Page 1

PART NO. 12189SL

Service Manual

(Models 04043 and 04042)

Greensmaster

Preface

The purpose of this publication is to providetheservice

technician with information for troubleshooting, testing

and repairing assemblies and components on the

Greensmaster eFlex 1800 (Model 04043) and eFlex

2100 (Model 04042).

REFER TO THE OPERATOR’SMANUALFOROPERATING, MAINTENANCE AND ADJUSTMENT

INSTRUCTIONS.Spaceisprovided inChapter 2of this

booktoinserttheOperator’sManualandPartsCatalogs

for your machine. Replacement Operator’s Manuals

and Parts Catalogs are available on the internet at

www.toro.com

TheToroCompanyreserves therighttochange product

specifications or this publication without notice.

R

eFlex 1800/2100

This safety symbol means DANGER, WARNING

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: A NOTE will givegeneral information aboutthe

correct operation, maintenance, service, testing or repair of the machine.

IMPORTANT: The IMPORTANT notice will give important in structions which must be followed to prevent damage to systems or components on the

machine.

E The Toro Company -- 2012

Page 2

This page is intentionally blank.

Greensmaster eFlex 1800/2100

Page 3

Table Of Contents

Chapter 1 -- Safety

General Safety Instructions 1 -- 2..................

Safety and Instruction Decals 1 -- 4................

Chapter 2 -- Product Records and Maintenance

Product Records 2 -- 1...........................

Maintenance 2 -- 1...............................

Equivalents and Conversions 2 -- 2................

Torque Specifications 2 -- 3.......................

Chapter 3 -- Traction and Reel Drive System

Specifications 3 -- 2..............................

General Information 3 -- 3........................

Special Tools 3 -- 6..............................

Adjustments 3 -- 8...............................

Service and Repairs 3 -- 11.......................

Chapter 4 -- Electrical System

General Information 4 -- 2........................

Electrical System Operation 4 -- 4.................

Lithium Battery Pack Charger Operation 4 -- 6......

Special Tools 4 -- 10.............................

Troubleshooting 4 -- 12...........................

InfoCenter Display 4 -- 16.........................

Adjustments 4 -- 22..............................

Component Testing 4 -- 26........................

Service and Repairs 4 -- 44.......................

Chapter 5 -- Chassis a nd Controls

Specifications 5 -- 2..............................

General Information 5 -- 3........................

Service and Repairs 5 -- 4........................

Chapter 6 -- Cutting Unit

Specifications 6 -- 3..............................

General Information 6 -- 4........................

Special Tools 6 -- 6..............................

Factors That Affect Quality Of Cut 6 -- 8............

Adjustments 6 -- 10..............................

Service and Repairs 6 -- 11.......................

Chapter 7 -- Groomer

Specifications 7 -- 2..............................

General Information 7 -- 3........................

Troubleshooting 7 -- 4............................

Adjustments 7 -- 6...............................

Service and Repairs 7 -- 7........................

Chapter 8 -- Foldout Drawings

Electrical Schematic 8 -- 3........................

Wire Harness Drawings 8 -- 4.....................

SafetyProduct Records

and Maintenance

Drive System

Traction and Reel

System

Electrical

Controls

Chassis andCutting Unit

Greensmaster eFlex 1800/2100

GroomerFoldout

Drawings

Page 4

This page is intentionally blank.

Greensmaster eFlex 1800/2100

Page 5

Table of Contents

GENERAL SAFETY INSTRUCTIONS 2............

Before Operating 2............................

While Operating 3............................

Maintenance and Service 3....................

Battery Pack Connection 4.....................

SAFETY AND INSTRUCTION DECALS 4..........

Chapter 1

Safety

Safety

Greensmaster eFlex 1800/2100 Page 1 -- 1 Safety

Page 6

General Safety Instructions

Greensmaster eFlex 1800 and eFlex 2100 machines

havebeen tested andcertified byTORO forcompliance

with existing safety standards and specifications. Although hazardcontrol and accidentprevention are partially dependent upon the design and configuration of

themachine, thesefactorsarealso dependentuponthe

awareness, concern and proper training of the personnel involved in the operation, transport, maintenance

and storage of the machine. Improper use or maintenanceof themachine canresult ininjury ordeath. To reduce the potential for injury or death, comply with the

following safety instructions.

WARNING

Toreduce thepotentialfor injury ordeath,comply with the following safety instructions.

Before Operating

WARNING

The eFlex battery pack contains high voltage

which could burn or electrocute you.

Never attempt to open the battery pack.

Do not place anything in the connector on

the battery pack other than the wire

harness connector that came with the

product.

Use extreme care when handling a battery

pack with a cracked case.

Only use the charger designed for the

battery pack.

1. Operatethemachineonlyafter reviewingandunderstandingthe contentsofthe Operator’sManual andOperator Training DVD.A replacement Operator’sManual

is available on the internet at www.toro.com

2. Never allowchildrento operatethe machineor allow

adults to operate it without proper instructions.

3. Become familiar with the controls and know how to

stop the machine and electric motor quickly.

4. Keep all shields, safety devices and decals in place.

Ifashield, safetydeviceor decalismalfunctioning,illegibleordamaged,repairorreplace it beforeoperating the

machine.

5. Always wear substantial shoes. Do not operate machine whilewearing sandals, tennis shoes or sneakers.

Donotwear loosefittingclothingwhich couldgetcaught

in moving parts and cause personal injury.

.

6. Wearing safety glasses, safety shoes, long pants,

ear protection and a hard hat is advisable and required

by some local safety and insurance regulations.

7. Ensure work area is clear of objects which might be

picked up and thrown by the cutting reel.

8. Keep everyone, especially children and pets, away

from the areas of operation.

9. The safety interlock switches are for the operator’s

protection;donotdisconnectthem. Check theoperation

oftheswitchesdailyto assuretheinterlocksystemis operating. If a switch isdefective, replace itbefore operating the machine. See Component Testing in Chapter 4

-- Electrical System.

Greensmaster eFlex 1800/2100Page 1 -- 2Safety

Page 7

While Operating

1. Always stand behind the handle when starting and

operating the machine.

2. To begin machine operation:

A. Make sure that themachine wire harness iscon-

nected to the battery pack

B. Verify that the control lever on handle is in NEU-

TRAL position for both traction and reel drives.

C. Move key switch to START position until the I nfo

Center display lights up, then release switch to the

RUN position.

3. Before leaving t he operator’s positionof the mower:

A. Stop the machine on level ground.

B. Disengage both the traction and reel drives with

the control lever and set the parking brake.

C. Move key switch to OFF position and wait for all

machine motion to stop.

4. Beforeemptyingbasketof clippings,disengage traction and reel drives, set the parking brake, move key

switchtoOFFpositionand wait forelectricmotortostop.

Waitfor allmachinemotiontostop beforeremovingbasket.

5. If thecutting unitstrikes asolid objector vibratesabnormally, stop machine operation immediately. Disengage the traction/mow lever, turn key switch to OFF

position, wait for all machine motion to stop. Then, disconnect battery pack (see Battery Pack Connection in

thissection)and inspect cuttingunitfordamage. Adamaged reel or bedknife must be repaired or replaced before operation is commenced.

6. Whenever machine is left unattended, be sure electricmotor is stopped,cuttingunit reelisnot spinningand

key switch is in the OFF position. Remove key from

switch.

Safety

Maintenance and Service

1. TheTraction Unit andCutting UnitOperator’s Manu-

alsprovide information regardingtheoperation,general

maintenance and maintenance intervals for your

Greensmaster machine. Refer to these publications for

additional information when servicing the machine.

2. Before servicing or making adjustments to the ma-

chine, set the parking brake, move key switch to OFF

positionandwaitforall machinemotiontostop.Remove

key from the ignition switch. Disconnect battery pack

(seeBattery PackConnection inthis section)to prevent

unintentional machine operation.

3. To make sure entire machine is in good condition,

keepallnuts, bolts, screwsandbeltsproperly tightened.

4. To reduce potential fire hazard, keep the battery

pack, electrical connectors, cutting unit and drive components free of debris.

5. Wear heavy gloves and use caution when checking

or servicing the cutting unit.

6. Ifthe electricmotormust berunningtoperformmain-

tenanceormakeanadjustment,keephands,feet,clothing and all parts of the body away from the cutting unit

and all moving parts. Keep bystanders away.

7. Before installing,removing or workingon the cutting

unit,disconnectthebatterypack(seeBatteryPackConnectionin thissection)to preventunintentionalmachine

operation.

8. Do not open or alter the battery pack in any way.

Openingthebatterypack may exposeyoutodangerous

electrical voltage. The warranty will be voided if you attempttoopen the batterypack.Withtheexception ofthe

battery pack fuse, fuse cover and labels, there are no

consumer serviceable parts on or in the battery pack.

9. If there ever is a need to ship the battery pack from

your eFlexmachine, you will needspecial packaging to

comply with shipping regulations. Refer to the Operator’s Manual for additional battery shipping information.

10.If major repairs are ever needed or assistance is required, contact your Authorized TORO Distributor.

11.At the time of manufacture, the machine conformed

to all applicable safety standards. To assure optimum

performance and continued safety certification of the

machine, use genuine Toro replacement parts and accessories. Replacement parts and accessories made

by othermanufacturers may result innon-conformance

with safety standards and the warranty may be voided.

Greensmaster eFlex 1800/2100 Page 1 -- 3 Safety

Page 8

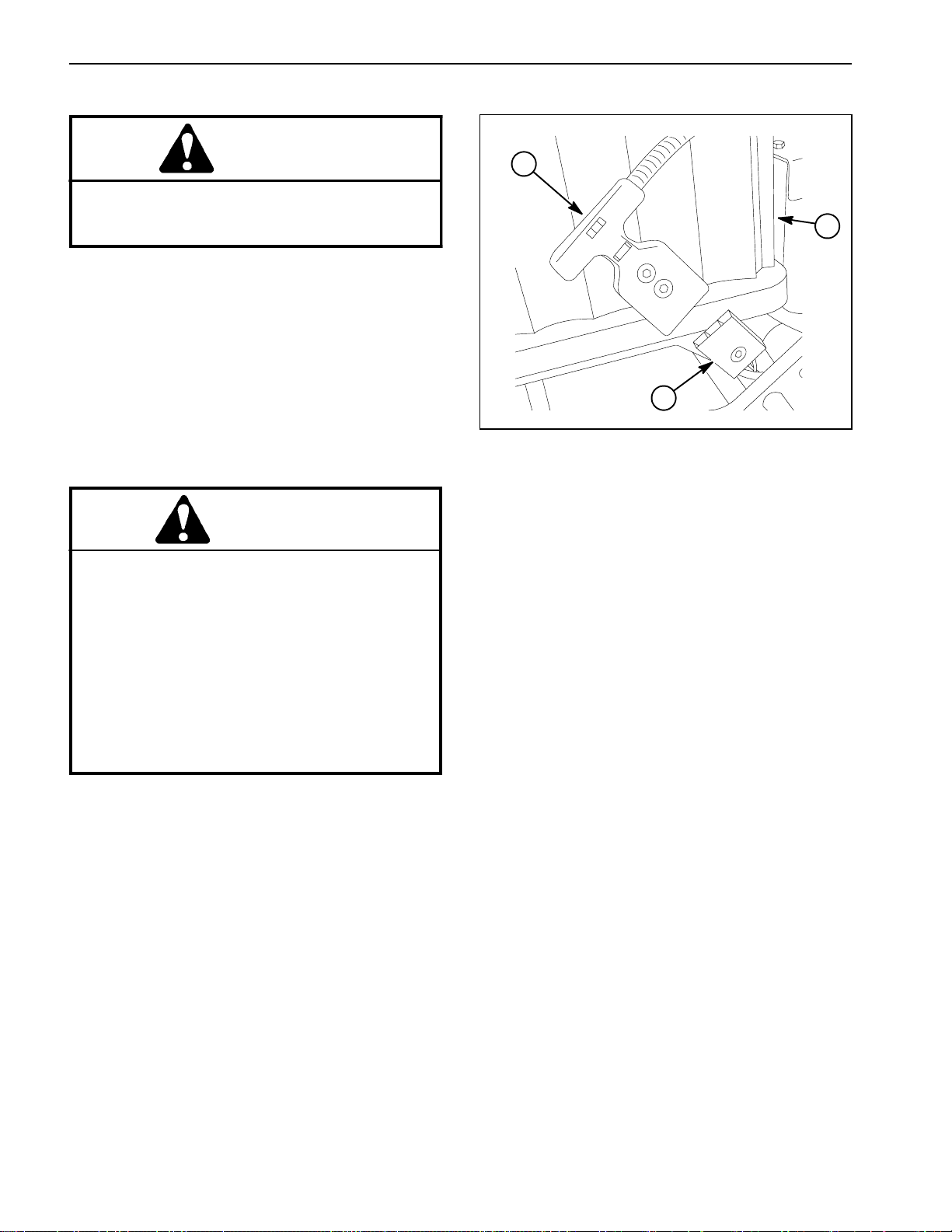

Battery Pack Connection

CAUTION

Before servicing the machine, disconnect the

the machine fromthe battery pack. This will prevent unexpected machine operation.

To prevent unexpected machine operation during service, disconnect the machine from the battery pack as

thefirst stepinany repair(Fig.1). Oncethe battery pack

hasbeendisconnected,the electrical systemonthemachinecanbesafelyworked on.Takecare during repairs,

however, to not allow tools or vehicle components to

complete the battery circuit that was opened with the

cable removal.

Connect the machine wire harness to the battery pack

as the last step in any repair.

WARNING

The eFlex battery pack contains high voltage

which could burn or electrocute you.

Never attempt to open the battery pack.

Do not place anything in the connector on

the battery pack other than the wire

harness connector that came with the

product.

Use extreme care when handling a battery

pack with a cracked case.

Only use the charger designed for the

battery pack.

3

1. Battery pack

2. Battery connector

1

2

Figure 1

3. Machine connector

Safety and Instruction Decals

Safety decals and instructions are easily visible to the

operatorand are locatednear any areaof potentialdanger. Replace any decal that is damaged or lost. Decal

part numbersare listed in yourParts Catalog. Orderreplacementdecals fromyour AuthorizedTORODistributor.

Greensmaster eFlex 1800/2100Page 1 -- 4Safety

Page 9

Product Records and Maintenance

Table of Contents

PRODUCT RECORDS 1.........................

MAINTENANCE 1..............................

EQUIVALENTS AND CONVERSIONS 2...........

Decimal and Millimeter Equivalents 2............

U.S. to Metric Conversions 2...................

TORQUE SPECIFICATIONS 3...................

Fastener Identification 3.......................

Standard Torque for Dry, Zinc Plated and Steel

Fasteners (Inch Series Fasteners) 4...........

Standard Torque for Dry, Zinc Plated and Steel

Fasteners (Metric Fasteners) 5...............

Other Torque Specifications 6..................

Conversion Factors 6.........................

Product Records

Chapter 2

Product Records

and Maintenance

Insert Operator’s Manual and Parts Catalog for your

Greensmaster eFlex 1800 or eFlex 2100 at the end of

this section. Additionally, if any optional equipment or

accessorieshave beeninstalled toyour machine,insert

the Installation Instructions, Operator’s Manuals and

PartsCatalogs forthose options at the endof thischapter.

Maintenance

Maintenanceproceduresand recommendedserviceintervals for the Greensmaster eFlex 1800 and eFlex

2100arecoveredintheOperator’sManual.Refertothat

publicationwhen p erforming regularequipmentmaintenance.

Greensmaster eFlex 1800/2100 Page 2 -- 1 Product Records and Maintenance

Page 10

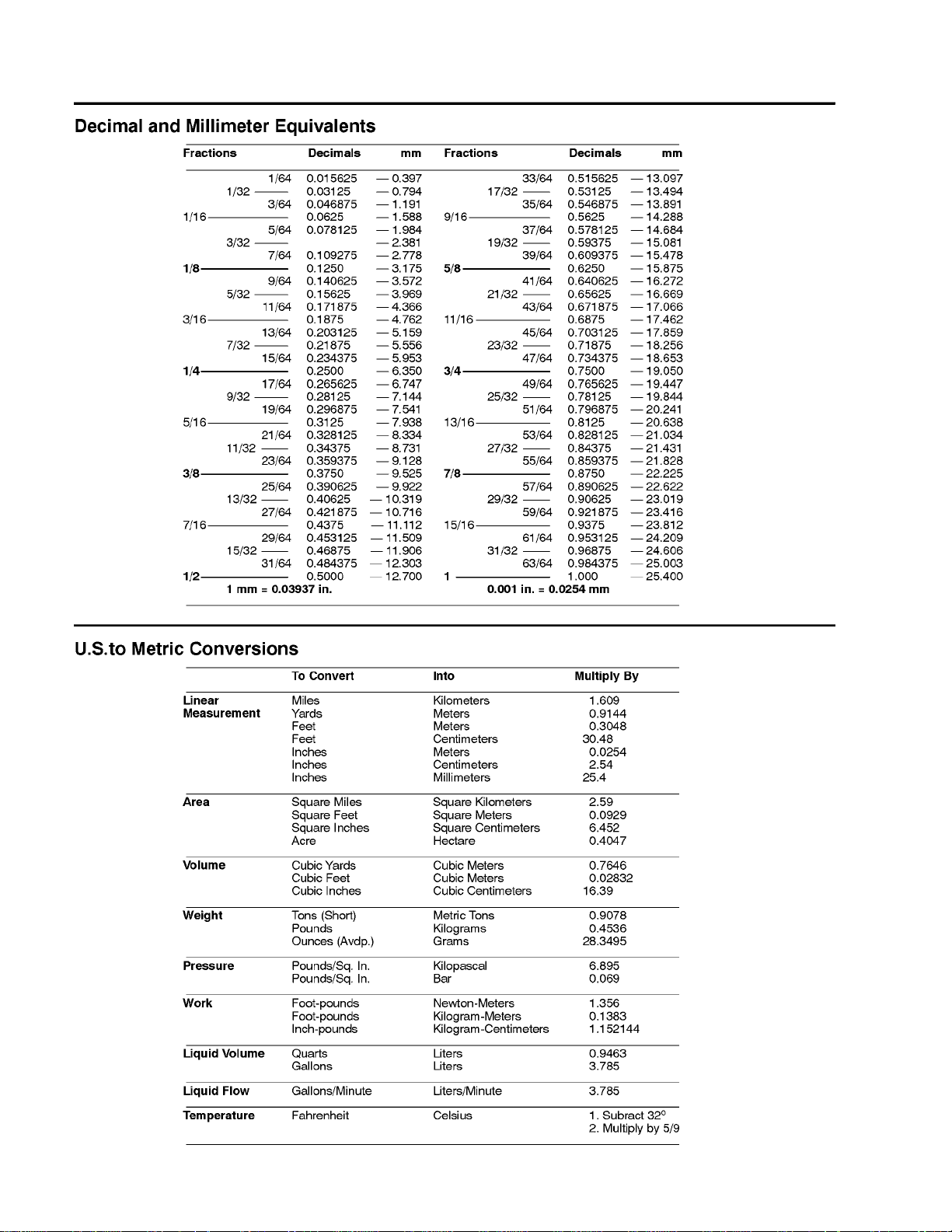

Equivalents and Conversions

0.09375

Greensmaster eFlex 1800/2100Page 2 -- 2Product Records and Maintenance

Page 11

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For criticalapplications, asdetermined

byToro,eitherthe recommendedtorqueora torquethat

is uniqueto the application isclearly identified andspecified in this Service Manual.

These Torque Specifications for the installation and

tightening of fasteners shall applyto all fastenerswhich

do nothave aspecific requirementidentified inthis Service Manual. The following factors shall be considered

when applying torque: cleanliness of the fastener, use

of a thread sealant (e.g. Loctite), degree of lubrication

on the fastener, presence of a prevailing torquefeature

(e.g. Nylock nut), hardness of the surface underneath

thefastener’shead orsimilarconditionwhich affectsthe

installation.

Fastener Identification

Asnotedin the followingtables,torquevaluesshould b e

reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener. Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based on the aluminum or brass

material strength, fastener size, length of thread engagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measurethe torquerequired to tightenthe fasteneruntil

thelinesmatchup.

Product Records

and Maintenance

Grade1 Grade5 Grade8

Inch Series Bolts and Screws

Class 8.8 Class 10.9

Metric Bolts and Screws

Greensmaster eFlex 1800/2100 Page 2 -- 3 Product Records and Maintenance

Page 12

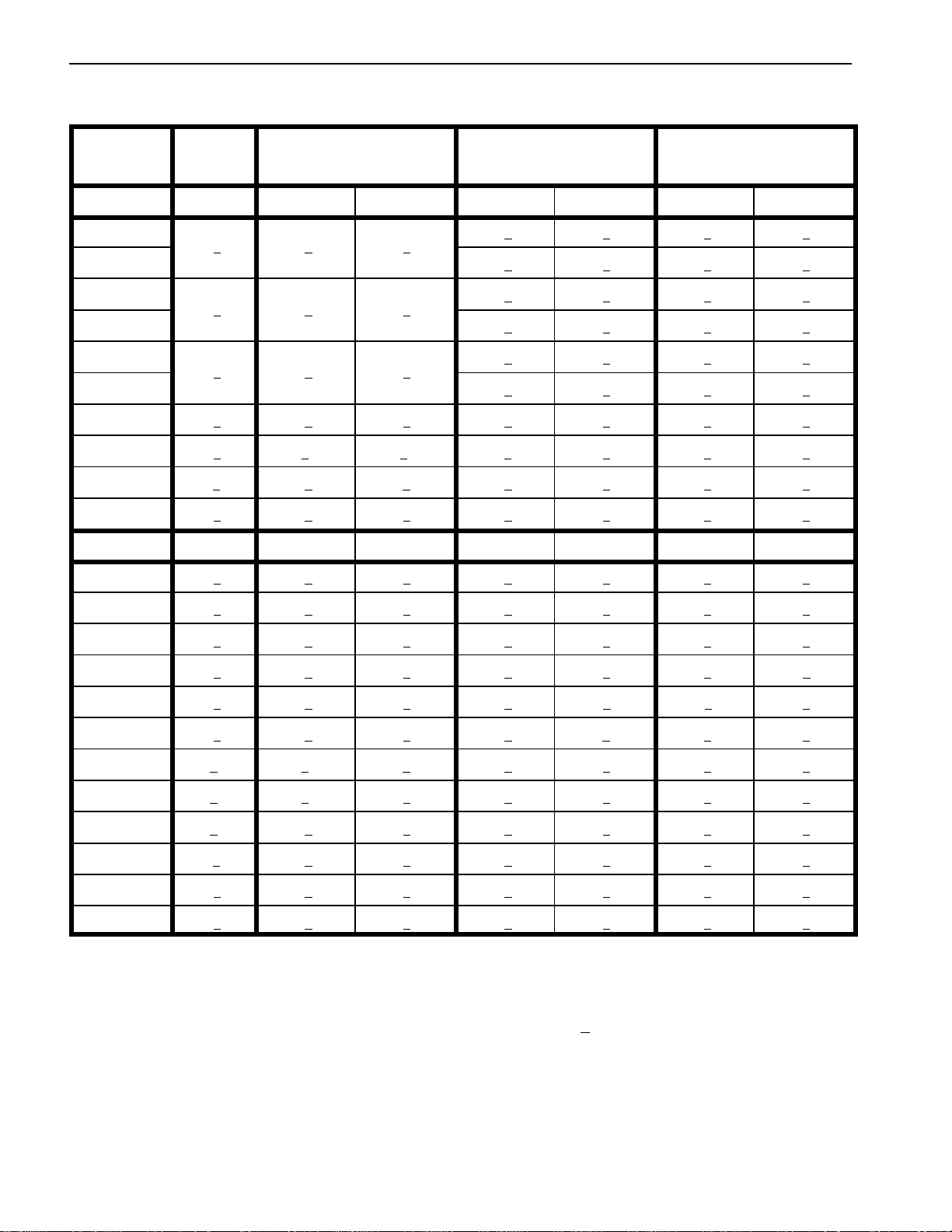

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series Fasteners)

Grade 1, 5 &

Thread Size

#6--32UNC

#6--40UNF 17 + 2 192 + 23 25 + 3 282 + 34

#8--32UNC

#8--36UNF 31 + 4 350 + 45 43 + 5 486 + 56

#10--24UNC

#10--32UNF 48 + 5 542 + 56 68 + 7 768 + 79

1/4 -- 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 1130+ 113 140 + 15 1582 + 169

1/4 -- 28 UNF 53 + 7 65 + 10 734 + 113 115 + 12 1299 + 136 160 + 17 1808 + 192

5/16 -- 18 UNC 115 + 15 105 + 15 1186 + 169 200 + 25 2 260+ 282 300 + 30 3390 + 339

5/16 -- 24 UNF 138 + 17 128 + 17 1446 + 192 225 + 25 2542 + 282 325 + 33 3672 + 373

3/8 -- 16 UNC 16 + 2 16 + 2 22 + 3 30 + 3 41 + 4 43 + 5 58 + 7

8withThin

Height Nuts

in--lb in--lb N--cm in--lb N--cm in--lb N--cm

10 + 2 13 + 2 147 + 23

13 + 2 25 + 5 282 + 30

18 + 2 30 + 5 339 + 56

ft--lb ft--lb N--m ft--lb N--m ft--lb N--m

SAE Grade 1 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

15 + 2 169 + 23 23 + 3 262 + 34

29 + 3 328 + 34 41 + 5 463 + 56

42 + 5 475 + 56 60 + 6 678 + 68

SAE Grade 8 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 5 or Stronger Nuts)

3/8 -- 24 UNF 17 + 2 18+ 2 24 + 3 35 + 4 47 + 5 50 + 6 68 + 8

7/16 -- 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 + 7 95 + 9

7/16 -- 20 UNF 29 + 3 29 + 3 39 + 4 55 + 6 75 + 8 77 + 8 104 + 11

1/2 -- 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 + 11 105 + 11 142 + 15

1/2 -- 20 UNF 32 + 4 53 + 7 72 + 9 85 + 9 115 + 12 120 + 12 163 + 16

5/8 -- 11 UNC 65 + 10 88 + 12 119 + 16 150 + 15 203 + 20 210 + 21 285 + 28

5/8 -- 18 UNF 75 + 10 95+ 15 129 + 20 170 + 18 230 + 24 240 + 24 325 + 33

3/4 -- 10 UNC 93 + 12 140 + 20 190 + 27 265 + 27 359+ 37 375+ 38 508+ 52

3/4 -- 16 UNF 115 + 15 165 + 25 224 + 34 300 + 30 407+ 41 420 + 43 569 + 58

7/8 -- 9 UNC 140 + 20 225 + 25 305 + 34 430 + 45 583 + 61 600 + 60 813 + 81

7/8 -- 14 UNF 155 + 25 260 + 30 353 + 41 475 + 48 644 + 65 667 + 66 904 + 89

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

NOTE: The nominal torque values listed above for

Grade 5 and8 fasteners are based on 75% of the minimum proof load specifiedin SAEJ429. The tolerance is

approximately +

10% of the nominal torque value. Thin

height nuts include jam nuts.

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

Greensmaster eFlex 1800/2100Page 2 -- 4Product Records and Maintenance

Page 13

Standard To rque for Dry, Zinc Plated and Steel Fasteners (Metric Fasteners)

Class 8.8 Bolts, Screws and Studs with

Thread Size

M5 X 0.8 57 + 6in--lb 644 + 68 N--cm 78 + 8in--lb 881 + 90 N--cm

M6 X 1.0 96 + 10 in--lb 1085 + 113 N- -cm 133 + 14 in--lb 1503 + 158 N--cm

M8 X 1.25 19 + 2ft--lb 26 + 3N--m 28 + 3ft--lb 38 + 4N--m

M10 X 1.5 38 + 4ft--lb 52 + 5N--m 54 + 6ft--lb 73 + 8N--m

M12 X 1.75 66 + 7ft--lb 90 + 10 N--m 93+ 10 ft--lb 126 + 14 N--m

M16 X 2.0 166+ 17 ft--lb 225 + 23 N--m 229 + 23 ft--lb 310 + 31 N--m

M20 X 2.5 325 + 33 ft--lb 440 + 45 N-- m 450 + 46 ft--lb 610 + 62 N--m

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

Regular Height Nuts

(Class 8 or Stronger Nuts)

NOTE: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAEJ1199.The toleranceisapproximately+

nominal torque value.

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

(Class 10 or Stronger Nuts)

10%ofthe

Product Records

and Maintenance

Greensmaster eFlex 1800/2100 Page 2 -- 5 Product Records and Maintenance

Page 14

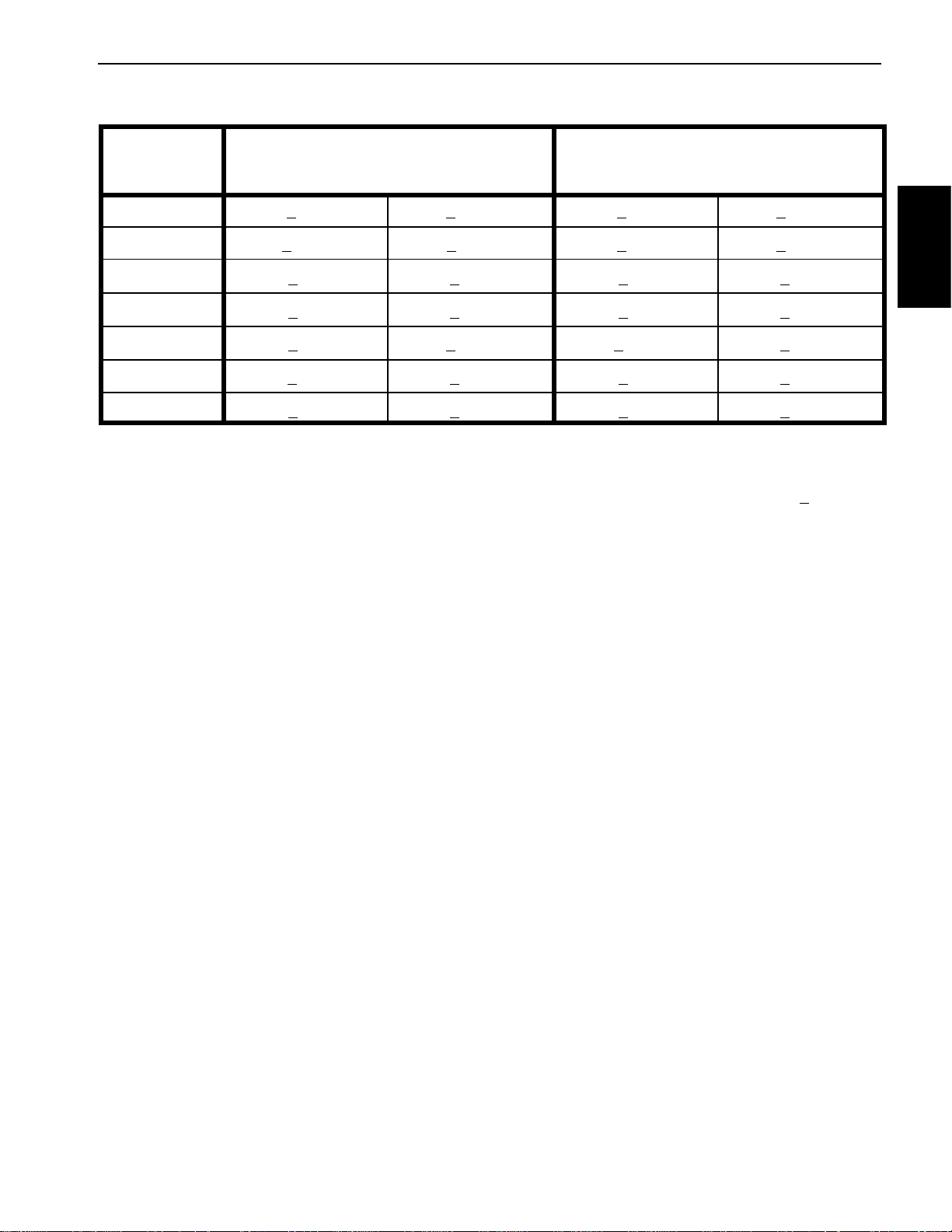

Other Torque Specifications

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 -- 20 UNC 140 + 20 in--lb 73 + 12 in--lb

5/16 -- 18 UNC 215 + 35 in--lb 145 + 20 in--lb

3/8 -- 16 UNC 35 + 10 ft--lb 18 + 3ft--lb

1/2 -- 13 UNC 75 + 15 ft--lb 50 + 10 ft--lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size Baseline Torque*

No. 6 -- 32 UNC 20 + 5in--lb

Wheel Bolts and Lug Nuts

Thread Size

7/16 -- 20 UNF

Grade 5

1/2 -- 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non--lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5in--lb

Threads per Inch

Type A Type B

Recommended Torque**

65 + 10 ft--lb 88 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

Baseline Torque*

No. 8 -- 32 UNC 30 + 5in--lb

No. 10 -- 24 UNC 38 + 7in--lb

1/4 -- 20 UNC 85 + 15 in--lb

5/16 -- 18 UNC 110 + 20 in--lb

3/8 -- 16 UNC 200 + 100 in--lb

Conversion Factors

in--lb X 11.2985 = N--cm N--cm X 0.08851 = in--lb

ft--lb X 1.3558 = N--m N--m X 0.7376 = ft--lb

No. 8 15 18 30 + 5in--lb

No. 10 12 16 38 + 7in--lb

No. 12 11 14 85 + 15 in--lb

*Holesize, materialstrength, materialthickness &finish

must be considered when determining specific torque

values. All torque values are based on non--lubricated

fasteners.

Greensmaster eFlex 1800/2100Page 2 -- 6Product Records and Maintenance

Page 15

Traction and Reel Drive System

Table of Contents

SPECIFICATIONS 2............................

GENERAL INFORMATION 3.....................

Operator’s Manuals 3.........................

Battery Pack Connection 3.....................

Disengaging Drum Drive From Transmission 4...

Transmission Belt Tensioner 5..................

SPECIAL TOOLS 6.............................

ADJUSTMENTS 8..............................

Cutting Unit Clip Adjustment 8..................

Reel Clutch Adjustment 9......................

SERVICE AND REPAIRS 11......................

Reel Drive Belt 11.............................

Reel Drive Assembly 12.......................

Reel Drive Bearing Housing 14.................

Drum Drive Belt 16............................

Drum Drive Idler Assembly 18..................

Traction Drums 20............................

Differential Assembly 24.......................

Differential Assembly Service 26................

Transmission Drive Belt 28.....................

Transmission Idler System 30..................

Transmission Reel Drive System 32.............

Removing Seized Reel Clutch Shaft From

Transmission 35............................

Transmission Drive System 36..................

Transmission Drum Drive System 38............

Transmission 40..............................

Chapter 3

Drive System

Traction and Reel

Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 1

Page 16

Specifications

Item Description

Transmission Permanent Magnet DC Motor Directly Coupled to

Traction Drive Transmission to Traction Drive uses Multi--Ribbed Poly--V Belt

Differential Spur Gear Planetary Differential

Traction Brake Band Style (at differential shaft drive)

Traction Drum Dual Cast Aluminum, 7.5 inch (19 cm) Diameter

Cutting Reel Drive Transmission Reel Clutch Shaft to Telescoping Drive Shaft

Final Reel Drive has Three (3) Pulleys with Positive Drive Belt

First Stage of a Multi--Ribbed Poly--V Belt Drive

Belt Tension Maintained by Spring Loaded Idler Pulley

Belt Tension Maintained by Spring Loaded Idler Pulley

Two Beam Style Couplers Used in Reel Drive System

Pulley Configuration Allows Six (6) Clip Adjustments

Greensmaster eFlex 1800/2100Traction and Reel Drive System Page 3 -- 2

Page 17

General Information

Operator’s Manuals

The Traction Unit and Cutting Unit Operator’s Manuals

provide information regarding the operation, general

maintenance and maintenance intervals for your

Greensmaster machine. Refer to these Operator’s

Manuals for additional information when servicing the

machine.

Battery Pack Connection

CAUTION

Before servicing the machine, disconnect the

the machine from the battery pack. This will prevent unexpected machine operation.

To prevent unexpected machine operation during service, disconnect the machine from the battery pack as

thefirst step inany repair (Fig.1). Once thebatterypack

hasbeendisconnected,the electrical systemonthemachinecanbesafelyworked on.Takecare duringrepairs,

however, to not allow tools or vehicle components to

complete the battery circuit that was opened with the

cable removal.

Connect the machine wire harness to the battery pack

as the last step in any repair.

WARNING

The eFlex battery pack contains high voltage

which could burn or electrocute you.

Never attempt to open the battery pack.

Do not place anything in t he connector on

the battery pack other than the wire

harness connector that came with the

product.

Use extreme care when handling a battery

pack with a cracked case.

Only use the charger designed for the

battery pack.

3

1. Battery pack

2. Battery connector

Drive System

Traction and Reel

1

2

Figure 1

3. Machine connector

Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 3

Page 18

Disengaging Drum Drive From Transmission

The tractiondrum is driven bya multi--ribbed belt thatis

tensionedwith aspring loaded idlerassembly.To disengage the traction drum drive from the transmission, follow the following procedure:

1. Parkmachineonlevelsurface.Turnkeyswitchtothe

OFF position and remove key from the switch. Disconnect the battery pack (see Battery Pack Connection in

this section).

2. Locate the traction engage/disengage lever next to

the RH drive housing drum (Fig. 2).

CAUTION

Becarefulwhen rotating thetractionengage/disengagelever.The lever isspring loaded andmay

cause personal injury. Push lever from the front

when removing belt tension to prevent unexpected movement of the lever.

3. Rotate traction engage/disengage lever toward the

rear of the machine to the disengaged position to remove tension from the drum drive belt.

4. To engage the drum drive, rotate traction engage/

disengage leverto the engaged position by rotatingthe

lever toward the front of the machine.

1

2

Figure 2

1. Traction lever (engaged) 2. RH handle clamp

5. Connectthebatterypack (seeBattery PackConnection in this section).

Greensmaster eFlex 1800/2100Traction and Reel Drive System Page 3 -- 4

Page 19

Transmission Belt Tensioner

The transmission pulleys are driven by a multi--ribbed

belt that is tensioned with a spring loaded idler assembly.Ifthe transmission belttensionneedstobe engaged

or disengaged, follow the following procedure:

1. Parkmachineonlevelsurface.Turnkeyswitchtothe

OFF position and remove key from the switch. Disconnect the battery pack (see Battery Pack Connection in

this section).

2. Locate the transmissionengage/disengage shaft on

the inside of the transmission next to the battery pack

(Fig. 3).

2

1

CAUTION

Be careful when rotating the transmission engage/disengage lever. The lever is spring loaded

and may cause personal injury.

3. To disengage the spring loaded idler from thetransmission drive belt, use a 3/8” wrench to rotate the engage/disengage shaft 1/4 turn clockwise.

4. To engage the idler into the transmission drive belt,

use a3/8” wrenchto rotate theengage/disengage shaft

1/4 turn counter--clockwise. The transmission belt is

properlytensionedwhenthealignmentmarksontheengage/disengage shaft and the transmission cover are

aligned (Fig. 4).

5. Connectthebatterypack (seeBattery PackConnection in this section).

Figure 3

1. Transmission

2. Engage/disengage shaft

3

Figure 4

1. Engage/disengage shaft

2. Alignment mark

3

3. Battery pack

1

2

3. Cover alignment mark

Drive System

Traction and Reel

Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 5

Page 20

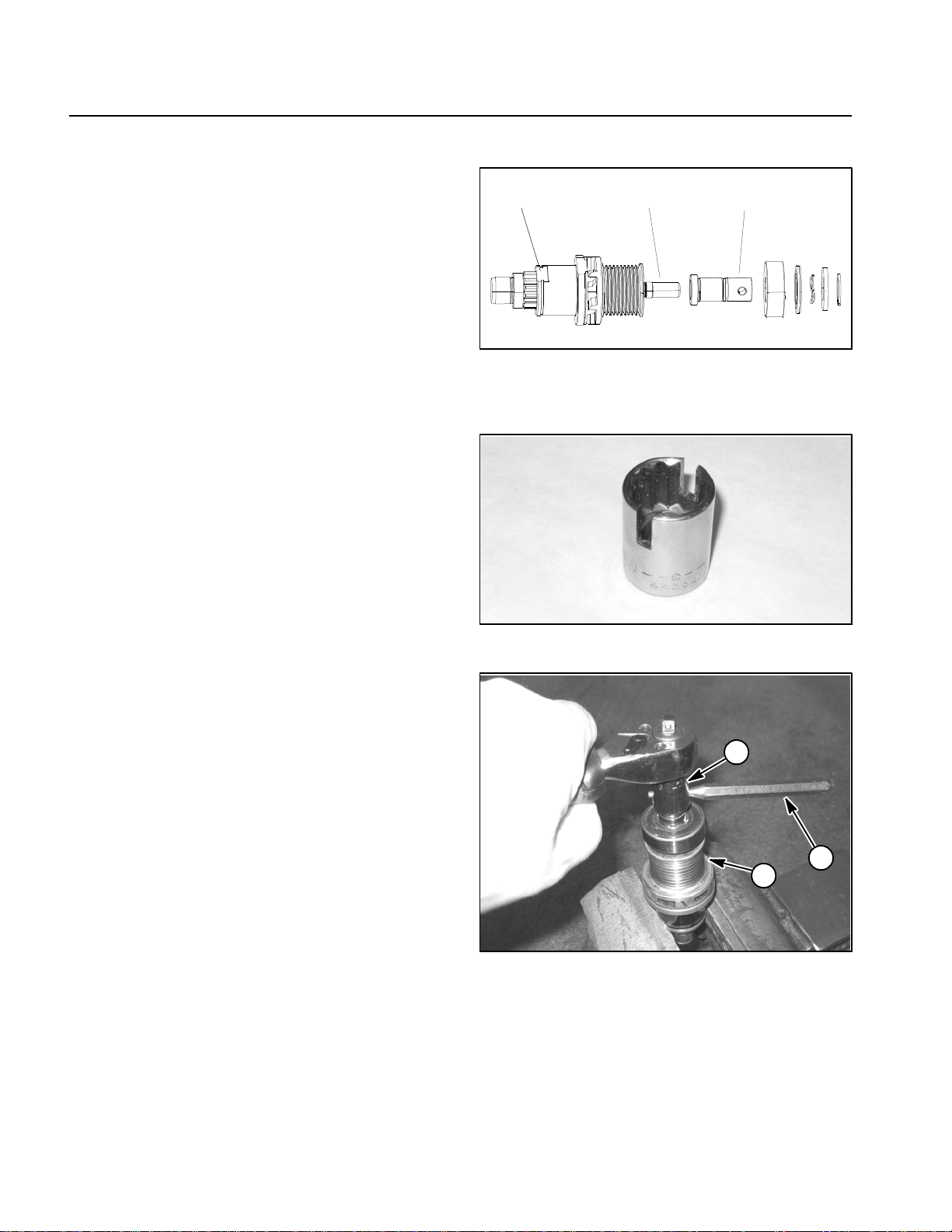

Special Tools

Modified Socket for Reel Clutch Bearing Collar

The modified socket is used to remove and install the

reel clutch bearing collar when servicing the transmission reel clutch shaft (Fig. 5). Refer to Transmission

ReelDrive Systeminthe ServiceandRepairs sectionof

this chapter for complete information on servicing the

reel clutch shaft assembly.

Socket Modification

1. Make sure that socket (9/16” or 15mm) to be modified fits over the reel clutch shaft bearing collar.

2. Drill a hole or grind slots in socket walls to allow a

5/32” pin to extend through socket. A modified socket

with ground slots is shown in Figure 6.

Modified Socket Use ( Fig. 7)

IMPORTANT: To prevent damage, avoid using ex-

cessive clamping pressure on the reel clutch shaft

assembly.

1. Bearing collar

2. Reel clutch shaft

123

Figure 5

3. Hub flat location

1. Use flats on reel drive hub to carefully secure reel

clutchshaft assemblyin avise. Usea visewith softjaws

to prevent damage to clutch shaft assembly components.

2. Slide modified socket over bearing collar.

3. Align modified socket so that 5/32” pin can be inserted through socket and hole in bearing collar.

4. Use modifiedsocket andsocket wrenchto loosenor

tighten bearing collar.

1. Modified socket

2. Reel clutch shaft assy

Figure 6

1

3

2

Figure 7

3. Pin

Greensmaster eFlex 1800/2100Traction and Reel Drive System Page 3 -- 6

Page 21

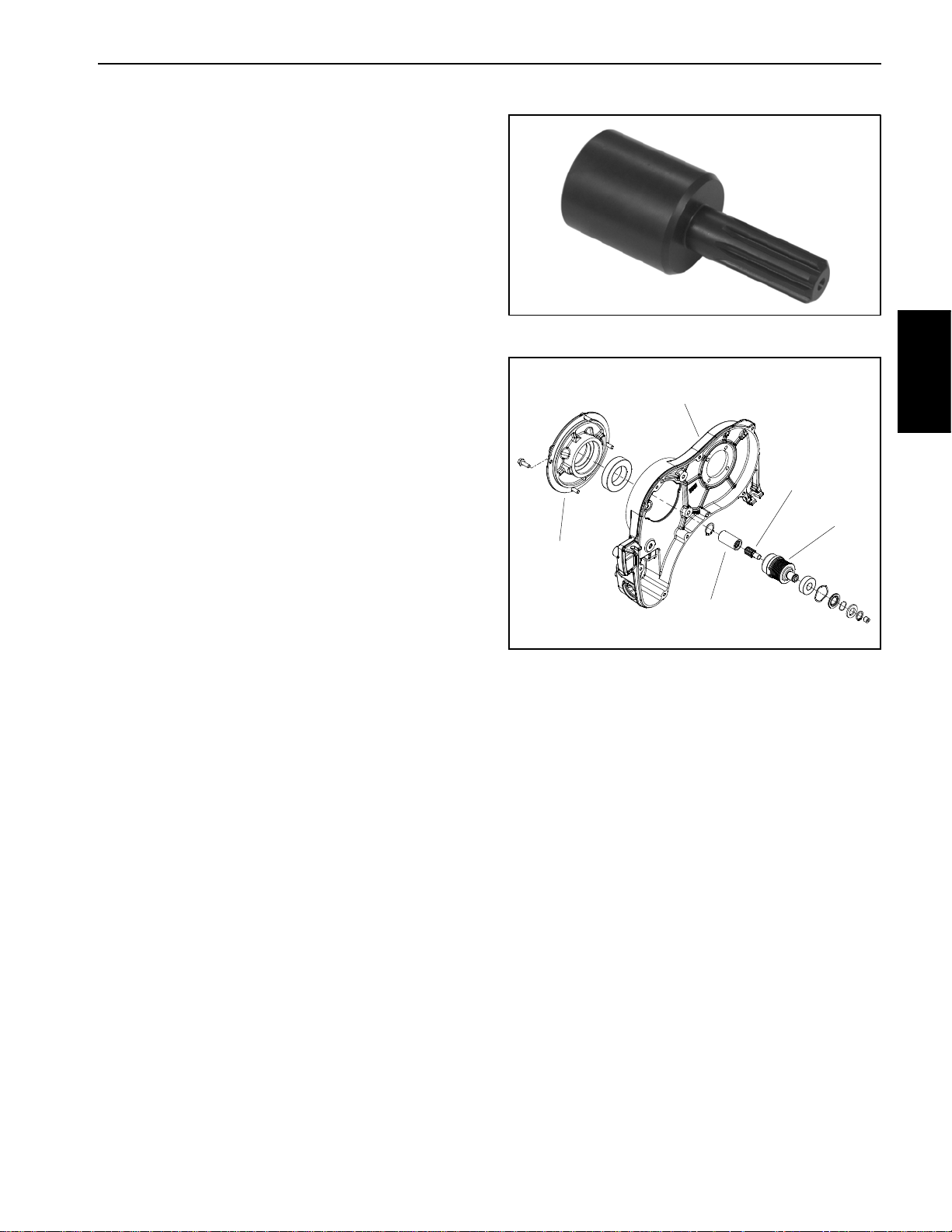

Spline Insert Tool

Usesplineinserttooltoremoveorinstalldrivesplineinto

transmission driven pulley. Referto Transmission Drive

System inthe Service andRepairs section ofthis chapter for complete information on servicing the transmission drive system.

Toro Part Number: TOR4112

Figure 8

2

Drive System

Traction and Reel

4

5

1

1. Motor adapter

2. Transmission housing

3. Splined coupler

3

Figure 9

4. Drive spline

5. Driven pulley

Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 7

Page 22

Adjustments

Cutting Unit Clip Adjustment

Cuttingunitclipadjustment on theeFlex1800and eFlex

2100 can bechanged by installing the cutting unit drive

pulleysto the appropriatelocations onthe reel driveassembly.Clip frequencypulley locationsfor 11 bladeand

14 blade cutting units are shown in Figure 11 below.

To adjust clip frequency, follow the following s teps:

1. Parkmachineonlevelsurface.Turnkeyswitchtothe

OFF position and remove key from the switch. Disconnect the battery pack (see Battery Pack Connection in

the General Information section of this chapter).

2. Removereeldrive coverandreel drivebeltfromside

ofcuttingunit (seeReelDriveBelt intheServiceand Repairs section of this chapter).

3. Loosen two(2)set screwsfrom drivepulleys thatare

to be removed. Slide pulleys from shafts.

4. Apply antiseize lubricant to top of woodruff keys.Arrange pulleys on reel drive assembly as needed for desired clip frequency (Fig. 11).

5. Secure all pulleys with two (2) set screws. To rque

screws from 60 to 65 in--lb (6.8 to 7.3 N--m).

2

1. Reel drive cover

2. Reel drive belt

3. Pulley

Antiseize

Lubricant

5

Figure 10

60 to 65 in--lb

(6.8 to 7.3 N--m)

4

3

4. Set screw

5. Woodruff key

1

6. Install reel drive belt and reel drive cover to cutting

unit(see Reel DriveBeltin theServiceand Repairssection of this chapter).

7. Connectthebatterypack (seeBattery PackConnection in the General Information section of this chapter).

POSITIONBLADES

A11 14 B C

0.147 0.115

0.153 0.120

0.160 0.126

CLIP

0.174 0.137

0.182 0.143

0.190 0.149

22

22

24

25

24

25

24 25

25 24

22 25

22 24

25 22

24 22

B

C

A

SET SCREW

60 -- 65 IN LBS

22 TOOTH PULLEY IS ALUMINUM COLOR

24 TOOTH PULLEY IS BLACK COLOR

25 TOOTH PULLEY IS RED COLOR

Figure 11

Greensmaster eFlex 1800/2100Traction and Reel Drive System Page 3 -- 8

Page 23

Reel Clutch Adjustment

To adjust the reel clutch, follow the following steps:

1. Parkmachineonlevelsurface.Turnkeyswitchtothe

OFF position and remove key from the switch. Disconnect the battery pack (see Battery Pack Connection in

the General Information section of this chapter).

2. Remove rubber plugfrom front oftransmission toallow viewing of reel drive clutch components (Fig. 12).

3. Releaseclutch cablespringtension byremovingreel

clutch cable from casting slot of transmission:

6

5

4

A. Loosen upper jam nut that secures reel cable to

casting slot of transmission.

B. Lift cable free from casting slot of transmission.

4. Loosen jam nut that secures set screw position in

reel clutch lever (Fig. 12).

5. Apply light upward pressure against the reel clutch

lever.

6. Backoutsetscrew inreel clutchlever untilreelclutch

hubcauses thetips ofthe reeldrive hubteeth tocontact

the mating reel clutch pulley.

7. While maintaining light pressure on reel clutchlever,

rotate set screw clockwise until a gap of 0.040” to

0.060”(1.0to1.5mm)isattainedbetweenthereeldrive

hub and reel clutch hub.

8. Tighten jam nut to secure adjustment. Make sure

that set screw does not rotate while tightening jam nut.

9. Install rubber plug into front of transmission.

10.Install reel cable to casting slot of transmission and

confirmthatcablespring lengthis properlyset(seeReel

Clutch Cable Replacement in Chapter 5 -- Chassis and

Controls).

7

3

0.040” to 0.060”

(1.0 to 1.5 mm)

1. Reel drive hub tooth

2. Reel drive hub

3. Reel clutch hub

4. Reel clutch lever

1

Drive System

Traction and Reel

12

Light Upward

Pressure

Figure 12

5. Set screw

6. Jam nut

7. Gap location

11.Connect thebattery pack(seeBatteryPackConnection in the General Information section of this chapter).

Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 9

2

1. Reel clutch lever

2. Reel clutch hub

4

3

Figure 13

3. Reel drive hub

4. Reel clutch pulley

Page 24

This page is intentionally blank.

Greensmaster eFlex 1800/2100Traction and Reel Drive System Page 3 -- 10

Page 25

Service and Repairs

Reel Drive Belt

EFlex machinesuse apositive drive belton the leftside

of the machine to operate the cutting unit.

Removal

1. Parkmachineonlevelsurface.Turnkeyswitchtothe

OFF position and remove key from the switch. Disconnect the battery pack (see Battery Pack Connection in

the General Information section of this chapter).

2. Remove reel drive cover to expose reel drive belt

(Fig. 14).

3. Loosen the bearing housing mounting nut (Fig. 15).

4. Using a 5/8” (16mm) wrench, rotate the bearing

housing to release tension on reel drive belt (Fig. 15).

5. Remove reel drive belt from the pulleys.

2

Figure 14

1. Reel drive cover 2. Flange head screw

1

Drive System

Traction and Reel

Installation

1. Makesurethat thebattery packisdisconnected(see

Battery Pack Connection in the General Information

section of this chapter).

2. Using a 5/8” (16mm) wrench, rotate and hold the

bearing housingto allow reel drive belt installation (Fig.

15).

3. Place a new drive belt onto the pulleys.

4. Release bearing housing to apply tension to reel

drivebelt. Makesure thatbearing housing rotatesfreely

which will allow accurate belt tension.

5. Rotate reel drive at least one (1) full turn to ensure

that drive belt is properly tensioned.

6. Tighten the bearing housing mounting nut (Fig. 15).

7. Install reel drive cover to machine and secure with

flange head screw (Fig. 14).

8. Connectthebatterypack (seeBattery PackConnection in the General Information section of this chapter).

1. Reel drive belt

2. Bearing housing nut

3

Figure 15

3. Compression spring

4. Bearing housing

4

2

1

Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 11

Page 26

Reel Drive Assembly

27

20

Antiseize

Lubricant

12

22

Antiseize

3

16

Lubricant

21

60 to 65 in--lb

2

(6.8 to 7.3 N--m)

17

18

24

25

22

4

23

10

14

26

6

9

1

23

19

24

7

22

28

RIGHT

FRONT

Antiseize

Lubricant

Figure 16

1. Reel drive housing

2. O--ring

3. Carriage screw

4. Washer head screw

5. Flange head screw (2 used)

6. Hex nut (2 used)

7. Reel drive shaft

8. Reel pulley (22 tooth) (aluminum)

9. O--ring

10. Reel idler shaft

11. Reel pulley (24 tooth) (black)

12. Bearing housing assembly

13. Cover plug

14. Reel pulley (25 tooth) (red)

15. Belt

16. Compression spring

17. Hardened washer

18. Hex nut

19. Reel drive cover

NOTE: Cutting unit clip adjustment on the eFlex 1800

and eFlex 2100 is adjusted by installing the cutting unit

drivepulleys(items8,11and14)tothe appropriate locations on the reel drive assembly (see Cutting Unit Clip

Adjustment in the Adjustments section of this chapter).

5

11

8

15

13

20. Shoulder bolt

21. Spring pin

22. Woodruff key (3 used)

23. Set screw (2 used per pulley)

24. Ball bearing (2 used)

25. Spacer

26. Push nut

27. Cutting unit

28. Flange head screw

Greensmaster eFlex 1800/2100Traction and Reel Drive System Page 3 -- 12

Page 27

Reel Drive Assembly Removal (Fig. 16)

1. Parkmachineonlevelsurface.Turnkeyswitchtothe

OFF position and remove key from the switch. Disconnect the battery pack (see Battery Pack Connection in

the General Information section of this chapter).

2. Slide the telescoping coupler off the cutting unit hex

shaft (Fig. 17).

3. Removereeldrive belt (seeReelDriveBeltReplacement in this section).

4. Loosen two (2) set screws (item 23) that secure reel

pulley (item 8) to reel drive shaft (item 7). Slide pulley

from drive shaft. Locateand retrieve woodruff key (item

22) from shaft.

5. Remove washer head screw (item 4) that secures

reel drive housing to cutting unit side plate.

NOTE: Hex nuts (item6) haveadhesive appliedduring

cutting unit production. The nuts should remain in cutting unit side plate during reel drive housing removal.

6. Remove two (2) flange headscrews (item5) thatsecure reel drive housing to cutting unit side plate.

3. Position reel drive assembly to cutting unit. Make

sure that spring pin (item 21) and compression spring

(item16) arepositionedbetween reeldrive housingand

bearing housing assembly.

4. Secure reeldrive assembly with two (2)flange head

screws (item 5) and washer head screw (item 4).

5. Install woodruff key(item 22) to reel driveshaft (item

7). Apply antiseize lubricant to top of key.

6. Slide reel pulley (item 8) onto reel drive shaft until it

contacts shoulder on shaft. Secure reel pulley with two

(2) set screws (item 23). Torque set screws from 60 to

65 in--lb (6.8 to 7.3 N--m).

7. Install reel drive belt (see Reel Drive Belt Replacement in this section). Make sure that reel drive cover is

securedtohousingafterbeltinstallation.

8. Slide the telescoping coupler onto the cutting unit

hex shaft (Fig. 17).

9. Connectthebatterypack (seeBatteryPackConnection in the General Information section of this chapter).

Drive System

Traction and Reel

7. Remove reel drive assembly from cutting unit.

8. Remove components from reel drive housing as

necessary using Figure 16 as a guide.

A. If idlershaft bearings(item24) are toberemoved,

use press to remove bearings and bearing spacer

from shaft. Discard bearings after removal.

NOTE: See Reel Drive Bearing Housing in this section

for disassembly and assembly information of bearing

housing assembly (item 12).

NOTE: Reel pulleys (items 8,11and 14) can beidentified by color and number of teeth. Pulley location can

vary based on desired cutting unit clip frequency (see

Cutting UnitClip Adjustment inthe Adjustments section

of this chapter).

Reel Drive Assembly Installation (Fig. 16)

1. Install allremoved components to reeldrive housing

using Figure 16 as a guide.

A. If bearings (item 24) were removed from idler

shaft, use press to install bearings and bearing

spacer onto shaft.

1

2

Figure 17

1. Telescoping coupler 2. Cutting unit hex shaft

2. Apply light coating of grease on reel drive housing

O--rings (items 2 and 9).

Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 13

Page 28

Reel Drive Bearing Housing

11

10

8

6

13

12

1. Retaining ring

2. Reel input shaft

3. Bearing (2 used)

4. Bearing spacer

5. Wave washer

9

7

Figure 18

6. Flocked bearing shield

7. Wave spring

8. Flat washer

9. Retaining ring

5

3

2

1

4

10. Bearing housing

11. Spring pin (2 used)

12. Flex coupling

13. Reel hex shaft

Greensmaster eFlex 1800/2100Traction and Reel Drive System Page 3 -- 14

Page 29

Disassembly (Fig. 18)

Assembly (Fig. 18)

1. Parkmachineonlevelsurface.Turnkeyswitchtothe

OFF position and remove key from the switch. Disconnect the battery pack (see Battery Pack Connection in

the General Information section of this chapter).

2. Remove reel drive bearing housing from reel drive

housing (see Reel Drive Assembly in this section).

3. Removeretainingring(item 1)from bearinghousing.

4. Slide reel input shaft assembly from bearing housing. Remove wave washer (item 5) from bearing housing.

IMPORTANT: When removing flexcoupler (item 12)

from reel input shaft (item 2), do not mar outer surface of coupler (e.g. grasping with pliers or mounting in vise) as coupler may be damaged and fail

prematurely.

5. Supportflex coupler(item12) to preventitfrombeing

damaged during spring pin removal. Push spring pin

fromflex couplerandreel inputshaft.Slide couplerfrom

shaft and discard spring pin.

6. Remove retaining r ing (item 9) from shaft. Then remove flat washer (item 8), wave spring (item 7) and

flocked bearing shield (item 6) from shaft. Note orientation of flocked shield for assembly purposes.

7. Press bearingsand bearingspacerfromshaft ifnecessary. Discard bearings if removed.

8. Clean all bearing housing components.

1. Ifbearingswereremovedfromreelinputshaft, install

new bearings onto shaft. Press first bearing fully onto

shaft. Position spacer on shaft and then press second

bearing onto shaft.

2. Install flocked bearing shield (item 6), wave spring

(item 7) and then flat washer (item 8) onto reel input

shaft. Secure components to shaft with retaining ring

(item 9). It may be necessary to drive the retaining ring

onto theinput shaft with atubular tool and mallet.Make

sure that retaining ring is fully seated into shaft groove

after installation.

3. Place wave washer (item 5) into bearing housing.

4. Fillcavitybetween bearingswithMobilHighTemperature XHP--222 grease (or equivalent).

5. Installreel inputshaftassembly into bearinghousing

andsecurewithretainingring(item1).

IMPORTANT: When installing flex coupler (item 12)

onto reel input shaft (item 2), do not mar outer surface of coupler (e.g. grasping with pliers or mount ing in vise) as coupler may be damaged and fail

prematurely.

6. Slide flex coupler onto reel input shaft, supportcoupler to prevent it from being damaged during spring pin

installation. Installnew spring pin into coupler to secure

it to shaft.

7. Install reel drive bearing housing to reel drive housing (see Reel Drive Assembly in this section).

Drive System

Traction and Reel

8. Connectthebatterypack (seeBatteryPackConnection in the General Information section of this chapter).

Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 15

Page 30

Drum Drive Belt

12

See text for

tightening

procedure

2

11

9

6

14

13

4

8

7

5

3

10

15 to 17 ft--lb

(21to23N--m)

18

17

16

15

1

2

Figure 19

1. Drum drive cover

2. Washer head screw (7 used)

3. Gasket

4. Wave washer

5. Gear assembly

6. Retaining ring

7. Brake band

8. Brake mount pin

9. Extension spring

10. Drum drive belt

11. Brake clevis pin

12. Drum drive housing

The drum drive system on eFlex 1800 and eFlex 2100

machines uses a multi--ribbed poly--V drive belt on the

right side of the traction drum.

Removal (Fig. 19)

1. Parkmachineonlevelsurface.Turnkeyswitchtothe

OFF position and remove key from the switch. Disconnect the battery pack (see Battery Pack Connection in

the General Information section of this chapter).

2. Remove transport wheelsif attached (see Transport

Wheelsin the Serviceand Repairs s ection of Chapter6

-- Chassis and Controls).

13. Retaining ring

14. Idler pulley assembly

15. Shoulder screw

16. Idler arm assembly

17. Washer head screw (4 used)

18. Drive pulley (from transmission)

3. Rotatetractionengage/disengagelever tothedisengaged position to remove tension from the drum drive

belt(Fig. 20) (seeDisengagingDrum DriveFromTransmission inthe General Information sectionof this chapter).

4. Remove seven (7) washer head screws that secure

the drum drive cover.Removecover to exposethe traction drive belt.

5. Remove and discard gasket (item 3) from between

cover and housing.

Greensmaster eFlex 1800/2100Traction and Reel Drive System Page 3 -- 16

Page 31

6. Remove retaining ring (item 6) that secures brake

band to brake clevis pin. Slide brake band from brake

clevis and brake mount pins and remove band from

drum drive housing.

7. Carefully remove one end of extension spring (item

9) from anchor point and rotate spring away from drive

belt.

8. Pivot the idler pulley away from the drum drive belt

to loosen belt tension (Fig. 21).

9. Remove drum drive belt from drive pulley and then

from differential pulley.

Installation (Fig. 19)

1. Makesurethat thebattery packisdisconnected(see

Battery Pack Connection in the General Information

section of this chapter).

2. Placedrumdrivebeltontodifferentialpulleyandthen

fit beltto drive pulley. Make sure thatbelt is onrear side

of idler pulley.

3. Carefully install removed end of extension spring

(item 9) to anchor point.

4. Install brake band over brake surface of differential

pulley. Slide ends of brake band onto brake clevis and

brakemountpins. Secure brakebandtobrake clevispin

with retaining ring (item 6).

1

2

Figure 20

1. Traction lever (engaged) 2. RH handle clamp

Drive System

Traction and Reel

2

3

1

5. Make surethat wave washer (item 4) is pressed into

bore of drum drive cover.

6. Position new gasket (item 3) to housing surface.

7. Slide drum drive cover onto drum drive assembly.

8. Install seven(7) washer head screws to securecover to housing. Tighten screws as follows:

A. F irst, using an alternating crossing pattern,

torque all screws from 15 to 40 in--lb (1.7 to 4.5

N--m).

B. Again using an alternating crossing pattern,

torque all screws from 85 to 95 in--lb (9.6 to 10.7

N--m).

9. Rotate traction engage/disengage lever to the engaged position to tension the drum drive b elt (Fig. 20).

10.Install transport wheels if they were attached (see

Transport Wheels in the Service and Repairs section of

Chapter 6 -- Chassis and Controls).

11.Connect thebattery pack(seeBatteryPackConnection in the General Information section of this chapter).

5

1. Traction drive belt

2. Drive pulley

3. Idler pulley

4

Figure 21

4. Differential pulley

5. Brake band

Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 17

Page 32

Drum Drive Idler Assembly

12

See text for

tightening

procedure

2

11

9

6

14

13

4

8

7

5

3

10

15 to 17 ft--lb

(21to23N--m)

18

17

16

15

1

2

Figure 22

1. Drum drive cover

2. Washer head screw (7 used)

3. Gasket

4. Wave washer

5. Gear assembly

6. Retaining ring

7. Brake band

8. Brake mount pin

9. Extension spring

10. Drum drive belt

11. Brake clevis pin

12. Drum drive housing

Removal

1. Parkmachineonlevelsurface.Turnkeyswitchtothe

OFF position and remove key from the switch. Disconnect the battery pack (see Battery Pack Connection in

the General Information section of this chapter).

2. Remove transport wheelsif attached (see Transport

Wheelsin the Serviceand Repairs s ection of Chapter6

-- Chassis and Controls).

3. Rotatetractionengage/disengageleverto the disengaged position to remove tension from the drum drive

belt (see Disengaging Drum Drive From Transmission

in the General Information section of this chapter).

13. Retaining ring

14. Idler pulley assembly

15. Shoulder screw

16. Idler arm assembly

17. Washer head screw (4 used)

18. Drive pulley (from transmission)

4. Remove seven (7) washer head screws that secure

thedrumdrive cover.Removecover toexposethe drum

drive system.

5. Remove and discard gasket (item 3) from between

cover and housing.

6. Carefully remove the end of the extension spring

(item9)fromidlerarm.

7. Remove shoulder screw (item 15) that secures the

idler arm assembly to the drum drive housing. Remove

idler arm assembly from housing.

Greensmaster eFlex 1800/2100Traction and Reel Drive System Page 3 -- 18

Page 33

8. Disassemble idler arm assembly as needed (Fig.

23). Replaceworn or damaged bearings and bushings.

A. Remove flange bushings from idler bracket.

B. Remove retaining ring from idler bracket. Slide

idler pulley from bracket shaft. Press ball bearings

from idler pulley.

2

3

Installation

1. If idler arm assembly was disassembled (Fig. 23):

A. Press new flange bushings into idler bracket.

B. Pressnewballbearingsfully intoidler pulleymak-

ingsure toapply pressuretoouter bearingrace only.

Slide pulley assembly onto idlerbracket and secure

with retaining ring.

2. Position idler arm assembly to drum drive housing

andsecurewith shoulderscrew (item15).Torqueshoulderscrewfrom15to17ft--lb(21to23 N--m).Checkthat

idler arm assembly can pivot freely after tightening

shoulder screw.

3. Carefully secure the end of the extension spring

(item 9) to idler arm.

4. Make surethat wave washer (item 4) is pressed into

bore of drum drive cover.

5. Position new gasket (item 3) to housing surface.

6. Slide drum drive cover onto drum drive assembly.

5

Figure 23

1. Flange bushing (2 used)

2. Idler bracket

3. Ball bearing (2 used)

1

4

4. Idler pulley

5. Retaining ring

Drive System

Traction and Reel

7. Install seven(7) washer head screws to securecov-

er to housing. Tighten screws as follows:

A. F irst, using an alternating crossing pattern,

torque all screws from 15 to 40 in--lb (1.7 to 4.5

N--m).

B. Again using an alternating crossing pattern,

torque all screws from 85 to 95 in--lb (9.6 to 10.7

N--m).

8. Rotate traction engage/disengage lever to the en-

gagedpositiontotensionthedrumdrive belt(see Disengaging Drum Drive From Transmission in the General

Information section of this chapter).

9. Install transport wheels if they were attached (see

Transport Wheels in the Service and Repairs section of

Chapter 6 -- Chassis and Controls).

10.Connectthe batterypack(seeBatteryPackConnec-

tion in the General Information section of this chapter).

Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 19

Page 34

Traction Drums

9

Antiseize

7

Lubricant

6

RIGHT

FRONT

10

11

140 to 160 ft--lb

(190 to 216 N--m)

75 to 90 ft--lb

(102 to 122 N--m)

12

29

17

6

8

17

13

14

70 to 80 ft--lb

(95 to 108 N--m)

27

28

15

30

5

3

4

3

1

18

2

3

22

21

20

3

19

26

22

14

23

24

16

25

Figure 24

1. Drum drive housing

2. Straight bushing

3. Flange bushing (4 used)

4. Brake lever

5. Traction lever

6. Square key (2 used)

7. Drum shaft

8. Long spur gear

9. Differential assembly

10. RH traction drum

11. Jam nut

12. Grease seal

13. LH traction drum

14. Ball bearing (2 used)

15. Bearing nut

16. LH hex shaft

17. Straight bushing (2 used)

18. Dowel pin (2 used)

19. Cap screw

20. Flat washer

Traction Drum Removal (Fig. 24)

1. Parkmachineonlevelsurface.Turnkeyswitchtothe

OFF position and remove key from the switch. Disconnect the battery pack (see Battery Pack Connection in

the General Information section of this chapter).

2. If installed, remove transport wheels (see Transport

Wheelsin the Serviceand Repairs s ection of Chapter6

-- Chassis and Controls).

21. Traction engage lever

22. Retaining ring (2 used)

23. Brake lever

24. Retaining ring

25. LH side plate

26. Washer head screw

27. Lock collar

28. Pin

29. Thrust washer

30. O--ring

3. Remove handle assembly from machine (see Handle Assembly in the Service and Repairs section of

Chapter 6 -- Chassis and Controls).

4. Supportbothsidesof machine framewithjackstands

or suitable blocking to prevent the machine from moving.

Greensmaster eFlex 1800/2100Traction and Reel Drive System Page 3 -- 20

Page 35

5. Separate LHside plate (item25) from machine(Fig.

25):

1

A. Remove flange nut, hardened washer and carriagescrew(items3,4and6inFig.25)thatsecure

LH side plate to rear frame.

B. Remove three (3) flange screws and hardened

washers (items 8 and 4 in Fig. 25) that secure LH

side plate to frame.

C. Slide LH side plate from supporting bearing and

remove from machine.

6. Insertbar stockorother suitable toolthroughspokes

of LH traction drum to keep drum from turning.

7. WhileretainingLHdrum,loosenandremovebearing

nut (item 15) from traction drum assembly. The ball

bearing(item14)ispressedontothebearingnutsoitwill

be removed with the nut.

8. SlideLH tractiondrum(item 13)fromdrum shaft.Lo-

cate and retrieve square key from shaft.

9. If necessary, carefullyremove grease seal (item 12)

from LH traction drum taking care to not damage bore

of drum. Discard removed seal.

2

3

4

1. Kickstand

2. Rear frame

3. Flange nut

4. Hardened washer

5. Frame

6. Carriage screw

5

Figure 25

11

10

6

7

4

8

7. LH side plate

8. Flange screw (3 used)

9. Counterweight

10. Offset handle clamp

11. Handle clamp

9

Drive System

Traction and Reel

10.If necessary, removeLH hex shaft (item 16) and ball

bearing (item 14) from bearing nut.

1 1.Insertbar stockor othersuitabletool throughspokes

of RH traction drum to keep drum from turning.

12.Remove O--ring (item 30),pin (item 28)and lock col-

lar (item 27) from drum shaft.

13.While retaining remainingdrum, loosen andremove

jam nut (item 11) from long spur gear.

14.Remove RH traction drum (item 10) from machine.

Locate and retrieve square key from spur gear.

NOTE: If removal of the drum shaft (item 7), long spur

gear (item 8) or differential assembly (Item 9) is necessary, see Differential Assembly in this section.

Traction Drum Installation (Fig. 24)

1. Make sure that drum shaft (item 7), long spur gear

(item 8) and differential assembly (Item 9) are installed

to drum drive housing (refer to Differential Assembly in

4. Align slot in RH traction drum (item 10) with key on

long spur gear and slide traction drum onto gear.

this section).

5. Insert barstock orother suitabletool throughspokes

2. Install LH hex shaft (item 16) and ball bearing (item

of RH traction drum to keep drum from turning.

14)to bearingnut (item 15) if they were removed. Press

bearing fullyonto bearing nut.Torque hexshaft from 70

to 80 ft--lb (95 to 108 N--m).

6. Install jam nut (item 11) onto threads of long spur

gear to secure RH traction drum. Torque jam nut from

140 to 160 ft--lb (190 to 216 N--m).

3. Place square key (item 6) into slot of long spurgear

(item 8). Apply antiseize lubricant to top surface of key.

Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 21

1

2

0.470” to 0.530”

(12.0 to 13.4 mm)

Figure 26

1. LH traction drum 2. Grease seal

Page 36

7. Slide lock collar (item 27) onto drum shaft. Align

holesin collarand shaftand theninstallpin (item28).Fit

O--ring (item 30) to slot in collar.

13.Secure LH side plate(item 25) to machine (Fig.25):

A. Slide LH side plate onto supporting bearing.

8. If grease seal (item 12) was removed from LH traction drum, installnew grease seal into drum. Makesure

that seal lip is orientated toward center of drum. Press

sealinto drumbore sothat sealis recessedfrom 0.470”

to0.530”(12.0to13.4mm)fromedgeofdrum(Fig.26).

9. Placesquare key(item 6) intoslot ofdrum shaft.Apply antiseize lubricant to top surface of key.

10.Align slot in LH traction drum (item 13) with key on

drum shaft and carefully slide traction drum onto shaft

taking care to not damage grease seal in drum.

11.Insert barstock orothersuitable t ool throughspokes

of LH traction drum to keep drum from turning.

12.Make sure thatball bearing (item14)is pressedonto

the bearing nut (item 15). While retaining LH drum, secure drum to traction drum assembly with bearing nut

(item 15). Torque bearing nut from 75 to 90 ft--lb (102

to 122 N--m).

B. Secure LH side plate to frame with three (3)

flange screws and hardened washers.

C. Secure LH side plate to rear frame with carriage

screw, hardened washer and flange nut.

14.Install handle assemblyto machine (see Handle As-

sembly in the Service and Repairs sectionof Chapter 6

-- ChassisandControls).Makesure thatallcableadjust-

ments are correct.

15.Install transport wheels if necessary (see Transport

Wheels in the Serviceand Repairs sectionof Chapter6

-- Chassis and Controls).

16.Connectthe battery pack(seeBatteryPackConnec-

tion in the General Information section of this chapter).

Greensmaster eFlex 1800/2100Traction and Reel Drive System Page 3 -- 22

Page 37

This page is intentionally blank.

Drive System

Traction and Reel

Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 23

Page 38

Differential Assembly

9

31

Antiseize

7

Lubricant

6

RIGHT

FRONT

10

11

140 to 160 ft--lb

(190 to 216 N--m)

75 to 90 ft--lb

(102 to 122 N--m)

12

29

17

6

8

17

13

14

70 to 80 ft--lb

(95 to 108 N--m)

27

28

15

30

5

3

4

3

1

18

2

3

22

21

20

3

19

26

14

22

23

24

Loctite #242

16

25

Figure 27

1. Drum drive housing

2. Straight bushing

3. Flange bushing (4 used)

4. Brake lever

5. Traction lever

6. Square key (2 used)

7. Drum shaft

8. Long spur gear

9. Differential assembly

10. RH traction drum

11. Jam nut

12. Grease seal

13. LH traction drum

14. Ball bearing (2 used)

15. Bearing nut

16. LH hex shaft (LH threads)

17. Straight bushing (2 used)

18. Dowel pin (2 used)

19. Cap screw

20. Flat washer

21. Traction engage lever

Disassembly (Fig. 27)

1. Parkmachineonlevelsurface.Turnkeyswitchtothe

OFF position and remove key from the switch. Disconnect the battery pack (see Battery Pack Connection in

the General Information section of this chapter).

22. Retaining ring (2 used)

23. Brake lever

24. Retaining ring

25. LH side plate

26. Washer head screw

27. Lock collar

28. Pin

29. Thrust washer

30. O--ring

31. Spur gear assembly

2. Remove traction drums from machine (see Traction

Drums in this section).

3. Slide spurgear assembly from differentialassembly

in drum drive housing (Fig. 28).

Greensmaster eFlex 1800/2100Traction and Reel Drive System Page 3 -- 24

Page 39

4. If necessary,disassemble spur gear assembly (Fig.

29).

A. The hex shaft has left hand threads. The shaft

also has thread locking compound on threads.

B. Press ball bearing and flange bushing from spur

gear as needed.

IMPORTANT: As drum shaft(item 7)and differential

assembly (item 9) are removed, make sure to retrieve and note location of thrust washer (item 29)

for assembly purposes.

4. Place thrust washer (item 29) onto drum shaft (item

7). Insert drum shaft into differential assembly. Make

surethatdrumshaftproperlyengagesdifferentialgears.

5. Install traction drums to machine (see Traction

Drums in this section).

6. Installdrum drive beltfrom machine(seeDrumDrive

Belt in this section).

7. Connectthebatterypack (seeBatteryPackConnection in the General Information section of this chapter).

5. Pushdrum shaft(item 7)out ofdifferential assembly.

Makesuretolocateand retrievethrustwasher(item29).

6. Slide differentialassembly from long spurgear (item

8) and drum drive housing (item 1).

NOTE: For differentialserviceprocedure, seeDifferential Assembly Service in this section.

7. If necessary, slide longspur gear (item 8) from drum

drive housing. Straight bushings (item 17) in long spur

gear should be inspected for wear or damage and replaced if needed.

8. Ballbearing (item14) thatsupports longspur gearis

pressed into drum drive housing. Make sure that bearing is in good condition and is pressed fully to shoulder

of housing.

Assembly (Fig. 27)

1. If long spur gear (item 8) was removed from drum

drive housing,slide gear into ballbearing in drivehousing.

2. If spur gear assembly (Fig. 29) was taken apart, as-

semble as necessary:

1

Drive System

Traction and Reel

2

Figure 28

1. Drum drive housing 2. Spur gear assembly

1

70 to 80 ft--lb

(95 to 108 N--m)

4

A. Press new ball bearing fully onto spur gear if removed.

B. Press new flange bushing into spur gear if removed.

C. If the hex shaft was removed from the spur gear,

apply Loctite #242 (or equivalent) to threads of hex

shaft. Install hex shaft (left hand threads) into spur

gearandtorquefrom 70to80 ft--lb (95to108N--m).

3. Make sure that differential housing cavity is packed

20% to 30% full of high temperature Mobil XHP--222

grease (or equivalent). Slide differential assembly into

drum drive housing (item 1) and onto long spur gear

(item8). Makesure thatspur gearproperlyengages differential gears.

Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 25

3

1. Spur gear

2. Ball bearing

2

Figure 29

3. Hex shaft (LH threads)

4. Flange bushing

Page 40

Differential Assembly Service

99 to 121 in--lb

(11.2 to 13.6 N--m)

5

3

1

5

4

6

6

7

8

3

6

2

Figure 30

1. Housing

2. Cover

3. Ball bearing (2 used)

4. Pin (6 used)

5. Dual spur gear (6 used)

6. Spacer (9 used)

Disassembly (Fig. 30)

1. Remove differential assembly from machine (see

Differential Assembly in this section).

2. Remove six(6) socket headscrews that securecovertohousing.Notealignmentof indexmarks onhousing

and cover for assembly purposes (Fig. 31).

3. Placedifferential assemblyonworkbenchso thatthe

differential is resting onthe cover withhousing orientated up.

4

7. Spur gear (3 used)

8. Socket head screw (6 used)

6. Slide each pin with gears and spacers from cover.

Notelocation of gearsandspacers oneachof thesix(6)

pins.

7. If necessary, remove ball bearings from cover and

housing. There are two (2) holes in thecover and housing that allow use of a pin punch to remove bearings.

Discard removed bearings.

Inspection (Fig. 30)

1. Clean all differential components.

4. Lift housing from differentialassembly leaving internalcomponents positionedon cover.Forassemblypurposes, note that index mark on housing is aligned with

a pin that has one (1) gear (Fig. 32).

5. Note locations of projections on inside of cover for

assemblypurposes. Theprojections needto be aligned

with the pins that have one (1) gear (Fig. 33).

2. Inspect all differential gears carefully looking for

chipped teeth, wear or other damage. Because gear

tooth damage is rarely isolated to one gear, replace

gears as a complete set if internal damage is found.

3. Inspect gear pins (item 4) for scoring or wear.

4. Replace all worn or damaged differential assembly

components.

Greensmaster eFlex 1800/2100Traction and Reel Drive System Page 3 -- 26

Page 41

Assembly (Fig. 30)

1. If ball bearing was removed from either cover or

housing,press newballbearing intobearing bore.Make

sure that bearing is fully pressed to shoulder of bore.

2. Place cover (with bearing installed) on workbench.

3. Slide each pin with gears and spacers into cover.

Makesurethatprojectionsoninsideofcover are aligned

with the pins that have one (1) gear (Fig. 33).

4. Positionhousingontoassembly makingsure thatpin

with one (1) gear is positioned next to index mark on

housing (Fig. 32). Also, align index marks on housing

and cover during assembly (Fig. 31).

5. After housing is installed, use one of the spur gears

(see Differential Assembly in this section) to rotate differential gears making sure that they rotate freely without binding. If binding is noted, identify and correct

cause before securing the cover.

6. Secure cover to housing with six (6) socket head

screws. Torque screws from 99 to 121 in--lb (11.2 to

13.6 N--m).

7. Pack differential housing cavity 20% to 30% full of

high temperature Mobil XHP --222 grease (or equivalent).

2

1

Figure 31

1. Cover index mark 2. Housing index mark

1

3

2

2

Drive System

Traction and Reel

8. Install differential assembly to machine (see Differ-

ential Assembly in this section).

3

2

1. Housing index mark

2. Pin with 2 gears

2

3

2

Figure 32

3. Pin with 1 gear

3

3

1

2

3

Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 27

1. Projection on cover

2. Pin with 2 gears

Figure 33

3. Pin with 1 gear

Page 42

Transmission Drive Belt

1

See text for

tightening

4

procedure

6

5

2

RIGHT

3

FRONT

1. Transmission assembly

2. Transmission belt

3. Gasket

4. Wave washer (2 used)

5. Transmission cover

6. Washer head screw (7 used)

Transmission removal from the machine is not necessary to service the transmission drive belt. The transmission drive belt can be replaced by removing the

battery packfrom the frame, removing thetransmission

cover and then removing the drive belt.

Drive Belt Removal (Fig. 34)

1. Parkmachineonlevelsurface.Turnkeyswitchtothe

OFF position and remove key from the switch. Disconnect the battery pack (see Battery Pack Connection in

the General Information section of this chapter).

2. Remove battery pack from machine (see Battery

Pack in the Service and Repairs section of Chapter 4 -Electrical System).

7

8

4

Figure 34

7. Drive shaft wire

8. Telescoping coupler

IMPORTANT: During disassembly, make sure that

tension is released from transmission belt before

removing transmission cover.

4. Remove tensionon transmission beltby rotatingthe

engage/disengage shaft clockwise (see Transmission

BeltTensioner inthe GeneralInformation sectionof this

chapter).

5. Remove seven (7) washer head screws that secure

transmission cover to transmission. Carefully remove

cover from transmission. Remove and discard gasket

(item 3).

6. Make sure that wave washers (item 4) remain in

bearing bores of transmission cover.

3. Usetips ofneedle nosepliersto spreadends ofdrive

shaft wire (item 7) in telescoping coupler (item 8). With

wireendsspread, slidecouplerfrom t ransmission shaft.

7. Note transmission belt routing for assembly purposes (Fig. 35).

Greensmaster eFlex 1800/2100Traction and Reel Drive System Page 3 -- 28

Page 43

8. Remove transmission belt from drive and idler pul-

leys in transmission.

9. Check conditionof all pulleys and idlercomponents.

10.Clean inside of transmission before installing new

belt.

2

4

5

1

Drive Belt Installation (Fig. 34)

IMPORTANT: During assembly, make sure that

transmissioncover isinstalled withfasteners properly torqued before applying tension to transmission belt.

1. Install new transmission belt onto pulleys in trans-

mission. Make sure that belt is correctly routed around

drive and idler pulleys (Fig. 35).

2. Make sure that wave washers (item 4) are pressed

into bearing bores of transmission cover. Also, make

surethat two(2)dowel pinsarepressed intoboresinthe

transmission housing.

3. Positionnew gasketto transmissionassembly.Align

gasket to two (2) dowel pins in transmission housing.

4. Installtransmissioncover.If n ecessary,usea rubber

mallet at dowel locations(Fig. 36)to seatcover totransmission.

5. Install seven(7) washer head screws to securecov-

er to transmission. Tighten screws as follows:

6

Figure 35

1. Engage/disengage shaft

2. Drive pulley

3. Reel clutch pulley

2

1

4

3

Drive System

Traction and Reel

4. Idler pulley

5. Drum drive pulley

6. Idler pulley

A. F irst, using an alternating crossing pattern,

torque all screws from 15 to 40 in--lb (1.7 to 4.5

N--m).

B. Again using an alternating crossing pattern,

torque all screws from 85 to 95 in--lb (9.6 to 10.7

N--m).

6. Applytension totransmission beltby rotating theen-

gage/disengage shaft counter--clockwise ( see Transmission Belt Tensioner in the General Information

section of this chapter).

7. Slide telescoping coupleronto transmission shaft so

thatdrive shaftwire engages hexshaft ontransmission.

Make sure that telescopingcoupler isproperly attached

to cutting unit hex shaft.

8. Install battery pack to machine (see Battery Pack in

theServiceand RepairssectionofChapter 4-- Electrical

System).

9. Connectthebatterypack (seeBattery PackConnec-

tion in the General Information section of this chapter).

2

Figure 36

1. Transmission cover 2. Dowel location

Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 29

Page 44

Transmission Idler System

4

2

5

7

13

15 to 17 ft--lb

(21 to 23 N--m)

7

10

12

14

11

10

6

3

9

8

1

RIGHT

FRONT

1. Transmission cover

2. Engage/disengage shaft

3. Transmission belt

4. Extension spring

5. Main drive idler

6. Driven pulley (drum drive)

7. Flange bushing (4 used)

8. Cap screw (2 used)

9. Idler pulley bushing (2 used)

10. Ball bearing (6 used)

Transmission removal from the machine is not necessaryto servicethe transmissionidler system.Transmissionidlercomponentscanbe accessed byremovingthe

battery packfrom the frame, removing thetransmission

cover and then removing the drive belt.

Figure 37

11. Idler pulley (2 used)

12. Idler pulley

13. Shoulder screw

14. Retaining ring

Greensmaster eFlex 1800/2100Traction and Reel Drive System Page 3 -- 30

Page 45

Disassembly (Fig. 37)

1. Parkmachineonlevelsurface.Turnkeyswitchtothe

OFF position and remove key from the switch. Disconnect the battery pack (see Battery Pack Connection in

the General Information section of this chapter).

2. Remove transmission drive belt (see Transmission

Drive Belt in this section).

3. Disassemble idler system as required using Figure

37as a guide.Discardball bearingsif theyare removed

from idler pulleys.

4

1

3

4. Checkbushings (items7 and9) forwear or damage.