PowerMax

ModelNo.38830—SerialNo.400000000andUp

®

HeavyDuty1030OHAESnowthrower

FormNo.3439-724RevB

Operator'sManual

Introduction

Thismachineisintendedtobeusedbyresidential

homeowners.Itisdesignedprimarilyforremoving

snowfrompavedsurfaces,suchasdrivewaysand

sidewalks,andothersurfacesfortrafconresidential

orcommercialproperties.Itisnotdesignedfor

removingmaterialsotherthansnow.Usingthis

productforpurposesotherthanitsintendedusecould

provedangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.T oro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

onthemachine.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

Figure1

1.Modelandserialnumberlocation

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Important:Ifyouareusingthismachineabove

1500m(5,000ft)foracontinuousperiod,ensure

thattheHighAltitudeKithasbeeninstalled

sothattheenginemeetsCARB/EPAemission

regulations.TheHighAltitudeKitincreases

engineperformancewhilepreventingspark-plug

fouling,hardstarting,andincreasedemissions.

Onceyouhaveinstalledthekit,attachthe

high-altitudelabelnexttotheserialdecalonthe

machine.ContactanyAuthorizedToroService

DealertoobtaintheproperHighAltitudeKitand

high-altitudelabelforyourmachine.T olocate

adealerconvenienttoyou,accessourwebsite

atwww.Toro.comorcontactourToroCustomer

CareDepartmentatthenumber(s)listedinyour

EmissionControlWarrantyStatement.Remove

thekitfromtheengineandrestoretheengineto

itsoriginalfactorycongurationwhenrunningthe

engineunder1500m(5,000ft).Donotoperatean

enginethathasbeenconvertedforhigh-altitude

useatloweraltitudes;otherwise,youcould

g296245

overheatanddamagetheengine.

Ifyouareunsurewhetherornotyourmachinehas

beenconvertedforhigh-altitudeuse,lookforthe

followinglabel(Figure3).

ModelNo.

SerialNo.

©2020—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3439-724*

Figure3

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Contents

OperatingtheSpeedSelector...........................14

OperatingtheAuger/ImpellerDrive...................14

OperatingtheQuickStick®...............................14

ClearingaCloggedDischargeChute................15

OperatingTips.................................................15

AfterOperation....................................................16

decal127-9363

AfterOperationSafety......................................16

PreventingFreeze-upafterUse........................16

Maintenance...........................................................17

RecommendedMaintenanceSchedule(s)...........17

MaintenanceSafety..........................................17

PreparingforMaintenance...............................17

CheckingtheEngine-OilLevel..........................18

CheckingandAdjustingtheSkidsand

Scraper.........................................................18

CheckingandAdjustingtheTraction

Cable............................................................19

CheckingandAdjustingtheAuger/Impeller

Cable............................................................19

CheckingtheAuger-Gearbox-OilLevel.............20

ChangingtheEngineOil...................................21

LubricatingtheHexShaft..................................22

ReplacingtheSparkPlug.................................22

ReplacingtheDriveBelts..................................23

ReplacingtheHeadlight....................................23

Storage...................................................................23

StorageSafety..................................................23

StoringtheMachine..........................................23

RemovingtheMachinefromStorage................24

Troubleshooting......................................................25

Introduction...............................................................1

Safety.......................................................................3

GeneralSafety...................................................3

SafetyandInstructionalDecals..........................3

Setup........................................................................5

1UnfoldingtheUpperHandle.............................5

2InstallingtheTraction-ControlLinkage.............5

3InstallingtheChute-ControlRod......................5

4InstallingtheSnow-CleanoutTool....................6

5CheckingtheEngine-OilLevel.........................7

6CheckingandAdjustingtheTire

Pressure.........................................................7

7CheckingtheSkidsandScraper......................7

8CheckingtheOperationoftheTraction

Drive...............................................................7

ProductOverview.....................................................8

Specications....................................................9

Attachments/Accessories...................................9

Operation..................................................................9

BeforeOperation...................................................9

BeforeOperationSafety.....................................9

FillingtheFuelT ank..........................................10

DuringOperation.................................................10

DuringOperationSafety...................................10

StartingtheEngine............................................11

ShuttingOfftheEngine.....................................13

OperatingtheHandwarmers.............................13

OperatingtheTractionDrive.............................13

2

Safety

x 3

1

2

3

4

5

120-9805

howtouseit,knowshowtoshutofftheengine

quickly,andunderstandsthewarnings.

Thismachinehasbeendesignedinaccordancewith

ANSI/OPEIB71.3specications.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury .

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

Ensurethateveryoneusingthisproductknows

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

•Shutofftheenginewheneveryouleavethe

operatingpositionforanyreason.

•Donotputyourhandsorfeetnearmovingparts

onthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

working.

•Keepclearofanydischargeopening.Keep

bystanders,especiallysmallchildren,outofthe

operatingarea.

•Neverallowchildrentooperatethemachine.

decal121-6817

121-6817

1.Cutting/dismembermenthazardofhandorfoot,impeller

decal120-9805

120-9805

1.Insertthekey.

2.Primetheengine3times.

3.Engagethechoke.

4.Pullthestartercord.

5.Oncetheengineisrunning,disengagethechoke.

andauger—keepbystandersaway.

3

decal136-7825

136-7825

121-6847

1.Cutting/dismembermenthazardofthengersorhand,

impeller—donotplaceyourhandinthechute;shutoffthe

enginebeforeusingthetooltoclearthechute.

125-1102

1.Engine—shutoff

2.Slow

3.Variablespeedcontrol

4.Fast

133-8061

decal121-6847

decal125-1102

decal133-8061

1.Fuel

2.Fuelshutoff

OrderPartNo.144-0333

144-0326

1.Fast

2.Forwardspeed4.Reversespeed

3.Slow

decal144-0326

137-6249

1.Squeezethelevertoengagethetractiondrive.4.Cutting/dismembermentofngersorhand,impeller

2.Warning—readtheOperator’sManual.

3.Cutting/dismembermentofngersorhand,impellerblade—do

notplaceyourhandinthechute;shutofftheenginebefore

usingthetooltoclearthechute.

blade—keepawayfrommovingparts;keepallguardsand

shieldsinplace;removethekeyfromtheignitionbefore

servicingthemachine.

5.Thrownobjecthazard—keepbystandersaway.

6.Squeezethelevertoengagetheimpeller.

4

decal137-6249

Setup

1

UnfoldingtheUpperHandle

NoPartsRequired

Procedure

g293415

2

InstallingtheTraction-ControlLinkage

NoPartsRequired

Procedure

g263628

5

3

InstallingtheChute-ControlRod

NoPartsRequired

Procedure

g252615

4

InstallingtheSnow-CleanoutTool

NoPartsRequired

Procedure

g257329

6

5

7

CheckingtheEngine-Oil

Level

NoPartsRequired

Procedure

Note:Yourmachinecomeswithoilintheengine

crankcase.Beforestartingtheengine,checktheoil

levelandaddoilifnecessary.

RefertoCheckingtheEngine-OilLevel(page18).

6

CheckingandAdjustingthe

TirePressure

CheckingtheSkidsand

Scraper

NoPartsRequired

Procedure

RefertoCheckingandAdjustingtheSkidsand

Scraper(page18).

8

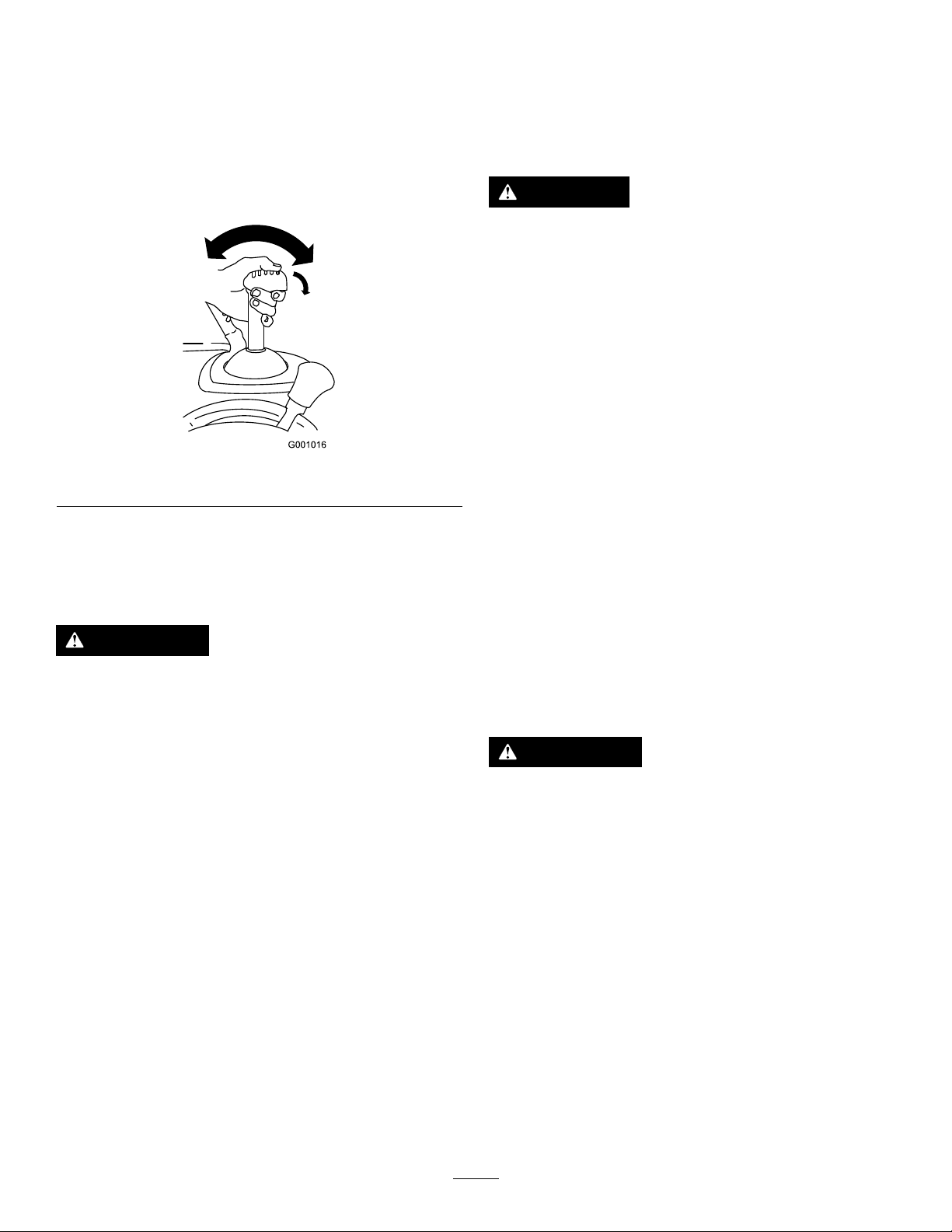

CheckingtheOperationof

theTractionDrive

NoPartsRequired

Procedure

NoPartsRequired

Procedure

g257835

CAUTION

Ifthetractiondriveisnotproperlyadjusted,

themachinemaymoveinthedirection

oppositeofwhatyouintended,causinginjury

and/orpropertydamage.

Carefullycheckthetractiondriveandadjustit

properly,ifnecessary.

1.Starttheengine;refertoStartingtheEngine

(page1 1).

2.MovethespeedselectortoPositionR1;referto

OperatingtheSpeedSelector(page14).

3.Squeezetheleft(traction)levertothehandgrip

(Figure9).

g322974

Figure9

7

Themachineshouldmoverearward.Ifthe

machinedoesnotmoveormovesforward,

completethefollowing:

A.Releasethetractionleverandshutoffthe

engine.

B.Disconnectthetrunnionfromthe

speed-selectorlever.

C.Turnthetrunniondownward(clockwise)on

thespeed-controlrod.

D.Connectthetrunniontothespeed-selector

lever.

4.Releasethetractionlever.

5.MovethespeedselectortoPosition1;referto

OperatingtheSpeedSelector(page14).

6.Squeezetheleft(traction)levertothehandgrip

(Figure9).

Themachineshouldmoveforward.Ifthe

machinedoesnotmoveormovesrearward,

completethefollowing:

A.Releasethetractionleverandshutoffthe

engine.

B.Disconnectthetrunnionfromthe

speed-selectorlever.

C.Turnthetrunnionupward(counterclockwise)

onthespeed-controlrod.

D.Connectthetrunniontothespeed-selector

lever.

7.Ifyoumadeanyadjustments,repeatthis

procedureuntilnoadjustmentsarerequired.

Important:Ifthemachinemoveswhenthe

tractionleverisinthereleasedposition,checkthe

tractioncable;refertoCheckingandAdjusting

theTractionCable(page19)ortakethemachine

toanAuthorizedServiceDealerforservice.

ProductOverview

Figure10

1.Handgrip(2)

2.Auger/impellerlever11.Scraper

3.Speed-selectorlever

4.Handwarmerswitch

5.QuickStick®

discharge-chutecontrol

6.Tractionlever15.Electric-startbutton

7.Fuel-tankcap16.Electric-startplug-in

8.Oil-lltube/dipstick

9.Chutedeector18.Snow-cleanouttool

10.Dischargechute

12.Auger

13.Skid(2)

14.Headlight

17.Recoil-starthandle

g322760

1.Primer5.Throttle

2.Key

3.Choke

4.Fuel-shutoffvalve

8

g016500

Figure11

6.Oil-drainplug

7.Recoil-starthandle

Figure12

1.Snow-cleanouttool(attachedtothehandle)

Operation

Note:Determinetheleftandrightsidesofthe

g004217

machinefromthenormaloperatingposition.

BeforeOperation

Specications

ModelWeightLengthWidthHeight

127kg160cm81cm114cm

38830

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.T oro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

(280lb)(63

inches)

(32

inches)

BeforeOperationSafety

GeneralSafety

(45

inches)

•Forelectric-startmodelsonly:Useextension

cordsandreceptaclesasspeciedinthemanual.

Inspecttheelectricalcordbeforepluggingitinto

apowersource.Ifthecordisdamaged,replace

it.Unplugthepowercordwheneveryouarenot

startingthemachine.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hair,securelooseclothing,anddonotwearloose

jewelry.

•Thoroughlyinspecttheareawhereyouwillusethe

machine,andremovealldoormats,sleds,boards,

wires,andotherforeignobjects.

•Ifashield,safetydevice,ordecalisdamaged,

illegible,ormissing,repairorreplaceitbefore

beginningoperation.Also,tightenanyloose

fasteners.

•Adjustthecollectorhousingheighttocleara

gravelorcrushed-rocksurface.

FuelSafety

Fuelisextremelyammableandexplosive.Areor

explosionfromfuelcanburnyouandothers.

•Topreventastaticchargefromignitingthefuel,

placethecontainerand/ormachineontheground

beforelling,notinavehicleoronanobject.

•Fillthefueltankoutdoorswhentheengineiscold.

Replacethefuelcapsecurelyandwipeupspills.

•Donothandlefuelwhensmokingoraroundan

openameorsparks.

•Storefuelinanapprovedfuelcontainer,outofthe

reachofchildren.

•Whenfuelisinthetank,tipthemachineonlyas

directedintheinstructions.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.

9

FillingtheFuelTank

TypeUnleadedgasoline

Minimumoctanerating

Ethanol

MethanolNone

MTBE(methyltertiarybutyl

ether)

OilDonotaddtothefuel

87(US)or91(research

octane;outsidetheUS)

Nomorethan10%byvolume

Lessthan15%byvolume

•Exercisecautiontoavoidslippingorfalling,

especiallywhenoperatingthemachineinreverse.

•Alwaysbesureofyourfooting,andkeeparm

holdonthehandles.Walk;neverrun.

•Exerciseextremecautionwhenoperatingthe

machineonaslope.

•Donotoperatethemachinewithoutgoodvisibility

orlight.

•Lookbehindandusecarewhenbackingupthe

machine.

Useonlyclean,fresh(nomorethan30daysold),fuel

fromareputablesource.

FillthefueltankasshowninFigure13;donotll

abovethebottomofthefueltankneck.

Figure13

Important:Forbestresults,purchaseonlythe

quantityoffuelthatyouexpecttousein30days.

Otherwise,addfuelstabilizer/conditionertofresh

fuelasdirectedbythefuel-stabilizer/conditioner

manufacturer.

DuringOperation

DuringOperationSafety

GeneralSafety

•Shutofftheenginebeforeuncloggingthe

machineandalwaysuseastickorthe

snow-cleanouttool(ifprovided).

•Whennotactivelyclearingsnow,disengagepower

totheauger.

•Exerciseextremecautionwhenoperatingthe

machineonorcrossinggraveldrives,walks,or

roads.Stayalertforhiddenhazardsortrafc.

•Neverattempttomakeanyadjustmentswhile

theengineisrunning,exceptasdirectedinthe

instructions.

•Afterstrikingaforeignobject,shutofftheengine,

removethekey,andinspectthemachinefor

g216203

damage.Repairanydamagebeforestartingthe

machine.

•Ifthemachinestartstovibrateabnormally,shutoff

theengineandcheckimmediatelyforthecause.

•Donotruntheengineindoors;exhaustfumesare

dangerous.

•Donotoverloadthemachinecapacityby

attemptingtoclearsnowattoofastarate.

•Disengageallclutchesandshiftintoneutralbefore

startingtheengine.

•Shutofftheenginewheneveryouleavethe

operatingposition,beforeclearingorunclogging

thecollector,impeller,ordischargechute,and

whenmakinganyrepairs,adjustments,or

inspections.

•Neveroperatethemachineathightransport

speedsonslipperysurfaces.

•Staybehindthehandlesandawayfromthe

dischargeopeningwhileoperatingthemachine.

Keepyourface,hands,feet,andanyotherpart

ofyourbodyorclothingawayfrommovingor

rotatingparts.

•Neverdirectthedischargetowardpeopleorareas

wherepropertydamagecanoccur.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

10

StartingtheEngine

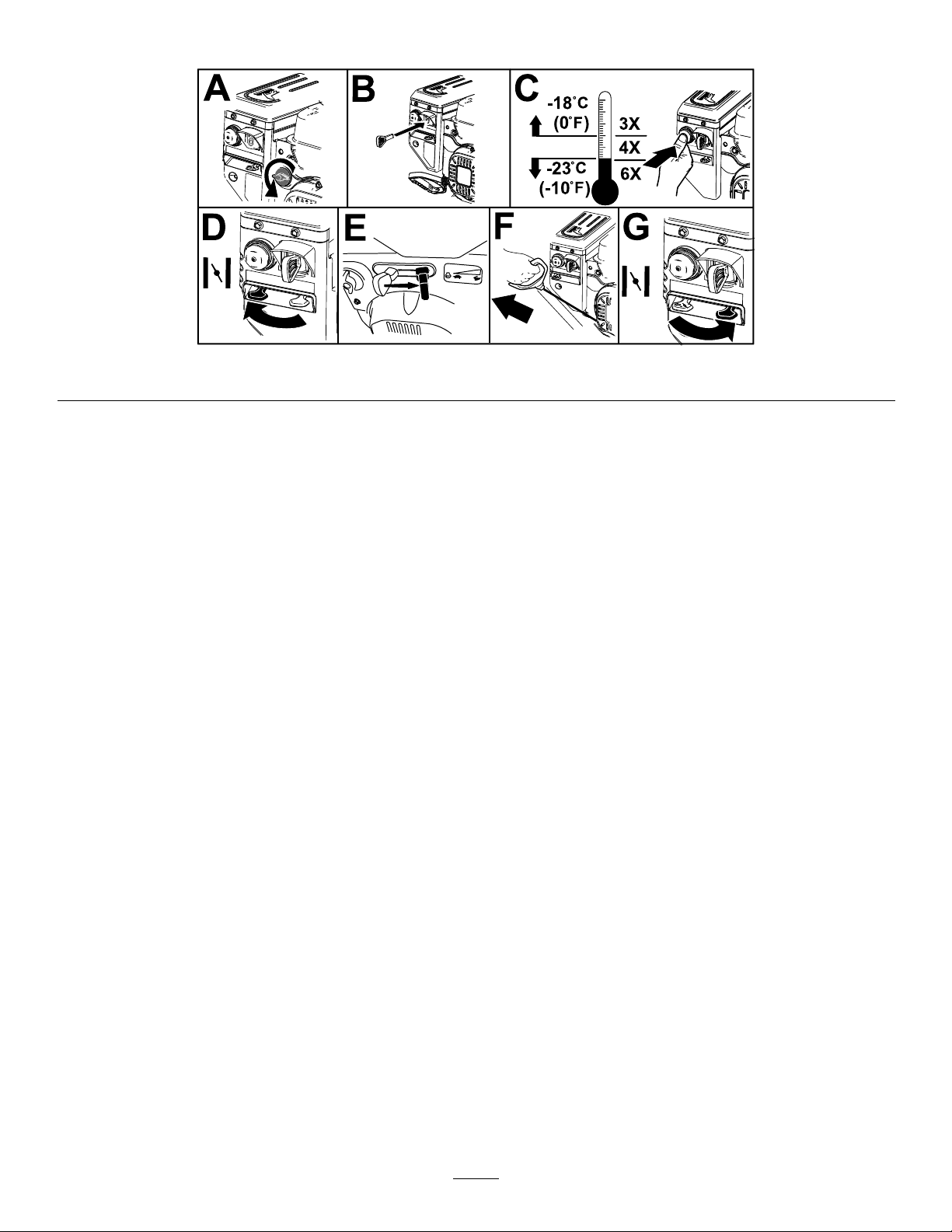

ElectricStart

Note:T ousetheelectricstarter(electric-startmodelsonly),connectapowercordtotheplug-inrstandthen

toapoweroutlet.UseonlyaUL-listed,16-gaugeextensioncordrecommendedforoutdoorusethatisnot

longerthan15m(50ft).

WARNING

Theelectricalcordcanbecomedamaged,causingashockorre.

Thoroughlyinspecttheelectricalcordbeforeusingthemachine.Ifthecordisdamaged,do

notuseit.Replaceorrepairthedamagedcordimmediately.ContactanAuthorizedService

Dealerforassistance.

CAUTION

Ifyouleavethemachinepluggedintoapoweroutlet,someonecaninadvertentlystartthe

machineandinjurepeopleordamageproperty.

Unplugthepowercordwheneveryouarenotstartingthemachine.

Figure14

g322740

11

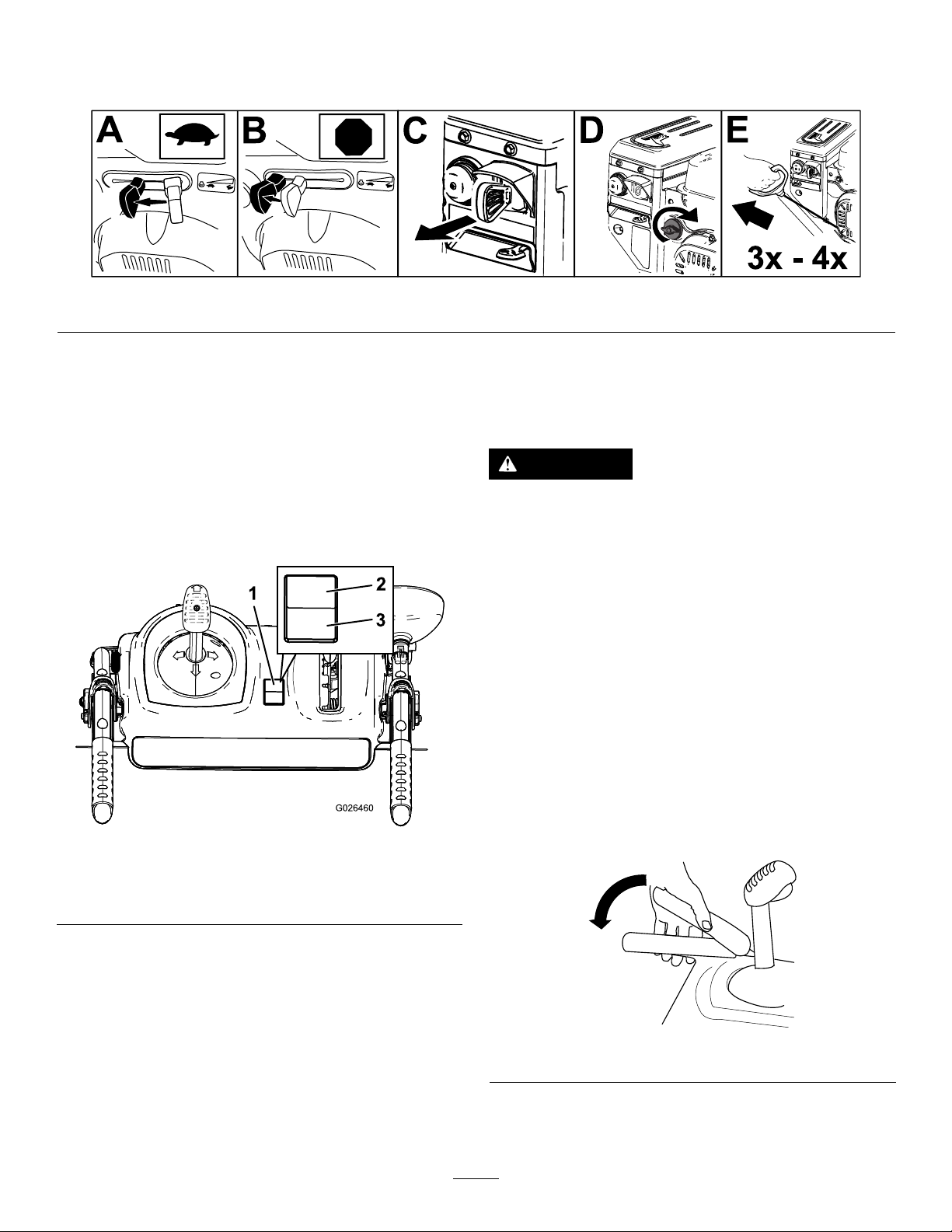

RecoilStart

g322741

Figure15

12

ShuttingOfftheEngine

Important:Waitforallmovingpartstostopbeforeleavingtheoperatingposition.

Figure16

g252411

Operatingthe

Handwarmers

Operatethehandwarmersasfollows:

•PresstheswitchtotheONpositiontoturnonthe

handwarmers.

•PresstheswitchtotheOFFpositiontoturnoffthe

handwarmers.

Figure17

OperatingtheTraction

Drive

CAUTION

Ifthetractiondriveisnotproperlyadjusted,

themachinemaymoveinthedirection

oppositeofwhatyouintended,causinginjury

and/orpropertydamage.

Carefullycheckthetractiondriveandadjustit

properly,ifnecessary.

Important:Ifthemachinemoveswhenthe

tractionleverisinthereleasedposition,checkthe

tractioncable;refertoCheckingandAdjusting

theTractionCable(page19)ortakethemachine

toanAuthorizedServiceDealerforservice.

Important:Tooperatethetractiondrive,you

mustoperatethemachinewiththeself-propel

featureengaged.

g026460

1.Toengagethetractiondrive,squeezetheleft

(traction)levertothehandgrip(Figure18).

1.On/Offswitch3.OFFposition

2.ONposition

g322974

Figure18

2.Tostopthetractiondrive,releasethetraction

lever.

13

OperatingtheSpeed

WARNING

Selector

Thespeedselectorhas6forwardand2reverse

gears.T ochangespeeds,releasethetractionlever

andshiftthespeed-selectorlevertothedesired

position(Figure19).Theleverlocksinanotchat

eachspeedselection.

Figure19

Operatingthe

Auger/ImpellerDrive

Iftheaugerandimpellercontinue

torotatewhenyoureleasethe

auger/impellerlever,youcouldseriously

injureyourselforothers.

Donotoperatethemachine.Takeittoan

AuthorizedServiceDealerforservice.

OperatingtheQuickStick®

HoldthebluetriggercapdowntousetheQuickStick

tomovethedischargechuteandthechutedeector.

Releasethetriggercaptolockthedischargechute

andchutedeectorintoposition(Figure21).

g322971

1.Toengagetheauger/impellerdrive,squeeze

theright(auger/impeller)levertothehandgrip

(Figure20).

Figure20

2.Tostoptheaugerandimpeller,releasetheright

lever.

Important:Whenyouengageboththe

auger/impellerleverandthetractionlever,

thetractionleverlockstheauger/impeller

leverdown,freeingyourrighthand.To

releasebothlevers,simplyreleasetheleft

(traction)lever.

g001014

Figure21

MovingtheDischargeChute

HoldthebluetriggercapdownandmovetheQuick

Sticktothelefttomovethedischargechutetothe

left;movetheQuickSticktotherighttomovethe

dischargechutetotheright(Figure22).

g322975

3.Iftheaugerandimpellercontinuetorotatewhen

youreleasetheauger/impellerlever,donot

operatethemachine.Checktheauger/impeller

cable;refertoCheckingandAdjustingthe

Auger/ImpellerCable(page19)andadjustitif

necessary.Otherwise,takethemachinetoan

AuthorizedServiceDealerforservice.

g018894

Figure22

14

Ifthechutedoesnotturnasfartotheleftasitdoesto

theright,ensurethatthecableisroutedtotheinside

ofthehandles.

theskidsandtightentheskidboltssecurely;

refertoCheckingandAdjustingtheSkidsand

Scraper(page18).

MovingtheChuteDeector

HoldthebluetriggercapdownandmovetheQuick

Stickforwardtolowerthechutedeector;moveit

rearwardtoraisethechutedeector(Figure23).

Figure23

ClearingaClogged

DischargeChute

WARNING

Iftheauger/impellerisrunningbutthereisno

snowcomingoutofthedischargechute,the

dischargechutemaybeclogged.

OperatingTips

DANGER

Whenthemachineisinoperation,theimpeller

andaugerrotateandcaninjureoramputate

handsorfeet.

•Beforeadjusting,cleaning,inspecting,

troubleshooting,orrepairingthemachine,

shutofftheengineandwaitforallmoving

partstostop.Disconnectthewirefrom

thesparkplugandkeepitawayfromthe

plugtopreventsomeonefromaccidentally

startingtheengine.

g001016

•Removeanobstructionfromthedischarge

chute;refertoClearingaClogged

DischargeChute(page15).Usethe

snow-cleanouttool(Figure13),notyour

hands,toremoveanobstructionfromthe

dischargechute.

•Staybehindthehandlesandawayfrom

thedischargeopeningwhileoperatingthe

machine.

•Keepyourface,hands,feet,andanyother

partofyourbodyorclothingawayfrom

concealed,moving,orrotatingparts.

Neveruseyourhandstoclearaclogged

dischargechute.Thiscouldresultinpersonal

injury.

•Tounclogthedischargechute,stayinthe

operatingpositionandreleasetheleft(traction)

lever.Whilerunningtheauger/impeller,pushdown

onthehandlestoraisethefrontofthemachinea

fewcentimeters(inches)offthepavement.Then

liftthehandlesquicklytobumpthefrontofthe

machineonthepavement.Repeatifnecessary

untilastreamofsnowcomesoutthedischarge

chute.

•Ifyoucannotunclogthedischargechuteby

bumpingthefrontofthemachine,shutoffthe

engine,waitforallmovingpartstostop,and

usethesnow-cleanouttool(Figure12).

Important:Uncloggingthedischargechute

bybumpingthefrontofthemachineonthe

pavementmaycausetheskidstomove.Adjust

WARNING

Theimpellercanthrowstones,toys,andother

foreignobjectsandcauseseriouspersonal

injurytoyouorbystanders.

•Keeptheareatobeclearedfreeofall

objectsthattheaugercouldpickupand

throw.

•Keepallchildrenandpetsawayfromthe

areaofoperation.

•AlwayssetthethrottletotheFASTpositionwhen

throwingsnow.

•Iftheengineslowsdownunderaloadorthe

wheelsslip,shiftthemachineintoalowergear.

•Ifthefrontofthemachineridesup,shiftthe

machineintoalowergear.Ifthefrontcontinuesto

rideup,liftuponthehandles.

15

AfterOperation

AfterOperationSafety

GeneralSafety

•Neverstorethemachinewithfuelinthefuel

tankinsideabuildingwhereignitionsourcesare

present,suchashotwaterheaters,spaceheaters,

orclothesdryers.Allowtheenginetocoolbefore

storingthemachineinanyenclosure.

•Whenstoringthemachineformorethan30

days,refertoStorage(page23)forimportant

information.

•Runthemachineafewminutesafterthrowing

snowtopreventfreeze-upofthecollectorand

impeller.

PreventingFreeze-upafter

Use

•Insnowyandcoldconditions,somecontrolsand

movingpartsmayfreeze.Donotuseexcessive

forcewhentryingtooperatefrozencontrols.

Ifyouhavedifcultyoperatinganycontrolorpart,

starttheengineandletitrunforafewminutes.

•Afterusingthemachine,lettheenginerunfor

afewminutestopreventmovingpartsfrom

freezing.Engagetheauger/impellertoclearany

remainingsnowfrominsidethehousing.Rotate

theQuickSticktopreventitfromfreezing.Shutoff

theengine,waitforallmovingpartstostop,and

removealliceandsnowfromthemachine.

•Withtheengineoff,pulltherecoil-starthandle

severaltimesandpushtheelectric-startbutton

oncetopreventtherecoilstarterandelectric

starterfromfreezingup.

16

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst5hours

Beforeeachuseordaily

Every50hours

Every100hours

Yearly

Yearlyorbeforestorage

MaintenanceSafety

MaintenanceProcedure

•Inspectthetractioncableandadjustitifnecessary.

•Inspecttheauger/impellercableandadjustitifnecessary .

•Changetheengineoil.

•Checktheengine-oillevelandaddoilifnecessary.

•Changetheengineoil.Changetheengineoilevery25operatinghourswhen

operatingtheengineunderaheavyload.

•Replacethesparkplug.

•Checktheskidsandthescraperandadjustthemifnecessary .

•Inspectthetractioncableandadjustorreplaceitifnecessary.

•Inspecttheauger/impellercableandadjustorreplaceitifnecessary.

•Checktheauger-gearboxoilandaddoilifnecessary.

•Lubricatethehexshaft.

•Checktheairpressureinthetiresandinatethemto116to137kPa(17to20psi).

•Runtheenginetodryoutthefueltankandthecarburetorattheendoftheseason.

•HaveanAuthorizedServiceDealerinspectandreplacethetractiondrivebeltand/or

theauger/impellerdrivebelt,ifnecessary.

Readthefollowingsafetyprecautionsbefore

performinganymaintenanceonthemachine:

•Shutofftheengine,removethekey ,andwait

forallmovementtostopbeforeyouleavethe

operator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

•Alwaysweareyeprotectionwhileperformingan

adjustmentorrepairtoprotectyoureyesfrom

foreignobjectsthatthemachinemaythrow.

•Checkallfastenersatfrequentintervalsforproper

tightnesstoensurethatthemachineisinsafe

workingcondition.

•Donotchangethegovernorsettingsontheengine.

PurchaseonlygenuineTororeplacementparts

andaccessories.

PreparingforMaintenance

1.Movethemachinetoalevelsurface.

2.Shutofftheengineandwaitforallmovingparts

tostop.

3.Disconnectthespark-plugwire.Referto

ReplacingtheSparkPlug(page22).

17

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily—Checktheengine-oillevelandaddoilifnecessary .

g257528

CheckingandAdjustingthe

SkidsandScraper

ServiceInterval:Y early—Checktheskidsand

thescraperandadjustthemif

necessary.

Checktheskidsandthescrapertoensurethatthe

augerdoesnotcontactthepavedorgravelsurface.

Adjusttheskidsandthescraperasneededto

compensateforwear.

1.Checkthetirepressure;referto6Checkingand

AdjustingtheTirePressure(page7).

2.Loosenthenutsthatsecurebothskidstothe

augersidesuntiltheskidsslideupanddown

easily.

Note:Ifthepavementiscracked,rough,or

uneven,adjusttheskidstoraisethescraper.For

gravelsurfaces,adjusttheskidsfurtherdownto

preventthemachinefrompickinguprocks.

4.Movetheskidsdownuntiltheyareevenwith

theground.

5.Firmlytightenthenutsthatsecurebothskids

totheaugersides.

Note:T oquicklyadjusttheskidsiftheyloosen,

supportthescraper3mm(1/8inch)offthe

pavement,thenadjusttheskidsdowntothe

pavement.

Note:Iftheskidsbecomeexcessivelyworn,

youcanturnthemoverandsettheunusedside

towardthepavement.

Figure25

1.3mm(1/8inch)

Important:Theaugerbladesmustbe

supportedabovethegroundbytheskids.

3.Ensurethatthescraperis3mm(1/8inch)above

andparalleltoalevelsurface.

g001570

18

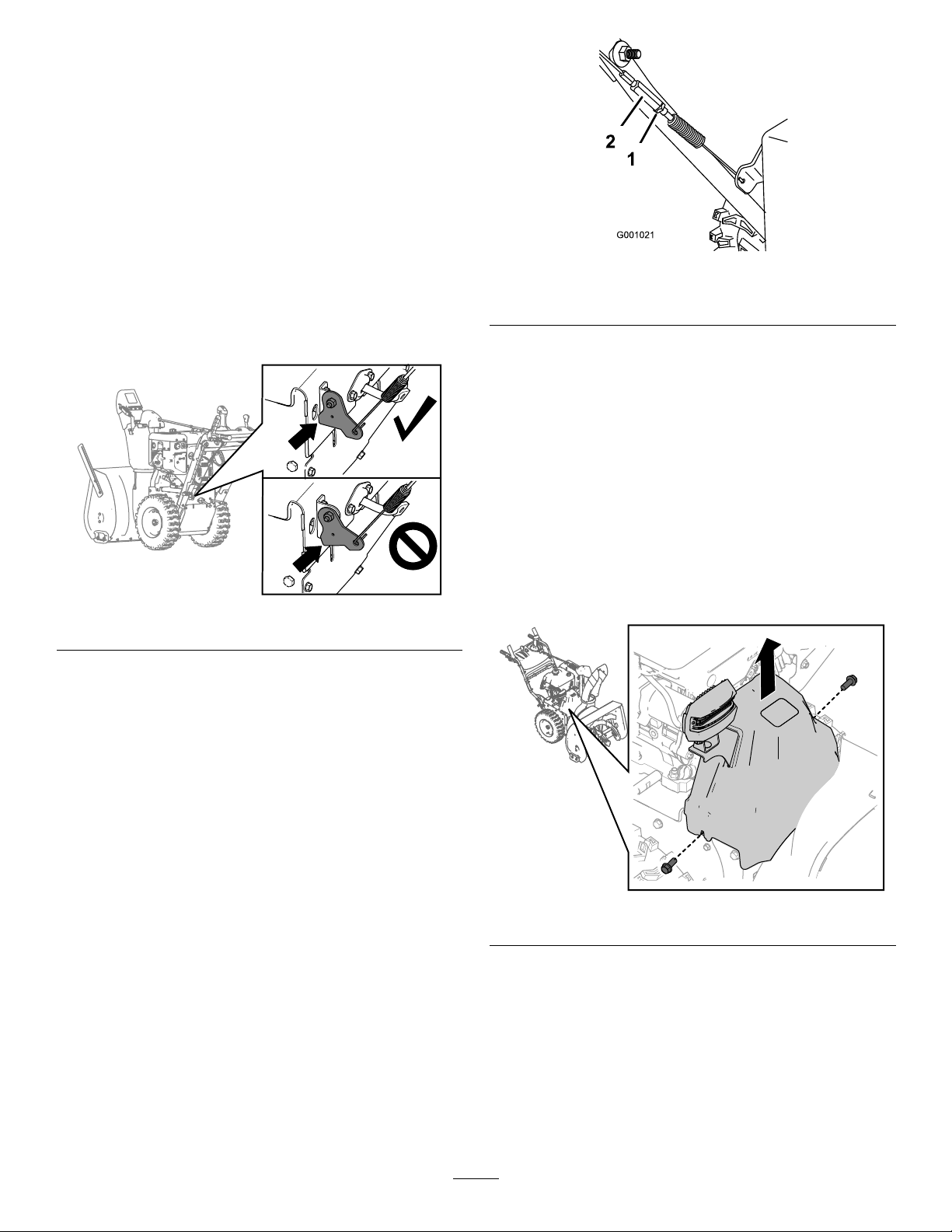

CheckingandAdjustingthe

TractionCable

ServiceInterval:Aftertherst2hours—Inspect

thetractioncableandadjustitif

necessary.

Yearly—Inspectthetractioncableandadjustor

replaceitifnecessary.

Ifthemachinedoesnotdriveintheforwardorreverse

speedsoritdriveswhenyoureleasethetractionlever,

adjustthetractioncable.

g001021

Figure27

Withthetractionleverdisengaged,ensurethatthe

bottomofthetraction-cablebracketistouchingthe

frameofthemachine(Figure24).

Figure26

Ifthebottomofthetraction-cablebracketisnot

touchingtheframeofthemachine,theleft(traction)

cableisnotproperlyadjusted.

Toadjustthetractioncable,dothefollowing:

1.Jamnut2.Turnbuckle

CheckingandAdjustingthe

Auger/ImpellerCable

ServiceInterval:Aftertherst2hours—Inspectthe

auger/impellercableandadjustitif

necessary.

Yearly—Inspecttheauger/impellercableand

adjustorreplaceitifnecessary.

1.Removethe2screwsthatareholdingthebelt

coverinplace(Figure28).

g259431

2.Removethebeltcover(Figure28).

1.Loosenthejamnut.

2.Loosenortightentheturnbuckletountilthe

cableistaughtandthebottomofthebracket

touchestheframeofthemachine.

3.Tightenthejamnut(Figure27).

g260066

Figure28

3.Withtheauger/impellerleverdisengaged,

ensurethatthegapbetweentheaugerclutch

armandtheframeofthemachineis1.5mm

(1/16inch)asshowninFigure29.

19

Figure29

Checkingthe

Auger-Gearbox-OilLevel

ServiceInterval:Yearly—Checktheauger-gearbox

oilandaddoilifnecessary.

1.Movethemachinetoalevelsurface.

2.Cleantheareaaroundthepipeplugandremove

thepipeplugfromthegearbox(Figure31).

Note:Ifneeded,useplierstoassistinremoving

thepipeplug.

g260108

1.1.5mm(1/16inch)

2.Frame

3.Augerclutcharm

4.Iftheauger/impellercableisnotproperly

adjusted,dothefollowingsteps:

5.Loosenthejamnut(Figure30).

Figure30

1.Jamnut2.Turnbuckle

g257725

Figure31

3.Checktheoillevelusingasuitablemeasuring

device,suchasacleancabletie.Theoilshould

beapproximately3.8cm(1.5inches)belowthe

lleropening(Figure32).

g322960

6.Loosenortightentheturnbucklethatadjuststhe

tensiononthecable(Figure30).

7.Adjusttheturnbuckleuntilyouobtaintheproper

gap.

8.Tightenthejamnut.

9.Insertthe2screwsthatyoupreviouslyremoved

onthebeltcover.

10.Iftheauger/impellercableisproperlyadjusted

butaproblemremains,contactanAuthorized

ServiceDealer.

g257737

Figure32

4.Iftheoillevelislow,addGL-5orGL-6,SAE

85-95EPgearoillubricanttothegearbox,then

checktheoillevelagain.

Note:Donotusesyntheticoil.

5.Installthepipepluginthegearbox.

20

ChangingtheEngineOil

ServiceInterval:Aftertherst5hours—Changethe

engineoil.

Every50hours—Changetheengineoil.

Changetheengineoilevery25operatinghours

whenoperatingtheengineunderaheavyload.

Ifpossible,runtheengineforafewminutesbefore

changingtheoilbecausewarmoilowsbetterand

carriesmorecontaminants.

Engineoilcapacity

OilviscosityRefertoFigure34.

APIserviceclassicationSJorhigher

0.95L(32oz)*

*Thereisresidualoilinthecrankcaseafteryoudrain

theoil.Donotpourtheentirecapacityofoilintothe

crankcase.Fillthecrankcasewithoilasdirectedin

thefollowingsteps.

1.Movethemachinetoalevelsurface.

2.Cleantheareaaroundtheoil-draincap(Figure

33).

Figure33

1.Oil-draincap

g011606

Figure34

9.Wait3minutesfortheoiltosettleintheengine.

10.Wipethedipstickcleanwithacleancloth.

11.Insertthedipstickintotheoil-lltubeandscrew

itin,thenremovethedipstick.

12.Readtheoillevelonthedipstick.

•Iftheoillevelonthedipstickistoolow,

carefullypourasmallamountofoilinto

theoil-lltube,wait3minutes,andrepeat

steps10through12untiltheoillevelonthe

dipstickiscorrect.

•Iftheoillevelonthedipstickistoohigh,

draintheexcessoiluntiltheoillevelonthe

dipstickiscorrect.

Important:Iftheoillevelintheengineistoo

g016496

lowortoohighandyouruntheengine,you

maydamagetheengine.

13.Installthedipstickintotheoil-lltubesecurely.

14.Recycletheusedoilproperly.

3.Slideanoil-drainpanunderthedrainextension

andremovetheoil-draincap.

Note:Whenremovingthecap,ensurethatthe

tubedoesnotloosen.

4.Draintheoil.

Note:Disposeoftheusedoilproperlyatalocal

recyclingcenter.

5.Installtheoil-draincapandtightenitsecurely.

6.Cleanaroundtheoilll/dipstick.

7.Unscrewthedipstickandremoveit.

8.Carefullypourabout3/4oftheenginecapacity

ofoilintotheoil-lltube.

UseFigure34toselectthebestoilviscosityfor

theoutdoortemperaturerangeexpected:

21

LubricatingtheHexShaft

ReplacingtheSparkPlug

ServiceInterval:Yearly—Lubricatethehexshaft.

Lightlylubricatethehexshaftyearlywithautomotive

engineoil(Figure35).

Figure35

1.Hexshaft

2.Aluminumfrictionplate

3.Rubberwheel

Important:Donotgetoilontherubberwheel

orthealuminumfrictiondriveplatebecausethe

tractiondrivewillslip(Figure35).

1.Drainthefuelfromthefueltank.

2.Tipthemachineforwardontoitsaugerhousing

andblockitsothatitcannotfall.

3.Removethebackcover(Figure36).

ServiceInterval:Every100hours—Replacethe

sparkplug.

WARNING

Replacingthesparkplugwhiletheengineis

hotcanresultinburns.

Waituntiltheengineiscooltoreplacethe

sparkplug.

UseaT orosparkplugorequivalent(Champion®

RN9YCorNGKBPR6ES).

1.Removetheboot(Figure37).

g001027

g016645

Figure37

1.Spark-plugboot

2.Cleanaroundthebaseofthesparkplug.

Figure36

1.Backcover

4.Movethespeed-selectorlevertoPositionR2.

5.Dipyourngerinautomotiveengineoiland

lightlylubricatehexshaft.

6.Movethespeed-selectorlevertoPosition6.

7.Lubricatetheotherendofthehexshaft.

8.Movethespeed-selectorleverforwardand

rearwardafewtimes.

9.Installthebackcoverandreturnthemachineto

theoperatingposition.

g001028

g016646

Figure38

3.Removeanddiscardtheoldsparkplug.

Note:Y ouwillneedaratchetwrenchextension

toremovethesparkplug.

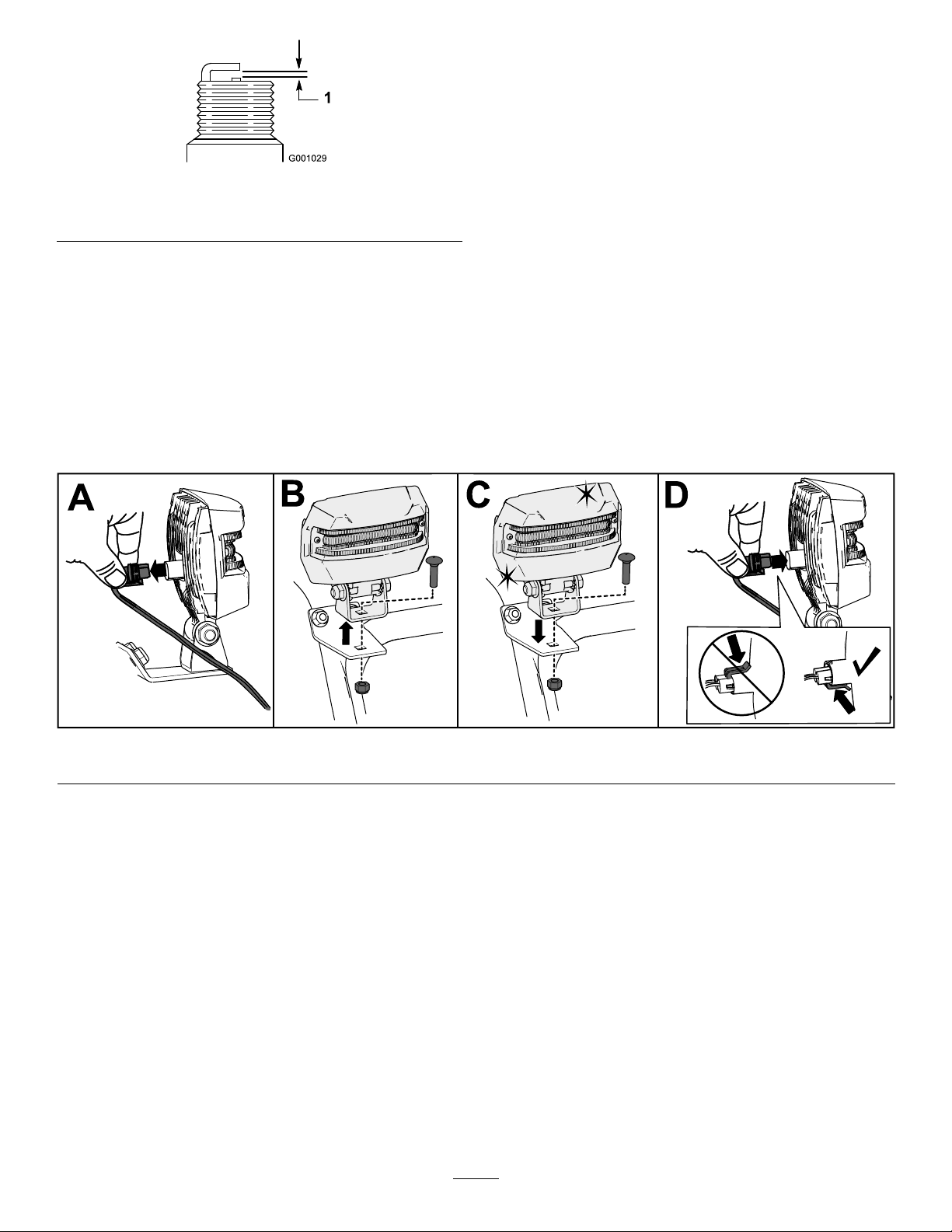

4.Setthegapbetweentheelectrodesonanew

sparkplugat0.76mm(0.030inch)asshown

inFigure39.

22

5.Installthenewsparkplug,tightenitrmly ,and

attachtheignitionwiretothesparkplug.

Note:Ensurethattheignitionwiresnaps

completelyintoplaceonthesparkplug.

g001029

Figure39

1.0.76mm(0.030inch)

ReplacingtheDriveBelts

Iftheauger/impellerdrivebeltorthetraction-drivebelt

becomesworn,oil-soaked,orotherwisedamaged,

haveanAuthorizedServiceDealerreplacethebelt.

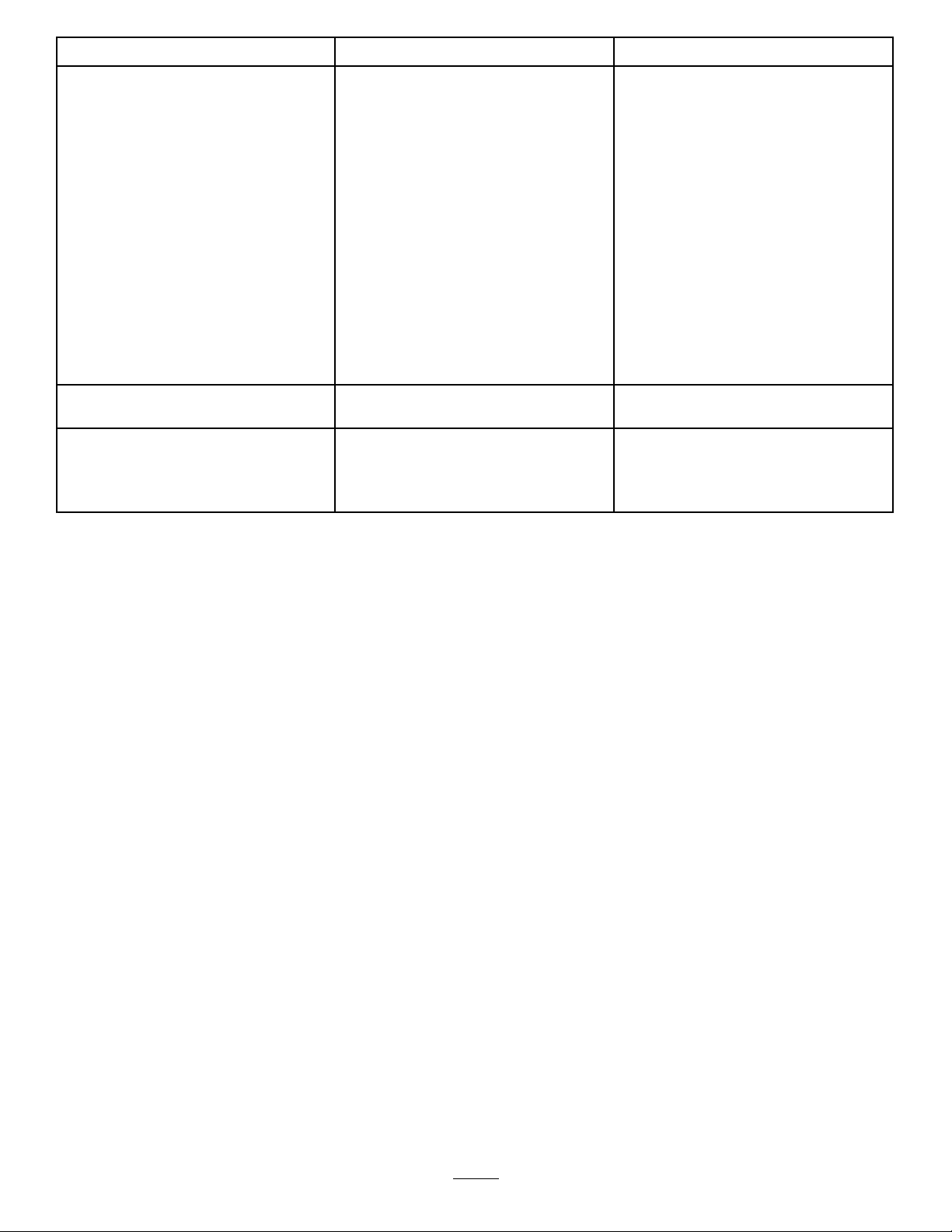

ReplacingtheHeadlight

Replacetheheadlightassembly(T oropartnumber138-0670)whenneeded.

1.Removetheheadlightwirefromthebackoftheheadlight(AofFigure40).

2.Removetheboltandnutholdingtheheadlightassemblyontotheheadlightbracketandthenremovethe

oldheadlightassembly(BofFigure40).

3.Securethenewheadlightassemblyontotheheadlightbracketwiththepreviouslyremovednutand

bolt(CofFigure40).

4.Inserttheheadlightwirestraightintothebackoftheheadlightuntilitissecurelyinplace(DofFigure40).

Storage

StorageSafety

•Shutofftheengine,removethekey ,andwait

forallmovementtostopbeforeyouleavethe

operator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

•Fuelfumesarehighlyammable,explosive,and

dangerousifinhaled.Ifyoustoretheproductinan

areawithanopename,thefuelfumesmayignite

andcauseanexplosion.

•Donotstorethemachineinahouse(living

area),basement,oranyotherareawhereignition

sourcesmaybepresent,suchashotwaterand

g256137

Figure40

spaceheaters,clothesdryers,furnaces,andother

appliances.

•Donottipthemachineeitherforwardorbackward

withfuelinthefueltank;otherwise,fuelmayleak

outofthemachine.

•Donotstorethemachinewithitshandletipped

downontotheground;otherwise,oilmayleakinto

theenginecylinderandontotheground,andthe

enginemaynotstart.

StoringtheMachine

1.Onthelastrefuelingoftheyear,addfuel

stabilizertofreshfuelasdirectedbythefuel

stabilizermanufacturer.

23

Important:Donotstorefuellonger

thanthatsuggestedbythefuelstabilizer

manufacturer.

2.Runtheenginefor10minutestodistributethe

conditionedfuelthroughthefuelsystem.

3.Runthemachineuntiltheenginerunsoutoffuel.

4.Primetheengineandstartitagain.

5.Allowtheenginetorununtilitshutsoff.

Whenyoucannolongerstarttheengine,itis

sufcientlydry.

6.Allowtheenginetocool.

7.Removethekey.

8.Cleanthemachinethoroughly.

9.Touchupchippedsurfaceswithpaintavailable

fromanAuthorizedServiceDealer.Sand

affectedareasbeforepainting,andusearust

preventativetopreventthemetalpartsfrom

rusting.

10.Tightenallloosescrews,bolts,andlocknuts.

Repairorreplaceanydamagedparts.

11.Coverthemachineandstoreitinaclean,dry

placeoutofthereachofchildren.

RemovingtheMachine

fromStorage

Performtheannualmaintenanceproceduresasgiven

intheRecommendedMaintenanceSchedule;referto

Maintenance(page17).

24

Troubleshooting

Problem

Theelectricstarterdoesnotturn

(electric-startmodelsonly).

Theenginedoesnotstartorstartshard.

PossibleCauseCorrectiveAction

1.Thepowercordisdisconnectedatthe

outletorthemachine.

2.Thepowercordisworn,corroded,or

damaged.

3.Thepoweroutletisnotenergized.

1.Thekeyisnotintheignition.1.Insertthekeyintotheignition.

2.ThechokeisintheOFFpositionand

theprimerhasnotbeenpressed.

3.Thefuel-shutoffvalveisnotopen.3.Openthefuel-shutoffvalve.

4.ThethrottleisnotintheFASTposition.4.MovethethrottletotheFASTposition.

5.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

6.Thespark-plugwireislooseor

disconnected.

7.Thesparkplugispitted,fouled,orthe

gapisincorrect.

8.Thefuel-ventcapisrestricted.

9.Theengine-oillevelintheengine

crankcaseistoolowortoohigh.

1.Connectthepowercordtotheoutlet

and/orthemachine.

2.Replacethepowercord.

3.Haveaqualiedelectricianenergize

theoutlet.

2.MovethechoketotheONpositionand

presstheprimer3times.

5.Drainand/orllthefueltankwith

freshfuel(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

6.Connectthewiretothesparkplug.

7.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

8.Removetheventrestrictionorreplace

thefuelcap.

9.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

Theenginerunsrough.

1.ThechokeisintheONposition.1.MovethechoketotheOFFposition.

2.Thefuel-shutoffvalveisnotcompletely

open.

3.Thefueltankisnearlyemptyor

containsstalefuel.

4.Thespark-plugwireisloose.

5.Thesparkplugispitted,fouled,orthe

gapisincorrect.

6.Theengine-oillevelintheengine

crankcaseistoolowortoohigh.

2.Openthefuel-shutoffvalve.

3.Drainandllthefueltankwithfresh

fuel(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

4.Connectthewiretothesparkplug.

5.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

6.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

25

Problem

PossibleCauseCorrectiveAction

Theengineruns,butthemachine

dischargessnowpoorlyornotatall.

Thedischargechuteeitherdoesnotlock

intoplaceordoesnotmove.

Themachinedoesnotproperlyclearthe

snowoffthesurface.

1.ThethrottleisnotintheFASTposition

whenthrowingsnow .

2.Themachineismovingtoofasttoclear

thesnow.

3.Y ouaretryingtoremovetoomuch

snowperswath.

4.Y ouaretryingtoremoveextremely

heavyorwetsnow.

5.Thedischargechuteisplugged.5.Unclogthedischargechute.

6.Theauger/impellerdrivebeltisloose

orisoffthepulley.

7.Theauger/impellerdrivebeltisworn

orbroken.

1.Thedischarge-chutelatchisnot

properlyadjusted.

1.Theskidsand/orscraperarenot

properlyadjusted.

2.Thepressureinthetiresisnotequal.

1.MovethethrottletotheFASTposition.

2.Shiftthemachineintoalowergear.

3.Reducetheamountofsnowremoved

perswath.

4.Donotoverloadthemachinewith

extremelyheavyorwetsnow.

6.Installand/oradjusttheauger/impeller

drivebelt;refertowww.Toro.com

forservicinginformationortakethe

machinetoanAuthorizedService

Dealer.

7.Replacetheauger/impellerdrivebelt;

refertowww.Toro.comforservicing

informationortakethemachinetoan

AuthorizedServiceDealer.

1.Adjustthedischarge-chutelatch.

1.Adjusttheskidsand/orthescraper.

2.Checkandadjustthepressurein1or

bothtires.

26

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer ,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually ,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproducts.Additionally,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerswithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.Toroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalsprovideexposurelimitrequirements.WhiletheexposurefromT oroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover,ifT orodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

Loading...

Loading...