Page 1

722EPowerThrow

ModelNo.38818—SerialNo.313000001andUp

®

Snowthrower

FormNo.3373-842RevA

Operator'sManual

Introduction

Thismachineisintendedtobeusedbyresidential

homeownersorprofessional,hiredoperators.Itis

designedprimarilyforremovingsnowfrompaved

surfaces,suchasdrivewaysandsidewalks,andother

surfacesfortrafconresidentialorcommercial

properties.Itisnotdesignedforremovingmaterials

otherthansnow,norisitdesignedforclearingoffgravel

surfaces.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourmachineproperlyandtoavoidinjuryand

machinedamage.Youareresponsibleforoperatingthe

machineproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comformachine

andaccessoryinformation,helpndingadealer,ortoregister

yourmachine.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourmachineready.Figure1identiesthelocationofthe

modelandserialnumbersonthemachine.Writethenumbers

inthespaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

ReplacementEngineOwner'sManualsmaybeordered

throughtheenginemanufacturer.

Contents

Introduction..................................................................1

Training.................................................................3

Preparation.............................................................3

Operation...............................................................3

ClearingaCloggedDischargeChute..........................4

MaintenanceandStorage..........................................4

ToroSnowthrowerSafety.........................................4

SoundPressure.......................................................5

SoundPower..........................................................5

Vibration................................................................5

SafetyandInstructionalDecals.................................6

Setup............................................................................8

1InstallingtheHandle.............................................9

2InstallingtheSpeedSelectorRod............................10

3InstallingtheTractionRod....................................10

4InstallingtheAuger/ImpellerDriveControl

Linkage.............................................................11

5InstallingtheChuteControlRod............................12

6FillingtheEnginewithOil.....................................13

7CheckingtheTirePressure....................................14

8CheckingtheSkidsandScraper..............................14

ProductOverview.........................................................14

Controls...............................................................15

Operation....................................................................15

FreewheelingorUsingtheSelf-propelDrive...............15

FillingtheFuelTank...............................................15

StartingtheEngine.................................................16

©2012—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3373-842*A

Page 2

StoppingtheEngine...............................................18

UncloggingtheDischargeChute..............................18

PreventingFreeze-up..............................................18

OperatingTips......................................................18

Maintenance.................................................................19

RecommendedMaintenanceSchedule(s)......................19

PreparingforMaintenance.......................................19

CheckingtheEngineOilLevel.................................19

AdjustingtheSkidsandScraper................................20

AdjustingtheSpeedSelector....................................20

CheckingtheAugerGearboxGrease.........................21

ChangingtheEngineOil.........................................21

ReplacingtheSparkPlug.........................................22

AdjustingtheTractionDriveBelt..............................23

ReplacingtheTractionDriveBelt.............................23

AdjustingtheAuger/ImpellerDriveBelt...................23

ReplacingtheAuger/ImpellerDriveBelt...................23

Storage........................................................................24

PreparingtheMachineforStorage............................24

RemovingtheMachinefromStorage.........................24

Troubleshooting...........................................................25

2

Page 3

Safety

ThismachinemeetsorexceedstheISO8437

specicationsoftheInternationalStandards

Organizationineffectatthetimeofproduction.

Readandunderstandthecontentsofthismanualbefore

youstarttheengine.

Thisisthesafetyalertsymbol.Itisusedtoalertyou

topotentialpersonalinjuryhazards.Obeyallsafety

messagesthatfollowthissymboltoavoidpossibleinjury

ordeath.

Improperlyusingormaintainingthismachinecould

resultininjuryordeath.Toreducethispotential,

complywiththefollowingsafetyinstructions.

isnotpossible,thenrefuelsuchmachineonatrailer

withaportablecontainer,ratherthanfromagasoline

dispensernozzle.

–Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimes,untilrefueling

iscomplete.Donotuseanozzlelock-opendevice.

–Replacegasolinecapsecurelyandwipeupspilledfuel.

–Iffuelisspilledonclothing,changeclothing

immediately.

•Useextensioncordsandreceptaclesasspeciedby

themanufacturerforallmachineswithelectricstarting

motors.

•Adjustthecollectorhousingheighttocleargravelor

crushedrocksurface.

Thismachineiscapableofamputatinghandsandfeetand

ofthrowingobjects.Failuretoobservethefollowingsafety

instructionscouldresultinseriousinjury.

Training

•Read,understandandfollowallinstructionsonthe

machineandinthemanual(s)beforeoperatingthis

machine.Bethoroughlyfamiliarwiththecontrolsand

theproperuseofthemachine.Knowhowtostopthe

machineanddisengagethecontrolsquickly.

•Neverallowchildrentooperatethemachine.Neverallow

adultstooperatethemachinewithoutproperinstruction.

•Keeptheareaofoperationclearofallpersons,particularly

smallchildren.

•Exercisecautiontoavoidslippingorfalling,especially

whenoperatingthemachineinreverse.

Preparation

•Thoroughlyinspecttheareawherethemachineistobe

usedandremovealldoormats,sleds,boards,wires,and

otherforeignobjects.

•Disengageallclutchesandshiftintoneutralbefore

startingtheengine.

•Donotoperatethemachinewithoutwearingadequate

wintergarments.Avoidloosettingclothingthatcanget

caughtinmovingparts.W earfootwearthatwillimprove

footingonslipperysurfaces.

•Handlefuelwithcare;itishighlyammable.

–Useanapprovedfuelcontainer.

–Neveraddfueltoarunningengineorhotengine.

–Fillfueltankoutdoorswithextremecare.Neverll

fueltankindoors.

–Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainers

ontheground,awayfromyourvehicle,beforelling.

–Whenpractical,removegas-poweredmachinefrom

thetruckortrailerandrefuelitontheground.Ifthis

•Neverattempttomakeanyadjustmentswhiletheengine

isrunning(exceptwhenspecicallyrecommendedby

manufacturer).

•Alwayswearsafetyglassesoreyeshieldsduringoperation

orwhileperforminganadjustmentorrepairtoprotect

eyesfromforeignobjectsthatmaybethrownfromthe

machine.

Operation

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Exerciseextremecautionwhenoperatingonorcrossing

graveldrives,walks,orroads.Stayalertforhidden

hazardsortrafc.

•Afterstrikingaforeignobject,stoptheengine,remove

thewirefromthesparkplug,thoroughlyinspectthe

machineforanydamage,andrepairthedamagebefore

restartingandoperatingthemachine.

•Ifthemachineshouldstarttovibrateabnormally,stopthe

engineandcheckimmediatelyforthecause.Vibrationis

generallyawarningoftrouble.

•Stoptheenginewheneveryouleavetheoperating

position,beforeuncloggingtheauger/impellerhousing

ordischargechute,andwhenmakinganyrepairs,

adjustmentsorinspections.

•Whencleaning,repairingorinspectingthemachine,stop

theengineandmakecertaintheauger/impellerandall

movingpartshavestopped.Disconnectthesparkplug

wireandkeepthewireawayfromtheplugtoprevent

someonefromaccidentallystartingtheengine.

•Donotruntheengineindoors,exceptwhenstarting

theengineandfortransportingthemachineinorout

ofthebuilding.Opentheoutsidedoors;exhaustfumes

aredangerous.

•Exerciseextremecautionwhenoperatingonslopes.

•Neveroperatethemachinewithoutproperguards,and

othersafetyprotectivedevicesinplaceandworking.

3

Page 4

•Neverdirectthedischargetowardpeopleorareaswhere

propertydamagecanoccur.Keepchildrenandothers

away.

•Donotoverloadthemachinecapacitybyattemptingto

clearsnowattoofastarate.

•Neveroperatethemachineathightransportspeeds

onslipperysurfaces.Lookbehindandusecarewhen

operatinginreverse.

•Disengagepowertotheauger/impellerwhenthemachine

istransportedornotinuse.

•Useonlyattachmentsandaccessoriesapprovedbythe

manufacturerofthemachine(suchaswheelweights,

counterweights,orcabs).

•Neveroperatethemachinewithoutgoodvisibilityor

light.Alwaysbesureofyourfooting,andkeeparm

holdonthehandles.Walk;neverrun.

MaintenanceandStorage

•Checkallfastenersatfrequentintervalsforproper

tightnesstobesurethemachineisinsafeworking

condition.

•Neverstorethemachinewithfuelinthefueltankinsidea

buildingwhereignitionsourcesarepresent,suchashot

waterheaters,spaceheaters,orclothesdryers.Allowthe

enginetocoolbeforestoringinanyenclosure.

•AlwaysrefertotheOperator’ sManualforimportantdetails

ifthemachineistobestoredforanextendedperiod.

•Maintainorreplacesafetyandinstructionlabels,as

necessary.

•Runthemachineafewminutesafterthrowingsnowto

preventfreeze-upoftheauger/impellerblades.

ToroSnowthrowerSafety

•Nevertouchahotengineormufer.

ClearingaCloggedDischarge Chute

WARNING

Handcontactwiththerotatingrotorbladesinside

thedischargechuteisthemostcommoncauseof

injuryassociatedwiththesetypesofmachines.

Neveruseyourhandtocleanoutthedischarge

chute.

Toclearthechute:

•Shuttheengineoff!

•Wait10secondstobesuretherotorbladeshavestopped

rotating.

•Alwaysuseacleanouttool,notyourhands.

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknow .

•Rotatingauger/impellercancutofforinjurengers

orhands.Staybehindthehandlesandawayfromthe

dischargeopeningwhileoperatingthemachine.Keep

yourface,hands,feet,andanyotherpartofyour

bodyorclothingawayfrommovingorrotatingparts.

•Beforeadjusting,cleaning,inspecting,troubleshooting,

orrepairingthemachine,stoptheengine,removethe

ignitionkey,andwaitforallmovingpartstostop.

Disconnectthewirefromthesparkplugandkeepit

awayfromthesparkplugtopreventsomeonefrom

accidentallystartingtheengine.

•Beforeleavingtheoperatingposition,stoptheengine,

removetheignitionkey,andwaitforallmovingpartsto

stop.

•Tounclogthedischargechute,stayintheoperating

positionandreleasethelefthand(traction)lever.While

runningtheauger/impeller,pushdownonthehandlesto

raisethefrontofthemachineafewinches(centimeters)

offthepavement.Thenliftthehandlesquicklytobump

thefrontofthemachineonthepavement.Repeatif

necessaryuntilastreamofsnowcomesoutthedischarge

chute.

•Ifyoucannotunclogthedischargechutebybumping

thefrontofthemachine,stoptheengine,waitforall

movingpartstostop,andusetheclean-outtool;

neveruseyourhand.

•Ifashield,safetydevice,ordecalisdamaged,illegible,or

lost,repairorreplaceitbeforebeginningoperation.

•Donotsmokewhilehandlinggasoline.

•Donotusethemachineonaroof.

•Donottouchtheenginewhileitisrunningorsoonafter

ithasstoppedbecausetheenginemaybehotenoughto

causeaburn.

•Performonlythosemaintenanceinstructionsdescribedin

thismanual.Beforeperforminganymaintenance,service,

4

Page 5

oradjustment,stoptheengine,removetheignitionkey,

anddisconnectthewirefromthesparkplug.Ifmajor

repairsareeverneeded,contactanAuthorizedService

Dealer.

•Donotchangethegovernorsettingsontheengine.

•Whenstoringthemachineformorethan30days,drain

thefuelfromthefueltanktopreventapotentialhazard.

Storefuelinanapprovedfuelcontainer.Removethekey

fromtheignitionswitchbeforestoringthemachine.

•PurchaseonlygenuineTororeplacementpartsand

accessories.

SoundPressure

Thismachinehasasoundpressurelevelattheoperator'sear

of90dBA,whichincludesanUncertaintyValue(K)of1

dBA.Thesoundpressurelevelwasdeterminedaccordingto

theproceduresoutlinedinENISO11201.

SoundPower

Thismachinehasaguaranteedsoundpowerlevelof107

dBA,whichincludesanUncertaintyValue(K)of3.75dBA.

Thesoundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO3744.

Vibration

Measuredvibrationlevelforthelefthand=6.0m/s

Measuredvibrationlevelfortherighthand=3.3m/s

UncertaintyValue(K)=2.4m/s

Themeasuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO20643.

2

.

2

.

2

.

5

Page 6

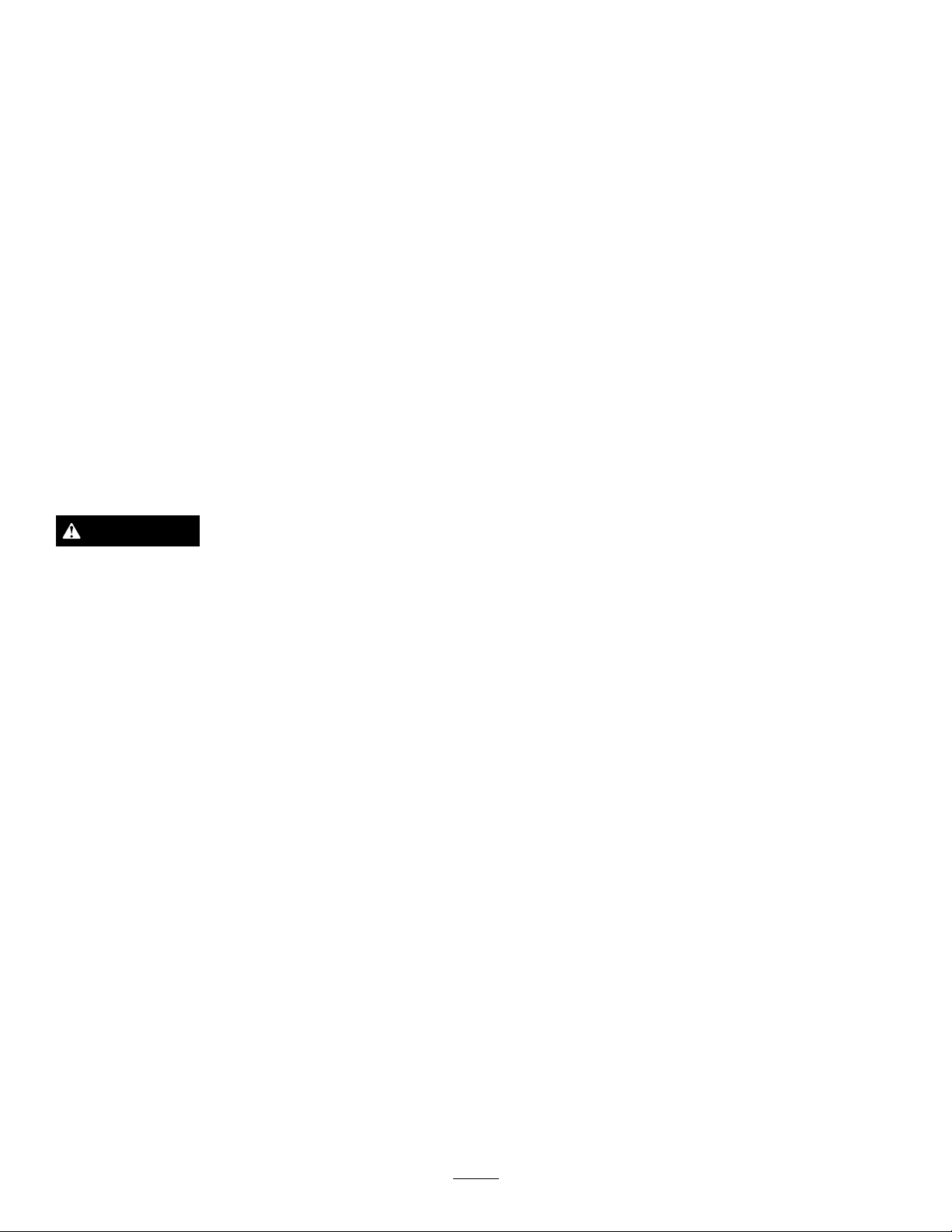

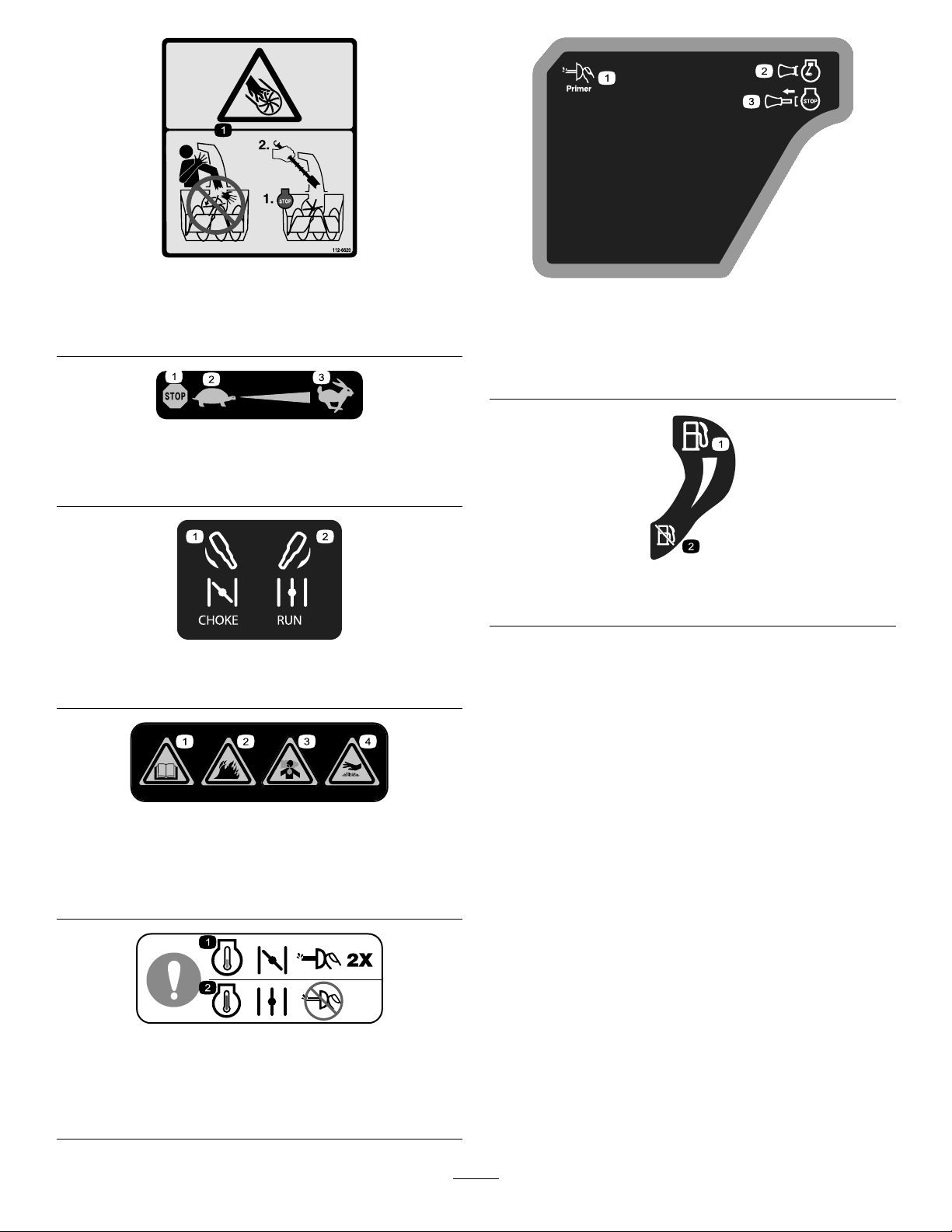

SafetyandInstructionalDecals

Important:Safetyandinstructiondecalsarelocatednearareasofpotentialdanger.Replacedamageddecals.

112-6624

1.Wheeldrive3.Disengage5.Thrownobject

2.Engage4.Warning—readthe

Operator'sManual.

hazard—keepbystanders

asafedistancefromthe

snowthrower.

6.Cutting/dismemberment

hazard,impellerand

auger—stayawayfrom

movingparts,keepall

guardsandshieldsinplace;

removetheignitionkeyand

readtheinstructionsbefore

servicingorperforming

maintenance.

7.Cutting/dismemberment

hazard,impeller—stop

theengineandwaitforall

movingpartstostopbefore

leavingtheoperator's

position.

8.Auger

1.Forwarddrivespeedsettings

2.Speedselector

119-1586

3.Reversedrivespeedsetting

6

Page 7

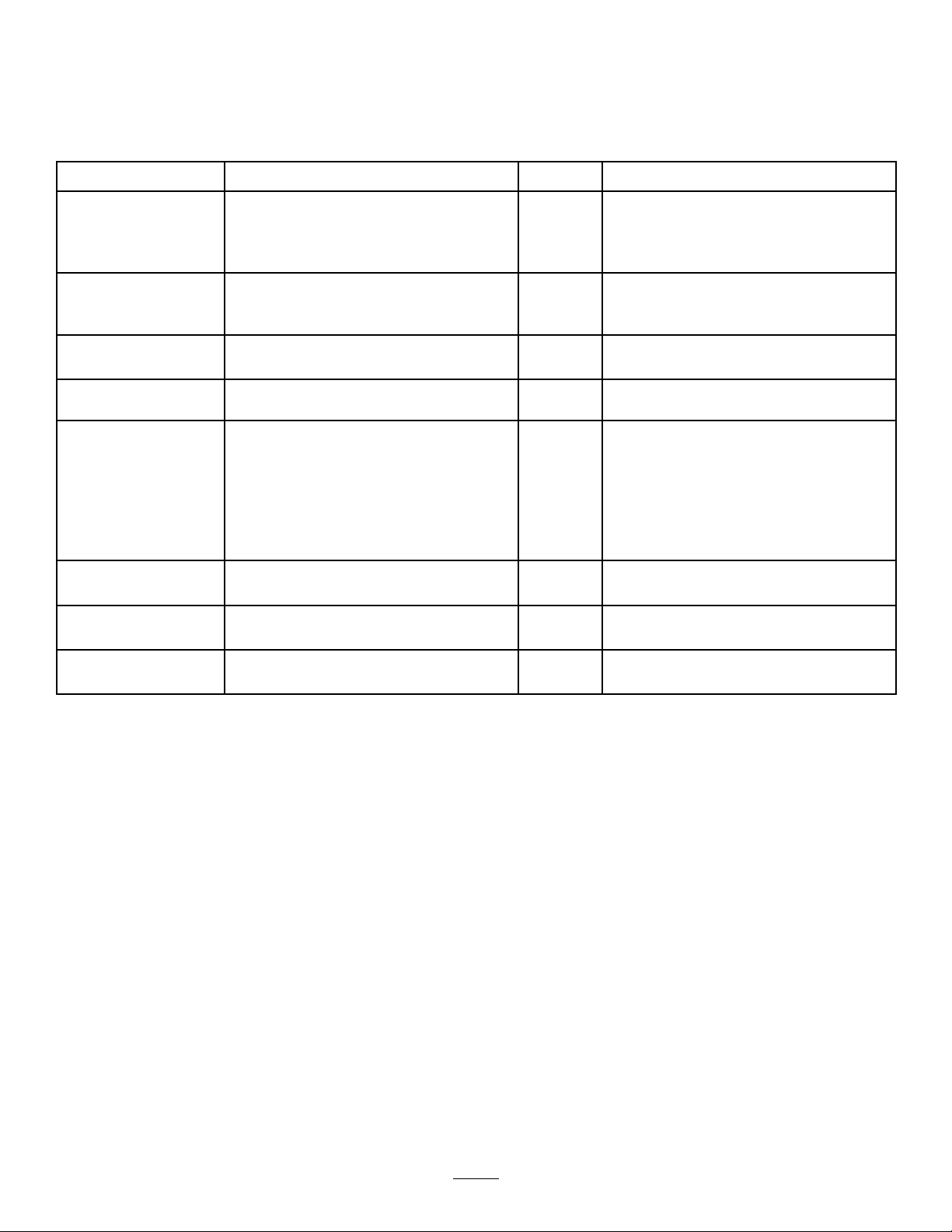

112-6620

1.Cutting/dismembermenthazard,impeller—donotplace

yourhandinthechute;stoptheenginebeforeleavingthe

operator'sposition,usethetoolclearthechute.

BriggsPartNo.273676

Briggs&StrattonPartNo.277588

1.Primer3.Ignitionkeyout

(Engine—Stop)

2.Ignitionkeyin

(Engine—Run)

1.Stop

2.Slow

3.Fast

Briggs&StrattonPartNo.275949

1.Chokeon(Choke)2.Chokeoff(Run)

BriggsPartNo.276925

1.Warning—readthe

Operator'sManual.

2.Warning—rehazard.

3.Warning—toxicgas

inhalationhazard.

4.Warning—hot

surface/burnhazard.

Briggs&StrattonPartNo.278866

1.Fuel—On2.Fuel—Off

1.Whenstartingacold

engine,closethechoke

andpresstheprimertwo

times.

BriggsPartNo.277566

2.Whenstartingawarm

engine,openthechoke

anddonotpressthe

primer.

7

Page 8

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

Qty.

Handleassembly1

Bolts4

Bellevillewashers4

Flangenut1

Speedselectorrod

Cotterpin

Flatwasher1

Flangelocknut1Installthetractionrod.

Clevispin

Cotterpin

Chutecontrolrodassembly(rodand

bracket,wormgear,andbracket)

Bellevillewasher1

Bolt2

Carriagebolt

Locknut3

Curvedwasher

Nopartsrequired

Nopartsrequired

1

1

1

1

1

1

1

–

–

Installthehandle.

Installthespeedselectorrod.

Installtheauger/impellerdrivecontrol

linkage.

Installthechutecontrolrod.

Filltheenginewithoil.

Checkthetirepressure.

Use

8

Nopartsrequired

–

Checktheskidsandscraper.

8

Page 9

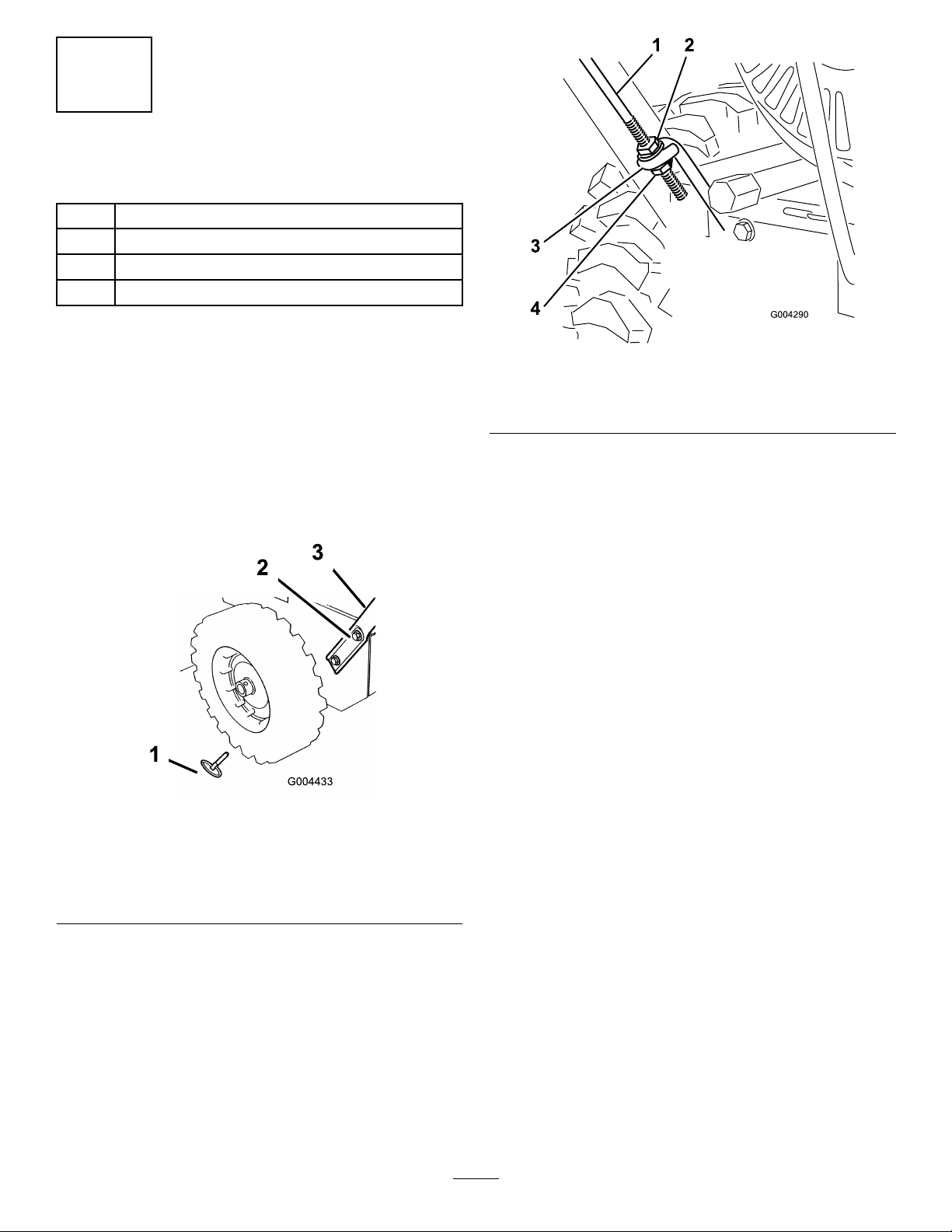

1

InstallingtheHandle

Partsneededforthisprocedure:

1Handleassembly

4Bolts

4Bellevillewashers

1Flangenut

Procedure

1.Removethetiestrapsthatsecurethecontrolrodsto

thehandle.

2.Removetheaxlepinsfrombothwheelsandslidethe

wheelsoutwardontheaxleapproximately1inch(3

cm)(Figure3).

Note:Savetheaxlepinssothatyoucaninstallthem

instep8.

Figure3

Figure4

1.Tractionrod3.Lowertractionrodloop

2.Flangenut4.Flangelocknut

4.Positiontheleftsideofthehandleagainstthesideof

themachineandinserttheendofthetractionrod

throughthelowertractionrodloopFigure4).

5.Aligntheholesintheleftsideofthehandlewiththe

holesintheleftsideplate,andsecurethehandlewith2

capscrewsandBellevillewashersuntiltheyarenger

tight(Figure3).

Note:TheconcavesideoftheBellevillewashergoes

againsttheoutsideofthehandle.

6.Aligntheholesintherightsideofthehandlewith

theholesintherightsideplate,andsecurethehandle

with2capscrewsandBellevillewashersuntiltheyare

ngertight.

7.Ensurethatthehandlesareatthesameheight,then

tightenthehandlefastenerssecurely .

8.Slidethewheelsoutwardandinserteachaxlepin

throughtheholeineachwheelhubandthroughthe

outerholeoftheaxle(Figure5).

1.Axlepin(2)

2.Capscrewandcurved

washer(4)

3.Threadaangenut(nottheangelocknut)withthe

angedownontothetractionrodattachedtotheleft

sideofthehandle(

3.Handle

Figure4).

9

Page 10

Figure5

1.Axlepin2.Holeinwheelhuband

Note:Ifyouinstalltirechains(optional),youmust

installtheaxlepinsthroughtheouteraxleholes.

outeraxleholealigned

2

InstallingtheSpeedSelector Rod

Partsneededforthisprocedure:

1

Speedselectorrod

1

Cotterpin

1Flatwasher

Procedure

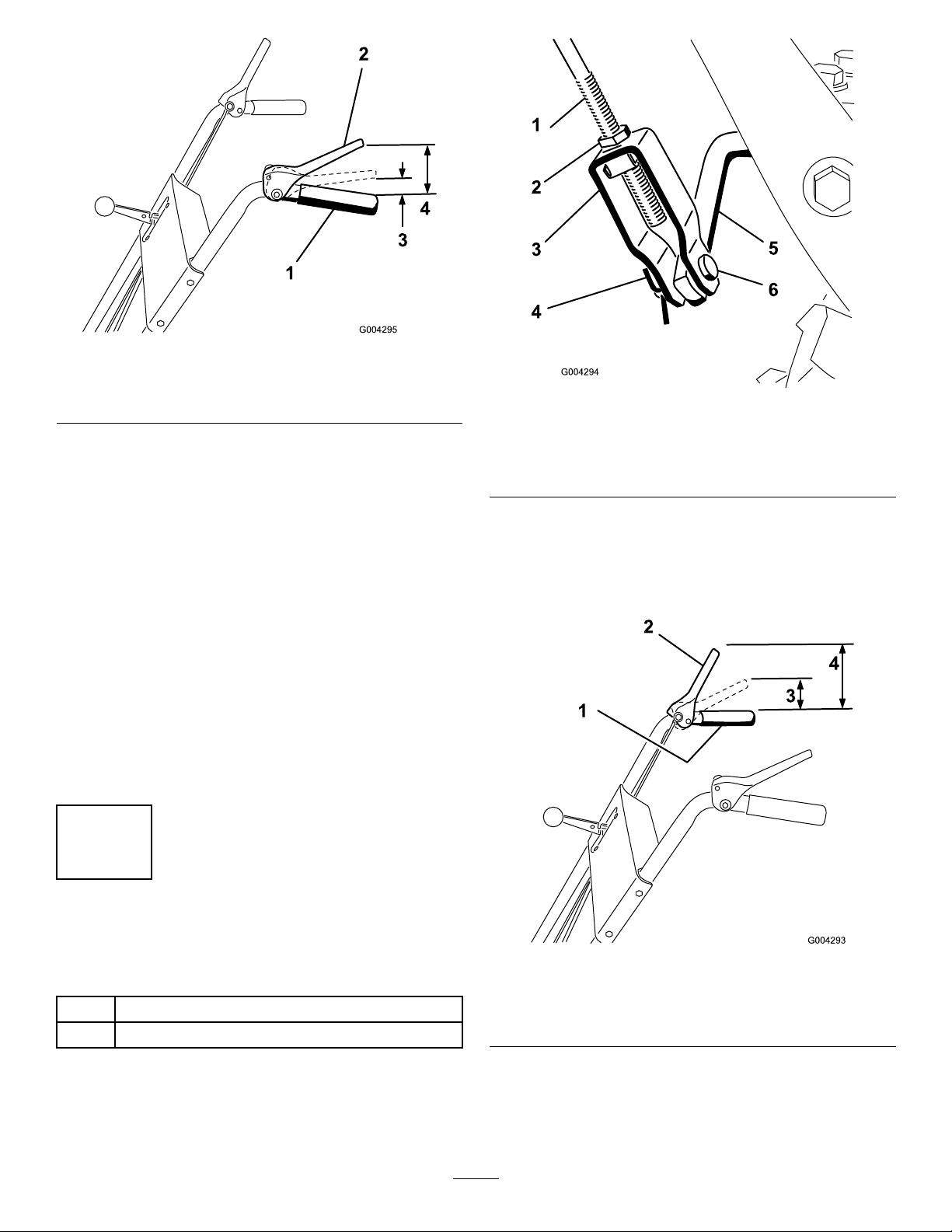

Figure6

1.Speedselectorarm3.Speedselectorrod

2.Flatwasherandcotterpin

2.Movethespeedselectorlever(Figure14)onthe

controlpaneltotheR(Reverse)position.

3.Installthespeedselectorrodintothespeedselector

arm,addaatwasherontheselectorrod,andsecureit

withacotterpin(Figure6).

3

InstallingtheTractionRod

Partsneededforthisprocedure:

1Flangelocknut

1.Pullthespeedselectorarm(Figure6)tothemost

outwardposition.

Procedure

1.Threadtheangelocknut(angesideup)ontothe

bottomofthetractioncontrolrod,belowtheloopin

thelowertractionrod(Figure4).

2.Adjustthe2angenutsupordownonthetraction

roduntilthedistancebetweenthetopofthehandgrip

andthebottomofthetractioncontrolleveris

approximately4-1/2inches(11.4cm)asshownin

Figure7.

10

Page 11

Figure7

1.Handgrip

2.Tractioncontrollever

3.Tightenthe2angenutsuntiltheyarengertight.

4.Movethespeedselectorlever(Figure14)intothird

gear.

Note:Ifthespeedselectorleverdoesnotmoveinto

thirdgear,adjustthespeedselectorbeforecontinuing.

RefertoAdjustingtheSpeedSelectorinMaintenance.

5.Slowlypullthemachinebackwardwhileslowlypressing

thetractioncontrollevertowardthehandgrip.

Note:Theadjustmentiscorrectwhenthewheelsstop

rollingbackwardandthedistancebetweenthetopof

thehandgripandthebottomofthetractioncontrol

leveris1to2inches(3to5cm)asshownin

6.Adjustthe2angenuts,ifnecessary,toobtainthe

properdistancebetweenthetopofthehandgripand

thebottomofthetractioncontrollever.

7.Tightentheangenutssecurely.

3.1to2inches(3to5cm)

4.4-1/2inches(11.4cm)

Figure7.

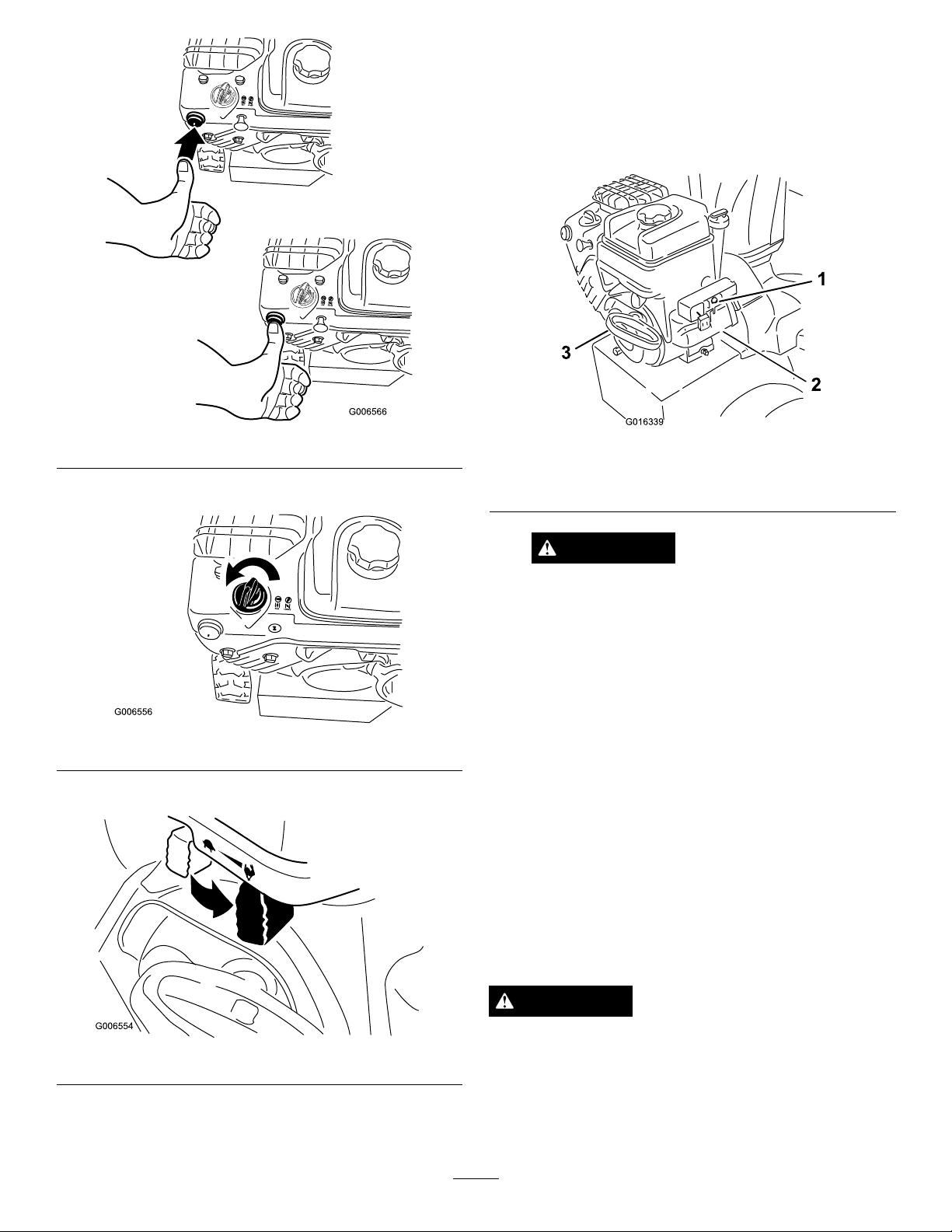

Figure8

1.Uppercontrolrod

2.Jamnut5.Lowercontrolrod

3.Clevis6.Clevispin

2.Aligntheholesintheclevisandthelowercontrolrod

andinserttheclevispin(Figure8).

3.Checkthedistancebetweenthetopofthehandgrip

andthebottomoftheauger/impellerdrivecontrol

lever(

Figure9).

4.Cotterpin

4

InstallingtheAuger/Impeller DriveControlLinkage

Partsneededforthisprocedure:

1

Clevispin

1

Cotterpin

Procedure

1.Loosenthejamnutabovetheclevisontheupper

controlrod(

Figure8).

Figure9

1.Handgrip

2.Auger/impellercontrol

lever

Note:Thedistanceshouldbeapproximately5inches

(12.7cm).

4.Presstheauger/impellerdrivecontrolleverslowly

towardthehandgrip.

11

3.1to2inches(3to5cm)

4.5inches(12.7cm)

Page 12

Note:Theamountofforceneededtocompressthe

leverincreasesnoticeablywhenyouremovetheslack

fromtheauger/impellerdrivebelt(approximately1/2

ofthelevermovement).Theadjustmentiscorrect

whentheforcebeginstoincreaseandthedistance

betweenthetopofthehandgripandthebottomofthe

auger/impellerdrivecontrolleveris1to2inches(3to

5cm)asshowninFigure9.

5.Toadjustthedistance:

A.Removetheclevispin.

B.Loosenthejamnut.

C.Threadtheclevisupordowntoincreaseor

decreasethedistancebetweenthetopofthe

handgripandthebottomoftheauger/impeller

drivecontrollever(

6.Whentheadjustmentiscorrect,installtheclevispin

andsecureitinplacewiththecotterpin(Figure8).

7.Tightenthejamnuttosecuretheclevis(Figure8).

Figure8).

5

InstallingtheChuteControl Rod

Partsneededforthisprocedure:

Chutecontrolrodassembly(rodandbracket,worm

1

gear,andbracket)

1Bellevillewasher

2Bolt

1

Carriagebolt

3Locknut

1

Curvedwasher

Procedure

1.Securetheupperchutecontrolbracket(attachedtothe

chutecontrolrod)totheupperleftsideofthehandle

withaboltandalocknut

Figure10.

Figure10

1.Chutecontrolrod

2.Wormgear,bracket,and

mountingange

3.Lowerchutecontrol

bracket

Note:Leavethelocknutloose.

2.Securethelowerchutecontrolbracket(attachedtothe

chutecontrolrod)tothelowerleftsideofthehandle

withabolt,acurvedwasher,aatwasher,andalocknut

(Figure10).

Note:Thebracketshouldbefastenedontheoutside

ofthehandle,andtherodshouldbeapproximately

paralleltothegroundandnottouchthehandle.

Note:Leavethelocknutloose.

3.ApplyNo.2generalpurposegreasetothewormgear

(

Figure11).

4.Upperchutecontrol

bracket

5.Curvedwasher

12

Page 13

Figure11

Figure12

1.Wormgear

2.Bracket4.Bolt,Bellevillewasher,

4.Looselymountthewormgearandthebrackettothe

mountingangewithabolt,aBellevillewasher,anda

locknutasshowninFigure11.

5.Slidethewormgearintotheteethofthechuteretaining

ringandtightenthelocknut(Figure11).

6.Tightenthelocknutsthatsecurethe2chutecontrol

brackets(Figure10).

7.Checktheoperationofthechutecontrolrod,and

movethewormgearslightlyoutwardifitbinds.

3.Mountingange

andlocknut

6

FillingtheEnginewithOil

NoPartsRequired

Procedure

Yourmachinecomeswith20oz.(0.6l)ofoilintheengine.

Note:Beforestartingtheengine,checktheoilleveland

addoilifnecessary.

Max.ll:20oz.(0.6l),type:automotivedetergentoilwithan

APIserviceclassicationofSF,SG,SH,SJ,SL,orhigher.

Referto

outdoortemperaturerangeexpected.

Figure12toselectthebestoilviscosityforthe

1.Movethemachinetoalevelsurfacetoensurean

accurateoillevelreading.

2.Cleanaroundthedipstick(Figure13).

Figure13

1.Dipstick2.Fillerhole

3.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

4.Slowlypourabout3/4ofthecrankcasecapacityofoil

intothecrankcase.

5.Wipethedipstickcleanwithacleancloth.

6.Installthedipstickintothellerneck,thenremoveit.

Note:Toensureanaccurateoillevelreading,you

mustfullyinstallthedipstick.

7.Readtheoillevelonthedipstick.

8.IftheoillevelisbelowtheAddmarkonthedipstick,

slowlypouronlyenoughoilintothellerholetoraise

theoilleveltotheFullmarkonthedipstick.

Important:Donotoverllthecrankcasewithoil

andruntheengine;enginedamagewillresult.

13

Page 14

Draintheexcessoiluntiltheoillevelonthe

dipstickreadsFull.

9.Insertthedipstickintothellerneckandrotatethecap

clockwiseuntilitistight.

7

CheckingtheTirePressure

NoPartsRequired

Procedure

Thetiresareoverinatedatthefactoryforshipping.Reduce

thepressureequallyinbothtirestobetween12and15psi

(82and103kPa).

ProductOverview

8

CheckingtheSkidsand Scraper

NoPartsRequired

Procedure

RefertoCheckingandAdjustingtheSkidsandScraperin

Maintenance.

1.Auger/impellerdrive

controllever

2.Tractioncontrollever

3.Dischargechutecontrol

4.Speedselectorlever

5.Fueltankcap

Figure14

6.Oilll/dipstick

7.Chutedeectorhandle

8.Snowclean-outtool

9.Auger

14

1.Choke

2.Ignitionswitch

3.Fuelshutoffvalve

4.Throttle

Figure15

5.Recoilstarter

6.Oildrainplug

7.Primer

Page 15

Controls

FreewheelingorUsingthe

•Auger/ImpellerDriveControlLever—Toengageboth

theaugerandimpeller,presstheleveragainsttheright

handgrip.Todisengage,releasethelever.

•TractionControlLever—Toengagethetraction(wheel

drive),presstheleveragainstthelefthandgrip.T ostop

thetraction,releasethelever.

•SpeedSelectorLever—Thiscontrolhas4positions:3

forwardspeedsand1reverse.Tochangespeeds,move

thespeedselectorlevertothedesiredposition.Thelever

locksinanotchateachspeedselection.

Note:Beforeshiftinggearsintooroutofreverse,you

mustreleasethetractioncontrollever.Youmayshift

betweenanyoftheforwardspeedswithoutreleasingthe

tractioncontrollever.

•DischargeChuteControl—Rotatethedischargechute

controlclockwisetomovethedischargechutetotheleft;

counterclockwisetomovethechutetotheright.

•ChuteDeectorHandle—Movethedeectorhandle

forwardtomovethesnowstreamdown;moveitrearward

tomovethesnowstreamup.

•FuelshutoffValve—Closethevalvebyrotating

clockwise.Openthevalvebyrotatingitcounterclockwise.

Closethevalvewhenyoudonotusethemachine.

Self-propelDrive

Youcanoperatethemachinewiththeself-propelfeature

engagedordisengaged(freewheeling).

Tofreewheel,slidethewheelsinwardandinserttheaxle

pinsthroughtheaxleholes,butnotthroughthewheelhubs

(Figure16).

Figure16

Toself-propel,slidethewheelsoutwardandinserttheaxle

pinsthroughtheholesinthewheelhubsandtheaxleholes

(Figure17).

•IgnitionSwitch—Inserttheignitionkeybeforestarting

theengine.T ostoptheengine,removethekey.

•Choke—RotatethechoketotheFullpositiontostarta

coldengine.Asenginewarmsup,graduallyrotatethe

choketotheOffposition.

•ThrottleLever—Movethethrottlelevertotherightto

increasetheenginespeed;moveittothelefttodecrease

theenginespeed.MovethethrottlelevertotheStop

positiontostoptheengine.

•Primer—Presstheprimertopumpasmallamount

ofgasolineintotheengineforimprovedcold-weather

starting.

•ElectricStarter—Theelectricstarterisontherightside

oftheengine.Tostartthemachine,connecttheelectric

startertoanelectricpowersourcewithanapproved

extensioncordandpressthestarterbutton.

•RecoilStarter—Therecoilstarterisonthebacksideof

theengine.Pulltherecoilstartertostarttheengine.

•SnowClean-outT ool—Thesnowclean-outtoolison

thetopoftheaugerhousing.Usethistooltounclogthe

dischargechutewhenitbecomescloggedwithsnow.

Figure17

FillingtheFuelTank

DANGER

Gasolineisextremelyammableandexplosive.A

reorexplosionfromgasolinecanburnyouand

others.

•Topreventastaticchargefromignitingthe

gasoline,placethecontainerand/ormachine

onthegroundbeforelling,notinavehicleor

onanobject.

•Fillthetankoutdoorswhentheengineiscold.

Wipeupspills.

•Donothandlegasolinewhensmokingoraround

anopenameorsparks.

•Storegasolineinanapprovedfuelcontainer,out

ofthereachofchildren.

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

•Forbestresults,useonlyclean,fresh,unleadedgasoline

withanoctaneratingof87orhigher((R+M)/2rating

method).

•Oxygenatedfuelwithupto10%ethanolor15%MTBE

byvolumeisacceptable.

15

Page 16

•DoNotuseethanolblendsofgasoline(suchasE15

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemayresult

whichmaynotbecoveredunderwarranty.

•DoNotusegasolinecontainingmethanol.

•DoNotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•DoNotaddoiltogasoline.

Important:Toreducestartingproblems,addfuel

stabilizertothefuelallseason,mixingitwithgasoline

lessthan30daysold.

Do not add oil to the gasoline.

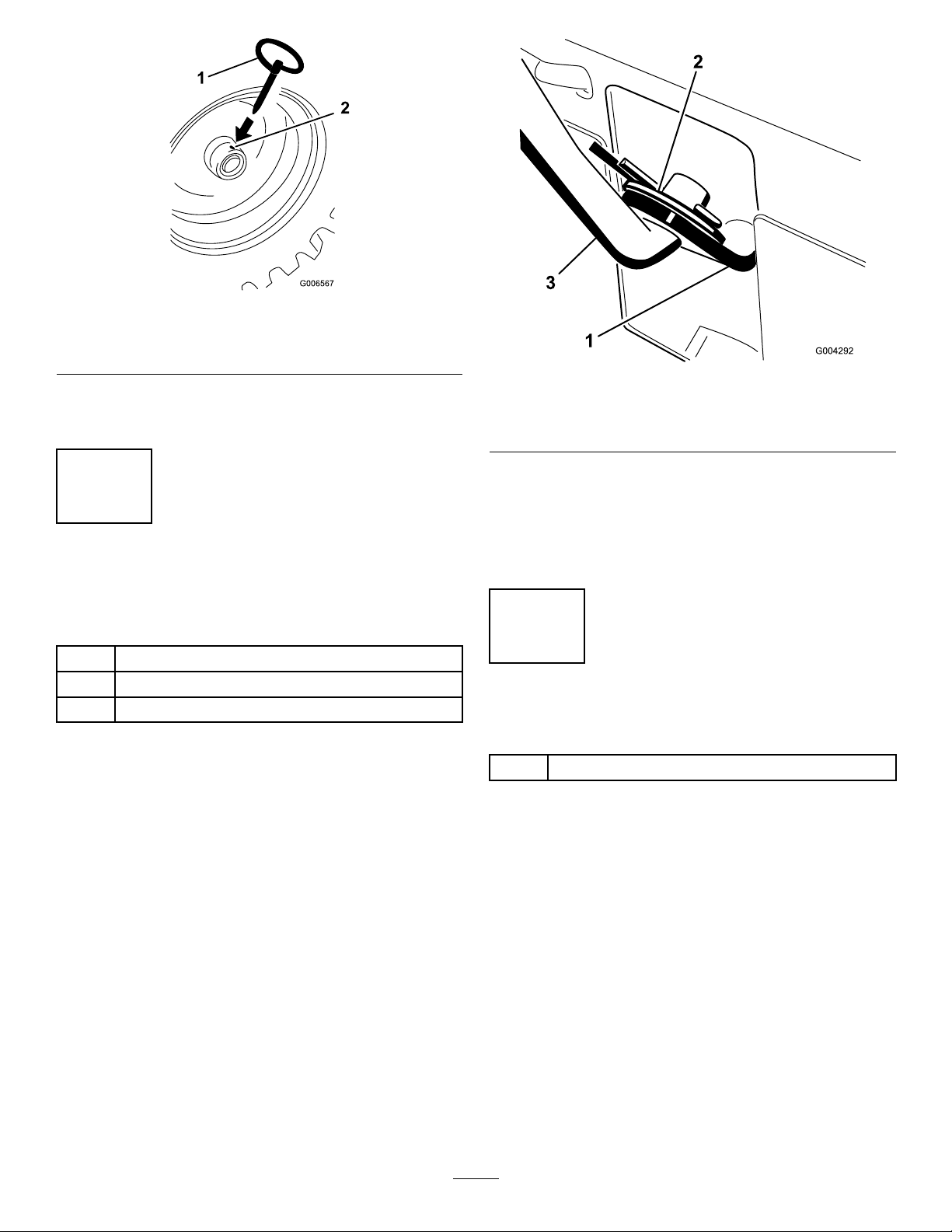

StartingtheEngine

1.Checktheengineoillevel.RefertoCheckingthe

EngineOilLevelinMaintenance.

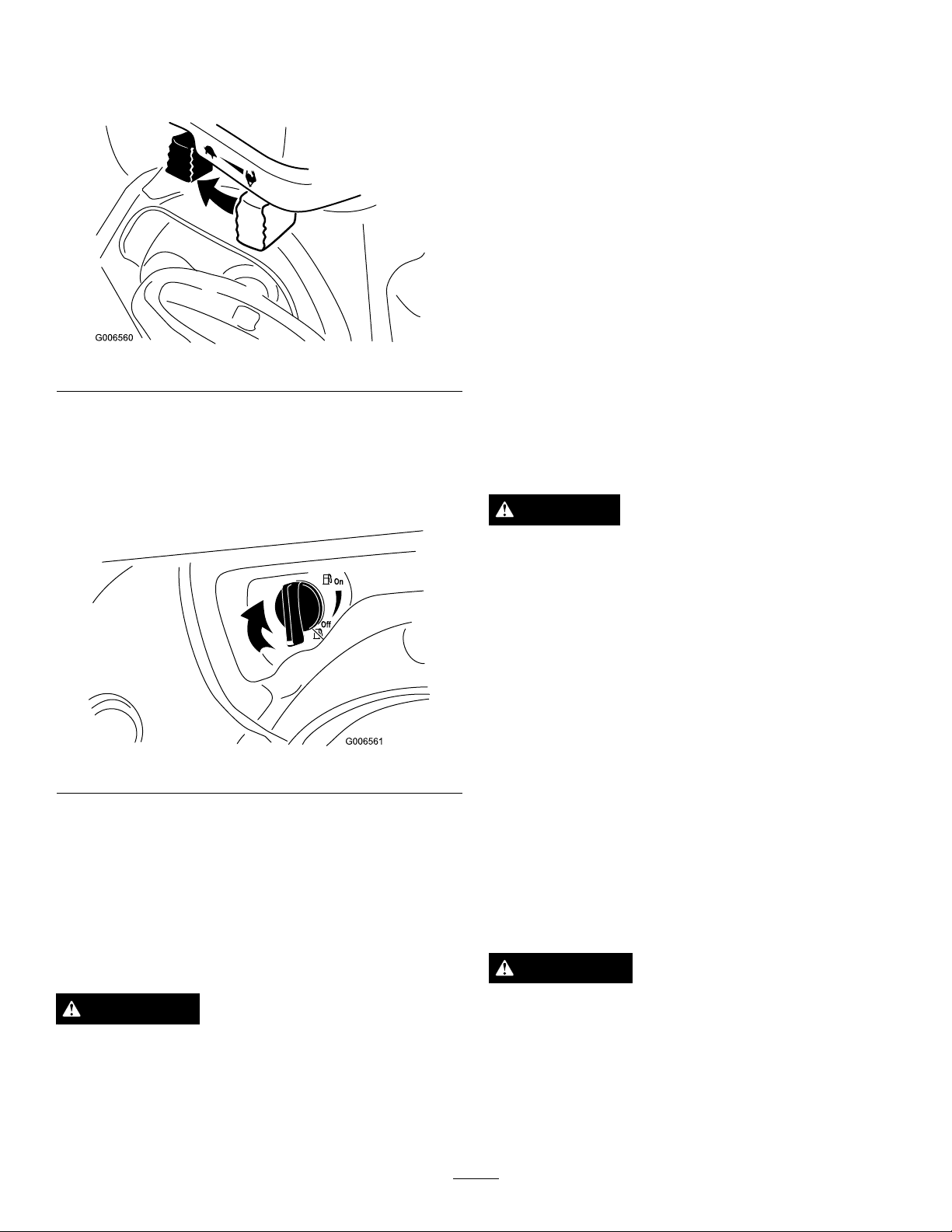

2.Turnthefuelshutoffvalve1/4turncounterclockwise

toopenit(Figure19).

Figure19

3.Inserttheignitionkey(Figure20).

Figure18

Figure20

1.Ignitionkey

4.Firmlypushintheprimerwithyourthumb2times

(15°For-9°Corabove)or4times(below15°For

-9°C),holdingtheprimerinforasecondbefore

releasingiteachtime(Figure21).

16

Page 17

Note:Tousetheelectricstarter,connectapowercord

G016339

totheelectricstarterplug-inrstandthentoapower

outlet.Useonlyanextensioncordrecommendedfor

outdoorusethatisnotlongerthan50feet(15m).

8.Startthemachinebypullingtherecoilstarteror

pressingtheelectric-startbutton(Figure24).

Figure21

5.RotatethechoketotheChokeposition(Figure22).

Figure22

6.MovethethrottletotheFastposition(Figure23).

Figure24

1.Electric-startbutton3.Recoilstarter

2.Electricstarterplug-in

WARNING

Theelectricalcordcanbecomedamaged,

causingashockorre.

Thoroughlyinspecttheelectricalcordbefore

usingthemachine.Ifthecordisdamaged,

donotoperatethemachine.Replaceorrepair

thedamagedcordimmediately.Contactan

AuthorizedServiceDealerforassistance.

Important:Topreventdamagingtheelectric

starter,runitinshortcycles(5secondsmaximum,

thenwaitoneminutebeforetryingtostartit

again).Iftheenginestilldoesnotstart,take

themachinetoanAuthorizedServiceDealerfor

service.

9.Disconnecttheextensioncordfromthepoweroutlet

rstandthenfromthemachine(electricstartonly).

Figure23

7.Connectanextensioncordtotheelectricstarterand

theoutlet.

10.Allowtheenginetowarmupforseveralminutes,then

movethechoketowardtheRunposition.W aitforthe

enginetorunsmoothlybeforeeachchokeadjustment.

WARNING

Ifyouleavethemachinepluggedintoapower

outlet,someonecaninadvertentlystartthemachine

andinjurepeopleordamageproperty.

Unplugthepowercordwheneveryouarenot

startingthemachine.

17

Page 18

StoppingtheEngine

1.MovethethrottletotheSlowposition,andthentothe

Stopposition(Figure25).

Figure25

2.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

Ifthedischargechutebecomesclogged,stoptheengine,

waitforallmovingpartstostop,andusetheclean-out

tool.

PreventingFreeze-up

•Insnowyandcoldconditions,somecontrolsandmoving

partsmayfreeze.Donotuseexcessiveforcewhen

tryingtooperatefrozencontrols.Ifyouhavedifculty

operatinganycontrolorpart,starttheengineandletit

runforafewminutes.

•Afterusingthemachine,lettheenginerunforafew

minutestopreventmovingpartsfromfreezing.Engage

theauger/impellertoclearanyremainingsnowfrom

insidethehousing.Rotatethedischargechutecontrol

topreventitfromfreezing.Stoptheengine,waitforall

movingpartstostop,andremovealliceandsnowfrom

themachine.

•Withtheengineoff,pulltherecoilstarterhandleseveral

timestopreventtherecoilstarterfromfreezingup.

3.Removetheignitionkey.

4.Closethefuelshutoffvalvebyrotatingitclockwise

(Figure26).

Figure26

5.Pulltherecoilstarter3or4times.Thishelpsprevent

therecoilstarterfromfreezingup.

6.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

UncloggingtheDischarge

OperatingTips

DANGER

Whenthemachineisinoperation,theimpellerand

augercanrotateandcutofforinjurehandsandfeet.

•Beforeadjusting,cleaning,inspecting,

troubleshooting,orrepairingthemachine,stop

theengineandwaitforallmovingpartstostop.

Disconnectthewirefromthesparkplugand

keepitawayfromtheplugtopreventsomeone

fromaccidentallystartingtheengine.

•Removeanobstructionfromthedischarge

chute;refertoUncloggingtheDischargeChute.

Ifnecessary ,usetheclean-outtool,notyour

hands,toremoveanobstructionfromthe

dischargechute.

•Staybehindthehandlesandawayfromthe

dischargeopeningwhileoperatingthemachine.

•Keepface,hands,feet,andanyotherpartof

yourbodyorclothingawayfromconcealed,

moving,orrotatingparts.

Chute

WARNING

Iftheauger/impellerisrunningbutthereisno

snowcomingoutofthedischargechute,the

dischargechutemaybeclogged.

Neveruseyourhandstoclearacloggeddischarge

chute.Thiscouldresultinpersonalinjury.

WARNING

Therotorbladescanthrowstones,toys,andother

foreignobjectsandcauseseriouspersonalinjuryto

theoperatorortobystanders.

•Keeptheareatobeclearedfreeofallobjects

thattherotorbladescouldpickupandthrow.

•Keepallchildrenandpetsawayfromthearea

ofoperation.

18

Page 19

•AlwayssetthethrottlelevertotheFastpositionwhen

throwingsnow .

•Iftheengineslowsdownunderaloadorthewheelsslip,

shiftthemachineintoalowergear.

•Ifthefrontofthemachineridesup,shiftthemachine

intoalowergear.Ifthefrontcontinuestorideup,liftup

onthehandles.

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

Aftertherst5hours

Beforeeachuseordaily

Every50hours

Every100hours

Yearly

Yearlyorbeforestorage

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.Forengineadjustments,

repairs,orwarrantyservicenotcoveredinthismanual,contactanAuthorizedBriggs&StrattonServicingDealer.

MaintenanceProcedure

•Inspectandadjustthetractiondrivebelt.

•Inspectandadjusttheauger/impellerdrivebelt.

•Changetheengineoil.

•Checktheengineoillevelandaddoilifnecessary.

•Inspectandadjustorreplacethetractiondrivebeltwhennecessary.

•Inspectandadjustorreplacetheauger/impellerdrivebeltwhennecessary .

•Changetheengineoil.

•Replacethesparkplug.

•Checktheskidsandthescraperandadjustthemifnecessary .

•Checktheaugergearboxoilandaddoilifnecessary .

•Changetheengineoil.

•Drainthegasolineandruntheenginetodryoutthefueltankandthecarburetorat

theendoftheseason.

CAUTION

Ifyouleavethewireonthesparkplug,someonecouldaccidentlystarttheengineandseriouslyinjure

youorbystanders.

Disconnectthewirefromthesparkplugbeforeyoudoanymaintenance.Setthewireasidesothatitdoes

notaccidentallycontactthesparkplug.

PreparingforMaintenance

1.Movethemachinetoalevelsurface.

2.Stoptheengineandwaitforallmovingpartstostop.

3.Disconnectthesparkplugwire.RefertoInspecting

andReplacingtheSparkPlug.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Eachtimebeforeusingthemachine,rstensurethattheoil

levelisbetweentheAddandtheFullmarksonthedipstick.

1.Cleanaroundthedipstick(

Figure13).

2.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

3.Wipethedipstickcleanwithacleancloth.

4.Installthedipstickintothellerneck,thenremoveit.

Note:Toensureanaccurateoillevelreading,you

mustfullyinstallthedipstick.

5.Readtheoillevelonthedipstick.

6.IftheoillevelisbelowtheAddmarkonthedipstick,

slowlypouronlyenoughoilintothellerholetoraise

theoilleveltotheFullmarkonthedipstick.

Note:Useonlyahigh-quality,SAE5W -30orSAE10

detergentoilthathastheAmericanPetroleumInstitute

(API)serviceclassicationSF,SG,SH,orSJ.For

19

Page 20

extremelycoldconditions(below0°For-18°C),use

0W-30detergentoilthathastheAmericanPetroleum

Institute(API)serviceclassicationSF,SG,SH,orSJ .

Important:Donotoverllthecrankcasewithoil

andruntheengine;enginedamagewillresult.

Draintheexcessoiluntiltheoillevelonthe

dipstickreadsFull.

7.Insertthedipstickintothellerneckandrotatethecap

clockwiseuntilitistight.

AdjustingtheSkidsand Scraper

ServiceInterval:Yearly

Adjusttheskidsandthescraperinitiallyandthenasneeded

toensurethattheaugerdoesnotcontactthepavedorgravel

surface.Also,adjustthemasneededtocompensateforwear.

1.Movethemachinetoalevelsurface.

2.Checkthetirepressureinthetires.RefertoChecking

theTirePressureinSetup.

3.Loosenthe4angenutsthatsecurebothskidstothe

augersideplates(

downeasily.

Figure27)untiltheskidsslideupand

Figure28

1.Augerblade

2.Scraper

5.Checkthescraperadjustment.Thescrapershouldbe

1/8inch(3mm)aboveandparalleltoalevelsurface.

A.ForConcreteandAsphaltSurfaces:

Ifthemachinedoesnotclearthesnowclose

enoughtothepavement,adjusttheskidstolower

thescraper;ifthepavementsurfacesarecracked,

rough,oruneven,adjusttheskidstoraisethe

scraper.

B.ForGravelSurfaces:

Supporttheaugerbladesafewinches(cm)above

theground,andadjusttheskidstopreventthe

machinefrompickinguprocks.

6.Toadjustthescraper,loosenthe5mountingscrews

(Figure28),levelthescraper,andtightenthemounting

screws.

7.Movetheskidsdownasfaraspossible.

3.Mountingscrew(5)

Figure27

1.Augersideplate(2)3.Skid(2)

2.Flangenuts(4)

4.Supporttheaugerbladessothattheyare1/8inch(3

mm)offtheground(Figure28).

8.Tightenthe4angenutsthatsecurebothskidstothe

augersideplates(

Figure27).

AdjustingtheSpeedSelector

Adjustthespeedselectorlinkageinitiallyandwhenthe

machineisslow,rstgearhasnospeed,orthespeedselector

leverdoesnotmoveintothirdgear.

1.Draingasolinefromthefueltankandtheengineoil

fromthecrankcase.RefertoEmptyingtheFuelTank

andtoChangingtheEngineOil.

2.Tipthemachineforwardandblockitsothatitcannot

fall.

3.Loosentheangenutsthatsecuretheselectorplateto

thecontrolpanel(

20

Figure29).

Page 21

ChangingtheEngineOil

ServiceInterval:Aftertherst5hours

Yearly

Every50hours

Ifpossible,runtheenginejustbeforechangingtheoilbecause

warmoilowsbetterandcarriesmorecontaminants.

Max.ll:20oz.(0.6l),type:automotivedetergentoilwithan

APIserviceclassicationofSF,SG,SH,SJ,SL,orhigher.

Figure29

1.Speedselectorplate

4.Shiftthespeedselectorlevertothirdgear.Pushdown

onthespeedselectorplateandtightentheangenuts

thatsecurethespeedselectorplate.

5.Ifthesestepsdonotresolvetheissue,taketheunitto

anauthorizedservicelocation.

2.Flangenuts

CheckingtheAugerGearbox Grease

ServiceInterval:Yearly

Theaugergearboxispackedwith5oz.(140g)ofLubriplate

MAG-1(alow-temperature,high-pressuregrease)andis

sealedatthefactory.Thepipeplug(Figure30)isforfactory

useonly;youdonotneedtocheckoraddgrease.Ifthe

gearboxisleakinggrease,contactanAuthorizedService

Dealer.

Referto

outdoortemperaturerangeexpected.

Figure31toselectthebestoilviscosityforthe

Figure31

1.Blockuptherearofthemachine.

2.Removetheleftwheel.

3.Cleantheareaaroundtheoildrainplug(Figure32).

1.Pipeplug

Figure32

1.Oildrainplug

2.Drainextension

Figure30

4.Slideanoildrainpanunderthedrainextensionand

removetheoildrainplug(Figure32).

21

Page 22

Note:Placeafunnelunderthedrainextensionsothe

oildrainsdirectlyintotheoildrainpanandawayfrom

themachine.

5.Draintheoil.

Note:Disposeoftheusedoilproperlyatalocal

recyclingcenter.

6.Installtheoildrainplug.

7.Installtheleftwheel.

8.Fillthecrankcasewithoil.RefertoFillingtheEngine

withOilinSetup.

9.Wipeupanyspilledoil.

ReplacingtheSparkPlug

ServiceInterval:Every100hours—Replacethesparkplug.

UseaChampionQC12YCorequivalentsparkplug.

Note:Toaccessthesparkplug,youmustrstremovethe

uppersnowhood(Figure33).

Figure33

1.Chokeknob

2.Uppersnowhood

3.Ignitionkey

4.Screw(2)

Figure34

1.Spark-plugwire

2.Bracket

3.Thumbscrew

5.Cleanaroundthebaseofthesparkplug(Figure34).

6.Removeanddiscardtheoldsparkplug.

Note:Y ouwillneedaratchetwrenchextensionto

removethesparkplug.

7.Setthegapbetweentheelectrodesonanewsparkplug

at0.030inch(0.76mm)(Figure35).

Figure35

1.0.030inch(0.76mm)

1.Removethechokeknobandtheignitionkey

(Figure33).

2.Removethe2screwsthatsecuretheuppersnowhood

tothemachine(Figure33).

3.Slowlyremovetheuppersnowhood,ensuringthat

theprimerbulbhoseandtheignitionwireremain

connected.

4.Removethebracketthumbscrewandthebracket

(Figure34).

8.Installthenewsparkplug,tightenitrmly,andattach

theignitionwiretothesparkplug.

9.Installthebracketwiththethumbscrewthatyou

removedinstep4.

10.Ensurethattheprimerbulbhoseandtheignitionwire

areconnectedandclearofthecarburetorbracket.

11.Securetheuppersnowhoodtothemachinewiththe2

screwsthatyoupreviouslyremoved.

12.Alignthetabonthechokecontrolknobwiththeslot

ontheuppersnowhood.

13.Connectthechokecontrolknobtothechokeshafton

thecarburetor.

22

Page 23

AdjustingtheTractionDrive Belt

ServiceInterval:Afterthersthour

Beforeeachuseordaily

Adjustthetractiondrivebeltaftertherstoperatinghour,

afterevery5operatinghoursthereafter,andwhenthespeed

selectorlevershiftsproperlybutthemachinedoesnotdrive

intheforwardorreversespeeds.

1.Checkandadjustthetractiondriveasdescribedin

InstallingtheTractionRodinSetup.

2.Iftheproblempersistsafteradjustingthelinkage,

contactanAuthorizedServiceDealer.

ReplacingtheTractionDrive Belt

Ifthetractiondrivebeltbecomesworn,oil-soaked,or

otherwisedamaged,taketheunittoanauthorizedservice

location.

2.Checkthebelttensionbyoperatingtheauger.

3.Ifthebeltstillslips,replaceit.RefertoReplacingthe

Auger/ImpellerDriveBelt.

Important:Donotoperatethemachineifthe

augerandtheimpellerrotatewhenyoudisengage

theauger/impellerdrivecontrollever.

ReplacingtheAuger/Impeller DriveBelt

Iftheauger/impellerdrivebeltbecomesworn,oil-soaked,or

otherwisedamaged,taketheunittoanauthorizedservice

location.

AdjustingtheAuger/Impeller DriveBelt

ServiceInterval:Afterthersthour

Beforeeachuseordaily

Operatingthemachinewithanauger/impellerdrivebeltthat

slipsdecreasesthesnowthrowingperformanceanddamages

thebelt.Checktheauger/impellerdrivebeltfortheproper

tensionaftertherstoperatinghour,thencheckandadjust

thebeltwhennecessary.

DANGER

Improperlyadjustingtheauger/impellermaycause

ittoturnwhendisengaged.Arotatingaugeror

impellercancutofforinjurengers,hands,orfeet.

•Keepyourface,hands,feet,andanyotherpart

ofyourbodyorclothingawayfromconcealed,

moving,orrotatingparts.

•Ensurethattheimpellerbrakearmclearance

ismaintained.

•Donotadjusttheauger/impellerdrivebelttoo

tightbecauseitmaycausetheauger/impellerto

turnwhenthecontrolleverisintheDisengaged

position.Ifthisoccurs,decreasethebelt

tension.

1.CheckandadjustthebeltasinstructedinInstallingthe

Auger/ImpellerDriveControlLinkageinSetup.

23

Page 24

Storage

WARNING

•Gasolinevaporscanexplode.

•Donotstoregasolinemorethan30days.

•Donotstorethemachineinanenclosurenear

anopename.

•Allowtheenginetocoolbeforestoringit.

PreparingtheMachinefor Storage

1.Onthelastrefuelingoftheyear,addfuelstabilizerto

freshfuelasdirectedbytheenginemanufacturer.

Note:Fuelshouldnotbestoredlongerthansuggested

bythefuelstabilizermanufacturer.

2.Runtheenginefor10minutestodistributethe

conditionedfuelthroughthefuelsystem.

3.Runthemachineuntiltheenginerunsoutoffuel.

4.Primetheengineandstartitagain.

5.Allowtheenginetorununtilitstops.Whenyoucan

nolongerstarttheengine,itissufcientlydry.

6.Stoptheengineandallowittocool.

7.Removetheignitionkey.

8.Cleanthemachinethoroughly.

9.Touchupchippedsurfaceswithpaintavailablefroman

AuthorizedServiceDealer.Sandaffectedareasbefore

painting,andusearustpreventativetopreventthe

metalpartsfromrusting.

10.Tightenallloosescrews,bolts,andlocknuts.Repairor

replaceanydamagedparts.

11.Coverthemachineandstoreitinaclean,dryplaceout

ofthereachofchildren.

RemovingtheMachinefrom Storage

1.Removethesparkplugandspintheenginerapidly

usingthestartertoblowtheexcessoilfromthe

cylinder.

2.Installthesparkplugandtightenitrmly.

3.Connectthesparkplugwire.

4.Performtheannualmaintenanceproceduresasgiven

intheRecommendedMaintenanceSchedule.

24

Page 25

Troubleshooting

Problem

Electricstarterdoesnotturn(electric-start

modelsonly)

Enginedoesnotstartorstartshard

PossibleCauseCorrectiveAction

1.Thepowercordisdisconnectedatthe

outletorthemachine.

2.Thepowercordisworn,corroded,or

damaged.

3.Thepoweroutletisnotenergized.

1.Thekeyisnotintheignitionorisinthe

Stopposition.

2.ThechokeisintheOffpositionandthe

primerhasnotbeenpressed.

3.Thefuelshutoffvalveisnotopen.3.Openthefuelshutoffvalve.

4.ThethrottleisnotintheFastposition.4.MovethethrottletotheFastposition.

5.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

6.Thesparkplugwireislooseor

disconnected.

7.Thesparkplugispitted,fouled,orthe

gapisincorrect.

8.Thefuelventcapisrestricted.

9.Theengineoillevelintheengine

crankcaseistoolowortoohigh.

1.Connectthepowercordtotheoutlet

and/orthemachine.

2.Replacethepowercord.

3.Haveaqualiedelectricianenergize

theoutlet.

1.Insertthekeyintotheignitionandturn

ittotheOnposition.

2.MovethechoketotheOnpositionand

presstheprimer3times.

5.Drainand/orllthefueltankwithfresh

gasoline(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

6.Connectthewiretothesparkplug.

7.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

8.Removetheventrestrictionorreplace

thefuelcap.

9.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

Enginerunsrough

1.ThechokeisintheOnposition.1.MovethechoketotheOffposition.

2.Thefuelshutoffvalveisnotcompletely

open.

3.Thefueltankisnearlyemptyor

containsstalefuel.

4.Thesparkplugwireisloose.

5.Thesparkplugispitted,fouled,orthe

gapisincorrect.

6.Theengineoillevelintheengine

crankcaseistoolowortoohigh.

2.Openthefuelshutoffvalve.

3.Drainandllthefueltankwithfresh

gasoline(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

4.Connectthewiretothesparkplug.

5.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

6.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

25

Page 26

Problem

PossibleCauseCorrectiveAction

Engineruns,butthemachinedischarges

snowpoorlyornotatall

Dischargechuteeitherdoesnotlockinto

placeordoesnotmove

Machinedoesnotproperlyclearthesnow

offthesurface

1.ThethrottleisnotintheFastposition

whenthrowingsnow .

2.Themachineismovingtoofasttoclear

thesnow.

3.Y ouaretryingtoremovetoomuch

snowperswath.

4.Y ouaretryingtoremoveextremely

heavyorwetsnow.

5.Thedischargechuteisplugged.5.Unclogthedischargechute.

6.Theauger/impellerdrivebeltisloose

orisoffthepulley .

7.Theauger/impellerdrivebeltisworn

orbroken.

1.Thedischargechutelatchisnot

properlyadjusted.

1.Theskidsand/orscraperarenot

properlyadjusted.

2.Thepressureinthetiresisnotequal.

1.MovethethrottletotheFastposition.

2.Shiftthemachineintoalowergear.

3.Reducetheamountofsnowremoved

perswath.

4.Don'toverloadthemachinewith

extremelyheavyorwetsnow.

6.Installand/oradjusttheauger/impeller

drivebelt;refertowww.Toro.com

forservicinginformationortakethe

machinetoanAuthorizedService

Dealer.

7.Replacetheauger/impellerdrivebelt;

refertowww.Toro.comforservicing

informationortakethemachinetoan

AuthorizedServiceDealer.

1.Adjustthedischargechutelatch.

1.Adjusttheskidsand/orthescraper.

2.Checkandadjustthepressureinone

orbothtires.

26

Page 27

InternationalDistributorList

Distributor:

AtlantisSuveSulamaSisstemleriLt

BalamaPrimaEngineeringEquip.HongKong85221552163

B-RayCorporation

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

EquiverMexico525553995444

FemcoS.A.Guatemala

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GuandongGoldenStarChina

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IbeaS.P .A.

IrriamcPortugal351212388260T oroEuropeNVBelgium3214562960

IrrigationProductsInt'lPvtLtd.India862283960789

Country:

Turkey902163448674JeanHeybroekb.v .Netherlands3130639461 1

Korea82325512076

PuertoRico7877888383

NorthernIreland442890813121

Japan81726325861

Norway4722907760

UnitedKingdom441279723444

UnitedArabEmirates97143479479

Egypt2025194308T-MarktLogisticsLtd.Hungary3626525500

Italy39033185361 1ToroAustraliaAustralia61395807355

PhoneNumber:Distributor:

MaquiverS.A.Colombia

MaruyamaMfg.Co.Inc.

AgrolancKft

5062391 138

94112746100

5024423277ParklandProductsLtd.NewZealand6433493760

30109350054

862087651338Riversa

4635100000

Mountelda.s.CzechRepublic

MunditolS.A.

OslingerTurfEquipmentSA

OyHakoGroundandGardenAb

Prochaska&Cie

RTCohen2004Ltd.

ScSvendCarlsenA/S

SolvertS.A.S.

SpyprosStavrinidesLimitedCyprus

SurgeSystemsIndiaLimited

Country:

Japan81332522285

Hungary3627539640

Argentina541148219999

Ecuador59342396970

Finland35898700733

Austria4312785100

Israel97298617979

Spain

Denmark4566109200

France33130817700

India911292299901

PhoneNumber:

5712364079

420255704220

34952837500

35722434131

EuropeanPrivacyNotice

TheInformationT oroCollects

ToroWarrantyCompany(T oro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalTorodealer.

TheTorowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMA TION

ASDESCRIBEDINTHISPRIVACYNOTICE.

TheW ayToroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaimsandtocontactyouintheeventofaproductrecall.Toromayshareyourinformation

withToro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnotusepersonalinformationprovidedfor

warrantypurposesformarketing,norshallwegiveorsellpersonalinformationprovidedforwarrantypurposestoanyothercompanyformarketing.We

reservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsandwithrequestsbytheappropriateauthorities,tooperateits

systemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw.

Toro'sCommitmenttoSecurityofY ourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oroDealer.

374-0269RevD

Page 28

TheToroWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuantto

anagreementbetweenthem,jointlypromisetotheoriginalpurchaser*

torepairtheT oroProductslistedbelowifdefectiveinmaterialsor

workmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

WalkPowerMowers

•CastDeck

5yearsResidentialUse

45DaysCommercialUse

•Engine

5yearsGTSPromise

Seeenginemanufacturer'swarranty

•SteelDeck

2yearsResidentialUse

45DaysCommercialUse

•Engine

2yearsGTSPromise

Seeenginemanufacturer'swarranty

ElectricHandHeldProducts2yearlimitedwarranty

Snowthrowers

•SingleStage

2yearsResidentialUse

45DaysCommercialUse

•TwoStage

3yearsResidentialUse

45DaysCommercialUse

•Electric2yearsResidentialUse

AllRide-OnUnitsBelow

•Engine

Seeenginemanufacturer'swarranty

1yearPartsonly

•Attachments1year

RearEngineRiders2yearsResidentialUse

90DaysCommercialUse

Lawn&GardenTractors

2yearsResidentialUse

90DaysCommercialUse

TimeCutterZMowers

3yearsResidentialUse

30DaysCommercialUse

TITANMowers3yearsor240hours

•Frame

Lifetime(originalowneronly)

TITANMXMowers3yearsor400hours

•Frame

ZMasterMowers—2000Series

•Frame

Lifetime(originalowneronly)

5yearsor1200hours

Lifetime(originalowneronly)

2

2

2

2

2

2

2

2

3

4

3

4

3

4

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator'sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.Contactyoursellertoarrangeserviceoftheproduct.Ifforany

reasonitisimpossibleforyoutocontactyourseller,youmaycontact

anyToroAuthorizedDistributortoarrangeservice.

1

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.IfforanyreasonyouaredissatisedwiththeService

Dealer’sanalysisorwiththeassistanceprovided,contactusat:

1

CustomerCareDepartment,RLCDivision

TheT oroCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

Manager:TechnicalProductSupport:001–952–887–8248

SeeattachedDistributorList

ItemsandConditionsNotCovered

1

Thisexpresswarrantydoesnotcoverthefollowing:

•Costofregularmaintenanceserviceorwearparts,suchasblades,

rotorblades(paddles),scraperblades,belts,fuel,lubricants,oil

changes,sparkplugs,cable/linkageorbrakeadjustments

•Anyproductorpartwhichhasbeenalteredormisusedandrequires

replacementorrepairduetoaccidentsorlackofpropermaintenance

•Repairsnecessaryduetofailuretousefreshfuel(lessthanone

monthold),orfailuretoproperlypreparetheunitpriortoanyperiod

ofnon-useoveronemonth

•Engineandtransmission.Thesearecoveredbytheappropriate

manufacturer’sguaranteeswithseparatetermsandconditions

Allrepairscoveredbythesewarrantiesmustbeperformedbyan

AuthorizedToroServiceDealerusingToroapprovedreplacementparts.

*OriginalPurchasermeansthepersonwhooriginallypurchasedtheToroProduct.

1

SomeenginesusedonT oroProductsarewarrantedbytheenginemanufacturer.

2

Residentialusemeansuseoftheproductonthesamelotasyourhome.Useatmorethanone

locationisconsideredcommercialuseandthecommercialusewarrantywouldapply .

3

Whicheveroccursrst.

4

LifetimeFrameWarranty-Ifthemainframe,consistingofthepartsweldedtogethertoformthe

tractorstructurethatothercomponentssuchastheenginearesecuredto,cracksorbreaksin

normaluse,itwillberepairedorreplaced,atToro'soption,underwarrantyatnocostforparts

andlabor.Framefailureduetomisuseorabuseandfailureorrepairrequiredduetorustor

corrosionarenotcovered.

Thiswarrantyincludesthecostofpartsandlabor,butyoumustpay

transportationcosts.

Warrantymaybedeniedifthehourmeterisdisconnected,altered,or

showssignsofbeingtamperedwith.

GeneralConditions

Thepurchaseriscoveredbythenationallawsofeachcountry .Therights

towhichthepurchaserisentitledwiththesupportoftheselawsarenot

restrictedbythiswarranty.

374-0268RevD

Loading...

Loading...