDistributorandbepreparedto

givethemthenfollowinginformation:

•Thetargetapplicationrateinlitersperhectare,US

gallonsperacre,orUSgallonsper1,000square

feet.

•Thetargetspeedofthevehicleinkilometersper

hourormilesperhour.

1.Threadorinsertthenozzleintothenozzle

receptaclefollowedbyagasket.

2.Slidethenozzlereceptacleoverthenozzle

ttingonaturret.

AssemblingtheMountBracketto

theFreshwaterTank

1.Assemblethefreshwatertanktothe

freshwater-tankmountwiththe2mountstraps,

4ange-headbolt(5/16x5/8inch),and4ange

locknuts(5/16inch)asshowninFigure45.

Note:Ensurethattheelbowandspigotare

alignedtothesamesideofthetankasthe

freshwater-tankdecal.

36

Figure45

1.Freshwater-tankmount4.Mountstrap

2.Flangelocknut(5/16inch)5.Flange-headbolt(5/16x

5/8inch)

3.Freshwatertank

InstallingtheTank-SupportTube

1.Alignthesupporttubeforthefreshwatertank

withthetank-supportchannel(Figure46).

g033572

Figure46

1.Jamnut(5/16inch)5.Bolt(5/16x1inch)

g033570

2.Supporttube(freshwater

tank)

3.Frontofthemachine7.Weldnut(support

4.Topofthemachine8.Shoulderbolt(1/2x

6.Flangelocknut(5/16inch)

channel—freshwater

tank)

1-15/16inches)

2.Torquetheboltsandnutsto20to25N∙m(175

to225in-lb).

2.Aligntheholesinthesupporttubewiththeholes

inthechannel(Figure46).

3.Securethetubetothechannel(Figure46)with

the2shoulderbolts(1/2x1-15/16inches)and2

angelocknuts(5/16inch).

4.Torquetheboltsandnutsto20to25N∙m(175

to225in-lb).

5.Threadthejamnut(5/16inch)intothebolt(5/16

x1inch)asshowninFigure46.

6.Threadthebolt(5/16x1inch)andjamnutinto

theweldnutatthebottomofthetanksupport

channelandtightentheboltandjamnutby

hand(Figure46).

37

InstallingtheTank

Note:TheMulti-ProWMturfsprayerrequiresa

4-postROPSorcabinstalledontotheWorkman

vehicle.

1.Assemblethefreshwatertankandmountonto

thesupporttubewiththe2bolts(5/16x2-1/4

inch)and2angelocknuts(5/16inch)asshown

inFigure47.

19

InstallingtheAnti-Siphon

FillReceptacle

Partsneededforthisprocedure:

1Fillreceptacleassembly

1

Flange-headbolt(5/16x3/4inch)

Procedure

Placethell-receptacleassemblyoverthethreaded

holeinthetank(Figure48)andsecureitwitha

ange-headbolt(5/16x3/4inch).

Figure47

1.Freshwatertankmount

2.Flangelocknut(5/16inch)5.Bolt(5/16x2-1/4inch)

3.Supporttube(freshwater

tank)

2.Torquetheboltsandnutsto20to25N∙m(175

to225in-lb).

4.Washer(5/16inch)

g033573

g208978

Figure48

1.Fill-receptacleassembly

2.Flangebolt(5/16x3/4

inch)

38

20

CheckingtheBoomHinge

Springs

NoPartsRequired

Procedure

Important:Operatingthespraysystemwith

theboomhingespringsundertheincorrect

compressioncoulddamagetheboomassembly.

Measurethespringsandusethejamnutto

compressthespringsto4cm(1-1/2inches)if

necessary.

Thesprayerisshippedwiththeboomextensions

swungforwardtofacilitatepackagingofthemachine.

Thespringsarenotfullytightenedatthetimeof

manufacturetoallowtheboomstobeinthisposition

fortransit.Beforeoperatingthemachine,adjustthe

springstothecorrectcompression.

1.Ifnecessary,removethepackingcomponents

thatsecuretherightandleftextensionbooms

duringshipping.

2.Supporttheboomswhiletheyareextendedto

thesprayposition.

Figure49

1.Boomhingespring

2.Jamnut

4.Repeattheprocedureforeachspringonboth

boomhinges.

5.Movetheboomsintothetransport“X”position.

Note:SeeUsingtheBoomTransportCradle

(page57)formoreinformation.

3.4cm(1-1/2inches)

g210326

3.Attheboomhinge,measurethecompressionof

theupperandlowerspringswhilethebooms

areintheirextendedposition(Figure49).

A.Compressallthespringsuntiltheymeasure

4cm(1-1/2inches).

B.Usethejamnuttocompressanyspringthat

measuresgreaterthan4cm(1-1/2inches).

21

StoringtheJackStands

(Optional)

Partsneededforthisprocedure:

2Frontjackstand

2Rearjackstand

4

Cotterpin

2

Clevispin(4-1/2inch)

2

Clevispin(3inch)

2Knob

Procedure

1.Insertthefrontjackstandsupsidedownintothe

framenearthefronttie-downpoints(Figure50).

39

Figure50

22

LearningMoreaboutYour

Product

Partsneededforthisprocedure:

1

Operator'sManual

1

Operatortrainingmaterial

1Registrationcard

1

Selectionguide

1Pre-deliveryinspectionsheet

g023740

1.Frontjackstand2.Knob

2.Securethefrontjackstandswith2clevispins(3

inch)and2cotterpinsthroughthemiddlehole

onthestands.

3.Inserttherearjackstandsfromthebottom,up

intotheframe,nearthereartie-downpoints

(Figure51).

Figure51

Procedure

1.Readthemanuals.

2.Viewtheoperatortrainingmaterial.

3.Usethenozzleselectionguidetochoosethe

correctnozzlesforyourspecicapplication.

4.Storethedocumentationinasafeplace.

g023739

1.Rearjackstand

4.Securetherearjackstandswith4clevispins

(4-1/2inch)and4cotterpinsthroughthelast

holeonthestands.

40

ProductOverview

Figure52

1.Master-boomswitch

2.Boom-sectionswitches(sprayerOn/Off)7.Sonic-boomswitch(optional)

3.Boomliftswitches

4.InfoCenter

5.Pressuregauge

Controls

6.Rinseswitch(optional)

8.Application-rateswitch

9.Agitationswitch

andmore(Figure52).Formoreinformation,referto

UsingtheInfoCenter(page44).

InfoCenterLCDDisplay

TheInfoCenterLCDdisplayshowsinformationabout

yourmachineandbatterypacksuchasthecurrent

batterycharge,thespeed,diagnosticsinformation,

41

g028854

Master-BoomSwitch

Themaster-boomswitchallowsyoutostartorstop

theallsprayoperation.Presstheswitchtorunorstop

thespraysystem(Figure52).

Boom-SectionSwitches

Theboom-sectionswitchesarelocatedalongthe

bottomofthecontrolpanel(Figure52).T oggle

eachswitchupwardtoturnthesprayersforthe

correspondingboomsectiononanddownwardtoturn

thesprayersoff.Whentheboom-sectionswitchisset

totheONposition,thelightontheswitchilluminates.

Theseswitchesonlyaffectthespraysystemwhenthe

master-boomswitchisintheONposition.

Application-RateSwitch

g028486

Figure53

Theapplication-rateswitchislocatedontheleft

sideofthecontrolpanel(Figure52).Pressand

holdtheswitchupwardtoincreasethespraysystem

applicationrate,orpressandholditdownwardto

decreaseapplicationrate.

Boom-LiftSwitches

Theelectricboom-liftswitchesraiseandlowertheir

respectivebooms(Figure52).Thereisaleftandright

liftswitch.Pressandholdtheswitchupwardtoraise

therespectiveboom,orpressandholdtheswitch

downwardtolowertherespectiveboom.

Sprayer-ModeSwitch(HDX-Auto

Model)

Usethesprayer-modeswitchtoselectbetweenthe

followingsprayingmethods:

•Usethemanualmodewhenyouwanttomanually

controlthesprayerapplicationrate.

•Usetheautomaticmodewhenyouwantthe

computertocontrolsprayerapplicationratewith

settingyouenterintheInfoCenter.

1.InfoCenterconsole

2.Sprayer-modeswitch

3.Automaticmode

(sprayer-modeswitch

position)

4.Manualmode

(sprayer-modeswitch

position)

Regulating(RateControl)Valve

Theregulatingvalvelocatedbehindthetank(Figure

54),Theregulatingvalvecontrolstheamountofuid

thatisroutedtotheboomsortheratereturntothe

tank.

Figure54

1.Regulating(ratecontrol)

valve

2.Agitationvalve5.Boomsectionvalves

3.Master-boomvalve

42

g028483

4.Flowmeter

Flowmeter

Theowmetermeasurestheowrateoftheuidto

theboomsectionvalves(Figure54).

Boom-SectionValves

Usetheboom-sectionvalvestoturnthesprayer

pressureonorofftothesprayernozzlesintheleft,

center,andrightboomsections(Figure54).

BoomSection-BypassValves

Theboomsection-bypassvalves(Figure55)redirect

theuidowfromaboomtothetankwhenyouturn

offtheboomsection.Y oucanadjustthesevalvesto

ensurethattheboompressureremainsconstantno

matterwhichcombinationofboomsyouareoperating;

refertoCalibratingtheBoomBypass(page62).

g033579

Figure56

1.Agitation-controlvalve

Note:HD-seriesmodelswithamanual

transmission—foragitationtoworkthePTOand

clutchmustbeengagedandtheenginemustbe

runningaboveanidle.Ifyoustopthesprayerand

needagitationcirculatingthecontentofthetank,

placetherangeshiftleverintheNEUTRALposition,let

outtheclutch,engagetheparkingbrake,andsetthe

handthrottle(ifequipped).

Figure55

1.Leftboomsection-bypass

valve

2.Centerboom

section-bypassvalve

3.Rightboom

section-bypassvalve

Agitation-ThrottleValve

Thisvalveislocatedontherearleftsideofthetank

(Figure56).Turntheknobonthevalvetothe6

o'clockpositiontoturnonthetankagitationandtothe

8o'clockpositiontoturnoffthetankagitation.

SprayerPump

Thesprayerpumpislocatedattherearofthemachine

(Figure57).

g028485

Controlthesprayerpumpbyperformingthefollowing:

•FortheHD-seriesmodelwithamanual

transmission—Atthecenterconsoleofthe

machine,movethePTOlevertotheENGAGE

positiontorunthepump;movethePTOleverto

theDISENGAGEpositiontostopthepump.Referto

theWorkmanHDX-AutoUtilityVehicleOperator’s

Manual.

•FortheHDX-Automodel—Atthedashpanelto

theleftofthesteering-wheelcolumn,pressthe

rockerswitchforthehigh-owhydraulicsystemup

totheONpositiontorunthesprayerpump(the

lightoftherockerswitchilluminates).Pressthe

rockerswitchdowntotheOFFpositionshutoffthe

sprayerpump.RefertotheHigh-FlowHydraulic

KitInstallationInstructions(thelightoftherocker

switchshutsoff).

43

Figure57

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Note:Ifyouneedtotransportthevehicleonatrailer

withthesprayerinstalled,makesurethatthebooms

g028857

aretieddownandsecure.

1.Sprayerpump

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Spraysystembaseweight

(vehicleweightnotincluded)

Tankcapacity

Overallvehiclelengthwiththe

standardspraysystem

Overallvehicleheightwith

standardspraysystemtothe

topofthetank

Overallvehicleheightwith

standardspraysystemand

theboomsstoredintheX

pattern

Overallvehiclewidthwiththe

standardspraysystemand

theboomsstoredintheX

pattern

757L(200USgallons)

424kg(935lb)

422cm(166inches)

147cm(58inches)

234cm(92inches)

175cm(69inches)

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsand

decalsinthesafetysection.Knowingthisinformation

couldhelpyouorbystandersavoidinjury.

UsingtheInfoCenter

TheInfoCenterLCDdisplayshowsinformationabout

yourmachine,suchastheoperatingstatus,various

diagnostics,andotherinformationaboutthemachine

(Figure58).Thereisasplashscreenandmain

informationscreenontheInfoCenter.Y oucanswitch

betweenthesplashscreenandmaininformation

screen,atanytime,bypressinganyoftheInfoCenter

buttonsandthenselectingtheappropriatedirectional

arrow.

Figure58

1.Indicatorlight3.Middlebutton

2.Rightbutton

4.Leftbutton

•Leftbutton,Menuaccess/Backbutton—press

thisbuttontoaccesstheInfoCentermenus.You

canalsouseittobackoutofanymenuyouare

currentlyusing.

•Middlebutton—usethisbuttontoscrolldown

menus.

•Rightbutton—usethisbuttontoopenamenu

wherearightarrowindicatedadditionalcontent.

Note:Thepurposeofeachbuttonmaychange

dependingonwhatfunctionisactiveatthetime.The

44

g020650

LCDdisplayshowsaniconaboveeachbuttonthat

indicatesitscurrentfunction.

StartingtheInfoCenter

1.Insertthekeyintothestarterswitchandrotateit

totheONposition.

Note:TheInfoCenterilluminatesanddisplays

theinitializationscreen(Figure59).

g029189

Figure61

Figure59

2.Afterapproximately15seconds,thehome

screenappears.Pressthecenterselection

buttontodisplaytheinformationcontext(Figure

60).

Figure60

•Pressthecenterselectionbuttonagainto

navigatetotheMainMenu.

•Rightselectionbutton:Totalareasprayed

(Figure61A)

•Rightselectionbutton:Applicationrate

(Figure61B)

•Leftselectionbutton:Sub-areasprayed

(Figure61C)

•Leftselectionbutton:Tankvolume(Figure

61D)

g028527

Note:RotatingthestarterswitchtotheSTART

positionandstartingtheenginecausesthevalues

indicatedintheInfoCenterdisplaytoreectthe

runningmachine.

AccessingtheSettingsMenu

1.StarttheInfoCenter;refertoStartingthe

InfoCenter(page45).

Note:TheHomescreendisplays.

2.Pressthecenterselectionbuttontoaccessthe

Informationcontext.

Note:Theinformationcontexticondisplays.

3.Pressthecenterselectionbuttontoaccessthe

MainMenu(Figure62).

g028528

45

Figure62

AdditionaloptionsfortheHDX-Automodelisnotshown.

1.Rightselectionbutton(selectcontext)

4.Presstherightselectionbuttontodisplaythe

Settingssub-menus.

Note:TheMainMenudisplayswiththeSettings

optionselected.

Note:Pressingthecenterselectionbutton(the

buttonbelowthedownarrowiconinthedisplay)

movestheselectedoptiondown.

g028416

Figure63

1.Listoptions(icon)3.Rightselectionbutton(list

context)

2.Scrolldown(icon)4.Centerselectionbutton

(scrollcontext)

g028519

Note:Pressingtheleftselectionbuttonsaves

yourselection,exitstheSettingsmenu,and

returnstotheMainMenu.

3.Tochangethelanguageusedinthedisplay,

pressthecenterselectionbutton(thebutton

belowthedownarrowinthedisplay)tomove

theselectedoptiontoLanguage(Figure63).

ChangingtheUnitsofMeasure

(EnglishandMetric)

1.AccesstheSettingsmenu;refertoAccessing

theSettingsMenu(page45).

2.Tochangetheunitofmeasure,presstheright

selectionbuttontochangethelistedunitsof

measure(Figure63).

•English:mph,gallons,andacre

•Turf:mph,gallons,and1,000ft

•SI(metric):kph,liter,hectare

Note:ThedisplayswitchesbetweenEnglish,

turf,andmetricunits.

4.Presstherightselectionbutton(thebutton

belowthelisticoninthedisplay)tohighlightthe

listedlanguageusedinthedisplay(Figure63).

Note:Availablelanguagesinclude:English,

Spanish,French,German,Portuguese,

Danish,Netherlands(Dutch),Finnish,Italian,

Norwegian,andSwedish.

5.Presstheleftselectionbuttontosaveyour

selection(s),exittheSettingsmenu,andreturn

2

totheMainMenu(Figure62).

6.Presstheleftselectionbuttontoreturntothe

Homescreen(Figure63).

AdjustingtheBacklightingand

ContractLevelsoftheDisplay

1.AccesstheSettingsmenu;refertoAccessing

theSettingsMenu(page45).

2.Toadjustthebacklightlevelofthedisplay,press

thecenterselectionbutton(thebuttonbelow

thedownarrowiconinthedisplay)tomovethe

selectedoptiondowntotheBacklightsetting

(Figure64).

46

selection,exittheBacklightmenu,andreturnto

theSettingsmenu(Figure64).

6.Toadjustthecontrastlevelofthedisplay,press

thecenterselectionbutton(thebuttonbelow

thedownarrowiconinthedisplay)tomovethe

selectedoptiondowntotheContrastsetting

(Figure64).

7.Presstherightselectionbuttontodisplaythe

valueadjustmentcontext(Figure64).

Note:Thedisplayshowsa(―)iconoverthe

centerselectionbuttonanda(+)iconoverthe

rightselectionbutton.

8.Presstheleftselectionbutton(thebutton

belowthelisticoninthedisplay)tosaveyour

selection,exittheContrastmenu,andreturnto

theSettingsmenu(Figure64).

9.PresstheleftselectionbuttontoexittheSettings

menuandreturntotheMainMenu(Figure62

andFigure64).

10.Presstheleftselectionbuttontoreturntothe

Homescreen(Figure64).

Figure64