Page 1

Snow Commander® Snowthrower

Model No. 38602 —Serial No. 260000001 and Up

Introduction

R ead this infor mation carefully to lear n ho w to operate and

maintain y our product properly and to a v oid injur y and

product damag e . Y ou are responsible for operating the

product properly and safely .

Form No. 3354-151 Rev B

Operator's Manual

Warning

CALIFORNIA

Pr oposition 65 W ar ning

T he engine exhaust fr om this pr oduct contains

chemicals kno wn to the State of Calif or nia to cause

cancer , bir th defects, or other r epr oducti v e har m.

Y ou ma y contact T oro directly at www .T oro .com for

product and accessor y infor mation, help finding a dealer ,

or to register y our product.

W henev er y ou need ser vice , g en uine T oro par ts , or

additional infor mation, contact an A uthorized Ser vice

Dealer or T oro Customer Ser vice and ha v e the model and

serial n umbers of y our product ready . Figure 1 identifies the

location of the model and serial n umbers on the product.

W rite the n umbers in the space pro vided.

Figure 1

1. Model and serial number location

Model No.

Serial No.

T his man ual identifies potential hazards and has safety

messag es identified b y the safety aler t symbol ( Figure 2 ),

whic h signals a hazard that ma y cause serious injur y or

death if y ou do not follo w the recommended precautions .

Important: T he 2-str ok e engine pr o vided on this

pr oduct meets the EP A Phase I Non-r oad Emissions

r egulations f or engines under 19 kW . T his pr oduct

does not meet CARB TIER 1 r egulations and cannot

be sold in Calif or nia.

T his spark ignition system complies with Canadian

ICES-002

Safety

T his sno wthr o w er meets or ex ceeds the B71.3

specifications of the American National Standards

Institute in ef fect at the time of pr oduction.

R ead and under stand the contents of this man ual

bef or e the engine is ev er star ted.

T his is the safety aler t symbol. It is used to aler t y ou

to potential per sonal injur y hazards. Obey all safety

messa ges that f ollo w this symbol to a v oid possible

injur y or death.

Impr oper l y using or maintaining this sno wthr o w er

could r esult in injur y or death. T o r educe this potential,

compl y with the f ollo wing safety instr uctions.

T he follo wing instr uctions ha v e been adapted from the

ANSI/OPEI standard B71.3-2005 and the ISO 8437:1989

standard.

Figure 2

1. Safety alert symbol

T his man ual uses 2 w ords to highlight infor mation.

Impor tant calls attention to special mec hanical infor mation

and Note emphasizes g eneral infor mation w or th y of special

attention.

© 2005—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

T his sno wthro w er is capable of amputating hands and feet

and thro wing objects . F ailure to obser v e the follo wing

safety instr uctions could result in serious injur y .

Training

• R ead, understand and follo w all instr uctions on the

mac hine and in the man ual(s) before operating this unit.

Be thoroughly familiar with the controls and the proper

use of the equipment. Kno w ho w to stop the unit and

diseng ag e the controls quic kly .

Register at www.Toro.com. Original Instructions (EN)

Printed in the USA

All Rights Reserved

Page 2

• Nev er allo w c hildren to operate the equipment. Nev er

allo w adults to operate the equipment without proper

instr uction.

• K ee p the area of operation clear of all persons ,

par ticularly small c hildren.

• Ex ercise caution to a v oid slipping or falling .

Preparation

• T horoughly inspect the area where the equipment is to

be used and remo v e all door mats , sleds , boards , wires ,

and other foreign objects .

• R elease the control bar to diseng ag e the rotor blades

before star ting the engine .

• Do not operate the equipment without w earing

adequate winter g ar ments . A v oid loose fitting clothing

that can g et caught in mo ving par ts . W ear footw ear that

will impro v e footing on slipper y surfaces .

• Handle fuel with care; it is highly flammable .

– Use an appro v ed fuel container .

– Nev er add fuel to a r unning engine or hot engine .

– Fill fuel tank outdoors with extreme care . Nev er fill

fuel tank indoors .

– Nev er fill containers inside a v ehicle or on a tr uc k

or trailer bed with a plastic liner . Alw a ys place

containers on the g round, a w a y from y our v ehicle ,

before filling .

– W hen practical, remo v e g as-po w ered equipment

from the tr uc k or trailer and refuel it on the g round.

If this is not possible , then refuel suc h equipment

on a trailer with a por table container , rather than

from a g asoline dispenser nozzle .

– K ee p the nozzle in contact with the rim of the fuel

tank or container opening at all times , until refueling

is complete . Do not use a nozzle loc k-open device .

– R e place g asoline cap securely and wipe up spilled

fuel.

– If fuel is spilled on clothing, c hang e clothing

immediately .

• Use extension cords and rece ptacles as specified b y

T oro for all units with electric star ting motors .

• Do not attempt to clear sno w from a g ra v el or cr ushed

roc k surface . T his product is intended for use only on

pa v ed surfaces .

• Nev er attempt to mak e any adjustments while the engine

is r unning (ex ce pt when specifically recommended b y

T oro).

• Alw a ys w ear safety glasses or eye shields during

operation or while perfor ming an adjustment or re pair

to protect eyes from foreign objects that ma y be thro wn

from the mac hine .

Operation

• Do not put hands or feet near or under rotating par ts .

K ee p clear of the disc harg e opening at all times .

• Ex ercise extreme caution when crossing g ra v el dri v es ,

w alks , or roads . Sta y aler t for hidden hazards or traffic .

• After striking a foreign object, stop the engine ,

disconnect the wire from the spark plug, thoroughly

inspect the sno wthro w er for any damag e , and re pair

the damag e before restar ting and operating the

sno wthro w er .

• If the unit should star t to vibrate abnor mally , stop the

engine and c hec k immediately for the cause . Vibration

is g enerally a w ar ning of trouble .

• Stop the engine whenev er y ou lea v e the operating

position, before unclog ging the collector/impeller

housing or disc harg e c hute , and when making any

re pairs , adjustments , or inspections .

• W hen cleaning, re pairing or inspecting the sno wthro w er ,

stop the engine and mak e cer tain the rotor blades and

all mo ving par ts ha v e stopped.

• Do not r un the engine indoors , ex ce pt when star ting

the engine and for transpor ting the sno wthro w er in or

out of the building . Open the outside doors; exhaust

fumes are dang erous .

• Ex ercise extreme caution when operating on slopes .

• Nev er operate the sno wthro w er without proper guards ,

and other safety protecti v e devices in place and w orking .

• Nev er direct the disc harg e to w ard people or areas where

proper ty damag e can occur . K ee p c hildren and others

a w a y .

• Do not o v erload the mac hine capacity b y attempting to

clear sno w at too fast a rate .

• Look behind and use care when bac king up with the

sno wthro w er .

• Nev er operate the sno wthro w er without g ood visibility

or light. Alw a ys be sure of y our footing, and k ee p a fir m

hold on the handles . W alk; nev er r un.

Clearing a Clogged Discharge

Chute

Hand contact with the rotor blades is a common cause of

injur y associated with sno wthro w ers . Nev er use y our hand

to clean out the disc harg e c hute .

T o clear the c hute:

• Shut the engine of f !

• W ait 10 seconds to be sure the rotor blades ha v e

stopped rotating .

• Alw a ys use a clean-out tool, not y our hands .

2

Page 3

Maintenance and Storage

• Chec k all fasteners at frequent inter v als for proper

tightness to be sure the equipment is in safe w orking

condition.

• Nev er store the mac hine with fuel in the fuel tank inside

a building where ignition sources are present suc h as hot

w ater heaters , space heaters , or clothes dr yers . Allo w

the engine to cool before storing in any enclosure .

• Alw a ys refer to this operator’ s man ual for impor tant

details if the sno wthro w er is to be stored for an

extended period.

• Maintain or re place safety and instr uction labels , as

necessar y .

• R un the mac hine a few min utes after thro wing sno w to

prev ent freeze-up of the rotor blades .

Toro Snowthrower Safety

T he follo wing list contains safety infor mation specific to

T oro products or other safety infor mation that y ou m ust

kno w .

• Do not c hang e the g o v er nor settings on the engine .

• W hen storing the sno wthro w er for more than 30 da ys ,

drain the fuel from the fuel tank to prev ent a potential

hazard. Store fuel in an appro v ed fuel container .

R emo v e the k ey from the ignition switc h before storing

the sno wthro w er .

• Purc hase only g en uine T oro re placement par ts and

accessories .

• R otating r otor blades can injur e finger s or hands.

Sta y behind the handles and a w a y from the disc harg e

opening while operating the sno wthro w er . K eep y our

f ace, hands, feet, and an y other par t of y our body or

clothing a w ay fr om mo ving or r otating par ts.

• Before adjusting, cleaning, re pairing, and inspecting

the sno wthro w er , and before unclog ging the disc harg e

c hute , stop the engine, r emo v e the k ey , and w ait f or

all mo ving par ts to stop .

• Use a stic k, not y our hands , to remo v e obstr uctions

from the disc harg e c hute .

• Bef or e lea ving the operating position, stop the engine ,

remo v e the k ey , and w ait for all mo ving par ts to stop .

• Do not w ear loose-fitting clothing that could g et caught

in mo ving par ts .

• If a shield, safety device , or decal is damag ed, illegible ,

or lost, re pair or re place it before beginning operation.

Also , tighten any loose fasteners .

• Do not smok e while handling g asoline .

• Do not use the sno wthro w er on a roof .

• Do not touc h the engine while it is r unning or soon

after it has stopped because the engine ma y be hot

enough to cause a bur n.

• P erfor m only those maintenance instr uctions described

in this man ual. Before perfor ming any maintenance ,

ser vice , or adjustment, stop the engine , remo v e the k ey ,

and disconnect the wire from the spark plug . If major

re pairs are ev er needed, contact an A uthorized Ser vice

Dealer .

3

Page 4

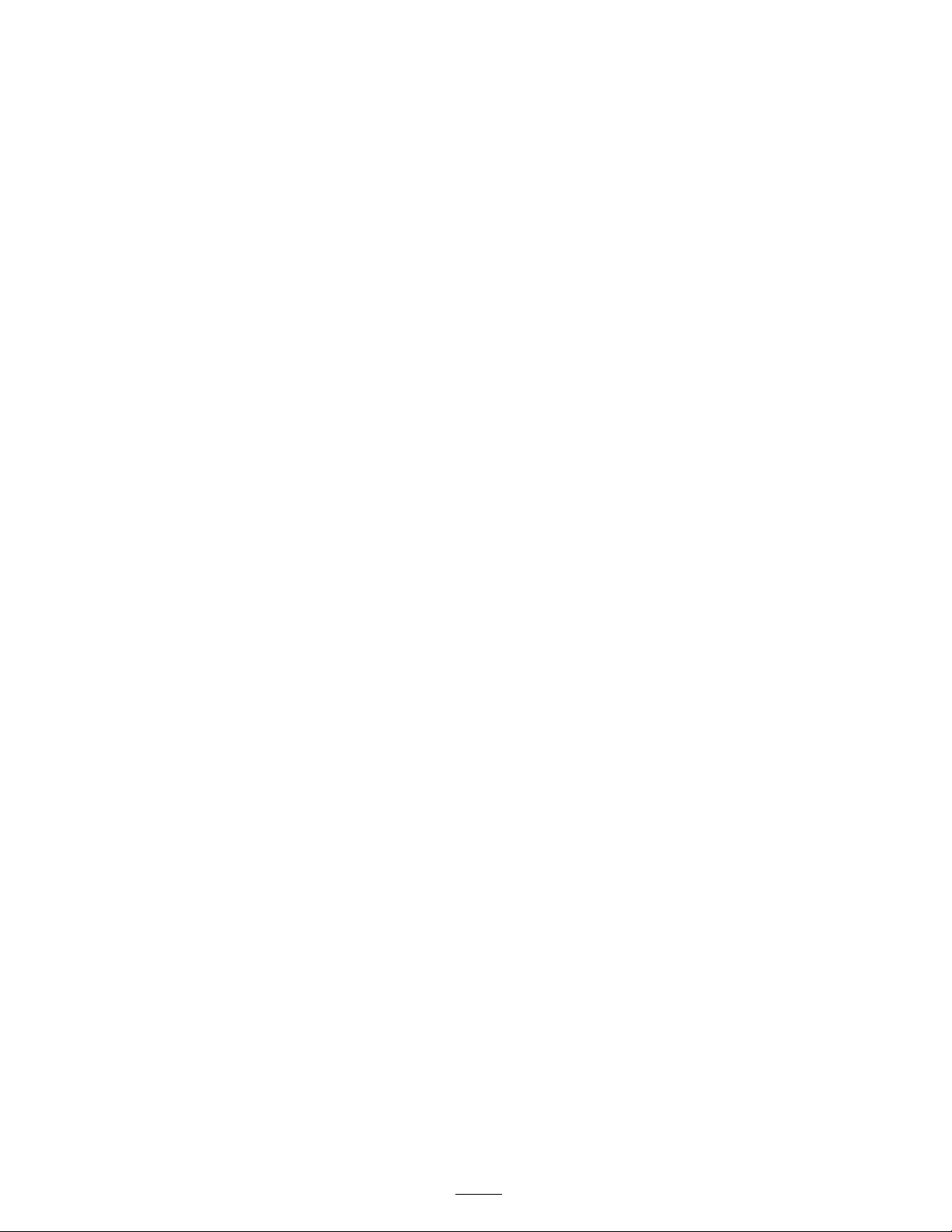

Safety and Instructional Decals

Important: Safety and instr uction decals ar e located near ar eas of potential danger . R eplace dama ged decals.

Note: Y our engine has one of the follo wing decals:

Phase 1 decal Phase 2 decal

F r ench translation of

U .S . EP A decal text:

Ce moteur est confor me à la

réglementation antipollution Phase

EP A relati v e aux moteurs ULGE.

F amille : XXXXX.XXXXXX F amille : XXXXX.XXXXXX

Nº de modèle : XXX-XXXX Nº de modèle : XXX-XXXX

CYLINDREE (CC) : 141 CYLINDREE (CC) : 141

P our plus de détails sur la

sécurité, l’entretien et les réglag es ,

re por tez-v ous au man uel de

l’utilisateur . Nº de téléphone des

ser vices de v ente et d’après-v ente

aux Etats-Unis : 1-800-526-6937

T he T oro® Company

Bloomington, MN

INFORMA TION IMPOR T ANTE CONCERNANT LE MOTEUR INFORMA TION IMPOR T ANTE CONCERNANT LE MOTEUR

F r ench translation of

U .S . EP A decal text:

Ce moteur est confor me à la

réglementation antipollution Phase

II EP A relati v e aux moteurs ULGE.

P endant une durée de vie mo yenne

(C).

P our plus de détails sur la

sécurité, l’entretien et les réglag es ,

re por tez-v ous au man uel de

l’utilisateur . Nº de téléphone des

ser vices de v ente et d’après-v ente

aux Etats-Unis : 1-800-526-6937

Canada: 1-866-854-9033

T he T oro® Company

Bloomington, MN

Note: T he Phase 2 engine identification decal includes

the engine life specification for the emission-related

useful life period of the engine . T his period relates to

the emission compliance life as cer tified b y EP A and/or

CARB . T he life period specification for y our engine is

designated as C (125 hours).

61-4790

4

Page 5

104-0897

Reorder Part No. 104-0863

104-2767

104-2775

104-4135

104-4125

5

Page 6

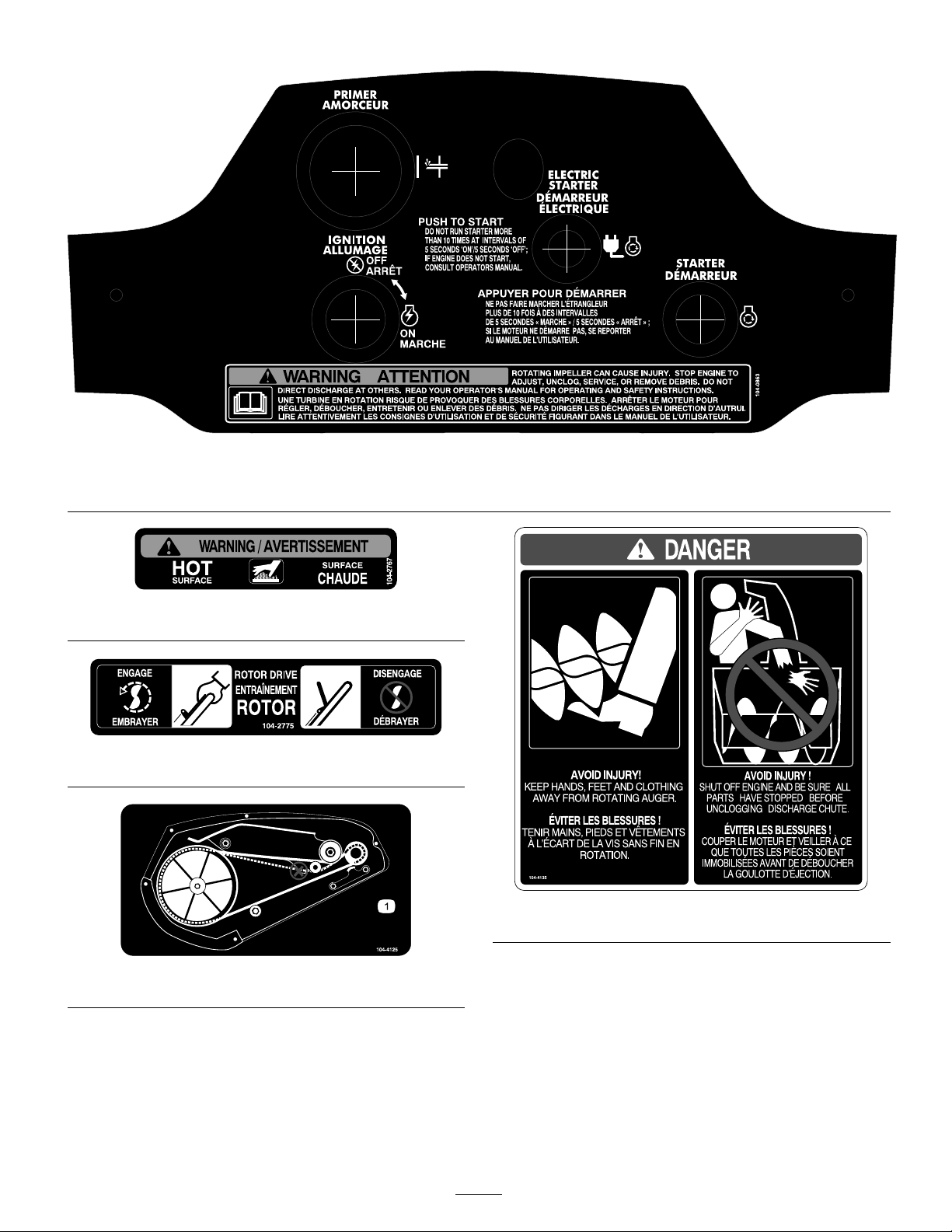

Setup

Loose Parts

Use the chart below to verify that all parts have been shipped.

105-1978

Reorder Part No. 104-0874

Step

1.

2.

No parts required

Discharge chute

Phillips head screws

Washers

Locknuts

Description

1. Unfolding the Handle

1. Cut the plastic tie that secures the control cable to the

handle .

2. Loosen the knobs and pull out the handle bolts ( Figure

3 ).

Qty.

–

1

3

3

3

Figure 4

4. Install the handle bolts , set the cable guide in position,

and tighten the knobs until they are sn ug ( Figure 5 ).

Unfold the handle.

Install the discharge chute.

Use

Figure 3

3. R otate the upper handle to the operating position

( Figure 4 ).

6

Page 7

Figure 5

5. Adjust the rotor control cable and the traction dri v e

cable . R efer to Adjusting the R otor Control Cable and

to Adjusting the T raction Dri v e Cable .

2. Installing the Discharge

Chute

Install the disc harg e c hute as sho wn ( Figure 6 ).

Product Overview

Figure 7

1. Discharge chute

2. Chute handle

3. Control bar 8. Rotor blades

4. Handle

5. Control panel

6. Knob (2)

7. Handle bolt (2)

9. Fuel tank cap (not shown)

Figure 6

Figure 8

1. Key switch 4. Recoil start

2. Primer

3. Electric-start button 6. Choke lever

7

5. Cord connection

Page 8

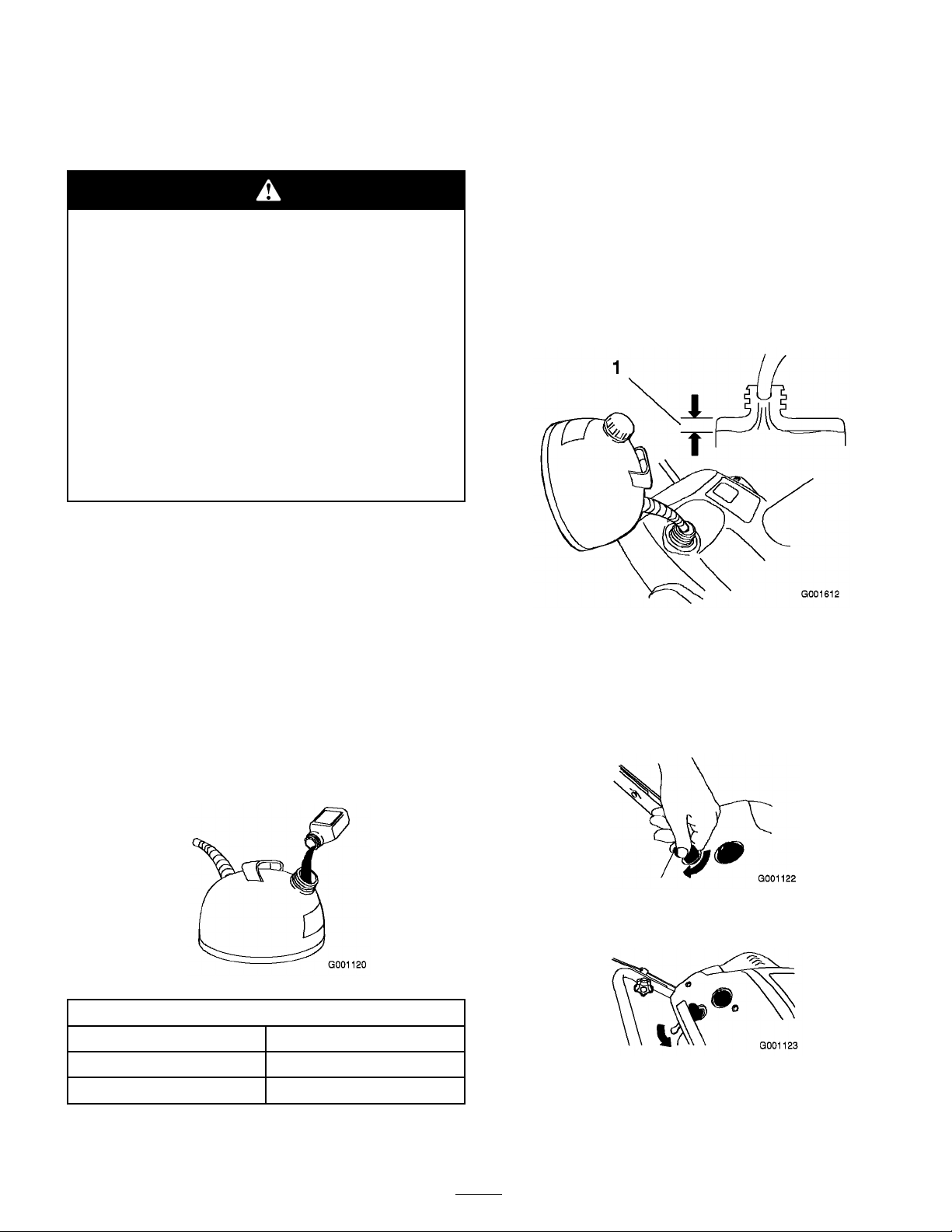

Operation

Note: Deter mine the left and right sides of the mac hine

from the nor mal operating position.

Gasoline is extr emel y flamma ble and explosi v e. A

fir e or explosion fr om gasoline can bur n y ou and

other s.

• T o pr ev ent a static charge fr om igniting the

gasoline, place the container and/or sno wthr o w er

on the g r ound bef or e filling , not in a v ehicle or

on an object.

• Fill the tank outdoor s when the engine is cold.

W ipe up spills.

• Do not handle gasoline when smoking or ar ound

an open flame or spar ks.

• Stor e gasoline in an appr o v ed fuel container , out

of the r each of childr en.

4. Shak e the container to mix the g asoline and oil

thoroughly .

5. Slo wly remo v e the cap and add the remaining amount

of g asoline .

Note: Do not mix g asoline and oil in the fuel tank. Oil

at room temperature mix es easier and more thoroughly

than cold oil. Oil belo w 32°F (0°C) requires additional

mixing .

Filling the Fuel Tank

Fill the fuel tank with a fresh mixture of g asoline and oil

mix ed at the proper ratio ( Figure 10 ).

Mixing the Gasoline and Oil

T his sno wthro w er uses a 50:1 g asoline-to-oil mixture . Use

T or o 50:1 2-Cy cle Oil (Fuel Sta biliz er Added) or an

equi v alent high-g rade , NMMA TCW -cer tified tw o-cycle oil.

Important: T o pr ev ent engine dama ge, do not use

automoti v e oil (such as SAE 30 or 10W30) or fuel mix ed

at the wr ong gasoline-to-oil ratio.

1. P our a half US g allon (1.9 liters) of fresh, unleaded

g asoline into an appro v ed fuel container .

2. Add tw o-cycle oil to the g asoline according to the c har t

belo w ( Figure 9 ):

Figure 9

Figure 10

1. 1/2 inch (1.3 cm)

Starting the Engine

1. T ur n the ignition k ey cloc kwise to the On position

( Figure 11 ).

Figure 11

2. Mo v e the c hok e lev er to the right ( Figure 12 ).

50:1 Gasoline-to-Oil Ratio Mixing Chart

Gasoline Oil

1 US gallon (3.8 liters) 2.6 ounces (80 ml)

2 US gallons (7.6 liters) 5.2 ounces (160 ml)

3. Install the cap on the fuel container .

Figure 12

3. Fir mly push in the primer 2 times with y our thumb ,

holding the primer in for a second before releasing it

eac h time ( Figure 13 ).

8

Page 9

Figure 13

4. Push the electric-star t button ( Figure 14 ) or pull the

recoil star ter ( Figure 15 ).

Figure 14

Stopping the Engine

T o stop the engine , tur n the ignition k ey countercloc kwise

to the Off position ( Figure 16 ).

Figure 16

Starting the Rotor Blades

T o star t the rotor blades , squeeze the control bar to w ard the

handle until the sno wthro w er begins to pi v ot ( Figure 17 ).

Figure 15

Important: R un the electric star ter no mor e than

10 times at inter v als of 5 seconds on, then 5 seconds

of f. R unning the electric star ter extensi v el y can

o v erheat and dama ge it. If the engine does not star t

after this series of attempts, w ait at least 40 min utes

to allo w the star ter to cool bef or e attempting to

star t it a gain. If the engine does not star t after the

second series of attempts, tak e the sno wthr o w er to

an Authoriz ed Ser vice Dealer f or ser vice.

5. With the engine r unning, mo v e the c hok e lev er to the

left slo wly .

If y ou lea v e the sno wthr o w er plug ged into a

po w er outlet, someone can inadv er tentl y star t

the sno wthr o w er and injur e people or dama ge

pr oper ty .

Unplug the po w er cord whenev er y ou ar e not

star ting the sno wthr o w er .

Figure 17

Stopping the Rotor Blades

T o stop the rotor blades , release the control bar ( Figure 18 ).

Figure 18

Note: W hen y ou release the control bar , the rotor blades

stop , but the engine contin ues to r un.

Starting the Traction Drive

T o star t the traction dri v e , slo wly squeeze the control bar

to w ard the handle . T he front of the sno wthro w er pi v ots

do wnw ard. W hen the rotor blades touc h the g round,

the sno wthro w er begins to mo v e forw ard. Squeezing the

control bar completely to the handle pro vides maxim um

traction.

9

Page 10

Stopping the Traction Drive

T o stop the traction dri v e , par tially release the control bar

until the rotor blades lift off the g round, diseng aging the

traction dri v e . R eleasing the control bar completely stops

both the traction dri v e and the rotor blades .

Adjusting the Discharge Chute

T o adjust the disc harg e c hute , mo v e the c hute handle and

the c hute deflector handle as sho wn ( Figure 19 ).

Figure 19

1. Chute handle 2. Chute deector handle

the handle , but allo w the sno wthro w er to w ork at its

o wn pace .

• Ov erlap eac h sw ath to ensure complete sno w remo v al.

• Disc harg e the sno w do wnwind whenev er possible .

• In sno wy and cold conditions , some controls and

mo ving par ts ma y freeze . Do not use ex cessi v e f orce

when tr ying to operate fr oz en contr ols. If y ou ha v e

difficulty operating any control or par t, star t the engine

and let it r un for a few min utes .

Preventing Freeze-up after Use

• Let the engine r un for a few min utes to prev ent mo ving

par ts from freezing . Stop the engine , w ait for all

mo ving par ts to stop , and remo v e ice and sno w from

the sno wthro w er .

• With the engine off , pull the recoil star ter handle

sev eral times and push the electric star t button once

(if applicable) to prev ent the recoil and electric star ters

from freezing up .

Operating Tips

T he r otor blades can thr o w stones, toys, and other

f or eign objects and cause serious per sonal injur y to

the operator or to bystander s.

• K eep the ar ea to be clear ed fr ee of all objects that

the r otor blades could pick up and thr o w .

• K eep all childr en and pets a w ay fr om the ar ea

of operation.

• R emo v e the sno w as soon as possible after it falls .

• T he sno wthro w er clears do wn to the g round and

propels itself forw ard when y ou eng ag e the traction

dri v e .

• If the sno wthro w er does not propel itself forw ard on

slipper y surfaces or in hea vy sno w , push forw ard on

10

Page 11

Maintenance

Note: Deter mine the left and right sides of the mac hine from the nor mal operating position.

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

After the rst operating

hour

Yearly

Yearly or before storage

Maintenance Procedure

• Check the rotor control cable and the traction drive cable both initially and after

the rst hour of operation; adjust them if necessary.

• Check for loose fasteners and tighten them if necessary.

• Check the rotor control cable and the traction drive cable and adjust them if

necessary.

• Inspect the rotor blades and have an Authorized Service Dealer replace the rotor

blades and the scraper if necessary.

• Have an Authorized Service Dealer inspect the spark plug and replace it if

necessary.

• Have an Authorized Service Dealer inspect the drive belt and replace it if necessary.

• Check for loose fasteners and tighten them if necessary.

• Prepare the snowthrower for storage.

Adjusting the Rotor Control

Cable

Checking the Rotor Control Cable

Chec k the rotor control cable for proper adjustment initially ,

after the first operating hour , and then ann ually thereafter .

1. Mo v e the control bar bac k to w ard the handle until y ou

remo v e the slac k in the cable ( Figure 20 ).

Important: T he r otor contr ol ca ble must ha v e

slack in it when y ou disenga ge the contr ol bar in

order f or the r otor blades to stop pr oper l y .

Adjusting the Rotor Control Cable

1. Unhook the spring end from the control bar brac k et.

( Figure 22 ).

Figure 20

2. Ensure that a 1/8 to 1/4 inc h (3 to 6 mm) g ap exists

betw een the control bar brac k et and the handle ( Figure

21 ).

Figure 21

1. 1/8 to 1/4 inch (3 to 6 mm)

2. Control bar bracket

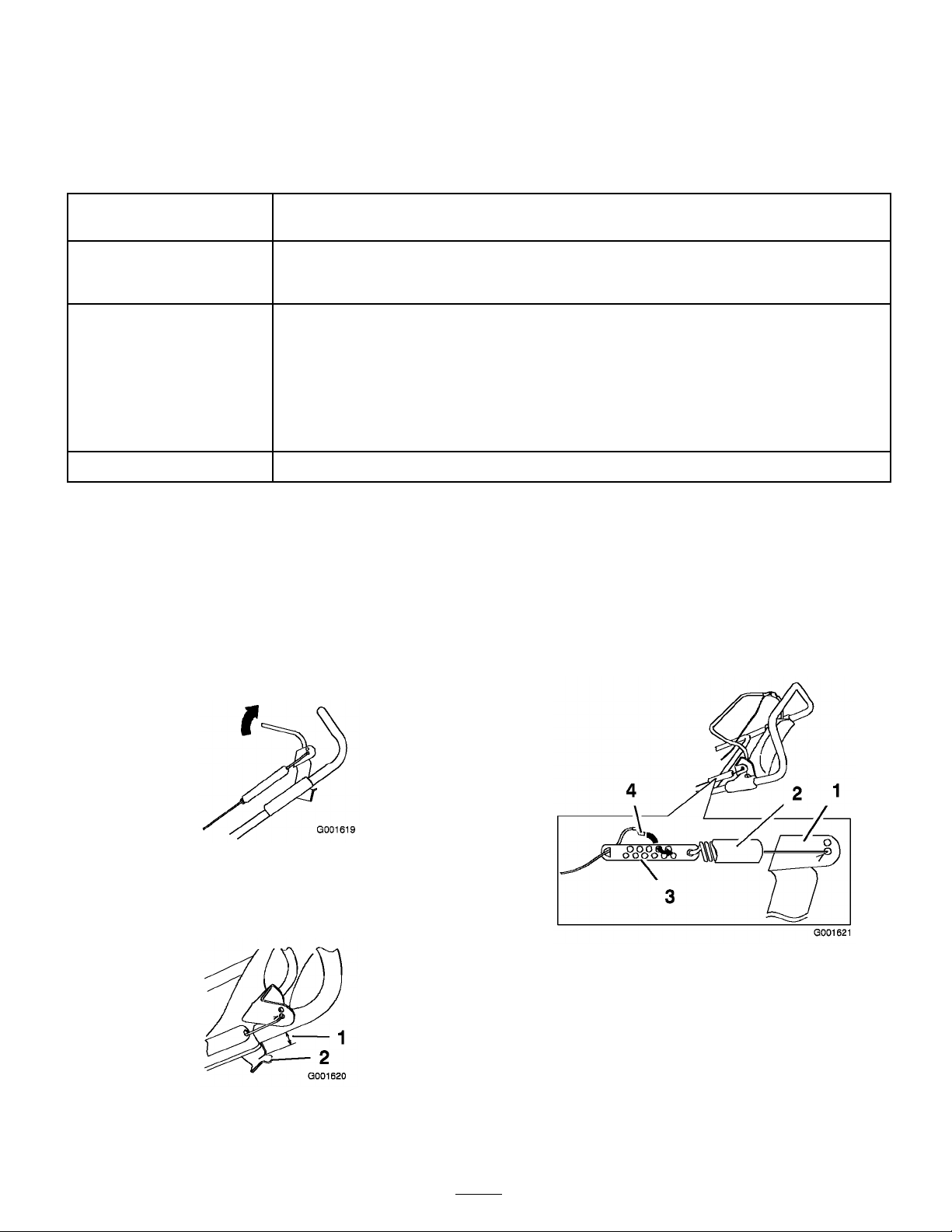

Figure 22

1. Control bar bracket 3. Cable adjuster

2. Spring cover

4. Z-tting

2. Slide the spring co v er up the cable adjuster . ( Figure 22 ).

3. Unhook the Z-fitting from the cable adjuster , and

position it in a different hole on the adjuster to obtain a

g ap of 1/8 to 1/4 inc h (3 to 6 mm) betw een the control

bar brac k et and the handle ( Figure 22 ).

11

Page 12

Note: Mo ving the Z-fitting to a hole closer to the

spring decreases the g ap betw een the control bar

brac k et and the handle; mo ving it to a hole far ther from

the spring increases the g ap .

4. Install the spring co v er o v er the cable adjuster .

5. Hook the spring end into the hole in the center of the

control bar brac k et.

6. Chec k the adjustment.

Note: After extended use , the dri v e belt ma y w ear and lose

its proper belt tension. If the dri v e belt slips (contin uously

squeals) under a hea vy load, increase the belt tension b y

inser ting the spring end into the other hole in the control

bar brac k et. T he belt ma y slip in w et conditions; to dr y out

the dri v e system, star t the rotor and operate it without a

load for 30 seconds . Adjust the g ap betw een the control bar

brac k et and the handle to 1/8 to 1/4 inc h (3 to 6 mm).

Adjusting the Traction Drive

Cable

Chec k the traction dri v e cable for proper adjustment initially ,

after the first operating hour , and then ann ually thereafter .

Checking the Traction Drive Cable

1. Squeeze the control bar ag ainst the right side of the

handle ( Figure 23 ).

Important: If the pi v ot plate touches the wheel

frame bef or e the contr ol bar touches the handle,

the ca ble is too tight.

Adjusting the Traction Drive Cable

Unhook the Z-fitting from the pi v ot cable adjuster , and

inser t it into a different hole to obtain the proper g ap

betw een the pi v ot plate and the wheel frame ( Figure 25 ).

Figure 25

1. Z-tting 4. Pivot plate

2. Pivot cable adjuster 5. Wheel frame

3. 0 to 1/8 inch (0 to 3 mm) gap

Note: Mo ving the Z-fitting to a hole closer to the g round

decreases the g ap betw een the pi v ot plate and the wheel

frame; mo ving it to a hole far ther from the g round increases

the g ap .

Figure 23

2. Ensure that the distance betw een the pi v ot plate and the

wheel frame is 0 to 1/8 inc h (0 to 3 mm) ( Figure 24 ).

Figure 24

1. 0 to 1/8 inch (0 to 3 mm)

2. Pivot plate

3. Wheel frame

Note: T he traction speed is fastest when the rotor blades

are new . If y ou w ant to reduce the traction speed, mo v e

the Z-fitting one hole far ther from the g round. T he g ap

betw een the pi v ot plate and the wheel frame will be about

1/4 inc h (6 mm).

Inspecting the Rotor Blades

Before eac h season, inspect the rotor blades for w ear . W hen

a rotor blade edg e has w or n do wn to the w ear indicator

12

Page 13

hole , ha v e an A uthorized Ser vice Dealer re place all 3 rotor

blades and the scraper ( Figure 26 )

Figure 26

1. Wear indicator hole

Storage

5. Star t the engine and r un it until it stops .

6. Chok e or prime the engine , star t it a third time , and r un

the engine until it will not star t.

7. Slo wly pull the recoil star ter until y ou feel resistance due

to compression pressure , then stop .

8. R elease the star ter tension g radually b y allo wing the

rope to g o bac k slo wly to prev ent the engine from

rev ersing due to compression pressure .

9. Dispose of un used fuel properly . R ecycle it according to

local codes , or use it in y our automobile .

Note: Do not store stabilized fuel for more than 90

da ys .

10. Tighten all loose screws , bolts , and loc kn uts . R e pair or

re place any damag ed par ts .

11. Clean the sno wthro w er thoroughly .

12. Co v er the sno wthro w er and store it in a clean, dr y place

out of the reac h of c hildren. Allo w the engine to cool

before storing it in any enclosure .

Storing the Snowthrower

Important: Stor e the sno wthr o w er in its operating

position and on its wheels. Storing the sno wthr o w er on

its fr ont housing may cause hard star ting .

• Gasoline fumes ar e highl y flamma ble, explosi v e,

and danger ous if inhaled. If y ou stor e the pr oduct

in an ar ea with an open flame, the gasoline fumes

may ignite and cause an explosion.

• Do not stor e the sno wthr o w er in a house (li ving

ar ea), basement, or an y other ar ea wher e ignition

sources may be pr esent, such as hot w ater and

space heater s, clothes dr y er s, fur naces, and other

lik e appliances.

Important: Do not use the chute handle to lift the

sno wthr o w er . T his can dama ge the chute handle.

1. Add a fuel stabilizer/conditioner to the fuel in the fuel

tank as directed.

Note: If y ou use T oro 50:1 2-Cycle Oil (Fuel

Stabilizer Added) , y ou do not need to add a fuel

stabilizer/conditioner .

2. R un the engine for 5 min utes to distribute the

conditioned fuel through the fuel system.

3. Stop the engine and allo w it to cool.

4. Use a hand pump to pump the fuel from the fuel tank

into an appro v ed fuel container , or r un the engine until

it stops .

Folding the Handle

1. Loosen the knobs and pull out the handle bolts .

2. F old the upper handle forw ard as sho wn ( Figure 27 ).

Figure 27

13

Page 14

Page 15

Federal Emission Control Warranty Statement

A Two-Year Limited Warranty

Your Warranty Rights and Obligations

The U.S. Environmental Protection Agency (EPA), Toro, and Toro Warranty

Company are pleased to explain the emission control system warranty on

your 1997 and later utility/lawn/garden equipment engine. 1997 and later

model year utility/lawn/garden equipment engines must be designed, built

and equipped, at the time of sale, to meet the U.S. EPA regulations for small

non-road engines. The equipment engine must be free from defects in materials

and workmanship, which cause it to fail to conform with U.S. EPA standards, for

the rst two years of engine use from the date of sale to the ultimate purchaser.

Toro and Toro Warranty Company warrant the emission control system on

your utility/lawn/garden equipment engine for the period of time listed above,

provided there has been no abuse, neglect, or improper maintenance of your

utility/lawn/garden equipment engine.

Your emission control system may include parts such as the carburetor or fuel

injection system, the ignition system, and catalytic converter. Also included may

be hoses, belts, connectors, and other emission related assemblies.

Where a warrantable condition exists, Toro and Toro Warranty Company

promise to repair your engine at no cost to you, including diagnosis, parts,

and labor.

Manufacturer’s Warranty Coverage

Toro and its afliate, Toro Warranty Company, pursuant to an agreement

between them, jointly warrant the 1997 and later utility/lawn/garden equipment

engines for two years from the date of delivery. If any emission-related part on

your engine is defective in materials or workmanship, we will repair or replace

the part, free of charge.

Owner Responsibilities

As the engine owner, you are responsible for the performance of the required

maintenance listed in your operator’s manual. We recommend that you

retain all receipts covering maintenance on your equipment, but we cannot

deny warranty solely for the lack of receipts or for your failure to ensure the

performance of all scheduled maintenance.

Any replacement part or service that is equivalent in performance and durability

may be used in non-warranty maintenance or repairs, and shall not reduce

our warranty obligation.

As the engine owner, you should be aware that we may deny you warranty

coverage if your engine or a part has failed due to abuse, neglect, improper

maintenance, or unapproved modications or parts.

You are responsible for presenting your equipment engine to an Authorized

Service Dealer as soon as a problem exists. The warranty repairs should be

completed in a reasonable amount of time, not to exceed thirty (30) days.

If you have any questions regarding your warranty rights and responsibilities,

contact us at:

Customer Care Department, Consumer Division

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

800-348-2424 (U.S. customers)

877-484-9255 (Canada customers)

Warranted Parts

The warranty period begins on the date the engine or equipment is delivered

to a retail purchaser. Toro and Toro Warranty Company jointly warrant to the

initial owner and each subsequent purchaser that the engine is free from defects

in materials and workmanship, which cause the engine to fail to conform with

applicable regulations, for a period of two years.

Failures caused by abuse, neglect, or improper maintenance are not covered.

The use of add-on or modied parts can be grounds for disallowing a warranty

claim. We are not liable to cover failures of warranted parts caused by the

use of add-on or modied parts. We are liable for damages to other engine

components caused by the failure of a warranted part still under warranty.

The owner is responsible for the performance of the required maintenance,

as dened in the operator’s manual.

Any warranted part which is not scheduled for replacement as required

maintenance, or which is scheduled only for regular inspection to the effect of

"repair or replace as necessary" shall be warranted for the warranty period. Any

warranted part which is scheduled for replacement as required maintenance

shall be warranted for the period of time up to the rst scheduled replacement

point for that part. Coverage under this warranty extends only to the parts listed

below (the emissions system parts) to the extent that these parts were present

on the engine when purchased.

• Fuel Metering System

– Cold start enrichment system including the choke mechanism or

priming system

– Fuel pump

– Air fuel ratio feedback system

– Carburetor and internal parts

– Fuel injection system

• Air Induction System

– Air cleaner

– Reed intake system

– Intake manifold

– Controlled hot air intake system

• Ignition System

– Spark plug(s)

– Ignition coils and electronics

– Advance/retard mechanisms

• Catalytic Converter/Thermal Reactor System

– Catalytic Converter

– Thermal reactor

– Exhaust manifold

• Air Injection System

– Air injection system or pulse valve

– Valves affecting distribution of air

• Exhaust Gas Recirculation (EGR) System

– EGR valve body and piping system connecting to the intake side of

the engine

– EGR control system

• Particulate Controls (Traps, lters, precipitators, and any other device used

to capture particulate emissions)

• Miscellaneous Items Used in the Above Systems

– Vacuum, temperature, and time-sensitive valves and switches

– Electronic controls

– Hoses, connectors, and assemblies of same

Instructions for Obtaining Warranty Service

If you think that your Toro Product contains a defect in materials or

workmanship, follow this procedure:

1. Contact any Toro Authorized or Master Service Dealer to arrange service at

their dealership. To locate a dealer convenient to you, refer to the Yellow

Pages of your telephone directory (look under "Lawn Mowers") or access

our website at www.Toro.com. U.S. Customers may also call 800-421-9684

to use our 24-hour Toro dealer locator system.

2. Bring the product and your proof of purchase (sales receipt) to the Service

Dealer.

The owner shall not be charged for diagnostic labor which leads to the

determination that a warranted part is defective, if the diagnostic work

is performed at a warranty station.

General Conditions

Neither The Toro Company nor Toro Warranty Company is liable for indirect,

incidental or consequential damages in connection with the use of the Toro

Products covered by this warranty, except for damages to other engine

components caused by the failure of a warranted part still under warranty.

All implied warranties of merchantability (that the product is t for ordinary use)

and tness for use (that the product is t for a particular purpose) are limited to

the duration of the express warranty.

Some states do not allow exclusions of incidental or consequential damages,

or limitations on how long an implied warranty lasts, so the above exclusions

and limitations may not apply to you.

This warranty gives you specic legal rights, and you may also have other rights

which vary from state to state.

374-0023 Rev C

Page 16

Snow Commander

and

Power Curve

Single-stage

Snow Products

The Toro 5-Year GTS Starting Guarantee and

The Toro 2-Year Total Coverage Guarantee

A Full Warranty (Limited Warranty for Commercial Use)

Conditions and Products Covered under The Toro Starting Guarantee

The Toro Company and its afliate, Toro Warranty Company, guarantee that your Toro GTS (Guaranteed to Start) engine, when used for residential purposes*,

will start on the rst or second pull for ve (5) years from the date of purchase, if you provide the routine maintenance it requires, or we will x it free of charge.

This warranty covers the cost of parts and labor, but you must pay transportation costs. This warranty applies to all Snow Commander® and Power Curve®

single-stage Toro Snowthrowers. (Not Powerlite® models.)

Conditions and Products Covered under The Toro Total Coverage Guarantee

The Toro Company and its afliate, Toro Warranty Company, promise to repair any Toro Product used for residential purposes* if defective in materials or

workmanship or if it stops functioning due to the failure of a component for a period of two (2) years from the date of purchase.

This warranty covers the cost of parts and labor, but you must pay transportation costs. This warranty applies to all Snow Commander® and Power Curve®

single-stage Toro Snowthrowers. (Not Powerlite® models.)

Limited Warranty for Commercial Use

Gas-powered Toro Snowthrowers used for commercial, institutional, or rental use are warranted for 45 days against defects in materials or workmanship.

Components failing due to normal wear are not covered by this warranty. The Toro Starting Guarantee does not apply when the product is used commercially.

Items and Conditions Not Covered

There is no other express warranty. This express warranty does not cover the following:

• Cost of regular maintenance service or parts, such as lters, fuel, lubricants, oil changes, spark plugs, cable/linkage adjustments, or brake and clutch

adjustments

• Any product or part which has been altered or misused or required replacement or repair due to accidents or lack of proper maintenance

• Repairs necessary due to electrical supply irregularities or failure to properly prepare the snowthrower prior to any period of non-use over three months

• Pickup and delivery charges

• Operational misuse, neglect, or accidents

• Repairs or attempted repairs by anyone other than a Toro Service outlet

• Repairs or adjustments to correct starting difculties due to the following:

– failure to follow proper maintenance procedures

– snowthrower auger/paddles striking an object

– contaminants in the fuel system

– improper fuel or fuel/oil mixture (consult your Operator’s Manual if in doubt)

– failure to drain the fuel system prior to any period of non-use over three months

• Special operational conditions where starting may require more than two pulls:

– rst time starts after extended period of non-use over three months or seasonal storage

– improper starting procedures

If you are having difculty starting your unit, please check the Operator’s Manual to ensure that you are using the correct starting procedures. This can

save an unnecessary visit to a Service Dealer.

Owner Responsibilities

You must maintain your Toro Product by following the maintenance procedures described in the Operator’s Manual . Such routine maintenance, whether

performed by a dealer or by you, is at your expense.

Instructions for Obtaining Warranty Service

If you think that your Toro Product contains a defect in materials or workmanship, or if a normal, able-bodied adult can no longer start your product’s engine

in one or two pulls, follow this procedure:

1. Contact any Toro Authorized or Master Service Dealer to arrange service at their dealership. To locate a dealer convenient to you, refer to the Yellow Pages of

your telephone directory (look under Lawn Mowers ) or access our website at www.Toro.com. You may also call our Toro Customer Care Department toll free

at 866-336-5205 (U.S. customers) or 866-854-9033 (Canadian customers).

2. Bring the product and your proof of purchase (sales receipt) to the Service Dealer.

3. If for any reason you are dissatised with the Service Dealer’s analysis or with the assistance provided, contact us at: Customer Care Department, Consumer

Division, Toro Warranty Company, 8111 Lyndale Avenue South, Bloomington, MN 55420-1196.

General Conditions

All repairs covered by these warranties must be performed by an Authorized or Master Toro Service Dealer using Toro approved replacement parts. Repair by a

Toro Service Dealer is your sole remedy under these warranties.

Neither The Toro Company nor Toro Warranty Company is liable for indirect, incidental, or consequential damages in connection with the

use of the Toro Products covered by these warranties, including any cost or expense of providing substitute equipment or service during

reasonable periods of malfunction or non-use pending completion of repairs under these warranties.

Some states do not allow exclusions of incidental or consequential damages, or limitations on how long an implied warranty lasts, so the

above exclusions and limitations may not apply to you. This warranty gives you specic legal rights, and you may also have other rights

which vary from state to state.

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer) to obtain guarantee

policies for your country, province, or state. If for any reason you are dissatised with your Distributor’s service or have difculty obtaining guarantee information,

contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty Company.

* Residential purposes means use of the product on the same lot as your home. Use at more than one location is considered commercial use, and the commercial

use warranty would apply.

374-0059 Rev A

Loading...

Loading...