Page 1

PowerMax

ModelNo.38597—SerialNo.311000001andUp

ModelNo.38629—SerialNo.311000001andUp

ModelNo.38637—SerialNo.311000001andUp

ModelNo.38639—SerialNo.311000001andUp

ModelNo.38657—SerialNo.311000001andUp

®

Snowthrowers

FormNo.3365-665RevA

Operator'sManual

Introduction

Thismachineisintendedtobeusedbyresidential

homeownersorprofessional,hiredoperators.It

isdesignedprimarilyforremovingsnowfrom

pavedsurfaces,suchasdrivewaysandsidewalks,

andothersurfacesfortrafconresidentialor

commercialproperties.Itisnotdesignedfor

removingmaterialsotherthansnow,norisamodel

withapivotingscraperdesignedforclearingoff

gravelsurfaces.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourmachineproperlyandtoavoidinjury

andmachinedamage.Youareresponsibleforoperating

themachineproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

machineandaccessoryinformation,helpndinga

dealer,ortoregisteryourmachine.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourmachineready .

identiesthelocationofthemodelandserialnumbers

onthemachine.Writethenumbersinthespace

provided.

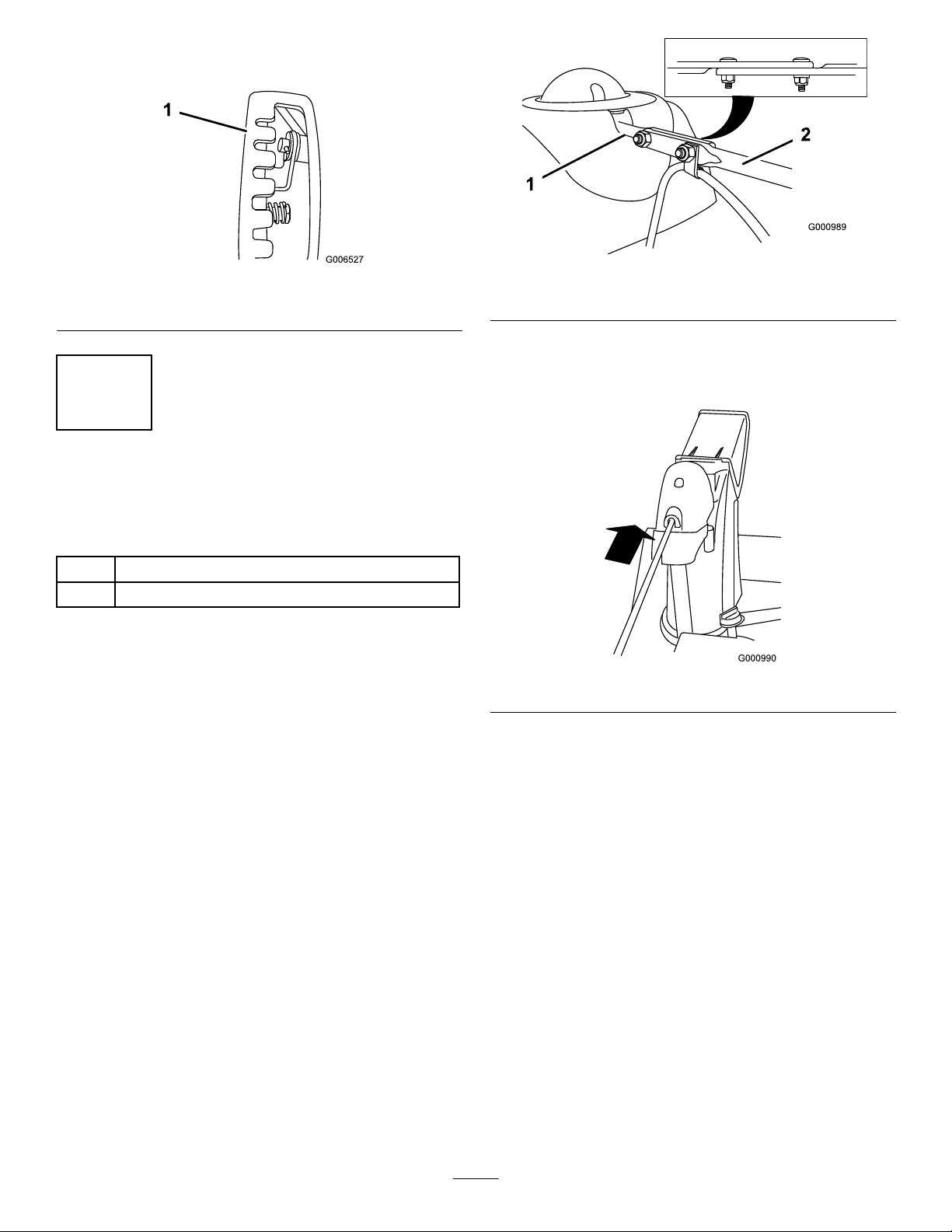

Figure1

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

ReplacementEngineOwner’sManualsmaybe

orderedthroughtheenginemanufacturer.

1.Modelandserialnumberlocation

©2010—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

Page 2

Safety

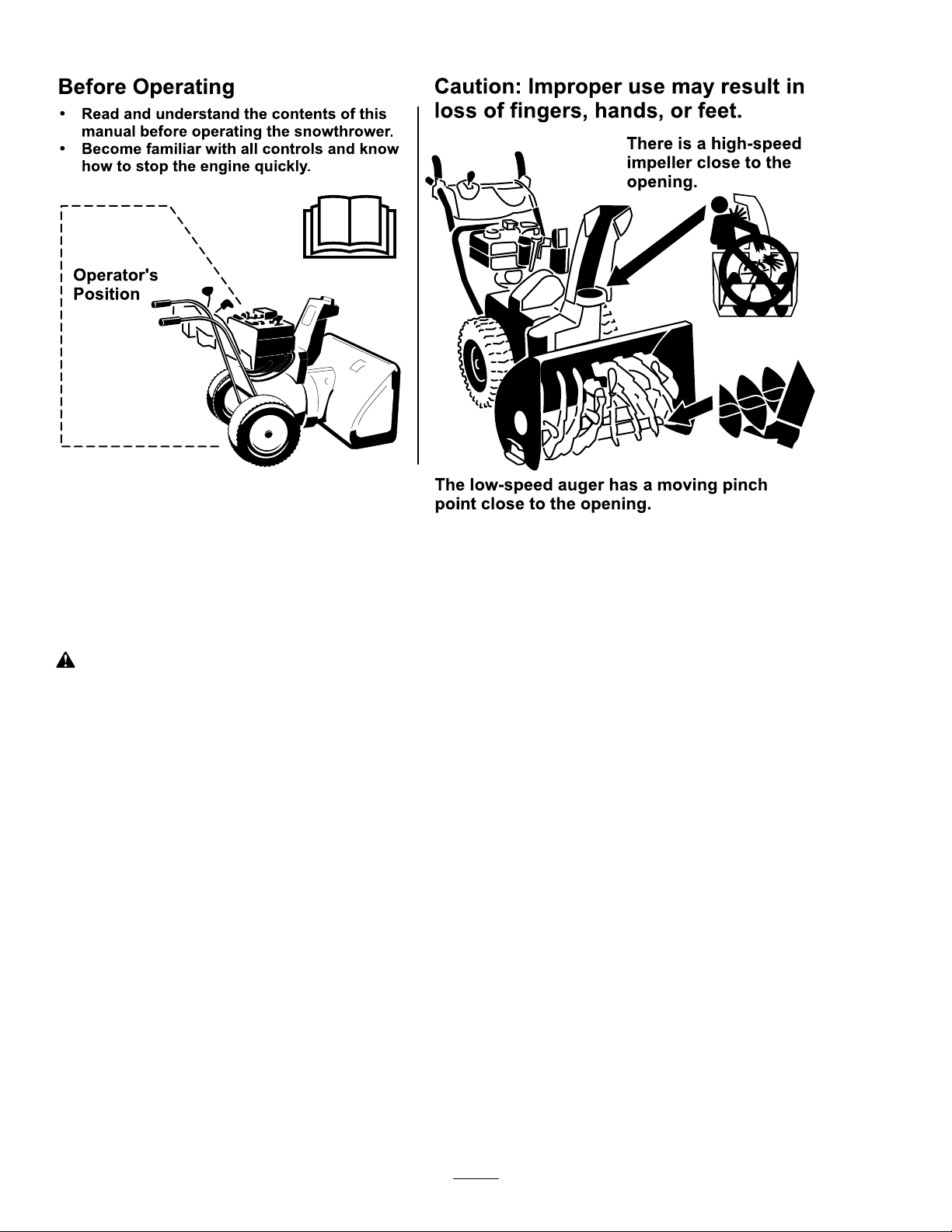

BeforeOperating

?

?

Readandunderstandthecontentsofthis

manualbeforeoperatingthesnowthrower .

Becomefamiliarwithallcontrolsandknow

howtostoptheenginequickly .

Operator 's

Position

Thelow-speedaugerhasamovingpinch

pointclosetotheopening.

Caution:Improperusemayresultin

lossoffingers,hands,orfeet.

Thereisahigh-speed

impellerclosetothe

opening.

ThismachinemeetsorexceedstheISOstandard

8437ineffectatthetimeofproduction.

Readandunderstandthecontentsofthismanual

beforetheengineiseverstarted.

Thisisthesafetyalertsymbol.Itisusedtoalert

youtopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollowthissymboltoavoid

possibleinjuryordeath.

Improperlyusingormaintainingthismachine

couldresultininjuryordeath.Toreducethis

potential,complywiththefollowingsafety

instructions.

Training

•Readtheoperatingandserviceinstructionmanual

carefully.Bethoroughlyfamiliarwiththecontrols

andtheproperuseofthemachine.Knowhowto

stopthemachineanddisengagethecontrolsquickly.

•Neverallowchildrentooperatethemachine.Never

allowadultstooperatethemachinewithoutproper

instruction.

•Keeptheareaofoperationclearofallpersons,

particularlysmallchildren,andpets.

Preparation

•Thoroughlyinspecttheareawherethemachineis

tobeusedandremovealldoormats,sleds,boards,

wires,andotherforeignobjects.

•Disengageallclutchesandshiftintoneutralbefore

startingtheengine.

•Donotoperatethemachinewithoutwearing

adequatewintergarments.Wearfootwearwhichwill

improvefootingonslipperysurfaces.

•Handlefuelwithcare;itishighlyammable.

–Useanapprovedfuelcontainer.

–Neveraddfueltoarunningorhotengine.

–Fillfueltankoutdoorswithextremecare.Never

–Replacegasolinecapssecurelyandwipeup

•Adjustthecollectorhousingheighttocleargravel

orcrushedrocksurface.

•Neverattempttomakeanyadjustmentswhile

theengineisrunning(exceptwherespecically

recommendedbymanufacturer).

•Letengineandmachineadjusttooutdoor

temperaturesbeforestartingtoclearsnow.

llfueltankindoors.

spilledfuel.

•Exercisecautiontoavoidslippingorfalling,

especiallywhenoperatinginreverse.

•Theoperationofanypoweredmachinecanresultin

foreignobjectsbeingthrownintotheeyes.Always

2

Page 3

wearsafetyglassesoreyeshieldsduringoperationor

whileperforminganadjustmentorrepair.

•Neveroperatethemachinewithoutgoodvisibility

orlight.Alwaysbesureofyourfooting,andkeepa

rmholdonthehandles.Walk;neverrun.

Operation

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Exerciseextremecautionwhenoperatingonor

crossinggraveldrives,walks,orroads.Stayalertfor

hiddenhazardsortrafc.

•Afterstrikingaforeignobject,stoptheengine,

removethewirefromthespark-plug,thoroughly

inspectthemachineforanydamage,andrepairthe

damagebeforerestartingandoperatingthemachine.

•Ifthemachineshouldstarttovibrateabnormally,

stoptheengineandcheckimmediatelyforthecause.

Vibrationisgenerallyawarningoftrouble.

•Stoptheenginewheneveryouleavetheoperating

position,beforeuncloggingthecollector/impeller

housingordischargeguide,andwhenmakingany

repairs,adjustments,orinspections.

•Whencleaning,repairing,orinspecting,makecertain

thecollector/impellerandallmovingpartshave

stopped.Disconnectthespark-plugwire,andkeep

thewireawayfromtheplugtopreventaccidental

starting.

•Donotruntheengineindoors,exceptwhenstarting

itandformovingthemachineinoroutofthe

building.Opentheoutsidedoors;exhaustfumes

aredangerous.

•Neveroperatethemachinewithoutgoodvisibility

orlight.

•Takeallpossibleprecautionswhenleavingthe

machineunattended.Shiftintoneutral,setthe

parkingbrake,stoptheengineandremovethekey.

MaintenanceandStorage

•Checkallfastenersatfrequentintervalsforproper

tightnesstobesurethemachineisinsafeworking

condition.

•Neverstorethemachinewithfuelinthefueltank

insideabuildingwhereignitionsourcesarepresent

suchashotwaterandspaceheaters,clothesdryers,

etc.Allowtheenginetocoolbeforestoringinany

enclosure.

•Alwaysrefertoowner’sguideinstructionsfor

importantdetailsifthemachineistobestoredfor

anextendedperiod.

•Maintainorreplacesafetyandinstructionslabels,

asnecessary.

•Runthemachineafewminutesafterthrowingsnow

topreventfreeze-upofthecollector/impeller.

ToroSnowthrowerSafety

•Donotclearsnowacrossthefaceofslopes.Exercise

extremecautionwhenchangingdirectiononslopes.

Donotattempttoclearsteepslopes.

•Neveroperatethemachinewithoutproperguards,

plates,orothersafetyprotectivedevicesinplace.

•Neveroperatethemachinenearglassenclosures,

automobiles,windowwells,drop-offs,etc.without

properadjustmentofthesnowdischargeangle.

Keepchildrenandpetsaway.

•Donotoverloadthemachinecapacitybyattempting

toclearsnowattoofastarate.

•Neveroperatethemachineathightransportspeeds

onslipperysurfaces.Usecarewhenreversing.

•Neverdirectdischargeatbystandersorallowanyone

infrontofthemachine.

•Disengagepowertothecollector/impellerwhen

machineistransportedornotinuse.

•Useonlyattachmentsandaccessoriesapprovedby

themanufacturerofmachine(suchaswheelweights,

counterweights,cabs,etc.).

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknow.

•Rotatingrotorbladescaninjurengersor

hands.Staybehindthehandlesandawayfromthe

dischargeopeningwhileoperatingthemachine.

Keepyourface,hands,feet,andanyotherpart

ofyourbodyorclothingawayfrommovingor

rotatingparts.

•Beforeadjusting,cleaning,repairing,andinspecting

themachine,andbeforeuncloggingthedischarge

chute,stoptheengine,removethekey ,andwait

forallmovingpartstostop.

•Usethesnowcleanouttool,notyourhands,to

removeobstructionsfromthedischargechute.

•Beforeleavingtheoperatingposition,stopthe

engine,removethekey,andwaitforallmovingparts

tostop.

•Donotwearloose-ttingclothingthatcouldget

caughtinmovingparts.

3

Page 4

•Ifashield,safetydevice,ordecalisdamaged,

illegible,orlost,repairorreplaceitbeforebeginning

operation.Also,tightenanyloosefasteners.

SafetyandInstructional

Decals

•Donotsmokewhilehandlinggasoline.

•Donotusethemachineonaroof.

•Donottouchtheenginewhileitisrunningorsoon

afterithasstoppedbecausetheenginemaybehot

enoughtocauseaburn.

•Performonlythosemaintenanceinstructions

describedinthismanual.Beforeperformingany

maintenance,service,oradjustment,stoptheengine,

removethekey,anddisconnectthewirefromthe

sparkplug.Ifmajorrepairsareeverneeded,contact

anAuthorizedServiceDealer.

•Donotchangethegovernorsettingsontheengine.

•Whenstoringthemachineformorethan30days,

drainthefuelfromthefueltanktopreventa

potentialhazard.Storefuelinanapprovedfuel

container.Removethekeyfromtheignitionswitch

beforestoringthemachine.

•PurchaseonlygenuineTororeplacementpartsand

accessories.

SoundPressure

Thismachinehasasoundpressurelevelattheoperator’s

earof87dBA(allmodelsexcept38657)or91dBA

(model38657only),whichincludesanUncertaintyValue

(K)of1dBA.Thesoundpressurelevelwasdetermined

accordingtotheproceduresoutlinedinENISO11201.

Important:Safetyandinstructiondecalsare

locatednearareasofpotentialdanger.Replace

damageddecals.

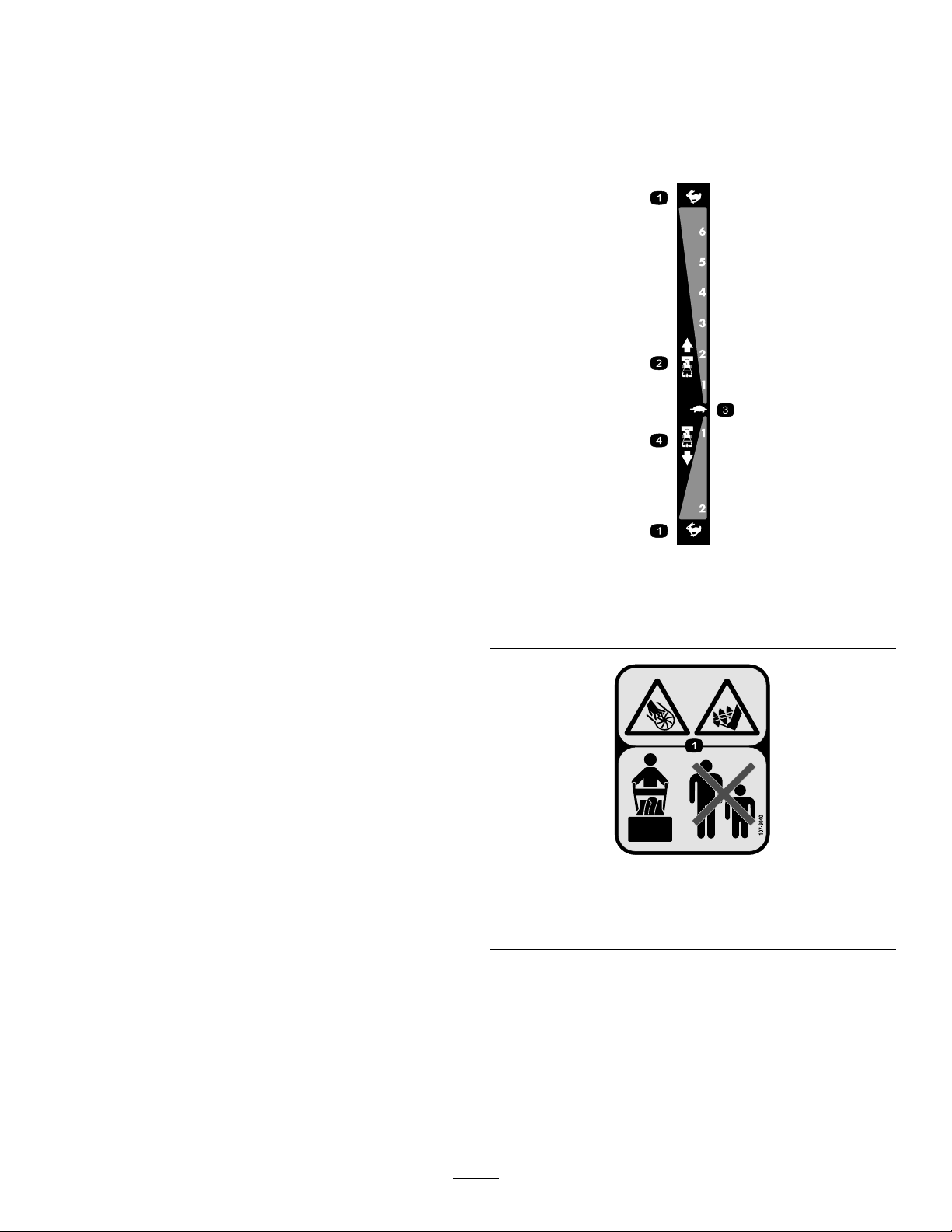

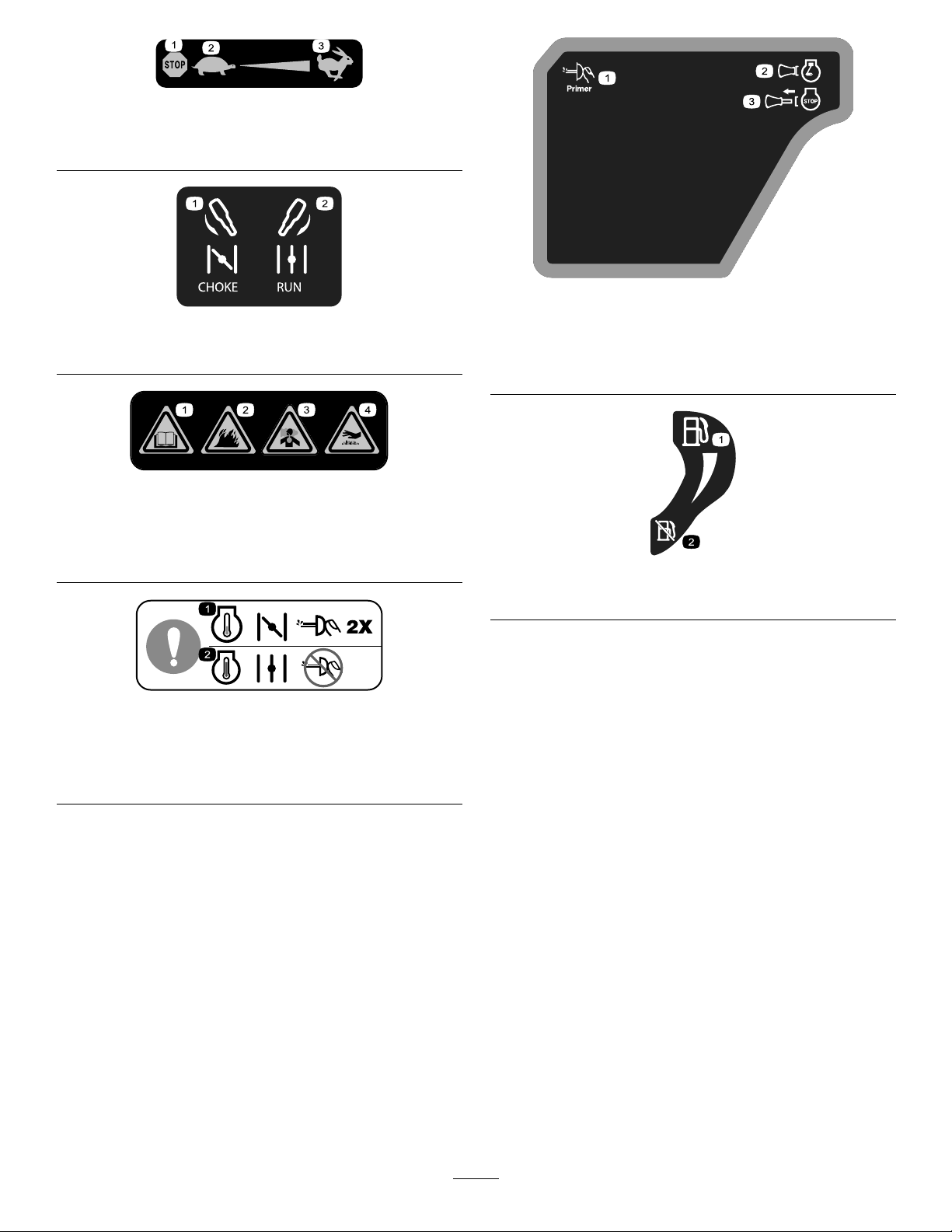

106-4525

Reorderpartno.112-6633

1.Fast

2.Forwardspeeds4.Reversespeeds

3.Slow

SoundPower

Thismachinehasaguaranteedsoundpowerlevelof

102dBA(allmodelsexcept38657)or105dBA(model

38657only),whichincludesanUncertaintyValue(K)

of2dBA.Thesoundpowerlevelwasdetermined

accordingtotheproceduresoutlinedinENISO3744.

Vibration

Measuredvibrationlevelforthelefthand=3.4m/s

modelsexcept38657)or7.1m/s

Measuredvibrationlevelfortherighthand=4.5m/s

(allmodelsexcept38657)or5.5m/s

only)

UncertaintyValue(K)=2.3m/s

38657)or2.8m/s

2

(model38657only)

Themeasuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO20643.

2

(model38657only)

2

(model38657

2

(allmodelsexcept

107-3040

1.Cuttingdismemberment,impellerandcutting

dismemberment,augerhazards—keepbystandersasafe

2

(all

2

4

distancefromthemachine.

Page 5

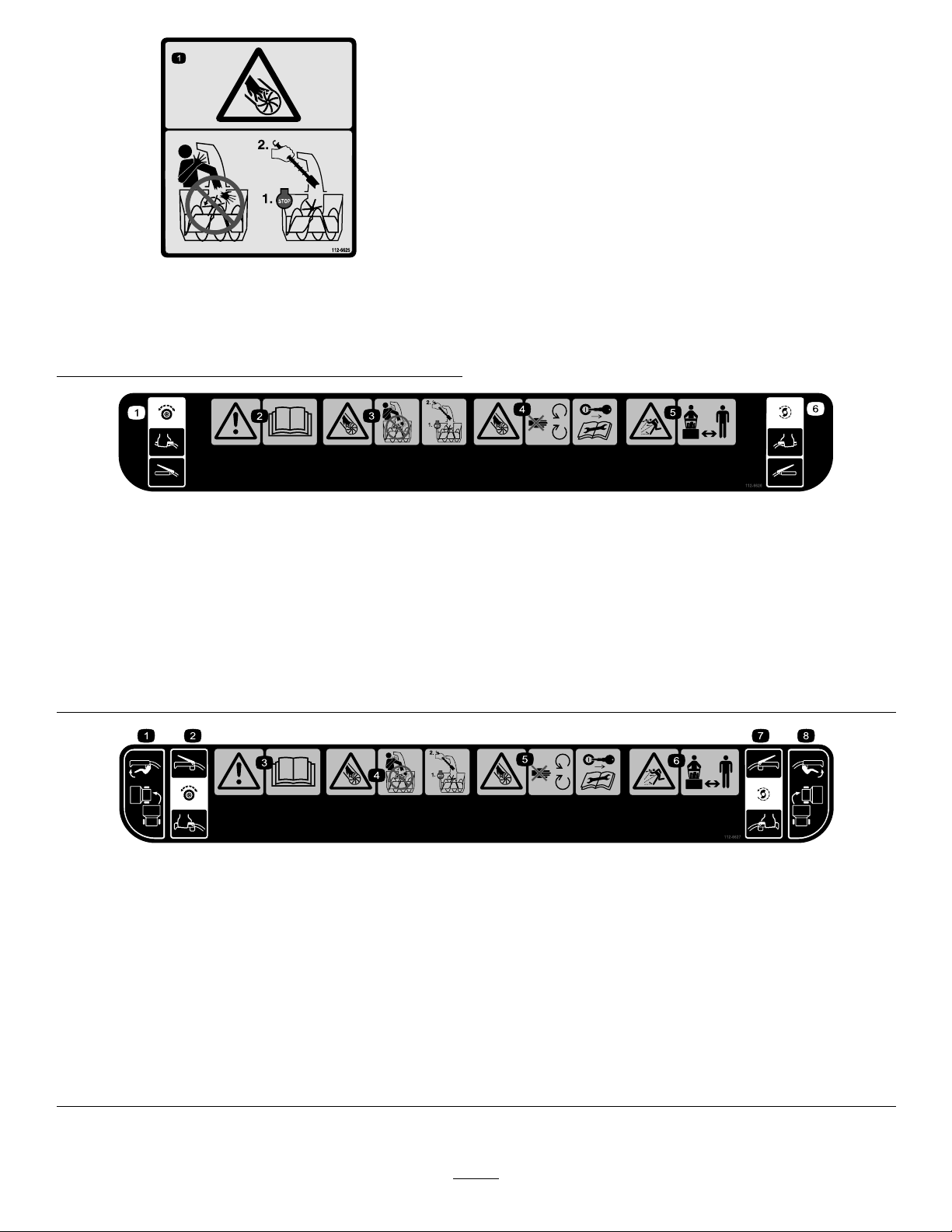

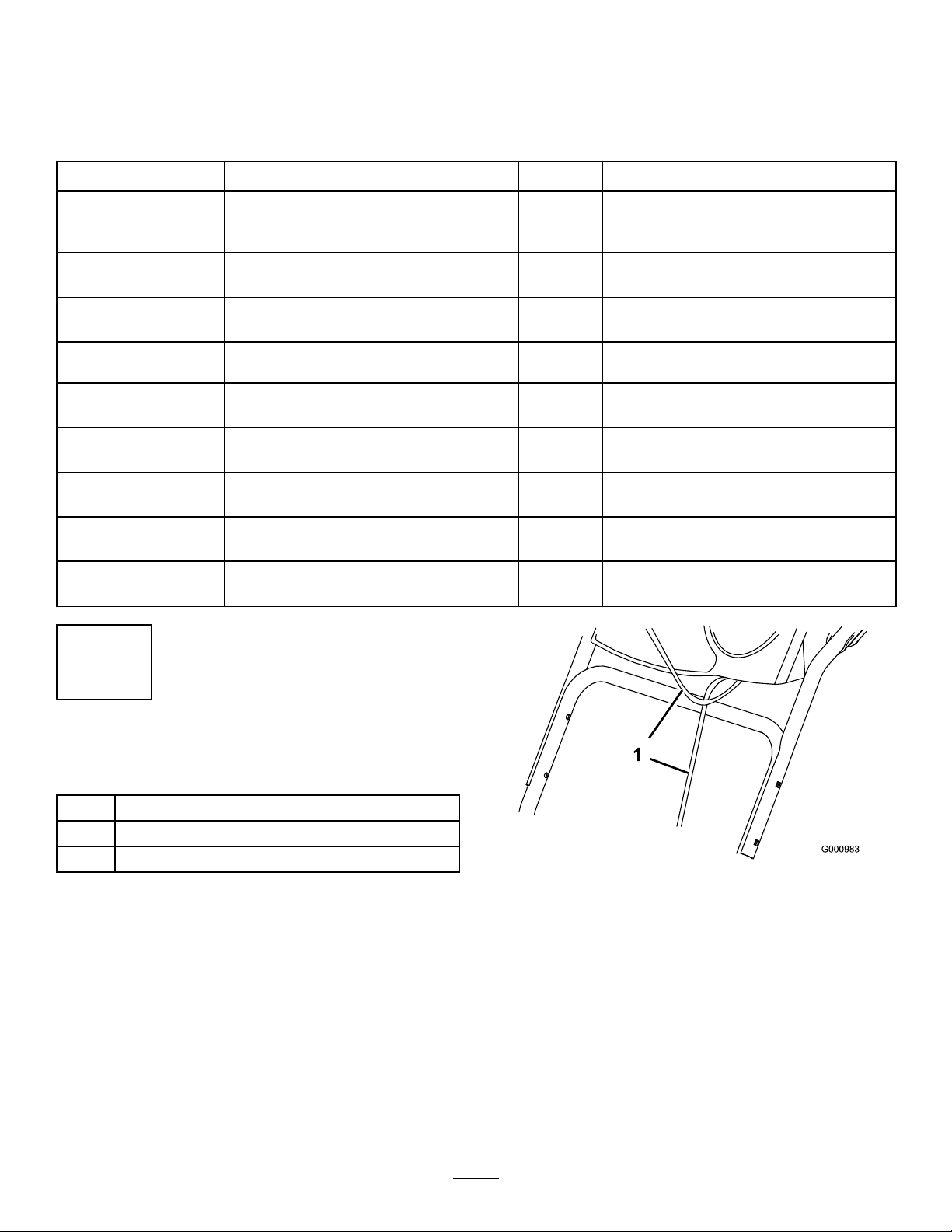

112-6625

Reorderpartno.112-6629

1.Cutting/dismembermenthazard,impeller—donotplace

yourhandinthechute;stoptheenginebeforeleavingthe

operator’sposition,usethetooltoclearthechute.

112-6626

1.Tractiondrive—squeezetheleverto

engage;releasethelevertodisengage.

2.Warning—readtheOperator’sManual.4.Cutting/dismembermenthazard,

3.Cutting/dismembermenthazard,

impeller—donotplaceyourhandinthe

chute;stoptheenginebeforeleaving

theoperator’sposition,usethetool

clearthechute.

impellerandauger—stayawayfrom

movingparts,keepallguardsand

shieldsinplace;removetheignition

keyandreadtheinstructionsbefore

servicingorperformingmaintenance.

5.Thrownobjecthazard—keep

bystandersasafedistancefromthe

machine.

6.Auger/impellerdrive—squeezethe

levertoengage;releasetheleverto

disengage.

1.Leftturncontrol

2.Tractiondrive—squeeze

thelevertoengage;release

thelevertodisengage.

3.Warning—readthe

Operator’sManual.

4.Cutting/dismemberment

hazard,impeller—do

notplaceyourhand

inthechute;stopthe

enginebeforeleavingthe

operator’sposition,usethe

tooltoclearthechute.

112-6627

5.Cutting/dismemberment

hazard,impeller—keep

awayfrommovingparts;

removetheignitionkeyand

readtheinstructionsbefore

servicingorperforming

maintenance.

6.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

7.Auger/impeller

drive—squeezetheleverto

engage;releasethelever

todisengage.

8.Rightturncontrol

5

Page 6

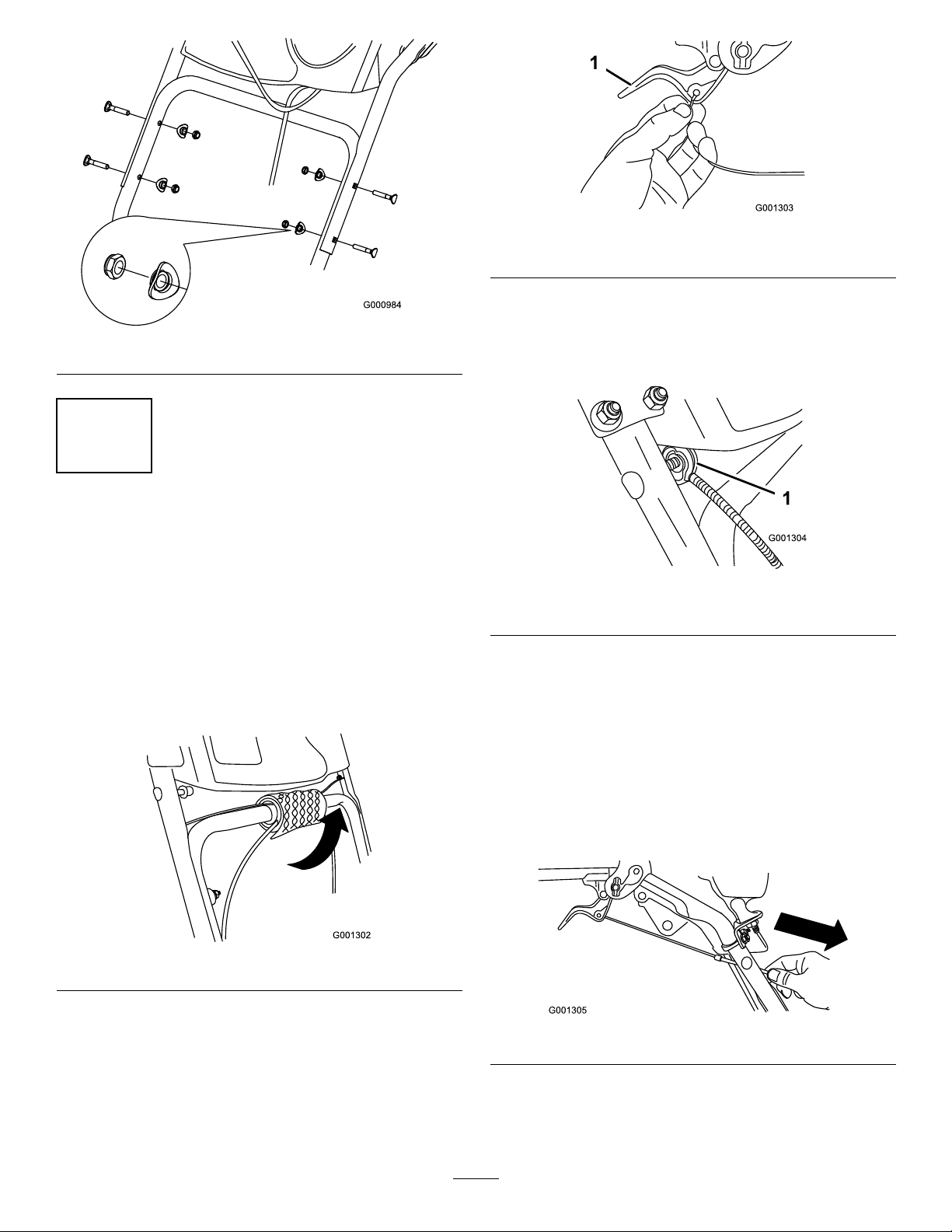

Briggs&StrattonPartNo.273676

1.Stop

2.Slow

3.Fast

Briggs&StrattonPartNo.275949

1.Chokeon(Choke)2.Chokeoff(Run)

Briggs&StrattonPartNo.276925

1.Warning—readthe

Operator’sManual.

2.Warning—rehazard.

3.Warning—toxicgas

inhalationhazard.

4.Warning—hot

surface/burnhazard.

Briggs&StrattonPartNo.277588

1.Primer3.Ignitionkeyout

(Engine—Stop)

2.Ignitionkeyin

(Engine—Run)

Briggs&StrattonPartNo.278866

1.Fuel—On2.Fuel—Off

Briggs&StrattonPartNo.277566

1.Whenstartingacold

engine,closethechoke

andpresstheprimertwo

times.

2.Whenstartingawarm

engine,openthechoke

anddonotpressthe

primer.

6

Page 7

Setup

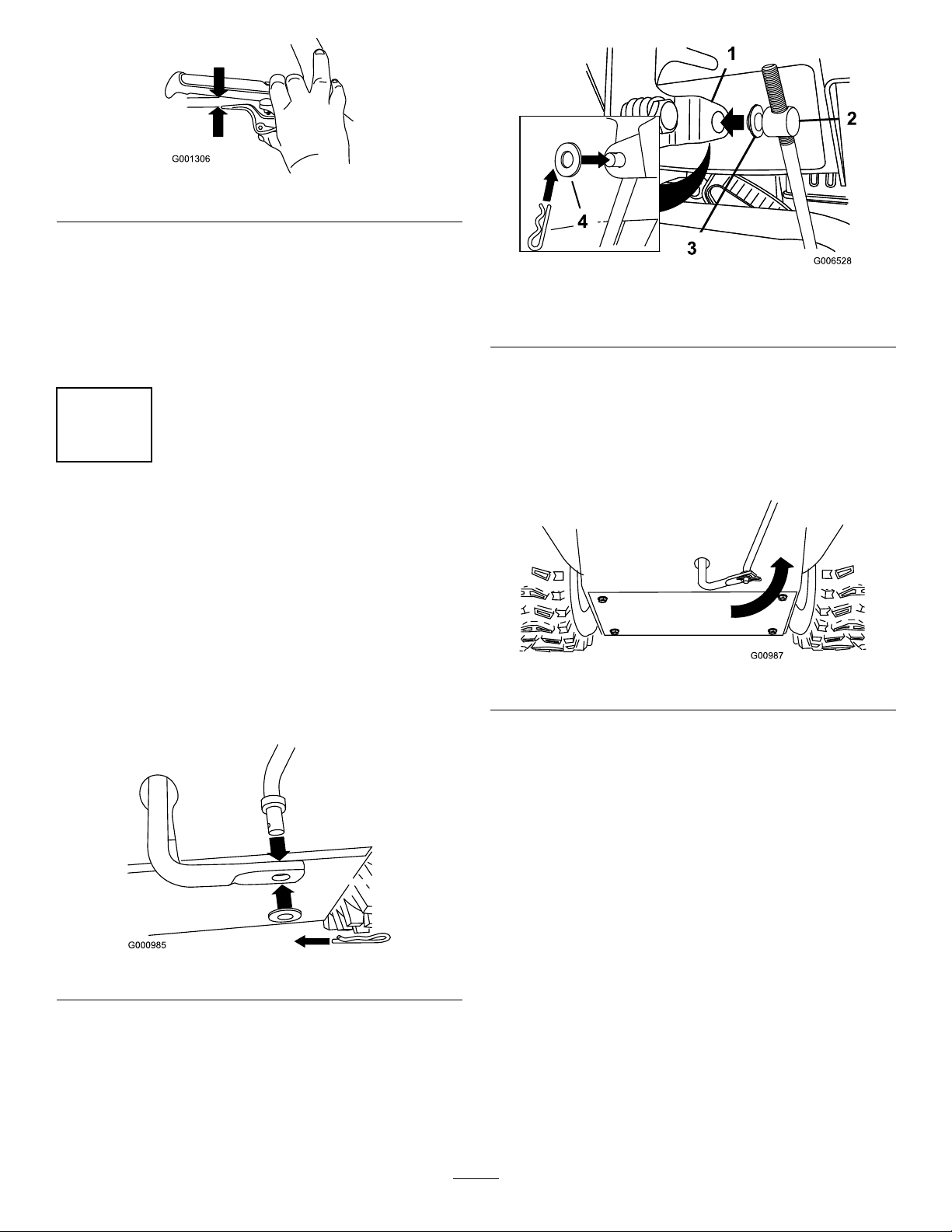

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

Handlebolts4

Curvedwashers

Locknuts4

Nopartsrequired

Nopartsrequired

Carriagebolts

Locknuts2

Cabletie

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Qty.

Use

4

–

–

2

1

–

–

–

–

Installtheupperhandle.

Installthewheelclutchcableends

Installthetractioncontrollinkage.

Installthechutecontrolrod.

Connectthewiretotheheadlight.

Filltheenginewithoil.

Checkthetirepressure.

Checktheskids.

Checktheoperationofthetractiondrive.

1

InstallingtheUpperHandle

Partsneededforthisprocedure:

4Handlebolts

4

Curvedwashers

4Locknuts

Procedure

Note:Donotremovetherubberbandonthecables

untilyouhaveinstalledtheupperhandle.

1.Liftandrotatetheupperhandleandpositionitover

thelowerhandle(Figure3).

Important:Routethecablesattachedtothe

QuickStickinsidetheupperhandlelegsand

ensurethatthecablesandthewireforthe

headlightarenotpinchedbetweenthehandle

sections.

Figure3

1.Cables

2.Securetheupperhandlewith4handlebolts,

4curvedwashers,and4locknutsfromtheloose

partsbag(Figure4).

7

Page 8

Figure4

2

InstallingtheWheelClutch

CableEnds

Figure6

1.Wheelclutchlever

3.Removethenutandwasherfromthehandle,attach

thecableclamponthecabletothehandle,install

thewasherandthenut,andhandtightenthenut

Figure7).

(

NoPartsRequired

Procedure

Models38637and38657only

1.Unwrapthecableendsfromthelowerhandle

Figure5).

(

Figure5

2.Routeeithertheleftorrightcableendoverthelower

handleandinsertthecableendintotheholeinthe

correspondingwheelclutchlever(Figure6).

Figure7

1.Cableclamp(2)

Important:Ensurethatthecurvedsideofthe

cableclampisagainstthehandleandthatthe

cableisroutedbelowtheclampbolt.Thecable

mustbeinastraightlinefromthecableclamp

tothepointwhereitattachestothewheelclutch

lever.

4.Pullthecablejacketdowngentlyuntilthewheel

clutchleverisdownandtheslackisoutofthecable,

thentightenthecableclampnutsecurely(

Figure8

Figure8).

5.Squeezetheleverfully,thencheckthegapbetween

thebottomofthehandleandthewheelclutchlever

end(Figure9).

8

Page 9

Figure9

Note:Thegapshouldbeapproximatelythe

thicknessofapencil(1/4inchor6mm).Ifitis

greater,loosenthecableclampnut,slidethecable

jacketupslightly,tightenthecableclampnut,and

checkthegapagain.

6.Repeatsteps2through5fortheothercable.

3

InstallingtheTractionControl

Linkage

NoPartsRequired

Procedure

Figure11

1.Speedselectorlever

2.Trunnion

Note:Tomakeinstallationeasier,leavetheat

washeronthetrunnion(

4.ShiftthespeedselectorleverintoPositionR2.

5.Rotatethelowerlinkarmfullyupward

(counterclockwise)(Figure12).

3.Innerwasher

4.Outerwasher

Figure11).

1.Removethehairpincotterandwasherfromthe

lowerendofthespeedcontrolrodandinsertthe

lowerendoftherodintothelowerlinkarmsothat

thebentendofthespeedcontrolrodfacesrearward

Figure10).

(

Figure10

2.Securethelowerendofthespeedcontrolrodwith

thewasherandhairpincotterthatyoupreviously

removed.

Figure12

6.Liftuponthespeedcontrolrodandinsertthe

trunnionintotheholeinthespeedselectorlever

Figure11).

(

Note:Ifthetrunniondoesnottintothehole

whenyouliftuponthespeedcontrolrod,rotatethe

trunnionupwardordownwardonthespeedcontrol

roduntilitts.

7.Securethetrunnionandupperendofthespeed

controlrodwiththeouterwasherandahairpin

cotteryoupreviouslyremoved.

3.Removethehairpincotterandtheouterwasher

fromthetrunnionontheupperendofthespeed

controlrod(

Figure11).

9

Page 10

Note:Foreasierinstallation,lookdownthrough

theopeninginthespeedselector(Figure13).

Figure13

1.Speedselector

4

InstallingtheChuteControl

Rod

Partsneededforthisprocedure:

2

Carriagebolts

2Locknuts

Procedure

1.UnwraptheQuickStickandrotateitsothatitis

uprightandinthecenter.

Figure14

1.Shortrod

4.Insertthefrontendoftherodintotheopeningin

thebackofthechutegearcoveruntilitslidesinto

thechutegear(Figure15).

2.Longchutecontrolrod

Figure15

2.Holdthebluetriggercapdownandpullthelever

fullyrearward.

Note:Thedischargechuteanddeectorshould

faceforward.Iftheydonot,holdthebluetrigger

capdown(butdonotmovetheQuickStick)and

rotatethedischargechuteuntiltheydo.

3.Aligntheattenedbackendofthelongchute

controlrodwiththeattenedfrontendoftheshort

rodthatextendsfromthecontrolpanelsothatthey

nesttogether(

Figure14).

5.Aligntheholesinthenestedendsoftherodsand

insert2carriagebolts(intheloosepartsbag)through

theshortrodfromtheleftsideofthemachine(from

theoperatingposition).

6.Insertthecableclipthatsupportsthedeector

cableontotheforwardcarriagebolt,andsecurethe

carriageboltswithlocknutsfromtheloosepartsbag

Figure16).

(

10

Page 11

Note:Ensurethattheplasticcliponthewire

connectorisonthebottom(Figure17).

2.Secureacabletie(fromtheloosepartsbag)around

thewireandthehandleaboutaninch(2.5cm)below

theU-bolt(

Figure17).

Figure16

1.Cableclip2.Deectorcable

7.HoldthebluetriggercapdownandrotatetheQuick

Stickinacircletoensurethatthechuteanddeector

operatesmoothly.

5

ConnectingtheWiretothe

Headlight

Partsneededforthisprocedure:

1

Cabletie

Procedure

1.Insertthewireconnectoronthelooseendofthe

wirestraightintothebackoftheheadlightuntilitis

securelyinplace(Figure17).

6

FillingtheEnginewithOil

NoPartsRequired

Procedure

Yourmachinecomeswithoilintheenginecrankcase.

Note:Beforestartingtheengine,checktheoillevel

andaddoilifnecessary.

UseautomotivedetergentoilwithanAPIservice

classicationofSF,SG,SH,SJ,SL,orhigher.Referto

yourengineowner’smanual.

UseFigure18belowtoselectthebestoilviscosityfor

theoutdoortemperaturerangeexpected:

1.Plasticcliponwire

connector

2.U-bolt

Figure17

3.Cabletie

1.UsingSAE30atoutdoor

EngineOilCapacities

11

temperaturesbelow40°F

(4°C)willresultinhard

starting.

Figure18

2.Using10W-30atoutdoor

temperaturesabove

80°F(27°C)mayresultin

increasedoilconsumption;

therefore,checktheoil

levelmorefrequentlyin

thesecircumstances.

Page 12

EngineOilCapacities(cont'd.)

Model

38597

38629

38637

38639

38657

1.Removethedipstickandslowlypouroilintothe

oillltubetoraisetheoilleveltotheFullmarkon

thedipstick.Donotoverll(Figure19).Referto

CheckingtheEngineOilLevelinMaintenance.

EngineOilCapacity

18to20oz.(0.53to0.59l)

26to28oz.(0.77to0.83l)

8

CheckingtheSkids

NoPartsRequired

Procedure

RefertoCheckingandAdjustingtheSkidsin

Maintenance.

9

CheckingtheTractionDrive

Operation

NoPartsRequired

Procedure

Figure19

2.Installthedipsticksecurely.

Note:Donotspilloilaroundtheoillltube;oil

couldleakontotractionpartsandcausethetraction

toslip.

7

CheckingtheTirePressure

NoPartsRequired

Procedure

CAUTION

Ifthetractiondriveisnotproperlyadjusted,the

machinemaymoveinthedirectionoppositeof

whatyouintended,causinginjuryand/orproperty

damage.

Carefullycheckthetractiondriveandadjustit

properly,ifnecessary.

1.Starttheengine;refertoStartingtheEngine.

2.MovethespeedselectortoPositionR1;referto

OperatingtheSpeedSelector.

3.Squeezethelefthand(traction)levertothehand-grip

Figure20).

(

Thetiresareoverinatedatthefactoryforshipping.

Reducethepressureequallyinbothtirestobetween17

and20psi(116and137kPa).

Figure20

Themachineshouldmoverearward.Ifthemachine

doesnotmoveormovesforward,completethe

following:

12

Page 13

A.Releasethetractionleverandstoptheengine.

B.Disconnectthetrunnionfromthespeedselector

lever(Figure11).

C.Turnthetrunniondownward(clockwise)onthe

speedcontrolrod(

Figure11).

D.Connectthetrunniontothespeedselectorlever

(Figure11).

4.Releasethetractionlever.

5.MovethespeedselectortothePosition1;referto

OperatingtheSpeedSelector.

6.Squeezethelefthand(traction)levertothehand-grip

Figure20).

(

Themachineshouldmoveforward.Ifthemachine

doesnotmoveormovesrearward,completethe

following:

A.Releasethetractionleverandstoptheengine.

ProductOverview

B.Disconnectthetrunnionfromthespeedselector

Figure11).

lever(

C.Turnthetrunnionupward(counterclockwise)on

thespeedcontrolrod(

Figure11).

D.Connectthetrunniontothespeedselectorlever

(Figure11).

7.Ifyoumadeanyadjustments,repeatthisprocedure

untilnoadjustmentsarerequired.

Important:Ifthemachinemoveswhenthetraction

leverisinthereleasedposition,checkthetraction

cable(refertoCheckingandAdjustingtheTraction

Cable)ortakethemachinetoanAuthorizedService

Dealerforservice.

Figure21

1.Hand-grip(2)10.Scraper

2.Auger/impellerlever

3.Speedselectorlever12.Skid(2)

4.QuickStick™discharge

chutecontrol

5.Tractionlever

6.Fueltankcap

7.Engineoillltube/dipstick16.Headlight(models38637,

8.Chutedeector17.Wheelclutchlever(2)

9.Dischargechute

11.Auger

13.Electricstarterbutton(all

modelsexcept38597)

14.Electricstarterplug(all

modelsexcept38597)

15.Snowcleanouttool

38639,and38657only)

(models38637and38657

only)

13

1.Choke

2.Ignitionswitch

3.Fuelshutoffvalve

4.Throttle

Figure22

5.Recoilstarter

6.Oildrainplug

7.Primer

Page 14

Figure23

1.Snowcleanouttool(attachedtothehandle)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

FillingtheFuelTank

DANGER

Gasolineisextremelyammableandexplosive.A

reorexplosionfromgasolinecanburnyouand

others.

•Topreventastaticchargefromignitingthe

gasoline,placethecontainerand/ormachine

onthegroundbeforelling,notinavehicleor

onanobject.

•Fillthetankoutdoorswhentheengineiscold.

Wipeupspills.

•Donothandlegasolinewhensmokingoraround

anopenameorsparks.

•Storegasolineinanapprovedfuelcontainer,out

ofthereachofchildren.

Fillthefueltankwithfreshunleadedregulargasoline

fromamajorname-brandservicestation(Figure24).

Important:T oreducestartingproblems,add

fuelstabilizertothefuelallseason,mixingitwith

gasolinelessthan30daysold.

the gasoline.

Do not add oil to

Figure24

1.1-1/2inch(3.8cm)

StartingtheEngine

1.Checktheengineoillevel.RefertoCheckingthe

EngineOilLevelinMaintenance.

2.Turnthefuelshutoffvalve1/4turncounterclockwise

toopenit(Figure25).

Figure25

3.Inserttheignitionkey(Figure26).

14

Page 15

Figure26

1.Ignitionkey

4.Firmlypushintheprimerwithyourthumb2times

(15°For-9°Corabove)or4times(below15°For

-9°C),holdingtheprimerinforasecondbefore

releasingiteachtime(Figure27).

Figure28

6.MovethethrottletotheFastposition(Figure29).

Figure29

7.Startthemachinepullingtherecoilstarteror

pressingtheelectric-starterbutton(allmodelsexcept

38597)(

Figure30).

Figure27

5.RotatethechoketotheChokeposition(Figure28).

1.Electric-starterbutton(all

modelsexcept38597)

2.Electricstarterplug(all

modelsexcept38597)

Note:T ousetheelectricstarter,connectapower

cordtotheelectricstarterplugrstandthentoa

poweroutlet(allmodelsexcept38597).

15

Figure30

3.Recoilstarter

Page 16

Important:T opreventdamagingtheelectric

starter,runitinshortcycles(5seconds

maximum,thenwaitoneminutebeforetrying

tostartitagain).Iftheenginestilldoesnot

start,takethemachinetoanAuthorizedService

Dealerforservice(allmodelsexcept38597).

8.Disconnectthepowercordfromthepoweroutlet

rstandthenfromthemachine(allmodelsexcept

38597).

9.Allowtheenginetowarmupforseveralminutes,

movethechoketowardtheRunposition.Wait

fortheenginetorunsmoothlybeforeeachchoke

adjustment.

CAUTION

Ifyouleavethemachinepluggedintoapower

outlet,someonecaninadvertentlystartthe

machineandinjurepeopleordamageproperty.

Unplugthepowercordwheneveryouarenot

startingthemachine.

StoppingtheEngine

1.MovethethrottletotheSlowposition,andthento

theStopposition(Figure31).

Figure32

5.Pulltherecoilstarter3or4times.Thishelpsprevent

therecoilstarterfromfreezingup.

OperatingtheTractionDrive

CAUTION

Ifthetractiondriveisnotproperlyadjusted,the

machinemaymoveinthedirectionoppositeof

whatyouintended,causinginjuryand/orproperty

damage.

Carefullycheckthetractiondriveandadjust

itproperly,ifnecessary;refertoCheckingthe

TractionDriveOperationinSetupformore

information.

Figure31

2.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheignitionkey.

4.Closethefuelshutoffvalvebyrotatingitclockwise

(Figure32).

Important:Ifthemachinemoveswhenthetraction

leverisinthereleasedposition,checkthetraction

cable(refertoCheckingandAdjustingtheTraction

Cable)ortakethemachinetoanAuthorizedService

Dealerforservice.

1.Toengagethetractiondrive,squeezethelefthand

(traction)levertothehand-grip(

Figure33

2.Tostopthetractiondrive,releasethetractionlever.

Figure33).

16

Page 17

UsingtheWheelClutchLevers

OperatingtheSpeedSelector

Models38637and38657only

Thewheelclutchleversallowyoutomomentarily

disengagethedrivetooneorbothwheelswiththe

tractiondriveleverstillengaged.Thisenablesyouto

turnandmaneuverthemachineeasily.

Note:Holdingdownthetractionleveragainstthe

handleengagesthetractiondrivetobothwheels.

Toturnthemachinetotheright,liftupontheright

wheelclutchleverandsqueezeittowardthehandle

Figure34).

(

Figure34

Note:Thisdisengagesthedrivetotherightwheel

whiletheleftwheelcontinuesdriving,andthemachine

turnstotheright.

Thespeedselectorhas6forwardand2reversegears.

Tochangespeeds,releasethetractionleverandshiftthe

speedselectorlevertothedesiredposition(Figure36).

Theleverlocksinanotchateachspeedselection.

Figure36

OperatingtheAuger/Impeller

Drive

1.Toengagetheauger/impellerdrive,squeezethe

righthand(auger/impeller)levertothehandgrip

(Figure37).

Note:Similarly,squeezingtheleftwheelclutchlever

turnsthemachinetotheleft.

Whenyoucompletetheturn,releasethewheelclutch

lever,andthedrivere-engagesbothwheels(

Figure35

Momentarilysqueezingandreleasingtheleftorright

wheelclutchleveralsoallowsforsteeringadjustments

tokeepthemachinegoinginastraightline,especially

indeepsnow .

Squeezingbothwheelclutchleverssimultaneously

disengagesthedrivetobothwheels.Thisenablesyouto

manuallymovethemachinebackwardwithoutstopping

toshiftitintoareversegear.Italsoallowsyouto

maneuverandtransportthemachinemoreeasilywhen

theengineisnotrunning.

Figure35).

Figure37

2.Tostoptheaugerandimpeller,releasetheright

handlever.

Important:Whenyouengageboththe

auger/impellerleverandthetractionlever,the

tractionleverlockstheauger/impellerlever

down,freeingyourrighthand.Toreleaseboth

levers,simplyreleasethelefthand(traction)

lever.

3.Iftheaugerandimpellercontinuetorotatewhen

youreleasetheauger/impellerlever,donotoperate

themachine.Checktheauger/impellercable(refer

toCheckingandAdjustingtheAuger/Impeller

Cable)andadjustitifnecessary.Otherwise,takethe

machinetoanAuthorizedDealerforservice.

17

Page 18

WARNING

Iftheaugerandimpellercontinuetorotate

whenyoureleasetheauger/impellerlever,you

couldseriouslyinjureyourselforothers.

Donotoperatethemachine.Takeittoan

AuthorizedServiceDealerforservice.

OperatingtheQuickStick

HoldthebluetriggercapdowntousetheQuickStick

tomovethedischargechuteandthechutedeector.

Releasethetriggercaptolockthedischargechuteand

chutedeectorintoposition(

Figure38).

®

•Ifthechutedoesnotmove,refertoAdjustingthe

DischargeChuteLatch.

•Ifthechutedoesnotturnasfartotheleftasitdoes

totheright,ensurethatthecableisroutedtothe

insideofthehandles.RefertoInstallingtheUpper

Handle.

•Ifthechutedoesnotlockintoplacewhenyourelease

thetriggercap,refertoAdjustingtheDischarge

ChuteLatch.

MovingtheChuteDeector

HoldthebluetriggercapdownandmovetheQuick

Stickforwardtolowerthechutedeector;moveit

rearwardtoraisethechutedeector(Figure40).

Figure38

MovingtheDischargeChute

HoldthebluetriggercapdownandmovetheQuick

Sticktothelefttomovethedischargechutetotheleft;

movetheQuickSticktotherighttomovethedischarge

chutetotheright(Figure39).

Figure39

Figure40

UncloggingtheDischarge

Chute

Iftheauger/impellerisrunningbutthereisnosnow

comingoutofthedischargechute,thedischargechute

maybeclogged.

•Tounclogthedischargechute,stayintheoperating

positionandreleasethelefthand(traction)lever.

Whilerunningtheauger/impeller,pushdownon

thehandlestoraisethefrontofthemachineafew

inches(centimeters)offthepavement.Thenliftthe

handlesquicklytobumpthefrontofthemachineon

thepavement.Repeatifnecessaryuntilastreamof

snowcomesoutthedischargechute.

•Ifyoucannotunclogthedischargechutebybumping

thefrontofthemachine,stoptheengine,waitfor

allmovingpartstostop,anduseastick;never

useyourhand.

Important:Uncloggingthedischargechute

bybumpingthefrontofthemachineonthe

18

Page 19

pavementmaycausetheskidstomove.Adjust

theskidsandtightentheskidboltssecurely.

PreventingFreeze-up

WARNING

Therotorbladescanthrowstones,toys,andother

foreignobjectsandcauseseriouspersonalinjuryto

theoperatorortobystanders.

•Insnowyandcoldconditions,somecontrolsand

movingpartsmayfreeze.Donotuseexcessive

forcewhentryingtooperatefrozencontrols.If

youhavedifcultyoperatinganycontrolorpart,

starttheengineandletitrunforafewminutes.

•Afterusingthemachine,lettheenginerunfora

fewminutestopreventmovingpartsfromfreezing.

Engagetheauger/impellertoclearanyremaining

snowfrominsidethehousing.RotatetheQuick

Sticktopreventitfromfreezing.Stoptheengine,

waitforallmovingpartstostop,andremoveallice

andsnowfromthemachine.

•Withtheengineoff,pulltherecoilstarterhandle

severaltimesandpushtheelectric-starterbutton

once(allmodelsexcept38597)topreventtherecoil

andelectricstartersfromfreezingup.

OperatingTips

DANGER

•Keeptheareatobeclearedfreeofallobjects

thattherotorbladescouldpickupandthrow.

•Keepallchildrenandpetsawayfromthearea

ofoperation.

•AlwayssetthethrottletotheFastpositionwhen

throwingsnow.

•Iftheengineslowsdownunderaloadorthewheels

slip,shiftthemachineintoalowergear.

•Ifthefrontofthemachineridesup,shiftthe

machineintoalowergear.Ifthefrontcontinuesto

rideup,liftuponthehandles.

•Thepivotingscraperonthemachineisnot

recommendedforuseongravelsurfaces.But

ifyoumustusethemachineonagravelsurface,

adjusttheskidsfurtherdowntopreventthepivoting

scraperfrompickinguprocks.

Whenthemachineisinoperation,theimpellerand

augercanrotateandcutofforinjurehandsandfeet.

•Beforeadjusting,cleaning,inspecting,

troubleshooting,orrepairingthemachine,stop

theengineandwaitforallmovingpartstostop.

Disconnectthewirefromthesparkplugand

keepitawayfromtheplugtopreventsomeone

fromaccidentallystartingtheengine.

•Removeanobstructionfromthedischarge

chute;refertoUncloggingtheDischargeChute.

Ifnecessary,useastick,notyourhands,to

removeanobstructionfromthedischargechute.

•Staybehindthehandlesandawayfromthe

dischargeopeningwhileoperatingthemachine.

•Keepface,hands,feet,andanyotherpartof

yourbodyorclothingawayfromconcealed,

moving,orrotatingparts.

19

Page 20

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst5hours

Beforeeachuseordaily

Every50hours

Yearly

Yearlyorbeforestorage

MaintenanceProcedure

•Inspectthetractioncableandadjustitifnecessary.

•Changetheengineoil.

•Checktheengineoillevelandaddoilifnecessary.

•Changetheengineoil.Changetheengineoilevery25operatinghourswhen

operatingtheengineunderaheavyload.

•Checktheskidsandthescraperandadjustthemifnecessary.

•Checktheskidsandadjustthemifnecessary.

•Inspectthetractioncableandadjustorreplaceitifnecessary.

•Checktheaugergearboxoilandaddoilifnecessary.

•Checktheairpressureinthetiresandinatethemto17–20psi(116–137kPa).

•Drainthegasolineandruntheenginetodryoutthefueltankandthecarburetorat

theendoftheseason.

•HaveanAuthorizedServiceDealerinspectandreplacethetractiondrivebeltand/or

theauger/impellerdrivebelt,ifnecessary.

Important:Youcanndmoreinformationaboutmaintainingandservicingyourmachineat

www.Toro.com.

Important:Refertoyourengineoperator’smanualforadditionalmaintenanceprocedures.Forengine

adjustments,repairs,orwarrantyservicenotcoveredinthismanual,contactanAuthorizedBriggs

&StrattonServicingDealer.

20

Page 21

PreparingforMaintenance

1.Movethemachinetoalevelsurface.

2.Stoptheengineandwaitforallmovingpartstostop.

3.Disconnectthesparkplugwire.RefertoReplacing

theSparkPlug.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily—Check

theengineoillevelandaddoilif

necessary.

1.Removethedipstick,wipeitclean,thenfullyinstall

thedipstick.

2.Removethedipstickandchecktheoillevel

Figure41).IftheoillevelisbelowtheAddmark

(

onthedipstick,addoil.RefertoFillingtheEngine

withOil.

Figure42

1.1/2inch(1.3cm)

3.Supportthesideplatessothattheyareatleast1/2

inch(1.3cm)abovealevelsurface.

Important:Theaugerbladesmustbe

supportedabovethegroundbytheskids.

4.Ensurethatthescraperis1/8inch(3mm)above

andparalleltoalevelsurface.

Note:Ifthepavementiscracked,rough,oruneven,

adjusttheskidstoraisethescraper.Forgravel

surfaces,adjusttheskidsfurtherdowntoprevent

themachinefrompickinguprocks.

5.Movetheskidsdownuntiltheyareevenwiththe

ground.

6.Firmlytightenthenutsthatsecurebothskidstothe

augersides.

Note:Toquicklyadjusttheskidsiftheyloosen,

supportthescraper1/8inch(3mm)offthe

pavement,thenadjusttheskidsdowntothe

pavement.

Figure41

CheckingandAdjustingthe

SkidsandScraper

ServiceInterval:Yearly—Checktheskidsandthe

scraperandadjustthemifnecessary.

Allmodelsexceptmodel38657

Checktheskidsandthescrapertoensurethattheauger

doesnotcontactthepavedorgravelsurface.Adjustthe

skidsandthescraperasneededtocompensateforwear.

1.Checkthetirepressure.RefertoCheckingtheTire

Pressure.

2.Loosenthenutsthatsecurebothskidstothe

augersidesuntiltheskidsslideupanddowneasily

(Figure42).

Note:Iftheskidsbecomeexcessivelyworn,you

canturnthemoverandsettheunusedsidetoward

thepavement.

CheckingandAdjustingthe

Skids

ServiceInterval:Yearly—Checktheskidsandadjust

themifnecessary.

Model38657only

Checktheskidstoensurethattheaugerdoesnot

contactthepavedorgravelsurface.Adjusttheskidsas

neededtocompensateforwear.

1.Checkthetirepressure.RefertoCheckingtheTire

Pressure.

2.Movethemachinetoalevelsurface.

3.Loosenthenutsthatsecurebothskidstothe

augersidesuntiltheskidsslideupanddowneasily

(

Figure43).

21

Page 22

Figure43

1.Skid

4.Pushdownonthehandlestoallowthepivoting

scrapertomovefullyforward,thensetthefront

ofthemachinedownsothatthefrontedgeofthe

pivotingscrapercontactstheground(Figure44).

CheckingandAdjustingthe

TractionCable

ServiceInterval:Aftertherst2hours—Inspect

thetractioncableandadjustitif

necessary.

Yearly—Inspectthetractioncable

andadjustorreplaceitifnecessary.

Ifthemachinedoesnotdriveintheforwardorreverse

speedsoritdriveswhenyoureleasethetractionlever,

adjustthetractioncable.

Withthetractionleverdisengaged,checkthepininthe

elongatedslotintheleftsideofthemachineabovethe

tire.Thereshouldbeagapof1/32to1/16inch(1to

1.5mm)fromthefrontoftheslottothefrontedgeof

thepin(

Figure45).

Figure44

1.Pivotingscraper

5.Movetheskidsdownuntiltheyareevenwiththe

ground.

Note:Forasmoothsurface,youcansettheskids

slightlyhighertoincreasethescrapingaction,but

settheskidsfarenoughdowntopreventtheauger

bladesfromcontactingtheground.

Note:Thepivotingscraperonthemachineis

notrecommendedforuseongravelsurfaces.

Butifyoumustusethemachineonagravelsurface,

adjusttheskidsfurtherdowntopreventthepivoting

scraperfrompickinguprocks.

6.Firmlytightenthenutsthatsecurebothskidstothe

augersides.

Note:Iftheskidsbecomeexcessivelyworn,you

canturnthemoverandsettheunusedsidetoward

thepavement.

Figure45

1.Pin

Ifthelefthand(traction)cableisnotproperlyadjusted,

dothefollowingsteps:

1.Loosenthejamnut.

2.Loosenortightentheturnbuckletoadjustthepin

untilitisthepropergapfromthefrontedgeofthe

slot.

3.Tightenthejamnut(

Figure46).

1.Jamnut2.Turnbuckle

22

Figure46

Page 23

CheckingtheAugerGearbox

OilLevel

ServiceInterval:Yearly—Checktheaugergearboxoil

andaddoilifnecessary.

1.Movethemachinetoalevelsurface.

2.Cleantheareaaroundthepipeplug(

Figure47

Figure47).

3.Removethepipeplugfromthegearbox.

4.Checktheoillevelinthegearbox.Theoilshouldbe

atthepointofoverowingatthelleropening.

5.Iftheoillevelislow,addGL-5orGL-6,SAE85-95

EPtransmissionoiltothegearboxuntilthepoint

ofoverow.

Note:Donotusesyntheticoil.

1.UsingSAE30atoutdoor

temperaturesbelow40°F

(4°C)willresultinhard

starting.

EngineOilCapacities

Model

38597

38629

38637

38639

38657

Figure48

2.Using10W-30atoutdoor

temperaturesabove

80°F(27°C)mayresultin

increasedoilconsumption;

therefore,checktheoil

levelmorefrequentlyin

thesecircumstances.

EngineOilCapacity

18to20oz.(0.53to0.59l)

26to28oz.(0.77to0.83l)

6.Installthepipepluginthegearbox.

ChangingtheEngineOil

ServiceInterval:Aftertherst5hours—Changethe

engineoil.

Every50hours—Changetheengine

oil.Changetheengineoilevery25

operatinghourswhenoperatingthe

engineunderaheavyload.

Ifpossible,runtheenginejustbeforechangingthe

oilbecausewarmoilowsbetterandcarriesmore

contaminants.

UseautomotivedetergentoilwithanAPIservice

classicationofSF,SG,SH,SJ,SL,orhigher.Referto

yourengineowner’smanual.

Figure48belowtoselectthebestoilviscosityfor

Use

theoutdoortemperaturerangeexpected:

1.Cleantheareaaroundtheoildraincap(Figure49).

Figure49

1.Oildraincap

2.Slideanoildrainpanunderthedrainextensionand

removetheoildraincap.

3.Draintheoil.

Note:Disposeoftheusedoilproperlyatalocal

recyclingcenter.

4.Installtheoildraincap.

5.Fillthecrankcasewithoil.RefertoFillingthe

EngineCrankcasewithOil.

23

Page 24

AdjustingtheDischargeChute

Latch

Ifthedischargechutedoesnotlockintothedesired

positionordoesnotunlocksothatyoucanmoveitto

anotherposition,adjustthedischargechutelatch.

1.Removethefasteneronthegearcover(Figure50),

liftthefrontofthecoverup,andslideitbackand

outoftheway.

Note:Thelatchisspringloadedandwillnaturally

moveintotheteethofthegear(Figure52).

4.Removeanyslackinthecablebypullingthecable

conduitrearward.

5.Tightentheboltonthecableclamp.

6.Installandsecurethegearcover.

ReplacingtheDriveBelts

Iftheauger/impellerdrivebeltorthetractiondrivebelt

becomesworn,oil-soaked,orotherwisedamaged,go

towww.Toro.comforadditionalserviceinformationor

haveanAuthorizedServiceDealerreplacethebelt.

ReplacingtheHeadlightBulb

Figure50

2.Loosentheboltonthecableclamp(Figure51).

Figure51

1.Cableconduit2.Cableclamp

3.Graspthecableconduitandmoveittowardthefront

ofthemachineuntilthedischargechutelatchfully

engagesthegearteeth(Figure51andFigure52).

Models38637,38639,and38657only

UseaGE89216Whalogenlightbulb.Donottouch

thebulbwithyourhandsorallowdirtormoistureto

comeintocontactwiththebulb.

1.Removethewireconnectorfromthebackofthe

headlight(

2.Turnthebaseofthebulbcounterclockwiseuntilit

stops(Figure54).

Figure53).

Figure53

1.Dischargechutelatch

Figure54

3.Removethebulbstraightoutfromthebackofthe

headlight(Figure55).

Figure52

2.Gearteeth

24

Page 25

Figure55

4.Insertanewbulbintothebackoftheheadlight

(Figure56).

Figure56

5.Turnthebaseofthebulbclockwiseuntilitissnug

(Figure57).

Figure57

6.Insertthewireconnectorstraightintothebackof

theheadlightuntilitissecurelyinplace(Figure58).

Storage

WARNING

•Gasolinevaporscanexplode.

•Donotstoregasolinemorethan30days.

•Donotstorethemachineinanenclosurenear

anopename.

•Allowtheenginetocoolbeforestoringit.

PreparingtheMachinefor

Storage

1.Onthelastrefuelingoftheyear,addfuelstabilizer

tofreshfuelasdirectedbytheenginemanufacturer.

2.Runtheenginefor10minutestodistributethe

conditionedfuelthroughthefuelsystem.

3.Loosenthehoseclampthatsecuresthefuellineto

thevalveandslidethefuellineoffthefuelshutoff

valve.

4.Openthefuelshutoffvalveandallowthefuelto

drainoutofthefueltankintoanapprovedfuel

container.

5.Installthefuellineontothefuelshutoffvalveand

secureitwithahoseclamp.

6.Runthemachineuntiltheenginestopsfromrunning

outoffuel.

7.Primetheengineandstartitagain.

8.Allowtheenginetorununtilitstops.Whenyoucan

nolongerstarttheengine,itissufcientlydry.

9.Stoptheengineandallowittocool.

10.Removetheignitionkey.

11.Disconnectthesparkplugwire.

12.Removethesparkplug,add1oz.(30ml)ofoil

throughthesparkplughole,andpullthestarterrope

slowlyseveraltimestodistributeoilthroughoutthe

cylindertopreventcylindercorrosionduringthe

off-season.

13.Looselyinstallthesparkplug.

14.Disposeofanyunusedfuelproperly.Recycleit

accordingtolocalcodes,oruseitinyourautomobile.

Figure58

Note:Donotstorestabilizedfuelformorethan

90days.

15.Cleanthemachinethoroughly .

16.Touchupchippedsurfaceswithpaintavailable

fromanAuthorizedServiceDealer.Sandaffected

areasbeforepainting,andusearustpreventativeto

preventthemetalpartsfromrusting.

25

Page 26

17.Tightenallloosescrews,bolts,andlocknuts.Repair

orreplaceanydamagedparts.

18.Coverthemachineandstoreitinaclean,dryplace

outofthereachofchildren.Allowtheengineto

coolbeforestoringitinanyenclosure.

RemovingtheMachinefrom

Storage

1.Removethesparkplugandspintheenginerapidly

usingthestartertoblowtheexcessoilfromthe

cylinder.

2.Installthesparkplugbyhandandthentorqueitto

15ft-lb(20.4N-m).

3.Connectthesparkplugwire.

4.Performtheannualmaintenanceproceduresasgiven

intheRecommendedMaintenanceSchedule.

26

Page 27

Troubleshooting

Problem

Electricstarterdoesnotturn(electric-start

modelsonly)

Enginedoesnotstartorstartshard

PossibleCauseCorrectiveAction

1.Thepowercordisdisconnectedatthe

outletorthemachine.

2.Thepowercordisworn,corroded,or

damaged.

3.Thepoweroutletisnotenergized.

1.Thekeyisnotintheignitionorisinthe

Stopposition.

2.ThechokeisintheOffpositionandthe

primerhasnotbeenpressed.

3.Thefuelshutoffvalveisnotopen.3.Openthefuelshutoffvalve.

4.ThethrottleisnotintheFastposition.4.MovethethrottletotheFastposition.

5.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

6.Thesparkplugwireislooseor

disconnected.

7.Thesparkplugispitted,fouled,orthe

gapisincorrect.

8.Thefuelventcapisrestricted.

9.Theengineoillevelintheengine

crankcaseistoolowortoohigh.

1.Connectthepowercordtotheoutlet

and/orthemachine.

2.Replacethepowercord.

3.Haveaqualiedelectricianenergize

theoutlet.

1.Insertthekeyintotheignitionandturn

ittotheOnposition.

2.MovethechoketotheOnpositionand

presstheprimer3times.

5.Drainand/orllthefueltankwithfresh

gasoline(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

6.Connectthewiretothesparkplug.

7.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

8.Removetheventrestrictionorreplace

thefuelcap.

9.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

Enginerunsrough

Engineruns,butthemachinedischarges

snowpoorlyornotatall

1.ThechokeisintheOnposition.1.MovethechoketotheOffposition.

2.Thefuelshutoffvalveisnotcompletely

open.

3.Thefueltankisnearlyemptyor

containsstalefuel.

4.Thesparkplugwireisloose.

5.Thesparkplugispitted,fouled,orthe

gapisincorrect.

6.Theengineoillevelintheengine

crankcaseistoolowortoohigh.

1.ThethrottleisnotintheFastposition

whenthrowingsnow .

2.Themachineismovingtoofasttoclear

thesnow.

3.Y ouaretryingtoremovetoomuch

snowperswath.

4.Y ouaretryingtoremoveextremely

heavyorwetsnow.

5.Thedischargechuteisplugged.5.Unclogthedischargechute.

6.Theauger/impellerdrivebeltisloose

orisoffthepulley.

2.Openthefuelshutoffvalve.

3.Drainandllthefueltankwithfresh

gasoline(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

4.Connectthewiretothesparkplug.

5.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

6.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

1.MovethethrottletotheFastposition.

2.Shiftthemachineintoalowergear.

3.Reducetheamountofsnowremoved

perswath.

4.Don’toverloadthemachinewith

extremelyheavyorwetsnow.

6.Installand/oradjusttheauger/impeller

drivebelt;refertowww.Toro.com

forservicinginformationortakethe

machinetoanAuthorizedService

Dealer.

27

Page 28

Problem

7.Theauger/impellerdrivebeltisworn

orbroken.

PossibleCauseCorrectiveAction

7.Replacetheauger/impellerdrivebelt;

refertowww.Toro.comforservicing

informationortakethemachinetoan

AuthorizedServiceDealer.

Dischargechuteeitherdoesnotlockinto

placeordoesnotmove

Themachinedoesnotproperlyclearthe

snowoffthesurface

1.Thedischargechutelatchisnot

properlyadjusted.

1.Theskidsand/orscraperarenot

properlyadjusted.

2.Thepressureinthetiresisnotequal.

1.Adjustthedischargechutelatch.

1.Adjusttheskidsand/orthescraper.

2.Checkandadjustthepressureinone

orbothtires.

28

Page 29

Notes:

29

Page 30

Notes:

30

Page 31

InternationalDistributorList

Distributor:

AtlantisSuveSulamaSisstemleriLt

BalamaPrimaEngineeringEquip.HongKong85221552163

B-RayCorporation

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

EquiverMexico525553995444

FemcoS.A.Guatemala

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GuandongGoldenStarChina

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IbeaS.P .A.

IrriamcPortugal351212388260

IrrigationProductsInt’lPvtLtd.India862283960789

JeanHeybroekb.v.Netherlands3130639461 1

Lely(U.K.)Limited

MaquiverS.A.Colombia

MaruyamaMfg.Co.Inc.

MetraKft

Mountelda.s.CzechRepublic

MunditolS.A.

OslingerTurfEquipmentSA

OyHakoGroundandGardenAb

ParklandProductsLtd.NewZealand6433493760

Prochaska&Cie

RTCohen2004Ltd.

Riversa

RothMotorgerateGmBh&Co.Germany

ScSvendCarlsenA/S

SolvertS.A.S.

SpyprosStavrinidesLimitedCyprus

SurgeSystemsIndiaLimited

T-MarktLogisticsLtd.Hungary3626525500

ToroAustraliaAustralia61395807355

ToroEuropeBVBABelgium3214562960

Country:

Turkey902163448674

Korea82325512076

PuertoRico7877888383

NorthernIreland442890813121

Japan81726325861

Norway4722907760

UnitedKingdom441279723444

UnitedArabEmirates97143479479

Egypt2025194308

Italy390331853611

UnitedKingdom441480226800

Japan81332522285

Hungary3613263880

Argentina541148219999

Ecuador59342396970

Finland35898700733

Austria4312785100

Israel97298617979

Spain

Denmark4566109200

France33130817700

India911292299901

PhoneNumber:

5062391138

941 12746100

5024423277

30109350054

862087651338

4635100000

5712364079

420255704220

34952837500

4971442050

35722434131

374-0269RevA

Page 32

TheToroWarranty

ConditionsandProductsCovered

TheToro®Companyanditsafliate,ToroWarrantyCompany,pursuantto

anagreementbetweenthem,jointlypromisetorepairtheT oroProduct

listedbelowifusedforresidentialpurposes*ifdefectiveinmaterialsor

workmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

WalkPowerMowers2yearlimitedwarranty

RearEngineRiders2yearlimitedwarranty

Lawn&GardenTractors

ElectricHandHeldProducts2yearlimitedwarranty

Snowthrowers

ConsumerZeroTurn

*OriginalPurchasermeansthepersonwhooriginallypurchasedtheToro

Product

*Residentialpurposesmeansuseoftheproductonthesamelotasyour

home.Useatmorethanonelocation,orinstitutionalorrentaluse,is

consideredcommercialuse,andthecommercialusewarrantywould

apply.

2yearlimitedwarranty

2yearlimitedwarranty

2yearlimitedwarranty

LimitedWarrantyforCommercialUse

ToroConsumerProductsandattachmentsusedforcommercial,

institutional,orrentaluse,arewarrantedagainstdefectsinmaterials

orworkmanshipforthefollowingtimeperiodsfromthedateoforiginal

purchase:

ProductsWarrantyPeriod

WalkPowerMowers90daywarranty

RearEngineRiders90daywarranty

Lawn&GardenTractors

ElectricHandHeldProducts90daywarranty

Snowthrowers

ConsumerZeroTurn

90daywarranty

90daywarranty

45daywarranty

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.Contactyoursellertoarrangeserviceoftheproduct.Ifforanyreason

itisimpossibleforyoutocontactyourseller,youmaycontactany

ToroAuthorizedDistributortoarrangeservice.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.IfforanyreasonyouaredissatisedwiththeService

Dealer’sanalysisorwiththeassistanceprovided,contactusat:

CustomerCareDepartment,ConsumerDivision

TheT oroCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

Manager:TechnicalProductSupport:001–952–887–8248

SeeattachedDistributorList

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator’sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

ItemsandConditionsNotCovered

Thisexpresswarrantydoesnotcoverthefollowing:

•Costofregularmaintenanceserviceorwearparts,suchasrotor

blades(paddles),scraperblades,belts,fuel,lubricants,oilchanges,

sparkplugs,cable/linkageorbrakeadjustments

•Anyproductorpartwhichhasbeenalteredormisusedandrequires

replacementorrepairduetoaccidentsorlackofpropermaintenance

•Repairsnecessaryduetofailuretousefreshfuel(lessthanone

monthold),orfailuretoproperlypreparetheunitpriortoanyperiod

ofnon-useoveronemonth

•Engineandtransmission.Thesearecoveredbytheappropriate

manufacturer’sguaranteeswithseparatetermsandconditions

Allrepairscoveredbythesewarrantiesmustbeperformedbyan

AuthorizedToroServiceDealerusingToroapprovedreplacementparts.

GeneralConditions

Thepurchaseriscoveredbythenationallawsofeachcountry.Therights

towhichthepurchaserisentitledwiththesupportoftheselawsarenot

restrictedbythiswarranty .

374-0268RevA

Loading...

Loading...