Page 1

PART NO. 03124SL (Rev. C)

Service Manual

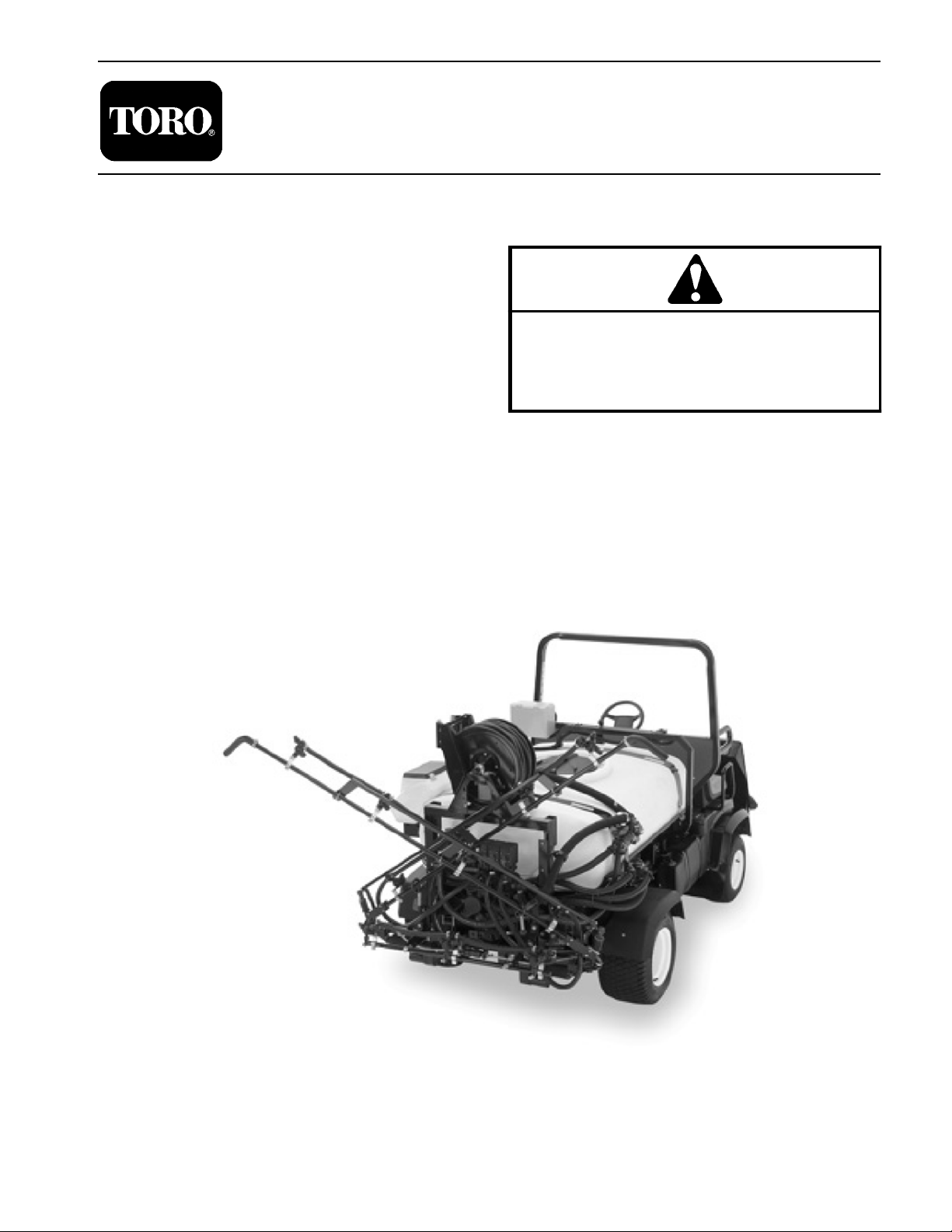

(Models 41229 and 41235)

Workman

Preface

The purpose of this publication is to provide the service

technician with information for troubleshooting, testing,

and repair of major systems and components on the

Workman 200 Spray System (Models 41229 and

41235).

REFER TO THE OPERATOR’S MANUAL FOR OPERATING, MAINTENANCE, AND ADJUSTMENT

INSTRUCTIONS. Keep the Operator’s Manual, Installation Instructions and Parts Catalog for your machine

with this Service Manual. Replacement Operator’s

Manuals and Parts Catalogs are available on the internet at www.Toro.com.

The T oroCompany reserves the right to change product

specifications or this publication without notice.

R

200 Spray System

This safety symbol means DANGER, WARNING,

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: A NOTE will give general information about the

correct operation, maintenance, service, testing, or repair of the machine.

IMPORTANT: The IMPORTANT notice will give important instructions which must be followed to prevent damage to systems or components on the

machine.

E The Toro Company -- 2003, 2005, 2011, 2014

Page 2

This page is intentionally blank.

Workman 200 Spray System

Page 3

Table Of Contents

Chapter 1 -- Safety and Product Records

Safety Instructions 1 -- 2..........................

Safety and Instruction Decals 1 -- 3................

Product Records 1 -- 3...........................

Chapter 2 -- Electrical System

Electrical Schematic and Electrical Harness and Con-

nector Drawings 2 -- 2..........................

Special Tools 2 -- 3..............................

Component Testing 2 -- 4.........................

Chapter 3 -- Spray System

Specifications 3 -- 2..............................

General Information 3 -- 3........................

Spray System Flow Diagram 3 -- 4.................

Spray System Operation 3 -- 5....................

Troubleshooting 3 -- 6............................

Service and Repairs 3 -- 8........................

Chapter 3.1 -- Sonic Boom System (Optional Kit)

General Information 3.1 -- 2......................

Special Tools 3.1 -- 3............................

Electrical Schematic 3.1 -- 4......................

Sonic Boom System Operation 3.1 -- 6.............

Troubleshooting 3.1 -- 16.........................

Service and Repairs 3.1 -- 22.....................

Chapter 3.2 -- Ultra Sonic Boom System (Optional

Kit)

Safety andElectrical

System

Spray

System

System

Sonic Boom

Product Records

General Information 3.2 -- 2......................

Special Tools 3.2 -- 3............................

Electrical Schematic 3.2 -- 4......................

Sonic Boom System Operation 3.2 -- 6.............

Troubleshooting 3.2 -- 17.........................

Service and Repairs 3.2 -- 26.....................

Chapter 4 -- Electrical Diagrams

Electrical Schematics 4 -- 3.......................

Wire Harness Drawings 4 -- 6.....................

Ultra Sonic

Boom System

Electrical

Diagrams

Workman 200 Spray System

Rev. C

Page 4

This page is intentionally blank.

Workman 200 Spray System

Page 5

Safety and Product Records

Table of Contents

SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . 2

Before Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

While Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Maintenance and Service . . . . . . . . . . . . . . . . . . . . 3

SAFETY AND INSTRUCTION DECALS . . . . . . . . . . 3

PRODUCT RECORDS . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 1

Safety and

Product Records

Workman 200 Spray System Page 1 – 1 Safety and Product Records

Page 6

Safety Instructions

The Workman 200 Spray System is designed and

tested to offer safe service when operated and maintained properly . Although hazard control and accident

prevention are partially dependent upon the design and

configuration of the machine, these factors are also dependent upon the awareness, concern, and proper

training of the personnel involved in the operation, transport, maintenance, and storage of the machine. Improper use or maintenance of the machine can result in injury

or death. To reduce the potential for injury or death,

comply with the following safety instructions.

Before Op erating

WARNING

To reduce the potential for injury or death,comply with the following safety instructions.

1. Read and understand the contents of the Operator’s

Manual before starting and operating the machine. Become familiar with the controls and know how to stop the

machine and engine quickly. A replacement Operator’s

Manual is available on the Internet at www.Toro.com.

While Operating

1. Sit on the seat when starting and operating the machine.

2. Before starting the engine:

A. Engage the parking brake.

B. Make sure drive system is in the NEUTRAL position and the pump switch is OFF.

3. Do not run engine in a confined area without adequate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

4. Do not touch engine, radiator, muffler or exhaust

pipe while engine is running or soon after it is stopped.

These areas could be hot enough to cause burns.

2. Keep all shields, safety devices, and decals in place.

If a shield, safety device, or decal is defective, illegible

or damaged, repair or replace it before operating the

machine. Also tighten any loose nuts, bolts or screws to

ensure machine is in safe operating condition.

5. Before getting off the seat:

A. Ensure that drive system is in the NEUTRAL

position.

B. Set parking brake.

C. Turn pump switch OFF.

D. Stop engine and remove key from ignition switch.

E. Do not park on slopes unless wheels are chocked

or blocked.

6. Follow spray chemical manufacturer ’s recommendations for handling precautions, protective equipment,

and mixing proportions.

Rev. B

Workman 200 Spray SystemPage 1 -- 2Safety and Product Records

Page 7

Maintenance and Service

1. Before servicing or making adjustments, turn PTO

off, put shift lever in neutral, stop engine, set parking

brake, and remove key from the switch.

2. Prior to servicing sprayer components, determine

what chemical(s) have been used in the sprayer. Follow

precautions and recommendations printed on chemical

container labels or Material Safety Data Sheets when

servicing sprayer components. Use appropriate protec

tive equipment: protective clothing, chemical resistant

gloves, and eye protection.

3. Make sure machine is in safe operating condition by

keeping all nuts, bolts and screws tight.

4. Never store the machine or fuel container inside

where there is an open flame, such as near a water heat

er or furnace.

5. If major repairs are ever needed or assistance is desired, contact an Authorized Toro Distributor.

6. If engine must be running to perform maintenance or

an adjustment, keep clothing, hands, feet, and other

parts of the body away from moving parts. Keep by

standers away.

-

-

-

7. Disconnect battery before servicing the machine.

Disconnect negative (–) battery cable first and positive

(+) cable last. If battery voltage is required for troubleshooting or test procedures, temporarily connect the

battery. Reconnect positive (+) cable first and negative

(–) cable last.

8. Battery acid is poisonous and can cause burns.

Avoid contact with skin, eyes, and clothing. Protect your

face, eyes, and clothing when working with a battery.

9. Battery gases can explode. Keep cigarettes, sparks,

and flames away from the battery.

10.To assure optimum performance and continued

safety of the machine, use genuine Toro replacement

parts and accessories. Replacement parts and acces

sories made by other manufacturers may result in nonconformance with safety standards, and the warranty

may be voided.

-

Safety and

Product Records

Safety and Instruction Decals

Numerous safety and instruction decals are affixed to

the Workman 200 Spray System. If any decal becomes

illegible or damaged, install a new decal. Part numbers

are listed in your Parts Catalog. Order replacement decals from your Authorized Toro Distributor.

Product Records

Insert Operator’s Manual, Installation Instructions and

Parts Catalog for your Workman 200 Spray System at

the end of this Chapter. Refer to Operator’s Manual for

recommended maintenance intervals. Additionally, in

sert Installation Instructions, Operator’s Manuals, and

Parts Catalogs for other accessories (e.g. Foam Mark

ing Kit, Hose Reel Kit) that have been installed on your

Workman vehicle at the end of this Chapter.

-

-

Workman 200 Spray System Page 1 – 3 Safety and Product Records

Page 8

This page is intentionally blank.

Safety and Product Records Page 1 – 4 Workman 200 Spray System

Page 9

Table of Contents

ELECTRICAL SCHEMATIC and ELECTRICAL

HARNESS and CONNECTOR DRAWINGS 2.....

SPECIAL TOOLS 3.............................

COMPONENT TESTING 4.......................

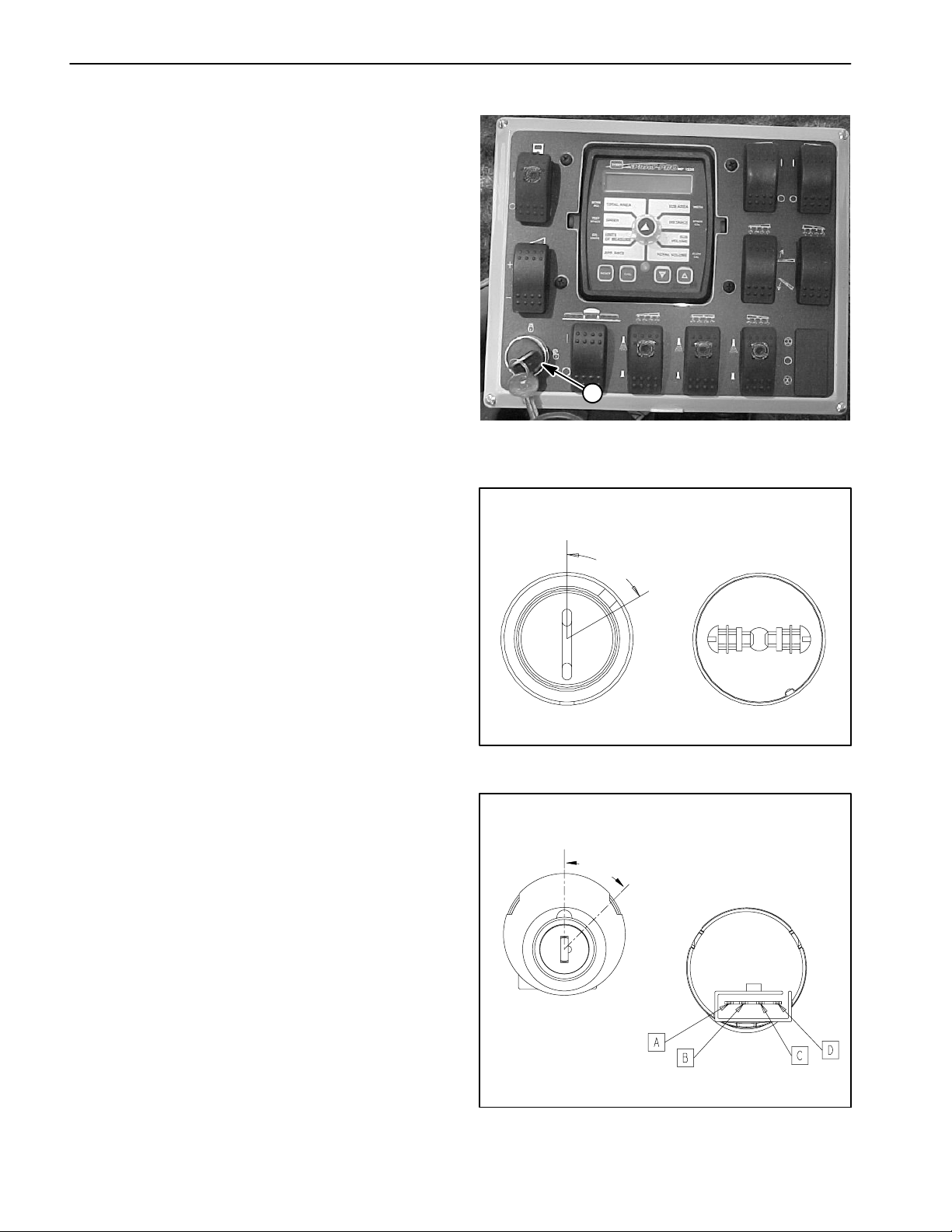

Master Boom Switch 4.........................

Rate Control and Boom Actuator Switches 5......

Supervisor Key Switch 6.......................

Boom Control and Monitor Power Switches 7.....

Hold and Boom Actuator (Serial Numbers

Above 260000000) Relays 8..................

Traction Speed Sensor 9.......................

Chapter 2

Electrical System

System

Electrical

Workman 200 Spray System Page 2 -- 1 Electrical System

Rev. B

Page 10

Electrical Schematic and Electrical Harness and

Connector Drawings

The electrical schematic and other electrical drawings

for the Workman 200 Spray System are located in Chap

ter 4 – Electrical Diagrams.

-

Electrical System

Page 2 – 2

Workman 200 Spray System

Page 11

Special Tools

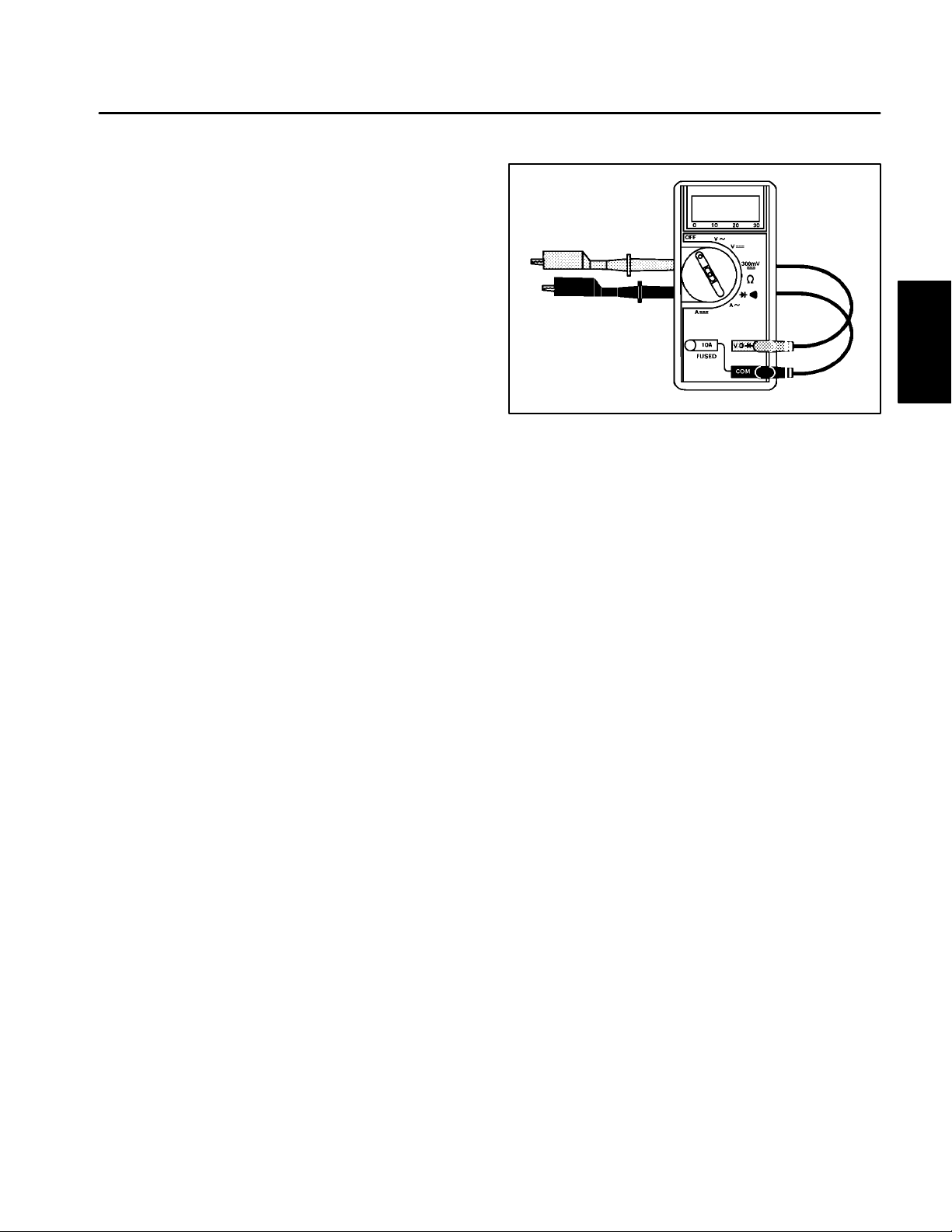

Multimeter

The multimeter can test electrical components and circuits for current, resistance, or voltage.

NOTE: Toro recommends the use of a DIGITAL Volt–

Ohm–Amp multimeter when testing electrical circuits.

The high impedance (internal resistance) of a digital me

ter in the voltage mode will make sure that excess current is not allowed through the meter. This excess

current can cause damage to circuits not designed to

carry it.

-

Figure 1

System

Electrical

Workman 200 Spray System

Page 2 – 3

Electrical System

Page 12

Component Testing

Master Boom Switch

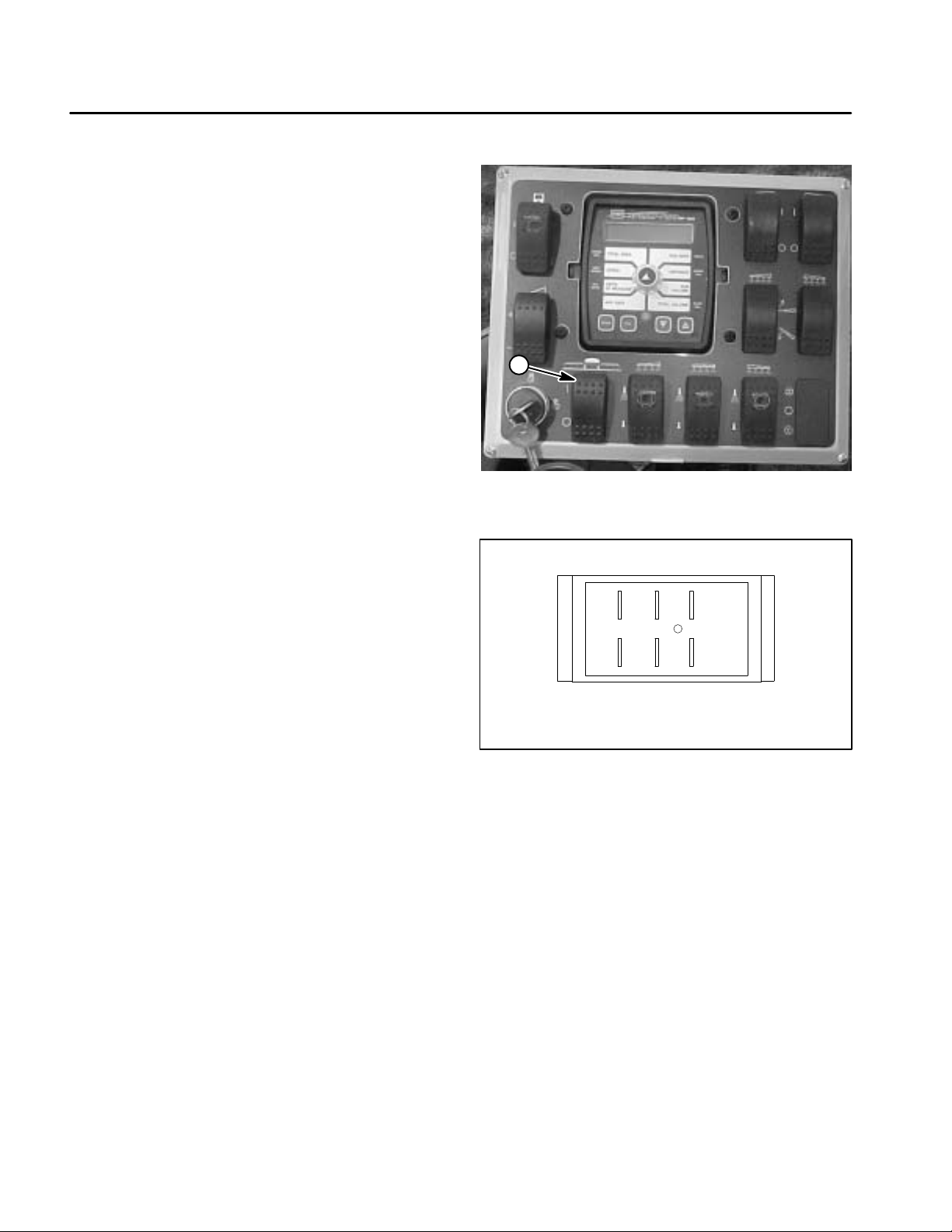

The master boom switch is located on the spray control

enclosure faceplate (Fig. 2).

Testing

1. Remove spray control enclosure faceplate, locate

master boom switch and unplug wire harness connector

from switch.

2. The switch terminals are marked as shown in Figure

3. In the ON position, continuity should exist between

terminals 2 and 3 and also between terminals 5 and 6.

In the OFF position, continuity should exist between ter

minals 1 and 2 and also between terminals 4 and 5.

3. Reconnect the harness connectors to the switch after testing. Install console panel to machine.

1

-

Figure 2

1. Master boom switch

4 5 6

1 2 3

BACK OF SWITCH

Figure 3

Electrical System

Page 2 – 4

Workman 200 Spray System

Page 13

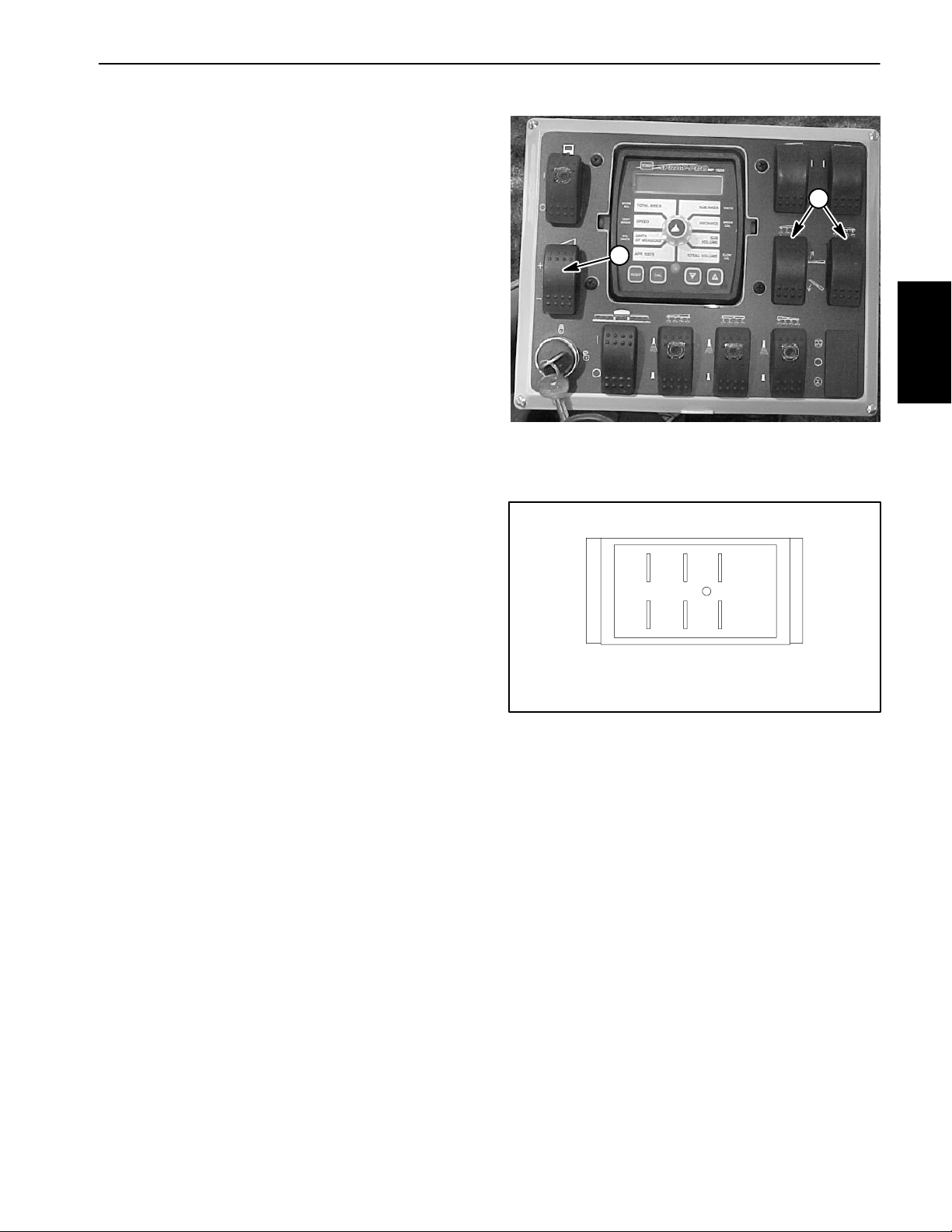

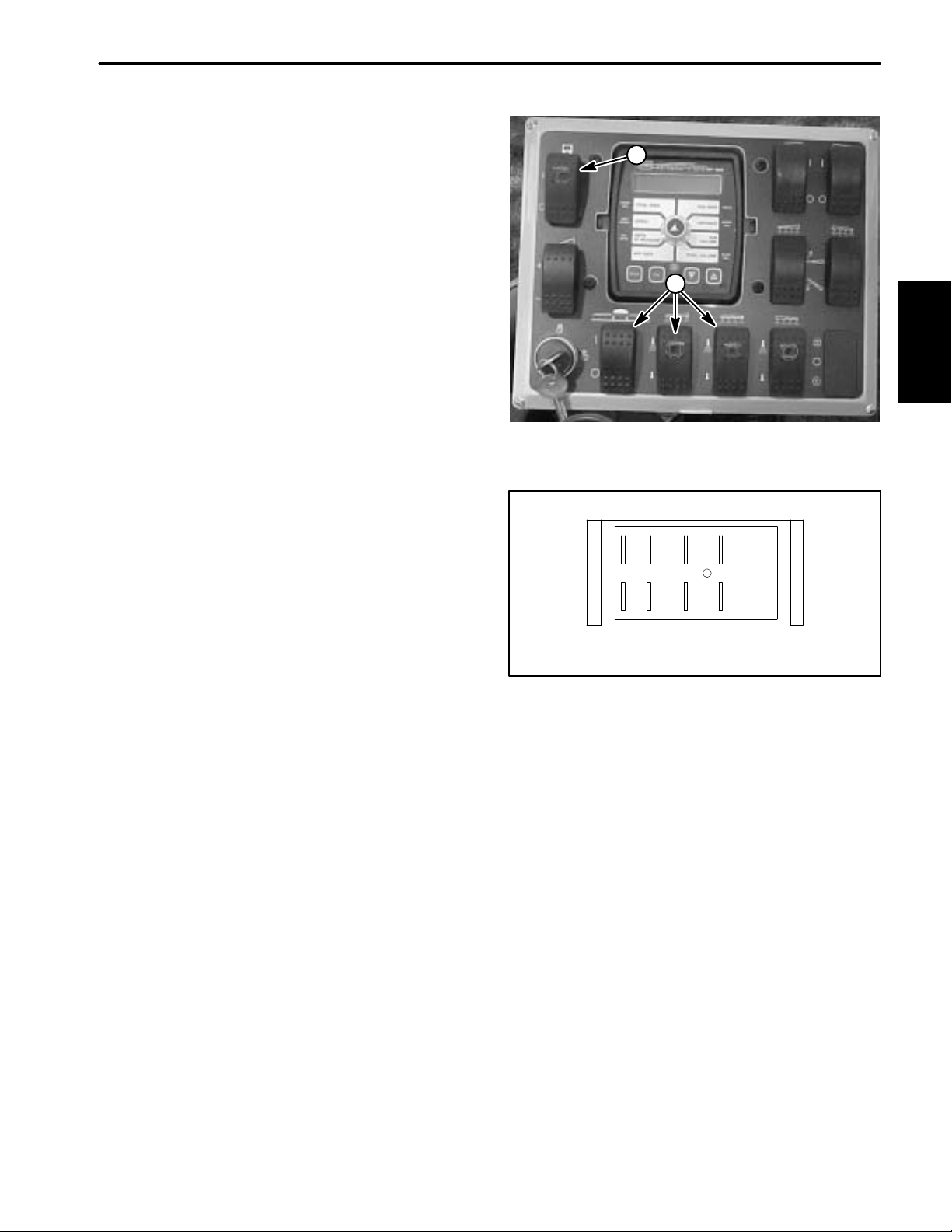

Rate Control and Boom Actuator Switches

The rate control (increase/decrease) switch is located

on the spray control enclosure faceplate (Fig. 4).

On machines equipped with the electric boom lift, this is

the same switch that is used to operate the boom actuators.

2

Testing

1. Remove spray control enclosure faceplate, locate

switch to be tested and unplug wire harness connector

from switch.

2. The switch terminals are marked as shown in Figure

5. In the INCREASE or boom raise position, continuity

should exist between terminals 2 and 3 and also between terminals 5 and 6. In the neutral, center position,

there should be no continuity between any switch terminals. In the DECREASE or boom lower position, continuity should exist between terminals 2 and 1 and also

between terminals 5 and 4.

3. Reconnect the harness connector to the switch after

testing. Install console panel to machine.

1

Figure 4

1. Rate control switch

2. Boom actuator switch

56

1243

BACK OF SWITCH

System

Electrical

Figure 5

Workman 200 Spray System Page 2 -- 5 Electrical System

Rev. B

Page 14

Supervisor Key Switch

The supervisor key switch (rate lockout) is located on

the spray control enclosure faceplate (Fig. 6). When the

supervisor key switch is in the OFF (locked) position, the

application rate switch is disabled.

The supervisor key switch used on sprayers with serial

numbers below 270000000 is shown in Figure 7. The

key switch used on s prayers with serial numbers above

270000000 is shown in Figure 8.

Testing

1. Remove spray control enclosure faceplate, locate

supervisor k ey switch and removewire harness connectors from switch.

2. Test switch for continuity as follows:

A. For sprayers with serial numbers below

270000000 (Fig. 7), when the key is in the ON position, continuity should exist between the two switch

terminals. In the OFF position, there should be no

continuity between the switch terminals.

B. For sprayers with serial numbers above

270000000 (Fig. 8), when the key is in the ON position, continuity should exist between switch terminals A and D. In the OFF position, there should be no

continuity between switch terminals A and D. Switch

terminals B and C are not used on the Workman 200

sprayer.

1

Figure 6

1. Supervisor key switch

SERIAL NUMBER BELOW 270000000

OFF

o

60

ON

3. Reconnect the harness connectors to the switch after testing. Install console panel to machine.

FRONTOFSWITCH

BACK OF SWITCH

Figure 7

SERIAL NUMBER ABOVE 270000000

OFF (LOCKED)

o

45

ON (UNLOCKED)

FRONTOFSWITCH

BACK OF SWITCH

Figure 8

Rev. B

Workman 200 Spray SystemPage 2 -- 6Electrical System

Page 15

Boom Control and Monitor Power Switches

The three boom control (on/off) and monitor power

switches are located on the spray control enclosure

faceplate (Fig. 8).

Testing

1. Remove spray control enclosure faceplate, locate

boom control switch and unplug wire harness connector

from switch.

2. The switch terminals are marked as shown in Figure

9. In the ON position, continuity should exist between

terminals 2 and 3 and also between terminals 5 and 6.

In the OFF position, continuity should exist between ter

minals 1 and 2 and also between terminals 4 and 5.

3. Terminals 7 (–) and 8 (+) are used for the indicator

light in the switch. The light should be illuminated when

the switch is in the ON position.

4. Reconnect the harness connector to the switch after

testing. Install console panel to machine.

-

2

1

Figure 8

1. Boom control switch 2. Monitor power switch

7 4 5 6

System

Electrical

8 1 2 3

BACK OF SWITCH

Figure 9

Workman 200 Spray System

Page 2 – 7

Electrical System

Page 16

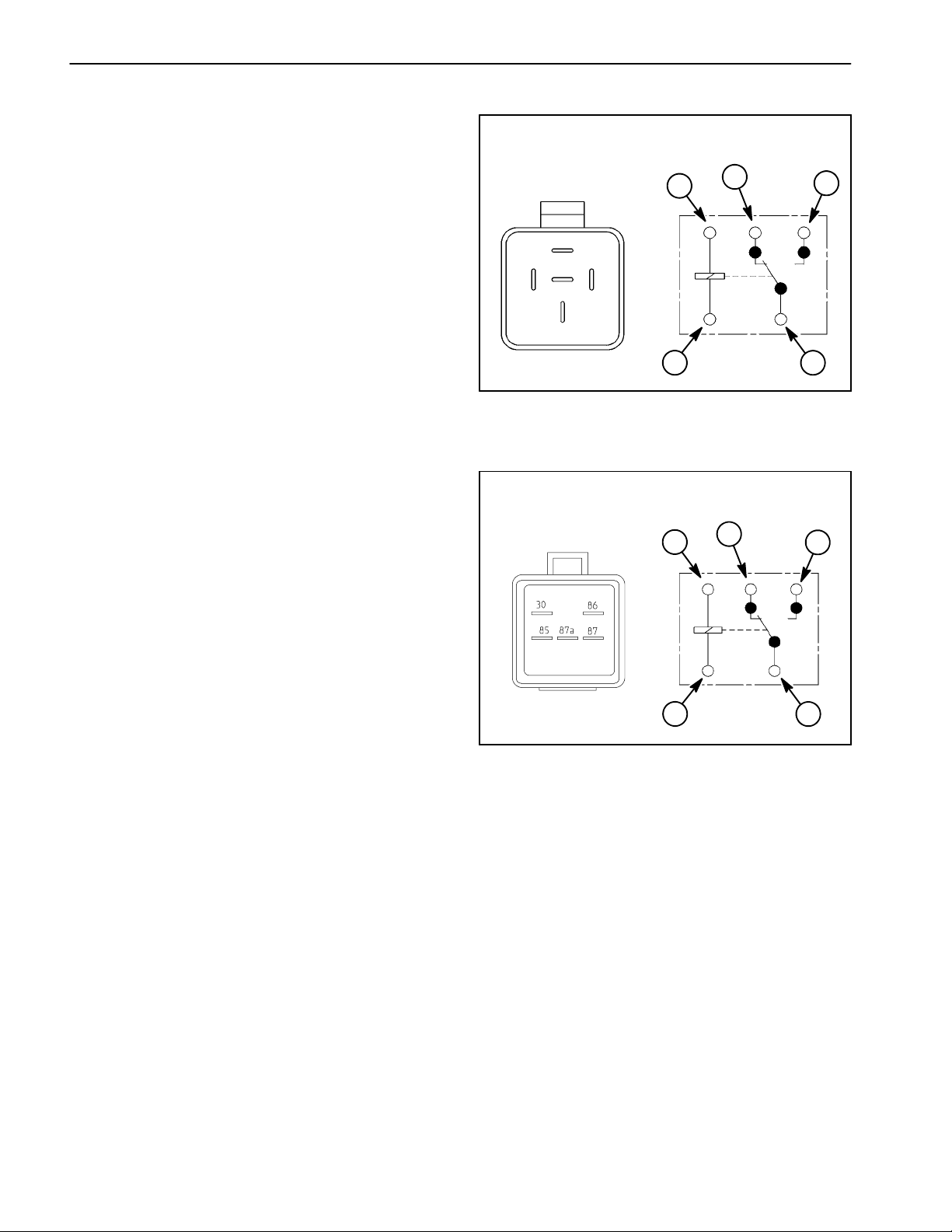

Hold and Boom Actuator (Serial Numbers Above 260000000) Relays

Workman sprayers with serial numbers below

260000000 use a single relay for the sprayer hold function. Sprayers with serial numbers above 260000000

use the hold relay and four (4) additional relays for the

boom actuators. The hold and boom actuator relays are

located in the spray control enclosure.The relays can be

identified by a tag at the relay wire harness connector.

SERIAL NUMBER BELOW 260000000

87

1

3

868587A 87

4

The relay used on sprayers with serial numbers below

260000000 (Fig. 11) has a different terminal layout than

relays used on sprayers with serial numbers above

260000000 (Fig. 12). Relay operation and circuit logic is

the same regardless of serial number.

Testing

1. Remove spray control enclosure faceplate, locate

relay that is to be tested and unplug wire harness connector from relay.

2. Connect multimeter (ohms setting) leads to relay terminals 30 and 87. Ground terminal 86 and apply +12

VDC to terminal 85. The relay should make and break

continuity between terminals 30 and 87 as +12 VDC is

applied and removed from terminal 85.

3. Disconnect voltage from terminal 85 and multimeter

lead from terminal 87.

4. Connect multimeter (ohms setting) leads to relay terminals 30 and 87A. Apply +12 VDC to terminal 85. The

relay should make and break continuity between terminals 30 and 87A as +12 VDC is applied and removed

from terminal 85.

87A

86

85

30

1

Figure 11

1. Coil terminal

2. Common terminal

3. Normally closed term.

4. Normally open term.

SERIAL NUMBER ABOVE 260000000

1

868587A 87

1

30

2

3

30

4

2

5. Disconnect voltage and multimeter leads from the

relay terminals. Reconnect relay to machine wire harness and install spray control enclosure faceplate.

1. Coil terminal

2. Common terminal

Rev. B

Figure 12

3. Normally closed term.

4. Normally open term.

Workman 200 Spray SystemPage 2 -- 8Electrical System

Page 17

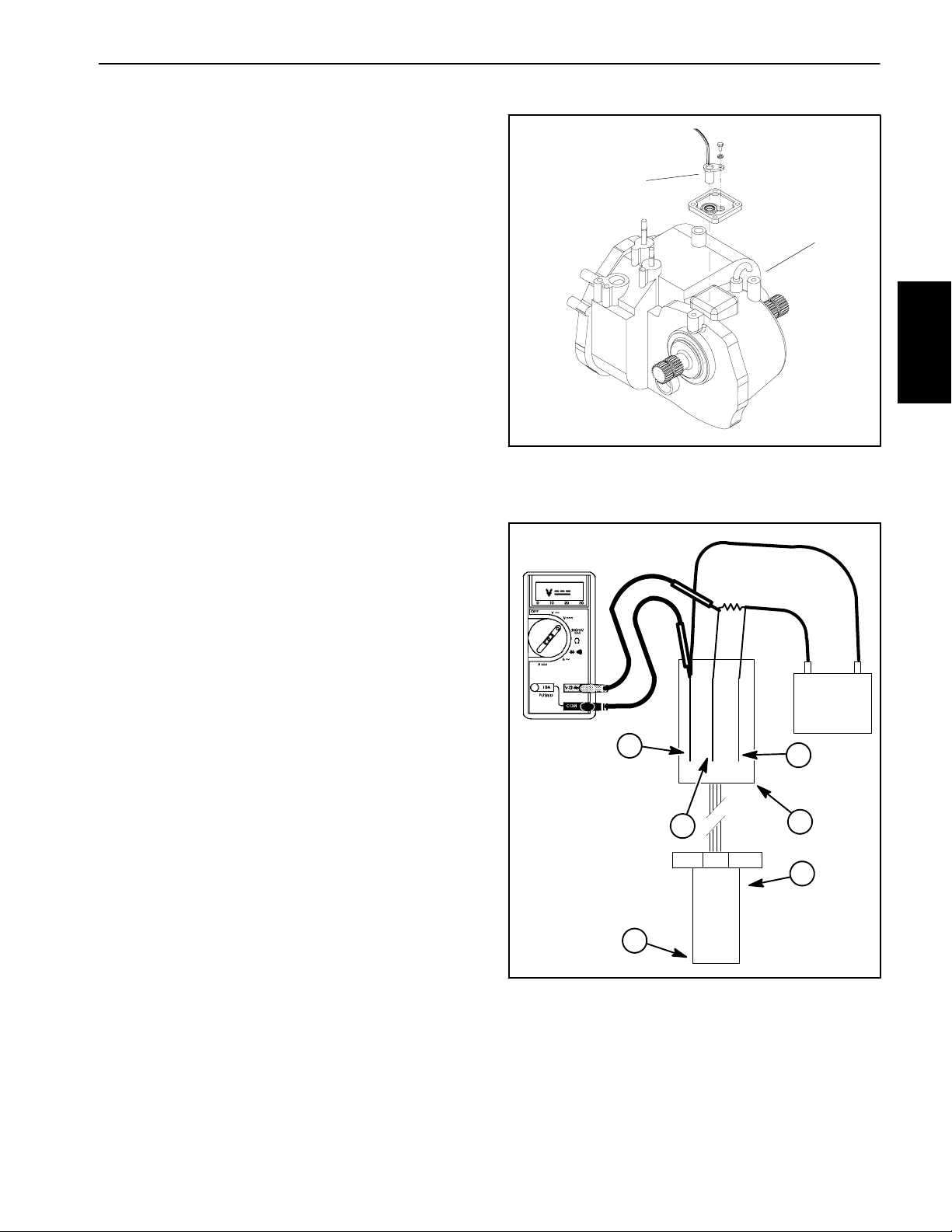

Traction Speed Sensor

The traction speed sensor is attached to the upper

transaxle cover (Fig. 13). It uses a magnetically based,

Hall Effect integrated circuit. As the differential in the

transaxle turns, the sensor accurately senses the movement of the differential ring gear teeth passing by the

sensor. The red striped connector wire is the positive

lead, the black wire is the ground lead, and the gray

striped wire is the signal output.

Testing

6. Locate traction speed sensor on the transaxle assembly. Disconnect the wire harness connector from the

traction speed sensor.

7. Remove cap screw and lock washer that secure

speed sensor to transaxle. Remove speed sensor from

transaxle.

2

1

System

Electrical

8. Connect positive multimeter test lead to the sensor

connector gray striped wire terminal and the negative

multimeter lead to the connector black wire terminal

(Fig. 14). Set multimeter to ohms setting.

IMPORTANT: Incorrect jumper wire connections

during testing can damage the sensor.

9. Using a +12 VDC battery, a multimeter, a 1K ohm resistor and appropriate jumper wires, connect the battery

and multimeter to the speed sensor using Figure 14 as

a guide.

10.Set multimeter to DC volts setting.

11. The multimeter should display very low voltage when

a metal object is held near the sensor tip. The multimeter

should display battery voltage when the metal object is

moved away from the sensor tip.

12.After testing is complete, remove jumper wires, resistor and multimeter leads from sensor connector.

13.Replace speed sensor if necessary.

14.After testing is complete, remove jumper wires and

multimeter leads from sensor connector. Reinstall

speed sensor into transaxle and secure with cap screw

and lock washer. Reconnect speed sensor to wire harness.

Figure 13

1. Transaxle assembly 2. Traction speed sensor

1K ohm

resistor

+

12 VDC

6

4

BAC

5

3

1

2

Figure 14

1. Speed sensor

2. Sensor tip

3. Sensor connector

4. Red striped wire

5. Gray striped wire

6. Black wire

--

Workman 200 Spray System Page 2 -- 9 Electrical System

Rev. B

Page 18

This page is intentionally blank.

Electrical System

Page 2 – 10

Workman 200 Spray System

Page 19

Table of Contents

Chapter 3

Spray System

SPECIFICATIONS 2.............................

GENERAL INFORMATION 3.....................

Precautions Concerning Chemicals Used in

Spray System 3.............................

Precautions for Removing or Adjusting Spray

System Components 3.......................

O--Ring Seal Kit 3.............................

SPRAY SYSTEM FLOW DIAGRAM 4..............

SPRAY SYSTEM OPERATION 5..................

TROUBLESHOOTING 6.........................

SERVICE AND REPAIRS 8......................

Suction Dampener 8..........................

Pressure Dampener 9.........................

Spray Pump 10...............................

Spray Pump Service 12........................

Agitation Control Valve 16......................

Agitation Nozzles (Tank Mounted) 18............

Pressure Relief Valve (Tank Mounted) 20.........

Spray Control (Serial Numbers Below

290999999) 22..............................

Spray Control (Serial Numbers Above

310000000) 23.1............................

Flowmeter (Serial Numbers Below 290999999) 24.

Flowmeter (Serial Numbers Above 310000000)25.1

Rate Control Motor (Serial Numbers Below

290999999) 26..............................

Regulating Valve Assembly (Serial Numbers

Above 310000000) 27.1.....................

Boom Valve Motor (Serial Numbers Below

290999999) 28..............................

Boom Valve Manifold Assembly (Serial Numbers

Above 310000000) 31.1.....................

Boom Bypass 32..............................

Tank Suction 34..............................

Tank Drain 36................................

Turret Bodies 38..............................

Turret Body Service 39........................

Boom Frame Breakaway Pivot Assembly

(Machines with Serial Numbers Below

260000000) 40..............................

Boom Hinge (Machines with Serial Numbers

Above 260000000) 42.......................

Boom Actuator (Optional) (Machines with

Serial Numbers Below 260000000) 44.........

Boom Actuator Service (Machines with Serial

Numbers Below 260000000) 46...............

Boom Actuator (Machines with Serial Numbers

Above 260000000) 48.......................

Boom Actuator Service (Machines with Serial

Numbers Above 260000000) 50...............

Spray

System

Workman 200 Spray System Page 3 -- 1 Spray System

Rev. B

Page 20

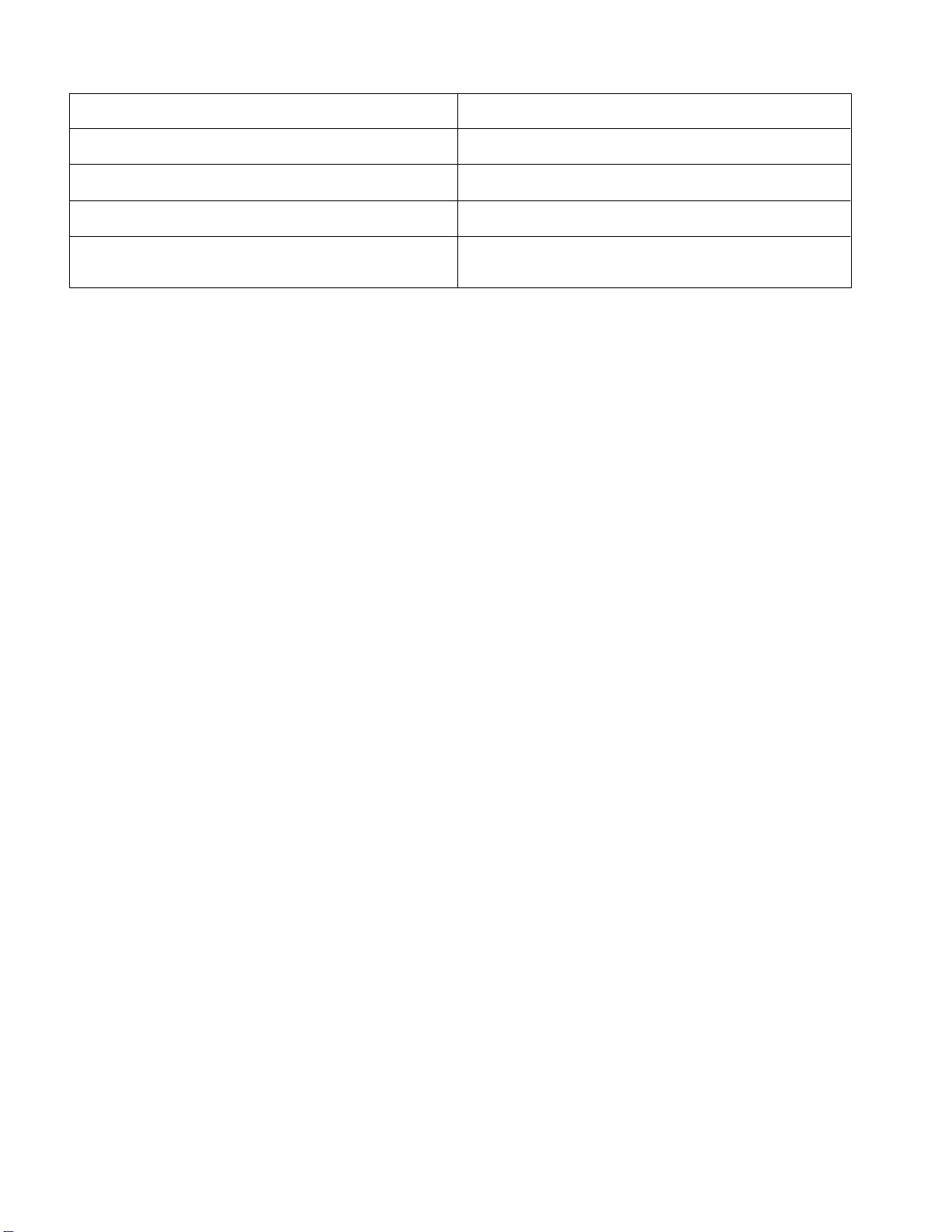

Specifications

Item Description

Spray Pump Diaphragm Pump, 29 GPM

Spray Pressure Relief Valve Poppet Style, 220 PSI Maximum

Sprayer Tank 200 Gallon (757 Liter), Polyethylene

Suction Strainer 50 Mesh, Stainless Steel, Tank Mounted

(30 Mesh and 90 Mesh Optional)

Spray System

Page 3 – 2

Workman 200 Spray System

Page 21

General Information

Precautions Concerning Chemicals Used in Spray System

Chemicals can injure persons, animals, plants, soil, or

other property. To eliminate environmental damage and

personal injury:

1. Select the proper chemical for the job.

2. Carefully read the directions printed on the chemical

manufacturer’s labels before handling chemicals. Instructions on chemical manufacturer’s container labels

regarding mixing proportions should be read and strictly

followed.

3. Keep spray material away from skin. If spray material

comes in contact with a person, wash it off immediately

in accordance with manufacturer’s recommendations

(container labels and Material Safety Data Sheets).

4. Always wear protective clothing, chemical resistant

gloves, eye protection, and other personal protective

equipment as recommended by the chemical manufacturer.

5. Properly dispose of chemical containers, unused

chemicals, and chemical solution.

Precautions for Removing or Adjusting Spray System Components

1. Stop the vehicle and set the parking brake.

2. Shut off the vehicle’s engine and remove the key

from the ignition switch.

3. Disengage all power and wait until all moving parts

have stopped.

4. Remove chemicals from pump, hoses, and other

spray components. Thoroughly neutralize and rinse

spray system before loosening or removing any spray

system component(s).

5. Make sure line pressure is relieved before loosening

any system component.

Spray

System

O--Ring Seal Kit (Serial Numbers Below 310000000)

Part Number: 106 --4846

The O--Ring Seal Kit includes an assortment of O--rings

used for sealing the spray c ontrol valves on Workman

sprayers with serial numbers below 310000000. It is

recommended that O--rings be replaced every two (2)

years or whenever a valve is loosened.

SPRAYER

O--RING SEAL KIT

PART NO. 106--4846

Figure 1

Workman 200 Spray System Page 3 -- 3 Spray System

Rev. B

Page 22

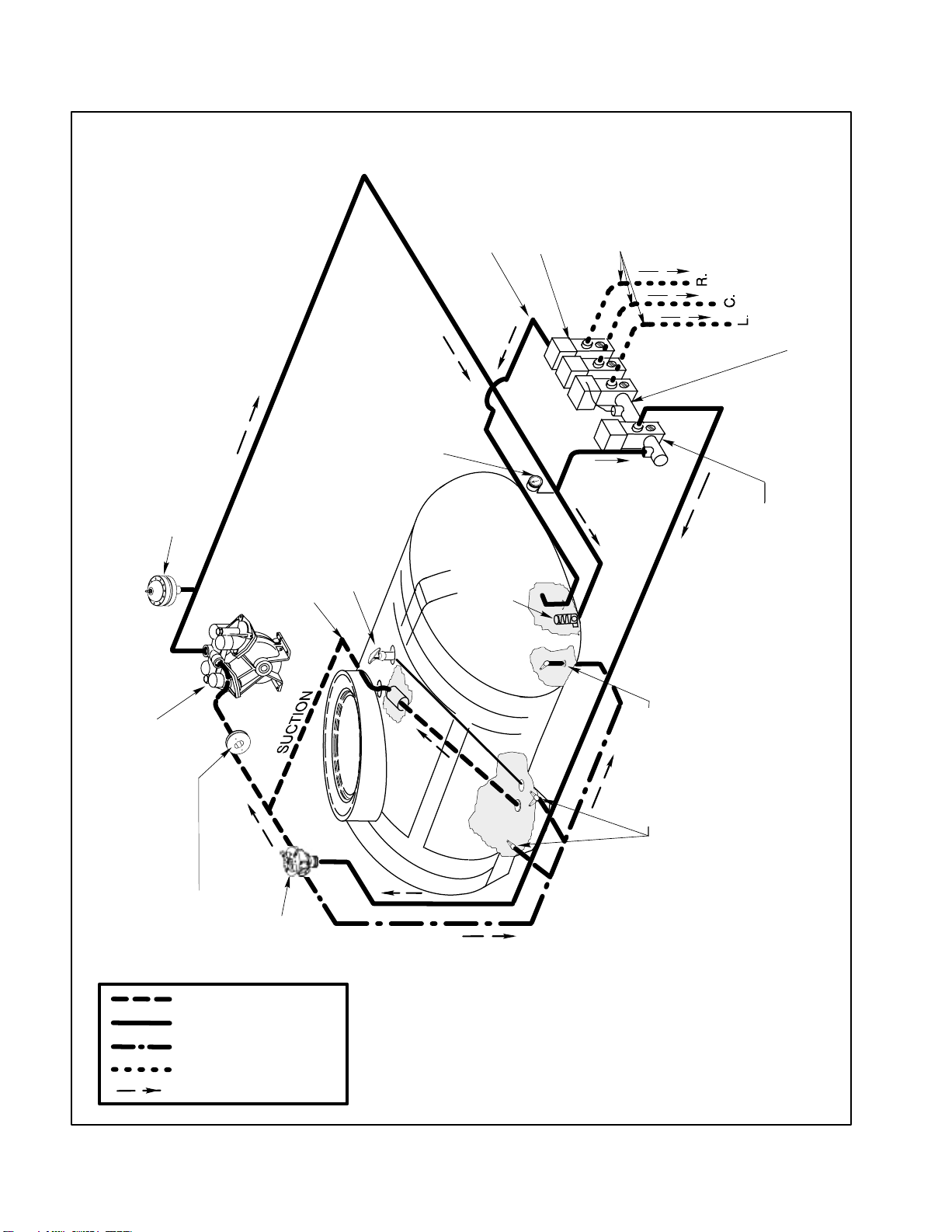

Spray System Flow Diagram

PRESSURE

PRESSURE DAMPENER

& SCREEN

TOP MOUNTED SUCTION

TOP MOUNTED TANK

DRAIN VALVE

BOOM BY–PASS

PRESSURE

GAUGE

PRESSURE

RELIEF

BOOM CONTROL

VALVES

VALVE

BOOM SUPPLY

PRESSURE

FLOWMETER

PRESSURE CONTROL

VALVE

DIAPHRAGM PUMP

CONNECTED TO PTO

Spray System

SUCTION

DAMPENER

SUCTION

PRESSURE

AGITATION

BOOM SUPPLY

FLOW DIRECTION

CONTROL

AGITATION

VALVE

TANK

AGITATION

Page 3 – 4

AGITATORS (4)

Workman 200 Spray System

Spray System Flow Diagram

Workman 200 Spray System

Page 23

Spray System Operation

The Workman 200 Spray System uses a positive displacement diaphragm pump to move spray solution

from the spray tank to the boom nozzles. The spray

pump is self–priming and has a dry crankcase. The

pump is driven by the transaxle PTO kit output shaft at

a speed that is proportional to the ground speed of the

vehicle. It should be noted that pump rotation will stop

whenever the vehicle clutch pedal is depressed.

The downward stroke of the pumps’ connecting rods

and diaphragms create suction to allow fluid to be drawn

from the spray tank to the pump through the suction

tube, suction strainer, hoses, and connectors. A suction

dampener placed in the suction line dampens suction

pulses to smooth suction flow. Suction valves positioned

in the pump valve chamber prevent fluid from being

pumped back into the suction line when the connecting

rods change direction. Leaks in the suction line will

cause system problems and often will be indicated by er

ratic suction line jumping and pump noise.

Once to the pump, the fluid is pushed by the upward

stroke of the pumps’ connecting rods and diaphragms

to the pressure side of the spray system through hoses,

connectors, control valves, and spray nozzles. A pres

sure dampener at the pump outlet smooths system

pressure pulsation. Pressure valves positioned in the

pump head prevent fluid from being drawn back into the

pump. Maximum pressure in the system is limited by a

pressure relief valve located in the tank. A pressure

gauge indicates system pressure.

-

-

The spray system is controlled electrically and consists

of a rate control valve and three boom control valves. A

manually adjustable boom bypass valve exists in each

of the boom control valves to prevent system pressure

changes when a boom section is shut off. Flow in excess

of control valve settings is directed back to the spray

tank.

An inline flowmeter in the pressure side of the system directly before the boom control valves measures flow to

the spray booms. The Spray Pro Monitor displays infor

mation regarding application rate based on input from

the flowmeter and the ground speed sensor in the trans

axle.

Flow for tank agitation comes from flow that is bypassed

by the rate control valve. A manual agitation control

valve directs flow to four agitation nozzles in the spray

tank.

-

-

Spray

System

Workman 200 Spray System

Page 3 – 5

Spray System

Page 24

Troubleshooting

Problem Possible Cause

Spray system leaks fluid. Fitting(s), hose(s), or tube(s) are loose or damaged.

O--ring(s) or seal(s) are missing or damaged.

Spray tank drain valve is leaking.

Fluid leaking from bottom of spray

pump.

Excessive suction hose vibration. Suction screen in tank is plugged.

Spray pressure is low. Suction line is restricted.

Faulty diaphragm(s) in spray pump.

Spray pump suction line has an air leak.

Suction tube in spray tank has air leak.

Suction line is restricted.

Suction dampener diaphragm is damaged.

Suction screen in tank is plugged.

Spray nozzles worn or damaged.

Pressure line or component is loose or leaking.

Engine speed is low.

Pressure relief valve in tank is stuck.

Spray pump is damaged.

Single spray boom nozzle leaks

when boom is turned off.

Nozzles on one spray boom leak

when boom is switched off.

Spray pump doesn’t rotate. Vehicle clutch pedal is depressed.

Diaphragm in turret body is leaking or damaged.

Diaphragm in turret body is leaking or damaged.

Boom valve motor for affected boom not seating.

Key on spray pump shaft is sheared.

Auxiliary PTO not engaged or faulty.

Auxiliary PTO output shaft damaged.

PTO drive shaft damaged or missing.

Workman 200 Spray SystemPage 3 -- 6Spray System

Page 25

Erratic spray operation from booms. Clogged strainer.

Damaged suction dampener.

Damaged pressure dampener.

Console boom switch(es) dirty, corroded, or damaged.

Rate control motor worn or sticking.

Boom valve motor seat loose or damaged.

Boom valve motor actuating cam worn or sticking.

No spray output from one spray

Hoses on boom are pinched or kinked.

boom.

Boom valve motor for affected boom not opening.

Console boom switch dirty, corroded, or damaged.

Check for 12 volts at affected boom valve motor in both directions

(on and off).

Low spray rate from one nozzle. Clogged or damaged spray nozzle(s).

Spray nozzles are different sizes.

Boom valve motor for affected boom not seating.

Spray

System

Workman 200 Spray System Page 3 -- 7 Spray System

Page 26

Service and Repairs

Suction Dampener

The suction dampener is mounted to the suction line at

the spray pump (Fig. 2) and is used to dampen suction

pulses and smooth suction flow. During pump operation,

the suction dampener diaphragm will move.

IMPORTANT: Make sure to neutralize and remove

chemicals from pump and hoses before loosening

and removing spray system components.

A damaged suction dampener diaphragm will allow a

suction leak and will cause improper pump operation. If

the diaphragm is damaged, remove diaphragm from

dampener housing and replace it (Fig. 3).

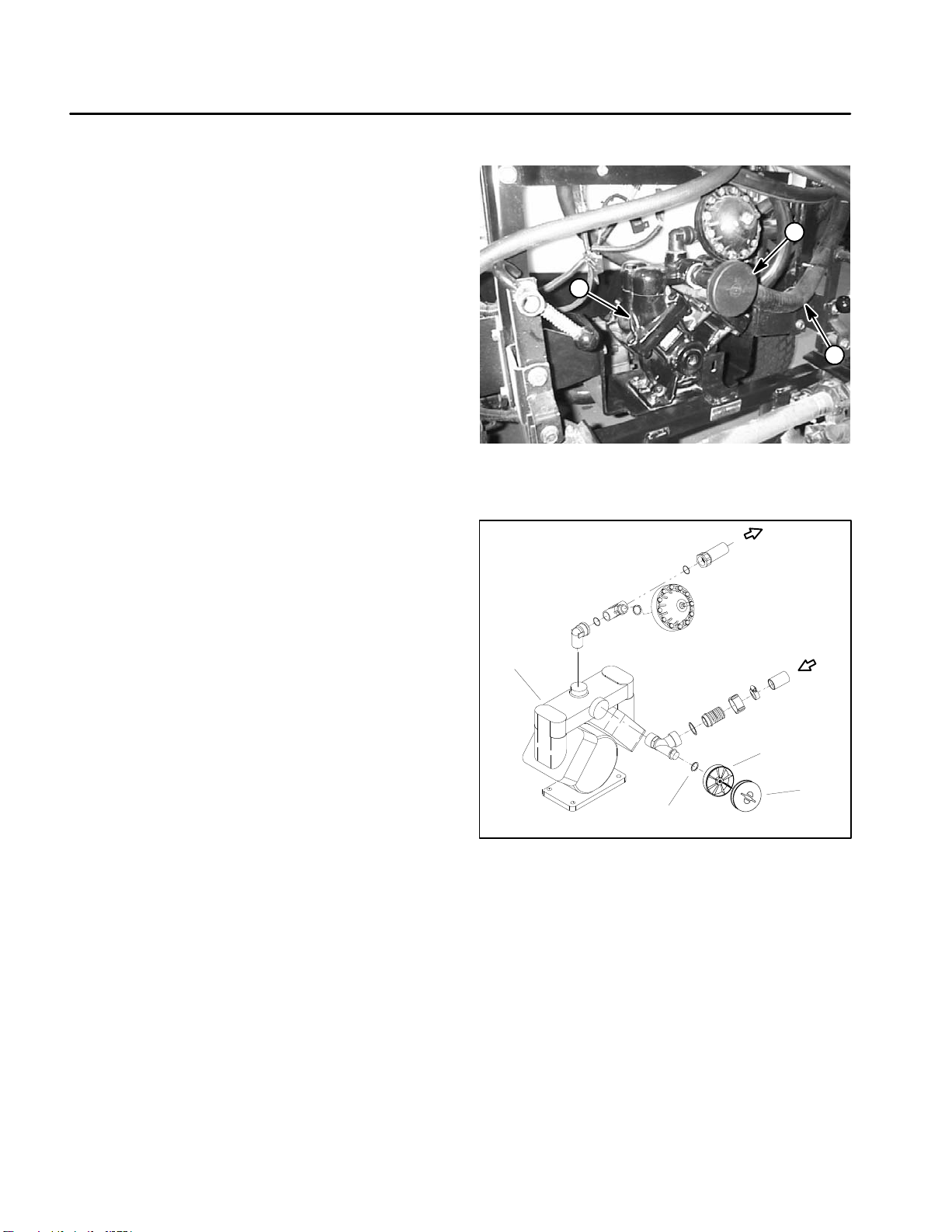

1

1. Spray pump

2. Suction dampener

2

3

Figure 2

3. Suction hose

1

1. Spray pump

2. O–ring

3

4

2

Figure 3

3. Dampener housing

4. Diaphragm

Spray System

Page 3 – 8

Workman 200 Spray System

Page 27

Pressure Dampener

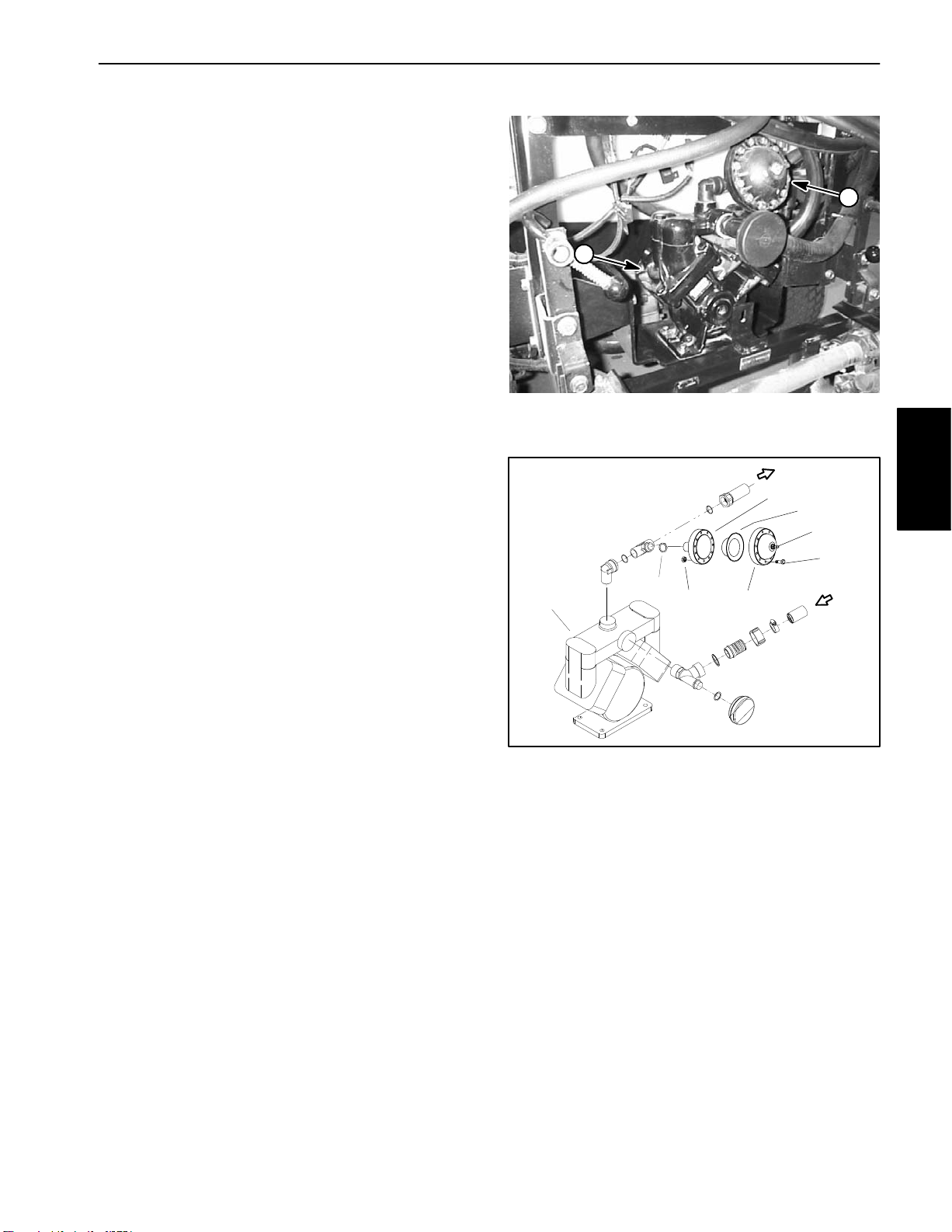

The pressure dampener is mounted to the pressure line

at the spray pump (Fig. 4) and is used to smooth system

pressure pulsation. Adjust air pressure on the pressure

dampener from 12 to 15 PSI (.82 to 1.03 bar).

IMPORTANT: Any fluid in the pressure dampener

will include spray system chemicals so take necessary precautions when working with the dampener.

Use appropriate protective equipment: protective

clothing, chemical resistant gloves, and eye protection.

If fluid is present when pressure in the dampener is

checked, the diaphragm in the pressure dampener is

damaged and should be replaced.

2

1

Dampener Service (Fig. 5)

IMPORTANT: Make sure to neutralize and remove

chemicals from pump and hoses before loosening

and removing spray system components.

1. Loosen and remove cap screws and nuts that secure

diaphragm between housings.

2. Remove diaphragm from dampener.

3. Replace diaphragm and reassemble dampener.

Figure 4

1. Spray pump 2. Pressure dampener

4

5

8

7

1

2

3

6

Figure 5

1. Spray pump

2. O–ring

3. Hex nut (12 used)

4. Rear housing

5. Diaphragm

6. Front housing

7. Cap screw (12 used)

8. Air valve

Spray

System

Workman 200 Spray System

Page 3 – 9

Spray System

Page 28

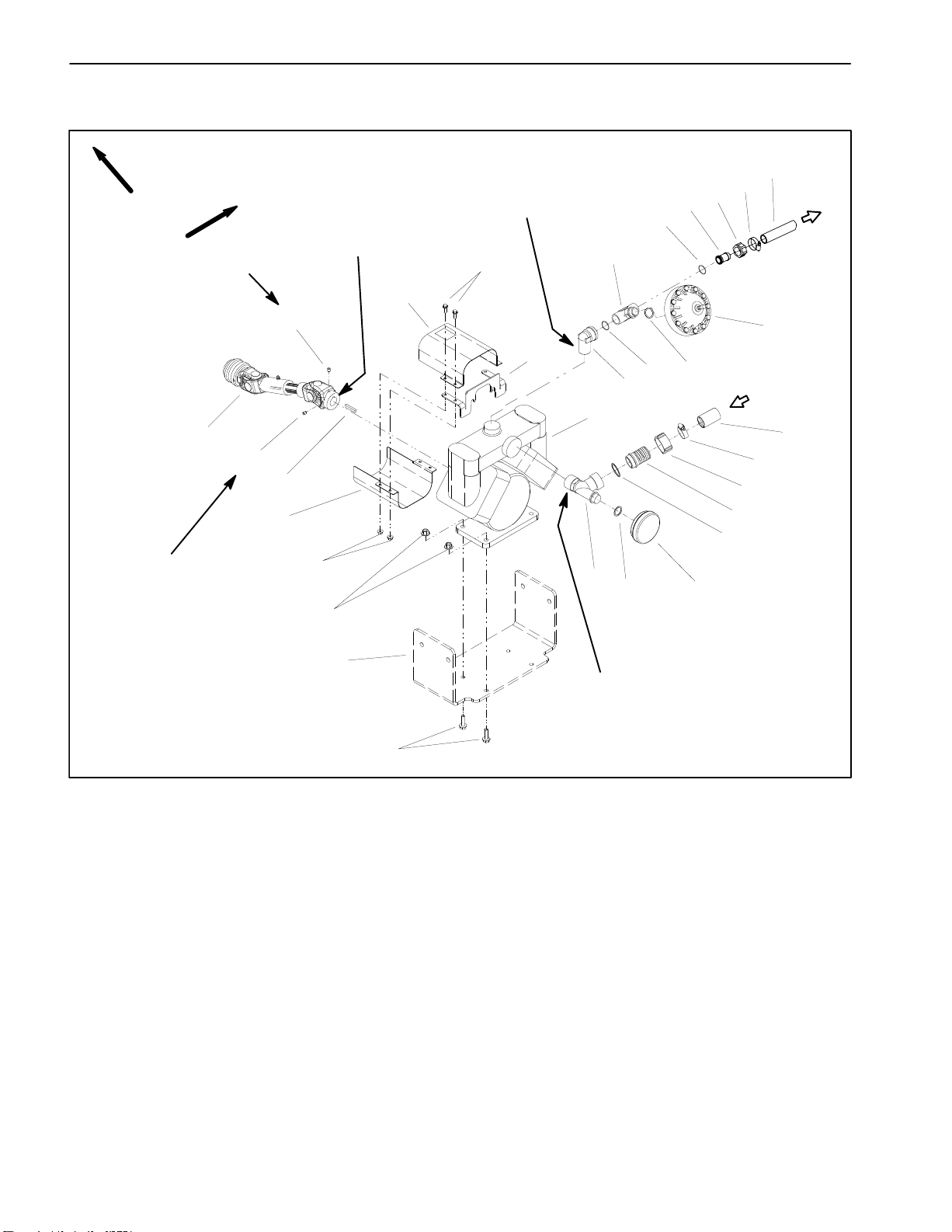

Spray Pump

p

FRONT

RIGHT

Loctite #242

Loctite #242

17

16

15

13

16

Anti–seize

Lubricant

18

19

13

Apply thread sealant

12

14

22

11

10

9

8

7

4

6

5

3

2

1

28

27

26

25

24

5

23

1. Spray pump assembly

2. Elbow (pressure)

3. Gasket

4. Pressure tee fitting

5. O–ring

6. Pressure dampener

7. O–ring

8. Hosebarb

9. Nut

10. Hose clam

20

21

Figure 6

11. Pressure hose

12. Flange head screw (4 used)

13. Pump drive shroud

14. Shroud bracket

15. Square key

16. Set screw

17. PTO driveshaft

18. Flange nut (4 used)

19. Flange nut (4 used)

Apply thread sealant

20. Pump mount bracket

21. Flange head screw (4 used)

22. Suction tee fitting

23. Suction dampener

24. Gasket

25. Hosebarb

26. Nut

27. Hose clamp

28. Suction hose

Spray System

Page 3 – 10

Workman 200 Spray System

Page 29

Removal (Fig. 6)

IMPORTANT: Make sure to neutralize and remove

chemicals from pump and hoses before loosening

and removing spray system components.

1. Park machine on a level surface, stop engine, engage parking brake, and remove key from the ignition

switch.

2. Loosen hose clamp that secures suction hose (item

28) to hosebarb (item 25). Pull suction hose from hose

-

barb.

3. Loosen hose clamp that secures pressure hose

(item 11) to hosebarb (item 8). Pull pressure hose from

hosebarb.

4. Remove PTO driveshaft (item 17) from output shaft

of transaxle PTO assembly.

5. Remove four (4) flange head screws and flange nuts

that secure pump assembly to pump mount bracket.

3. Install elbow (pressure), pressure tee fitting, and

pressure dampener to pump outlet. Orientate elbow to

-

ward right side of machine (Fig. 7).

4. Remove set screws (item 16) from PTO driveshaft.

Clean threads of set screws and set screw threads in dri

-

veshaft.

5. Apply anti–seize lubricant to pump shaft. Position

square key in pump shaft and slide PTO driveshaft fully

onto pump shaft.

6. Apply Loctite #242 (or equivalent) to threads of set

screws. Install set screws into PTO drive shaft to secure

PTO shaft to pump shaft.

7. Position pump drive shrouds (item 13) to shroud

bracket (item 14). Install four (4) flange head screws and

flange nuts to secure shrouds to bracket.

8. Position pump on pump mount bracket. Install flange

head screws and flange nuts to pump and mount brack

-

et. Secure pump to mount bracket.

6. Remove pump assembly (with PTO driveshaft and

drive shrouds attached) from machine.

7. Remove four (4) flange head screws and flange nuts

that secure pump drive shrouds (item 13) to shroud

bracket (item 14). Remove pump drive shrouds.

8. Loosen two (2) set screws (item 16) that secure PTO

drive shaft to pump shaft. Separate PTO drive shaft from

pump. Locate and remove key from pump shaft.

9. As needed, remove pressure and suction components from pump using Figure 6 as a guide. Discard any

removed o–rings and gaskets.

Installation (Fig. 6)

NOTE: Coat all o–rings with vegetable oil before instal-

lation to reduce the chance of damage during assembly.

1. Apply thread sealant to threads of pressure tee fitting, elbow (pressure), and suction tee fitting. Position

new o–rings and gaskets on suction and pressure fit

-

tings that were removed during disassembly.

2. Install suction tee fitting and suction dampener to

pump inlet. Orientate tee toward right side of machine

(Fig. 7).

9. Attach PTO driveshaft to output shaft of transaxle

PTO assembly.

10.Install pressure and suction hoses to correct barb fittings. Secure hoses with hose clamps.

1

2

Figure 7

1. Elbow (pressure) 2. Suction hose

Spray

System

Workman 200 Spray System

Page 3 – 11

Spray System

Page 30

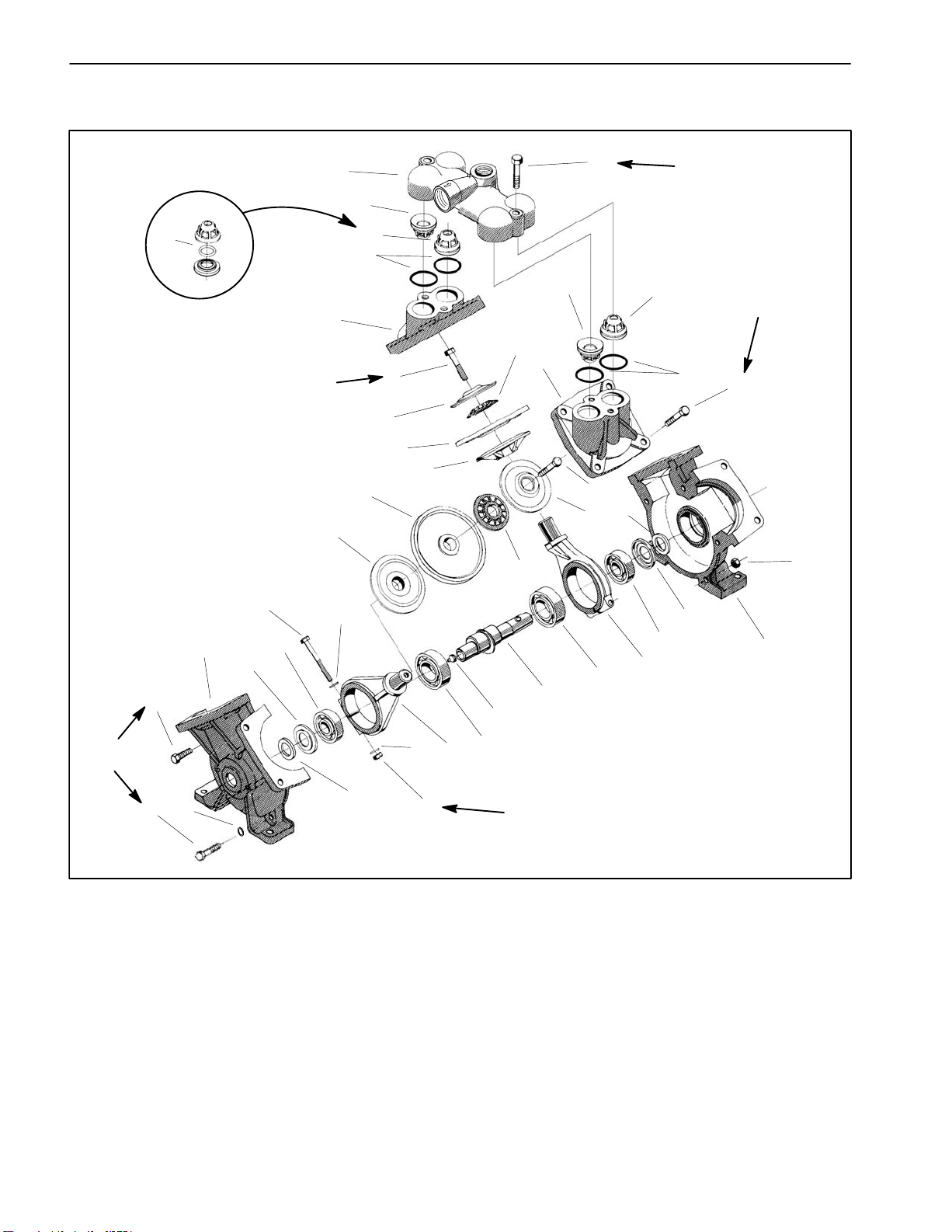

Spray Pump Service

15

28

14

13

11

60 ft–lb

(81 N–m)

12

1

2

25

3

4

9

4

5

6

7

8

7

8

9

10

23

22

26

2

5

18

6

21

20

25

12

60 ft–lb

(81 N–m)

3

13

55 ft–lb

(75 N–m)

16

24

14

32 ft–lb

(43 N–m)

27

17

1. Valve chamber

2. Valve (inlet position)

3. O–ring

4. Diaphragm cover

5. Hex bolt

6. Washer

7. Diaphragm

8. Diaphragm back disc

9. Nylon washer

10. Lock washer

Spray System

20

21

25 ft–lb

(34 N–m)

18

10

19

Figure 8

11. Hex bolt

12. Ball bearing (crankshaft)

13. Dust plate

14. Pump casing

15. Hex bolt (30 mm long) (3 used)

16. Hex bolt (4 used per cover)

17. Hex bolt (55 mm long) (2 used)

18. Felt seal

19. Hex nut

Page 3 – 12

20. Connecting rod

21. Ball bearing (connecting rod)

22. Grease fitting

23. Crankshaft

24. Hex nut (5 used)

25. Valve (outlet position)

26. Hex bolt (2 used)

27. Washer (2 used)

28. Poly o–ring

Workman 200 Spray System

Page 31

Disassembly (Fig. 8)

IMPORTANT: Make sure to remove and neutralize

chemicals from pump before disassembly. Wear

protective clothing, chemical resistant gloves, and

eye protection during pump repair.

NOTE: Many pump components can be easily re-

versed. During disassembly, make note of component

position (e.g. crankshaft, valve chamber) to assure cor

-

rect assembly.

1. Remove two (2) hex bolts that retain valve chamber

to pump. Separate valve chamber from pump.

2. Remove inlet and outlet valves and o–rings from

each diaphragm cover. Note orientation of valves. Dis

card valves and o–rings. Clean valve and o–ring seats

in the valve chambers and diaphragm covers.

3. Remove hex bolts that secure diaphragm covers to

pump. Remove diaphragm covers.

D. Position dust plate and felt seal on both ends of

crankshaft.

IMPORTANT: If connecting rod position is incorrect, pump will not operate properly.

E. Slide crankshaft assembly into pump casing. The

rear connecting rod should be positioned to the left

side and the connecting rod closest to you to the right

side (Fig. 9).

2. Place second pump casing onto assembly. Pump

casing surfaces should mate together.

3. Install three (3) shorter (30 mm) bolts and two (2) longer (55 mm) bolts with washers into pump casing assembly (Fig. 10). Thread hex nuts onto bolts but do not

fully tighten. Check that crankshaft turns freely.

4. Remove hex bolt, washer, nylon washer, diaphragm,

and diaphragm back disc from each connecting rod.

Discard diaphragms.

5. Remove five (5) hex bolts and nuts that secure pump

casing halves together. Note location of two (2) longer

hex bolts with washers. Carefully separate pump casing

halves.

6. Clean grease from bottom of housing and check condition of bearings on crankshaft. If bearings require replacement, remove and disassemble crankshaft:

A. Remove crankshaft assembly from pump casing.

B. Slide felt seal and dust plate from both ends of

crankshaft.

C. Loosen hex bolt and hex nut that secure connecting rods to crankshaft. Slide connecting rods from

crankshaft. Press ball bearings from crankshaft.

Assembly (Fig. 8)

1. If disassembled, reassemble crankshaft.

A. Hand pack new bearings with #2 general purpose

lithium base grease.

2

Figure 9

1. Closest connecting rod (to right side)

2. Rear connecting rod (to left side)

1

1

2

2

Spray

System

1

1

B. Pressing on bearing inner race, install two connecting rod and two crankshaft ball bearings onto

crankshaft.

C. Slide connecting rods onto connecting rod bearings. Offsets of the connecting rods should face each

other. Install hex bolt, flat washers, and hex nut to

each connecting rod. Torque hex nuts to 25 ft–lb (34

N–m) to secure connecting rods to crankshaft.

Workman 200 Spray System

1. Hex bolt (30 mm long) 2. Hex bolt (55 mm long)

Page 3 – 13

Figure 10

Spray System

Page 32

4. Place diaphragm back disc and new diaphragm onto

each connecting rod. The connecting rods should ex

tend above the diaphragms when correctly installed

(Fig. 11). Position nylon washer and washer on each

connecting rod and then thread hex bolt into connecting

rod. Torque bolt to 60 ft–lb (81 N–m).

5. Make sure that pump casings align and then secure

pump casing assembly by torquing five (5) bolts to 32 ft–

lb (43 N–m).

6. Secure diaphragm covers to pump using hex bolts (4

per cover). Torque bolts to 55 ft–lb (75 N–m).

7. Place new o–rings and valves into diaphragm cover

openings (Fig. 12). Inlet valves should be installed with

the spring down into the cover and should be on the

same side of the pump as the crankshaft grease fitting.

Outlet valves should be installed with the spring up and

away from cover and should be on the same side of the

pump as the crankshaft extension.

8. Place valve chamber over valves noting orientation

of chamber inlet and outlet. Secure valve chamber with

two (2) hex bolts. Torque bolts 60 ft–lb (81 N–m).

2

1

Figure 11

1. Diaphragm 2. Connecting rod

1

3

2

2

Figure 12

1. Inlet (suction) 3. Outlet valve

2. Inlet valve

Spray System

Page 3 – 14

Workman 200 Spray System

Page 33

This page is intentionally blank.

Spray

System

Workman 200 Spray System

Page 3 – 15

Spray System

Page 34

Agitation Control Valve

FRONT

8

A

RIGHT

4

1

4

2

7

3

6

5

A

8

1. Agitation control valve

2. Fork

3. Hosebarb/hose (to agitation nozzles)

Spray System

Figure 13

4. O–ring

5. O–ring

6. Hosebarb/hose (from spray control)

Page 3 – 16

NOTE: ARROWS SHOW FLUID

FLOW DIRECTION

7. Connector

8. Pump suction hose

Workman 200 Spray System

Page 35

Removal (Fig. 13)

IMPORTANT: Make sure to remove and neutralize

chemicals from spray components before disas

sembly. Wear protective clothing, chemical resistant gloves, and eye protection during repair.

1. Park machine on a level surface, stop engine, engage parking brake, and remove key from the ignition

switch.

4

-

3

1

2. Label disconnected hoses for proper installation after repairs are completed.

3. Remove agitation control valve using Figures 13 and

14 as guides.

4. Disassemble agitation valve as required (Fig 15).

Installation (Fig. 13)

NOTE: Coat all o–rings with vegetable oil before instal-

lation to reduce the chance of damage during assembly.

1. Assemble agitation control valve (Fig 15). Align arrow on valve handle with large hole in valve ball during

assembly (Fig. 16).

2. Install agitation valve using Figures 13 and 14 as

guides.

3. Check spray system for leaks.

2

Figure 14

1. Agitation control valve 3. Suction hose (from tank)

2. Control bypass hose 4. Suction hose (to pump)

10

12

13

15

14

3

2

4

7

5

16

9

11

7

4

8

3

6

5

2

1

Figure 15

1. Valve housing

2. Ball seat

3. O–ring

4. O–ring

5. Washer (8 used)

6. Cap screw (4 used)

7. End cover

8. Screw (4 used)

9. Screw

10. Button

11. Valve handle

12. Disc

13. O–ring

14. Spindle

15. Valve ball

16. Lock nut (4 used)

Spray

System

Workman 200 Spray System

1. Valve handle arrow 2. Valve ball large hole

Page 3 – 17

2

1

Figure 16

Spray System

Page 36

Agitation Nozzles (Tank mounted)

FRONT

11

19

RIGHT

6

C

17

18

16

20

4

8

7

11

22

10

7

8

11

4

9

16

B

15

C

2

12

11

10

9

12

7

13

14

A

4

8

6

4

6

B

23

A

5

1

2

3

21

1. Agitation supply

2. Tee fitting

3. Hosebarb/hose

4. O–ring

5. Connector

6. Bulkhead nut

7. Gasket

8. Bulkhead fitting

Figure 17

9. Hosebarb

10. Agitation nozzle

11. Nut

12. Fork (12 used)

13. Hosebarb/hose

14. Hosebarb/hose

15. Hosebarb/hose

16. Agitation nozzle

NOTE: ARROWS SHOW FLUID

FLOW DIRECTION

17. Hosebarb/hose

18. Tee fitting

19. Nipple

20. Adapter

21. O–ring

22. Elbow

23. Hosebarb/hose

Spray System

Page 3 – 18

Workman 200 Spray System

Page 37

Disassembly (Fig. 17)

Assembly (Fig. 17)

IMPORTANT: Make sure to remove and neutralize

chemicals from tank and other components before

disassembly. Wear protective clothing, chemical re

sistant gloves, and eye protection during repair.

1. Park machine on a level surface, stop engine, engage parking brake, and remove key from the ignition

switch.

2. Drain spray tank (see Operator’s Manual).

3. Label hoses for proper installation after repairs are

completed.

4. Remove agitation nozzles as required using Figure

17 as a guide. Discard all removed o–rings and gaskets.

NOTE: Coat all o–rings with vegetable oil before installation to reduce the chance of damage during assembly.

-

1. Install agitation nozzles using Figure 17 as a guide.

Replace all removed o–rings and gaskets.

2. Check spray system for leaks.

Spray

System

Workman 200 Spray System

Page 3 – 19

Spray System

Page 38

Pressure Relief Valve (Tank Mounted)

FRONT

RIGHT

1. Hosebarb/hose

2. Ringnut

3. Pressure relief valve

Figure 18

4. Gasket

5. Hosebarb/hose

6. O–ring

5

6

A

8

7

3

4

A

NOTE: ARROWS SHOW FLUID

1

2

FLOW DIRECTION

7. Fork

8. Hosebarb/hose (from spray pump)

Spray System

Page 3 – 20

Workman 200 Spray System

Page 39

Removal (Fig. 18)

IMPORTANT: Make sure to remove and neutralize

chemicals from tank and other components before

disassembly. Wear protective clothing, chemical re

sistant gloves, and eye protection during repair.

-

1. Park machine on a level surface, stop engine, engage parking brake, and remove key from the ignition

switch.

2. Drain spray tank (see Operator’s Manual).

3. Label disconnected hoses for proper installation after repairs are completed.

4. Remove pressure relief valve from spray tank using

Figure 18 and 19 as guides. Discard all removed o–rings

and gaskets.

5. Disassemble pressure relief valve using Figure 20

as a guide.

Assembly (Fig. 18)

NOTE: Coat all o–rings with vegetable oil before instal-

lation to reduce the chance of damage during assembly.

1. Assemble and install pressure relief valve using Figure 18, 19 and 20 as guides. Replace all removed o–

rings and gaskets.

2. Check spray system for leaks.

2

3

1

Figure 19

1. Hose to pressure relief 3. Control supply hose

2. Hose from spray pump

4

3

2

1

5

Spray

System

Figure 20

1. Nut 4. Cone

2. Seat 5. Relief valve housing

3. Spring

Workman 200 Spray System

Page 3 – 21

Spray System

Page 40

Spray Control (Serial Numbers Below 290999999)

FRONT

71 in--lb

(8 N--m)

1

RIGHT

2

NOTE: ARROWS SHOW FLUID

FLOW DIRECTION

21

22

23

10

41

5

26

7

7

71 in--lb

(8 N--m)

3

1

29

28

10

30

13

7

29

19

25

40

20

39

7

24

29

30

17

18

16

15

14

11

8

7

7

12

6

5

4

3

10

9

31

29

29

7

32

33

12

Figure 21

1. Nut

2. Threaded rod

3. Washer

4. Bushing

5. O--ring

6. Cap

7. O--ring

8. Tee piece

9. Hose: control supply (1”)

10. Hose clamp

11. Fork

12. Screw

13. Control valve bracket

14. Rate control valve housing

15. Rate control motor

16. Screw (4 used)

17. Screw

18. O--ring

19. Lock washer

20. Handgrip

21. Flowmeter assembly

22. Flowmeter housing

23. Hose: control bypass (1”)

24. Hosebarb

25. O--ring

26. End cap

27. Hose: boom bypass (1”)

28. Hosebarb

IMPORTANT: Rate control and boom valve motors

may have a fuse for circuit protection. Make sure

that correct fuse is installed in the in--line fuse holder located in the motor harness.

32

35

34

32

36

38

35

12

32

32

32

34

37

29. Fork

30. Joiner

31. LH boom valve motor/manifold

32. O--ring

33. End cap

34. Joiner

35. Boom valve bracket

36. O--ring (3 used)

37. Hosebarb: boom supply (3 used)

38. Nut (3 used)

39. Coupler (pressure gauge)

40. Center boom valve motor/manifold

41. RH boom valve motor/manifold

27

Rev. B

Workman 200 Spray SystemPage 3 -- 22Spray System

Page 41

IMPORTANT: Make sure to remove and neutralize

chemicals from spray components before disas

sembly. Wear protective clothing, chemical resistant gloves, and eye protection during repair.

-

1

3

4

5

Removal (Fig. 21)

1. Park machine on a level surface, stop engine, engage parking brake, and remove key from the ignition

switch.

2. Label hoses for proper installation after repairs are

completed. Loosen hose clamps and disconnect hoses

from spray control.

3. Unplug electrical connectors from rate control motor,

flowmeter, and three (3) boom valve motors from ma

chine electrical harness.

4. Remove pressure gauge tube from coupler on back

of flowmeter housing (Fig. 23).

5. Remove three (3) flange head screws that secure

spray control assembly to valve mounting bar. Remove

spray control assembly from machine.

6. Remove spray control components as required using Figure 21 as a guide. Discard all removed o–rings

and gaskets.

Assembly (Fig. 21)

NOTE: Coat all o–rings with vegetable oil before instal-

lation to reduce the chance of damage during assembly.

2

6

-

1. Rate control motor 4. Center boom valve motor

2. Flowmeter 5. RH boom valve motor

3. LH boom valve motor 6. Valve mounting bar

2

3

Figure 22

1

Spray

System

1. Install spray control components using Figure 21 as

a guide. Replace all removed o–rings and gaskets.

2. Before installing rod (Item 2) into assembly, thread

nut (item 1) fully onto rod end that has fewer threads.

Make sure that o–ring (Item 3) is not damaged during

installation over rod. To secure assembly, torque nut 71

in–lb (8 N–m).

3. Position spray control assembly to valve mounting

bar and secure with three (3) flange head screws.

4. Install hoses to correct locations on spray control assembly. Secure hoses with hose clamps.

5. Install pressure gauge tube to coupler on back of

flowmeter housing (Fig. 23).

6. Plug electrical connectors from rate control motor,

flowmeter, and three (3) boom valve motors to machine

electrical harness.

7. Operate spray system and check for leaks.

Figure 23

1. Flowmeter 3. Coupler

2. Pressure gauge tube

Workman 200 Spray System

Page 3 – 23

Spray System

Page 42

Spray Control (Serial Numbers Above 310000000)

1

FRONT

RIGHT

2

10

9

11

5

8

6

7

5

6

13

4

17

19

18

8

16

3

12

20

12

13

14

15

NOTE: ARROWS SHOW FLUID

FLOW DIRECTION

1. Flange nut (2 used)

2. Flange nut (8 used)

3. Flange head screw (2 used)

4. Valve mount

5. Flange head screw (8 used)

6. Gasket (2 used)

7. Flowmeter

Figure 23.1

8. Clamp (2 used)

9. Boom valve manifold

10. Pressure gauge tube

11. Coupler (pressure gauge)

12. Hose clamp (3 used)

13. Hose clamp (3 used)

14. Hose: boom bypass

15. Hose: RH boom supply

16. Hose: center boom supply

17. Hose: LH boom supply

18. Regulating valve assembly

19. Hose: control bypass

20. Hose: control supply

Page 3 -- 23.1 Workman 200 Spray SystemSpray System

Rev. B

Page 43

Disassembly (Fig. 23.1)

IMPORTANT: Make sure to remove and neutralize

chemicals from tank and spray components before

disassembly. Wear protective clothing, chemical resistant gloves, and eye protection during repair.

1. Park machine on a level surface, stop engine, engage parking brake, and remove key from the ignition

switch.

2. Label all spray control assembly hoses for proper

installation after repairs are completed. Loosen hose

clamps and disconnect hoses from spray control.

3. Label all wire harness leads for assembly purposes.

Disconnect wire harness connectors from regulating

valve, flowmeter and three (3) boom valve motors.

4. Remove pressure gauge tube (item 10) from coupler

on pressure gauge port on right side of boom valve manifold assembly.

3. Using labels placed during disassembly, install

hoses to correct locations on spray control assembly.

Secure hoses with hose clamps.

4. Install pressure gauge tube (item 10) to coupler on

pressure gauge port on right side of boom valve manifold assembly.

5. Using labels placed during disassembly, secure wire

harness connectors to regulating valve, flowmeter and

three (3) boom valve motors.

6. Operate spray system and check for leaks. Repair all

leaks before returning the sprayer to service.

3

2

1

5. Support spray control assembly to prevent it from falling.

6. Remove eight (8) flange head screws, flat washers

and flange nuts that secure spray control assembly to

valve mount. Remove spray control assembly from machine.

IMPORTANT: Before removing flowmeter from

spray control assembly, note direction of arrow on

top of flowmeter (Fig. 23.3). The arrow should point

toward boom valve manifold assembly.

7. Separate spray control assembly as required using

Figure 23.1 as a guide. Discard all removed gaskets.

Assembly (Fig. 23.1)

NOTE: Coat all gaskets and o--rings with vegetable oil

before installation to reduce the chance of damage during assembly.

1. Assemble spray control using Figure 23.1 as a

guide. Replace all removed gaskets. Make sure that arrow on flowmeter body points toward boom valve manifold assembly (Fig. 23.3).

2. Position spray control assembly to valve mounting

bar and secure with eight (8) flange head screws, flat

washers and flange nuts.

Figure 23.2

1. Boom valve manifold

2. Flowmeter

NOTE ARROW

DIRECTION

FROM

REGULATING

VALV E

Figure 23.3

3. Regulating valve

TO BOOM

VALV E

MANIFOLD

Spray

System

Page 3 -- 23.2Workman 200 Spray System Spray System

Rev. B

Page 44

Flowmeter (Serial Numbers Below 290999999)

1

71 in--lb

(8 N--m)

FRONT

RIGHT

10

24

22

20

23

17

28

19

25

71 in--lb

(8 N--m)

57

3

1

21

18

14

11

8

7

6

2

7

12

13

5

4

3

9

10

26

15

7

16

27

1. Nut

2. Threaded rod

3. Washer

4. Bushing

5. O--ring

6. Cover

7. O--ring

8. Tee piece

9. Hose: control supply (1”)

10. Hose clamp

Figure 24

11. Fork

12. Screw

13. Control valve bracket

14. Rate control motor/housing

15. O--ring

16. Hosebarb

17. Hose: control bypass (1”)

18. Coupler (pressure gauge)

19. Flowmeter housing

NOTE: ARROWS SHOW FLUID

FLOW DIRECTION

20. O--ring

21. Flowmeter rotor shaft

22. Flowmeter rotor

23. Flow sensor

24. Nut

25. End cap

26. LH boom control motor

27. Center boom control motor

28. RH boom control motor

Rev. B

Workman 200 Spray SystemPage 3 -- 24Spray System

Page 45

Removal and Inspection (Fig. 24)

IMPORTANT: Make sure to remove and neutralize

chemicals from spray components before disas

sembly. Wear protective clothing, chemical resistant gloves, and eye protection during repair.

1. Park machine on a level surface, stop engine, engage parking brake, and remove key from the ignition

switch.

2. Loosen and remove nut that secures flow sensor to

flowmeter housing. Carefully remove flow sensor from

housing.

-

1

2

3. Inspect for worn rotor shaft and/or bushings. Make

sure that rotor magnets are not missing or damaged.

4. Clean rotor, rotor shaft, and flowmeter sensor if required (see Operator’s Manual).

5. With the flow sensor harness connected to the machine and the ignition key in the ON position, slowly spin

the flowmeter rotor. The flowmeter LED should illumi

nate as a rotor magnet passes the flow sensor and

should go out as the next magnet passes the sensor.

NOTE: When using a magnet to check the flowmeter,

make sure to alternately use both north and south poles

of the magnet.

6. If the flowmeter LED does not flash, remove rotor

and rotor shaft from sensor. With the flowmeter harness

connected to the machine and the ignition key in the ON

position, slowly pass alternate poles of a magnet past

the flow sensor. If the flowmeter LED flashes as the

magnet poles pass the sensor, replace the rotor and ro

tor shaft. If the flowmeter LED does not flash as the magnet poles pass the sensor, replace the flow sensor.

7. If necessary, remove flowmeter housing using Figures 24 and 26 as guides (also see Spray Control) in this

section). Discard all removed o–rings and gaskets.

Figure 25

1. Rotor shaft 2. Rotor

1

3

2

4

5

Figure 26

1. Rate control motor 4. Center boom valve motor

2. Flowmeter 5. RH boom valve motor

3. LH boom valve motor

Spray

System

Assembly (Fig. 24)

NOTE: Coat all o–rings with vegetable oil before instal-

lation to reduce the chance of damage during assembly.

NOTE: When installing flow sensor into housing, make

sure to align locating pin on sensor flange with hole in

housing.

1. Reassemble flowmeter using Figures 24 and 26 as

guides. Replace all removed o–rings and gaskets.

2. Operate spray system and check for leaks.

Workman 200 Spray System

Page 3 – 25

Spray System

Page 46

Flowmeter (Serial Numbers Above 310000000)

7

9

NOTCH

8

5

NOTE ARROW

DIRECTION

1

NOTCH

5

4

1. Flowmeter body

2. Rotor/magnet assembly

3. Upstream hub with bearing

2

3

6

THREAD

SEALANT

Figure 26.1

4. Downstream hub

5. Retaining ring (2 used)

6. Turbine stud with bearing

7. Sensor assembly

8. Cable clamp

9. Screw

Page 3 -- 25.1 Workman 200 Spray SystemSpray System

Rev. B

Page 47

Removal and Inspection (Fig. 26.1)

IMPORTANT: Make sure to remove and neutralize

chemicals from spray components before disassembly. Wear protective clothing, chemical resistant gloves, and eye protection during repair.

1. Remove spray control assembly from machine and

separate flowmeter from spray control (see Spray Control Assembly (Serial Numbers Above 310000000) Removal in this section).

2. Disassemble flowmeter as required using Figures

26.1 and 26.3 as guides.

3. Clean rotor (item 2), both hubs (items 3 and 4) and

flowmeter body to remove any metal filings, spray

chemicals or other materials.

3

Figure 26.2

1. Boom valve manifold

2. Flowmeter

2

3. Regulating valve

1

Assembly (Fig. 26.1)

1. Assemble flowmeter using Figures 26.1 and 26.3 as

guides. Check the following items during flowmeter assembly.

A. If turbine stud (item 6) was removed from upstream hub, apply thread sealant to threads of stud

before installation.

B. Check that rotor spins freely with very little drag. If

necessary, loosen the turbine stud 1/16 of a turn and

check rotor drag. Continue the process of loosening

stud until rotor spins freely.

C. When installing hubs (items 3 and 4) into housing, make sure to align locating notch on each hub

with boss in housing bore.

D. If sensor (item 7) was removed from flowmeter

body, thread sensor into housing so that it lightly bottoms in the housing. Secure sensor in position by

tightening jam nut.

E. Make sure that retaining rings are fully seated in

grooves of flowmeter housing.

6

5

2

1. Flowmeter body

2. Retaining ring

3. Upstream hub

Figure 26.3

4. Rotor

5. Downstream hub

6. Sensor

1

Spray

System

3

2

4

2. Attach flowmeter assembly to spray control and then

install spray control assembly to machine (see Spray

Control Assembly (Serial Numbers Above 310000000)

Installation in this section).

Page 3 -- 25.2Workman 200 Spray System Spray System

Rev. B

Page 48

Rate Control Motor (Serial Numbers Below 290999999)

1

12

13

3

1

5

8

11

2

4

6

7

9

14

Figure 27

1. Phillips head screw (5 used)

2. Lock washer

3. Hand grip

4. O--ring

5. Phillips head screw (4 used)

6. Rate control motor assembly

7. Gasket

8. Phillips head screw (4 used)

9. Rate valve spindle section

10. Rate control valve housing

The rate control motor allows the operator to vary the

spray application rate. The pressure increase/decrease

switch on the spray console energizes the rate control

motor which adjusts the valve opening and allows some

flow to bypass the spray booms.

NOTE: The rate control motor affects flow to all spray

booms. Therefore, a problem with the rate control motor

will affect all booms and nozzles.

Disassembly and Inspection (Fig. 27)

IMPORTANT: Make sure to remove and neutralize

chemicals from spray components before disassembly. Wear protective clothing, chemical resistant gloves, and eye protection during repair.

10

11. O - -ring

12. Cone

13. Control valve

14. Seal

1. To remove the rate control motor:

A. Adjust the rate control to maximum to allow the

rate control motor spring to relax. This can be done

with either the increase/decrease switch on the

spray console or by rotating the hand grip on the motor fully in a clockwise direction.

B. Unplug rate control motor electrical connector

from machine electrical harness.

C. Loosen four (4) phillips head screws (item 5)

evenly to allow removal of the rate control motor.

D. The inside of motor housing should be free of excessive moisture, corrosion, and dirt.

Rev. B

Workman 200 Spray SystemPage 3 -- 26Spray System

Page 49

2. Remove four (4) phillips head screws (item 8) that

secure spindle section to housing. Remove spindle sec

tion.

3. Locate, remove, and discard o–ring (item 11) and

seal (item 14).

4. Remove valve (item 13) and inspect for wear and/or

damage. Replace if needed.

5. If needed, the spindle shaft can be removed by removing lock nut that secures cone (item 12) to shaft.

NOTE: Many individual components for the rate control

motor and spindle section are not available separately.

If individual components are worn or damaged, assem

blies must be replaced. Refer to Parts Catalog.

6. If necessary, remove rate control valve housing from

machine (see Spray Control in this section).

Assembly (Fig. 27)

NOTE: Coat all o–rings with vegetable oil before instal-

lation to reduce the chance of damage during assembly.

-

1

3

2

4

5

-

Figure 28

1. Rate control motor 4. Center boom valve motor

2. Flowmeter 5. RH boom valve motor

3. LH boom valve motor

Spray

System

1. If removed, install rate control valve housing to machine (see Spray Control in this section).

2. If spindle shaft was removed, assemble by reversing

disassembly process. Make sure that spindle shaft sup

port aligns with notches in housing during assembly. Secure spindle assembly with lock nut.

3. Align control valve with tabs in spindle section and

install control valve. Rotate spindle to fully retract control

valve.

4. Install new o–ring (item 11) and seal (item 14) to

spindle section.

5. Position spindle section to rate control valve housing. Secure spindle section with four (4) phillips head

screws (item 8).

6. To ease assembly of the motor, rotate spindle shaft

so the post is about 1/2” (13 mm) from the spindle sec

tion housing. Align slot in motor with post in spindle and

install motor.

7. Secure motor to assembly by evenly tightening four

(4) phillips head screws (item 5).

-

-

Workman 200 Spray System

Page 3 – 27

Spray System

Page 50

Regulating Valve Assembly (Serial Numbers Above 310000000)

10

1

12

11

7

5

4

7

3

10

9

12

6

14

11

9

Figure 28.1

1. Regulating valve motor

2. Hose barb

3. Flange

4. Adaptor

5. Flynut

6. Elbow fitting

7. Mounting bracket (2 used)

8. Fork

9. Washer (4 used)

10. Cap screw (4 used)

The regulating valve allows the operator to vary the

spray application rate. The pressure increase/decrease

switch on the spray console energizes the regulating

valve motor which adjusts the valve opening and allows

some flow to bypass the spray booms.

NOTE: The r egulating valve affects flow to all spray

booms. Therefore, a problem with the regulating valve

will affect all booms and nozzles.

Removal and Inspection (Fig. 28.1)

IMPORTANT: Make sure to remove and neutralize

chemicals from spray components before disassembly. Wear protective clothing, chemical resistant gloves, and eye protection during repair.

1. Remove spray control assembly from machine and

separate regulating valve assembly from spray control

(see Spray Control Assembly (Serial Numbers Above

310000000) Removal in this section).

13

8

2

11. Lock nut (4 used)

12. O--ring (2 used)

13. O--ring

14. O--ring

2. Disassemble regulating valve assembly as needed

using Figure 28.1 as a guide. Discard all removed O-rings and gaskets.

NOTE: There are limited replacement parts available

for regulating valve motor assembly. Check your parts

catalog for parts that are available.

3. To remove valve motor cover from regulating valve

motor (Fig. 28.3):

A. Loosen three (3) screws that secure valve motor

cover to valve motor assembly.

B. Carefully lift and rotate cover from valve motor.

C. Unplug wire connections and remove cover.

D. Make sure that screws that secure valve motor

are tight.

Page 3 -- 27.1 Workman 200 Spray SystemSpray System

Rev. B

Page 51

Assembly (Fig. 28.1)

1. To install valve motor cover to regulating valve motor

(Fig. 28.3):

A. Connect cover wires to motor wires. Make sure

that cover wire c olor is the same as the motor wire

color when connecting wires.

B. Carefully rotate cover onto valve motor taking

care to not damage wires.

C. Tighten screws to secure cover to valve motor.

3

2

1

NOTE: Coat all O--rings with vegetable oil before instal-

lation to reduce the chance of damage during assembly.

2. Assemble regulating valve assembly using Figure

28.1 as a guide.

3. Attach regulating valve assembly to spray control

and then install spray control assembly to machine (see

Spray Control Assembly (Serial Numbers Above

310000000) Installation in this section).

Piston Valve Service (Fig. 28.4)

1. Remove hosebarb from bottom of valve motor to allow access to piston valve.

2. Make sure that valve is closed. If valve is not closed,

spring above piston valve will be under compression

and may damage valve motor or piston valve during disassembly. End of piston valve will extend into bottom of

valve motor housing when valve is closed. If necessary,

reconnect motor to machine wire harness and close

valve before removing piston valve.

3. Use 3mm allen wrench to loosen and remove piston

valve assembly from valve motor. Locate and retrieve

spring from above piston valve.

Figure 28.2

1. Boom valve manifold

2. Flowmeter

3

2

Figure 28.3

1. Valve motor assembly

2. Valve motor cover

3. Wire connector

3. Regulating valve

5

3

1

4. Socket screw (4 used)

5. Phillips screw (2 used)

Spray

System

4

4. Inspect seals on piston valve assembly.O--ring in top

groove of piston valve assembly is available separately.

If lower two (2) seals in piston valve are worn or damaged, replace piston valve assembly. The piston valve

is not designed to be disassembled.

5. Apply silicone grease to seals on piston valve assembly.

6. Position spring into valve motor housing. Use 3mm

allen wrench to secure piston valve assembly to valve

motor.

7. Secure hosebarb to bottom of valve motor.

Page 3 -- 27.2Workman 200 Spray System Spray System

1

Figure 28.4

1. Valve motor assembly

2. Piston valve assembly

3. Valve seal

Rev. B

5

4

3

2

4. Spring

5. Valve motor cover

Page 52

Boom Valve Motor (Serial Numbers Below 290999999)

12

9

10

18

24

27

16

20

26

22

14

29

32

33

70 in--lb

(8 N--m)

28

30

31

1

4

5

7

2

3

6

4

8

11

13

15

17

19

21

23

25

Figure 29

1. Housing cover

2. Cover seal

3. Boom valve motor

4. Phillips head screw (5 used)

5. O--ring

6. Lock washer

7. Hand grip

8. Roller

9. Roller pin

10. Spindle

11. Spr in g

12. Spring seat

13. O--ring

14. Spindle housing

15. Phillips head screw (4 used)

16. O--ring

17. O--ring

18. Flat washer

19. Seat outer o-- ring

20. Seat

21. Seat inner o-- ring

22. Seat base

The Workman 200 Sprayer (serial numbers below

290999999) uses three boom valve motor assemblies

to control the spray booms. Each boom valve motor assembly includes a motor section (Fig. 29, Items 1

through 7), a spindle section (Fig. 29, Items 8 through

27), and a manifold assembly (Fig. 29, Items 28 through

33).

Disassembly and Inspection (Fig. 29)

IMPORTANT: Make sure to remove and neutralize

chemicals from spray components before disassembly. Wear protective clothing, chemical resistant gloves, and eye protection during repair.

1. Remove spray control from machine. Separate

spray control components to allow boom valve motor

disassembly (see Spray Control in this section).

23. Flat washer

24. Spring

25. Flat washer

26. Cone

27. Screw

28. Boom valve manifold housing

29. Fork

30. O--ring

31. Balancing valve

32. Roll pin

33. Balancing valve knob

2. To remove the motor and spindle section assembly

from the manifold assembly:

A. Remove the fork (item 29) that secures the motor

and spindle sections to the manifold assembly.

B. Lift the motor and spindle section assembly from

the manifold.

3. To allow easier separation of the motor and spindle

sections, make sure that boom valve motor is in the

closed position (green indicator is recessed into the

spindle housing). Remove four phillips head screws

(item 15) and separate spindle section from motor section.

Rev. B