Page 1

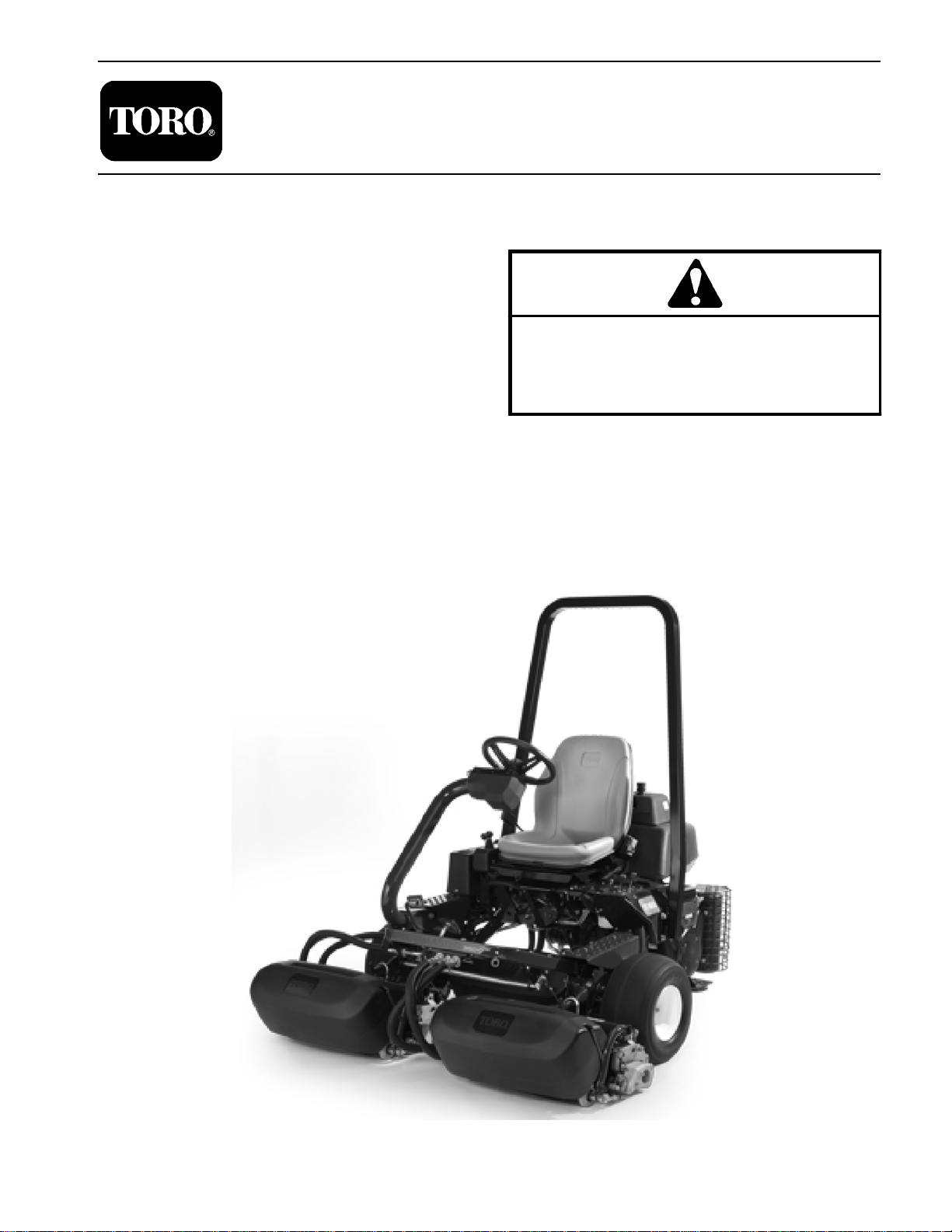

Part No. 12191SL

Service Manual

(Model 04358)

Preface

The purpose of this publication is to provide the service

technician with information for troubleshooting, testing

and repair of major systems and components on the

Greensmaster 3150 (Model 04358).

REFER TO THE TRACTION UNIT AND CUTTING

UNIT OPERATOR’S MANUALS FOR OPERATING,

MAINTENANCE AND ADJUSTMENT INSTRUCTIONS. For reference, insert a copy of the Operator’s

Manuals and Parts Catalogs for your machine into

Chapter 2 of this service manual. Additional copies of

theOperator’s ManualsandParts Catalogare available

on the internet at www.Toro.com.

TheT oroCompany reservesthe right tochangeproduct

specifications or this publication without notice.

Greensmaster

This safety symbol means DANGER, WARNING

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: ANOTE will give general information about the

correct operation, maintenance, service, testing or repair of the machine.

IMPORTANT: The IMPORTANT notice will give importantinstructionswhichmustbefollowedtoprevent damage to systems or components on the

machine.

3150

R

E The Toro Company -- 2012

Page 2

This page is intentionally blank.

Greensmaster 3150

Page 3

Table Of Contents

Chapter 1 -- Safety

Safety Instructions 1 -- 2..........................

Jacking Instructions 1 -- 5.........................

Safety and Instruction Decals 1 -- 5................

Chapter 2 -- Product Records and Maintenance

Product Records 2 -- 1...........................

Maintenance 2 -- 1...............................

Equivalents and Conversions 2 -- 2................

Torque Specifications 2 -- 3.......................

Chapter 3 -- Engine

General Information 3 -- 2........................

Specifications 3 -- 3..............................

Service and Repairs 3 -- 4........................

BRIGGS & STRATTON VANGUARD V-TWIN OHV

REPAIR MANUAL

Chapter 4 -- Hydraulic System

Specifications 4 -- 2..............................

General Information 4 -- 3........................

Hydraulic Schematic 4 -- 8........................

Hydraulic Flow Diagrams 4 -- 10...................

Special Tools 4 -- 18.............................

Troubleshooting 4 -- 21...........................

Testing 4 - - 26...................................

Adjustments 4 -- 49..............................

Service and Repairs 4 -- 50.......................

EATON, MEDIUM DUTY PISTON PUMP , REP AIR IN-

FORMATION, MODEL 70160 VARIABLE DISPLACEMENT PISTON PUMP

PARKER TORQMOTOR

(TC, TB, TE, TJ, TF, TG, TH and TL SERIES)

SAUER/DANFOSS STEERING UNIT TYPE OSPM

SERVICE MANUAL

TM

SERVICE PROCEDURE

Chapter 5 -- Electrical System

General Information 5 -- 2........................

Special Tools 5 -- 3..............................

Turf Guardian Leak Detector

System Operation 5 -- 5........................

Troubleshooting 5 -- 6............................

Electrical System Quick Checks 5 -- 11.............

Component Testing 5 -- 12........................

Service and Repairs 5 -- 28.......................

Chapter 6 -- Chassis

Specifications 6 -- 2..............................

General Information 6 -- 3........................

Special Tools 6 -- 3..............................

Service and Repairs 6 -- 4........................

Chapter 7 -- DPA Cutting Units

Specifications 7 -- 2..............................

General Information 7 -- 3........................

Special Tools 7 -- 4..............................

Factors That Can Affect Cutting Performance 7 -- 6..

Set Up and Adjustments 7 -- 10....................

Service and Repairs 7 -- 12.......................

Chapter 8 -- Groomer

Specifications 8 -- 2..............................

General Information 8 -- 3........................

Troubleshooting 8 -- 4............................

Adjustments 8 -- 6...............................

Service and Repairs 8 -- 7........................

Chapter 9 -- Foldout Drawings

Hydraulic Schematic 9 -- 3........................

Electrical Schematic 9 -- 4........................

Electrical Circuit Diagrams 9 -- 5...................

Wire Harness Drawings 9 -- 12....................

SafetyDPA Cutting

Product Records

Engine

Hydraulic

Electrical

ChassisGroomer

and Maintenance

System

System

Units

Greensmaster 3150

Foldout

Drawings

Page 4

This page is intentionally blank.

Greensmaster 3150

Page 5

Table of Contents

SAFETY INSTRUCTIONS 2......................

Before Operating 2............................

While Operating 3............................

Maintenance and Service 4....................

JACKING INSTRUCTIONS 5.....................

SAFETY AND INSTRUCTION DECALS 5..........

Chapter 1

Safety

Safety

Greensmaster 3150 Page 1 -- 1 Safety

Page 6

Safety Instructions

The Greensmaster 3150 was tested and certified by

Toro for compliancewithnationaland international standards as specified in the Operator’s Manual. Although

hazard control and accident prevention partially are dependent upon the design and configuration of the machine, these factors are also dependent upon the

awareness, concern and proper training of the personnel involved in the operation, transport, maintenance

and storage of the machine. Improper use or maintenance of the machine can result in injury or death.

Before Operating

WARNING

Toreducethepotentialfor injury ordeath,comply

with the following safety instructions.

1. Read and understand thecontents of the Operator’s

Manual before starting and operating the machine. Become familiar with all controls and know how to stop

quickly. Copies of the Operator’s Manual are available

on the internet at www.Toro.com.

2. Never allow children to operate the machine. Never

allow adults to operate it without proper instructions.

3. Become familiar with the controls and know how to

stop the engine quickly.

4. Keep all shields, safety devices and decals in place.

Ifa shield, safety deviceordecal is defective, illegibleor

damaged: repair or replace it before operating the machine.

5. Always wear substantial shoes. Do not operate machine while wearing sandals, tennis shoes or sneakers.

Donotwearloosefittingclothingwhichcouldgetcaught

in moving parts and cause personal injury.

6. Wearing safety glasses, safety shoes, long pants

and a helmet is advisable and required by some local

safety and insurance regulations.

7. Make sure work area is clear of objects which might

be picked up and thrown by the reels.

8. Do not carry passengers on the machine. Keep everyone, especially children and pets, away from the

areas of operation.

9. Gasoline(fuel) is highly flammable; handle itcarefully.

A. Store fuel in containers specifically designed for

this purpose.

B. Add fuel before starting the engine. Never removethecapofthefueltankoraddfuelwhiletheengine is running or when the engine is hot.

C. Refuel outdoors only and do not smoke while

refuelling.

D. Fillfueltanktoalevelnohigherthantothebottom

of fuel tank filler neck. Do not overfill.

E. Replaceallfueltanksandcontainercaps securely.

F. If fuel is spilled,do notattempt tostart the engine

butmovethemachineawayfromthearea of spillage

andavoidcreatingany sourceofignitionuntilfuelvapors have dissipated.

G. Wipe up any spilled fuel.

Greensmaster 3150Page 1 -- 2Safety

Page 7

While Operating

1. Donotruntheengineinaconfinedareawithoutadequate ventilation. Exhaust fumes are hazardous and

couldbedeadly.

2. Sit on the seat when starting and operating the machine.

3. Check the safety interlockswitchdaily for properoperation; see VerifyInterlockSystem Operation in Chapter 5 -- Electrical System. Replace any malfunctioning

switches before operating the machine.

4. To start the engine:

A. Sitontheseat,makesure cutting units are disengaged.

B. Verify that functional control lever is in neutral.

C. Verify that parking brake is set.

D. Proceed to start engine.

5. Using the machine demands attention. To prevent

loss of machine control:

A. Mow only in daylight or when there is good artificial light.

B. Watch for holes or other hidden hazards.

C. Do not drive close to sand traps, ditches, creeks

or other hazards.

D. Reduce speed when making sharp turns. Avoid

sudden stops and starts.

E. Before backing up, look to the rear to be sure no

one is behind the machine.

F. Watchoutfor traffic when near orcrossingroads.

Always yield the right--of--way.

G. Apply the service brakes when going downhill to

keep forward speed slow and to maintain control of

the machine.

6. Keep hands, feet and clothing away from moving

parts and the reel discharge area. The grass baskets

must be in place during operation of the reels or thatchersformaximumsafety.Shuttheengineoffbefore emptying the baskets.

7. Wearappropriateclothingincluding substantial footwear, hard hat, safety glasses and ear protection.

8. Raise the cutting units when driving from one work

area to another.

9. Do not touch engine, muffler or exhaust pipe while

engine is running or soon after it is stopped because

these areas could be hot enough to cause burns.

10.If a cutting unit strikes a solid object or vibrates abnormally, stop immediately, turn engine off, wait for all

motionto stop and inspect for damage.A damaged reel

or bedknife must be repaired or replaced before operation is continued.

11.Before getting off the seat:

A. Make sure cutting units are disengaged.

B. Verify that functional control lever is in neutral.

C. Set the parking brake.

D. Stop the engine and remove key from ignition

switch.

12.Traverse slopes carefully. Do not start or stop sud-

denly when traveling uphill or downhill.

13.Operator must be skilled and trained in how to drive

on hillsides. Avoid wet slopes. Failure to use caution on

slopes or hills may cause loss of control and vehicle to

tip or roll possibly resulting in personal injury or death.

14.If engine stalls or loses headway and cannot make

it to the top of a slope, do not turn machine around. Always back slowly straight down the slope.

15.DON’T TAKE AN INJURY RISK! Whenapersonor

pet appears unexpectedly in or near the mowing area,

STOP MOWING. Careless operation, combined with

terrain angles, ricochets or improperly positioned

guardscanlead to thrownobjectinjuries.Donotresume

mowing until area is cleared.

16.Whenever machine is left unattended, make sure

cutting units are fully raised and reels are not spinning,

key is removed from ignition switch and parking brake

is set.

Safety

Greensmaster 3150 Page 1 -- 3 Safety

Page 8

Maintenance and Service

1. Before servicing or making adjustments to the machine, stop the engine, remove key from switch to prevent accidental starting of the engine.

2. Be sure entire machine is in good operating condition. Keep all nuts, bolts, screws and hydraulic fittings

tight.

3. Make sure allhydraulic line connectorsare tight,and

all hydraulic hoses and lines are in good condition before applying pressure to the system.

4. Keep body and hands away from pin hole leaks or

nozzles that eject hydraulic fluid under high pressure.

Use paper or cardboard, not hands, to search for leaks.

Hydraulic fluid escaping under pressure can have sufficient force to penetrate skin and do serious damage. If

fluidisejectedintotheskinitmustbesurgically removed

within a few hours by a doctor familiar with this form of

injury or gangrene may result.

5. Before disconnecting or performing any work on the

hydraulic system, all pressure in system must be relievedbystoppingengineandloweringcuttingunitsand

attachments to the ground.

6. Toreducepotential fire hazard, keeptheenginearea

free of excessive grease, grass, leaves and accumulation of dirt.Never wash a warm engineor electrical connections with water.

7. Check all fuel linesfor tightness andwear on aregular basis. Tighten or repair fuel lines as needed.

9. Do not overspeed the engine by changing governor

settings.Toassuresafetyandaccuracy,have an Authorized Toro Distributor check maximum engine speed

with a tachometer. Maximum governed engine speed

should be 2850 +

10.Enginemustbeshutoffbeforechecking oiloradding

oil to the crankcase.

11.If major repairs are ever needed or if assistance is

desired, contact your Authorized Toro Distributor.

12.At the time of manufacture, the machine conformed

tothe safety standards for ridingmowers. To assure optimumperformanceandcontinuedsafetycertificationof

the machine, use genuine Toro replacement parts and

accessories.Replacementpartsandaccessoriesmade

by other manufacturers may result in non-conformance

with the safety standards and the warranty may be

voided.

13.When changing attachments, tires or performing

other service, use correct blocks, hoists and jacks.

Make sure machine is parkedonasolidlevelsurface

suchasaconcretefloor.Priortoraisingthemachine,remove any attachments that may interfere with the safe

and proper raising of the machine. Always chock or

block wheels. Use appropriate jack stands to support

the raised machine. If the machine is not properly supported by jack stands, the machine may move or fall,

which may result in personal injury.

50 RPM.

8. If the engine must be running to perform a maintenance adjustment, keep hands, feet, clothing and any

other parts of the body away from the cutting units, attachmentsandany moving parts.Keep everyone away.

Greensmaster 3150Page 1 -- 4Safety

Page 9

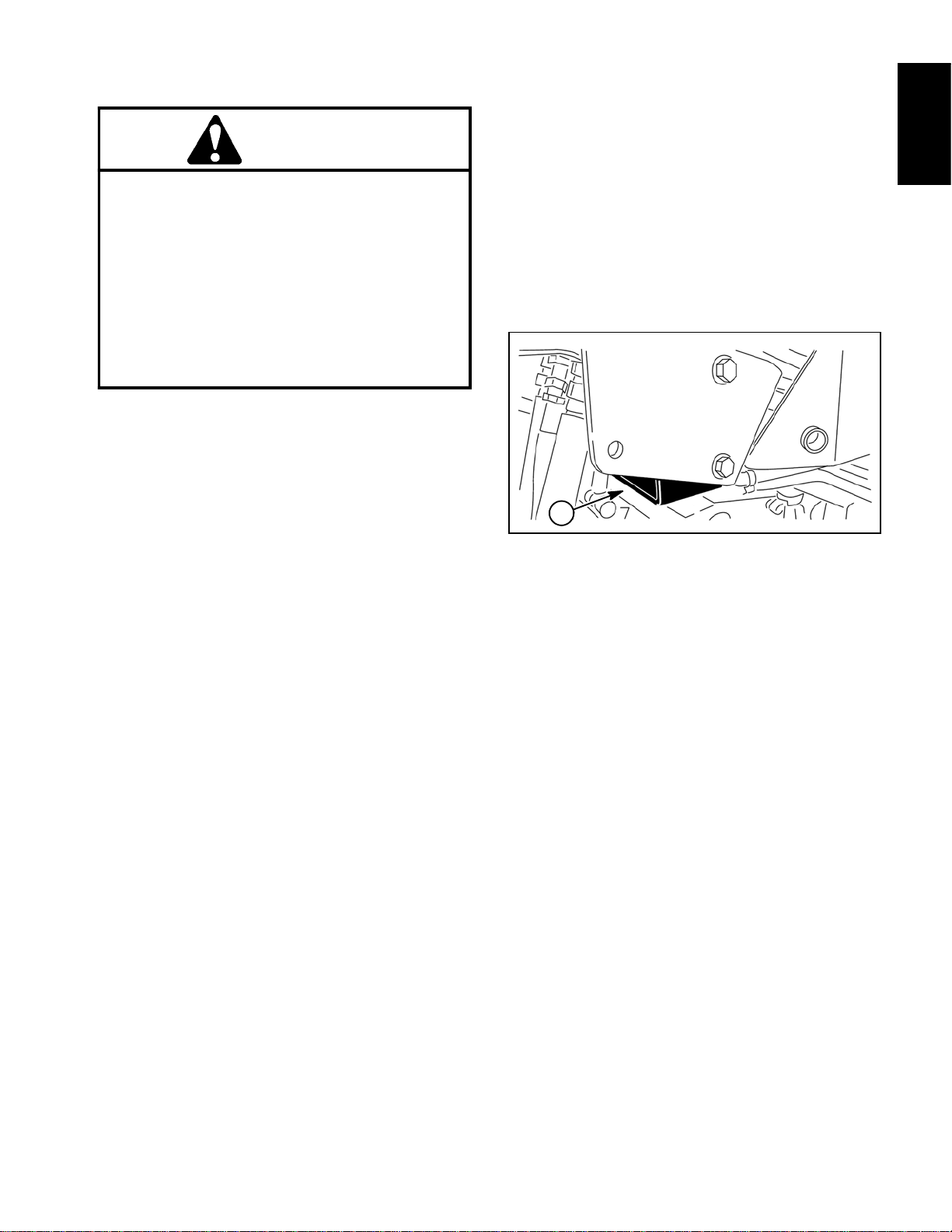

Jacking Instructions

CAUTION

When changing attachments, tires or performing other service, use correct jacks and supports. Make sure machine is parked on a solid,

level surface such as a concrete floor. Prior to

raising machine, remove any attachments that

may interfere with the safe and proper raising of

themachine.Always chockorblockwheels.Use

jack stands to supportthe raised machine. If the

machine is not properly supported by jack

stands, the machine may move or fall, which

may result in personal injury.

Front End Jacking

1. Apply parking brake and chock rear tire to prevent

the machine from moving. Make sure that cutting units

are fully lowered.

2. Position jack securelyunder the framejacking point:

Rear End Jacking

1. Applyparkingbrakeandchock both front tirestopre-

vent the machine from moving. Make sure that cutting

units are fully lowered.

2. Place jack securely below the rear castor fork.

3. Jack rear of machine off the ground.

4. Position appropriate jack stands under the frame to

support the machine.

1

Safety

A. The left side jacking point is the frame channel

under the step behind the LH front wheel.

B. The right side jacking point is the ROPS support

bracket behind the RH front wheel (Fig. 1).

3. Jack front of machine off the ground.

4. Position appropriate jack stands under the frame as

close to the wheel as possible to support the machine.

Safety and Instruction Decals

Numerous safety and instruction decals are affixed to

the traction unit and the cutting units of the Greensmaster 3150. If any decal becomes illegible or damaged, install a new decal. Part numbers are listed in your Parts

CatalogandOperator’s Manual. Order replacement decals from your Authorized Toro Distributor.

Figure 1

1. ROPS support bracket

Greensmaster 3150 Page 1 -- 5 Safety

Page 10

This page is intentionally blank.

Greensmaster 3150Page 1 -- 6Safety

Page 11

Product Records and Maintenance

Table of Contents

PRODUCT RECORDS 1.........................

MAINTENANCE 1..............................

EQUIVALENTS AND CONVERSIONS 2...........

Decimal and Millimeter Equivalents 2............

U.S. to Metric Conversions 2...................

TORQUE SPECIFICATIONS 3...................

Fastener Identification 3.......................

Using a Torque Wrench with an Offset Wrench 3..

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Inch Series). 4...............

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Metric Fasteners). 5..........

Other Torque Specifications 6..................

Conversion Factors 6.........................

Chapter 2

Product Records

and Maintenance

Product Records

Insert a copy of the Operator’s Manual and Parts Catalog for your Greensmaster 3150 at the end of this chapter. Additionally, if any optional equipment or

accessorieshavebeen installed to yourmachine, insert

the Installation Instructions, Operator’s Manuals and

PartsCatalogs for thoseoptions at theend of thischapter.

Maintenance

Maintenanceproceduresandrecommendedserviceintervals for the Greensmaster 3150 are covered in the

Traction Unit Operator’s Manual. Maintenance procedures and recommended service intervals for the

Greensmaster Cutting Units are covered in the Cutting

Unit Operator’s Manual. Refer to these publications

when performing regular equipment maintenance. Refer to the Engine Operator’s Manual for additional engine specific maintenance procedures.

Greensmaster 3150 Page 2 -- 1 Product Records and Maintenance

Page 12

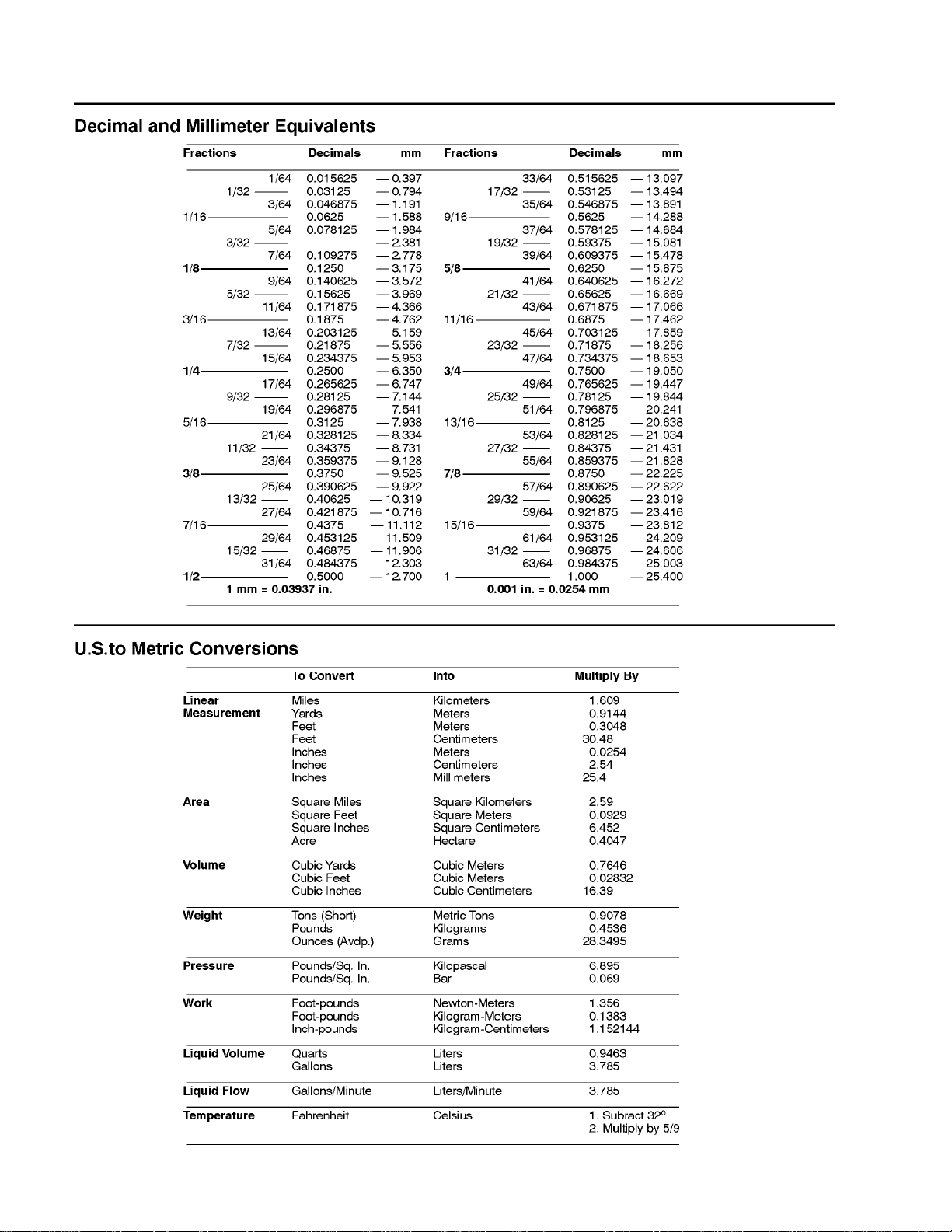

Equivalents and Conversions

0.09375

Greensmaster 3150Page 2 -- 2Product Records and Maintenance

Page 13

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as determined

byToro,eithertherecommendedtorque or atorquethat

is unique to the application is clearly identified and specified in this Service Manual.

Thesetorquespecificationsfortheinstallationandtightening of fasteners shall apply to all fasteners which do

nothave a specific requirement identifiedinthis Service

Manual.The following factors shall beconsideredwhen

applying t orque: cleanliness of the fastener, use of a

threadsealant(e.g.L octite), degree oflubricationonthe

fastener,presence of a prevailing torque feature, hardness of the surface underneath the fastener’s head or

similar condition which affects the installation.

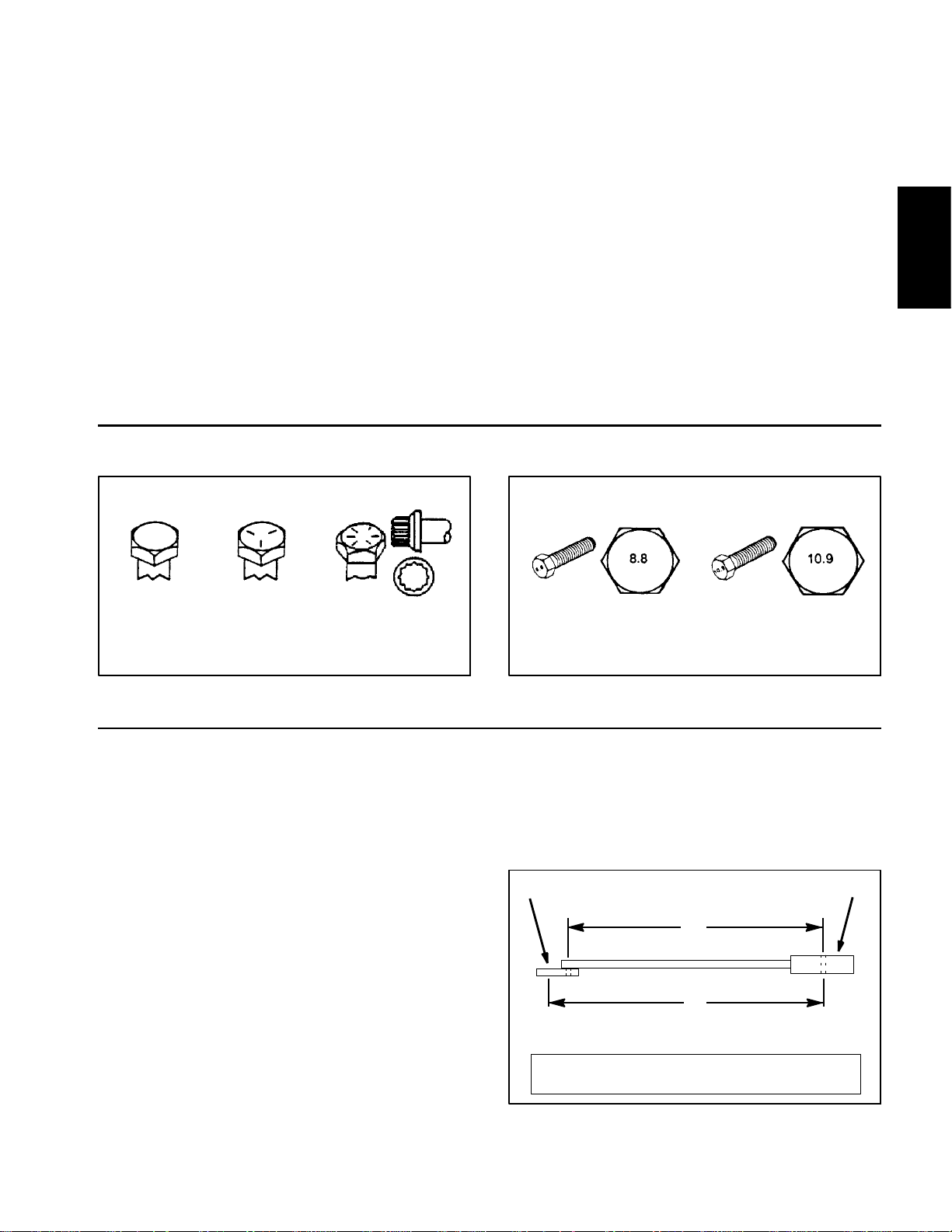

Fastener Identification

Asnotedinthefollowingtables, torque valuesshouldbe

reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener. Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based on the aluminum or brass

material strength, fastener size, length of thread engagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measurethetorque required to tightenthefasteneruntil

thelinesmatchup.

Product Records

and Maintenance

Grade 1 Grade 5 Grade 8

Inch Series Bolts and Screws

Figure 1

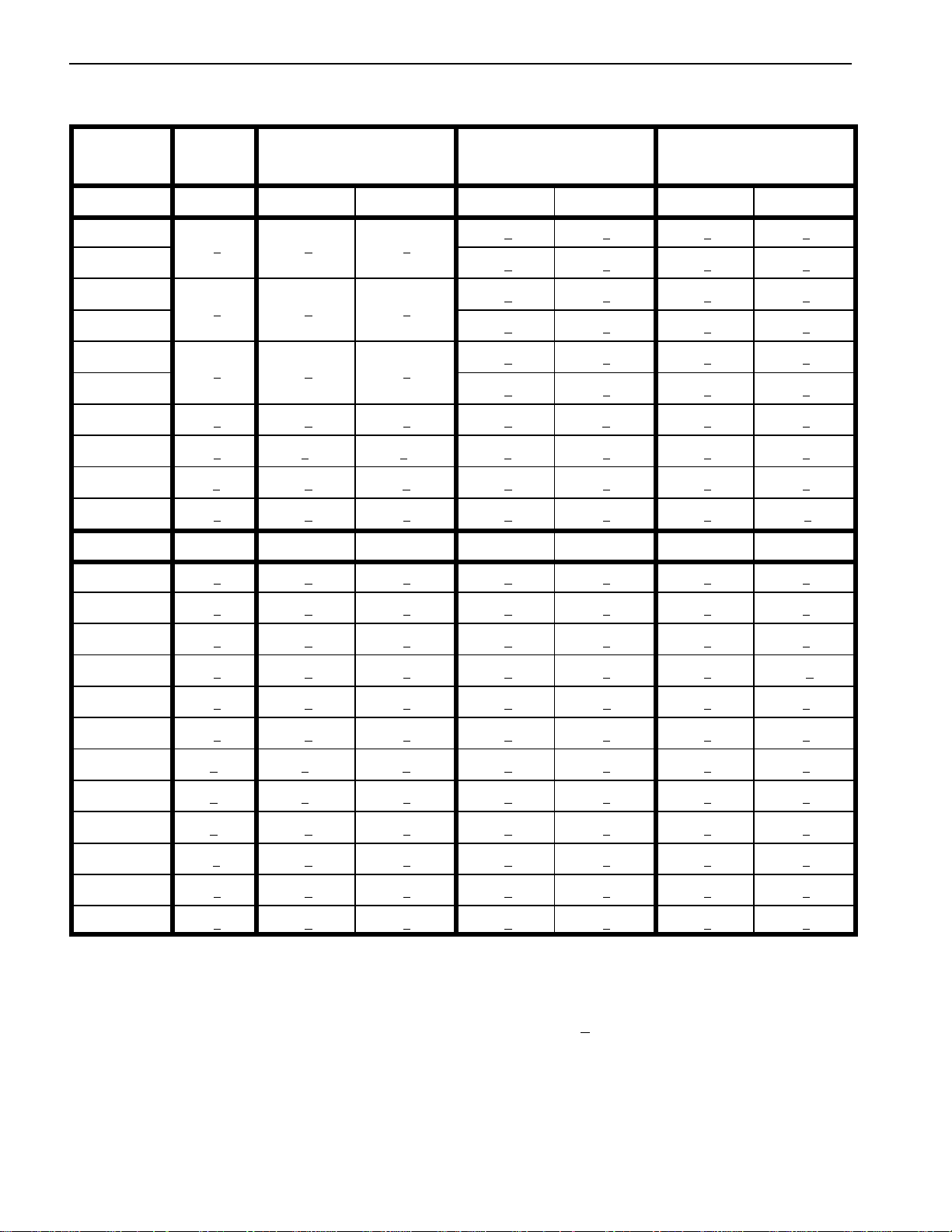

Using a Torque Wrench with an Offset Wrench

Useofanoffsetwrench(e.g.crowfootwrench)willaffect

torquewrench calibration dueto theeffectivechange of

torque wrench length. When usinga torque wrenchwith

an offset wrench, multiply the listed torque recommendation by the calculated torque conversion factor (Fig.

3) to determine proper tightening torque. Tightening

torque when using a torque wrench with an offset

wrench will be lower than the listed torque recommendation.

Example: The measured effective length of the torque

wrench (distance from the center of the handle to the

center of the square drive) is 18”.

Themeasuredeffectivelengthofthetorquewrenchwith

the offset wrench installed (distance from the center of

the handle to the center of the offset wrench) is 19”.

Class 8.8 Class 10.9

Metric Bolts and Screws

Figure 2

If the listed torque recommendation for a fastener is

from 76 to 94 ft--lb, the proper torque when using this

torque wrench with an offset wrench would be from 72

to 89 ft--lb.

(effective length of

torque wrench)

A

B

(effective length of torque

wrench + offset wrench)

TORQUE CONVERSION FACTOR = A / B

T orque wrenchOffset wrench

The calculated t orque conversion factor for this torque

wrenchwith this offsetwrench would be18 / 19 = 0.947.

Greensmaster 3150 Page 2 -- 3 Product Records and Maintenance

Figure 3

Page 14

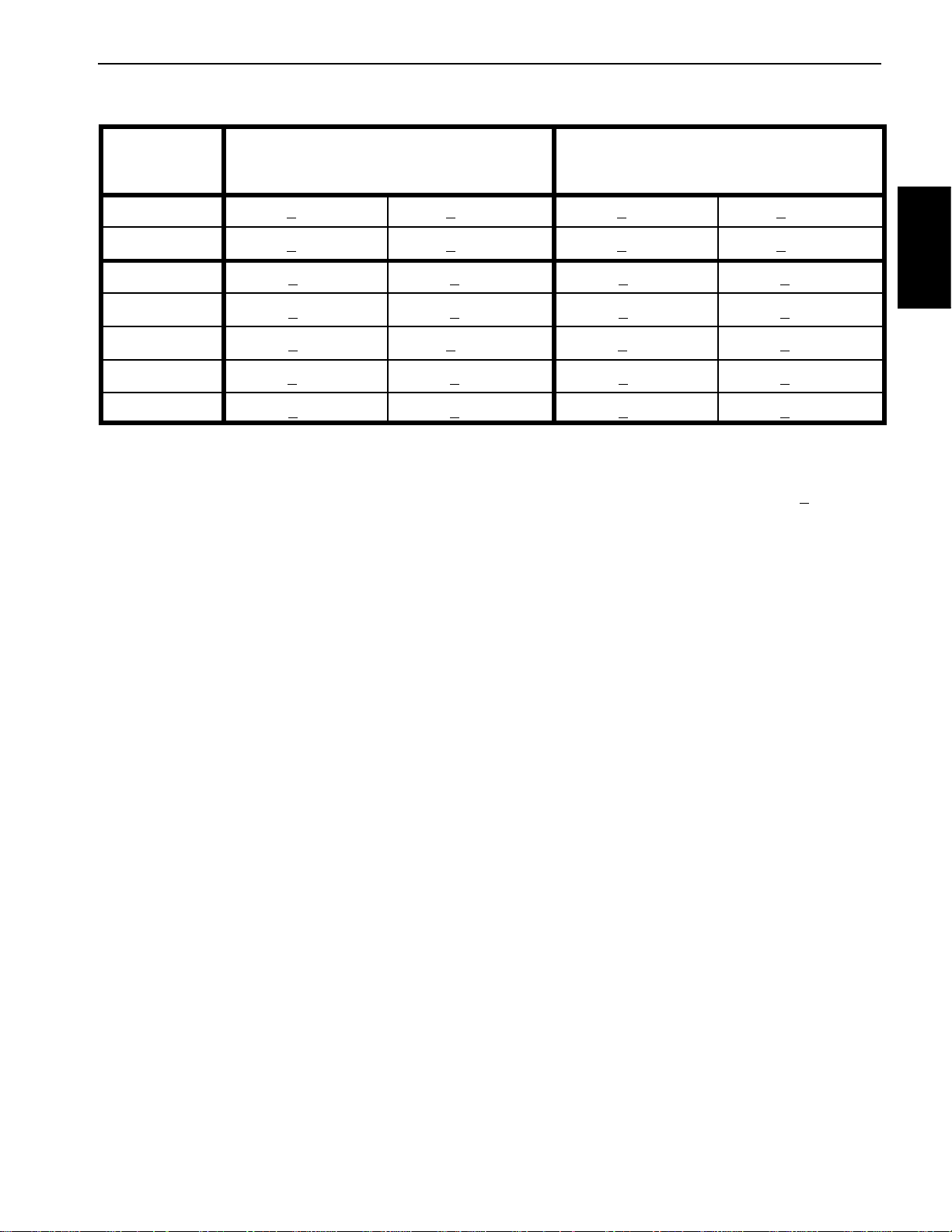

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

Grade1,5,&

Thread Size

#6--32UNC

#6--40UNF 17 + 2 190 + 20 25 + 2 280 + 20

#8--32UNC

#8--36UNF 31 + 3 350 + 30 43 + 4 485 + 45

#10--24UNC

#10--32UNF 48 + 4 540 + 45 68 + 6 765 + 70

1/4 -- 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 1125+ 100 140 + 15 1580+ 170

1/4 -- 28 UNF 53 + 7 65 + 10 734 + 113 115 + 10 1300 + 100 160 + 15 1800 + 170

5/16 -- 18 UNC 115 + 15 105 + 17 1186 + 169 200 + 25 2250 + 280 300 + 30 3390 + 340

5/16 -- 24 UNF 138 + 17 128 + 17 1446 + 192 225 + 25 2540+ 280 325 + 30 3670 + 340

3/8 -- 16 UNC 16 + 2 16 + 2 22 + 3 30 + 3 41 + 4 43 + 4 58 + 5

8withThin

Height Nuts

in--lb in--lb N--cm in--lb N--cm in--lb N--cm

10 + 2 13 + 2 147 + 23

13 + 2 25 + 5 282 + 30

18 + 2 30 + 5 339 + 56

ft--lb ft--lb N--m ft--lb N--m ft--lb N--m

SAE Grade 1 Bolts, Screws, Studs, &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws, Studs, &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

15 + 2 170 + 20 23 + 2 260 + 20

29 + 3 330 + 30 41 + 4 460 + 45

42 + 4 475 + 45 60 + 6 675 + 70

SAE Grade 8 Bolts, Screws, Studs, &

Sems with Regular Height Nuts

(SAE J995 Grade 5 or Stronger Nuts)

3/8 -- 24 UNF 17 + 2 18 + 2 24 + 3 35 + 3 47 + 4 50 + 4 68 + 5

7/16 -- 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 + 7 95 + 9

7/16 -- 20 UNF 29 + 3 29 + 3 39 + 4 55 + 5 75 + 7 77 + 7 104 + 9

1/2 -- 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 + 11 105 + 10 142 + 14

1/2 -- 20 UNF 32 + 3 53 + 7 72 + 9 85 + 8 115 + 11 120 + 10 163 + 14

5/8 -- 11 UNC 65 + 10 88 + 12 119 + 16 150 + 15 203 + 20 210 + 20 285 + 27

5/8 -- 18 UNF 75 + 10 95 + 15 129 + 20 170 + 15 230 + 20 240 + 20 325 + 27

3/4 -- 10 UNC 93 + 12 140 + 20 190 + 27 265 + 25 359 + 34 375 + 35 508 + 47

3/4 -- 16 UNF 115 + 15 165 + 25 224 + 34 300 + 25 407 + 34 420 + 35 569 + 47

7/8 -- 9 UNC 140 + 20 225 + 25 305 + 34 430 + 45 583 + 61 600 + 60 813 + 81

7/8 -- 14 UNF 155 + 25 260 + 30 353 + 41 475 + 45 644 + 61 660 + 60 895 + 81

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such a s

oil, graphite or thread sealant such as Loctite.

NOTE: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the minimum proof load specified in SAEJ429. The tolerance is

approximately +

10% of t he nominal torque value. Thin

height nuts include jam nuts.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Greensmaster 3150Page 2 -- 4Product Records and Maintenance

Page 15

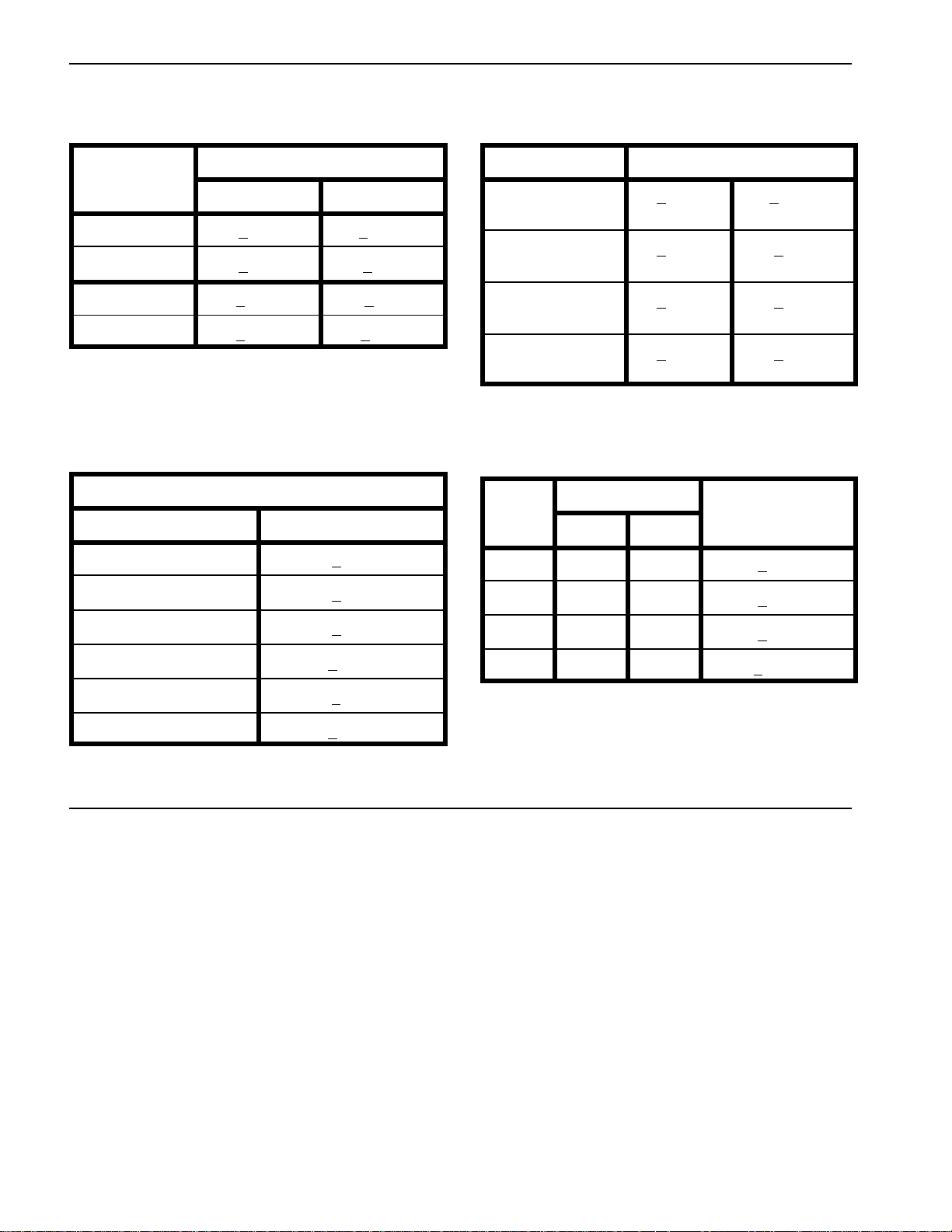

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Fasteners)

Class 8.8 Bolts, Screws and Studs with

Thread Size

M5 X 0.8 57 + 5in--lb 640 + 60 N--cm 78 + 7in--lb 885 + 80 N--cm

M6 X 1.0 96 + 9in--lb 1018 + 100 N--cm 133 + 13 in--lb 1500 + 150 N--cm

M8 X 1.25 19 + 2ft--lb 26 + 3N--m 27 + 2ft--lb 36 + 3N--m

M10 X 1.5 38 + 4ft--lb 52 + 5N--m 53 + 5ft--lb 72 + 7N--m

M12 X 1.75 66 + 7ft--lb 90 + 10 N--m 92 + 9ft--lb 125 + 12 N--m

M16 X 2.0 166+ 15 ft--lb 225 + 20 N--m 229 + 22 ft--lb 310 + 30 N--m

M20 X 2.5 325 + 33 ft--lb 440 + 45 N--m 450 + 37 ft--lb 610 + 50 N--m

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite or thread sealant such as Loctite.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Regular Height Nuts

(Class 8 or Stronger Nuts)

NOTE: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAEJ1199.Thetoleranceisapproximately+

nominal torque value.

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

(Class 10 or Stronger Nuts)

10%ofthe

Product Records

and Maintenance

Greensmaster 3150 Page 2 -- 5 Product Records and Maintenance

Page 16

Other Torque Specifications

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 -- 20 UNC 140 + 20 in--lb 73 + 12 in--lb

5/16 -- 18 UNC 215 + 35 in--lb 145 + 20 in--lb

3/8 -- 16 UNC 35 + 10 ft--lb 18 + 3ft--lb

1/2 -- 13 UNC 75 + 15 ft--lb 50 + 10 ft--lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size Baseline Torque*

No. 6 -- 32 UNC 20 + 5in--lb

Wheel Bolts and Lug Nuts

Thread Size

7/16 -- 20 UNF

Grade 5

1/2 -- 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

* For steel wheels and non--lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5in--lb

Threads per Inch

Type A Type B

Recommended Torque*

65 + 10 ft--lb 88 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

Baseline Torque**

No. 8 -- 32 UNC 30 + 5in--lb

No. 10 -- 24 UNC 38 + 7in--lb

1/4 -- 20 UNC 85 + 15 in--lb

5/16 -- 18 UNC 110 + 20 in--lb

3/8 -- 16 UNC 200 + 100 in--lb

Conversion Factors

in--lb X 11.2985 = N--cm N--cm X 0.08851 = in--lb

ft--lb X 1.3558 = N--m N--m X 0.7376 = ft--lb

No. 8 15 18 30 + 5in--lb

No. 10 12 16 38 + 7in--lb

No. 12 11 14 85 + 15 in--lb

** Hole size, material strength, material thickness & finish must be considered when determining specific

torquevalues.Alltorquevaluesarebasedonnon--lubricated fasteners.

Greensmaster 3150Page 2 -- 6Product Records and Maintenance

Page 17

Table of Contents

GENERAL INFORMATION 2.....................

Operator’s Manual 2..........................

SPECIFICATIONS 3............................

SERVICE AND REPAIRS 4......................

Fuel Tank 4..................................

Engine 6.....................................

Engine Removal 7...........................

Engine Installation 7.........................

Fuel Evaporative Control System 10.............

BRIGGS&STRATTONVANGUARDV--TWIN OHVRE-

PAIR MANUAL

Chapter 3

Engine

Engine

Greensmaster 3150 Page 3 -- 1 Engine

Page 18

General Information

This Chapter gives information about specifications,

maintenance, troubleshooting, testing and repair of the

engine used in the Greensmaster 3150.

Most repairs and adjustments require tools which are

commonly available in many service shops. Special

tools are described in the Briggs & Stratton Vanguard

V-Twin OHV Repair Manual. The use of some specialized test equipment is explained. However, the cost of

the test equipment and the specialized nature of some

repairs may dictate that the work be done at an engine

repair facility.

Operator’s Manual

The TractionUnit Operator’s Manual provides information regarding the operation, general maintenance and

maintenanceintervalsfor your Greensmaster 3150 machine. Refer to the Operator’s Manual for additional information when servicing the machine.

Service and repair parts for Briggs& Stratton Vanguard

V-Twin OHV engines are suppliedthrough your locallocalTorodistributor.Ifno parts list is available, be sure to

provide your distributor with the Toro model and serial

numberalongwith the enginemodeland serial number.

Greensmaster 3150Page 3 -- 2Engine

Page 19

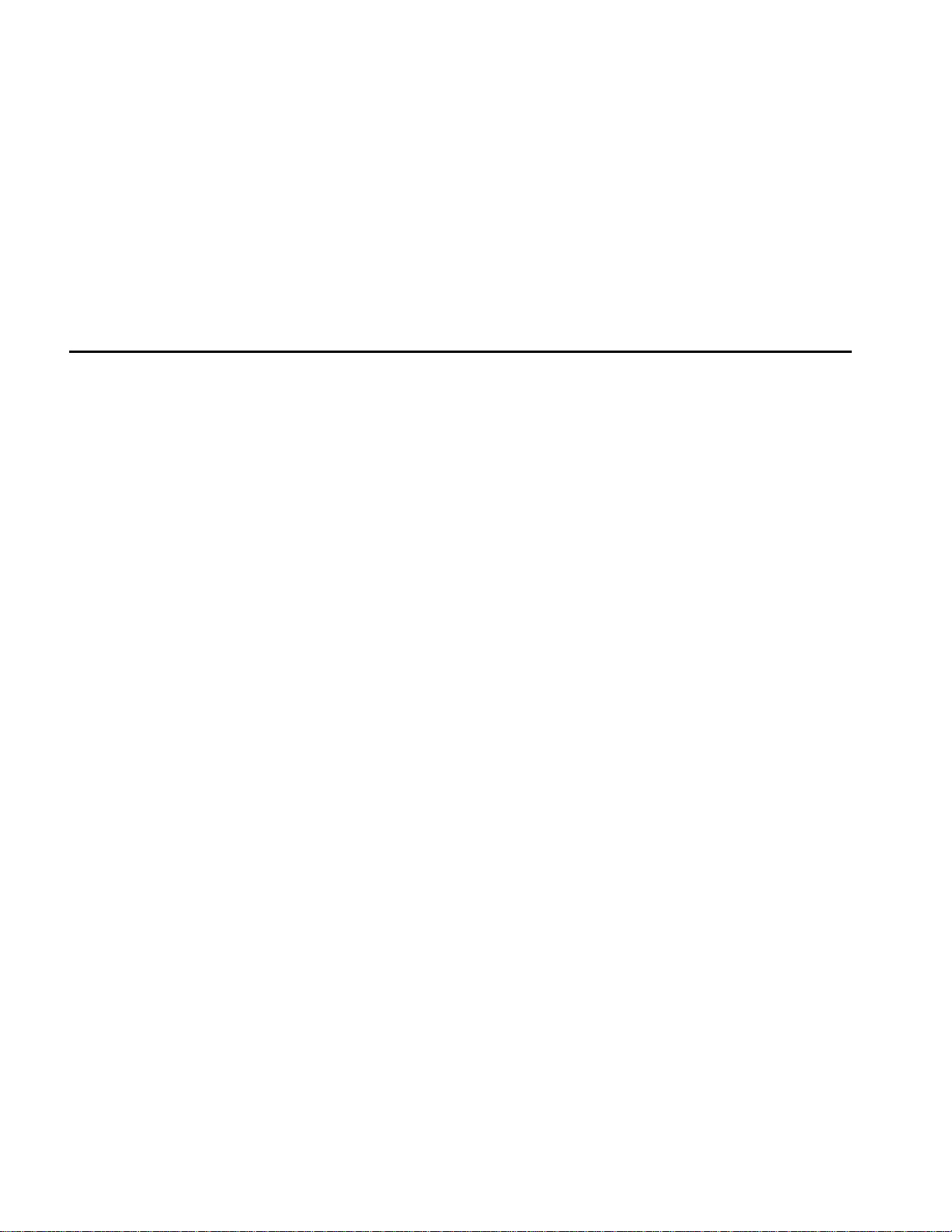

Specifications

Item Description

Make / Designation Briggs and Stratton, 4--cycle, V--Twin Cylinder,

OHV, Air Cooled, Gasoline Engine -- Model 356447

Bore x Stroke 2.83” x 2.76” (72 mm x 70 mm)

Total Displacement 34.8 in3(570 cc)

Governor Mechanical Governor

Carburetor Float Feed

Fuel Pump Pulsating Crankcase Vacuum

Fuel Unleaded, regular grade gasoline

Fuel TankCapacity 7.0 U.S. gallons (26.5 liters)

Low Idle (no load) 1650 + 100 RPM

High Idle (no load) 2850 + 50 RPM

Lubrication System Pressure Lubrication, Gear Driven Geroter Oil Pump

Engine Oil See Operator’s Manual

Crankcase Oil Capacity 1.75 U.S. quarts (1.65 liters) with new filter

Engine

Ignition System Flywheel magneto, twin electronic armatures

Spark Plugs Champion RC 14YC (or equivalent)

Spark Plug Gap 0.030” (0.76 mm)

Alternator 16 Amp

Dry Weight (approximate) 84 lb (38 kg)

Greensmaster 3150 Page 3 -- 3 Engine

Page 20

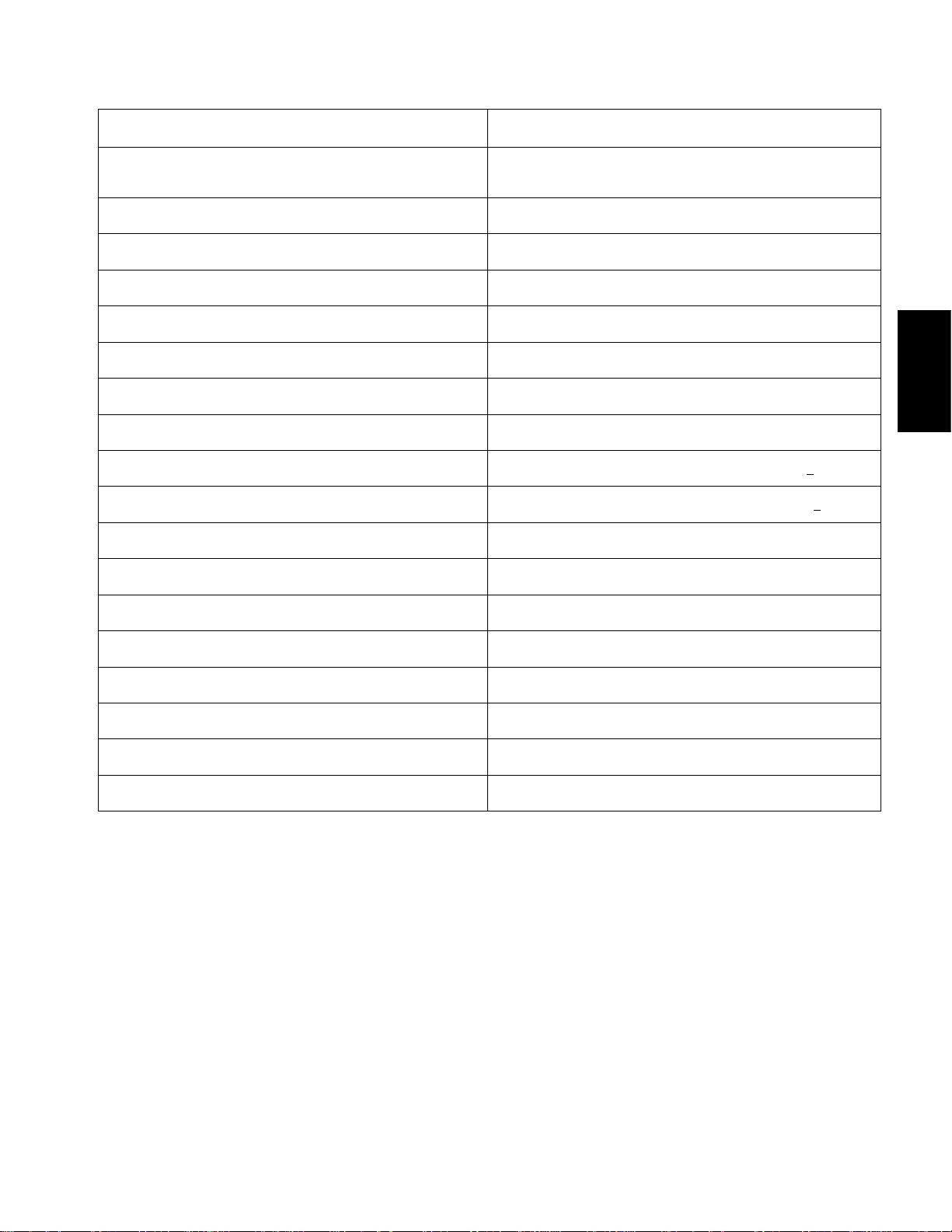

Service and Repairs

Fuel Tank

15

RIGHT

FRONT

1

2

14

2

Antiseize

Lubricant

30 to 60 in--lb

(3.4 to 6.7 N--m)

18

16

13

4

20

21

22

5

3

12

16

6

17

6

7

9

7

8

9

10

6

11

7

18

8

19

1. Fuel filter

2. Hose clamp

3. Fuel hose (filter to engine)

4. Fuel cap

5. Fuel tank

6. Grommet (4 used)

7. Flat washer (4 used)

8. Hose support clamp

Figure 1

9. Cap screw (4 used)

10. Cap screw

11. Hose support clamp

12. Vehicle frame

13. Fuel tank vent fitting

14. Fuel hose (shut--off valve to filter)

15. Fuelshut--off valve

16. Hose clamp

17. Fuel hose (tank to shut--off valve)

18. Hose clamp

19. Spacer

20. Hose clamp

21. Fuel vent hose (fitting to cannister)

22. Grommet

Greensmaster 3150Page 3 -- 4Engine

Page 21

Fuel Tank Removal (Fig. 1)

Fuel Tank installation (Fig. 1)

1. Park machine on a level surface, lower cutting units,

stop the engine, engage parking brake and remove the

key from the ignition switch.

CAUTION

The muffler and exhaust manifold may be hot.

Avoid possible burns, allow exhaust system to

cool before working on the engine.

DANGER

Gasolineisflammable.Use caution whenstoring

or handling it. Do not smoke while filling the fuel

tank. Do not fill fuel tank while engine is running

or in an enclosed area. Always fill fuel tank outside and wipe up any spilled fuel before starting

the engine. Store fuel in a clean, safety--approved container and keep the cap in place. Use

gasoline for the engine only; not for any other

purpose.

IMPORTANT: After fuel tank is installed, make sure

that clearance between hydraulic reservoir and fuel

tank if from 0.125” to 0.375” (3.2 to 9.5 mm).

1. Position fuel tank on the vehicle frame.

A. Applyantiseizelubricantto the threads ofthefour

(4) cap screws (item 9).

B. Securethe fuel tanktothe vehicle framewith four

(4) flat washers (item 7), grommets (item 6) and cap

screws (item 9). Make sure the grommets are

between the flat washers and the frame. Also, make

sure that fuelhose support clamps (item 8) are positioned correctly.

C. Torquecapscrewsfrom30to60in--lb(3.4 to6.7

N--m).

2. Connect vent hose (item 21) to fuel tank vent fitting

(item 13) on top of tank and secure with hose clamp.

Make sure that hose is not kinked or obstructed.

3. Connectfuelhose (item 14) to thefuelshut--off valve

(item15)andsecurewithhoseclamp.

Engine

2. Drain fuel tank as follows:

A. Close fuel shut--off valve (item 15).

B. Disconnectfuelhose(item14) atthe fuelshut--off

valve and drain any fuel trapped in the fuel filter and

fuel hose into a suitable container.

C. Installoneendofasparelengthoffuelhoseto the

fuel shut--off valve and place the other end of the

hose into a suitable container for draining the tank.

D. Drain fuel tank completely by opening the fuel

shut off valve.

E. Remove the spare length of fuel hose from the

fuel shut--off valve.

3. Disconnectventhose(item21)fromfueltankventfit-

ting (item 13) on top of tank.

4. Remove four (4) cap screws (item 9), grommets

(item 6) and flat washers (item 7) securing the fuel tank

to the vehicle frame. Remove the fuel tank from the vehicle frame.

4. Open fuel shut--off valve and fill fuel tank with fuel.

Check all fuel hoses and tank for leaks.

Greensmaster 3150 Page 3 -- 5 Engine

Page 22

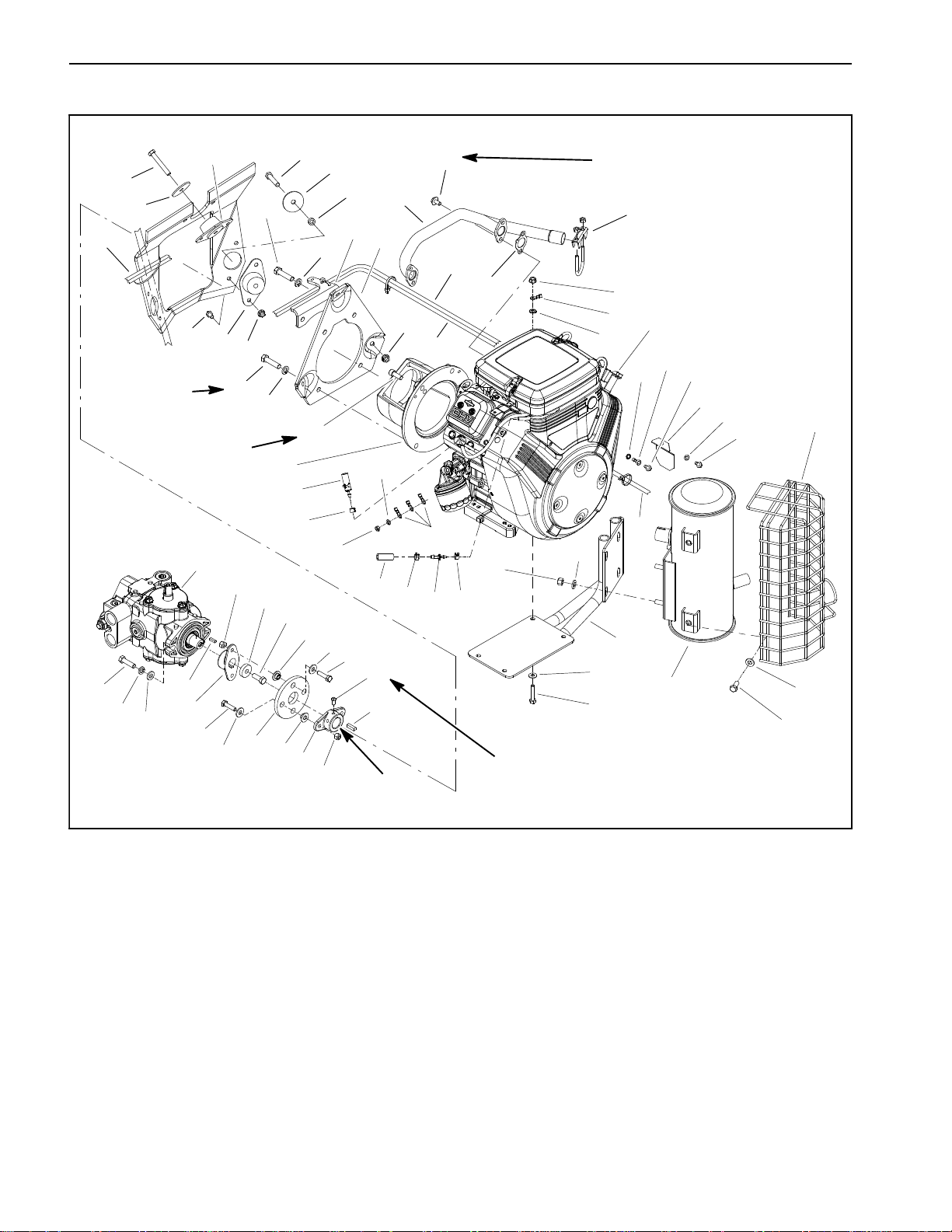

Engine

1

2

29

25 to 38 ft--lb

(34to51N--m)

18 to 23 ft--lb

(25to31N--m)

53

52

51

56

54

25

46

55

24

45

24

23

42

16

44

39

22

50

43

19

33

49

34

41

1

20

43

22

38

42

2

3

40

45

46

Antiseize

Lubricant

27

37

47

48

21

30

170 to 200 in--lb

(20 to 22 N--m)

4

6

29

31

7

32

17

11

16

27

8

11

28

5

27

10

28

11

12

29

26

36

35

34

13

15

9

12

14

18

Loctite #242

90 to 110 in--lb

(10.2 to 12.4 N--m)

1. Cap screw (3 used)

2. Flat washer (3 used)

3. Spacer (3 used)

4. Exhaust manifold

5. Regulator shield

6. Muffler clamp

7. Flange nut (3 used)

8. Engine assembly

9. Muffler

10. Muffler shield

11. Ground wires

12. Flat washer (8 used)

13. Muffler mount

14. Cap screw (4 used)

15. Flat washer (4 used)

16. Hex flange nut (10 used)

17. Lock washer

18. Cap screw (4 used)

19. Pump adapter

Figure 2

20. Socket head screw (2 used)

21. Engine mount plate

22. Lock washer (4 used)

23. Cap screw (2 used)

24. Engine mount (3 used)

25. Cap screw (6 used)

26. Lock nut (4 used)

27. Spring washer (3 used)

28. Washer head screw (2 used)

29. Engine wire harness

30. Flange head screw (4 used)

31. Gasket (2 used)

32. Battery cable

33. Purge hose assy (to intake manifold)

34. Hose clamp (2 used)

35. Barbed fitting

36. Hose clamp

37. Hose (to air cleaner base)

38. Hex nut

39. Cap screw (2 used)

40. Spring bracket

41. Engine hub

42. Lock nut (4 used)

43. Coupling spacer (4 used)

44. Rubber coupling

45. Flat washer (4 used)

46. Cap screw (4 used)

47. Square head set screw (2 used)

48. Key

49. Cap screw

50. Spacer

51. Hardened washer (2 used)

52. Lock washer (2 used)

53. Cap screw (2 used)

54. Pump hub

55. Piston pump assembly

56. Key

Greensmaster 3150Page 3 -- 6Engine

Page 23

Engine Removal (Fig. 2)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

11.Carefully move the engine away from the piston

pump until the crankshaft clears the engine hub. Remove the engine from the machine. Locate and retrieve

key (item 48) from crankshaft.

2. Disconnect negative (--) battery cable from battery.

CAUTION

The muffler and exhaust manifold may be hot.

Avoid possible burns, allow exhaust system to

cool before working on the engine.

DANGER

Gasolineisflammable.Use caution whenstoring

or handling it. Do not smoke while filling the fuel

tank. Do not fill fuel tank while engine is running

or in an enclosed area. Always fill fuel tank outside and wipe up any spilled fuel before starting

the engine. Store fuel in a clean, safety--approved container and keep the cap in place. Use

gasoline for the engine only; not for any other

purpose.

3. Close fuel shut--off valve on fuel tank.

1

1. Engine assembly

2. Fuel supply hose

3. Cap screw

4. Support clamp

25 to 38 ft--lb

(34to51N--m)

2

Figure 3

3

6

7

5. Hose clamp

6. Spacer screw

7. Washer

4

3

4

5

Engine

2

4. Removethefuelhosesupportclampanddisconnect

fuelhoseatthefuelpump(Fig.3).Drainany fueltrapped

in the fuel filter and fuel hose into a suitable container.

5. Disconnect the fuel evaporative control system

hoses from engine (see Fuel Evaporative Control System in this section).

6. Disconnect the engine wiring harness (item 29), the

choke control cable, the throttle control cable and the

ground wires (item 11) at the engine.

7. Carefully disconnect extension spring on piston

pump control assembly from spring bracket that is a ttached to engine mount plate (Fig. 4).

8. Loosen the two(2) set screws(item 47) securing the

engine hub (item 41) to the engine shaft.

9. Support the piston pump assembly and remove the

two(2)capscrews(item 53), lockwashers(item52)and

hardened washers (item 51) securing the pump to the

pumpadapter (item 19). Do Not disconnectthe hydraulic hoses or neutral control linkage from the pump.

10.Support the engine assembly and remove the three

(3) engine mount flange nuts (item 7), cap screws (item

1), flat washers (item 2) and spacers (item 3).

5

6

7

1

Figure 4

1. Engine mount plate

2. Spring bracket

3. Lock washer (2 used)

4. Cap screw (2 used)

5. Dampener hose

6. Extension spring

7. Piston pump assembly

Engine Installation (Fig. 2)

1. Make sure that all parts removed from the engine

duringmaintenanceorrebuildingareinstalledto the engine.

2. Apply antiseize lubricant to bore of engine hub.

Place key (item 48) into slot on the engine crankshaft.

Greensmaster 3150 Page 3 -- 7 Engine

Page 24

IMPORTANT: Make sure to not damage engine, fuel

hose, hydraulic hoses, electrical harness, control

cables or other parts while installing the engine.

Makesureenginehubisinpositionbeforeinstalling

the engine mount cap screws.

3. Align the engine hub (item 41) with the engine shaft

and key (item 48). Slide crankshaft into hub and move

engine until the engine mount plate (item 21) is aligned

with the three (3) engine mounts (item 24). Takecare to

notdamage therubber coupling(item 44) duringengine

installation.

4. Install the three (3) engine mount cap screws (item

1), flat washers (item 2), spacers (item 3) and flange

nuts (item 7).

8. Carefully connect extension spring on piston pump

controlassemblytospringbracket thatisattachedtoengine mount plate (Fig. 4).

9. Connect the engine wiring harness (item 29) and

ground wires (item 11) to the engine.

10.Connect and adjust the choke and throttle control

cables.

11.Connect the f uel evaporative control system hoses

to engine (see Fuel Evaporative Control System in this

section).

12.Connect fuel hose to the fuel pump and secure with

hose clamp. Install the fuel hose support clamp.

5. Position the piston pump assembly to the pump

adapter (item 19) and secure with two (2) cap screws

(item53)lock washers (item 52)andhardenedwashers

(item 51).

6. Position engine hub on crankshaft to best align the

rubber coupling.

7. Apply Loctite #242 (or equivalent) to threads of enginehubset screws (item 47).Securehub to crankshaft

with two (2) set screws. Torque set screws from 90 to

110 in--lb (10.2 to 12.4N--m).

13.Secure negative (--) battery cable to battery.

14.Open fuel shut--off valve on fuel tank. Check fuel

hose for leaks.

15.Check engine oil level and adjust if necessary.

16.Start the engine and check for proper engine operation.

Greensmaster 3150Page 3 -- 8Engine

Page 25

This page is intentionally blank.

Engine

Greensmaster 3150 Page 3 -- 9 Engine

Page 26

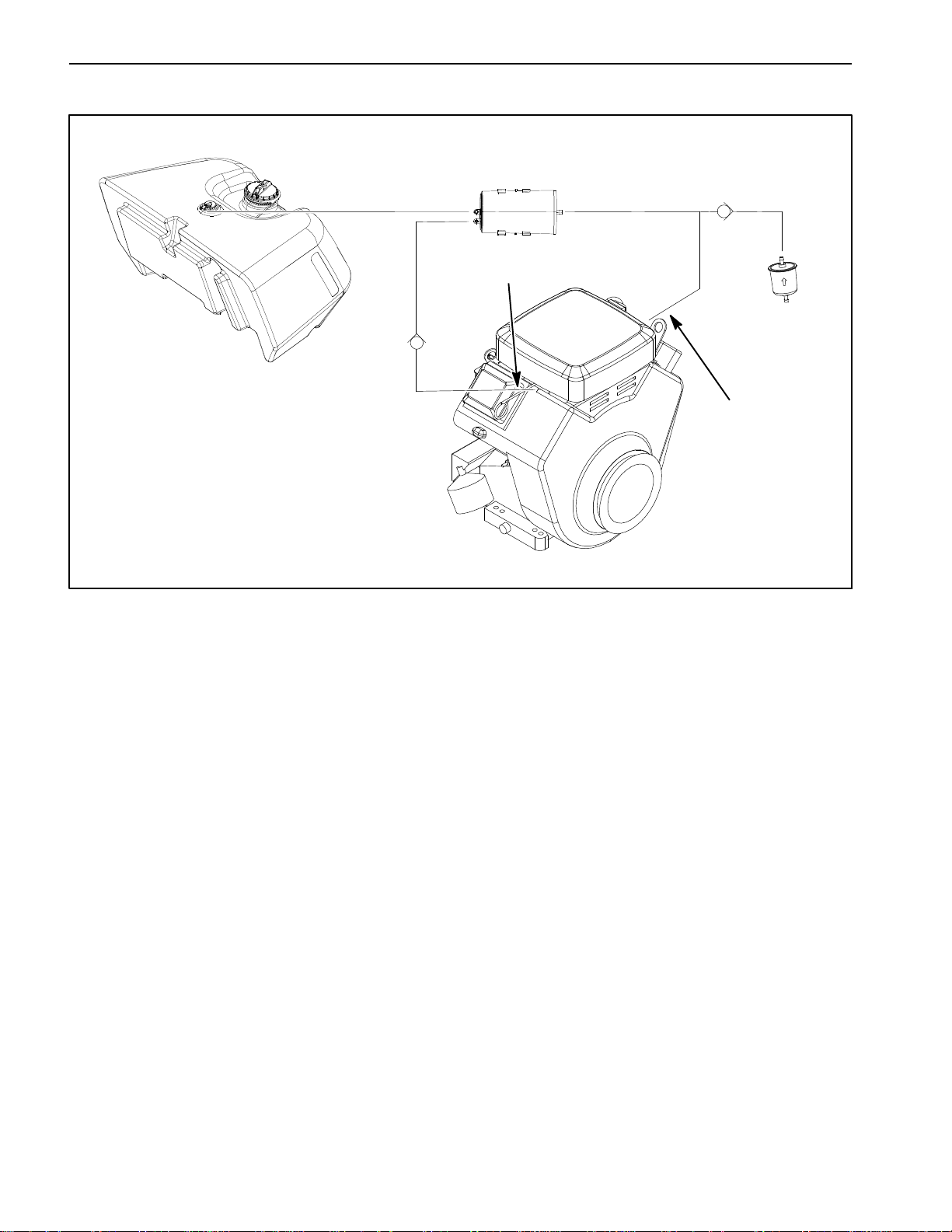

Fuel Evaporative Control System

FUEL

TANK

CHECK

VALVE

TO INTAKE

MANIFOLD

Figure 5

CARBON

CANNISTER

CHECK

VALVE

FRESH AIR

FILTER

TO AIR

CLEANER

ENGINE

Greensmaster 3150 machines are equipped with a fuel

evaporative control system designed to collect and

store evaporative emissions from the fuel tank. The

evaporate control system uses a carbon cannister to

collect these evaporative emissions. Fuel vapors from

the fuel tank are vented to the canister. Vaporsfrom the

canister are consumed when the engine is running.

The fuel tank on Greensmaster 3150 machines uses a

non--vented fuel cap. Toconnect the tank to the evaporativecontrolsystem,afuel tankventfittingispositioned

inthetop of the tankthatallows tank ventingthroughthe

carbon cannister.

NOTE: If there is restriction in the carbon cannister or

the fuel tank vent fitting, the fuel tank may distort due to

venting issues. If the fuel tank returns to it’s normal

shape when the fuel cap is removed, restriction in the

evaporative control system is likely.

The carbon canister is mounted on the hydraulic leak

detector tank (Fig. 6). The evaporative system includes

two(2)connections totheengine:onetotheintakemanifold and the second to the air cleaner base. Venting

hose assemblies (purgehose assembly and t--hose assembly) include check valves in two (2) locations as

showninFigure5.

NOTE: The purge hose assembly (item 5 in Fig. 6) and

teehoseassembly(item10inFig.6)bothincludea

check valve asa componentof t he hose assembly.The

check valve is not available as a separate part. To ensureproperoperationof check valves, donot attempt to

remove them from the hose assembly.If either of these

hose assemblies is removed, make sure that they are

correctly installed to ensure proper operation of the

evaporative control system.

Greensmaster 3150Page 3 -- 10Engine

Page 27

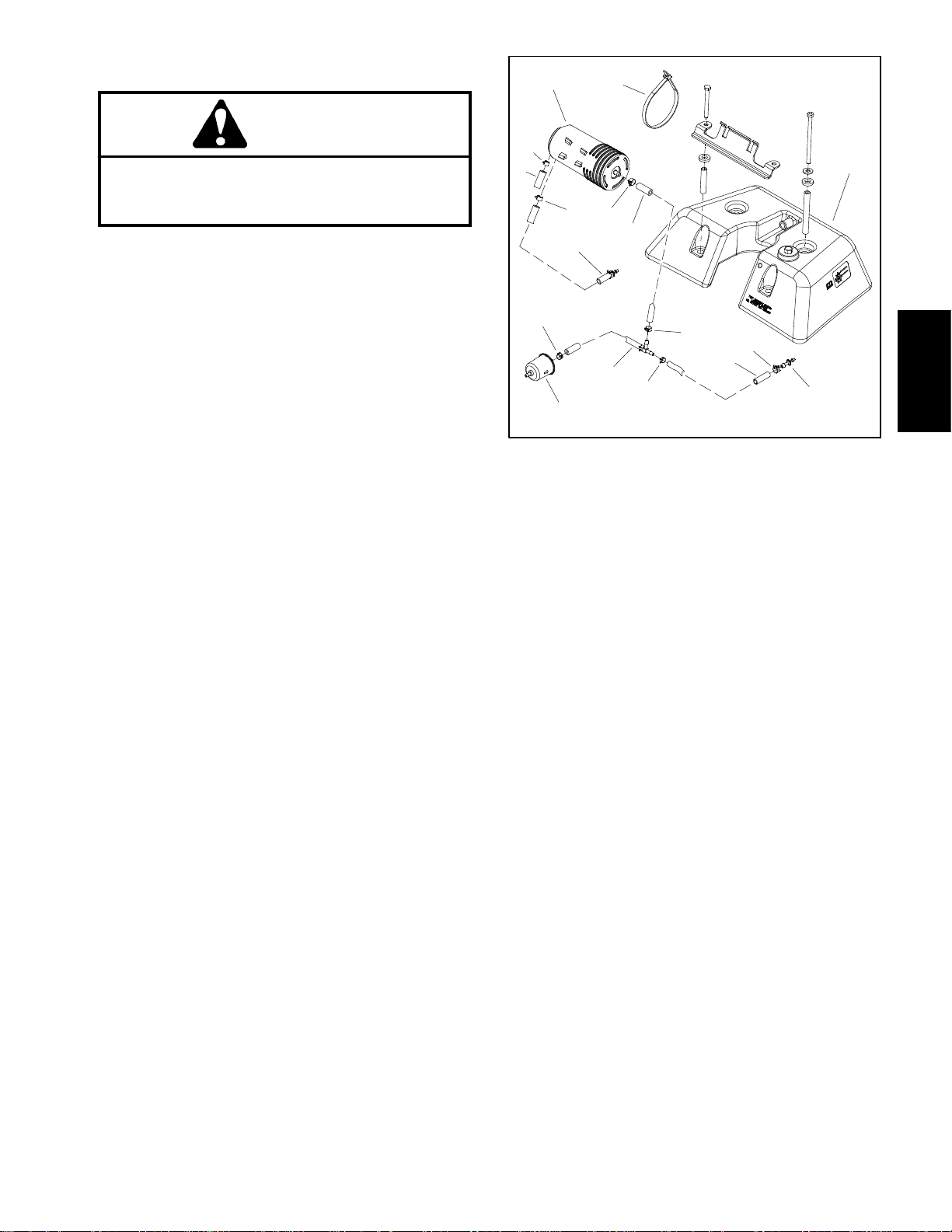

Disassembly (Fig. 6)

DANGER

Gasolineisflammable.Use caution whenstoring

or handling it. Wipe up any spilled fuel before

starting the engine.

1. Inspect carbon cannister and attached hoses for

damageorobviousleaks. Adamagedorleakingcannister should be replaced.

2. Remove components as needed using Figure 6 as

a guide.

A. If either purgehose assembly(item 5) or T--hose

assembly (item 10) is to be removed, label ends of

hose for assembly purposes. Both of these assembliesincludea check valve so direction ofinstallation

is important for correct operation of the evaporative

controlsystem. The check valveisnot available as a

separatepartsohose assembly replacement is necessary if the check valve or hose is faulty. To ensure

proper operation of check valves, do not attempt to

remove them from the hose assembly.

2

6

7

4

11

1. Leak detector tank

2. Carbon cannister

3. Cable tie (2 used)

4. Hose clamp

5. Purge hose assembly

6. Hose clamp

7. Hose (to fuel tank vent)

3

4

8

5

9

10

4

8

4

12

Figure 6

8. Hose clamp

9. Hose (to t--fitting)

10. T--hose assembly

11. Fresh air filter

12. Hose (to air cleaner)

13. Barbed fitting

13

1

Engine

Assembly

1. Install all removed components using Figure 6 as a

guide.

A. If either purgehose assembly(item 5) or T--hose

assembly (item 10) was removed, make sure that

installation is correct.

B. Make sure that fuel hoses are not kinked after

installation.Also,secureallhoseswithhoseclamps.

Greensmaster 3150 Page 3 -- 11 Engine

Page 28

This page is intentionally blank.

Greensmaster 3150Page 3 -- 12Engine

Page 29

Table of Contents

Chapter 4

Hydraulic System

SPECIFICATIONS 2............................

GENERAL INFORMATION 3.....................

Operator’s Manual 3...........................

Check Hydraulic System Fluid 3.................

Towing Traction Unit 4.........................

Hydraulic Hoses 4.............................

Hydraulic Hose and Tube Installation (O--Ring

Face Seal Fitting) 5..........................

Hydraulic Fitting Installation (SAE Straight Thread

O--Ring Fitting into Component Port) 6.........

HYDRAULIC SCHEMATIC 8.....................

HYDRAULIC FLOW DIAGRAMS 10...............

Traction Forward and Reverse 10................

Raise and Lower Cutting Units 12................

Mow and Backlap 14...........................

Right and Left Turn 16.........................

SPECIAL TOOLS 18............................

TROUBLESHOOTING 21........................

General Hydraulic System Problems 21..........

Traction Circuit Problems 22...................

Mow Circuit Problems 23......................

Lift/Lower Circuit Problems 24..................

Steering Circuit Problems 25...................

TESTING 26...................................

Precautions for Hydraulic T esting 26.............

Charge Relief Valve Pressure Test 28............

Wheel Motor Efficiency Test 30..................

Piston (Traction) Pump Flow Test 32.............

Gear Pump (Rear Section) Flow Test 34..........

Implement Relief Valve Pressure Test 36.........

Lower Cutting Units Relief Valve (R2)

Pressure Test 38.............................

Gear Pump (Front Section) Flow Test 40.........

Mow Circuit Relief Valve (S1R1) Pressure Test 42.

Reel Motor Case Drain Flow Test 44.............

Steering Control V alve Test 46..................

ADJUSTMENTS 49.............................

Adjust Manifold Relief Valves (R2) 49............

SERVICE AND REPAIRS 50.....................

General Precautions for Removing and

Installing Hydraulic System Components 50.....

Flush Hydraulic System 51......................

Filtering Closed--Loop Traction Circuit 52.........

Hydraulic System Start--up 53...................

Gear Pump 54................................

Gear Pump Service 56.........................

Piston (Traction) Pump 60......................

Piston (Traction) Pump Service 64...............

Piston Pump Crush Ring Replacement 66........

Front Wheel Motors 68.........................

Rear Wheel Motor (Optional 3WD) 70............

eel Motor Service 72........................

Wh

Cutting Reel Motors 74.........................

Cutting Reel Motor Service 78...................

Front Lift Cylinders 82..........................

Center Lift Cylinder 84.........................

Lift Cylinder Service 86.........................

Hydraulic Manifold 88..........................

Hydraulic Manifold Service 90...................

Steering Control Valve 94.......................

Steering Control Valve Service 96...............

Steering Cylinder 98...........................

Steering Cylinder Service 100...................

Leak Detector 102.............................

Hydraulic Reservoir 106........................

EATON, MEDIUM DUTY PISTON PUMP, REPAIR

INFORMATION, MODEL 70160 VARIABLE DISPLACEMENT PISTON PUMP

PARKER TORQMOTOR

(TC, TB, TE, TJ, TF, TG, TH and TL SERIES)

SAUER/DANFOSS STEERING UNIT TYPE OSPM

SERVICE MANUAL

TM

SERVICE PROCEDURE

System

Hydraulic

Greensmaster 3150 Hydraulic SystemPage 4 -- 1

Page 30

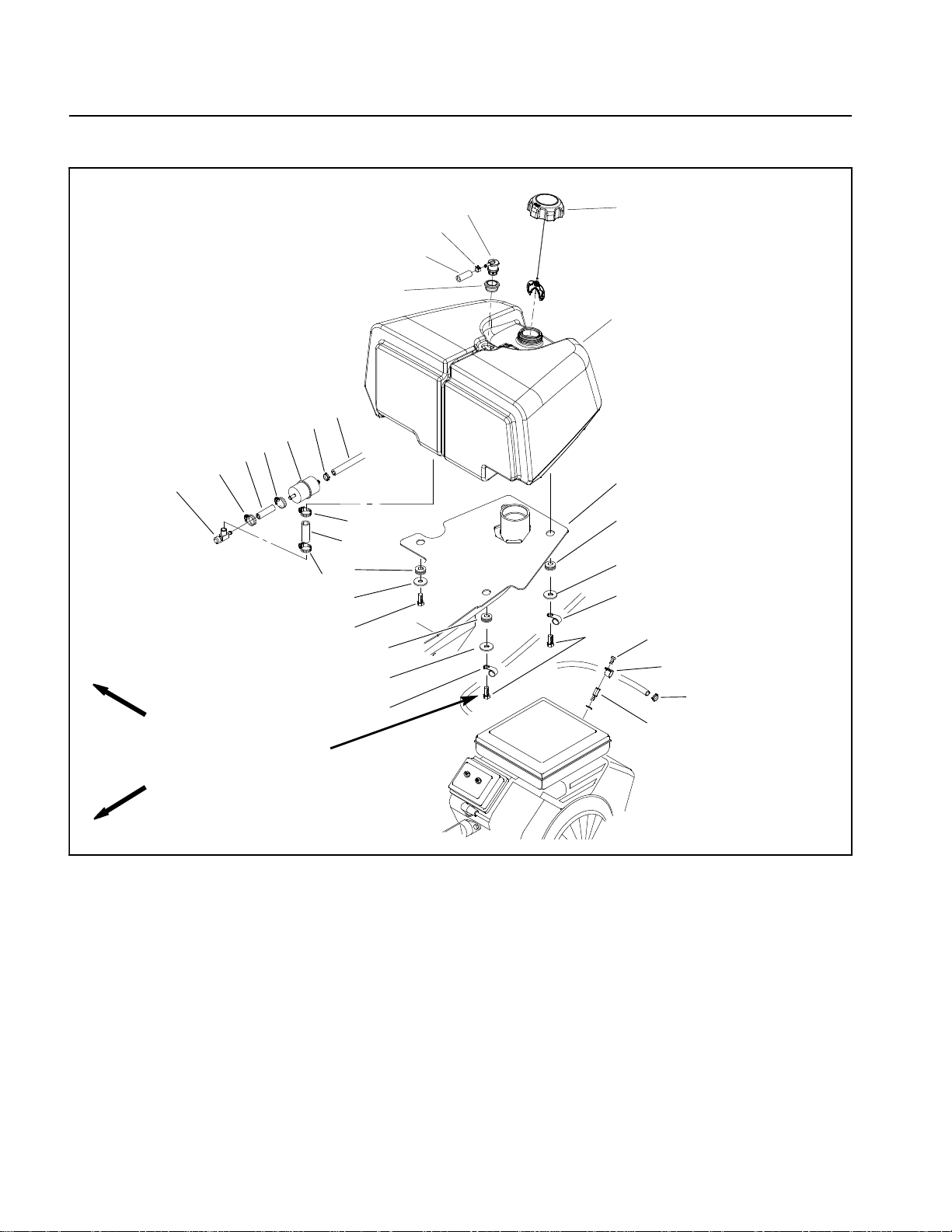

Specifications

Item Description

Piston (Traction) Pump Variabledisplacement piston pump

Maximum Pump Displacement (per revolution) 1.24 in

Charge Pressure 110to150PSI(8to10bar)

Gear Pump 2 section, positive displacement gear pump

Front Section (cutting reels) Displacement (per revolution) 0.58 in

Rear Section (steering/lift) Displacement (per revolution) 0.33 in

Front Wheel Motors Orbital rotor motor

Displacement (per revolution) 10.3 in

Rear Wheel Motor (Optional 3WD Kit) Orbital rotor motor

Displacement (per revolution) 20.6 in

Cutting Reel Motor Gear motor

Displacement (per revolution) 0.73 in

Steering Control Valve Distributor valve with rotary meter

Implement (Steering and Lift) Relief Pressure 1160PSI (80 bar) above Charge Pressure

Hydraulic Manifold Relief Valves

Mow Circuit (S1R1) 3000 PSI (207 bar)

Cutting Unit Lower (R2) 400 PSI (28 bar) above Charge Pressure

Hydraulic Filter Spin--on cartridge type

3

(20.3 cc)

3

(9.5 cc)

3

(5.4 cc)

3

(169 cc)

3

(337 cc)

3

(12 cc)

Hydraulic Oil See Operator’s Manual

Hydraulic Reservoir Reservoir (with leak detector) capacity 8.5 gal. U.S. (32.2 L)

Greensmaster 3150Hydraulic System Page 4 -- 2

Page 31

General Information

Operator’s Manual

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervalsforyourGreensmaster3150.Refer to thatpublication for additional information when servicing the

machine.

Check Hydraulic System Fluid

The hydraulic system on the Greensmaster 3150 is designed to operate on high quality hydraulic fluid. Refer

to the Operator’s Manual for hydraulic fluid recommendations.

IMPORTANT: Check level of hydraulic fluid before

engine is first started and daily thereafter. Do not

overfill hydraulic reservoir.

2

NOTE: If changing from one type of hydraulic fluid to

another, be certain to remove all the old fluid from the

system, as some fluids are incompatible with others.

IMPORTANT: Use only types of hydraulic fluids

specifiedintheOperator’sManual. Otherfluidsmay

cause system damage.

NOTE: Ared dyeadditive for the hydraulicsystem fluid

is available in 2/3 oz bottles. One bottle is sufficient for

4 to 6gallons of hydraulicfluid. Order PartNo. 44--2500

from your Authorized Toro Distributor.

1

Figure 1

1. Sight window 2. Hydraulic oil cap

System

Hydraulic

Greensmaster 3150 Hydraulic SystemPage 4 -- 3

Page 32

Towing Traction Unit

In case of emergency, the Greensmaster 3150 can be

towed for a short distance. However,Toro does not recommend this as a standard practice.

IMPORTANT: Do not tow the machine faster than 2

to 3 mph because drive system may be damaged. If

machine must be moved a considerable distance,

transport it on a truck or trailer.

1

1. Locate by--pass valve on the rear side of the piston

pump.Rotatevalve90

2. Before starting engine,close by--pass valve byrotating it back 90

not start engine when the valve is open.

o

so the slot in the valve is horizontal. Do

o

sotheslotinthevalveisvertical.

Hydraulic Hoses

Hydraulichoses a re subject to extreme conditions such

aspressure differentialsduring operation and exposure

to weather, sun, chemicals, very warm storage conditionsormishandlingduringoperationandmaintenance.

These conditions can cause hose damage and deterioration. Some hoses are more susceptible to these

conditions than others. Inspect all machine hydraulic

hoses frequently for signs of deterioration or damage:

Hard, cracked, cut, abraded, charred, leaking or

otherwise damaged hose.

Kinked, crushed, flattened or twisted hose.

Blistered, soft, degraded or loose hose cover.

Cracked, damaged or badly corroded hose fittings.

When replacing a hydraulic hose, be sure that the hose

is straight (not twisted) before tightening the fittings.

This can be done by observing the imprint (layline) on

thehose. Usetwo wrenches; hold the hosestraight with

one wrench and tighten the hose swivel nut onto the fitting with the other wrench (see Hydraulic Hose and

Tube Installation in this section). If the hose has an elbowatoneend,tightentheswivelnut on that end before

tightening the nut on the straight end of the hose.

2

Figure 2

1. Piston pump 2. By--pass valve

WARNING

Beforedisconnecting or performing any work on

hydraulic system, relieve all pressure in system

(seeRelieving Hydraulic System Pressure in this

section).

Keepbodyand handsawayfrompin holeleaksor

nozzles that eject hydraulic fluid under high

pressure. Use paper or cardboard, not hands, to

search for leaks. Hydraulic fluid escaping under

pressure can have sufficient force to penetrate

the skin and cause serious injury. If fluid is injected into the skin, it must be surgically removed within a few hours by a doctor familiar

withthistypeofinjury.Gangrenemayresultfrom

such an injury.

For additional hydraulic hose information, refer to Toro

Service Training Book, Hydraulic Hose Servicing (Part

Number 94813SL).

Greensmaster 3150Hydraulic System Page 4 -- 4

Page 33

Hydraulic Hose and Tube Installation (O --Ring Face Seal Fitting)

1. Make sure threads andsealing surfaces ofthe hose/

tube and the fitting are free of burrs, nicks, scratches or

any foreign material.

2. Asa preventative measure againstleakage,it is recommended that the face seal O--ring be replaced any

time the connection is opened. Make sure the O--ring is

installedandproperly seatedinthefittinggroove.Lightly

lubricate the O--ring with clean hydraulic oil.

3. Place the hose/tube against the fitting body so that

theflatfaceof the hose/tubesleevefullycontactstheO-ring in the fitting.

4. Thread the swivel nut onto the fitting by hand. While

holding the hose/tube with a wrench, use a torque

wrench to tighten the swivel nut to the recommended

installation torque shown in Figure 5. This tightening

process will require the use of an offset wrench (e.g.

crowfoot wrench). Use of an offset wrench will affect

torque wrench calibration due to the effective length

change of the torque wrench. Tightening torque when

usingatorque wrenchwithanoffsetwrenchwillbelower

than the listed installation torque (see Using a Torque

Wrench with an Offset Wrench in the Torque Specificationssection of Chapter 2 -- Product Records and Maintenance).

C. Useasecondwrenchtotightenthenuttothecorrect Flats From Wrench Resistance (F.F.W.R.). The

markingsonthenutandfittingbody willverifythatthe

connection has been properly tightened.

Size F.F.W.R.

4 (1/4 in. nominal hose or tubing) 1/2 to 3/4

6 (3/8 in.) 1/2 to 3/4

8 (1/2 in.) 1/2 to 3/4

10 (5/8 in.) 1/2 to 3/4

12 (3/4 in.) 1/3 to 1/2

16 (1 in.) 1/3 to 1/2

Swivel Nut

Tubeor Hose

O--ring

Fitting Body

Figure 3

System

Hydraulic

5. If a torque wrench is not available or if space at the

swivelnutpreventsuseof a torque wrench, an alternate

method of assembly is the Flats From Wrench Resist-

Mark Nut

and Fitting

Body

Final

Position

ance (F.F.W.R.) method (Fig. 2).

A. Usingawrench,tightenthe swivel nut onto the fittinguntillight wrench resistance is reached(approximately 30 in--lb).

B. Mark the swivel nut and fitting body. Hold the

hose/tube with a wrench to prevent it from turning.

AT WRENCH RESISTANCE

Extend Line

Figure 4

Fitting Dash Size Hose/Tube Side Thread Size Installation Torque

4 9/16 -- 18 18to22ft--lb(25to29N--m)

6 11/16 -- 16 27to33ft--lb(37to44N--m)

8 13/16 -- 16 37to47ft--lb(51to63N--m)

10 1--14 60 to 74 ft--lb (82 to 100 N--m)

12 13/16--12 85to105ft--lb(116to142N--m)

16 17/16--12 110to136ft--lb(150to184N--m)

Initial

Position

AFTER TIGHTENING

20 1 11/16 -- 12 140 to 172 ft--lb (190 to 233 N--m)

Figure 5

Greensmaster 3150 Hydraulic SystemPage 4 -- 5

Page 34

Hydraulic Fitting Installation (SAE Straight Thread O--Ring Fitting into Component Port)

Non--Adjustable Fitting (Fig. 6)

1. Make sure all threads and sealing surfaces of fitting

and component port are free of burrs, nicks, scratches

or any foreign material.

2. As a preventative measure against leakage, it isrecommended that the O--ring be replaced any time the

connection is opened.

3. Lightly lubricate the O--ring with clean hydraulic oil.

Fittingthreadsshould becleanwithnolubricantapplied.

IMPORTANT: Before installing fitting into port, determine port material. If fitting is to be installed into

an aluminum port, installation torque is reduced.

4. Install the fitting into the port. Then, use a torque

wrench and socket to tighten the fitting to the recommended installation torque shown in Figure 7.

NOTE: Use of an offset wrench (e.g. crowfoot wrench)

will affect torque wrench calibration due to the effective

length change of the torque wrench. Tightening torque

when using a torque wrench with an offset wrench will

be less than the recommended installation torque. See

UsingaTorqueWrenchwithanOffsetWrenchinthe

Torque Specifications section of Chapter 2 -- Product

RecordsandMaintenancetodeterminenecessaryconversion information.

5. If a torque wrench is not available, or if space at the

portprevents use of a torque wrench,analternatemethod of assembly is the Flats From Finger Tight (F.F.F.T.)

method.

A. Install the fitting into the port and tighten it down

full length until finger tight.

B. If port material is steel, tighten the fitting to the

listed F.F.F.T. If port material is aluminum, tighten fitting to 60% of listed F.F.F.T.

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00+

6 (3/8 in.) 1.50 +

8 (1/2 in.) 1.50 +

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

Fitting

O--ring

0.25

0.25

0.25

0.25

0.25

0.25

Figure 6

Fitting

Dash Size

Fitting Port Side

Thread Size

Installation Torque Into

Steel Port

Installation Torque Into

Aluminum Port

4 7/16 -- 20 15to19ft--lb(21to25N--m) 9to11ft--lb(13to15N--m)

5 1/2 -- 20 18to22ft--lb(25to29N--m) 11 to 15 ft--lb (15 to 20 N--m)

6 9/16 -- 18 34to42ft--lb(47to56N--m) 20to26ft--lb(28to35N--m)

8 3/4 -- 16 58to72ft--lb(79to97N--m) 35to43ft--lb(48to58N--m)

10 7/8 -- 14 99to121ft--lb(135to164N--m) 60 to 74 ft--lb (82 to 100 N--m)

12 11/16--12 134to164ft--lb(182to222N--m) 81 to 99 ft--lb (110 to 134 N--m)

14 13/16--12 160to196ft--lb(217to265N--m) 96to118ft--lb(131to160N--m)

16 15/16--12 202to248ft--lb(274to336N--m) 121to149ft--lb(165to202N--m)

20 15/8--12 247to303ft--lb(335to410N--m) 149to183ft--lb(202to248N--m)

Figure 7

Greensmaster 3150Hydraulic System Page 4 -- 6

Page 35

Adjustable Fitting (Fig. 8)

1. Make sure all threads and sealing surfaces of fitting

and component port are free of burrs, nicks, scratches

or any foreign material.

2. Asa preventative measure againstleakage,it is recommended that the O--ring be replaced any time the

connection is opened.

3. Lightly lubricate the O--ring with clean hydraulic oil.

Fittingthreadsshouldbe clean withnolubricantapplied.

4. Turnback the lock nut as far aspossible. Make sure

the back up washer is not loose and is pushed up as far

aspossible(Step1inFigure9).

IMPORTANT: Before installing fitting into port, determine port material. If fitting is to be installed into

an aluminum port, installation torque is reduced.

Lock Nut

Back--up Washer

O--ring

Figure 8

5. Install the fitting into the port and tighten finger tight

until the washer contacts the face of the port (Step 2).

6. Toputthefittingin the desired position, unscrew it by

the required amount, but no more than one full turn

(Step 3).

7. Hold the fitting in the desired position with a wrench

and use a torque wrench to tighten the fitting to the recommended installation torque shown in Figure 7. This

tightening process will require the use of an offset

wrench (e.g. crowfoot wrench). Use of an offset wrench

will affect torque wrench calibration due to the effective

length change of the torque wrench. Tightening torque

when using a torque wrench with an offset wrench will

be lower than the listed installation torque (see Using a

Torque Wrench with an Offset Wrench in the Torque

Specifications section of Chapter 2 -- Product Records

and Maintenance).

8. If a torque wrench is not available, or if space at the

portpreventsuseofatorquewrench, an alternatemethod of assembly is the Flats From Finger Tight (F.F.F.T.)

method.Holdthefittinginthedesiredpositionwitha

wrench and, if port material is steel, tighten the lock nut

withasecondwrenchtothelistedF.F.F.T(Step4).Ifport

material is aluminum, tighten fitting to 60% of listed

F.F.F.T.

Step 3Step 1

Step 2 Step 4

Figure 9

System

Hydraulic

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00+

6(3/8in.) 1.50+

8(1/2in.) 1.50+

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

0.25

0.25

0.25

0.25

0.25

0.25

Greensmaster 3150 Hydraulic SystemPage 4 -- 7

Page 36

Hydraulic Schematic

VALVE

STEERING

Right

Motor

10.3

10.3

Left

Motor

3WD KIT

OPTIONAL

20.6

Steering Cylinder

L3A L3BL2B L1B

L2A

4.5

0.055

0.030

FC2

1.5” Bore

0.75” Rod

6.19” Stroke

LR

Raise

CU #3

2.0” Bore

0.75” Rod

1.88” Stroke

CU #1

0.75” Rod

1.50” Bore

3.38” Stroke

Lower

1160 PSI

S4

R2

400 PSI

PET

ST

S2

S3

2850/1650

ENGINE RPM

BYPASS

VALVE

A

TOP

PORT

TRANSPORT = 14.1 GPM

PT

4.0 GPM

TRACTION PUMP

P2

7.0 GPM

3000

PSI

3000

PSI

1.24

.33 .58

PUMP

GEAR

B

BOTTOM

PORT

70 to

100 PSI

110 to

150 PSI

G2

MB

MA L1A

0.055

MR

550 PSI

PRV

(SW)

SWITCH

BACKLAP

OR1

FC1

T

LC

0.013

S1R1

OR2

0.060

P1

G1

CU #2

2.0” Bore

0.75” Rod

1.88” Stroke

Center

Reel (#1)

.73

.73

Right Front

Reel (#3)

de--energized

All solenoids are shown as

Hydraulic Schematic

Greensmaster 3150

.73

Reel (#2)

Left Front

25 PSI

FILTER

OPTIONAL

OIL COOLER

SUCTION

STRAINER

IN

LEAK DETECTOR

LEAK

OUT

VOLUME

DETECTOR

TANK

EXPANSION

BREATHER

Greensmaster 3150Hydraulic System Page 4 -- 8

Page 37

This page is intentionally blank.

System

Hydraulic

Greensmaster 3150 Hydraulic SystemPage 4 -- 9

Page 38

Hydraulic Flow Diagrams

Steering Cylinder

1.5” Bore

0.75” Rod

6.19” Stroke

LR

4.5

1160 PSI

PET

VALVE

STEERING

TOP

Motor

Right

10.3

10.3

Left

Motor

2850/1650

ENGINE RPM

BYPASS

VALVE

A

PORT

3WD KIT

OPTIONAL

20.6

B

BOTTOM

PORT

70 to

100 PSI

TRANSPORT = 14.1 GPM

Raise

Lower

L3A L3BL2B L1B

L2A

MB

MA L1A

0.055

0.030

FC2

0.055

MR

BACKLAP

550 PSI

SWITCH

S4

R2

400 PSI

PRV

(SW)

CU #3

2.0” Bore

0.75” Rod

1.88” Stroke

CU #1

0.75” Rod

1.50” Bore

3.38” Stroke

de--energized.

All solenoids are shown as

Right Front

Reel (#3)

CU #2

2.0” Bore

0.75” Rod

1.88” Stroke

Center

Reel (#1)

.73

.73

.73

Reel (#2)

Left Front

ST

PT

4.0 GPM

TRACTION PUMP

S2

S3

P2

G2

T

0.013

OR2

LC

S1R1

0.060

P1

G1

OR1

FC1

7.0 GPM

25 PSI

FILTER

3000

PSI

3000

PSI

110 to

150 PSI

1.24

.33 .58

PUMP

GEAR

OPTIONAL

OIL COOLER

SUCTION

STRAINER

Greensmaster 3150

Traction Forward

IN

OUT

LEAK

VOLUME

DETECTOR

High Pressure

Low Pressure (Charge)

Return or Suction

Flow

LEAK DETECTOR

TANK

EXPANSION

BREATHER

Greensmaster 3150Hydraulic System Page 4 -- 10

Page 39

Traction Forward a nd Reverse

Forward

The piston (traction) pump is driven directly by the engine.Thetractioncircuitofthe hydraulic system acts essentiallyasaclosedloop.Takingitssuctiondirectlyfrom

thereturnsideofthewheelmotorsofthetractioncircuit,

the piston pump supplies oil flow to the wheel motors

through the supply side of the traction circuit.

Withtheengine runningandtraction pedal intheneutral

position, the piston pump supplies no flow to the wheel

motors. When the traction pedal is pressed to the forward position, the linkage from the pedal positions the

swash plate in the piston pump so oil flows out the top

port of the pump. Oil flow out of the top port goes to the

wheel motors and turns them in the forward direction.

Oilflowing out of thewheel motors returns to thebottom

port of the piston pumpand is continuously pumped out

the top port as long as the traction pedal is pressed for

the forward direction.

Hydraulic oil is supplied to the traction charge circuit

from the rear gear pump section though the steering

valve,control manifold and backthroughthe charge circuit check valves in the piston (traction) pump. This oil

replaces oil losses f rom flow through the internal case

drain, shuttle valve andsmall amounts of traction circuit

leakage. Charge circuit pressure is maintained by the

charge relief valve that is attached to the piston pump

back plate.

Reverse

The traction circuit operates essentially the same in reverse as it does in the forward direction. However, the

flow through the circuit is reversed.

Withtheenginerunningandtractionpedalintheneutral

position, the piston pump supplies no flow to the wheel

motors. When the traction pedal is pressed to t he reverse position, the linkage from the pedal positions the

swashplateinthepistonpumpsooilflowsoutthebottomportofthepump. Oilflowoutofthebottomportgoes

tothe wheel motors andturnsthem in the reversedirection.

Oilflowingoutofthewheelmotorsreturns to the top port

of the piston pump and is continuously pumped out the

bottom port as long as the traction pedal is pressed for

the reverse direction.

Thechargecircuitfunctions the same in reverse as it

does in the forward direction.

Traction Circuit Cooling

The piston pump includes a shuttle valve that bleeds off

asmallamountof hydraulicfluidforcoolingoftheclosed

looptraction circuit. This valve allowsa small amountof

hydraulic oil to pass from the low pressure side of the

traction circuit while operating the traction unit in either

direction. A relief valve in the piston pump back plate

prevents shuttle valve bleed off until the relief valve

opens(70 to100 PSI / 5to 7 bar). The charge circuit replenishes oil that is bled from the traction circuit by the

shuttle valve.

System

Hydraulic

NOTE: Theshuttlevalveassemblyislocatedinthepiston pump back plate. Access to the shuttle valve requires removal of the back plate from the piston pump.

Greensmaster 3150 Hydraulic SystemPage 4 -- 11

Page 40

Motor

Right

10.3

10.3

1.5” Bore

0.75” Rod

6.19” Stroke

Steering Cylinder

LR

4.5

1160PSI

PET

Left

Motor

2850/1650

ENGINE RPM

BYPASS

VALVE

A

TOP

PORT

3WD KIT

OPTIONAL

20.6

B

BOTTOM

PORT

SolenoidsS2andS3areshown

in the energized position.

Right Front

VALVE

STEERING

TRANSPORT = 14.1 GPM

All other solenoids are shown

Reel (#3)

as de--energized.

CU #3

2.0” Bore

0.75” Rod

1.88” Stroke

CU #1

0.75” Rod

1.50” Bore

3.38” Stroke

CU #2

2.0” Bore

0.75” Rod

1.88” Stroke

.73

Raise

Lower

0.055

L3A L3BL2B L1B

0.030

FC2

L2A

0.055

Center

Reel (#1)

.73

.73

Reel (#2)

Left Front

MB

MA L1A

MR

BACKLAP

550 PSI

SWITCH

S4

R2

400 PSI

PRV

(SW)

OR1

FC1

0.013

OR2

ST

PT

4.0 GPM

TRACTION PUMP

S2

S3

P2

G2

T

LC

S1R1

0.060

P1

G1

7.0 GPM

3000

25 PSI

FILTER

70 to

100 PSI

3000

PSI

PSI

110 to

150 PSI

1.24

.33 .58

PUMP

GEAR

OPTIONAL

OIL COOLER

SUCTION

STRAINER

Greensmaster 3150

High Pressure

Raise Cutting Units

Low Pressure (Charge)

IN

OUT

LEAK

VOLUME

DETECTOR

Return or Suction

Flow

LEAK DETECTOR

TANK

EXPANSION

BREATHER

Greensmaster 3150Hydraulic System Page 4 -- 12

Page 41

Raise and Lower Cutting Units

The t andem gear pump is directly coupled to the piston

(traction) pump. The rear gear pump section supplies

hydraulic flow for the steering circuit (priority flow), for

raisingand lowering thecutting units andfor the traction

charge circuit. The gear pumptakes itssuction from the

hydraulic reservoir. Maximum circuit pressure of 1160

PSI (80 bar) is limited by the relief valve located in the

steering valve.

During cutting unit hold (not raising or lowering) conditions,flowfromthereargearpumpsectionisby--passed

through the steering valve and de--energized solenoid

valve (S2) in the hydraulic manifold directly to the traction charge circuit. Flow in excess of charge circuit requirements then returns to the gear pump inlet.

Raise Cutting Units

When the cutting units are to be raised, hydraulic manifoldsolenoidvalve (S2) is energized andblocksflowdirectly to the traction charge circuit. Flow is directed to

energizedsolenoidvalve (S3), whichdirects flow tode-energized solenoid valve (S4) and the lift cylinders. Hydraulic pressure against the cylinder pistons moves

their shafts causing the cutting units to raise. At the

sametime,thepistonspushthehydraulicfluidoutofthe

lift cylinders and back through energized solenoidvalve

(S3) to the charge circuit. Raise speed for the front cutting units is controlled by a 0.055 orifice.A 0.030 orifice

inthereturn line for the centercutting unit allows a slight

delay in raising that cutting unit.

Lower Cutting Units

Circuit operation for lowering the lift cylinders is similar

to raising them. However, the solenoid valve (S3) remains de--energized and solenoid valve (S4) is energized. Flow is reversed to and from the lift cylinders,

lowering the cutting units.

Whenthecuttingunits are to belowered,solenoidvalve

(S2) is energized and blocks flow directly to the traction

charge circuit. Flow is directed to de--energized solenoid valve (S3), which directs flow to the lift cylinders.

Hydraulic pressure against the cylinder pistons moves

their shafts causing the cutting units to lower. At the

sametime,thepistonspushthehydraulicfluidoutofthe

liftcylindersto energized solenoid valve (S4).Flowcontinues back through solenoid valve (S3) to the charge

circuit. Lower speed for the front cutting units is controlled by the 0.055 orifice. A 0.030 orifice and adjustable flow control valve for the center cutting unit allows

a slight delay in lowering that cutting unit.

To control pressure while lowering the cutting units, the

system is equipped with adjustable relief valve (R2) in

the hydraulic manifold.

When solenoid valves (S2) and (S4) de--energize,

spring action returns the valves to their original position

and by--passes flow back to the traction charge circuit

stopping lift cylinder movement.

System

Hydraulic

When solenoid valves (S2) and (S3) de--energize,

spring action returns the valves to their original position

and by--passes flow back to the traction charge circuit

stoppingliftcylindermovement.Theliftcylinderposition

is locked in place since there is no complete circuit of

flow to and from the lift cylinders.

Greensmaster 3150 Hydraulic SystemPage 4 -- 13

Page 42

Motor

Right

VALVE

STEERING

10.3

10.3

Left

Motor

3WD KIT

OPTIONAL

20.6

Steering Cylinder

Solenoid S1R1 is shown

in the energized position.

Lower

L3A L3BL2B L1B

L2A

MB

MA L1A

4.5

0.055

0.030

FC2

0.055

550 PSI

MR

BACKLAP

1.5” Bore

0.75” Rod

6.19” Stroke

All other solenoids are shown

as de--energized.

.73

Right Front

Reel (#3)

LR

Raise

CU #3

2.0” Bore

0.75” Rod

1.88” Stroke

CU #1

0.75” Rod

1.50” Bore

3.38” Stroke

CU #2

2.0” Bore

0.75” Rod

1.88” Stroke

Center

Reel (#1)

.73

.73

Left Front

Reel (#2)

SWITCH

1160 PSI

PET

ST

PT

4.0 GPM

S4

R2

400 PSI

OR1

PRV

(SW)

0.013

OR2

0.060

FC1

S2

S3