Page 1

PowerMax

ModelNo.38814—SerialNo.400000000andUp

ModelNo.38819—SerialNo.400000000andUp

®

726OEand826OXESnowthrower

FormNo.3423-376RevA

Operator'sManual

Introduction

Thismachineisintendedtobeusedbyresidential

homeowners.Itisdesignedprimarilyforremoving

snowfrompavedsurfaces,suchasdrivewaysand

sidewalks,andothersurfacesfortrafconresidential

orcommercialproperties.Itisnotdesignedfor

removingmaterialsotherthansnow.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactT orodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

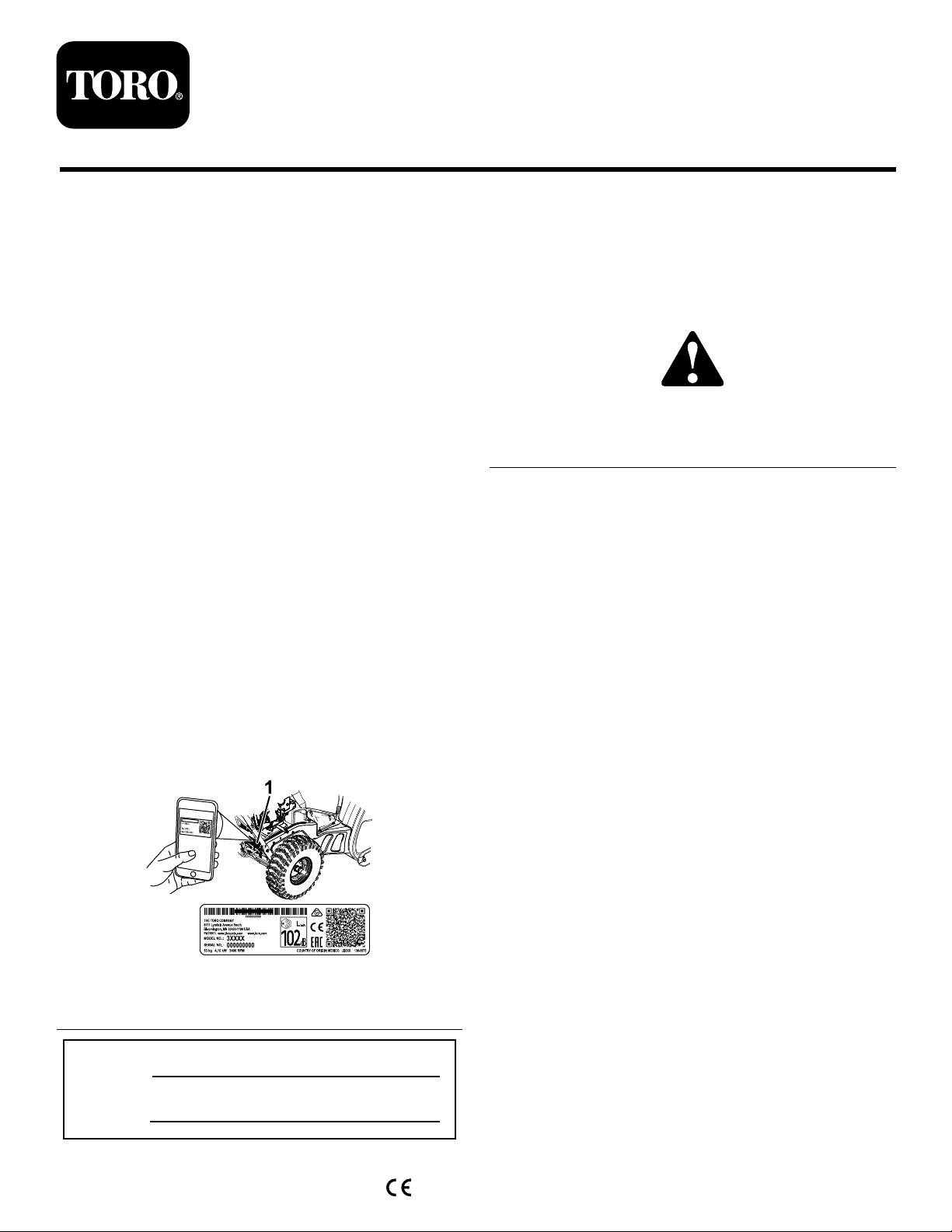

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

g219962

©2018—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedinMexico

AllRightsReserved

*3423-376*A

Page 2

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Important:Ifyouareusingthismachineabove

1500m(5,000ft)foracontinuousperiod,ensure

thattheHighAltitudeKithasbeeninstalled

sothattheenginemeetsCARB/EPAemission

regulations.TheHighAltitudeKitincreases

engineperformancewhilepreventingspark-plug

fouling,hardstarting,andincreasedemissions.

Onceyouhaveinstalledthekit,attachthe

high-altitudelabelnexttotheserialdecalonthe

machine.ContactanyAuthorizedToroService

DealertoobtaintheproperHighAltitudeKitand

high-altitudelabelforyourmachine.T olocate

adealerconvenienttoyou,accessourwebsite

atwww.Toro.comorcontactourToroCustomer

CareDepartmentatthenumber(s)listedinyour

EmissionControlWarrantyStatement.Remove

thekitfromtheengineandrestoretheengineto

itsoriginalfactorycongurationwhenrunningthe

engineunder1500m(5,000ft).Donotoperatean

enginethathasbeenconvertedforhigh-altitude

useatloweraltitudes;otherwise,youcould

overheatanddamagetheengine.

Ifyouareunsurewhetherornotyourmachinehas

beenconvertedforhigh-altitudeuse,lookforthe

followinglabel(Figure3).

decal127-9363

Figure3

Contents

Introduction...............................................................1

Safety.......................................................................3

GeneralSafety...................................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................6

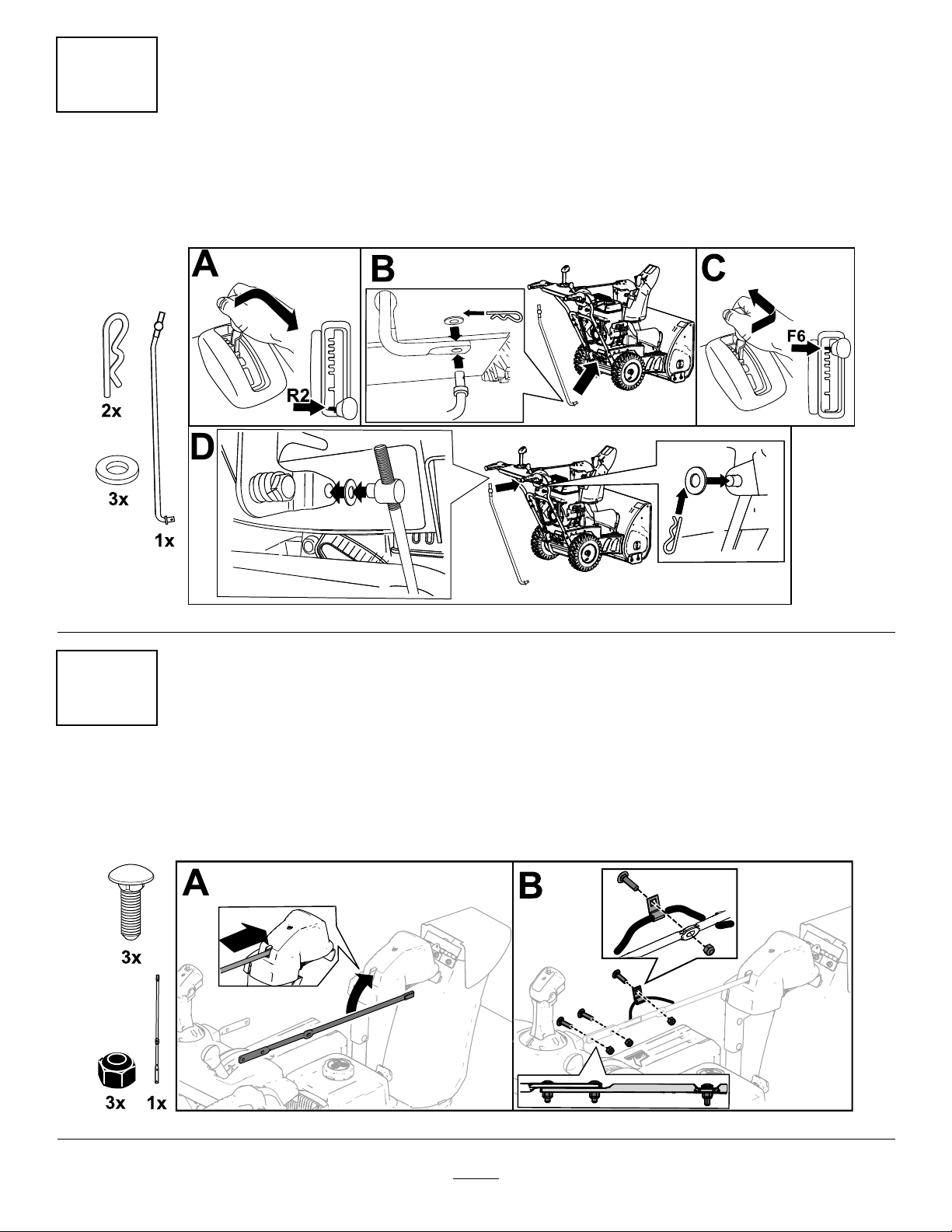

1InstallingtheUpperHandle..............................6

2InstallingtheChute..........................................6

3InstallingtheTraction-ControlLinkage.............6

4InstallingtheChute-ControlRod......................7

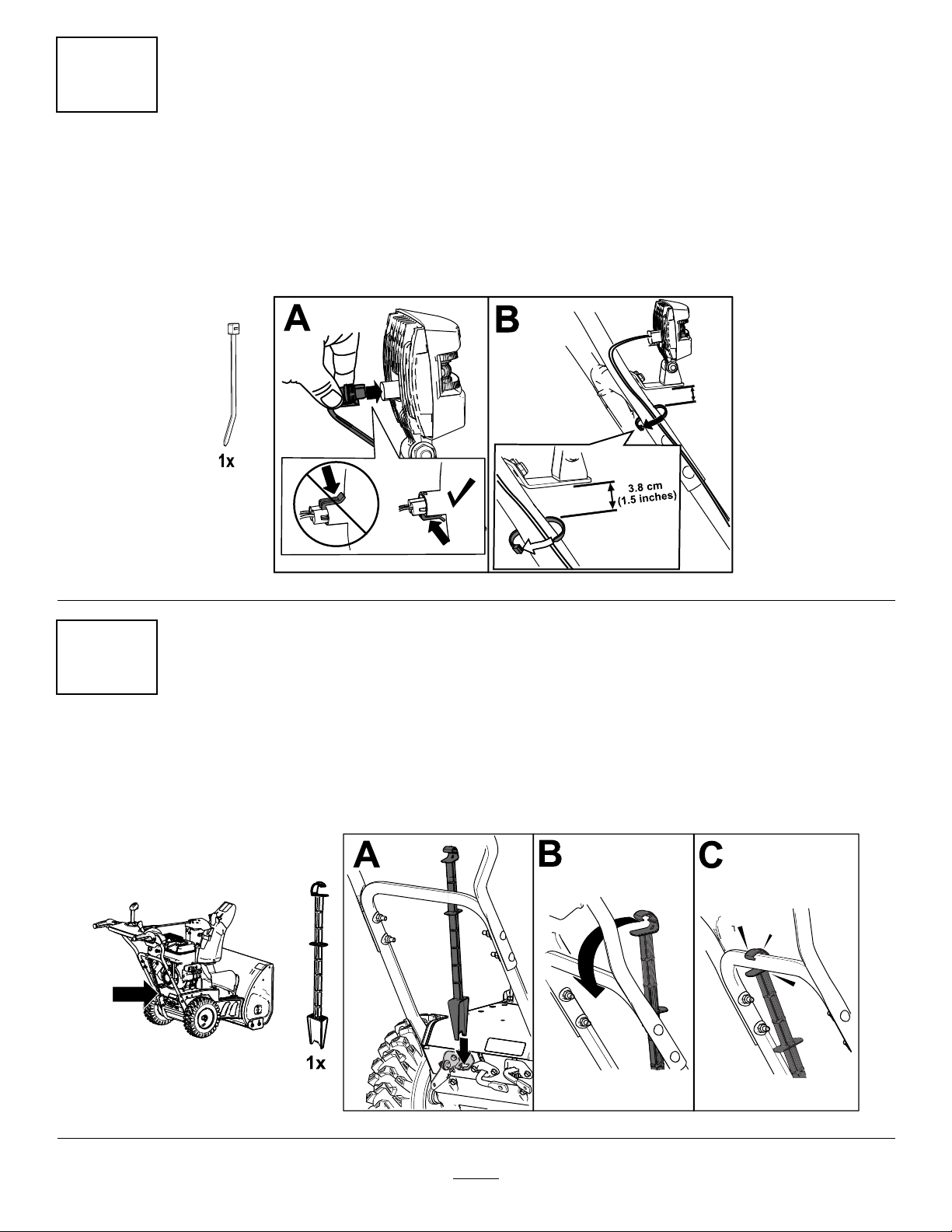

5ConnectingtheHeadlightWire.........................7

6InstallingtheSnow-CleanoutT ool....................8

7CheckingtheEngine-OilLevel.........................8

8CheckingtheTirePressure..............................9

9CheckingtheSkidsandScraper......................9

10CheckingtheOperationoftheTraction

Drive...............................................................9

ProductOverview....................................................11

Specications...................................................11

Attachments/Accessories..................................11

Operation................................................................12

BeforeOperation.................................................12

BeforeOperationSafety...................................12

FillingtheFuelT ank..........................................12

DuringOperation.................................................12

DuringOperationSafety...................................12

StartingtheEngine...........................................13

ShuttingOfftheEngine.....................................15

OperatingtheTractionDrive.............................15

OperatingtheSpeedSelector...........................15

OperatingtheAuger/ImpellerDrive...................15

OperatingtheQuickStick®...............................16

ClearingaCloggedDischargeChute................17

OperatingTips.................................................17

AfterOperation....................................................18

AfterOperationSafety......................................18

PreventingFreeze-upafterUse........................18

Maintenance...........................................................19

RecommendedMaintenanceSchedule(s)...........19

MaintenanceSafety..........................................19

PreparingforMaintenance...............................19

CheckingtheEngine-OilLevel..........................20

CheckingandAdjustingtheSkidsand

Scraper.........................................................20

CheckingandAdjustingtheTraction

Cable............................................................21

CheckingandAdjustingtheAuger/Impeller

Cable............................................................21

CheckingtheAuger-Gearbox-OilLevel.............22

ChangingtheEngineOil...................................22

LubricatingtheHexShaft..................................23

ReplacingtheSparkPlug.................................23

AdjustingtheDischarge-ChuteLatch................24

ReplacingtheDriveBelts..................................24

ReplacingtheHeadlight....................................25

Storage...................................................................25

StoringtheMachine..........................................25

RemovingtheMachinefromStorage................25

Troubleshooting......................................................26

2

Page 3

Safety

Thissnowthroweriscapableofinjuringhandsand

feetandofthrowingobjects.Failuretoobservethe

followingsafetyinstructionscouldresultinserious

injury.

GeneralSafety

ThismachinecomplieswithISO8437specications.

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

Ensurethateveryoneusingthisproductknows

howtouseit,knowshowtoshutofftheengine

quickly,andunderstandsthewarnings.

•Shutofftheenginewheneveryouleavethe

operatingpositionforanyreason.

•Donotputyourhandsorfeetnearmovingparts

onthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

working.

•Keepclearofanydischargeopening.Keep

bystanders,especiallysmallchildren,outofthe

operatingarea.

•Neverallowchildrentooperatethemachine.

3

Page 4

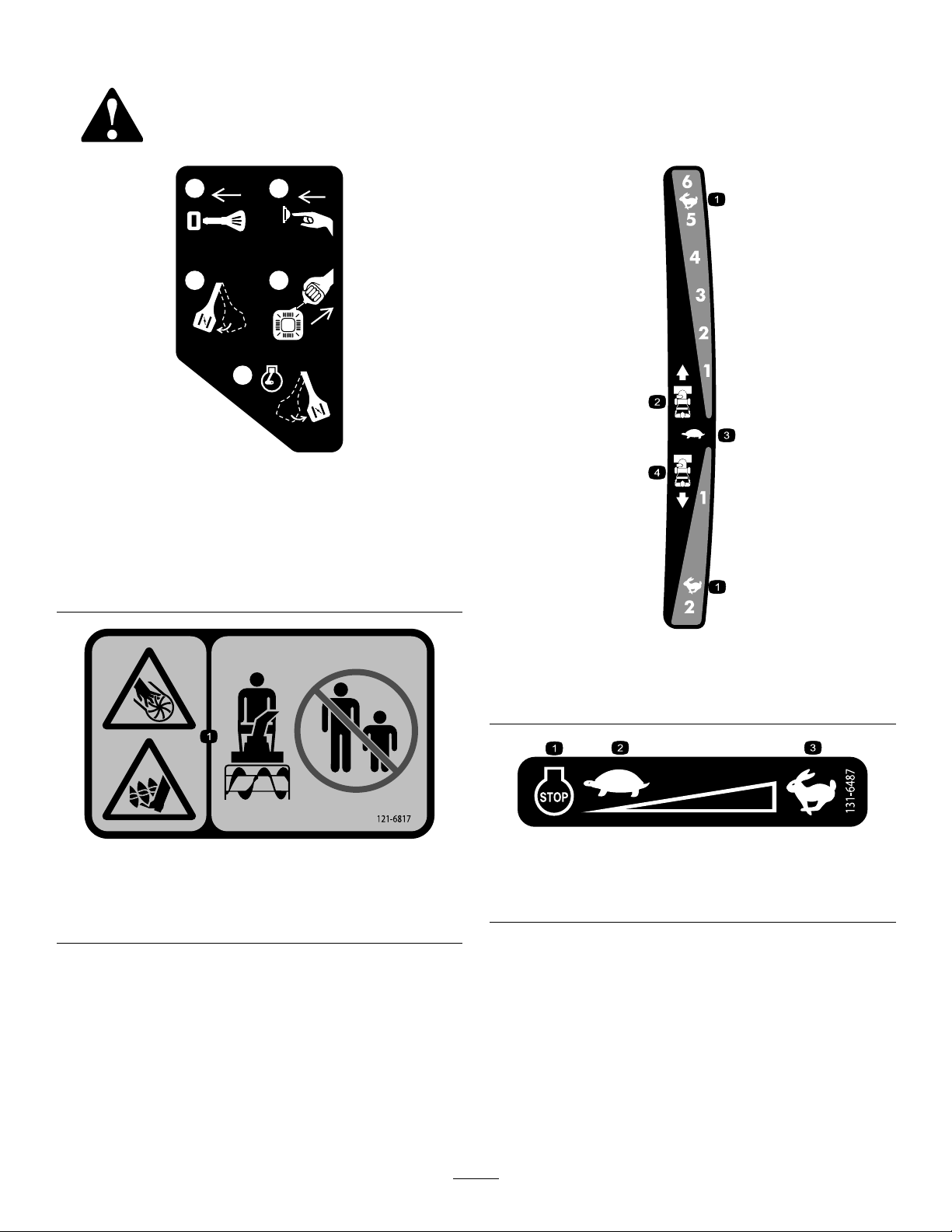

SafetyandInstructionalDecals

x 3

1

2

3

4

5

120-9805

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

120-9805

1.Insertthekey.

2.Primetheengine3times.

3.Engagethechoke.

4.Pullthestartercord.

5.Oncetheengineisrunning,disengagethechoke.

decal120-9805

decal121-6823

121-6823

1.Fast

2.Forwardspeeds4.Reversespeeds

decal121-6817

121-6817

1.Cutting/dismembermenthazardsofhandorfoot,impeller

andauger—keepbystandersasafedistanceawayfrom

themachine.

1.Engine—shutoff

2.Slow

3.Slow

decal131-6487

131-6487

3.Fast

4

Page 5

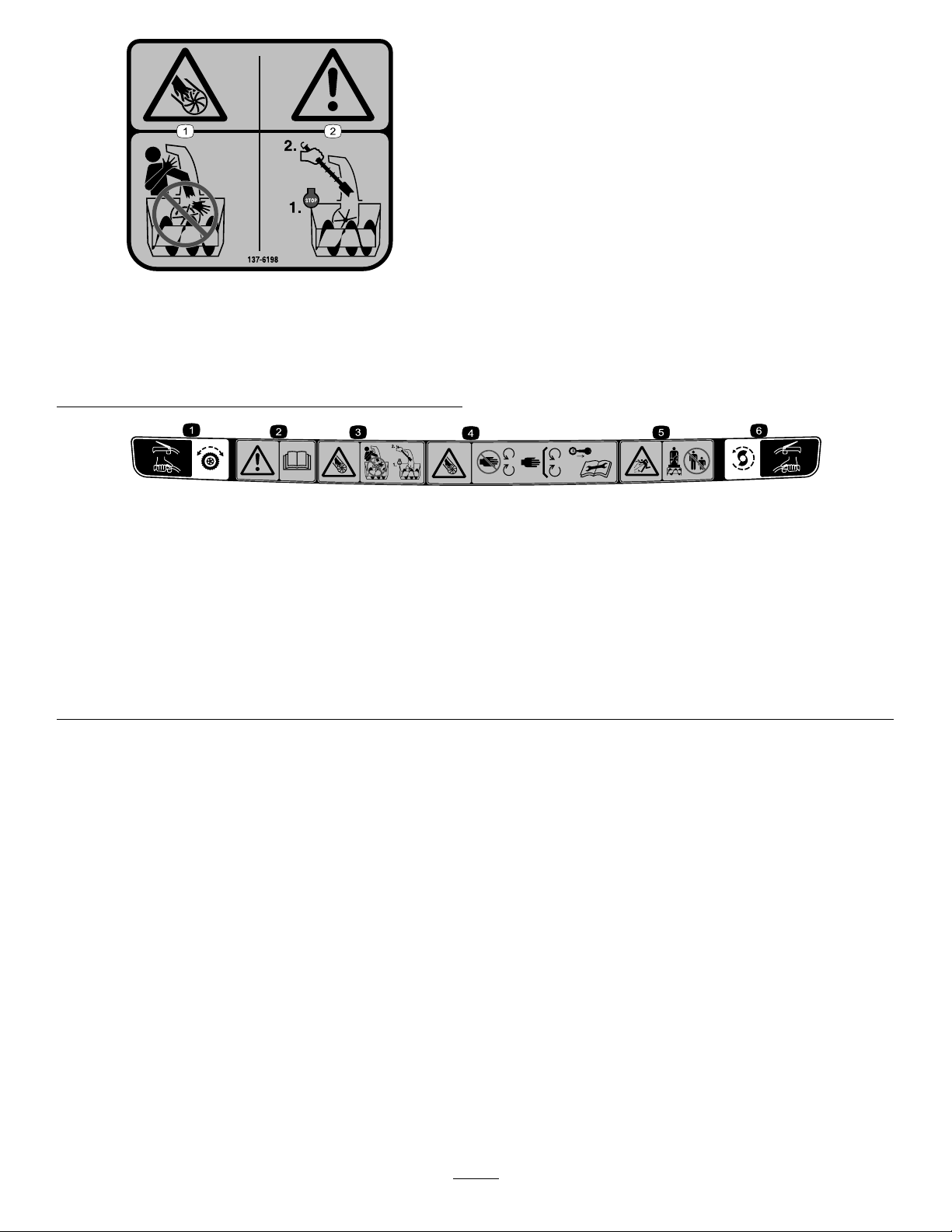

decal137-6198

137-6198

1.Cutting/dismemberment

hazardofthengersor

hand,impeller—donot

2.Warning—shutoffthe

enginebeforeusingthe

tooltoclearthechute.

placeyourhandinthe

chute.

121-1240

OrderPartNo.120-7194

1.Tractiondrive—squeezethelevertoengage;releasethe

levertodisengage.

2.Warning—readtheOperator’sManual.5.Thrownobjecthazard—keepbystandersasafedistance

3.Cutting/dismembermenthazard,impeller—donotplaceyour

handinthechute;shutofftheenginebeforeleavingthe

operator’spositionanduseatooltoclearthechute.

4.Cutting/dismembermenthazard,impeller—stayawayfrom

movingparts;keepallguardsandshieldsinplace;remove

theignitionkeyandreadtheinstructionsbeforeservicingor

performingmaintenance.

awayfromthemachine.

6.Auger/impellerdrive—squeezethelevertoengage;release

thelevertodisengage.

decal121-1240

5

Page 6

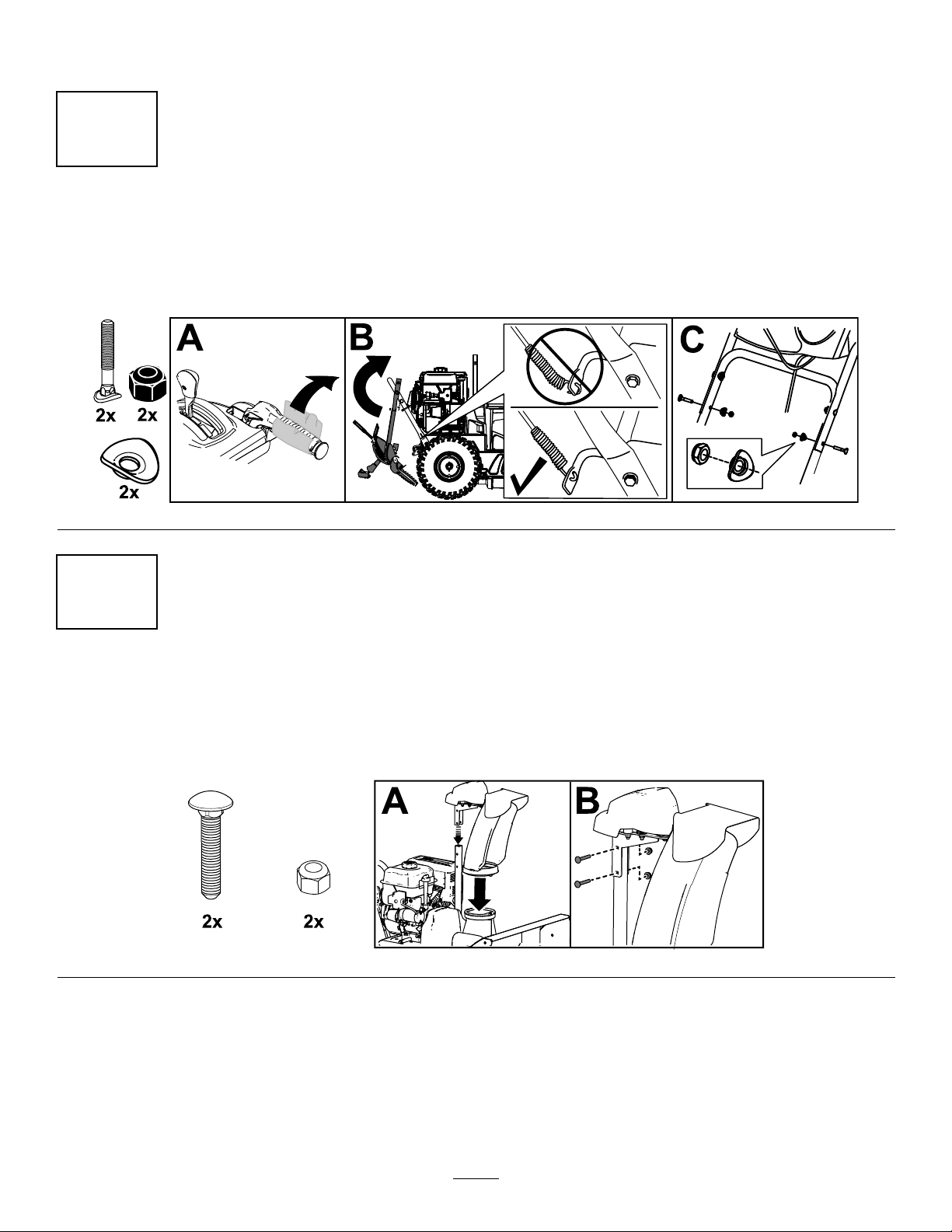

Setup

1

InstallingtheUpperHandle

NoPartsRequired

Procedure

g252379

2

InstallingtheChute

NoPartsRequired

Procedure

g252568

6

Page 7

3

InstallingtheTraction-ControlLinkage

NoPartsRequired

Procedure

4

InstallingtheChute-ControlRod

NoPartsRequired

Procedure

g252391

g252615

7

Page 8

5

ConnectingtheHeadlightWire

Model38819only

NoPartsRequired

Procedure

6

InstallingtheSnow-CleanoutTool

NoPartsRequired

Procedure

g254700

g252394

8

Page 9

7

CheckingtheEngine-OilLevel

NoPartsRequired

Procedure

Note:Yourmachinecomeswithoilintheenginecrankcase.Beforestartingtheengine,checktheoillevel

andaddoilifnecessary.

RefertoCheckingtheEngine-OilLevel(page20).

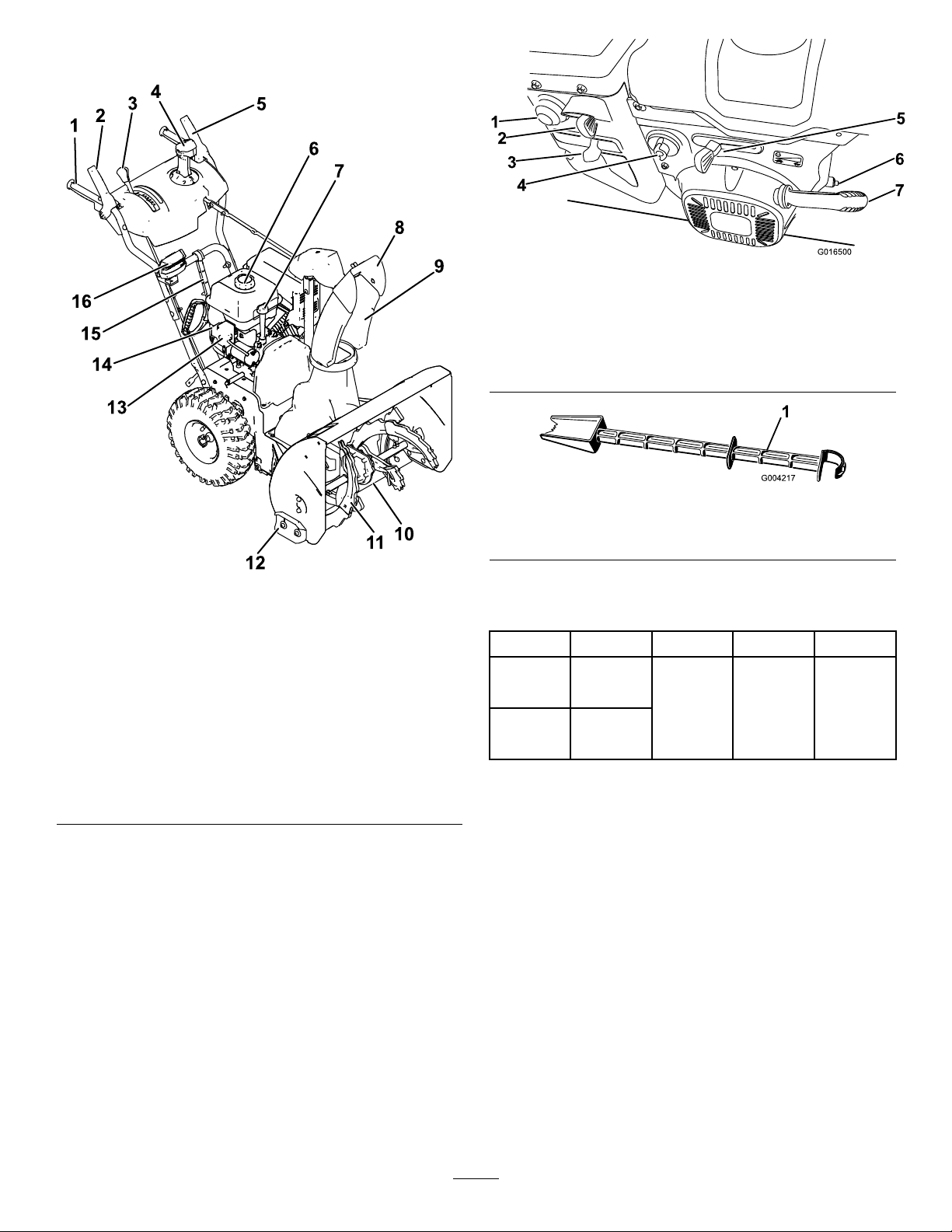

8

CheckingtheTirePressure

NoPartsRequired

Procedure

9

CheckingtheSkidsand Scraper

NoPartsRequired

g252396

Procedure

RefertoCheckingandAdjustingtheSkidsand

Scraper(page20).

9

Page 10

5.MovethespeedselectortoPosition1;referto

OperatingtheSpeedSelector(page15).

10

CheckingtheOperationof

theTractionDrive

NoPartsRequired

Procedure

CAUTION

Ifthetractiondriveisnotproperlyadjusted,

themachinemaymoveinthedirection

oppositeofwhatyouintended,causinginjury

and/orpropertydamage.

Carefullycheckthetractiondriveandadjustit

properly,ifnecessary.

1.Starttheengine;refertoStartingtheEngine

(page13).

6.Squeezetheleft(traction)levertothehandgrip

(Figure1 1).

Themachineshouldmoveforward.Ifthe

machinedoesnotmoveormovesrearward,

completethefollowing:

A.Releasethetractionleverandshutoffthe

engine.

B.Disconnectthetrunnionfromthe

speed-selectorlever.

C.Turnthetrunnionupward(counterclockwise)

onthespeed-controlrod.

D.Connectthetrunniontothespeed-selector

lever.

7.Ifyoumadeanyadjustments,repeatthis

procedureuntilnoadjustmentsarerequired.

Important:Ifthemachinemoveswhenthe

tractionleverisinthereleasedposition,checkthe

tractioncable;refertoCheckingandAdjusting

theTractionCable(page21)ortakethemachine

toanAuthorizedServiceDealerforservice.

2.MovethespeedselectortoPositionR1;referto

OperatingtheSpeedSelector(page15).

3.Squeezetheleft(traction)levertothehandgrip

(Figure1 1).

Figure11

Themachineshouldmoverearward.Ifthe

machinedoesnotmoveormovesforward,

completethefollowing:

A.Releasethetractionleverandshutoffthe

engine.

B.Disconnectthetrunnionfromthe

speed-selectorlever.

g001011

C.Turnthetrunniondownward(clockwise)on

thespeed-controlrod.

D.Connectthetrunniontothespeed-selector

lever.

4.Releasethetractionlever.

10

Page 11

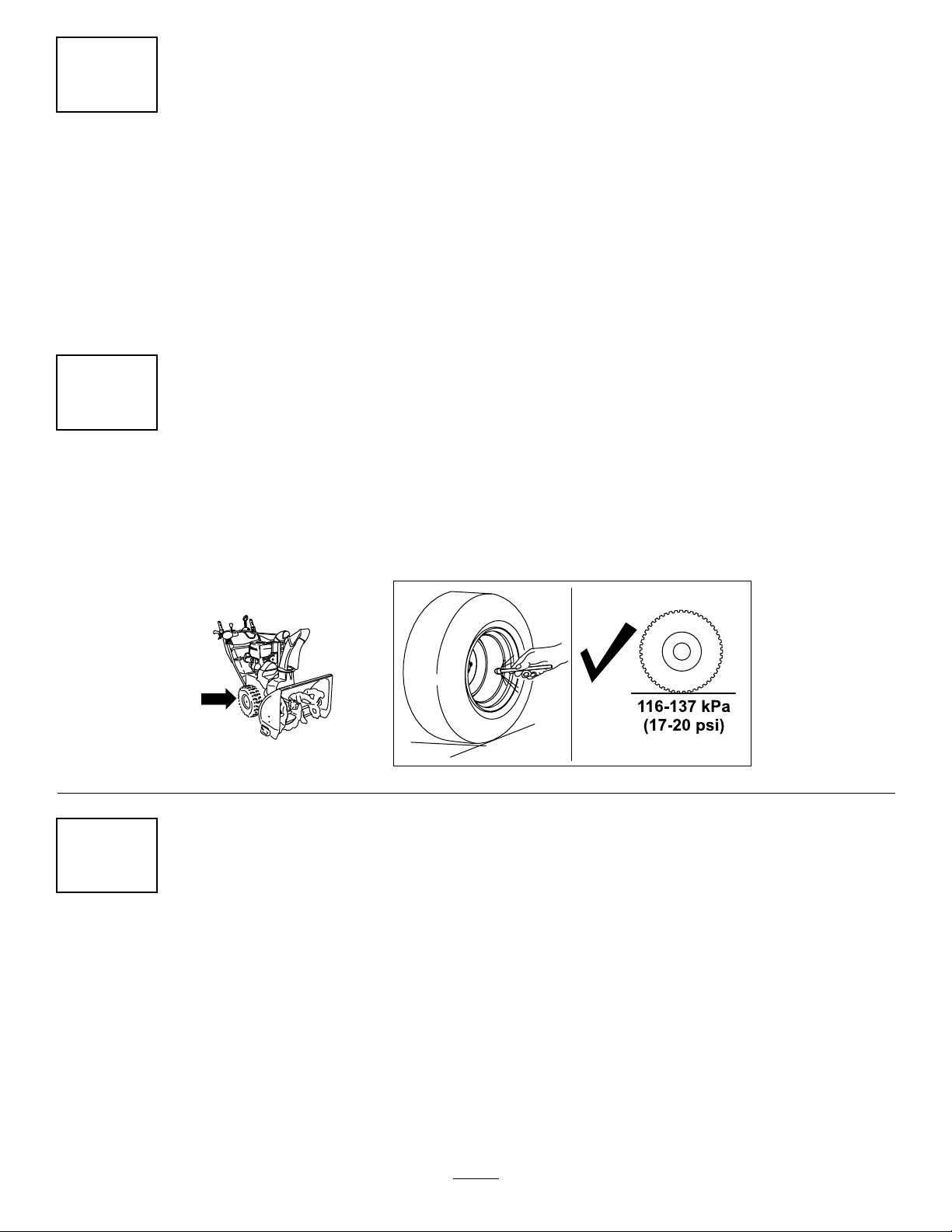

ProductOverview

g016500

Figure13

1.Primer5.Throttle

2.Ignitionswitch

3.Choke

4.Fuel-shutoffvalve

6.Oil-drainplug

7.Recoil-starthandle

g004217

Figure14

Figure12

1.Handgrip(2)

2.Auger/impellerlever10.Scraper

3.Speed-selectorlever

4.QuickStick®

discharge-chutecontrol

5.Tractionlever13.Electric-startbutton

6.Fuel-tankcap14.Electric-startplug-in

7.Oil-lltube/dipstick15.Snow-cleanouttool

8.Chutedeector16.Headlight(Model38819

9.Dischargechute

11.Auger

12.Skid(2)

only)

1.Snow-cleanouttool(attachedtothehandle)

g254701

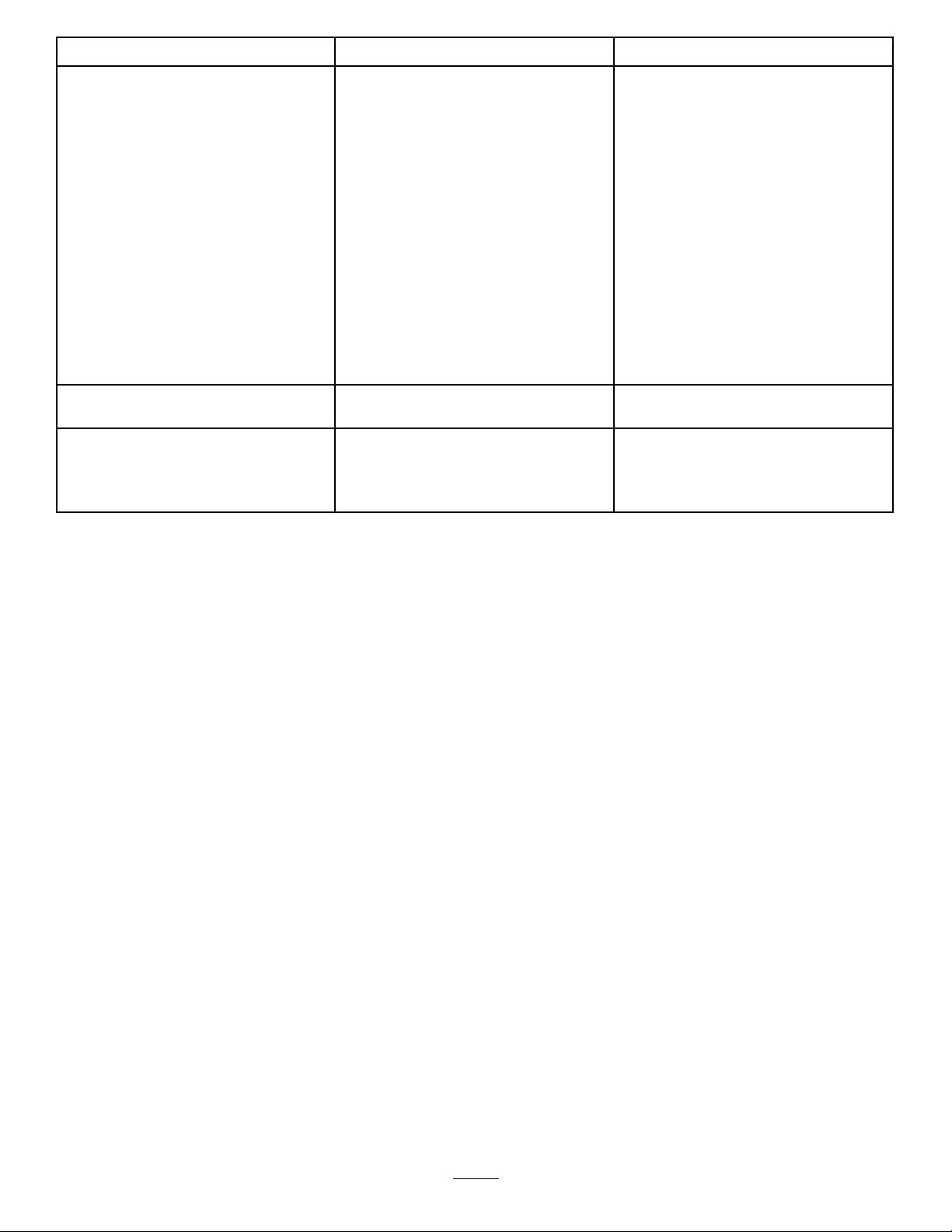

Specications

ModelWeightLengthWidthHeight

38814

38819

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.T oro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

79.4kg

(175lb)142cm71cm117cm

81.6kg

(180lb)

(56

inches)

(28

inches)

(46

inches)

11

Page 12

Operation

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Forelectric-startmodelsonly:Useextension

cordsandreceptaclesasspeciedinthemanual.

Inspecttheelectricalcordbeforepluggingitinto

apowersource.Ifthecordisdamaged,replace

it.Unplugthepowercordwheneveryouarenot

startingthemachine.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hair,securelooseclothing,anddonotwearloose

jewelry.

•Thoroughlyinspecttheareawhereyouwillusethe

machine,andremovealldoormats,sleds,boards,

wires,andotherforeignobjects.

•Ifashield,safetydevice,ordecalisdamaged,

illegible,ormissing,repairorreplaceitbefore

beginningoperation.Also,tightenanyloose

fasteners.

•Two-stagemodelsonly:Adjustthecollector

housingheighttoclearagravelorcrushed-rock

surface.

•Oxygenatedfuelwithupto10%ethanolor15%

MTBEbyvolumeisacceptable.

•Donotuseethanolblendsofgasoline(such

asE15orE85)withmorethan10%ethanolby

volume.Performanceproblemsand/orengine

damagemayresultwhichmaynotbecovered

underwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

Donotllabovethebottomofthefueltankneck

(Figure9).

g216203

Figure15

Important:Forbestresults,purchaseonlythe

quantityoffuelthatyouexpecttousein30days.

Otherwise,youmayusefuelstabilizer/conditioner

inthemachineatalltimestokeepthefuelfresh

longerwhenusedasdirectedbythefuel-stabilizer

manufacturer.

FuelSafety

Fuelisextremelyammableandexplosive.Areor

explosionfromfuelcanburnyouandothers.

•Topreventastaticchargefromignitingthefuel,

placethecontainerand/ormachineontheground

beforelling,notinavehicleoronanobject.

•Fillthefueltankoutdoorswhentheengineiscold.

Replacethefuelcapsecurelyandwipeupspills.

•Donothandlefuelwhensmokingoraroundan

openameorsparks.

•Storefuelinanapprovedfuelcontainer,outofthe

reachofchildren.

•Whenfuelisinthetank,tipthemachineonlyas

directedintheinstructions.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.

FillingtheFuelTank

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

DuringOperation

DuringOperationSafety

•Shutofftheenginebeforeuncloggingthe

machineandalwaysuseastickorthe

snow-cleanouttool(ifprovided).

•Staybehindthehandlesandawayfromthe

dischargeopeningwhileoperatingthemachine.

Keepyourface,hands,feet,andanyotherpart

ofyourbodyorclothingawayfrommovingor

rotatingparts.

•Neverdirectthedischargetowardpeopleorareas

wherepropertydamagecanoccur.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Exercisecautiontoavoidslippingorfalling,

especiallywhenoperatingthemachineinreverse.

•Alwaysbesureofyourfooting,andkeeparm

holdonthehandles.Walk;neverrun.

12

Page 13

•Exerciseextremecautionwhenoperatingthe

machineonaslope.

only),inspectthemachinefordamage.Repairany

damagebeforestartingthemachine.

•Donotoperatethemachinewithoutgoodvisibility

orlight.

•Lookbehindandusecarewhenbackingupthe

machine.

•Whennotactivelyclearingsnow,disengagepower

totheauger.

•Exerciseextremecautionwhenoperatingthe

machineonorcrossinggraveldrives(2-stage

modelsonly),walks,orroads.Stayalertforhidden

hazardsortrafc.

•Neverattempttomakeanyadjustmentswhile

theengineisrunning,exceptasdirectedinthe

instructions.

•Afterstrikingaforeignobject,shutofftheengine,

removetheignitionkey(electric-startmodels

StartingtheEngine

Electric-StartModel

•Ifthemachinestartstovibrateabnormally,shutoff

theengineandcheckimmediatelyforthecause.

•Donotruntheengineindoors;exhaustfumesare

dangerous.

•Donotoverloadthemachinecapacityby

attemptingtoclearsnowattoofastarate.

•Disengageallclutchesandshiftintoneutralbefore

startingtheengine.

•Shutofftheenginewheneveryouleavethe

operatingposition,beforeclearingorunclogging

thecollector,impeller,ordischargechute,and

whenmakinganyrepairs,adjustments,or

inspections.

•Neveroperatethemachineathightransport

speedsonslipperysurfaces.

Note:T ousetheelectricstarter(electric-startmodelsonly),connectapowercordtotheplug-inrstandthen

toapoweroutlet.UseonlyaUL-listed,16-gaugeextensioncordrecommendedforoutdoorusethatisnot

longerthan50ft(15m).

WARNING

Theelectricalcordcanbecomedamaged,causingashockorre.

Thoroughlyinspecttheelectricalcordbeforeusingthemachine.Ifthecordisdamaged,do

notuseit.Replaceorrepairthedamagedcordimmediately .ContactanAuthorizedService

Dealerforassistance.

CAUTION

Ifyouleavethemachinepluggedintoapoweroutlet,someonecaninadvertentlystartthe

machineandinjurepeopleordamageproperty.

Unplugthepowercordwheneveryouarenotstartingthemachine.

13

Page 14

StandardModel

g254927

Figure16

g254928

Figure17

14

Page 15

ShuttingOfftheEngine

g252411

Figure18

OperatingtheTraction Drive

CAUTION

Ifthetractiondriveisnotproperlyadjusted,

themachinemaymoveinthedirection

oppositeofwhatyouintended,causinginjury

and/orpropertydamage.

Carefullycheckthetractiondriveandadjust

itproperly,ifnecessary;refertoChecking

andAdjustingtheTractionCable(page21)for

moreinformation.

Important:Ifthemachinemoveswhenthe

tractionleverisinthereleasedposition,checkthe

tractioncable;refertoCheckingandAdjusting

theTractionCable(page21)ortakethemachine

toanAuthorizedServiceDealerforservice.

1.Toengagethetractiondrive,squeezetheleft

(traction)levertothehandgrip(Figure19).

OperatingtheSpeed Selector

Thespeedselectorhas6forwardand2reverse

gears.T ochangespeeds,releasethetractionlever

andshiftthespeed-selectorlevertothedesired

position(Figure20).Theleverlocksinanotchat

eachspeedselection.

g001012

Figure20

Operatingthe

Figure19

2.Tostopthetractiondrive,releasethetraction

lever.

Auger/ImpellerDrive

1.Toengagetheauger/impellerdrive,squeeze

theright(auger/impeller)levertothehandgrip

(Figure21).

g001011

g001013

Figure21

2.Tostoptheaugerandimpeller,releasetheright

lever.

15

Page 16

Important:Whenyouengageboththe

auger/impellerleverandthetractionlever,

thetractionleverlockstheauger/impeller

leverdown,freeingyourrighthand.To

releasebothlevers,simplyreleasetheleft

(traction)lever.

3.Iftheaugerandimpellercontinuetorotatewhen

youreleasetheauger/impellerlever,donot

operatethemachine.Checktheauger/impeller

cable;refertoCheckingandAdjustingthe

Auger/ImpellerCable(page21)andadjustitif

necessary.Otherwise,takethemachinetoan

AuthorizedServiceDealerforservice.

WARNING

OperatingtheQuickStick®

HoldthebluetriggercapdowntousetheQuickStick

tomovethedischargechuteandthechutedeector.

Releasethetriggercaptolockthedischargechute

andchutedeectorintoposition(Figure22).

Iftheaugerandimpellercontinue

torotatewhenyoureleasethe

auger/impellerlever,youcouldseriously

injureyourselforothers.

Donotoperatethemachine.Takeittoan

AuthorizedServiceDealerforservice.

g001014

Figure22

MovingtheDischargeChute

HoldthebluetriggercapdownandmovetheQuick

Sticktothelefttomovethedischargechutetothe

left;movetheQuickSticktotherighttomovethe

dischargechutetotheright(Figure23).

Figure23

•Ifthechutedoesnotmove,refertoAdjustingthe

Discharge-ChuteLatch(page24).

•Ifthechutedoesnotturnasfartotheleftasit

doestotheright,ensurethatthecableisroutedto

theinsideofthehandles.Referto1Installingthe

UpperHandle(page6).

•Ifthechutedoesnotlockintoplacewhenyou

releasethetriggercap,refertoAdjustingthe

Discharge-ChuteLatch(page24).

16

g018894

Page 17

MovingtheChuteDeector

HoldthebluetriggercapdownandmovetheQuick

Stickforwardtolowerthechutedeector;moveit

rearwardtoraisethechutedeector(Figure24).

OperatingTips

DANGER

Whenthemachineisinoperation,theimpeller

andaugerrotateandcaninjureoramputate

handsorfeet.

•Beforeadjusting,cleaning,inspecting,

troubleshooting,orrepairingthemachine,

shutofftheengineandwaitforallmoving

partstostop.Disconnectthewirefrom

thesparkplugandkeepitawayfromthe

plugtopreventsomeonefromaccidentally

startingtheengine.

Figure24

ClearingaClogged DischargeChute

WARNING

Iftheauger/impellerisrunningbutthereisno

snowcomingoutofthedischargechute,the

dischargechutemaybeclogged.

Neveruseyourhandstoclearaclogged

dischargechute.Thiscouldresultinpersonal

injury.

•Tounclogthedischargechute,stayinthe

operatingpositionandreleasetheleft(traction)

lever.Whilerunningtheauger/impeller,pushdown

onthehandlestoraisethefrontofthemachinea

fewcentimeters(inches)offthepavement.Then

liftthehandlesquicklytobumpthefrontofthe

machineonthepavement.Repeatifnecessary

untilastreamofsnowcomesoutthedischarge

chute.

•Ifyoucannotunclogthedischargechuteby

bumpingthefrontofthemachine,shutoffthe

engine,waitforallmovingpartstostop,and

usethesnow-cleanouttool(Figure14).

Important:Uncloggingthedischargechute

bybumpingthefrontofthemachineonthe

pavementmaycausetheskidstomove.Adjust

theskidsandtightentheskidboltssecurely;

refertoCheckingandAdjustingtheSkidsand

Scraper(page20).

g001016

chute;refertoClearingaClogged

DischargeChute(page17).Usethe

snow-cleanouttool(Figure9),notyour

hands,toremoveanobstructionfromthe

dischargechute.

•Staybehindthehandlesandawayfrom

thedischargeopeningwhileoperatingthe

machine.

•Keepyourface,hands,feet,andanyother

partofyourbodyorclothingawayfrom

concealed,moving,orrotatingparts.

WARNING

Theimpellercanthrowstones,toys,andother

foreignobjectsandcauseseriouspersonal

injurytoyouorbystanders.

•Keeptheareatobeclearedfreeofall

objectsthattheaugercouldpickupand

throw.

•Keepallchildrenandpetsawayfromthe

areaofoperation.

•AlwayssetthethrottletotheFASTpositionwhen

throwingsnow.

•Iftheengineslowsdownunderaloadorthe

wheelsslip,shiftthemachineintoalowergear.

•Ifthefrontofthemachineridesup,shiftthe

machineintoalowergear.Ifthefrontcontinuesto

rideup,liftuponthehandles.

•Removeanobstructionfromthedischarge

17

Page 18

AfterOperation

AfterOperationSafety

•Neverstorethemachinewithfuelinthefuel

tankinsideabuildingwhereignitionsourcesare

present,suchashotwaterheaters,spaceheaters,

orclothesdryers.Allowtheenginetocoolbefore

storingthemachineinanyenclosure.

•Whenstoringthemachineformorethan30

days,refertoStorage(page25)forimportant

information.

•Runthemachineafewminutesafterthrowing

snowtopreventfreeze-upofthecollectorand

impeller.

PreventingFreeze-upafter Use

•Insnowyandcoldconditions,somecontrolsand

movingpartsmayfreeze.Donotuseexcessive

forcewhentryingtooperatefrozencontrols.

Ifyouhavedifcultyoperatinganycontrolorpart,

starttheengineandletitrunforafewminutes.

•Afterusingthemachine,lettheenginerunfor

afewminutestopreventmovingpartsfrom

freezing.Engagetheauger/impellertoclearany

remainingsnowfrominsidethehousing.Rotate

theQuickSticktopreventitfromfreezing.Shutoff

theengine,waitforallmovingpartstostop,and

removealliceandsnowfromthemachine.

•Withtheengineoff,pulltherecoil-starthandle

severaltimesandpushtheelectric-startbutton

oncetopreventtherecoilstarterandelectric

starterfromfreezingup.

18

Page 19

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst5hours

Beforeeachuseordaily

Every100hours

Yearly

Yearlyorbeforestorage

MaintenanceProcedure

•Inspectthetractioncableandadjustitifnecessary.

•Inspecttheauger/impellercableandadjustitifnecessary .

•Changetheengineoil.

•Checktheengine-oillevelandaddoilifnecessary.

•Replacethesparkplug.

•Checktheskidsandthescraperandadjustthemifnecessary.

•Inspectthetractioncableandadjustorreplaceitifnecessary.

•Inspecttheauger/impellercableandadjustorreplaceitifnecessary.

•Checktheauger-gearboxoilandaddoilifnecessary.

•Changetheengineoil.

•Lubricatethehexshaft.

•Checktheairpressureinthetiresandinatethemto1 16to137kPa(17to20psi).

•Drainthegasolineandruntheenginetodryoutthefueltankandthecarburetorat

theendoftheseason.

•HaveanAuthorizedServiceDealerinspectandreplacethetraction-drivebeltand/or

theauger/impellerdrivebelt,ifnecessary.

Important:Y oucanndmoreinformationaboutmaintainingandservicingyourmachineat

www.Toro.com.

MaintenanceSafety

Readthefollowingsafetyprecautionsbefore

performinganymaintenanceonthemachine:

•Beforeservicing,adjusting,orcleaningthe

machine,shutofftheengineandremovethe

key.Ifmajorrepairsareeverneeded,contactan

AuthorizedServiceDealer.

•Alwaysweareyeprotectionwhileperformingan

adjustmentorrepairtoprotectyoureyesfrom

foreignobjectsthatthemachinemaythrow.

•Checkallfastenersatfrequentintervalsforproper

tightnesstoensurethatthemachineisinsafe

workingcondition.

•Donotchangethegovernorsettingsontheengine.

PurchaseonlygenuineTororeplacementparts

andaccessories.

PreparingforMaintenance

1.Movethemachinetoalevelsurface.

2.Shutofftheengineandwaitforallmovingparts

tostop.

3.Disconnectthespark-plugwire.Referto

ReplacingtheSparkPlug(page23).

19

Page 20

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily—Checktheengine-oillevelandaddoilifnecessary.

g252395

CheckingandAdjustingthe SkidsandScraper

ServiceInterval:Y early—Checktheskidsand

thescraperandadjustthemif

necessary.

Checktheskidsandthescrapertoensurethatthe

augerdoesnotcontactthepavedorgravelsurface.

Adjusttheskidsandthescraperasneededto

compensateforwear.

1.Checkthetirepressure;referto8Checkingthe

TirePressure(page9).

2.Loosenthenutsthatsecurebothskidstothe

augersidesuntiltheskidsslideupanddown

easily.

Important:Theaugerbladesmustbe

supportedabovethegroundbytheskids.

3.Ensurethatthescraperis3mm(1/8inch)above

andparalleltoalevelsurface.

Note:Ifthepavementiscracked,rough,or

uneven,adjusttheskidstoraisethescraper.For

gravelsurfaces,adjusttheskidsfurtherdownto

preventthemachinefrompickinguprocks.

4.Movetheskidsdownuntiltheyareevenwith

theground.

5.Firmlytightenthenutsthatsecurebothskids

totheaugersides.

Note:T oquicklyadjusttheskidsiftheyloosen,

supportthescraper3mm(1/8inch)offthe

pavement,thenadjusttheskidsdowntothe

pavement.

Note:Iftheskidsbecomeexcessivelyworn,

youcanturnthemoverandsettheunusedside

towardthepavement.

1.3mm(1/8inch)

g019046

Figure26

20

Page 21

CheckingandAdjustingthe TractionCable

ServiceInterval:Aftertherst2hours—Inspect

thetractioncableandadjustitif

necessary.

Yearly—Inspectthetractioncableandadjustor

replaceitifnecessary.

Ifthemachinedoesnotdriveintheforwardorreverse

speedsoritdriveswhenyoureleasethetractionlever,

adjustthetractioncable.

Iftheleft(traction)cableisnotproperlyadjusted,do

thefollowingsteps:

1.Loosenthejamnut.

2.Engagethetractionleverandholditinplace

(Figure27).

g030998

Figure28

Figure27

3.Loosenortightentheturnbuckletoadjustthe

springlengthto5.5cm(2–3/16inches)as

showninFigure28.

g001011

1.Jamnut

2.Turnbuckle

4.Tightenthejamnut(Figure28),ensuringthat

thereisslighttensiononthecable.

5.Ifthetractioncableisproperlyadjustedbuta

problemremains,contactanAuthorizedService

Dealer.

3.Spring

4.5.5cm(2–3/16inches)

CheckingandAdjustingthe Auger/ImpellerCable

ServiceInterval:Aftertherst2hours—Inspectthe

auger/impellercableandadjustitif

necessary.

Yearly—Inspecttheauger/impellercableand

adjustorreplaceitifnecessary.

1.Loosenthejamnut.

2.Engagetheauger/impellerleverandholditin

place(Figure29).

g001013

Figure29

21

Page 22

3.Loosenortightentheturnbuckletoadjustthe

springlengthto7cm(2-3/4inches)asshown

inFigure30.

Figure30

1.Jamnut

2.Turnbuckle

3.Spring

4.7cm(2-3/4inches)

3.Removethepipeplugfromthegearbox.

4.Checktheoillevelinthegearbox.Theoilshould

be9.5mm(3/8inch)belowthelleropening.

5.Iftheoillevelislow,addGL-5orGL-6,SAE

80-90EPgearoillubricanttothegearboxuntil

theoillevelis9.5mm(3/8inch)belowtheller

opening.

Note:Donotusesyntheticoil.

6.Installthepipepluginthegearbox.

ChangingtheEngineOil

ServiceInterval:Aftertherst5hours—Changethe

engineoil.

Yearly—Changetheengineoil.

Ifpossible,runtheengineforafewminutesbefore

changingtheoilbecausewarmoilowsbetterand

carriesmorecontaminants.

g031000

Engineoilcapacity

OilviscosityRefertoFigure32.

APIserviceclassicationSJorhigher

0.70L(24oz)

4.Tightenthejamnut(Figure30),ensuringthat

thereisslighttensiononthecable.

5.Iftheauger/impellercableisproperlyadjusted

butaproblemremains,contactanAuthorized

ServiceDealer.

Checkingthe Auger-Gearbox-OilLevel

ServiceInterval:Y early—Checktheauger-gearbox

oilandaddoilifnecessary.

1.Movethemachinetoalevelsurface.

2.Cleantheareaaroundthepipeplug(Figure31).

UseFigure32belowtoselectthebestoilviscosityfor

theoutdoortemperaturerangeexpected:

g019049

Figure32

1.Cleantheareaaroundtheoil-draincap(Figure

33).

1.Pipeplug

Figure31

g016782

Figure33

1.Oil-draincap

22

g001026

Page 23

2.Slideanoil-drainpanunderthedrainextension

andremovetheoil-draincap.

3.Draintheoil.

Note:Disposeoftheusedoilproperlyatalocal

recyclingcenter.

4.Installtheoil-draincap.

5.Fillthecrankcasewithoil.

LubricatingtheHexShaft

ServiceInterval:Yearly—Lubricatethehexshaft.

Lightlylubricatethehexshaftyearlywithautomotive

engineoil(Figure34).

Figure34

1.Hexshaft

2.Steelfrictionpulley

3.Rubberwheel

Important:Donotgetoilontherubberwheelor

thesteelfrictionpulleybecausethetractiondrive

willslip(Figure34).

1.Drainthefuelfromthefueltank.

2.Tipthemachineforwardontoitsaugerhousing

andblockitsothatitcannotfall.

3.Removethebackcover(Figure35).

g019019

Figure35

1.Screws

4.Movethespeed-selectorlevertoPositionR2.

5.Dipyourngerinautomotiveengineoiland

lightlylubricatethehexshaft.

6.Movethespeed-selectorlevertoPosition6.

7.Lubricatetheotherendofthehexshaft.

8.Movethespeed-selectorleverforwardand

rearwardafewtimes.

9.Installthebackcoverandreturnthemachineto

g019018

theoperatingposition.

ReplacingtheSparkPlug

ServiceInterval:Every100hours—Replacethe

sparkplug.

WARNING

Replacingthesparkplugwhiletheengineis

hotcanresultinburns.

Waituntiltheengineiscooltoreplacethe

sparkplug.

UseaT orosparkplugorequivalent(Champion®

RN9YCorNGKBPR6ES).

1.Removetheboot(Figure36).

23

Page 24

Note:Ensurethattheignitionwiresnaps

completelyintoplaceonthesparkplug.

Adjustingthe Discharge-ChuteLatch

Ifthedischargechutedoesnotlockintothedesired

positionordoesnotunlocksothatyoucanmoveitto

anotherposition,adjustthedischarge-chutelatch.

Figure36

1.Spark-plugboot

2.Cleanaroundthebaseofthesparkplug.

Figure37

3.Removeanddiscardtheoldsparkplug.

Note:Y ouwillneedaratchetwrenchextension

toremovethesparkplug.

4.Setthegapbetweentheelectrodesonanew

sparkplugat0.76mm(0.030inch)asshown

inFigure38.

g016645

1.Loosentheclampfasteneronthechute-support

plateuntilthecableisfree.

g019021

g016646

1.Cableconduit3.Clampfastener

2.Cableclamp

Figure39

2.Removeanyslackinthecablebypullingthe

cableconduitrearward.

3.Tightentheclampfastenerwhileholdingthe

cableinplace.

Figure38

1.0.76mm(0.030inch)

5.Installthenewsparkplug,tightenitrmly ,and

attachtheignitionwiretothesparkplug.

ReplacingtheDriveBelts

Iftheauger/impellerdrivebeltorthetraction-drivebelt

becomesworn,oil-soaked,orotherwisedamaged,

haveanAuthorizedServiceDealerreplacethebelt.

g001029

24

Page 25

ReplacingtheHeadlight

Model38819only

Replacetheheadlightassembly(T oropartnumber138-0670)whenneeded.

1.Removetheheadlightwirefromthebackoftheheadlight(AofFigure40).

2.Removetheboltandnutholdingtheheadlightassemblyontotheheadlightbracketandthenremovethe

oldheadlightassembly(BofFigure40).

3.Securethenewheadlightassemblyontotheheadlightbracketwiththepreviouslyremovednutand

bolt(CofFigure40).

4.Inserttheheadlightwirestraightintothebackoftheheadlightuntilitissecurelyinplace(DofFigure40).

Storage

StoringtheMachine

1.Onthelastrefuelingoftheyear,addfuel

stabilizertofreshfuelasdirectedbythefuel

stabilizermanufacturer.

Important:Donotstorefuellonger

thanthatsuggestedbythefuelstabilizer

manufacturer.

2.Runtheenginefor10minutestodistributethe

conditionedfuelthroughthefuelsystem.

3.Runthemachineuntiltheenginerunsoutoffuel.

4.Primetheengineandstartitagain.

5.Allowtheenginetorununtilitshutsoff.

Whenyoucannolongerstarttheengine,itis

sufcientlydry.

6.Allowtheenginetocool.

7.Removetheignitionkey.

8.Cleanthemachinethoroughly.

9.Touchupchippedsurfaceswithpaintavailable

fromanAuthorizedServiceDealer.Sand

affectedareasbeforepainting,andusearust

g256137

Figure40

preventativetopreventthemetalpartsfrom

rusting.

10.Tightenallloosescrews,bolts,andlocknuts.

Repairorreplaceanydamagedparts.

11.Coverthemachineandstoreitinaclean,dry

placeoutofthereachofchildren.

RemovingtheMachine fromStorage

Performtheannualmaintenanceproceduresasgiven

intheRecommendedMaintenanceSchedule;referto

Maintenance(page19).

25

Page 26

Troubleshooting

Problem

Theelectricstarterdoesnotturn

(electric-startmodelsonly).

Theenginedoesnotstartorstartshard.

PossibleCauseCorrectiveAction

1.Thepowercordisdisconnectedatthe

outletorthemachine.

2.Thepowercordisworn,corroded,or

damaged.

3.Thepoweroutletisnotenergized.

1.Thekeyisnotintheignitionorisinthe

STOPposition.

2.ThechokeisintheOFFpositionand

theprimerhasnotbeenpressed.

3.Thefuel-shutoffvalveisnotopen.3.Openthefuel-shutoffvalve.

4.ThethrottleisnotintheFASTposition.4.MovethethrottletotheFASTposition.

5.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

6.Thespark-plugwireislooseor

disconnected.

7.Thesparkplugispitted,fouled,orthe

gapisincorrect.

8.Thefuel-ventcapisrestricted.

9.Theengine-oillevelintheengine

crankcaseistoolowortoohigh.

1.Connectthepowercordtotheoutlet

and/orthemachine.

2.Replacethepowercord.

3.Haveaqualiedelectricianenergize

theoutlet.

1.Insertthekeyintotheignitionandturn

ittotheONposition.

2.MovethechoketotheONpositionand

presstheprimer3times.

5.Drainand/orllthefueltankwith

freshfuel(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

6.Connectthewiretothesparkplug.

7.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

8.Removetheventrestrictionorreplace

thefuelcap.

9.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

Theenginerunsrough.

1.ThechokeisintheONposition.1.MovethechoketotheOFFposition.

2.Thefuel-shutoffvalveisnotcompletely

open.

3.Thefueltankisnearlyemptyor

containsstalefuel.

4.Thespark-plugwireisloose.

5.Thesparkplugispitted,fouled,orthe

gapisincorrect.

6.Theengine-oillevelintheengine

crankcaseistoolowortoohigh.

2.Openthefuel-shutoffvalve.

3.Drainandllthefueltankwithfresh

fuel(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

4.Connectthewiretothesparkplug.

5.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

6.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

26

Page 27

Problem

PossibleCauseCorrectiveAction

Theengineruns,butthemachine

dischargessnowpoorlyornotatall.

Thedischargechuteeitherdoesnotlock

intoplaceordoesnotmove.

Themachinedoesnotproperlyclearthe

snowoffthesurface.

1.ThethrottleisnotintheFASTposition

whenthrowingsnow .

2.Themachineismovingtoofasttoclear

thesnow.

3.Y ouaretryingtoremovetoomuch

snowperswath.

4.Y ouaretryingtoremoveextremely

heavyorwetsnow.

5.Thedischargechuteisplugged.5.Unclogthedischargechute.

6.Theauger/impellerdrivebeltisloose

orisoffthepulley.

7.Theauger/impellerdrivebeltisworn

orbroken.

1.Thedischarge-chutelatchisnot

properlyadjusted.

1.Theskidsand/orscraperarenot

properlyadjusted.

2.Thepressureinthetiresisnotequal.

1.MovethethrottletotheFASTposition.

2.Shiftthemachineintoalowergear.

3.Reducetheamountofsnowremoved

perswath.

4.Donotoverloadthemachinewith

extremelyheavyorwetsnow.

6.Installand/oradjusttheauger/impeller

drivebelt;refertowww.Toro.com

forservicinginformationortakethe

machinetoanAuthorizedService

Dealer.

7.Replacetheauger/impellerdrivebelt;

refertowww.Toro.comforservicing

informationortakethemachinetoan

AuthorizedServiceDealer.

1.Adjustthedischarge-chutelatch.

1.Adjusttheskidsand/orthescraper.

2.Checkandadjustthepressurein1or

bothtires.

27

Page 28

EuropeanPrivacyNotice

TheInformationT oroCollects

ToroWarrantyCompany(T oro)respectsyourprivacy .Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer .

TheTorowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.T oromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany .Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw.

Toro'sCommitmenttoSecurityofY ourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToroDealer .

374-0282RevC

Loading...

Loading...