FormNo.3409-326RevA

Walk-BehindRotaryBroom

ModelNo.38700—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3409-326*A

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

TheenclosedEngineOwner'sManualissuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

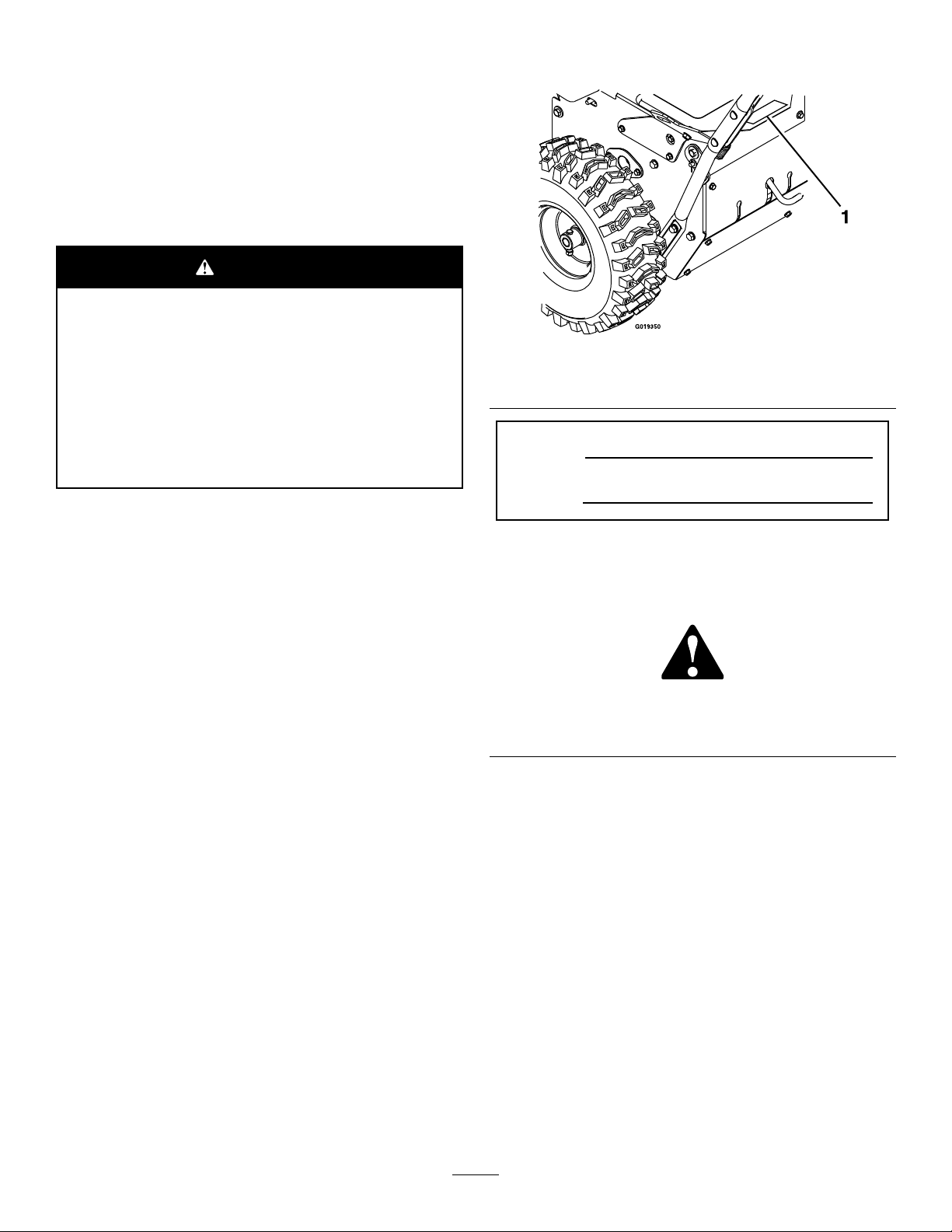

modelandserialnumbersonthemachine.Writethenumbers

inthespaceprovided.

g019350

Figure1

1.Modelandserial-numberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Introduction

Toacquireasparkarresterforyourmachine,seeyourEngine

ServiceDealer.

Thismachineisintendedtobeusedbyresidential

homeownersorprofessional,hiredoperators.Itis

designedforremovingsnow,dust,anddirtfrom

pavedsurfaces,suchasdrivewaysandsidewalks,and

othersurfacesfortrafconresidentialorcommercial

properties,aswellasthatchfromgrass.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourmachineproperlyandtoavoidinjuryand

machinedamage.Youareresponsibleforoperatingthe

machineproperlyandsafely .

YoumaycontactTorodirectlyatwww .Toro.comformachine

andaccessoryinformation,helpndingadealer,ortoregister

yourmachine.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourmachineready .Figure1identiesthelocationofthe

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety...........................................................................4

Training.................................................................4

Preparation.............................................................4

Operation...............................................................4

ClearingaCloggedBroom........................................5

MaintenanceandStorage..........................................5

SoundPressure.......................................................5

SoundPower..........................................................5

Hand/ArmVibration..............................................5

SlopeIndicator.......................................................6

SafetyandInstructionalDecals.................................7

ProductOverview..........................................................9

Controls................................................................9

Specications........................................................10

Attachments/Accessories........................................10

Operation....................................................................11

FuelingtheMachine...............................................11

OperatingtheEngine..............................................12

DrivingtheMachine...............................................13

OperatingtheBroom..............................................14

CheckingtheSweepingPath....................................15

AdjustingtheBroomHeight....................................15

AdjustingtheBroomSideAngle...............................16

UsingtheAlternateCasterLocation..........................16

ClearingaCloggedBroom.......................................16

PreventingFreeze-up..............................................17

TransportingtheMachine........................................17

Maintenance.................................................................18

RecommendedMaintenanceSchedule(s)......................18

PreparingforMaintenance.......................................19

Lubrication............................................................19

EngineMaintenance...............................................19

FuelSystemMaintenance........................................22

DriveSystemMaintenance.......................................23

BroomMaintenance...............................................24

MaintainingtheBelts..............................................26

MaintainingtheChassis...........................................28

Storage........................................................................29

PreparingtheMachineforStorage............................29

RemovingtheMachinefromStorage.........................29

Troubleshooting...........................................................30

3

Safety

–Fillthefueltankoutdoorswithextremecare.Never

llthefueltankindoors.

Readandunderstandthecontentsofthismanualbefore

theengineiseverstarted.

Thisisthesafetyalertsymbol.Itisusedtoalertyou

topotentialpersonalinjuryhazards.Obeyallsafety

messagesthatfollowthissymboltoavoidpossibleinjury

ordeath.

Improperlyusingormaintainingthismachinecould

resultininjuryordeath.T oreducethispotential,

complywiththefollowingsafetyinstructions.

Training

•Readtheoperatingandserviceinstructionmanual

carefully.Bethoroughlyfamiliarwiththecontrolsand

theproperuseofthemachine.Knowhowtostopthe

machineanddisengagethecontrolsquickly.

•Donotallowadultstooperatethemachinewithout

properinstruction.

Preparation

CAUTION

Theoperationofanypoweredmachinecanresult

inforeignobjectsbeingthrownintotheeyes.

Alwayswearsafetyglassesoreyeshieldsduring

operationorwhileperforminganadjustmentor

repair.

CAUTION

Thismachineproducessoundlevelsinexcessof85

dBAattheoperator’searandcancausehearingloss

throughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Keeptheareaofoperationclearofallpersons,particularly

smallchildren,andpets.

•Thoroughlyinspecttheareawhereyouwillusethe

machineandremovealldoormats,sleds,boards,wires,

andotherforeignobjects.

•Donotoperatethemachinewithoutwearingappropriate

personalprotectiveequipmentsuchashearingprotection,

safetyglassesorgoggles,dustmask,andgarments.

Wearfootwear,whichwillimprovetractiononslippery

surfaces.

•Handlefuelwithcare;itishighlyammable.

–Useanapprovedfuelcontainer.

–Neveraddfueltoarunningorhotengine.

–Securethefuelcapafterfuelingandwipeupany

spilledfuel.

•Lettheengineandmachineadjusttooutdoor

temperaturesbeforestartingtoclearsnow.

Operation

•Neverallowchildrentooperatethemachine.

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Neverdirectdischargeatbystandersorallowanyonein

frontofthemachine.

•Takeallpossibleprecautionswhenleavingthemachine

unattended.Releasethebroom-drivelever,traction-drive

lever,stoptheengine,andremovethekey.

•Alwaysbesureofyourfooting,andkeeparmholdon

thehandles.Walk;neverrun.

•Neveroperatethemachinewithoutgoodvisibilityor

light.

•Donotoperatethemachinewhileill,tired,orunderthe

inuenceofalcoholordrugs.

•Exercisecautiontoavoidslippingorfalling,especially

whenoperatingthemachineinthereversetraveldirection.

•Stoptheenginewheneveryouleavetheoperating

position,beforeuncloggingthebroomhousing,and

whenmakinganyrepairs,adjustments,orinspections.

•Exerciseextremecautionwhenoperatingonorcrossing

graveldrives,walks,orroads.Stayalertforhidden

hazardsortrafc.

•Neveroperatethemachineathightransportspeedson

slipperysurfaces.Usecarewhenreversing.

•Donotclearsnow,dirt,orthatchacrossthefaceof

slopes.Exerciseextremecautionwhenchangingdirection

onslopes.Donotattempttoclearsteepslopes.

•Neveroperatethemachinenearglassenclosures,

automobiles,windowwells,dropoffs,etc.withoutproper

adjustmentofthesnowdischargeangle.Keepchildren

andpetsaway.

•Donotoverloadthemachinecapacitybyattemptingto

clearsnow,dirt,orthatchattoofastofarate.

•Donotruntheengineindoors,exceptwhenstartingit

andformovingthemachineinoroutofthebuilding.

Opentheoutsidedoors;exhaustfumesaredangerous.

•Whencleaning,repairing,orinspecting,ensurethat

therotarybroomandallmovingpartshavestopped.

Disconnectthespark-plugwire,andkeepthewireaway

fromtheplugtopreventaccidentalstarting.

•Disengagethepowertotherotarybroomwhenthe

machineistransportedornotinuse.

4

•Afterstrikingaforeignobject,stoptheengine,remove

thewirefromthesparkplug,thoroughlyinspectthe

machineforanydamage,andrepairthedamagebefore

restartingandoperatingthemachine.

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof89

dBA,whichincludesanUncertaintyValue(K)of1dBA.

•Ifthemachineshouldstarttovibrateabnormally,stopthe

engineandcheckimmediatelyforthecause.Vibrationis

generallyawarningoftrouble.

•Neveroperatethemachinewithoutproperguards,plates,

orothersafetyprotectivedevicesinplace.

•Useonlyattachmentsandaccessoriesapprovedbythe

manufacturerofthemachine(suchaswheelweights,

counterweights,cabs,etc.).

ClearingaCloggedBroom

WARNING

Therotatingbroomcouldcauseseriousinjury.

Alwaysusecautionwhencleaningthebroom.

Toclearthebroom:

•Parkthemachineonlevelground,stoptheengine,wait

forallmovingpartstostop,andremovethespark-plug

wire(s).

•Sharpobjectscanbecomeentangledinthebristles.Wear

glovesandusecautionwhencleaningoutthebroomof

foreignobjects;neveruseyourbarehands.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof101dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

Hand/ArmVibration

Measuredvibrationlevelforlefthand=6.4m/s

Measuredvibrationlevelforrighthand=5.5m/s

UncertaintyValue(K)=2.6m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO20643.

2

2

2

MaintenanceandStorage

•Neverattempttomakeanyadjustmentswhiletheengine

isrunning(exceptwherespecicallyrecommendedby

themanufacturer).

•Checkallofthefastenersatfrequentintervalsforproper

tightnesstoensurethatthemachineisinsafe,working

condition.

•Neverstorethemachinewithfuelinthefueltankinside

abuildingwhereignitionsourcesarepresent,suchas

hotwaterandspaceheaters,clothingdryers,etc.Allow

theenginetocoolbeforestoringthemachineinany

enclosure.

•AlwaysrefertotheinstructionsintheOperator’sManual

forimportantdetailsifthemachineistobestoredfor

anextendedperiod.

•Maintainorreplacethesafetyandinstructionlabels,as

necessary.

•Whenoperatinginsnowconditions,runthemachinefor

afewminutesafterthrowingsnowtopreventfreezeup

ofthebroomandhousing.

5

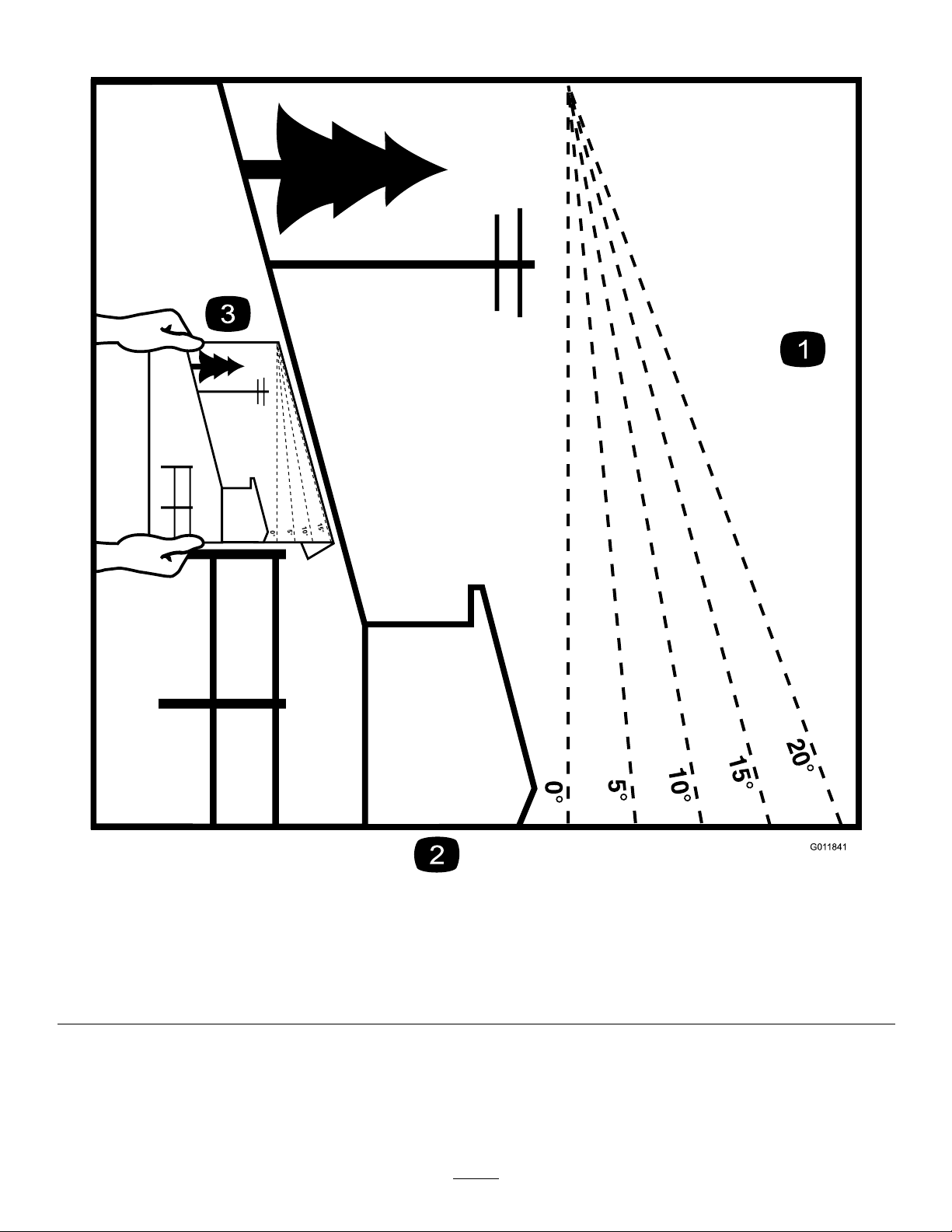

SlopeIndicator

G011841

Figure3

1.Themaximumslopeyoucansafelyoperatethemachineonis10°.Usetheslopeindicatortodeterminethedegreeofslopeof

hillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan10°.Foldalongtheappropriatelinetomatchthe

recommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

6

g011841

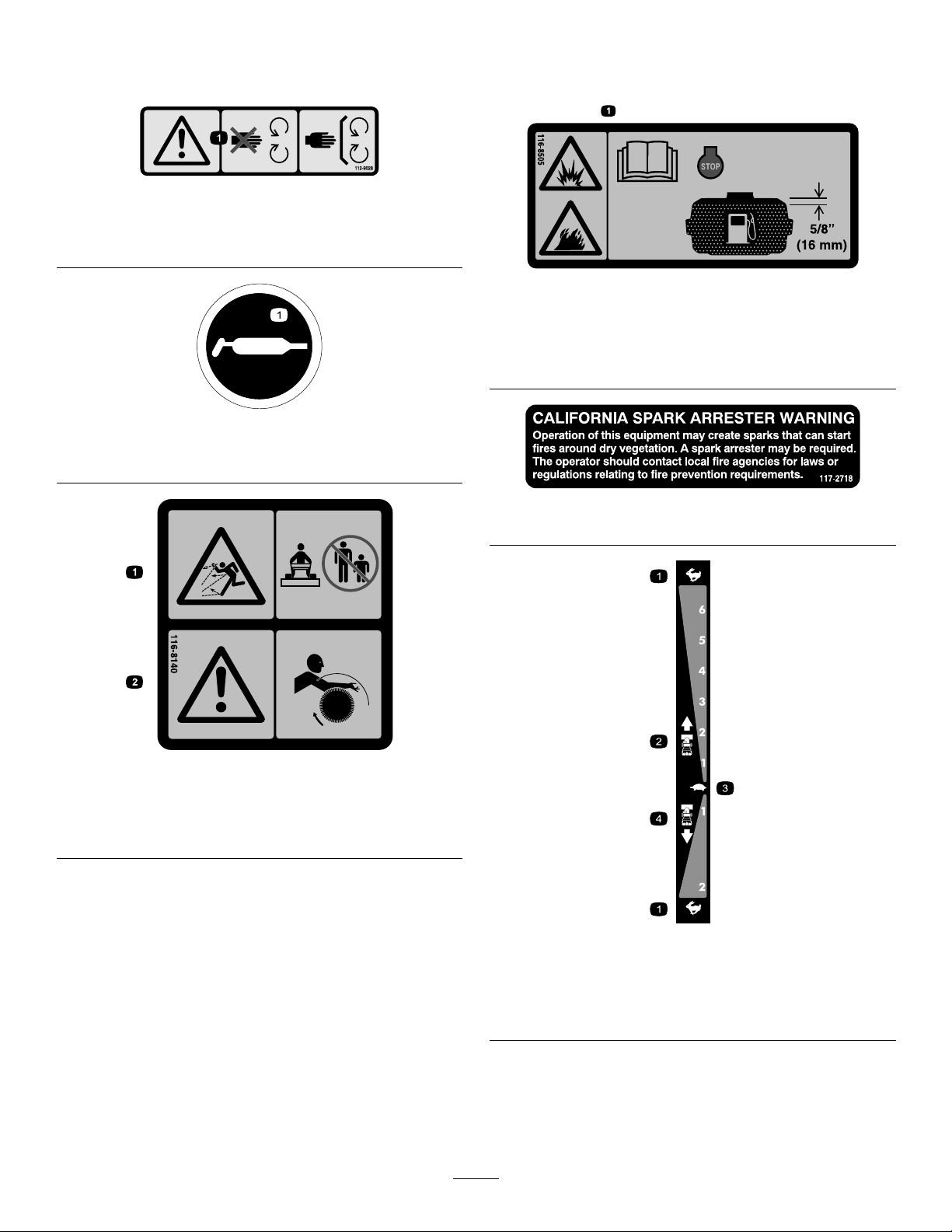

SafetyandInstructionalDecals

Important:Safetyandinstructiondecalsarelocatednearareasofpotentialdanger.Replacedamageddecals.

decal112-9028

112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

116-8505

1.Explosion/Firehazard—ReadtheOperator'sManual.Stop

theenginebeforellingthefueltank.Leave16mm(5/8

inch)atthetopofthetankforfuelexpansion.Donotoverll

thetank.

decal115-2903

115-2903

1.Grease

117–2718

decal116-8505

decal117-2718

1.Thrownobjecthazard—Do

notoperatewhenpeople

andpetsareinthearea.

decal116-8140

116-8140

2.Warning—Entanglement

hazard—stayclearofthe

rotatingbroom.

decal106-4525

106-4525

OrderPartNo.1 12-6633

1.Fast

2.Forwardspeeds4.Reversespeeds

3.Slow

7

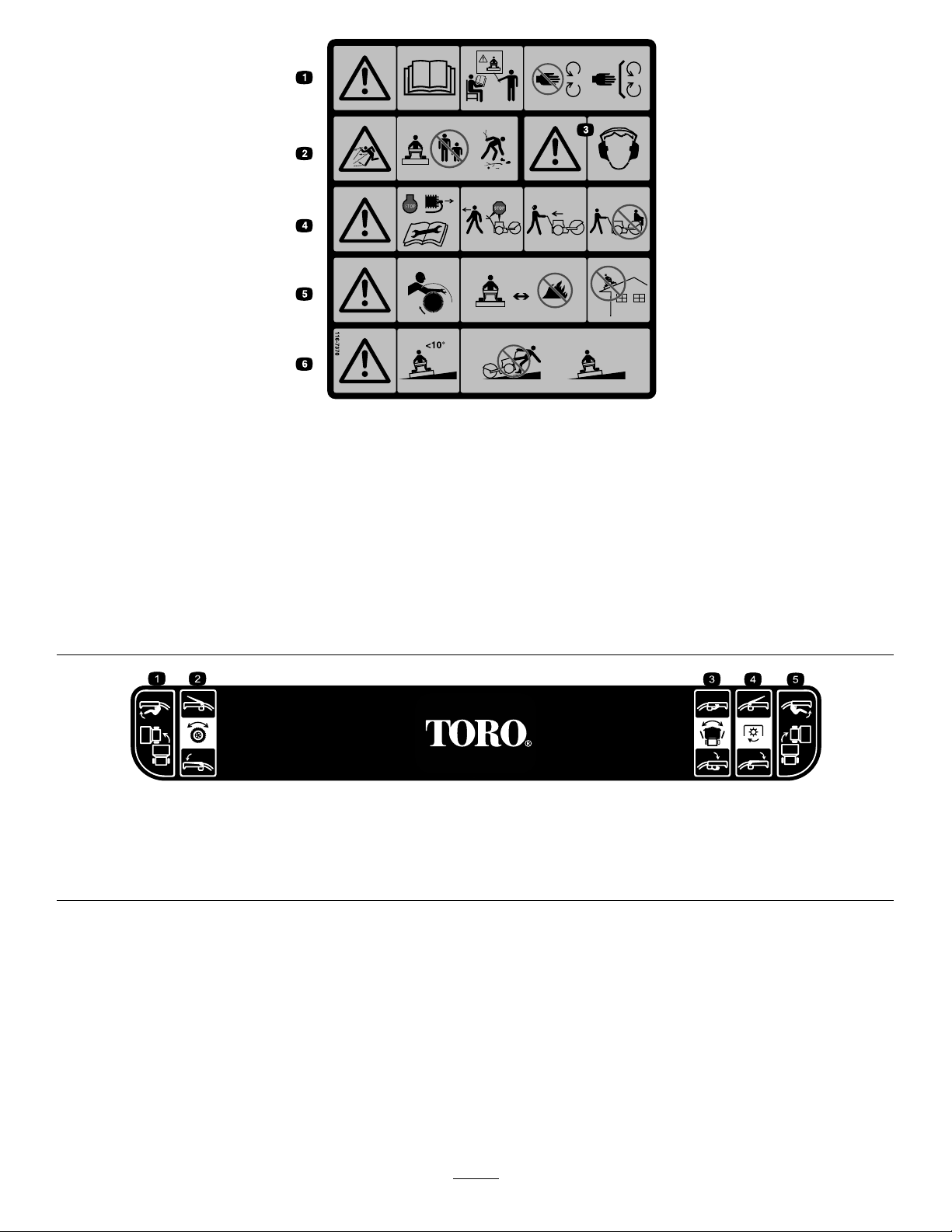

decal116-7370

116-7370

1.Warning—ReadtheOperator’sManual.Donotoperatethis

machineunlessyouaretrained.Stayawayfrommoving

parts;keepallguardsinplace.

4.Warning—Stoptheengineandremovesparkplugbefore

adjusting,servicing,orcleaningmachineandattachments.

Beforeleavingtheoperator’sposition,disengagebroom,

tractiondrive,andstopengine.Lookbehindandtotheside

beforechangingdirections.Donotcarrypassengers.

2.Thrownobjecthazard—Donotoperatewhenpeopleandpets

areinthearea;pickupobjectsthatcouldbethrownbybroom.

5.Warning—Entanglementhazard—stayclearoftherotating

broom.Broombristleswillmeltorburn—keepawayfrom

extremeheatorame.Donotoperateonanyrooforother

elevatedsurface.

3.Warning—Wearhearingprotection.6.Warning—Donotoperateonslopesgreaterthan10degrees.

Useextremecautionwhenoperatingonslopes;operate

acrossslopesnotupanddown.

126–0017

1.Engagetheleft-turnlevertoturnleft.4.EngagethePTOlevertoactivatethePTO.

2.Engagethetraction-controllevertoactivatethetractiondrive.5.Engagetheright-turnlevertoturnright.

3.Engagethebroom-anglelevertoadjustthebroom.

decal126-0017

8

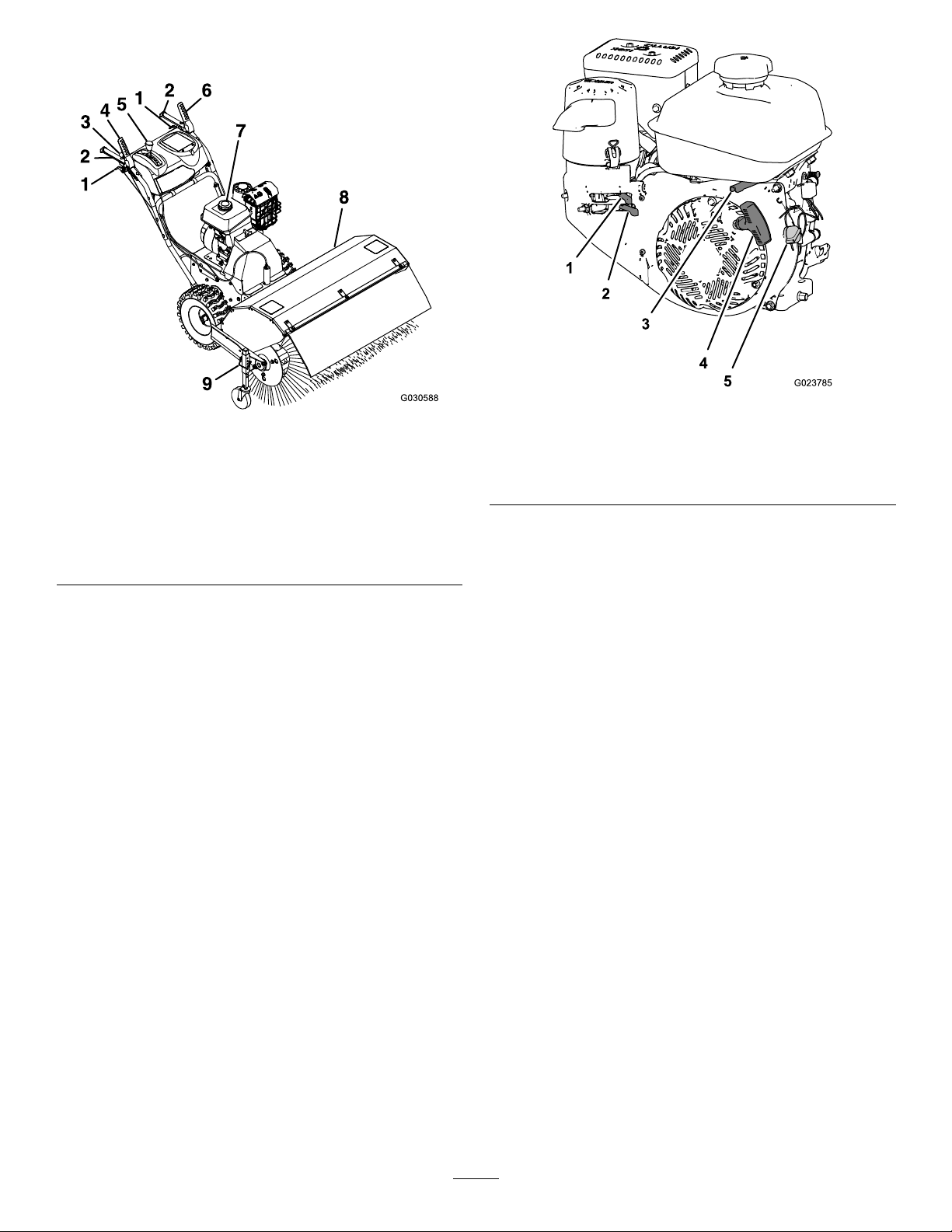

ProductOverview

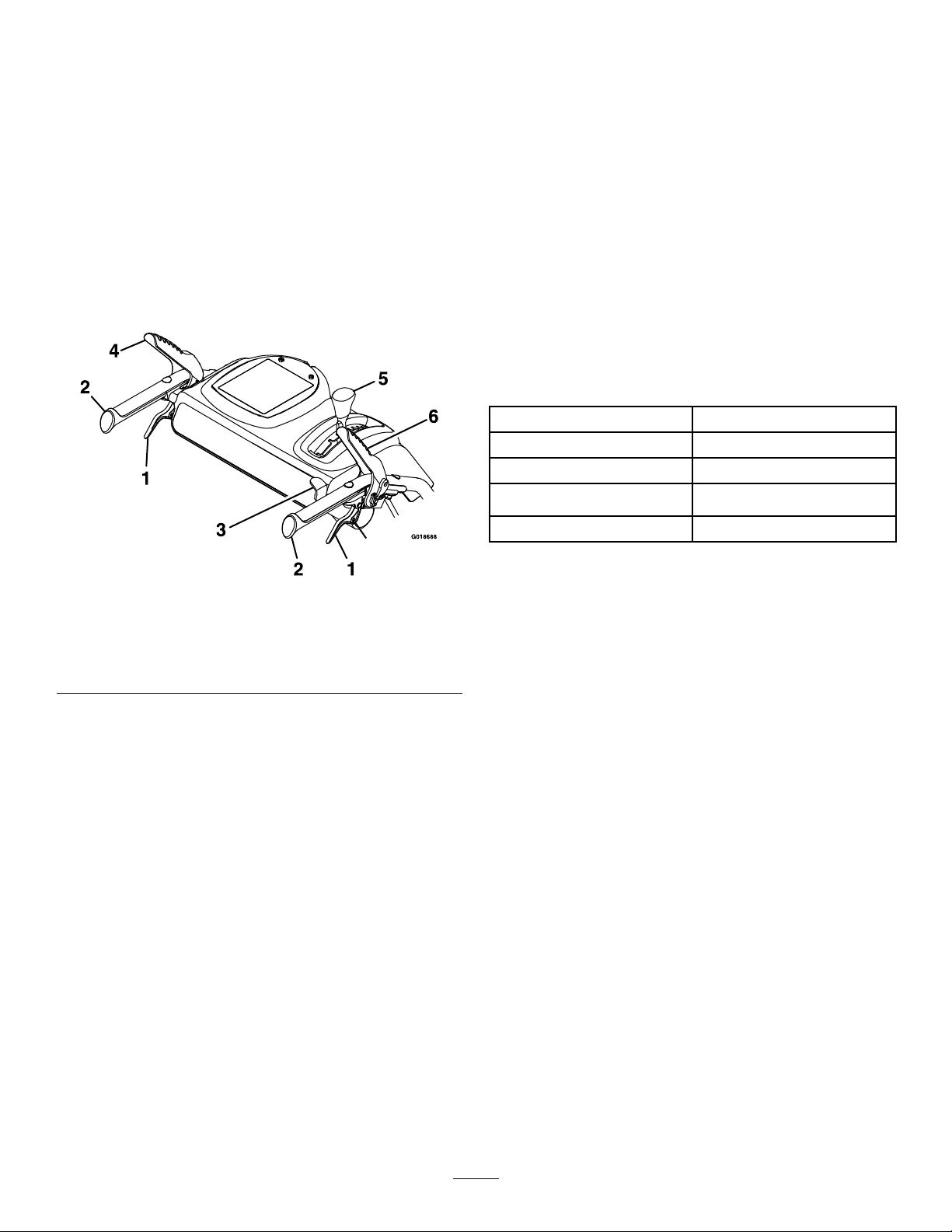

Figure4

1.Wheel-clutchlever6.Traction-drivelever

2.Handle7.Fuelcap

3.Broom-anglelever8.Broom

4.Broom-drivelever9.Broom-height-adjustment

pin

5.Speed-selectorlever

Controls

g023785

g030588

1.Chokecontrol

2.Fuel-shutoffvalve5.EngineOn/Offswitch

3.Throttlecontrol

Figure5

4.Engine-recoilhandle

Fuel-ShutoffValve

Usethefuel-shutoffvalvetoshutofftheowoffuelwhen

youwillnotusethemachineforafewdays,parkthemachine

insideabuilding,ortransportthemachinetoandfromthe

jobsite(Figure5).

Determinetheleftandrightsidesofthemachinefromthe

normaloperatingposition.

ChokeControl

Thechokecontrolisthetopleverlocatedontherear,left

sideoftheengineabovethefuel-shutoffvalve(Figure5).

Thechokeisusedtoaidinstartingacoldengine.Movethe

leverlefttotheONpositionforacoldstart.Donotruna

warmenginewiththechokeintheONposition.

Movethelevertothelefttoshutoffthefuel.Movethelever

totherighttoturnonthefuel.

ThrottleControl

Thethrottlecontrolislocatedontherear,rightsideofthe

engineandbelowthefueltank(Figure5).

Thethrottleisusedtocontrolenginespeed.Movingthe

throttlecontroltotheleftincreasestheenginespeed,and

movingitrightdecreasestheenginespeed.

EngineOn/OffSwitch

Locatedontherightsideoftheengine(Figure5).

RotatetheswitchclockwisetotheONpositionbeforestarting

theengine.RotatetheswitchcounterclockwisetotheOFF

positiontostoptheengine.

9

Wheel-ClutchLevers

Speed-SelectorLever

Thewheel-clutchleversarelocatedbelowtherightandleft

handles.

Thewheelclutchleversallowthedrivetomomentarily

disengageto1orbothwheelswiththetraction-drivelever

squeezed.Thisallowsforeasierturningandmaneuvering

themachine(Figure6).

Note:Squeezingbothwheelclutchleverssimultaneously

disengagesthedrivetobothwheels(free-wheeling).This

enablesyoutomanuallymovethemachinebackwardwithout

stoppingtoshiftitintoareversegear.Italsoallowsyouto

maneuverandtransportthemachinemoreeasilywhenthe

engineisnotrunning.

Thespeed-selectionleverislocatedonthemainconsole

panel(Figure6).

Thespeedselectorhas6forwardand2reversesettings.To

changespeeds,releasethetraction-drivelever,andshiftthe

speed-selectorlevertothedesiredsetting.Theleverlocksina

notchateachspeedsetting.

Broom-AngleLever

Thebroom-angleleverislocatedattherighthandle(Figure6).

Thebroom-anglelevercontrolstheanglelock.Thebroom

anglecanbelockedinto3positions:straightahead,orangled

totheleftorright19°.

Specications

Width

Length

Height

Weight

Enginespeed(noload)

118cm(46.5inches)

185.5cm(73inches)

105.5cm(41.5inches)

146.5kg(323lb)

Fullspeed:3600±100rpm

Figure6

1.Wheel-clutchlever4.Traction-drivelever

2.Handle

3.Broom-anglelever6.Broom-drivelever

5.Speed-selectorlever

Broom-DriveLever

Thebroom-driveleverislocatedabovetherighthandle

(Figure6).

Toengagethebroom,squeezethelevertothehandle.To

disengagethebroom,releasetherightlever.

Traction-DriveLever

Thetraction-driveleverislocatedabovethelefthandle

(Figure6).

Thetraction-drivelevercontrolstheforwardandreverse

motionofthemachine.Toengagethetractiondrive,squeeze

thelevertothehandle.

g018688

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

Note:Holdingdownthetraction-driveleveragainstthe

handleengagesthetractiondrivetobothwheels.

10

Operation

FuelingtheMachine

Fueltankcapacity:4.1L(1.0USgallon)

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

Important:Donotusefueladditivesotherthanafuel

stabilizer/conditioner.Donotusefuelstabilizerswithan

alcoholbasesuchasethanol,methanol,orisopropanol.

DANGER

Whenfueling,undercertaincircumstances,astatic

chargecandevelop,ignitingthegasoline.Areor

explosionfromgasolinecanburnyouandothers

anddamageproperty.

•Alwaysplacegasolinecontainersontheground

andawayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegasoline-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheround.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,notfromagasolinedispensernozzle.

•Ifyoumustuseagasolinedispensernozzle,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

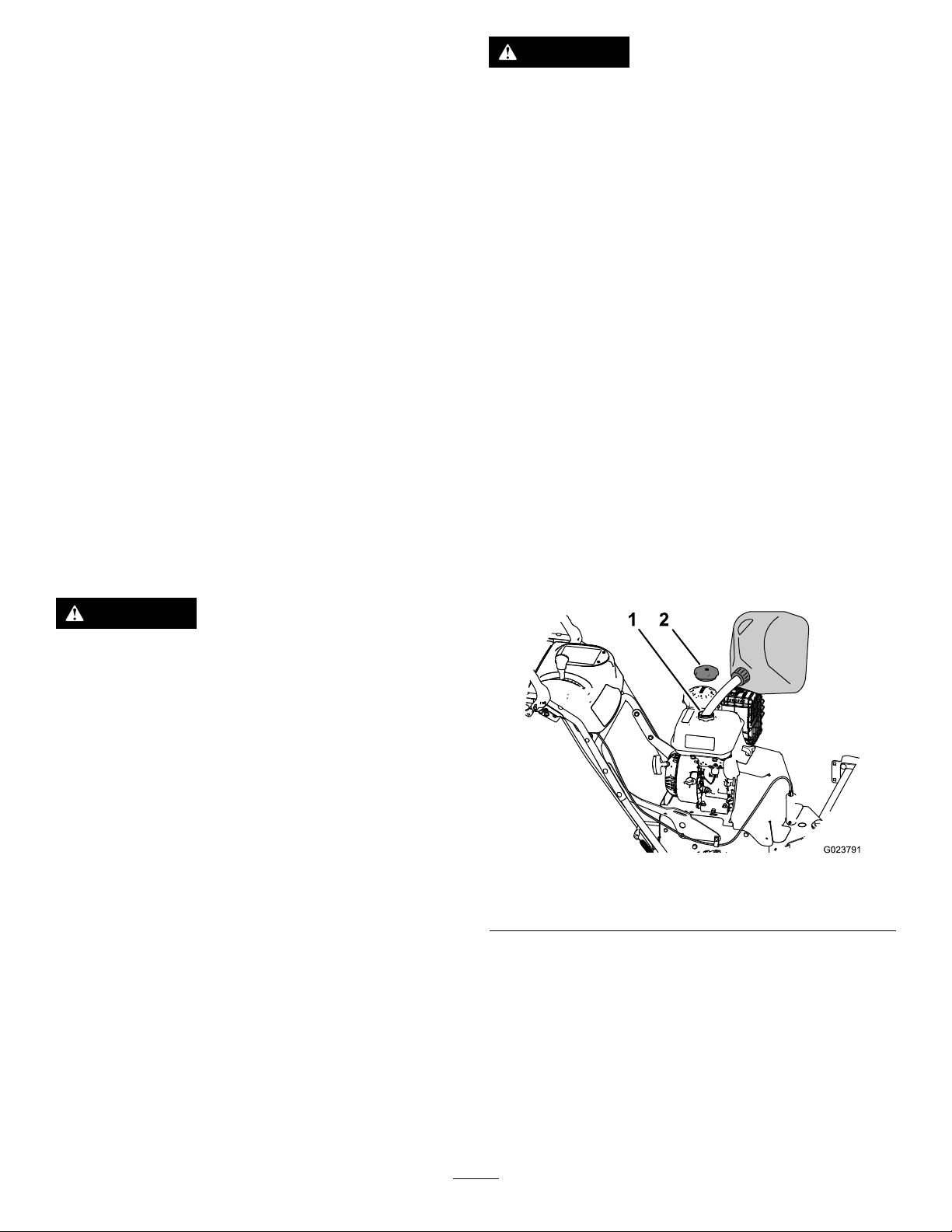

AddingFueltotheFuelTank

1.Cleanaroundthefuel-tankcap(Figure7).

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,and

whentheengineiscold.Wipeupanygasoline

thatspills.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

thegasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

•Storegasolineinanapprovedfuelcontainerand

keepitoutofthereachofchildren.

•Neverbuymorethana30-daysupplyof

gasoline.

g023791

Figure7

1.Fillerneck2.Fuel-tankcap

2.Removethecapfromthefueltank(Figure7).

3.Fillthefueltankwithunleadedgasolinetowithin6to

13mm(1/4to1/2inch)fromthetopofthetank.Do

notllintothellerneck.

Important:Donotllthetankmorethan6mm

(1/4inch)fromthetopofthetankbecausethe

gasolinemusthaveroomtoexpand.

4.Installthefuel-tankcapandwipeupanyspilled

gasoline(Figure7).

11

OperatingtheEngine

PositioningtheAir-CleanerCoverfor

ColdorWarmAirTemperature

Important:Runningtheenginewiththeair-cleaner

coverpositionedforcold-weatheroperationinnormal

conditionscandamagetheengine.

Theair-cleanercoverhas2positions:thecoldornormal,

ambientairpositions:

Adjusttheair-cleanercoverasfollows:

•Whenoperatinginacoldambientaircondition(cold

airtemperatureandhumidity)—positiontheair-cleaner

coverwithsnowakedecalfacingout(Figure8).

Note:Usethispositionifyourmachineexhibits

carburetoricing.Symptomsincludetheengineruns

roughatidleorlowspeed,anditdischargesblackor

whitesmokeintheexhaust.

•Whenoperatinginanormalambientair

condition—positiontheair-cleanercoverwithsundecal

facingout(Figure8).

Note:Usethispositionifyourmachineisnotexhibiting

carburetoricing.

OpeningtheFuel-ShutoffValve

Movethefuel-shutoffvalvelocatedbelowthechoke,tothe

righttoturnonfuel(Figure9).

g023826

Figure9

1.FUELONposition3.Choke

2.Fuel-shutoffvalve

StartingtheEngine

1.Ontherightsideoftheengine,rotatetheengine

On/OffswitchclockwisetotheONposition(Figure

10).

1.Normalambientair

position

Figure8

2.Coldambientairposition

g023827

g023829

Figure10

1.Engine-recoilhandle

2.Throttle

3.Engineswitch(OFF

position)

4.Engineswitch(ON

position)

2.Ontherear,leftsideoftheengine,movethechoke

levertothelefttotheONposition.Onawarmengine,

leavethechokeintheOFFposition(Figure9).

12

3.PlacethethrottlemidwaybetweentheSLOWandFAST

positionslocatedonrear,rightsideoftheengine

(Figure10).

4.Slowlypulltheengine-recoilhandleuntilyoufeel

resistanceandthenstop(Figure10).

Note:Allowtherecoilhandletoreturnandthen

sharplypullitstraightout.

Note:Allowtheropetoreturnslowly.

5.Allowtheenginetowarmupforseveralminutes,then

movethechoketowardtheOFFposition(Figure9).

StoppingtheEngine

1.Releasethebroom-driveleverandthetraction-drive

lever.

2.PlacethethrottlemidwaybetweentheSLOWandFAST

positions(Figure10).

3.Allowtheenginetorunforaminimumof15seconds,

thenturntheengineOn/OffswitchtotheOFF

positiontostoptheengine(Figure10).

4.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

g001012

Figure11

Note:Ifthegroundspeedistoofast,debrisorsnow

willpileupinfrontofthebroomcausingthebroom

tobulldozeinsteadofsweep.Thiscandamagethe

bristlesandthedriveline.

2.Slowlysqueezethelefttraction-drivelevertothe

handle(Figure12).

Note:Holdingdownthetraction-driveleveragainst

thehandleengagesthetractiondrivetobothwheels.

5.Usethefuel-shutoffvalvetoshutofftheowoffuel

whenyouwillnotusethemachineforafewdays,park

themachineinsideabuilding,ortransportthemachine

toandfromthejobsite(Figure9).

DrivingtheMachine

CAUTION

Ifthetractiondriveisnotproperlyadjusted,the

machinemaymoveinthedirectionoppositeof

whatyouintended,causinginjuryand/orproperty

damage.

Carefullycheckthetractiondriveandadjustit

properly,ifnecessary.

Important:Ifthemachinemoveswhenthetraction

leverisinthereleasedposition,checkthetractioncable;

refertoCheckingtheTractionCable(page23)and

AdjustingtheTractionCable(page23)orcontactyour

authorizedT orodealer.

g017789

Figure12

3.Tostopthetractiondrive,releasethetraction-drive

lever.

4.Tomoveforward,engagethetractiondriveandslowly

squeezethelefthandtractionlevertothehandle

(Figure13).

Note:Momentarilysqueezingandreleasingtheleftor

rightwheel-clutchleverallowsforsteeringadjustments

tokeepthemachinegoinginastraightline,especially

indeepsnow.

Note:Toturnright,liftupontherightwheel-clutch

leverandsqueezeittowardthehandle.Thisdisengages

thedrivetotherightwheel,whiletheleftwheel

continuesdriving,andthemachineturnstotheright.

DrivingForward

1.Placethespeedselectorlevertothedesiredforward

position,makingsurethatitlocksinthenotch(Figure

11).

13

OperatingtheBroom

DANGER

Whenthemachineisinoperation,contactwith

rotatingormovingpartswillseverelyinjurehands

andfeet.

Figure13

Note:Similarly,squeezingtheleftwheel-clutchlever

turnsthemachinetotheleft.

Note:Whenyoucompletetheturn,releasethe

wheel-clutchlever.Thedriveengagesbothwheels

(Figure14).

Figure14

5.Tostopthetractiondrive,releasethetraction-drive

lever.

DrivingtheMachineRearward

g001307

•Beforeadjusting,cleaning,inspecting,

troubleshooting,orrepairingthemachine,stop

theengineandwaitforallmovingpartstostop.

Disconnectthewirefromthesparkplugand

keepitawayfromtheplugtopreventsomeone

fromaccidentallystartingtheengine.

•Staybehindthehandlesandawayfromthe

broomwhileoperatingthemachine.

•Keepface,hands,feet,andanyotherpartof

yourbodyorclothingawayfromconcealed,

moving,orrotatingparts.

WARNING

Contactwitharotatingbroomcanresultin

g001308

seriouspersonalinjuryordeathtotheoperatoror

bystanders.

•Toremoveanobstructionfromthebroom;refer

toClearingaCloggedBroom(page16).

•Donotoperatethemachineifthebroomdrive

leverisnotfunctioningproperly.Contactyour

authorizedT orodealer.

1.Placethespeed-selectorleverintothedesired

reverse-speedrange,makingsurethatthespeed

selectorlocksinthenotch.

2.Tomoverearward,engagethetractiondriveandslowly

squeezethelefttractionlevertothehandle.

Note:Momentarilysqueezingandreleasingtheleftor

rightwheel-clutchleverallowsforsteeringadjustments

tokeepthemachinegoinginastraightline.

Note:Toturnright,squeezetherightwheel-clutch

levertowardthehandle.Thisdisengagesthedriveto

therightwheelwhiletheleftwheelcontinuesdriving,

andthemachineturnstotheright.

Note:Similarly,squeezingtheleftwheel-clutchlever

turnsthemachinetotheleft.

Note:Squeezingbothwheel-clutchleverssimultaneously

disengagesthedrivetobothwheels.Thisenablesyouto

movethemachinerearwardwithoutstoppingtoshiftitintoa

reversegear.Italsoallowsyoutomaneuverandtransportthe

machinemoreeasilywhentheengineisnotrunning.

WARNING

Therotatingbroomcanthrowstonesandother

foreignobjects,causingseriouspersonalinjuryto

theoperatorortobystanders.

•Keeptheworkingareaclearandfreeofall

objectsthatthebroomcouldpickupandthrow.

•Keepallchildrenandpetsawayfromthearea

ofoperation.

CAUTION

Whenthebroomisengaged,itmaydrivethe

machineinthereversedirection.Ifthebroom

heightisadjustedtoolow,themachinemaymove

moreforcefullyinthereversedirection,causing

injuryand/orpropertydamage.

Carefullycheckthebroomheightandadjustit

properlyorcontactyourauthorizedT orodealer.

1.SettheenginethrottletotheFastposition.

14

2.Placethespeedselectorleverintothedesiredposition

andslowlysqueezethelefthandtractiondrivelever.

Important:Makesurethatthetractiondriveis

engagedbeforeoperatingthebroom;otherwise,

thebroommaydrivethemachineinthereverse

direction.

3.Toengagethebroom,slowlysqueezetherightbroom

levertothehandle(Figure15).

g017922

Figure16

Figure15

•Iftheengineslowsdownunderaloadorthe

wheelsslip,shiftthemachineintoalowergear.

•Ifthefrontofthemachineridesup,shiftthe

machineintoalowergear.Ifthefrontcontinues

torideup,liftuponthehandles.

4.Tostopthebroom,releasetherightlever.

CheckingtheSweepingPath

Abroomsweepswiththetipsofitsbristles.Whenyouapply

toomuchdownwardpressure,thebroomnolongerusesits

tips;thebroomisnowworkingwiththesidesofthebristles.

Thislimitstheickingactionofthebristlesandsweeping

effectiveness,decreasingtheservicelifeofthebroom.

1.Drivetoaat,dustyareaandstopthemachine.

2.Withtheenginerunningmovethethrottlemidway

betweenSLOWANDFAST.

g001013

1.51to102mm(2to4

inches)maximumwidth

2.Lengthofbroom

3.Sweptarea

8.Adjustthebroomheight,ifnecessary.

AdjustingtheBroomHeight

1.Drivetoaat,dustyareaandstopthemachine.

2.Disengagethebroomandstoptheengine.

3.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

4.TurntheengineOn/OffswitchtotheOFFposition.

5.Toadjustthebroomheight,removeandretainthepin

fromtheadjustersleeveandwheeltubeofthecaster

(Figure17).

3.Engagethebroomandallowthebroomtosweepfor

approximately30seconds.

4.Disengagethebroomandstoptheengine.

5.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

6.TurntheengineOn/OffswitchtotheOFFposition.

7.Makesuretheareasweptequalsthelengthofthe

broomandamaximumwidthof51to102mm(2to

4inches).

1.Caster-wheeltube

2.Positionstoachieve3mm

(1/8inch)increments

15

g030413

Figure17

3.Pin

4.Adjustersleeve

6.Raiseorlowerthecasterwheeltubetoachievethe

sweepareaasstatedinCheckingtheSweepingPath

(page15).

UsingtheAlternateCaster Location

Note:Selectanyholecombinationthatisinalignment

toplaceandlatchtheretainingpin;matchthesame

positionontheotherside.

7.Fornetuningadjustments,slidetheadjustersleeve

1pinholeupordownonthecasterwheeltubeto

adjustthebroomheightin3mm(1/8inch)increments

(Figure17).Repeatsteps5through7fortheother

casterwheel.

•Toraisethebroomin3mm(1/8inch)increments,

slightlyraisetheadjustersleeveandinsertthepin

intothenextpinholebelowthecurrentholeused.

•Tolowerthebroomin3mm(1/8inch)increments,

slightlylowertheadjustersleeveandinsertthepin

intothenextpinholeabovethecurrentholeused.

8.Whenyouattainthedesiredheight,securethepinon

eachcasterwheel,andcheckthesweepingarea.

AdjustingtheBroomSide Angle

1.Disengagethebroomandstoptheengine.

Whenworkinginsnow ,mountthecastersbehindthebroom

bristles(Figure18).

Figure18

1.Hardware

2.Caster

ClearingaCloggedBroom

g030284

2.Waitforallmovingpartstostop.

3.Pushtheleverdownwiththethumbofyourrighthand

(Figure6).

4.Squeezetheleftwheel-clutchlevertothehandleand

pushthebroomhousingtothedesiredangle.

Note:Thebroomcanrotate19°totherightorleft,

orstraightahead.

5.Oncethebroomispositioned,releasethebroomangle

lever.

6.Releasetheleftwheel-clutchleverandmakesurethat

thebroomislockedintoplace.

WARNING

Therotatingbroomcouldcauseseriousinjury.

Shutoffthemachineandallowallrotatingpartsto

stopbeforecleaningthebroom.

•Ifthebroombecomesclogged,stayintheoperating

positionandreleasethelefttraction-drivelever.While

engagingthebroom,pushdownonthehandlestoraise

thefrontofthemachineafewcentimeters(inches)offthe

pavement.Thenliftthehandlesquicklytobumpthefront

ofthemachineonthepavement.Repeatifnecessary.

•Ifyoucannotunclogthebroombybumpingthefront

ofthemachine:

–Parkthemachineonlevelground.Stoptheengine,

waitforallmovingpartstostop,anddisconnectthe

spark-plugwire.

–Sharpobjectscanbecomeentangledinbristles.Use

glovesandcautionwhenremovingforeignobjects

fromthebroom;donotuseyourhands.

16

PreventingFreeze-up

•Insnowyandcoldconditions,somecontrolsandmoving

partsmayfreeze.Donotuseexcessiveforcewhen

tryingtooperatefrozencontrols.Ifyouhavedifculty

operatinganycontrolorpart,starttheengineandletit

runforafewminutes.

•Afterusingthemachine,lettheenginerunforafew

minutestopreventmovingpartsfromfreezing.Engage

thebroomtoclearanyremainingsnowfrominsidethe

housing.Stoptheengineandwaitforallmovingpartsto

stop,anddisconnectthespark-plugwire.Removeallice,

snow,orotherdebrisfromthemachine.

•Connectthespark-plugwire.Withtheengineswitchin

theOFFposition,pulltherecoil-starterhandleseveral

timestopreventtherecoilstarterfromfreezingup.

TransportingtheMachine

WARNING

Usingrampsthatarenotstrongenoughorproperly

supportedtoloadthemachineontothetransport

vehiclecouldbedangerous.Therampscould

collapse,causingthemachinetofall,whichcould

causeinjury.

•Useproperrampsthataresecuredtothetruck

ortrailer.

•Keepfeetandlegsoutfromunderthemachine

whenloadingandunloading.

PreparingtoTransporttheMachine

Performthefollowingbeforetransportingthemachine:

•Besurethatthefuel-shutoffvalveisclosed.

•Useaheavy-dutytrailertotransportthemachine.Place

themachineineitheraforwardorreversegear,then

blockthewheels.

•Securelyfastenthemachinetothetrailerwithstraps,

chains,cables,orropes.

•Besurethatthetrailerhasallthenecessarylightingand

markingasrequiredbylaw.

17

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst5hours

Beforeeachuseordaily

Every50hours

Every100hours

Every200hours

Every300hours

Yearly

Yearlyorbeforestorage

MaintenanceProcedure

•Checkthetractioncable.

•Checkthebroomcable.

•Changetheengineoil.

•Checktheengineoillevel.

•Checkthebroom-shaftshearpin.

•Checkforloosehardware.

•Cleanthefoampre-cleaner(morefrequentlyindustyconditions).

•Checkthetirepressure.

•Checktheconditionofthebelts.

•Lubricatethebroom-angle-lockpin.

•Changetheengineoil(morefrequentlyinsevereconditions).

•Checkthesparkplug.

•Replacethefoampre-cleaner.

•Replacethepaperairlter(morefrequentlyindustyconditions).

•Lubricatethehexshaft.

•Checkthetractioncable.

•Checkthebroomcable.

•Checktheairpressureinthedrivetiresandinatethemto116to137kPa(17

to20psi).

•Drainthegasolineandruntheenginetodryoutthefueltankandthecarburetorat

theendoftheseason.

•Haveanauthorizedservicedealerinspectandreplacethetraction-drivebelt,if

necessary.

Important:Youcanndmoreinformationaboutmaintainingandservicingyourmachineatwww.Toro.com.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.Forengineadjustments,

repairs,orwarrantyservicenotcoveredinthismanual,contacttheauthorizedengineservicedealer.

18

PreparingforMaintenance

1.Movethemachinetoalevelsurface.

2.Shutofftheengineandallowittocool.

3.Disconnectthespark-plugwirefromthesparkplug

andkeepthewireawayfromtheplug,toprevent

accidentalstarting(Figure19).

2.Removethebeltcoverandtheengineshield.

3.Movethespeed-selectorlevertotheR2position.

4.Dipalong,clean,small-tippedpaintbrushin

automotiveengineoilandlightlylubricatethehexshaft

(Figure21).

Important:Donotgetoilontherubberwheelor

thealuminumfriction-driveplateasthetraction

drivewillslip(Figure21).

Note:Rockthemachineforwardandrearwardto

rotatethehexshaft.

Figure19

1.Spark-plugwire

Lubrication

LubricatingtheBroom-Angle-LockPin

andtheHexShaft

ServiceInterval:Every100hours

Yearly

1.Lubricatethebroom-angle-lockpinttingwithNo.2

lithiumgrease(Figure20).

g023810

Figure21

1.Aluminumfriction-drive

plate

2.Hexshaft

g019054

5.Movethespeedselectorlevertoposition6.

6.Lubricatetheotherendofthehexshaft.

7.Movethespeedselectorleverforwardandrearward

afewtimes.

8.Installthebeltcoverandtheengineshield.

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Every50hours—Cleanthefoam

pre-cleaner(morefrequentlyindusty

conditions).

Every200hours—Replacethefoampre-cleaner.

Every300hours—Replacethepaperairlter(more

frequentlyindustyconditions).

1.Broom-angle-lockpin

Figure20

Important:Donotoperatetheenginewithouttheair

lterassembly;extremeenginedamagemayoccur.

1.Releasethelatchesonthecoverfortheaircleaner.

2.Removethecoverandcleanitthoroughly(Figure22).

g030414

Note:Becarefultopreventdirtanddebrisfrom

fallingintothebase.

19

Figure22

G023796

1.Air-lterbase4.Cover

2.Paperairlter

3.Foampre-cleaner

5.Latchontheair-cleaner

cover(2)

3.Removethefoampre-cleaner,washitwithamild

detergentandwater,andthenblotitdry(Figure22).

4.Removeandinspectthepaperairlter(Figure22);

discarditifitisexcessivelydirty.

Important:Donottrytocleanapaperlter.

5.Wipedirtawayfromthebaseandthecoverwitha

moistrag.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

6.Installthefoampre-cleanerontothepaperairlter

(Figure22).

g023809

Figure23

1.Alignment-arrowdecal(normalambientairpositionshown)

9.Securetheair-ltercovertothebasewiththelatches.

g023795

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

EngineOilType:Toro4–CyclePremiumEngineOil

Usehigh-qualitydetergentoils(includingsynthetic)ofAPI

(AmericanPetroleumInstitute)serviceclassSJorhigher.

Selecttheviscositybasedontheairtemperatureattimeof

operationasshowninthetablebelow .

g023796

Figure24

Note:Useanewpaperairlterifyoudiscardedthe

oldone.

7.Installtheairlterassemblytotheair-lterbase

(Figure22).

8.Alignthearrowdecalontheair-cleanercoverandthe

arrowdecalonthebase(Figure23).

Checktheoillevelwhentheengineiscold.

1.Cleantheareaaroundthedipstick.

2.Removethedipstickandreadtheoillevel(Figure25).

20

Figure25

ChangingtheEngineOil

ServiceInterval:Aftertherst5hours

Every100hours(morefrequentlyinsevere

conditions).

Oilcapacity:0.60L(0.63qt)

Note:Draintheengineoilwhiletheengineiswarm.

1.Placeapanunderdrainttingandremovetheoil-drain

cap(Figure26).

g023794

1.Fillerneck2.Dipstick

3.Removethedipstickandwipeofftheoilwithaclean

rag.

4.Insertthedipstickintothellerneck,restitontheoil

llerneck,andturnitcounterclockwiseuntilthecap

dropsdowntolowestpointofthethreadleads.

Note:Donotthreadthecapontothetube.

5.Removedipstickandcheckoillevel.

Note:Donotoperatetheenginewiththeoillevel

belowtheAddmarkorabovetheFullmarkonthe

dipstick.

Note:Theoillevelshouldbeattopoftheindicator

onthedipstick(Figure25).

•Iftheoillevelislow ,performthefollowing:

A.Pourthespeciedoilintothellerneck

(Figure25).

Note:Donotoverlltheenginewithoil.

B.Repeatsteps3through5.

•Iftheoillevelishigh,preformthefollowing:

A.Removethecapfromthedraintting.

B.Draintheoiluntiltheoillevelisatthetopof

theindicatorondipstick;refertosteps1of

ChangingtheEngineOil(page21).

C.Installthecapontothedraintting;referto

step2ofChangingtheEngineOil(page21).

6.Insertthedipstickintothellerneckandtightenthe

dipstickbyhand.

Figure26

1.Draintting

2.Cap

3.Drainpan

2.Allowtheoiltodrainandtheninstalltheoil-draincap.

3.Cleanaroundthellerneckandremovethedipstick.

4.Filltothespeciedcapacitywiththespeciedoiland

replacethedipstick;refertoCheckingtheEngine-Oil

Level(page20).

Note:Donotoverlltheenginewithoil.

5.Wipeupanyspilledoil.

6.Starttheengineandcheckforleaks.

7.Stoptheengineandchecktheoillevel;referto

CheckingtheEngine-OilLevel(page20).

g023792

21

CheckingtheSparkPlug

G019300

1 2

4

3

ServiceInterval:Every100hours

Sparkplugtype:Champion®RC12YC,Kohler®12132

02-S,orKoher2513214-S(RFIcompliant)

Spark-pluggap:0.76mm(0.030inch)

1.Disconnectthespark-plugwirefromtheterminalof

thesparkplug(Figure19).

2.Cleantheareaaroundthebaseofthesparkplug.

3.Removethesparkplugfromthecylinderheadby

rotatingtheplugcounterclockwise.

4.Examinetheplugforwearanddamage(Figure27).

Important:Replaceacracked,fouled,ordirty

sparkplug.Donotcleantheelectrodes,because

gritenteringthecylindercandamagetheengine.

FuelSystemMaintenance

DrainingtheFuelSystem

1.Locatethedrainboltthatisinthesideportofthe

carburetorbowl(Figure28).

Figure27

1.Groundelectrode

2.Centerelectrode4.Spark-pluggap0.76mm

3.Insulator

(0.030inch)

5.Checkthespark-pluggapwithawiregauge(Figure27).

Note:Ifnecessary,adjustthegapto0.76mm(0.030

inch)bycarefullybendingthegroundelectrode.

6.Installthesparkplugbythreadingitintothecylinder

headandtorquingtheplugto20N-m(14lb-ft).

7.Connectthespark-plugwiretotheterminalofthe

sparkplug.

g023828

Figure28

g019300

1.Bowl-retainingscrew2.Drainbolt

2.Aligntheequipmentthatyouwillusetocollectthefuel

beneaththedrainscrew .

3.Removethedrainscrewfromthecarburetorandallow

thefueltodrainfromthefueltankandthecarburetor.

Note:Donotremovethebowl-retainingscrewfrom

carburetor.

22

Figure30

3

g019016

g001568

Figure29

1.Sideportofthecarburetor

bowl

2.Drainbolt

4.Installthedrainboltintothesideportofthecarburetor.

DriveSystemMaintenance

CheckingtheTirePressure

ServiceInterval:Every50hours

1.Turnofftheengine,waitforallmovingpartstostop,

andleaveengineswitchintheOFFposition.

2.Checkthetirepressureinthedrivetires.

1.Pin

2.6mm(1/4inch)

AdjustingtheTractionCable

g023831

Ifthemachinedoesnotdriveintheforwardorreversespeeds

oritdriveswhenyoureleasethetractionlever,adjustthe

tractioncable.

Withthetractionleverdisengaged,checkthepininthe

elongatedslotintheleftsideofthemachineabovethetire.

Thereshouldbeagapof6mm(1/4inch)fromthefront

oftheslottothefrontedgeofthepin;refertoChecking

theTractionCable(page23).

Ifthelefttractioncableisnotproperlyadjusted,dothe

followingsteps:

1.Loosenthejamnut(Figure31).

2.Loosenortightentheturnbuckletoadjustthepinuntil

itisthepropergapfromthefrontedgeoftheslot

(Figure31).

3.Tightenthejamnut(Figure31).

3.Inatethedrivetiresto117to138kPa(17to20psi).

CheckingtheTractionCable

ServiceInterval:Aftertherst2hours

Yearly

1.Turnofftheengine,waitforallmovingpartstostop,

anddisconnectthespark-plugwire.

2.Withthetractionleverdisengaged,checkthepinin

theelongatedslotintheleftsideofthemachineabove

thetire(Figure30).

Note:Thereshouldbeagapof6mm(1/4inch)

fromthefrontoftheslottothefrontedgeofthepin

(Figure30).

Note:Ifadjustmentisnecessary,refertoAdjusting

theTractionCable(page23).

g019016

Figure31

1.Jamnut2.Turnbuckle

AdjustingtheWheel-ClutchCable

1.Squeezetheleverfully,thencheckthegapbetweenthe

bottomofthehandleandthewheel-clutchleverend

(Figure32).

23

Figure32

Note:Thegapshouldbeapproximatelythethickness

ofapencil(6mmor1/4inch).Ifitisgreater,loosen

thecableclampnut,slidethecablejacketupslightly,

tightenthecableclampnut,andcheckthegapagain.

2.Repeatfortheothercable(Figure32).

BroomMaintenance

g001306

CheckingtheBroom-ShaftShearPin

ServiceInterval:Beforeeachuseordaily

1.Movethemachinetoalevelsurface.

2.Turnofftheengine,waitforallmovingpartstostop,

anddisconnectthespark-plugwire.

3.Checktheshearpinlocatedonthebroomshafton

eithersideofthegearbox.

Figure33

1.Nut

2.Shearpin

g023811

Figure34

1.Broomsupport4.Endbearing

2.Locknut

3.Washer

5.Carriagebolt

3.Manuallypullthepowerunitrearwardtoremovethe

broomassemblyfromthemachine.

4.Supportthesplineshaftoneithersideofthegearbox.

5.Standthebroomcoreassemblyonendsothattheend

retainerplatefacesupward(Figure35).

g019073

4.Iftheshearpinisdamaged,removethepin,replaceit,

andsecuretheitwithanut.

ReplacingWornorDamagedBroom

Segments

ServiceInterval:Asrequired.

1.Raisethebroombysettingthecasterpositions.

2.Onbothsidesofthemachine,removeandretainthe

carriagebolts,washers,andlocknutsthatsecurethe

endbearingstothebroomsupport.

1.Hardware

2.End-retainerplate

3.Broomsegment

6.Removeandretainthehardwarefromtheend-retainer

plate(Figure35).

24

g018760

Figure35

4.Supportshaft

5.Alignmentngers

7.Removethedamagedbroomsegment(s).

AdjustingtheBroomDrive

8.Installthenewsegment(s)bystaggeringthemetalring

alignmentngersasshowninFigure35.

Important:Y oumaydamagethebroomassembly

ifyoudonotproperlyinstallthebroomsegments.

9.Installthebroomassemblyontothemachine.

Important:Makesurethatthebearingsetscrews

aretightenedbeforeoperatingthebroom.

CheckingtheBroomCable

ServiceInterval:Aftertherst2hours

Yearly

1.Turnofftheengine,waitforallmovingpartstostop,

anddisconnectthespark-plugwire.

2.Removethebeltcoverandengineshield.

3.Withthebroomleverdisengaged,ensurethegap

betweenthebroom-clutchassemblyandthetabis3.2

mm(1/8inch).

Note:Ifthebroomisnotproperlyadjusted,referto

AdjustingtheBroomDrive(page25).

Ifthebroomcableisnotproperlyadjusted;refertoChecking

theBroomCable(page25),andthenperformthefollowing

steps:

1.Loosenthejamnut(Figure37).

g001024

Figure37

1.Jamnut2.Turnbuckle

1.Broom-clutchassembly

2.Tab

2.Loosenortightentheturnbucklethatadjuststhe

tensiononthecable(Figure37).

3.Adjusttheturnbuckleuntilthegapbetweenthebroom

clutchassemblyandthetabis3.2mm(1/8inch)

(Figure36).

4.Tightenthejamnut.

5.Ifthebroomcableisproperlyadjustedbutaproblem

remains,contactyourAuthorizedToroServiceDealer.

g019072

Figure36

3.3.2mm(1/8inch)

25

MaintainingtheBelts

CheckingtheConditionoftheBelts

ServiceInterval:Every50hours

1.Removetheknobandwasherthatsecurestheengine

coverandthebeltcovertothemachine(Figure38).

g023815

Figure39

Figure38

1.Knob4.Platenut

2.Washer5.Beltcover

3.Enginecover

2.Checkthe2beltsfordamageorwear.

Note:Replaceanydamagedorexcessivelyworn

belt(s).

3.Alignthebeltcoverandtheenginecovertothe

machineandtheplatenut(Figure38).

4.Securethebeltcoverandtheenginecovertothe

machinewiththeknobandwasher(Figure38).

1.Spacer

2.Pulleyshield5.Bolt

3.Beltguide

4.Washer

3.Slipthebeltforwardovertheforwardgrooveofthe

enginepulley(Figure40).

g023812

g023819

Figure40

RemovingtheBroom-DriveBelt

1.Removetheenginecoverandthebeltcoverfromthe

machine;refertostep1ofCheckingtheConditionof

theBelts(page26).

2.Removethe2boltsand2washersthatsecurethebelt

guidetothemachine,andremovethebeltguideand

thespacer(Figure39).

Note:Thespacerislocatedbetweentheengineand

thepulleyshield.

1.Enginepulley3.Broom-gearboxpulley

2.Broomdrivebelt4.Traction-controlbracket

4.Slipthebeltoffofthebroom-gearboxpulley,

movethebeltrearwardbetweenthepulleyandthe

traction-controlbracket,andremovethebeltfromthe

machine(Figure40).

InstallingtheBroom-DriveBelt

1.Alignthereplacementbeltbetweenthepulleyandthe

traction-controlbracket(Figure40).

2.Slipthebeltontothegrooveatthebottomofthe

broom-gearboxpulley(Figure40).

26

3.Slipthebeltontotheforwardgrooveoftheengine

pulley(Figure40).

Note:Ensurethatthebeltisnottwisted.

4.Alignthespacerbetweentheengineandthepulley

shinedandaligntheholesinthespacer,engine,and

shield(Figure39).

5.Securethepulleyguidetothemachinewiththebolts

andwashers(Figure39)thatyouremovedinstep2of

RemovingtheBroom-DriveBelt(page26).

RemovingtheTractionBelt

1.Removethebroom-drivebelt;refertoRemovingthe

Broom-DriveBelt(page26).

2.Removethehairpinfromthetraction-controlrod

(Figure41).

Figure42

1.Tensionpulley4.Tractionpulley

2.Reargroove(engine

pulley)

3.Tractionbelt

5.Traction-controlbracket

5.Pullthetensionpulleyoutward(Figure42).

6.Slipthetractionbeltoutofthegrooveofthetraction

pulleyandupbetweenthepulleyandthefrictionwheel

(Figure43).

g023817

Figure41

1.Hairpin3.Traction-controlbracket

2.Traction-controlrod

3.Removetraction-controlrodfromthetraction-control

bracketbymovingtherodinward(Figure41).

4.Pivotthetraction-controlbracketandtractionpulley

forward(Figure42).

g023818

g023820

Figure43

1.Tractionpulley3.Frictionwheel

2.Belt

7.Slipthebeltoffthereargrooveoftheenginepulley

andremovethebeltfromthemachine(Figure42).

27

InstallingtheTractionBelt

1.Alignthetractionbeltbetweenthefrictionwheeland

thetractionpulley(Figure43).

2.Alignthebeltintothegrooveatthebottomofthe

tractionpulley(Figure42).

3.Pullthetensionpulleyoutward(Figure42).

4.Alignthebeltintothereargrooveoftheenginepulley

(Figure42).

Note:Releasethetensionpulley.

5.Movethetraction-controlbracketrearwardandalign

theholeinthebracketwiththetraction-controlrod

(Figure41).

6.Sliptherodthroughthebracketandsecuretherod

withthehairpin(Figure41).

7.Installthebroom-drivebelt;refertoInstallingthe

Broom-DriveBelt(page26).

8.Installtheenginecoverandthebeltcover;refertostep

1ofCheckingtheConditionoftheBelts(page26).

MaintainingtheChassis

CheckingforLooseHardware

ServiceInterval:Beforeeachuseordaily

1.Visuallyinspectthemachineforanyloosemissing

hardwareoranyotherpossibleproblem.

2.Tightenallloosehardwarebeforeoperatingthe

machine.

3.Replaceallmissinghardwarebeforeoperatingthe

machine.

28

Storage

WARNING

Gasolinefumesarehighlyammable,explosive,

anddangerousifinhaled.Ifyoustorethemachine

inanareawithanopename,thegasolinefumes

mayigniteandcauseanexplosion.

•Donotstorethemachineinahouse(living

area),basement,oranyotherareawhereignition

sourcesmaybepresent,suchashotwaterand

spaceheaters,clothesdryers,furnaces,and

otherlikeappliances.

•Donottipthemachinebackwardwithfuelin

thetank;otherwise,fuelmayleakoutofthe

machine.

15.Cleanthemachinethoroughly.

16.Touchupchippedsurfaceswithpaintavailablefroman

AuthorizedToroServiceDealer.Sandaffectedareas

beforepainting,andusearustpreventativetoprevent

themetalpartsfromrusting.

17.Tightenallloosescrews,bolts,andlocknuts.Repairor

replaceanydamagedparts.

18.Coverthemachineandstoreitinaclean,dryplace

outofthereachofchildren.Allowtheenginetocool

beforestoringitinanyenclosure.

RemovingtheMachinefrom Storage

1.Removethesparkplugandspintheenginerapidly

usingthestartertoblowtheexcessoilfromthe

cylinder.

PreparingtheMachinefor Storage

1.Supporttheframe,sothebristlesarenottouching

theground.

Note:Thebristleswillbecomedeformedandthe

broomwillbeoutofalignmentifthebristlesare

touchingthegroundforanextendedperiodoftime.

2.Keepthebroomawayfromsunlight,weather,and

temperaturechangestopreventbrittleness.

3.Thoroughlycleanthebroomandensurethatitisfree

ofallcausticchemicalsand/orresidue.

4.Onthelastrefuelingoftheyear,addfuelstabilizerto

freshfuel.

5.Addthetreatedfueltothemachineandruntheengine

for10minutes.

6.Drainthefuelfromthefuelsystem;refertoDraining

theFuelSystem(page22).

7.Runthemachineuntiltheenginestopsfromrunning

outoffuel.

8.Primetheengineandstartitagain.

2.Installthesparkplugbyhandandthentorqueitto

20.4N-m(15ft-lb).

3.Connectthespark-plugwire.

4.Performtheannualmaintenanceproceduresasgiven

intheRecommendedMaintenanceSchedule;referto

Maintenance(page18).

9.Allowtheenginetorununtilitstops.

10.Allowittocool.

11.Disconnectthespark-plugwire.

12.Removethesparkplug,add30ml(1oz)ofengineoil

throughthespark-plughole,andpullthestarterrope

slowlyseveraltimes.

13.Looselyinstallthesparkplug.

14.Disposeofanyunusedfuelproperly.Recycleit

accordingtolocalcodes,oruseitinyourautomobile.

Note:Donotstorestabilizedfuelformorethan

90days.

29

Troubleshooting

Problem

Theenginedoesnotstart,startshard,or

failstokeeprunning.

Theenginelosespower.

PossibleCauseCorrectiveAction

1.Thefueltankisempty.1.Fillthefueltank.

2.Thefuel-shutoffvalveisclosed.2.Openthefuel-shutoffvalve.

3.Thethrottleandchokearenotinthe

correctposition.

4.Thereisdirtinfuelvalve.4.Cleanthefuel-valvescreenandcup.

5.Thefuel-capventisblocked.5.Cleanthefuel-capvent.

6.Dirt,water,orstalefuelisinthefuel

system.

7.Theaircleanerisdirty.

8.Thesparkplugisfaulty.8.Clean,adjustorreplacethesparkplug.

9.Thespark-plugwireisnotconnected.

1.Theengineloadisexcessive.1.Reducethegroundspeedoradjust

2.Theaircleanerisdirty.

3.Theoillevelinthecrankcaseis

incorrect.

4.Thereisdirtinfueltanklter.4.Cleanthefuel-tanklter.

5.Dirt,water,orstalefuelisinthefuel

system.

3.Besurethethrottlecontrolismidway

betweentheSlowandFastpositions,

andthechokeisintheOnpositionfor

acoldengineortheOffpositionfora

warmengine.

6.Contactanauthorizedengineservice

dealer.

7.Cleanorreplacetheaircleaner

element.

9.Checkthespark-plugwireconnection.

thebroom.

2.Cleanorreplacetheaircleaner

element.

3.Checktheoillevelinthecrankcase.

5.Contactanauthorizedengineservice

dealer.

Thebroomdoesnotcleanthesurface.

Thebroomdoesnotrotate.

Themachinepullsleftorright.

Thereisabnormalvibration.

1.Thebroomheightisincorrect.1.Adjustthebroomheight.

2.Thetirepressureinthedrivetiresis

notcorrect.

3.Youarecleaningtoomuchdebrisat

onetime.

1.Thebroomisclogged.1.Unclogthebroom.

2.Thebroomdriveleverisnotengaged.2.Engagethebroomdrivelever.

3.Thebroomdrivebeltisslipping.3.Adjustorreplacethebelt.

4.Thebeltisbroken.4.Replacethebelt.

5.Theshearpinisbroken.5.Replacetheshearpin.

1.Thetirepressureinthedrivetiresis

notcorrect.

1.Thedrivebeltisworn,looseorbroken.1.Installanewbelt. Themachinedoesnotdrive.

2.Thedrivebeltisoffapulley.

1.Thebroomassemblyislooseor

damaged.

2.Theenginemountingboltsareloose.2.Tightentheengine-mountingbolts.

3.Theenginepulleyoridlerpulleyis

loose.

4.Theenginepulleyisdamaged.

5.Thebeltisdamaged.5.Installanewbelt.

2.Adjustthetirepressureinthedrive

tires.

3.Slowdownandclearsmallerareasof

debris.

1.Adjustthetirepressureinthedrive

tires.

2.Replaceoradjustthebelt.

1.Tightenthehardware,replacethe

broomassembly,orcontactan

AuthorizedToroServicedealer.

3.Tightentheappropriatepulley .

4.ContactanAuthorizedT oroService

dealer.

Thebroomdoesnotstopwhenthedrive

leverisreleased.

1.Thebroom-drivebeltisoutof

adjustment.

30

1.Checkthebroom-driveadjustment.

Problem

PossibleCauseCorrectiveAction

Thebroomwearsoutprematurely .1.Youareusingtheincorrectbroom

Thespeedselectorisdifculttomoveor

frozeninplace.

height.

1.Thehexshaftneedslubrication.1.Lubricatethehexshaft.

1.Adjustthebroomheight.

31

Notes:

Notes:

Notes:

EuropeanPrivacyNotice

TheInformationToroCollects

ToroWarrantyCompany(T oro)respectsyourprivacy .Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer .

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.ToromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw .

Toro'sCommitmenttoSecurityofY ourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oroDealer.

374-0282RevC

Alimitedwarranty(seewarrantyperiodsbelow)

TheToroWarranty

TurfRenovation

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroW arrantyCompany ,pursuanttoan

agreementbetweenthem,jointlywarrantyourToroProductslistedbelowto

befreefromdefectsinmaterialsorworkmanship.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromtheoriginaldateofpurchase:

ProductsWarrantyPeriod

Walk-BehindAerator1year

1

•Engine

Stand-OnAerator

•Battery90daysPartsandLabor

1

•Engine

Dethatcher1year

1

•Engine

TurfSeeder

1

•Engine

1

•Engine

Stand-OnSpreaderSprayer

•Battery90daysPartsandLabor

1

•Engine

Walk-BehindRotaryBroom1year

1

•Engine

BrushCutter

1

•Engine

Whereawarrantableconditionexists,wewillrepairtheProductatnocost

toyouincludingdiagnosis,labor,andparts.

1

SomeenginesusedonT oroProductsarewarrantedbytheengine

manufacturer.

2years

1year

1yearPartsOnly

2years

2years

1year

Honda–2years

Subaru–5years

1year

1yearPartsOnly

5years

2years

1year

2years

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure

1.ContactanyAuthorizedServicingOutlettoarrangeserviceattheir

dealership.T olocateoneconvenienttoyou,accessourwebsiteat

www.T oro.com.Select“WheretoBuy”andselect“Contractor”under

producttype.Y oumayalsocallourtollfreenumberbelow.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothem.

3.IfforanyreasonyouaredissatisedwiththeServiceOutlet’sanalysis

orwiththeassistanceprovided,contactusat:

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

TollFree:888-384-9939

**

ToroAuthorizedRentalCustomerswhohavepurchasedproductsdirectlyfromT oroandhave

signedtheT oroRentalCustomerAgreementhavetheabilitytoperformtheirownwarrantywork.

PleasevisitT oro’sRentalPortalforelectronicwarrantyclamlingproceduresorcallthetollfree

numberabove.

**

:

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutinemaintenance,

whetherperformedbyadealerorbyyou,isatyourexpense.Parts

scheduledforreplacementasrequiredmaintenance(“MaintenanceParts”),

arewarrantedfortheperiodoftimeuptothescheduledreplacementtime

forthatpart.Failuretoperformrequiredmaintenanceandadjustmentscan

begroundsfordisallowingawarrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarrantyperiod

aredefectsinmaterialsorworkmanship.Thisexpresswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfrominstallationanduseofadd-on,

modied,orunapprovedaccessories

•Failuretoperformrequiredmaintenanceand/oradjustments

•Repairsnecessaryduetofailuretofollowrecommendedfuel

procedure(consultOperator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontains

morethan10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

•Productfailureswhichresultfromoperatingtheproductinanabusive,

negligent,orrecklessmanner

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,include,belts,cutters,

clutches,blades,teeth,sparkplugs,tires,lters,etc.

•Failurescausedbyoutsideinuenceinclude,weather,storage,

contamination,lubricants,additives,orchemicals,etc.

•Normal“wearandtear”itemsincudespaintedsurfacesandscratched

decals,etc.

•Anycomponentcoveredbyaseparatemanufacturer’swarranty

•Pickupanddeliverycharges

GeneralConditions

RepairbyanAuthorizedServicingOutletorSelf-ServiceasanAuthorized

RentalCustomerisyoursoleremedyunderthewarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthiswarranty .Allimpliedwarrantiesofmerchantability

andtnessforusearelimitedtothedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

ExceptfortheenginewarrantycoverageandtheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .The

EmissionsControlSystemonyourProductmaybecoveredbyaseparate

warrantymeetingrequirementsestablishedbytheU.S.Environmental

ProtectionAgency(EPA)ortheCaliforniaAirResourcesBoard(CARB).

RefertotheCaliforniaEmissionControlWarrantyStatementsuppliedwith

yourProductorcontainedintheenginemanufacturer’sdocumentationfor

details.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguarantee

policiesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguarantee

information,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oro

Dealer.

374-0289RevF

Loading...

Loading...