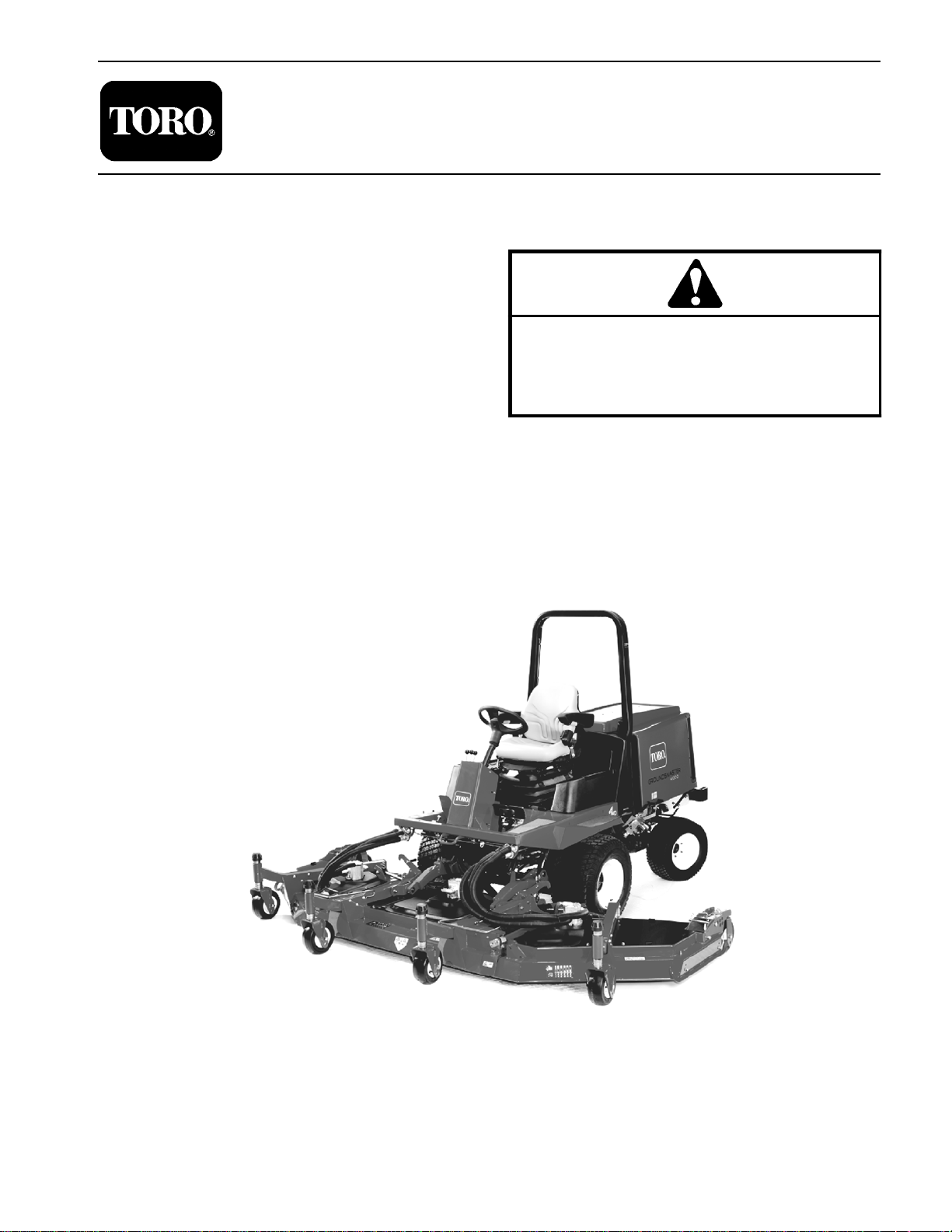

Page 1

Part No. 08162SL (Rev. A)

Service Manual

(Model 30413)

Groundsmaster

Preface

The purpose of this publication is to provide the service

technician with information for troubleshooting, testing

and repair of major systems and components on the

Groundsmaster 4100--D (Model 30413).

REFER TOTHEOPERATOR’S MANUALFOROPERATING, MAINTENANCE AND ADJUSTMENT

INSTRUCTIONS. For reference, insert a copy of the

Operator’sManualandParts Catalog for your machine

into Chapter 2 of this service manual. Additional copies

of the Operator’s Manual and Parts Catalog are available on the internet at www.Toro.com.

TheToroCompany reservestheright tochange product

specifications or this publication without notice.

R

4100--D

This safety symbol means DANGER, WARNING

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: ANOTE willgivegeneral informationabout the

correct operation, maintenance, service, testing or repair of the machine.

IMPORTANT: The IMPORTANT notice will give im portantinstructionswhichmustbefollowed to prevent damage to systems or components on the

machine.

E The Toro Company -- 2008, 2012

Page 2

This page is intentionally blank.

Groundsmaster 4100--D

Page 3

Table Of Contents

Chapter 1 -- Safety

General Safety Instructions 1 -- 2..................

Jacking Instructions 1 -- 4.........................

Safety and Instruction Decals 1 -- 5................

Chapter 2 -- Product Records and Maintenance

Product Records 2 -- 1...........................

Maintenance 2 -- 1...............................

Equivalents and Conversions 2 -- 2................

Torque Specifications 2 -- 3.......................

Chapter 3 -- Kubota Diesel Engine

General Information 3 -- 2........................

Specifications 3 -- 3..............................

Service and Repairs 3 -- 4........................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

V2403--M--T--E3B SERIES

Chapter 4 -- Hydraulic System

Specifications 4 -- 2..............................

General Information 4 -- 3........................

Hydraulic Schematic 4 -- 8........................

Hydraulic Flow Diagrams 4 -- 10...................

Special Tools 4 -- 26.............................

Troubleshooting 4 -- 28...........................

Testing 4 - - 31...................................

Adjustments 4 -- 60..............................

Service and Repairs 4 -- 61.......................

EATON MODEL 72400 SERVO CONTROLLED PIS-

TON PUMP REPAIRINFORMATION

EATONMODEL 74318 and 74348 PISTONMOTORS:

FIXED DISPLACEMENT, VALVE PLATE DESIGN

REPAIR INFORMATION

Chapter 5 -- Electrical System

General Information 5 -- 2........................

Special Tools 5 -- 3..............................

Troubleshooting 5 -- 5............................

Electrical System Quick Checks 5 -- 8..............

Adjustments 5 -- 9...............................

Component Testing 5 -- 11........................

Service and Repairs 5 -- 37.......................

Chapter 6 -- Axles, Planetaries and Brakes

Specifications 6 -- 2..............................

General Information 6 -- 3........................

Service and Repairs 6 -- 4........................

Chapter 7 -- Chassis

General Information 7 -- 1........................

Service and Repairs 7 -- 2........................

Chapter 8 -- Cutting Deck

Specifications 8 -- 2..............................

General Information 8 -- 3........................

Troubleshooting 8 -- 4............................

Service and Repairs 8 -- 6........................

Chapter 9 -- Foldout Drawings

Hydraulic Schematic 9 -- 3........................

Electrical Schematic 9 -- 4........................

Circuit Diagrams 9 -- 6...........................

Wire Harness Drawings 9 -- 12....................

SafetyProduct Records

and Maintenance

Kubota

Diesel Engine

System

Hydraulic

System

Electrical

Axles, Planetaries

and Brakes

Groundsmaster 4100--D

Cutting Deck Chassis

Foldout

Drawings

Page 4

This page is intentionally blank.

Groundsmaster 4100--D

Page 5

Table of Contents

GENERAL SAFETY INSTRUCTIONS 2............

Before Operating 2............................

While Operating 2.............................

Maintenance and Service 3....................

JACKING INSTRUCTIONS 4.....................

Jacking the Front End 4........................

Jacking the Rear End 4........................

SAFETY AND INSTRUCTION DECALS 5..........

Chapter 1

Safety

Safety

Groundsmaster 4100--D

Page 1 -- 1

Safety

Page 6

General Safety Instructions

TheGROUNDSMASTER 4100-D was tested and certified by TORO for compliance with existing safety standards and specifications. Although hazard control and

accident prevention partially are dependent upon the

design and configuration of the machine, these factors

are also dependent upon the awareness, concern and

proper training of the personnel involved in the operation, transport, maintenance and storage of the machine.Improper use or maintenance ofthemachinecan

resultin injury or death. To reduce thepotentialforinjury

or death, comply with the following safety instructions.

Before Operating

WARNING

To reduce the potential for injury or death,

comply with the following safety instructions.

1. Review and understand the contents of the Operator’s Manual and Operator’s DVD before starting and

operatingthe vehicle. Become familiar with the controls

and know how to stop the vehicle and engine quickly.

AdditionalcopiesoftheOperator’sManualareavailable

on the internet at www.Toro.com.

2. Keepall shields, safetydevices and decals in place.

Ifa shield, safety device or decal isdefective,illegibleor

damaged, repair or replace it before operating the machine.Also tighten anyloosenuts,bolts or screws toensure machine is in safe operating condition.

3. Assure interlock switches are adjusted correctly so

engine cannot be started unless traction pedal is in

NEUTRAL and cutting deck is DISENGAGED.

While Operating

1. Sit on the seat when starting and operating the machine.

2. Before starting the engine:

A. Apply the parking brake.

B. Make sure traction pedal is in neutral and the

PTO switch is OFF (disengaged).

C. Afterengineis started,releaseparking brakeand

keepfootofftraction pedal. Machine must not move.

If movement is evident, the traction pedal linkage is

adjusted incorrectly; therefore, shut engine off and

adjust linkage until machine does not move when

traction pedal is released.

4. Sincediesel fuel is highly flammable, handle it carefully:

A. Use an approved fuel container.

B. Donotremovefuel tank capwhileengine ishotor

running.

C. Do not smoke while handling fuel.

D. Fillfueltankoutdoors and onlytowithinan inch of

the top of the tank, not the filler neck. Do not overfill.

E. Wipe up any spilled fuel.

5. Before getting off the seat:

A. Ensure that traction pedal is in neutral.

B. Apply parking brake.

C. Disengage cutting deck and wait for blades to

stop.

D. Stop engine and remove key from switch.

E. Toro recommends that anytime the machine is

parked (short or long term), the cutting deck should

be lowered to the ground. This relieves pressure

from the lift circuit and eliminates the risk of the cutting deck unexpectedly lowering to the ground.

3. Do not run engine in a confined area without adequate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

4. Do not touch engine, muffler or exhaust pipe while

engineisrunningorsoonafteritisstopped.Theseareas

could be hot enough to cause burns.

Safety

Page 1 -- 2

F. Donotparkonslopesunlesswheels arechocked

or blocked.

Groundsmaster 4100--D

Page 7

Maintenance and Service

1. Beforeservicing ormakingadjustments, lower deck,

stop engine, apply parking brake and remove key from

the switch.

2. Makesure machine isin safe operating condition by

keeping all nuts, bolts and screws tight.

3. Never store the machine or fuel container inside

wherethereisanopenflame,suchasnearawaterheater or furnace.

4. Makesureall hydraulic line connectors are tight and

all hydraulic hoses and lines are in good condition before applying pressure to the system.

5. Keepbodyandhandsaway frompin holeleaks inhydrauliclinesthateject high pressure hydraulic fluid. Use

cardboard or paper to find hydraulic leaks. Hydraulic

fluid escaping under pressure can penetrate skin and

cause injury. Fluid accidentally injected into the skin

mustbe surgically removed within a few hours by a doctor familiar with this form of injury or gangrene may result.

6. Beforedisconnecting or performing any work on the

hydraulic system, all pressure in system must be relieved by stopping engine and lowering cutting deck to

the ground.

10.Do not overspeed the engine by changing governor

setting.Toassuresafety andaccuracy,checkmaximum

engine speed.

11.Shut engine off before checking or adding oil to the

crankcase.

12.Disconnect battery before servicing the machine.

Disconnect negative cable first and positive cable last.

If battery voltage is required for troubleshooting or test

procedures,temporarilyconnectthebattery.Reconnect

positive cable first and negative cable last.

13.Battery acid is poisonous and can cause burns.

Avoidcontact with skin, eyes and clothing. Protect your

face, eyes and clothing when working with a battery.

14.Battery gases can explode. Keep cigarettes, sparks

and flames away from the battery.

15.At the time of manufacture, the machine conformed

tothesafety standards for riding mowers. Toassure optimumperformance and continuedsafetycertificationof

the machine, use genuine Toro replacement parts and

accessories.Replacementparts andaccessoriesmade

by other manufacturers may result in non-conformance

with the safety standards and the warranty may be

voided.

Safety

7. Ifmajor repairs are everneeded or assistance is desired, contact an Authorized Toro Distributor.

8. To reduce potential fire hazard, keep engine area

free of excessive grease, grass, leaves and dirt. Clean

protective screen on machine frequently.

9. Ifengine must berunningtoperformmaintenanceor

an adjustment, keep hands, feet, clothing and other

partsof the bodyawayfromcutting deck and othermoving parts. Keep bystanders away.

16.When changing attachments, tires or performing

other service, use correct blocks, hoists and jacks.

Make sure machine is parked on a solid level surface

suchasaconcrete floor.Priortoraising themachine,remove any attachments that may interfere with the safe

and proper raising of the machine. Always chock or

block wheels. Use appropriate jack stands to support

the raised machine. If the machine is not properly supported by jack stands, the machine may move or fall,

whichmay resultinpersonal injury(seeJacking Instructions in this chapter).

Groundsmaster 4100--D

Page 1 -- 3

Safety

Page 8

Jacking Instructions

CAUTION

When changing attachments, tires or performing other service, use correct jacks and supports. Make sure machine is parked on a solid,

level surface such as a concrete floor. Prior to

raising machine, remove any attachments that

may interfere with the safe and proper raising of

themachine.Always chockorblockwheels.Use

jackstands to support the raised machine.If the

machine is not properly supported by jack

stands, the machine may move or fall, which

may result in personal injury.

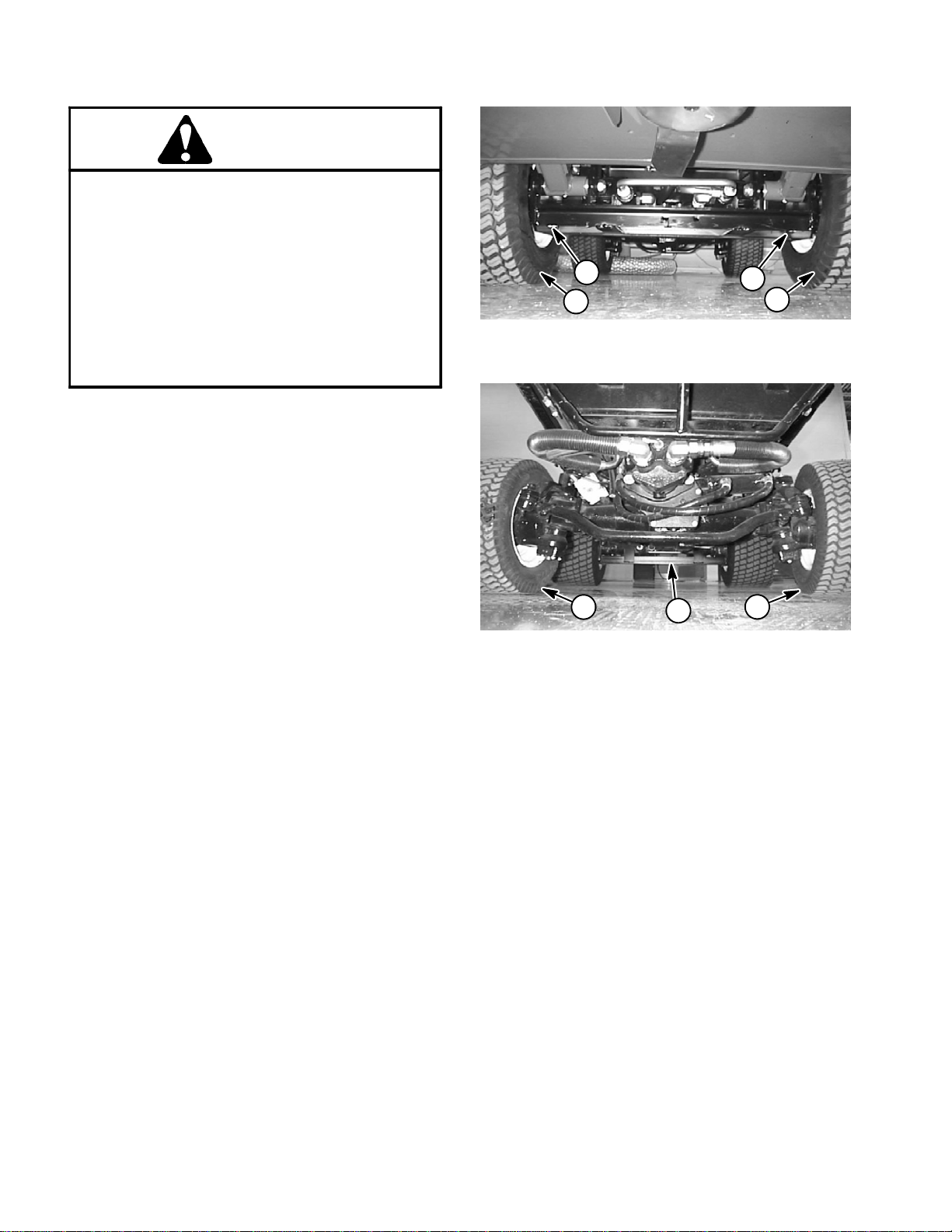

Jacking the Front End (Fig. 1)

1. Set parking brake and chock both rear tires to prevent the machine from moving.

2. Positionjack securelyunder the frame, just to the inside of the front tire. Jack front wheel off the ground.

1

2

Figure 1

1. Frame jacking point 2. Front tire

1

2

3. Once the machine is raised, position suitable jack

standunder the frame as close to the wheel aspossible

to support the machine.

Jacking the Rear End (Fig. 2)

1. Place jack securely under the center of rear axle.

2. Chock both front tires. Jack rear of machine off the

ground.

3. Oncethe machine israised,usesuitablejack stands

under the rear axle to support the machine.

2

1. Rear axle jacking point 2. Rear tire

1

Figure 2

2

Safety

Page 1 -- 4

Groundsmaster 4100--D

Page 9

Safety and Instruction Decals

Numerous safety and instruction decals are affixed to

theGroundsmaster4100--D.If anydecalbecomes illegible or damaged, install a new decal. Decal part numbers are listed in your Parts Catalog.

Safety

Groundsmaster 4100--D

Page 1 -- 5

Safety

Page 10

This page is intentionally blank.

Safety

Page 1 -- 6

Groundsmaster 4100--D

Page 11

Product Records and Maintenance

Table of Contents

PRODUCT RECORDS 1.........................

MAINTENANCE 1..............................

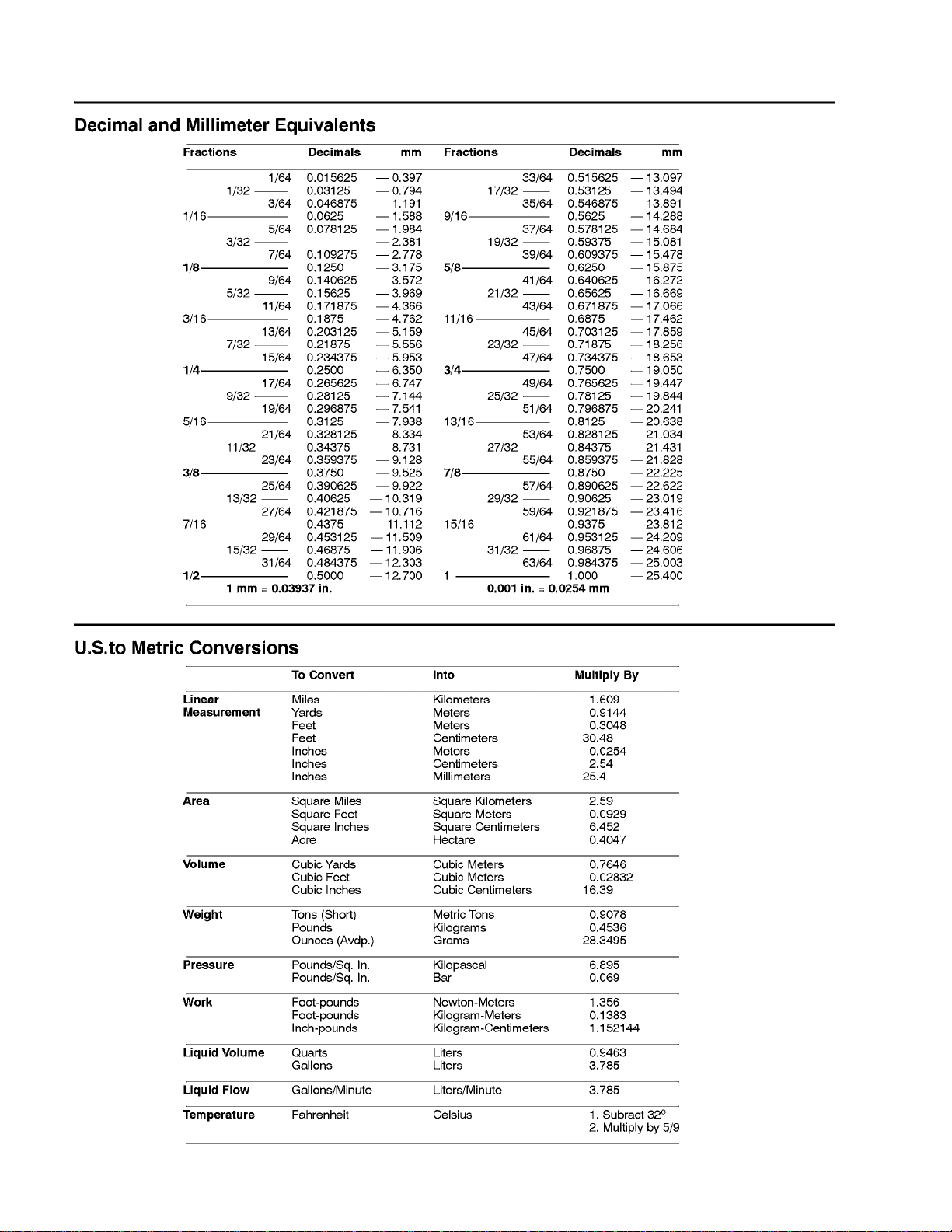

EQUIVALENTS AND CONVERSIONS 2...........

Decimal and Millimeter Equivalents 2............

U.S. to Metric Conversions 2...................

TORQUE SPECIFICATIONS 3...................

Fastener Identification 3.......................

Using a Torque Wrench with an Offset Wrench 3..

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Inch Series) 4...............

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Metric) 5....................

Other Torque Specifications 6..................

Conversion Factors 6.........................

Chapter 2

Product Records

and Maintenance

Product Records

Insert Operator’s Manual and Parts Catalog f or your

Groundsmaster4100--Datthe endofthis chapter.Refer

to Operator’s Manual for recommended maintenance

intervals. Additionally, insert Installation Instructions,

Operator’sManuals and Parts Catalogs for any accessories that have been installed on your Groundsmaster

at the end of this section.

Maintenance

Maintenanceprocedures and recommended service intervals for the Groundsmaster 4100--D are covered in

the Operator’s Manual. Refer to that publication when

performing regular equipment maintenance. Several

maintenanceprocedureshave break--inintervalsidentifiedin the Operator’sManual.Referto the Engine Operator’s Manual for additional engine specific

maintenance procedures.

Groundsmaster 4100--D Page 2 -- 1 Product Records and Maintenance

Rev. A

Page 12

Equivalents and Conversions

0.09375

Groundsmaster 4100--DPage 2 -- 2Product Records and Maintenance

Page 13

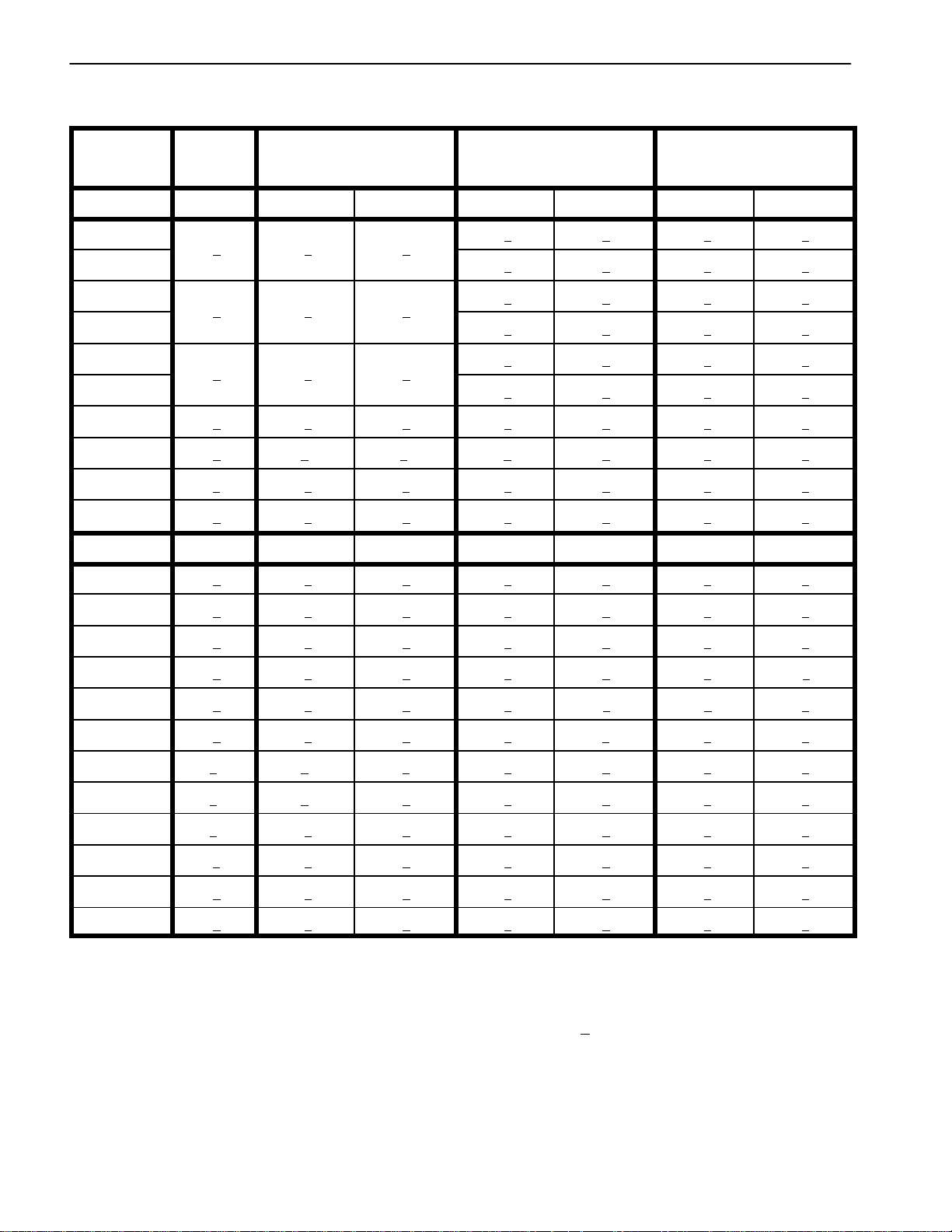

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For criticalapplications,as determined

byToro,eitherthe recommended torque or a torquethat

is unique to the application is clearly identified and specified in this Service Manual.

These Torque Specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specific requirement identified in this Service Manual. The following factors shall be considered

when applying torque: cleanliness of the fastener, use

of a thread sealant (e.g. Loctite), degree of lubrication

on the fastener,presence of a prevailing torque feature

(e.g. Nylock nut), hardness of the surface underneath

thefastener’sheador similar conditionwhichaffectsthe

installation.

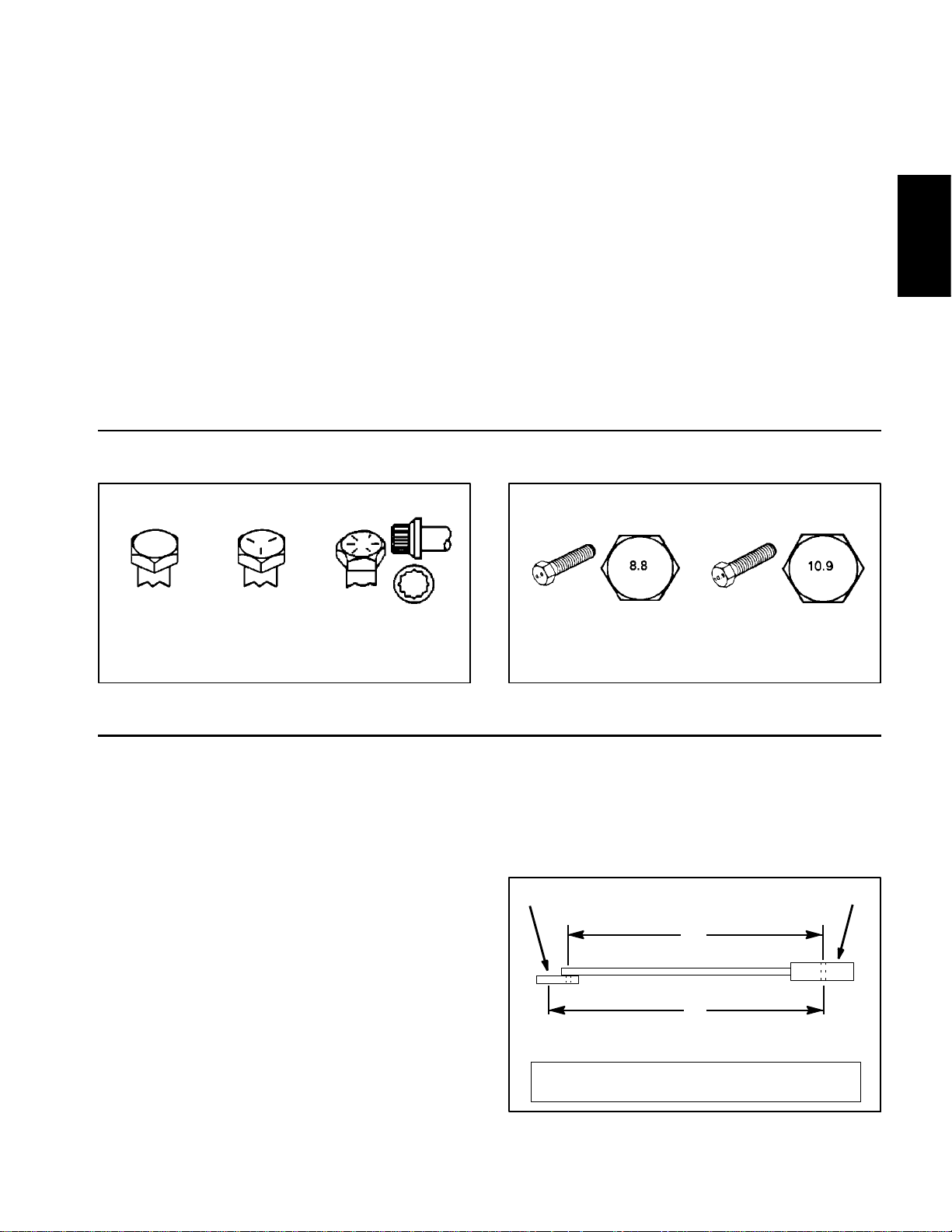

Fastener Identification

Asnoted inthefollowingtables, torquevaluesshould be

reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener. Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based on the aluminum or brass

material strength, fastener size, length of thread engagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measurethetorquerequiredto tighten the fastener until

thelinesmatchup.

Product Records

and Maintenance

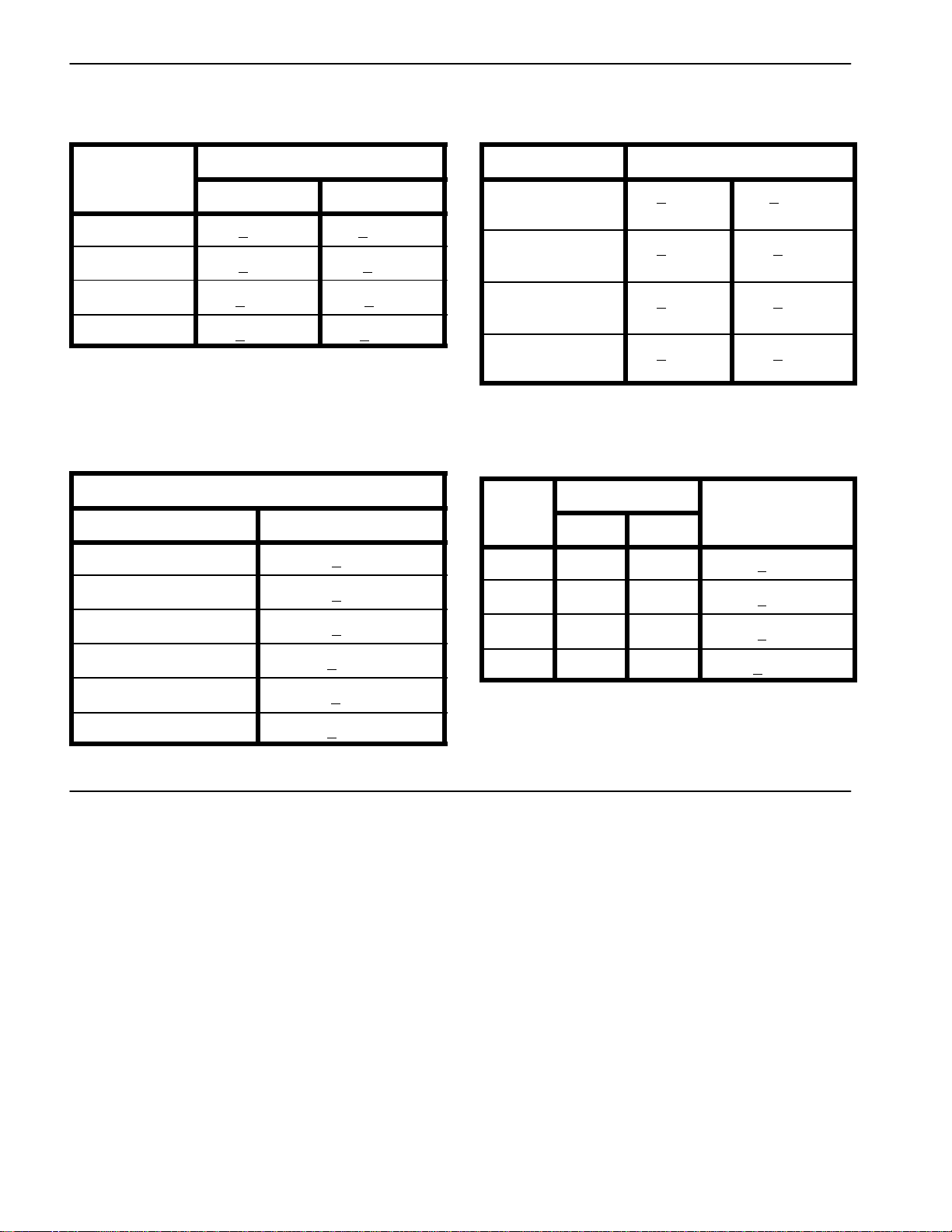

Grade 1 Grade 5 Grade 8

Inch Series Bolts and Screws

Figure 1

Using a Torque Wrench with an Offset Wrench

Useof anoffsetwrench(e.g.crowfoot wrench)willaffect

torquewrench calibration due to the effective change of

torque wrench length.When using atorque wrench with

an offset wrench, multiply the listed torque recommendation by the calculated torque conversion factor (Fig.

3) to determine proper tightening torque. Tightening

torque when using a torque wrench with an offset

wrench will be lower than the listed torque recommendation.

Example: The measured effective length of the torque

wrench (distance from the center of the handle to the

center of the square drive) is 18”.

Themeasuredeffectivelengthofthe torquewrenchwith

the offset wrench installed (distance from the center of

the handle to the center of the offset wrench) is 19”.

Class 8.8 Class 10.9

Metric Bolts and Screws

Figure 2

If the listed torque recommendation for a fastener is

from 76 to 94 ft--lb, the proper torque when using this

torque wrench with an offset wrench would be from 72

to 89 ft--lb.

(effective length of

torque wrench)

A

B

(effective length of torque

wrench + offset wrench)

TORQUE CONVERSION FACTOR = A / B

T orque wrenchOffset wrench

The calculated t orque conversion factor for this torque

wrenchwith this offset wrench would be 18 / 19= 0.947.

Groundsmaster 4100--D Page 2 -- 3 Product Records and Maintenance

Rev. A

Figure 3

Page 14

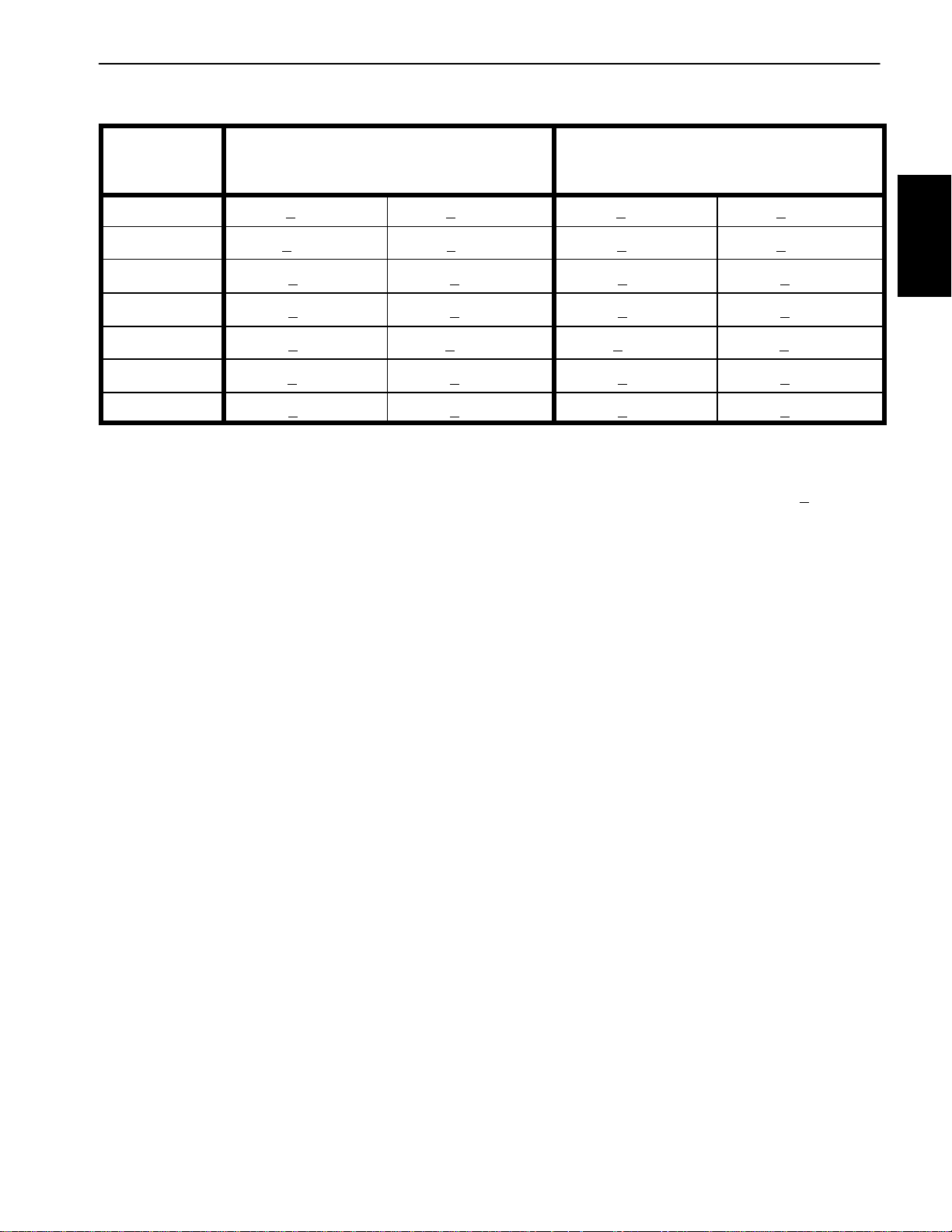

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

Thread Size

# 6 -- 32 UNC

# 6 -- 40 UNF

# 8 -- 32 UNC

# 8 -- 36 UNF

#10--24UNC

#10--32UNF

1/4 -- 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 1130+ 113 140 + 15 1582+ 169

1/4 -- 28 UNF 53 + 7 65+ 10 734 + 113 115 + 12 1299 + 136 160+ 17 1808 + 192

5/16 -- 18 UNC 115 + 15 105 + 15 1186+ 169 200 + 25 2260 + 282 300 + 30 3390 + 339

5/16 -- 24 UNF 138 + 17 128 + 17 1446 + 192 225 + 25 2542 + 282 325 + 33 3672+ 373

3/8 -- 16 UNC 16 + 2 16 + 2 22 + 3 30 + 3 41 + 4 43 + 5 58 + 7

Grade 1, 5 &

8withThin

Height Nuts

in--lb in--lb N--cm in--lb N--cm in--lb N--cm

10 + 2 13 + 2 147 + 23

13 + 2 25 + 5 282 + 56

18 + 2 30 + 5 339 + 56

ft--lb ft--lb N--m ft--lb N--m ft--lb N--m

SAE Grade 1 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

15 + 2 169 + 23 23 + 3 262 + 34

17 + 2 192 + 23 25 + 3 282 + 34

29 + 3 328 + 34 41 + 5 463 + 56

31 + 4 350 + 45 43 + 5 486 + 56

42 + 5 475 + 56 60 + 6 678 + 68

48 + 5 542 + 56 68 + 7 768 + 79

SAE Grade 8 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 5 or Stronger Nuts)

3/8 -- 24 UNF 17 + 2 18 + 2 24 + 3 35 + 4 47 + 5 50 + 6 68 + 8

7/16 -- 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 + 7 95 + 9

7/16 -- 20 UNF 29 + 3 29 + 3 39 + 4 55 + 6 75 + 8 77 + 8 104 + 11

1/2 -- 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 + 11 105 + 11 142 + 15

1/2 -- 20 UNF 32 + 4 53 + 7 72 + 9 85 + 9 115 + 12 120 + 12 163 + 16

5/8 -- 11 UNC 65 + 10 88 + 12 119 + 16 150+ 15 203 + 20 210 + 21 285 + 28

5/8 -- 18 UNF 75 + 10 95 + 15 129 + 20 170 + 18 230 + 24 240 + 24 325 + 33

3/4 -- 10 UNC 93 + 12 140 + 20 190 + 27 265 + 27 359 + 37 375 + 38 508+ 52

3/4 -- 16 UNF 115 + 15 165 + 25 224 + 34 300 + 30 407 + 41 420 + 43 569 + 58

7/8 -- 9 UNC 140 + 20 225+ 25 305 + 34 430 + 45 583+ 61 600 + 60 813 + 81

7/8 -- 14 UNF 155 + 25 260 + 30 353 + 41 475 + 48 644 + 65 667 + 66 904 + 89

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the minimumproof load specified in SAE J429. The tolerance is

approximately +

10% of the nominal torque value. Thin

height nuts include jam nuts.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Groundsmaster 4100--DPage 2 -- 4Product Records and Maintenance

Page 15

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Series)

Class 8.8 Bolts, Screws and Studs with

Thread Size Regular Height Nuts

(Class 8 or Stronger Nuts)

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

(Class 10 or Stronger Nuts)

M5 X 0.8 57 + 6in--lb 644 + 68 N--cm 78 + 8in--lb 881 + 90 N--cm

M6 X 1.0 96 + 10 in--lb 1085 + 113 N- -cm 133 + 14 in--lb 1503 + 158 N--cm

M8 X 1.25 19 + 2ft--lb 26 + 3N--m 28 + 3ft--lb 38 + 4N--m

M10 X 1.5 38 + 4ft--lb 52 + 5N--m 54 + 6ft--lb 73 + 8N--m

M12 X 1.75 66 + 7ft--lb 90 + 10 N--m 93 + 10 ft--lb 126 + 14 N--m

M16 X 2.0 166+ 17 ft--lb 225 + 23 N--m 229 + 23 ft--lb 310 + 31 N--m

M20 X 2.5 325 + 33 ft--lb 440 + 45 N--m 450 + 46 ft--lb 610 + 62 N--m

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAEJ1199.Thetoleranceisapproximately+

nominal torque value.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

10%ofthe

Product Records

and Maintenance

Groundsmaster 4100--D Page 2 -- 5 Product Records and Maintenance

Page 16

Other Torque Specifications

*

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 -- 20 UNC 140 + 20 in--lb 73 + 12 in--lb

5/16 -- 18 UNC 215 + 35 in--lb 145 + 20 in--lb

3/8 -- 16 UNC 35 + 10 ft--lb 18 + 3ft--lb

1/2 -- 13 UNC 75 + 15 ft--lb 50 + 10 ft--lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size Baseline Torque*

No. 6 -- 32 UNC 20 + 5in--lb

Wheel Bolts and Lug Nuts

Thread Size

7/16 -- 20 UNF

Grade 5

1/2 -- 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non--lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5in--lb

Threads per Inch

Type A Type B

Recommended Torque**

65 + 10 ft--lb 88 + 14N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

Baseline Torque

No. 8 -- 32 UNC 30 + 5in--lb

No. 10 -- 24 UNC 38 + 7in--lb

1/4 -- 20 UNC 85 + 15 in--lb

5/16 -- 18 UNC 110 + 20 in--lb

3/8 -- 16 UNC 200 + 100 in--lb

Conversion Factors

in--lb X 11.2985 = N--cm N--cm X 0.08851 = in--lb

ft--lb X 1.3558 = N--m N--m X 0.7376 = ft--lb

No. 8 15 18 30 + 5in--lb

No. 10 12 16 38 + 7in--lb

No. 12 11 14 85 + 15 in--lb

*Holesize,materialstrength,materialthicknessandfinish must be considered when determining specific

torquevalues. Alltorquevalues arebasedonnon--lubricated fasteners.

Groundsmaster 4100--DPage 2 -- 6Product Records and Maintenance

Page 17

Table of Contents

GENERAL INFORMATION 2.....................

Operator’s Manual 2..........................

Stopping the Engine 2.........................

SPECIFICATIONS 3.............................

SERVICE AND REPAIRS 4......................

Air Filter System 4............................

Exhaust System 6............................

Fuel System 8................................

Check Fuel Lines and Connections 9...........

Empty and Clean Fuel Tank 9.................

Fuel Tank Removal 9........................

Fuel Tank Installation 9.......................

Radiator 10..................................

Engine 12....................................

Engine Removal 13..........................

Engine Installation 14........................

Spring Coupler 16.............................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

V2403--M--T--E3B SERIES

Chapter 3

Kubota Diesel Engine

Kubota

Diesel Engine

Groundsmaster 4100--D Page 3 -- 1 Kubota Diesel Engine

Page 18

General Information

ThisChapter gives informationaboutspecificationsand

repair of the diesel engine used in the Groundsmaster

4100--D.

Generalmaintenance procedures are described inyour

Operator’sManual.Informationonenginetroubleshooting,testing, disassembly and reassemblyis identifiedin

the Kubota Workshop Manual, Diesel Engine,

V2403--M--T--E3Bthat is included at the endofthissection.

Most repairs and adjustments require tools which are

commonly available in many service shops. Special

Operator’s Manual

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervalsfor yourGroundsmastermachine.Refer tothat

publicationfor additional informationwhenservicingthe

machine.

Stopping the Engine

tools are described in the Kubota Workshop Manual,

DieselEngine,V2403--M--T--E3B.Theuseofsomespecialized test equipment is explained. However,the cost

of the test equipment and the specialized nature of

somerepairsmaydictatethattheworkbedoneatanengine repair facility.

Service and repair parts for Kubota engines are supplied through your Authorized Toro Distributor. If no

partslistisavailable,bepreparedtoprovideyourdistributor with the Toro model and serial number of your machine.

IMPORTANT: Before stopping the engine after

mowing or full load operation, cool the turbo-charger by allowing the engine to run at low idle speed

for 5 minutes. Failure to do so may lead to turbocharger trouble.

Groundsmaster 4100--DPage 3 -- 2Kubota Diesel Engine

Page 19

Specifications

Item Description

Make / Designation Kubota Model V2403--M--T--E3B: 4--Cycle, 4 Cylinder,

Water Cooled, Turbocharged, Diesel Engine

Bore 3.43” (87.0 mm)

Stroke 4.031” (102.4 mm)

Total Displacement cc (cu. in.) 148.5 in3(2434 cc)

Firing Order 1 (closest to gear case end) -- 3 -- 4 (closest to flywheel end) -- 2

Combustion Chamber Spherical Type (E--TVCS)

Compression Ratio 23.0:1

Direction of Rotation Counterclockwise (viewed from flywheel)

Fuel Diesel or Biodiesel (up to B20) Fuel with Low or Ultra Low

Sulfur Content

Fuel Capacity 19.0 U.S. gallons (72 liters)

Fuel Injection Pump Denso PFR 4M Type Mini Pump

Injection Nozzle Denso OPD Mini Nozzle

Kubota

Diesel Engine

Governor Centrifugal Mechanical

Low Idle (no load) 1450 + 50 RPM

High Idle (no load) 2870 +50/--120 RPM

Engine Oil API CH--4, CI--4 or higher

Engine Oil Viscosity See Operator’s Manual

Crankcase Oil Capacity 10.0 U.S. Quarts (9.5 Liters) with Filter

Oil Pump Trochoid Type

Coolant Capacity 13 U.S. Quarts (12.3 Liters)

Starter 12 VDC, 2.0 kW

Alternator/Regulator 12 VDC

Standard Alternator 40 amp

Optional Alternator 90 amp

Engine Dry Weight 419 U.S. pounds (190 kg)

Groundsmaster 4100--D Page 3 -- 3 Kubota Diesel Engine

Page 20

Service and Repairs

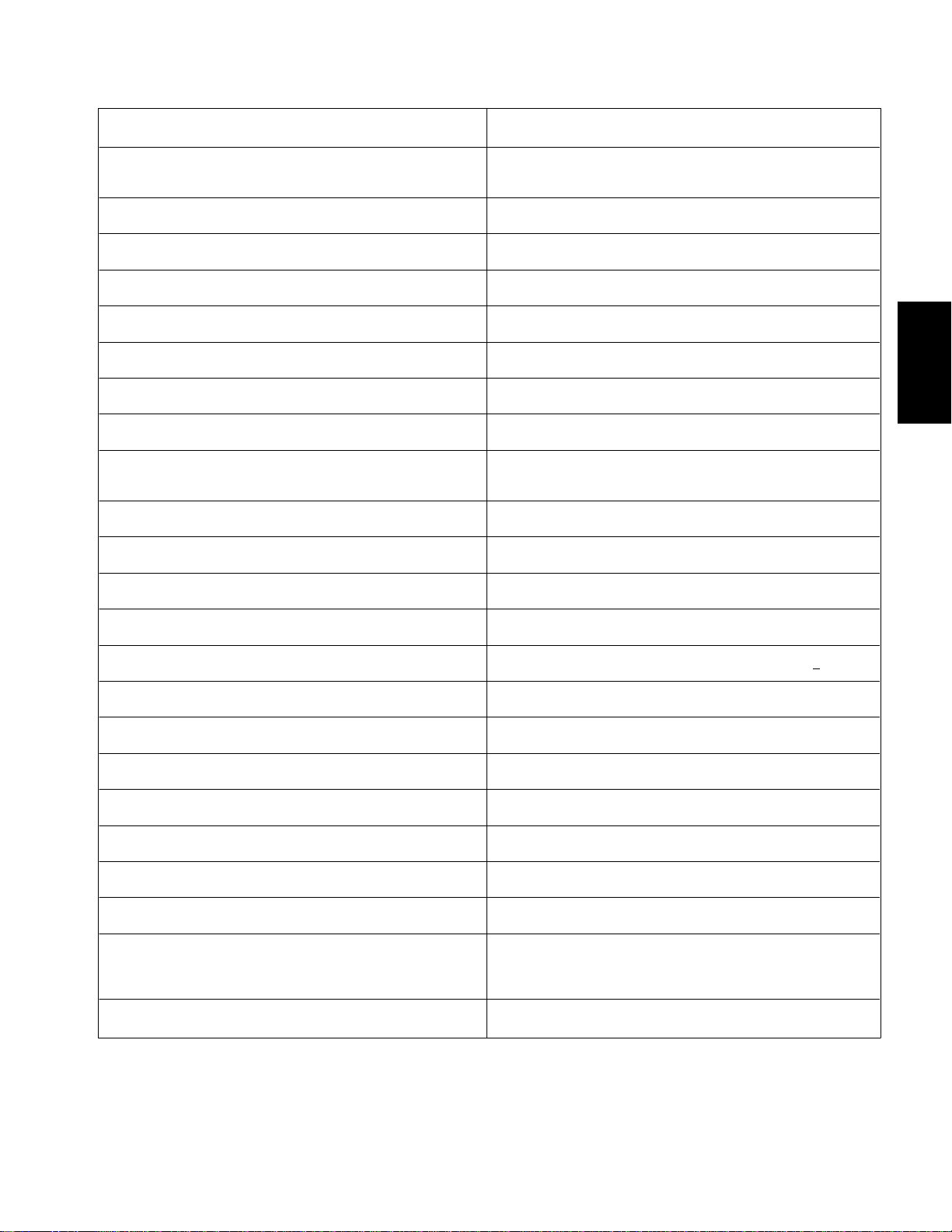

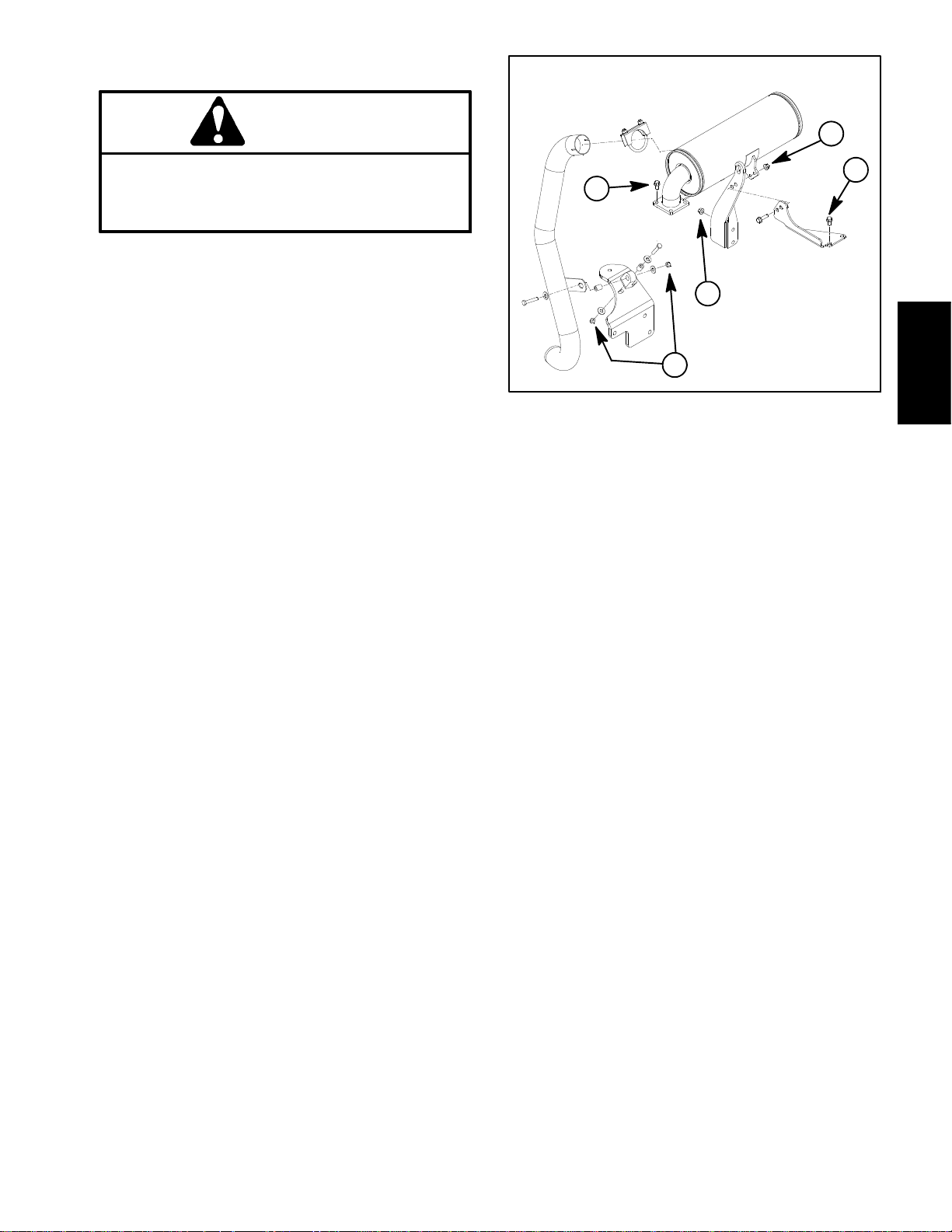

Air Filter System

RIGHT

7

FRONT

10

11

1. Air cleaner hose

2. Hose clamp

3. Air cleaner assembly

4. Indicator

5. Air cleaner strap

6. Lock nut (2 used)

Figure 1

7. Hose clamp

8. Air cleaner hose

9. Hose clamp

10. Cap screw (2 used)

11. Flat washer (4 used)

12. Spring (2 used)

1

9

12 to 15 in--lb

(1.4 to 1.6 N--m)

12

6

11

13

14

4

15

8

2

5

16

17

3

13. Flat washer (2 used)

14. Cap screw (2 used)

15. Adapter

16. Lock nut (2 used)

17. Flat washer (2 used)

VACUATOR

DIRECTION

Groundsmaster 4100--DPage 3 -- 4Kubota Diesel Engine

Page 21

Removal (Fig. 1)

1. Parkmachineon a level surface, lower cutting deck,

stop engine, apply parking brake and remove key from

the ignition switch.

2. Raise and support hood.

3. Remove air cleaner components as needed using

Figure 1 as a guide.

Installation (Fig. 1)

IMPORTANT: Any leaks in the air filter system will

causeserious engine damage.Make surethat allair

cleaner components are in good condition and are

properly secured during assembly.

1. Assemble air cleaner system using Figure 1 as a

guide.

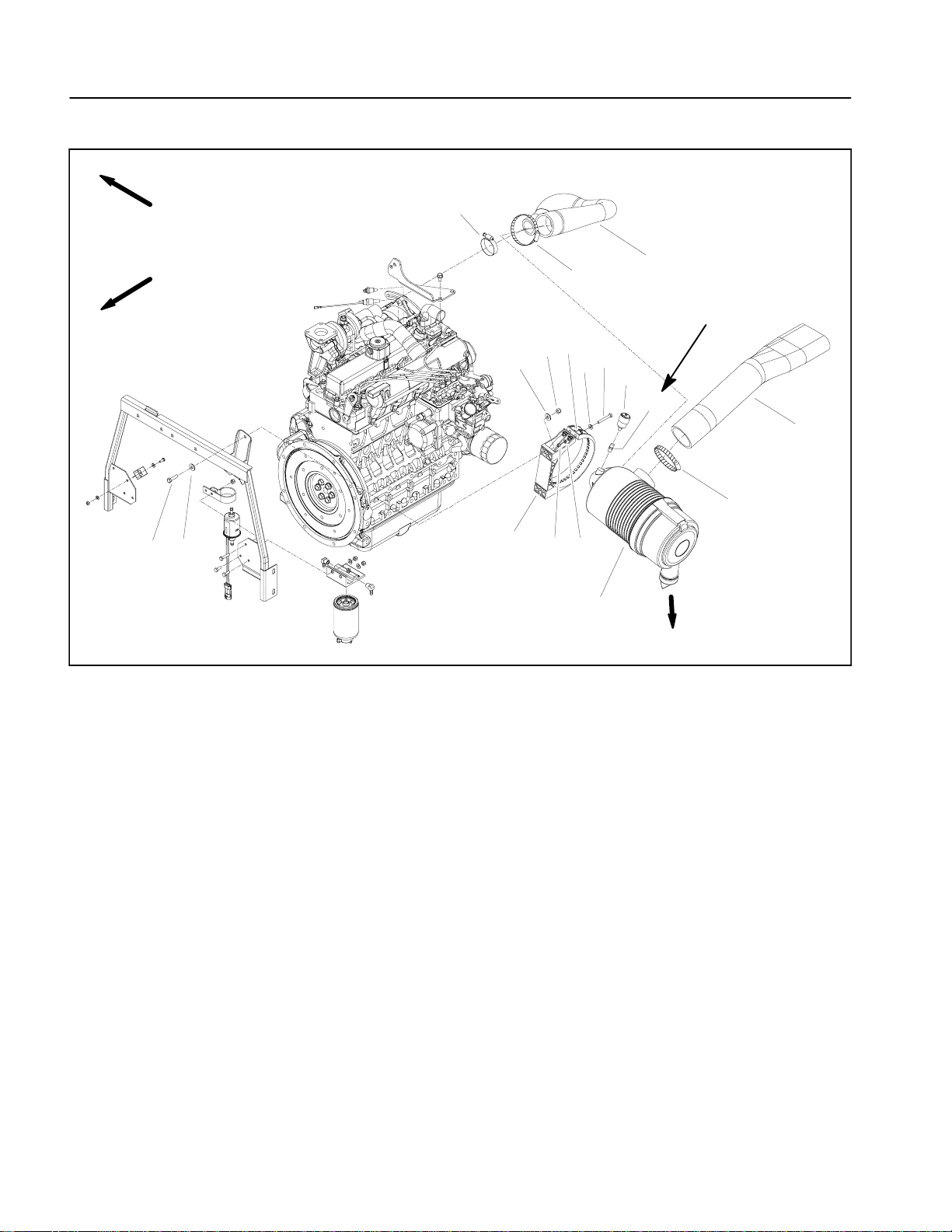

A. If service indicator (item 8) and adapter (item 9)

wereremovedfromaircleanerhousing,applythread

sealant to adapter threads before installing adapter

and indicator to housing. Install adapter so that

groovesinadapter hexandadapterfilter elementare

installed toward serviceindicator (Fig. 3). Torque indicator from 12 to 15 in--lb (1.4 to 1.6 N--m).

4

5

1. Air cleaner housing

2. Safety filter element

3. Air filter element

2

1

3

Figure 2

4. Air cleaner cover

5. Vacuator valve

Kubota

Diesel Engine

2

3

2. When installing air cleaner hose (8) between air

cleaner and turbo--charger (Fig. 4):

A. Make sure that hose does not contact engine

valve cover. To ensure clearance, move and/or rotate air cleaner body in air cleaner strap.

B. Position hose to allow maximum clearance between air cleaner hose and muffler bracket.

3. Lower and secure hood.

1

1. Air cleaner assembly

2. Service indicator

4

3

2

1. Air cleaner hose

2. Engine valve cover

3. Air cleaner strap

Figure 3

3. Adapter

1

5

Figure 4

4. Air cleaner slots

5. Muffler bracket

Groundsmaster 4100--D Page 3 -- 5 Kubota Diesel Engine

Page 22

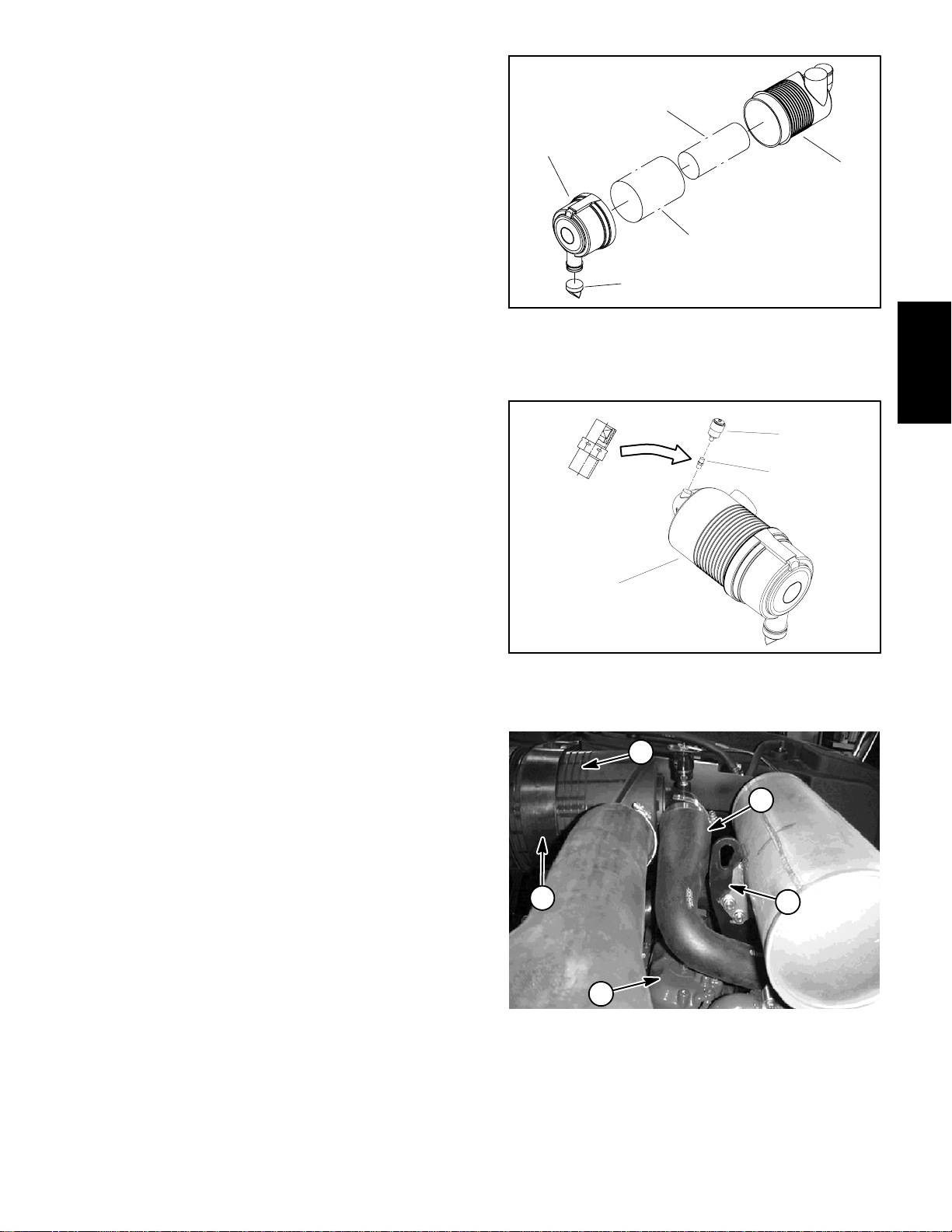

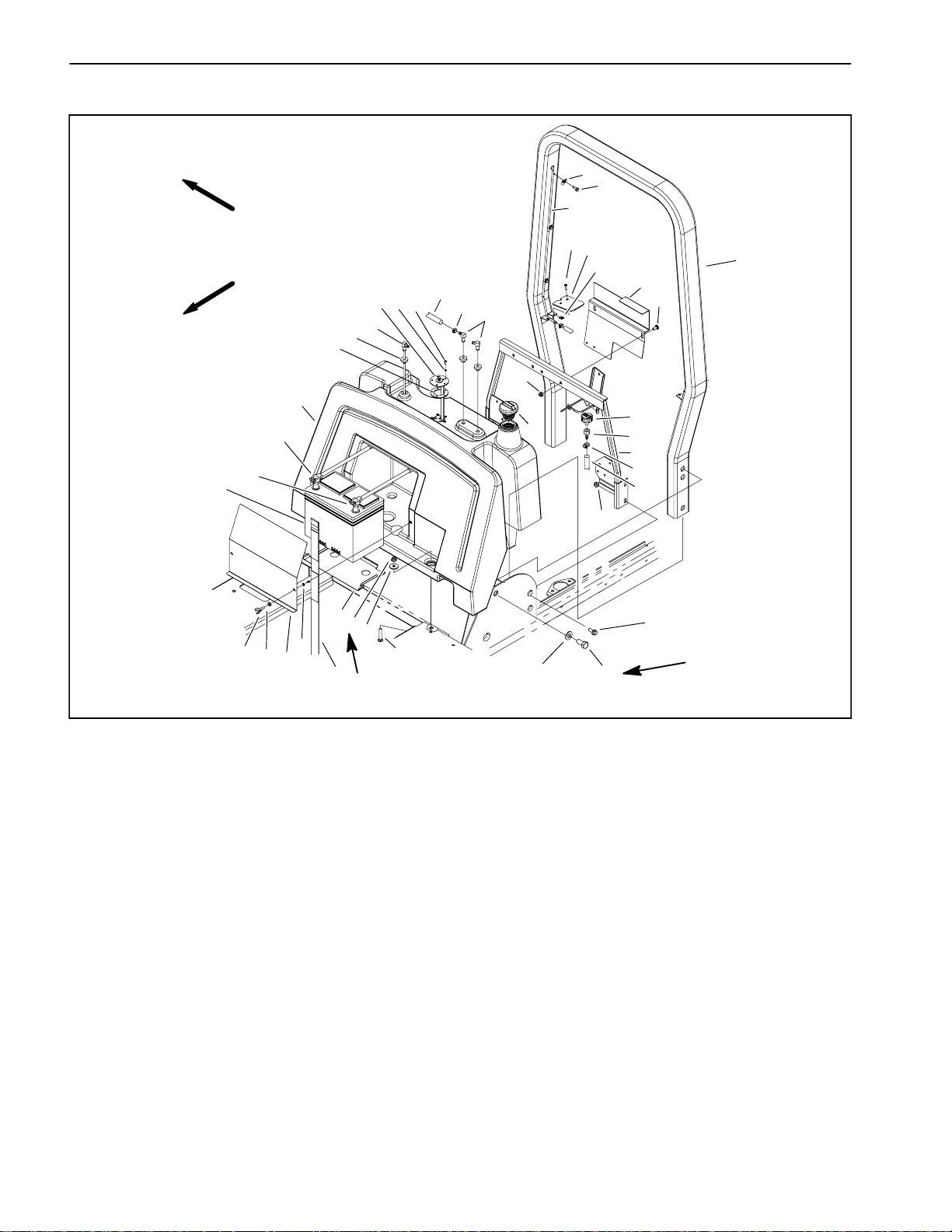

Exhaust System

RIGHT

FRONT

16 to 22 ft--lb

(21to29N--m)

16 to 22 ft--lb

(21to29N--m)

3

7

8

14

4

5

7

8

9

6

13

8

10

16 to 22 ft--lb

(21to29N--m)

11

12

1

16 to 22 ft--lb

(21to29N--m)

11

2

15

16

13 ft--lb

(17.6 N--m)

8

6

1. Muffler

2. Muffler bracket

3. Exhaust pipe

4. Flange head screw (4 used)

5. Exhaust gasket

6. Lock nut (2 used)

Figure 5

7. Cap screw (2 used)

8. Flat washer (4 used)

9. Spacer (2 used)

10. Rubber hanger

11. Flange nut (4 used)

12. Flange head screw (2 used)

13. Engine mount

14. Muffler clamp

15. Exhaust mount

16. Flange head screw (2 used)

Groundsmaster 4100--DPage 3 -- 6Kubota Diesel Engine

Page 23

Removal (Fig. 5)

CAUTION

The muffler and exhaust pipe may be hot. To

avoid possible burns, allow the engine and exhaust system to c ool before working on the muffler.

1. Parkmachine on a level surface, lower cutting deck,

stop engine, apply parking brake and remove key from

the ignition switch.

2. Raise and support hood.

3. Remove exhaust system components from the engine as necessary using Figure 5 as a guide.

Installation (Fig. 5)

IMPORTANT: If exhaust studs were removed from

engine cylinder head, thoroughly clean threads in

head and apply Loctite #277 (or equivalent) to stud

threads before installing studs into head.

NOTE: Make sure muffler flange and exhaust manifold

sealing surfaces are free of debris or damage that may

prevent a tight seal.

B

E

C

D

A

Kubota

Figure 6

Diesel Engine

1. Install new exhaust gasket if original gasket is damaged or torn.

IMPORTANT: Failure to follow the suggested muffler fastener sequencemay result in prematuremuffler failure.

2. Installexhaust system components to theengineusing Figure 5 as a guide. Hand tighten exhaust system

fastenersand thentorqueinthesequence showninFig.

6 as follows:

A. Torque lock nuts used on rubber hanger cap

screws from 16 to 22 ft--lb (21 to 29 N--m).

B. Torque flange nuts that secure muffler to muffler

bracket from 16 to 22 ft--lb (21 to 29 N--m).

C. Torque flange head screws that secure muffler

flange to engine from 16 to 22 ft--lb (21 to 29 N--m).

D. T orqueflangenuts that securemuffler bracketto

engine from 16 to 22 ft--lb (21 to 29 N--m).

E. Torqueflange screws that secure exhaust mount

to engine to 1 3 f t -- l b ( 1 7 . 6 N -- m ) .

3. Tailpipeshouldhave equalclearancebetweenframe

and engine after installation.

4. Lower and secure hood.

Groundsmaster 4100--D Page 3 -- 7 Kubota Diesel Engine

Rev. A

Page 24

Fuel System

RIGHT

FRONT

14

20

21

38

39

37

36

24

25

26

27

28

29

30

35

34

2

22

31

41

23

33

1

3

32

4

5

40

6

7

1. Fuel tank

2. Fuel tank bracket

3. Air breather

4. Female hose barb

5. Tank support assembly

6. Fuel hose

7. Flange nut

8. Cap screw (4 used)

9. Flat washer

10. Cap screw (4 used)

11. Carriage screw (2 used)

12. Washer

13. Battery strap

14. Battery

18

17

16

15

19

7

12

11

13

60 to 80 in--lb

(7 to 9 N--m)

Figure 7

15. Retaining ring (2 used)

16. Battery cover

17. Flat washer (2 used)

18. Knob (2 used)

19. Battery plate

20. Negative battery cable

21. Positive battery cable

22. Carriage screw (2 used)

23. Gasket

24. Bushing (3 used)

25. Stand pipe

26. Fuel sender

27. Lock washer (5 used)

28. Phillips head screw (5 used)

8

135 to 165 ft--lb

9

10

29. Fuel hose

30. Hose clamp

31. Elbow fitting

32. Fuel cap

33. Locking flange nut

34. Speed nut

35. Tank cover (2 used)

36. Phillips head screw

37. Vent tube

38. Insulated clip (3 used)

39. Washer head screw (3 used)

40. Hose clamp

41. ROPS assembly

(183 to 223 N--m)

Groundsmaster 4100--DPage 3 -- 8Kubota Diesel Engine

Page 25

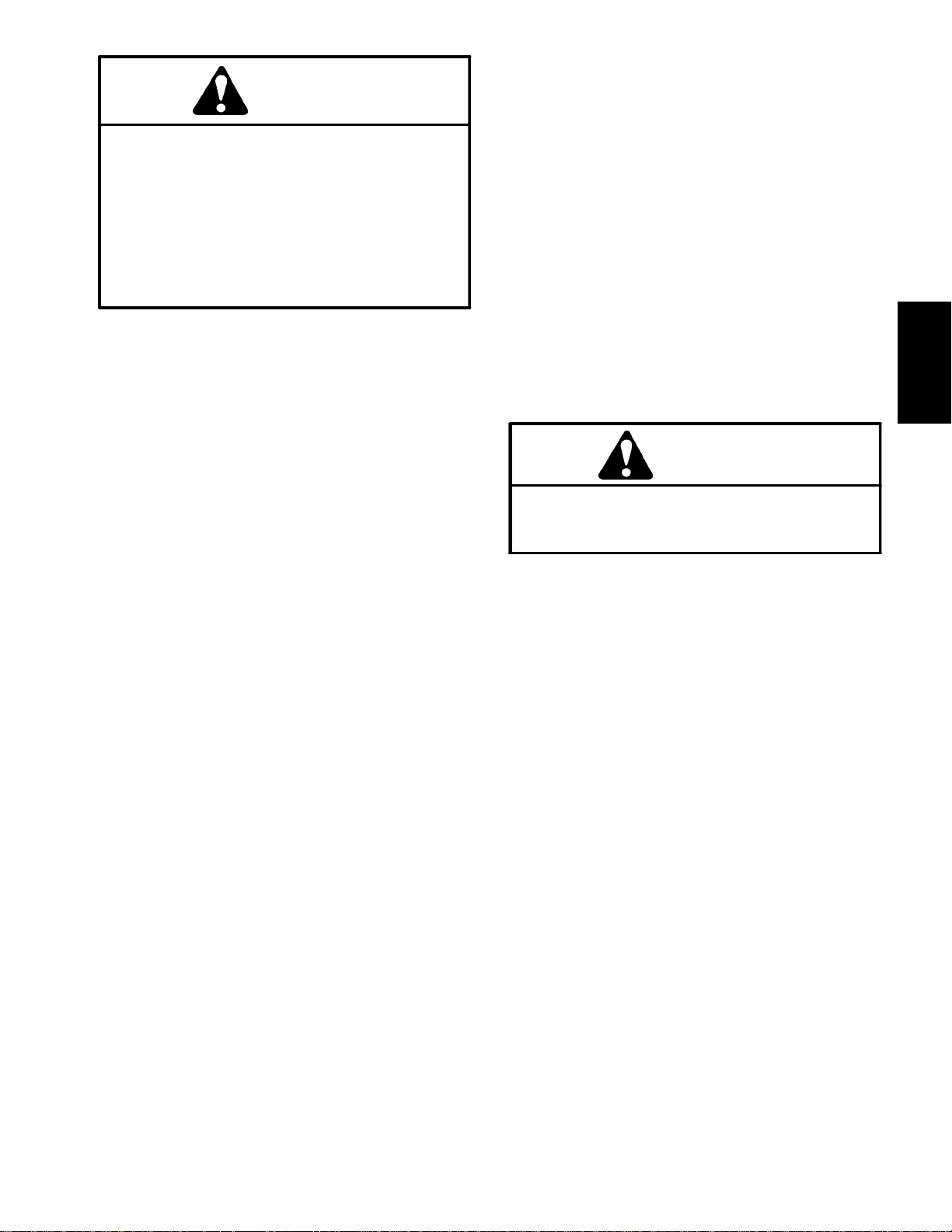

Fuel Tank Installation (Fig. 7)

DANGER

Becausedieselfuel ishighly flammable,use caution when storing or handling it. Do not smoke

while filling the fuel tank. Do not fill fuel tank

while engine is running, hot or when machine is

in an enclosed area. Always fill fuel tank outside

and wipe up any spilled diesel fuel before starting the engine. Store fuel in a clean, safety--approved container and keep cap in place. Use diesel fuel for the engine only; not for any other

purpose.

Check Fuel Lines and Connections

Checkfuel lines and connectionsperiodicallyasrecommendedinthe Operator’sManual.Check lines for deterioration,damage, leaks or loose connections. Replace

hoses, clamps and connections as necessary.

Empty and Clean Fuel Tank

Empty and clean the fuel tank periodically as recommended in the Operator’s Manual. Also, empty and

clean the fuel tank if the fuel system becomes contaminated or if the machine is to be stored for an extended

period.

To clean fuel tank, flush tank out with clean diesel fuel.

Make sure tank is free of contaminates and debris.

1. Install fuel tank using Figure 7 as a guide.

A. Torque two (2) flange nuts that secure the fuel

tank to the frame from 60 to 80 in--lb (7 to 9 N--m).

2. Install two (2) tank covers to ROPS assembly.

3. Connect fuel hose to the standpipe and venting

hoses to the elbow fittings.

4. Connect electrical wiring to the fuel sender.

A. Connect white wire to the center terminal and

black wire to any of the screws that secure the fuel

sender to the fuel tank.

B. Apply skin--over grease to the wire terminal connections.

CAUTION

Connecting battery cables to the wrong battery

post could result in personal injury and/or damage to the electrical system.

5. Positionbatteryinmachine.Connectpositivebattery

cable first and then negative battery cable. Install battery strap and cover.

Kubota

Diesel Engine

Fuel Tank Removal (Fig. 7)

1. Parkmachineon a level surface, lower cutting deck,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Raise and support seat and hood.

3. Remove battery cover and strap. Disconnect negative battery cable first and then positive battery cable.

Remove battery from machine.

4. Usea fuel transfer pump toremove fuelfrom the fuel

tank and into a suitable container.

5. Disconnect electrical wiring from the fuel sender on

the fuel tank.

6. Disconnectfuelhosefromthestandpipe andventing

hoses from elbow fittings in top of tank.

7. Remove phillips head screws that secure two (2)

tank covers to ROPS assembly.Remove tank covers.

8. Remove fuel tank using Figure 7 as a guide.

6. Lower seat and hood.

7. Fill fuel tank.

Groundsmaster 4100--D Page 3 -- 9 Kubota Diesel Engine

Page 26

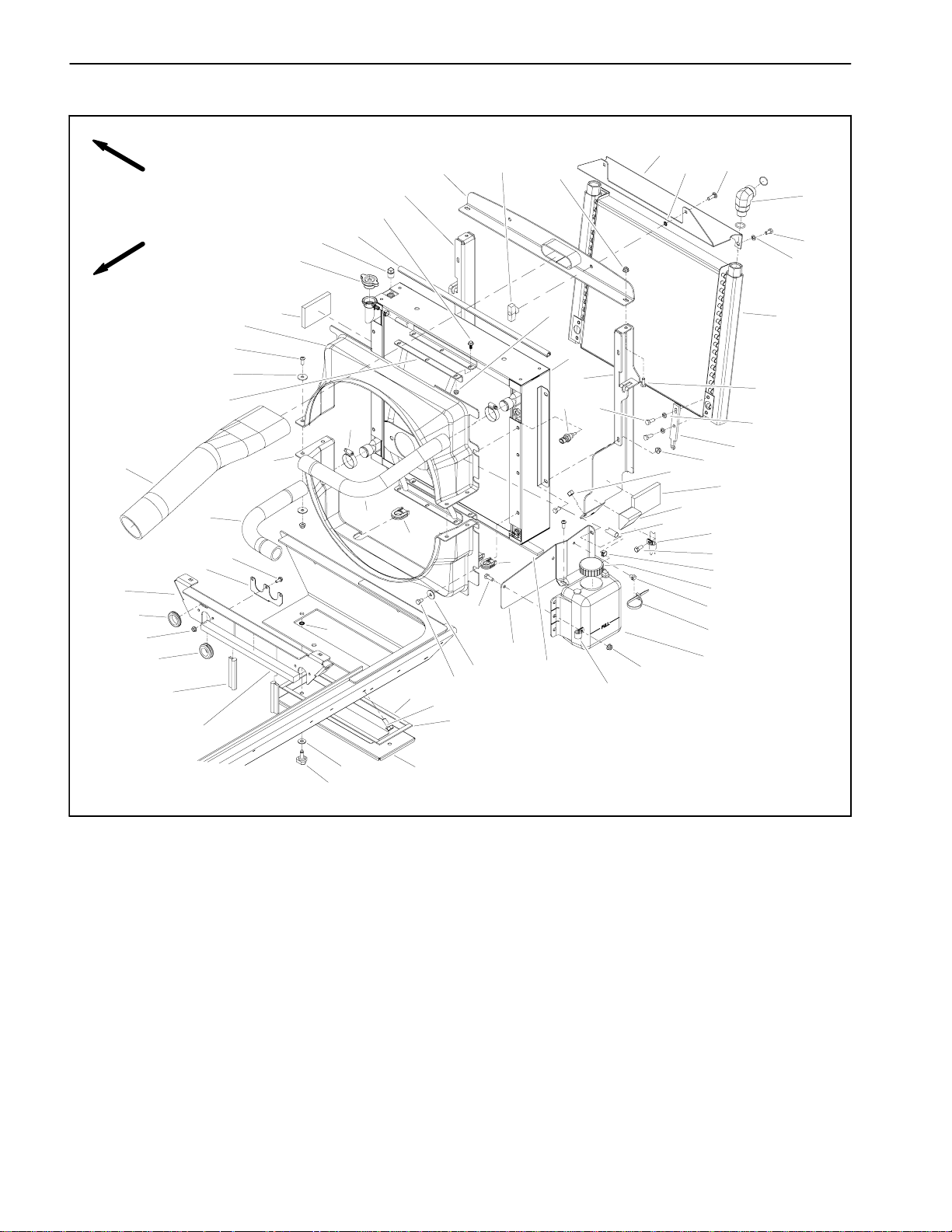

Radiator

61

32

13

RIGHT

FRONT

14

35

34

38

48

20

19

28

22

23

24

25

21

49

25

26

45

54

12

27

7

46

18

16

28

51

53

17

62

1

52

9

50

8

6

41

30

59

4

5

55

37

56

11

29

58

49

10

60

57

42

43

15

41

44

45

47

2

31

33

28

58

3

1. Radiator cap

2. Foam strip (2 used)

3. Foam strip (2 used)

4. Lower radiator hose

5. Upper radiator hose

6. Clamp (4 used)

7. Lower radiator shroud

8. Temperature sender

9. Radiator

10. Hose clamp (3 used)

11.Hose(2used)

12. Screw (4 used)

13. Rubber grommet

14. Flange nut (4 used)

15. Retaining ring (2 used)

16. Knob (2 used)

17. Bulb seal

18. Top radiator support

19. Retaining ring (2 used)

20. Oil cooler bracket

21. Oil cooler

3639

40

Figure 8

22. Carriage screw (2 used)

o

23. 90

hydraulic fitting (2 used)

24. Cap screw (6 used)

25. Lock washer (6 used)

26. Oil cooler mount plate (2 used)

27. Upper radiator shroud

28. Flange nut (10 used)

29. Foam plug (2 used)

30. Lock nut (6 used)

31. Foam strip

32. Base bracket

33. Flange head screw (6 used)

34. Bulb seal (2 used)

35. Grommet (2 used)

36. Cover

37. Flange head screw (4 used)

38. Plate (2 used)

39. Flat washer (2 used)

40. Knob (2 used)

41. Cap screw (6 used)

42. Cable tie

43. Coolant reservoir

44. Tank bracket

45. Flat washer (10 used)

46. Foam pad

47. Cap screw (7 used)

48. Foam seal

49. Cap screw (3 used)

50. LH radiator support

51. RH radiator support

52. Flange nut (6 used)

53. Cap screw (6 used)

54. Fan motor bracket

55. Grommet (2 used)

56. Grommet

57. Harness clip

58. R--clamp (2 used)

59. Foam pad

60. Reservoir cap

61. Air cleaner hose

62. Plug

Groundsmaster 4100--DPage 3 -- 10Kubota Diesel Engine

Page 27

Removal (Fig. 8)

Installation (Fig. 8)

1. Parkmachineon a level surface, lower cutting deck,

stop engine, apply parking brake and remove key from

the ignition switch.

2. Open and support hood.

CAUTION

Do not open radiator cap or drain coolant if the

radiator or engine is hot. Pressurized, hot coolant can escape and cause burns.

Ethylene--glycol antifreeze is poisonous. Dispose of coolant properly or store it in a properly

labeled container away from children and pets.

3. Drain radiator into a suitable container using the radiator drain. The radiator drain hose is located near the

engine oil filter.

4. Disconnectupper and lower radiator hoses fromthe

radiator.

5. Remove air cleaner hose (item 61).

6. Disconnect reservoir hose from the vent tube near

the radiator cap.

1. Remove all plugs placed during the removal procedure.

2. Carefully position radiator to the support frame. Secure radiator to the support frame with cap screws and

flange nuts.

3. Positionlower radiatorshroudandfan motor bracket

assembly to the radiator.

4. Secure fan motor bracket to radiator with six (6)

flange head screws and flange nuts.

5. Position upper radiator shroud to lower radiator

shroud to radiator. Secure shrouds with removed fasteners.

6. Attach radiator shroud assembly to the radiator with

cap screws and flat washers. Make sure that clearance

between shroud and cooling fan is at least 0.180” (4.6

mm) at all points.

7. Connectreservoir hose to the vent tube near the radiator cap.

8. Connectupperandlowerradiatorhosesto theradiator.

9. Reinstall air cleaner hose (item 61).

Kubota

Diesel Engine

7. Detach upper radiator shroud from the radiator and

lower radiator shroud. Remove upper shroud from machine.

8. Removefasteners that secure lower radiatorshroud

to radiator.

9. Remove six (6) flange head screws and flange nuts

that secure fan motor bracket to radiator.

10.Position lowerradiatorshroudand fan motorbracket

assembly away from radiator.

11.Removecapscrewsand flangenutssecuringthe radiator to the support frame. Carefully pull radiator from

the machine.

12.Plugallradiatororhoseopeningstopreventcontamination.

10.Make sure radiator drain is closed. Fill radiator with

coolant.

11.Close and secure hood.

Groundsmaster 4100--D Page 3 -- 11 Kubota Diesel Engine

Page 28

Engine

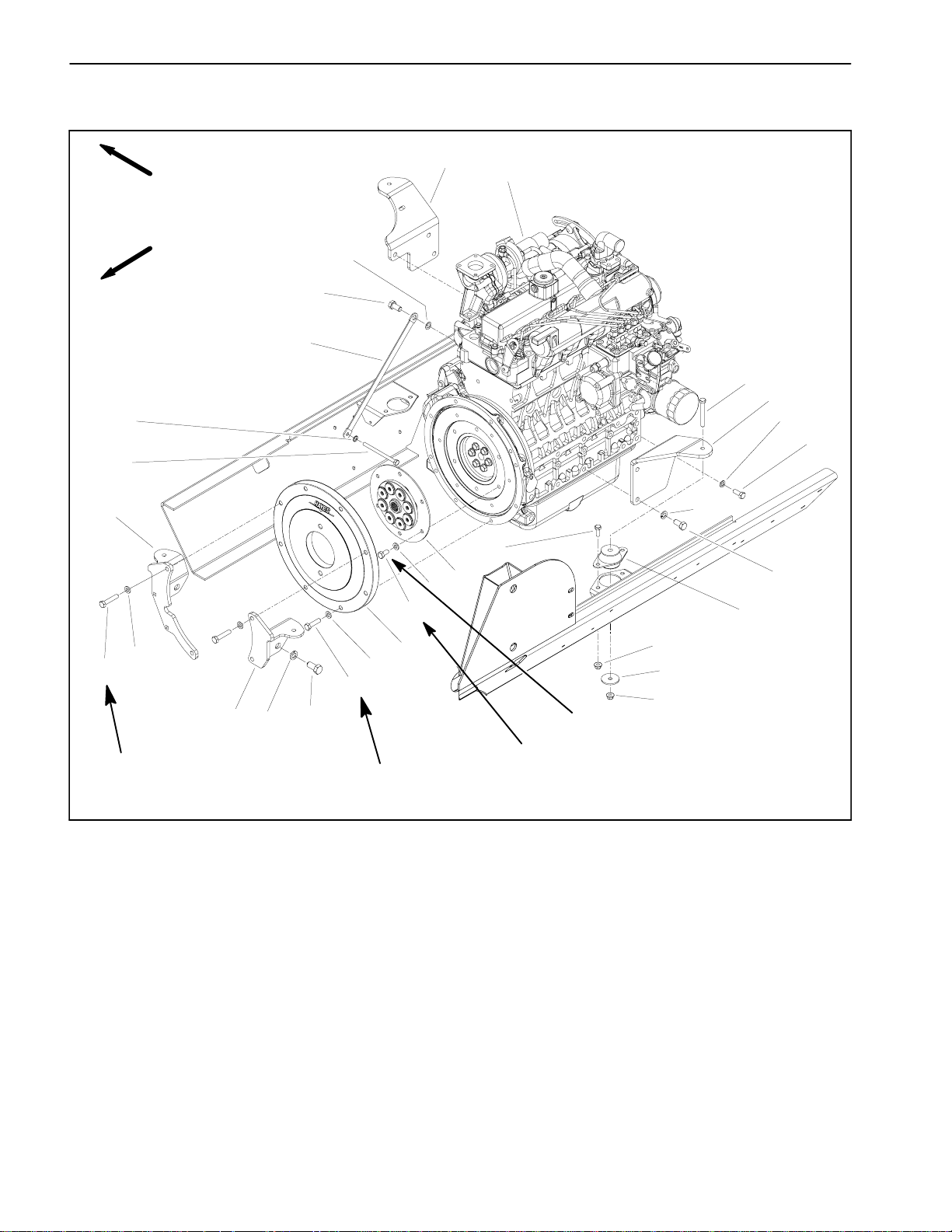

21

20

23

22

13

RIGHT

FRONT

19

18

24

25

17

26

16

13

15

14

13

27

12

1

2

3

4

5

6

11

7

8

9

10

9

Loctite #242

28 to 32 ft--lb

(38to43N--m)

1. Engine

2. Cap screw (4 used)

3. LH engine mount

4. Lock washer

5. Cap screw

6. Lock washer (5 used)

7. Cap screw (5 used)

8. Engine support (4 used)

9. Flange nut (12 used)

29 to 33 ft--lb

28 to 32 ft--lb

(38to43N--m)

(40to44N--m)

Figure 9

10. Rebound washer (4 used)

11. Cap screw (8 used)

12. Spring coupler

13. Washer (14 used)

14. Cap screw (6 used)

15. Flywheel plate

16. Cap screw (4 used)

17. Cap screw (2 used)

18. Lock washer (2 used)

19. LH engine mount

20. Cap screw (4 used)

21. RH engine mount

22. Cap screw (PTO manifold)

23. Lock washer

24. Ground cable

25. Cap screw

26. Lock washer

27. RH engine mount

Groundsmaster 4100--DPage 3 -- 12Kubota Diesel Engine

Page 29

Engine Removal (Fig. 9)

1. Parkmachineon a level surface, lower cutting deck,

stop engine, apply parking brake and remove key from

the ignition switch.

2. Remove battery cover and strap. Disconnect negative battery cable first and then positive battery cable.

Remove battery from machine.

2

3. Open and support hood.

CAUTION

Do not open radiator cap or drain coolant if the

radiator or engine is hot. Pressurized, hot coolant can escape and cause burns.

Ethylene--glycol antifreeze is poisonous. Dispose of coolant properly or store it in a properly

labeled container away from children and pets.

4. Drain coolant from the radiator into a suitable container (see Radiator Removal in this section). Disconnect upper and lower hoses from the radiator.

CAUTION

The muffler and exhaust pipe may be hot. To

avoid possible burns, allow the exhaust system

to cool before working on or near the muffler.

5. Remove exhaust system from engine (see Exhaust

System Removal in this section).

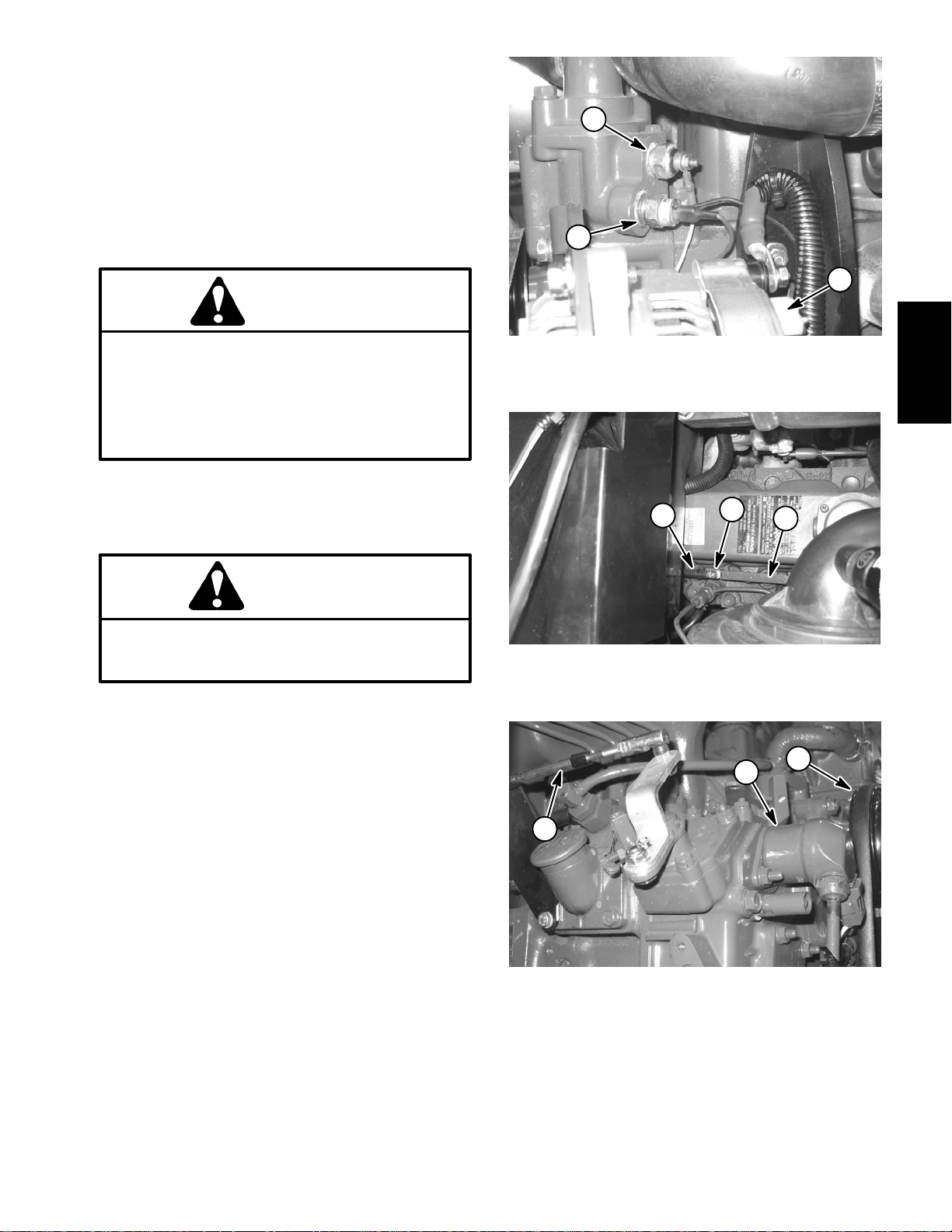

1

Figure 10

1. Dual temperature switch

2. Temperature sender

1

Figure 11

1. Glow plug wire

2. Glow plug lead

3

3. Alternator

3

3. Cylinder #4 glow plug

2

Kubota

Diesel Engine

6. Removeaircleaner system from engine (see Air Filter System Removal in this section).

1

2

7. Note location of cable ties used to secure wire harness to the machine. Disconnect wires and/or electrical

3

connections from the following electrical components:

A. The dual temperature switch, temperature sender and alternator (Fig 10).

B. The glow plug lead (Fig. 11).

C. The engine run solenoid (Fig. 12).

D. Battery,frameandwireharness groundattheen-

1. Engine run solenoid

2. Alternator belt

Figure 12

3. Throttle cable

gine block.

E. The electric starter and low oil pressure switch

(on RH side of engine).

8. Disconnect fuel supply hose from injection pump

(Fig. 13).

Groundsmaster 4100--D Page 3 -- 13 Kubota Diesel Engine

Page 30

9. Disconnect throttle cable from the speed control lever by removing the flat washer and lock nut (Fig. 14).

Loosenjam nut andseparate cable from cable support.

Position cable away from engine.

10.Remove fasteners that secure the upper radiator

shroud to the lower shroud and radiator (see Radiator

Removal in this section). Position coolant reservoir and

bracket away from the radiator. Remove upper radiator

shroud from machine.

1

3

11.Remove fan hub and fan from hydraulic fan motor

(Fig. 15).

A. Removehex nut(item9)and washer (item8)that

secure fan hub and fan assembly to fan motor.

NOTE: The fan motor shaft is tapered.

B. Usesuitablepullertoremove fanhub(with fanat-

tached) from fan motor shaft taking care to not damage fan. Remove fan hub and fan from machine.

IMPORTANT: The hydraulic pump assembly can remain in machine during engine removal. Toprevent

pump from shifting or falling, make sure to support

pump assembly before mounting fasteners are removed.

12.Support hydraulic pump assembly. Remove fasteners that secure pump assembly to engine (see Pump

Assembly Removal in the Service and Repairs section

of Chapter 4 -- Hydraulic System).

13.Make sure all cable ties securingthewiringharness,

fuellines or hydraulic hoses to the engine are removed.

14.Connect hoist or lift to the lift tabs on engine.

15.Remove flange nuts, rebound washers and cap

screws securing the engine mounts to the engine supports.

1. Fuel pump

2. Fuel supply hose

1. Lock nut

2. Flat washer

3. Throttle lever

4. Lock nut

5. Flange head screw

6. Cap screw

Figure 13

3. Throttle cable

1

12

Figure 14

7. Flange head screw

8. Spring washer (2 used)

9. Ball joint

10. Cap screw (2 used)

11. Throttle cable

12. Cable support

2

3

2

4

5

8

6

7

9

10

11

CAUTION

One person should operate lift or hoist while

another person guides the engine out of the machine.

IMPORTANT: Make sure not to damage the engine,

fuel and hydraulic lines, electrical harness or other

components while removing the engine.

16.Slowly remove engine assembly from the machine.

17.Ifnecessary,removeengine mountsfromthe engine

using Figure 9 as a guide.

Engine Installation (Fig. 9)

1. Ifremoved,installengine mountstothe engineusing

Figure 9 as a guide.

2. Connect hoist or lift to the engine lift tabs.

CAUTION

One person should operate lift or hoist while

another person guides the engine into the machine.

IMPORTANT: Make sure not to damage the engine,

fuel and hydraulic lines, electrical harness or other

parts while installing the engine.

Groundsmaster 4100--DPage 3 -- 14Kubota Diesel Engine

Page 31

3. Slowly lower engine into the machine.

4. Align engine to the engine supports and hydraulic

pumpinputshaft.Secureenginetoenginesupportswith

cap screws, rebound washers and flange nuts.

5. Secure hydraulic pump assembly to engine (see

Pump Assembly Installation in the Service and Repairs

section of Chapter 4 -- Hydraulic System).

6. Thoroughly clean tapered surfaces of fan motor

shaft and fan hub. Position fan hub (with fan attached)

onto motor shaft and secure with washer and hex nut

(Fig.15). Torquenutfrom27to33ft--lb (37 to 44 N--m).

7. Positionupper radiator shroudandcoolantreservoir

withbrackettotheradiator.Secureshroudandreservoir

bracket to the radiator and lower radiator bracket with

removedfasteners (seeRadiatorInstallationin this section).Make sure thatclearancebetweenshroud and fan

is at least 0.180” (4.6 mm) at all points.

8. Connectthrottle cable tothespeedcontrollever with

washer and lock nut (Fig. 14). Secure cable to cable

support. Adjust throttle cable.

9. Connect fuel line to the injection pump.

27 to 33 ft--lb

(37to44N--m)

11

9

8

6

7

10

5

12 to 14 ft--lb

(17to18N--m)

1

2

3

4

Figure 15

1. Fan motor

2. Cap screw (2 used)

3. Flat washer (2 used)

4. Fan motor bracket

5. Lock nut (2 used)

6. Washer (4 used)

7. Cap screw (4 used)

8. Hex nut

9. Washer

10. Fan hub

11. Fan

13.Connect coolant hosestotheradiator.Makesureradiator drain is shut. Fill radiator and reservoir with coolant.

Kubota

Diesel Engine

10.Connect wires and/or electrical connections to the

following electrical components:

A. Thedual temperature switch, temperature sender and alternator (Fig 10).

B. Theengine run solenoid and fuel pump (Fig. 13).

C. The glow plug (Fig. 11).

D. Battery,frameandwireharness groundtotheen-

gine block.

E. The starter and low oil pressure switch (near

starter).

11.Installaircleanerassembly totheengine (seeAirFilter System Installation in this section).

12.Installexhaustsystemtomachine(seeExhaustSystem Installation in this section).

14.Check position of wires, fuel lines, hydraulic hoses

andcables for proper clearance with rotating, high temperature and moving components.

15.Position battery to machine. Connect positive battery cable first and then negative battery cable. Secure

battery to machine with strap and cover.

16.Check and adjust engine oil as needed.

17.Check and adjust hydraulic oil as needed.

18.Bleed fuel system.

19.Start engine and operate hydraulic controls to properlyfill hydraulic system(see Charge Hydraulic System

in Chapter 4 -- Hydraulic System).

20.Close and secure hood.

Groundsmaster 4100--D Page 3 -- 15 Kubota Diesel Engine

Page 32

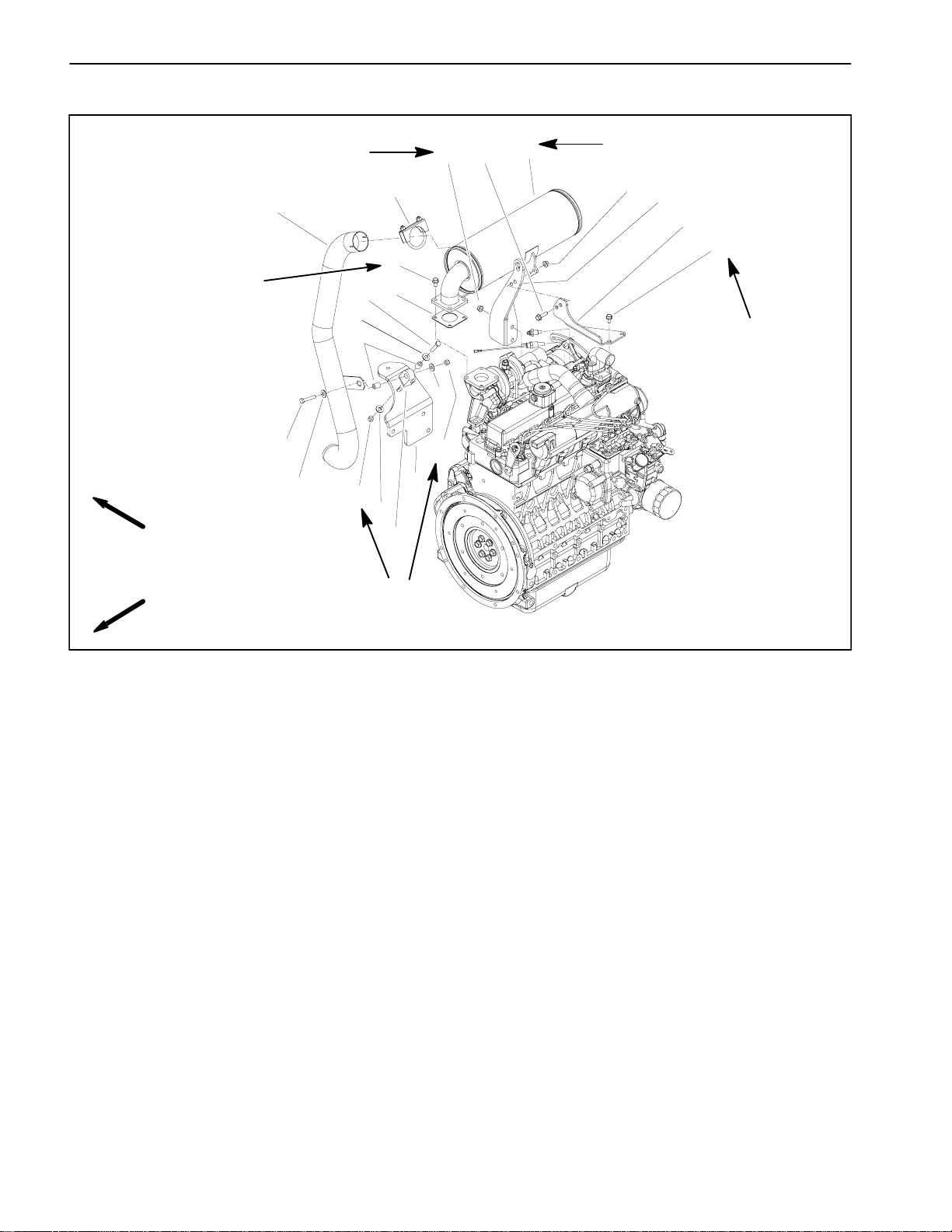

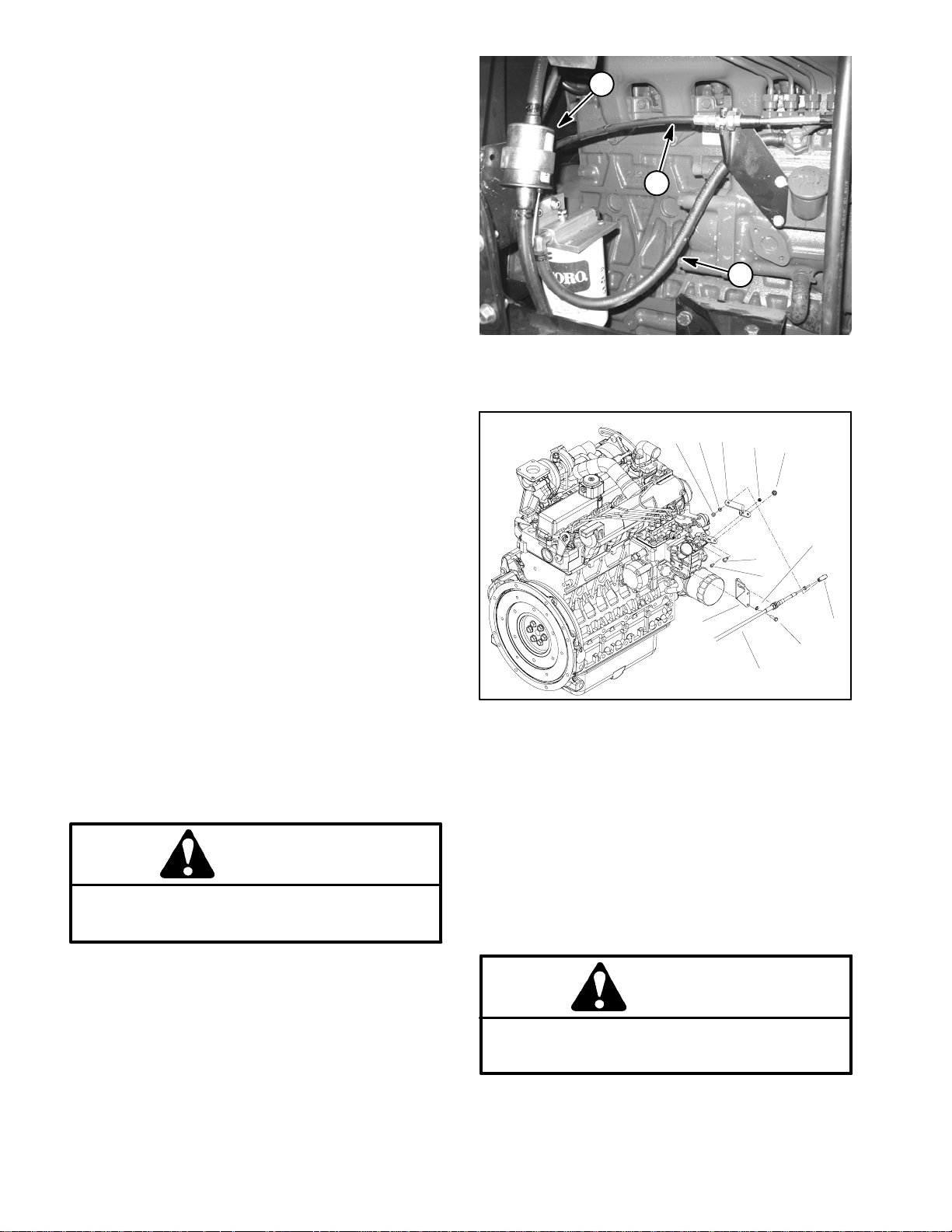

Spring Coupler

RIGHT

FRONT

8

2

2

1

2

3

Loctite #242

4

2

5

29 to 33 ft--lb

(40to44N--m)

6

7

28 to 32 ft--lb

(38to43N--m)

1. Spring coupler

2. Washer (14 used)

3. Cap screw (6 used)

Figure 16

4. Flywheel plate

5. Cap screw (4 used)

6. LH engine mount

7. Cap screw (2 used)

8. RH engine mount

Groundsmaster 4100--DPage 3 -- 16Kubota Diesel Engine

Page 33

Coupler Removal (Fig. 16)

NOTE: The hydraulic pump assembly needs to be re-

moved from engine before coupler can be removed.

1. Ifengine is in machine,supportenginefrom below to

prevent it from shifting while removing hydraulic pump

assembly (see Piston (Traction) Pump Removal in the

Service and Repairs section of Chapter 4 -- Hydraulic

System), transport cylinder assembly, flywheel plate,

engine mounts and spring coupler.

2. Remove flywheel plate and spring coupler from engine using Figure 16 as a guide.

Coupler Installation (Fig. 16)

1. Position spring coupler to engine flywheel and align

mounting holes. Make sure that coupler hub is away

from engine flywheel (Fig. 17).

2. Apply Loctite #242 (or equivalent) to threads of cap

screws (item 3). Secure coupler to flywheel with six (6)

capscrews and washers. Torquecapscrewsin a crossing pattern from 29 to 33 ft--lb (40 to 44 N--m).

Engine Side Hydraulic

Figure 17

1. Spring coupler

2. Engine flywheel

3. Coupler hub

Pump Side

1

3

2

Kubota

Diesel Engine

3. Positionflywheelplate toengineandenginemounts.

Secure flywheel plate and mounts with cap screws

(items 5 and 7) and washers using a crossing pattern

tightening procedure. Torque cap screws in a crossing

pattern from 28 to 32 ft--lb (38 to 43 N--m).

4. If engine is in machine, install hydraulic pump assembly (see Piston (Traction) Pump Installation in the

Service and Repairs section of Chapter 4 -- Hydraulic

System).

Groundsmaster 4100--D Page 3 -- 17 Kubota Diesel Engine

Page 34

This page is intentionally blank.

Groundsmaster 4100--DPage 3 -- 18Kubota Diesel Engine

Page 35

Table of Contents

Chapter 4

Hydraulic System

SPECIFICATIONS 2.............................

GENERAL INFORMATION 3.....................

Operator’s Manual 3..........................

Towing Traction Unit 3.........................

Check Hydraulic Fluid 3.......................

Hydraulic Hoses 4............................

Hydraulic Hose and Tube Installation 5..........

Hydraulic Fitting Installation 6...................

HYDRAULIC SCHEMATIC 8.....................

HYDRAULIC FLOW DIAGRAMS 10...............

Traction Circuit: 4WD (Mow) 10.................

Traction Circuit: Transport (2WD) 12.............

Lower Cutting Deck 14........................

Raise Cutting Deck 16.........................

Mow Circuit 18...............................

Mow Circuit Cutting Deck Blade Braking 20.......

Steering Circuit 22............................

Engine Cooling Fan Circuit 24..................

SPECIAL TOOLS 26............................

TROUBLESHOOTING 28........................

TESTING 31...................................

Traction Circuit Charge Pressure 32.............

Traction Circuit Relief Pressure 34..............

Counterbalance Pressure 36...................

Rear Traction Circuit (RV) Relief Pressure 38.....

Traction Circuit Reducing Valve (PR)

Pressure 40................................

Cutting Deck Circuit Pressure 42................

PTO Relief Pressure 44........................

Cutting Deck Gear Pump Flow 46...............

Cutting Deck Motor Case Drain Leakage 48......

Steering Circuit Relief Pressure 50..............

Lift/Lower Circuit Relief Pressure 52.............

Steering and Lift/Lower Gear Pump Flow 54......

Engine Cooling Fan Circuit 56..................

Engine Cooling Fan Circuit Gear Pump Flow 58...

ADJUSTMENTS 60.............................

Adjust Cutting Deck Flow Control Valve 60.......

SERVICE AND REPAIRS 61.....................

General Precautions for Removing and

Installing Hydraulic System Components 61....

Check Hydraulic Lines and Hoses 61............

Flush Hydraulic System 62.....................

Charge Hydraulic System 63...................

Hydraulic Reservoir 64........................

Hydraulic Oil Cooler 66........................

Gear Pump 68................................

Gear Pump Service 70.........................

Traction Circuit 72.............................

Piston (Traction) Pump 74......................

Piston (Traction) Pump Service 76..............

Rear Axle Motor 78

Wheel Motors 80........................

Front

Rear Axle and Front Wheel Motor Service 82.....

4WD Manifold 84.............................

4WD Manifold Service 86......................

Filter Manifold 88.............................

Filter Manifold Service 90......................

Steering and Cooling Fan Circuits 92............

Steering Valve 94.............................

Steering Valve Service 96......................

Steering Cylinder 98...........................

Steering Cylinder Service 100..................

Engine Cooling Fan Motor 102..................

Engine Cooling Fan Motor Service 104...........

Fan Drive Manifold 108........................

Fan Drive Manifold Service 110.................

Mow Circuit 112..............................

Cutting Deck Motor 113........................

Cutting Deck Motor Service 114.................

Deck Manifolds 118...........................

Deck Manifold Service 120.....................

Lift/Lower Circuit 122..........................

Lift/Lower Control Valve 124....................

Lift/Lower Control Valve Service 126.............

Front Deck Lift Cylinder 128....................

Wing Deck Lift Cylinder 130....................

Deck Lift Cylinder Service 132..................

Counterbalance Manifold 134...................

Counterbalance Manifold Service 136............

EATON MODEL 72400 SERVO CONTROLLED PIS-

TON PUMP REPAIR INFORMATION

EATON MODEL 74318 and 74348 PISTON MOTORS:

FIXED DISPLACEMENT, VALVE PLA TE DESIGN

REPAIR INFORMATION

...........................

System

Hydraulic

Groundsmaster 4100--D Hydraulic SystemPage 4 -- 1

Page 36

Specifications

Item Description

Piston (Traction) Pump Eaton Variable Displacement Piston Pump

System Relief Pressure: Forward 4000 PSI (274 bar)

System Relief Pressure: Reverse 5000PSI (343 bar)

Charge Pressure 250 PSI (17 bar)

Front Wheel Motors Eaton Fixed Displacement Piston Motors

Rear Axle Motor Eaton Fixed Displacement Piston Motor

Gear Pump Casappa 4 section, positive displacement gear type pump

Section P1/P2 Displacement (per revolution) 1.37 Cubic Inches (22.46 cc)

Section P3/P4 Displacement (per revolution) 0.56 Cubic Inches (9.16 cc)

Steering Control Valve Eaton Steering Unit, Series 5

Steering Relief Pressure 1350 PSI (93 bar)

Lift/Lower Relief Pressure 2525 PSI (174 bar)

Cutting Deck Motors Sauer Danfoss Gear Motor

Cutting Deck Circuit Relief Pressure

Center and Left Side 3000 PSI (207 bar)

Right Side 2000 PSI (137 bar)

(Model 72400)

(Model 74328)

(Model 74315)

Engine Cooling Fan Motor Casappa Gear Motor

Displacement (per revolution) 0.50 Cubic Inches (8.3 cc)

Engine Cooling Fan Circuit Relief Pressure 3000 PSI (207 bar)

Hydraulic Filters Spin--on cartridge type

In--line Suction Strainer 100 mesh (in reservoir)

Hydraulic Reservoir 8 U.S. Gallons (30.3 Liters)

Hydraulic Oil See Operator’s Manual

Groundsmaster 4100--DHydraulic System Page 4 -- 2

Page 37

General Information

Operator’s Manual

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervalsfor yourGroundsmastermachine.Refer tothat

publicationfor additional informationwhenservicingthe

machine.

Towing Traction Unit

IMPORTANT: If towing limits are exceeded, severe

damage to the piston pump may occur.

If it becomes necessary to tow (or push) the machine,

tow (or push) in a forward direction only and at a

speed below 3 mph. The piston (traction) pump is

equipped with a by--pass valve that needs to be turned

o

for towing. See Operator’s Manual for Towing Pro-

90

cedures.

Check Hydraulic Fluid

The Groundsmaster 4100--D hydraulic system is designed to operate on anti--wear hydraulic fluid. The reservoir holds approximately 8 gallons (30.3 liters) of

hydraulic fluid. Check level of hydraulic fluid daily.

See Operator’s Manual for fluid level checking procedure and hydraulic oil recommendations.

1

Figure 1

1. By--pass valve location

1

System

Hydraulic

Groundsmaster 4100--D Hydraulic SystemPage 4 -- 3

Figure 2

1. Hydraulic reservoir cap

Page 38

Hydraulic Hoses

Hydraulichoses are subject to extremeconditions such

aspressuredifferentialsduring operationandexposure

to weather, sun, chemicals, very warm storage conditionsormishandlingduring operationandmaintenance.

These conditions can cause hose damage and deterioration. Some hoses are more susceptible to these

conditions than others. Inspect all machine hydraulic

hoses frequently for signs of deterioration or damage:

WARNING

Beforedisconnectingorperformingany work on

hydraulic system, relieve all pressure in system

(seeRelievingHydraulicSystemPressure in this

section).

Hard, cracked, cut, abraded, charred, leaking or

otherwise damaged hose.

Kinked, crushed, flattened or twisted hose.

Blistered, soft, degraded or loose hose cover.

Cracked, damaged or badly corroded hose fittings.

When replacing a hydraulic hose, be sure that the hose

is straight (not twisted) before tightening the fittings.

This can be done by observing the imprint (layline) on

thehose. Usetwo wrenches; hold the hose straight with

one wrench and tighten the hose swivel nut onto the fitting with the other wrench ( See Hydraulic Hose and

Tube Installation in this section). If the hose has an elbowat oneend,tightenthe swivelnutonthat endbefore

tightening the nut on the straight end of the hose.

For additional hydraulic hose information, refer to Toro

Service Training Book, Hydraulic Hose Servicing (Part

Number 94813SL).

Keepbodyand handsaway frompinholeleaksor

nozzles that eject hydraulic fluid under high

pressure. Use paper or cardboard, not hands, to

search for leaks. Hydraulic fluid escaping under

pressure can have sufficient force to penetrate

the skin and cause serious injury. If fluid is injected into the skin, it must be surgically removed within a few hours by a doctor familiar

withthis typeofinjury.Gangrenemayresult from

such an injury.

Groundsmaster 4100--DHydraulic System Page 4 -- 4

Page 39

Hydraulic Hose and Tube Installation (O--Ring Face Seal Fitting)

1. Makesure threads and sealing surfaces of the hose/

tube and the fitting are free of burrs, nicks, scratches or

any foreign material.

2. Asa preventative measure against leakage, it is recommended that the face seal O--ring be replaced any

time the connection is opened. Make sure the O--ring is

installedandproperly seatedinthefittinggroove.Lightly

lubricate the O--ring with clean hydraulic oil.

3. Place the hose/tube against the fitting body so that

theflatfaceofthehose/tube sleevefullycontactstheO-ring in the fitting.

4. Thread the swivel nut onto the fitting by hand. While

holding the hose/tube with a wrench, use a torque

wrench to tighten the swivel nut to the recommended

installation torque shown in Figure 5. This tightening

process will require the use of an offset wrench (e.g.

crowfoot wrench). Use of an offset wrench will affect

torque wrench calibration due to the effective length

change of the torque wrench. Tightening torque when

usingatorquewrenchwithanoffsetwrenchwillbelower

than the listed installation torque (see Using a Torque

Wrench with an Offset Wrench in the Torque Specificationssection of Chapter 2 --Product Records and Maintenance).

C. Useasecondwrench totightenthenut tothecorrect Flats From Wrench Resistance (F.F.W.R.).The

markingsonthe nutandfittingbodywillverifythatthe

connection has been properly tightened.

Siz e F.F.W.R.

4 (1/4 in. nominal hose or tubing) 1/2 to 3/4

6 (3/8 in.) 1/2 to 3/4

8 (1/2 in.) 1/2 to 3/4

10 (5/8 in.) 1/2 to 3/4

12 (3/4 in.) 1/3 to 1/2

16 (1 in.) 1/3 to 1/2

Swivel Nut

Tube or Hose

O--ring

Fitting Body

Figure 3

System

Hydraulic

5. If a torque wrench is not available or if space at the

swivelnut prevents use of a torquewrench,analternate

method of assembly is the Flats From Wrench Resistance (F.F.W.R.) method (Fig. 2).

Mark Nut

and Fitting

Body

Final

Position

A. Usingawrench,tighten the swivelnutonto thefittinguntillightwrench resistanceisreached (approxi-

Extend Line

mately 30 in--lb).

B. Mark the swivel nut and fitting body. Hold the

hose/tube with a wrench to prevent it from turning.

AT WRENCH RESISTANCE

Figure 4

Fitting Dash Size Hose/Tube Side Thread Size Installation Torque

4 9/16 -- 18 18to22ft--lb(25to29N--m)

6 11/16 - - 16 27to33ft--lb(37to44N--m)

8 13/16 -- 16 37to47ft--lb(51to63N--m)

10 1--14 60 to 74 ft--lb (82 to 100 N--m)

12 13/16--12 85 to 105 ft--lb (116 to 142 N--m)

Initial

Position

AFTER TIGHTENING

16 17/16--12 110 to 136 ft--lb (150 to 184 N--m)

20 1 11/16 -- 12 140 to 172 ft--lb (190 to 233 N--m)

Figure 5

Groundsmaster 4100--D Hydraulic SystemPage 4 -- 5

Page 40

Hydraulic Fitting Installation (SAE Straight Thread O--Ring Fitting into Component Port)

Non--Adjustable Fitting (Fig. 6)

1. Make sure all threads and sealing surfaces of fitting

and component port are free of burrs, nicks, scratches

or any foreign material.

2. Asa preventative measure against leakage, it is recommended that the O--ring be replaced any time the

connection is opened.

3. Lightly lubricate the O--ring with clean hydraulic oil.

Fittingthreadsshouldbecleanwith nolubricantapplied.

IMPORTANT: Before installing fitting into port, determine port material. If fitting is to be installed into

an aluminum port, installation torque is reduced.

4. Install the fitting into the port. Then, use a torque

wrench and socket to tighten the fitting to the recommended installation torque shown in Figure 7.

NOTE: Useof an offset wrench (e.g. crowfoot wrench)

will affect torque wrench calibration due to the effective

length change of the torque wrench. Tightening torque

when using a torque wrench with an offset wrench will

be less than the recommended installation torque. See

Using a Torque Wrench with an Offset Wrench in the

Torque Specifications section of Chapter 2 -- Product

Recordsand Maintenancetodetermine necessary conversion information.

5. If a torque wrench is not available, or if space at the

portpreventsuseof atorquewrench, analternatemethod of assembly is the Flats From Finger Tight (F.F.F.T.)

method.

A. Install the fitting into the port and tighten it down

full length until finger tight.

B. If port material is steel, tighten the fitting to the

listed F.F.F.T.If port material is aluminum, tighten fitting to 60% of listed F.F.F.T.

Siz e F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00 +

6(3/8in.) 1.50+

8(1/2in.) 1.50+

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

Fitting

O--ring

0.25

0.25

0.25

0.25

0.25

0.25

Figure 6

Fitting

Dash Size

Fitting Port Side

Thread Size

Installation Torque Into

Steel Port

Installation Torque Into

Aluminum Port

4 7/16 -- 20 15to19ft--lb(21to25N--m) 9to11ft--lb(13to15N--m)

5 1/2 -- 20 18to22ft--lb(25to29N--m) 11to15ft--lb(15to20N--m)

6 9/16 -- 18 34to42ft--lb(47to56N--m) 20to26ft--lb(28to35N--m)

8 3/4 -- 16 58to72ft--lb(79to97N--m) 35to43ft--lb(48to58N--m)

10 7/8 -- 14 99 to 121 ft--lb (135 to 164 N--m) 60 to 74 ft--lb (82 to 100 N--m)

12 11/16--12 134 to 164 ft--lb (182 to 222 N--m) 81 to 99 ft--lb (110 to 134 N--m)

14 13/16--12 160 to 196 ft--lb (217 to 265 N--m) 96 to 118 ft--lb (131 to 160 N--m)

16 15/16--12 202 to 248 ft--lb (274 to 336 N--m) 121 to 149 ft--lb (165 to 202 N--m)

20 15/8--12 247 to 303 ft--lb (335 to 410 N--m) 149 to 183 ft--lb (202 to 248 N--m)

Figure 7

Groundsmaster 4100--DHydraulic System Page 4 -- 6

Page 41

Adjustable Fitting (Fig. 8)

1. Make sure all threads and sealing surfaces of fitting

and component port are free of burrs, nicks, scratches

or any foreign material.

2. Asa preventative measure against leakage, it is recommended that the O--ring be replaced any time the

connection is opened.

3. Lightly lubricate the O--ring with clean hydraulic oil.

Fittingthreadsshouldbecleanwith nolubricantapplied.

4. Turnback the lock nut as far as possible. Make sure

the back up washer is not loose andis pushed up as far

as possible (Step 1 in Figure 9).

IMPORTANT: Before installing fitting into port, determine port material. If fitting is to be installed into

an aluminum port, installation torque is reduced.

Lock Nut

Back--up Washer

O--ring

Figure 8

5. Install the fitting into the port and tighten finger tight

until the washer contacts the face of the port (Step 2).

6. Toput the fitting in the desired position,unscrew itby

the required amount, but no more than one full turn

(Step 3).

7. Hold the fitting in the desired position with a wrench

and use a torque wrench to tighten the fitting to the recommended installation torque shown in Figure 7. This

tightening process will require the use of an offset

wrench (e.g. crowfoot wrench). Use of an offset wrench

will affect torque wrench calibration due to the effective

length change of the torque wrench. Tightening torque

when using a torque wrench with an offset wrench will

be lower than the listed installation torque (see Using a

Torque Wrench with an Offset Wrench in the Torque

Specifications section of Chapter 2 -- Product Records

and Maintenance).

8. If a torque wrench is not available, or if space at the

portpreventsuseof atorquewrench, analternatemethod of assembly is the Flats From Finger Tight (F.F.F.T.)

method. Hold the fitting in the desired position with a

wrench and, if port material is steel, tighten the lock nut

witha secondwrenchtothe listedF.F.F.T(Step 4).Ifport

material is aluminum, tighten fitting to 60% of listed

F.F.F.T.

Step 3Step 1

Step 2 Step 4

Figure 9

System

Hydraulic

Siz e F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00 +

6(3/8in.) 1.50+

8(1/2in.) 1.50+

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

0.25

0.25

0.25

0.25

0.25

0.25

Groundsmaster 4100--D Hydraulic SystemPage 4 -- 7

Page 42

Hydraulic Schematic

COUNTERBALANCE

MANIFOLD

4WD

MANIFOLD

FILTER

MANIFOLD

NOTE: A larger hydraulic schematic is

included in Chapter 9: Foldout Drawings

MANIFOLD

CENTER DECK

MANIFOLD

LH WING DECK

MANIFOLD

RH WING DECK

MANIFOLD

FAN DRIVE

Groundsmaster 4100--DHydraulic System Page 4 -- 8

Page 43

This page is intentionally blank.

System

Hydraulic

Groundsmaster 4100--D Hydraulic SystemPage 4 -- 9

Page 44

Hydraulic Flow Diagrams

COUNTERBALANCE

MANIFOLD

4WD

MANIFOLD

Traction Circuit (4WD Forward Shown)

Groundsmaster 4100--D

Working Pressure

Low Pressure (Charge)

Flow

Return or Suction

CENTER DECK

MANIFOLD

MANIFOLD

FAN DRIVE

M1 M2 ST L

LH WINGDECK

MANIFOLD

P1

LC1

RV1

RV2

M1

P2

S

OR

LC2

M2

RH WINGDECK

MANIFOLD

P1

RV1

RV2

M1

P1

LC1

RV1

RV2

M1

P2

S

LC2

M2

P1 P2T

P2

LC1

S

OR

LC2

M2

Groundsmaster 4100--DHydraulic System Page 4 -- 10

Page 45

Traction Circuit: 4WD (Mow)

The traction circuit piston pump is a variable displacement pump that is directly coupled to the engine flywheel. Pushing the traction pedal engages a hydraulic

servo valve which controls the variable displacement

piston pump swash plate to create a flow of oil. This oil

isdirectedtothefrontwheeland rearaxlemotors.Operating pressure on the high pressure side of the closed

traction circuit loop is determined by the amount of load

developedatthefixeddisplacementwheelandaxlemotors. As the load increases, circuit pressure can increase to relief valve settings: 4000 PSI (274 bar) in

forward and 5000 PSI (343 bar) in reverse. If pressure

exceeds the relief setting, oil flows through the relief

valveto the low pressure side of the closed loop traction

circuit. The traction circuit provides operation in either

4WD (mow) or transport (2WD).

Traction circuit pressure (forward and reverse) can be

measured at test ports on the sides of the machine.

The traction circuit pump and motors use a small

amount of hydraulic fluid for internal lubrication. Fluid is

designed to leak across traction pump and motor components into the case drain. This leakage results in the

lossofhydraulicfluidfromtheclosedloop tractioncircuit

thatmust be replaced. Thecharge circuit is designed to

replace this traction circuit leakage.

The gear pump section that supplies oil to the steering

andlift/lower circuits alsoprovides oil forthe charge circuit. This gear pump is driven directly off the traction

pump. It provides a constant supply of charge oil to

make up for oil that is lost due to internal leakage in the

traction pump and motors.

Pump flow for the charge circuit is directed through the