Toro 41086, Multi-Pro 5700-D, Multi-Pro 5600 Operator's Manual

ProControlSpraySystem

FormNo.3365-343RevA

Multi-Pro

ModelNo.41086—SerialNo.310000001andUp

®

5600and5700-DTurfSprayer

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Thisattachmentcontrolsthesprayfunctionsofaturf

G013320

1

sprayerbasedoncalculationfromuserinputandis

intendedtobeusedbyprofessional,hiredoperatorsin

commercialapplications.Itisprimarilydesignedfor

sprayinggolfcourseapplications,parks,sportselds,

andoncommercialgrounds.Itisdesignedtoonlybe

usedinconjunctionwithmachinesdesignatedbythe

manufacturer.

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Figure2

1.Safetyalertsymbol.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

Introduction

Readthismanualcarefullytolearnhowtooperateand

maintainyourproductproperly.Theinformationinthis

manualcanhelpyouandothersavoidinjuryandproduct

damage.AlthoughTorodesignsandproducessafe

products,youareresponsibleforoperatingtheproduct

properlyandsafely.YoumaycontactTorodirectlyat

www.Toro.comforproductandaccessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.

illustratesthelocationofthemodelandserialnumbers

ontheproduct.

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Figure1

Contents

Introduction.................................................................2

Safety...........................................................................3

Setup............................................................................4

InstallingtheProControlForModelYear2009

andOlderonly..................................................5

InstallingtheProControlForModelYear2010

andNeweronly.................................................6

ProductOverview........................................................9

Controls...............................................................9

Operation...................................................................11

InitiallyProgrammingtheConsole

Computer.......................................................11

ProgrammingtheConsoleComputer..................12

Self-TestingtheConsoleComputer.....................14

ActivatingtheDataLock....................................14

ChangingtheDataLock.....................................14

EnteringtheModeSequencewiththeData

LockActivated...............................................15

SettingthePowerDownDelayTime...................15

UsingtheConsoleComputerAlarm...................15

SettingtheLowLimitFlowSetPointandLow

LimitAlarm...................................................15

SettingUptheSystem.........................................15

InitiallyField-testingtheSystem..........................16

Maintenance...............................................................17

RecommendedMaintenanceSchedule(s)................17

CleaningtheFlowmeter......................................17

CalibratingtheFlowmeter..................................17

TestingtheFlowmeterCable...............................18

Troubleshooting.........................................................19

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

©2010—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

2

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved

Safety

Readandunderstandthecontentsofthismanual

beforeoperatingtheconsolecomputer.

•KeepthisdocumentwiththeOperator’sManualfor

theMultiPro

•Itisveryimportantthatallwhooperatethis

equipmenthavereadyaccesstotheseinstructions

atalltimes.

•Readtheseinstructionsandtheinstructionsinthe

Operator’sManualfortheMultiPro®5600or

5700-DTurfSprayercarefully .Befamiliarwiththe

controlsandtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethecontrols.

•Neverspraywhilepeople,especiallychildren,orpets

arenearby.

•Chemicalscaninjurepeople,animals,plants,soils,

orotherproperty.Toavoidpersonalinjuryand

environmentaldamage:

®

5600or5700-DTurfSprayer.

–Selecttheproperchemicalsforthejob.

–Followthemanufacturer’sinstructionsonthe

chemicalcontainerlabels.Applyandhandle

chemicalsasrecommended.

–Handleandapplythechemicalswithcare.

–W earallnecessaryprotectiveequipment.

–Handlechemicalsinwell-ventilatedareas.

–Neversmokewhenhandlingchemicals.

–Properlydisposeofunusedchemicalsand

containers.

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

fordamagetoproperty.

3

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

Description

Grommet,large

Carriagebolt(5/16x3/4inch)

Locknut(5/16inch)

Computerconsoleassembly

HandKnob2

Pivotbracket(2009andolderonly)

Hosebarbtting,90degree

Hose,long1

Hoseclamp

Screw,angehead(1/4x3/4inch)

Locknut(1/4inch)

Flowmeter1

Gasket

Flowmeterbarbtting,straight

Hoseclamp,wormscrew2

Hose,short1

Boomvalvecaps3

Plug1

O-ring,large

Grommet,large

Mountingbracket(2010andneweronly)

Carriagebolt(5/16x3/4inch)

Locknut(5/16inch)

Computerconsoleassembly

HandKnob2

Pivotbracket(2010andneweronly)

Hosebarbtting,90degree

Hose(49inlength)

Hoseclamp

Screw,angehead(1/4x3/4inch)

Locknut(1/4inch)

Flowmeter1

Gasket

Flowmeterbarbtting,straight

Hoseclamp,wormscrew2

Hose,(53inlength)

Boomvalvecaps3

Plug1

O-ring,large

Qty.

Use

1

2

2

1

1

1

5

2

2

2

2

1

1

1

4

4

1

1

1

1

5

2

2

2

2

1

1

InstalltheProControl(formodelyear2009andolderonly).

InstalltheProControl(formodelyear2010andnewer

only).

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Note:Duplicationsinthepartslististodistinguishneededpartsforthedifferentinstallationproceduresasthey

pertaintochangesinthemachinefrommodelyeartomodelyear.Usethepartslistforthemodelyearofthe

machinetargetedforinstallation.Surpluspartsmayremain.

4

CAUTION

G013301

3

4

5

2

4

1

4

5

G013302

2

6

1 6

3

4

5

50 in. (1.3 m)

27 in. (69 cm) 15 in. (38 cm)

To boom valves

To pump

G013303

1 2

Manychemicalsarehazardousandcancause

personalinjuryorenvironmentaldamageifyou

applythemimproperly.

Ensurethatsprayerhoseconnectionsaresecure

beforeoperatingthespraysystem.

7.Securethecablestotheconsolecomputerby

rotatingthelockingrings.

8.Attachtheconsolecomputertothemounting

bracketandsecureitwiththe2mountingknobs

Figure3).

(

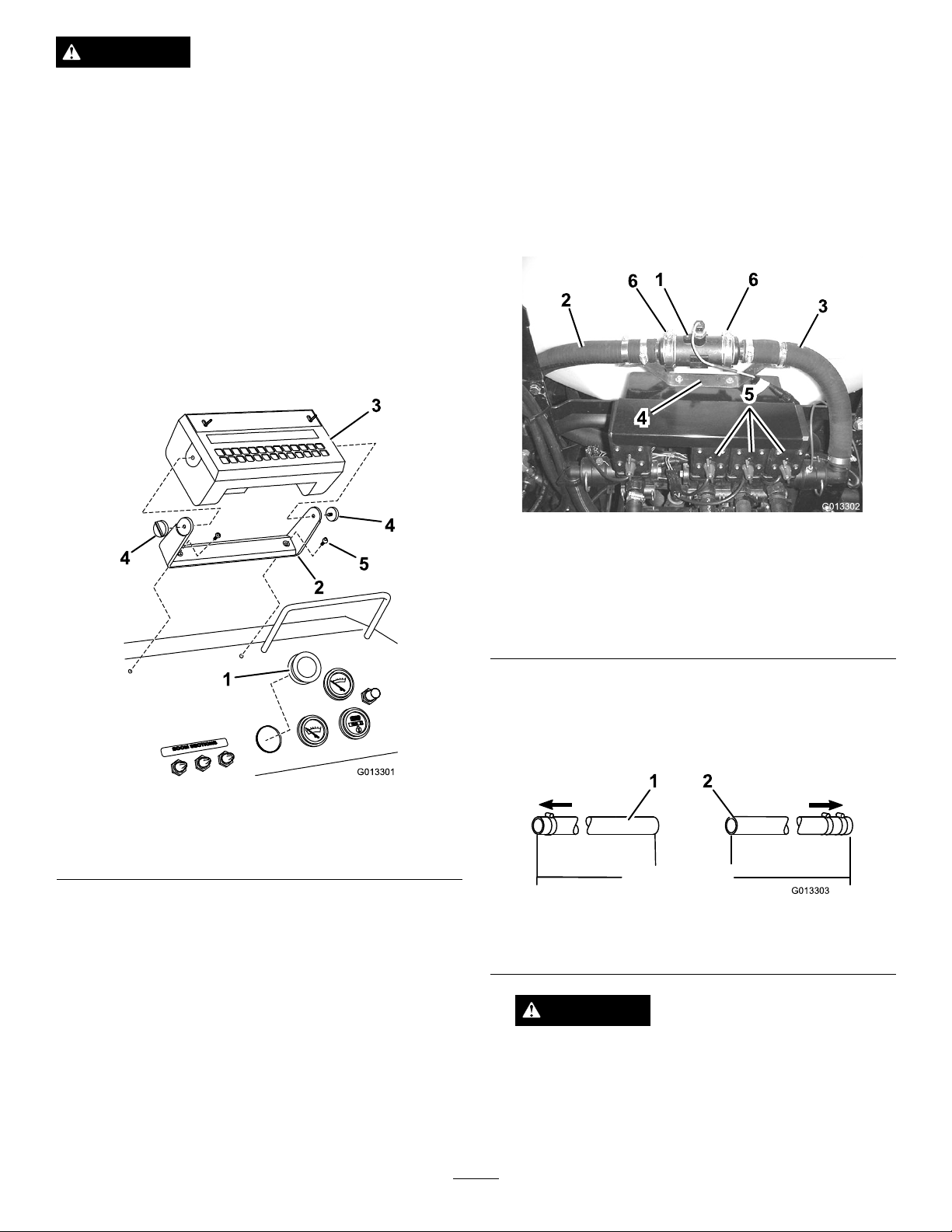

MountingtheFlowmeter

InstallingtheProControl

ForModelYear2009andOlder

only.

InstallingtheConsoleComputer

1.Removetheknockoutpluginthedashboardand

insertthelargegrommet(

Figure3).

1.Disconnecttheboomsupplyhosettingfromthe

boomvalveassembly(Figure4).

Figure4

1.Flowmeter4.Flowmetermounting

2.Boomsupplyhose(longer

section)

3.Boomsupplyhose(shorter

section)

bracket

5.Boomvalveassembly

6.Wormgearscrewclamp

Figure3

1.Largegrommet4.Mountingknobs

2.Mountingbracket

3.Consolecomputer

5.Flangeheadscrew(2)

2.Removethemountingbracketfromtheconsole

computerandsecurethemountingbrackettothe

dashboardwith2angeheadscrews(

3.Cuttheplastictiethatsecurestheconsolecomputer

wiringharnessunderthedashboard.

4.Removethe2protectivecapsfromthecableends.

5.Inserttheconsolecontrolcableandspeedsensor

Figure3).

cablefromunderthedashboardthroughthehole

withthelargegrommet.

6.Plugthecablesintotheirproperreceptaclesinthe

rearoftheconsolecomputer.

2.Disconnecttheboomsupplyhosettingfromthe

teelocatedbehindtheboomvalveassembly .

3.Measure,mark,andcutthesupplyhoseasshown

inFigure5.

Figure5

1.Longersupplyhose

section

2.Shortersupplyhose

section

CAUTION

Manychemicalsarehazardousandcancause

personalinjuryorenvironmentaldamageifyou

applythemimproperly.

Ensurethatsprayerhoseconnectionsaresecure

beforeoperatingthespraysystem.

5

4.Installabarbedttingintotheendofthelonger

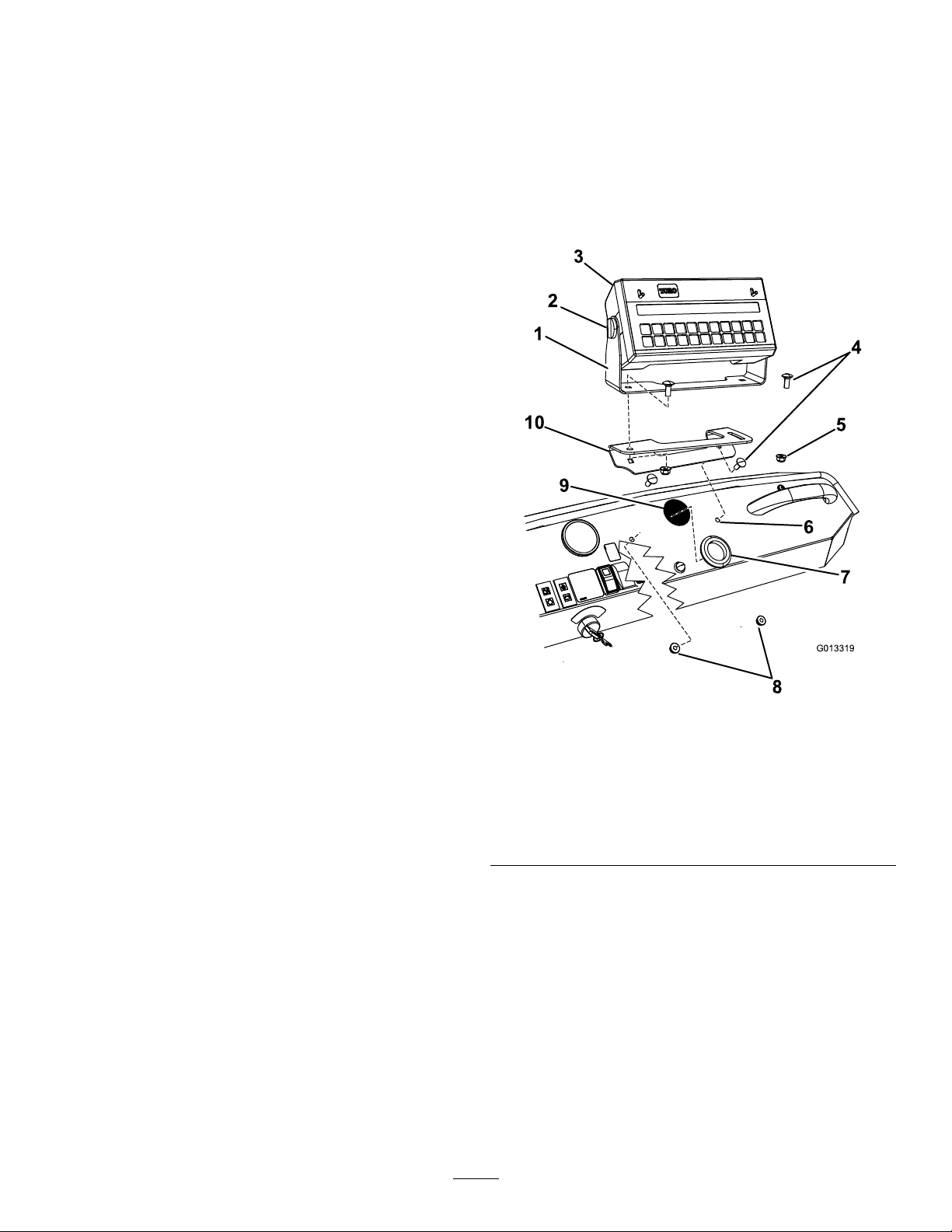

G013319

1

2

3

4

5

6

7

8

9

10

supplyhosesectionandsecureitwithahoseclamp

nexttothettingbody.

Important:Applyliquidsoaptothebarbed

ttingtolubricateit.Youmustinstallthe

hoseallthewayontothebarb.Donotuse

petroleum-basedlubricantssuchasgreaseor

oilbecausetheycandamagethehoseand

contaminatethesystem.

5.Attachthettingontheendofthelongersupply

hosesectiontothetee.

6.Attachthettingontheendoftheshortersupply

hosesectiontotheboomvalveassembly.

7.Attachtheowmeterbrackettotherearoftheboom

valvemountingbracketusing2angeheadscrews

(1/4in.)andangenuts.

8.Assemblethegasketsandbarbedttingsonthe

hosestotheowmeterusing2wormscrewclamps

Figure4).

Important:Notethedirectionoftheowon

thesideoftheowmeterandensurethatthe

owmeterisinstalledproperly(Figure4).

InstallingtheProControl

ForModelYear2010and

Neweronly.

InstallingtheConsoleComputer

1.Locateandremovetheknockoutpluginthe

dashboard.Installthelargegrommetintothe

openinginthedash(Figure6).

9.Securetheowmetertothehoseswith2-inchworm

screwclamps.

10.Securethesupplyhosestotheowmetermounting

bracketwith2hoseclamps(

Figure4).

11.Installabarbedttingintotheendoftheshorter

supplyhosesectionandsecureitwithahoseclamp

nexttothettingbody.

12.Connecttheplugfromtheowmetertoitsmate

pluginthewiringharness.

ClosingtheBoomValves

Thissystemisdesignedtoworkwithadiaphragmpump

andmustoperatewiththeboombypassvalvesclosed.

Important:Beforeoperatingthespraysystemwith

theconsolecomputer,closeallbypassesonyour

boomvalvesbyturningintheredadjustmentknob

atthebottomoftheboomvalvesclockwiseasfar

aspossible.

Figure6

1.Pivotbracket(2010and

neweronly)

2.Handknob7.Largegrommet

3.Consolecomputer8.Locknut(5/16inch)

4.Carriagebolt(5/16x3/4

inch)

5.Locknut(5/16inch)

2.Locatethemountingbracketwiththecurvedslotin

6.Mountingholein

dashboard,existing

9.Knockedoutholeindash

10.Mountingbracket

looseparts.Installthebrackettothedashboardand

secureitwithtwocarriagebolts(5/16x3/4inch)

andtwolocknuts(5/16inch)asshownin

Figure6.

3.Locatetheround,multi-pinconsolecomputer

connectorsonthemainharnesssecuredtotheright

framememberunderthedashboard.

4.Cuttheplastictiethatsecurestheconsolecomputer

wiringtotheframeunderthedashboard.Remove

the2protectivecapsfromthecableends.

5.Routetheconsolecomputercablesfromunderthe

dashboardthroughtheholewiththelargegrommet.

6

Loading...

Loading...