Toro 41-20OE02, 41-20OE03, 51-12KE01, 51-12KE02, 51-16OE01 Service Manual

...

3/4/500 EATON 11 HYDROSTATIC TRANSMISSION - WH TRANSAXLE

Table of Contents – Page 1 of 2

FOREWORD

SPECIFICATIONS

TRANSMISSION:

TRANSAXLE:

MAINTENANCE:

GENERAL INFORMATION

TRANSMISSION DESCRIPTION AND IDENTIFICATION MARKINGS

PRINCIPLES OF OPERATION

TRANSMISSION S YST EM

SYSTEM OPERATION

TRANSMISSION OPERATION

TROUBLESHOOTING

PROBLEM DIAGNOSIS

GENERAL SYSTEM CHECKS

OIL SYSTEM

COOLING SYSTEM

ENGINE AND INPUT DRIVE

MOTION CONTROL LINKAGE

TRANSAXLE

HYDROSTATIC TRANSMISSION

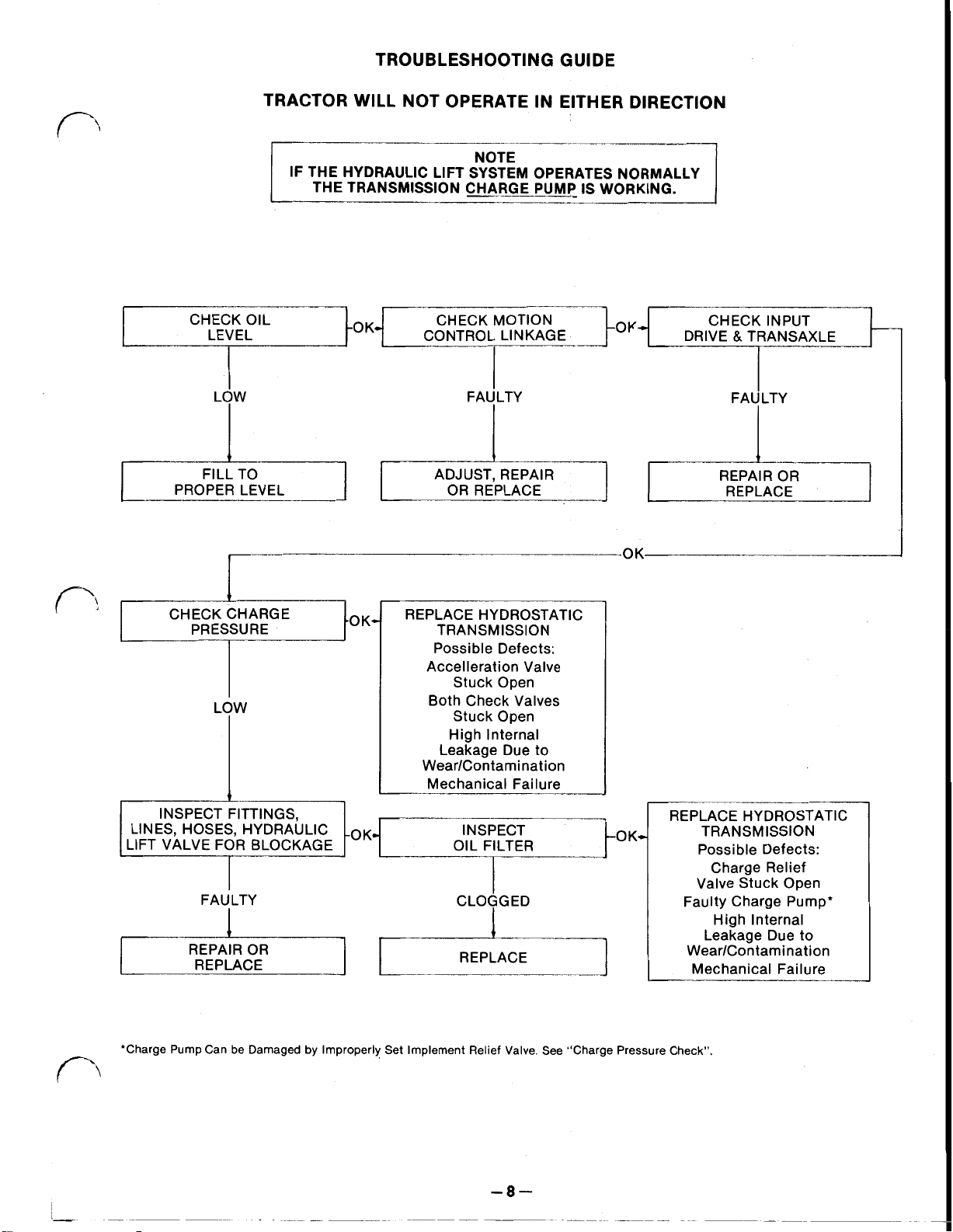

TROUBLESHOOTING GUIDE

TRACTOR WILL NOT OPERATE IN EITHER DIRECTION

TRACTOR OPERATES IN BOTH DIRECTIONS, BUT LOSES POWER AS OIL

TRACTOR DOES NOT RETURN TO NEUTRAL.

HYDRAULIC LIFT SYSTEM DOES NOT OPERATE

ADJUSTMENTS

GENERAL

SINGLE ACTION BRAKE BAND ADJUSTMENT

DUAL ACTION BRAKE BAND ADJUSTMENT

MOTION CONTROL FRICTION

NEUTRAL

TESTING

SYSTEM PERFORMANC E

PRESSURE CHECKS

IMPLEMENT LIFT SYSTEM

CHARGE PRESSURE

3/4/500 EATON 11 HYDROSTATIC TRANSMISSION - WH TRANSAXLE

Table of Contents – Page 2 of 2

REPAIR OPERATIONS

GENERAL INFORMATION

HYDRAULIC HOSES - HYDRAULIC LIFT CONTROL VALVE

REMOVAL

INSTALLATION

TRANSMISSION

REMOVAL

PULLEY, GEAR AND CAM PLATE REMOVAL

INSTALLATION

TRANSAXLE

IN-VEHICLE SERVICE

CASE HALF SERVICE

INTERMEDIATE GEAR AND DIFFERENTIAL SERVICE

TRANSAXLE REASSE MB L Y

TRANSMISSION SYSTEM

REMOVAL

INSTALLATION

INTERNAL TRANSMISSION SERVICE

TRANSAXLE

TRANSAXLE

TRANSMISSION AND FILTER

TRANSMISSION AND FILTER

MOTION CONTROL, CLUTCH LINKAGE

MOTION CONTROL, CLUTCH LINKAGE

BRAKE AND LINKAGE SINGLE ACTION BRAKE BAND

BRAKE, AND LINKAGE SINGLE ACTION BRAKE BAND

BRAKE AND LINKAGE DUAL ACT I ON BRAK E BAND

BRAKE AND LINKAGE DUAL ACT I ON BRAK E BAND

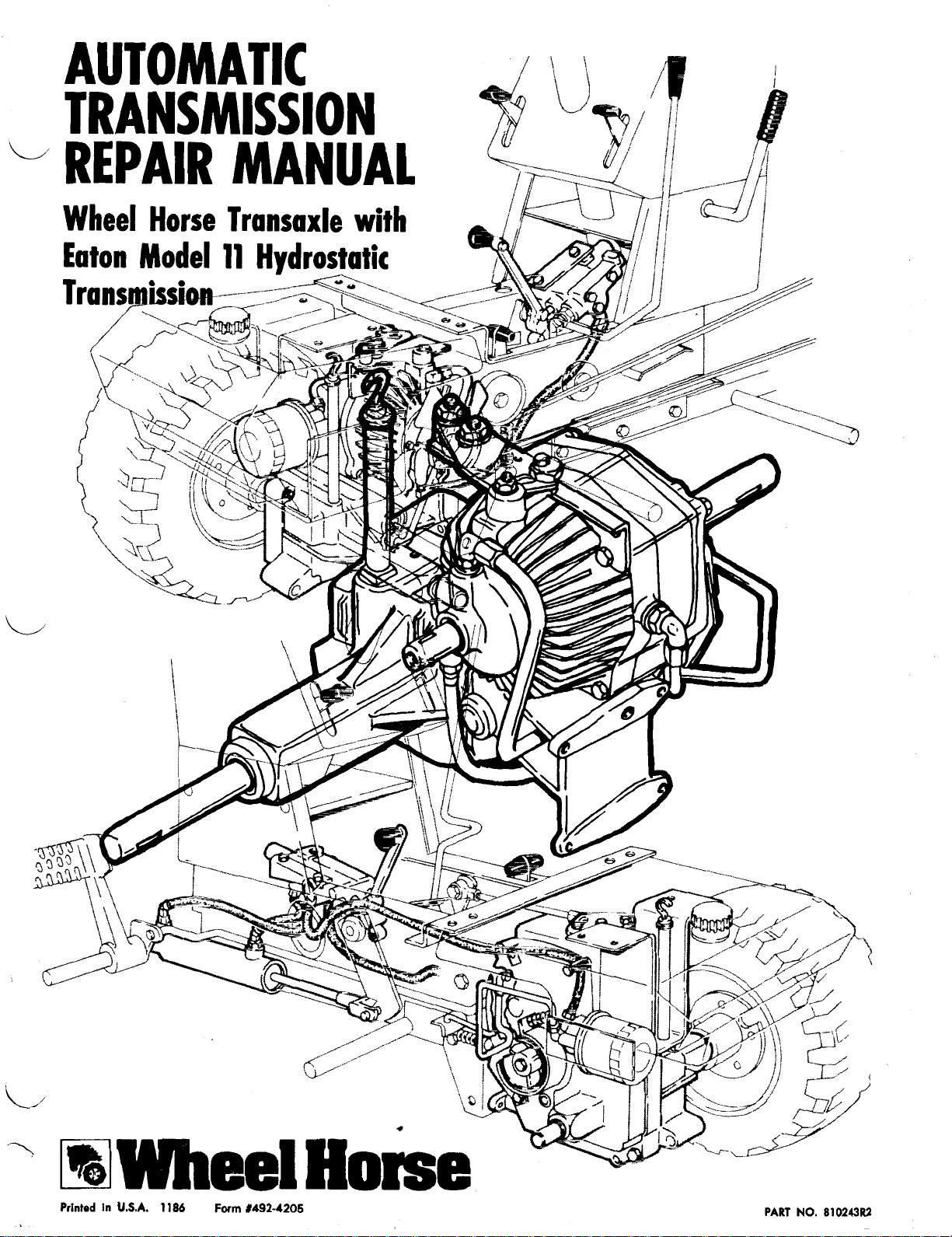

EATON MODEL 11 TRANSMISSION

TRANSMISSION

REPAIR

MANUAL

Printed in

U.S.A.

1186

Form

1492-4205

PART

NO.

810243R

FOREWORD

This

service and repair manual has been compiled to provide

authorized Wheel Horse service personnel with

and techniques for servicing the

11

with Eaton Model

The

following Table of Contents lists all areas covered.

advisable to read all of the introductory sections first to gain a proper

understanding

The automatic transmission and transaxle are sophisticated

of machinery. Maintain strict cleanliness control during all stages

service and repair. Cover or cap all hose ends and fittings whenever

they are exposed. Even a small amount of dirt or other contamination

can severely damage the system.

This

1980-87

model tractors equipped with the Eaton Model

model year. It may

of

manual covers

hydrostatic transmission.

the Wheel Horse automatic transmission system.

the

be

Wheel

transmission system as

used to

the

the

proper procedures

Horse automatic transaxle

It

pieces

used

during

extent applicable for later

11

hydrostatic trans-

the

is

of

mission and Wheel Horse transaxle.

SPECIFICATIONS

TRANSMISSION:

Pump and Motor with Auxiliary Charge Pump.

Displacement:

Pump, Variable

Motor, Fixed. 2.09 cu. in./rev.

Speed (as used):

Input 3400

Output 0-1750

Torque Output (Max.)

Continuous 360

Intermittent

Operating Temperature:

Maximum Continuous 18OoF

Cooling:

8” Diameter Fan Plus Oil Flow From Charge Pump

Oil Filter (as used)

10

Micron, Full-flow, Spin-on Type

Charge Pump (3400

3.8 GPM Free Flow

1.4

GPM @ 700

TRANSAXLE:

Drive 8-pinion Differential and Double Reduction

Gears.

Gears and Shafts

Heat-Treated Steel

Bearings:

Ball

Needle

Case Halves and Hubs:

Cast Iron

Seals:

3, Double-lip, Spring-loaded

Ratios and Speeds:

Drive Belt Pulley Ratio

Overall Reduction Ratio

Axle Shaft Speed:

Tractor Speeds (approx.):

2

@

1750

Forward 0-7 MPH

Reverse 0-4.2 MPH

MAINTENANCE:

Oil Check Before Each Use

Replace

Oil

Initial After First

Periodic Once a Year, or After Every

of Use, Whichever Occurs

Oil Specification

1OW-30 or 1OW-40 Premium Motor Oil

Oil Capacity (approx.)

Oil Filter Wheel Horse 108335

Adjustments

Foot/Parking Brake

Motion Control Friction

Motion Control Neutral

Torque Value (Thread Sizes)

1/4-20 8

5/16-18 17-22 ft. Ibs.

3/8-16

1/2-135-13

Wheel Hub Set Screw 28-32

Eaton Model

0-1.10

11;

cu. in/rev.

Radial, Ball-piston

RMP

RPM

in.

Ibs.

540

in. Ibs.

RPM

Input)

PSI

Wheel Horse; Single-speed, with Uni-

6

1:l

15.64:l

RPM

Eaton Output

and Filter:

ft.

Ibs.

30-35

ft.

75-80 ft. Ibs.

100

Ibs.

112

Hours of

First

5

quarts

As

RPM

Use

Required

ft.

Ibs.

100

Hours

GENERAL INFORMATION

TRANSMISSION DESCRIPTION AND

IDENTIFICATION MARKINGS

NOTE

This

manual uses the terms transmission,

hydrostatic transmission] and hydrostatic unit"

11

to refer to the Eaton Model

Transmission. The term "transaxle"

refer to the assembly of intermediate gears,

differential and case halves, less hydrostatic

unit. "Transmission System" and "Automatic

Transmission System" are used to refer to entire drive train as an assembly, including engine, transmission, transaxle, hydraulic

system, and all related parts.

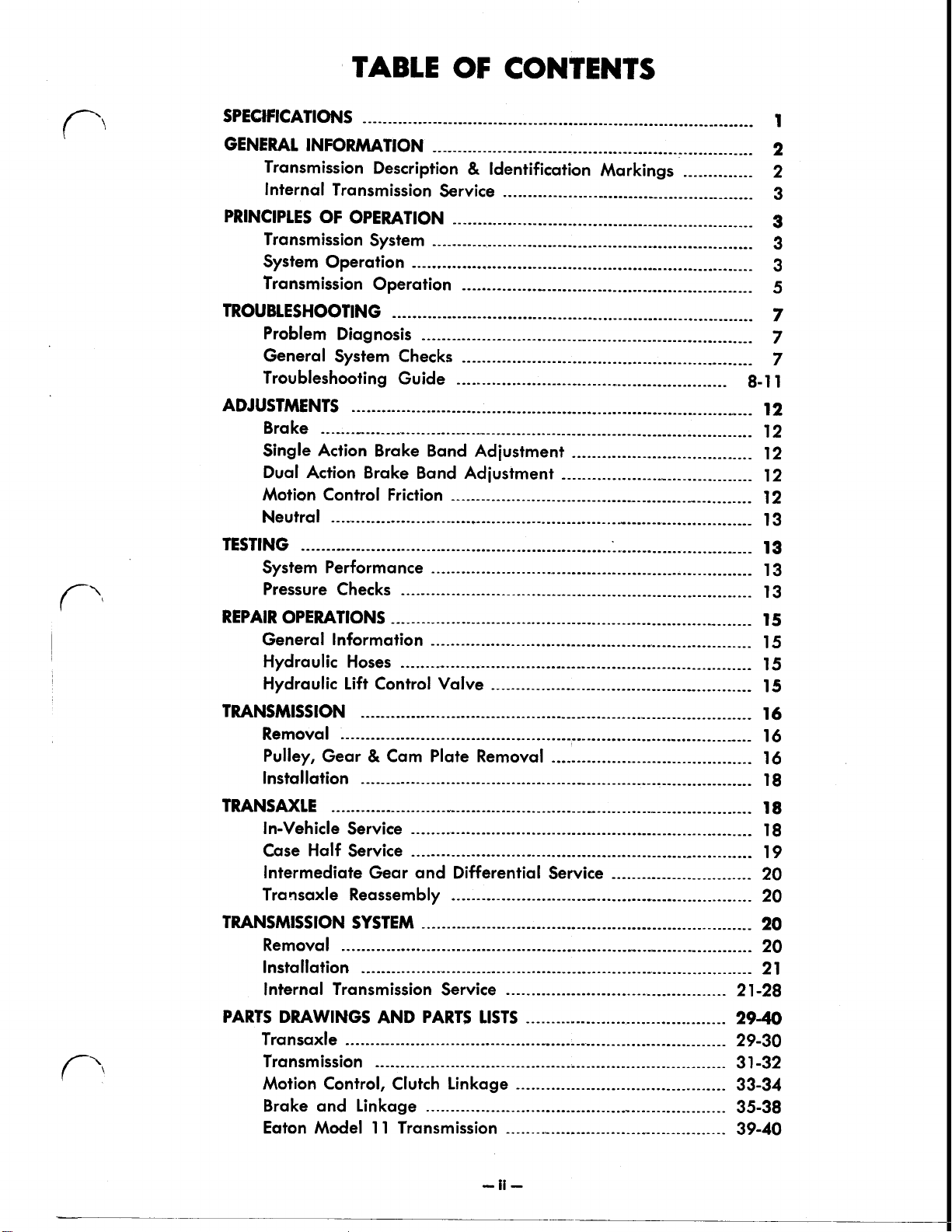

RADIAL BALL-PISTON MOTOR RADIAL BALL-PISTON PUMP

Hydrostatic

is

used to

lift

The Eaton Model

used by Wheel Horse,

charge pressure relief valve, forward and reverse

check :and acceleration valves, and vibration dampening pistons. Transmission has a splined output shaft

and keyed input shaft, both of

by ball bearings. Besides making up for normal internal transmission leakage, charge pump

operate tractor's hydraulic lift system. Charge pressure used to operate transmission

lated by a relief valve inside transmission. Implement

lift

system pressure

valve in hydraulic lift control valve.

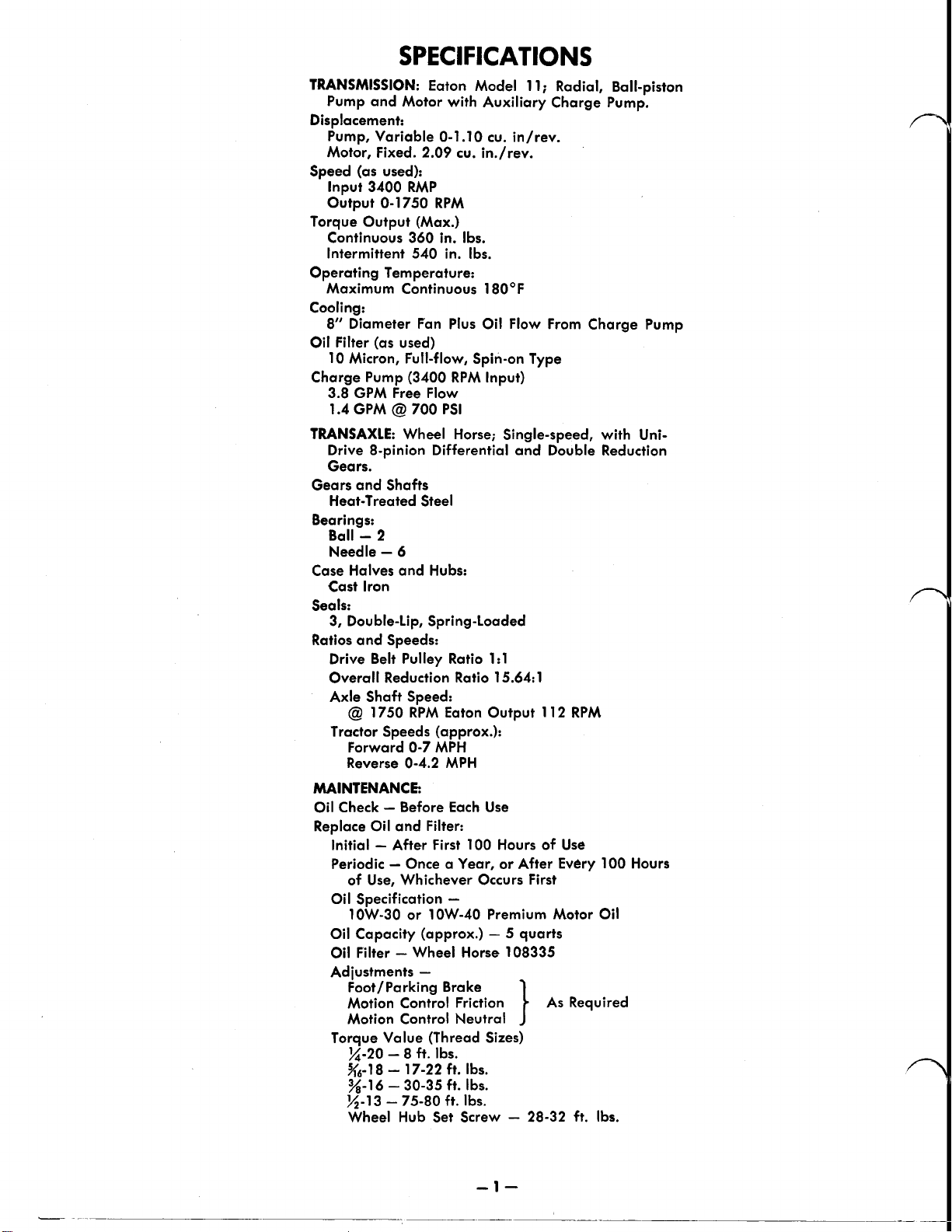

Transmission

facturing date code, and direction of rotation. Rebuilt

units are also marked with a

angle used in photo, this information will appear

upide-down as- in Figure

11

hydrostatic transmission, as

is

equipped with an internal

which

is

700

PSI,

regulated by a relief

is

stamped with model number, manu-

"1".

are supported

is

30-90

If

viewed from

is

used to

PSI,

2.

regu-

CHECK VALVE

(TWO USED)

(CONTROLS TRANSMISSION OUTPUT

UP WHEN INSTALLED IN WHEEL

CONTROL SHAFT

SPEED AND DIRECTION

OF ROTATION-SHAFT POINTS

HORSE TRANSAXLE)

FIG.

1.

Internal Transmission Features

CHARGE

IMPLEMENT

SHAFT

CHARGE PUMP

PRESSURE

I

LIFT PRESSURE

30-90

PSI

700

PSI

-2-

FIG.

4.

left

Side

DIRECTION

MANUFACTURING DATE

PRINCIPLES

FIG.

OF

INPUT SHAFT

2.

Identification Markings

OF

OPERATION

TRANSMISSION SYSTEM

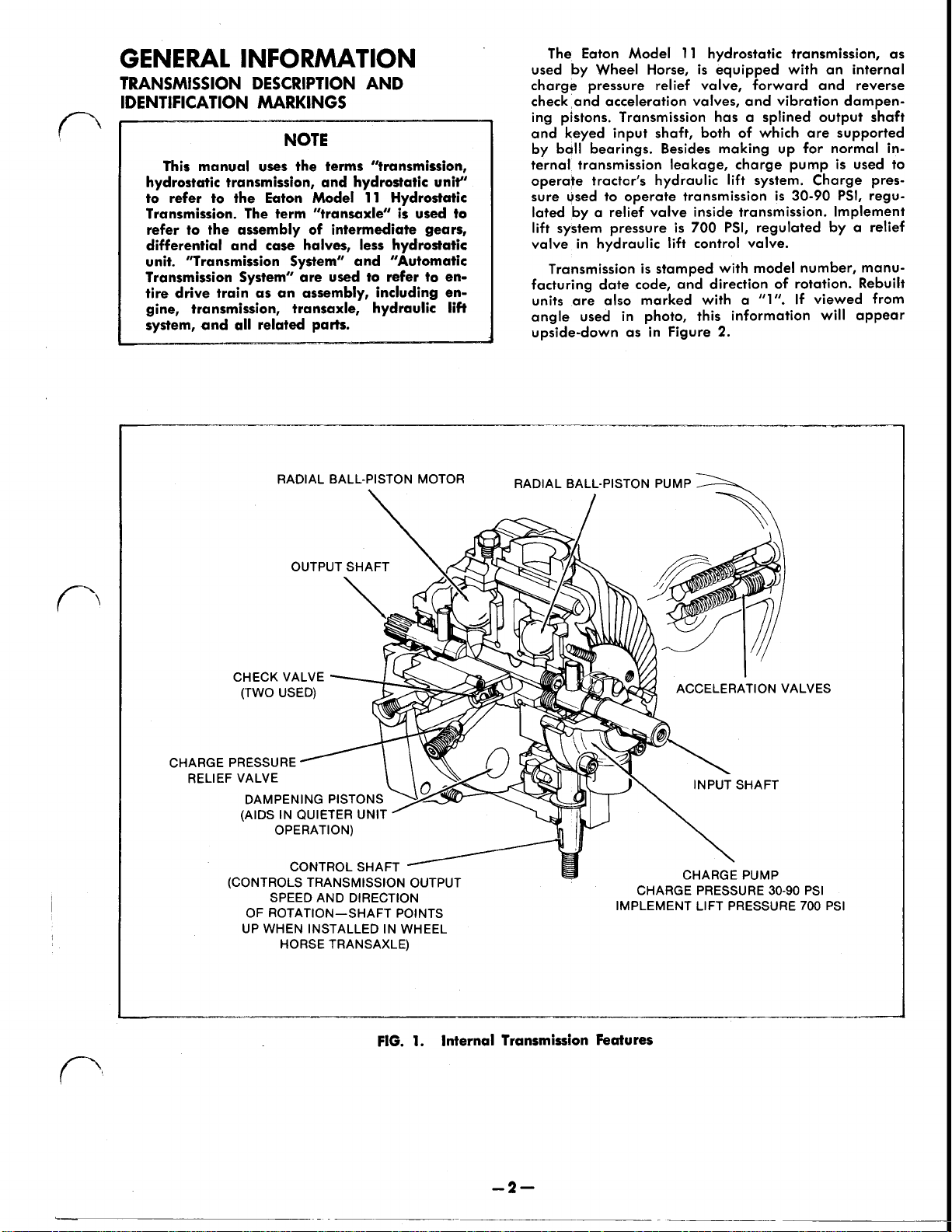

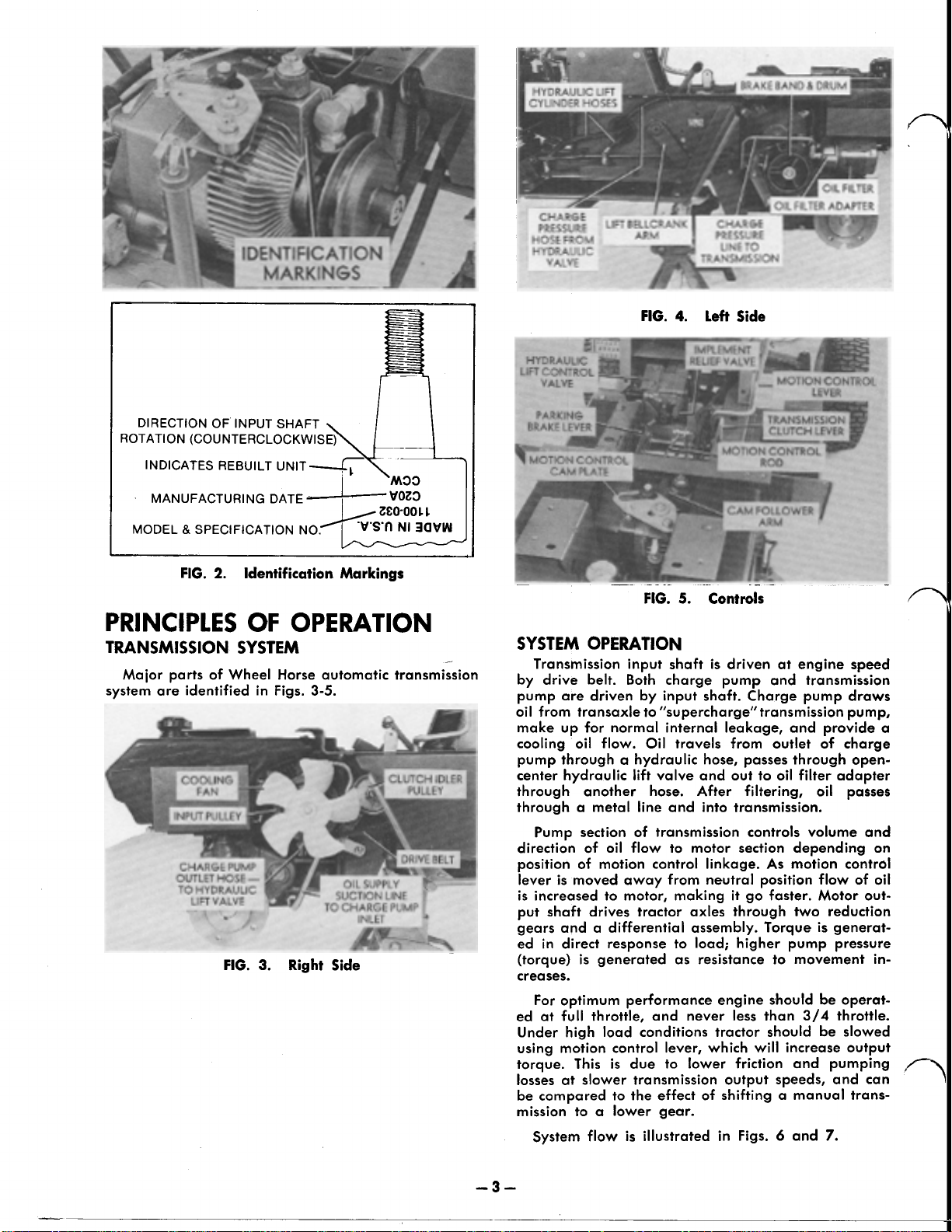

Major parts of Wheel Horse automatic transmission

system are identified in Figs.

FIG.

3.

3-5.

Right Side

5.

FIG.

SYSTEM

Transmission input shaft

by drive belt. Both charge pump and transmission

pump are driven by input shaft. Charge pump draws

oil from transaxle

make up for normal internal leakage, and provide a

cooling oil flow. Oil travels from outlet of charge

pump through a hydraulic hose, passes through opencenter hydraulic lift valve and out to oil filter adapter

through another hose. After filtering,

through a metal line and into transmission.

Pump section of transmission controls volume and

direction of oil flow to motor section depending on

position of motion control linkage.

lever

is

increased to motor, making it go faster. Motor output shaft drives tractor axles through two reduction

gears and a differential assembly. Torque

ed in direct response to load; higher pump pressure

(torque)

creases.

For optimum performance engine should

ed

at full throttle, and never less than

Under high load conditions tractor should

using motion control lever, which will increase output

torque.

losses at slower transmission output speeds, and can

be

compared

mission to

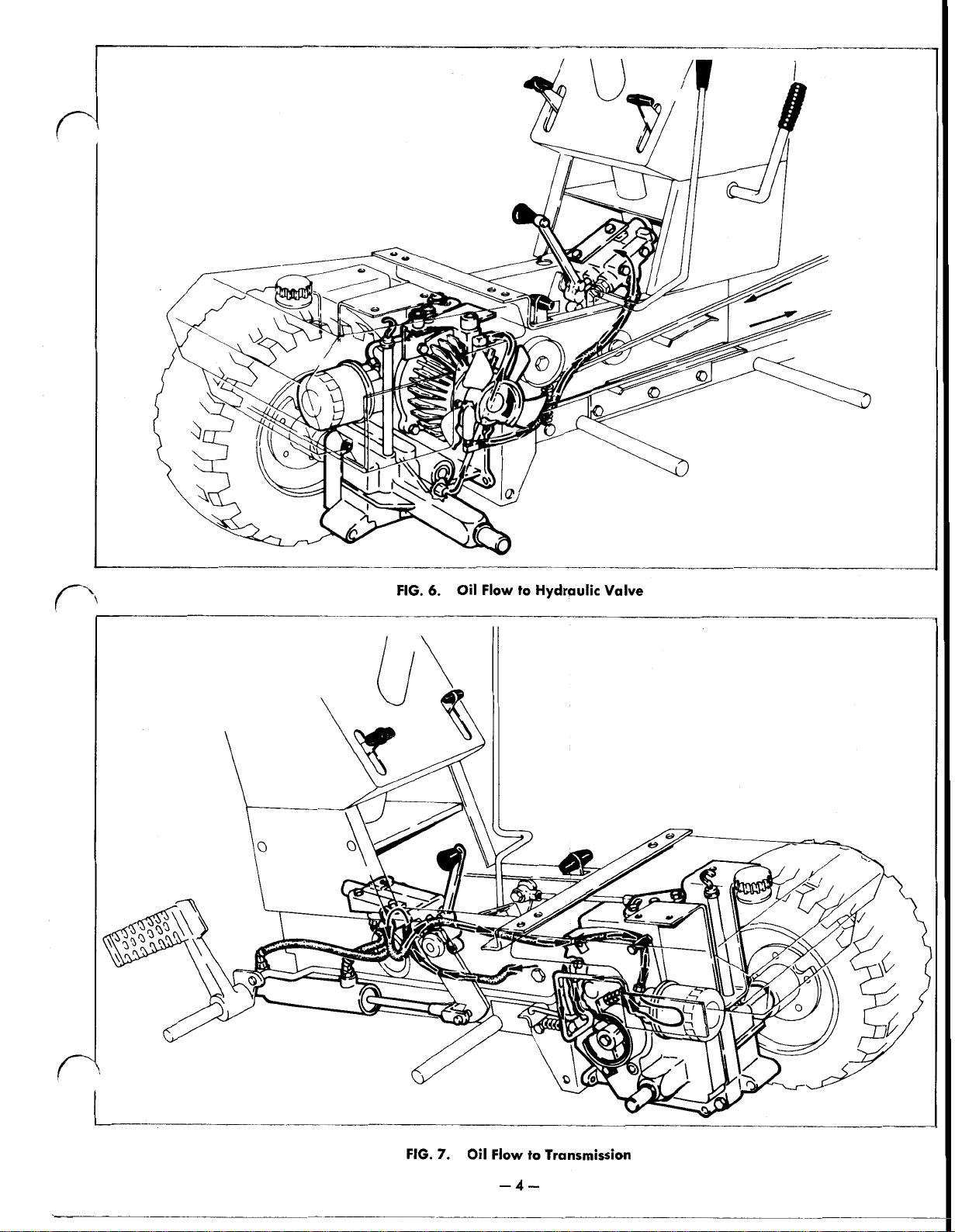

System flow

OPERATION

to "supercharge "transmission

is

moved away from neutral position flow of

is

generated as resistance to movement in-

This

is

due to lower friction and pumping

to

the effect of shifting a manual trans-

a

lower gear.

is

illustrated in Figs. 6 and

Controls

is

driven at engine speed

oil

As

motion control

is

generat-

be

3/4

throttle.

be

7.

pump,

passes

oil

operat-

slowed

-3-

FIG.

6.

Oil

Flow

to

Hydraulic

Valve

Hydraulic lift circuit

pump. When lift control valve

Lower position, charge pump output

of hoses attached to lift cylinder. Other hose

nected through control valve to charge pressure hose

leading to oil filter, permitting bleed-off of oil on that

side

of lift cylinder's piston. Implement relief valve

located in control valve regulates

700

PSI.

to

into charge pressure hose leading to oil filter.

When this valve opens excess oil

is

also operated

is

by

charge

moved to Raise or

is

diverted to one

is

lift

system pressure

is

bled

con-

off

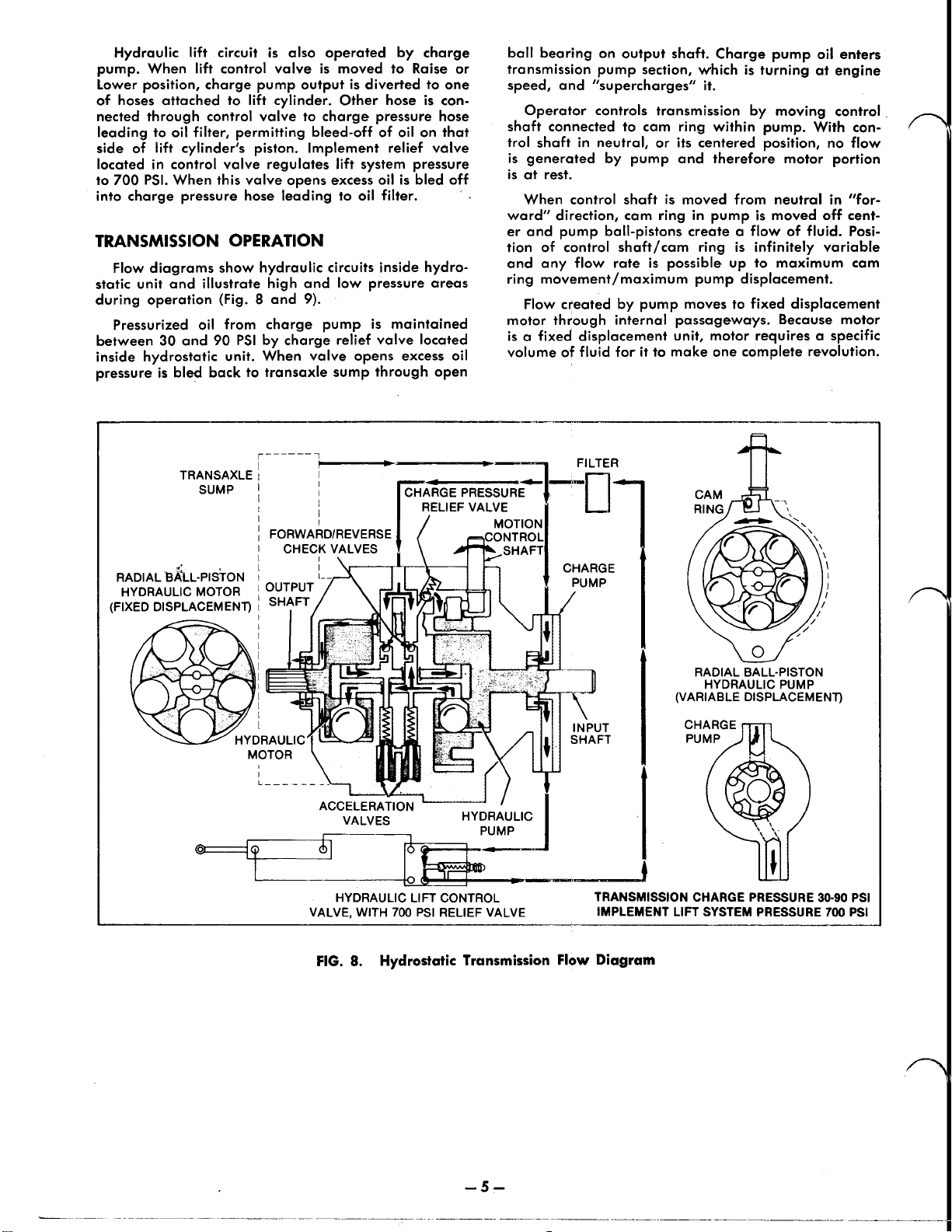

TRANSMISSION OPERATION

Flow diagrams show hydraulic circuits inside hydrostatic unit and illustrate high and low pressure areas

during operation (Fig.

Pressurized oil from charge pump

30

between

inside hydrostatic unit. When valve opens excess oil

pressure

and

is

bled

TRANSAXLE

SUMP

8

and

9).

is

maintained

90

PSI

by charge relief valve located

back to transaxle sump through open

ball bearing on output shaft. Charge pump oil enters

transmission pump section,

speed, and "supercharges" it.

Operator controls transmission by moving control

shaft connected to cam ring within pump. With control shaft in neutral, or its centered position, no flow

is

generated by pump and therefore motor portion

is

at rest.

When control shaft

ward" direction, cam ring in pump

er and pump ball-pistons create a flow of fluid. Position of control shaft/cam ring

and any flow rate

ring movement/maximum pump displacement.

Flow created by pump moves to fixed displacement

motor through internal passageways. Because motor

is

a fixed displacement unit, motor requires a specific

volume of fluid for it to make one complete revolution.

is

which

is

moved from neutral in "for-

possible up to maximum cam

is

turning at engine

is

moved

is

infinitely variable

off

cent-

RADIAL

(FIXED DISPLACEMENT)

BALL-PISTON

HYDRAULIC MOTOR

I

FORWARD/REVERSE

CHECK VALVES SHAFT

ACCELERATION

VALVES HYDRAULIC

HYDRAULIC LIFT CONTROL

VALVE, WITH

FIG.

700 PSI RELIEF VALVE

8.

Hydrostatic Transmission

MOTION

PUMP

I

I

Flow

RADIAL BALL-PISTON

HYDRAULIC PUMP

(VARIABLE DISPLACEMENT)

I

TRANSMISSION CHARGE PRESSURE

IMPLEMENT LIFT SYSTEM PRESSURE

Diagram

\

I

I

30-90

700 PSI

PSI

-5-

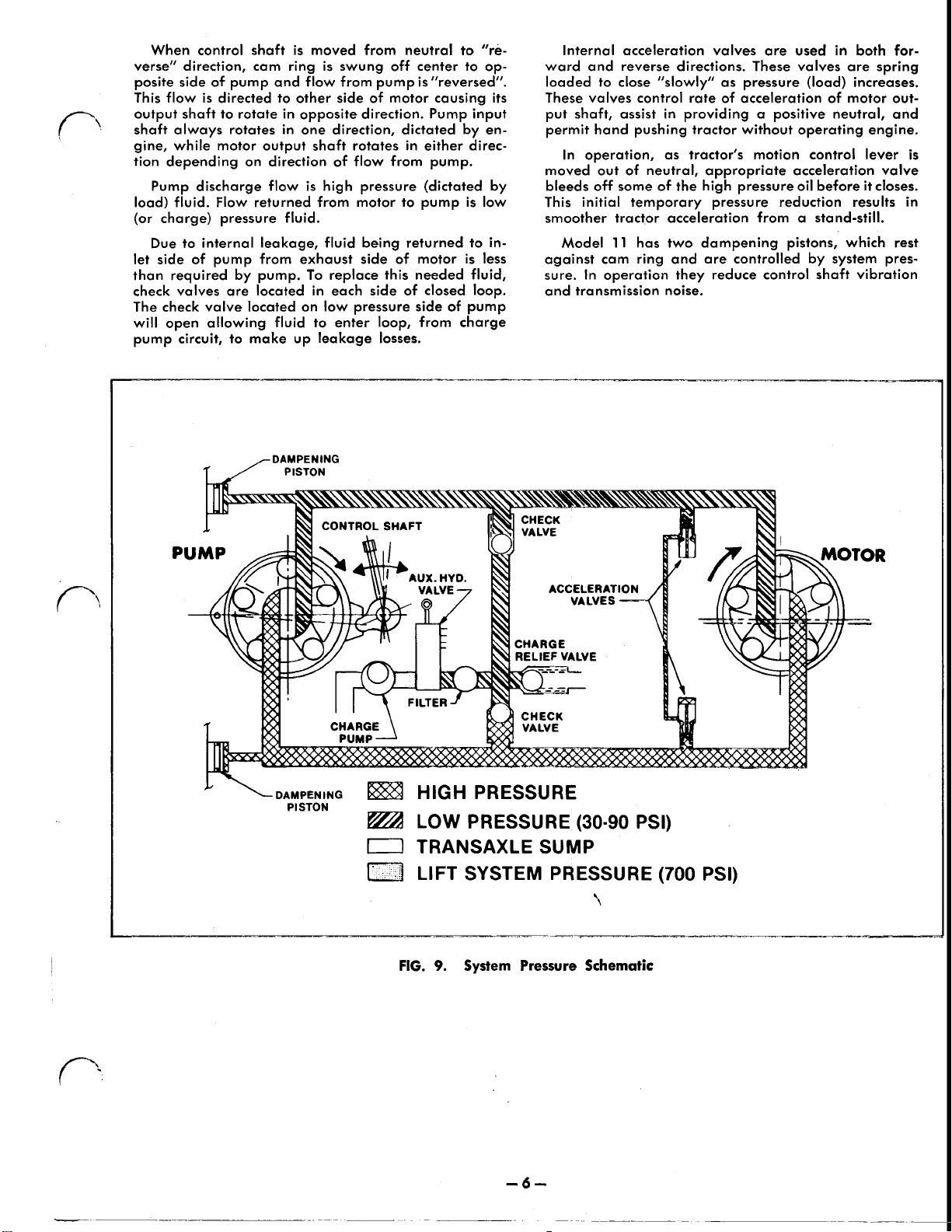

When control shaft

verse" direction, cam ring

side

posite

This

output shaft to rotate in opposite direction. Pump input

shaft always rotates in one direction, dictated by engine, while motor output shaft rotates in either direction depending on direction of flow from pump.

Pump discharge flow

load) fluid. Flow returned from motor to pump

(or charge) pressure fluid.

Due to internal leakage, fluid being returned to in- Model

let side of pump from exhaust side of motor

than required by pump. To replace this needed fluid, sure. In operation they reduce control shaft vibration

check valves are located in each side of closed loop. and transmission noise.

The check valve located on low pressure side of pump

will open allowing fluid to enter loop, from charge

pump circuit, to make up leakage losses.

of pump and flow from pump is "reversed".

flow

is

directed to other side of motor causing its

is

moved from neutral to "re-

is

swung off center to op-

is

high pressure (dictated by

Internal acceleration valves are used in both for-

ward and reverse directions. These valves are spring

loaded to close "slowly" as pressure (load) increases.

These valves control rate of acceleration of motor output shaft, assist in providing a positive neutral, and

permit hand pushing tractor without operating engine.

In operation, as tractor's motion control lever

moved out of neutral, appropriate acceleration valve

bleeds off some of the high pressure oil before it closes.

This

is

low

is

less against cam ring and are controlled by system pres-

initial temporary pressure reduction results in

smoother tractor acceleration from a stand-still.

11

has two dampening pistons,

which

rest

is

PISTON

HIGH

LOW PRESSURE

PRESSURE

(30-90

TRANSAXLE SUMP

LIFT SYSTEM PRESSURE

FIG.

9.

System

Pressure

-6-

Schematic

PSI)

(700

PSI)

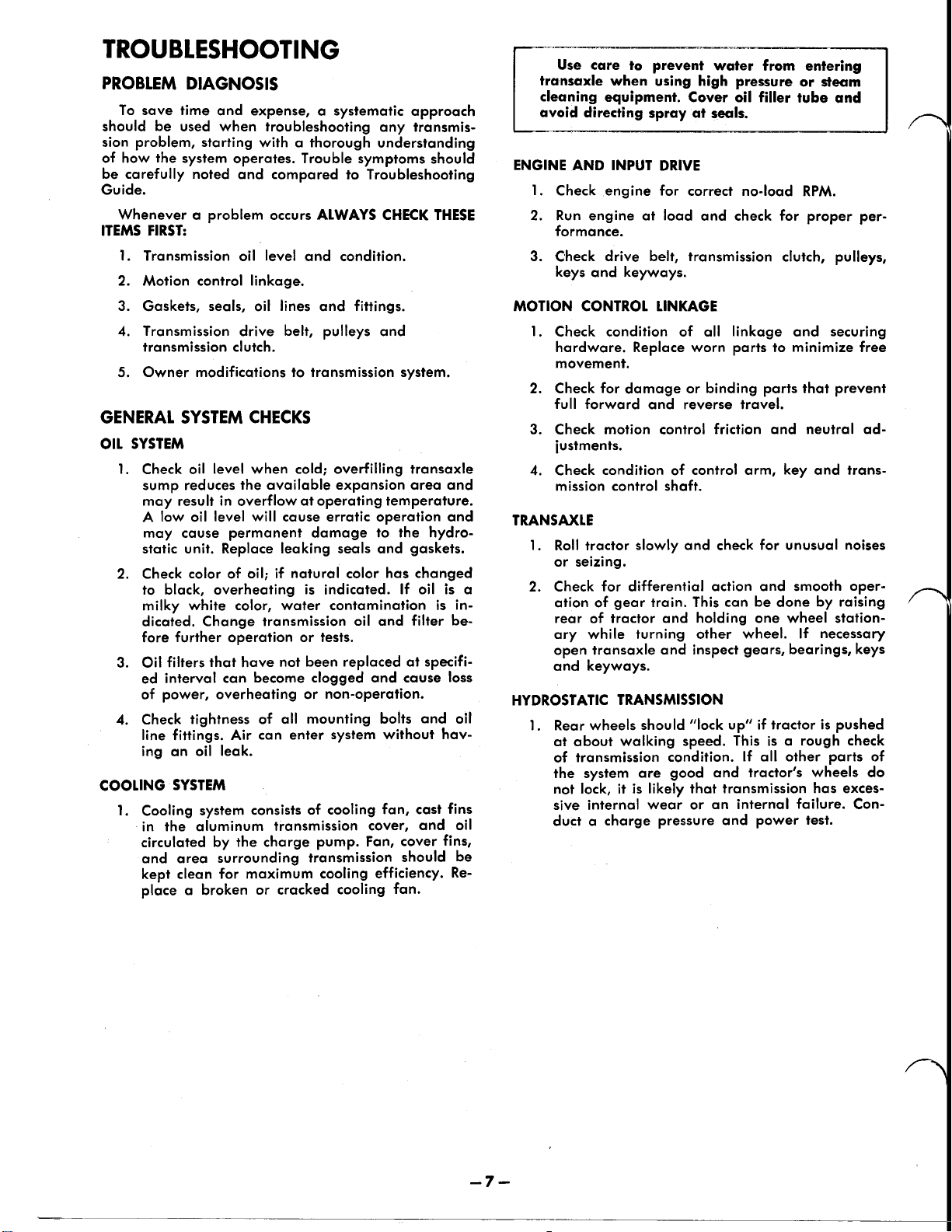

TROUBLESHOOTING

PROBLEM DIAGNOSIS

To save time and expense, a systematic approach

be

should

sion problem, starting with a thorough understanding

of how the system operates. Trouble symptoms should

be carefully noted and compared to Troubleshooting

Guide.

Whenever a problem occurs

ITEMS

1.

2.

3.

4.

5.

GENERAL

OIL SYSTEM

1.

2.

3.

4.

COOLING SYSTEM

I.

used when troubleshooting any transmis-

ALWAYS CHECK THESE

FIRST:

Transmission oil level and condition.

Motion control linkage.

Gaskets, seals, oil lines and fittings.

Transmission drive belt, pulleys and

transmission clutch.

Owner modifications to transmission system.

SYSTEM

Check

oil level when cold; overfilling transaxle

sump reduces the available expansion area and

may result in overflow at operating temperature.

A

low oil level will cause erratic operation and

may cause permanent damage to the hydro-

static unit. Replace leaking

Check

color of oil;

to black, overheating

milky white color, water contamination

dicated. Change transmission oil and filter before further operation or tests.

Oil

filters that have not been replaced at specified interval can become clogged and cause

of power, overheating or non-operation.

Check

line fittings. Air can enter system without having an oil leak.

Cooling system consists of cooling fan, cast fins

in the aluminum transmission cover, and oil

circulated by the charge pump. Fan, cover fins,

and area surrounding transmission should be

kept clean for maximum cooling efficiency.

place a broken or cracked cooling fan.

tightness of all mounting bolts and

CHECKS

seals

if

natural color has changed

is

indicated.

and gaskets.

If

oil

is

is

loss

in-

oil

Re-

ENGINE AND INPUT DRIVE

1.

Check engine for correct no-load

2.

Run engine at load and

formance.

3.

Check drive belt, transmission clutch, pulleys,

keys

and keyways.

check

RPM.

for proper

per-

MOTION CONTROL LINKAGE

1.

Check

hardware. Replace worn parts to minimize free

movement.

2.

Check

full forward and reverse travel.

3.

Check

justments.

4.

Check

mission control shaft.

condition of all linkage and securing

for damage or binding parts that prevent

motion control friction and neutral ad-

condition of control arm, key and trans-

TRANSAXLE

1.

Roll tractor slowly and check for unusual noises

or seizing.

2.

Check

a

open transaxle and inspect gears, bearings, keys

and keyways.

for differential action and smooth oper-

This

ation of gear train.

rear

of

tractor and holding one wheel station-

ary while turning other wheel.

can be done by raising

If

necessary

HYDROSTATIC TRANSMISSION

1.

Rear wheels should "lock up"

at about walking speed.

of transmission condition.

the system are good and tractor's wheels do

not lock,

sive internal wear or an internal failure. Conduct a charge pressure and power test.

it

is

likely that transmission has exces-

if

tractor

This

is

a rough

If

all other parts of

is

pushed

check

-7-

TROUBLESHOOTING GUIDE

TRACTOR WILL NOT OPERATE IN EITHER DIRECTION

IF

THE HYDRAULIC LIFT SYSTEM OPERATES NORMALLY

IS

THE TRANSMISSION CHARGE PUMP

CHECK MOTION

CONTROL LINKAGE

WORKING.

I

I

I

FAULTY FAULTY

I

PROPER LEVEL

CHECK CHARGE

PRESSURE

LOW

INSPECT FITTINGS,

LINES, HOSES, HYDRAULIC

LIFT VALVE FOR BLOCKAGE

FAULTY CLOGGED

REPAIR

REPLACE

OR

.OK-

ADJUST, REPAIR

OR

REPLACE

REPLACE HYDROSTATIC

TRANSMISSION

Possible Defects:

Acceleration Valve

Stuck Open

Both Check Valves

Stuck Open

High Internal

Leakage Due to

Wear/Contamination

Mechanical Failure

INSPECT

OIL FILTER

REPLACE

REPAIR

REPLACE

REPLACE HYDROSTATIC

TRANSMISSION

Possible Defects:

Charge Relief

Valve Stuck Open

Faulty Charge Pump*

High Internal

Leakage Due to

Wear/Contamination

Mechanical Failure

OR

'Charge Pump Can be Damaged by Improperly Set Implement Relief Valve. See "Charge Pressure Check"

-8-

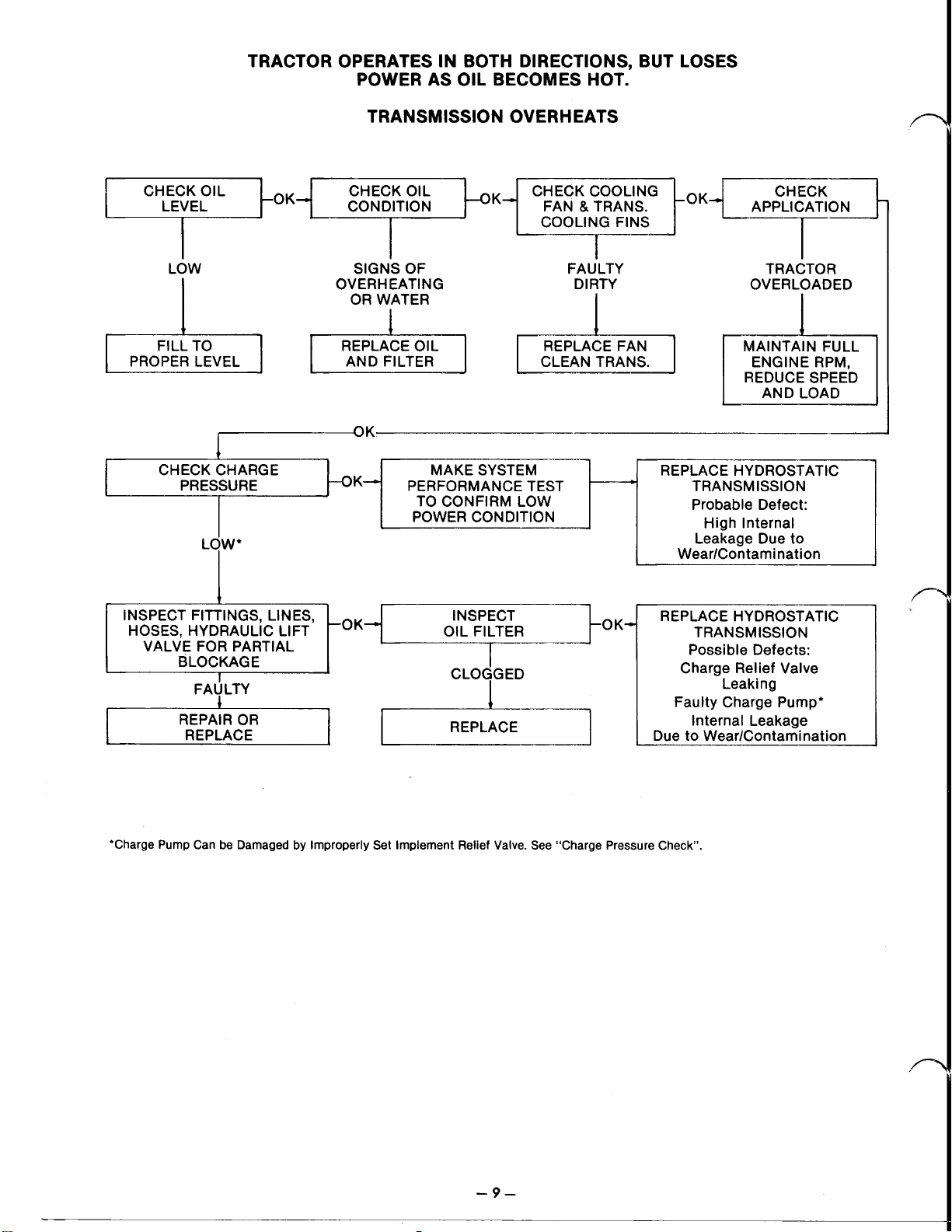

TRACTOR OPERATES

POWER AS OIL BECOMES HOT.

TRANSMISSION OVERHEATS

CHECK OIL

CONDITION

IN

BOTH DIRECTIONS, BUT LOSES

COOLING FINS

LOW SIGNS OF FAULTY

I

PROPER LEVEL AND FILTER CLEAN TRANS.

CHECK CHARGE MAKE SYSTEM REPLACE HYDROSTATIC

INSPECT FITTINGS, LINES,

HOSES, HYDRAULIC LIFT

VALVE FOR PARTIAL

BLOCKAGE

OVERHEATING DlRTY OVERLOADED

OR

WATER

PERFORMANCE TEST TRANSMISSION

TO CONFIRM LOW

POWER CONDITION

INSPECT

OIL FILTER

CLOGGED

TRACTOR

I I

MAINTAIN FULL

ENGINE RPM,

REDUCE SPEED

AND LOAD

Probable Defect:

High Internal

Leakage Due to

Wear/Contamination

REPLACE HYDROSTATIC

TRANSMISSION

Possible Defects:

Charge Relief Valve

Leaking

Faulty Charge Pump*

Internal Leakage

Due

to

Wear/Contamination

*Charge Pump Can be Damaged by Improperly Set Implement Relief Valve. See “Charge Pressure Check”.

-9-

Loading...

Loading...