Page 1

PowerClearSnowthrower

ModelNo.38588—SerialNo.311000001andUp

ModelNo.38589—SerialNo.311000001andUp

FormNo.3365-636RevC

Operator'sManual

Introduction

Thismachineisintendedtobeusedbyresidential

homeowners.Itisdesignedforremovingsnowfrom

pavedsurfaces,suchasdrivewaysandsidewalks,

andothersurfacesfortrafconresidentialor

commercialproperties.Itisnotdesignedfor

removingmaterialsotherthansnow,norisit

designedforclearingoffgravelsurfaces.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourmachineproperlyandtoavoidinjury

andmachinedamage.Youareresponsibleforoperating

themachineproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comfor

machineandaccessoryinformation,helpndinga

dealer,ortoregisteryourmachine.

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorToroCustomerServiceandhave

themodelandserialnumbersofyourmachineready.

Figure1identiesthelocationofthemodelandserial

numbersonthemachine.Writethenumbersinthe

spaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Safety

Readandunderstandthecontentsofthismanual

beforeyoustarttheengine.

1.Modelandserialnumberlocation

©2011—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

Registeratwww.Toro.com.

Thisisthesafetyalertsymbol(

Figure2)isusedto

alertyoutopotentialpersonalinjuryhazards.Obey

allsafetymessagesthatfollowthissymboltoavoid

possibleinjuryordeath.

Improperlyusingormaintainingthismachine

couldresultininjuryordeath.Toreducethis

potential,complywiththefollowingsafety

instructions.

Thismachineiscapableofamputatinghandsand

feetandofthrowingobjects.Failuretoobservethe

followingsafetyinstructionscouldresultinserious

injury.

Training

•Read,understand,andfollowallinstructionsonthe

machineandinthemanual(s)beforeoperatingthis

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

Page 2

machine.Bethoroughlyfamiliarwiththecontrols

andtheproperuseofthemachine.Knowhowto

stopthemachineanddisengagethecontrolsquickly.

•Neverallowchildrentooperatethemachine.Never

allowadultstooperatethemachinewithoutproper

instruction.

•Keeptheareaofoperationclearofallpersons,

particularlysmallchildren.

•Exercisecautiontoavoidslippingorfalling.

Preparation

•Thoroughlyinspecttheareawherethemachineis

tobeusedandremovealldoormats,sleds,boards,

wires,andotherforeignobjects.

•Donotoperatethemachinewithoutwearing

adequatewintergarments.Avoidloosetting

clothingthatcangetcaughtinmovingparts.Wear

footwearthatwillimprovefootingonslippery

surfaces.

•Handlefuelwithcare;itishighlyammable.

–Useanapprovedfuelcontainer.

–Neveraddfueltoarunningengineorhotengine.

–Fillfueltankoutdoorswithextremecare.Never

llfueltankindoors.

–Neverllcontainersinsideavehicleorona

truckortrailerbedwithaplasticliner.Always

placecontainersontheground,awayfromyour

vehicle,beforelling.

–Whenpractical,removegas-poweredmachinery

fromthetruckortrailerandrefuelitonthe

ground.Ifthisisnotpossible,thenrefuelsuch

machineryonatrailerwithaportablecontainer,

ratherthanfromagasolinedispensernozzle.

–Keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimes,until

refuelingiscomplete.Donotuseanozzle

lock-opendevice.

–Replacegasolinecapsecurelyandwipeupspilled

fuel.

–Iffuelisspilledonclothing,changeclothing

immediately.

•Useextensioncordsandreceptaclesasspecied

bythemanufacturerforallmachineswithelectric

startingmotors.

•Donotattempttoclearsnowfromagravelor

crushedrocksurface.Thismachineisintendedfor

useonlyonpavedsurfaces.

•Neverattempttomakeanyadjustmentswhile

theengineisrunning(exceptwhenspecically

recommendedbymanufacturer).

•Alwayswearsafetyglassesoreyeshieldsduring

operationorwhileperforminganadjustmentor

repairtoprotecteyesfromforeignobjectsthatmay

bethrownfromthemachine.

Operation

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Exerciseextremecautionwhenoperatingonor

crossinggraveldrives,walks,orroads.Stayalertfor

hiddenhazardsortrafc.

•Afterstrikingaforeignobject,stoptheengine,

removetheignitionkey,thoroughlyinspectthe

machineforanydamage,andrepairthedamage

beforerestartingandoperatingthemachine.

•Ifthemachineshouldstarttovibrateabnormally,

stoptheengineandcheckimmediatelyforthecause.

Vibrationisgenerallyawarningoftrouble.

•Stoptheenginewheneveryouleavetheoperating

position,beforeuncloggingtherotorbladehousing

ordischargechute,andwhenmakinganyrepairs,

adjustmentsorinspections.

•Whencleaning,repairing,orinspectingthemachine,

stoptheengineandmakecertainthattherotor

bladesandallmovingpartshavestopped.

•Donotruntheengineindoors,exceptwhenstarting

theengineandfortransportingthemachineinor

outofthebuilding.Opentheoutsidedoors;exhaust

fumesaredangerous.

•Exerciseextremecautionwhenoperatingonslopes.

•Neveroperatethemachinewithoutproperguards

andothersafetyprotectivedevicesinplaceand

working.

•Neverdirectthedischargetowardpeopleorareas

wherepropertydamagecanoccur.Keepchildren

andothersaway.

•Donotoverloadthemachinecapacitybyattempting

toclearsnowattoofastarate.

•Lookbehindandusecarewhenbackingupwiththe

machine.

•Disengagepowertotherotorbladeswhenmachine

istransportedornotinuse.

•Neveroperatethemachinewithoutgoodvisibility

orlight.Alwaysbesureofyourfooting,andkeepa

rmholdonthehandles.Walk;neverrun.

•Nevertouchahotengineormufer(

Figure3).

2

Page 3

Figure3

1.Symbolstampedontheexhaustbafeindicatingahot

surface.

thedischargeopeningwhileoperatingthemachine.

Keepyourface,hands,feet,andanyotherpart

ofyourbodyorclothingawayfrommovingor

rotatingparts.

•Beforeadjusting,cleaning,repairing,andinspecting

themachine,andbeforeuncloggingthedischarge

chute,stoptheengine,removethekey,andwait

forallmovingpartstostop.

•Beforeleavingtheoperatingposition,stopthe

engine,removetheignitionkey,andwaitforall

movingpartstostop.

ClearingaCloggedDischarge

Chute

Handcontactwiththerotatingrotorbladesinsidethe

dischargechuteisthemostcommoncauseofinjury

associatedwithsnowthrowers.Neveruseyourhandto

cleanoutthedischargechute.

Toclearthechute:

•Shuttheengineoff!

•Wait10secondstobesuretherotorbladeshave

stoppedrotating.

•Alwaysuseaclean-outtool,notyourhands.

MaintenanceandStorage

•Checkallfastenersatfrequentintervalsforproper

tightnesstobesurethemachineisinsafeworking

condition.

•Neverstorethemachinewithfuelinthefueltank

insideabuildingwhereignitionsourcesarepresent,

suchashotwaterheaters,spaceheaters,orclothes

dryers.Allowtheenginetocoolbeforestoringin

anyenclosure.

•Ifashield,safetydevice,ordecalisdamaged,

illegible,orlost,repairorreplaceitbeforebeginning

operation.Also,tightenanyloosefasteners.

•Donotsmokewhilehandlinggasoline.

•Donotusethemachineonaroof.

•Donottouchtheenginewhileitisrunningorsoon

afterithasstoppedbecausetheenginemaybehot

enoughtocauseaburn.

•Performonlythosemaintenanceinstructions

describedinthismanual.Beforeperformingany

maintenance,service,oradjustment,stoptheengine

andremovethekey.Ifmajorrepairsareeverneeded,

contactanAuthorizedServiceDealer.

•Donotchangethegovernorsettingsontheengine.

•Whenstoringthemachineformorethan30days,

drainthefuelfromthefueltanktopreventa

potentialhazard.Storefuelinanapprovedfuel

container.Removethekeyfromtheignitionswitch

beforestoringthemachine.

•PurchaseonlygenuineTororeplacementpartsand

accessories.

•AlwaysrefertotheOperator’sManualforimportant

detailsifthemachineistobestoredforanextended

period.

•Maintainorreplacesafetyandinstructionlabels,as

necessary.

•Runthemachineafewminutesafterthrowingsnow

topreventfreeze-upoftherotorblades.

ToroSnowthrowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknow.

•Rotatingrotorbladescaninjurengersor

hands.Staybehindthehandlesandawayfrom

3

Page 4

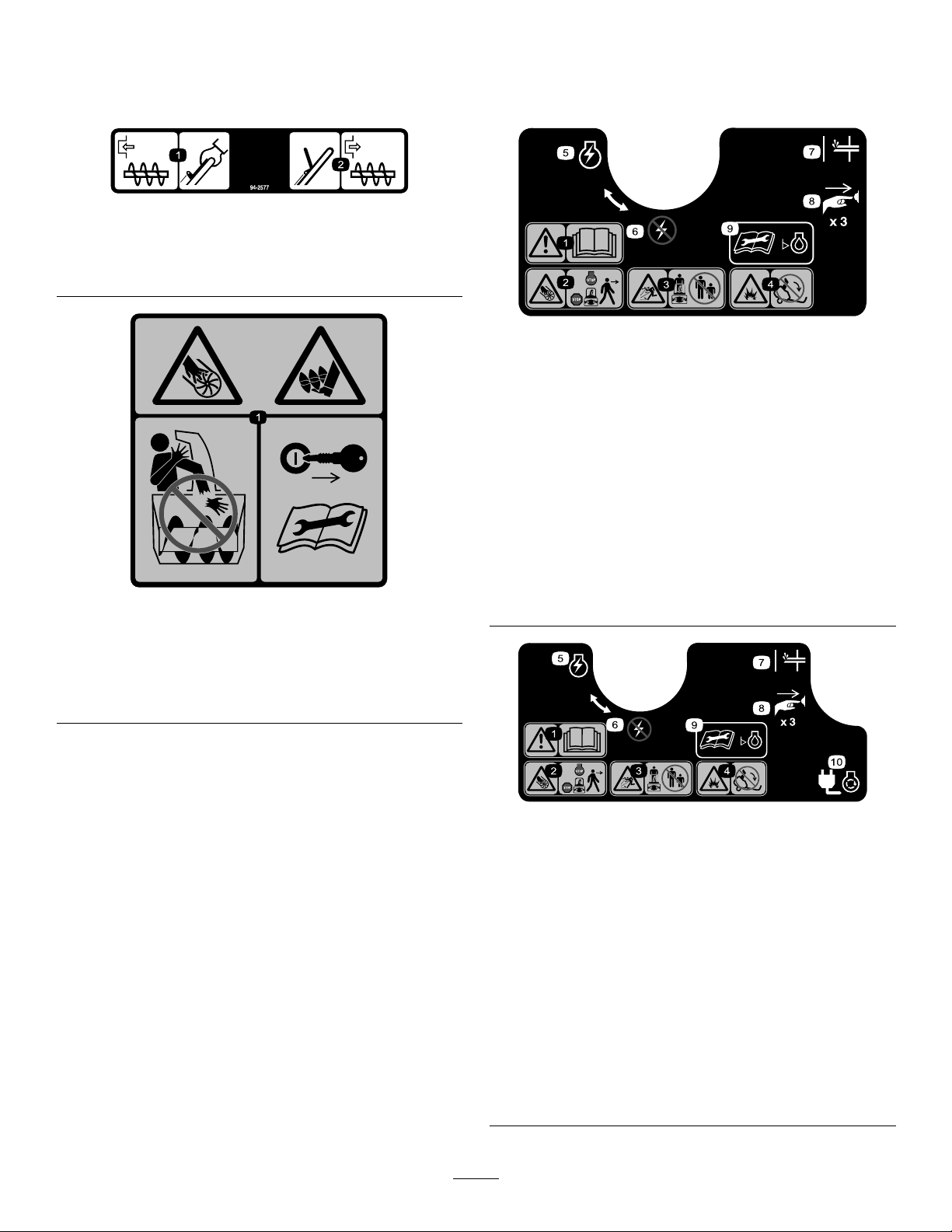

SafetyandInstructionalDecals

Important:Safetyandinstructiondecalsarelocatednearareasofpotentialdanger.Replacedamaged

decals.

94-2577

1.Toengagetherotorblades,holdthecontrolbaragainst

thehandle.

2.Todisengagetherotorblades,releasethecontrolbar.

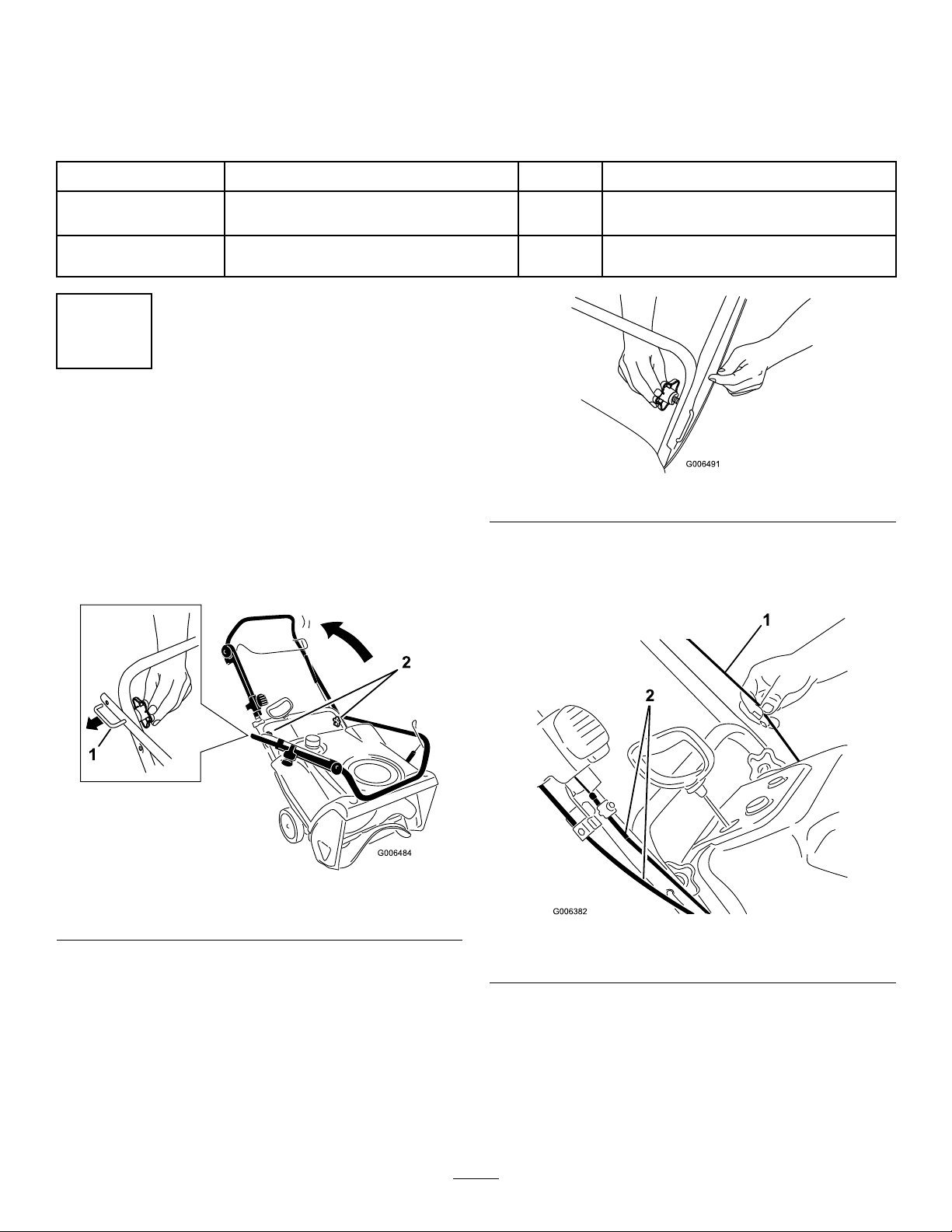

117-9102(Model38588only)

Orderpartno.1 17-6036

115-5698

Orderpartno.1 17-9121

1.Cuttingdismembermenthazards,impellerandauger—do

notplaceyourhandinthechute;removetheignitionkey

andreadtheinstructionsbeforeservicingorperforming

maintenance.

1.Warning—readthe

Operator'sManual.

2.Cutting/dismemberment

hazard,impeller—stopthe

enginebeforeleavingthe

machine.

3.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

4.Fuelspillhazard—donot

tipmachinebackward.

5.EngineswitchOn

117-9103(Model38589only)

Orderpartno.1 17-6046

6.EngineswitchOff

7.Primer

8.Pushtheprimerthree

timestoprimetheengine.

9.ReadtheOperator's

Manualbeforechecking

engineoillevel.

1.Warning—readthe

Operator'sManual.

2.Cutting/dismemberment

hazard,impeller—stopthe

enginebeforeleavingthe

machine.

3.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

4.Fuelspillhazard—donot

tipmachinebackward.

5.EngineswitchOn

4

6.EngineswitchOff

7.Primer

8.Pushtheprimerthree

timestoprimetheengine.

9.ReadtheOperator's

Manualbeforechecking

engineoillevel.

10.Plugthemachineinto

powertheelectricstarter.

Page 5

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

Nopartsrequired

Screws

Chuteassembly

1

UnfoldingtheHandle

NoPartsRequired

Procedure

1.Loosenthehandleknobs,pulloutthe“U”-shaped

handlelocksuntilyoucanmovethehandlefreely,

androtatethehandletotheoperatingposition

Figure4).

(

Qty.

–

3

1

Important:Ensurethatyoudonotpinchor

kinkthecontrolcableortheQuickShoot™

cables(Figure6).

Unfoldthehandle.

Installthedischargechute.

Figure5

Use

Figure4

1.“U”-shapedhandlelock(2)

2.Inserttheendofthe“U”-shapedhandlelockinto

theopenholeinthehandleandtightenthehandle

knobsuntiltheyaresnug(Figure5).

2.Handleknobs

Figure6

1.Controlcable2.QuickShoot™cables

5

Page 6

Note:Thebottleofoilmaycontainmorethanis

required.Donotoverllorunderlltheengine.

2

InstallingtheDischargeChute

Partsneededforthisprocedure:

3

Screws

1

Chuteassembly

Procedure

Installthedischargechuteasshown(Figure7).

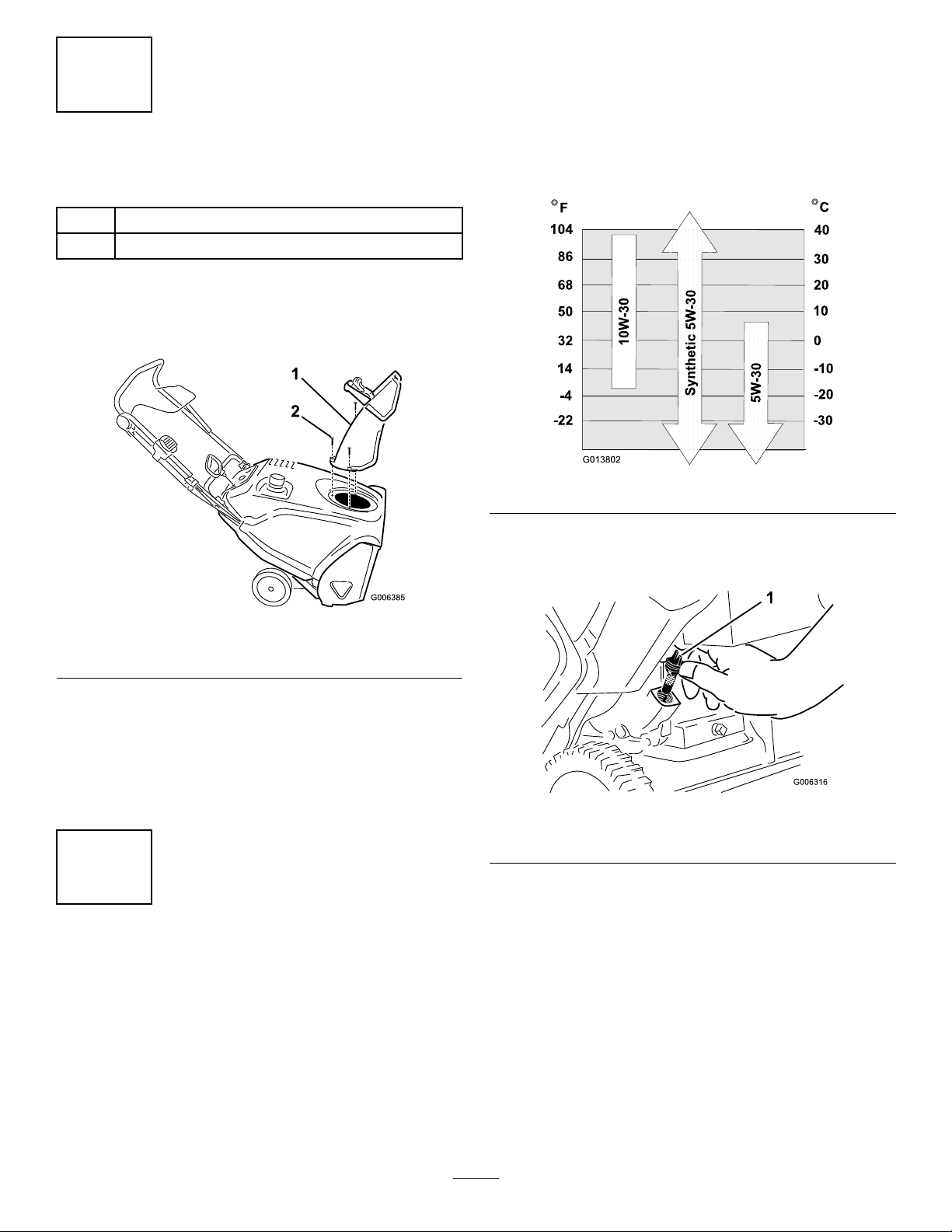

Maxll:20oz.(0.6l),type:automotivedetergentoil

withanAPIserviceclassicationofSJ,SL,orhigher.

Figure8belowtoselectthebestoilviscosityforthe

Use

outdoortemperaturerangeexpected:

Figure8

1.Movethemachinetoalevelsurface.

Figure7

1.Dischargechute

Note:Foreasierinstallation,useasmallratchetwrench

totightenthescrews.

Important:Donotovertightenthescrews;

otherwiseyoumaydamagethedischargechuteand

preventitfromturningfreely.

2.Screw(3)

3

FillingtheEnginewithOil

NoPartsRequired

Procedure

Yourmachinedoesnotcomewithoilintheengine,but

itdoescomewithabottleofoil.

2.Cleanaroundtheoilllcap(Figure9).

Figure9

1.Oilllcap

3.Unscrewtheoilllcapandremoveit.

4.Withthemachineintheoperatingposition,

carefullypouroilintothecrankcaseuntilthepoint

ofoverow.

5.Wait3minutesfortheoiltosettleandaddenough

tobringittothepointofoverll.

6.Screwtheoilllcapintotheoilllholeandtighten

itsecurely.

Important:Beforestartingtheengine,llthe

enginewithoil.

6

Page 7

Operation

4

AdjustingtheControlCable

NoPartsRequired

Procedure

RefertoAdjustingtheControlCableinMaintenance.

ProductOverview

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

DANGER

Gasolineisextremelyammableandexplosive.A

reorexplosionfromgasolinecanburnyouand

others.

•Topreventastaticchargefromignitingthe

gasoline,placethecontainerand/ormachine

onthegroundbeforelling,notinavehicleor

onanobject.

•Fillthetankoutdoorswhentheengineiscold.

Wipeupspills.

•Donothandlegasolinewhensmokingoraround

anopenameorsparks.

•Storegasolineinanapprovedfuelcontainer,out

ofthereachofchildren.

•Donottipthemachinebackwardwithfuelin

thefueltank;otherwise,fuelmayleakoutof

themachine.

Figure10

1.Chutedeectortrigger

2.Dischargechute9.Ignitionkey

3.Fueltankcap

4.Controlbar11.Oildrainplug

5.QuickShoot™control12.Oilllcap

6.Recoilstarthandle

7.Primer

8.Electric-startbutton

(model38589only)

10.Chokelever

13.Chutedeector

FillingtheFuelTank

Fillthefueltankwithfreshunleadedgasolinehavingan

octaneratingatornear87fromamajorname-brand

servicestation(Figure11).

Figure11

1.1/4inch(6mm)

Important:Donotaddoiltothegasoline.

Important:DonotuseE85orE20fuel.Alternative

fuelswithhighalcoholcontentcancausehard

7

Page 8

starting,poorengineperformance,andmaycause

internalenginedamage.

Note:Forbestresults,purchaseonlythequantityof

gasolinethatyouexpecttousein30days.Otherwise,

youmayaddfuelstabilizertonewlypurchasedgasoline

tokeepitfreshforupto6months.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily—Check

theengineoillevelandaddoilif

necessary.

1.Movethemachinetoalevelsurface.

Figure13

2.Pulloutthechokelever(Figure14andFigure15).

2.Cleanaroundtheoilllcap(

Figure12

1.Oilllcap

Figure12).

3.Unscrewtheoilllcapandremoveit.

4.Iftheoillevelislow,keepthemachineinthe

operatingpositionandcarefullypouroilintothe

crankcaseuntilthepointofoverow.(Max.ll:20

oz.(0.6l),type:SAE30detergentoilwithanAPI

serviceclassicationofSJ,SL,orhigher.)

5.Wait3minutesfortheoiltosettleandaddenough

tobringittothepointofoverll.

6.Screwtheoilllcapintotheoilllholeandhand

tightenitsecurely.

Figure14

1.Chokelever

Figure15

1.Symbolsonthechokeleverindicatingtomovethechoke

levertotherighttoactivatethechoke.

3.Firmlypushintheprimer3timeswithyourthumb,

holdingtheprimerinaforasecondbeforereleasing

iteachtime(

Figure16).

StartingtheEngine

1.TurntheignitionkeyclockwisetotheOnposition

(Figure13).

8

Page 9

Figure16

Note:Removeyourglovewhenyoupushinthe

primersothataircannotescapefromtheprimer

hole.

Important:Donotusetheprimerorthechoke

iftheenginehasbeenrunningandishot.

Excessiveprimingmayoodtheengineand

preventitfromstarting.

4.Connectanextensioncordtoapowersourceand

themachine,andpushtheelectric-startbutton

(model38589only)(

starthandle(Figure18).

Figure17),orpulltherecoil

Figure18

Important:Runtheelectricstarternomore

than10timesatintervalsof5secondson,then

5secondsoff.Runningtheelectricstarter

extensivelycanoverheatanddamageit.Ifthe

enginedoesnotstartafterthisseriesofattempts,

waitatleast40minutestoallowthestarterto

coolbeforeattemptingtostartitagain.Ifthe

enginedoesnotstartafterthesecondseriesof

attempts,takethemachinetoanAuthorized

ServiceDealerforservice(model38589only).

Note:Ifyoupulltherecoilhandleandfeelno

resistance,thestartermaybefrozen.Thawoutthe

starterbeforeattemptingtostartthemachine.

5.Whiletheengineisrunning,pushinthechokelever

slowly.

6.Unplugtheextensioncordfromthepowersource

andthemachine(model38589only).

Figure17

Note:UseonlyaUL-listed,16-gaugeextension

cordrecommendedforoutdoorusethatisnot

longerthan50feet(15m).

WARNING

Theelectricalcordcanbecomedamaged,

causingashockorre.

Thoroughlyinspecttheelectricalcordbefore

pluggingitintoapowersource.Ifthe

cordisdamaged,donotuseittostartthe

machine.Replaceorrepairthedamagedcord

immediately.ContactanAuthorizedService

Dealerforassistance.

CAUTION

Ifyouleavethemachinepluggedintoapower

source,someonecaninadvertentlystartthe

machineandinjurepeopleordamageproperty

(model38589only).

Unplugthepowercordwheneveryouarenot

startingthemachine.

EngagingtheRotorBlades

Toengagetherotorblades,holdthecontrolbaragainst

thehandle(Figure19).

9

Page 10

Figure19

1.Controlbar

DisengagingtheRotorBlades

Todisengagetherotorblades,releasethecontrolbar

(Figure20).

AdjustingtheDischargeChute

andChuteDeector

Toadjustthedischargechute,pressthetriggerofthe

QuickShoot™controlontherighthandsideofthe

handleandmoveitupordownalongthehandle.Moving

thecontroldownthehandlerotatesthedischargechute

totheleft;movingthecontrolupthehandlerotatesthe

dischargechutetotheright(

Figure22).

Figure20

StoppingtheEngine

Tostoptheengine,turntheignitionkeycounterclockwise

totheOffposition(Figure21).

Figure21

Figure22

Toraiseorlowertheangleofthechutedeector,press

thetriggeronthechutedeectorandmovethechute

deectorupordown(Figure23).

Figure23

1.Chutedeectortrigger2.Chutedeector

10

Page 11

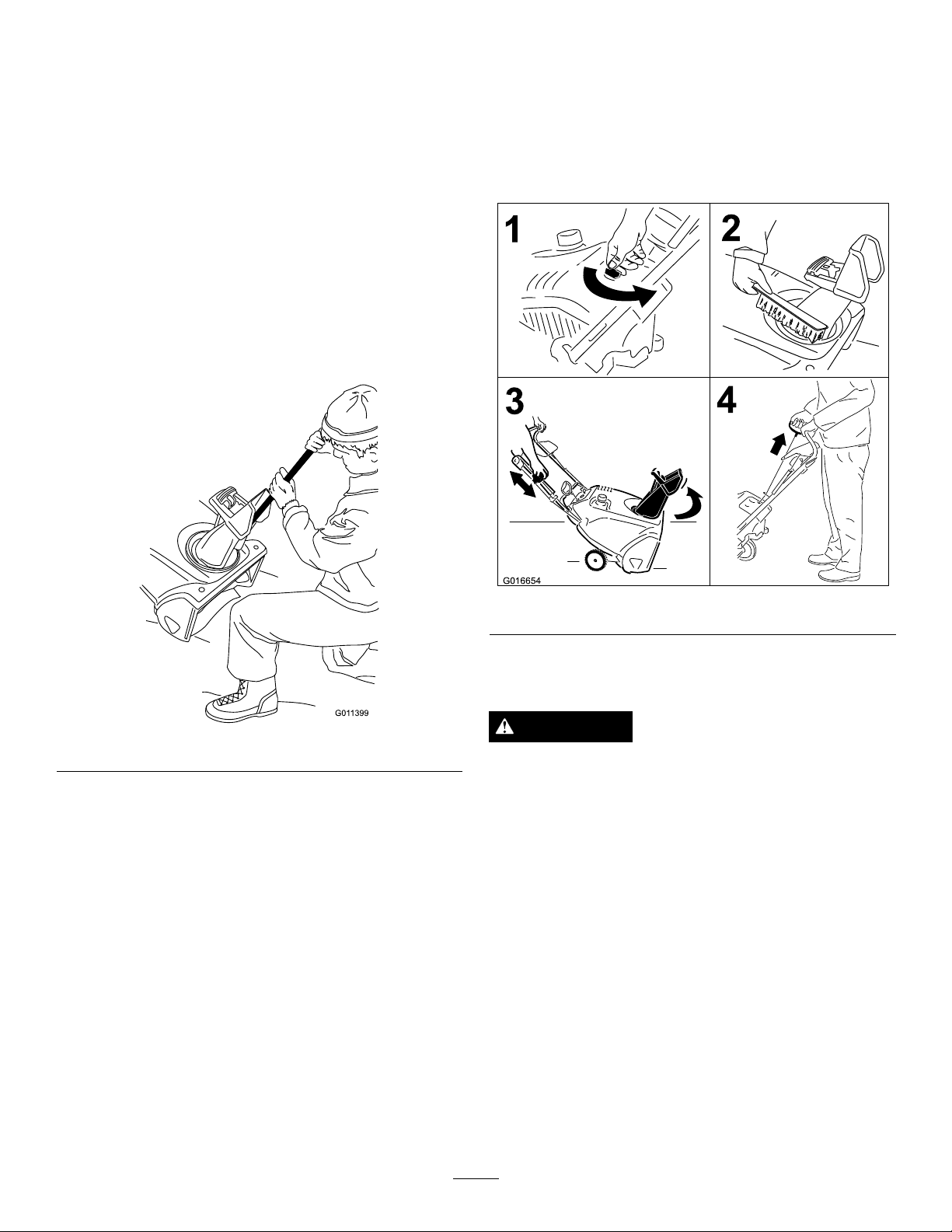

ClearingaCloggedDischarge

1

2

G016654

3

4

Chute

Important:Handcontactwiththerotating

rotorbladesinsidethedischargechuteisthe

mostcommoncauseofinjuryassociatedwith

snowthrowers.Neveruseyourhandtocleanout

thedischargechute.

Toclearthechute:

•Shuttheengineoff!

•Wait10secondstobesuretherotorbladeshave

stoppedrotating.

•Alwaysuseaclean-outtool,notyourhands

Figure24).

(

only)topreventtherecoilstarterand/ortheelectric

starterfromfreezingup.

•Insnowyandcoldconditions,somecontrolsand

movingpartsmayfreeze.Donotuseexcessiveforce

whentryingtooperatefrozencontrols.Ifyouhave

difcultyoperatinganycontrolorpart,startthe

engineandletitrunforafewminutes.

Figure24

PreventingFreeze-upafterUse

•Lettheenginerunforafewminutestoprevent

movingpartsfromfreezing.Stoptheengine,wait

forallmovingpartstostop,andremoveiceand

snowfromthemachine.

•Cleanoffanysnowandicefromthebaseofthe

chute.

•Rotatethedischargechuteleftandrighttofreeit

fromanyicebuildup.

•WiththeignitionkeyintheOffposition,pullthe

recoilstarterhandleseveraltimesorconnectthe

electricalcordtoapowersourceandthemachine

andpushtheelectricstartbuttononce(model38589

Figure25

OperatingTips

WARNING

Therotorbladescanthrowstones,toys,andother

foreignobjectsandcauseseriouspersonalinjuryto

theoperatorortobystanders.

•Keeptheareatobeclearedfreeofallobjects

thattherotorbladescouldpickupandthrow.

•Keepallchildrenandpetsawayfromthearea

ofoperation.

•Removethesnowassoonaspossibleafteritfalls.

•Ifthemachinedoesnotpropelitselfforwardon

slipperysurfacesorinheavysnow,pushforwardon

thehandle,butallowthemachinetoworkatitsown

pace.

•Overlapeachswathtoensurecompletesnow

removal.

•Dischargethesnowdownwindwheneverpossible.

11

Page 12

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

Aftertherst2hours

Beforeeachuseordaily

Yearly

Yearlyorbeforestorage

MaintenanceProcedure

•Checkthecontrolcableandadjustitifnecessary.

•Checkforloosefastenersandtightenthemifnecessary .

•Changetheengineoil.

•Checktheengineoillevelandaddoilifnecessary.

•Checkthecontrolcableandadjustitifnecessary.

•InspecttherotorbladesandhaveanAuthorizedServiceDealerreplacetherotor

bladesandscraperifnecessary.

•Changetheengineoil.

•Servicethesparkplugandreplaceitifnecessary.

•Checkforloosefastenersandtightenthemifnecessary .

•HaveanAuthorizedServiceDealerinspectthedrivebeltandreplaceitifnecessary.

•Preparethemachineforstorage.

AdjustingtheControlCable

CheckingtheControlCable

ServiceInterval:Afterthersthour—Check

thecontrolcableandadjustitif

necessary.

Yearly—Checkthecontrolcableand

adjustitifnecessary.

Important:Thecontrolcablemustcontainsome

slackwhenyoudisengagethecontrolbarforthe

rotorbladestostopproperly.

AdjustingtheControlCable

1.Slideupthespringcoverandunhookthespring

fromtheadjusterlink(

Figure27).

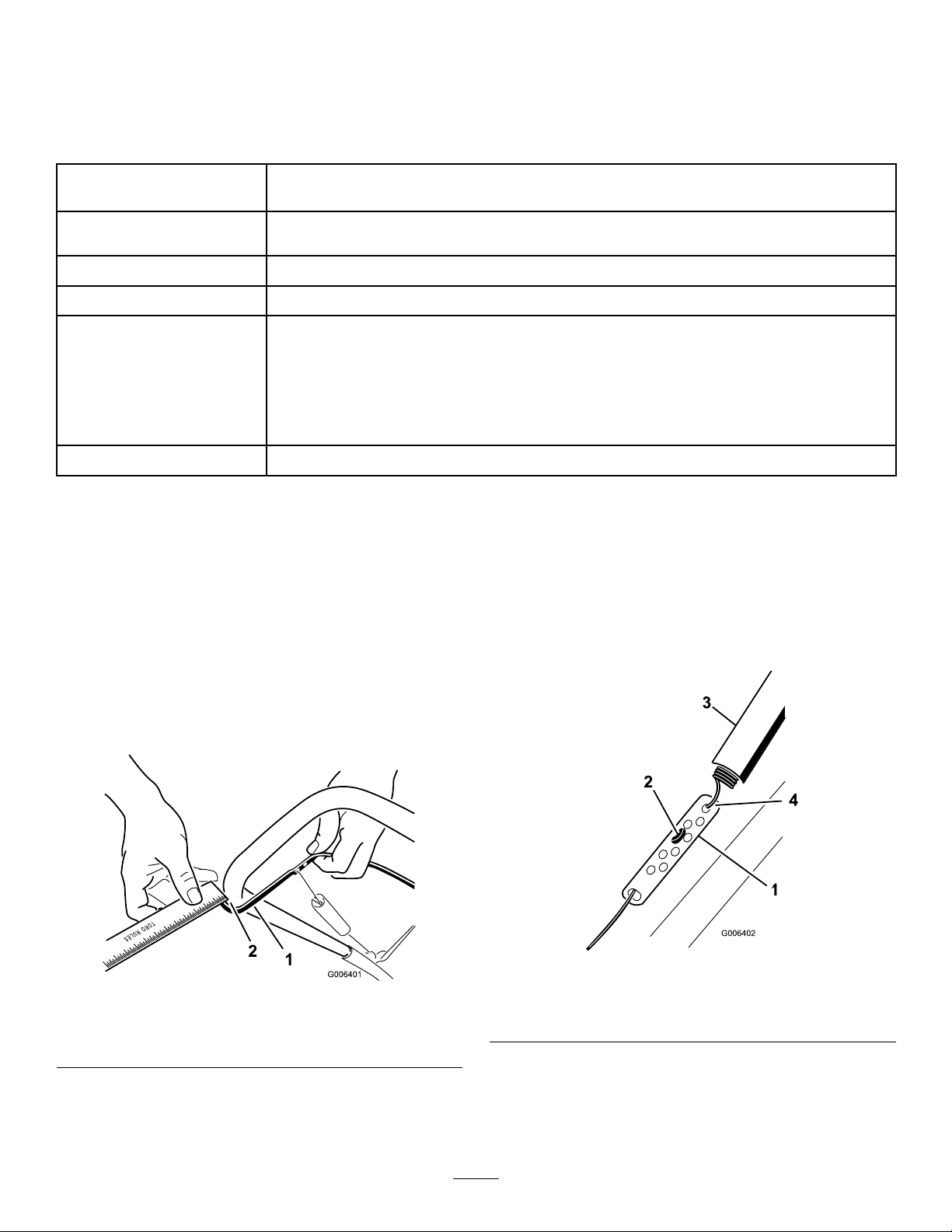

Movethecontrolbarbacktowardthehandletoremove

theslackinthecontrolcable(

Figure26

1.Controlbar2.1/16-inchto1/8-inch(2

Figure26).

mmto3mm)gap

Note:Ensurethata1/16-inchto1/8-inch(2mmto3

mm)gapexistsbetweenthecontrolbarandthehandle

(Figure26).

Figure27

1.Adjusterlink

2.Z-tting

3.Springcover

4.Unhookthespringhere.

Note:Youcanpulluptheadjusterlinkandcableto

makeunhookingthespringeasier.

2.MovetheZ-ttingtoahigherorlowerholeonthe

adjusterlinkasneededtoobtainthe1/16-inchto

12

Page 13

1/8-inch(2mmto3mm)gapbetweenthecontrol

barandthehandle(Figure26).

Note:MovingtheZ-ttinghigherdecreasesthe

gapbetweenthecontrolbarandthehandle;moving

itlowerincreasesthegap.

3.Hookthespringtotheadjusterlinkandslidethe

springcoverovertheadjusterlink.

4.Checktheadjustment;refertoCheckingtheControl

Cable.

Note:Afterextendeduse,thedrivebeltmaywear

andloseitsproperbelttension.Ifthedrivebelt

slips(continuouslysqueals)underaheavyload,

disconnectthespringfromtheadjustorlinkand

movetheupperendofthespringtotheholethat

isfurtherfromthepivotpointinthecontrolbar

Figure28).Thenconnectthespringtotheadjustor

(

linkandadjustthecontrolcable.

Figure28

Figure29

1.Thewearindicatorholeis

intact;youdonotneedto

replacetherotorblades.

2.Thewearindicatorholeis

exposed;replacetherotor

blades.

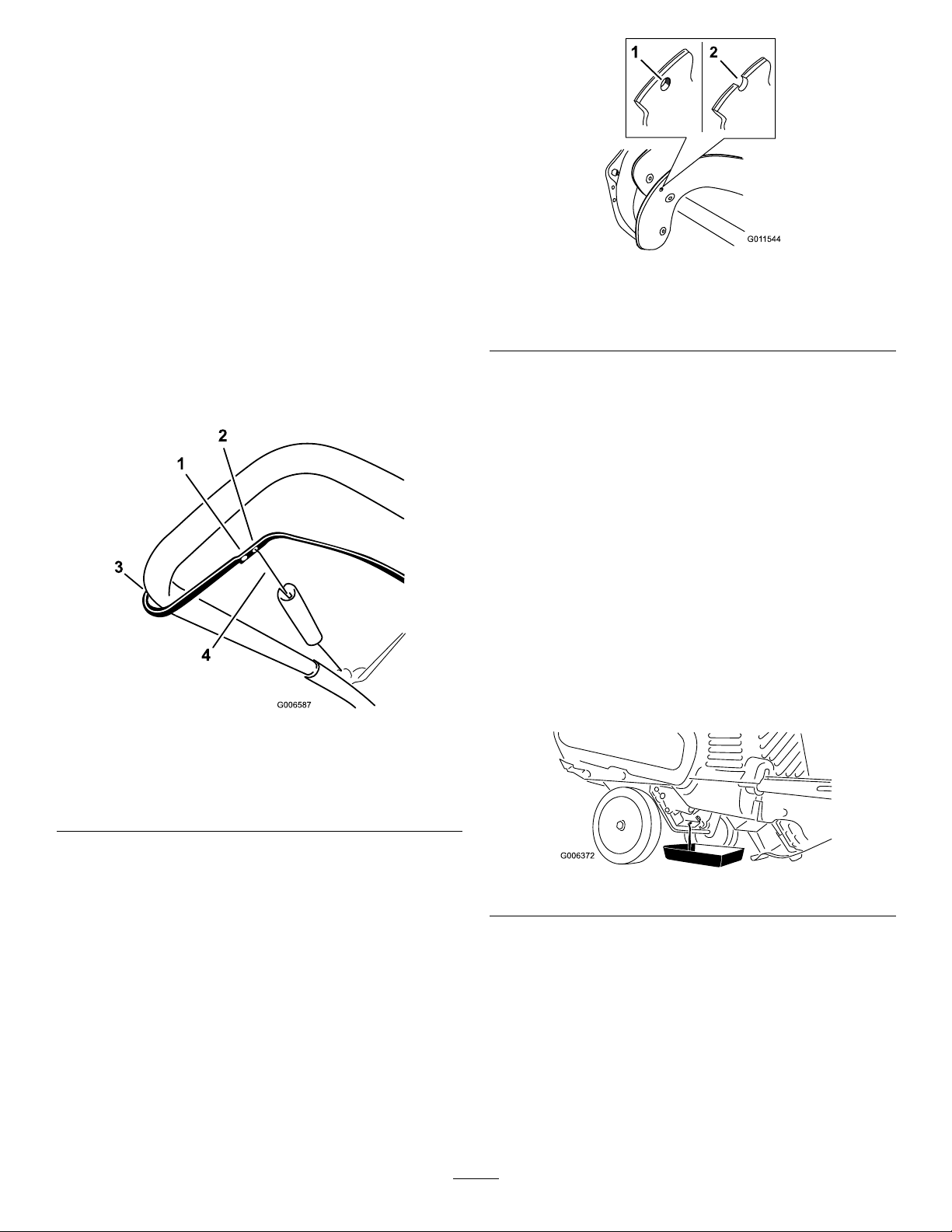

ChangingtheEngineOil

ServiceInterval:Aftertherst2hours

Yearly

Runtheengineafewminutesbeforechangingtheoil

towarmit.W armoilowsbetterandcarriesmore

contaminants.

1.Siphonthefuelfromthefueltankintoanapproved

fuelcontainer,orruntheengineuntilitstops.

2.Movethemachinetoalevelsurface.

3.Placeanoildrainpanundertheoildrainplug,

removetheoildrainplug,andtipthemachine

backwardanddraintheusedoilintheoildrainpan

Figure30).

1.Removetheupperendof

springfromthishole

2.Inserttheupperendof

springintothishole

3.Pivotpoint

4.Upperendofspring

Note:Thebeltmayslip(squeal)inwetconditions;

todryoutthedrivesystem,starttherotorandrun

itwithoutaloadfor30seconds.

InspectingtheRotorBlades

ServiceInterval:Yearly—Inspecttherotorbladesand

haveanAuthorizedServiceDealer

replacetherotorbladesandscraperif

necessary.

Beforeeachsession,inspecttherotorbladesforwear.

Whenarotorbladeedgehasworndowntothewear

indicatorhole,haveanAuthorizedServiceDealer

replacetherotorbladesandthescraper(Figure29).

Figure30

4.Afterdrainingtheusedoil,returnthemachinetothe

operatingposition.

5.Installtheoildrainplugandtightenitsecurely.

6.Cleanaroundtheoilllcap(

13

Figure31).

Page 14

9.Wait3minutesfortheoiltosettleandaddenough

tobringittothepointofoverll.

10.Screwtheoilllcapintotheoilllhole,andhand

tightenitsecurely.

11.Wipeupanyspilledoil.

12.Disposeoftheusedoilproperlyatalocalrecycling

center.

Figure31

1.Oilllcap

7.Unscrewtheoilllcapandremoveit(Figure31).

8.Withthemachineintheoperatingposition,carefully

pouroilintotheoilllholetothepointofoverow

(Figure33).

Maxll:20oz.(0.6l),type:automotivedetergentoil

withanAPIserviceclassicationofSJ,SL,orhigher.

Figure32belowtoselectthebestoilviscosity

Use

fortheoutdoortemperaturerangeexpected:

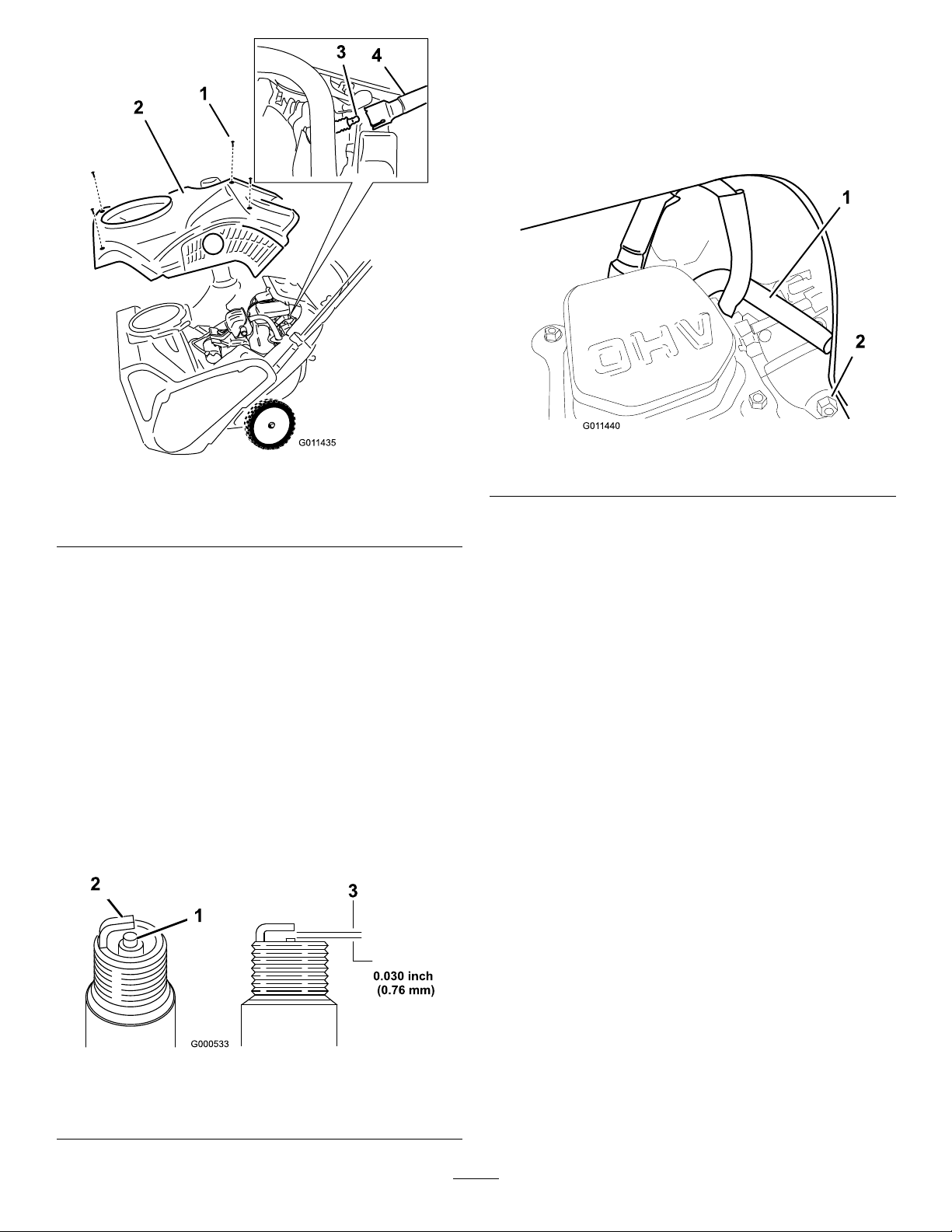

ServicingtheSparkPlug

ServiceInterval:Yearly—Servicethesparkplugand

replaceitifnecessary.

UseaNGKBPR6ESorChampionRN9YCspark

plugorequivalent.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Rotatethedischargechutesothatitfacesforward.

3.Removethedischargechute,thedischargechute

handle,andthechutesealbyremovingthe3large

screwsandonesmallscrew(Figure34).

Figure32

Figure33

Figure34

1.Fueltankcap

2.Largescrews(3)5.Chuteseal

3.Dischargechute

4.Removethe4screwsthatsecuretheshroud

(Figure35).

14

4.Smallscrew

Page 15

12.Installthesparkplugandtorqueitto20–22ft-lb

(27–30N-m).

13.Connectthewiretothesparkplug.

Note:Ensurethatthebreathertubeisroutedabove

thesparkplugwireasshownin

Figure37

Figure37.

Figure35

1.Screw(4)3.Sparkplug

2.Shroud4.Spark-plugwire

5.Removethefueltankcap.

6.Removetheshroud(Figure35).

7.Installthefueltankcap.

8.Disconnectthewirefromthesparkplug.

9.Cleanaroundthesparkplug.

10.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotcleantheelectrodes

becausegritenteringthecylindercandamage

theengine.

11.Setthegapontheplugto0.030inch(0.76mm)

(

Figure36).

1.Breathertube

2.Carburetordrainbolt

14.Removethefueltankcap.

15.Installtheshroudwiththescrewsyouremovedin

4.

step

Note:Ensurethattheupperandlowershroudst

togetherinthesidegrooves.

16.Installthefueltankcap.

17.Installthechuteseal,thedischargechute,andthe

dischargechutehandleontothemachineusingthe

hardwareyouremovedinstep

3.

Note:Thesmallscrewgoesthroughthesmallhole

inthechutesealatthefrontofthedischargechute

opening.

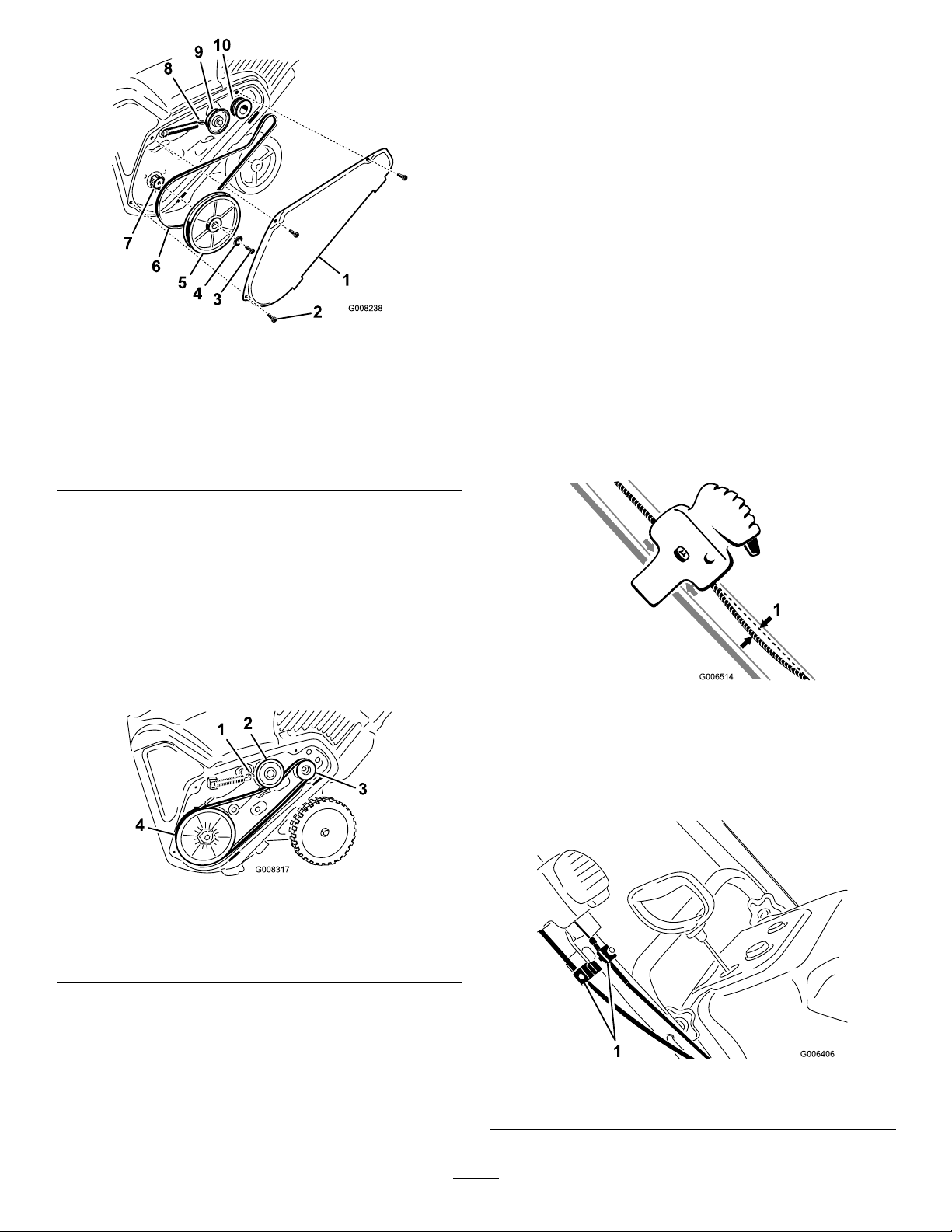

ReplacingtheDriveBelt

Ifdrivebeltbecomesworn,oil-soaked,excessively

cracked,frayed,orotherwisedamaged,replacethebelt.

Figure36

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

1.Removethedrivebeltcoverbyremovingthe3bolts

asshowninFigure38.

15

Page 16

7.Installthecurvedwasherandtherotorpulleybolt

andtightenthemsecurely(Figure38).

Note:Theconcavesideofthecurvedwashergoes

againsttheoutsideofthepulley.

Figure38

1.Drivebeltcover6.Drivebelt

2.Bolt(3)7.Rotorshaft

3.Rotorpulleybolt

4.Curvedwasher

5.Rotorpulley10.Enginepulley

8.Brakespring(unhookfrom

idlerarmhere)

9.Idlerpulley

2.Unhookthebrakespringfromtheidlerarmto

releasethebelttension(

Figure38).

3.Removethescrewandcurvedwasherthatholdsthe

rotorpulley(Figure38).

8.Installthebrakespringontotheidlerarm(

Figure39).

9.Installthedrivebeltcoverwiththeboltsyou

removedinstep1.

Note:Ensurethatthedrivebeltisproperlyadjusted

andoperating;refertoCheckingtheControlCable

andAdjustingtheControlCable.

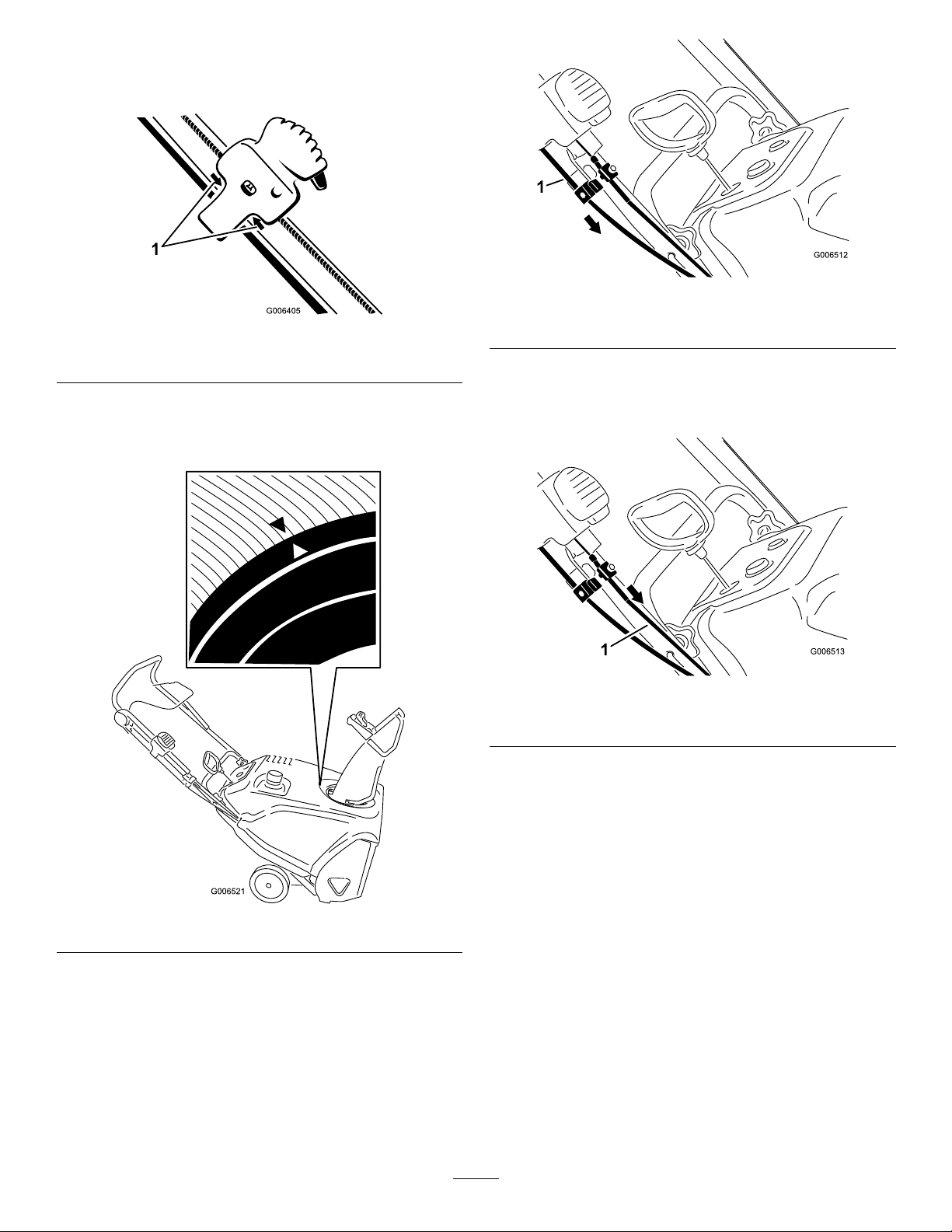

AdjustingtheQuickShoot™

Control

Ifthereismorethan1/2inch(13mm)ofslackinthe

QuickShootcable(Figure40)orthedischargechute

doesnotrotateleftandrightinequalangles,adjustthe

QuickShootcontrolcables.

4.Removetherotorpulleyandthedrivebelt

Figure38).

(

5.Installthenewdrivebelt,routingitasshownin

(Figure39).

Figure39

1.Brakespring(installon

idlerarmhere)

2.Idlerpulley4.Rotorpulley

3.Enginepulley

Note:Routethenewdrivebeltrstaroundthe

enginepulley,thentheidlerpulley,andnallyaround

thelooserotorpulleypositionedjustabovetherotor

shaft(Figure38).

Figure40

1.1/2inch(13mm)maximumslack

1.LoosenthetwoQuickShootcontrolcableclamps

(Figure41).

Figure41

6.Installtherotorpulleyontotherotorshaft

(Figure38).

1.Cableclamps

16

Page 17

2.PositiontheQuickShootcontrolbetweenthetwo

arrowslocatedontherighthandsideoftheupper

handle(Figure42).

Figure44

Figure42

1.Arrows

3.Rotatethedischargechutesothatitfacesstraight

aheadandthearrowonthebackofthedischarge

chutealignswiththearrowontheshroud(Figure43).

1.Lowercablecasing

5.Pulltheuppercablecasingforwarduntilyouremove

theslackinthecable,andtightenthescrewonthe

uppercableclampsecurely(Figure45).

Figure45

1.Uppercablecasing

Figure43

4.Holdthedischargechuteinthestraight-ahead

position,pullthelowercablecasingdownwarduntil

youremovetheslackinthecable,andtightenthe

screwonthelowercableclampsecurely(Figure44).

Note:Donotover-tensionthecables.Ifthecables

areover-tensioned,theQuickShootwillbehardto

operate.

17

Page 18

Storage

areasbeforepainting,andusearustpreventativeto

preventthemetalpartsfromrusting.

StoringtheSnowthrower

WARNING

•Gasolinefumesarehighlyammable,explosive,

anddangerousifinhaled.Ifyoustorethe

machineinanareawithanopename,the

gasolinefumesmayigniteandcausean

explosion.

•Donotstorethemachineinahouse(living

area),basement,oranyotherareawhereignition

sourcesmaybepresent,suchashotwaterand

spaceheaters,clothesdryers,furnaces,and

otherlikeappliances.

•Donottipthemachinebackwardwithfuelin

thefueltank;otherwise,fuelmayleakoutof

themachine.

1.Onthelastrefuelingoftheseason,addfuelstabilizer

tofreshfuelasdirectedbytheenginemanufacturer.

2.Runtheenginefor10minutestodistributethe

conditionedfuelthroughthefuelsystem.

15.Tightenanyloosefasteners.Repairorreplaceany

damagedparts.

16.Coverthemachineandstoreitinaclean,dryplace

outofthereachofchildren.Allowtheengineto

coolbeforestoringitinanyenclosure.

3.Stoptheengine,allowittocool,andsiphonthefuel

tankorruntheengineuntilitstops.

4.Starttheengineandrunituntilitstops.

5.Chokeorprimetheengine,startitathirdtime,and

runtheengineuntilitwillnotstart.

6.Drainthefuelinthecarburetorthroughthe

carburetordrainbolt(

gasolinecontainer.

7.Disposeofunusedfuelproperly .Recycleitaccording

tolocalcodes,oruseitinyourautomobile.

8.Whiletheengineisstillwarm,changetheengineoil.

RefertoChangingtheEngineOil.

9.Removethesparkplug.

10.Squirt2teaspoonsofoilintothesparkplughole.

11.Installthesparkplugbyhandandthentorqueitto

20–22ft-lb(27–30N-m).

12.WiththeignitionkeyintheOffposition,pullthe

recoilstarterslowlytodistributetheoilontheinside

ofthecylinder.

Figure37)intoanapproved

13.Cleanthemachine.

14.Touchupchippedsurfaceswithpaintavailable

fromanAuthorizedServiceDealer.Sandaffected

18

Page 19

FederalEmissionControlWarrantyStatement

ATwo-YearLimitedWarranty

YourWarrantyRightsandObligations

TheU.S.EnvironmentalProtectionAgency(EP A),TheT oroCompany ,and

itsafliate,ToroWarrantyCompany,arepleasedtoexplaintheemission

controlsystemwarrantyonyour2009andlaterutility/lawn/garden

equipmentengine.2009andlatermodelyearutility/lawn/garden

equipmentenginesmustbedesigned,builtandequipped,atthetime

ofsale,tomeettheU.S.EPAregulationsforsmallnon-roadengines.

Theequipmentenginemustbefreefromdefectsinmaterialsand

workmanship,whichcauseittofailtoconformwithU.S.EP Astandards,

forthersttwoyearsofengineusefromthedateofsaletotheultimate

purchaser.TheToroCompanyanditsafliate,T oroWarrantyCompany ,

warranttheemissioncontrolsystemonyourutility/lawn/gardenequipment

enginefortheperiodoftimelistedabove,providedtherehasbeenno

abuse,neglect,orimpropermaintenanceofyourutility/lawn/garden

equipmentengine.

Youremissioncontrolsystemmayincludepartssuchasthecarburetor

orfuelinjectionsystem,theignitionsystem,andcatalyticconverter.Also

includedmaybefuellines,fuellinefasteners,connectors,andother

emission-relatedassemblies.

Whereawarrantableconditionexists,TheT oroCompanyanditsafliate,

ToroWarrantyCompany ,promisetorepairyourengineatnocosttoyou,

includingdiagnosis,parts,andlabor .

Manufacturer’sWarrantyCoverage

TheT oroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantthe2009andlater

utility/lawn/gardenequipmentenginesfortwoyearsfromthedateof

delivery.Ifanyemission-relatedpartonyourengineisdefectivein

materialsorworkmanship,wewillrepairorreplacethepart,freeofcharge.

OwnerResponsibilities

Astheengineowner,youareresponsiblefortheperformanceofthe

requiredmaintenancelistedinyourOperator'sManual.Werecommend

thatyouretainallreceiptscoveringmaintenanceonyourequipment,but

wecannotdenywarrantysolelyforthelackofreceiptsorforyourfailureto

ensuretheperformanceofallscheduledmaintenance.

Anyreplacementpartorservicethatisequivalentinperformanceand

durabilitymaybeusedinnon-warrantymaintenanceorrepairs,andshall

notreduceourwarrantyobligation.

Astheengineowner,youshouldbeawarethatwemaydenyyouwarranty

coverageifyourengineoraparthasfailedduetoabuse,neglect,

impropermaintenance,orunapprovedmodicationsorparts.

YouareresponsibleforpresentingyourequipmentenginetoanAuthorized

ServiceDealerassoonasaproblemexists.Thewarrantyrepairsshould

becompletedinareasonableamountoftime,nottoexceedthirty(30)

days.

Ifyouhaveanyquestionsregardingyourwarrantyrightsand

responsibilities,contactusat:

CustomerCareDepartment,ConsumerDivision

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

Tollfreeat800–348–2424(U.S.customers)

Tollfreeat800–544–5364(Canadiancustomers)

WarrantedParts

Thewarrantyperiodbeginsonthedatetheengineorequipmentis

deliveredtoaretailpurchaser.TheT oroCompanyanditsafliate,

ToroWarrantyCompany,jointlywarranttotheinitialownerandeach

subsequentpurchaserthattheengineisfreefromdefectsinmaterialsand

workmanship,whichcausetheenginetofailtoconformwithapplicable

regulations,foraperiodoftwoyears.

Failurescausedbyabuse,neglect,orimpropermaintenancearenot

covered.Theuseofadd-onormodiedpartscanbegroundsfor

disallowingawarrantyclaim.Wearenotliabletocoverfailuresof

warrantedpartscausedbytheuseofadd-onormodiedparts.Weare

liablefordamagestootherenginecomponentscausedbythefailureof

awarrantedpartstillunderwarranty .Theownerisresponsibleforthe

performanceoftherequiredmaintenance,asdenedintheOperator's

Manual.

Anywarrantedpartwhichisnotscheduledforreplacementasrequired

maintenance,orwhichisscheduledonlyforregularinspectiontotheeffect

of“repairorreplaceasnecessary”shallbewarrantedforthewarranty

period.Anywarrantedpartwhichisscheduledforreplacementasrequired

maintenanceshallbewarrantedfortheperiodoftimeuptotherst

scheduledreplacementpointforthatpart.Coverageunderthiswarranty

extendsonlytothepartslistedbelow(theemissionssystemparts)tothe

extentthatthesepartswerepresentontheenginewhenpurchased.

•FuelMeteringSystem

—Coldstartenrichmentsystemincludingthechokemechanismor

primingsystem

—Fuelpump

—Carburetorandinternalparts

•AirInductionSystem

—Aircleaner

—Intakemanifold

—Controlledhotairintakesystem

•IgnitionSystem

—Sparkplug(s)

—Ignitioncoilsandelectronics

—Advance/retardmechanisms

•Mufer

•MiscellaneousItemsUsedintheAboveSystems

—Vacuum,temperature,andtime-sensitivevalvesandswitches

—Hoses,connectors,andassembliesofsame

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedToroServiceDealertoarrangeserviceat

theirdealership.T olocateadealerconvenienttoyou,refertothe

YellowPagesofyourtelephonedirectory(lookunder“LawnMowers”)

oraccessourwebsiteatwww.T oro.com.Youmayalsocallthe

numberslistedabovetousethe24-hourT oroDealerlocatorsystem.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.

Theownershallnotbechargedfordiagnosticlaborwhichleadstothe

determinationthatawarrantedpartisdefective,ifthediagnosticwork

isperformedatawarrantystation.

GeneralConditions

NeitherTheT oroCompanynorToroWarrantyCompanyisliablefor

indirect,incidental,orconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythesewarranties,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthesewarranties.

Allimpliedwarrantiesofmerchantability(thattheproductistforordinary

use)andtnessforuse(thattheproductistforaparticularpurpose)are

limitedtothedurationoftheexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,sotheaboveexclusionsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

374-0267RevA

Page 20

TheToro2-YearGTSStartingGuaranteeand

TheToroT otalCoverageGuarantee

AT wo-YearFullWarranty(45DayLimitedWarrantyforCommercialUse)

CCR

PowerClear

Single-StageSnowthrowers

TheToroStartingGuarantee

TheT oroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlyguaranteethatyourToroGTS

(GuaranteedtoStart)engine,whenusedforresidentialpurposes*,will

startontherstorsecondpullfortwo(2)yearsfromthedateofpurchase,

ifyouprovidetheroutinemaintenanceitrequires,orwewillxitfreeof

charge.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany ,pursuantto

anagreementbetweenthem,jointlypromisetorepairtheToroProduct

listedbelowifusedforresidentialpurposes*,ifdefectiveinmaterialsor

workmanshiporifitstopsfunctioningduetothefailureofacomponent

fortheperiodlistedbelow.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

PowerClearSnowthrowersandAttachments

2years

LimitedWarrantyforCommercialUse

Gas-poweredT oroProductsusedforcommercial,institutional,or

rentaluse,arewarrantedfor45daysagainstdefectsinmaterialsor

workmanship.Componentsfailingduetonormalweararenotcovered

bythiswarranty.

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedT oroServiceDealertoarrangeserviceattheir

dealership.Tolocateadealerconvenienttoyou,refertotheYellow

Pagesofyourtelephonedirectory(lookunder“LawnMowers”)or

accessourwebsiteatwww.T oro.com.Y oumayalsocallthenumbers

listedinitem#3tousethe24-hourT oroDealerlocatorsystem.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.Thedealerwilldiagnosetheproblemanddetermine

ifitiscoveredunderwarranty.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

CustomerCareDepartment,ConsumerDivision

TheT oroCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

Tollfreeat866-336-5205(U.S.customers)

Tollfreeat866-854–9033(Canadiancustomers)

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator'sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

ItemsandConditionsNotCovered

Thereisnootherexpresswarrantyexceptforspecialemissionsystem

coverageandenginewarrantycoverageonsomeproducts.Thisexpress

warrantydoesnotcoverthefollowing:

•Costofregularmaintenanceorwearparts,suchasrotorblades

(paddles),scraperblades,belts,fuel,lubricants,oilchanges,spark

plugs,cable/linkageorbrakeadjustments

•Anyproductorpartwhichhasbeenalteredormisusedandrequires

replacementorrepairduetoaccidentsorlackofpropermaintenance

•Repairsnecessaryduetofailuretousefreshfuel(lessthanone

monthold),orfailuretoproperlypreparetheunitpriortoanyperiod

ofnon-useoveronemonth

•Pickupanddeliverycharges

•Operationalmisuse,neglect,oraccidents

•RepairsorattemptedrepairsbyanyoneotherthananAuthorized

ToroServiceDealer

•Repairsoradjustmentstocorrectstartingdifcultiesduetothe

following:

–failuretofollowpropermaintenanceprocedures

–snowthrowerauger/paddlesstrikinganobject

–contaminantsinthefuelsystem

–improperfuelorfuel/oilmixture(consultyourOperator'sManual

ifindoubt)

–failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

•Specialoperationalconditionswherestartingmayrequiremorethan

twopulls:

–rsttimestartsafterextendedperiodofnon-useoverthree

monthsorseasonalstorage

–improperstartingprocedures

–startingin-10°F(-23°C)orbelowtemperatures

Ifyouarehavingdifcultystartingyourunit,pleasechecktheOperator's

Manualtoensurethatyouareusingthecorrectstartingprocedures.This

cansaveanunnecessaryvisittoaServiceDealer.

GeneralConditions

Allrepairscoveredbythesewarrantiesmustbeperformedbyan

AuthorizedToroServiceDealerusingToroapprovedreplacementparts.

RepairbyanAuthorizedT oroServiceDealerisyoursoleremedyunder

thiswarranty .

NeitherTheT oroCompanynorToroWarrantyCompanyisliablefor

indirect,incidental,orconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythesewarranties,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthesewarranties.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,sotheaboveexclusionsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedToroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatToroWarrantyCompany .

*Residentialpurposesmeansuseoftheproductonthesamelotasyourhome.Useatmorethanonelocation,orinstitutionalorrentaluse,isconsidered

commercialuse,andthecommercialusewarrantywouldapply.

374-0264RevB

Loading...

Loading...