Toro 41177 Multi-Pro 1250, 41179, Multi-Pro 1250, 41178, Multi-Pro 1200 Operator's Manual

Form No. 3356-699 Rev B

Multi-Pro 1250 Turf Sprayer

Model No. 41177 —Serial No. 270000001 and Up

Register your product at www.Toro.com Original Instructions (EN)

Warning

G001788

1

CALIFORNIA

Pr oposition 65 W ar ning

T he engine exhaust fr om this pr oduct

contains chemicals kno wn to the State of

Calif or nia to cause cancer , bir th defects, or

other r epr oducti v e har m.

Important: T his engine is not equipped

with a spar k ar r ester muf fler . It is a

violation of Calif or nia Public R esource Code

Section 4442 to use or operate the engine

on an y f or est-co v er ed, br ush-co v er ed, or

g rass-co v er ed land. Other states or federal

ar eas may ha v e similar la ws.

T his spark ignition system complies with Canadian

ICES-002

Figure 1

1. Location of the model and serial numbers

T he enclosed Engine Owner’ s Man ual is

Model No.

supplied f or inf or mation r egarding the US

En vir onmental Pr otection Agency (EP A) and

Serial No.

the Calif or nia Emission Contr ol R egulation of

emission systems, maintenance, and w ar ranty .

R eplacements may be order ed thr ough the

engine man uf actur er .

T his man ual identifies potential hazards and has

safety messag es identified b y the safety aler t

symbol ( Figure 2 ), whic h signals a hazard that ma y

cause serious injur y or death if y ou do not follo w

the recommended precautions .

Introduction

R ead this man ual carefully to lear n ho w to

operate and maintain y our product properly . T he

infor mation in this man ual can help y ou and

others a v oid injur y and product damag e . Although

1. Safety alert symbol.

T oro designs and produces safe products , y ou are

responsible for operating the product properly

and safely . Y ou ma y contact T oro directly

at www .T oro .com for product and accessor y

infor mation, help finding a dealer , or to register

T his man ual uses tw o other w ords to highlight

infor mation. Impor tant calls attention to special

mec hanical infor mation and Note emphasizes

g eneral infor mation w or th y of special attention.

y our product.

W henev er y ou need ser vice , g en uine T oro par ts ,

or additional infor mation, contact an A uthorized

Ser vice Dealer or T oro Customer Ser vice and ha v e

the model and serial n umbers of y our product

ready . Figure 1 illustrates the location of the model

and serial n umbers on the product.

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safe Operating Practices . . . . . . . . . . . . . . . . . . . . . . 4

Chemical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

W hile Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Sound Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 2

© 2007—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Contact us at www.Toro.com.

2

Printed in the USA.

All Rights Reserved

Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety and Instr uctional Decals . . . . . . . . . . . . 8

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1 Installing the Anti-siphon Fill

R ece ptacle . . . . . . . . . . . . . . . . . . . . . . . . . 13

2 Installing the Spra y Pro

Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 Chec king the Boom Hing e

Springs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Completing the Setup: Lear ning

more about y our

product. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Product Ov er view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

T hink Safety First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Before Dri ving the Spra yer for the

First Time . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Pre-Star ting Chec ks . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Dri ving the Spra yer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

New Spra yer Break-In . . . . . . . . . . . . . . . . . . . . . . . 27

Operating the Spra yer . . . . . . . . . . . . . . . . . . . . . . . . 28

Filling the F resh W ater T ank . . . . . . . . . . . . . . . 28

Filling the Spra y T ank . . . . . . . . . . . . . . . . . . . . . . . . 28

Operating the Booms . . . . . . . . . . . . . . . . . . . . . . . . 29

Spra ying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Spra ying Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cleaning the Spra yer . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Calibrating the Spra y Pro

Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Calibrating the Boom Bypass

V alv es . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

T ranspor ting the Spra yer . . . . . . . . . . . . . . . . . . . . 36

T o wing the Spra yer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

R ecommended Maintenance

Sc hedule(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Daily Maintenance Chec klist . . . . . . . . . . . . . . 40

Notation for Areas of

Concer n . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Premaintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . 41

J ac king the Spra yer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Greasing the Spra yer . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Greasing the Boom Hing es . . . . . . . . . . . . . . . . 43

Greasing the Actuator R od

Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Chec king the Air Intak e

Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Ser vicing the Air Cleaner . . . . . . . . . . . . . . . . . . . 45

Ser vicing the Engine Oil . . . . . . . . . . . . . . . . . . . . 46

Changing the Spark Plugs . . . . . . . . . . . . . . . . . . . 47

Fuel System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 48

R e placing the Fuel Filter . . . . . . . . . . . . . . . . . . . . 48

Electrical System Maintenance . . . . . . . . . . . . . . . . . . . 49

R e placing the Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Ser vicing the Batter y . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Dri v e System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 51

Maintaining the Primar y Dri v e

Clutc h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Inspecting the W heels/Tires . . . . . . . . . . . . . . 52

Adjusting the F ront W heel

T oe-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Brak e Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Chec king the Brak e Fluid . . . . . . . . . . . . . . . . . . . 53

Inspecting the Brak es . . . . . . . . . . . . . . . . . . . . . . . . . 53

Adjusting the P arking Brak e . . . . . . . . . . . . . . . 53

Belt Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Ser vicing the Dri v e Belt . . . . . . . . . . . . . . . . . . . . . 54

Adjusting the Steering Pump

Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Hy draulic System Maintenance . . . . . . . . . . . . . . . . . . 55

Chec king the T ransaxle/Hy draulic

Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Changing T ransaxle/Hy draulic

Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

R e placing the Hy draulic Filter . . . . . . . . . . . . 56

Spra y System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 57

Inspecting the Hoses . . . . . . . . . . . . . . . . . . . . . . . . . 57

Pump Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Adjusting the Boom Actuator . . . . . . . . . . . . 57

Emerg ency Man ual Operation

of the Boom

Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Inspecting the Nylon Pi v ot

Bushings . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Cleaning the Flo wmeter . . . . . . . . . . . . . . . . . . . . . 59

Cleaning the Suction Strainer . . . . . . . . . . . . . 59

Storag e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

T roubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Sc hematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

3

Safety

Improper use or maintenance b y the operator or

o wner can result in injur y . T o reduce the potential

for injur y , comply with these safety instr uctions

and alw a ys pa y attention to the safety aler t

symbol, whic h means CA UTION , W ARNING , or

D ANGER—personal safety instr uction. F ailure to

comply with the instr uction ma y result in personal

injur y or death.

Super visors , operators , and ser vice persons should

be familiar with the follo wing standards and

publications: (T he material ma y be obtained from

the address sho wn).

• Flammable and Combustible Liquids Code:

ANSI/NFP A 30

• National Fire Protection Association:

ANSI/NFP A #505; P o w ered Industrial T r uc ks

National Fire Prev ention Association

Bar r ymarc h P ark

Quincy , Massac husetts 02269

U .S .A.

• SAE 2258 Light Utility V ehicles

Society of A utomoti v e Engineers

SAE W orld Headquar ters

400 Commonw ealth Dri v e

W ar rendale , P A 15096-0001

• ANSI/UL 558; Inter nal Combustion

Engine P o w ered Industrial T r uc ks

American National Standards Institute , Inc .

1430 Broadw a y New Y ork,

New Y ork 10018 U .S .A.

or

Underwriters Laboratories

333 Pfingsten R oad

Nor thbrook, Illinois 60062

U .S .A.

Safe Operating Practices

Supervisor’s Responsibilities

• Mak e sure that operators are thoroughly

trained and familiar with the Operator’ s Manual ,

Engine Man ual, and all labels on the spra yer .

• Establish y our o wn special procedures and

w ork r ules for un usual operating conditions

(e .g . slopes too stee p for spra yer operation).

Chemical Safety

Chemicals ar e hazardous and can injur e

y ou, bystander s, animals, plants, soils, or

other pr oper ty .

• Car efull y r ead and f ollo w the chemical

man uf actur er’ s instr uctions f or the safe

pr eparation, use, and disposal of the

chemical.

• K eep chemicals of f of y our or bystander’ s

skin. If contact should occur , w ash it

of f immediatel y with clean w ater and

detergent.

• W ear go g g les and other pr otecti v e

equipment as instr ucted by the chemical

man uf actur er .

• Obtain proper training before using or

handling c hemicals .

• Use the cor rect c hemical for the job .

• F ollo w the c hemical man ufacturer’ s

instr uctions for the safe application of the

c hemical.

• Handle c hemicals in a w ell v entilated area.

• W ear g og gles and other protecti v e equipment

as instr ucted b y the c hemical man ufacturer .

Ensure that as little skin as possible is exposed

while using c hemicals .

T he spray er is an of f-highw ay v ehicle

onl y and is not designed, equipped, or

man uf actur ed f or use on public str eets,

r oads, or highw ays.

• Ha v e clean w ater a v ailable especially when

filling the spra y tank.

• Do not eat, drink, or smok e while w orking

with c hemicals .

• Alw a ys w ash y our hands and other exposed

areas as soon as possible after finishing the

w ork.

4

• Properly dispose of un used c hemicals and

c hemical containers as instr ucted b y the

c hemical man ufacturer and y our local codes .

• Chemicals and fumes in the tanks are

dang erous; nev er enter the tank or place y our

head o v er or in the opening .

Before Operating

• Operate the mac hine only after reading and

understanding the contents of this man ual.

• Nev er allo w c hildren to operate the spra yer .

Any one who operates the spra yer should ha v e

a motor v ehicle license .

• Nev er allo w other adults to operate the spra yer

without first reading and understanding the

Operator’ s Manual . Only trained and authorized

persons should operate this spra yer . Mak e sure

that all operators are ph ysically and mentally

capable of operating the spra yer .

• T his spra yer is designed to car r y onl y y ou , the

operator . Nev er car r y any passeng ers on the

spra yer .

• Nev er operate the spra yer when under

the influence of dr ugs or alcohol. Ev en

prescription dr ugs and cold medicines can

cause dro wsiness .

• Be extremely careful when operating around

people . Alw a ys be a w are of where b ystanders

might be and k ee p them a w a y from the w ork

area.

• Before operating the spra yer , alw a ys c hec k the

designated areas of the spra yer that are stated

in the Pre-Star ting Chec ks in the Operation

section. If the mac hine does not function

cor rectly or is damag ed in any w a y , do not use

the spra yer . Mak e sure that the problem is

cor rected before the spra yer or attac hment is

operated.

• Ensure that all fluid line connectors are tight

and all hoses are in g ood condition before

applying pressure to the system.

• Since g asoline is highly flammable , handle it

carefully .

– Use an appro v ed g asoline container .

– Do not remo v e the cap from the fuel tank

when the engine is hot or r unning .

– Do not smok e while handling g asoline .

– Fill the fuel tank outdoors , and fill it to

about 1 inc h (25 mm) belo w the top of the

tank (the bottom of the filler nec k). Do

not o v erfill it.

• Do not dri v e the spra yer when y ou are tired.

Be sure to tak e occasional breaks . It is v er y

impor tant that y ou sta y aler t at all times .

• Become familiar with the controls and kno w

ho w to stop the engine quic kly .

• K ee p all shields , safety devices , and decals in

place . If a shield, safety device , or decal is

malfunctioning, illegible , or damag ed, re pair or

re place it before operating the mac hine .

• Alw a ys w ear substantial shoes . Do not operate

the mac hine while w earing sandals , tennis

shoes , or sneak ers . Do not w ear loose fitting

clothing or jew elr y whic h could g et caught in

mo ving par ts and cause personal injur y .

• W earing safety glasses , safety shoes , long pants ,

and a helmet is advisable and required b y some

local safety and insurance regulations .

• A v oid dri ving when it is dark, especially in

unfamiliar areas . If y ou m ust dri v e when it

is dark, be sure to dri v e cautiously , use the

headlights , and ev en consider adding additional

lights .

– Wipe up any spilled g asoline .

While Operating

Engine exhaust contains carbon mono xide,

which is an odor less, deadl y poison that can

kill y ou.

Do not r un engine indoor s or in an enclosed

ar ea.

• T he operator should remain seated whenev er

the spra yer is in motion. T he operator

should k ee p both hands on the steering wheel

whenev er possible . K ee p y our ar ms and legs

within the spra yer body at all times .

• Alw a ys w atc h out for and a v oid lo w o v erhangs

suc h as tree limbs , door jambs , and o v erhead

w alkw a ys . Mak e sure there is enough room

o v er head to easily clear the spra yer and y our

head.

5

• F ailure to operate the spra yer safely ma y result

in an accident, tip o v er of the spra yer , and

serious injur y or death. Dri v e carefully . T o

prev ent tipping or loss of control:

– Use extreme caution, reduce speed, and

maintain a safe distance around sand traps ,

ditc hes , creeks , ramps , unfamiliar areas ,

or any areas that ha v e abr upt c hang es in

g round conditions or elev ation.

– W atc h for holes or other hidden hazards .

– Use extra caution when operating the

spra yer on w et surfaces , in adv erse w eather

conditions , at higher speeds , or with a

full load. Stopping time and distance will

increase with a full load.

– A v oid sudden stops and star ts . Do not

g o from rev erse to forw ard or forw ard to

rev erse without first coming to a complete

stop .

– Slo w do wn before tur ning . Do not attempt

shar p tur ns or abr upt maneuv ers or other

unsafe dri ving actions that ma y cause a loss

of spra yer control.

– Before bac king up , look to the rear and

ensure that no one is behind y ou. Bac k up

slo wly .

– W atc h out for traffic when y ou are near or

crossing roads . Alw a ys yield the right of

w a y to pedestrians and other v ehicles . T his

spra yer is not designed for use on streets or

highw a ys . Alw a ys signal y our tur ns or stop

early enough so that other people kno w

what y ou plan to do . Obey all traffic r ules

and regulations .

– T he electrical and exhaust systems of the

spra yer can produce sparks capable of

igniting explosi v e materials . Nev er operate

the spra yer in or near an area where there is

dust or fumes in the air whic h are explosi v e .

– If y ou are ev er unsure about safe operation,

stop w or k and ask y our super visor .

• Do not touc h the engine or m uffler while the

engine is r unning or soon after it has stopped.

T hese areas ma y be hot enough to cause bur ns .

• If the mac hine ev er vibrates abnor mally , stop

immediately , w ait for all motion to stop , and

inspect the spra yer for damag e . R e pair all

damag e before resuming operation.

• Before g etting off of the seat:

1. Stop the mo v ement of the mac hine .

2. Place the rang e selector in Neutral and set

the parking brak e .

3. T ur n the ignition k ey to Off .

4. R emo v e the ignition k ey .

Note: If the spra yer is stopped on an

incline , bloc k the wheels after g etting off

the spra yer .

Braking

• Slo w do wn before y ou approac h an obstacle .

T his gi v es y ou extra time to stop or tur n a w a y .

Hitting an obstacle can damag e the spra yer and

its contents . More impor tant, it can injure y ou.

• Gross V ehicle W eight (GVW) has a major

impact on y our ability to stop and/or tur n.

Hea vy loads and attac hments mak e a spra yer

harder to stop or tur n. T he hea vier the load,

the long er it tak es to stop .

• T urf and pa v ement are m uc h more slipper y

when they are w et. It can tak e 2 to 4 times

as long to stop on w et surfaces as on dr y

surfaces . If y ou dri v e through standing w ater

dee p enough to g et the brak es w et, they will

not w ork w ell until they are dr y . After dri ving

through w ater , y ou should test the brak es to

mak e sure they w ork properly . If they do not,

dri v e slo wly while putting light pressure on the

brak e pedal. T his will dr y the brak es out.

Operating on Hills and Rough Terrain

Operating the spra yer on a hill ma y cause tipping

or rolling of the spra yer , or the engine ma y stall

and y ou could lose headw a y on the hill. T his could

result in personal injur y .

• Do not accelerate quic kly or slam on the brak es

when bac king do wn a hill, especially with a

load.

• Nev er dri v e across a stee p hill; alw a ys dri v e

straight up or do wn or g o around the hill.

• If the engine stalls or y ou begin to lose headw a y

while climbing a hill, g radually apply the brak es

and slo wly bac k straight do wn the hill.

• T ur ning while tra v eling up or do wn hills can

be dang erous . If y ou ha v e to tur n while on a

hill, do it slo wly and cautiously . Nev er mak e

shar p or fast tur ns .

6

• Hea vy loads affect stability . R educe the w eight

of the load and y our speed when operating on

hills .

• A v oid stopping on hills , especially with a load.

Stopping while g oing do wn a hill will tak e

long er than stopping on lev el g round. If the

spra yer m ust be stopped, a v oid sudden speed

c hang es , whic h ma y initiate tipping or rolling

of the spra yer . Do not slam on the brak es

when rolling bac kw ard, as this ma y cause the

spra yer to o v er tur n.

• T he T oro Company strongly recommends

installing the optional R OPS Kit when

operating on hilly ter rain. If y ou install a

R OPS , alw a ys w ear the seat belt when dri ving

the spra yer .

Do not suddenly apply the brak es . Use extra

caution on slopes .

• Be a w are that hea vy loads increase y our

stopping distance and reduce y our ability to

tur n quic kly without tipping o v er .

Maintenance

• Only per mit qualified and authorized personnel

to maintain, re pair , adjust, or inspect the

spra yer .

• Before ser vicing or making adjustments to

the mac hine , stop the engine , set the parking

brak e , and remo v e the k ey from the ignition

to prev ent someone from accidentally star ting

the engine .

• R educe speed and load when operating on

rough ter rain, unev en g round, and near curbs ,

holes , and other sudden c hang es in ter rain.

Loads ma y shift, causing the spra yer to become

unstable .

Sudden changes in ter rain may cause

a br upt steering wheel mo v ement,

possibl y r esulting in hand and ar m

injuries.

• R educe y our speed when operating on rough

ter rain and near curbs .

• Grip the steering wheel loosely around the

perimeter . K ee p y our hands clear of the

steering wheel spok es .

Loading

T he w eight of the carg o can c hang e the spra yer

center of g ra vity and spra yer handling . T o a v oid

loss of control and personal injur y , follo w these

guidelines:

• R educe the w eight of the load when operating

on hills and rough ter rain to a v oid tipping or

o v er tur ning of the spra yer .

• Liquid loads can shift. T his shifting happens

most often while tur ning, g oing up or do wn

hills , suddenly c hanging speeds , or while

dri ving o v er rough surfaces . Shifting loads can

cause the spra yer to tip o v er .

• W hen operating with a hea vy load, reduce y our

speed and allo w for sufficient braking distance .

• T o mak e sure that the entire mac hine is in

g ood condition, k ee p all n uts , bolts , and screws

properly tightened.

• T o reduce the potential for fire , k ee p the engine

area free of ex cessi v e g rease , g rass , lea v es , and

accum ulation of dir t.

• Nev er use an open flame to c hec k the lev el or

leakag e of fuel or batter y electrolyte .

• If the engine m ust be r unning to perfor m a

maintenance adjustment, k ee p y our hands ,

feet, clothing, and any par ts of y our body a w a y

from the engine and any mo ving par ts . K ee p

ev er y one a w a y .

• Do not use open pans of fuel or flammable

cleaning fluids when cleaning par ts .

• Do not adjust the g round speed g o v er nor . T o

ensure safety and accuracy , ha v e an A uthorized

T oro Distributor c hec k the g round speed.

• K ee p y our body and hands a w a y from pin

hole leaks or nozzles that eject high pressure

fluid. Use cardboard or paper to find leaks .

Fluid escaping under pressure can penetrate

skin and cause injur y requiring surg er y within a

few hours b y a qualified surg eon or g ang rene

ma y result.

• If major re pairs are ev er needed or assistance

is required, contact an A uthorized T oro

Distributor .

• T o be sure of optim um perfor mance and safety ,

alw a ys purc hase g en uine T oro re placement

par ts and accessories . R e placement par ts and

accessories made b y other man ufacturers

7

could be dang erous . Altering this spra yer in

any manner that ma y affect spra yer operation,

perfor mance , durability , or its use , ma y result

in injur y or death. Suc h use could v oid the

product w ar ranty .

Sound Pressure

T his unit has a maxim um sound pressure lev el

at the operator’ s ear of 82 dB A, based on

measurements of identical mac hines per EN

11094.

Safety and Instructional Decals

Safety decals and instr uctions are easily visible to the operator and are located near any

area of potential dang er . R e place any decal that is damag ed or lost.

Vibration

T his unit does not ex ceed a hand/ar m vibration

lev el of 2.5 m/s

identical mac hines per EN 1033.

T his unit does not ex ceed a whole body vibration

lev el of 0.5 m/s

identical mac hines per EN 1032.

2

, based on measurements of

2

, based on measurements of

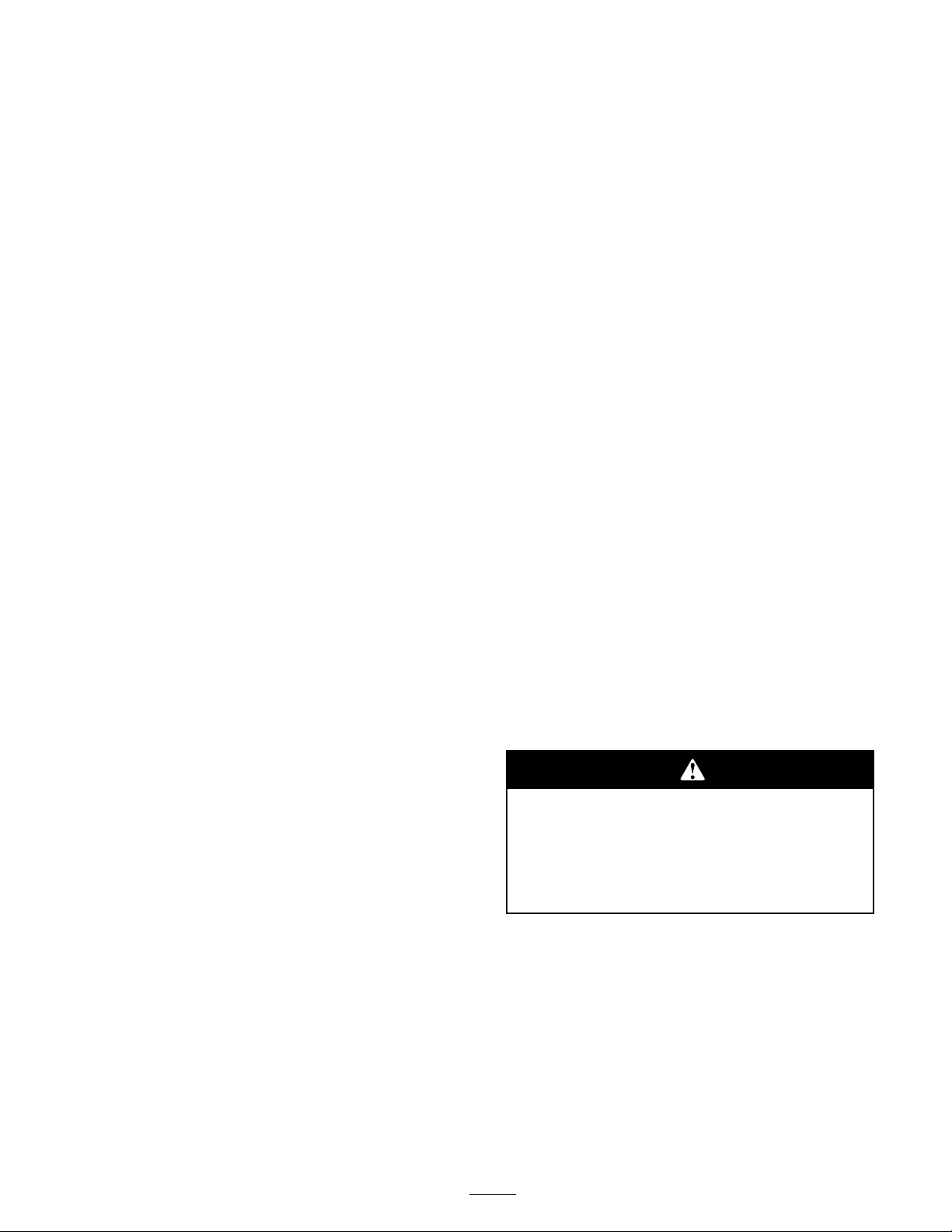

104-7628

1. Read the Operator’s Manual.

100-8458

1. Machine speed

2. To set the machine to a slow speed, reduce pressure on the

accelerator and pull up on the speed limiter.

3. To set the machine to a fast speed, press the accelerator

pedal and push down on the speed limiter.

100-8619

1. Spray on

100-8386

1. Fuel 3. Half-full

2. Empty

2. Spray off

4. Full

8

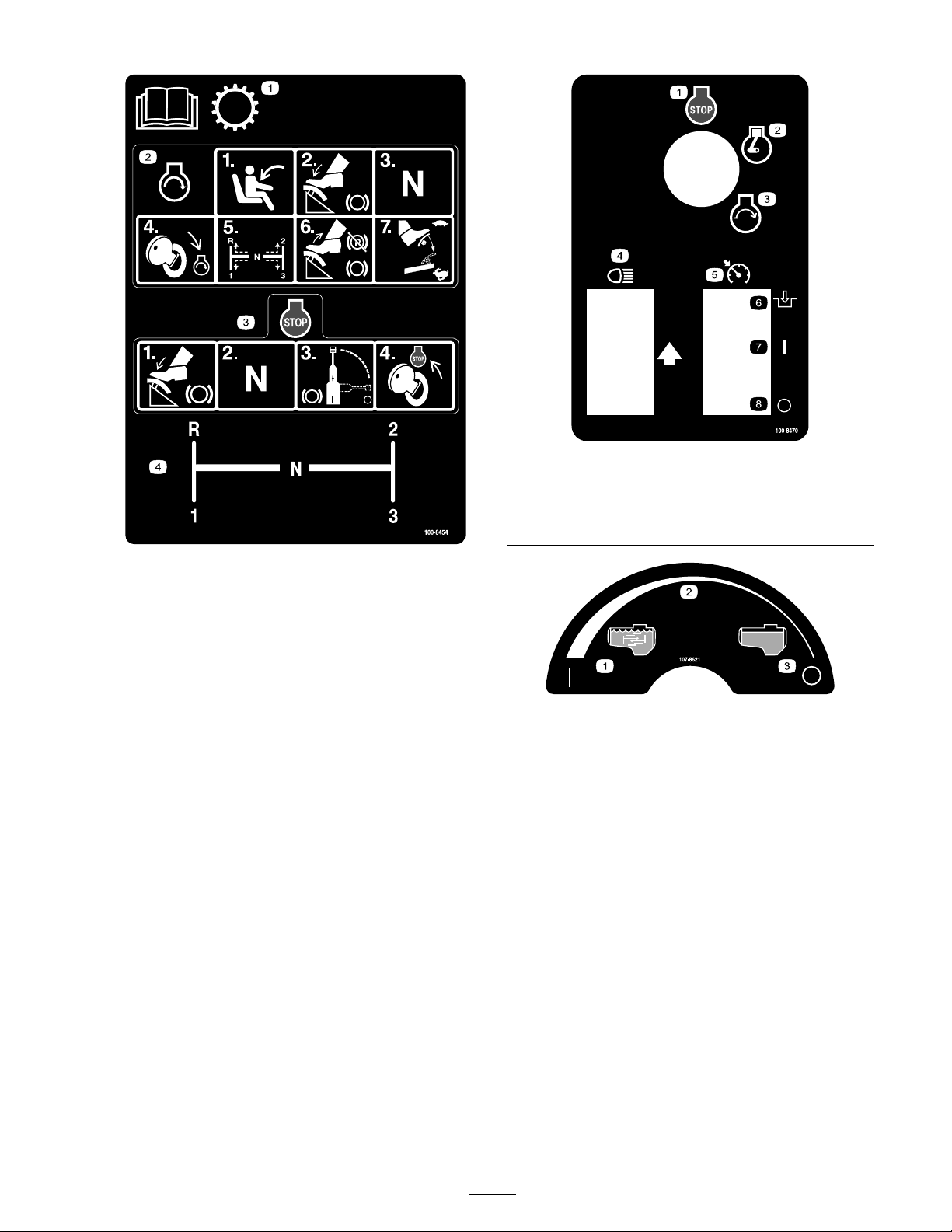

100-8454

1. Read the Operator’s Manual for information on the

transmission.

2. To start the engine, sit on the operator’s seat, press the

brake, set the range selector to Neutral, turn the ignition

key to Engine-start, set the range selector to the desired

gear, release the brake and parking brake, and press the

accelerator pedal to the desired speed.

3. To stop the engine, press the brake, set the range selector

to Neutral, set the brake, and turn the ignition key to

Engine-stop.

4. Range selector gear pattern

100-8470

1. Engine—stop

2. Engine—run

3. Engine—start

4. Headlights 8. Off

107-8621

1. Agitation on

2. Continuous variable setting

5. Neutral engine speed lock

6. Engage

7. On

3. Agitation off

9

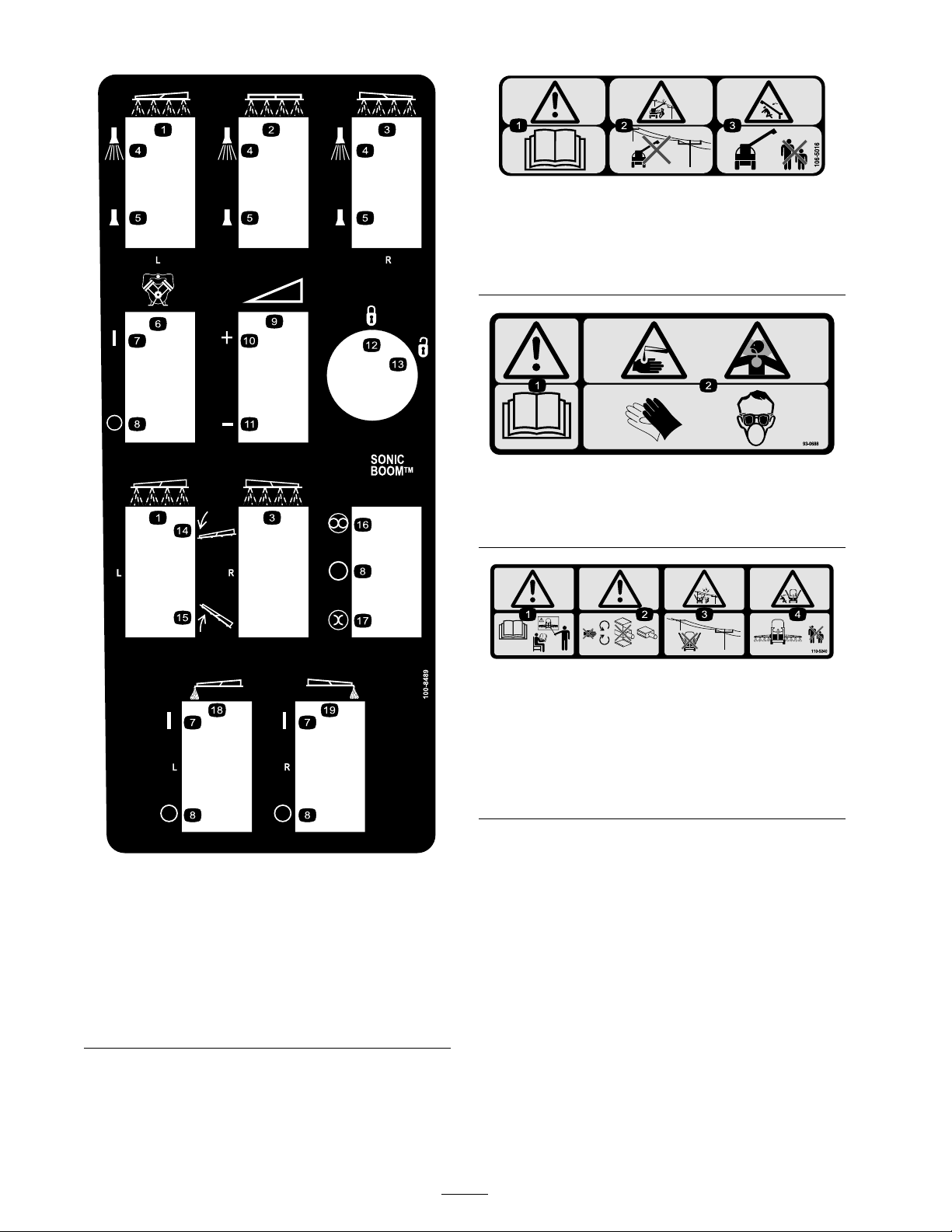

106-5016

1. Warning—read the Operator’s Manual .

2. Electric shock hazard, overhead power lines—stay away from

overhead power lines.

3. Crushing hazard, boom—keep bystanders a safe distance

from the machine.

93-0688

1. Warning—read the Operator’s Manual .

2. Caustic liquid/chemical burn and toxic gas inhalation

hazards—wear hand, skin, eye, and respiratory protection.

100-8489

1. Left boom

2. Center boom 12. Locked

3. Right boom 13. Unlocked

4. Spray on

5. Spray off 15. Raise the boom.

6. Pump

7. On

8. Off 18. Left boom foam marker

9. Continuous variable

setting, spray pressure

10. Increase

11. Decrease

14. Lower the boom.

16. Automatic

17. Manual

19. Right boom foam marker

110-5240

1. Warning—read the Operator’s Manual and receive training

before operating.

2. Warning—stay away from moving parts, do not operate

with covers removed.

3. Electric shock hazard, overhead power lines—stay away from

overhead power lines.

4. Crushing hazard, boom—keep bystanders a safe distance

from the machine.

10

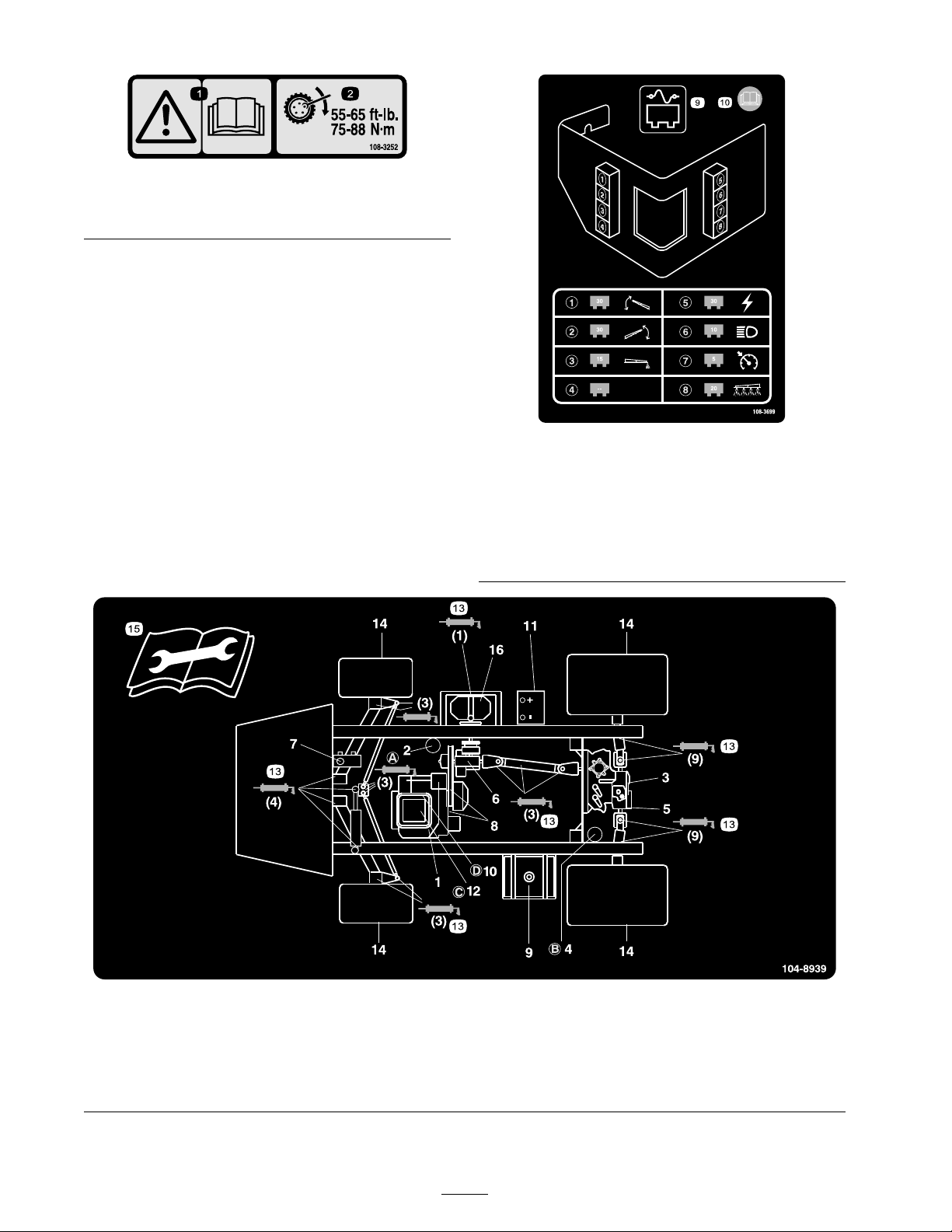

110-5143

1. Warning—read the Operator’s Manual .

2. Tipping Hazard—drive slowly over rough terrain and when

turning.

3. Falling and arm/leg injury hazards—do not carry passengers

and keep arms and legs inside of the vehicle at all times.

4. To stop the engine, press the brake, move the range selector

to Neutral, set the parking brake, release the brake pedal,

turn the ignition key to Engine-stop, and remove the key.

107-8640

1. Warning—read the Operator’s Manual ; use fresh, clean water

for rinsing the tank.

106-5051

1. Warning—read the Operator’s Manual ; use fresh, clean water

for rst-aid washing.

108-3307

1. Warning—do not enter the tank.

108-3309

1. Total area 8. Width

2. Boom select

106-1355

3. Speed 10. Speed calibration

4. Units of measure 11. Sub volume

5. Select units 12. Total volume

6. Application rate 13. Flowmeter calibration

7. Sub area

9. Distance

11

1. Warning—read the

Operator’s Manual .

108-3252

2. Torque lug nuts to 55-65

ft-lb (75-88 N·m).

108-3699

1. 3o amp fuse, left boom

actuator

2. 3o amp fuse, right boom

actuator

3. 15 amp fuse, foam marker 8. 20 amp fuse, spray system

4. Empty

5. 30 amp fuse, power

6. 10 amp fuse, headlights

7. 5 amp fuse, cruise control

9. Fuse panel

10. Read the Operator’s Manual

for more information.

104-8939

1. Engine oil level (dipstick)

2. Engine oil lter 6. Gear box uid level 10. Fuel lter

3. Transaxle/hydraulic uid

level (dipstick)

4. Transaxle hydraulic lter 8. Belts, steering and drive 12. Air cleaner

5. Hydraulic strainer 9. Fuel, unleaded only

7. Brake uid

11. Battery

12

13. Grease

14. Tire pressure

15. Read the instructions before

servicing or performing

maintenance.

16. Pump

Setup

Loose Parts

Use the chart below to verify that all parts have been shipped.

Step

90 degree tting

Quick coupler

Hose adapter

1

2

3

4

Fill receptacle bracket

Flange-head bolt, 5/16 x 3/4 inch

Anti-siphon hose

Spray Pro Monitor

Spray Pro Decal

Bracket

Flange-head bolt, 3/4 inch

Flange nut, 1/4 inch

Knob

Washer

Carriage bolt

No parts required

Ignition key

Operator’s Manual

Engine Operator’s Manual

Parts Catalog

Operator Training Material

Registration Card

Pre-delivery Inspection Sheet

Description

Qty.

1

1

1

1

1

1

1

1

1

2

2

2

2

2

–

1

1

1

1

1

1

1

Install the anti-siphon ll receptacle.

Install the Spray-Pro monitor.

Check the boom hinge springs.

Read the manuals and view the

training material before operating

the machine.

Use

Note: Deter mine the left and right sides of the

mac hine from the nor mal operating position.

13

Step

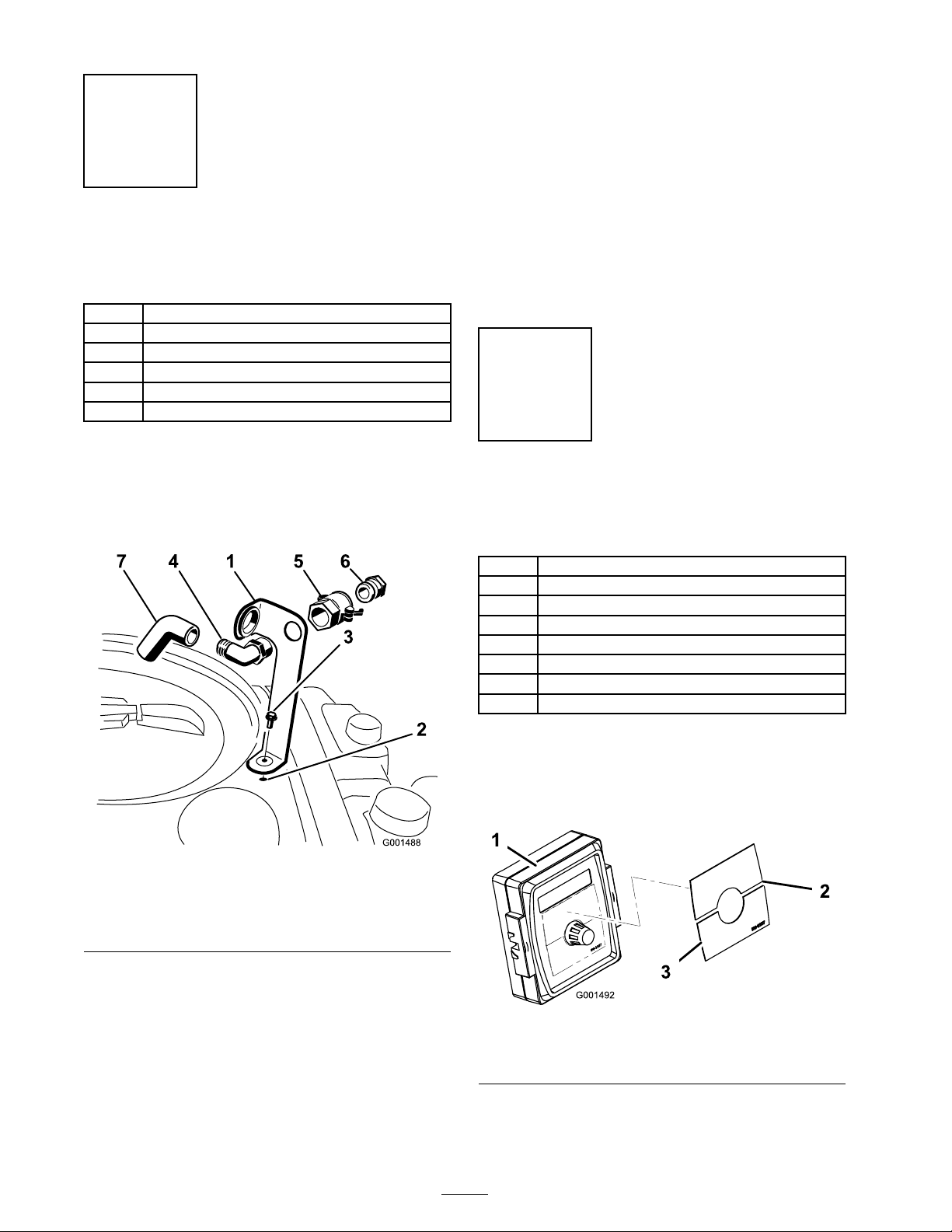

3. Install the hose adapter into the quic k coupler

( Figure 3 ).

4. Loc k the adapter into place b y swinging the

1

lev ers to w ard the adapter and then secure them

with the hair pin cotters ( Figure 3 ).

Installing the Anti-siphon

Fill Receptacle

Parts needed for this step:

1

90 degree tting

1

Quick coupler

1

Hose adapter

1

Fill receptacle bracket

1

Flange-head bolt, 5/16 x 3/4 inch

1

Anti-siphon hose

Procedure

1. Place the fill rece ptacle brac k et o v er the

threaded hole in the tank and secure it with a

flang e-head bolt (5/16 x 3/4 inc h) ( Figure 3 ).

5. Install the anti-siphon hose through the larg e

opening on the brac k et and onto the barbed

end of the 90 deg ree elbo w fitting ( Figure 3 ).

Important: Do not lengthen the hose to

allo w contact with the tank fluids.

Step

2

Installing the Spray Pro

Monitor

Parts needed for this step:

1

Spray Pro Monitor

1

Spray Pro Decal

1

Bracket

2

Flange-head bolt, 3/4 inch

2

Flange nut, 1/4 inch

2

Knob

2

Washer

2

Carriage bolt

Figure 3

1. Fill receptacle bracket 5. Quick coupler

2. Threaded hole in the tank 6. Hose adapter

3. Flange bolt, 5/16 x 3/4 inch 7. Anti-siphon hose

4. 90 degree elbow tting

2. Place the threaded end of the 90 deg ree elbo w

fitting through the brac k et and thread the

quic k coupler onto it, securing it to the brac k et

( Figure 3 ).

Note: Install the fitting with the open end

pointing to w ard the larg e opening in the

brac k et and to w ard the tank opening so the

w ater will arc into the tank when y ou fill it.

Procedure

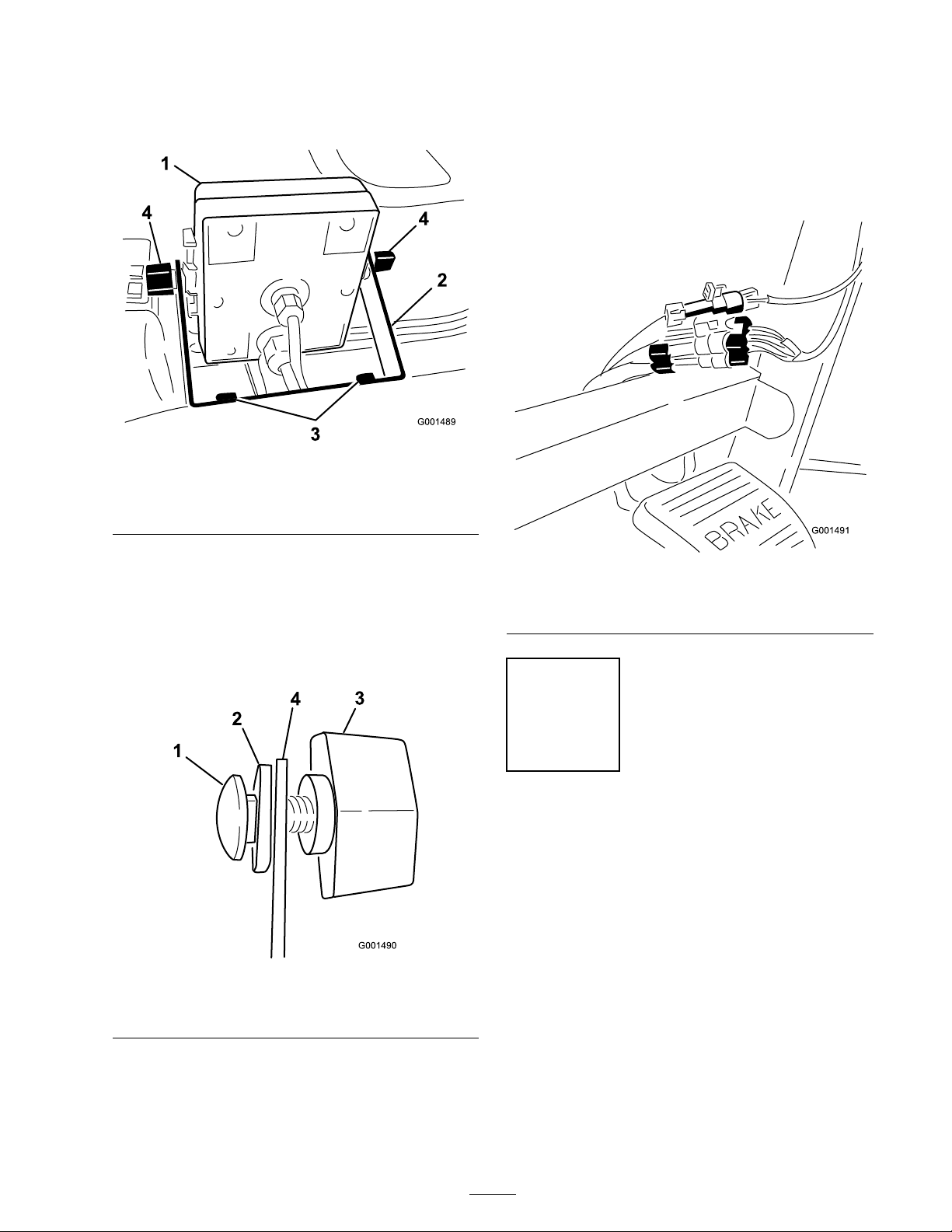

1. Install the Spra y Pro Decal to the monitor

( Figure 4 ).

Figure 4

1. Spray pro monitor

2. Decal, Upper half

3. Decal, Lower half

Note: Be sure to orient the decal as sho wn

in Figure 20 .

14

2. Install the monitor brac k et on the dash

( Figure 5 ) using 2 flang e-head bolts

(1/4 x 3/4 inc h) and 2 flang e n uts (1/4 inc h).

Figure 5

1. Spray Pro monitor

2. Bracket 4. Knob

3. Flange-head bolts,

1/4 x 3/4 inch

6. Install the Spra y Pro monitor o v er the car riag e

bolt heads ( Figure 5 ) and tighten the knobs to

secure it.

7. Connect the Spra y Pro wire connectors to

the wire connectors located under the dash

( Figure 7 ).

3. Loosely install the 2 car riag e bolts , r ubber

w ashers , and knobs on the brac k et as illustrated

in Figure Figure 5 and Figure 6 .

Note: Install the car riag e bolts and r ubber

w ashers inside of the brac k et and the knobs

on the outside .

Figure 6

1. Carriage bolt 3. Knob

2. Rubber washer 4. Bracket

4. R emo v e the larg e g rommet from the hole in

the dash and thread the cables on the monitor

through the g rommet and the dash.

5. Install the g rommet into the dash.

Figure 7

1. Connectors from the

sprayer

2. Connectors from the

monitor

Step

3

Checking the Boom Hinge

Springs

No Parts Required

Procedure

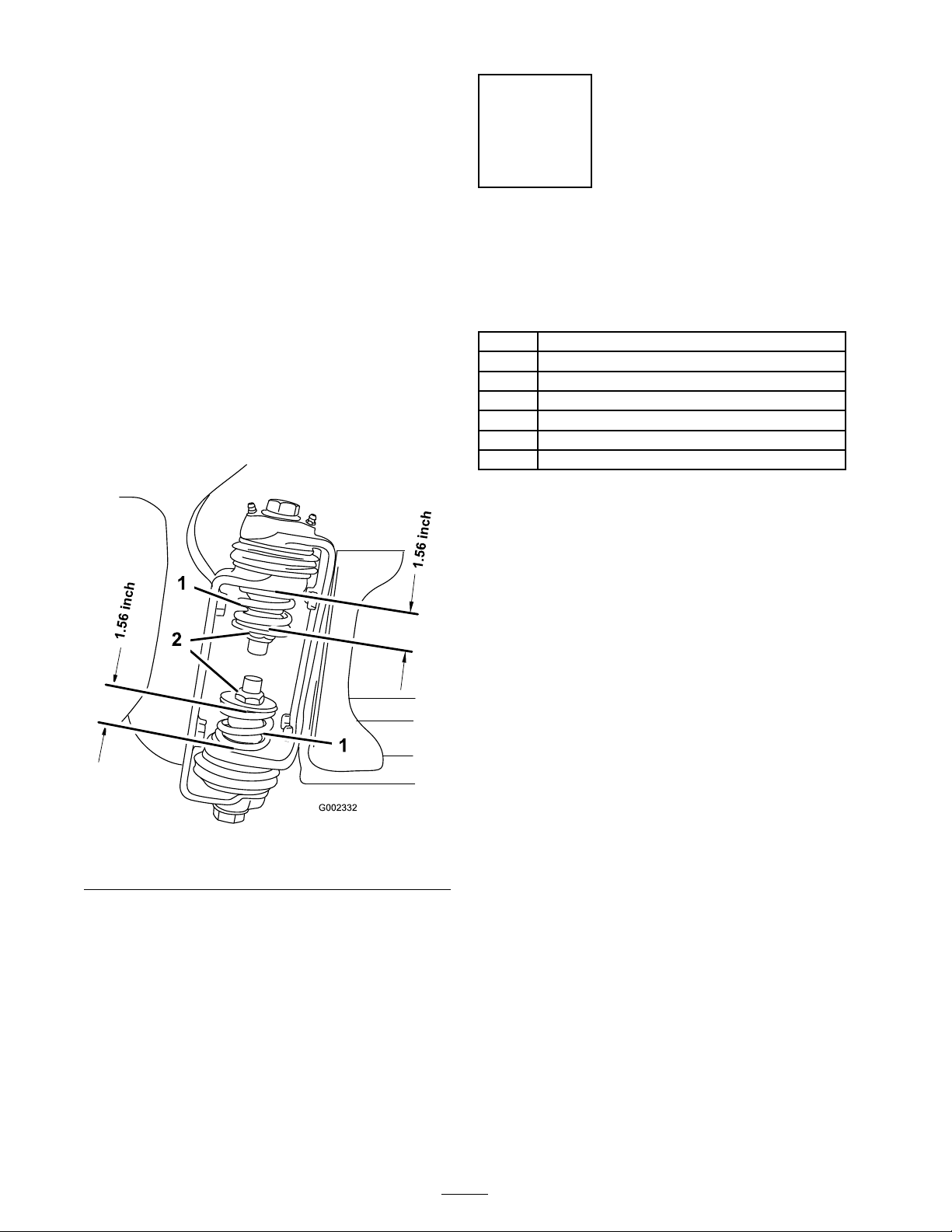

Important: Operating the spray system

with the boom hinge springs under the

incor r ect compr ession could dama ge the

boom assembl y . Measur e the springs and use

the jam n ut to compr ess the springs to 1.56

inches if necessar y .

T he spra yer is shipped with the boom extensions

swung forw ard to facilitate pac kaging of the

mac hine . T he springs are not fully tightened at

15

the time of man ufacture to allo w the booms to

be in this position for transit. Before operating

the mac hine , the springs m ust be adjusted to the

cor rect compression.

1. If necessar y , remo v e the pac king components

that secure the right and left extension booms

during shipping .

2. Suppor t the booms while they are extended

to the spra y position.

Step

4

Completing the Setup:

Learning more about your

product.

3. At the boom hing e , measure the compression

of the upper and lo w er springs while the booms

are in their extended position ( Figure 8 ).

A. All springs m ust be compressed until they

measure 1.56 inc hes .

B . Use the jam n ut to compress any spring

that measure g reater than 1.56 inc hes .

Parts needed for this step:

1

Ignition key

1

Operator’s Manual

1

Engine Operator’s Manual

1

Parts Catalog

1

Operator Training Material

1

Registration Card

1

Pre-delivery Inspection Sheet

Procedure

1. R ead the man uals .

2. View the Operator training material.

3. Complete the registration card and retur n to

T oro .

4. Store the documentation in a safe place .

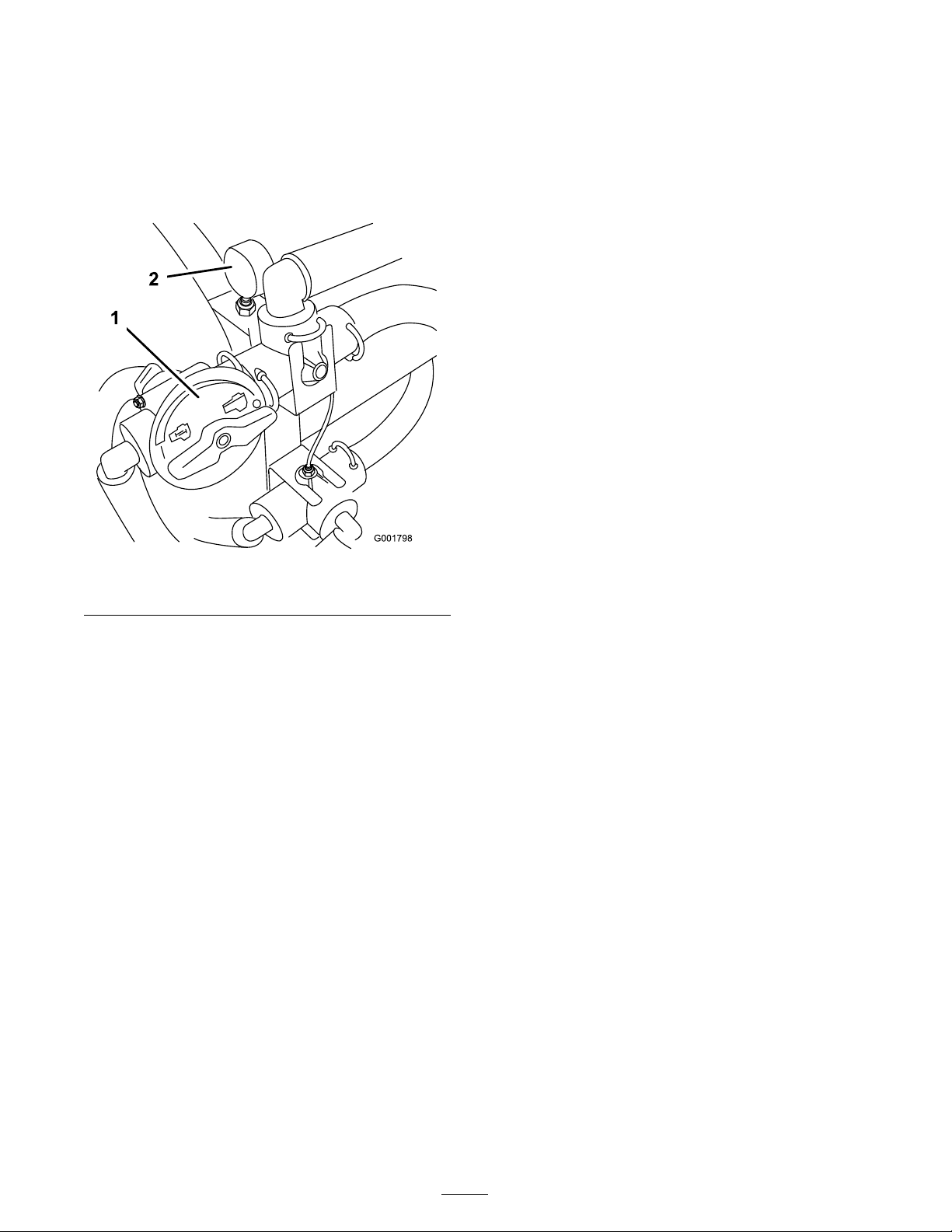

Figure 8

1. Boom hinge spring

2. Jam nut

4. R e peat the procedure for eac h spring on both

boom hing es .

5. Mo v e the booms into the transpor t “X”

position. See Operating the Booms in

Operation , pag e 25 for more infor mation.

16

Product Overview

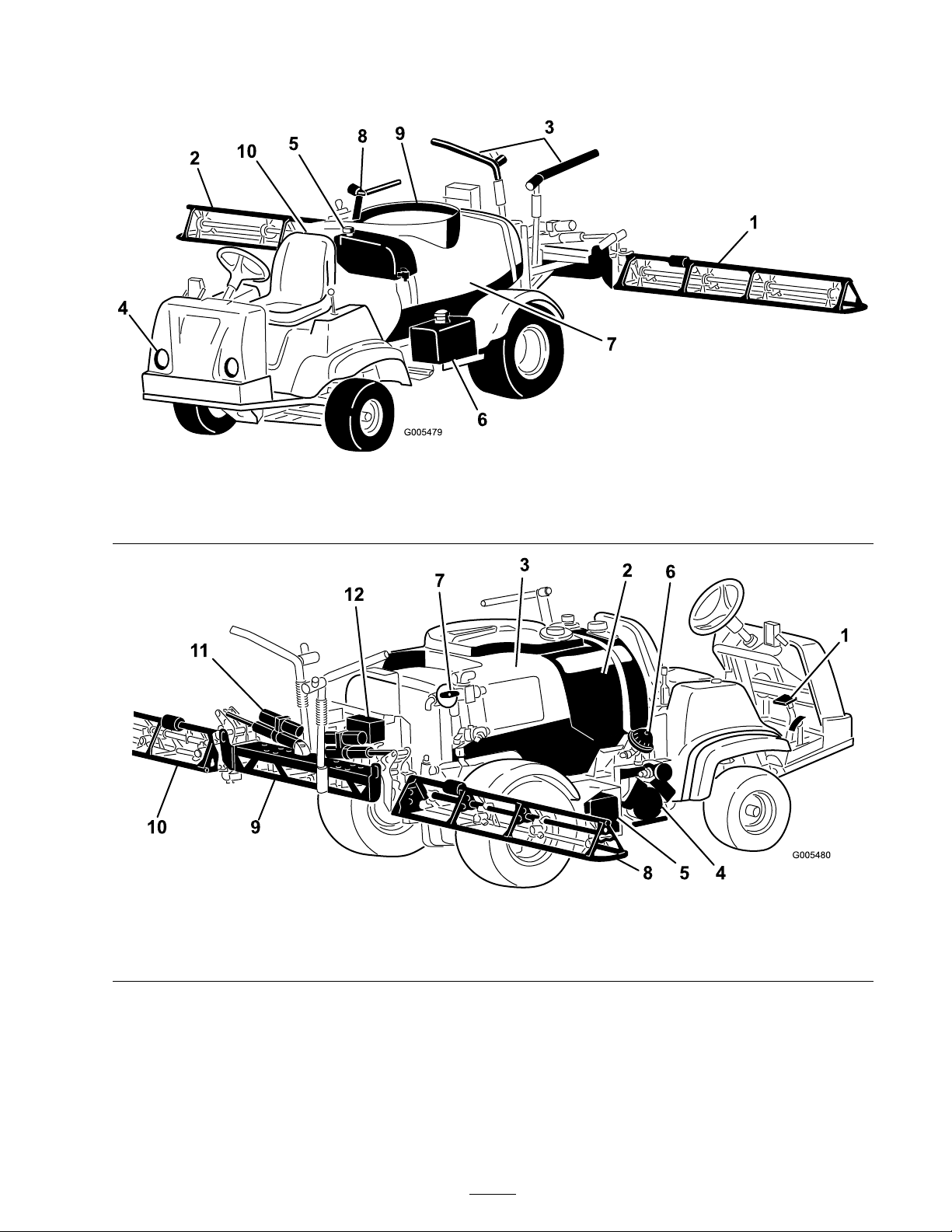

Figure 9

1. Left boom 4. Headlight 7. Chemical tank

2. Right boom 5. Fresh water tank 8. Anti-Siphon Receptacle

3. Boom transport cable 6. Gas tank 9. Tank lid

10. Operator’s position

Figure 10

1. Pedals

2. Rinse tank

3. Chemical tank 6. Pump pressure dampener 9. Center boom 12. Valve cluster

4. Pump

5. Battery

7. Agitation control valve 10. Left boom

8. Right boom 11. Boom control cylinder

17

Controls

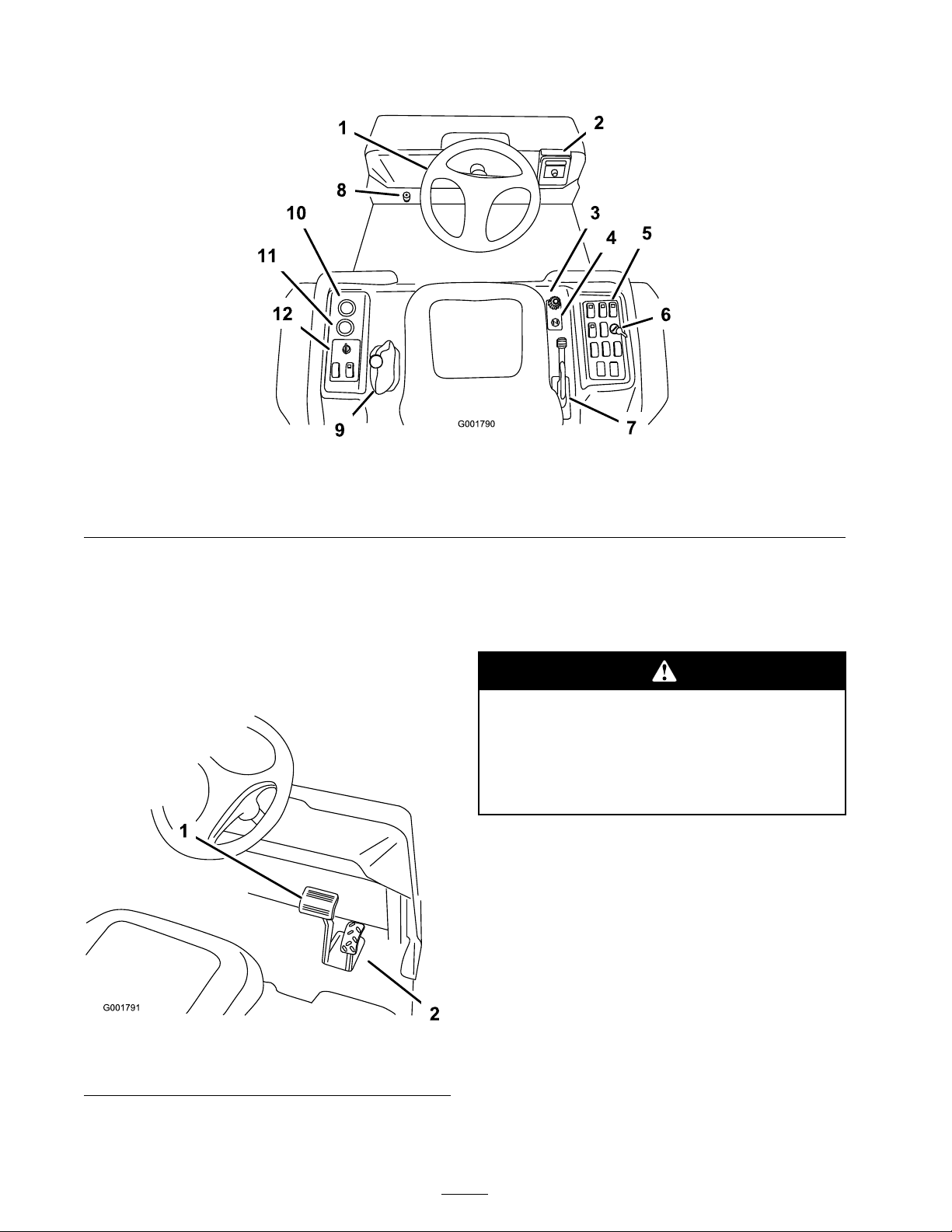

Figure 11

1. Steering wheel 4. Choke 7. Parking brake 10. Voltmeter

2. Spray-Pro monitor

3. Speed limiter 6. Rate lockout switch 9. Range Selector 12. Vehicle controls

5. Sprayer controls 8. Master boom foot switch

11. Hour meter

Accelerator Pedal

T he accelerator pedal ( Figure 12 ) gi v es y ou

the ability to v ar y g round speed of the spra yer .

Pressing the pedal increases g round speed.

R eleasing the pedal will slo w the spra yer and the

engine will idle .

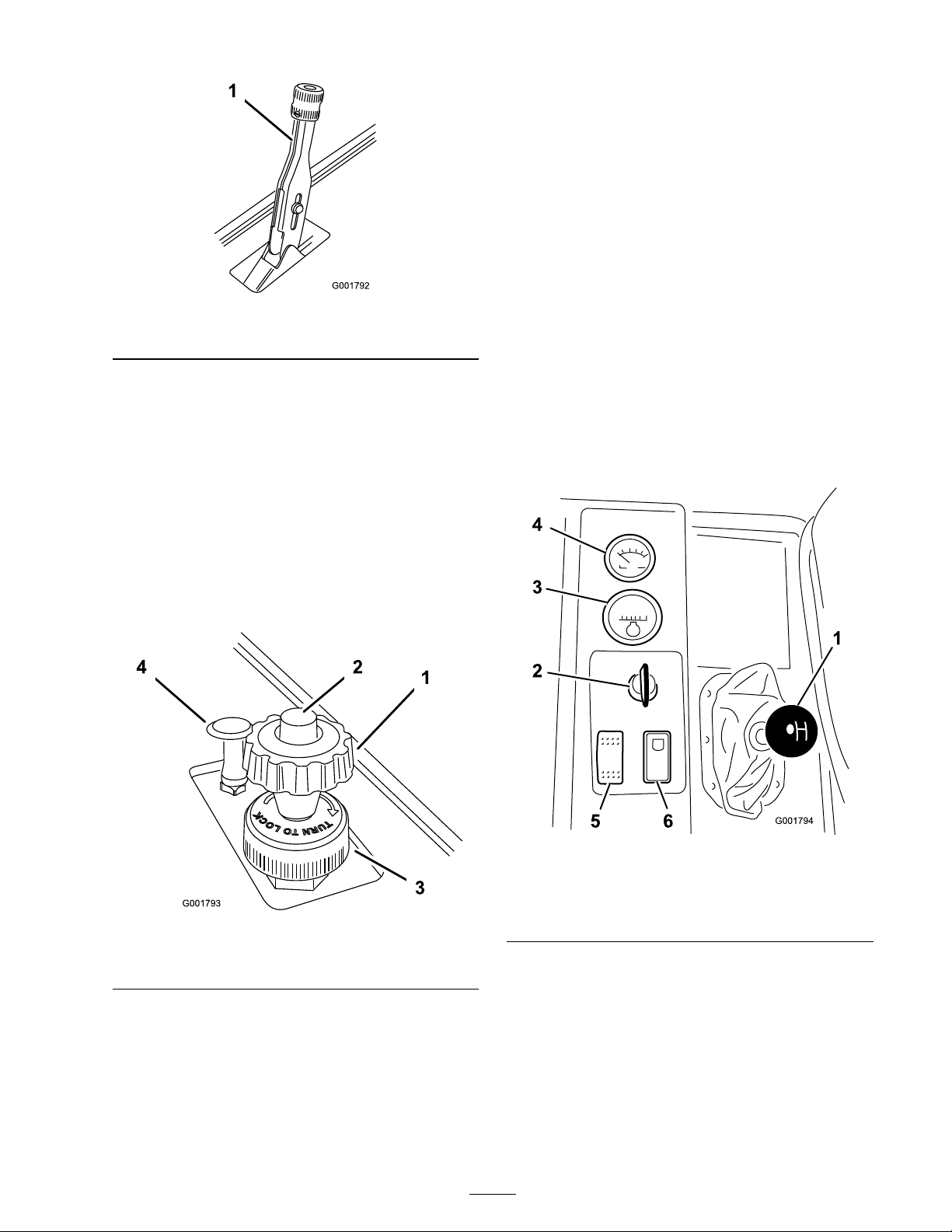

Figure 12

1. Brake pedal 2. Accelerator pedal

Brake Pedal

Use the brak e pedal to stop or slo w the spra yer

( Figure 12 ).

Brak es can become w or n or can be adjusted

incor r ectl y r esulting in per sonal injur y .

If brak e pedal tra v els to within 1 inch

(2.5 cm) of the spray er floor board, the

brak es must be adjusted or r epair ed.

Parking Brake

T he parking brak e is a larg e lev er to the right of

the seat. ( Figure 13 ). Eng ag e the parking brak e

whenev er y ou plan on lea ving the seat to prev ent

accidental mo v ement of the spra yer . T o eng ag e

the parking brak e , pull up and bac k on the lev er .

T o diseng ag e , push it forw ard and do wn. If the

spra yer is park ed on a stee p g rade , apply the

parking brak e and place bloc ks at the do wnhill

side of the wheels .

18

Figure 13

1. Parking brake lever

Speed Limiter

T he speed limiter is a larg e knob located to the

right of the seat ( Figure 14 ). It allo ws y ou to set

the maxim um do wnw ard tra v el of the accelerator

pedal, thereb y limiting the maxim um r pm of the

engine . T his indirectly limits the speed of the

spra yer .

smoothly . As soon as possible , push the control

do wn to the Off position. A w ar m engine requires

little or no c hoking .

Range Selector

T he rang e selector , located to the left of the seat,

has 5 positions: 3 forw ard speeds , Neutral, and

R ev erse ( Figure 15 ). T he engine will star t only

when the rang e selector is in the Neutral position.

Y ou m ust also fully press the brak e with the

spra yer stopped to c hang e rang es .

Important: Do not shift out of or change

ranges while the v ehicle is mo ving . Attempting

to change ranges while the v ehicle is mo ving

can dama ge the transmission. Onl y stopping

the spray er completel y , and full y enga ging the

brak e will safel y disenga ge the locking pin

and allo w the ranges to be changed.

Note: T he v ehicle controls the application rate

based on y our speed and y ou do not need to k ee p

a constant speed to apply at a constant rate .

Figure 14

1. Speed limiter knob 3. Locking ring

2. Speed limiter button 4. Choke control

Choke Control

T he c hok e control is a small knob to the right

of the seat. ( Figure 14 ). T o star t a cold engine ,

pull the c hok e control up . After the engine star ts ,

regulate the c hok e to k ee p the engine r unning

Figure 15

1. Range Selector 4. Voltmeter

2. Ignition switch 5. Headlight switch

3. Hour meter

6. Neutral engine speed lock

switch

Ignition Switch

T he ignition switc h ( Figure 15 ), used to star t

and stop the engine , has 3 positions: Stop , R un,

and Star t. R otate the k ey cloc kwise to the Star t

position to star t the engine and release it to the

R un position when star ted. R otate the k ey to the

Stop position to stop the engine .

19

Hour Meter

T he hour meter ( Figure 15 ) indicates the total

n umber of hours the engine has r un. T he hour

meter star ts to function whenev er the k ey is tur ned

to the R un position.

Voltmeter

T he v oltmeter ( Figure 15 ) indicates the lev el of

c harg e in the batter y . W hen the batter y is fully

c harg ed, the v oltmeter will read in the center of

the dial when the k ey is in the R un position with

the engine off . W hen the engine is r unning the

v oltmeter needle should be to the right.

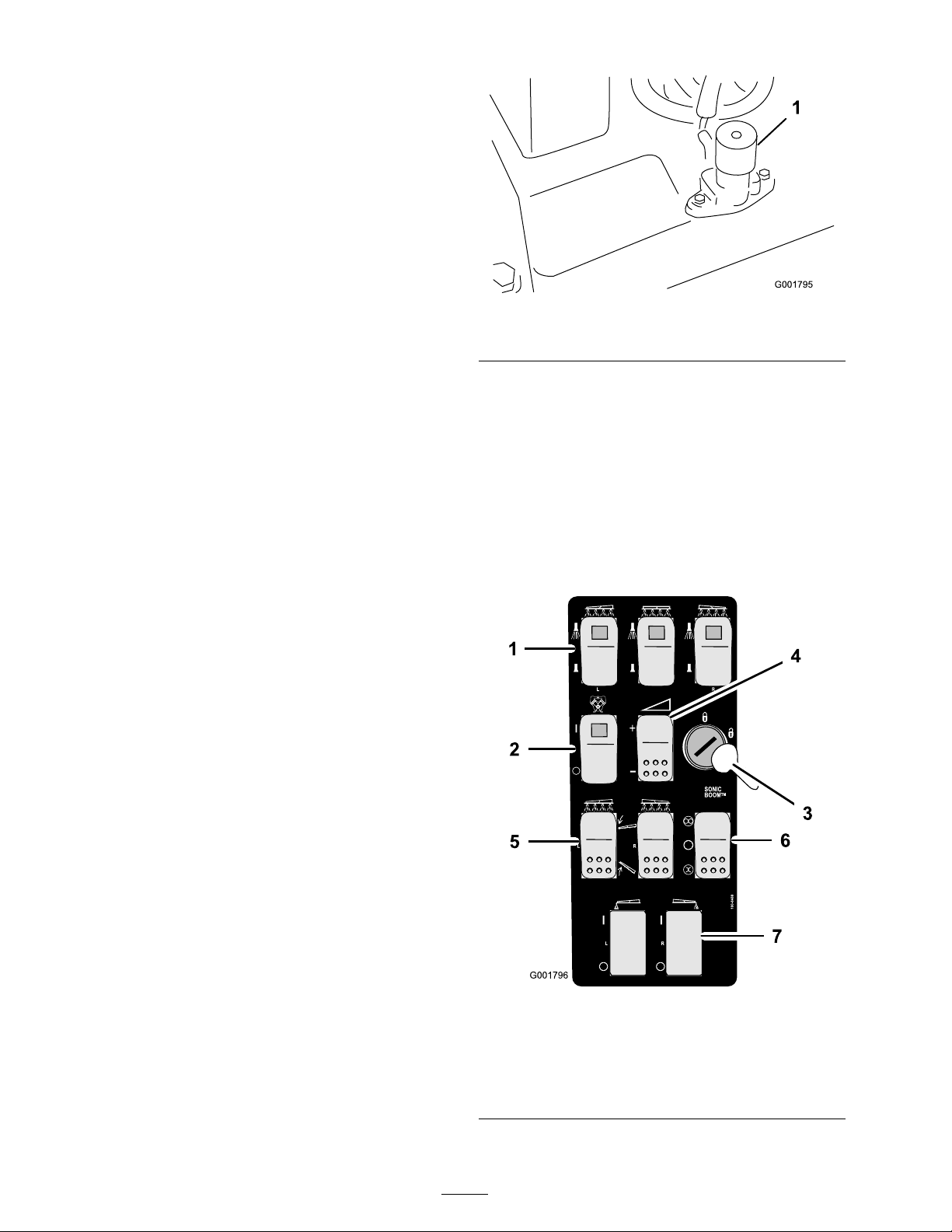

Figure 16

1. Master boom switch

Headlight Switch

T og gle the switc h to operate the headlights

( Figure 15 ). Push it forw ard to tur n the lights on

and rearw ard to tur n them off .

Neutral Engine Speed Lock Switch

W hen the rang e selector is in the Neutral position,

y ou can use the accelerator pedal to speed up the

engine , then push this switc h forw ard to set the

engine at that speed. T his is necessar y to r un the

c hemical agitation while stationar y or operating

attac hments suc h as the hand spra yer ( Figure 15 ).

Important: T he range selector must be in

the neutral position f or the s witch to w or k.

Fuel Gauge

T he fuel g aug e is located on top of the fuel tank,

on the right side of the mac hine and sho ws the

amount of fuel in the tank.

Boom Switches

T he boom switc hes are located at the front

of the control panel to the right of the seat

( Figure 17 ). T og gle eac h switc h forw ard to tur n

the cor responding boom section on and rearw ard

to tur n them off . W hen the switc h is tur ned on,

a light on the switc h illuminates . T hese switc hes

will only affect the spra y system when the master

boom switc h is on.

Master Boom Switch

T he master boom switc h is located on the floor

board of the mac hine cab and to the left of the

operator . It allo ws y ou to star t or stop the spra y

operation. Press the switc h with y our foot to

enable or disable the spra y system ( Figure 16 ).

W hen the master switc h is off , the Spra y Pro

monitor screen reads “Hold."

Figure 17

1. Boom switches, left, right

and center

2. Pump switch 6. Sonic boom switch

3. Rate lockout key 7. Foam marker switch, left

4. Application rate switch

20

5. Boom lift switch, left and

right

and right

Pump Switch

Rate Control Valve

T he pump switc h is located on the control panel

to the right of the seat ( Figure 17 ). T og gle this

switc h forw ard to r un the pump or rearw ard to

stop the pump .

Important: Onl y enga ge the pump s witch

when the engine is at lo w idle to a v oid

dama ging the pump dri v e.

Application Rate Switch

T he application rate switc h is located on the

control panel to the right of the seat Figure 17 ).

Press and hold the switc h forw ard to increase

the spra y system pressure , or press and hold it

rearw ard to decrease pressure .

Rate Lockout Key Switch

T he rate loc k out k ey switc h is located on the

control panel to the right of the seat ( Figure 17 ).

T ur n the k ey countercloc kwise to the loc k ed

position to disable the application rate switc h,

thereb y k ee ping any one from accidentally c hanging

the application rate . T ur n the k ey cloc kwise to the

unloc k ed position to enable the application rate

switc h.

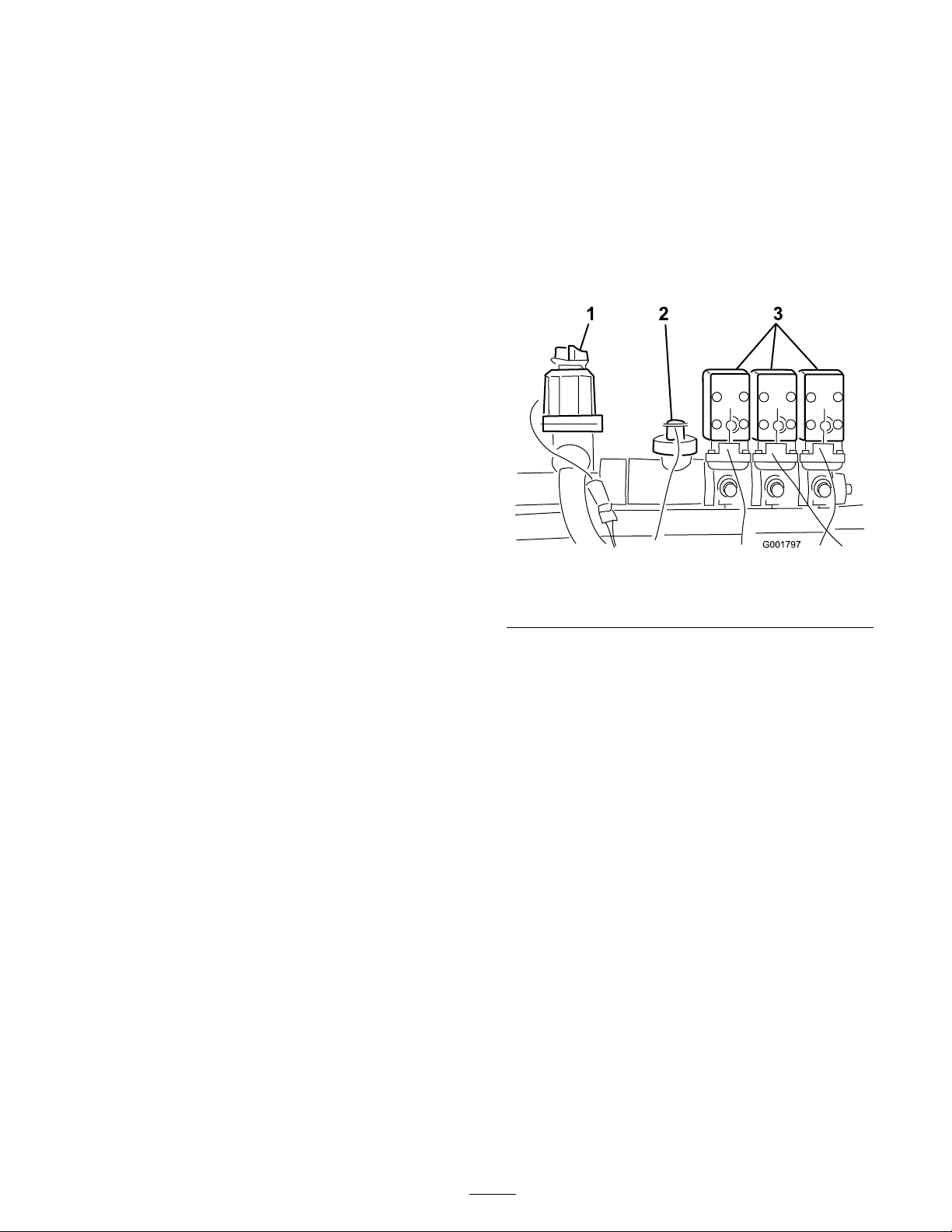

T his v alv e , located behind the tank ( Figure 18 ),

controls the amount of fluid that is routed to the

booms b y directing fluid flo w to the booms or

the b ypass hose to the tank. Y ou can control this

v alv e in tw o w a ys: the application rate switc h or

man ually . T o control it man ually , y ou need to

disconnect the wire connector on the v alv e , then

y ou can rotate the knob on top of the v alv e to

man ually obtain the desired pressure .

Figure 18

1. Rate control valve 3. Boom valves

2. Flowmeter

Important: Do not attempt to mo v e the

range selector while the rate lock out k ey is

enga ged. F orcing the selector while mo ving

will dama ge lock out k ey components.

Boom Lift

T he boom lift switc hes are used to raise the left

and right boom respecti v ely .

Sonic Boom (Optional)

T he Sonic Boom switc h is a roc k er switc h used to

operate the Sonic Boom. T og gle switc h forw ard

for automatic , rearw ard for man ual and center for

Off .

Foam Marker Switch Locations

(Optional)

If y ou install the electric boom lift, sonic boom,

and foam mark er kit, y ou will add switc hes to the

control panel for controlling their operation. T he

spra yer comes with plastic plugs in these locations .

Flowmeter

T he flo wmeter measures the flo w rate of the fluid

for use b y the Spra y Pro™ system ( Figure 18 ).

Boom Valves

T hese v alv es tur n the three booms on or off

( Figure 18 ). If y ou do not ha v e a boom installed

or do not w ant a boom to be able to be tur ned

on, y ou can man ually operate eac h v alv e b y

disconnecting the wire connector in the v alv e , then

rotate the knob on the v alv e cloc kwise to tur n the

v alv e off or countercloc kwise to tur n it on.

Boom Bypass Valves

T he boom b ypass v alv es redirect the fluid flo w for

a boom to the tank when y ou tur n off the boom

section. Y ou can adjust these v alv es to ensure that

the boom pressure remains constant no matter

ho w many booms are on. R efer to Calibrating the

Boom Bypass V alv es , in the Operation section.

21

Agitation Control Valve

Pressure Gauge

T his v alv e is located on the right side of the tank

( Figure 19 ). T ur n the knob on the v alv e to the

9 o’cloc k position to tur n on the tank agitation

and to the 3 o’cloc k position to tur n off the tank

agitation.

Figure 19

1. Agitation control valve

2. Pressure gauge

T he pressure g aug e is located to the right of the

tank ( Figure 19 ). T his g aug e sho ws the pressure

of the fluid in the system in psi and kP a. Use the

g aug e to adjust the b y-pass v alv es whenev er y ou

c hang e nozzles .

Anti-siphon Fill Receptacle

T o the front of the tank co v er is a hose rece ptacle

with a threaded fitting, a 90 deg ree barbed fitting,

and a shor t hose whic h y ou can direct to w ard

the tank opening . T his rece ptacle allo ws y ou to

connect a w ater hose to it and fill the tank with

w ater without contaminating the hose with the

c hemicals in the tank.

Important: Do not lengthen the hose to

allo w contact with the tank fluids.

Note: F or agitation to w ork, the pump m ust

be on and the engine m ust be r unning abo v e an

idle . If y ou stop the spra yer and need agitation on,

place the rang e selector in the Neutral position, set

the parking brak e , press the accelerator pedal to

the floor , tur n the pump On and tur n the neutral

engine speed loc k On.

22

Spray Pro™ Monitor

T he Spra y Pro monitor displa ys and monitors

v arious system perfor mance data suc h as v ehicle

speed and application rates . It does not control

the application rate .

T he monitor has an LCD screen that displa ys the

data y ou select, a selection dial, and 4 buttons for

calibrating the monitor ( Figure 20 ).

Figure 20

1. LCD screen

2. Selection dial

3. Total area 8. Sub Area 13. Decrease, calibration button 18. Speed calibration

4. Speed 9. Sub volume 14. Increase, calibration button 19. Flowmeter calibration

5. Units of measure 10. Total volume 15. Boom selection

Monitor Display Selection Dial

Use the dial to set the LCD screen displa y to the

follo wing:

• T otal ar ea

Displa ys the total acres (US), hectares (SI), or

sq feet (TURF) that y ou ha v e co v ered since

y ou last pressed the R eset calibration button

for this setting .

• Speed

Displa ys the g round speed in miles per hour (if

the Units of Measure is set to US or TURF) or

kilometers per hour (if the Units of Measure

is set to SI).

• Units of Measur e

Displa ys the cur rent measurement unit

selection as follo ws:

6. Application rate 11. Reset, calibration button 16. Select units

7. Distance

12. Calibrate, calibration button 17. Width

20. LED

– SI (metric system)

– TURF (as US but the v olumes are in US

g allons per 1000 sq ft instead of US g allons

per acre)

• Application R ate

Displa ys the application rate in US g allons per

acre (US), liters pre hectare (SI), or US g allons

per 1000 sq ft (TURF).

• Sub Ar ea

Displa ys the total acres (US), hectares (SI), or

sq feet (TURF) that y ou ha v e co v ered since

y ou last pressed the R eset calibration button

for this setting, without affecting the T otal

Area displa y . If y ou press the R eset calibration

button, the Sub V olume resets .

• Distance

– US (United States measuring system)

23

Loading...

Loading...