FormNo.3412-564RevB

30inStand-OnAerator

ModelNo.39519—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3412-564*B

ThissparkignitionsystemcomplieswithCanadian

ICES-002

Important:Thisengineisnotequippedwith

asparkarrestermufer.Itisaviolationof

CaliforniaPublicResourceCodeSection4442to

useoroperatetheengineonanyforest-covered,

brush-covered,orgrass-coveredland.Other

statesorfederalareasmayhavesimilarlaws.

TheenclosedEngineOwner'sManualis

suppliedforinformationregardingtheUS

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenance,andwarranty.

Replacementsmaybeorderedthroughtheengine

manufacturer.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

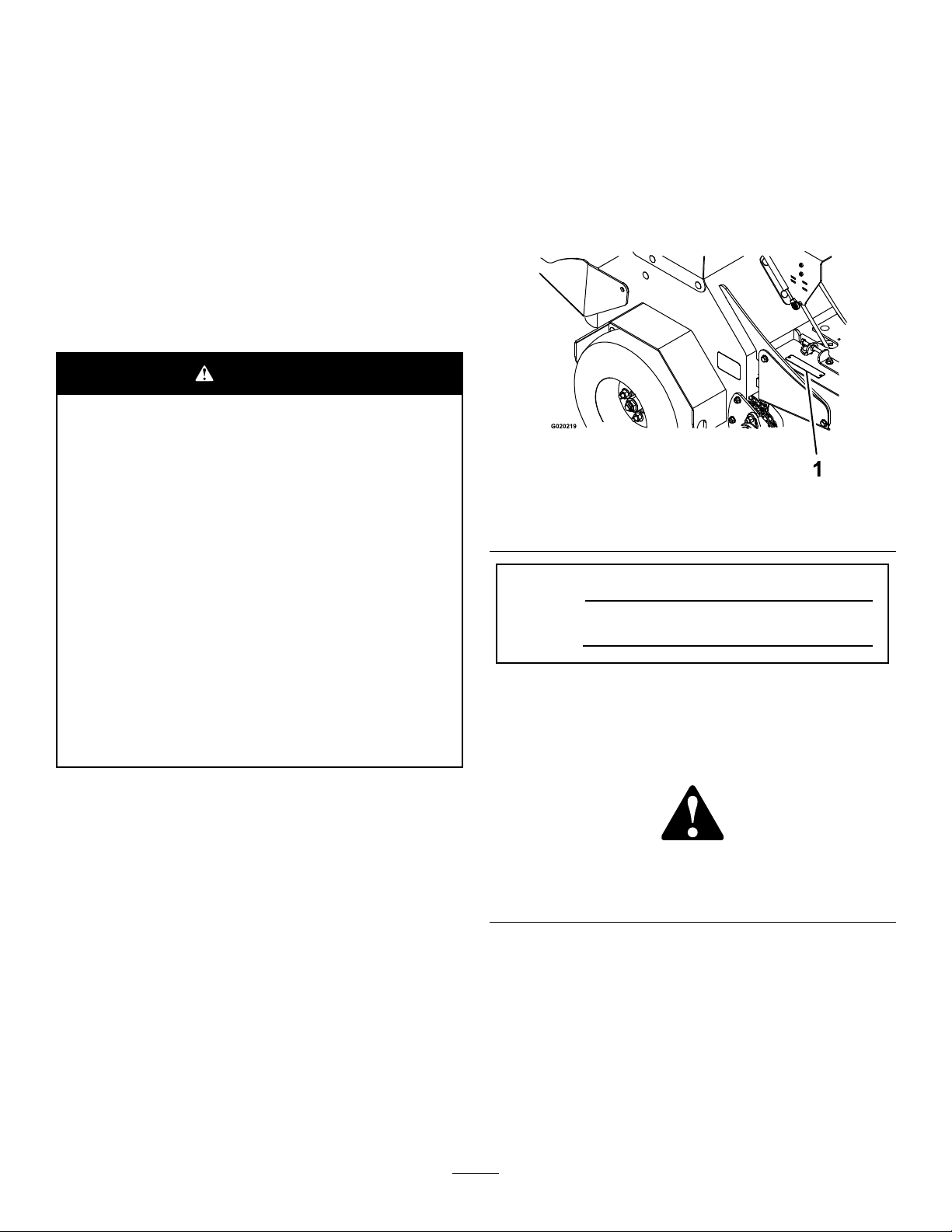

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g020219

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Introduction

Thisaeratorisintendedtobeusedbytrained

operatorsinresidentialandcommercialapplications.

Itisprimarilydesignedforaeratingareasof

well-maintainedlawnsonresidentialgrounds,parks,

sportselds,andcommercialgrounds.Usingthis

productforpurposesotherthanitsintendedusecould

provedangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

©2020—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

2

g000502

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

AeratorSafety....................................................6

SlopeIndicator...................................................7

SafetyandInstructionalDecals..........................8

Setup......................................................................12

1CheckingTirePressure..................................12

2ServicingtheBattery......................................12

3CheckingFluidLevels....................................13

4RemovingtheCylinderStop...........................14

ProductOverview...................................................15

Controls...........................................................15

Specications..................................................18

Operation................................................................18

CheckingtheEngine-OilLevel..........................18

AddingFuel......................................................19

LubricatingtheChains......................................20

CheckingtheSafety-InterlockSystem..............22

CheckingforLooseHardware...........................22

OperatingtheMachine.....................................22

TransportingtheMachine.................................25

LoadingtheMachine........................................26

Maintenance...........................................................27

RecommendedMaintenanceSchedule(s)...........27

Pre-MaintenanceProcedures..............................28

PreparingfortheMachinefor

Maintenance.................................................28

AccessingtheConsoleCompartment...............28

Lubrication..........................................................29

LubricatingtheGreaseFittings.........................29

LubricatingtheCasters.....................................30

EngineMaintenance...........................................32

ServicingtheAirCleaner..................................32

ServicingtheEngineOil....................................33

CheckingtheSparkPlugs.................................35

ServicingtheSparkPlug...................................35

CheckingtheSparkArrester(if

equipped)......................................................36

FuelSystemMaintenance...................................36

ServicingtheFuelFilter....................................36

ElectricalSystemMaintenance...........................37

ServicingtheBattery.........................................37

ServicingtheFuses..........................................39

DriveSystemMaintenance..................................39

CheckingtheAirPressureintheTires...............39

CheckingtheWheelHubNuts..........................39

CheckingtheT orqueoftheWheelLug

Nuts..............................................................39

AdjustingtheCasterPivotBearings

Pre-Load.......................................................40

MaintainingtheChain.......................................40

CheckingtheTransmissionOutputShaftNut

Torque...........................................................41

BrakeMaintenance.............................................42

AdjustingtheParkingBrake..............................42

AdjustingtheBrakeSwitch...............................42

BeltMaintenance................................................43

CheckingtheConditionandTensionofthe

Belts..............................................................43

AdjustingtheAuxiliaryPumpDrive

Belt................................................................43

ReplacingtheTransmission-DriveBelt.............43

ControlsSystemMaintenance.............................44

AdjustingtheTraction-ControlLinkage.............44

HydraulicSystemMaintenance...........................45

MaintainingtheAuxiliaryHydraulic

System..........................................................45

MaintainingtheTransmission...........................47

TineMaintenance.................................................50

CheckingtheTines...........................................50

AdjustingtheTine-DriveChain.........................50

Cleaning..............................................................51

CleaningtheEngineandtheExhaust

SystemArea.................................................51

RemovingtheEngineShroudsandCleaning

theCoolingFins............................................51

CleaningtheDebrisfromtheMachine...............51

WasteDisposal.................................................51

Storage...................................................................52

Troubleshooting......................................................53

Schematics.............................................................55

3

Safety

Improperuseormaintenancecanresultininjury.

Toreducethepotentialforinjury ,complywith

thesesafetyinstructions,andpayattentiontothe

safety-alertsymbol,whichmeansCaution,Warning,

orDanger—personalsafetyinstruction.Failureto

complywiththeinstructionsmayresultinpersonal

injuryordeath.

WARNING

Removalormodicationoforiginal

equipment,partsand/oraccessoriesmay

alterthewarranty,controllability,andsafety

ofthemachine.Unauthorizedmodications

totheoriginalequipmentorfailuretouse

originalToropartscouldleadtoserious

injuryordeath.Unauthorizedchangestothe

machine,engine,fuelorventingsystem,may

violateapplicablesafetystandardssuchas:

ANSI,OSHAandNFPAand/orgovernment

regulationssuchasEPAandCARB.

Replaceallpartsincluding,butnotlimitedto,

tires,belts,andfuelsystemcomponentswith

originalT oroparts.

Important:Thismachinewasmanufactured

accordingtotheappropriateregulatorystandards

ineffectatthetimeofmanufacture.Modifying

thismachineinanywaymaycauseittobe

outofcompliancewiththosestandardsand

withtheinstructionsinthisOperator’sManual.

Modicationstothismachineshouldonlybe

madebyeitherthemanufactureroranAuthorized

ToroDealer.

Thisproductiscapableofinjuringyourhandsand

feet.Followallsafetyinstructionstoavoidserious

injuryordeath.

Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeople,ordamage

toproperty.

Anyuseofthismachineotherthanaeratingturfgrass

couldprovedangeroustotheuserandbystanders.

Important:Theadditionofattachmentsmade

byothermanufacturersthatdonotmeetANSI

certicationmaycausenoncomplianceofthis

machine.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.4-2012.

Training

•ReadtheOperator'sManualandothertraining

material.

Note:Iftheoperator(s)ormechanic(s)cannot

readthemanuallanguage,itistheowner's

responsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.

Note:Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtopeopleor

damagetoproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothing;includingsafety

glasses,longpants,substantialslip-resistant

footwear,gloves,andhearingprotection.

•Tiebacklonghair.Donotwearjewelry.

•Inspecttheareawheretheequipmentistobe

usedandensurethatallobjectsareremovedfrom

theareabeforeuse.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

Operation

•Lightningcancausesevereinjuryordeath.If

lightningisseen,orthunderisheardinthearea,

donotoperatethemachine;seekshelter.

•Donotrunanengineinanenclosedarea.

•Onlyoperateinwell-litareas,keepingawayfrom

holesandhiddenhazards.

•Ensurethatalldrivesareinneutralandthatthe

parkingbrakeisengagedbeforestartingengine.

Onlystarttheenginefromtheoperator’sposition.

•Makesurethatyouhavegoodfootingwhileusing

thismachine,especiallywhenbackingup.

4

Note:Reducedfootingcouldcauseslipping.

•Slowdownanduseextracareonhillsides.Be

suretotravelsidetosideonhillsides.Turf

conditionscanaffectthestabilityofthemachine.

Usecautionwhileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturns

andwhenchangingdirectionsonslopes.

•Donotoperatethemachinewithouttheshields

orotherguardssecurelyinplace.Besureall

interlocksareattached,adjustedproperly,and

functioningproperly.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Beforeleavingtheoperator’sposition:

–Stoponlevelground.

–Disengagetheparkingbrake(ifprovided).

–Shutofftheengine.

•Stoponlevelground,disengagedrives,engage

theparkingbrake(ifprovided),shutofftheengine

beforeleavingtheoperator'spositionforany

reason.

•Stopequipmentandinspectthetinesafterstriking

objectsorifanabnormalvibrationoccurs.Make

thenecessaryrepairsbeforeresumingoperations.

•Keepyourhandsandfeetawayfromthetine

assembly.

•Lookbehindanddownbeforebackingupto

ensureaclearpath.

•Keeppetsandbystandersawayfromanoperating

machine.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Fullyraisethe

tinesifyouarenotaerating.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlingfuel.Fuelisextremely

ammableandthevaporsareexplosive.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfuelwiththe

enginerunning.

•Allowtheenginetocoolbeforefueling.

•Neverrefuelordrainthemachineindoorsanddo

notsmokewhilerefuelingordraining.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlightsuchas

onawaterheateroronotherappliances.

•Donotllcontainersinsideavehicle,onatruck,

oronatrailerbedwithaplasticliner.Alwaysplace

containersonthegroundawayfromyourvehicle

beforelling.

•Removeequipmentfromthetruckortrailerand

fuelitontheground.Ifthisisnotpossible,

thenaddfuelwithsuchequipmentasaportable

container,ratherthanfromafuel-dispensernozzle.

•Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntilfueling

iscomplete.Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeyourclothing

immediately.

•Donotoverllfueltank.Replacefuelcapand

tightensecurely.

MaintenanceandStorage

•Donotallowuntrainedpersonneltoservice

machine.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowallofthepartsof

themachinetocoolbeforeattemptingtomaintain,

adjust,orservicethemachine.

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Disengagethedrives,raisethetines,engagethe

parkingbrake,shutofftheengine,andremove

thekeyordisconnectthespark-plugwire.Waitfor

allmovementtostopbeforeadjusting,cleaning,

orrepairing.

•Disconnectthebatteryorremovethespark-plug

wirebeforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositiveterminal

last.Reconnectthepositiverstandnegativelast.

•Usecarewhencheckingthetines.Wrapthetine(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplacetines;donotstraightenorweld

them.

•Cleangrass,dirt,anddebrisfromthetines,drives,

mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Parkthemachineonlevel,hardground.Never

allowuntrainedpersonneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Lettheenginecoolbeforestoring.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

5

Hauling

•Usecarewhenloadingorunloadingthemachine

intoatraileroratruck.

•Donotaerateslopesgreaterthan15degrees.

•Avoidsuddenstartsandstopswhenaeratinguphill

becausethemachinemaytipbackward.

•Usefull-widthrampsforloadingmachineintoa

traileroratruck.

•Tiethemachinedownsecurelyusingstraps,

chains,cable,orropes.Bothfrontandrearstraps

shouldbedirecteddownandoutwardfromthe

machine.

AeratorSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsandothersafetyinformationyou

mustknow.

GeneralOperation

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires,etc.)before

operatingunderanyobjects,anddonotcontact

them.

•Usecautionwhenyouareridingontheplatform

anddrivingthemachineovercurbs,rocks,roots,

orotherobstructions.

•Donotjerkthecontrols;useasteadymotion.

•Donotcarrypassengers.

•Donotcarryequipmentonthemachine.

SlopeOperation

Useextremecautionwhenaeratingand/orturning

onslopesaslossoftractionand/ortip-overcould

occur.Theoperatorisresponsibleforsafeoperation

onslopes.

•UseFigure3tohelpyoudeterminetheappropriate

slopeangleofareatoaerate

Note:Themachineismorestablegoinguphill

withthetinesraised.

•Keepallmovementonslopesslowandgradual.

•Donotmakesuddenchangesinspeedor

direction.

•Reducethetine-downpressuretopreventthe

drivetiresfromraisingoffthegroundandto

preventthefronttiresfromraisingofftheground

whileaeratinguphill.

•Followthemanufacturer’srecommendationsfor

wheelweightsorcounterweightstoimprove

stability.

•Useextracarewithattachments.

Note:Useofattachmentscanchangethestability

ofthemachine.

Service

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineT ororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

•Neverremoveortamperwithsafetydevices.

Checktheirproperoperationregularly.Neverdo

anythingtointerferewiththeintendedfunctionofa

safetydeviceortoreducetheprotectionprovided

byasafetydevice.

•Checkbrakeoperationfrequently.Adjustand

serviceasrequired.

•Removeormarkobstaclessuchasrocks,tree

limbs,etc.fromtheaeratingarea.

•Watchforholes,rutsorbumps.

Note:T allgrasscanhideobstacles.

•Usecautionneardrop-offs,ditches,or

embankments.

Note:Themachinecouldsuddenlyturnoverifa

wheelgoesovertheedgeofaclifforditch,orif

anedgecavesin.

•Beawarethatoperatingonwetgrass,across

steepslopesordownhillmaycausethemachine

tolosetraction.Lossoftractiontothedrivewheels

mayresultinslidingandalossofbrakingand

steering.

6

SlopeIndicator

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

g011841

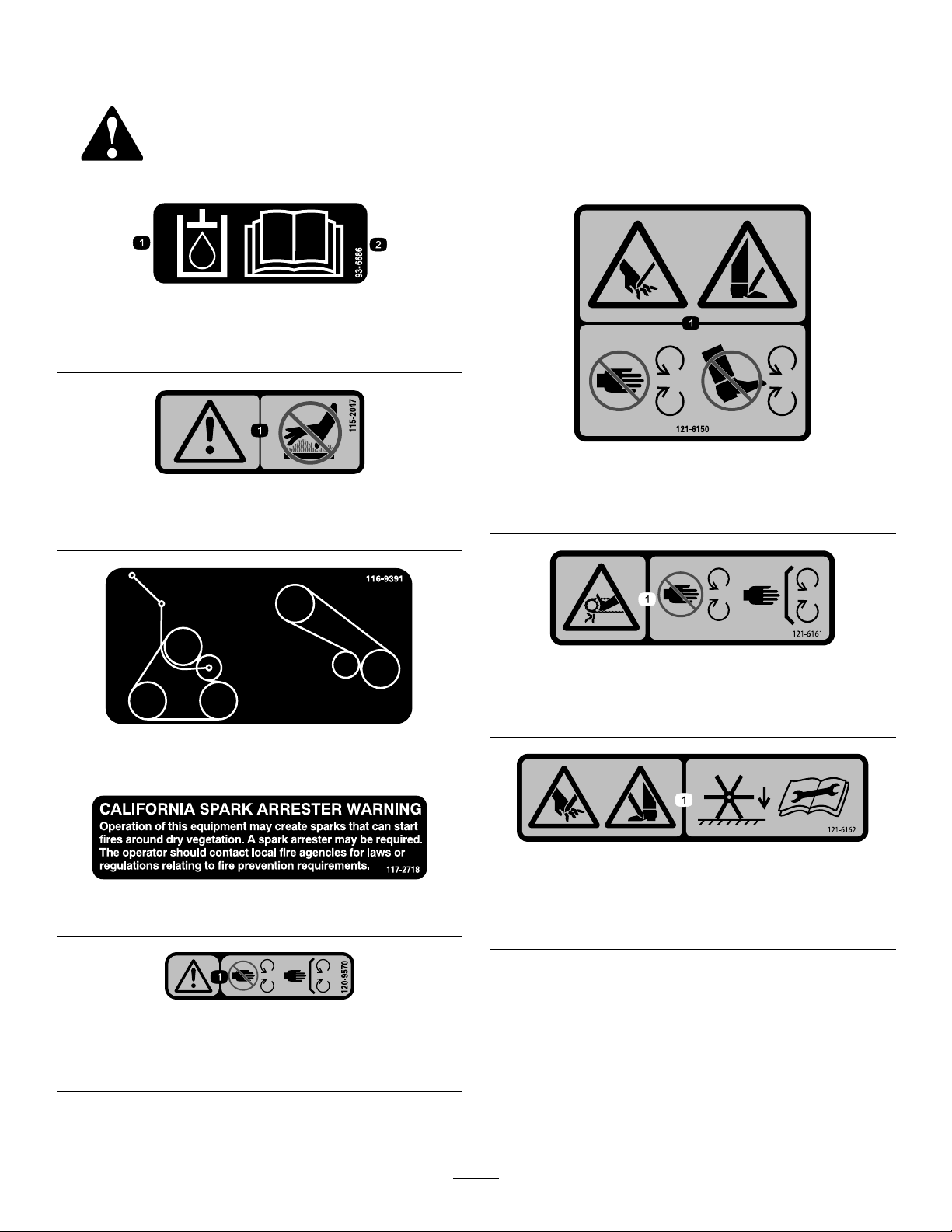

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

93-6686

decal93-6686

1.Hydraulicuid2.ReadtheOperator's

115-2047

1.Warning—donottouchthehotsurface.

116-9391

Manual.

decal121-6150

121-6150

decal115-2047

1.Cuttinghazardofhandandfoot–stayawayfrommoving

parts.

decal121-6161

121-6161

1.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsinplace.

decal116-9391

117-2718

120-9570

1.Warning—stayawayfrommovingparts,keepallguards

andshieldsinplace.

decal121-6162

121-6162

decal117-2718

decal120-9570

1.Cutting/dismembermenthazardofhandorfoot—lower

thetinestotheground;readtheOperator’sManualfor

disassemblyprocedure.

8

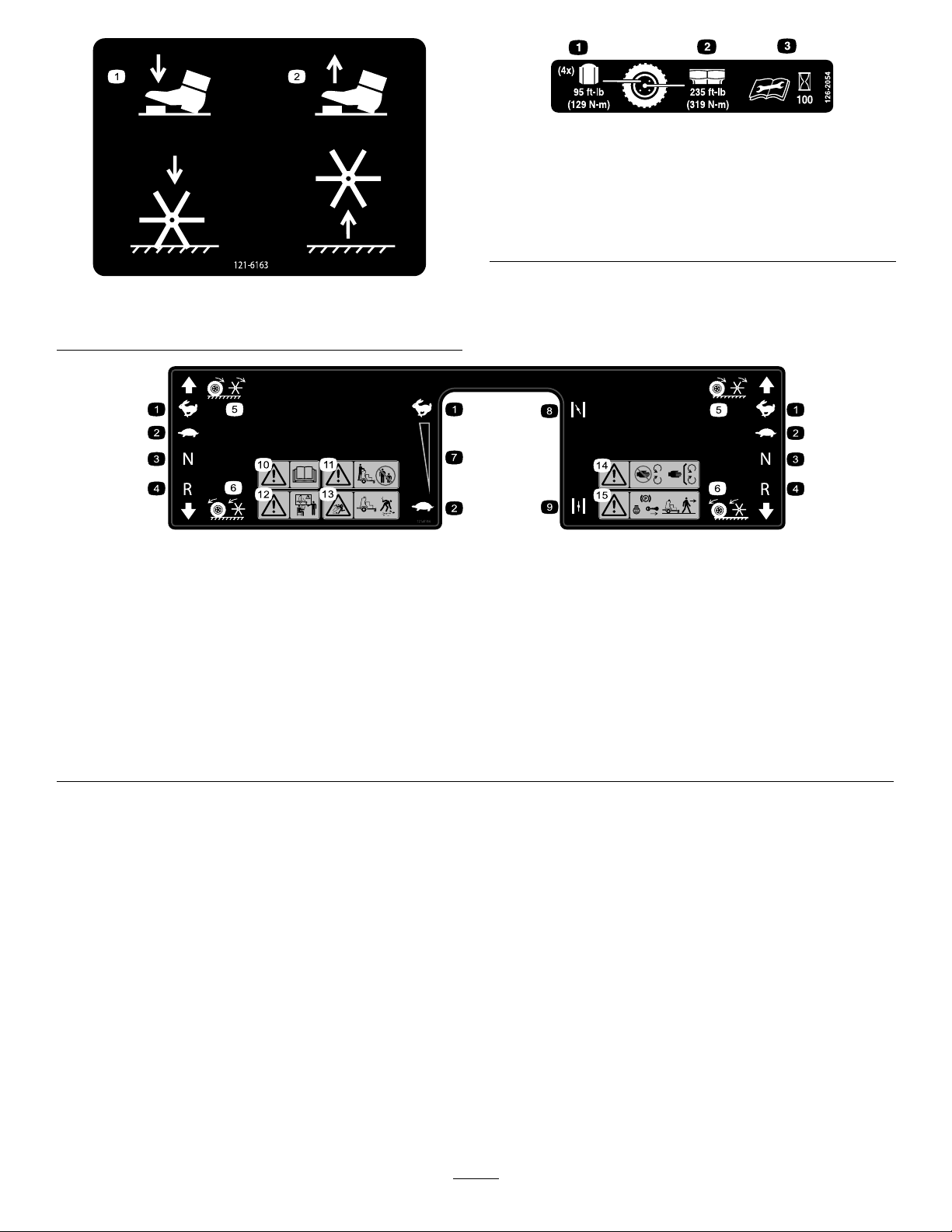

121-6163

1.Presstolowerthetines.2.Releasetoraisethetines.

decal126-2054

126-2054

1.Wheellugnuttorque129N∙m(95ft-lb)(4x)

2.Wheelhubnuttorque319N∙m(235ft-lb)

3.ReadandunderstandtheOperator’sManualbefore

performinganymaintenance;checkthetorqueevery100

hours.

decal121-6163

decal121-6164

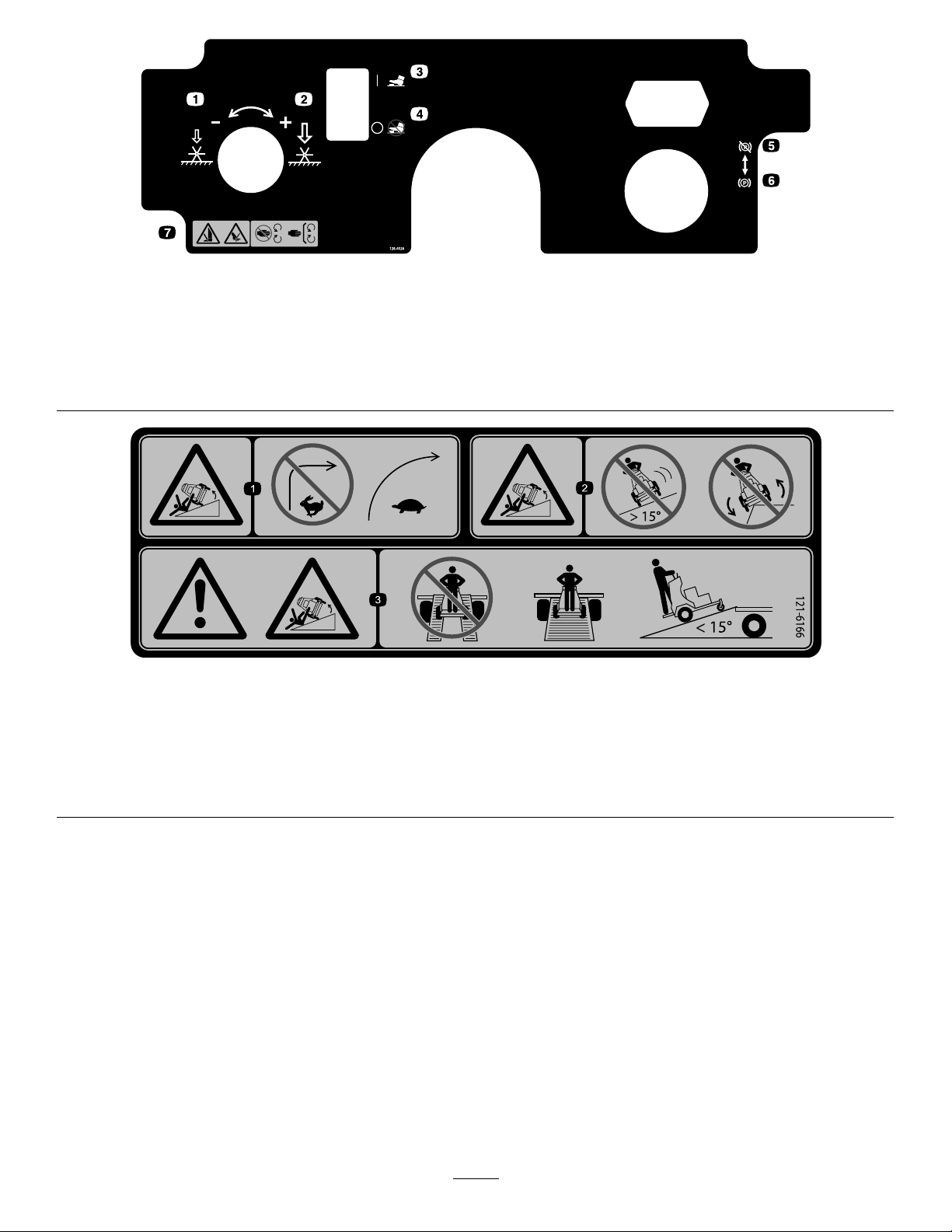

121-6164

1.Fast6.Wheelsandtinesrotatewhenmoving

backward

2.Slow7.Continuousvariablesetting

3.Neutral

4.Reverse

5.Wheelsandtinesrotatewhenmoving

8.Choke—on

9.Choke—off14.Warning—stayawayfrommoving

10.Warning—readtheOperator’sManual.15.Warning—shutofftheengine,engage

forward

11.Warning—keepbystandersaway .

12.Warning—donotoperatethemachine

unlessyouaretrained.

13.Thrownobjecthazard—pickupdebris

beforeoperatingthemachine.

parts;keepallguardsinplace.

theparkingbreak,andremovethekey

beforeleavingthemachine.

9

126-4528

1.Rotatecounterclockwisetodecreasepressure5.Parkingbrake-release

2.Rotateclockwisetoincreasepressure6.Parkingbrake-engage

3.On-tinegroundengagementfootswitch7.Cutting/dismembermenthazardofhandorfoot,tines–stay

awayfrommovingparts;keepallguardsinplace

4.Off-tinegroundengagementfootswitch

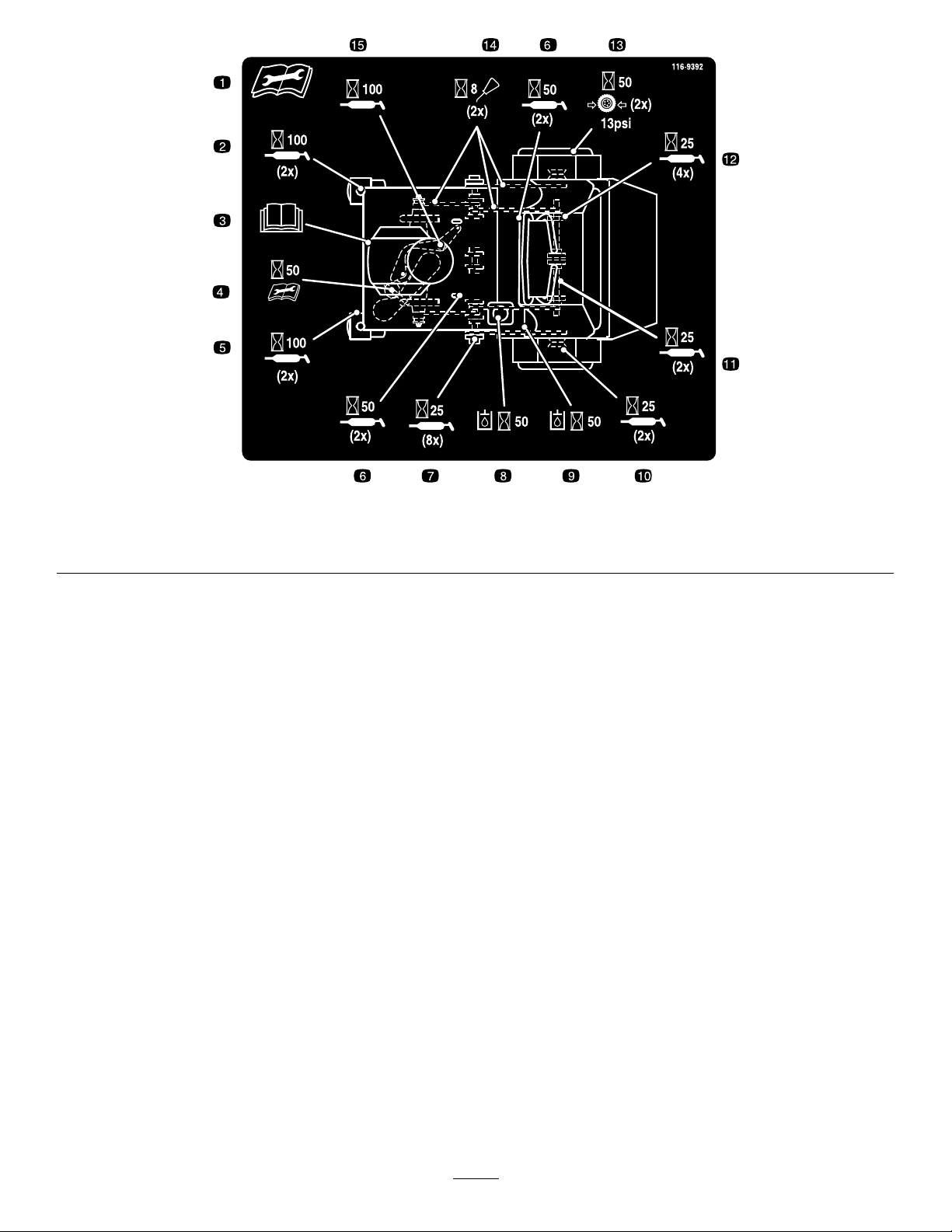

121-6166

decal126-4528

decal121-6166

1.Tippinghazard—donotturnsharplywhiletravellingfast;slow

downandturngradually.

2.Tippinghazard—donotoperatethemachineonslopes

greaterthan15degrees;donotoperatethemachinenear

drop-offs.

3.Warning;tippinghazard—donotusesplitramps;usefull

widthrampstoloadamachinefortransport;usealoading

rampatamaximumof15degrees.

10

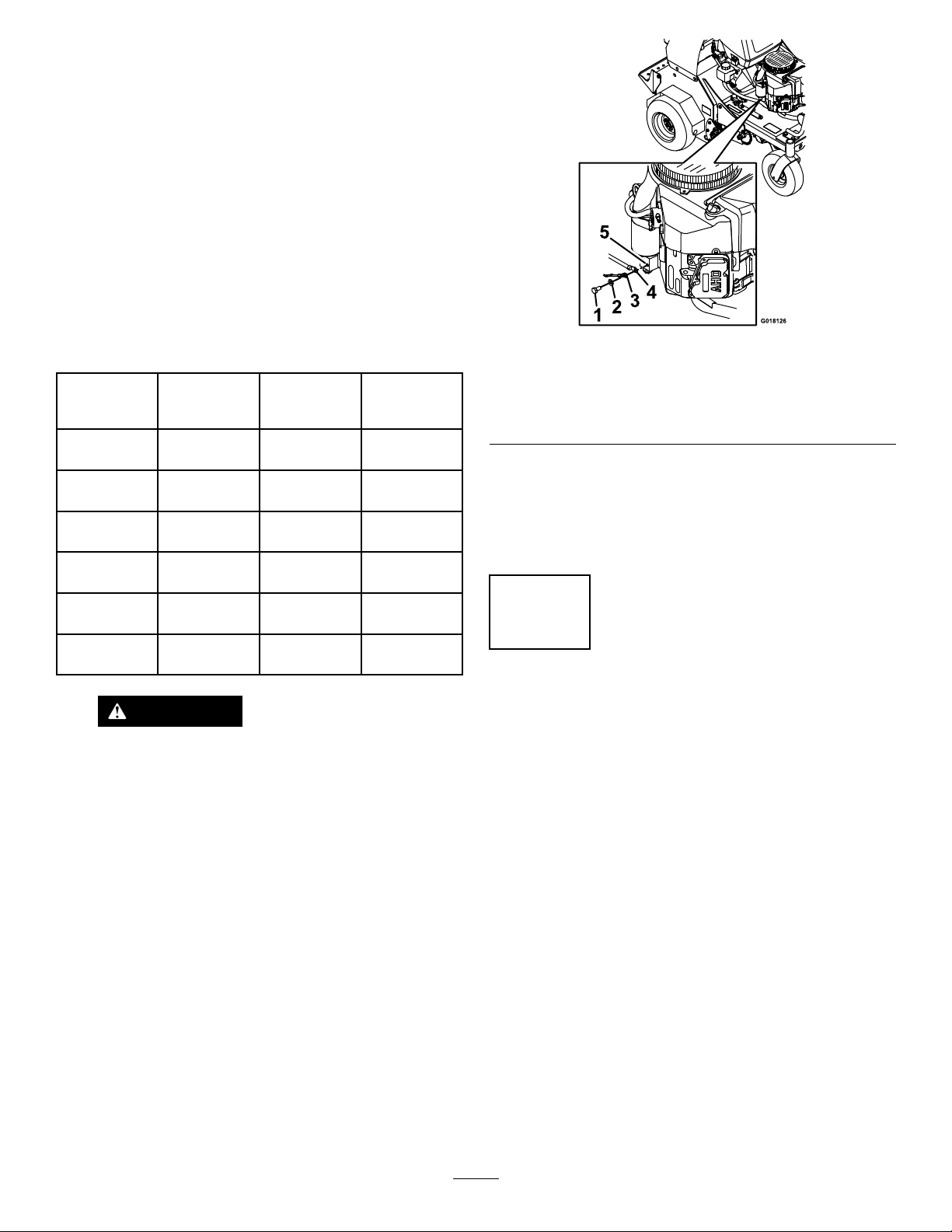

116–9392

1.Readtheinstructionsbeforeservicingorperformingmaintenance;readtheOperator’sManualforinformationonlubricating

themachine.

decal116-9392

11

Setup

MediaandAdditionalParts

Description

Operator'sManual

Key2

1

CheckingTirePressure

NoPartsRequired

Procedure

1.Checkthetirepressureinthedrivetires.

Note:Properinationfordrivetiresis83to97

kPa(12to14psi).

2.Adjustthetirepressureifnecessary.

Qty.

Use

1

Readbeforeoperatingthemachine.

Startthemachine.

2

ServicingtheBattery

NoPartsRequired

Procedure

Note:Themachineisshippedwithalled,lead-acid

battery.

DANGER

Chargingorjumpstartingthebatterymay

produceexplosivegases.Batterygasescan

explodecausingseriousinjury.

•Keepsparks,ames,orcigarettesaway

frombattery.

•Ventilatewhenchargingorusingbatteryin

anenclosedspace.

•Makesurethattheventingpathofbattery

isalwaysopenoncethebatteryislled

withacid.

•Alwaysshieldeyesandfacefrombattery.

DANGER

Batteryelectrolytecontainssulfuricacid,

whichispoisonousandcancausesevere

burns.Swallowingelectrolytecanbefatalor

ifittouchesskincancausesevereburns.

•Wearsafetyglassestoshieldyoureyes

andrubberglovestoprotectyourskinand

clothingwhenhandlingelectrolyte.

•Donotswallowelectrolyte.

•Intheeventofanaccident,ushwithwater

andcalladoctorimmediately.

12

1.TurnthekeyintheignitionswitchtotheOFF

positionandremovethekey.

2.Measurethevoltageofthebatterywitha

voltmeter.

3.Usethetablebelowtolocatethechargestate

orthebattery,andifneeded,thebattery-charger

settingandchargingintervalrecommendedto

chargethebatteryto12.6Vorgreater.

Important:Makesurethatthenegative

batterycableisdisconnectedandthe

batterychargerusedforchargingthebattery

hasanoutputof16Vand7Aorlessto

avoiddamagingthebattery(seechartfor

recommendedchargersettings).

BatteryChargeTable

Voltage

Reading

12.6or

greater

12.4–12.6

12.2–12.4

12.0–12.2

11.7–12.0

11.7orless

Percent

Charge

100%16volts/

75–100%16volts/

50–75%16volts/

25–50%14.4volts/

0–25%14.4volts/

0%14.4volts/

Maximum

Charger

Settings

7amps

7amps

7amps

4amps

4amps

2amps

Charging

Interval

NoCharging

Required

30Minutes

1Hour

2Hours

3Hours

6Hoursor

More

Figure4

1.Screw

2.Washer5.Engine

3.Groundwire

4.Negativebatterycable

Note:Iftimedoesnotpermitchargingthe

batteryorifchargingequipmentisnotavailable,

connectthenegativebatterycablesandrun

thevehiclecontinuouslyfor20to30minutesto

chargethebattery.

3

CheckingFluidLevels

g018126

CAUTION

IftheignitionisintheONpositionthere

ispotentialforsparksandengagement

ofcomponents.Sparkscouldcause

anexplosionormovingpartscould

accidentallyengagecausingpersonal

injury.

BesureignitionswitchisintheOFF

positionbeforechargingthebattery.

4.Ifthepositivecableisalsodisconnected,

connectthepositive(red)cabletothepositive

batteryterminalandslipterminalcoveroverthe

positiveterminal.

5.Removethescrew,washer,andgroundcable

fromtheengine.Connectthenegativebattery

cableasshowninFigure4.

NoPartsRequired

Procedure

Checktheengine-oillevelbeforetheengineisrst

started;refertoCheckingtheEngine-OilLevel(page

18).

Checkthetransmission-oillevelbeforetheengineis

rststarted;refertoCheckingtheTransmission-Oil

Level(page47).

Checktheauxiliaryhydraulic-uidlevelbeforethe

engineisrststarted;refertoCheckingtheAuxiliary

Hydraulic-FluidLevel(page45).

13

4

RemovingtheCylinder

Stop

NoPartsRequired

Procedure

Note:Raisethetinesbeforeremovingthecylinder

stop.Runningtheenginechargesthehydraulic

systemandraisesthetines.

1.Addasmallamountoffueltothefueltank;refer

toAddingFuel(page19).

2.Openthefuel-shutoffvalvebyaligningthelever

forthefuel-shutoffvalvewiththefuelline;refer

toFuel-ShutoffValve(page17).

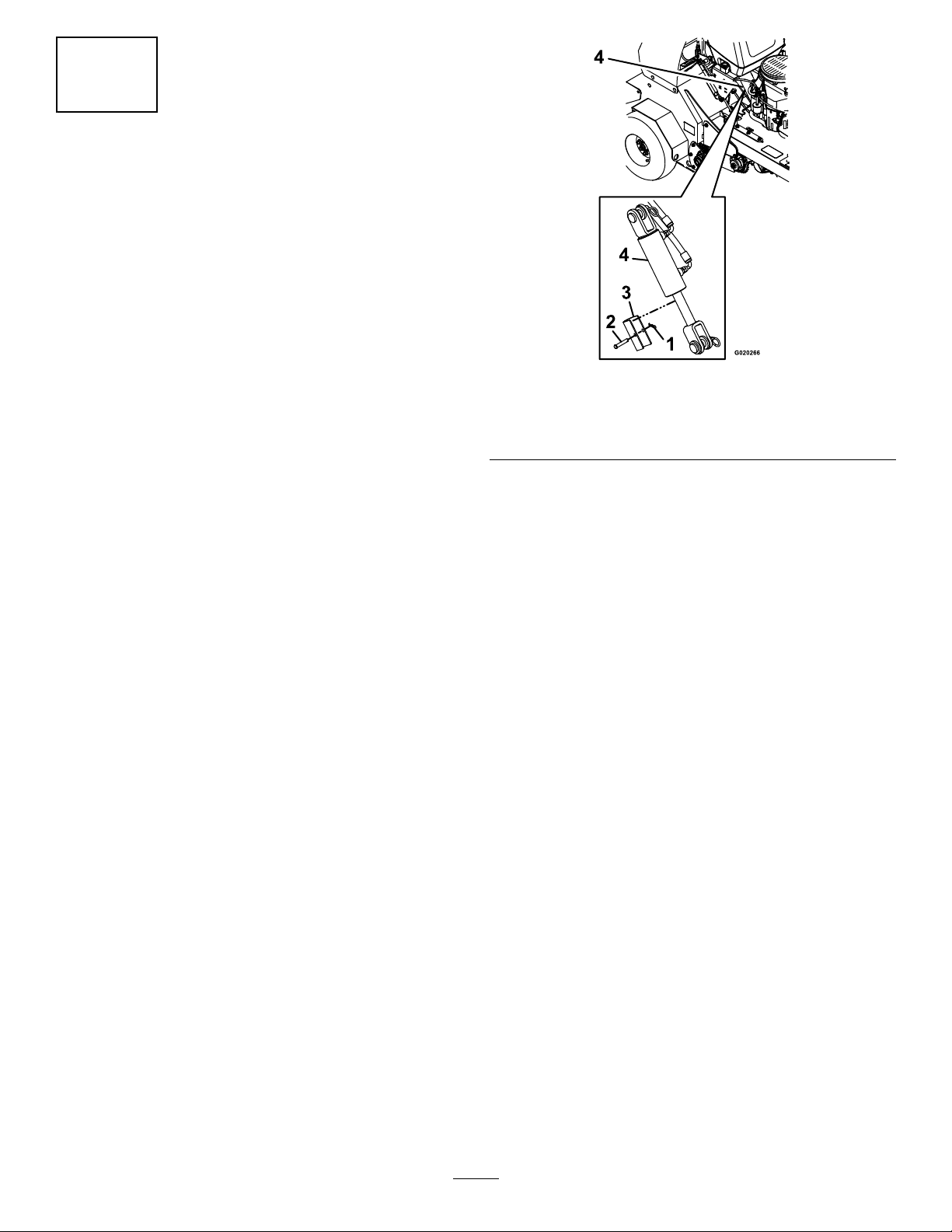

Figure5

1.Hairpin

2.Clevispin4.Cylinder

g020266

3.Cylinderstop

3.Movethemotion-controlleverstotheneutral

positionandengagetheparkingbrake;referto

Traction-ControlLevers(page15).

4.PlacethethrottlemidwaybetweentheSLOWand

FASTpositions;refertoThrottleLever(page16).

5.Pushforwardthechokelevertosetthechoketo

theONposition;refertoChokeLever(page16).

6.TurnthekeyswitchtotheSTARTposition;refer

toIgnitionSwitch(page16).

Note:Releasetheswitchassoonastheengine

starts.

Important:Donotcranktheengine

continuouslyformorethan10secondsat

atime.Iftheenginedoesnotstart,allowa

60-secondcooldownperiodbetweenstarting

attempts.Failuretofollowtheseguidelines

canburnoutthestartermotor.

7.Graduallymovetheleverforthechokeleverto

theOFFpositionastheenginewarmsup.

Note:Allowtheenginetorunanadditional30

seconds

11.Connectthespark-plugwires.

8.TurnthekeyswitchtotheOFFpositiontoshut

offtheengine.

9.Removethekeyandpullthewiresoffthespark

plugs.

Note:Pushthewiresasidesotheydonot

accidentallycontactthesparkplugs.

10.Removeandretainthehairpin,clevispin,and

cylinderstopasshowninFigure5.

14

ProductOverview

g025895

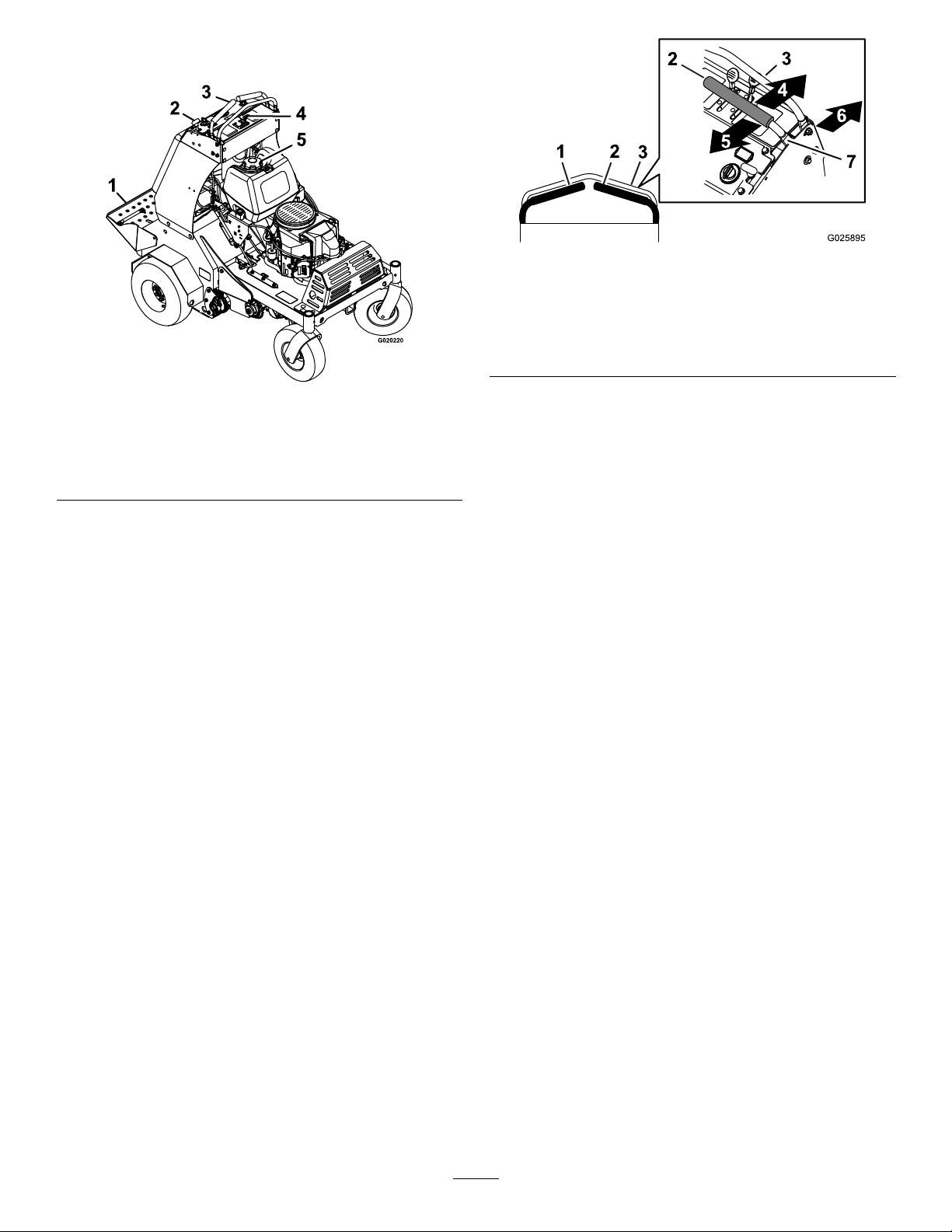

Figure7

Figure6

1.Platform

2.Parking-brakeknob5.Fuelcap

3.Traction-controllevers

4.Enginecontrols

Controls

Traction-ControlLevers

Thetraction-controlleversarelocatedoneachsideof

thetopconsole,andcontroltheforwardandreverse

motionofthemachine.

Movetheleversforwardorbackwardtocontrolthe

drivewheelonthesamesideforwardorreverse

respectively.Thewheelspeedisproportionaltothe

amounttheleverismoved.

1.Lefttraction-controllever

2.Righttraction-controllever

3.Frontreferencebar

4.Forward

g020220

5.Reverse

6.Frontofthemachine

7.Neutral

Tine-PressureControl

Thetine-pressurecontrolislocatedontheleftsideof

thecontrolconsole(Figure8).

Usethetine-pressurecontroltoadjustthedownward

pressureonthetinesandcoredepth.Rotatethe

controlcounterclockwisetodecreasethepressure

andthelengthoftheaerationplug;rotateclockwise

toincreasepressureandincreasethelengthofthe

aerationplug.

Important:Thetinesrotatewhenthe

traction-controlleversaremovedoutofthe

Neutralposition.

15

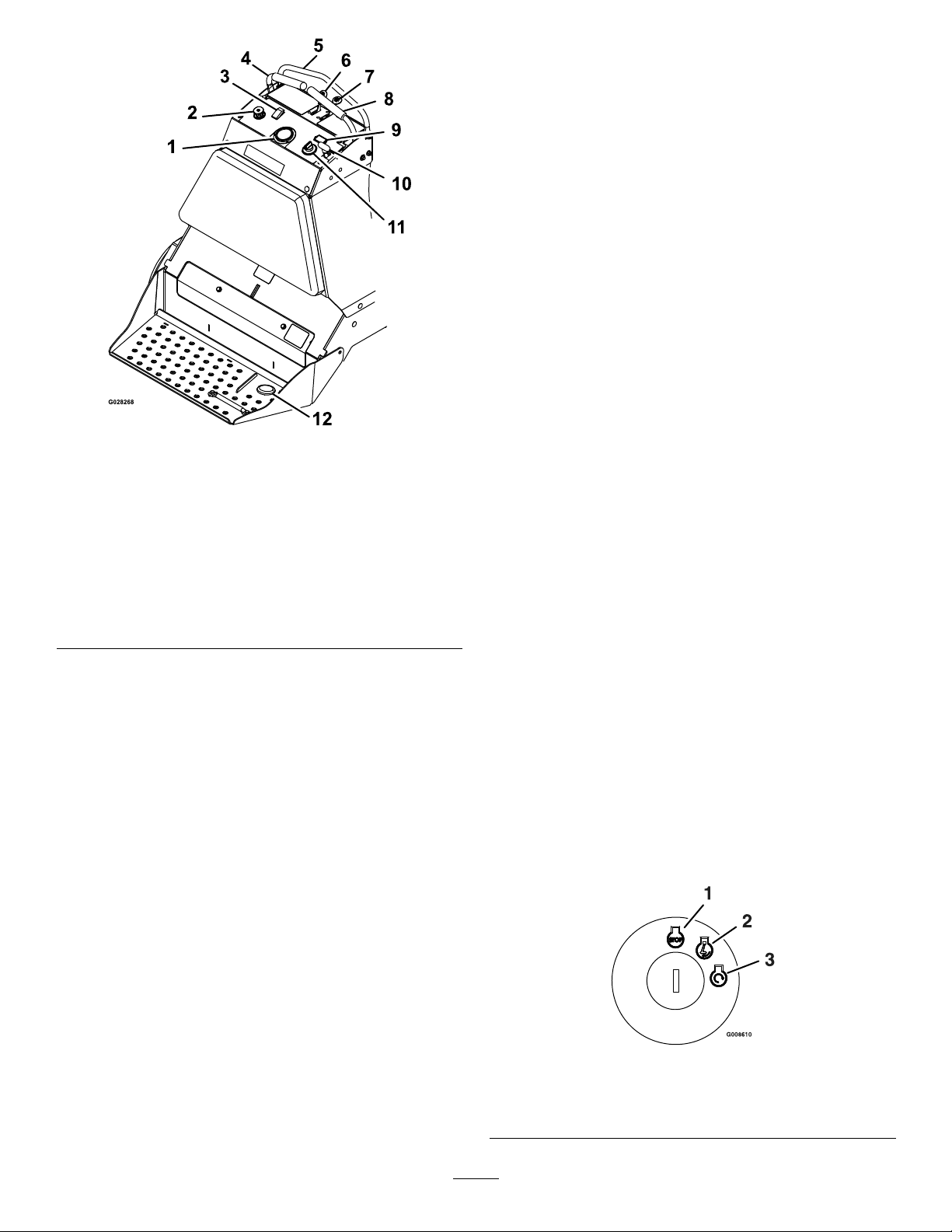

Figure8

1.Tinedownpressuregauge

2.Tinedownpressure

control

3.On/Off-tineground

engagementfootswitch

4.Leftmotion-controllever

5.Frontreferencebar

6.Throttle12.Tinegroundengagement

7.Choke

8.Rightmotion-controllever

9.Hourmeter

10.Parkbrake

11.Ignitionswitch

ChokeLever

Thechokelever(Figure8)islocatedonthecontrol

console(blacklever).

Thechokeleverisusedtoaidinstartingacold

engine.TosetthechoketotheONposition,move

thechokeleverforward.T oreducethechoke,move

thechokeleverbackward.

Note:Pullthechokeleverbackintothedetenttoset

thechoketotheOFFposition.

Note:Donotrunawarmenginewiththechokein

theONposition.

Parking-BrakeHandle

Theparking-brakehandleislocatedonthecontrol

console,totherightoftheignitionswitch(Figure8).

Note:Thebrakehandlesetsaparkingbrakeineach

g028268

footswitch

ofthetransmissions.

Tosetthebrake,pullthehandleoutandslideit

backward.T orelease,pushthehandleforwardinto

thedetent.

Whenparkingonasteepslope,thewheelsmustbe

chockedorblockedinadditiontothebrakebeingset.

Themachinemustbetieddownandbrakesetwhen

transporting.

HourMeter

ThrottleLever

Thethrottlelever(Figure8)islocatedonthecontrol

console(redlever).

Toincreaseenginespeed,movethethrottlelever

forward.T odecreaseenginespeed,movethethrottle

leverbackward.

Note:Movethethrottleleverforwardintothedetent

forfullthrottle.

Thehourmeterislocatedabovetheignitionswitch

(Figure8).

Thehourmeterdisplaysthetotalnumberofhours

thatyouhaverunthemachine.

IgnitionSwitch

Theignitionswitchislocatedontherightsideofthe

controlconsole(Figure8).

Theswitchhas3positions:OFF,ON,andST ART

(Figure9).

g008610

Figure9

1.Off3.Start

2.On

16

On/OffTineGroundEngagement

FootSwitch

Locatedabovethetinedownpressurecontrolonthe

controlconsole.

Toenablethetinesgroundengagement,pushdown

onthetopoftheswitch.T odisablethetinesground

engagement,pushdownontherearoftheswitch.

Tine-PressureGauge

Thetine-pressuregaugeislocatedinthemiddleof

thecontrolconsole(Figure8).

Thetine-pressuregaugetoindicatesthedownward

pressurethemachineexertsonthetineswhen

aerating.

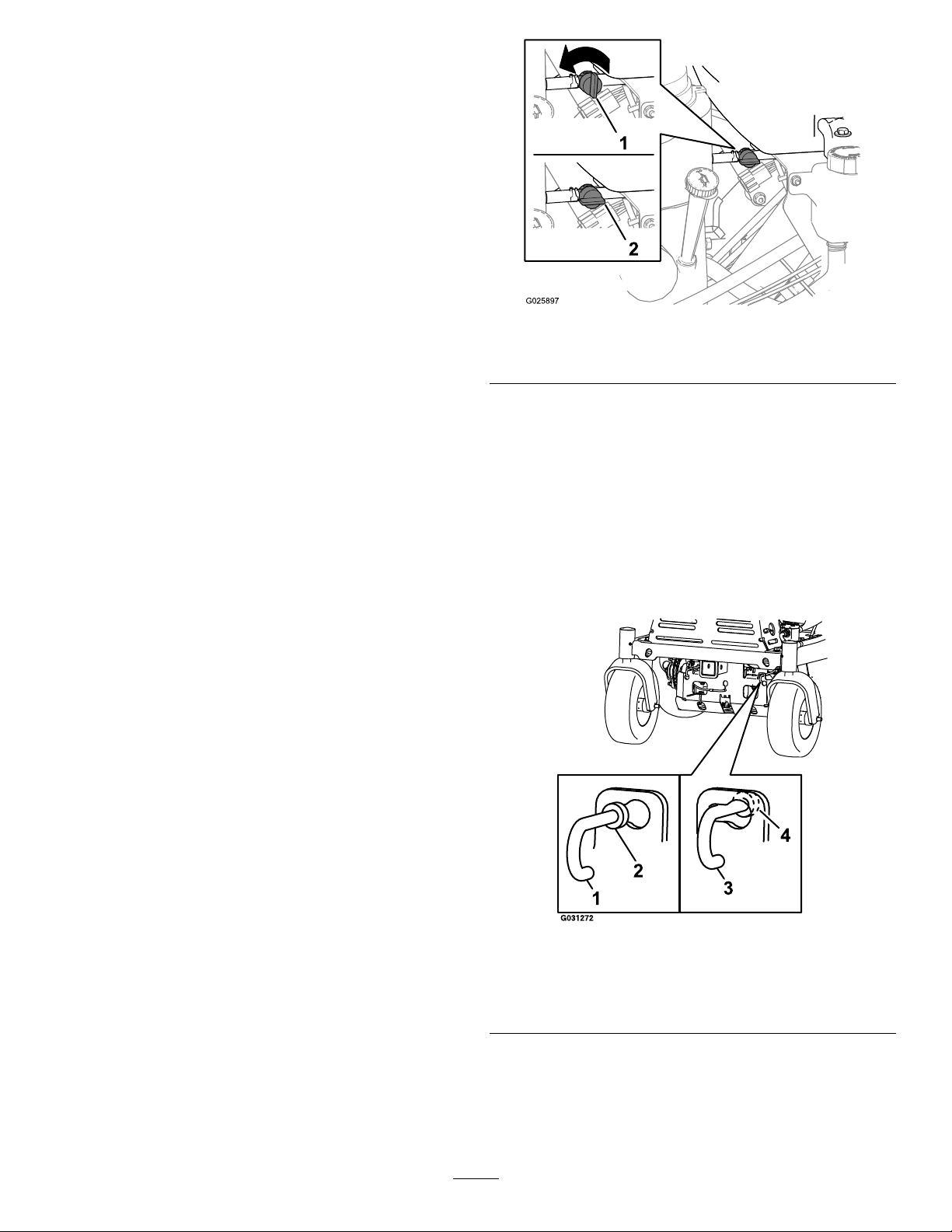

g025897

Figure10

1.Offposition2.Onposition

Tines-ElevationSwitch

Keepyouhandsandfeetawayfromthetines.

Makesurethatthetinesareaisclearofany

obstructionsbeforeloweringit.

Thetine-elevationswitchislocatedontheoperator

platform(Figure8).

Tolowerthetinesintotheground,standonthe

tine-elevationswitch.T oraisethetines,removeyour

footfromtheswitch.

Fuel-ShutoffValve

Thefuel-shutoffvalveislocatedbehindtheengine

andunderthefueltank(Figure10).

Usethefuel-shutoffvalvetoshutoffthefuelwhen

themachinewillnotbeusedforafewdays,when

transportingthemachinetoandfromthejobsite,or

whenthemachineisparkedinsideabuilding.

Toopenforfuel-shutoffvalve,rotatethehandleofthe

fuel-shutoffvalveuntilitisalignedwiththefuelline.

Toclosethefuel-shutoffvalve,rotatethehandle90°

tothefuelline.

DriveWheelReleaseValves

Thedrivewheelreleasevalvesarelocatedontheleft

andrightsidesunderneaththefrontoftheunit.

Note:Duringnormaloperatingconditions,the

washerontheleverispositionedinsidetheslots.

Ifyouneedtopushthemachinebyhand,makesure

thatthevalvesareinthe“released”position(Figure

11).

Figure11

1.Leverpositiontopushthe

machine

2.Washeroutsideofslot

Toreleasethedrivewheels,movethelevertothe

largeropeningoftheslot,pullitoutuntilthewasher

isoutsidetheframe,thenmovetheleverbacktothe

narrowportionoftheslot.Repeatthisoneachside

ofthemachine.

17

3.Leverpositionfor

operatingthemachine

4.Washerinsideslot

g031272

Disengagetheparkingbraketoallowyoutopushthe

machinebyhand.

Operation

Important:Donottowthemachine.

Toresetthedrivesystembacktotheoperating

position,movethelevertothelargeropeningofthe

slot,pushinwarduntilthewasherisinsidetheframe,

thenmovetheleverbacktothenarrowportionofthe

slot.Repeatthisoneachsideofthemachine.

Specications

Height

Length

Width

AerationWidth

Coringrange5to13cm(2to5inches)

Weight

132cm(52inches)

162cm(64inches)

121cm(48inches)

76cm(30inches)

460kg(1,015lb)

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

CheckingtheEngine-Oil

Level

ServiceInterval:Beforeeachuseordaily

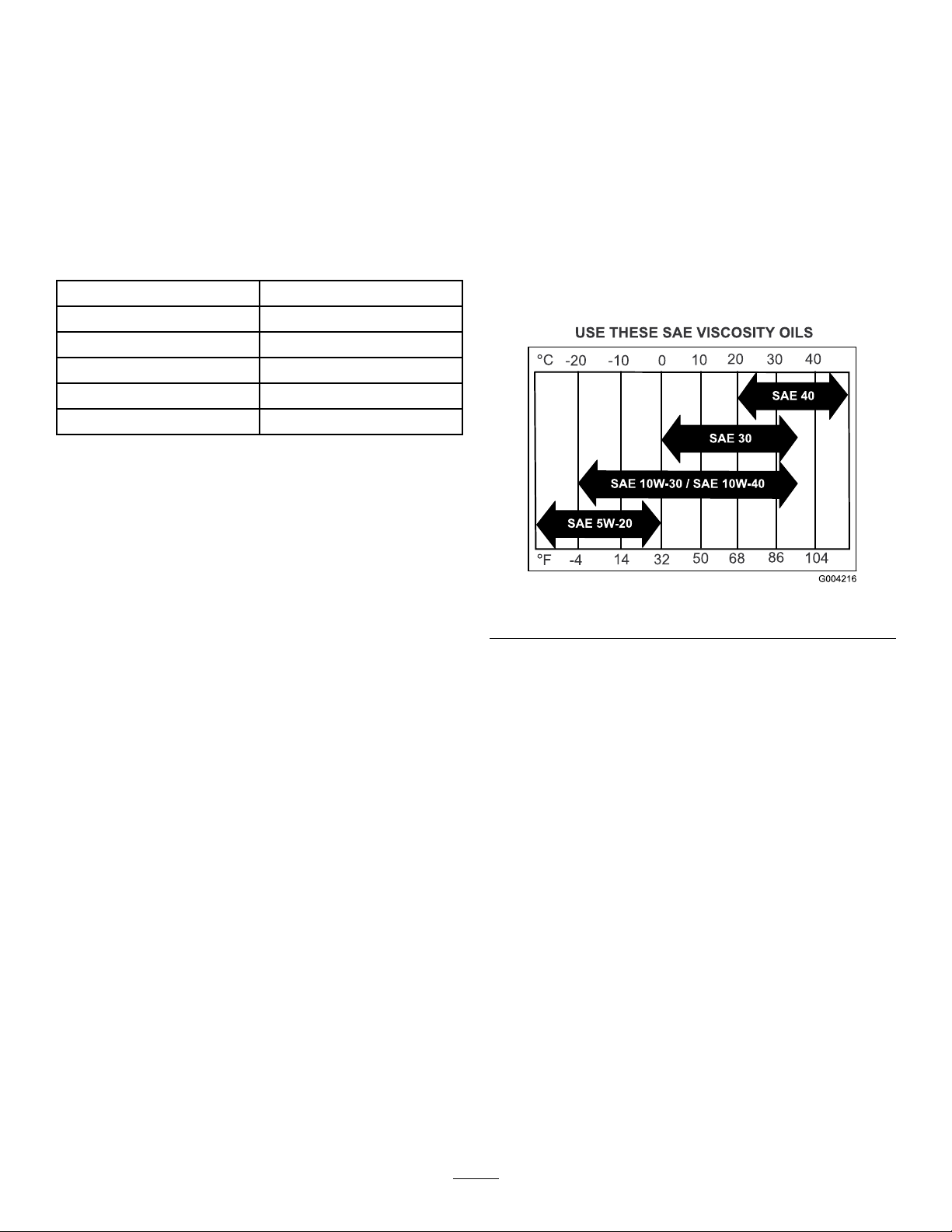

OilType:Detergentoil(APIserviceSJorhigher)

Oilviscosity:Refertothetablebelow.

Figure12

Important:Donotoperatetheenginewiththeoil

levelbelowtheLow(orAdd)markonthedipstick,

orovertheFullmark.

1.TurnthekeyintheignitionswitchtotheOFF

position,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperating

position

2.Allowtheenginetocool.

3.Checktheengine-oillevelasshowninFigure

13.

g004216

18

AddingFuel

Fueltankcapacity:18.9L(5USGallons)

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

g025899

•ETHANOL:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan10%

ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused.

Figure13

4.Iftheoillevelislow,wipeofftheareaaround

theoilllcap,removecapandaddthespecied

oiluntiltheoillevelisattheFullmarkonthe

dipstick.

•Donotaddoiltogasoline

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

andwhentheengineiscold.Wipeupany

fuelthatspills.

•Donotllthefueltankcompletelyfull.

Addfueltothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

g025898

awayfromanopenameorwhereaspark

mayignitethefuelfumes.

•Storefuelinanapprovedfuelcontainer

andkeepitoutofthereachofchildren.

•Neverbuymorethana30-daysupplyof

fuel.

Note:Donotoverlltheenginewithoil.

19

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuel.T ominimize

thechanceofvarnishdepositsinthefuelsystem,

usefuelstabilizeratalltimes.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removefuel-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

fuel-dispensernozzle.

•Ifafuel-dispensernozzlemustbeused,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

FuelingtheMachine

1.Cleanaroundthefuel-tankcap.

2.Removethecapfromthetank.

3.Fillthefueltankwithunleadedfueltowithin6to

13mm(1/4to1/2inch)fromthetopofthetank.

Donotllintothellerneck.

Important:Donotllthetankmorethan

6mm(1/4inch)fromthetopofthetank

becausethefuelmusthaveroomtoexpand.

4.Installthefuel-tankcapandwipeupanyspilled

fuel.

LubricatingtheChains

CheckingtheConditionofthe

Sprockets

ServiceInterval:Beforeeachuseordaily

1.TurnthekeyintheignitionswitchtotheOFF

position,engagetheparkingbrake,waitforall

movingpartstostop,andremovekey.

2.Inspectsprocketsforwearandreplaceas

required(Figure14).

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandfueltank

orconditionerbottleopening.

•Avoidcontactwithskin;washoffspillage

withsoapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsfuelfreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefuel

tankbedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

20

1.TurnthekeyintheignitionswitchtotheOFF

position,engagetheparkingbrake,waitforall

movingpartstostop,andremovekey.

2.Raisethemachineandsupportitwithjack

standswitha460kg(1,015lb)capacity.

CAUTION

Raisingthemachineforservice

ormaintenancerelyingsolelyon

mechanicalorhydraulicjackscouldbe

dangerous.Themechanicalorhydraulic

jacksmaynotbeenoughsupportormay

malfunctionallowingthemachinetofall,

whichcouldcauseinjury .

Donotrelysolelyonmechanical

orhydraulicjacksforsupport.Use

adequatejackstandsorequivalent

support.

3.TurnthekeyintheignitionswitchtotheON

position,andmovethrottlelevelaheadto1/2

throttleposition.

Figure14

1.Sprockets2.Chains

CheckingtheConditionofthe

Chains

ServiceInterval:Beforeeachuseordaily

1.TurnthekeyintheignitionswitchtotheOFF

position,engagetheparkingbrake,waitforall

movingpartstostop,andremovekey.

2.Checkthechaintension(Figure14)atboth

sidesofthemachine.

Note:Thechainsshouldmoveupanddown6

to12mm(1/4to1/2inch).

3.Ifchainspoporsnap;refertoAdjustingthe

JackshaftDriveChainTension(page40),

AdjustingtheTensionontheDrive-WheelChain

(page41),orAdjustingtheTine-DriveChain

(page50).

g025984

WARNING

Enginemustberunninganddrivewheels

mustbeturningsoadjustmentscanbe

performed.Contactwithmovingpartsor

hotsurfacesmaycausepersonalinjury.

Keepngers,hands,andclothingclear

ofrotatingcomponentsandhotsurfaces.

4.Disengagetheparkingbrake.

5.Withtheenginerunning,slowlymovethe

traction-controlleversforwardandlubricateall6

chains(Figure14).

6.Checktheconditionandtensionofthechains;

refertoCheckingtheConditionoftheChains

(page21).

LubricatingtheChains

ServiceInterval:Beforeeachuseordaily

Important:Donotlubricatechainswith

penetratingoilorsolvents.Useoilorchain

lubricant.

21

Checkingthe

Safety-InterlockSystem

ServiceInterval:Beforeeachuseordaily

CAUTION

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

UnderstandingtheSafety-InterlockSystem

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingunlessthetraction-controllevers

areintheneutralposition.

CheckingtheSafety-InterlockSystem

1.Disconnectthespark-plugwires;referto

RemovingtheSparkPlug(page35).

OperatingtheMachine

OpeningtheFuel-ShutoffValve

Rotatetheleverofthefuel-shutoffvalvetoalignthe

leverwiththefuelline.

g025897

Figure15

1.Offposition2.Onposition

2.Whileonlevelground,blockthewheelsofthe

machinetopreventunintendedmovement.

3.Disengagetheparkingbrake;referto

Parking-BrakeHandle(page16).

4.Withthetraction-controlleversintheneutral

positionturnthekeytothestartposition—the

startermustnotcrank;refertoTraction-Control

Levers(page15)andIgnitionSwitch(page16).

Note:Ifthemachinedoesnotpassthistest,donot

operate.ContactyourauthorizedT oroServiceDealer.

Important:Itisessentialthattheoperator

safetymechanismsbeconnectedandinproper

operatingconditionpriortouseforaerating.

CheckingforLoose

Hardware

ServiceInterval:Beforeeachuseordaily

1.TurnthekeyintheignitionswitchtotheOFF

position,engagetheparkingbrake,waitforall

movingpartstostop,andremovekey.

2.Visuallyinspectmachineforanyloosehardware

oranyotherpossibleproblem.

Note:Tightenallloosehardwareorrepairthe

problembeforeoperatingthemachine.

22

StartingtheEngine

1.Movethetraction-controlleverstotheNEUTRAL

positionandengagetheparkingbrake;refer

toTraction-ControlLevers(page15)and

Parking-BrakeHandle(page16).

Note:Tostarttheengine,theparkingbrake

mustbeengaged.(Itisnotnecessaryforthe

operatortobeontheplatform.)

2.Placethethrottlelevermidwaybetweenthe

SLOWandFASTpositions;refertoThrottleLever

(page16).

3.Iftheengineiscold,pushthechokelever

forwardtotheONposition;refertoChokeLever

(page16).

Note:Iftheengineiswarm,pullthechoke

levertotheOFFposition.

4.TurnthekeyintheignitionswitchtotheSTART

position;refertoIgnitionSwitch(page16).

Note:Releasethekeyintheignitionswitchas

soonastheenginestarts.

3.Standontheswitchandmovethetraction-control

leversforwardtoaerate(Figure16);referto

Traction-ControlLevers(page15).

4.Adjustthethrottlefortheworkingconditions;

refertoThrottleLever(page16).

AdjustingtheTineDownPressure

Important:Keepthedrivetiresonthegroundat

alltimes.

Adjusttheplugdepthbyrotatingthetinepressure

controlasfollows:

Note:Firsttimeuse:setthetinepressurecontrol

sothatthetine-pressuregauge(Figure17)indicates

24bar(350psi).

Important:Donotcranktheengine

continuouslyformorethantensecondsata

time.Iftheenginedoesnotstart,allowa60

secondcool-downperiodbetweenstarting

attempts.Failuretofollowtheseguidelines

canburnoutthestartermotor

5.IfthechokeleverisintheONposition,gradually

movethelevertowardtheOFFpositionasthe

enginewarmsup.

LoweringtheTines

1.SetthrottlelevertotheMIDWAYposition;referto

ThrottleLever(page16).

2.Steponthetine-elevationswitchtolowerthe

tines(Figure16).

Figure17

1.Tine-pressurecontrol3.Decreasepressure

2.Tine-pressuregauge

(shorterplug)

4.Increasepressure(longer

plug)

•Rotatethetine-pressurecontrol

counterclockwise(Figure17)todecrease

thedownwardpressureinordertoremovea

shorterplug.

•Rotatethetine-pressurecontrolclockwise(Figure

17)toincreasedownwardpressureinorderto

removealongerplug.

Note:Idealplugdepthis7.6to10cm(3to4inches).

Rotatethetine-pressurecontroltoadapttothesoil

conditions.

g025901

1.Tine-elevationswitch

Figure16

RaisingtheTines

Toraisethetines,removeyourfootfromthe

tine-elevationswitch(Figure16).

g025900

Important:Thetinesrotatewhenthe

traction-controlleverismovedoutoftheNEUTRAL

position.

23

StoppingtheEngine

1.Movethetraction-controlleverstotheNEUTRAL

positionandbringthemachinetoafullstop;

refertoTraction-ControlLevers(page15).

2.Liftyourfootoffofthetinegroundengagement

footswitchcontroltoraisethetines;referto

RaisingtheTines(page23).

3.Placethethrottleinthemidwaybetweenthe

SLOWandFASTpositions;refertoThrottleLever

(page16).

4.Allowtheenginetorunforaminimumof15

seconds,thenturnthekeyintheignitionswitch

totheOFFpositiontoshutofftheengine;refer

toIgnitionSwitch(page16).

5.Engagetheparkingbrake;refertoParking-Brake

Handle(page16).

6.Removethekeytopreventchildrenorother

unauthorizedpersonsfromstartingtheengine.

7.Closethefuel-shutoffvalvewhenthemachine

willnotbeinuseforafewdays,when

transporting,orwhenthemachineisparked

insideabuilding;refertoFuel-ShutoffValve

(page17).

Figure18

1.Lefttraction-controllever

2.Righttraction-controllever6.Neutral

3.Frontreferencebar

4.Frontofthemachine

5.Forward

7.Reverse

DrivingForward

1.Makesurethatthetraction-controlleversarein

theNEUTRALposition.

2.Disengagetheparkingbrake.

3.T omoveforwardinastraightline,moveboth

leversforwardwithequalpressure.

g020241

DrivingtheMachine

CAUTION

Machinecanspinveryrapidlybypositioning

1levertoomuchaheadoftheother.Operator

maylosecontrolofthemachine,whichmay

causedamagetothemachineorinjury .

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

Important:Tobeginmovement(forwardor

backward),thebrakelevermustbedisengaged

(pushedforward)beforethetraction-control

leverscanbemoved.

g016672

Figure19

Toturnleftorright,pullthetraction-controllever

backtowardneutralinthedesiredturndirection.

Thetinescanbeinthedownpositionwhen

makinggradualturns.

Tomakezeroturns,liftyourfootoffofthetine

engagementfootswitchcontroltoraisethe

tines.Theheadraisesin1second.

Important:Donotmakeazeroturnwhen

thetinesaredownasturftearingwillresult.

24

Themachinemovesfasterthefartheryoumove

thetraction-controlleversfromtheneutral

position.

4.T ostop,positionbothtraction-controlleversin

theneutraloperateposition.

DrivinginReverse

1.Movethetraction-controlleverstothe

NEUTRAL/OPERATEposition.

2.T omoverearwardinastraightline,slowlymove

bothleversrearwardwithequalpressure.

CAUTION

Thismachinedoesnothaveproperturn

signals,lights,reectivemarkings,ora

slowmovingvehicleemblem.Drivingona

streetorroadwaywithoutsuchequipment

isdangerousandcanleadtoaccidents

causingpersonalinjury.Drivingonastreetor

roadwaywithoutsuchequipmentmayalsobe

aviolationofStatelawsandtheoperatormay

besubjecttotrafcticketsand/ornes.

Donotdriveamachineonapublicstreetor

roadway.

Totransportthemachine:

1.Raisethetinesofthemachinebeforedriving

ontothetrailerortruck.

2.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

3.Ifapplicable,connectthetrailerbrakes.

4.Loadthemachineontothetrailerortruck.

Figure20

Toturnleftorright,releasepressureonthe

traction-controllevertowardthedesiredturn

direction.

Tomakezeroturns,liftyourfootoffofthe

tine-elevationswitchtoraisethetines.Thehead

raisesin1second.

Important:Donotmakeazeroturnwhen

thetinesareinthedownposition.

3.T ostop,positionbothtraction-controlleversin

theNEUTRAL/OPERATEposition.

TransportingtheMachine

Machineweight:460kg(1,015lb)

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

thenecessarybrakes,lighting,andmarkingas

requiredbylaw.Pleasecarefullyreadallthesafety

instructions.

5.Shutofftheengine,removethekey,setthe

g016673

brake,andclosethefuelvalve.

6.Engagetheparkingbrakeandblockthetires.

7.Usethetie-downpointsonthemachineto

securelybindthemachinetothetrailerortruck

withstraps,chains,cable,orropes(Figure21).

Note:Refertoyourlocalordinancesforspecic

trailerandtie-downregulations.

g025949

Figure21

1.Tie-downpoints

25

LoadingtheMachine

Useextremecautionwhenloadingunitsontotrailers

ortrucks.Use1full-widthrampthatiswideenoughto

extendbeyondthereartiresisrecommendedinstead

ofindividualrampsforeachsideofthemachine

(Figure22).Theplatform,whendownandlockedinto

position,mustextendbackbetweentherearwheels

andservesasastopfortippingbackward.Havinga

full-widthrampprovidesasurfacefortheplatformto

contactifthemachinestartstotipbackward.Withthe

platformup,afull-widthrampprovidesasurfaceto

walkonbehindthemachine.

Therampshouldbelongenoughsothattheangles

donotexceed15degrees(Figure22).Asteeper

anglemaycausetinecomponentstogetcaught,as

themachinemovesfromramptotrailerortruck.A

steeperanglemayalsocausethemachinetotip

backward.Ifloadingonornearaslope,positionthe

trailerortrucksoitisonthedownsideoftheslope

andtherampextendsuptheslope.Thisminimizes

therampangle.Thetrailerortruckshouldbeaslevel

aspossible.

Figure22

1.Trailer3.Notgreaterthan15

2.Full-widthramp

degrees

4.Full-widthramp(sideview)

g000951

WARNING

Loadingthemachineontoatrailerortruck

increasesthepossibilityofbackwardtip-over,

andcouldcauseseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Useonlyasingle,full-widthramp;donot

useindividualrampsforeachsideofthe

machine.

•Ifindividualrampsmustbeused,use

enoughrampstocreateanunbrokenramp

surfacewiderthanthemachine.

•Donotexceeda15-degreeanglebetween

rampandground,orbetweenaramp,a

trailer,oratruck.

•Avoidsuddenaccelerationwhiledriving

machineuparamptoavoidtipping

backward.

•Avoidsuddendecelerationwhilebacking

machinedownaramptoavoidtipping

backward.

Theoperatorshoulddetermineifitisbesttohave

theplatformupordownwhenloading,dependingon

conditions.Ifitisnotpossibletouse1full-widthramp,

useenoughindividualrampstosimulateafull-width,

continuousramp.

Avoidsuddenaccelerationwhendrivinguparamp

andsuddendecelerationwhenbackingdowna

ramp.Bothmaneuverscancausethemachinetotip

backward.

26

Maintenance

WARNING

Whileyouaremaintainingoradjustingthe

machine,someonecouldstarttheengine.

Accidentallystartingtheenginecould

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionswitch,

engageparkingbrake,andpullthewire(s)

offthesparkplug(s)beforeyoudoany

maintenance.Alsopushthewire(s)asideso

itdoesnotaccidentallycontactthespark

plug(s).

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst100hours

Beforeeachuseordaily

MaintenanceProcedure

•Changetheauxiliaryhydraulicreservoirlteranduid.

•Changethetransmissionlters.

•Fillthetransmissionwithoilwhenchangingthelter.

•Checktheengine-oillevel.

•Checktheconditionofthesprockets.

•Checktheconditionandtensionofthechains.

•Lubricatethechains.

•Checkthesafetyinterlocksystem.

•Checkforloosehardware.

•Checkthetines.

•Cleantheengineandtheexhaustsystemarea.

•Cleanthegrassanddebrisbuildupfromthemachine.

WARNING

Theenginecanbecomeveryhot.Touchinga

hotenginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheengine

area.

Every25hours

Every50hours

Every80hours

Every100hours

Every160hours

Every200hours

•Greasethejackshaftbearings.

•Greasethewheelbearings.

•Greasethetineshaftbearings.

•Greasethetineassemblyidlers.

•Greasethecontrolpivots.

•Checksparkarrester(ifequipped).

•Checkthepressureinthetires.

•Checktheconditionandtensionofthebelts.

•Checktheauxiliaryhydraulic-uidlevel.

•Checkthehydraulictransmissionoil-level.

•Removetheengineshroudsandcleanthecoolingns.

•Check,cleanandgapthesparkplug.

•Checkthebattery.

•Checkthesparkplugs.

•Checkthepaperair-cleanerelement(moreoftenundersevereconditions).

•Changetheengine-oillter.

27

MaintenanceService

Every250hours

Every500hours

Interval

MaintenanceProcedure

•Replacetheprimaryaircleanerelement—checksecondaryaircleanerelement;

replaceifdirty.(Mayneedmoreoftenundersevereconditions.SeetheEngine

Owner’sManualforadditionalinformation.)

•Cleanthefoamair-cleanerelement(moreoftenundersevereconditions).

•Changetheauxiliaryhydraulicreservoirlteranduid.

•Changethetransmissionlters.

•Fillthetransmissionwithoilwhenchangingthelter.

•Replacethesecondaryaircleanerelement.(Mayneedmoreoftenundersevere

conditions.SeetheEngineOwner’sManualforadditionalinformation.)

•Replacethepaperair-cleanerelement(moreoftenundersevereconditions).

Every800hours

Yearly

Yearlyorbeforestorage

•Replacethefuellter.

•Greasethefrontcasterpivots.

•Greasethebeltidlerpivot.

•Greasethecasterpivotsandhubs.

•Lubricatethecasterwheelhubs.

•Lubricatethecasterwheelhubs.

•Checkthetorqueofthewheelhubnuts.

•Checkthetorqueonthewheellugnuts.

•Checkthetorqueofthetransmissionoutputshaftnut.

•T ouchupchippedpaint

Pre-Maintenance

Procedures

CAUTION

Raisingthemachineforserviceor

maintenancerelyingsolelyonmechanical

orhydraulicjackscouldbedangerous.The

mechanicalorhydraulicjacksmaynotbe

enoughsupportormaymalfunctionallowing

themachinetofall,whichcouldcauseinjury.

AccessingtheConsole

Compartment

RemovingtheConsolePad

1.Loosenthe4anged-headboltsthatsecurethe

padtotheleftandrightconsolepanels(Figure

23).

Donotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstands

orequivalentsupport.

PreparingfortheMachine

forMaintenance

Performthefollowingbeforeservicing,cleaning,or

makinganyadjustmentstothemachine.

1.Movethemachinetoalevelsurface.

2.TurnthekeyintheignitionswitchtotheOFF

position,engagetheparkingbrake,waitforall

movingpartstostop.

3.Removethekeyfromthekeyswitch.

Figure23

1.Keyholeslot(console

panel)

2.Fanged-headbolt

2.Liftuptheconsolepad(Figure23)approximately

13mm(1/2inch).

3.Pulltheconsolepadstraightbackandremove

thepadfromthemachine(Figure23).

28

g025880

3.Pad

InstallingtheConsolePad

1.Alignthe4anged-headboltsattheforward

faceoftheconsolepadtothe4keyholeslotsin

theframeoftheconsole(Figure23).

Lubrication

LubricatingtheGrease

2.Movethepadforwarduntilthepadisushto

theconsoleframe(Figure23).

3.Movethepaddownuntiltheanged-headbolts

areseatedinthekeyholeslots(Figure23).

4.T orquetheanged-headboltsto1978to2542

N-cm(175to225lb-in).

Fittings

Greasetype:NationalLubricatingGreaseInstitute

(NGLI)grade#2multi-purposegungrease.

Note:Refertothelubricationchartforservice

intervals.

LubricationChart

Fitting

Locations

1.FrontCaster

Pivots

2.Jackshaft

Bearings

3.Wheel

Bearings

4.TineShaft

Bearings

5.Tine

AssemblyIdlers

6.Control

Pivots

7.BeltIdler

Pivot

8.FrontCaster

Hubs

Initial

Pumps

*0

1825hours

1225hours

1425hours

1225hours

1450hours

11Y early

*0

Numberof

Places

Service

Interval

2Yearly

2Yearly

Figure24

1.TurnthekeyintheignitionswitchtotheOFF

position,engagetheparkingbrake,waitforall

movingpartstostop,andremovethekey .

2.Wipecleanthegreasettingswitharag(Figure

24).

29

g020222

3.Connectagreaseguntothetting(Figure24).

RemovingtheCaster-WheelAssembly

4.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

5.Wipeupanyexcessgrease.

LubricatingtheCasters

Greasetype:NationalLubricatingGreaseInstitute

(NGLI)grade#2multi-purposegungrease.

GreasingtheCasterPivots

ServiceInterval:Yearly

1.Removecapandhexplugfromthetopofthe

casterpivot(Figure25).

1.TurnthekeyintheignitionswitchtotheOFF

position,engagetheparkingbrake,waitforall

movingpartstostop,andremovekey.

2.Liftthefrontofthemachineandsupportitwith

jackstands.

3.Removethewheelnutandbolt,andremovethe

caster-wheelassemblyfromthefork(Figure26).

g025953

Figure26

1.Wheelbolt3.Wheelnut

2.Caster-wheelassembly

Figure25

1.Hexplug

2.Greasetting4.Cap

2.Threadgreasettinginhole(Figure25).

3.Pumpgreaseintothettinguntilgreaseoozes

outaroundtopbearing(Figure25).

4.Removegreasettingandinstalltheplugthat

youremovedin1(Figure25).

5.Installthecapthatyouremovedinstep1(Figure

25).

3.Casterpivot

DisassemblingtheCaster-WheelHuband

GreasingtheBearings

ServiceInterval:Yearly

Important:Usenewbearingsealswhen

lubricatingthecaster-wheelhubs.

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoften.Spinthe

g025955

castertire.Thetireshouldnotspinfreely(more

than1or2revolutions)orhaveanysideplay.If

thewheelspinsfreely,adjusttorqueonspacer

nutuntilthereisaslightamountofdrag.Reapply

thread-lockingadhesive.

Greasetype:NationalLubricatingGreaseInstitute

(NGLI)grade#2multi-purposegungrease.

1.Removethe2sealguardsfromthewheelhub

(Figure27).

6.Repeatsteps1through5totheothercaster.

LubricatingtheCaster-Hubs

Bearings

ServiceInterval:Yearly

30

Figure27

1.Axle(spacernutstill

assembled)

2.Hub5.Bearingseal

3.Bearing

4.Spacernut

6.Sealguard

2.Remove1ofthespacernutsfromtheaxle

assemblyinthecasterwheel(Figure27).

Note:Notethatthread-lockingadhesivehas

beenappliedtolockthespacernutstotheaxle

(Figure27).

3.Removetheaxle(withtheotherspacernutstill

assembledtoit)fromthecaster-wheelassembly

(Figure27).

4.Pryoutbothofthebearingseals(Figure27).

Note:Discardtheoldseals.

5.Removebothofthebearingsandinspecteach

ofthemforwearordamage(Figure27).

Note:Replacethebearingifitiswornor

damaged.

6.Packthe2bearingswiththespeciedgrease.

AssemblingtheCaster-WheelHub

1.Install1bearingintothehubofthewheel(Figure

27).

2.Installthebearingsealintothehubatthe

bearing(Figure27).

3.Ifyouremoved(orbrokeloose)bothofthe

spacernutsfromtheaxleassembly,perform

thefollowing:

A.Cleanthethreadsoftheaxleandspacer

nut.

B.Applythread-lockingadhesivetothe

threadsat1endoftheaxle.

C.Threadtheaxlenut,withthewrenchats

facingoutward,ontotheendoftheaxlethat

ispreparedwiththread-lockingcompound

(Figure27).

mm(1/8inch)fromtheoutersurfaceofthe

spacernuttotheendoftheaxleinsidethe

nut.

4.Inserttheassemblednutandaxleintothewheel

atthesideofthewheelwiththenewsealand

bearing(Figure27).

5.Withtheopenendofthewheelfacingup,llthe

areainsidewheelcavity(aroundtheaxle)with

thespeciedgrease.

g025954

6.Installtheotherbearingandnewsealintothe

wheel(Figure27).

7.Applythread-lockingadhesivetothe2ndspacer

nutandthreadontotheaxlewiththewrench

atsfacingoutward.

8.T orquethespacernutto8to9N∙m(75to80

in-lb),loosen,thenre-torqueto2to3N∙m(20

to25in-lb).

Note:Makesureaxledoesnotextend

beyondeithernut.

9.Installthesealguardsoverthewheelhub

(Figure27).

InstallingtheCaster-WheelAssembly

1.Aligntheholeintheaxleofthecaster-wheel

assemblybetweentheholesintheforkofthe

caster(Figure26).

2.Securethetotheforkwiththewheelnutand

bolt(Figure26)thatyouremovedinstep3of

RemovingtheCaster-WheelAssembly(page

30).

3.T orquethewheelnutto91to113N∙m(67to

83ft-lb).

Note:Donotthreadspacernutallofthe

wayontotheaxle.Leaveapproximately3

31

EngineMaintenance

5.Carefullypullthefoamelementoffthepaper

element(Figure28).

ServicingtheAirCleaner

ServiceInterval:Every250hours—Replacethe

primaryaircleanerelement—

checksecondaryaircleaner

element;replaceifdirty.(Mayneed

moreoftenundersevereconditions.

SeetheEngineOwner’sManualfor

additionalinformation.)

Every500hours

Inspectthefoamandpaperelements,andreplace

themiftheyaredamagedorexcessivelydirty .

Important:Donotapplyoiltothefoamorpaper

element.

RemovingtheFoamandPaper

Elements

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage

(Figure28).

ServicingtheFoamAir-Cleaner

Element

ServiceInterval:Every250hours(moreoftenunder

severeconditions).

1.Inspecttheelementfortears,anoilylm,or

damaged(Figure28).

Important:Replacethefoamelementifit

iswornordamaged.

2.Washthefoamelementinliquidsoapand

warmwater.Whentheelementisclean,rinse

itthoroughly.

3.Drytheelementbysqueezingitinacleancloth.

ServicingthePaperAir-Cleaner

Element

ServiceInterval:Every200hours—Checkthepaper

air-cleanerelement(moreoften

undersevereconditions).

Every500hours—Replacethepaperair-cleaner

element(moreoftenundersevereconditions).

Important:Donotwashthepaperair-cleaner

element.

1.Inspecttheelementfortears,anoilylm,or

damagetotherubberseal(Figure28).

Figure28

1.Cover

2.Hoseclamp4.Foamelement

3.Rotatethecoverknobs1/4turncounterclockwise

andremovetheair-cleanercover(Figure28).

4.Rotatethethumbscrewofthehoseclamp

counterclockwiseuntilyoucanseparatethe

air-cleanerassemblyfromtheinletduct(Figure

28).

3.Paperelement

Note:Replacethepaperelementifitis

damaged.

2.Cleanthepaperelementbygentlytappingitto

removedustanddebris.

Note:Iftheelementisverydirty ,replacethe

air-cleanerelement.

Note:Donotusepressurizedairtocleanthe

paperelement.

InstallingtheFoamandPaper

g012352

Elements

Important:Topreventenginedamage,always

operatetheenginewiththecompletefoamand

paperair-cleanerassemblyinstalled.

1.Carefullyslidethefoamelementontothepaper

air-cleanerelement(Figure28).

2.Aligntheair-cleanerassemblyontotheinletduct

andsecureitwiththehoseclamp(Figure28).

3.Aligntheair-cleanercoverontoenginecover

andsecurethecoverbyrotatingthecoverknobs

1/4tunclockwise(Figure28).

32

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSJorlater)

EngineOilCapacity:1.7L(1.8USqt)withthelter

removed;1.5L(1.6UDqt)withoutthelterremoved

Oilviscosity:Refertothetablebelow.

Figure29

g004216

ChangingtheEngineOil

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoil

drainscompletely.

2.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.ChangetheengineoilasshowninFigure31.

Note:Torquedrainplugto27-33N∙m(20-24

ft-lb).

Figure30

g025979

Figure31

4.Slowlypourapproximately80%ofthespecied

oilintothellertube,andslowlyaddthe

additionaloiltobringittotheFullmark(Figure

32).

g025980

33

Figure32

5.Starttheengineanddrivetoaatarea.

6.Checktheengine-oillevel.

ChangingtheEngine-OilFilter

g025976

g026005

ServiceInterval:Every200hours

Note:Changetheengine-oilltermorefrequently

whenoperatingconditionsareextremelydustyor

sandy.

1.Draintheoilfromtheengine;refertoChanging

theEngineOil(page33).

2.Placearagundertheoilltertosoakupany

spilledoil.

Important:Spilledoilmaydrainunderthe

engineandontotheclutch.Oilspilledon

theclutchmaydamagetheclutch,cause

thebladestostopslowlywhentheclutchis

intheOffposition,andcausetheclutchto

slipwhentheclutchisswitchedtotheOn

position.Wipeupanyspilledoil.

3.Changetheengine-oillter(Figure33).

g026006

Figure33

Note:Ensuretheoil-ltergaskettouchesthe

engine,andthenanextra3/4turniscompleted.

4.Fillthecrankcasewiththespeciedtypeofnew

oil;refertoFigure29.

34

CheckingtheSparkPlugs

CheckingtheSparkPlug

ServiceInterval:Every160hours

Removesparkplugs,checkconditionandresetgaps,

orreplacewithnewplugs.Seetheengineowner's

manual.

ServicingtheSparkPlug

ServiceInterval:Every100hours

TypeforallEngines:NGKBPR4ESorequivalent

AirGap:0.75mm(0.03inch)

Makesurethattheairgapbetweenthecenterand

sideelectrodesiscorrectbeforeinstallingthespark

plug.

Useasparkplugwrenchforremovingandinstalling

thesparkplug(s)andagappingtool/feelergaugeto

checkandadjusttheairgap.Installanewspark

plug(s)ifnecessary.

RemovingtheSparkPlug

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithasa

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty .

Setthegapto0.75mm(0.03inch).

g027479

Figure35

InstallingtheSparkPlug

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.RemovethesparkplugasshowninFigure34.

Figure34

Tightenthesparkplug(s)to22N∙m(16ft-lb).

g025981

g027661

Figure36

g027478

35

Checkingthe

FuelSystem

SparkArrester

(ifequipped)

ServiceInterval:Every50hours

WARNING

Hotexhaustsystemcomponentsmayignite

fuelvaporsevenaftertheengineisstopped.

Hotparticlesexhaustedduringengine

operationmayigniteammablematerials.

Firemayresultinpersonalinjuryorproperty

damage.

Donotrefuelorrunengineunlessspark

arresterisinstalled.

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Allowthemufertocool.

3.Checkthesparkarresterforbreaksinthe

spark-arresterscreenorwelds.

Maintenance

ServicingtheFuelFilter

ReplacingtheFuelFilter

ServiceInterval:Every800hours/Yearly(whichever

comesrst)

Note:Wipeupanyspilledfuel.

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Closethefuel-shutoffvalve;refertoFuel-Shutoff

Valve(page17).

3.Squeezetheendsofthehoseclampstogether

andslidethemawayfromthelter(Figure37).

Note:Replacearresterifitiswornordamaged.

4.Ifyouseethatthescreenisplugged,perform

thefollowing:

A.Removethesparkarrester.

B.Shakeloosetheparticlesfromofthe

arresterandcleanscreenwithawirebrush.

Note:Soakthearresterscreeninsolvent

ifnecessary.

C.Installsparkarresterontoexhaustoutlet.

g025982

Figure37

1.Hoseclamp3.Hose

2.Flowdirectionarrow(fuel

lter)

4.Removethelterfromthefuelhoses(Figure

37).

Note:Donotinstalladirtylterifitisremoved

fromthefuelline.

5.Installanewlterwiththeow-directionarrow

alignedasillustratedinFigure37.

Note:Ensurethatthefuelhosesarefully

seatedontothehosettingsofthefuellter.

6.Alignthehoseclampsoverthehoseandthe

fuel-lterttings(Figure37).

36

7.Openthefuel-shutoffvalve;refertoOpeningthe

Fuel-ShutoffV alve(page22).

ElectricalSystem

8.Checkforfuelleaksandrepairifneeded.

9.Wipeupanyspilledfuel.

Maintenance

ServicingtheBattery

ServiceInterval:Every100hours

Alwayskeepthebatterycleanandfullycharged.Use

apapertoweltocleanthebatterycase.Ifthebattery

terminalsarecorroded,cleanthemwithasolutionof

4partswaterand1partbakingsoda.Applyalight

coatingofgreasetothebatteryterminalstoprevent

corrosion.

Voltage:12volts

DANGER

Donotdrinkelectrolyte,andavoidcontact

withskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

Batteryelectrolytecontainssulfuricacid

whichisfatalifconsumedandcausessevere

burns.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponentscausing

sparks.Sparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

WARNING

Incorrectbattery-cableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

37

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Removetheconsolepad;refertoRemovingthe

ConsolePad(page28).

4.Slidetheredterminalcoveroverthe

positive-batteryterminal.

5.Installthenegativebatterycableandtheground

wiretothenegative(-)batteryterminalwitha

angedboltandangednut(Figure38).

3.Atthebattery,lifttheblackterminalcoveronthe

negativecable(Figure38).

Figure38

1.Flangedbolt

2.Terminalcover

(black—negative-battery

terminal)

3.Terminalcover

(red—positive-battery

terminal)

4.Positive(+)battery

terminal

5.Negative(-)battery

terminal

6.Flangednut

7.Batterytray

8.Batterystrap

4.Disconnectthenegativebatterycablefromthe

negative(-)batteryterminal,andremovethe

cablefromthebattery(Figure38).

5.Slidetheredterminalcoveroffthepositive

batteryterminal(Figure38).

6.Slidetheblackterminalcoveroverthe

negative-batteryterminal.

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthat

canexplode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery .

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity)topreventbatterydamage

whenthetemperatureisbelow32°F(0°C).

1.Removethebatteryfromthechassis;referto

RemovingtheBattery(page37).

g025881

2.Checktheelectrolytelevel.

3.Ensurethatthellercapsareinstalledonthe

battery.

4.Chargethebatteryfor1hourat25to30amps

or6hoursat4to6amps.

5.Whenthebatteryisfullycharged,unplugthe

chargerfromtheelectricaloutlet,anddisconnect

thechargerleadsfromthebatteryposts(Figure

39).

6.Installthebatteryontothemachineandconnect

thebatterycables;refertoInstallingtheBattery

(page38).

Note:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccur.

6.Disconnectthepositive(red)batterycable,and

removethecablefromthebattery(Figure38).

7.Removethehookofthebatterystrapfromthe

batterytray(Figure38),andremovethebattery.

InstallingtheBattery

1.Placethebatteryontothemachine(Figure38).

2.Securethebatterytothebatterytraywiththe

batterystrap.

3.Installthepositive(red)batterycabletopositive

(+)batteryterminalwithaangedboltand

angednut(Figure38).

1.Positivebatterypost

2.Negativebatterypost

38

g000538

Figure39

3.Red(+)chargerlead

4.Black(-)chargerlead

ServicingtheFuses

DriveSystem

Theelectricalsystemisprotectedbyfuses,and

requiresnomaintenance.Ifafuseblows,checkthe

componentorcircuitforamalfunctionorshort.

1.Releasethecushionfromtherearofthe

machine.

2.Removethenegative-batterycablefromthe

batteryterminal;refertosteps4and5of

RemovingtheBattery(page37).

Note:Ensurethatthenegativebatterycable

doesnottouchthebatteryterminal.

3.Pullthefusefromthesocketofthefuseblock

(Figure40).

Maintenance

CheckingtheAirPressure

intheTires

ServiceInterval:Every50hours

Note:Thesemi-pneumaticcastertiresdonotneed

tobeinated.

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Checktirepressureindrivetires.

3.Inatedrivetiresto83-97kPa(12-14psi).

CheckingtheWheelHub

Nuts

ServiceInterval:Yearly

Figure40

1.Fuseblock

4.Installafuseofthesametypeandamperesinto

thesocketofthefuseblock(Figure40).

5.Installthenegative-batterycablefromthebattery

terminal;refertosteps5and6ofInstallingthe

Battery(page38).

Torquethewheelhubnuts(Figure41)to285to350

N∙m(210to260ft-lb).

Note:Donotuseanti-seizecompoundonthewheel

hub.

g025983

g026029

Figure41

1.Lugnut2.Hubnut

CheckingtheTorqueofthe

WheelLugNuts

ServiceInterval:Yearly

Torquethewheellugnuts(Figure41)to122to129

N∙m(90to95ft-lb).

39

AdjustingtheCasterPivot

BearingsPre-Load

andtensionerplate,andthe2nutssecuringthe

adjustmentboltatthetensionerplateasshown

inFigure43.

Note:Ifyoudisassemblethecasterpivotbearings,

ensurethatthespring-discwashersareinstalledas

showninFigure42.

1.Removedustcapfromcasterhub(Figure42).

Figure42

Note:Youmustloosenthenutsandboltsthat

securethetransmissionmountandtensioner

plateatbothsidesofthemachine.

g026022

1.Dustcap

2.Locknut

3.Spring-discwashers

2.Tightenthelocknutclockwiseuntilspring-disc

washersareat(Figure42).

3.Rotatethelocknutcounterclockwise1/4ofa

turn(Figure42).

4.Installthedustcap(Figure42).

4.Spindle

5.Casterhub

MaintainingtheChain

AdjustingtheJackshaftDrive

ChainTension

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Lifttherearofthemachineandsupportitusing

jackstandsorequivalentsupport.

3.Checkthechainsonbothsidesofthemachine

forpropertension.

Figure43

1.Hydromountingboltsand

nuts

2.Nuts

3.Adjustmentbolt

5.Turntheadjustmentbolttomovetransmission

adjustmentplatesandtransmission.

6.Whenthechainscanmoveupanddown6to12

mm(1/4to1/2inch),tightenthenutsonboth

sidesoftheadjustmentbolts.

7.Tightennutsandboltsthatsecurethehydro

mounting.

8.Adjusttraction-controllinkage,refertoAdjusting

theTraction-ControlLinkage(page44).

4.6-12mm(1/4-1/2inch)

5.Guardremovedforclarity

g020261

Note:Thechainsshouldmoveupanddown6

to12mm(1/4to1/2inch).

4.Ateachsideofthemachine,loosenthe3nuts

andboltsthatsecurethetransmissionmount

40

AdjustingtheTensiononthe

Drive-WheelChain

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Lifttherearofthemachineandsupportitusing

jackstands.

3.Checkthetensionofthedrive-wheelchains

(Figure44).

Note:Thechainsshouldmoveupanddown6

to12mm(1/4to1/2inch).

CheckingtheTransmission

OutputShaftNutTorque

ServiceInterval:Yearly

Torquethenut(Figure45)onthetransmissionoutput