Toro 41198 Multi-Pro 1250, Multi-Pro 1250, 41177, 41179 Operator's Manual

FormNo.3365-118RevB

g013107

Multi-Pro

ModelNo.41198—SerialNo.310000001andUp

®

1250TurfSprayer

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.Toro.com.OriginalInstructions(EN)

TheMulti-Pro®turfsprayerisadedicatedturfspray

G001788

1

applicationvehicleandisintendedtobeusedby

professional,hiredoperatorsincommercialapplications.

Itisprimarilydesignedforsprayingonwell-maintained

lawnsinparks,golfcourses,sportselds,andon

commercialgrounds.

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Theenclosed

Engine Owner’ s Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Introduction

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

Readthismanualcarefullytolearnhowtooperateand

maintainyourproductproperly.Theinformationinthis

manualcanhelpyouandothersavoidinjuryandproduct

damage.AlthoughTorodesignsandproducessafe

products,youareresponsibleforoperatingtheproduct

properlyandsafely.YoumaycontactTorodirectlyat

www.T oro.comforproductandaccessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

illustratesthelocationofthemodelandserialnumbers

ontheproduct.

©2011—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ChemicalSafety....................................................4

BeforeOperating.................................................5

WhileOperating...................................................5

Maintenance.........................................................7

SoundPower........................................................7

SoundPressure.....................................................7

Hand-ArmVibration............................................7

WholeBodyVibration..........................................7

SafetyandInstructionalDecals.............................8

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Setup..........................................................................13

1InstallingtheAnti-siphonFill

Receptacle......................................................13

2InstallingtheSprayProMonitor.......................14

3CheckingtheBoomHingeSprings...................15

4AdjustingtheBoomstoLevel..........................16

5CompletingtheSetup:Learningmoreabout

yourproduct...................................................16

ProductOverview......................................................17

Controls.............................................................18

Specications.....................................................24

Operation...................................................................25

ThinkSafetyFirst...............................................25

BeforeDrivingtheSprayerfortheFirst

Time..............................................................25

Pre-StartingChecks............................................26

DrivingtheSprayer.............................................27

NewSprayerBreak-In........................................27

OperatingtheSprayer.........................................28

FillingtheFreshWaterTank...............................28

FillingtheSprayTank.........................................29

OperatingtheBooms.........................................29

Spraying.............................................................30

SprayingTips.....................................................30

CleaningtheSprayer...........................................30

CalibratingtheSprayProMonitor.......................33

CalibratingtheBoomBypassValves....................35

Pump.................................................................35

TransportingtheSprayer....................................36

TowingtheSprayer.............................................36

Maintenance...............................................................37

RecommendedMaintenanceSchedule(s)................37

DailyMaintenanceChecklist...............................38

NotationforAreasofConcern...........................39

PremaintenanceProcedures....................................40

JackingtheSprayer.............................................40

Lubrication.............................................................41

GreasingtheSprayer...........................................41

GreasingtheBoomHinges.................................42

GreasingtheActuatorRodBearings...................42

EngineMaintenance...............................................44

CheckingtheAirIntakeScreen...........................44

ServicingtheAirCleaner....................................44

ServicingtheEngineOil.....................................45

ChangingtheSparkPlugs...................................46

FuelSystemMaintenance.......................................47

ReplacingtheFuelFilter.....................................47

DrainingtheFuelTank.......................................47

ElectricalSystemMaintenance................................48

Fuses..................................................................48

ServicingtheBattery...........................................48

DriveSystemMaintenance.....................................51

InspectingtheWheels/Tires...............................51

AdjustingtheFrontWheelT oe-In.......................51

BrakeMaintenance.................................................52

CheckingtheBrakeFluid....................................52

InspectingtheBrakes.........................................52

AdjustingtheParkingBrake................................52

BeltMaintenance....................................................53

ServicingtheDriveBelt......................................53

AdjustingtheSteeringPumpBelt........................53

HydraulicSystemMaintenance...............................54

CheckingtheTransaxle/HydraulicFluid.............54

ChangingTransaxle/HydraulicFluid..................54

ReplacingtheHydraulicFilter............................55

SpraySystemMaintenance......................................55

InspectingtheHoses..........................................55

PumpMaintenance.............................................55

AdjustingtheBoomActuator.............................56

EmergencyManualOperationoftheBoom

Actuators.......................................................57

InspectingtheNylonPivotBushings...................57

Cleaning.................................................................58

CleaningtheFlowmeter......................................58

CleaningtheSuctionStrainer..............................58

Storage.......................................................................59

Troubleshooting.........................................................61

Schematics.................................................................65

3

Safety

ChemicalSafety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans

CAUTION,WARNING,orDANGER—personal

safetyinstruction.Failuretocomplywiththeinstruction

mayresultinpersonalinjuryordeath.

Supervisors,operators,andservicepersonsshouldbe

familiarwiththefollowingstandardsandpublications:

(Thematerialmaybeobtainedfromtheaddressshown).

•FlammableandCombustibleLiquidsCode:

ANSI/NFPA30

•NationalFireProtectionAssociation:

ANSI/NFPA#505;PoweredIndustrialTrucks

NationalFirePreventionAssociation

BarrymarchParkQuincy,Massachusetts

02269U .S.A.

•SAEJ2258LightUtilityV ehicles

SocietyofAutomotiveEngineers

SAEWorldHeadquarters400CommonwealthDrive

Warrendale,P A15096-0001

•ANSI/UL558;InternalCombustion

EnginePoweredIndustrialTrucks

AmericanNationalStandardsInstitute,Inc.

1430BroadwayNewYork,NewYork10018U.S.A.

orUnderwritersLaboratories333PngstenRoad

Northbrook,Illinois60062U.S.A.

SafeOperatingPractices

WARNING

Thesprayerisanoff-highwayvehicleonlyandis

notdesigned,equipped,ormanufacturedforuseon

publicstreets,roads,orhighways.

Supervisor’sResponsibilities

•Makesurethatoperatorsarethoroughlytrainedand

familiarwiththeOperator’sManual,EngineManual,

andalllabelsonthesprayer.

•Establishyourownspecialproceduresandwork

rulesforunusualoperatingconditions(e.g.slopes

toosteepforsprayeroperation).

WARNING

Chemical substances used in the spray system may

be hazardous and to xic to y ou, bystander s, animals,

plants, soils or other pr oper ty .

•Carefullyreadandfollowthechemical

warninglabelsandMaterialSafetyData

Sheets(MSDS)forallchemicalsusedand

protectyourselfaccordingtothechemical

manufacturer’srecommendations.Forexample,

useappropriatePersonalProtectiveEquipment

(PPE)includingfaceandeyeprotection,gloves,

orotherequipmenttoguardagainstpersonal

contactwiththechemical.

•Keepinmindthattheremaybemorethanone

chemicalusedandinformationoneachshould

beassessed.

R efuse to operate or w or k on the spray er if this

•

inf or mation is not a v aila ble!

•Beforeworkingonaspraysystemmakesurethe

systemhasbeentriplerinsedandneutralized

accordingtotherecommendationsofthe

chemicalmanufacturer(s).

•Verifythereisanadequatesupplyofcleanwater

andsoapnearby,andimmediatelywashoffany

chemicalsthatcontactyou.

•Obtainpropertrainingbeforeusingorhandling

chemicals.

•Usethecorrectchemicalforthejob.

•Followthechemicalmanufacturer’sinstructionsfor

thesafeapplicationofthechemical.

•Handlechemicalsinawellventilatedarea.

•Weargogglesandotherprotectiveequipmentas

instructedbythechemicalmanufacturer.Ensure

thataslittleskinaspossibleisexposedwhileusing

chemicals.

•Havecleanwateravailableespeciallywhenllingthe

spraytank.

•Donoteat,drink,orsmokewhileworkingwith

chemicals.

•Alwayswashyourhandsandotherexposedareasas

soonaspossibleafternishingthework.

•Properlydisposeofunusedchemicalsand

chemicalcontainersasinstructedbythechemical

manufacturerandyourlocalcodes.

•Chemicalsandfumesinthetanksaredangerous;

neverenterthetankorplaceyourheadoverorin

theopening.

4

BeforeOperating

•Operatethemachineonlyafterreadingand

understandingthecontentsofthismanual.

•Neverallowchildrentooperatethesprayer.

•Neverallowotheradultstooperatethesprayer

withoutrstreadingandunderstandingtheOperator’ s

Manual.Onlytrainedandauthorizedpersonsshould

operatethissprayer.Makesurethatalloperators

arephysicallyandmentallycapableofoperatingthe

sprayer.

•Thissprayerisdesignedtocarryonlyyou,the

operator.Nevercarryanypassengersonthesprayer.

•Neveroperatethesprayerwhenundertheinuence

ofdrugsoralcohol.Evenprescriptiondrugsand

coldmedicinescancausedrowsiness.

•Donotdrivethesprayerwhenyouaretired.Besure

totakeoccasionalbreaks.Itisveryimportantthat

youstayalertatalltimes.

•Becomefamiliarwiththecontrolsandknowhowto

stoptheenginequickly.

•Keepallshields,safetydevices,anddecalsinplace.

Ifashield,safetydevice,ordecalismalfunctioning,

illegible,ordamaged,repairorreplaceitbefore

operatingthemachine.

•Alwayswearsubstantialshoes.Donotoperate

themachinewhilewearingsandals,tennisshoes,

orsneakers.Donotwearloosettingclothingor

jewelrywhichcouldgetcaughtinmovingpartsand

causepersonalinjury.

•Wearingsafetyglasses,safetyshoes,longpants,anda

helmetisadvisableandrequiredbysomelocalsafety

andinsuranceregulations.

•Avoiddrivingwhenitisdark,especiallyinunfamiliar

areas.Ifyoumustdrivewhenitisdark,besure

todrivecautiously ,usetheheadlights,andeven

consideraddingadditionallights.

•Beextremelycarefulwhenoperatingaroundpeople.

Alwaysbeawareofwherebystandersmightbeand

keepthemawayfromtheworkarea.

•Beforeoperatingthesprayer,alwayscheckthe

designatedareasofthesprayerthatarestatedin

thePre-StartingChecksintheOperationsection.

Ifthemachinedoesnotfunctioncorrectlyoris

damagedinanyway,donotusethesprayer.Make

surethattheproblemiscorrectedbeforethesprayer

orattachmentisoperated.

•Ensurethatalluidlineconnectorsaretightandall

hosesareingoodconditionbeforeapplyingpressure

tothesystem.

•Sincegasolineishighlyammable,handleitcarefully.

–Useanapprovedgasolinecontainer.

–Donotremovethecapfromthefueltankwhen

theengineishotorrunning.

–Donotsmokewhilehandlinggasoline.

–Fillthefueltankoutdoors,andllittoabout

1inch(25mm)belowthetopofthetank(the

bottomofthellerneck).Donotoverllit.

–Wipeupanyspilledgasoline.

WhileOperating

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

•Theoperatorshouldremainseatedwheneverthe

sprayerisinmotion.Theoperatorshouldkeepboth

handsonthesteeringwheelwheneverpossible.

Keepyourarmsandlegswithinthesprayerbody

atalltimes.

•Alwayswatchoutforandavoidlowoverhangssuch

astreelimbs,doorjambs,andoverheadwalkways.

Makesurethereisenoughroomoverheadtoeasily

clearthesprayerandyourhead.

•Failuretooperatethesprayersafelymayresultinan

accident,tipoverofthesprayer,andseriousinjury

ordeath.Drivecarefully.Topreventtippingorloss

ofcontrol:

–Useextremecaution,reducespeed,andmaintain

asafedistancearoundsandtraps,ditches,creeks,

ramps,unfamiliarareas,oranyareasthathave

abruptchangesingroundconditionsorelevation.

–Watchforholesorotherhiddenhazards.

–Useextracautionwhenoperatingthesprayeron

wetsurfaces,inadverseweatherconditions,at

higherspeeds,orwithafullload.Stoppingtime

anddistancewillincreasewithafullload.

–Avoidsuddenstopsandstarts.Donotgofrom

reversetoforwardorforwardtoreversewithout

rstcomingtoacompletestop.

–Slowdownbeforeturning.Donotattempt

sharpturnsorabruptmaneuversorotherunsafe

drivingactionsthatmaycausealossofsprayer

control.

–Beforebackingup,looktotherearandensure

thatnooneisbehindyou.Backupslowly.

–Watchoutfortrafcwhenyouarenearor

crossingroads.Alwaysyieldtherightofway

5

topedestriansandothervehicles.Thissprayer

isnotdesignedforuseonstreetsorhighways.

Alwayssignalyourturnsorstopearlyenough

sothatotherpeopleknowwhatyouplantodo.

Obeyalltrafcrulesandregulations.

–Theelectricalandexhaustsystemsofthesprayer

canproducesparkscapableofignitingexplosive

materials.Neveroperatethesprayerinornear

anareawherethereisdustorfumesintheair

whichareexplosive.

–Ifyouareeverunsureaboutsafeoperation,stop

workandaskyoursupervisor.

•Donottouchtheengineormuferwhiletheengine

isrunningorsoonafterithasstopped.Theseareas

maybehotenoughtocauseburns.

•Ifthemachineevervibratesabnormally,stop

immediately,waitforallmotiontostop,andinspect

thesprayerfordamage.Repairalldamagebefore

resumingoperation.

•Beforegettingoffoftheseat:

1.Stopthemovementofthemachine.

2.PlacetherangeselectorinNeutralandsetthe

parkingbrake.

3.TurntheignitionkeytoOff.

4.Removetheignitionkey.

Important:Donotparkthemachineonan

incline.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

Braking

•Slowdownbeforeyouapproachanobstacle.This

givesyouextratimetostoporturnaway.Hittingan

obstaclecandamagethesprayeranditscontents.

Moreimportant,itcaninjureyou.

•GrossVehicleWeight(GVW)hasamajorimpacton

yourabilitytostopand/orturn.Heavyloadsand

attachmentsmakeasprayerhardertostoporturn.

Theheaviertheload,thelongerittakestostop.

•Turfandpavementaremuchmoreslipperywhen

theyarewet.Itcantake2to4timesaslongtostop

onwetsurfacesasondrysurfaces.Ifyoudrive

throughstandingwaterdeepenoughtogetthe

brakeswet,theywillnotworkwelluntiltheyare

dry.Afterdrivingthroughwater,youshouldtestthe

brakestomakesuretheyworkproperly.Iftheydo

not,driveslowlywhileputtinglightpressureonthe

brakepedal.Thiswilldrythebrakesout.

OperatingonHillsandRoughTerrain

Operatingthesprayeronahillmaycausetippingor

rollingofthesprayer,ortheenginemaystallandyou

couldloseheadwayonthehill.Thiscouldresultin

personalinjury.

•Donotacceleratequicklyorslamonthebrakes

whenbackingdownahill,especiallywithaload.

•Neverdriveacrossasteephill;alwaysdrivestraight

upordownorgoaroundthehill.

•Iftheenginestallsoryoubegintoloseheadway

whileclimbingahill,graduallyapplythebrakesand

slowlybackstraightdownthehill.

•Turningwhiletravelingupordownhillscanbe

dangerous.Ifyouhavetoturnwhileonahill,do

itslowlyandcautiously.Nevermakesharporfast

turns.

•Heavyloadsaffectstability.Reducetheweightofthe

loadandyourspeedwhenoperatingonhills.

•Avoidstoppingonhills,especiallywithaload.

Stoppingwhilegoingdownahillwilltakelonger

thanstoppingonlevelground.Ifthesprayermust

bestopped,avoidsuddenspeedchanges,whichmay

initiatetippingorrollingofthesprayer.Donotslam

onthebrakeswhenrollingbackward,asthismay

causethesprayertooverturn.

•TheToroCompanystronglyrecommendsinstalling

theoptionalROPSKitwhenoperatingonhilly

terrain.IfyouinstallaROPS,alwaysweartheseat

beltwhendrivingthesprayer.

•Reducespeedandloadwhenoperatingonrough

terrain,unevenground,andnearcurbs,holes,and

othersuddenchangesinterrain.Loadsmayshift,

causingthesprayertobecomeunstable.

WARNING

Suddenchangesinterrainmaycauseabrupt

steeringwheelmovement,possiblyresultingin

handandarminjuries.

•Reduceyourspeedwhenoperatingonroughterrain

andnearcurbs.

•Gripthesteeringwheellooselyaroundtheperimeter.

Keepyourhandsclearofthesteeringwheelspokes.

Loading

Theweightofthecargocanchangethesprayercenter

ofgravityandsprayerhandling.Toavoidlossofcontrol

andpersonalinjury,followtheseguidelines:

6

•Reducetheweightoftheloadwhenoperating

onhillsandroughterraintoavoidtippingor

overturningofthesprayer.

•Liquidloadscanshift.Thisshiftinghappensmost

oftenwhileturning,goingupordownhills,suddenly

changingspeeds,orwhiledrivingoverrough

surfaces.Shiftingloadscancausethesprayertotip

over.

•Whenoperatingwithaheavyload,reduceyour

speedandallowforsufcientbrakingdistance.Do

notsuddenlyapplythebrakes.Useextracautionon

slopes.

•Beawarethatheavyloadsincreaseyourstopping

distanceandreduceyourabilitytoturnquickly

withouttippingover.

accessories.Replacementpartsandaccessoriesmade

byothermanufacturerscouldbedangerous.Altering

thissprayerinanymannerthatmayaffectsprayer

operation,performance,durability,oritsuse,may

resultininjuryordeath.Suchusecouldvoidthe

productwarranty.

SoundPower

Thisunithasaguaranteedsoundpowerlevelofof96

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressure

Maintenance

•Onlypermitqualiedandauthorizedpersonnelto

maintain,repair,adjust,orinspectthesprayer.

•Beforeservicingormakingadjustmentstothe

machine,stoptheengine,settheparkingbrake,

andremovethekeyfromtheignitiontoprevent

someonefromaccidentallystartingtheengine.

•Tomakesurethattheentiremachineisingood

condition,keepallnuts,bolts,andscrewsproperly

tightened.

•Toreducethepotentialforre,keeptheengine

areafreeofexcessivegrease,grass,leaves,and

accumulationofdirt.

•Neveruseanopenametocheckthelevelor

leakageoffuelorbatteryelectrolyte.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keepyourhands,feet,

clothing,andanypartsofyourbodyawayfromthe

engineandanymovingparts.Keepeveryoneaway.

•Donotuseopenpansoffuelorammablecleaning

uidswhencleaningparts.

•Donotadjustthegroundspeedgovernor.To

ensuresafetyandaccuracy,haveanAuthorizedToro

Distributorcheckthegroundspeed.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressureuid.Use

cardboardorpapertondleaks.Fluidescaping

underpressurecanpenetrateskinandcauseinjury

requiringsurgerywithinafewhoursbyaqualied

surgeonorgangrenemayresult.

•Ifmajorrepairsareeverneededorassistanceis

required,contactanAuthorizedToroDistributor.

•Tobesureofoptimumperformanceandsafety,

alwayspurchasegenuineTororeplacementpartsand

Thisunithasasoundpressurelevelattheoperator’s

earof83dBA,whichincludesanUncertaintyValue(K)

of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

Hand-ArmVibration

Measuredvibrationlevelforrighthand=1.00m/s

Measuredvibrationlevelforlefthand=0.90m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN1032.

2

WholeBodyVibration

Measuredvibrationlevel=0.2m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN1032.

2

2

2

2

7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

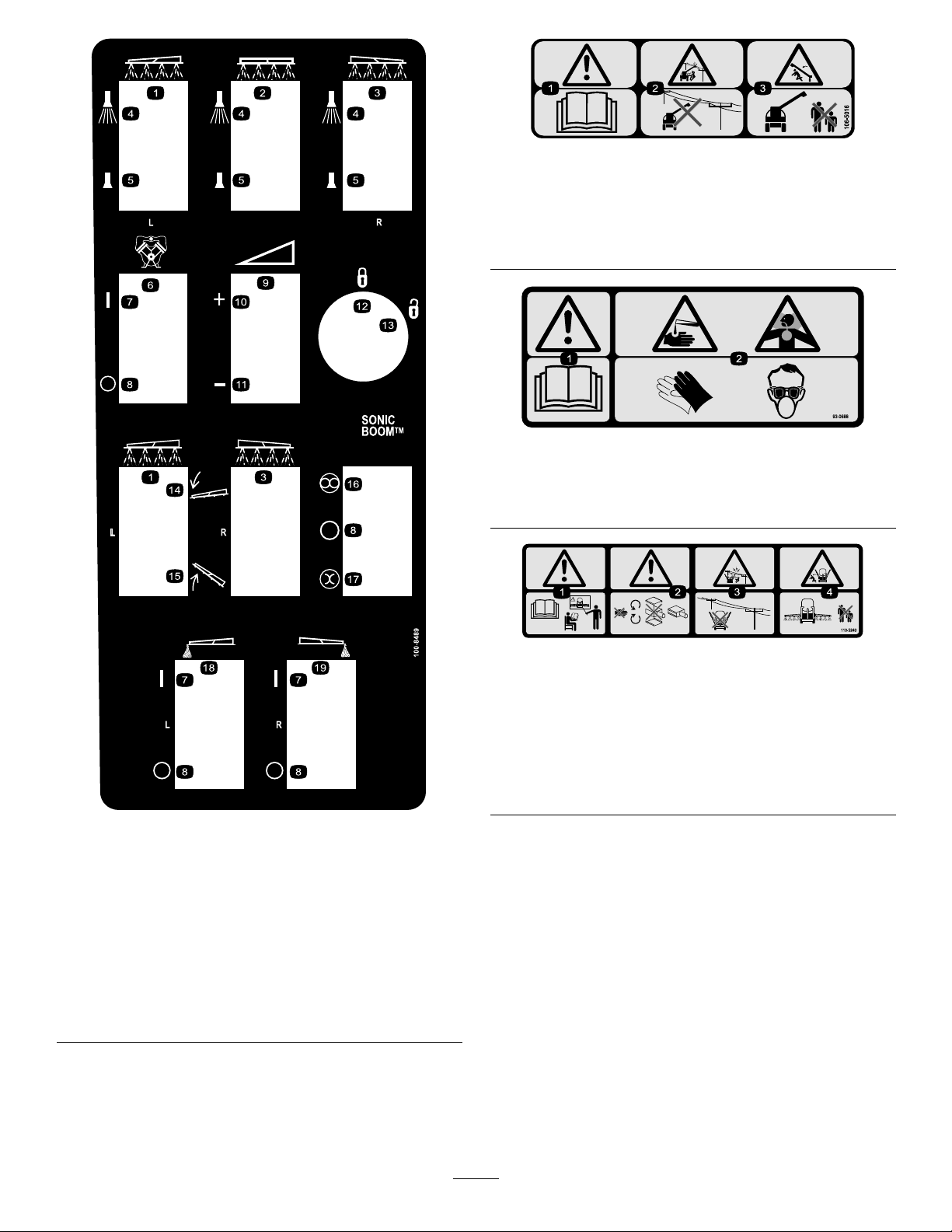

104-7628

1.ReadtheOperator’sManual.

100-8386

1.Fuel

2.Empty4.Full

3.Half-full

100-8458

1.Machinespeed

2.Tosetthemachinetoaslowspeed,reducepressureonthe

acceleratorandpulluponthespeedlimiter.

3.Tosetthemachinetoafastspeed,presstheaccelerator

pedalandpushdownonthespeedlimiter.

100-8619

1.Sprayon2.Sprayoff

117–2718

114-9576

1.Pinchpoint,hand—keephandawayfromhinge.

8

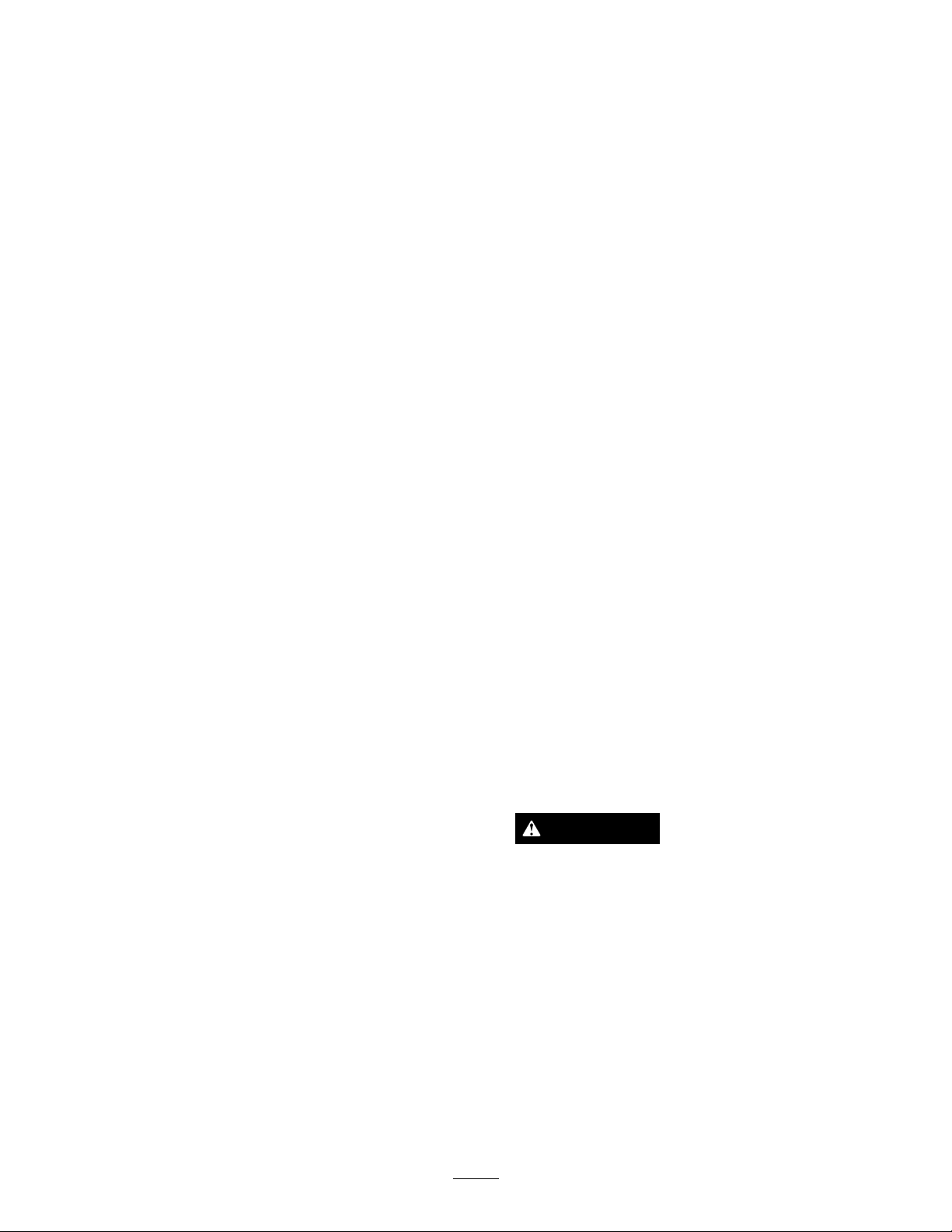

100-8454

1.ReadtheOperator’sManualforinformationonthe

transmission.

2.Tostarttheengine,sitontheoperator’sseat,pressthe

brake,settherangeselectortoNeutral,turntheignition

keytoEngine-start,settherangeselectortothedesired

gear,releasethebrakeandparkingbrake,andpressthe

acceleratorpedaltothedesiredspeed.

3.Tostoptheengine,pressthebrake,settherangeselector

toNeutral,settheparkingbrake,andturntheignitionkey

toEngine-stop.

4.Rangeselectorgearpattern

100-8470

1.Engine—stop5.Neutralenginespeedlock

2.Engine—run6.Engage

3.Engine—start

4.Headlights

7.On

8.Off

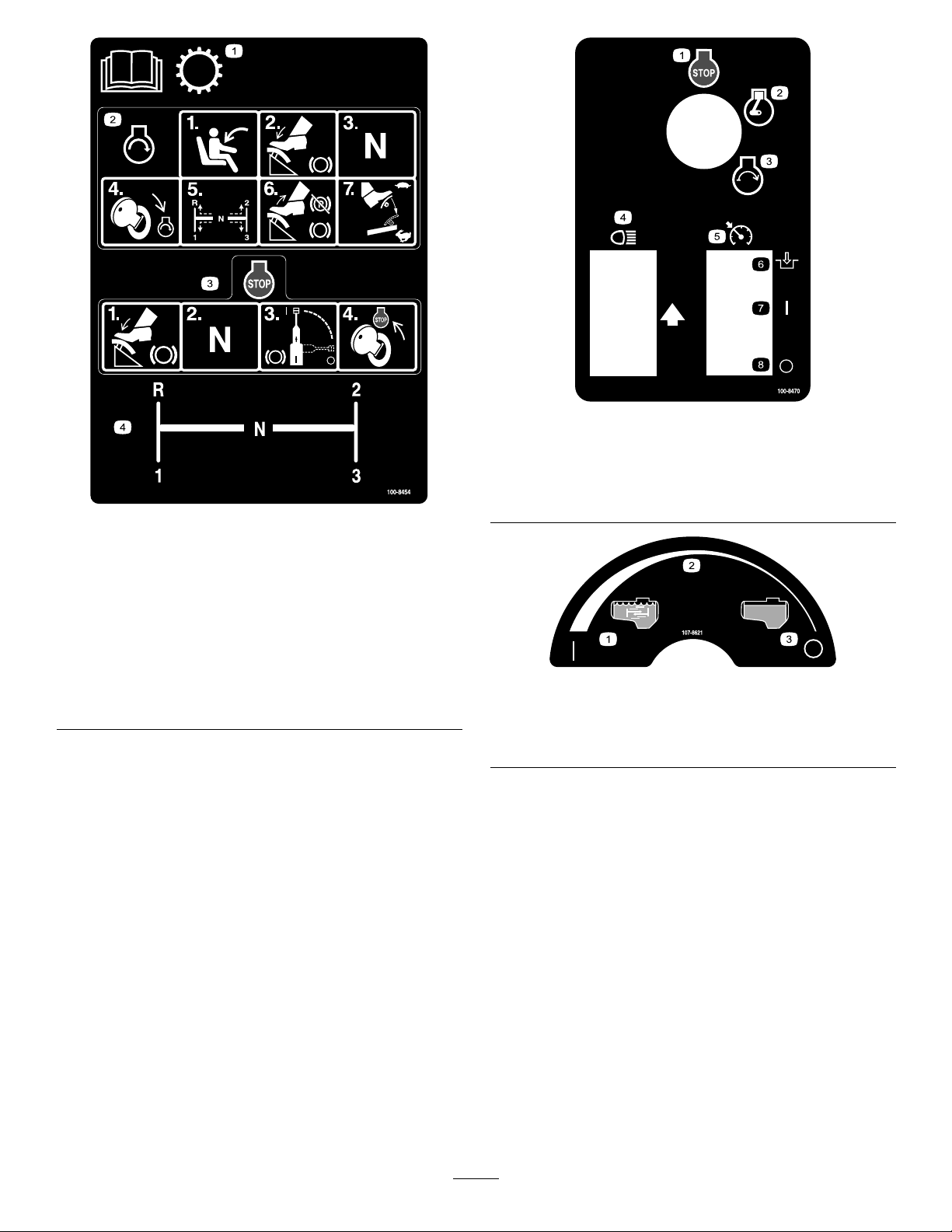

107-8621

1.Agitationon

2.Continuousvariable

setting

3.Agitationoff

9

106-5016

1.Warning—readtheOperator’sManual.

2.Electricshockhazard,overheadpowerlines—stayaway

fromoverheadpowerlines.

3.Crushinghazard,boom—keepbystandersasafedistance

fromthemachine.

93-0688

1.Warning—readtheOperator’sManual.

2.Causticliquid/chemicalburnandtoxicgasinhalation

hazards—wearhand,skin,eye,andrespiratoryprotection.

100-8489

1.Leftboom

2.Centerboom

3.Rightboom13.Unlocked

4.Sprayon

5.Sprayoff

6.Pump16.Automatic

7.On

8.Off18.Leftboomfoammarker

9.Continuousvariable

setting,spraypressure

10.Increase

11.Decrease

12.Locked

14.Lowertheboom.

15.Raisetheboom.

17.Manual

19.Rightboomfoammarker

110-5240

1.Warning—readtheOperator’sManualandreceivetraining

beforeoperating.

2.Warning—stayawayfrommovingparts,donotoperate

withcoversremoved.

3.Electricshockhazard,overheadpowerlines—stayaway

fromoverheadpowerlines.

4.Crushinghazard,boom—keepbystandersasafedistance

fromthemachine.

10

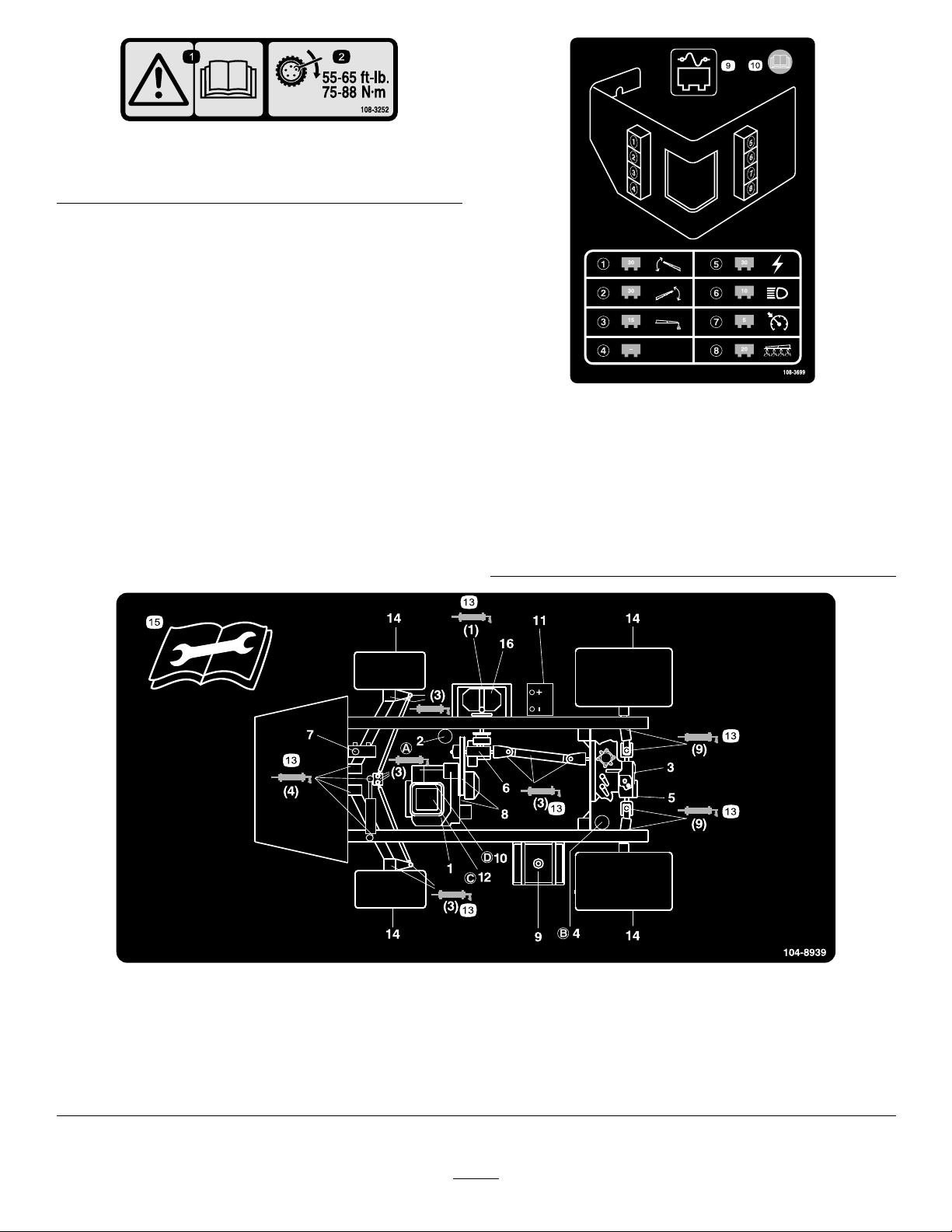

110-5143

1.Warning—readtheOperator’sManual.

2.TippingHazard—driveslowlyoverroughterrainandwhen

turning.

3.Fallingandarm/leginjuryhazards—donotcarrypassengers

andkeeparmsandlegsinsideofthevehicleatalltimes.

4.Tostoptheengine,pressthebrake,movetherange

selectortoNeutral,settheparkingbrake,releasethebrake

pedal,turntheignitionkeytoEngine-stop,andremovethe

key.

106-5051

1.Warning—readtheOperator’sManual;usefresh,clean

waterforrst-aidwashing.

108-3307

107-8640

1.Warning—readtheOperator’sManual;usefresh,clean

waterforrinsingthetank.

106-1355

1.Warning—donotenterthetank.

1.Totalarea8.Width

2.Boomselect9.Distance

3.Speed10.Speedcalibration

4.Unitsofmeasure11.Subvolume

5.Selectunits

6.Applicationrate13.Flowmetercalibration

7.Subarea

11

108-3309

12.Totalvolume

1.Warning—readthe

Operator’sManual.

108-3252

2.Torquelugnutsto55-65

ft-lb(75-88N·m).

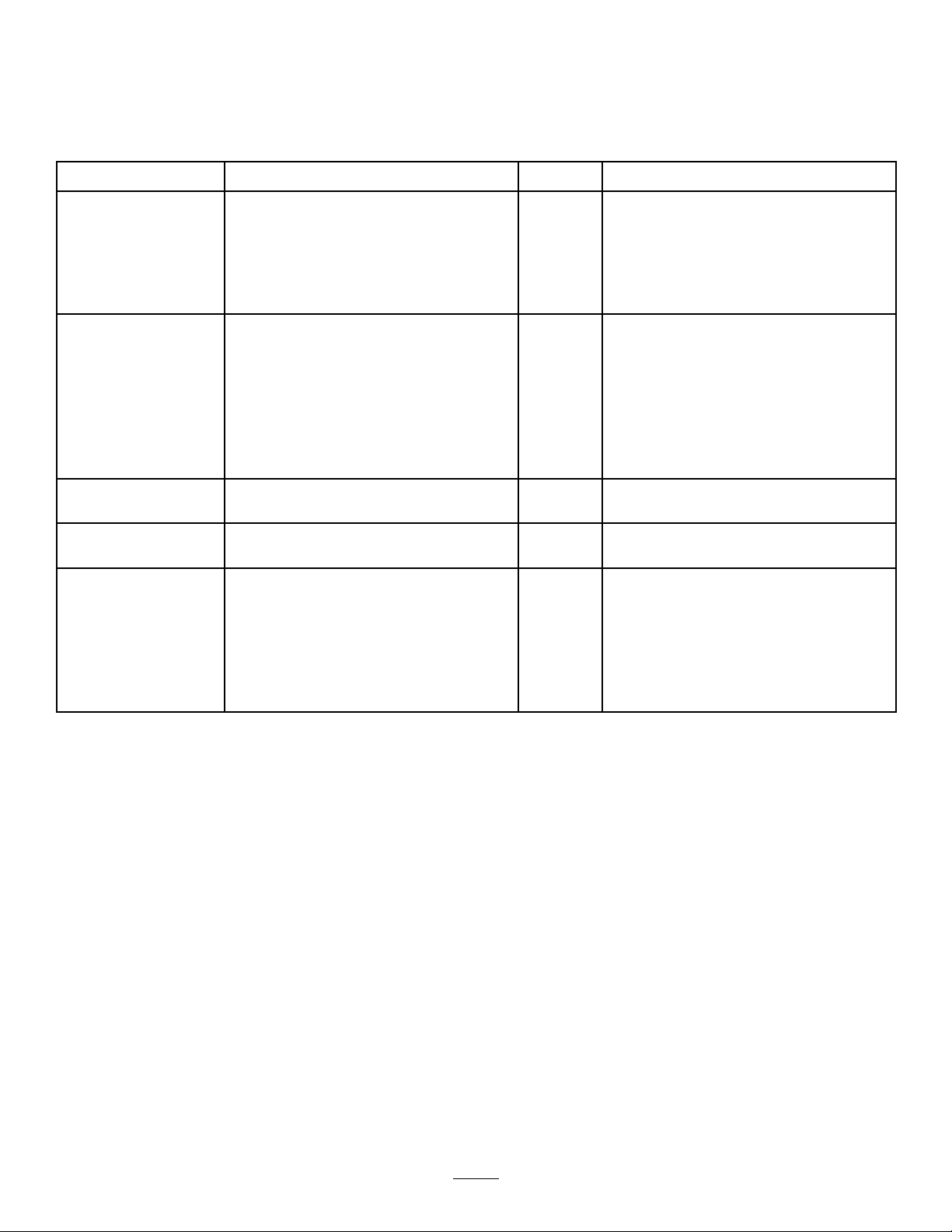

108-3699

1.30ampfuse,leftboom

actuator

2.30ampfuse,rightboom

actuator

3.15ampfuse,foammarker8.20ampfuse,spraysystem

4.Empty9.Fusepanel

5.30ampfuse,power10.ReadtheOperator’s

6.10ampfuse,headlights

7.5ampfuse,cruisecontrol

Manualformore

information.

104-8939

1.Engineoillevel(dipstick)

2.Engineoillter6.Gearboxuidlevel10.Fuellter

3.Transaxle/hydraulicuid

level(dipstick)

4.Transaxlehydrauliclter

5.Hydraulicstrainer9.Fuel,unleadedonly

7.Brakeuid

8.Belts,steeringanddrive12.Aircleaner16.Pump

11.Battery15.Readtheinstructions

12

13.Grease

14.Tirepressure

beforeservicingor

performingmaintenance.

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

90degreetting

Quickcoupler

Hoseadapter1

Fillreceptaclebracket1

Flange-headbolt,5/16x3/4inch

Anti-siphonhose1

SprayProMonitor

SprayProDecal

Bracket1

Flange-headbolt,3/4inch

Flangenut,1/4inch

Knob2

Washer2

Carriagebolt

Nopartsrequired

Nopartsrequired

Ignitionkey1

Operator’sManual

EngineOperator’sManual

PartsCatalog

OperatorTrainingMaterial

RegistrationCard

Pre-deliveryInspectionSheet

Qty.

Use

1

1

Installtheanti-siphonllreceptacle.

1

1

1

2

2

2

–

–

1

1

1

1

1

1

InstalltheSpray-Promonitor.

Checktheboomhingesprings.

Adjusttheboomstolevel.

Readthemanualsandviewthetraining

materialbeforeoperatingthemachine.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

13

1

InstallingtheAnti-siphonFill

Receptacle

Partsneededforthisprocedure:

1

90degreetting

1

Quickcoupler

1Hoseadapter

1Fillreceptaclebracket

1

Flange-headbolt,5/16x3/4inch

1Anti-siphonhose

4.Locktheadapterintoplacebyswingingthelevers

towardtheadapterandthensecurethemwiththe

hairpincotters(Figure3).

5.Installtheanti-siphonhosethroughthelarge

openingonthebracketandontothebarbedendof

the90degreeelbowtting(

Important:Donotlengthenthehosetoallow

contactwiththetankuids.

Figure3).

2

InstallingtheSprayPro

Monitor

Procedure

1.Placethellreceptaclebracketoverthethreaded

holeinthetankandsecureitwithaange-headbolt

(5/16x3/4inch)(Figure3).

Figure3

1.Fillreceptaclebracket

2.Threadedholeinthetank6.Hoseadapter

3.Flangebolt,5/16x3/4inch

4.90degreeelbowtting

5.Quickcoupler

7.Anti-siphonhose

Partsneededforthisprocedure:

1

SprayProMonitor

1

SprayProDecal

1Bracket

2

Flange-headbolt,3/4inch

2

Flangenut,1/4inch

2Knob

2Washer

2

Carriagebolt

Procedure

1.InstalltheSprayProDecaltothemonitor(Figure4).

2.Placethethreadedendofthe90degreeelbowtting

throughthebracketandthreadthequickcoupler

ontoit,securingittothebracket(Figure3).

Note:Installthettingwiththeopenendpointing

towardthelargeopeninginthebracketandtoward

thetankopeningsothewaterwillarcintothetank

whenyoullit.

3.Installthehoseadapterintothequickcoupler

(

Figure3).

Figure4

1.Spraypromonitor3.Decal,Lowerhalf

2.Decal,Upperhalf

Note:Besuretoorientthedecalasshownin

Figure20.

2.Installthemonitorbracketonthedash(

using2ange-headbolts(1/4x3/4inch)and2

angenuts(1/4inch).

14

Figure5)

Figure5

1.SprayPromonitor

2.Bracket4.Knob

3.Looselyinstallthe2carriagebolts,rubber

washers,andknobsonthebracketasillustratedin

FigureFigure5andFigure6.

3.Flange-headbolts,

1/4x3/4inch

1.Connectorsfromthe

sprayer

3

Figure7

2.Connectorsfromthe

monitor

Note:Installthecarriageboltsandrubberwashers

insideofthebracketandtheknobsontheoutside.

Figure6

1.Carriagebolt

2.Rubberwasher4.Bracket

4.Removethelargegrommetfromtheholeinthedash

andthreadthecablesonthemonitorthroughthe

grommetandthedash.

5.Installthegrommetintothedash.

6.InstalltheSprayPromonitoroverthecarriagebolt

heads(Figure5)andtightentheknobstosecureit.

7.ConnecttheSprayProwireconnectorstothewire

connectorslocatedunderthedash(Figure7).

3.Knob

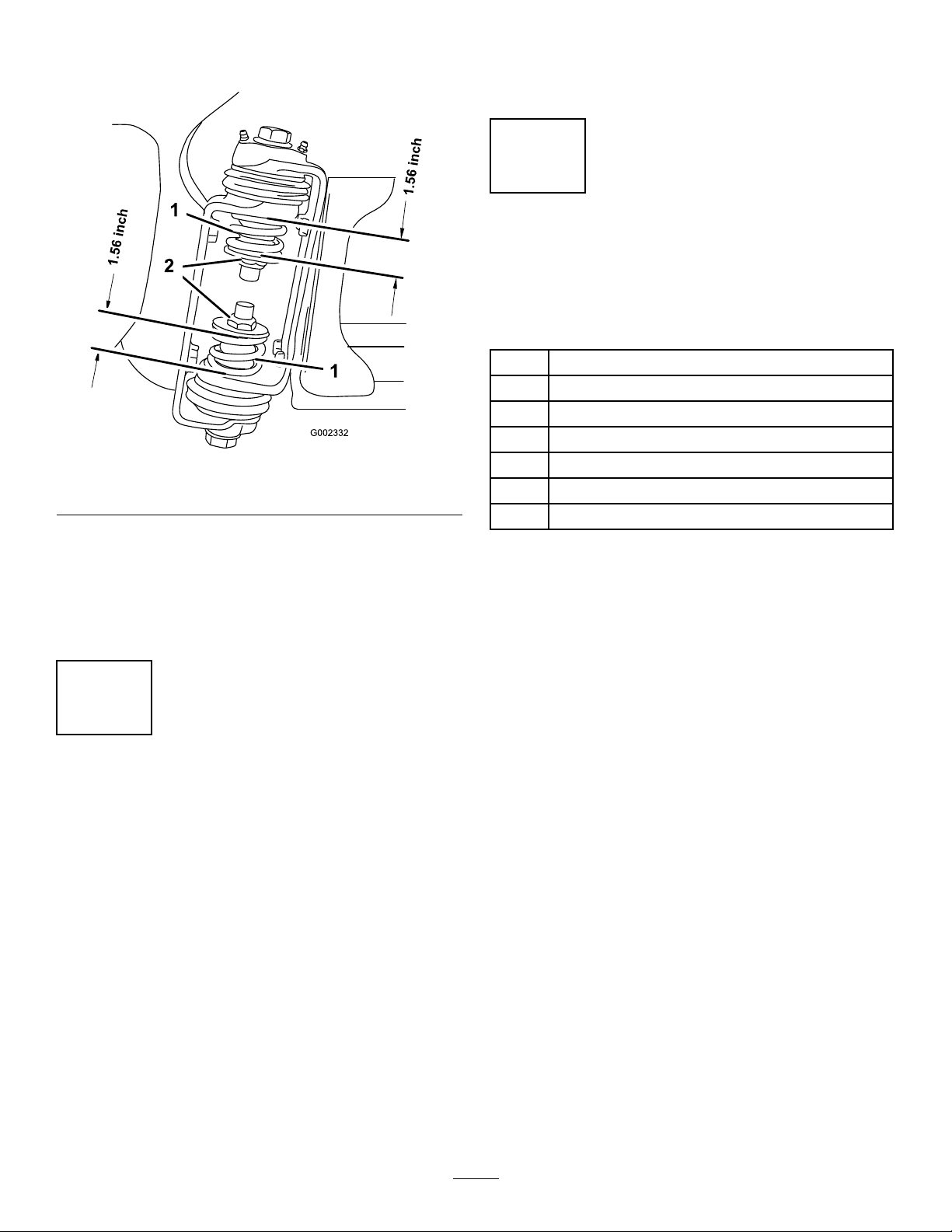

CheckingtheBoomHinge

Springs

NoPartsRequired

Procedure

Important:Operatingthespraysystemwith

theboomhingespringsundertheincorrect

compressioncoulddamagetheboomassembly .

Measurethespringsandusethejamnutto

compressthespringsto1.56inchesifnecessary.

Thesprayerisshippedwiththeboomextensionsswung

forwardtofacilitatepackagingofthemachine.The

springsarenotfullytightenedatthetimeofmanufacture

toallowtheboomstobeinthispositionfortransit.

Beforeoperatingthemachine,thespringsmustbe

adjustedtothecorrectcompression.

1.Ifnecessary,removethepackingcomponentsthat

securetherightandleftextensionboomsduring

shipping.

2.Supporttheboomswhiletheyareextendedtothe

sprayposition.

3.Attheboomhinge,measurethecompressionofthe

upperandlowerspringswhiletheboomsareintheir

extendedposition(

A.Allspringsmustbecompresseduntilthey

measure1.56inches.

Figure8).

15

B.Usethejamnuttocompressanyspringthat

measuregreaterthan1.56inches.

Figure8

1.Boomhingespring2.Jamnut

4.Repeattheprocedureforeachspringonbothboom

hinges.

5.Movetheboomsintothetransport“X”position.

SeeOperatingtheBoomsintheOperationsection

formoreinformation.

Note:Thebumpermayexperiencesomecompression

overtime.Iftheboomsdropbelowlevel,usethis

proceduretoreadjustthebumperpositionneeded.

5

CompletingtheSetup:

Learningmoreaboutyour

product.

Partsneededforthisprocedure:

1Ignitionkey

1

Operator’sManual

1

EngineOperator’sManual

1

PartsCatalog

1

OperatorTrainingMaterial

1

RegistrationCard

1

Pre-deliveryInspectionSheet

Procedure

1.Readthemanuals.

2.ViewtheOperatortrainingmaterial.

4

AdjustingtheBoomstoLevel

NoPartsRequired

Procedure

1.Attheoperator’ sposition,turntheignitionkeyto

Ontoenergizethesystem.

2.Movetheboomsintopositionsothattheyarelevel

withtheground.

3.Removethekeyandexittheoperator’sposition.

4.Atthehinge,adjustthepositionofthebumpersso

theboomcannotmovepastlevelwiththeground.

Takecaretomakesurethebumperislevel.

5.Tightentheboltandnuttolockthebumpersintothe

adjustedposition.T orquethefastenersto135-165

ft-lbs(183-223N-m).

3.CompletetheregistrationcardandreturntoToro.

4.Storethedocumentationinasafeplace.

16

ProductOverview

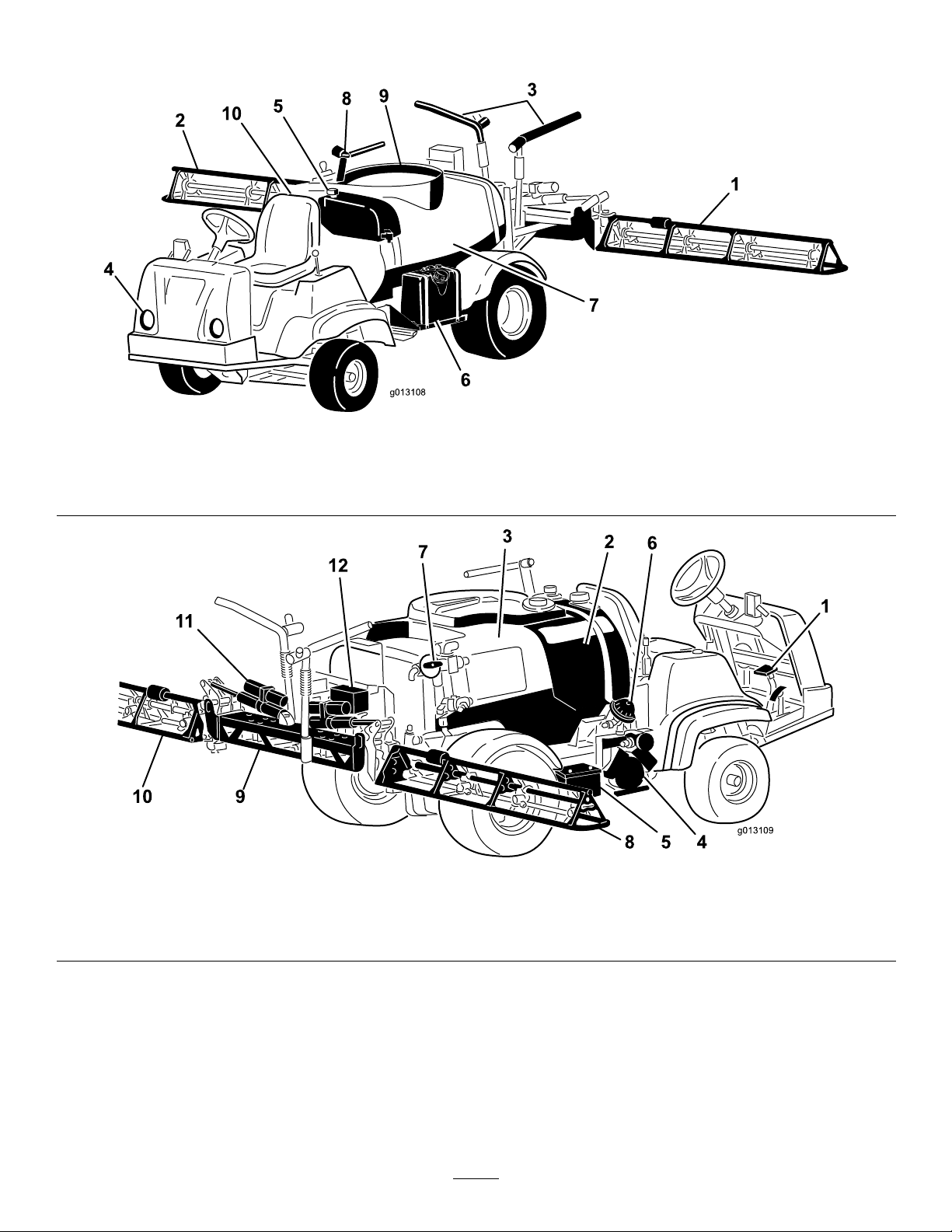

g013108

g013109

Figure9

1.Leftboom

2.Rightboom5.Freshwatertank

3.Boomtransportcable6.Fueltank9.Tanklid

4.Headlight

7.Chemicaltank10.Operator’sposition

8.Anti-SiphonReceptacle

Figure10

1.Pedals4.Pump7.Agitationcontrolvalve

2.Rinsetank5.Battery8.Rightboom11.Boomcontrolcylinder

3.Chemicaltank

6.Pumppressuredampener

17

9.Centerboom

10.Leftboom

12.Valvecluster

Controls

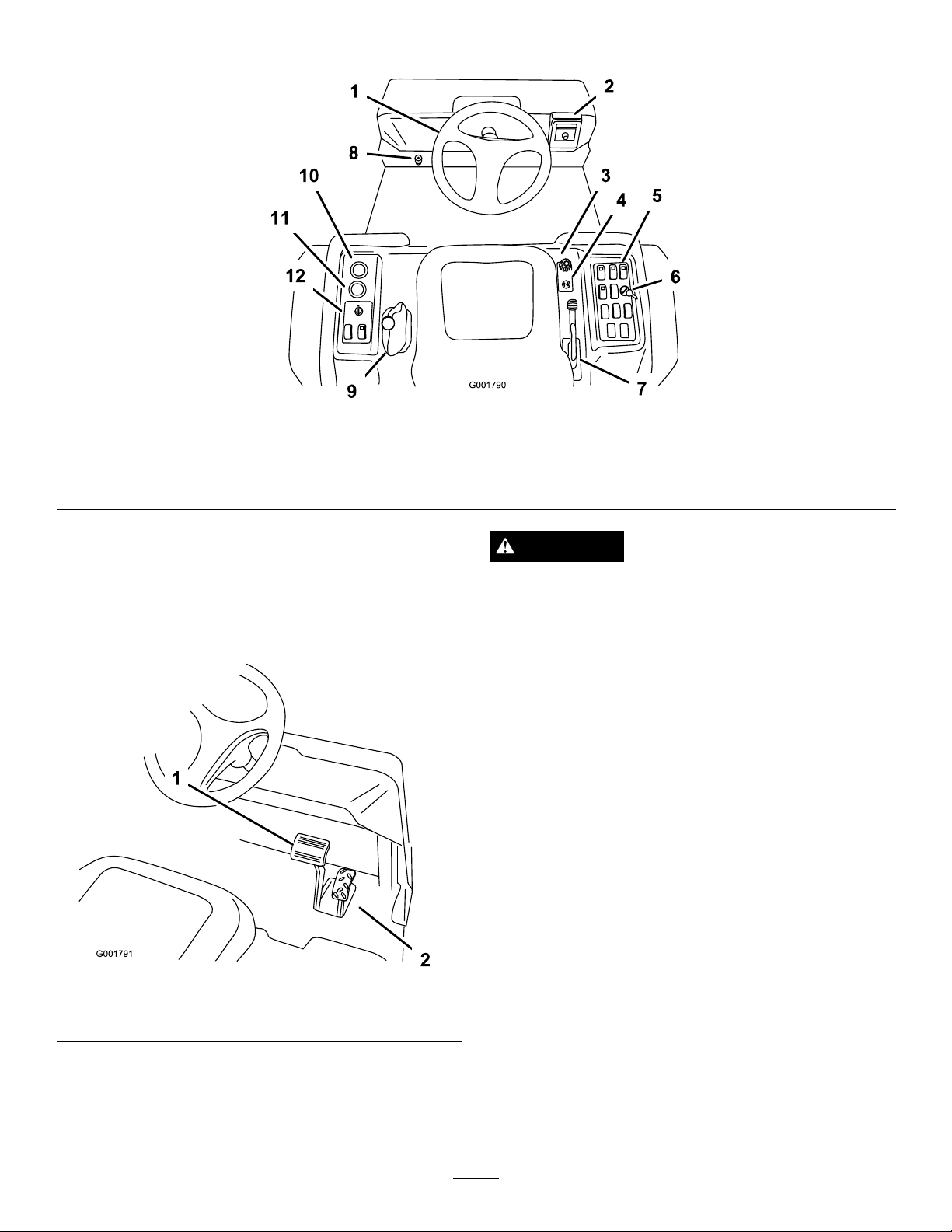

Figure11

1.Steeringwheel4.Choke

2.Spray-Promonitor5.Sprayercontrols8.Masterboomfootswitch

3.Speedlimiter

6.Ratelockoutswitch

7.Parkingbrake10.Voltmeter

9.RangeSelector

11.Hourmeter

12.Vehiclecontrols

AcceleratorPedal

Theacceleratorpedal(Figure12)givesyoutheabilityto

varygroundspeedofthesprayer.Pressingthepedal

increasesgroundspeed.Releasingthepedalwillslow

thesprayerandtheenginewillidle.

Figure12

1.Brakepedal2.Acceleratorpedal

CAUTION

Brakescanbecomewornorcanbeadjusted

incorrectlyresultinginpersonalinjury .

Ifbrakepedaltravelstowithin1inch(2.5cm)ofthe

sprayeroorboard,thebrakesmustbeadjusted

orrepaired.

ParkingBrake

Theparkingbrakeisalargelevertotherightoftheseat.

(Figure13).Engagetheparkingbrakewheneveryou

planonleavingtheseattopreventaccidentalmovement

ofthesprayer.Toengagetheparkingbrake,pullupand

backonthelever.Todisengage,pushitforwardand

down.Ifthesprayerisparkedonasteepgrade,apply

theparkingbrakeandplaceblocksatthedownhillside

ofthewheels.

BrakePedal

Usethebrakepedaltostoporslowthesprayer

(Figure12).

18

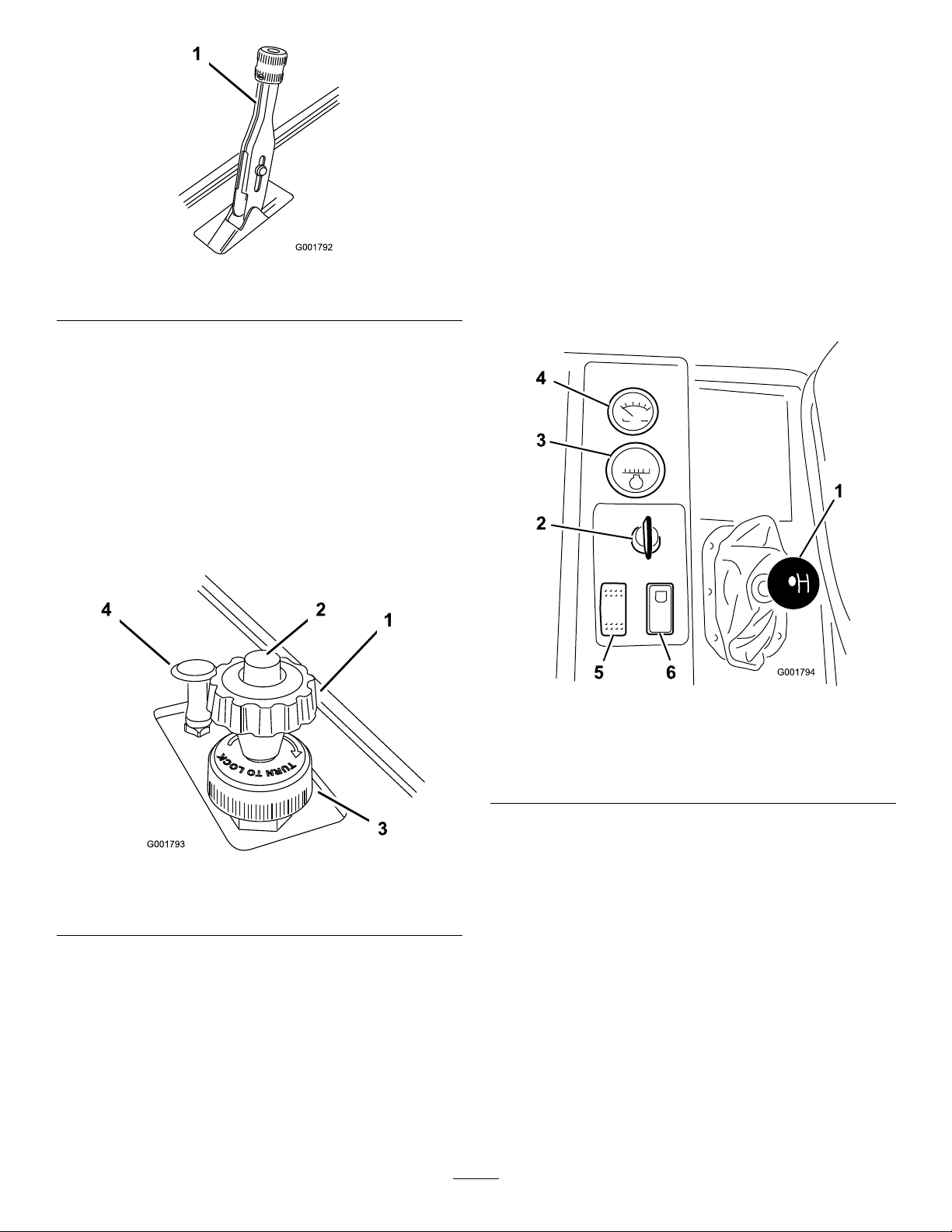

Figure13

1.Parkingbrakelever

SpeedLimiter

Thespeedlimiterisalargeknoblocatedtotherightof

theseat(Figure14).Itallowsyoutosetthemaximum

downwardtraveloftheacceleratorpedal,thereby

limitingthemaximumrpmoftheengine.Thisindirectly

limitsthespeedofthesprayer.

RangeSelector

Therangeselector,locatedtotheleftoftheseat,has

5positions:3forwardspeeds,Neutral,andReverse

Figure15).Theenginewillstartonlywhentherange

(

selectorisintheNeutralposition.Youmustalsofully

pressthebrakewiththesprayerstoppedtochange

ranges.

Important:Donotshiftoutoforchangeranges

whilethevehicleismoving.Attemptingtochange

rangeswhilethevehicleismovingcandamagethe

transmission.Onlystoppingthesprayercompletely,

andfullyengagingthebrakewillsafelydisengage

thelockingpinandallowtherangestobechanged.

Note:Thevehiclecontrolstheapplicationratebased

onyourspeedandyoudonotneedtokeepaconstant

speedtoapplyataconstantrate.

Figure14

1.Speedlimiterknob

2.Speedlimiterbutton4.Chokecontrol

3.Lockingring

ChokeControl

Figure15

1.RangeSelector

2.Ignitionswitch5.Headlightswitch

3.Hourmeter6.Neutralenginespeedlock

4.Voltmeter

switch

IgnitionSwitch

Theignitionswitch(Figure15),usedtostartandstop

theengine,has3positions:Stop,Run,andStart.Rotate

thekeyclockwisetotheStartpositiontostarttheengine

andreleaseittotheRunpositionwhenstarted.Rotate

thekeytotheStoppositiontostoptheengine.

Thechokecontrolisasmallknobtotherightofthe

seat.(Figure14).Tostartacoldengine,pullthechoke

controlup.Aftertheenginestarts,regulatethechoketo

keeptheenginerunningsmoothly.Assoonaspossible,

pushthecontroldowntotheOffposition.Awarm

enginerequireslittleornochoking.

HourMeter

Thehourmeter(Figure15)indicatesthetotalnumber

ofhourstheenginehasrun.Thehourmeterstartsto

functionwheneverthekeyisturnedtotheRunposition.

19

Voltmeter

BoomSwitches

Thevoltmeter(Figure15)indicatesthelevelofcharge

inthebattery.Whenthebatteryisfullycharged,the

voltmeterwillreadinthecenterofthedialwhenthe

keyisintheRunpositionwiththeengineoff.When

theengineisrunningthevoltmeterneedleshouldbe

totheright.

HeadlightSwitch

Toggletheswitchtooperatetheheadlights(Figure15).

Pushitforwardtoturnthelightsonandrearwardto

turnthemoff.

NeutralEngineSpeedLockSwitch

WhentherangeselectorisintheNeutralposition,you

canusetheacceleratorpedaltospeeduptheengine,

thenpushthisswitchforwardtosettheengineatthat

speed.Thisisnecessarytorunthechemicalagitation

whilestationaryoroperatingattachmentssuchasthe

handsprayer(

Important:Therangeselectormustbeinthe

neutralpositionfortheswitchtowork.

Figure15).

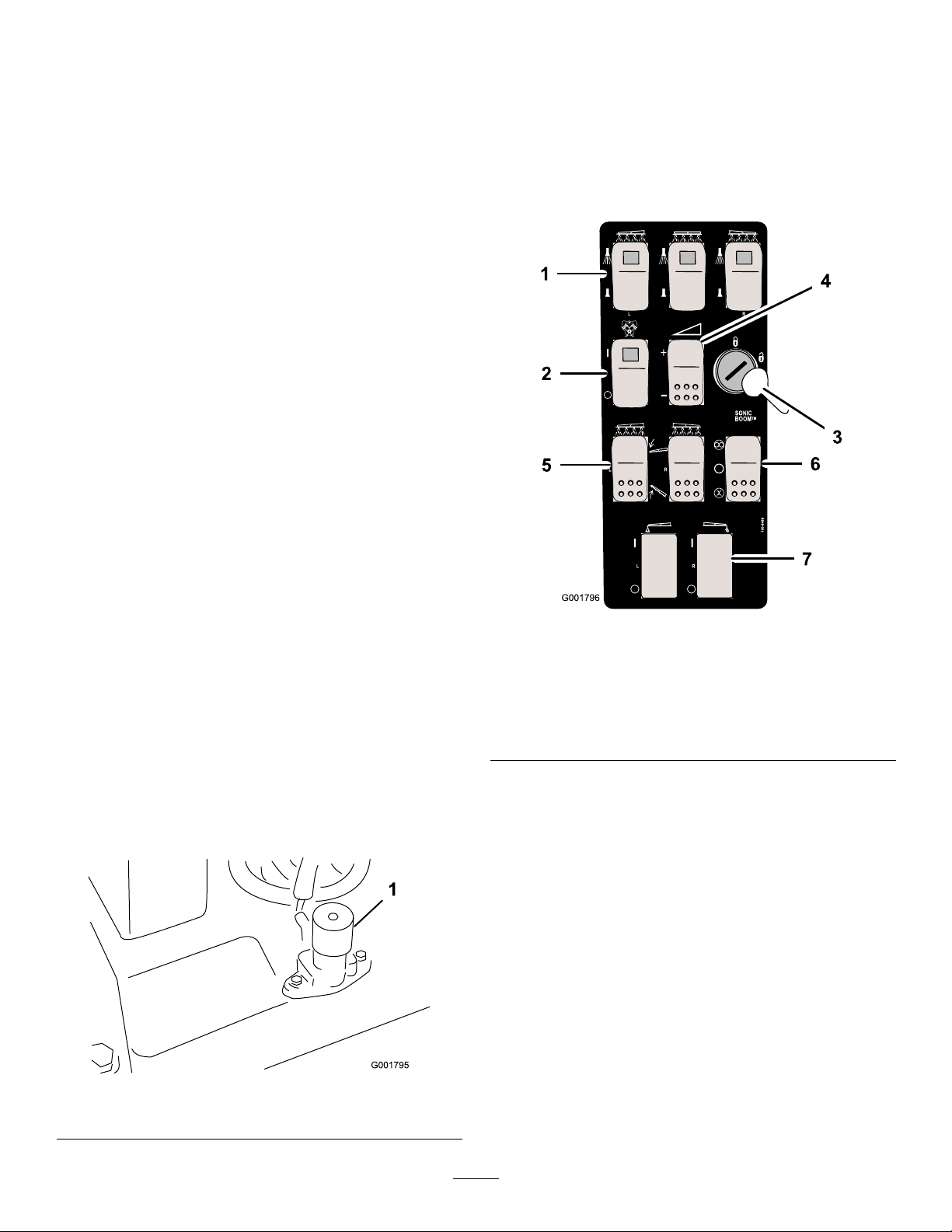

Theboomswitchesarelocatedatthefrontofthe

controlpaneltotherightoftheseat(

Figure17).Toggle

eachswitchforwardtoturnthecorrespondingboom

sectiononandrearwardtoturnthemoff.Whenthe

switchisturnedon,alightontheswitchilluminates.

Theseswitcheswillonlyaffectthespraysystemwhen

themasterboomswitchison.

FuelGauge

Thefuelgaugeislocatedontopofthefueltank,on

therightsideofthemachineandshowstheamountof

fuelinthetank.

MasterBoomSwitch

Themasterboomswitchislocatedontheoorboard

ofthemachinecabandtotheleftoftheoperator.It

allowsyoutostartorstopthesprayoperation.Press

theswitchwithyourfoottoenableordisablethespray

system(

SprayPromonitorscreenreads“Hold."

Figure16).Whenthemasterswitchisoff,the

Figure17

1.Boomswitches,left,right

andcenter

2.Pumpswitch

3.Ratelockoutkey

4.Applicationrateswitch

5.Boomliftswitch,leftand

right

6.Sonicboomswitch

7.Foammarkerswitch,left

andright

PumpSwitch

Thepumpswitchislocatedonthecontrolpaneltothe

rightoftheseat(Figure17).T ogglethisswitchforward

torunthepumporrearwardtostopthepump.

Important:Onlyengagethepumpswitchwhen

theengineisatlowidletoavoiddamagingthe

pumpdrive.

ApplicationRateSwitch

1.Masterboomswitch

Figure16

Theapplicationrateswitchislocatedonthecontrol

paneltotherightoftheseat(Figure17).Pressandhold

theswitchforwardtoincreasethespraysystempressure,

orpressandholditrearwardtodecreasepressure.

20

RateLockoutKeySwitch

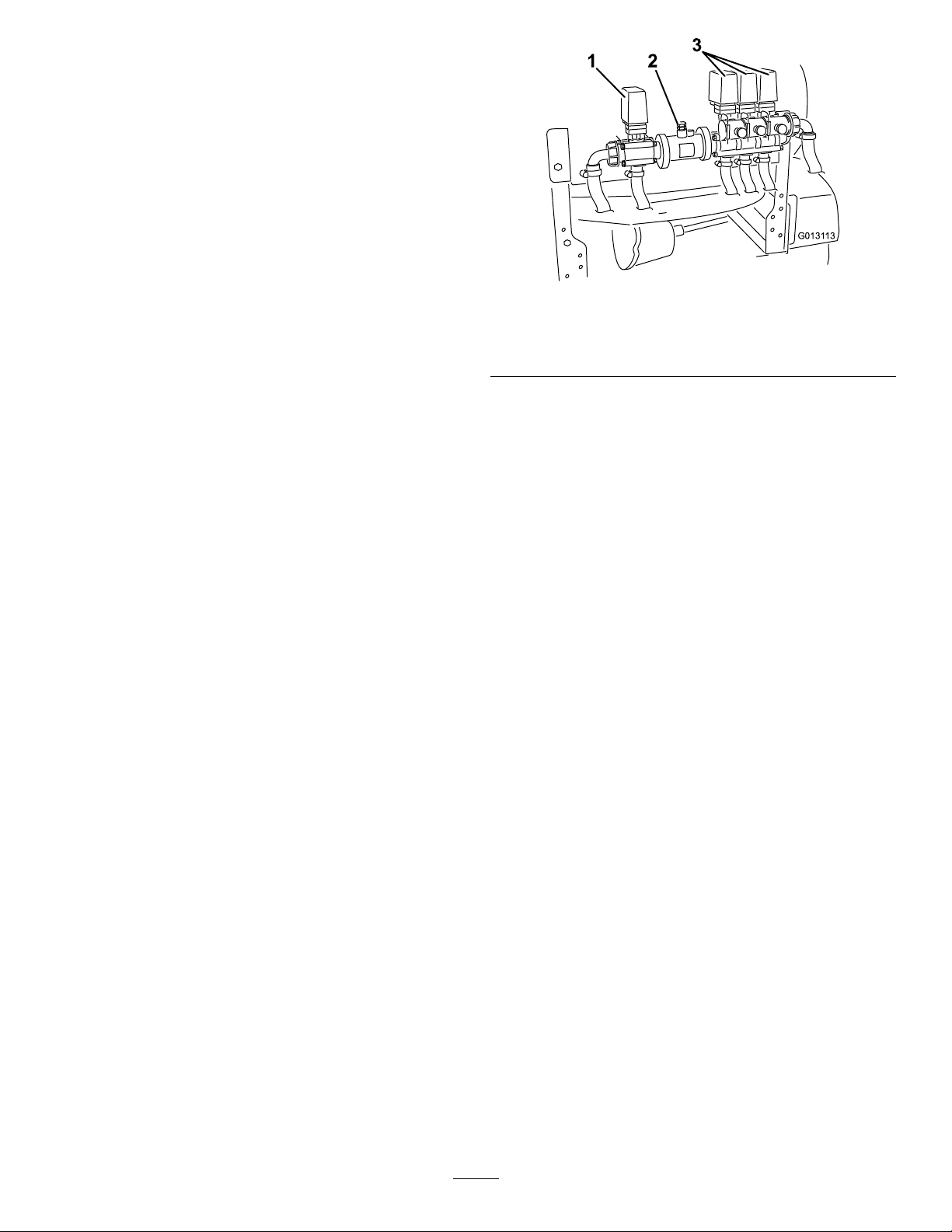

G0131 13

1 2

3

Theratelockoutkeyswitchislocatedonthecontrol

paneltotherightoftheseat(

Figure17).Turnthekey

counterclockwisetothelockedpositiontodisablethe

applicationrateswitch,therebykeepinganyonefrom

accidentallychangingtheapplicationrate.Turnthe

keyclockwisetotheunlockedpositiontoenablethe

applicationrateswitch.

Important:Donotattempttomovetherange

selectorwhiletheratelockoutkeyisengaged.

Forcingtheselectorwhilemovingwilldamage

lockoutkeycomponents.

BoomLift

Theboomliftswitchesareusedtoraisetheleftand

rightboomrespectively .

1.Regulating(ratecontrol)

valve

2.Flowmeter

Flowmeter

Figure18

3.Boomvalves

SonicBoom(Optional)

TheSonicBoomswitchisarockerswitchusedto

operatetheSonicBoom.Toggleswitchforwardfor

automatic,rearwardformanualandcenterforOff.

FoamMarkerSwitchLocations

(Optional)

Ifyouinstalltheelectricboomlift,sonicboom,and

foammarkerkit,youwilladdswitchestothecontrol

panelforcontrollingtheiroperation.Thesprayercomes

withplasticplugsintheselocations.

Regulating(RateControl)Valve

Thisvalve,locatedbehindthetank(Figure18),controls

theamountofuidthatisroutedtotheboomsby

directinguidowtotheboomsorthebypasshose

totheagitationvalve.

Theowmetermeasurestheowrateoftheuidfor

usebytheSprayPro™system(Figure18).

BoomValves

Thesevalvesturnthethreeboomsonoroff(Figure18).

Ifyoudonothaveaboominstalledordonotwant

aboomtobeabletobeturnedon,youcanmanually

operateeachvalvebydisconnectingthewireconnector

inthevalve,thenrotatetheknobonthevalveclockwise

toturnthevalveofforcounterclockwisetoturniton.

BoomBypassValves

Theboombypassvalvesredirecttheuidowfora

boomtothetankwhenyouturnofftheboomsection.

Youcanadjustthesevalvestoensurethattheboom

pressureremainsconstantnomatterhowmanybooms

areon.RefertoCalibratingtheBoomBypassValves,

intheOperationsection.

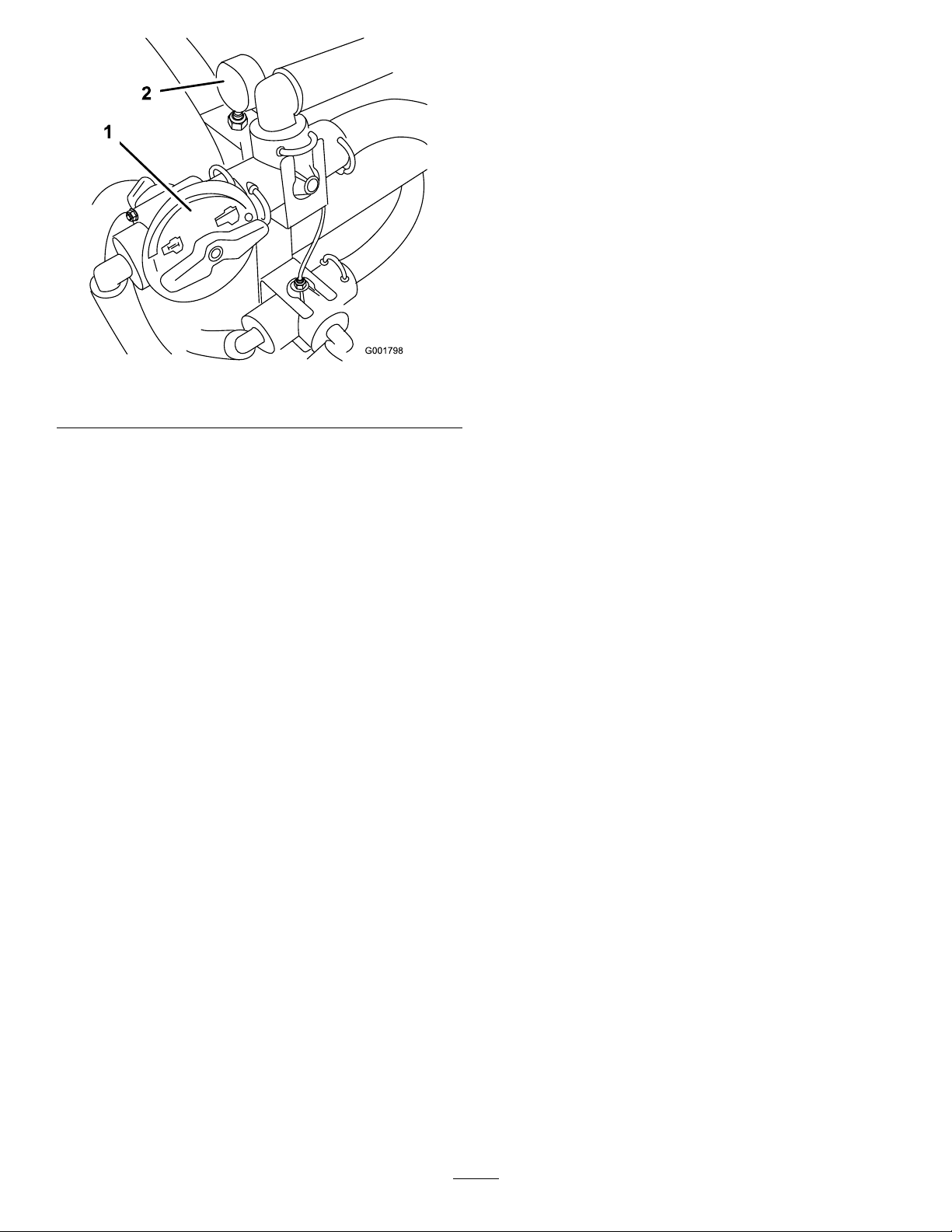

AgitationControlValve

Thisvalveislocatedontherightsideofthetank

(Figure19).Turntheknobonthevalvetothe9o’clock

positiontoturnonthetankagitationandtothe3

o’clockpositiontoturnoffthetankagitation.

21

PressureGauge

Thepressuregaugeislocatedtotherightofthetank

Figure19).Thisgaugeshowsthepressureoftheuid

(

inthesysteminpsiandkPa.Usethegaugetoadjustthe

by-passvalveswheneveryouchangenozzles.

Anti-siphonFillReceptacle

Tothefrontofthetankcoverisahosereceptaclewitha

threadedtting,a90degreebarbedtting,andashort

hosewhichyoucandirecttowardthetankopening.This

receptacleallowsyoutoconnectawaterhosetoitand

llthetankwithwaterwithoutcontaminatingthehose

withthechemicalsinthetank.

Figure19

1.Agitationcontrolvalve2.Pressuregauge

Note:Foragitationtowork,thepumpmustbeon

andtheenginemustberunningaboveanidle.Ifyou

stopthesprayerandneedagitationon,placetherange

selectorintheNeutralposition,settheparkingbrake,

presstheacceleratorpedaltotheoor,turnthepump

OnandturntheneutralenginespeedlockOn.

Important:Donotlengthenthehosetoallow

contactwiththetankuids.

22

Loading...

Loading...