Page 1

FormNo.3421-850RevB

24inStand-OnAerator

ModelNo.39514—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3421-850*B

Page 2

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442tooperatethe

engineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

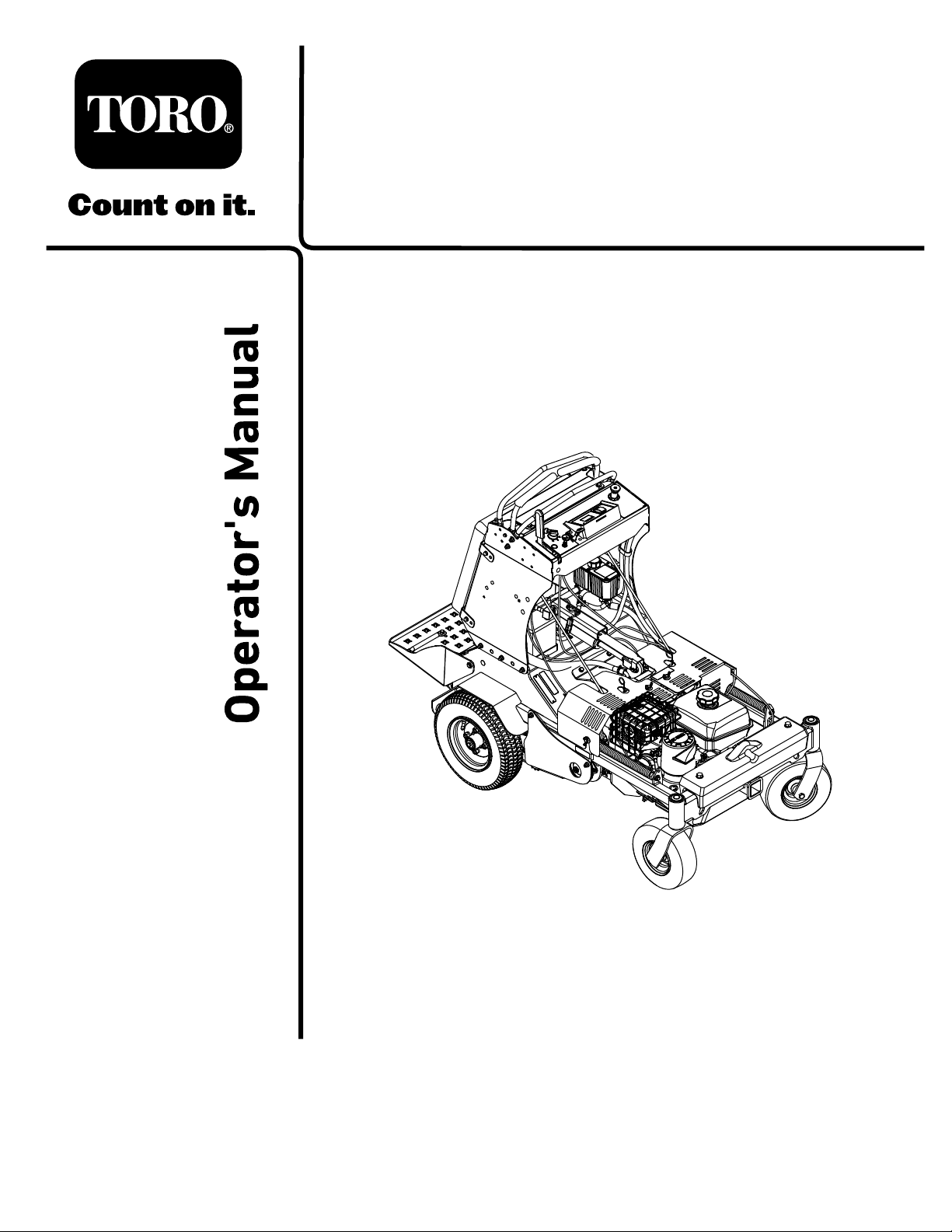

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g246050

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Introduction

Thisaeratorisintendedforusebytrainedoperators

inresidentialandcommercialapplications.The

machineisprimarilydesignedforaeratingareasof

well-maintainedlawnsonresidentialgrounds,parks,

sportselds,andoncommercialgrounds.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

AeratorSafety....................................................6

SafetyandInstructionalDecals..........................7

Setup.......................................................................11

1CheckingTireAirPressure.............................11

2ServicingtheEngineOil..................................11

3CheckingtheBatteryCharge..........................11

4CheckingtheTransmissionFluid...................12

5ChecktheAuxiliaryHydraulicFluid

Level.............................................................12

ProductOverview...................................................13

Controls...........................................................13

Specications..................................................20

Operation................................................................20

AddingFuel......................................................20

OpeningandClosingtheFuelShutoff

Valve.............................................................21

StartingtheEngine...........................................21

CheckingtheSafetyInterlock...........................22

LoweringtheTines...........................................22

ChangingtheTineDepthSetting......................22

Locking/UnlockingtheTineDepth

Setting...........................................................22

AdjustingtheOperatorWeightControl

Valve.............................................................22

RaisingtheTines..............................................23

ShuttingOfftheEngine.....................................23

DrivingtheMachine..........................................23

PositioningtheAir-CleanerCoverforColdor

WarmAirT emperature..................................24

AdjustingtheFrontReference/Speed

ControlBar....................................................25

LoadingtheMachine........................................25

TransportingtheMachine.................................25

Maintenance...........................................................27

RecommendedMaintenanceSchedule(s)...........27

Pre-MaintenanceProcedures..............................28

PreparingforMaintenance...............................28

Lubrication..........................................................29

LubricatingtheChains......................................29

LubricatingtheGreaseFittings.........................29

EngineMaintenance...........................................30

ServicingtheAirCleaner..................................30

ServicingtheEngineOil....................................30

ServicingtheSparkPlug...................................32

CheckingtheSparkArrester.............................33

ElectricalSystemMaintenance...........................34

JumpStartingtheMachine...............................34

ServicingtheBattery.........................................35

DriveSystemMaintenance..................................36

CheckingtheDriveTireAirPressure.................36

CheckingtheWheelHubBolts..........................36

CheckingtheT orqueoftheWheelLug

Nuts..............................................................36

CheckingtheConditionoftheChains...............36

CheckingtheSprocketCondition......................36

MaintainingtheChain.......................................36

CheckingtheT orqueoftheTransmission

OutputShaftNut...........................................37

AdjustingtheMotionControlLinkage................37

AdjustingtheMotionControlTracking...............37

BrakeMaintenance.............................................38

AdjustingtheParkingBrake..............................38

BeltMaintenance................................................38

CheckingtheConditionandT ensionofthe

Belts..............................................................38

AdjustingtheAuxiliaryPumpDrive

Belt................................................................38

CheckingtheTransmissionDriveBelt

Tension.........................................................38

HydraulicSystemMaintenance...........................39

AuxiliaryHydraulicFluidSpecication..............39

CheckingtheAuxiliaryHydraulicFluid

Level.............................................................39

ChangingtheAuxiliaryHydraulicReservoir

FluidandFilter..............................................39

TransmissionFluidSpecication......................39

CheckingtheTransmissionFluidLevel.............40

ChangingtheHydraulicTransmissionFilters

andFluid.......................................................40

TineMaintenance.................................................41

CheckingtheTines...........................................41

AdjustingtheTineDriveChain..........................42

AdjustingtheReturn-to-UpSpring....................42

Cleaning..............................................................43

CleaningtheEngineandtheExhaust

SystemArea.................................................43

RemovingtheEngineShroudsandCleaning

theCoolingFins............................................43

CleaningtheDebrisfromtheMachine...............43

DisposingofWaste...........................................43

Storage...................................................................44

Troubleshooting......................................................45

3

Page 4

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol(Figure2),which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

WARNING

Removingormodifyingoriginalequipment,

partsand/oraccessoriesmayalterthe

warranty,controllability ,andsafetyofthe

machine.Unauthorizedmodicationstothe

originalequipmentorfailuretouseoriginal

Toropartscouldleadtoseriousinjuryor

death.Unauthorizedchangestothemachine,

engine,fuelorventingsystem,mayviolate

applicablesafetyandgovernmentstandards.

Replaceallpartsincluding,butnotlimitedto,

tires,belts,andfuelsystemcomponentswith

originalT oroparts.

Thisproductiscapableofinjuringyourhandsand

feet.Followallsafetyinstructionstoavoidserious

injuryordeath.

Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeople,ordamage

toproperty.

Anyuseofthismachineotherthanaeratingturfgrass

couldprovedangeroustoyouandbystanders.

Important:Theadditionofattachmentsmade

byothermanufacturersthatdonotmeetANSI

certicationmaycausenoncomplianceofthis

machine.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.4-2012.

Training

•ReadtheOperator'sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readthemanuallanguage,itistheowner's

responsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeople,ordamagetoproperty.

Preparation

•Locateandmarkundergroundhazards.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Useonlyaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothing;includingsafety

glasses,longpants,substantial,slip-resistant

footwear,gloves,andhearingprotection.Tieback

longhair.Donotwearloosejewelry.

•Inspecttheareawhereyouwillusetheequipment

andremoveallobjectsfromtheareabeforeusing

themachine.

•Useextracarewhenhandlingfuels.Theyare

ammableanditsvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Donotremovethefuelcaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmokenearthemachine

whentheengineisrunning.

–Donotrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

4

Page 5

Operation

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Donotrunanengineinanenclosedarea.

•Operatethemachineonlyinwell-litareas,keeping

awayfromholesandhiddenhazards.

•Ensurethatalldrivesareinneutralandthatthe

parkingbrakeisengagedbeforestartingthe

engine.Starttheengineonlyfromtheoperator’s

position.

•Ensurethatyouhavegoodfootingwhileusingthis

machine,especiallywhenbackingup.Reduced

footingcouldcauseslipping.

•Slowdownanduseextracareonhillsides.Be

suretotravelsidetosideonhillsides.Turf

conditionscanaffectthestabilityofthemachine.

Usecautionwhileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturns

andwhenchangingdirectionsonslopes.

•Donotoperatethemachinewithouttheshields

orotherguardssecurelyinplace.Ensurethatall

interlocksareattached,adjustedproperly,and

functioningproperly.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,disengagedrives,engage

theparkingbrake(ifprovided),shutofftheengine,

andremovethekeybeforeleavingtheoperator's

positionforanyreason.

•Stopequipment,shutofftheengine,removethe

key,andinspectthetinesafterstrikingobjectsorif

anabnormalvibrationoccurs.Makethenecessary

repairsbeforeresumingoperations.

•Keepyourhandsandfeetawayfromthetine

assembly.

•Lookbehindanddownbeforebackingupto

ensureaclearpath.

•Stopthemachineifanyoneentersthearea.Keep

petsandbystandersawayfromanoperating

machine.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Fullyraisethe

tinesifyouarenotaerating.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoorfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlingfuel.Fuelisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfuelwiththe

enginerunning.

•Allowtheenginetocoolbeforefueling.

•Donotfuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Donotllcontainersinsideavehicle,onatruck,

oronatrailerbedwithaplasticliner.Alwaysplace

containersonthegroundawayfromyourvehicle

beforelling.

•Removeequipmentfromthetruckortrailerand

fuelitontheground.Ifthisisnotpossible,

thenaddfuelwithsuchequipmentasaportable

containerratherthanfromafuel-dispensernozzle.

•Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntilfueling

iscomplete.Donotuseanozzlelock-opendevice.

•Iffuelisspilledonclothing,changeyourclothing

immediately.

•Donotoverllthefueltank.Replacethefuelcap

andtightenitsecurely.

MaintenanceandStorage

•Donotallowuntrainedpersonneltoservicethe

machine.

•Donottouchequipmentorattachmentpartsthat

maybehotfromoperation.Allowallofthepartsof

themachinetocoolbeforeattemptingtomaintain,

adjust,orservicethemachine.

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Disengagethedrives,raisethetines,engagethe

parkingbrake,shutofftheengine,andremove

thekeyordisconnectthespark-plugwire.Waitfor

allmovementtostopbeforeadjusting,cleaning,

orrepairing.

•Disconnectthebatteryorremovethespark-plug

wirebeforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositiveterminal

last.Connectthepositiverstandnegativelast.

•Usecarewhencheckingthetines.Wrapthetine(s)

orweargloves,andusecautionwhenservicing

them.Onlyreplacetines;donotstraightenorweld

them.

5

Page 6

•Cleangrass,dirt,anddebrisfromthetines,drives,

mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Parkmachineonlevel,hardground.Neverallow

untrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Donotstorefuelnearamesordrainthefuel

indoors.

•Lettheenginecoolbeforestoringthemachine.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

Hauling

•Usecarewhenloadingorunloadingthemachine

intoatraileroratruck.

•Useafull-widthrampforloadingthemachineinto

atraileroratruck.

•Tiethemachinedownsecurelyusingstraps,

chains,cable,orropes.Bothfrontandrearstraps

shouldbedirecteddownandoutwardfromthe

machine.

AeratorSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsandothersafetyinformationyou

mustknow.

GeneralOperation

•Checkcarefullyforoverheadclearances(i.e.,

branches,doorways,electricalwires,etc.)before

operatingunderanyobjects,anddonotcontact

them.

•Usecautionwhenyouareridingontheplatform

anddrivingthemachineovercurbs,rocks,roots,

orotherobstructions.

•Donotjerkthecontrols;useasteadymotion.

•Donotcarrypassengers.

•Donotcarryequipmentonthemachine.

SlopeOperation

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.Operatingthemachineon

anysloperequiresextracaution.Beforeusingthe

machineonaslope,dothefollowing:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

operation.Usecommonsenseandgood

judgmentwhenperformingthisevaluation.

Changesintheterrain,suchasmoisture,can

quicklyaffecttheoperationofthemachineon

aslope.

•Operateacrossslopes,neverupanddown.Avoid

operationonexcessivelysteeporwetslopes.

•Identifyhazardsatthebaseoftheslope.Do

notoperatethemachineneardrop-offs,ditches,

embankments,waterorotherhazards.The

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecollapses.Keepasafe

distance(twicethewidthofthemachine)between

themachineandanyhazard.Useawalkbehind

machineorahandheldtooltooperateinthese

areas.

•Avoidstarting,stoppingorturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction;turnslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steeringorstabilityisinquestion.

Beawarethatoperatingthemachineonwet

grass,acrossslopesordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.Themachinecanslideeven

ifthedrivewheelsarestopped.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocksorotherhiddenhazards.T all

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

•Useextracarewhileoperatingwithaccessoriesor

attachments.Thesecanchangethestabilityof

themachineandcausealossofcontrol.Follow

directionsforcounterweights.

•Ifyoulosecontrolofthemachine,stepoffand

awayfromthedirectionoftravelofthemachine.

6

Page 7

Service

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineT ororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

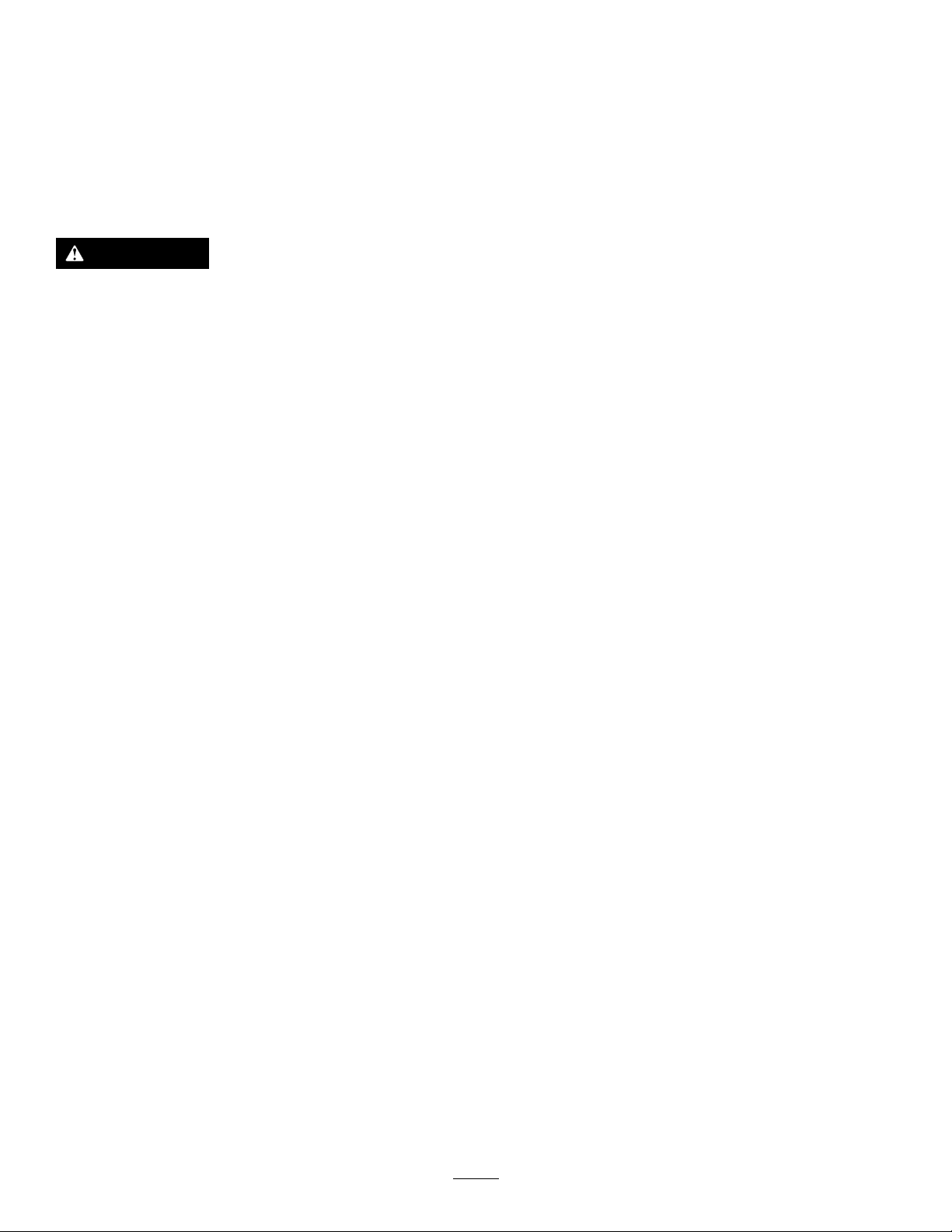

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

•Neverremoveortamperwithsafetydevices.

Checktheirproperoperationregularly.Neverdo

anythingtointerferewiththeintendedfunctionofa

safetydeviceortoreducetheprotectionprovided

byasafetydevice.

•Checkthebrakeoperationfrequently.Adjustand

servicethebrakesasrequired.

115-4212

1.Hydraulic-uidlevel

2.ReadtheOperator's

Manual.

3.Warning—donottouchthe

hotsurface.

117-2718

120-9570

1.Warning—stayawayfrommovingparts;keepallguards

andshieldsinplace.

decal115-4212

decal121-6150

121-6150

1.Cuttinghazardofhandandfoot—stayawayfrommoving

parts.

decal117-2718

decal121-6161

121-6161

1.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsinplace.

decal120-9570

7

Page 8

decal126-7875

126-7875

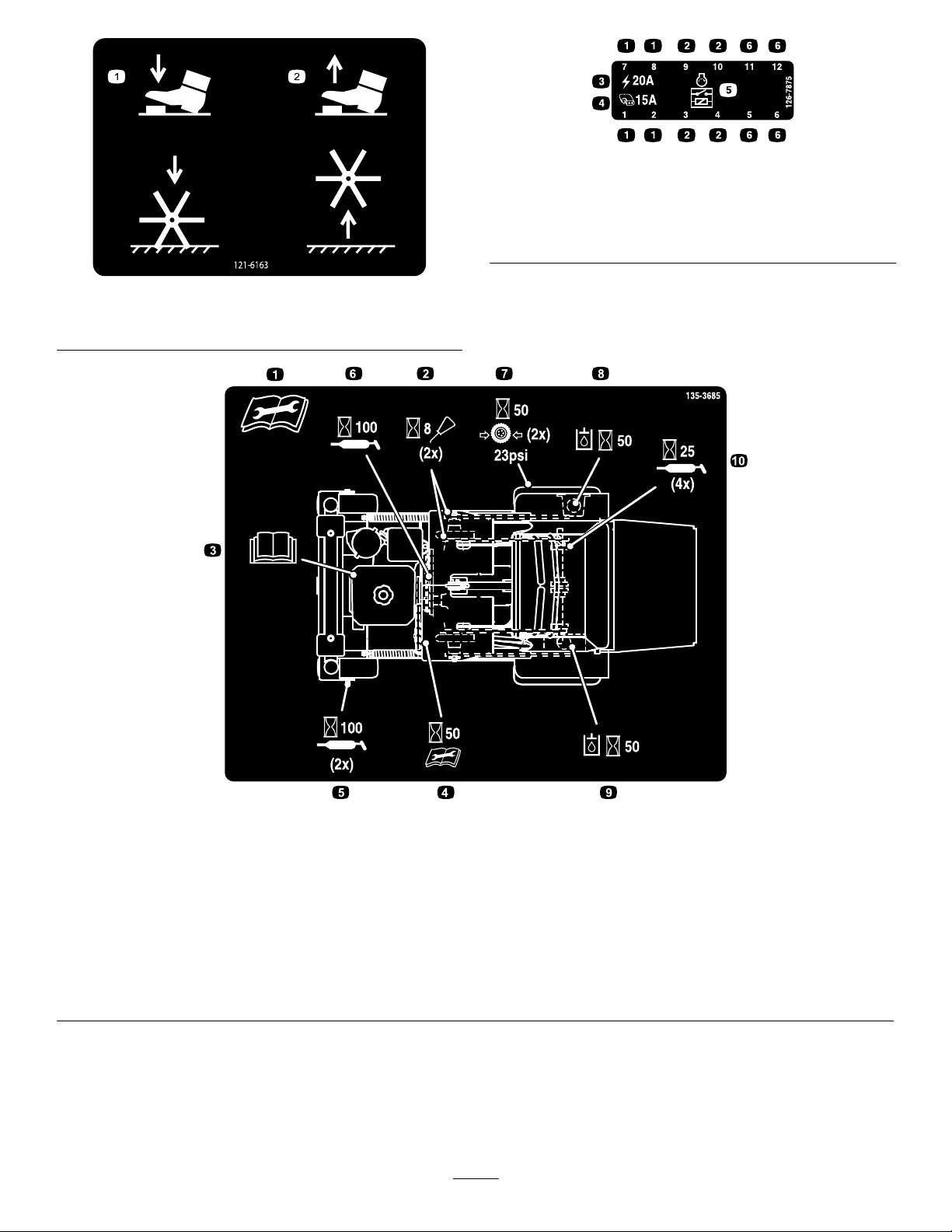

121-6163

1.Presstolowerthetines.2.Releasetoraisethetines.

1.Fuselocation

2.Relaylocation

3.Main(20A)

decal121-6163

4.Auxiliary(15A)

5.Startrelay

6.Notused

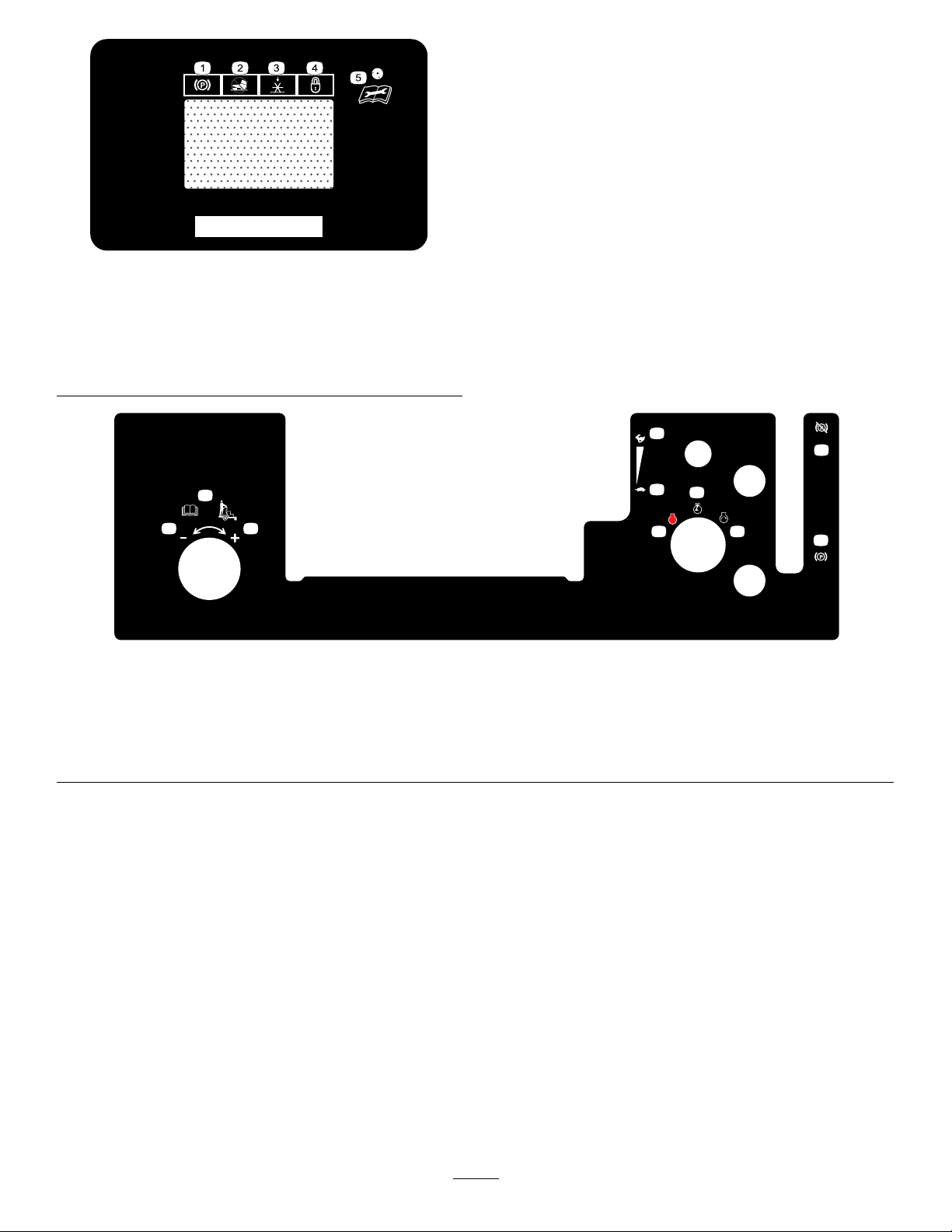

135-3685

1.ReadandunderstandtheOperator’sManualbeforeservicing

thismachine.

2.Cleanandoilthechainsandcheckthechaintensiontwice

every8hours

3.Seetheengineowner’smanualforservice8.Checkthehydraulicoilleveltwice(Useonlyrecommended

4.Checktheauxiliarypumpdrivebelttensionevery50hours9.Checktheauxiliaryhydraulictank(UseonlyAW-32hydraulic

5.Greasethefrontcasterwheelbearingstwiceevery100hours10.Greasethetineshaftbearings4timesevery25hours

6.Greasethebeltidlerpivotevery100hours

7.Checkthetirepressure-23psitwiceevery50hours

hydraulicuid)every50hours

uid)every50hours

8

decal135-3685

Page 9

135-1854

STOP

LB

KG

135-2013

2

1

3

4

5

6

7

8

9

10

1.Parkingbrake4.Depthsetting—lock

2.Tineengagementlockout

switch

3.Tines—down

decal135-1854

5.ReadtheOperator’s

Manualbeforeperforming

maintenance.

decal135-2013-1

135-2013

1.Operatorweightadjustment

5.Throttle—slow9.Parkingbrake—engage

2.Increase6.Engine—on10.Parkingbrake—release

3.Decrease7.Engine—start

4.Throttle—fast8.Engine—off

9

Page 10

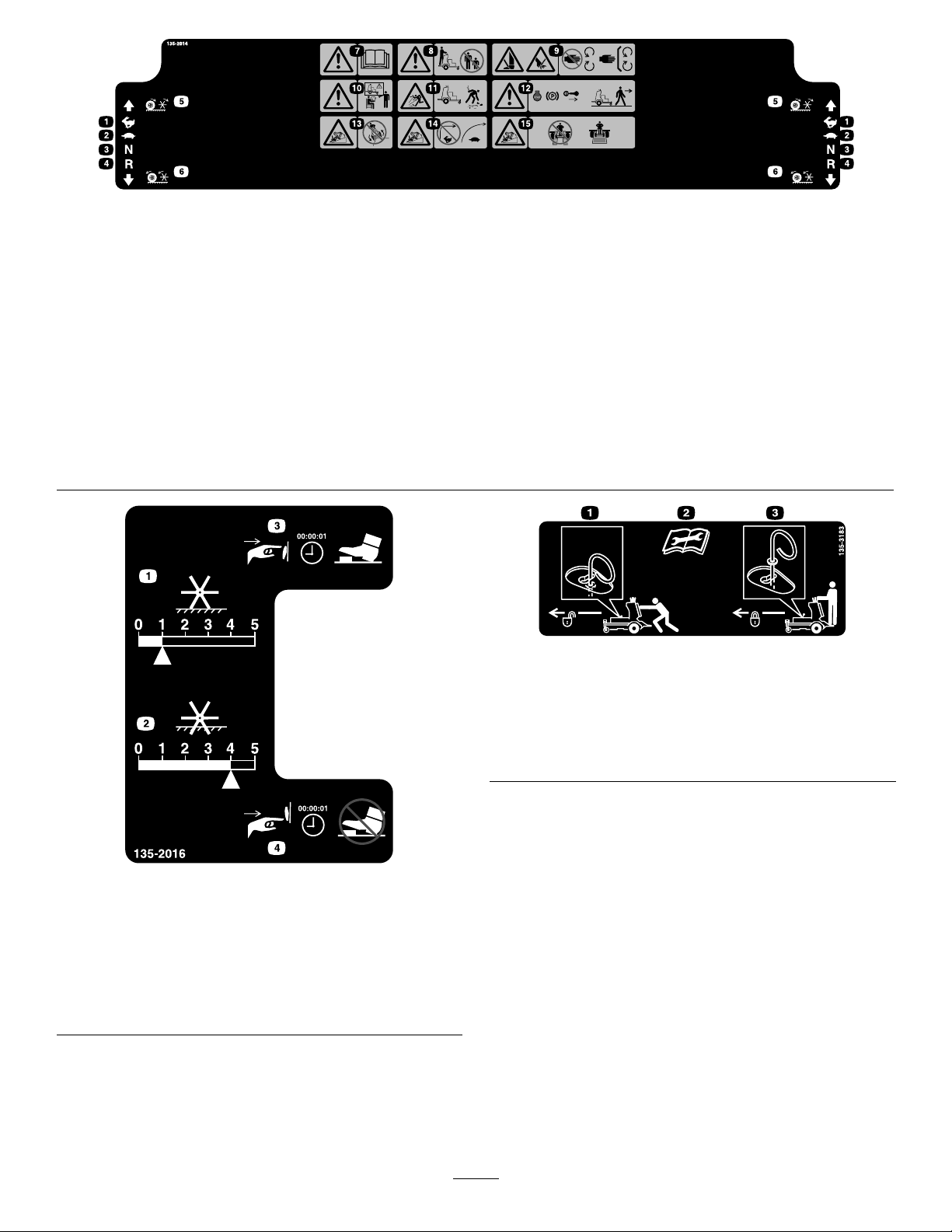

decal135-2014b

135-2014

1.Fast6.Wheelsandtinesrotatewhenmoving

backward

11.Thrownobjecthazard—pickupdebris

beforeoperatingthemachine.

2.Slow7.Warning—readtheOperator’sManual.12.Warning—shutofftheengine,engage

theparkingbreak,andremovethe

ignitionkeybeforeleavingthemachine.

3.Neutral

8.Warning—keepbystandersasafe

distanceawayfromthemachine.

4.Reverse

9.Warning—Cutting/dismemberment

hazardofhandorfoot;tines—stay

awayfrommovingparts;keepall

13.Tippinghazard–Donotoperatethe

machineneardrop-offs.

14.Tippinghazard–Donotturnsharply

whiletravelingfast;slowdownandturn

gradually.

guardsinplace.

5.Wheelsandtinesrotatewhenmoving

forward

10.Warning—Donotoperatethemachine

unlessyouaretrained.

15.Tippinghazard–Donotusesplitramps;

usefullwidthrampstoloadamachine

fortransport.

135-3183

1.Bypassleverpositionfor

pushingthemachine.

2.Readtheinstructions

beforeservicingor

performingmaintenance.

3.Bypassleverpositionfor

operatingthemachine.

decal135-3183

135-2016

1.Electronictinedepth-decrease

2.Electronictinedepth-increase

3.Pressandhold1secondtoturnon—tineground

engagementfootswitchunlock

4.Pressandhold1secondtoturnoff—tineground

engagementfootswitchlock

decal135-2016

10

Page 11

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

3

4

5

MediaandAdditionalParts

Description

Operator'sManual

Key2

Nopartsrequired

Nopartsrequired

Nopartsrequired

1

CheckingTireAirPressure

NoPartsRequired

Qty.

Qty.

–

–

–

1

Readbeforeoperatingthemachine.

Startthemachine.

Checkthebatterycharge.

Checkingthetransmissionuid.

Checktheauxiliaryhydraulicuidlevel.

Use

Use

3

CheckingtheBattery Charge

Procedure

Checktheairpressureinthedrivetires,andadjust

thepressureasneeded;refertoCheckingtheDrive

TireAirPressure(page36).

Note:Youdonotadjustairpressureforthe

semi-pneumaticcastertires.

2

ServicingtheEngineOil

NoPartsRequired

Procedure

Theengineisshippedwithoil;checktheengine-oil

leveland,ifnecessary,addoiltothespeciedlevel;

refertoEngine-OilSpecication(page30)and

CheckingtheEngine-OilLevel(page31).

NoPartsRequired

Procedure

Themachineisshippedwithalled,lead-acidbattery ,

Checkthechargeofthebatteryand,ifnecessary ,

chargeit;refertoChargingtheBattery(page35).

11

Page 12

4

CheckingtheTransmission Fluid

NoPartsRequired

Procedure

Thetransmissionisshippedwithtransmissionuid.

Checkthetransmissionuidleveland,ifnecessary,

adduidtothespeciedlevel;refertoTransmission

FluidSpecication(page39)andCheckingthe

TransmissionFluidLevel(page40).

5

ChecktheAuxiliary HydraulicFluidLevel

NoPartsRequired

Procedure

Theauxiliaryhydraulicreservoirisshippedwith

hydraulicuid.Checkthehydraulicreservoiruid

leveland,ifnecessary,adduidtothespeciedlevel;

refertoAuxiliaryHydraulicFluidSpecication(page

39)CheckingtheAuxiliaryHydraulicFluidLevel(page

39).

12

Page 13

ProductOverview

g232039

Figure3

Controls

1.Platform

2.Parkingbrakelever5.Fuelcap

3.Enginecontrols

4.Motion-controllevers

Figure4

1.Tinegroundengagement

footswitch

2.Operatorweight

adjustmentcontrol

3.Multi-functionswitch

4.Leftmotion-controllever

5.Frontreferencebar

6.Throttle

7.Choke

8.Rightmotion-controllever

9.Hourmeter

10.Parking-brakehandle

11.Ignitionswitch

Motion-ControlLevers

Themotion-controlleversarelocatedoneachsideof

thetopconsoleandcontroltheforwardandreverse

motionofthemachine.

Movetheleversforwardorbackwardtocontrolthe

drivewheelonthesamesideforwardorreverse

respectively.Thewheelspeedisproportionaltothe

amountyoumovethelever.

g223341

Important:Thetinesrotatewhenthe

motion-controlleversaremovedoutofthe

NEUTRALposition.

13

Page 14

Figure6

g008610

Figure5

1.Leftmotion-controllever

2.Rightmotion-controllever6.Neutral

3.Frontreferencebar

4.Frontofmachine8.Rearreferencebar

5.Forward

7.Reverse

ThrottleLever

Thethrottlelever(Figure4)islocatedonthecontrol

console(redlever).

Usethethrottlelevertocontrolenginespeed.Move

thethrottleleverforwardtoincreaseenginespeed;

movingthethrottleleverrearwardtodecreasethe

enginespeed.

Note:Movethethrottleleverforwardintothedetent

forfullthrottle.

ChokeControl

Thechokecontrol(Figure4)islocatedonthecontrol

console.

Usethechokecontroltoaidinstartingacoldengine.

PulloutthechokecontroltosetthechoketotheON

position;pressinthechokelevertoreducethechoke.

g223330

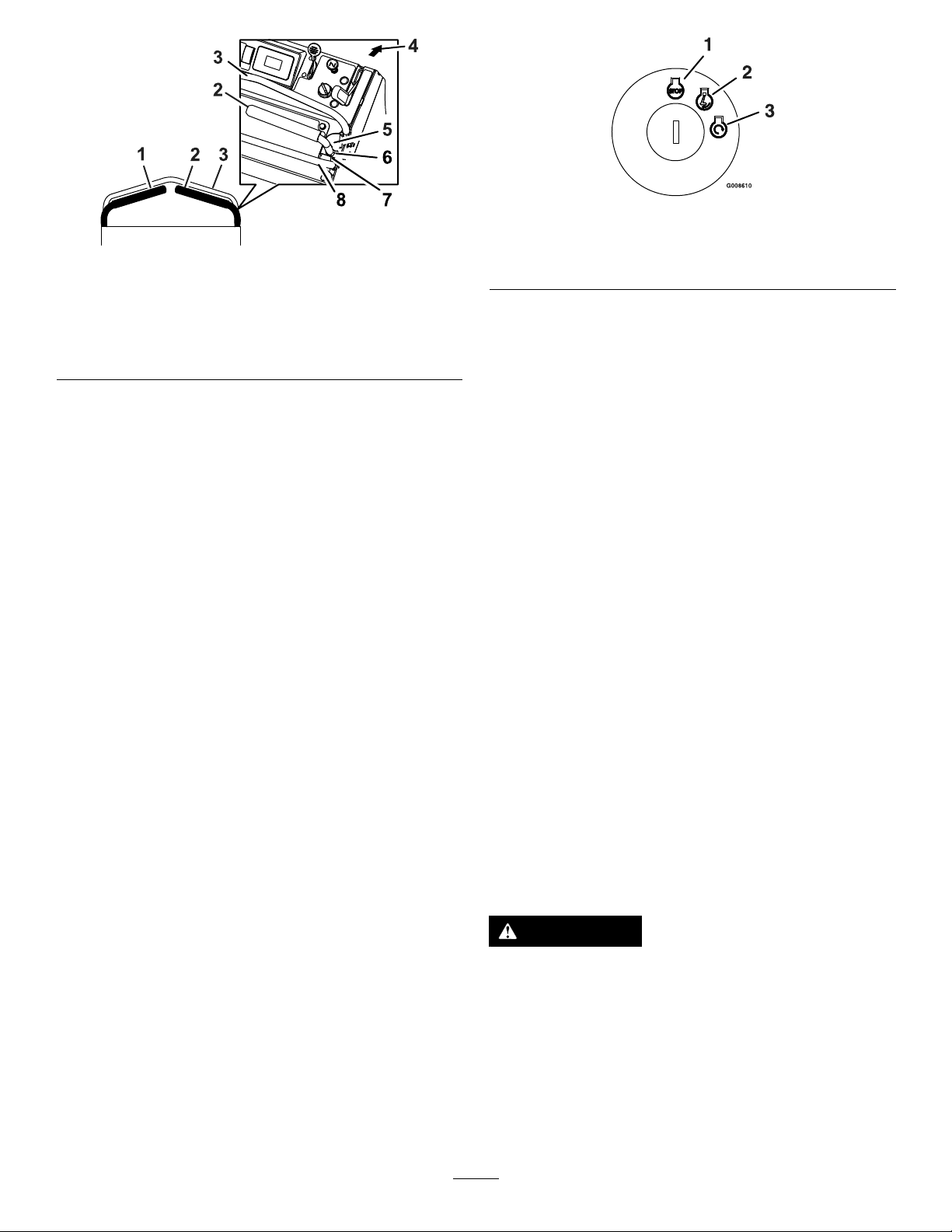

1.OFF3.START

2.ON

Parking-BrakeHandle

Theparking-brakehandleislocatedonthecontrol

console,totherightofthekeyswitch(Figure4).

Note:Thebrakehandleengagesaparkingbrakein

eachofthetransmissions.

•T oengagetheparkingbrake,pullthehandleback

towardyou.

•T oreleasetheparkingbrake,pushthehandleall

thewayforwardawayfromyou.

Whenparkingonaslope,chockorblockthewheels

inadditiontoengagingtheparkingbrake.Tiedown

themachineandengagetheparkingbrakewhen

transportingthemachine.

Fuel-ShutoffLever

Locatedundertheaircleaneronthefrontrightside.

Thefuel-shutoffleverisusedtoshutoffthefuelwhen

youwillnotusethemachineforafewdays,whileyou

aretransportingthemachinetoandfromthejobsite,

andwhenthemachineisparkedinsideabuilding.

Note:Pulloutthechokecontroltosetthechoketo

theONposition.

Note:Donotrunawarmenginewiththechokein

theONposition.

IgnitionSwitch

TheIgnitionswitchislocatedontherightsideofthe

controlconsole(Figure4).

UsetheIgnitionkeytostartandshutofftheengine.

Theswitchhas3positions:OFF,ON,andSTART

(Figure6).

Rotatethehandlecounterclockwisetoopen;rotate

clockwiseto90°toclose.

Drive-WheelReleaseValves

WARNING

Handsmaybecomeentangledintherotating

drivecomponentsbetweentheengineand

transaxles,whichcouldresultinserious

injuryordeath.

Shutofftheengine,removethekey,andallow

allthemovingpartstostopbeforeaccessing

thedrive-wheelreleasevalves.

14

Page 15

WARNING

Theengineandhydraulicdriveunitscan

becomeveryhot.Touchingahotengineor

hydraulicdriveunitscancausesevereburns.

Allowtheengineandhydraulicdriveunits

tocoolcompletelybeforeaccessingthe

drive-wheelreleasevalves.

Locatedontheleftandrightsidesabovethe

transaxles.

Duringnormaloperatingconditions,thewasheron

theleverispositionedoutsidetheslots.Ifyoumust

pushthemachinebyhand,thevalvesmustbeinthe

releasedposition(seeFigure7).

OperatorWeightAdjustment

Control

Theoperatorweightadjustmentvalveislocatedatthe

leftsideofthecontrolconsole(Figure8).

g249578

Figure8

1.Operatorweightadjustmentcontrol

Usetheoperatorweightadjustmentvalvetohelp

compensatefortheweightoftheoperatorsothatthe

machineachievesthecorrectaeratingpressure,plug

length,andtohelpmaximizelateralmachinestability.

Figure7

1.Leverpositionfor

operatingthemachine

2.Washeroutsideofslot

Toreleasethedrivewheels,movethelevertothe

largeropeningoftheslot,pushitinuntilthewasher

isinsidetheframe,thenmovetheleverbacktothe

narrowportionoftheslot.Repeatthisoneachside

ofthemachine.

Releasetheparkingbrake.Y oucannowpushthe

machinebyhand.

Donottowthemachine.

Toresetthedrivesystembacktotheoperating

position,movethelevertothelargeropeningofthe

slot,pulloutwarduntilthewasherisoutsideofthe

frame,thenmovetheleverbacktothenarrowportion

oftheslotoneachsideofthemachine.

3.Leverpositiontopushthe

machine

4.Washerinsideslot

Note:Eachoperatormustadjustthesystempressure

sothatthedrivetireslightlytouchtheground.

Important:Keepthedrivetiresonthegroundat

alltimestomaximizelateralmachinestability.

g211754

Tine-PressureControl

Thetine-pressurecontrolislocatedontheleftsideof

thecontrolconsole(Figure4).

Usethetine-pressurecontroltoadjustthedownward

pressureonthetinesandcoredepth.Rotatethe

controlcounterclockwisetodecreasethepressure

andthelengthoftheaerationplug;rotateitclockwise

toincreasethepressureandincreasethelengthof

theaerationplug.

TineGroundEngagementFoot

Switch

Keepyourhandsandfeetawayfromthe

tines.Ensurethatthetinesareaisclearofany

obstructionsbeforeloweringit.

Theswitchislocatedontheoperatorplatform.

Tolowerthetinesintotheground,standonthe

tinegroundengagementswitch.T oraisethetines,

removeyourfootfromtheswitch.

Thisswitchcanbelockedout(disabled)withthe

multi-functionswitch.

15

Page 16

•T apandholdthebottomoftheswitchtooverride

andlockout(disable)thefootswitch.TheLED

illuminatesinthehourmeter/tineengagement

display.Usethisfeaturewhentransportingthe

aerator.

•T ounlock,tapandholdthetopofthemulti-function

switchuntiltheLEDlightdisappears.

Note:Thelockoutfeatureisengagedeachtimethe

engineisswitchedoff.

Multi-FunctionSwitch

Themulti-functionswitchislocatedtotheleftofthe

hourmeter/tineengagementdisplay.

Thisswitchallowstheoperatortodothefollowing:

Note:TheLCDindicatorappearsintheparking

brakesettingwhenitmeetsthesafetostartmode

(parkingbrakeengaged).

•Thetineengagementdisplaymonitorsand

displaystheelectronictinedepthsetting.

•increaseordecreasethedepthofaerationplug

•lockorunlockthetinedepthsetting

•resetmaintenanceservicereminderscreens

SmartController/ElectronicDepth

Control

HourMeter/TineEngagementDisplay

Locatedtotheleftoftheignitionswitchonthecontrol

console.

•Thehourmetermonitorsanddisplaysengine

hours.

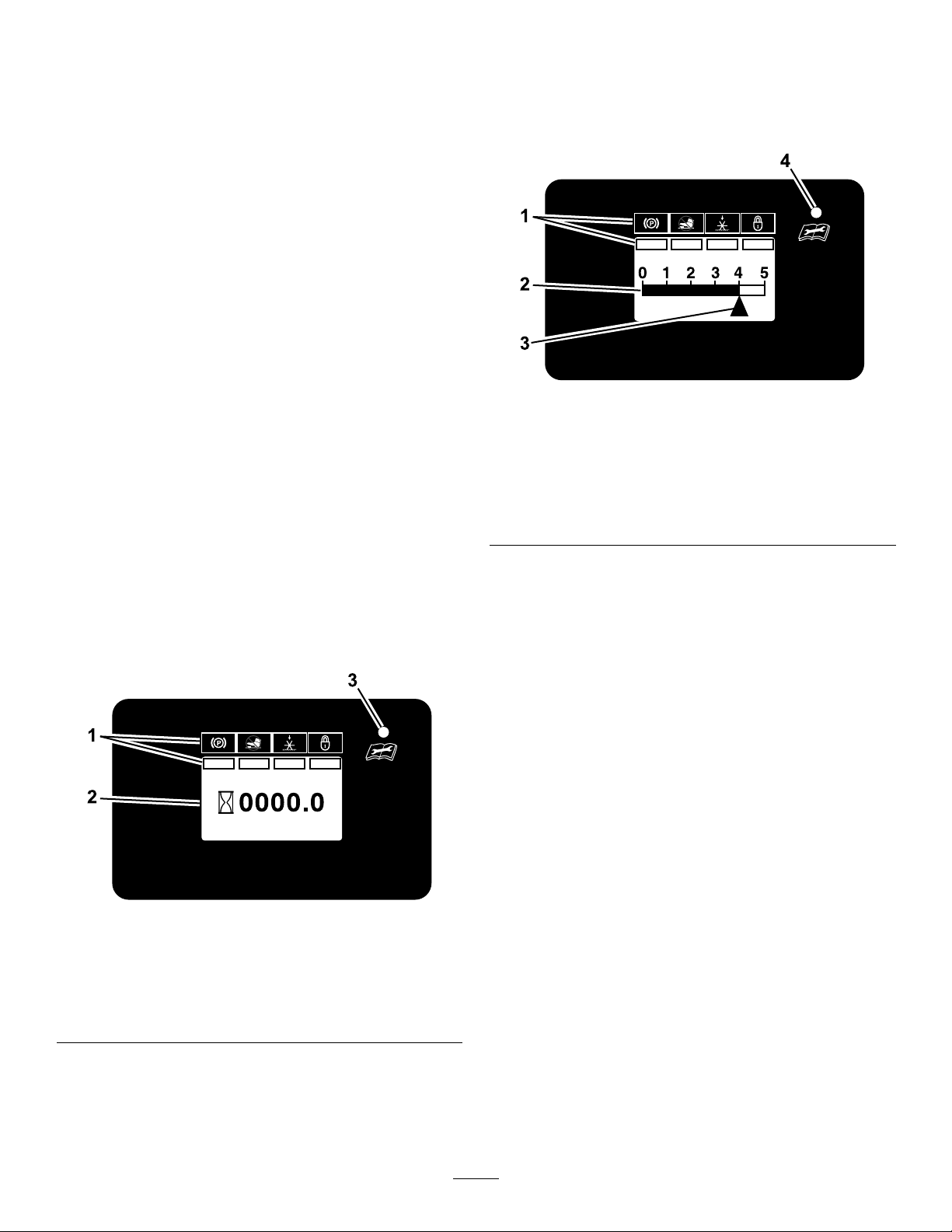

g211731

Figure10

TineEngagementDisplay

1.LCDIndicators/Informationscreen

2.Tinedepthstatusbar

3.Tinedepthsettingindicator

4.LEDstatuslight

Therearetwowaystoactivatethedisplay.

1.T apthemulti-functionswitcheitherupordown

todisplaythetineengagementmeter.

2.Steponthetinegroundengagementfootswitch.

Ahighernumberonthestatusbarincreasesthe

lengthoftheaerationplugandalowernumber

decreasesit.

Note:Ifthepluglengthisnotthedesiredlength,you

mayneedtoadjustthemachinetoaccommodate

foryourweight;refertotheAdjustingtheOperator

WeightControlV alve(page22).

Figure9

HourMeterDisplay

1.LCDIndicators/Informationscreen

2.Hourdisplay

3.LEDstatuslight

Hoursaredisplayedwhenthekeyisofforwhen

themachineisrunning.Hoursarenotdisplayed

whenthemachineisaerating.

LEDStatusLights

Locatedontherightsideofthehourmeter/tine

g211730

engagementdisplay.

TheLEDismulti-coloredtoindicatethesystemstatus

andislocatedontherightsideofthepanel.

•SolidGreen—indicatesnormaloperatingactivity

•BlinkingRed—indicatesthatafaultisactive

•SolidRed—indicatesthatmaintenanceis

required

16

Page 17

ScreenIcons

Start-upScreens

Theinformationscreenusesthefollowingicons:

AeratingHoursParkingbrake

BatteryVoltageEngineOilMaintenance

HourMeter

TransmissionOil

Maintenance

WhenthekeyisswitchedfromOFFtoRUNposition,

thefollowingscreensdisplayfor2seconds.TheLED

statuslightchangesfromredtoorangetogreen.

Therstscreendisplaysthermwareversion.

g212116

Figure11

Thesecondscreendisplaystheaerationhourstothe

tenthofanhour.

VoltageErrorValveSolenoidError

ValveSolenoidConnection

Error

g212114

Figure12

Thethirdscreendisplaysthebatteryvoltagetothe

tenthofavolt.

g212115

Figure13

Thefourthscreendisplaysthehoursuntiltheengine

oilmaintenanceisrequired.Iftheserviceisnot

performed,thetimeisrecordedasnegativehoursto

indicatethenumberofhourspastduefortheservice

(upto-500hours).

17

Page 18

Figure14

Thenalscreendisplayedisthehoursuntil

transmissionoilmaintenanceisrequired.Ifthe

serviceisnotperformed,thetimeisrecordedas

negativehourstoindicatethenumberofhourspast

duefortheservice(upto-500hours).

enginehoursandthencountsdownfrom100

hoursforeachserviceintervalthereafter.

g212117

g030960

Figure16

2.ServiceTransmission

Thetransmissionoilmaintenancereminder

countsdownfromtheinitialbreak-inservice

intervalof250enginehoursandthencounts

downfrom500hoursforeachserviceinterval

thereafter.

Figure15

MaintenanceReminderScreens

Thehourmeterdisplaysthenumberofengine

hoursuntileithertheengineoilortransmissionoil

maintenanceisdue.Thereminderashesandthe

LEDdisplaysasteadyredlight.

Analertoccurswhenthehourcounterreacheszero.

Iftheserviceisnotperformed,thetimeisrecorded

asnegativehourstoindicatethenumberofhours

pastduefortheservice(upto-500hours)(reference

Figure16andFigure17).Thehourmeterswitches

betweenthedefaultscreenandtheactivealert

screen.Ifmorethan1alertisactive,thedisplay

cyclesbetweenthealertsintheorderthatthey

occurredbeforecyclingbacktothedefaultscreen.

Thealertsonlydisplaywhenthedefaultscreenhas

beenactivefor2seconds;howeverifthekeyismoved

totheSTARTposition,thealertsoccurimmediately.

Whenthemachineisaerating,thealertscreendoes

notdisplaybuttheLEDstatuslightremainsasteady

red.

Therearetwomaintenancereminders:

1.ServiceEngine

Theengine-oilserviceremindercountsdown

fromtheinitialbreak-inserviceintervalof5

g212118

g030965

Figure17

Youcanresetmaintenanceremindersmanually.

•Y oucanentertheengineservicereminderreset

modebycyclingthekeyswitchbetweentheRUN

positionandtheOFFposition4timeswithin8

secondswiththeparkingbrakeengaged.

WhentheServiceEnginescreendisplays

andashes,youcanresettheengine-oil

maintenancereminderbypressingthedownon

themulti-functionswitch.Oncethereminder

resets,thescreenexitstheServiceEngine

screenandreturnstothedefaultscreen.

YoucanexittheServiceEnginescreenatany

timebyturningthekeytoeithertheOFForthe

STARTposition.

•Y oucanenterthetransmission-oilmaintenance

reminderresetmodebycyclingthekeyswitch

fromtheRUNpositiontotheOFFpositionandback

totheRUNposition,6timeswithin8seconds,with

theparkingbrakeengaged.

WhentheServiceTransmissionscreendisplays

andashes,youcanresetthetransmission-oil

18

Page 19

maintenancereminderbypressingdownonthe

multi-functionswitch.

YoucanexittheServiceEnginescreenatany

timebyturningthekeytoeithertheOFForthe

STARTposition.

AlertsandErrorMessages

Thesystemiscapableofdisplayingthefollowing

errors:

•VoltageError

ThisoccurswhentheKey-Runvoltageislessthan

12.3orgreaterthan16,avoltageerrorashes.

TheLEDashesaredlight.

Figure18

•ValveSolenoidOpenError

•ValveSolenoidOvercurrentError

Ifanovercurrenteventoccurs,thenumber2

displaysinthelowerleftcornerofthescreen.

Checkthevalvesolenoidandinspectitfordamage

andwear.TheLEDashesaredlight.

g030972

Figure20

1.Number2displays

•ValveSolenoidConnectionError

ThesystemdisplaystheValveSolenoid

ConnectionErroralertandtheLEDashesred

whenthesystemdetectsanerror.Ifthevalve

g030966

solenoidsareconnectedincorrectly(i.e.the

connectorforthereliefvalveisconnectedtothe

othervalvesolenoid)thetinesdonotoperateuntil

thefaultiscorrected.

Ifeither1ofthe2valvesolenoidsdisconnect,the

number6displaysinthelowerleftcornerofthe

screen.TheLEDashesaredlight.

Figure19

1.Number6displays

g030977

Figure21

g030971

19

Page 20

Specications

Height

Length

Width

RPM(FullSpeed)3800±100rpm(noload)

Aerationwidth

Coringrange1.3to12.7cm(0.5to5inches)

Holespersquarefoot

Tines36

Weight

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.Toro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

129.5cm(51inches)

173.2cm(68.6inches)

90.2cm(35.5inches)

61cm(24inches)

4.6

388kg(856lb)

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

AddingFuel

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

andwhentheengineiscold.Wipeupany

fuelthatspills.

•Donotllthefueltankcompletelyfull.

Addfueltothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwhereaspark

mayignitethefuelfumes.

•Storefuelinanapprovedfuelcontainer

andkeepitoutofthereachofchildren.

•Neverbuymorethana30-daysupplyof

fuel.

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleand

fueltankorconditionerbottleopening.

•Avoidcontactwithskin;washoffspills

withsoapandwater.

20

Page 21

FuelSpecication

Petroleum

fuel

Ethanol

blended

fuel

Important:Forbestresults,useonlyclean,fresh

fuel(lessthan30daysold).

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

Useunleadedgasolinewithanoctaneratingof87

orhigher((R+M)/2ratingmethod).

Useanunleaded-gasolineblendwithupto10%

ethanol(gasohol)or15%MTBE(methyltertiary

butylether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeis

notapprovedforuse.Neverusegasolinethat

containsmorethan10%ethanolbyvolume,such

asE15(contains15%ethanol),E20(contains

20%ethanol),orE85(containsupto85%

ethanol).Usingunapprovedgasolinemaycause

performanceproblemsand/orenginedamage

whichmaynotbecoveredunderwarranty.

UsingStabilizer/Conditioner

OpeningandClosingthe FuelShutoffValve

Controlfuelowtotheenginewiththefuelshutoff

valveasfollows:

•T oopenthefuel-shutoffvalve,fullyrotatethe

handleforthevalveleft.

•T oclosethefuel-shutoffvalve,fullyrotatethe

handleofthevalveright.

Figure22

1.Fueltank

2.Fuel-shutoffvalve(open

position)

3.Fuel-shutoffvalve(closed

position)

g249775

Usefuelstabilizer/conditionerinthemachineatall

timestokeepthefuelfreshlongerwhenusedas

directedbythefuel-stabilizermanufacturer.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addtheamountoffuelstabilizer/conditionertofresh

fuelasdirectedbythefuel-stabilizermanufacturer.

FuelingtheMachine

Fuel-tankcapacity:7L(1.9USgallons)

1.Cleanaroundthefuel-tankcap.

2.Removethecapfromthetank.

3.Fillthefueltankwithfueltowithin6to13mm

(1/4to1/2inch)fromthetopofthetank.Donot

llintothellerneck.

Important:Donotllthetankmorethan

6mm(1/4inch)fromthetopofthetank

becausethefuelmusthaveroomtoexpand.

4.Installthefuel-tankcapandwipeupanyspilled

fuel.

StartingtheEngine

1.Leavethemotion-controlleversinneutraland

engagetheparkingbrake.

2.PlacethethrottlemidwaybetweentheSLOW

andFASTpositions.

3.Onacoldengine,pushthechokeleverforward

intotheONposition.Onawarmengine,leave

thechokeintheOFFposition.

4.TurnignitionswitchtotheSTARTposition.

Releasetheswitchassoonastheenginestarts.

Important:Donotcranktheengine

continuouslyformorethan10secondsat

atime.Iftheenginedoesnotstart,allow

a60-secondcool-downperiodbetween

startingattempts.Failuretofollowthese

guidelinescanburnoutthestartermotor

5.IfthechokeisintheONposition,gradually

returnchoketotheOFFpositionastheengine

warmsup.

21

Page 22

CheckingtheSafety Interlock

Important:Ensurethattheoperatorsafety

mechanismsareconnectedandarefullyfunction

priortouse.

Note:Ifthemachinedoesnotpasseitherofthetests

thatfollow,Donotoperatethemachine.Contact

yourauthorizedT orodistributor.

CheckingtheEngineStarting Circuit

Note:Thestateparkingbrakeinterlockyouare

checkingisshowninbold.

EngagetheparkingbrakeThestarterrotates

CheckParkingBrakeInterlock

switchforyourcomfort.T oadjustit,loosenthe

footrockerbarhardware,slidethebarforward

orrearward,andtightenthehardware.

ChangingtheTineDepth Setting

1.Stopthemachineandengagetheparkingbrake.

2.Pressthemulti-functionswitchtoactivatethe

display.

3.CyclethekeyswitchbetweentheRUNposition

andtheOFFposition5times.Thetinedepth

settingindicator(triangle)onthedisplaywill

begintoash.

4.T apthemulti-functionswitchupordownto

settheaerationdepth.T apthebottomofthe

multi-functionswitchtolowerthetinedepthto

removealongerplug.Tapthetopoftheswitch

toraisethetinedepthtoremoveashorterplug.

Note:Theidealplugdepthis2.5to3inches(6.4

to7.6cm).Adjustthecontrolstoadapttothesoil

conditions.

Note:Thestateparkingbrakeinterlockyouare

checkingisshowninbold.

DisengagetheparkingbrakeThestartershouldnot

rotate

LoweringtheTines

DANGER

Therotatingtinesundertheenginedeckare

dangerous.Tinecontactcancauseserious

injuryorkillyou.

Donotputhandsorfeetunderthemachine

whentheengineisrunning.

1.SetthrottletotheFASTposition.

2.T aptheswitchoncetodisplaythetine

engagementdepthsetting;adjustifnecessary.

3.Lowerthetinesbypressingonthetineground

engagementfootswitch.

4.Standontheswitchandmovethemotion-control

leversforwardtoaerate.

Locking/UnlockingtheTine DepthSetting

Thesettingscanbelockedorleftunlocked.

•T olockthesetting,Turntheignitionkeyfromthe

OFFtotheONposition5times.TheLEDstatus

lightilluminatesinthetineengagementdisplay

(referenceFigure10).

•T ounlockthesetting,pressandholdthebottom

oftheswitchfor1second.TheLEDstatuslight

turnsoff.

SwitchthekeytotheOFForSTARTpositionwhenyou

arenished.

AdjustingtheOperator WeightControlValve

Note:Adjustthesystempressuresothatthedrive

tireslightlytouchtheground.

Important:Keepthedrivetiresonthegroundat

alltimestomaximizelateralmachinestability.

1.Raisethetines,drivetheaeratortoahard,at

turfsurface,andstoptheaerator,butleavethe

enginerunning.

2.Standontheoperator’splatform.

Note:Youcanadjustthefootrockerbar,

locatedbehindthetinegroundengagementfoot

3.Pressthetinegroundengagementfootswitch

tolowerthetines.

22

Page 23

•Ifthemachineraisesandthegroundtires

arenolongertouching,rotatetheknob

fortheoperatorweightadjustmentcontrol

counterclockwise(Figure23)tolowerthe

machineuntilthetirestouchtheground.

•Ifthetinesarenottouchingtheground,

rotatetheknobcontrolclockwiseuntilthe

tineslowerandtouchtheground(butnot

raisethemachine).

Figure23

1.Knob(operatorweightadjustmentcontrol)

Important:Keepthedrivetiresonthe

groundatalltimestomaximizelateral

machinestability.

4.Releasethetinegroundengagementfootswitch

toraisethetines.

5.Whileholdingthepositionoftheknobforthe

weightcontrolvalve,tightenthejamnut.

Note:Ifyouarehavingdifcultymaintainthe

valveadjustmentwhiletighteningthejamnut,

useahexkeyintheshaftoftheweightcontrol

valve.

3.Activatethetineengagementfootswitchlockout.

4.PlacethethrottlemidwaybetweentheSLOW

andFASTpositions.

5.Allowtheenginetorunforaminimumof15

seconds,thenturntheignitionswitchtotheOFF

positiontoshutofftheengine.

6.Engagetheparkingbrake.

7.Removethekeytopreventchildrenorother

unauthorizedpersonsfromstartingtheengine.

8.Closethefuel-shutoffvalvewhenyouwillnot

usethemachineforafewdays,whenyouare

transportingthemachine,orwhenthemachine

isparkedinsideabuilding.

DrivingtheMachine

CAUTION

Machinecanspinveryrapidlybypositioning

g249872

onelevertoomuchaheadoftheother.

Operatormaylosecontrolofthemachine,

whichmaycausedamagetothemachineor

injury.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

Important:Tobeginmovement(forwardor

backward),thebrakelevermustbedisengaged

(pushedforward)beforethemotion-controllevers

canbemoved.

RaisingtheTines

1.Removeyourfootfromthetineground

engagementfootswitch

2.TurntheignitionkeyfromtheONpositiontothe

OFFposition.

Important:Thetinesarerotatingwhenthe

motion-controlleverismovedoutoftheneutral

position.

ShuttingOfftheEngine

1.Movethemotion-controlleversbacktothe

neutralpositionandbringthemachinetoafull

stop.

2.Liftyourfootoffofthetinegroundengagement

footswitchcontroltoraisethetines.

Figure24

1.Leftmotion-controllever

2.Rightmotion-controllever6.Neutral

3.Frontreferencebar

4.Frontofmachine8.Rearreferencebar

DrivingForward

1.Ensurethatthemotion-controlleversareinthe

neutralposition.

2.Releasetheparkingbrake.

23

5.Forward

7.Reverse

g223330

Page 24

3.T omoveforwardinastraightline,moveboth

leversforwardwithequalpressure.

g016673

Figure26

Toturnleftorright,releasepressureonthe

motion-controllevertowardthedesiredturn

direction.

Figure25

Toturnleftorright,pullthemotion-controllever

backtowardneutralinthedesiredturndirection.

Thetinescanbeinthedownpositionwhen

makinggradualturns.

Tomakezero-degreeturns,liftyourfootoffthe

tineengagementfootswitchcontroltoraisethe

tines.Theheadwillraisein1second.

Important:Donotmakeazero-degreeturn

whenthetinesaredownasturftearingwill

result.

Important:Donotdriveinreversewhenthe

tinesaredownasturftearingwilloccur.

Themachinemovesfasterthefartherthe

motion-controlleversaremovedfromtheneutral

position.

4.T ostop,positionbothmotion-controlleversin

theneutraloperatingposition.

DrivinginReverse

1.Movethemotion-controlleverstotheneutral

operatingposition.

2.T omoverearwardinastraightline,slowlymove

bothleversrearwardwithequalpressure.

g016672

Tomakezeroturns,liftyourfootoffofthetine

groundengagementfootswitchtoraisethe

tines.Theheadwillraiseinhalfsecond.

Important:Donotmakeazeroturnwhen

thetinesareinthedownposition.

3.T ostop,positionbothmotion-controlleversin

theneutraloperatingposition.

PositioningtheAir-Cleaner CoverforColdorWarmAir Temperature

Important:Runningtheenginewiththe

air-cleanercoverpositionedforcold-weather

operationinnormalconditionscandamagethe

engine.

Theair-cleanercoverhas2positions:thecoldor

normal,ambientairpositions:

Adjusttheair-cleanercoverasfollows:

•Whenoperatinginacoldambientaircondition

(coldairtemperatureandhumidity)—positionthe

air-cleanercoverwithsnowakedecalfacingout

(Figure27).

Note:Usethispositionifyourmachineexhibits

carburetoricing.Symptomsincludetheengine

runsroughatidleorlowspeed,anditdischarges

blackorwhitesmokeintheexhaust.

•Whenoperatinginanormalambientair

condition—positiontheair-cleanercoverwithsun

decalfacingout(Figure27).

Note:Usethispositionifyourmachineisnot

exhibitingcarburetoricing.

24

Page 25

Figure27

1.Normalambientair

position

2.Coldambientairposition

AdjustingtheFront Reference/SpeedControl Bar

Adjustthefrontreference/speedcontrolbarfor

desiredmaximumforwardspeed.

1.Shutofftheengine,engagetheparkingbrake,

andmovethemotioncontrolleverstotheneutral

position.

2.Loosentheboltsonbothsidesofthecontrol

towerbylooseningthetwonutsoneachside

(fourtotal)oftheconsole(seeFigure28).

Important:Makesurethenutsandboltsaretight

sothefrontreference/speedcontrolbardoesnot

moveduringoperation.

LoadingtheMachine

Useextremecautionwhenloadingmachineson

trailersortrucks.Useafull-widthramptoextend

g023827

beyondthereartiresinsteadofindividualrampsfor

eachsideofthemachine.Withtheplatformup,a

full-widthrampprovidesasurfacetowalkonbehind

themachine.

Asteeprampanglemaycausecomponentstoget

caughtasthemachinemovesfromramptotraileror

truck.Steeperanglesmayalsocausethemachineto

tipbackward.Ifloadingonornearaslope,position

thetrailerortrucksothatitisonthedownsideof

theslopeandtherampsextendsuptheslope.This

minimizestherampangle.Thetrailerortruckshould

beaslevelaspossible.

Important:Donotattempttoturnthemachine

whileontheramp,youmaylosecontrolanddrive

offtheside.

Avoidsuddenaccelerationwhendrivinguparamp

andsuddendecelerationwhenbackingdowna

ramp.Bothmaneuverscancausethemachinetotip

backward.

Figure28

1.Twonuts

3.Movethebarforwardtoobtainthefastestspeed.

Movethebarbackwardtoobtaintheslowest

speed.

4.Onbothsides,tightenthenutsandbolts.

2.Frontreference/speed

controlbar

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasallthe

necessarylightingandmarkingasrequiredbylaw.

Whenusingatrailer,secureitwiththesafetychains.

1.Loadthemachineontothetransportvehicle.

2.Lockthetinesintheuppositionbytappingand

holdingthemulti-functionswitchinthedown

positionuntiltheLEDindicatorappearsonthe

hourmeter/tineengagementdisplay.

3.Engagetheparkingbrake,shutofftheengine,

andremovethekey.

g231460

4.Closethefuel-shutoffvalve.

5.Blockthewheelsandsecurelybindthemachine

tothetrailerortruckwithstraps,chains,cable,

orropes.Ifpossible,bothfrontandrearstraps

shouldbedirecteddownandoutwardfromthe

machine.

Important:Useonlythe4designated

tie-downlocationsonthemachine—2onthe

leftsideand2ontheright;refertoFigure29.

25

Page 26

Figure29

Leftsideshown

1.Tie-downlocation

CAUTION

Thismachinedoesnothaveproperturn

signals,lights,reectivemarkings,ora

slow-moving-vehicleemblem.Drivingona

streetorroadwaywithoutsuchequipment

isdangerousandcanleadtoaccidents

causingpersonalinjury.Drivingonastreetor

roadwaywithoutsuchequipmentmayalsobe

aviolationofstatelawsandtheoperatormay

besubjecttotrafcticketsand/ornes.

Donotdrivethemachineonapublicstreet

orroadway.

WARNING

g212139

Loadingamachineonatrailerortruck

increasesthepossibilityofbackwardtip-over.

Backwardtip-overcouldcauseseriousinjury

ordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Useonlyasingle,full-widthramp;Donot

useindividualrampsforeachsideofthe

machine.

•Avoidsuddenaccelerationordeceleration

whiledrivingmachineupordownaramp

toavoidtippingbackward.

26

Page 27

Maintenance

Downloadafreecopyoftheelectricalorhydraulicschematicbyvisitingwww.Toro.comandsearchingforyour

machinefromtheManualslinkonthehomepage.

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitchbeforeyouperformanymaintenance.

WARNING

Theenginecanbecomeveryhot.Touchingahotenginecancausesevereburns.

Allowtheenginetocoolcompletelybeforeserviceormakingrepairsaroundtheenginearea.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Aftertherst100hours

Beforeeachuseordaily

Every25hours

Every50hours

Every80hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthetransmissionoutputshaftnuttorquespecication.

•Changetheauxiliaryhydraulicreservoirlteranduid.

•Changethehydraulictransmissionlteranduid.

•Lubricatethechains.

•Checktheengine-oillevel.

•Checktheconditionandtensionofthechains.

•Checktheconditionofthesprockets.

•Checkthetines.

•Cleantheengineandtheexhaustsystemarea(moreoftenindryordirtyconditions).

•Cleanthegrassanddebrisbuildupfromthemachine.

•Greasethefrontwheelbearings.

•Greasetineshaftbearings.

•Greasehydrooutputshaftangedbearings.

•Cleanthefoampre-cleaner(morefrequentlyindustyconditions).

•Checksparkarrester(ifequipped).

•Checktheairpressureinthedrivetires.

•Checktheconditionandtensionofthebelts.

•Checkthetransmissionuidlevel.

•Removetheengineshroudsandcleanthecoolingns.

Every100hours

Every160hours

Every200hours

Every250hours

Every300hours

•Changetheengineoil.(moreoftenundersevereconditions.)

•Check,cleanandgapthesparkplug.

•Replacethefoampre-cleaner.

•Changetheauxiliaryhydraulicreservoirlteranduid.

•Changethehydraulictransmissionlteranduid.

•Replacethepaperairlter(morefrequentlyindustyconditions).

Monthly

•Servicethebattery.

27

Page 28

MaintenanceService

Interval

Yearly

MaintenanceProcedure

•Greasebeltidlerpivot.

•Greasefrontcasterhubs.

•Checkthetorqueofthewheelhubbolts.

•Checkthetorqueonthewheellugnuts.

•Checkthetorqueofthetransmissionoutputshaftnut.

Yearlyorbeforestorage

•T ouchupareaswithchippedpaint.

Pre-Maintenance

Procedures

CAUTION

Raisingthemachineforserviceor

maintenancerelyingsolelyonmechanical

orhydraulicjackscouldbedangerous.The

mechanicalorhydraulicjacksmaynotbe

enoughsupportormaymalfunctionallowing

themachinetofall,whichcouldcauseinjury.

Donotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstands

orequivalentsupport.

PreparingforMaintenance

1.Parkthemachineonalevelsurfaceandengage

theparkingbrake.

g023810

Figure30

1.Spark-plugwire

2.Shutofftheengine,removethekey ,andwaitfor

allmovingpartstostop.

3.Allowtheenginetocool.

4.Disconnectthespark-plugwirefromthespark

plugandkeepthewireawayfromtheplug,to

preventaccidentalstarting(Figure30).

28

Page 29

Lubrication

LubricatingtheGrease Fittings

LubricatingtheChains

ServiceInterval:Beforeeachuseordaily

Important:Donotlubricatethechainswith

penetratingoilorsolvents.Useanoilorchain

lubricant.

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethekey.Engagetheparking

brake.

2.Lifttherearofthemachineandsupportusing

jackstandsorequivalentsupport.

CAUTION

Raisingthemachineforservice

ormaintenancerelyingsolelyon

mechanicalorhydraulicjackscouldbe

dangerous.Themechanicalorhydraulic

jacksmaynotbeenoughsupportormay

malfunctionallowingthemachinetofall,

whichcouldcauseinjury .

Donotrelysolelyonmechanical

orhydraulicjacksforsupport.Use

adequatejackstandsorequivalent

support.

Note:Seethechartbelowforserviceintervals.

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethekey.Engagetheparking

brake.

2.LubricatethettingswithNLGIgradeNo.2

multi-purposegrease.

Refertothefollowingchartforttinglocations

andlubricationschedule.

LubricationChart

Fitting

Locations

1.FrontWheel

CasterHubs

2.TineShaft

Bearings

3.BeltIdler

Pivot

Initial

Pumps

12Yearly

1425hours

11Yearly

Numberof

Places

Service

Interval

3.Starttheengineandmovethrottlecontrolahead

to1/2throttleposition.Disengagetheparking

brake.

WARNING

Theenginemustberunningandthe

drivewheelsmustbeturningsothat

adjustmentscanbeperformed.Contact

withmovingpartsorhotsurfacesmay

causepersonalinjury.

Keepyourngers,hands,andclothing

clearofrotatingcomponentsandhot

surfaces.

4.Withtheenginerunning,slowlymovethe

motion-controlleversforwardandlubricateall4

chains.

5.Checktheconditionandtensionofthechains;

refertoCheckingtheConditionoftheChains

(page36).

g230394

Figure31

1.Frontwheelcasterhubs3.Beltidlerpivot

2.Tineshaftbearings

29

Page 30

EngineMaintenance

5.Wipedirtawayfromthebaseandthecoverwith

amoistrag.

ServicingtheAirCleaner

ServiceInterval:Every50hours—Cleanthefoam

pre-cleaner(morefrequentlyin

dustyconditions).

Every200hours—Replacethefoam

pre-cleaner.

Every300hours—Replacethepaperairlter

(morefrequentlyindustyconditions).

Important:Donotoperatetheenginewithoutthe

airlterassembly;extremeenginedamagemay

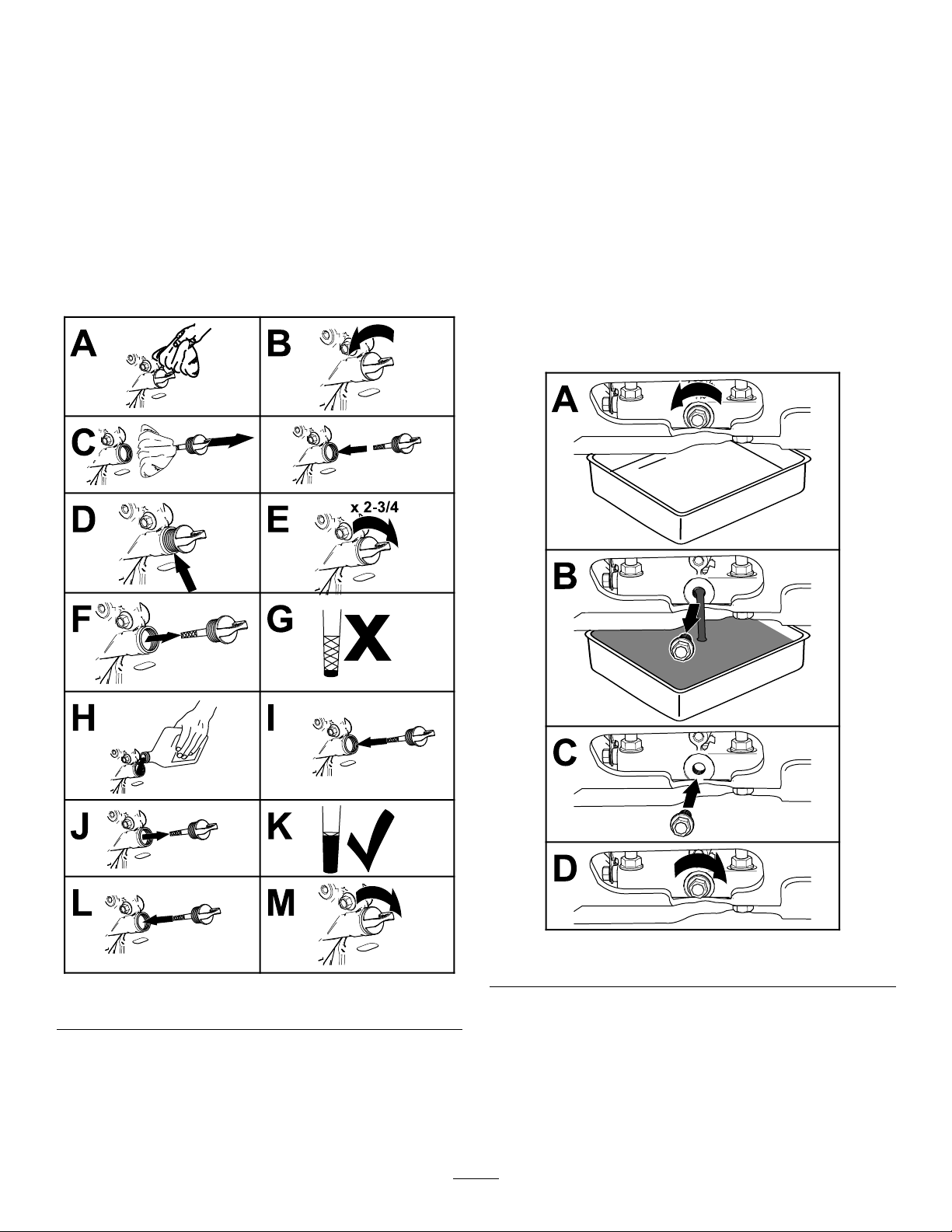

occur.

1.Releasethelatchesonthecoverfortheair

cleaner.

2.Removethecoverandcleanitthoroughly

(Figure32).

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

6.Installthefoampre-cleanerontothepaperair

lter(Figure32).

Note:Useanewpaperairlterifyoudiscarded

theoldone.

7.Installtheairlterassemblytotheair-lterbase

(Figure32).

8.Alignthearrowdecalontheair-cleanercover

andthearrowdecalonthebase(Figure33).

Figure32

1.Air-lterbase4.Cover

2.Paperairlter

3.Foampre-cleaner

3.Removethefoampre-cleaner,washitwitha

milddetergentandwater,andthenblotitdry

(Figure32).

4.Removeandinspectthepaperairlter(Figure

32);discarditifitisexcessivelydirty.

5.Latchontheair-cleaner

cover(2)

g023809

Figure33

1.Alignment-arrowdecal(normalambientairpositionshown)

9.Securetheair-ltercovertothebasewiththe

latches.

ServicingtheEngineOil

Engine-OilSpecication

OilType:Detergentoil(APIserviceSJorlater)

g023795

EngineOilCapacity:1.7L(1.8USqt)withoutthe

lter;1.5L(1.6USqt)withthelter.

Oilviscosity:Refertothetablebelow.

g023796

Figure34

Important:Donottrytocleanapaperlter.

30

Page 31

CheckingtheEngine-OilLevel

ChangingtheEngineOil

ServiceInterval:Beforeeachuseordaily

Important:Donotoperatetheenginewiththeoil

levelbelowtheLow(orAdd)markonthedipstick,

orovertheFullmark.

1.Movethemachinetoalevelsurface.

2.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Allowtheenginetocool.

4.Checktheengine-oillevelasshowninFigure

35.

ServiceInterval:Aftertherst5hours

Every100hours(moreoftenundersevere

conditions.)

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoil

drainscompletely.

2.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.ChangetheengineoilasshowninFigure36.

Note:T orquedrainplugto18N∙m(13ft-lb).

Figure35

5.Iftheoillevelislow,wipeofftheareaaround

theoilllcap,removecapandaddthespecied

oiluntiltheoillevelisattheFullmarkonthe

dipstick.

Note:Donotoverlltheenginewithoil.

g249685

Figure36

g249636

4.Slowlypourapproximately80%ofthespecied

oilintothellertube,andslowlyaddthe

additionaloiltobringittotheFullmark(Figure

37).

31

Page 32

ServicingtheSparkPlug

ServiceInterval:Every160hours

TypeforallEngines:NGKBR6HS,Champion

RTL86C,orequivalent

AirGap:0.76mm(0.030inch)

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstalling

thesparkplug(s)andagappingtool/feelergaugeto

checkandadjusttheairgap.Installanewspark

plug(s)ifnecessary.

Figure37

5.Starttheengineanddrivetoaatarea.

6.Checktheengine-oillevel.

g249684

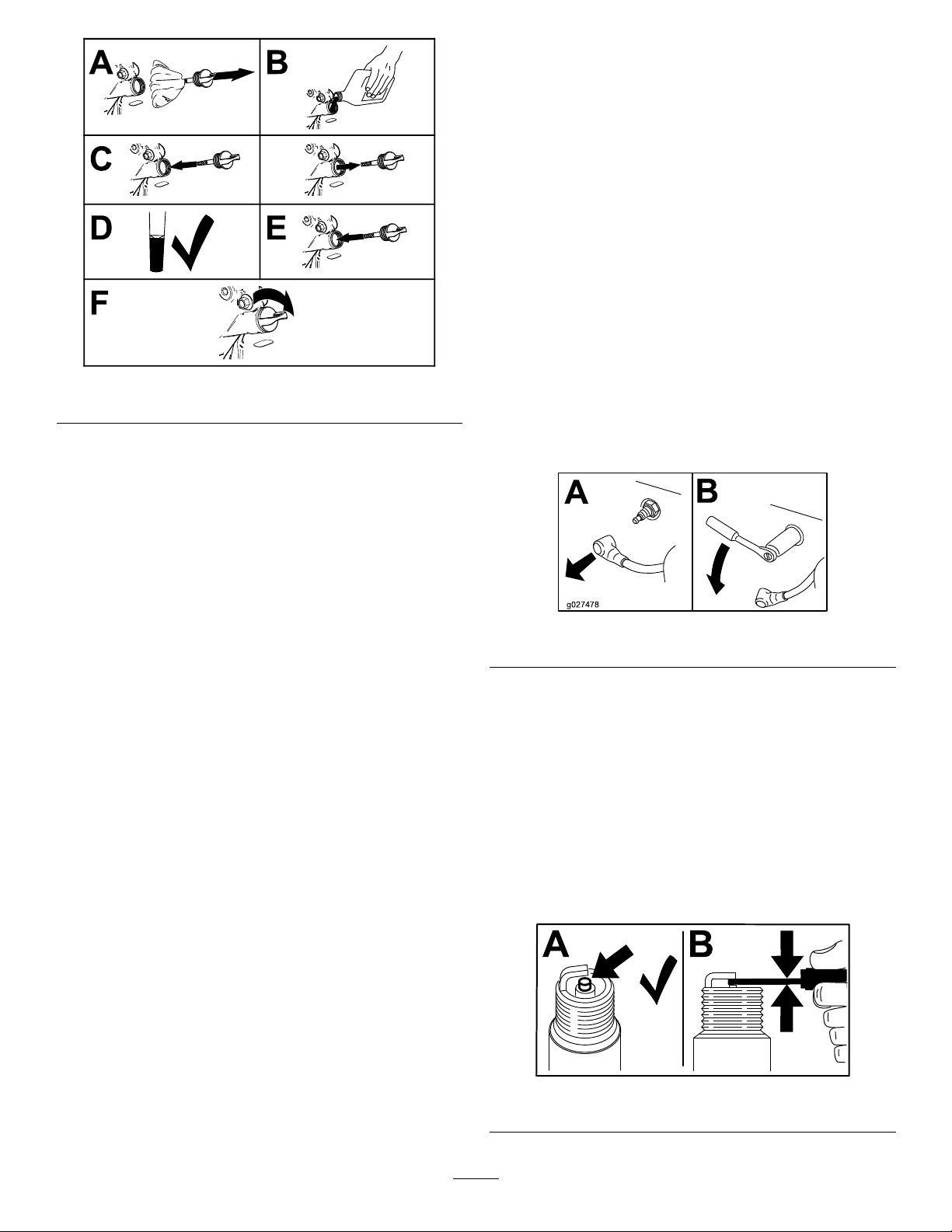

RemovingtheSparkPlug

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.RemovethesparkplugasshowninFigure38.

g027478

Figure38

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithasa

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty .

Setthegapto0.75mm(0.03inch).

Figure39

32

g206628

Page 33

InstallingtheSparkPlug

CheckingtheSpark

Tightenthesparkplug(s)to22N∙m(16ft-lb).

Figure40

Arrester

MachineswithaSparkArrester

Only

ServiceInterval:Every50hours

WARNING

Hotexhaustsystemcomponentsmayignite

fuelvaporsevenaftertheengineisshut

off.Hotparticlesexhaustedduringengine

operationmayigniteammablematerials.

Firemayresultinpersonalinjuryorproperty

damage.

Donotrefuelorrunengineunlessaspark

g027735

arresterisinstalled.

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Allowthemufertocool.

3.Checkthesparkarresterforbreaksinthe

screenorwelds.

Note:Replacethesparkarresterifitisworn

ordamaged.

4.Ifyouseethatthescreenisplugged,perform

thefollowing:

A.Removethesparkarrester.

B.Shakeloosetheparticlesfromthearrester

andcleanscreenwithawirebrush.

Note:Soakthearresterscreeninsolvent

ifnecessary.

C.Installsparkarresterontoexhaustoutlet.

33

Page 34

ElectricalSystem

Maintenance

JumpStartingtheMachine

1.Checktheweakbatteryforterminalcorrosion

andcleanitpriortojumpstarting.Cleanand

tightenconnectionsasnecessary.

CAUTION

Corrosionorlooseconnectionscan

causeunwantedelectricalvoltagespikes

atanytimeduringthejump-starting

procedure.

Donotattempttojumpstartwithloose

orcorrodedbatteryterminalsordamage

totheenginemayoccur.

DANGER

Note:Ensurethattheventcapsaretightand

level.Placeadampcloth,ifavailable,overany

ventcapsonbothbatteries.Ensurethatthe

vehiclesdonottouchandthatbothelectrical

systemsareoffandatthesameratedsystem

voltage.Theseinstructionsarefornegative

groundsystemsonly.

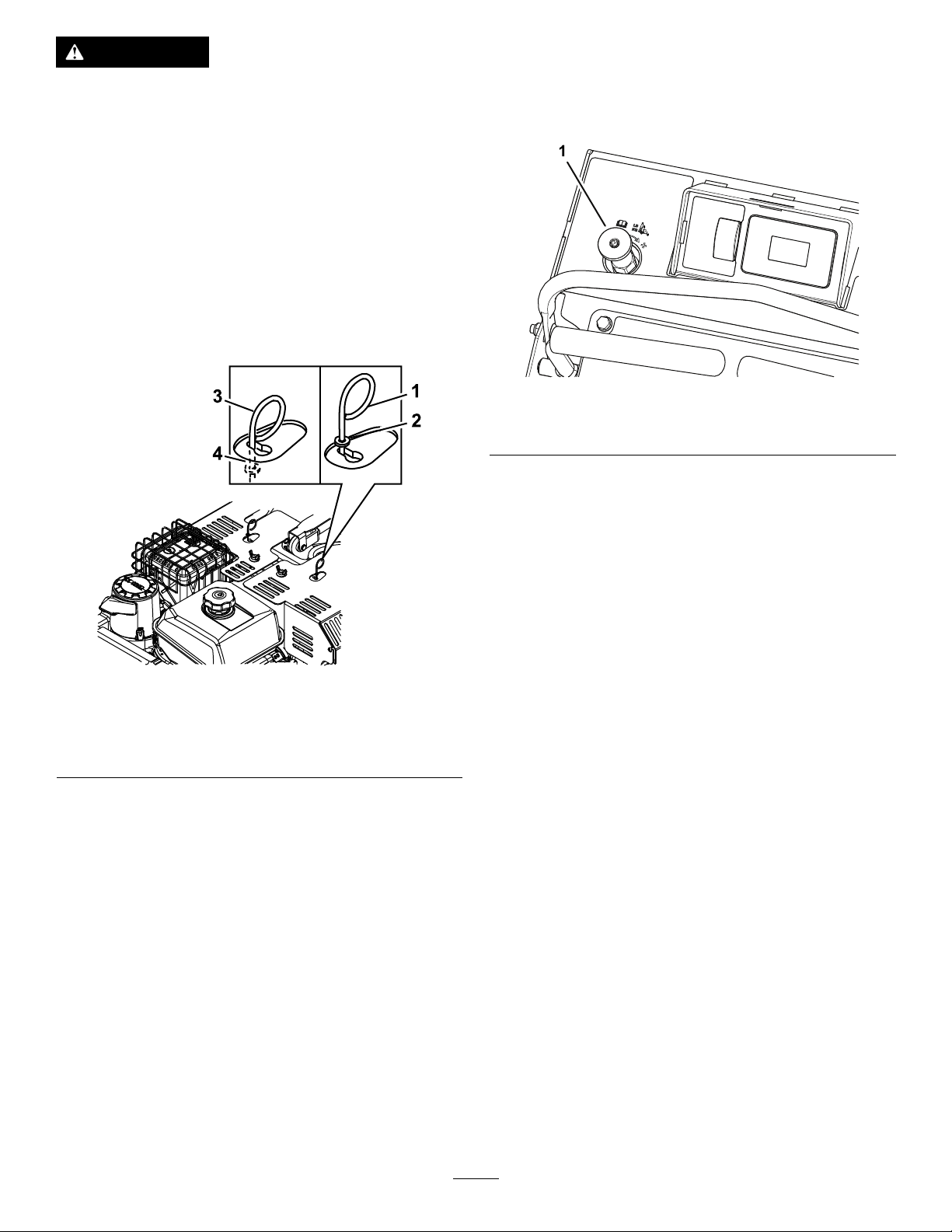

3.Connectthepositive(+)cabletothepositive(+)

terminalofthedischargedbatterythatiswired

tothestarterorsolenoidasshowninFigure41.

g012785

Figure41

Jumpstartingaweakbatterythatis

cracked,frozen,haslowelectrolytelevel,

oranopen/shortedbatterycell,can

causeanexplosionresultinginserious

personalinjury.

Donotjumpstartaweakbatteryifthese

conditionsexist.

2.Ensurethattheboosterisagoodandfully

chargedleadacidbatteryat12.6Vorgreater.

Useproperlysizedjumpercables(4to6

AWG)withshortlengthstoreducevoltagedrop

betweensystems.Ensurethatthecablesare

colorcodedorlabeledforthecorrectpolarity.

CAUTION

Connectingthejumpercablesincorrectly

(wrongpolarity)canimmediatelydamage

theelectricalsystem.

Becertainofthebatteryterminalpolarity

andjumpercablepolaritywhenhooking

upthebatteries.

1.Positive(+)cableondischargedbattery

2.Positive(+)cableonboosterbattery

3.Negative(–)cableontheboosterbattery

4.Negative(–)cableontheengineblock

5.Boosterbattery

6.Dischargedbattery

7.Engineblock

4.Connecttheotherendofthepositivecableto

thepositiveterminaloftheboosterbattery.

5.Connecttheblacknegative(–)cabletotheother

terminal(negative)oftheboosterbattery.

6.Makethenalconnectionontheengineblock

ofthestalledvehicle(nottothenegativepost)

awayfromthebattery.Standback.

7.Startthevehicleandremovethecablesinthe

reverseorderofconnection(theengineblock

(black)connectionisthersttodisconnect).

WARNING

Batteriescontainacidandproduce

explosivegases.

•Shieldyoureyesandfacefromthe

batteriesatalltimes.

•Donotleanoverthebatteries.

34

Page 35

ServicingtheBattery

DANGER

Chargingorjump-startingthebatterymay

produceexplosivegases.Batterygasescan

explode,causingseriousinjury .

ChargingtheBattery

ServiceInterval:Monthly

1.MovethekeyswitchtotheOFFpositionand

removethekey.

2.Measurethevoltageofthebatterywitha

voltmeter.

•Keepsparks,ames,orcigarettesaway

fromthebattery.

•Ventilatewhenchargingorusingthe

batteryinanenclosedspace.

•Ensurethattheventingpathofthebattery

isalwaysopenoncethebatteryislled

withacid.

•Alwaysshieldyoureyesandfacefromthe

battery.

DANGER

Batteryelectrolytecontainssulfuricacid,

whichisfatalifconsumedandcancause

severeburns.

•Wearsafetyglassestoshieldyoureyes

andrubberglovestoprotectyourskinand

clothingwhenhandlingelectrolyte.

•Donotswallowelectrolyte.

•Intheeventofanaccident,ushwithwater

andcalladoctorimmediately.

CAUTION

IfthekeyswitchisintheONposition,there

ispotentialforsparksandengagement

ofcomponents.Sparkscouldcausean

explosionormovingpartscouldaccidentally

engage,causingpersonalinjury.

EnsurethatthekeyswitchisintheOFF

positionbeforechargingthebattery.

Allowingbatteriestostandforanextendedperiod

oftimewithoutrechargingthemresultsinreduced

performanceandservicelife.Topreserveoptimum

batteryperformanceandlife,chargebatteriesin

storagewhentheopencircuitvoltagedropsto12.4V.

Note:Topreventdamageduetofreezing,thebattery

shouldbefullychargedbeforeputtingawayforwinter

storage.

3.Usethetablebelowtolocatethechargestate

orthebattery,andifneeded,thebattery-charger

settingandchargingintervalrecommendedto

chargethebatteryto12.6Vorgreater;referto

thebatterychargetablebelow.

Important:Ensurethatthenegativebattery

cableisdisconnectedandthebattery

chargerusedforchargingthebattery

hasanoutputof16Vand7Aorlessto

avoiddamagingthebattery(seechartfor

recommendedchargersettings).

BatteryChargeTable

Voltage

Reading

12.6or

greater

12.4to12.6

12.2to12.4

12.0to12.2

11.7to12.0

11.7orless

4.Ifthepositivecableisalsodisconnected,

connectthepositive(red)cabletothepositive

batteryterminalandsliptheterminalcoverover

thepositiveterminal.

5.Removethescrew,washer,andgroundcable

fromtheengine.Connectthenegativebattery

cable.

Percent

Charge

100%

75to100%

50to75%

25to50%

0to25%

0%

Maximum

Charger

Settings

16V/

7A

16V/

7A

16V/

7A

14.4V/

4A

14.4V/

4A

14.4V/

2A

Note:Iftimedoesnotpermitchargingthe

batteryorifchargingequipmentisnotavailable,

connectthenegativebatterycablesandrun

thevehiclecontinuouslyfor20to30minutesto

chargethebattery.

Charging

Interval

Nocharging

required

30minutes

1hour

2hours

3hours

6hoursor

more

Note:Themachineisshippedwithalled,lead-acid

battery.

35

Page 36

DriveSystem

CheckingtheConditionof

Maintenance

CheckingtheDriveTireAir Pressure

ServiceInterval:Every50hours

Note:Youdonotadjustairpressureforthe

semi-pneumaticcastertires.

1.Shutofftheengine,engagetheparkingbrake,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Checktheairpressureofthedrivetires.

3.Adjusttheairpressureinthedrivetiresto152

to165kPa(22to24psi).

CheckingtheWheelHub Bolts

ServiceInterval:Yearly

Torquethewheelhubbolts(Figure42)to37to45

N∙m(27to33ft-lb).

theChains

ServiceInterval:Beforeeachuseordaily

1.Shutofftheengine,engagetheparkingbrake,

waitforallmovingpartstostop,andremove

thekey.

2.Checkthechainsonbothsidesofthemachine

forpropertension.Thechainsshouldbeableto

moveupanddown1/4to1/2inch(6to12mm).

3.IfchainspoporsnaprefertoAdjustingtheDrive

WheelChainT ension(page36)andAdjusting

theTineDriveChain(page42).

CheckingtheSprocket Condition

ServiceInterval:Beforeeachuseordaily

1.Shutofftheengine,engagetheparkingbrake,

waitforallmovingpartstostop,andremove

thekey.

2.Inspectsprocketsforwearandreplaceas

required.

Note:Donotuseanti-seizecompoundonthewheel

hub.

Figure42

1.Lugnut2.Hubbolt

CheckingtheTorqueofthe WheelLugNuts

MaintainingtheChain

AdjustingtheDriveWheelChain Tension

1.Shutofftheengine,engagetheparkingbrake,

waitforallmovingpartstostop,andremove

thekey.

2.Lifttherearofthemachineandsupportusing

jackstandsorequivalentsupport.

3.Checkthechainsoneachsideoftheidler

sprocket,onbothsidesofthemachine,for

propertension.Thechainsshouldbeableto

g249686

moveupanddown1/4to1/2inch(6to12mm).

4.T oadjustthechaintension,loosentheidlerbolt

andpushuponthesprockettotightenthechain.

Important:Donotovertightenthechain.

Signicantchainwearcanoccurandwill

shortenthelifeofanovertightenedchain.

5.Checkthechaintensionandtightentheidler

bolt.

ServiceInterval:Yearly

Torquethewheellugnuts(Figure42)to1 15to142

N∙m(85to105ft-lb).

36

Page 37

CheckingtheTorqueofthe

AdjustingtheMotion

TransmissionOutputShaft

Nut

ServiceInterval:Aftertherst5hours

Yearly

Torquethenutsonthetransmissionoutputtapered

shaftsto285to353N∙m(210to260ft-lb).

AdjustingtheMotion ControlLinkage

1.RefertoPreparingforMaintenance(page28).

2.Pushthecontrolleversallthewayforwardtothe

frontreferencebar;Ifeitherofthecontrollevers

contactthereferencebardothefollowing:

A.Allowthecontrolleverstoreturntoneutral

andloosenthe2jamnutsonthehex

adjustmentlinkage.

Note:Onejamnutisaright-handthread

andtheotherisleft-hand.

ControlTracking

Ifthemachinetravelsorpullstoonesidewhenthe

motioncontrolleversareinthefullforwardposition,

adjustthetracking.

1.Pushbothcontrolleversforwardthesame

distance.

2.Checkifthemachinepullstooneside;Ifitdoes,

stopthemachineandsettheparkingbrake.

3.Loosenthelocknutsontherightmotioncontrol

linkage(asviewedfromtherearofthemachine.

Pushtherightcontrolleverforwardandrotate

theadjustmentroduntilthereis1/8to1/4inch

(3to6mm)gapbetweentherightcontrollever

andthefrontreferencebar.

4.Placethefrontreference/speedcontrolbarinthe

maximumforwardposition;refertoAdjustingthe

FrontReference/SpeedControlBar(page25).

5.Rotatetheadjustmentrodontheleftsideofthe

machine(Figure44).

B.Turnthehexadjustmentlinkageuntilthere

is1/8to1/4inch(3to6mm)gapbetween

thecontrolleverandthefrontreferencebar.

C.Tightenthejamnuts.

D.Proceedwithstep3.

Figure43

1.Hexadjustmentlinkagejamnut

g233418

Figure44

1.Adjustmentrod

6.Lookingdowntowardstheadjustmentrod—

rotateitcounterclockwise,in1/4turnincrements,

toincreasespeedorclockwisetodecrease

speed.

g231567

7.Drivethemachineandcheckthefullforward

tracking.

8.Repeatsteps5through7untildesiredtracking

isobtained.

3.Allowthecontrolleverstoreturntoneutral.

Turnthelefthexadjustmentlinkuntilthemotion

controlleversareapproximatelyevenwitheach

other.

4.Repeatsteps2and3fortheothermotion

controllinkage.

37

Page 38

BrakeMaintenance

BeltMaintenance

AdjustingtheParking Brake

Iftheparkingbrakedoesnotholdsecurely ,an

adjustmentisrequired.

1.RefertoPreparingforMaintenance(page28).

2.Checktheairpressureinthedrivetires.If

needed,adjusttotherecommendedination;

refertoCheckingtheDriveTireAirPressure

(page36).

3.Disengagetheparkingbrake.

4.Loosenthecableclamponthebrakecables

undertheconsole(Figure45).

5.Adjustbothcableconduitsdownward

approximately1/8to1/4inch(3to6mm).

CheckingtheCondition andTensionoftheBelts

ServiceInterval:Every50hours

1.Shutofftheengine,engagetheparkingbrake,

waitforallmovingpartstostop,andremove

thekey.

2.Checktheauxiliarypumpdrivebeltcondition

andtension;thebeltshouldbesnug.Referto

AdjustingtheAuxiliaryPumpDriveBelt(page

38).

3.Checktheconditionofthetransmissiondrive

belt.

AdjustingtheAuxiliary PumpDriveBelt

1.Shutofftheengine,engagetheparkingbrake,

waitforallmovingpartstostop,andremove

thekey.

2.T otightenthebelt,loosenbothnuts(3/8inch)

ontheauxiliarypump.Slidethepumpoutward

inslotsandtightenthenuts.

Figure45

1.Cableclamp