Page 1

FormNo.3391-863RevA

G017540

CommercialWalk-BehindMower

FixedDeck,PistolGrip,HydroDrivewith

36inand48inTURBOFORCE

ModelNo.30934—SerialNo.315000001andUp

ModelNo.30938—SerialNo.315000001andUp

ModelNo.39934—SerialNo.315000001andUp

®

CuttingUnit

ModelNo.39938—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3391-863*A

Page 2

WARNING

Introduction

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

WARNING

Removingstandardoriginalequipmentpartsand

accessoriesmayalterthewarranty,traction,and

safetyofthemachine.FailuretouseoriginalToro

partscouldcauseseriousinjuryordeath.Making

unauthorizedchangestotheengine,fuelorventing

system,mayviolateEPAandCARBregulations.

Thisrotary-blade,lawnmowerisintendedtobeused

byresidentialhomeownersorprofessional,hired

operators.Itisdesignedprimarilyforcuttinggrasson

well-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Replaceallpartsincluding,butnotlimitedto,tires,

belts,blades,andfuelsystemcomponentswith

originalToroparts.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Engine Owner's Man ual

issuppliedfor

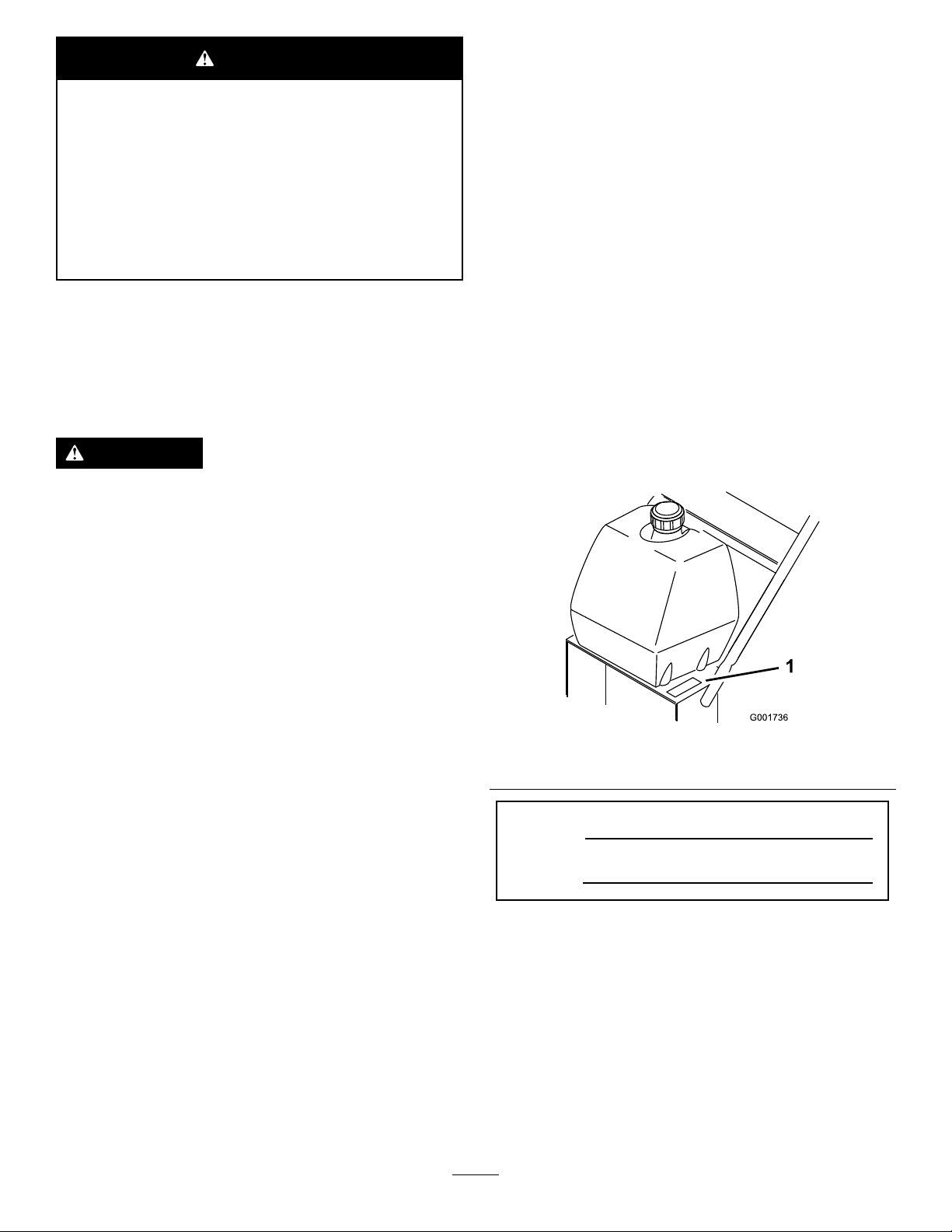

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................6

SlopeIndicator.......................................................7

SafetyandInstructionalDecals.................................8

ProductOverview.........................................................13

Controls...............................................................13

Specications........................................................14

Attachments/Accessories........................................14

Operation....................................................................14

AddingFuel...........................................................14

CheckingtheEngine-OilLevel.................................15

PuttingSafetyFirst.................................................15

OperatingtheParkingBrake....................................16

StartingandStoppingtheEngine..............................16

OperatingtheNeutralLocks....................................17

OperatingtheMower-Blade-ControlKnob

(PTO)...............................................................18

TheSafety-InterlockSystem....................................18

DrivingtheMachineForwardandBackward..............19

BringingtheMachinetoNeutralPosition...................19

StoppingtheMachine.............................................19

PushingtheMachinebyHand..................................19

AdjustingtheFlowBafe........................................20

PositioningtheFlowBafe......................................20

TransportingtheMachine........................................21

SideDischargingorMulchingtheGrass.....................21

AdjustingtheHeight-of-Cut....................................21

AdjustingtheCasterPosition...................................22

AdjustingtheHandleHeight....................................23

Height-of-CutChart...............................................24

Maintenance.................................................................25

RecommendedMaintenanceSchedule(s)......................25

Lubrication...............................................................26

LubricatingtheMachine..........................................26

LubricatingtheCasterandWheelBearings.................26

GreasingtheMower-BeltIdler.................................26

GreasingthePumpControlandtheBell

Crank................................................................26

EngineMaintenance..................................................27

ServicingtheAirCleaner.........................................27

ServicingtheEngineOil..........................................27

ServicingtheSparkPlugs.........................................29

FuelSystemMaintenance...........................................30

ServicingtheFuelTank...........................................30

ServicingtheFuelFilter...........................................31

ServicingtheFuel-VentSystem................................31

DriveSystemMaintenance.........................................32

AdjustingtheSpeed-ControlLinkage........................32

AdjustingtheNeutralControlLinkages.....................32

AdjustingtheHydroControlLinkages.......................33

AdjustingtheControlRod.......................................35

AdjustingtheTracking...........................................36

AdjustingtheSpringAnchorLinks...........................36

CheckingtheTirePressure......................................37

CoolingSystemMaintenance......................................37

3

Page 4

CleaningtheAir-IntakeScreen.................................37

CleaningtheCoolingSystem....................................37

BrakeMaintenance....................................................38

ServicingtheBrake.................................................38

BeltMaintenance......................................................39

CheckingtheBelts..................................................39

ReplacingtheMowerBelt........................................39

AdjustingtheMowerBeltTension............................40

HydraulicSystemMaintenance....................................43

ServicingtheHydraulicSystem.................................43

MowerDeckMaintenance...........................................46

ServicingtheCuttingBlades.....................................46

AdjustingtheBladeBrake........................................48

ReplacingtheGrassDeector..................................48

Storage........................................................................49

CleaningandStorage..............................................49

Troubleshooting...........................................................51

Schematics...................................................................53

Safety

Note:Theadditionofattachmentsmadebyother

manufacturersthatdonotmeetAmericanNationalStandards

Institutecerticationwillcausenoncomplianceofthis

machine.

Improperlyusingormaintainingthemachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeans

Danger

withtheinstructionmayresultinpersonalinjuryor

death.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

—personalsafetyinstruction.Failuretocomply

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromANSI

B71.4-2012.

Caution, W ar ning ,

or

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadorunderstand

theinformationitistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleordamageto

property.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glasses,andhearingprotection.Longhair,looseclothing,

orjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwirewhichcan

bethrownbythemachine.

•Checkthatoperator'spresencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

4

Page 5

Operation

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingtheengine.Onlystarttheengine

fromtheoperator'sposition.

•Besureofyourfootingwhileusingthismachine,

especiallywhenbackingup.Walk;donotrun.Never

operateonwetgrass.Reducedfootingcouldcause

slipping.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

thestabilityofthemachine.Usecautionwhileoperating

neardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neverraisedeckwiththebladesrunning.

•NeveroperatewiththePTOshieldorotherguardsnot

securelyinplace.Besureallinterlocksareattached,

adjustedproperly ,andfunctioningproperly.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,disengagedrives,engagethe

parkingbrake(ifprovided),andshutofftheenginebefore

leavingtheoperator'spositionforanyreason,including

emptyingthecatchersoruncloggingthechute.

•Stopequipmentandinspectbladesafterstrikingobjects

orifanabnormalvibrationoccurs.Makenecessary

repairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Nevercarrypassengersonthemachine.

•Keeppetsandbystandersaway .

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesifnotmowing.

•Beawareofthemowerdischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

•Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Disengagedrives,settheparkingbrake,stoptheengine

andremovethekeyordisconnectthespark-plugwire.

Waitforallmovementtostopbeforeadjusting,cleaning

orrepairingthemachine.

•Cleangrassanddebrisfromthecuttingunit,thedrives,

themufers,andtheenginetohelppreventres.Clean

upoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Shutoffthefuelwhilestoringortransporting.Donot

storefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Settheparkingbrake.

Neverallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorthespark-plugwirebefore

makinganyrepairs.Disconnectthenegativeterminal

rstandthepositivelast.Connectthepositiverstand

negativelast.

5

Page 6

•Usecarewhencheckingtheblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.Only

replaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

mowingarea.

•Watchforholes,rutsorbumps.Tallgrasscanhide

obstacles.

•Usecautionneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyturnoverifawheelgoes

overtheedgeofaclifforditch,orifanedgecavesin.

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonT oro

genuineparts.Whenitcomestoreliability,T orodelivers

replacementpartsdesignedtotheexactengineering

specicationsofourequipment.Forpeaceofmind,insist

onTorogenuineparts.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsandothersafetyinformationyoumustknow.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

•Useextracarewithgrasscatchersorotherattachments.

Thesecanchangethestabilityofthemachine.

•Keepallmovementonslopesslowandgradual.Donot

makesuddenchangesinspeedordirection.

•Mowslopessidetoside.

•Donotmowslopesgreaterthan20degrees.

Service

•Neverstorethemachineorfuelcontainerinsidewhere

thereisanopename,suchasnearawaterheateror

furnace.

•Keepnutsandboltstight,especiallythebladeattachment

bolts.Keepequipmentingoodcondition.

•Nevertamperwithsafetydevices.Checksafetysystems

forproperoperationbeforeeachuse.

•Useonlygenuinereplacementpartstoensurethatoriginal

standardsaremaintained.

•Checkbrakeoperationfrequently.Adjustandserviceas

required.

Thisproductisdesignedforcuttingandrecyclinggrassor,

whenequippedwithagrassbagger,forcatchingcutgrass.

Anyuseforpurposesotherthanthesecouldprovedangerous

touserandbystanders.

GeneralOperation

•Besuretheareaisclearofotherpeoplebeforemowing.

Stopthemachineifanyoneentersthearea.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowtocoolbeforeattempting

tomaintain,adjustorservice.

•UseonlyToroapprovedattachments.Warrantymaybe

voidedifusedwithunapprovedattachments.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforeoperatingunderany

objectsanddonotcontactthem.

SlopeOperation

Allslopesandrampsrequireextracaution.Ifyoufeeluneasy

onaslope,donotmowit.

6

Page 7

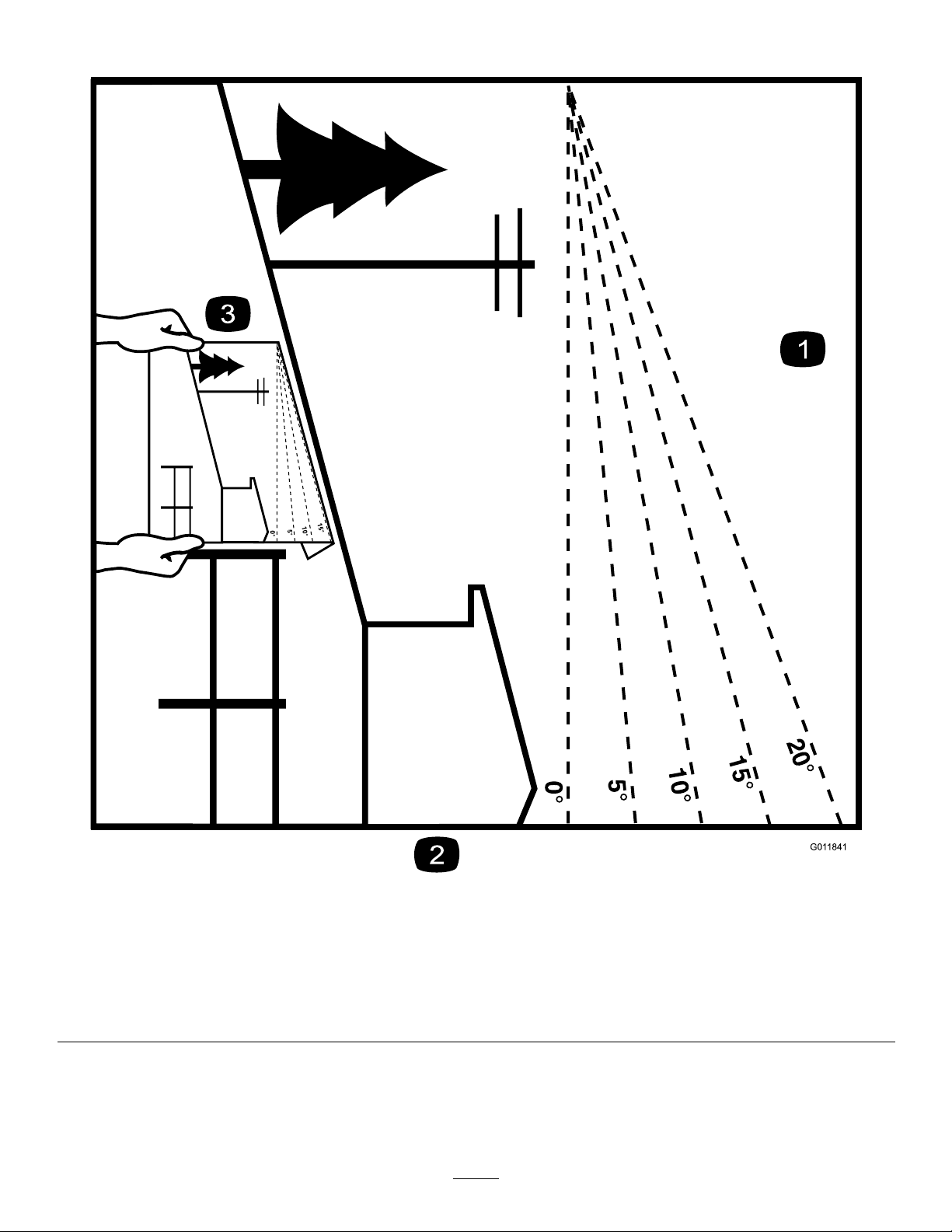

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis20degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan20degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

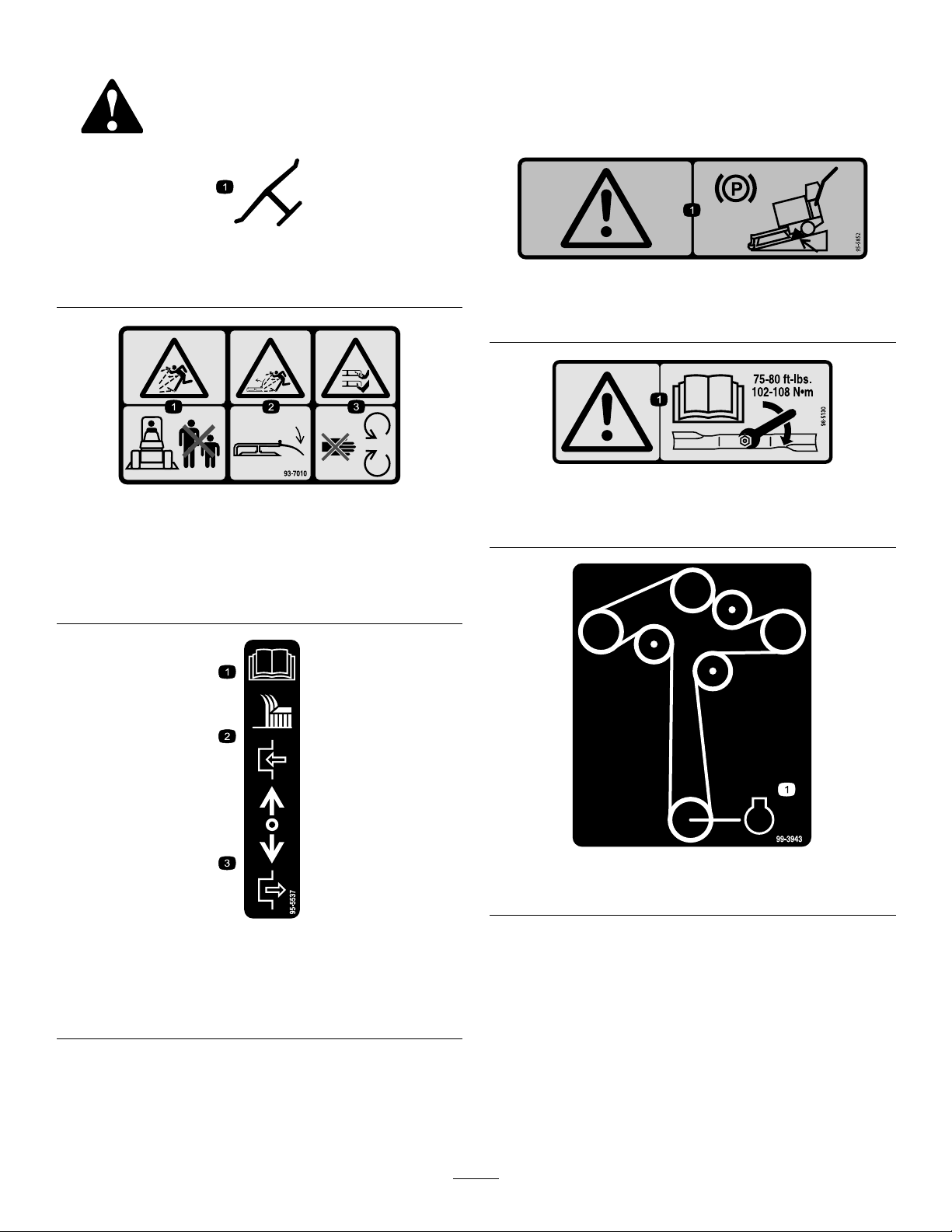

93-7010

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—keepthedeectorinplace.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

95-5852

1.Warning—engagetheparkingbrakeandchockorblockthe

wheelswhenparkingthemachineonaslope.

98-5130

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto102-106N⋅m(75-80ft-lb).

1.ReadtheOperator's

Manualforinstructionson

operatingthecuttingblade

2.Pushforwardtoengage

99-3943

1.Engine

95-5537

3.Pullbacktodisengage

8

Page 9

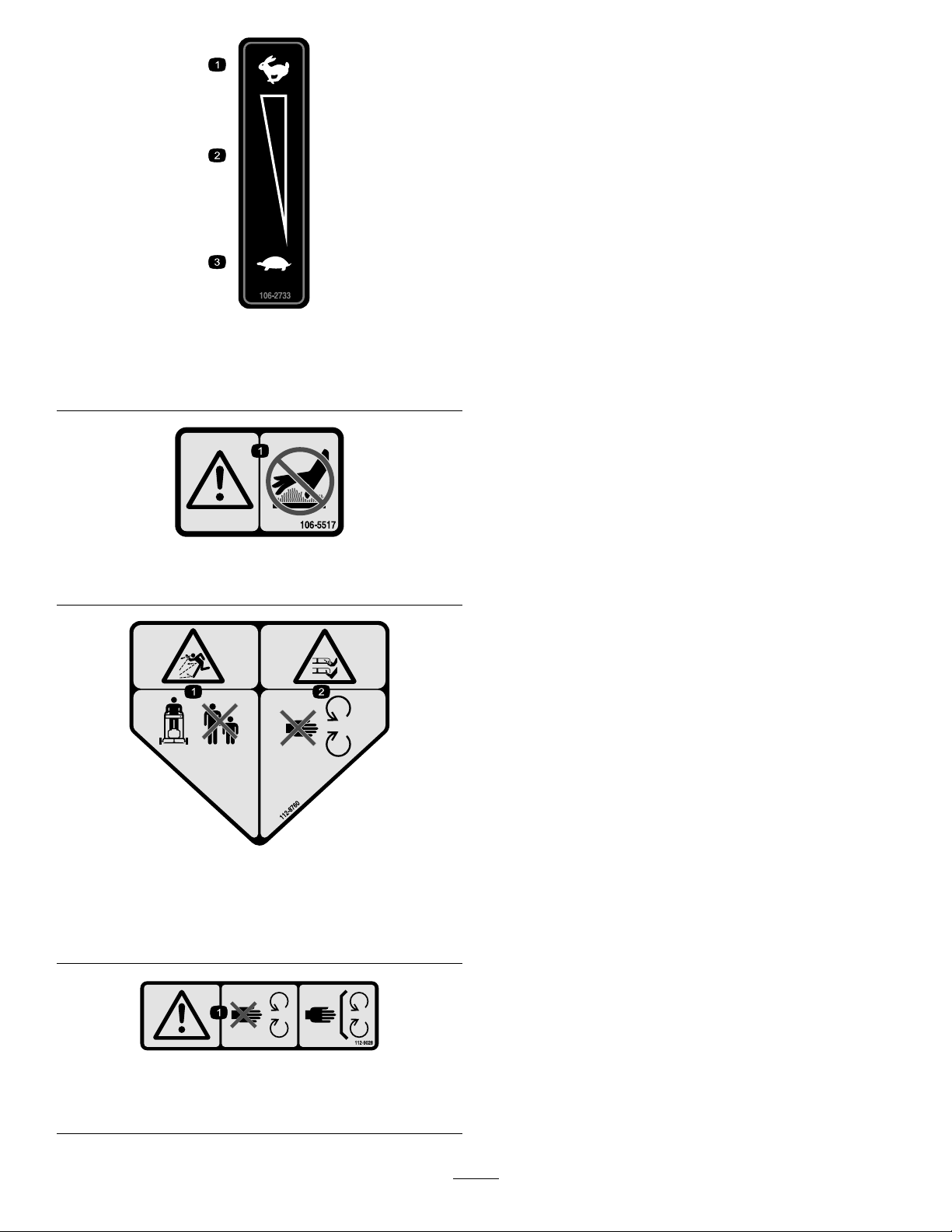

106-2733

1.Fast

2.Continuousvariable

setting

1.Warning—donottouchthehotsurface.

3.Slow

106-5517

112-8760

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

9

Page 10

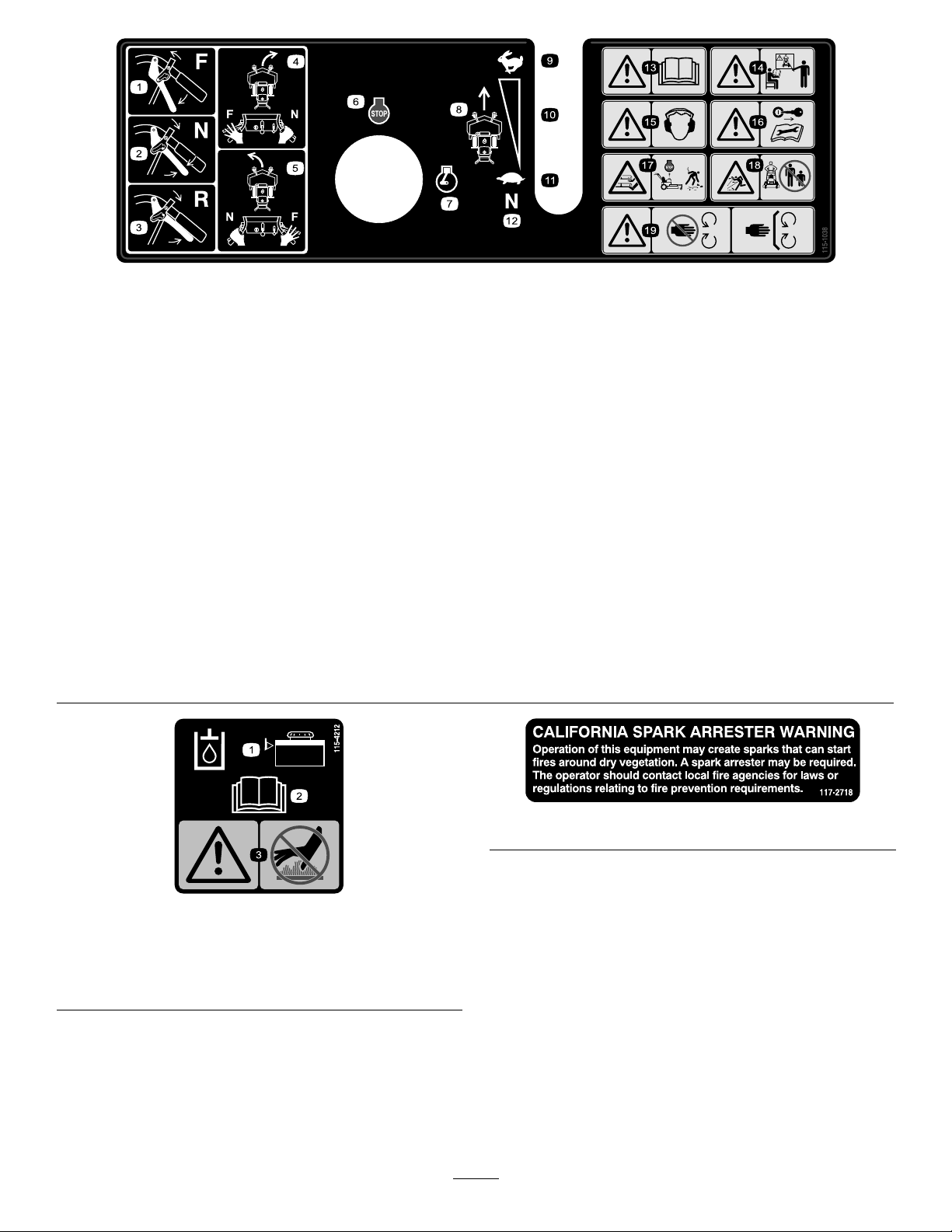

115-1038

1.Forward

2.Neutral

3.Reverse

4.Toturnrightmovethelefthandleverintotheforwardpositionwhiletherighthandleverisintheneutralposition.

5.Toturnleftmovetherighthandleverintotheforwardpositionwhilethelefthandleverisintheneutralposition.

6.Engine—stop

7.Engine—run

8.Groundspeed

9.Fast

10.Continuousvariablesetting

11.Slow

12.Neutral

13.Warning—readtheOperator'sManual.

14.Warning—donotoperatethismachineunlessyouaretrained.

15.Warning—wearhearingprotection.

16.Warning—removetheignitionkeybeforeperformingmaintenanceonthemachine.

17.Cutting/dismembermenthazardofhandorfoot,mowerblade—stoptheenginebeforeleavingtheoperatingposition.

18.Thrownobjecthazard—keepbystandersasafedistancefromthemachine.

19.Warning—stayawayfrommovingparts;keepallguardsinplace.

115-4212

1.Hydraulicoillevel3.Warning—donottouchthe

hotsurface.

2.ReadtheOperator's

Manual.

117-2718

10

Page 11

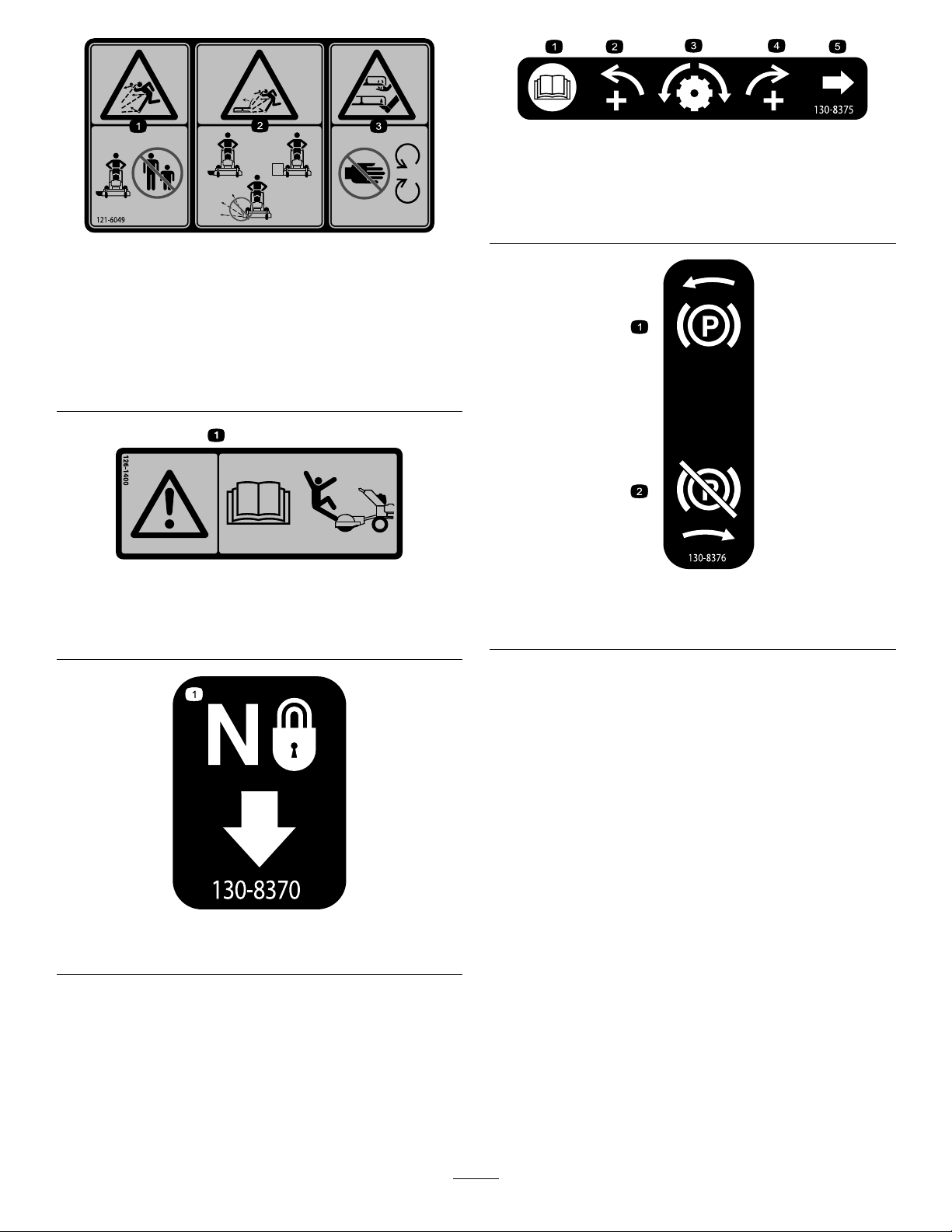

130-8375

121-6049

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

mower—donotoperate

themowerwithguardsor

shieldsremoved.

3.Cutting/dismemberment

hazardofhandorfoot,

mowerblade—keephands

awayfrommovingparts.

126-1400

1.Warning-ReadtheOperator’smanual.UseonlyTororiding

attachments.Useofotherridingattachmentsmaycreatea

hazardousconditionresultingininjury.

1.ReadtheOperator's

Manual.

2.Increaseleft

3.Trackingadjustment

4.Increaseright

5.Trackingadjustmentknob

130-8376

1.Engagetheparkingbrake.2.Disengagetheparking

brake.

1.Neutrallock

130-8370

11

Page 12

131-1180

1.ReadtheOperator's

Manual.

2.Short,lightgrass;dry

conditions;maximum

dispersion

3.Baggingsetting

4.Tall,densegrass;wet

conditions;maximum

groundspeed

12

Page 13

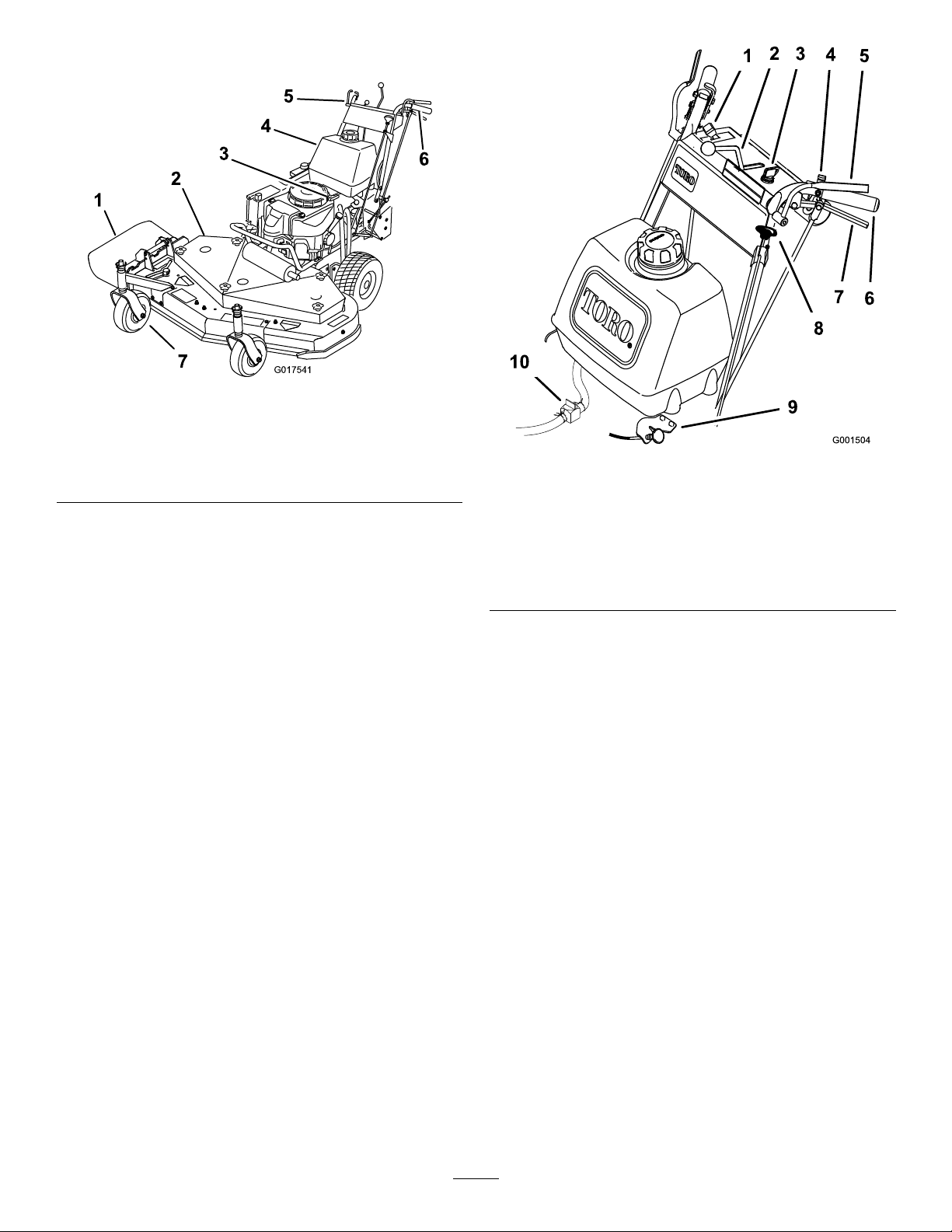

ProductOverview

G017541

Figure4

1.Sidedischarge5.Controls

2.Mowerdeck6.Handle

3.Recoil-starthandle

4.Gastank

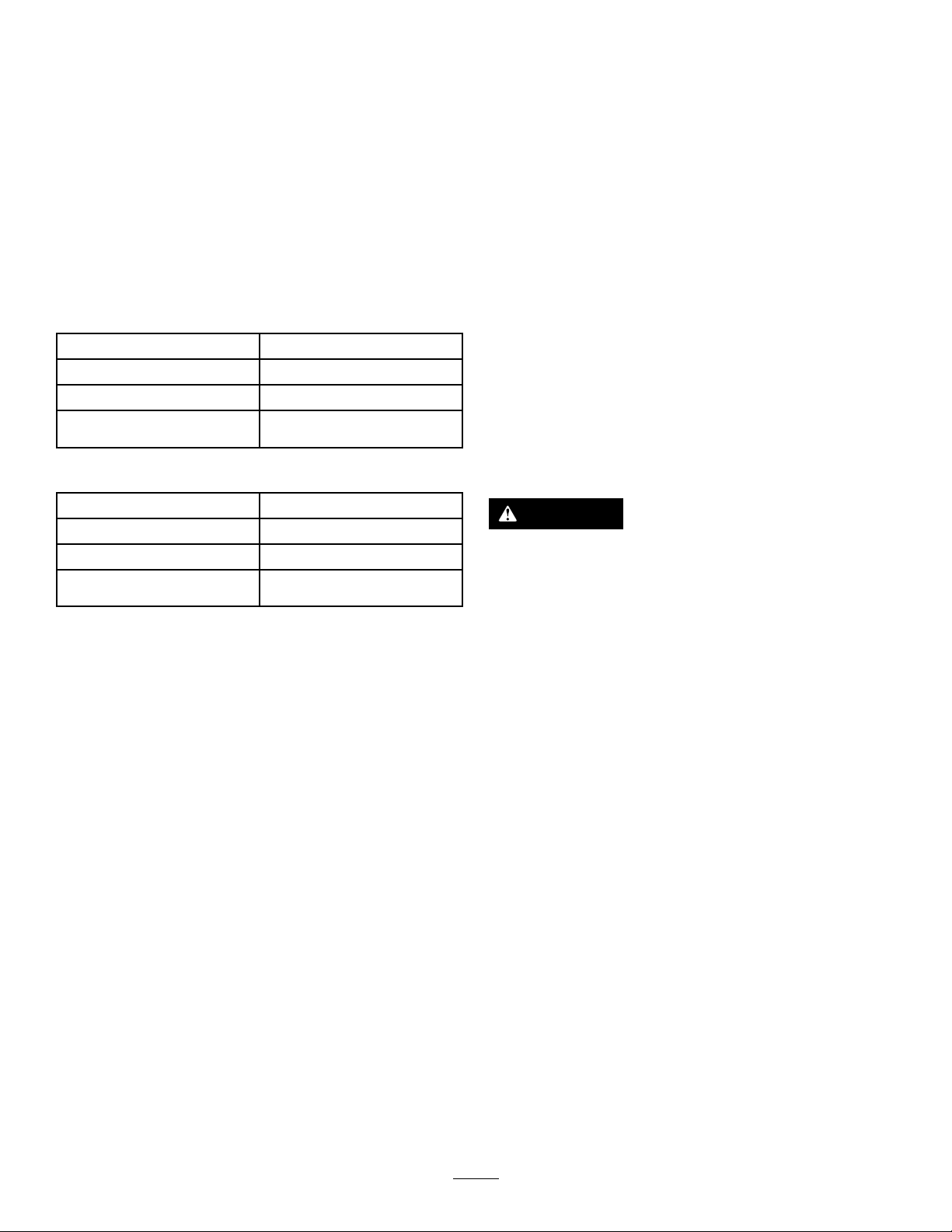

Controls

Becomefamiliarwithallthecontrols(Figure5)beforeyou

starttheengineandoperatethemachine.

7.Casterwheel

Figure5

1.Throttlecontrol6.Handle

2.Speed-controllever

3.Ignitionswitch

4.Neutrallock

5.Operator-presence-control

levers(OPC)

7.Drivelever

8.Blade-controlknob(PTO)

9.Choke

10.Fuel-shutoffvalve

ThrottleControl

Thethrottlecontrolhas2positions:FastandSlow.

Operator-Presence-Control(OPC)

Levers

WhenyousqueezetheOPCleversagainstthehandles,

theOPCsystemsensesthattheoperatorisinthenormal

operatingposition.WhenyoureleasetheOPClevers,the

OPCsystemsensesthattheoperatorhasleftthenormal

operatingposition,andthesystemwillstoptheengineif

eitherthespeed-controlleverisnotintheNeutralpositionor

theblade-control(PTO)knobisengaged.

Blade-ControlKnob(PTO)

Theblade-controlknob(PTO)isusedtoengageand

disengagethedrivebelttodrivethemowerbladeswiththe

OPCleverspressedagainstthehandles.Pulltheknobupto

engagethebladesanddowntodisengagetheblades.

IgnitionSwitch

Thisswitchisusedinconjunctionwithrecoilstarterandhas

2positions:RunandOff.

Speed-ControlLever

Thismachinehasavariable-speedcontrolwithaNeutral

position.Thiscontrolshowfastthemachinetravelsforward.

DriveLevers

Releasethedriveleverstoengageforwardtractionoperation

andsqueezetheleversuntilanincreaseinforceisfeltto

gointoneutralpositionandcontinuetosqueezetogoin

reverse.Squeezetheright-sidedrivelevertoturnrightand

theleft-sidedrivelevertoturnleft.

NeutralLock

Squeezethedriveleversbackuntilanincreaseinforceisfelt,

andmovethelockstotherearforneutrallock.

Recoil-StartHandle

Pulltherecoil-starthandletostarttheengine(notshown

inFigure4).

13

Page 14

Fuel-ShutoffValve

Closethefuel-shutoffvalvewhentransportingorstoringthe

machine.

Operation

AddingFuel

Choke

Usethechoketostartacoldengine.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

36-inchmowers:

Widthwithdeectordown118.4cm(46.6inches)

Length

Height

Weight

48-inchmowers:

Widthwithdeectordown161.3cm(63-1/2inches)

Length

Height

Weight

203.2cm(80inches)

11 1.8cm(44inches)

241kg(532lb)

198.9cm(78-3/8inches)

11 1.8cm(44inches)

259kg(570lb)

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

85%ethanol).Usingunapprovedgasolinemaycause

performanceproblemsand/orenginedamagewhichmay

notbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

14

Page 15

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

UsingFuelStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetokeepthe

fuelfreshduringstorageof90daysorless.Ifyouarestoring

themachineforlonger,drainthefueltank;refertoDraining

theFuelTank(page30).

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditionertothe

fuel,andfollowthedirectionsofthemanufacturer.

Note:Fuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Keepgasawayfromeyesandskin.

FillingtheFuelTank

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundthefuel-tankcapandremovethecap.

Addunleadedregulargasolinetothefueltank,untilthe

levelis6to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisspaceinthetankallowsgasoline

toexpand.Donotllthefueltankcompletelyfull.

3.Installthefuel-tankcapsecurely.Wipeupanygasoline

thatmayhavespilled.

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page28).

PuttingSafetyFirst

Carefullyreadallthesafetyinstructionsanddecalsinthe

safetysection.Knowingthisinformationcouldhelpyouor

anybystandersavoidinjury.

Theuseofprotectiveequipmentforeyes,hearing,feetand

headisrecommended.

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator'searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Figure6

1.Warning—wearhearingprotection.

15

Page 16

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.Beforeeachuse,checktheparkingbrake

forproperoperation.

Iftheparkingbrakedoesnotholdsecurely,adjustit.Referto

ServicingtheParkingBrake.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

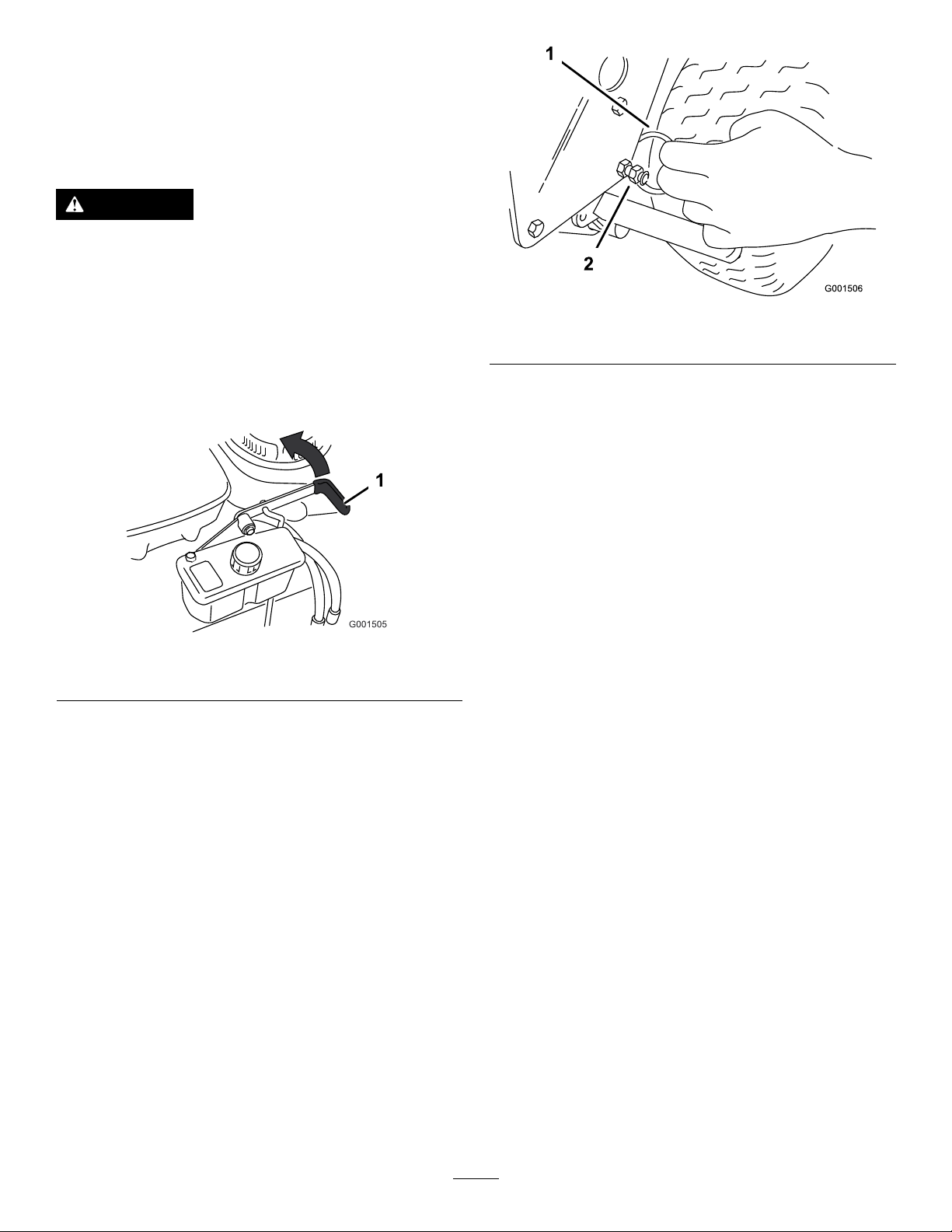

SettingtheParkingBrake

Pulltheparking-brakeleverrearward(Figure7).

Figure7

1.Parking-brakelever(inthereleasedposition)

ReleasingtheParkingBrake

Pushtheparking-brakeleverforward.

StartingandStoppingthe Engine

StartingtheEngine

1.Connectthewirestothesparkplugs.

2.Openthefuelvalve.

Note:Acold-weatherstartingkithasbeen

incorporatedtoassistenginestartingincoldweather

orwhenthemachinehasnotbeenrunforaperiod

oftime.

Tousethecold-weatherstartingkit:

•Graspthesplitring(Figure8)ontherightsideof

themachine,pulltheringandchainstraightout

fromthesideofthemachine,andhookthering

overthecontrol-shieldbolt.

Figure8

1.Splitring2.Control-shieldbolt

•Aftertheengineisstarted,pullthechainstraight

outfromthesideofthemachineuntiltheringcan

beremovedfromshieldbolt.Slowlyreleasethe

tensiononthechain.

3.Disengagetheblade-controlknob(PTO)andmove

thespeed-controllevertotheneutralposition.

4.Movethedriveleverstotheneutralpositionandset

theneutrallocks.

5.Settheparkingbrake.

6.Turntheignitionkeytotherunposition(Figure5).

7.Tostartacoldengine,movethethrottlecontrol

midwaybetweenthefastandslowpositions.

8.Tostartawarmengine,movethethrottlecontrolto

thefastposition.

9.Pullthechokeknobiftheengineiscold(Figure5).

Note:Awarmorhotengineusuallydoesnotrequire

anychoking.

10.Grasptherecoil-starthandlermlyandpullitout

untilpositiveengagementresults;thenpullthehandle

vigorouslytostarttheengine.Allowtheropetorecoil

slowly.

11.Pushthechoketotheoffpositionastheenginewarms

up(Figure9).

12.Iftheengineiscold,allowittowarmupandthen

movethethrottlecontroltothefastposition.

StoppingtheEngine

1.Movethethrottlelevertotheslowposition(Figure9).

2.Movethedriveleverstotheneutralpositionandset

theneutrallocks.

3.Disengagetheblade-controlknob(PTO)andmove

thespeed-controllevertotheneutralposition.

4.Lettheengineidlefor30to60secondsbeforeturning

theengineoff.

5.Tostoptheengine,turntheignitionkeytooff.

16

Page 17

Figure9

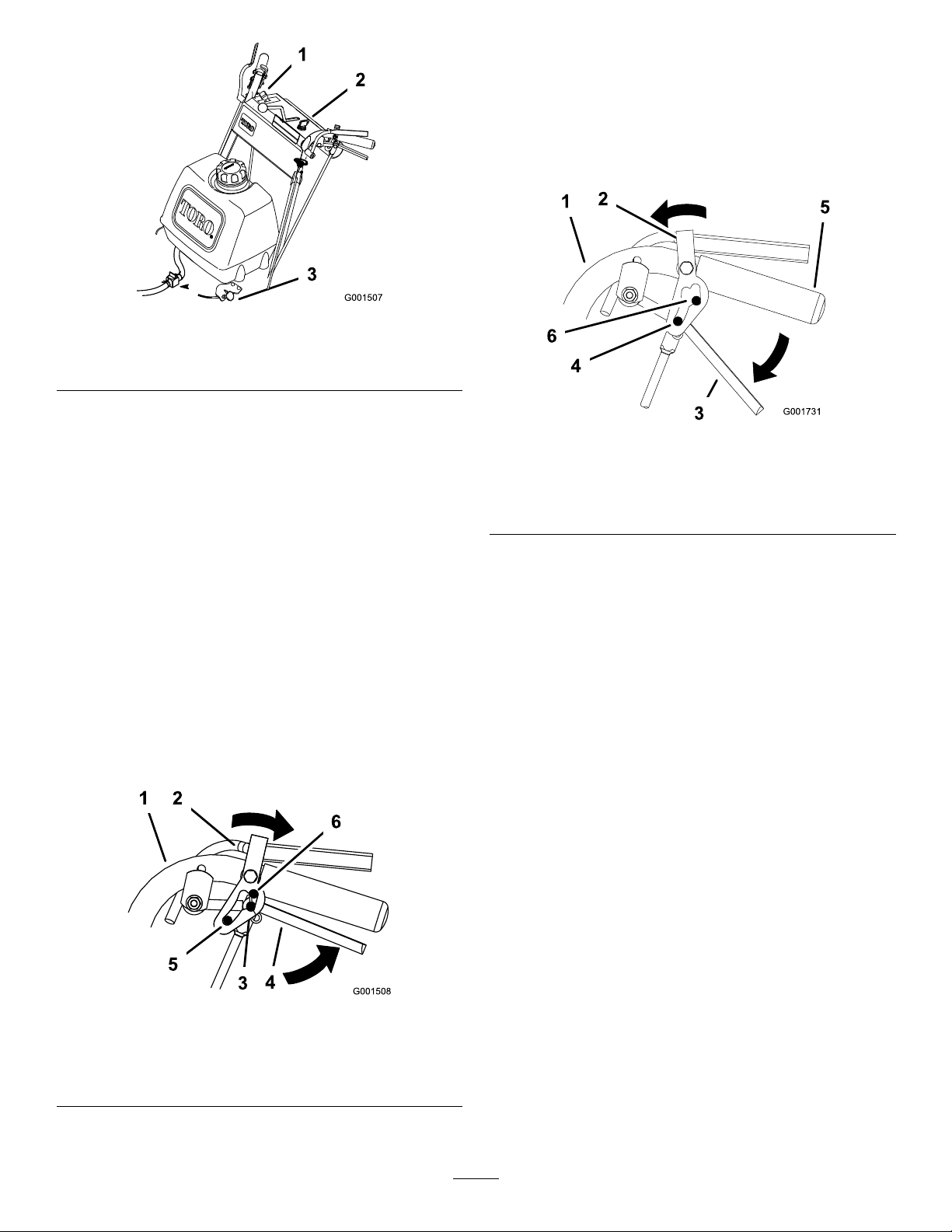

ReleasingtheNeutralLock

1.Squeezethedriveleversbackuntilanincreaseinforce

isfelt.

2.Placeyourthumbsontheupperpartofthelocksand

movethemforwarduntilthepinsareintheforward

slot(Figure11).

1.Throttlelever

2.Ignitionswitch

3.Choke

Important:Makesurethatthefuel-shutoff

valveisclosedbeforetransportingorstoringthe

machine,asfuelleakagemayoccur.Beforestoring

themachine,disconnectthewiresfromthespark

plugstopreventthepossibilityofaccidentally

startingtheengine.

OperatingtheNeutralLocks

Alwayssettheneutrallockwhenyoustopthemachine.Set

theparkingbrakeifitisleftunattended.

SettingtheNeutralLock

1.Squeezethedriveleversbackuntilanincreaseinforce

isfelt.

2.Placethumbsontheupperpartofthelocksandmove

themback(Figure10).

Figure11

1.Handle

2.Neutrallock5.Handle

3.Drivelever6.Forwardslot

4.Pininfullspeedforward

Figure10

1.Handle4.Drivelever

2.Neutrallock

3.Neutralposition6.Reverseposition

5.Fullspeedforward

17

Page 18

Operatingthe

TheSafety-InterlockSystem

Mower-Blade-ControlKnob

(PTO)

Theblade-controlknob(PTO)isusedinconjunctionwith

theOperatorPresenceControl(OPC)leverstoengageand

disengagethemowerblades.

EngagingtheMowerBlades(PTO)

1.Toengagetheblades,squeezetheOperatorPresence

Control(OPC)leversagainstthehandlegrips(Figure

12).

2.Pulltheblade-controlknob(PTO)up.HoldtheOPC

leversagainstthehandlegrip.

Note:TheenginewillstopiftheOPCleversare

releasedifthemowerisrunningandthespeed-control

leverisnotinneutral.

3.Starttheengineandrepeattheproceduretoengagethe

mowerbladesiftheoperatorpresencecontrol(OPC)

leversarereleased.

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafety-Interlock

System

Thesafetyinterlocksystemisdesignedtopreventthemower

fromstartingunless:

•Theblade-controlknob(PTO)ispushedoff.

•Thespeed-controlleverisintheNeutralposition.

Thesafetyinterlocksystemisdesignedtostoptheengine

when:

•Theoperator-presence-control(OPC)leversarereleased

withthemowerengagedand/orthespeedcontrolisout

ofneutral.

•Thespeed-controlleverisshiftedoutofneutralwithout

holdingOPCleversorwiththebrakeengaged.

•Theblade-controlknob(PTO)ispulledupwithout

holdingtheOPClevers.

Figure12

1.Throttlelever4.DriveLever

2.OperatorPresence

Controllevers(OPC)

3.Handle

5.Blade-controlknob(PTO)

DisengagingtheMowerBlades(PTO)

Themowerbladescanbedisengagedbyoneofthefollowing

steps.

1.Pushtheblade-controlknob(PTO)downtotheoff

position(Figure12).

2.ReleasingtheOperatorPresenceControl(OPC)levers

willstoptheengineandstoptheblades(Figure12)

withtheblade-controlleverengaged.

TestingtheSafety-InterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed,

haveanAuthorizedServiceDealerrepairthesafetysystem

immediately.

WARNING

Whiletestingthesafety-interlocksystem,the

machinemaymoveforwardandcausepersonal

injuryorpropertydamage.

•Performthesafety-interlocktestinanopenarea.

•Ensurethatnooneisstandinginfrontofthe

machinewhileperformingthesafety-interlock

test.

1.Settheneutrallocksandplacespeed-controlleverin

neutral.

2.Starttheengine;refertoStartingandStoppingthe

Engine.

3.WithoutholdingtheOperatorPresenceControl(OPC)

levers,pulltheblade-controlknob(PTO)up.The

engineshouldstop.

18

Page 19

4.Pushtheblade-controlknobdowntooff.

DrivingBackward

5.Withenginerunning,holddowntheOPClevers.

Pulltheblade-controlknob(PTO)up.Thedrivebelt

shouldengageandthemowerbladesshouldbegin

rotating.

6.Withenginerunning,releasetheOPClevers.The

engineshouldstop.

7.Withtheenginerunning,movethespeed-controllever

forwardslightly.ReleasetheOPClevers.Theengine

shouldstop.

8.Ifalltheaboveconditionsarenotmet,havean

AuthorizedServiceDealerrepairthesafetysystem

immediately.

DrivingtheMachineForward andBackward

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

theFastpositionforbestmowingperformance.

DrivingForward

1.Releasetheparkingbrake.

2.Togoforward,movethespeed-controllevertothe

desiredspeed.

3.Releasetheneutrallock.RefertoReleasingtheNeutral

Lock(page17).

4.Slowlyreleasethedriveleverstomoveforward(Figure

13).

Togostraight,releasethedriveleversequally(Figure

13).

Toturn,squeezethedriveleveronthesideofthe

directionwhichyouwanttoturn(Figure13).

Fromneutral,slowlysqueezethedriveleverstomove

rearward(Figure13).

BringingtheMachineto NeutralPosition

Alwayssettheneutrallockandparkingbrakewhenyoustop

themachine.

1.Squeezethedriveleverstoneutralposition.

2.Settheneutrallocks.RefertoOperatingtheNeutral

Locks(page17).

3.Movespeed-controllevertoneutralposition.

Note:Thespeed-controllevercanalsobeusedto

bringthemowertoneutralpositionandthensetthe

neutrallocks.

StoppingtheMachine

1.Tostopthemachine,squeezethedriveleverstothe

neutralpositionandengageneutrallocks.

2.Movespeed-controlleverintoneutral.

3.Stoptheengine;refertoStoppingtheEngine.

4.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.Settheparkingbrake.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

1.Drivelever

Figure13

2.Speed-controllever

PushingtheMachinebyHand

Thebypassvalvesallowthemachinetobepushedbyhand

withouttheenginerunning.

Important:Alwayspushthemachinebyhand.Never

towthemachinebecausehydraulicdamagemayoccur.

1.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

2.Openthebypassvalvesbyturningthemcounter

clockwise1to2turns.Thisallowshydraulicuidto

bypassthepumpsandthewheelstoturn(Figure14).

3.Releasetheparkingbrake.

4.Pushthemachinetothedesiredlocation.

5.Settheparkingbrake.

6.Closethebypassvalves,butdonotovertightenthem.

19

Page 20

Note:Rotatethebypassvalvesamaximumof2turns

g012676

1 2

G012677

G012678

sothevalvedoesnotcomeoutofthebodycausing

uidtorunout.

Important:Donotstartoroperatethemachine

withthebypassvalvesopen.Damagetosystem

mayoccur.

Figure14

1.Bypassvalve

PositioningtheFlowBafe

Thefollowingguresareonlyrecommendationsforuse.

Adjustmentswillvarybygrasstype,moisturecontent,and

heightofgrass.

Note:Iftheenginepowerdrawsdownandthemower

groundspeedisthesame,openupthebafe.

PositionA

Thisisthefullrearposition(seeFigure16).Thesuggested

useforthispositionisafollows:

•Useforshort,lightgrassmowingconditions.

•Useindryconditions.

•Forsmallergrassclippings.

•Propelsgrassclippingsfartherawayfromthemower.

AdjustingtheFlowBafe

Themowerdischargeowcanbeadjustedfordifferenttypes

ofmowingconditions.Positionthecamlockandbafeto

givethebestqualityofcut.

1.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Toadjustthebafe,loosenthenut(Figure15).

4.Adjustthebafeandnutintheslottothedesired

dischargeowandtightenthenut.

Figure16

PositionB

Usethispositionwhenbagging(Figure17).

Figure15

2.Nut

Figure17

20

1.Slot

Page 21

PositionC

G012679

SideDischargingorMulching

Thisisthefullopenposition.Thesuggesteduseforthis

positionisasfollows(Figure18):

•Useintall,densegrassmowingconditions.

•Useinwetconditions.

•Lowerstheenginepowerconsumption.

•Allowsincreasedgroundspeedinheavyconditions.

Figure18

theGrass

Thismowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutthegrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately .

•Neverputyourhandsorfeetunderthemower.

•Nevertrytocleardischargeareaormower

bladesunlessyoureleasethebailandthepower

takeoff(PTO)isoff.Rotatetheignitionkeyto

Off.Alsoremovethekeyandpullthewireoff

thesparkplug(s).

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarylightingand

markingasrequiredbylaw.Pleasecarefullyreadallthesafety

instructions.Knowingthisinformationcouldhelpyou,your

family,petsorbystandersavoidinjury.

1.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

2.Securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes.

3.Secureatrailertotowingvehiclewithsafetychains.

4.Ifapplicable,connectthetrailerbrakes.

AdjustingtheHeight-of-Cut

Thismachinehasa26to108mm(1to4-1/4inch)rangefor

theheightofcut.Thiscanbeachievedbyadjustingblade

spacers,rearaxleheight,andfrontcasterspacers.Usethe

Height-of-CutCharttoselectthecombinationofadjustments

required.

AdjustingtheBladeHeight

Adjustthebladesbyusingthe4spacers(6mm)(1/4inch)

onthebladespindlebolts.Thisallowsfora25mm(1inch)

adjustmentrange,in6mm(1/4inch)increments,ofcutting

heightinanyaxleposition.Usethesamenumberofblade

spacersonallbladestoachievealevelcut(2aboveand

2below ,1aboveand3below,etc.).

1.DisengagethePTOandpullthethrottletotheslow

position.

2.Turntheignitionswitchtooff.

3.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.Settheparkingbrake.

4.Holdthebladeboltandremovethenut.Slidethebolt

downthroughthespindle,andchangethespacersas

needed(Figure19).

21

Page 22

Figure20

1.Topaxlebolt2.Loweraxlebolt

7.Raiseorlowerthemountingbracketsothatyoucan

installthe2axleadjustmentboltsinthedesiredhole

location(Figure20).

Note:Useataperedpunchtohelpaligntheholes.

8.Tightenall4bolts.

9.Installthedrivewheelsandlowerthemachine.

Figure19

1.Blade

2.Bladebolt5.Thinwasher

3.Curvedwasher

4.Spacer

6.Nut

5.Installthebolt,thecurvedwasher,andtheblade;add

extraspacers,andsecurethemwithathinwasheranda

nut(Figure19).

6.Torquethebladeboltto101to108N-m(75to

80ft-lb).

AdjustingtheAxleHeight

Adjusttheaxlepositiontotheselectedheight-of-cutsetting.

1.DisengagethePTOandpullthethrottletothestop

position.

2.Waitforallmovingpartstostopbeforeleavingthe

operatingposition,andthensettheparkingbrake.

3.Placeajackundertherearcenteroftheengineframe.

Raisethebackendoftheengineframeupenoughto

removethedrivewheels.

4.Removethedrivewheels.

5.Loosen,butdonotremove,the2topaxlebolts(Figure

20).

6.Removethe2loweraxlebolts(Figure20).

AdjustingtheCasterPosition

1.UsingtheHeight-of-CutChart(page24),adjustthe

casterspacerstomatchwiththeaxleholeselected

(Figure21).

Figure21

1.Latchpin

2.Spacer,5mm(3/16inch)

2.Removethelatchpin,slidethecasterfromthesupport,

andchangethespacers(Figure21).

3.Installthecasterinthesupportandinsertthelatchpin

(Figure21).

3.Spacer,13mm(1/2inch)

22

Page 23

AdjustingtheHandleHeight

Thehandlepositioncanbeadjustedtomatchtheoperator's

heightpreference.

1.Removethehairpincotterpinsandclevispinsfrom

thedriveleversandneutrallocks(Figure22).

Figure23

Figure22

1.Controlrod5.Lefthandle

2.Clevispin

3.Drivelever7.Hairpincotter

4.Operator-presence-control

(OPC)lever

6.Neutrallock

2.Loosentheupperangebolts(3/8x1-1/4inch)and

angenutsecuringhandletorearframe(Figure23).

3.Removethelowerangebolts(3/8x1inch)andange

nutssecuringhandletorearframe(Figure23).

4.Pivotthehandletothedesiredoperatingpositionand

installthelowerangebolts(3/8x1inch)andange

nutsintothemountingholes.Tightenalltheange

bolts.

1.Controlrodtting

2.Lowermountingholes7.Lowerposition

3.Rearframe

4.Lowerangebolt(3/8x1

inch)

5.Upperangebolt(3/8x

1-1/4inches)

6.Highposition

8.Uppermountinghole

9.Handle

10.Flangenut(3/8inch)

5.Adjustthecontrolrodlengthbyrotatingthecontrol

rodintherodtting(Figure23).

6.Installthehairpincotterbetweenthedriveleversand

theneutrallocksandintotheclevispins(Figure22).

Note:Makesurethattheclevispinsareinsertedinto

theneutrallocks.

7.Performthehydrauliclinkageadjustmentswhenthe

handleheightischanged;referHydraulicLinkage

Adjustments.

23

Page 24

Height-of-CutChart

Numberofspacersbelow

Axle

position

A00

A01

A10

B01

B10

B11

B20

C

C

C

C

D21

D30

D31

D40

E31

E40

E41

thecaster

13mm

(1/2inch)

11

20

21

30

Numberof1/4inchbladespacersbelowthespindle

5mm

(3/16inch)

43210

26mm

(1inch)

29mm

(1-1/8inch)

35mm

(1-3/8inch)

35mm

(1-3/8inch)

41mm

(1-5/8inch)

45mm

(1-3/4inch)

51mm

(2inch)

48mm

(1-7/8inch)

55mm

(2-1/8inch)

57mm

(2-1/4inch)

64mm

(2-1/2inch)

61mm

(2-3/8inch)

64mm

(2-1/2inch)

70mm

(2-3/4inch)

76mm

(3inch)

73mm

(2-7/8inch)

79mm

(3-1/8inch)

82mm

(3-1/4inch)

32mm

(1-1/4inch)

35mm

(1-3/8inch)

41mm

(1-5/8inch)

41mm

(1-5/8inch)

48mm

(1-7/8inch)

51mm

(2inch)

57mm

(2-1/4inch)

54mm

(2-1/8inch)

60mm

(2-3/8inch)

64mm

(2-1/2inch)

70mm

(2-3/4inch)

67mm

(2-5/8inch)

70mm

(2-3/4inch)

76mm

(3inch)

82mm

(3-1/4inch)

79mm

(3-1/8inch)

86mm

(3-3/8inch)

89mm

(3-1/2inch)

38mm

(1-1/2inch)

41mm

(1-5/8inch)

48mm

(1-7/8inch)

48mm

(1-7/8inch)

54mm

(2-1/8inch)

57mm

(2-1/4inch)

64mm

(2-1/2inch)

60mm

(2-3/8inch)

67mm

(2-5/8inch)

70mm

(2-3/4inch)

76mm

(3inch)

73mm

(2-7/8inch)

76mm

(3inch)

82mm

(3-1/4inch)

89mm

(3-1/2inch)

86mm

(3-3/8inch)

92mm

(3-5/8inch)

95mm

(3-3/4inch)

45mm

(1-3/4inch)

48mm

(1-7/8inch)

54mm

(2-1/8inch)

54mm

(2-1/8inch)

60mm

(2-3/8inch)

64mm

(2-1/2inch)

70mm

(2-3/4inch)

67mm

(2-5/8inch)

73mm

(2-7/8inch)

76mm

(3inch)

83mm

(3-1/4inch)

79mm

(3-1/8inch)

82mm

(3-1/4inch)

89mm

(3-1/2inch)

95mm

(3-3/4inch)

92mm

(3-5/8inch)

98mm

(3-7/8inch)

102mm

(4inch)

51mm

(2inch)

54mm

(2-1/8inch)

60mm

(2-3/8inch)

60mm

(2-3/8inch)

67mm

(2-5/8inch)

70mm

(2-3/4inch)

76mm

(3inch)

73mm

(2-7/8inch)

79mm

(3-1/8inch)

83mm

(3-1/4inch)

89mm

(3-1/2inch)

86mm

(3-3/8inch)

89mm

(3-1/2inch)

95mm

(3-3/4inch)

102mm

(4inch)

98mm

(3-7/8inch)

105mm

(4-1/8inch)

108mm

(4-1/4inch)

24

Page 25

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst25hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthemowerbelttension.

•Checkthehydraulicuidlevel.

•Changethehydrauliclter.

•Checkthemowerbelttension.

•Checkthesafetysystem.

•Greasethecasterwheelsandthecasterpivots.

•Checktheengineoillevel.

•Cleantheair-intakescreen.

•Inspecttheblades.

•Cleanthemowerdeck.

•Cleanthefoamair-cleanerelement.

•Checkthehydraulicuidlevel.

•Greasethemower-beltidler.

•Greasethepump-drive-idlerpivot.

•Greasethepumpcontrol.

•Checkthepaperair-cleanerelement.

•Checkthetirepressure.

•Checkthebelts.

•Checkthemowerbelttension.

•Greasethebladeengagementbellcrank.

•Changetheengineoil.

•Checkthesparkplugs.

•Checkandcleantheengine-coolingnsandshrouds.

•Checkthehydraulichoses.

•Replacethepaperair-cleanerelement.

•Changetheoillter.

Every200hours

Every400hours

Beforestorage

•Replacethefuellter.

•Replacethefuel-ventlter.

•Changethehydrauliclter.

•Lubricatethecamlockwithanti-seizecompound.

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthesparkplugwirefromthesparkplug(s)beforeyoudo

anymaintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

25

Page 26

Lubrication

GreasingthePumpControl

UseFigure24forlocatingthegreasepointsonthemachine.

GreaseType:#2general-purposelithium-basedor

molybdenum-basedgrease

LubricatingtheMachine

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanthegreasettingswitharag.Makesuretoscrape

anypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutofthe

bearings.

5.Wipeupanyexcessgrease.

LubricatingtheCasterand WheelBearings

ServiceInterval:Beforeeachuseordaily—Greasethecaster

wheelsandthecasterpivots.

andtheBellCrank

ServiceInterval:Every50hours—Greasethe

pump-drive-idlerpivot.

Every50hours—Greasethepumpcontrol.

Every100hours—Greasethebladeengagement

bellcrank.

Every400hours—Lubricatethecamlockwith

anti-seizecompound.

Greasethettingonthepumpdriveidlerpivotandthe

pumpcontrol.

Greasethebladeengagement(PTO)bellcrank(Figure24).

Lubricatethefrontwheelbearingsandthefrontspindles.

GreasingtheMower-BeltIdler

ServiceInterval:Every50hours—Greasethemower-belt

idler.

Greasethettingonthemower-belt-idlerarmpivot(Figure

24).

Note:Removethemower-deckcovertoaccessthegrease

ttingforthemower-belt-idlerarm.

Figure24

48-inchmowerdeckshown

1.Pump-drive-idlerarm4.Mower-belt-idlerarm

2.Pump-controlarm

3.Bellcrank

5.Caster-wheelbearing

6.Casterpivot

26

Page 27

EngineMaintenance

ServicingtheAirCleaner

CleaningtheFoamAir-CleanerElement

1.Washthefoamelementinliquidsoapandwarmwater.

Whentheelementisclean,rinseitthoroughly .

2.Drytheelementbysqueezingitinacleancloth.

ServiceInterval/Specication

ServiceInterval:Every25hours—Cleanthefoam

air-cleanerelement.

Every50hours—Checkthepaperair-cleanerelement.

Every200hours—Replacethepaperair-cleaner

element.

Note:Servicetheaircleanermorefrequently(everyfew

operatinghours)iftheoperatingconditionsareextremely

dustyorsandy .

Important:Donotoilthefoamorpaperelement.

RemovingtheFoamandPaper

Elements

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage(Figure25).

4.Unscrewthecoverknobsandremovetheair-cleaner

cover(Figure25).

Important:Replacethefoamelementifitistorn

orworn.

ServicingthePaperAir-Cleaner

Element

1.Donotcleanthepaperlter,replaceit(Figure25).

2.Inspecttheelementfortears,anoilylm,ordamageto

therubberseal.

3.Replacethepaperelementifitisdamaged.

InstallingtheFoamandPaperElements

Important:Topreventenginedamage,alwaysoperate

theenginewiththecompletefoamandpaperaircleaner

assemblyinstalled.

1.Carefullyslidethefoamelementontothepaper

air-cleanerelement(Figure25).

2.Placetheaircleanerassemblyontotheaircleanerbase

andsecureitwiththe2wingnuts(Figure25).

3.Placetheair-cleanercoverintopositionandtighten

thecoverknob(Figure25).

5.Unscrewthehoseclampandremovetheaircleaner

assembly(Figure25).

6.Carefullypullthefoamelementoffthepaperelement

(Figure25).

Figure25

1.Cover

2.Hoseclamp4.Foamelement

3.Paperelement

ServicingtheEngineOil

ServiceInterval:Beforeeachuseordaily—Checktheengine

oillevel.

Aftertherst8hours—Changetheengineoil.

Every100hours—Changetheengineoil.

Every200hours—Changetheoillter.

Note:Changetheoilmorefrequentlywhentheoperating

conditionsareextremelydustyorsandy.

OilType:Detergentoil(APIserviceSF,SG,SH,SJorSL)

CrankcaseCapacity:1.7L(1.8USqt)withthelter

removed;1.5L(1.6USqt)withoutthelterremoved

Viscosity:Refertothetable(Figure26).

27

Page 28

ChangingtheEngineOil

1.Parkthemachinesothatthedrainsideisslightlylower

thantheoppositesidetoensurethattheoildrains

completely.

2.DisengagethePTOandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Slidethedrainhoseovertheoildrainvalve.

5.Placeapanbelowthedrainhose.Rotateoildrainvalve

toallowoiltodrain(Figure28).

Figure26

CheckingtheEngine-OilLevel

1.Parkthemachineonalevelsurface.

2.DisengagethePTOandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Cleanaroundtheoildipstick(Figure27)sothatdirt

cannotfallintothellerholeanddamagetheengine.

6.Whenoilhasdrainedcompletely,closethedrainvalve.

7.Removethedrainhose(Figure28).

Note:Disposeoftheusedoilatarecyclingcenter.

Figure27

1.Oildipstick

2.Fillertube

5.Unscrewtheoildipstickandwipetheendclean(Figure

27).

6.Slidetheoildipstickfullyintothellertube,butdonot

threaditontothetube(Figure27).

7.Pullthedipstickoutandlookattheend.Iftheoillevel

islow,slowlypouronlyenoughoilintothellertube

toraisetheleveltotheFullmark.

Important:Donotoverllthecrankcasewithoil

andruntheengine;enginedamagecanresult.

Figure28

1.Oil-drainvalve2.Oil-drainhose

8.Slowlypourapproximately80%ofthespeciedoil

intothellertube(Figure27).

9.Checktheoillevel;refertoCheckingtheEngine-Oil

Level(page28).

10.SlowlyaddtheadditionaloiltobringittotheFull

mark.

ChangingtheOilFilter

Note:Changetheoilltermorefrequentlywhenthe

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil(page28).

2.Removetheoldlter(Figure29).

28

Page 29

Figure29

1

1.Oillter

2.Adapter

3.Applyathincoatofnewoiltotherubbergasketon

thereplacementlter(Figure29).

4.Installthereplacementoilltertothelteradapter,

turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional3/4turn(Figure29).

5.Fillthecrankcasewiththepropertypeofnewoil;refer

toServicingtheEngineOil(page27).

6.Runtheengineforabout3minutes,stoptheengine,

andcheckforoilleaksaroundtheoillteranddrain

valve.

7.Checktheengineoillevelandaddoilifneeded.

8.Wipeupanyspilledoil.

ServicingtheSparkPlugs

ServiceInterval:Every100hours—Checkthesparkplugs.

Ensurethattheairgapbetweenthecenterelectrodeandthe

sideelectrodeiscorrectbeforeinstallingeachsparkplug.Use

aspark-plugwrenchforremovingandinstallingthespark

plugsandagappingtoolorafeelergaugetocheckandadjust

theairgap.Installnewsparkplugsifnecessary.

Figure30

1.Spark-plugwire/sparkplug

4.Cleanaroundthesparkplugstopreventdirtfrom

fallingintotheengineandpotentiallycausingdamage.

5.Removethesparkplugsandthemetalwashers.

CheckingtheSparkPlugs

1.Lookatthecenterofthesparkplugs(Figure31).If

youseelightbrownorgrayontheinsulator,theengine

isoperatingproperly.Ablackcoatingontheinsulator

usuallymeansthattheaircleanerisdirty.

2.Ifneeded,cleanthesparkplugwithawirebrushto

removecarbondeposits.

Type:Champion®RCJ8Yorequivalent

AirGap:0.75mm(0.030inch)

RemovingtheSparkPlugs

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Disconnectthewiresfromthesparkplugs(Figure30).

Figure31

1.Centerelectrode;insulator3.Airgap(nottoscale)

2.Sideelectrode

Important:Alwaysreplacethesparkplugswhen

theyhavewornelectrodes,anoilylm,ora

crackedinsulator.

3.Checkthegapbetweenthecenterelectrodeandthe

sideelectrode(Figure31).Bendthesideelectrode

(Figure31)ifthegapisnotcorrect.

29

Page 30

InstallingtheSparkPlugs

1.Installthesparkplugsandthemetalwasher.Ensure

thattheairgapissetcorrectly.

2.Tightenthesparkplugsto22N-m(16ft-lb).

3.Connectthewirestothesparkplugs(Figure31).

FuelSystem

Maintenance

ServicingtheFuelTank

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

DrainingtheFuelTank

1.Parkthemachineonalevelsurface,toassurefueltank

drainscompletely .Thendisengagethepowertakeoff

(PTO),settheparkingbrake,andturntheignitionkey

tooff.Removethekey .

2.Closethefuelshut-offvalveatthefueltank(Figure32).

3.Squeezetheendsofthehoseclamptogetherandslide

itupthefuellineawayfromfuellter(Figure32).

4.Pullthefuellineoffthefuellter(Figure32).Open

thefuelshut-offvalveandallowthegasolinetodrain

intoagascanordrainpan.

Note:Nowisthebesttimetoinstallanewfuellter

becausethefueltankisempty.RefertoReplacingthe

FuelFilter.

5.Installthefuellineontothefuellter.Slidethehose

clampclosetothevalvetosecurethefuelline.

1.Fuel-shutoffvalve2.Clamp

30

Figure32

Page 31

ServicingtheFuelFilter

g014686

1 2

ServiceInterval:Every200hours/Yearly(whichevercomes

rst)

ReplacingtheFuelFilter

Neverinstalladirtylterifitisremovedfromthefuelline.

Note:Notehowthefuellterisinstalledinordertoinstall

thenewltercorrectly.

Note:Wipeupanyspilledfuel.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Closefuelshut-offvalveatthefueltank(Figure32).

4.Installanewlter.

4.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure33).

Figure33

1.Hoseclamp3.Filter

2.Fuelline

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclampscloseto

thelter.

Figure34

1.Fuel-ventlter2.Rightsideofmotor

7.Openfuelshut-offvalveatfueltank(Figure32).

8.Checkforfuelleaksandrepairifneeded.

9.Wipeupanyspilledfuel.

ServicingtheFuel-Vent System

ServiceInterval:Every200hours/Yearly(whichevercomes

rst)

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removetheexistingfuel-ventlter(Figure34).

31

Page 32

DriveSystem

Maintenance

Performthefollowinglinkageadjustmentswhenthemachine

needsmaintenance.PerformthestepsAdjusttheSpeed

ControlLinkagethroughAdjustingtheTracking.Ifany

adjustmentsareneeded,dothemintheorderthattheyare

listed.

AdjustingtheSpeed-Control Linkage

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Movethespeed-controllever(locatedontheconsole)

tothefullforwardposition.

4.Checktheorientationofthetabsontheendsofthe

speed-controlcrank.Thesetabsshouldbepointing

straightdownatthe6o'clockpositionapproximately

(Figure35).

8.Ifneeded,adjusttheswitchlocationtocreatethe8mm

(5/16inch)space(Figure36).

5.Adjustthethreadedyokeatthebottomofthespeed

controllinkageuntilthetabsareatthe6o'clock

position(Figure35).

Figure35

1.Speed-controlrod

2.Yoke5.Jamnut

3.Speed-controlcrank

4.Tabs,6o'clockposition

Figure36

1.Actuatingtab

2.8mm(5/16inch)space

3.Safetyswitch

AdjustingtheNeutralControl Linkages

WARNING

Enginemustberunningsothatcontrollinkage

adjustmentscanbeperformed.Contactwith

movingpartsorhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothing,andotherbody

partsawayfromrotatingparts,themufer,and

otherhotsurfaces.

WARNING

Mechanicalorhydraulicjacksmayfailtosupport

machineandcauseaseriousinjury.

6.Pullthespeed-controlleverbacktoneutral.

7.Checktomakesurethatthesafetyswitchispressed

andthereisa8mm(5/16inch)spacebetweenthe

actuatingtabandtheswitch.(Figure36).

•Usejackstandswhensupportingmachine.

•Donotusehydraulicjacks.

1.DisengagethePTOandsettheparkingbrake.

32

Page 33

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Raisetherearofthemachineontojackstandstoraise

thedrivewheelsofftheground.

4.Disengagetheparkingbrake.

5.Starttheengineandmovethethrottleaheadtothefull

throttleposition.

6.Placetheneutrallocksinthefullforwardpositionand

movethespeed-controllevertothemediumspeed

position.

7.HoldtheOPCleversdown.

Note:HoldtheOPCleversdownwheneverthe

speed-controlleverisoutoftheNeutralposition;

otherwise,theenginewillstop.

WARNING

Electricalsystemwillnotperformpropersafety

shutoffwiththeoperator-presence-control

(OPC)levershelddowninplace.

Figure37

1.Neutralcontrollinkage3.Adjustingbolt

2.Yoke4.Nut

AdjustingtheHydroControl

•MakesurethattheOPCleversareworking

whenadjustmentiscompleted.

•NeveroperatethismachinewiththeOPC

levershelddowninplace.

8.Squeezeonedriveleveruntilanincreasedresistanceis

felt.Thisiswhereneutralshouldbe.

Note:Makesureyouhavenotreachedtheendofthe

neutrallockslot.Ifyouhave,shortenthecontrollever

linkage.RefertoAdjustingtheControlRod(page35).

9.Ifthewheelturnswhileholdingthedriveleverin

neutral,theneutralcontrollinkagesneedtobeadjusted

(Figure37).Ifwheelstopsthengotostep12.

10.Loosenthenutagainsttheneutralcontrollinkageyoke

(Figure37).

11.Adjusttheneutralcontrollinkageuntiltherespective

drivewheelstopswhilethedriveleverispulledagainst

theneutralspring(Neutralposition)(Figure37).

12.Turntheadjustingboltapproximately1/4turn

clockwiseifthewheelisturninginreverseorturnthe

boltapproximately1/4turncounter-clockwiseifthe

wheelisturningforward(Figure37).

13.Releasethedrivelevertotheforwarddriveposition

andsqueezebackintotheneutralposition.Check

toseeifthewheelstops.Ifnot,repeattheabove

adjustmentprocedure.

Linkages

WARNING

Theenginemustberunningsothatthecontrol

linkageadjustmentscanbeperformed.Contact

withmovingpartsorhotsurfacesmaycause

personalinjury.

Keephands,feet,face,clothingandotherbody

partsawayfromrotatingparts,mufer,andother

hotsurfaces.

WARNING

Mechanicalorhydraulicjacksmayfailtosupport

machineandcauseaseriousinjury.

•Usejackstandswhensupportingmachine.

•Donotusehydraulicjacks.

AdjustingtheLeftLinkage

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Raisetherearofthemachineontojackstandshigh

enoughtoraisethedrivewheelsofftheground.

14.Afteradjustmentsaremade,tightenthenutsagainst

theyokes.

15.Repeatthisprocedurefortheoppositeside.

4.Disengagetheparkingbrake.

5.Starttheengineandmovethethrottleaheadtothefull

throttleposition.

33

Page 34

6.Placetheleftdriveleverinthefullforwardposition.

1

1

2

4

3

4

5

G024291

7.Placethespeed-controlleverintheNeutralposition.

Note:TheOPCleversmustbehelddownwhenever

thespeed-controlleverisoutoftheneutralpositionor

theenginewillstop.

WARNING

Electricalsystemwillnotperformproper

safetyshutoffwithOperatorPresenceControl

(OPC)leversheldinplace.

•MakesurethattheOPCleversareworking

whenadjustmentiscompleted.

•NeveroperatethismachinewiththeOPC

leversheldinplace.

8.Loosenthefrontadjustingnutonlefthydrocontrol

linkageasshowninFigure39.

9.Turntheleftrearadjustingnutcounterclockwiseuntil

thewheelrotatesforward(Figure39).

10.Turntherearadjustingnutclockwise1/4ofaturnata

time.Thenmovethespeed-controlleverforwardand

backtotheNeutralposition.Repeatthisuntiltheleft

wheelstopsrotatingforward(Figure39).

11.Turntherearnutanadditional1/2turnandtightenthe

frontadjustingnut.

Note:Makesurethattheatpartofthelinkageis

perpendiculartothepinpartoftheswivel.

14.Makesurethatthespeed-controlleverisintheneutral

positionandthetiredoesnotrotate.

15.Repeattheadjustmentifneeded.

Figure39

1.Hydrocontrollinkage3.Rearadjustingnut

2.Frontadjustingnut

4.Controlarm

Note:Ifinconsistentneutraloccurs,checktobe

surethatbothspringsareproperlytightenedonthe

speed-controlleverundertheconsole,especiallythe

rearpivotspring.Repeattheaboveadjustmentsif

necessary(Figure40).

1.Hydrocontrollinkage

2.Frontnut5.90degrees

3.Rearnut

12.Afteradjustingthelefthydrocontrollinkage,move

Figure38

4.Swivel

thespeed-controlleverforwardandthenbacktothe

neutralposition.

13.HoldtheOPCleversdown.

Figure40

1.Speed-controllever

2.Rearpivotspring

3.spring

AdjustingtheRightLinkage

1.Placethespeed-controlleverintheneutralposition.

2.Placetherightdriveleverinthefullforwardposition.

3.Adjusttherightlinkagebyturningthequicktrackknob

counterclockwiseuntilthetirebeginstorotateforward

(Figure41).

34

Page 35

4.Turntheknobclockwise1/4ofaturnatatime.Then

movethespeed-controlforwardandbacktoneutral.

Repeatthisuntiltherightwheelstopsrotatingforward

(Figure41).

5.HoldtheOPCleversdown.

Note:TheOPCleversmustbehelddownwhenever

thespeed-controlleverisoutoftheNeutralposition

ortheenginewillstop.

6.Thespringthatkeepstensionontheknobshould

normallynotneedadjustment.Howeverifan

adjustmentisneeded,adjustthelengthofthespringto

26mm(1inch)betweenthewashers(Figure41).

7.Adjustthespringlengthbyturningthenutatthefront

ofspring(Figure41).

AdjustingtheControlRod

1.Adjusttherodlengthbyreleasingthedriveleverand

removingthehairpincotterpinandclevispin.Rotate

therodintherodtting(Figure42).

2.Lengthenthecontrolrodifthetireisturninginreverse

andshortentherodifthetireisturningforward.

3.Rotatetherodseveralturnsifthetireisrotatingfast.

Then,adjusttherodin1/2turnincrements.

4.Placetheclevispinintothedrivelever(Figure42).

Figure41

1.Hydrocontrollinkage

2.Quicktrackknob4.26mm(1inch)

3.Spring

AdjustingtheControlRod

CheckingtheControlRod

1.Withtherearofthemachinestillonjackstandsandthe

enginerunningatfullthrottle,movethespeed-control

levertothemediumspeedposition.

Note:TheOPCleversmustbehelddownwhenever

thespeed-controlleverisoutoftheneutralposition,or

theenginewillstop.

Figure42

1.Controlrod5.Lefthandleshown

2.Clevispin

3.Drivelever7.Hairpincotterpin

4.Operator-presence-control

lever(OPC)

6.Neutrallock

5.Releaseandengagetheneutrallock,checkingthatthe

tiredoesnotrotate(Figure43).Continuethisprocess

untilthetiredoesnotrotate.

6.Installthehairpincotterpinbetweenthedrivelevers

andtheneutrallocksandintotheclevispins(Figure

42).

7.Repeatthisadjustmentfortheoppositeside.

2.Movetherespectivedriveleverupwarduntilitreaches

theneutralpositionandengagetheneutrallocks.

3.Ifthetirerotatesineitherdirection,thelengthofthe

controlrodwillneedtobeadjusted.

35

Page 36

Figure43

1.Handle5.Neutralposition

2.Neutrallock6.Drivelever

3.Handle

4.Neutral-lockslot

7.Fullspeedforward

8.Controlrod

AdjustingtheTracking

1.Removethemachinefromanyjackstands.

2.Checkthereartirepressure.RefertoCheckingtheTire

Pressure(page37).

3.Runthemachineandobservethetrackingonalevel,

smooth,hardsurfacesuchasconcreteorasphalt.

4.Ifthemachinetrackstoonesideortheother,turnthe

quicktrackknob.Turntheknobrighttosteerright

andturntheknoblefttosteerleft(Figure44).

Figure44

1.Quicktrackknob

AdjustingtheSpringAnchor Links

Formedium-dutyorheavy-dutydriveconditions,suchas

operatingwithasulkyonsteepslopes,ahigherspringforce

mayberequiredonthehydropumpcontrolarmstoprevent

thedrivesystemfromstalling.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

36

Page 37

3.Foraheavierdrivesetting,relocatethespringanchor

linkstoeitherthemediumorheavydutypositions

(Figure45).Thespringanchorlinksareattachedtothe

upperrearcornerofthehydrodriveshieldsontheleft

andrightsidesofthemachine.

CoolingSystem

Maintenance

Note:Inthemedium-dutyorheavy-dutypositions,

thedriveleverforcesattheupperhandlewillalsobe

increased

Figure45

1.Springanchor

2.Standardsetting

3.Mediumsetting

4.Heavy-dutysetting

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)—Checkthetirepressure.

CleaningtheAir-IntakeScreen

Beforeeachuse,removeanybuildupofgrass,dirt,or

otherdebrisfromthecylinderandcylinder-headcooling

ns,theair-intakescreenontheywheelend,andthe

carburetor-governorleversandlinkage.Thiswillhelpensure

adequatecoolingandcorrectenginespeedandwillreduce

thepossibilityofoverheatingandmechanicaldamagetothe

engine.

CleaningtheCoolingSystem

ServiceInterval:Every100hours/Yearly(whichevercomes

rst)

Cleantheairintakescreenfromgrassanddebrisbeforeeach

use.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removetheair-intakescreen,therecoilstarter,and

thefanhousing(Figure47).

4.Cleanthedebrisandgrassfromtheengineparts.

5.Installtheair-intakescreen,therecoilstarter,andthe

fanhousing(Figure47).

Checkthepressureatthevalvestem(Figure46).

Maintaintheairpressureinthereartiresat83to97kPa(12

to14psi).Uneventirepressurecancauseanunevencut.

Note:Thefronttiresaresemi-pneumatictiresanddonot

requireairpressuremaintenance.

Figure46

Figure47

1.Air-intakescreen4.Bolt

2.Fanhousing5.Nut

3.Recoilstarter

37

Page 38

BrakeMaintenance

yokecounterclockwiseoutoftheyokeouttoloosen

theparkingbrake(Figure48).

ServicingtheBrake

Beforeeachuse,checktheparkingbrakeforproperoperation.

Alwayssettheparkingbrakewhenyoustopthemachine

orleaveitunattended.Iftheparkingbrakedoesnothold

securely,adjustit.

CheckingtheParkingBrake

1.Movethemachineontoalevelsurface.

2.Disengagethepowertake-off(PTO)andstopthe

engine.

3.Settheparkingbrake.

Note:Settingtheparkingbrakeshouldtakea

reasonableamountofforce.Ifitengagestoohardor

tooeasily,anadjustmentisrequired.RefertoAdjusting

theParkingBrake(page38).

AdjustingtheParkingBrake

Theparkingbrakeleverisontherightsideofthemachine

(Figure45).Iftheparkingbrakedoesnotholdsecurely,

adjustit.

Note:Thereshouldbeapproximately6mm(1/4inch)

clearancebetweenthetireandtheatbarwiththe

parkingbrakeinthereleasedposition(Figure48).

5.Securethelowerlinktothelowerbrakeleverwiththe

hairpincotterandtheclevispin(Figure48).

6.Checkthebrakeoperationagain;refertoCheckingthe

ParkingBrake(page38).

1.Checktheparkingbrakebeforeyouadjustit;referto

CheckingtheParkingBrake(page38).

2.Releasetheparkingbrake;refertoReleasingthe

ParkingBrake(page16).

3.Removethespringclevispinfromthelowerbrakelink

(Figure48).

Figure48

1.Brakelinkageyoke4.Lowerbrakelink

2.Lowerbrakelever

3.Springclevispin

5.6mm(1/4inch)

6.Hairpincotter

4.Rotatethelowerbrakelinkyokeclockwiseintothe

yoketotightentheparkingbrake;rotatethebrakelink

38

Page 39

BeltMaintenance

10.Removethehairpincotterpinandtheclevispinfrom

thebellcrank.

CheckingtheBelts

ServiceInterval:Every50hours/Monthly(whichever

comesrst)—Checkthebelts.

Checkthebeltsforcracks,frayededges,burnmarks,wear,

signsofoverheating,oranyotherdamage.Replaceany

damagedbelts.

ReplacingtheMowerBelt

Important:Adjustthebrakewheneveryouadjustthe

belttensionorthebrakelinkage.

1.Disengagetheblade-control(PTO)leverandsetthe

parkingbrakes.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Removetheknobsandthebeltcoveronthemower.

4.Removetheidlerpulleyandthewornbelt.

5.Installthenewmowerbelt.

6.Installtheidlerpulley.

11.Rotatetheclevisclockwiseontherodtoincreasethe

clearance;rotateitcounterclockwisetodecreaseit

(Figure49).

12.Disengagetheblade-control(PTO)lever.

Note:Iftheassistarmdoesnotcontactthefrontstop

onthemowerdeck(Figure50orFigure51),adjustthe

clevistobringthebellcrankclosertothetransmission

outputshaft(Figure49).

7.Engagetheblade-control(PTO)leverandcheck

thebelttension.RefertoAdjustingtheMowerBelt

Tension(page40).

Note:Thepropermowerbelttensionis44to67N-m

(10to15ft-lb)withthebeltdeected13mm(1/2inch)

halfwaybetweenthepulleys(Figure50orFigure51).

8.Engagetheblade-control(PTO)lever.

9.Checktheclearancebetweenthebellcrankandthe

transmissionoutputshaft(Figure49).

Figure49

Figure50

36-inchmowerdeck

1.13mm(1/2inch)deection

here

2.Assistarm5.Turnbuckle

3.Frontstop

4.Locknut

1.2to3mm(1/16to1/8inch)

2.Bellcrank

3.Transmissionoutputshaft6.Clevis

Note:Theclearanceshouldbe2to3mm(1/16to

1/8inch).

4.Hairpincotter

5.Clevispin

39

Page 40

1.Disengagetheblade-control(PTO)leverandsetthe

parkingbrakes.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Loosenthelocknutontheturnbuckle(Figure52).

4.Rotatetheturnbuckletowardtherearofthemowerto