Toro Power Max 1128 OXE 38828, 38828 Power Max HD 1128 OXE Operator's Manual

FormNo.3373-868RevB

PowerMaxHeavyDuty1128OXESnowthrower

ModelNo.38828—SerialNo.313000001andUp

Operator'sManual

Introduction

Thismachineisintendedtobeusedbyresidential

homeownersorprofessional,hiredoperators.Itis

designedprimarilyforremovingsnowfrompaved

surfaces,suchasdrivewaysandsidewalks,andother

surfacesfortrafconresidentialorcommercial

properties.Itisnotdesignedforremovingmaterials

otherthansnow,norisamodelwithapivotingscraper

designedforclearingoffgravelsurfaces.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourmachineproperlyandtoavoidinjuryand

machinedamage.Youareresponsibleforoperatingthe

machineproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comformachine

andaccessoryinformation,helpndingadealer,ortoregister

yourmachine.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourmachineready.Figure1identiesthelocationofthe

modelandserialnumbersonthemachine.Writethenumbers

inthespaceprovided.

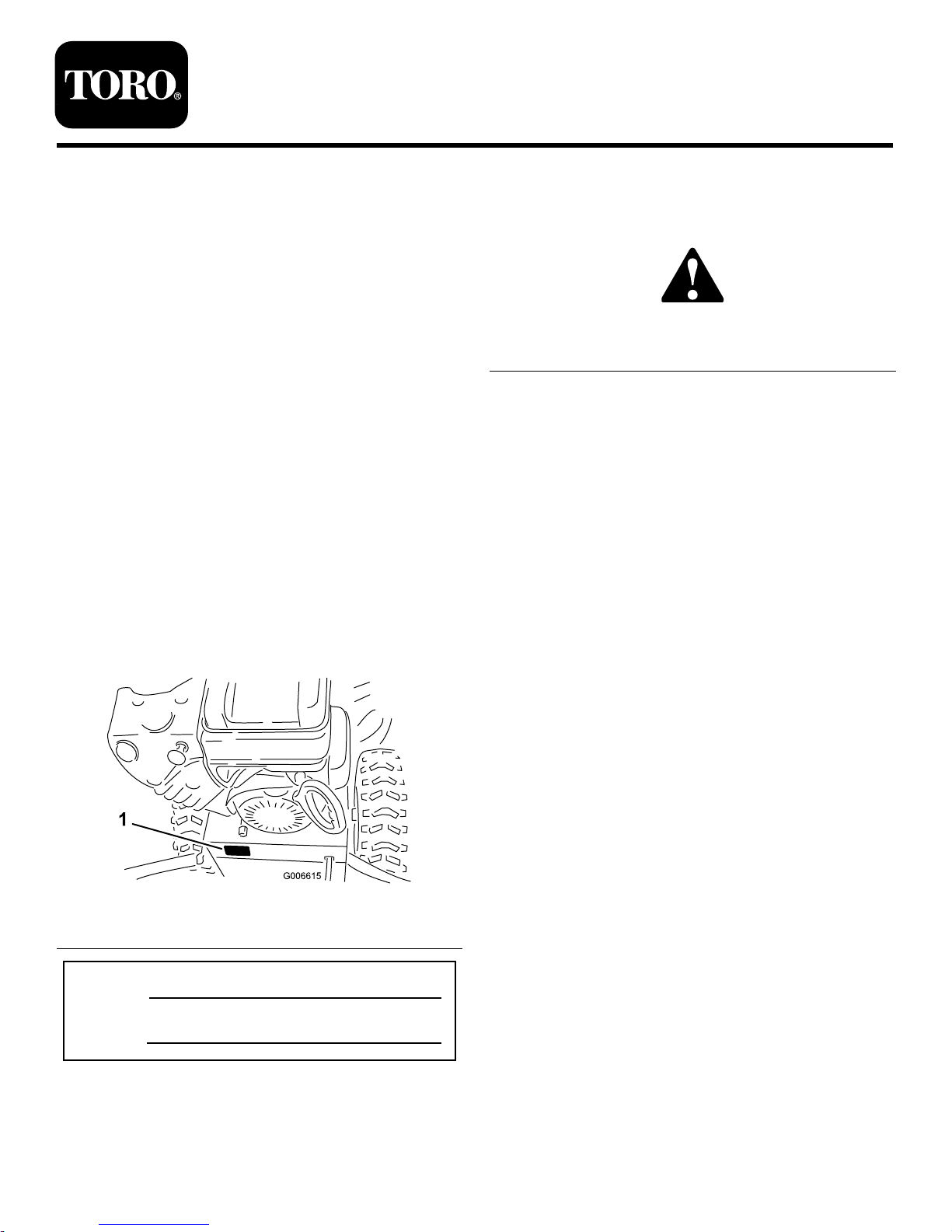

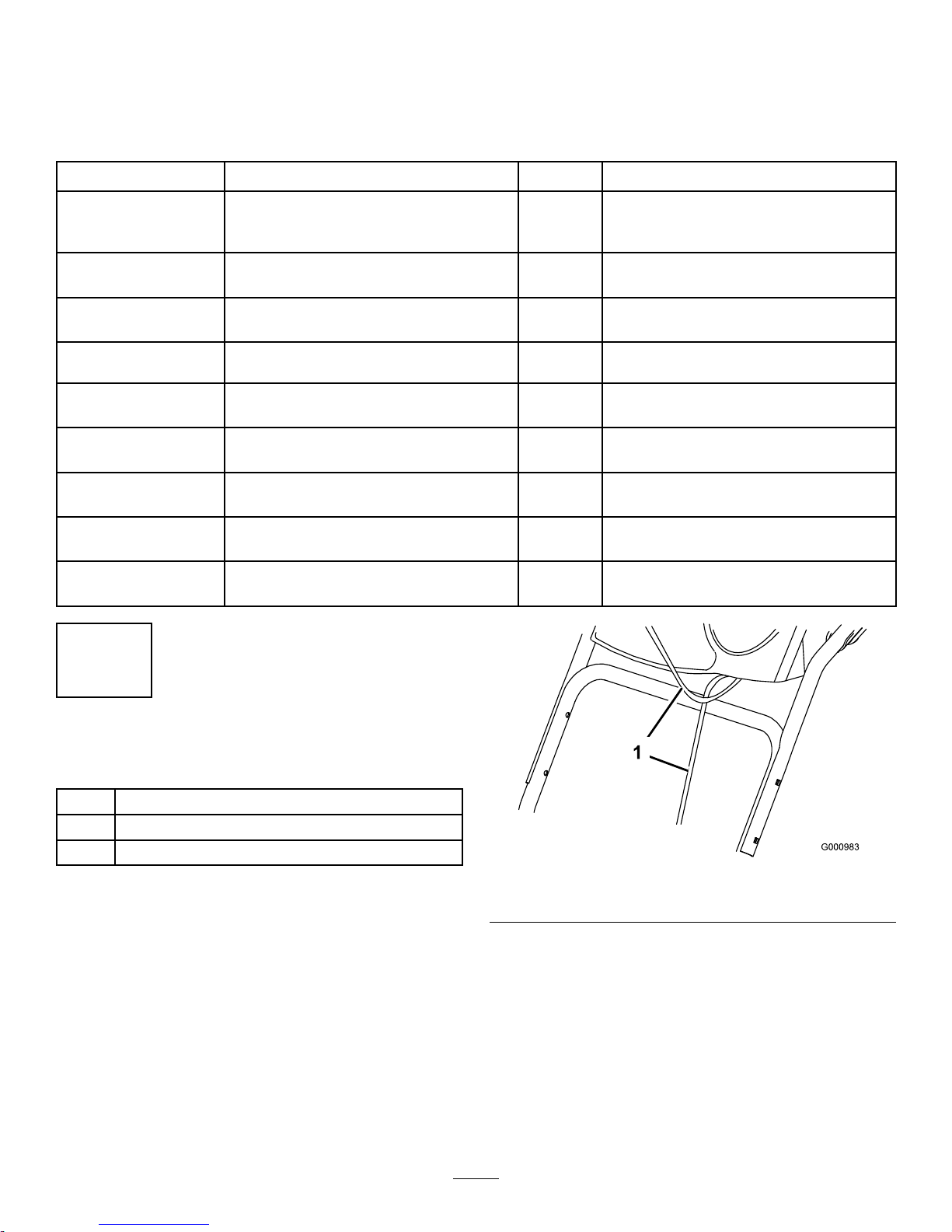

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

ReplacementEngineOwner’sManualsmaybeordered

throughtheenginemanufacturer.

Contents

Introduction..................................................................1

Training.................................................................3

Preparation.............................................................3

Operation...............................................................3

MaintenanceandStorage..........................................4

ToroSnowthrowerSafety.........................................4

SoundPressure.......................................................4

SoundPower..........................................................4

Vibration................................................................4

SafetyandInstructionalDecals.................................4

Setup............................................................................7

1InstallingtheUpperHandle....................................7

2InstallingtheWheelClutchCableEnds....................8

3InstallingtheTractionControlLinkage....................9

4InstallingtheChuteControlRod............................10

5ConnectingtheWiretotheHeadlight......................11

6FillingtheEnginewithOil.....................................11

7CheckingtheTirePressure....................................12

8CheckingtheSkids...............................................12

9CheckingtheTractionDriveOperation...................12

ProductOverview.........................................................13

Operation....................................................................14

FillingtheFuelTank...............................................14

StartingtheEngine.................................................14

StoppingtheEngine...............................................16

OperatingtheTractionDrive...................................16

UsingtheWheelClutchLevers.................................17

OperatingtheSpeedSelector...................................17

OperatingtheAuger/ImpellerDrive.........................17

©2012—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3373-868*B

OperatingtheQuickStick®......................................17

UncloggingtheDischargeChute..............................18

PreventingFreeze-up..............................................18

OperatingTips......................................................19

Maintenance.................................................................20

RecommendedMaintenanceSchedule(s)......................20

PreparingforMaintenance.......................................21

CheckingtheEngineOilLevel.................................21

CheckingandAdjustingtheSkids.............................21

CheckingandAdjustingtheTractionCable................21

CheckingtheAugerGearboxOilLevel......................22

ChangingtheEngineOil.........................................22

AdjustingtheDischargeChuteLatch........................23

ReplacingtheDriveBelts.........................................24

ReplacingtheHeadlightBulb...................................24

Storage........................................................................25

PreparingtheMachineforStorage............................25

RemovingtheMachinefromStorage.........................25

Troubleshooting...........................................................26

2

Safety

ThismachinemeetsorexceedstheISOstandard8437

ineffectatthetimeofproduction.

Readandunderstandthecontentsofthismanualbefore

theengineiseverstarted.

Thisisthesafetyalertsymbol.Itisusedtoalertyou

topotentialpersonalinjuryhazards.Obeyallsafety

messagesthatfollowthissymboltoavoidpossibleinjury

ordeath.

Improperlyusingormaintainingthismachinecould

resultininjuryordeath.Toreducethispotential,

complywiththefollowingsafetyinstructions.

Training

•Readtheoperatingandserviceinstructionmanual

carefully.Bethoroughlyfamiliarwiththecontrolsand

theproperuseofthemachine.Knowhowtostopthe

machineanddisengagethecontrolsquickly.

•Neverallowchildrentooperatethemachine.Neverallow

adultstooperatethemachinewithoutproperinstruction.

•Keeptheareaofoperationclearofallpersons,particularly

smallchildren,andpets.

•Exercisecautiontoavoidslippingorfalling,especially

whenoperatinginreverse.

Preparation

•Thoroughlyinspecttheareawherethemachineistobe

usedandremovealldoormats,sleds,boards,wires,and

otherforeignobjects.

•Disengageallclutchesandshiftintoneutralbefore

startingtheengine.

•Donotoperatethemachinewithoutwearingadequate

wintergarments.Wearfootwearwhichwillimprove

footingonslipperysurfaces.

•Handlefuelwithcare;itishighlyammable.

–Useanapprovedfuelcontainer.

–Neveraddfueltoarunningorhotengine.

–Fillfueltankoutdoorswithextremecare.Neverll

fueltankindoors.

–Replacegasolinecapssecurelyandwipeupspilled

fuel.

•Adjustthecollectorhousingheighttocleargravelor

crushedrocksurface.

•Neverattempttomakeanyadjustmentswhiletheengine

isrunning(exceptwherespecicallyrecommendedby

manufacturer).

•Letengineandmachineadjusttooutdoortemperatures

beforestartingtoclearsnow.

•Theoperationofanypoweredmachinecanresultin

foreignobjectsbeingthrownintotheeyes.Alwayswear

safetyglassesoreyeshieldsduringoperationorwhile

performinganadjustmentorrepair.

Operation

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Exerciseextremecautionwhenoperatingonorcrossing

graveldrives,walks,orroads.Stayalertforhidden

hazardsortrafc.

•Afterstrikingaforeignobject,stoptheengine,remove

thewirefromthespark-plug,thoroughlyinspectthe

machineforanydamage,andrepairthedamagebefore

restartingandoperatingthemachine.

•Ifthemachineshouldstarttovibrateabnormally,stopthe

engineandcheckimmediatelyforthecause.Vibrationis

generallyawarningoftrouble.

•Stoptheenginewheneveryouleavetheoperating

position,beforeuncloggingthecollector/impeller

housingordischargeguide,andwhenmakinganyrepairs,

adjustments,orinspections.

•Whencleaning,repairing,orinspecting,makecertainthe

collector/impellerandallmovingpartshavestopped.

Disconnectthespark-plugwire,andkeepthewireaway

fromtheplugtopreventaccidentalstarting.

•Donotruntheengineindoors,exceptwhenstartingit

andformovingthemachineinoroutofthebuilding.

Opentheoutsidedoors;exhaustfumesaredangerous.

•Donotclearsnowacrossthefaceofslopes.Exercise

extremecautionwhenchangingdirectiononslopes.Do

notattempttoclearsteepslopes.

•Neveroperatethemachinewithoutproperguards,plates,

orothersafetyprotectivedevicesinplace.

•Neveroperatethemachinenearglassenclosures,

automobiles,windowwells,drop-offs,etc.withoutproper

adjustmentofthesnowdischargeangle.Keepchildren

andpetsaway.

•Donotoverloadthemachinecapacitybyattemptingto

clearsnowattoofastarate.

•Neveroperatethemachineathightransportspeedson

slipperysurfaces.Usecarewhenreversing.

•Neverdirectdischargeatbystandersorallowanyonein

frontofthemachine.

•Disengagepowertothecollector/impellerwhenmachine

istransportedornotinuse.

•Useonlyattachmentsandaccessoriesapprovedby

themanufacturerofmachine(suchaswheelweights,

counterweights,cabs,etc.).

•Neveroperatethemachinewithoutgoodvisibilityor

light.Alwaysbesureofyourfooting,andkeeparm

holdonthehandles.W alk;neverrun.

3

•Neveroperatethemachinewithoutgoodvisibilityor

light.

•Takeallpossibleprecautionswhenleavingthemachine

unattended.Shiftintoneutral,settheparkingbrake,stop

theengineandremovethekey.

MaintenanceandStorage

•Checkallfastenersatfrequentintervalsforproper

tightnesstobesurethemachineisinsafeworking

condition.

•Neverstorethemachinewithfuelinthefueltankinsidea

buildingwhereignitionsourcesarepresentsuchashot

waterandspaceheaters,clothesdryers,etc.Allowthe

enginetocoolbeforestoringinanyenclosure.

•Alwaysrefertoowner’sguideinstructionsforimportant

detailsifthemachineistobestoredforanextended

period.

•Maintainorreplacesafetyandinstructionslabels,as

necessary.

•Runthemachineafewminutesafterthrowingsnowto

preventfreeze-upofthecollector/impeller.

ToroSnowthrowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknow .

•Rotatingrotorbladescaninjurengersorhands.

Staybehindthehandlesandawayfromthedischarge

openingwhileoperatingthemachine.Keepyourface,

hands,feet,andanyotherpartofyourbodyor

clothingawayfrommovingorrotatingparts.

•Beforeadjusting,cleaning,repairing,andinspectingthe

machine,andbeforeuncloggingthedischargechute,stop

theengine,removethekey,andwaitforallmoving

partstostop.

•Usethesnowcleanouttool,notyourhands,toremove

obstructionsfromthedischargechute.

•Beforeleavingtheoperatingposition,stoptheengine,

removethekey,andwaitforallmovingpartstostop.

•Donotwearloose-ttingclothingthatcouldgetcaught

inmovingparts.

•Ifashield,safetydevice,ordecalisdamaged,illegible,or

lost,repairorreplaceitbeforebeginningoperation.Also,

tightenanyloosefasteners.

•Donotsmokewhilehandlinggasoline.

•Donotusethemachineonaroof.

•Donottouchtheenginewhileitisrunningorsoonafter

ithasstoppedbecausetheenginemaybehotenoughto

causeaburn.

•Performonlythosemaintenanceinstructionsdescribedin

thismanual.Beforeperforminganymaintenance,service,

oradjustment,stoptheengine,removethekey,and

disconnectthewirefromthesparkplug.Ifmajorrepairs

areeverneeded,contactanAuthorizedServiceDealer.

•Donotchangethegovernorsettingsontheengine.

•Whenstoringthemachineformorethan30days,drain

thefuelfromthefueltanktopreventapotentialhazard.

Storefuelinanapprovedfuelcontainer.Removethekey

fromtheignitionswitchbeforestoringthemachine.

•PurchaseonlygenuineTororeplacementpartsand

accessories.

SoundPressure

Thismachinehasasoundpressurelevelattheoperator’sear

of91dBA,whichincludesanUncertaintyValue(K)of1

dBA.Thesoundpressurelevelwasdeterminedaccordingto

theproceduresoutlinedinENISO11201.

SoundPower

Thismachinehasaguaranteedsoundpowerlevelof105

dBA,whichincludesanUncertaintyValue(K)of2dBA.

Thesoundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO3744.

Vibration

Measuredvibrationlevelforthelefthand=7.1m/s

2

.

Measuredvibrationlevelfortherighthand=5.5m/s

2

.

UncertaintyValue(K)=2.8m/s

2

.

Themeasuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO20643.

SafetyandInstructional

Decals

Important:Safetyandinstructiondecalsarelocated

nearareasofpotentialdanger.Replacedamageddecals.

4

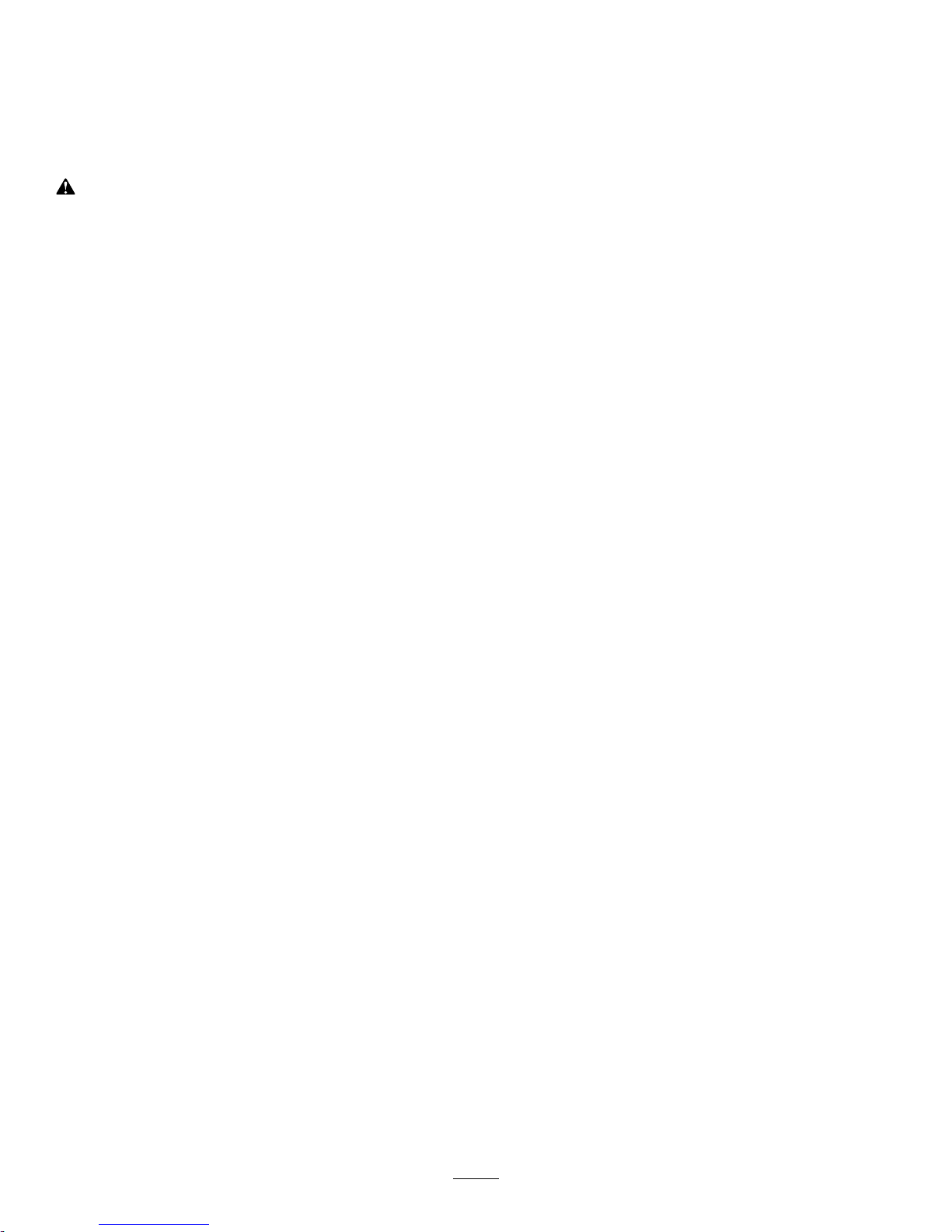

106-4525

Reorderpartno.112-6633

1.Fast

3.Slow

2.Forwardspeeds4.Reversespeeds

107-3040

1.Cuttingdismemberment,impellerandcutting

dismemberment,augerhazards—keepbystandersasafe

distancefromthemachine.

112-6625

Reorderpartno.112-6629

1.Cutting/dismembermenthazard,impeller—donotplace

yourhandinthechute;stoptheenginebeforeleavingthe

operator'sposition,usethetooltoclearthechute.

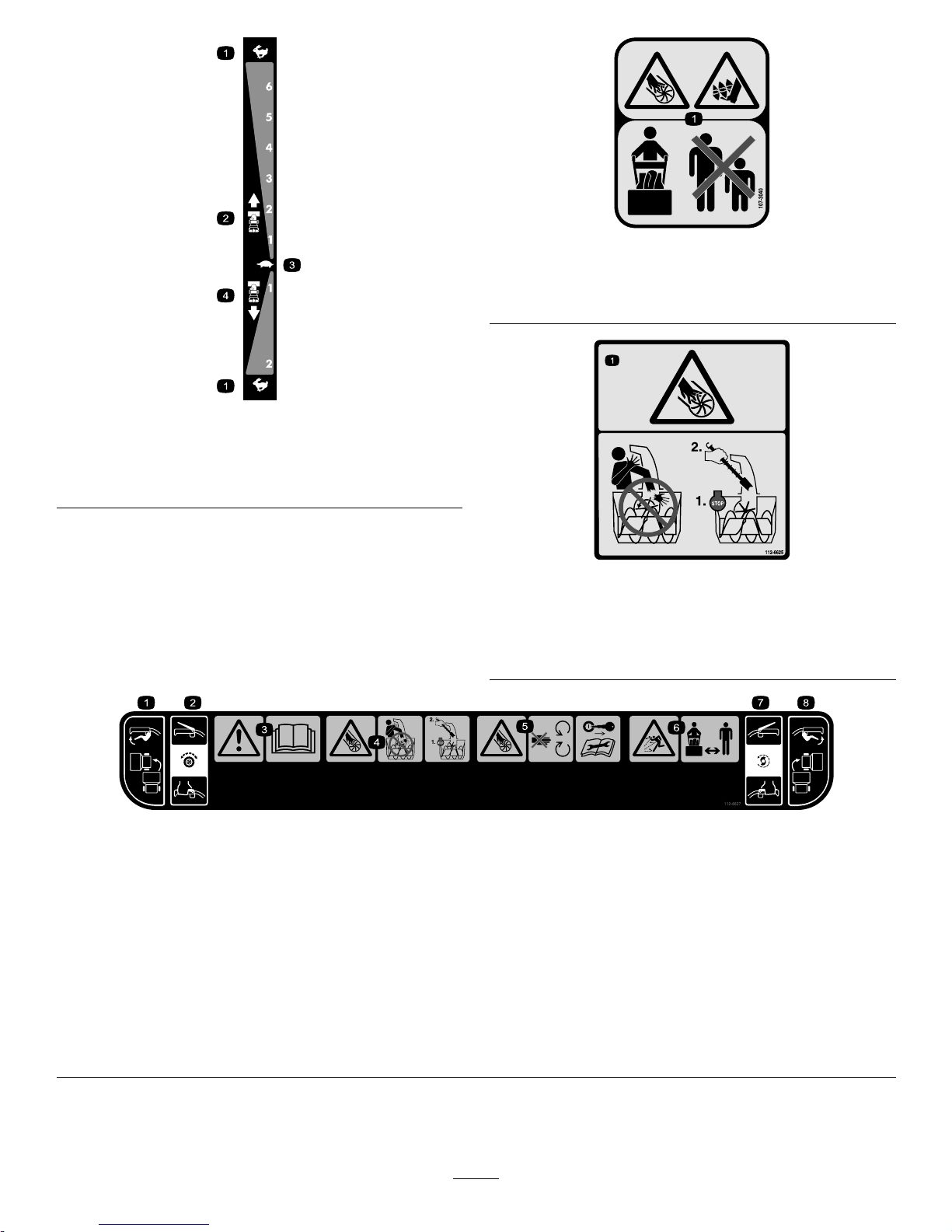

112-6627

1.Leftturncontrol

3.Warning—readthe

Operator'sManual.

5.Cutting/dismemberment

hazard,impeller—keep

awayfrommovingparts;

removetheignitionkeyand

readtheinstructionsbefore

servicingorperforming

maintenance.

7.Auger/impeller

drive—squeezetheleverto

engage;releasethelever

todisengage.

2.Tractiondrive—squeeze

thelevertoengage;release

thelevertodisengage.

4.Cutting/dismemberment

hazard,impeller—do

notplaceyourhand

inthechute;stopthe

enginebeforeleavingthe

operator'sposition,usethe

tooltoclearthechute.

6.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

8.Rightturncontrol

5

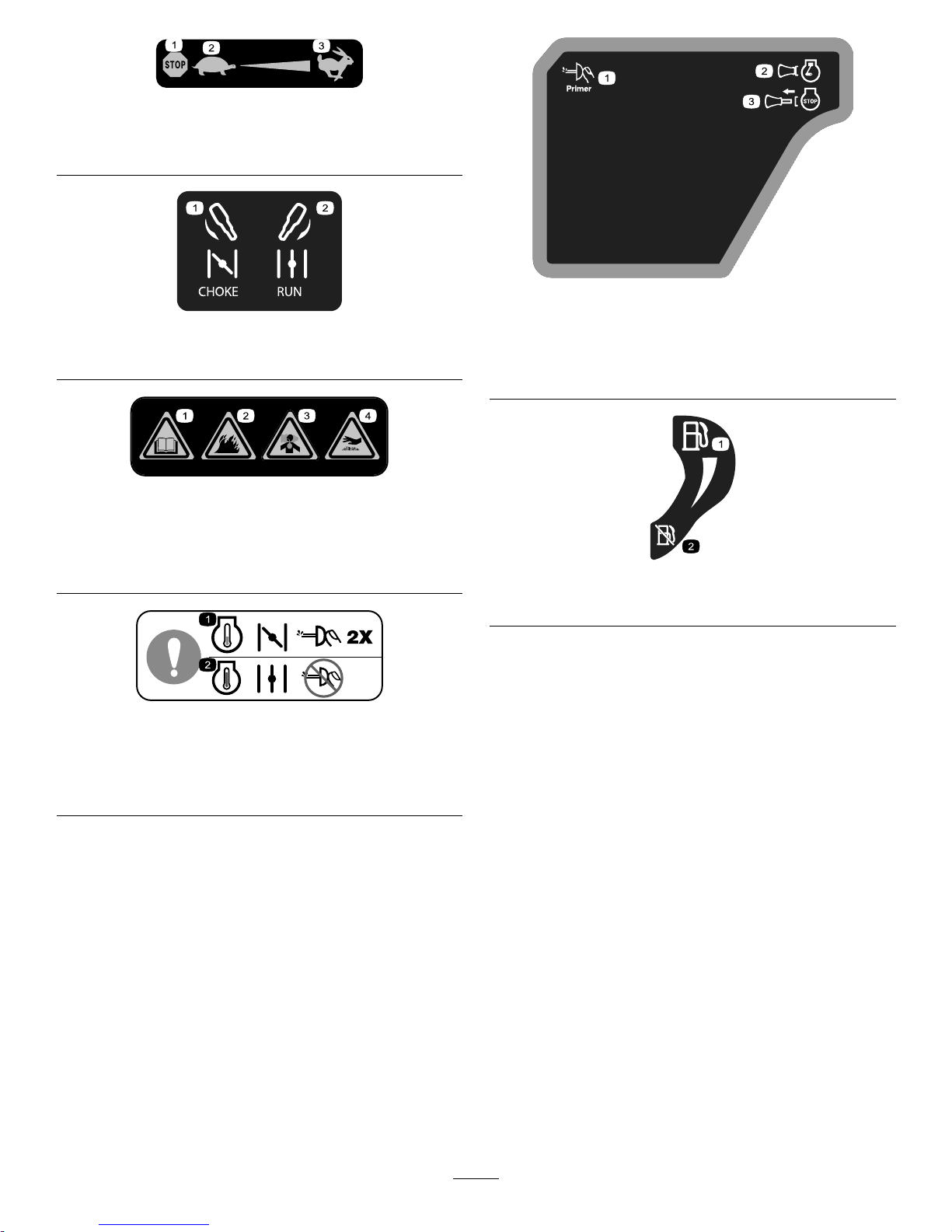

Briggs&StrattonPartNo.273676

1.Stop

3.Fast

2.Slow

Briggs&StrattonPartNo.275949

1.Chokeon(Choke)2.Chokeoff(Run)

Briggs&StrattonPartNo.276925

1.Warning—readthe

Operator'sManual.

3.Warning—toxicgas

inhalationhazard.

2.Warning—rehazard.

4.Warning—hot

surface/burnhazard.

Briggs&StrattonPartNo.277566

1.Whenstartingacold

engine,closethechoke

andpresstheprimertwo

times.

2.Whenstartingawarm

engine,openthechoke

anddonotpressthe

primer.

Briggs&StrattonPartNo.277588

1.Primer3.Ignitionkeyout

(Engine—Stop)

2.Ignitionkeyin

(Engine—Run)

Briggs&StrattonPartNo.278866

1.Fuel—On2.Fuel—Off

6

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Qty.

Use

Handlebolts4

Curvedwashers

4

1

Locknuts4

Installtheupperhandle.

2

Nopartsrequired

–

Installthewheelclutchcableends

3

Nopartsrequired

–

Installthetractioncontrollinkage.

Carriagebolts

2

4

Locknuts2

Installthechutecontrolrod.

5

Cabletie

1

Connectthewiretotheheadlight.

6

Nopartsrequired

–

Filltheenginewithoil.

7

Nopartsrequired

–

Checkthetirepressure.

8

Nopartsrequired

–

Checktheskids.

9

Nopartsrequired

–

Checktheoperationofthetractiondrive.

1

InstallingtheUpperHandle

Partsneededforthisprocedure:

4Handlebolts

4

Curvedwashers

4Locknuts

Procedure

Note:Donotremovetherubberbandonthecablesuntil

youhaveinstalledtheupperhandle.

1.Liftandrotatetheupperhandleandpositionitover

thelowerhandle(

Figure3).

Important:Routethecablesattachedtothe

QuickStickinsidetheupperhandlelegsand

ensurethatthecablesandthewireforthe

headlightarenotpinchedbetweenthehandle

sections.

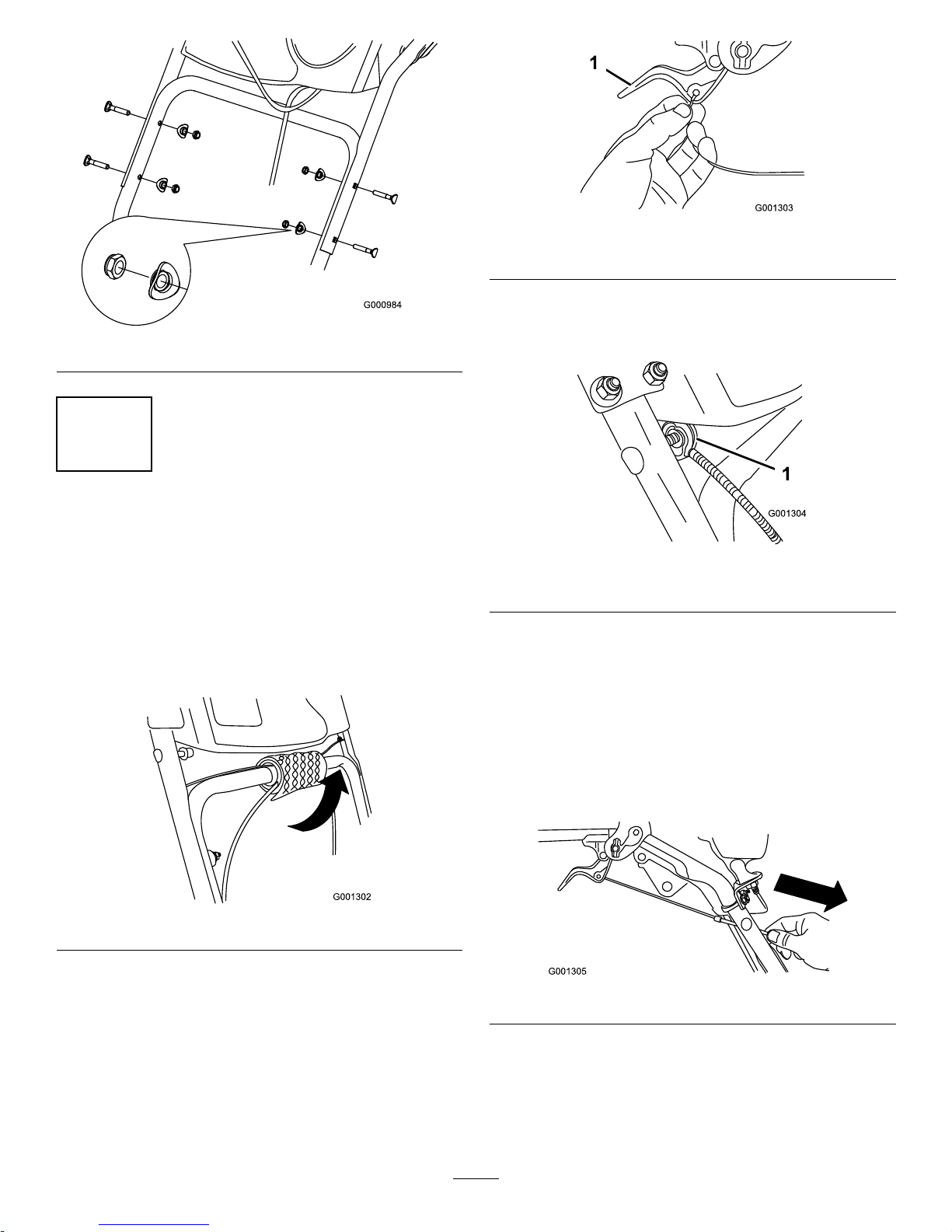

Figure3

1.Cables

2.Securetheupperhandlewith4handlebolts,4curved

washers,and4locknutsfromtheloosepartsbag

(Figure4).

7

Figure4

2

InstallingtheWheelClutch

CableEnds

NoPartsRequired

Procedure

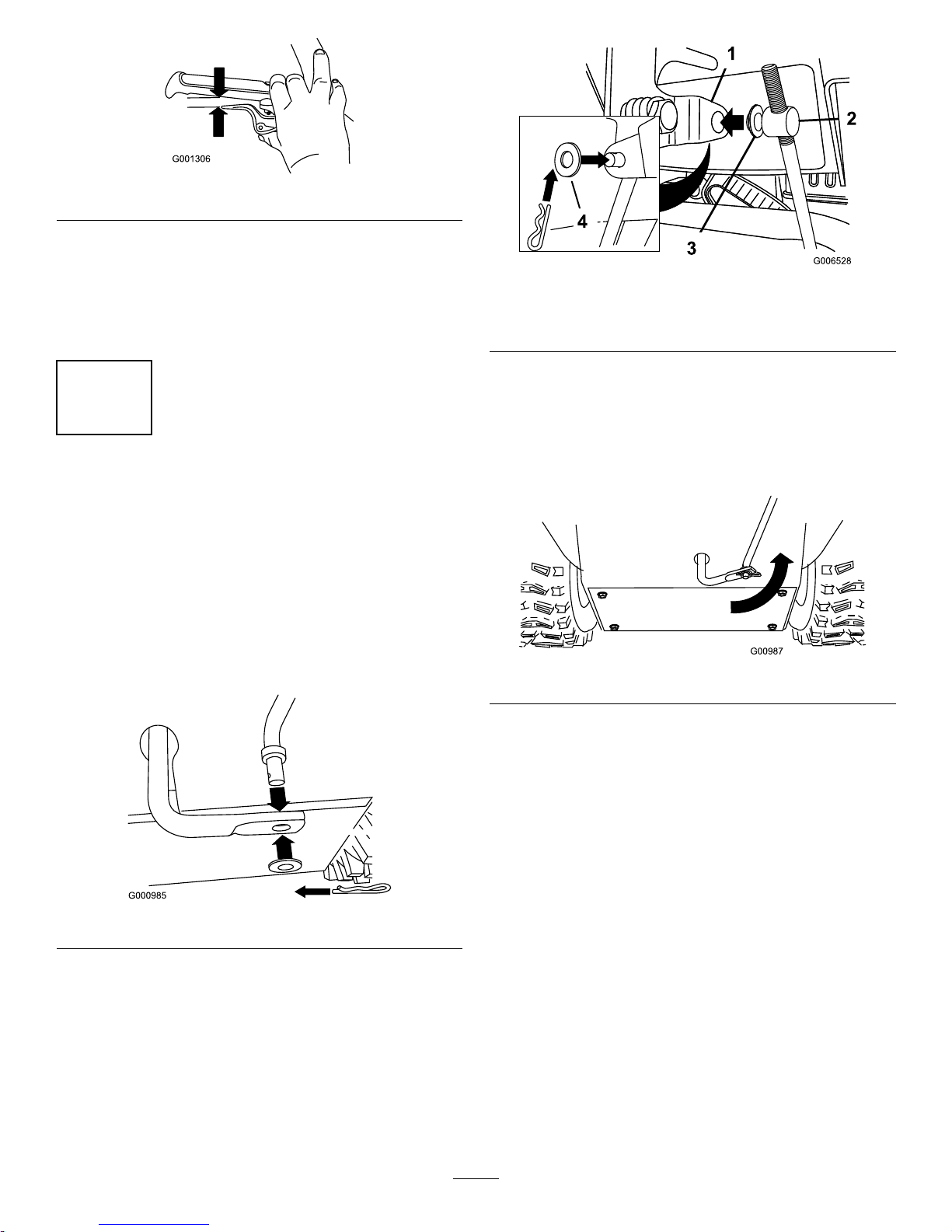

1.Unwrapthecableendsfromthelowerhandle

(Figure5).

Figure5

2.Routeeithertheleftorrightcableendoverthelower

handleandinsertthecableendintotheholeinthe

correspondingwheelclutchlever(Figure6).

Figure6

1.Wheelclutchlever

3.Removethenutandwasherfromthehandle,attach

thecableclamponthecabletothehandle,installthe

washerandthenut,andhandtightenthenut(Figure7).

Figure7

1.Cableclamp(2)

Important:Ensurethatthecurvedsideofthe

cableclampisagainstthehandleandthatthe

cableisroutedbelowtheclampbolt.Thecable

mustbeinastraightlinefromthecableclamp

tothepointwhereitattachestothewheelclutch

lever.

4.Pullthecablejacketdowngentlyuntilthewheelclutch

leverisdownandtheslackisoutofthecable,then

tightenthecableclampnutsecurely(Figure8).

Figure8

5.Squeezetheleverfully,thencheckthegapbetween

thebottomofthehandleandthewheelclutchlever

end(Figure9).

8

Figure9

Note:Thegapshouldbeapproximatelythethickness

ofapencil(1/4inchor6mm).Ifitisgreater,loosen

thecableclampnut,slidethecablejacketupslightly ,

tightenthecableclampnut,andcheckthegapagain.

6.Repeatsteps2through5fortheothercable.

3

InstallingtheTractionControl

Linkage

NoPartsRequired

Procedure

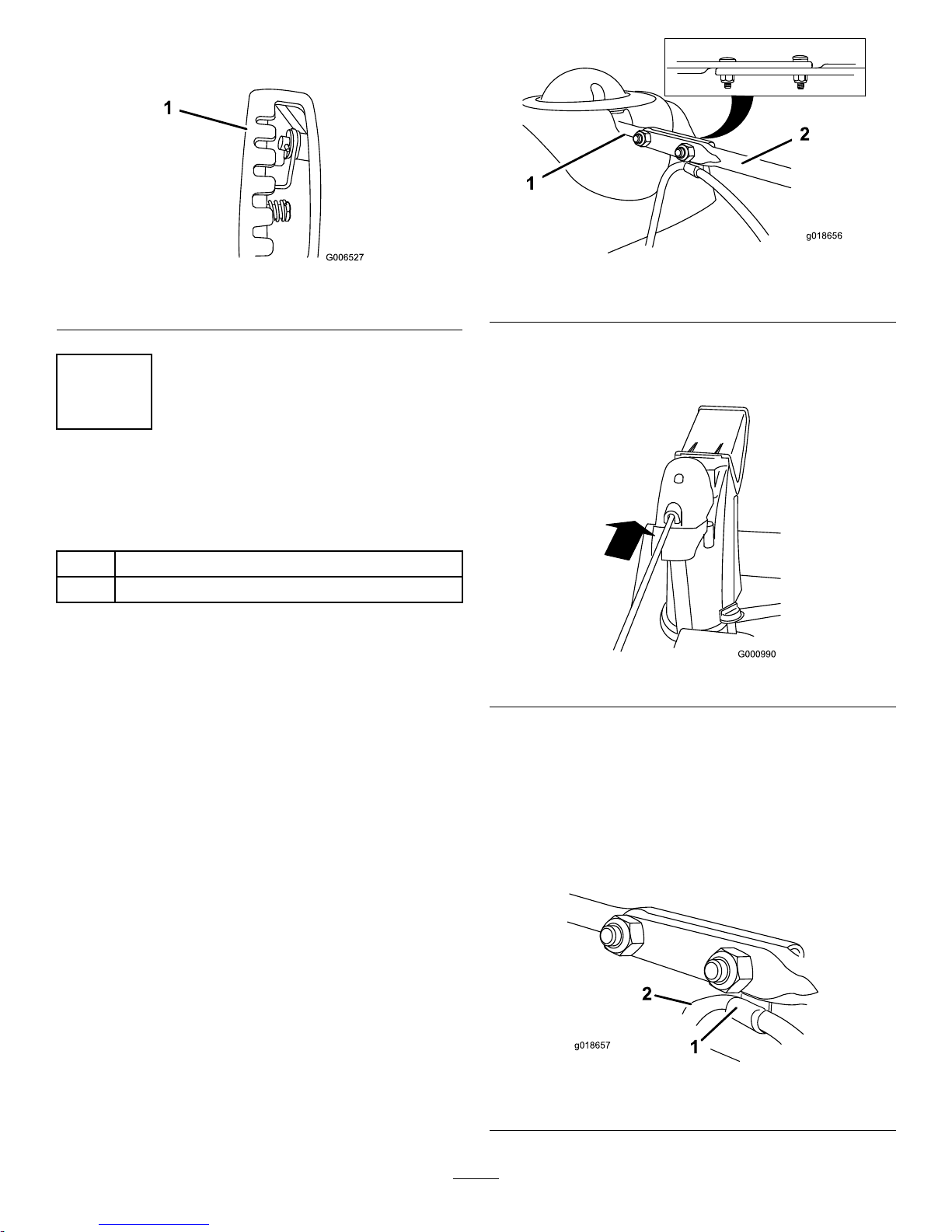

1.Removethehairpincotterandwasherfromthelower

endofthespeedcontrolrodandinsertthelowerend

oftherodintothelowerlinkarmsothatthebentend

ofthespeedcontrolrodfacesrearward(Figure10).

Figure10

2.Securethelowerendofthespeedcontrolrodwiththe

washerandhairpincotterthatyoupreviouslyremoved.

3.Removethehairpincotterandtheouterwasherfrom

thetrunnionontheupperendofthespeedcontrol

rod(Figure11).

Figure11

1.Speedselectorlever

3.Innerwasher

2.Trunnion

4.Outerwasher

Note:Tomakeinstallationeasier,leavetheatwasher

onthetrunnion(Figure11).

4.ShiftthespeedselectorleverintoPositionR2.

5.Rotatethelowerlinkarmfullyupward

(counterclockwise)(Figure12).

Figure12

6.Liftuponthespeedcontrolrodandinsertthetrunnion

intotheholeinthespeedselectorlever(Figure11).

Note:Ifthetrunniondoesnottintothehole

whenyouliftuponthespeedcontrolrod,rotatethe

trunnionupwardordownwardonthespeedcontrol

roduntilitts.

7.Securethetrunnionandupperendofthespeedcontrol

rodwiththeouterwasherandahairpincotteryou

previouslyremoved.

9

Note:Foreasierinstallation,lookdownthroughthe

openinginthespeedselector(Figure13).

Figure13

1.Speedselector

4

InstallingtheChuteControl

Rod

Partsneededforthisprocedure:

2

Carriagebolts

2Locknuts

Procedure

1.UnwraptheQuickStickandrotateitsothatitis

uprightandinthecenter.

2.Holdthebluetriggercapdownandpulltheleverfully

rearward.

Note:Thedischargechuteanddeectorshouldface

forward.Iftheydonot,holdthebluetriggercap

down(butdonotmovetheQuickStick)androtatethe

dischargechuteuntiltheydo.

3.Aligntheattenedbackendofthelongchutecontrol

rodwiththeattenedfrontendoftheshortrod

thatextendsfromthecontrolpanelsothattheynest

together(Figure14).

g018656

Figure14

1.Shortrod

2.Longchutecontrolrod

4.Insertthefrontendoftherodintotheopeningin

thebackofthechutegearcoveruntilitslidesintothe

chutegear(Figure15).

Figure15

5.Aligntheholesinthenestedendsoftherodsand

insert2carriagebolts(intheloosepartsbag)through

theshortrodfromtheleftsideofthemachine(from

theoperatingposition).

6.Insertthecableclipthatsupportsthedeectorcable

undertheheadoftheforwardcarriagebolt,andsecure

thecarriageboltswithlocknutsfromthelooseparts

bag(Figure16).

g018657

Figure16

1.Cableclip2.Deectorcable

10

Loading...

Loading...