FormNo.3393-823RevE

MultiPro

ModelNo.41188—SerialNo.315000001andUp

®

1750TurfSprayer

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3393-823*E

TheMultiProturfsprayerisadedicatedturfspray

applicationvehicleandisintendedtobeused

byprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforsprayingon

well-maintainedlawnsinparks,golfcourses,sports

elds,andoncommercialgrounds.

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Important:Thisengineisnotequippedwith

asparkarrestermufer.Itisaviolationof

CaliforniaPublicResourceCodeSection4442to

useoroperatetheengineonanyforest-covered,

brush-covered,orgrass-coveredland.Other

statesorfederalareasmayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

TheenclosedEngineOwner'sManualis

suppliedforinformationregardingtheUS

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenance,andwarranty.

Replacementsmaybeorderedthroughtheengine

manufacturer.

Introduction

Readthismanualcarefullytolearnhowtooperate

andmaintainyourproductproperly.Theinformation

inthismanualcanhelpyouandothersavoidinjury

andproductdamage.AlthoughT orodesignsand

producessafeproducts,youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

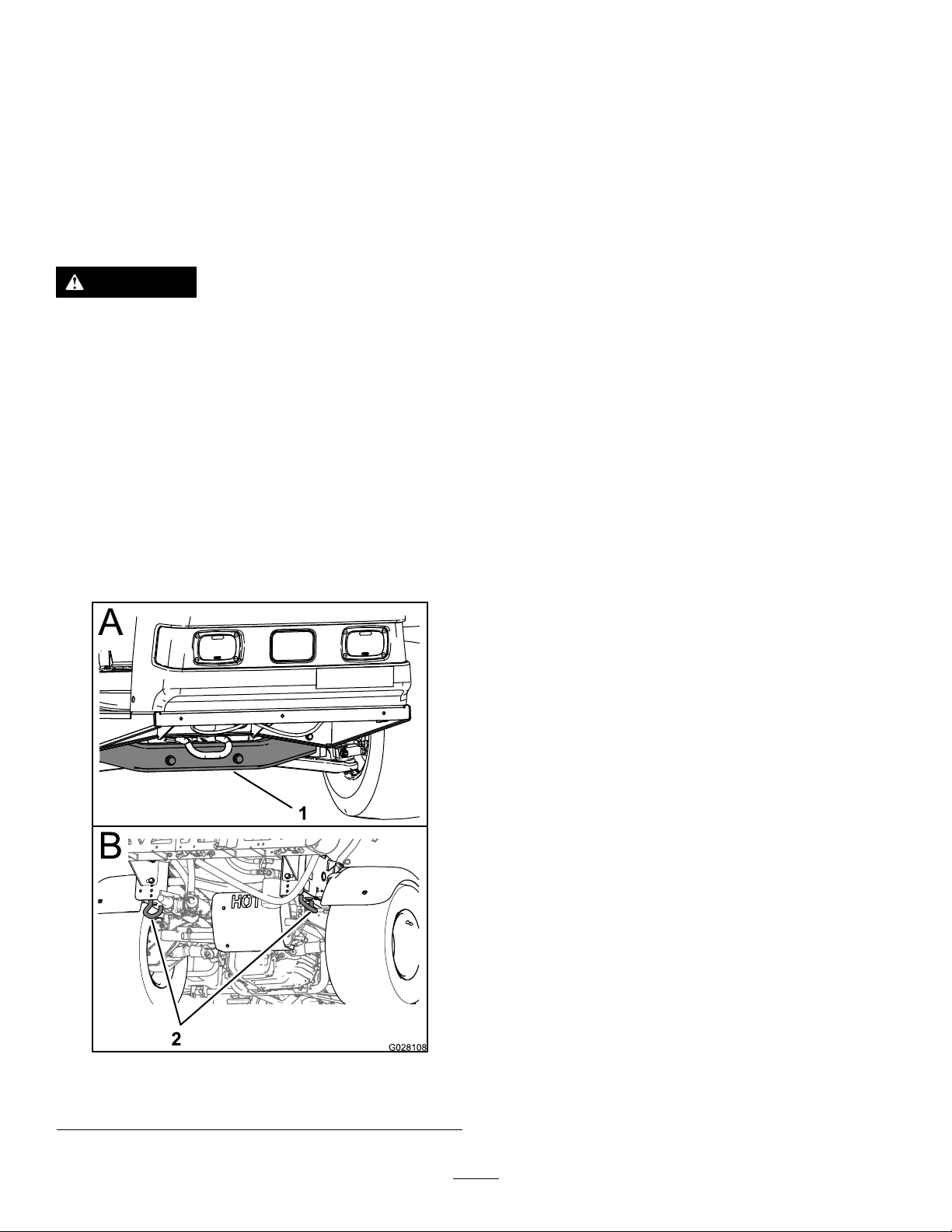

andserialnumbersofyourproductready.Figure1

illustratesthelocationofthemodelandserialnumbers

ontheproduct.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

g023031

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safetyalertsymbol.

©2019—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

2

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

ChemicalSafety.................................................5

WhileOperating..................................................6

Maintenance.......................................................7

SoundPower......................................................8

SoundPressure..................................................8

Hand-ArmVibration............................................8

WholeBodyVibration.........................................8

SafetyandInstructionalDecals..........................9

Setup......................................................................15

1InstallingtheAnti-siphonFill

Receptacle....................................................15

2CheckingtheBoomHingeSprings.................15

3LearningMoreaboutYourProduct.................16

ProductOverview...................................................17

Controls...........................................................19

Specications..................................................22

Attachments/Accessories.................................22

Operation................................................................23

SafetyFirst.......................................................23

PreparingtoDrivetheSprayerfortheFirst

Time..............................................................23

PerformingthePre-StartingChecks.................24

DrivingtheSprayer...........................................25

BreakinginaNewSprayer...............................25

AdjustingtheBoomstoLevel............................26

OperatingtheSprayer......................................27

FillingtheFreshWaterTank..............................27

FillingtheSprayTank........................................27

OperatingtheBooms........................................28

Spraying...........................................................28

SprayingTips....................................................28

CleaningtheSprayer........................................29

UsingtheInfoCenterLCDDisplay....................30

CalibratingtheSprayerFlow.............................32

CalibratingtheSprayerSpeed..........................33

CalibratingtheBoom-SectionBypass

Valves...........................................................33

AgitationBypassValveKnobPosition...............34

CalibratingtheAgitationBypassValve..............34

AdjustingtheMasterBoomBypass

Valve.............................................................35

LocatingthePump............................................35

TowingtheSprayer...........................................35

TransportingtheSprayer..................................35

Maintenance...........................................................36

RecommendedMaintenanceSchedule(s)...........36

DailyMaintenanceChecklist.............................37

NotationforAreasofConcern...........................38

Pre-MaintenanceProcedures..............................39

JackingUptheSprayer.....................................39

Lubrication..........................................................39

GreasingtheSprayer........................................39

GreasingtheBoomHinges...............................39

EngineMaintenance...........................................40

CheckingtheAirIntakeScreen.........................40

ServicingtheAirCleaner..................................40

ServicingtheEngineOil....................................41

ChangingtheSparkPlugs................................43

FuelSystemMaintenance...................................44

ReplacingtheFuelFilter...................................44

DrainingtheFuelT ank......................................44

ElectricalSystemMaintenance...........................45

LocatingtheFuses...........................................45

ServicingtheBattery.........................................45

DriveSystemMaintenance..................................47

InspectingtheWheelsandTires.......................47

AdjustingtheFrontWheelToe-in......................47

BrakeMaintenance.............................................48

CheckingtheBrakeFluid..................................48

InspectingtheBrakes.......................................48

AdjustingtheParkingBrake..............................48

HydraulicSystemMaintenance...........................49

CheckingtheTransaxle/Hydraulic

Fluid..............................................................49

ChangingTransaxle/HydraulicFluid.................49

ReplacingtheHydraulicFilter..........................50

SpraySystemMaintenance.................................50

InspectingtheHoses........................................50

ChangingthePressureFilter............................51

InspectingthePump.........................................51

InspectingtheNylonPivotBushings.................51

SprayerFlowDiagram......................................53

Cleaning..............................................................54

CleaningtheFlowmeter....................................54

CleaningtheSuctionStrainer...........................54

CleaningtheSprayerV alves.............................55

Storage...................................................................64

Troubleshooting......................................................66

3

Safety

equipment,operatorcontrols,andsafetysigns.

•Becomefamiliarwiththesafeoperationofthe

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—“personalsafety

instruction.”Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

ThemachinemeetstherequirementsofSAEJ2258.

SafeOperatingPractices

Important:Themachineisdesignedprimarily

asanoff-roadvehicleandisnotintendedfor

extensiveuseonpublicroads.Whenusing

themachineonpublicroads,followalltrafc

regulationsanduseanyadditionalaccessories

thatmayberequiredbylaw,suchaslights,turn

signals,slowmovingvehicle(SMV)sign,and

othersasrequired.

TheMulti-Pro1750TurfSprayerwasdesigned

andtestedtooffersafeservicewhenoperatedand

maintainedproperly.Althoughhazardcontroland

accidentpreventionpartiallyaredependentuponthe

designandcongurationofthemachine,thesefactors

arealsodependentupontheawareness,concern,

andpropertrainingofthepersonnelinvolvedinthe

operation,maintenanceandstorageofthemachine.

Improperuseormaintenanceofthemachinecan

resultininjuryordeath.

NotalloftheattachmentsthatadapttotheMulti-Pro

1750TurfSprayerarecoveredinthismanual.See

thespecicOperator’sManualprovidedwitheach

attachmentforadditionalsafetyinstructions.Read

thesemanuals.

Toreducethepotentialforinjuryordeath,complywith

thefollowingsafetyinstructions:

Supervisor'sResponsibilities

•Makesurethatoperatorsarethoroughlytrained

andfamiliarwiththeOperator'sManual,Engine

Manual,andalllabelsonthesprayer.

•Establishyourownspecialproceduresandwork

rulesforunusualoperatingconditions(e.g.slopes

toosteepforsprayeroperation).

Training

•ReadtheOperator'sManualandothertraining

materialbeforeoperatingthemachine.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverallowuntrainedpeopletooperateorservice

theequipment.

Note:Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeople,ordamagetoproperty.

BeforeOperating

•Operatethemachineonlyafterreadingand

understandingthecontentsofthismanual.

•Neverallowchildrentooperatethesprayer.

•Neverallowotheradultstooperatethesprayer

withoutrstreadingandunderstandingthe

Operator'sManual.Onlytrainedandauthorized

personsshouldoperatethissprayer.Makesure

thatalloperatorsarephysicallyandmentally

capableofoperatingthesprayer.

•Thissprayerisdesignedtocarryonlyyou,the

operator.Nevercarryanypassengersonthe

sprayer.

•Neveroperatethesprayerwhenunderthe

inuenceofdrugsoralcohol.Evenprescription

drugsandcoldmedicinescancausedrowsiness.

•Donotdrivethesprayerwhenyouaretired.Be

suretotakeoccasionalbreaks.Itisveryimportant

thatyoustayalertatalltimes.

•Becomefamiliarwiththecontrolsandknowhow

tostoptheenginequickly .

•Keepallshields,safetydevices,anddecals

inplace.Ifashield,safetydevice,ordecalis

malfunctioning,illegible,ordamaged,repairor

replaceitbeforeoperatingthemachine.

•Wearappropriateclothing;includingahardhat,

safetyglasses,longpants,safetyshoes,rubber

boots,gloves,andhearingprotection.Donotwear

loosettingclothingorjewelrywhichcouldget

caughtinmovingpartsandcausepersonalinjury.

Note:Wearingsafetyglasses,safetyshoes,long

pants,andahelmetisadvisableandrequiredby

somelocalsafetyandinsuranceregulations.

Note:Iftheoperator(s)ormechanic(s)cannot

readthemanuallanguage,itistheowner's

responsibilitytoexplainthismaterialtothem.

4

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperating

thismachine.

ChemicalSafety

WARNING

•Chemicalsubstancesusedinthesprayer

systemmaybehazardousandtoxicto

you,bystanders,animals,plants,soilsor

otherproperty.

•Avoiddrivingwhenitisdark,especiallyin

unfamiliarareas.Ifyoumustdrivewhenitisdark,

besuretodrivecautiously ,usetheheadlights,and

evenconsideraddingadditionallights.

•Beextremelycarefulwhenoperatingaround

people.Alwaysbeawareofwherebystanders

mightbeandkeepthemawayfromtheworkarea.

•Beforeoperatingthesprayer,alwayscheckthe

designatedareasofthesprayerthatarestatedin

thePre-StartingChecksintheOperationsection.

Ifthemachinedoesnotfunctioncorrectlyoris

damagedinanyway ,donotusethesprayer.

Makesurethattheproblemiscorrectedbeforethe

sprayerorattachmentisoperated.

•Makesuretheoperator’sareaiscleanandfree

fromchemicalresidueanddebrisbuildup.

•Ensurethatalluidlineconnectorsaretightand

allhosesareingoodconditionbeforeapplying

pressuretothesystem.

•Sincefuelishighlyammable,handleitcarefully.

–Useanapprovedfuelcontainer.

–Donotremovethecapfromthefueltankwhen

theengineishotorrunning.Allowtheengine

tocoolbeforefuelingthemachine.

–Donotsmokewhilehandlinggasoline.

–Fillthefueltankofthemachineoutdoors.

–Fillthefueltankofthemachinetoabout25mm

(1inch)belowthetopofthetank(thebottom

ofthellerneck).Donotoverllthefueltank.

–Wipeupanyspilledfuel.

•Carefullyreadandfollowthechemical

warninglabelsandMaterialSafetyData

Sheets(MSDS)forallchemicalsusedand

protectyourselfaccordingtothechemical

manufacturer'srecommendations.Ensure

thataslittleskinaspossibleisexposed

whileusingchemicals.Useappropriate

PersonalProtectiveEquipment(PPE)

toguardagainstpersonalcontactwith

chemicals,suchas:

–safetyglasses,goggles,and/orface

shield

–respiratororltermask

–chemicalresistantgloves

–rubberbootsorothersubstantial

footwear

–hearingprotection

–cleanchangeofclothes,soap,and

disposabletowels,tobekepton-hand,

intheeventofachemicalspill.

Important:Keepinmindthattheremaybemore

thanonechemicalused,andinformationoneach

chemicalshouldbeassessed.

Refusetooperateorworkonthesprayerifthis

informationisnotavailable!

Beforeworkingonasprayersystem,make

surethatthesystemhasbeentriplerinsedand

neutralizedaccordingtotherecommendationsof

thechemicalmanufacturer(s)andallofthevalves

havebeencycled3times.

Verifythereisanadequatesupplyofcleanwater

andsoapnearby,andimmediatelywashoffany

chemicalsthatcontactyou.

•Obtainpropertrainingbeforeusingorhandling

chemicals.

•Usethecorrectchemicalforthejob.

•Followthechemicalmanufacturer'sinstructionsfor

thesafeapplicationofthechemical.Donotexceed

recommendedsystemapplicationpressure.

•Donotll,calibrate,orcleantheunitwhenpeople,

especiallychildren,orpetsareinthearea.

•Handlechemicalsinawellventilatedarea.

5

•Havecleanwateravailableespeciallywhenlling

thespraytank.

•Donoteat,drink,orsmokewhileworkingwith

chemicals.

•Donotcleanspraynozzlesbyblowingthrough

themorplacinginmouth.

•Alwayswashyourhandsandotherexposedareas

assoonaspossibleafteryounishworkingwith

chemicals.

•Keepchemicalsintheiroriginalpackagesand

storedinasafelocation.

•Properlydisposeofunusedchemicalsand

chemicalcontainersasinstructedbythechemical

manufacturerandyourlocalcodes.

•Chemicalsandfumesaredangerous;neverenter

thetankorplaceyourheadoverorintheopening

ofatank.

•Followalllocal,state,andfederalregulationsfor

spreadingorsprayingchemicals.

WhileOperating

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorless,deadlypoisonthatcan

killyou.

Donotrunengineindoorsorinanenclosed

area.

•Theoperatorshouldremainseatedwhenever

thesprayerisinmotion.Theoperatorshould

keepbothhandsonthesteeringwheelwhenever

possible.Keepyourarmsandlegswithinthe

sprayerbodyatalltimes.

•Failuretooperatethesprayersafelymayresultin

anaccident,tipoverofthesprayer,andserious

injuryordeath.Drivecarefully.T opreventtipping

orlossofcontrol:

–Useextremecaution,reducespeed,and

maintainasafedistancearoundsandtraps,

ditches,creeks,ramps,unfamiliarareas,or

anyareasthathaveabruptchangesinground

conditionsorelevation.

–Watchforholesorotherhiddenhazards.

–Useextracautionwhenoperatingthesprayer

onwetsurfaces,inadverseweatherconditions,

athigherspeeds,orwithafullload.Stopping

timeanddistancewillincreasewithafullload.

–Avoidsuddenstopsandstarts.Donotgo

fromreversetoforwardorforwardtoreverse

withoutrstcomingtoacompletestop.

–Slowdownbeforeturning.Donotattempt

sharpturnsorabruptmaneuversorother

unsafedrivingactionsthatmaycausealoss

ofsprayercontrol.

–Beforebackingup,looktotherearandensure

thatnooneisbehindyou.Backupslowly.

–Watchoutfortrafcwhenyouarenearor

crossingroads.Alwaysyieldtherightofwayto

pedestriansandothervehicles.Thissprayeris

notdesignedforuseonstreetsorhighways.

Alwayssignalyourturnsorstopearlyenough

sothatotherpeopleknowwhatyouplantodo.

Obeyalltrafcrulesandregulations.

–Theelectricalandexhaustsystemsofthe

sprayercanproducesparkscapableofigniting

explosivematerials.Neveroperatethesprayer

inornearanareawherethereisdustorfumes

intheairwhichareexplosive.

–Ifyouareeverunsureaboutsafeoperation,

stopworkandaskyoursupervisor.

•Donottouchtheengineormuferwhiletheengine

isrunningorsoonafterithasstopped.These

areasmaybehotenoughtocauseburns.

•Ifthemachineevervibratesabnormally ,stop

immediately,waitforallmotiontostop,andinspect

thesprayerfordamage.Repairalldamagebefore

resumingoperation.

•Beforegettingoffoftheseat:

1.Stopthemovementofthemachine.

2.PlacetherangeselectorinNeutralandset

theparkingbrake.

3.TurntheignitionkeytoOff.

4.Removetheignitionkey .

Important:Donotparkthemachineon

anincline.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

Braking

•Slowdownbeforeyouapproachanobstacle.

Thisgivesyouextratimetostoporturnaway.

Hittinganobstaclecandamagethesprayerand

itscontents.Moreimportant,itcaninjureyou.

•GrossVehicleWeight(GVW)hasamajorimpact

onyourabilitytostopand/orturn.Heavyloadsand

attachmentsmakeasprayerhardertostoporturn.

Theheaviertheload,thelongerittakestostop.

•Turfandpavementaremuchmoreslipperywhen

theyarewet.Itcantake2to4timesaslongto

stoponwetsurfacesasondrysurfaces.Ifyou

drivethroughstandingwaterdeepenoughtoget

thebrakeswet,theywillnotworkwelluntiltheyare

dry.Afterdrivingthroughwater,youshouldtest

thebrakestomakesuretheyworkproperly .Ifthey

6

donot,driveslowlywhileputtinglightpressureon

thebrakepedal.Thiswilldrythebrakesout.

ROPSSafety

WARNING

Suddenchangesinterrainmaycause

abruptsteeringwheelmovement,possibly

resultinginhandandarminjuries.

Note:ForeachmachinecoveredinthisOperator’s

Manual,acabinstalledbyT oroisaROPS.

•DonotremovetheROPSfromthemachine.

•Fastentheseatbeltandensurethatyoucan

releaseitquicklyinanemergency.Alwayswear

yourseatbeltwhentherollbarisuporona

machinewithacabinstalledbyToro.

•Checkcarefullyforoverheadobstructionsanddo

notcontactthem.

•KeeptheROPSinsafeoperatingconditionby

thoroughlyinspectingitperiodicallyfordamage

andkeepingallthemountingfastenerstight.

•ReplaceanydamagedROPScomponent.Donot

repairoralterit.

OperatingonHillsandRough

Terrain

Operatingthesprayeronahillmaycausetippingor

rollingofthesprayer,ortheenginemaystallandyou

couldloseheadwayonthehill.Thiscouldresultin

personalinjury.

•Donotacceleratequicklyorslamonthebrakes

whenbackingdownahill,especiallywithaload.

•Neverdriveacrossasteephill;alwaysdrive

straightupordownorgoaroundthehill.

•Reduceyourspeedwhenoperatingonrough

terrainandnearcurbs.

•Gripthesteeringwheellooselyaroundthe

perimeter.Keepyourhandsclearofthesteering

wheelspokes.

Loading

Theweightofthecargocanchangethesprayer

centerofgravityandsprayerhandling.T oavoidloss

ofcontrolandpersonalinjury,followtheseguidelines:

•Reducetheweightoftheloadwhenoperating

onhillsandroughterraintoavoidtippingor

overturningofthesprayer.

•Liquidloadscanshift.Thisshiftinghappens

mostoftenwhileturning,goingupordownhills,

suddenlychangingspeeds,orwhiledrivingover

roughsurfaces.Shiftingloadscancausethe

sprayertotipover.

•Whenoperatingwithaheavyload,reduceyour

speedandallowforsufcientbrakingdistance.Do

notsuddenlyapplythebrakes.Useextracaution

onslopes.

•Beawarethatheavyloadsincreaseyourstopping

distanceandreduceyourabilitytoturnquickly

withouttippingover.

•Iftheenginestallsoryoubegintoloseheadway

whileclimbingahill,graduallyapplythebrakes

andslowlybackstraightdownthehill.

•Turningwhiletravelingupordownhillscanbe

dangerous.Ifyouhavetoturnwhileonahill,doit

slowlyandcautiously.Nevermakesharporfast

turns.

•Heavyloadsaffectstability.Reducetheweightof

theloadandyourspeedwhenoperatingonhills.

•Avoidstoppingonhills,especiallywithaload.

Stoppingwhilegoingdownahillwilltakelonger

thanstoppingonlevelground.Ifthesprayermust

bestopped,avoidsuddenspeedchanges,which

mayinitiatetippingorrollingofthesprayer.Donot

slamonthebrakeswhenrollingbackward,asthis

maycausethesprayertooverturn.

•Reducespeedandloadwhenoperatingonrough

terrain,unevenground,andnearcurbs,holes,and

othersuddenchangesinterrain.Loadsmayshift,

causingthesprayertobecomeunstable.

Maintenance

•Onlypermitqualiedandauthorizedpersonnelto

maintain,repair,adjust,orinspectthesprayer.

•Beforeservicingormakingadjustmentstothe

machine,stoptheengine,settheparkingbrake,

andremovethekeyfromtheignitiontoprevent

someonefromaccidentallystartingtheengine.

•Tomakesurethattheentiremachineisingood

condition,keepallnuts,bolts,andscrewsproperly

tightened.

•Toreducethepotentialforre,keeptheengine

areafreeofexcessivegrease,grass,leaves,and

accumulationofdirt.

•Neveruseanopenametocheckthelevelor

leakageoffuelorbatteryelectrolyte.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keepyourhands,feet,

clothing,andanypartsofyourbodyawayfrom

7

theengineandanymovingparts.Keepeveryone

away.

•Donotuseopenpansoffuelorammable

cleaninguidswhencleaningparts.

•Donotadjustthegroundspeedgovernor.To

ensuresafetyandaccuracy,haveanAuthorized

ToroDistributorcheckthegroundspeed.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressureuid.Use

cardboardorpapertondleaks.Fluidescaping

underpressurecanpenetrateskinandcause

injuryrequiringsurgerywithinafewhoursbya

qualiedsurgeon;otherwise,gangrenemayresult.

•Ifmajorrepairsareeverneededorassistanceis

required,contactanAuthorizedToroDistributor.

•Tobesureofoptimumperformanceandsafety,

alwayspurchasegenuineT ororeplacement

partsandaccessories.Replacementpartsand

accessoriesmadebyothermanufacturerscould

bedangerous.Alteringthissprayerinanymanner

thatmayaffectsprayeroperation,performance,

durability,oritsuse,mayresultininjuryordeath.

Suchusecouldvoidtheproductwarranty.

WholeBodyVibration

Measuredvibrationlevel=0.58m/s

UncertaintyValue(K)=0.29m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN1032.

2

2

SoundPower

Thisunithasaguaranteedsoundpowerlevelofof

98dBA,whichincludesanUncertaintyValue(K)of

1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO1 1094.

SoundPressure

Thisunithasasoundpressurelevelattheoperator’s

earof86dBA,whichincludesanUncertaintyValue

(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingto

theproceduresoutlinedinENISO1 1201.

Hand-ArmVibration

Measuredvibrationlevelforrighthand=3.00m/s

Measuredvibrationlevelforlefthand=3.20m/s

UncertaintyValue(K)=1.6m/s

2

2

2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO20643.

8

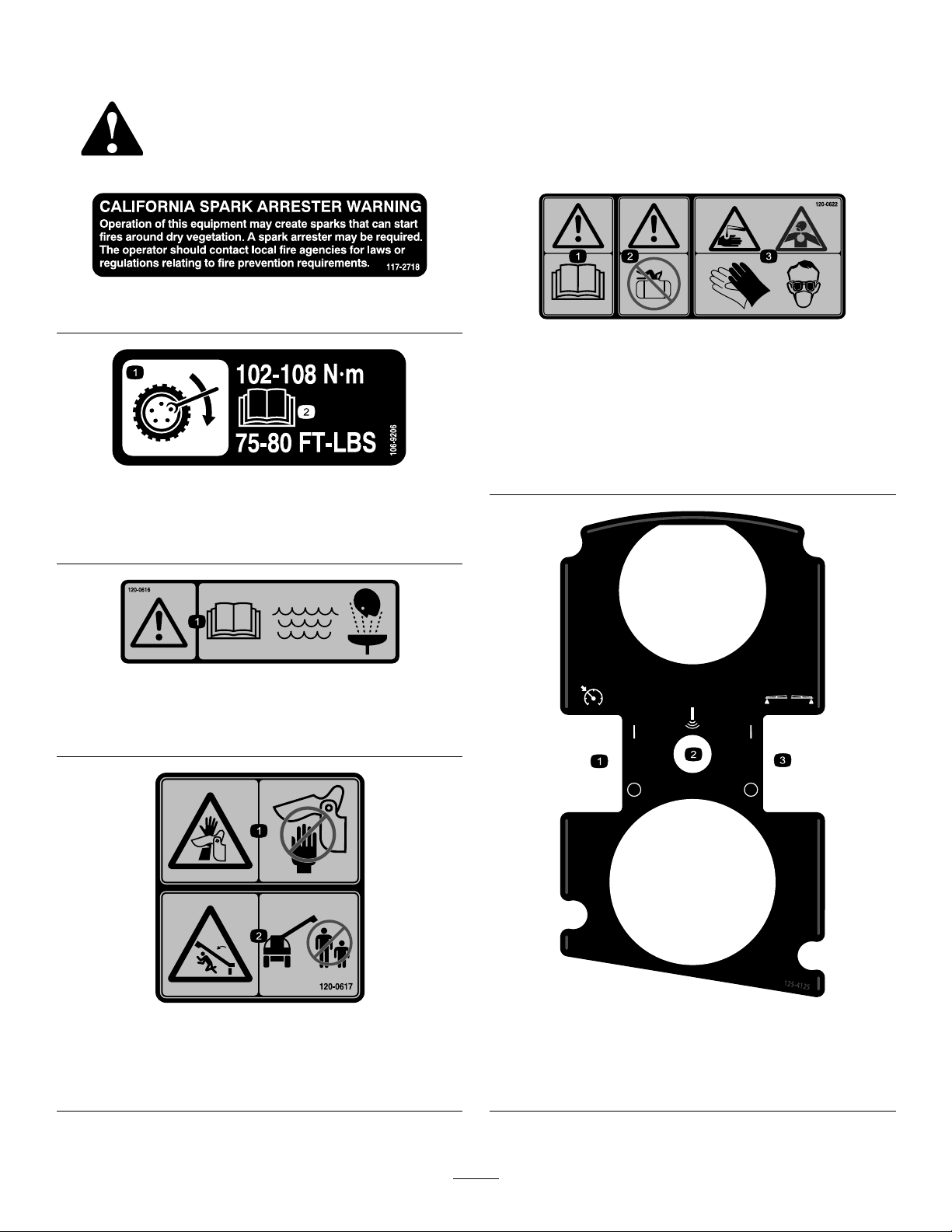

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedorlost.

117–2718

decal117-2718

decal120-0622

120–0622

106-9206

1.Wheeltorquespecications

2.ReadtheOperator'sManual.

120–0616

1.Warning—readtheOperator’sManual;usefresh,clean

waterforrst-aidwashing.

1.Warning—readthe

Operator’sManual.

3.Chemicalburnhazard;

toxicgasinhalation

hazard—wearhandand

skinprotection;weareye

andrespiratoryprotection.

2.Warning—donotenterthe

decal106-9206

decal120-0616

sprayertank.

1.Severinghazardofhand,

pinchingpoint—keep

awayfromactuatedjoints.

decal120-0617

120–0617

2.Crushinghazard—keep

bystandersawayfromthe

machine.

1.Turnthethrottle

lock/speedlockon/off

2.Sonicboom(optional)

125–4125

3.Turnthefoammakers

on/off(optional)

decal125-4125

9

decal130-8293

130-8293

1.Sprayeroff

2.Sprayeron

5.Increasespeed

6.Decreasespeed

3.Engineon7.Agitationon

4.Engineoff8.Agitationoff

125–4128

1.Raise/lowerleftboom

2.Raise/lowerrightboom

3.Engine—start

4.Engine—run

5.Engine—stop

decal125-6694

125–6694

1.Tiedownlocation

decal125-4128

1.Leftboom

2.Centerboom

decal125-8113

125–8113

decal125-4129

125–4129

3.Rightboom

1.Gearselection5.Automatic(optional)

2.Lockdifferentiallock6.Manual(optional)

3.Unlockdifferentiallock

7.Rewindhosereel

4.Toggleheadlightson/off

(optional)

10

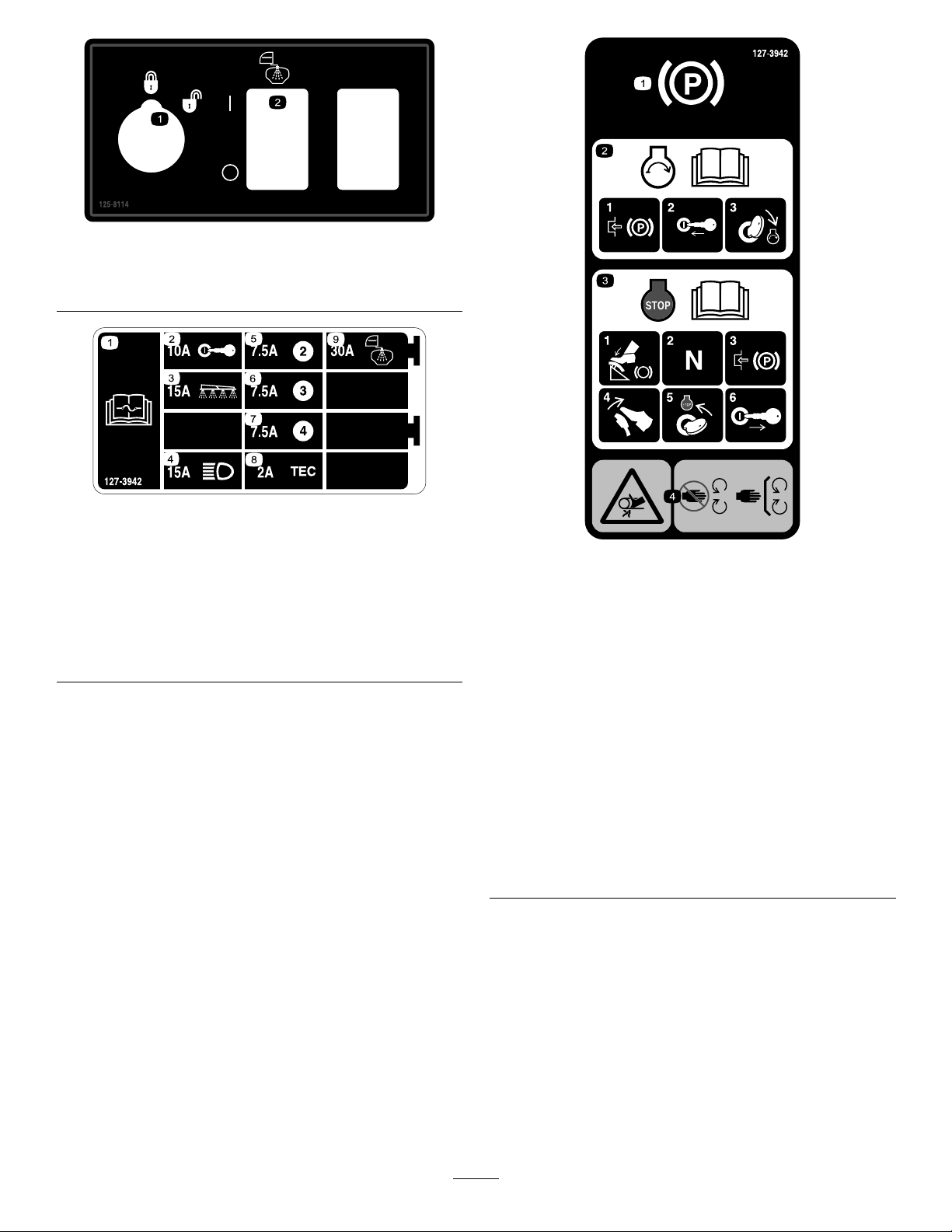

125–8114

decal125-8114

1.Ratelockout

locked/unlocked

127–3942

1.ReadtheOperator’s

Manualforinformationon

fuses.

2.10A—Ignition7.7.5A

3.15A—Sprayerboom8.2A—TEC

4.15A—Headlights

5.7.5A

2.Togglerinsepumpon/off

decal127-3942

6.7.5A

9.30A—Rinsetank

1.Parkingbrake

2.Forinformationonstarting

theengine,readthe

Operator’sManual—1)

Engagetheparkingbrake;

2)Insertthekeyintothe

ignition;3)Turnthekeyto

theenginerunposition.

decal127-3935

127–3935

3.Forinformationon

stoppingtheengine,read

theOperator’sManual—1)

Pressdownonthebrake

pedal;2)Setthegearto

neutral;3)Engagethe

parkingbrake;4)Release

thebrakepedal;5)Turn

theignitionkeytothe

enginestopposition;6)

Removethekeyfromthe

ignition.

4.Entanglementhazard,

belt—keepawayfrom

movingparts;keepall

guardsandshieldsin

place.

11

decal127-3937

127–3937

1.Warning—donotstep.3.Entanglementhazard,

belt—keepawayfrom

movingparts;keepall

guardsandshieldsin

place.

2.Warning—keepawayfrom

hotsurfaces.

1.Warning—readthe

Operator’sManual;always

wearaseatbeltwhen

operatingthemachine;do

nottipthemachine.

2.Fallinghazard—donot

carrypassengersonthe

sprayertank.

decal127-3939

127–3939

3.Cutting/dismemberment

hazard—keeparmsand

legsinsidethevehicleat

alltimes.

4.Warning—donotdrill,

weld,oraltertheROPS

system.

12

1.ReadtheOperator’sManual.

decal127-3938

127–3938

decal127-3941

127–3941

1.Warning—donotoperatethemachinewithoutpropertraining;

readtheOperator’sManual.

2.Warning—keepbystandersawaywhenoperatingthe

machine.

3.Warning—keepawayfrommovingparts;keepallguardsand

shieldsinplace.

4.Electricalshockhazard,overheadpowerlines—checkthe

areaforoverheadpowerlinesbeforeoperatingthemachine

inthearea.

5.Warning—Engagetheparkingbrake,stoptheengine,and

removethekeyfromtheignitionbeforeleavingthemachine.

6.Tippinghazard—Moveslowlywhenthesprayertankisfull;

moveslowlywhendrivingoverroughterrain;donotturnat

highspeed;turnslowly;driveslowlywhendrivingacrossor

upslopes.

13

127-6976

1.Decrease2.Increase

decal127-6976

decal127-6982

127-6982

127-6979

1.Bypass-returnow3.Agitationow

2.Flow

1.Bypass-returnow

decal127-6979

2.Boomspray

decal127-6984

127-6984

1.Flow

2.Tank-returnow

1.Bypass-returnow

2.Flow

decal127-6981

127-6981

3.Boomspray

14

Setup

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

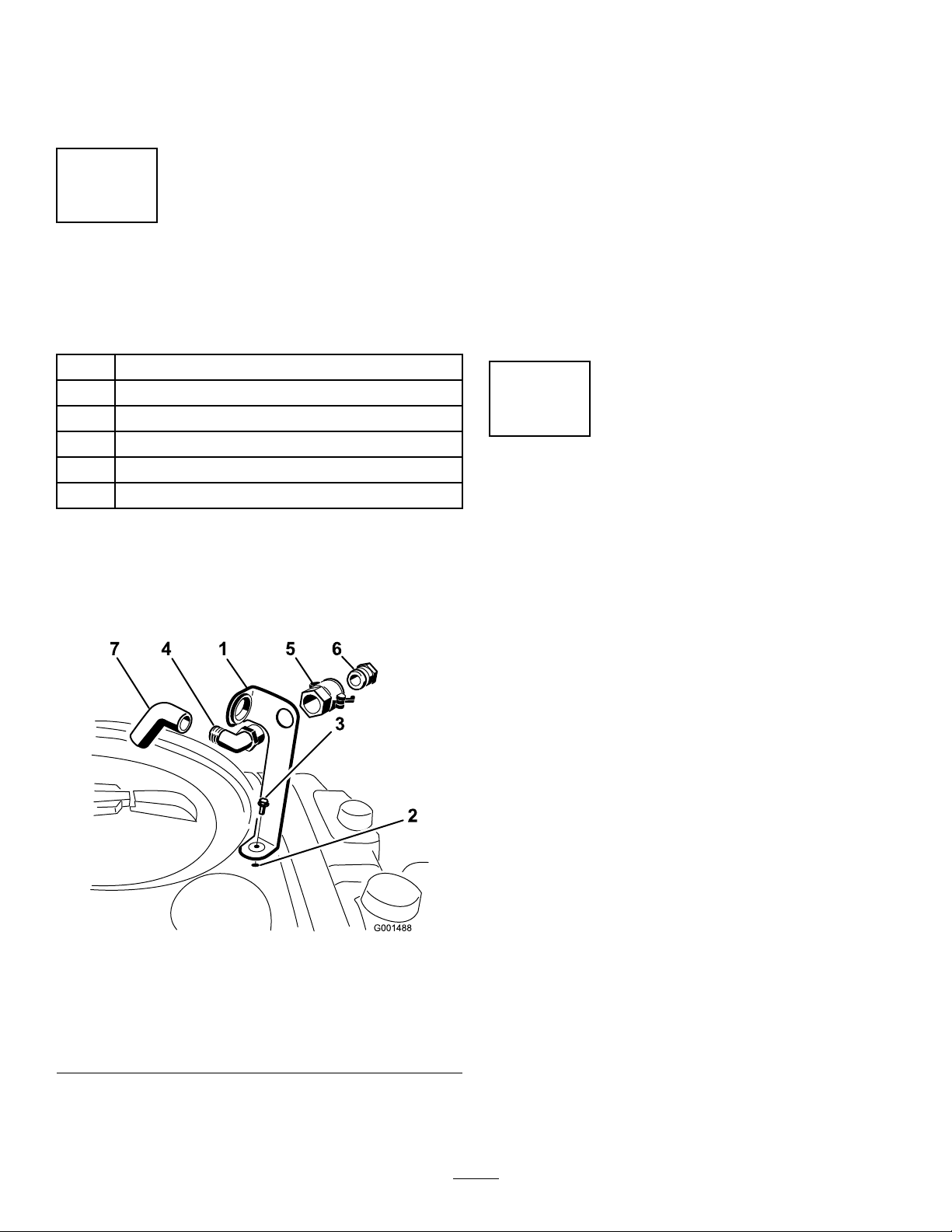

1

Note:Installthettingwiththeopenend

pointingtowardthelargeopeninginthebracket

andtowardthetankopeningsothewaterwill

arcintothetankwhenyoullit.

3.Installthehoseadapterintothequickcoupler

(Figure3).

4.Locktheadapterintoplacebyswingingthe

leverstowardtheadapterandthensecurethem

withthehairpincotters(Figure3).

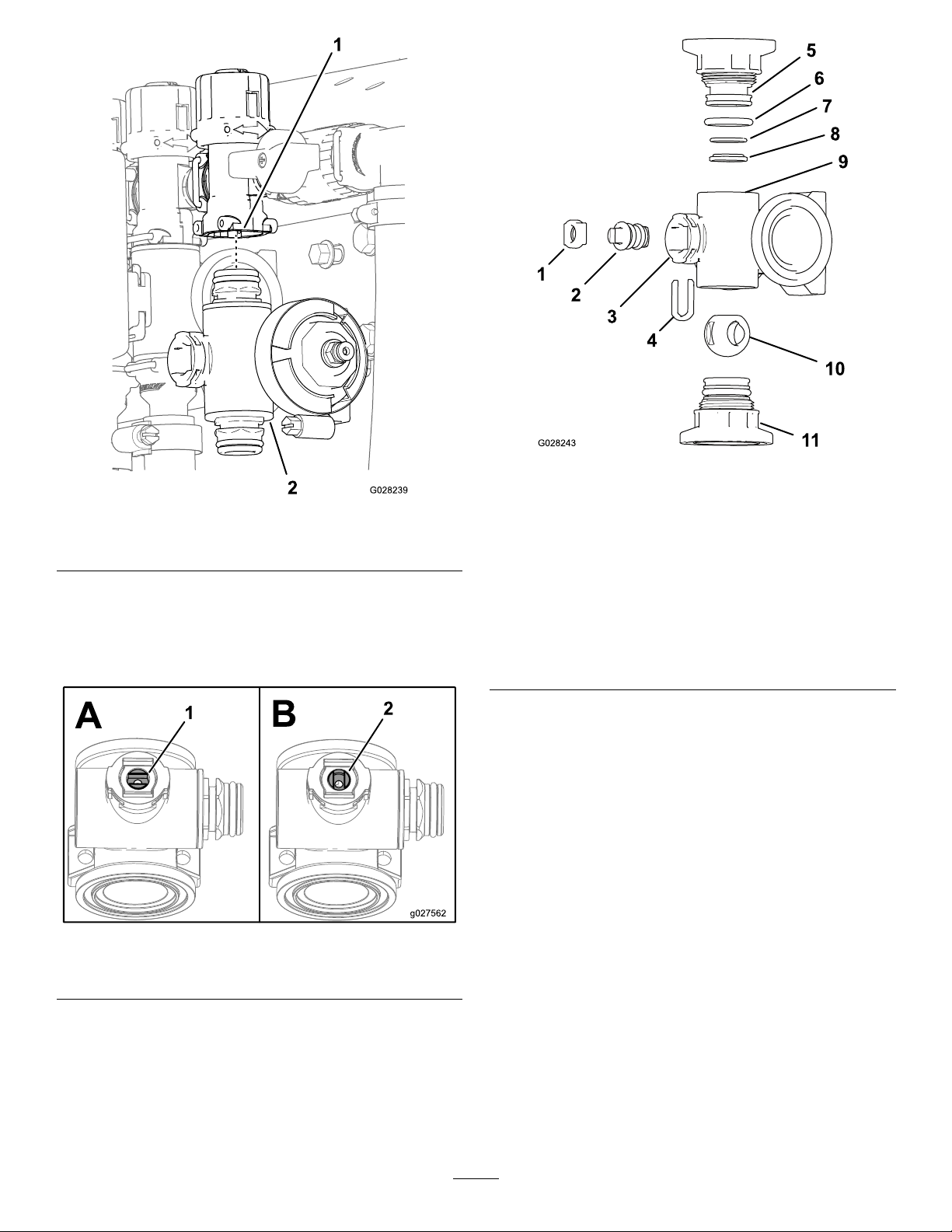

InstallingtheAnti-siphon

FillReceptacle

Partsneededforthisprocedure:

1

90°tting

1

Quickcoupler

1Hoseadapter

1Fillreceptaclebracket

1

Flange-headbolt,5/16x3/4inch

1Anti-siphonhose

Procedure

1.Placethellreceptaclebracketoverthe

threadedholeinthetankandsecureitwitha

ange-headbolt(5/16x3/4inch)(Figure3).

5.Installtheanti-siphonhosethroughthelarge

openingonthebracketandontothebarbedend

ofthe90°elbowtting(Figure3).

Important:Donotlengthenthehoseto

allowcontactwiththetankuids.

2

CheckingtheBoomHinge

Springs

NoPartsRequired

Procedure

Important:Operatingthespraysystemwith

theboomhingespringsundertheincorrect

compressioncoulddamagetheboomassembly.

Measurethespringsandusethejamnutto

compressthespringsto4cm(1–1/2inches)if

necessary.

Figure3

1.Fillreceptaclebracket

2.Threadedholeinthetank6.Hoseadapter

3.Flangebolt,5/16x3/4inch

4.90°elbowtting

2.Placethethreadedendofthe90°elbowtting

throughthebracketandthreadthequickcoupler

ontoit,securingittothebracket(Figure3).

5.Quickcoupler

7.Anti-siphonhose

Thesprayerisshippedwiththeboomextensions

swungforwardtofacilitatepackagingofthemachine.

Thespringsarenotfullytightenedatthetimeof

manufacturetoallowtheboomstobeinthisposition

fortransit.Beforeoperatingthemachine,thesprings

mustbeadjustedtothecorrectcompression.

1.Ifnecessary,removethepackingcomponents

thatsecuretherightandleftextensionbooms

duringshipping.

g001488

2.Supporttheboomswhiletheyareextendedto

thesprayposition.

3.Attheboomhinge,measurethecompressionof

theupperandlowerspringswhilethebooms

areintheirextendedposition(Figure4).

A.Allspringsmustbecompresseduntilthey

measure4cm(1–1/2inches).

B.Usethejamnuttocompressanyspringthat

measuregreaterthan4cm(1–1/2inches).

15

Figure4

1.Boomhingespring2.Jamnut

4.Repeattheprocedureforeachspringonboth

boomhinges.

5.Movetheboomsintothetransport“X”position.

SeeUsingtheBoomTransportCradle(page28)

formoreinformation.

3

LearningMoreaboutYour

Product

Partsneededforthisprocedure:

1Ignitionkey

1

Operator'sManual

1

EngineOperator'sManual

1

PartsCatalog

1

Operatortrainingmaterial

g002332

1Registrationcard

1

Pre-deliveryInspectionSheet

Procedure

1.Readthemanuals.

2.Viewtheoperatortrainingmaterial.

3.Completetheregistrationcardandreturnitto

Toro.

4.Storethedocumentationinasafeplace.

16

ProductOverview

Figure5

1.ROPSbar4.Valvemanifolds

2.Anti-siphonreceptacle5.Rightboom8.Agitationthrottlevalve11.Fueltank

3.Chemicaltanklid6.Centerboom9.Pressurelter

7.Boomcontrolcylinder

17

10.Leftboom

12.Parkingbrake

g028639

Figure6

1.Rightboom4.Freshwatertank

2.Boomtransportcradle

3.Leftboom

5.Operator’sseat

g028072

18

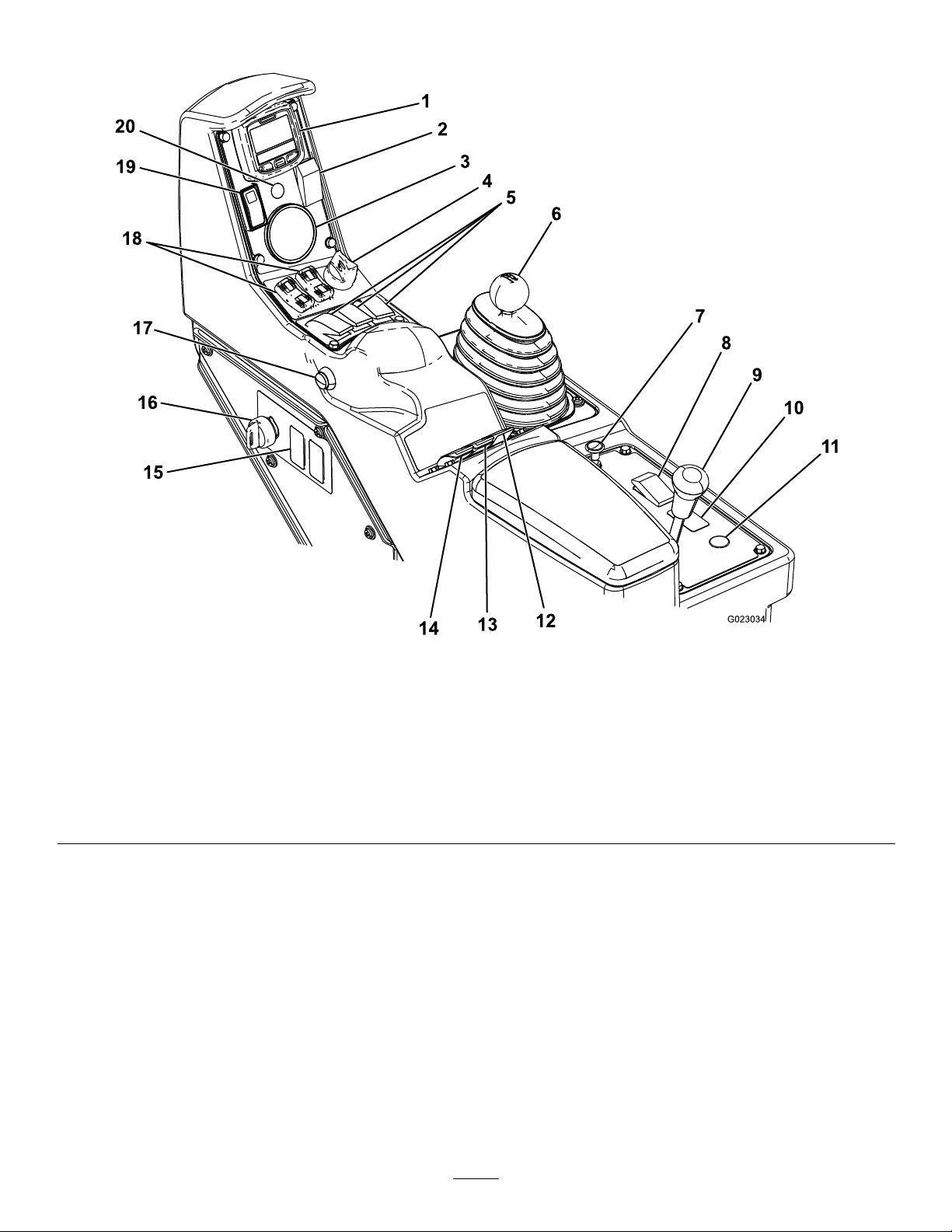

Controls

1.InfoCenter

2.Foammarkerswitch

(optional)

3.Pressuregauge8.Headlightswitch

4.Engineswitch

5.Boom-Sectionswitches10.Sonicboomswitch

6.Rangeselector11.Hosereelrewindbutton

7.Choke

9.Differentiallock

(optional)

Figure7

(optional)

12.Agitationswitch17.Masterboomswitch

13.Spraypressureswitch18.Boomliftswitches

14.Pumpswitch

15.Rinsetankswitch(optional)20.Sonicboomindicator

16.Supervisor(ratelockout)

19.Throttle/speedlockswitch

g023034

switch

(optional)

19

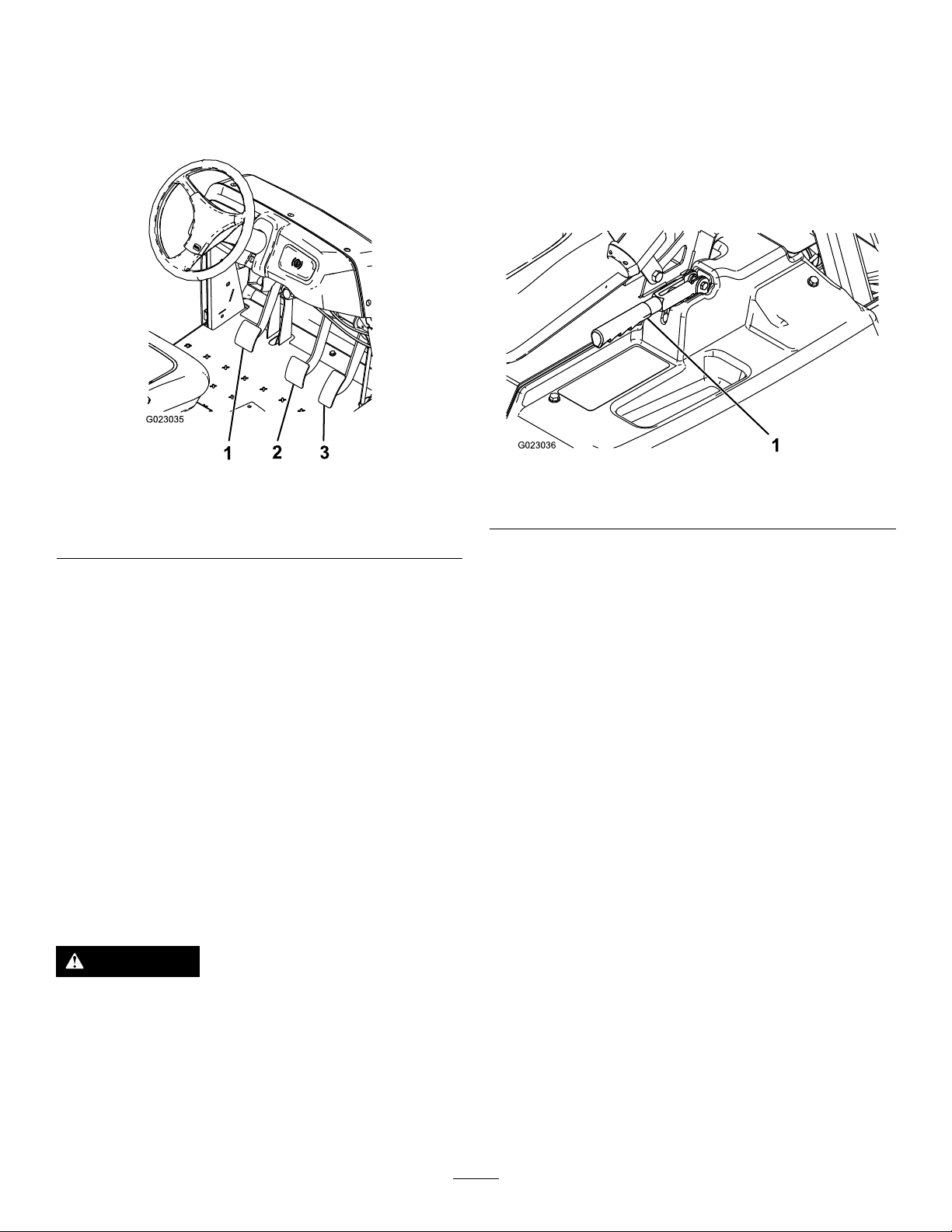

AcceleratorPedal

ParkingBrake

Theacceleratorpedal(Figure8)givesyoutheability

tovarythegroundspeedofthesprayer.Pressingthe

pedalincreasesgroundspeed.Releasingthepedal

willslowthesprayerandtheenginewillidle.

Figure8

1.Clutchpedal

2.Brakepedal

3.Acceleratorpedal

Theparkingbrakeisalargelevertotheleftofthe

seat(Figure9).Engagetheparkingbrakewhenever

youplanonleavingtheseattopreventaccidental

movementofthesprayer.T oengagetheparking

brake,pullupandbackonthelever.Todisengage,

pushitforwardanddown.Ifthesprayerisparked

onasteepgrade,applytheparkingbrakeandplace

blocksatthedownhillsideofthewheels.

g023035

1.Parkingbrakelever

Figure9

g023036

ClutchPedal

Theclutchpedal(Figure8)mustbefullypressedto

disengageclutchwhenstartingtheengineorshifting

transmissiongears.Releasethepedalsmoothlywhen

thetransmissionisingeartopreventunnecessary

wearonthetransmissionandotherrelatedparts.

Important:Donotridetheclutchpedalduring

operation.Theclutchpedalmustbefullyoutor

theclutchwillslipcausingheatandwear.Never

holdthevehiclestoppedonahillusingtheclutch

pedal.Damagetotheclutchmayoccur.

BrakePedal

Usethebrakepedaltostoporslowthesprayer

(Figure8).

CAUTION

Brakescanbecomewornorcanbeadjusted

incorrectlyresultinginpersonalinjury.

ChokeControl

Thechokecontrolisasmallknobbehindtherange

selector(Figure7).T ostartacoldengine,pullthe

chokecontrolup.Aftertheenginestarts,regulatethe

choketokeeptheenginerunningsmoothly.Assoon

aspossible,pushthecontroldowntotheOffposition.

Awarmenginerequireslittleornochoking.

RangeSelector

Therangeselector(Figure7)has5positions:3

forwardspeeds,Neutral,andReverse.Theengine

willstartonlywhentherangeselectorisintheNeutral

position.

IgnitionSwitch

Theignitionswitch(Figure7),usedtostartandstop

theengine,has3positions:Stop,Run,andStart.

RotatethekeyclockwisetotheStartpositiontostart

theengineandreleaseittotheRunpositionwhen

started.RotatethekeytotheStoppositiontostop

theengine.

Ifbrakepedaltravelstowithin2.5cm(1inch)

ofthesprayeroorboard,adjustorrepairthe

brakes.

HeadlightSwitch

Toggletheswitchtooperatetheheadlights(Figure

7).Pushitforwardtoturnthelightsonandrearward

toturnthemoff.

20

Throttle/SpeedLockSwitch

WhentherangeselectorisintheNeutralposition,you

canusetheacceleratorpedaltospeeduptheengine,

thenpushtheswitchbelowtheInfoCenterforwardto

settheengineatthatspeed.Thisisnecessarytorun

thechemicalagitationwhilestationaryoroperating

attachmentssuchasthehandsprayer(Figure7).

Important:Therangeselectormustbeinthe

Neutralpositionandtheparkingbrakemustbe

setfortheswitchtowork.

FuelGauge

Thefuelgaugeislocatedontopofthefueltank,on

theleftsideofthemachine,andshowstheamountof

fuelinthetank.

MasterBoomSwitch

Themasterboomswitch(Figure7)islocatedonthe

sideoftheconsoleandtotherightoftheoperator.It

allowsyoutostartorstopthesprayoperation.Press

theswitchtoenableordisablethespraysystem.

accidentallychangingtheapplicationrate.Turnthe

keyclockwisetotheunlockedpositiontoenablethe

applicationrateswitch.

BoomLift

Theboomliftswitchesarelocatedonthecontrol

panelandareusedtoraisetheleftandrightboom

respectively.

HourMeter

Thehourmeterindicatesthetotalnumberofhours

theenginehasrun.Thisnumberisdisplayedonthe

rstscreenoftheInfoCenter.Thehourmeterstarts

tofunctionwheneverthekeyisturnedtotheRun

position.

SonicBoom(Optional)

TheSonicBoomswitchisarockerswitchusedto

operatetheSonicBoom.Toggletheswitchforward

forautomatic,rearwardformanualandcenterforOff.

FoamMarkerSwitchLocations

Boom-SectionSwitches

Theboomswitchesarelocatedonthecontrolpanel

(Figure7).Toggleeachswitchforwardtoturnthe

correspondingboomsectiononandrearwardtoturn

themoff.Whentheswitchisturnedon,alightonthe

switchilluminates.Theseswitcheswillonlyaffectthe

spraysystemwhenthemasterboomswitchison.

PumpSwitch

Thepumpswitchislocatedonthecontrolpaneltothe

rightoftheseat(Figure7).Togglethisswitchforward

torunthepumporrearwardtostopthepump.

Important:Thepumpswitchwillonlyengage

whentheengineisatlowidletoavoiddamaging

thepumpdrive.

ApplicationRateSwitch

Theapplicationrateswitchislocatedonthecontrol

paneltotherightoftheseat(Figure7).Pressand

holdtheswitchforwardtoincreasethespraysystem

pressure,orpressandholditrearwardtodecrease

thepressure.

Supervisor(RateLockout)Switch

Thesupervisorswitchislocatedonthecontrolpanel

totherightoftheseat(Figure7).Turnthekey

counterclockwisetothelockedpositiontodisablethe

applicationrateswitch,therebykeepinganyonefrom

(Optional)

IfyouinstalltheFoamMarkerkit,youwilladdswitches

tothecontrolpanelforcontrollingtheiroperation.The

sprayercomeswithplasticplugsintheselocations.

Regulating(RateControl)Valve

Thisvalve,locatedbehindthetank(Figure9),controls

theamountofuidthatisroutedtotheboomsorthe

ratereturntothetank.

Figure10

1.Regulating(ratecontrol)

valve

2.Agitationvalve5.Boom-sectionvalves

3.Masterboomvalve

4.Flowmeter

g028051

21

MasterBoomValve

Themasterboomvalve(Figure10)isusedtostopthe

owtotheowmeterandboomvalves.

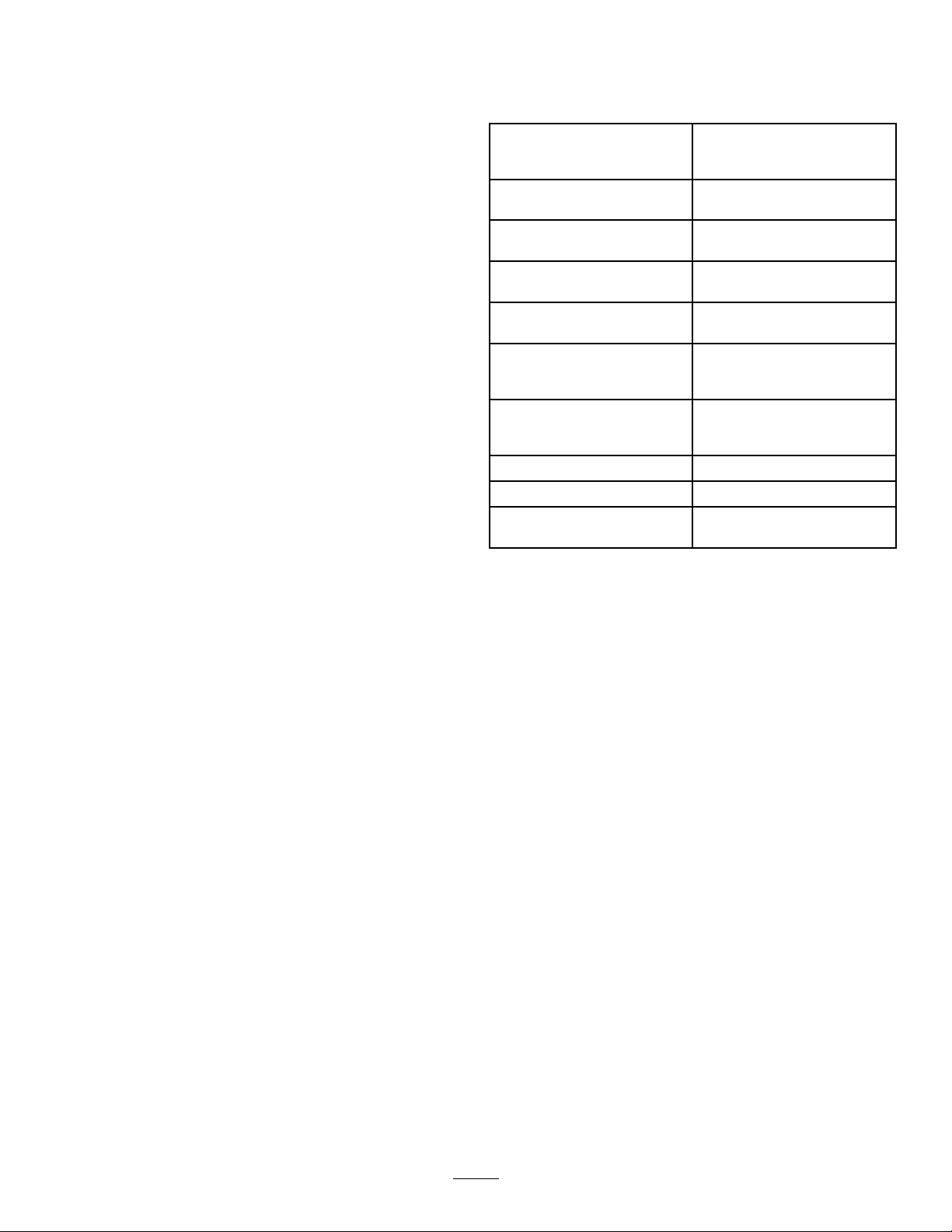

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Flowmeter

Theowmetermeasurestheowrateoftheuidfor

usebytheInfoCentersystem(Figure10).

Boom-SectionValves

Thesevalvesturnthethreeboomsectionsonoroff

(Figure10).

Boom-SectionBypassValve

Theboombypassredirectstheuidowforaboom

sectiontothetankwhenyouturnofftheboomsection.

Youcanadjusttheboombypasstoensurethatthe

boompressureremainsconstantnomatterhowmany

boomssectionsareon.RefertoCalibratingthe

Boom-SectionBypassV alves(page33).

AgitationValve

Thisvalveislocatedontherearofthetank(Figure

10).Whenagitationison,theowisdirectedthrough

theagitationnozzlesinthetank.Whenagitationisoff,

theowisdirectedthroughthepumpsuction.

PressureGauge

Thepressuregaugeislocatedonthecontrolpanel

(Figure7).Thisgaugeshowsthepressureoftheuid

inthesysteminpsiandkPa.

Weightwithstandardspray

system,empty,without

operator

Weightwithstandardspray

system,full,withoutoperator

Maximumgrossvehicleweight

(GVW)(onlevelground)

Overalllengthwithstandard

spraysystem

Overallheightwithstandard

spraysystem

Overallheightwithstandard

spraysystemtothetopofthe

boomsstoredintheXposition

Overallwidthwithstandard

spraysystemboomsstoredin

theXposition

Groundclearance14cm(5.5inches)

Wheelbase

Tankcapacity(includesthe

CE5%overow)

953kg(2,100lb)

1,678kg(3,700lb)

1,814kg(4,000lb)

343cm(135inches)

191cm(75inches)

246cm(97inches)

178cm(70inches)

155cm(61inches)

662L(175USgallons)

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

InfoCenterLCDDisplay

TheInfoCenterLCDdisplayshowsinformationabout

yourmachineandbatterypack,suchasthecurrent

batterycharge,thespeed,diagnosticsinformation,

andmore(Figure7).

Formoreinformation,refertoUsingtheInfoCenter

LCDDisplay(page30).

22

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

CheckingtheTirePressure

Checkthetirepressureevery8hoursordailyto

ensureproperlevels.Fillthetiresto138kPa(20psi).

Also,checkthetiresforwearordamage.

SafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsand

decalsinthesafetysection.Knowingthisinformation

couldhelpyouorbystandersavoidinjury.

PreparingtoDrivethe

SprayerfortheFirstTime

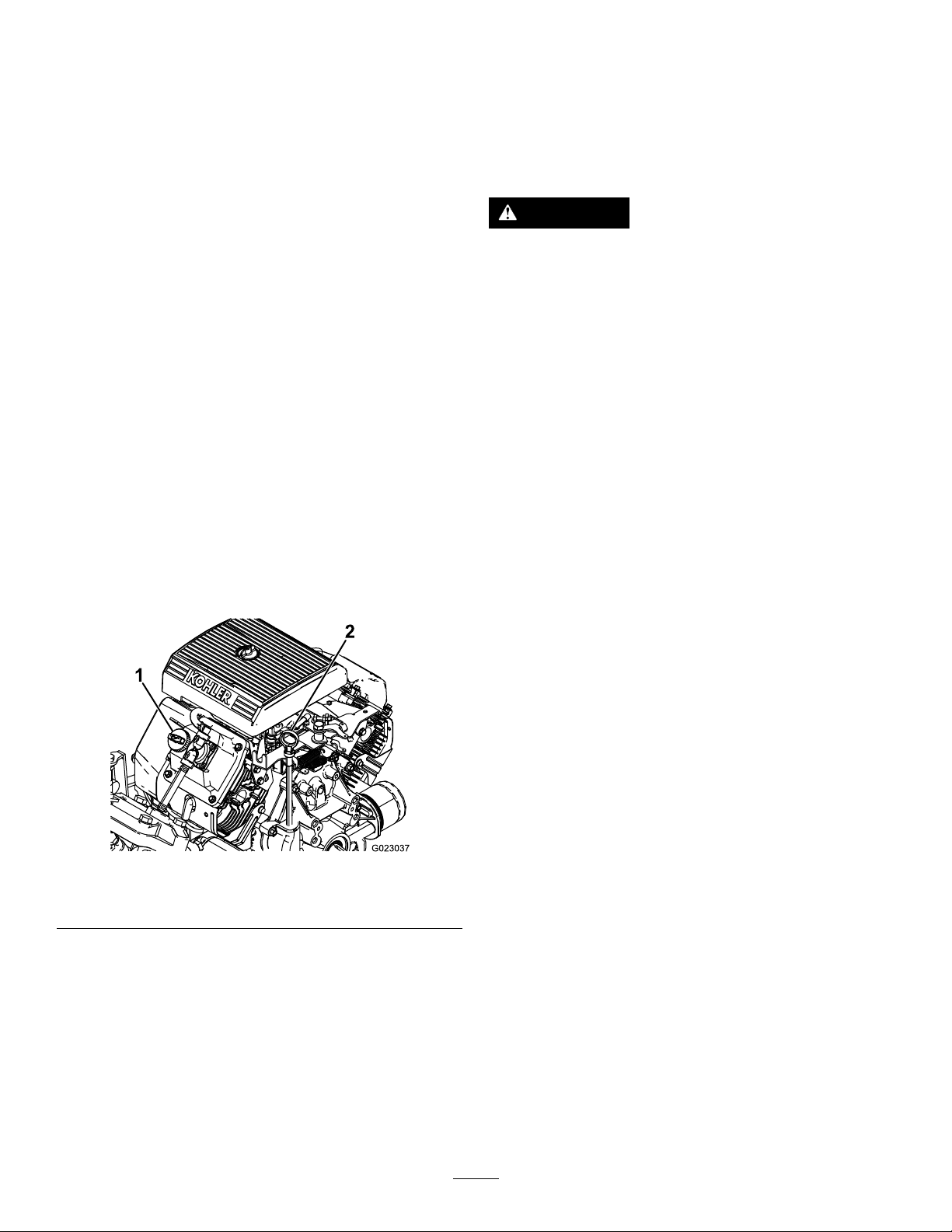

CheckingtheEngineOil

Theengineisshippedwithoilinthecrankcase;

however,thelevelofoilmustbecheckedbeforeyou

rststarttheengineandafteryouhaverunit.

1.Positionthemachineonalevelsurface.

2.Removethedipstickandwipeitwithacleanrag

(Figure11).

3.Insertthedipstickintothetubeandmakesureit

isseatedfully .Removethedipstickandcheck

theoillevel.

AddingFuel

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupany

gasolinethatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsgasolinetoexpand.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyaspark.

Figure11

1.Fillercap2.Dipstick

4.Iftheoillevelislow,removethellercapfrom

thevalvecover(Figure11)andpouroilintothe

openinguntiltheoillevelisuptotheFullmark

onthedipstick;refertoChangingtheEngineOil

(page42)fortheproperoiltypeandviscosity .

Addtheoilslowlyandchecktheleveloften

duringthisprocess.Donotoverll.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

Neverbuymorethana30-daysupplyof

gasoline.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

g023037

5.Installthedipstickrmlyinplace.

23

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethegasolinevapors.Are

orexplosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•Donotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•ETHANOL:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.EthanolandMTBE

arenotthesame.Gasolinewith15%ethanol

(E15)byvolumeisnotapprovedforuse.Never

usegasolinethatcontainsmorethan10%ethanol

byvolume,suchasE15(contains15%ethanol),

E20(contains20%ethanol),orE85(containsup

to85%ethanol).Usingunapprovedgasoline

maycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused.

•Donotaddoiltogasoline.

FillingtheFuelTank

Thefueltankcapacityisapproximately19L(5US

gallons).

Note:Thefueltankcapcontainsagaugewhich

showsthefuellevel;checkitfrequently.

1.Shuttheengineoffandsettheparkingbrake.

2.Cleantheareaaroundthefuel-tankcap(Figure

12).

g023038

Figure12

1.Fuel-tankcap2.Fuelgauge

3.Removethefueltankcap.

4.Fillthetanktoaboutoneinchbelowthetopof

thetank,(bottomofthellerneck).Thisspace

inthetankallowsgasolinetoexpand.Donot

overll.

5.Installthefuel-tankcapsecurely.

6.Wipeupanyfuelthatmayhavespilled.

PerformingthePre-Starting

Checks

Checkthefollowingitemseachtimeyoubeginusing

thesprayerfortheday:

•Checkthetirepressure.

Note:Thesetiresaredifferentthancartires;they

requirelesspressuretominimizeturfcompaction

anddamage.

•Checkalluidlevelsandaddtheappropriate

amountofspecieduids,ifanyarefoundtobe

low.

•Checkthebrakepedaloperation.

•Checktoseethatthelightsareworking.

•Turnthesteeringwheeltotheleftandrightto

checksteeringresponse.

•Checkforoilleaks,looseparts,andanyother

noticeablemalfunctions.Makesurethatthe

engineisoffandallmovingpartshavestopped

beforecheckingforoilleaks,looseparts,and

othermalfunctions.

Ifanyoftheaboveitemsarenotcorrect,notifyyour

mechanicorcheckwithyoursupervisorbeforetaking

thesprayeroutfortheday.Yoursupervisormaywant

youtocheckotheritemsonadailybasis,soaskwhat

yourresponsibilitiesare.

24

DrivingtheSprayer

StartingtheEngine

1.Sitintheoperator'sseat,insertthekeyintothe

ignitionswitch,androtatethekeyclockwiseto

theRunposition.

Note:LeavingtheignitionswitchintheOn

positionforlongperiodsoftimewithoutrunning

theenginewilldischargethebattery .

Important:Donotattempttopushortow

thevehicletogetitstarted.Damagetothe

drivetraincouldresult.

2.Presstheclutchandmovetherangeselector

totheNeutralposition.

3.EnsurethatthepumpswitchisintheOff

position.

4.Iftheengineiscold,pullthechokeknobup.

Important:Donotusethechokeifthe

engineiswarm.

5.TurnthekeytotheStartpositionuntiltheengine

starts.

Important:DonotholdthekeyintheStart

positionformorethan10seconds.Ifthe

enginehasnotstartedafter10seconds,wait

1minutebeforetryingagain.Donotattempt

topushortowthesprayertostarttheengine.

6.Oncetheenginestarts,pushthechokeknob

downslowly.

Driving

1.Releasetheparkingbrake.

2.Fullypresstheclutchpedal.

3.Movethegearshiftleverto1stgear.

4.Releasetheclutchpedalsmoothlywhile

pressingtheacceleratorpedal.

5.Whenthevehiclegainsenoughspeed,remove

yourfootfromtheacceleratorpedal,fullypress

theclutchpedal,movethegearshiftlevertothe

nextgearandreleasetheclutchpedalwhile

pressingtheacceleratorpedal.Repeatthe

procedureuntilthedesiredspeedisattained.

Important:Alwaysstopthevehiclebefore

shiftingfromaforwardgeartoreverseor

fromreversetoaforwardgear.

Note:Avoidlongperiodsofengineidling.

SettingtheThrottleLock

Note:Theparkingbrakeandspraypumpmustbeon

andtherangeselectorinneutraltosetthethrottle

lock.

1.Pressdownontheacceleratorpedaltoobtain

thedesiredenginerpm.

2.Togglethethrottlelockswitchonthecontrol

paneltotheOnposition.

3.Toreleasethethrottlelock,toggletheswitch

totheOffposition,orpressthebrakeorclutch

pedal.

SettingtheSpeedLock

Note:Beforesettingthespeedlock,theoperator

mustbesittingintheoperator’sseatwiththeparking

brakeoff,thepumpon,andtherangeselectoringear.

1.Pressdownontheacceleratorpedaltoobtain

thedesiredenginespeed.

2.Togglethespeedlockswitchonthecontrol

paneltotheOnposition.

3.Toreleasethespeedlock,toggletheswitchto

theOffposition,orpressthebrakeorclutch

pedal.

StoppingtheEngine

1.Presstheclutchandapplythebraketostopthe

sprayer.

2.Pulltheparkingbrakeleverupandbacktosetit.

3.Movetherangeselectoroutofgearintothe

Neutralposition.

4.TurntheignitionkeytotheStopposition.

5.Removethekeyfromtheswitchtoprevent

accidentalstarting.

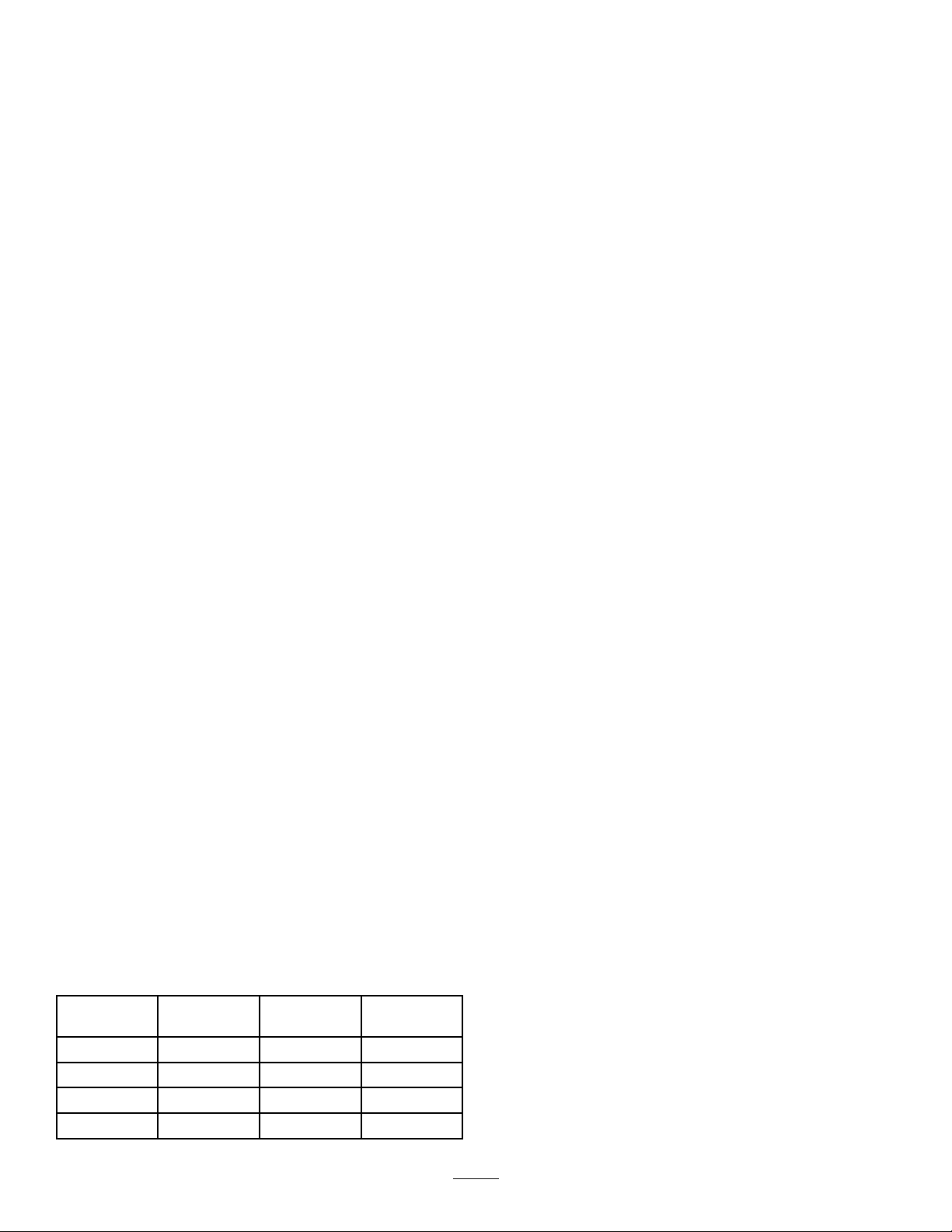

Usethechartbelowtodeterminetheground

speedofanemptyvehicleat3400rpm.

Gear

166.4:15.63.5

238.1:19.86.1

319.6:119.211.9

R80.7:14.72.9

Ratio

Speed

(km/h)

BreakinginaNewSprayer

Toprovideproperperformanceandlongsprayerlife,

Speed(mph)

followtheseguidelinesfortherst100operating

hours:

•Checktheuidandengineoillevelsregularly

andbealertforindicationsofoverheatinginany

componentofthesprayer.

•Afterstartingacoldengine,letitwarmupforabout

15secondsbeforeaccelerating.

25

•Tooptimizethebrakesystem,burnish(breakin)

thebrakesasfollows:

3.Liftupontheboomandremovethepin(Figure

13),andslowlylowertheboomtotheground.

1.Load454L(120USgallons)ofwaterinto

thetank.

2.Movethemachinetoandopen-levelarea.

3.Drivethemachineatfullspeed.

4.Applythebrakesrapidly .

Note:Stopthemachineinastraightline

withoutlockingupthetires.

5.Wait1minutetoallowthebrakestocool.

6.Repeatsteps3through5an9additional

times.

•Avoidracingtheengine.

•Varythesprayerspeedduringoperation.Avoid

faststartsandquickstops.

•RefertotheMaintenance(page36)foranyspecial

low-hourchecks.

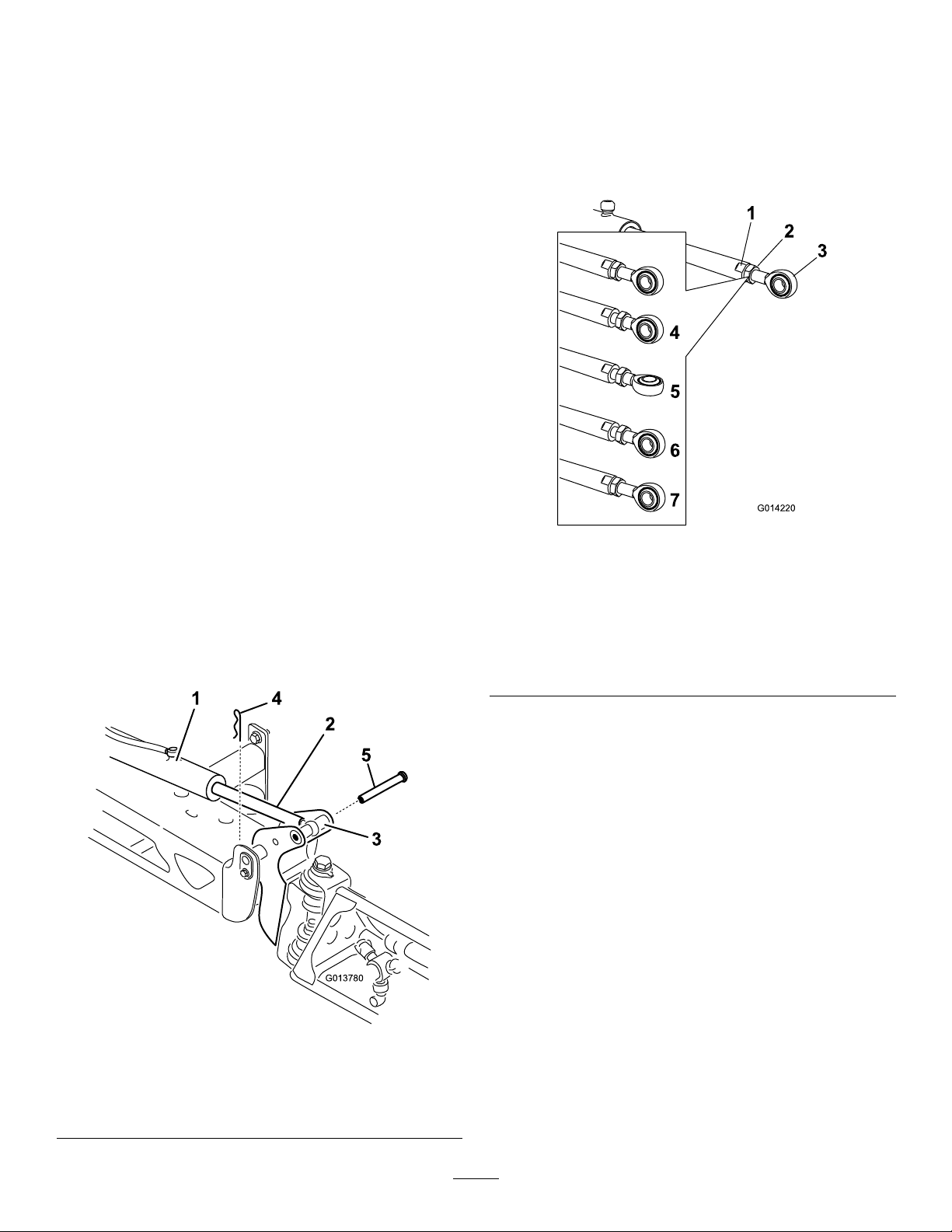

AdjustingtheBoomsto

Level

Thefollowingprocedurecanbeusedtoadjustthe

actuatorsonthecenterboomtokeeptheleftand

rightboomsatlevel.

1.Extendtheboomstothesprayposition.

2.Removethecotterpinfromthepivotpin(Figure

13).

4.Inspectthepinforanydamage,andreplaceit

ifnecessary.

5.Useawrenchontheatsidesoftheactuatorrod

toimmobilizeit,thenloosenthejamnuttoallow

theeyeletrodtobemanipulated(Figure14).

Figure14

1.Flatontheactuatorrod5.Eyeletadjusted

2.Jamnut

3.Eyelet7.Jamnuttightenedtolock

4.Jamnutloosened

6.Eyeletpositionfor

assembly

newposition

g014220

Figure13

1.Actuator

2.Actuatorrod5.Pin

3.Boompivotpinhousing

6.Turntheeyeletrodintheactuatorrodtoshorten

orlengthentheextendedactuatortothedesired

position(Figure14).

Note:Theeyeletrodmustbeturnedinhalfor

completerevolutionstoallowthereassembly

oftherodtotheboom.

7.Oncethedesiredpositionhasbeenachieved,

tightenthejamnuttosecuretheactuatorand

eyeletrod.

8.Raisetheboomtoalignthepivotwiththe

actuatorrod.Whileholdingtheboom,insertthe

pinthroughbothboompivotandactuatorrod

(Figure13).

9.Withthepininplace,releasetheboomand

g013780

4.Cotter

securethepinwiththecotterpreviously

removed.

10.Repeatthisprocedureforeachactuatorrod

bearing,ifnecessary.

26

OperatingtheSprayer

FillingtheSprayTank

TooperatetheMultiProSprayer,rstllthespray

tank,thenapplythesolutiontotheworkarea,and

nallycleanthetank.Itisimportantthatyoucomplete

all3ofthesestepsinsuccessiontoavoiddamaging

thesprayer.Forexample,donotmixandadd

chemicalsinthespraytankatnightandthenspray

inthemorning.Thiswouldleadtoseparationofthe

chemicalsandtopossibledamagetothesprayer

components.

CAUTION

Chemicalsarehazardousandcancause

personalinjury.

•Readthedirectionsonthechemicallabels

beforehandlingthechemicals,andfollow

allmanufacturerrecommendationsand

precautions.

•Keepchemicalsawayfromyourskin.

Shouldcontactoccur,washtheaffected

areathoroughlywithsoapandcleanwater.

•Weargogglesandanyotherprotective

equipmentrecommendedbythechemical

manufacturer.

TheMultiProSprayerhasbeenspecicallydesigned

tohavehighdurabilityinordertogiveitthelong

sprayerlifeyouneed.Differentmaterialshavebeen

chosenforspecicreasonsatdifferentlocationson

yoursprayertomeetthisgoal.Unfortunately,thereis

nosinglematerialwhichisperfectforallforeseeable

applications.

Somechemicalsaremoreaggressivethanothers,

andeachchemicalinteractsdifferentlywithvarious

materials.Someconsistencies(e.g.wettable

powders,charcoal)aremoreabrasiveandlead

tohigher-than-normalwearrates.Ifachemicalis

availableinaformulationthatwouldprovideincreased

lifetothesprayer,usethisalternativeformulation.

Asalways,remembertocleanyoursprayerthoroughly

afterallapplications.Thiswilldothemosttoensure

thatyoursprayerhasalongandtrouble-freelife.

FillingtheFreshWaterTank

Alwaysllthefreshwatertankwithcleanwaterbefore

handlingormixinganychemicals.

Thefreshwatertankislocatedontheleftsideofthe

ROPSbar.Itsuppliesasourceoffreshwaterforyou

towashchemicalsoffofyourskin,eyes,orother

surfacesinthecaseofaccidentalexposure.

InstalltheChemicalPre-MixKitforoptimalmixingand

exteriortankcleanliness.

Important:Ensurethatthechemicalsyouwill

beusingarecompatibleforusewithViton(see

themanufacturer'slabel;itshouldindicateifit

isnotcompatible).Usingachemicalthatisnot

compatiblewithVitonwilldegradetheO-ringsin

thesprayer,causingleaks.

Important:Verifythattheproperapplication

ratehasbeensetpriortollingthetankwith

chemicals.

1.Stopthesprayeronalevelsurface,movethe

rangeselectortotheNeutralposition,stopthe

engine,andsettheparkingbrake.

2.Ensurethatthetankdrainvalveisclosed.

3.Determinetheamountofwaterneededtomix

theamountofchemicalyouneedasprescribed

bythechemicalmanufacturer.

4.Openthetankcoveronthespraytank.

Note:Thetankcoverislocatedinthecenterof

thetopofthetank.Toopenit,turnthefronthalf

ofthecovercounterclockwiseandswingitopen.

Youcanremovethestrainerinsideforcleaning.

Tosealthetank,closethecoverandrotatethe

fronthalfclockwise.

5.Add3/4oftherequiredwatertothespraytank

usingtheanti-siphonllreceptacle.

Important:Alwaysusefreshcleanwaterin

thespraytank.Donotpourconcentrateinto

anemptytank.

6.Starttheengineandsetthepumpswitchtothe

Onposition.

7.Presstheacceleratorpedaltotheoorandset

thethrottlelocktotheOnposition.

8.SetthemasterboomswitchtotheOffposition.

9.TurntheagitationvalvetotheOnposition.

10.Addtheproperamountofchemicalconcentrate

tothetankasdirectedbythechemical

manufacturer.

Important:Ifyouareusingawettable

powderwithoutfullagitation,mixthepowder

withasmallamountofwatertoformaslurry

beforeaddingittothetank.

11.Addtheremainingwatertothetank.

Toopenthefreshwatertankspigot,turntheleveron

thespigot.

27

OperatingtheBooms

Theboomliftswitchesonthesprayercontrolpanel

allowsyoutomovetheboomsbetweentransport

positionandspraypositionwithoutleavingthe

operator'sseat.Itisrecommendedtochangeboom

positionswhilethemachineisstationary .

ChangingtheBoomPosition

1.Stopthesprayeronlevelground.

2.Usetheboomliftswitchestolowerthebooms.

Note:Waituntiltheboomsreachthefull,

extendedsprayposition.

3.Whentheboomsneedtoberetracted,stopthe

sprayeronlevelground.

4.Usetheboomliftswitchestoraisethebooms,

untiltheyhavemovedcompletelyintoboom

transportcradleformingthe“X”transport

positionandtheboomcylindersarefully

retracted.

andneedagitationon:settheparkingbrake,turn

thepumpOn,presstheacceleratorpedaltooor,

andswitchthethrottlelocktotheOnposition.

Note:Thisprocedureassumesthatthepumpison

fromtheFillingtheSprayT ank(page27)procedure.

1.Lowertheboomsintoposition.

2.WiththemasterboomswitchintheOffposition,

setthe3boomswitchestotheOnposition.

3.Drivetothelocationwhereyouwillbespraying.

4.SetthemasterboomswitchtotheOnposition

tobeginspraying.

Note:TheInfoCenterwillshowtheboomswith

thesprayon.

Note:Whenthetankisnearlyempty,the

agitationmaycausefoaminginthetank.

Topreventthis,turntheagitationvalveoff.

Alternatively,youcanuseananti-foamingagent

inthetank.

5.Usetherateswitchtoadjustandsetatarget.

Important:T opreventdamagetothe

boomactuatorcylinder,makesurethatthe

actuatorsarefullyretractedbeforetransport.

UsingtheBoomTransportCradle

Thesprayerisequippedwithaboomtransportcradle

thathasauniquesafetyfeature.Intheeventof

accidentalboomcontactwithalowoverheadobject

whileinthetransportposition,theboom(s)canbe

pushedoutofthetransportcradles.Ifthisoccurs,the

boomswillcometorestinanearhorizontalposition

totherearofthevehicle.Whiletheboomswillnot

bedamagedduetothismovement,theyshouldbe

immediatelyputbackintothetransportcradle.

Important:Theboomscanbedamagedby

transportingtheminanypositionotherthanthe

“X”transportpositionusingtheboomtransport

cradle.

Toputtheboomsbackintothetransportcradle,lower

theboom(s)tothesprayposition,andthenraisethe

boom(s)backintothetransportposition.Makesure

thattheboomcylindersarefullyretractedtoprevent

actuatorroddamage.

6.Whennishedspraying,setthemasterboom

switchtotheOffpositiontoturnoffallbooms,

thensetthepumpswitchtotheOffposition.

SprayingTips

•Donotoverlapareasthatyouhavepreviously

sprayed.

•Watchforpluggednozzles.Replaceallwornor

damagednozzles.

•Usethemasterboomswitchtostopthesprayow

beforestoppingthesprayer.Oncestopped,place

therangeselectorintheNeutralpositionanduse

theneutralenginespeedlocktoholdtheengine

speeduptokeeptheagitationrunning.

•Youwillobtainbetterresultsifthesprayeris

movingwhenyouturntheboomson.

•Watchforchangesintheapplicationratethatmay

indicatethatyourspeedhaschangedbeyondthe

rangeofthenozzlesorthereisaproblemwiththe

spraysystem.

Spraying

Important:Toensurethatyoursolutionremains

wellmixed,usetheagitationfeaturewhenever

youhaveasolutioninthetank.Foragitationto

work,thepumpmustbeonandtheenginemust

berunningaboveanidle.Ifyoustopthevehicle

28

CleaningtheSprayer

Important:Youmustalwaysemptyandclean

thesprayerimmediatelyaftereachuse.Failure

todosomaycausethechemicalstodryor

thickeninthelines,cloggingthepumpandother

components.

Note:InstalltheTankCleanRinseKitforoptimal

tankcleaning.

1.Stopthesprayer,settheparkingbrake,place

therangeselectorintheNeutralposition,and

turnofftheengine.Thetankwilldraintotheleft

sideofthemachine.

2.Locatethetankdrainvalveontheleftsideof

themachine(Figure15).

Note:Thevalveisbehindtheleftfender

bracketnexttothefueltank.

7.Starttheengine.

8.SetthepumpswitchtotheOnpositionand

usetheapplicationrateswitchtoincreasethe

pressuretoahighsetting.

9.WiththerangeselectorintheNeutralposition,

presstheacceleratorpedaltotheoorand

togglethethrottlelockswitchtotheOnposition.

10.EnsurethattheagitationvalveisintheOn

position.

11.Setthemasterboomswitchandboomcontrol

switchestotheOnpositiontobeginspraying.

12.Allowallofthewaterinthetanktosprayout

thoughthenozzles.

13.Checkthenozzlestoensurethattheyareall

sprayingcorrectly.

14.SetthemasterboomswitchtotheOffposition,

setthepumpswitchtotheOffposition,andstop

theengine.

15.Repeatsteps6through14atleast2moretimes

toensurethatthespraysystemisfullycleaned.

Figure15

1.Tankdrain

3.Removethevalvefromthebracket,andletthe

valverestontheground.

4.Openthevalvetodrainanyunusedmaterial

fromthetankanddisposeofitaccordingto

localcodesandthematerialmanufacturer's

instructions(Figure15).

Note:Thisallowsanyresidualmaterialinthe

linetodrain.

16.Onthelastcycle,runthelastfewgallonsof

waterthroughthedrainvalvetoclearthedrain

tubing.

17.Cleanthestrainer;refertoCleaningtheSuction

Strainer(page54).

Important:Ifyouusedwettablepowder

chemicals,cleanthestraineraftereachtank.

18.Usingagardenhose,sprayofftheoutsideofthe

g023039

sprayerwithcleanwater.

19.Removethenozzlesandcleanthembyhand.

Note:Replacedamagedorwornnozzles.

5.Whenthetankhasdrainedcompletely,closethe

drainvalveandinstallthevalveontothebracket

(Figure15).

6.Rinsetheinsideofthetankwithatleast22L

(6USgallons)ofcleanfreshwaterandclose

thecover.

Note:Y oucanuseacleaning/neutralizing

agentinthewaterasneeded.Onthenalrinse,

useonlyclean,clearwater.

29

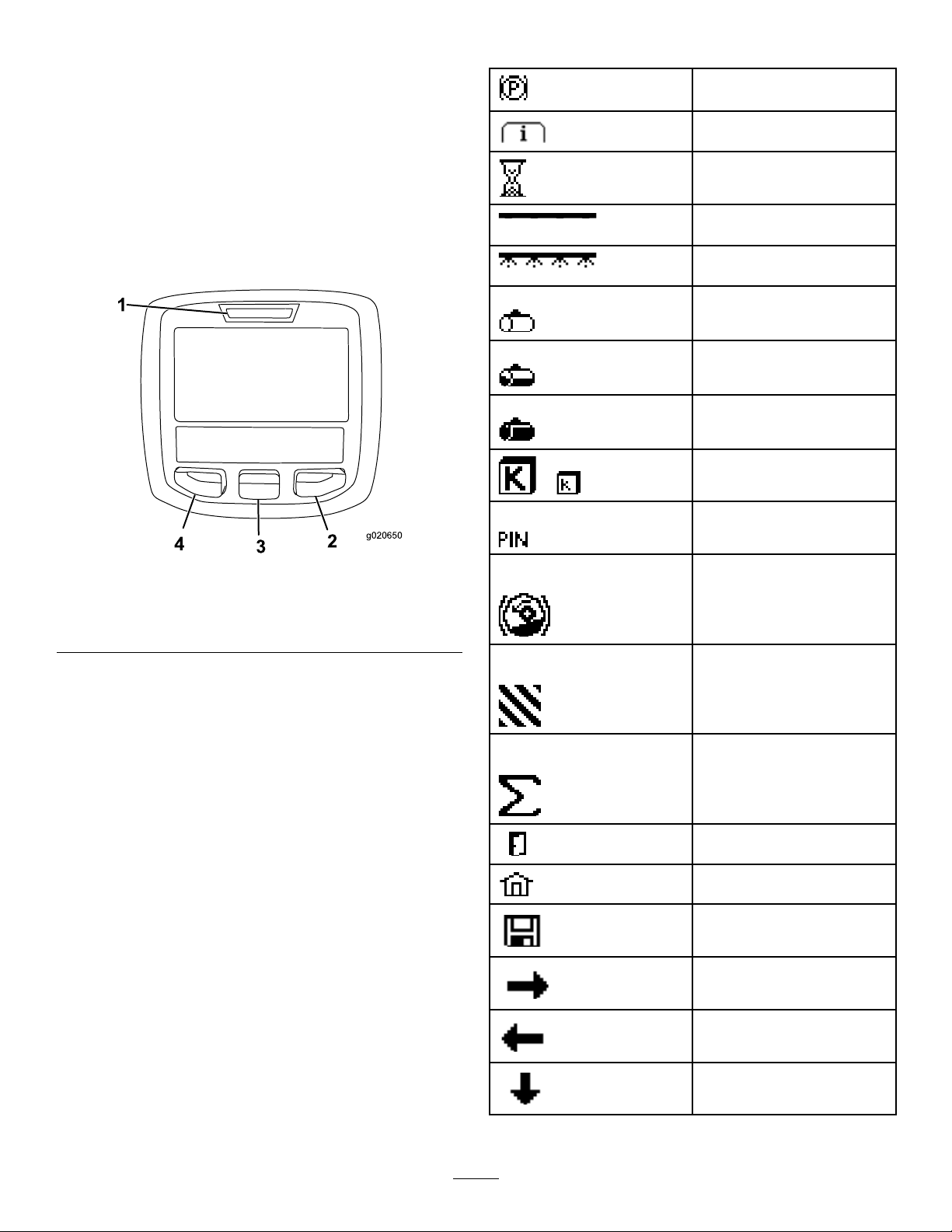

UsingtheInfoCenterLCD

Display

InfoCenterIconDescriptions

Parkingbrakeactive

TheInfoCenterLCDdisplayshowsinformationabout

yourmachine,suchastheoperatingstatus,various

diagnostics,andotherinformationaboutthemachine

(Figure16).Thereisasplashscreenandmain

informationscreenontheInfoCenter.Youcanswitch

betweenthesplashscreenandmaininformation

screenatanytimebypressinganyoftheInfoCenter

buttonsandthenselectingtheappropriatedirectional

arrow.

Figure16

Informationicon

Hourmeter

MasterboomOn/Boom

sectionOff

MasterboomOn/Boom

sectionOn

Emptyspraytank

Spraytankathalf

Fullspraytank

TURFunits(1,000square

or

g020650

feet)

CorrectPINcodeentered

Hill-assist

1.Indicatorlight3.Middlebutton

2.Rightbutton

4.Leftbutton

•Leftbutton,Menuaccess/Backbutton—pressthis

buttontoaccesstheInfoCentermenus.Youcan

alsouseittobackoutofanymenuthatyouare

currentlyusing.

•Middlebutton—usethisbuttontoscrolldown

menus.

•Rightbutton—usethisbuttontoopenamenu

wherearightarrowindicatedadditionalcontent.

Note:Thepurposeofeachbuttonmaychange

dependingonwhatisrequiredatthetime.Each

buttonwillhaveanicondisplayingitscurrentfunction.

Areasprayed

Volumesprayed

Exitmenu

Gotothehomescreen

Savevalue

Next

Previous

Scrolldown

30

Enter

UsingtheMenus

Increase

Decrease

Adjusttankvolume

Throttlelockisactive

Homescreen

Inactivescreen

Activescreen

Activehomescreen

Clearactivearea

Clearallareas

Changethenextvalueinthe

list

Adjustdigit

CheckPINentry/Calibration

verication

Selectthenextareafor

accumulation

ToaccesstheInfoCentermenusystem,pressthe

menuaccessbuttonwhileatthemainscreen.This

willbringyoutothemainmenu.Refertothefollowing

tablesforasynopsisoftheoptionsavailablefrom

themenus:

Calibration

MenuItemDescription

TestSpeedThismenusetsthetestspeedforcalibration.

Flow

Calibration

Speed

Calibration

SettingsMenu

MenuItemDescription

LowTankAlertThismenusetsthelowtankvolumealert.

UnitsThismenuchangestheunitsusedbythe

LanguageThismenuchangesthelanguageusedon

LCDBacklight

LCDContrast

Protected

Menus

ServiceMenu

MenuItemDescription

Faults

Hours

Thismenucalibratestheowmeter.

Thismenucalibratesthespeedsensor.

InfoCenter.ThemenuchoicesareEnglish,

SI(Metric),andTurf.

theInfoCenter.

Thismenuincreasesordecreasesthe

brightnessoftheLCDdisplay.

Thismenuchangesthecontrastbetweenthe

darkandlightareasoftheLCDdisplay.

Thismenugrantsaccesstoprotectedmenus.

Thismenudisplaysthemostrecentfaults

andlastclearedfault.

Thismenuliststhetotalnumberofhoursfor

keyon,machinerun,andpumpon.Italso

liststheserviceduehourandservicereset.

Tanklevellow

DiagnosticsMenu

MenuItemDescription

PumpsThismenuaccessesthepumpinputs,

momentaryrinse,andtimerinseoptions.

BoomsThismenuaccessestheboominputs,

qualiers,andoutputs.

ThrottleLockThismenuaccessesthethrottlelockinputs,

quantiers,andoutputs.

EngineRunThismenuaccessestheengineruninputs

andoutputs.

31

AboutMenu

MenuItemDescription

Model

SerialNumberThismenuliststheserialnumberofthe

S/WRev.Thismenuliststherevisionnumberofthe

Thismenuliststhemodelnumberofthe

machine.

machine.

machinesoftware.

Note:Ifyouinadvertentlychangethelanguage

orcontrasttoasettingwhereyoucannolonger

understandorviewthedisplay,contactyour

AuthorizedT oroDistributorforassistanceinresetting

thedisplay.

CalibratingtheSprayer

Flow

Operatorsuppliedequipment:Stopwatchcapable

ofmeasuring±1/10secondandacontainergraduated

in50ml(1-oz)increments.

Note:Beforeusingthesprayerforthersttime,if

youchangethenozzles,orasneeded,calibratethe

sprayerow,speed,andboombypass.

1.Fillthespraytankwithcleanwater.

Note:Ensurethatthereisenoughwaterinthe

tanktocompletethecalibration.

2.Settheparkingbrakeandturntheengineon.

3.SetthepumpswitchtotheOnposition,andturn

ontheagitation.

4.Pressdownontheacceleratorpedaluntilyou

reachthemaximumenginespeed,andtoggle

thethrottlelockswitchtotheOnposition.

5.Setall3boomswitchesandthemasterboom

switchtotheOnposition.

6.Turnthesupervisor(ratelockout)switchtothe

Unlockposition.

7.Preparetoperformacatchtestusingthe

graduatedcontainer.

8.Startat40psi(2.75bar)andusetheapplication

rateswitchtoadjustthespraypressuresoa

catchtestyieldstheamountslistedinthetable

below.

Note:Repeatthetest3timesandusethe

average.

NozzleColor

Yellow1896.4

Red37812.8

Brown47316.0

Gray

White

Blue94632.0

Green

Milliliters

collectedin15

seconds

56719.2

757

1,41948.0

Ouncescollected

in15seconds

25.6

9.Oncethecatchtesthasyieldedtheamounts

listedinthetableabove,setthesupervisorrate

lockoutswitchtotheLockposition.

10.Turnoffthemasterboomswitch.

11.OntheInfoCenter,navigatetotheCalibration

menuandselectFlowCalibrationasfollows:

Note:SelectingtheHomeScreeniconatany

timewillcancelcalibrations.

A.Pressthecenterbuttonoftheinfocenter

twicetoaccessthemenus.

B.Enterthecalibrationmenubypressingthe

RHbuttonontheinfocenter.

C.SelectFlowCalbyhighlightingFlowCal

andpresstheRHbuttonontheInfoCenter.

D.Inthenextscreen,entertheknownquantity

ofwaterthatwillbesprayedoutofthe

boomsforthecalibrationprocedure;referto

thechartbelow.

E.Oncetheknownquantityhasbeenentered

presstheRHbuttonontheinfocenter.

12.Usingtheplus(+)andminus(-)symbols,enter

theowvolumeaccordingtothetablebelow.

NozzleColor

Yellow4211

Red8322

Brown10628

Gray

White16744

Blue208

Green

Liters

12533

31483

USGallons

55

13.Turnonthemasterboomswitchfor5minutes.

32

Note:Asthemachinesprays,theinfocenter

willdisplaythequantityofuidit'scounting.

14.Aftertheveminutedurationofsprayingclick

thecheckmarkbypressingthecenterbutton

ontheinfocenter.

Note:Itisacceptableifthegallonsdisplayed

duringthecalibrationprocessdonotmatch

theknownquantityofwaterenteredintothe

InfoCenter.

15.After5minutes,turnoffthemasterboomswitch

andselectthecheckmarkontheInfoCenter.

Note:Calibrationisnowcomplete.

Calibratingthe

Boom-SectionBypass

Valves

Note:Beforeusingthesprayerforthersttime,if

youchangethenozzles,orasneeded,calibratethe

sprayerow,speed,andboombypass.

Selectanopenatareatoperformthisprocedure.

1.Fillthespraytankhalfwaywithcleanwater.

2.Lowerthesprayerbooms.

3.MovetherangeselectortotheNeutralposition,

andsettheparkingbrake.

CalibratingtheSprayer

Speed

Note:Beforeusingthesprayerforthersttime,if

youchangethenozzles,orasneeded,calibratethe

sprayerow,speed,andboombypass.

1.Fillthetankwithfreshwater.

2.Onanopen,atarea,markoffadistance

between45–152m(150–500ft).

Note:Tororecommendsmarkingoff152m

(500ft)formoreaccurateresults.

3.Starttheengineanddrivetothestartofthe

marked-offdistance.

Note:Alignthecenterofthefronttireswiththe

startinglineforthemostaccuratemeasurement.

4.OntheInfoCenter,navigatetotheCalibration

menuandselectSpeedCalibration.

Note:SelectingtheHomeScreeniconatany

timewillcancelcalibrations.

5.SelecttheNextarrow(→)ontheInfoCenter.

6.Usingtheplus(+)andminus(-)symbols,enter

themarked-offdistanceintotheInfoCenter.

7.Shiftthemachineintorstgearanddrivethe

markeddistanceinastraightlineatfullthrottle.

8.Stopthemachineatthemarked-offdistance

andselectthecheckmarkontheInfoCenter.

Note:Slowdownandrolltoastoptoalignthe

centerofthefronttireswiththenishline,for

themostaccuratemeasurement.

Note:Calibrationisnowcomplete.

4.Setthe3boomswitchestotheOnposition,but

leavethemasterboomswitchoff.

5.SetthepumpswitchtotheOnposition,andturn

ontheagitation.

6.Pressdownontheacceleratorpedaluntilyou

reachthemaximumenginespeed,andtoggle

thethrottlelockswitchtotheOnposition.

7.OntheInfoCenter,navigatetotheCalibration

menuandselectT estSpeed.

Note:SelectingtheHomeScreeniconatany

timewillcancelcalibrations.

8.Usingtheplus(+)andminus(-)symbols,enter

atestspeedof5.6Km/h(3.5mph),thenselect

theHomeicon.

9.Turnthesupervisor(ratelockout)switchto

theUnlockposition,andturnthemasterboom

switchon.

10.Usingtheapplicationrateswitch,adjustthe

applicationrateaccordingtothetablebelow.

NozzleApplicationRateT able

NozzleColorSI(Metric)

Yellow

Red

Brown

Gray478L/ha

White

Blue

Green1,190L/ha

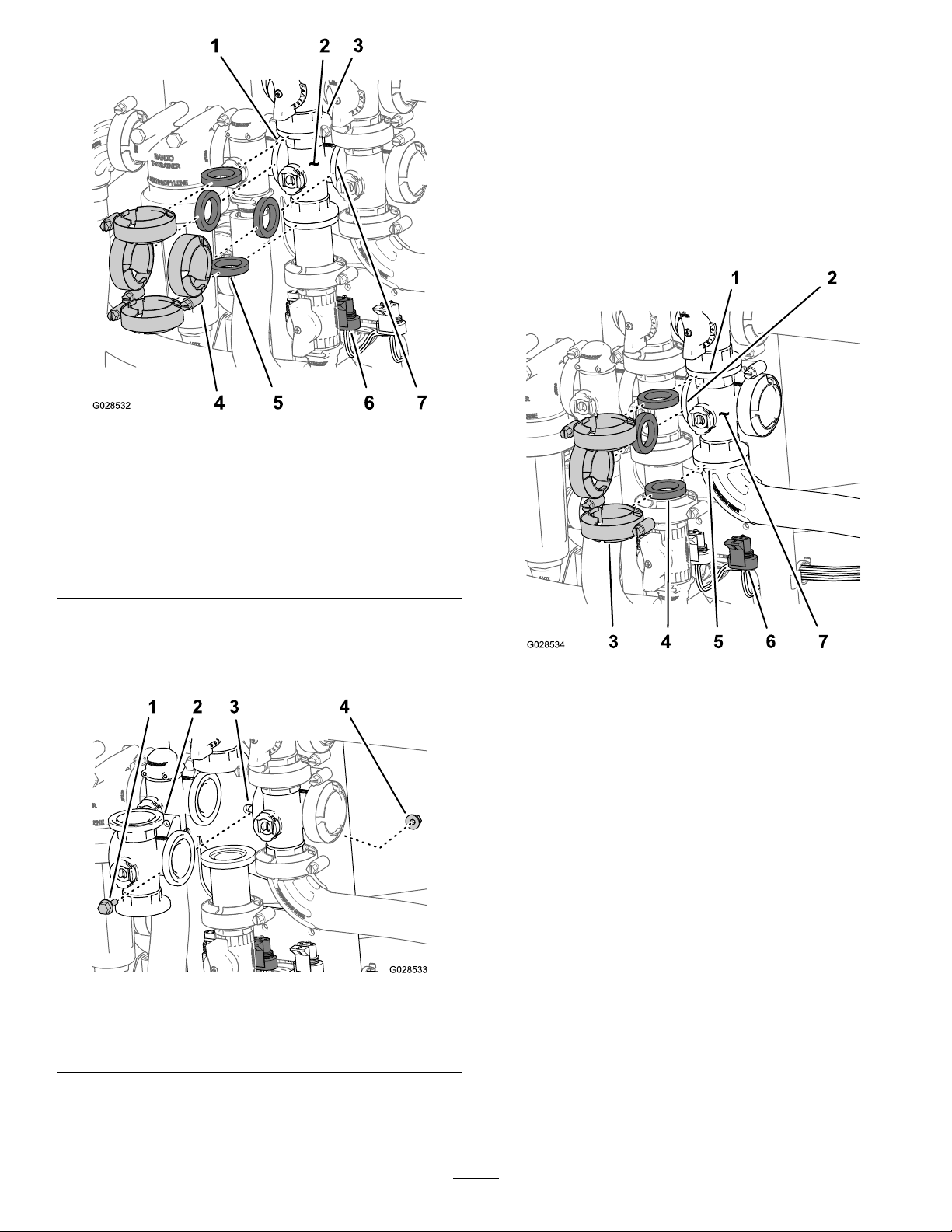

11.Turnofftheleftboomandadjusttheboom

bypassknob(Figure17)untilthepressure

readingisatthepreviouslyadjustedlevel

(typically40psior2.75bar).

159L/ha

319L/ha

394L/ha

637L/ha

796L/ha

English

17gpa0.39gpk

34gpa0.78gpk

42gpa0.96gpk

51gpa1.17gpk

68gpa1.56gpk

85gpa1.95gpk

127gpa2.91gpk

Turf

Note:Thenumberedindicatorsonthebypass

knobandneedleareforreferenceonly.

33

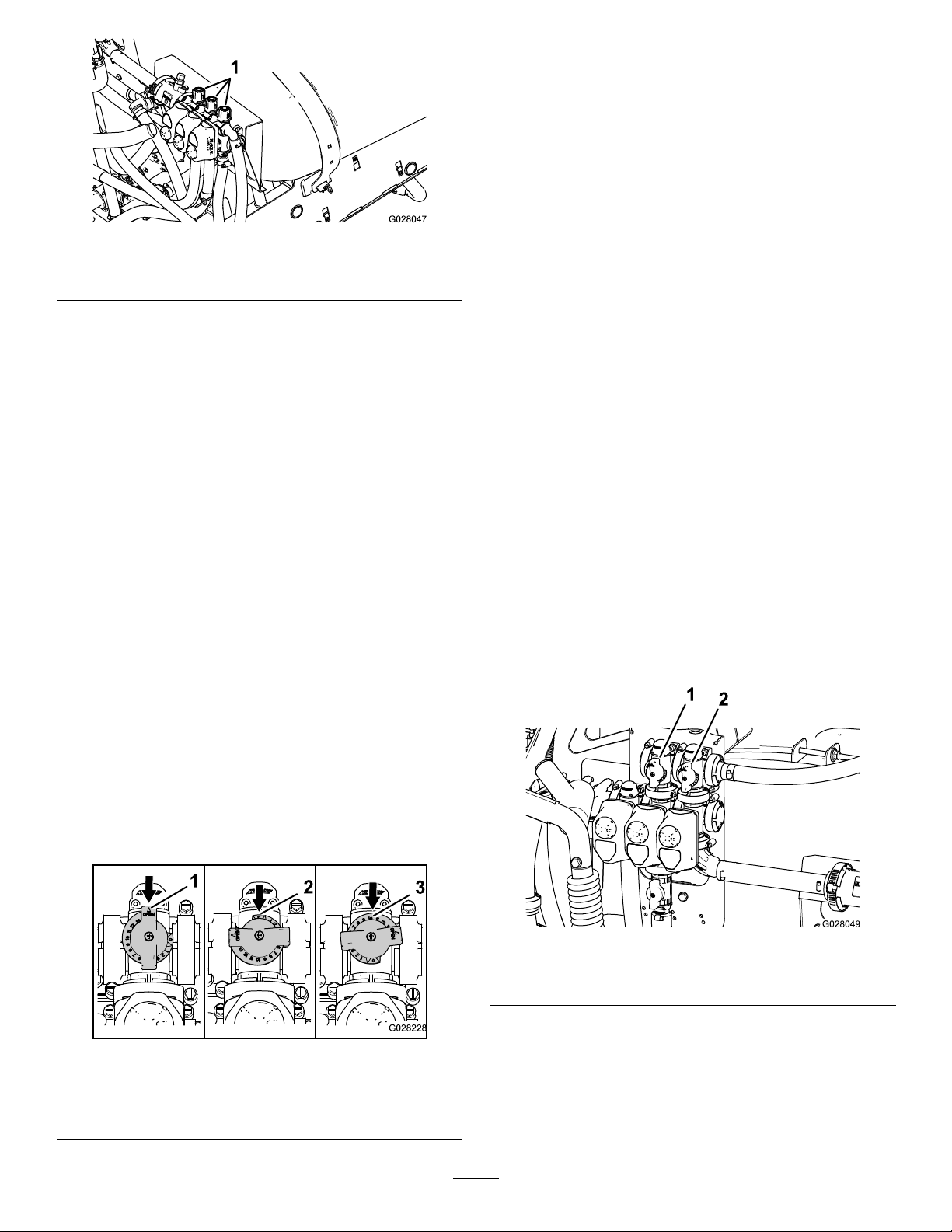

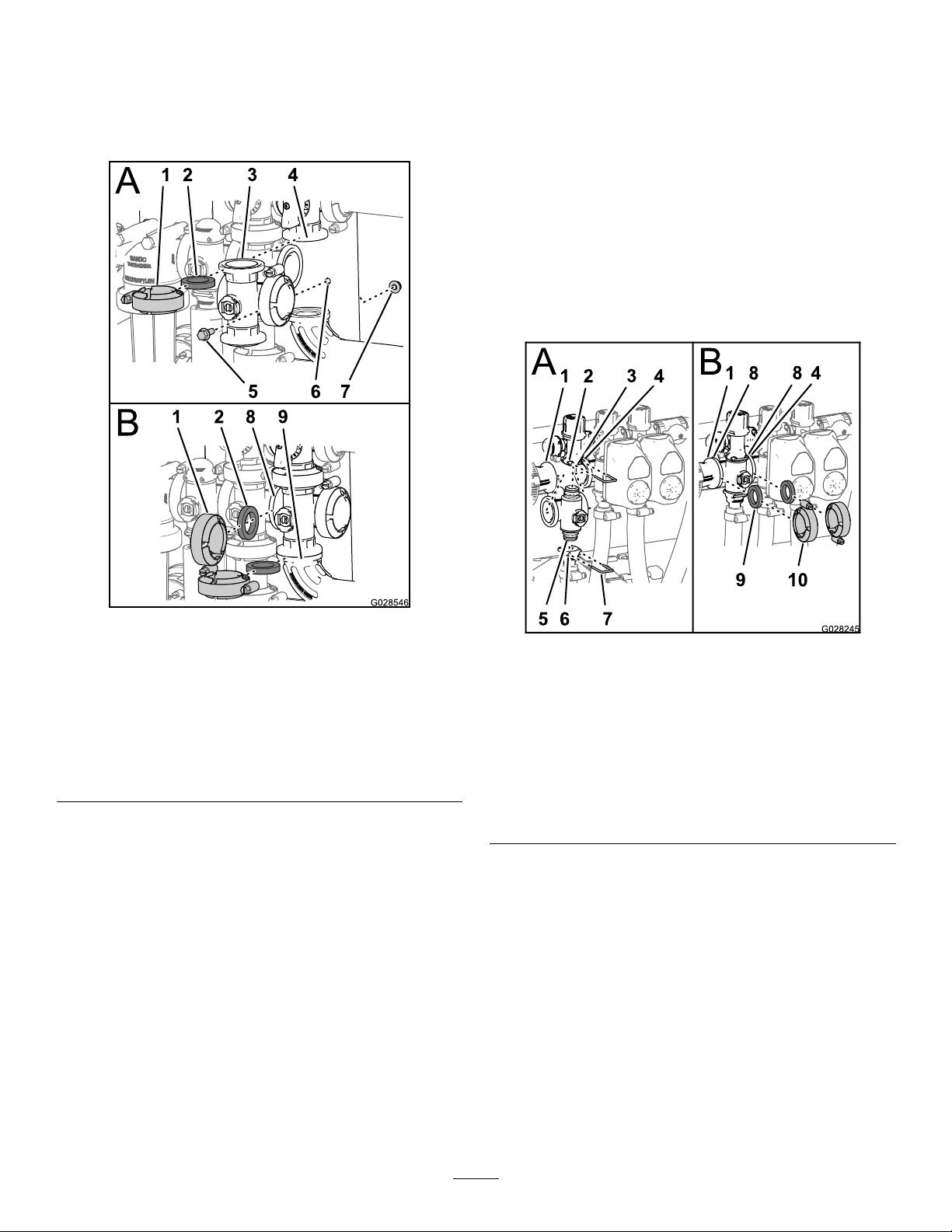

Figure17

1.Boom-sectionbypassadjustmentknobs

CalibratingtheAgitation

BypassValve

ServiceInterval:Y early

Selectanopenatareatoperformthisprocedure.

1.Fillthespraytankwithcleanwater.

2.Verifytheagitationcontrolvalveisopen.Ifithas

g028047

beenadjusted,openitcompletelyatthistime.

3.Settheparkingbrakeandstarttheengine.

4.SettherangeselectortoNeutral.

12.Turnontheleftboomandturnofftherightboom.

13.Adjusttherightboombypassknob(Figure17)

untilthepressurereadingisatthepreviously

adjustedlevel(typically40psior2.75bar).

14.Turnontherightboomandturnoffthecenter

boom.

15.Adjustthecenterboombypassknob(Figure17)

untilthepressurereadingisatthepreviously

adjustedlevel(typically40psior2.75bar).

16.Turnalltheboomsoff.

17.Turnthepumpoff.

Note:Calibrationisnowcomplete.

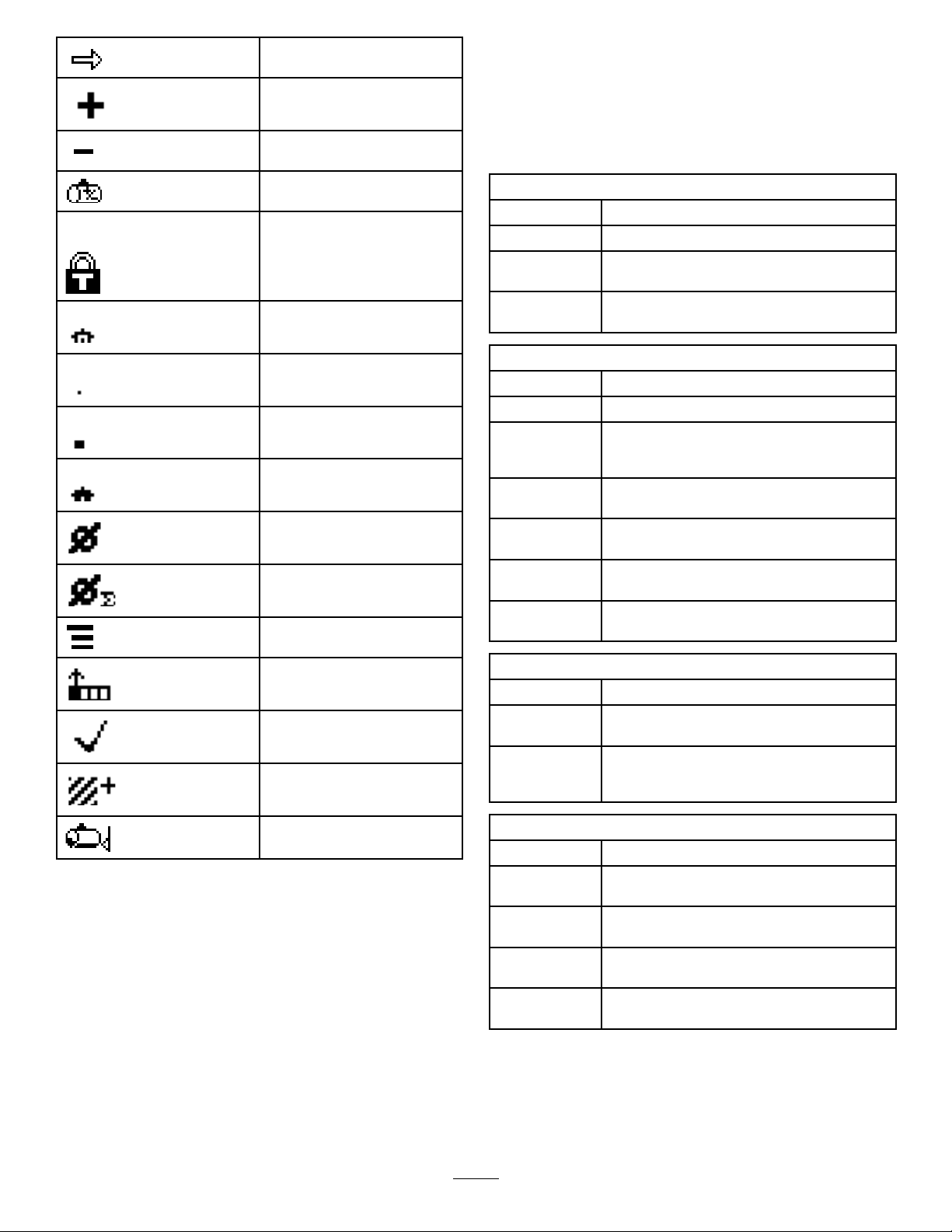

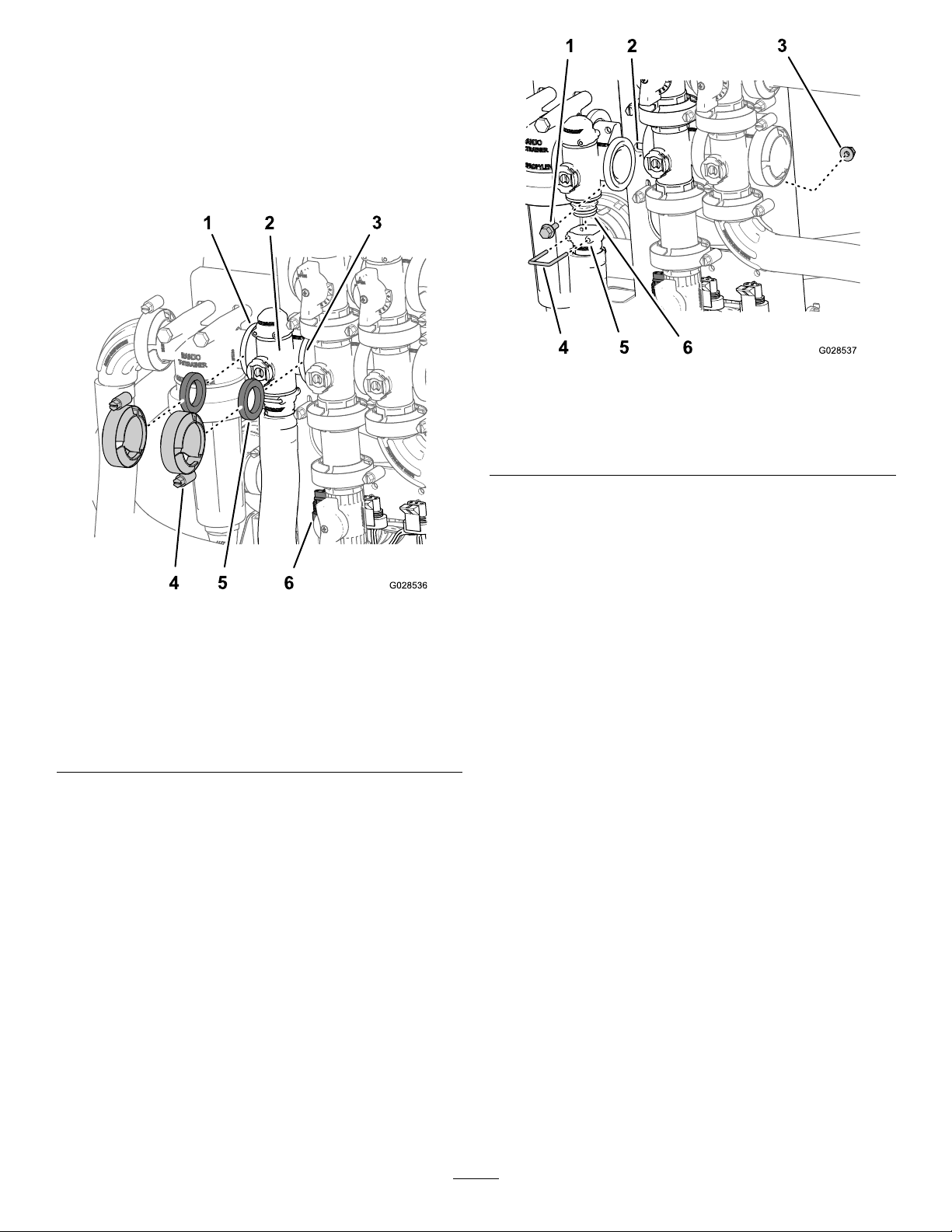

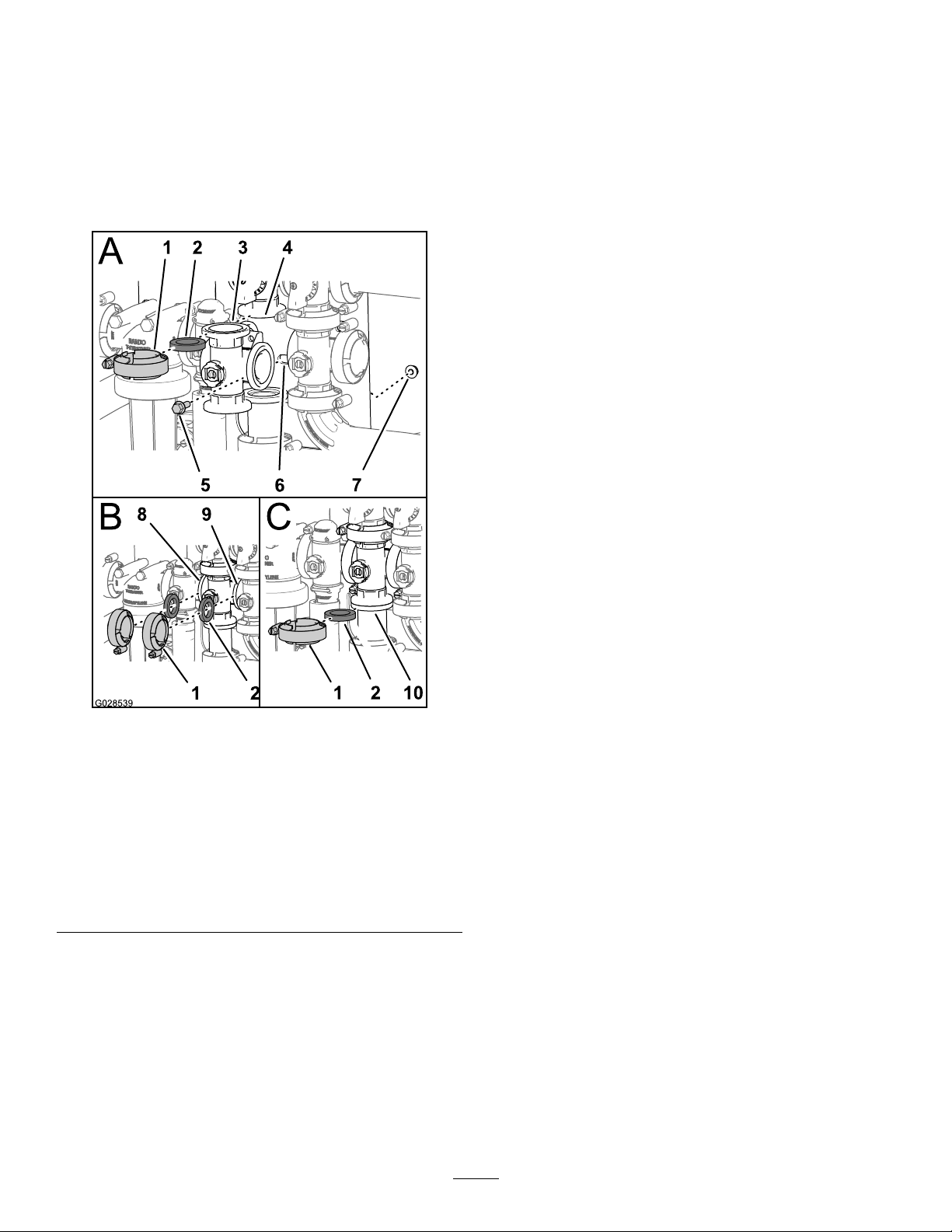

AgitationBypassValve

KnobPosition

•TheagitationbypassvalveisinthefullOpen

positionasshowninAofFigure18.

•TheagitationbypassvalveisintheClose(0)

positionasshowninBofFigure18.

5.SetthepumpswitchtotheOnposition.

6.Presstheacceleratorpedaltoachievemaximum

enginespeedandsetthethrottlelock.

7.Setthe3boom-sectionvalvestotheOffposition.

8.SetthemasterboomswitchtotheOnposition.

9.SetthesystempressuretoMaximum.

10.PresstheagitationswitchtotheOffpositionand

readthepressuregauge.

•Ifthereadingremainsat6.9bar(100psi)the

agitationbypassvalveisproperlycalibrated.

•Ifthepressuregaugereadsdifferently

continuetothenextstep.

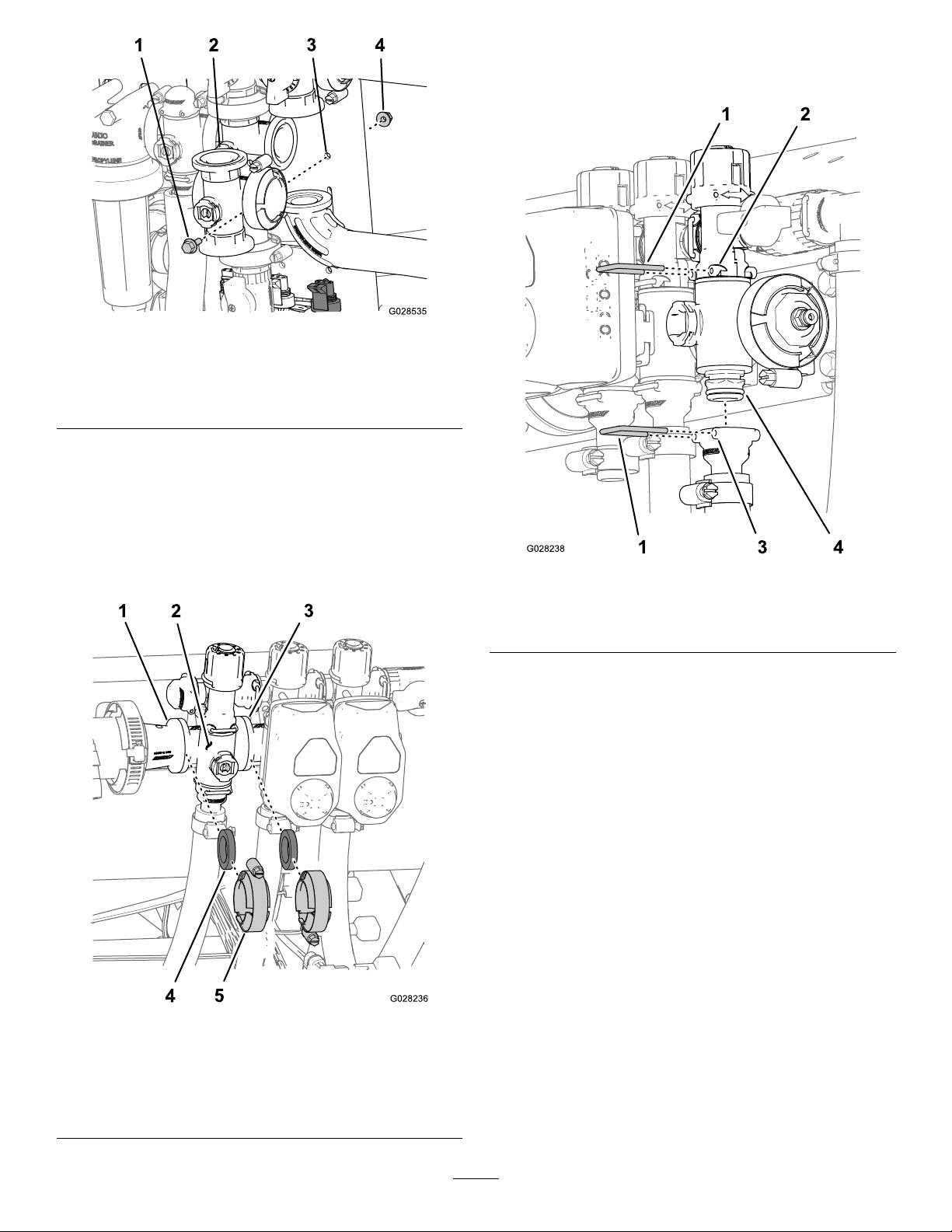

11.Adjusttheagitationbypassvalve(Figure19)

onthebacksideoftheagitationvalveuntilthe

pressurereadingonthegaugeis6.9bar(100

psi).

•Theagitationbypassvalveisinanintermediate

(adjustedrelativetothepressuregaugeforthe

sprayersystem)positionasshowninCofFigure

18

Figure18

1.Open

2.Closed(0)

3.Intermediateposition

g028049

Figure19

1.Agitationbypassvalve2.Masterboombypass

12.PressthepumpswitchtotheOffposition,shift

g028228

34

thethrottlelevertotheIdleposition,andturn

theignitionswitchOff.

AdjustingtheMasterBoom

WARNING

BypassValve

Note:Adjustingthemasterboombypassvalve

reducesorincreasestheamountofowsenttothe

agitationnozzlesinthetankwhenthemasterboom

switchissettotheOffposition.

1.Fillthesprayertank1/2fullwithcleanwater.

2.Movethemachinetoanopenlevelsurface.

3.Settheparkingbrake.

4.SettherangeselectortotheNeutralposition.

5.SetthepumpswitchtotheOnposition.

6.SettheagitationswitchtotheOnposition.

7.SetthemasterboomswitchtotheOffposition.

8.Increasetheenginespeedtofullthrottleandset

thethrottlelocktotheOnposition.

9.Adjustthemasterboombypasshandleto

controltheamountofagitationoccurringinthe

tank(Figure19).

10.Reducethethrottlespeedtoidle.

11.Settheagitationswitchandpumpswitchtothe

Offposition.

Towingatexcessivespeedscouldcausea

lossofsteeringcontrol,resultinginpersonal

injury.

Nevertowthesprayerfasterthan8km/h

(5mph).

Towingthesprayerisa2–personjob.Ifthemachine

mustbemovedaconsiderabledistance,transportit

onatruckortrailer;refertoTransportingtheSprayer

(page35).

1.Attachatowlinetotheframe.

2.PuttherangeselectorintheNeutralposition

andreleasetheparkingbrake.

3.Towthesprayeratlessthan8km/h(5mph).

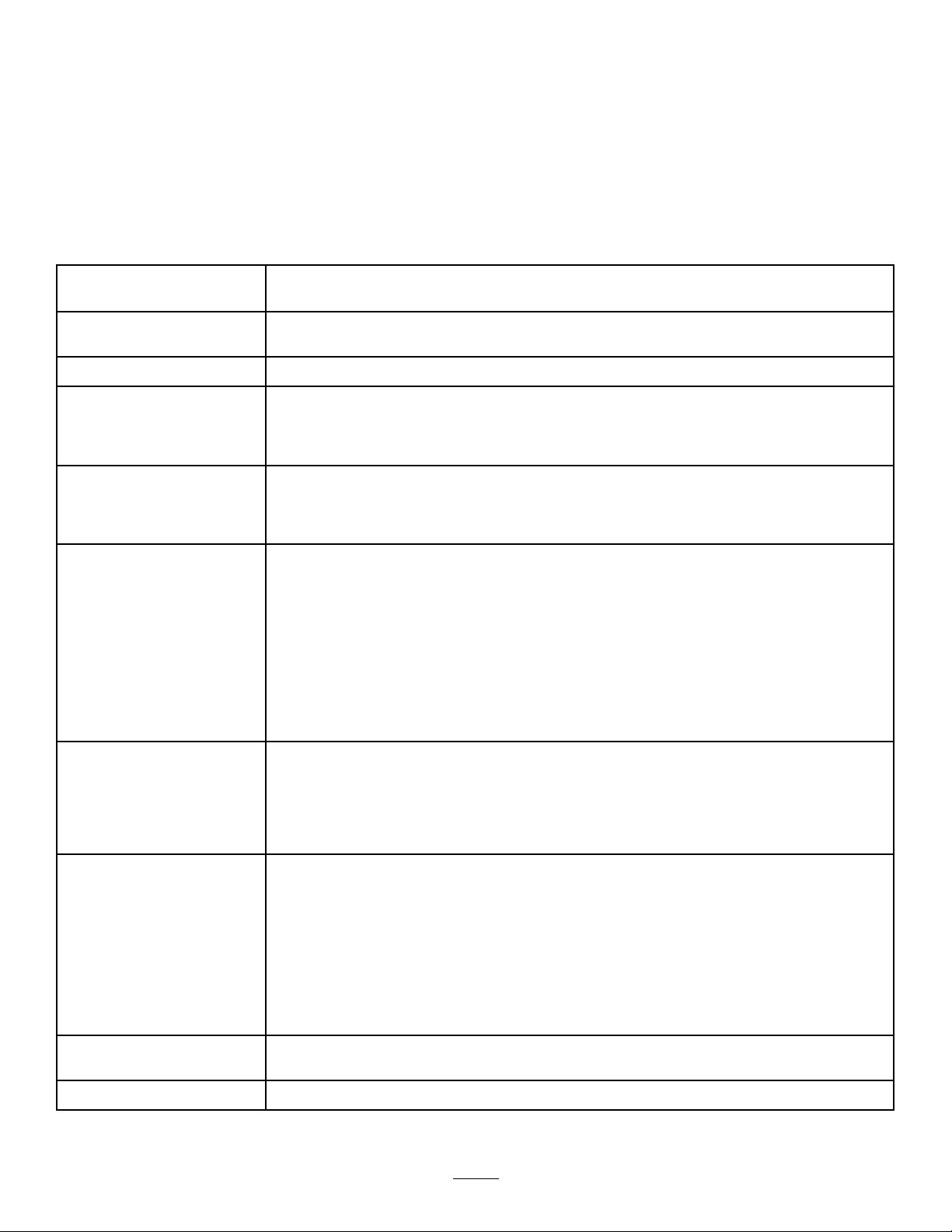

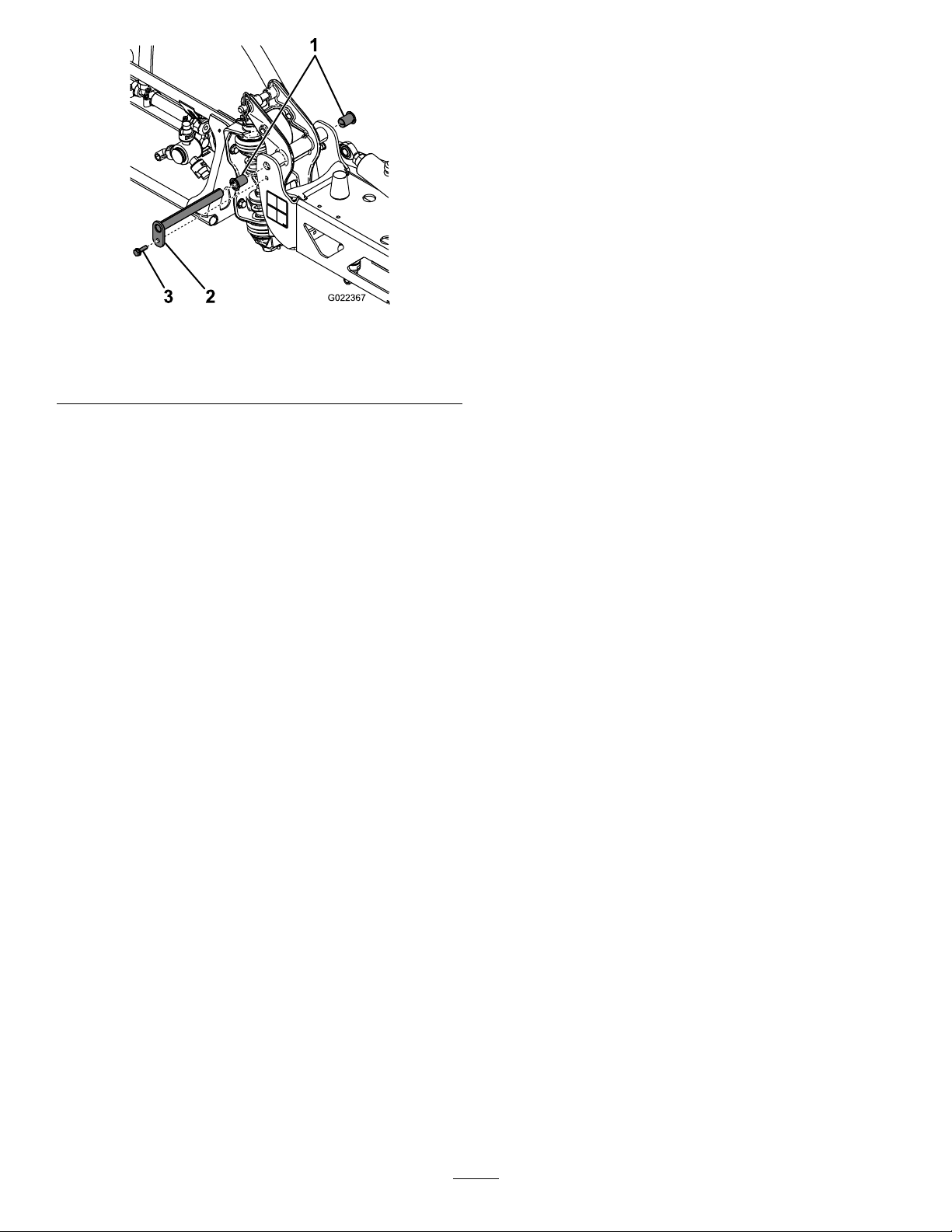

TransportingtheSprayer

Formovingthesprayerlongdistances,useatrailer.

Securethesprayertothetrailer.Also,makesurethat

theboomsaretieddownandsecure.Thereis1metal

looponthefrontoftheframeand2loopsontherear

oftheframe(Figure21).

12.Shutoffthemachine.

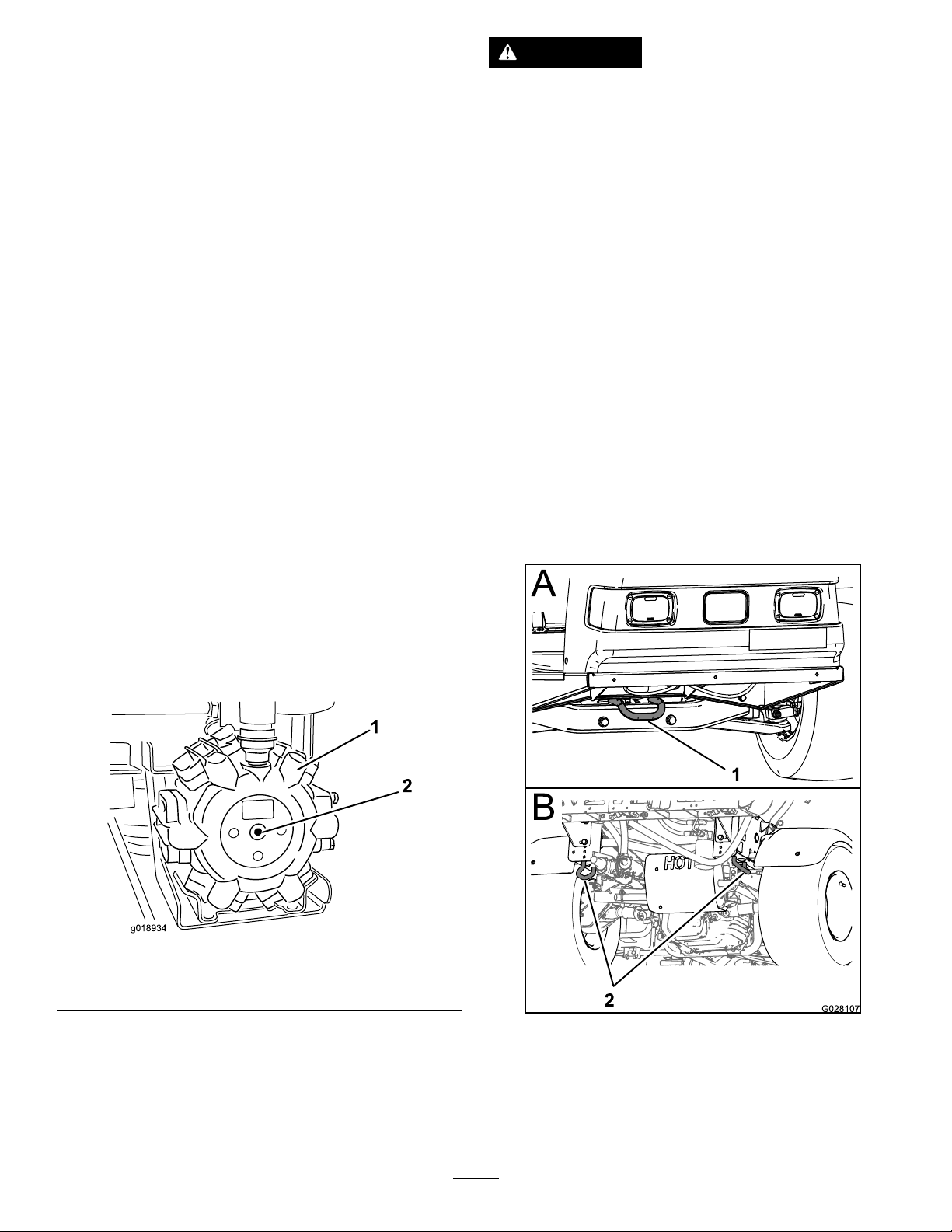

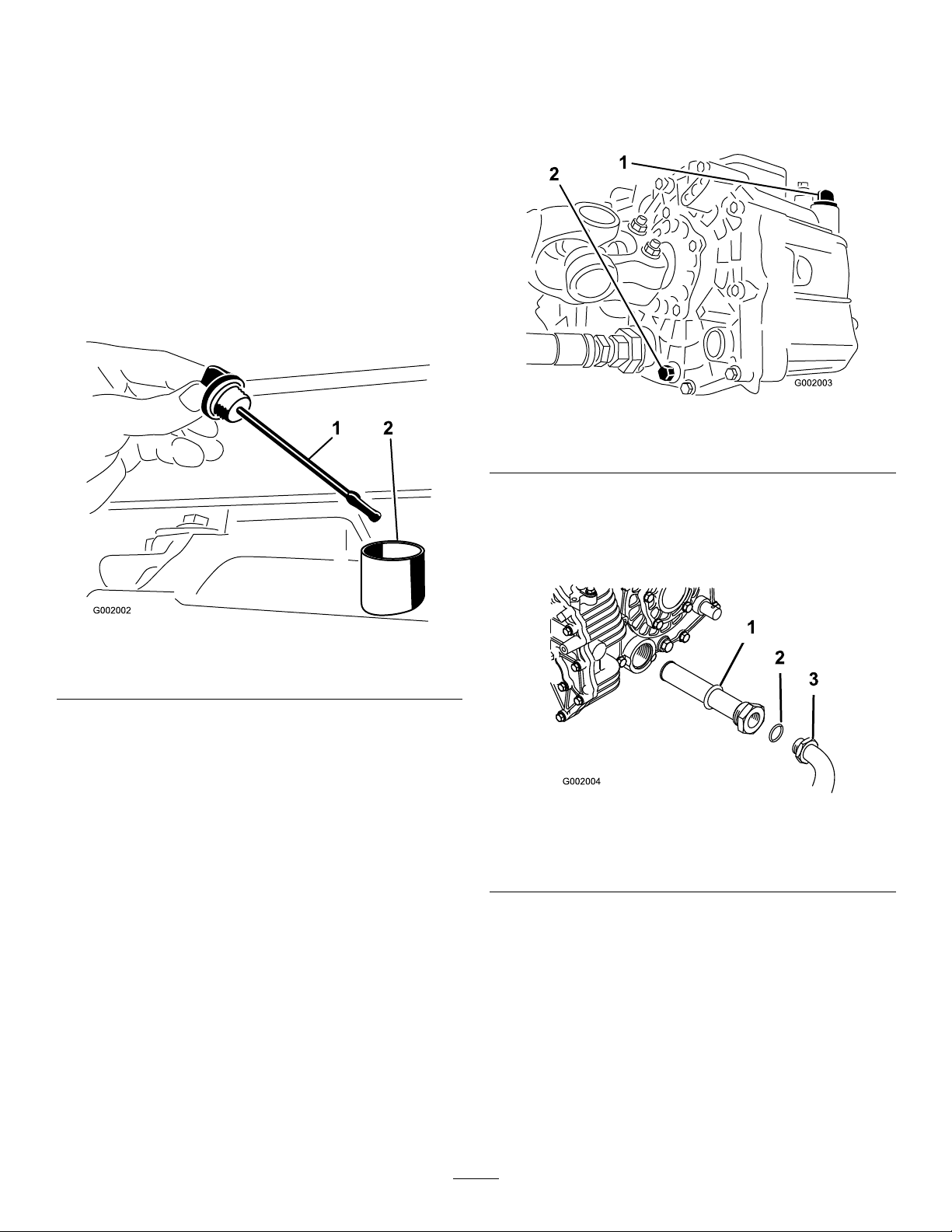

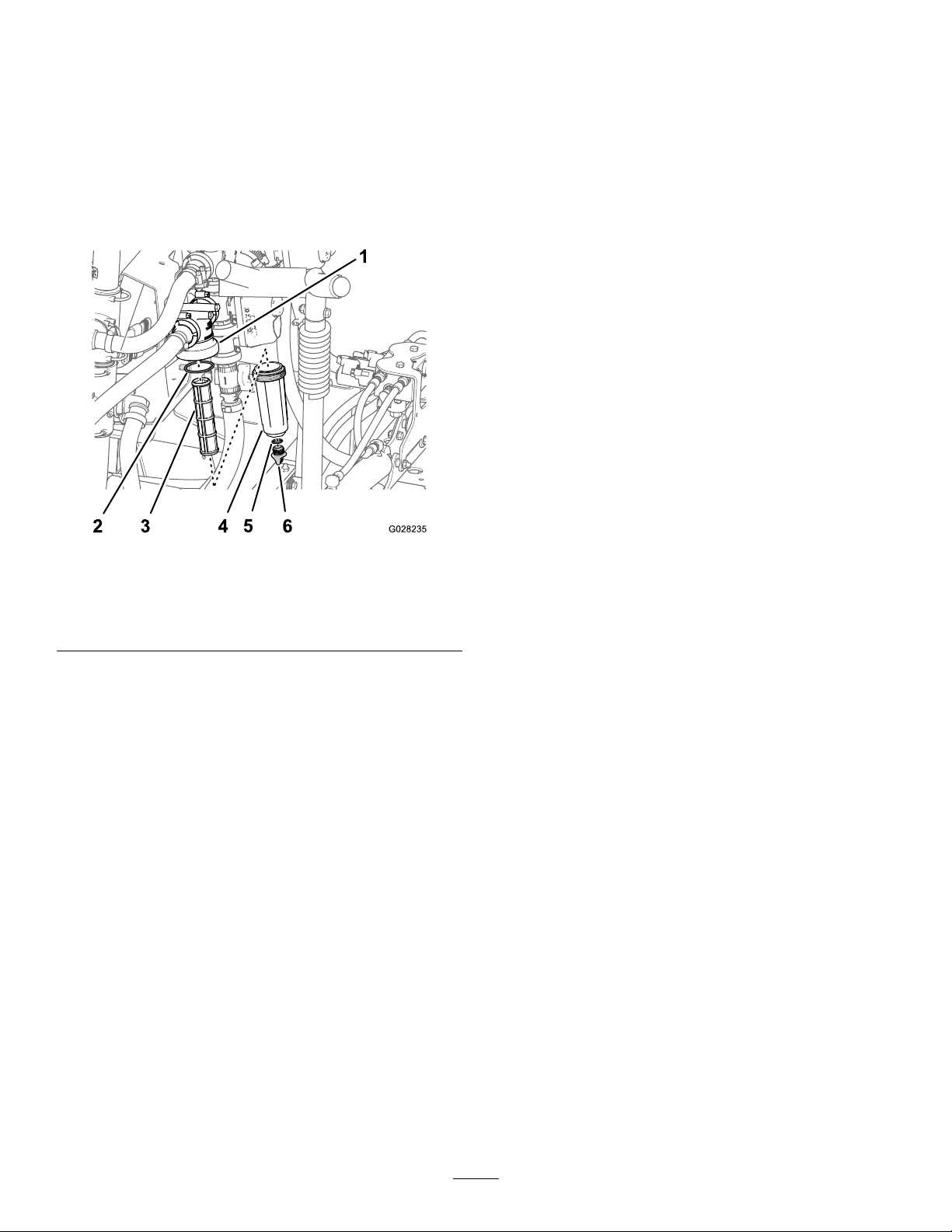

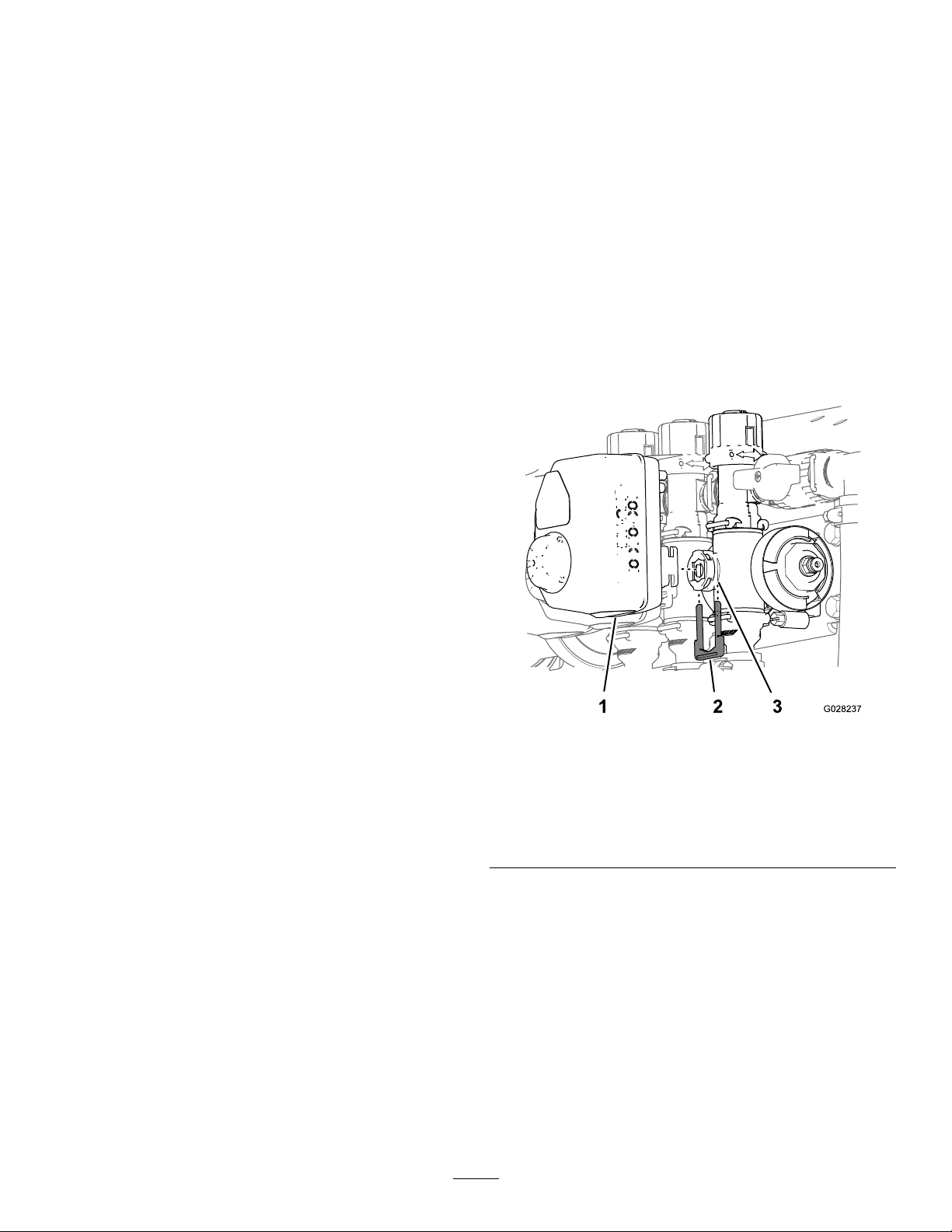

LocatingthePump

Thepumpislocatedundertheseat(Figure20).

Figure20

1.Pump

2.Greasetting

g018934

g028107

Figure21

TowingtheSprayer

Incaseofanemergency ,thesprayercanbetowed

forashortdistance.However,wedonotrecommend

thisasastandardprocedure.

1.Fronttie-downpoint2.Reartie-downpoints

35

Maintenance