Page 1

722PowerThrow

ModelNo.38608—SerialNo.311000001andUp

®

Snowthrower

FormNo.3365-707RevA

Operator'sManual

Introduction

Thismachineisintendedtobeusedbyresidential

homeownersorprofessional,hiredoperators.It

isdesignedprimarilyforremovingsnowfrom

pavedsurfaces,suchasdrivewaysandsidewalks,

andothersurfacesfortrafconresidentialor

commercialproperties.Itisnotdesignedfor

removingmaterialsotherthansnow,norisit

designedforclearingoffgravelsurfaces.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourmachineproperlyandtoavoidinjury

andmachinedamage.Youareresponsibleforoperating

themachineproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

machineandaccessoryinformation,helpndinga

dealer,ortoregisteryourmachine.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourmachineready .

identiesthelocationofthemodelandserialnumbers

onthemachine.Writethenumbersinthespace

provided.

Figure1

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

ReplacementEngineOwner’sManualsmaybe

orderedthroughtheenginemanufacturer.

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

©2010—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

Page 2

Safety

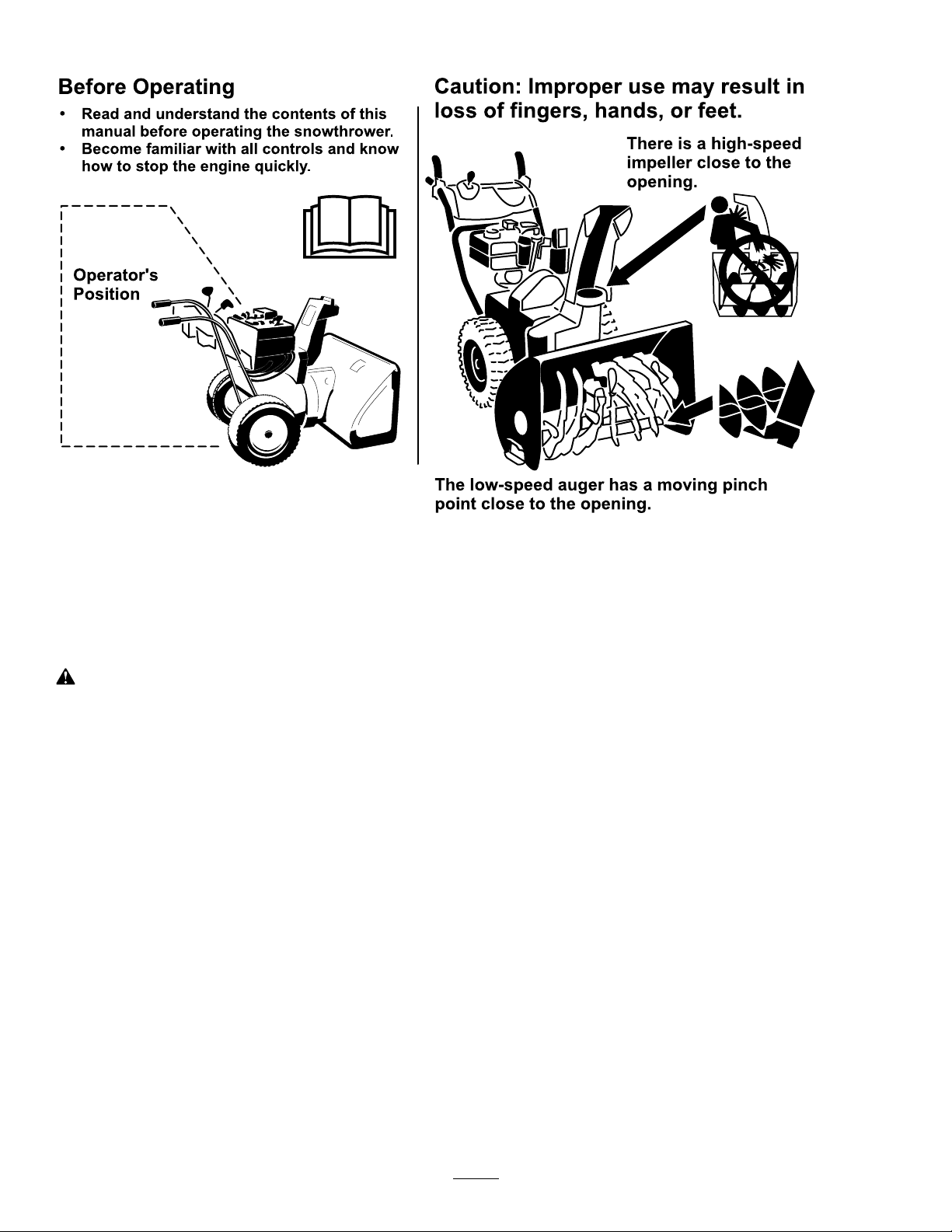

BeforeOperating

?

?

Readandunderstandthecontentsofthis

manualbeforeoperatingthesnowthrower .

Becomefamiliarwithallcontrolsandknow

howtostoptheenginequickly .

Operator 's

Position

Thelow-speedaugerhasamovingpinch

pointclosetotheopening.

Caution:Improperusemayresultin

lossoffingers,hands,orfeet.

Thereisahigh-speed

impellerclosetothe

opening.

ThismachinemeetsorexceedstheB71.3

specicationsoftheAmericanNationalStandards

Instituteineffectatthetimeofproduction.

Readandunderstandthecontentsofthismanual

beforeyoustarttheengine.

Thisisthesafetyalertsymbol.Itisusedtoalert

youtopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollowthissymboltoavoid

possibleinjuryordeath.

Improperlyusingormaintainingthismachine

couldresultininjuryordeath.Toreducethis

potential,complywiththefollowingsafety

instructions.

Thismachineiscapableofamputatinghandsandfeet

andofthrowingobjects.Failuretoobservethefollowing

safetyinstructionscouldresultinseriousinjury.

Training

•Read,understandandfollowallinstructionsonthe

machineandinthemanual(s)beforeoperatingthis

machine.Bethoroughlyfamiliarwiththecontrols

andtheproperuseofthemachine.Knowhowto

stopthemachineanddisengagethecontrolsquickly.

•Neverallowchildrentooperatethemachine.Never

allowadultstooperatethemachinewithoutproper

instruction.

•Keeptheareaofoperationclearofallpersons,

particularlysmallchildren.

•Exercisecautiontoavoidslippingorfalling,

especiallywhenoperatingthemachineinreverse.

Preparation

•Thoroughlyinspecttheareawherethemachineis

tobeusedandremovealldoormats,sleds,boards,

wires,andotherforeignobjects.

•Disengageallclutchesandshiftintoneutralbefore

startingtheengine.

•Donotoperatethemachinewithoutwearing

adequatewintergarments.Avoidloosetting

clothingthatcangetcaughtinmovingparts.Wear

footwearthatwillimprovefootingonslippery

surfaces.

•Handlefuelwithcare;itishighlyammable.

–Useanapprovedfuelcontainer.

–Neveraddfueltoarunningengineorhotengine.

–Fillfueltankoutdoorswithextremecare.Never

–Neverllcontainersinsideavehicleorona

llfueltankindoors.

truckortrailerbedwithaplasticliner.Always

placecontainersontheground,awayfromyour

vehicle,beforelling.

2

Page 3

–Whenpractical,removegas-poweredmachine

fromthetruckortrailerandrefuelitonthe

ground.Ifthisisnotpossible,thenrefuelsuch

machineonatrailerwithaportablecontainer,

ratherthanfromagasolinedispensernozzle.

–Keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatalltimes,

untilrefuelingiscomplete.Donotuseanozzle

lock-opendevice.

–Replacegasolinecapsecurelyandwipeupspilled

fuel.

–Iffuelisspilledonclothing,changeclothing

immediately.

•Useextensioncordsandreceptaclesasspecied

bythemanufacturerforallmachineswithelectric

startingmotors.

•Adjustthecollectorhousingheighttocleargravel

orcrushedrocksurface.

•Neverattempttomakeanyadjustmentswhile

theengineisrunning(exceptwhenspecically

recommendedbymanufacturer).

•Alwayswearsafetyglassesoreyeshieldsduring

operationorwhileperforminganadjustmentor

repairtoprotecteyesfromforeignobjectsthatmay

bethrownfromthemachine.

•Donotruntheengineindoors,exceptwhenstarting

theengineandfortransportingthemachineinor

outofthebuilding.Opentheoutsidedoors;exhaust

fumesaredangerous.

•Exerciseextremecautionwhenoperatingonslopes.

•Neveroperatethemachinewithoutproperguards,

andothersafetyprotectivedevicesinplaceand

working.

•Neverdirectthedischargetowardpeopleorareas

wherepropertydamagecanoccur.Keepchildren

andothersaway.

•Donotoverloadthemachinecapacitybyattempting

toclearsnowattoofastarate.

•Neveroperatethemachineathightransportspeeds

onslipperysurfaces.Lookbehindandusecarewhen

operatinginreverse.

•Disengagepowertotheauger/impellerwhenthe

machineistransportedornotinuse.

•Useonlyattachmentsandaccessoriesapprovedby

themanufacturerofthemachine(suchaswheel

weights,counterweights,orcabs).

•Neveroperatethemachinewithoutgoodvisibility

orlight.Alwaysbesureofyourfooting,andkeepa

rmholdonthehandles.Walk;neverrun.

Operation

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Exerciseextremecautionwhenoperatingonor

crossinggraveldrives,walks,orroads.Stayalertfor

hiddenhazardsortrafc.

•Afterstrikingaforeignobject,stoptheengine,

removethewirefromthesparkplug,thoroughly

inspectthemachineforanydamage,andrepairthe

damagebeforerestartingandoperatingthemachine.

•Ifthemachineshouldstarttovibrateabnormally,

stoptheengineandcheckimmediatelyforthecause.

Vibrationisgenerallyawarningoftrouble.

•Stoptheenginewheneveryouleavetheoperating

position,beforeuncloggingtheauger/impeller

housingordischargechute,andwhenmakingany

repairs,adjustmentsorinspections.

•Whencleaning,repairingorinspectingthemachine,

stoptheengineandmakecertaintheauger/impeller

andallmovingpartshavestopped.Disconnectthe

sparkplugwireandkeepthewireawayfromthe

plugtopreventsomeonefromaccidentallystarting

theengine.

•Nevertouchahotengineormufer.

ClearingaCloggedDischarge

Chute

Handcontactwiththerotatingrotorbladesinsidethe

dischargechuteisthemostcommoncauseofinjury

associatedwithsnowthrowers.Neveruseyourhandto

cleanoutthedischargechute.

Toclearthechute:

•Shuttheengineoff!

•Wait10secondstobesuretheimpellerbladeshave

stoppedrotating.

•Alwaysuseaclean-outtool,notyourhands.

3

Page 4

MaintenanceandStorage

•Checkallfastenersatfrequentintervalsforproper

tightnesstobesurethemachineisinsafeworking

condition.

•Ifashield,safetydevice,ordecalisdamaged,

illegible,orlost,repairorreplaceitbeforebeginning

operation.

•Donotsmokewhilehandlinggasoline.

•Neverstorethemachinewithfuelinthefueltank

insideabuildingwhereignitionsourcesarepresent,

suchashotwaterheaters,spaceheaters,orclothes

dryers.Allowtheenginetocoolbeforestoringin

anyenclosure.

•AlwaysrefertotheOperator’sManualforimportant

detailsifthemachineistobestoredforanextended

period.

•Maintainorreplacesafetyandinstructionlabels,as

necessary.

•Runthemachineafewminutesafterthrowingsnow

topreventfreeze-upoftheauger/impellerblades.

ToroSnowthrowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknow.

•Rotatingauger/impellercancutofforinjure

ngersorhands.Staybehindthehandlesandaway

fromthedischargeopeningwhileoperatingthe

machine.Keepyourface,hands,feet,andany

otherpartofyourbodyorclothingawayfrom

movingorrotatingparts.

•Donotusethemachineonaroof.

•Donottouchtheenginewhileitisrunningorsoon

afterithasstoppedbecausetheenginemaybehot

enoughtocauseaburn.

•Performonlythosemaintenanceinstructions

describedinthismanual.Beforeperformingany

maintenance,service,oradjustment,stoptheengine,

removetheignitionkey ,anddisconnectthewire

fromthesparkplug.Ifmajorrepairsareeverneeded,

contactanAuthorizedServiceDealer.

•Donotchangethegovernorsettingsontheengine.

•Whenstoringthemachineformorethan30days,

drainthefuelfromthefueltanktopreventa

potentialhazard.Storefuelinanapprovedfuel

container.Removethekeyfromtheignitionswitch

beforestoringthemachine.

•PurchaseonlygenuineTororeplacementpartsand

accessories.

•Beforeadjusting,cleaning,inspecting,

troubleshooting,orrepairingthemachine,

stoptheengine,removetheignitionkey,and

waitforallmovingpartstostop.Disconnect

thewirefromthesparkplugandkeepitaway

fromthesparkplugtopreventsomeonefrom

accidentallystartingtheengine.

•Beforeleavingtheoperatingposition,stopthe

engine,removetheignitionkey,andwaitforall

movingpartstostop.

•Tounclogthedischargechute,stayintheoperating

positionandreleasethelefthand(traction)lever.

Whilerunningtheauger/impeller,pushdownon

thehandlestoraisethefrontofthemachineafew

inches(centimeters)offthepavement.Thenliftthe

handlesquicklytobumpthefrontofthemachineon

thepavement.Repeatifnecessaryuntilastreamof

snowcomesoutthedischargechute.

•Ifyoucannotunclogthedischargechutebybumping

thefrontofthemachine,stoptheengine,waitfor

allmovingpartstostop,andusetheclean-out

tool;neveruseyourhand.

4

Page 5

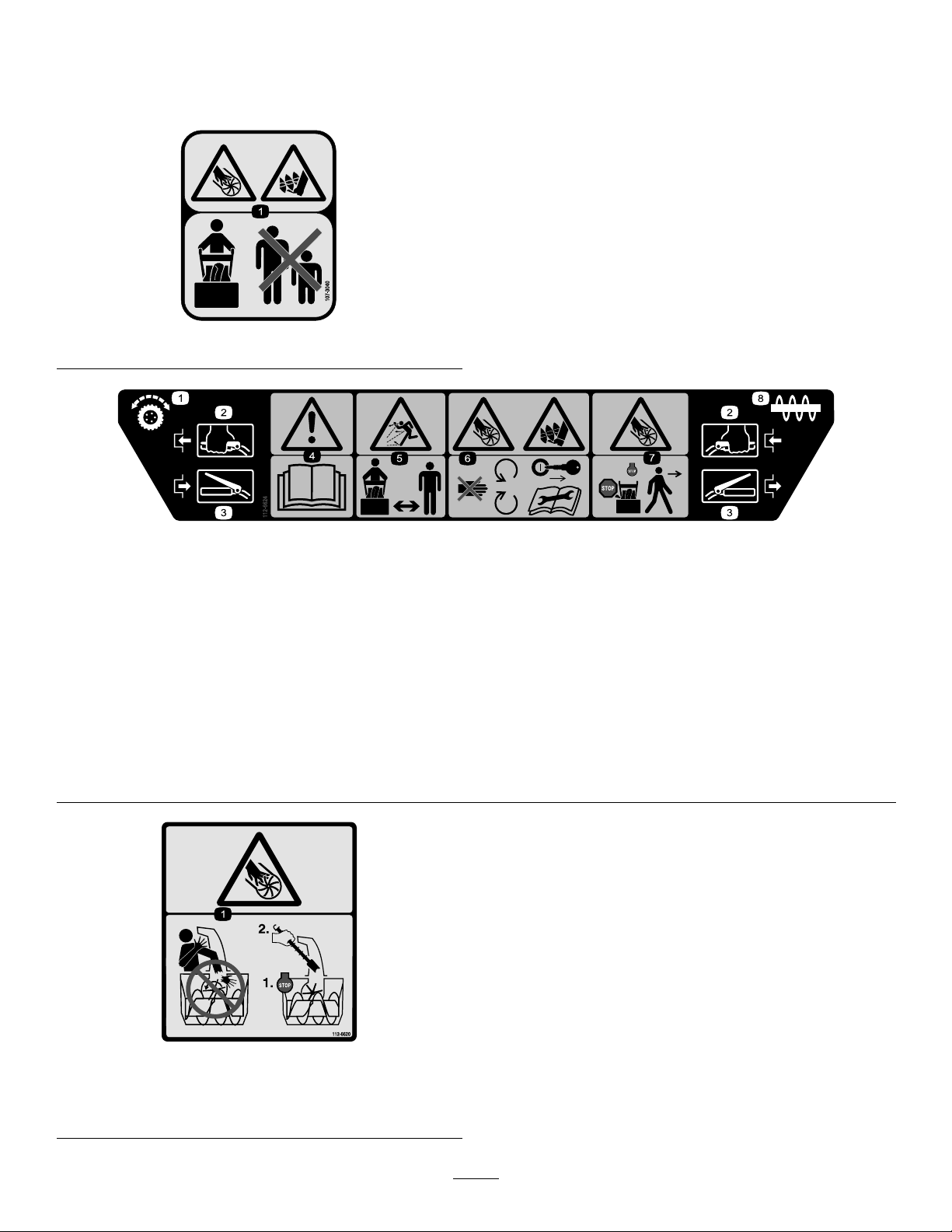

SafetyandInstructionalDecals

Important:Safetyandinstructiondecalsarelocatednearareasofpotentialdanger.Replacedamaged

decals.

107-3040

112-6624

1.Wheeldrive3.Disengage5.Thrownobject

2.Engage4.Warning—readthe

Operator’sManual.

hazard—keepbystanders

asafedistancefromthe

snowthrower.

6.Cutting/dismemberment

hazard,impellerand

auger—stayawayfrom

movingparts,keepall

guardsandshieldsinplace;

removetheignitionkeyand

readtheinstructionsbefore

servicingorperforming

maintenance.

7.Cutting/dismemberment

hazard,impeller—stop

theengineandwaitforall

movingpartstostopbefore

leavingtheoperator’s

position.

8.Auger

112-6620

1.Cutting/dismembermenthazard,impeller—donotplace

yourhandinthechute;stoptheenginebeforeleavingthe

operator’sposition,usethetoolclearthechute.

5

Page 6

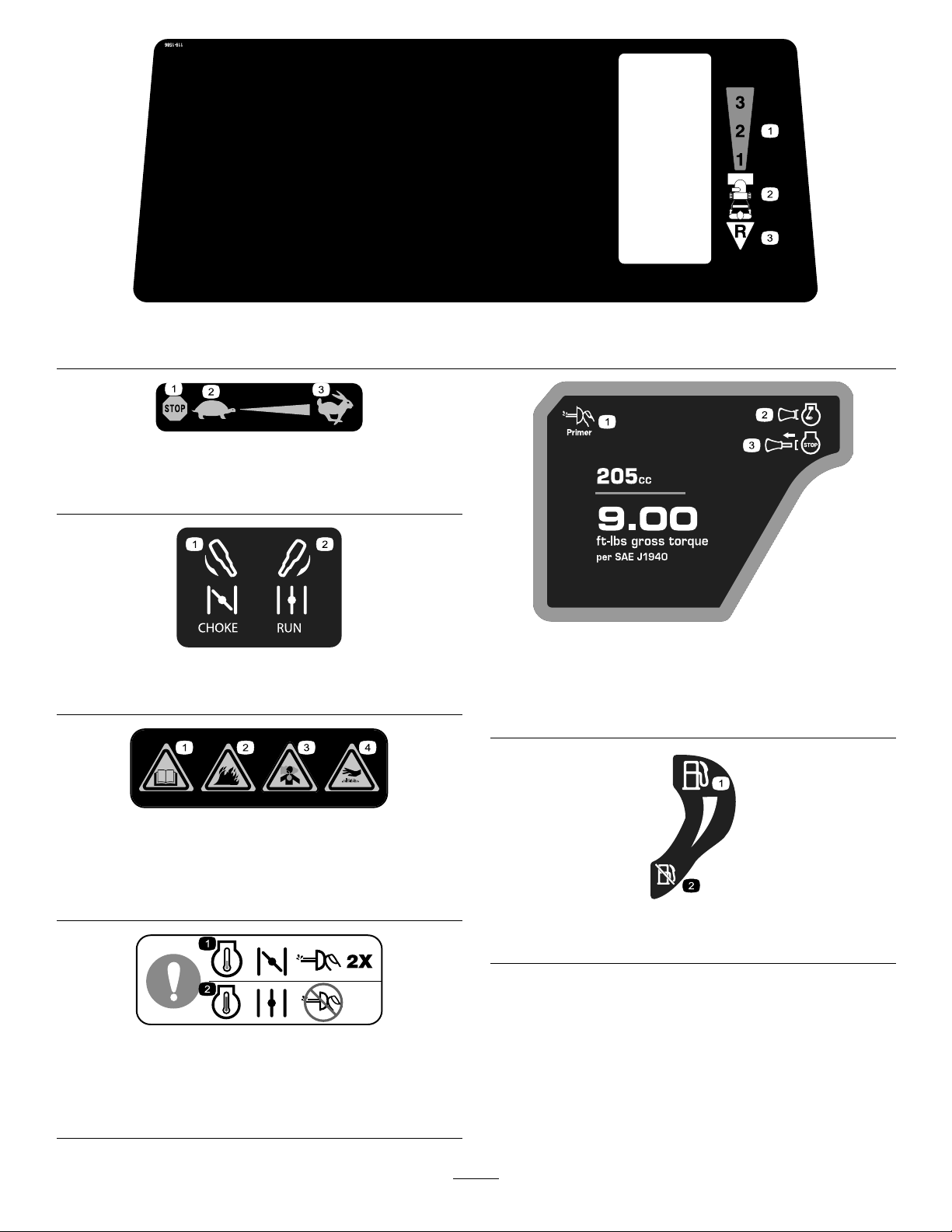

1.Forwarddrivespeedsettings

BriggsPartNo.273676

1.Stop

2.Slow

3.Fast

Briggs&StrattonPartNo.275949

1.Chokeon(Choke)2.Chokeoff(Run)

2.Speedselector

119-1586

3.Reversedrivespeedsetting

Briggs&StrattonPartNo.277588

1.Primer3.Ignitionkeyout

(Engine—Stop)

2.Ignitionkeyin

(Engine—Run)

1.Warning—readthe

Operator’sManual.

2.Warning—rehazard.

1.Whenstartingacold

engine,closethechoke

andpresstheprimertwo

times.

BriggsPartNo.276925

3.Warning—toxicgas

inhalationhazard.

4.Warning—hot

surface/burnhazard.

Briggs&StrattonPartNo.278866

1.Fuel—On2.Fuel—Off

BriggsPartNo.277566

2.Whenstartingawarm

engine,openthechoke

anddonotpressthe

primer.

6

Page 7

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

Qty.

Handleassembly1

Bolts4

Bellevillewashers4

Flangenut1

Speedselectorrod

Cotterpin

Flatwasher1

Flangelocknut1Installthetractionrod.

Clevispin

Cotterpin

Chutecontrolrodassembly(rodand

bracket,wormgear,andbracket)

Bellevillewasher1

Bolt2

Carriagebolt

Locknut3

Curvedwasher

Nopartsrequired

Nopartsrequired

1

1

1

1

1

1

1

–

–

Installthehandle.

Installthespeedselectorrod.

Installtheauger/impellerdrivecontrol

linkage.

Installthechutecontrolrod.

Filltheenginewithoil.

Checkthetirepressure.

Use

8

Nopartsrequired

1

InstallingtheHandle

Partsneededforthisprocedure:

1Handleassembly

4Bolts

4Bellevillewashers

1Flangenut

Procedure

1.Removethetiestrapsthatsecurethecontrolrods

tothehandle.

2.Removetheaxlepinsfrombothwheelsandslidethe

wheelsoutwardontheaxleapproximately1inch(3

Figure3).

cm)(

–

Note:Savetheaxlepinssothatyoucaninstall

theminstep8.

Checktheskidsandscraper.

7

Page 8

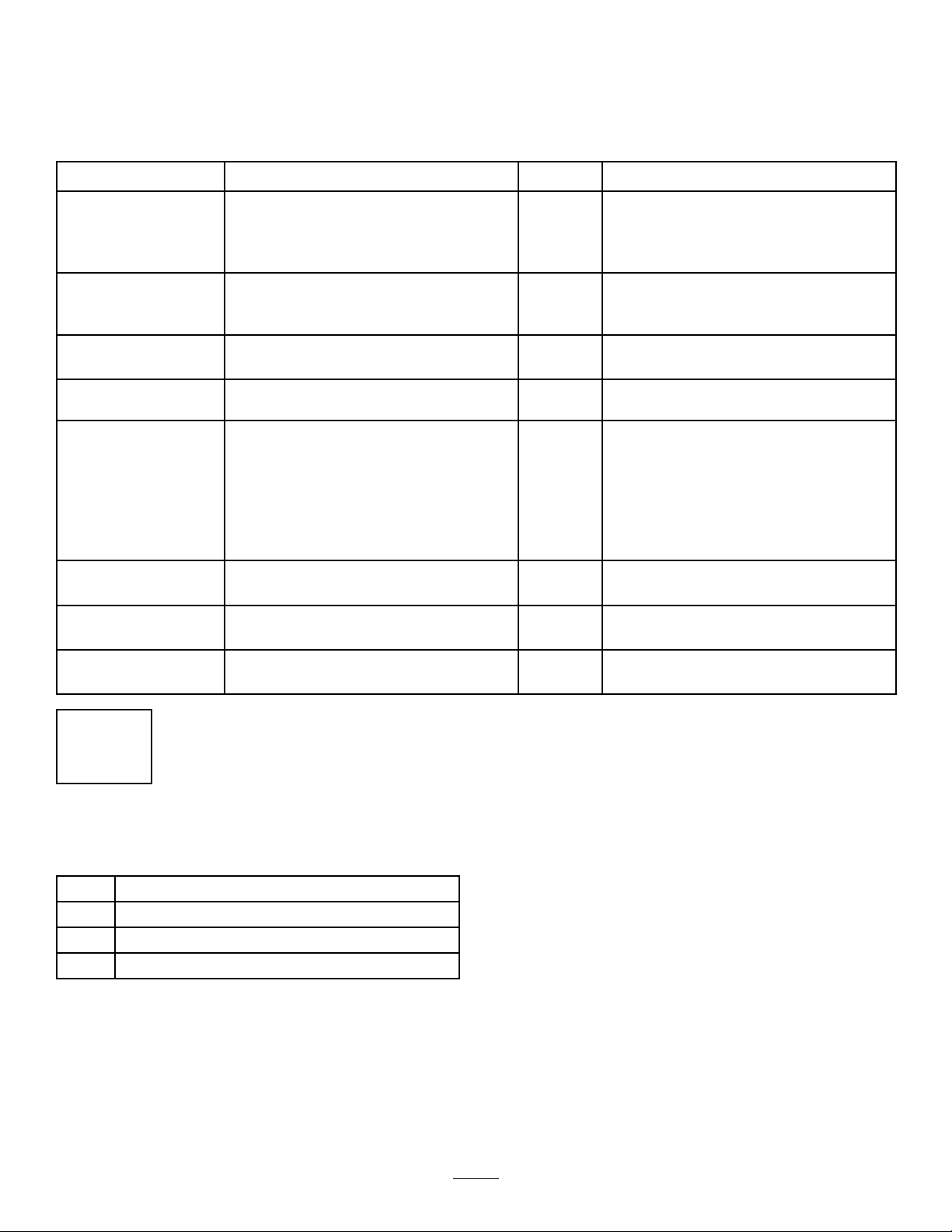

Figure3

1.Axlepin(2)

2.Capscrewandcurved

washer(4)

3.Threadaangenut(nottheangelocknut)withthe

angedownontothetractionrodattachedtothe

leftsideofthehandle(Figure4).

3.Handle

6.Aligntheholesintherightsideofthehandlewith

theholesintherightsideplate,andsecurethe

handlewith2capscrewsandBellevillewashersuntil

theyarengertight.

7.Ensurethatthehandlesareatthesameheight,then

tightenthehandlefastenerssecurely .

8.Slidethewheelsoutwardandinserteachaxlepin

throughtheholeineachwheelhubandthroughthe

outerholeoftheaxle(

Figure5).

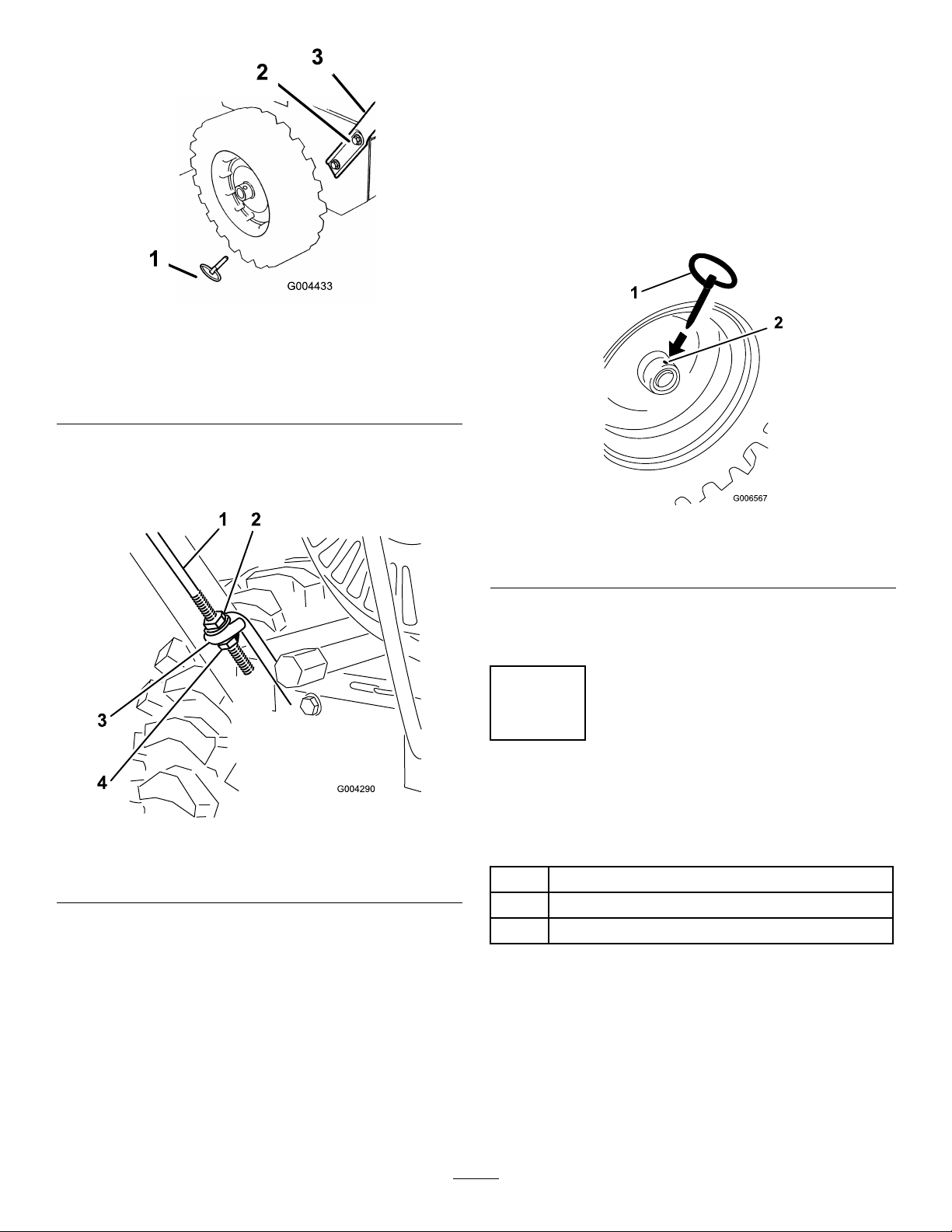

Figure4

1.Tractionrod3.Lowertractionrodloop

2.Flangenut4.Flangelocknut

4.Positiontheleftsideofthehandleagainsttheside

ofthemachineandinserttheendofthetractionrod

throughthelowertractionrodloopFigure4).

5.Aligntheholesintheleftsideofthehandlewith

theholesintheleftsideplate,andsecurethehandle

with2capscrewsandBellevillewashersuntilthey

arengertight(Figure3).

Figure5

1.Axlepin2.Holeinwheelhuband

Note:Ifyouinstalltirechains(optional),youmust

installtheaxlepinsthroughtheouteraxleholes.

outeraxleholealigned

2

InstallingtheSpeedSelector

Rod

Partsneededforthisprocedure:

1

Speedselectorrod

1

Cotterpin

1Flatwasher

Procedure

1.Pullthespeedselectorarm(Figure6)tothemost

outwardposition.

Note:TheconcavesideoftheBellevillewasher

goesagainsttheoutsideofthehandle.

8

Page 9

Figure6

1.Speedselectorarm3.Speedselectorrod

2.Flatwasherandcotterpin

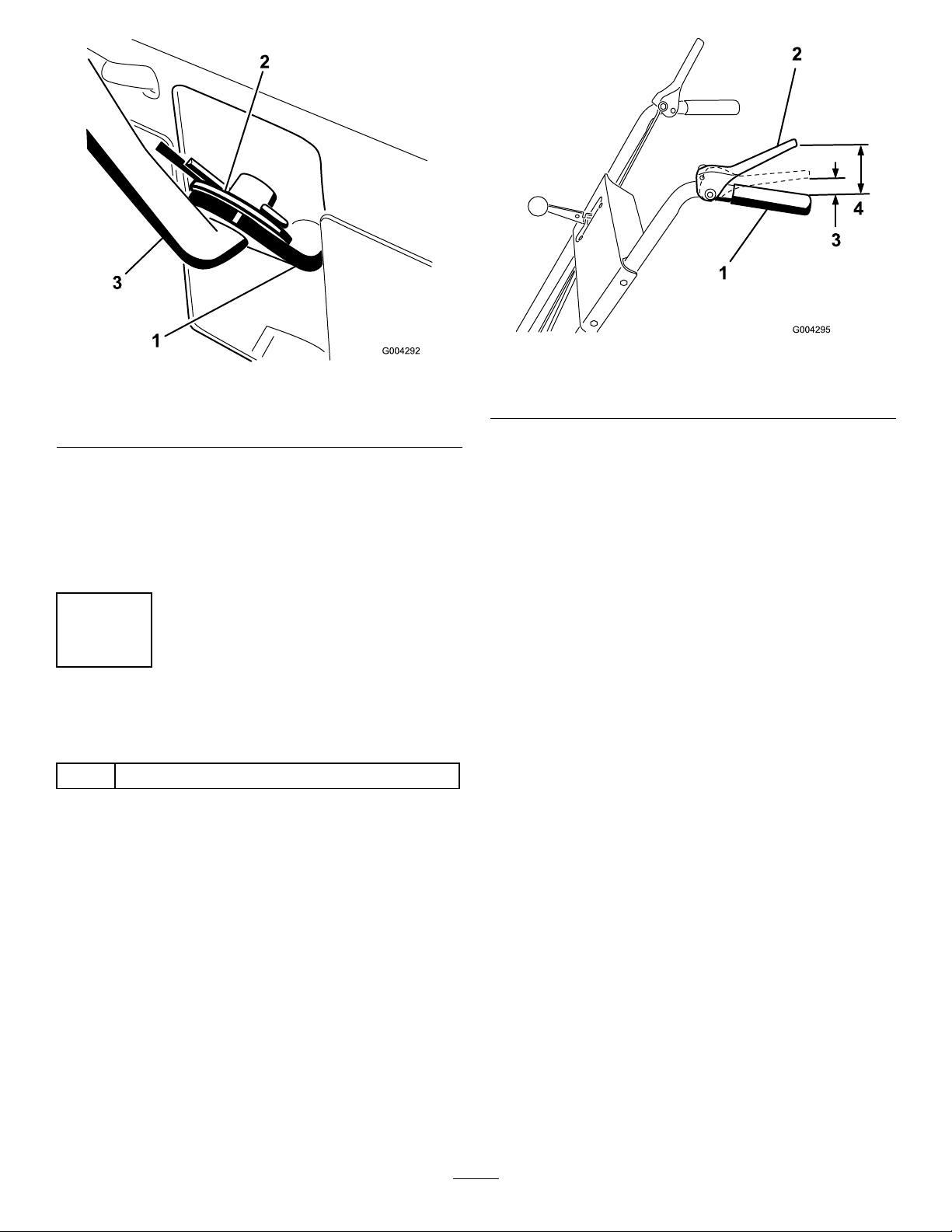

Figure7

1.Handgrip

2.Tractioncontrollever

3.Tightenthe2angenutsuntiltheyarengertight.

3.1to2inches(3to5cm)

4.4-1/2inches(11.4cm)

2.Movethespeedselectorlever(Figure14)onthe

controlpaneltotheR(Reverse)position.

3.Installthespeedselectorrodintothespeedselector

arm,addaatwasherontheselectorrod,andsecure

itwithacotterpin(

Figure6).

3

InstallingtheTractionRod

Partsneededforthisprocedure:

1Flangelocknut

Procedure

1.Threadtheangelocknut(angesideup)ontothe

bottomofthetractioncontrolrod,belowtheloop

inthelowertractionrod(

Figure4).

4.Movethespeedselectorlever(Figure14)intothird

gear.

Note:Ifthespeedselectorleverdoesnotmove

intothirdgear,adjustthespeedselectorbefore

continuing.RefertoAdjustingtheSpeedSelector

inMaintenance.

5.Slowlypullthemachinebackwardwhileslowly

pressingthetractioncontrollevertowardthe

handgrip.

Note:Theadjustmentiscorrectwhenthewheels

stoprollingbackwardandthedistancebetweenthe

topofthehandgripandthebottomofthetraction

controlleveris1to2inches(3to5cm)asshown

Figure7.

in

6.Adjustthe2angenuts,ifnecessary,toobtainthe

properdistancebetweenthetopofthehandgripand

thebottomofthetractioncontrollever.

7.Tightentheangenutssecurely .

2.Adjustthe2angenutsupordownonthetraction

roduntilthedistancebetweenthetopofthe

handgripandthebottomofthetractioncontrol

leverisapproximately4-1/2inches(11.4cm)as

showninFigure7.

9

Page 10

4

InstallingtheAuger/Impeller

DriveControlLinkage

Partsneededforthisprocedure:

1

Clevispin

1

Cotterpin

Procedure

1.Loosenthejamnutabovetheclevisontheupper

controlrod(

1.Uppercontrolrod

2.Jamnut5.Lowercontrolrod

3.Clevis6.Clevispin

2.Aligntheholesintheclevisandthelowercontrol

rodandinserttheclevispin(

Figure8).

Figure8

4.Cotterpin

Figure8).

Figure9

1.Handgrip

2.Auger/impellercontrol

lever

Note:Thedistanceshouldbeapproximately5

inches(12.7cm).

4.Presstheauger/impellerdrivecontrolleverslowly

towardthehandgrip.

Note:Theamountofforceneededtocompressthe

leverincreasesnoticeablywhenyouremovetheslack

fromtheauger/impellerdrivebelt(approximately

1/2ofthelevermovement).Theadjustmentis

correctwhentheforcebeginstoincreaseandthe

distancebetweenthetopofthehandgripandthe

bottomoftheauger/impellerdrivecontrolleveris1

to2inches(3to5cm)asshownin

Note:Iftheforcedoesnotnoticeablyincrease,

removethebeltcover(refertostep2ofReplacing

theTractionDriveBeltinMaintenance)andmeasure

2inches(5cm)abovethehandgripatthepoint

whereyouremovetheslackfromtheauger/impeller

drivebelt.

5.Toadjustthedistance:

3.1to2inches(3to5cm)

4.5inches(12.7cm)

Figure9.

3.Checkthedistancebetweenthetopofthehandgrip

andthebottomoftheauger/impellerdrivecontrol

lever(Figure9).

A.Removetheclevispin.

B.Loosenthejamnut.

C.Threadtheclevisupordowntoincreaseor

decreasethedistancebetweenthetopofthe

handgripandthebottomoftheauger/impeller

drivecontrollever(

6.Whentheadjustmentiscorrect,installtheclevispin

andsecureitinplacewiththecotterpin(

7.Tightenthejamnuttosecuretheclevis(Figure8).

10

Figure8).

Figure8).

Page 11

5

InstallingtheChuteControl

Rod

Partsneededforthisprocedure:

Chutecontrolrodassembly(rodandbracket,worm

1

gear,andbracket)

1Bellevillewasher

2Bolt

1

Carriagebolt

3Locknut

1

Curvedwasher

Procedure

1.Securetheupperchutecontrolbracket(attachedto

thechutecontrolrod)totheupperleftsideofthe

handlewithaboltandalocknutFigure10.

Figure10

1.Chutecontrolrod

2.Wormgear,bracket,and

mountingange

3.Lowerchutecontrol

bracket

4.Upperchutecontrol

bracket

5.Curvedwasher

Note:Leavethelocknutloose.

2.Securethelowerchutecontrolbracket(attachedto

thechutecontrolrod)tothelowerleftsideofthe

handlewithabolt,acurvedwasher,aatwasher,

andalocknut(

Figure10).

Note:Thebracketshouldbefastenedonthe

outsideofthehandle,andtherodshouldbe

approximatelyparalleltothegroundandnottouch

thehandle.

Note:Leavethelocknutloose.

3.ApplyNo.2generalpurposegreasetotheworm

gear(Figure11).

11

Page 12

Figure11

1.Wormgear

2.Bracket4.Bolt,Bellevillewasher,

4.Looselymountthewormgearandthebrackettothe

mountingangewithabolt,aBellevillewasher,and

alocknutasshowninFigure11.

5.Slidethewormgearintotheteethofthechute

retainingringandtightenthelocknut(

6.Tightenthelocknutsthatsecurethe2chutecontrol

brackets(Figure10).

7.Checktheoperationofthechutecontrolrod,and

movethewormgearslightlyoutwardifitbinds.

3.Mountingange

andlocknut

Figure11).

6

FillingtheEnginewithOil

Figure12

1.Movethemachinetoalevelsurfacetoensurean

accurateoillevelreading.

2.Cleanaroundthedipstick(Figure13).

Figure13

1.Dipstick2.Fillerhole

NoPartsRequired

Procedure

Yourmachinecomeswith20oz.(0.6l)ofoilinthe

engine.

Note:Beforestartingtheengine,checktheoillevel

andaddoilifnecessary.

Max.ll:20oz.(0.6l),type:automotivedetergentoil

withanAPIserviceclassicationofSF ,SG,SH,SJ,SL,

orhigher.

Referto

outdoortemperaturerangeexpected.

Figure12toselectthebestoilviscosityforthe

3.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

4.Slowlypourabout3/4ofthecrankcasecapacityof

oilintothecrankcase.

5.Wipethedipstickcleanwithacleancloth.

6.Installthedipstickintothellerneck,thenremoveit.

Note:Toensureanaccurateoillevelreading,you

mustfullyinstallthedipstick.

7.Readtheoillevelonthedipstick.

8.IftheoillevelisbelowtheAddmarkonthedipstick,

slowlypouronlyenoughoilintothellerholeto

raisetheoilleveltotheFullmarkonthedipstick.

Important:Donotoverllthecrankcasewith

oilandruntheengine;enginedamagewill

12

Page 13

result.Draintheexcessoiluntiltheoillevelon

thedipstickreadsFull.

9.Insertthedipstickintothellerneckandrotatethe

capclockwiseuntilitistight.

7

CheckingtheTirePressure

NoPartsRequired

Procedure

Thetiresareoverinatedatthefactoryforshipping.

Reducethepressureequallyinbothtirestobetween12

and15psi(82and103kPa).

ProductOverview

8

CheckingtheSkidsand

Scraper

NoPartsRequired

Procedure

RefertoCheckingandAdjustingtheSkidsandScraper

inMaintenance.

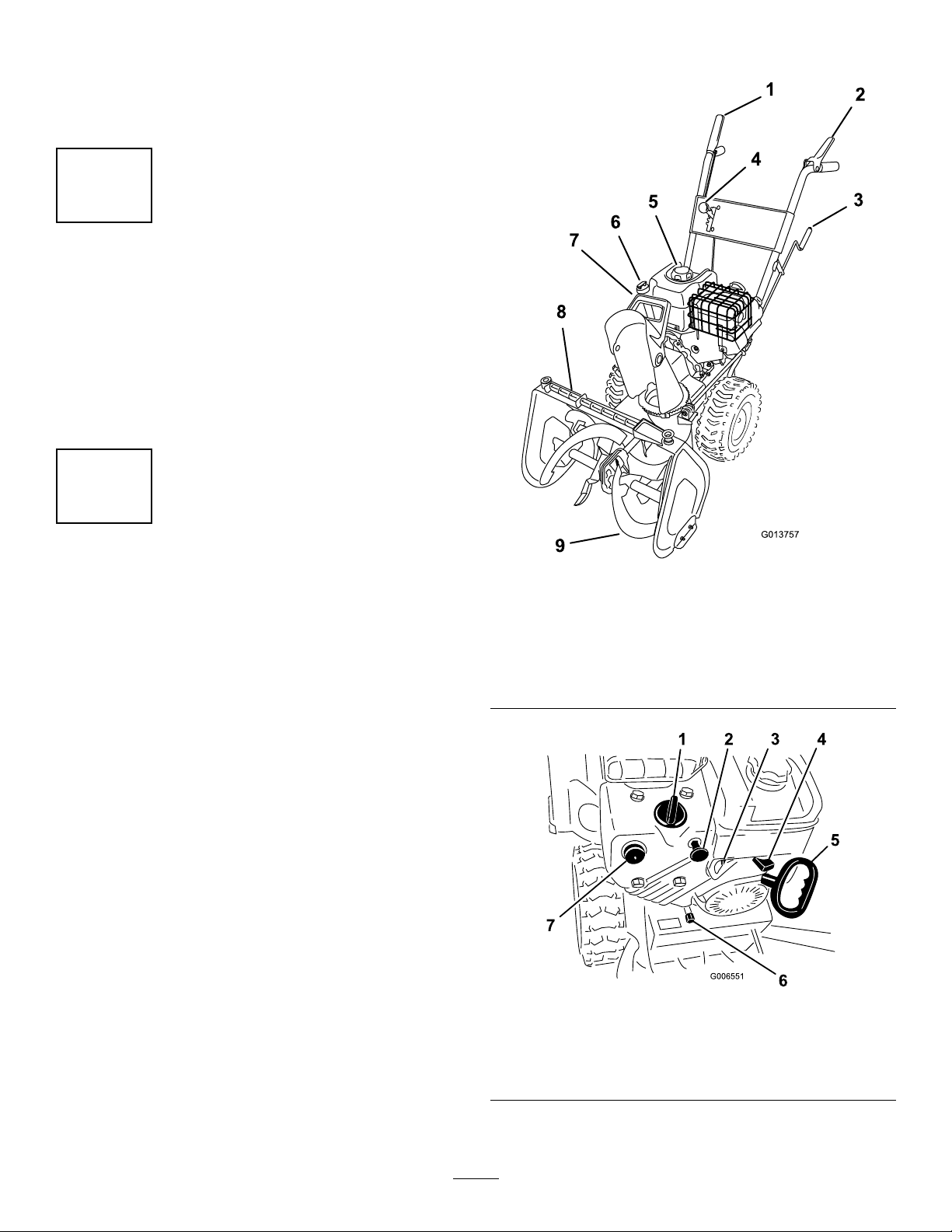

1.Auger/impellerdrive

controllever

2.Tractioncontrollever

3.Dischargechutecontrol

4.Speedselectorlever

5.Fueltankcap

Figure14

6.Oilll/dipstick

7.Chutedeectorhandle

8.Snowclean-outtool

9.Auger

13

1.Choke

2.Ignitionswitch

3.Fuelshutoffvalve

4.Throttle

Figure15

5.Recoilstarter

6.Oildrainplug

7.Primer

Page 14

Controls

•Auger/ImpellerDriveControlLever—T oengage

boththeaugerandimpeller,presstheleveragainst

therighthandgrip.Todisengage,releasethelever.

•TractionControlLever—Toengagethetraction

(wheeldrive),presstheleveragainsttheleft

handgrip.Tostopthetraction,releasethelever.

•SpeedSelectorLever—Thiscontrolhas4

positions:3forwardspeedsand1reverse.Tochange

speeds,movethespeedselectorlevertothedesired

position.Theleverlocksinanotchateachspeed

selection.

Note:Beforeshiftinggearsintooroutofreverse,

youmustreleasethetractioncontrollever.Youmay

shiftbetweenanyoftheforwardspeedswithout

releasingthetractioncontrollever.

•DischargeChuteControl—Rotatethedischarge

chutecontrolclockwisetomovethedischargechute

totheleft;counterclockwisetomovethechuteto

theright.

•ChuteDeectorHandle—Movethedeector

handleforwardtomovethesnowstreamdown;

moveitrearwardtomovethesnowstreamup.

•FuelshutoffValve—Closethevalvebyrotating

clockwise.Openthevalvebyrotatingit

counterclockwise.Closethevalvewhenyoudonot

usethemachine.

•IgnitionSwitch—Inserttheignitionkeybefore

startingtheengine.Tostoptheengine,removethe

key.

•Choke—RotatethechoketotheFullpositionto

startacoldengine.Asenginewarmsup,gradually

rotatethechoketotheOffposition.

•ThrottleLever—Movethethrottlelevertotheright

toincreasetheenginespeed;moveittotheleftto

decreasetheenginespeed.Movethethrottleleverto

theStoppositiontostoptheengine.

•Primer—Presstheprimertopumpasmall

amountofgasolineintotheengineforimproved

cold-weatherstarting.

•ElectricStarter—Theelectricstarterisontheright

sideoftheengine.Tostartthemachine,connect

theelectricstartertoanelectricpowersourcewith

anapprovedextensioncordandpressthestarter

button.

•RecoilStarter—Therecoilstarterisontheback

sideoftheengine.Pulltherecoilstartertostartthe

engine.

•SnowClean-outTool—Thesnowclean-outtool

isonthetopoftheaugerhousing.Usethistoolto

unclogthedischargechutewhenitbecomesclogged

withsnow.

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

FreewheelingorUsingthe

Self-propelDrive

Youcanoperatethemachinewiththeself-propelfeature

engagedordisengaged(freewheeling).

Tofreewheel,slidethewheelsinwardandinserttheaxle

pinsthroughtheouteraxleholes,butnotthroughthe

wheelhubs(

Toself-propel,slidethewheelsoutwardandinsertthe

axlepinsthroughtheholesinthewheelhubsandthe

outeraxleholes(

Figure16).

Figure16

Figure17).

Figure17

14

Page 15

FillingtheFuelTank

StartingtheEngine

DANGER

Gasolineisextremelyammableandexplosive.A

reorexplosionfromgasolinecanburnyouand

others.

•Topreventastaticchargefromignitingthe

gasoline,placethecontainerand/ormachine

onthegroundbeforelling,notinavehicleor

onanobject.

•Fillthetankoutdoorswhentheengineiscold.

Wipeupspills.

•Donothandlegasolinewhensmokingoraround

anopenameorsparks.

•Storegasolineinanapprovedfuelcontainer,out

ofthereachofchildren.

Fillthefueltankwithfreshunleadedregulargasoline

fromamajorname-brandservicestation(Figure18).

Important:T oreducestartingproblems,add

fuelstabilizertothefuelallseason,mixingitwith

gasolinelessthan30daysold.

the gasoline.

Do not add oil to

1.Checktheengineoillevel.RefertoCheckingthe

EngineOilLevelinMaintenance.

2.Turnthefuelshutoffvalve1/4turncounterclockwise

toopenit(Figure19).

Figure19

3.Inserttheignitionkey(Figure20).

Figure18

Figure20

1.Ignitionkey

4.Firmlypushintheprimerwithyourthumb2times

(15°For-9°Corabove)or4times(below15°For

-9°C),holdingtheprimerinforasecondbefore

releasingiteachtime(

15

Figure21).

Page 16

Figure21

5.RotatethechoketotheChokeposition(Figure22).

Note:Tousetheelectricstarter,connectapower

cordtotheelectricstarterplug-inrstandthen

toapoweroutlet.UseonlyaUL-listed,16-gauge

extensioncordrecommendedforoutdoorusethat

isnotlongerthan50feet(15m).

8.Startthemachinebypullingtherecoilstarteror

pressingtheelectric-startbutton(Figure24).

Figure24

1.Electric-startbutton3.Recoilstarter

2.Electricstarterplug-in

Figure22

6.MovethethrottletotheFastposition(Figure23).

WARNING

Theelectricalcordcanbecomedamaged,

causingashockorre.

Thoroughlyinspecttheelectricalcordbefore

usingthemachine.Ifthecordisdamaged,

donotoperatethemachine.Replaceorrepair

thedamagedcordimmediately.Contactan

AuthorizedServiceDealerforassistance.

Important:T opreventdamagingtheelectric

starter,runitinshortcycles(5seconds

maximum,thenwaitoneminutebeforetrying

tostartitagain).Iftheenginestilldoesnot

start,takethemachinetoanAuthorizedService

Dealerforservice.

9.Disconnecttheextensioncordfromthepoweroutlet

rstandthenfromthemachine(electricstartonly).

10.Allowtheenginetowarmupforseveralminutes,

thenmovethechoketowardtheRunposition.Wait

fortheenginetorunsmoothlybeforeeachchoke

adjustment.

Figure23

7.Connectanextensioncordtotheelectricstarterand

theoutlet.

16

Page 17

WARNING

UncloggingtheDischarge

Ifyouleavethemachinepluggedintoapower

outlet,someonecaninadvertentlystartthemachine

andinjurepeopleordamageproperty.

Unplugthepowercordwheneveryouarenot

startingthemachine.

StoppingtheEngine

1.MovethethrottletotheSlowposition,andthento

theStopposition(

Figure25).

Figure25

Chute

Iftheauger/impellerisrunningbutthereisnosnow

comingoutofthedischargechute,thedischargechute

maybeclogged.

Ifthedischargechutebecomesclogged,stopthe

engine,waitforallmovingpartstostop,anduse

theclean-outtool—neveruseyourhand.

PreventingFreeze-up

•Insnowyandcoldconditions,somecontrolsand

movingpartsmayfreeze.Donotuseexcessive

forcewhentryingtooperatefrozencontrols.If

youhavedifcultyoperatinganycontrolorpart,

starttheengineandletitrunforafewminutes.

•Afterusingthemachine,lettheenginerunfora

fewminutestopreventmovingpartsfromfreezing.

Engagetheauger/impellertoclearanyremaining

snowfrominsidethehousing.Rotatethedischarge

chutecontroltopreventitfromfreezing.Stopthe

engine,waitforallmovingpartstostop,andremove

alliceandsnowfromthemachine.

2.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheignitionkey.

4.Closethefuelshutoffvalvebyrotatingitclockwise

Figure26).

(

Figure26

5.Pulltherecoilstarter3or4times.Thishelpsprevent

therecoilstarterfromfreezingup.

6.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

•Withtheengineoff,pulltherecoilstarterhandle

severaltimestopreventtherecoilstarterfrom

freezingup.

OperatingTips

DANGER

Whenthemachineisinoperation,theimpellerand

augercanrotateandcutofforinjurehandsandfeet.

•Beforeadjusting,cleaning,inspecting,

troubleshooting,orrepairingthemachine,stop

theengineandwaitforallmovingpartstostop.

Disconnectthewirefromthesparkplugand

keepitawayfromtheplugtopreventsomeone

fromaccidentallystartingtheengine.

•Removeanobstructionfromthedischarge

chute;refertoUncloggingtheDischargeChute.

Ifnecessary,usetheclean-outtool,notyour

hands,toremoveanobstructionfromthe

dischargechute.

•Staybehindthehandlesandawayfromthe

dischargeopeningwhileoperatingthemachine.

•Keepface,hands,feet,andanyotherpartof

yourbodyorclothingawayfromconcealed,

moving,orrotatingparts.

17

Page 18

WARNING

•AlwayssetthethrottlelevertotheFastposition

whenthrowingsnow.

Therotorbladescanthrowstones,toys,andother

foreignobjectsandcauseseriouspersonalinjuryto

theoperatorortobystanders.

•Keeptheareatobeclearedfreeofallobjects

thattherotorbladescouldpickupandthrow.

•Keepallchildrenandpetsawayfromthearea

•Iftheengineslowsdownunderaloadorthewheels

slip,shiftthemachineintoalowergear.

•Ifthefrontofthemachineridesup,shiftthe

machineintoalowergear.Ifthefrontcontinuesto

rideup,liftuponthehandles.

ofoperation.

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

Aftertherst5hours

Beforeeachuseordaily

Every20hours

Every50hours

Every100hours

Yearly

Yearlyorbeforestorage

MaintenanceProcedure

•Inspectandadjustthetractiondrivebelt.

•Inspectandadjusttheauger/impellerdrivebelt.

•Changetheengineoil.

•Checktheengineoillevelandaddoilifnecessary.

•Inspectandadjustorreplacethetractiondrivebeltwhennecessary.

•Inspectandadjustorreplacetheauger/impellerdrivebeltwhennecessary.

•Lubricatethemachine.

•Changetheengineoil.

•Inspectthesparkplug.Replaceand/orgapitifnecessary.

•Checktheskidsandthescraperandadjustthemifnecessary.

•Checktheaugergearboxoilandaddoilifnecessary.

•Changetheengineoil.

•Lubricatethemachine.

•Drainthegasolineandruntheenginetodryoutthefueltankandthecarburetorat

theendoftheseason.

Important:Refertoyourengineoperator’smanualforadditionalmaintenanceprocedures.Forengine

adjustments,repairs,orwarrantyservicenotcoveredinthismanual,contactanAuthorizedBriggs

&StrattonServicingDealer.

CAUTION

Ifyouleavethewireonthesparkplug,someonecouldaccidentlystarttheengineandseriouslyinjure

youorbystanders.

Disconnectthewirefromthesparkplugbeforeyoudoanymaintenance.Setthewireasidesothatitdoes

notaccidentallycontactthesparkplug.

PreparingforMaintenance

1.Movethemachinetoalevelsurface.

2.Stoptheengineandwaitforallmovingpartstostop.

3.Disconnectthesparkplugwire.RefertoInspecting

andReplacingtheSparkPlug.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Eachtimebeforeusingthemachine,rstensurethat

theoillevelisbetweentheAddandtheFullmarkson

thedipstick.

18

Page 19

1.Cleanaroundthedipstick(Figure13).

2.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

3.Wipethedipstickcleanwithacleancloth.

4.Installthedipstickintothellerneck,thenremoveit.

Note:Toensureanaccurateoillevelreading,you

mustfullyinstallthedipstick.

5.Readtheoillevelonthedipstick.

6.IftheoillevelisbelowtheAddmarkonthedipstick,

slowlypouronlyenoughoilintothellerholeto

raisetheoilleveltotheFullmarkonthedipstick.

Note:Useonlyahigh-quality,SAE5W-30or

SAE10detergentoilthathastheAmerican

PetroleumInstitute(API)serviceclassicationSF,

SG,SH,orSJ.Forextremelycoldconditions(below

0°For-18°C),use0W -30detergentoilthathas

theAmericanPetroleumInstitute(API)service

classicationSF,SG,SH,orSJ.

Figure27

1.Augersideplate(2)3.Skid(2)

2.Flangenuts(4)

4.Supporttheaugerbladessothattheyare1/8inch(3

mm)offtheground(

Figure28).

Important:Donotoverllthecrankcasewith

oilandruntheengine;enginedamagewill

result.Draintheexcessoiluntiltheoillevelon

thedipstickreadsFull.

7.Insertthedipstickintothellerneckandrotatethe

capclockwiseuntilitistight.

AdjustingtheSkidsand

Scraper

ServiceInterval:Yearly

Adjusttheskidsandthescraperinitiallyandthenas

neededtoensurethattheaugerdoesnotcontactthe

pavedorgravelsurface.Also,adjustthemasneededto

compensateforwear.

1.Movethemachinetoalevelsurface.

2.Checkthetirepressureinthetires.RefertoChecking

theTirePressureinSetup.

3.Loosenthe4angenutsthatsecurebothskidsto

theaugersideplates(

upanddowneasily.

Figure27)untiltheskidsslide

Figure28

1.Augerblade

2.Scraper

3.Mountingscrew(5)

5.Checkthescraperadjustment.Thescrapershouldbe

1/8inch(3mm)aboveandparalleltoalevelsurface.

A.ForConcreteandAsphaltSurfaces:

Ifthemachinedoesnotclearthesnowclose

enoughtothepavement,adjusttheskidsto

lowerthescraper;ifthepavementsurfacesare

cracked,rough,oruneven,adjusttheskidsto

raisethescraper.

B.ForGravelSurfaces:

Supporttheaugerbladesafewinches(cm)above

theground,andadjusttheskidstopreventthe

machinefrompickinguprocks.

6.Toadjustthescraper,loosenthe5mounting

screws(Figure28),levelthescraper,andtightenthe

mountingscrews.

19

Page 20

7.Movetheskidsdownasfaraspossible.

8.Tightenthe4angenutsthatsecurebothskidsto

theaugersideplates(Figure27).

AdjustingtheSpeedSelector

Adjustthespeedselectorlinkageinitiallyandwhenthe

machineisslow,rstgearhasnospeed,orthespeed

selectorleverdoesnotmoveintothirdgear.

1.Draingasolinefromthefueltankandtheengine

oilfromthecrankcase.RefertoEmptyingtheFuel

TankandtoChangingtheEngineOil.

2.Tipthemachineforwardandblockitsothatit

cannotfall.

3.Removethe4ange-headboltsthatsecurethe

bottomcovertotheframeandremovethecover

Figure34).

(

4.Loosentheangenutsthatsecuretheselectorplate

tothecontrolpanel(Figure29).

Figure30

1.Rollpin

2.Driveassembly

3.1/8inch(3mm)

6.Withthedriveassembly1/8inch(3mm)fromthe

rollpin,tightentheangenutsthatsecurethespeed

selectorplate.

7.ShiftthespeedselectorlevertotheR(Reverse)

positionandbacktothirdgeartocheckthe

adjustment.

8.Ifthespacebetweentherollpinandthedrive

assemblyismorethan3/16inch(5mm),repeat

3through6.

steps

9.Installthebottomcoverandreturnthemachineto

theuprightposition.

CheckingtheAugerGearbox

Grease

Figure29

1.Speedselectorplate

2.Flangenuts

5.Shiftthespeedselectorlevertothirdgearandpush

downonthespeedselectorplatetomovethedrive

assemblytotheright.

Note:Thedriveassemblyshouldbe1/8inch(3

mm)fromtherollpin;ifnot,slidetheselectorplate

(

Figure29)untilthegapis1/8inch(3mm);refer

toFigure30.

ServiceInterval:Yearly

Theaugergearboxispackedwith5oz.(140g)of

LubriplateMAG-1(alow-temperature,high-pressure

grease)andissealedatthefactory.Thepipeplug

(Figure31)isforfactoryuseonly;youdonotneedto

checkoraddgrease.Ifthegearboxisleakinggrease,

contactanAuthorizedServiceDealer.

20

Page 21

Figure31

1.Pipeplug

ChangingtheEngineOil

Figure33

1.Oildrainplug

2.Drainextension

ServiceInterval:Aftertherst5hours

Yearly

Every50hours

Ifpossible,runtheenginejustbeforechangingthe

oilbecausewarmoilowsbetterandcarriesmore

contaminants.

Max.ll:20oz.(0.6l),type:automotivedetergentoil

withanAPIserviceclassicationofSF ,SG,SH,SJ,SL,

orhigher.

RefertoFigure32toselectthebestoilviscosityforthe

outdoortemperaturerangeexpected.

4.Slideanoildrainpanunderthedrainextensionand

removetheoildrainplug(Figure33).

Note:Placeafunnelunderthedrainextensionso

theoildrainsdirectlyintotheoildrainpanandaway

fromthemachine.

5.Draintheoil.

Note:Disposeoftheusedoilproperlyatalocal

recyclingcenter.

6.Installtheoildrainplug.

7.Installtheleftwheel.

8.Fillthecrankcasewithoil.RefertoFillingthe

EnginewithOilinSetup.

9.Wipeupanyspilledoil.

LubricatingtheMachine

ServiceInterval:Every20hours

Yearlyorbeforestorage

Lightlylubricateallmovingpartsofthemachine

afterevery20operatinghoursandattheendofthe

snowthrowingseason.

Figure32

1.Blockuptherearofthemachine.

2.Removetheleftwheel.

3.Cleantheareaaroundtheoildrainplug(Figure33).

Important:Donotgetoilorgreaseontherubber

wheelorfrictiondriveplatebecausethewheelwill

slipandtherubbermaydeteriorate.

1.Draingasolinefromthefueltankandtheoilfrom

thecrankcase.RefertoEmptyingtheFuelTankand

toChangingtheEngineOil.

2.Tipthemachineforwardontotheauger/impeller

housingandblockitsothatitcannotfall.

3.Removethe4ange-headboltsthatsecurethe

bottomcoverandremovethecover(Figure34).

21

Page 22

Figure34

1.Flange-headbolts

4.Lightlylubricatethemachinewithlightoilasshown

Figure35.

in

InspectingandReplacingthe

SparkPlug

ServiceInterval:Every100hours

UseaChampionQC12YCorequivalentsparkplug.

Checkandgapthesparkyearly,andreplacetheplug

ifnecessary.

1.Cleanaroundthebaseofthesparkplug.

2.Removethesparkplug.

3.Examinethesparkplugandreplaceitifitiscracked,

fouled,dirty,oriftheelectrodesareworn.

Important:Donotcleantheelectrodesbecause

gritcouldenterthecylinderanddamagethe

engine.

4.Setthegapbetweentheelectrodesonthesparkplug

at0.030inch(0.76mm)(

Figure36).

Figure35

Important:Donotexcessivelyoilthemachine;

extraoilmayenterthetractiondriveandcause

thetractiondrivebelttoslip.

5.Wipeupanyexcessoil.

6.Greasethemachineasshownin

7.Wipeupanyexcessgrease.

Figure35.

Figure36

1.0.030inch(0.76mm)

5.Installthesparkplugbyhandandthentorqueitto

15ft-lb(20.4N-m).

Note:Ifyoudonothaveatorquewrench,tighten

theplugrmly.

AdjustingtheTractionDrive

Belt

ServiceInterval:Afterthersthour

Beforeeachuseordaily

Adjustthetractiondrivebeltaftertherstoperating

hour,afterevery5operatinghoursthereafter,andwhen

thespeedselectorlevershiftsproperlybutthemachine

doesnotdriveintheforwardorreversespeeds.

1.Checkandadjustthetractiondriveasdescribedin

InstallingtheTractionRodinSetup.

8.Installthebottomcover.

9.Returnthemachinetoitsuprightposition.

2.Iftheproblempersistsafteradjustingthelinkage,

contactanAuthorizedServiceDealer.

22

Page 23

ReplacingtheTractionDrive

Belt

Ifthetractiondrivebeltbecomesworn,oil-soaked,or

otherwisedamaged,replacethebelt.

1.Draingasolinefromthefueltankandtheoilfrom

thecrankcase.RefertoEmptyingtheFuelTankand

toChangingtheEngineOil.

2.Removethe2ange-headboltsthatholdthebelt

coverinplaceandsetthecoveraside(Figure37).

4.Removetheauger/impellerdrivebeltfromthe

enginepulleyandthelargeauger/impellerpulley

(Figure38).

5.Tipthemachineforwardandblockitsothatit

cannotfall.

6.Removethe4ange-headboltsthatsecurethe

bottomcovertotheframeandremovethecover

Figure34).

(

7.Disconnectthespringfromthenotchinthebottom

edgeofthesideplate(Figure39).

Figure37

1.Flange-headbolt(2)

2.Beltcover

3.Loosenthebeltguide(Figure38).

Figure38

1.Idlerpulley

2.Enginepulley5.Beltguide

3.Tractiondrivebelt

4.Auger/impellerdrivebelt

6.Largeauger/impeller

pulley

Figure39

1.Notchinsideplate3.Largetractionpulley

2.Spring

CAUTION

Thespringisunderheavytensionandcould

injuretheyouorabystanderifyoudonot

carefullyremoveit.

Carefullyremovethespring.

8.Setthemachineupright.

9.Removethetractiondrivebeltfromtheengine

pulleyandthelargetractionpulley(Figure38).

10.Installanewbeltaroundthelargetractionpulley.

11.Loopthebeltovertheenginepulley,ensuringthat

thebeltisontheinsideofthebeltguide(Figure38).

12.Tipthemachineforwardandblockitsothatit

cannotfall.

13.Hookthespringintothenotchinthebottomedge

ofthesideplate(Figure39).

14.Replacethebottomcoverwiththe4ange-head

bolts.

15.Setthemachineupright.

23

Page 24

16.Installtheauger/impellerdrivebeltaroundthelarge

auger/impellerpulleyandenginepulley,ensuring

thatthebeltisontheinsideoftheidlerpulleyand

thebeltguide(

17.Adjustthebeltguidesothatthereis1/8inch(3mm)

ofclearancebetweentheauger/impellerdrivebelt

andtheguide,andsecurethebeltguidewhenthe

auger/impellerdrivebeltistight.

18.Checktheauger/impellerdrivelinkageandadjustit

ifnecessary.Refertosteps4through7ofInstalling

theAuger/ImpellerDriveControlLinkageinSetup.

19.Installthebeltcover.

Figure38).

AdjustingtheAuger/Impeller

DriveBelt

ServiceInterval:Afterthersthour

Beforeeachuseordaily

Operatingthemachinewithanauger/impellerdrivebelt

thatslipsdecreasesthesnowthrowingperformanceand

damagesthebelt.Checktheauger/impellerdrivebelt

forthepropertensionaftertherstoperatinghour,then

checkandadjustthebeltwhennecessary.

DANGER

Improperlyadjustingtheauger/impellermaycause

ittoturnwhendisengaged.Arotatingaugeror

impellercancutofforinjurengers,hands,orfeet.

ReplacingtheAuger/Impeller

DriveBelt

Iftheauger/impellerdrivebeltbecomesworn,

oil-soaked,orotherwisedamaged,replacethebelt.

1.Removethe2ange-headboltsthatholdthebelt

coverinplaceandsetthecoveraside(

2.Loosenthebeltguide(Figure38).

3.Removetheauger/impellerdrivebeltfromthe

enginepulleyandthelargeauger/impellerpulley

Figure38).

(

4.Installanewbeltaroundthelargeauger/impeller

pulley(Figure38).

5.Loopthebeltovertheenginepulley,ensuringthat

thebeltisontheinsideoftheidlerpulleyandthe

beltguide(Figure38).

6.Adjustthebeltguidesothatthereis1/8inch(3mm)

ofclearancebetweentheauger/impellerdrivebelt

andtheguide,andsecurethebeltguide.

7.Checkandadjusttheauger/impellerdrivebeltas

instructedinInstallingtheAuger/ImpellerDrive

ControlLinkageinSetup.

8.Installthebeltcover.

Important:Donotoperatethemachineif

theaugerandtheimpellerrotatewhenyou

disengagetheauger/impellerdrivecontrollever.

Figure37).

•Keepyourface,hands,feet,andanyotherpart

ofyourbodyorclothingawayfromconcealed,

moving,orrotatingparts.

•Ensurethattheimpellerbrakearmclearance

ismaintained.

•Donotadjusttheauger/impellerdrivebelttoo

tightbecauseitmaycausetheauger/impellerto

turnwhenthecontrolleverisintheDisengaged

position.Ifthisoccurs,decreasethebelt

tension.

1.CheckandadjustthebeltasinstructedinInstalling

theAuger/ImpellerDriveControlLinkageinSetup.

2.Connectthewiretothesparkplug.

3.Checkthebelttensionbyoperatingtheauger.

4.Ifthebeltstillslips,replaceit.RefertoReplacingthe

Auger/ImpellerDriveBelt.

Important:Donotoperatethemachineif

theaugerandtheimpellerrotatewhenyou

disengagetheauger/impellerdrivecontrollever.

Storage

WARNING

•Gasolinevaporscanexplode.

•Donotstoregasolinemorethan30days.

•Donotstorethemachineinanenclosurenear

anopename.

•Allowtheenginetocoolbeforestoringit.

PreparingtheMachinefor

Storage

1.Onthelastrefuelingoftheyear,addfuelstabilizer

tofreshfuelasdirectedbytheenginemanufacturer.

2.Runtheenginefor10minutestodistributethe

conditionedfuelthroughthefuelsystem.

24

Page 25

3.Loosenthehoseclampthatsecuresthefuellineto

thevalveandslidethefuellineoffthefuelshutoff

valve.

4.Openthefuelshutoffvalveandallowthefuelto

drainoutofthefueltankintoanapprovedfuel

container.

5.Installthefuellineontothefuelshutoffvalveand

secureitwithahoseclamp.

6.Runthemachineuntiltheenginestopsfromrunning

outoffuel.

7.Primetheengineandstartitagain.

8.Allowtheenginetorununtilitstops.Whenyoucan

nolongerstarttheengine,itissufcientlydry.

9.Stoptheengineandallowittocool.

10.Removetheignitionkey.

11.Disconnectthesparkplugwire.

12.Removethesparkplug,add1/2oz.(15ml)ofoil

throughthesparkplughole,andpullthestarterrope

slowlyseveraltimestodistributeoilthroughoutthe

cylindertopreventcylindercorrosionduringthe

off-season.

13.Looselyinstallthesparkplugbyhand.

14.Disposeofanyunusedfuelproperly.Recycleit

accordingtolocalcodes,oruseitinyourautomobile.

Note:Donotstorestabilizedfuelformorethan

90days.

15.Lubricatethemachine.RefertoLubricatingthe

Machine.

16.Cleanthemachinethoroughly .

17.Touchupchippedsurfaceswithpaintavailable

fromanAuthorizedServiceDealer.Sandaffected

areasbeforepainting,andusearustpreventativeto

preventthemetalpartsfromrusting.

18.Tightenanyloosefasteners.Repairorreplaceany

damagedparts.

19.Coverthemachineandstoreitinaclean,dryplace

outofthereachofchildren.Allowtheengineto

coolbeforestoringitinanyenclosure.

RemovingtheMachinefrom

Storage

1.Removethesparkplugandspintheenginerapidly

usingthestartertoblowtheexcessoilfromthe

cylinder.

2.Installthesparkplugandtightenitrmly.

3.Connectthesparkplugwire.

4.Performtheannualmaintenanceproceduresasgiven

intheRecommendedMaintenanceSchedule.

25

Page 26

Troubleshooting

Problem

Electricstarterdoesnotturn(electric-start

modelsonly)

Enginedoesnotstartorstartshard

PossibleCauseCorrectiveAction

1.Thepowercordisdisconnectedatthe

outletorthemachine.

2.Thepowercordisworn,corroded,or

damaged.

3.Thepoweroutletisnotenergized.

1.Thekeyisnotintheignitionorisinthe

Stopposition.

2.ThechokeisintheOffpositionandthe

primerhasnotbeenpressed.

3.Thefuelshutoffvalveisnotopen.3.Openthefuelshutoffvalve.

4.ThethrottleisnotintheFastposition.4.MovethethrottletotheFastposition.

5.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

6.Thesparkplugwireislooseor

disconnected.

7.Thesparkplugispitted,fouled,orthe

gapisincorrect.

8.Thefuelventcapisrestricted.

9.Theengineoillevelintheengine

crankcaseistoolowortoohigh.

1.Connectthepowercordtotheoutlet

and/orthemachine.

2.Replacethepowercord.

3.Haveaqualiedelectricianenergize

theoutlet.

1.Insertthekeyintotheignitionandturn

ittotheOnposition.

2.MovethechoketotheOnpositionand

presstheprimer3times.

5.Drainand/orllthefueltankwithfresh

gasoline(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

6.Connectthewiretothesparkplug.

7.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

8.Removetheventrestrictionorreplace

thefuelcap.

9.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

Enginerunsrough

Engineruns,butthemachinedischarges

snowpoorlyornotatall

1.ThechokeisintheOnposition.1.MovethechoketotheOffposition.

2.Thefuelshutoffvalveisnotcompletely

open.

3.Thefueltankisnearlyemptyor

containsstalefuel.

4.Thesparkplugwireisloose.

5.Thesparkplugispitted,fouled,orthe

gapisincorrect.

6.Theengineoillevelintheengine

crankcaseistoolowortoohigh.

1.ThethrottleisnotintheFastposition

whenthrowingsnow .

2.Themachineismovingtoofasttoclear

thesnow.

3.Y ouaretryingtoremovetoomuch

snowperswath.

4.Y ouaretryingtoremoveextremely

heavyorwetsnow.

5.Thedischargechuteisplugged.5.Unclogthedischargechute.

6.Theauger/impellerdrivebeltisloose

orisoffthepulley.

2.Openthefuelshutoffvalve.

3.Drainandllthefueltankwithfresh

gasoline(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

4.Connectthewiretothesparkplug.

5.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

6.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

1.MovethethrottletotheFastposition.

2.Shiftthemachineintoalowergear.

3.Reducetheamountofsnowremoved

perswath.

4.Don’toverloadthemachinewith

extremelyheavyorwetsnow.

6.Installand/oradjusttheauger/impeller

drivebelt;refertowww.Toro.com

forservicinginformationortakethe

machinetoanAuthorizedService

Dealer.

26

Page 27

Problem

7.Theauger/impellerdrivebeltisworn

orbroken.

PossibleCauseCorrectiveAction

7.Replacetheauger/impellerdrivebelt;

refertowww.Toro.comforservicing

informationortakethemachinetoan

AuthorizedServiceDealer.

Dischargechuteeitherdoesnotlockinto

placeordoesnotmove

Machinedoesnotproperlyclearthesnow

offthesurface

1.Thedischargechutelatchisnot

properlyadjusted.

1.Theskidsand/orscraperarenot

properlyadjusted.

2.Thepressureinthetiresisnotequal.

1.Adjustthedischargechutelatch.

1.Adjusttheskidsand/orthescraper.

2.Checkandadjustthepressureinone

orbothtires.

27

Page 28

AThree-Y earLimitedWarranty(45DayLimitedWarrantyforCommercialUse)

TheToroT otalCoverageGuarantee

PowerMax

PowerThrow

Two-StageSnowthrowers

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuantto

anagreementbetweenthem,jointlypromisetorepairtheT oroProduct

listedbelowifusedforresidentialpurposes*,ifdefectiveinmaterialsor

workmanshiporifitstopsfunctioningduetothefailureofacomponent

fortheperiodlistedbelow.

Thiswarrantycoversthecostofpartsandlabor ,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

PowerMaxSnowthrowersandAttachments

—PowerMaxChute

—PowerMaxDeector

—PowerMaxImpellerHousingCover

PowerThrowSnowthrowersandAttachments

3years

5years

5years

5years

3years

LimitedWarrantyforCommercialUse

Gas-poweredT oroProductsusedforcommercial,institutional,or

rentaluse,arewarrantedfor45daysagainstdefectsinmaterialsor

workmanship.Componentsfailingduetonormalweararenotcovered

bythiswarranty.

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedT oroServiceDealertoarrangeserviceattheir

dealership.Tolocateadealerconvenienttoyou,refertotheYellow

Pagesofyourtelephonedirectory(lookunder“LawnMowers”)or

accessourwebsiteatwww.Toro.com.Youmayalsocallthenumbers

listedinitem#3tousethe24-hourT oroDealerlocatorsystem.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.Thedealerwilldiagnosetheproblemanddetermine

ifitiscoveredunderwarranty.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

CustomerCareDepartment,ConsumerDivision

TheT oroCompany

811 1L yndaleAvenueSouth

Bloomington,MN55420-1196

Tollfreeat866-336-5205(U.S.customers)

Tollfreeat866-854–9033(Canadiancustomers)

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

ItemsandConditionsNotCovered

Thereisnootherexpresswarrantyexceptforspecialemissionsystem

coverageandenginewarrantycoverageonsomeproducts.Thisexpress

warrantydoesnotcoverthefollowing:

•Costofregularmaintenanceserviceorwearparts,suchasrotor

blades(paddles),scraperblades,belts,fuel,lubricants,oilchanges,

sparkplugs,cable/linkageorbrakeadjustments

•Anyproductorpartwhichhasbeenalteredormisusedandrequires

replacementorrepairduetoaccidentsorlackofpropermaintenance

•Repairsnecessaryduetofailuretousefreshfuel(lessthanone

monthold),orfailuretoproperlypreparetheunitpriortoanyperiod

ofnon-useoveronemonth

•Pickupanddeliverycharges

•Operationalmisuse,neglect,oraccidents

•RepairsorattemptedrepairsbyanyoneotherthananAuthorized

ToroServiceDealer

GeneralConditions

Allrepairscoveredbythesewarrantiesmustbeperformedbyan

AuthorizedToroServiceDealerusingT oroapprovedreplacementparts.

RepairbyanAuthorizedToroServiceDealerisyoursoleremedyunder

thiswarranty .

NeitherTheT oroCompanynorT oroWarrantyCompanyisliablefor

indirect,incidental,orconsequentialdamagesinconnectionwiththe

useoftheT oroProductscoveredbythesewarranties,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthesewarranties.

Allimpliedwarrantiesofmerchantability(thattheproductistforordinary

use)andtnessforuse(thattheproductistforaparticularpurpose)are

limitedtothedurationoftheexpressedwarranty.Somestatesdonot

allowexclusionsofincidentalorconsequentialdamages,orlimitationson

howlonganimpliedwarrantylasts,sotheaboveexclusionsmaynot

applytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor’sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter .Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

*Residentialpurposesmeansuseoftheproductonthesamelotasyourhome.Useatmorethanonelocation,orinstitutionalorrentaluse,isconsidered

commercialuse,andthecommercialusewarrantywouldapply .

374-0251RevB

Loading...

Loading...