Page 1

FormNo.3403-609RevA

Groundsmaster

®

5900or5910

RotaryMower

ModelNo.31598—SerialNo.316000001andUp

ModelNo.31598N—SerialNo.316000001andUp

ModelNo.31599—SerialNo.316000001andUp

ModelNo.31599N—SerialNo.316000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3403-609*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Thismachineisaride-on,rotary-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrasson

well-maintainedlawnsinparks,golfcourses,sportselds,

andoncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongsidehighways,

orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

GeneralSafety.........................................................4

SafetyandInstructionalDecals.................................5

Setup...........................................................................13

1RemovingtheSide-DeckShippingStrapand

Brace................................................................13

2LoweringtheFront-DeckWinglets.........................14

3LevelingtheFront,CenterDeck.............................15

4LevelingtheWingletDeckstotheFront,Center

Deck.................................................................15

5PreparingtheMachine..........................................16

ProductOverview.........................................................16

Controls...............................................................16

CabControls......................................................18

Specications........................................................23

Attachments/Accessories........................................23

BeforeOperation......................................................23

BeforeOperationSafety..........................................23

CheckingtheEngine-OilLevel.................................24

CheckingtheCoolingSystem...................................24

CheckingtheHydraulicSystem................................24

FillingtheFuelTank...............................................24

CheckingtheTirePressure......................................25

CheckingtheTorqueoftheWheel-Lug

Nuts.................................................................25

AdjustingtheHeightofCut.....................................26

AdjustingtheSkids.................................................28

AdjustingtheMowerDeckAnti-Scalp

Rollers...............................................................28

CheckingaMismatchBetweenMower

Decks................................................................29

AdjustingtheMirrors..............................................30

AimingtheHeadlights............................................30

CheckingtheSafety-InterlockSwitches......................31

DuringOperation.....................................................31

DuringOperationSafety.........................................31

StartingandStoppingtheEngine..............................32

UnderstandingtheOperatingCharacteristics..............33

AutomaticReversing-FanCycle................................33

OperatingTips......................................................33

AfterOperation........................................................34

AfterOperationSafety............................................34

IdentifyingtheTie-DownPoints..............................35

PushingorTowingtheMachine................................35

Maintenance.................................................................36

RecommendedMaintenanceSchedule(s)......................36

ServiceIntervalChart.............................................37

PremaintenanceProcedures........................................37

Pre-MaintenanceSafety...........................................37

PreparingtheMachineforMaintenance.....................38

RaisingtheMachine................................................38

RemovingandInstallingtheInner-Wing-Deck

Covers...............................................................38

Lubrication...............................................................39

GreasingtheBearingsandBushings..........................39

EngineMaintenance..................................................42

EngineSafety.........................................................42

Air-CleanerMaintenance.........................................42

ServicingtheEngineOil..........................................43

AdjustingtheValveClearance..................................44

FuelSystemMaintenance...........................................44

ServicingtheFuelSystem........................................44

ServicingtheWaterSeparator..................................45

ReplacingtheFuelFilter..........................................45

ElectricalSystemMaintenance....................................46

ElectricalSystemSafety...........................................46

LocatingtheFuses..................................................46

CheckingtheBatteryCondition................................47

ChargingtheBattery...............................................48

UsingtheAlternatePositivePost..............................48

CalibratingtheTractionPedal..................................48

DriveSystemMaintenance.........................................49

AdjustingtheTraction-PedalAngle...........................49

CheckingthePlanetary-DriveGear/Brake-Oil

Level.................................................................49

ChangingthePlanetary-DriveGear/Brake

Oil....................................................................49

CheckingtheRear-WheelToe-in...............................50

CoolingSystemMaintenance......................................51

CoolingSystemSafety.............................................51

CheckingtheCoolingSystem...................................51

ServicingtheEngine-CoolingSystem........................52

BrakeMaintenance....................................................52

AdjustingtheServiceBrakes....................................52

BeltMaintenance......................................................53

ServicingtheAlternatorBelt....................................53

ServicingtheCompressorBelt.................................53

ReplacingtheBlade-DriveBelts................................53

HydraulicSystemMaintenance....................................55

HydraulicSystemSafety..........................................55

CheckingtheHydraulicFluid...................................55

ChangingtheHydraulicFluidandFilters....................56

CheckingtheHydraulicLinesandHoses....................57

InspectingtheHydraulic-SystemTestPorts................57

MowerMaintenance...................................................57

Pivoting(Tilting)theFrontMowerDeck

Upright.............................................................57

Pivoting(Tilting)theFrontMowerDeck

Down................................................................58

AdjustingtheMower-DeckPitch..............................58

ServicingtheCastor-ArmBushings...........................59

ServicingtheCasterWheelsandBearings...................60

BladeMaintenance.....................................................60

BladeSafety...........................................................60

CheckingforaBentBlade........................................60

RemovingandInstallingaBlade...............................61

InspectingandSharpeningtheCutterBlade(s)............61

CorrectingaMower-DeckMismatch.........................62

MiscellaneousMaintenance.........................................62

ServicingtheSpark-ArrestorMufer.........................62

CleaningtheCabAirFilters.....................................63

CleaningtheAir-ConditioningAssembly

........................................................................63

Cleaning...................................................................64

3

Page 4

CleaningtheCab....................................................64

DisposingofWaste.................................................64

Storage........................................................................64

PreparingforSeasonalStorage.................................64

Safety

ThismachinehasbeendesignedinaccordancewithANSI

B71.4-2012.

GeneralSafety

Thisproductiscapableofamputatinghandsandfeetand

ofthrowingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustoyouandbystanders.

•ReadandunderstandthecontentsofthisOperator’ sManual

beforeyoustarttheengine.Ensurethateveryoneusing

thisproductknowshowtouseitandunderstandsthe

warnings.

•Donotputyourhandsorfeetnearmovingcomponents

ofthemachine.

•Donotoperatethemachinewithoutallguardsandother

safetyprotectivedevicesinplaceandworkingonthe

machine.

•Keepclearofanydischargeopening.Keepbystandersa

safedistancefromthemachine.

•Keepchildrenoutoftheoperatingarea.Neverallow

childrentooperatethemachine.

•Stopthemachineandshutofftheenginebeforeservicing,

fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theseinstructionsmayresultinpersonalinjuryordeath.

Youcanndadditionalitemsofsafetyinformationintheir

respectivesectionsthroughoutthismanual.

4

Page 5

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-6674

1.Crushinghazard,hand—readtheinstructionsbefore

servicingorperformingmaintenance.

93-6686

1.Hydraulicoil

2.ReadtheOperator'sManual.

93-6687

1.Donotstephere.

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

93-7275

1.ReadtheOperator’sManual—donotusestartinguidto

starttheengine.

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto1 15to149N·m(85to1 10

ft-lb).

1.Windshieldwipers—off

2.Windshieldwipers

5

125-9688

ModelwithCabOnly

3.Windshieldwipers—on

4.Spraywindshieldwasher

uid

Page 6

114-0135

132-3600

ModelwithCabOnly

1.ReadtheOperator's

Manualformore

informationonfuses.

2.Headlight—25A6.Auxiliarypower—15A

3.CondenserfanandA/C

clutch—30A

4.Fan—25A8.Windshieldwipers—15A

5.Workinglight—20A

7.Cablight—15A

1.Raisecuttingunits—left

2.Raisecutting

units—center

3.Raisecuttingunits—right

114-0133

1.Headlights7.Tractionassist—engage

2.On

3.Off9.Lowercuttingunits—left

4.Headlightswitchlocation10.Lowercutting

5.Cruisecontrol—engage

6.Cruisecontrol—disengage

8.Traction

assist—disengage

units—center

11.Lowercuttingunits—right

114-0844

1.Leftturnsignal

2.Rightturnsignal5.T ounlocktheparking

3.ReadtheOperators

Manual.

4.Tolockthebrakes,close

thelatch,pressthebrake

pedal,andpulluponthe

parking-brakeknob.

brake,pressthebrake.

6.Parkingbrake

114-0845

1.Tiltsteeringlever2.Horn

6

Page 7

114-0846

1.ReadtheOperatorsManual;tostarttheengine,movethe

tractionpedaltoNeutral,applythebrake,movethethrottle

switchtolow,turntheignitionkeytoPreheat.Whenthe

WaittoStartAdvisoryclearsontheInfoCenter,turnthe

ignitionkeytoStart.

2.ReadtheOperatorsManual;tostoptheengine,movethe

throttlelevertoslow,disengagethePTO,settheparking

brake,wait5minutes,turntheignitionkeytoStop,and

removethekey;readtheOperatorsManual.

3.ReadtheOperatorsManual.

4.ToengagethePTO,pulluponthePTOswitch.

5.TodisengagethePTO,pushdownonthePTOswitch.

6.Toswitchthetransmissiontohighspeed,fullyraisethe

attachmentsandswitchthespeedcontroltoHigh.

114-0848

1.Highrange6.Lowidle

2.Transmission7.Increaseenginespeed

3.Lowrange8.Engine

4.Highidle

5.Mididle10.Decreaseenginespeed

9.ReadtheOperator’s

Manual.

7

Page 8

114-0865

114-0922

1.Height-of-cutadjustment

114-0849

1.Warning—disengagethePTOthenraisethedeck.

2.Nostep

3.Tractioncontrolpedal

4.Forward

5.Reverse

114-0864

1.Height-of-cutadjustment

114-0922

1.Beltrouting

114-0974

1.Beltrouting

8

Page 9

1.Beltrouting

1.ReadtheOperator'sManual.

117-4979

1.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

114-4883

114-9600

115-5459

1.Electricshockhazard—donotremovecover;keepcoverin

place.

130-0611

ModelwithCabOnly

1.Warning—1)Removethepin;2)Raisethedoors;3)Exit

thecab

120-6604

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Cutting/dismembermenthazardofhand,mower

blade—stayawayfrommovingparts,keepallguardsand

shieldsinplace.

3.Cutting/dismembermenthazardoffoot,mowerblade—stay

awayfrommovingparts,keepallguardsandshieldsin

place.

121-3883

1.DisengagethePTO3.ReadtheOperator’s

117-2718

2.EngagethePTO

Manual

9

Page 10

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Engine—stop3.Engine—start

2.Engine—preheat

1.Explosionhazard

2.Nore,opename,or

smoking.

121-3884

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

125-5263

1.ReadtheOperator’sManualforinformationonfuses.

10

Page 11

114-0975

1.Heightofcut

117-2754

1.Warning—readtheOperator'sManual.

2.Warning—donotoperatethismachineunlessyouaretrained.

3.Warning—weartheseatbeltwhenseatedintheoperator'sposition.

4.Warning—wearhearingprotection.

5.Thrownobjecthazard—keepbystandersasafedistancefromthemachine.

6.Cuttinghazardofhandorfoot—stayawayfrommovingparts;keepallguardsinplace.

7.Tippinghazard—lowerthecuttingunitwhendrivingdownslopes;slowthemachinebeforeturning,donotturnathighspeeds

8.Warning—locktheparkingbrake,stoptheengine,andremovetheignitionkeybeforeleavingthemachine.

11

Page 12

121-8378

ModelwithCabOnly

1.Fan—off3.Coldair

2.Fan—onfull

4.Hotair6.Internalair8.Airconditioner—on

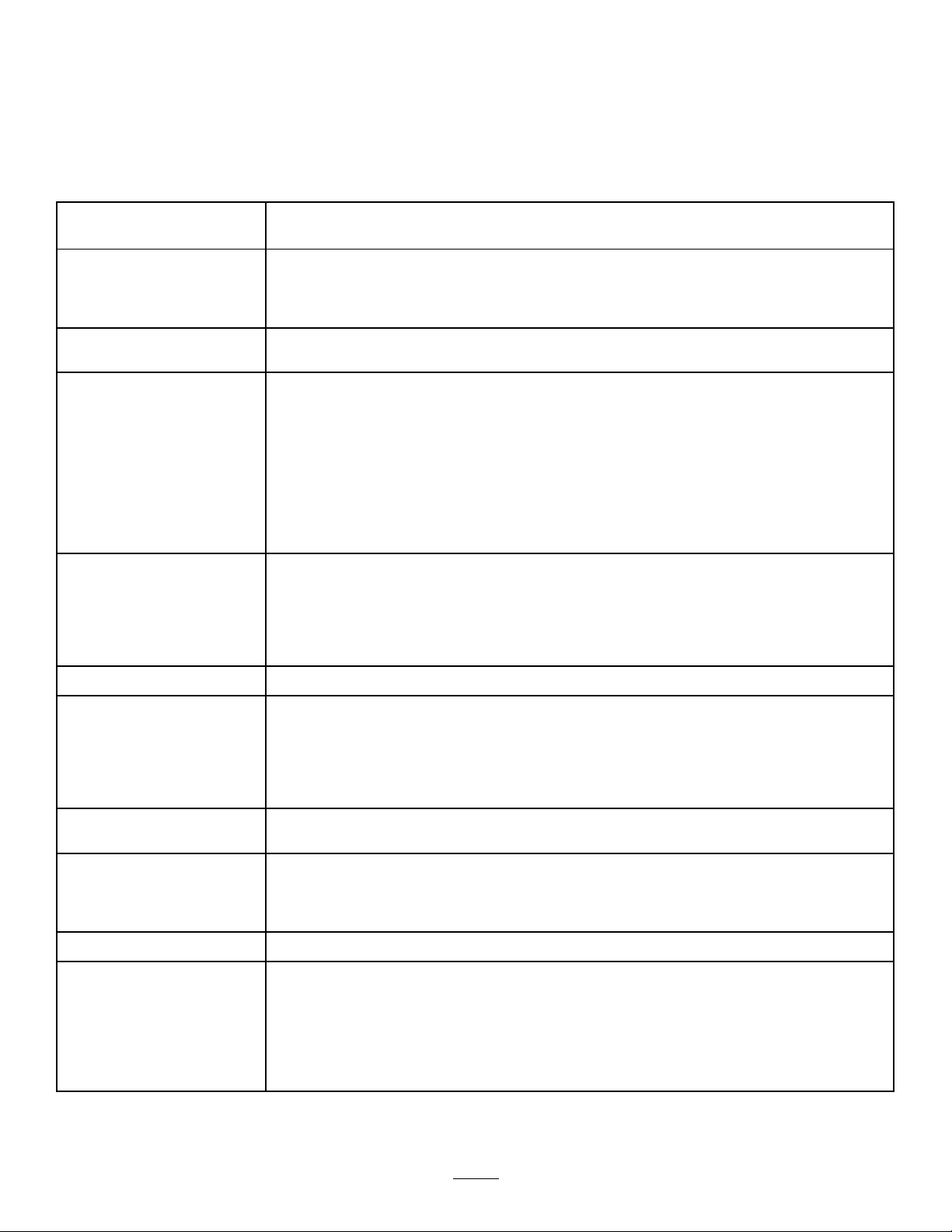

130-2449

5.Externalair

7.Airconditioner—off

1.ReadtheOperator’sManualforinformationonmaintenance.

12

Page 13

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

MediaandAdditionalParts

Description

Operator'sManual

EngineOwner'sManual

PartsCatalog

Nopartsrequired

Rightdeckcover1

Leftdeckcover

V-Belt2

Nopartsrequired

Nopartsrequired

Nopartsrequired

Qty.

1

1

1

Reviewitbeforeoperatingthemachine.

Useittoreferenceengineinformation.

Useittoreferencepartnumbersandorderreplacement

parts.

Qty.

Use

–

1

–

–

–

Removetheside-deckshippingstraps

andbrace.

Lowerthefrontdeckwinglets.

Levelthefront,centerdeck.

Levelthewingletdeckstothefront,

centerdeck.

Preparethemachine.

Use

Operatortrainingmaterials

Declarationofconformity

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Note:Somepartsmayhavealreadybeeninstalledatthefactory.

1

1

Readthematerialsbeforeoperatingthemachine.

ForCEcompliance

1

RemovingtheSide-Deck ShippingStrapandBrace

NoPartsRequired

Procedure

Removethestrapandbracesecuringthesidedecksfor

shipping.

13

Page 14

2

LoweringtheFront-Deck Winglets

Partsneededforthisprocedure:

1Rightdeckcover

1

Leftdeckcover

2V-Belt

Procedure

1.Removethenutssecuringthefrontandrearstopbolts

totherightwinglet-deckmounts(Figure3).

Figure4

1.Winglet4.Eccentric

2.Hingepin5.Lowerhole

3.Bolt

5.Installthenutssecuringthestopbolts.

Figure3

1.Winglet4.Eccentric

2.Hingepin5.Upperhole

3.Stopbolt

2.Whilesupportingtherightwinglet,removethefront

andrearstopboltsfromthedeckmounts(Figure3).

Note:Leavetheeccentricspositionedbetweenthe

deckmounts.

6.Deckmounts

Note:Donottightenthenutsatthistime.

6.Repeatthisprocedureonleftwinglet.

7.Installthewingletbeltsasfollows:

A.Startthebeltaroundthewinglet-spindlepulley

andthefront-deck-spindlepulley(Figure5).

Figure5

1.Winglet-spindlepulley3.Idlerpulley

2.Front-deck-spindlepulley

3.Lowerthewinglettotheoperatingposition.

4.Installthefrontandrearstopboltsthroughthe

upper-mountingholesandeccentrics(Figure4).

Note:Ensurethatthestopboltengagesthetabon

thehingepin.

B.Usingaratchetwrenchorasimilartool,movethe

idlerpulleyawayfromthepulleys(Figure5).

C.Routethebeltaroundthewinglet-spindlepulley

andtheupper-spindlepulleyonthefrontdeck.

D.Releasetheidlerpulleytoputtensiononthebelt.

14

Page 15

8.Installthewinglet-deckcoverandsecureitwiththe

rubberlatch(Figure6).

Note:Ensurethatyouslidethecoverunderthefront,

centerdeck-covertabsbeforeinsertingitontothe

mountinghooksandpost.

9.Repeatthisprocedureontheotherwinglet.

Figure6

1.Cover

2.Rubberlatch4.Mounthooks

3.Front,centerdeck-cover

tabs

4

LevelingtheWingletDecksto theFront,CenterDeck

NoPartsRequired

Procedure

1.Rotatethebladeoneachwingletsothatitpointsside

toside.

2.Loosentheboltsandnutssecuringthe2eccentric

spacerstothewinglets(Figure7).

3

LevelingtheFront,Center Deck

NoPartsRequired

Procedure

RefertoAdjustingtheHeightofCut(page26).

1.Rotatethebladeoneachouterspindleuntiltheends

faceforwardandbackward.

2.Measurefromtheoortothefronttipoftheblade.

3.Adjustthe1/8inchshimsonthefrontcasterfork(s)

tomatchthedesiredheightofcut.

4.Rotatetheblades180°andmeasurefromtheoorto

therear-facingtipoftheblade.

5.Loosenthelowerjamnutsontheheight-of-cutchain

U-bolt.

6.Adjustthenutstoraiseorlowertherearofthemower

decksothatthetipsofthefrontandrearbladeshave

thesamemeasurement.

Figure7

1.Winglet4.Eccentric

2.Hingepin5.Upperhole

3.Stopbolt

3.Rotatetherear(closesttothetractionunit)eccentric

untiltheoutsidebladetipisabout3mm(1/8inch)

higherthanthedesiredheightofcut(Figure7).

Note:Thereisanotchontheeccentrichex,whichis

180°fromthelobeontheeccentriccam(Figure8).

Usethenotchestoreferencethelocationofthelobes

whenadjustingtheeccentrics.

7.Tightenthejamnuts.

15

Page 16

Figure8

1.Eccentricnotch

4.Tightentheboltandnutforthiseccentricto149N·m

(110ft-lb).

5.Adjusttheforwardeccentricuntilitjustmakescontact

withtheinnerslotsurfaceofthewinglet-pivotbrackets.

ProductOverview

Controls

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

6.Tightentheboltandnutforthiseccentricto149N·m

(110ft-lb).

7.Repeattheprocedureontheoppositewinglet.

5

PreparingtheMachine

NoPartsRequired

CheckingtheTirePressure

Checkthetirepressurebeforeuse;refertoCheckingtheTire

Pressure(page25).

Important:Maintainpressureinalltirestoensurea

goodquality-of-cutandpropermachineperformance.

Do not underinate the tir es.

CheckingtheFluidLevels

1.Checktheengine-oillevelbeforestartingtheengine;

refertoCheckingtheEngine-OilLevel(page43).

2.Checkthehydraulic-uidlevelbeforestartingthe

engine;refertoCheckingtheHydraulicFluid(page55).

Figure9

1.Brakepedals7.Variablethrottleswitch

2.Pedal-lockinglatch8.Throttleswitch

3.Parking-brakelatch9.Horn

4.Turn-signalswitch10.Tractionpedal

5.Infocenter11.Steering-levertilt

6.High-Lowrange-speed

switch

TractionPedal

Thetractionpedalcontrolstheforwardandreverseoperation.

Pressthetopofthepedaltomovethemachineforwardand

thebottomtomoveitbackward.Groundspeeddependson

howfaryoupressthepedal.Fornoload,maximumground

speed,fullypressthepedalwhilethethrottleisintheHIGH

IDLEposition(Figure9).

Tostopthemachine,reduceyourfootpressureonthe

tractionpedalandallowittoreturntothecenterposition.

Pedal-LockingLatch

Thepedal-lockinglatchconnectsthepedalstogetherto

engagetheparkingbrake(Figure9).

3.Checkthecoolingsystembeforestartingtheengine;

refertoCheckingtheCoolingSystem(page51).

GreasingtheMachine

Greasethemachinebeforeuse;refertoLubrication(page39).

Failuretoproperlygreasethemachineresultsinpremature

failureofcriticalparts.

Parking-BrakeLatch

Theknobontheleftsideoftheconsoleactuatesthe

parking-brakelock.Toengagetheparkingbrake,connect

thepedalswiththepedal-lockinglatch,pushdownonboth

pedals,andpulltheparking-brakelatchout.Toreleasethe

parkingbrake,pressbothpedalsuntiltheparking-brakelatch

retracts(Figure9).

16

Page 17

Steering-LeverTilt

Presstheleverdowntotiltthesteeringwheeltothedesired

position.Releasethelevertolocktheadjustment(Figure9).

Turn-SignalSwitch

Presstheleftsideoftheturn-signalswitchtoactivatethe

left-turnsignalandtherightsideoftheswitchtoactivatethe

right-turnsignal(Figure9).

Note:Thecenterpositionisoff.

High-LowRangeSpeedSwitch

PressthefrontoftheswitchtoselectHIGH-SPEEDRANGE.

PresstherearoftheswitchtoselectLOW-SPEEDRANGE.The

machinemustbestationaryortravelingataveryslowspeed,

lessthan3.2km/h(2mph),toshifttoHIGH–LOW(Figure9).

HornButton

Pressthehornbuttontoactivatethehorn(Figure9).

ThrottleSwitch

Thethrottleswitchhas3positionsLOWIDLE,MIDIDLE,and

HIGHIDLE(Figure9).

Figure10

1.PTOswitch5.Cruisecontrol

2.Keyswitch6.Lightswitch

3.Traction-assistswitch

4.Liftswitches

7.Powerpoint(ontheright

sideofconsole)

LiftSwitches

Theliftswitchesraiseandlowerthemowerdecks(Figure10).

Presstheswitchesforwardtolowerthemowerdeckand

backwardtoraiseit.

Variable-ThrottleSwitch

Thevariable-throttleswitchallowstheenginespeedtobe

adjustedinsmallincrements.Pressthe“+”oncetoincrease

theenginespeedandthe“-”oncetodecreasetheengine

speed(Figure10).

Note:Movingthethrottleswitchoverridesandcancelsthe

variable-throttlesetting.

Important:Donotoperatetheenginebelow1350rpm.

KeySwitch

Thekeyswitch(Figure10)has3positions:STOP,

RUN/PREHEAT,andSTART.

Note:Thedecksdonotlowerwhilethemachineisinthe

HIGH-speedrange,andthedecksdonotraiseorlowerifyou

areoutoftheseatwhiletheengineisrunning.

LightSwitch

PressthelightswitchupwardtoturnthelightstotheON

position(Figure10).

Pressthelightswitchdownwardtoturnthelightstothe

OFFposition.

PTOSwitch

ThePTOswitchhas2positions:OUT(start)andIN(stop).

PulloutthePTObuttontoengagetheimplementor

mower-deckblades.Pushinthebuttontodisengagethe

implementoperation(Figure10).

Traction-AssistSwitch

Whenmowing(lowspeedrange),pressandholdthe

traction-assistswitchtoenhancethetraction-drive

performanceincompromisedoperatingconditions(Figure

10).

Note:ThetractionassistonlyengagesinMow-Forward.

ThetractionassistdoesnotengageinMow-ReverseorHigh

speedrange.

17

Page 18

Cruise-ControlSwitch

Windshield-WiperSwitch

Thecruise-controlswitchsetsyourdesiredspeedofthe

machine.

Presstheswitchforwardtoengagethecruisecontroland

rearwardtodisengageit(Figure10).

AudibleAlarm(Console)

Thealarmisactivatedwhenafaultisdetected.

Thebuzzersoundswhenthefollowingoccur:

•Whentheenginesendsastopfault

•Whentheenginesendsacheck-enginefault

•Whenthefuellevelislow

CabControls

Usethewindshield-wiperswitchtoturnthewindshield

wiperstotheONorOFFposition(Figure11).

LightsSwitch

Usethelightsswitchtoturntheheadlightsandtail-lightsto

theONorOFFposition(Figure10).

FlashersSwitch

Usetheashersswitchtoturntheashers(hazardlights)to

theONorOFFposition(Figure10).

Air-ConditioningSwitch

Usetheair-conditioningswitchtoturntheairconditioning

onoroff(Figure11).

WindshieldLatch

Liftupthelatchtoopenthewindshield(Figure12).Pressin

thelatchtolockthewindshieldintheopenposition.Pullout

anddownonthelatchtocloseandsecurethewindshield.

Figure11

1.Air-conditioningswitch4.Temperaturecontrol

2.Air-recirculationcontrol5.Windshield-wiperswitch

3.Fancontrol

Air-RecirculationControl

6.Blankswitchesforoptional

kits

Thiscontroleitherrecirculatestheairinthecabinordraws

outsideairintothecabin(Figure11).

•Setittorecirculatetheairwhenusingairconditioning.

•Setittodrawairinwhenusingtheheaterorfan.

FanControl

Rotatethefan-controlknobtoregulatethespeedofthefan

(Figure11).

TemperatureControl

Rotatethetemperature-controlknobtoregulatetheair

temperatureinthecab(Figure11).

Figure12

1.Windshieldlatch

Rear-WindowLatch

Liftupthelatchtoopentherearwindow.Pressinthelatch

tolockthewindowintheopenposition.Pulloutanddown

onthelatchtocloseandsecurethewindow(Figure12).

Important:Y oumustclosetherearwindowbefore

openingthehood;otherwise,youmaydamagethe

window.

PowerPoint

Thepowerpoint,locatednexttotheconsoleontheside

ofthepowercenter,isusedtopoweroptionalelectrical

accessories(Figure10).

Seat-AdjustingLever

Pulloutthelevertoslidetheseatforwardorrearward.

18

Page 19

Seat-Back-AdjustingLever

1.PTOEngaged

Movethelevertoadjusttheseat-backangle.

Armrest-AdjustingKnob

Rotatetheknobtoadjusttheangleofthearmrest.

InfoCenter

ScreenFunctions

•Pressthecorrespondingbuttontoviewscreen1orscreen

2,tostoptheaudiblealarm,toviewthefaultscreen,orto

exit(Figure13).

2.ParkingBrakeEngaged

3.FanReversing

4.CruiseControlEngaged

5.H/L(High/Lowspeedrange)

•Bottom,LeftCorner—Air-IntakeHeaterActive

•Bottom,Middle—TractionAssistEngaged

•Bottom,Right—MachineHours

Screen2displaysthefollowing:

•Top,LeftCorner—Enginerpm

•Top,RightCorner—Hydraulic-OilTemperature

•Lower,LeftCorner—BatteryV oltage

•Lower,RightCorner—ServiceDue

Figure13

1.Screen1

2.Screen2

3.Audiblealarm

4.Faultscreen

5.Exit

•Ifafaultappearsonthescreen,pressanykeytoviewthe

activefaultadvisory.

Note:Contactyoursupervisorormechanictorelaythe

faultadvisoryanddeterminethecourseofaction.

•Pressthearrowkeystonavigatethefaultscreen.

•Pressanykeytorevealtheinformationkeysonthescreen.

OperatorInformation

Thereare2screensthatmonitoranddisplaythemachine

functionsthatyoucanuse.

Screen1displaysthefollowing:

•Top,LeftGauge—Engine-CoolantTemperature

•Top,RightGauge—FuelLevel

•LefttoRightontheBottomHalf

19

Page 20

Engine-Coolant-TemperatureIndicator

Thisdisplayindicatesthetemperatureoftheenginecoolant

(Figure14).

Figure14

H/L(High/LowRange)Speed-Range

Indicator

Thisdisplayindicatestheselectedspeedrange(Figure14).

Air-Intake-HeaterIndicator

Thisdisplayindicateswhenthesystemispreheating(Figure

14).

Traction-AssistIndicator

Thisdisplayindicateswhenthetractionassistisengaged

(Figure14).

Machine-HoursIndicator

Thisdisplayshowsthetotalhoursthatthemachinehasbeen

operated(Figure15).

1.Engine-coolant-temperature

indicator

2.Fuel-levelindicator7.Traction-assistindicator

3.PTOindicator8.Cruise-controlindicator

4.Air-intake-heaterindicator9.Machine-hoursindicator

5.Parking-brakeindicator

6.Fan-reverseindicator

10.H/L(High/Low)

speed-rangeindicator

Fuel-LevelIndicator

Thisdisplayindicatestheleveloffuelinthetank(Figure14).

PTOIndicator

ThisdisplayindicateswhenthePTOinengaged(Figure14).

Parking-BrakeIndicator

Thisdisplayindicatesthattheparkingbrakeisengaged

(Figure14).

Fan-ReverseIndicator

Figure15

1.Tachometer3.Batteryvoltage

2.Hydraulic-oiltemperature

4.Servicedue

Tachometer

Thisdisplayshowstheengine-operatingspeedinrpm(Figure

15).

Thisdisplayindicateswhenthefanisoperatinginreverse

(Figure14).Thefanspeediscontrolledbythehydraulic-oil

temperature,air-intaketemperature,orengine-coolant

temperature,andautomaticallyreverses.Areversecycleis

automaticallyinitiatedtohelpblowdebrisofftherear-hood

screen,wheneitherthetemperatureoftheenginecoolantor

thehydraulic-oilreachesacertainpoint.

Cruise-ControlIndicator

Thisdisplayindicateswhenthecruisecontrolisinoperation

(Figure14).

Hydraulic-Oil-TemperatureIndicator

Thisdisplayindicatesthehydraulic-oiltemperature(Figure

15).

BatteryVoltage

Thisdisplayshowsthebatteryvoltage(Figure15).

Service-DueIndicator

Thisdisplayindicatesthetimeuntilthenextregularservice

interval(Figure15).

20

Page 21

Note:Afteryouservicethemachine,resettheindicator.

g021 157

ResettingtheService-IntervalIndicator

1.Pressandholdthefar,rightbuttonontheInfoCenter.

Note:TheMainMenuscreenappears.

2.SelectServiceusingthe2buttonsontheleft;pressthe

buttonbelowtherightarrowtocontinue.

3.SelectHoursandpressthebuttonbelowtheright

arrow.

4.PressthebuttonbelowResetHours.

5.SelecttheHoursfortheappropriatenextservicetime

andpressthebuttonbelowtherightarrow .

Note:Acheckmarkappearsoncetheindicatorhas

beenreset.

6.Whenyouarenished,pressthebuttonbelowtheexit

icon(pictureofanopendoor)toreturntothemain

screen,orpresscanceltoexit.

Figure17

FaultExample

EngineAirFilterRestrictionIndicator

Thisdisplayindicateswhentheengineairlterisrestricted

(Figure16).

Figure16

Alarm(InfoCenter)

ThealarmontheInfoCentersoundswhenthefollowing

occurs:

•Itreceivesanenginefault.

•ItreceivesanadvisoryorfaultfromtheTECcontrollers.

•Youarestartingthemachine.

1.Faultscreen

ChecktheengineifyoureceiveaCheckEngineindication

foramaintenancefault.Youshouldtakethemachinetoa

servicecenterassoonaspossible.

InfoCenterAdvisories

TheInfoCenteradvisoriesprovideadditionalinformationto

operatecertainfunctionsonthemachine(Figure18).

InfoCenterFaultIndicators

StopthemachineifthedriverreceivesaStopindication.

Youshouldceaseoperatingthemachineandtheengineas

quicklyandassafelyaspossibletoreducedamagetothe

engine(Figure17).

Figure18

AdvisoryExample

1.Advisoryscreen

21

Page 22

ToSettheCruiseControl

2.DisengagethePTO.

Increasethegroundspeed.

ToFloattheDeck

Lowerthedecks.

ToLowertheDeck

1.Theoperatormustbeseated.

2.Selectthelowrange.

3.Settheparkingbrake.

ElectronicsIssues

1.FixtheHigh/Lowrangeswitch.

2.Controllerrmwareincompatible.

3.Blownthefuse.

4.HHDTready.

Engine

1.Lowertheenginespeed.

2.Waittoshutofftheengine.

3.MovethetractionpedaltoNEUTRAL.

4.Insertthejumperinteachplug.

5.Enginerunning.

6.Operatormustbeseatedorsettheparkingbrake.

7.Turnthekeyswitchoffthenon.

8.Wait.

ForT each(TractionPedalCalibration)

Turnthekeyswitchoffthenon.

ForTraction

1.Fixthecriticalsensorerror.

2.Fixthecriticalvoltageerror.

3.Releasetheparkingbrake.

4.MovethetractionpedaltoNEUTRAL.

5.Operatormustbeseated.

ForTractionAssist

FuelLevel

Addthefuel.

ToEngagePTO

1.Solvetheenginefault.

2.Lettheenginewarmup.

3.Letthehydraulicoilwarm.

4.Lowerthedecks.

5.Mustbeinthelowrange.

6.Operatormustbeseated.

ToSetHighRange

1.Disengagethecruise.

2.DisengagethePTO.

3.Lifttheleftdeck.

4.Liftthecenterdeck.

5.Lifttherightdeck.

6.Reducethegroundspeed.

1.Mustbeinthelowrange.

2.Operatormustbeseated.

TractionDerateDueTo

1.Requiresservice.

2.Engineorhydraulicstoohot.

3.Tractionpedalsensorneedscalibration.

4.Reserved1

5.Reserved2

6.Reserved3

ToSetLowRange

1.Disengagethecruise.

2.Reducethegroundspeed.

ToStart

1.Disengagethedeckswitch.

22

Page 23

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Widthofcut

Overall488cm(192inches)

Frontmowerdeck

Sidemowerdeck145cm(57inches)

Frontandonesidemower

deck

Overallwidth

Mowerdecksdown

Mowerdecksup(transports)251cm(99inches)

Overallheight

WithROPS226cm(89inches)

WithoutROPS152cm(60inches)

Withcab

Overalllength445cm(175inches)

Minimumgroundclearance(at

machinecenterline)

Wheeltread(tocenteroftire)

Front

Rear

Wheeltread(tooutsideoftire)

Front

Rear

Wheelbase

NetWeight(withmowerdecks)

Withoutcab

Withcab

Attachments/Accessories

234cm(92inches)

361cm(142inches)

505cm(199inches)

236cm(93inches)

24cm(9.5inches)

63inches(160cm)

56inches(142cm)

193cm(76inches)

168cm(66inches)

193cm(76inches)

2706kg(5966lb)

2929kg(6457lb)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopletooperateor

servicethemachine.Localregulationsmayrestrictthe

ageoftheoperator.Theownerisresponsiblefortraining

alloperatorsandmechanics.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.Knowhowtostop

themachineandenginequickly.

•Checkthatallsafetydevicesareattachedand

functioningproperly.Thisincludes,butisnotlimitedto,

operator-presencecontrols;safetyswitchesandshields;

therolloverprotectionsystem(ROPS);attachments;and

brakes.Donotoperatethemachineunlessallsafety

devicesareinpositionandfunctioningasintendedby

themanufacturer.

•Alwaysinspectthemachinetoensurethattheblades,

bladebolts,andcuttingassemblyarenotwornor

damaged.Replacewornordamagedbladesandboltsin

setstopreservebalance.

•Inspecttheareawhereyouwillusethemachineand

removeallobjectsthatthemachinecouldpotentially

throw .

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessoriesrequiredto

operatethemachineproperlyandsafely.

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonTorogenuine

parts.Whenitcomestoreliability ,Torodeliversreplacement

partsdesignedtotheexactengineeringspecicationofour

equipment.Forpeaceofmind,insistonT orogenuineparts.

23

Page 24

FuelSafety

CheckingtheEngine-OilLevel

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana180-daysupplyoffuel.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepyourhandsandfaceawayfromthenozzle

andthefuel-tankopening.

•Keepfuelawayfromyoureyesandskin.

•Useonlyanapprovedfuelcontainer.

•Neverremovethefuelcaporaddfueltothefueltank

whiletheengineisrunning.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundandawayfromyourvehiclebeforelling.

•Removetheequipmentfromthetruckortrailerandadd

fueltoitwhileitisontheground.Ifthisisnotpossible,

thenaddfuelusingaportablecontainerratherthanfrom

afuel-dispensernozzle.

•Keepthefuel-dispensernozzleincontactwiththerimof

thefueltankorcontaineropeningatalltimesuntilfueling

iscomplete.Donotuseanozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyourclothing

immediately.

•Fillthefueltankuntilthefuellevelis25mm(1inch)

belowthebottomofthellerneck.Donotoverllthe

fueltank.Replacethefuel-tankcapandtightenitsecurely .

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page43).

CheckingtheCoolingSystem

Beforeyoustarttheengineandusethemachine,checkthe

coolingsystem;refertoCheckingtheCoolingSystem(page

51).

CheckingtheHydraulic System

Beforeyoustarttheengineandusethemachine,checkthe

hydraulicsystem;refertoCheckingtheHydraulicFluid(page

55).

FillingtheFuelTank

RecommendedFuel

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchasefuelin

quantitiesthatyoucanusewithin180daystoensurethat

thefuelisfresh.

Fuel-tankcapacity:132L(35USgallons)

Usesummer-gradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Usingwinter-grade

fuelatlowertemperaturesprovidealowerashpointand

cold-owcharacteristicswhicheasesstartingandreduces

pluggingofthefuellter.

Usingsummer-gradefuelabove-7°C(20°F)contributes

towardlongerlifeofthefuelpumpandincreasedpower

comparedtowinter-gradefuel.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultralowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather.

24

Page 25

•Monitorseals,hoses,andgasketsincontactwithfuelas

theymaydegradeovertime.

•Fuel-lterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblended.

•Contactyourdistributorifyouwishmoreinformation

onbiodiesel.

FillingtheFuelTank

Note:Ifpossible,llthefueltankaftereachuse.This

minimizespossiblebuildupofcondensationinsidethefuel

tank.

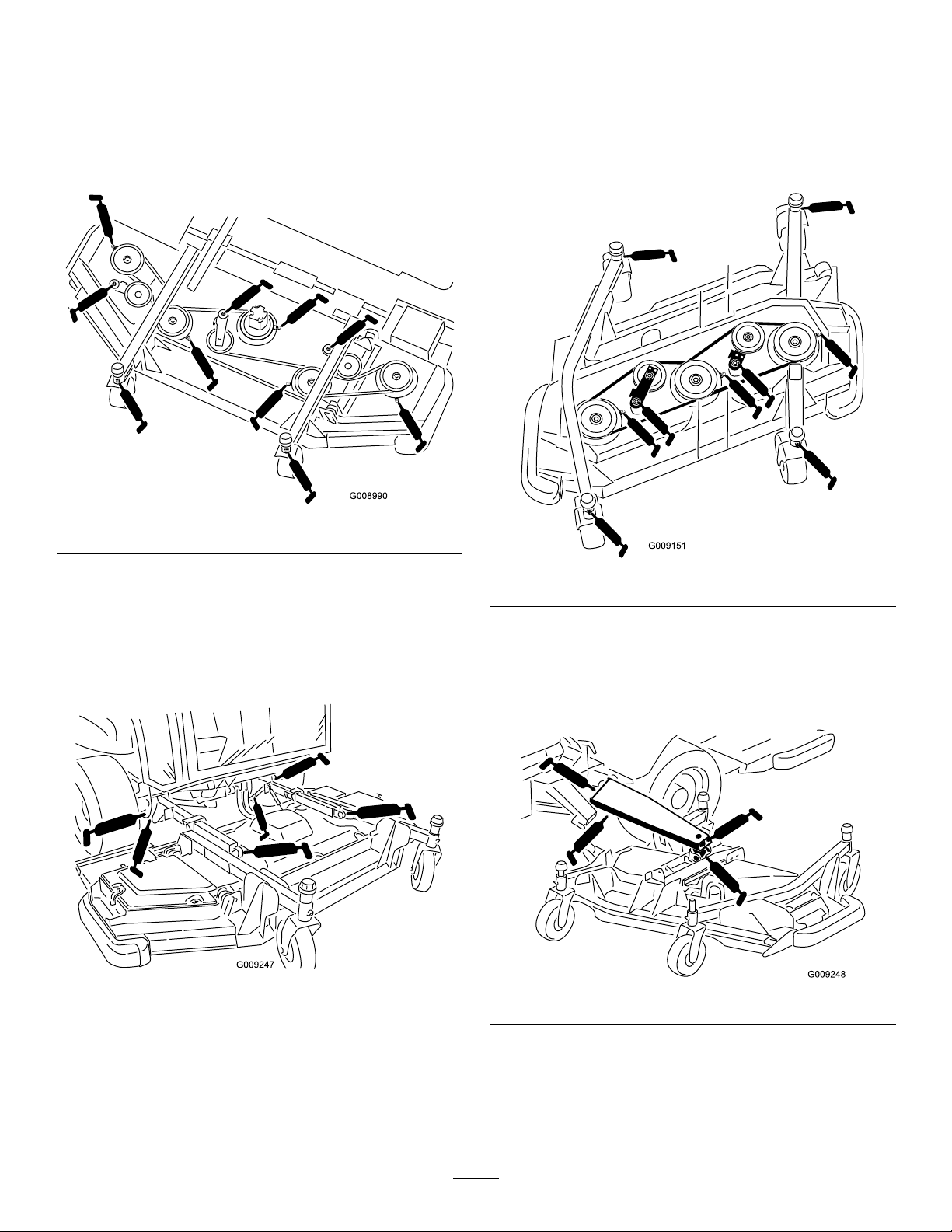

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Thecorrectairpressureinthefronttiresis345kPa(50psi)

andthereartiresis207kPa(30psi)asshownin(Figure20).

Important:Maintainpressureinalltirestoensurea

goodqualityofcutandpropermachineperformance.

Do not underinate the tir es.

Checktheairpressureinallthetiresbeforeoperating

themachine.

Figure20

Figure19

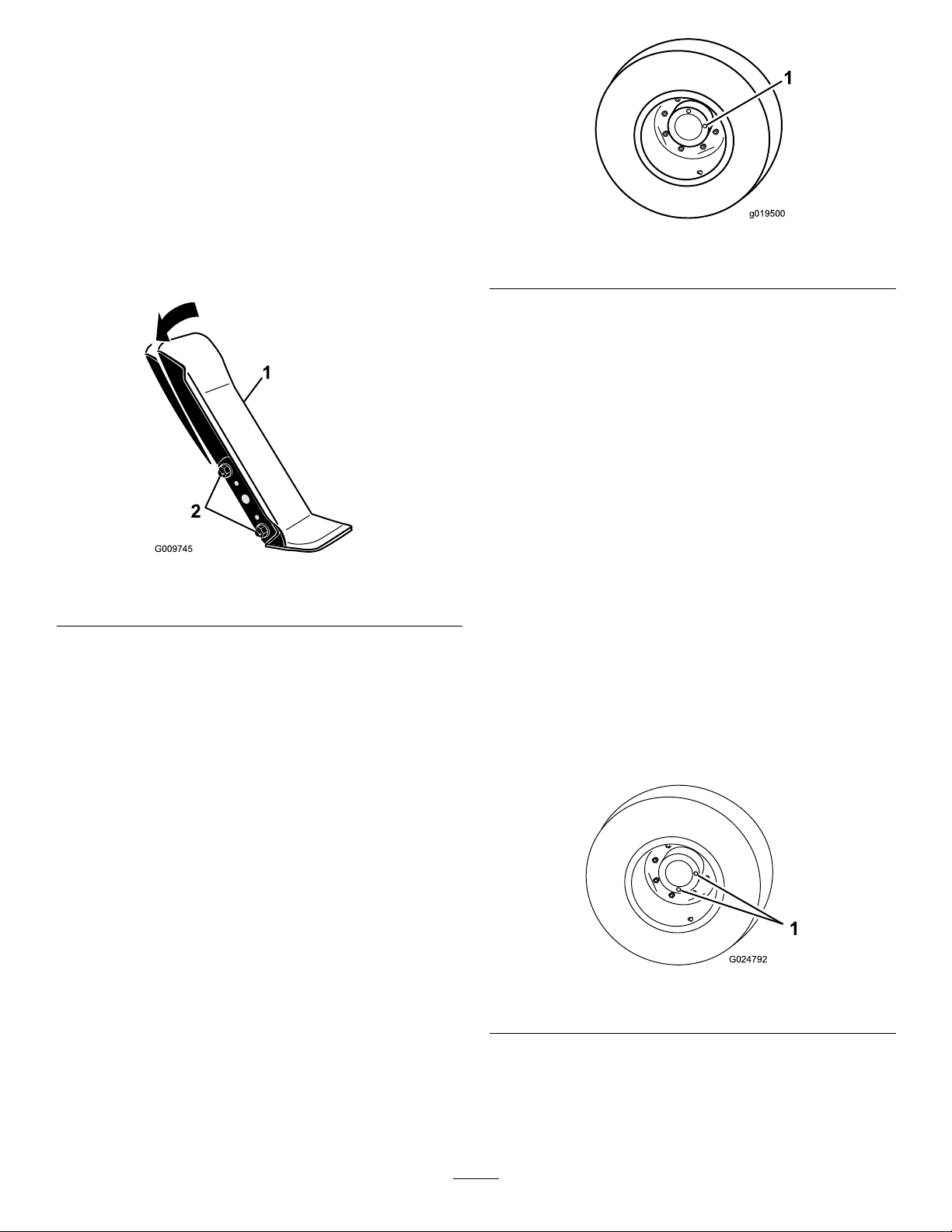

CheckingtheTorqueofthe Wheel-LugNuts

ServiceInterval:Aftertherst10hours

Every250hours

WARNING

Failuretomaintainthepropertorqueofthewheel

nutscouldresultinfailureorlossofawheel,and

mayresultinpersonalinjury.

Torquethefrontandrearwheelnutsto95to122

N·m(70to90ft-lb)after10hoursofoperation.

Torquethenutsevery250hoursthereafter.

25

Page 26

AdjustingtheHeightofCut

Youcanadjusttheheightofcutfrom25to153mm(1to6

inches)in13mm(1/2inch)increments.Toadjusttheheight

ofcut,positionthecastor-wheelaxlesintheupperorlower

holesofthecastorforks,addorremoveanequalnumberof

spacersfromthecastorforks,andadjusttherearchain(front

deckonly)tothedesiredholes.

AdjustingtheFrontMowerDeck

1.Starttheengineandraisethemowerdeckssoyoucan

changetheheightofcut.

2.Shutofftheengineandremovethekeyafterraising

themowerdeck.

3.Positionthecastor-wheelaxlesinthesameholesinall

castorforks;refertothechart(Figure21)todetermine

thecorrectholesforthesetting.

Note:Topreventgrassbuildupbetweenthewheel

andthefork,operatethemachineatthe64mm(2-1/2

inch)heightofcutorhigherandinstalltheaxlebolt

inthebottomcaster-forkhole.Whenoperatingthe

machineataheightofcutlowerthan64mm(2-1/2

inches)andwhenyoudetectgrassbuildup,reversethe

directionofthemachinetopullanyclippingsaway

fromthewheelandfork.

Figure22

1.Tensioningcap4.Topaxlemountingbolt

2.Spacers(4)5.Castorwheel

3.Shims(4)

7.Installthetensioningcaptosecuretheassembly

(Figure22).

8.Removethehairpincotterandclevispinsecuringthe

height-of-cutchainstotherearofthemowerdeck

(Figure23).

Figure21

1.Castor-armheight-ofcut

mountingholes

2.Castor-forkheight-ofcut

mountingholes

3.Castor-forkheight-ofcut

spacers

4.Install2shimsontothecastershaftasoriginally

installedandslidetheappropriatenumberofspacers

ontotheshafttogetthedesiredheightofcut.

Note:Refertothecharttodeterminethe

combinationsofspacersforthesetting(Figure21).

Note:Youmayusetheshimsinanycombination

aboveorbelowthecaster-armhub(asrequired)to

achievethedesiredheightofcutordecklevel.

5.Pushthecastershaftthroughthefrontcasterarm.

6.Installtheshims(asoriginallyinstalled)andthe

remainingspacersontotheshaft(Figure22).

Figure23

1.Height-of-cutchain

2.Clevispin

9.Mounttheheight-of-cutchainstothedesired

height-of-cutholewiththeclevispinandhairpincotter

(Figure24).

26

3.Hairpincotter

Page 27

Note:Whenmowingataheightofcutbelow51mm

(2-1/2inches),movetheskids,gagewheels,androllers

tothehighestholes.

Note:Topreventgrassbuildupbetweenthewheel

andthefork,operatethemachineatthe64mm(2-1/2

inch)heightofcutorhigherandinstalltheaxlebolt

inthebottomcaster-forkhole.Whenoperatingthe

machineataheightofcutlowerthan64mm(2-1/2

inches)andwhenyoudetectgrassbuildup,reversethe

directionofthemachinetopullanyclippingsaway

fromthewheelandfork.

Figure24

10.Toattainthe102to153mm(5to6inch)height-of

cutsettings,removethemountingboltssecuringthe

deck-hangerbracketstotheheight-ofcutcastorarms

andmountthedeck-hangerbracketstotheheight-of

cutcastorarmsusingthelowersetofholes(Figure25).

Figure26

4.Removethetensioningcapfromthecaster-spindle

shaftandslidethecastershaftoutofthecasterarm

(Figure27).

Note:Youmayuseshimsinanycombinationabove

orbelowthecasterarmhubasrequiredtoachievethe

desiredheightofcutordecklevel.

Figure25

1.Lowermountingbolts

AdjustingtheSideMowerDecks

1.Starttheengineandraisethemowerdeckssoyoucan

changetheheightofcut.

2.Shutofftheengineandremovethekeyafteryouraise

themowerdeck.

3.Positionthecastorwheelaxlesinthesameholesinall

castorforks;refertothechart(Figure26)todetermine

thecorrectholesfortheheight-ofcutsetting.

Figure27

1.Tensioningcap4.Topaxle-mountinghole

2.Spacers(6)5.Casterwheel

3.Shims(2topand2bottom)

5.Install2shimsontotheshaftasoriginallyinstalledand

slidetheappropriatenumberofspacersontotheshaft

togetthedesiredheightofcut.

6.Pushthecastershaftthroughthecasterarm.

7.Installtheshims(asoriginallyinstalled)andthe

remainingspacersontotheshaft.

8.Installthetensioningcaptosecuretheassembly.

27

Page 28

AdjustingtheSkids

AdjustingtheMowerDeck

Mounttheskidsinthelowerpositionwhenoperatingat

heightsofcutgreaterthan64mm(2-1/2inches)andinthe

higherpositionwhenoperatingatheightsofcutlowerthan

64mm(2-1/2inches).

Note:Whentheskidsbecomeworn,youcanswitchthemto

theoppositesidesofthemowerbyippingthemover.This

allowsyoutousetheouterskidslongerbeforereplacingthem.

Adjusttheskids(Figure28).

Important:T orquethescrewatthefrontofeachskidto

9to11N·m(80to100in-lb).

Anti-ScalpRollers

Mountthemower-deckgagewheelsandrollerinthelower

positionwhenoperatingatheightsofcutgreaterthan64mm

(2-1/2inches)andinthehigherpositionwhenoperatingat

heightsofcutlowerthan64mm(2-1/2inches).

AdjustingtheRoller

1.Removethescrewandnutsecuringtherollershaftto

thedeckbracket(Figure29).

Figure28

Figure29

1.Gagewheel2.Screwandnut

2.Slidetheshaftoutofthelowerbracketholes,alignthe

rollerwiththetopholes,andinstalltheshaft(Figure

30).

Figure30

1.Roller

3.Installthescrewandnuttosecuretheassemblies.

28

2.Rollershaft,screw,and

nut

Page 29

AdjustingtheGageWheels

1.Removetheboltandnutsecuringthegagewheelto

themower-deckbrackets(Figure29).

2.Aligntherollerandspacerwiththetopholesinthe

bracketsandsecurethemwiththeboltandnut.

MatchingtheHeightofCutBetween

MowerDecks

1.Positionthebladesidetosideontheoutsidespindle

ofbothsidemowerdecks.

2.Measurefromtheoortothetipofthecuttingedge

onbothunitsandcomparethemeasurements.

CheckingaMismatchBetween MowerDecks

Duetodifferencesingrassconditionsandthecounterbalance

settingofthetractionunit,youshouldcutthegrassandcheck

theappearancebeforeyoubegincuttingtheentirearea.

1.Setallmowerdeckstothedesiredheightofcut;refer

toAdjustingtheHeightofCut(page26).

2.Checkandadjustfrontandreartirepressure.

Note:Thecorrectairpressureinthefronttiresis345

kPa(50psi)andthereartiresis207kPa(30psi).

3.Checkandadjustallcastortirepressuresto345kPa

(50psi).

4.Checktheliftandcounterbalancepressureswithengine

atHIGHIDLEusingthetestports;refertoInspecting

theHydraulic-SystemTestPorts(page57).

5.Checkforbentblades;refertoCheckingforaBent

Blade(page60).

6.Cutgrassinatestareatodetermineifallmowerdecks

arecuttingatthesameheight.

7.Ifyouneedtoadjustamowerdeck,ndaatsurface

usinga2m(6ft)orlongerstraightedgetoensurethat

thesurfaceisat.

Note:Thesenumbersshouldbewithin3mm(1/8

inch)ofeachother.Makenoadjustmentatthistime.

3.Positionthebladesidetosideontheinsidespindle

ofsidemowerdeckandthecorrespondingoutside

spindleofthefrontmowerdeck.

4.Measurefromtheoortothetipofthecuttingedge

ontheinsideedgeofthesidemowerdecktothe

correspondingoutsideedgeofthefrontmowerdeck

andcompare.

Note:Thesidemower-deckcasterwheelsshould

remainonthegroundwithcounterbalanceapplied.

Note:Ifyouneedtomakeanadjustmenttomatch

thecutbetweenthefrontandsidemowerdecks,make

themtothesidemowerdecksonly.

5.Iftheinsideedgeofthesidemowerdeckistoohigh

relativetotheoutsideedgeofthefrontmowerdeck,

remove1shimfromthebottomofthefront,inside

casterarmonthesidemowerdeck(Figure31and

Figure32).

Note:Checkthemeasurementbetweentheoutside

edgesofbothsidemowerdecksandtheinsideedge

ofthesidemowerdecktooutsideedgeofthefront

mowerdeckagain.

8.Toeasemeasuringbladeplane,raisetheheightofcut

tothehighestposition;refertoAdjustingtheHeight

ofCut(page26).

9.Lowerthemowerdecksontotheatsurfaceand

removethecoversfromthetopofthemowerdecks.

SideMowerDecks

1.Rotatethebladeofeachspindleuntiltheendsface

forwardandbackward.

2.Fortheoutsidebladespindleonly ,equallyadjustthe

shimsonthefrontcasterforkstomatchthedesired

heightofcut.

3.Measurefromtheoortothefronttipofthecutting

blade.

4.Rotatetheblade180°andmeasurefromtheoorto

thetipofthecuttingblade.

Note:Therearofthebladeshouldbe7.5mm(0.3

inch)higherthanthefront.

Note:Ifyouneedtomakeanadjustment,adjustthe

shimsontherearcasterforks.

Figure31

1.Tensioningcap4.Topaxle-mountinghole

2.Spacers(6)5.Casterwheel

3.Shims(2topand2bottom)

29

Page 30

Figure32

AdjustingtheMirrors

Rear-ViewMirror

Whilesittingintheseat,adjusttherear-viewmirrortoattain

thebestviewoutoftherearwindow.Pulltheleverrearward

totiltthemirrortoreducethebrightnessandglareoflight

(Figure33).

1.Left,front,outsidecaster

arm

2.Left,front,insidecaster

arm

3.Right,front,insidecaster

arm

4.Right,front,outsidecaster

arm

6.Iftheinsideedgeisstilltoohigh,removeanadditional

shimfromthebottomofthefront,insidecasterarm

ofthesidemowerdeckand1shimfromthefront,

outsidecasterarmofthesidemowerdeck(Figure31

andFigure32).

7.Iftheinsideedgeofthesidemowerdeckistoolow

relativetotheoutsideedgeofthefrontmowerdeck,

add1shim(1/8inch)tothebottomofthefront,inside

casterarmonthesidemowerdeck(Figure31and

Figure32).

Note:Checkthemeasurementbetweentheoutside

edgesofbothsidemowerdecksandtheinsideedgeof

thesidemowerdecktotheoutsideedgeofthefront

mowerdeckagain.

8.Iftheinsideedgeisstilltoolow ,addanadditionalshim

tothebottomoffront,insidecasterarmoftheside

mowerdeckand1shimtothefront,outsidecasterarm

ofthesidemowerdeck.

9.Oncethecuttingheightmatchesattheedgesof

thefrontandsidemowerdecks,verifythattheside

mower-deckpitchisstill7.6mm(0.3inch).

Figure33

1.Side-viewmirrors

2.Rear-viewmirror

3.Lever

Side-ViewMirrors

Whilesittingintheseat,haveanotherpersonadjustthe

side-viewmirrorstoattainthebestviewaroundthesideof

themachine(Figure33).

AimingtheHeadlights

1.Loosenthemountingnutsandpositioneachheadlight

sothatitpointsstraightahead.

Note:Tightenthemountingnutjustenoughtohold

theheadlightinposition.

2.Placeaatpieceofsheetmetaloverthefaceofthe

headlight.

3.Mountamagneticprotractorontotheplate.

4.Whileholdingtheassemblyinplace,carefullytiltthe

headlightdownward3°thentightenthenut.

5.Repeatthisprocedureontheotherheadlight.

30

Page 31

CheckingtheSafety-Interlock Switches

Note:Theengineshouldshutoff.Ifitdoesnotshut

off,thereisamalfunctionintheinterlocksystemthat

youshouldcorrectbeforeresumingoperation.

CAUTION

Ifsafety-interlockswitchesaredisconnectedor

damaged,themachinecouldpotentiallyoperate

unexpectedly,causingpersonalinjury.

•Donottamperwithordisablethesafetysystems.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Themachinehasinterlockswitchesintheelectricalsystem.

Theseswitchesaredesignedtostoptheenginewhenyouget

offtheseatwhenthetractionpedalisnotintheNEUTRAL

positionorthePTOisengaged.However,youmaygetoff

theseatwhiletheengineisrunning,thetractionpedalisin

NEUTRAL,andtheparkingbrakeisengaged.

1.Drivethemachineslowlytoalarge,openarea.

2.Lowerthemowerdeck(s),shutofftheengine,and

engagetheparkingbrake.

CheckingtheTraction-Neutral

Safety-InterlockFunction

1.MovethetractionpedaloutoftheNEUTRALposition

andstarttheengine.

Note:Theengineshouldnotstart.Ifitdoesstart,

thereisamalfunctionintheinterlocksystemthatyou

shouldcorrectbeforeresumingoperation.

2.Removeyourfootfromthetractionpedal,startthe

engine,andengagetheparkingbrake.

3.Withtheenginerunning,movethetractionpedalout

oftheNEUTRALposition.

Note:Thetractiondriveshouldnotfunction.Ifit

doesfunction,thereisamalfunctionintheinterlock

systemthatyoushouldcorrectbeforeresuming

operation.

CheckingthePTOSafety-Interlock

Function

1.Starttheengine.

2.Withtheenginerunning,risefromtheseatandengage

thePTO.

5.Sitontheseat,disengagethePTO,andstarttheengine.

6.Withtheenginerunning,engagethePTOandraise

eachmowerdeckindividually.

Note:Thebladesoftheraisedmowerdeckshould

stop.Ifthebladesdonotstop,thereisamalfunction

intheinterlocksystemthatyoushouldcorrectbefore

resumingoperation.

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/usercanpreventandisresponsiblefor

accidentsthatmaycauseinjuriestohimself/herselfand

othersandfordamagetoproperty.

•Wearappropriateclothing,includingeyeprotection;

slip-resistant,substantialfootwear;andhearing

protection.Wearingsafetyshoesandlongpantsis

advisableandrequiredbysomelocalordinancesand

insuranceregulations.Tiebacklonghair,secureloose

clothing,anddonotwearjewelry.

•EnsurethatalldrivesareintheNEUTRALposition,the

parkingbrakeisengaged,andyouareintheoperating

positionbeforeyoustarttheengine.

•Keepallbodyparts,includinghandsandfeet,awayfrom

allmovingparts.

•Donotoperatethemachinewhileill,tired,orunderthe

inuenceofalcoholordrugs.

•Keepthedirectionofthemowerdischargeawayfrom

peopleandpets.

•Donotmowinreverseunlessitisabsolutelynecessary.If

youmustmowinreverse,lookbehindanddownforsmall

childrenbeforeandwhilemovingthemachineinreverse.

Stayalertandstopthemachineifachildentersthearea.

•Useextremecarewhenapproachingblindcorners,

shrubs,trees,orotherobjectsthatmayblockyourview.

•Donotmowneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyrolloverifawheelgoes

overtheedgeoriftheedgecavesin.

Note:ThePTOshouldnotengage.Ifitdoesengage,

thereisamalfunctionintheinterlocksystemthatyou

shouldcorrectbeforeresumingoperation.

3.SitontheseatanddisengagethePTO.

4.Withtheenginerunning,engagethePTOandrise

fromtheseat.

•Nevercarrypassengersonthemachine.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperatethe

machinewhenthereistheriskoflighting.

•Donotmowonwetgrass.Reducedtractioncouldcause

themachinetoslide.

31

Page 32

•Neverraisethemowerdeckwiththebladesrunning.

•Stopthemachineandinspectthebladesafterstrikingan

objectorifthereisanabnormalvibrationinthemachine.

Makeallnecessaryrepairsbeforeresumingoperation.

•Stopthebladeswheneveryouarenotmowing,especially

whilecrossinglooseterrainsuchasgravel.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalkswiththemachine.Always

yieldtheright-of-way.

•Turnontheashingwarninglightsonthemachine

wheneveryoutravelonapublicroad,exceptwheresuch

useisprohibitedbylaw.

•Disengagethedrivetotheattachmentandshutoffthe

enginebeforeaddingfuelandadjustingtheheightofcut.

•Reducethethrottlesettingbeforestoppingtheengine

and,iftheenginehasafuel-shutoffvalve,shutoffthe

fuelwhenyouhavenishedoperatingthemachine.

•Neverrunanengineinanareawhereexhaustgasesare

enclosed.

•Neverleavearunningengineunattended.

•Beforeleavingtheoperatingposition,dothefollowing:

–Stopthemachineonlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Settheparkingbrake.

–Shutofftheengineandremovethekey .

–Waitforallmovingpartstostop.

•Donotchangethegovernorsettingsonoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethepotentialforpersonalinjury.

•Donotusethemachineasatowingvehicle.

•UseaccessoriesandattachmentsapprovedbyTheToro®

Companyonly.

RolloverProtectionSystem(ROPS)

Safety

•DonotremovetheROPSfromthemachine.

•Ensurethattheseatbeltisattachedandthatyoucan

releaseitquicklyintheeventofanemergency.

•AlwayswearyourseatbeltwhentheROPSisup.

•Checkcarefullyforoverheadclearances,suchasbranches,

doorways,andelectricalwires,beforedrivingthemachine

underthem.Donotcontactthem.

•KeeptheROPSinsafeoperatingconditionbythoroughly

inspectingitperiodicallyfordamageandkeepingallthe

mountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorreviseit.

•AnyalterationstoaROPSmustbeapprovedbyThe

Toro®Company.

SlopeSafety

•Slowdownthemachineanduseextracareonhillsides.

Travelintherecommendeddirectiononhillsides.Turf

conditionscanaffectthestabilityofthemachine.

•Avoidstarting,stopping,orturningthemachineona

slope.Ifthetireslosetraction,disengagetheblade(s)and

proceedslowlystraightdowntheslope.

•Donotturnthemachinesharply .Usecarewhenreversing

themachine.

•Whenoperatingthemachineonaslope,alwayskeepall

cuttingunitslowered.

•Avoidturningthemachineonslopes.Ifyoumustturn,

turnslowlyandgraduallydownhill,ifpossible.

•Useextracarewhileoperatingthemachinewith

attachments;theycanaffectthestabilityofthemachine.

StartingandStoppingthe Engine

1.Ensurethattheparkingbrakeisengaged.

2.Removeyourfootfromthetractionpedalandensure

thatitisintheNEUTRALposition.

3.SetthethrottleswitchtotheLOW-IDLEposition.

4.TurntheignitionkeytotheRUNposition.

5.Whentheglowindicatordims,turntheignitionkeyto

theSTARTposition.

6.Releasethekeyimmediatelywhentheenginestartsand

allowittoreturntotheRUNposition.

7.Allowtheenginetowarmupatlowspeed(without

load)for3to5minutes,thenactuatethethrottleswitch

toattainthedesiredenginespeed.

Important:Donotrunthestartermotormore

than30secondsatatimeorprematurestarter

failuremayresult.Iftheenginefailstostartafter

30seconds,turnthekeytotheOFFposition,check

thecontrolsandproceduresagain,wait2minutes,

andrepeatthestartingprocedure.

Note:Whenthetemperatureisbelow-7°C(20°F),

letthemachinewarmupforaminimumof10minutes.

8.Tostoptheengine,setthethrottleswitchtothe

LOW-IDLEposition,movethePTOswitchtotheOFF

position,settheparkingbrake,andturntheignition

keytoOFF.

9.Removethekeyfromtheswitchtopreventaccidental

starting.

Important:Idletheenginefor5minutesbefore

shuttingitoffafterafull-loadoperation.Failuretodoso

mayleadtoturbo-chargercomplications.

32

Page 33

UnderstandingtheOperating

G010392

Characteristics

Practicedrivingthemachine,asithasahydrostatic

transmission,anditscharacteristicsmaydifferfromother

turf-maintenancemachines.

Tomaintainenoughpowerforthetractionunitand

implementwhileoperating,regulatethetractionpedalto

keeptheenginespeed(rpm)highandconstant.Decreasethe

groundspeedastheloadontheimplementincreases,and

increasethegroundspeedastheloaddecreases.

Allowthetractionpedaltomovebackwardastheengine

speed(rpm)decreases,andpressthepedalslowlyasthe

enginespeedincreases.Bycomparison,whendrivingbetween

workareas,withnoloadandthemowerdeckraised,setthe

throttleinthehighestpositionandpressthetractionpedal

slowly,butfully,toattainmaximumgroundspeed.

Figure35

Beforestoppingtheengine,disengageallcontrolsandmove

thethrottletotheslowestposition,whichreducestheengine

speed(rpm),noise,andvibration.Turntheignitionkeyto

theOFFpositiontoshutofftheengine.

Beforetransportingthemachine,raisethemowerdecksand

securethetransportlatchesonthesidemowerdeck(Figure

34).

Figure34

1.Transportlatch

OperatingTips

SelectingtheProperHeight-of-Cut

Setting

Removeapproximately25mm(1inch)ornomorethan1/3

ofthegrassbladewhencutting.Inexceptionallylushand

densegrass,youmayneedtoraisetheheight-of-cuttothe

nextsetting(Figure36).

Figure36

MowingWhenGrassisDry

AutomaticReversing-Fan Cycle

Thehydraulic-fanspeediscontrolledbythehydraulic-oil

temperature.Theradiator-fanspeediscontrolledbythe

engine-coolanttemperature.Areversecycleautomatically

initiateswheneithertheenginecoolantorhydraulic-oil

temperaturereachesacertainpoint.Thisreversalblows

debrisoffthescreens,loweringtheengineandhydraulic-oil

temperatures(Figure35).

Moweitherinthelatemorningtoavoidthedew ,whichcauses

grassclumping,orinlateafternoontoavoidthedamagethat

directsunlightcandotosensitive,freshlymowedgrass.

MowingatProperIntervals

Undermostnormalconditionsyouwillneedtomow

approximatelyevery4to5days.However,grassgrowsat

differentratesatdifferenttimes.Tomaintainthesameheight

ofcut,whichisagoodpractice,youwillneedtocutmore

frequentlyinearlyspring;asthegrassgrowthrateslowsin

midsummer,cutonlyevery8to10days.Ifyouareunable

tomowforanextendedperiodduetoweatherconditionsor

otherreasons,mowrstwithahighheightofcut;thenmow

again2to3dayslaterwithalowerheightsetting.

33

Page 34

TransportingtheMachine

Usethetransportlatcheswhentransportingthemachineover

longdistancesorroughterrainorwhentrailering.

AfterOperation

AfterOperationSafety

GeneralSafety

•Cleangrassanddebrisfromthecuttingunits,drives,

mufers,andenginetohelppreventres.Cleanupoil

orfuelspills.

•Shutoffthefuelwhilestoringortransportingthe

machine.

•Disengagethedrivetotheattachmentwheneveryouare

transportingornotusingthemachine.

Figure37

1.Transportlatch

AfterOperatingtheMachine

Toensureoptimumperformance,cleantheundersideofthe

mowerhousingaftereachuse.Ifresidueisallowedtobuild

upinthemowerhousing,cuttingperformancewilldecrease.

Mower-DeckPitch

Mower-deckpitchisthedifferenceinheightofcutfromthe

frontofthebladeplanetothebackofthebladeplane.Use

abladepitchof7.6mm(0.3inch).Apitchlargerthan7.6

mm(0.3inch)resultsinlesspowerrequired,largerclippings,

andapoorerqualityofcut.Apitchlessthan7.6mm(0.3

inch)resultsinmorepowerrequired,smallerclippings,and

abetterqualityofcut.

MaximizingAir-Conditioner

Performance

•Tolimitsolarheating,parkthemachineinashadedarea

orleavethedoorsopenindirectsun.

•Usefull-widthrampsforloadingthemachineintoa

trailerortruck.Donotexceeda15°anglebetweenthe

rampandthetrailerortruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

•Allowtheenginetocoolbeforestoringthemachinein

anyenclosure.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlight,suchasonawater

heateroronotherappliances.

TowingSafety

•Towonlywithamachinethathasahitchdesignedfor

towing.Donotattachtowedequipmentexceptatthe

hitchpoint.

•Followthemanufacturer’ srecommendationforweight

limitsfortowedequipmentandtowingonslopes.On

slopes,theweightofthetowedequipmentmaycauseloss

oftractionandlossofcontrol.

•Neverallowchildrenorothersinorontowedequipment.

•Travelslowlyandallowextradistancetostopwhen

towing.

•Ensurethattheair-conditioningscreenisclean.

•Ensurethattheair-conditioning-condensernsareclean.

•Operatetheair-conditionerbloweratthemid-speed

setting.

•Ensurethatthereisacontinuoussealbetweentheroof

andtheheadlinerandcorrectitasneeded.

•Measuretheairtemperatureatthefront,centerventin

theheadliner.Thisshouldtypicallystabilizeatlessthan

orequalto10°C(50°F).

•RefertotheServiceManualforadditionalinformation.

34

Page 35

IdentifyingtheTie-Down

G021 160

1

2

3

Points

Frontofthemachine—underthefrontoftheoperator's

platform(Figure38)

Figure38

1.Fronttiedowns

Figure40

1.Bypassvalve

2.Rotateeachvalve3turnscounter-clockwisetoopen

andallowoiltobypassinternally.

Rearofthemachine—onthebumper(Figure39)

Figure39

1.Reartiedowns

PushingorTowingthe Machine

Important:Donotpushortowthemachinefasterthan3

to4.8km/h(2to3mph),becauseinternal-transmission

damagemayoccur.Ensurethatthebypassvalvesare

openwheneveryoupushortowthemachine.

1.Raisethehoodandlocatethebypassvalvesonthe

pump(Figure40).

Important:Donotopenthevalvesmorethan

3turns.

Note:Becauseuidisbypassed,youcanslowlymove

themachinewithoutdamagingthetransmission.

3.Closethebypassvalvesbeforestartingtheengine.

Torqueto70N·m(52ft-lb)toclosethevalve.

Important:Ifyoumustpushortowthemachine

inreverse,youmustalsobypassthecheckvalvein

the4-wheel-drivemanifold.T obypassthecheck

valve,connectahoseassembly(HosePartNo.

95-8843,CouplerFittingNo.95-0985[Qty.2],

andHydraulicFittingNo.340-77[Qty.2])tothe

reverse-traction-pressuretestportMB,locatedon

thehydrostatandonthetestportG2ontherear

tractionmanifold,locatedbehindthefronttire.

Figure41

1.Reverse

4-wheel-drive-pressure

testport(PortG2)

2.Hoseassembly

3.Reverse-traction-pressure

testport(PortMB)

35

Page 36

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst10hours

Aftertherst250hours

Beforeeachuseordaily

Every50hours

MaintenanceProcedure

•T orquethewheel-lugnuts.

•Checkthealternator-belttension.

•Checkthecompressor-belttension.

•Checkbladebolttorque

•Adjustthevalveclearance.

•Changetheplanetary-drivegear/brakeoil.

•Checkthetirepressure.

•Lubricatethecaster-armbushings.

•Checktheengine-oillevel.

•Drainthewaterseparator.

•Checkthecoolantlevel.

•Removedebrisandchafffromtheenginecompartment,oilcooler,andradiator

(moreoftenindustyordirtyconditions).

•Checkthehydraulicuidlevel.

•Checkmowerbladecondition

•Checkthesafety-interlock-switchoperation

•Lubricateallgreasettings.

•RemoveaircleanercoverandcleanoutdebrisDonotremovelter.

•Checktheconditionofthebattery.

•Inspecttheblade-drivebelts.

•Checkbladebolttorque

•Removealldebrisandchafffromtheenginecompartment,radiator,andoilcooler.

Every100hours

Every250hours

Every400hours

Every500hours

Every800hours

Every1,000hours

•Inspectthecooling-systemhoses.

•T orquethewheel-lugnuts.

•Changetheengineoilandlter.

•Servicethesparkarrestor.

•Cleanthecabairlters;replacethemiftheyaretornorexcessivelydirty .

•Cleantheair-conditioningassembly(morefrequentlyinextremelydustyordirty

conditions).

•Checktheplanetary-drivegear/brake-oillevel(checkifyouobserveexternal

leakage).

•Inspectthefuellinesandconnections.

•Replacethefuel/waterseparatorelement.

•Replacethefuel-lterelement

•Inspectthemower-deckcaster-wheelassemblies.

•Changetheplanetarydrivegear/brakeoil(Oryearly,whichevercomesrst).

•Drainandcleanthefueltank.

•Calibratethetractionpedal.

•Checktherear-wheeltoe-in.

•Checkthealternator-belttension.

•Checkthecompressor-belttension.

•Replacetheblade-drivebelts.

•Changethehydraulicuidandlters.

36

Page 37

MaintenanceService

Interval

MaintenanceProcedure

Every2,000hours

Every2years

•Adjustthevalveclearance.

•Flushthecoolingsystemandreplaceuid.

•Replacemovinghoses.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

ServiceIntervalChart

Premaintenance

Procedures

Pre-MaintenanceSafety

•Keepallpartsofthemachineingoodworkingcondition

andallhardwaretightened,especiallyblade-attachment

hardware.Replaceallwornordamageddecals.

•Neverallowuntrainedpersonneltoservicethemachine.

•Beforeadjusting,cleaning,orrepairingthemachine,do

thefollowing:

1.Movethemachinetolevelground.

2.Disengagethedrives.

3.Lowerthecuttingunits.

4.MovethetractionpedaltotheNEUTRALposition.

5.Engagetheparkingbrake.

Figure42

6.MovethethrottleswitchtotheLOW-IDLEposition.

7.Shutofftheengineandremovethekey.

8.Waitforallmovingpartstostop.

•Wheneveryouparkorstorethemachine,orleaveit

unattended,lowerthecuttingunitsunlessyouusea

positivemechanicallock.

•Ifpossible,donotperformmaintenanceonthemachine

whiletheengineisrunning.Ifyoumustruntheengineto

performmaintenanceonthemachine,keepyourhands,

feet,otherbodyparts,andclothingawayfromallmoving

parts,themower-dischargearea,andtheundersideof

themowers.

•Donottouchpartsofthemachineoranattachment

thatmaybehotfromoperation.Allowthepartstocool

beforeattemptingtomaintain,adjust,orservicethem.

•Usejackstandstosupportthemachineand/orits

componentswhenrequired.

37

Page 38

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Ifyourmachinerequiresmajorrepairsorifyoudesire

assistance,contactanAuthorizedToroDistributor.

•UseonlygenuineTororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadebyother

manufacturerscouldbedangerous,andsuchusecould

voidtheproductwarranty.

PreparingtheMachinefor Maintenance

1.EnsurethatthePTOisdisengaged.

2.Parkthemachineonalevelsurface.

3.Settheparkingbrake.

4.Lowerthecuttingunit(s)ifnecessary.

5.Shutofftheengineandwaitforallmovingpartsto

stop.

6.TurntheignitionkeytotheSTOPpositionandremove

it.

7.Allowmachinecomponentstocoolbeforeperforming

maintenance.

RaisingtheMachine

Usethefollowingaspointstojackupthemachine:

Frontofthemachine—ontheframe,ontheinsideofeach

drivetire(Figure43)

Figure44

1.Rearjackingpoint

RemovingandInstallingthe Inner-Wing-DeckCovers

RemovingtheInner-Wing-DeckCovers

1.Lowerthewingdeckontoalevelsurface.

2.Disengagethecoverlatch.

3.Removetheboltsecuringthebeltcover(ifequipped).

4.Lifttherearandinsidecoveredgesoffthemounting

posts(Figure45).

Figure43

1.Frontjackingpoint(2)

Rearofthemachine—atthecenteroftheaxle(Figure44)

Figure45

1.Mountingposts

5.Whileliftingthecover,slideittowardthetractionunit

approximately2.5cm(1inch),todisengagetheouter

coveredgefromthedeck(Figure46).

38

Page 39

Lubrication

GreasingtheBearingsand Bushings

ServiceInterval:Beforeeachuseordaily—Lubricatethe

caster-armbushings.

Every50hours—Lubricateallgreasettings.

Figure46

1.Slidethecoverinward

approximately2.5cm(1

inch).

6.Liftthefrontedgeandguideitbetweentheliftarm

andtherollertoremoveit(Figure47).

2.Disengagethesecover

edges.

Figure47

Themachinehasgreasettingsthatyoumustlubricate

regularlywithNo.2lithiumgrease.Also,lubricatethe

machineimmediatelyaftereverywashing.

Note:Lubricatethecaster-fork-shaftbushingsbefore

eachuseordaily.

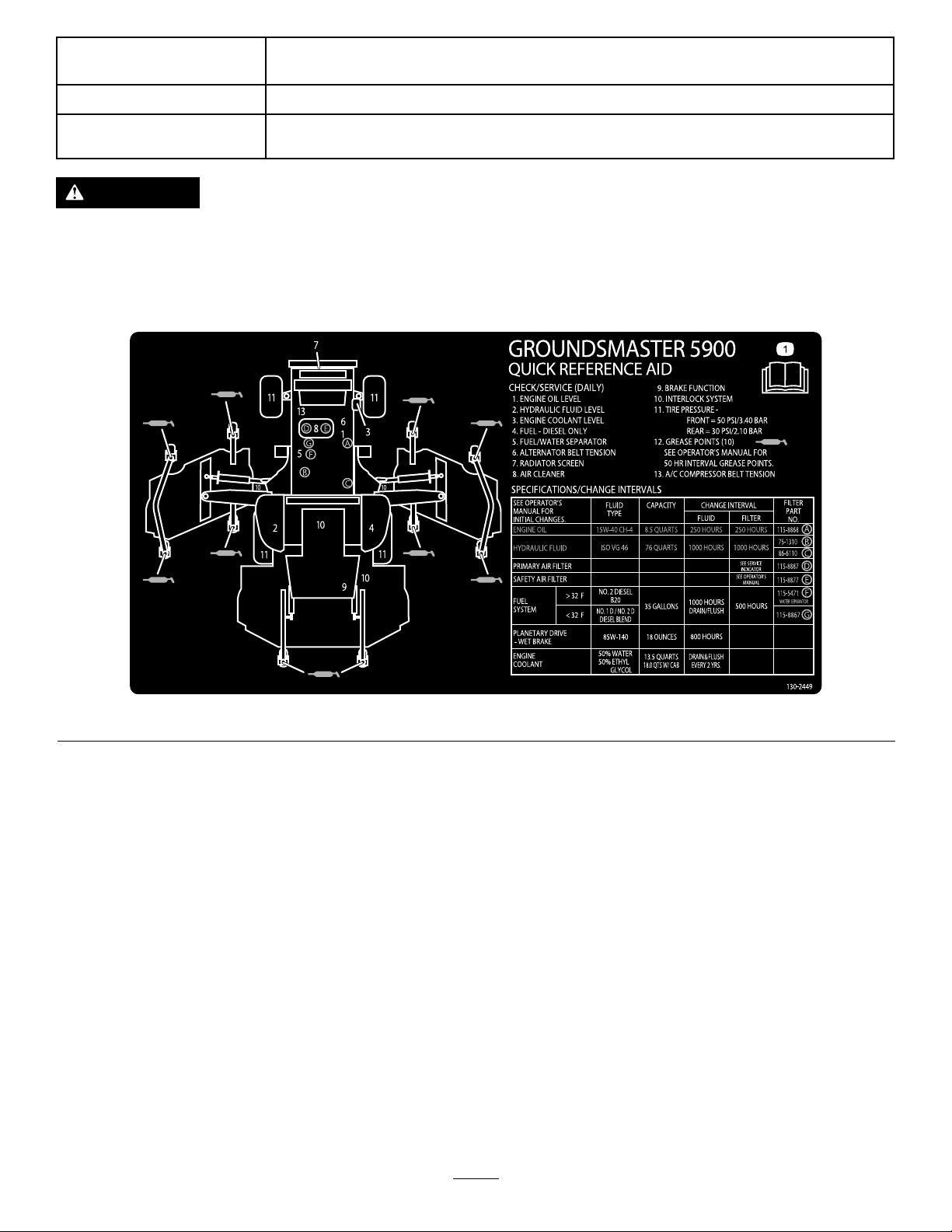

TractionUnit

•2impactarms(Figure48)

•2frontdeck-lift-cylinderpivots(Figure48)

•2sidedeck-lift-cylinderpivots(Figure48)

•4steering-cylinder-balljoints(Figure49)

•2tie-rod-balljoints(Figure49)

•2king-pinbushings(Figure49)

•1rearaxle-pivotbushing(Figure50)

•1brake-shaft-pivotbearing(Figure51)

1.Slidethecoveroutbetweentheliftarmandroller.

InstallingtheInner-Wing-DeckCovers

1.Lowerthewingdeckontoalevelsurface.

2.Slidethecoverintopositionbyguidingtherearedge

betweentheliftarmandtheroller.

3.Whileslidingthecoverawayfromthetractionunit,

guidetheoutsideedgeunderthefrontandrearbrackets

onthedeck.

4.Alignthedeckmountingpostswiththeholesinthe

coverandlowerthecoverintoposition.

5.Installtheboltsecuringthebeltcover,ifsoequipped.

6.Engagethedeck-coverlatch.

39

Page 40

Figure49

Figure48

Figure51

Figure50

40

Page 41

FrontMowerDeck

SideMowerDecks(EachSide)

•2caster-fork-shaftbushings(Figure52)

•5spindle-shaftbearings(locatedonthespindlehousing)

asshowninFigure52

•3idler-arm-pivotbushings(locatedontheidler-pivot

shaft)asshowninFigure52

Figure52

•4caster-fork-shaftbushings(Figure54)

•3spindle-shaftbearings(locatedonthespindlehousing)

asshowninFigure54

•2idler-arm-pivotbushings(locatedontheidler-pivot

shaft)asshowninFigure54

FrontLiftAssemblies

•2lift-armbushings(Figure53)