Page 1

POWER SHIFT SNOWTHROWER SERVICE MANUAL

Table of Contents – Page 1 of 5

ABOUT THIS MANUAL

SAFETY INSTRUCTIONS

FOR YOUR SAFETY...

IDENTIFICATION

MODEL AND SERIAL NUMBERS

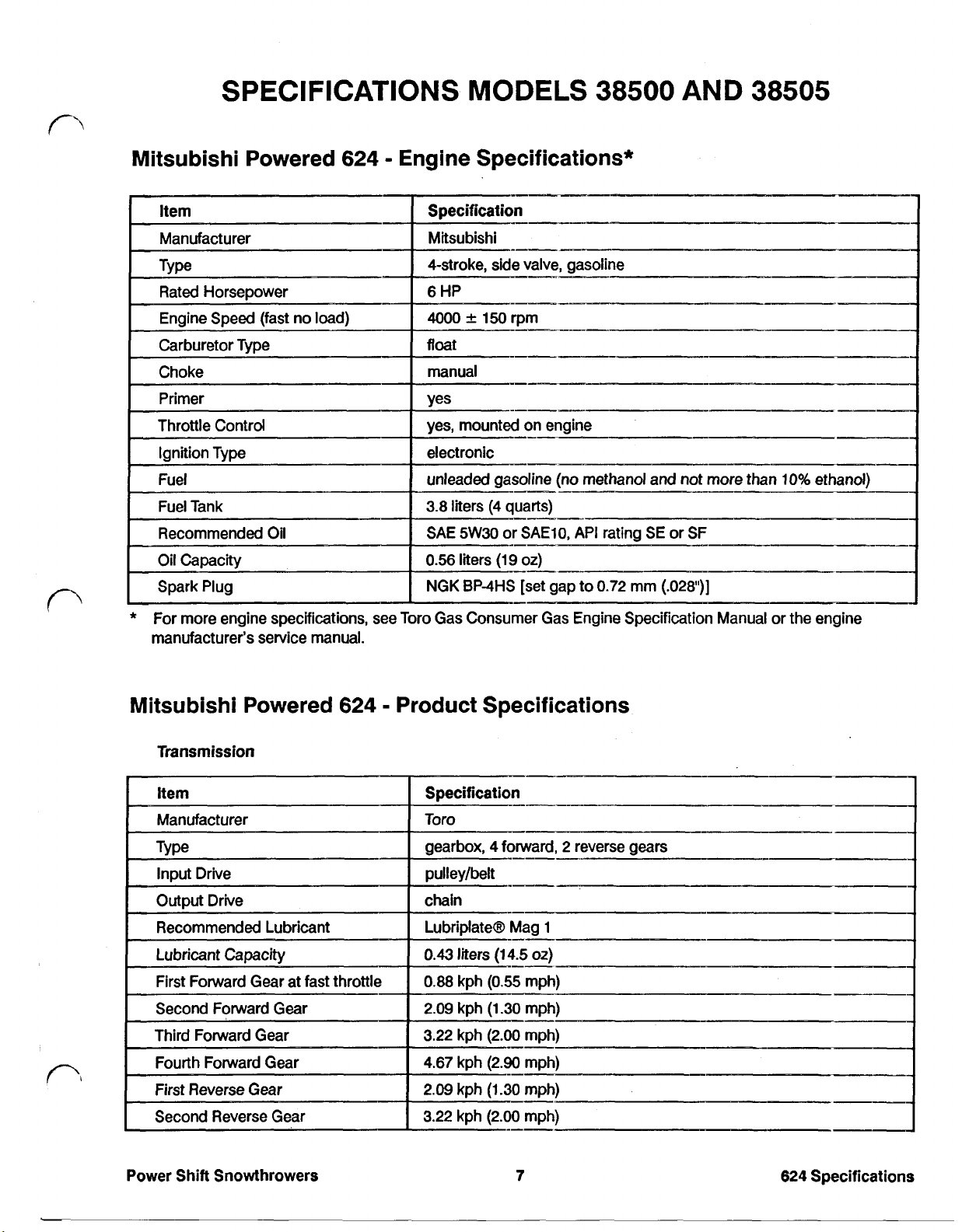

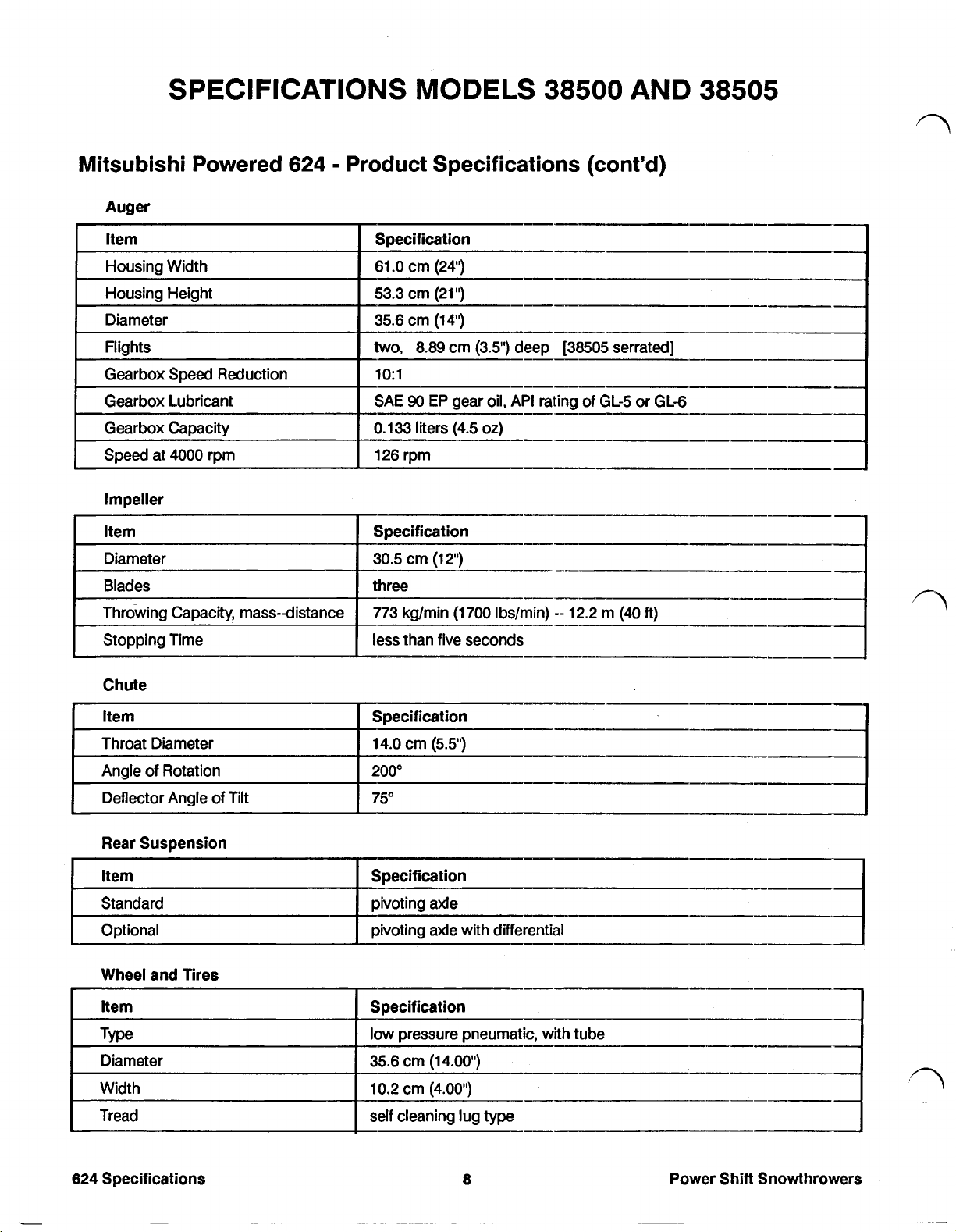

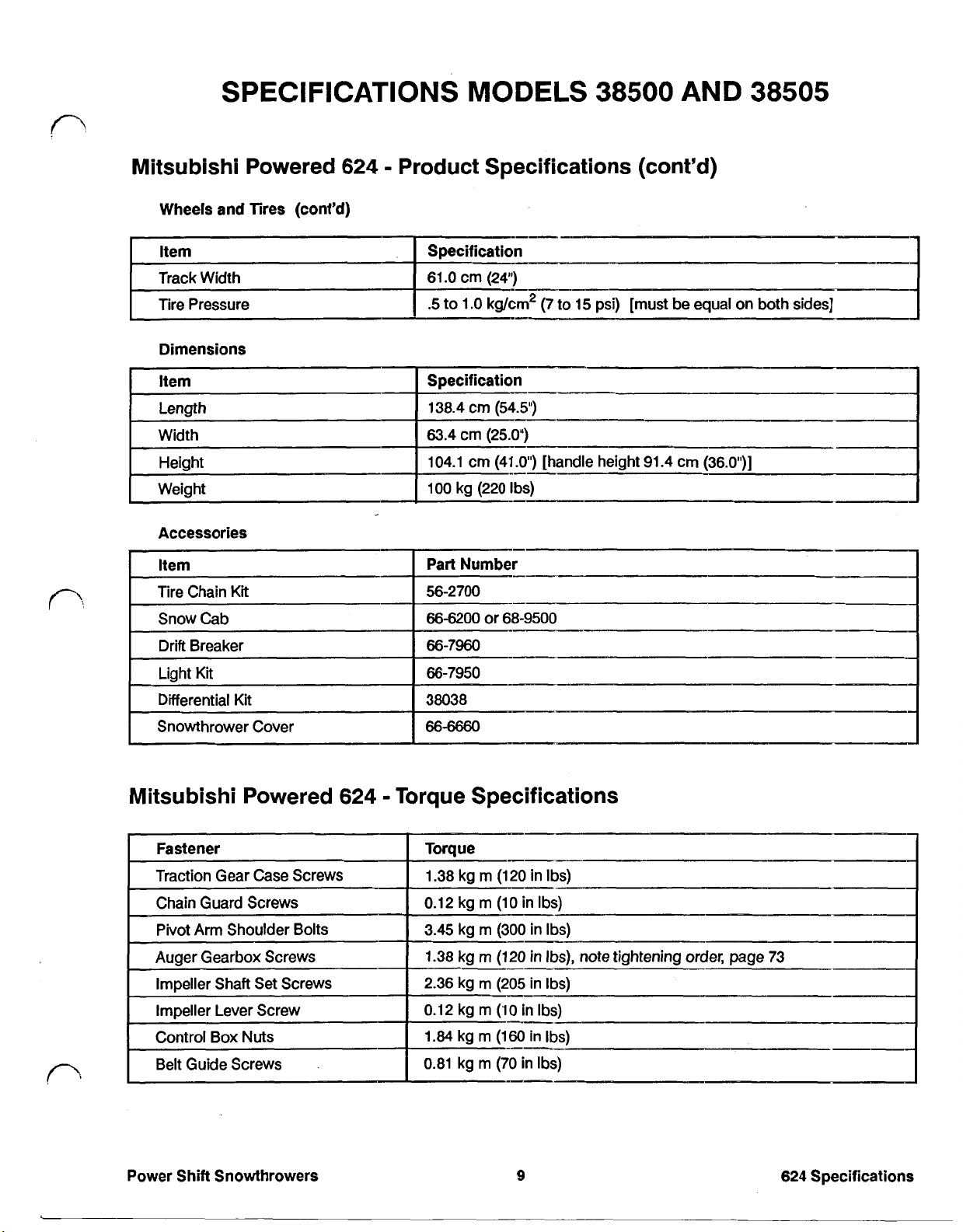

SPECIFICATIONS MODELS 38500 AND 38505

MITSUBISHI POWERED 624 - ENGINE SPECIFICATIONS*

MITSUBISHI POWERED 624 - PRODUCT SPECIFICATIONS

MITSUBISHI POWERED 624 - TORQUE SPECIFICATIONS

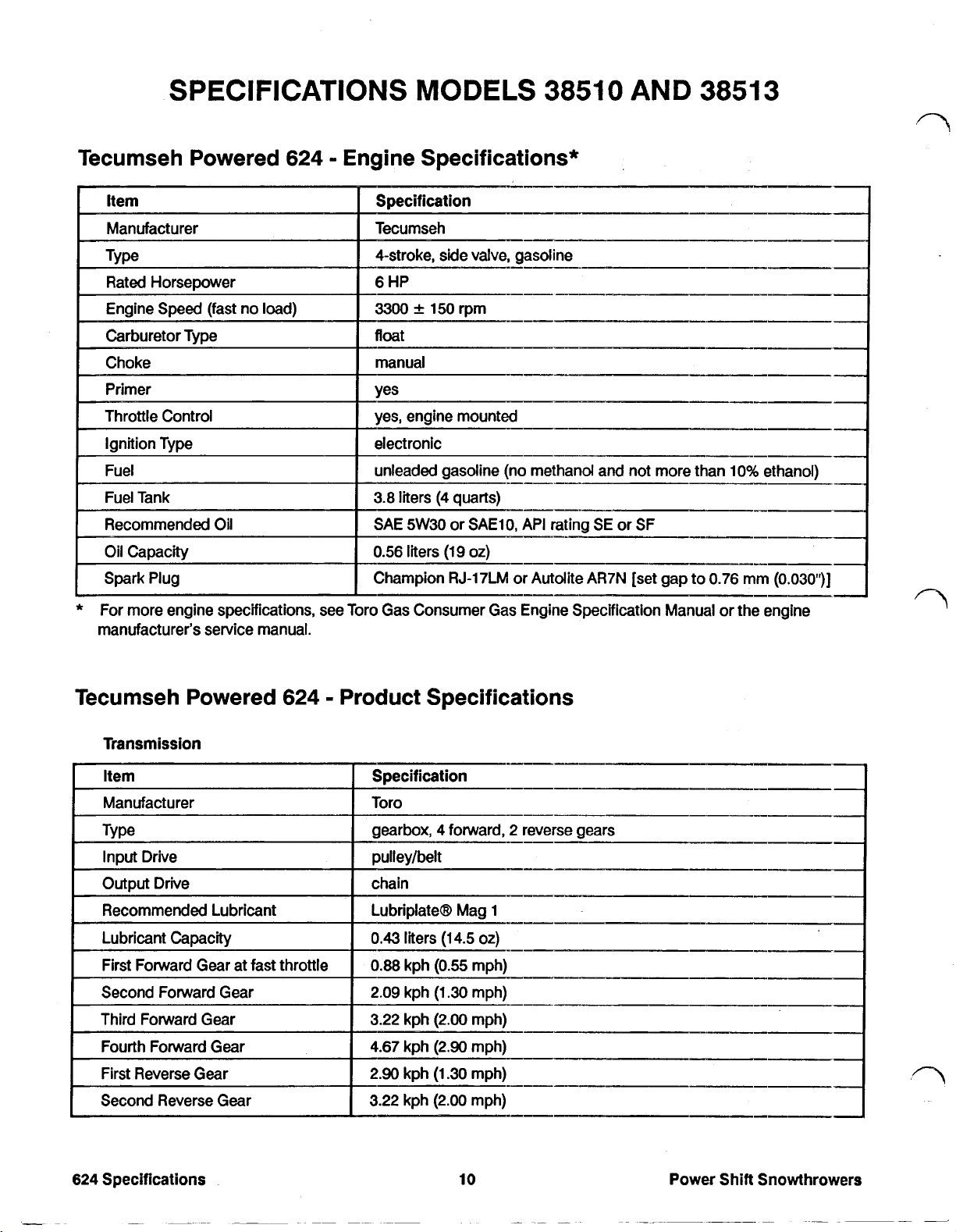

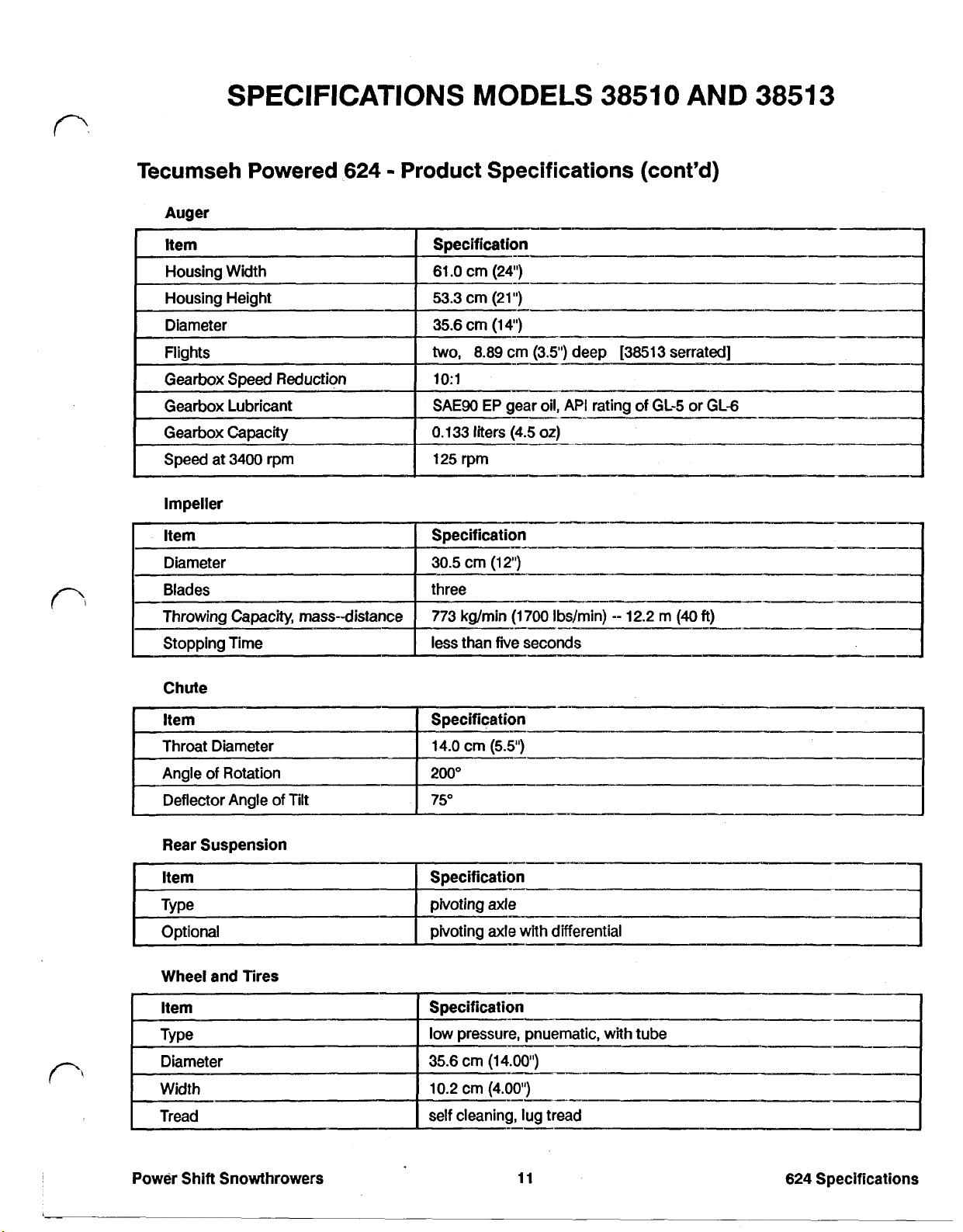

SPECIFICATIONS MODELS 38510 AND 38513

TECUMSEH POWERED 624 - ENGINE SP ECIFIC ATIONS*

TECUMSEH POWERED 624 - PRODUCT SPECIFICATIONS

TORQUE SPECIFICATIONS

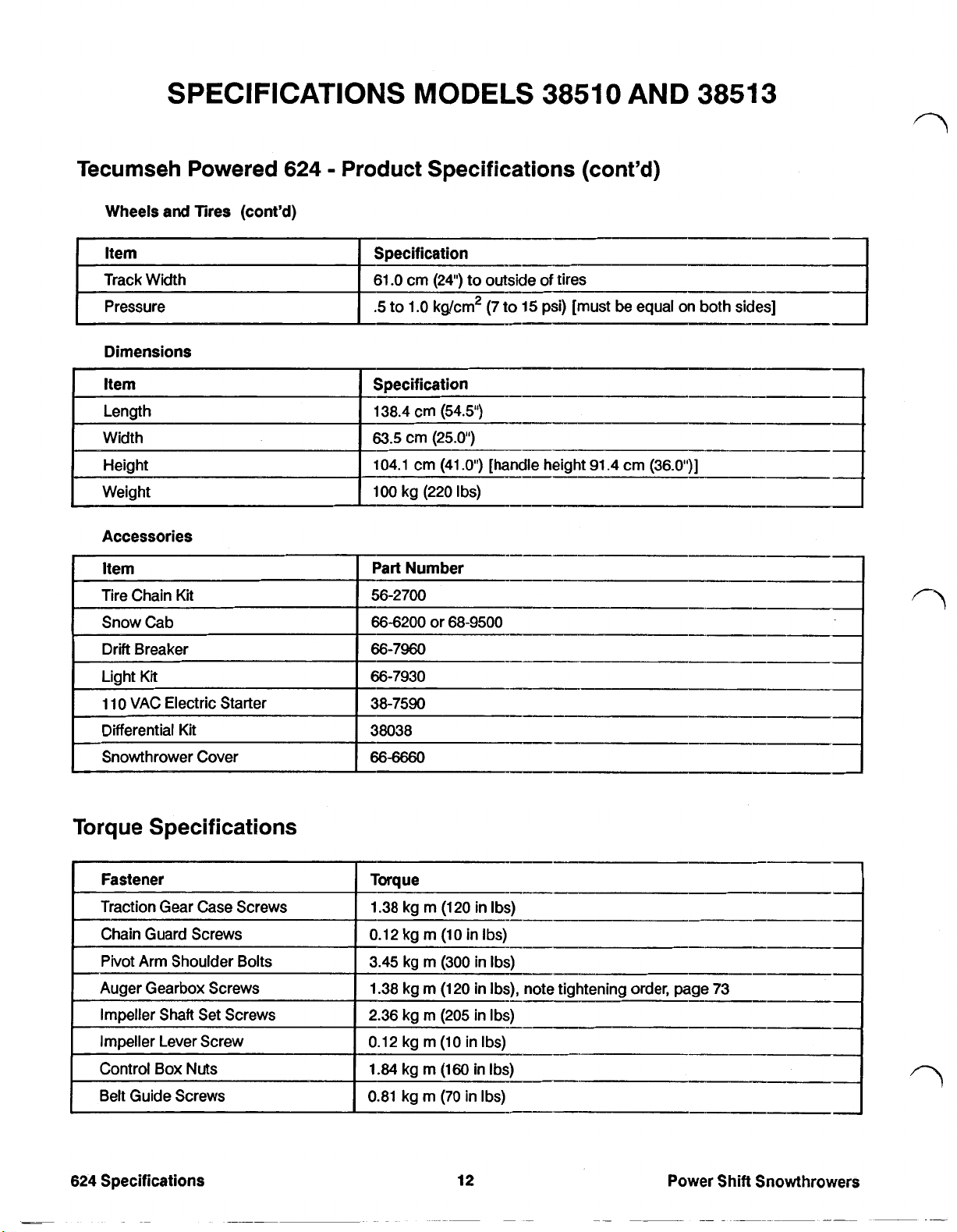

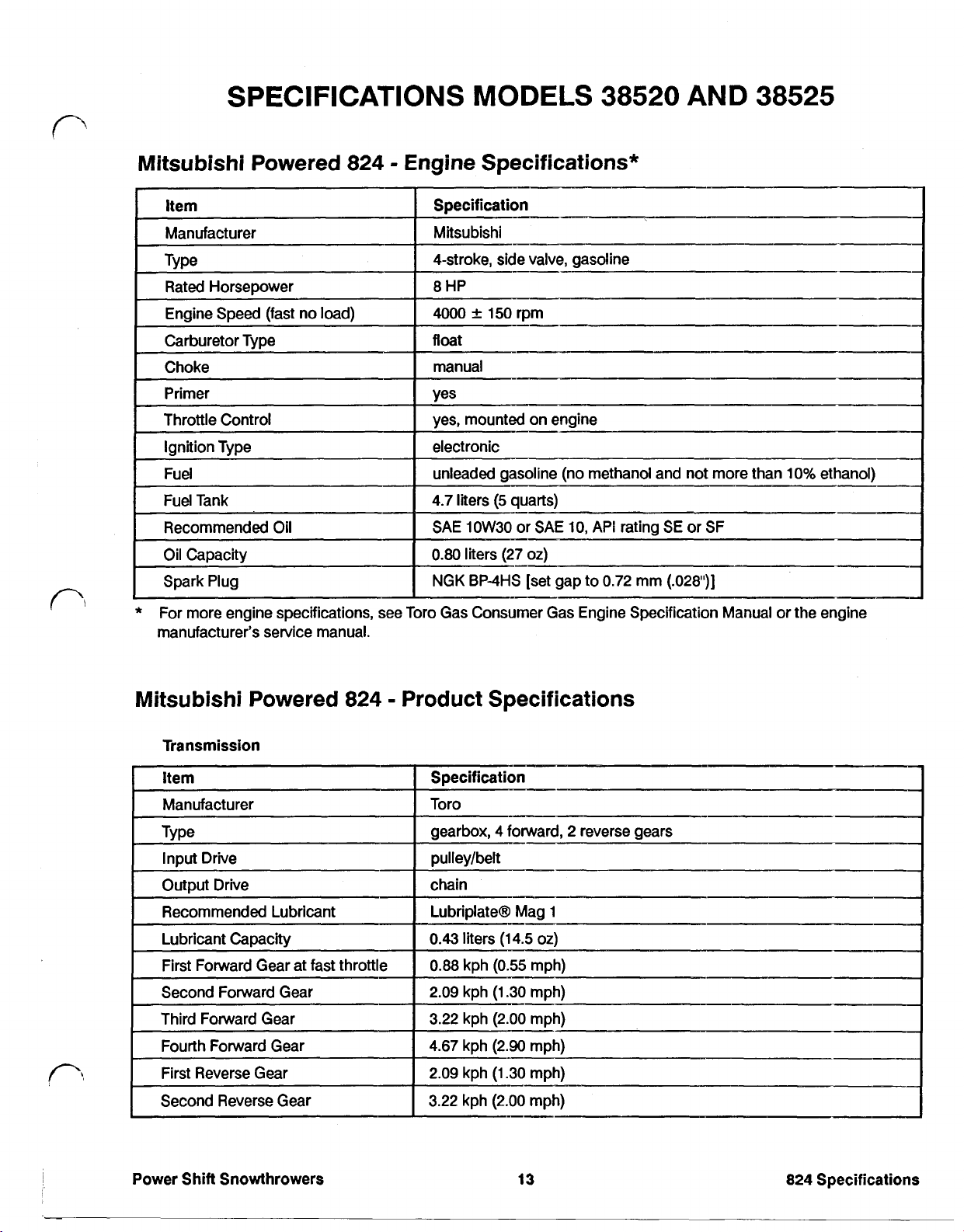

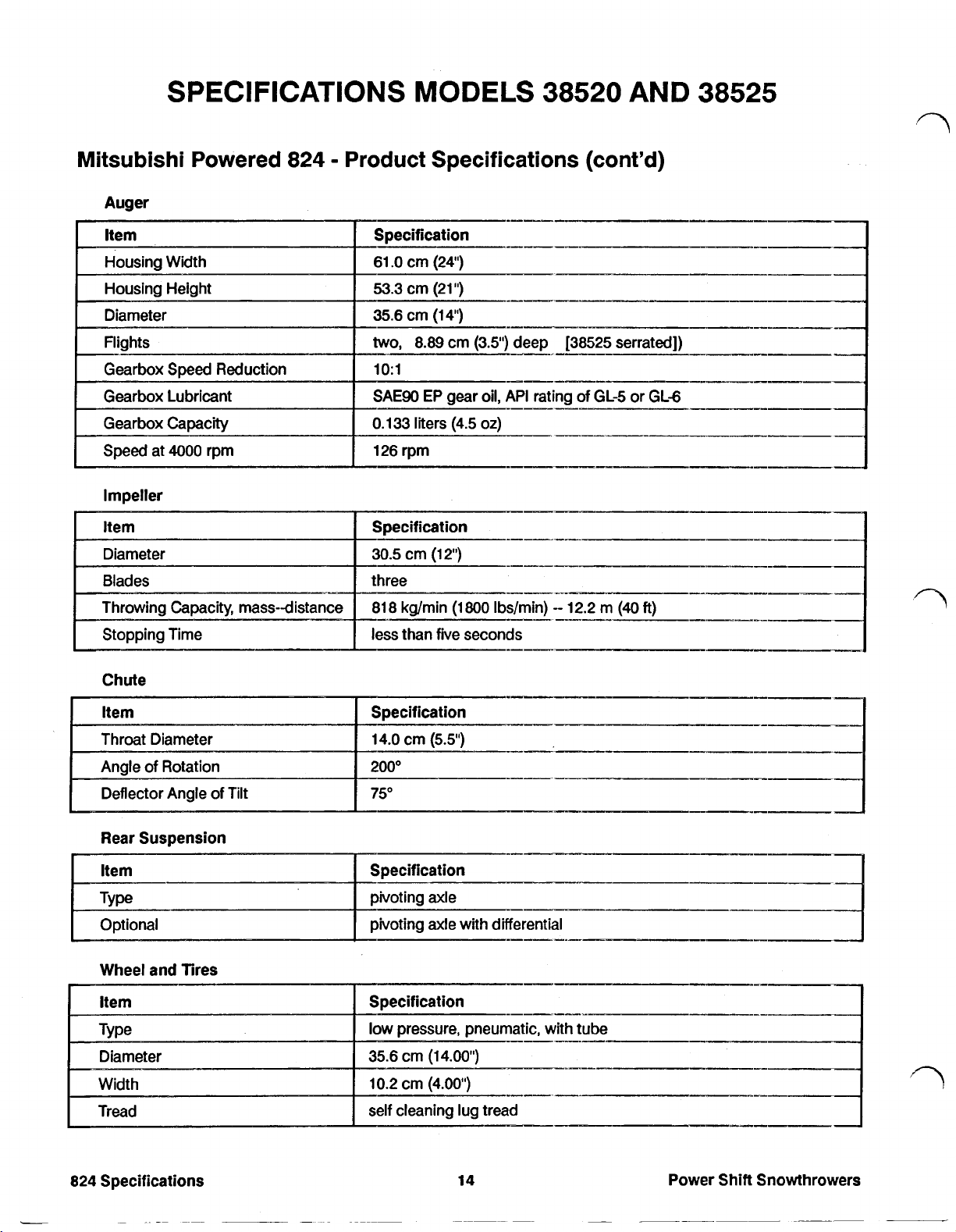

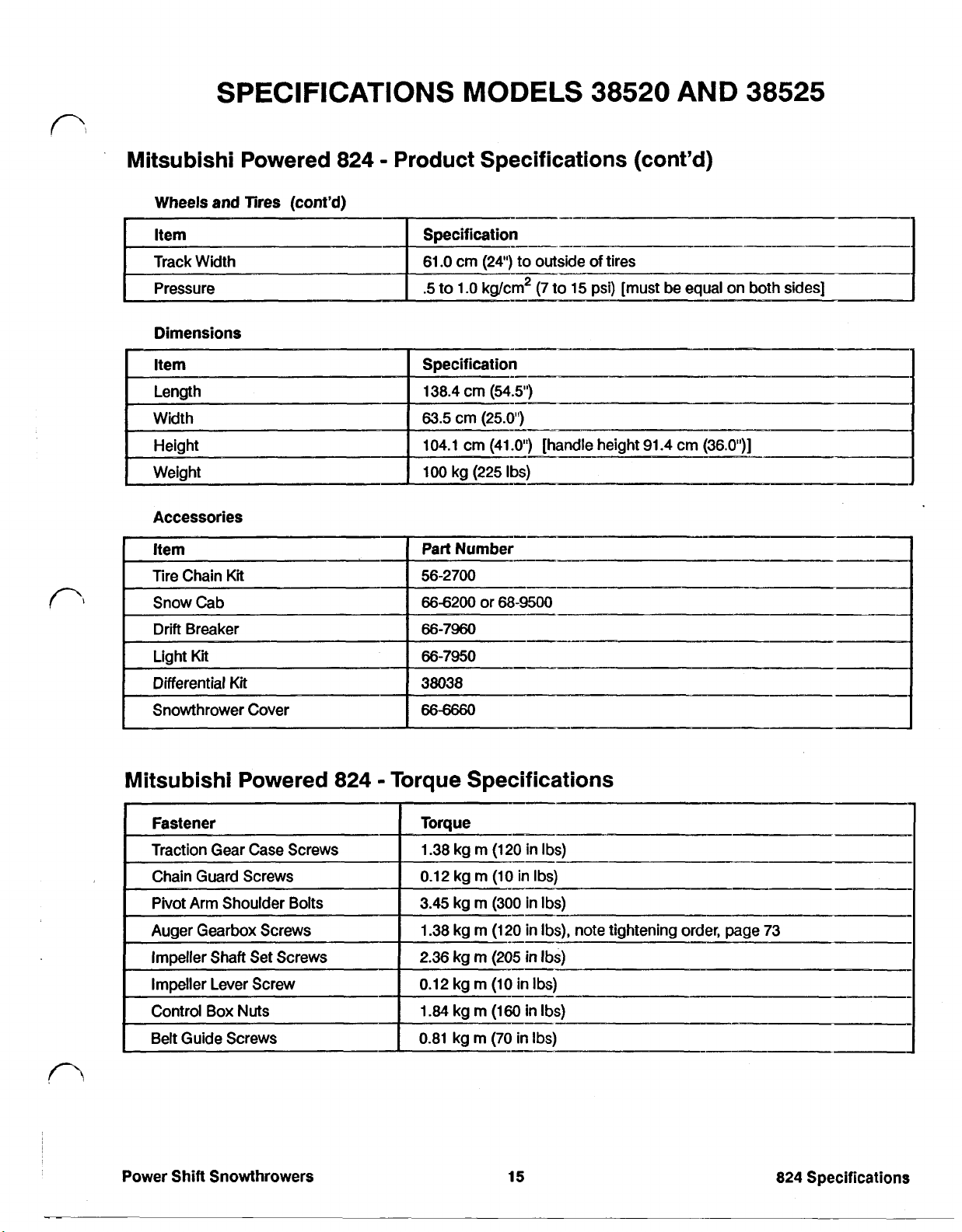

SPECIFICATIONS MODELS 38520 AND 38525

MITSUBISHI POWERED 824 - ENGINE SPECIFICATIONS*

MITSUBISHI POWERED 824 - PRODUCT SPECIFICATIONS

MITSUBISHI POWERED 824 - TORQUE SPECIFICATIONS

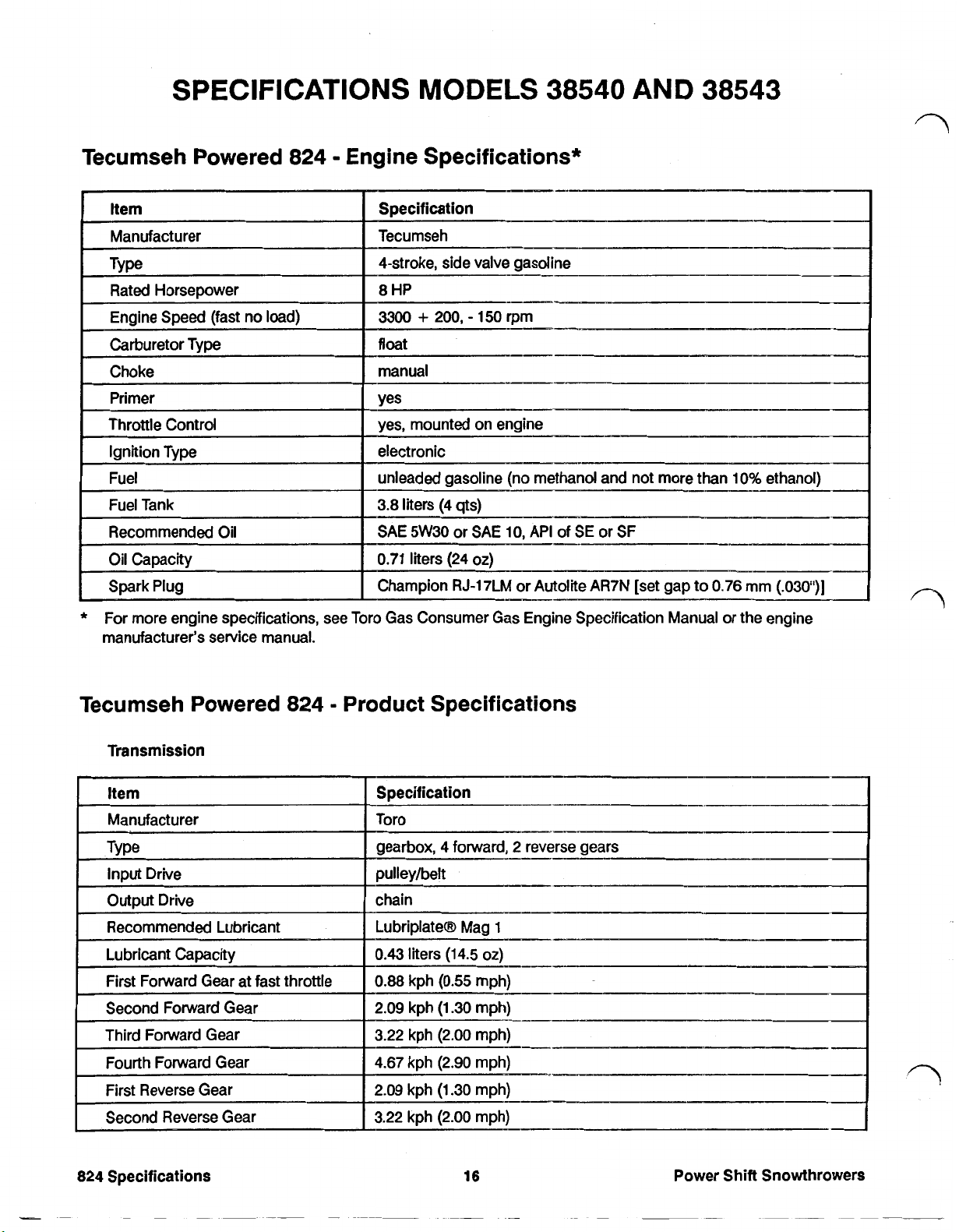

SPECIFICATIONS MODELS 38540 AND 38543

TECUMSEH POWERED 824 - ENGINE SP ECIFIC ATIONS*

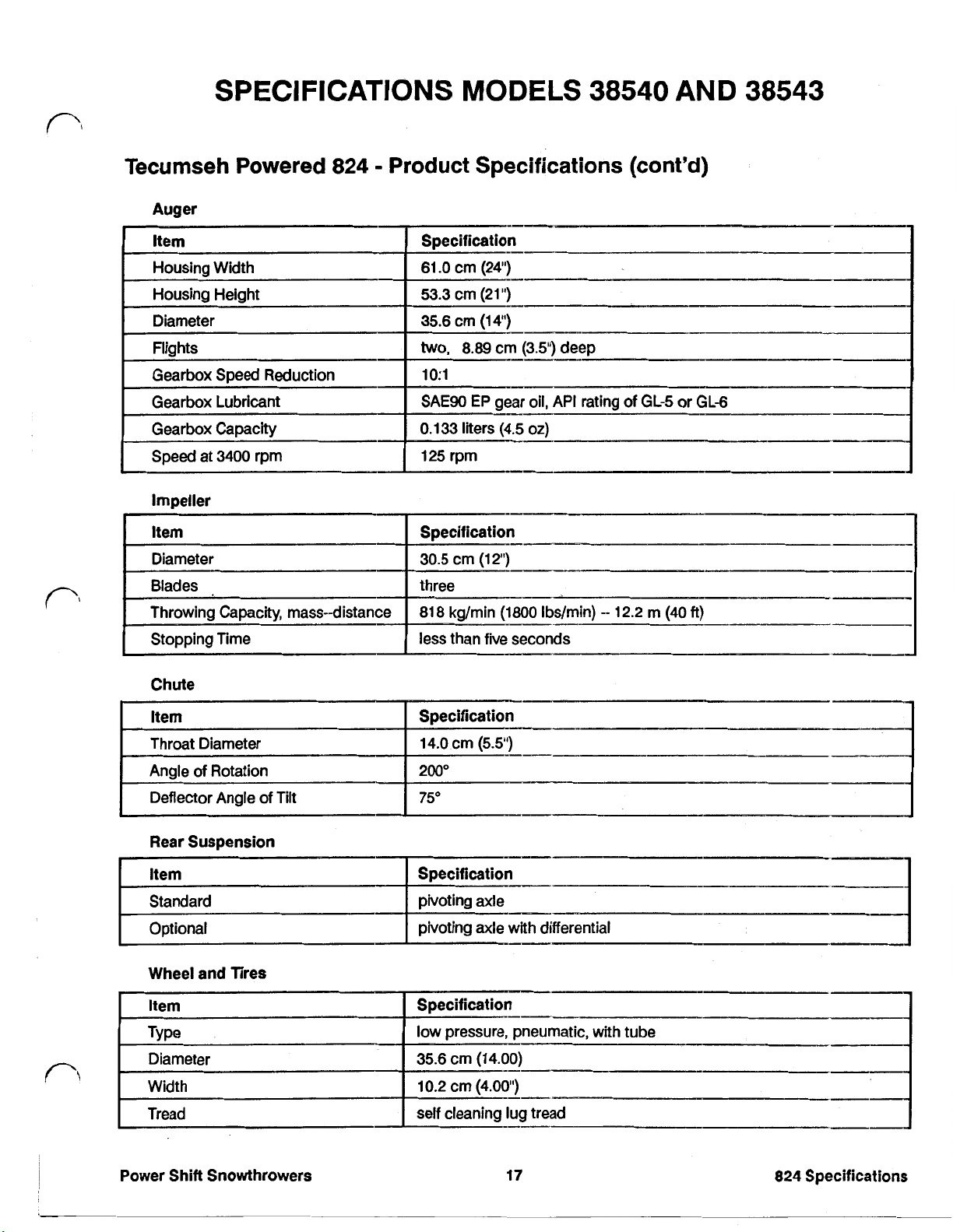

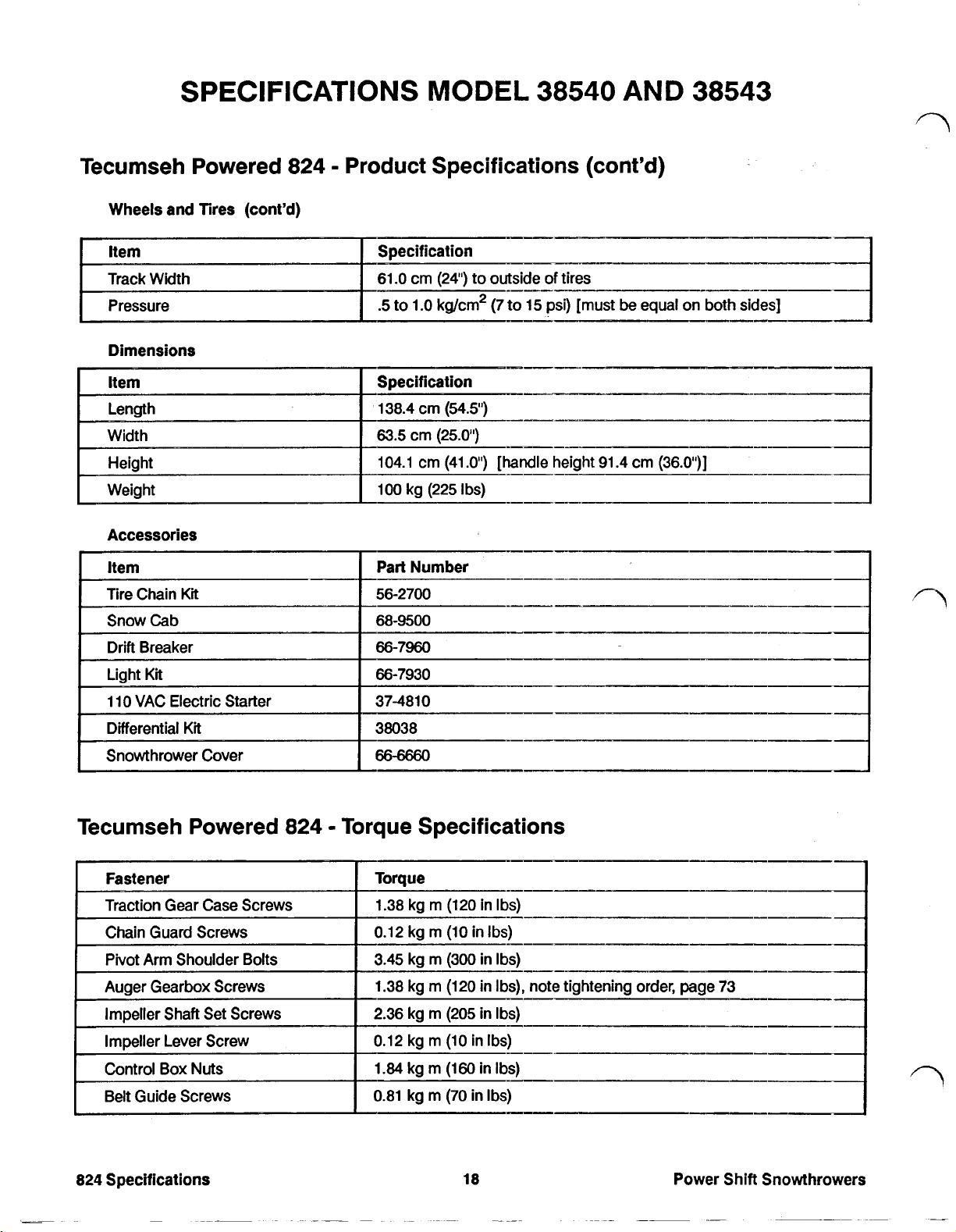

TECUMSEH POWERED 824 - PRODUCT SPECIFICATIONS

TECUMSEH POWERED 824 - TORQUE SPECIFICATIONS

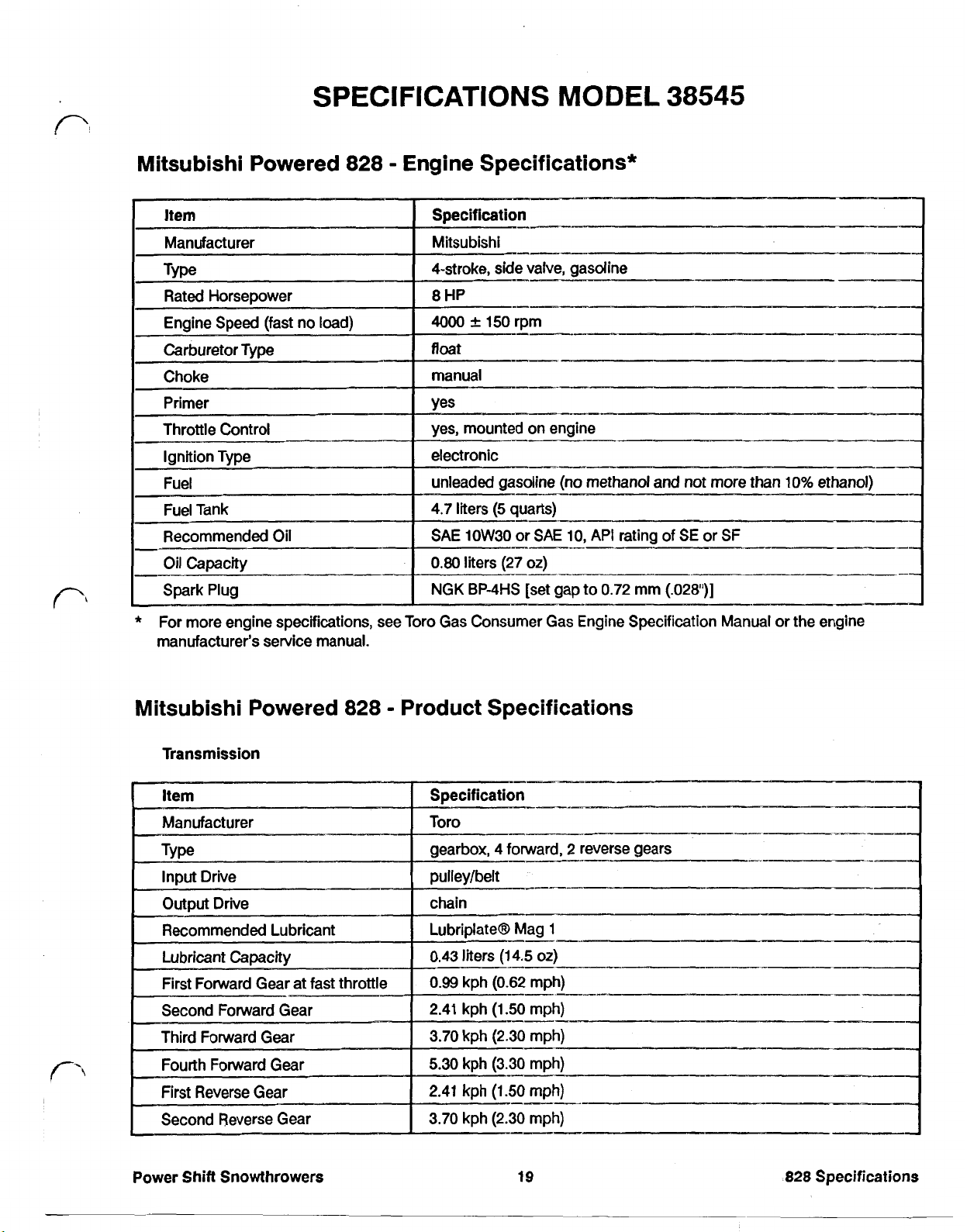

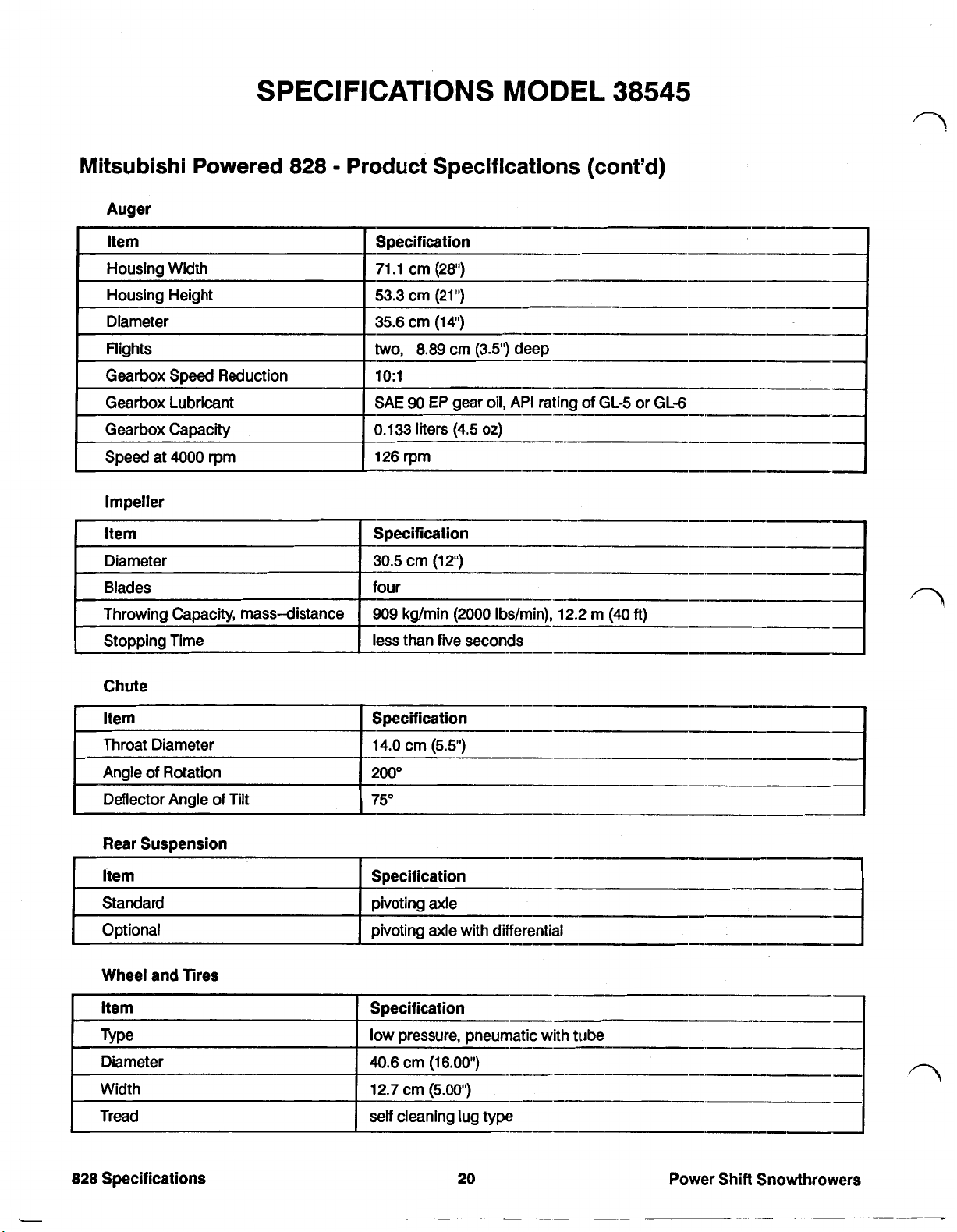

SPECIFICATIONS MODEL 38545

MITSUBISHI POWERED 828 - ENGINE SPECIFICATIONS*

MITSUBISHI POWERED 828 - PRODUCT SPECIFICATIONS

MITSUBISHI POWERED 828 - TORQUE SPECIFICATIONS

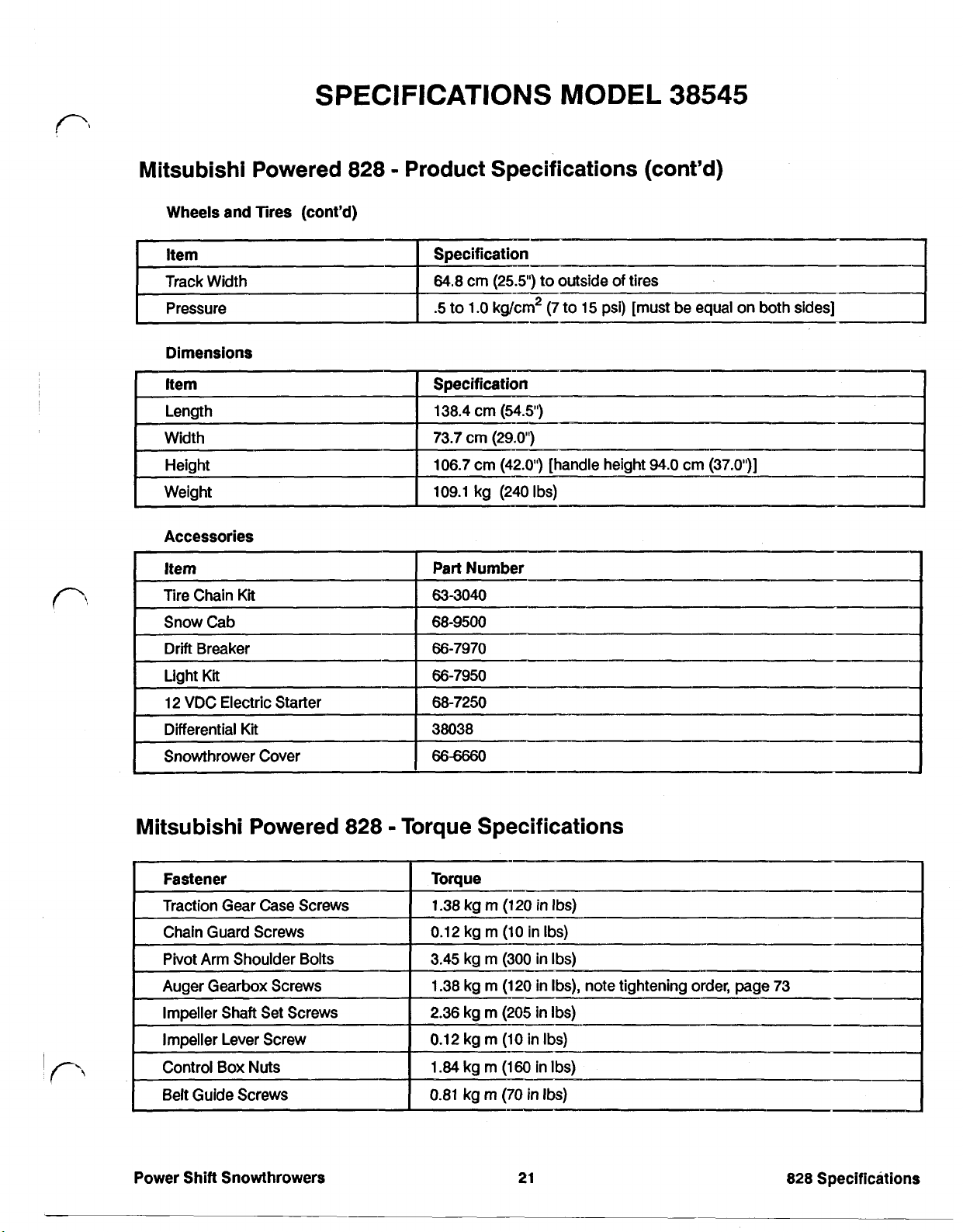

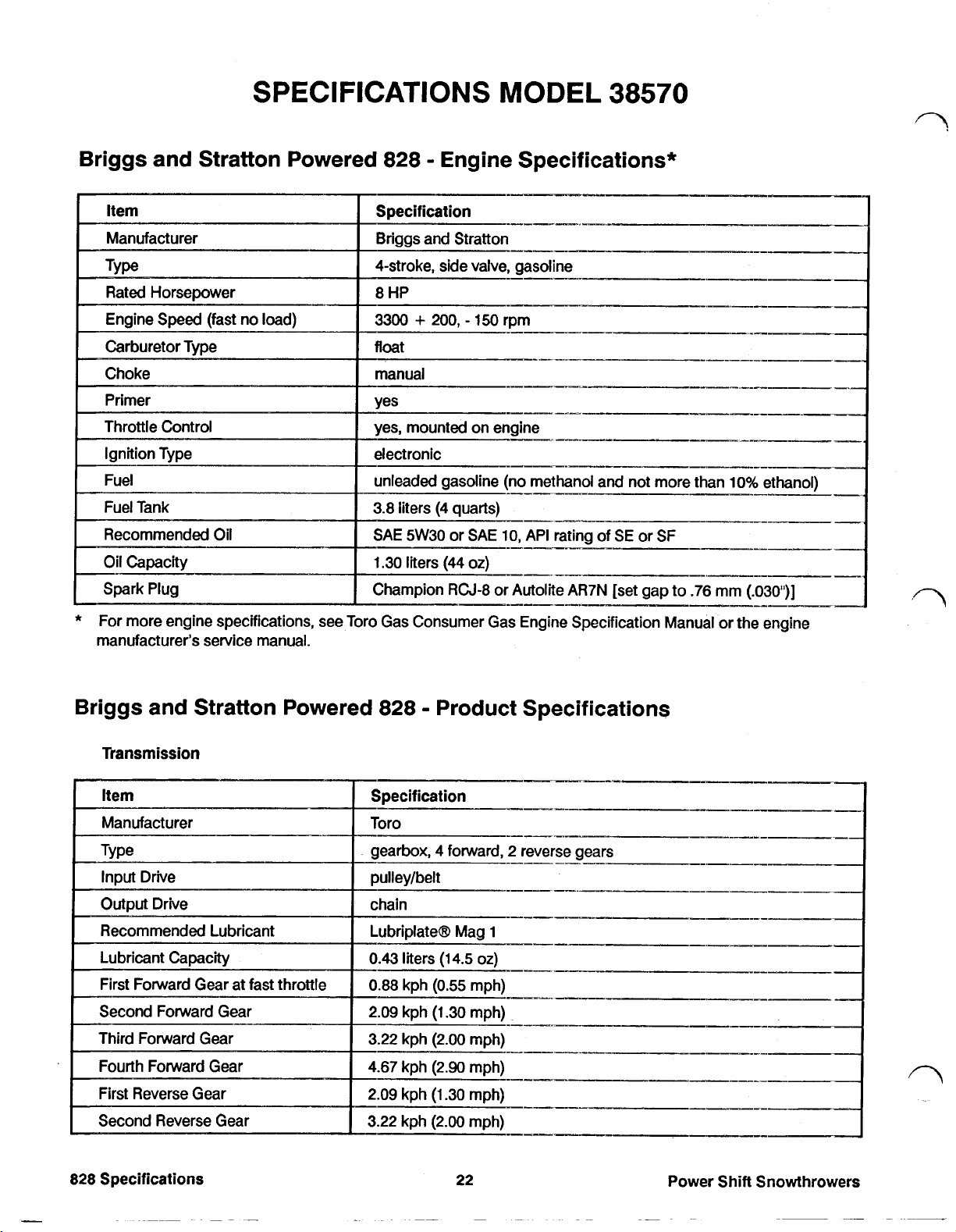

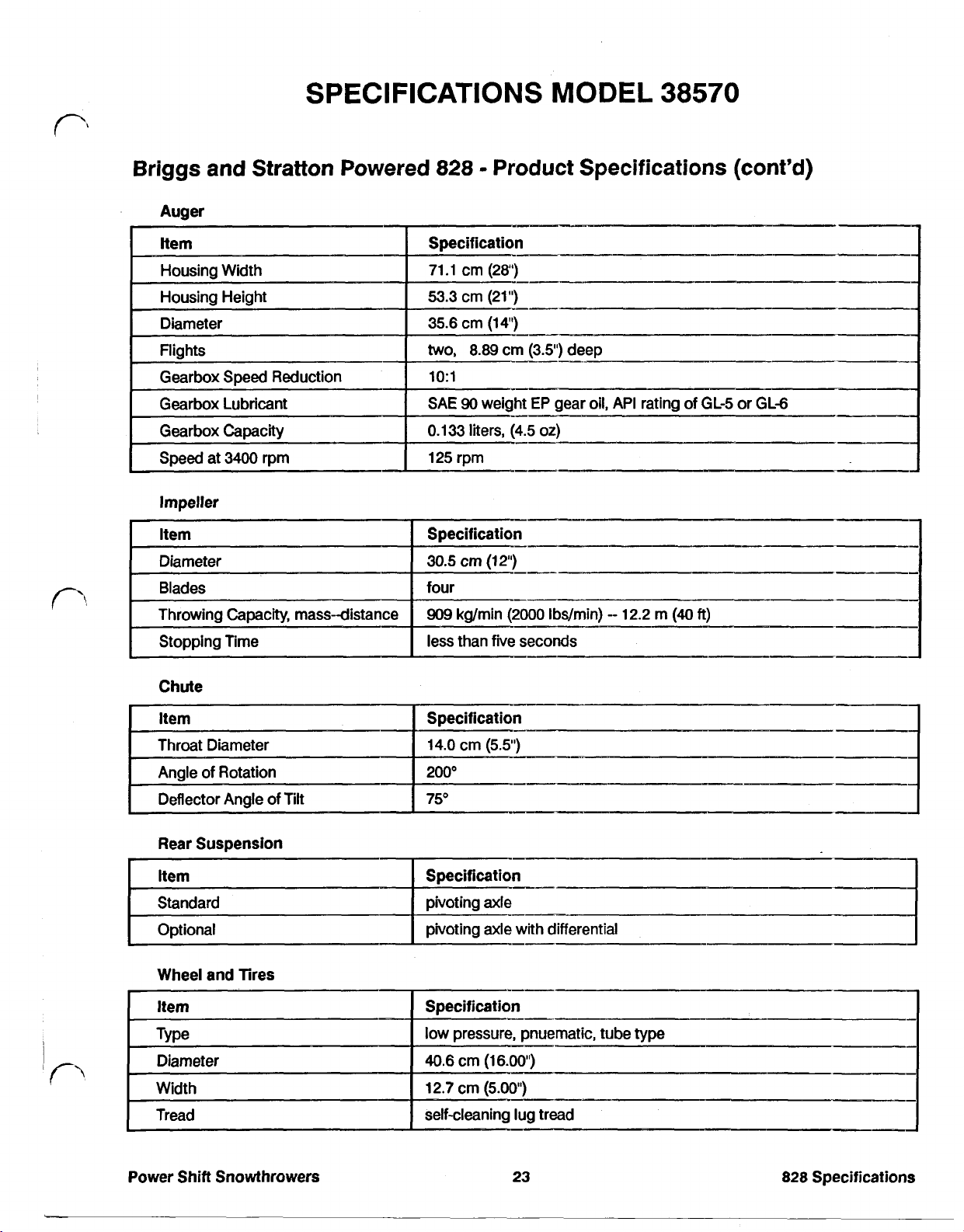

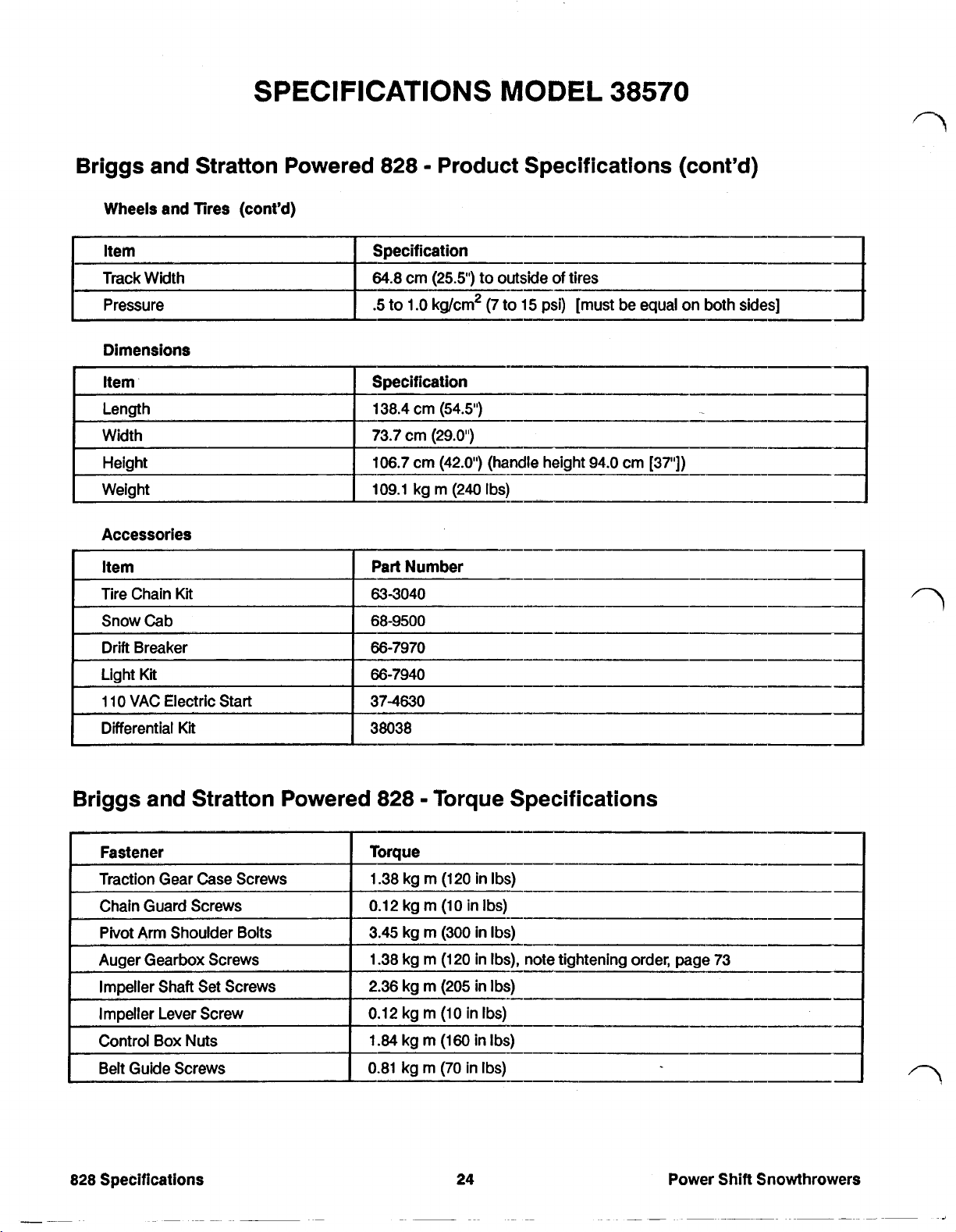

SPECIFICATIONS MODEL 38570

BRIGGS AND STRATTON POWERED 828 - ENGINE SPECIFICATIONS*

BRIGGS AND STRATTON POWERED 828 - PRODUCT SPECIFICATIONS

BRIGGS AND STRATTON POWERED 828 - TORQUE SPECIFICATIONS

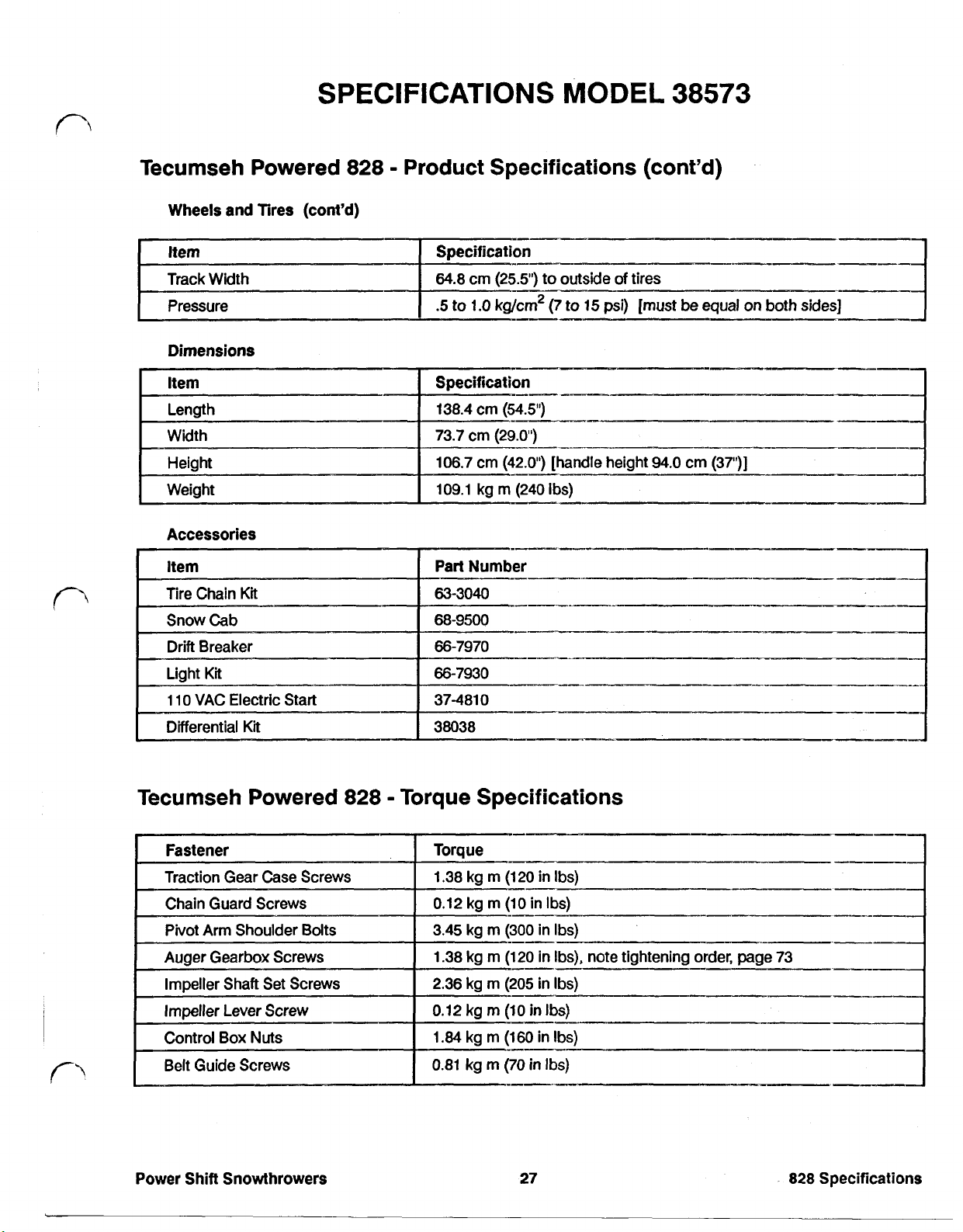

SPECIFICATIONS MODEL 38573

TECUMSEH POWERED 828 - ENGINE SP ECIFIC ATIONS*

TECUMSEH POWERED 828 - PRODUCT SPECIFICATIONS

TECUMSEH POWERED 828 - TORQUE SPECIFICATIONS

Page 2

POWER SHIFT SNOWTHROWER SERVICE MANUAL

Table of Contents – Page 2 of 5

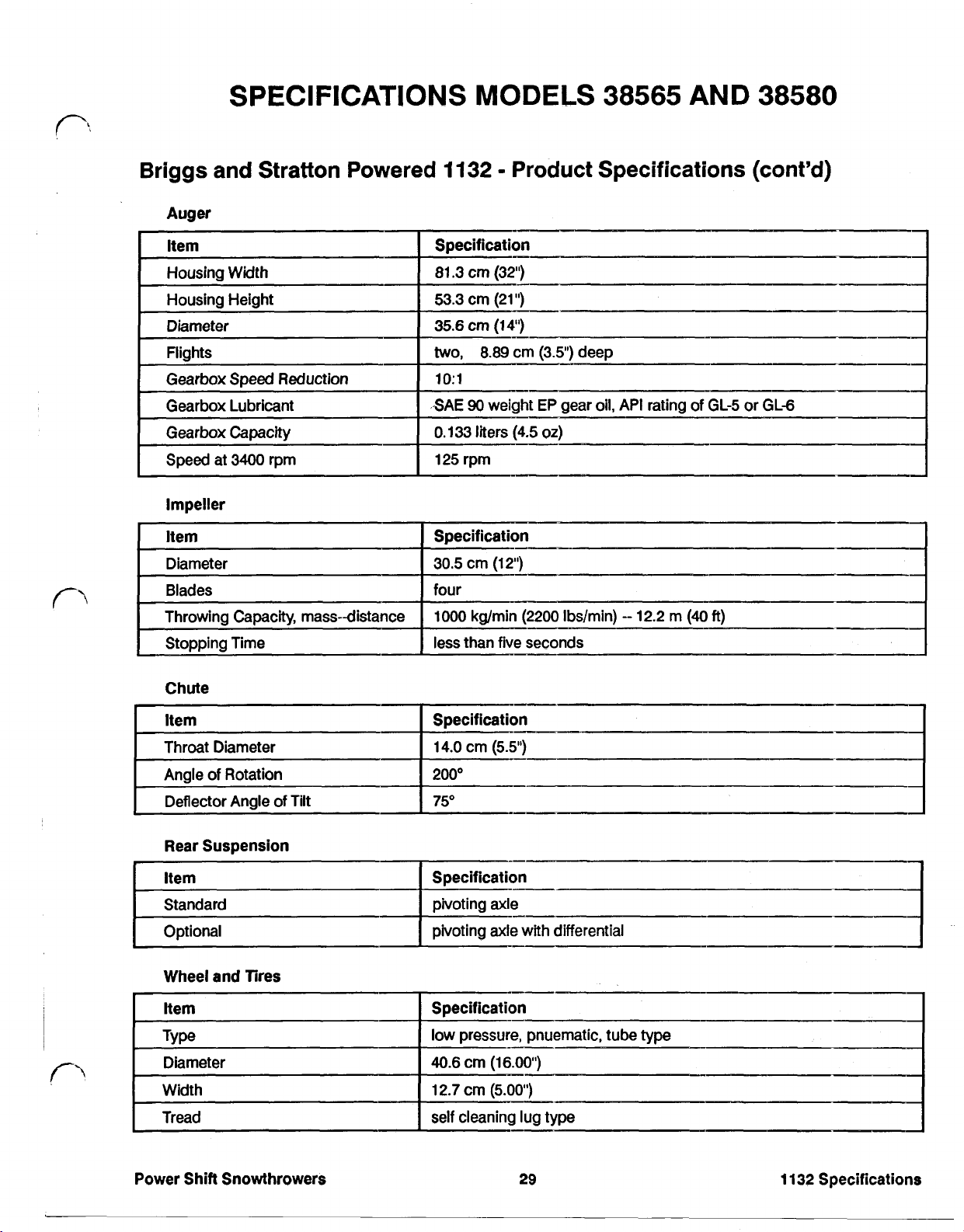

SPECIFICATIONS MODELS 38565 AND 38580

BRIGGS AND STRATTON POWERED 1132 - ENGINE SPECIFICATIONS*

BRIGGS AND STRATTON POWERED 1132 - PRODUCT SPECIFICATIONS

TORQUE SPECIFICATIONS

SPECIAL TOOLS AND OTHER NECESSITIES

TROUBLESHOOTING

UNIT DOES NOT PROPEL FORWARD

UNIT WILL NOT PROPEL BACKWARD

NEUTRAL NOT IN CORRECT LOCATION

SHIFT LEVER WILL NOT LOCK IN POWER SHIFT OR REVERSE

OPERATOR CAN SHIFT BETWEEN FORWARD AND REVERSE WHILE TRACTION LEVER IS

WHEELS WILL NOT SWING WHEN POWER SHIFTING

MACHINE DOES NOT PROPEL IN A STRAIGHT LINE

ENGINE KILLS WHEN AUGER OR TRACTION ARE ENGAGED

POOR SNOWTHROW ING PERFORMANC E

IMPELLER OR AUGER DOES NOT TURN

TRACTION OR IMPELLER DOES NOT DISENGAGE

CHUTE PLUGS WITH SNOW

SCRAPER CATCHES ON UNEVEN PAVEMENT

SNOWTHROWER LEAVES SNOW BEHIND

RAPID SKID AND SCRAPER W EAR

FRONT END RISES

MAINTENANCE

MAINTENANCE - DRAINING GASOLINE

MAINTENANCE - CHAIN LUBRICATION

MAINTENANCE - CHANGING CRANKCASE OIL

MAINTENANCE - AUGER GEAR BOX OIL SERVICE

MAINTENANCE - IMPELLER DRIVE BELT ADJUSTMENT

MAINTENANCE - TRACTION DRIVE BELT ADJUSTMENT

MAINTENANCE - REPLACING DRIVE BELTS

MAINTENANCE - DRIVE CHAIN ADJUSTMENT

MAINTENANCE - SPARK PLUG SERVICE

PREPARING SNOWTHROWER FOR STORAGE

SECTION I POWER SHIFT CONTROLS

CONTROL BOX OPERATION

OPERATION - LATCH RELEASE MECHANISM

CONTROL BOX OPERATION - REVERSE CONTROL

CONTROL BOX OPERATION - SHIFT LOCKOUT

CONTROL BOX OPERATION - INDEXING MECHANISM

CONTROL BOX SERVICE

CONTROL BOX SERVICE - TESTING

Page 3

POWER SHIFT SNOWTHROWER SERVICE MANUAL

Table of Contents – Page 3 of 5

SECTION I POWER SHIFT CONTROLS - Continued

CONTROL BOX SERVICE - DISASSEMBLY

CONTROL BOX SERVICE - REASSEMBLY

CONTROL BOX SERVICE - INSTALLATION

CONTROL BOX SERVICE - ADJUSTMENTS

SECTION 2 TRACTION AND IMPELLER CONTROLS

OPERATION

OPERATION - IMPELLER CONTROL

OPERATION - IMPELLER LOCKING MECHANISM

TRACTION AND IMPELLER CONTROLS

TRACTION AND IMPELLER CONTROLS - INSPECTION

TRACTION AND IMPELLER CONTROLS - REASSEMBLY

TRACTION AND IMPELLER CONTROLS - TRACTION CABLE ADJUSTMENT

TRACTION AND IMPELLER CONTROLS - IMPELLER CABLE ADJUSTMENT

SECTION 3 DISCHARGE CHUTE

CHUTE CONTROL

DISCHARGE CHUTE

DISCHARGE CHUTE - REMOVAL

DISCHARGE CHUTE - INSTALLATION

SECTION 4 IDLER SYSTEM

IDLER SYSTEM - OPERATION

IDLER SYSTEM - REMOVAL

IDLER SYSTEM - DISASSEMBLY

IDLER SYSTEM - REASSEMBLY

IDLER SYSTEM - INSTALLATION

IDLER SYSTEM - ADJUSTMENT

SECTION 5 PIVOT AND LATCH SYSTEM

PIVOT SYSTEM

PIVOT SYSTEM - REASSEMBLY

LATCH SYSTEM

SECTION 6 TRANSMISSION

TRANSMISSION - OPERATION

TRANSMISSION - REMOVAL

TRANSMISSION - DISASSEMBLY

TRANSMISSION - REASSEMBLY

TRANSMISSION - INSTALLATION

SECTION 7 AUGER

AUGER

Page 4

POWER SHIFT SNOWTHROWER SERVICE MANUAL

Table of Contents – Page 4 of 5

SECTION 8 AUGER GEAR BOX

AUGER GEAR BOX - OPERATION

AUGER GEAR BOX - REMOVAL

AUGER GEAR BOX - DISASSEMBLY

AUGER GEAR BOX - REASSEMBLY

AUGER GEAR BOX - INSTALLATION

SECTION 9 IMPELLER AND PULLEY SYSTEM

IMPELLER AND PULLEY - OPER ATION

IMPELLER AND PULLEY - REMOV AL

IMPELLER AND PULLEY - INST ALL ATION

SECTION 10 FRONT HOUSING

FRONT HOUSING - OPERATION

FRONT HOUSING - INSTALLATION

SKIDS - OPERATION

SKIDS - REMOVAL

SKIDS - INSTALLATION

SCRAPER- OPERATION

SCRAPER- REMOVAL

SCRAPER- INSTALLATION

SECTION 11 CONTROL PANEL AND HANDLES

CONTROL PANEL - OPERATION

CONTROL PANEL - INSTALLATION

HANDLES

RIGHT HANDLE - INSTALLATION

LEFT HANDLE - REMOVAL

LEFT HANDLE- INSTALLATION

SECTION 12 WHEELS, TIRES AND CHAINS

WHEELS - OPERATION

WHEELS - REMOVAL

WHEELS- INSTALLATION

TIRES - OPERATION

TIRES - SERVICE

CHAINS - OPERATION

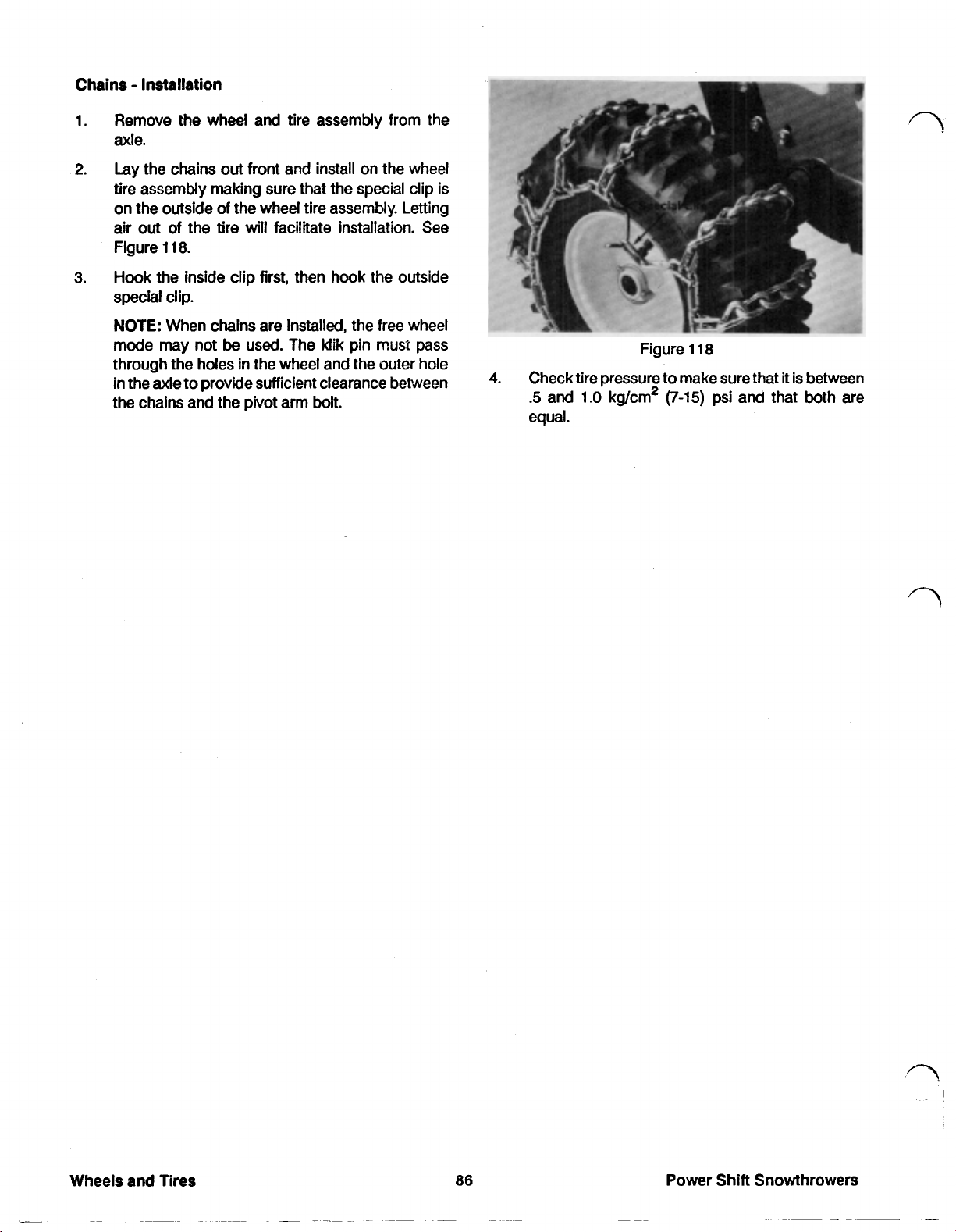

CHAINS- INSTALLATION

SECTION 13 ENGINES

ENGINES - SERVICE INFORMATION

SECTION 14 DIFFERENTIAL KIT

DIFFERENTIAL KIT - OPERATION

DIFFERENTIAL KIT - REMOVAL

Page 5

POWER SHIFT SNOWTHROWER SERVICE MANUAL

Table of Contents – Page 5 of 5

SECTION 14 DIFFERENTIAL KIT - Continued

DIFFERENTIAL KIT - DISASSEMBLY

DIFFERENTIAL KIT - ASSEMBLY

DIFFERENTIAL KIT- INSTALLAT ION

SECTION 15 LIGHT KIT

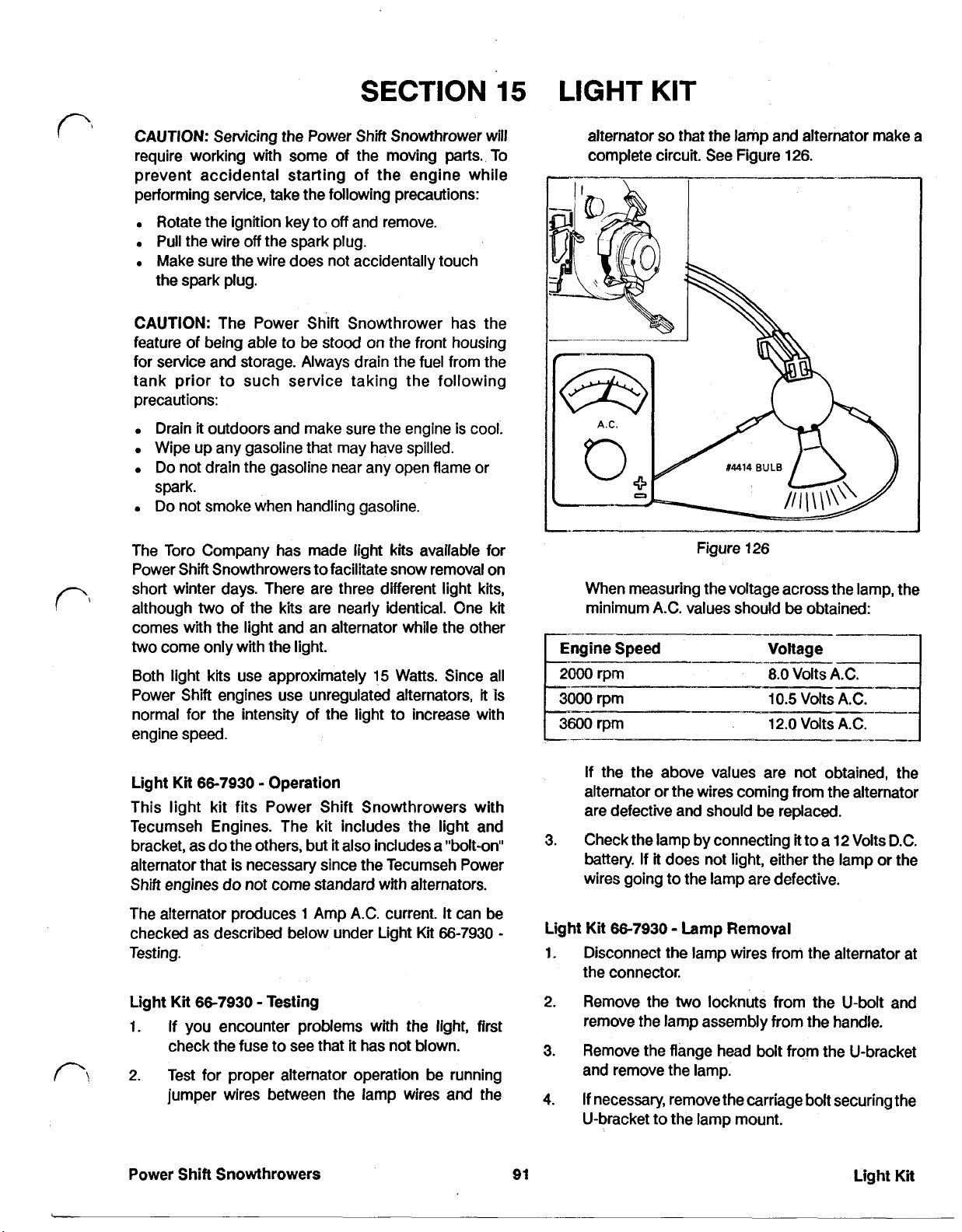

LIGHT KIT 66-7930 - OPERATION

LIGHT KIT 66-7930 - TESTING

LIGHT KIT 66-7930 - LAMP REMOVAL

LIGHT KIT 66-7930 - LAMP INSTALLATION

LIGHT KIT 66-7930 - ALTERNATOR REMOVAL

LIGHT KIT 66-9730 - ALTERNATOR INSTALLATION

LIGHT KITS 66-7940 AND 66-7950 - OPERATION

LIGHT KITS 66-7940 AND 66-7950 - LAMP REMOVAL

LIGHT KIT 66-7940 AND 66-7950 - LAMP INSTALLATION

SECTION 16 SNOW CAB

SNOW CAB - OPERATION

SNOW CAB - REMOVAL

SNOW CAB - INSTALLATION

SECTION 17 DRIFT BREAKER

DRIFT BREAKER - OPERATION

DRIFT BREAKER- DISASSEMBLY

DRIFT BREAKER - ASSEMBLY

Page 6

Page 7

ABOUT THIS MANUAL

This service manual was written expressly for the Tor0 624, 824, 828 and

Power Shift Snowthrowers. The Tor0 Company has made every effort to make the

information in this manual complete and correct.

This manual was written with the service technician in mind.

information used most often

information on safety, identification, specifications, special tods, troubleshooting

and maintenance, all in the front third of the manual.

Disassembly, inspection and reassembly procedures are covered in the last

two-thirds of the manual and are grouped by component.

common repair with its own section or sub-section. For example, you will find that

auger service and auger gearbox service are addressed separately.

And,

because the Power Shift Snowthrower

sections will include some component theory. This information can be found at the

front of each service procedure section.

We are hopeful that you will

you have any questions

the following address:

is

up front.

find

this manual a valuable addition to your shop.

or

comments regarding this manual, please contact

The

81II

Lyndale Avenue South

Minneapolis,

As

a result, you will find reference

is

a relatively complex machine, most

Tor0 Company

MN

55420

It

is organized

We

tried

1132

so

that

to cover each

If

us

at

The Tor0 Company reserves the right to change product specifications or this

manual without notice.

@COPYRIGHT

The

Minneapolis,

ALL

Toro

RIGHTS

Company

MN

55420

RESERVED

1989

-USA

Page 8

TABLE

Reference Information Page

OF CONTENTS

I

Safety Instructions

5

Service Procedures

Section

1

Identification

Specifications

Tool Requirements

Troubleshooting

Maintenance

Power Shift Controls Page

control Box Operation

gear selector control

latch release mechanism

reversecontrol

shiftlockout

indexing mechanism

Control Box Service

removal

testing

disassembly

31

32

36

41

41

41

43

43

45

6

7

Section

Power Shift Snowthrowers

2

Traction and Impeller Controls

Operation

Traction and Impeller Controls

reassembly

installation

adjustments

tractioncontrol

impellercontrol

impeller locking mechanism

disassembly

inspection

reassembly

traction cable adjustment

impeller cable adjustment

1

48

49

50

50

50

51

52

52

53

53

Table of Contents

Page 9

TABLE

Service Procedures (cont’d)

OF

CONTENTS

(cont’d)

Section

Section

3

4

Discharge Chute

Chute Control

operation 54

knobremoval

knob installation

upper rod removal

upper rod installation

lower rod removal

lower rod installation

Discharge Chute

operation

removal

installation 56

Idler System

operation 57

removal 57

disassembly

reassembly

installation

adjustment

54

54

54

55

55

55

55

56

57

58

58

59

Section

!

Section 6 Transmission

5

Pivot and Latch System

Pivot System

operation

disassembly

reassembly 61

latch System

disassembly 61

reassembly 62

operation

removal

disassembly

reassembly

installation 67

60

60

63

64

65

Table

of

Contents

2

Power Shift Snowthrowers

Page 10

TABLE-

Service Procedures (cont’d)

Section 7 Auger Page

OF

CONTENTS

(cont’d)

Section

Section

Section 10 Front Housing

8

9

operation

removal

installation 70

Auger Gearbox

operation 71

removal 71

disassembly 71

reassembly 72

Impeller and Pulley System

operation 75

removal 75

installation 76

Front Housing

operation 78

removal 78

installation 78

69

69

Section

11

Skids

operation 78

removal 78

installation 78

Scraper

removal 79

installation 79

Control Panel and Handles

Control Panel

operation

removal

installation

Handles

right handle removal 81

right handle installation

left handle removal

left handle installation

80

80

80

82

83

84

Power

Shift

Snowthrowers

3

Table

of

Contents

Page 11

TABLE

Service Procedures (cont’d)

OF

CONTENTS

(cont’d)

Section 12

Section

Section 14

Section

13

15

Wheels and Tires

wheels

tires

chains

Engines

servicing information 87

Differential

Light

Light

Kii

Kit

operation 88

removal 88

disassembly 88

reassembly

installation

Kit

66-7930

operation 91

testing 91

lampremoval 91

lamp installation 92

alternator removal 92

alternator installation

Page

85

85

86

89

89

92

Table

Section

Section 17

of

Contents

16

Light

Kits

66-7940 and 66-7950

operation 93

lampremoval

lamp installation

Snow Cab

operation

removal 95

installation

Drift Breaker

operation 98

removal 98

installation 98

4

94

94

95

95

Power Shift Snowthrowers

Page 12

SAFETY

INSTRUCTIONS

Servicing of any outdoor

power' equipment requires

A

statements have been placed thoughout this information on the operation of the Power Shift

manual to enhance safety. Whenever you Snowthrowers.

encounter

instruction because

Failure to comply with the instruction may

result

in

personal injury or death.

I

care and common sense to

prevent injury. "CAUTION"

the

word CAUTION Read the

it

has to do with safety.

FOR

YOUR

This manual is intended as a service and repair manual

only. The safety instructions provided in this manual are

for the troubleshooting and service of the product only.

The individual Operator's Manuals will contain safety

Operator's Manuals with complete operational safety

instruction are available through:

The Toro Company

Publications Department

8111

Lyndale Avenue South

Minneapolis, MN

55420

U.S.A.

SAFETY

Avoid electrocution

Always use a grounded three wire plug and cord when

starting or troubleshooting a snowthrower equipped

with and electric starter.

Avoid possible fires and explosions

Use a container designed for gasoline.

gasoline and never smoke while working around

gasoline.

Avoid fires and falls

Wipe up any spilled fuel or oil.

Avoid lacerations and amputations

Stay clear of all moving parts when running the machine.

Treat all moving parts as

the engine is running or has the potential to start.

Avoid burns

Do not touch engine while running or shortly after

running.

Avoid falls

Do not operate snowthrower at fast speeds on slippery

surfaces.

if

they were moving whenever

Avoid

spilling

Avoid asphyxiation

Never operate an engine in a confined area without

proper ventilation.

Avoid possible eye injuries

Wear eye protection when working with springs or

cables.

Avoid unexpected starting of engine

Always turn

before attempting any cleaning, adjustment or repair.

Avoid accidental misuse of fuel

Always store fuel

that is properly labeled.

Avoid possible injury due to inferior parts

Use only Toro original

safety criteria are met.

Avoid injury to bystanders

Always clear area of bystanders before starting or

testing a snowthrower.

off

key and disconnect spark plug wire

in

a container designed for gasoline

parts

to insure that important

Power Shift Snowthrowers

5

Safety !nstructions

Page 13

Model

and

Serial

Numbers

The snowthrower itself has

a model number and a serial number. The

are stamped on a decal which is located on back

engine mounting plate. These numbers are required number must be included on warranty claims related to

whenever a warranty claim is being filed on a Toro

two

identification numbers: Each engine also has a model and serial number.

two

numbers

of

the location of these numbers. Engine

part.

Consult the engine manufacturers manual for the

model

a failed engine component. This applies even when the

claim is being filed

to

The Toro Company.

and serial

Power Shift Snowthrowers

Page 14

SPECIFICATIONS

MODELS

38500 AND 38505

Mitsubishi Powered 624 Engine Specifications*

I

Choke

Primer

manual

I

--yes

(no methanol and not

r

SAE10,

set gap to

*

For more engine specifications, see Toro Gas Consumer Gas Engine Specification Manual or the engine

manufacturer's service manual.

API

rating

0.72

SE

mm

more

or

SF

(.028')]

than

10%

ethanol)

Mitsubishi Powered 624 Product Specifications

Transmission

Item Specification

Manufacturer

Type

Toro

gearbox, 4 forward, 2 reverse gears

pulley/belt

chain

Lubriplate(R) Mag

-I_

1

Power

Shift

Snowthrowers

0.43

0.88

2.09

3.22

4.67

2.09

3.22

liters

kph

kph

kph

kph

kph

kph

(14.5

(0.55

(1.30

(2.00

(2.90

(1.30

(2.00

7

oz)

mph)

mph)

mph)

mph)

mph)

mph)

624

Specifications

~-

Page 15

SPECIFICATIONS

MODELS

38500 AND 38505

Mitsubishi Powered

Auger

Item

Housing Width

Housing Height

Diameter

Flights

Gearbox Capacity

Impeller

624

Product Specifications (cont'd)

Specification

61

.O

cm

(24)

53.3

cm

(21")

cm

35.6

two,

1O:l

0.133

(14”)

8.89

cm

(3.5")

90

EP

gear oil, API rating

liters

(4.5

oz)

deep

(38505

serrated1

of

GL-5 or GL-6

Chute

Throat Diameter

Angle

of

Rotation

Deflector Angle

Rear Suspension

Item Specification

Standard pivoting axle

Optional pivoting axle with differential

Item Specification

Type low pressure pneumatic, with tube

Diameter

Width

Tread self cleaning lug type

of

Tilt

14.0

200"

75"

35.6

10.2

cm

(5.5")

cm

(14.00")

cm

(4.00")

a

Power

Shift

Snowthrowers

Page 16

SPECIFICATIONS

MODELS

38500

AND

38505

Mitsubishi Powered

Wheels and Tires (cont’d)

Tire Pressure

Dimensions

I

Item

Accessories

624

Product Specifications (cont’d)

Specification

Mitsubishi Powered

Fastener Toque

Traction Gear Case Screws 1.38 kg

-Chain Guard Screws

Pivot

Power Shift Snowthrowers

Arm

Shoulder Bolts

Auger Gearbox Screws 1.38 kg

Control Box

Belt Guide Screws

Nuts

624

Torque Specifications

m

(120

in

Ibs)

m

(10 in

(120 in

(205

(70 in

9

Ibs)

in

Ibs)

Ibs)

Ibs)

Ibs),

Ibs)

0.12 kg

3.45

kg m (300 in

m

2.36 kg

0.12 kg m (10 in

1.84 kg m (160 in Ibs)

0.81 kg

m

m

note tightening order, page 73

624

Specifications

I

Page 17

SPECIFICATIONS MODELS 38510

Tecumseh Powered 624 Engine Specifications*

_I-

AND

38513

*

For more engine specifications, see Toro Gas Consumer Gas Engine Specification Manual or the engine

manufacturer’s service manual.

Tecumseh Powered 624 Product Specifications

Transmission

I

Item

Input Drive pulley/belt

output

Drive chain

Specification

Toro Manufacturer

4

gearbox,

forward, 2 reverse gears

624

Specifications

10

Power

Shift Snowthrowers

Page 18

Tecumseh Powered

Auger

Impeller

624

Product Specifications (cont'd)

30.5

cm

(12'”)

Chute

Throat Diameter

Angle

of

Deflector Angle

I

Rear Suspension

Item

Type pivoting axle

Optional

Wheel and Tires

Rotation

of

Tilt

14.0

cm

I

200"

75"

pivoting axle

(5.5”)

with

differential

I

I

Power

Shift

Snowthrowers

11

624

Specifications

Page 19

SPECIFICATIONS MODELS 38510 AND 38513

Tecumseh Powered

Wheels and Tires (cont'd)

Track Width

Dimensions

I

Item

Weight

624

Product Specifications (cont'd)

61

.O

cm (24") to outside

.5

to 1

.O

kg/cm2 (7

Specification

138.4 cm (54.5")

63.5

cm (25.0")

104.1 cm (41

100 kg (220 I bs)

.O'”)

[handle height 91.4 cm (36.O'”)

of

tires

to

15 psi) [must be equal on both sides] Pressure

I

I

I

Torque Specifications

Fastener

Traction Gear Case Screws

Chain Guard Screws

Pivot Arm Shoulder Bolts

Auger Gearbox Screws

Impeller Shaft Set Screws

Impeller Lever Screw

Control Box

Belt Guide Screws

624

Specifications

Nuts

Torque

1.38 kg m (120 in Ibs)

0.12 kg

3.45 kg m (300 in Ibs)

1.38 kg m (120 in Ibs), note tightening order, page 73

2.36 kg m (205 in Ibs)

0.12 kg m (10 in Ibs)

1.84 kg m (160 in

0.81 kg m (70 in Ibs)

m

(10 in

12

Ibs)

Ibs)

I---

Power Shift Snowthrowers

Page 20

Mitsubishi Powered 824 Engine Specifications*

Item

Manufacturer

Type

Rated Horsepower

Engine Speed (fast no load)

Carburetor Type

Choke

Primer

Throttle Control

Fuel unleaded gasoline (no methanol and not more than 10% ethanol)

Fuel Tank 4.7 liters

Recommended Oil

Oil Capacity

Spark Plug NGK BP-4HS [set gap to 0.72 mm (.028')

*

For more engine specifications, see Toro Gas Consumer Gas Engine Specification Manual or the engine

manufacturer's service manual.

Specification

Mitsubishi

4-stroke, side valve, gasoline

8

HP

4000

float

manual

yes

I

yes, mounted on engine

I

electronic

SAE 10W30 or SAE 10, API rating SE or SF

0.80

150 rpm

liters (27

(5

quarts)

oz)

Mitsubishi Powered 824 Product Specifications

Transmission

Second Forward Gear 2.09 kph (1.30 mph)

Third Forward Gear

Fourth Forward Gear 4.67 kph (2.90 mph)

First Reverse Gear

Second Reverse Gear

3.22 kph (2.00 mph)

2.09 kph (1.30 mph)

3.22 kph

(2.00

mph)

Power Shift Snowthrowers

13

824

Specifications

Page 21

SPECIFICATIONS MODELS 38520 AND 38525

Mitsubishi Powered

Auger

Housing Width

I

ltem

824

Product Specifications (cont'd)

61

.O

cm

(24")

I

[

Stopping Time less than five seconds

Rear Suspension

ltem

Type pivoting axle

Optional pivoting axle with differential

824

Specifications

Power

Shift

Snowthrowers

Page 22

SPECIFICATIONS

MODELS

38520

AND

Mitsubishi Powered 824 Product Specifications (cont'd)

Wheels and Tires (cont'd)

I

Item

Track Width

I

Specification

61.O cm (24") to outside of tires

38525

Pressure

Dimensions

Accessories

.5

to

1.O

56-2700

66-6200

66-7960

66-7950

38038

66-6660

kg/cm2 (7 to 15 psi) [must be equal on both sides]

)

[handle height 91.4 cm (36.0'”)

or 68-9500

Mitsubishi Powered 824 Torque Specifications

in

Ibs),

note tightening order, page 73

Power

Shift Snowthrowers

15

824

Specifications

_I

Page 23

SPECIFICATIONS

MODELS

38540

AND

38543

Tecumseh Powered

824

Engine Specifications*

Specification

Tecumseh

4-stroke, side valve gasoline

8 HP

+

200,

150

3300

float

manual

Yes

yes, mounted on engine

electronic

unleaded gasoline (no methanol and not more than

3.8

liters (4

SAE 5W30

0.71

Champion

liters

qts)

or

(24

RJ-17LM

rpm

_-

SAE 10, API

oz)

or Autolite

of

SE

AR7N

or

SF

[set gap to

I

-_._-I-

I---

_._.___

10%

0.76

ethanol)

mm

(.030'))

*

For more engine specifications, see Toro Gas Consumer Gas Engine Specification Manual

manufacturer's service manual.

Tecumseh Powered

Transmission

824

Product Specifications

or

the engine

824

Specifications

16

Power Shift Snowthrowers

Page 24

SPECIFICATIONS MODELS 38540 AND 38543

Tecumseh Powered

Auger

Impeller

Item

Diameter

Blades

Throwing Capacity, mass-distance

Stopping Time

824

Product Specifications (cont'd)

Specification

30.5

cm

(12')

three

818 kg/min

less than fie seconds

(1800

Ibs/min)

12.2

m (40

ft)

Chute

Rear Suspension

Wheel and Tires

Specification

14.0 cm

200"

75"

(5.5')

Power Shift Snowthrowers

17

824

Specifications

Page 25

SPECIFICATIONS

MODEL

38540

AND

38543

Tecumseh Powered

Wheels and Tires (cont’d)

Dimensions

824

Product Specifications (cont’d)

15

psi) [must

eight

91.4

be

equal

cm

on

(36.0’)

-~I--

both si

Tecumseh Powered

824

Specifications

824

Torque Specifications

18

Power Shift Snowthrowers

Page 26

Mitsubishi Powered

828

Engine Specifications*

*

For more engine specifications, see

manufacturer's service manual.

Mitsubishi Powered

Transmission

828

Toro

Gas Consumer Gas Engine Specification Manual or the engine

Product Specifications

Power

Shift

Snowthrowers

19

828

Specifications

Page 27

SPECIFICATIONS

MODEL

38545

Mitsubishi Powered

Impeller

Item Specification

Diameter

Blades

Throwing Capacity, mass-distance

Stopping Time

828

Product Specifications (cont'd)

30.5

cm

four

909

kg/min

less than five seconds

(12")

(2000

Ibs/min),

12.2

m

(40

ft)

Chute

Item

Throat Diameter

Angle

of

Rotation

Deflector Angle of Tilt

Rear Suspension

Wheel and Tires

Item

Type low pressure, pneumatic with tube

Diameter

Width

Tread

Specification

14.0

200°

75"

Specification

40.6

12.7

self cleaning lug type

cm

cm

cm

(5.5")

(16.00')

(5.00')

828

Specifications

20

Power Shift Snowthrowers

Page 28

SPECIFICATIONS MODEL

38545

Mitsubishi Powered

Wheels and Tires (cont'd)

I

Item

Track

Width

Pressure

Dimensions

Accessories

828

Product Specifications (cont'd)

64.8

cm

(25.5')

.5

to

1.O

kg/cm2

to outside

(7

to

of

tires

15

psi) [must be equal

on

both sides]

I

I

Mitsubishi Powered

Power Shift Snowthrowers

828

Torque Specifications

21

828

Specifications

Page 29

SPECIFICATIONS

MODEL

38570

Briggs and Stratton Powered

Champion RCJ-8 or Autolite AR7N [set gap to

828

Engine Specifications*

_I-

.76

mm

(.030'”)

*

For more engine specifications, see Toro Gas Consumer Gas Engine Specification Manual or the engine

manufacturer's service manual.

Briggs and Stratton Powered

Transmission

828

Product Specifications

Page 30

SPECIFICATIONS

MODEL

38570

Briggs

Auger

Impeller

and

Stratton

Powered

828

Product Specifications (cont'd)

i

r'

Chute

Wheel and

Tires

self-cleaning lug

tread

Power

Shift Snowthrowers

23

828

Specifications

Page 31

SPECIFICATIONS

MODEL

38570

Briggs and Stratton Powered 828 Product Specifications (cont'd)

Wheels and Tires (cont'd)

Specification

Track Width 64.8 cm (25.5) to outside

.5 to

1.O

Pressure

Dimensions

Item

Length

Width

Height

Weight

Specification

138.4 cm

73.7 cm

106.7 cm (42.0') (handle height 94.0 crn [37"])

109.1

kg/cm2 (7 to

(54.5")

(29.0")

kg m (240 Ibs)

of

tires

15

psi) [must be equal

on

both sides]

Briggs and Stratton Powered 828 Torque Specifications

Power

Shift

Snowthrowers

Page 32

SPECIFICATIONS

MODEL

Tecumseh Powered 828 Engine Specifications*

38573

Item

Manufacturer

Ignition Type electronic

Fuel Tank

oil

Capacity

Spark Plug Champion

*

For more engine specifications, see Toro Gas Consumer Gas Engine Specification Manual or the engine

manufacturer's service manual.

Specification

Tecumseh

yes, mounted on engine

unleaded gasoline (no methanol and not more than

3.8

liters

(4

quarts)

SAE

5W30

or

SAE10, API

RJ-17LM

or

Autolite

rating

of

SE

AR7N

or SF

[set gap to

0.76

10%

ethanol)

mm

(.030'”)

Tecumseh Powered 828 Product Specifications

Transmission

Specification

Toro

4

Manufacturer

gearbox,

pulley/belt

chain

Lubriplate(R) Mag

0.43

0.88

2.09

3.22

4.67

2.09

3.22

forward, 2 reverse gears

1

liters

(14.5 oz)

kph

(0.55

mph)

kph

(1.30

mph)

kph

(2.00

mph)

kph

(2.90

mph)

kph

(1.30

mph)

kph

(2.00

mph)

Power

Shift

Snowthrowers

25

828

Specifications

Page 33

Tecumseh Powered

Impeller

828

Product Specifications (cont'd)

Specification

30.5

cm

(12")

four

909

kg/min

less than five seconds

(2000

lbs/min)

12.2

rn

(40

ft)

Rear Suspension

Item

Optional pivoting axle

Wheel

I

Item

I

Type

Diameter

Tread

828

Specifications

and

Tires

Specification

low

pressure, pnuematic, tube type

40.6

cm

(16.00")

with

differential

Power

Shift

Snowthrowers

I

I

Page 34

SPECIFICATIONS MODEL

38573

Tecumseh Powered 828 Product Specifications (cont'd)

Wheels and Tires (cont'd)

I

Item

Pressure

Dimensions

Width

Height

Weight

Accessories

Specification

64.8

crn

(25.5") to outside

.5

to

1.0

kg/cm2

cm

73.7

106.7

109.1

(29.0")

crn

(42.0') [handle height

kg m (240 Ibs)

(7 to

15

of

psi)

tires

[must

94.0

be

cm

equal on both

(37")]

I

sides]

I

Tecumseh Powered 828 Torque Specifications

Torque

1.38 kg

0.12

3.45

1.38

2.36

0.12 kg

1.84

0.81

Power Shift Snowthrowers

m

(120

in Ibs)

kg

rn

(10

in

Ibs)

kg

m

(300 in Ibs)

kg m

(120

in Ibs), note tightening order, page 73

kg

m (205 in

m

(10

kg

m

(160

kg m (70 in Ibs)

in Ibs)

-_I__.

in

27

Ibs)

Ibs)

I_.--

--__-

828

Specifications

Page 35

SPECIFICATIONS

MODELS

38565 AND 38580

Briggs and Stratton Powered 1132 Engine Specifications*

no methanol and not more

_.-

*

For more engine specifications, see Toro Gas Consumer Gas Engine Specification Manual or the engine

manufacturer’s service manual.

Briggs and Stratton Powered 1132 Product Specifications

1132

Specifications

28

Power Shift Snowthrowers

Page 36

Briggs and Stratton Powered

Auger

Impeller

1132

Product Specifications (cont'd)

Chute

Rear Suspension

Wheel and Tires

Item

Type

Diameter

Width

Tread

Specification

low

pressure, pneumatic tube type

40.6

cm

(16.00'1

12.7 cm

self cleaning lug type

(5.00')

I

I

Power Shift Snowthrowers

29

1132

Specifications

Page 37

SPECIFICATIONS MODELS 38565 AND 38580

Briggs and Stratton Powered

Wheels and Tires (cont'd)

Track Width

Pressure

64.8

.5

1132

cm

to

1.O

Product Specifications (cont'd)

(25.5")

kg/cm2

to outside

(7

to

of

tires

15

psi) [must be equal on both sides]

Torque Specifications

1132

Specifications

30

Power Shift Snowthrowers

Page 38

SPECIAL TOOLS AND OTHER NECESSITIES

The Power Shift Snowthrowers do not require any

complex tools for most servicing. Servicing can be

accomplished with the following:

Necessary

Complete English Socket Wrench Set (1/4" thru 1")

Complete English End Wrench Set (1/4" through 1")

Phillips Screwdrivers

Standard Screwdrivers

Pocket Knife

Rubber Mallot

Pliers (regular, needle nose and linesman)

Snap Ring Pliers (outside)

Tools

it

is a

In addition to those tools,

following

Lubricants, Sealants and Adhesives

on

hand:

good

idea to have the

Power Shift Snowthrowers

31

Special Tools

Page 39

TROUBLESHOOTING

Unit Does Not Propel Forward

Remedy

Check tire pressure, lock differential, install chains

Position klik Pin through wheel and

Adjust cable

Adjust traction cable

Remove ice accumulation in lower belt cover.

Repair gear or jaw damage

Unit will not Propel Backward

Possible Causes

Wheels not pinned to axle

Reverse cable too loose

Traction belt slipping

Reverse bevel gear or jaw

clutch malfunction

Remedy

Position klik pin through wheel and axle

Adjust reverse cable

Adjust traction cable

Repair reverse gear or jaw clutch damage

axle

I

Neutral Not in Correct Location

I I

Possible Causes Remedy

Lower shift rod not adjusted correctly

Shift bracket incorrectly assembled Reassemble control box correctly

Adjust lower shift rod

I

Shift Lever Will Not Lock in Power Shift or Reverse

Possible Causes Remedy

Lockout lever

Lockout lever binding

Lockout lever spring malfunction

tabs

broken Replace lockout lever

Free by spraying with WD40

Replace lock out lever spring

Power

Shift

Snowthrowers

I

I

Page 40

TROUBLESHOOTING

(cont'd)

Operator Can Shift Between Forward and Reverse While Traction Lever is

Engaged

Possible Causes

Lock out lever tabs broken

Lockout lever binding

Lock out lever spring malfunction Replace lock out lever spring

Remedy

Replace lock out lever

Free by spraying with WD40

I

Wheels Will Not Swing When Power Shifting

Possible Causes

Indexing mechanism out

sequence with wheels

Insufficient traction

of

Remedy

Release shift lever then

Assist axle swing by lifting on handles slightly during Power Shift

Units with differential: push down on handles, lock differential

Adjust latch cable

Free pivot arms

push

into Power Shift again

I

Machine Does Not Propel in a Straight Line

I

Possible Causes Remedy

Uneven tire pressure

Uneven traction on pavement

Skids not adjusted evenly

Both wheels not pinned to axle Position klik pin through both wheel and axle

Adjust tire pressure to

Consider chain installing chains

Adjust

skids

.5

to

.O

1.0

kg/cm2

Engine Kills When Auger or Traction are Engaged

Possible Causes

Engine not sufficiently warmed up

Debris jammed

Auger or impeller frozen with ice

in

auger or impeller

Remedy

Allow engine to warm

Clear auger and impeller

Allow snowthrower to warm

up

before engagement

(7

to

15

psi) equally.

-I

I

Power Shift Snowthrowers

33

Troubleshooting

Page 41

TROUBLESHOOTING

Poor Snowthrowing Performance

Impeller or Auger Does Not Turn

Remedy

Clear debris

Allow snowthrower to warm

Adjust impeller belt

(cont'd)

Gear malfunction

in

auger gearbox

Traction or Impeller Does

-Possible Causes

Cable too tight

Belt guide broken

Incorrect belt

Chute Plugs With Snow

Possible Causes

Engine rpm too slow

Belt slippage

Tighten pulley fasteners

Replace auger bolt

Tighten impeller shaft fasteners

Repair auger gearbox

Not

Disengage

Replace belt guide

Check parts catalog for correct belt

Always throw snow at full throttle

Adjust impeller belt

Ground speed not matched

Snow too wet

Troubleshooting

in

Select slower gear in heavy conditions, faster gear

Sand, paint and wax chute and rough areas in housing and chute

Allow snow to melt or freeze

34

Power Shift Snowthrowers

light conditions

Page 42

TROUBLESHOOTING

Scraper Catches on Uneven Pavement

Snowthrower Leaves Snow Behind

Remedy

(cont’d)

per Operator’s Manual

Scraper improperly adjusted or worn

Skids improperly adjusted or worn

Adjust scraper

Adjust skid

Rapid Skid and Scraper Wear

Possible Causes

Operator snowthrowing with wheels

in rear position unnecessarily

Defective or scraper

Remedy

Use forward wheel position

Replace skid or scraper

Front End Rises

___-

for

light snow

Power

Shift

Snowthrowers

35

Troubleshooting

Page 43

CAUTION: To prevent accidental starting of the engine

while performing maintenance, rotate the ignition key to

off

and remove

it

from the switch. Next, pull the wire

off

the spark plug and make sure the wire does not

accidentally touch the plug.

Maintenance Draining Gasoline

Stop the engine and pull the wire

1.

2.

Remove the cap from the fuel tank and use a

off

spark plug.

pump-type syphon to drain fuel into clean gas can.

NOTE: This is the only procedure recommended

for draining

fuel.

CAUTION: Since gasoline is highly flammable,

it

drain

outdoors and make sure the engine is cool

to prevent a potential fire hazard. Wipe up any

gasoline that may have spilled.

Do

not drain

gasoline near any open flame or where the

gasoline fumes may be ignited by a spark.

Do

not

smoke a cigar, cigarette or a pipe when handling

gasoline.

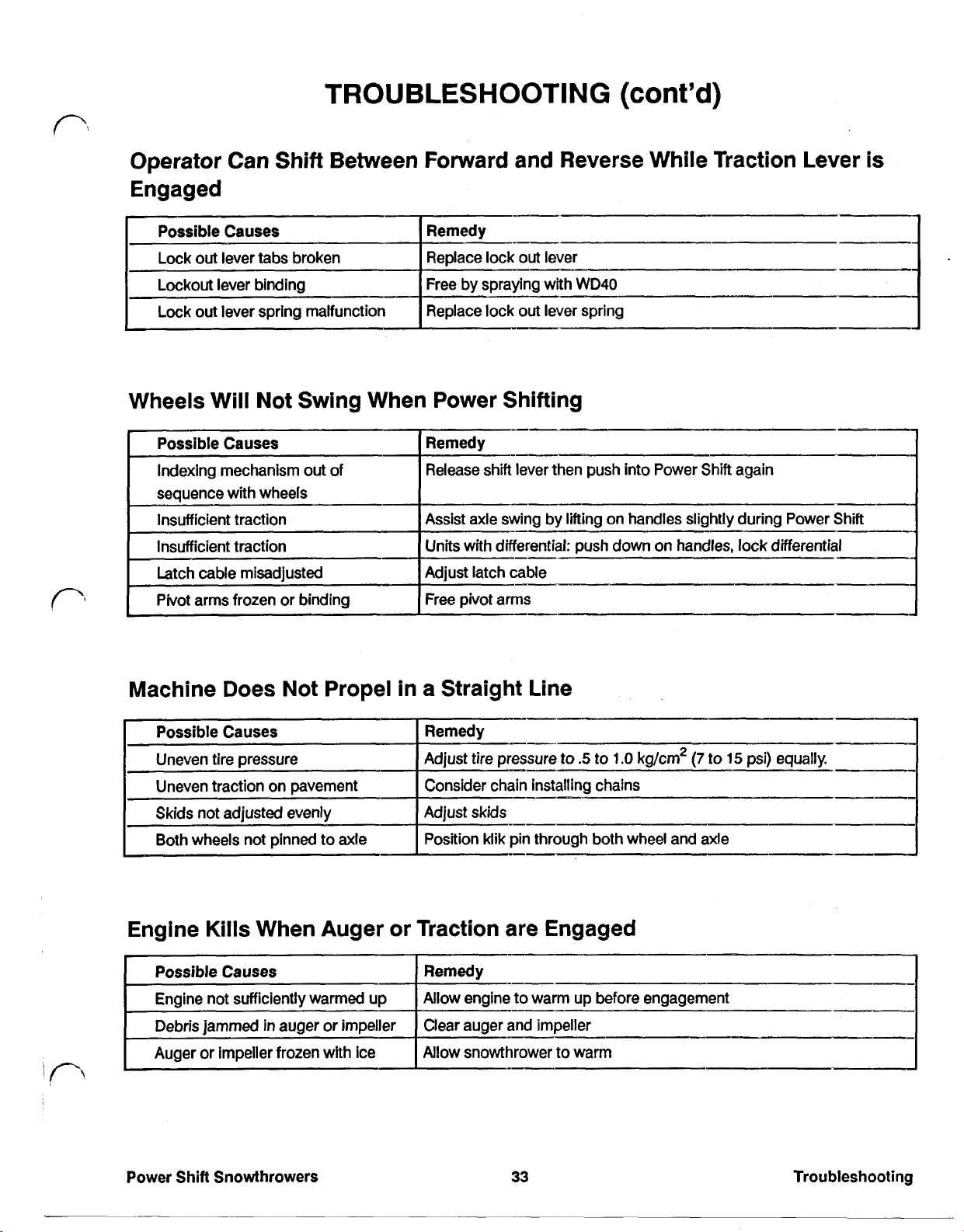

Maintenance Chain Lubrication

1.

Annually lubricate the drive chain with chain

lubricant. See Figure

1.

Wipe up any excess oil.

just before changing oil because warm oil flows better

and carries more contaminants the cold oil.

1.

Pull the wire

off

the spark plug and make sure the

wire does not contact the plug accidentally.

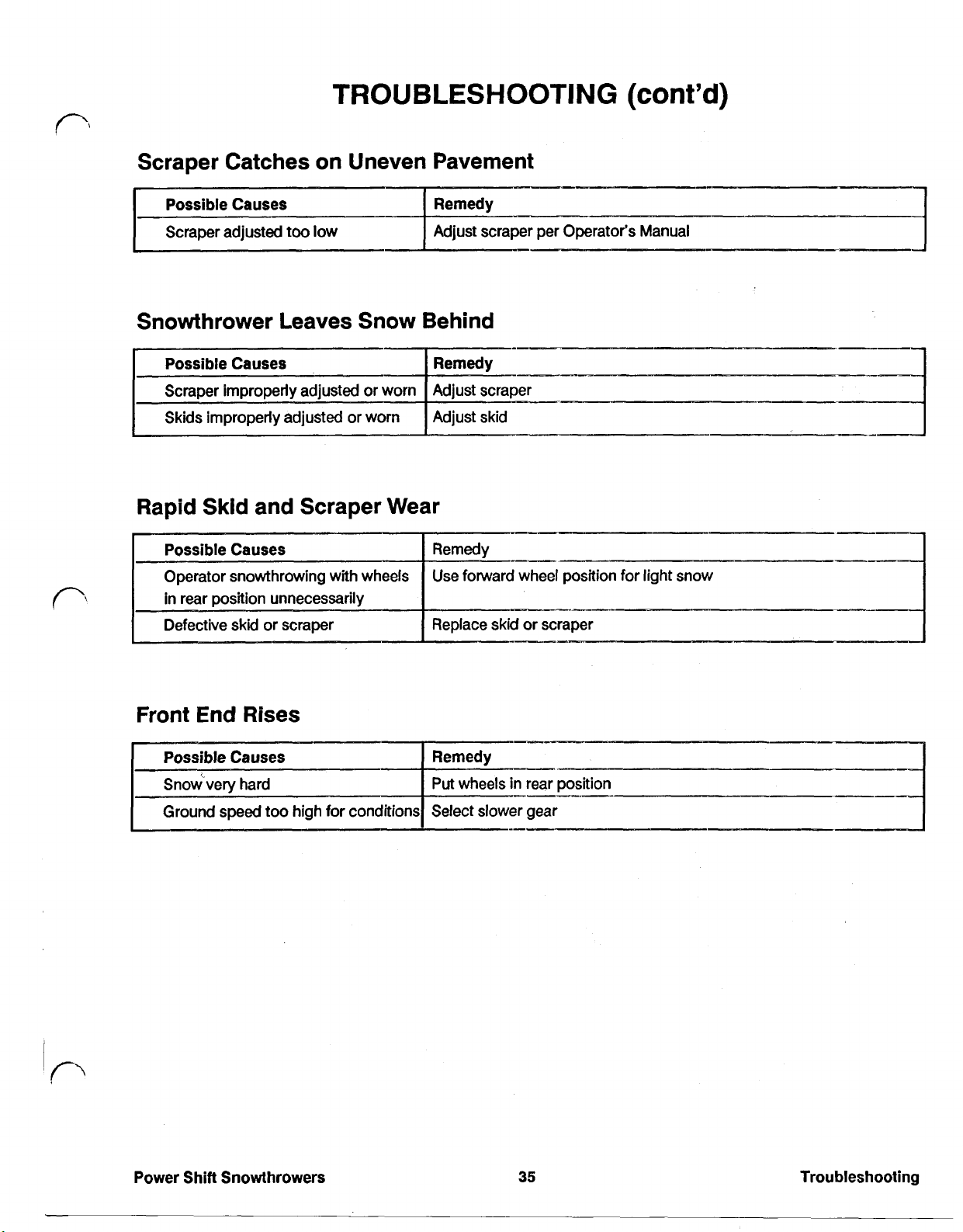

2.

Clean the area around the oil drain cap. Next, slide

the oil drain pan below the drain extension; then

remove the oil drain cap.

3.

After all the oil is drained, install the oil drain cap.

4.

Position the snowthrower on a level surface. Next,

fill

the crankcase with oil. See Specifications

Section for capacity

See

Figure

Oil

Drain

of

your engine. Wipe up any

2.

Extension

oil that may have spilled.

Box

Maintenance Auger Gear

The auger gear box is filled with oil at the factory

regular maintenance is not required. However,

Oil Service

if

the oil

so

must be replaced in gear box:

Figure

1

Maintenance Changing Crankcase Oil

2

Initially change oil after the first

operation; thereafter, change oil after every

hours of engine

25

hours of

engine operation or annually. If possible, run the engine

1.

Drain gasoline from the fuel tank. Wipe up any

spilled gas.

2.

Position the snowthrower on a level surface.

3.

Clean the area around pipe plug

removed. See Figure

4.

Put a drain pan below the front of auger box and

3.

remove the pipe plug.

Tip the snowthrower forward and hold

5.

all oil drains from the gear box.

Carefully let the snowthrower down to its normal

6.

position. Make sure it is on a level surface. Next,

full the auger gear box with

85-95

EP

transmission oil to the point

7.

Install pipe plug in gear box.

GL-5

or

Power Shift Snowthrowers

so

it

up until

GL-6

of

overflow.

dirt is

SAE

Page 44

Maintenance Auger Gear Box Oil Service (cont'd)

Figure

3

Maintenance Impeller Drive Belt Adjustment

If

the auger/impeller

belt

slips resulting in decreased

snowthrowing performance, an adjustment is required.

WHENEVER

ADJUSTMENT

1.

Remove the three flanged head capscrews

A

NEW BELT

IS

REQUIRED.

IS

INSTALLED, AN

securing the belt cover to engine frame and slide

belt cover up the cables.

2.

Check idler and brake adjustment. There should

be

a minimum clearance of 3 mm

(1/8”)

between

the tab on the impeller idler arm and the brake

arm. See Figure

clearance, the

4.

If there is less than 3 mm

belt

must be replaced.

(1/8'”)

Rotate the bottom jam nut upward to increase belt

4.

tension.

NOTE: When adjusting the cable, always rotate

the nut one turn at a time.

belt

NOTE: Do not adjust the

too tight because

may cause the auger/impeller to turn when the

auger/impeller is in

the

disengaged position.

occurs, readjust the lever by loosening belt

tension.

Tighten upper jam nut against bracket.

5.

CAUTION: Improper adjustment may cause

injury if auger/impeller turns when the lever

disengages. Use only genuine Toro replacement

parts.

Recheck the idler and brake adjustment referring

6.

to step

Reinstall the belt cover.

7.

Check tension of belt by operating the auger.

8.

2.

belt slips, repeat procedure.

If

this

If

the

it

Figure

3.

Loosen the upper jam nut securing the auger/

4

impeller cable to the mounting bracket. See

Figure

5.

Power Shift Snowthrowers

Maintenance Traction Drive Belt Adjustment

If

the traction belt slips during operation, an adjustment

is

required. Whenever the belt is replaced, an

adjustment is required.

1.

Loosen the upper jam nut securing the traction

cable to the mounting bracket.

2.

Rotate the bottom jam nut upward to increase belt

tension.

37

Maintenance

Page 45

Maintenance Traction Drive Belt Adjustment

(cont'd)

NOTE:

When adjusting cable, always rotate nut

one turn at a time.

3.

Tighten the upper jam nut against the bracket.

4.

Check the tension of the belt by operating the

machine. If the belt slips, repeat the procedure.

CAUTION: Do not adjust the belt too tight

because

it

may cause the snowthrower to creep

when traction lever is in the disengaged position.

If

this occurs, readjust by loosening belt tension.

Maintenance Replacing Drive Belts

If

the auger/impeller belt or traction belt become worn,

glazed, stretched, oil-soaked, or otherwise defective,

belt replacement is required.

1.

Pull wire

off

the spark plug and make sure

it

does

not contact the plug accidentally.

2.

Remove the three thread forming screws holding

the belt cover in place, and slide the belt cover up

cables.

7.

If

replacing the traction belt, slide the mid section

of the on pulley and belt

off

crankshaft and remove

belt from transmission pulley.

8.

On the control cable which corresponds to the

belt being replaced, loosen the jam nuts securing

cable to bracket. Cable must

be

free to slide in the

bracket when changing the belt(s).

9.

Reinstall the belts by reversing procedure. Make

sure tabs

in

half sheave are inserted into the

mounting grooves in the auger/impeller pulley

when reinstalling.

NOTE:

Make sure the idler pulleys are aligned

with the belts when reinstalling idler pulley

assembly.

10.

Readjust the belts, referring to Maintenance

Impeller Drive Belt Adjustment or Maintenance

Traction Drive Belt Adjustment, pages

38.

CAUTION: Improper adjustment may cause

injury

if

auger/impeller turns when the lever

disengages. Use only genuine Toro replacement

parts.

37

and

3.

Move the speed shift control to

4.

Remove the two flanged head capscrews

N,

neutral.

securing the idler pulley assembly to the engine

frame. Remove the idler pulley assembly. See

Figure

5.

Remove the capscrew and lockwasher securing

6.

Figure

6

the half sheave to front of pulley assembly.

Maintenance Drive Chain Adjustment

The drive chain must be adjusted to maintain

1/8-3/8

of

an inch deflection at mid span between transmission

and axle sprocket. Check chain deflection after every

25

hours of operation.

1.

Check deflection of the chain by lifting up on the

chain with moderate pressure at mid span. There

should be

1/8-3/8”

specified an adjustment is required.

deflection.

If

deflection is not as

See

Figure

Deflection

3/8”

7.

6.

Slide auger/impeller half sheave and belt

crankshaft and remove belt from impeller pulley.

Maintenance

off

38

Figure

7

Power Shift Snowthrowers

I

Page 46

Maintenance Drive Chain Adjustment (cont'd)

NOTE:

To

adjust the drive chain,

the

snowthrower

must be tipped up on the auger housing. However,

before the snowthrower is tipped, siphon all

gasoline from fuel tank.

2.

Make sure the wheels are positioned in rear

position. Move the shift control into

2nd

gear and

tip the snowthrower up onto auger housing.

3.

Loosen the four flanged head capscrews (two

each side) securing transmission frame to engine

frame. See Figure

4.

Lightly

9

mm

lift

up on the transmission frame until 3 to

(1/8

to 3/8”) chain deflection is attained, then

8.

retighten the flanged head capscrews.

Figure

NOTE:

lifting

Do not pry or use excessive force when

the transmission frame, as transmission

8

damage may occur.

NOTE:

If

gear shift lever

is

not aligned with the

Power Shift slot in control panel (see Figure

inset), shift rod length must beadjusted as follows:

a. Disconnect the

move

the

jam

b. Rotate the

ball

joint from bellcrank and

nut

up shift rod. See Figure

ball

joint up or down until the gear

shift lever is aligned with the Power Shift slot.

c. Reinstall

the

ball

joint to the bellcrank and

tighten the jam nut.

5.

Recheck the chain deflection and lower the

snowthrower to

its

normal position.

9.

9

Figure

9

Maintenance Spark Plug Service

Check the Specifications Section for the proper spark

plug and gap. Since the air gap between the center and

side electrodes of the spark plug increases gradually

during normal engine operation, install a new plug after

25

hours of engine operation.

1.

Clean the area around the spark plug

so

foreign

matter cannot fall into cylinder when plug is

removed.

2.

Pull the wire

off

the spark plug and remove the

plug from cylinder head.

NOTE:

A

cracked, fouled, or dirty spark plug must

be replaced. Do not sand blast, scrape or clean

the electrodes because grit may eventually

release from the plug and fall into the cylinder. The

result will likely be engine damage.

3.

Set air gap between electrodes of new spark plug.

See Figure

cylinder head. Torque plug to

wrench

10.

Next, install the spark plug in the

15

is

not used, tighten plug firmly.

ft-lb. If torque

Power Shift Snowthrowers

39

Maintenance

Page 47

Maintenance Spark Plug Service (cont’d)

2.

Start the engine and let

it

run until

it

stops because

there is no gasoline in the fuel system.

Remove the spark plug from the cylinder head.

3.

Next, pour

two

teaspoons of engine oil into spark

plug hole in cylinder head. Install the spark plug

in the cylinder head,

but

do not install the wire on

the plug. Then pull recoil starter slowly to

distribute the oil on the inside of the cylinder.

Lubricate the snowthrower: refer to Maintenance

4.

Chain Lubrication, page

36.

Change crankcase

oil: see Operator’s Manual.

Clean the snowthrower. Touch up chipped

5.

surfaces with paint. Sand the affected areas

before painting. Use a rust preventative to prevent

metal parts from rusting.

Figure

4.

Push the wire onto the spark plug.

10

Preparing Snowthrower For Storage

1.

Siphon or remove the gasoline from the fuel tank,

referring to Maintenance Draining Gasoline,

page

36.

Wipe up any gasoline that may have

spilled.

Tighten all screws and nuts.

6.

If

any parts are

damaged, repair or replace them.

7.

Store the snowthrower in

cover

it

to give protection.

The snowthrower may be stored tipped up on the

8.

a

clean, dry place and

auger housing. Make sure to drain gas before

tipping snowthrower.

Page 48

SECTION

1

POWER SHIFT CONTROLS

CAUTION:

require working with some of- the moving

prevent accidental starting of

performing service, take the following precautions:

Rotate the ignition key to

Pull the wire

Make sure the wire does not accidentally touch

the spark plug.

CAUTION:

feature of being able to

for service and storage. Always drain the fuel from the

tank prior to such service taking the following

precautions:

Drain

Wipe up any gasoline that may have spilled.

Do

spark.

Do

Servicing the Power Shift Snowthrower will this motion down to a bellcrank that moves the linkage

parts.

To

the

engine while

off

and remove.

off

the spark plug.

The Power Shift Snowthrower has the

be

stood on the front housing

it

outdoors and make sure the engine

not drain the gasoline near any open flame or

not smoke when handling gasoline.

is

cool.

on top of the transmission.

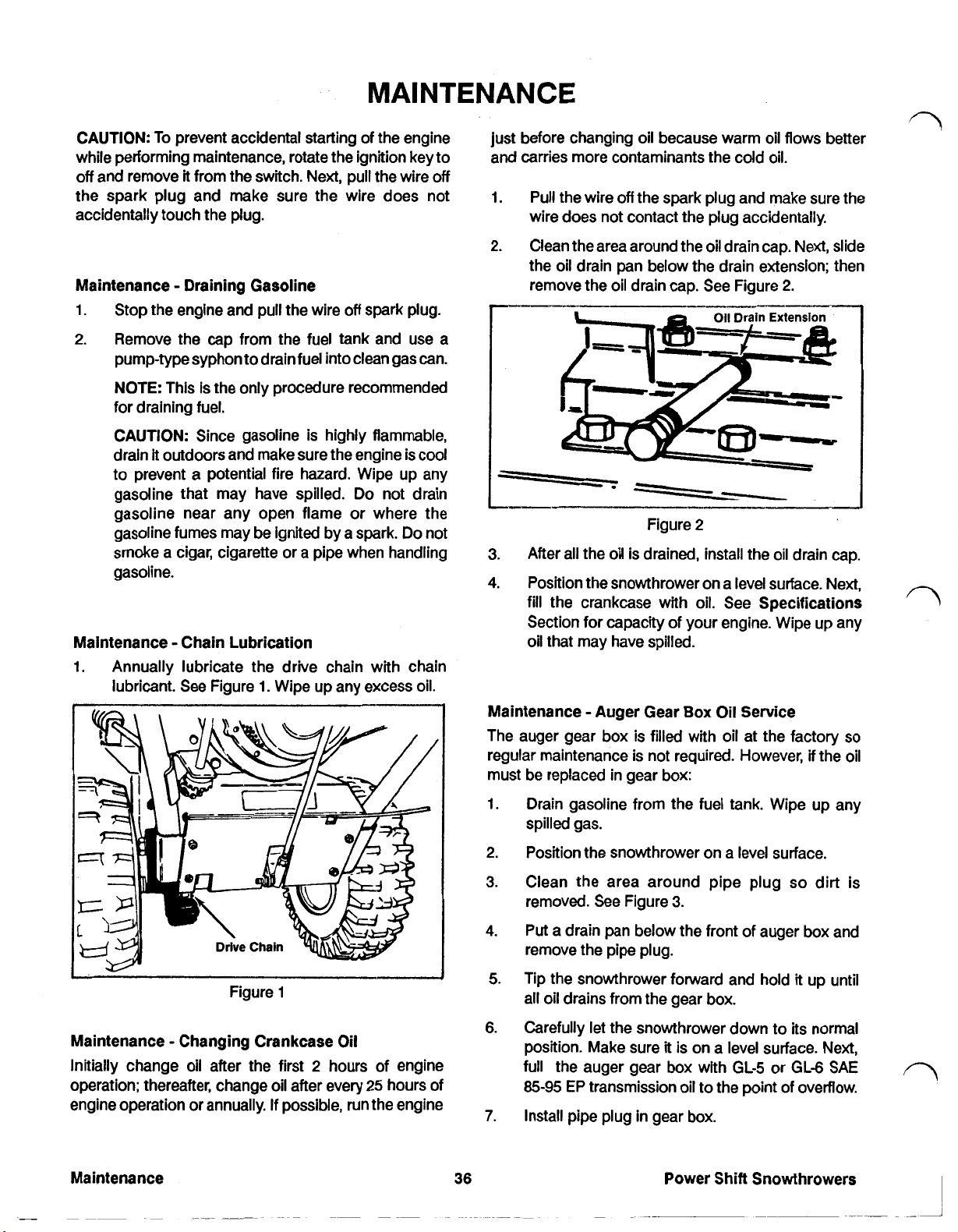

Operation Latch Release Mechanism

A

latch mechanism holds

forward or rear position. See Figure

the

pivot arms

12.

in

either a

Power Shift Snowthrowers

41

Power Shift Controls

Page 49

Control

Box

Operation Reverse Control (cont'd)

in reverse. The other is when the wheels are Power

Shifted from the forward to the rear position.

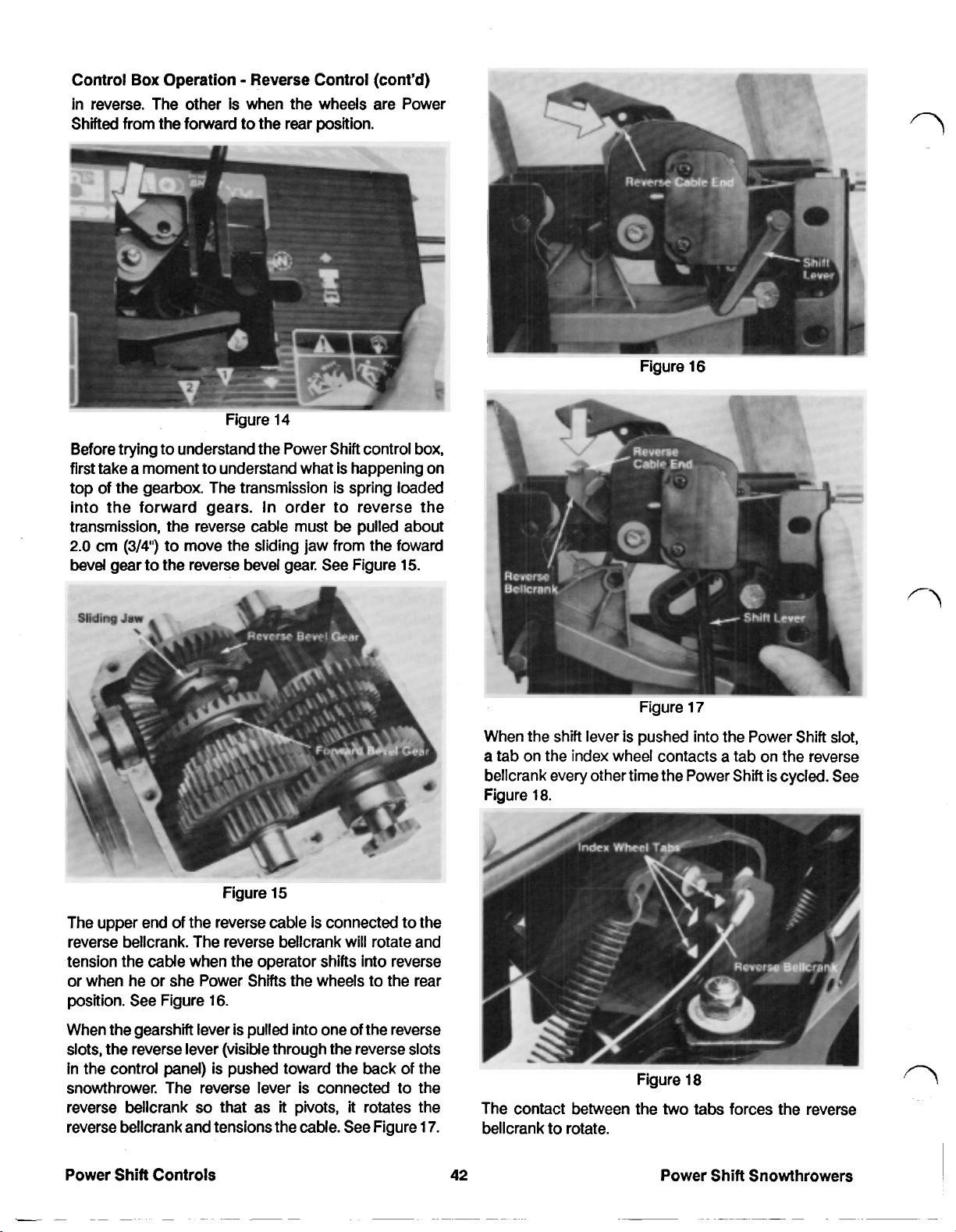

Figure

14

Before trying to understand the Power Shift control box,

first take a moment to understand what is happening on

top of the gearbox. The transmission is spring loaded

into the forward gears.

In

order to reverse the

transmission, the reverse cable must be pulled about

2.0

cm

(3/4”)

to move the sliding jaw from the forward

bevel gear to the reverse bevel gear. See Figure

15.

Figure

Figure

16

17

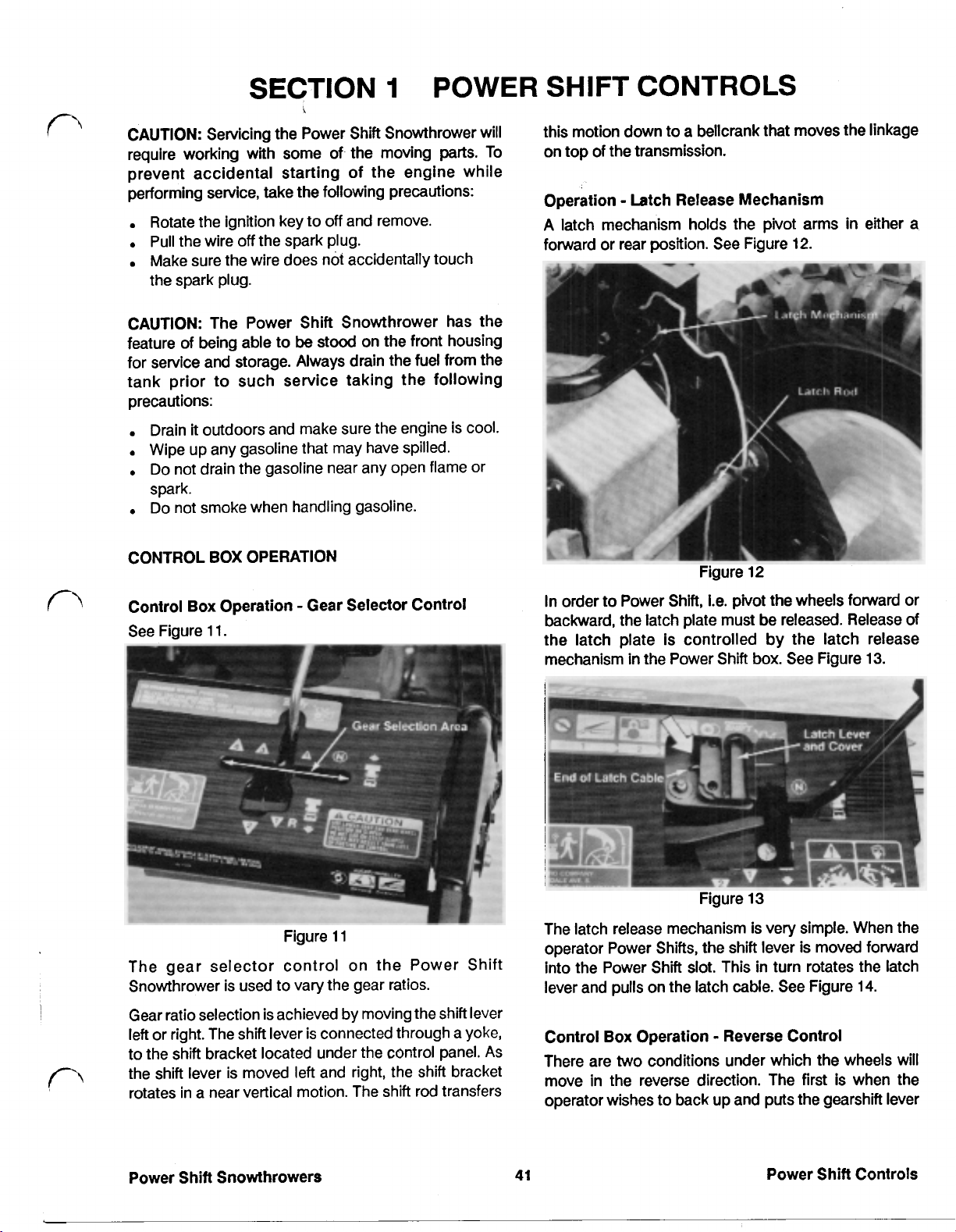

When the shift lever is pushed into the Power Shift slot,

a tab on the index wheel contacts a tab on the reverse

bellcrank every other time the Power Shift is cycied. See

Figure

18.

Figure

15

The upper end of the reverse cable is connected to the

reverse bellcrank. The reverse bellcrank will rotate and

tension the cable when the operator shifts into reverse

or when he or she Power Shifts the wheels to the rear

position. See Figure

When the gearshift lever is pulled into one

16.

of

the reverse

slots, the reverse lever (visible through the reverse slots

in the control panel) is pushed toward the back of the

snowthrower. The reverse lever is connected to the

reverse bellcrank

reverse bellcrank and tensions the cable. See Figure

Power

Shift

so

Controls

that as

it

pivots,

it

rotates the

17.

42

Figure

The contact between the

bellcrank

to

rotate.

18

two

tabs forces the reverse

Power Shift Snowthrowers

1

Page 50

Control

The

index

Box

Operation Reverse Control (cont'd)

wheel

is

necessary because

the

wheels must

alternate between forward backward movement

when Power Shifting. bellcrank and the wheels power forward when the

the

When Power Shifting

wheels forward, the indexing

mechanism does nothing but index. The tabs On the

bottom

traction lever is engaged.

Of

the index wheel miss the tab On the reverse

See

Figure

20.

Control

Transmission damage could result

Box

Operation Shift

Lockout

if

the operator were

to shift the transmission into reverse while the unit were

moving forward and vice versa. To prevent this, a shift

lockout is used. This lockout physically prevents the

operator from switching directions without first stopping

the unit.

The lockout base pivots on a shoulder bolt and rotates

whenever the shift lever is moved to either the Power

Shift or reverse slots. See Figure Note however, that 19.

the lockout base does not rotate when the gearshift lever

is

moved from side to side.

When the wheels are to be moved to the rear position,

a

corresponding tab on the reverse bellcrank and the

wheels power backward when the traction lever

engaged. See Figure 21.

Figure 20

tab on the bottom of the index wheel contacts a

is

Figure 19

When

engaged, the

the

traction lever on the left handle

lockout

base

is

free

to

move in either

is

not

direction. However, once the traction lever is engaged,

the

two

tabs on the lockout lever engage the lockout

base. This prevents the shift lever from being moved

forward or backward.

An added benefit

of

the shift lockout is that

it

allows the

operator to lock the gearshift lever in either the Power

Shift or reverse slots by depressing the traction lever.

This allows the operator one hand operation

of

Power

Shift or reverse leaving the other hand free to rotate the

chute.

Control

An indexing mechanism is used

of wheel movement while Power Shifting. This

Box

Operation Indexing Mechanism

to

control the direction

is

necessary because the wheels need to alternate

between forward and reverse when the Power Shift

is

cycled.

Figure

21

The index tang and a flat spring control the rotation of

the index wheel. When the shift lever is pushed into the

Power Shift slot, the index tang rotates the index wheel

1/8

revolution and then prevents the wheel from rotating

backwards when the tabs on the index wheel and

reverse bellcrank make contact. See Figure

As

the shift lever returns to its "at rest" position,

22.

the

index

wheel has a natural tendency to turn backwards due to

the pressure from the index tang. The flat spring

prevents backward rotation by engaging the index

wheel at one of the teeth.

Power Shift Snowthrowers

43

Power Shift Controls

Page 51

Control

Box

Operation Indexing Mech. (cont'd)

4. Using a 1/2" deep well socket, remove the four

nylon locknuts securing the power shift control

box to the control panel.

See

Figure 24.

Figure 22

The index wheel is mounted on a piece called the index

fits

wheel lever. This piece

rotate slightly.

It

provides the small amount of rotation

inside the lever latch and can

necessary to index the index wheel.

CONTROL

Control

BOX

SERVICE

Box

Service Removal

1. Tip the snowthrower up onto the auger housing.

2. Pull the shift selector knob

off

of the shift selector

lever.

3. Disconnect the shift rod from the power shift

control box. See Figure 23.

Figure 24

5.

Remove the latch cover from the latch lever,

6.

Disconnect the latch control cable and the reverse

cable from the power shift control box.

7. Remove the power shift control box as an

assembly, from the control panel.

Control Box Service Testing

All

major functions of the power shift control box can be

tested, with the Power Shift control box removed from

so,

the control panel. To do

hole at the end

of

the reverse lever.

insert a 7/16' bolt into the

1. Check for proper operation of the shift lockout

mechanism. With the lock

shown in Figure 25, the lock

out

lever in the position

out

base should

prevent the shift lever from forward and backward

movement.

Power Shift Controls

Figure 23

.44

Figure

2.

When the lockout lever is pulled back to the

25

position shown in Figure 26, the shift lever should

be

free to move forward and backward.

Power Shift Snowthrowers

Page 52

Control

Box

Service Testing ( cont’d)

serve the indexing wheel underneath the latch

lever. See Figure

28.

Figure

3.

The reverse lever is spring loaded forward

26

reverse lever return spring.

Check for proper operation of the reverse lever by

pulling backward. Reverse bellcrank movement

as shown in Figure

27

should be noticed.

by

the

Figure 28

Check to insure that the indexing wheel is free to

rotate clockwise when viewed from the bottom of

the power shift control box.

Also

check to insure

that both the flat spring and the index tang are

spring loaded toward the index wheel.

Now observe the index wheel as you again cycle

the latch lever. The tabs on

the

bottom of the index

wheel and on the reverse bellcrank should

alternate between meeting and missing on each

subsequent cycle. See Figure

29.

Figure 27

4.

The latch lever is spring loaded clockwise by the

latch lever return spring.

Check for proper operation of the latch lever and

the indexing mechanism by repeatedly rotating

the latch lever about

clockwise and then releasing gently

60

degrees counter

(if

allowed to

spring back quickly, the “stop” on the bottom of

the latch lever may break.) Every other time the

latch lever is cycled, the reverse lever should

move toward the back of the Power Shift control

box

as

it

did in Figure 27.

5.

If a problem is noticed in step 4 of testing, the

indexing mechanism may not be functioning

properly.

To

check the indexing mechanism, ob-

Power Shift Snowthrowers

Control

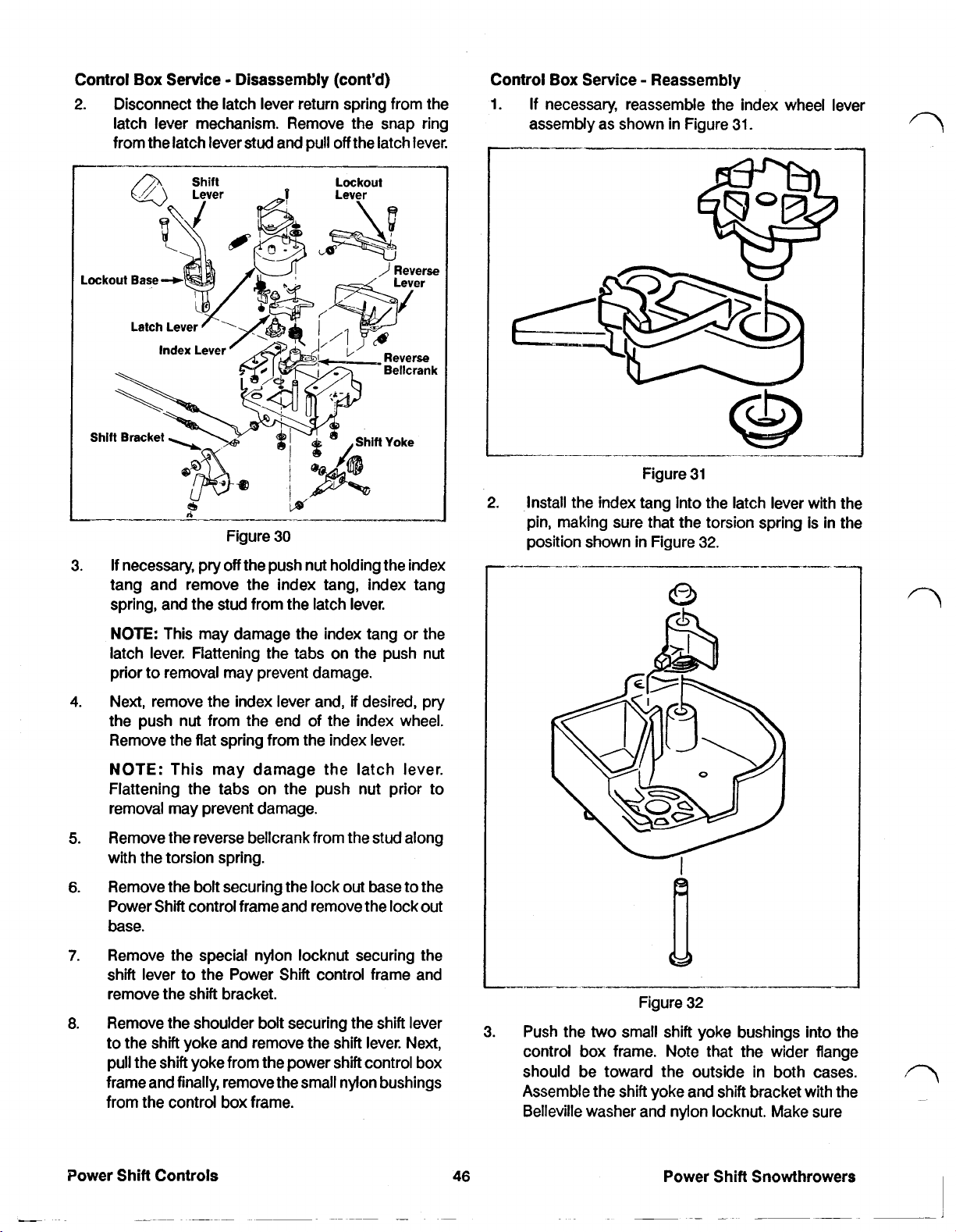

See Figure

1.

45

Figure 29

Box

Service Disassembly

30.

With the Power Shift control box removed from the

control panel, begin disassembly by

disconnecting the reverse lever return spring from

the Power Shift control box and removing the

reverse lever.

Power Shift Controls

Page 53

Control

Box

Service Disassembly (cont’d)

2. Disconnect the latch lever return spring from the

latch lever mechanism. Remove the snap ring

from the latch lever stud and pull

Lockout

off

the

Lockout

latch lever.

Figure 30

If necessary, pry

3.

off

the push nut holding the index

tang and remove the index tang, index tang

spring, and the stud from the latch lever.

Control

Box

Service Reassembly

1. If necessary, reassemble the index wheel lever

assembly as shown in Figure 31.

Figure 31

2.

Install

the

index tang into the latch lever with the

pin, making sure that the torsion spring

position shown in Figure 32.

I._____----~

is

in the

I

NOTE:

This may damage the index tang or the

latch lever. Flattening the tabs on the push nut

prior to removal may prevent damage.

4.

Next, remove the index lever and,

if

desired, pry

the push nut from the end of the index wheel.

Remove the flat spring from the index lever.

NOTE:

This may damage the latch lever.

Flattening the tabs on the push nut prior to

removal may prevent damage.

Remove the reverse bellcrank from the stud along

5.

with the torsion spring.

Remove the bolt securing the lock out base to the

6.

Power Shift control frame and remove the lock out

base.

Remove the special nylon locknut securing the

7.

shift lever to the Power Shift control frame and

remove the shift bracket.

Remove the shoulder bolt securing the shift lever

8.

to the shift yoke and remove the shift lever. Next,

pull the shift yoke from the power shift control box

frame and finally, remove the small nylon bushings

from the control box frame.

Figure 32

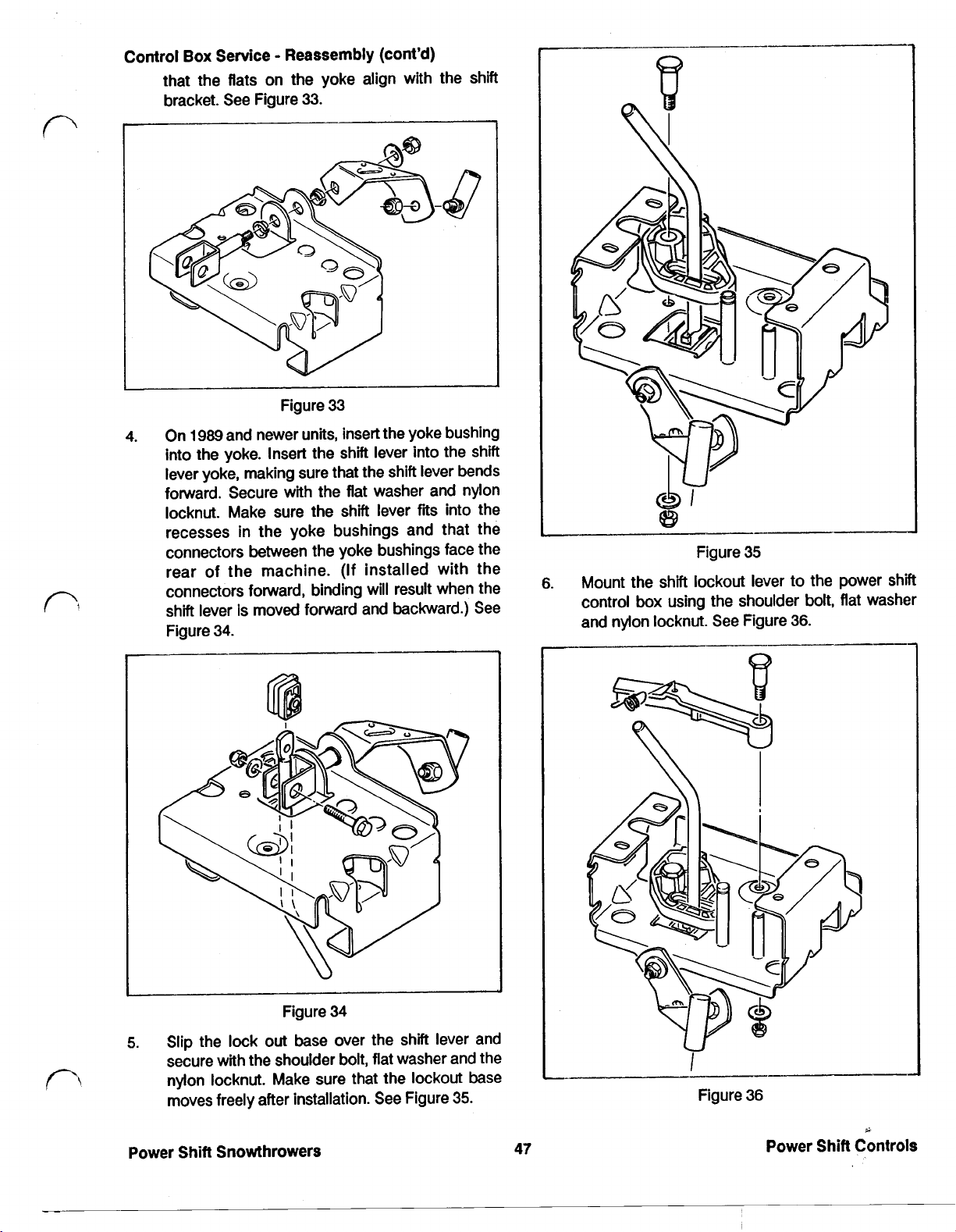

3.

Push the

two

small shift yoke bushings into the

control box frame. Note that the wider flange

should be toward the outside in both cases.

Assemble the shift yoke and shift bracket with the

Belleville washer and nylon locknut. Make sure

Power Shift Snowthrowers

Page 54

Control

Box

that

the

bracket. See Figure

Service Reassembly (cont'd)

flats on the yoke align with the shift

33.

Figure

4.

On

1989

and newer units, insert the yoke bushing

into the yoke. Insert the shift lever into the shift

lever yoke, making sure that the shift lever bends

forward. Secure with the flat washer and nylon

locknut. Make sure the shift lever

recesses in the yoke bushings and that the

connectors between the yoke bushings face the

rear of the machine. (If installed with the

connectors forward, binding will result when the

shift lever is moved forward and backward.)

Figure

34.

33

fits

into the

See

Figure

6.

Mount the shift lockout lever to

control box using the shoulder bolt, flat washer

and nylon locknut. See Figure

35

36.

the

power shift

Figure

34

5.

Slip the lock

secure with

nylon locknut. Make sure that the lockout base

moves freely after installation. See Figure

Power Shift Snowthrowers

out

base over the shift lever and

the

shoulder bolt, flat washer and the

35.

47

Figure

36

Power Shift Controls

Page 55

Control

7.

Box

Service Reassembly (cont’d)

NOTE:

compound Toro

corrosion and subsequent binding.

Slip the reverse bellcrank and torsion spring onto

the stud as shown in Figure

wheel lever assembly onto the stud. Make sure

that the ends

positions shown in Figure

NOTE:

anti-seize compound Toro part number

to prevent corrosion and subsequent binding.

Coat the shoulder

part

of

the

bolt

with an anti-seize

number

torsion spring are in the

505-109)

37.

Slide the index

38.

Coat the reverse bellcrank with an

to prevent

505-109)

lever back and forth to insure that the index wheel

is rotating properly. Secure with the flat washer

and snap ring. See Figure

NOTE:

compound Toro part number

corrosion and subsequent binding.

9.

Next, install

return spring as shown in Figure

that the boss at the bottom

engages the reverse bellcrank.

Coat the latch lever with an anti-seize

the

reverse lever and reverse lever

38.

505-109)

39.

of

the reverse lever

to prevent

Make sure

Figure

Figure

Install the latch lever and spring into the position

8.

shown in Figure

38.

37

38

Once installed, rotate the latch

Figure

10.

Make sure that all three control box springs are in

the position shown in Figure

Control

1.

2.

Box

Service Installation

Install the end of the reverse cable into the reverse

bellcrank from the bottom of the reverse bellcrank.

Secure with the

cable sheath. Adjust as described in Control

Service Adjustments, page

Insert the end

small hole in the top

described in Control

49.

page

two

of

39

40.

jam nuts at the end

of

49.

the latch release cable into the

of

the latch lever. Adjust as

Box

Service -Adjustments,

the

Box

Power

Shift

Controls

48

Power

Shift

Snowthrowers

Page 56

Control

3.

Box

Service Installation (cont'd)

Install the latch lever cover with 2 Phillips screws.

Do

not overtighten. Adjust the latch cable as

described in Control

Lockout Lever

Box

-Adjustments, page

49.

Control

1.

Box

Service Adjustments

Latch Cable Adjustment: Adjust the latch control

cable by removing slack between the end

sheath and the end of the cable.

Do

beyond the point of removing slack. See Figure

42.

of

the

not tighten

U

I

Figure

4.

Install the Power Shift control box on the control

panel, making sure that the reverse lever

properly mounted on the upper left stud. Secure

with

4

nylon locknuts. Before proceeding, be sure

all levers are working smoothly.

5.

Attach the lower shift rod to the shift bracket with

the nylon locknut

certain that the ball joint is in the position shown

or the shift mechanism will not work properly.

as

40

shown

in

Figure

41.

is

Make

Figure

2.

Reverse Cable Adjustment: Adjust the reverse

cable

so

that there is 1.5 mm (1/16") side play in

42

the reverse bellcrank as shown in Figure

cable is too loose,

cable is too tight,

loss

of reverse will result.

loss

of the forward gears

occur.

Figure

43

43.

If

If

the

the

will

Lower

Shift

Rod

Figure

41

6. Push the rubber-shift knob onto

it

is fully seated. Note that

it

is a press

installed the knob should point forward.

Power Shift Snowthrowers

the

shift lever until

fit

only. Once

49

3.

Shift

Lever Adjustment: The shift

adjusted when the transmission

and the lever slides

power shift slot.

right

down the center of the

If

adjustment is necessary,

lever is properiy

is

in second gear

remove the lower shift rod from the bellcrank near

the transmission and manually place the bellcrank

in second (ie. second notch from the top). Loosen

the jam nut at the ball joint and move

up

or down until the shift lever rides in the center

of

the power shift slide. Secure by attaching the

ball joint

to

the bellcrank with a nylon locknut and

the

ball joint

tightening the jam nut.

Power Shift Controls

Page 57

CAUTION: Servicing the Power Shift Snowthrower will

require working with some of the moving parts. To

prevent accidental starting of the engine while

performing service, take the following precautions:

Rotate the ignition key to

Pull the wire

off

the spark plug.

off

and remove.

Make sure the wire does not accidentally touch

the spark plug.

CAUTION: The Power Shift Snowthrower has the

feature of being able to be stood on the front housing

for service and storage. Always drain the fuel from the

tank prior to such service taking the following

precautions:

Drain

it

outdoors and make sure the engine

is

cool.

Wipe up any gasoline that may have spilled.

Do not drain the gasoline near any open flame or

spark.

Do not smoke when handling gasoline.

OPERATION

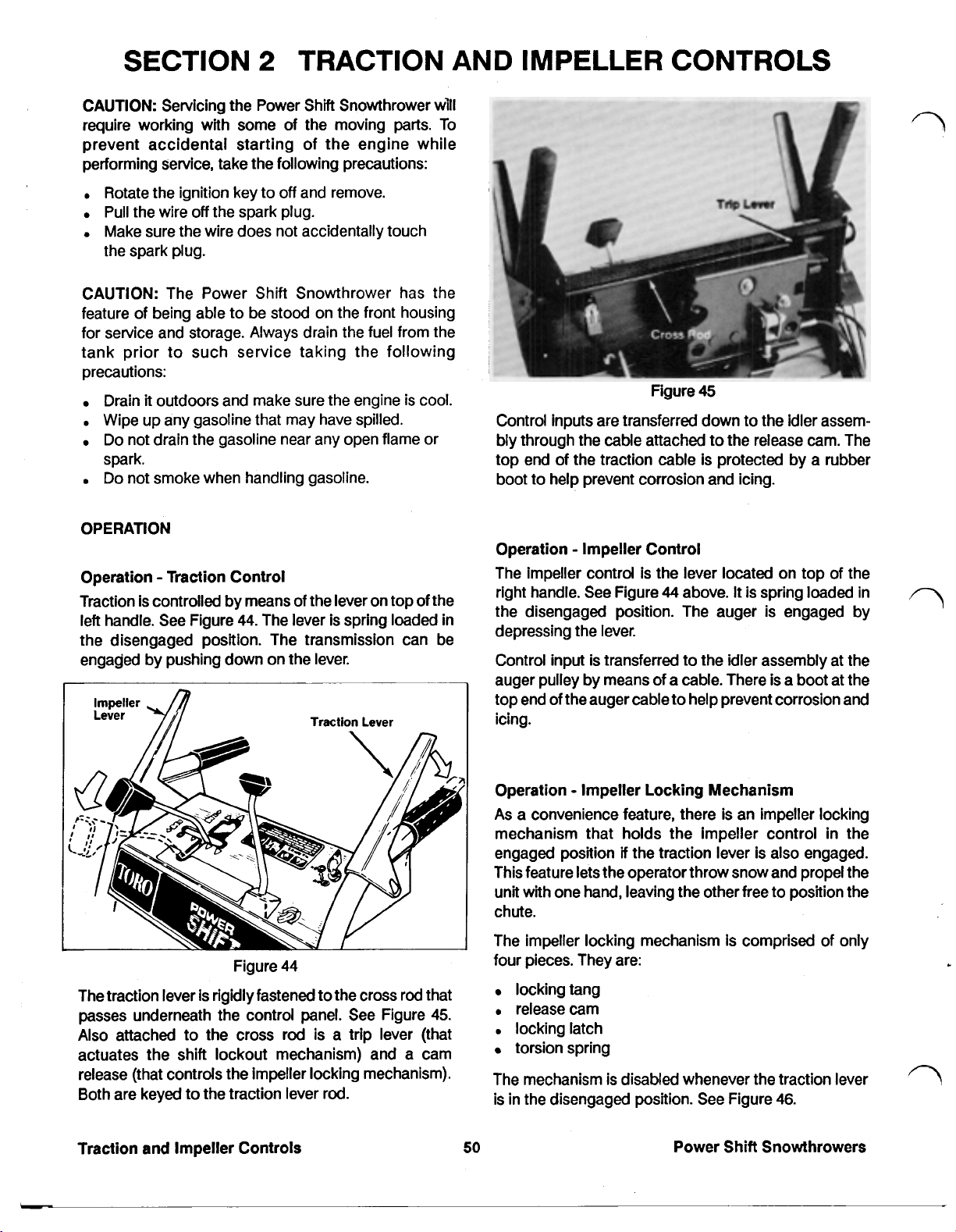

Operation Traction Control

Traction is controlled by means of the lever on top of the

left

handle. See Figure

44.

The lever is spring loaded in

the disengaged position. The transmission can be

engaged by pushing down on the lever.

Impeller

Lever

Traction

Lever

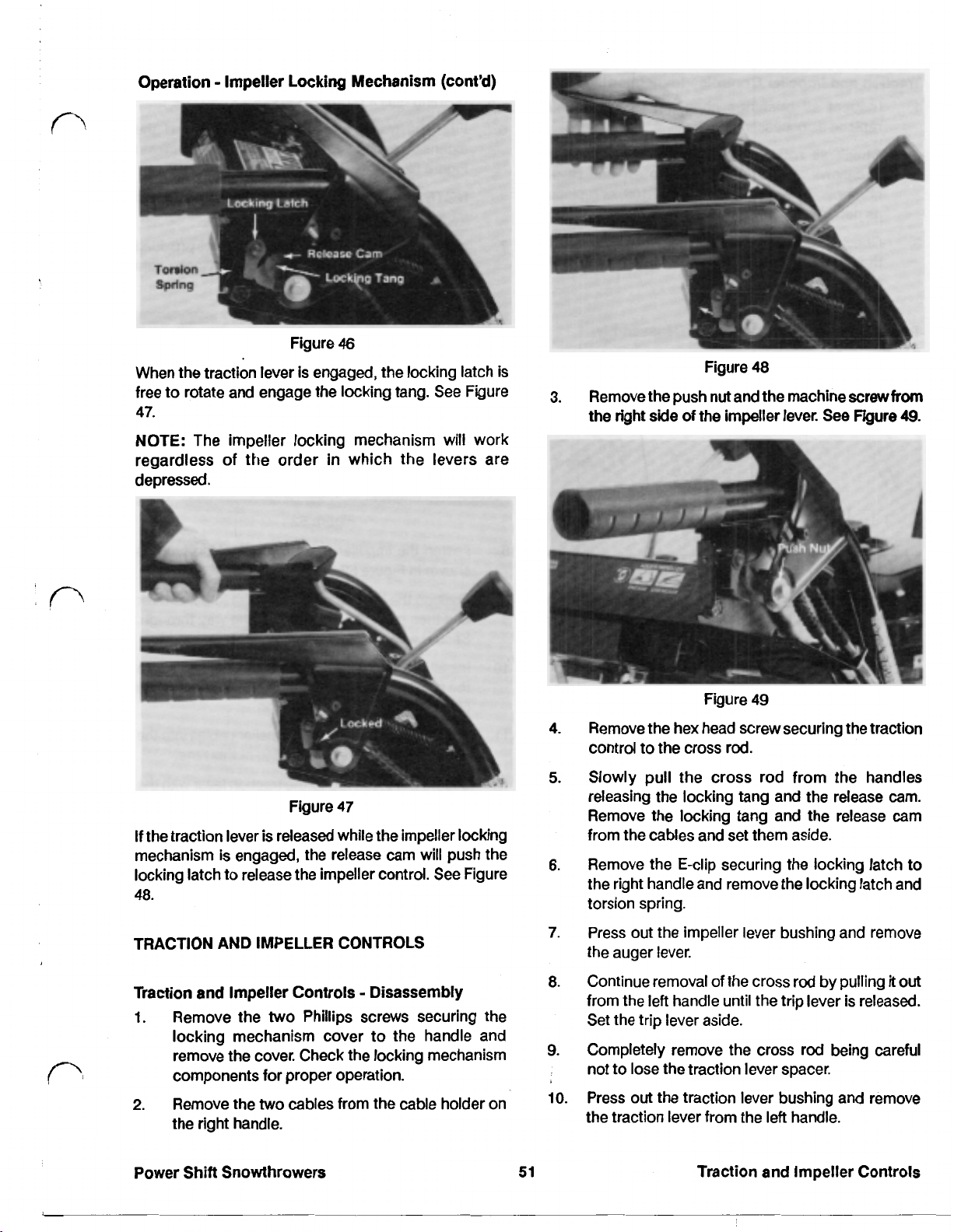

Figure

45

Control inputs are transferred down to the idler assembly through

the

cable attached to the release cam. The

top end of the traction cable is protected by a rubber

boot to help prevent corrosion and icing.

Operation Impeller Control

The impeller control is the lever located on top of the

right handle. See Figure

44

above.

It

is spring loaded in

the disengaged position. The auger is engaged by

depressing the lever.

Control input is transferred to the idler assembly at the

auger pulley by means of

a

cable. There is a boot at the

top end of the auger cable to help prevent corrosion and

icing.

Figure

The traction lever

is

rigidly fastened to the cross rod that

passes underneath the control panel. See Figure

44

45.

Also attached to the cross rod is a trip lever (that

actuates the shift lockout mechanism) and a cam

release (that controls the impeller locking mechanism).

Both are keyed to the traction lever rod.

Traction and Impeller Controls

Operation Impeller Locking Mechanism

As

a convenience feature, there is an impeller locking

mechanism that holds the impeller control in the

if

engaged position

the traction lever is also engaged.

This feature lets the operator throw snow and propel the

unit with one hand, leaving the other free to position the

chute.

The impeller locking mechanism

is

comprised of only

four pieces. They are:

locking tang

release cam

locking latch

torsion spring

The mechanism is disabled whenever the traction lever

is in the disengaged position. See Figure

50

Power Shift Snowthrowers

46.

Page 58

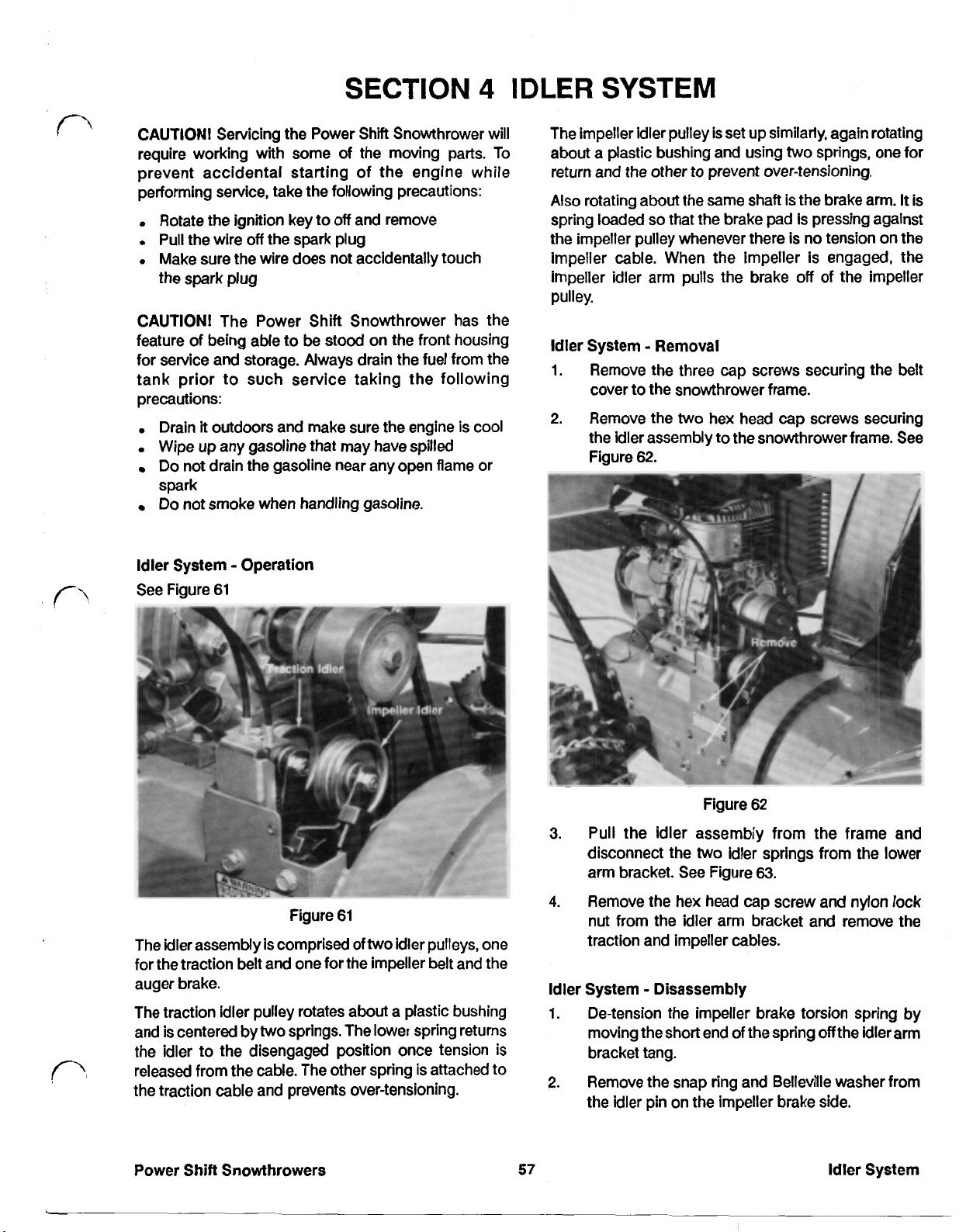

Operation Impeller

When the traction lever is engaged, the locking latch is

free to rotate and engage the locking tang.

47.

NOTE: The impeller locking mechanism will work

regardless of the order

depressed.

Locking

Figure

in

Mechanism (cont’d)

46

See

Figure

which the levers are

Figure

48

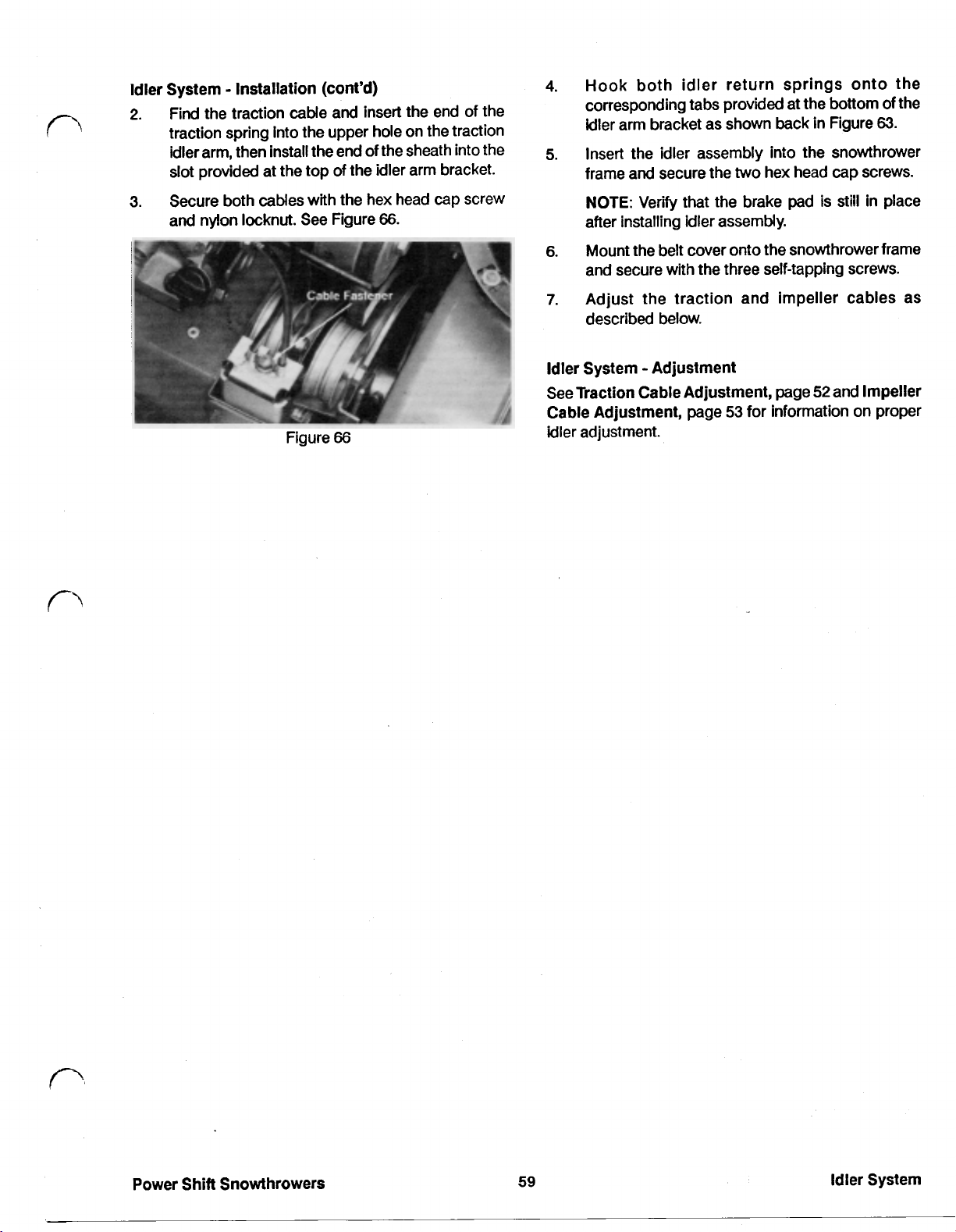

3.

Remove the push nut and the machine screw

the

right side of the impeller lever. See Figure

from

49.

Figure

If the traction lever is released while the impeller locking

mechanism

locking latch to release the impeller control. See Figure

48.

TRACTION AND IMPELLER CONTROLS

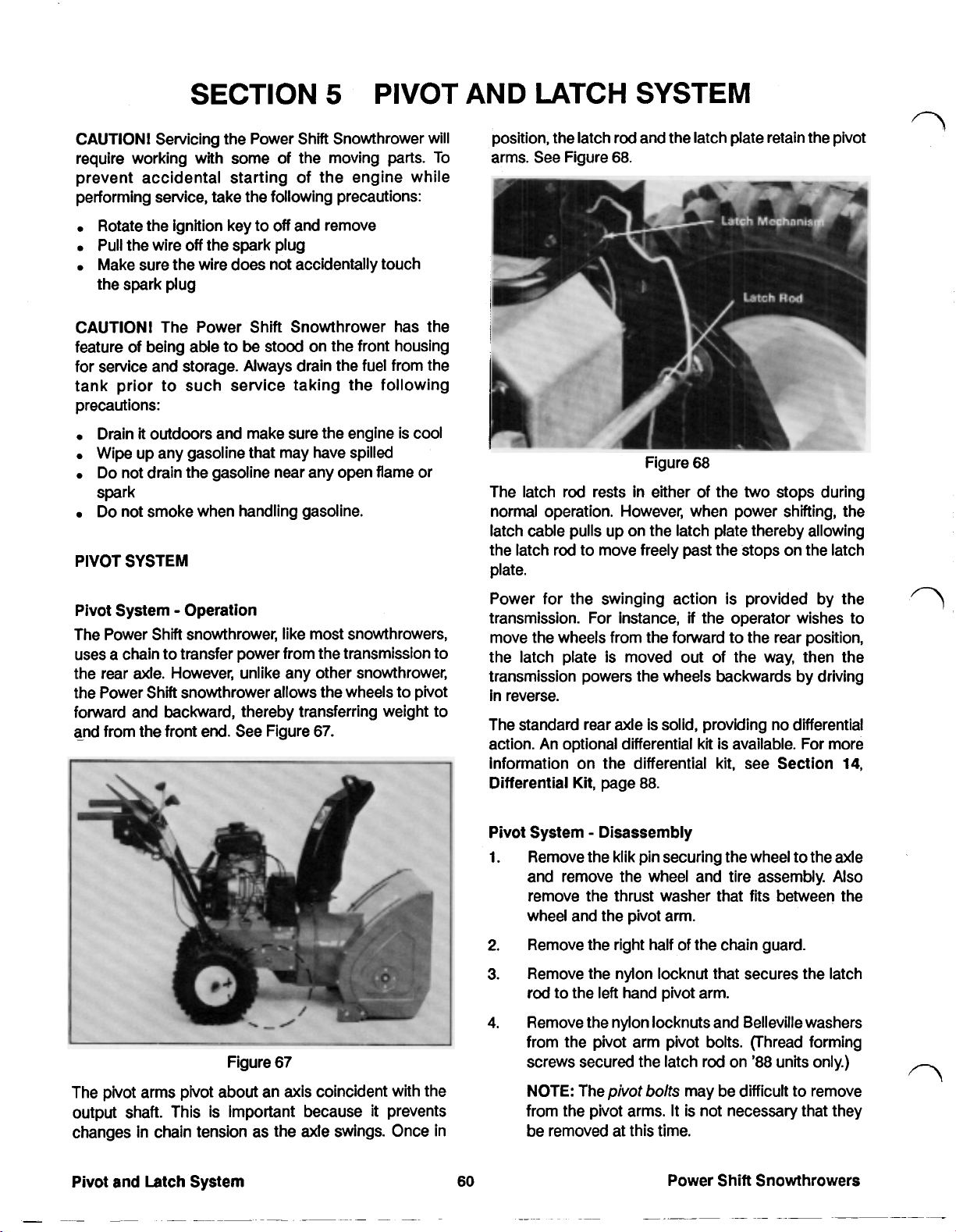

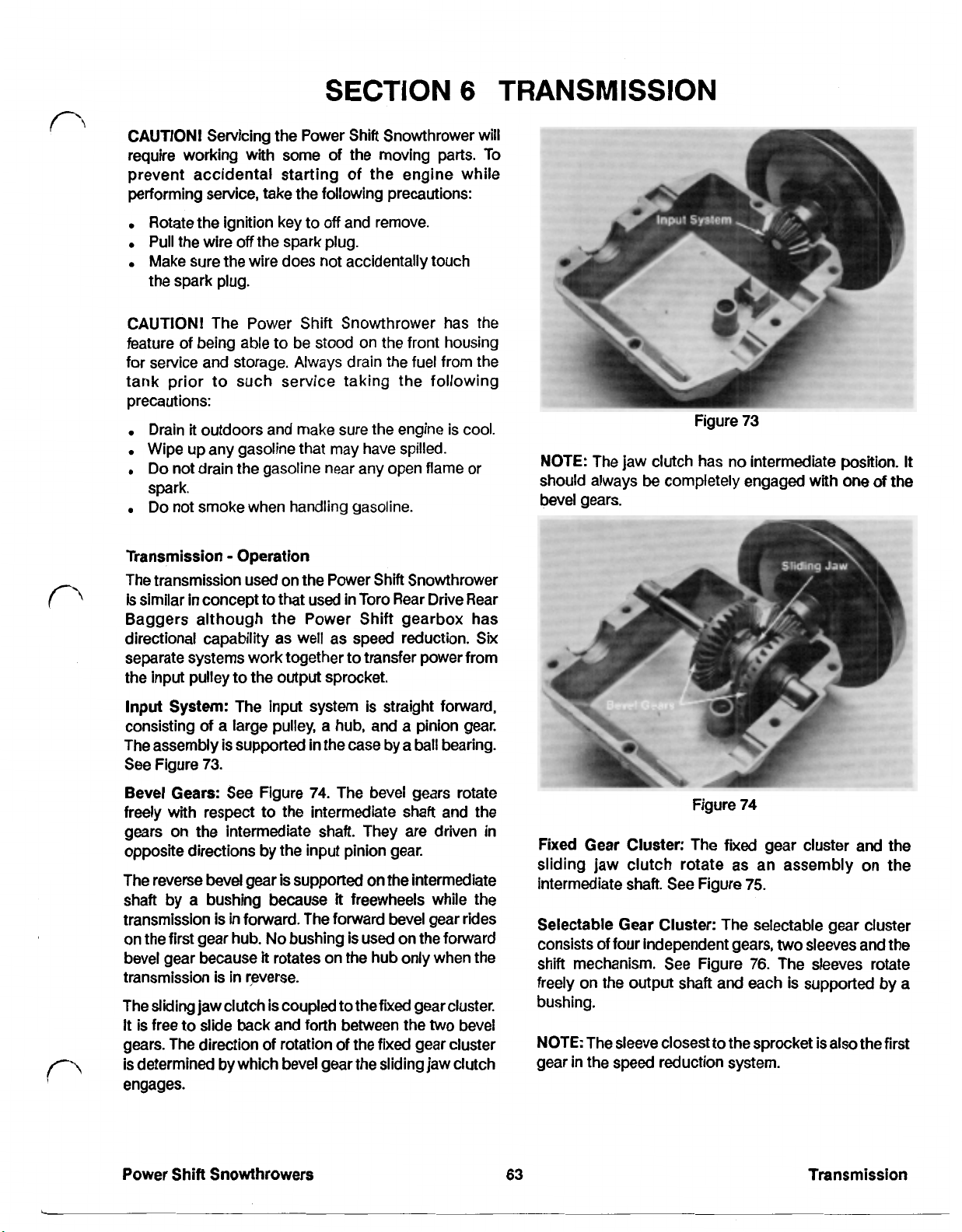

Traction and Impeller Controls Disassembly

1.

locking mechanism cover to the handle and

remove the cover. Check the locking mechanism

components for proper operation.

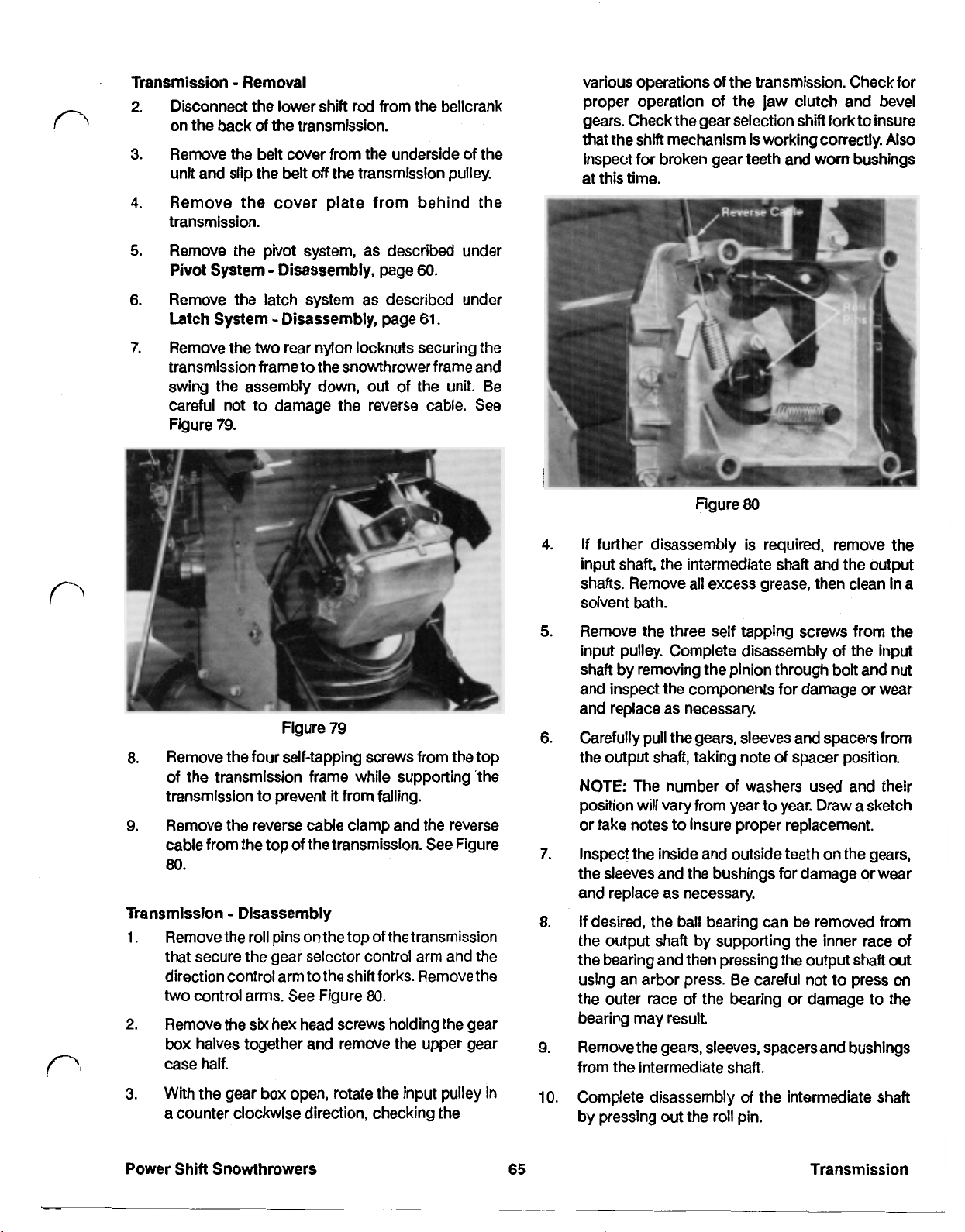

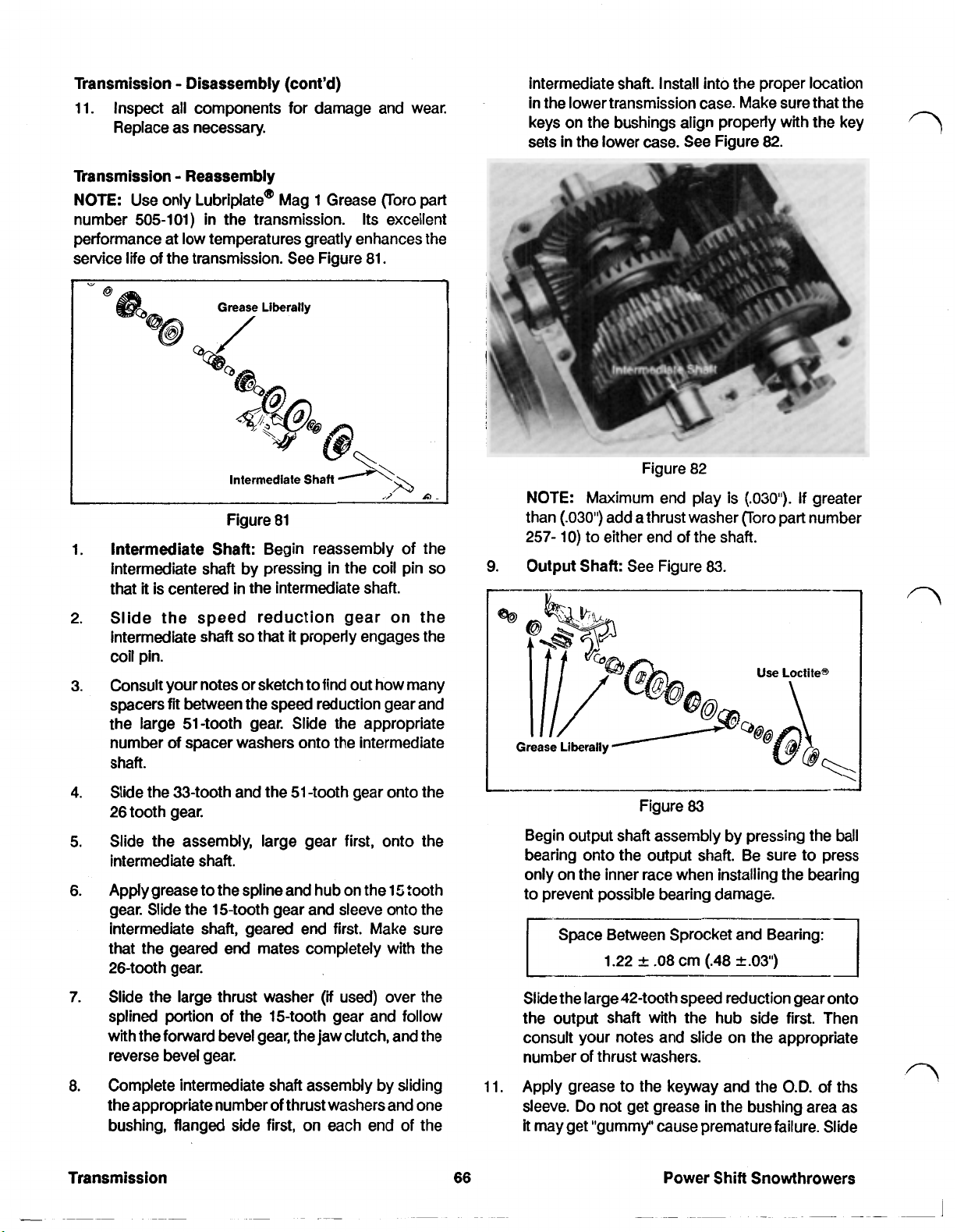

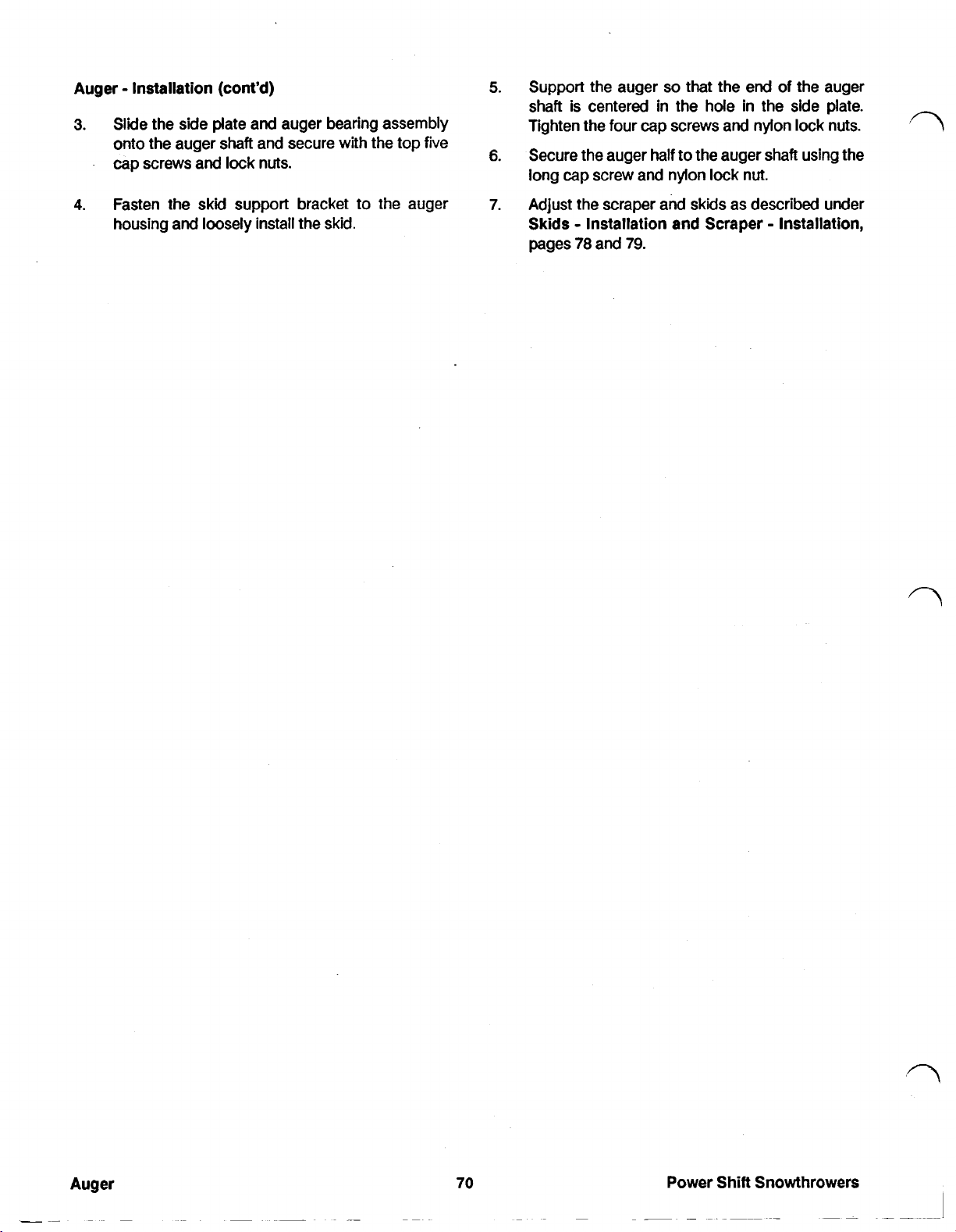

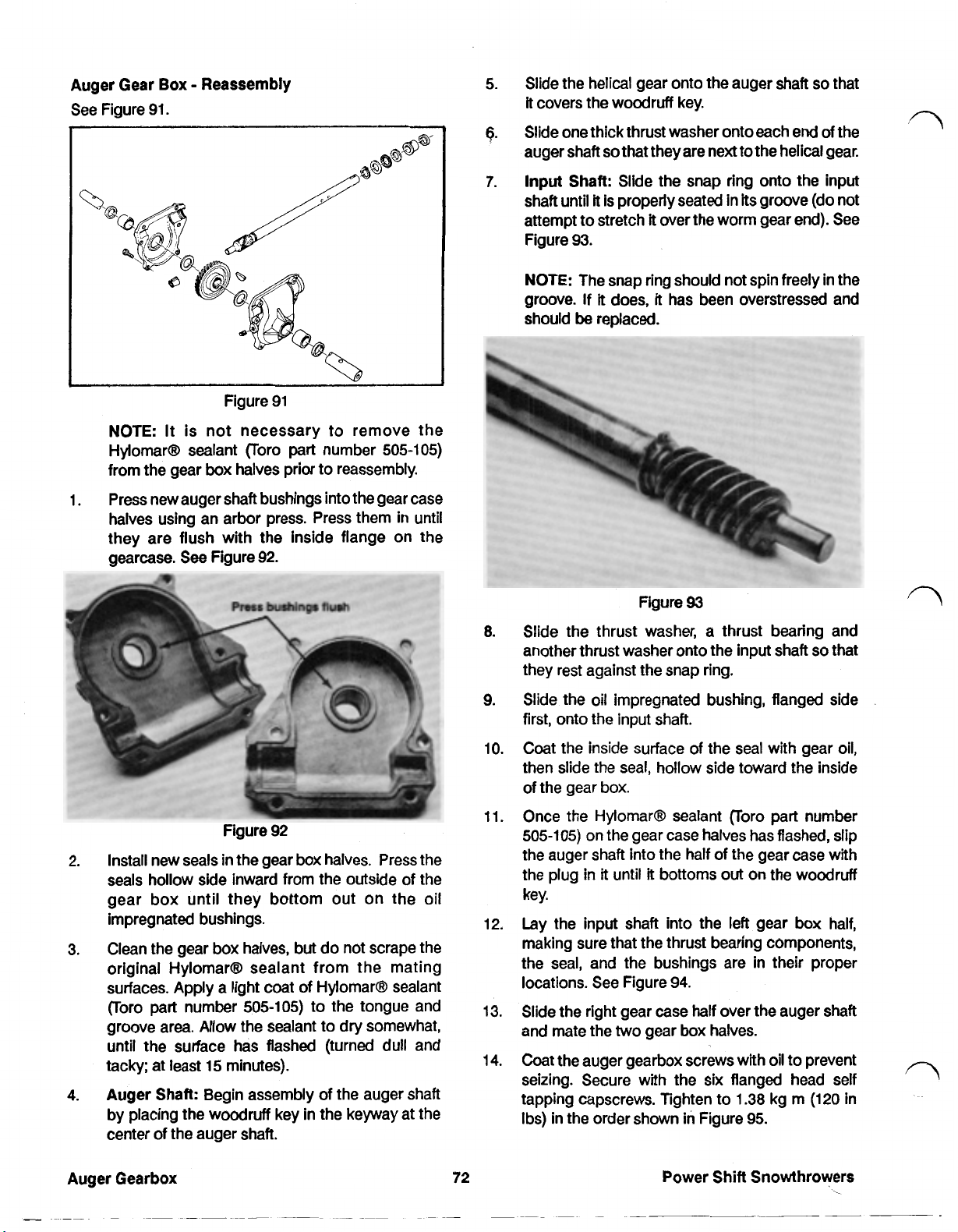

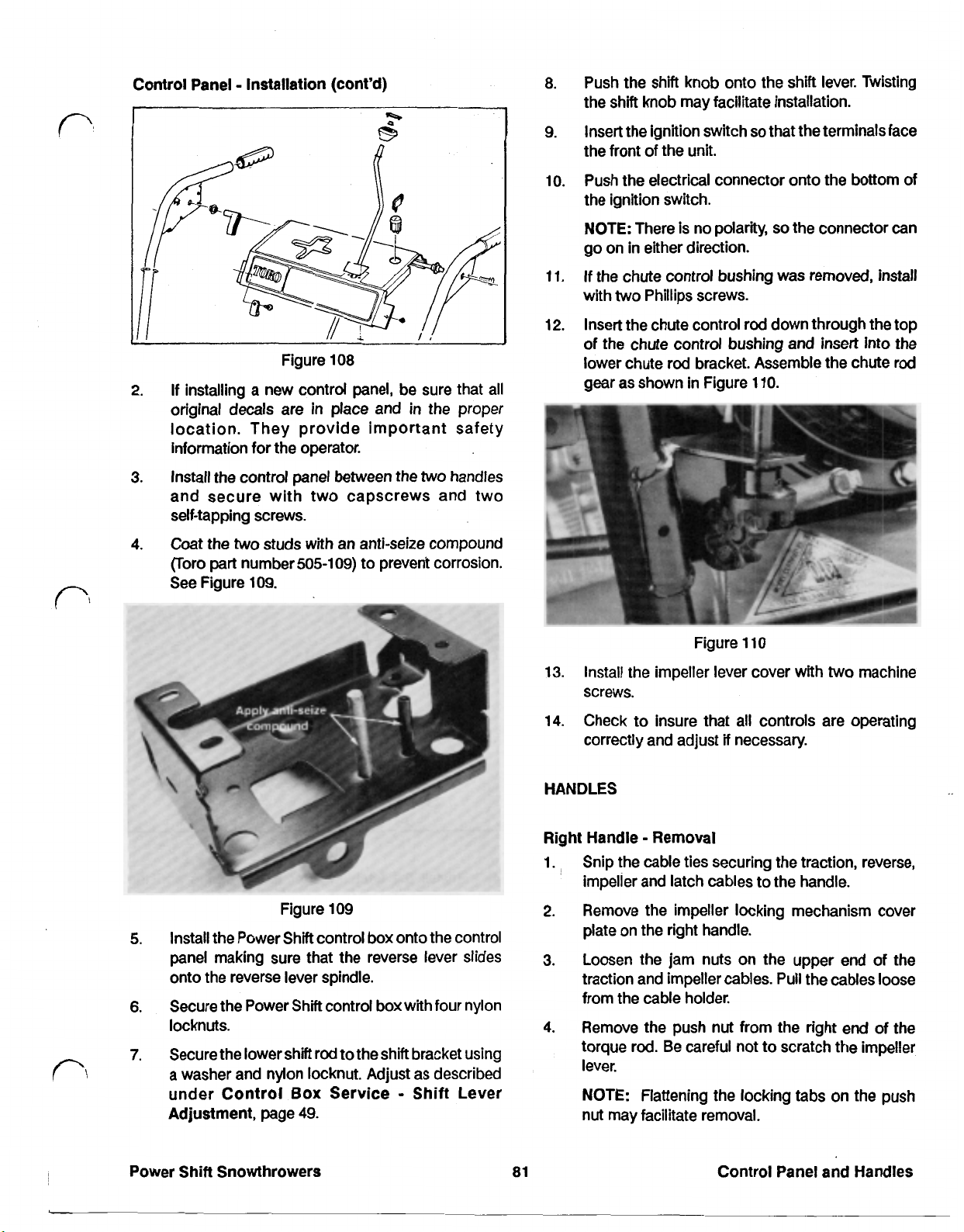

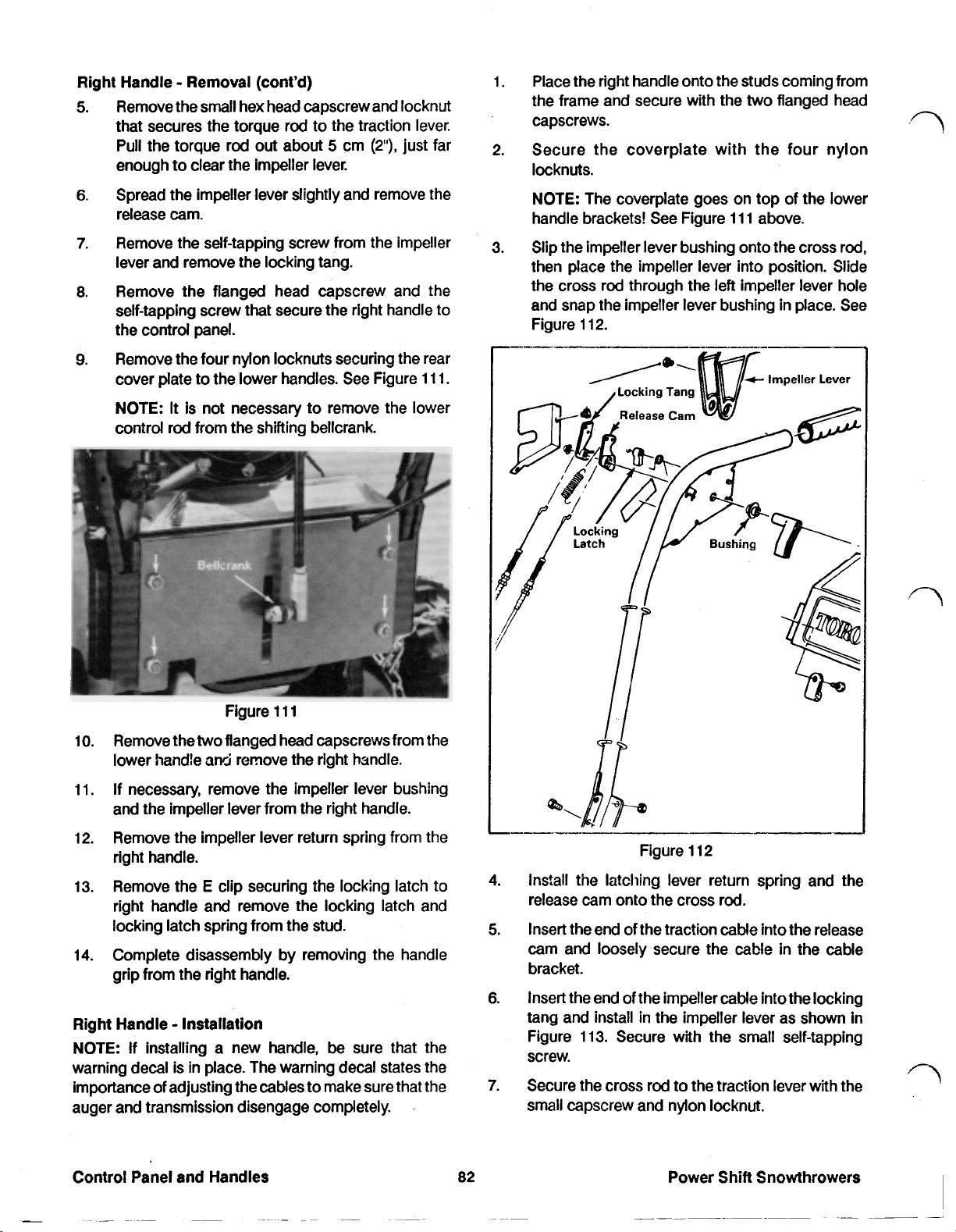

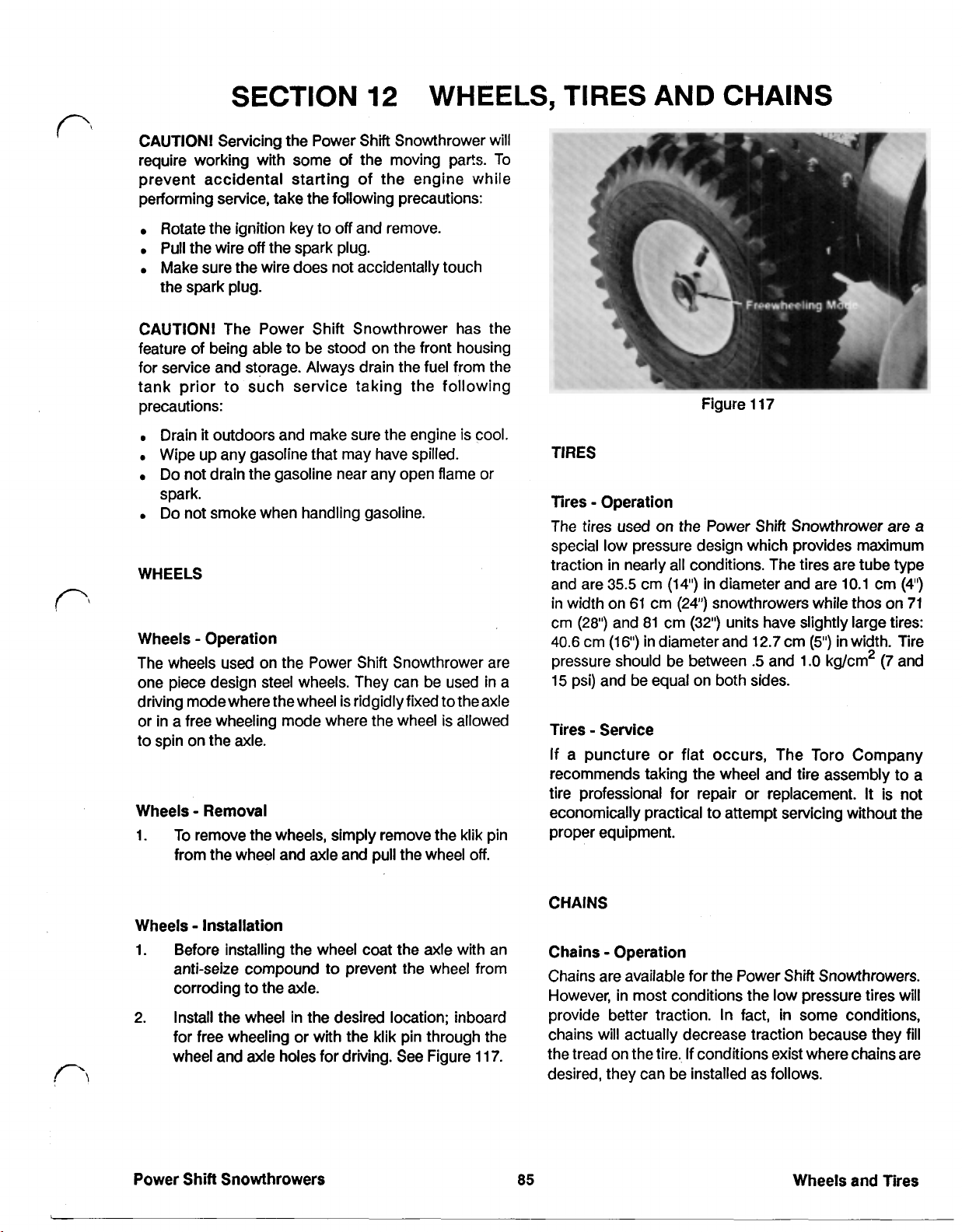

2.