PowerBroom

38701

KehrmaschinePowerBroom

38701

Barredora

38701

Balayeuseélectrique

38701

FormNo.3439-918RevB

Motoraangedrevenrolbezem

38701

www.T oro.com.

*3439-918*

FormNo.3439-892RevB

PowerBroom

ModelNo.38701—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3439-892*

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

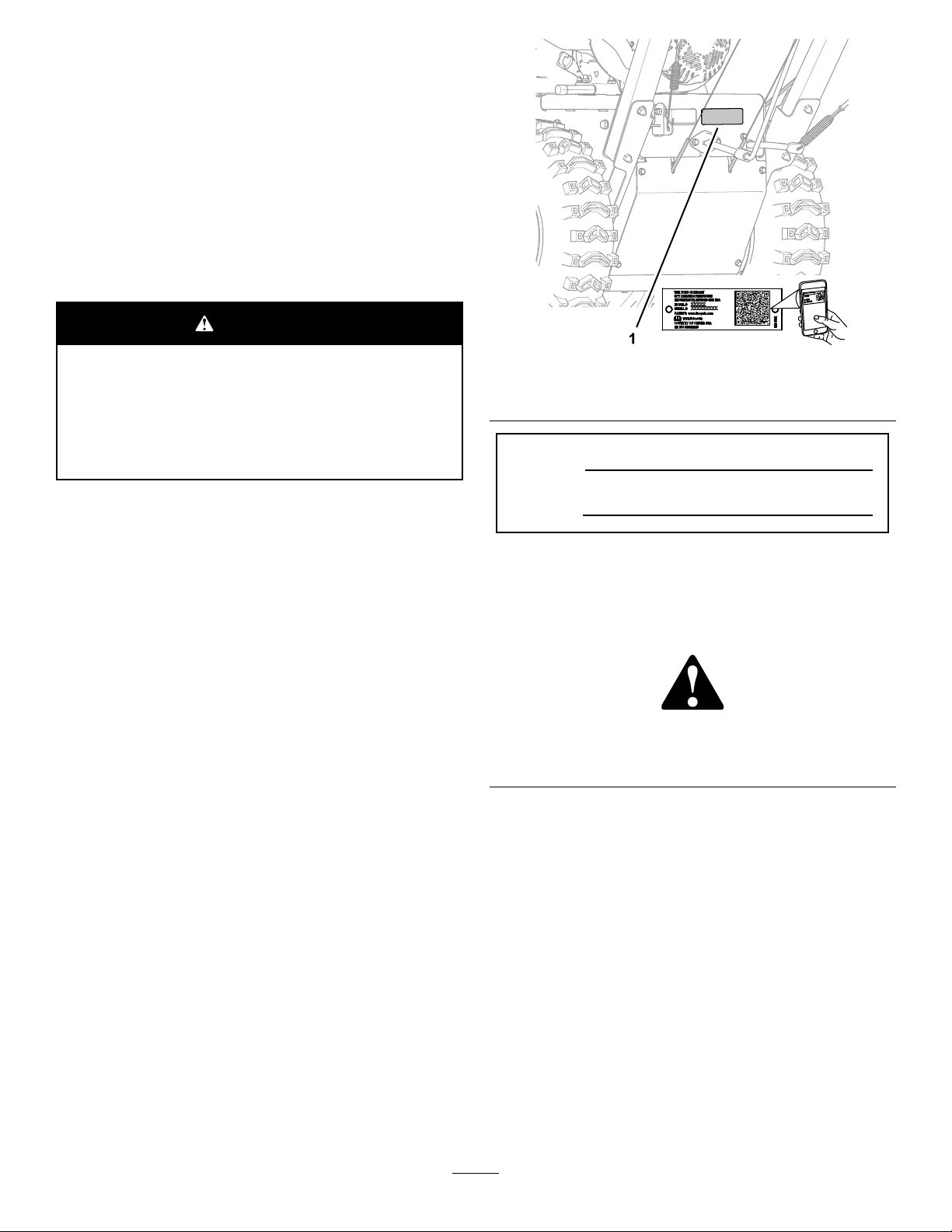

g325100

Figure1

1.Modelandserial-numberlocation

ModelNo.

Introduction

Thismachineisintendedtobeusedbyresidential

homeownersorprofessional,hiredoperators.Itis

designedforremovingsnow,dust,anddirtfrompaved

surfaces,suchasdrivewaysandsidewalks,and

othersurfacesfortrafconresidentialorcommercial

properties,aswellasthatchfromgrass.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

©2020—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety

Safety.......................................................................3

GeneralSafety...................................................3

SlopeIndicator...................................................4

SafetyandInstructionalDecals..........................5

ProductOverview.....................................................7

Controls.............................................................7

Specications....................................................8

Attachments/Accessories...................................8

BeforeOperation...................................................9

BeforeOperationSafety.....................................9

FillingtheFuelTank............................................9

CheckingtheSweepingPath..............................9

AdjustingtheBroomHeight..............................10

DuringOperation.................................................10

DuringOperationSafety...................................10

OperatingtheEngine.........................................1 1

DrivingtheMachine..........................................13

OperatingtheBroom........................................14

AdjustingtheBroomSideAngle........................15

UsingtheAlternateCasterLocation..................16

ClearingaCloggedBroom................................16

AfterOperation....................................................16

AfterOperationSafety......................................16

PreventingFreeze-upafterUse........................17

TransportingtheMachine.................................17

Maintenance...........................................................18

RecommendedMaintenanceSchedule(s)...........18

MaintenanceSafety..........................................18

PreparingforMaintenance...............................18

Lubrication........................................................19

EngineMaintenance.........................................19

FuelSystemMaintenance................................22

DriveSystemMaintenance...............................23

BroomMaintenance.........................................24

BeltMaintenance..............................................26

ChassisMaintenance.......................................30

Storage...................................................................30

StorageSafety..................................................30

PreparingtheMachineforStorage...................30

RemovingtheMachinefromStorage................31

Troubleshooting......................................................32

Thismachinehasbeendesignedinaccordancewith

ANSI/OPEIB71.3andANSIB71.4specications.

Thisproductiscapableofinjuringhandsandfeetand

ofthrowingobjects.Failuretoobservethefollowing

safetyinstructionscouldresultinseriousinjury.

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

GeneralSafety

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

•Ensurethateveryoneusingthisproductknows

howtouseit,knowshowtoshutofftheengine

quickly,andunderstandsthewarnings.

•Releasethebroom-drivelever,traction-drivelever,

shutofftheengine,andwaitforallmovingparts

tostopwheneveryouleavetheoperatingposition

foranyreason.

•Donotputyourhandsorfeetnearorunder

movingpartsonthemachine.Keepclearofthe

dischargeopeningatalltimes.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

working.

•Keepbystanders,especiallysmallchildren,outof

theoperatingarea.

•Neverallowchildrentooperatethemachine.

3

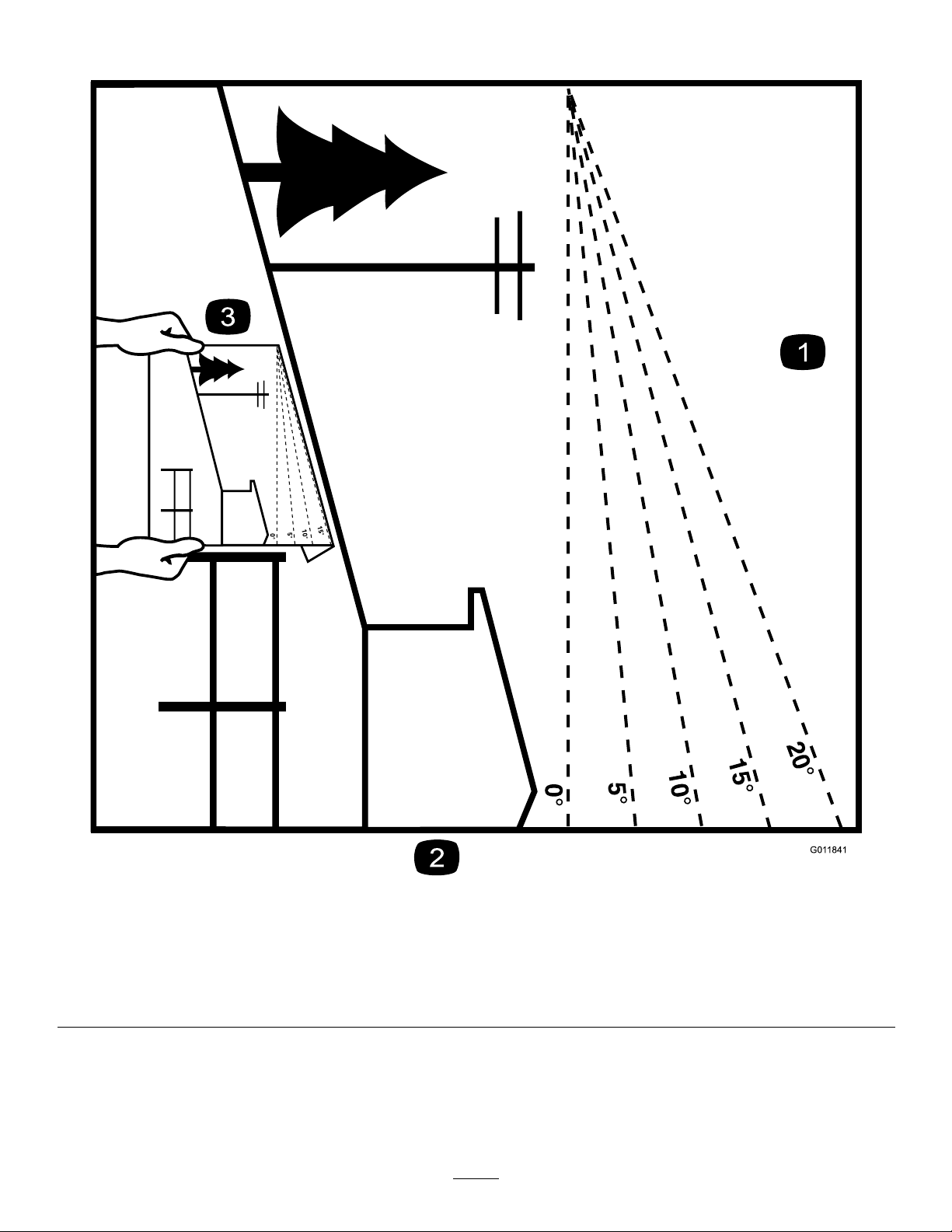

SlopeIndicator

Figure3

1.Themaximumslopeyoucansafelyoperatethemachineonis10°.Usetheslopeindicatortodeterminethedegreeofslopeof

hillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan10°.Foldalongtheappropriatelinetomatchthe

recommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

4

g011841

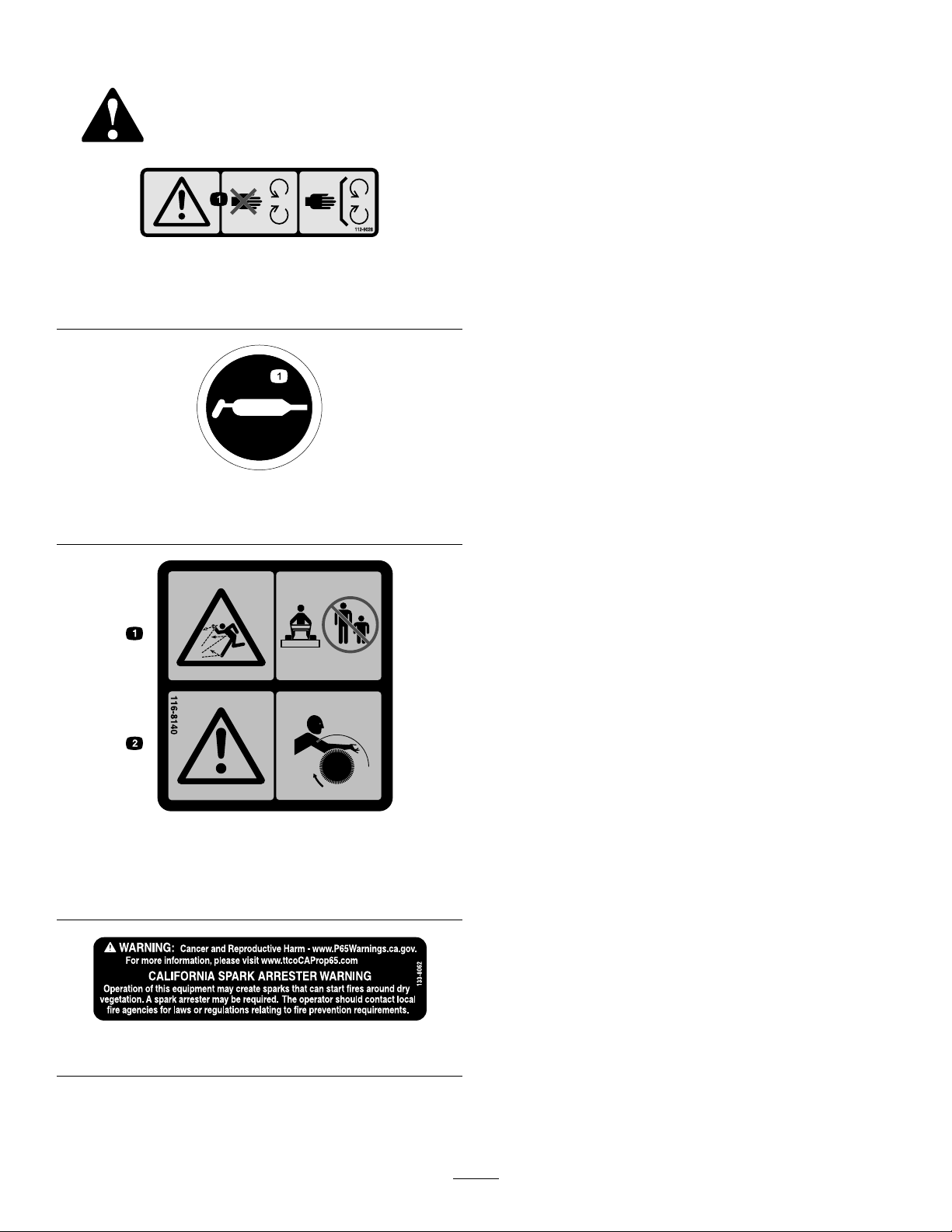

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

115-2903

decal112-9028

decal115-2903

1.Grease

1.Thrownobjecthazard—Do

notoperatewhenpeople

andpetsareinthearea.

decal116-8140

116-8140

2.Warning—Entanglement

hazard—stayclearofthe

rotatingbroom.

decal133-8062

133-8062

5

decal135-2867

135-2867

1.Warning-ReadtheOperator’sManual.DoNotoperatethis

machineunlessyouaretrained.Stayawayfrommoving

parts;keepallguardsinplace.

4.Warning-Stopengineandremovesparkplugbeforeadjusting,

servicing,orcleaningmachineandattachments.Before

leavingtheoperator’sposition,disengagebroom,traction

drive,andstopengine.Lookbehindandtothesidebefore

changingdirections.DoNotcarrypassengers.

2.Thrownobjecthazard-DoNotoperatewhenpeopleandpets

areinthearea;pickupobjectsthatcouldbethrownbybroom.

5.Warning-Entanglementhazard-stayclearofrotatingbroom.

Broombristleswillmeltorburn-keepawayfromextreme

heatorame.DoNotoperateonanyrooforotherelevated

surface.

3.Warning-Wearhearingprotection.

6.Warning-Operateacrossslopesnotupanddown.Use

extremecautionwhenoperatingonslopes.

144-0316

1.Engagethetraction-controllevertoactivatethetractiondrive.4.Engagetheright-turnlevertoturnright.

2.Engagetheleft-turnlevertoturnleft.5.EngagethePTOlevertoactivatethePTO.

3.Engagethebroom-anglelevertoadjustthebroom.

decal144-0316

6

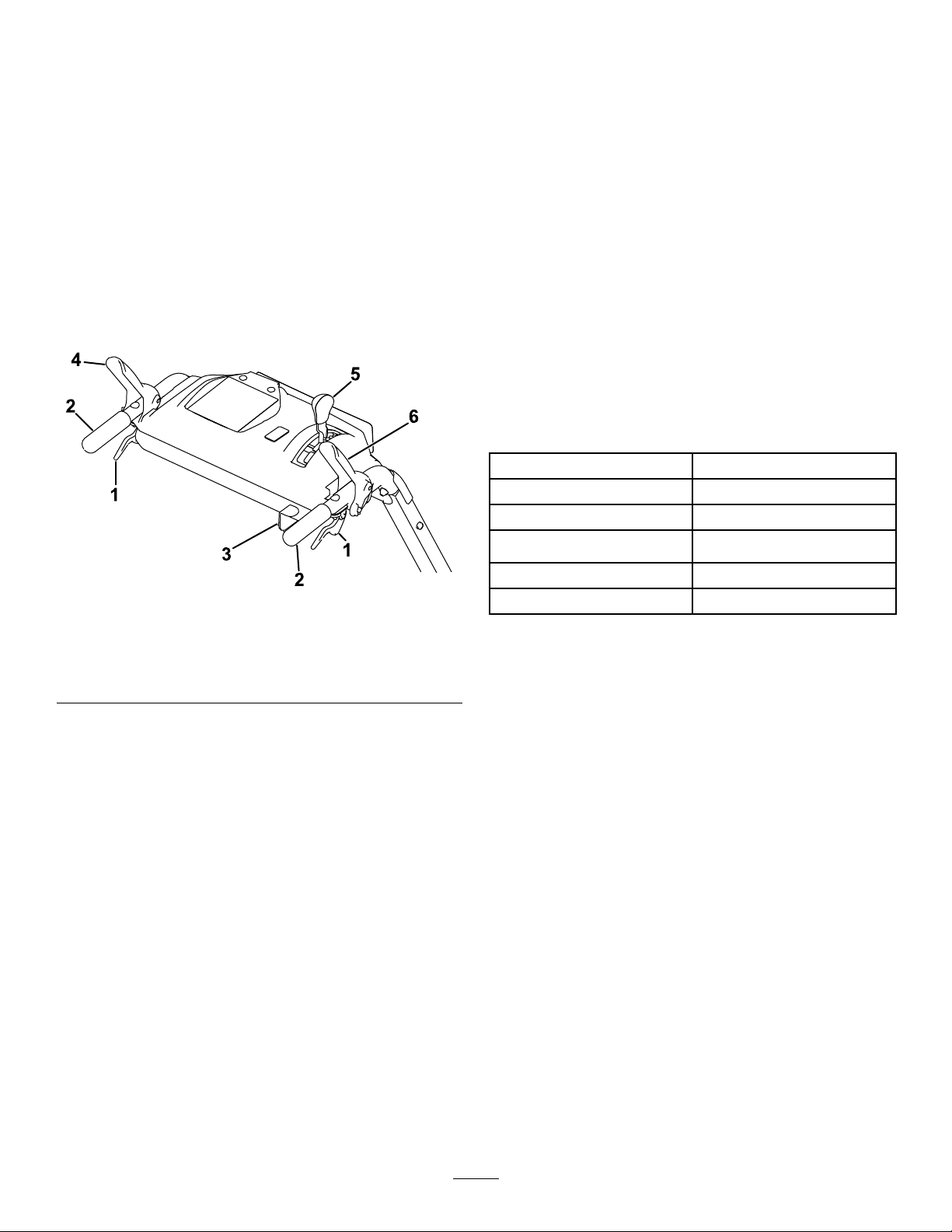

ProductOverview

g326826

Figure5

g325102

Figure4

1.Wheel-clutchlever6.Traction-drivelever

2.Broom-anglelever7.Fuel-tankcap

3.Broom-drivelever8.Broomandhood

4.Speed-selectorlever

5.Handbargrip

9.Broom-height-adjustment

pin

Controls

Determinetheleftandrightsidesofthemachinefrom

thenormaloperatingposition.

ChokeControl

Thechokecontrolisthetopleverlocatedontherear,

leftsideoftheengineabovethefuel-shutoffvalve

(Figure5).

Thechokeisusedtoaidinstartingacoldengine.

MovetheleverlefttotheONpositionforacoldstart.

DonotrunawarmenginewiththechokeintheON

position.

1.Chokecontrol

2.Fuel-shutoffvalve5.EngineOn/Offswitch

3.Throttlecontrol

4.Recoil-starthandle

Fuel-ShutoffValve

Usethefuel-shutoffvalvetoshutoffthefuelwhen

youwillnotusethemachineforafewdays,parkthe

machineinsideabuilding,ortransportthemachineto

andfromthejobsite(Figure5).

Movethelevertothelefttoshutoffthefuel.Movethe

levertotherighttoturnonthefuel.

ThrottleControl

Thethrottlecontrolislocatedontherear,rightsideof

theengineandbelowthefueltank(Figure5).

Thethrottleisusedtocontrolenginespeed.Moving

thethrottlecontroltotheleftincreasestheengine

speed,andmovingitrightdecreasestheengine

speed.

EngineOn/OffSwitch

Locatedontherightsideoftheengine(Figure5).

RotatetheswitchclockwisetotheONposition

beforestartingtheengine.Rotatetheswitch

counterclockwisetotheOFFpositiontoshotoffthe

engine.

7

Wheel-ClutchLevers

Speed-SelectorLever

Thewheel-clutchleversarelocatedbelowtheright

andlefthandles.

Thewheelclutchleversallowthedrivetomomentarily

disengageto1orbothwheelswiththetraction-drive

leversqueezed.Thisallowsforeasierturningand

maneuveringthemachine(Figure6).

Note:Squeezingbothwheelclutchlevers

simultaneouslydisengagesthedrivetobothwheels

(free-wheeling).Thisenablesyoutomanuallymove

themachinebackwardwithoutstoppingtoshiftitinto

areversegear.Italsoallowsyoutomaneuverand

transportthemachinemoreeasilywhentheengine

isnotrunning.

Thespeed-selectionleverislocatedonthemain

consolepanel(Figure6).

Thespeedselectorhas6forwardand2reverse

settings.T ochangespeeds,releasethetraction-drive

lever,andshiftthespeed-selectorlevertothedesired

setting.Theleverlocksinanotchateachspeed

setting.

Broom-AngleLever

Thebroom-angleleverislocatedattherighthandle

(Figure6).

Thebroom-anglelevercontrolstheanglelock.The

broomanglecanbelockedinto3positions:straight

ahead,orangledtotheleftorright19°.

Specications

Width

Length

Height

Weight

118cm(46.5inches)

185.5cm(73inches)

105.5cm(41.5inches)

151kg(333lb)

Figure6

1.Wheel-clutchlever4.Traction-drivelever

2.Handle

3.Broom-anglelever6.Broom-drivelever

5.Speed-selectorlever

Broom-DriveLever

Thebroom-driveleverislocatedabovetheright

handle(Figure6).

Toengagethebroom,squeezethelevertothehandle.

Todisengagethebroom,releasetherightlever.

Traction-DriveLever

Thetraction-driveleverislocatedabovetheleft

handle(Figure6).

Thetraction-drivelevercontrolstheforwardand

reversemotionofthemachine.T oengagethetraction

drive,squeezethelevertothehandle.

g325105

Enginespeed(noload)

Fueltankcapacity

Fullspeed:3600±100rpm

4.1L(1.0USgallon)

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.Toro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

Note:Holdingdownthetraction-driveleveragainst

thehandleengagesthetractiondrivetobothwheels.

8

Operation

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection;alsoweara

respiratorordustmaskindustyconditions.Tie

backlonghair,securelooseclothing,anddonot

wearloosejewelry.

•Thoroughlyinspecttheareawhereyouwillusethe

machine,andremovealldoormats,sleds,boards,

wires,andotherforeignobjects.

•Ifashield,safetydevice,ordecalisdamaged,

illegible,ormissing,repairorreplaceitbefore

beginningoperation.Also,tightenanyloose

fasteners.

FuelSafety

Fuelisextremelyammableandexplosive.Areor

explosionfromfuelcanburnyouandothers.

•Topreventastaticchargefromignitingthefuel,

placethecontainerand/ormachineontheground

beforelling,notinavehicleoronanobject.

•Fillthefueltankoutdoorswhentheengineiscold.

•Replacethefuelcapsecurelyandwipeupspills.

•Donothandlefuelwhensmokingoraroundan

openameorsparks.

•Storefuelinanapprovedfuelcontainer,outofthe

reachofchildren.

•Whenfuelisinthetank,tipthemachineonlyas

directedintheinstructions.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.

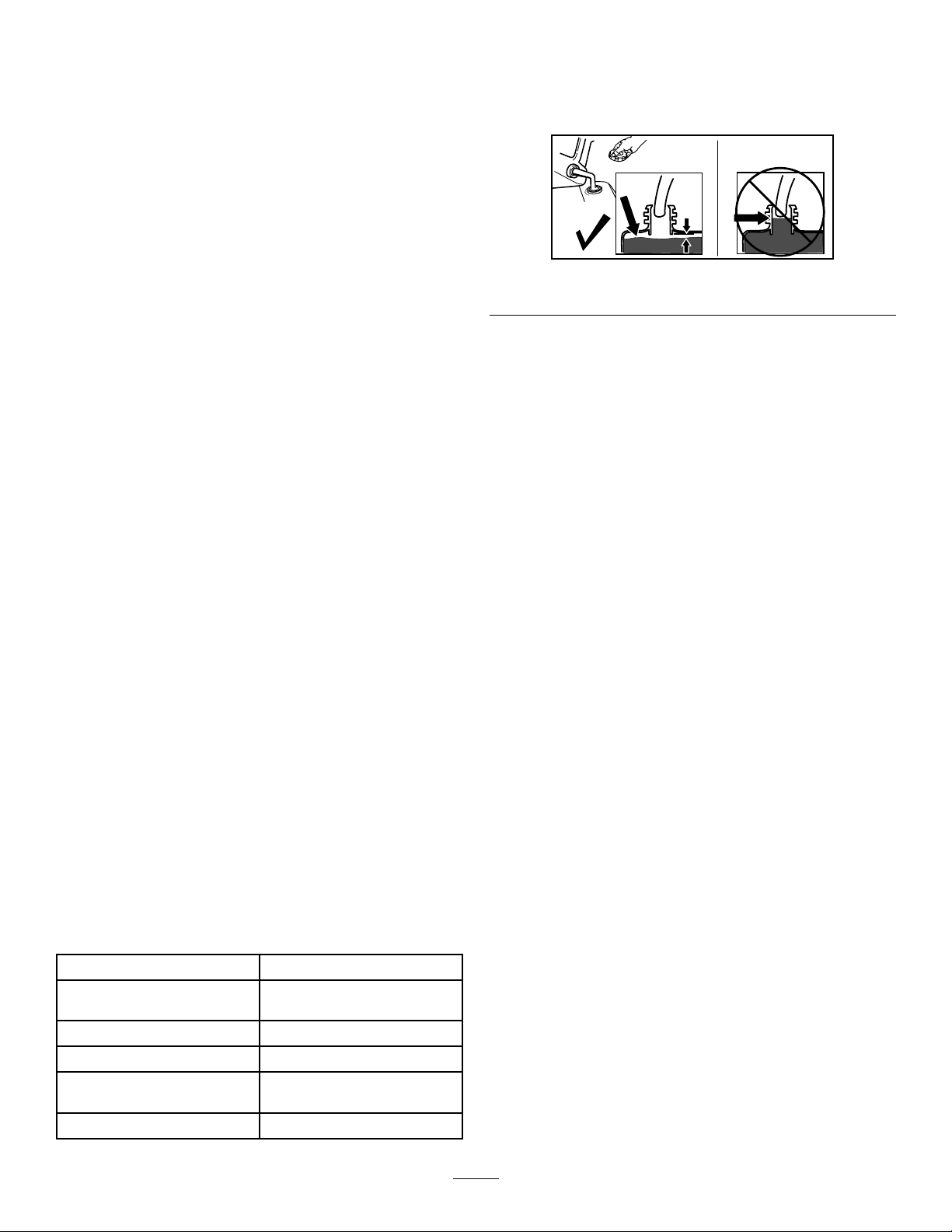

FillingtheFuelTank

Useonlyclean,fresh(nomorethan30daysold),fuel

fromareputablesource.

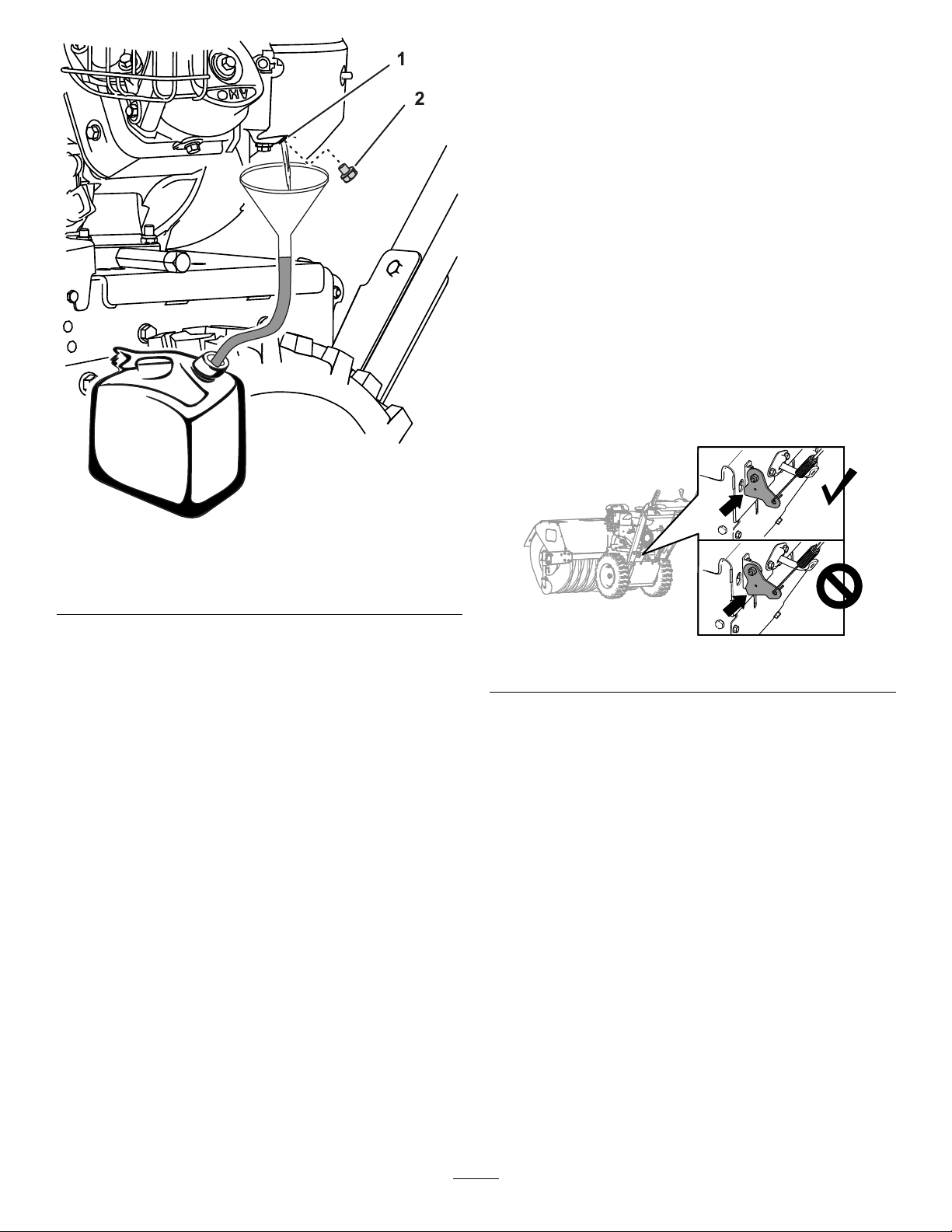

FillthefueltankasshowninFigure7;donotllabove

thebottomofthefueltankneck.

g216203

Figure7

Important:Forbestresults,purchaseonlythe

quantityoffuelthatyouexpecttousein30days.

Otherwise,addfuelstabilizer/conditionertofresh

fuelasdirectedbythefuel-stabilizer/conditioner

manufacturer.

CheckingtheSweeping

Path

Abroomsweepswiththetipsofitsbristles.Whenyou

applytoomuchdownwardpressure,thebroomno

longerusesitstips;thebroomisnowworkingwiththe

sidesofthebristles.Thislimitstheickingactionof

thebristlesandsweepingeffectiveness,decreasing

theservicelifeofthebroom.

1.Drivethemachinetoaat,dustyareaandstop

themachine.

2.Withtheenginerunning,movethethrottle

midwaybetweentheSLOWandFASTpositions.

3.Squeezethebroom-drivecontrol,andallowthe

broomtorotatefor30seconds.

4.Releasethebroom-drivecontrol,shutoffthe

engine,andwaitforallmovingpartstostop.

5.Checktheareasweptbythebroom.The

broom-sweepareashouldequalthefullbroom

widthandamaximumdepthof51to102mm(2

to4inches).

TypeUnleadedgasoline

Minimumoctanerating

Ethanol

MethanolNone

MTBE(methyltertiarybutyl

ether)

OilDonotaddtothefuel

87(US)or91(research

octane;outsidetheUS)

Nomorethan10%byvolume

Lessthan15%byvolume

9

1.51to102mm(2to4

inches)maximumdepth

2.Fullbroomwidth

Figure8

3.Sweptarea

4.Raiseorlowerthecasterwheeltubetoadjust

theareasweptbythebroomasstatedin

CheckingtheSweepingPath(page9).

Note:Selectanyholecombinationthatisin

alignmenttoplaceandlatchtheretainingpin;

matchthesamepositionontheotherside.

5.Forneradjustment,slidetheadjustersleeve1

pinholeupordownonthecasterwheeltube

toadjustthebroomheightin3mm(1/8inch)

increments(Figure9).Repeatsteps3through5

fortheothercasterwheel.

•Toraisethebroomin3mm(1/8inch)

increments,slightlyraisetheadjustersleeve

g017922

andinsertthepinintothenextpinholebelow

thecurrentholeused.

•Tolowerthebroomin3mm(1/8inch)

increments,slightlylowertheadjustersleeve

andinsertthepinintothenextpinhole

abovethecurrentholeused.

6.Ifthebroom-sweepareaistoolarge,toosmall,

oruneven,adjustthebroomheight;referto

AdjustingtheBroomHeight(page10).

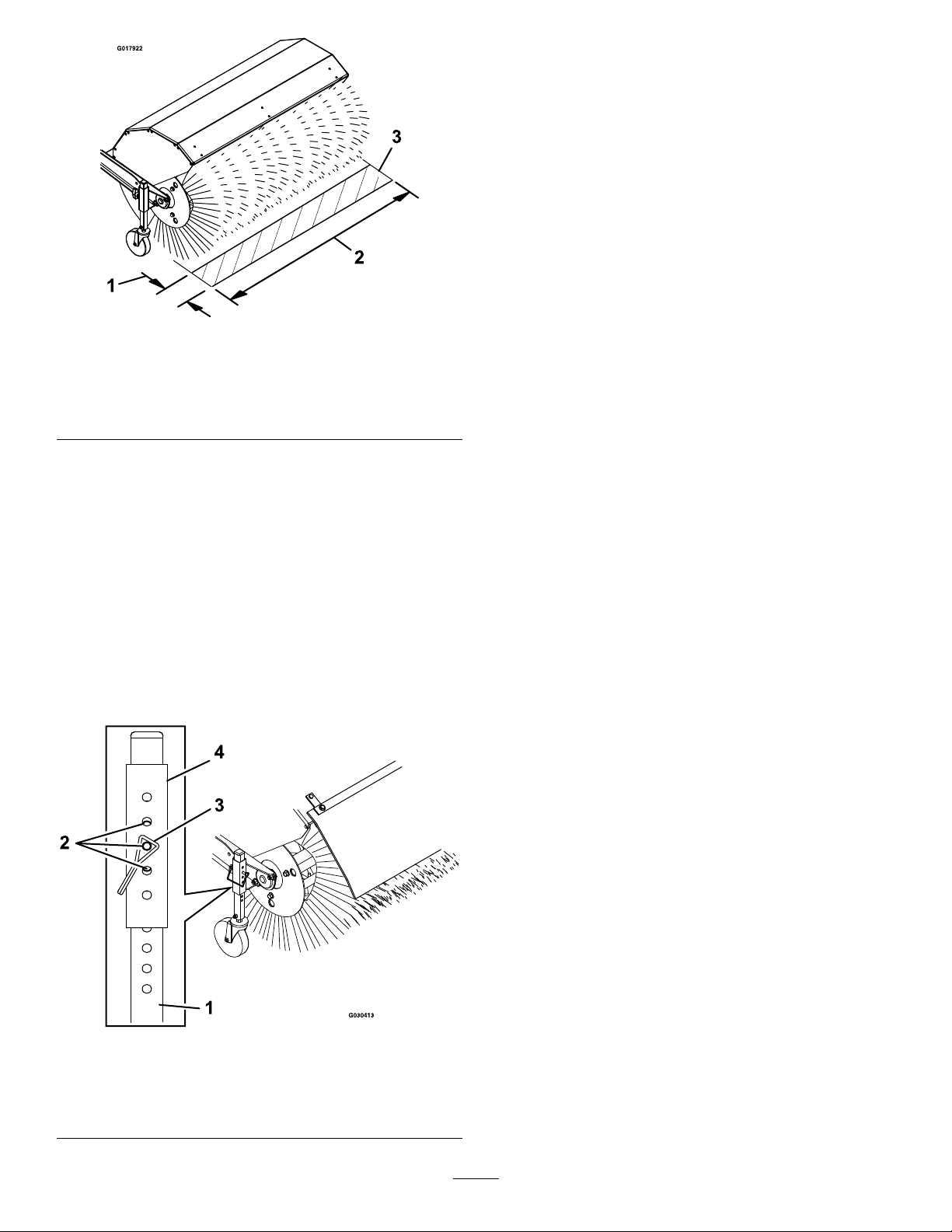

AdjustingtheBroomHeight

1.Drivetoaat,dustyareaandstopthemachine.

2.Ensurethatthebroom-driveleverisreleased,

shutofftheengine,andwaitforallmovingparts

tostop.

3.Toadjustthebroomheight,removeandretain

thepinfromtheadjustersleeveandwheeltube

ofthecaster(Figure9).

6.Whenthebroomheightisadjusted,secure

thepinoneachcasterwheel,andcheckthe

broom-sweeparea;refertoCheckingthe

SweepingPath(page9).

DuringOperation

DuringOperationSafety

GeneralSafety

•Staybehindthehandlesandawayfromthe

dischargeopeningwhileoperatingthemachine.

Keepyourface,hands,feet,andanyotherpart

ofyourbodyorclothingawayfrommovingor

rotatingparts.

•Neverdirectthedischargetowardpeopleorareas

wherepropertydamagecanoccur.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

1.Caster-wheeltube

2.Positionstoachieve3mm

(1/8inch)increments

Figure9

3.Pin

4.Adjustersleeve

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Exercisecautiontoavoidslippingorfalling,

especiallywhenoperatingthemachineinreverse.

g030413

•Alwaysbesureofyourfooting,andkeeparm

holdonthehandles.Walk;neverrun.

•Donotclearsnow,dirt,orthatchacrossthefaceof

slopes.Exerciseextremecautionwhenchanging

directiononslopes.Donotattempttoclearsteep

slopes.

10

•Donotoperatethemachinenearglassenclosures,

automobiles,windowwells,dropoffs,etc.without

properlyadjustingthebroomdischargeangle.

•Donotoperatethemachinewithoutgoodvisibility

orlight.

•Lookbehindandusecarewhenbackingupthe

machine.

•Exerciseextremecautionwhenoperatingthe

machineonorcrossinggraveldrives,walks,or

roads.Stayalertforhiddenhazardsortrafc.

•Neverattempttomakeanyadjustmentswhile

theengineisrunning,exceptasdirectedinthe

instructions.

•Afterstrikingaforeignobject,shutofftheengine,

andinspectthemachinefordamage.Repairany

damagebeforestartingthemachine.

•Ifthemachinestartstovibrateabnormally,shutoff

theengineandcheckimmediatelyforthecause.

•Donotruntheengineindoors,exceptwhen

startingitandformovingthemachineinoroutof

thebuilding;exhaustfumesaredangerous.

•Donotoverloadthemachinecapacityby

attemptingtoclearsnow,dirt,orthatchattoofast

ofarate.

•Shutofftheenginewheneveryouleavethe

operatingposition,beforeuncloggingthe

broomhousing,andwhenmakinganyrepairs,

adjustments,orinspections.

OperatingtheEngine

PositioningtheAir-CleanerCover

forColdorWarmAirTemperature

Important:Runningtheenginewiththe

air-cleanercoverpositionedforcold-weather

operationinnormalconditionscandamagethe

engine.

Theair-cleanercoverhas2positions:thecoldor

normal,ambientairpositions:

Adjusttheair-cleanercoverasfollows:

•Whenoperatinginacoldambientaircondition

(coldairtemperatureandhumidity)—positionthe

air-cleanercoverwithsnowakedecalfacingout

(Figure10).

Note:Usethispositionifyourmachineexhibits

carburetoricing.Symptomsincludetheengine

runsroughatidleorlowspeed,anditdischarges

blackorwhitesmokeintheexhaust.

•Whenoperatinginanormalambientair

condition—positiontheair-cleanercoverwithsun

decalfacingout(Figure10).

Note:Usethispositionifyourmachineisnot

exhibitingcarburetoricing.

•Beforeclearingthebroom,parkthemachine

onlevelground,shutofftheengine,waitfor

allmovingpartstostop,anddisconnectthe

spark-plugwire(s).Sharpobjectscanbecome

entangledinthebristles.Wearglovesanduse

cautionwhencleaningoutthebroomofforeign

objects;donotuseyourbarehands.

•Neveroperatethemachineathightransport

speedsonslipperysurfaces.

•Useonlyattachmentsandaccessoriesapproved

bythemanufacturerofthemachine.

1.Normalambientair

position

g326835

Figure10

2.Coldambientairposition

11

OpeningtheFuel-ShutoffValve

StartingtheEngine

Movethefuel-shutoffvalvelocatedbelowthechoke,

totherighttoturnonfuel(Figure11).

Figure11

1.FUELONposition3.Choke

2.Fuel-shutoffvalve

1.Ontherightsideoftheengine,rotatetheengine

On/OffswitchclockwisetotheONposition

(Figure12).

g325099

g325098

Figure12

1.Recoil-starthandle

2.Throttle

3.Engineswitch(OFF

position)

4.Engineswitch(ON

position)

2.Ontherear,leftsideoftheengine,movethe

chokelevertothelefttotheONposition.On

awarmengine,leavethechokeintheOFF

position(Figure11).

3.PlacethethrottlemidwaybetweentheSLOW

andFASTpositionslocatedonrear,rightsideof

theengine(Figure12).

4.Slowlypulltherecoil-starthandleuntilyoufeel

resistanceandthenstop(Figure12).

5.Allowtheropeoftherecoil-starthandletoretract

andthensharplypullthehandlestraightout.

Note:Allowtheropetoretractslowly.

6.Allowtheenginetowarmupforseveralminutes,

thenmovethechoketowardtheOFFposition

(Figure11).

StoppingtheEngine

1.Releasethebroom-driveleverandthe

traction-drivelever.

2.PlacethethrottlemidwaybetweentheSLOW

andFASTpositions(Figure12).

12

3.Allowtheenginetorunforaminimumof15

seconds,thenturntheengineOn/Offswitchto

theOFFpositiontostoptheengine(Figure12).

4.Waitforallmovingpartstostopbeforeleaving

theoperatingposition.

5.Usethefuel-shutoffvalvetoshutofffuelwhen

youwillnotusethemachineforafewdays,park

themachineinsideabuilding,ortransportthe

machinetoandfromthejobsite(Figure11).

g326524

Figure14

DrivingtheMachine

CAUTION

Ifthetractiondriveisnotproperlyadjusted,

themachinemaymoveinthedirection

oppositeofwhatyouintended,causinginjury

and/orpropertydamage.

Carefullycheckthetractiondriveandadjustit

properly,ifnecessary .

Important:Ifthemachinemoveswhenthe

tractionleverisdisengaged,checkandadjustthe

tractioncable;refertoCheckingtheBroomDrive

Adjustment(page25)andAdjustingtheTraction

Cable(page24),orcontactyourAuthorized

ServiceDealer.

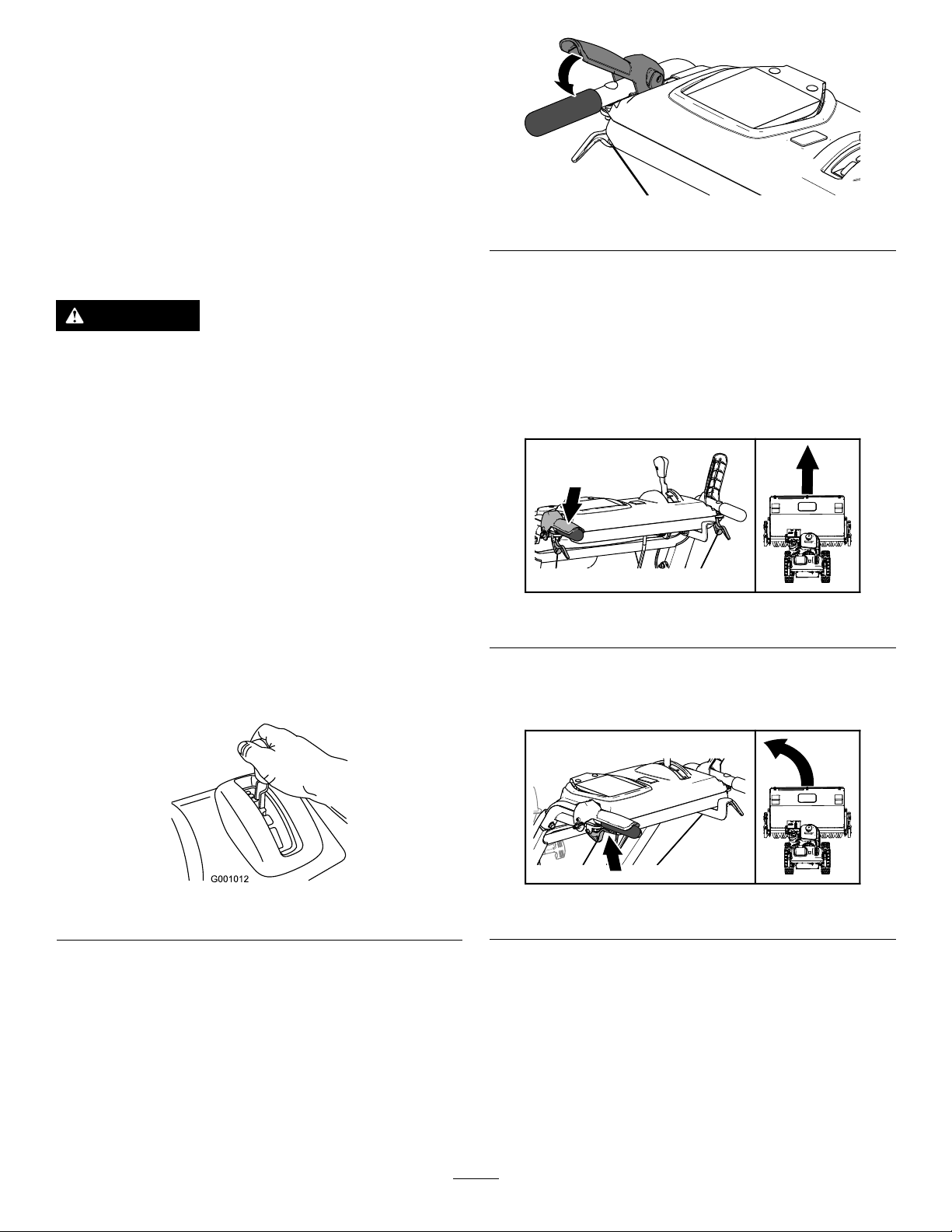

DrivingForward

1.Placethespeedselectorlevertothedesired

forwardposition,makingsurethatitlocksinthe

notch(Figure13).

3.Tostopthetractiondrive,releasethe

traction-drivelever.

4.Usethewheelclutchesleversasfollows:

Note:

•Todrivestraight,squeezethetraction-drive

leverbutdonotsqueezethewheel-clutch

levers(Figure15).

g326528

Figure15

•Toturnleft,squeezethetraction-drivelever

andsqueezetheleftwheel-clutchlever

(Figure16).

Figure13

Note:Ifthegroundspeedistoofast,debrisor

snowwillpileupinfrontofthebroomcausing

thebroomtoplowinsteadofsweep.Thiscan

damagethebristlesandthedriveline.

2.Slowlysqueezethetraction-drivelevertothe

lefthandle(Figure14).

Note:Holddownthetraction-driveleveragainst

thehandletoengagethetractiondriveforboth

wheels.

g001012

Figure16

g326521

Note:Whenyoucompletetheturn,release

thewheel-clutchlever.Thetractiondrive

engagesbothwheels.

•Toturnright,squeezethetraction-drivelever

andsqueezetherightwheel-clutchlever

(Figure17).

13

Figure17

Note:Whenyoucompletetheturn,release

thewheel-clutchlever.Thetractiondrive

engagesbothwheels.

•Momentarilysqueezeandreleasetheleft

orrightwheel-clutchlevertomakesteering

adjustmentsandkeepthemachinemoving

inastraightline,especiallyindeepsnow.

5.Toshutoffthetractiondrive,releasethe

traction-drivelever.

DrivingtheMachineRearward

PivotingtheMachinewiththe

EngineShutoff

Squeezebothwheel-clutchleverssimultaneouslyand

pivotthemachine(Figure18).

g326522

1.Placethespeed-selectorleverintothedesired

reverse-speedrange,makingsurethatthe

speedselectorlocksinthenotch.

2.Tomoverearward,engagethetractiondrive

andslowlysqueezethelefttractionlevertothe

handle.

Note:Momentarilysqueezingandreleasingthe

leftorrightwheel-clutchleverallowsforsteering

adjustmentstokeepthemachinegoingina

straightline.

Note:Toturnright,squeezetheright

wheel-clutchlevertowardthehandle.This

disengagesthedrivetotherightwheelwhilethe

leftwheelcontinuesdriving,andthemachine

turnstotheright.

Note:Similarly ,squeezingtheleftwheel-clutch

leverturnsthemachinetotheleft.

Note:Squeezingbothwheel-clutchlevers

simultaneouslydisengagesthedrivetobothwheels.

Thisenablesyoutomovethemachinerearward

withoutstoppingtoshiftitintoareversegear.Italso

allowsyoutomaneuverandtransportthemachine

moreeasilywhentheengineisnotrunning.

g326520

Figure18

OperatingtheBroom

DANGER

Whenthemachineisinoperation,contact

withrotatingormovingpartswillseverely

injurehandsandfeet.

•Beforeadjusting,cleaning,inspecting,

troubleshooting,orrepairingthemachine,

shutofftheengineandwaitforallmoving

partstostop.Disconnectthewirefrom

thesparkplugandkeepitawayfromthe

plugtopreventsomeonefromaccidentally

startingtheengine.

•Staybehindthehandlesandawayfromthe

broomwhileoperatingthemachine.

•Keepface,hands,feet,andanyother

partofyourbodyorclothingawayfrom

concealed,moving,orrotatingparts.

14

WARNING

Contactwitharotatingbroomcanresult

inseriouspersonalinjuryordeathtothe

operatororbystanders.

•Toremoveanobstructionfromthebroom;

refertoClearingaCloggedBroom(page

16).

•Donotoperatethemachineifthebroom

driveleverisnotfunctioningproperly.

ContactyourAuthorizedServiceDealer.

g326523

Figure19

WARNING

Therotatingbroomcanthrowstonesand

otherforeignobjects,causingserious

personalinjurytoyouorbystanders.

•Keeptheworkingareaclearandfreeofall

objectsthatthebroomcouldpickupand

throw.

•Keepallchildrenandpetsawayfromthe

areaofoperation.

CAUTION

Whenthebroomisengaged,itmaydrivethe

machineinthereversedirection.Ifthebroom

heightisadjustedtoolow,themachinemay

movemoreforcefullyinthereversedirection,

causinginjuryand/orpropertydamage.

Carefullycheckthebroomheightandadjust

itproperlyorcontactyourAuthorizedService

Dealer.

•Iftheengineslowsdownunderaloadorthe

wheelsslip,shiftthemachineintoalower

gear.

•Ifthefrontofthemachineridesup,shift

themachineintoalowergear.Ifthefront

continuestorideup,liftthehandles.

4.Tostopthebroom,releasetherightlever.

AdjustingtheBroomSide

Angle

1.Disengagethebroomandshutofftheengine.

2.Waitforallmovingpartstostop.

3.Pushtheleverdownwiththethumbofyourright

hand(Figure20).

1.SettheenginethrottletotheFASTposition.

2.Placethespeedselectorleverintothedesired

positionandslowlysqueezethelefthand

tractiondrivelever.

Important:Makesurethatthetractiondrive

isengagedbeforeoperatingthebroom;

otherwise,thebroommaydrivethemachine

inthereversedirection.

3.Engagethebroombyslowlysqueezingtheright

broomlevertothehandle(Figure19).

g326519

Figure20

4.Squeezetheleftwheel-clutchlevertothehandle

(Figure20)andpushthebroomhousingto

followingpositions.

15

•19°totheleft

•Straightahead

ClearingaCloggedBroom

•19°totheright

5.Oncethebroomispositioned,releasethe

broomanglelever.

Important:Ensurethatthebroomlocksinto

placeatoneofthe3positions.

6.Releasetheleftwheel-clutchlever.

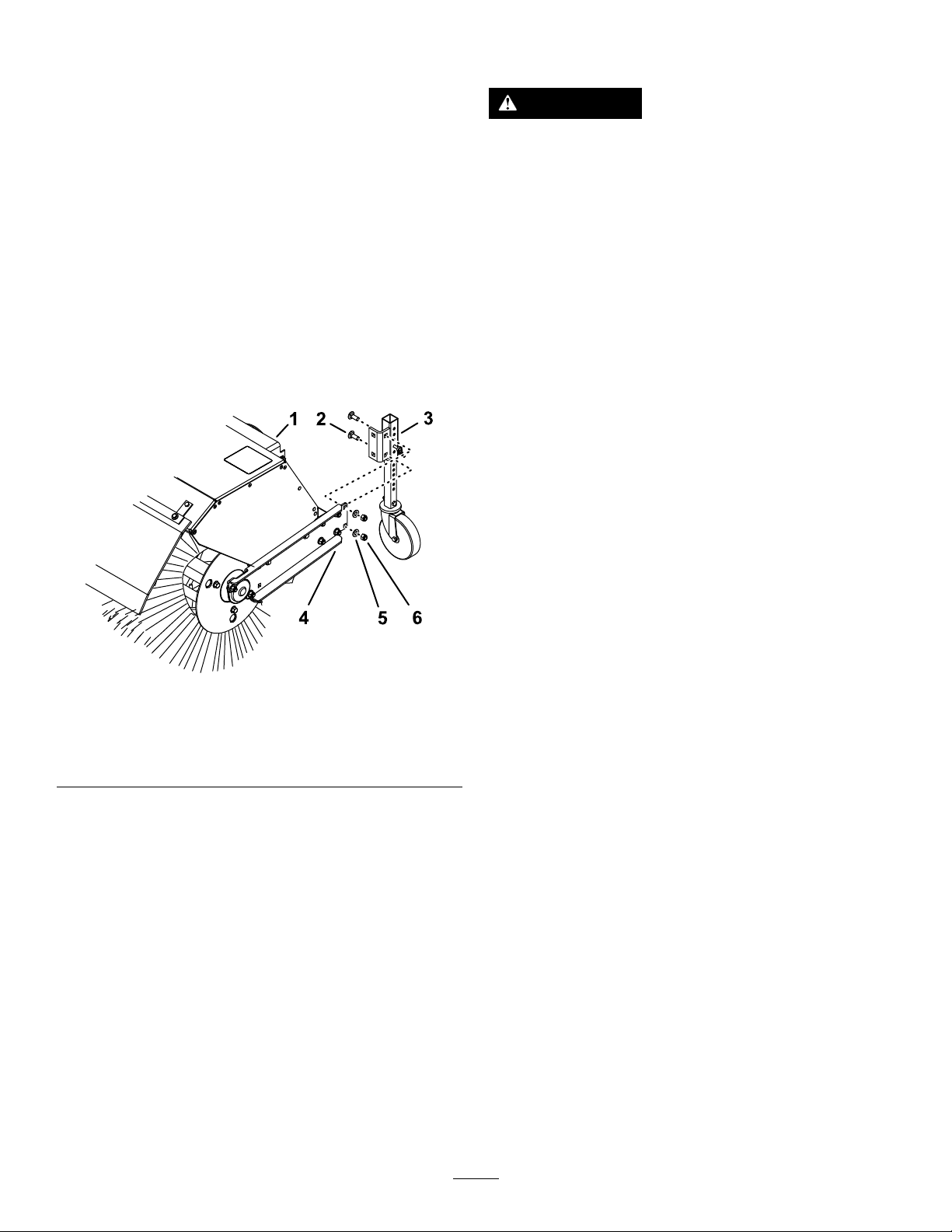

UsingtheAlternateCaster

Location

Whenworkinginsnow,movethecastersfromthe

frontofthebroomarmtothebackthebroomhood

(Figure21).

WARNING

Therotatingbroomcouldcauseserious

injury.

Shutofftheengineandallowallrotatingparts

tostopbeforecleaningthebroom.

•Ifthebroombecomesclogged,stayinthe

operatingpositionandreleasethetraction-drive

lever.Whileengagingthebroom,pushdownon

thehandlestoraisethefrontofthemachinea

fewcentimeters(inches)offthepavement.Then

liftthehandlesquicklytobumpthefrontofthe

machineonthepavement.Repeatifnecessary.

•Ifyoucannotunclogthebroombybumpingthe

frontofthemachine,dothefollowing:

–Parkthemachineonlevelground.shutoffthe

engine,waitforallmovingpartstostop,and

disconnectthespark-plugwire.

–Sharpobjectscanbecomeentangledin

bristles.Useglovesandcautionwhen

removingforeignobjectsfromthebroom;do

notuseyourhands.

Figure21

1.Broomhood4.Broomarm

2.Carriagebolt

3.Casterbracket

1.Supportthebroom.

2.Removethe2locknuts,2washers,and2

carriagebolts(Figure21)thatsecurethecaster

brackettothebroomarm.

3.Atthebackofthebroomhood,aligntheholesin

thecasterbracketwiththeholesontheinboard

sideofthebroomarm(Figure21).

4.Securethecasterbrackettothebroomarmwith

the2locknuts,2washers,and2carriagebolts

(Figure21).

5.Washer

6.Locknut

AfterOperation

g326877

AfterOperationSafety

GeneralSafety

•Neverstorethemachinewithfuelinthefuel

tankinsideabuildingwhereignitionsourcesare

present,suchashotwaterheaters,spaceheaters,

orclothesdryers.Allowtheenginetocoolbefore

storingthemachineinanyenclosure.

•Whenstoringthemachineformorethan30

days,refertotheStoragesectionforimportant

information.

•Whenoperatinginsnowyconditions,runthe

machineforafewminutesafterremovingsnowto

preventfreeze-upofthebroomandhousing.

•Whencleaning,repairing,orinspectingthe

machine,ensurethattherotarybroomandall

movingpartshavestopped.Disconnectthe

spark-plugwireandkeepitawayfromtheplugto

preventaccidentalstarting.

•Disengagethepowertotherotarybroomwhen

transportingorstoringthemachine.

16

PreventingFreeze-upafter

Use

•Insnowyandcoldconditions,somecontrolsand

movingpartsmayfreeze.Donotuseexcessive

forcewhentryingtooperatefrozencontrols.Ifyou

havedifcultyoperatinganycontrolorpart,start

theengineandletitrunforafewminutes.

•Afterusingthemachine,lettheenginerunfora

fewminutestopreventmovingpartsfromfreezing.

Engagethebroomtoclearanyremainingsnow

frominsidethehousing.Shutofftheengineand

waitforallmovingpartstostop,anddisconnect

thespark-plugwire.Removeallice,snow,orother

debrisfromthemachine.

•Connectthespark-plugwire.Withtheengine

switchintheOFFposition,pulltherecoil-starter

handleseveraltimestopreventtherecoilstarter

fromfreezingup.

TransportingtheMachine

WARNING

Usingrampsthatarenotstrongenoughor

properlysupportedtoloadthemachineonto

thetransportvehiclecouldbedangerous.The

rampscouldcollapse,causingthemachineto

fall,whichcouldcauseinjury.

•Useproperrampsthataresecuredtothe

truckortrailer.

•Keepyourfeetandlegsoutfromunderthe

machinewhenloadingandunloading.

PreparingtoTransportthe

Machine

Performthefollowingbeforetransportingthemachine:

•Closethefuel-shutoffvalve.

•Useaheavy-dutytrailertotransportthemachine.

Placethemachineineitheraforwardorreverse

gear,thenblockthewheels.

•Securelyfastenthemachinetothetrailerwith

straps,chains,cables,orropes.

•Ensurethatthetrailerhasallthenecessary

lightingandmarkingasrequiredbylaw.

17

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

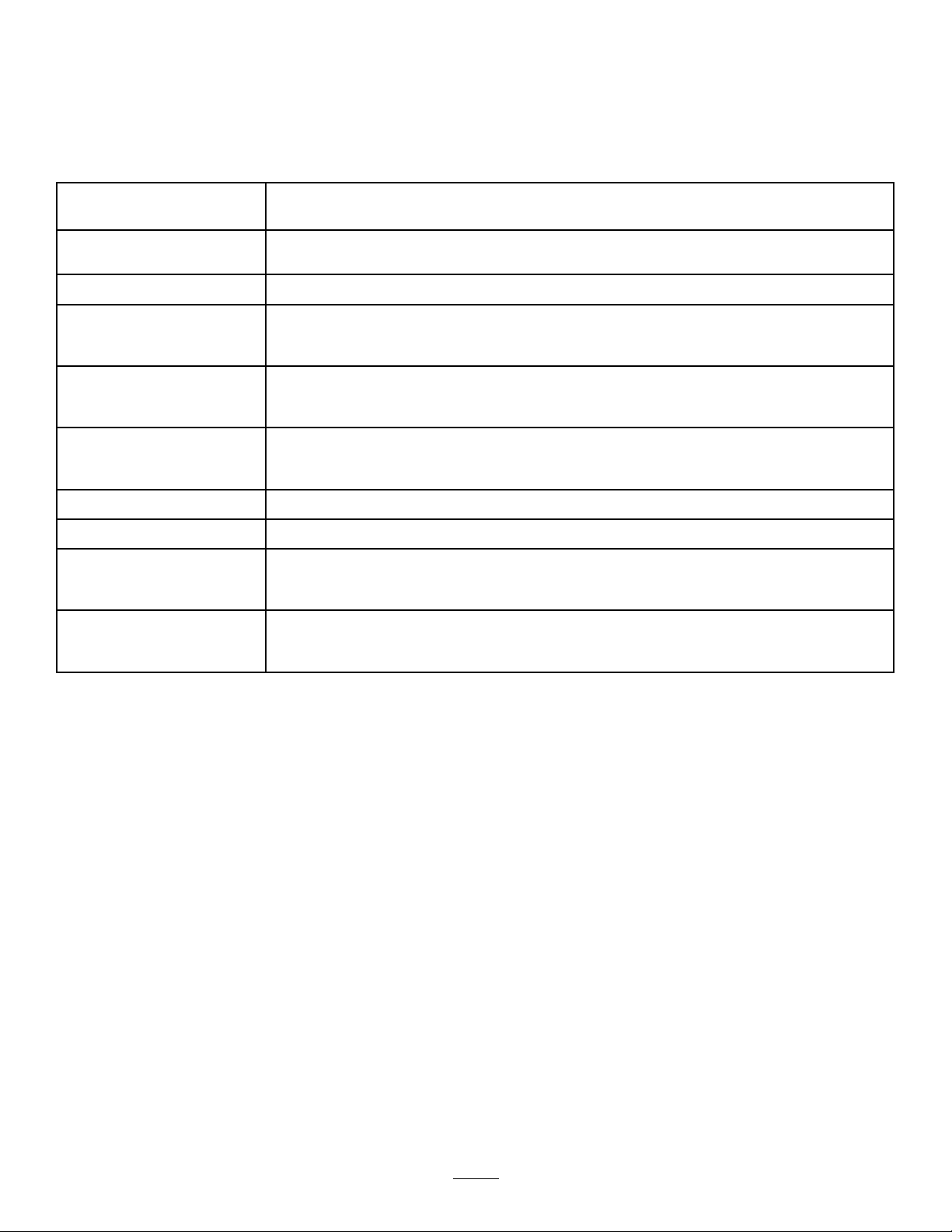

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst5hours

Beforeeachuseordaily

Every50hours

Every100hours

Every200hours

Every300hours

Yearly

Yearlyorbeforestorage

MaintenanceProcedure

•Checkthetractioncableadjustmentandcorrectitifnecessary .

•Checkthebroomdriveadjustmentandcorrectitifnecessary .

•Changetheengineoil.

•Checktheengineoillevel.

•Checkthebroom-shaftshearpin.

•Checkforloosehardware.

•Cleanthefoampre-cleaner(morefrequentlyindustyconditions).

•Checkthetireairpressure.

•Checktheconditionofthebelts.

•Lubricatethebroom-angle-lockpin.

•Changetheengineoil(morefrequentlyinsevereconditions).

•Checkthesparkplug.

•Replacethefoampre-cleaner.

•Replacethepaperairlter(morefrequentlyindustyconditions).

•Lubricatethehexshaft.

•Checkthetractioncableadjustmentandcorrectitifnecessary .

•Checkthebroomdriveadjustmentandcorrectitifnecessary .

•Drainthefuelsystemandruntheengineoutthefuelattheendoftheoperating

season.

•Checkthetireairpressure.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.Forengine

adjustments,repairs,orwarrantyservicenotcoveredinthismanual,contacttheauthorizedengine

servicedealer.

MaintenanceSafety

Readthefollowingsafetyprecautionsbefore

performinganymaintenanceonthemachine:

•Beforeservicing,adjusting,orcleaningthe

machine,shutofftheengineandwaitforall

movingpartstostop.Ifmajorrepairsareever

needed,contactyourAuthorizedServiceDealer.

PreparingforMaintenance

1.Movethemachinetoalevelsurface.

2.Shutofftheengineandallowittocool.

3.Disconnectthespark-plugwirefromthespark

plugandkeepthewireawayfromtheplug,to

preventaccidentalstarting(Figure22).

•Alwaysweareyeprotectionwhileperformingan

adjustmentorrepairtoprotectyoureyesfrom

foreignobjectsthatthemachinemaythrow.

•Checkallfastenersatfrequentintervalsforproper

tightnesstoensurethatthemachineisinsafe

workingcondition.

•Donotchangethegovernorsettingsontheengine.

•PurchaseonlygenuineT ororeplacementparts

andaccessories.

18

1.Spark-plugwire

Lubrication

2.Removethebeltcoverandtheengineshield.

3.Movethespeed-selectorlevertotheR2position.

4.Dipalong,clean,small-tippedpaintbrushin

automotiveengineoilandlightlylubricatethe

hexshaft(Figure24).

Important:Donotgetoilontherubber

wheelorthealuminumfriction-driveplateas

thetractiondrivewillslip(Figure24).

Note:Rockthemachineforwardandrearward

torotatethehexshaft.

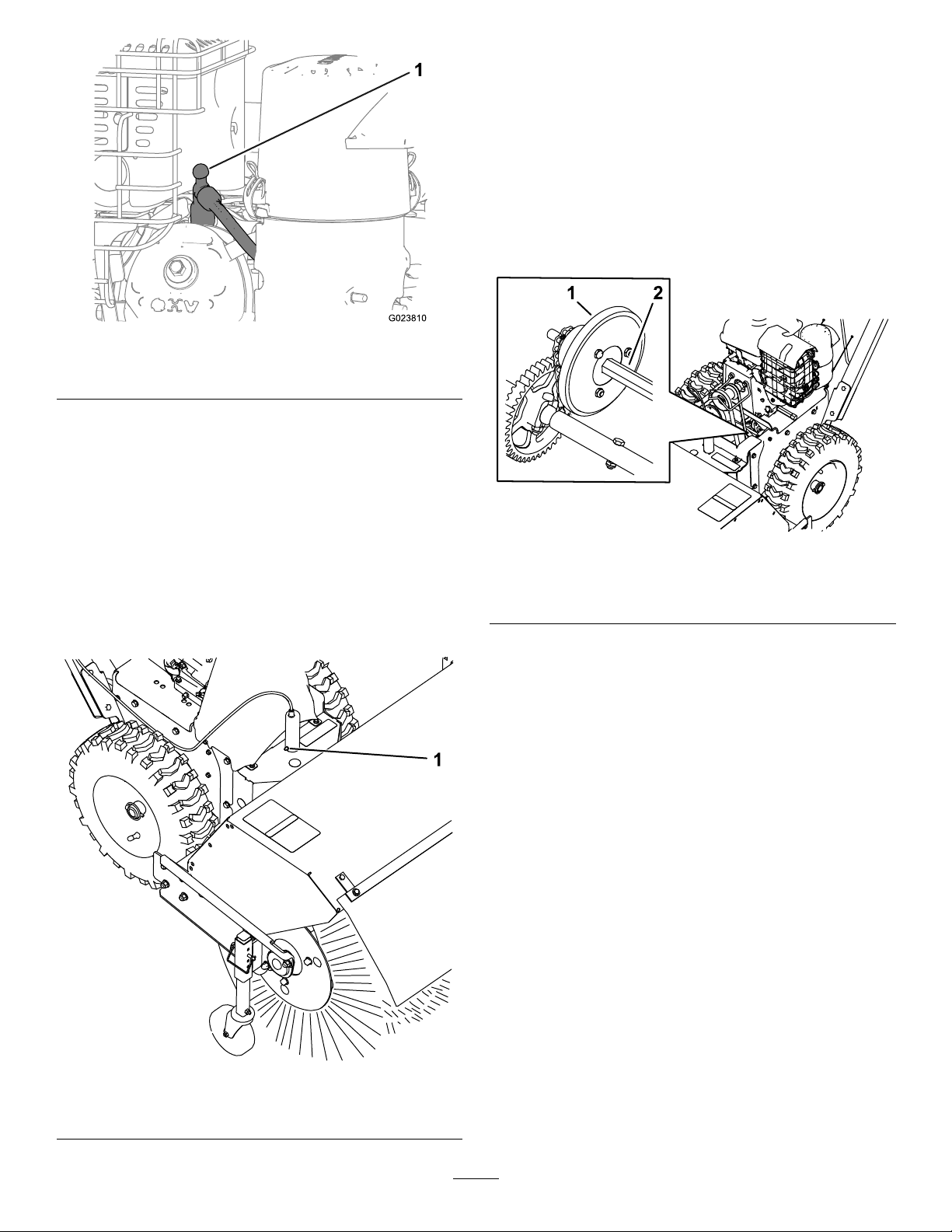

g023810

Figure22

LubricatingtheBroom-Angle-Lock

PinandtheHexShaft

ServiceInterval:Every100hours

Yearly

1.Lubricatethebroom-angle-lockpinttingwith

No.2lithiumgrease(Figure23).

Figure24

1.Aluminumfriction-drive

plate

5.Movethespeedselectorlevertoposition6.

6.Lubricatetheotherendofthehexshaft.

7.Movethespeedselectorleverforwardand

rearwardafewtimes.

8.Installthebeltcoverandtheengineshield.

2.Hexshaft

EngineMaintenance

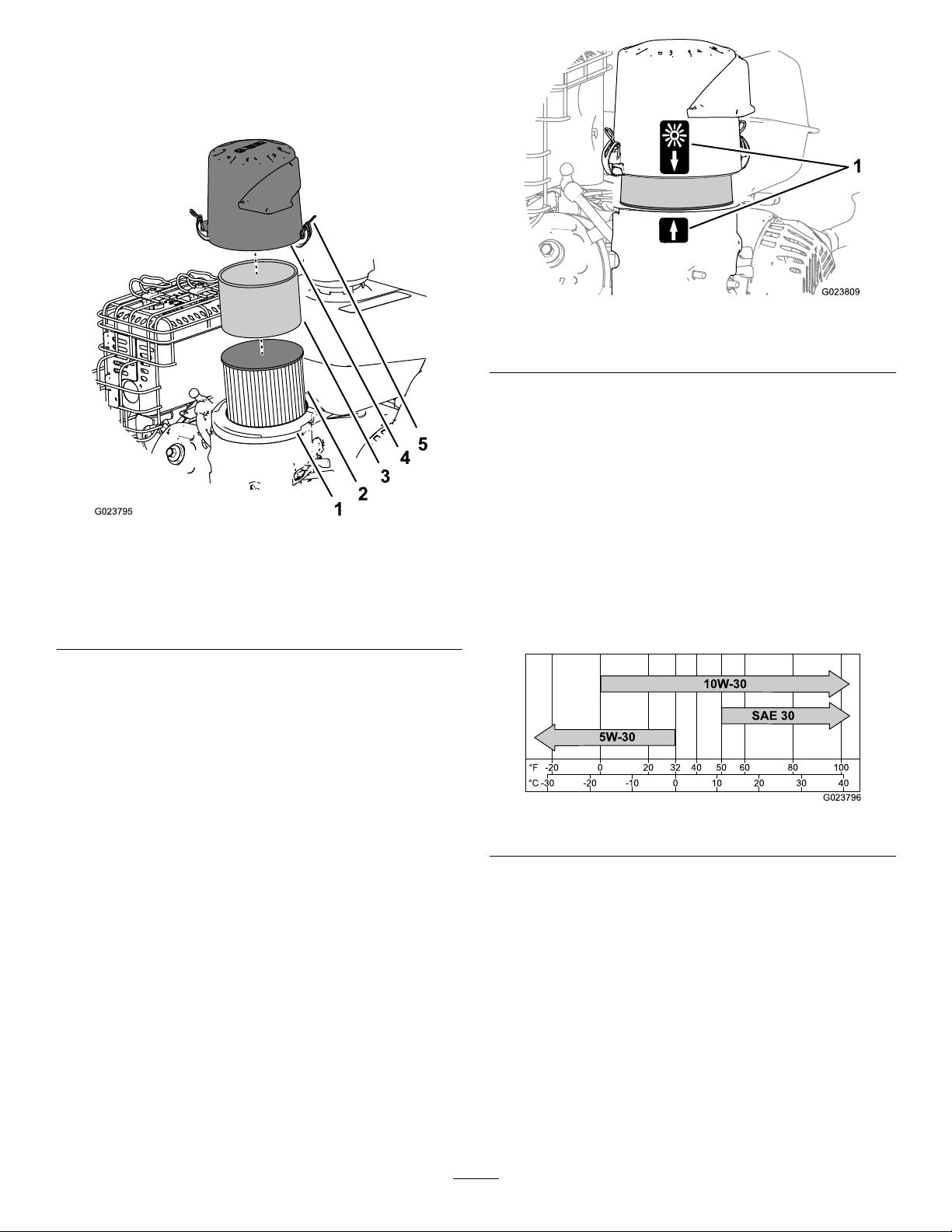

ServicingtheAirCleaner

ServiceInterval:Every50hours—Cleanthefoam

pre-cleaner(morefrequentlyin

dustyconditions).

Every200hours—Replacethefoam

pre-cleaner.

g325104

1.Broom-angle-lockpin

Figure23

Every300hours—Replacethepaperairlter

(morefrequentlyindustyconditions).

Important:Donotoperatetheenginewithoutthe

g325097

airlterassembly;extremeenginedamagemay

occur.

1.Releasethelatchesonthecoverfortheair

cleaner.

19

2.Removethecoverandcleanitthoroughly

(Figure25).

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

Figure25

1.Air-lterbase4.Cover

2.Paperairlter

3.Foampre-cleaner

5.Latchontheair-cleaner

cover(2)

g023809

Figure26

1.Alignment-arrowdecal(normalambientairpositionshown)

9.Securetheair-ltercovertothebasewiththe

latches.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

g023795

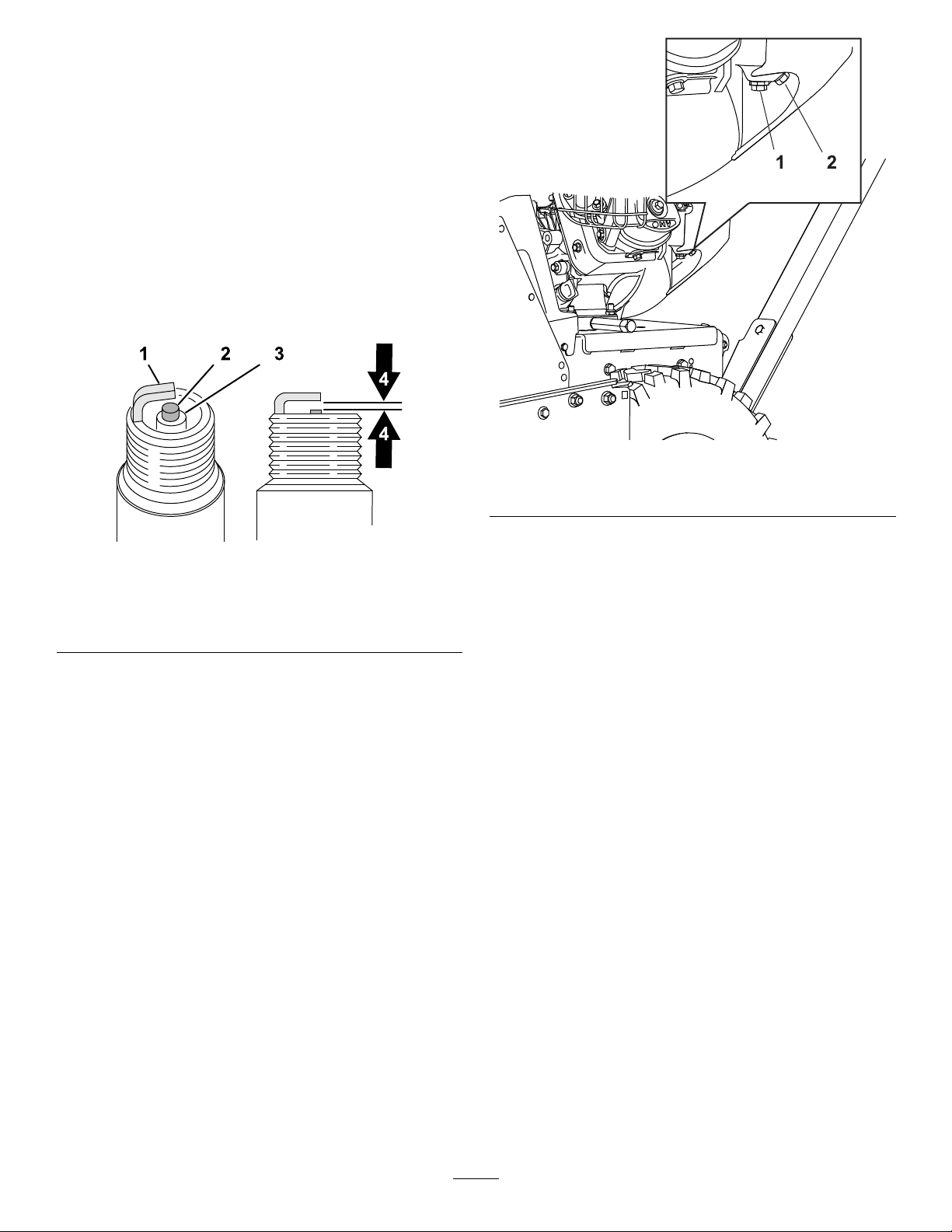

EngineOilType:T oro4–CyclePremiumEngineOil

Usehigh-qualitydetergentoils(includingsynthetic)

ofAPI(AmericanPetroleumInstitute)serviceclass

SJorhigher.Selecttheviscositybasedontheair

temperatureattimeofoperationasshowninthetable

below.

3.Removethefoampre-cleaner,washitwitha

milddetergentandwater,andthenblotitdry

(Figure25).

4.Removeandinspectthepaperairlter(Figure

25);discarditifitisexcessivelydirty.

Important:Donottrytocleanapaperlter.

5.Wipedirtawayfromthebaseandthecoverwith

amoistrag.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

6.Installthefoampre-cleanerontothepaperair

lter(Figure25).

Note:Useanewpaperairlterifyoudiscarded

theoldone.

7.Installtheairlterassemblytotheair-lterbase

(Figure25).

8.Alignthearrowdecalontheair-cleanercover

andthearrowdecalonthebase(Figure26).

g023796

Figure27

Checktheoillevelwhentheengineiscold.

1.Cleantheareaaroundthedipstick.

2.Removethedipstickandreadtheoillevel

(Figure28).

20

Figure28

6.Insertthedipstickintothellerneckandtighten

thedipstickbyhand.

ChangingtheEngineOil

ServiceInterval:Aftertherst5hours

Every100hours(morefrequentlyinsevere

conditions).

Oilcapacity:0.60L(0.63qt)

Note:Draintheengineoilwhiletheengineiswarm.

1.Placeapanunderdrainttingandremovethe

oil-draincap(Figure29).

g023794

1.Fillerneck2.Dipstick

3.Removethedipstickandwipeofftheoilwitha

cleanrag.

4.Insertthedipstickintothellerneck,restiton

theoilllerneck,andturnitcounterclockwise

untilthecapdropsdowntolowestpointofthe

threadleads.

Note:Donotthreadthecapontothetube.

5.Removedipstickandcheckoillevel.

Note:Donotoperatetheenginewiththeoil

levelbelowtheAddmarkorabovetheFullmark

onthedipstick.

Note:Theoillevelshouldbeattopofthe

indicatoronthedipstick(Figure28).

•Iftheoillevelislow,performthefollowing:

A.Pourthespeciedoilintothellerneck

(Figure28).

Note:Donotoverlltheenginewithoil.

B.Repeatsteps3through5.

•Iftheoillevelishigh,preformthefollowing:

A.Removethecapfromthedraintting.

B.Draintheoiluntiltheoillevelisatthetop

oftheindicatorondipstick;refertosteps

1ofChangingtheEngineOil(page21).

C.Installthecapontothedraintting;refer

tostep2ofChangingtheEngineOil

(page21).

Figure29

1.Draintting

2.Cap

3.Drainpan

2.Allowtheoiltodrainandtheninstalltheoil-drain

cap.

3.Cleanaroundthellerneckandremovethe

dipstick.

4.Filltothespeciedcapacitywiththespeciedoil

andreplacethedipstick;refertoCheckingthe

Engine-OilLevel(page20).

Note:Donotoverlltheenginewithoil.

5.Wipeupanyspilledoil.

6.Starttheengineandcheckforleaks.

7.Shutofftheengineandchecktheoillevel;refer

toCheckingtheEngine-OilLevel(page20).

CheckingtheSparkPlug

ServiceInterval:Every100hours

Sparkplugtype:Champion®RC12YC,Kohler®12

13202-S,orKohler2513214-S(RFIcompliant)

g32511 1

21

Spark-pluggap:0.76mm(0.030inch)

1.Disconnectthespark-plugwirefromtheterminal

ofthesparkplug(Figure22).

2.Cleantheareaaroundthebaseofthespark

plug.

3.Removethesparkplugfromthecylinderhead

byrotatingtheplugcounterclockwise.

4.Examinetheplugforwearanddamage(Figure

30).

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotcleantheelectrodes,

becausegritenteringthecylindercan

damagetheengine.

g325109

Figure31

1.Bowl-retainingscrew2.Drainbolt

Figure30

1.Groundelectrode

2.Centerelectrode4.Spark-pluggap0.76mm

3.Insulator

(0.030inch)

5.Checkthespark-pluggapwithawiregauge

(Figure30).

Note:Ifnecessary ,adjustthegapto0.76mm

(0.030inch)bycarefullybendingtheground

electrode.

6.Installthesparkplugbythreadingitintothe

cylinderhead,andtorquetheplugto20N∙m(14

lb-ft).

7.Connectthespark-plugwiretotheterminalof

thesparkplug.

FuelSystemMaintenance

DrainingtheFuelSystem

g326888

2.Aligntheequipmentthatyouwillusetocollect

thefuelbeneaththedrainscrew.

3.Removethedrainscrewfromthecarburetor

andallowthefueltodrainfromthefueltankand

thecarburetor.

Note:Donotremovethebowl-retainingscrew

fromcarburetor.

ServiceInterval:Yearlyorbeforestorage

1.Locatethedrainboltthatisinthesideportof

thecarburetorbowl(Figure31).

22

CheckingtheTractionCable

Adjustment

ServiceInterval:Aftertherst2hours—Check

thetractioncableadjustmentand

correctitifnecessary .

Yearly—Checkthetractioncableadjustment

andcorrectitifnecessary.

Important:Ifthemachinedoesnotdriveinthe

forwardorreversespeedsoritdriveswhenyou

releasethetractionlever,adjustthetractioncable;

refertoAdjustingtheTractionCable(page24).

1.Disengagethetractionlevel.

2.Checktheclearancebetweenthebottomofthe

traction-cablebracketandthetopplateofthe

machine(Figure33).

Note:Thetraction-cablebracketshouldtouch

thetopplate.

Figure32

1.Sideportofthecarburetor

bowl

4.Installthedrainboltintothesideportofthe

carburetor.

5.Starttheengineandrunituntilitrunsoutoffuel.

2.Drainbolt

DriveSystemMaintenance

CheckingtheTireAirPressure

ServiceInterval:Every50hours

Yearlyorbeforestorage

1.Shutofftheengine,waitforallmovingparts

tostop,andleaveengineswitchintheOFF

position.

2.Measurethetireairpressureinthedrivetires.

Important:Thetireairpressureshould

measure117to138kPa(17to20psi).

g325110

g326108

Figure33

3.Ifthetraction-cablebracketdoesnottouch

thetopplate,adjustthetractioncable;referto

AdjustingtheTractionCable(page24).

3.Addairtoorremoveairfromthedrivetiresuntil

youmeasureto117to138kPa(17to20psi).

23

AdjustingtheTractionCable

1.Loosenthejamnut(Figure34).

g019073

Figure36

Figure34

1.Adjustertube

2.Jamnut

3.Spring-tensionadjuster

4.Spring

2.Rotatethespring-tensionadjusteruntilthecable

istaught(Figure34)andthebottomofthe

brackettouchesthetopplateofthemachine

(Figure35).

Figure35

1.Nut

g325108

4.Iftheshearpinisdamaged,removethepin,

2.Shearpin

replaceit,andsecuretheitwithanut.

ReplacingWornorDamaged

BroomSegments

ServiceInterval:Asrequired.

1.Raisethebroombysettingthecasterpositions.

2.Onbothsidesofthemachine,removeandretain

thecarriagebolts,washers,andlocknutsthat

securetheendbearingstothebroomsupport.

g326108

3.Tightenthejamnut(Figure34).

BroomMaintenance

CheckingtheBroom-ShaftShear

Pin

ServiceInterval:Beforeeachuseordaily

1.Movethemachinetoalevelsurface.

2.Shutofftheengine,waitforallmovingpartsto

stop,anddisconnectthespark-plugwire.

3.Checktheshearpinlocatedonthebroomshaft

oneithersideofthegearbox.

1.Broomsupport4.Endbearing

2.Locknut

3.Washer

24

g023811

Figure37

5.Carriagebolt

3.Manuallypullthepowerunitrearwardtoremove

thebroomassemblyfromthemachine.

4.Supportthesplineshaftoneithersideofthe

gearbox.

5.Standthebroomcoreassemblyonendsothat

theendretainerplatefacesupward(Figure38).

Figure38

CheckingtheBroomDrive

Adjustment

ServiceInterval:Aftertherst2hours—Checkthe

broomdriveadjustmentandcorrect

itifnecessary.

Yearly—Checkthebroomdriveadjustmentand

correctitifnecessary.

1.Removethebeltcover;refertoRemovingthe

BeltCover(page26).

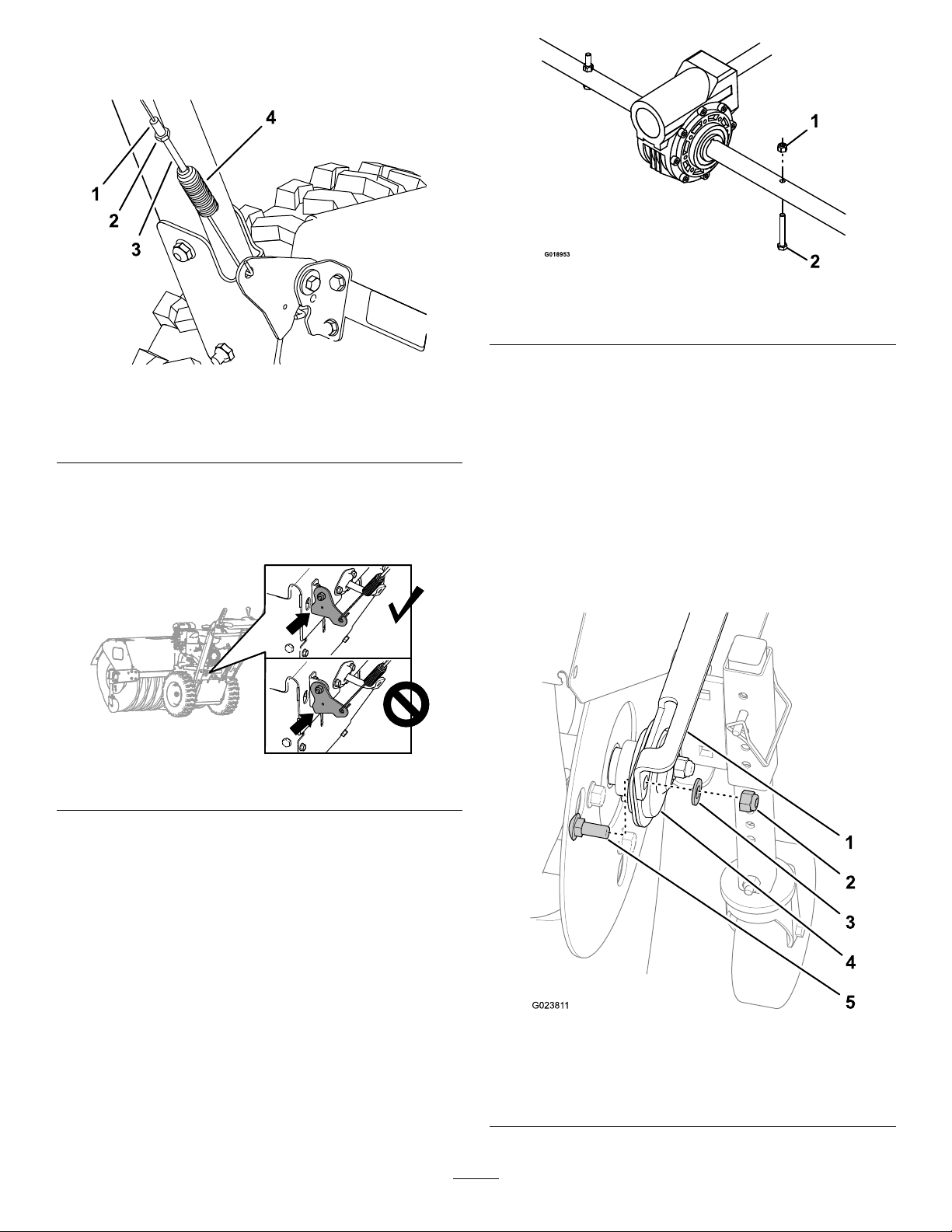

2.Withthebroomdriveleverdisengaged,ensure

thatthegapbetweenthebroomclutcharmand

theframeofthemachineis1.5mm(1/16inch)

asshowninFigure39.

Important:Ifthegapbetweenthebroom

clutcharmandtheframeistoosmallortoo

large,adjustthebroomdrivecable;referto

AdjustingtheBroomDriveCable(page26).

g326889

1.Hardware

2.End-retainerplate

3.Broomsegment

4.Supportshaft

5.Alignmentngers

6.Removeandretainthehardwarefromthe

end-retainerplate(Figure38).

7.Removethedamagedbroomsegment(s).

8.Installthenewsegment(s)bystaggeringthe

metalringalignmentngersasshowninFigure

38.

Important:Y oumaydamagethebroom

assemblyifyoudonotproperlyinstallthe

broomsegments.

9.Installthebroomassemblyontothemachine.

Important:Makesurethatthebearing

setscrewsaretightenedbeforeoperatingthe

broom.

Figure39

1.1.5mm(1/16inch)gap

2.Frame

3.Broomclutcharm

3.Ifthegapbetweenthebroomclutcharmand

theframeis1.5mm(1/16inch),installthebelt

cover;refertoInstallingtheBeltCover(page

26).

g326890

25

AdjustingtheBroomDriveCable

1.Loosenthejamnut(Figure40).

Figure40

BeltMaintenance

RemovingtheBeltCover

1.Loosenthe2ange-headscrewsthatsecure

thebeltcovertothemachine(Figure42).

g325107

1.Adjustertube

2.Jamnut

3.Spring-tensionadjuster

4.Spring

2.Rotatethespring-tensionadjusteruntilyou

measurea1.5mm(1/16inch)gapbetweenthe

frameandthebroomclutcharm(Figure40and

Figure41).

Figure41

g325103

Figure42

1.Screw

2.Beltcover

2.Removethecoverfromthemachine.

InstallingtheBeltCover

1.Aligntheslotsinthebeltcoverwiththe2

ange-headscrews(Figure43).

g326890

1.1.5mm(1/16inch)gap

2.Frame

3.Broomclutcharm

3.Tightenthejamnut(Figure40).

4.Installthebeltcover;refertoInstallingtheBelt

Cover(page26).

Important:Ifthebroomcableisproperlyadjusted

butaproblemremains,contactyourAuthorized

ServiceDealer.

g325103

Figure43

2.Assemblethebeltcoverontothemachine

(Figure43).

3.Tightentheange-headscrews.

26

CheckingtheConditionofthe

Belts

ServiceInterval:Every50hours

1.Removethebeltcover;refertoRemovingthe

BeltCover(page26).

2.Checkthe2beltsfordamageorwear.

Note:Replacedamagedorexcessivelyworn

belt(s);refertoReplacingtheBroomDriveBelt

(page27)andReplacingtheTractionBelt(page

28).

3.Installthebeltcover;refertoInstallingtheBelt

Cover(page26).

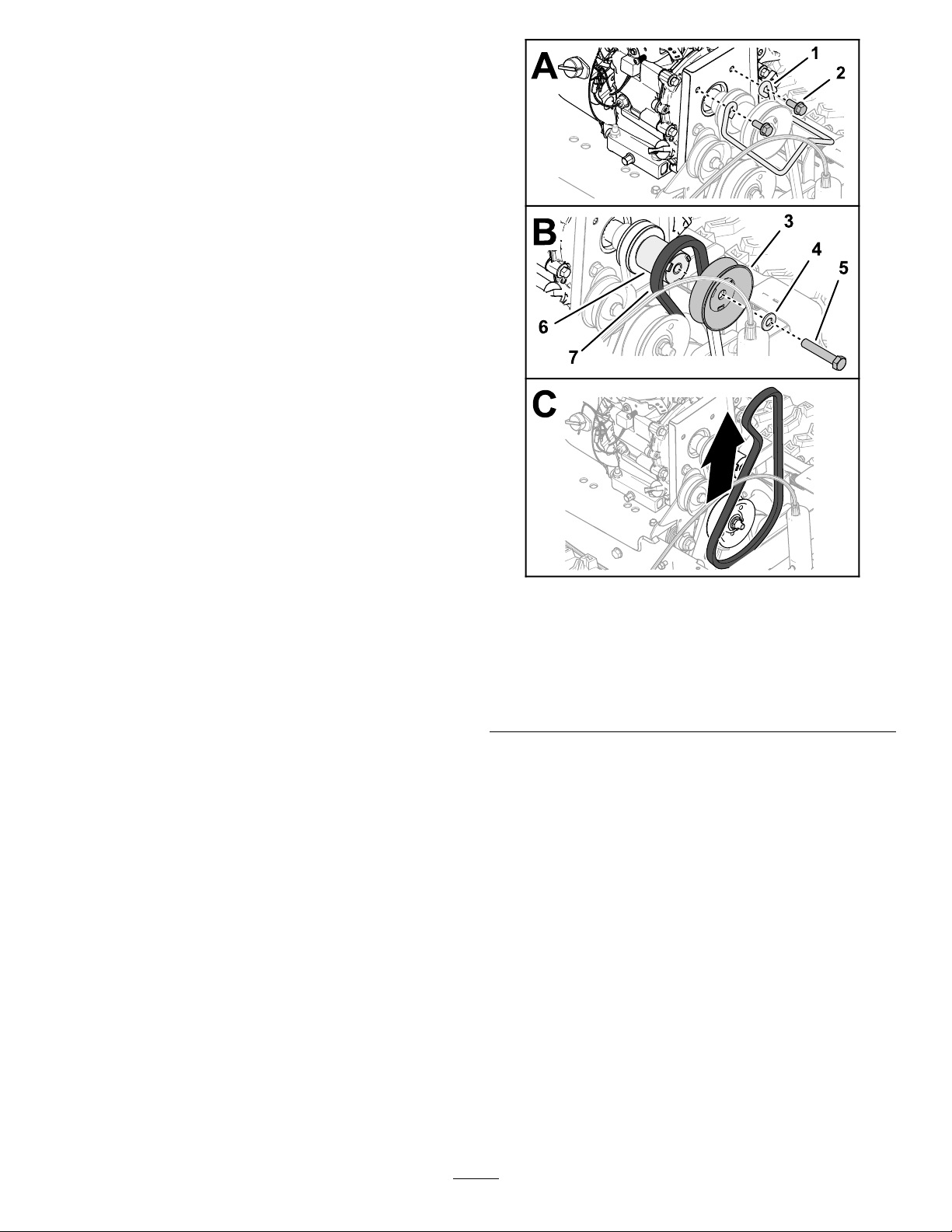

ReplacingtheBroomDriveBelt

RemovingtheBroom-DriveBelt

1.Parkthemachineonalevelsurface,shutoffthe

engine,andwaitforallmovingpartstostop.

2.Removethebeltcover;refertoRemovingthe

BeltCover(page26).

3.Removethe2angecapscrewsthatsecure

thebeltguide,andremovetheguidefromthe

engine(Figure44).

Important:Donotbendthebeltguidewhile

removingit.

g326318

Figure44

1.Beltguide

2.Flangecapscrew6.Pulleyspacer

3.Broom-drivepulley7.Broom-drivebelt96cm

4.Flatwasher

5.Capscrew(3/8x2inches)

(37-1/4inch)

4.Removethecapscrew(3/8x2inches)and

washerthatsecuresthebroom-drivepulleyto

thecrankshaftoftheengine,andremovethe

pulley(Figure44).

Note:Ifnecessary,holdthepulleyspacer

betweenthebroom-drivepulleyandengineto

keepthecrankshaftfromturning.

Youdonotneedtoremovethepulleyspacer

fromthecrankshaft.

5.Slipthebroom-drivebelt96cm(37-1/4inch)off

thedriveshaftpulley ,andremovethebeltfrom

themachine.

27

InstallingtheBroomDriveBelt

Ownerprovidedmaterials:medium-strength

thread-lockingcompound

1.Assemblethewasheroverthecapscrew(3/8x

2inches),andapplyacoatofmedium-strength

thread-lockingcompoundtothethreadsofthe

capscrew.

2.Assemblethebelt96cm(37-1/4inch)intothe

grooveofthedriveshaftpulley(Figure45).

6.Torquethecapscrewto42to52N∙m(31to39

ft-lb).

7.Assemblethebeltguidetotheenginewiththe

2angecapscrew(Figure45).

8.Torquethecapscrewsto23to29N∙m(17to21

ft-lb).

9.Installthebeltcover;refertoInstallingtheBelt

Cover(page26).

ReplacingtheTractionBelt

RemovingtheTractionBelt

1.Drainthefuelsystem;refertoDrainingtheFuel

System(page22).

2.Removethebeltcover;refertoRemovingthe

BeltCover(page26).

3.Removethebroom-drivebelt;refertoRemoving

theBroom-DriveBelt(page27).

4.Removethepulleyspacer,theforwardsheave

half,andtractionbelt87.6cm(34-1/2inches)

fromthecrankshaftoftheengine(Figure46).

Figure45

1.Broom-drivepulleyand

belt96cm(37-1/4inch)

2.Flatwasher5.Beltguide

3.Capscrew(3/8x2inches)

4.Pulleyspacer

6.Flangecapscrew

3.Assemblethebeltintothegrooveofthe

broom-drivepulley(Figure45).

4.Assemblethebroom-drivepulleyontothepulley

spacer(Figure45).

Important:Alignthedrivekeysofthe

spacerwiththeslotsinthepulley.

5.Securethepulleyandspacertothedriveshaft

(Figure45)withthecapscrew(3/8x2inches).

g326388

Figure46

g326353

1.Sheavehalf4.Shaftspacer

2.Tractionbelt87.6cm

(34-1/2inches)

3.Pulleyspacer

5.Crankshaft(engine)

5.Atthebackofthemachine,loosenthe2top

ange-headcapscrew(1/4x5/8inch)that

securetherearcovertothemachine(Figure47).

28

Figure47

1.Flange-headcapscrew

(1/4x5/8inch—loosen)

2.Bottomcover5.Rearcover

3.Flange-headcapscrew

(1/4x5/8inch)

4.Flange(sideplate)

6.Removethe6ange-headcapscrew(1/4x

5/8inch)thatsecurethebottomcovertothe

machine,andremovethecover(Figure47).

7.Slipthetractionbeltbetweenthefrictionwheel

andthetractionpulley ,andremovethebeltfrom

themachine(Figure48).

g326389

g326387

1.Frictionwheel3.Tractionpulley

2.Tractionbelt

Figure49

2.Atthetopofthemachine,alignthetractionbelt

intothegrooveofthetractionpulley,andslipthe

tractionbeltoverthecrankshaftoftheengine

(Figure50).

g326388

Figure50

Figure48

1.Frictionwheel3.Tractionpulley

2.Tractionbelt

InstallingtheTractionBelt

1.Slipthetractionbeltbetweenthefrictionwheel

andthetractionpulley,andintothemachine

(Figure49).

1.Sheavehalf4.Shaftspacer

2.Tractionbelt87.6cm

(34-1/2inches)

3.Pulleyspacer

g326386

5.Crankshaft(engine)

3.Installthebroomdrivebelt;refertoInstallingthe

BroomDriveBelt(page28).

4.Atthebottomofthemachine,aligntheholesin

thebottomcoverwiththeholesintheangesof

theleftandrightsideplates(Figure51).

Note:Ensurethattherearcoveroverlapsthe

bottomcover.

29

Figure51

1.Flange-headcapscrew

(1/4x5/8inch—loosen)

2.Bottomcover5.Rearcover

3.Flange-headcapscrew

(1/4x5/8inch)

4.Flange(sideplate)

Storage

StorageSafety

•Shutofftheengineandwaitforallmovement

tostopbeforeyouleavetheoperator'sposition.

Allowthemachinetocoolbeforeadjusting,

servicing,cleaning,orstoringit.

•Fuelfumesarehighlyammable,explosive,and

dangerousifinhaled.Ifyoustoretheproductinan

areawithanopename,thefuelfumesmayignite

andcauseanexplosion.

g326387

•Neverstorethemachinewithfuelinthefuel

tankinsideabuildingwhereignitionsourcesare

present,suchashotwaterandspaceheaters,

clothingdryers,etc.Allowtheenginetocool

beforestoringthemachineinanyenclosure.

•Disengagethepowertotherotarybroomwhen

transportingorstoringthemachine.

5.Assemblethebottomcovertothemachine

(Figure51)withthe6ange-headcapscrew(1/4

x5/8inch).

6.tightenthe2topange-headcapscrew(1/4

x5/8inch)thatsecuretherearcovertothe

machine(Figure51).

ChassisMaintenance

CheckingforLooseHardware

ServiceInterval:Beforeeachuseordaily

1.Inspectthemachineforanyloosehardware,

missinghardware,oranyotherpossible

problem.

2.Tightenallloosehardwarebeforeoperatingthe

machine.

3.Replaceanymissinghardwarebeforeoperating

themachine.

PreparingtheMachinefor

Storage

PreparingtheFuelSystem

1.Onthelastrefuelingoftheyear,addfuel

stabilizertofreshfuel.

2.Addthetreatedfueltothemachineandrunthe

enginefor10-minutes.

3.Drainthefuelfromthefuelsystem;referto

DrainingtheFuelSystem(page22).

Note:Donotstorestabilizedfuelformorethan

90days.

4.Runthemachineuntiltheenginestopsfrom

runningoutoffuel.

5.Primetheengineandstartitagain.

6.Allowtheenginetorununtilitstops.

7.Allowittocool.

PreparingtheEngine

1.Disconnectthespark-plugwire.

2.Removethesparkplug,add30ml(1oz)of

engineoilthroughthespark-plughole,andpull

thestarterropeslowlyseveraltimes.

3.Looselyinstallthesparkplug.

PreparingtheChassis

1.Supporttheframe,sothebristlesarenot

touchingtheground.

Important:Thebristleswillbecome

deformedandthebroomwillbeoutof

30

alignmentifthebristlesaretouchingthe

groundforanextendedperiod.

2.Thoroughlycleanthebroomandensurethatitis

freeofallcausticchemicalsand/orresidue.

3.Cleanthemachinethoroughly.

4.Touchupchippedsurfaceswithpaintavailable

fromyourAuthorizedServiceDealer.Sand

affectedareasbeforepainting,andusearust

preventativetopreventthemetalpartsfrom

rusting.

5.Tightenallloosescrews,bolts,andlocknuts.

Repairorreplaceanydamagedparts.

6.Coverthemachineandstoreitinaclean,dry

placeoutofthereachofchildren.Allowthe

enginetocoolbeforestoringitinanyenclosure.

Important:Keepthebroomawayfrom

sunlight,weather,andtemperaturechanges

topreventbrittleness.

RemovingtheMachine

fromStorage

1.Removethesparkplugandpulltherecoil-start

handletorapidlyspintheengineandpumpthe

excessoilfromthecylinder.

2.Installthesparkplugbyhandandthentorqueit

to20.4N∙m(15ft-lb).

3.Connectthespark-plugwire.

4.Performtheannualmaintenanceprocedures

asgivenintheRecommendedMaintenance

Schedule;refertoMaintenance(page18).

31

Troubleshooting

Problem

Theenginedoesnotstart,startshard,or

failstokeeprunning.

Theenginelosespower.

PossibleCauseCorrectiveAction

1.Thefueltankisempty.1.Fillthefueltank.

2.Thefuel-shutoffvalveisclosed.2.Openthefuel-shutoffvalve.

3.Thethrottleandchokearenotinthe

correctposition.

4.Thereisdirtinfuelvalve.4.Cleanthefuel-valvescreenandcup.

5.Thefuel-capventisblocked.5.Cleanthefuel-capvent.

6.Dirt,water,orstalefuelisinthefuel

system.

7.Theaircleanerisdirty.

8.Thesparkplugisfaulty.8.Clean,adjustorreplacethesparkplug.

9.Thespark-plugwireisnotconnected.

1.Theengineloadisexcessive.1.Reducethegroundspeedoradjust

2.Theaircleanerisdirty.

3.Theoillevelinthecrankcaseis

incorrect.

4.Thereisdirtinfueltanklter.4.Cleanthefuel-tanklter.

5.Dirt,water,orstalefuelisinthefuel

system.

3.Ensurethatthethrottlecontrolis

midwaybetweentheSlowandFast

positions,andthechokeisintheOn

positionforacoldengineortheOff

positionforawarmengine.

6.Contactanauthorizedengineservice

dealer.

7.Cleanorreplacetheaircleaner

element.

9.Checkthespark-plugwireconnection.

thebroom.

2.Cleanorreplacetheaircleaner

element.

3.Checktheoillevelinthecrankcase.

5.Contactanauthorizedengineservice

dealer.

Thebroomdoesnotcleanthesurface.

Thebroomdoesnotrotate.

Themachinepullsleftorright.

Themachinevibratesabnormally .

1.Thebroomheightisincorrect.1.Adjustthebroomheight.

2.Thetirepressureinthedrivetiresis

notcorrect.

3.Y ouarecleaningtoomuchdebrisat

onetime.

1.Thebroomisclogged.1.Unclogthebroom.

2.Thebroomdriveleverisnotengaged.2.Engagethebroomdrivelever.

3.Thebroomdrivebeltisslipping.3.Adjustorreplacethebelt.

4.Thebeltisbroken.4.Replacethebelt.

5.Theshearpinisbroken.5.Replacetheshearpin.

1.Thetirepressureinthedrivetiresis

notcorrect.

1.Thedrivebeltisworn,looseorbroken.1.Installanewbelt. Themachinedoesnotdrive.

2.Thedrivebeltisoffapulley.

1.Thebroomassemblyislooseor

damaged.

2.Theenginemountingboltsareloose.2.Tightentheengine-mountingbolts.

3.Theenginepulleyoridlerpulleyis

loose.

4.Theenginepulleyisdamaged.

5.Thebeltisdamaged.5.Installanewbelt.

2.Adjustthetirepressureinthedrive

tires.

3.Slowdownandclearsmallerareasof

debris.

1.Adjustthetirepressureinthedrive

tires.

2.Replaceoradjustthebelt.

1.Tightenthehardware,replacethe

broomassembly,orcontactyour

AuthorizedServiceDealer .

3.Tightentheappropriatepulley.

4.ContactyourAuthorizedService

Dealer.

Thebroomdoesnotstopwhenthedrive

leverisreleased.

1.Thebroom-drivebeltisoutof

adjustment.

32

1.Checkthebroom-driveadjustment.

Problem

PossibleCauseCorrectiveAction

Thebroomwearsoutprematurely .1.Y ouareusingtheincorrectbroom

Thespeedselectorisdifculttomoveor

locked.

height.

1.Thehexshaftneedslubrication.1.Lubricatethehexshaft.

1.Adjustthebroomheight.

33

Notes:

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproducts.Additionally,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerswithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalsprovideexposurelimitrequirements.WhiletheexposurefromT oroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover,ifTorodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

FormNo.3439-894RevB

KehrmaschinePowerBroom

Modellnr.38701—Seriennr.400000000undhöher

RegistrierenSieIhrProduktunterwww.T oro.com.

Originaldokuments(DE)

*3439-894*

EntsprechenddemCaliforniaPublicResourceCode

Section4442oder4443istderEinsatzdesMotorsin

bewaldetenoderbewachsenenGebietenohnerichtig

gewartetenundfunktionsfähigenFunkenfänger,

wieinSection4442deniert,oderohneeinen

Motorverboten,dernichtfürdieBrandvermeidung

konstruiert,ausgerüstetundgewartetist.

DiebeiliegendeMotoranleitungenthältAngabenzu

denEmissionsbestimmungenderUSEnvironmental

ProtectionAgency(EPA)unddenKontrollvorschriften

vonKalifornienzuEmissionsanlagen,derWartung

undGarantie.SiekönneneinenErsatzbeim

Motorherstelleranfordern.

WARNUNG:

KALIFORNIEN

WarnungzuProposition65

DieMotorauspuffgasediesesProdukts

enthaltenChemikalienwirkenlautden

BehördendesStaatesKalifornien

krebserregend,verursaschen

GeburtsschädenoderandereDefekte

desReproduktionssystems.

amProdukt.TragenSiehierbittedieModell-und

SeriennummerndesGerätsein.

Wichtig:ScannenSiemitIhremMobilgerätden

QR-CodeaufdemSeriennummernaufkleber(falls

vorhanden),umaufGarantie-,Ersatzteil-oder

andereProduktinformationenzuzugreifen.

g325100

Bild1

Einführung

DieseMaschinesolltevonPrivatleutenoder

geschultenLohnarbeiternverwendetwerden.Die

MaschineistfürdasRäumenvonSchnee,Staub

oderSchmutzvonbefestigtenOberächen,wie

z.B.EinfahrtenoderGehwegen,undanderen

GehbereichenaufprivatemoderöffentlichemGelände

sowiedasEntfernenvonabgestorbenemGras

gedacht.

LesenSiedieseInformationensorgfältigdurch,

umsichmitdemordnungsgemäßenEinsatzund

derWartungdesGerätsvertrautzumachenund

VerletzungenundeineBeschädigungdesGerätszu

vermeiden.SietragendieVerantwortungfüreinen

ordnungsgemäßenundsicherenEinsatzdesGeräts.

BesuchenSieToro.com,hinsichtlichProduktsicherheit

undSchulungsunterlagen,Zubehörinformationen,

StandorteinesHändlers,oderRegistrierungdes

Produkts.

WendenSiesichandenToro-Vertragshändler

oderKundendienst,wennSieeineServiceleistung,

OriginalersatzteilevonT orooderweitere

Informationenbenötigen.HabenSiedafürdieModellundSeriennummernderMaschinegriffbereit.Bild1

zeigtdiePositionderModell-undSeriennummern

1.TypenschildmitModell-undSeriennummer

Modellnr.

Seriennr.

IndieserAnleitungwerdenpotenzielleGefahren

angeführt,undSicherheitshinweisewerdenvom

Sicherheitswarnsymbol(Bild2)gekennzeichnet.

DiesesWarnsymbolweistaufeineGefahrhin,diezu

schwerenodertödlichenVerletzungenführenkann,

wennSiedieempfohlenenSicherheitsvorkehrungen

nichteinhalten.

g000502

Bild2

1.Sicherheitswarnsymbol

IndieserAnleitungwerdenzweiBegriffezur

HervorhebungvonInformationenverwendet.Wichtig

weistaufspezielletechnischeInformationenhin,und

HinweishebtallgemeineInformationenhervor,die

IhrebesondereBeachtungverdienen.

©2020—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

KontaktierenSieunsunterwww.Toro.com.

2

AlleRechtevorbehalten

Druck:USA

Inhalt

Sicherheit

Sicherheit..................................................................3

AllgemeineSicherheit.........................................3

Winkelanzeige...................................................4

Sicherheits-undBedienungsschilder.................5

Produktübersicht.......................................................7

Bedienelemente................................................7

TechnischeDaten..............................................8

Anbaugeräte/Zubehör........................................8

VordemEinsatz....................................................9

SicherheitshinweisevorderInbetrieb-

nahme.............................................................9

Betanken............................................................9

PrüfendesKehrpfades.......................................9

EinstellenderKehrbürstenhöhe.......................10

WährenddesEinsatzes........................................11

HinweisezurSicherheitwährenddes

Betriebs..........................................................11

VerwendendesMotors.....................................12

FahrenmitderMaschine..................................13

VerwendenderKehrbürste...............................15

EinstellendesseitlichenWinkelsder

Kehrbürste....................................................16

VerwendenderalternativenLaufradposi-

tion................................................................17

ReinigeneinerverstopftenKehrbürste..............17

NachdemEinsatz...............................................17

HinweisezurSicherheitnachdem

Betrieb..........................................................17

VerhinderneinesEinfrierensnach

Gebrauch......................................................18

TransportierenderMaschine............................18

Wartung..................................................................19

EmpfohlenerWartungsplan.................................19

Wartungssicherheit...........................................19

VorbereitenfürdieWartung..............................20

Einfetten...........................................................20

Motorwartung...................................................21

WartungderKraftstoffanlage............................24

WartungderAntriebsanlage.............................24

WartungderKehrbürste...................................25

Riemenwartung................................................28

WartendesChassis..........................................32

Einlagerung............................................................32

SicherheitbeiderEinlagerung..........................32

VorbereitenderMaschinefürdie

Einlagerung...................................................32

HerausnehmenderMaschineausder

Einlagerung...................................................33

Fehlersucheund-behebung...................................34

DieseMaschineerfülltdieVorgabenaus

ANSI/OPEIB71.3undANSIB71.4.

DiesesProduktkannHändeundFüßeverletztenund

Gegenständeaufschleudern.DasNichtbeachten

derfolgendenSicherheitsvorschriftenkannzu

schwerenVerletzungenführen.BefolgenSiezum

VermeidenvonschwerenVerletzungenimmeralle

Sicherheitshinweise.

AllgemeineSicherheit

•LesenSievordemAnlassendesMotorsdenInhalt

dieserBedienungsanleitungsorgfältigdurch.

•StellenSiesicher,dassallePersonen,welche

diesesProduktverwendenwissen,wiesie

denMotorschnellabstellenkönnensowiedie

Warnhinweiseverstehen.

•LassenSiedenKehrbürstenantriebshebelund

denFahrantriebshebellos,schaltenSiedenMotor

abundwartenSie,bisallebeweglichenTeile

zumStillstandgekommensind,bevorSieaus

irgendeinemGrunddieBedienpositionverlassen.

•HaltenSieHändeundFüßevonbeweglichen

TeilenderMaschinefern.BleibenSieimmervon

derAuswurföffnungfern.

•BedienenSiedieMaschineniemals,wennnicht

alleSchutzvorrichtungenundAbdeckungen

angebrachtundfunktionstüchtigsind.

•HaltenSieUnbeteiligte,besonderskleineKinder,

ausdemArbeitsbereichfern.

•DieMaschinedarfniemalsvonKindernbetrieben

werden.

3

Winkelanzeige

Bild3

1.DasmaximaleGefälle,andemdieMaschinesichereingesetztwerdenkann,beträgt10°.ErmittelnSiemitderNeigungsanzeige

dasGefällederHängevordemEinsatz.SetzenSiedieseMaschinenichtaufHanglagenein,dieeinGefällevonmehrals

10°aufweisen.FaltenSieentlangderentsprechendenLinie,umdemempfohlenenGefällezuentsprechen.

2.FluchtenSiedieseKantemiteinervertikalenOberächeaus(Baum,Gebäude,Zaunpfahl,Pfostenusw.)

3.Beispiel,wieSieGefällemitdergefaltetenKantevergleichen.

4

g011841

Sicherheits-undBedienungsschilder

DieSicherheits-undAnweisungsaufklebersindgutsichtbar;siebendensichinderNähe

dermöglichenGefahrenbereiche.TauschenSiebeschädigteoderverlorengegangene

Aufkleberaus.

112-9028

1.Warnung:BerührenSiekeinebeweglichenTeileundlassen

SiealleSchutzvorrichtungenmontiert.

115-2903

decal112-9028

decal115-2903

1.Fett

1.Gefahrdurch

herausgeschleuderte

Gegenstände:Setzen

SiedieMaschinenicht

ein,wennsichPersonen

undHaustiereimBereich

aufhalten.

decal116-8140

116-8140

2.Warnung–

Verhedderungsfahr:

BerührenSienichtdie

Kehrbürste:

decal133-8062

133-8062

5

decal135-2867

135-2867

1.Warnung:LesenSiedieBedienungsanleitung.Setzen

SiedasGerätnurnachentsprechenderSchulungein.

BerührenSiekeinebeweglichenTeileundnehmenSiekeine

Schutzvorrichtungenab.

4.Warnung:StellenSiedenMotorabundziehenSieden

Zündkerzensteckerab,bevorSieEinstellungenoder

WartungsarbeitenausführenoderdieMaschineunddie

Anbaugerätereinigen.KuppelnSiedieKehrbürstesowie

denFahrantriebausundstellendenMotorab,bevorSie

dieBedienerpositionverlassen.SchauenSienachhinten

undzurSeite,bevorSiedieRichtungändern.NehmenSie

niePassagieremit.

2.GefahrdurchherausgeschleuderteGegenstände:SetzenSie

dieMaschinenichtein,wennsichPersonenundHaustiere

imBereichaufhalten;sammelnSieObjekteauf,dievonder

Kehrbürsteaufgeworfenwerdenkönnen.

5.Warnung–Verhedderungsfahr:BerührenSienichtdie

rotierendeKehrbürste:BorstenderKehrbürsteschmelzen

oderbrennen:KommenSieextremerWärmeoderFlammen

nichtzunahe.ArbeitenSienichtaufDächernoderanderen

höhergelegenenFlächen.

3.Warnung:TragenSieeinenGehörschutz.6.Warnung:FahrenSieimmerquerzumHang,nicht

hangaufwärtsoder-abwärts.GehenSiebeiderArbeitan

Hanglagenäußerstvorsichtigvor.

144-0316

1.AktivierenSiedenFahrantriebshebel,umden

Fahrantriebshebeleinzukuppeln.

2.AktivierenSiedenlinkenHebelzumWenden,umnachlinks

zufahren.

3.AktivierenSiedenHebelfürdenKehrbürstenwinkel,umdie

Kehrbürsteeinzustellen.

4.AktivierenSiedenrechtenHebelzumWenden,umnach

rechtszufahren.

5.AktivierenSiedenZapfwellenhebelein,umdieZapfwelle

einzukuppeln.

decal144-0316

6

Produktübersicht

g326826

Bild5

Bild4

1.Radkupplungshebel

2.Kehrbürstenwinkel-Hebel

3.Kehrbürstenantriebshebel

4.Geschwindigkeitsschalthebel

5.Handgriff

6.Fahrantriebshebel

7.Tankdeckel

8.KehrbürsteundHaube

9.EinstellstiftfürdieKehrbürstenhöhe

Bedienelemente

BestimmenSiedielinkeundrechteSeiteder

MaschineanhandderüblichenEinsatzposition.

Chokehebel

DerChokehebelistderobersteHebelhintenlinksam

MotorüberdemKraftstoffhahn(Bild5).

DerChokevereinfachtdasAnlasseneineskalten

Motors.StellenSiedenHebelfürdasAnlasseneines

kaltenMotorsindieEIN-Stellung.Beieinemwarmen

MotorsolltederChokenichtinderEIN-Stellungsein.

g325102

1.Chokehebel4.Rücklaufstartergriff

2.Kraftstoffhahn5.Ein-/Aus-Schalterfür

Motor

3.Gasbedienungshebel

Kraftstoffhahn

StellenSiemittelsdemKraftstoffhahndie

Kraftstoffzufuhrab,wennSiedieMaschinefür

einigeT agenichtverwenden,dieMaschineineinem

GebäudelagernoderSiesievoneinerArbeitsstelle

zueineranderentransportieren(Bild5).

SchiebenSiedenHahnnachlinks,umdenKraftstoff

abzustellen.SchiebenSiedenHahnnachrechts,um

ihnzuöffnen.

Gasbedienungshebel

DerGasbedienungshebelbendetsichhintenrechts

amMotorunterdemKraftstofftank(Bild5).

MitderGasbedienungsteuernSiedieMotordrehzahl.

WennSiedieGasbedienungnachlinksbewegen,

wirddieMotordrehzahlerhöht,wennSiesienach

rechtsbewegen,wirddieMotordrehzahlverringert.

Ein-/Aus-SchalterfürMotor

BendetsichanderrechtenSeitedesMotors(Bild5).

DrehenSiedenSchalternachrechtsindie

EIN-Stellung,bevorSiedenMotoranlassen.Drehen

SiedenSchaltergegendenUhrzeigersinnindie

AUS-Stellung,umdenMotorabzustellen.

7

Radkupplungshebel

Geschwindigkeitsschalthebel

DieRadkupplungshebelbendensichunterdem

rechtenundlinkenHolm.

MitdenRadkupplungshebelnkönnenSiebei

gedrücktemFahrantriebshebeldenAntriebvoneinem

RadodervonbeidenRäderntemporärauskuppeln.

DieserleichtertdasWendenundManövrierender

Maschine(Bild6).

Hinweis:WennSiebeideKupplungshebel

gleichzeitigdrücken,wirdderAntriebbeiderRäder

ausgekuppelt(Freilauf).SiekönnendieMaschine

dannmanuellrückwärtsbewegen,ohneanzuhalten,

umdenRückwärtsgangeinzulegen.Dieserleichtert

auchdasBewegenundTransportierenderMaschine,

wennderMotorabgestelltist.

Bild6

1.Radkupplungshebel4.Fahrantriebshebel

2.Holm

3.Kehrbürstenwinkel-Hebel6.Kehrbürstenantriebshebel

5.Geschwindigkeitsschalthebel

DerGeschwindigkeitsschalthebelbendetsicham

Hauptbedienfeld(Bild6).

DerSchalthebelhatsechsEinstellungenfürvorwärts

undzweifürrückwärts.LassenSiezumÄndern

derGeschwindigkeitdenFahrantriebshebellosund

stellendenGeschwindigkeitsschalthebelaufdie

gewünschteEinstellung.DerHebelrastetinjeder

GeschwindigkeitseinstellungineinerKerbeein.

Kehrbürstenwinkelhebel

DerKehrbürstenwinkelhebelbendetsichamrechten

Holm(Bild6).

DerKehrbürstenwinkelhebelsteuertdasArretieren

desWinkels.DerKehrbürstenwinkelkannindrei

Stellungenarretiertwerden,geradeausoderum19°

nachlinksoderrechtsabgewinkelt.

TechnischeDaten

Breite118cm

Länge185,5cm

Höhe105,5cm

Gewicht

g325105

Motordrehzahl(keineLast)Vollgas:3.600±100U/min

Kraftstofftank-Füllmenge

Anbaugeräte/Zubehör

151kg

4,1Liter

Kehrbürstenantriebshebel

DerKehrbürstenantriebshebelbendetsichüberdem

rechtenHolm(Bild6).

DrückenSiedenHebelzumHolm,umdieKehrbürste

einzukuppeln.LassenSiedenrechtenHebellos,um

dieKehrbürsteauszukuppeln.

Fahrantriebshebel

DerFahrantriebshebelbendetsichüberdemlinken

Holm(Bild6).

MitdemFahrantriebshebelsteuernSiedieVorwärtsundRückwärtsbewegungderMaschine.Drücken

SiedenHebelzumHolm,umdenFahrantrieb

einzukuppeln.

Hinweis:WennSiedenFahrantriebshebelgegen

denHolmdrücken,wirdderFahrantriebfürbeide

Rädereingekuppelt.

EinSortimentanvonT orozugelassenen

AnbaugerätenundZubehörwirdfürdieseMaschine

angeboten,umdenFunktionsumfangdesGerätszu

erhöhenundzuerweitern.WendenSiesichaneinen

ofziellenT oro-VertragshändlerodernavigierenSie

aufwww.Toro.comfüreineListederzugelassenen

AnbaugeräteunddesZubehörs.

VerwendenSie,umdieoptimaleLeistungund

Sicherheitzugewährleisten,nurOriginalersatzteile

und-zubehörteilevonToro.ErsatzteileundZubehör

andererHerstellerkönnengefährlichseinundeine

VerwendungkönntedieGarantieungültigmachen.

8

Betrieb

VordemEinsatz

Sicherheitshinweisevor

derInbetriebnahme

AllgemeineSicherheit

•TragenSiegeeigneteKleidung,einschließlich

Augenschutz,langeHosen,festes,rutschfestes

SchuhwerkundGehörschutz;tragenSiein

staubigerUmgebungaucheineAtemschutzmaske