Page 1

PowerMax

ModelNo.38836—SerialNo.400000000andUp

®

HeavyDuty1028OHXESnowthrower

Introduction

Thismachineisintendedtobeusedbyresidential

homeowners.Itisdesignedprimarilyforremoving

snowfrompavedsurfaces,suchasdrivewaysand

sidewalks,andothersurfacesfortrafconresidential

orcommercialproperties.Itisnotdesignedfor

removingmaterialsotherthansnow,norisitdesigned

forclearingoffgravelsurfaces.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactT orodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

FormNo.3415-877RevA

Operator'sManual

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

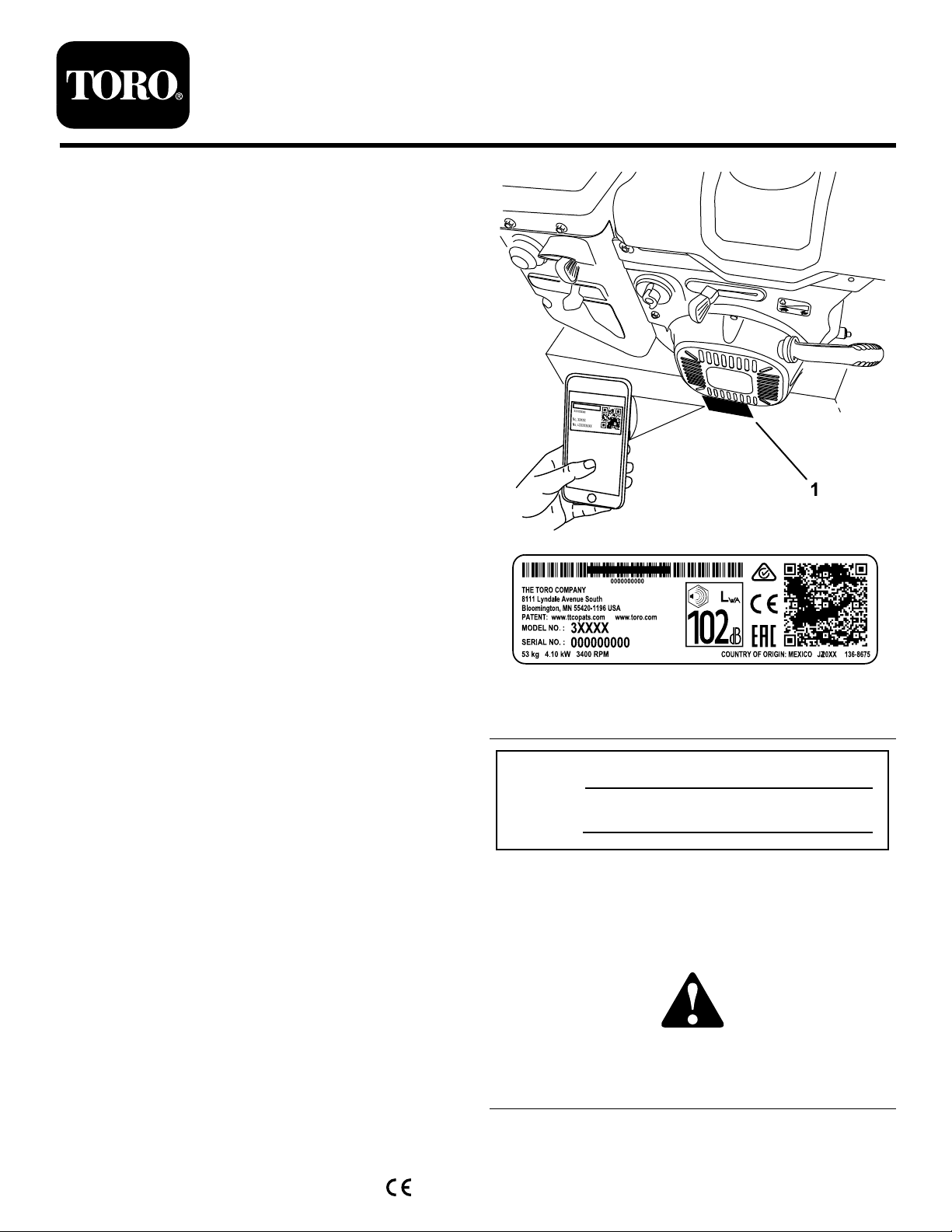

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyoursmartphoneortablet,scan

theQRcodeontheserialnumberdecaltoaccess

warranty,parts,andotherproductinformation.

g216798

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

©2017—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

Figure2

Safety-alertsymbol

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

g000502

*3415-877*A

Page 2

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Important:Ifyouareusingthismachineabove

1500m(5,000ft)foracontinuousperiod,ensure

thattheHighAltitudeKithasbeeninstalled

sothattheenginemeetsCARB/EPAemission

regulations.TheHighAltitudeKitincreases

engineperformancewhilepreventingspark-plug

fouling,hardstarting,andincreasedemissions.

Onceyouhaveinstalledthekit,attachthe

high-altitudelabelnexttotheserialdecalonthe

machine.ContactanyAuthorizedToroService

DealertoobtaintheproperHighAltitudeKitand

high-altitudelabelforyourmachine.T olocate

adealerconvenienttoyou,accessourwebsite

atwww.Toro.comorcontactourToroCustomer

CareDepartmentatthenumber(s)listedinyour

EmissionControlWarrantyStatement.Remove

thekitfromtheengineandrestoretheengineto

itsoriginalfactorycongurationwhenrunningthe

engineunder1500m(5,000ft).Donotoperatean

enginethathasbeenconvertedforhigh-altitude

useatloweraltitudes;otherwise,youcould

overheatanddamagetheengine.

Ifyouareunsurewhetherornotyourmachinehas

beenconvertedforhigh-altitudeuse,lookforthe

followinglabel(Figure3).

Figure3

Contents

5ConnectingtheHeadlightandHandwarmer

WiretotheEngine.........................................10

6CheckingtheEngine-OilLevel.......................10

7CheckingtheTirePressure.............................11

8CheckingtheSkidsandScraper.....................11

9CheckingtheOperationoftheTraction

Drive..............................................................11

ProductOverview...................................................12

Operation................................................................13

BeforeOperation.................................................13

BeforeOperationSafety...................................13

FillingtheFuelT ank..........................................13

DuringOperation.................................................14

DuringOperationSafety...................................14

StartingtheEngine...........................................14

ShuttingOfftheEngine.....................................16

OperatingtheHandwarmers.............................17

OperatingtheTractionDrive.............................17

UsingtheWheel-ClutchLevers.........................17

OperatingtheSpeedSelector...........................18

OperatingtheAuger/ImpellerDrive...................18

OperatingtheQuickStick®...............................18

ClearingaCloggedDischargeChute................19

OperatingTips.................................................20

AfterOperation....................................................20

AfterOperationSafety......................................20

PreventingFreeze-upafterUse........................20

Maintenance...........................................................21

RecommendedMaintenanceSchedule(s)...........21

MaintenanceSafety..........................................21

PreparingforMaintenance...............................21

CheckingtheEngine-OilLevel..........................22

CheckingandAdjustingtheSkidsand

Scraper.........................................................22

CheckingandAdjustingtheTraction

Cable............................................................23

CheckingandAdjustingtheAuger/Impeller

Cable............................................................23

CheckingtheAuger-Gearbox-OilLevel.............24

ChangingtheEngineOil...................................25

decal127-9363

ReplacingtheSparkPlug.................................25

AdjustingtheDischarge-ChuteLatch................26

ReplacingtheDriveBelts..................................27

ReplacingtheHeadlightBulb............................27

Storage...................................................................28

PreparingtheMachineforStorage...................28

RemovingtheMachinefromStorage................28

Troubleshooting......................................................29

Introduction...............................................................1

Safety.......................................................................3

GeneralSafety...................................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................6

1InstallingtheUpperHandle..............................7

2InstallingtheWheel-Clutch-Cable

Ends................................................................7

3InstallingtheTraction-ControlLinkage.............8

4InstallingtheChute-ControlRod......................9

2

Page 3

Safety

GeneralSafety

ThismachinecomplieswithANSIB71.3specications.

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

Ensurethateveryoneusingthisproductknows

howtousetheproductandunderstandsthe

warnings.

•Donotputyourhandsorfeetnearmoving

componentsonthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystanderssafedistanceawayfromthemachine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Shutofftheenginebeforeunclogging,servicing,

orfuelingthemachine.

Youcanndadditionalitemsofsafetyinformationin

theirrespectivesectionsthroughoutthismanual.

3

Page 4

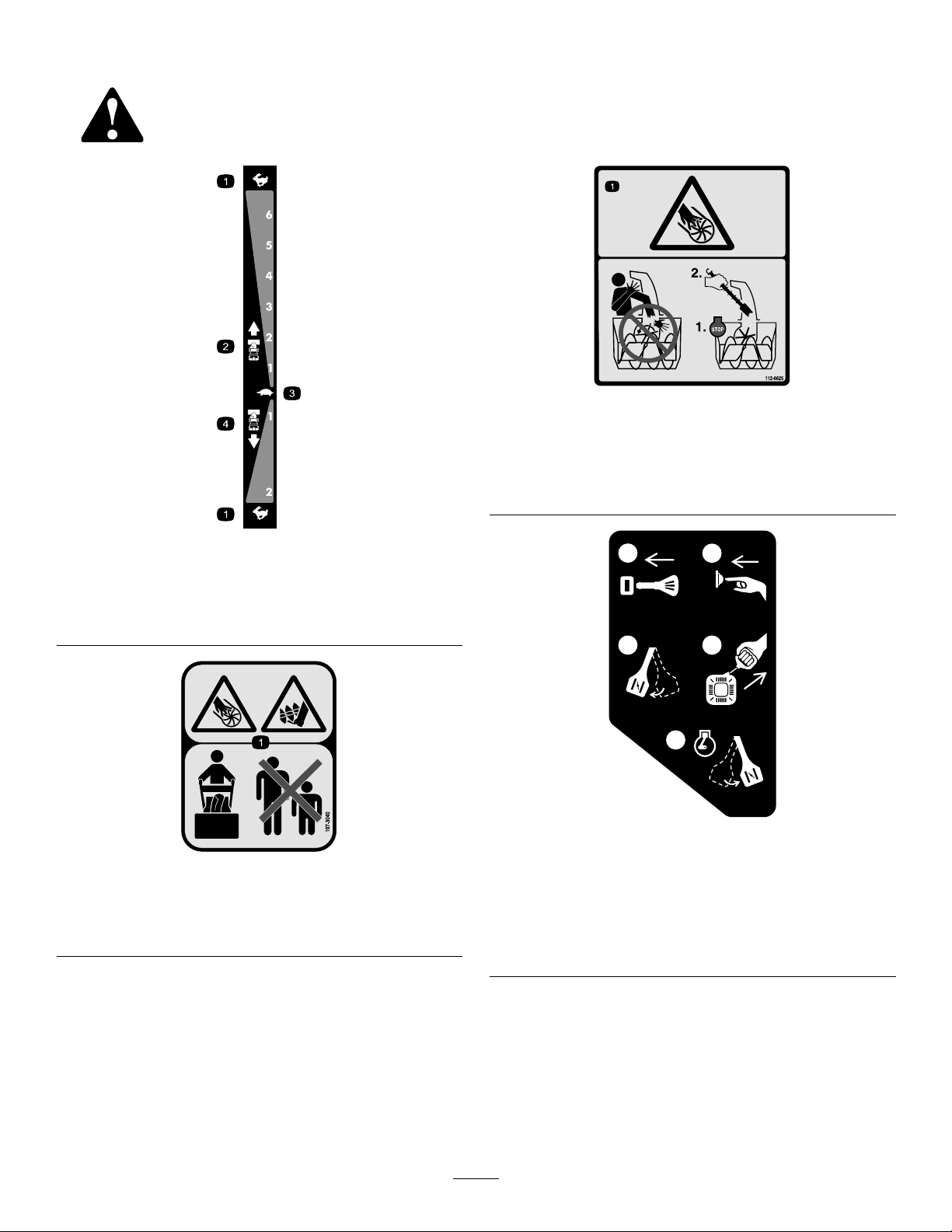

SafetyandInstructionalDecals

x 3

1

2

3

4

5

120-9805

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal112-6625

112-6625

OrderPartNo.112-6629

1.Cutting/dismembermenthazard,impeller—donotplace

yourhandinthechute;shutofftheenginebeforeleaving

theoperator'spositionanduseatooltoclearthechute.

decal106-4525

106-4525

OrderPartNo.112-6633

1.Fast

2.Forwardspeeds4.Reversespeeds

3.Slow

decal120-9805

120-9805

decal107-3040

107-3040

1.Cutting/dismembermenthazardsofhandorfoot,impeller

andauger—keepbystandersasafedistanceawayfrom

themachine.

1.Insertthekey.

2.Primetheengine3times.

3.Engagethechoke.

4.Pullthestartercord.

5.Oncetheengineisrunning,disengagethechoke.

4

Page 5

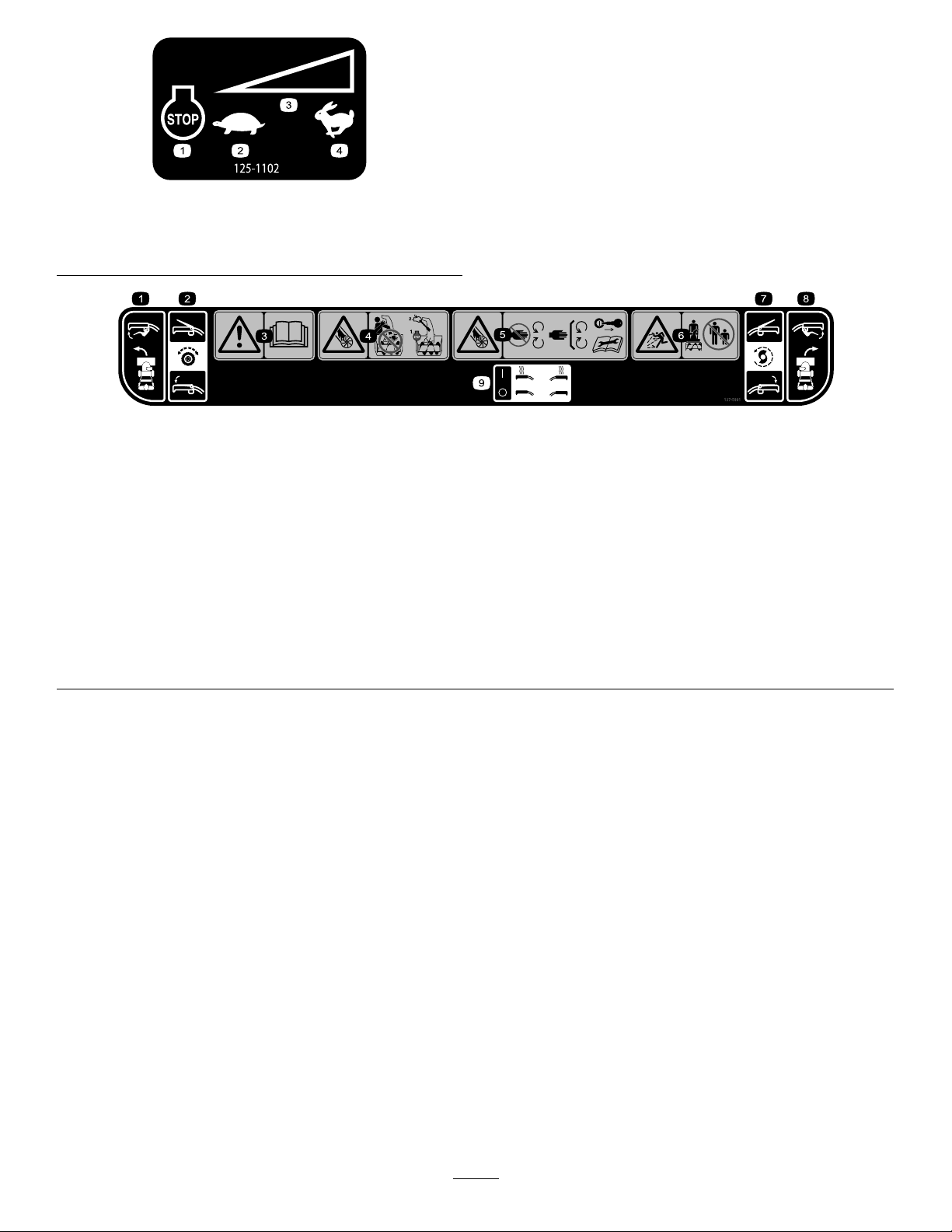

125-1102

decal125-1102

1.Engine—shutoff

2.Slow

3.Variablespeedcontrol

4.Fast

127–5991

1.Leftturncontrol4.Cutting/dismembermenthazard,

2.Tractiondrive—squeezetheleverto

engage;releasethelevertodisengage.

3.Warning—readtheOperator'sManual.

impeller—donotplaceyourhandin

thechute;shutofftheenginebefore

leavingtheoperator'spositionanduse

atooltoclearthechute.

5.Cutting/dismembermenthazard,

impeller—stayawayfrommoving

parts;keepallguardsandshieldsin

place;removetheignitionkeyand

readtheinstructionsbeforeservicing

orperformingmaintenance.

6.Thrownobjecthazard—keep

bystandersasafedistancefromthe

machine.

decal127-5991

7.Auger/impellerdrive—squeezethe

levertoengage;releasetheleverto

disengage.

8.Rightturncontrol

9.Handwarmercontrols

5

Page 6

Setup

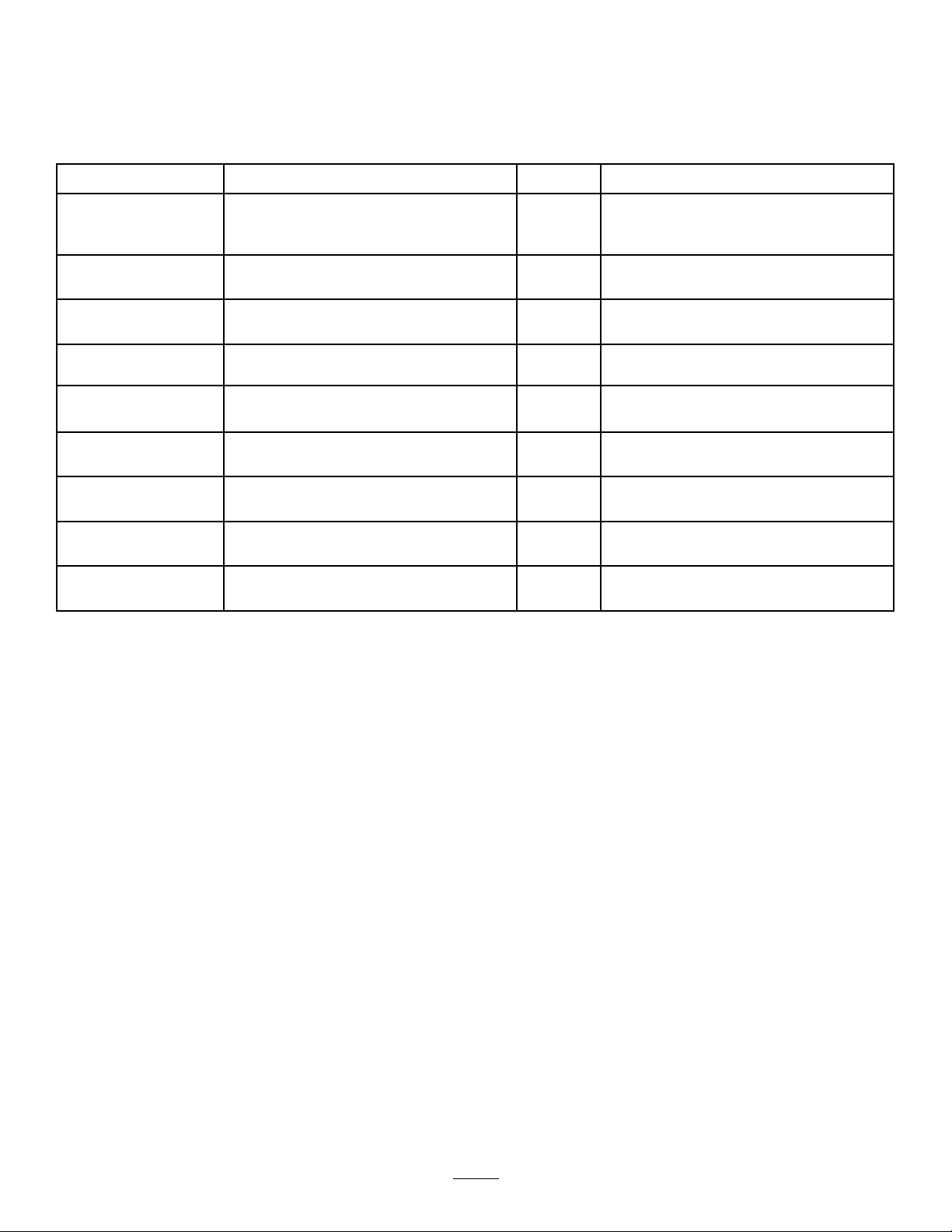

LooseParts

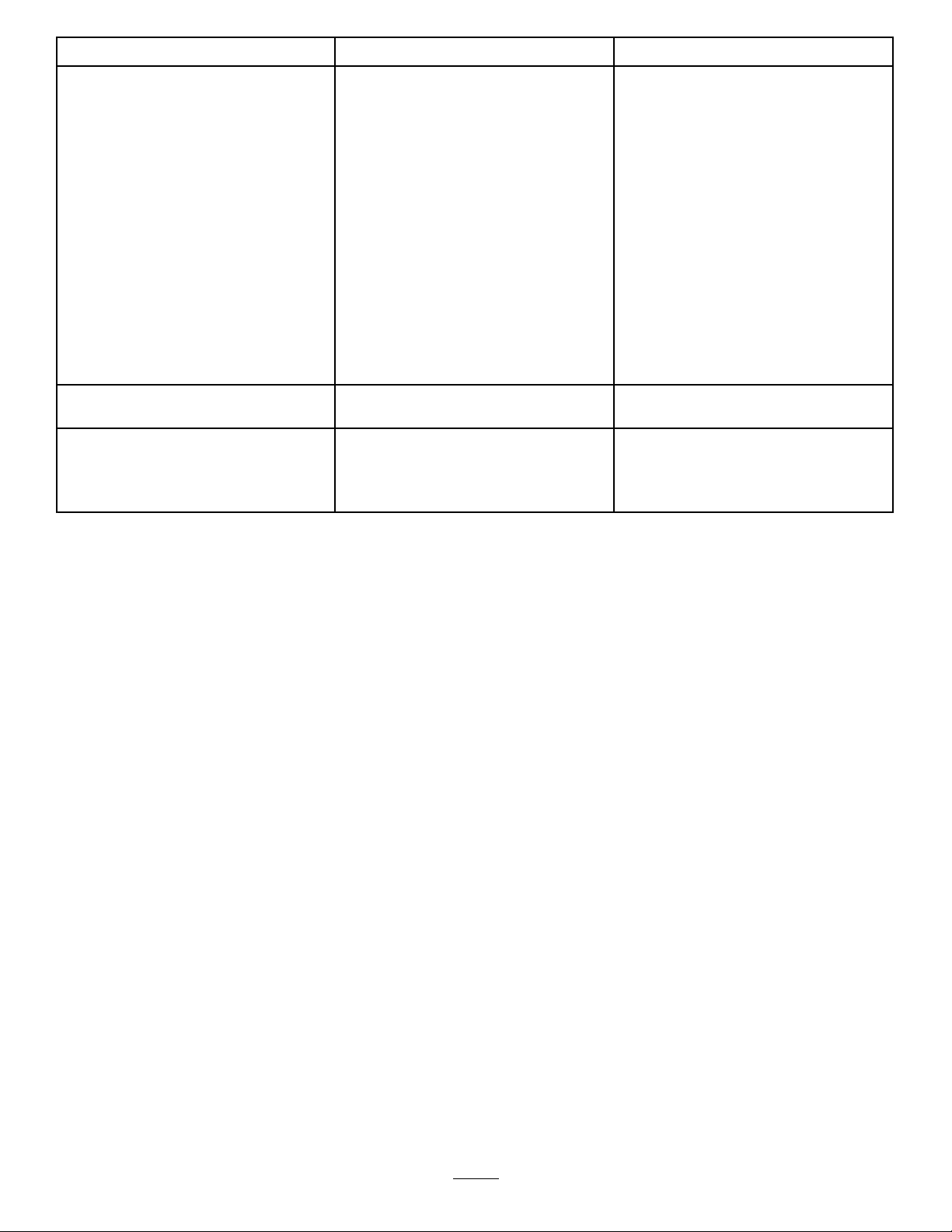

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

Handlebolt4

Curvedwasher

Locknut4

Nopartsrequired

Nopartsrequired

Carriagebolt

Locknut2

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Qty.

Use

4

–

–

2

–

–

–

–

–

Installtheupperhandle.

Installthewheel-clutch-cableends.

Installthetraction-controllinkage.

Installthechute-controlrod.

Connecttheheadlightandhandwarmer

wiretotheengine.

Checktheengine-oillevel.

Checkthetirepressure.

Checktheskidsandscraper.

Checktheoperationofthetractiondrive.

6

Page 7

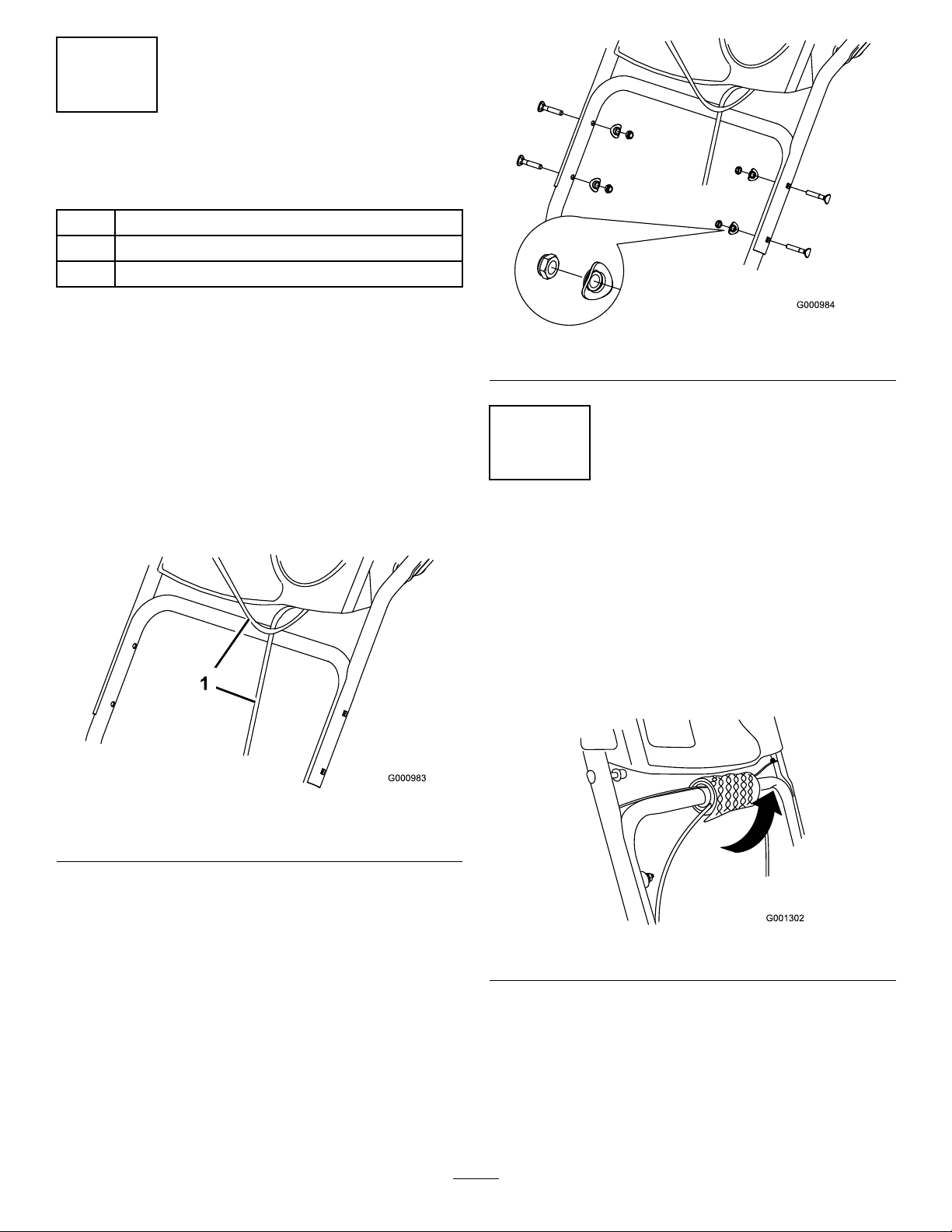

1

InstallingtheUpperHandle

Partsneededforthisprocedure:

4Handlebolt

4

Curvedwasher

4Locknut

Procedure

Note:Donotremovetherubberbandonthecables

untilyouhaveinstalledtheupperhandle.

1.Liftandrotatetheupperhandleandpositionit

overthelowerhandle(Figure4).

Important:Routethecablesattachedtothe

QuickStick

andensurethatthecablesandthewirefor

theheadlightarenotpinchedbetweenthe

handlesections.

®

insidetheupperhandlelegs

g000984

Figure5

2

Installingthe Wheel-Clutch-CableEnds

NoPartsRequired

Procedure

1.Unwrapthebubblewrapfromthecablesonthe

lowerhandle(Figure6).

Figure4

1.Cables

2.Securetheupperhandlewith4handlebolts,

4curvedwashers,and4locknutsfromthe

loose-partsbag(Figure5).

g000983

g001302

Figure6

2.Routeeithertheleftorrightcableendoverthe

lowerhandleandinsertthecableendintothe

holeinthecorrespondingwheel-clutchlever

(Figure7).

7

Page 8

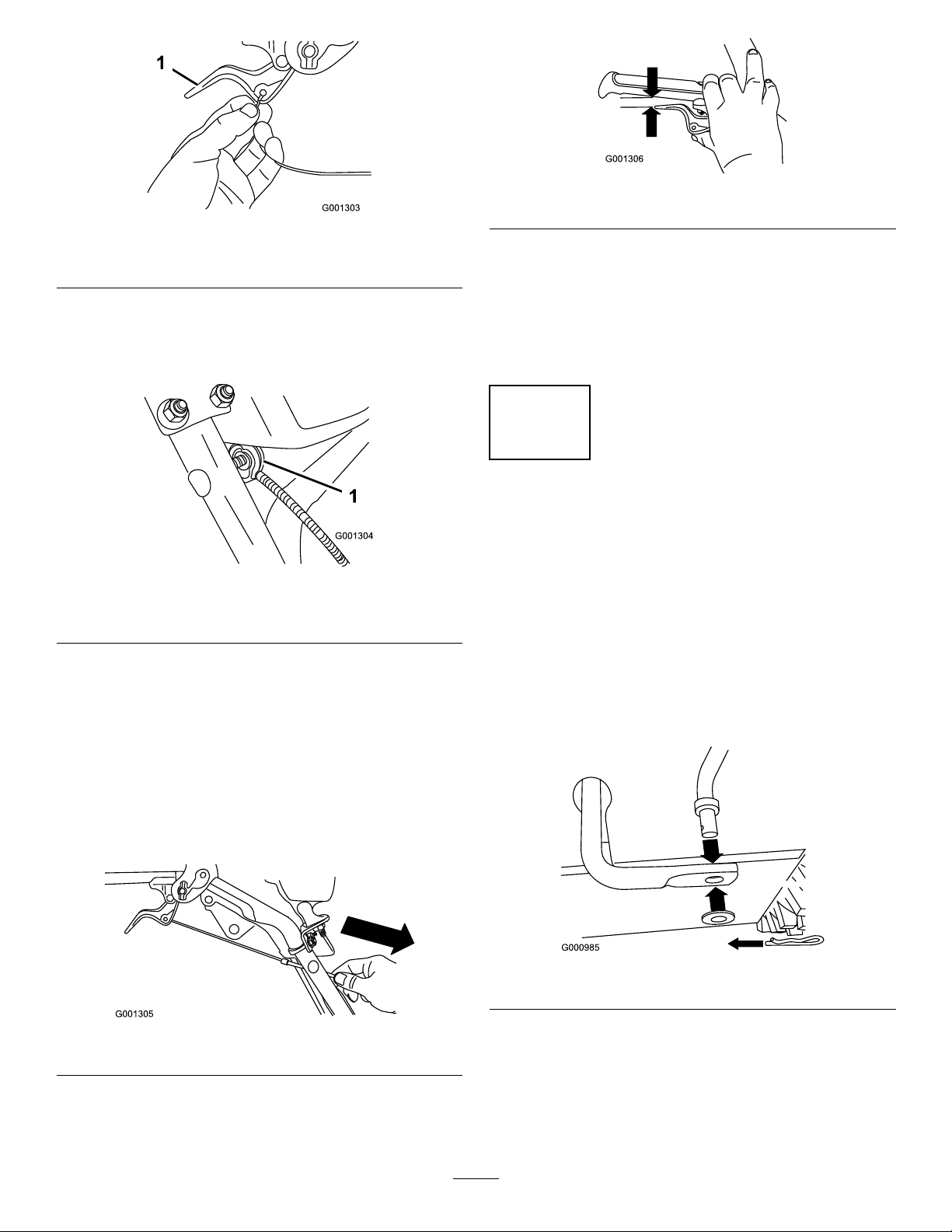

Figure7

1.Wheel-clutchlever

3.Removethenutandwasherfromthehandle,

attachthecableclamponthecabletothe

handle,installthewasherandthenut,and

tightenthenutbyhand(Figure8).

g001306

Figure10

g001303

Note:Thegapshouldbeapproximatelythe

thicknessofapencil(1/4inchor6mm).Ifitis

greater,loosenthecable-clampnut,slidethe

cablejacketupslightly,tightenthecable-clamp

nut,andcheckthegapagain.

6.Repeatsteps2through5fortheothercable.

3

Installingthe Traction-ControlLinkage

Figure8

1.Cableclamp(2)

Important:Ensurethatthecurvedsideof

thecableclampisagainstthehandleand

thatthecableisroutedbelowtheclampbolt.

Thecablemustbeinastraightlinefromthe

cableclamptothepointwhereitattachesto

thewheel-clutchlever.

4.Pullthecablejacketdowngentlyuntilthe

wheel-clutchleverisdownandtheslackisout

ofthecable,thentightenthecable-clampnut

securely(Figure9).

g001304

NoPartsRequired

Procedure

1.Removethehairpincotterandwasherfromthe

lowerendofthespeed-controlrodandinsertthe

lowerendoftherodintothelowerlinkarmso

thatthebentendofthespeed-controlrodfaces

rearward(Figure11).

g000985

Figure11

Figure9

5.Squeezetheleverfully ,thencheckthegap

betweenthebottomofthehandleandtheend

ofthewheel-clutchlever(Figure10).

g001305

2.Securethelowerendofthespeed-controlrod

withthewasherandhairpincotterthatyou

previouslyremoved.

3.Removethehairpincotterandouterwasher

fromthetrunnionontheupperendofthe

speed-controlrod(Figure12).

8

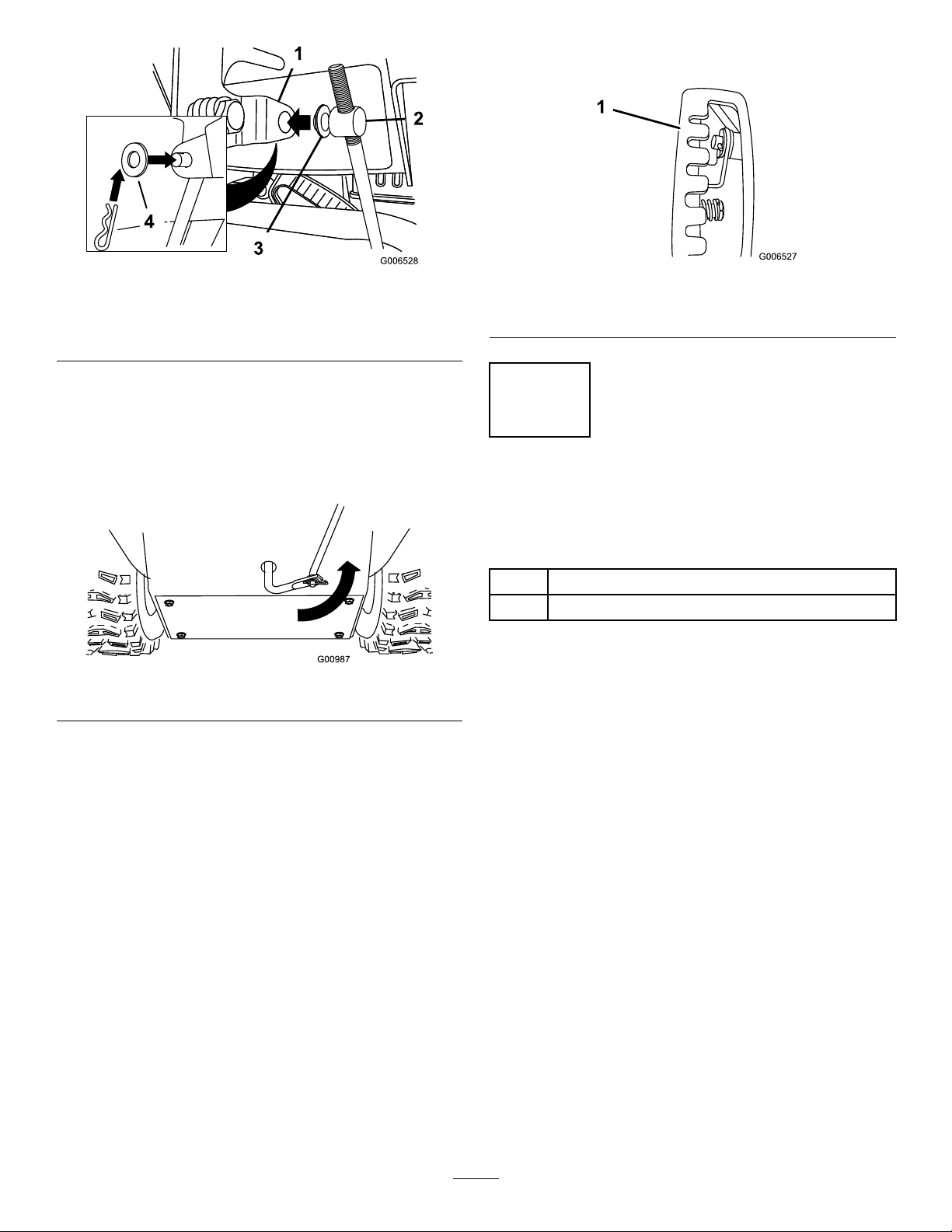

Page 9

Note:Foreasierinstallation,lookdownthrough

theopeninginthespeedselector(Figure14).

Figure12

1.Speed-selectorlever

2.Trunnion

3.Innerwasher

4.Outerwasher

Note:Foreasierinstallation,leavetheat

washeronthetrunnion(Figure12).

4.Shiftthespeed-selectorleverintoR2position.

5.Rotatethelowerlinkarmfullyupward

(counterclockwise)(Figure13).

Figure13

g006528

Figure14

1.Speedselector

g006527

4

InstallingtheChute-Control Rod

Partsneededforthisprocedure:

2

Carriagebolt

2Locknut

g000987

Procedure

1.UnwraptheQuickStick®androtateitsothatit

isuprightandinthecenter.

6.Liftuponthespeed-controlrodandinsertthe

trunnionintotheholeinthespeed-selectorlever

(Figure12).

Note:Ifthetrunniondoesnottintothehole

whenyouliftuponthespeed-controlrod,

rotatethetrunnionupwardordownwardonthe

speed-controlroduntilitts.

7.Securethetrunnionandupperendofthe

speed-controlrodwiththeouterwasherand

hairpincotterthatyoupreviouslyremoved.

2.Holdthebluetriggercapdownandpullthelever

fullyrearward.

Note:Thedischargechuteanddeectorshould

faceforward.Iftheydonot,holdthebluetrigger

capdown(butdonotmovetheQuickStick)and

rotatethedischargechuteuntiltheydo.

3.Aligntheattenedbackendofthelong

chute-controlrodwiththeattenedfrontendof

theshortrodthatextendsfromthecontrolpanel

sothattheynesttogether(Figure15).

9

Page 10

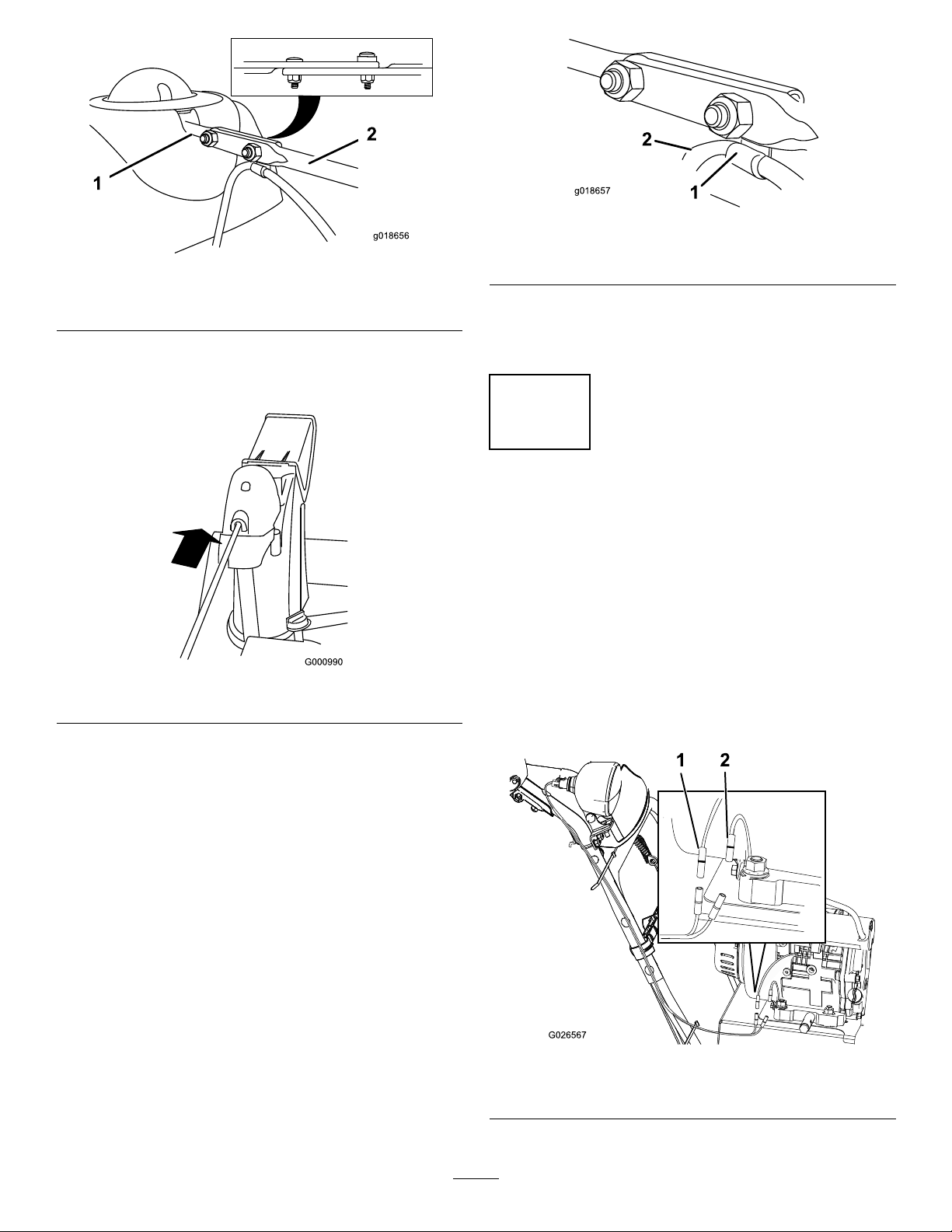

g018656

g018657

Figure17

g018657

Figure15

1.Shortrod

4.Insertthefrontendoftherodintotheopening

inthebackofthechute-gearcoveruntilitslides

intothechutegear(Figure16).

2.Longchute-controlrod

Figure16

g018656

1.Cableclip2.Deectorcable

7.Holdthebluetriggercapdownandrotatethe

QuickStickinacircletoensurethatthechute

anddeectoroperatesmoothly .

5

ConnectingtheHeadlight andHandwarmerWireto theEngine

NoPartsRequired

Procedure

g000990

Plugaconnectorintothestarterwireandanotherinto

theground(Figure18).

5.Aligntheholesinthenestedendsoftherods

andinsert2carriagebolts(fromtheloose-parts

bag)throughtheshortrodfromtheleftsideof

themachine(fromtheoperatingposition).

6.Insertthecableclipthatsupportsthedeector

cableontotheforwardcarriagebolt,andsecure

thecarriageboltswiththelocknutsfromthe

loose-partsbag(Figure17).

Note:Thepigtailsarecolor-coded.

g026567

Figure18

1.Starter-wireconnector2.Groundconnector

10

Page 11

6

9

CheckingtheEngine-Oil

Level

NoPartsRequired

Procedure

Note:Yourmachinecomeswithoilintheengine

crankcase.Beforestartingtheengine,checktheoil

levelandaddoilifnecessary.

RefertoCheckingtheEngine-OilLevel(page22).

7

CheckingtheTirePressure

NoPartsRequired

Procedure

Thetiresareoverinatedatthefactoryforshipping.

Reducethepressureequallyinbothtirestobetween

116and137kPa(17and20psi).

CheckingtheOperationof theTractionDrive

NoPartsRequired

Procedure

CAUTION

Ifthetractiondriveisnotproperlyadjusted,

themachinemaymoveinthedirection

oppositeofwhatyouintended,causinginjury

and/orpropertydamage.

Carefullycheckthetractiondriveandadjustit

properly,ifnecessary.

Note:Tochecktheoperationofthetractiondrive,you

mustengagetheself-propelfeaturebypinningthe

wheelsintheaxle;referto9CheckingtheOperation

oftheTractionDrive(page11).

1.Starttheengine;refertoStartingtheEngine

(page14).

2.MovethespeedselectortoPositionR1;referto

OperatingtheSpeedSelector(page18).

3.Squeezetheleft(traction)levertothehandgrip

(Figure19).

8

CheckingtheSkidsand Scraper

NoPartsRequired

Procedure

RefertoCheckingandAdjustingtheSkidsand

Scraper(page22).

g001011

Figure19

Themachineshouldmoverearward.Ifthe

machinedoesnotmoveormovesforward,

completethefollowing:

A.Releasethetractionleverandshutoffthe

engine.

B.Disconnectthetrunnionfromthe

speed-selectorlever(Figure12).

C.Turnthetrunniondownward(clockwise)on

thespeed-controlrod(Figure12).

11

Page 12

D.Connectthetrunniontothespeed-selector

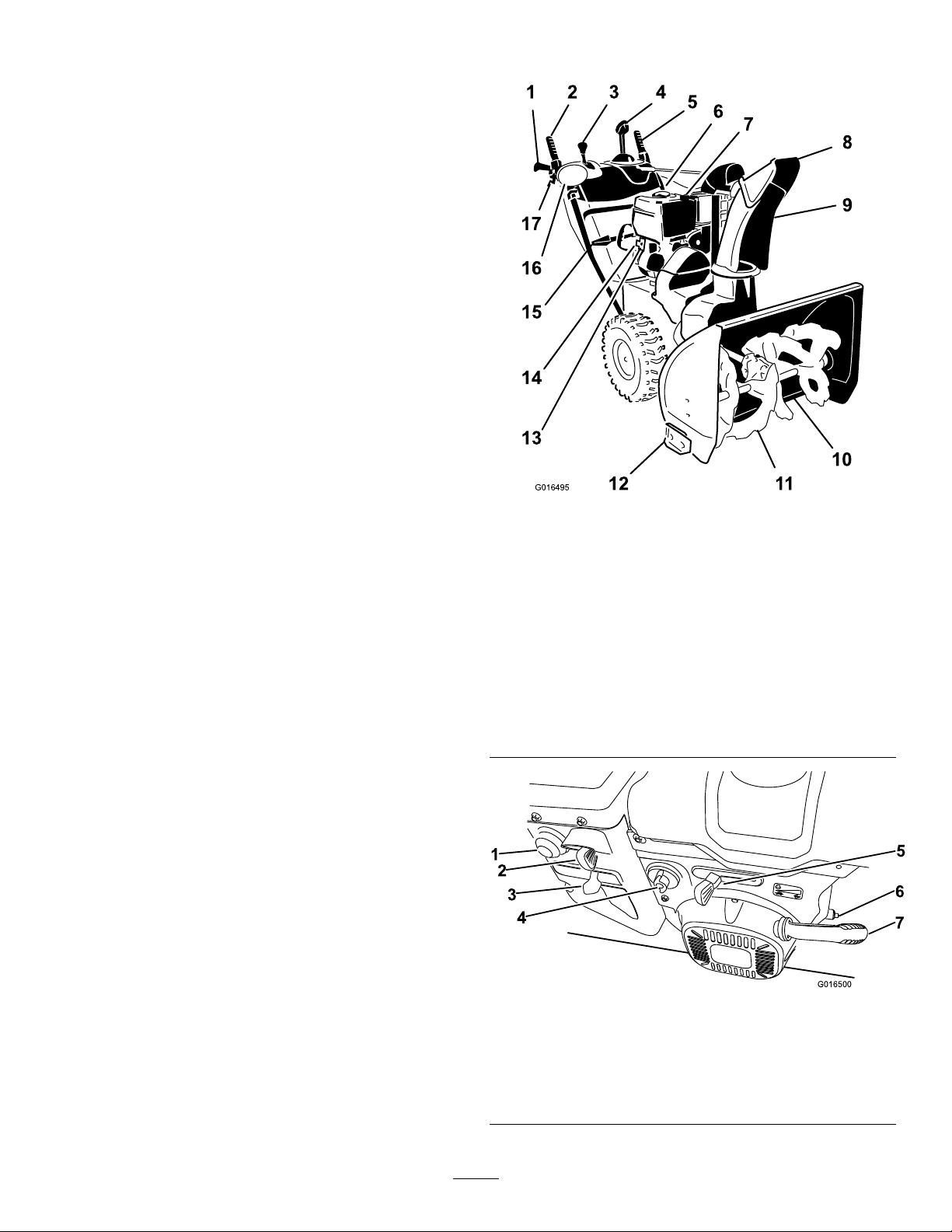

G016495

ST

OP

1

2

3

4

5

6

7

G016500

lever(Figure12).

4.Releasethetractionlever.

5.MovethespeedselectortoPosition1;referto

OperatingtheSpeedSelector(page18).

6.Squeezetheleft(traction)levertothehandgrip

(Figure19).

Themachineshouldmoveforward.Ifthe

machinedoesnotmoveormovesrearward,

completethefollowing:

A.Releasethetractionleverandshutoffthe

engine.

B.Disconnectthetrunnionfromthe

speed-selectorlever(Figure12).

C.Turnthetrunnionupward(counterclockwise)

onthespeed-controlrod(Figure12).

D.Connectthetrunniontothespeed-selector

lever(Figure12).

7.Ifyoumadeanyadjustments,repeatthis

procedureuntilnoadjustmentsarerequired.

Important:Ifthemachinemoveswhenthe

tractionleverisinthereleasedposition,checkthe

tractioncable;refertoCheckingandAdjusting

theTractionCable(page23)ortakethemachine

toanAuthorizedServiceDealerforservice.

ProductOverview

Figure20

1.Hand-grip(2)10.Scraper

2.Auger/impellerlever

3.Speed-selectorlever12.Skid(2)

4.QuickStick®discharge

chutecontrol

5.Tractionlever14.Electric-starterplug-in

6.Fuel-tankcap

7.Oil-lltube/dipstick

8.Chutedeector17.Wheel-clutchlever(2)

9.Dischargechute

11.Auger

13.Electric-startbutton

15.Snow-cleanouttool

16.Headlight

g016495

g016500

Figure21

1.Primer5.Throttle

2.Ignitionswitch

3.Choke

4.Fuel-shutoffvalve

6.Oil-drainplug

7.Recoil-starthandle

12

Page 13

Figure22

1.Snow-cleanouttool(attachedtothehandle)

DANGER

Fuelisextremelyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

g004217

others.

•Topreventastaticchargefromignitingthe

fuel,placethecontainerand/ormachineon

thegroundbeforelling,notinavehicle

oronanobject.

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

•Forelectric-startmodelsonly:Useextension

cordsandreceptaclesasspeciedinthemanual.

Thoroughlyinspecttheelectricalcordbefore

pluggingitintoapowersource.Ifthecordis

damaged,donotuseit.Replacethedamaged

cord.Unplugthepowercordwheneveryouare

notstartingthemachine.

•Wearadequatewintergarmentswhenever

youoperatethemachine.Wearsubstantial,

slip-resistantfootwearthatimprovesfootingon

slipperysurfaces.Avoidloose-ttingclothingthat

cangetcaughtinmovingparts.

•Alwaysweareyeprotectionduringoperationor

whileperforminganadjustmentorrepairtoprotect

youreyesfromforeignobjectsthatthemachine

maythrow.

•Thoroughlyinspecttheareawhereyouwillusethe

machine,andremovealldoormats,sleds,boards,

wires,andotherforeignobjects.

•Ifashield,safetydevice,ordecalisdamaged,

illegible,ormissing,repairorreplaceitbefore

beginningoperation.Also,tightenanyloose

fasteners.

•Fillthetankoutdoorswhentheengineis

cold.Wipeupspills.

•Donothandlefuelwhensmokingor

aroundanopenameorsparks.

•Storefuelinanapprovedfuelcontainer,

outofthereachofchildren.

•Donottipthemachineeitherforward

orbackwardwithfuelinthefueltank;

otherwise,fuelmayleakoutofthe

machine.

FillingtheFuelTank

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Oxygenatedfuelwithupto10%ethanolor15%

MTBEbyvolumeisacceptable.

•Donotuseethanolblendsofgasoline(such

asE15orE85)withmorethan10%ethanolby

volume.Performanceproblemsand/orengine

damagemayresultwhichmaynotbecovered

underwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

Donotllabovethebottomofthefueltank(Figure

23).

13

Page 14

Figure23

G016512

•Exerciseextremecautionwhenoperatingonor

crossinggraveldrives,walks,orroads.Stayalert

forhiddenhazardsortrafc.

•Neverattempttomakeanyadjustmentswhilethe

engineisrunning.

•Afterstrikingaforeignobject,shutofftheengine,

removetheignitionkey(electric-startmodels

only),thoroughlyinspectthemachineforany

damage,andrepairthedamagebeforestarting

andoperatingthemachine.

•Ifthemachineshouldstarttovibrateabnormally,

shutofftheengineandcheckforthecause.

•Donotruntheengineindoorsunlessthereis

adequateventilation(e.g.,leavingtheoutsidedoor

g215907

open);exhaustfumesaredangerous.

•Donotoverloadthemachinecapacityby

attemptingtoclearsnowattoofastarate.

Note:Forbestresults,purchaseonlythequantity

offuelthatyouexpecttousein30days.Otherwise,

youmayaddfuelstabilizertonewlypurchasedfuelto

keepitfreshforupto6months.

DuringOperation

DuringOperationSafety

•Shutofftheenginebeforeuncloggingthe

machineandalwaysuseastickorthe

snow-cleanouttool(ifprovided).

•Arotatingaugercaninjurehandsorfeet.Stay

behindthehandlesandawayfromthedischarge

openingwhileoperatingthemachine.Keepyour

face,hands,feet,andanyotherpartofyour

bodyorclothingawayfrommovingorrotating

parts.

•Neverdirectthedischargetowardpeopleorareas

wherepropertydamagecanoccur.

•Exercisecautiontoavoidslippingorfalling.

Alwaysbesureofyourfooting,andkeeparm

holdonthehandles.Walk;neverrun.

•Nevertouchahotengineormufer.

StartingtheEngine

1.Checktheengine-oillevel.RefertoChecking

theEngine-OilLevel(page22).

2.Turnthefuel-shutoffvalve1/4turn

counterclockwisetoopenit(Figure24).

•Exerciseextremecautionwhenoperatingon

slopes.

•Neveroperatethemachinewithoutgoodvisibility

orlight.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Lookbehindandusecarewhenbackingupwith

themachine.

•Whennotactivelyclearingsnow,disengagepower

totheauger.

g016512

Figure24

3.Fullyinserttheignitionkey(Figure25).

14

Page 15

1

G016498

Figure25

g037221

G016501

STOP

G016504

1.Ignitionkey

4.Firmlypushintheprimerwithyourthumbas

indicatedbythefollowingtable,holdingthe

primerinforasecondbeforereleasingiteach

time(Figure26).

5.MovethechoketotheCHOKEposition(Figure

27).

g016498

g016501

Figure27

Temperature

Above-18°C(0°F)

-23°Cto-18°C(-10°Fto0°F)

Below-23°C(-10°F)

Figure26

SuggestedNumberof

Primes

3

4

6

6.MovethethrottletotheFASTposition(Figure

28).

g016504

Figure28

g037221

7.Startthemachinebypullingtherecoilstarteror

pressingtheelectric-starterbutton(Figure29).

15

Page 16

Figure29

STOP

G016505

G016499

1.Electric-starterbutton3.Recoil-starthandle

2.Electricstarterplug-in

Note:T ousetheelectricstarter(electric-start

modelsonly),connectapowercordtothe

plug-inrstandthentoapoweroutlet.Use

onlyaUL-listed,16-gaugeextensioncord

recommendedforoutdoorusethatisnotlonger

than50feet(15m).

WARNING

Theelectricalcordcanbecomedamaged,

causingashockorre.

Thoroughlyinspecttheelectricalcord

beforeusingthemachine.Ifthecord

isdamaged,donotuseit.Replaceor

repairthedamagedcordimmediately.

ContactanAuthorizedServiceDealerfor

assistance.

ShuttingOfftheEngine

1.MovethethrottletotheSLOWposition,andthen

totheSTOPposition(Figure30).Y oucanalso

shutofftheenginebypullingtheignitionkey

outwardtothemiddleposition.

g215361

g016505

Figure30

2.Waitforallmovingpartstostopbeforeleaving

theoperatingposition.

3.Removetheignitionkeytopreventaccidental

starting.

4.Closethefuelshutoffvalvebyrotatingit

clockwise(Figure31).

Important:T opreventdamagingtheelectric

starter,runitinshortcycles(5secondson,

5secondsoff),nomorethan10times.Ifthe

enginestilldoesnotstart,takethemachine

toanAuthorizedServiceDealerforservice.

8.Disconnectthepowercordfromthepoweroutlet

rstandthenfromthemachine(electric-start

modelsonly).

9.Allowtheenginetowarmup;graduallymove

thechoketowardtheRunposition.Waitfor

theenginetorunsmoothlybeforeeachchoke

adjustment.

CAUTION

Ifyouleavethemachinepluggedintoa

poweroutlet,someonecaninadvertently

startthemachineandinjurepeopleor

damageproperty.

Unplugthepowercordwheneveryouare

notstartingthemachine.

g016499

Figure31

5.Pulltherecoilstarter3or4times.

Note:Thishelpspreventtherecoilstarterfrom

freezingup.

16

Page 17

Operatingthe Handwarmers

Operatethehandwarmersasfollows:

•PresstheswitchtotheONpositiontoturnonthe

handwarmers.

•PresstheswitchtotheOFFpositiontoturnoffthe

handwarmers.

Figure32

1.On/Offswitch3.OFFposition

2.ONposition

g001011

Figure33

2.Tostopthetractiondrive,releasethetraction

lever.

UsingtheWheel-Clutch Levers

Thewheel-clutchleversallowyoutomomentarily

disengagethedriveto1orbothwheelswiththe

traction-driveleverstillengaged.Thisenablesyouto

g026460

turnandmaneuverthemachineeasily.

Note:Holdingdownthetractionleveragainstthe

handleengagesthetractiondrivetobothwheels.

Toturnthemachinetotheright,liftuptheright

wheel-clutchleverandsqueezeittowardthehandle

(Figure34).

OperatingtheTraction Drive

CAUTION

Ifthetractiondriveisnotproperlyadjusted,

themachinemaymoveinthedirection

oppositeofwhatyouintended,causinginjury

and/orpropertydamage.

Carefullycheckthetractiondriveandadjust

itproperly,ifnecessary;refertoChecking

andAdjustingtheTractionCable(page23)for

moreinformation.

Important:Ifthemachinemoveswhenthe

tractionleverisinthereleasedposition,checkthe

tractioncable;refertoCheckingandAdjusting

theTractionCable(page23)ortakethemachine

toanAuthorizedServiceDealerforservice.

Important:Tooperatethetractiondrive,you

mustoperatethemachinewiththeself-propel

featureengaged.Referto9Checkingthe

OperationoftheTractionDrive(page11).

g001307

Figure34

Note:Thisdisengagesthedrivetotherightwheel

whiletheleftwheelcontinuesdriving,andthemachine

turnstotheright.

Note:Similarly,squeezingtheleftwheel-clutchlever

turnsthemachinetotheleft.

Whenyoucompletetheturn,releasethewheel-clutch

lever,andthedrivere-engagesbothwheels(Figure

35).

1.Toengagethetractiondrive,squeezetheleft

(traction)levertothehandgrip(Figure33).

17

Page 18

Figure35

Momentarilysqueezingandreleasingtheleftorright

wheel-clutchleveralsoallowsforsteeringadjustments

tokeepthemachinegoinginastraightline,especially

indeepsnow.

Squeezingbothwheel-clutchleverssimultaneously

disengagesthedrivetobothwheels.Thisenables

youtomanuallymovethemachinebackwardwithout

stoppingtoshiftitintoareversegear.Italsoallows

youtomaneuverandtransportthemachinemore

easilywhentheengineisnotrunning.

OperatingtheSpeed Selector

Thespeedselectorhas6forwardand2reverse

gears.T ochangespeeds,releasethetractionlever

andshiftthespeed-selectorlevertothedesired

position(Figure36).Theleverlocksinanotchat

eachspeedselection.

Operatingthe Auger/ImpellerDrive

1.Toengagetheauger/impellerdrive,squeeze

theright(auger/impeller)levertothehandgrip

(Figure37).

g001308

g001013

Figure37

2.Tostoptheaugerandimpeller,releasetheright

lever.

Important:Whenyouengageboththe

auger/impellerleverandthetractionlever,

thetractionleverlockstheauger/impeller

leverdown,freeingyourrighthand.To

releasebothlevers,simplyreleasetheleft

(traction)lever.

3.Iftheaugerandimpellercontinuetorotatewhen

youreleasetheauger/impellerlever,donot

operatethemachine.Checktheauger/impeller

cable;refertoCheckingandAdjustingthe

Auger/ImpellerCable(page23)andadjustitif

necessary.Otherwise,takethemachinetoan

AuthorizedDealerforservice.

Figure36

WARNING

Iftheaugerandimpellercontinue

torotatewhenyoureleasethe

auger/impellerlever,youcouldseriously

g001012

injureyourselforothers.

Donotoperatethemachine.Takeittoan

AuthorizedServiceDealerforservice.

OperatingtheQuickStick®

HoldthebluetriggercapdowntousetheQuickStick

tomovethedischargechuteandthechutedeector.

Releasethetriggercaptolockthedischargechute

andchutedeectorintoposition(Figure38).

18

Page 19

Figure38

g018894

MovingtheDischargeChute

HoldthebluetriggercapdownandmovetheQuick

Sticktothelefttomovethedischargechutetothe

left;movetheQuickSticktotherighttomovethe

dischargechutetotheright(Figure39).

MovingtheChuteDeector

HoldthebluetriggercapdownandmovetheQuick

Stickforwardtolowerthechutedeector;moveit

rearwardtoraisethechutedeector(Figure40).

g001014

g001016

Figure40

ClearingaClogged

Figure39

•Ifthechutedoesnotmove,refertoAdjustingthe

Discharge-ChuteLatch(page26).

•Ifthechutedoesnotturnasfartotheleftasit

doestotheright,ensurethatthecableisroutedto

theinsideofthehandles.Referto1Installingthe

UpperHandle(page7).

•Ifthechutedoesnotlockintoplacewhenyou

releasethetriggercap,refertoAdjustingthe

Discharge-ChuteLatch(page26).

DischargeChute

WARNING

Iftheauger/impellerisrunningbutthereisno

snowcomingoutofthedischargechute,the

dischargechutemaybeclogged.

Neveruseyourhandstoclearaclogged

dischargechute.Thiscouldresultinpersonal

injury.

•Tounclogthedischargechute,stayinthe

operatingpositionandreleasetheleft(traction)

g018894

lever.Whilerunningtheauger/impeller,pushdown

onthehandlestoraisethefrontofthemachinea

fewcentimeters(inches)offthepavement.Then

liftthehandlesquicklytobumpthefrontofthe

machineonthepavement.Repeatifnecessary

untilastreamofsnowcomesoutthedischarge

chute.

•Ifyoucannotunclogthedischargechuteby

bumpingthefrontofthemachine,shutoffthe

engine,waitforallmovingpartstostop,and

usethesnow-cleanouttool(Figure22).

Important:Uncloggingthedischargechute

bybumpingthefrontofthemachineonthe

pavementmaycausetheskidstomove.Adjust

theskidsandtightentheskidboltssecurely;

refertoCheckingandAdjustingtheSkidsand

Scraper(page22).

19

Page 20

OperatingTips

AfterOperation

DANGER

Whenthemachineisinoperation,theimpeller

andaugerrotateandcaninjureoramputate

handsorfeet.

•Beforeadjusting,cleaning,inspecting,

troubleshooting,orrepairingthemachine,

shutofftheengineandwaitforallmoving

partstostop.Disconnectthewirefrom

thesparkplugandkeepitawayfromthe

plugtopreventsomeonefromaccidentally

startingtheengine.

•Removeanobstructionfromthedischarge

chute;refertoClearingaClogged

DischargeChute(page19).Usethe

snow-cleanouttool(Figure23),notyour

hands,toremoveanobstructionfromthe

dischargechute.

•Staybehindthehandlesandawayfrom

thedischargeopeningwhileoperatingthe

machine.

•Keepyourface,hands,feet,andanyother

partofyourbodyorclothingawayfrom

concealed,moving,orrotatingparts.

AfterOperationSafety

•Neverstorethemachinewithfuelinthefuel

tankinsideabuildingwhereignitionsourcesare

present,suchashotwaterheaters,spaceheaters,

orclothesdryers.Allowtheenginetocoolbefore

storinginanyenclosure.

•Whenstoringthemachineformorethan30days,

refertoStorage(page28)forimportantdetails.

PreventingFreeze-upafter Use

•Insnowyandcoldconditions,somecontrolsand

movingpartsmayfreeze.Donotuseexcessive

forcewhentryingtooperatefrozencontrols.

Ifyouhavedifcultyoperatinganycontrolorpart,

starttheengineandletitrunforafewminutes.

•Afterusingthemachine,lettheenginerunfor

afewminutestopreventmovingpartsfrom

freezing.Engagetheauger/impellertoclearany

remainingsnowfrominsidethehousing.Rotate

theQuickSticktopreventitfromfreezing.Shutoff

theengine,waitforallmovingpartstostop,and

removealliceandsnowfromthemachine.

WARNING

Theimpellercanthrowstones,toys,andother

foreignobjectsandcauseseriouspersonal

injurytoyouorbystanders.

•Keeptheareatobeclearedfreeofall

objectsthattheaugercouldpickupand

throw.

•Keepallchildrenandpetsawayfromthe

areaofoperation.

•AlwayssetthethrottletotheFASTpositionwhen

throwingsnow.

•Iftheengineslowsdownunderaloadorthe

wheelsslip,shiftthemachineintoalowergear.

•Ifthefrontofthemachineridesup,shiftthe

machineintoalowergear.Ifthefrontcontinuesto

rideup,liftuponthehandles.

•Withtheengineoff,pulltherecoil-starthandle

severaltimesandpushtheelectric-startbutton

oncetopreventtherecoilstarterandelectric

starterfromfreezingup.

20

Page 21

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst5hours

Beforeeachuseordaily

Every50hours

Every100hours

Yearly

Yearlyorbeforestorage

MaintenanceProcedure

•Inspectthetractioncableandadjustitifnecessary.

•Inspecttheauger/impellercableandadjustitifnecessary .

•Changetheengineoil.

•Checktheengine-oillevelandaddoilifnecessary.

•Changetheengineoil.Changetheengineoilevery25operatinghourswhen

operatingtheengineunderaheavyload.

•Replacethesparkplug.

•Checktheskidsandscraperandadjustthemifnecessary .

•Inspectthetractioncableandadjustorreplaceitifnecessary.

•Inspecttheauger/impellercableandadjustorreplaceitifnecessary.

•Checktheauger-gearboxoilandaddoilifnecessary.

•Checktheairpressureinthetiresandinatethemto116–137kPa(17–20psi).

•Runtheenginetodryoutthefueltankandthecarburetorattheendoftheseason.

•HaveanAuthorizedServiceDealerinspectandreplacethetractiondrivebeltand/or

theauger/impellerdrivebelt,ifnecessary.

Important:Y oucanndmoreinformationaboutmaintainingandservicingyourmachineat

www.Toro.com.

MaintenanceSafety

Readthefollowingsafetyprecautionsbefore

performinganymaintenanceonthemachine:

•Beforeperforminganymaintenance,service,or

adjustment,shutofftheengineandremovethe

key.Ifmajorrepairsareeverneeded,contactan

AuthorizedServiceDealer.

•Checkallfastenersatfrequentintervalsforproper

tightnesstoensurethatthemachineisinsafe

workingcondition.

•Donotchangethegovernorsettingsontheengine.

•PurchaseonlygenuineTororeplacementparts

andaccessories.

PreparingforMaintenance

1.Movethemachinetoalevelsurface.

2.Shutofftheengineandwaitforallmovingparts

tostop.

3.Disconnectthespark-plugwire.Referto

ReplacingtheSparkPlug(page25).

21

Page 22

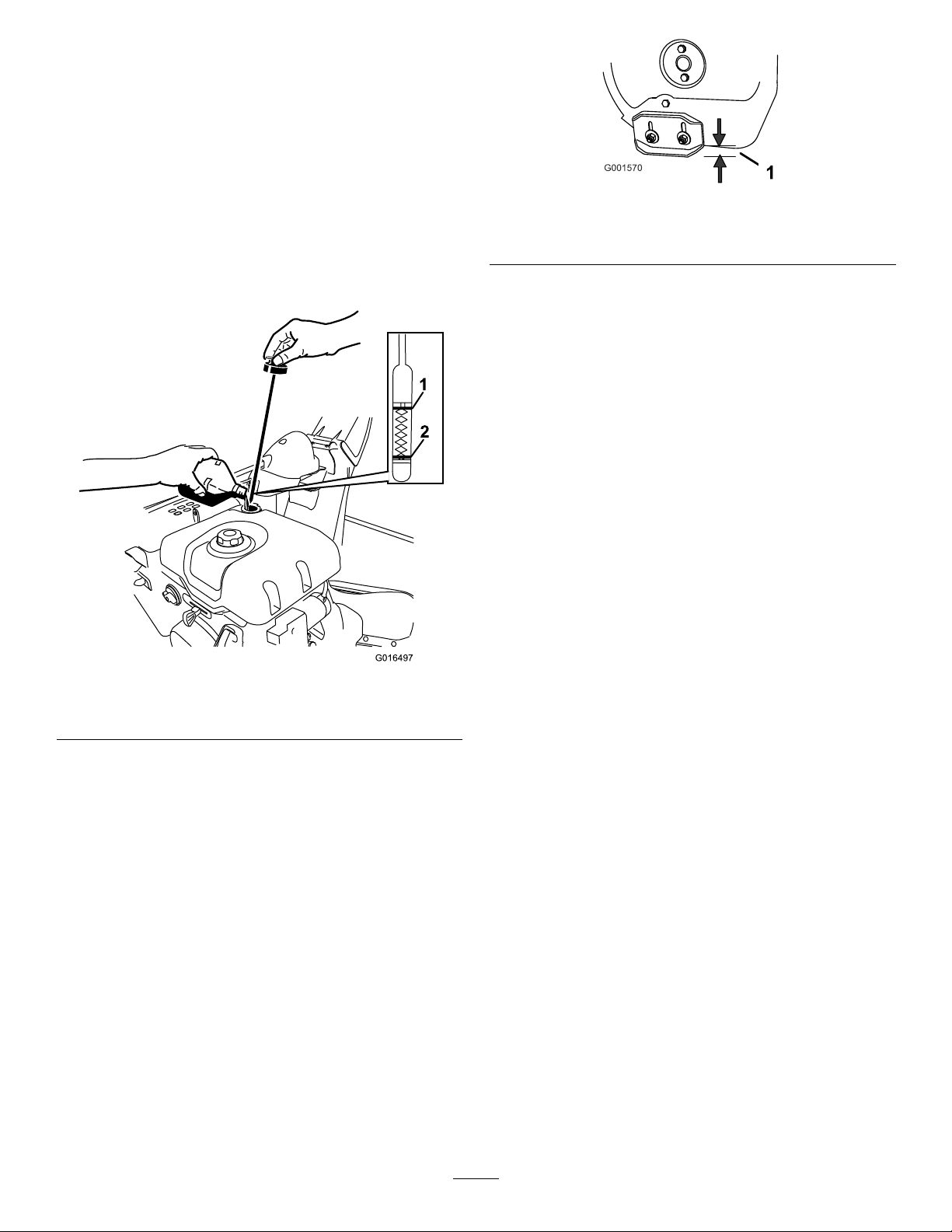

CheckingtheEngine-Oil

G016497

1

2

Level

ServiceInterval:Beforeeachuseordaily—Check

theengine-oillevelandaddoilif

necessary.

1.Removethedipstick,wipeitclean,thenfully

installthedipstick.

2.Removethedipstickandchecktheoillevel

(Figure41).IftheoillevelisbelowtheAddmark

onthedipstick,addoil.RefertoCheckingthe

Engine-OilLevel(page22).

Figure41

1.Full2.Addoil

g001570

Figure42

1.1.3cm(1/2inch)

3.Supportthesideplatessothattheyareatleast

1.3cm(1/2inch)abovealevelsurface.

Important:Theaugerbladesmustbe

supportedabovethegroundbytheskids.

4.Ensurethatthescraperis3mm(1/8inch)above

andparalleltoalevelsurface.

Note:Ifthepavementiscracked,rough,or

uneven,adjusttheskidstoraisethescraper.For

gravelsurfaces,adjusttheskidsfurtherdownto

preventthemachinefrompickinguprocks.

5.Movetheskidsdownuntiltheyareevenwith

theground.

6.Firmlytightenthenutsthatsecurebothskids

totheaugersides.

Note:T oquicklyadjusttheskidsiftheyloosen,

supportthescraper3mm(1/8inch)offthe

pavement,thenadjusttheskidsdowntothe

g016497

pavement.

Note:Iftheskidsbecomeexcessivelyworn,

youcanturnthemoverandsettheunusedside

towardthepavement.

CheckingandAdjustingthe SkidsandScraper

ServiceInterval:Y early—Checktheskidsand

scraperandadjustthemif

necessary.

Checktheskidstoensurethattheaugerdoesnot

contactthepavedorgravelsurface.Adjusttheskids

asneededtocompensateforwear.

1.Checkthetirepressure;referto7Checkingthe

TirePressure(page1 1).

2.Loosenthenutsthatsecurebothskidstothe

augersidesuntiltheskidsslideupanddown

easily(Figure42).

22

Page 23

CheckingandAdjustingthe TractionCable

ServiceInterval:Aftertherst2hours—Inspect

thetractioncableandadjustitif

necessary.

Yearly—Inspectthetractioncableandadjustor

replaceitifnecessary.

Ifthemachinedoesnotdriveintheforwardorreverse

speedsoritdriveswhenyoureleasethetractionlever,

adjustthetractioncable.

g001021

Figure44

Withthetractionleverdisengaged,checkthepin

intheelongatedslotintheleftsideofthemachine

abovethetire.Thereshouldbeagapof1to1.5mm

(1/32to1/16inch)fromthefrontoftheslottothefront

edgeofthepin(Figure43).

Figure43

1.Pin

2.1to1.5mm(1/32to1/16inch)

Iftheleft(traction)cableisnotproperlyadjusted,do

thefollowingsteps:

1.Jamnut2.Turnbuckle

CheckingandAdjustingthe Auger/ImpellerCable

ServiceInterval:Aftertherst2hours—Inspectthe

auger/impellercableandadjustitif

necessary.

Yearly—Inspecttheauger/impellercableand

adjustorreplaceitifnecessary.

1.Removethe2screwsfromtherightsideofthe

beltcoverasshown.

2.Liftuptherightsideofthebeltcover(Figure45).

g001568

1.Loosenthejamnut.

2.Loosenortightentheturnbuckletoadjustthe

pinuntilitisthepropergapfromthefrontedge

oftheslot.

3.Tightenthejamnut(Figure44).

g001022

Figure45

3.Withtheauger/impellerleverdisengaged,

ensurethatthegapbetweentheaugerclutch

assemblyandthetabis1.5mm(1/16inch)as

showninFigure46.

23

Page 24

Figure46

1

G016782

1.Tab

2.1.5mm(1/16inch)

4.Iftheauger/impellercableisnotproperly

adjusted,dothefollowingsteps:

5.Loosenthejamnut(Figure47).

Checkingthe Auger-Gearbox-OilLevel

ServiceInterval:Yearly—Checktheauger-gearbox

oilandaddoilifnecessary.

1.Movethemachinetoalevelsurface.

2.Cleantheareaaroundthepipeplug(Figure48).

g001569

g016782

Figure48

1.Pipeplug

Figure47

1.Jamnut2.Turnbuckle

6.Loosenortightentheturnbucklethatadjuststhe

tensiononthecable(Figure47).

7.Adjusttheturnbuckleuntilyouobtaintheproper

gap.

8.Tightenthejamnut.

9.Insertthe2screwsthatyoupreviouslyremoved

onthebeltcover.

3.Removethepipeplugfromthegearbox.

4.Checktheoillevelinthegearbox.Theoilshould

beatthepointofoverowingatthelleropening.

5.Iftheoillevelislow,addGL-5orGL-6,SAE

85-95EPgearoillubricanttothegearboxuntil

thepointofoverow.

Note:Donotusesyntheticoil.

6.Installthepipepluginthegearbox.

g001024

10.Iftheauger/impellercableisproperlyadjusted

butaproblemremains,contactanAuthorized

ServiceDealer.

24

Page 25

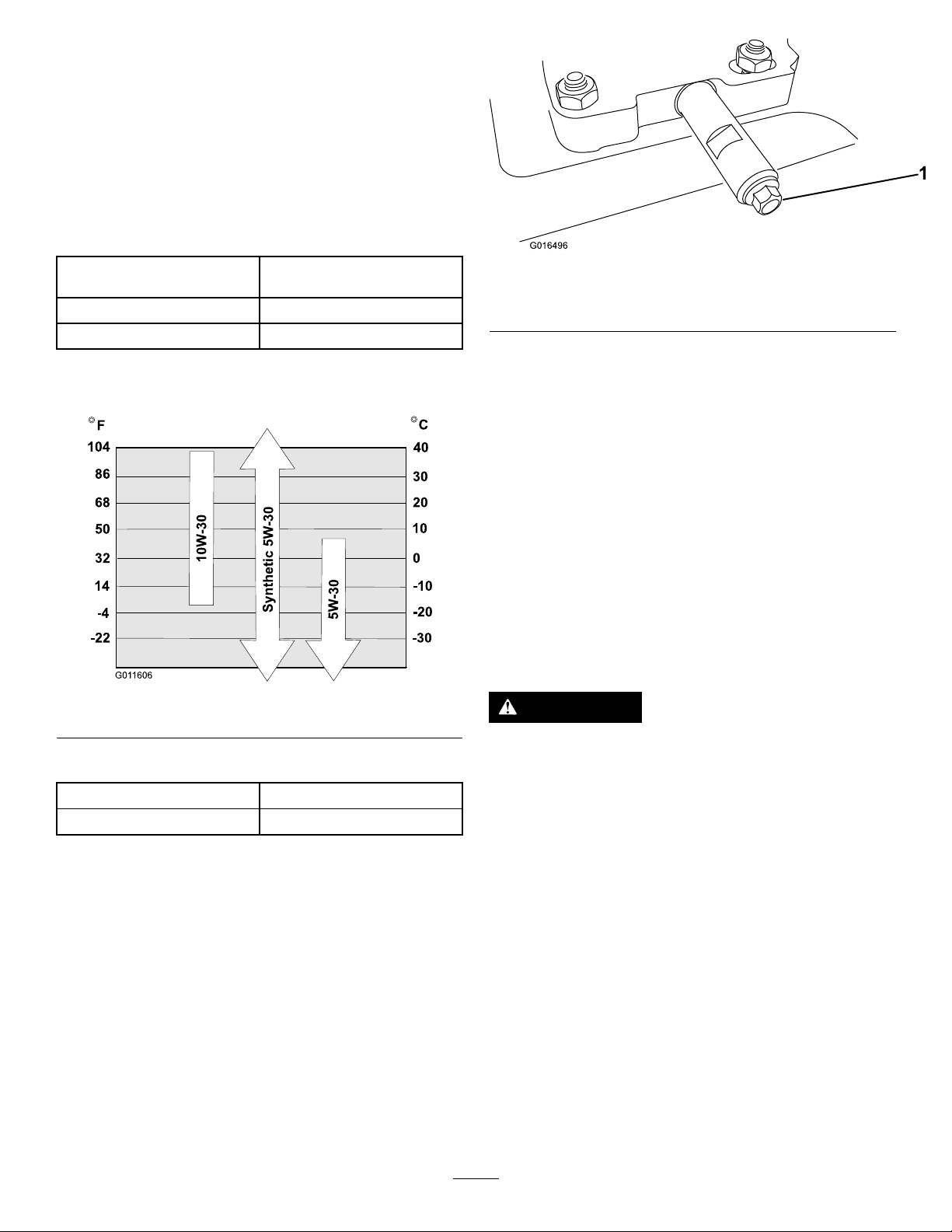

ChangingtheEngineOil

G016496

1

ServiceInterval:Aftertherst5hours—Changethe

engineoil.

Every50hours—Changetheengineoil.

Changetheengineoilevery25operatinghours

whenoperatingtheengineunderaheavyload.

Ifpossible,runtheengineforafewminutesbefore

changingtheoilbecausewarmoilowsbetterand

carriesmorecontaminants.

EngineoilcapacityModels38836:0.89to0.95L

(30to32oz)

OilviscosityRefertoFigure49.

APIserviceclassicationSJorhigher

UseFigure49belowtoselectthebestoilviscosityfor

theoutdoortemperaturerangeexpected:

g016496

Figure50

1.Oil-drainplug

2.Slideanoil-drainpanunderthedrainextension

andremovetheoil-drainplug.

Note:Whenremovingtheplug,ensurethatthe

tubedoesnotloosen.

3.Draintheoil.

Note:Disposeoftheusedoilproperlyatalocal

recyclingcenter.

Figure49

EngineOilCapacities

Model

38836

1.Cleantheareaaroundtheoil-draincap(Figure

50).

EngineOilCapacity

0.89to0.95L(30to32oz)

4.Installtheoil-drainplug.

5.Fillthecrankcasewithoil.

ReplacingtheSparkPlug

ServiceInterval:Every100hours—Replacethe

sparkplug.

g011606

WARNING

Replacingthesparkplugwhiletheengineis

hotcanresultinburns.

Waituntiltheengineiscooltoreplacethe

sparkplug.

UseaT orosparkplugorequivalent(Champion®

RN9YCorNGKBPR6ES).

1.Removetheboot(Figure51).

25

Page 26

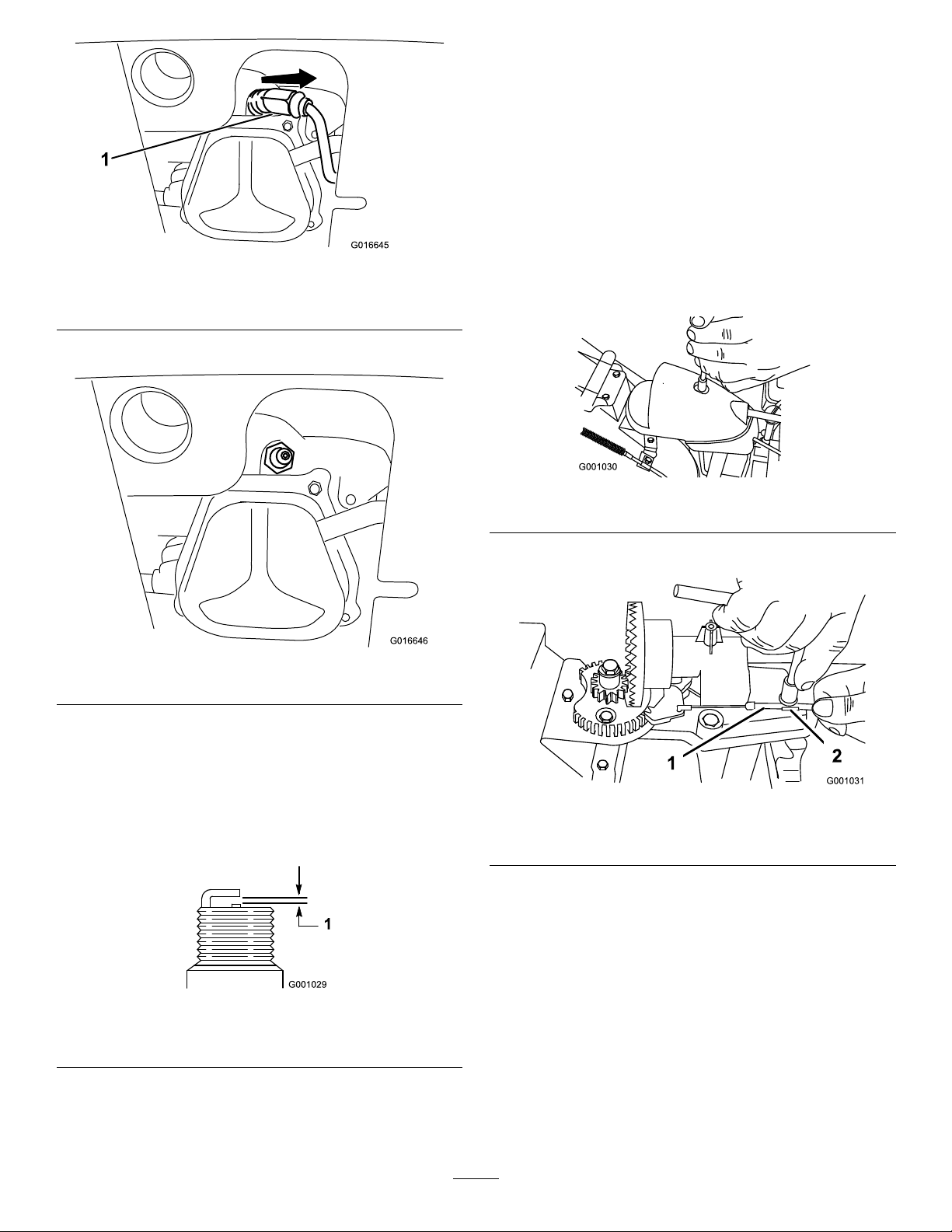

G016645

1

G016646

Note:Ensurethattheignitionwiresnaps

completelyintoplaceonthesparkplug.

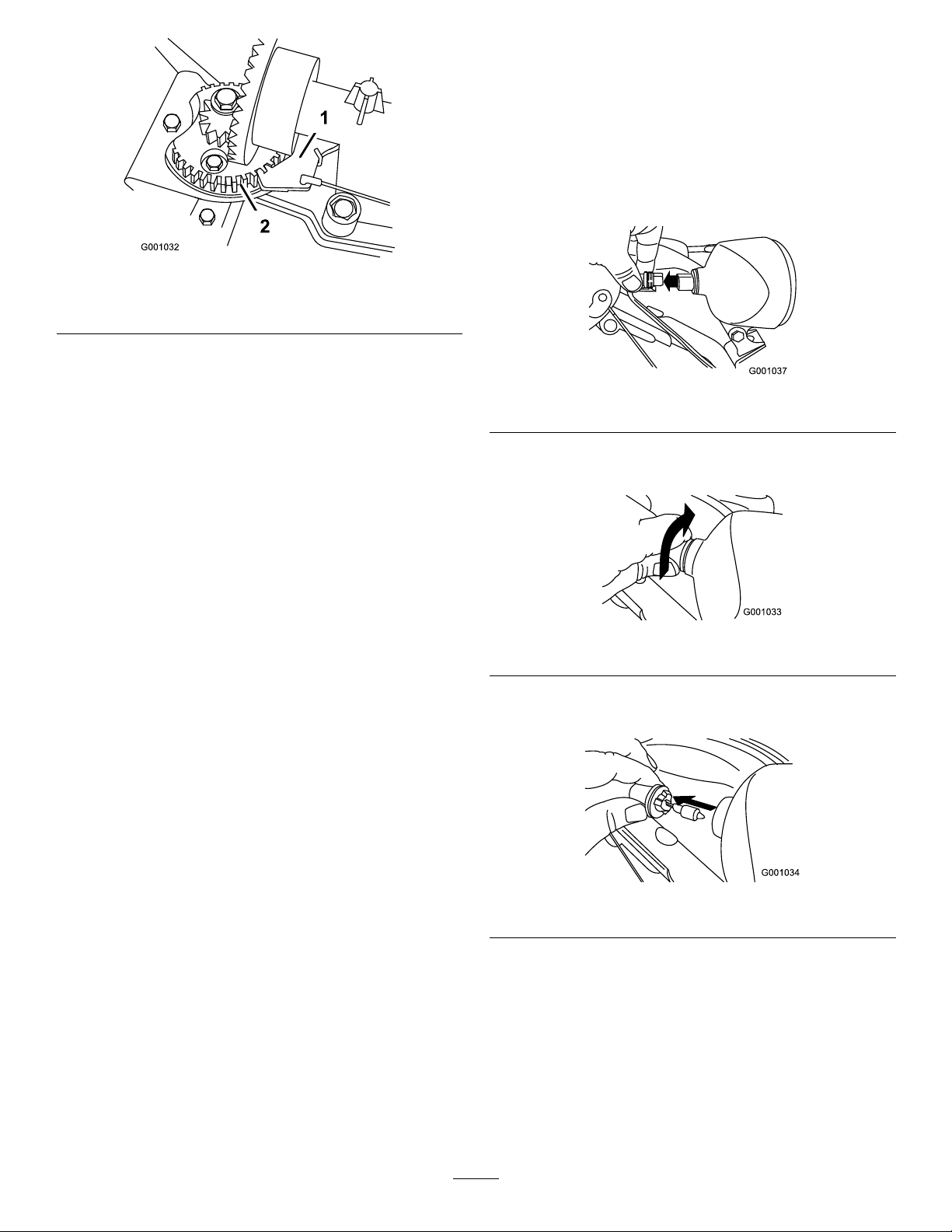

Adjustingthe Discharge-ChuteLatch

Ifthedischargechutedoesnotlockintothedesired

positionordoesnotunlocksothatyoucanmoveitto

anotherposition,adjustthedischarge-chutelatch.

Figure51

1.Spark-plugboot

2.Cleanaroundthebaseofthesparkplug.

Figure52

g016645

1.Removethefasteneronthegearcover(Figure

54),liftthefrontofthecoverup,andslideitback

andoutoftheway.

g001030

Figure54

2.Loosentheboltonthecableclamp(Figure55).

g016646

3.Removeanddiscardtheoldsparkplug.

Note:Y ouwillneedaratchetwrenchextension

toremovethesparkplug.

4.Setthegapbetweentheelectrodesonanew

sparkplugat0.76mm(0.030inch)asshown

inFigure53.

Figure53

1.0.76mm(0.030inch)

5.Installthenewsparkplug,tightenitrmly,and

attachtheignitionwiretothesparkplug.

g001031

Figure55

1.Cableconduit2.Cableclamp

3.Graspthecableconduitandmoveittowardthe

frontofthemachineuntilthedischarge-chute

latchfullyengagesthegearteeth(Figure55

andFigure56).

g001029

26

Page 27

Figure56

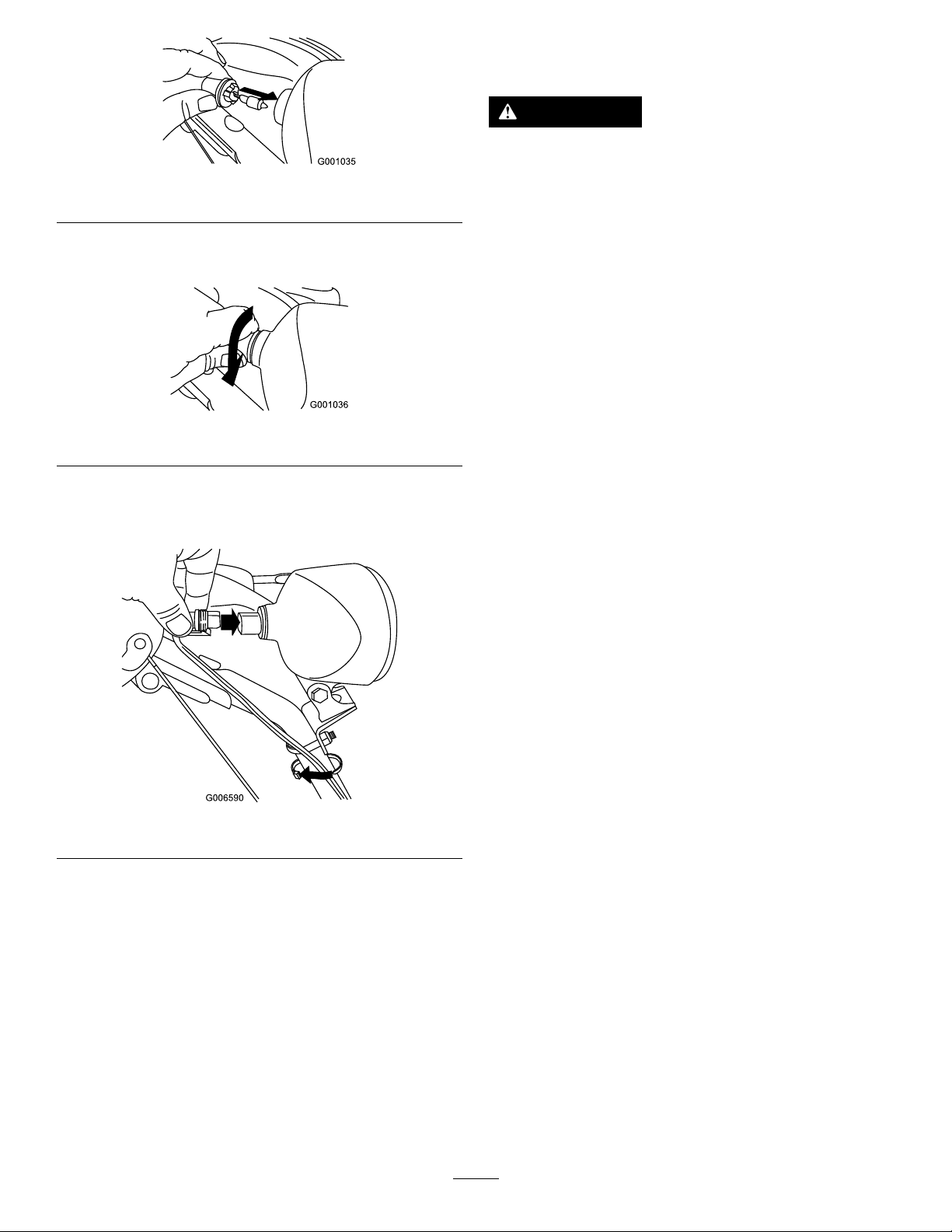

ReplacingtheHeadlight Bulb

UseaGE89937Whalogenlightbulb.Donottouch

thebulbwithyourhandsorallowdirtormoistureto

comeintocontactwiththebulb.

1.Removethewireconnectorfromthebackofthe

headlight(Figure57).

g001032

1.Discharge-chutelatch

2.Gearteeth

Note:Thelatchisspringloadedandnaturally

movesintotheteethofthegear(Figure56).

4.Removeanyslackinthecablebypullingthe

cableconduitrearward.

5.Tightentheboltonthecableclamp,being

carefulnottostriptheplasticpart.

6.Installandsecurethegearcover.

ReplacingtheDriveBelts

Iftheauger/impellerdrivebeltorthetraction-drivebelt

becomesworn,oil-soaked,orotherwisedamaged,

haveanAuthorizedServiceDealerreplacethebelt.

g001037

Figure57

2.Turnthebaseofthebulbcounterclockwiseuntil

itstops(Figure58).

g001033

Figure58

3.Removethebulbstraightoutfromthebackof

theheadlight(Figure59).

Figure59

4.Insertanewbulbintothebackoftheheadlight

(Figure60).

27

g001034

Page 28

Figure60

5.Turnthebaseofthebulbclockwiseuntilitis

snug(Figure61).

Figure61

6.Insertthewireconnectorstraightintothebackof

theheadlightuntilitissecurelyinplace(Figure

62).

Storage

WARNING

•Gasolinevaporscanexplode.

g001035

g001036

•Donotstoregasolinemorethan30days.

•Donotstorethemachineinanenclosure

nearanopename.

•Allowtheenginetocoolbeforestoringit.

PreparingtheMachinefor Storage

1.Onthelastrefuelingoftheyear,addfuel

stabilizertofreshfuelasdirectedbytheengine

manufacturer.

Important:Donotstorefuellonger

thanthatsuggestedbythefuel-stabilizer

manufacturer.

2.Runtheenginefor10minutestodistributethe

conditionedfuelthroughthefuelsystem.

Figure62

3.Runthemachineuntiltheenginerunsoutoffuel.

4.Primetheengineandstartitagain.

5.Allowtheenginetorununtilitshutsoff.

Whenyoucannolongerstarttheengine,itis

sufcientlydry.

6.Shutofftheengineandallowittocool.

7.Removetheignitionkey.

8.Cleanthemachinethoroughly.

9.Touchupchippedsurfaceswithpaintavailable

fromanAuthorizedServiceDealer.Sand

g006590

affectedareasbeforepainting,andusearust

preventativetopreventthemetalpartsfrom

rusting.

10.Tightenallloosescrews,bolts,andlocknuts.

Repairorreplaceanydamagedparts.

11.Coverthemachineandstoreitinaclean,dry

placeoutofthereachofchildren.

RemovingtheMachine fromStorage

Performtheannualmaintenanceproceduresasgiven

intheRecommendedMaintenanceSchedule;referto

Maintenance(page21).

28

Page 29

Troubleshooting

Problem

Theelectricstarterdoesnotturn(electric

startonly).

Theenginedoesnotstartorstartshard.

PossibleCauseCorrectiveAction

1.Thepowercordisdisconnectedatthe

outletorthemachine.

2.Thepowercordisworn,corroded,or

damaged.

3.Thepoweroutletisnotenergized.

1.Thekeyisnotintheignitionorisinthe

STOPposition.

2.ThechokeisintheOFFpositionand

theprimerhasnotbeenpressed.

3.Thefuel-shutoffvalveisnotopen.3.Openthefuel-shutoffvalve.

4.ThethrottleisnotintheFASTposition.4.MovethethrottletotheFASTposition.

5.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

6.Thespark-plugwireislooseor

disconnected.

7.Thesparkplugispitted,fouled,orthe

gapisincorrect.

8.Thefuel-ventcapisrestricted.

9.Theengine-oillevelintheengine

crankcaseistoolowortoohigh.

1.Connectthepowercordtotheoutlet

and/orthemachine.

2.Replacethepowercord.

3.Haveaqualiedelectricianenergize

theoutlet.

1.Insertthekeyintotheignitionandturn

ittotheONposition.

2.MovethechoketotheONpositionand

presstheprimer3times.

5.Drainand/orllthefueltankwith

freshfuel(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

6.Connectthewiretothesparkplug.

7.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

8.Removetheventrestrictionorreplace

thefuelcap.

9.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

Theenginerunsrough.

1.ThechokeisintheONposition.1.MovethechoketotheOFFposition.

2.Thefuel-shutoffvalveisnotcompletely

open.

3.Thefueltankisnearlyemptyor

containsstalefuel.

4.Thespark-plugwireisloose.

5.Thesparkplugispitted,fouled,orthe

gapisincorrect.

6.Theengine-oillevelintheengine

crankcaseistoolowortoohigh.

2.Openthefuel-shutoffvalve.

3.Drainandllthefueltankwithfresh

fuel(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

4.Connectthewiretothesparkplug.

5.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

6.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

29

Page 30

Problem

PossibleCauseCorrectiveAction

Theengineruns,butthemachine

dischargessnowpoorlyornotatall.

Thedischargechuteeitherdoesnotlock

intoplaceordoesnotmove.

Themachinedoesnotproperlyclearthe

snowoffthesurface.

1.ThethrottleisnotintheFASTposition

whenthrowingsnow .

2.Themachineismovingtoofasttoclear

thesnow.

3.Y ouaretryingtoremovetoomuch

snowperswath.

4.Y ouaretryingtoremoveextremely

heavyorwetsnow.

5.Thedischargechuteisplugged.5.Unclogthedischargechute.

6.Theauger/impellerdrivebeltisloose

orisoffthepulley.

7.Theauger/impellerdrivebeltisworn

orbroken.

1.Thedischarge-chutelatchisnot

properlyadjusted.

1.Theskidsand/orscraperarenot

properlyadjusted.

2.Thepressureinthetiresisnotequal.

1.MovethethrottletotheFASTposition.

2.Shiftthemachineintoalowergear.

3.Reducetheamountofsnowremoved

perswath.

4.Don'toverloadthemachinewith

extremelyheavyorwetsnow.

6.Installand/oradjusttheauger/impeller

drivebelt;refertowww.Toro.com

forservicinginformationortakethe

machinetoanAuthorizedService

Dealer.

7.Replacetheauger/impellerdrivebelt;

refertowww.Toro.comforservicing

informationortakethemachinetoan

AuthorizedServiceDealer.

1.Adjustthedischarge-chutelatch.

1.Adjusttheskidsand/orthescraper.

2.Checkandadjustthepressurein1or

bothtires.

30

Page 31

Notes:

Page 32

EuropeanPrivacyNotice

TheInformationT oroCollects

ToroWarrantyCompany(T oro)respectsyourprivacy .Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheTorowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.T oromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany .Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw.

Toro'sCommitmenttoSecurityofY ourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToroDealer .

374-0282RevC

Loading...

Loading...