Page 1

HYDRAULIC LIFT VALVE/CYLINDER MANUAL - WHEEL HORSE

Table of Contents – Page 1 of 1

FOREWORD

CONTROL VALVE SERVICE

GENERAL INFORMATION

MANUFACTURING DATE CODE (OMCO)

VALVE DESCRIPTION (OMCO)

OVERHAUL KIT CONTENTS (OMCO)

OVERHAUL PROCEDURE (OMCO) SERVICE NOTES

DISASSEMBLY & R EA SS EM BL Y

VALVE DESCRIPTION (VICTOR)

OVERHAUL KIT CONTENTS (VICTOR) VICTOR 110068 & 111066 CONTROL

VICTOR 110492 CONTROL VALVE

OVERHAUL PROCEDURE (VICTOR) SERVICE NOTES

DISASSEMBLY & REASSEMBLY (SINGLE SPOOL VICTOR)

DISASSEMBLY (TWO SPOOL VICTOR)

ASSEMBLY (TWO SPOOL VICTOR)

LIFT CYLINDER SERVICE

GENERAL INFORMATION

CYLINDER DESCRIPTION

O-RING & GASKET KIT CONTENTS

OVERHAUL PROCEDURE SERVICE NOTES

DISASSEMBLY & R EA SS EM BL Y

Page 2

HYDRAULIC

LIFT

VALVE

&

CYLINDER

REPAIR

MANUAL

Printed in U.S.A.

0984

PART

NO.

810242R3

Page 3

FOREWORD

This

service and repair manual has been compiled to provide

authorized Wheel Horse service personnel with proper procedures and

techniques for servicing hydraulic

used on Wheel Horse equipment.

Following Table of Contents

to read all sections first to become familiar with repair procedures.

Since valves and cylinders are hydraulic components, strict cleanliness must be maintained during all stages of service and repair.

Even a small amount of

components. Always use clean solvent when cleaning parts.

of

tamination

clean entire system. Clean

Transmission and transaxle must be cleaned to insure all contaminants

are removed.

hydraulic system has occurred or

dirt

or contamination can severely damage

lift

lift

control valves and cylinders

lists

all areas covered.

is

suspected, be sure to

cylinder, valve, all hoses and lines.

It

is

adviseable

If

con-

CONTROL VALVE SERVICE

GENERAL INFORMATION

MANUFACTURING DATE CODE (OMCO)

VALVE DESCRIPTION (OMCO)

OVERHAUL

OVERHAUL PROCEDURE (OMCO)

VALVE DESCRIPTION (VICTOR)

OVERHAUL

OVERHAUL PROCEDURE (VICTOR)

KIT

CONTENTS (OMCO)

KIT

CONTENTS (VICTOR)

________________________________________-~----.--~~~

- - - - -

- - - - - - - - - - - - - -

1

1

1

1

2

........................................

2

3

4

4

Page 4

GENERAL INFORMATION

This manual covers the overhaul of

lift control valves listed below.

&

102874

1973 18

tractors with Sundstrand hydrostatic transmission.

lift

relief valve located in the hydrostatic transmission.

103204

1973 16

tors with Sundstrand hydrostatic transmission.

system pressure

valve located in the hydrostatic transmission.

108494 (OMCO) Fig. 2

1980-82

Eaton hydrostatic transmission, except C-195. lift

system pressure

valve located to the right of the valve handle.

109679 (OMCO) Fig.

1982-83 C-195 Twin Automatic tractors.

pressure

located next to the outside valve handle.

110068

1983 & later

Eaton hydrostatic transmission, except C-195. AI-

though the valves are made by different vendors

and require different overhaul

changeable as complete assemblies. lift system

pressure

located next to the valve handle.

110492 (VICTOR) Fig. 11

1984 & later C-195 Twin Automatic tractors with

Eaton hydrostatic transmission.

is

inside valve handle.

10668 1 (OMCO) Fig. 1

HP

Automatic, 1974-80 D-Series Automatic

system pressure

&

106680 (OMCO)

HP

and 1974-80 C-Series Automatic trac-

is

is

regulated by an implement relief

-

C

&

GT-Series Automatic tractors with

is

regulated by an implement relief

2

-

is

regulated by an implement relief valve

&

11 1066 (VICTOR) Fig. 11

C

&

GT-Series Automatic tractors with

is

regulated by an implement relief valve

-

regulated by a relief valve located next to the

-

regulated by an implement

Fig.

1

-

the

-

kits,

they are inter-

lift

system pressure

hydraulic

lift

system

lift

set at 700

Severe transmission damage may result. Refer to the,

applicable repair manual for system pressure tests

and adjustments.

When the valve handle

valve inward, hydraulic port "A"

port

the spool valve

is

pressurized and port "A"

port. The spool valve

middle, "neutral" position, where ports "A" and

are sealed off from both the pressure and outlet ports.

These

to flow from the pressure port to the outlet port when

the spool

plished mechanically by the tractor's

MANUFACTURING

102874

PSI

-

do not attempt to alter this setting.

is

moved to push the spool

is

pressurized and

"B"

is

connected to the outlet port (Fig. 3). When

is

pulled outward, hydraulic port

is

connected to the outlet

is

spring loaded to return to

are open-center valves,

is

in neutral. Attachment "float"

so

hydraulic oil

lift

DATE

CODE

I03204

&

&

106681

VALVE

FIG

1.

OMCO

(Sundstrand Transmission)

MANUFACTURING

Control Valves

DATE

CODE

linkage.

I

06680

is

VALVE

"B"

"B"

is

free

accom-

a

MANUFACTURING DATE CODE (OMCO)

The month and year a particular hydraulic valve

was manufactured

outlet cover as shown in Figures 1

lines of information may be on the cover, which are

decoded as follows:

Example (on all valves): 0948 1 9

Example (on some valves): SR115 4

Manufacturer's Control numbers

Month Built

(1

=

January; 12

Year Built

(9

=

1979;

is

stamped on the flat side of the

&

2. One or two

=

December)

0

=

1980; 1 = 1981, etc)

0

VALVE DESCRIPTION (OMCO)

The hydraulic control valves are made up of one

or two

inlet and outlet cover. Normal working pressure

500-700

can be field adjusted. On Eaton systems the implement

relief valve

spool

valves and bodies, secured between an

PSI.

Sundstrand implement system pressure

is

part of the control valve and

is

factory

is

-1-

108494

VALVE

FIG.

FIG.

3.

109679

IMPLEMENT

2.

OMCO

(Eaton Transmission)

PRESSURE

FROM

TRANS.

OUTLET

TO

OMCO

Valve

VALVE

RELIEF

VALVE

Control Valves

INLET

TRANS.

Port

Identification

Page 5

OVERHAUL

The 105178 Overhaul Kit for OMCO control valves

contains the parts listed below. Two kits are required

service 102874, 106681

KIT

CONTENTS

(OMCO)

&

109679 two-spool control

2.

Remove the parts shown in

applicable.

Fig.

5A

or 5B, as

ITEM

10

11

12

13

14

15

16

17

*Refer

Except for the valve handle, supplied as Kit 105145,

no other repair parts are available. The valve must be

replaced

QTY.

1

1

2

3

4

5

6

7

8

9

1

2

2

1

6

1

2

2

1

1

1

1

1

1

1

1

to

overhaul procedure

if

the overhaul

O-ring, Outlet Cover

O-ring, Valve Body (Large)

O-ring, Valve Body (Small)

O-ring, Spool Valve

O-ring, Spool Valve (Special)*

Mylar Shim

Spool Cap

Screw, Spool Cap

Lockwasher, Spool Cap

Spacer Block, Spool Cap

Spring, Spool Valve

Washer, Spool Valve

Spring Retainer, Spool Valve

Shoulder Screw, Spool Valve

"S"

Link, Handle

Pin, Handle

Push Nut, Handle Pin

PROCEDURE

Service

Disassembly

Notes

1. Use a clean, dirt-free work surface and clean

solvent to prevent system contamination.

2.

When separating valve sections, remove each

section carefully and note the quantity and

location of mylar shims,

located around bolt holes between sections.

3. Section O-rings may be greased to hold them

in place. lubricate spool valve O-rings and

spool valve with oil when reassembling.

&

Reassembly

1. Remove the push nut from the valve handle

pin and remove the valve handle (or handles).

DESCRIPTION

for

application.

kit

fails to correct the problem.

(OMCO)

if

used. These will be

&

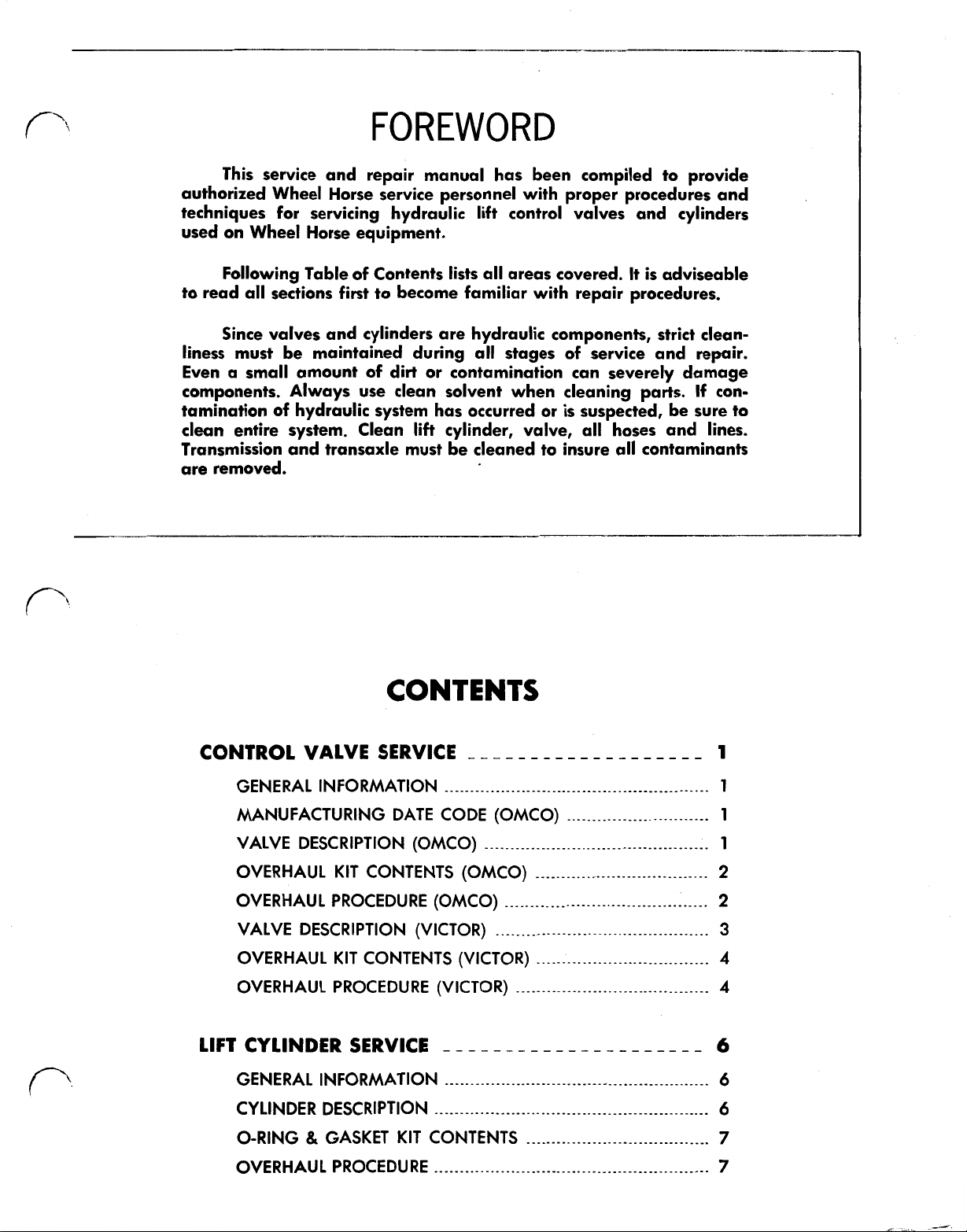

SCREWS

FIG.

5A.

Spool

SPOOL CAP & SCREWS

FIG.

5B.

Spool

Cap

Valve

with

3. Push the spool valve out toward the spool cap

end. Remove and discard the spool valve

O-rings.

USE PAPER CLIP MADE INTO HOOK

TO REMOVE O-RING INSIDE VALVE BODY

(Fig.

6).

SHOULDER SCREW

Cap

&

Valve Disassembly

SPACER BLOCK

DETENT

&

Valve Disassembly

Detented

HOUSING

SHOULDER

Float

SCREW

-

Position

Spool

ASSEMBLING A DOUBLE VALVE

FIG.

4.

Remove Valve Handle(s)

(Double Valve

Shown)

IMPORTANT

SPOOL VALVE

A SELECT

PARTS

BE

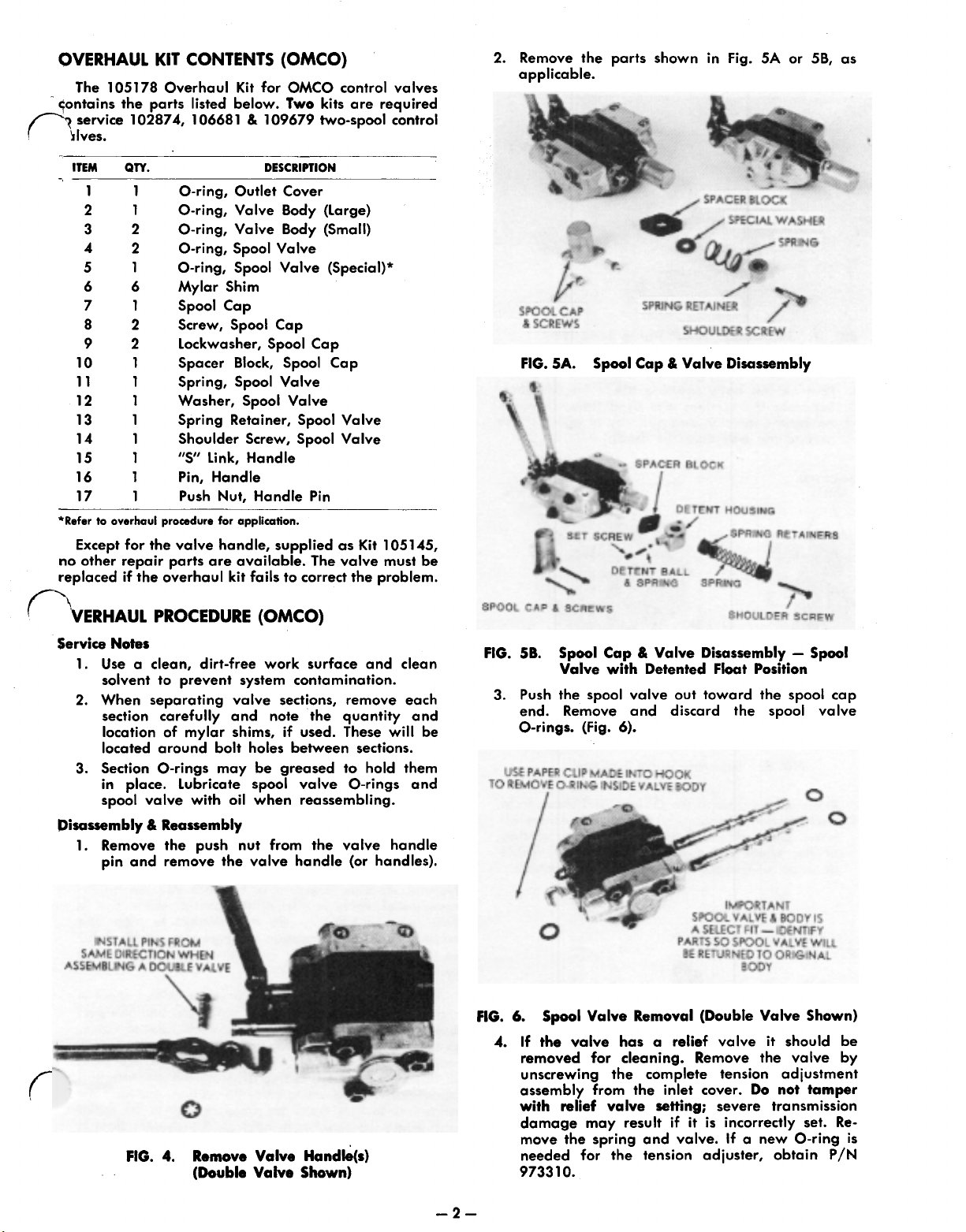

FIG.

6.

Spool

Valve Removal (Double Valve Shown)

4.

If

the valve

removed for cleaning. Remove the valve by

unscrewing the complete tension adjustment

assembly from the inlet cover. Do not tamper

with

relief valve setting; severe transmission

damage may result

move the spring and valve.

needed for the tension adjuster, obtain P/N

9733 10.

has

a relief valve

if

it

FIT

SO

SPOOL VALVE WILL

RETURNED TO ORIGINAL

BODY

is

incorrectly set.

If

a new O-ring

&

BODY

-

IDENTIFY

it

should be

IS

Re-

is

Page 6

IO

SPRING

TENSION ADJUSTER

(IMPLEMENT CIRCUIT PRESSURE)

FIG.

7.

Implement Relief Valve Removed

(

108494/

5.

Remove the bolts securing the valve together.

Separate the sections one at a time, carefully

noting the location and quantity of mylar shims

around the bolt holes (if used).

CHECK FOR

SHIMS

FIG.

8.

6.

Remove and discard the O-rings and shims from

each section. Thoroughly clean and inspect all

parts. Generally, any deep scratches or scoring

of

the spool valve or bore, or other visible

damage will make the valve unserviceable.

FIG. 9.

109679

Separate Valve Sections

Single Valve Disassembled

Va Ives)

FIG.

10.

Double Valve Disassembled

7.

Reassemble the valve in reverse order, using

the new parts supplied in the overhaul kit. The

following assembly notes apply:

a. Use care not to pinch O-rings between sec-

tions. Torque bolts to

b.

Install an O-ring in valve body. Insert spool

valve from spool cap end, then install valve

handle.

c.

Install an O-ring in the groove at the spool

cap end

made before

Code"), use the special oversize O-ring,

which

ring.

d. When securing the shoulder screw (Fig.

be sure the shoulder passes through the

center of the special washer, or the spool

valve will operate in only one direction.

e. The float detent, on valves

(Fig.

the bottom of the valve. Properly adjusted,

the spool valve

tion when engaged, yet release easily when

light

VALVE

or two spool valves and a cast iron valve body.

Normal working pressure

ment relief valve

factory set at

setting. Severe transmission damage may

to the applicable repair manual for system pressure

tests and adjustments.

moved into valve, one port

becomes an outlet. When spool

ports are reversed.

return to a middle, "neutral" position, where both

lift

outlet ports. These are open-center valves,

oil

port when the spool

accomplished mechanically by the tractor's

age, or through a detented

one spool of the two-spool control valve.

DESCRIPTION

The hydraulic control valves are made up

There are two ports for each spool. When spool

cylinder ports are sealed

is

free to flow from the pressure port to the outlet

of

the valve body.

6-75

is

slightly thicker than the standard

5B),

is

adjusted using the set screw on

pressure

is

(VICTOR)

is

part of the control valve and

700

PSI

-

do not attempt

Spool

is

in neutral. Attachment float

72-75

(see "Manufacturing Date

will

lock into the float posi-

applied to the handle.

is

500-700

is

pressurized and one port

is

valve

off

from the pressure and

in. Ibs.

If

the valve was

so

equipped

PSI.

An imple-

to

alter this

result.

moved out of valve,

is

spring loaded to

so

hydraulic

lift

float

position provided on

of

5),

one

Refer

link-

is

is

is

3-

Page 7

1100

8

&

1

1

VALVE

RELIEF

VALVE

FIG. 11.

ATTACHMENT

BASE END

ATTACHMENT

CYL. ROD EN

FIG. 12.

OVERHAUL

VICTOR

contains the parts listed below.

The

1

10068 & 1

109081

VICTOR Control Valves

(Eaton Transmission)

TRANS. TRANS.

KIT

Overhaul Kit for VICTOR control valves

io

VICTOR Valve

CONTENTS (VICTOR)

1 1066

Control Valves

Port

Identification

10492

VALVE

i

TTACHMENT

YL. BASE END

ATTACHMENT

CYL.

ROD

TPH CYL.

BASE END

END

ITEM

10

11

12

13

14

15

16

17

Except for the valve handle, handle link, clevis pin

and cotter

The valve must be replaced if the overhaul kit fails

to solve the problem.

QTY.

1

2

3

4

5

6

7

8

9

2

4

4

1

2

3

1

1

1

1

1

2

2

1

1

2

1

pins,

"O"

"O"

Screw With Lockwasher

Spacer Screw

Steel

Washer

Spacer

Return Spring

Return Spring

Detent Spacer Screw

Spacer

Spring

Spring

Spring

Ball Retainer

Gasket

Steel

no other repair parts are available.

DESCRIPTION

Ring - Load Check Plug

Ring - Spool

Ball - Detent

-

Spool w/o Detent

-

Spool w/o Detent

-

Spool With Detent

-

Spool With Detent

-

Load

Check

Valve

-

Detent

-

Relief Valve

-

Relief Valve

Ball - Relief Valve

OVERHAUL PROCEDURE (VICTOR)

Service

Disassembly

Notes

1.

Use

a clean, dirt-free work surface and clean

solvent to prevent system contamination.

2.

lubricate spool valve O-rings and spool valve

with oil when reassembling.

&

Reassembly

1.

Remove the snap ring from

cap (Fig.

2.

Remove the screw and washer from the retainer

cap and remove the cap, spring and washer.

3.

Remove the clevis pin from

remove the handle and handle link (Fig.

4.

Pull the spool out of the valve body. Remove

and discard

13).

the

(SINGLE

O-rings.

SPOOL

the

spool retainer

the

handle and

VICTOR)

14).

ITEM

Except for the valve handle, handle link, clevis

pin and cotter pins, no other repair parts are avail-

\

able.

fails to correct the problem.

VICTOR

Tho

contains the parts listed below.

1

2

3

4

5

6

7

8

9

10

QTY.

2

The

valve must be replaced

1

10492

109097

O-ring,

Washer (Under Return Spring)

1

Spool Return Spring

1

1

Spool Retainer Cap

Snap Ring

1

Washer (Under

1

1

Screw,

1

Ball (Relief Valve)

1

Spring, White (Relief Valve)

1

Gasket,

Control Valve

Overhaul Kit for VICTOR control valves

Spool

Spool

Relief

DESCRIPTION

Valve

7)

Retainer

Valve Cap

if

the overhaul kit

4-

FIG.

RETAINER CAP

SCREW

SPRING

13.

Remove Retainer Cap and Return Spring

FIG.

14.

Remove Handle and

&

WASHER

SNAP RING

Spool

Page 8

5.

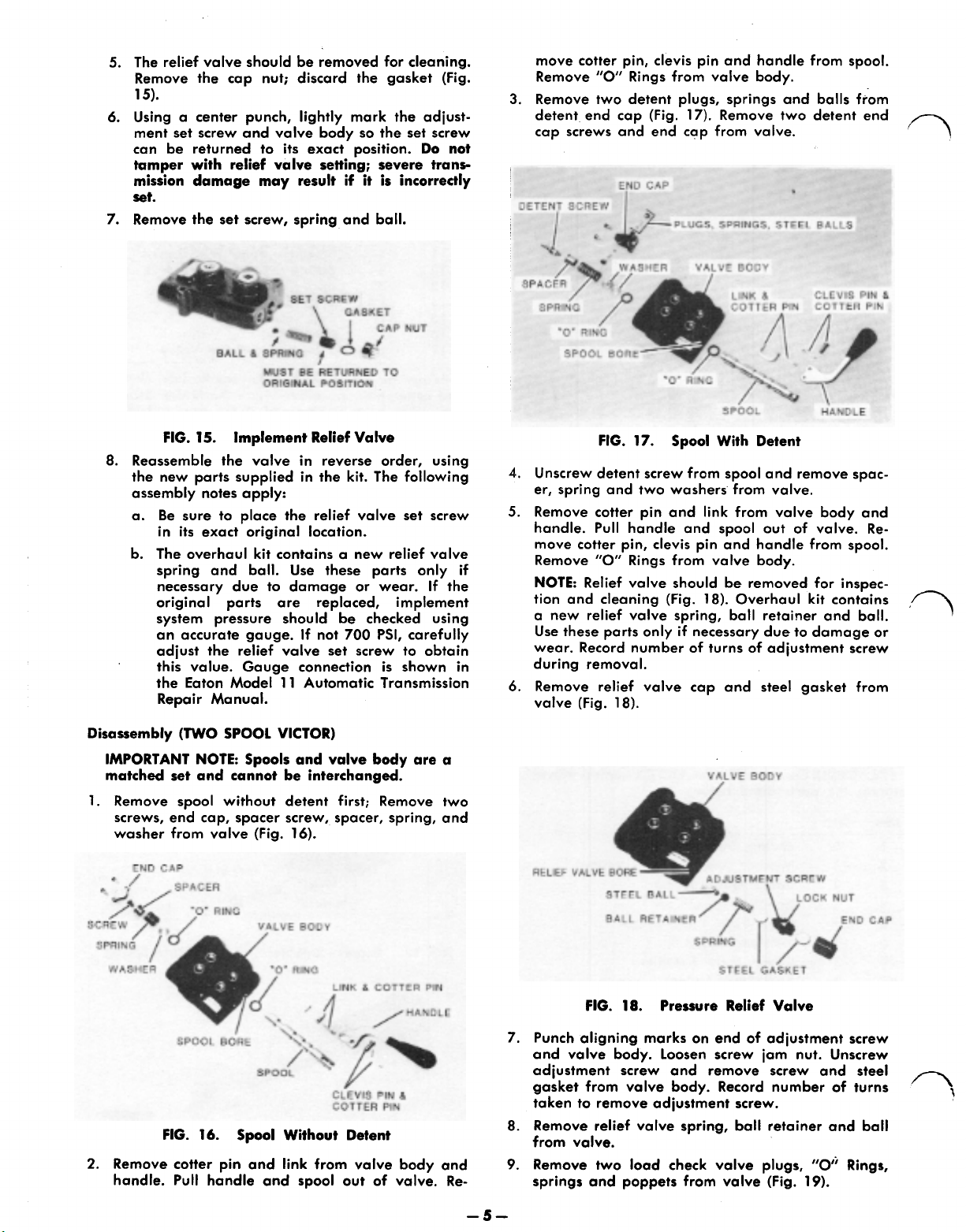

The

relief valve should be removed for cleaning.

Remove the cap nut; discard the gasket (Fig.

15).

6.

Using a center punch, lightly mark the adjustment set screw and valve body

can be returned to

tamper

mission damage may result

set.

7.

Remove the set screw, spring and ball.

8.

Reassemble the valve in reverse order, using

the new parts supplied in the kit. The following

assembly notes apply:

a. Be sure to place the relief valve set screw

b.

with

relief valve setting; severe trans-

FIG.

15.

Implement Relief Valve

in its exact original location.

The overhaul

spring and ball. Use these parts only

necessary due to damage or wear.

original parts are replaced, implement

system pressure should be checked using

an accurate gauge.

adjust the relief valve set screw to obtain

this value. Gauge connection

the Eaton Model

Repair Manual.

its

exact position. Do not

MUST

ORIGINAL POSITION

kit

contains a new relief valve

If

11

Automatic Transmission

BE

RETURNED

not

so

the set screw

if

it

is incorrectly

700

PSI,

is

TO

shown in

If

the

carefully

if

move cotter pin, clevis pin and handle from spool.

Remove

3.

Remove two detent plugs, springs and balls from

detent end cap (Fig.

cap screws and end cap from valve.

4.

Unscrew detent screw from spool and remove spac-

er, spring and two washers from valve.

5.

Remove cotter pin and link from valve body and

handle. Pull handle and spool out of valve.

move cotter pin, clevis pin and handle from spool.

Remove

NOTE: Relief valve should be removed for inspection and cleaning (Fig.

a new relief valve spring, ball retainer and ball.

Use

wear. Record number of turns of adjustment screw

during removal.

6.

Remove relief valve cap and steel gasket from

valve (Fig.

“O”

Rings from valve body.

FIG.

17.

"0"

Rings from valve body.

these parts only

18).

17).

Remove two detent end

Spool With Detent

18).

Overhaul

if

necessary due to damage or

kit

Re-

contains

Disassembly

IMPORTANT NOTE: Spools and valve body are

matched set and cannot be interchanged.

1.

Remove spool without detent first; Remove two

screws, end cap, spacer screw, spacer, spring, and

washer from valve (Fig.

2.

Remove cotter pin and link from valve body and

handle. Pull handle and spool out

FIG.

(TWO

SPOOL

16.

SPOOL VICTOR)

16).

BORE

SPOOL

Spool

Without Detent

LINK

a

COTTER

CLEVIS

PIN

COTTER PIN

of

valve. Re-

a

VALVE BODY

PIN

FIG.

18.

Pressure Relief Valve

7.

Punch aligning marks on end of adjustment screw

and valve body. loosen screw jam nut. Unscrew

adjustment screw and remove screw and steel

a

gasket from valve body. Record number of turns

taken to remove adjustment screw.

8.

Remove relief valve spring, ball retainer and ball

from valve.

9.

Remove two load check valve plugs,

springs and poppets from valve (Fig.

“O”

19).

Rings,

-5

Page 9

FIG.

19.

Load

Check Valves

Assembly

1.

2.

3.

(TWO

SPOOL

Coat two load check poppets and

lithium base grease (Fig. 19). Install plugs,

Rings, check poppets and springs into top center

bores of valve.

Position valve body

vertical (Fig. 18). Drop ball into bore

rests on relief seat. Apply grease to ball retainer

and spring and assemble. Enough grease should

be used

Insert spring and ball retainer assembly into bore

against ball.

screw and install screw into valve bore number of

turns recorded during disassembly. Hold adjustment screw and tighten jam nut to

torque. Insert metal gasket over adjustment screw

and screw cap onto adjustment screw.

Coat detent spool with oil and slide spool into

valve bore from relief valve side (Fig. 17). Push

spool into bore only far enough to expose handle

side

with lithium grease and install in groove of valve

body. Check that

groove. Push spool over

so

in valve body.

Coat

groove of valve body. Check that

properly seated in groove. Push spool over

so

spring and ball retainer

"0"

Ring groove in valve body. Coat

that other end of spool exposes

"0"

Ring with lithium grease and install in

VICTOR)

"0"

so

that relief valve bore

Slide

metal gasket on adjustment

"0"

Ring

is

properly seated in

"0"

Ring only far enough

"0"

Rings with

so

stick

45-52

Ring groove

"0"

"0"

that ball

together.

ft.

Ibs.

"0"

Ring

Ring

"0"

is

is

Ring until end of spool

Position handle into slot of spool and align bottom hole of handle and hole in spool. Install

clevis pin into handle and spool and secure using

cotter pin. Install link into holes of handle and

valve body and secure using cotter pin.

Apply grease to inside and outside of spacer and

install on spring. Slide two washers onto end of

spool. Install detent screw into spacer and spring

assembly. Install detent screw, spacer and spring

on end of spool. Torque to

in flat surface of end cover.

spring with notch positioned down and secure to

valve using two screws. Apply lithium grease into

holes

of

end cap and on two detent springs. Install steel balls, springs and plugs into holes in

end cap.

4.

Coat remaining spool with oil and slide spool into

valve bore from

spool into bore only far enough to expose handle

side

"0"

Ring groove in valve body. Coat

Ring with lithium grease and install in groove of

valve body. Check that

in groove. Push spool over

enough

Ring groove in valve body.

Coat

groove of valve body. Check that

properly seated in groove. Push spool over

Ring until end of spool

Position handle into slot of spool and align bottom

hole

into handle and spool and secure using cotter pin.

Install link into holes of handle and valve body

and secure using cotter pin.

Apply grease to inside and outside of spacer and

install on spring.

Install detent screw into spacer and spring assem-

bly. Install detent screw, spacer and spring on end

of

flat surface of end cap. Position end cap on valve

with notch down and secure to valve using two

screws.

so

that other end

"0"

Ring with lithium grease and install in

of

handle and hole in spool. Install clevis pin

spool. Torque to

is

flush with end of valve.

2-3

ft.

Ibs.

Slide

relief

valve side (Fig. 16). Push

"0"

Ring

is

properly seated

"O"

Ring only far

of

spool exposes

is

flush with end of valve.

Slide

washer onto end of spool.

2-3

ft.

Ibs.

Locate notch in

Locate notch

end cap over

"0"

Ring

"0"

"0"

is

"0"

LIFT

GENERAL

This

(lift

cylinders listed below. The

GT-14, 18HP Automatic and D-Series Automatic tractors

D-250

105254

1976-77

prior tractors where original equipment 6618

cylinder has been replaced by 105254.

106249

1978

INFORMATION

manual covers the overhaul of the hydraulic

is

not repairable, nor are the cylinders used on

tractors.

-

C-Series Automatic tractors, and 1975 and

&

108872

&

later

-

C

&

GT-Series Automatic tractors.

CYLINDER SERVICE

8365

cylinder used on

CYLINDER DESCRIPTION

The

lift

piston

cylinder consists

'secured to a chrome plated piston rod. The

of

a bidirectional steel

piston works in a machined steel cylinder, and the

direction of travel

valve. The cylinder

has a sealed piston rod guide bushing at the opposite

end.

Three

types

The

first has the piston welded to the piston rod and

uses a threaded clevis at the exposed end. The second

type has a piston secured with a nut and the clevis

is

welded to the exposed end. The welded clevis type

of cylinder was first used during the 1981 model year.

The third type has a piston threaded onto the piston

rod and the clevis

cylinder was

is

controlled by, the hydraulic lift

is

welded closed at one end and

of piston and rod construction are used.

is

welded to the exposed end.

first

used during the

1983

model year.

This

Page 10

ROUND-WIRE

FIG.

21.

O-RING & GASKET

The 101699 O-ring and Gasket

following items, and

(Fig. 21):

\

RETAINING

Hydraulic

KIT

CONTENTS

is

used on cylinders

Lift

THREADED CLEVIS

CLEVIS SHAPE

VARIES

RING

Cylinders

Kit

contains the

A

&

B

FIG.

22A.

Remove Clevis & Snap

. WORK POINTED TOOL

UNDER RETAINING RING

TO EASE REMOVAL

Ring

ITEM

*Removeable

The 109088 Service Kit contains the following

items, and

ITEM

No

must be replaced

problem.

QTY.

1

2

3

4

5

6

QTY.

1

2

3

4

5

6 1

7

8

other repair parts are available.

O-ring Piston and Guide Bushing

2

O-ring, Guide Bushing

1

Rod Wiper, Guide Bushing

1

Gasket, Piston

2

Snap Ring, Cylinder

1

O-ring, Piston Rod*

1

Piston Construction.

is

used on cylinder C (Fig. 21):

1

O-ring, Piston Rod

O-ring, Guide Bushing

1

Back-up Washer, (Wiper

1

1

1

1 O-ring, Piston

1 Retaining Ring

Guide Bushing O-ring)

Wiper, Guide Bushing

O-ring, Guide Bushing

Rectangular Section Seal, Piston

if

the service

DESCRIPTION

DESCRIPTION

kit

fails to solve the

O.D.

The

I.D.

I.D.

Side

lift

cylinder

of

O.D.

RETAINING RIN

1.

TAP

GUIDE

INTO CYLINDER

FIG.

22B.

3.

Thread

if

bushing and piston with a soft-faced mallet.

4. Cylinders serviced with 101699

in Fig. 24. Cylinders serviced with 109088

are shown in Fig.

card all O-rings and seals. Straighten out a

paper clip and form a hook in one end to

remove O-rings from grooves.

the

clevis partially onto the piston rod,

applicable. Tap the cylinder off the rod

BUSHING

Remove Retaining Ring

25

and 26. Remove and

114

DOWN

in.

Kit

are shown

Kit

dis-

OVERHAUL PROCEDURE

Service Notes

1. Use a clean, dirt-free work surface and clean

solvent to prevent system contamination.

2.

lubricate all internal parts with oil when

reassembling.

&

Disassembly

Loosen the setscrew and remove the clevis

1.

(threaded type).

with locking pliers just behind the clevis, if

necessary. and

Remove the snap ring or retaining ring from

2.

the cylinder (Fig.

Reassembly

The

22A

piston rod may be held

or

22B). unserviceable.

-7-

FlG. 23.

5.

Clean and carefully inspect all parts. In general, any deep scratches or scoring of the piston

its

bore,

of

the rod bushing will make the cylinder

Cylinder Removal

or

of the piston

rod

and the

I.D.

Page 11

FIG.

USE TAPE ON

\

24.

Piston, Rod & Bushing

THREADS WHEN INSTALLING O-RING AND CLEVIS

PISTON ROD

Seals

S

1/4

in.

DEEP)

TO REMOVE, USE STRAP WRENCH

DRILL TWO HOLES IN END, AS SHOWN,

FOR

PINS

RE-STAKE AFTER ASSEMBLY.

FIG.

25.

Piston Removal

USE TAPE ON THREADS

WHEN INSTALLING O-RING

ROD

GUIDE BUSHING

Y STAKED TO

OR

SPANNER WRENCH.

I

O-RING & BACK-UP

WASHER (WIPER SIDE)

FIG.

26.

Piston,

install the new O-rings, gaskets and seals con-

6.

tained

in

the service

on each side

cylinders). Use masking tape as indicated in

Fig.

24 & 26 to protect the O-rings from damage

during assembly.

7.

Use extreme care when installing parts into the

cylinder. Be sure the piston and bushing O-rings

are not cut on the grooves inside the cylinder.

Carefully align the parts before attempting to

insert them into the cylinder.

8.

After reinstalling the retaining ring

fully extend the piston rod until the piston

pushes the rod guide bushing up to "capture"

the retaining ring.

Rod

&

Bushing Seals

kit.

One gasket should be

of.

the piston O-ring (Fig. 24

(Fig.

ROD

OR

22B),

-

-8-

Page 12

of

Product Information and specifications are shown here in as

time

of printing Wheel Horse Products. Inc reserves the right to

change product specifications, designs and standard equipment without

notice and without incurring obligation

the

WHEEL

HOME

Loading...

Loading...