Page 1

Part No. 10176SL (Rev. A)

Service Manual

(Models 30448 and 30446)

Groundsmaster

Preface

The purpose of this publication is to provide the service

technician with information for troubleshooting, testing

and repair of major systems and components on the

Groundsmaster 4000--D (Model 30448) and 4010--D

(Model 30446).

REFER TOTHEOPERATOR’SMANUALFOROPERATING, MAINTENANCE AND ADJUSTMENT

INSTRUCTIONS. For reference, insert a copy of the

Operator’sManualandParts Catalog for your machine

into Chapter 2 of this service manual. Additional copies

of the Operator’s Manual and Parts Catalog are available on the internet at www.Toro.com.

TheToroCompany reservestheright tochange product

specifications or this publication without notice.

R

4000--D & 4010--D

This safety symbol means DANGER, WARNING,

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: ANOTE willgivegeneral informationabout the

correct operation, maintenance, service, testing or repair of the machine.

IMPORTANT: The IMPORTANT notice will give importantinstructionswhichmustbefollowed to prevent damage to systems or components on the

machine.

Groundsmaster4000--D

E The Toro Company -- 2010, 2012

Groundsmaster4010--D

Page 2

This page is intentionally blank.

Groundsmaster 4000--D/4010--D

Page 3

Table Of Contents

Chapter 1 -- Safety

General Safety Instructions 1 -- 2..................

Jacking Instructions 1 -- 5.........................

Safety and Instruction Decals 1 -- 6................

Chapter 2 -- Product Records and Maintenance

Product Records 2 -- 1...........................

Maintenance 2 -- 1...............................

Equivalents and Conversions 2 -- 2................

Torque Specifications 2 -- 3.......................

Chapter 3 -- Kubota Diesel Engine

General Information 3 -- 2........................

Specifications 3 -- 3..............................

Service and Repairs 3 -- 4........................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

V2403--M--T--E3B SERIES

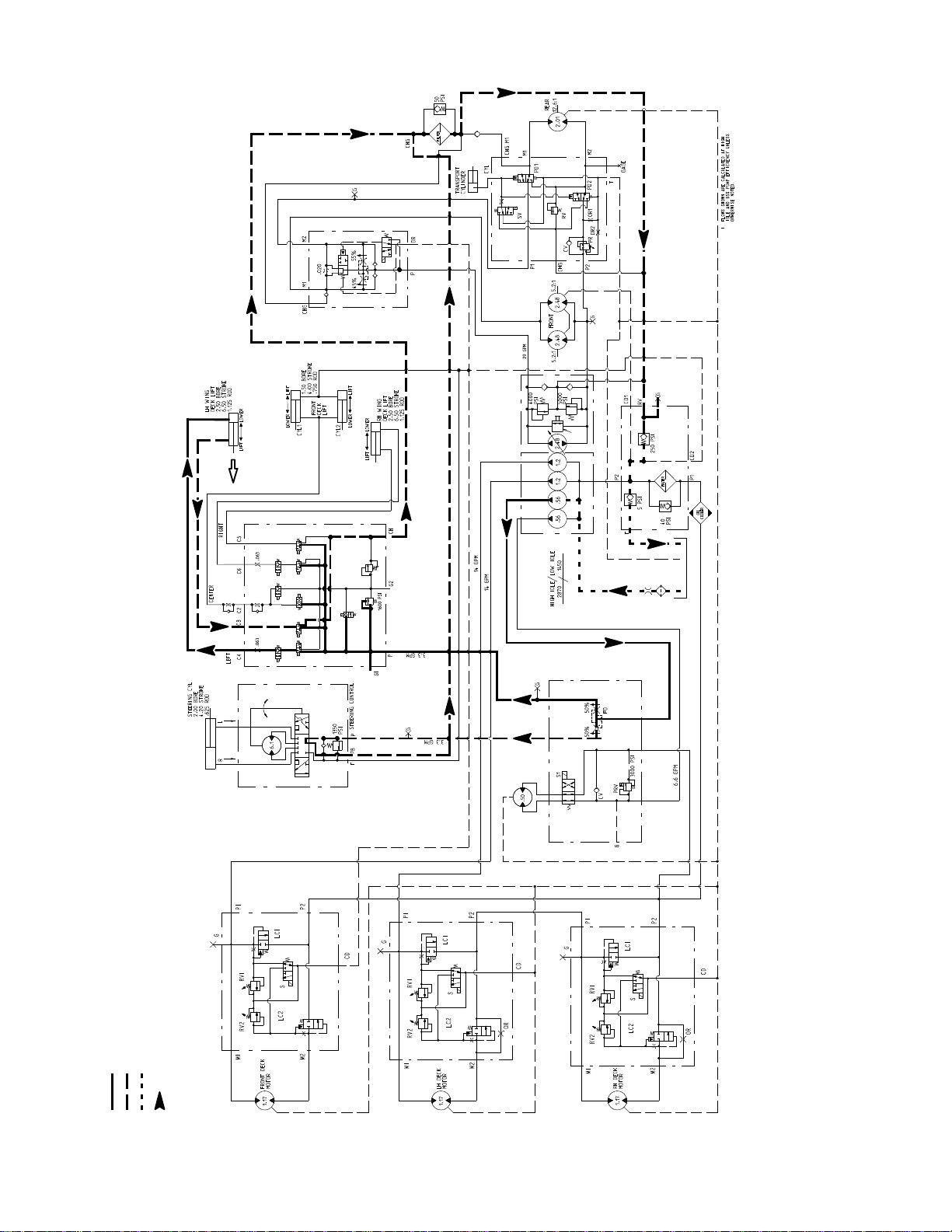

Chapter 4 -- Hydraulic System

Specifications 4 -- 2..............................

General Information 4 -- 3........................

Hydraulic Schematic 4 -- 9........................

Hydraulic Flow Diagrams 4 -- 10...................

Special Tools 4 -- 26.............................

Troubleshooting 4 -- 30...........................

Testing 4 - - 36...................................

Adjustments 4 -- 70..............................

Service and Repairs 4 -- 72.......................

EATON MODEL 72400 SERVO CONTROLLED PIS-

TON PUMP REPAIRINFORMATION

EATONMODEL 74318 and 74348 PISTONMOTORS:

FIXED DISPLACEMENT, VALVE PLATE DESIGN

REPAIR INFORMATION

Chapter 5 -- Electrical System

General Information 5 -- 2........................

Special Tools 5 -- 3..............................

Troubleshooting 5 -- 6............................

Adjustments 5 -- 17..............................

Electrical System Quick Checks 5 -- 18.............

Component Testing 5 -- 20........................

Service and Repairs 5 -- 47.......................

Chapter 6 -- Axles, Planetaries and Brakes

Specifications 6 -- 2..............................

General Information 6 -- 3........................

Service and Repairs 6 -- 4........................

Chapter 7 -- Chassis

General Information 7 -- 1........................

Service and Repairs 7 -- 2........................

Chapter 8 -- Cutting Decks

Specifications 8 -- 2..............................

General Information 8 -- 3........................

Troubleshooting 8 -- 4............................

Service and Repairs 8 -- 6........................

SafetyProduct Records

and Maintenance

Kubota

Diesel Engine

System

Hydraulic

System

Electrical

Groundsmaster 4000--D/4010--D

Axles, Planetaries

Chassis

Cutting

and Brakes

Decks

Page 4

This page is intentionally blank.

Groundsmaster 4000--D/4010--D

Page 5

Table Of Contents (Continued)

Chapter 9 -- Operator Cab

General Information 9 -- 2........................

Service and Repairs 9 -- 3........................

SANDEN SD COMPRESSOR SERVICE GUIDE

Chapter 10 -- Foldout Drawings

Hydraulic Schematic 10 -- 3.......................

Electrical Schematics 10 -- 4......................

Wire Harness Drawings 10 -- 9....................

Cab

OperatorFoldout

Drawings

Groundsmaster 4000--D/4010--D

Page 6

This page is intentionally blank.

Groundsmaster 4000--D/4010--D

Page 7

Chapter 1

Safety

Table of Contents

GENERAL SAFETY INSTRUCTIONS 2............

Before Operating 2............................

While Operating 3.............................

Maintenance and Service 4....................

JACKING INSTRUCTIONS 5.....................

SAFETY AND INSTRUCTION DECALS 6..........

Safety

Groundsmaster 4000--D/4010--D Page 1 -- 1 Safety

Page 8

General Safety Instructions

TheGroundsmaster4000-Dand4010--Daretestedand

certified by Toro for compliance with existing safety

standards and specifications. Although hazard control

and accident prevention partially are dependent upon

the design and configuration of the machine, these factors are also dependent upon the awareness, concern

and proper training of the personnel involved in the operation, transport, maintenance and storage of the machine.Improper use or maintenance ofthemachinecan

resultin injury or death. Toreducethepotentialforinjury

or death, comply with the following safety instructions.

Before Operating

WARNING

To reduce the potential for injury or death,

comply with the following safety instructions.

1. Review and understand the contents of the Operator’s Manual and Operator’s DVD before starting and

operatingthe vehicle. Become familiar with the controls

and know how to stop the vehicle and engine quickly.

AdditionalcopiesoftheOperator’sManualareavailable

on the internet at www.Toro.com.

2. Keep all shields, safety devices and decals in place.

Ifa shield, safety device or decal isdefective,illegibleor

damaged, repair or replace it before operating the machine.Also tighten anyloosenuts,bolts or screws toensure machine is in safe operating condition.

3. Assure interlock switches are adjusted correctly so

engine cannot be started unless traction pedal is in

NEUTRAL and cutting decks are DISENGAGED.

4. Since diesel fuel is highly flammable, handle it carefully:

A. Use an approved fuel container.

B. Donotremovefuel tank capwhileengine ishotor

running.

C. Do not smoke while handling fuel.

D. Fillfueltankoutdoors and onlytowithinan inch of

the top of the tank, not the filler neck. Do not overfill.

E. Wipe up any spilled fuel.

Groundsmaster 4000--D/4010--DPage 1 -- 2Safety

Page 9

While Operating

1. Sit on the seat when starting and operating the machine.

2. Before starting the engine:

A. Apply the parking brake.

B. Make sure traction pedal is in neutral and the

PTO switch is OFF (disengaged).

C. Afterengineis started,releaseparking brakeand

keepfootofftraction pedal. Machine must not move.

If movement is evident, the traction pedal linkage is

adjusted incorrectly; therefore, shut engine off and

adjust until machine does not move when traction

pedal is released.

3. Do not run engine in a confined area without adequate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

4. Do not touch engine, muffler or exhaust pipe while

engineisrunningorsoonafteritisstopped.Theseareas

could be hot enough to cause burns.

5. Before getting off the seat:

A. Ensure that traction pedal is in neutral.

B. Apply the parking brake.

Safety

C. Disengage cutting decks and wait for blades to

stop.

D. Stop engine and remove key from switch.

E. Toro recommends that anytime the machine is

parked(shortor long term), the cutting decksshould

be lowered to the ground. This relieves hydraulic

pressurefrom the lift circuit and eliminates the risk of

the cutting decks unexpectedly lowering to the

ground.

F. Do notpark ons lopes unlesswheelsarechocked

or blocked.

Groundsmaster 4000--D/4010--D Page 1 -- 3 Safety

Page 10

Maintenance and Service

1. Before servicing or making adjustments, lower

decks, stop engine, apply parking brake and remove

key from the ignition switch.

2. Make sure machine is in safe operating condition by

keeping all nuts, bolts and screws tight.

3. Never store the machine or fuel container inside

wherethereisanopenflame,suchasnearawaterheater or furnace.

4. Make sure all hydraulic connectors are tight and all

hydraulic hoses and lines are in good condition before

applying pressure to the system.

5. Keepbodyandhandsawayfrompinholeleaksinhydrauliclinesthateject high pressure hydraulic fluid. Use

cardboard or paper to find hydraulic leaks. Hydraulic

fluid escaping under pressure can penetrate skin and

cause injury. Fluid accidentally injected into the skin

mustbe surgically removed within a few hours by a doctor familiar with this form of injury or gangrene may result.

6. Before disconnecting or performing any work on the

hydraulic system, all pressure in system must be relievedbyloweringcutting decks to the ground andstopping engine.

7. If major repairs areever needed orassistance is desired, contact an Authorized Toro Distributor.

8. To reduce potential fire hazard, keep engine area

free of excessive grease, grass, leaves and dirt. Clean

protective screen on machine frequently.

9. Ifenginemust be running to perform maintenanceor

an adjustment, keep hands, feet, clothing and other

parts of the body away from cutting decks and other

moving parts. Keep bystanders away.

10.Do not overspeed the engine by changing governor

setting.Toassuresafety andaccuracy,checkmaximum

engine speed.

12.Disconnect battery before servicing the machine.

Disconnect negative cable first and positive cable last.

If battery voltage is required for troubleshooting or test

procedures,temporarilyconnectthebattery.Reconnect

positive cable first and negative cable last.

13.Battery acid is poisonous and can cause burns.

Avoidcontact with skin, eyes and clothing. Protect your

face, eyes and clothing when working with a battery.

14.Battery gases can explode. Keep cigarettes, sparks

and flames away from the battery.

15.At the time of manufacture, the machine conformed

tothesafety standards for riding mowers. Toassure optimumperformance and continuedsafetycertificationof

the machine, use genuine Toro replacement parts and

accessories.Replacementparts andaccessoriesmade

by other manufacturers may result in non-conformance

with the safety standards and the warranty may be

voided.

16.When changing attachments, tires or performing

other service, use correct blocks, hoists and jacks.

Make sure machine is parked on a solid level surface

suchasaconcrete floor.Priortoraising themachine,remove any attachments that may interfere with the safe

and proper raising of the machine. Always chock or

block wheels. Use appropriate jack stands to support

the raised machine. If the machine is not properly supported by jack stands, the machine may move or fall,

whichmay resultinpersonal injury(seeJacking Instructions in this chapter).

17.When welding on machine, disconnect all battery

cables to prevent damage to machine electronic equipment. Disconnect negative battery cable first and positivecablelast.Also,disconnectwire harness connector

fromboth of the TEC controllers and disconnect the terminal connector from the alternator. Attach welder

ground cable no more than two (2) feet (0.61 meters)

from the welding location.

11.Shut engine off before checking or adding oil to the

crankcase.

Groundsmaster 4000--D/4010--DPage 1 -- 4Safety

Page 11

Jacking Instructions

CAUTION

When changing attachments, tires or performing other service, use correct jacks and supports. Make sure machine is parked on a solid,

level surface such as a concrete floor. Prior to

raising machine, remove any attachments that

may interfere with the safe and proper raising of

themachine.Always chockorblockwheels.Use

jackstands to support the raised machine.If the

machine is not properly supported by jack

stands, the machine may move or fall, which

may result in personal injury.

Jacking the Front End (Fig. 1)

1. Set parking brake and chock both rear tires to prevent the machine from moving.

2. Positionjack securely under the frame,justtotheinside of the front tire. Jack front wheel off the ground.

2

1. Front jacking point 2. Front tire

1

Figure 1

1

Safety

2

3. Once the machine is raised, position jack stand under the frame as close to the wheel as possible to support the machine.

Jacking the Rear End (Fig. 2)

1. Place jack securely under the center of rear axle.

2. Chock both front tires. Jack rear of machine off the

ground.

3. Once the machine is raised, use jack stands under

the axle to support the machine.

2

1. Rear axle jacking point 2. Rear tire

1

Figure 2

2

Groundsmaster 4000--D/4010--D Page 1 -- 5 Safety

Page 12

Safety and Instruction Decals

Numerous safety and instruction decals are affixed to

your Groundsmaster machine. If any decal becomes illegibleor damaged,installanew decal.Decalpartnumbers are listed in your Parts Catalog.

Groundsmaster 4000--D/4010--DPage 1 -- 6Safety

Page 13

Product Records and Maintenance

Table of Contents

PRODUCT RECORDS 1.........................

MAINTENANCE 1...............................

EQUIVALENTS AND CONVERSIONS 2...........

Decimal and Millimeter Equivalents 2............

U.S. to Metric Conversions 2...................

TORQUE SPECIFICATIONS 3....................

Fastener Identification 3.......................

Using a Torque Wrench with an Offset Wrench 3..

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Inch Series) 4...............

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Metric) 5....................

Other Torque Specifications 6..................

Conversion Factors 6..........................

Chapter 2

Product Records

and Maintenance

Product Records

Insert Operator’s Manuals and Parts Catalogs for your

Groundsmaster at the end of this chapter. Additionally,

if any optional equipment or accessories have been

installedto your machine, insert the Installation Instructions, Operator’s Manuals and Parts Catalogs for those

options at the end of this chapter.

Maintenance

Maintenanceprocedures andrecommendedservice intervalsforyourGroundsmasterarecoveredintheOperator’sManual.Refertothatpublicationwhenperforming

regular equipment maintenance.

Groundsmaster 4000--D/4010--D Page 2 -- 1 Product Records and Maintenance

Page 14

Equivalents and Conversions

0.09375

Groundsmaster 4000--D/4010--DPage 2 -- 2Product Records and Maintenance

Page 15

Torque Specifications

Recommended fastener torque values are listed in the

followingtables.Forcriticalapplications,as determined

byToro,eitherthe recommended torque or atorquethat

is unique to the application is clearly identified and specified in this Service Manual.

These Torque Specifications for the installation and

tightening of fasteners shall apply toall fasteners which

donot have a specificrequirement identified in this Service Manual. The following factors shall be considered

when applying torque: cleanliness of the fastener, use

of a thread sealant (e.g. Loctite), degree of lubrication

on the fastener,presence of a prevailing torque feature

(e.g. Nylock nut), hardness of the surface underneath

thefastener’sheadorsimilarcondition whichaffectsthe

installation.

Fastener Identification

Asnoted inthefollowingtables,torquevaluesshouldbe

reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener.Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based on the aluminum or brass

material strength, fastener size, length of thread engagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measurethe torque required to tighten the fastener until

the lines match up.

Product Records

and Maintenance

Grade 1 Grade 5 Grade 8

Inch Series Bolts and Screws

Figure 1

Using a Torque Wrench with an Offset Wrench

Useofanoffsetwrench(e.g.crowfootwrench)willaffect

torquewrench calibration due to theeffectivechangeof

torquewrench length. When using a torque wrench with

an offset wrench, multiply the listed torque recommendation by the calculated torque conversion factor (Fig.

3) to determine proper tightening torque. Tightening

torque when using a torque wrench with an offset

wrench will be lower than the listed torque recommendation.

Example: The measured effective length of the torque

wrench (distance from the center of the handle to the

center of the square drive) is 18”.

Themeasuredeffectivelengthofthetorquewrenchwith

the offset wrench installed (distance from the center of

the handle to the center of the offset wrench) is 19”.

Class 8.8 Class 10.9

Metric Bolts and Screws

Figure 2

If the listed torque recommendation for a fastener is

from 76 to 94 ft--lb, the proper torque when using this

torque wrench with an offset wrench would be from 72

to 89 ft--lb.

(effective length of

torque wrench)

A

B

(effective length of torque

wrench + offset wrench)

TORQUE CONVERSION FACTOR = A / B

Torque wrenchOffset wrench

The calculated torque conversion factor for this torque

wrenchwiththisoffsetwrenchwouldbe 18 / 19 = 0.947.

Groundsmaster 4000--D/4010--D Page 2 -- 3 Product Records and Maintenance

Figure 3

Page 16

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

Thread Size

# 6 -- 32 UNC

# 6 -- 40 UNF

# 8 -- 32 UNC

# 8 -- 36 UNF

#10--24UNC

#10--32UNF

1/4 -- 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 1130+ 113 140 + 15 1582+ 169

1/4 -- 28 UNF 53 + 7 65 + 10 734 + 113 115 + 12 1299 + 136 160+ 17 1808 + 192

5/16 -- 18 UNC 115 + 15 105 + 15 1186 + 169 200 + 25 2260+ 282 300+ 30 3390 + 339

5/16 -- 24 UNF 138 + 17 128 + 17 1446 + 192 225 + 25 2542+ 282 325 + 33 3672 + 373

3/8 -- 16 UNC 16 + 2 16 + 2 22 + 3 30 + 3 41 + 4 43 + 5 58 + 7

Grade 1, 5 &

8withThin

Height Nuts

in--lb in--lb N--cm in--lb N--cm in--lb N--cm

10 + 2 13 + 2 147 + 23

13 + 2 25 + 5 282 + 30

18 + 2 30 + 5 339 + 56

ft--lb ft--lb N--m ft--lb N--m ft--lb N--m

SAE Grade 1 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

15 + 2 169 + 23 23 + 3 262 + 34

17 + 2 192 + 23 25 + 3 282 + 34

29 + 3 328 + 34 41 + 5 463 + 56

31 + 4 350 + 45 43 + 5 486 + 56

42 + 5 475 + 56 60 + 6 678 + 68

48 + 5 542 + 56 68 + 7 768 + 79

SAE Grade 8 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 5 or Stronger Nuts)

3/8 -- 24 UNF 17 + 2 18 + 2 24 + 3 35 + 4 47 + 5 50 + 6 68 + 8

7/16 -- 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 + 7 95 + 9

7/16 -- 20 UNF 29 + 3 29 + 3 39 + 4 55 + 6 75 + 8 77 + 8 104 + 11

1/2 -- 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 + 11 105 + 11 142 + 15

1/2 -- 20 UNF 32 + 4 53 + 7 72 + 9 85 + 9 115 + 12 120 + 12 163 + 16

5/8 -- 11 UNC 65 + 10 88 + 12 119 + 16 150 + 15 203 + 20 210 + 21 285 + 28

5/8 -- 18 UNF 75 + 10 95 + 15 129 + 20 170 + 18 230 + 24 240 + 24 325 + 33

3/4 -- 10 UNC 93 + 12 140 + 20 190 + 27 265 + 27 359 + 37 375 + 38 508 + 52

3/4 -- 16 UNF 115 + 15 165 + 25 224 + 34 300 + 30 407 + 41 420 + 43 569 + 58

7/8 -- 9 UNC 140 + 20 225+ 25 305 + 34 430 + 45 583 + 61 600 + 60 813 + 81

7/8 -- 14 UNF 155 + 25 260 + 30 353 + 41 475 + 48 644 + 65 667 + 66 904 + 89

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the minimumproof load specified in SAE J429. The tolerance is

approximately +

10% of the nominal torque value. Thin

height nuts include jam nuts.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Groundsmaster 4000--D/4010--DPage 2 -- 4Product Records and Maintenance

Page 17

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Series)

Class 8.8 Bolts, Screws and Studs with

Thread Size Regular Height Nuts

(Class 8 or Stronger Nuts)

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

(Class 10 or Stronger Nuts)

M5 X 0.8 57 + 6in--lb 644 + 68 N--cm 78 + 8in--lb 881 + 90 N--cm

M6 X 1.0 96 + 10 in--lb 1085 + 113 N- -cm 133 + 14 in--lb 1503 + 158 N--cm

M8 X 1.25 19 + 2ft--lb 26 + 3N--m 28 + 3ft--lb 38 + 4N--m

M10 X 1.5 38 + 4ft--lb 52 + 5N--m 54 + 6ft--lb 73 + 8N--m

M12 X 1.75 66 + 7ft--lb 90 + 10 N--m 93 + 10 ft--lb 126 + 14 N--m

M16 X 2.0 166 + 17 ft--lb 225 + 23 N--m 229 + 23 ft--lb 310 + 31 N--m

M20 X 2.5 325 + 33 ft--lb 440 + 45 N--m 450 + 46 ft--lb 610 + 62 N--m

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAEJ1199.Thetoleranceisapproximately+

nominal torque value.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

10%ofthe

Product Records

and Maintenance

Groundsmaster 4000--D/4010--D Page 2 -- 5 Product Records and Maintenance

Page 18

Other Torque Specifications

*

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 -- 20 UNC 140 + 20 in--lb 73 + 12 in--lb

5/16 -- 18 UNC 215 + 35 in--lb 145 + 20 in--lb

3/8 -- 16 UNC 35 + 10 ft--lb 18 + 3ft--lb

1/2 -- 13 UNC 75 + 15 ft--lb 50 + 10 ft--lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size Baseline Torque*

No. 6 -- 32 UNC 20 + 5in--lb

Wheel Bolts and Lug Nuts

Thread Size

7/16 -- 20 UNF

Grade 5

1/2 -- 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non--lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5in--lb

Threads per Inch

Type A Type B

Recommended Torque**

65 + 10 ft--lb 88 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

Baseline Torque

No. 8 -- 32 UNC 30 + 5in--lb

No. 10 -- 24 UNC 38 + 7in--lb

1/4 -- 20 UNC 85 + 15 in--lb

5/16 -- 18 UNC 110 + 20 in--lb

3/8 -- 16 UNC 200 + 100 in--lb

Conversion Factors

in--lb X 11.2985 = N--cm N--cm X 0.08851 = in--lb

ft--lb X 1.3558 = N--m N--m X 0.7376 = ft--lb

No. 8 15 18 30 + 5in--lb

No. 10 12 16 38 + 7in--lb

No. 12 11 14 85 + 15 in--lb

*Holesize,materialstrength,materialthicknessandfinish must be considered when determining specific

torquevalues. Alltorquevalues arebasedonnon--lubricated fasteners.

Groundsmaster 4000--D/4010--DPage 2 -- 6Product Records and Maintenance

Page 19

Table of Contents

SPECIFICATIONS 2.............................

GENERAL INFORMATION 3.....................

Operator’s Manual 3..........................

Stopping the Engine 3.........................

SERVICE AND REPAIRS 4......................

Air Filter System 4............................

Exhaust System 6............................

Fuel System 8................................

Check Fuel Lines and Connections 9...........

Empty and Clean Fuel Tank 9.................

Fuel Tank Removal 9........................

Fuel Tank Installation 9.......................

Radiator 10..................................

Engine 12....................................

Engine Removal 13..........................

Engine Installation 15........................

Spring Coupler 18.............................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

03--M--E3B SERIES

Chapter 3

Kubota Diesel Engine

Kubota

Diesel Engine

Groundsmaster 4000--D/4010--D Page 3 -- 1 Kubota Diesel Engine

Page 20

Specifications

Item Description

Make / Designation Kubota Model V2403--M--T--E3B: 4--Cycle, 4 Cylinder,

Bore 3.43 in (87.0 mm)

Stroke 4.031 in (102.4 mm)

Total Displacement 148.5 in3(2434 cc)

Firing Order 1 (closest to gear case end) -- 3 -- 4 (closest to flywheel end) -- 2

Combustion Chamber Spherical Type (E--TVCS)

Compression Ratio 23.0:1

Direction of Rotation Counterclockwise (viewed from flywheel)

Fuel Diesel or Biodiesel (up to B20) Fuel with Low or

Fuel Capacity 19 U.S. gallons (72 liters)

Fuel Injection Pump Denso PFR 4M Type Mini Pump

Injection Nozzle Denso OPD Mini Nozzle

Water Cooled, Turbocharged, Diesel Engine

Ultra Low Sulfur Content

Governor Centrifugal Mechanical

Low Idle (no load) 1425 + 50 RPM

High Idle (no load) 2870 + 50/--120 RPM

Engine Oil API CH--4, CI--4 or higher

Engine Oil Viscosity See Operator’s Manual

Crankcase Oil Capacity 10 U.S. quarts (9.5 liters) with Filter

Oil Pump Trochoid Type

Coolant Capacity

Groundsmaster 4000--D 13 U.S. quarts (12.3 liters)

Groundsmaster 4010--D 17 U.S. quarts (16.1 liters)

Starter 12 VDC, 2.0 kW

Alternator/Regulator 12 VDC

Groundsmaster 4000--D 40 amp

Groundsmaster 4010--D 90 amp

Engine Dry Weight 419 U.S. pounds (190 kg)

Groundsmaster 4000--D/4010--DPage 3 -- 2Kubota Diesel Engine

Page 21

General Information

ThisChapter gives informationaboutspecificationsand

repair of the diesel engine used in Groundsmaster

4000--D and 4010--D machines.

Generalmaintenance procedures are described inyour

Operator’sManual.Informationonenginetroubleshooting,testing, disassembly and reassemblyis identifiedin

the Kubota Workshop Manual, Diesel Engine,

03--M--E3B that is included at the end of this section.

Most repairs and adjustments require tools which are

commonly available in many service shops. Special

Operator’s Manual

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervalsfor yourGroundsmastermachine.Refer tothat

publicationfor additional informationwhenservicingthe

machine.

Stopping the Engine

tools are described in the Kubota Workshop Manual,

Diesel Engine, 03--M--E3B. The use of some specialized test equipment is explained. However, the cost of

the test equipment and the specialized nature of some

repairs may dictate that the work be done at an engine

repair facility.

Service and repair parts for Kubota engines are supplied through your Authorized Toro Distributor. If no

partslistisavailable,bepreparedtoprovideyourdistributor with the Toro model and serial number of your machine.

Kubota

Diesel Engine

IMPORTANT: Before stopping the engine after

mowing or full load operation, cool the turbo-charger by allowing the engine to run at low idle speed

for five (5) minutes. Failure to do so may lead to turbo-charger trouble.

Groundsmaster 4000--D/4010--D Page 3 -- 3 Kubota Diesel Engine

Page 22

Service and Repairs

Air Filter System

RIGHT

7

FRONT

11

10

18

1. Air cleaner hose

2. Hose clamp

3. Air cleaner assembly

4. Indicator

5. Air cleaner strap

6. Lock nut (2 used)

Figure 1

7. Hose clamp

8. Air cleaner hose

9. Hose clamp

10. Cap screw (2 used)

11. Flat washer (4 used)

12. Spring (2 used)

11

5

1

9

12 to 15 in--lb

(1.4 to 1.6 N--m)

12

6

13

14

4

15

8

2

16

17

3

13. Flat washer (2 used)

14. Cap screw (2 used)

15. Adapter

16. Lock nut (2 used)

17. Flat washer (2 used)

18. Overflow bracket

VACUATOR

DIRECTION

Groundsmaster 4000--D/4010--DPage 3 -- 4Kubota Diesel Engine

Page 23

Removal (Fig. 1)

1. Park machine on a level surface, lower cutting

decks, stop engine, apply parking brake and remove

key from the ignition switch.

2. Raise and support hood.

3. Remove air cleaner components as needed using

Figure 1 as a guide.

Installation (Fig. 1)

IMPORTANT: Any leaks in the air filter system will

causeserious engine damage.Make surethat allair

cleaner components are in good condition and are

properly secured during assembly.

1. Assemble air cleaner system using Figure 1 as a

guide.

A. Ifservice indicator (item 4) and adapter (item 15)

wereremovedfromaircleanerhousing,applythread

sealant to adapter threads before installing adapter

and indicator to housing. Install adapter so that

groovesinadapter hexandadapterfilter elementare

installed toward serviceindicator (Fig. 3). Torqueindicator from 12 to 15 in--lb (1.4 to 1.6 N--m).

4

5

1. Air cleaner housing

2. Safety filter element

3. Air filter element

2

Figure 2

3

4. Air cleaner cover

5. Vacuator valve

3

1

2

Kubota

Diesel Engine

B. When securing air cleaner in air cleaner strap,

tighten cap screws (item 14) only enough to prevent

air cleaner from rotating in strap.

2. Wheninstallingair cleaner hose (item 1) betweenair

cleaner and turbo--charger (Fig. 4):

A. Make sure that hose does not contact engine

valve cover. To ensure clearance, move and/or rotate air cleaner body in air cleaner strap.

B. Position hose to allow maximum clearance between air cleaner hose and muffler bracket.

3. Lower and secure hood.

1

1. Air cleaner assembly

2. Service indicator

4

3

1. Air cleaner hose

2. Muffler bracket

Figure 3

3. Adapter

1

2

Figure 4

3. Air cleaner strap

4. Air cleaner slots

Groundsmaster 4000--D/4010--D Page 3 -- 5 Kubota Diesel Engine

Page 24

Exhaust System

16 to 22 ft--lb

(21to29N--m)

RIGHT

FRONT

16 to 22 ft--lb

(21to29N--m)

3

7

8

14

4

5

7

8

9

6

13

8

10

16 to 22 ft--lb

(21to29N--m)

11

12

1

16 to 22 ft--lb

(21to29N--m)

11

2

15

16

13 ft--lb

(17.6 N--m)

8

6

1. Muffler

2. Muffler bracket

3. Exhaust pipe

4. Flange head screw (4 used)

5. Exhaust gasket

6. Lock nut (2 used)

Figure 5

7. Cap screw (2 used)

8. Flat washer (4 used)

9. Spacer (2 used)

10. Rubber hanger

11. Flange nut (4 used)

12. Flange head screw (2 used)

13. Engine mount

14. Muffler clamp

15. Exhaust mount

16. Flange head screw (2 used)

Groundsmaster 4000--D/4010--DPage 3 -- 6Kubota Diesel Engine

Page 25

Removal (Fig. 5)

CAUTION

The muffler and exhaust pipe may be hot. To

avoid possible burns, allow the engine and exhaust system to c ool before working on the muffler.

1. Park machine on a level surface, lower cutting

decks, stop engine, apply parking brake and remove

key from the ignition switch.

2. Raise and support hood.

3. Remove exhaust system components from the engine as necessary using Figure 5 as a guide.

Installation (Fig. 5)

IMPORTANT: If exhaust studs were removed from

engine cylinder head, thoroughly clean threads in

head and apply Loctite #277 (or equivalent) to stud

threads before installing studs into head.

NOTE: Make sure muffler flange and exhaust manifold

sealing surfaces are free of debris or damage that may

prevent a tight seal.

C

E

B

D

A

Figure 6

Kubota

Diesel Engine

1. Install new exhaust gasket if original gasket is damaged or torn.

IMPORTANT: Failure to follow the suggested muffler fastener sequencemay result in prematuremuffler failure.

2. Installexhaustsystemcomponentsto the engine using Figure 5 as a guide. Hand tighten exhaust system

fastenersand thentorqueinthesequence showninFig.

6 as follows:

A. Torque lock nuts used on rubber hanger cap

screws from 16 to 22 ft--lb (21 to 29 N--m).

B. Torque flange head screws that secure muffler

flange to engine from 16 to 22 ft--lb (21 to 29 N--m).

C. Torque flange nuts that secure muffler t o muffler

bracket from 16 to 22 ft--lb (21 to 29 N--m).

D. T orqueflangenuts that securemuffler bracketto

engine from 16 to 22 ft --lb (21 to 29 N-- m).

E. Torqueflange screws thatsecure exhaust m ount

to engine to 1 3 f t -- l b ( 1 7 . 6 N -- m ) .

3. Tailpipeshouldhaveequalclearancebetweenframe

and engine after installation.

4. Lower and secure hood.

Rev. AGroundsmaster 4000--D/4010--D Page 3 -- 7 Kubota Diesel Engine

Page 26

Fuel System

6

4

37

23

26

25

24

39

40

27

38

29

30

31

28

33

36

35

34

29

3

2

22

1

20

14

RIGHT

18

FRONT

1. Fuel tank

2. Fuel tank bracket

3. ROPS assembly

4. Washer head screw (3 used)

5. Tank support assembly

6. Insulated clip (3 used)

7. Flange nut (6 used)

8. Cap screw (4 used)

9. Flat washer (4 used)

10. Cap screw (4 used)

11. Carriage screw (2 used)

12. Washer (2 used)

13. Battery strap

14. Battery

17

21

16

15

19

7

12

11

13

60 to 80 in--lb

(7 to 9 N--m)

Figure 7

15. Retaining ring (2 used)

16. Battery cover

17. Flat washer (2 used)

18. Knob (2 used)

19. Battery plate

20. Negative cable

21. Positive cable

22. Carriage screw

23. Gasket

24. Bushing (3 used)

25. Stand pipe

26. Fuel sender

27. Lock washer (5 used)

32

5

7

8

9

10

135 to 165 ft--lb

(183 to 223 N--m)

28. Phillips head screw (5 used)

29. Vent hose

30. Hose clamp

31. Elbow fitting (2 used)

32. Fuel cap

33. Locking flange nut (2 used)

34. Speed nut (4 used)

35. Tank cover (2 used)

36. Phillips head screw (4 used)

37. Vent tube

38. Overflow hose

39. Hose clamp

40. Fuel supply hose

Groundsmaster 4000--D/4010--DPage 3 -- 8Kubota Diesel Engine

Page 27

Fuel Tank Installation (Fig. 7)

DANGER

Becausedieselfuel ishighly flammable,use caution when storing or handling it. Do not smoke

while filling the fuel tank. Do not fill fuel tank

while engine is running, hot or when machine is

in an enclosed area. Always fill fuel tank outside

and wipe up any spilled diesel fuel before starting the engine. Store fuel in a clean, safety--approved container and keep cap in place. Use diesel fuel for the engine only; not for any other

purpose.

Check Fuel Lines and Connections

Checkfuel lines and connectionsperiodicallyasrecommendedinthe Operator’sManual.Check lines for deterioration, damage, leaking or loose connections.

Replace hoses, clamps and connections as necessary.

Empty and Clean Fuel Tank

Empty and clean the fuel tank periodically as recommended in the Operator’s Manual. Also, empty and

clean the fuel tank if the fuel system becomes contaminated or if the machine is to be stored for an extended

period.

To clean fuel tank, flush tank out with clean diesel fuel.

Make sure tank is free of contaminates and debris.

Fuel Tank Removal (Fig. 7)

1. Park machine on a level surface, lower cutting

decks, stop engine, apply parking brake and remove

key from the ignition switch.

2. Raise and support operator seat and hood.

1. Install fuel tank using Figure 7 as a guide.

A. Torque two(2)flange nuts(item7) thatsecurethe

fuel tank to the frame from 60 to 80 in--lb (7 to 9

N--m).

2. Install two (2) tank covers to ROPS assembly.

3. Connect fuel supply hose to the standpipe and vent

andoverflow hoses to theelbow fittings (Fig. 8). Secure

hoses with clamps.

4. Connect wire harness connections to the fuel send-

er.

A. Connect white wire to the center terminal and

black wire to any of the screws that secure the fuel

sender to the fuel tank.

B. Apply skin--overgrease to the wire terminal connections.

Kubota

Diesel Engine

CAUTION

Connecting battery cables to the wrong battery

post could result in personal injury and/or damage to the electrical system.

5. Positionbatteryinmachine.Connectpositivebattery

cable first and then negative battery cable. Install battery strap and cover.

6. Lower and secure operator seat and hood.

7. Fill fuel tank.

3. Remove battery cover and strap. Disconnect negative battery cable first and then positive battery cable.

Remove battery from machine.

4. Useafueltransferpump toremove fuel from the fuel

tank and into a suitable container.

5. Disconnect wire harness connections from the fuel

sender (item 26).

6. Disconnect fuel supply hose from standpipe and

ventandoverflowhoses fromelbowfittingsintop oftank

(Fig. 8).

7. Remove phillips head screws that secure two (2)

tank covers (item 35) to ROPS assembly.Remove tank

covers.

8. Remove fuel tank using Figure 7 as a guide.

Groundsmaster 4000--D/4010--D Page 3 -- 9 Kubota Diesel Engine

1

1. Fuel supply hose

2. Vent hose

4

Figure 8

3. Overflow hose

4. Fuel sender

3

2

Page 28

Radiator

61

32

13

RIGHT

FRONT

14

35

34

48

38

20

19

28

22

23

24

25

21

49

25

26

45

54

12

27

7

46

18

16

28

51

53

17

62

1

52

9

50

8

6

41

30

59

4

5

55

37

56

11

29

58

49

10

60

57

42

43

15

41

44

45

47

2

31

33

28

58

3

1. Radiator cap

2. Foam strip (2 used)

3. Foam strip (2 used)

4. Lower radiator hose

5. Upper radiator hose

6. Clamp (4 used)

7. Lower radiator shroud

8. Temperature sender

9. Radiator

10. Hose clamp (3 used)

11. Hose(2used)

12. Screw (4 used)

13. Rubber grommet

14. Flange nut (4 used)

15. Retaining ring (2 used)

16. Knob (2 used)

17. Bulb seal

18. Top radiator support

19. Retaining ring (2 used)

20. Oil cooler bracket

21. Oil cooler

3639

40

Figure 9

22. Carriage screw (2 used)

o

23. 90

hydraulic fitting (2 used)

24. Cap screw (6 used)

25. Lock washer (6 used)

26. Oil cooler mount plate (2 used)

27. Upper radiator shroud

28. Flange nut (10 used)

29. Foam plug (2 used)

30. Lock nut (6 used)

31. Foam strip

32. Base bracket

33. Flange head screw (6 used)

34. Bulb seal (2 used)

35. Grommet (2 used)

36. Cover

37. Flange head screw (4 used)

38. Plate (2 used)

39. Flat washer (2 used)

40. Knob (2 used)

41. Cap screw (6 used)

42. Cable tie

43. Coolant reservoir

44. Tank bracket

45. Flat washer (10 used)

46. Foam pad

47. Cap screw (7 used)

48. Foam seal

49. Cap screw (3 used)

50. LH radiator support

51. RH radiator support

52. Flange nut (6 used)

53. Cap screw (6 used)

54. Fan motor bracket

55. Grommet (2 used)

56. Grommet

57. Harness clip

58. R--clamp (2 used)

59. Foam pad

60. Reservoir cap

61. Air cleaner hose

62. Plug

Groundsmaster 4000--D/4010--DPage 3 -- 10Kubota Diesel Engine

Page 29

Removal (Fig. 9)

Installation (Fig. 9)

1. Park machine on a level surface, lower cutting

decks, stop engine, apply parking brake and remove

key from the ignition switch.

2. Open and support hood.

CAUTION

Do not open radiator cap or drain coolant if the

radiator or engine is hot. Pressurized, hot coolant can escape and cause burns.

Ethylene--glycol antifreeze is poisonous. Dispose of coolant properly or store it in a properly

labeled container away from children and pets.

3. Drain radiator into a suitable container using the radiator drain. The radiator drain hose is located near the

engine oil filter.

4. Disconnect upper and lower radiator hoses from the

radiator.

5. Remove air cleaner hose (item 61).

6. Disconnect reservoir hose from the vent tube near

the radiator cap.

1. Remove all plugs placed during the removal procedure.

2. Carefully position radiator to the support frame. Secure radiator to the support frame with cap screws and

flange nuts.

3. Iftemperaturesender(item8)wasremovedfromradiator,install new O--ring on sender and thread sender

into radiator. Torque sender from 9to11ft--lb(12.3to

14.9 N--m). Reconnect wire harness connector to sender.

4. Positionlower radiator shroud andfanmotorbracket

assembly to the radiator.

5. Secure fan motor bracket to radiator with six (6)

flangehead screws and flangenuts.Positionbracketas

far as possible from radiator to maximize distance between radiator and fan motor location.

6. Position upper radiator shroud to lower radiator

shroud to radiator. Secure shrouds with removed fasteners.

7. Attach radiator shroud assembly to the radiator with

cap screws and flat washers. Make sure that clearance

between shroud and cooling fan is at least 0.180” (4.6

mm) at all points.

Kubota

Diesel Engine

7. Detach upper radiator shroud from the radiator and

lower radiator shroud. Remove upper shroud from machine.

8. Removefastenersthatsecurelower radiator shroud

to radiator.

9. Remove six (6) flange head screws and flange nuts

that secure fan motor bracket to radiator.

10.Position lowerradiatorshroudand fan motorbracket

assembly away from radiator.

11.Disconnect wire harness connector from temperature sender (item 8).

12.Removecapscrewsand flangenutssecuringthe radiator to the support frame. Carefully pull radiator from

the machine.

13.Plug all radiator and hose openings to prevent contamination.

8. Connect reservoir hose to the vent tube near the radiator cap.

9. Connectupper andlowerradiator hosestothe radiator.

10.Reinstall air cleaner hose (item 61).

11.Make sure radiator drain is closed. Fill radiator with

coolant.

12.Close and secure hood.

Groundsmaster 4000--D/4010--D Page 3 -- 11 Kubota Diesel Engine

Page 30

Engine

21

23

22

RIGHT

FRONT

25

24

28

27

13

12

26

1

2

3

4

5

6

11

7

13

20

19

28 to 32 ft--lb

(38to43N--m)

1. Engine

2. Cap screw (4 used)

3. LH engine mount

4. Lock washer

5. Cap screw

6. Lock washer (5 used)

7. Cap screw (5 used)

8. Engine support (4 used)

9. Flange nut (12 used)

10. Rebound washer (4 used)

18

13

16

17

28 to 32 ft--lb

(38to43N--m)

11. Cap screw (8 used)

12. Spring coupler

13. Washer (14 used)

14. Cap screw (6 used)

15. Flywheel plate

16. Cap screw (4 used)

17. Cap screw (2 used)

18. Lock washer (2 used)

19. LH engine mount

14

15

Figure 10

29 to 33 ft--lb

(40to44N--m)

9

10

9

Loctite #242

20. Cap screw (4 used)

21. RH engine mount

22. Cap screw (PTO manifold)

23. Lock washer

24. Ground cable

25. Cap screw

26. Lock washer

27. RH engine mount

28. Ground harness

8

Groundsmaster 4000--D/4010--DPage 3 -- 12Kubota Diesel Engine

Page 31

Engine Removal (Fig. 10)

1. Park machine on a level surface, lower cutting

decks, stop engine, apply parking brake and remove

key from the ignition switch.

2. Remove battery from machine (see Battery Service

intheService andRepairs sectionof Chapter5 --Electrical System).

3. Raise and support hood.

CAUTION

Do not open radiator cap or drain coolant if the

radiator or engine is hot. Pressurized, hot coolant can escape and cause burns.

Ethylene--glycol antifreeze is poisonous. Dispose of coolant properly or store it in a properly

labeled container away from children and pets.

4. Drain coolant from the radiator into a suitable container (see Radiator Removal in this section). Disconnect upper and lower hoses from the radiator.

2

1

Figure 11

1. Alternator 2. Temperature sender

1

3

2

Kubota

Diesel Engine

CAUTION

The muffler and exhaust pipe may be hot. To

avoid possible burns, allow the exhaust system

to cool before working on or near the muffler.

5. Remove exhaust system from engine (see Exhaust

System Removal in this section).

6. Remove air cleaner systemfrom engine (see Air Filter System Removal in this section).

7. Note location of cable ties used to secure wire harness to the machine. Disconnect wires and/or electrical

connections from the following electrical components:

A. The temperature sender and alternator (Fig 11).

B. The glow plugs (Fig. 12).

C. The engine run solenoid.

D. Battery,frameandwireharness groundattheen-

gine block.

E. The electric starter and low oil pressure switch

(near electric starter).

1. Glow plug wire

2. Glow plug lead

5

3

1. Cable swivel

2. Cable stop

3. Throttle cable

4

Figure 12

3. Cylinder #4 glow plug

Figure 13

4. Cable clamp

5. Fuel supply hose

1

2

F. The air conditioning compressor (Groundsmaster 4010--D machines).

Groundsmaster 4000--D/4010--D Page 3 -- 13 Kubota Diesel Engine

Page 32

8. Disconnect fuel supply hose from injection pump

(Fig. 13).

9. Removethrottle cablefromengine (Figs.13and 14):

A. Removelock nut thatsecuresthrottlecableswiv-

el to speed control lever.

B. Loosen cable clamp and remove throttle cable

from under clamp.

C. Position throttle cable away from the engine.

IMPORTANT: Thehydraulic pump assembly can remain in machine during engine removal. Toprevent

pump from shifting or falling, make sure to support

pump assembly before mounting fasteners are removed.

14.Support hydraulic pump assembly. Remove fasteners that secure pump assembly to engine (see Pump

Assembly Removal in the Service and Repairs section

of Chapter 4 -- Hydraulic System).

10.Remove fasteners that secure the upper radiator

shroud to the lower shroud and radiator (see Radiator

Removal in this section). Position coolant reservoir and

bracket away from the radiator. Remove upper radiator

shroud from machine.

11.Remove cooling fan motor and fan assembly (Fig.

15).

A. To prevent contamination of hydraulic system,

thoroughly clean exterior of fan motor and fittings.

B. Disconnecthydraulic hoses fromcoolingfanmo-

tor.Putcaps orplugsonfittings and hosestoprevent

contamination. Label hydraulic lines for proper assembly.

C. Remove six ( 6) cap screws and flange nuts that

secure fan motor bracket to radiator.

D. Carefullyremovefanmotor,fan and motorbracket assembly from machine.

12.Remove transport cylinder assembly from engine

mount (Fig. 16). It is not necessary to remove the hydraulichose from thecylinder.Locateandremove cylinder spacer from between transport cylinder and engine

mount.

13.On Groundsmaster 4010--D machines:

1. Lock nut

2. Throttle cable

3. Cable support

4. Lock nut

5. Washer head screw

6. Cap screw (2 used)

4

Figure 14

7. Cable clamp

8. Spring washer (2 used)

9. Lock nut

10. Cable swivel

11. Cable stop

6

3

10

4

11

1

9

7

5

2

3

8

6

A. Removewindshield washer reservoir from reservoir mount on engine (Fig. 17). Position reservoir

away from engine. Do not remove reservoir mount

from engine.

B. Removeair conditioningcompressorfrombrackets (see Air Conditioning Compressor Removal in

theServiceandRepairssectionofChapter9 --Operator Cab). Position compressor away from engine

taking care to not damage compressor or hoses.

Support compressor to make sure it willnot fall during engine removal.

C. Disconnect coolant hose from fitting on engine

water flange.

1

1. Fan

2. Fan motor bracket

3. Fan motor

5

2

Figure 15

4. Cap screw (6 used)

5. Flange nut (6 used)

6. Radiator

Groundsmaster 4000--D/4010--DPage 3 -- 14Kubota Diesel Engine

Page 33

15.Make sure all cable ties securingthewiringharness,

fuellines or hydraulic hoses to the engine are removed.

16.Connect hoist or lift to the lift tabs on engine.

17.Remove flange nuts, rebound washers and cap

screws securing the engine mounts to the engine supports.

RIGHT

FRONT

12

11

10

13

3

14

1

CAUTION

One person should operate lift or hoist while

another person guides the engine out of the machine.

IMPORTANT: Make sure not to damage the engine,

fuel and hydraulic lines, electrical harness or other

components while removing the engine.

18.Carefully remove engine assembly from machine.

19.Ifnecessary,removeengine mountsfromthe engine

using Figure 10 as a guide.

Engine Installation (Fig. 10)

1. Make sure that all parts removed from the engine

duringmaintenance or rebuilding are installedtotheengine.

2. Ifremoved, installenginemounts totheengine using

Figure 10 as a guide.

3. Connect hoist or lift to the engine lift tabs.

CAUTION

9

15

16

Figure 16

1. Carriage screw (2 used)

2. Cylinder spacer

3. Transport cylinder

4. Lock nut (2 used)

5. Piston

6. Backup ring (2 used)

7. O--ring (2 used)

8. Retaining ring

6

3

7

6

7

8

9. Seal

10. O--ring

11. Fitting

12. O--ring

13. Hydraulic hose

14. RH engine mount

15. Jam nut

16. Cap screw

2

4

5

Kubota

Diesel Engine

2

1

4

5

One person should operate lift or hoist while

another person guides the engine into the machine.

IMPORTANT: Make sure not to damage the engine,

fuel and hydraulic lines, electrical harness or other

parts while installing the engine.

4. Carefully lower engine into the machine.

Figure 17

5. Align engine to the engine supports and hydraulic

pumpinputshaft.Secureenginetoenginesupportswith

cap screws, rebound washers and flange nuts.

1. Reservoir

2. Mount

3. Carriage screw (3 used)

4. Washer (3 used)

5. Nut (3 used)

6. Flange head screw

7. Exhaust mount

6. Secure hydraulic pump assembly to engine (see

Pump Assembly Installation in the Service and Repairs

section of Chapter 4 -- Hydraulic System).

Groundsmaster 4000--D/4010--D Page 3 -- 15 Kubota Diesel Engine

Page 34

7. Install fan motor and fan assembly (Fig. 15).

A. Carefullypositionfanmotor,fanand motorbrack-

et assembly to radiator.

13.Connect wires and/or electrical connections to the

following electrical components:

A. The temperature sender and alternator (Fig 11).

B. Secure fan motor bracket to radiator with six (6)

cap screws and flange nuts.

C. Remove caps and plugs placed in hoses and fittings during removal to prevent contamination.

D. Connect hydraulic hoses to cooling fan motor

(see Hydraulic Hose and Tube Installation in the

GeneralInformationsectionofChapter4 -- Hydraulic

System).

8. Positionupperradiator shroud and coolant reservoir

withbrackettotheradiator.Secureshroudandreservoir

bracket to the radiator and lower radiator bracket with

removedfasteners (seeRadiatorInstallationin this section).Make sure thatclearancebetweenshroud and fan

is at least 0.180” (4.6 mm) at all points.

9. Connectthrottlecabletoinjectorpump(Figs.13and

14):

A. Secure throttle cable swivel to speed control le-

ver with lock nut.

B. Place throttle cable under cable clamp.

C. Adjust throttle cable position in cable clamp so

that engine governor lever contacts the high speed

stop bolt at the same time that the throttle lever contacts the end of the slot in the control console.

D. Tighten cable clamp to secure throttle cable.

B. The glow plug (Fig. 12).

C. The engine run solenoid.

D. Battery,frameandwireharness groundtotheen-

gine block.

E. The starter and low oil pressure switch (near

starter).

F. The air conditioning compressor (Groundsmas-

ter 4010--D machines).

14.Install aircleanerassembly totheengine (seeAirFilter System Installation in this section).

15.Installexhaustsystemtomachine(seeExhaustSystem Installation in this section).

16.Connect coolant hosestotheradiator.Makesureradiator drain is shut. Fill radiator and reservoir with coolant.

17.Check position of wires, fuel lines, hydraulic hoses

andcables for proper clearance with rotating, high temperature and moving components.

18.Install battery tomachine (see Battery Service in the

Service and Repairs section of Chapter 5 -- Electrical

System). Make sure to connect positive battery cable

first and then negative battery cable. Secure battery to

machine with strap and cover.

10.Connect fuel line to the injection pump (Fig. 13).

11.Installtransportcylinder assembly to engineadapter

plate (Fig. 16). Make sure that cylinder spacer is positioned between transport cylinder and engine mount.

12.On Groundsmaster 4010--D machines:

A. Position windshield washer reservoir to bracket

onengine (Fig. 17). Secure with removed fasteners.

B. Install air conditioning compressor to brackets

(see Air Conditioning Compressor Installation in the

Serviceand Repairs section of Chapter9 -- Operator

Cab).Makesurethatdrivebeltisproperly tensioned.

C. Connect coolant hose to fitting on engine water

flange.

19.Check and adjust engine oil as needed.

20.Check and adjust hydraulic oil as needed.

21.Bleed fuel system.

22.Start engine and operate hydraulic controls to properlyfill hydraulic system(see Charge Hydraulic System

in the Service and Repairs section of Chapter 4 -- Hydraulic System).

23.Close and secure hood.

Groundsmaster 4000--D/4010--DPage 3 -- 16Kubota Diesel Engine

Page 35

This page is intentionally blank.

Kubota

Diesel Engine

Groundsmaster 4000--D/4010--D Page 3 -- 17 Kubota Diesel Engine

Page 36

Spring Coupler

RIGHT

FRONT

21

20

19

18

17

13

14

15

16

23

22

1. Spring coupler

2. Washer (14 used)

3. Cap screw (6 used)

4. Flywheel plate

5. Cap screw (4 used)

6. LH engine mount

7. Cap screw (2 used)

8. Carriage screw (2 used)

9. Cylinder spacer

10

12

11

1

2

3

4

Loctite #242

29 to 33 ft--lb

(40to44N--m)

2

9

24

5

25

6

8

7

Loctite #242

28 to 32 ft--lb

(38to43N--m)

Figure 18

10. Transport cylinder

11. Lock nut (2 used)

12. Cylinder piston

13. O--ring (2 used)

14. Backup ring (2 used)

15. Retaining ring

16. Seal

17. O--ring

18. Hydraulic fitting

19. O--ring

20. Hydraulic hose

21. RH engine mount

22. Cap screw

23. Jam nut

24. Lock washer (2 used)

25. Cap screw (2 used)

Groundsmaster 4000--D/4010--DPage 3 -- 18Kubota Diesel Engine

Page 37

Coupler Removal (Fig. 18)

NOTE: The hydraulic pump assembly needs to be re-

moved from engine before coupler can be removed.

1. Ifengineis in machine, support enginefrombelowto

prevent it from shifting. Remove the following:

A. Removehydraulicpumpassembly frommachine

(seePiston (Traction) Pump Removal in the Service

and Repairs section of Chapter 4 -- Hydraulic System).

B. Removetransportcylinderassemblyfromengine

mount. It is not necessary to remove the hydraulic

hose from the cylinder. Locate and remove cylinder

spacer from between transport cylinder and engine

mount.

2. Remove flywheel plate and spring coupler from engine using Figure 18 as a guide.

Coupler Installation (Fig. 18)

1. Position spring coupler to engine flywheel and align

mounting holes. Make sure that coupling hub is away

from engine flywheel (Fig. 19).

Engine Side Hydraulic

Pump Side

1

2

Figure 19

1. Coupler 2. Engine flywheel

Kubota

Diesel Engine

2. Apply Loctite #242 (or equivalent) to threads of cap

screws (item 3). Secure coupler to flywheel with six (6)

capscrews and washers. Torquecapscrewsin a crossing pattern from 29 to 33 ft--lb (40 to 44 N--m) .

3. Apply Loctite #242 (or equivalent) to threads of cap

screws (items 5 and 7) used to secure flywheel plate to

engine. Position flywheel plate to engine and engine

mounts. Secure flywheel plate and mounts with cap

screws (items 5 and 7) and washers using a crossing

pattern tightening procedure. Torque cap screws in a

crossing pattern from 28 to 32 ft--lb (38 to 43 N-- m).

4. If engine is in machine, install the following:

A. Install transport cylinder assembly to engine

mount. Make sure that cylinder spacer is placed between transport cylinder and engine mount. Check

transport cylinder adjustment (see Transport Cylinderin the ServiceandRepairssection of Chapter 4 -Hydraulic System).

B. Installhydraulic pump assembly tomachine(see

Piston (Traction) Pump Installation in the Service

and Repairs section of Chapter 4 -- Hydraulic System).

Groundsmaster 4000--D/4010--D Page 3 -- 19 Kubota Diesel Engine

Page 38

This page is intentionally blank.

Groundsmaster 4000--D/4010--DPage 3 -- 20Kubota Diesel Engine

Page 39

Table of Contents

Chapter 4

Hydraulic System

SPECIFICATIONS 2............................

GENERAL INFORMATION 3.....................

Operator’s Manual 3..........................

Check Hydraulic Fluid 3.......................

Towing Traction Unit 3.........................

Relieving Hydraulic System Pressure 4..........

Traction Circuit Component Failure 4............

Hydraulic Hoses 5............................

Hydraulic Hose and Tube Installation 6..........

Hydraulic Fitting Installation 7..................

HYDRAULIC SCHEMATIC 9.....................

HYDRAULIC FLOW DIAGRAMS 10...............

Traction Circuit: Low Speed (4WD) 10...........

Traction Circuit: Hi Speed (2WD) 12.............

Lower Cutting Deck 14........................

Raise Cutting Deck 16.........................

Mow 18......................................

Mow Circuit Cutting Deck Blade Braking 20......

Steering Circuit 22............................

Engine Cooling Fan Circuit 24..................

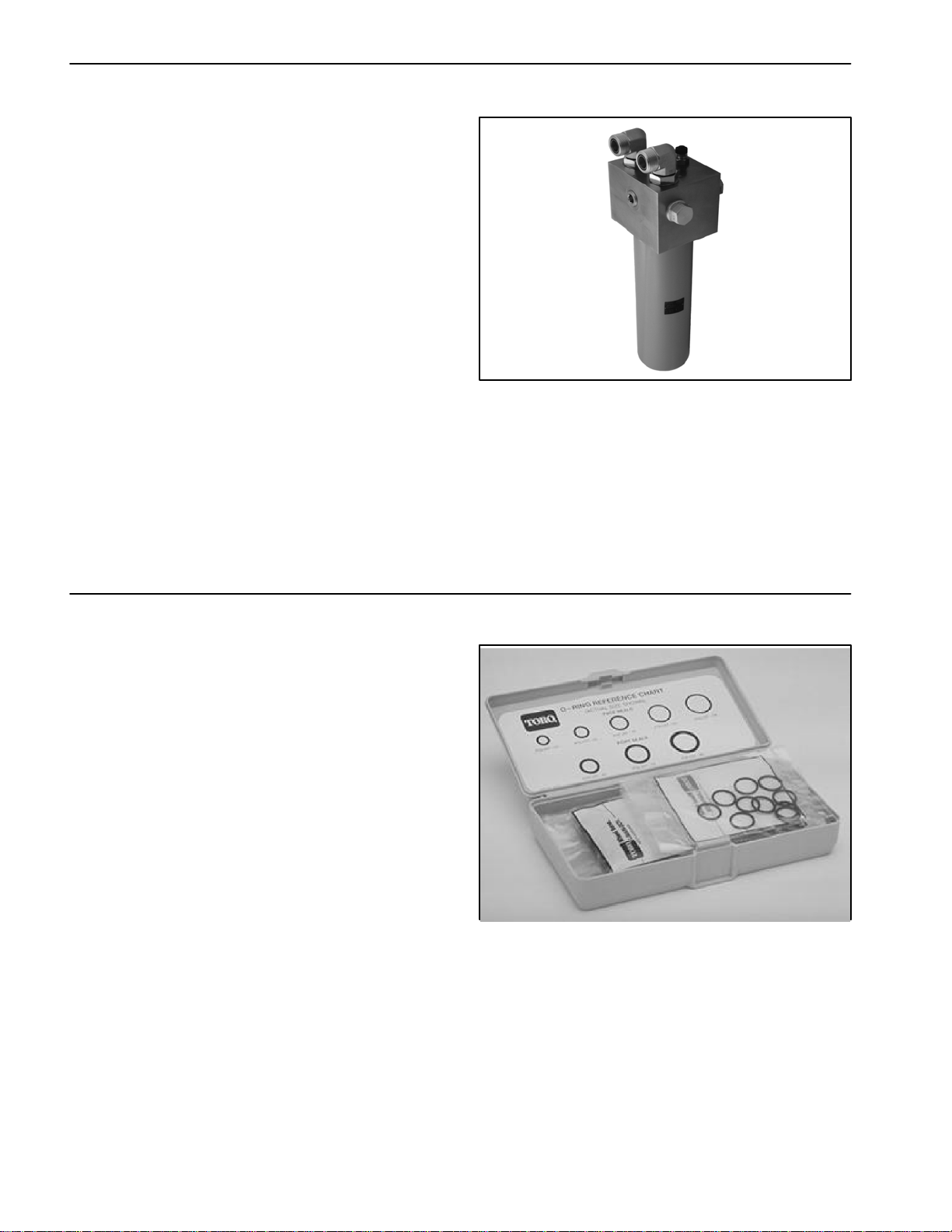

SPECIAL TOOLS 26............................

TROUBLESHOOTING 30........................

TESTING 36...................................

Traction Circuit Charge Pressure 38.............

Traction Circuit Relief Pressure 40..............

Counterbalance Pressure 42...................

Traction Circuit Reducing Valve (PR) Pressure 44.

Rear Traction Circuit (RV) Relief Pressure 46.....

Piston (Traction) Pump Flow 48.................

Cutting Deck Circuit Pressure 50................

PTO Relief Pressure 52........................

Cutting Deck Motor Case Drain Leakage 54......

Cutting Deck Gear Pump Flow 56...............

Lift/Lower Circuit Relief Pressure 58.............

Steering Circuit Relief Pressure 60..............

Steering Cylinder Internal Leakage 62...........

Steering and Lift/Lower Gear Pump Flow 64......

Engine Cooling Fan Circuit 66..................

Engine Cooling Fan Circuit Gear Pump Flow 68..

ADJUSTMENTS 70.............................

Traction Linkage Adjustment 70.................

SERVICE AND REPAIRS 72.....................

General Precautions for Removing and

Installing Hydraulic System Components 72....

Check Hydraulic Lines and Hoses 72............

Flush Hydraulic System 73.....................

Filtering Closed--Loop Traction Circuit 74........

Charge Hydraulic System 75...................

Hydraulic Reservoir 76........................

Hydraulic Oil Cooler 78........................

Gear Pump 80.....

Gear Pump Service 82........................

Traction Circuit 84............................

Transport Cylinder 85.........................

Piston (Traction) Pump 86.....................

Piston (Traction) Pump Service 88..............

Rear Axle Motor 90...........................

Front Wheel Motor 92.........................

Rear Axle and Front Wheel Motor Service 94.....

4WD Manifold 96.............................

4WD Manifold Service 98......................

Traction (Flow Divider) Manifold 100.............

Traction (Flow Divider) M anifold Service 102.....

Filter Manifold 104............................

Filter Manifold Service 106.....................

Steering and Engine Cooling Fan Circuits 108....

Steering Control Valve 110.....................

Steering Control Valve Service 112..............

Steering Cylinder 114.........................

Steering Cylinder Service 116..................

Engine Cooling Fan Motor 118..................

Engine Cooling Fan Motor Service 120..........

Fan Drive Manifold 124........................

Fan Drive Manifold Service 126.................

PTO Circuit 128...............................

Cutting Deck Motor 129........................

Cutting Deck Motor Service 130................

PTO Manifold 134.............................

PTO Manifold Service 136.....................

Cutting Deck Lift/Lower Circuit 138..............

Lift/Lower Manifold 140........................

Lift/Lower Manifold Service 142.................

Side Deck Lift Cylinder 144.....................

Front Deck Lift Cylinder 146....................

Lift Cylinder Service 148.......................

EA TON MODEL 72400 SERVO CONTROLLED

PISTON PUMP REPAIR INFORMATION

EATON MODEL 74318 and 74348 PISTON MOTORS:

FIXED DISPLACEMENT, VALVE PLATE DESIGN

REPAIR INFORMATION

.......

....................

System

Hydraulic

Rev. AGroundsmaster 4000--D/4010--D Hydraulic SystemPage 4 -- 1

Page 40

Specifications

Item Description

Piston (Traction) Pump Eaton Variable Displacement Piston Pump

Maximum Displacement (per revolution) 2.48 in

System Relief Pressure: Forward 4000 PSI (274 bar)

System Relief Pressure: Reverse 5000PSI (343 bar)

Charge Pressure 250 PSI (17 bar)

Front Wheel Motors Eaton Fixed Displacement Piston Motors

Displacement (per revolution) 2.48 in

Rear Axle Motor Eaton Fixed Displacement Piston Motor

Displacement (per revolution) 2.01 in

Gear Pump Casappa 4 Section, Positive Displacement Gear pump

Section P1/P2 Displacement (per revolution) 1.16 in

Section P3/P4 Displacement (per revolution) 0.56 in

Steering Control Valve Eaton Steering Unit, Series 5

Displacement (per revolution) 6.1 in

Steering Circuit Relief Pressure 1350 PSI (93 bar)

Lift/Lower Circuit Relief Pressure 1600 PSI (110bar)

Cutting Deck Motors Sauer Danfoss Gear Motor

Displacement (per revolution) 1.17 in

(Model 72400)

3

(40.6 cc)

(Model 74318)

3

(40.6 cc)

(Model 74315)

3

(32.9 cc)

3

(19.09 cc)

3

(9.16 cc)

3

(100 cc)

3

(19.2 cc)

PTO Circuit Relief Pressure

Front and Left Side 3000 PSI (207 bar)

Right Side 2000 PSI (137 bar)

Engine Cooling Fan Motor Casappa Gear Motor

Displacement (per revolution) 0.50 in

Engine Cooling Fan Circuit Relief Pressure 3000 PSI (207 bar)

Hydraulic Filters Spin--on Cartridge Type

In--line Suction Strainer 100 Mesh (In Reservoir)

Hydraulic Reservoir 8 U.S. Gallons (30.3 Liters)

Hydraulic Oil See Operator’s Manual

3

(8.3 cc)

Groundsmaster 4000--D/4010--DHydraulic System Page 4 -- 2

Page 41

General Information

Operator’s Manual

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervalsfor yourGroundsmastermachine.Refer tothat

publicationfor additional informationwhenservicingthe

machine.

Check Hydraulic Fluid

TheGroundsmasterhydraulicsystemisdesignedtooperate on anti--wear hydraulic fluid. The hydraulic reservoir located beneath the operator seat holds

approximately 8 U.S. gallons (30.3 liters) of hydraulic

fluid. Check level of hydraulic fluid daily. See Operator’s Manual for fluid level checking procedure and oil

recommendations.

2

1

Towing Traction Unit

IMPORTANT: If towing limits are exceeded, severe

damage to the piston (traction) pump may occur.

If it becomes necessary to tow (or push) the machine,

tow (or push) in a forward direction only and at a

speedbelow 3 mph (5 kph). Thepiston(traction)pump

isequippedwith aby--passvalvethatneedstobeturned

o

(one quarter turn) for towing. Refer to your Opera-

90

tor’s Manual for additional towing instructions.

IMPORTANT: Do not turn by--pass valve when en gine is running.

Figure 1

1. Hydraulic reservoir cap 2. Operator seat

1

2

Figure 2

1. Bypass valve location 2. Operator seat

System

Hydraulic

Groundsmaster 4000--D/4010--D Hydraulic SystemPage 4 -- 3

Page 42

Relieving Hydraulic System Pressure

Beforedisconnectingor performing any work onthehydraulic system, all pressure in the hydraulic system

mustberelieved.Parkmachineonalevelsurface,make

sure that PTO switch is OFF, lower cutting decks fully,

stopengine and engage parking brake.Waitfor all moving parts to come to a complete stop.

To relieve hydraulic pressure in traction circuit, move

tractionpedal to both forward and reverse directions. To

relieve hydraulic pressure in steering circuit, rotate

steering wheel in both directions.

Traction Circuit Component Failure

The traction circuit on Groundsmaster 4000--D and

4010--Dmachines is a closedloop system that includes

the piston (traction) pump, two (2) front wheel motors

and the rear axle motor. If a component in the traction

circuit should fail, debris and contamination from the

failed component will circulate throughout the traction

circuit. This contamination can damage other components in the circuit so it must be removed to prevent

additional component failure.

The recommended method of removing traction circuit

contamination would be to temporarily install the Toro

high flow hydraulic filter (see Special Toolsin this chapter) into the circuit. This filter should be used when connecting hydraulic test gauges in order to test traction

circuitcomponentsorafter replacingafailedtractioncircuit component (e.g. traction (piston) pump or wheel

motor). The filter will ensure that contaminates are removedfromthe closedloopandthus,donotcauseadditional component damage.

To relieve hydraulic pressure in lift circuit, start engine

andfully lowerthecuttingdecks.Turnkeyswitch toOFF

and remove key from the ignition switch.

System pressure in mow circuit is relieved when the

PTO switch is disengaged.

Once the Toro high flow hydraulic filter kit has been

placedin the circuit, raise andsupport the machine with

all wheels off the ground. Then, operate the traction circuit to allow oil flow throughout the circuit.The filter will

remove contamination from the traction circuit during

operation. Because the Toro high flow filter is bi--directional,the tractioncircuitcan be operatedinboththe forward and reverse direction. The filter should be

removed from the machine after contamination has

been removed from the traction circuit. See Filtering

Closed--LoopTractionCircuitintheServiceandRepairs

section of this chapter for additional information on using the Toro high flow hydraulic filter.

Thealternative tousingthe Torohigh flowhydraulicfilter

kit after a traction circuit component failure would be to

disassemble, drain and thoroughly clean all components, tubes and hoses in the traction circuit. If any debris remains in the traction circuit and the machine is

operated,thedebriscancauseadditionalcircuitcomponent failure.

Groundsmaster 4000--D/4010--DHydraulic System Page 4 -- 4

Page 43

Hydraulic Hoses

Hydraulichoses are subject to extremeconditions such

aspressuredifferentialsduring operationandexposure

to weather, sun, chemicals, very warm storage conditionsormishandlingduring operationandmaintenance.

These conditions can cause hose damage and deterioration. Some hoses are more susceptible to these

conditions than others. Inspect all machine hydraulic

hoses frequently for signs of deterioration or damage:

WARNING

Beforedisconnectingorperformingany work on

hydraulic system, relieve all pressure in system

(seeRelievingHydraulicSystemPressure in this

section).

Hard, cracked, cut, abraded, charred, leaking or

otherwise damaged hose.

Kinked, crushed, flattened or twisted hose.

Blistered, soft, degraded or loose hose cover.

Cracked, damaged or badly corroded hose fittings.

When replacing a hydraulic hose, be sure that the hose

is straight (not twisted) before tightening the fittings.

This can be done by observing the imprint (layline) on

the hose. Use two wrenches when tightening a hose;

hold the hose straight with one wrench and tighten the

hose swivel nut onto the fitting with the second wrench

(see Hydraulic Hose and Tube Installation in this section). If the hose has an elbow at one end, tighten the

swivel nut on that end before tightening the nut on the

straight end of the hose.

For additional hydraulic hose information, refer to Toro

Service Training Book, Hydraulic Hose Servicing (Part

Number 94813SL).

Keepbodyand handsaway frompinholeleaksor

nozzles that eject hydraulic fluid under high

pressure. Use paper or cardboard, not hands, to

search for leaks. Hydraulic fluid escaping under

pressure can have sufficient force to penetrate

the skin and cause serious injury. If fluid is injected into the skin, it must be surgically removed within a few hours by a doctor familiar

withthis typeofinjury.Gangrenemayresult from

such an injury.

System

Hydraulic

Groundsmaster 4000--D/4010--D Hydraulic SystemPage 4 -- 5

Page 44

Hydraulic Hose and Tube Installation (O--Ring Face Seal Fitting)

1. Makesurethreadsandsealingsurfacesofthehose/

tube and the fitting are free of burrs, nicks, scratches or

any foreign material.

2. Asapreventativemeasureagainstleakage,itis recommended that the face seal O--ring be replaced any

time the connection is opened. Make sure the O--ringis

installedandproperly seatedinthefittinggroove.Lightly

lubricate the O--ring with clean hydraulic oil.

3. Place the hose/tube against the fitting body so that

theflatfaceofthehose/tube sleevefullycontactstheO-ring in the fitting.

4. Thread the swivel nut onto the fitting by hand. While

holding the hose/tube with a wrench, use a torque

wrench to tighten the swivel nut to the recommended

installation torque shown in Figure 5. This tightening

process will require the use of an offset wrench (e.g.

crowfoot wrench). Use of an offset wrench will affect

torque wrench calibration due to the effective length

change of the torque wrench. Tightening torque when

usingatorquewrenchwithanoffsetwrenchwillbelower

than the listed installation torque (see Using a Torque

Wrench with an Offset Wrench in the Torque Specificationssection of Chapter 2 -- Product Records and Maintenance).

C. Useasecondwrench totightenthenut tothecorrect Flats From Wrench Resistance (F.F.W.R.). The

markingsonthe nutandfittingbodywillverifythatthe

connection has been properly tightened.

Siz e F.F.W.R.

4 (1/4 in. nominal hose or tubing) 1/2 to 3/4

6 (3/8 in.) 1/2 to 3/4

8 (1/2 in.) 1/2 to 3/4

10 (5/8 in.) 1/2 to 3/4

12 (3/4 in.) 1/3 to 1/2

16 (1 in.) 1/3 to 1/2

Swivel Nut

Tube or Hose