Toro 41165, Multi-Pro 1250, Multi-Pro 1200, 41106, 41163 Operator's Manual

Form No. 3351-876

Multi-Pro) 1250 Turf Sprayer

Model No. 41165—Serial No. 240000401 and Up

Operator’s Manual

Register your product at www.Toro.com

Original Instructions (EN, GB)

Warning

CALIFORNIA

Proposition 65 Warning

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

Important The engine in this product is not equipped

with a spark arrester muffler. It is a violation of California

Public Resource Code Section 4442 to use or operate this

engine on any forest-covered, brush-covered, or

grass-covered land as defined in CPRC 4126. Other states

or federal areas may have similar laws.

This spark ignition system complies with Canadian

ICES-002.

Ce système d’allumage par étincelle de véhicule est

conforme à la norme NMB-002 du Canada.

Contents

Page

Introduction 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 3. . . . . . . . . . . . . . . . . . . .

Chemical Safety 4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Before Operating 4. . . . . . . . . . . . . . . . . . . . . . . . . .

While Operating 5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sound Pressure 7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vibration 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 7. . . . . . . . . . . . . . . . .

Specifications 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Equipment 11. . . . . . . . . . . . . . . . . . . . . . . .

Setup 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Anti-siphon Fill Receptacle 13. . . . . . .

Installing the Spray Pro Monitor 13. . . . . . . . . . . . . .

Before Operating 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking the Engine Oil 14. . . . . . . . . . . . . . . . . . . .

Checking the Tire Pressure 14. . . . . . . . . . . . . . . . . .

Adding Fuel 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking the Air Intake Screen 15. . . . . . . . . . . . . . .

Checking the Brake Fluid 15. . . . . . . . . . . . . . . . . . . .

Checking the Transaxle/Hydraulic Fluid 16. . . . . . . .

Filling the Fresh Water Tank 16. . . . . . . . . . . . . . . . .

Operation 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Think Safety First 17. . . . . . . . . . . . . . . . . . . . . . . . . .

Vehicle Controls 17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre-Starting Checks 18. . . . . . . . . . . . . . . . . . . . . . . .

Starting the Engine 19. . . . . . . . . . . . . . . . . . . . . . . . .

Driving the Sprayer 19. . . . . . . . . . . . . . . . . . . . . . . .

Stopping the Engine 19. . . . . . . . . . . . . . . . . . . . . . . .

New Sprayer Break-In 19. . . . . . . . . . . . . . . . . . . . . .

Transporting the Sprayer 19. . . . . . . . . . . . . . . . . . . .

Towing the Sprayer 20. . . . . . . . . . . . . . . . . . . . . . . .

Sprayer Controls and Components 20. . . . . . . . . . . .

Spray Pro Monitor 23. . . . . . . . . . . . . . . . . . . . . . . . .

Calibrating the Spray Pro Monitor 24. . . . . . . . . . . . .

Adjusting the Boom Bypass Valves 25. . . . . . . . . . . .

Operating the Sprayer 26. . . . . . . . . . . . . . . . . . . . . .

Maintenance 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 28. . . . . . . . .

Daily Maintenance Checklist 30. . . . . . . . . . . . . . . . .

Jacking the Sprayer 31. . . . . . . . . . . . . . . . . . . . . . . .

Inspecting the Wheels/Tires 31. . . . . . . . . . . . . . . . . .

Servicing the Air Cleaner 31. . . . . . . . . . . . . . . . . . . .

Servicing the Engine Oil 33. . . . . . . . . . . . . . . . . . . .

Greasing the Sprayer 34. . . . . . . . . . . . . . . . . . . . . . .

Replacing the Fuel Filter 35. . . . . . . . . . . . . . . . . . . .

Changing Transaxle/Hydraulic Fluid 36. . . . . . . . . . .

Replacing the Hydraulic Filter 36

Changing the Pump Drive Gearbox Fluid 37. . . . . . .

Inspecting the Brakes 37. . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Parking Brake 37. . . . . . . . . . . . . . . . .

Adjusting the Front Wheel Toe-In 37. . . . . . . . . . . . .

Servicing the Drive Belt 38. . . . . . . . . . . . . . . . . . . . .

Adjusting the Steering Pump Belt 39. . . . . . . . . . . . .

Maintaining the Primary Drive Clutch 39. . . . . . . . . .

Changing the Spark Plugs 40. . . . . . . . . . . . . . . . . . .

Replacing the Fuses 41. . . . . . . . . . . . . . . . . . . . . . . .

Servicing the Battery 41. . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Suction Strainer 43. . . . . . . . . . . . . . . .

Cleaning the Flowmeter 43. . . . . . . . . . . . . . . . . . . . .

Storage 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting the Engine and Vehicle 45. . . . . . . .

Troubleshooting the Spray System 48. . . . . . . . . . . .

Troubleshooting the Spray Pro Monitor 48. . . . . . . .

The Toro General Commercial Products Warranty 52. . .

. . . . . . . . . . . . . . . .

Page

W 2004 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Contact us at www.Toro.com

All Rights Reserved

2

Printed in the USA

Introduction

Safety

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

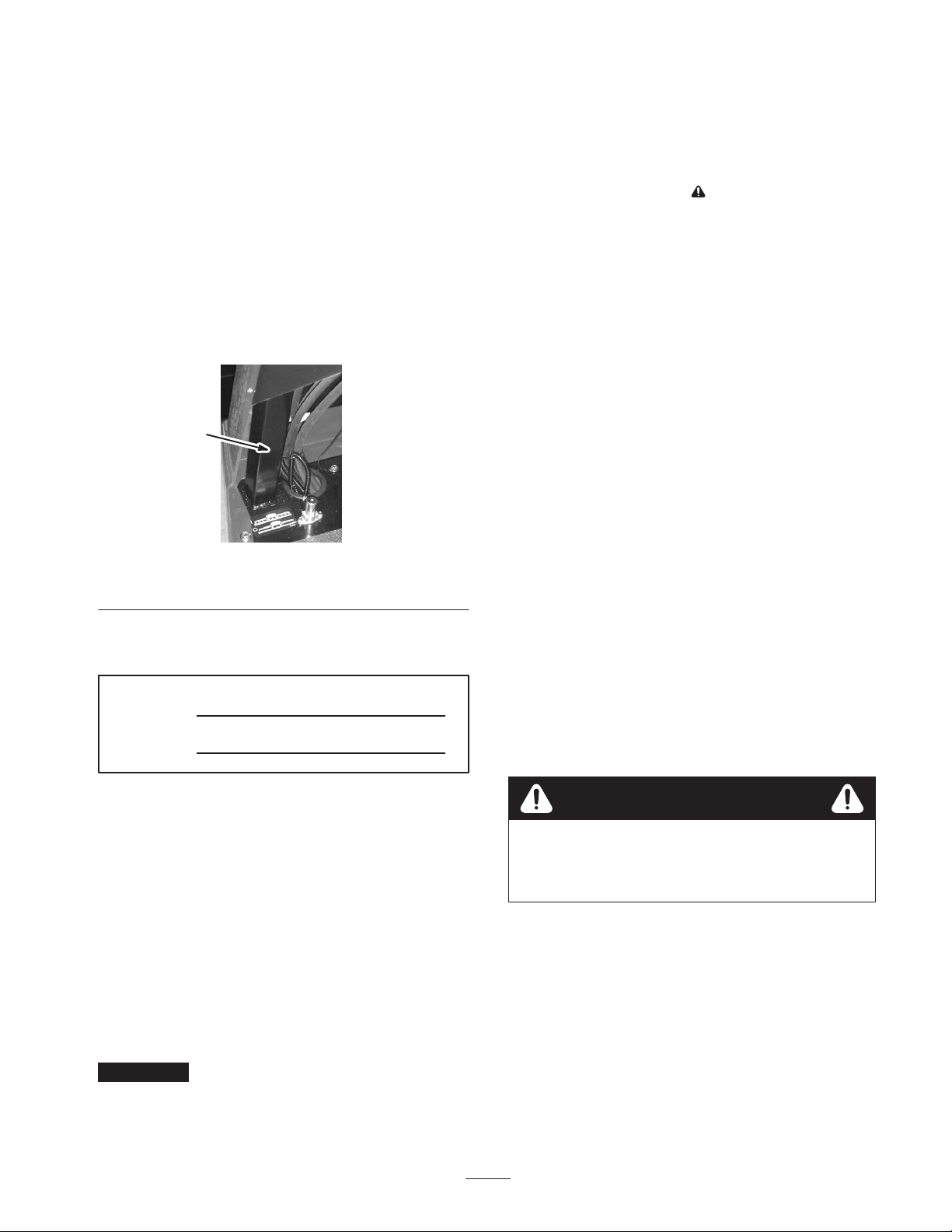

serial numbers of your product ready. Figure 1 illustrates

the location of the model and serial numbers on the

product.

1

Figure 1

1. Location of the model and serial numbers

Write the product model and serial numbers in the space

below:

Model No.

Improper use or maintenance by the operator or owner

can result in injury. To reduce the potential for injury,

comply with these safety instructions and always pay

attention to the safety alert

CAUTION, WARNING, or DANGER—“personal

safety instruction.” Failure to comply with the

instruction may result in personal injury or death.

Supervisors, operators, and service persons should be

familiar with the following standards and publications:

(The material may be obtained from the address shown).

• Flammable and Combustible Liquids Code:

ANSI/NFPA 30

• National Fire Protection Association:

ANSI/NFPA #505; Powered Industrial Trucks

National Fire Prevention Association

Barrymarch Park

Quincy, Massachusetts 02269 U.S.A.

• ANSI/ASME B56.8 Personal Burden Carriers

American National Standards Institute, Inc.

1430 Broadway

New York, New York 10018 U.S.A.

• ANSI/UL 558; Internal Combustion Engine Powered

Industrial Trucks

American National Standards Institute, Inc.

1430 Broadway

New York, New York 10018 U.S.A.

or

Underwriters Laboratories

333 Pfingsten Road

Northbrook, Illinois 60062 U.S.A.

symbol, which means

Serial No.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses two other words to highlight information.

Important calls attention to special mechanical

information and Note: emphasizes general information

worthy of special attention.

Safe Operating Practices

Warning

The sprayer is an off-highway vehicle only and is

not designed, equipped, or manufactured for use

on public streets, roads, or highways.

Supervisor’s Responsibilities

• Make sure that operators are thoroughly trained and

familiar with the Operator’s Manual, Engine Manual,

and all labels on the sprayer.

• Establish your own special procedures and work rules

for unusual operating conditions (e.g. slopes too steep

for sprayer operation).

3

Chemical Safety

Warning

• Never allow other adults to operate the sprayer without

first reading and understanding the Operator’s Manual.

Only trained and authorized persons should operate this

sprayer. Make sure that all operators are physically and

mentally capable of operating the sprayer.

Chemicals are hazardous and can injure you,

bystanders, animals, plants, soils, or other

property.

• Carefully read and follow the chemical

manufacturer’s instructions for the safe

preparation, use, and disposal of the chemical.

• Keep chemicals off of your or bystander’s skin.

if contact should occur, wash it off immediately

with clean water and detergent.

• Wear goggles and other protective equipment as

instructed by the chemical manufacturer.

• Obtain proper training before using or handling

chemicals.

• Use the correct chemical for the job.

• Follow the chemical manufacturer’s instructions for the

safe application of the chemical.

• Handle chemicals in a well ventilated area.

• Wear goggles and other protective equipment as

instructed by the chemical manufacturer. Ensure that as

little skin as possible is exposed while using chemicals.

• Have clean water available especially when filling the

spray tank.

• Do not eat, drink, or smoke while working with

chemicals.

• Always wash your hands and other exposed areas as

soon as possible after finishing the work.

• Properly dispose of unused chemicals and chemical

containers as instructed by the chemical manufacturer

and your local codes.

• Chemicals and fumes in the tanks are dangerous; never

enter the tank or place your head over or in the opening.

Before Operating

• Operate the machine only after reading and

understanding the contents of this manual.

• Never allow children to operate the sprayer. Anyone

who operates the sprayer should have a motor vehicle

license.

• This sprayer is designed to carry only you, the operator.

Never carry any passengers on the sprayer.

• Never operate the sprayer when under the influence of

drugs or alcohol. Even prescription drugs and cold

medicines can cause drowsiness.

• Do not drive the sprayer when you are tired. Be sure to

take occasional breaks. It is very important that you stay

alert at all times.

• Become familiar with the controls and know how to

stop the engine quickly.

• Keep all shields, safety devices, and decals in place. If a

shield, safety device, or decal is malfunctioning,

illegible, or damaged, repair or replace it before

operating the machine.

• Always wear substantial shoes. Do not operate the

machine while wearing sandals, tennis shoes, or

sneakers. Do not wear loose fitting clothing or jewelry

which could get caught in moving parts and cause

personal injury.

• Wearing safety glasses, safety shoes, long pants, and a

helmet is advisable and required by some local safety

and insurance regulations.

• Avoid driving when it is dark, especially in unfamiliar

areas. If you must drive when it is dark, be sure to drive

cautiously, use the headlights, and even consider adding

additional lights.

• Be extremely careful when operating around people.

Always be aware of where bystanders might be and

keep them away from the work area.

• Before operating the sprayer, always check the

designated areas of the sprayer that are stated in the

Pre-Starting section of this manual, page 18. If

something is wrong, do not use the sprayer. Make sure

that the problem is corrected before the sprayer or

attachment is operated.

• Ensure that all fluid line connectors are tight and all

hoses are in good condition before applying pressure to

the system.

• Since gasoline is highly flammable, handle it carefully.

– Use an approved gasoline container.

– Do not remove the cap from the fuel tank when the

engine is hot or running.

– Do not smoke while handling gasoline.

4

– Fill the fuel tank outdoors, and fill it to about 1 inch

(25 mm) below the top of the tank (the bottom of

the filler neck). Do not overfill it.

– Wipe up any spilled gasoline.

While Operating

Warning

– The electrical and exhaust systems of the sprayer

can produce sparks capable of igniting explosive

materials. Never operate the sprayer in or near an

area where there is dust or fumes in the air which

are explosive.

– If you are ever unsure about safe operation, stop

work and ask your supervisor.

• Do not touch the engine or muffler while the engine is

running or soon after it has stopped. These areas may be

hot enough to cause burns.

Engine exhaust contains carbon monoxide, which

is an odorless, deadly poison that can kill you.

Do not run engine indoors or in an enclosed area.

• The operator should remain seated whenever the

sprayer is in motion. The operator should keep both

hands on the steering wheel whenever possible. Keep

your arms and legs within the sprayer body at all times.

• Always watch out for and avoid low overhangs such as

tree limbs, door jambs, and over-head walkways. Make

sure there is enough room over head to easily clear the

sprayer and your head.

• Failure to operate the sprayer safely may result in an

accident, tip over of the sprayer, and serious injury or

death. Drive carefully. To prevent tipping or loss of

control:

– Use extreme caution, reduce speed, and maintain a

safe distance around sand traps, ditches, creeks,

ramps, unfamiliar areas, or any areas that have

abrupt changes in ground conditions or elevation.

– Watch for holes or other hidden hazards.

– Use extra caution when operating the sprayer on wet

surfaces, in adverse weather conditions, at higher

speeds, or with a full load. Stopping time and

distance will increase with a full load.

– Avoid sudden stops and starts. Do not go from

reverse to forward or forward to reverse without

first coming to a complete stop.

– Slow down before turning. Do not attempt sharp

turns or abrupt maneuvers or other unsafe driving

actions that may cause a loss of sprayer control.

– Before backing up, look to the rear and ensure that

no one is behind you. Back up slowly.

– Watch out for traffic when you are near or crossing

roads. Always yield the right of way to pedestrians

and other vehicles. This sprayer is not designed for

use on streets or highways. Always signal your turns

or stop early enough so that other people know what

you plan to do. Obey all traffic rules and

regulations.

• If the machine ever vibrates abnormally, stop

immediately, wait for all motion to stop, and inspect the

sprayer for damage. Repair all damage before resuming

operation.

• Before getting off of the seat:

A. Stop the movement of the machine.

B. Place the range selector in Neutral and set the

parking brake.

C. Turn the ignition key to Off.

D. Remove the ignition key.

Note: If the sprayer is stopped on an incline, block the

wheels after getting off the sprayer.

Braking

• Slow down before you approach an obstacle. This gives

you extra time to stop or turn away. Hitting an obstacle

can damage the sprayer and its contents. More

important, it can injure you and your passenger.

• Gross Vehicle Weight (GVW) has a major impact on

your ability to stop and/or turn. Heavy loads and

attachments make a sprayer harder to stop or turn. The

heavier the load, the longer it takes to stop.

• Turf and pavement are much more slippery when they

are wet. It can take 2 to 4 times as long to stop on wet

surfaces as on dry surfaces. If you drive through

standing water deep enough to get the brakes wet, they

will not work well until they are dry. After driving

through water, you should test the brakes to make sure

they work properly. If they do not, drive slowly while

putting light pressure on the brake pedal. This will dry

the brakes out.

Operating on Hills and Rough Terrain

Operating the sprayer on a hill may cause tipping or rolling

of the sprayer, or the engine may stall and you could lose

headway on the hill. This could result in personal injury.

• Do not accelerate quickly or slam on the brakes when

backing down a hill, especially with a load.

5

• Never drive across a steep hill; always drive straight up

or down or go around the hill.

• If the engine stalls or you begin to lose headway while

climbing a hill, gradually apply the brakes and slowly

back straight down the hill.

• Turning while traveling up or down hills can be

dangerous. If you have to turn while on a hill, do it

slowly and cautiously. Never make sharp or fast turns.

• Heavy loads affect stability. Reduce the weight of the

load and your speed when operating on hills.

• Avoid stopping on hills, especially with a load.

Stopping while going down a hill will take longer than

stopping on level ground. If the sprayer must be

stopped, avoid sudden speed changes, which may

initiate tipping or rolling of the sprayer. Do not slam on

the brakes when rolling backward, as this may cause the

sprayer to overturn.

• The Toro Company strongly recommends installing the

optional ROPS Kit when operating on hilly terrain. If

you install a ROPS, always wear the seat belt when

driving the sprayer.

• Reduce speed and load when operating on rough terrain,

uneven ground, and near curbs, holes, and other sudden

changes in terrain. Loads may shift, causing the sprayer

to become unstable.

Warning

Sudden changes in terrain may cause abrupt

steering wheel movement, possibly resulting in

hand and arm injuries.

• Reduce your speed when operating on rough

terrain and near curbs.

• Grip the steering wheel loosely around the

perimeter. Keep your hands clear of the steering

wheel spokes.

• Be aware that heavy loads increase your stopping

distance and reduce your ability to turn quickly without

tipping over.

Maintenance

• Only permit qualified and authorized personnel to

maintain, repair, adjust, or inspect the sprayer.

• Before servicing or making adjustments to the machine,

stop the engine, set the parking brake, and remove the

key from the ignition to prevent someone from

accidentally starting the engine.

• To make sure that the entire machine is in good

condition, keep all nuts, bolts, and screws properly

tightened.

• To reduce the potential for fire, keep the engine area

free of excessive grease, grass, leaves, and

accumulation of dirt.

• Never use an open flame to check the level or leakage

of fuel or battery electrolyte.

• If the engine must be running to perform a maintenance

adjustment, keep your hands, feet, clothing, and any

parts of your body away from the engine and any

moving parts. Keep everyone away.

• Do not use open pans of fuel or flammable cleaning

fluids when cleaning parts.

• Do not adjust the ground speed governor. To ensure

safety and accuracy, have an Authorized Toro

Distributor check the ground speed.

• Keep your body and hands away from pin hole leaks or

nozzles that eject high pressure fluid. Use cardboard or

paper to find leaks. Fluid escaping under pressure can

penetrate skin and cause injury requiring surgery within

a few hours by a qualified surgeon or gangrene may

result.

• If major repairs are ever needed or assistance is

required, contact an Authorized Toro Distributor.

Loading

The weight of the cargo can change the sprayer center of

gravity and sprayer handling. To avoid loss of control and

personal injury, follow these guidelines:

• Reduce the weight of the load when operating on hills

and rough terrain to avoid tipping or overturning of the

sprayer.

• Liquid loads can shift. This shifting happens most often

while turning, going up or down hills, suddenly

changing speeds, or while driving over rough surfaces.

Shifting loads can cause the sprayer to tip over.

• When operating with a heavy load, reduce your speed

and allow for sufficient braking distance. Do not

suddenly apply the brakes. Use extra caution on slopes.

• To be sure of optimum performance and safety, always

purchase genuine Toro replacement parts and

accessories. Replacement parts and accessories made by

other manufacturers could be dangerous. Altering this

sprayer in any manner that may affect sprayer

operation, performance, durability, or its use, may result

in injury or death. Such use could void the product

warranty.

6

Sound Pressure

Vibration

This unit has a maximum sound pressure level at the

operator’s ear of 82 dBA, based on measurements of

identical machines per Directive 98/37/EC.

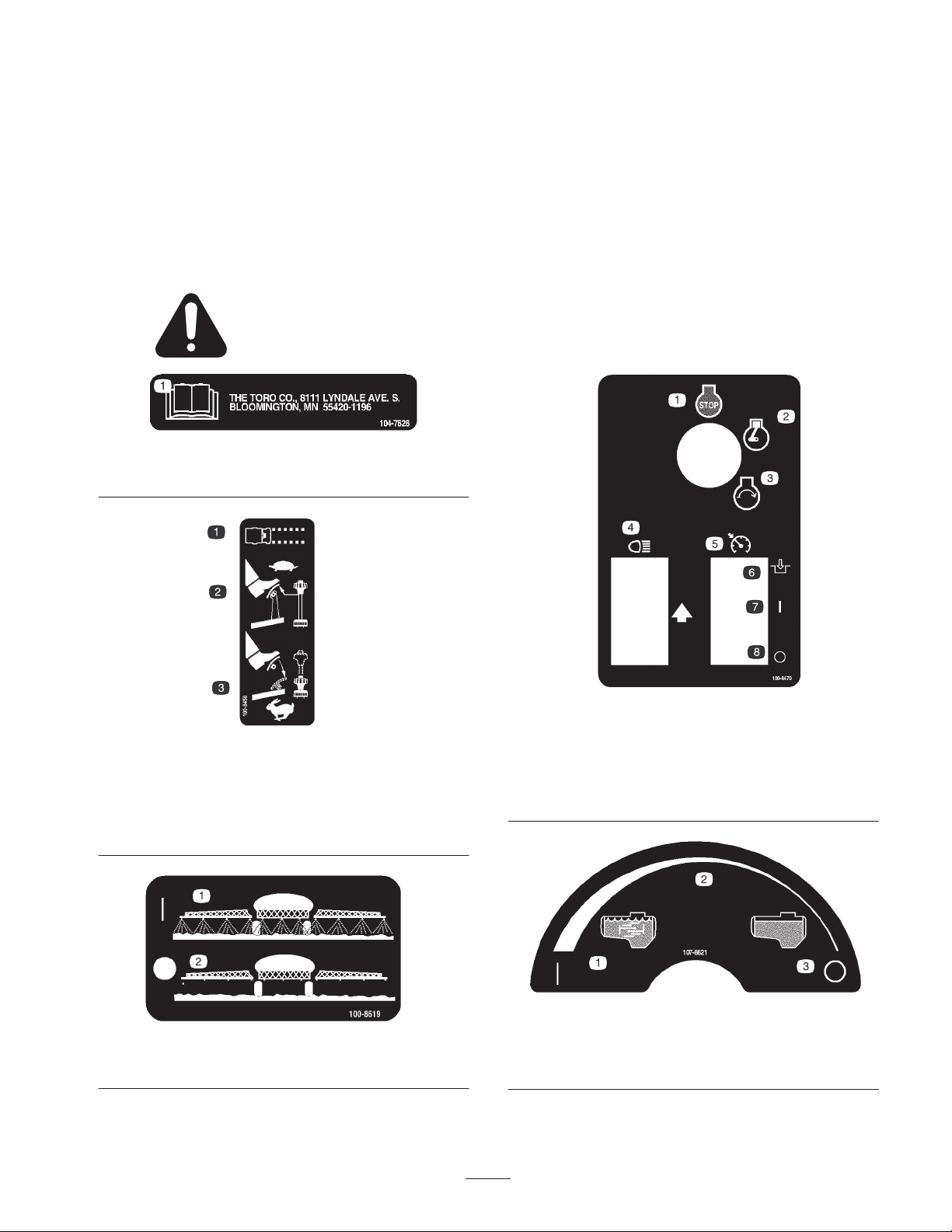

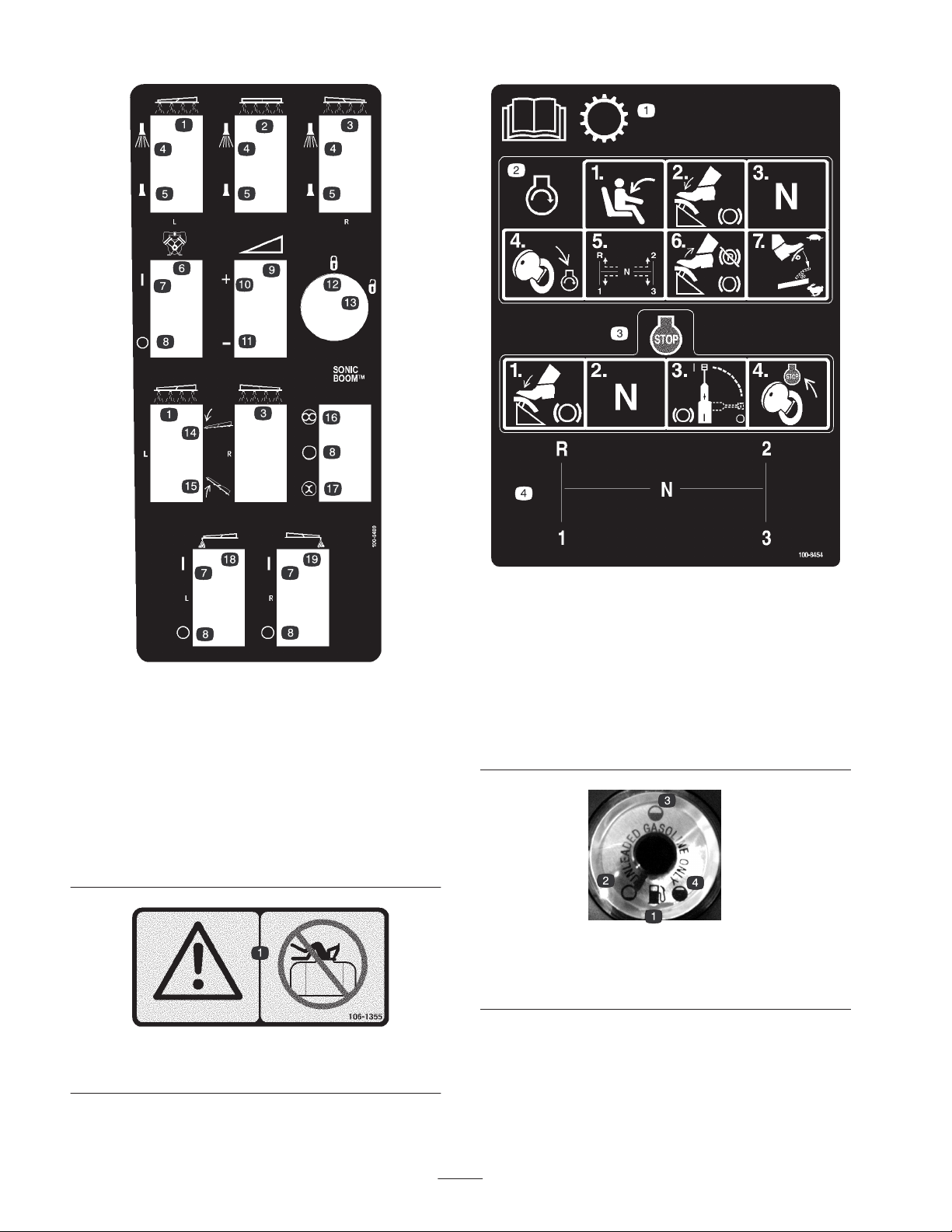

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area

of potential danger. Replace any decal that is damaged or lost.

104-7628

1. Read the Operator’s Manual.

This unit does not exceed a hand/arm vibration level of

2

2.5 m/s

, based on measurements of identical machines per

Directive 98/37/EC.

This unit does not exceed a whole body vibration level of

2

0.5 m/s

, based on measurements of identical machines per

Directive 98/37/EC.

100-8458

1. Machine speed

2. To set the machine to a slow speed, reduce pressure on the

accelerator and pull up on the speed limiter.

3. To set the machine to a fast speed, press the accelerator pedal

and push down on the speed limiter.

100-8619

1. Spray on 2. Spray off

1. Engine—stop

2. Engine—run

3. Engine—start

4. Headlights

1. Agitation on

2. Continuous variable

setting

100-8470

5. Neutral engine speed

control

6. Engage

7. On

8. Off

107-8621

3. Agitation off

7

1. Left boom

2. Center boom

3. Right boom

4. Spray on

5. Spray off

6. Pump

7. On

8. Off

9. Continuous variable

setting, spray pressure

100-8489

10. Increase

11. Decrease

12. Locked

13. Unlocked

14. Lower the boom.

15. Raise the boom.

16. Automatic

17. Manual

18. Left boom foam marker

19. Right boom foam marker

100-8454

1. Read the Operator’s Manual for information on the

transmission.

2. To start the engine, sit on the operator’s seat, press the brake,

set the range selector to Neutral, turn the ignition key to

Engine-start, set the range selector to the desired gear, release

the brake pedal and parking brake, and press the accelerator

pedal to the desired speed.

3. To stop the engine, press the brake, set the range selector to

Neutral, set the brake, and turn the ignition key to Engine-stop.

4. Range selector gear pattern

100-8386

1. Fuel

2. Empty

3. Half-full

4. Full

106-1355

1. Warning—do not enter the tank.

8

1. Engine oil level (dipstick)

2. Engine oil filter

3. Transaxle/hydraulic fluid

level (dipstick)

4. Transaxle hydraulic filter

1. Warning—read the

Operator’s Manual.

2. Electric shock hazard,

overhead power

lines—stay away from

overhead power lines.

5. Hydraulic strainer

6. Gear box fluid level

7. Brake fluid

8. Belts, steering and drive

9. Fuel, unleaded only

106-5016

3. Crushing hazard,

boom—keep bystanders

a safe distance from the

machine.

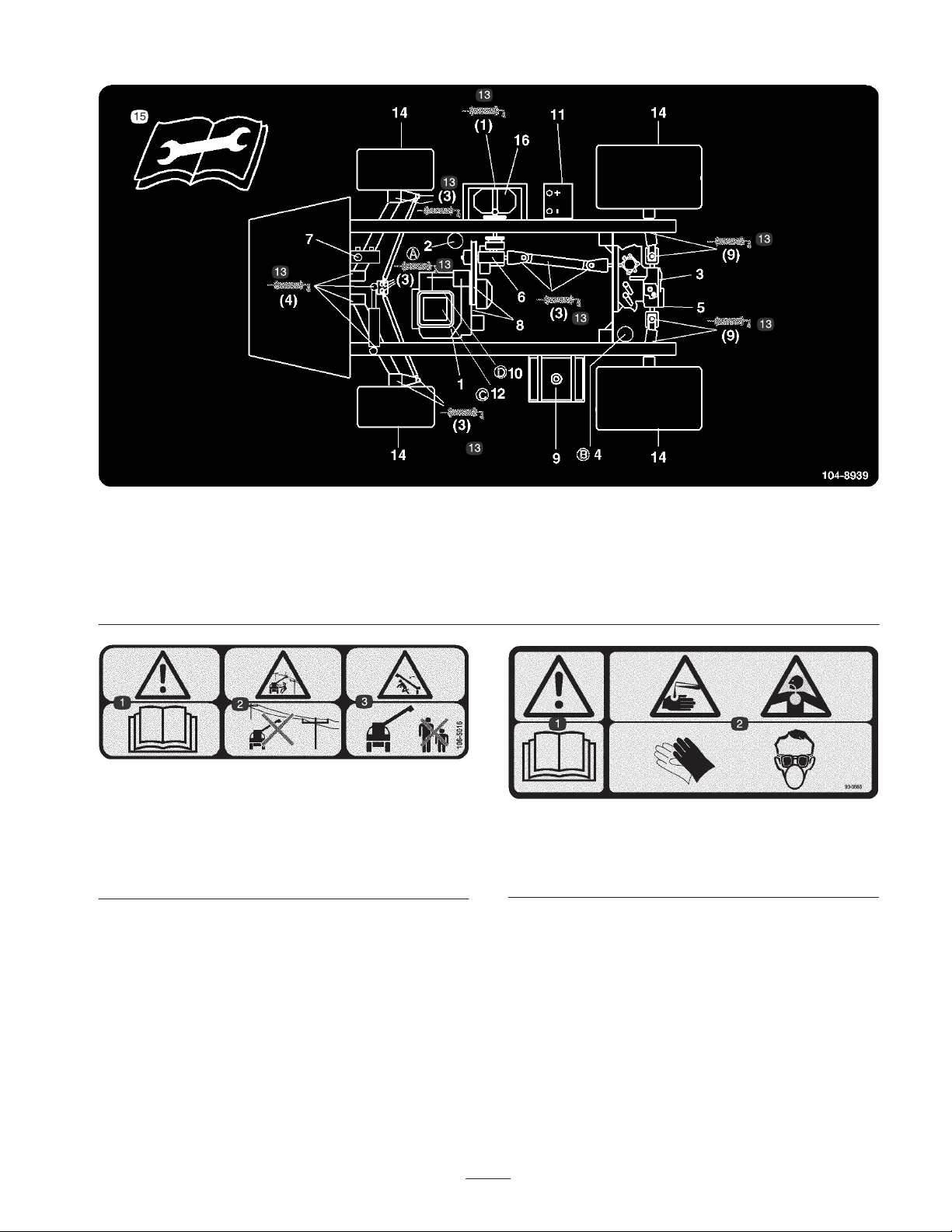

104-8939

10. Fuel filter

11. Battery

12. Air cleaner

13. Grease

14. Tire pressure

1. Warning—read the Operator’s Manual.

2. Caustic liquid/chemical burn and toxic gas inhalation

15. Read the instructions before

servicing or performing

maintenance.

16. Pump

93-0688

hazards—wear hand, skin, eye, and respiratory protection.

9

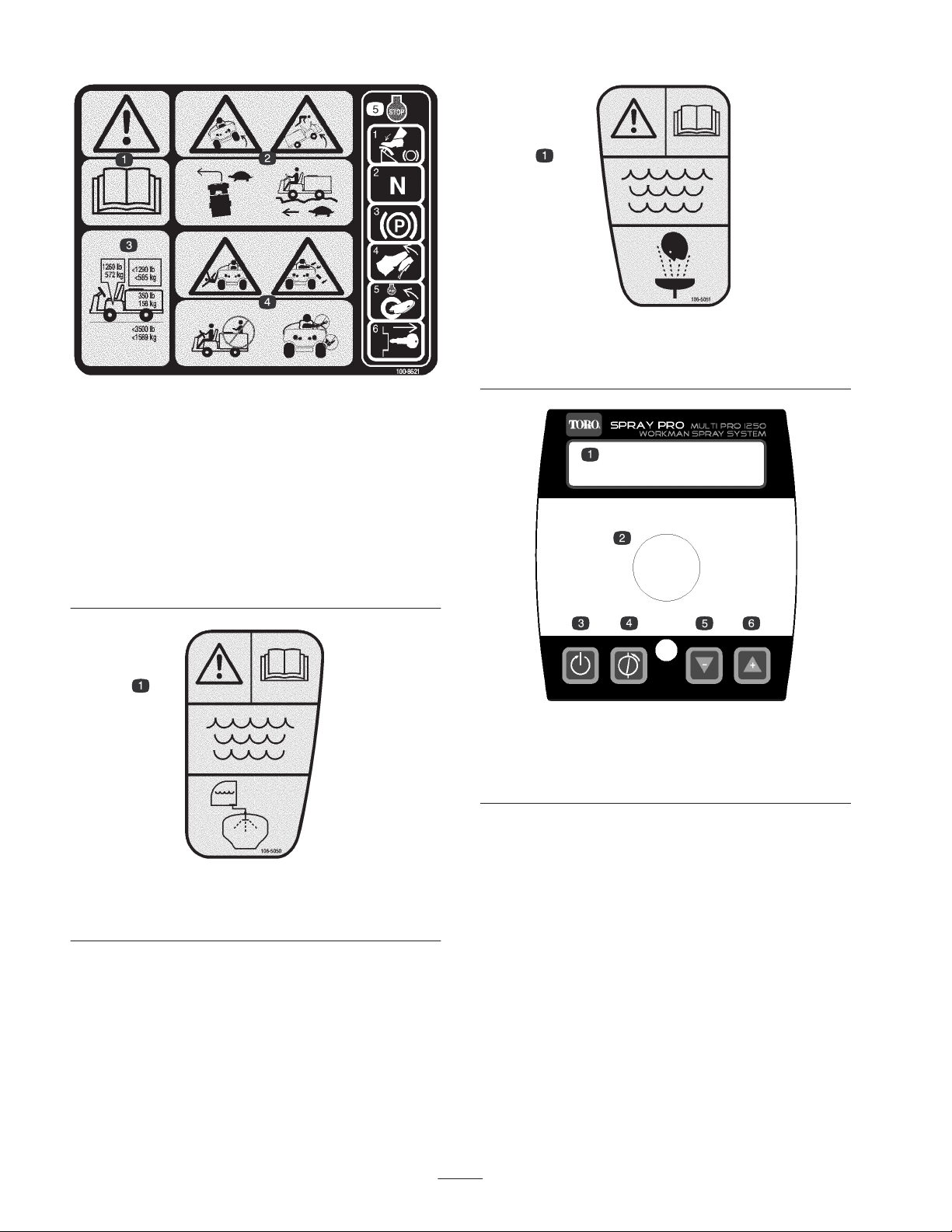

100-8621

1. Warning—read the Operator’s Manual.

2. Tipping Hazard—drive slowly over rough terrain and when

turning.

3. The maximum load is 1290 lb (585 kg), the operator and

accessory weight is 350 lb (158 kg), the vehicle weight is

1260 lb (572 kg), and the maximum gross vehicle weight is

3500 lb (1589 kg).

4. Falling and arm/leg injury hazards—do not carry passengers

and keep arms and legs inside of the vehicle at all times.

5. To stop the engine, press the brake, move the range selector to

Neutral, set the parking brake, release the brake pedal, turn the

ignition key to Engine-stop, and remove the key.

106-5051

1. Warning—read the Operator’s Manual; use fresh, clean water

for first-aid washing.

108-3312

1. LCD screen

2. Selection dial

3. Reset

4. Calibrate

5. Decrease

6. Increase

106-5050

1. Warning—read the Operator’s Manual; use fresh, clean water

for rinsing the tank.

10

Specifications

Note: Specifications and design are subject to change

without notice.

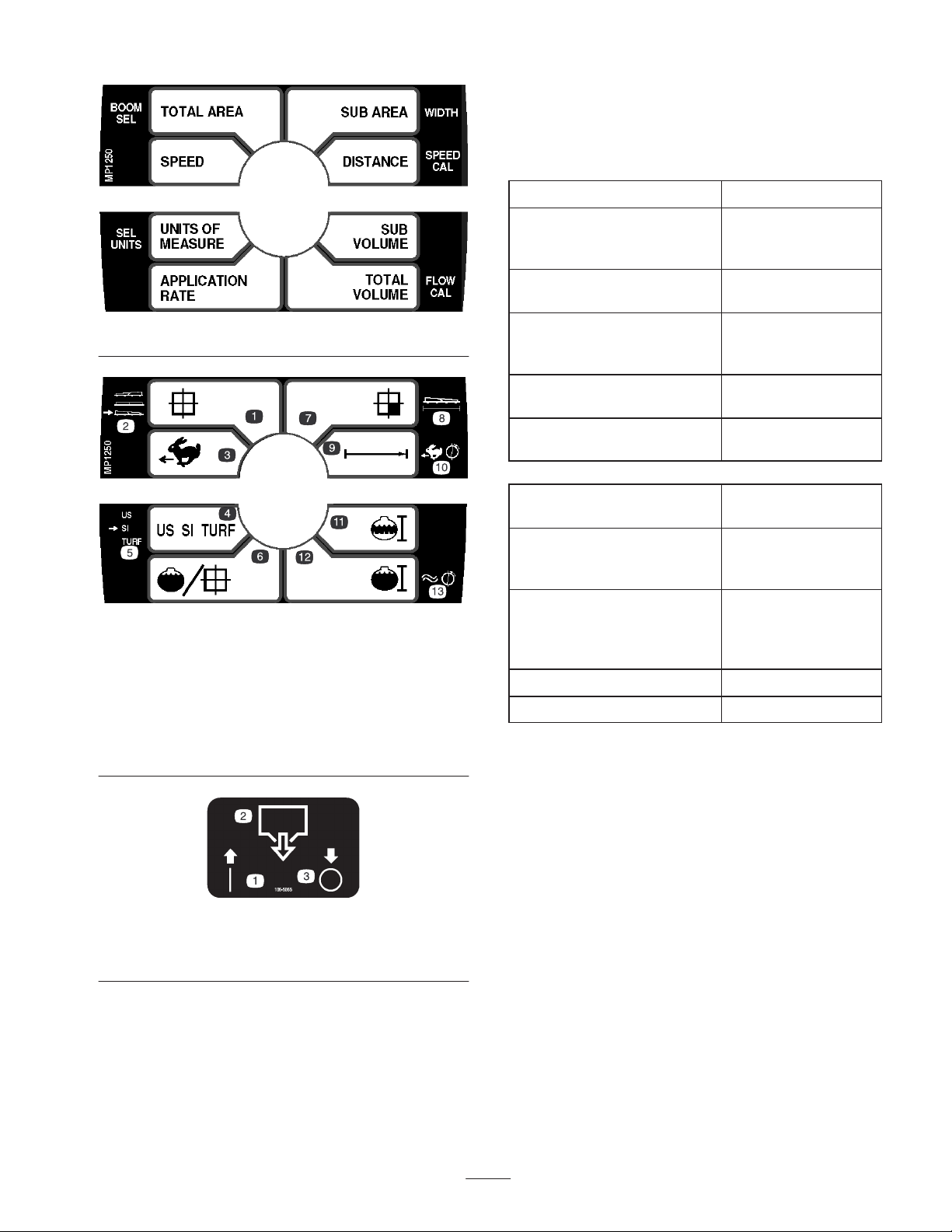

1. Total area

2. Boom select

3. Speed

4. Units of Measure

5. Select units

6. Application rate

7. Sub area

108-3307

108-3309

8. Width

9. Distance

10. Speed calibration

11. Sub volume

12. Total volume

13. Flowmeter calibration

Base weight

Weight with standard spray

1,673 lb (759 kg)

1,778 lb (806.5 kg)

system, empty, without

operator

Weight with standard spray

3,378 lb (1,532 kg)

system, full, without operator

Maximum gross vehicle

3,626 lb (1,645 kg)

weight (GVW)

(on level ground)

Tank capacity (includes the

CE 5% overflow)

Overall width without

175 US gallons

(662 L)

56 inches (142 cm)

standard spray system

Overall length with standard

120 inches (305 cm)

spray system

Overall height with standard

spray system to the top of

37.5 inches

(95.25 cm)

the tank

Overall height with standard

74 inches (188 cm)

spray system to the top of

the booms stored in the X

pattern

Ground clearance 4.5 inches (11.4 cm)

Wheel base 62 inches (157 cm)

Optional Equipment

The Toro Company has optional equipment and accessories

that you can purchase separately and install on your

sprayer. Contact your Authorized Service Dealer for a

complete list of optional equipment that is currently

available for your sprayer.

1. On

2. Tank drain

106-5065

3. Off

11

Setup

Note: Determine the left and right sides of the machine from the normal operating position.

To use the sprayer, you must obtain and install a boom kit and nozzles. Contact your Authorized Toro Distributor for

information on the available boom kits and accessories. After you install your booms and nozzles and before using the

sprayer for the first time, adjust the boom bypass valves so that the pressure and application rate remains the same for all

booms when you turn one or more booms off. Refer to Adjusting the Boom Bypass valves, page 25.

Caution

Without a boom kit installed, the sprayer may spray chemicals out of the boom valves, possibly

injuring bystanders or causing property damage.

Do not run the sprayer without a boom kit and nozzles installed.

Loose Parts

Note: Use the chart below to verify that all parts have been shipped.

Description Qty. Use

90 degree fitting

Quick coupler

Hose adapter

Fill receptacle bracket

Flange-head bolt, 5/16 x 3/4 inch

Anti-siphon hose

Spray Pro Monitor

Spray Pro Decal

Bracket

Flange-head bolt, 3/4 inch

Flange nut, 1/4 inch

Knob

Washer

Carriage bolt

Key 2 Use in the ignition switch.

Operator’s Manual

Engine Operator’s Manual

Operator Video 1 Watch before operating the machine.

1

1

1

1

1

1

1

1

1

2

2

2

2

2

1

1

Install the anti-siphon fill receptacle.

Install the Spray Pro monitor.

Read before operating the machine.

Parts Catalog 1 Use for ordering replacement parts.

Registration Card 1 Complete and return to Toro.

Predelivery Inspection Form 1 Complete and file in your customer history portfolio.

12

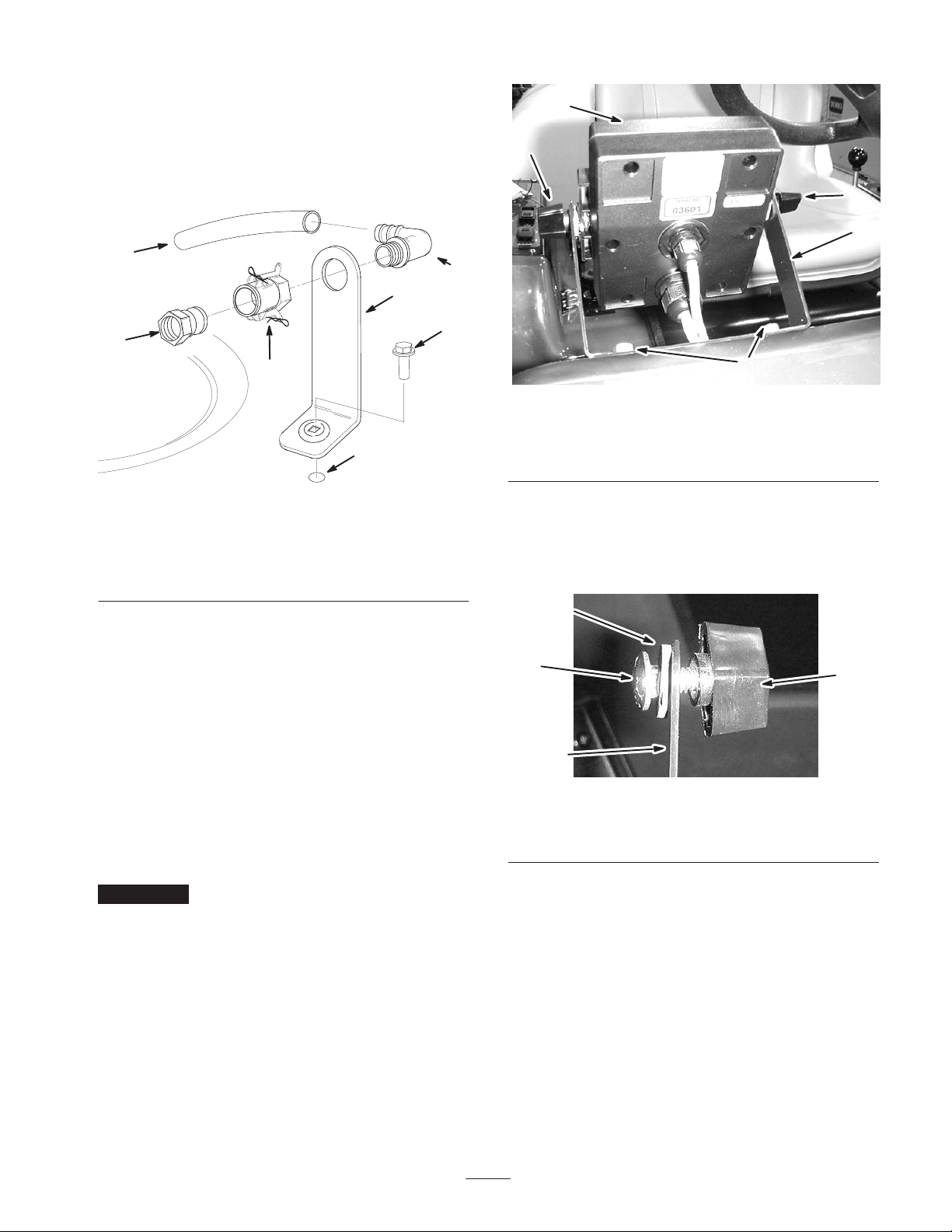

Installing the Anti-siphon Fill

Receptacle

1. Place the fill receptacle bracket over the threaded hole

in the tank and secure it with a flange-head bolt

(5/16 x 3/4 inch) (Fig. 2).

7

1

6

5

2

m-7368

Figure 2

1. Fill receptacle bracket

2. Threaded hole in the tank

3. Flange bolt,

5/16 x 3/4 inch

4. 90 degree elbow fitting

5. Quick coupler

6. Hose adapter

7. Anti-siphon hose

1

4

4

2

4

3

3

Figure 3

1. Spray Pro monitor

2. Bracket

3. Flange-head bolts,

1/4 x 3/4 inch

4. Knob

2. Loosely install the 2 carriage bolts, rubber washers, and

knobs on the bracket as illustrated in Figure 3 and 4.

Note: Install the carriage bolts and rubber washers inside of

the bracket and the knobs on the outside.

2. Place the threaded end of the 90 degree elbow fitting

through the bracket and thread the quick coupler onto it,

securing it to the bracket (Fig. 2).

Note: Install the fitting with the open end pointing

toward the tank opening so the water will arc into the

tank when you fill it.

3. Install the hose adapter into the quick coupler (Fig. 2).

4. Lock the adapter into place by swinging the levers

toward the adapter and then secure them with the

hairpin cotters (Fig. 2).

5. Install the anti-siphon hose on the barbed end of the 90

degree elbow fitting (Fig. 2).

Important Do not lengthen the hose to allow contact

with the tank fluids.

Installing the Spray Pro

Monitor

1. Install the monitor bracket on the dash (Fig. 3) using 2

flange-head bolts (1/4 x 3/4 inch) and 2 flange nuts

(1/4 inch).

2

1

3

4

Figure 4

1. Carriage bolt

2. Rubber washer

3. Knob

4. Bracket

3. Remove the large grommet from the hole in the dash

and thread the cables on the monitor through the

grommet and the dash.

4. Install the grommet into the dash.

5. Apply the Spray Pro Decal to the monitor. Be sure to

orient the decal as shown in Figure 27.

6. Install the Spray Pro monitor over the carriage bolt

heads (Fig. 3) and tighten the knobs to secure it.

7. Connect the Spray Pro wire connectors to the wire

connectors located under the dash (Fig. 5).

13

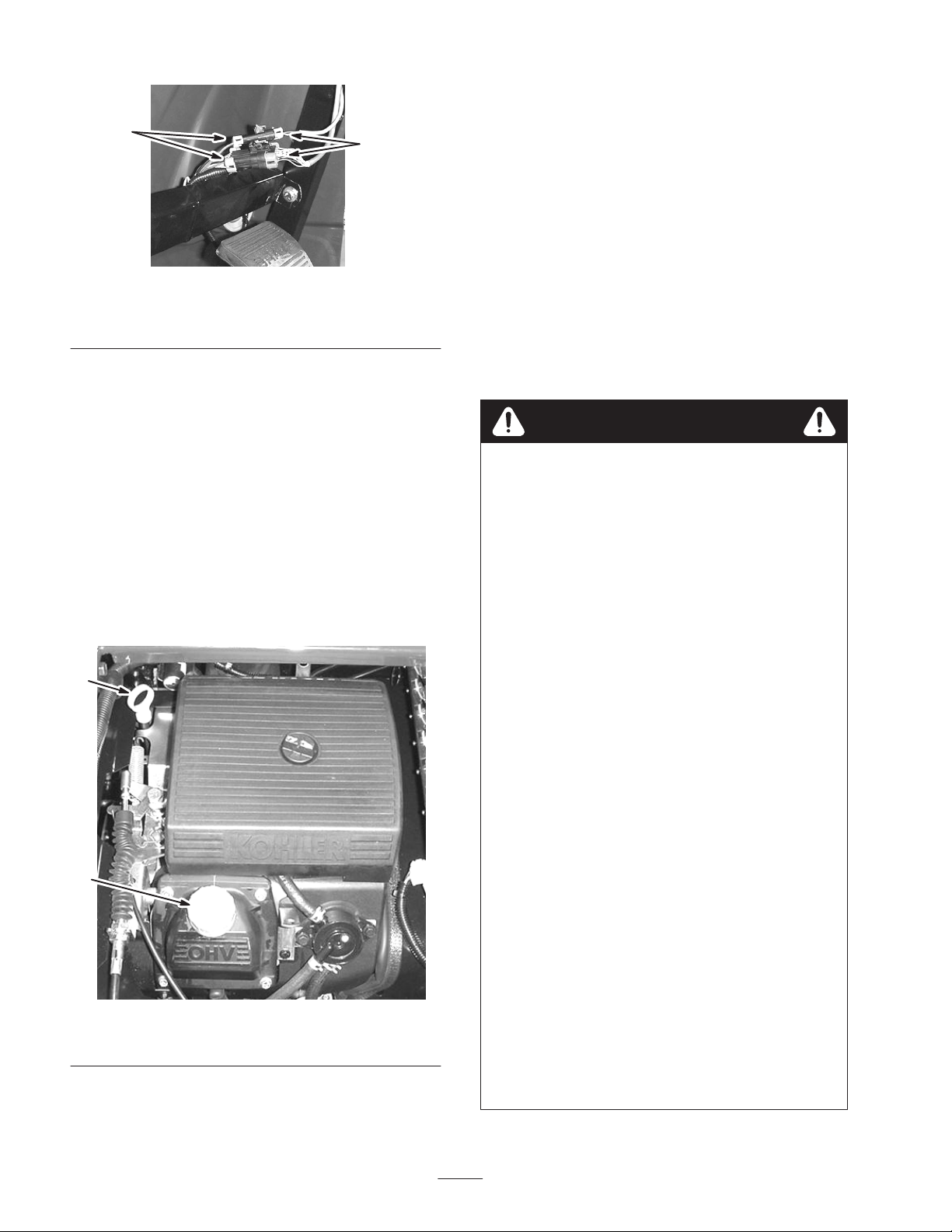

3. If the oil level is low, remove the filler cap from the

valve cover (Fig. 6) and pour oil into the opening until

1

2

the oil level is up to the Full mark on the dipstick; refer

to Servicing Engine Oil, page 33, for the proper oil type

and viscosity. Add the oil slowly and check the level

often during this process. Do not overfill.

4. Install the dipstick firmly in place.

Checking the Tire Pressure

Figure 5

1. Connectors from the

sprayer

2. Connectors from the

monitor

Before Operating

Checking the Engine Oil

The engine is shipped with oil in the crankcase; however,

the level of oil must be checked before you first start the

engine and after you have run it.

1. Position the machine on a level surface.

2. Remove the dipstick and wipe it with a clean rag

(Fig. 6). Insert the dipstick into the tube and make sure

it is seated fully. Remove the dipstick and check the oil

level.

1

2

Figure 6

1. Dipstick 2. Filler cap

Check the tire pressure every 8 hours or daily to ensure

proper levels. Fill the tires to 18 psi (124 kPa). Also,

check the tires for wear or damage.

Adding Fuel

Danger

In certain conditions, gasoline is extremely

flammable and highly explosive. A fire or

explosion from gasoline can burn you and others

and can damage property.

• Fill the fuel tank outdoors, in an open area,

when the engine is cold. Wipe up any gasoline

that spills.

• Do not fill the fuel tank completely full. Add

gasoline to the fuel tank until the level is 1 inch

(25 mm) below the bottom of the filler neck.

This empty space in the tank allows gasoline to

expand.

• Never smoke when handling gasoline and stay

away from an open flame or where gasoline

fumes may be ignited by a spark.

• Store gasoline in an approved container and

keep it out of the reach of children. Never buy

more than a 30-day supply of gasoline.

• Always place gasoline containers on the ground

away from your sprayer before filling.

• Do not fill gasoline containers inside a vehicle or

on a truck or trailer bed because interior

carpets or plastic truck bed liners may insulate

the container and slow the loss of any static

charge.

• When practical, remove gas-powered equipment

from the truck or trailer and refuel the

equipment with its wheels on the ground.

• If this is not possible, then refuel such

equipment on a truck or trailer from a portable

container, rather than from a gasoline dispenser

nozzle.

• If a gasoline dispenser nozzle must be used, keep

the nozzle in contact with the rim of the fuel

tank or container opening at all times until

fueling is complete.

14

Recommended Gasoline

Use fresh, clean, unleaded regular gasoline suitable for

automotive use (87 pump octane minimum). Leaded

gasoline may be used if unleaded regular is not available.

Important Never use gasoline containing methanol,

gasoline containing more than 10% ethanol, gasoline

additives, or white gas because engine fuel system damage

could result.

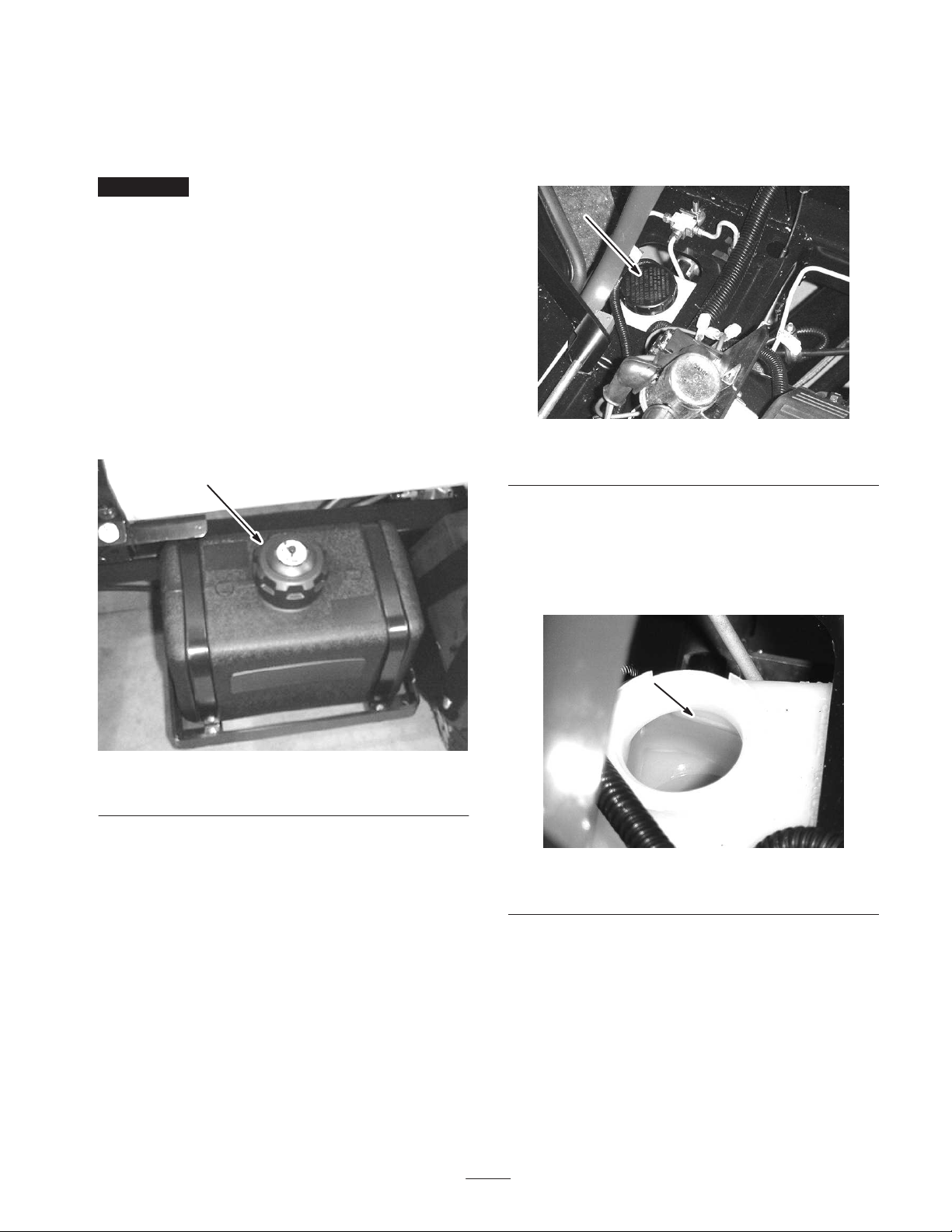

Filling the Fuel Tank

The fuel tank capacity is approximately 6 US gallons

(21 L).

Note: The fuel tank cap contains a gauge which shows the

fuel level; check it frequently.

1. Shut the engine off and set the parking brake.

Checking the Brake Fluid

The brake fluid reservoir is shipped from the factory filled

with DOT 3 brake fluid. Check the level before starting the

engine each day.

1

2. Clean the area around the fuel tank cap (Fig. 7).

1

Figure 7

1. Fuel tank cap

3. Remove the fuel tank cap.

4. Fill the tank to about one inch below the top of the tank,

(bottom of the filler neck). This space in the tank allows

gasoline to expand. Do not overfill.

Figure 8

1. Brake fluid reservoir

1. Position the sprayer on a level surface, set the parking

brake, stop the pump, stop the engine, and remove the

ignition key.

2. The fluid level should be up to the Full line on the

reservoir (Fig. 9).

1

Figure 9

1. Full line

5. Install the fuel tank cap securely.

6. Wipe up any fuel that may have spilled.

Checking the Air Intake Screen

Check and clean as necessary the air intake screen on the

front of the engine every 8 operating hours.

3. If the fluid level is low, clean the area around the

reservoir cap, remove the cap, and fill the reservoir to

the proper level. Do not overfill it.

15

Checking the

Filling the Fresh Water Tank

Transaxle/Hydraulic Fluid

1. Position the sprayer on a level surface, set the parking

brake, stop the pump, stop the engine, and remove the

ignition key.

2. Remove the transaxle dipstick and wipe it with a clean

rag (Fig. 10).

1

2

Figure 10

1. Dipstick 2. Fill hole

Important Be very careful not to get dirt or other

contaminants into the opening when checking the

transmission oil.

The sprayer is equipped with a fresh water tank (Fig. 11)

for you to wash chemicals off of your skin, eyes, or other

surfaces in the case of accidental exposure. Always fill the

fresh water tank with clean water before handling or

mixing any chemicals.

1

2

3

Figure 11

1. Filler cap

2. Fresh water tank

To open the fresh water tank spigot, turn the lever on the

spigot.

3. Spigot

3. Insert the dipstick into the tube and make sure it is

seated fully. Remove the dipstick and check the oil

level.

4. The transaxle fluid level should be at the top of the flat

portion of the dipstick. If it is not, fill the reservoir with

the appropriate fluid; refer to Changing the

Transaxle/Hydraulic Fluid, page 36.

5. Install the dipstick firmly in place.

16

Loading...

Loading...