Page 1

FormNo.3391-812RevA

Groundsmaster

®

5900and5910

RotaryMower

ModelNo.31598N—SerialNo.315000001andUp

ModelNo.31599N—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3391-812*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisincorporatedwith

themuferassembly.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:Thisengineisequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

Introduction

Thismachineisaride-on,rotary-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrasson

well-maintainedlawnsinparks,golfcourses,sportselds,

andoncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongsidehighways,

orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactT orodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

YoumaycontactT orodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................6

SafetyandInstructionalDecals.................................7

Setup...........................................................................15

1RemoveSideDeckShippingStrapand

Brace................................................................15

2LoweringtheFrontDeckWinglets.........................15

3LevelingtheFrontCenterDeck.............................17

4LevelingtheWingletDeckstotheFrontCenter

Deck.................................................................17

5CheckingtheTirePressure....................................18

6CheckingtheFluidLevels.....................................18

7GreasingtheMachine...........................................18

ProductOverview.........................................................19

Controls...............................................................19

Specications........................................................26

Attachments/Accessories........................................26

Operation....................................................................27

CheckingtheEngineOilLevel.................................27

CheckingtheCoolingSystem...................................27

CheckingtheHydraulicSystem................................27

AddingFuel...........................................................27

CheckingtheTirePressure......................................28

CheckingtheTorqueofWheelLugNuts....................28

AdjustingtheHeight-of-Cut....................................28

AdjustingtheSkids.................................................31

AdjustingtheCuttingUnitAnti-ScalpRollers.............31

CheckingtheMismatchBetweenCutting

Units.................................................................32

AdjustingtheMirrors..............................................33

AimingtheHeadlights............................................33

StartingandStoppingtheEngine..............................33

CheckingtheInterlockSwitches...............................34

PushingorTowingtheMachine................................34

JackingPoints........................................................35

TieDowns............................................................35

OperatingCharacteristics........................................36

ReversingFanOperation.........................................36

OperatingTips......................................................37

Maintenance.................................................................38

RecommendedMaintenanceSchedule(s)......................38

ServiceIntervalChart.............................................39

PremaintenanceProcedures........................................39

InnerWingDeckCovers.........................................39

Lubrication...............................................................40

GreasingtheBearingsandBushings..........................40

EngineMaintenance..................................................43

AirCleanerMaintenance.........................................43

ServicingtheEngineOil..........................................44

AdjustingtheValveClearance..................................45

FuelSystemMaintenance...........................................45

ServicingtheFuelSystem........................................45

ServicingtheWaterSeparator..................................45

ReplacingtheFuelFilter..........................................46

ElectricalSystemMaintenance....................................47

Fuses....................................................................47

BatteryCare...........................................................48

JumpStarting/BatteryCharging..............................48

RecalibrateTractionPedal.......................................48

DriveSystemMaintenance.........................................49

AdjustingtheTractionPedalAngle...........................49

CheckingthePlanetaryDriveGear/Brake

Oil....................................................................49

ChangingthePlanetaryDriveGear/Brake

Oil....................................................................49

CheckingtheRearWheelToe-In..............................50

CoolingSystemMaintenance......................................51

CheckingtheCoolingSystem...................................51

ServicingtheEngineCoolingSystem........................52

BrakeMaintenance....................................................52

AdjustingtheServiceBrakes....................................52

BeltMaintenance......................................................53

ServicingtheAlternatorBelt....................................53

ServicingtheCompressorBelt.................................53

ReplacingtheBladeDriveBelts................................53

FrontCuttingUnit..................................................53

SideCuttingDecks.................................................54

HydraulicSystemMaintenance....................................55

CheckingtheHydraulicFluid...................................55

ChangingtheHydraulicFluidandFilters....................56

CheckingtheHydraulicLinesandHoses....................56

HydraulicSystemTestPorts.....................................57

MowerMaintenance...................................................57

Pivoting(Tilting)theFrontCuttingUnit

Upright.............................................................57

PivotingtheFrontCuttingUnitDown.......................58

AdjustingtheCuttingUnitPitch...............................58

ServicingtheCastorArmBushings...........................59

ServicingtheCastorWheelsandBearings..................59

BladeMaintenance.....................................................60

CheckingforaBentBlade........................................60

RemovingandInstallingtheCutterBlade(s)...............60

InspectingandSharpeningtheCutterBlade(s)............61

CorrectingtheCuttingUnitMismatch.......................62

MiscellaneousMaintenance.........................................62

ServicingtheSparkArrestorMufer.........................62

CleaningtheCabAirFilters(For31599N

Models).............................................................62

CleaningtheAirConditioningCoil...........................63

Storage........................................................................64

PreparingforSeasonalStorage.................................64

3

Page 4

Safety

Thismachinehasbeendesignedinaccordancewith

ANSIB71.4-2012.

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Replacefaultysilencers/mufers.

•Beforeusing,alwaysvisuallyinspecttoseethatthe

blades,bladebolts,andcuttingassemblyarenotworn

ordamaged.Replacewornordamagedbladesandbolts

insetstopreservebalance.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

SafeOperatingPractices

Training

•ReadtheOperator'sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethemower.Localregulationsmay

restricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtohimselforherself,other

people,orproperty.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

•Checkthatoperatorspresencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,long

trousers,hardhat,safetyglasses,andearprotection.Long

hair,looseclothingorjewelrymaygettangledinmoving

parts.Donotoperatetheequipmentwhenbarefootor

wearingopensandals.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengagethePTO,

shiftintoneutral,andengagetheparkingbrake.Only

4

Page 5

starttheenginefromtheoperatorsposition.Useseat

belts,ifprovided.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.Toguardagainst

overturning:

–Donotstoporstartsuddenlywhengoingupor

downhill.

–Themachinespeedshouldbekeptlowonslopesand

duringtightturns.

–Stayalertforhumpsandhollowsandotherhidden

hazards.

–Nevermowacrossthefaceoftheslope,unlessthe

machineisdesignedforthatpurpose.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Usecarewhenusingheavyequipment.

–Donotturnsharply.Usecarewhenreversing.

–Usecounterweight(s)orwheelweightswhen

suggestedintheOperator'sManual.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesfromrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besureall

interlocksareattached,adjustedproperly ,andfunctioning

properly.

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperatorsposition:

–Stoponlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Changeintoneutralandsettheparkingbrake.

–Stoptheengineandremovethekey.

•Disengagedrivetoattachments,stoptheengineand

removetheignitionkey:

–beforeclearingblockages;

–beforechecking,cleaning,orworkingonthemachine;

–afterstrikingaforeignobject.Inspectthemachine

fordamageandmakerepairsbeforerestartingand

operatingtheequipment.Torqueallthespindlepulley

nutsto176to203N-m(130to150ft-lb)andallthe

bladeboltsto115to149N-m(85to110ft-lb),

–ifthemachinestartstovibrateabnormally(check

immediately).

•Disengagedrivetoattachmentswhentransportingornot

isuse.

•Stoptheengineanddisengagedrivetoattachment:

–beforerefuelling;

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperatorsposition.

•Reducethethrottlesettingbeforestoppingengineand,if

theengineisprovidedwithafuelshut-offvalve,turnthe

fueloffattheconclusionofmowing.

•Neverraisedeckwiththebladesrunning.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Theoperatorshallturnonashingwarninglights

whenevertravelingonapublicroad,exceptwheresuch

useisprohibitedbylaw.

MaintenanceandStorage

•Keepallnuts,bolts,andscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure

anddonotstorenearame.

•Toreducetherehazard,keeptheenginecompartment,

silencer/mufer,batterycompartment,cuttingunits,

drives,andfuelstorageareafreeofgrass,leaves,or

excessivegrease.Cleanupoilorfuelspillage.

•Replacewornordamagedpartsforsafety.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Onmulti-bladedmachines,takecareasrotatingoneblade

cancauseotherbladestorotate.

•Whenmachineistobeparked,stored,orleftunattended,

lowerthecuttingunitsunlessapositivemechanicallock

isprovided.

•Disengagedrives,lowerthecuttingunits,movetraction

pedaltoNeutral,setparkingbrake,movethethrottle

switchtothelowidleposition,stopengineandremove

ignitionkey.Waitforallmovementtostopbefore

adjusting,cleaningorrepairing.

•Shutofffuelwhilestoringortransporting.Donotstore

fuelnearames.

•Parkmachineonlevelground.Neverallowuntrained

personneltoservicemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

5

Page 6

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

•Usecarewhencheckingblades.Wrapthebladesor

weargloves,andusecautionwhenservicingthem.Only

replaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.W earprotectiveclothing

anduseinsulatedtools.

•Makesureallhydrauliclineconnectorsaretightandall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Ifuidisinjectedintotheskinitmustbesurgically

removedwithinafewhoursbyadoctorfamiliarwiththis

formofinjuryorgangrenemayresult.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCEN,ISO,orANSIstandards.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

Operation

•Beforeoperatingthemachinebecertainthattheseat

beltsareattached.

•Knowhowtostopthemachineandenginequickly .

•Donotoperatethemachinewhilewearingtennisshoes

orsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Keephands,feet,andclothingawayfrommovingparts

andthemowerdischargeareaandundersideofthe

mowerwhiletheengineisrunning.

•Fillfueltankuntillevelis25mm(1inch)belowthe

bottomofthellerneck.Donotoverll.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•Donotmowinreverseunlessabsolutelynecessary.

•Reducespeedwhenmakingsharpturns.

•Avoidstartingorstoppingonaslope.Iftireslosetraction,

disengagethebladesandproceedslowlystraightdown

theslope.Avoidraisingthesidecuttingunitsonaslope.

•Avoidturningonslopes.Ifyoumustturn,turnslowly

andgraduallydownhill,ifpossible.

•NeverremovetheROPSfromthemachine.

•Alwaysweartheseatbeltwhenoperatingthemachine.

•Becertainthattheseatbeltcanbereleasedquicklyifthe

machineisdrivenorrollsintoapondorwater.

•Watchfortrafcwhennearorcrossingroads.Always

yieldtheright-of-way.

•Donotmowneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyturnoverifawheelgoes

overtheedgeofaclifforditchorifanedgegivesway .

•Donotmowonwetgrass.Reducedtractioncouldcause

sliding.

•Machineshouldnotbeusedasatowvehicle.

•Useextracarewithotherattachments.Thesecanchange

thestabilityofthemachine.

•Turnoffthebladeswhennotmowing.

•Foroperatingenvironmentsexceeding43degreesC(110

degreesF),consultToroforspecialmachineneeds.

•Donotoperatetheenginebelow1350rpm.

MaintenanceandStorage

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowtocoolbeforeattempting

tomaintain,adjust,orservice.

•Neverstorethemachineorfuelcontainerinsidewhere

thereisanopename,suchasnearawaterheateror

furnace.

•Keepnutsandboltstight,especiallythebladeattachment

bolts.Keepequipmentingoodcondition.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts.Keepeveryoneaway.

6

Page 7

•Checkbrakeoperationfrequently.Adjustandserviceas

required.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks,and

amesawayfromthebattery.

•DonotusehighpressurewaternearInfoCenter.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

•Theenginemustbeshutoffbeforecheckingtheoilor

addingoiltothecrankcase.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•Tomakesureofoptimumperformanceandcontinued

safetycerticationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

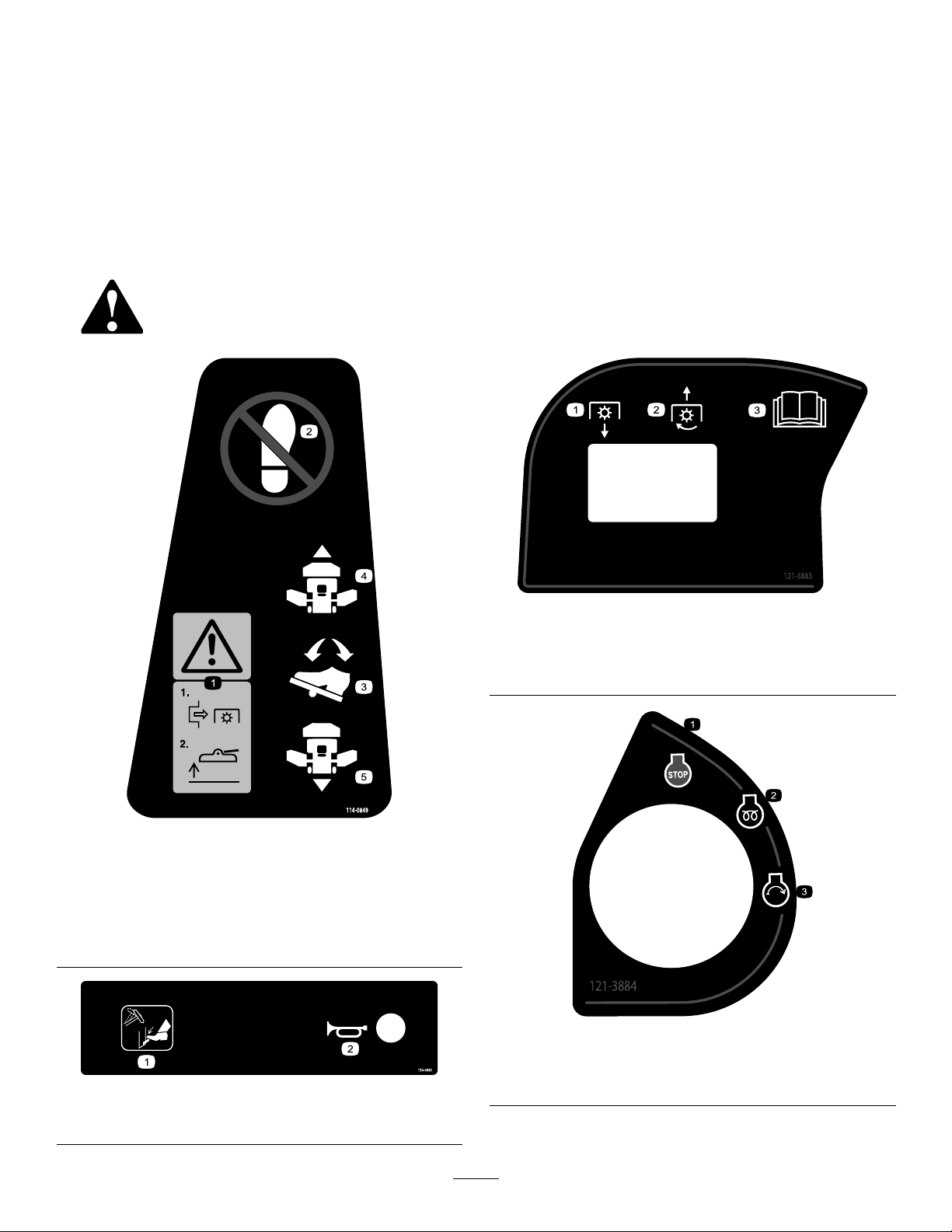

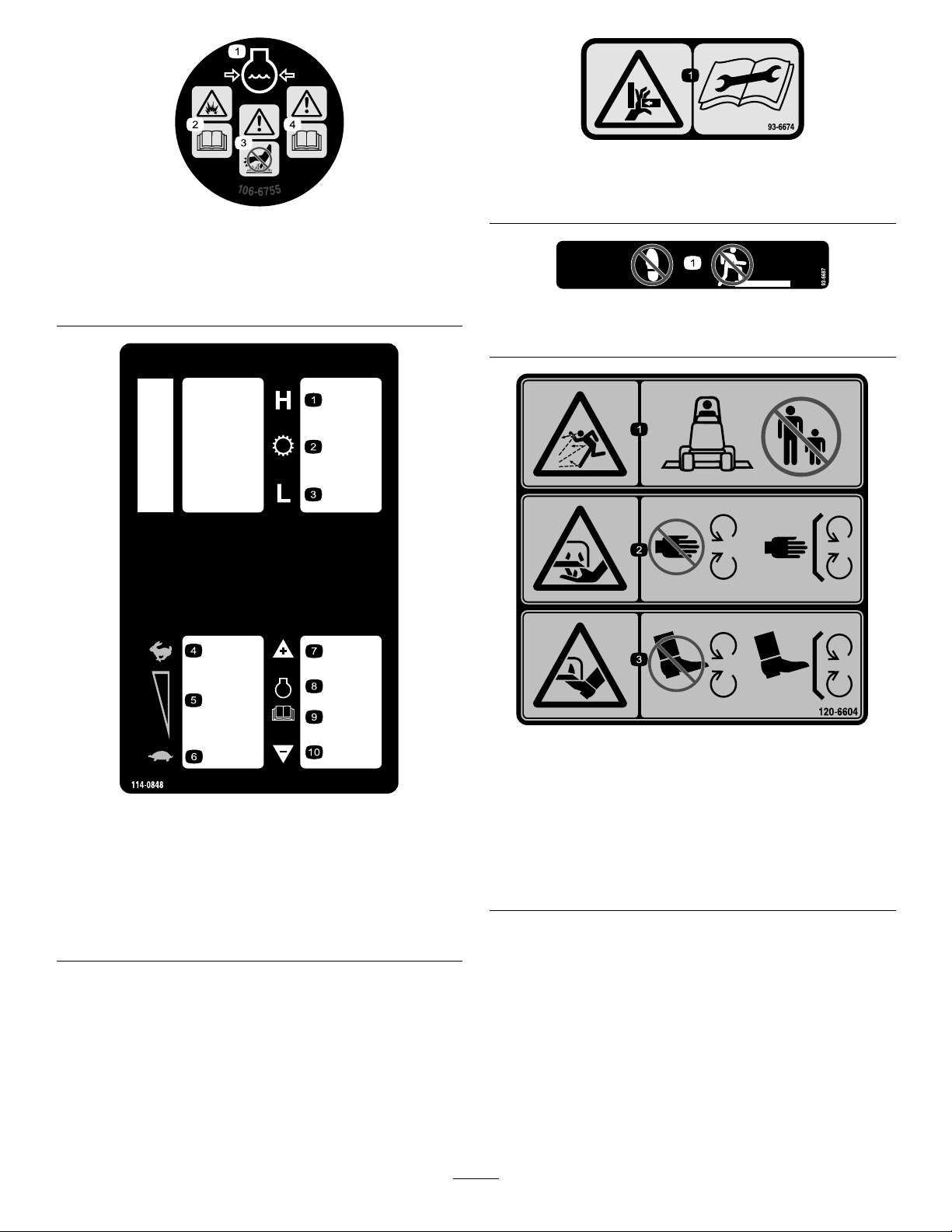

114-0849

1.Warning—disengagethePTOthenraisethedeck.

2.Nostep

3.Tractioncontrolpedal

4.Forward

5.Reverse

121–3883

1.DisengagethePTO3.ReadtheOperator’s

Manual

2.EngagethePTO

121–3884

114-0845

1.Tiltsteeringlever2.Horn

1.Engine—stop3.Engine—start

2.Engine—preheat

7

Page 8

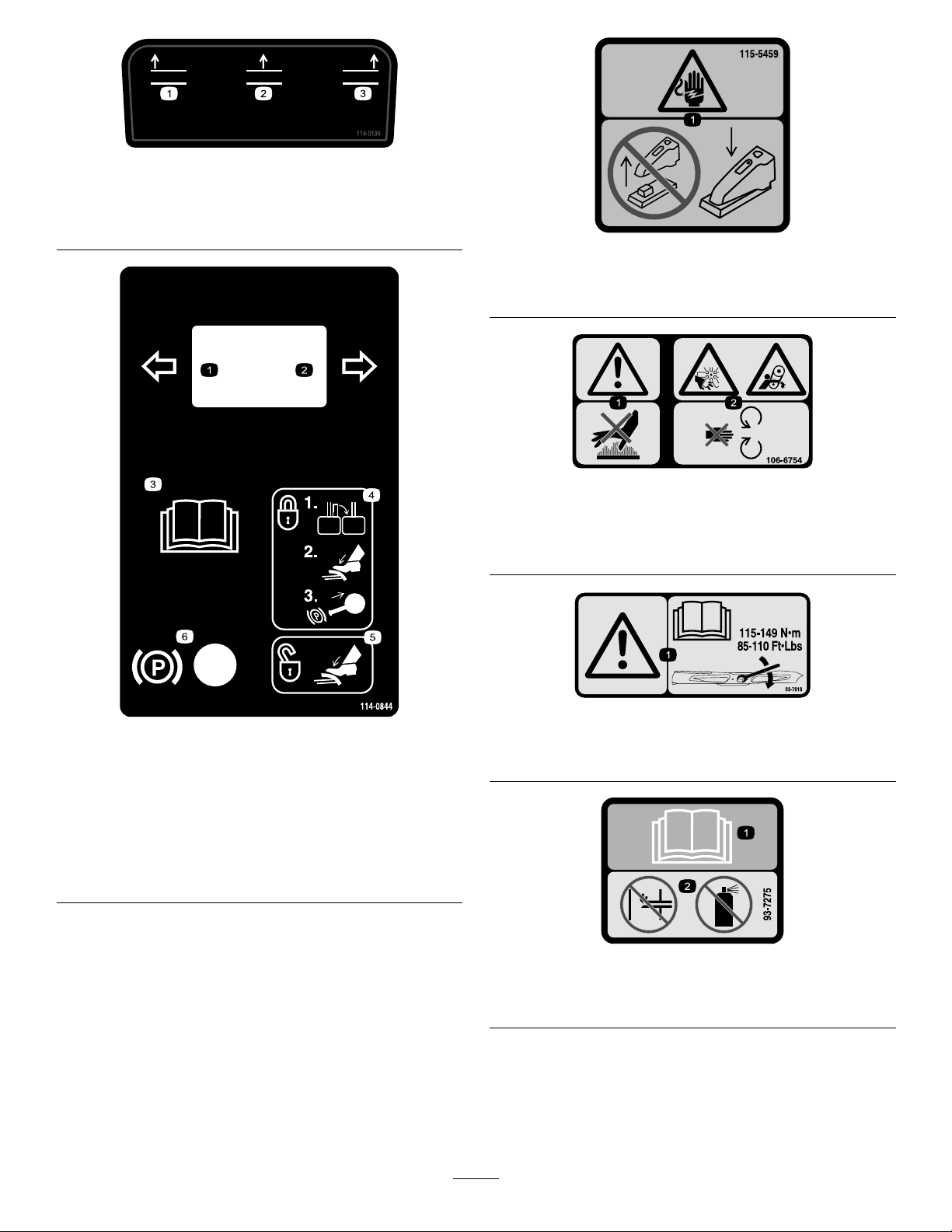

114-0135

1.Raisecuttingunits—left

2.Raisecutting

units—center

3.Raisecuttingunits—right

115-5459

1.Electricshockhazard—donotremovecover;keepcoverin

place.

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

114-0844

1.Lefthandturnsignal

2.Righthandturnsignal5.Tounlocktheparking

3.ReadtheOperators

Manual.

4.Tolockthebrakes,close

latch,pressthebrake

pedalandpulluponthe

parkingbrakeknob.

brake,pressthebrake.

6.Parkingbrake

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N-m(85-110ft-lb).

93–7275

1.ReadtheOperator’sManual—donotusestartinguidto

starttheengine.

8

Page 9

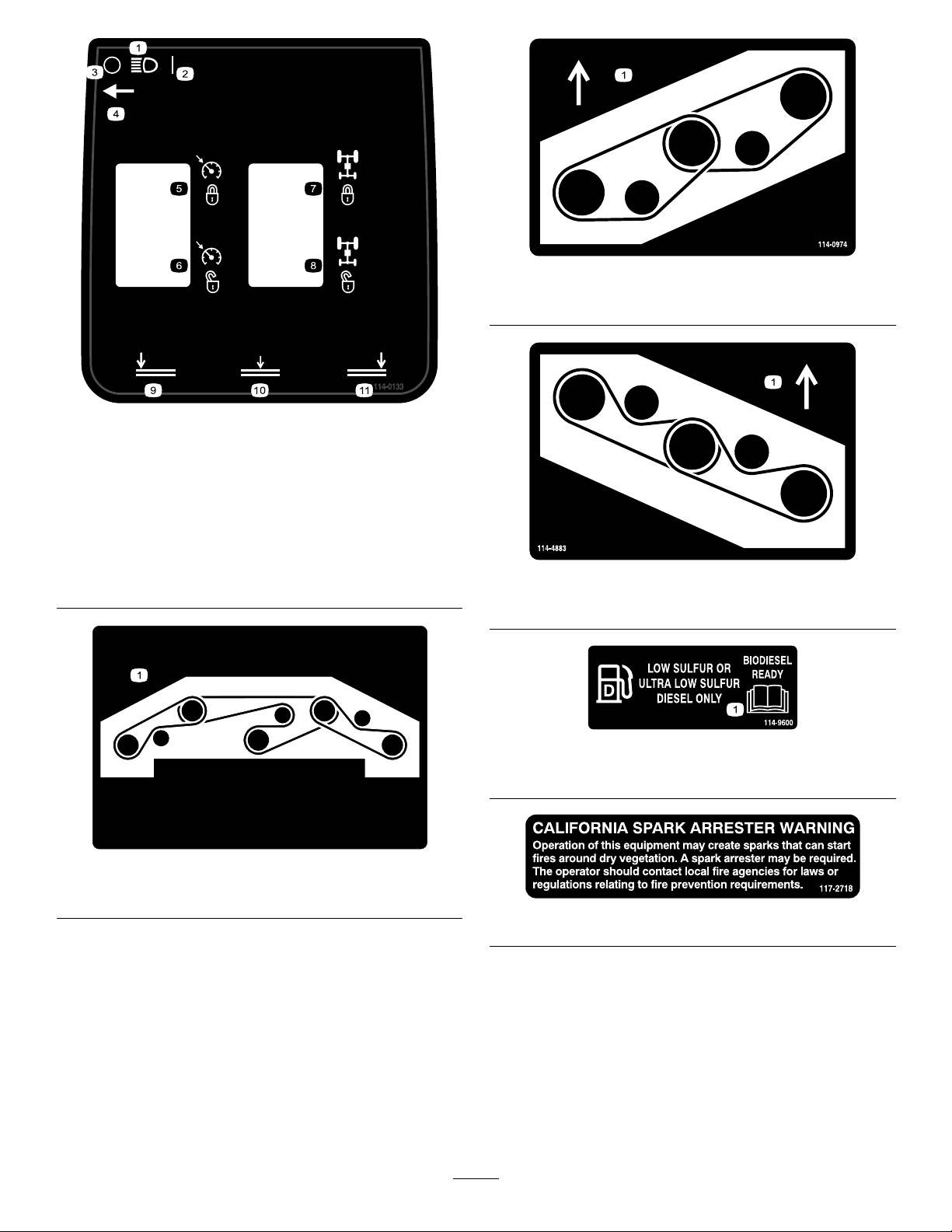

93-6674

1.Crushinghazard,hand—readtheinstructionsbefore

servicingorperformingmaintenance.

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

93-6687

1.Donotstephere.

114-0848

1.Highrange6.Lowidle

2.Transmission7.Increaseenginespeed

3.Lowrange8.Engine

4.Highidle

5.Mididle10.Decreaseenginespeed

9.ReadtheOperator’s

Manual.

120-6604

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Cutting/dismembermenthazardofhand,mower

blade—stayawayfrommovingparts,keepallguardsand

shieldsinplace.

3.Cutting/dismembermenthazardoffoot,mowerblade—stay

awayfrommovingparts,keepallguardsandshieldsin

place.

9

Page 10

114-0133

114-0922

1.Headlights7.Tractionassist—engage

2.On

3.Off9.Lowercuttingunits—left

4.Headlightswitchlocation10.Lowercutting

5.Cruisecontrol—engage

6.Cruisecontrol—disengage

8.Traction

assist—disengage

units—center

11.Lowercuttingunits—right

114-0974

1.Beltrouting

114-4883

1.Beltrouting

114-9600

1.ReadtheOperator'sManual.

114-0922

1.Beltrouting

117–2718

10

Page 11

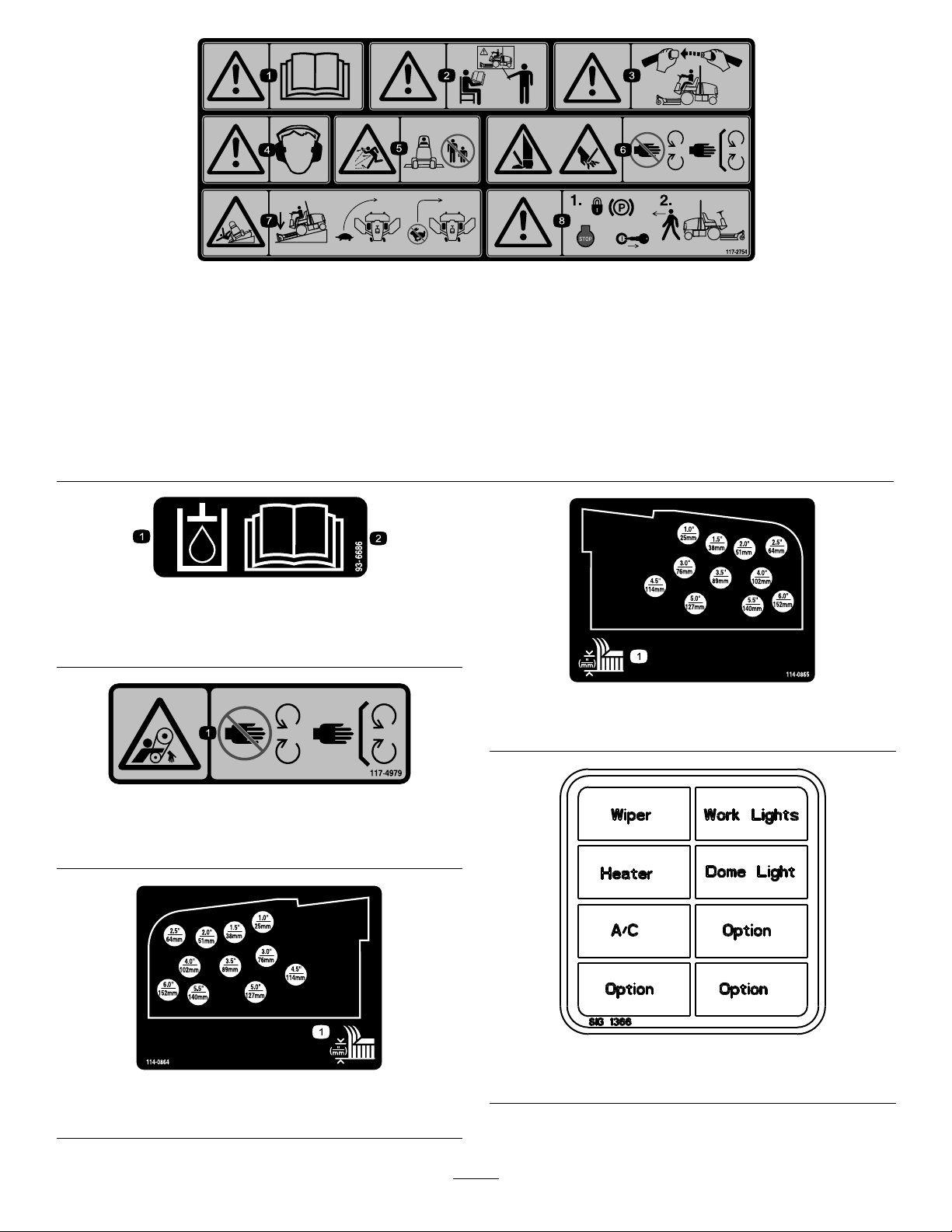

117–2754

1.Warning—readtheOperator'sManual.

2.Warning—donotoperatethismachineunlessyouaretrained.

3.Warning—weartheseatbeltwhenseatedintheoperator'sposition.

4.Warning—wearhearingprotection.

5.Thrownobjecthazard—keepbystandersasafedistancefromthemachine.

6.Cuttinghazardofhandorfoot—stayawayfrommovingparts;keepallguardsinplace.

7.Tippinghazard—lowerthecuttingunitwhendrivingdownslopes;slowmachinebeforeturning,donotturnathighspeeds

8.Warning—locktheparkingbrake,stoptheengineandremovetheignitionkeybeforeleavingthemachine.

93-6686

1.Hydraulicoil

2.ReadtheOperator'sManual.

114-0865

1.Heightofcutadjustment

117–4979

1.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

114-0864

1.Heightofcutadjustment

115-5509

(Model31599Nonly)

11

Page 12

115-5489

(Model31599Nonly)

1.Warning—whenthecabwindowsareopenwearhearing

protection.

2.Closetherearwindowbeforeattemptingtoopenthehood.

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

114-0975

1.Height-of-cut

12

Page 13

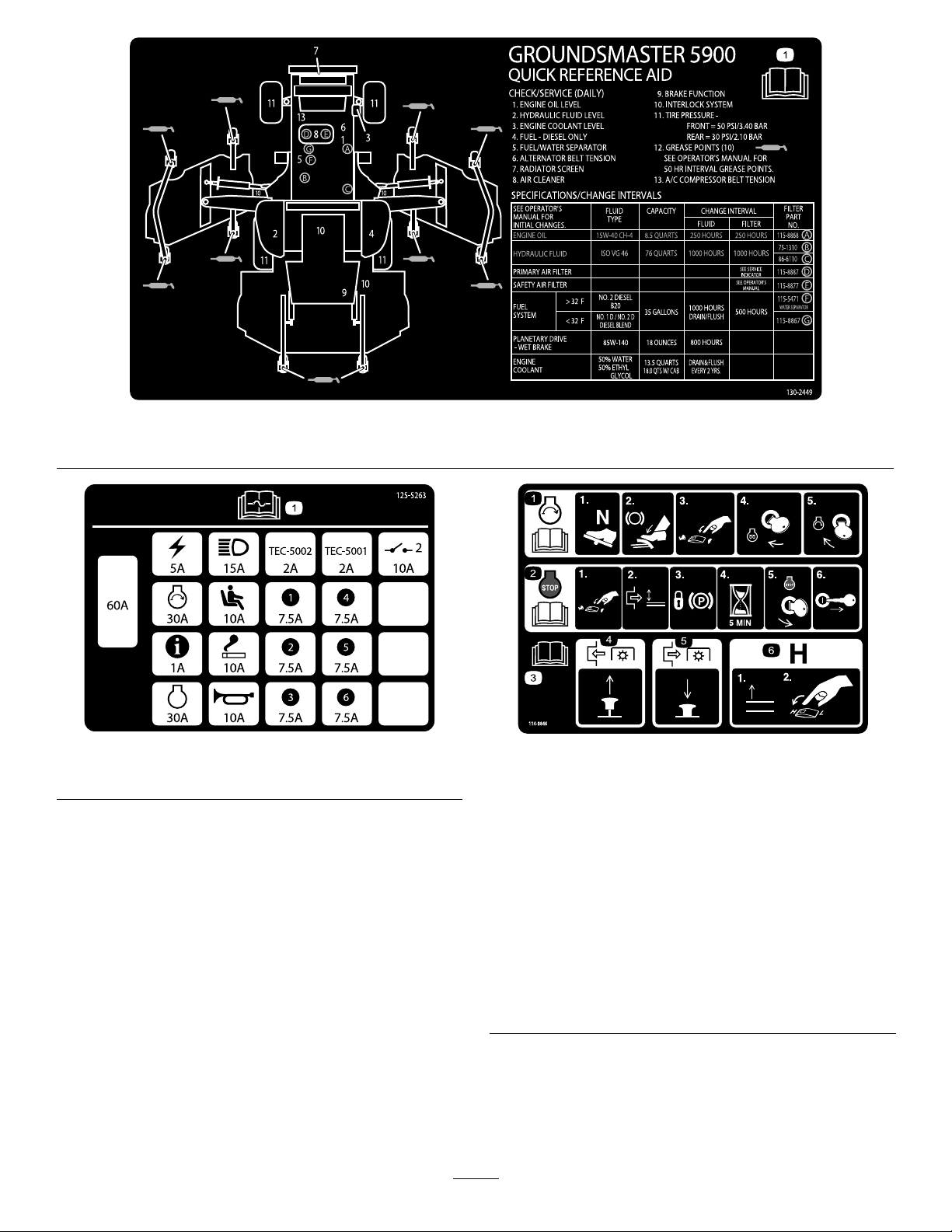

1.ReadtheOperator’sManualforinformationonmaintenance.

130–2449

125–5263

1.ReadtheOperator’sManualforinformationonfuses.

114-0846

1.ReadtheOperatorsManual;tostarttheengine,movethe

tractionpedaltoNeutral,applythebrake,movethethrottle

switchtolow,turntheignitionkeytoPreheat.Whenthe

WaittoStartAdvisoryclearsontheInfoCenterthenturn

theignitionkeytoStart.

2.ReadtheOperatorsManual;tostoptheengine,movethe

throttlelevertoslow,disengagethePTO,settheparking

brake,wait5minutes,turntheignitionkeytoStop,and

removethekey;readtheOperatorsManual.

3.ReadtheOperatorsManual.

4.ToengagethePTO,pulluponthePTOswitch.

5.TodisengagethePTO,pushdownonthePTOswitch.

6.Toswitchthetransmissiontohighspeed,fullyraisethe

attachmentsandswitchthespeedcontroltoHigh.

13

Page 14

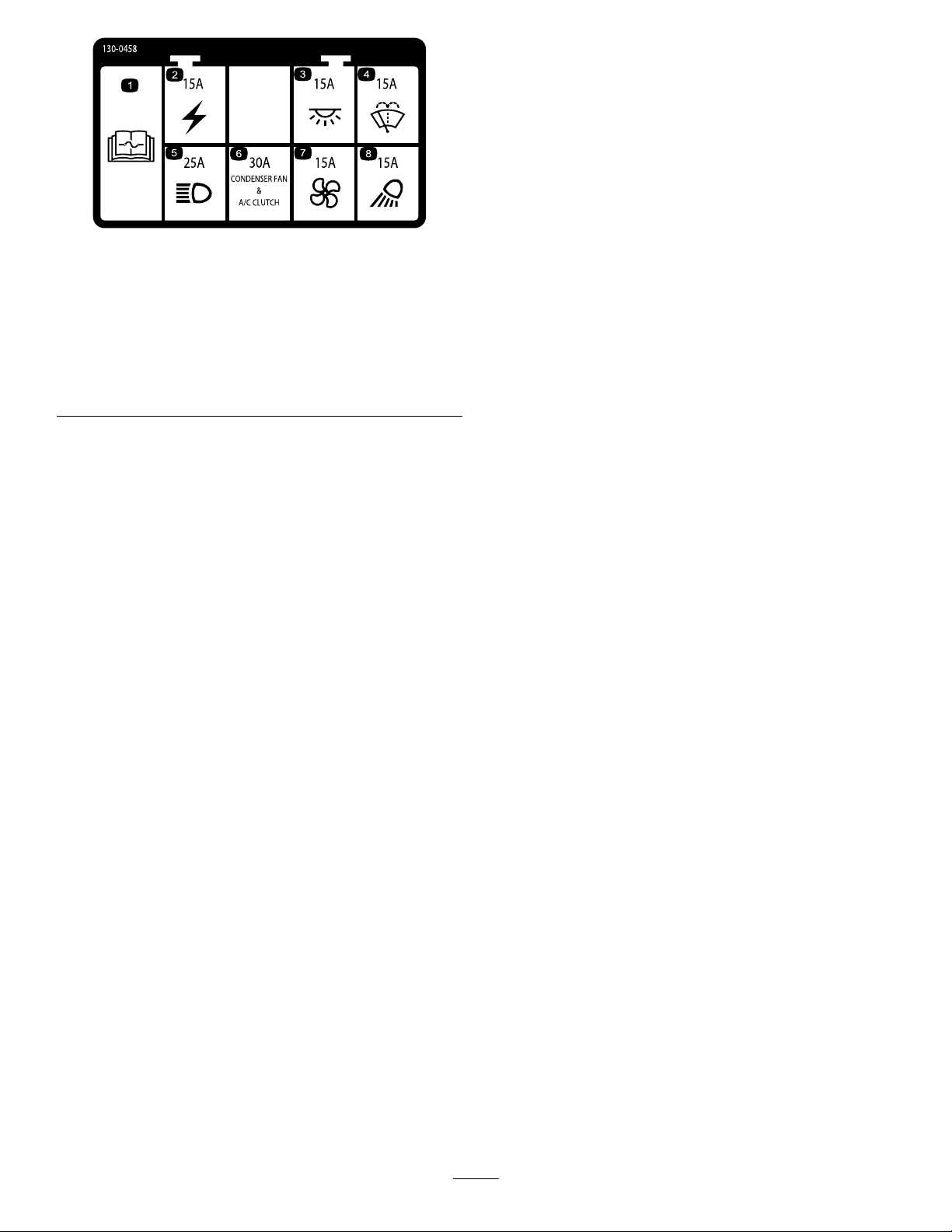

130-0458

1.ReadtheOperator's

Manualformore

informationonfuses

2.Electricalpower

accessory—15A

3.Domelight—15A7.Fan—15A

4.Windshieldwiper

uid—15A

5.Headlights—25A

6.CondenserfanandA/C

clutch—30A

8.Worklight—15A

14

Page 15

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

MediaandAdditionalParts

Description

Operator'sManual

EngineOperator'sManual

OperatorTrainingMaterial

PartsCatalog

Nopartsrequired

DeckcoverR.H.1

DeckcoverL.H.1

V-Belt2

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Qty.

1

1

1

1

Providetheoperatorwithinformationontheuseand

maintenanceofthemachine

Orderingparts

Qty.

Use

–

–

–

–

–

–

Removethesidedeckstrapsandbrace

Lowerthefrontdeckwinglets

Levelthefrontcenterdeck

Levelthewingletdeckstothefront

centerdeck

Checkthetirepressure

Checktheuidlevels

Greasethemachine.

Use

DeclarationofConformity

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Note:Somepartsmayhavealreadybeeninstalledatthe

factory.

1

RemoveSideDeckShipping StrapandBrace

NoPartsRequired

Procedure

Removethestrapandbracesecuringthesidedecksfor

shipping.

1

2

LoweringtheFrontDeck Winglets

Partsneededforthisprocedure:

1DeckcoverR.H.

1DeckcoverL.H.

2V-Belt

Procedure

1.Removethenutssecuringthefrontandrearstopbolts

totherightwingletdeckmounts(Figure3).

2.Whilesupportingtherightwinglet,removethefront

andrearstopboltsfromthedeckmounts(Figure

15

Page 16

3).Leavetheeccentricspositionedbetweenthedeck

mounts.

3.Lowerthewinglettotheoperatingposition.

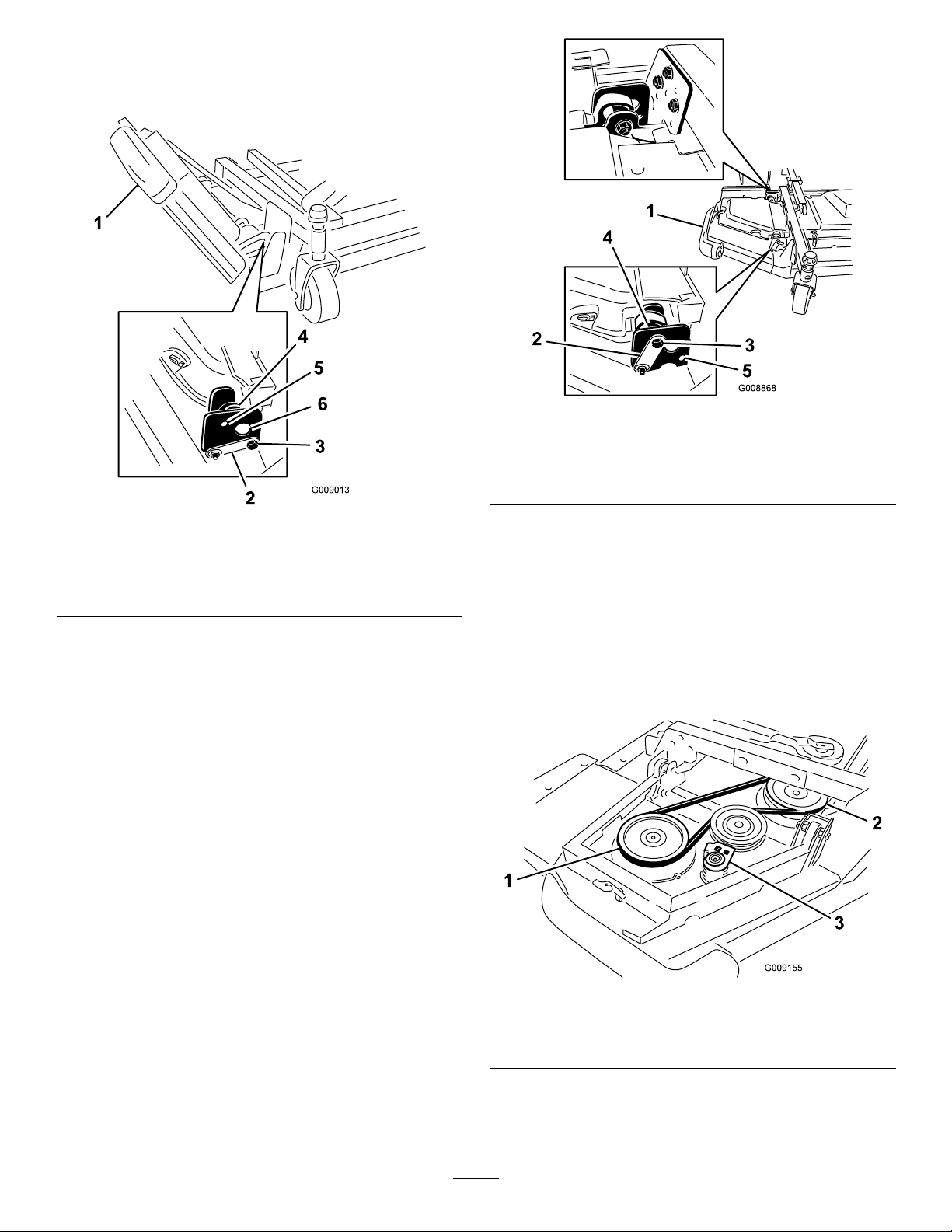

Figure4

1.Winglet4.Eccentric

2.Hingepin5.Lowerhole

3.Bolt

Figure3

1.Winglet4.Eccentric

2.Hingepin5.Upperhole

3.Stopbolt

6.Deckmounts

4.Installthefrontandrearstopboltsthroughtheupper

mountingholesandeccentrics.Makesurethestopbolt

engagesthetabonthehingepin.

5.Installthenutssecuringthestopboltsbutdonot

tightenatthistime.

6.Repeattheprocedureonleftwinglet.

7.Installthewingletbeltsasfollows:

•Startthebeltaroundthewingletspindlepulleyand

thefrontdeckspindlepulley(Figure5).

•Usingaratchetwrenchorsimilartool,movethe

idlerpulleyawayfromthepulleys(Figure5).

•Routethebeltaroundthewingletspindlepulley

andtheupperspindlepulleyonthefrontdeck.

•Releasetheidlerpulleytoputtensiononthebelt.

Figure5

1.Wingletspindlepulley3.Idlerpulleyassembly

2.Frontdeckspindlepulley

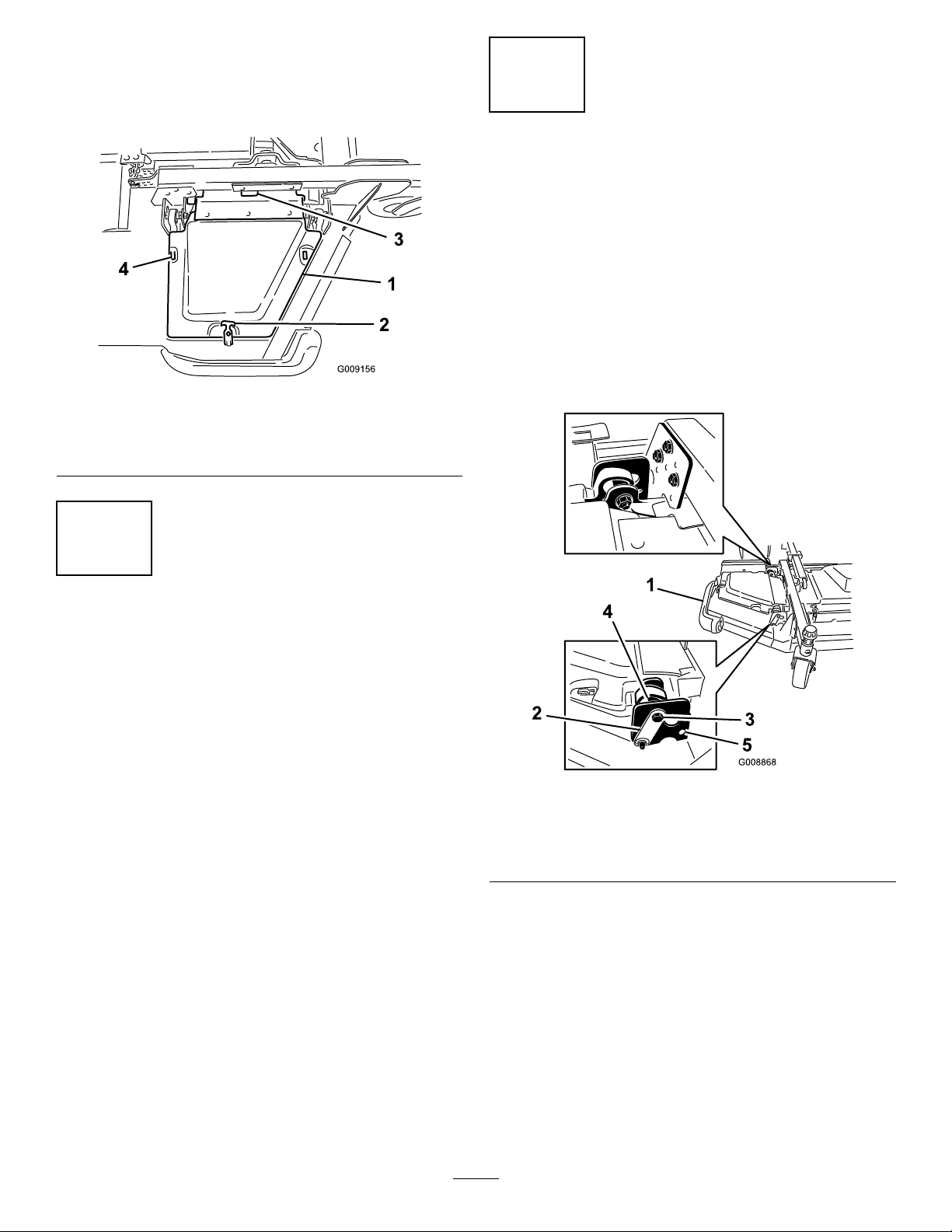

8.Installthewingletdeckcoverandsecurewithrubber

latch(Figure6).

16

Page 17

Note:Makesuretoslidethecoverunderthefront

centerdeckcovertabsbeforeinsertingitontothe

mountinghooksandpost.

9.Repeattheprocedureontheotherwinglet.

Figure6

4

LevelingtheWingletDecksto theFrontCenterDeck

NoPartsRequired

Procedure

Levelthewingletdeckstothefrontdeckasfollows:

•Rotatethebladeoneachwingletsothatitpointsside

toside.

•Loosentheboltsandnutssecuringthetwoeccentric

spacerstothewinglets(Figure7).

1.Cover

2.Rubberlatch4.Mounthooks

3.Frontcenterdeckcover

tabs

3

LevelingtheFrontCenterDeck

NoPartsRequired

Procedure

RefertoAdjustingtheHeight-of-CutinOperation.

1.Rotatebladeoneachouterspindleuntiltheendsface

forwardandbackward.

2.Measurefromtheoortothefronttipoftheblade.

Adjustthe1/8inchshimsonthefrontcastorfork(s)

tomatchthedesiredheightofcut.

3.Rotatetheblades180°andnowmeasurefromtheoor

tothe(rearfacing)tipoftheblade.

4.Loosenthelowerjamnutsontheheight-of-cutchain

U-bolt.

5.Adjustthenutstoraiseorlowertherearofthecutting

unitsothatthefrontandrearbladetipshavethesame

measurement.Tightenthejamnuts.

6.Proceedtoprocedure4andlevelthewingletdecksto

thefrontcenterdeck.

Figure7

1.Winglet4.Eccentric

2.Hingepin5.Upperhole

3.Stopbolt

•Rotatetherear(closesttotractionunit)eccentricuntilthe

outsidebladetipisabout3mm(1/8inch)higherthan

thedesiredheightofcut(Figure7).

Note:Thereisanotchontheeccentrichexwhichis

180°fromthelobeontheeccentriccam(Figure8).Use

thenotchestoreferencethelocationofthelobeswhen

adjustingtheeccentrics.

17

Page 18

6

CheckingtheFluidLevels

NoPartsRequired

Procedure

Figure8

1.Eccentricnotch

•Tightentheboltandnutforthiseccentricto149N-m

(110ft-lb).

•Adjusttheforwardeccentricuntilitjustmakescontact

withtheinnerslotsurfaceofthewingletpivotbrackets.

•Tightentheboltandnutforthiseccentricto149N-m

(110ft-lb).

•Repeattheprocedureontheoppositewinglet.Referto

AdjustingtheCuttingUnitPitchprocedureinMower

Maintenance.

5

CheckingtheTirePressure

NoPartsRequired

Procedure

Checktheairpressureinallthetiresbeforeoperatingthe

machine.Thecorrectairpressureinthefronttiresis345kPa

(50psi)andthereartiresis207kPa(30psi)(Figure9).

1.Checktheengineoillevelbeforestartingtheengine,

refertoCheckingtheEngineOilLevelinEngine

Maintenance.

2.Checkthehydraulicuidlevelbeforestartingthe

engine,refertoCheckingtheHydraulicFluidLevelin

HydraulicSystemMaintenance.

3.Checkthecoolingsystembeforestartingtheengine;

refertoCheckingtheCoolingSysteminCooling

SystemMaintenance.

7

GreasingtheMachine

NoPartsRequired

Procedure

Beforethemachineisoperated,itmustbegreasedto

ensureproperlubricatingcharacteristics;refertoGreasing

theBearingsandBushingsprocedureinLubricationinthe

MaintenanceSection.Failuretoproperlygreasethemachine

willresultinprematurefailureofcriticalparts.

Important:Maintainpressureinalltirestoensurea

goodquality-of-cutandpropermachineperformance.

Do not under -inate.

Figure9

18

Page 19

ProductOverview

Controls

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CAUTION

Thismachineproducessoundlevelsinexcessof85

dBAattheoperatorsearandcancausehearingloss

throughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

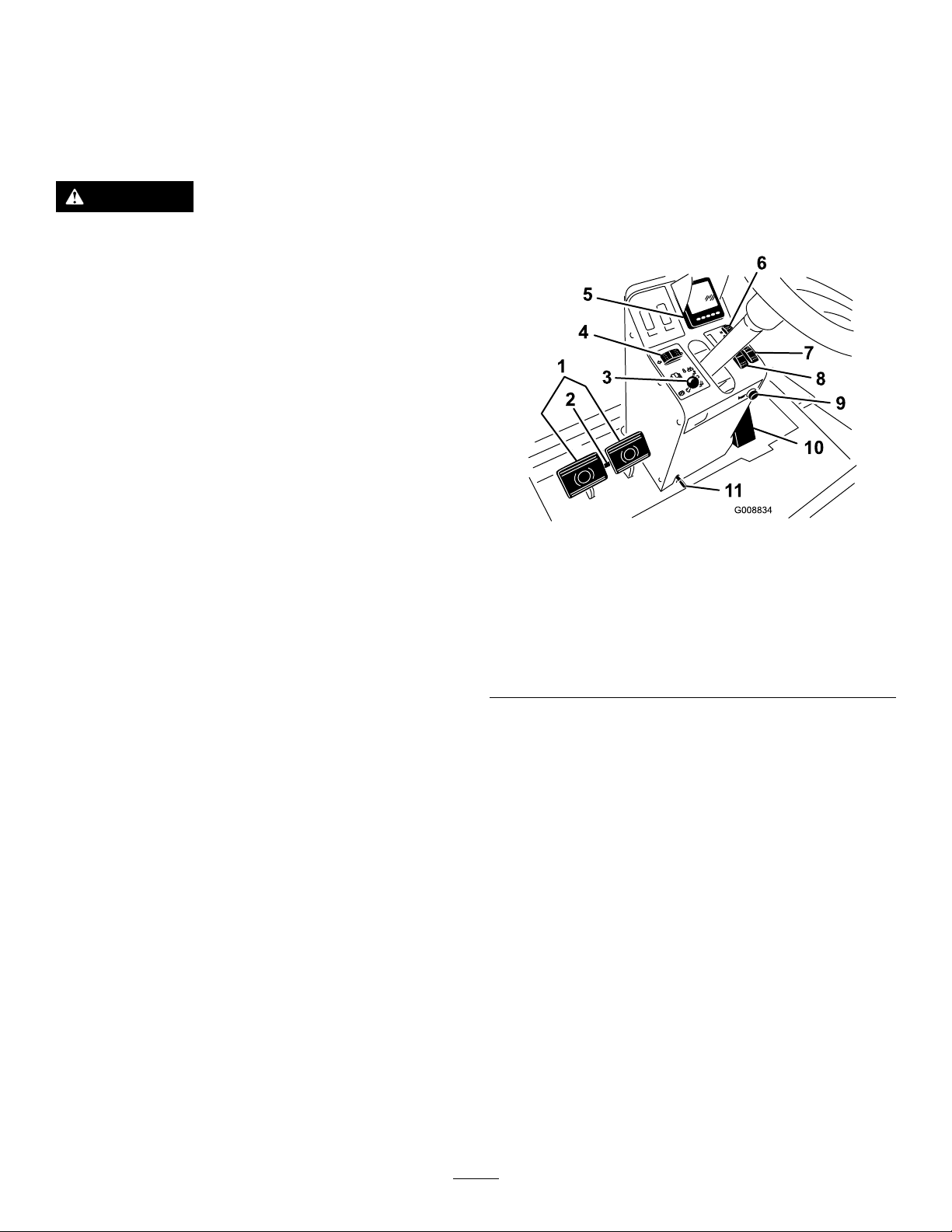

TractionPedal

Thetractionpedal(Figure10)controlsforwardandreverse

operation.Pressthetopofthepedaltomoveforwardand

thebottomtomovebackward.Groundspeeddependson

howfaryoupressthepedal.Fornoload,maximumground

speed,fullypressthepedalwhilethethrottleisintheHi

idleposition.

HornButton

Pressthehornbutton(Figure10)toactivatethehorn.

ParkingBrakeLatch

Theknobontheleftsideoftheconsoleactuatestheparking

brakelock(Figure10).Toengagetheparkingbrake,connect

thepedalswiththelockinglatch,pushdownonbothpedals,

andpulltheparkingbrakelatchout.Toreleasetheparking

brake,pressbothpedalsuntiltheparkingbrakelatchretracts.

Tostop,reduceyourfootpressureonthetractionpedaland

allowittoreturntothecenterposition.

BrakePedals

Twofootpedals(Figure10)operateindividualwheelbrakes

forturningassistance,parking,andtoaidinobtainingbetter

sidehilltraction.Alatchconnectsthepedalsforparking

brakeoperationandtransport.

PedalLockingLatch

Thepedallockinglatch(Figure10)connectsthepedals

togethertoengagetheparkingbrake.

TiltSteeringLever

Pressthelever(Figure10)downtotiltthesteeringwheel

tothedesiredposition.Thenreleasethelevertolockthe

adjustment.

TurnSignalSwitch

Presstheleftsideoftheturnsignalswitch(Figure10)to

activatetheleftturnsignalandtherightsideoftheswitchto

activatetherightturnsignal.Thecenterpositionisoff.

Figure10

1.Brakepedals7.Variablethrottleswitch

2.Pedallockinglatch8.Throttleswitch

3.Parkingbrakelatch9.Horn

4.Turnsignalswitch10.Tractionpedal

5.Infocenter

6.Hi-lorangespeedcontrol

11.Tiltsteeringlever

ThrottleSwitch

Thethrottleswitch(Figure11)hasthreepositionslowidle,

mididleandhighidle.

VariableThrottleSwitch

Thevariablethrottleswitch(Figure11)allowstheengine

speedtobeadjustedinsmallincrements.Pressthe“+”once

toincreasetheenginespeedandthe“-”oncetodecrease

theenginespeed.

Note:Movingthethrottleswitchwilloverrideandcancel

thevariablethrottlesetting.

Important:Donotoperatetheenginebelow1350rpm.

Hi-LoRangeSpeedSwitch

Pressthefrontoftheswitch(Figure10)toselecthighspeed

range.Presstherearoftheswitchtoselectlowspeedrange.

Themachinemustbestationaryortravelingataveryslow

speed,lessthan2mph,toshifttoHiorLo.

LiftSwitches

Theliftswitches(Figure11)raiseandlowerthecuttingunits.

Presstheswitchesforwardtolowerthecuttingunitand

backwardtoraisethecuttingunits.

19

Page 20

Note:ThedeckswillnotlowerwhileintheHispeedrange.

andthedeckswillnotraiseorloweriftheoperatorisoutof

theseatwhentheengineisrunning.

LightSwitch

Presstheloweredgeoftheswitch(Figure11)toturnonthe

lights.Presstheupperedgeoftheswitchtoturnoffthelights.

KeySwitch

Thekeyswitch(Figure11)hasthreepositions:Stop,

Run/Preheat,andStart.

Figure11

1.PTOswitch5.Cruisecontrol

2.Keyswitch6.Lightswitch

3.Tractionassistswitch

4.Liftswitches

7.Powerpoint(ontheright

sideofconsole)

AudibleAlarm(Console)

Thealarmisactivatedwhenafaultisdetected.

Thebuzzersounds:

•continuouswhentheenginesendsastopfault.

•withashortpulsewhentheenginesendsacheckengine

fault.

•whenthereislowfuel.

PowerPoint

Thepowerpoint,locatednexttotheconsoleontheside

ofthepowercenter,isusedtopoweroptionalelectrical

accessories(Figure11).

SeatAdjustments

Weightgauge

Indicateswhentheseatisadjustedtotheweightofthe

operator(Figure12).Heightadjustmentismadeby

positioningthesuspensionwithintherangeofthegreen

region.

PTOSwitch

ThePTOswitch(Figure11)hastwopositions:Out(start)

andIn(stop).PullthePTObuttonouttoengagethe

implementorcuttingunitblades.Pushinthebuttonto

disengagetheimplementoperation.

TractionAssistSwitch

Whenmowing(lowspeedrange),pressandholdthe

tractionassistswitch(Figure11)toenhancetractiondrive

performanceincompromisedoperatingconditions.

Note:ThetractionassistonlyengagesinMow-Forward.

ThetractionassistwillnotengageinMow-ReverseorHi

speedrange.

CruiseControlSwitch

Thecruisecontrolswitch(Figure11)setsthespeedofthe

machine.Pressingtherearoftheswitchturnsoffthecruise

control,themiddlepositionoftheswitchenablesthecruise

controlfunctionandthefrontoftheswitchsetsthedesired

groundspeed.

Note:Pressingeitherbrakepedalormovingthetraction

pedalintothereverseposition,foronesecond,willalso

disengagethecruisecontrol.

Figure12

1.Weightgauge

2.Weightadjustinglever5.Armrestadjustingknob

3.ForeandAftadjusting

lever

WeightAdjustingLever

Adjustforoperatorweight(Figure12).Pulluponthelever

toincreasetheairpressureandpushdowntodecreasetheair

4.Seatbackadjustinglever

20

Page 21

pressure.Theproperadjustmentisattainedwhentheweight

gaugeisinthegreenregion.

ForeandAftAdjustingLever

Pulloutonthelevertoslidetheseatforeoraft(Figure12).

SeatBackAdjustingLever

Movethelevertoadjusttheseatbackangle(Figure12).

SeatArmRestAdjustingKnob

Rotatetheknobtoadjusttheseatarmrestangle(Figure12).

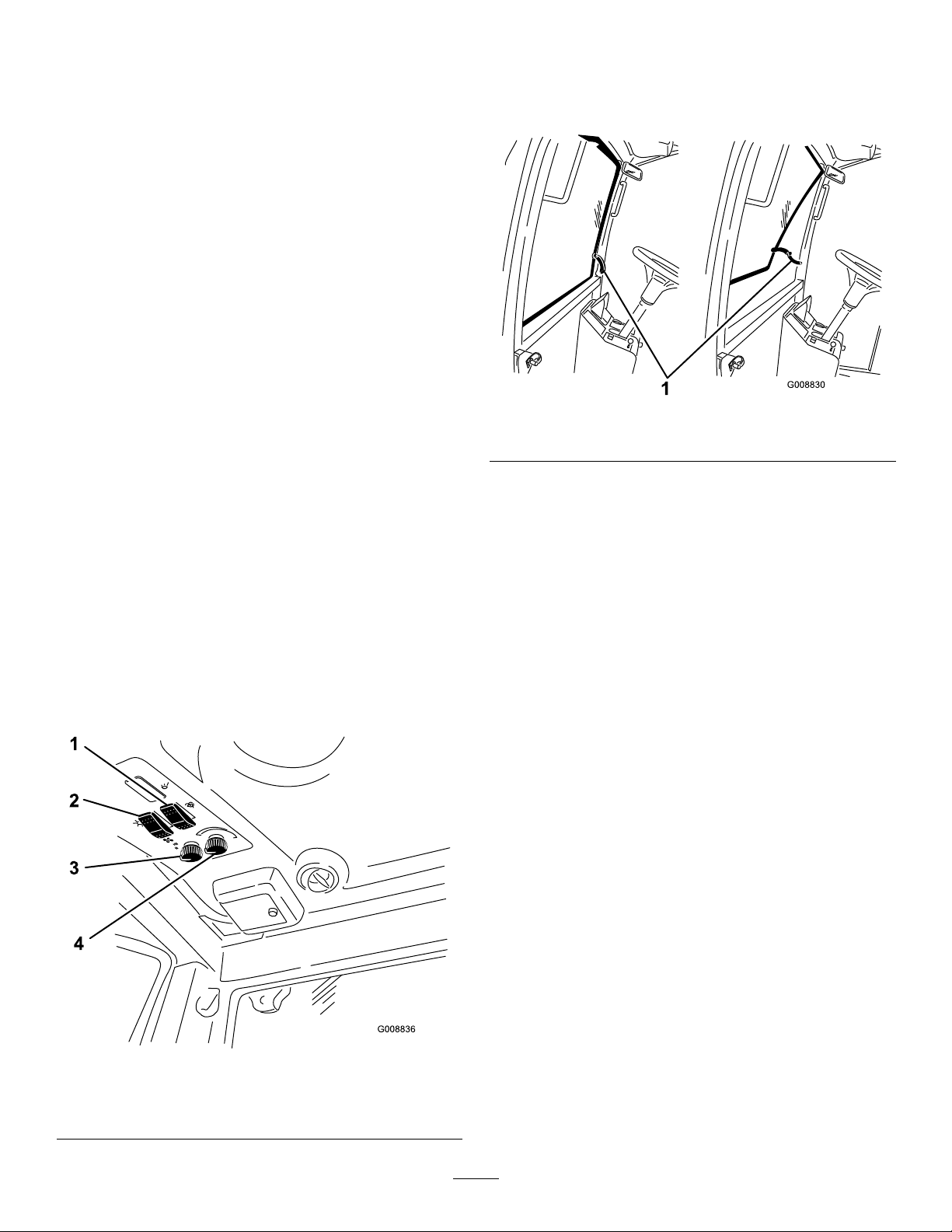

CabControls

Model31599and31599Nonly

WindShieldLatch

Liftuponlatchestoopenthewindshield(Figure14).Press

inonlatchtolockwindshieldinopenposition.Pulloutand

downonlatchtocloseandsecurewindshield.

WindShieldWiperSwitch

Pressfrontofswitchtoactivatethewindshieldwipers

(Figure13)andrearofswitchtoturnoffthewipers.

AirConditioningSwitch

Pressfrontofswitchtoactivatetheairconditioning(Figure

13)andrearofswitchtoturnofftheairconditioning.

FanControl

Rotatethefancontrolknobtoregulatethespeedofthefan

(Figure13).

TemperatureControl

Rotatethetemperaturecontrolknobtoregulatetheair

temperatureinthecab(Figure13).

Figure14

1.Windshieldlatch

RearWindowLatch

Liftuponlatchestoopentherearwindow .Pressinonlatch

tolockwindowinopenposition.Pulloutanddownonlatch

tocloseandsecurewindow(Figure14).

Important:Therearwindowmustbeclosedbefore

openingthehoodordamagemayoccur.

InfoCenter

ScreenFunctions

•Pressthecorrespondingbuttontoviewscreen1orscreen

2,tostopaudiblealarm,toviewfaultscreenortoexit

(Figure15).

•Ifafaultappearsonthescreen,pressanykeytoviewthe

activefaultadvisory.Contactyoursupervisorormechanic

torelayfaultadvisoryanddeterminecourseofaction.

Figure13

1.Windshieldwiperswitch3.Fancontrol

2.Airconditioningswitch4.T emperaturecontrol

•Pressthearrowkeystonavigatethefaultscreen.

•Pressanykeytorevealtheinformationkeysonthescreen.

21

Page 22

1.Screen1

2.Screen2

3.Audiblealarm

Figure15

4.Faultscreen

5.Exit

EngineCoolantTemperatureIndicator

Thisdisplayindicatestheenginecoolanttemperature(Figure

16).

ParkingBrakeIndicator

Thisdisplayindicatesthattheparkingbrakeisactuated

(Figure16).

PTOIndicator

Thisdisplayindicates(Figure16)whenthePTOinengaged.

FanReverseIndicator

Thisdisplayindicates(Figure16)whenthefanisoperating

inreverse.Thefanspeedwillbecontrolledbythehydraulic

oiltemperature,airintaketemperatureorenginecoolant

temperatureandwillautomaticallyreverse.Areversecycleis

automaticallyinitiated,tohelpblowdebrisoffoftherear

hoodscreen,wheneithertheenginecoolanttemperatureor

hydraulicoiltemperatureacertainpoint.

OperatorInformation

Therearetwoscreensthatwillmonitoranddisplaythe

machinefunctionsthattheoperatorcanuse.

Screen1willdisplay:

TopLeftGauge-EngineCoolantTemperature

TopRightGauge-FuelLevel

LefttoRightontheBottomHalf

1.PTOEngaged

2.ParkingBrakeEngaged

3.FanReversing

4.CruiseControlEngaged

5.H/L(Hi/Lowspeedrange)

BottomLeftCorner-AirIntakeHeaterActive

BottomMiddle-TractionAssistEngaged

BottomRight-MachineHours

Screen2willdisplay:

TopLeftCorner-EngineRPM

TopRightCorner-HydraulicOilTemperature

LowerLeftCorner-BatteryVoltage

LowerRightCorner-ServiceDue

CruiseControlIndicator

Thisdisplayindicates(Figure16)whenthecruisecontrolis

inoperation.

FuelLevelIndicator

Thisdisplayindicatestheleveloffuelinthetank(Figure16).

Figure16

1.Enginecoolant

temperatureindicator

2.Fuelindicator7.Tractionassistindicator

3.PTOindicator8.Cruisecontrolindicator

4.Airintakeheaterindicator9.Machinehoursindicator

5.Parkingbrakeindicator

6.Fanreverseindicator

10.H/L(Hi/Low)speed

rangeindicator

22

Page 23

H/L(Hi/Low)SpeedRangeIndicator

g021 157

Thisdisplayindicateswhichspeedrangehasbeenselected

(Figure16).

Note:Whenservicehasbeenperformed,makesuretoreset

theindicator.

ResettingtheServiceIntervalIndicator

AirIntakeHeaterIndicator

Thisdisplayindicateswhenthesystemispreheating(Figure

16).

TractionAssistIndicator

Thisdisplayindicateswhenthetractionassistisengaged

(Figure16).

MachineHoursIndicator

Thisdisplayshowsthetotalhoursthatthemachinehasbeen

operated(Figure17).

1.PressandholdthefarrightbuttonontheInfoCenter.

2.TheMainMenuscreenwillcomeup.SelectSERVICE

usingthe2buttonsontheleft;pressthebuttonbelow

therightarrowtocontinue.

3.SelectHOURSandpressthebuttonbelowtheright

arrow.

4.PressthebuttonbelowRESETHOURS.

5.SelecttheHOURSfortheappropriatenextservice

timeandpressthebuttonbelowtherightarrow .A

checkmarkwillappearonceithasbeenreset.When

nished,pressthebuttonbelowtheexiticon(picture

ofadooropen)toreturntothemainscreen,orpress

canceltoexit.

EngineAirFilterRestrictionIndicator

Thisdisplay(Figure18)indicateswhentheengineairlter

isrestricted.

Figure17

1.Tachometer3.Batteryvoltage

2.Hydraulicoiltemperature

4.Servicedue

Tachometer

ThisdisplayshowstheengineoperatingspeedinRPM

(Figure17).

BatteryVoltage

Thisdisplayshowsthebatteryvoltage(Figure17).

HydraulicOilTemperatureIndicator

Thisdisplayindicatesthehydraulicoiltemperature(Figure

17).

ServiceDueIndicator

Thisdisplayindicatesthetimeuntilthenextregularservice

interval(Figure17).

Figure18

Alarm(InfoCenter)

TheInfoCenter'salarmsoundswhen:

•anenginefaultisreceived

•anadvisoryorfaultisreceivedfromtheTECcontrollers

•startingthemachine

InfoCenter

FaultIndicators

Stop-IfthedriverreceivesaSTOPindication,thedriver

shouldceaseoperationofthemachineandtheengineas

quicklyandassafelyaspossibletoreducedamagetothe

engine(Figure19).

23

Page 24

CheckEngine-IfthedriverreceivesaCheckEngine

indicationforamaintenancefault,thedrivershouldtakethe

machinetoaservicecenterassoonaspossible.

Figure19

FaultExample

ToSetCruiseControl

Increasegroundspeed

ToFloatDeck

Lowerdecks

ToLowerDeck

1.Operatormustbeseated

2.Selectlowrange

3.Setparkingbrake

ElectronicsIssues

1.FixHigh/Lowrangeswitch

2.Controllerrmwareincompatible

3.Blownfuse

4.HHDTready

Engine

1.Lowerenginespeed

2.Waittoshutoffengine

FuelLevel

1.Faultscreen

Advisories

Advisoriesprovidetheoperatoradditionalinformationto

operatecertainfunctionsonthemachine(Figure20).

Addfuel

ToEngagePTO

1.Solveenginefault

2.Letenginewarmup

3.Lethydraulicoilwarm

4.Lowerdecks

5.Mustbeinlowrange

6.Operatormustbeseated

ToSetHighRange

1.Disengagecruise

2.DisengagePTO

3.Liftleftdeck

4.Liftcenterdeck

5.Liftrightdeck

6.Reducegroundspeed

ToSetLowRange

1.Disengagecruise

2.Reducegroundspeed

1.Advisoryscreen

ToStart

Figure20

AdvisoryExample

1.Disengagedeckswitch

2.DisengagePTO

3.Movetractionpedaltoneutral

4.Insertjumperinteachplug

24

Page 25

5.Enginerunning

6.Mustbeseatedorsetparkingbrake

7.Turnkeyswitchoffthenon

8.Wait

ForT each(TractionPedalCalibration)

Turnkeyswitchoffthenon

ForTraction

1.Fixcriticalsensorerror

2.Fixcriticalvoltageerror

3.Moveforward

4.Movetractionpedaltoneutral

5.Releaseparkingbrake

6.Operatormustbeseated

ForTractionAssist

1.Mustbeinlowrange

2.Operatormustbeseated

TractionDerateDueT o

1.Requiresservice

2.Engineorhydraulicstoohot

3.Tractionpedalsensorneedscalibration

4.Reserved1

5.Reserved2

6.Reserved3

25

Page 26

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Widthofcut

overall

frontcuttingunit234cm(92inches)

sidecuttingunit

frontandonesidecuttingunit361cm(142inches)

Overallwidth

cuttingunitsdown

cuttingunitsup(transports)251cm(99inches)

Overallheight

withROPS226cm(89inches)

withoutROPS152cm(60inches)

withcab

Overalllength445cm(175inches)

Minimumgroundclearance(atmachinecenterline)24cm(9.5inches)

Wheeltread(tocenteroftire)

front160cm(63inches)

rear

Wheeltread(tooutsideoftire)

front193cm(76inches)

rear

Wheelbase

NetWeight(withcuttingunits)

withoutcab

withcab

488cm(192inches)

145cm(57inches)

505cm(199inches)

236cm(93inches)

142cm(56inches)

168cm(66inches)

193cm(76inches)

2929kg(6,457lb)

2706kg(5,966lb)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

26

Page 27

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

CAUTION

Thismachineproducessoundlevelsinexcessof85

dBAattheoperatorsearandcancausehearingloss

throughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,checktheoil

levelintheenginecrankcase;refertoCheckingOilLevelin

EngineMaintenance.

CheckingtheCoolingSystem

Beforeyoustarttheengineandusethemachine,checkthe

coolingsystem;refertoCheckingtheCoolingSystemin

CoolingSystemMaintenance.

CheckingtheHydraulic System

Beforeyoustarttheengineandusethemachine,checkthe

hydraulicsystem;refertoCheckingtheHydraulicSystemin

HydraulicSystemMaintenance.

AddingFuel

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchasefuelin

quantitiesthatcanbeusedwithin180daystoensurefuel

freshness.

Fueltankcapacity:132liters(35USgallons)

Usesummergradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Useofwintergrade

fuelatlowertemperaturesprovideslowerashpointand

coldowcharacteristicswhichwilleasestartingandreduce

fuellterplugging.

Useofsummergradefuelabove-7°C(20°F)willcontribute

towardlongerfuelpumplifeandincreasedpowercompared

towintergradefuel.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandfueltankor

conditioneropening.

•Keepfuelawayfromeyesandskin.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultralowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather.

•Monitorseals,hoses,gasketsincontactwithfuelasthey

maybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblended.

•Contactyourdistributorifyouwishmoreinformation

onbiodiesel.

Incertainconditionsduringfueling,staticelectricitycanbe

releasedcausingasparkwhichcanignitethefuelvapors.A

reorexplosionfromfuelcanburnyouandothersandcan

damageproperty.

•Alwaysplacefuelcontainersonthegroundawayfrom

yourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoronatruck

ortrailerbedbecauseinteriorcarpetsorplastictruckbed

linersmayinsulatethecontainerandslowthelossofany

staticcharge.

•Whenpractical,removeequipmentfromthetruckor

trailerandrefueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuchequipmenton

atruckortrailerfromaportablecontainer,ratherthan

fromafueldispensernozzle.

•Ifafueldispensernozzlemustbeused,keepthenozzlein

contactwiththerimofthefueltankorcontaineropening

atalltimesuntilfuelingiscomplete.

27

Page 28

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana180-daysupplyoffuel.

•Donotoperatemachinewithoutentireexhaust

systeminplaceandinproperworkingcondition.

Checktheairpressureinallthetiresbeforeoperating

themachine.

Figure22

CheckingtheTorqueofWheel

FillingtheFuelTank

1.Parkthemachineonalevelsurface.

2.Usingacleanrag,cleanareaaroundfueltankcap.

3.Removecapfromthefueltank(Figure21).

Figure21

1.Fueltankcap

4.Fillthetankuntilthelevelistothebottomoftheller

neckwithdieselfuel.

5.Installfueltankcaptightlyafterllingtank.

Note:Ifpossible,llthefueltankaftereachuse.This

willminimizepossiblebuildupofcondensationinside

thefueltank.

LugNuts

ServiceInterval:Aftertherst10hours

Every250hours

WARNING

Failuretomaintainpropertorqueofthewheelnuts

couldresultinfailureorlossofwheelandmay

resultinpersonalinjury.

Torquethefrontandrearwheelnutsto95to122

N-m(70to90ft-lb)after10hoursofoperation.

Torqueevery250hoursthereafter.

AdjustingtheHeight-of-Cut

Theheight-of-cutisadjustablefrom25to153mm(1to

6inches)in13mm(1/2inch)increments.Toadjustthe

height-of-cut,positionthecastorwheelaxlesintheupper

orlowerholesofthecastorforks,addorremoveanequal

numberofspacersfromthecastorforks,andadjusttherear

chain(frontdeckonly)tothedesiredholes.Thehigher

heightsofcutareattainedbyrepositioningthedeckcaster

armstothelowersetofholesonthedeckmountingbrackets.

FrontCuttingUnit

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Thecorrectairpressureinthefronttiresis345kPa(50psi)

andthereartiresare207kPa(30psi)(Figure22).

Important:Maintainpressureinalltirestoensurea

goodquality-of-cutandpropermachineperformance.

Do not under -inate.

1.Starttheengineandraisethecuttingunitssothatthe

height-of-cutcanbechanged.Stoptheengineand

removethekeyafterthecuttingunitisraised.

2.Positionthecastorwheelaxlesinthesameholesinall

castorforks.Refertothechart(Figure23)todetermine

thecorrectholesforthesetting.

28

Page 29

Figure23

1.Castorarmheightofcut

mountingholes

2.Castorforkheightofcut

mountingholes

3.Castorforkheightofcut

spacers

Note:Whenoperatingat64mm(2-1/2inch)height

ofcutorhigher,theaxleboltshouldbeinstalledin

thebottomcastorforkholetopreventgrassbuildup

betweenthewheelandthefork.Whenoperatingat

heightsofcutlowerthan64mm(2-1/2inch)andgrass

buildupisdetected,reversethemachinesdirectionto

pullanyclippingsawayfromthewheel/forkarea.

3.Removethetensioningcapfromthecastorshaft

(Figure24).andslidetheshaftoutofthecastorarm.

Put2shims(3mm[1/8inch])ontothecastorshaft

asoriginallyinstalled.Slidetheappropriatenumber

of1/2inchspacersontotheshafttogetthedesired

height-of-cut.

Note:Theshimwashersmaybeusedinany

combinationaboveorbelowthecastorarmhubas

requiredtoachievethedesiredheightofcutordeck

level.

Figure24

1.Tensioningcap4.Topaxlemountinghole

2.Spacers(4)5.Castorwheel

3.Shims(2top&2bottom

5.Removethehairpincotterandclevispinsecuringthe

height-of-cutchainstotherearofthecuttingunit

(Figure25).

Refertothechart(Figure23)todeterminethe

combinationsofspacersforthesetting:

4.Pushthecastorshaftthroughthefrontcastorarm.

Installtheshims(asoriginallyinstalled)andthe

remainingspacersontotheshaft.Installthetensioning

captosecuretheassembly(Figure24).

Figure25

1.Height-of-cutchain

2.Clevispin

6.Mounttheheight-of-cutchainstothedesired

height-of-cuthole(Figure26)withtheclevispinand

hairpincotter.

29

3.Hairpincotter

Page 30

Figure26

Figure28

Note:Whenmowingatheight-of-cutsbelow64mm

(2-1/2inch),movetheskids,gagewheelsandrollers

tothehighestholes.

7.Toattainthe102to153mm(5to6inch)heightofcut

settings,removethemountingboltssecuringthedeck

hangerbracketstotheheightofcutcastorarmsand

remountthedeckhangerbracketstotheheightofcut

castorarmsusingthelowersetofholes(Figure27).

Note:Whenoperatingat64mm(2-1/2inch)height

ofcutorhigher,theaxleboltshouldbeinstalledin

thebottomcastorforkholetopreventgrassbuildup

betweenthewheelandthefork.Whenoperatingat

heightsofcutlowerthan64mm(2-1/2inch)andgrass

buildupisdetected,reversethemachinesdirectionto

pullanyclippingsawayfromthewheel/forkarea.

3.Removethetensioningcapfromthecastorspindle

shaft(Figure29)andslidethecastorshaftoutofthe

castorarm.Put2shims(3mm[1/8inch])onto

theshaftasoriginallyinstalled.Slidetheappropriate

numberof1/2inchspacersontotheshafttogetthe

desiredheight-of-cut.

Note:Theshimwashersmaybeusedinany

combinationaboveorbelowthecastorarmhubas

requiredtoachievethedesiredheightofcutordeck

level.

Figure27

1.Lowermountingbolts

SideCuttingUnits

1.Starttheengineandraisethecuttingunitssothatthe

height-of-cutcanbechanged.Stoptheengineand

removethekeyafterthecuttingunitisraised.

2.Positionthecastorwheelaxlesinthesameholesinall

castorforks.Refertothechart(Figure28)todetermine

thecorrectholesfortheheightofcutsetting.

Figure29

1.Tensioningcap4.Topaxlemountinghole

2.Spacers(4)5.Castorwheel

3.Shims(2topand2bottom)

4.Pushthecastorshaftthroughthecastorarm.Install

theshims(asoriginallyinstalled)andtheremaining

spacersontotheshaft.Installthetensioningcapto

securetheassembly.

30

Page 31

AdjustingtheSkids

Theskidsshouldbemountedinthelowerpositionwhen

operatingatheightsofcutgreaterthan64mm(2-1/2inch)

andinthehigherpositionwhenoperatingatheightsofcut

lowerthan64mm(2-1/2inch).

Note:Whentheskidsbecomeworn,youcanswitchtheskid

totheoppositesidesofthemower,ippingthemover.This

willallowyoutousetheskidslongerbeforereplacingthem.

1.Loosenthescrewatthefrontofeachskid(Figure30).

Figure31

1.Gagewheel2.Screwandnut

2.Slidetheshaftoutofthelowerbracketholes,alignthe

rollerwiththetopholes,andinstalltheshaft(Figure

32).

Figure30

1.Skid

2.Removetheange-headboltsandnutsfromeachskid

(Figure30).

3.Moveeachskidtothedesiredpositionandsecurethem

withtheange-headboltsandnuts.

Note:Onlyusethetoporcentersetsofholesto

adjusttheskids.Thebottomholesareusedwhen

switchingsidesatwhichtimetheybecomethetop

holesontheothersideofthemower.

4.Torquethescrewatthefrontofeachskidto9to11

N-m(80to100in-lb).

AdjustingtheCuttingUnit Anti-ScalpRollers

Thecuttingunitgagewheelsandrollershouldbemountedin

thelowerpositionwhenoperatingatheightsofcutgreater

than64mm(2-1/2inch)andinthehigherpositionwhen

operatingatheightsofcutlowerthan64mm(2-1/2inch).

Figure32

1.Roller

3.Installthescrewandnuttosecuretheassemblies.

2.Rollershaft,screwandnut

AdjustingtheGageWheels

1.Removetheboltandnutsecuringthegagewheelto

thecuttingunitbrackets(Figure31).

AdjustingtheRoller

1.Removethescrewandnutsecuringtherollershaftto

thedeckbracket(Figure31).

2.Aligntherollerandspacerwiththetopholesinthe

bracketsandsecurethemwiththeboltandnut.

31

Page 32

CheckingtheMismatch BetweenCuttingUnits

Duetodifferencesingrassconditionsandthecounterbalance

settingofthetractionunit,itisadvisedthatgrassbecutand

appearancecheckedbeforeformalcuttingisstarted.

1.Setallcuttingunitstothedesiredheightofcut;referto

AdjustingtheHeightofCut.

2.Checkandadjustfrontandreartractortirepressure.

Thecorrectairpressureinthefronttiresis345kPa(50

psi)andthereartiresis207kPa(30psi).

3.Checkandadjustallcastortirepressuresto345kPa

(50psi).

4.Checkliftandcounterbalancepressureswithengineat

highidleusingtestportsdenedinHydraulicSystems

TestPorts.Adjustasrequired.

5.Checkforbentblades;refertoCheckingforaBent

BladeprocedureinMowerMaintenance.

6.Cutgrassinatestareatodetermineifallcuttingunits

arecuttingatthesameheight.

7.Ifcuttingunitadjustmentsarestillneeded,ndaat

surfaceusinga2m(6foot)orlongerstraightedgeto

ensurethesurfaceisat.

8.Toeasemeasuringbladeplane,raisetheheightofcut

tothehighestposition;refertoAdjustingtheHeight

ofCut.

9.Lowercuttingunitsontotheatsurface.Removethe

coversfromthetopofthecuttingunits.

SideCuttingUnits

1.Rotatebladeofeachspindleuntiltheendsfaceforward

andbackward

2.Fortheoutsidebladespindleonly,equallyadjustthe

1/8inchshimsonthefrontcastorforkstomatchthe

desiredheightofcut

correspondingoutsideedgeoffrontcuttingunitand

compare.

Note:Thesidecuttingunitcastorwheelsshould

remainonthegroundwithcounterbalanceapplied.

Note:Ifadjustmentsneedtobemadetomatchthe

cutbetweenthefrontandsidecuttingunits,makethe

adjustmentstothesidecuttingunitsonly.

3.Iftheinsideedgeofthesidecuttingunitistoohigh

relativetotheoutsideedgeofthefrontcuttingunit,

removeone1/8inchshimfromthebottomofthe

frontinsidecastorarmonthesidecuttingunit(Figure

33andFigure34).Recheckmeasurementbetween

outsideedgesofbothsidecuttingunitsandinsideedge

ofsidecuttingunittooutsideedgeoffrontcuttingunit.

4.Ifinsideedgeisstilltoohigh,removeanadditional1/8

inchshimfrombottomoffrontinsidecastorarmof

thesidecuttingunitandone1/8inchshimfromthe

frontoutsidecastorarmofthesidecuttingunit(Figure

33andFigure34).

5.Iftheinsideedgeofthesidecuttingunitistoolow

relativetotheoutsideedgeofthefrontcuttingunit,

addone1/8inchshimtothebottomofthefront

insidecastorarmonthesidecuttingunit(Figure33

andFigure34).Checkmeasurementbetweenoutside

edgesofbothsidecuttingunitsandinsideedgeofside

cuttingunittooutsideedgeoffrontcuttingunit.

6.Ifinsideedgeisstilltoolow ,addanadditional1/8inch

shimtothebottomoffrontinsidecastorarmofthe

sidecuttingunitandaddone1/8inchshimtothe

frontoutsidecastorarmofthesidecuttingunit.

7.Oncecuttingheightmatchesattheedgesoffrontand

sidecuttingunits,verifythatsidecuttingunitpitchis

still7.6mm(.300inch).Adjustasnecessary.

3.Measurefromoortothefronttipofthecuttingblade.

4.Rotatetheblade180°andmeasurefromoortothe

tipofthecuttingblade.

5.Therearofthebladeshouldbe7.5mm(.300inch)

higherthanthefront.Ifadjustmentisrequired,adjust

1/8inchshimsonrearcastorforks.

MatchingHeightOfCutBetweenCuttingUnits

1.Positionbladesidetosideonoutsidespindleofboth

sidecuttingunits.Measurefromtheoortothetipof

thecuttingedgeonbothunitsandcompare.These

numbersshouldbewithin3mm(1/8inch)ofeach

other.Makenoadjustmentatthistime.

2.Positionbladesidetosideoninsidespindleofside

cuttingunitandcorrespondingoutsidespindleoffront

cuttingunit.Measurefromtheoortothetipofthe

cuttingedgeoninsideedgeofsidecuttingunitto

Figure33

1.Tensioningcap4.Topaxlemountinghole

2.Spacers(4)5.Castorwheel

3.Shims(2topand2bottom)

32

Page 33

AimingtheHeadlights

1.Loosenthemountingnutsandpositioneachheadlight

sothatitpointsstraightahead.Tightenthemounting

nutjustenoughtoholdtheheadlightinposition.

2.Placeaatpieceofsheetmetaloverthefaceofthe

headlight.

3.Mountamagneticprotractorontotheplate.While

holdingtheassemblyinplace,carefullytilttheheadlight

downward3degrees,thentightenthenut.

4.Repeattheprocedureontheotherheadlight.

StartingandStoppingthe

Figure34

1.Leftfrontoutsidecastor

arm

2.Leftfrontinsidecastorarm4.Rightfrontoutsidecastor

3.Rightfrontinsidecastor

arm

arm

AdjustingtheMirrors

RearViewMirror

Whilesittingintheseat,adjusttherearviewmirror(Figure

35)toattainthebestviewouttherearwindow .Pullthelever

rearwardtotiltthemirrortoreducethebrightnessandglare

oflight.

SideViewMirrors

Whilethesittingintheseat,haveahelperadjustthesideview

mirrors(Figure35)toattainthebestviewaroundthesideof

themachine.

Engine

1.Ensurethattheparkingbrakeisset.Removeyourfoot

fromthetractionpedalandensurethatitisinneutral.

2.Setthethrottleswitchtothelow-idleposition.

3.TurntheignitionkeytotheRunposition.Theairintake

heatericonontheinfocenterwillshow/disappear.

4.Whentheglowindicatordims,turntheignitionkey

totheStartposition.Releasethekeyimmediately

whentheenginestartsandallowittoreturntothe

Runposition.Allowenginetowarmupatlowspeed

(withoutload)for3to5minutes,thenactuatethe

throttleswitchestoattainthedesiredenginespeed.

Important:Donotrunthestartermotormore

than30secondsatatimeorprematurestarter

failuremayresult.Iftheenginefailstostart

after30seconds,turnthekeytotheOffposition,

recheckthecontrolsandprocedures,wait2

minutes,andrepeatthestartingprocedure.

Whenthetemperatureisbelow-75°C(20°F),letthe

machinewarmupforaminimumof10minutes.

5.Tostoptheengine,setthethrottleswitchtolow

idle,movethePTOswitchtotheOffposition,set

theparkingbrake,androtatetheignitionkeytoOff.

Removethekeyfromtheswitchtopreventaccidental

starting.

1.Sideviewmirrors

2.Rearviewmirror

Important:Allowenginetoidlefor5minutesbefore

shuttingitoffafterafullloadoperation.Failuretodo

somayleadtoturbo-chargertrouble.

Figure35

3.Lever

33

Page 34

CheckingtheInterlock

G021 160

1

2

3

Switches

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Themachinehasinterlockswitchesintheelectricalsystem.

Theseswitchesaredesignedtostoptheenginewhenoperator

getsoffoftheseatwhenthetractionpedalisdepressed.

However,theoperatormaygetoffoftheseatwhilethe

engineisrunning,thetractionpedalisinneutralandthe

parkingbrakeengaged.

Figure36

1.Bypassvalves(2)

Tochecktheoperationoftheinterlockswitches,perform

thefollowingprocedure:

1.Drivethemachineslowlytoalarge,relativelyopen

area.Lowerthecuttingunit,stoptheengine,andapply

theparkingbrake.

2.Sitontheseatanddepressthetractionpedal.Tryto

starttheengine.Theengineshouldnotcrank.Ifthe

enginecranks,thereisamalfunctionintheinterlock

systemthatshouldbecorrectedbeforebeginning

operation.

3.Sitontheseatandstarttheengine.Risefromtheseat

andmovethePTOlevertoOn.ThePTOshouldnot

engage.IfthePTOengages,thereisamalfunctionin

theinterlocksystemthatshouldbecorrectedbefore

beginningoperation.

4.Sitontheseat,engagetheparkingbrakeandstartthe

engine.Movethetractionpedaloutoftheneutral

position.Thetractiondriveshouldnotfunction.Ifthe

tractiondrivestillfunctionsthereisamalfunctionin

theinterlocksystemthatshouldbecorrectedbefore

beginningoperation.

2.Rotateeachvalve3turnscounter-clockwisetoopen

andallowoiltobypassinternally.Donotopenmore

than3turns.Becauseuidisbypassed,themachinecan

beslowlymovedwithoutdamagingthetransmission.

3.Closethebypassvalvesbeforestartingtheengine.

Torqueto70N-m(52ft-lb)toclosethevalve.

Important:Ifthemachinemusttobepushedor

towedinreverse,thecheckvalveinthefour-wheel

drivemanifoldmustalsobebypassed.T obypass

thecheckvalve,connectahoseassembly(Hose

PartNo.95-8843,CouplerFittingNo.95-0985

[Qty.2],andHydraulicFittingNo.340-77[Qty .

2])tothereversetractionpressuretestportMB,

locatedonthehydrostat,andonthetestportG2

onthereartractionmanifoldwhichislocated

behindthefronttire.

PushingorTowingthe Machine

Inanemergency,themachinecanbemovedforwardby

actuatingthebypassvalveinthevariabledisplacement

hydraulicpumpandpushingortowingthemachine.

Important:Donotpushortowthemachinefasterthan

3-4.8km/h(2-3MPH)becauseinternaltransmission

damagemayoccur.Thebypassvalvesmustbeopen

wheneverthemachineispushedortowed.

1.Raisethehoodandlocatethebypassvalvesonthe

pump(Figure36).

1.Reversefour-wheeldrive

pressuretestport(Port

G2)

2.Hoseassembly

34

Figure37

3.Reversetractionpressure

testport(PortMB)

Page 35

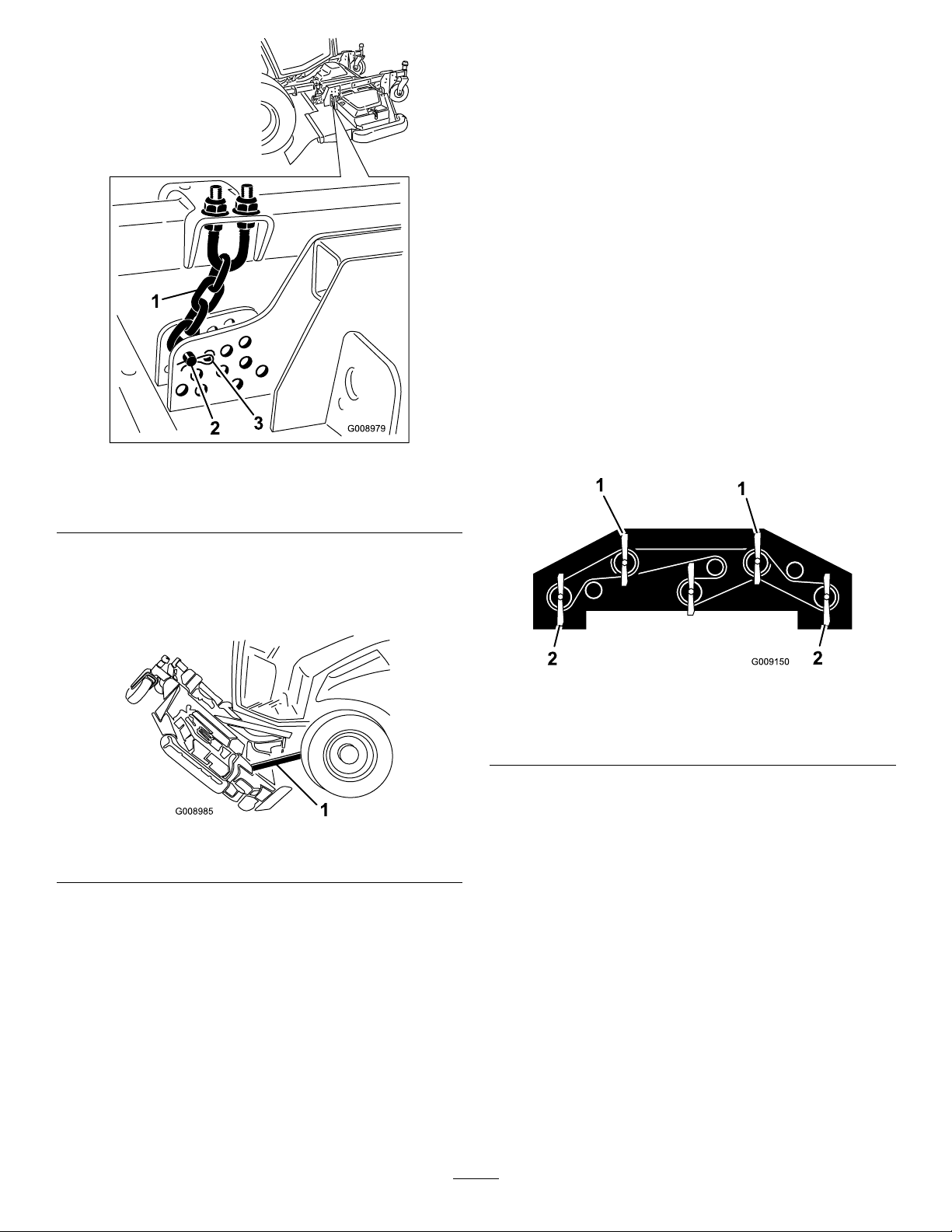

JackingPoints

TieDowns

•Onthefrontofthemachineontheframeontheinside

ofeachdrivetire(Figure38).

Figure38

1.Frontjackingpoint(2)

•Ontherearofthemachineatthecenteroftheaxle

(Figure39).

•Underthefrontoftheoperator'splatform(2places)

(Figure40).

Figure40

1.Fronttiedown(2)

•Therearbumper(2places)(Figure41).

1.Rearjackingpoint

Figure39

Figure41

1.Reartiedown(2)

35

Page 36

OperatingCharacteristics

G010392

Practicedrivingthemachinebecauseithasahydrostatic

transmissionanditscharacteristicsaredifferentthanmany

turfmaintenancemachines.Somepointstoconsiderwhen

operatingthetractionunit,cuttingunit,orotherimplements

arethetransmission,enginespeed,loadonthecuttingblades

orotherimplementcomponents,andtheimportanceofthe

brakes.

Tomaintainenoughpowerforthetractionunitand

implementwhileoperating,regulatethetractionpedalto

keeptheenginespeed(RPM)highandsomewhatconstant.

Agoodruletofollowistodecreasethegroundspeedasthe

loadontheimplementincreases,andincreasetheground

speedastheloaddecreases.

Therefore,allowthetractionpedaltomovebackwardasthe

enginespeed(RPM)decreases,anddepressthepedalslowly

astheenginespeed(RPM)increases.Bycomparison,when

drivingfromoneworkareatoanother,withnoloadand

cuttingunitraised,havethethrottleinthehighestposition

anddepressthetractionpedalslowlybutfullytoattain

maximumgroundspeed.

Thetractionassistenhancestractiondriveperformancein

compromisedoperatingconditions.Thetractionassistis

foruseinlowspeedrangeonly.Whenapproachinganarea

knowntocausewheelspin,depressandholdtractionassist

switchuntilcompletelypastthearea.Ifatirespinswhile

climbingormaneuveringonslopes,depressswitchandslowly

driveoutofarea.Ifbothafrontandrearwheelspins,the

steeringbrakecanbefeatheredtotransferthetorquefrom

thespinningwheelstooppositefrontwheel.

Thebrakescanbeusedtoassistinturningthemachine.

However,usethemcarefully,especiallyonsoftorwetgrass

becausetheturfmaybetornaccidentally.Anotherbenet

ofthebrakesistomaintaintraction.Forexample,insome

slopeconditions,theuphillwheelslipsandlosestraction.If

thissituationoccurs,depresstheuphillturnpedalgradually

andintermittentlyuntiltheuphillwheelstopsslipping,thus,

increasingtractiononthedownhillwheel.

Beforestoppingtheengine,disengageallcontrolsandmove

thethrottletotheslowestposition.Movingthethrottletothe

slowestpositionreduceshighenginespeed(RPM),noise,and

vibration.TurnthekeytoOfftostoptheengine.

Beforetransportingthemachine,raisethecuttingunitsand

securethesidecuttingunittransportlatches(Figure42).

Figure42

1.Transportlatch

ReversingFanOperation

Thefanspeedwillbecontrolledbyhydraulicoiltemperature,

airintaketemperatureandenginecoolanttemperature.A

reversecycleisautomaticallyinitiatedandonlyhappenswhen

eithertheenginecoolantorhydraulicoiltemperaturereaches

acertainpoint.Thisreversalwillhelpblowdebrisofftherear

screenandlowertheengineandhydraulicoiltemperatures

(Figure43).

Useextracarewhenoperatingthemachineonslopes.Make

suretheseatbeltisbuckled.Driveslowlyandavoidsharp

turnsonslopestopreventrollovers.Forsteeringcontrol,the

cuttingunitmustbeloweredwhengoingdownhill.

WARNING

Thisproductisdesignedtodriveobjectsintothe

groundwheretheyloseenergyquicklyingrass

areas.However,carelessoperation,combinedwith

terrainangle,ricochets,orimproperlypositioned

safetyguardcanleadtothrownobjectinjuries.

•Whenapersonorpetappearssuddenlyinor

nearthemowingarea,

•Donotresumemowinguntiltheareaiscleared.

stop mo wing

Figure43

.

36

Page 37

OperatingTips

SelecttheProperHeight-of-CutSetting

toSuitConditions

Removeapproximately25mm(1inch)ornomorethan1/3

ofthegrassbladewhencutting.Inexceptionallylushand

densegrass,youmayhavetoraisetheheight-of-cuttothe

nextsetting.

Figure45

1.Transportlatch

AfterOperating

Figure44

MowWhenGrassisDry

Moweitherinthelatemorningtoavoidthedew ,whichcauses

grassclumping,orinlateafternoontoavoidthedamage

thatcanbecausedbydirectsunlightonthesensitive,freshly

mowedgrass.

MowatProperIntervals

Undermostnormalconditionsyouwillneedtomow

approximatelyevery4-5days.Butremember,grassgrowsat

differentratesatdifferenttimes.Thismeansthatinorderto

maintainthesameheight-of-cut,whichisagoodpractice,

youwillneedtocutmorefrequentlyinearlyspring;asthe

grassgrowthrateslowsinmidsummer,cutonlyevery8-10

days.Ifyouareunabletomowforanextendedperioddue

toweatherconditionsorotherreasons,mowrstwiththe

height-of-cutatahighlevel;thenmowagain2-3dayslater

withalowerheightsetting.

Toensureoptimumperformance,cleantheundersideofthe

mowerhousingaftereachuse.Ifresidueisallowedtobuild

upinthemowerhousing,cuttingperformancewilldecrease.

CuttingUnitPitch

Cuttingunitpitchisthedifferenceinheight-of-cutfrom

thefrontofthebladeplanetothebackofthebladeplane.

Abladepitchof7.6mm(.300inch)isrecommended.A

pitchlargerthan7.6mm(.300inch)willresultinlesspower

required,largerclippings,andapoorerqualityofcut.A

pitchlessthan7.6mm(.300inch)willresultinmorepower

required,smallerclippingsandabetterqualityofcut.

MaximizingAirConditioner

Performance

•Tolimitsolarheating,parkthemachineinashadedarea

orleavethedoorsopenindirectsun.

•Checktomakesuretheairconditioningscreenisclean.

•Checktomakesuretheairconditioningcondenserns

areclean.

Transporting

Usethetransportlatcheswhentransportingoverlong

distances,roughterrain,orwhentrailering.

•Operatetheairconditionerbloweratthemidspeed

setting.

•Verifycontinuoussealbetweentheroofandtheheadliner.

Correctasrequired.

•Measuretheairtemperatureatthefrontcenterventin

theheadliner(Typicallystabilizeatlessthanorequalto

50degreesF .)

•RefertotheServiceManualforadditionalinformation

37

Page 38

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst10hours

Aftertherst250hours

Beforeeachuseordaily

Every50hours

Every100hours

MaintenanceProcedure

•Torquethewheellugnuts.

•Checkthealternatorbelttension.

•Checkthecompressorbelttension.

•Checkbladebolttorque

•Adjustthevalveclearance

•Changetheplanetarydrivegear/brakeoil

•Checkthetirepressure.

•Lubricatecastorarmbushings.

•Checktheengineoillevel.

•Drainthewaterseparator

•Checkthecoolantlevel.

•Checkthehydraulicuidlevel.