Toro 38805 Operator's Manual

PowerMax

ModelNo.38805—SerialNo.400010798andUp

®

HeavyDuty826OXESnowthrower

Introduction

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

FormNo.3406-749RevA

Operator'sManual

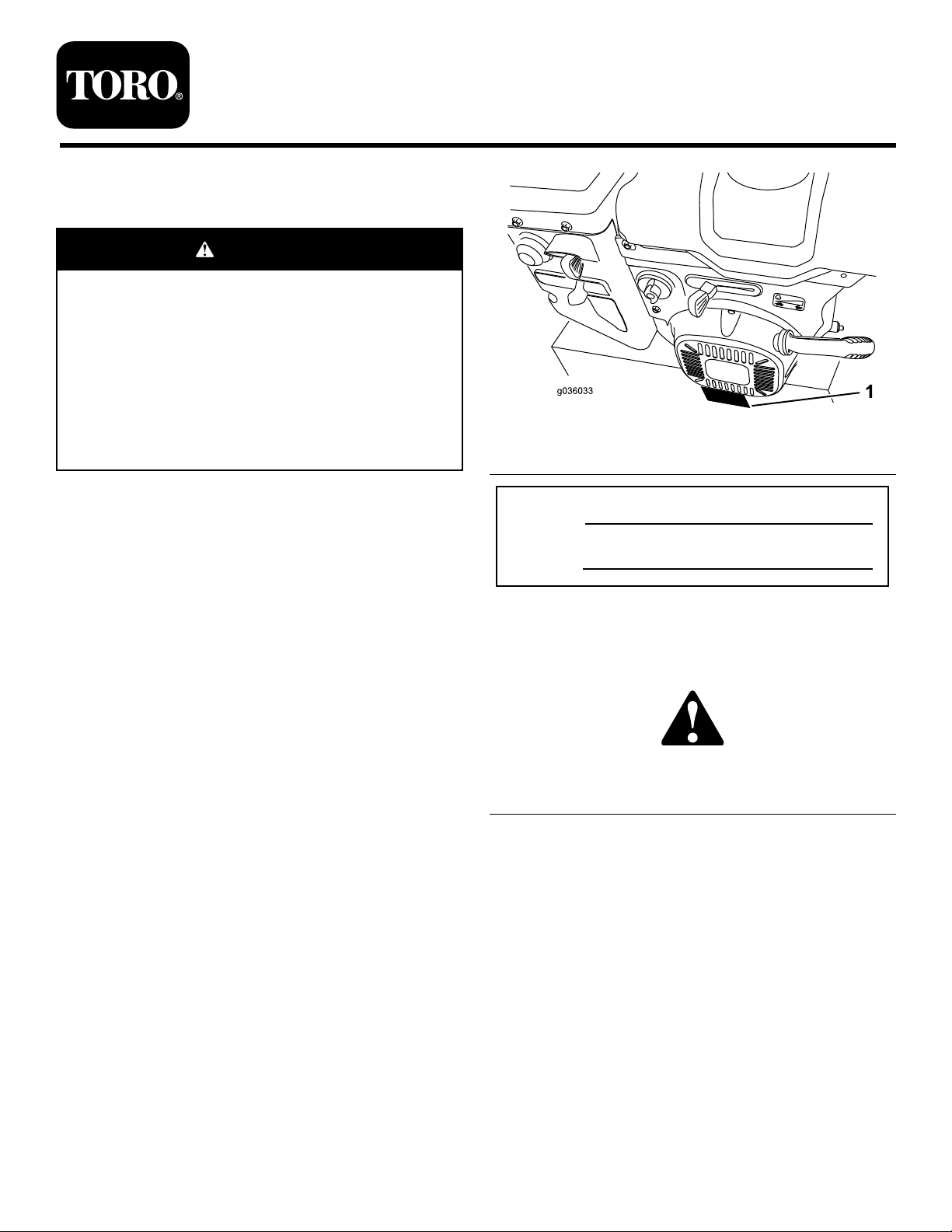

Figure1

1.Modelandserialnumberlocation

Thismachineisintendedtobeusedbyresidential

homeownersorprofessional,hiredoperators.Itis

designedforremovingsnowfrompavedsurfaces,such

asdrivewaysandsidewalks,andothersurfacesfor

trafconresidentialorcommercialproperties.Itisnot

designedforremovingmaterialsotherthansnow,noris

amodelwithapivotingscraperdesignedforclearingoff

gravelsurfaces.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourmachineproperlyandtoavoidinjuryand

machinedamage.Youareresponsibleforoperatingthe

machineproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comformachine

andaccessoryinformation,helpndingadealer,ortoregister

yourmachine.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourmachineready.Figure1identiesthelocationofthe

modelandserialnumbersonthemachine.Writethenumbers

inthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2016—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3406-749*A

Important:Ifyouareusingthismachineabove1500m

(5,000ft)foracontinuousperiod,ensurethattheHigh

AltitudeKithasbeeninstalledsothattheenginemeets

CARB/EPAemissionregulations.TheHighAltitude

Kitincreasesengineperformancewhilepreventing

spark-plugfouling,hardstarting,andincreased

emissions.Onceyouhaveinstalledthekit,attach

thehigh-altitudelabelnexttotheserialdecalonthe

machine.ContactanyAuthorizedT oroServiceDealer

toobtaintheproperHighAltitudeKitandhigh-altitude

labelforyourmachine.T olocateadealerconvenientto

you,accessourwebsiteatwww.Toro.comorcontactour

ToroCustomerCareDepartmentatthenumber(s)listed

inyourEmissionControlWarrantyStatement.

Removethekitfromtheengineandrestoretheengine

toitsoriginalfactorycongurationwhenrunningthe

engineunder1500m(5,000ft).Donotoperateanengine

thathasbeenconvertedforhigh-altitudeuseatlower

altitudes;otherwise,youcouldoverheatanddamage

theengine.

Ifyouareunsurewhetherornotyourmachinehasbeen

convertedforhigh-altitudeuse,lookforthefollowing

label(Figure3).

Figure3

ThissparkignitionsystemcomplieswithCanadianICES-002.

DuringOperation.....................................................12

Safety....................................................................12

FreewheelingorUsingtheSelf-Propel

Drive................................................................12

StartingtheEngine.................................................13

ShuttingOfftheEngine..........................................15

OperatingtheTractionDrive...................................15

UsingtheWheel-ClutchLevers................................15

OperatingtheSpeedSelector...................................16

OperatingtheAuger/ImpellerDrive.........................16

OperatingtheQuickStick®.....................................17

UncloggingtheDischargeChute..............................17

OperatingTips......................................................18

AfterOperation........................................................18

Safety....................................................................18

PreventingFreeze-upafterUse.................................18

Maintenance.................................................................19

RecommendedMaintenanceSchedule(s)......................19

MaintenanceSafety.................................................19

PreparingforMaintenance.......................................19

CheckingtheEngine-OilLevel.................................20

CheckingandAdjustingtheSkidsand

Scraper..............................................................20

CheckingandAdjustingtheTractionCable................20

CheckingandAdjustingtheAuger/Impeller

Cable................................................................21

CheckingtheAuger-Gearbox-OilLevel.....................22

ChangingtheEngineOil.........................................22

LubricatingtheHexShaft........................................23

ReplacingtheSparkPlug.........................................23

AdjustingtheDischarge-ChuteLatch........................24

ReplacingtheDriveBelts.........................................25

ReplacingtheHeadlightBulb...................................25

Storage........................................................................26

PreparingtheMachineforStorage............................26

RemovingtheMachinefromStorage.........................26

Troubleshooting...........................................................27

Contents

Introduction..................................................................1

Safety...........................................................................2

SafetyandInstructionalDecals.................................3

Setup............................................................................5

1InstallingtheUpperHandle....................................5

2InstallingtheWheel-Clutch-CableEnds...................6

3InstallingtheTraction-ControlLinkage....................7

4InstallingtheChute-ControlRod............................8

5ConnectingtheWiretotheHeadlight......................9

6CheckingtheEngine-OilLevel...............................9

7CheckingtheTirePressure.....................................9

8CheckingtheSkidsandScraper...............................9

9CheckingtheOperationoftheTraction

Drive.................................................................9

ProductOverview.........................................................11

Operation....................................................................11

BeforeOperation......................................................11

Safety....................................................................11

FillingtheFuelTank...............................................11

Safety

ThismachinemeetsorcomplieswithANSIB71.3

specicationsineffectatthetimeofproduction.

•ReadandunderstandthecontentsofthisOperator’s

Manualbeforeyoustarttheengine.Ensurethateveryone

usingthisproductknowshowtousetheproductand

understandsthewarnings.

•Donotyourputhandsorfeetnearmovingcomponents

onthemachine.

•Donotoperatemachinewithoutallguardsandother

safetyprotectivedevicesinplaceandworkingonthe

machine.

•Keepclearofanydischargeopening.Keepbystandersa

safedistanceawayfromthemachine.

2

•Keepchildrenoutoftheoperatingarea.Neverallow

childrentooperatethemachine.

•Shutofftheenginebeforeunclogging,servicing,or

fuelingthemachine.

Youcanndadditionalitemsofsafetyinformationintheir

respectivesectionsthroughoutthismanual.

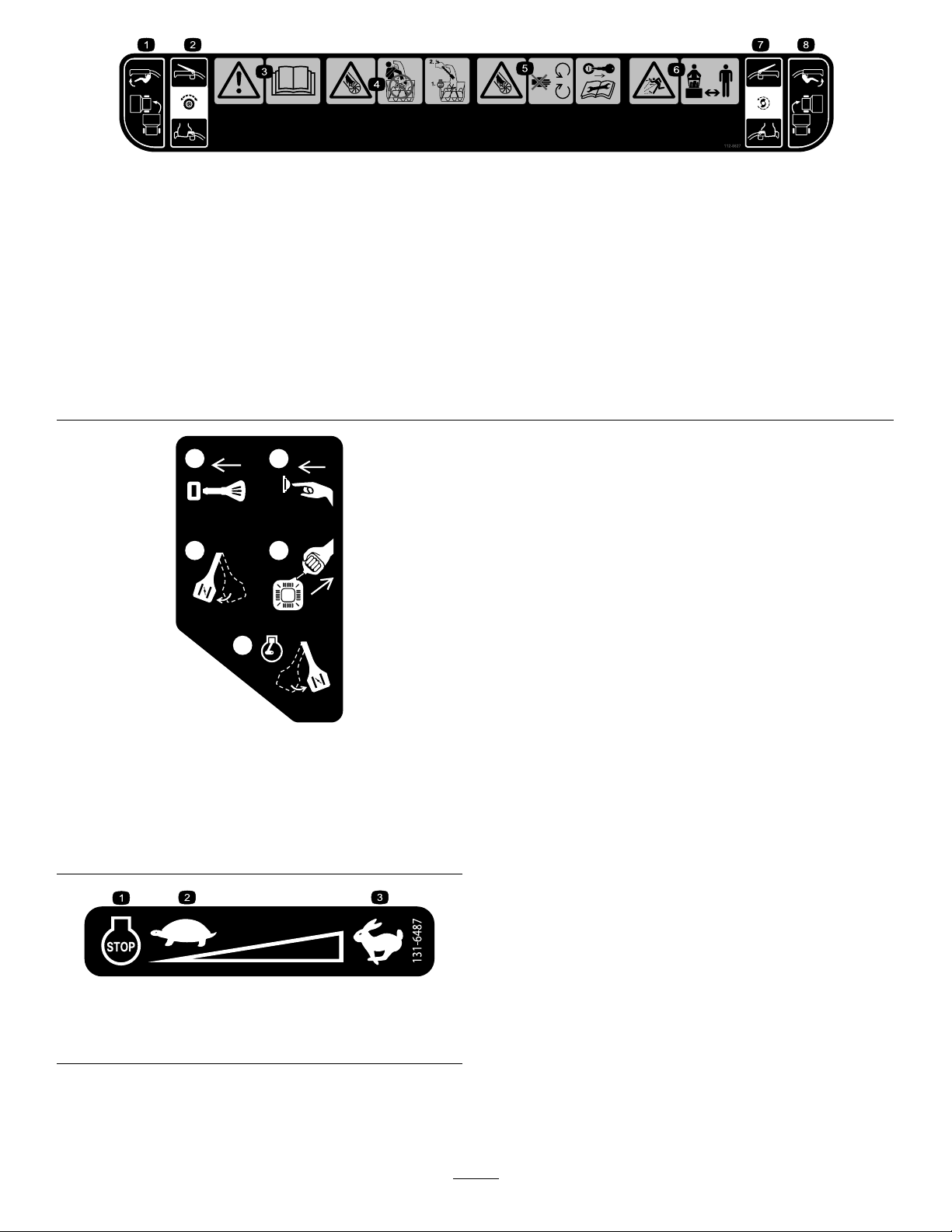

SafetyandInstructionalDecals

Safetyandinstructiondecalsarelocatednearareasofpotentialdanger.Replacedamagedor

missingdecals.

106-4525

OrderPartNo.112-6633

1.Fast

2.Forwardspeeds4.Reversespeeds

3.Slow

112-6625

OrderPartNo.112-6629

1.Cutting/dismembermenthazard,impeller—donotplace

yourhandinthechute;shutofftheenginebeforeleaving

theoperator'sposition;usethetooltoclearthechute.

107-3040

1.Cuttingdismemberment,impellerandcutting

dismemberment,augerhazards—keepbystandersasafe

distanceawayfromthesnowthrower.

3

112-6627

x 3

1

2

3

4

5

120-9805

1.Leftturncontrol

2.Tractiondrive—squeeze

thelevertoengage;release

thelevertodisengage.

3.Warning—readthe

Operator'sManual.

4.Cutting/dismemberment

hazard,impeller—do

notplaceyourhandin

thechute;shutoffthe

enginebeforeleavingthe

operator'sposition;usethe

tooltoclearthechute.

5.Cutting/dismemberment

hazard,impeller—keep

awayfrommovingparts;

removetheignitionkeyand

readtheinstructionsbefore

servicingorperforming

maintenance.

6.Thrownobject

hazard—keepbystanders

asafedistanceawayfrom

thesnowthrower.

7.Auger/impeller

drive—squeezetheleverto

engage;releasethelever

todisengage.

8.Rightturncontrol

120-9805

1.Insertthekey.

2.Primetheengine3times.

3.Engagethechoke.

4.Pullthestartercord.

5.Oncetheengineisrunning,disengagethechoke.

131-6487

1.Engine—shutoff

2.Slow

3.Fast

4

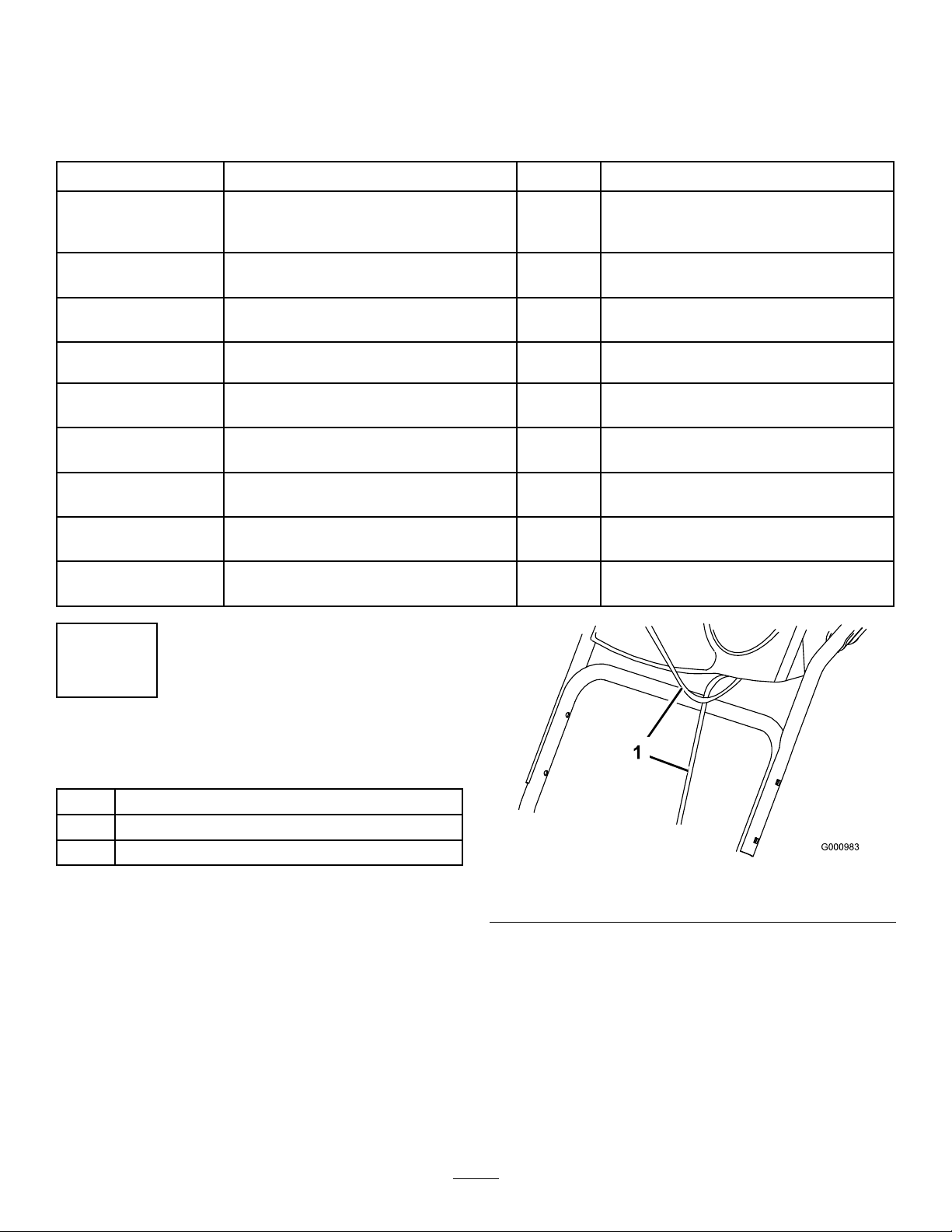

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

Handlebolt4

Curvedwasher

Locknut4

Nopartsrequired

Nopartsrequired

Carriagebolt

Locknut2

Cabletie

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Qty.

Use

4

–

–

2

1

–

–

–

–

Installtheupperhandle.

Installthewheel-clutch-cableends.

Installthetraction-controllinkage.

Installthechute-controlrod.

Connectthewiretotheheadlight.

Checktheengine-oillevel.

Checkthetirepressure.

Checktheskidsandscraper.

Checktheoperationofthetractiondrive.

1

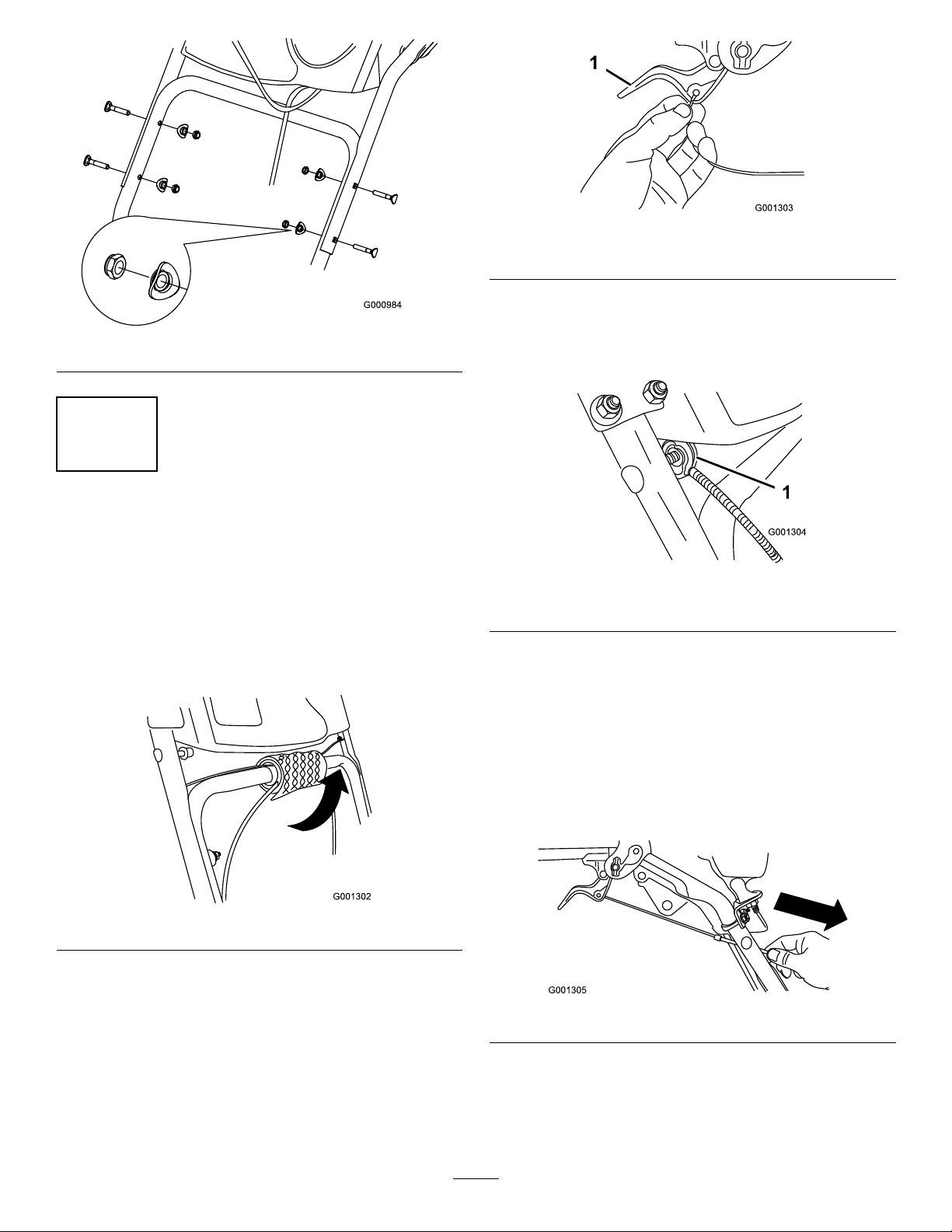

InstallingtheUpperHandle

Partsneededforthisprocedure:

4Handlebolt

4

Curvedwasher

4Locknut

Procedure

Note:Donotremovetherubberbandonthecablesuntil

youhaveinstalledtheupperhandle.

1.Liftandrotatetheupperhandleandpositionitover

thelowerhandle(Figure4).

Important:Routethecablesattachedtothe

QuickStickinsidetheupperhandlelegsand

ensurethatthecablesandthewireforthe

headlightarenotpinchedbetweenthehandle

sections.

Figure4

1.Cables

2.Securetheupperhandlewith4handlebolts,4curved

washers,and4locknutsfromtheloose-partsbag

(Figure5).

5

Figure5

2

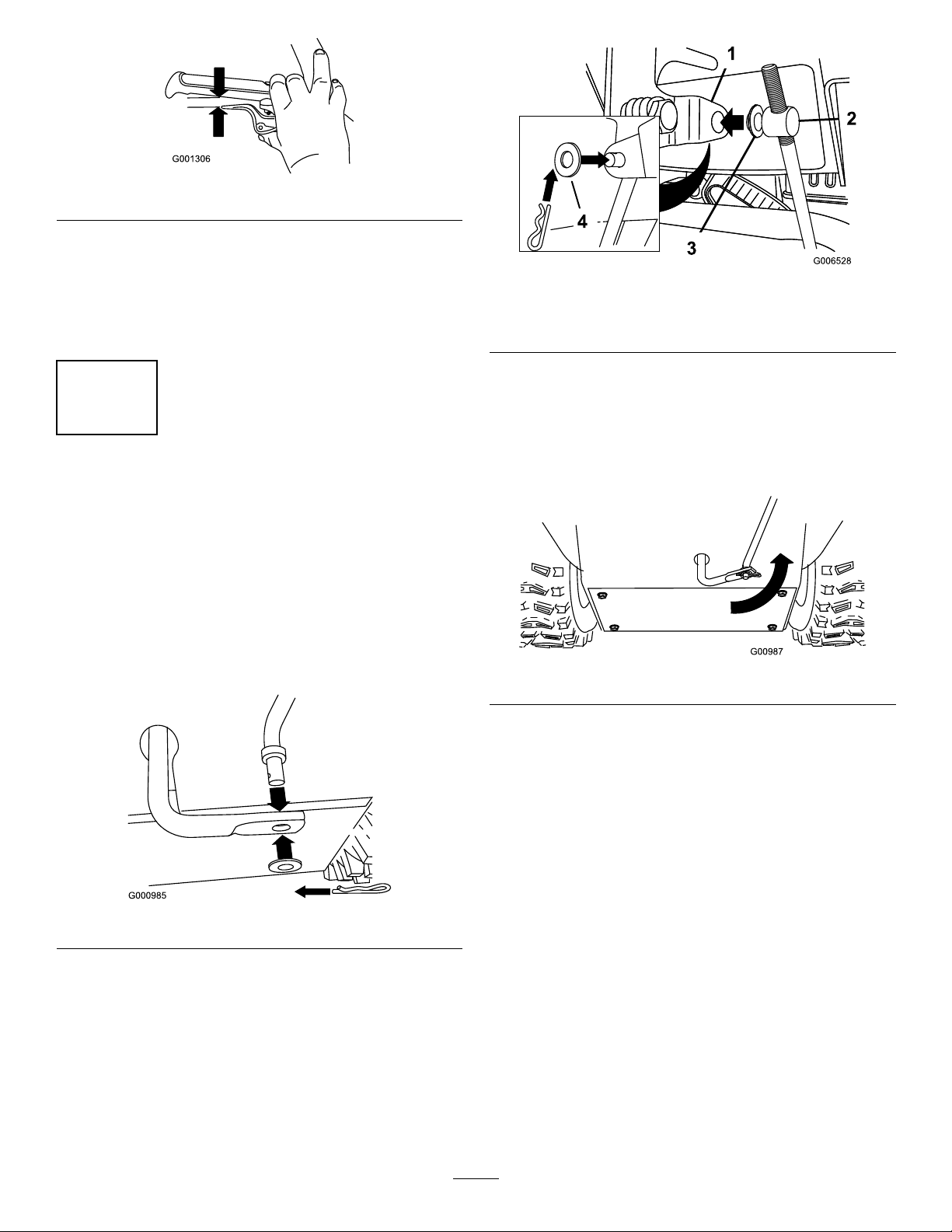

Installingthe Wheel-Clutch-CableEnds

Figure7

1.Wheel-clutchlever

3.Removethenutandwasherfromthehandle,attach

thecableclamponthecabletothehandle,installthe

washerandthenut,andtightenthenutbyhand(Figure

8).

NoPartsRequired

Procedure

1.Unwrapthecableendsfromthelowerhandle(Figure

6).

Figure6

2.Routeeithertheleftorrightcableendoverthelower

handleandinsertthecableendintotheholeinthe

correspondingwheel-clutchlever(Figure7).

Figure8

1.Cableclamp(2)

Important:Ensurethatthecurvedsideofthe

cableclampisagainstthehandleandthatthe

cableisroutedbelowtheclampbolt.Thecable

mustbeinastraightlinefromthecableclamp

tothepointwhereitattachestothewheel-clutch

lever.

4.Pullthecablejacketdowngentlyuntilthewheel-clutch

leverisdownandtheslackisoutofthecable,then

tightenthecable-clampnutsecurely(Figure9).

Figure9

5.Squeezetheleverfully,thencheckthegapbetweenthe

bottomofthehandleandthewheel-clutchleverend

(Figure10).

6

Figure10

Note:Thegapshouldbeapproximatelythethickness

ofapencil(6mmor1/4inch).Ifitisgreater,loosen

thecableclampnut,slidethecablejacketupslightly,

tightenthecableclampnut,andcheckthegapagain.

6.Repeatsteps2through5fortheothercable.

3

Figure12

1.Speed-selectorlever

2.Trunnion

Note:Tomakeinstallationeasier,leavetheatwasher

onthetrunnion(Figure12).

4.Shiftthespeed-selectorleverintoPositionR2.

3.Innerwasher

4.Outerwasher

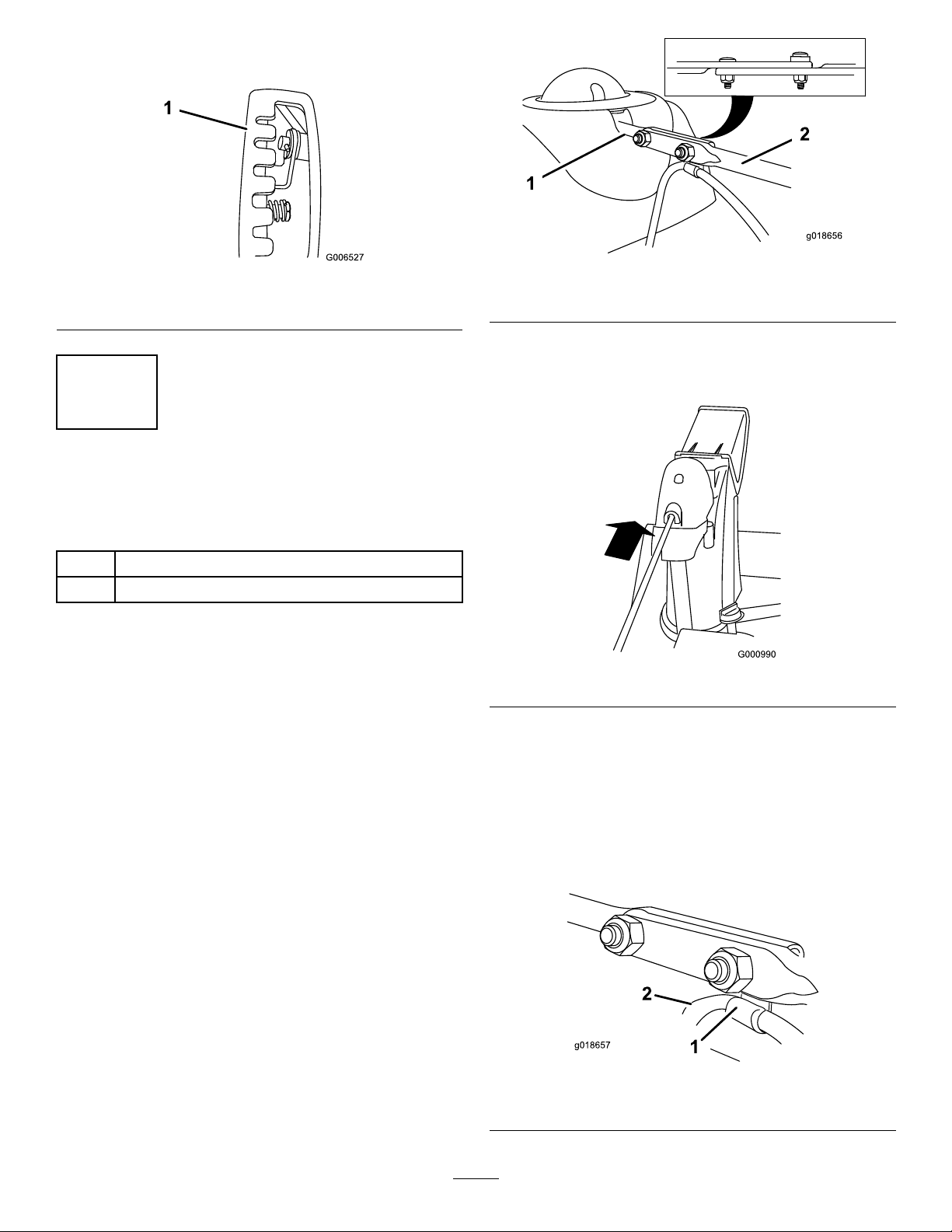

InstallingtheTraction-Control Linkage

NoPartsRequired

Procedure

1.Removethehairpincotterandwasherfromthelower

endofthespeed-controlrodandinsertthelowerend

oftherodintothelowerlinkarmsothatthebentend

ofthespeed-controlrodfacesrearward(Figure11).

Figure11

5.Rotatethelowerlinkarmfullyupward

(counterclockwise)asshowninFigure13.

Figure13

6.Liftupthespeed-controlrodandinsertthetrunnion

intotheholeinthespeed-selectorlever(Figure12).

Note:Ifthetrunniondoesnottintothehole

whenyouliftuponthespeed-controlrod,rotatethe

trunnionupwardordownwardonthespeed-control

roduntilitts.

7.Securethetrunnionandupperendofthespeedcontrol

rodwiththeouterwasherandthehairpincotterthat

youpreviouslyremoved.

2.Securethelowerendofthespeed-controlrodwiththe

washerandhairpincotterthatyoupreviouslyremoved.

3.Removethehairpincotterandtheouterwasherfrom

thetrunnionontheupperendofthespeed-control

rod(Figure12).

7

Note:Foreasierinstallation,lookdownthroughthe

g018656

g018657

openinginthespeedselector(Figure14).

Figure14

1.Speedselector

4

InstallingtheChute-Control Rod

Partsneededforthisprocedure:

2

Carriagebolt

2Locknut

Procedure

1.UnwraptheQuickStickandrotateitsothatitis

uprightandinthecenter.

Figure15

1.Shortrod

4.Insertthefrontendoftherodintotheopeningin

thebackofthechute-gearcoveruntilitslidesintothe

chutegear(Figure16).

2.Longchute-controlrod

Figure16

2.Holdthebluetriggercapdownandpulltheleverfully

rearward.

Note:Thedischargechuteanddeectorshouldface

forward.Iftheydonot,holdthebluetriggercap

down(butdonotmovetheQuickStick)androtatethe

dischargechuteuntiltheydo.

3.Aligntheattenedbackendofthelongchute-control

rodwiththeattenedfrontendoftheshortrod

thatextendsfromthecontrolpanelsothattheynest

together(Figure15).

5.Aligntheholesinthenestedendsoftherodsand

insert2carriagebolts(intheloose-partsbag)through

theshortrodfromtheleftsideofthemachine(from

theoperatingposition).

6.Insertthecableclipthatsupportsthedeectorcable

ontotheforwardcarriagebolt,andsecurethecarriage

boltswithlocknutsfromtheloose-partsbag(Figure

17).

Figure17

1.Cableclip2.Deectorcable

8

7.HoldthebluetriggercapdownandrotatetheQuick

1

2

3

G016761

Stickinacircletoensurethatthechuteanddeector

operatesmoothly.

6

CheckingtheEngine-OilLevel

5

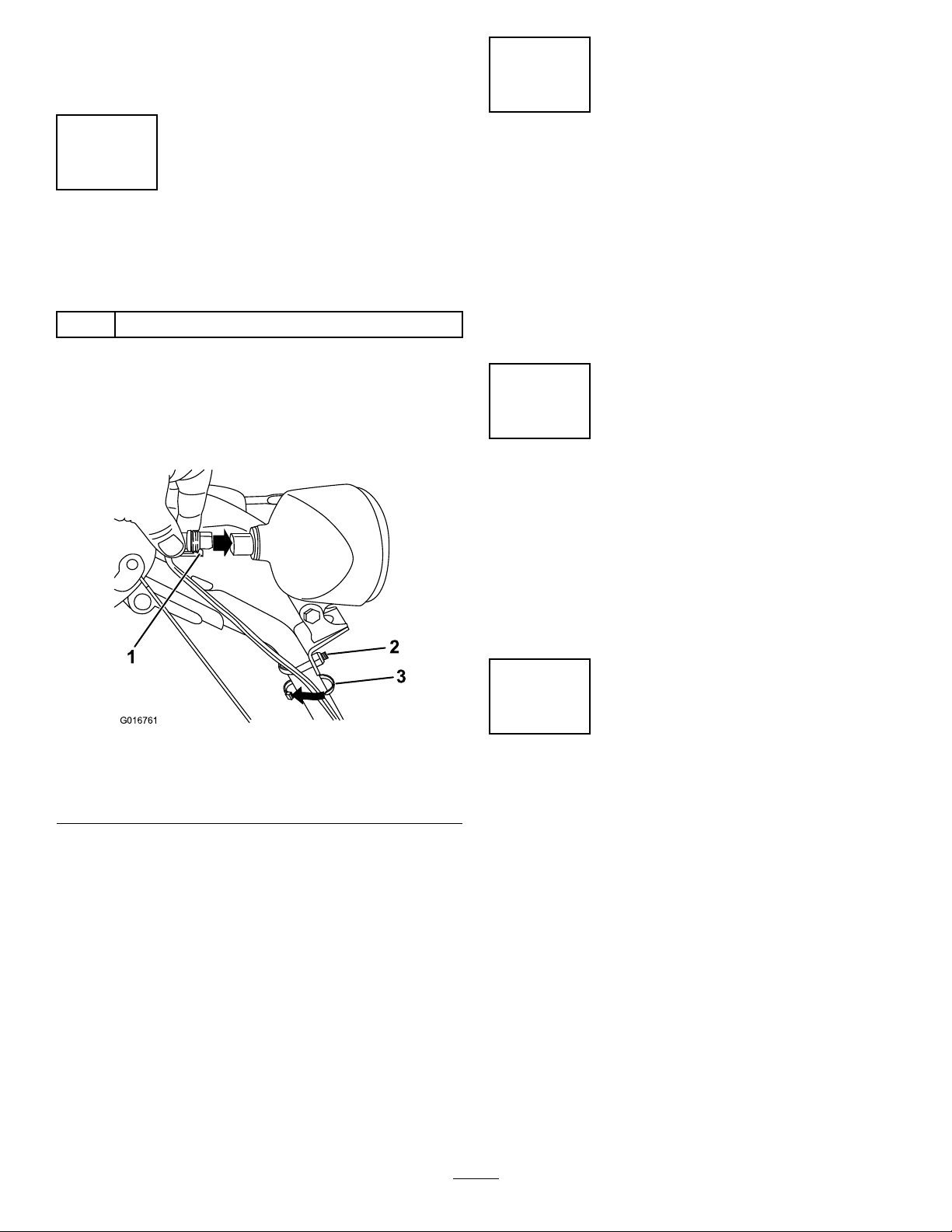

ConnectingtheWiretothe Headlight

Partsneededforthisprocedure:

1

Cabletie

Procedure

1.Insertthewireconnectoronthelooseendofthewire

straightintothebackoftheheadlightuntilitissecurely

inplace(Figure18).

NoPartsRequired

Procedure

Note:Yourmachinecomeswithoilintheengine

crankcase.Beforestartingtheengine,checktheoillevel

andaddoilifnecessary.

RefertoCheckingtheEngine-OilLevel(page20).

7

CheckingtheTirePressure

NoPartsRequired

Procedure

Thetiresareoverinatedatthefactoryforshipping.Reduce

thepressureequallyinbothtirestobetween116and137

kPa(17and20psi).

Figure18

8

1.Plasticcliponwire

connector

2.U-bolt

Note:Ensurethattheplasticcliponthewire

connectorisonthebottom(Figure18).

2.Secureacabletie(fromtheloose-partsbag)aroundthe

wireandthehandleabout2.5cm(1inch)belowthe

U-bolt(Figure18).

3.Cabletie

CheckingtheSkidsand Scraper

NoPartsRequired

Procedure

RefertoCheckingandAdjustingtheSkidsandScraper(page

20).

9

9

CheckingtheOperationofthe

TractionDrive

NoPartsRequired

4.Releasethetractionlever.

5.MovethespeedselectortothePositionF1;referto

OperatingtheSpeedSelector(page16).

6.Squeezetheleft(traction)levertothehandgrip(Figure

19).

Themachineshouldmoveforward.Ifthemachine

doesnotmoveormovesrearward,completethe

following:

A.Releasethetractionleverandshutofftheengine.

Procedure

CAUTION

Ifthetractiondriveisnotproperlyadjusted,the

machinemaymoveinthedirectionoppositeof

whatyouintended,causinginjuryand/orproperty

damage.

Carefullycheckthetractiondriveandadjustit

properly,ifnecessary.

Note:Tochecktheoperationofthetractiondrive,the

self-propelfeaturemustbeengagedbyensuringthewheels

arepinnedintheaxle.RefertoFreewheelingorUsingthe

Self-PropelDrive(page12).

1.Starttheengine;refertoStartingtheEngine(page13).

2.MovethespeedselectortoPositionR1;referto

OperatingtheSpeedSelector(page16).

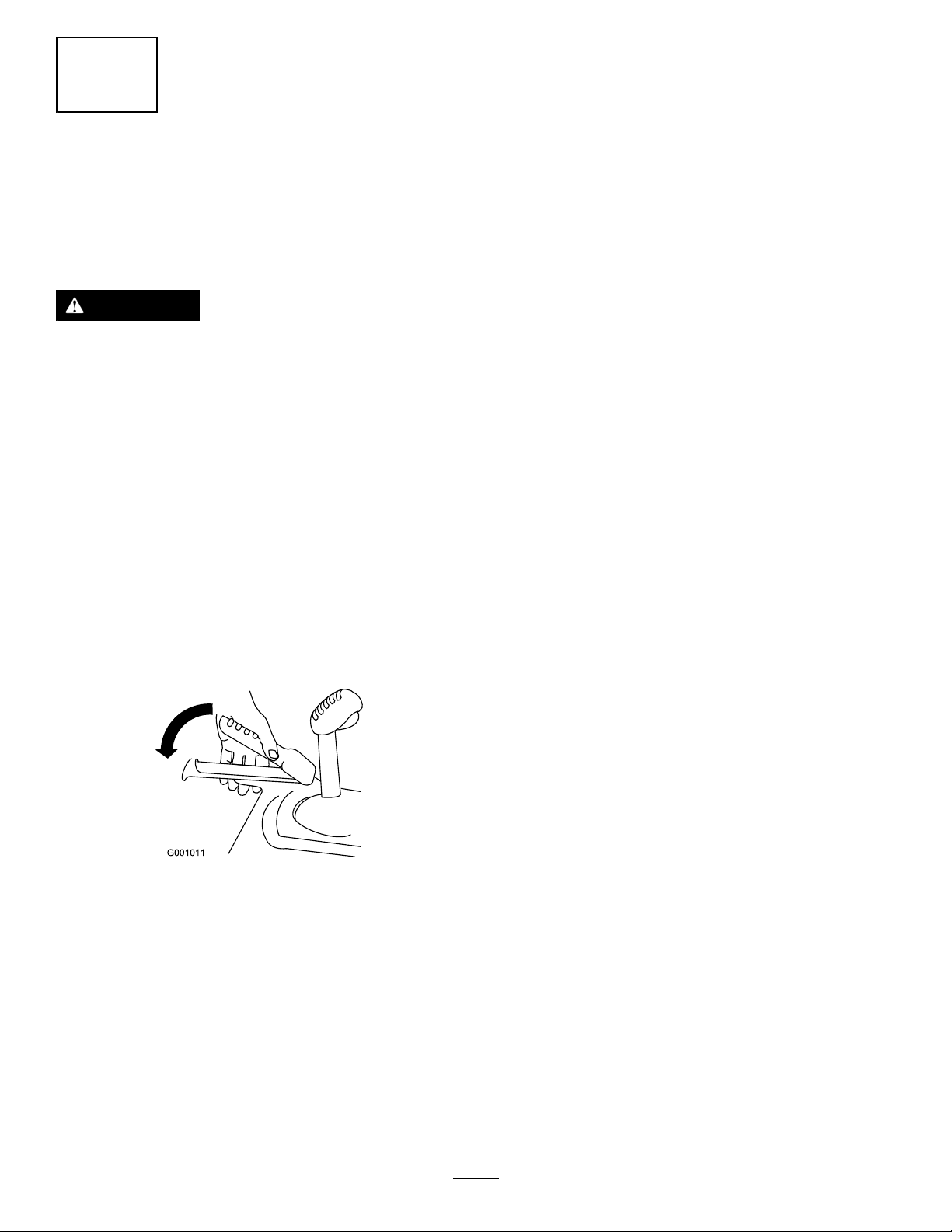

3.Squeezetheleft(traction)levertothehandgrip(Figure

19).

B.Disconnectthetrunnionfromthespeed-selector

lever(Figure12).

C.Turnthetrunnionupward(counterclockwise)on

thespeed-controlrod(Figure12).

D.Connectthetrunniontothespeed-selectorlever

(Figure12).

7.Ifyoumadeanyadjustments,repeatthisprocedure

untilnoadjustmentsarerequired.

Important:Ifthemachinemoveswhenthetraction

leverisinthereleasedposition,checkthetractioncable;

refertoCheckingandAdjustingtheTractionCable

(page20)ortakethemachinetoanAuthorizedService

Dealerforservice.

Figure19

Themachineshouldmoverearward.Ifthemachine

doesnotmoveormovesforward,completethe

following:

A.Releasethetractionleverandshutofftheengine.

B.Disconnectthetrunnionfromthespeed-selector

lever(Figure12).

C.Turnthetrunniondownward(clockwise)onthe

speed-controlrod(Figure12).

D.Connectthetrunniontothespeed-selectorlever

(Figure12).

10

Loading...

Loading...