Page 1

PowerMax

PowerMax

ModelNo.38801—SerialNo.402082000andUp

ModelNo.38802—SerialNo.402082000andUp

®

HeavyDuty928OHXESnowthrower

®

HeavyDuty1028OHXESnowthrower

FormNo.3415-663RevA

Operator'sManual

Introduction

Thismachineisintendedtobeusedbyresidential

homeowners.Itisdesignedprimarilyforremoving

snowfrompavedsurfaces,suchasdrivewaysand

sidewalks,andothersurfacesfortrafconresidential

orcommercialproperties.Itisnotdesignedfor

removingmaterialsotherthansnow.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactT orodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourmachineready.Figure1

identiesthelocationofthemodelandserialnumbers

onthemachine.Writethenumbersinthespace

provided.

Important:Withyoursmartphoneortablet,scan

theQRcodeontheserialnumberdecaltoaccess

warranty,parts,andotherproductinformation.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

1.Modelandserialnumberlocation

©2017—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

Registeratwww.Toro.com.

Important:Ifyouareusingthismachineabove

g219961

1500m(5,000ft)foracontinuousperiod,ensure

thattheHighAltitudeKithasbeeninstalled

sothattheenginemeetsCARB/EPAemission

regulations.TheHighAltitudeKitincreases

engineperformancewhilepreventingspark-plug

fouling,hardstarting,andincreasedemissions.

Onceyouhaveinstalledthekit,attachthe

high-altitudelabelnexttotheserialdecalonthe

machine.ContactanyAuthorizedToroService

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3415-663*A

Page 2

DealertoobtaintheproperHighAltitudeKitand

high-altitudelabelforyourmachine.T olocate

adealerconvenienttoyou,accessourwebsite

atwww.Toro.comorcontactourToroCustomer

CareDepartmentatthenumber(s)listedinyour

EmissionControlWarrantyStatement.Remove

thekitfromtheengineandrestoretheengineto

itsoriginalfactorycongurationwhenrunningthe

engineunder1500m(5,000ft).Donotoperatean

enginethathasbeenconvertedforhigh-altitude

useatloweraltitudes;otherwise,youcould

overheatanddamagetheengine.

Ifyouareunsurewhetherornotyourmachinehas

beenconvertedforhigh-altitudeuse,lookforthe

followinglabel(Figure3).

decal127-9363

Figure3

Contents

Introduction...............................................................1

Safety.......................................................................3

GeneralSafety...................................................3

SafetyandInstructionalDecals..........................3

Setup........................................................................5

InstallingtheUpperHandle.................................5

InstallingtheWheel-Clutch-CableEnds..............5

InstallingtheTraction-ControlLinkage................6

InstallingtheChute-ControlRod.........................7

ConnectingtheHeadlightandHandwarmer

WirestotheEngine.........................................7

InstallingtheSnow-CleanoutT ool.......................8

CheckingtheEngine-OilLevel............................8

CheckingandAdjustingtheTirePressure...........8

CheckingtheSkidsandScraper.........................8

CheckingtheOperationoftheTraction

Drive...............................................................8

ProductOverview.....................................................9

Operation................................................................10

BeforeOperation.................................................10

BeforeOperationSafety...................................10

FillingtheFuelT ank..........................................10

DuringOperation..................................................11

DuringOperationSafety....................................11

StartingtheEngine............................................11

ShuttingOfftheEngine.....................................13

OperatingtheHandwarmers.............................13

OperatingtheTractionDrive.............................14

UsingtheWheel-ClutchLevers.........................14

OperatingtheSpeedSelector...........................14

OperatingtheAuger/ImpellerDrive...................15

OperatingtheQuickStick®...............................15

ClearingaCloggedDischargeChute................16

OperatingTips.................................................16

AfterOperation....................................................17

AfterOperationSafety......................................17

PreventingFreeze-upafterUse........................17

Maintenance...........................................................18

RecommendedMaintenanceSchedule(s)...........18

MaintenanceSafety..........................................18

PreparingforMaintenance...............................18

CheckingtheEngine-OilLevel..........................19

CheckingandAdjustingtheSkidsand

Scraper.........................................................19

CheckingandAdjustingtheTraction

Cable............................................................20

CheckingandAdjustingtheAuger/Impeller

Cable............................................................20

CheckingtheAuger-Gearbox-OilLevel.............21

ChangingtheEngineOil...................................21

LubricatingtheHexShaft..................................22

ReplacingtheSparkPlug.................................23

AdjustingtheDischarge-ChuteLatch................23

ReplacingtheDriveBelts..................................24

ReplacingtheHeadlightBulb............................24

Storage...................................................................25

StoringtheMachine..........................................25

RemovingtheMachinefromStorage................25

Troubleshooting......................................................26

2

Page 3

Safety

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Donotoperatethemachinewithoutallguards

GeneralSafety

ThismachinecomplieswithANSIB71.3specications.

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

Ensurethateveryoneusingthisproductknows

howtousetheproductandunderstandsthe

warnings.

•Donotputyourhandsorfeetnearmoving

componentsonthemachine.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

•Keepclearofanydischargeopening.Keep

bystandersasafedistanceawayfromthe

machine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Shutofftheenginebeforeunclogging,servicing,

orfuelingthemachine.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthismanual.

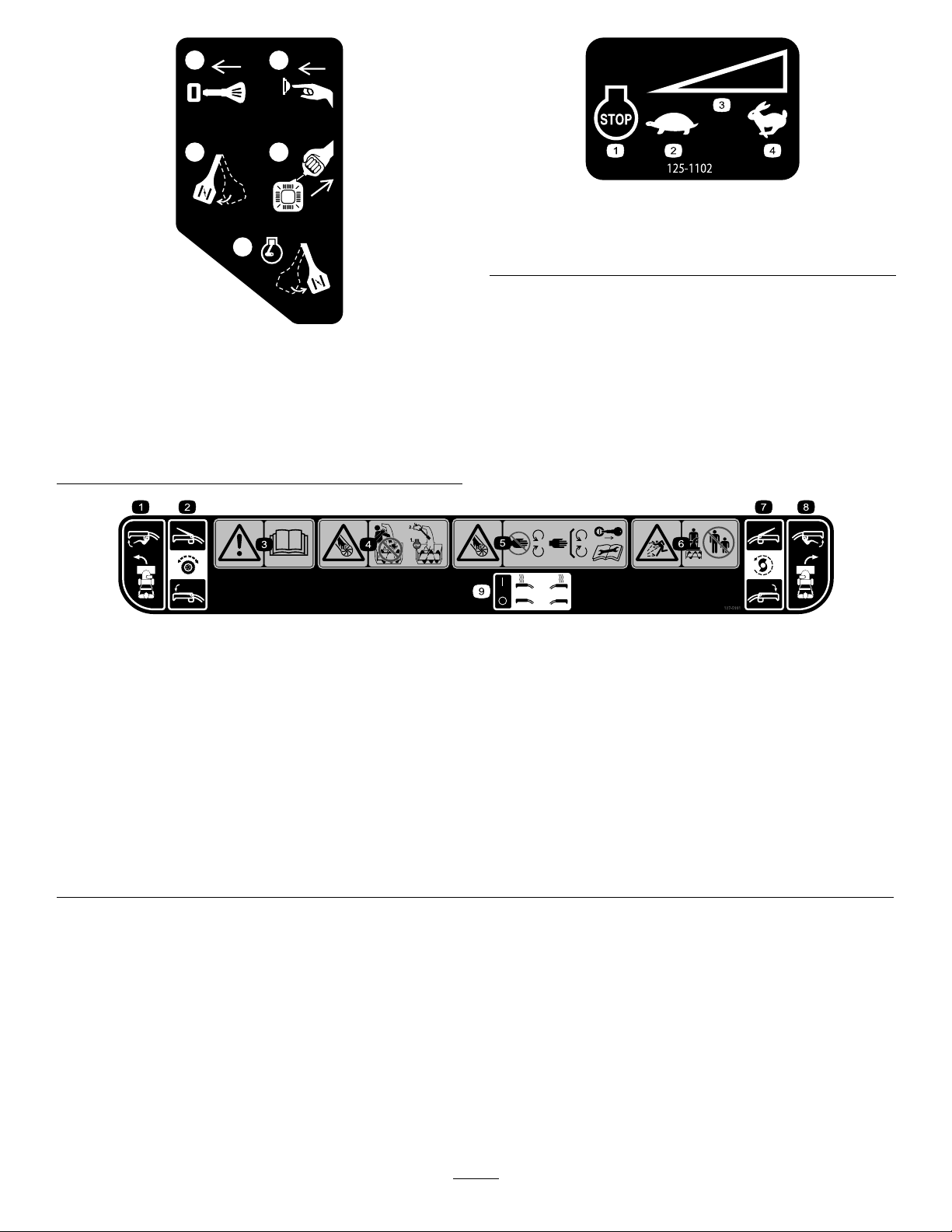

106-4525

OrderPartNo.1 12-6633

1.Fast

2.Forwardspeeds4.Reversespeeds

3.Slow

decal107-3040

107-3040

1.Cutting/dismembermenthazardsofhandorfoot,impeller

andauger—keepbystandersasafedistanceawayfrom

themachine.

decal106-4525

decal112-6625

112-6625

OrderPartNo.1 12-6629

1.Cutting/dismembermenthazard,impeller—donotplace

yourhandinthechute;shutofftheenginebeforeleaving

theoperator'spositionanduseatooltoclearthechute.

3

Page 4

x 3

1

2

3

4

5

120-9805

125-1102

decal125-1102

decal120-9805

120-9805

1.Insertthekey.

2.Primetheengine3times.

3.Engagethechoke.

4.Pullthestartercord.

5.Oncetheengineisrunning,disengagethechoke.

127-5991

1.Leftturncontrol4.Cutting/dismembermenthazard,

2.Tractiondrive—squeezetheleverto

engage;releasethelevertodisengage.

3.Warning—readtheOperator'sManual.

impeller—donotplaceyourhandin

thechute;shutofftheenginebefore

leavingtheoperator'spositionanduse

atooltoclearthechute.

5.Cutting/dismembermenthazard,

impeller—stayawayfrommoving

parts;keepallguardsandshieldsin

place;removetheignitionkeyand

readtheinstructionsbeforeservicing

orperformingmaintenance.

6.Thrownobjecthazard—keep

bystandersasafedistanceawayfrom

themachine.

1.Engine—shutoff

2.Slow

3.Variablespeedcontrol

4.Fast

decal127-5991

7.Auger/impellerdrive—squeezethe

levertoengage;releasetheleverto

disengage.

8.Rightturncontrol

9.Handwarmercontrols

4

Page 5

Setup

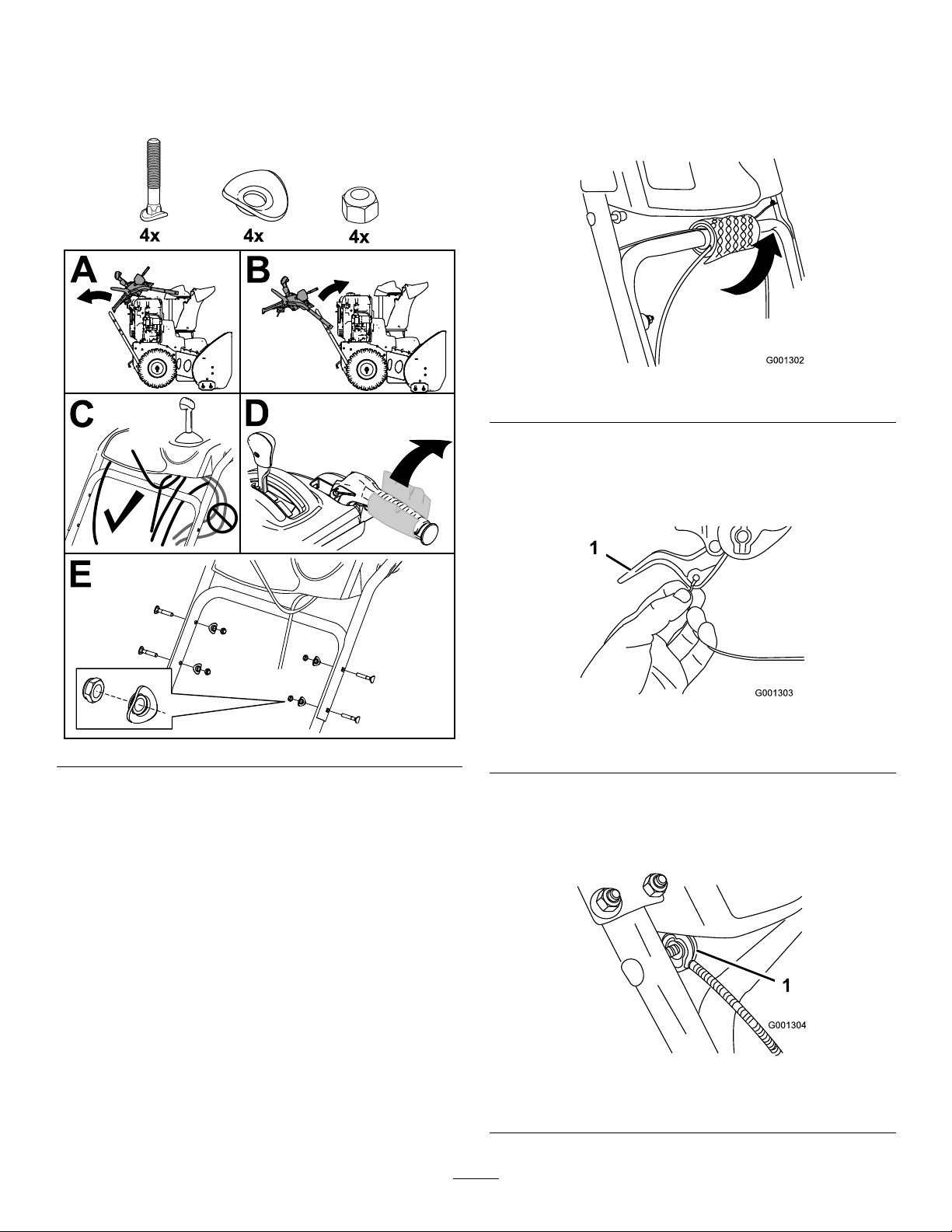

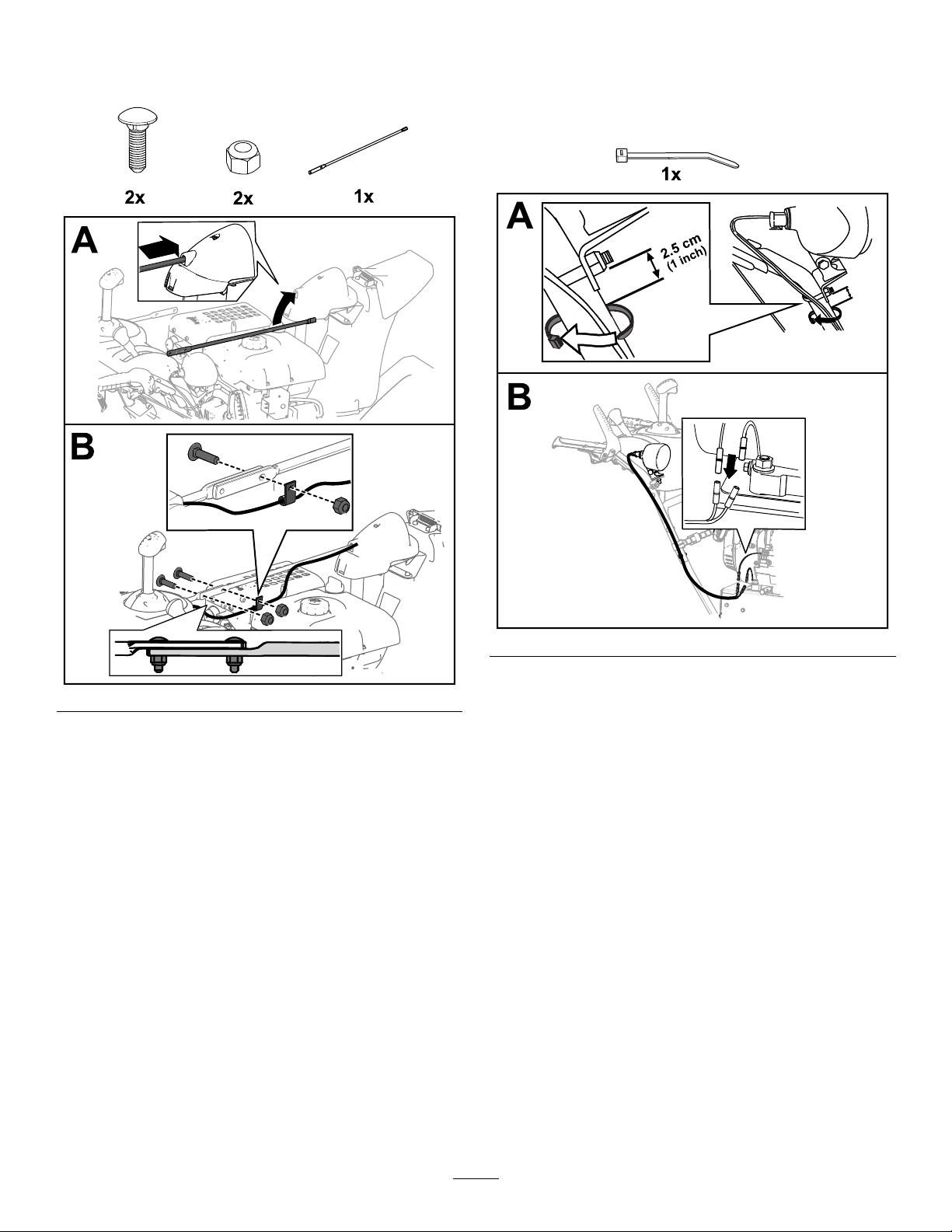

InstallingtheUpperHandle

Installingthe

Wheel-Clutch-CableEnds

1.Unwrapanddiscardthebubblewrapfromthe

cablesonthelowerhandle(Figure5).

g001302

Figure5

2.Routeeithertheleftorrightcableendoverthe

lowerhandleandinsertthecableendintothe

holeinthecorrespondingwheel-clutchlever

(Figure6).

Note:Donotremovetherubberbandonthecables

untilyouhaveinstalledtheupperhandle.

g001303

Figure6

g220055

1.Wheel-clutchlever

3.Removethenutandwasherfromthehandle,

attachthecableclamponthecabletothe

handle,installthewasherandthenut,and

tightenthenutbyhand(Figure7).

g001304

Figure7

1.Cableclamp(2)

5

Page 6

Important:Ensurethatthecurvedsideof

thecableclampisagainstthehandleand

thatthecableisroutedbelowtheclampbolt.

Thecablemustbeinastraightlinefromthe

cableclamptothepointwhereitattachesto

thewheel-clutchlever.

4.Pullthecablejacketdowngentlyuntilthe

wheel-clutchleverisdownandtheslackisout

ofthecable,thentightenthecable-clampnut

securely(Figure8).

Figure8

5.Squeezetheleverfully,thencheckthegap

betweenthebottomofthehandleandtheend

ofthewheel-clutchlever(Figure9).

Installingthe

Traction-ControlLinkage

g001305

Figure9

Note:Thegapshouldbeapproximatelythe

thicknessofapencil(1/4inchor6mm).Ifitis

greater,loosenthecable-clampnut,slidethe

cablejacketupslightly,tightenthecable-clamp

nut,andcheckthegapagain.

6.Repeatsteps2through5fortheothercable.

g001306

g220056

6

Page 7

InstallingtheChute-Control

ConnectingtheHeadlight

Rod

andHandwarmerWiresto

theEngine

g220058

g220057

7

Page 8

Installingthe

CheckingandAdjustingthe

Snow-CleanoutTool

TirePressure

g219877

CheckingtheSkidsand

Scraper

CheckingtheEngine-Oil

Level

Note:Yourmachinecomeswithoilintheengine

crankcase.Beforestartingtheengine,checktheoil

levelandaddoilifnecessary.

RefertoCheckingtheEngine-OilLevel(page19).

RefertoCheckingandAdjustingtheSkidsand

Scraper(page19).

CheckingtheOperationof

theTractionDrive

g220085

CAUTION

Ifthetractiondriveisnotproperlyadjusted,

themachinemaymoveinthedirection

oppositeofwhatyouintended,causinginjury

and/orpropertydamage.

Carefullycheckthetractiondriveandadjustit

properly,ifnecessary.

1.Starttheengine;refertoStartingtheEngine

(page1 1).

2.MovethespeedselectortoPositionR1;referto

OperatingtheSpeedSelector(page14).

3.Squeezetheleft(traction)levertothehandgrip

(Figure15).

8

Page 9

Figure15

Themachineshouldmoverearward.Ifthe

machinedoesnotmoveormovesforward,

completethefollowing:

A.Releasethetractionleverandshutoffthe

engine.

B.Disconnectthetrunnionfromthe

speed-selectorlever.

C.Turnthetrunniondownward(clockwise)on

thespeed-controlrod.

ProductOverview

g001011

D.Connectthetrunniontothespeed-selector

lever.

4.Releasethetractionlever.

5.MovethespeedselectortoPosition1;referto

OperatingtheSpeedSelector(page14).

6.Squeezetheleft(traction)levertothehandgrip

(Figure15).

Themachineshouldmoveforward.Ifthe

machinedoesnotmoveormovesrearward,

completethefollowing:

A.Releasethetractionleverandshutoffthe

engine.

B.Disconnectthetrunnionfromthe

speed-selectorlever.

C.Turnthetrunnionupward(counterclockwise)

onthespeed-controlrod.

D.Connectthetrunniontothespeed-selector

lever.

7.Ifyoumadeanyadjustments,repeatthis

procedureuntilnoadjustmentsarerequired.

Figure16

1.Handgrip(2)

2.Auger/impellerlever11.Scraper

3.Speed-selectorlever

4.Handwarmerswitch

5.QuickStick®

discharge-chutecontrol

6.Tractionlever15.Electric-startplug-in

7.Fuel-tankcap

8.Oil-lltube/dipstick

9.Chutedeector18.Wheel-clutchlever(2)

10.Dischargechute

12.Auger

13.Skid(2)

14.Electric-startbutton

16.Snow-cleanouttool

17.Headlight

g220972

Important:Ifthemachinemoveswhenthe

tractionleverisinthereleasedposition,checkthe

tractioncable;refertoCheckingandAdjusting

theTractionCable(page20)ortakethemachine

toanAuthorizedServiceDealerforservice.

1.Primer5.Throttle

2.Ignitionswitch

3.Choke

4.Fuel-shutoffvalve

9

g016500

Figure17

6.Oil-drainplug

7.Recoil-starthandle

Page 10

Figure18

1.Snow-cleanouttool(attachedtothehandle)

Operation

DANGER

Fuelisextremelyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

g004217

others.

•Topreventastaticchargefromignitingthe

fuel,placethecontainerand/ormachineon

thegroundbeforelling,notinavehicle

oronanobject.

•Fillthetankoutdoorswhentheengineis

cold.Wipeupspills.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

•Forelectric-startmodelsonly:Useextension

cordsandreceptaclesasspeciedinthemanual.

Thoroughlyinspecttheelectricalcordbefore

pluggingitintoapowersource.Ifthecordis

damaged,donotuseit.Replacethedamaged

cord.Unplugthepowercordwheneveryouare

notstartingthemachine.

•Wearadequatewintergarmentswhenever

youoperatethemachine.Wearsubstantial,

slip-resistantfootwearthatimprovesfootingon

slipperysurfaces.Avoidloose-ttingclothingthat

cangetcaughtinmovingparts.

•Alwaysweareyeprotectionduringoperationor

whileperforminganadjustmentorrepairtoprotect

youreyesfromforeignobjectsthatthemachine

maythrow.

•Thoroughlyinspecttheareawhereyouwillusethe

machine,andremovealldoormats,sleds,boards,

wires,andotherforeignobjects.

•Ifashield,safetydevice,ordecalisdamaged,

illegible,ormissing,repairorreplaceitbefore

beginningoperation.Alsotightenanyloose

fasteners.

•Donothandlefuelwhensmokingor

aroundanopenameorsparks.

•Storefuelinanapprovedfuelcontainer,

outofthereachofchildren.

•Donottipthemachineeitherforward

orbackwardwithfuelinthefueltank;

otherwise,fuelmayleakoutofthe

machine.

FillingtheFuelTank

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Oxygenatedfuelwithupto10%ethanolor15%

MTBEbyvolumeisacceptable.

•Donotuseethanolblendsofgasoline(such

asE15orE85)withmorethan10%ethanolby

volume.Performanceproblemsand/orengine

damagemayresultwhichmaynotbecovered

underwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

Donotllabovethebottomofthefueltankneck

(Figure19).

Figure19

Note:Forbestresults,purchaseonlythequantity

offuelthatyouexpecttousein30days.Otherwise,

youmayaddfuelstabilizertonewlypurchasedfuelto

keepitfreshforupto6months.

10

g216203

Page 11

DuringOperation

DuringOperationSafety

•Shutofftheenginebeforeuncloggingthe

machineandalwaysuseastickorthe

snow-cleanouttool(ifprovided).

•Arotatingaugercaninjurehandsorfeet.Stay

behindthehandlesandawayfromthedischarge

openingwhileoperatingthemachine.Keepyour

face,hands,feet,andanyotherpartofyour

bodyorclothingawayfrommovingorrotating

parts.

•Neverdirectthedischargetowardpeopleorareas

wherepropertydamagecanoccur.

•Exercisecautiontoavoidslippingorfalling.

Alwaysbesureofyourfooting,andkeeparm

holdonthehandles.Walk;neverrun.

•Exerciseextremecautionwhenoperatingon

slopes.

•Neveroperatethemachinewithoutgoodvisibility

orlight.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Lookbehindandusecarewhenbackingupwith

themachine.

•Whennotactivelyclearingsnow,disengagepower

totheauger.

•Exerciseextremecautionwhenoperatingonor

crossinggraveldrives,walks,orroads.Stayalert

forhiddenhazardsortrafc.

•Neverattempttomakeanyadjustmentswhilethe

engineisrunning.

•Afterstrikingaforeignobject,shutofftheengine,

removetheignitionkey(electric-startmodels

only),thoroughlyinspectthemachineforany

damage,andrepairthedamagebeforestarting

andoperatingthemachine.

•Ifthemachineshouldstarttovibrateabnormally,

shutofftheengineandcheckforthecause.

•Donotruntheengineindoorsunlessthereis

adequateventilation(e.g.,leavinganoutsidedoor

open);exhaustfumesaredangerous.

•Donotoverloadthemachinecapacityby

attemptingtoclearsnowattoofastarate.

•Nevertouchahotengineormufer.

g016512

Figure20

3.Fullyinserttheignitionkey(Figure21).

g016498

Figure21

1.Ignitionkey

StartingtheEngine

1.Checktheengine-oillevel.RefertoChecking

theEngine-OilLevel(page19).

2.Turnthefuel-shutoffvalve1/4turn

counterclockwisetoopenit(Figure20).

4.Firmlypushintheprimerwithyourthumbas

indicatedbythefollowingtable,holdingthe

primerinforasecondbeforereleasingiteach

time(Figure22).

11

Page 12

6.MovethethrottletotheFASTposition(Figure

24).

Figure24

g016504

Figure22

Temperature

Above-18°C(0°F)

-23°Cto-18°C(-10°Fto0°F)

Below-23°C(-10°F)

SuggestedNumberof

5.MovethechoketotheCHOKEposition(Figure

23).

g037221

7.Startthemachinebypullingtherecoilstarteror

pressingtheelectric-starterbutton(Figure25).

Primes

3

4

6

g019055

Figure25

1.Electric-starterbutton3.Recoil-starthandle

2.Electricstarterplug-in

Note:Useonlyanextensioncordthatis

UL-listed,16gauge,notlongerthan15m(50

ft),andisdesignedforoutdooruse.

Figure23

WARNING

Theelectricalcordcanbecomedamaged,

causingashockorre.

Thoroughlyinspecttheelectricalcord

beforeusingthemachine.Ifthecord

isdamaged,donotuseit.Replaceor

repairthedamagedcordimmediately.

ContactanAuthorizedServiceDealerfor

g016501

12

assistance.

Important:Topreventdamagingtheelectric

starter,runitinshortcycles(5secondson,

5secondsoff),nomorethan10times.Ifthe

Page 13

enginestilldoesnotstart,takethemachine

toanAuthorizedServiceDealerforservice.

8.Disconnectthepowercordfromthepoweroutlet

rstandthenfromthemachine(electric-start

modelsonly).

9.Allowtheenginetowarmup;graduallymove

thechoketowardtheRUNposition.Waitfor

theenginetorunsmoothlybeforeeachchoke

adjustment.

CAUTION

Ifyouleavethemachinepluggedintoa

poweroutlet,someonecaninadvertently

startthemachineandinjurepeopleor

damageproperty.

Unplugthepowercordwheneveryouare

notstartingthemachine.

ShuttingOfftheEngine

1.MovethethrottletotheSLOWposition,andthen

totheSTOPposition(Figure26).Youcanalso

shutofftheenginebypullingtheignitionkey

outwardtothemiddleposition.

Figure26

2.Waitforallmovingpartstostopbeforeleaving

theoperatingposition.

g016499

Figure27

5.Pulltherecoilstarter3or4times.

Note:Thishelpspreventtherecoilstarterfrom

freezingup.

Operatingthe Handwarmers

Operatethehandwarmersasfollows:

•PresstheswitchtotheONpositiontoturnonthe

handwarmers.

•PresstheswitchtotheOFFpositiontoturnoffthe

handwarmers.

g016505

3.Removetheignitionkeytopreventaccidental

starting.

4.Closethefuelshutoffvalvebyrotatingit

clockwise(Figure27).

g026460

Figure28

1.On/Offswitch3.OFFposition

2.ONposition

13

Page 14

OperatingtheTraction Drive

CAUTION

Ifthetractiondriveisnotproperlyadjusted,

themachinemaymoveinthedirection

oppositeofwhatyouintended,causinginjury

and/orpropertydamage.

Carefullycheckthetractiondriveandadjustit

properly,ifnecessary.

Important:Ifthemachinemoveswhenthe

tractionleverisinthereleasedposition,checkthe

tractioncable;refertoCheckingandAdjusting

theTractionCable(page20)ortakethemachine

toanAuthorizedServiceDealerforservice.

Important:Tooperatethetractiondrive,you

mustoperatethemachinewiththeself-propel

featureengaged.

1.Toengagethetractiondrive,squeezetheleft

(traction)levertothehandgrip(Figure29).

g001307

Figure30

Note:Thisdisengagesthedrivetotherightwheel

whiletheleftwheelcontinuesdriving,andthemachine

turnstotheright.

Note:Similarly,squeezingtheleftwheel-clutchlever

turnsthemachinetotheleft.

Whenyoucompletetheturn,releasethewheel-clutch

lever,andthedrivere-engagesbothwheels(Figure

31).

Figure29

2.Tostopthetractiondrive,releasethetraction

lever.

UsingtheWheel-Clutch Levers

Thewheel-clutchleversallowyoutomomentarily

disengagethedriveto1orbothwheelswiththe

traction-driveleverstillengaged.Thisenablesyouto

turnandmaneuverthemachineeasily.

Note:Holdingdownthetractionleveragainstthe

handleengagesthetractiondrivetobothwheels.

Toturnthemachinetotheright,liftuptheright

wheel-clutchleverandsqueezeittowardthehandle

(Figure30).

g001011

g001308

Figure31

Momentarilysqueezingandreleasingtheleftorright

wheel-clutchleveralsoallowsforsteeringadjustments

tokeepthemachinegoinginastraightline,especially

indeepsnow.

Squeezingbothwheel-clutchleverssimultaneously

disengagesthedrivetobothwheels.Thisenables

youtomanuallymovethemachinebackwardwithout

stoppingtoshiftitintoareversegear.Italsoallows

youtomaneuverandtransportthemachinemore

easilywhentheengineisnotrunning.

OperatingtheSpeed Selector

Thespeedselectorhas6forwardand2reverse

gears.Tochangespeeds,releasethetractionlever

andshiftthespeed-selectorlevertothedesired

position(Figure32).Theleverlocksinanotchat

eachspeedselection.

14

Page 15

Figure32

Operatingthe Auger/ImpellerDrive

1.Toengagetheauger/impellerdrive,squeeze

theright(auger/impeller)levertothehandgrip

(Figure33).

OperatingtheQuickStick®

HoldthebluetriggercapdowntousetheQuickStick

tomovethedischargechuteandthechutedeector.

Releasethetriggercaptolockthedischargechute

andchutedeectorintoposition(Figure34).

g001012

g001014

Figure34

MovingtheDischargeChute

HoldthebluetriggercapdownandmovetheQuick

Sticktothelefttomovethedischargechutetothe

left;movetheQuickSticktotherighttomovethe

dischargechutetotheright(Figure35).

Figure33

2.Tostoptheaugerandimpeller,releasetheright

lever.

Important:Whenyouengageboththe

auger/impellerleverandthetractionlever,

thetractionleverlockstheauger/impeller

leverdown,freeingyourrighthand.To

releasebothlevers,simplyreleasetheleft

(traction)lever.

3.Iftheaugerandimpellercontinuetorotatewhen

youreleasetheauger/impellerlever,donot

operatethemachine.Checktheauger/impeller

cable;refertoCheckingandAdjustingthe

Auger/ImpellerCable(page20)andadjustitif

necessary.Otherwise,takethemachinetoan

AuthorizedDealerforservice.

WARNING

Iftheaugerandimpellercontinue

torotatewhenyoureleasethe

auger/impellerlever,youcouldseriously

injureyourselforothers.

Donotoperatethemachine.Takeittoan

AuthorizedServiceDealerforservice.

g001013

g018894

Figure35

•Ifthechutedoesnotmove,refertoAdjustingthe

Discharge-ChuteLatch(page23).

•Ifthechutedoesnotturnasfartotheleftasit

doestotheright,ensurethatthecableisrouted

totheinsideofthehandles.RefertoInstallingthe

UpperHandle(page5).

•Ifthechutedoesnotlockintoplacewhenyou

releasethetriggercap,refertoAdjustingthe

Discharge-ChuteLatch(page23).

15

Page 16

MovingtheChuteDeector

HoldthebluetriggercapdownandmovetheQuick

Stickforwardtolowerthechutedeector;moveit

rearwardtoraisethechutedeector(Figure36).

OperatingTips

DANGER

Whenthemachineisinoperation,theimpeller

andaugerrotateandcaninjureoramputate

handsorfeet.

•Beforeadjusting,cleaning,inspecting,

troubleshooting,orrepairingthemachine,

shutofftheengineandwaitforallmoving

partstostop.Disconnectthewirefrom

thesparkplugandkeepitawayfromthe

plugtopreventsomeonefromaccidentally

startingtheengine.

Figure36

ClearingaClogged DischargeChute

WARNING

Iftheauger/impellerisrunningbutthereisno

snowcomingoutofthedischargechute,the

dischargechutemaybeclogged.

Neveruseyourhandstoclearaclogged

dischargechute.Thiscouldresultinpersonal

injury.

•Tounclogthedischargechute,stayinthe

operatingpositionandreleasetheleft(traction)

lever.Whilerunningtheauger/impeller,pushdown

onthehandlestoraisethefrontofthemachinea

fewcentimeters(inches)offthepavement.Then

liftthehandlesquicklytobumpthefrontofthe

machineonthepavement.Repeatifnecessary

untilastreamofsnowcomesoutthedischarge

chute.

•Ifyoucannotunclogthedischargechuteby

bumpingthefrontofthemachine,shutoffthe

engine,waitforallmovingpartstostop,and

usethesnow-cleanouttool(Figure18).

Important:Uncloggingthedischargechute

bybumpingthefrontofthemachineonthe

pavementmaycausetheskidstomove.Adjust

theskidsandtightentheskidboltssecurely;

refertoCheckingandAdjustingtheSkidsand

Scraper(page19).

g001016

chute;refertoClearingaClogged

DischargeChute(page16).Usethe

snow-cleanouttool(Figure19),notyour

hands,toremoveanobstructionfromthe

dischargechute.

•Staybehindthehandlesandawayfrom

thedischargeopeningwhileoperatingthe

machine.

•Keepyourface,hands,feet,andanyother

partofyourbodyorclothingawayfrom

concealed,moving,orrotatingparts.

WARNING

Theimpellercanthrowstones,toys,andother

foreignobjectsandcauseseriouspersonal

injurytoyouorbystanders.

•Keeptheareatobeclearedfreeofall

objectsthattheaugercouldpickupand

throw.

•Keepallchildrenandpetsawayfromthe

areaofoperation.

•AlwayssetthethrottletotheFASTpositionwhen

throwingsnow.

•Iftheengineslowsdownunderaloadorthe

wheelsslip,shiftthemachineintoalowergear.

•Ifthefrontofthemachineridesup,shiftthe

machineintoalowergear.Ifthefrontcontinuesto

rideup,liftuponthehandles.

•Removeanobstructionfromthedischarge

16

Page 17

AfterOperation

AfterOperationSafety

•Neverstorethemachinewithfuelinthefuel

tankinsideabuildingwhereignitionsourcesare

present,suchashotwaterheaters,spaceheaters,

orclothesdryers.Allowtheenginetocoolbefore

storinginanyenclosure.

•Whenstoringthemachineformorethan30days,

refertoStorage(page25)forimportantdetails.

PreventingFreeze-upafter Use

•Insnowyandcoldconditions,somecontrolsand

movingpartsmayfreeze.Donotuseexcessive

forcewhentryingtooperatefrozencontrols.

Ifyouhavedifcultyoperatinganycontrolorpart,

starttheengineandletitrunforafewminutes.

•Afterusingthemachine,lettheenginerunfor

afewminutestopreventmovingpartsfrom

freezing.Engagetheauger/impellertoclearany

remainingsnowfrominsidethehousing.Rotate

theQuickSticktopreventitfromfreezing.Shutoff

theengine,waitforallmovingpartstostop,and

removealliceandsnowfromthemachine.

•Withtheengineoff,pulltherecoil-starthandle

severaltimesandpushtheelectric-startbutton

oncetopreventtherecoilstarterandelectric

starterfromfreezingup.

17

Page 18

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst5hours

Beforeeachuseordaily

Every50hours

Every100hours

Yearly

Yearlyorbeforestorage

MaintenanceProcedure

•Inspectthetractioncableandadjustitifnecessary.

•Inspecttheauger/impellercableandadjustitifnecessary .

•Changetheengineoil.

•Checktheengine-oillevelandaddoilifnecessary.

•Changetheengineoil.Changetheengineoilevery25operatinghourswhen

operatingtheengineunderaheavyload.

•Replacethesparkplug.

•Checktheskidsandscraperandadjustthemifnecessary.

•Inspectthetractioncableandadjustorreplaceitifnecessary.

•Inspecttheauger/impellercableandadjustorreplaceitifnecessary.

•Checktheauger-gearboxoilandaddoilifnecessary.

•Lubricatethehexshaft.

•Checktheairpressureinthetiresandinatethemto1 16to137kPa(17to20psi).

•Runtheenginetodryoutthefueltankandthecarburetorattheendoftheseason.

•HaveanAuthorizedServiceDealerinspectandreplacethetractiondrivebeltand/or

theauger/impellerdrivebelt,ifnecessary.

Important:Y oucanndmoreinformationaboutmaintainingandservicingyourmachineat

www.Toro.com.

MaintenanceSafety

Readthefollowingsafetyprecautionsbefore

performinganymaintenanceonthemachine:

•Beforeperforminganymaintenance,service,or

adjustment,shutofftheengineandremovethe

key.Ifmajorrepairsareeverneeded,contactan

AuthorizedServiceDealer.

•Checkallfastenersatfrequentintervalsforproper

tightnesstoensurethatthemachineisinsafe

workingcondition.

•Donotchangethegovernorsettingsontheengine.

•PurchaseonlygenuineTororeplacementparts

andaccessories.

PreparingforMaintenance

1.Movethemachinetoalevelsurface.

2.Shutofftheengineandwaitforallmovingparts

tostop.

3.Disconnectthespark-plugwire.Referto

ReplacingtheSparkPlug(page23).

18

Page 19

CheckingtheEngine-Oil

CheckingandAdjustingthe

Level

ServiceInterval:Beforeeachuseordaily—Check

theengine-oillevelandaddoilif

necessary.

SkidsandScraper

ServiceInterval:Y early—Checktheskidsand

scraperandadjustthemif

necessary.

Checktheskidstoensurethattheaugerdoesnot

contactthepavedorgravelsurface.Adjusttheskids

asneededtocompensateforwear.

1.Checkthetirepressure;refertoCheckingand

AdjustingtheTirePressure(page8).

2.Loosenthenutsthatsecurebothskidstothe

augersidesuntiltheskidsslideupanddown

easily(Figure38).

g001570

Figure38

1.1.3cm(1/2inch)

3.Supportthesideplatessothattheyareatleast

1.3cm(1/2inch)abovealevelsurface.

Important:Theaugerbladesmustbe

supportedabovethegroundbytheskids.

4.Ensurethatthescraperis3mm(1/8inch)above

andparalleltoalevelsurface.

Note:Ifthepavementiscracked,rough,or

uneven,adjusttheskidstoraisethescraper.For

gravelsurfaces,adjusttheskidsfurtherdownto

preventthemachinefrompickinguprocks.

5.Movetheskidsdownuntiltheyareevenwith

theground.

6.Firmlytightenthenutsthatsecurebothskids

g219890

totheaugersides.

Note:Toquicklyadjusttheskidsiftheyloosen,

supportthescraper3mm(1/8inch)offthe

pavement,thenadjusttheskidsdowntothe

pavement.

Note:Iftheskidsbecomeexcessivelyworn,

youcanturnthemoverandsettheunusedside

towardthepavement.

19

Page 20

CheckingandAdjustingthe TractionCable

ServiceInterval:Aftertherst2hours—Inspect

thetractioncableandadjustitif

necessary.

Yearly—Inspectthetractioncableandadjustor

replaceitifnecessary.

Ifthemachinedoesnotdriveintheforwardorreverse

speedsoritdriveswhenyoureleasethetractionlever,

adjustthetractioncable.

g001021

Figure40

Withthetractionleverdisengaged,checkthepin

intheelongatedslotintheleftsideofthemachine

abovethetire.Thereshouldbeagapof1to1.5mm

(1/32to1/16inch)fromthefrontoftheslottothefront

edgeofthepin(Figure39).

Figure39

1.Pin

2.1to1.5mm(1/32to1/16inch)

Iftheleft(traction)cableisnotproperlyadjusted,do

thefollowingsteps:

1.Jamnut2.Turnbuckle

CheckingandAdjustingthe Auger/ImpellerCable

ServiceInterval:Aftertherst2hours—Inspectthe

auger/impellercableandadjustitif

necessary.

Yearly—Inspecttheauger/impellercableand

adjustorreplaceitifnecessary.

1.Removethe2screwsfromtherightsideofthe

beltcoverasshown.

2.Liftuptherightsideofthebeltcover(Figure41).

g001568

1.Loosenthejamnut.

2.Loosenortightentheturnbuckletoadjustthe

pinuntilitisthepropergapfromthefrontedge

oftheslot.

3.Tightenthejamnut(Figure40).

g001022

Figure41

3.Withtheauger/impellerleverdisengaged,

ensurethatthegapbetweentheaugerclutch

assemblyandthetabis1.5mm(1/16inch)as

showninFigure42.

20

Page 21

Figure42

1.Tab

2.1.5mm(1/16inch)

4.Iftheauger/impellercableisnotproperly

adjusted,dothefollowingsteps:

5.Loosenthejamnut(Figure43).

Checkingthe Auger-Gearbox-OilLevel

ServiceInterval:Yearly—Checktheauger-gearbox

oilandaddoilifnecessary.

1.Movethemachinetoalevelsurface.

2.Cleantheareaaroundthepipeplug(Figure44).

g001569

g016782

Figure44

1.Pipeplug

Figure43

1.Jamnut2.Turnbuckle

6.Loosenortightentheturnbucklethatadjuststhe

tensiononthecable(Figure43).

7.Adjusttheturnbuckleuntilyouobtaintheproper

gap.

8.Tightenthejamnut.

9.Insertthe2screwsthatyoupreviouslyremoved

onthebeltcover.

10.Iftheauger/impellercableisproperlyadjusted

butaproblemremains,contactanAuthorized

ServiceDealer.

3.Removethepipeplugfromthegearbox.

4.Checktheoillevelinthegearbox.Theoilshould

beatthepointofoverowingatthelleropening.

5.Iftheoillevelislow,addGL-5orGL-6,SAE

85-95EPgearoillubricanttothegearboxuntil

thepointofoverow.

Note:Donotusesyntheticoil.

6.Installthepipepluginthegearbox.

g001024

ChangingtheEngineOil

ServiceInterval:Aftertherst5hours—Changethe

engineoil.

Every50hours—Changetheengineoil.

Changetheengineoilevery25operatinghours

whenoperatingtheengineunderaheavyload.

Ifpossible,runtheengineforafewminutesbefore

changingtheoilbecausewarmoilowsbetterand

carriesmorecontaminants.

EngineoilcapacityModels38801and38802:

0.89to0.95L(30to32oz)

OilviscosityRefertoFigure39.

APIserviceclassicationSJorhigher

UseFigure45belowtoselectthebestoilviscosityfor

theoutdoortemperaturerangeexpected:

21

Page 22

Figure45

LubricatingtheHexShaft

ServiceInterval:Yearly—Lubricatethehexshaft.

Lightlylubricatethehexshaftyearlywithautomotive

engineoil(Figure47).

g011606

1.Cleantheareaaroundtheoil-draincap(Figure

46).

Figure46

1.Oil-drainplug

2.Slideanoil-drainpanunderthedrainextension

andremovetheoil-drainplug.

Note:Whenremovingtheplug,ensurethatthe

tubedoesnotloosen.

3.Draintheoil.

Note:Disposeoftheusedoilproperlyatalocal

recyclingcenter.

4.Installtheoil-drainplug.

5.Fillthecrankcasewithoil.

g001027

Figure47

1.Hexshaft

2.Aluminumfrictionplate

3.Rubberwheel

Important:Donotgetoilontherubberwheel

orthealuminumfrictiondriveplatebecausethe

tractiondrivewillslip(Figure47).

1.Drainthefuelfromthefueltank.

2.Tipthemachineforwardontoitsaugerhousing

andblockitsothatitcannotfall.

g016496

3.Removethebackcover(Figure48).

g001028

Figure48

1.Backcover

4.Movethespeed-selectorlevertoPositionR2.

5.Dipyourngerinautomotiveengineoiland

lightlylubricatehexshaft.

6.Movethespeed-selectorlevertoPosition6.

7.Lubricatetheotherendofthehexshaft.

8.Movethespeed-selectorleverforwardand

rearwardafewtimes.

9.Installthebackcoverandreturnthemachineto

theoperatingposition.

22

Page 23

ReplacingtheSparkPlug

ServiceInterval:Every100hours—Replacethe

sparkplug.

WARNING

Replacingthesparkplugwhiletheengineis

hotcanresultinburns.

Waituntiltheengineiscooltoreplacethe

sparkplug.

UseaT orosparkplugorequivalent(Champion®

RN9YCorNGKBPR6ES).

1.Removetheboot(Figure49).

g001029

Figure51

1.0.76mm(0.030inch)

5.Installthenewsparkplug,tightenitrmly ,and

attachtheignitionwiretothesparkplug.

Note:Ensurethattheignitionwiresnaps

completelyintoplaceonthesparkplug.

Adjustingthe Discharge-ChuteLatch

Ifthedischargechutedoesnotlockintothedesired

positionordoesnotunlocksothatyoucanmoveitto

anotherposition,adjustthedischarge-chutelatch.

Figure49

1.Spark-plugboot

2.Cleanaroundthebaseofthesparkplug.

Figure50

1.Removethefasteneronthegearcover(Figure

52),liftthefrontofthecoverup,andslideitback

g016645

andoutoftheway.

g001030

Figure52

2.Loosentheboltonthecableclamp(Figure53).

g016646

3.Removeanddiscardtheoldsparkplug.

Note:Youwillneedaratchetwrenchextension

toremovethesparkplug.

4.Setthegapbetweentheelectrodesonanew

sparkplugat0.76mm(0.030inch)asshown

inFigure51.

g001031

Figure53

1.Cableconduit2.Cableclamp

23

Page 24

3.Graspthecableconduitandmoveittowardthe

frontofthemachineuntilthedischarge-chute

latchfullyengagesthegearteeth(Figure53

andFigure54).

Figure54

2.Turnthebaseofthebulbcounterclockwiseuntil

itstops(Figure56).

g001033

Figure56

3.Removethebulbstraightoutfromthebackof

theheadlight(Figure57).

g001032

1.Discharge-chutelatch

2.Gearteeth

Note:Thelatchisspringloadedandnaturally

movesintotheteethofthegear(Figure54).

4.Removeanyslackinthecablebypullingthe

cableconduitrearward.

5.Tightentheboltonthecableclamp,being

carefulnottostriptheplasticpart.

6.Installandsecurethegearcover.

ReplacingtheDriveBelts

Iftheauger/impellerdrivebeltorthetraction-drivebelt

becomesworn,oil-soaked,orotherwisedamaged,

haveanAuthorizedServiceDealerreplacethebelt.

ReplacingtheHeadlight Bulb

UseaT orolightbulborequivalent(GE89937W

halogenbulb).Donottouchthebulbwithyourhands

orallowdirtormoisturetocomeintocontactwiththe

bulb.

1.Removethewireconnectorfromthebackofthe

headlight(Figure55).

g001034

Figure57

4.Insertanewbulbintothebackoftheheadlight

(Figure58).

g001035

Figure58

5.Turnthebaseofthebulbclockwiseuntilitis

snug(Figure59).

Figure55

g001036

Figure59

6.Insertthewireconnectorstraightintothebackof

theheadlightuntilitissecurelyinplace(Figure

g001037

24

60).

Page 25

Figure60

Storage

StoringtheMachine

1.Onthelastrefuelingoftheyear,addfuel

stabilizertofreshfuelasdirectedbythefuel

stabilizermanufacturer.

Important:Donotstorefuellonger

thanthatsuggestedbythefuel-stabilizer

manufacturer.

2.Runtheenginefor10minutestodistributethe

g006590

conditionedfuelthroughthefuelsystem.

3.Runthemachineuntiltheenginerunsoutoffuel.

4.Primetheengineandstartitagain.

5.Allowtheenginetorununtilitshutsoff.

Whenyoucannolongerstarttheengine,itis

sufcientlydry.

6.Shutofftheengineandallowittocool.

7.Removetheignitionkey.

8.Cleanthemachinethoroughly.

9.Touchupchippedsurfaceswithpaintavailable

fromanAuthorizedServiceDealer.Sand

affectedareasbeforepainting,andusearust

preventativetopreventthemetalpartsfrom

rusting.

10.Tightenallloosescrews,bolts,andlocknuts.

Repairorreplaceanydamagedparts.

11.Coverthemachineandstoreitinaclean,dry

placeoutofthereachofchildren.

RemovingtheMachine fromStorage

Performtheannualmaintenanceproceduresasgiven

intheRecommendedMaintenanceSchedule;referto

Maintenance(page18).

25

Page 26

Troubleshooting

Problem

Theelectricstarterdoesnotturn

(electric-startmodelsonly).

Theenginedoesnotstartorstartshard.

PossibleCauseCorrectiveAction

1.Thepowercordisdisconnectedatthe

outletorthemachine.

2.Thepowercordisworn,corroded,or

damaged.

3.Thepoweroutletisnotenergized.

1.Thekeyisnotintheignitionorisinthe

STOPposition.

2.ThechokeisintheOFFpositionand

theprimerhasnotbeenpressed.

3.Thefuel-shutoffvalveisnotopen.3.Openthefuel-shutoffvalve.

4.ThethrottleisnotintheFASTposition.4.MovethethrottletotheFASTposition.

5.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

6.Thespark-plugwireislooseor

disconnected.

7.Thesparkplugispitted,fouled,orthe

gapisincorrect.

8.Thefuel-ventcapisrestricted.

9.Theengine-oillevelintheengine

crankcaseistoolowortoohigh.

1.Connectthepowercordtotheoutlet

and/orthemachine.

2.Replacethepowercord.

3.Haveaqualiedelectricianenergize

theoutlet.

1.Insertthekeyintotheignitionandturn

ittotheONposition.

2.MovethechoketotheONpositionand

presstheprimer3times.

5.Drainand/orllthefueltankwith

freshfuel(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

6.Connectthewiretothesparkplug.

7.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

8.Removetheventrestrictionorreplace

thefuelcap.

9.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

Theenginerunsrough.

1.ThechokeisintheONposition.1.MovethechoketotheOFFposition.

2.Thefuel-shutoffvalveisnotcompletely

open.

3.Thefueltankisnearlyemptyor

containsstalefuel.

4.Thespark-plugwireisloose.

5.Thesparkplugispitted,fouled,orthe

gapisincorrect.

6.Theengine-oillevelintheengine

crankcaseistoolowortoohigh.

2.Openthefuel-shutoffvalve.

3.Drainandllthefueltankwithfresh

fuel(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

4.Connectthewiretothesparkplug.

5.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

6.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

26

Page 27

Problem

PossibleCauseCorrectiveAction

Theengineruns,butthemachine

dischargessnowpoorlyornotatall.

Thedischargechuteeitherdoesnotlock

intoplaceordoesnotmove.

Themachinedoesnotproperlyclearthe

snowoffthesurface.

1.ThethrottleisnotintheFASTposition

whenthrowingsnow .

2.Themachineismovingtoofasttoclear

thesnow.

3.Y ouaretryingtoremovetoomuch

snowperswath.

4.Y ouaretryingtoremoveextremely

heavyorwetsnow.

5.Thedischargechuteisplugged.5.Unclogthedischargechute.

6.Theauger/impellerdrivebeltisloose

orisoffthepulley.

7.Theauger/impellerdrivebeltisworn

orbroken.

1.Thedischarge-chutelatchisnot

properlyadjusted.

1.Theskidsand/orscraperarenot

properlyadjusted.

2.Thepressureinthetiresisnotequal.

1.MovethethrottletotheFASTposition.

2.Shiftthemachineintoalowergear.

3.Reducetheamountofsnowremoved

perswath.

4.Donotoverloadthemachinewith

extremelyheavyorwetsnow.

6.Installand/oradjusttheauger/impeller

drivebelt;refertowww.Toro.com

forservicinginformationortakethe

machinetoanAuthorizedService

Dealer.

7.Replacetheauger/impellerdrivebelt;

refertowww.Toro.comforservicing

informationortakethemachinetoan

AuthorizedServiceDealer.

1.Adjustthedischarge-chutelatch.

1.Adjusttheskidsand/orthescraper.

2.Checkandadjustthepressurein1or

bothtires.

27

Page 28

Loading...

Loading...