Page 1

FormNo.3420-243RevB

CommercialWalk-Behind

TractionUnit

18HPPistol-GripHydroDrive

ModelNo.31914—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3420-243*B

Page 2

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Introduction

Thisrotary-blade,lawnmowerisintendedtobe

usedbyprofessional,hiredoperators.Itisdesigned

primarilyforcuttinggrassonwell-maintainedlawnson

residentialorcommercialproperties.Itisnotdesigned

forcuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Thismanualshouldbe

consideredaspartofthemachine,asitcontains,

safety,operationalandmaintenanceinformation.The

mowerisaprecisionbuiltmachinedesignedsolelyfor

cuttinggrassandsimilarlowlyinggroundvegetation

withinthelimitationsstatedinthismanual.Youare

responsibleforoperatingtheproductproperlyand

safely.

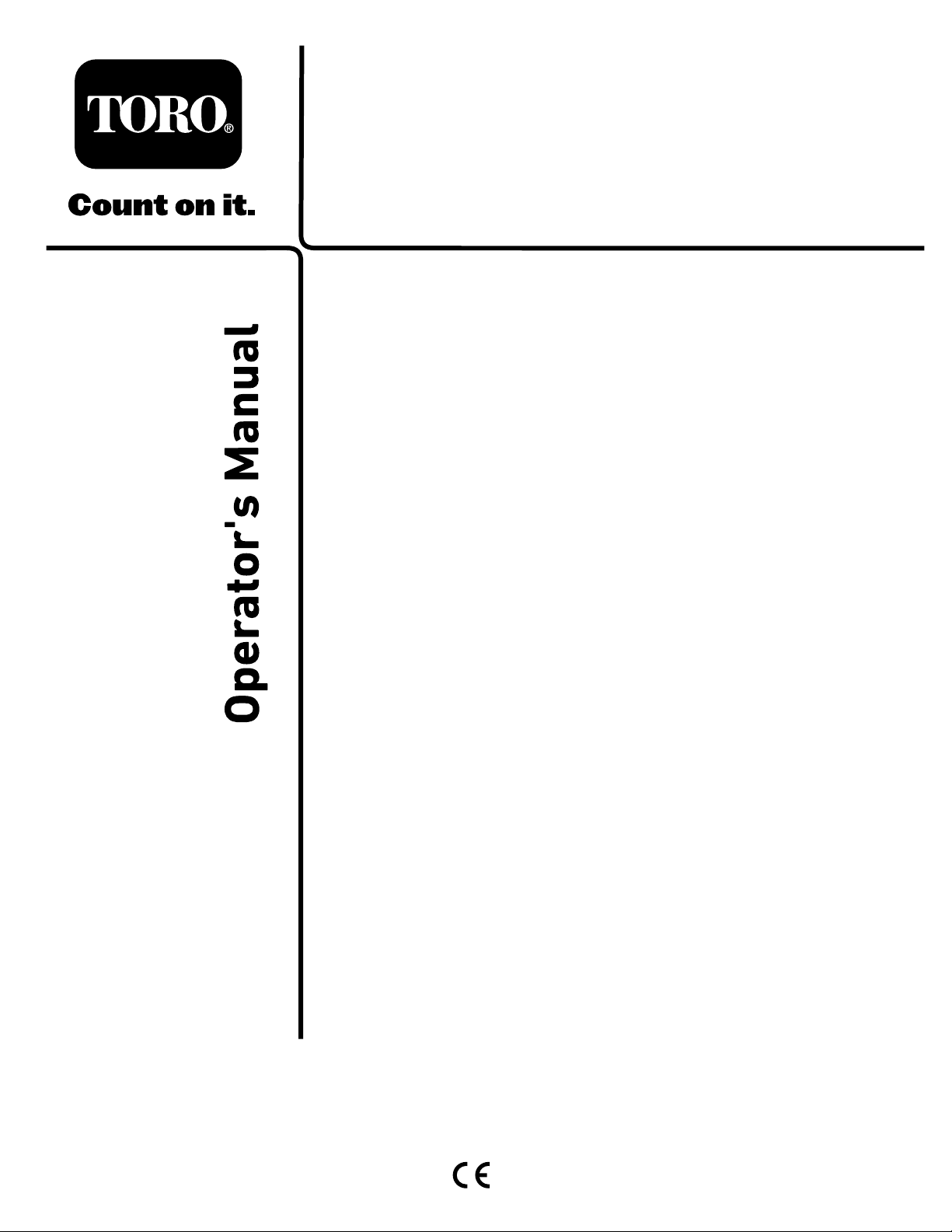

g250801

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

YoumaycontactT orodirectlyforproductsafetyand

operationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct

atToroCommercialProductsServiceDepartment

Spellbrook,BishopsStortford,CM234BU,England,

+44(0)1279603019,Email:uk.service@toro.com.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

andFigure2identifythelocationofthemodeland

serialnumbersontheproduct.Writethenumbersin

thespaceprovided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

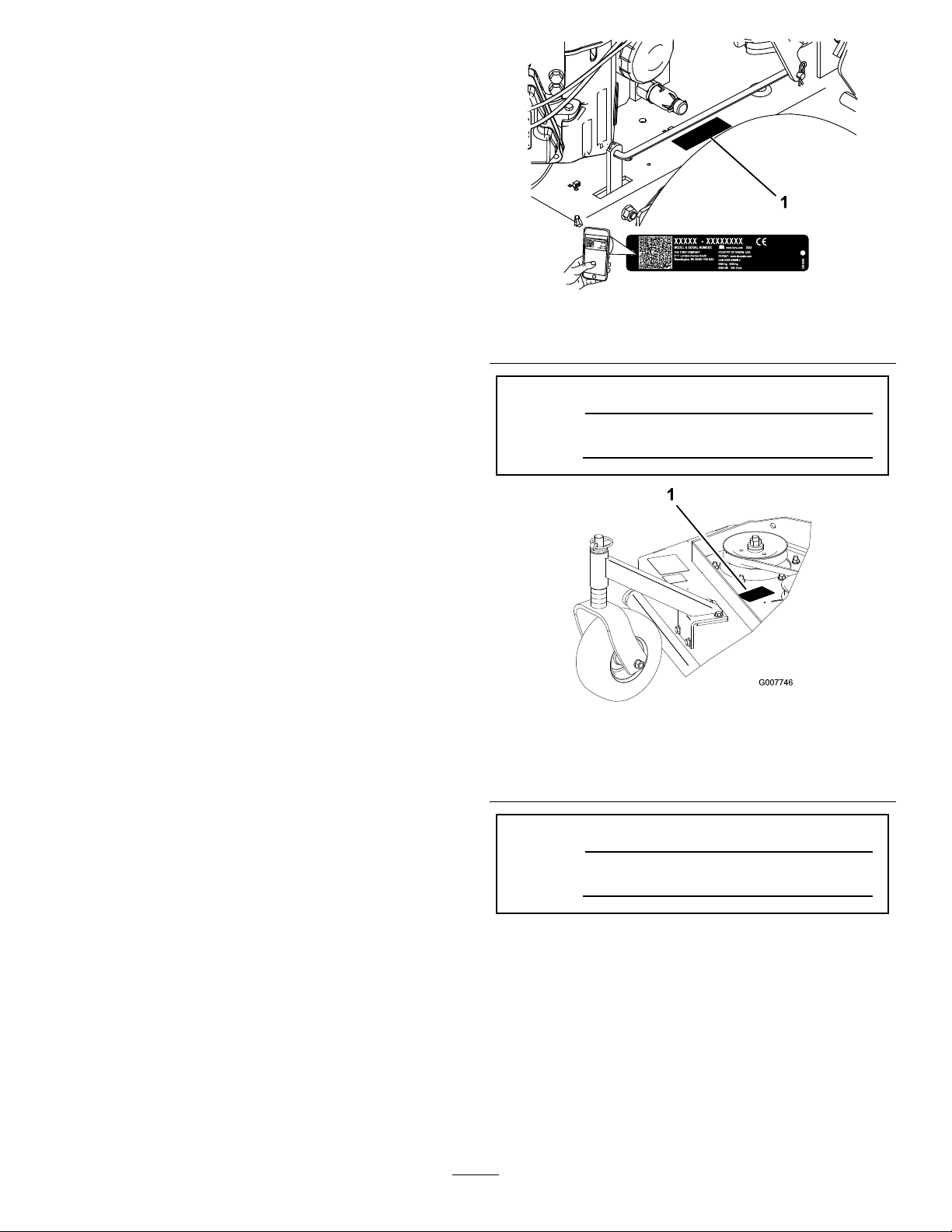

g007746

Figure2

Rear-dischargedeckshown

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure3),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Figure3

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

SafetyandInstructionalDecals..........................5

Setup........................................................................8

1CheckingtheFluidsandTirePressure.............8

2InstallingtheWheelKit.....................................8

3ReadingtheManualandViewingthe

OperatorTrainingMaterial..............................8

ProductOverview.....................................................9

Controls.............................................................9

Specications..................................................10

Attachments/Accessories.................................10

Operation.................................................................11

AddingFuel.......................................................11

ThinkSafetyFirst..............................................12

OperatingtheParkingBrake.............................12

StartingtheEngine...........................................12

ShuttingOfftheEngine.....................................13

OperatingtheNeutralLocks.............................13

OperatingtheBlade-ControlKnob

(PTO)............................................................14

UsingtheSafety-InterlockSystem....................14

DrivingtheMachineForwardand

Backward......................................................15

BringingtheMachinetoNeutral........................15

PushingtheMachinebyHand..........................15

TransportingtheMachine.................................16

AdjustingtheHeightofCut...............................16

AdjustingtheCasterPosition............................17

AdjustingtheHandleHeight.............................18

Height-of-CutChart..........................................19

Maintenance...........................................................20

RecommendedMaintenanceSchedule(s)...........20

Lubrication..........................................................21

LubricatingtheCasterandWheel

Bearings........................................................21

GreasingtheMower-BeltIdler..........................21

GreasingthePumpControlandBell

Crank............................................................21

EngineMaintenance...........................................22

ServicingtheAirCleaner..................................22

ServicingtheEngineOil....................................23

ServicingtheSparkPlug...................................25

FuelSystemMaintenance...................................26

g000502

ServicingtheFuelT ank.....................................26

ServicingtheFuelFilter....................................27

DriveSystemMaintenance..................................28

AdjustingtheSpeed-ControlLinkage................28

AdjustingtheNeutralControlLinkages.............29

AdjustingtheHydraulicControl

Linkages.......................................................30

AdjustingtheControlRod.................................31

AdjustingtheTracking.....................................32

AdjustingtheSpringAnchorLinks....................32

CheckingtheTirePressure...............................33

CoolingSystemMaintenance..............................33

CleaningtheAirIntakeScreen..........................33

BrakeMaintenance.............................................34

ServicingtheBrake..........................................34

BeltMaintenance................................................35

CheckingtheBelts............................................35

ReplacingtheMowerBelt.................................35

AdjustingtheMowerBeltT ension.....................35

HydraulicSystemMaintenance...........................38

ServicingtheHydraulicSystem........................38

MowerDeckMaintenance....................................41

ServicingtheCuttingBlades.............................41

AdjustingtheBladeBrake.................................43

Storage...................................................................43

Troubleshooting......................................................45

Schematics.............................................................47

3

Page 4

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Thismachinehasbeendesignedinaccordancewith

ENISO5395:2013.

SafeOperatingPractices

Training

•ReadtheOperator'sManualandothertraining

material.

•Iftheoperator(s)ormechanic(s)cannotreadthe

manuallanguage,itistheowner'sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtopeople,or

damagetoproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsyouneedtoproperlyandsafely

performthejob.Useonlyaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludingeyeprotection,

longplants,substantialslip-resistantfootwear,and

hearingprotection.Tiebacklonghairanddonot

wearlooseclothingorloosejewelry.

•Inspecttheareawhereyouwillusetheequipment

andremoveallobjectssuchasrocks,toys,and

wire,whichcanbecontactedbythemachine.

•Checkthattheoperator-presencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly.Donotoperateunlessthey

arefunctioningproperly.

SafeHandlingofFuels

•Useextracarewhenhandlingfuel.Theyare

ammableandvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

Operation

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Lightningcancausesevereinjuryordeath.If

lightningisseen,orthunderisheardinthearea,

donotoperatethemachine;seekshelter.

•Donotrunanengineinanenclosedarea.

•Operateonlyinwell-litareas,keepingawayfrom

holesandhiddenhazards.

•Ensurethatalldrivesareinneutralandthatthe

parkingbrakeisengagedbeforestartingengine.

Starttheengineonlyfromtheoperator’sposition.

•Makesurethatyouhavegoodfootingwhile

usingthismachine,especiallywhenbackingup.

Reducedfootingcouldcauseslipping.

•Donotraisethemowerdeckwiththeblades

running.

•DonotoperatethemachinewithoutthePTO

shieldorotherguardssecurelyinplace.Besure

thatallinterlocksareattached,adjustedproperly ,

andfunctioningproperly.

•Donotoperatewiththedischargedeectorraised,

removedoraltered,unlessyouareusingagrass

catcher.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Parkthemachineonalevelsurface,disengage

drives,engagetheparkingbrake,shutoffthe

engine,andremovethekeybeforeleavingthe

operator'spositionforanyreason,including

emptyingthecatchersoruncloggingthechute.

•Stopthemachine,shutofftheengine,removethe

key,andinspectthebladesafterstrikingobjects

orifanabnormalvibrationoccurs.Makethe

necessaryrepairsbeforeresumingoperation.

4

Page 5

•Keepyourhandsandfeetawayfromthecutting

unit.

•Lookbehindanddownbeforebackingupto

ensureaclearpath.

•Keeppetsandbystandersawayfromanoperating

machine.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Stopthe

bladesifyouarenotmowing.

•Beawareofthemower-dischargedirectionand

donotpointitatanyone.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoorfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SlopeSafety

•Mowacrossthefaceofslopes;neverupand

down.Useextremecautionwhenchanging

directiononslopes.

•Donotmowonexcessivelysteepslopes.Poor

footingcouldcauseaslip-and-fallaccident.

•Mowwithcautionneardrop-offs,ditches,or

embankments.

MaintenanceandStorage

•Parkthemachineonalevelsurface,disengage

drives,engagetheparkingbrake,shutoffthe

engine,andremovethekeyordisconnect

spark-plugwire.Waitforallmovementtostop

beforeadjusting,cleaning,orrepairing.

•Cleangrassanddebrisfromthecuttingunit,

drives,mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Lettheenginecoolbeforestoringthemachine.

•Donotstorefuelnearamesordrainfuelindoors.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatteryorremovethespark-plug

wirebeforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositiveterminal

last.Connectthepositiveterminalrstand

negativelast.

•Usecarewhencheckingtheblades.Wrapthe

blade(s)orwearthicklypaddedgloves,anduse

cautionwhenservicingthem.Onlyreplaceblades;

donotstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

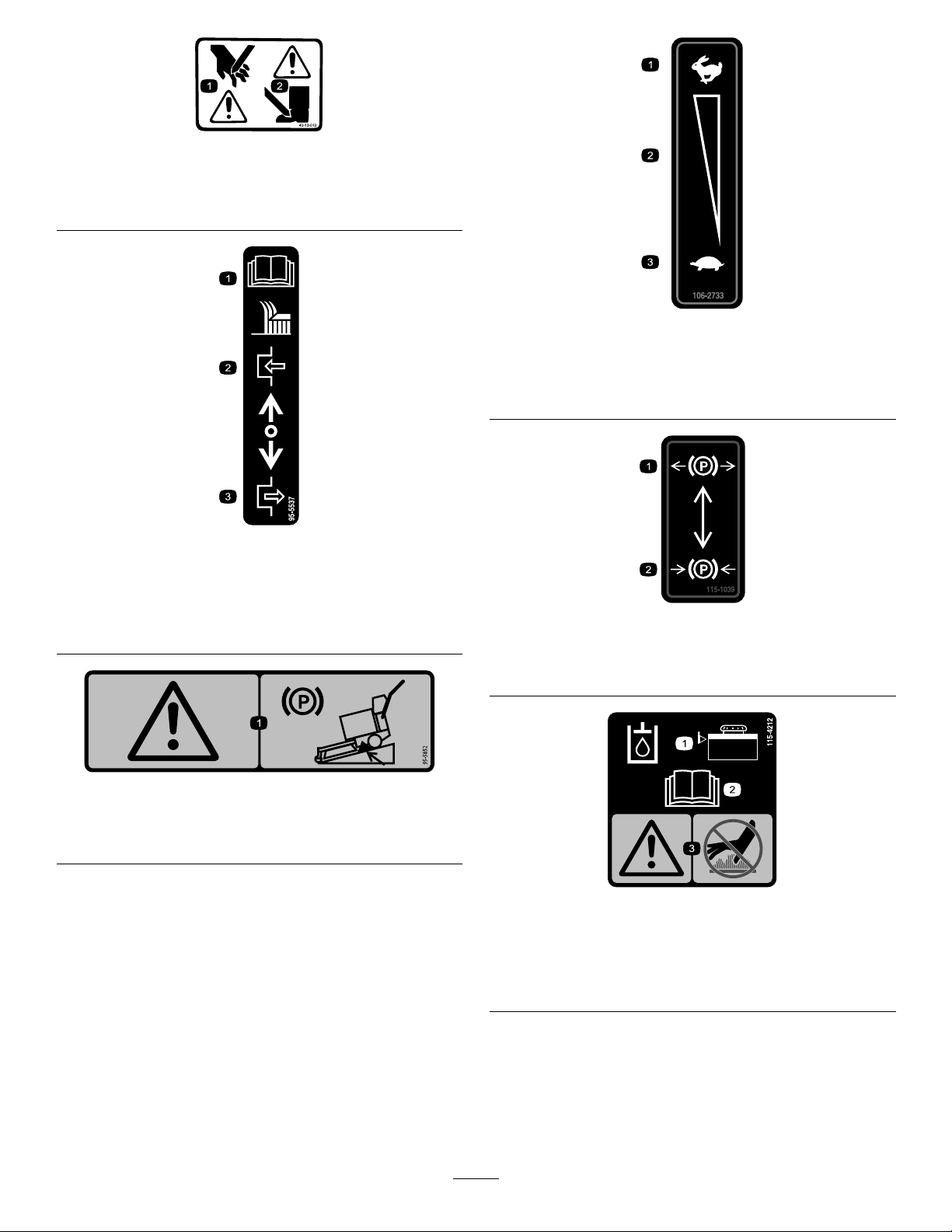

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Keepsafetysignsclearandvisible,replaceanydecalthatisdamaged

ormissing.

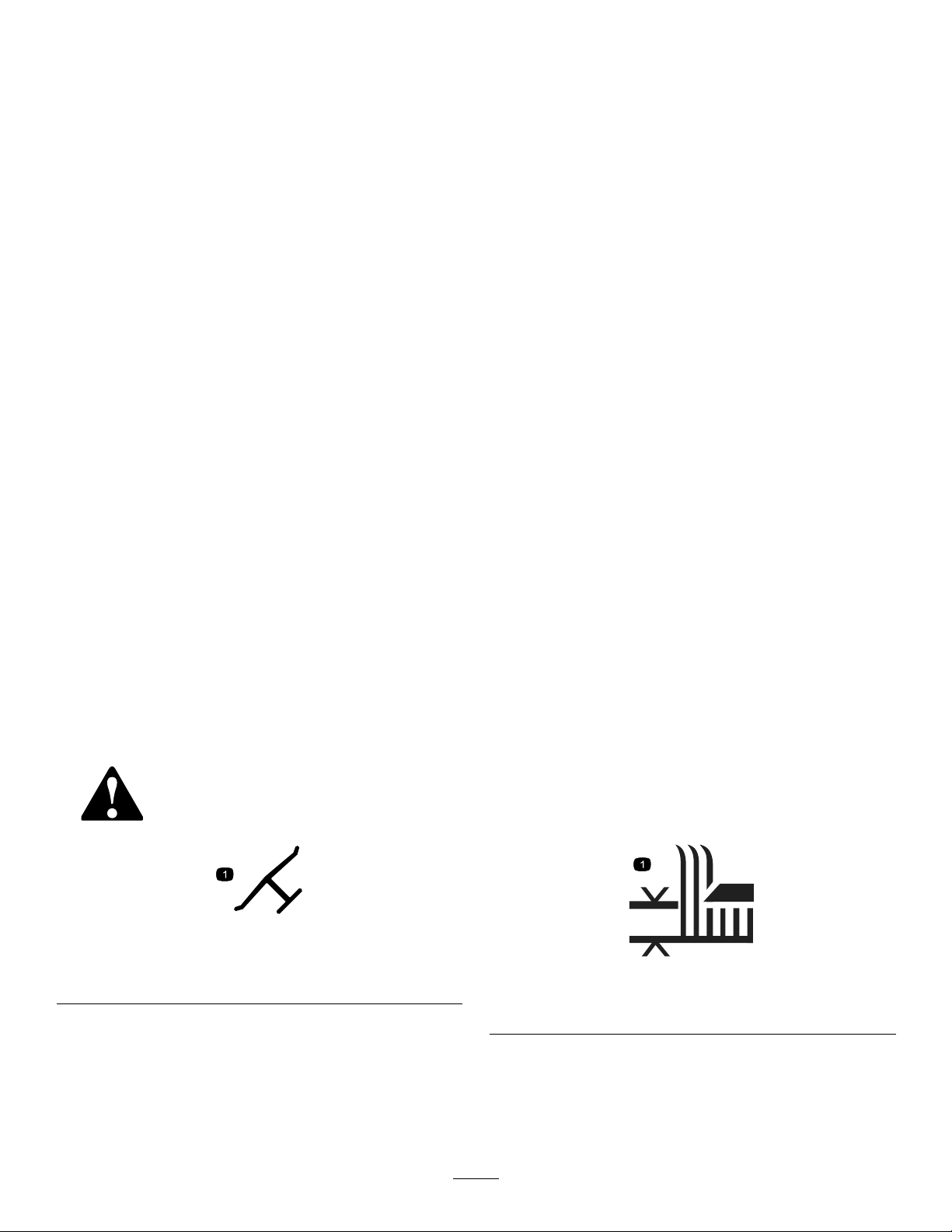

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

decaloemmarkt

decal320006

320006

1.Heightofcut

5

Page 6

1.Cuttinghazardofhand

2.Cuttinghazardoffoot

decal40-13-010

40-13–010

decal106-2733

106-2733

1.ReadtheOperator's

Manualforinstructionson

operatingthecuttingblade

2.Pushforwardtoengage

1.Fast

3.Slow

2.Continuousvariable

setting

decal95-5537(hydro)

95-5537

3.Pullbacktodisengage

decal115-1039

115-1039

1.Parking

brake—disengaged

decal95-5852

2.Parkingbrake—engaged

95-5852

1.Warning—engagetheparkingbrakeandblockthewheels

whenparkingonaslope.

1.Hydraulic-uidlevel

2.ReadtheOperator's

6

decal115-4212

115-4212

3.Warning—donottouchthe

hotsurface.

Manual.

Page 7

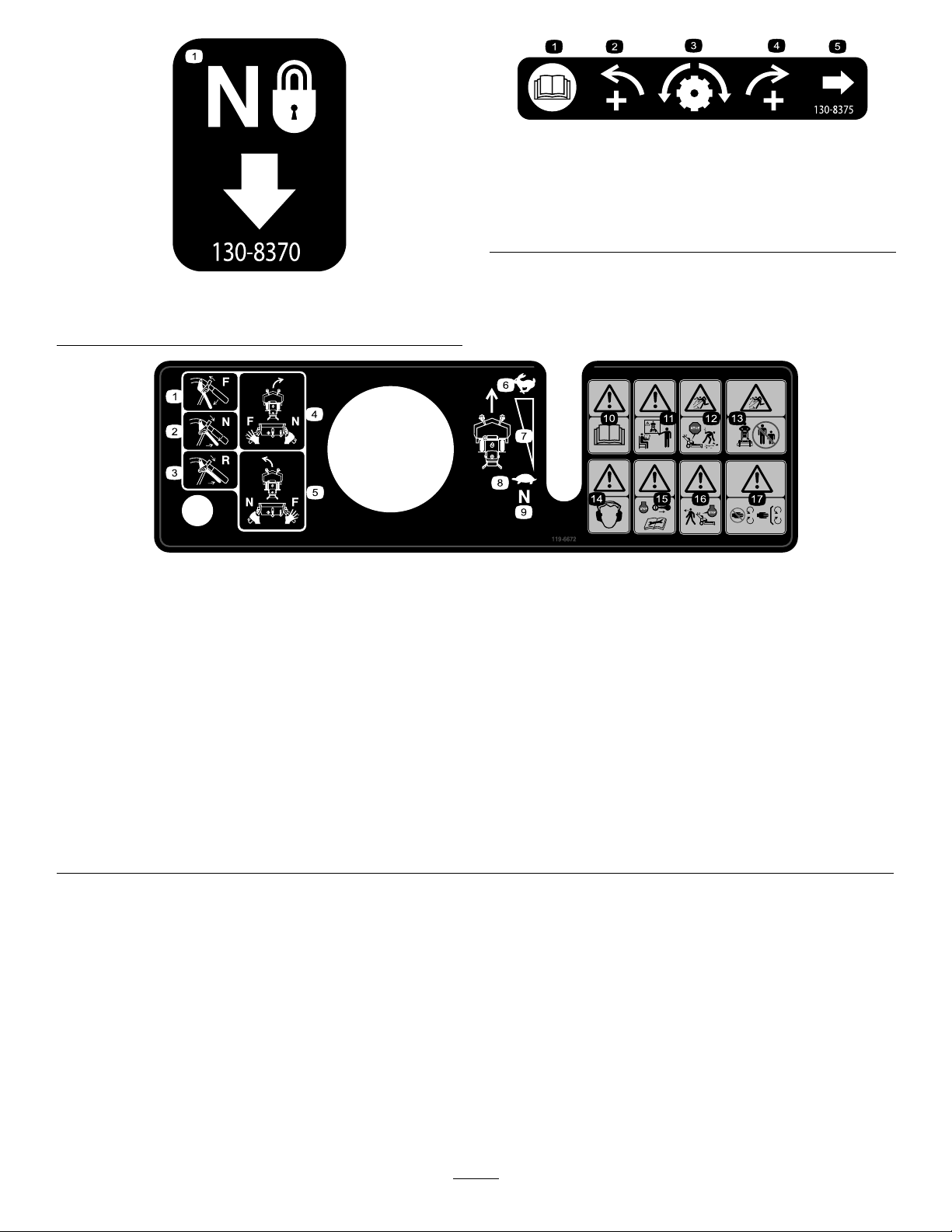

decal130-8375

130-8375

1.ReadtheOperator's

4.Increaseright

Manual.

2.Increaseleft

5.Trackingadjustmentknob

3.Trackingadjustment

decal130-8370

130-8370

1.Neutrallock

119-6672

1.Forward

2.Neutral11.Warning—donotoperatethismachineunlessyouaretrained.

3.Reverse

4.Toturnthemachineright,engageNEUTRALontherighthandle

whilethelefthandleisintheFORWARDposition.

5.Toturnthemachineleft,engageNEUTRALonthelefthandle

whiletherighthandleisintheFORWARDposition.

6.Fast

7.Continuous-variablesetting16.Warning—shutofftheenginebeforeleavingthemachine.

8.Slow17.Cutting,dismembermenthazardofhand—stayawayfrom

9.Neutral

10.Warning—readtheOperator'sManual.

12.Thrownobjecthazard—shutofftheenginebeforeclearing

debris.

13.Thrownobjecthazard—keepbystandersasafedistance

awayfromthemachine.

14.Warning—wearearprotection.

15.Warning—shutofftheengineandremovethekeybefore

performinganymaintenanceonthemachine.

movingparts,keepallguardsandshieldsinplace.

decal119-6672

7

Page 8

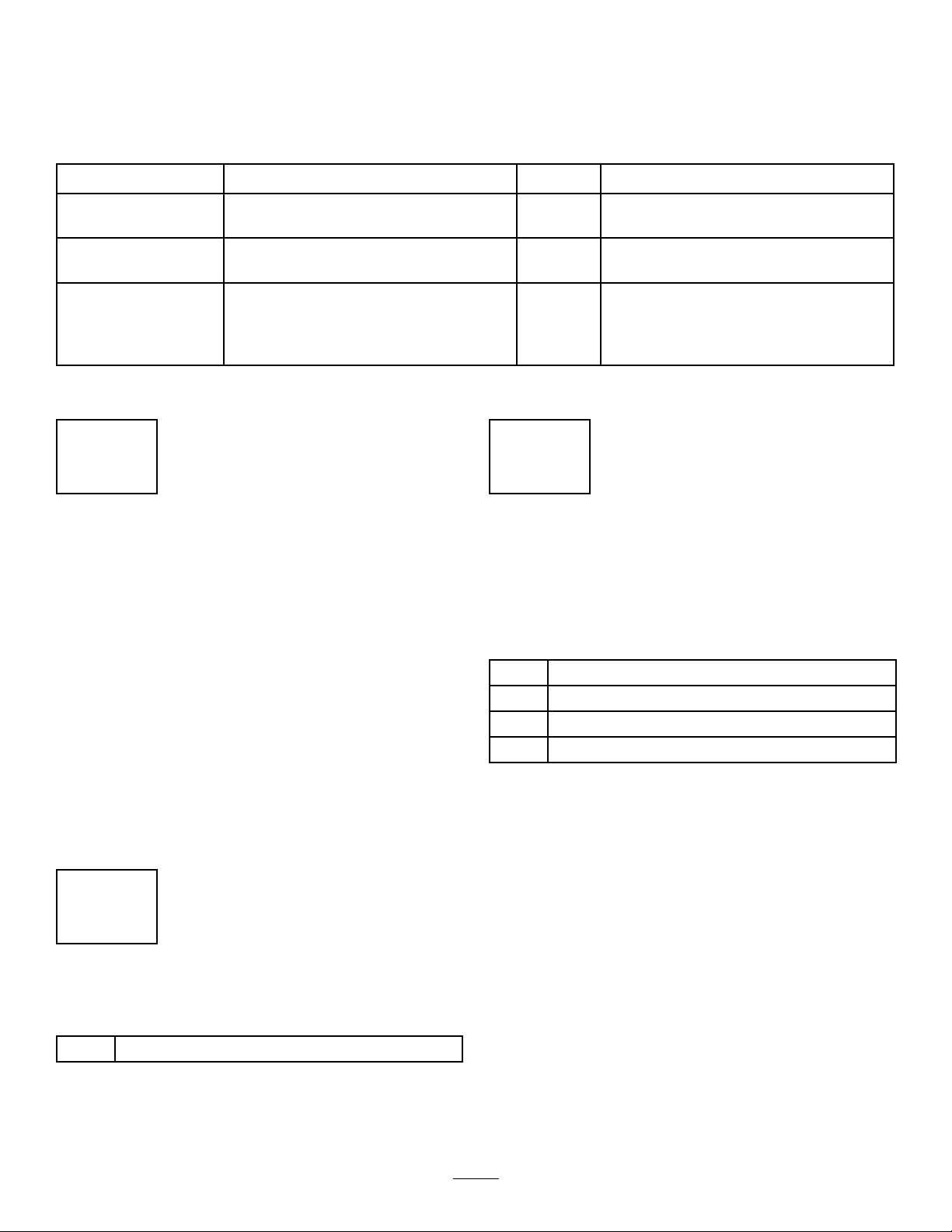

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Nopartsrequired

WheelKit(soldseparately)

Operator'sManual

Engineowner’smanual1

Operatortrainingmaterial

Oil-drainhose

1

CheckingtheFluidsand TirePressure

ReadingtheManualand

ViewingtheOperator

Qty.

–

1InstalltheWheelKit.

1

1

1

3

TrainingMaterial

NoPartsRequired

Use

Checktheuidsandtirepressure.

ReadtheOperator'sManualandwatch

theoperatortrainingmaterialbefore

operatingthemachine.

Procedure

•Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;refer

toCheckingtheEngine-OilLevel(page23).

•Checkthegreaseforthemachineandmower

deck.

Note:Thecuttingbladesaresettoa51mm(2inch)

heightofcutatinitialpurchase.TheaxlepositionisB,

with2spacesbelowthecastersand4spacesbelow

thespindle.

2

InstallingtheWheelKit

Partsneededforthisprocedure:

1

WheelKit(soldseparately)

Partsneededforthisprocedure:

1

Operator'sManual

1Engineowner’smanual

1

Operatortrainingmaterial

1

Oil-drainhose

Procedure

•ReadtheOperator'sManual.

•Viewtheoperatortrainingmaterialbefore

operatingthemachine.Thisisgeneraltraining

materialandthemachinemaydifferfromthat

supplied.

•Usetheoil-drainhosewhenchangingtheengine

oil.

Procedure

RefertotheInstallationInstructionsforthewheelkit

8

Page 9

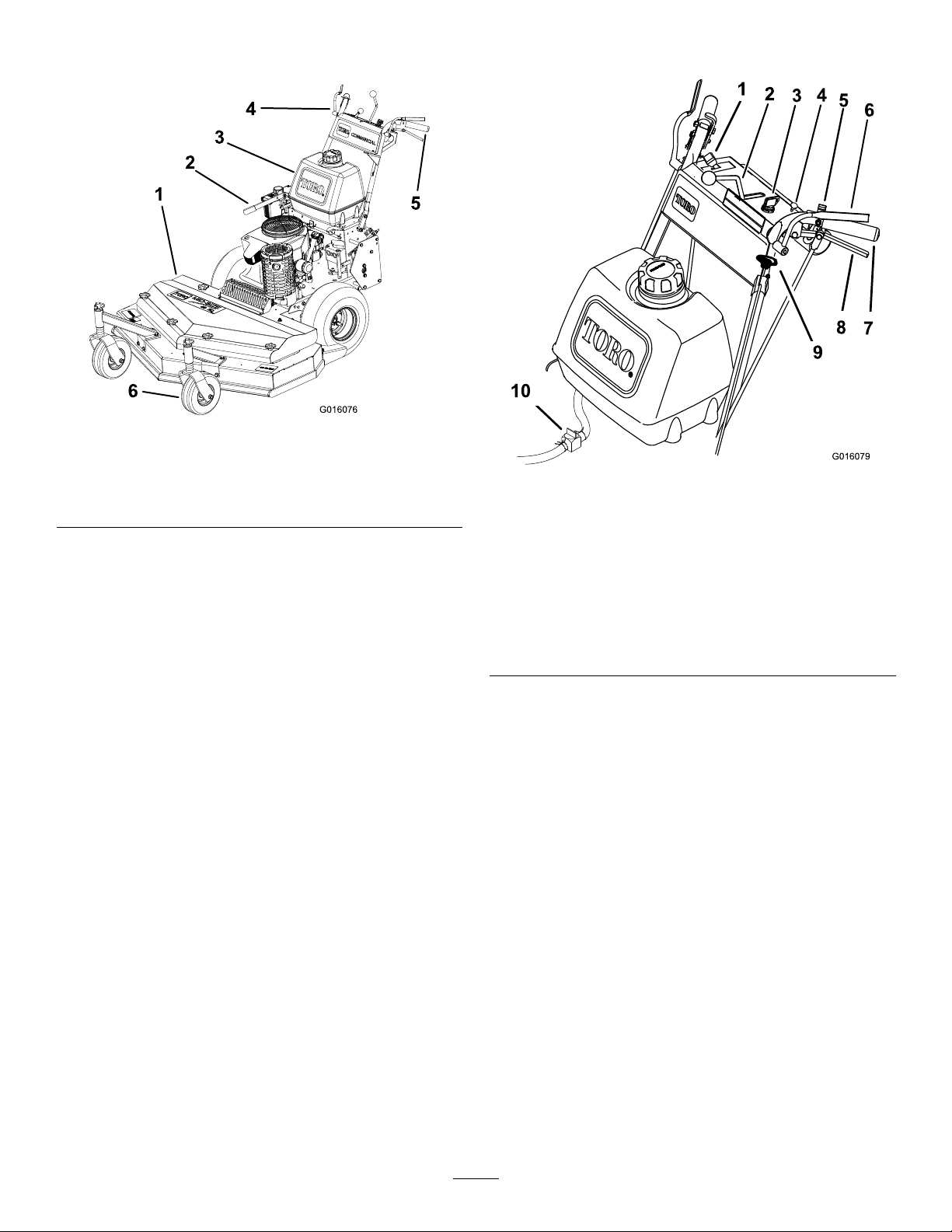

ProductOverview

g016076

Figure4

ControlPanel

1.Mowerdeck

2.Brake5.Handle

3.Fueltank

4.Controls

6.Casterwheel

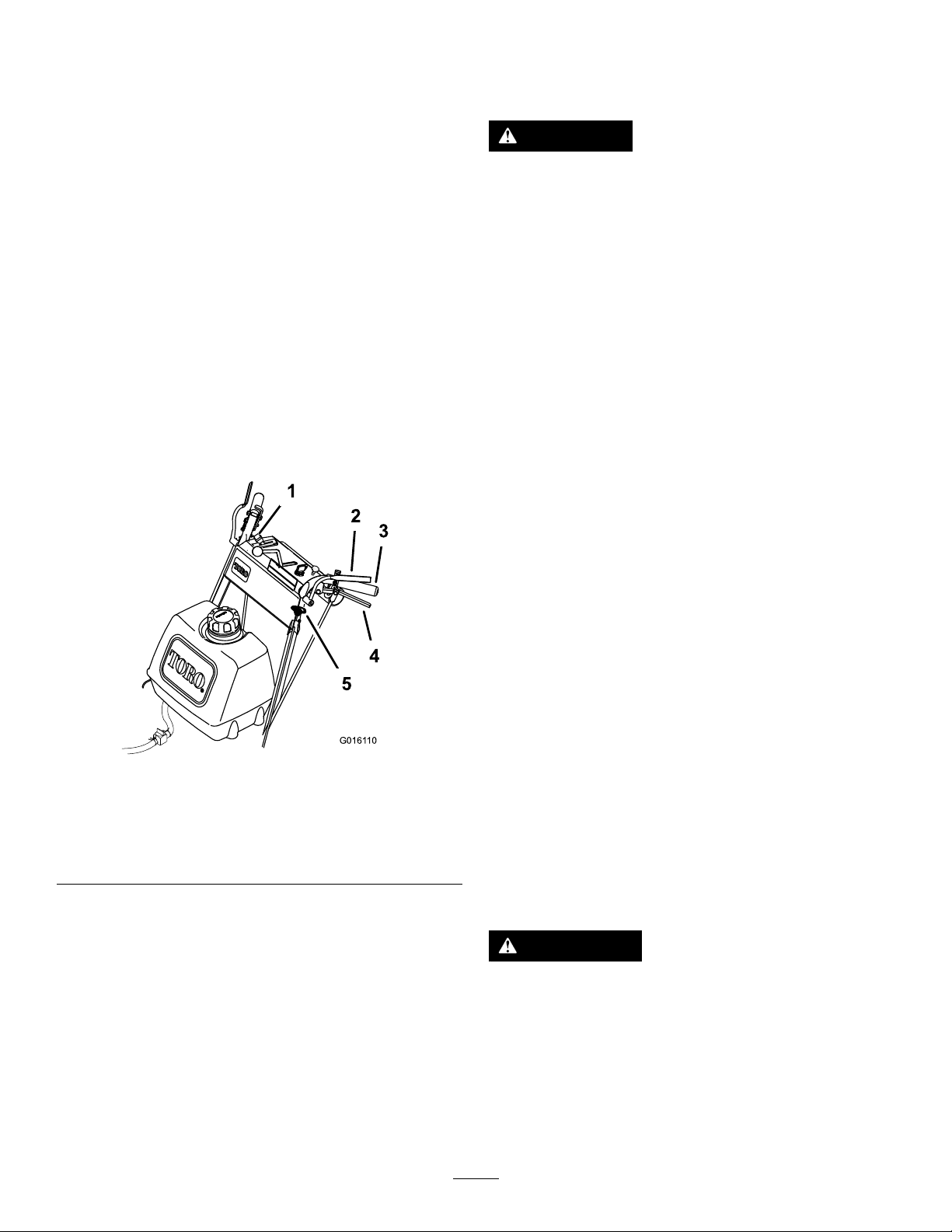

Controls

Becomefamiliarwithallthecontrols(Figure5)before

youstarttheengineandoperatethemachine.

Figure5

1.Throttlecontrol

2.Speed-controllever

3.Keyswitch8.DriveLever

4.Choke9.Blade-controlknob(PTO)

5.Neutrallock

6.Operator-presencecontrol

(OPC)levers

7.Handle

10.Fuel-shutoffvalve

ThrottleControl

Thethrottlecontrolstheenginespeedandhas2

positions:SLOWandFAST.

Operator-PresenceControl(OPC)

Levers

WhenyousqueezetheOPCleversagainstthe

handles,theOPCsystemsensesthatyouareinthe

normaloperatingposition.Whenyoureleasethe

OPClevers,theOPCsystemsensesthatyouhave

leftthenormaloperatingposition,andthesystem

shutsofftheengineifeitherthespeed-controllever

isnotintheNEUTRALpositionortheblade-control

(PTO)knobisengaged.

g016079

9

Page 10

Blade-ControlKnob(PTO)

Specications

Usetheblade-controlknob(PTO),withtheOPC

leverspressedagainstthehandles,toengageand

disengagethedrivebelttodrivethemowerblades.

Pulltheknobuptoengagethebladesandpushdown

todisengagetheblades.

KeySwitch

Thisswitchisusedinconjunctionwithrecoilstarter

andhas3positions:OFF,RUN,andSTART.

Speed-ControlLever

Thismachinehasavariablespeedcontrolwitha

NEUTRALposition.Thiscontrolshowfastthemachine

travels.

DriveLevers

Releasethedriveleverstodrivethemachineforward;

squeezetheleversuntilyoufeelanincreaseinforce

togointotheNEUTRALpositionandthencontinue

tosqueezethemtodrivethemachineinreverse.

Squeezetherightdrivelevertoturnrightandsqueeze

theleftlevertoturnleft.

NeutralLock

Squeezethedriveleversuntilyoufeelanincreasein

forceandmovelockstotherearforneutrallock.

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

82cm(32inch)mowerdecks:

Cuttingwidth82cm(32inches)

Width

Length

Height

Weight

89cm(35inches)

203cm(80inches)

112cm(44inches)

231kg(509lb)

91cm(36inch)mowerdecks:

Cuttingwidth91cm(36inches)

Width

Length

Height

Weight

94cm(37inches)

203cm(80inches)

112cm(44inches)

232kg(511lb)

122cm(48inch)mowerdecks:

Cuttingwidth122cm(48inches)

Width

Length

Height

Weight

126cm(49-1/2inches)

194cm(76-1/2inches)

112cm(44inches)

248kg(547lb)

Fuel-ShutoffValve

Closethefuel-shutoffvalvewhentransportingor

storingthemachine.

ChokeControl

Usethechokecontroltostartacoldengine.

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

10

Page 11

Operation

AddingFuel

FuelSafety

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlingfuel.Fuelvaporsare

ammableandexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfueltothefuel

tankwhiletheengineisrunningorwhilehot.

•Donotrefuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Donotllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

containersontheground,awayfromyourvehicle

beforelling.

•Removetheequipmentfromthetruckortrailer

andrefuelitwhileitisontheground.Ifthisisnot

possible,thenrefuelfromaportablecontainer

ratherthanafuel-dispensernozzle.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.Wipeupanyfuelthatspills.

•Neveroverllthefueltank.Replacethefuelcap

andtightenitsecurely.

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

UsingStabilizer/Conditioner

Usefuelstabilizer/conditionerinthemachinetokeep

thefuelfreshlongerwhenusedasdirectedbythe

fuel-stabilizermanufacturer.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addtheamountoffuelstabilizer/conditionertofresh

fuelasdirectedbythefuel-stabilizermanufacturer.

FillingtheFuelTank

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

4.Cleanaroundthefuel-tankcap.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymorethan

a30-daysupplyoffuel.

•Donotllthefueltankcompletelyfull.Addfuelto

thefueltankuntilthelevelis6to13mm(1/4to

1/2inch)belowthebottomofthellerneck.This

emptyspaceinthetankallowsfueltoexpand.

–Avoidprolongedbreathingofvapors.

–Keepyourfaceawayfromthenozzleandfuel

tankopening.

–Avoidcontactwithskin;washoffspillswith

soapandwater.

5.Fillthefueltankuntilthelevelis6to13mm(1/4

to1/2inch)belowthebottomofthellerneck.

Note:Thisspaceinthetankallowsthefuelto

expand.Donotllthefueltankcompletelyfull.

6.Installthefueltankcapsecurely.Wipeupany

fuelthatmayhavespilled.

11

Page 12

ThinkSafetyFirst

Carefullyreadallthesafetyinstructionsanddecals

inthesafetysection.Knowingthisinformationcould

helpyouoranybystandersavoidinjury.

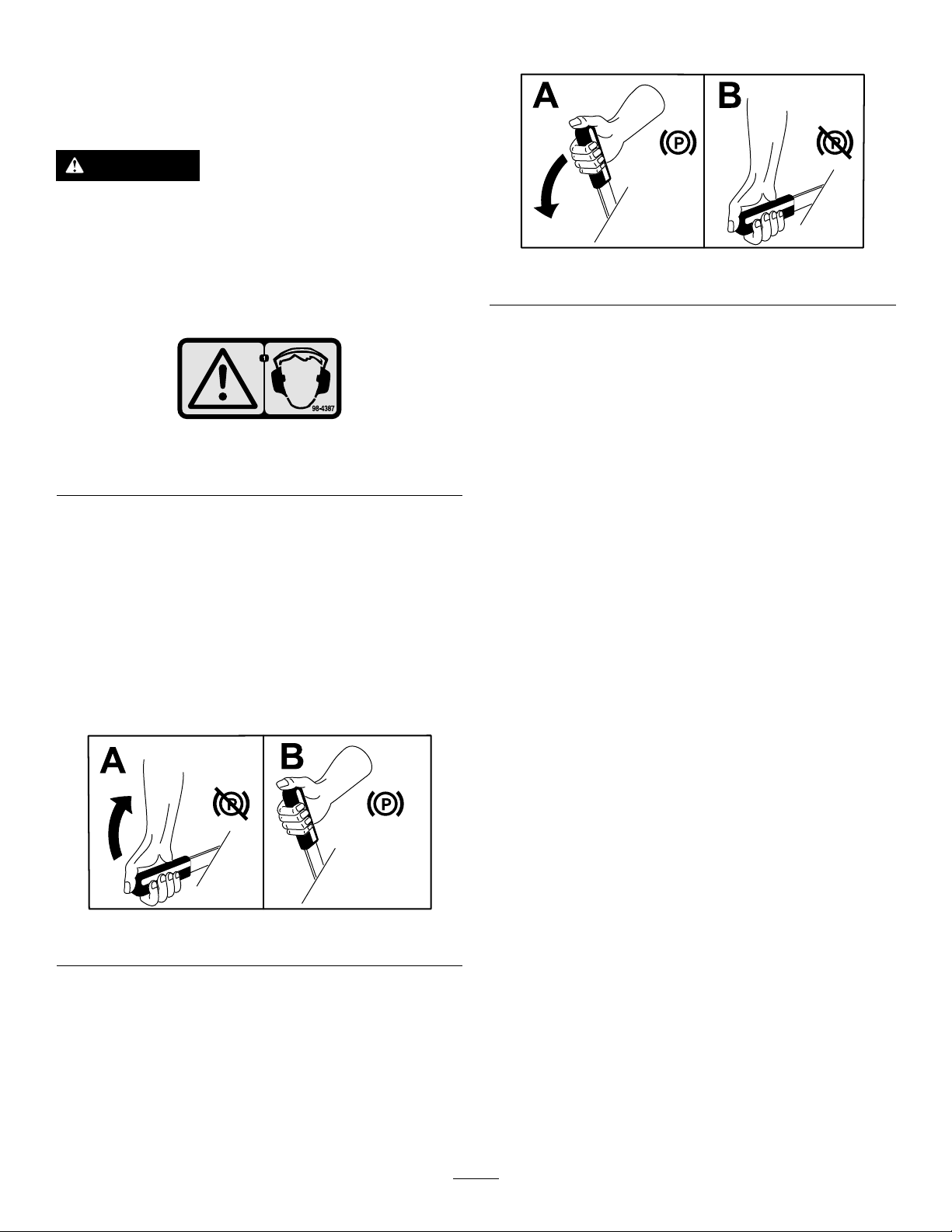

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator'searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

DisengagingtheParkingBrake

g241312

Figure8

StartingtheEngine

1.Connectthewirestothesparkplugs.

Figure6

1.Warning—wearhearingprotection.

OperatingtheParking Brake

Alwaysengagetheparkingbrakewhenyoustopthe

machineorleaveitunattended.

EngagingtheParkingBrake

Parkthemachineonalevelsurface.

decal98-4387

2.Openthefuelvalve.

3.Disengagetheblade-controlknob(PTO)and

movethespeed-controllevertotheNEUTRAL

position.

4.MovethedriveleverstotheNEUTRALposition

andengagetheneutrallocks.

5.Engagetheparkingbrake.

6.TurnthekeytotheRUNposition(Figure5).

7.Tostartacoldengine,movethethrottlecontrol

midwaybetweentheFASTandSLOWpositions.

8.Tostartawarmengine,movethethrottlecontrol

totheFASTposition.

9.Engagethechokeiftheengineiscold(Figure

5).

Note:Awarmorhotengineusuallydoesnot

requireanychoking.

10.TurnthekeytotheST ARTpositiontoenergize

thestarter.Whentheenginestarts,releasethe

key.

Figure7

Note:Donotengagethestarterformorethan

5secondsatatime.Iftheenginefailstostart,

g241313

12

allowfora15secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructionscan

burnoutthestartermotor.

11.Disengagethechokeastheenginewarmsup

(Figure9).

12.Iftheengineiscold,allowittowarmupandthen

movethethrottlecontroltotheFASTposition.

Page 13

ShuttingOfftheEngine

Important:Inanemergency,youcanshutoff

theengineimmediatelybyturningthekeytothe

OFFposition.

1.MovethedriveleverstotheNEUTRALposition

andengagetheneutrallocks.

2.MovethethrottlelevertotheSLOW(Figure9).

3.Disengagetheblade-controlknob(PTO)and

movethespeed-controllevertotheNEUTRAL

position.

4.Lettheengineidlefor30to60seconds

2.Placeyourthumbsontheupperpartofthelocks

andmovethembackuntilthepinsareinthe

NEUTRALposition(Figure10).

5.TurnthekeytotheOFFposition.

6.Engagetheparkingbrakeandremovethekey.

Important:Closethefuel-shutoffvalve

beforetransportingorthestoringthe

machinetopreventfuelleakage.

Figure10

1.Handle4.Drivelever

2.Neutrallock

3.NEUTRALposition6.REVERSEposition

5.Fullspeedforward

ReleasingtheNeutralLock

1.Squeezethedriveleversuntilyoufeelan

increaseinforce.

2.Placeyourthumbsontheupperpartoflocks

andmovethemforwarduntilthepinsareinthe

forwardslot(Figure11).

g001508

Figure9

1.Throttlelever

2.Keyswitch

3.Choke

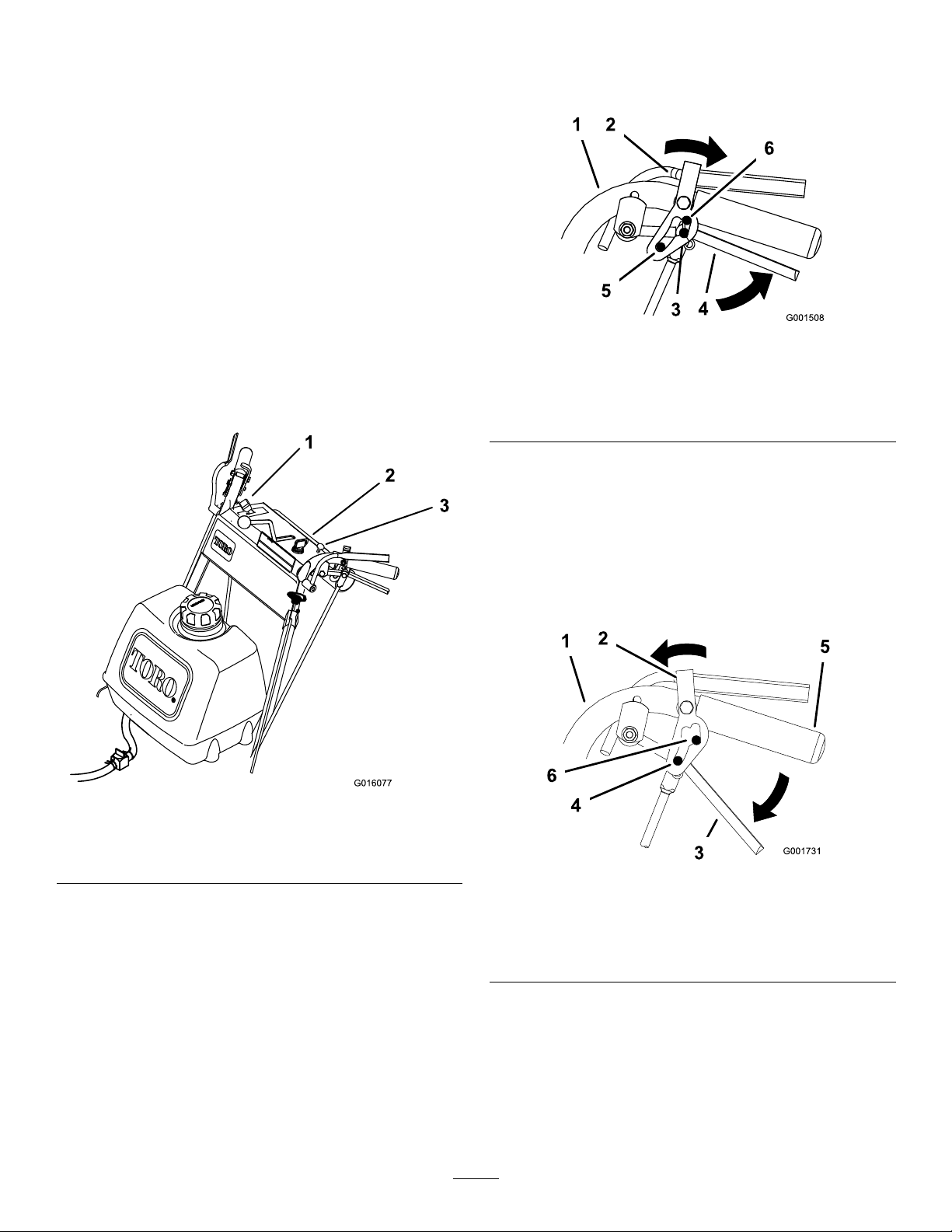

OperatingtheNeutral Locks

Alwaysengagetheneutrallockwhenyoustop

themachine.Engagetheparkingbrakeifitisleft

unattended.

SettingtheNeutralLock

1.Squeezethedriveleversuntilyoufeelan

increaseinforce.

g027797

g001731

Figure11

1.Handle

2.Neutrallock5.Handle

3.Drivelever6.Forwardslot

13

4.Pininfullspeedforward

Page 14

Operatingthe

UsingtheSafety-Interlock

Blade-ControlKnob(PTO)

Theblade-controlknob(PTO)isusedinconjunction

withtheoperator-presencecontrol(OPC)leversto

engageanddisengagethemowerblades.

EngagingtheMowerBlades(PTO)

1.Toengagethemowerblades,squeezethe

operator-presencecontrol(OPC)leversagainst

handlegrips(Figure12).

2.Pulltheblade-controlknob(PTO)up.Holdthe

OPCleversagainsthandlegrip.

Note:ReleasingtheOPCleverswiththe

mowerbladesrunningshutsofftheengine.

3.Starttheengineandrepeattheprocedure

toengagethemowerbladesifthe

operator-presencecontrol(OPC)levers

arereleased.

System

CAUTION

Ifsafety-interlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Understandingthe Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtopreventthe

machinefromstartingunless:

•Theblade-controlknob(PTO)isdisengaged.

•Thespeed-controlleverisintheNEUTRALposition.

Thesafety-interlocksystemisdesignedtoshutoff

theenginewhen:

Figure12

1.Throttlelever4.DriveLever

2.Operator-presencecontrol

(OPC)levers

3.Handle

5.Blade-controlknob(PTO)

DisengagingtheMowerBlades (PTO)

Themowerbladescanbedisengagedby2ofthe

followingsteps.

1.Pushtheblade-controlknob(PTO)downtothe

OFFposition(Figure12).

2.Releasingtheoperator-presencecontrol(OPC)

leversshutsofftheengineandstopstheblades

(Figure12)withtheblade-controlleverengaged.

•Theoperator-presencecontrol(OPC)levers

arereleasedwiththemowerbladesengaged

and/orthespeed-controlleveroutoftheNEUTRAL

position.

•Thespeed-controlleverisshiftedoutofthe

NEUTRALwithoutholdingOPCleversorwiththe

brakeengaged.

•Theblade-controlknob(PTO)ispulledupwithout

holdingtheOPClevers.

g016110

TestingtheSafety-Interlock System

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribed,haveanAuthorizedService

Dealerrepairthesafetysystemimmediately.

WARNING

Whiletestingthesafety-interlocksystem,

themachinemaymoveforwardandcause

personalinjuryorpropertydamage.

•Testthesafety-interlocksysteminanopen

area.

•Ensurethatnooneisstandingin

frontofthemachinewhiletestingthe

safety-interlocksystem.

14

Page 15

1.Engagetheneutrallocksandmovethe

speed-controllevertotheNEUTRALposition.

2.Starttheengine;refertoStartingtheEngine

(page12).

3.Withoutholdingtheoperator-presencecontrol

(OPC)levers,pulltheblade-controlknob(PTO)

up.Theengineshouldshutoff.

4.Disengagetheblade-controlknob(PTO).

5.Withenginerunning,holddowntheOPClevers.

Pulltheblade-controlknob(PTO)up.Thedrive

beltshouldengageandthemowerbladesbegin

rotating.

6.ReleasetheOPClevers.Theengineshould

shutoff.

7.Withtheenginerunning,movethespeed-control

leverforward.ReleasetheOPClevers.The

engineshouldshutoff.

1.Drivelever

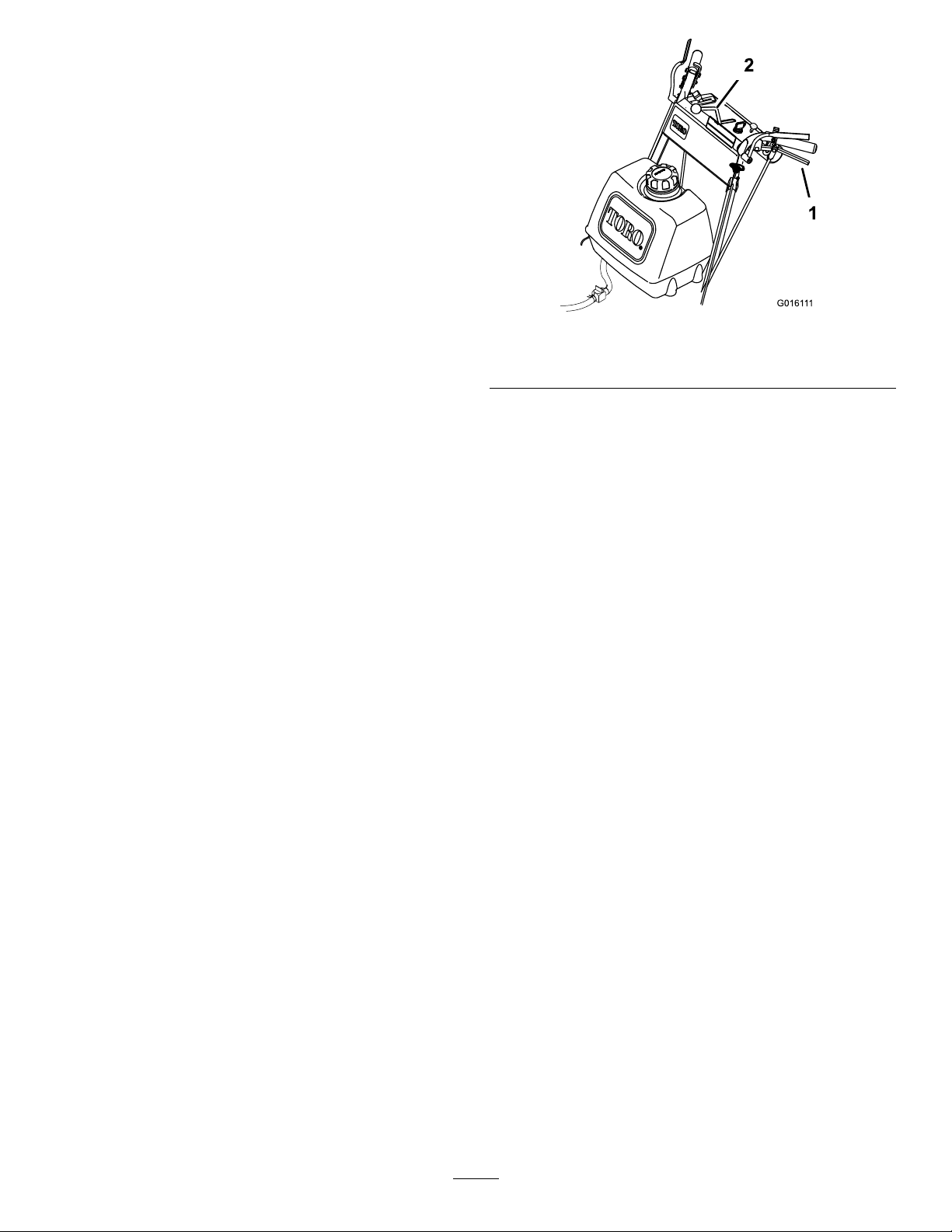

g01611 1

Figure13

2.Speed-controllever

8.Ifalltheaboveconditionsarenotmethave

anAuthorizedServiceDealerrepairthesafety

systemimmediately.

DrivingtheMachine ForwardandBackward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Placethe

throttlecontrolintheFASTpositionforbestmowing

performance.

DrivingForward

1.Disengagetheparkingbrake.

2.Movethespeed-controllevertodesiredspeed.

3.Releasetheneutrallock.RefertoReleasingthe

NeutralLock(page13).

4.Slowlyreleasethedriveleverstomoveforward

(Figure13).

Togostraight,releasedriveleversequally

(Figure13).

Toturn,squeezethedriveleveronthesideand

directionyouwanttoturn(Figure13).

DrivingBackward

Slowlysqueezethedriveleverstothehandletomove

rearward(Figure13).

BringingtheMachineto Neutral

Alwaysengagetheneutrallockandparkingbrake

whenyoustopthemachine.

1.SqueezethedriveleverstotheNEUTRAL

position.

2.Engagetheneutrallocks.RefertoOperating

theNeutralLocks(page13).

3.Movethespeed-controllevertotheNEUTRAL

position.

PushingtheMachineby Hand

Thebypassvalvesenableyoutopushthemachine

byhandwithouttheenginerunning.

Important:Alwayspushthemachinebyhand.

Nevertowthemachine,becausehydraulic

damagemayoccur.

ToPushtheMachine

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

15

Page 16

3.Openthebypassvalvesbyturningthemcounter

clockwise1to2times(Figure14).

Note:Thisallowshydraulicuidtobypassthe

pumpsandthewheelstoturn.

4.Disengagetheparkingbrake.

5.Pushthemachinetothedesiredlocation.

6.Engagetheparkingbrake.

7.Closethebypassvalvesbutdonotovertighten

them.

Note:Rotatethebypassvalvesamaximumof

2turnssothevalvedoesnotcomeoutofthe

bodyandcauseuidtorunout.

heightofcut.RefertoHeight-of-CutChart(page19)

toselectthecombinationofadjustmentsrequired.

AdjustingtheBladeHeight

Adjustthebladesbyusingthe4spacers(1/4inch)

spacersonthebladespindlebolts.Thisallowsfora

25mm(1inch)adjustmentrangeofcuttingheight,in

6mm(1/4inch)increments,inanyaxleposition.Use

thesamenumberofbladespacersonallbladesto

achievealevelcut(2aboveand2below,1above

and3below,etc.).

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

Important:Donotstartoroperatethe

machinewiththebypassvalvesopen.

Damagetosystemmayoccur.

Figure14

1.Hydraulicpump2.Bypassvalve

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarylightingandmarkingasrequiredbylaw.

Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

petsorbystandersavoidinjury.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Holdthebladeboltandremovethenut.Slide

theboltdownthroughthespindle,andchange

thespacersasneeded(Figure15).

g007735

1.Secureatrailertotowingvehiclewithsafety

chains.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Securelyfastenthemachinetothetraileror

truckwithstraps,chains,cable,orropes.

AdjustingtheHeightofCut

Thismachinehasa26to108mm(1to4-1/4inch)

rangeforheightofcut.Adjustthebladespacers,rear

axleheightorfrontcasterspacerstogetthecorrect

1.Blade

2.Bladebolt5.Thinwasher

3.Curvedwasher

16

g001454

Figure15

4.Spacer

6.Nut

Page 17

4.Installthebolt,curvedwasher,blade,addextra

spacers,andsecurethemwithathinwasher

andanut(Figure15).

5.Torquethebladeboltto101to108N∙m(75to

80ft-lb).

AdjustingtheAxleHeight

Adjusttheaxlepositiontotheselectedheight-of-cut

setting.RefertoHeight-of-CutChart(page19).

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Placeajackundertheengineframe.Raisethe

backendoftheengineframeenoughtoremove

thedrivewheels.

4.Removethedrivewheels.

5.Loosen,butdonotremove,the2topaxlebolts

(Figure16).

6.Removethe2loweraxlebolts(Figure16).

AdjustingtheCaster Position

1.Adjustthecasterspacerstomatchwiththeaxle

holeselected(Figure17);refertoHeight-of-Cut

Chart(page19)and.

Figure17

1.Latchpin

2.Spacer—5mm(3/16inch)

3.Spacer—13mm(1/2inch)

g001456

Figure16

1.Topaxlebolt2.Loweraxlebolt

7.Raiseorlowerthemountingbracket,sothat

youcaninstallthe2axleadjustmentboltsinthe

desiredholelocation(Figure16).

Note:Ataperedpunchcanbeusedtohelp

aligntheholes.

2.Removethelatchpin,slidethecasterfromthe

support,andchangethespacers(Figure17).

3.Installthecasterinthesupportandinsertthe

latchpin(Figure17).

g001512

8.Tightenall4bolts.

9.Installthedrivewheelsandlowerthemachine.

17

Page 18

AdjustingtheHandle Height

Thehandlepositioncanbeadjustedtomatchyour

heightpreference.

1.Removethehairpincottersandclevispinsfrom

thedriveleversandneutrallocks(Figure18).

g001734

Figure19

Figure18

1.Controlrod5.Lefthandleshown

2.Clevispin

3.Drivelever7.Hairpincotter

4.Operator-presencecontrol

lever(OPC)

6.Neutrallock

2.Loosentheupperangebolts(3/8x1-1/4

inches)andangenutsecuringhandletorear

frame(Figure19).

3.Removethelowerangebolts(3/8x1inch)

andangenutssecuringhandletorearframe

(Figure19).

4.Pivothandletodesiredoperatingpositionand

installlowerangebolts(3/8x1inch)andange

nutsintomountingholes.Tightenallange

bolts.

1.Controlrodtting

2.Lowermountingholes7.Lowerposition

3.Rearframe

g001733

4.Lowerangebolt(3/8x1

inch)

5.Upperangebolt(3/8x

1-1/4inches)

6.Highposition

8.Uppermountinghole

9.Handle

10.Flangenut(3/8inch)

5.Adjustthecontrolrodlengthbyrotatingthe

controlrodintherodtting(Figure18and

Figure19).

6.Installhairpincotterbetweendriveleversand

neutrallocksandintoclevispins(Figure18).

Note:Makesurethattheclevispinsare

insertedintotheneutrallocks.

7.Performthehydrauliclinkageadjustmentswhen

thehandleheightischanged;referAdjustingthe

HydraulicControlLinkages(page30).

18

Page 19

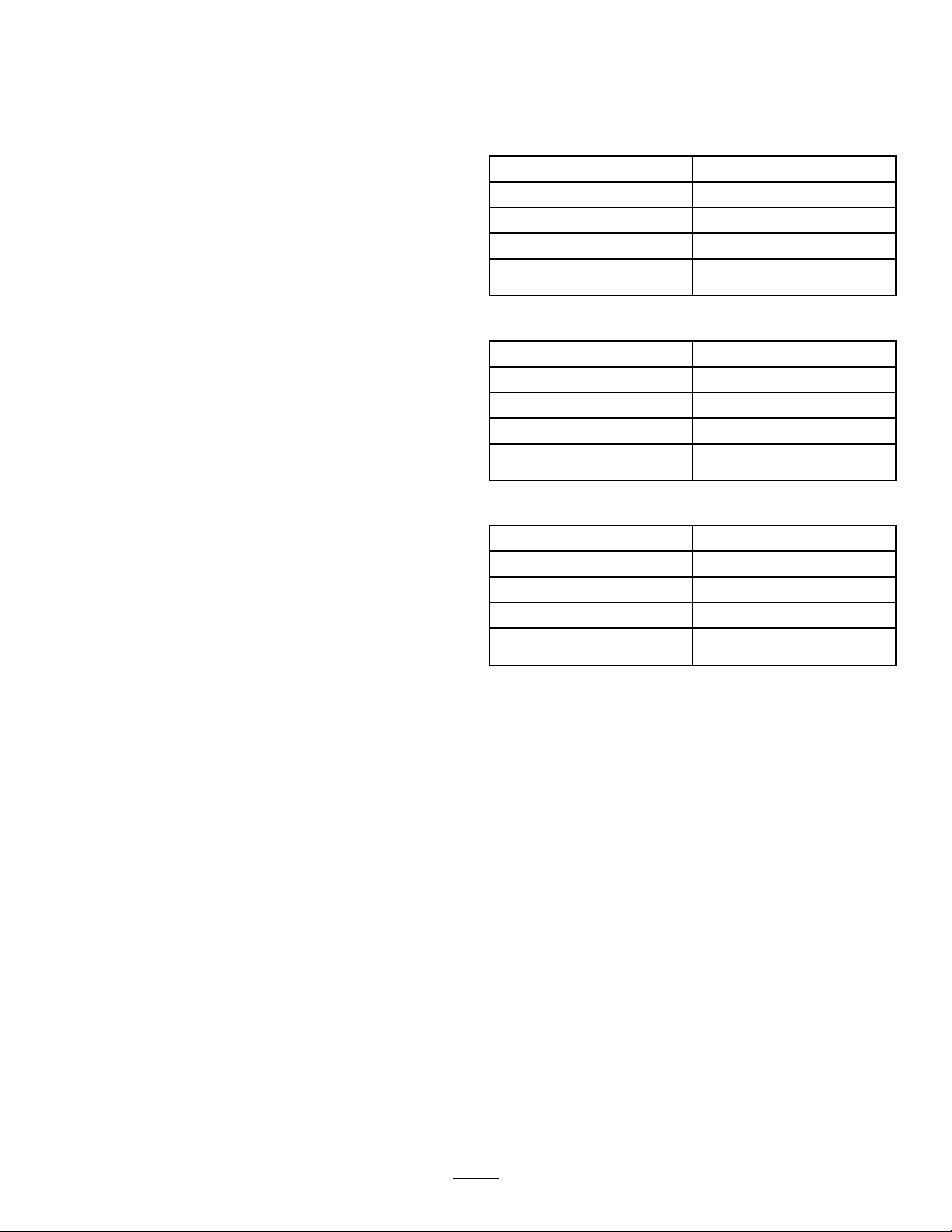

Height-of-CutChart

Numberofspacers

Axle

Position

A00

A01

A10

B01

B10

B11

B20

C

C

C

C

D21

D30

D31

D40

E31

E40

E41

belowcaster

13mm5mm

(1/2inch)(3/16inch)

11

20

21

30

Numberof6mm(1/4inch)bladespacersbelowspindle

43210

26mm32mm38mm45mm51mm

(1inch)(1-1/4inch)(1-1/2inch)(1-3/4inch)(2inch)

29mm35mm41mm48mm54mm

(1-1/8inch)(1-3/8inch)(1-5/8inch)(1-7/8inch)(2-1/8inch)

35mm41mm48mm54mm60mm

(1-3/8inch)(1-5/8inch)(1-7/8inch)(2-1/8inch)(2-3/8inch)

35mm41mm48mm54mm60mm

(1-3/8inch)(1-5/8inch)(1-7/8inch)(2-1/8inch)(2-3/8inch)

41mm48mm54mm60mm67mm

(1-5/8inch)(1-7/8inch)(2-1/8inch)(2-3/8inch)(2-5/8inch)

45mm51mm

(1-3/4inch)(2inch)(2-1/4inch)(2-1/2inch)(2-3/4inch)

51mm

(2inch)(2-1/4inch)(2-1/2inch)(2-3/4inch)(3inch)

48mm54mm60mm67mm73mm

(1-7/8inch)(2-1/8inch)(2-3/8inch)(2-5/8inch)(2-7/8inch)

54mm60mm67mm73mm79mm

(2-1/8inch)(2-3/8inch)(2-5/8inch)(2-7/8inch)(3-1/8inch)

57mm

(2-1/4inch)(2-1/2inch)(2-3/4inch)(3inch)(3-1/4inch)

64mm70mm76mm83mm89mm

(2-1/2inch)(2-3/4inch)(3inch)(3-1/4inch)(3-1/2inch)

60mm67mm73mm79mm86mm

(2-3/8inch)(2-5/8inch)(2-7/8inch)(3-1/8inch)(3-3/8inch)

64mm70mm76mm83mm89mm

(2-1/2inch)(2-3/4inch)(3inch)(3-1/4inch)(3-1/2inch)

70mm76mm83mm89mm95mm

(2-3/4inch)(3inch)(3-1/4inch)(3-1/2inch)(3-3/4inch)

76mm83mm89mm95mm102mm

(3inch)(3-1/4inch)(3-1/2inch)(3-3/4inch)(4inch)

73mm79mm86mm92mm98mm

(2-7/8inch)(3-1/8inch)(3-3/8inch)(3-5/8inch)(3-7/8inch)

79mm86mm92mm98mm105mm

(3-1/8inch)(3-3/8inch)(3-5/8inch)(3-7/8inch)(4-1/8inch)

83mm89mm95mm102mm108mm

(3-1/4inch)(3-1/2inch)(3-3/4inch)(4inch)(4-1/4inch)

57mm

64mm70mm76mm83mm

57mm

64mm70mm76mm

64mm70mm

19

Page 20

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst25hours

Beforeeachuseordaily

Every25hours

Every50hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthemowerbelttension.

•Checkthehydraulic-uidlevel.

•Replacethehydraulicuidlter.

•Checkthemowerbelttension.

•Checkthesafetysystem.

•Greasethecasterwheelsandcasterpivot.

•Checktheengine-oillevel.

•Cleantheairintakescreen.

•Checktheparkingbrake.

•Inspecttheblades.

•Cleanthemowerdeck.

•Cleanthefoamair-cleanerelement(moreoftenindirtyordustyconditions).

•Checkthehydraulic-uidlevel.

•Greasethemower-beltidler .

•Greasethepump-driveidlerpivot.

•Greasethepumpcontrol.

•Checkthepaperair-cleanerelement(moreoftenindirtyordustyconditions).

•Checkthetirepressure.

•Checkthebelts.

•Checkthemowerbelttension.

•Greasetheblade-engagementbellcrank.

Every100hours

Every200hours

Every300hours

Every400hours

Beforestorage

•Changetheengineoil(moreoftenindirtyordustyconditions).

•Replaceorcleanandgapthesparkplug.

•Checkhydrauliclinesandhoses.

•Replacethepaperair-cleanerelement(moreoftenindirtyordustyconditions).

•Changetheengine-oillter(moreoftenindirtyordustyconditions).

•Replacethefuellter.

•Replacethehydraulicuidlter.

•Checkandadjustthevalveclearance.SeeanAuthorizedServiceDealer.

•Lubricatethecamlockwithanti-seizecompound.

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertotheengineowner’smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitchbeforeyouperformanymaintenance.

20

Page 21

Lubrication

GreasingthePumpControl

UseFigure20forlocatingthegreasepointsonthe

machine.

Greasetype:No.2lithiumormolybdenumgrease

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettingswitharag.Scrapeany

paintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pump

greaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

5.Wipeupanyexcessgrease.

LubricatingtheCasterand WheelBearings

ServiceInterval:Beforeeachuseordaily

andBellCrank

ServiceInterval:Every50hours—Greasethe

pump-driveidlerpivot.

Every50hours—Greasethepumpcontrol.

Every100hours—Greasethe

blade-engagementbellcrank.

Every400hours—Lubricatethecamlockwith

anti-seizecompound.

Greasethettingonthepump-driveidlerpivotand

thepumpcontrol.

Greasethebladeengagement(PTO)bellcrank

(Figure20).

Lubricatecamlockwithanti-seizecompound.

Note:Removetheguardsttedunderthemachineto

accessthegreasettingonthepump-driveidlerpivot.

Lubricatethefrontwheelbearingsandfrontspindles

(Figure20).

GreasingtheMower-Belt Idler

ServiceInterval:Every50hours

Greasethettingonthemower-beltidlerarmpivot

(Figure20).

Note:Removethemowerdeckcovertoaccessthe

greasettingforthemower-beltidlerarm.

Figure20

1.Pump-driveidlerarm4.Mowerbeltidlerarm

2.Pumpcontrolarm

3.Bellcrank

5.Casterwheelbearing

6.Casterpivot

g001514

21

Page 22

EngineMaintenance

CleaningtheFoamAir-Cleaner Element

ServicingtheAirCleaner

ServiceInterval:Every25hours(moreoftenindirty

ordustyconditions).

Every50hours(moreoftenindirtyordusty

conditions).

Every200hours/Yearly(whichevercomesrst)

(moreoftenindirtyordustyconditions).

Inspectthefoamandpaperelementsandreplace

themiftheyaredamagedorexcessivelydirty .

Important:Donotoilthefoamorpaperelement.

RemovingtheFoamandPaper Elements

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage

(Figure21).

4.Unscrewthecoverknobsandremovethe

air-cleanercover(Figure21).

5.Unscrewthehoseclampandremovethe

air-cleanerassembly(Figure21).

6.Carefullypullthefoamelementoffthepaper

element(Figure21).

1.Washthefoamelementinliquidsoapand

warmwater.Whentheelementisclean,rinse

itthoroughly.

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifit

istornorworn.

ServicingthePaperAir-Cleaner Element

1.Donotcleanthepaperlter.Replaceit(Figure

21).

2.Inspecttheelementfortears,anoilylm,or

damagetotherubberseal.

3.Replacethepaperelementifitisdamaged.

InstallingtheFoamandPaper Elements

Important:Topreventenginedamage,always

operatetheenginewiththecompletefoamand

paperair-cleanerassemblyinstalled.

1.Carefullyslidethefoamelementontothepaper

air-cleanerelement(Figure21).

2.Placetheair-cleanerassemblyontothe

air-cleanerbaseandsecureitwiththe2wing

nuts(Figure21).

3.Placetheair-cleanercoverintopositionand

tightenthecoverknob(Figure21).

Figure21

1.Cover

2.Hoseclamp4.Foamelement

3.Paperelement

g012352

22

Page 23

ServicingtheEngineOil

EngineOilSpecications

OilCapacity:withalterchange—1.7L(57oz);

withoutalterchange—1.5L(51oz)

Viscosity:Seethetablebelow.

Figure22

g017470

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

Important:Ifyouoverllorunderlltheengine

crankcasewithoilandruntheengine,youmay

damagetheengine.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

Note:Ensurethattheengineiscoolsothatthe

oilhashadtimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outofthe

engine,cleantheareaaroundtheoil-llcapand

dipstickbeforeremovingit(Figure23).

g194611

Figure23

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours—Changethe

engineoil.

Every100hours—Changetheengineoil(more

oftenindirtyordustyconditions).

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoensurethatthe

oildrainscompletely.

2.DisengagethePTOandengagetheparking

brake.

3.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.Draintheoilfromtheengine(Figure24).

23

Page 24

Figure24

5.Slowlypourapproximately80%ofthespecied

oilintothellertubeandslowlyaddthe

additionaloiltobringittotheFullmark(Figure

25).

g194610

Figure25

6.Disposeoftheusedoilatarecyclingcenter.

g027476

24

Page 25

ChangingtheEngine-OilFilter

ServicingtheSparkPlug

ServiceInterval:Every200hours—Changethe

engine-oillter(moreoftenindirty

ordustyconditions).

1.Draintheoilfromtheengine;refertoChanging

theEngineOil(page23).

2.Changetheengine-oillter(Figure26).

ServiceInterval:Every100hours

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstalling

thesparkplugandagappingtoolorfeelergaugeto

checkandadjusttheairgap.Installanewsparkplug

ifnecessary .

TypeofSparkPlug:NGK

AirGap:0.75mm(0.03inch)

®

BPR4ESorequivalent

RemovingtheSparkPlug

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleantheareaaroundthebaseoftheplugto

keepdirtanddebrisoutoftheengine.

4.Removethesparkplug(Figure27).

Figure26

Note:Ensurethattheoil-ltergaskettouches

theengine,andthenturntheoillteranextra

3/4turn.

3.Fillthecrankcasewiththepropertypeofnew

oil(Figure25).

g027478

Figure27

g027477

25

Page 26

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithasa

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty .

Setthegapto0.75mm(0.03inch).

Figure28

FuelSystem

Maintenance

ServicingtheFuelTank

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Drainfuelfromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopen

area.Wipeupanyfuelthatspills.

•Neversmokewhendrainingfuel,andstay

g206628

awayfromanopenameorwhereaspark

mayignitethefuelfumes.

DrainingtheFuelTank

InstallingtheSparkPlug

Figure29

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Closethefuel-shutoffvalveatthefueltank

(Figure30).

4.Squeezetheendsofthehoseclamptogether

andslideitupthefuellineawayfromfuellter

(Figure30).

5.Pullthefuellineoffthefuellter(Figure30).

Openthefuel-shutoffvalveandallowthefuelto

drainintoafuelcanordrainpan.

Note:Nowisthebesttimetoinstallanewfuel

lterbecausethefueltankisempty.Referto

g027661

ReplacingtheFuelFilter(page27).

6.Installthefuellineontothefuellter.Slidethe

hoseclampclosetothevalvetosecurethefuel

line.

26

Page 27

Figure30

g001467

1.Fuel-shutoffvalve2.Fuellter

ServicingtheFuelFilter

ReplacingtheFuelFilter

ServiceInterval:Every200hours/Yearly(whichever

comesrst)

Neverinstalladirtylterafterremovingitfromthe

fuelline.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Closefuel-shutoffvalveatthefueltank(Figure

30).

4.Squeezetheendsofthehoseclampstogether

andslidethemawayfromthelter(Figure31).

g001468

Figure31

1.Hoseclamp3.Filter

2.Fuelline

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclamps

closetothelter.

7.Openfuel-shutoffvalveatfueltank(Figure30).

8.Checkforfuelleaksandrepairifneeded.

9.Wipeupanyspilledfuel.

Note:Notehowthefuellterisinstalledin

ordertoinstallthenewltercorrectly.

27

Page 28

DriveSystem

Maintenance

Performthefollowinglinkageadjustments,Adjusting

theSpeed-ControlLinkage(page28)through

AdjustingtheTracking(page32),whenthemachine

needsmaintenance.Ifanyadjustmentisneeded,do

themintheorderthattheyarelisted.

Adjustingthe Speed-ControlLinkage

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Movethespeed-controllever(locatedonthe

console)tothefullforwardposition.

4.Checktheorientationofthetabsontheends

ofthespeedcontrolcrank.Ensurethatthese

tabsarepointingstraightdownatthe6o'clock

positionapproximately(Figure32).

7.Checktomakesurethatthesafetyswitchis

pressedandthereisa8mm(5/16inch)space

betweentheactuatingtabandtheswitch(Figure

33).

8.Ifneeded,adjustswitchlocationtocreatethe

8mm(5/16inch)space(Figure33).

5.Adjustthethreadedyokeatthebottomofthe

speed-controllinkageuntilthetabsareatthe

6o'clockposition(Figure32).

Figure32

g007736

Figure33

1.Safetyswitch

2.8mm(5/16inch)space

g001516

3.Actuatingtab

1.Speedcontrolrod

2.Yoke5.Jamnut

3.Speedcontrolcrank

6.Pullthespeed-controlleverbacktotheNEUTRAL

position.

4.Tabs,6o'clockposition

28

Page 29

AdjustingtheNeutral ControlLinkages

WARNING

Theenginemustberunningwhenyou

performthecontrollinkageadjustments.

Contactwithmovingpartsorhotsurfaces

maycausepersonalinjury.

Keepyourhands,feet,face,clothingand

otherbodypartsawayfromrotatingparts,

muferandotherhotsurfaces.

WARNING

Mechanicalorhydraulicjacksmayfailto

supportmachineandcauseaseriousinjury.

•Usejackstandswhensupportingmachine.

•Donotusehydraulicjacks.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Raisetherearofthemachineontojackstands

toraisethedrivewheelsofftheground.

8.Squeeze1driveleveruntilyoufeelanincreased

resistance.ThisistheNEUTRALposition.

Note:Makesurethatyouhavenotreachedthe

endoftheneutrallockslot.Ifyouhave,shorten

thecontrolleverlinkage.RefertoAdjustingthe

ControlRod.

9.Ifthewheelturnswhileholdingthedriveleverin

theNEUTRAL,theneutralcontrollinkagesneed

adjustment(Figure34).Ifthewheelstopsthen

gotostep12.

10.Loosenthenutagainsttheneutralcontrol

linkageyoke(Figure34).

11.Adjusttheneutralcontrollinkageuntilthe

respectivedrivewheelstopswhilethedrivelever

ispulledagainsttheneutralspring(NEUTRAL

position)(Figure34).

12.Turntheadjustingboltapproximately1/4turn

clockwiseifthewheelisturninginreverseorturn

theboltapproximately1/4turncounter-clockwise

ifthewheelisturningforward(Figure34).

13.Releasethedrivelevertotheforwarddrive

positionandsqueezebackintotheNEUTRAL

position.Checktoseeifthewheelstops.Ifnot,

repeattheaboveadjustmentprocedure.

14.Afteradjustmentsaremade,tightenthenuts

againsttheyokes.

15.Repeatthisprocedurefortheoppositeside.

4.Disengagetheparkingbrake.

5.Starttheengineandmovethethrottletothefull

throttleposition.

6.Placetheneutrallocksinthefullforward

positionandmovethespeed-controllevertothe

medium-speedposition.

7.HoldOPCleversdown.

Note:HoldtheOPCleversdownwhenever

thespeed-controlleverisoutoftheNEUTRAL

positionortheenginewillshutoff.

WARNING

Theelectricalsystemdoesnot

performpropersafetyshutoffwiththe

operator-presencecontrol(OPC)levers

helddowninplace.

•Makesurethattheoperator-presence

control(OPC)leversareworking

whenadjustmentiscompleted.

•Neveroperatethisunitwiththe

operator-presencecontrol(OPC)

levershelddowninplace.

g007737

Figure34

1.Neutralcontrollinkage3.Adjustingbolt

2.Yoke4.Nut

29

Page 30

AdjustingtheHydraulic ControlLinkages

WARNING

Theenginemustberunningwhenyou

performthecontrollinkageadjustments.

Contactwithmovingpartsorhotsurfaces

maycausepersonalinjury.

Keepyourhands,feet,face,clothingand

otherbodypartsawayfromrotatingparts,

muferandotherhotsurfaces.

WARNING

Mechanicalorhydraulicjacksmayfailto

supportmachineandcauseaseriousinjury.

•Usejackstandswhensupportingmachine.

•Donotusehydraulicjacks.

8.Loosenthefrontadjustingnutonlefthydraulic

controllinkageasshowninFigure36.

9.Turntheleftrearadjustingnutcounter-clockwise

untilwheelrotatesforward(Figure36).

10.Turntherearadjustingnutclockwise1/4turn

atatime.Thenmovethespeed-controllever

forwardandbacktotheNEUTRALposition.

Repeatthisuntilleftwheelstopsrotatingforward

(Figure36).

11.Turntherearnutanadditional1/2turnand

tightenthefrontadjustingnut.

Note:Makesurethattheatpartoflinkageis

perpendiculartopinpartofswivel(Figure35).

AdjustingtheLeftSideLinkage

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Raisetherearofthemachineontojackstands

highenoughtoraisethedrivewheelsofthe

ground.

4.Disengagetheparkingbrake.

5.Starttheengineandmovethethrottletothefull

throttleposition.

6.Placetheleftdriveleverinthefullforward

position.

7.Placethespeed-controlleverintheNEUTRAL

position.

WARNING

Theelectricalsystemdoesnot

performpropersafetyshutoffwiththe

operator-presencecontrol(OPC)levers

helddowninplace.

•Makesurethattheoperator-presence

control(OPC)leversareworking

whenadjustmentiscompleted.

Figure35

1.Hydrauliccontrollinkage

2.Swivelwithpin4.Correctpositionfor

12.Afteradjustingthelefthydrauliccontrollinkage,

movethespeed-controlleverforwardandthen

backtotheNEUTRALposition.

13.HoldtheOPCleversdown.

3.Incorrectpositionfor

hydrauliccontrollinkage

Hydrauliccontrollinkage,

90degrees

Note:HoldtheOPCleversdownwhenever

thespeed-controlleverisoutoftheNEUTRAL

positionortheenginewillshutoff.

14.Makesurethatthespeed-controlleverisinthe

NEUTRALpositionandthetiredoesnotrotate.

15.Repeattheadjustmentifneeded.

g001735

•Neveroperatethisunitwiththe

operator-presencecontrol(OPC)

levershelddowninplace.

30

Page 31

Figure36

1.Hydrauliccontrollinkage3.Rearadjustingnut

2.Frontadjustingnut

4.Controlarm

NEUTRALposition.Repeatthisuntilrightwheel

stopsrotatingforward(Figure38).

5.HoldtheOPCleversdown.

Note:HoldtheOPCleversdownwhenever

thespeed-controlleverisoutoftheNEUTRAL

positionortheenginewillshutoff.

6.Thespringthatkeepstensionontheknob

shouldnormallynotneedadjustment.However

ifanadjustmentisneeded,adjustthelengthof

springto26mm(1inch)betweenthewashers

(Figure38).

7.Adjustspringlengthbyturningnutatfrontof

spring(Figure38).

g007738

Note:Ifinconsistentneutraloccurs,ensure

thatbothspringsareproperlytightenedon

thespeed-controlleverundertheconsole,

especiallytherearpivotspring.Repeatthe

adjustmentsaboveifnecessary(Figure37).

Figure37

1.Speed-controllever

2.Rearpivotspring

3.spring

AdjustingtheRightSideLinkage

1.Placethespeed-controlleverintheNEUTRAL

position.

2.Placetherightdriveleverinthefullforward

position.

3.Adjusttherightsidelinkagebyturningthequick

trackknobcounterclockwiseuntilthetirebegins

torotateforward(Figure38).

4.Turntheknobclockwise1/4turnatatime.Then

movethespeedcontrolforwardandbacktothe

g007880

Figure38

1.Hydrauliccontrollinkage

2.Spring4.26mm(1inch)

g001520

AdjustingtheControlRod

3.Quicktrackknob

CheckingtheControlRod

1.Withrearofmachinestillonjackstands

andenginerunningatfullthrottle,movethe

speed-controllevertothemediumspeed

position.

Note:HoldtheOPCleversdownwhenever

thespeed-controlleverisoutoftheNEUTRAL

positionortheenginewillshutoff.

2.Movetherespectivedriveleverupwarduntil

itreachestheNEUTRALpositionandengage

neutrallocks.

3.Ifthetirerotateseitherdirection,adjustthe

lengthofthecontrolrod;refertoAdjustingthe

ControlRod(page32)..

31

Page 32

AdjustingtheControlRod

1.Adjusttherodlengthbyreleasingthedrivelever

andremovingthehairpincotterandclevispin.

Rotatetherodintherodtting(Figure39).

2.Lengthenthecontrolrodifthetireisturningin

reverseandshortentherodifthetireisturning

forward.

3.Rotatetherodseveralturnsifthetireisrotating

fast.Then,adjusttherodin1/2turnincrements.

4.Placetheclevispinintothedrivelever(Figure

39).

Figure39

1.Controlrod5.Lefthandleshown

2.Clevispin

3.Drivelever7.Hairpincotter

4.Operator-presencecontrol

(OPC)lever

6.Neutrallock

g001732

Figure40

1.Handle5.Neutralposition

2.Neutrallock6.Drivelever

3.Handle

4.Neutrallockslot

7.Fullspeedforward

8.Controlrod

AdjustingtheTracking

1.Removemachinefromanyjackstands.

2.Checkthereartirepressure.RefertoChecking

theTirePressure(page33).

g001733

3.Runtheunitandobservethetrackingona

level,smooth,hardsurfacesuchasconcrete

orasphalt.

4.Iftheunittracksto1sideortheother,turnthe

quicktrackknob.Turntheknobrighttosteer

rightandturntheknoblefttosteerleft(Figure

41).

5.Releaseandengagetheneutrallock,checking

thatthetiredoesnotrotate(Figure40).Continue

thisprocessuntilthetiredoesnotrotate.

6.Installthehairpincotterbetweenthedrivelevers

andtheneutrallocksandintotheclevispins

(Figure39).

7.Repeatthisadjustmentfortheoppositeside.

g001523

Figure41

1.Quicktrackknob

AdjustingtheSpring AnchorLinks

Formediumorheavydutydriveconditions,suchas

operatingwithasulkyonsteepslopes,ahigherspring

forcemayberequiredonthehydraulicpumpcontrol

armstopreventthedrivesystemfromstalling.

32

Page 33

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Foraheavierdrivesetting,relocatethespring

anchorlinkstoeitherthemediumorheavyduty

positions(Figure42).Thespringanchorlinks

areattachedtotheupperrearcornerofthe

hydraulicdriveshieldsontheleftandrightsides

ofthemachine.

Note:Inthemediumorheavydutypositions,

thedriveleverforcesattheupperhandlewill

alsoincrease.

CoolingSystem

Maintenance

CleaningtheAirIntake Screen

ServiceInterval:Beforeeachuseordaily

Beforeeachuseremoveanybuildupofgrass,dirt

orotherdebrisfromthecylinderandcylinderhead

coolingns,airintakescreenonywheelend,

andcarburetor-governorleversandlinkage.This

helpsensureadequatecoolingandcorrectengine

speedandreducesthepossibilityofoverheatingand

mechanicaldamagetotheengine.

Figure42

1.Springanchor

2.Standardsetting

3.Mediumsetting

4.Heavydutysetting

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthereartiresasspecied.

Checkthepressureatthevalvestem(Figure43).

RearTirePressure:15psi(1bar)

g001524

Figure43

g001055

33

Page 34

BrakeMaintenance

ServicingtheBrake

Beforeeachuse,checktheparkingbrakeforproper

operation.

Alwaysengagetheparkingbrakewhenyoustopthe

machineorleaveitunattended.Iftheparkingbrake

doesnotholdsecurely ,adjustit.

CheckingtheParkingBrake

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Settheparkingbrake.

Note:Settingtheparkingbrakeshouldtakea

reasonableamountofforce.Ifitengagestoo

hardortooeasily,anadjustmentisrequired.

RefertoAdjustingtheParkingBrake.

AdjustingtheParkingBrake

Theparking-brakeleverisontherightsideofthe

machine.Iftheparkingbrakedoesnotholdsecurely ,

adjustit.

1.Checktheparkingbrakebeforeyouadjustit;

refertoCheckingtheParkingBrake(page34).

Figure44

1.Brakelinkageyoke4.Lowerbrakelink

2.Lowerbrakelever

3.Springclevispin

4.Rotatethelowerbrakelinkyokeclockwiseinto

theyoketotightentheparkingbrake;rotatethe

brakelinkyokecounterclockwiseoutoftheyoke

outtoloosentheparkingbrake(Figure44).

5.6mm(1/4inch)

6.Hairpin

Note:Withtheparkingbrakeinthereleased

position,theclearancebetweenthetireandthe

atbarisapproximately6mm(1/4inch)(Figure

44).

5.Securethelowerlinktothelowerbrakelever

withthehairpincotterandtheclevispin(Figure

44).

6.Checkthebrakeoperationagain;referto

CheckingtheParkingBrake(page34).

g001513

2.Disengagetheparkingbrake;referto

DisengagingtheParkingBrake(page12).

3.Removethespringhairpinfromthelowerbrake

link(Figure44).

34

Page 35

BeltMaintenance

CheckingtheBelts

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Checkthebeltsforsquealingwhenthebeltisrotating,

bladesslippingwhencuttinggrass,frayedbeltedges,

burnmarksandcracksaresignsofawornmower

belt.Replacethemowerbeltifanyoftheseconditions

areevident.

ReplacingtheMowerBelt

ForRear-DischargeDecks

Note:FortheFlailAttachment,refertotheOperator’s

Manualforthecuttingunit.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheknobsandthebeltcoveronthe

mowerdeck.

4.Removetheidlerpulleyandthewornbelt

(Figure45).

5.Installthenewmowerbelt.

6.Installtheidlerpulley.

7.Engagethebladecontrol(PTO)leverandcheck

thebelttension.RefertoAdjustingtheMower

BeltT ension(page35).

Note:Thepropermowerbelttensionis44to

67N(10to15lb)withthebeltdeected13mm

(1/2inch)halfwaybetweenthepulleys(Figure

45).

g007739

Figure45

1.Idlerpulley2.Mowerbeltwith13mm

(1/2inch)deection

AdjustingtheMowerBelt Tension

ForRear-DischargeDecks

Note:FortheFlailAttachment,refertotheOperator’s

Manualforthecuttingunit.

AdjustingtheTension

ServiceInterval:Aftertherst8hours

Aftertherst25hours

Every50hours

Important:Whenthebelttensionorthebrake

linkageisadjusted,thebrakeneedsadjustment.

Important:Thebeltmustbetightenoughto

notslipduringheavyloadswhilecuttinggrass.

Overtensioningthebeltreducesthespindle

bearinglife,thebeltlifeandtheidlerpulleylife.

Thebeltmustbetightenoughsoitdoesnotslip

duringheavyloadswhilecuttinggrass;overtensioning

reducesbeltandspindlebearinglife.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Loosenthelocknutontheturnbuckle(Figure

46).

4.Rotatetheturnbuckletowardtherearofthe

mowerdecktoincreasethetensiononthebelt.

35

Page 36

Rotatetheturnbuckletowardthefrontofthe

mowerdecktodecreasethetensiononthebelt

(Figure46).

Note:Ensurethattheeyeboltthreadsonboth

endsoftheturnbuckleareengagedaminimum

of8mm(5/16inch).

Figure46

1.Locknut4.Assistarm

2.Turnbuckle

3.Frontstop

5.EngagethePTOandcheckthebelttension.

6.Ifthereisnoadjustmentleftintheturnbuckle

andthebeltisstillloose,positiontherearidler

pulleyinthemiddleorfronthole(Figure47).

Usetheholethatgivesthecorrectadjustment.

5.13mm(1/2inch)deection

here

g001848

Figure47

1.Rearidlerpulley4.Beltguideinbackposition

2.Middlehole

3.Fronthole

g007740

5.Frontidlerpulley(122

cm(48inch)mowerdeck

only)

8.Checkthebeltguideundertheengineframefor

properadjustment(Figure48).

Note:Whenthemowerbeltisengaged,ensure

thatthedistancebetweenthebeltguideand

themowerbeltis19mm(3/4inch)(Figure48).

Adjustthemowerbeltguideasnecessary.The

disengagedbeltshouldnotdragorfalloffthe

pulleywhentheguidesareproperlyadjusted.

7.Whentheidlerpulleyismovedthebeltguide

mustbemoved.Movethebeltguidetothefront

position(Figure47).

g016078

Figure48

1.Beltguide

9.Checkthebladebrakeadjustment;referto

AdjustingtheBladeBrake(page43).

AdjustingthePTOEngagement Linkage

ThePTOengagementlinkageadjustmentislocated

beneaththefrontlefthandcorneroftheenginedeck.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

36

Page 37

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.EngagethePTO.

4.Adjustthelinkagelengthtowherethelower

endofthebellcrankjustclearstheaxlesupport

gusset(Figure49).

Figure49

1.Bellcrank4.Yoke

2.Safetyswitchlocated

underenginedeck

3.Bellcrankjustclearsthe

gussetwiththePTO

engageded

5.Nut

6.Assistarmlink

g001849

Figure50

1.Assistarm5.Assistarmlink

2.Frontassistarmstop6.Y oke

3.Rearassistarmstop7.Hairpincotter

4.Turnbuckle

8.Toadjusttheassistarmlink,removethehairpin

cotterfromtheassistarm(Figure50).

g001847

9.Loosenthenutagainsttheyoke(Figure49).

10.Removetheassistarmlinkfromtheassistarm

androtatethelinktoadjustthelength.

11.Installtheassistarmlinkintotheassistarmand

secureitwiththehairpincotter(Figure50).

12.Checkiftheassistarmhitsagainstthestops

correctly.

5.Makesurethattheassistarmisagainsttherear

assistarmstoponthedeck(Figure50).

6.Pushthebladecontrolknob(PTO)downtothe

DISENGAGEDposition.

7.Theassistarmshouldcontactthefrontassist

armstoponthedeck.Ifitdoesnotcontact,

adjustthebellcranksoitisclosertothegusset

(Figure50).

AdjustingthePTOSafetySwitch

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.DisengagethePTO.Makesurethattheassist

armisagainstthefrontassiststoparm.

4.Ifneeded,adjustthebladesafetyswitchby

looseningtheboltsholdingtheswitchbracket

(Figure51).

5.Movethemountingbracketuntilthebellcrank

pressestheplungerby6mm(1/4inch).

Makesurethatthebellcrankdoesnottouch

theswitchbodyordamagetotheswitchcould

occur(Figure51).

6.Tightentheswitchmountingbracket.

37

Page 38

1.Bellcrank

2.Boltsandnuts

Figure51

3.Switchmountingbracket

4.Switchbody

HydraulicSystem

Maintenance

ServicingtheHydraulic System

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury .

•Ifhydraulicuidisinjectedintotheskinit

mustbesurgicallyremovedwithinafew

g001855

hoursbyadoctorfamiliarwiththistypeof

injury.Gangrenemayresultifthisisnot

done.

•Keepbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Makesurethatallhydraulicuidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsare

tightbeforeapplyingpressuretohydraulic

system.

HydraulicFluidSpecications

FluidType:Mobil115W-50syntheticmotoroilor

equivalentsyntheticoil.

Important:Usetheuidspeciedorequivalent.

Otheruidscouldcausesystemdamage.

HydraulicSystemCapacity:2.3L(77oz)

CheckingtheHydraulicFluid

ServiceInterval:Aftertherst8hours

Every25hours

Note:Thereare2waysofcheckingthehydraulic

uid:checkingtheuidwhenitiswarmandchecking

theuidwhenitiscold.Thebafeinsidethetankhas

2levels,dependingiftheuidiswarmorcold.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

38

Page 39

3.Waitforallmovingpartstostopbeforeleaving

theoperatingpositionandthenengagethe

parkingbrake.

4.Cleanareaaroundcapandllerneckof

hydraulictank(Figure52).

4.Locatelterunderenginebaseandplacedrain

panunderlter(Figure53).

5.Removetheoldlterandwipethelteradapter

gasketsurfaceclean(Figure53).

Figure52

1.Cap3.Colduidlevel—full

2.Bafe4.Hotuidlevel—full

5.Removecapfromllerneck.Lookinsideto

checkifthereisuidinthereservoir(Figure52).

6.Ifthereisnouid,adduidtothereservoiruntil

itreachesthecoldlevelofthebafe.

7.Runthemachineatlowidlefor15minutesto

allowanyairtopurgeoutofthesystemand

warmuid.RefertoStartingandStoppingthe

Engine.

8.Checktheuidlevelwhiletheuidiswarm.

Ifrequired,adduidtothereservoiruntilit

reachesthehotlevelofthebafe.

Note:Whentheuidiswarm,theuidlevelis

atthetopofthehotlevelofthebafe(Figure52).

9.Installcaponllerneck.

ReplacingtheHydraulic-Fluid Filter

ServiceInterval:Aftertherst8hours

Every200hours

Important:Donotsubstituteanautomotiveoil

lter,otherwiseseverehydraulicsystemdamage

mayresult.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removehydraulicreservoircapandtemporarily

covertheopeningwithaplasticbagandrubber

bandtopreventallhydraulicuidfromdraining

out.

g001045

Figure53

1.Hydrauliclter

2.Gasket

3.Adapter

g001043

6.Applyathincoathydraulicuidtotherubber

gasketonthereplacementlter.

7.Installreplacementhydrauliclterontothelter

adapter.Donottighten.

8.Removeplasticbagfromreservoiropeningand

allowltertollwithhydraulicuid.

9.Whenthehydrauliclterisfull,turntheoillter

clockwiseuntiltherubbergasketcontactsthe

lteradapter,thentightenthelteranadditional

1/2turn(Figure53).

10.Cleanupanyspilleduid.

11.Ifthereisnouid,hydraulicuidtoapproximately

6mm(1/4inch)belowthetopofreservoirbafe.

Important:UsetheoilspeciedinHydraulic

FluidSpecications(page38)orequivalent.

Otheruidscouldcausesystemdamage.

12.Startengineandletrunforabout2minutesto

purgeairfromthesystem.Shutofftheengine

andcheckforleaks.If1orbothwheelsdonot

drive,refertoBleedingtheHydraulicSystem

(page39).

13.Checklevelandadduid,ifrequired.Donot

overll.

BleedingtheHydraulicSystem

Thetractionsystemisselfbleeding,however,itmay

benecessarytobleedthesystemifuidischanged

orafterworkisperformedonthesystem.

Purgetheairfromthehydraulicsystemwhenany

hydrauliccomponents,includingoillter,areremoved

oranyofthehydrauliclinesaredisconnected.The

39

Page 40

criticalareaforpurgingairfromthehydraulicsystem

isbetweentheoilreservoirandeachchargepump

locatedonthetopofeachvariabledisplacement

pump.Airinotherpartsofthehydraulicsystemwill

bepurgedthroughnormaloperationoncethecharge

pumpisprimed.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Raisetherearofthemachineupontojack

standshighenoughtoraisethedrivewheels

offtheground.

4.Checkthehydraulic-uidlevel.

C.Liftthechargepumphousingupwardand

waitforasteadyowofuidtoowoutfrom

underthehousing.Tightenthecapscrews.

D.Repeatthisforbothpumps.

Note:Thehydraulicreservoircanbe

pressurizedtoupto5psi(0.35bar)tospeedup

thisprocess.

8.Ifeitherdrivewheelstilldoesnotrotate,stop

andrepeatsteps4and5ontherespective

pump.Ifwheelsrotateslowly ,thesystem

mayprimeafteradditionalrunning.Checkthe

hydraulic-uidlevel.

9.Allowunittorunseveralminutesafterthecharge

pumpsareprimedwithdrivesysteminthefull

speedposition.

5.Starttheengineandmovethethrottlecontrolto

thefullthrottleposition.Movethespeed-control

levertothemiddlespeedpositionandplacethe

driveleversintothedriveposition.

Ifeitherdrivewheeldoesnotrotate,itispossible

toassistthepurgingofthechargepumpby

carefullyrotatingthetireintheforwarddirection.

Note:Itisnecessarytolightlytouchthecharge

pumpcapwithyourhandtocheckthepump

temperature.Ifthecapistoohottotouch,turn

offengine.Thepumpsmaybedamagedifthe

pumpbecomestoohot.Ifeitherdrivewheelstill

doesnotrotate,continuetothenextstep.

10.Checkthehydrauliccontrollinkageadjustment.

RefertoAdjustingtheHydraulicControl

Linkages(page30).

CheckingtheHydraulicLines

ServiceInterval:Every100hours

Checkthehydrauliclinesandhosesforleaks,loose

ttings,kinkedlines,loosemountingsupports,wear,

weatherandchemicaldeterioration.Makenecessary

repairsbeforeoperating.

Note:Keepareasaroundhydraulicsystemclean