PowerTRX

™

Commercial1428OHXEand1432

OHXESnowthrower

ModelNo.38870—SerialNo.400000000andUp

ModelNo.38875—SerialNo.400000000andUp

FormNo.3439-453RevA

Operator'sManual

Introduction

Thismachineisintendedtobeusedbyresidential

homeownersandprofessional,hiredoperators.It

isdesignedprimarilyforremovingsnowfrompaved

surfaces,suchasdrivewaysandsidewalks,and

othersurfacesfortrafconresidentialorcommercial

properties.Itisnotdesignedforremovingmaterials

otherthansnow.Usingthisproductforpurposes

otherthanitsintendedusecouldprovedangerousto

youandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.T oro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

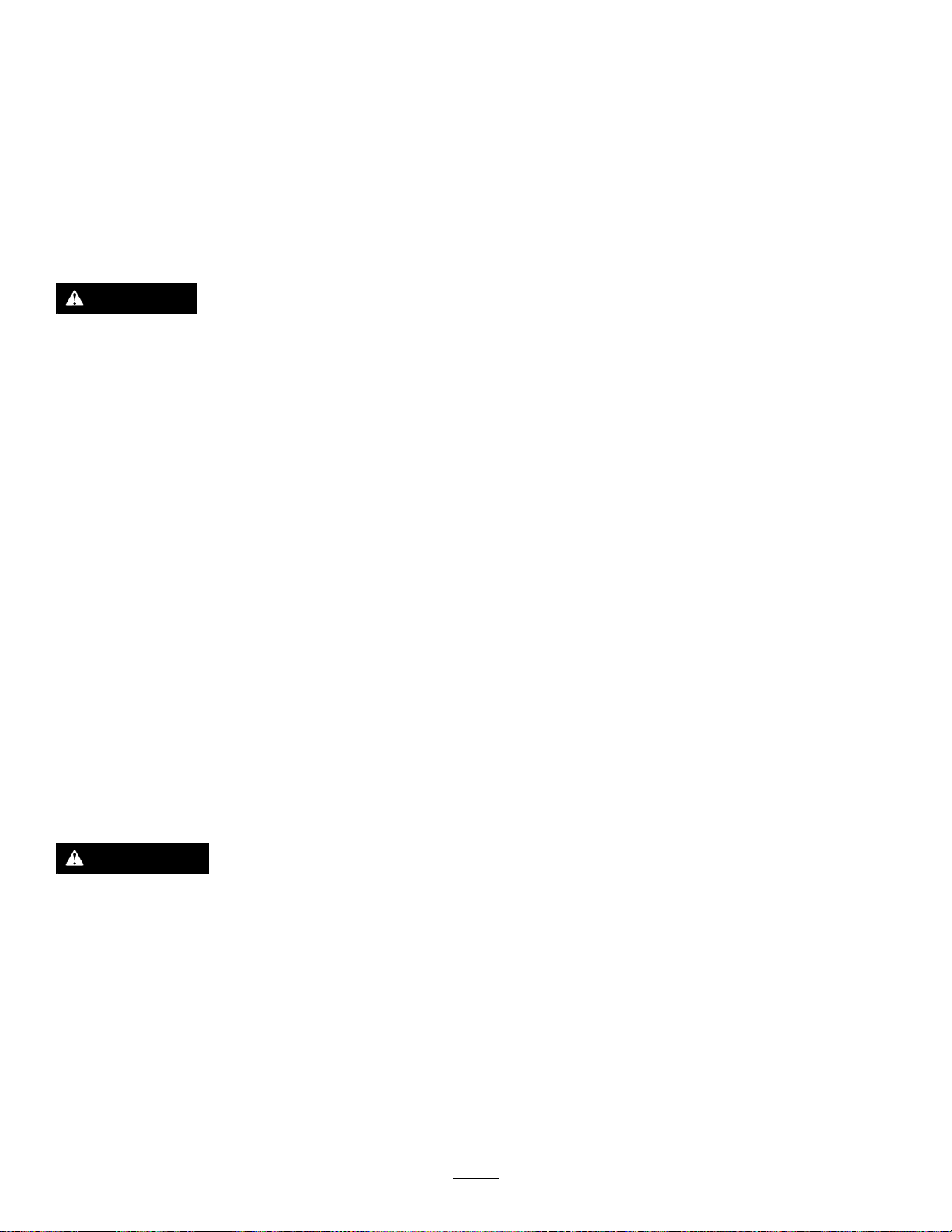

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Important:Ifyouareusingthismachineabove

1500m(5,000ft)foracontinuousperiod,ensure

thattheHighAltitudeKithasbeeninstalled

sothattheenginemeetsCARB/EPAemission

regulations.TheHighAltitudeKitincreases

engineperformancewhilepreventingspark-plug

fouling,hardstarting,andincreasedemissions.

Onceyouhaveinstalledthekit,attachthe

high-altitudelabelnexttotheserialdecalonthe

machine.ContactanyAuthorizedToroService

DealertoobtaintheproperHighAltitudeKitand

high-altitudelabelforyourmachine.Tolocate

adealerconvenienttoyou,accessourwebsite

atwww.Toro.comorcontactourToroCustomer

g323171

CareDepartmentatthenumber(s)listedinyour

EmissionControlWarrantyStatement.Remove

thekitfromtheengineandrestoretheengineto

itsoriginalfactorycongurationwhenrunningthe

engineunder1500m(5,000ft).Donotoperatean

enginethathasbeenconvertedforhigh-altitude

©2020—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

CV

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3439-453*A

useatloweraltitudes;otherwise,youcould

overheatanddamagetheengine.

Ifyouareunsurewhetherornotyourmachinehas

beenconvertedforhigh-altitudeuse,lookforthe

followinglabel(Figure3).

Figure3

Contents

Introduction...............................................................1

Safety.......................................................................3

GeneralSafety...................................................3

SafetyandInstructionalDecals..........................3

Setup........................................................................5

1CheckingtheEngine-OilLevel.........................5

2CheckingtheSkidsandScraper......................5

3CheckingtheOperationoftheTraction

Drive...............................................................5

decal127-9363

4ExtendingtheDriftBreakers............................6

ProductOverview.....................................................7

Specications....................................................7

Attachments/Accessories...................................7

Operation..................................................................8

BeforeOperation...................................................8

BeforeOperationSafety.....................................8

FillingtheFuelT ank............................................8

DuringOperation...................................................8

DuringOperationSafety.....................................8

StartingtheEngine.............................................9

ShuttingOfftheEngine......................................11

OperatingtheHandwarmers..............................11

OperatingtheAuger-HeightLever.....................11

OperatingtheTractionDrive.............................12

UsingtheWheel-ClutchLevers.........................12

OperatingtheSpeedSelector...........................12

OperatingtheAuger/ImpellerDrive...................13

OperatingtheQuickStick®...............................13

ClearingaCloggedDischargeChute................13

OperatingTips.................................................14

AfterOperation....................................................14

AfterOperationSafety......................................14

PreventingFreeze-upafterUse........................14

Maintenance...........................................................15

RecommendedMaintenanceSchedule(s)...........15

MaintenanceSafety..........................................15

PreparingforMaintenance...............................15

CheckingtheEngine-OilLevel..........................16

CheckingandAdjustingtheAugerSkidsand

Scraper.........................................................16

CheckingandAdjustingtheTrack

Skids.............................................................17

CheckingandAdjustingtheTrack

Tension.........................................................17

CheckingandAdjustingtheTraction

Cable............................................................18

CheckingandAdjustingtheAuger/Impeller

Cable............................................................19

CheckingtheAuger-Gearbox-OilLevel.............19

ChangingtheEngineOil...................................20

ReplacingtheSparkPlug.................................21

ReplacingtheDriveBelts..................................21

ReplacingtheHeadlight....................................22

Storage...................................................................22

StorageSafety..................................................22

StoringtheMachine..........................................22

2

RemovingtheMachinefromStorage................23

x 3

1

2

3

4

5

120-9805

Troubleshooting......................................................24

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO8437specications.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury .

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

Ensurethateveryoneusingthisproductknows

howtouseit,knowshowtoshutofftheengine

quickly,andunderstandsthewarnings.

•Shutofftheenginewheneveryouleavethe

operatingpositionforanyreason.

•Donotputyourhandsorfeetnearmovingparts

onthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

working.

•Keepclearofanydischargeopening.Keep

bystanders,especiallysmallchildren,outofthe

operatingarea.

•Neverallowchildrentooperatethemachine.

decal121-6817

121-6817

1.Cutting/dismembermenthazardofhandorfoot,impeller

decal120-9805

120-9805

1.Insertthekey.

2.Primetheengine3times.

3.Engagethechoke.

4.Pullthestartercord.

5.Oncetheengineisrunning,disengagethechoke.

andauger—keepbystandersaway.

3

decal131-6487

131-6487

121-6847

1.Cutting/dismembermenthazardofthengersorhand,

impeller—donotplaceyourhandinthechute;shutoffthe

enginebeforeusingthetooltoclearthechute.

1.Engine—shutoff

3.Fast

2.Slow

decal121-6847

decal136-7825

136-7825

1.Fuel

2.Fuelshutoff

decal138-0650

138-0650

1.Squeezethelowerlevertoturnleft.5.Cutting/dismembermentofngersorhand,impeller

blade—keepawayfrommovingparts;keepallguardsand

shieldsinplace;removethekeyfromtheignitionbefore

servicingthemachine.

2.Squeezetheupperlevertoengagethetractiondrive.

6.Thrownobjecthazard—keepbystandersaway.

3.Warning—readtheOperator’sManual.7.Squeezetheupperlevertoengagetheimpeller.

4.Cutting/dismembermentofngersorhand,impellerblade—do

8.Squeezethelowerlevertoturnright.

notplaceyourhandinthechute;shutofftheenginebefore

usingthetooltoclearthechute.

4

Setup

1

CheckingtheEngine-OilLevel

NoPartsRequired

Procedure

Note:Yourmachinecomeswithoilintheenginecrankcase.Beforestartingtheengine,checktheoillevel

andaddoilifnecessary.

RefertoCheckingtheEngine-OilLevel(page16).

1.Starttheengine;refertoStartingtheEngine

(page9).

2

CheckingtheSkidsand

Scraper

NoPartsRequired

Procedure

RefertoCheckingandAdjustingtheAugerSkidsand

Scraper(page16).

3

CheckingtheOperationof

theTractionDrive

NoPartsRequired

Procedure

2.Pullthespeedselectorslightlyoutoftheneutral

position;refertoOperatingtheSpeedSelector

(page12).

3.Squeezetheleft(traction)levertothehandgrip

(Figure4).

g322974

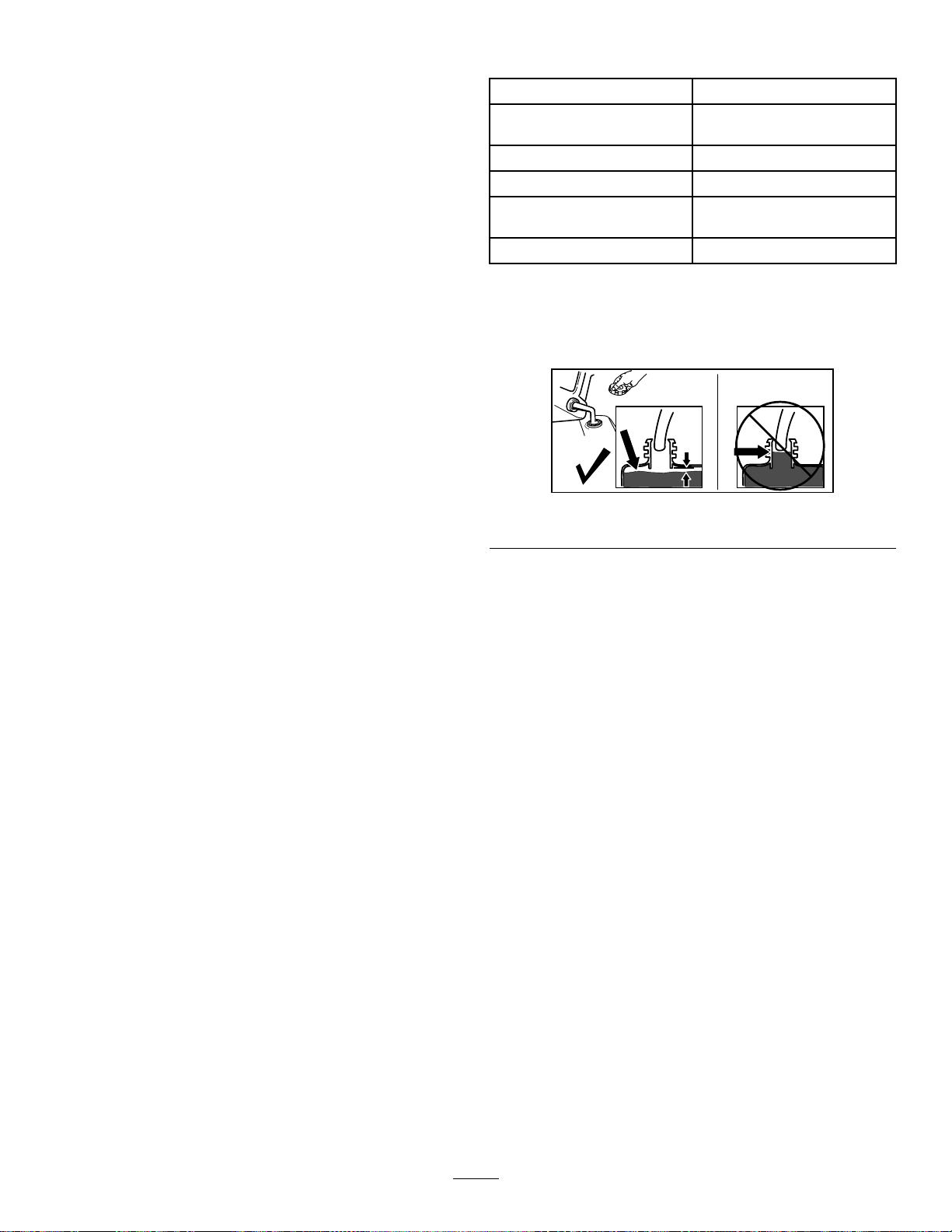

Figure4

Themachineshouldmoverearward.Ifthe

machinedoesnotmoveormovesforward,

completethefollowing:

A.Releasethetractionleverandshutoffthe

engine.

B.Loosenthe2nutsonthespeedcable

restingonthespeed-selector-leverbracket,

locatedunderthecontrolpanel(Figure5).

CAUTION

Ifthetractiondriveisnotproperlyadjusted,

themachinemaymoveinthedirection

oppositeofwhatyouintended,causinginjury

and/orpropertydamage.

Carefullycheckthetractiondriveandadjustit

properly,ifnecessary.

5

5.Pushthespeedselectorslightlyoutofthe

neutralposition;refertoOperatingtheSpeed

Selector(page12).

6.Squeezetheleft(traction)levertothehandgrip

(Figure4).

Themachineshouldmoveforward.Ifthe

machinedoesnotmoveormovesrearward,

completethefollowing:

A.Releasethetractionleverandshutoffthe

engine.

B.Loosenthe2nutsonthespeedcable

restingonthespeed-selector-leverbracket,

locatedunderthecontrolpanel(Figure5).

C.Pushthecableupward.

Figure5

1.Nutsonthespeedcable

C.Pullthecabledownward.

D.Tightenthe2nuts.

4.Releasethetractionlever.

4

ExtendingtheDriftBreakers

NoPartsRequired

Procedure

Extendthedriftbreakersasneeded.

g326129

D.Tightenthe2nuts.

7.Ifyoumadeanyadjustments,repeatthis

procedureuntilnoadjustmentsarerequired.

Important:Ifthemachinemoveswhenthe

tractionleverisinthereleasedposition,checkthe

tractioncable;refertoCheckingandAdjusting

theTractionCable(page18)ortakethemachine

toanAuthorizedServiceDealerforservice.

g258084

6

ProductOverview

g016500

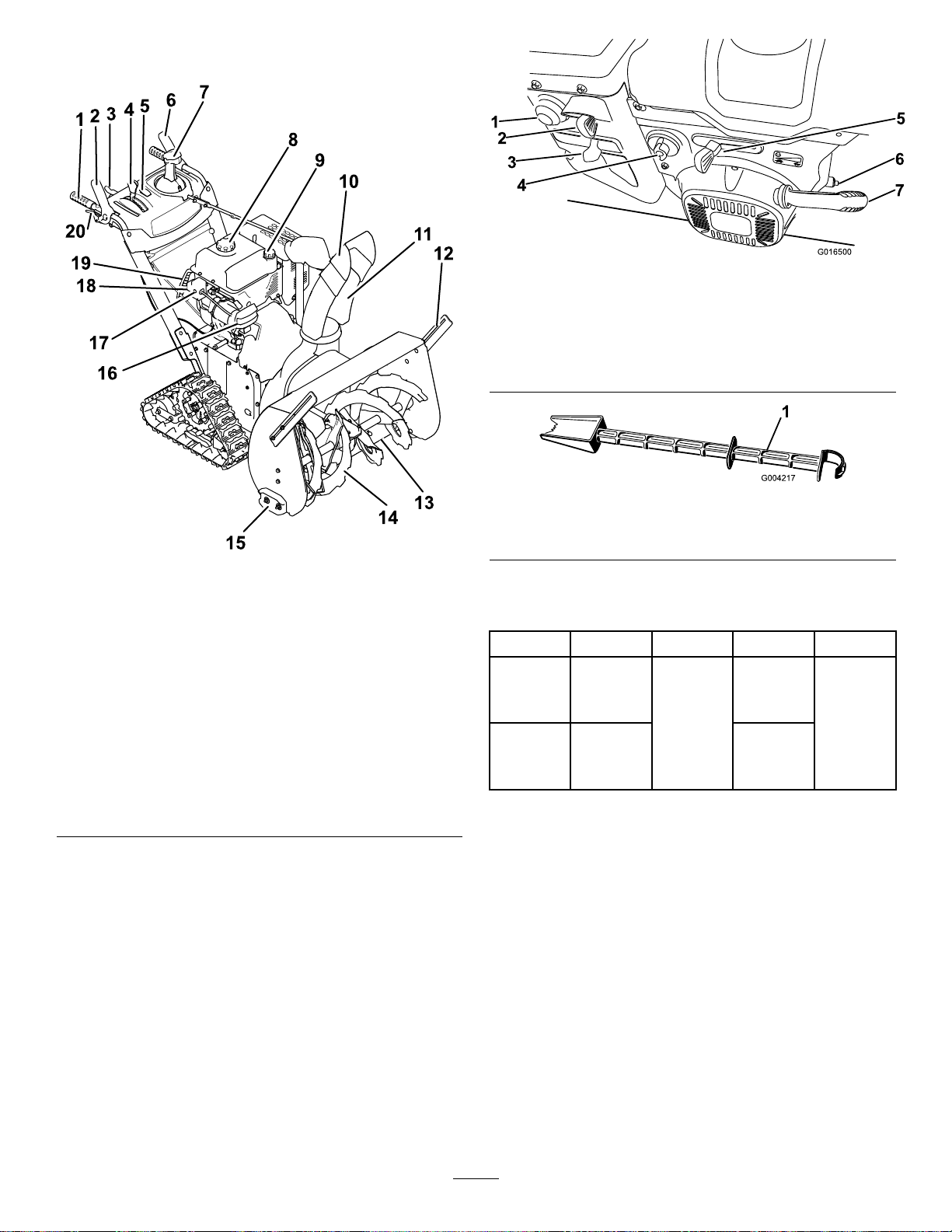

Figure8

1.Primer5.Throttle

2.Key

3.Choke

4.Fuel-shutoffvalve

6.Oil-drainplug

7.Recoil-starthandle

g004217

Figure9

Figure7

1.Handgrip(2)

2.Auger/impellerlever12.Driftbreaker(2)

3.Auger-heightlever

4.Speed-selectorlever

5.Handwarmerswitch

6.Tractionlever16.Headlight

7.QuickStick®

discharge-chutecontrol

8.Fuel-tankcap18.Electric-startplug-in

9.Oil-lltube/dipstick

10.Chutedeector20.Wheel-clutchlever(2)

11.Dischargechute

13.Scraper

14.Auger

15.Skid(2)

17.Electric-startbutton

19.Recoil-starthandle

1.Snow-cleanouttool(attachedtothehandle)

g323249

Specications

ModelWeightLengthWidthHeight

138kg74cm

38870

38875

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.T oro.comforalistofall

approvedattachmentsandaccessories.

(304lb)

141kg84cm

(311lb)

160cm

(63

inches)

(29

inches)

(33

inches)

114cm

(45

inches)

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

7

Operation

FillingtheFuelTank

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Forelectric-startmodelsonly:Useextension

cordsandreceptaclesasspeciedinthemanual.

Inspecttheelectricalcordbeforepluggingitinto

apowersource.Ifthecordisdamaged,replace

it.Unplugthepowercordwheneveryouarenot

startingthemachine.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hair,securelooseclothing,anddonotwearloose

jewelry.

TypeUnleadedgasoline

Minimumoctanerating

Ethanol

MethanolNone

MTBE(methyltertiarybutyl

ether)

OilDonotaddtothefuel

Useonlyclean,fresh(nomorethan30daysold),fuel

fromareputablesource.

FillthefueltankasshowninFigure10;donotll

abovethebottomofthefueltankneck.

87(US)or91(research

octane;outsidetheUS)

Nomorethan10%byvolume

Lessthan15%byvolume

Figure10

g216203

•Thoroughlyinspecttheareawhereyouwillusethe

machine,andremovealldoormats,sleds,boards,

wires,andotherforeignobjects.

•Ifashield,safetydevice,ordecalisdamaged,

illegible,ormissing,repairorreplaceitbefore

beginningoperation.Also,tightenanyloose

fasteners.

•Adjustthecollectorhousingheighttocleara

gravelorcrushed-rocksurface.

FuelSafety

Fuelisextremelyammableandexplosive.Areor

explosionfromfuelcanburnyouandothers.

•Topreventastaticchargefromignitingthefuel,

placethecontainerand/ormachineontheground

beforelling,notinavehicleoronanobject.

•Fillthefueltankoutdoorswhentheengineiscold.

Replacethefuelcapsecurelyandwipeupspills.

•Donothandlefuelwhensmokingoraroundan

openameorsparks.

•Storefuelinanapprovedfuelcontainer,outofthe

reachofchildren.

•Whenfuelisinthetank,tipthemachineonlyas

directedintheinstructions.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.

Important:Forbestresults,purchaseonlythe

quantityoffuelthatyouexpecttousein30days.

Otherwise,addfuelstabilizer/conditionertofresh

fuelasdirectedbythefuel-stabilizer/conditioner

manufacturer.

DuringOperation

DuringOperationSafety

GeneralSafety

•Shutofftheenginebeforeuncloggingthe

machineandalwaysuseastickorthe

snow-cleanouttool(ifprovided).

•Staybehindthehandlesandawayfromthe

dischargeopeningwhileoperatingthemachine.

Keepyourface,hands,feet,andanyotherpart

ofyourbodyorclothingawayfrommovingor

rotatingparts.

•Neverdirectthedischargetowardpeopleorareas

wherepropertydamagecanoccur.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Exercisecautiontoavoidslippingorfalling,

especiallywhenoperatingthemachineinreverse.

8

•Alwaysbesureofyourfooting,andkeeparm

holdonthehandles.Walk;neverrun.

•Exerciseextremecautionwhenoperatingthe

machineonaslope.

•Donotoperatethemachinewithoutgoodvisibility

orlight.

•Lookbehindandusecarewhenbackingupthe

machine.

•Whennotactivelyclearingsnow,disengagepower

totheauger.

•Exerciseextremecautionwhenoperatingthe

machineonorcrossinggraveldrives,walks,or

roads.Stayalertforhiddenhazardsortrafc.

•Neverattempttomakeanyadjustmentswhile

theengineisrunning,exceptasdirectedinthe

instructions.

•Afterstrikingaforeignobject,shutofftheengine,

removethekey,andinspectthemachinefor

StartingtheEngine

damage.Repairanydamagebeforestartingthe

machine.

•Ifthemachinestartstovibrateabnormally,shutoff

theengineandcheckimmediatelyforthecause.

•Donotruntheengineindoors;exhaustfumesare

dangerous.

•Donotoverloadthemachinecapacityby

attemptingtoclearsnowattoofastarate.

•Disengageallclutchesandshiftintoneutralbefore

startingtheengine.

•Shutofftheenginewheneveryouleavethe

operatingposition,beforeclearingorunclogging

thecollector,impeller,ordischargechute,and

whenmakinganyrepairs,adjustments,or

inspections.

•Neveroperatethemachineathightransport

speedsonslipperysurfaces.

UsingElectricStart

Note:Tousetheelectricstarter(electric-startmodelsonly),connectapowercordtotheplug-inrstand

thentoapoweroutlet.Useacertied1.3mm²extensioncordrecommendedforoutdoorusethatisnot

longerthan15m(50ft).

WARNING

Theelectricalcordcanbecomedamaged,causingashockorre.

Thoroughlyinspecttheelectricalcordbeforeusingthemachine.Ifthecordisdamaged,do

notuseit.Replaceorrepairthedamagedcordimmediately.ContactanAuthorizedService

Dealerforassistance.

CAUTION

Ifyouleavethemachinepluggedintoapoweroutlet,someonecaninadvertentlystartthe

machineandinjurepeopleordamageproperty.

Unplugthepowercordwheneveryouarenotstartingthemachine.

9

UsingRecoilStart

g326777

Figure11

g260415

Figure12

10

ShuttingOfftheEngine

g252411

Figure13

Operatingthe

Handwarmers

Operatethehandwarmersasfollows:

•PresstheswitchtotheONpositiontoturnonthe

handwarmers.

•PresstheswitchtotheOFFpositiontoturnoffthe

handwarmers.

Figure14

OperatingtheAuger-Height

Lever

Usetheauger-heightlevertoadjusttheheightofthe

augerhousing.

Presstheauger-heightleverdownwhilemovingthe

handlesupordownasneededtoobtainthedesired

augerheightposition.

Releasethelevertolocktheaugerinthedesired

heightposition.

g026460

1.On/Offswitch3.OFFposition

2.ONposition

g313864

Figure15

1.Auger-heightlever

11

OperatingtheTraction

Drive

CAUTION

Ifthetractiondriveisnotproperlyadjusted,

themachinemaymoveinthedirection

oppositeofwhatyouintended,causinginjury

and/orpropertydamage.

Carefullycheckthetractiondriveandadjust

itproperly ,ifnecessary;referto3Checking

theOperationoftheTractionDrive(page5)

formoreinformation.

Important:Ifthemachinemoveswhenthe

tractionleverisinthereleasedposition,checkthe

tractioncable;refertoCheckingandAdjusting

theTractionCable(page18)ortakethemachine

toanAuthorizedServiceDealerforservice.

1.Toengagethetractiondrive,squeezetheleft

(traction)levertothehandgrip(Figure16).

g001307

Figure17

Note:Thisdisengagesthedrivetotherightwheel

whiletheleftwheelcontinuesdriving,andthemachine

turnstotheright.

Note:Similarly,squeezingtheleftwheel-clutchlever

turnsthemachinetotheleft.

Whenyoucompletetheturn,releasethewheel-clutch

lever,andthedrivere-engagesbothwheels(Figure

18).

Figure16

2.Tostopthetractiondrive,releasethetraction

lever.

UsingtheWheel-Clutch

Levers

Thewheel-clutchleversallowyoutomomentarily

disengagethedriveto1orbothwheelswiththe

traction-driveleverstillengaged.Thisenablesyouto

turnandmaneuverthemachineeasily.

Note:Holdingdownthetractionleveragainstthe

handleengagesthetractiondrivetobothwheels.

Toturnthemachinetotheright,liftuptheright

wheel-clutchleverandsqueezeittowardthehandle

(Figure17).

g001308

Figure18

g322974

Momentarilysqueezingandreleasingtheleftorright

wheel-clutchleveralsoallowsforsteeringadjustments

tokeepthemachinegoinginastraightline,especially

indeepsnow.

Squeezingbothwheel-clutchleverssimultaneously

disengagesthedrivetobothwheels.Thisenables

youtomanuallymovethemachinebackwardwithout

stoppingtoshiftitintoareversegear.Italsoallows

youtomaneuverandtransportthemachinemore

easilywhentheengineisnotrunning.

OperatingtheSpeed

Selector

Thespeedselectorhasforwardandreversegears.

Tochangespeeds,releasethetractionleverand

shiftthespeed-selectorlevertothedesiredposition

(Figure19).Theleverlocksinanotchateachspeed

selection.

12

Figure19

Operatingthe

Auger/ImpellerDrive

1.Toengagetheauger/impellerdrive,squeeze

theright(auger/impeller)levertothehandgrip

(Figure20).

OperatingtheQuickStick®

Note:Fullypresstheblueknobtoreleasethelatch

andoperatetheQuickStick®.

g326462

Figure20

2.Tostoptheaugerandimpeller,releasetheright

lever.

Important:Whenyouengageboththe

auger/impellerleverandthetractionlever,

thetractionleverlockstheauger/impeller

leverdown,freeingyourrighthand.T o

releasebothlevers,simplyreleasetheleft

(traction)lever.

3.Iftheaugerandimpellercontinuetorotatewhen

youreleasetheauger/impellerlever,donot

operatethemachine.Checktheauger/impeller

cable;refertoCheckingandAdjustingthe

Auger/ImpellerCable(page19)andadjustitif

necessary.Otherwise,takethemachinetoan

AuthorizedServiceDealerforservice.

WARNING

Iftheaugerandimpellercontinue

torotatewhenyoureleasethe

auger/impellerlever,youcouldseriously

injureyourselforothers.

Donotoperatethemachine.Takeittoan

AuthorizedServiceDealerforservice.

g030118

g322975

Figure21

ClearingaClogged

DischargeChute

WARNING

Iftheauger/impellerisrunningbutthereisno

snowcomingoutofthedischargechute,the

dischargechutemaybeclogged.

Neveruseyourhandstoclearaclogged

dischargechute.Thiscouldresultinpersonal

injury.

•Tounclogthedischargechute,stayinthe

operatingpositionandreleasetheleft(traction)

lever.Whilerunningtheauger/impeller,pushdown

onthehandlestoraisethefrontofthemachinea

fewcentimeters(inches)offthepavement.Then

liftthehandlesquicklytobumpthefrontofthe

machineonthepavement.Repeatifnecessary

untilastreamofsnowcomesoutthedischarge

chute.

•Ifyoucannotunclogthedischargechuteby

bumpingthefrontofthemachine,shutoffthe

13

engine,waitforallmovingpartstostop,and

usethesnow-cleanouttool(Figure9).

•Iftheengineslowsdownunderaloadorthetracks

slip,shiftthemachineintoalowergear.

Important:Uncloggingthedischargechute

bybumpingthefrontofthemachineonthe

pavementmaycausetheskidstomove.Adjust

theskidsandtightentheskidboltssecurely;

refertoCheckingandAdjustingtheAuger

SkidsandScraper(page16).

OperatingTips

DANGER

Whenthemachineisinoperation,theimpeller

andaugerrotateandcaninjureoramputate

handsorfeet.

•Beforeadjusting,cleaning,inspecting,

troubleshooting,orrepairingthemachine,

shutofftheengineandwaitforallmoving

partstostop.Disconnectthewirefrom

thesparkplugandkeepitawayfromthe

plugtopreventsomeonefromaccidentally

startingtheengine.

•Removeanobstructionfromthedischarge

chute;refertoClearingaClogged

DischargeChute(page13).Usethe

snow-cleanouttool(Figure10),notyour

hands,toremoveanobstructionfromthe

dischargechute.

•Staybehindthehandlesandawayfrom

thedischargeopeningwhileoperatingthe

machine.

•Keepyourface,hands,feet,andanyother

partofyourbodyorclothingawayfrom

concealed,moving,orrotatingparts.

WARNING

Theimpellercanthrowstones,toys,andother

foreignobjectsandcauseseriouspersonal

injurytoyouorbystanders.

•Keeptheareatobeclearedfreeofall

objectsthattheaugercouldpickupand

throw.

•Ifthefrontofthemachineridesup,shiftthe

machineintoalowergear.Ifthefrontcontinuesto

rideup,liftuponthehandles.

AfterOperation

AfterOperationSafety

GeneralSafety

•Neverstorethemachinewithfuelinthefuel

tankinsideabuildingwhereignitionsourcesare

present,suchashotwaterheaters,spaceheaters,

orclothesdryers.Allowtheenginetocoolbefore

storingthemachineinanyenclosure.

•Whenstoringthemachineformorethan30

days,refertoStorage(page22)forimportant

information.

•Runthemachineafewminutesafterthrowing

snowtopreventfreeze-upofthecollectorand

impeller.

PreventingFreeze-upafter

Use

•Insnowyandcoldconditions,somecontrolsand

movingpartsmayfreeze.Donotuseexcessive

forcewhentryingtooperatefrozencontrols.

Ifyouhavedifcultyoperatinganycontrolorpart,

starttheengineandletitrunforafewminutes.

•Afterusingthemachine,lettheenginerunfor

afewminutestopreventmovingpartsfrom

freezing.Engagetheauger/impellertoclearany

remainingsnowfrominsidethehousing.Rotate

theQuickSticktopreventitfromfreezing.Shutoff

theengine,waitforallmovingpartstostop,and

removealliceandsnowfromthemachine.

•Withtheengineoff,pulltherecoil-starthandle

severaltimesandpushtheelectric-startbutton

oncetopreventtherecoilstarterandelectric

starterfromfreezingup.

•Keepallchildrenandpetsawayfromthe

areaofoperation.

•AlwayssetthethrottletotheFASTpositionwhen

throwingsnow.

14

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst5hours

Beforeeachuseordaily

Every50hours

Every100hours

Monthly

Yearly

Yearlyorbeforestorage

MaintenanceProcedure

•Inspectthetractioncableandadjustitifnecessary .

•Inspecttheauger/impellercableandadjustitifnecessary.

•Changetheengineoil.

•Checktheengine-oillevelandaddoilifnecessary .

•Changetheengineoil.Changetheengineoilevery25operatinghourswhen

operatingtheengineunderaheavyload.

•Replacethesparkplug.

•Checkthetracktensionandadjustifneeded.

•Checktheskidsandthescraperandadjustthemifnecessary.

•Checkandadjustthetrackskids.

•Inspectthetractioncableandadjustorreplaceitifnecessary.

•Inspecttheauger/impellercableandadjustorreplaceitifnecessary.

•Checktheauger-gearboxoilandaddoilifnecessary.

•Drainthefuelandruntheenginetodryoutthefueltankandthecarburetoratthe

endoftheseason.

•HaveanAuthorizedServiceDealerinspectandreplacethetractiondrivebeltand/or

theauger/impellerdrivebelt,ifnecessary.

MaintenanceSafety

Readthefollowingsafetyprecautionsbefore

performinganymaintenanceonthemachine:

•Shutofftheengine,removethekey,andwait

forallmovementtostopbeforeyouleavethe

operator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

•Alwaysweareyeprotectionwhileperformingan

adjustmentorrepairtoprotectyoureyesfrom

foreignobjectsthatthemachinemaythrow.

•Checkallfastenersatfrequentintervalsforproper

tightnesstoensurethatthemachineisinsafe

workingcondition.

•Donotchangethegovernorsettingsontheengine.

PurchaseonlygenuineTororeplacementparts

andaccessories.

PreparingforMaintenance

1.Movethemachinetoalevelsurface.

2.Shutofftheengine,removethekey ,andwaitfor

allmovingpartstostop.

3.Disconnectthespark-plugwire.Referto

ReplacingtheSparkPlug(page21).

15

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily—Checktheengine-oillevelandaddoilifnecessary .

g257528

CheckingandAdjustingthe

AugerSkidsandScraper

ServiceInterval:Yearly—Checktheskidsand

thescraperandadjustthemif

necessary.

Checktheskidsandthescrapertoensurethatthe

augerdoesnotcontactthepavedorgravelsurface.

Adjusttheskidsandthescraperasneededto

compensateforwear.

1.Loosenthenutsthatsecurebothskidstothe

augersidesuntiltheskidsslideupanddown

easily.

2.Ensurethatthescraperis3mm(1/8inch)above

andparalleltoalevelsurface.

Note:Ifthepavementiscracked,rough,or

uneven,adjusttheskidstoraisethescraper.For

gravelsurfaces,adjusttheskidsfurtherdownto

preventthemachinefrompickinguprocks.

3.Movetheskidsdownuntiltheyareevenwith

theground.

4.Firmlytightenthenutsthatsecurebothskids

totheaugersides.

Note:T oquicklyadjusttheskidsiftheyloosen,

supportthescraper3mm(1/8inch)offthe

pavement,thenadjusttheskidsdowntothe

pavement.

Note:Iftheskidsbecomeexcessivelyworn,

youcanturnthemoverandsettheunusedside

towardthepavement.

Figure23

1.3mm(1/8inch)

Important:Theaugerbladesmustbe

supportedabovethegroundbytheskids.

g019046

16

CheckingandAdjustingthe

CheckingandAdjustingthe

TrackSkids

ServiceInterval:Y early

1.RefertoPreparingforMaintenance(page15).

2.Loosentheskidbolts(AofFigure24).

3.Lowertheskidsothatitistangentwiththefront

andreartrackrollers(BofFigure24).

4.Tightentheskidbolts(CofFigure24).

TrackTension

ServiceInterval:Monthly

1.RefertoPreparingforMaintenance(page15).

2.Apply44N(10lbf)betweenthemiddleandrear

roller(Figure25).

g325787

Figure25

3.Ensurethatthedeectionofthetrackis

approximately9.5mm(3/8inch).

4.Ifthetrackdeectionisnotapproximately9.5

mm(3/8)inchorifthetracksarejumping,adjust

thetracktensionasfollows:

A.Slightlyloosenthenutsontherearroller

yoke(Figure26).

Figure26

1.Rear-roller-yokenuts

B.Adjustthehexheadboltasneeded(Figure

27).

Note:Turntheboltclockwiseifthetrack

hasmorethan9.5mm(3/8inch)deection.

Turntheboltcounterclockwiseifthetrack

haslessthan9.5mm(3/8inch)deection.

g325788

Figure24

g325810

17

Figure27

1.Hexheadadjustmentbolts

C.Ensurethatthedeectionofthetrackis

approximately9.5mm(3/8inch).

D.Tightenthenutsontherearrolleryoke.

Ifthereisslackinthetractioncable,theleft(traction)

cableisnotproperlyadjusted.

Toadjustthetractioncable,dothefollowing:

1.Loosenthejamnut(Figure29).

2.Loosenortightentheturnbuckleuntilthecable

istaught.

3.Tightenthejamnut.

g325789

E.Repeatfortheothertrack.

CheckingandAdjustingthe

TractionCable

ServiceInterval:Aftertherst2hours—Inspect

thetractioncableandadjustitif

necessary.

Yearly—Inspectthetractioncableandadjustor

replaceitifnecessary.

Ifthemachinedoesnotdriveintheforwardorreverse

speedsoritdriveswhenyoureleasethetractionlever,

adjustthetractioncable.

Withthetractionleveldisengaged,ensurethatthe

thereisnoslackinthetractioncable(Figure28).

g325791

Figure29

1.Turnbuckle2.Jamnut

Figure28

g325790

18

CheckingandAdjustingthe

Auger/ImpellerCable

ServiceInterval:Aftertherst2hours—Inspectthe

auger/impellercableandadjustitif

necessary.

Yearly—Inspecttheauger/impellercableand

adjustorreplaceitifnecessary.

1.Removethe2screwsthatareholdingthebelt

coverinplace(Figure30).

2.Removethebeltcover(Figure30).

g322960

Figure32

1.Jamnut2.Turnbuckle

6.Loosenortightentheturnbucklethatadjuststhe

tensiononthecable(Figure32).

7.Adjusttheturnbuckleuntilyouobtaintheproper

gap.

8.Tightenthejamnut.

9.Insertthe2screwsthatyoupreviouslyremoved

onthebeltcover.

Figure30

3.Withtheauger/impellerleverdisengaged,

ensurethatthegapbetweentheaugerclutch

armandtheframeofthemachineis1.5mm

(1/16inch)asshowninFigure31.

Figure31

10.Iftheauger/impellercableisproperlyadjusted

butaproblemremains,contactanAuthorized

g323250

ServiceDealer.

Checkingthe

Auger-Gearbox-OilLevel

ServiceInterval:Yearly—Checktheauger-gearbox

oilandaddoilifnecessary.

1.Movethemachinetoalevelsurface.

2.Cleantheareaaroundthepipeplugandremove

thepipeplugfromthegearbox(Figure33).

Note:Ifneeded,useplierstoassistinremoving

thepipeplug.

g260108

1.1.5mm(1/16inch)

2.Frame

4.Iftheauger/impellercableisnotproperly

adjusted,dothefollowingsteps:

5.Loosenthejamnut(Figure32).

3.Augerclutcharm

19

Figure33

3.Checktheoillevelusingasuitablemeasuring

device,suchasacleancabletie.Theoilshould

beapproximately3.8cm(1.5inches)belowthe

lleropening(Figure34).

*Thereisresidualoilinthecrankcaseafteryoudrain

theoil.Donotpourtheentirecapacityofoilintothe

crankcase.Fillthecrankcasewithoilasdirectedin

thefollowingsteps.

1.Movethemachinetoalevelsurface.

2.Cleantheareaaroundtheoil-drainnut(Figure

35).

g323263

g016496

Figure35

1.Oil-drainnut

Figure34

4.Iftheoillevelislow,addGL-5orGL-6,SAE

85-95EPgearoillubricanttothegearbox,then

checktheoillevelagain.

Note:Donotusesyntheticoil.

5.Installthepipepluginthegearbox.

ChangingtheEngineOil

ServiceInterval:Aftertherst5hours—Changethe

engineoil.

Every50hours—Changetheengineoil.

Changetheengineoilevery25operatinghours

whenoperatingtheengineunderaheavyload.

3.Slideanoil-drainpanunderthedrainextension

andremovetheoil-drainnut.

4.Draintheoil.

Note:Disposeoftheusedoilproperlyatalocal

recyclingcenter.

g257737

5.Installtheoil-drainnutandtightenitsecurely.

6.Cleanaroundtheoilll/dipstick.

7.Unscrewthedipstickandremoveit.

8.Carefullypourabout3/4oftheenginecapacity

ofoilintotheoil-lltube.

UseFigure36toselectthebestoilviscosityfor

theoutdoortemperaturerangeexpected:

Ifpossible,runtheengineforafewminutesbefore

changingtheoilbecausewarmoilowsbetterand

carriesmorecontaminants.

Engineoilcapacity

OilviscosityRefertoFigure36.

APIserviceclassicationSJorhigher

0.95L(32oz)*

g011606

Figure36

20

9.Wait3minutesfortheoiltosettleintheengine.

10.Wipethedipstickcleanwithacleancloth.

11.Insertthedipstickintotheoil-lltubeandscrew

itin,thenremovethedipstick.

12.Readtheoillevelonthedipstick.

•Iftheoillevelonthedipstickistoolow,

carefullypourasmallamountofoilinto

theoil-lltube,wait3minutes,andrepeat

steps10through12untiltheoillevelonthe

dipstickiscorrect.

•Iftheoillevelonthedipstickistoohigh,

draintheexcessoiluntiltheoillevelonthe

dipstickiscorrect.

Important:Iftheoillevelintheengineistoo

lowortoohighandyouruntheengine,you

maydamagetheengine.

13.Installthedipstickintotheoil-lltubesecurely.

g016646

Figure38

3.Removeanddiscardtheoldsparkplug.

Note:Y ouwillneedaratchetwrenchextension

toremovethesparkplug.

ReplacingtheSparkPlug

ServiceInterval:Every100hours—Replacethe

sparkplug.

WARNING

Replacingthesparkplugwhiletheengineis

hotcanresultinburns.

Waituntiltheengineiscooltoreplacethe

sparkplug.

UseaT orosparkplugorequivalent(Champion®

RN9YCorNGKBPR6ES).

1.Removetheboot(Figure37).

4.Setthegapbetweentheelectrodesonanew

sparkplugat0.76mm(0.030inch)asshown

inFigure39.

g001029

Figure39

1.0.76mm(0.030inch)

5.Installthenewsparkplug,tightenitrmly ,and

attachtheignitionwiretothesparkplug.

Note:Ensurethattheignitionwiresnaps

completelyintoplaceonthesparkplug.

ReplacingtheDriveBelts

Iftheauger/impellerdrivebeltorthetraction-drivebelt

becomesworn,oil-soaked,orotherwisedamaged,

haveanAuthorizedServiceDealerreplacethebelt.

Figure37

1.Spark-plugboot

2.Cleanaroundthebaseofthesparkplug.

g016645

21

ReplacingtheHeadlight

Replacetheheadlightassembly(T oropartnumber138-0670)whenneeded.

1.Removetheheadlightwirefromthebackoftheheadlight(AofFigure40).

2.Removetheboltandnutholdingtheheadlightassemblyontotheheadlightbracketandthenremovethe

oldheadlightassembly(BofFigure40).

3.Securethenewheadlightassemblyontotheheadlightbracketwiththepreviouslyremovednutand

bolt(CofFigure40).

4.Inserttheheadlightwirestraightintothebackoftheheadlightuntilitissecurelyinplace(DofFigure40).

Figure40

g326789

Storage

StorageSafety

•Shutofftheengine,removethekey,andwait

forallmovementtostopbeforeyouleavethe

operator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

•Fuelfumesarehighlyammable,explosive,and

dangerousifinhaled.Ifyoustoretheproductinan

areawithanopename,thefuelfumesmayignite

andcauseanexplosion.

•Donotstorethemachineinahouse(living

area),basement,oranyotherareawhereignition

sourcesmaybepresent,suchashotwaterand

spaceheaters,clothesdryers,furnaces,andother

appliances.

•Donottipthemachineeitherforwardorbackward

withfuelinthefueltank;otherwise,fuelmayleak

outofthemachine.

•Donotstorethemachinewithitshandletipped

downontotheground;otherwise,oilmayleakinto

theenginecylinderandontotheground,andthe

enginemaynotstart.

StoringtheMachine

1.Onthelastrefuelingoftheyear,addfuel

stabilizertofreshfuelasdirectedbythefuel

stabilizermanufacturer.

Important:Donotstorefuellonger

thanthatsuggestedbythefuelstabilizer

manufacturer.

2.Runtheenginefor10minutestodistributethe

conditionedfuelthroughthefuelsystem.

3.Runthemachineuntiltheenginerunsoutoffuel.

4.Primetheengineandstartitagain.

5.Allowtheenginetorununtilitshutsoff.

Whenyoucannolongerstarttheengine,itis

sufcientlydry.

6.Allowtheenginetocool.

7.Removethekey.

8.Cleanthemachinethoroughly.

9.Touchupchippedsurfaceswithpaintavailable

fromanAuthorizedServiceDealer.Sand

affectedareasbeforepainting,andusearust

preventativetopreventthemetalpartsfrom

rusting.

10.Tightenallloosescrews,bolts,andlocknuts.

Repairorreplaceanydamagedparts.

22

11.Coverthemachineandstoreitinaclean,dry

placeoutofthereachofchildren.

RemovingtheMachine

fromStorage

Performtheannualmaintenanceproceduresasgiven

intheRecommendedMaintenanceSchedule;referto

Maintenance(page15).

23

Troubleshooting

Problem

Theelectricstarterdoesnotturn

(electric-startmodelsonly).

Theenginedoesnotstartorstartshard.

PossibleCauseCorrectiveAction

1.Thepowercordisdisconnectedatthe

outletorthemachine.

2.Thepowercordisworn,corroded,or

damaged.

3.Thepoweroutletisnotenergized.

1.Thekeyisnotintheignition.1.Insertthekeyintotheignition.

2.ThechokeisintheOFFpositionand

theprimerhasnotbeenpressed.

3.Thefuel-shutoffvalveisnotopen.3.Openthefuel-shutoffvalve.

4.ThethrottleisnotintheFASTposition.4.MovethethrottletotheFASTposition.

5.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

6.Thespark-plugwireislooseor

disconnected.

7.Thesparkplugispitted,fouled,orthe

gapisincorrect.

8.Thefuel-ventcapisrestricted.

9.Theengine-oillevelintheengine

crankcaseistoolowortoohigh.

1.Connectthepowercordtotheoutlet

and/orthemachine.

2.Replacethepowercord.

3.Haveaqualiedelectricianenergize

theoutlet.

2.MovethechoketotheONpositionand

presstheprimer3times.

5.Drainand/orllthefueltankwith

freshfuel(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

6.Connectthewiretothesparkplug.

7.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

8.Removetheventrestrictionorreplace

thefuelcap.

9.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

Theenginerunsrough.

1.ThechokeisintheONposition.1.MovethechoketotheOFFposition.

2.Thefuel-shutoffvalveisnotcompletely

open.

3.Thefueltankisnearlyemptyor

containsstalefuel.

4.Thespark-plugwireisloose.

5.Thesparkplugispitted,fouled,orthe

gapisincorrect.

6.Theengine-oillevelintheengine

crankcaseistoolowortoohigh.

2.Openthefuel-shutoffvalve.

3.Drainandllthefueltankwithfresh

fuel(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

4.Connectthewiretothesparkplug.

5.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

6.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

24

Problem

PossibleCauseCorrectiveAction

Theengineruns,butthemachine

dischargessnowpoorlyornotatall.

Thedischargechuteeitherdoesnotlock

intoplaceordoesnotmove.

Themachinedoesnotproperlyclearthe

snowoffthesurface.

1.ThethrottleisnotintheFASTposition

whenthrowingsnow .

2.Themachineismovingtoofasttoclear

thesnow.

3.Youaretryingtoremovetoomuch

snowperswath.

4.Youaretryingtoremoveextremely

heavyorwetsnow.

5.Thedischargechuteisplugged.5.Unclogthedischargechute.

6.Theauger/impellerdrivebeltisloose

orisoffthepulley .

7.Theauger/impellerdrivebeltisworn

orbroken.

1.Thedischarge-chutelatchisnot

properlyadjusted.

1.Theskidsand/orscraperarenot

properlyadjusted.

1.MovethethrottletotheFASTposition.

2.Shiftthemachineintoalowergear.

3.Reducetheamountofsnowremoved

perswath.

4.Donotoverloadthemachinewith

extremelyheavyorwetsnow.

6.Installand/oradjusttheauger/impeller

drivebelt;refertowww.T oro.com

forservicinginformationortakethe

machinetoanAuthorizedService

Dealer.

7.Replacetheauger/impellerdrivebelt;

refertowww.Toro.comforservicing

informationortakethemachinetoan

AuthorizedServiceDealer.

1.Adjustthedischarge-chutelatch.

1.Adjusttheskidsand/orthescraper.

25

Notes:

EEA/UKPrivacyNotice

Toro’sUseofYourPersonalInformation

TheT oroCompany(“T oro”)respectsyourprivacy.Whenyoupurchaseourproducts,wemaycollectcertainpersonalinformationaboutyou,eitherdirectly

fromyouorthroughyourlocalT orocompanyordealer.Torousesthisinformationtofullcontractualobligations-suchastoregisteryourwarranty,

processyourwarrantyclaimortocontactyouintheeventofaproductrecall-andforlegitimatebusinesspurposes-suchastogaugecustomer

satisfaction,improveourproductsorprovideyouwithproductinformationwhichmaybeofinterest.T oromayshareyourinformationwithoursubsidiaries,

afliates,dealersorotherbusinesspartnersinconnectiontheseactivities.Wemayalsodisclosepersonalinformationwhenrequiredbylaworin

connectionwiththesale,purchaseormergerofabusiness.Wewillneversellyourpersonalinformationtoanyothercompanyformarketingpurposes.

RetentionofyourPersonalInformation

Torowillkeepyourpersonalinformationaslongasitisrelevantfortheabovepurposesandinaccordancewithlegalrequirements.Formoreinformation

aboutapplicableretentionperiodspleasecontactlegal@toro.com.

Toro’sCommitmenttoSecurity

YourpersonalinformationmaybeprocessedintheUSoranothercountrywhichmayhavelessstrictdataprotectionlawsthanyourcountryofresidence.

Wheneverwetransferyourinformationoutsideofyourcountryofresidence,wewilltakelegallyrequiredstepstoensurethatappropriatesafeguardsare

inplacetoprotectyourinformationandtomakesureitistreatedsecurely .

AccessandCorrection

Youmayhavetherighttocorrectorreviewyourpersonaldata,orobjecttoorrestricttheprocessingofyourdata.T odoso,pleasecontactusbyemail

atlegal@toro.com.IfyouhaveconcernsaboutthewayinwhichT orohashandledyourinformation,weencourageyoutoraisethisdirectlywithus.

PleasenotethatEuropeanresidentshavetherighttocomplaintoyourDataProtectionAuthority .

374-0282RevC

Loading...

Loading...