Toro 38180, 38180C, 38181, 38185, 38185C Service Manual

...

2-CYCLE GTS 120 ENGINE SERVICE MANUAL

Table of Contents – Page 1 of 1

PREFACE

I. GENERAL INFORMATION

SAFETY INSTRUCTIONS

MAINTENANCE

MODEL AND SERIAL NUMBERS

TWO-CYCLE ENGINE THEORY AND OPERATION

CARBURETOR THEORY AND OPERATION

SPECIAL TOOLS LIST

II. MAINTENANCE

AIR CLEANER

SPARK PLUG

EXHAUST SYSTEM

DECARBONING CYLINDER HEAD

IGNITION TIMING (MODEL 47PZ2 ONLY)

IGNITION TIMING (DIAL INDICATOR)

CONTACT POINTS AND CONDENSER MODEL47PZ2 ONLY

IGNITION COIL

GOVERNOR

GOVERNOR OPERATION

FUEL TANK

CARBURETOR

STORAGE

III. TROUBLESHOOTING AND TEST PROCEDURES

PRELIMINARY TROUBLESHOOTING

ENGINE BRAKE AND IGNITION SWITCH

BBC APPLICATIONS

FUEL TANK

TESTING COMPRESSION

CRANKCASE

ENGINE TROUBLESHOOTING CHART

IV. ENGINE REMOVAL, DISASSEMBLY, ASSEMBLY AND REPAIR INSTRUCTIONS

ENGINE REMOVAL

ENGINE DISASSEMBLY AND REPAIR

RECOIL STARTER REPAIR

CARBURETOR REPAIR

ENGINE ASSEMBLY AND REPAIR

SERVICE DATA SPECIFICATIONS

PREFACE

This service manual was written expressly for TORO Two-Cycle Rotary Mowers.

All

units with the model number

have been taken into consideration.

The Toro Company has made every

tool for the service and maintenance of your

assure proper and effective performance, you are urged to read this manual

carefully.

of

The purpose

this manual is to provide the Service Dealer with working

guidelines of maintenance, troubleshooting, test, and overhaul procedures.

The Toro Company reserves the right to change product specifications or this

manual without notice.

47P22,47PD3,47PE4,

effort

to make this service manual a useful

TORO

Rotary Mower Engine. To

and

47PF5

engines

The Toro Company

Service

Department

COPYRIGHT ALL RIGHTS RESERVED

The

Toro

MINNEAPOLIS,

Company

MN

55420

1986

U.S.A.

i

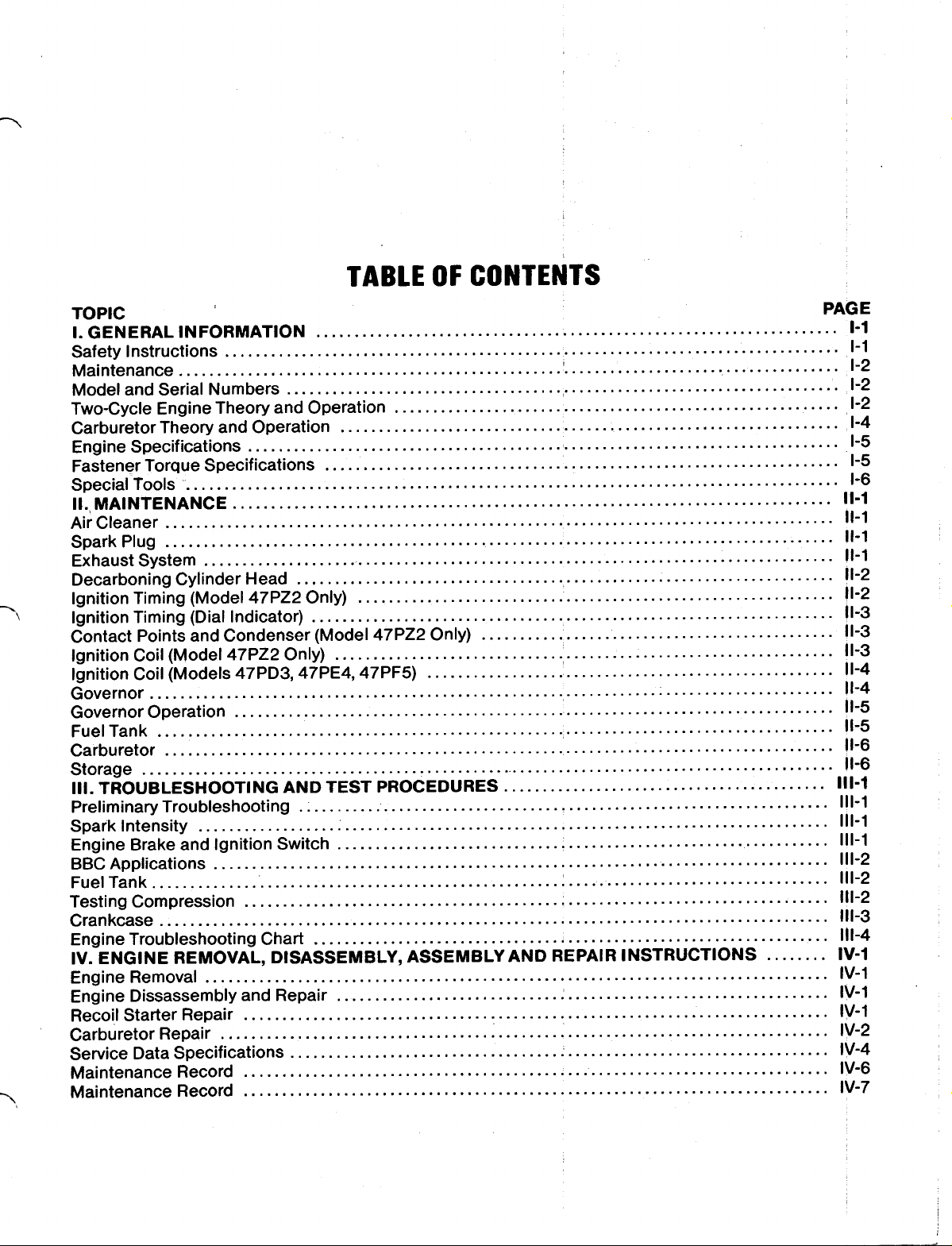

TABLE

TOPIC PAGE E

1

.

GENERAL INFORMATION

Safety Instructions

Maintenance

Model and Serial Numbers

Two-cycle Engine Theory and Operation

Carburetor Theory and Operation

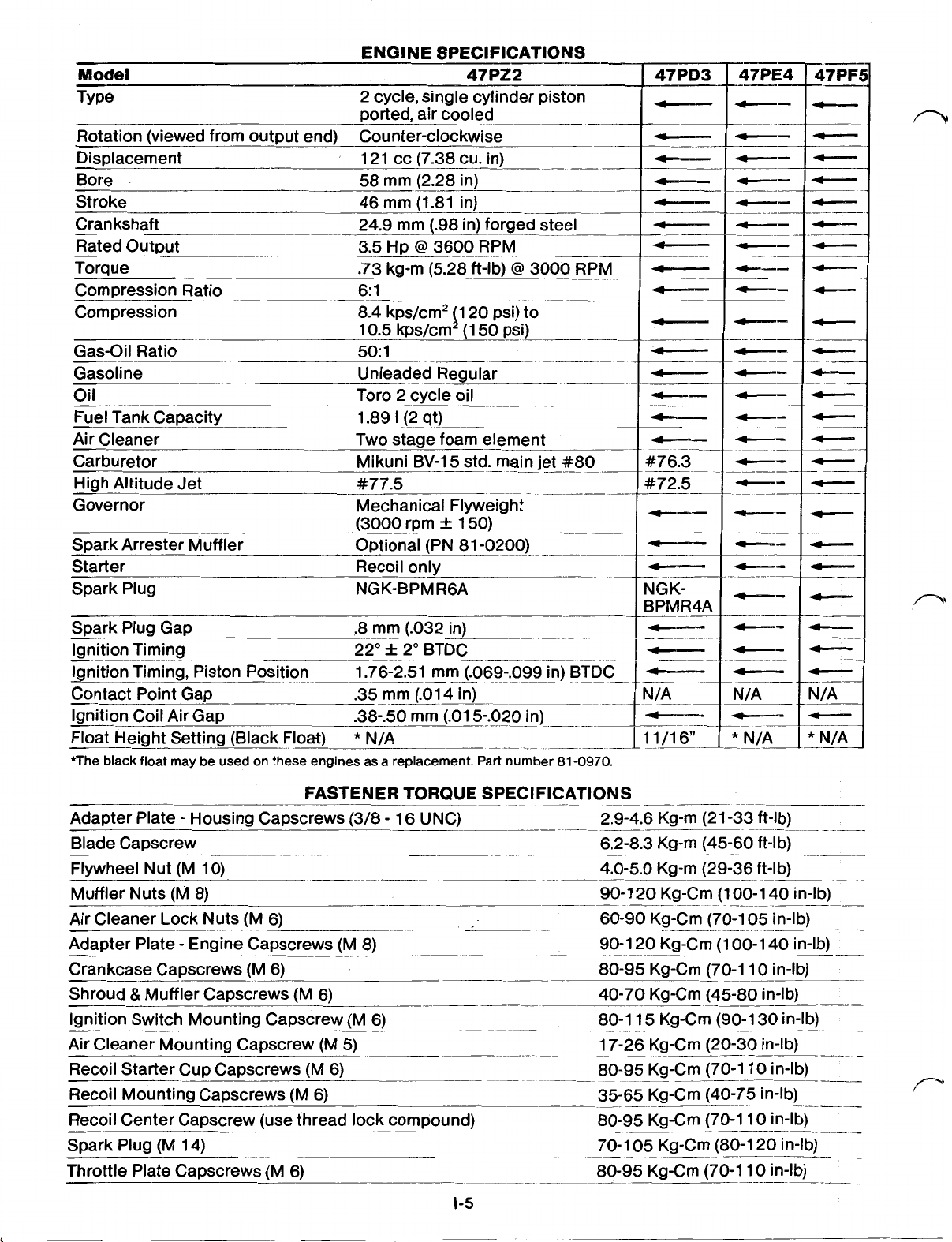

Engine Specifications

Fastener Torque Specifications

Special Tools

II.>

MAINTENANCE

Air Cleaner

Spark Plug

Exhaust System

Decarboning Cylinder Head

Ignition Timing (Model 47PZ2 Only)

Ignition Timing (Dial Indicator)

Contact Points and Condenser (Model 47PZ2 Only)

Ignition Coil (Model 47P22 Only)

Ignition Coil (Models 47PD3.47PE4. 47PF5)

Governor

Governor Operation

Fuel Tank

Carburetor

Storage

111

.

TROUBLESHOOTING AND TEST PROCEDURES

Preliminary Troubleshooting

Spark Intensity

Engine Brake and Ignition Switch

BBC Applications

Fuel Tank

Testing Compression

Crankcase

Engine Troubleshooting Chart

IV

.

ENGINE REMOVAL, DISASSEMBLY, ASSEMBLY AND REPAIR INSTRUCTIONS

Engine Removal

Engine Disassembly and Repair

Recoil Starter Repair

Carburetor Repair

Service Data Specifications

Maintenance Record

Maintenance Record

.......................................................................................

.......................................................................................

..................................................................

........................................................................................

.......................................................................................

...........................................................................................

.....................................................

.......................................................................................

................................................................................

.......................................................................................

.............................................................................

......................................................................................

..............................................................................

..................................................................................

..............................................................................

..................................................................................

................................................................................

............................................................................

.................................................................................

............................................................................

...............................................................................

............................................................................

............................................................................

....................................................................

...................................

.................................................................

...................................................................

......................................................................

..............................................................

....................................................................

.................................................................

.....................................................................

................................................................

...................................................................

................................................................

......................................................................

OF

CONTENTS

.,.

...................................

..........................................................

..............................................

..................

..................................

......................

..........................................

..................................

........

1-1

1-1

1-2

1-2

1-2

1-4

1-5

1-5

1-6

11-1

11-1

11-1

11-1

11-2

11-2

11-3

11-3

11-3

11-4

11-4

11-5

11-5

11-6

11-6

111-1

111-1

111-1

111-1

111-2

111-2

111-2

111-3

111-4

1v-1

1v-1

1v-1

1v-1

1v-2

1v-4

1v-6

1v-7

SAFETY INSTRUCTIONS

Your rotary mower at the time of its manufacture,

meets the blade safety requirements of the Consumer Product Safety Commissions Safety Standard for Walk Behind Power Lawn Mowers.

representative sample was tested and verified by

an independent laboratory for compliance with

the B71.1-1980 Specifications of the American

National Standards Institute. However, improper

use or maintenance by the operator or owner

can still result in injury. To reduce the potential

for injury follow these safety instructions.

This machine is equipped with a blade brake

which is designed to stop the blade within

seconds when the control lever is released.

Check to be sure the control and brake function

correctly before each use of the mower. Repair

any defective or damaged safety components

before operation is commenced. To further

reduce the possibility of injury, always stop the E. Wipe up any spilled gasoline.

engine before leaving the operator’s position.

This safety symbol means

WARNING

PERSONAL SAFETY INSTRUCTION

Read the instruction because

do

with safety. Failure to comply with

the instruction may result in personal

injury.

Before Operating

1.

Operate your mower only after reading the engine is running. Stay behind the handle

Operators Manual.

available by sending the complete model 12. During operation the grass defector

and serial number to: The Toro Company, plete bagging assembly must be installed on

81 11 Lyndale Avenue South, Minneapolis, the mower.

Minnesota

2.

Never allow children to operate the mower

or adults to operate mower without

proper instructions.

3. Become familiar with the controls and know

how to stop the engine quickly.

4.

Keep everyone, especially children and pets,

away from the area of operation. Remove

sticks, stones, wire and any other debris that

might be picked up and thrown by the blade.

5.

TAMPERING WITH

SAFETY DEVICE

RESULTS IN NONCONFORMANCE WITH

SAFETY STANDARD, MAY RESULT IN PER-

SONAL INJURY. Each time before operating

the mower, check for damage or abnormal

wear.

defective or damaged, repair or replace it

before operation is commenced.

55420.

If

a safety device, shield, or decal

Attn: Publications. 13. Stop the engine and wait for all moving parts

OR

or

CAUTION

it

has to

A

replacement manual is

OR

DEFEATING

COMPONENT WHICH

A

3

-

-

A

A

is

1-1

6. Wear long pants and substantial shoes.

not operate the mower while wearing

sandals, tennis shoes, sneakers or shorts.

Do not wear loose fitting clothing that could

get caught in moving parts.

If

long grass will be cut, set the height-of-cut

7.

in the highest position. After mowing, reinspect the area and remove all debris. Then

lower the height-of-cut and mow the grass

again.

8. Since gasoline is highly flammable, handle it

carefully

A. Use an approved gasoline container.

B.

Do not

hot or running.

C. Do not smoke while handling gasoline.

D.

Fill the fuel tank outdoors and up to about

one-half inch from the top of the tank, not

the filler neck.

While Operating

9. Cutting the grass with a rotary mower demands attention. Always maintain secure

footing, balance and control.

10. Cut the grass during the daytime or when

there

from side to side, but avoid slopes when the

grass is wet.

is dry for best results.

11. Keep face, hands and feet away from the

mower housing and cutter blade while the

until the engine and all moving parts stop.

to stop before removing the bag, bagging

assembly, or unclogging the discharge

chute.

the high tension wire from the spark plug to

prevent the possibility

Use a stick to remove the obstruction.

If

a solid object is hit by the blade or

14.

mower vibrates abnormally, stop the engine

immediately. Disconnect the high tension

wire from the spark plug to prevent the

possibility of accidental starting. Then check

the mower for possible damage, bent blade,

an obstruction or loose parts. Repair the

mower before using it again.

15. Stop the engine before adjusting the

height-of-cut.

If

16.

a gravel driveway, road or path must be

crossed, stop the engine

fill

the fuel tank when the engine is

is

adequate artificial light. Cut slopes

If

possible, mow when the grass

or

If

the chute must be unclogged, pull

of

accidental starting.

so

loose sand and

Do

com-

if

the

-

rocks are not thrown.

17.

Before leaving the operator’s position behind

the handle, stop the engine and wait for all

moving parts to stop. Do not walk in front of

the mower while the engine is running. Disconnect the high tension wire from the spark

plug

if

the mower will be unattended.

18.

Do

not touch any part of the engine while it is

running or shortly after it is stopped because

the engine will be hot enough to cause a

burn.

Muffler

children and pets away.

MAINTENANCE

Before the mower is serviced or adjusted,

19.

stop the engine and remove the key from the

switch. Disconnect the high tension wire from

the spark plug to prevent the possibility of

accidental starting.

20.

To assure the mower is in safe operating

condition, keep all nuts, bolts and screws

tight. Assure the blade capscrew is tightened

to the proper torque.

21.

If

major repairs are ever needed or

tance is desired, contact an Authorized

TORO Service Dealer.

22.

If

the mower must be tipped when it is

serviced or adjusted, drain the gasoline from

the fuel tank.

23.

If

a guard, safety device or safety decal is

damaged, replace the defective part(s) be-

fore operating the mower.

24.

To reduce potential fire hazards, assure the

mower is free

leaves and accumulations of dirt.

25.

The grass bag must always be in good condition; therefore, check it before each use to

assure the bag is not torn

Always replace a defective grass bag.

26.

Allow the engine to cool before storing the

mower in any enclosure such as a garage or

storage shed.

any open flame or where gasoline fumes

may be ignited by a spark.

27.

Do not overspeed the engine by changing

the governor settings. Recommended speed

of the engine is

and accuracy, have an Authorized TORO

Service Dealer check the engine speed with

a tachometer.

28.

At the time of manufacture the mower conformed to the safety standards in effect for

is

extremely hot. Keep

of

excessive grease, grass,

or

deteriorated.

Do

not store the mower near

3000

rpm. To assure safety

if

assis-

rotary mowers. To assure optimum performance and continued safety certification of

the mower, use genuine TORO replacement

parts and accessories. Replacement parts

and accessories made by other manufacturers may result in nonconformance with

the safety standards.

MODEL AND SERIAL NUMBERS

The TORO Two-cycle Rotary Mower has two sets

of identification numbers. There is a model and

serial number to identify the engine and a model

and serial number to identify the chassis. The

engine identification numbers are stamped into

the blower housing behind the air cleaner. Model

I

47PF5 engines built for

identification numbers stamped in the blower

housing above the spark plug. Engine models

47PE4 and 47PF5 have serial numbers that start

with the number

zone start application. The number 2 indicates

BBC application and the number

commercial application.

The chassis identification numbers are located on

a decal on the back

the rear wheels.

In any correspondence concerning the mower,

supply the model and serial numbers to assure

that thecorrect information and replacement parts

are obtained. Genuine TORO replacement parts

may be ordered through your

rized Service Dealer.

TWO-CYCLE ENGINE THEORY AND

OPERATION

Theory

Two-cycle engines have special advantages

which make their use more practical in certain

applications. Two-cycle engines are lightweight

with an excellent power to weight ratio and can

be operated in any position. They are also

notably easy to maintain and service because of

their uncomplicated design.

The TORO Two-cycle Engine used on the TORO

Rotary Mowers is a third-port, loop scavenged

design. This design name describes the path of

/

the fuel

bustion chamber, and the exhausting of spent

gases.

In a loop-scavenge engine, a high pressure area

is created in the crankcase by the downward

movement of the piston. Pressurized fuel-air

mixture rushes into the combustion chamber

through the intake ports and is directed toward

the cylinder head. This fresh mixture then strikes

the cylinder head and loops down forcing burnt

gases in the combustion chamber out through

air mixture into the crankcase and com-

1, 2 or

of

1986

3. The

the mower housing, between

have the engine

number 1 indicates

local

3

indicates

TORO Autho-

a

1-2

the exhaust ports. The third port design engine

has the carburetor mounted on the side of the

cylinder. The passage from the carburetor into

the crankcase is called the third port.

All

ports

within the engine are opened and closed by the

piston skirt as the piston moves up and down

within the cylinder.

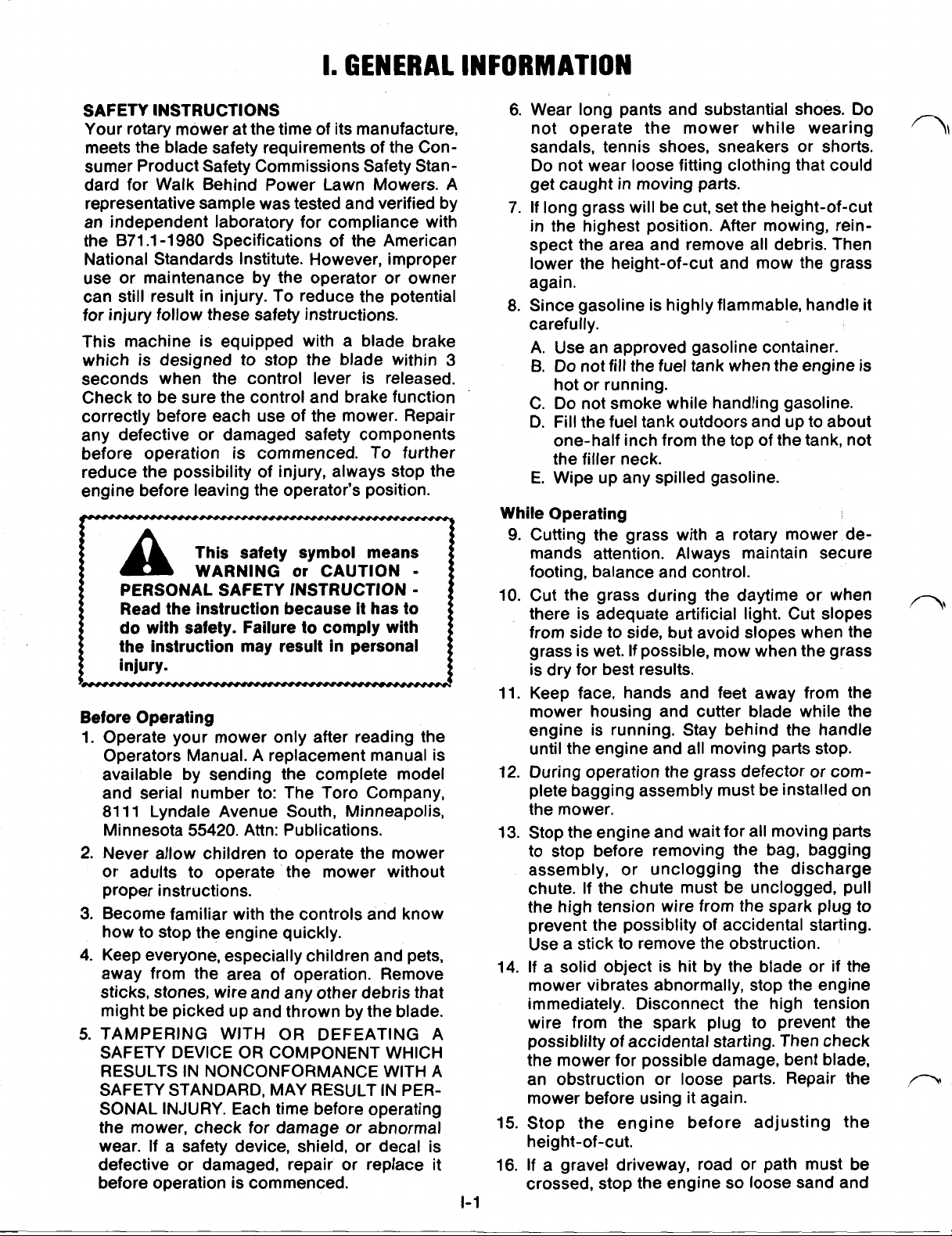

Operation

The piston closes all engine ports as it moves

toward the combustion chamber (Figure 1-1). The

moving piston creates a high pressure in the combustion chamber and a partial vacuum in the

crankcase.

Intake Ports Closed

Co

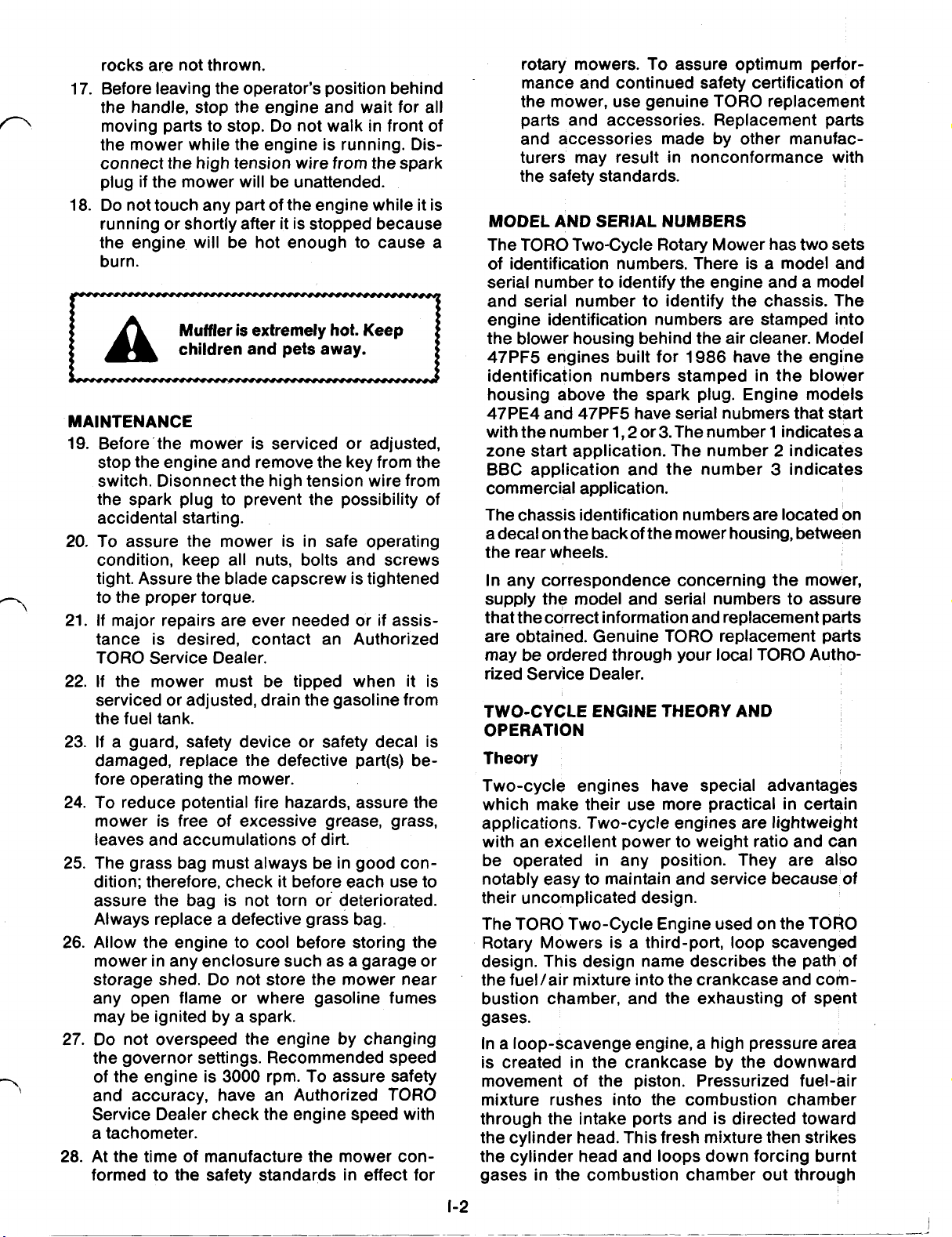

gases begin to be expelled from the combustion

chamber (Figure 1-3).

__-

Intake Ports Closed

Exhaust Port

~

Figure

--l_____m_

I

Third

Port Closed

1-3

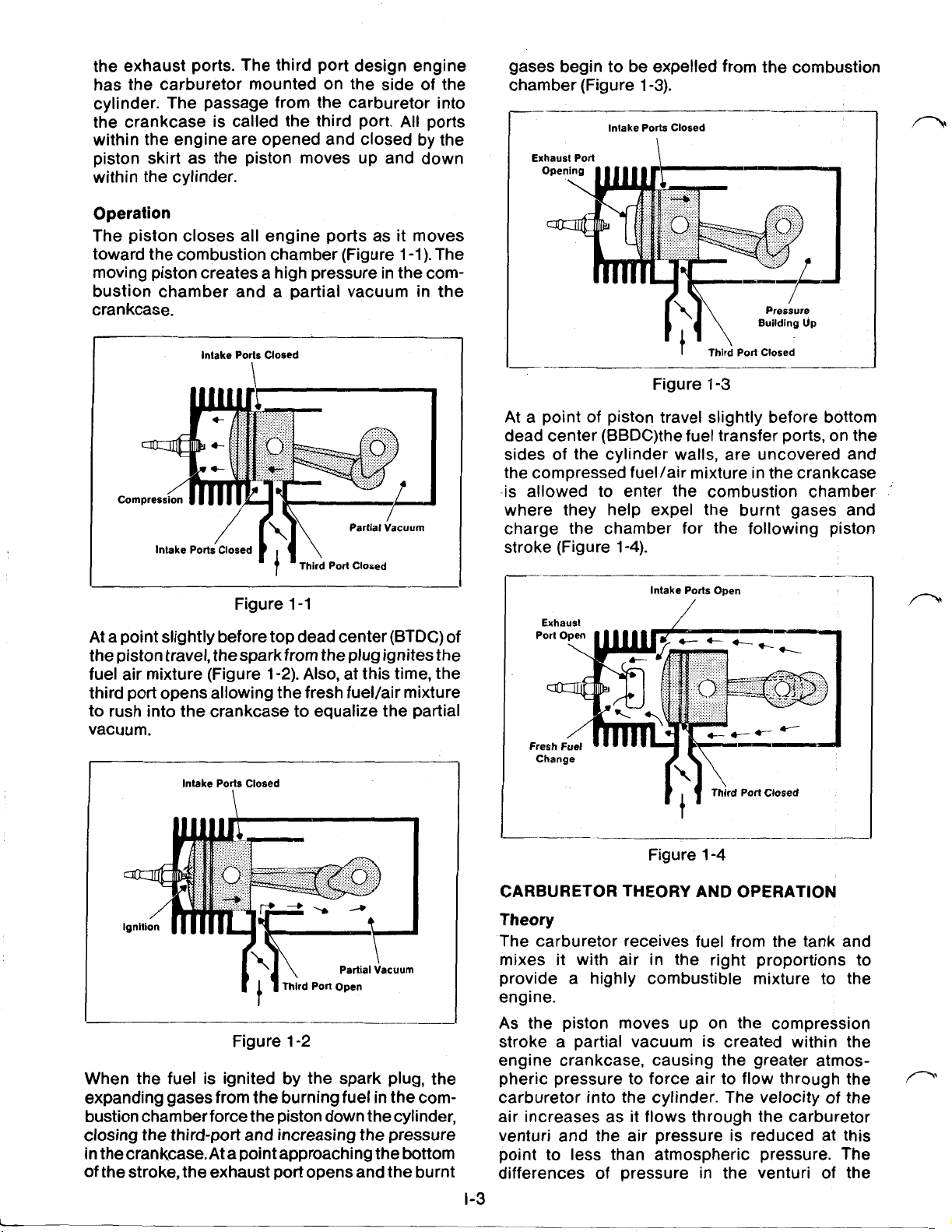

At a point of piston travel slightly before bottom

dead center (BBDC)

the

fuel transfer ports, on the

sides of the cylinder walls, are uncovered and

the compressed fuel/air mixture in the crankcase

-is allowed to enter the combustion chamber

where they help expel the burnt gases and

charge the chamber for the following piston

stroke (Figure 1-4).

Figure 1-1

At

a point slightly before top dead center (BTDC) of

the piston travel, from the plug ignitesthe

fuel air mixture (Figure 1-2). Also, at this time, the

third port opens allowing the fresh fuel/air mixture

to rush into the crankcase to equalize the partial

vacuum.

Intake Ports Closed

\

Figure 1-2

When the fuel is ignited by the spark plug, the

expanding gases from the burning fuel in the combustion chamber force the piston down thecylinder,

closing the third-port and increasing the pressure

in the

crankcase. At

of the stroke, the exhaust port opens and the burnt

a point approaching the bottom

Intake Ports

Exhaust

Change

Open

__-__

Figure 1-4

CARBURETOR THEORY AND OPERATION

Theory

The carburetor receives fuel from the tank and

it

mixes

with air in the right proportions to

provide a highly combustible mixture to the

engine.

As the piston moves up on the compression

stroke a partial vacuum is created within the

engine crankcase, causing the greater atmospheric pressure to force air to flow through the

carburetor into the cylinder. The velocity of the

air increases as it flows through the carburetor

venturi and the air pressure is reduced at this

point to less than atmospheric pressure. The

differences of pressure in the venturi of the

1-3

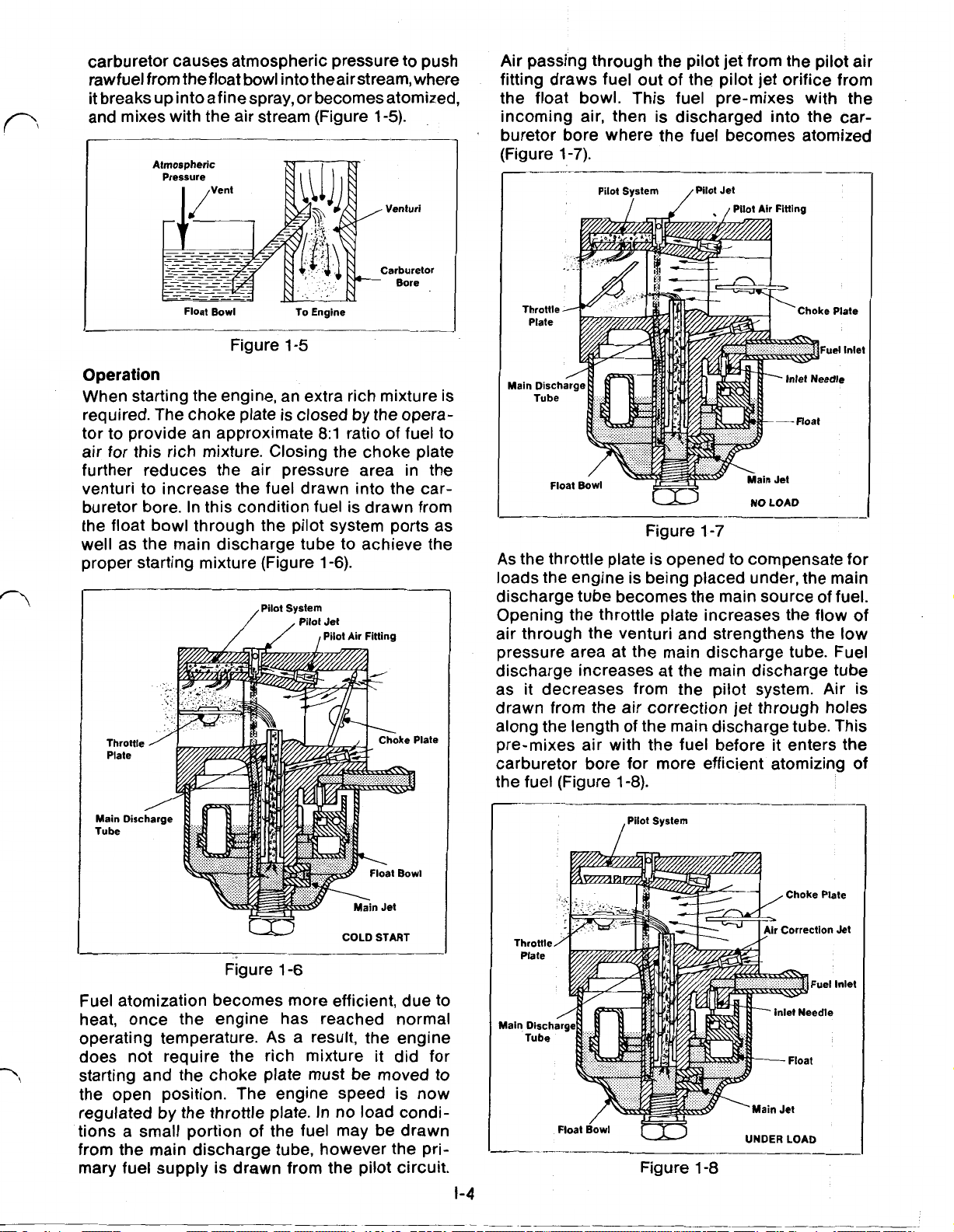

carburetor causes atmospheric pressure to push

rawfuel from the

bowl into theair

stream, where

float

it breaks up into a fine spray, or becomes atomized,

and mixes with the air stream (Figure

1-5).

Air passing through the pilot jet from the pilot air

fitting draws fuel out of the pilot jet orifice from

the float bowl. This fuel pre-mixes with the

incoming air, then is discharged into the carburetor bore where the fuel becomes atomized

Float

Bowl

(Figure

To Engine

1-7).

Figure

1-5

Operation

When starting the engine, an extra rich mixture is

required. The choke plate is closed by the opera-

tor to provide an approximate

8:1

ratio of fuel to

air for this rich mixture. Closing the choke plate

further reduces the air pressure area in the

venturi to increase the fuel drawn into the car-

buretor bore. In this condition fuel is drawn from

the float bowl through the pilot system ports as

well as the main discharge tube to achieve the

proper starting mixture (Figure

Pilot System

1-6).

Pilot

Jet

Pilot Air Fitting

NO

LOAD

Figure

As

the throttle plate is opened to compensate for

1-7

loads the engine is being placed under, the main

discharge tube becomes the main source of fuel.

Opening the throttle plate increases the flow of

air through the venturi and strengthens the low

pressure area at the main discharge tube. Fuel

discharge increases at the main discharge tube

as

it

decreases from the pilot system. Air

is

drawn from the air correction jet through holes

along the length of the main discharge tube. This

pre-mixes air with the fuel before it enters the

carburetor bore for more efficient atomizing of

:he fuel (Figure

1-8).

COLD START

Figure

1-6

Fuel atomization becomes more efficient, due to

heat, once the engine has reached normal

operating temperature.

As

a result, the engine

does not require the rich mixture it did for

starting and the choke plate must be moved

to

the open position. The engine speed is now

regulated by the throttle plate. In no load condi-

tions a small portion of the fuel may be drawn

from the main discharge tube, however the pri-

mary fuel supply is drawn from the pilot circuit.

1-4

Float

Bowl

/pilot

System

Figure

UNDER LOAD

1-8

ENGINE SPECIFICATIONS

Model

~---

47P22

Type 2 cycle, single cylinder piston

ported, air cooled

Rotation (viewed from output end) Counter-clockwise

Displacement 121 cc (7.38 cu. in)

Bore 58 mm (2.28 in)

Stroke 46 mm (1.81 in)

Crankshaft 24.9 mm (.98in) forged steel

Rated Output

Torque .73 kg-m (5.28 ft-lb)

3.5

Hp @ 3600 RPM

@

3000

Compression Ratio 6: 1

Compression

Gas-Oil Ratio

8.4kps/cm2 20 psi) to

50

10.5 kps/cm (1

50:

1

psi)

Gasoline Unleaded Regular

TTO

Oil 2 cycle oil

Fuel Tank Capacity

Air Cleaner

Carburetor Mikuni

High Altitude Jet

Governor Mechanical Flyweight

-~

1.89

I

(2 qt)

Two stage foam element

BV-15std.

main jet #80

#77.5

~-

RPM

--

47PD3

#76.3

#72.5

Spark Arrester Muffler Optional (PN 81-0200)

Starter Recoil only

Spark Plug NGK-BPMR6A

~-

NGKBPMR4A

Ignition Timing 22" 2" BTDC

Ignition Timing, Piston Position 1.76-2.51mm (.069-.099in) BTDC

Contact Point Gap .35 mm (.014in)

~-

N/A

Ignition Coil Air Gap .38-.50 mm (.015-.020in)

Float Height Setting (Black Float)

*The black float may be used on these engines as a replacement. Part number

*

N/A

.

11/16"

81-0970.

*

N/A

FASTENER TORQUE SPECIFICATIONS

Adapter Plate Housing Capscrews (3/8-16UNC) 2.9-4.6 Kg-m (21

-33

ft-lb)

Blade Capscrew 6.2-8.3 Kg-m (45-60 ft-lb)

Flywheel Nut (M 10) 4.0-5.0 Kg-m (29-36 ft-lb)

Muffler Nuts (M 8)

Air Cleaner Lock Nuts (M 6)

Adapter Plate Engine Capscrews (M 8)

90-120Kg-Cm (100-140 in-lb)

60-90 Kg-Cm (70-1

05

.

in-lb)

90-120Kg-Cm (100-140in-lb)

Crankcase Capscrews (M 6) 80-95 Kg-Cm (70-1 10 in-lb)

&

Shroud

Ignition Switch Mounting Capscrew (M 6) 80-1 15 Kg-Cm (90-1

Air Cleaner Mounting Capscrew (M

Muffler Capscrews (M 6)

-..-

5)

40-70 Kg-Cm (45-80 in-lb)

30

in-lb)

17-26 Kg-Cm (20-30 in-lb)

Recoil Starter Cup Capscrews (M 6) 80-95 Kg-Cm (70-1 10 in-lb)

Recoil Mounting Capscrews (M 6) 35-65 Kg-Cm (40-75 in-lb)

Recoil Center Capscrew (use thread lock compound) 80-95 Kg-Cm (70-1 10 in-lb)

05

Spark Plug (M 14) 70-1

__-

Kg-Cm (80-1 20 in-lb)

Throttle Plate Capscrews (M 6) 80-95 Kg-Cm (70-1 10 in-lb)

.-

1-5

Loading...

Loading...