Page 1

SINGLE STAGE SNOWTHROWER SERVICE MANUAL

Table Of Contents – Page 1 of 2

ENGINE APPLICATIONS

GENERAL INFORMATION

GENERAL SAFETY INSTRUCTIONS

IDENTIFICATION AND ORDERING

MIXING INSTRUCTIONS FOR GASOLINE AND OIL

PROPER FUEL AND OIL

OFF SEASON STORAGE

CONTROLS/LOCATION AND OPERATION

PRIMER

CHOKE

ON/OFF IGNITION SWITCH

CHECKING THE IGNITION SWITCH

VANE CONTROL - SNOW PUP - SNOWMASTER S-200 - S-620

CHUTE CONTROL

CHUTE ROTATION AND DETENT SYSTEMS

ENGINE REMOVAL AND INSTALLAT I ON

1965 - 1985 MODELS, ENGINE REMOVAL

1965 - 1985 MODELS, ENGINE INSTALLATION

POWERLITE, ENGINE REMOVAL

POWERLITE, ENGINE INSTALLATION

20” CCR, ALL MODELS, ENGINE REMOVAL

20” CCR, ALL MODELS, ENGINE ASSEMBLY

DRIVE SYSTEMS

DRIVE SYSTEM (BELT) SNOWMASTER - S-200, S-620

BELT REPLACEMENT

BELT/PULLEY ALIGNMENT

ADJUSTING PULLEY ALIGNMENT

ENGINE PULLEY REPLACEMENT

ROTOR PULLEY REPLACEMENT

IDLER ARM / IDLER PULLEY REPLACEMENT

ASSEMBLY

20” CCR STYLE IDLER ARM

CCR2000 IDLER ARM REMOVAL

ROTOR BEARING/ ROTOR SHAFT REPLACEMENT

DRIVE SYSTEM (CHAIN) SNOW PUP - S-140

ELECTRIC START SYSTEM

INTRODUCTION

CCR POWERLITE STARTER REMOVAL

CCR 1000/TECUMSEH HSK 635 STARTER REMOVAL

20” CCR/R TEK STARTER REMOVAL

SNOWMASTER 20”, 5200 – 5620/ TECUMSEH AH520 STARTER REMOVAL

STARTER SWITCH WITH RECTIFIER TROUBLESHOOTING

TROUBLESHOOTING

CHECKING THE STARTER SWITCH

STARTER SWITCH INSPECTION

Page 2

SINGLE STAGE SNOWTHROWER SERVICE MANUAL

Table Of Contents – Page 2 of 2

MAINTENANCE

WHEEL BRACKET REPLACEMENT (1975 AND OLDER MODELS)

SCRAPER REPLACEMENT

PADDLE REPLACEMENT - STRAIGHT PADDLE

REPLACING ROTOR BLADES (CURVED ROTOR MODELS)

VANE REPLACEMENT

VANE CONTROL SERVICING ON 14” AND 21” SNOWTHROWERS FROM 1965-1967

VANE CONTROL SERVICING

VANE CONTROL SERVICING: ALL 16” POWERLITE AND 20” SINGLE STAGE SNOWTHROWERS

TROUBLESHOOTING

TROUBLESHOOTING TIPS - FAILURE TO START

OLD FUEL

SPARK PLUGS

THE ENGINE RUNS BUT IT DOES NOT THROW SNOW

GAS POWER SHOVEL

GENERAL INSTRUCTIONS

PERSONAL SAFETY

BEFORE OPERATING

WHILE OPERATING

MAINTENANCE AND STORAGE

IDENTIFICATION AND ORDERING

MIXING INSTRUCTIONS FOR GASOLINE AND OIL

CONTROLS — LOCATION AND OPERATION

PRIMER OPERATION

CHOKE OPERATION

TESTING THE SWITCH

ENGINE OPERATING THEORY

CARBURETOR ADJUSTMENT

CARBURETOR SERVICE

CARBURETOR ASSEMBLY

ENGINE SERVICE

CHECKING FOR SPARK

COMPRESSION TEST

ENGINE REMOVAL

ENGINE SHORT BLOCK

FLYWHEEL REMOVAL

IGNITION TIMING/GOVERNOR

DECARBONING THE EXHAUST PORT AND THE MUFFLER

RECOIL STARTER SERVICING

DRIVE SYSTEM

REMOVING ROTOR

REPLACE SCRAPER

STORAGE

MAINTENANCE RECORD

Page 3

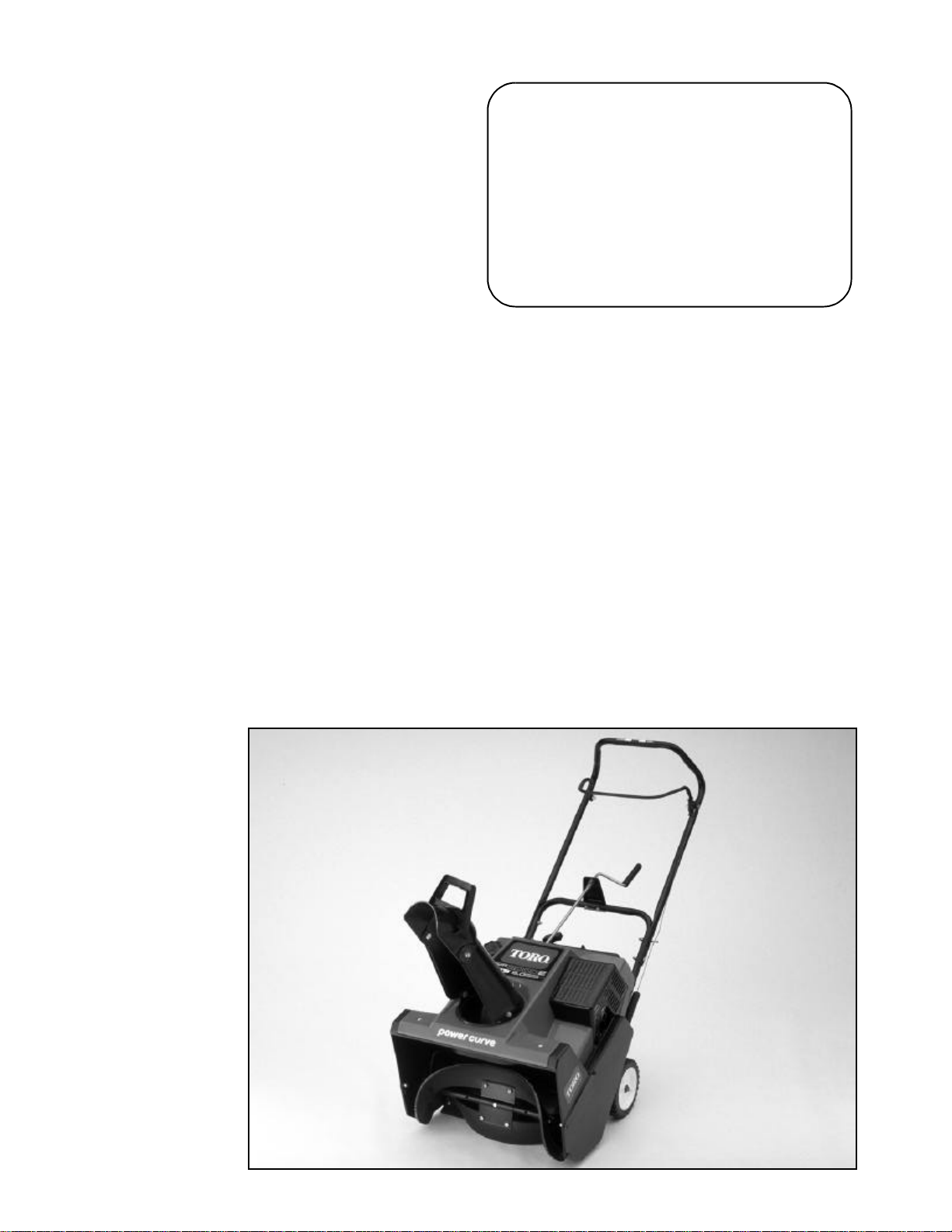

TORO

®

Single Stage

Snowthrower

Service Manual

Page 4

PREFACE

ABOUT THIS MANUAL

This manual was written expressly for the Toro brand single stage snowthrowers. The Toro

Company has made every effort to make the information in this manual complete and correct.

This manual was written with the assumption that the reader has basic mechanical and

electrical knowledge and skills. The book contains material covering snowthrowers built by The

Toro Company from 1965 through 2000, and will be specified for use on machines built after

2000 that are similar in design.

We hope that you find this manual a valuable addition to your service shop. If you have

questions or comments regarding this manual, please contact us at the following address:

The Toro Company

Consumer Service Department

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

The Toro Company reserves the right to change product specifications or this manual without

notice.

COPYRIGHT© – ALL RIGHTS RESERVED

The Toro Company – 2000

Bloomington, MN 55420 – U.S.A.

Page 5

TABLE OF CONTENTS

This book covers a variety of models built over several years. Look in the following Table Of Contents for the

portion of the machine that you wish to work on. Within that section we will cover each of the systems used.

ENGINE APPLICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

GENERAL INFORMATION

General Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

Identification And Ordering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 2

Mixing Instructions For Gasoline And Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 3

Proper Fuel And Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 3

Off Season Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 5

CONTROLS/LOCATION AND OPERATION

Primer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 2

Choke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 3

On/off Ignition Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 3

Checking The Ignition Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 4

Vane Control - Snow Pup - Snowmaster S-200 - S-620 . . . . . . . . . . . . . . . . . . . . . .3 - 5

Chute Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 5

Chute Rotation And Detent Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 6

ENGINE REMOVAL AND INSTALLATION

1965 - 1985 Models, Engine Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

1965 - 1985 Models, Engine Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 3

Powerlite, Engine Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 5

Powerlite, Engine Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 7

20” CCR, All Models, Engine Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 7

20” CCR, All Models, Engine Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 9

Single Stage Snowthrower Service Manual i

Page 6

TABLE OF CONTENTS

DRIVE SYSTEMS

Drive System (Belt) Snowmaster - S-200, S-620 . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

Belt Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 14

Belt/Pulley Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 15

Adjusting Pulley Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 15

Engine Pulley Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 15

Rotor Pulley Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 16

Idler Arm / Idler Pulley Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 17

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 17

20” CCR Style Idler Arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 17

CCR2000 Idler Arm Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 17

Rotor Bearing/ Rotor Shaft Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 18

Drive System (Chain) Snow Pup - S-140 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 19

ELECTRIC START SYSTEM

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 1

CCR Powerlite Starter Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 1

CCR 1000/Tecumseh HSK 635 Starter Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 2

20” CCR/R Tek Starter Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 4

Snowmaster 20”, 5200 – 5620/ Tecumseh AH520 Starter Removal . . . . . . . . . . . . .6 - 6

Starter Switch With Rectifier Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 9

Checking The Starter Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 10

Starter Switch Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 10

ii Single Stage Snowthrower Service Manual

Page 7

TABLE OF CONTENTS

MAINTENANCE

Wheel Bracket Replacement (1975 And Older Models) . . . . . . . . . . . . . . . . . . . . . .7 - 1

Scraper Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 1

Paddle Replacement - Straight Paddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 2

Replacing Rotor Blades (Curved Rotor Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 4

Vane Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 6

Vane Control Servicing On 14” And 21” Snowthrowers From 1965-1967 . . . . . . . . .7 - 7

Vane Control Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 7

Vane Control Servicing: All 16” Powerlite And 20” Single Stage Snowthrowers . . . .7 - 8

TROUBLESHOOTING

Troubleshooting Tips - Failure To Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 - 1

Old Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 - 1

Spark Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 - 3

The Engine Runs But It Does Not Throw Snow . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 - 3

GAS POWER SHOVEL

General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 1

Personal Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 1

Before Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 1

While Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 1

Maintenance And Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 2

Identification And Ordering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 2

Mixing Instructions For Gasoline And Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 3

Controls — Location And Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 5

Single Stage Snowthrower Service Manual iii

Page 8

TABLE OF CONTENTS

Primer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 6

Choke Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 6

Testing The Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 6

Engine Operating Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 7

Carburetor Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 9

Carburetor Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 10

Carburetor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 12

Engine Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 14

Checking For Spark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 15

Compression Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 16

Engine Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 16

Engine Short Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 17

Flywheel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 19

Ignition Timing/Governor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 19

Decarboning The Exhaust Port And The Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 20

Recoil Starter Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 20

Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 21

Removing Rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 22

Replace Scraper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 23

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 23

Maintenance Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 - 28

iv Single Stage Snowthrower Service Manual

Page 9

TABLE OF CONTENTS

ENGINES

Several different engines have been used on the single stage snowthrower product line. Refer to the chart

beginning on page 1 - 1 to determine the engine manufacturer. Engine manuals may be obtained from the

following sources.

Tecumseh Products Co.

900 North St.

Grafton, WI 53024

Tecumseh Engine Models:

• AH520, AH600, HSK600

Toro Engines:

Order the following service manuals through any Authorized Toro Service Dealer:

• Model 38350 Gas Power Shovel (the engine is covered in this book).

• Toro 47P series - Use Toro manual 492-0260.

• Toro R tek (E engine) series - Use Toro manual 492-0647.

Single Stage Snowthrower Service Manual v

Page 10

THIS PAGE INTENTIONALLY LEFT BLANK

vi Single Stage Snowthrower Service Manual

Page 11

ENGINE APPLICATIONS

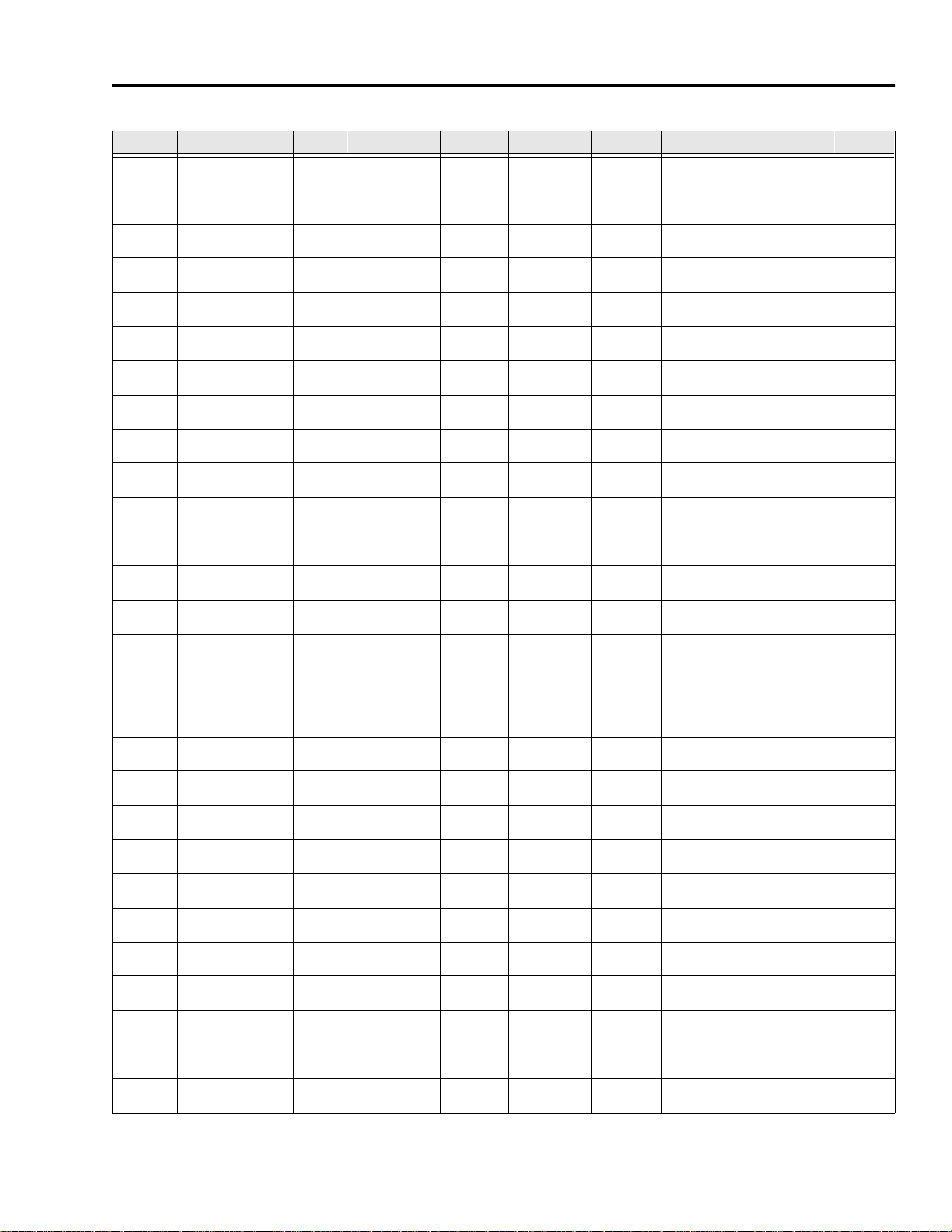

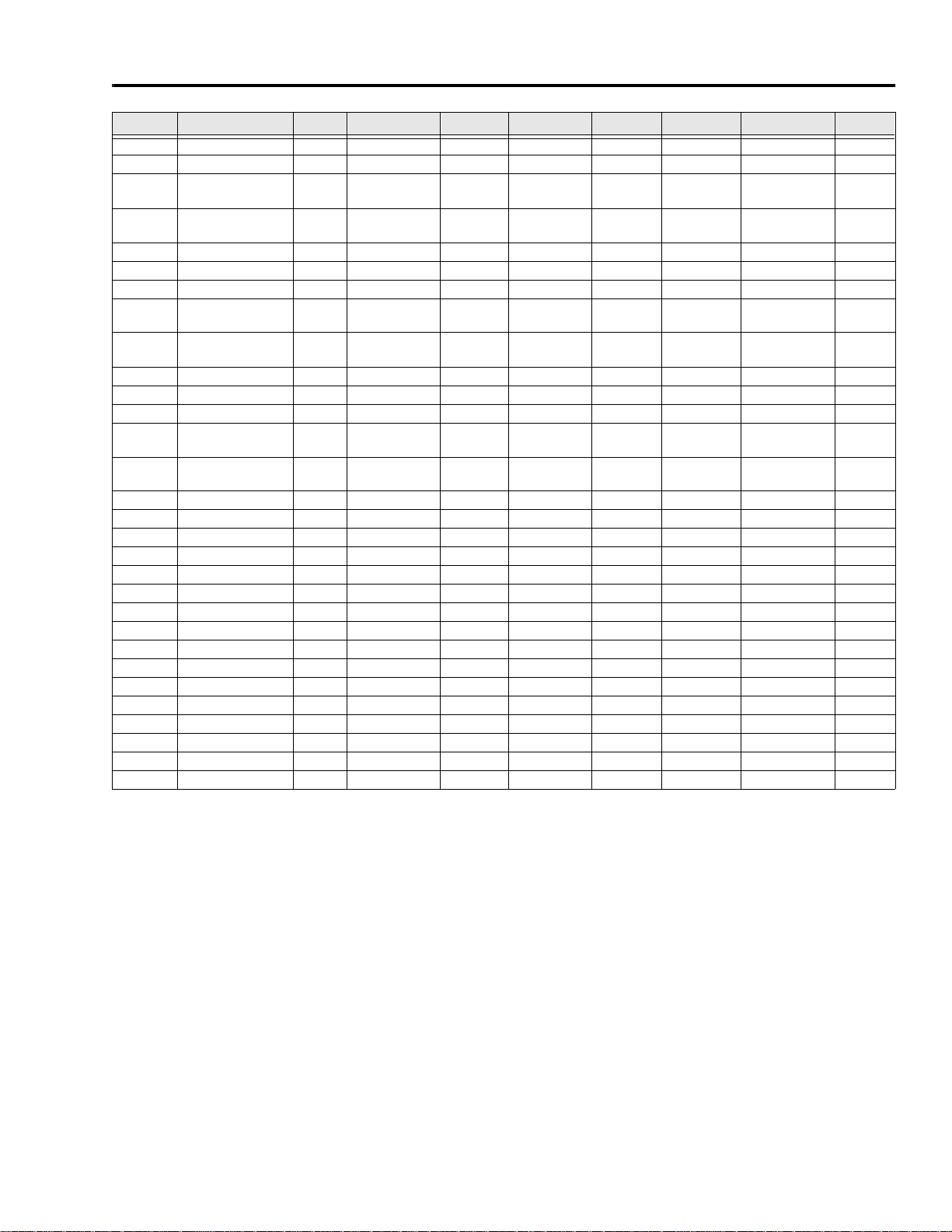

Model # Model Name Width Years of Mfg Eng Mfg Eng Model Mix Ratio Max RPM Spark Plug * Gap (in.)

31405 Snow Pup 14” 1976-1977 Tec. AH520 32:1 4100-4500 Champion

RJ18YC

31410 Snow Pup 14" 1966-1967 Tec. AH520 16:1 4300-4700 Champion

RJ18YC

31411 Snow Pup 14" 1968-1971 Tec. AH520 16:1 4100-4500 Champion

RJ18YC

31412 Snow Pup 14" 1972-1975 Tec. AH520 16:1 4300-4700 Champion

RJ18YC

31500 Snow Husky 21" 1966-1967 Tec. AH520 16:1 4300-4700 Champion

RJ18YC

31501 Snow Pup 21” 1968-1971 Tec. AH520 16:1 4300-4700 Champion

RJ18YC

31502 Snow Pup 21" 1972-1974 Tec. AH520 16:1 4300-4700 Champion

RJ18YC

31505 Snowmaster 20" 1975 Tec. AH520 32:1 4100-4500 Champion

RJ18YC

31506 Snowmaster 20" 1976-1977 Tec. AH520 32:1 4100-4500 Champion

RJ18YC

38014 Snowmaster 14” 1978 Tec. AH520 32:1 4100-4500 Champion

RJ18YC

38020 Snowmaster 20" 1978 Tec. AH520 32:1 4100-4500 Champion

RJ18YC

38030 Snowmaster 20" 1978 Tec. AH520 32:1 4100-4500 Champion

RJ18YC

38100 S140 14" 1979-1981 Tec. AH520 32:1 4100-4500 Champion

RJ18YC

38110C CR20 20" 1987-1990 Tec. AH600 32:1 4300-4500 Champion

RCJ8Y

38111C CR20 20" 1987 Tec. AH600 32:1 4300-4500 Champion

RCJ8Y

38115C CR20 20" 1987-1990 Tec. AH600 32:1 4300-4700 Champion

RCJ8Y

38116 CR20 20" 1988-1989 Tec. AH600 32:1 4300-4700 Champion

RCJ8Y

38116C CR20 20" 1987 Tec. AH600 32:1 4300-4700 Champion

RCJ8Y

38120 S200 20" 1979-1984 Tec. AH520 32:1 4100-4500 Champion

RJ18YC

38130 S200 20" 1979-1981 Tec. AH520 32:1 4100-4500 Champion

RJ18YC

38162 S620 20" 1984-1991 Tec. AH600 32:1 4300-4700 Champion

RCJ8Y

38162C S620 20" 1984-1986 Tec. AH600 32:1 4300-4700 Champion

RCJ8Y

38165 S620 20" 1985-1991 Tec. AH600 32:1 4300-4700 Champion

RCJ8Y

38165C S620 20" 1986 Tec. AH600 32:1 4300-4700 Champion

RCJ8Y

38167C S620 20" 1986 Tec. AH600 32:1 4300-4700 Champion

RCJ8Y

38170 Powerlite 16" 1991-2000 Tec. HSK600 50:1 4300-4700 Champion

RCJ8Y

38171 Powerlite 16" 1992-1998 Tec. HSK600 50:1 4300-4700 Champion

RCJ8Y

38172 Powerlite 16" 2000 Tec. HSK600 50:1 4300-4700 Champion

RCJ8Y

.035

.035

.035

.035

.035

.035

.035

.035

.035

.035

.035

.035

.035

.030

.030

.030

.030

.030

.035

.035

.030

.030

.030

.030

.030

.030

.030

.030

Single Stage Snowthrower Service Manual 1 - 1

Page 12

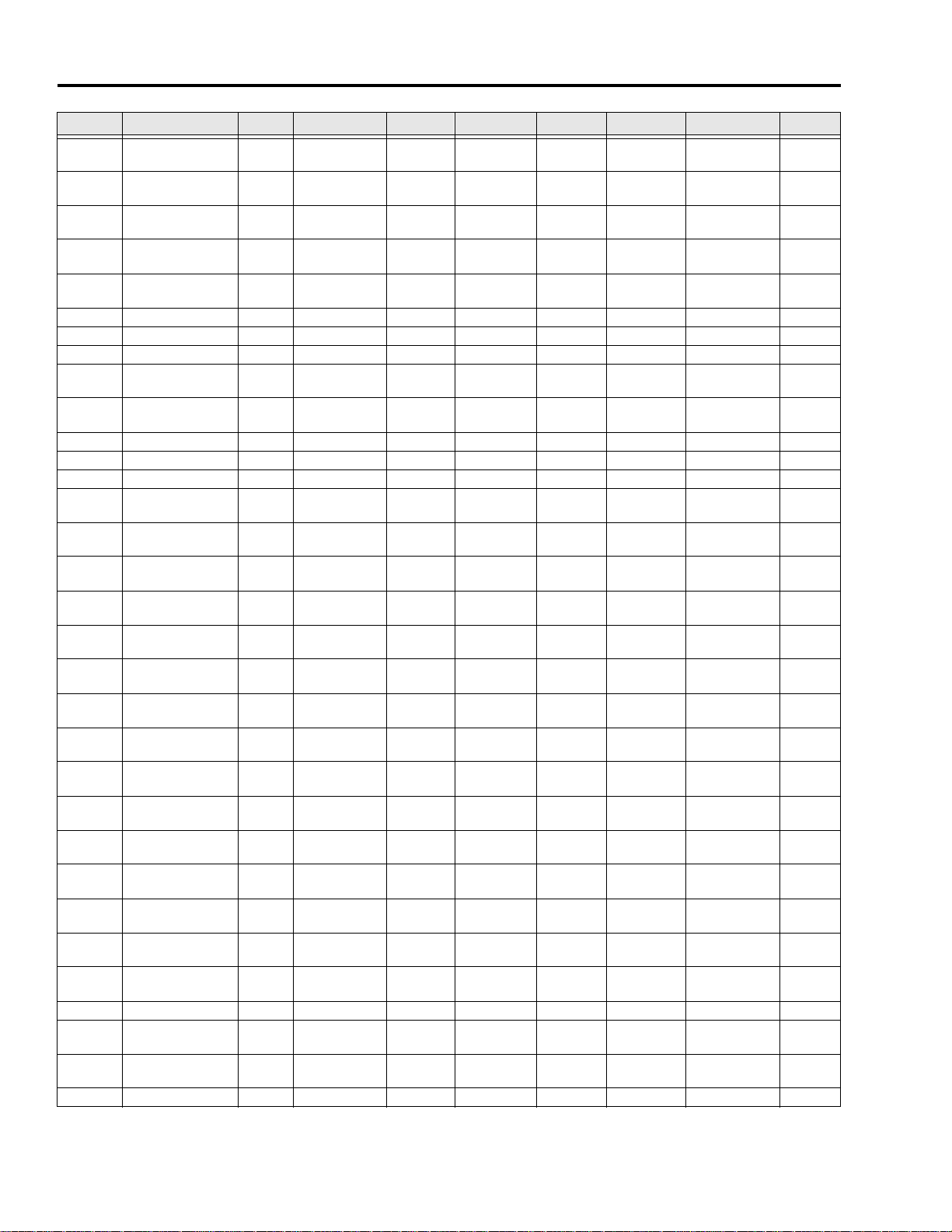

ENGINE APPLICATIONS

Model # Model Name Width Years of Mfg Eng Mfg Eng Model Mix Ratio Max RPM Spark Plug * Gap (in.)

38173 Powerlite 16" 2000 Tec. HSK600 50:1 4300-4700 Champion

RCJ8Y

38175 Powerlite 16" 1991-1999 Tec. HSK600 50:1 4300-4700 Champion

RCJ8Y

38176 Powerlite 16" 1992-1998 Tec. HSK600 50:1 4300-4700 Champion

RCJ8Y

38177 Powerlite 16" 1999 Tec. HSK600 50:1 4300-4700 Champion

RCJ8Y

38178 Powerlite 16" 1999 Tec. HSK600 50:1 4300-4700 Champion

RCJ8Y

38180 CCR2000 20" 1986-1996 Toro 47P** 50:1 3550-3850 NGK BPMR4A .032

38180C CCR2000 20" 1987-1989 Toro 47P** 50:1 3550-3850 NGK BPMR4A .032

38181 CCR2000 20" 1990-1996 Toro 47P** 50:1 3550-3850 NGK BPMR4A .032

38182 Powerlite 16" 2000 Tec. HSK600 50:1 4300-4700 Champion

RCJ8Y

38183 Powerlite 16" 2000 Tec. HSK600 50:1 4300-4700 Champion

RCJ8Y

38185 CCR2000 20" 1987-1996 Toro 47P** 50:1 3550-3850 NGK BPMR4A .032

38185C CCR2000 20" 1988-1998 Toro 47P** 50:1 3550-3850 NGK BPMR4A .032

38186 CCR2000 20" 1990-1996 Toro 47P** 50:1 3550-3850 NGK BPMR4A .032

38190 CCR1000 20" 1990-1996 Tec. HSK600 50:1 4300-4700 Champion

RCJ8Y

38191 CCR1000 20" 1992-1996 Tec. HSK600 50:1 4300-4700 Champion

RCJ8Y

38195 CCR1000 20" 1990-1996 Tec. HSK600 50:1 4300-4700 Champion

RCJ8Y

38196 CCR1000 20" 1992-1996 Tec. HSK600 50:1 4300-4700 Champion

RCJ8Y

38210 S140 14" 1979-1980 Tec. AH520 32:1 4100-4500 Champion

RJ18YC

38220 S200 20" 1979 Tec. AH520 32:1 4100-4500 Champion

RJ18YC

38225 S200 20" 1980 Tec. AH520 32:1 4100-4500 Champion

RJ18YC

38230 S200 20" 1979 Tec. AH520 32:1 4100-4500 Champion

RJ18YC

38232 S200 20" 1981-1985 Tec. AH520 32:1 4100-4500 Champion

RJ18YC

38235 S200 20" 1980-1983 Tec. AH520 32:1 4100-4500 Champion

RJ18YC

38242 S200 20" 1981-1983 Tec. AH520 32:1 4100-4500 Champion

RJ18YC

38252 S200 20" 1981 Tec. AH520 32:1 4100-4500 Champion

RJ18YC

38350 Gas Power Shovel 14" 1983-1985 Toro NA 32:1 7800-8800 Champion

RCJ8

38400 CCR1000 20" 1999-2000 Tec. HSK635 50:1 4300-4700 Champion

RCJ8Y

38405 CCR1000 20" 1999-2000 Tec. HSK635 50:1 4300-4700 Champion

RCJ8Y

38409 CCR2400 20" 1998-1999 Toro R tek 50:1 3450-3950 NGK BPMR4A .032

38410 CCR2400 20" 1997 Tec. HSK850 50:1 3550-3850 Champion

RCJ8Y

38411 CCR2400 20" 1997 Tec. HSK850 50:1 3550-3850 Champion

RCJ8Y

38412 CCR2400 20" 1998-1999 Toro R tek 50:1 3450-3950 NGK BPMR4A .032

.030

.030

.030

.030

.030

.030

.030

.030

.030

.030

.030

.035

.035

.035

.035

.035

.035

.035

.035

.022

.030

.030

.030

.030

1 - 2 Single Stage Snowthrower Service Manual

Page 13

ENGINE APPLICATIONS

Model # Model Name Width Years of Mfg Eng Mfg Eng Model Mix Ratio Max RPM Spark Plug * Gap (in.)

38413 CCR2450 20" 2000 Toro R tek 50:1 3550-4050 NGK BPMR4A .032

38414 CCR2400 20" 1998-1999 Toro R tek 50:1 3450-3950 NGK BPMR4A .032

38415 CCR2400 20" 1997 Tec. HSK850 50:1 3550-3850 Champion

RCJ8Y

38416 CCR2400 20" 1997 Tec. HSK850 50:1 3550-3850 Champion

RCJ8Y

38417 CCR2400 20" 1998 Toro R tek 50:1 3450-3950 NGK BPMR4A .032

38418 CCR2400 20" 1999 Toro R tek 50:1 3450-3950 NGK BPMR4A .032

38419 CCR2450 20" 2000 Toro R tek 50:1 3550-4050 NGK BPMR4A .032

38420 CCR2500 20" 1997 Tec. HSK850 50:1 3550-3850 Champion

RCJ8Y

38421 CCR2500 20" 1997 Tec. HSK850 50:1 3550-3850 Champion

RCJ8Y

38422 CCR2500 20" 1998-1999 Toro R tek 50:1 3550-4050 NGK BPMR4A .032

38423 CCR2500 20" 1998 Toro R tek 50:1 3550-4050 NGK BPMR4A .032

38424 CCR2500 20" 1998-1999 Toro R tek 50:1 3550-4050 NGK BPMR4A .032

38425 CCR2500 20" 1997 Tec. HSK850 50:1 3550-3850 Champion

RCJ8Y

38426 CCR2500 20" 1997 Tec. HSK850 50:1 3550-3850 Champion

RCJ8Y

38427 CCR2500 20" 1998 Toro R tek 50:1 3550-4050 NGK BPMR4A .032

38428 CCR2450 20" 2000 Toro R tek 50:1 3550-4050 NGK BPMR4A .032

38429 CCR2450 20" 2000 Toro R tek 50:1 3550-4050 NGK BPMR4A .032

38430 CCR3000 20" 1997-1999 Toro 47P** 50:1 3550-3850 NGK BPMR4A .032

38431 CCR3000 20" 1997-1998 Toro 47P** 50:1 3550-3850 NGK BPMR4A .032

38432 CCR3000 20" 1999 Toro R tek 50:1 3650-4150 NGK BPMR4A .032

38433 CCR3000 20" 1999 Toro R tek 50:1 3650-4150 NGK BPMR4A .032

38435 CCR3000 20" 1997-1999 Toro 47P** 50:1 3550-3850 NGK BPMR4A .032

38436 CCR3000 20" 1997-1998 Toro 47P** 50:1 3550-3850 NGK BPMR4A .032

38437 CCR3000 20" 1999 Toro R tek 50:1 3650-4150 NGK BPMR4A .032

38438 CCR3000 20" 1999 Toro R tek 50:1 3650-4150 NGK BPMR4A .032

38439 CCR3600 20" 2000 Toro R tek 50:1 3650-4150 NGK BPMR4A .032

38440 CCR3650 20" 2000 Toro R tek 50:1 3750-4250 NGK BPMR4A .032

38441 CCR3650 20" 2000 Toro R tek 50:1 3750-4250 NGK BPMR4A .032

38442 CCR3650 20" 2000 Toro R tek 50:1 3750-4250 NGK BPMR4A .032

38445 CCR3650 20" 2000 Toro R tek 50:1 3750-4250 NGK BPMR4A .032

.030

.030

.030

.030

.030

.030

* RJ18YC replaces RJ18Y

Single Stage Snowthrower Service Manual 1 - 3

Page 14

THIS PAGE INTENTIONALLY LEFT BLANK

1 - 4 Single Stage Snowthrower Service Manual

Page 15

GENERAL INFORMATION

GENERAL SAFETY INSTRUCTIONS

This safety alert symbol means CAUTION

- PERSONAL SAFETY INSTRUCTION.

Read the instruction because it has to do

with safety. Failure to comply with the instruction

may result in personal injury.

Personal Safety

• Never allow children to operate the snowthrower.

Adults should operate the snowthrower only after

reading the owner’s manual and receiving proper

instructions.

• Keep everyone, especially children and pets, away

from the area of operation.

• Wear adequate winter clothing and footwear that

will improve footing on slippery surfaces.

Before Operating

• Familiarize yourself with the controls. Know how to

stop the engine and disengage controls quickly.

• Since fuel is highly flammable, handle it with care.

Fill the fuel tank with a mixture of gasoline and oil

before trying to start the engine.

• Use an approved fuel container for storing the

gasoline/oil mixture. Store fuel outside unless it is

stored in a fireproof cabinet.

• Fill fuel tank outdoors, not indoors. The fuel tank

must not be filled when engine is running or when

engine is hot.

• Install the gasoline container cap, fuel tank cap,

and wipe up any spilled gasoline before starting the

engine.

• Keep all shields and safety devices in place. If a

shield or safety device is defective, make all

repairs before operating the snowthrower. Also

tighten all nuts, bolts, and screws.

During Operation

• Keep face, hands, feet, and other parts of your

body or clothing away from concealed, moving, or

rotating parts. Stay behind the handle while

operating the snowthrower. STAY CLEAR OF

DISCHARGE OPENING AT ALL TIMES.

• Do not attempt to make adjustments while engine

is running.

• Use extreme caution when clearing snow from

walk, road, or a gravel drive. Push down on the

handle to raise skid and impeller blades to avoid

picking up rocks and throwing them. Stay alert for

hidden hazards and traffic on roads.

• Never direct discharge of the snowthrower at

bystanders, glass enclosures, automobiles, trucks,

and window wells. Keep children and pets away.

• If a solid object is hit or if the snowthrower vibrates

abnormally, turn key to OFF so engine stops.

Next, remove high tension wire from the spark

plug; then check snowthrower for possible

damage, an obstruction, or loose parts. Repair

damage before starting and operating the

snowthrower.

• Before adjusting, cleaning, repairing, or inspecting

the snowthrower, and before unclogging the

discharge guide, shut engine off and wait for all

moving parts to stop. Next remove high tension

wire from spark plug, and keep wire away from

plug to prevent accidental starting.

• Use caution when operating snowthrower as the

exhaust pipe is hot and could cause personal injury

or damage to clothing.

Electric Start Safety Precautions

• Use the extension cord provided with the Electric

Start (P.N. 28-9170) or any 16 gauge 2 or 3 wire

cord.

• Do not plug the extension cord into the outlet while

standing in water or when hands are wet.

• Do not use or connect the cord if gasoline has

been spilled on it.

• Never operate the snowthrower without good

visibility or light. Always maintain a secure footing

and keep a firm grip on the handle when clearing

snow: WALK, NEVER RUN. DO NOT USE

SNOWTHROWER ON A ROOF.

• Do not run the engine indoors.

Single Stage Snowthrower Service Manual 2 - 1

• Always replace a damaged extension cord

immediately.

• Authorized Toro Service Dealers are certified for

electrical repairs and electrical servicing. Do not

attempt to repair 110V products.

Page 16

GENERAL INFORMATION

Storage During Snow Season

• When storing the snowthrower, REMOVE THE

KEY FROM SWITCH. Store the key in a

memorable place.

• Never leave gasoline in a snowthrower fuel tank

when snowthrower is stored in a building where a

flame or spark may be present. Allow the engine to

cool before storing. Never store a snowthrower in

the house or basement because of potential fire

hazard.

• Before performing any maintenance or servicing to

the snowthrower, turn key to OFF and wait for

engine and all moving parts to stop. Remove the

key switch and pull high tension wire from spark

plug.

• Reinstall the fuel cap when the top cover is

removed for maintenance procedures. Perform

maintenance and use storage instructions

described in this manual.

• Keep all nuts, bolts, and screws tight to assure

snowthrower is in safe working condition. Be sure

to check the rotor and the engine mounting bolts.

• ALWAYS USE TORO REPLACEMENT PARTS

AND ACCESSORIES TO ASSURE SAFETY AND

OPTIMUM PERFORMANCE. NEVER USE

“WILL-FIT” REPLACEMENT PARTS AND

ACCESSORIES.

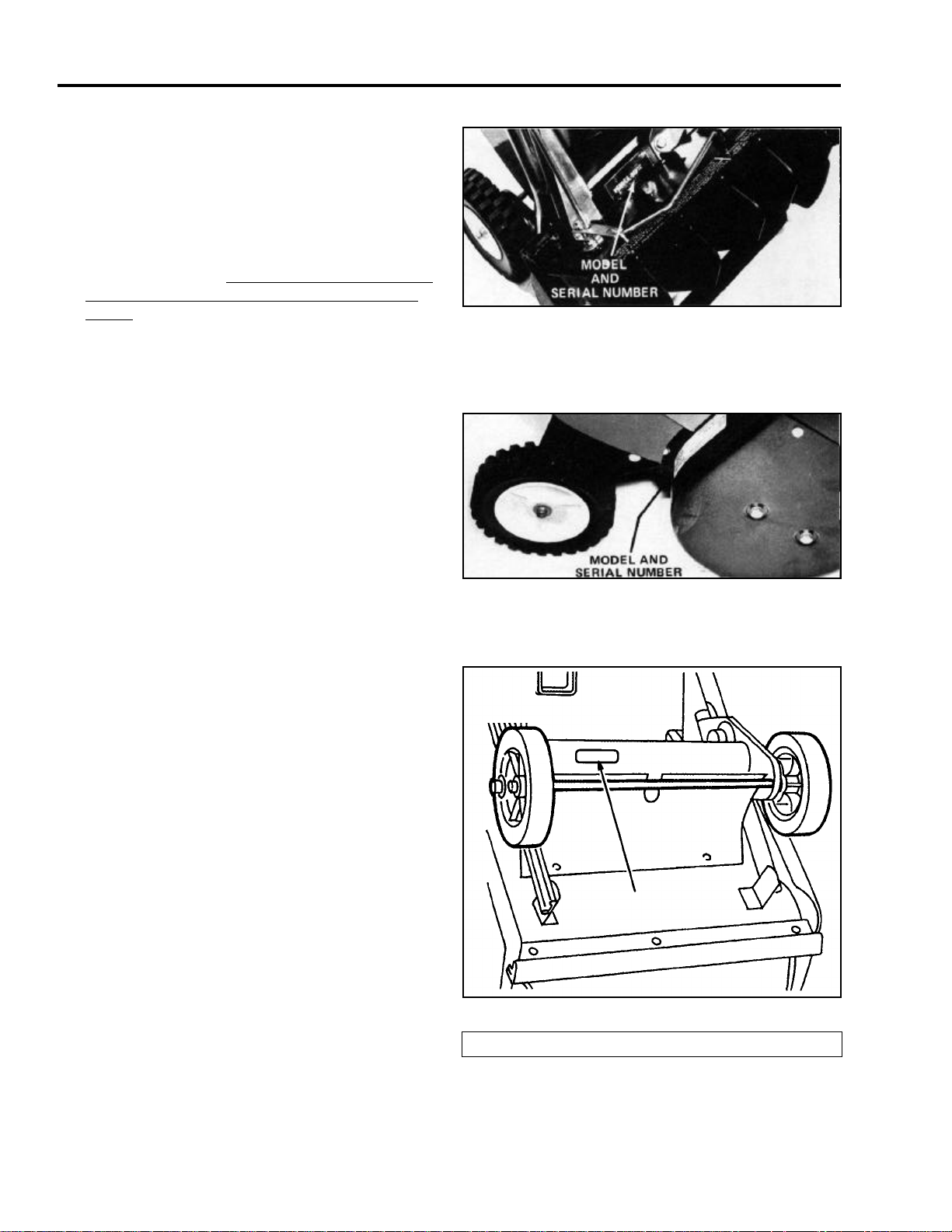

14” and 21” Models

Figure 1 0217-001

Location: Right side of the square tubing on the main

frame. Shroud will need removal to read.

20” Models

Figure 2 0217-002

Location: Right side of the impeller housing just ahead

of the right wheel.

IDENTIFICATION AND ORDERING

IDENTIFICATION:

All Toro Products, including single stage

snowthrowers, have two identification numbers: a

model number and serial number. In any

correspondence concerning your snowthrower, always

supply the model and serial number, to assure the

correct information or replacement parts are obtained.

The two numbers are stamped on a decal, which are

located in various places on the snowthrowers. The

location will vary depending on the model and year the

unit was manufactured. Please note the diagrams to

determine the location of the model and serial number

decal on your unit (Figure 1 through Figure 3).

A

Figure 3 0530-01

(A) Model and Serial Number Decal

2 - 2 Single Stage Snowthrower Service Manual

Page 17

GENERAL INFORMATION

ORDERING: Toro parts are available through your

local Authorized Toro Service Dealer.

NOTE: To find the nearest Authorized Toro Service

Dealer in your area, please consult your yellow pages

under “lawn mowers” or “snowthrowers”.

Parts:

To order replacement parts from an authorized TORO

Dealer, the following information is needed:

1. Model and serial number of the snowthrower.

2. Description of the part(s) and quantity of part(s)

desired. If a parts manual is being used, use the

PART NUMBER and the description.

Manuals:

Should a replacement owner’s manual or parts manual

be needed, please send the complete model and serial

number along with your name and address to:

The Toro Company

8111 Lyndale Avenue South

Minneapolis, MN 55420

ATTN: Parts Department

MIXING INSTRUCTIONS FOR GASOLINE

AND OIL

Safety Instructions

CAUTION

Gasoline is flammable and caution must be used

when handling or storing it. Do not fill the fuel

tank while snowthrower is running, while it is hot,

or when it is in an enclosed area. Keep away from

an open flame, an electrical spark, and DO NOT

SMOKE while mixing fuel or filling the fuel tank.

Fill the fuel tank to within 1/4 - 1/2 inch from top of

the tank to provide space for expansion of fuel.

Never fill the fuel tank to the top of filler neck.

Always fill the fuel tank outdoors and use a funnel

or spout to prevent spilling. Make sure to wipe up

any spilled fuel before starting the engine.

Store gasoline in a clean, approved container, and

keep the cap in place on the container. Keep

gasoline in a cool, well ventilated place; never in

the house. Never buy more than a 30 day supply

of gasoline to assure volatility. Gasoline is

intended to be used as a fuel for internal

combustion engines; therefore, do not use

gasoline for any other purpose. Since many

children like the smell of gasoline, keep it out of

their reach because the fumes are dangerous to

inhale, as well as being explosive.

PROPER FUEL AND OIL

Three basic engine configurations have been used in

this product group. Due to internal differences, there

are three different fuel/oil mix ratios. See the charts on

page 2 - 4 and 2 - 5 for the proper ratio for your model.

Mixing Procedures

Use the following procedures to assure the fuel is

properly mixed:

1. Add 1 quart of unleaded REGULAR gasoline to a

gasoline container.

2. If your snowthrower requires a 16:1 gas to oil

ratio; pour one cup or 8 ounces of Toro 2-cycle

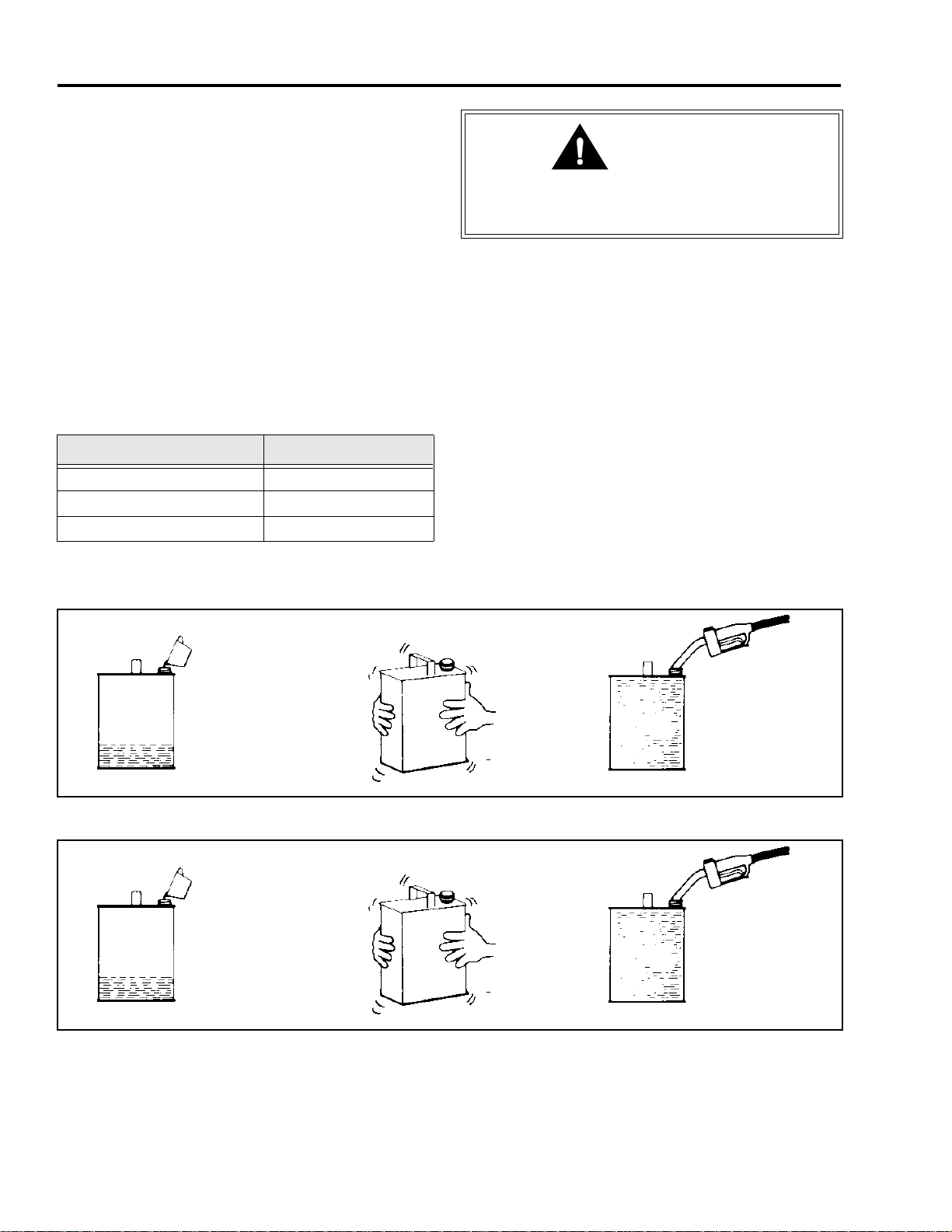

engine oil into the gasoline container (Figure 4).

Single Stage Snowthrower Service Manual 2 - 3

Page 18

GENERAL INFORMATION

3. If your unit requires a gasoline/oil ratio of 32:1,

pour 1/2 cup or 4 ounces of TORO 2-cycle engine

oil into the gasoline container (Figure 5).

CAUTION

4. If your snowthrower requires a 50:1 gas to oil

ratio; pour 2.6 oz. of Toro 2-cycle oil into the

gasoline container (Figure 6).

5. Shake the gasoline container vigorously so oil

mixes with gasoline. Remember to install cap on

gasoline container before shaking.

6. Add an additional 3 quarts of gasoline to the

premixed gasoline. Fuel mixture is now ready to

use in your snowthrower.

Mix With One U.S. Gallon

Ratio Oil

16:1 8 oz.

32:1 4 oz.

50:1 2.6 oz.

16:1 RATIO MIX

Do not store the oil near an open flame or in an

extremely warm environment as the oil is

flammable.

IMPORTANT: If the fuel and Toro 2-cycle oil are not

mixed at the correct ratio for your snowthrower,

(either 16:1, 32:1, or 50:1) piston damage and other

engine damage may occur. It is important that the

fuel and oil be mixed at temperatures above 40° F

to ensure complete mixing.

Note: To assure the fuel and oil mixes completely,

store your Toro 2-cycle Oil indoors, so it will be at room

temperature (above 50° F).

Filling The Fuel Tank

IMPORTANT: Do not fill the fuel tank with gasoline

that has not been mixed with Toro 2-cycle engine

oil in the correct ratio for your snowthrower. Do

not use gasoline additives, engine damage could

result.

OIL

(1 CUP OR 8 OZ.) (0.236 l)

GAS

(1 U.S. QUART (0.946 l)

GASOLINE CONTAINER

OIL

(1/2 CUP OR 4 OZ.) (0.118 l)

GAS

(1 U.S. QUART (0.946 l)

GASOLINE CONTAINER

SHAKE

CAN

Figure 4

32:1 RATIO MIX

SHAKE

CAN

Figure 5

ADD

MORE

GAS

(3 U.S. QUARTS)

(2.84 l)

GASOLINE CONTAINER

ADD

MORE

GAS

(3 U.S. QUARTS)

(2.84 l)

GASOLINE CONTAINER

2 - 4 Single Stage Snowthrower Service Manual

Page 19

GENERAL INFORMATION

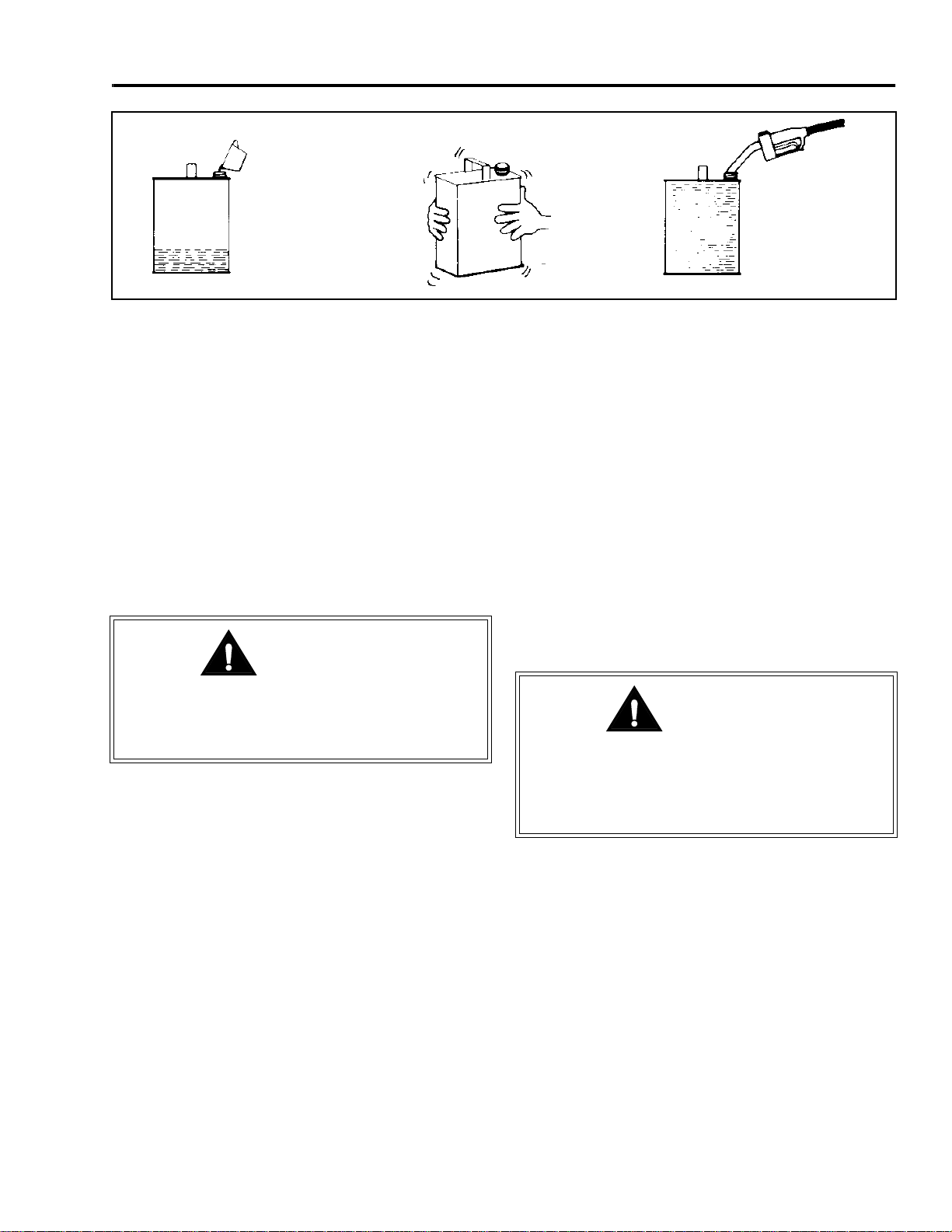

50:1 RATIO MIX

OIL

(1/3 CUP OR 2.6 OZ.) (0.079 l)

GAS

(1 U.S. QUART (0.946 l)

GASOLINE CONTAINER

Figure 6

1. Mix the gasoline and oil in the correct ratio for your

unit. Refer to “MIXING INSTRUCTIONS FOR

GASOLINE AND OIL” on page 2 - 3.

2. Clean the area around snowthrower fuel tank cap

so foreign matter does not get into the fuel tank.

Remove the cap from the fuel tank.

3. Fill snowthrower fuel tank to within 1/4 - 1/2 inch

from the top of the tank, not the filler neck.

4. Install the cap securely on snowthrower fuel tank.

Draining The Fuel Tank

ADD

MORE

GAS

SHAKE

CAN

GASOLINE CONTAINER

2. Use the primer and choke and start the engine. It

should run several minutes to consume the fuel in

the carburetor and fuel line. When the engine

stops, attempt to start it again. Use the primer

and choke. The engine may start and stop 2 or 3

times. Repeat until you cannot start the engine.

Note: Draining the fuel tank and letting the

unit run out of fuel is a critical servicing

procedure when preparing your snowthrower

for storage. Expending fuel from the engine

will prevent gum-like varnish deposits from

forming in the carburetor, fuel line, and fuel

tank. Such deposits, if allowed to form, will

cause starting problems the following season.

(3 U.S. QUARTS)

(2.84 l)

CAUTION

Because the gasoline/oil mixture in the

snowthrower fuel tank is explosive, the fuel

mixture must be drained outdoors, away from fire

and flame. Do not smoke while draining gasoline.

To assure safe servicing of your snowthrower, it is

critical that the fuel tank be drained. To drain the fuel

tank on your snowthrower, use the following procedure:

1. Use a pump type siphon to remove as much fuel

from the tank as possible. Dispose of fuel

properly. One method of disposing of left over fuel

is to put it in the car. If you have a half tank of fuel

in the car, a gallon or two of fuel mix will blend with

the gas and have no effect. If the fuel is extremely

old and does not smell like gasoline, we would not

recommend its use in any engine. Contact your

local authorities for disposal instructions.

OFF SEASON STORAGE

CAUTION

Because gasoline/oil mixture in the snowthrower

fuel tank is explosive, the fuel mixture must be

drained outdoors, away from fire and flame. Do

not smoke while draining gasoline. If fuel mixture

explodes, personal injury may result.

Properly preparing the machine for off season storage

is the single most important thing that can be done to

prevent problems. The summer heat will rapidly

evaporate fuel in the tank and carburetor. Dried fuel in

the carburetor can and often does plug the fuel

passages and prevent starting the following snow

season. We recommend the use of a petroleum based

fuel stabilizer during the snow season. The stabilizer

will help keep fuel fresh and assist with starting.

Single Stage Snowthrower Service Manual 2 - 5

Page 20

GENERAL INFORMATION

1. Use a pump type siphon to remove as much fuel

from the tank as possible. Dispose of fuel

properly. One method of disposing of left over fuel

is to put it in the car. If you have a half tank of fuel

in the car, a gallon or two of fuel mix will blend with

the gas and have no affect. If the fuel is extremely

old and does not smell like gasoline, we would not

recommend its use in any engine. Contact your

local authorities for disposal instructions.

2. Use the primer and choke and start the engine. It

should run several minutes to consume the fuel in

the carburetor and fuel line. When the engine

stops, attempt to start it again. Use the primer

and choke. The engine may start and stop 2 or 3

times. Repeat until you cannot start the engine.

3. With the key off, slowly pull the starter rope until

resistance is felt, release the starter rope.

4. Tighten loose nuts and bolts.

5. On the 14” models with chain drive (Snow Pup),

remove the chain guard and lightly oil the chain

with 30 wt. engine oil. Install the chain guard.

6. Store the machine in a clean dry area, cover if you

wish. (DO NOT store any gasoline powered

machine in the house, basement, or near any

appliance that contains fire or flame.)

7. Remove the key and place in a memorable place.

2 - 6 Single Stage Snowthrower Service Manual

Page 21

CONTROLS/LOCATION AND OPERATION

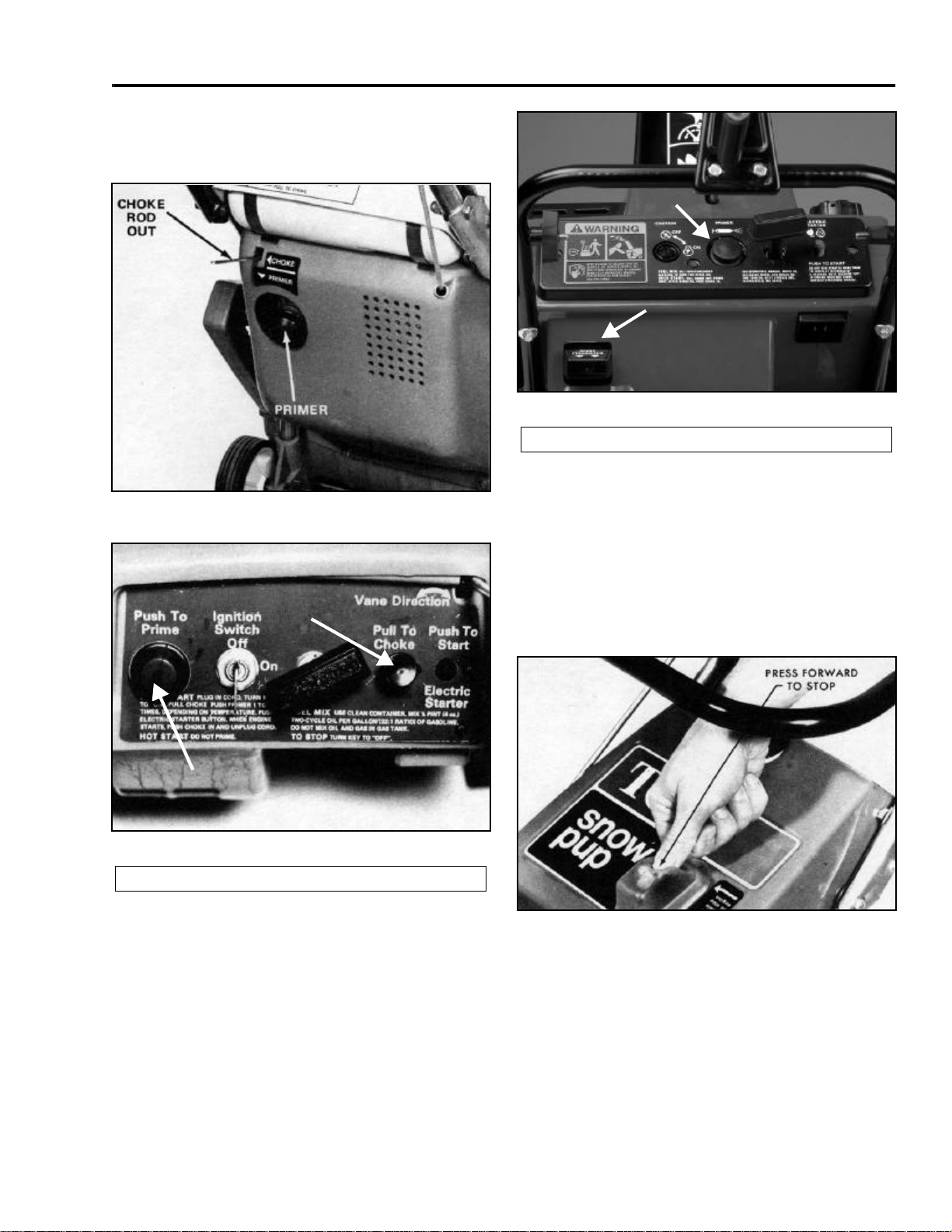

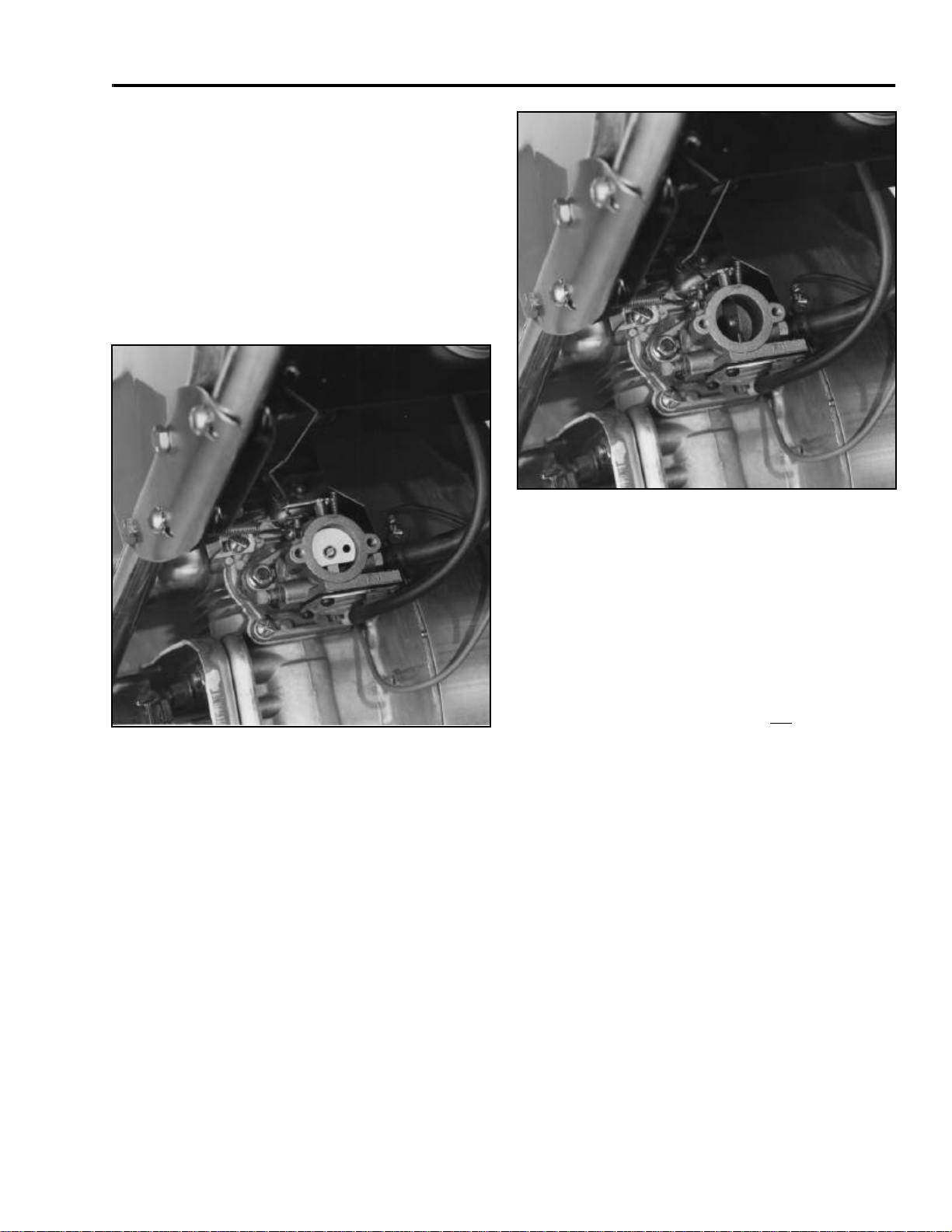

The primer and choke controls have been located in

different areas throughout the years. Figure 7, Figure

8, Figure 9, and show the various locations.

Figure 7 0217-004

B

B

A

Figure 9 1854-28

(A) Choke (B) Primer

The ignition switch has been located in the same

position on the control panel since introduction of the

1975 Snowmaster (Figure 8). Prior to 1975, the unit’s

engine was stopped by depressing the spark plug kill

lever. This lever was located below a translucent boot

on the upper shroud. The lever would ground the

spark to frame of the snowthrower when depressed

(Figure 10). Press and hold until the engine stops

completely.

A

Figure 8 0217-005

(A) Primer (B) Choke

Figure 10 0217-006

Single Stage Snowthrower Service Manual 3 - 1

Page 22

CONTROLS/LOCATION AND OPERATION

PRIMER

The primer, used on most single stage snowthrowers,

is designed to pump a small amount of fuel from the

carburetor into the carburetor throat. This extra fuel

mixture allows the engine to be started in cold

temperatures.

The primer is operated by depressing the primer bulb

with a finger, ensuring the finger covers the vent hole in

the bulb. Depress the primer button, release, wait

about 3 seconds, then depress the primer again.

Repeat as often as needed. The pause in between

primes allows time for the prime well in the carburetor

to refill.

Operator priming instructions vary depending on the

year your snowthrower was manufactured. On those

units manufactured from 1972 and before, in a cold

start application, the primer should be pressed

approximately 10 times (Figure 11). The 1973 through

1977 single stage snowthrower primer should be

pressed 5 times. Snowthrowers produced from 1978

through 1980, the primer should be pushed one to four

times (Figure 8, Figure 11, or Figure 12). For

temperatures above +20° F (-7° C) use one or two

primes; below +20° F (-7° C) use three or four primes.

For extremely cold temperatures below -10° F (-23° C)

use five or six primes. For 1981 and newer models,

depress the primer one or two times, with a pause in

between. Additional primes may be necessary in

colder temperatures.

Note: On early production, the diaphragm cover was

vented, and on later production, the primer bulb

incorporates the vent. Those models with a vented

diaphragm cover require more primes.

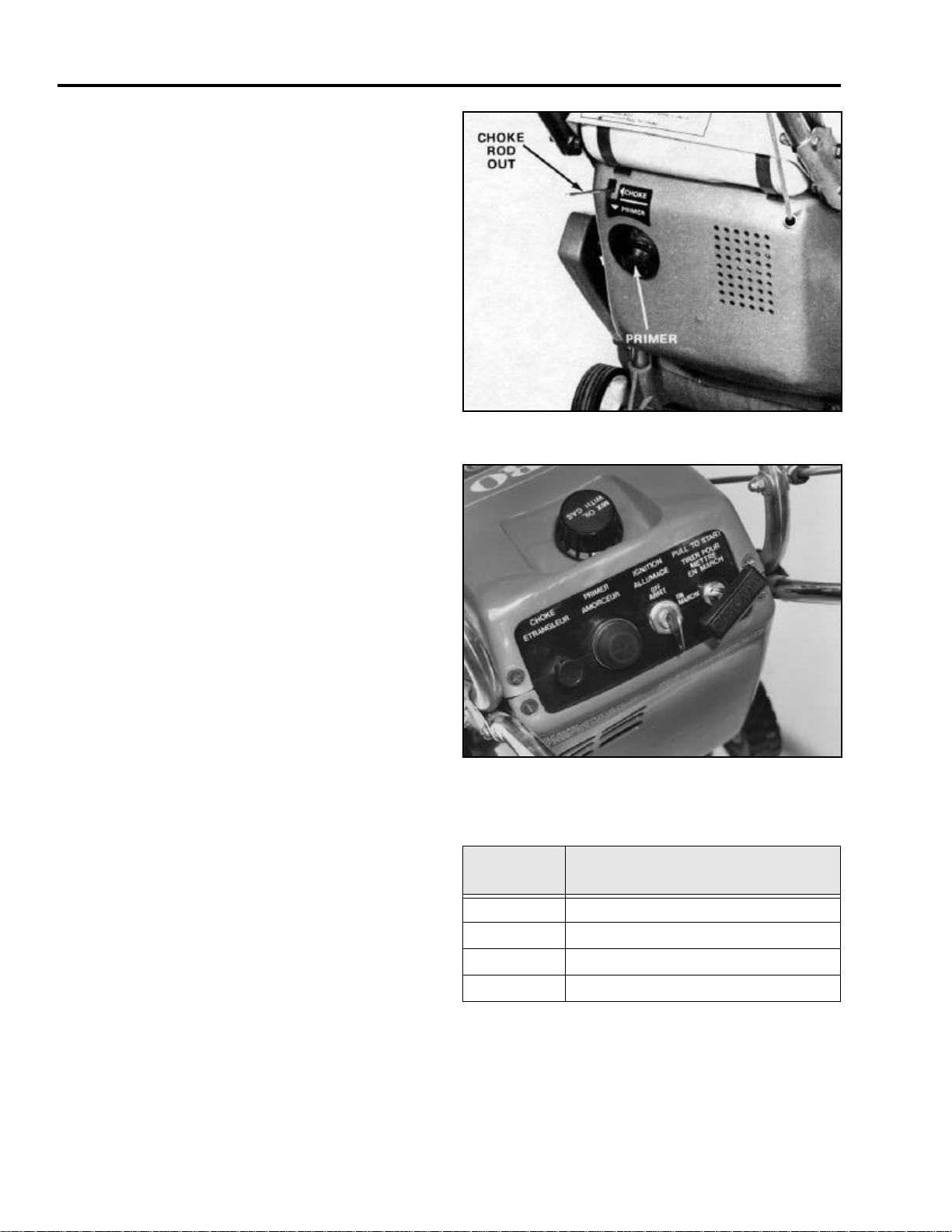

Years

Figure 11 0217-007

Figure 12 0217-008

PRIMING CHART

Number of times primer is

depressed

1965-1972 10

1973- 1977 5

1978- 1980

1981 - Up

3 - 2 Single Stage Snowthrower Service Manual

1-4

1-2

Page 23

CONTROLS/LOCATION AND OPERATION

CHOKE

The carburetor choke control, or shutter, meters the

amount of air passing into the engine. When starting

the engine, the carburetor choke should be closed

(Figure 13). If your snowthrower has either the choke

cable, choke rod, or handle design to close the choke

shutter, the cable, rod, or handle should be pulled out.

If you have a single stage snowthrower manufactured

in 1980, the choke control should be rotated clockwise

to close the shutter, counterclockwise to open the

shutter.

Figure 14 0217-010

Figure 13 0217-009

Closing the choke shutter allows air to enter the

carburetor only through openings in and around the

choke shutter (Figure 14). When the engine is

cranked, a low pressure area is created in the engine

and it extends into the carburetor. Since only a limited

amount of air can enter this low pressure area because

of the closed choke shutter, a greater amount of fuel is

drawn through the fuel passages to fill the void. This

creates the richer mixture needed for engine starting

and restarting after the engine is warm.

After the engine starts, more air must pass into the

engine. Therefore, after the engine is started, open the

choke shutter to allow more air to pass into the engine.

Again, to open the choke shutter on those models that

have a choke cable, rod, or handle, push the choke

control lever in. On 1980 snowthrowers, the choke

control lever should be rotated counterclockwise.

THROTTLE: On Toro applications, the carburetor

throttle is controlled by the governor only. Therefore,

Toro single stage snowthrowers, are not equipped with

an engine speed control for the operator.

ON/OFF IGNITION SWITCH

The ignition switch found on Toro single stage

snowthrowers produced since 1975, allows the engine

to be started when the key is in the ON position.

Rotating the key to the OFF position will stop the

engine by allowing magneto current to flow to ground

(Figure 12).

Single Stage Snowthrower Service Manual 3 - 3

Page 24

CONTROLS/LOCATION AND OPERATION

∞

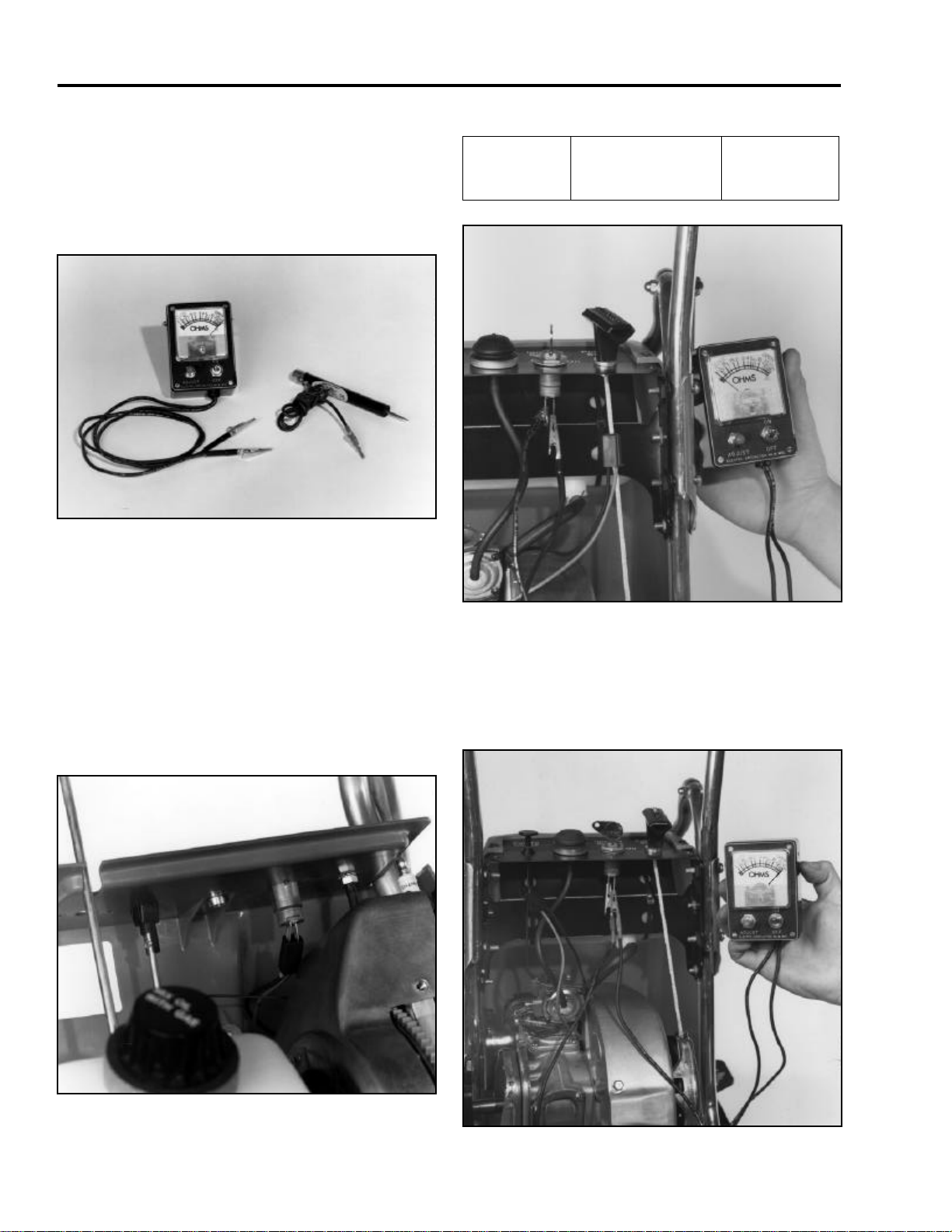

CHECKING THE IGNITION SWITCH

The tools used to check for defective switches are a

continuity tester/light or an ohmmeter (Figure 15). A

continuity tester or ohmmeter, as the names imply, are

used to test for a completed current flow in an electrical

circuit. To test the ignition switch on your snowthrower:

Figure 15 0217-011

1. Remove the upper shroud.

CONTINUITY CHART FOR SWITCHING

Switch

ON

OFF

Continuity Light

light off

light on

Ohm Meter

Zero Ohms

Ohms

2. Slide the terminal connector off the ignition switch

(Figure 16). With the key in the OFF position,

place the continuity light or ohmmeter leads, one

to each terminal on the ignition switch (Figure 17);

the light or meter, depending on the instrument

used, should show continuity. (The continuity light

should be on or the ohmmeter needle should

move to a zero ohms reading.) If not, the switch is

defective and needs to be replaced.

Figure 17 0217-013

Now, turn the key to the ON position, the meter or

light from the tester should not indicate continuity

(Figure 18). (The continuity light, if being used,

should be OFF. An ohmmeter should move close

to ∞.) If not, replace the switch.

Figure 16 0217-012

Figure 18 0217-015

3 - 4 Single Stage Snowthrower Service Manual

Page 25

CONTROLS/LOCATION AND OPERATION

3. Slide the terminal connector back onto the ignition

switch terminals (Figure 16).

4. Replace the upper shroud.

Note: Toro single stage snowthrowers produced

between 1965 and 1975 did not utilize an ignition

switch. These units were equipped with a

translucent boot in the upper shroud. By

depressing the boot on these models, the engine

could be stopped (Figure 10). A small metal lever,

which was attached to the frame, would ground

the spark to the frame when depressed.

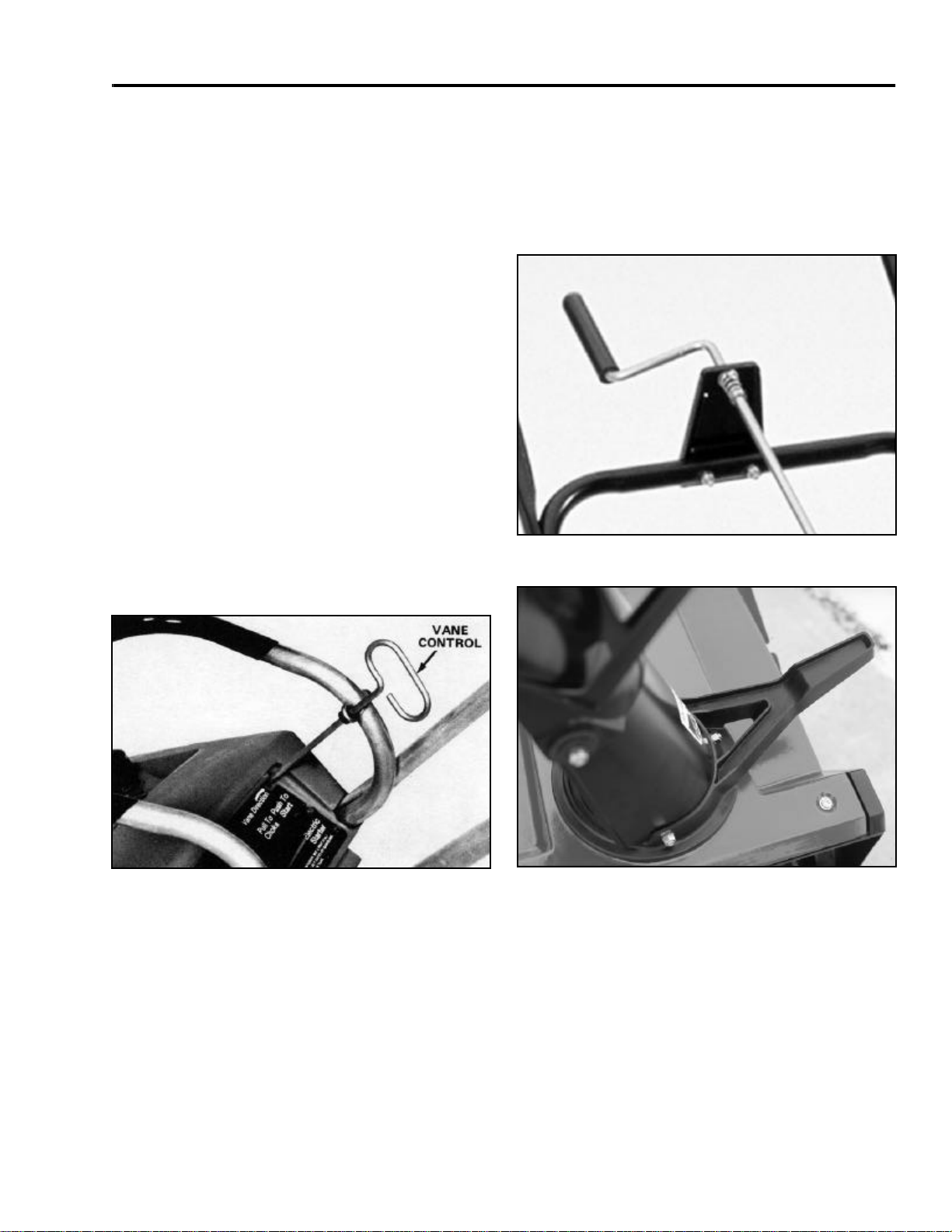

VANE CONTROL - SNOW PUP SNOWMASTER S-200 - S-620

The vane control, found on Toro single stage

snowthrowers, directs the discharge of snow to the left,

right, or straight forward (Figure 19).

Note: It is a good practice to set the vanes in a vertical

position (place the vane control so the vanes are

positioned straight forward), when your unit is not in

use. This helps prevent the vanes from taking a

permanent curved shape.

CHUTE CONTROL

All Powerlite and 20” CCR models use a chute to direct

the snow (Figure 20). There are three methods to

control the chute rotation. The crank style and two

types of the lever style (Figure 21). However, the chute

itself is basically the same.

Figure 20 2261-04

Figure 19 0217-016

Single Stage Snowthrower Service Manual 3 - 5

Figure 21 2261-01

Page 26

CONTROLS/LOCATION AND OPERATION

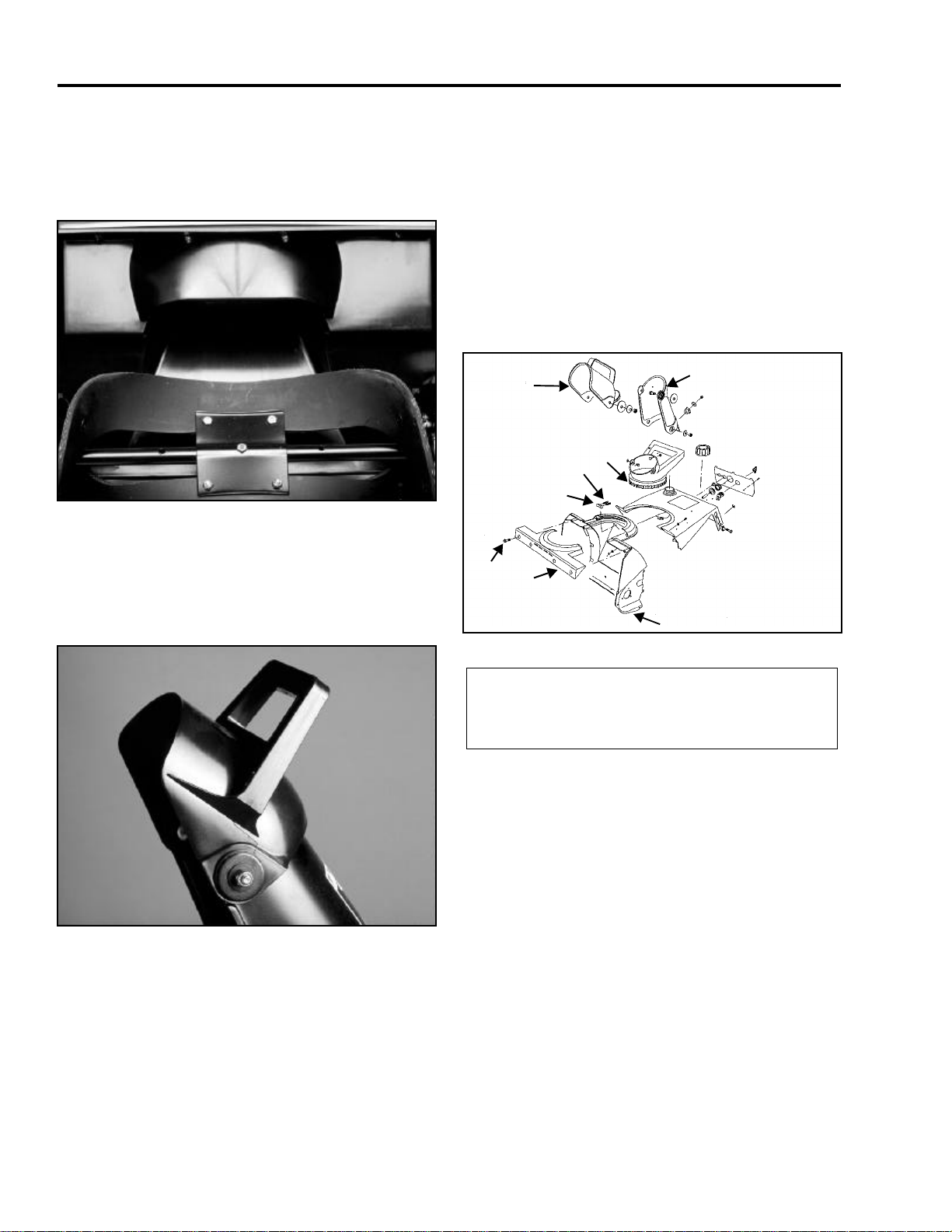

The curved rotor is necessary to draw the snow

towards the center, where the chute is (Figure 22). The

upper part of the rotor housing is an inverted cone,

which has two functions. This directs the snow

towards the chute, and also serves to resist plugging.

Figure 22 1352-01

The discharge chute and deflector are not

interchangeable from model to model (Figure 23).

However, they are made from the same basic design.

The deflector mounts on top of the chute and

determines the height of the snow stream.

CHUTE ROTATION AND DETENT

SYSTEMS

Powerlite Chute System

On Powerlite models, the chute attaches to a handle,

which also is the base and contains detents which

resemble gear teeth. The handle or base sets in a

groove at the top of the rotor housing. The front of the

housing is open to allow the handle to slip in. The front

opening is closed by the addition of the chute retainer,

which is held in place by four screws (Figure 24).

G

F

E

D

H

C

Figure 24 0310-01

A

B

Figure 23 1352-05

The bolts on either side of the deflector must be

sufficiently tight to prevent the snow stream from

causing the deflector to move.

(A) Discharge Chute

(B) Rotor Housing

(C) Chute Retainer

(D) Chute Detent

(E) Detent Spring

(F) Chute Handle

(G) Chute Deflector

(H) Screw (4)

3 - 6 Single Stage Snowthrower Service Manual

Page 27

CONTROLS/LOCATION AND OPERATION

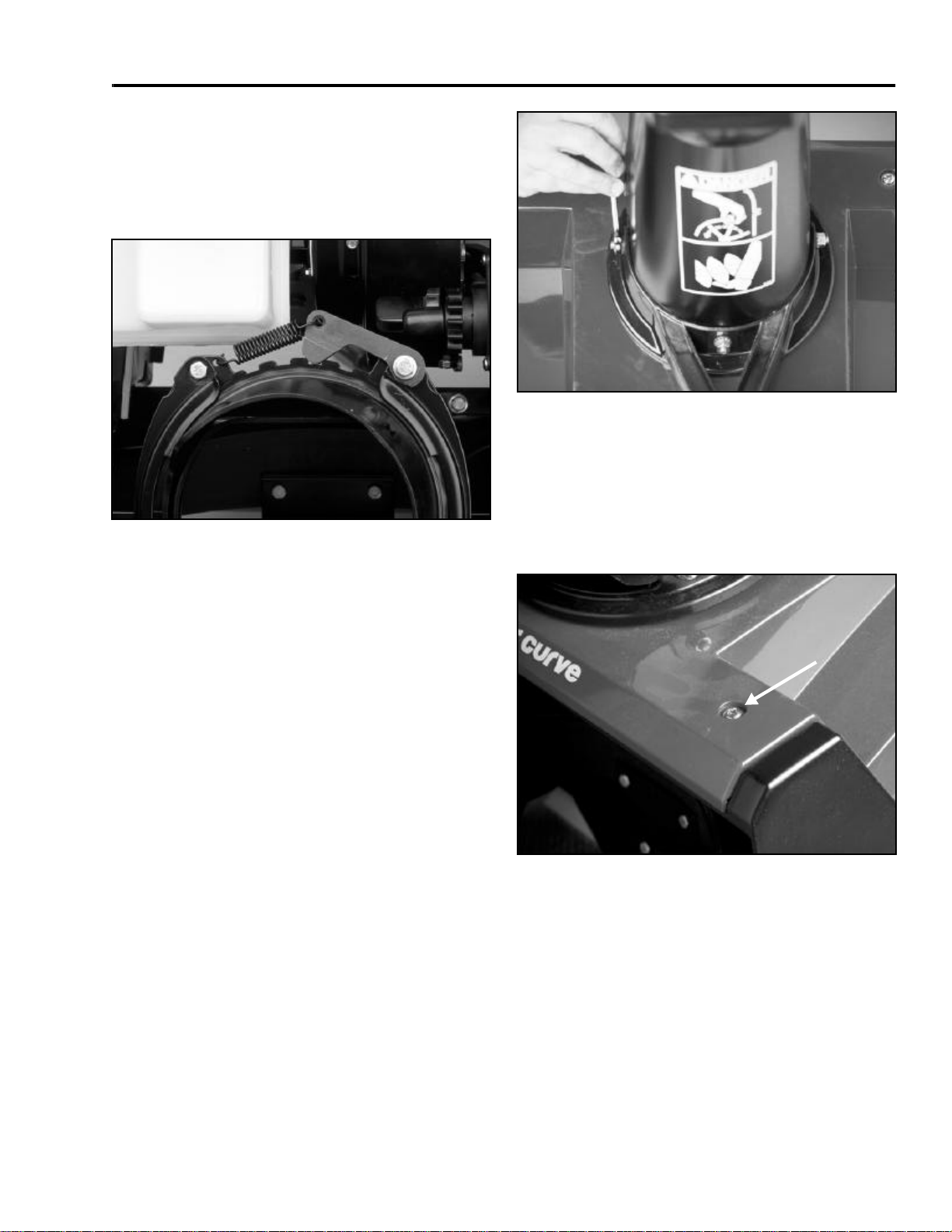

To keep the chute in the desired position, a spring

loaded chute detent is located in the rear of the

housing (Figure 25). As the chute is rotated manually,

a ratchet sound indicates that the detent is working

properly. As the handle, housing, and chute retainer

are all made of plastic, no lubrication is necessary

Figure 25 1854-40

To access the chute assembly, remove the 4 screws

holding the chute retainer to the housing and remove

the chute retainer. The chute assembly can then be

pulled forward and removed from the housing.

Figure 26 1854-12

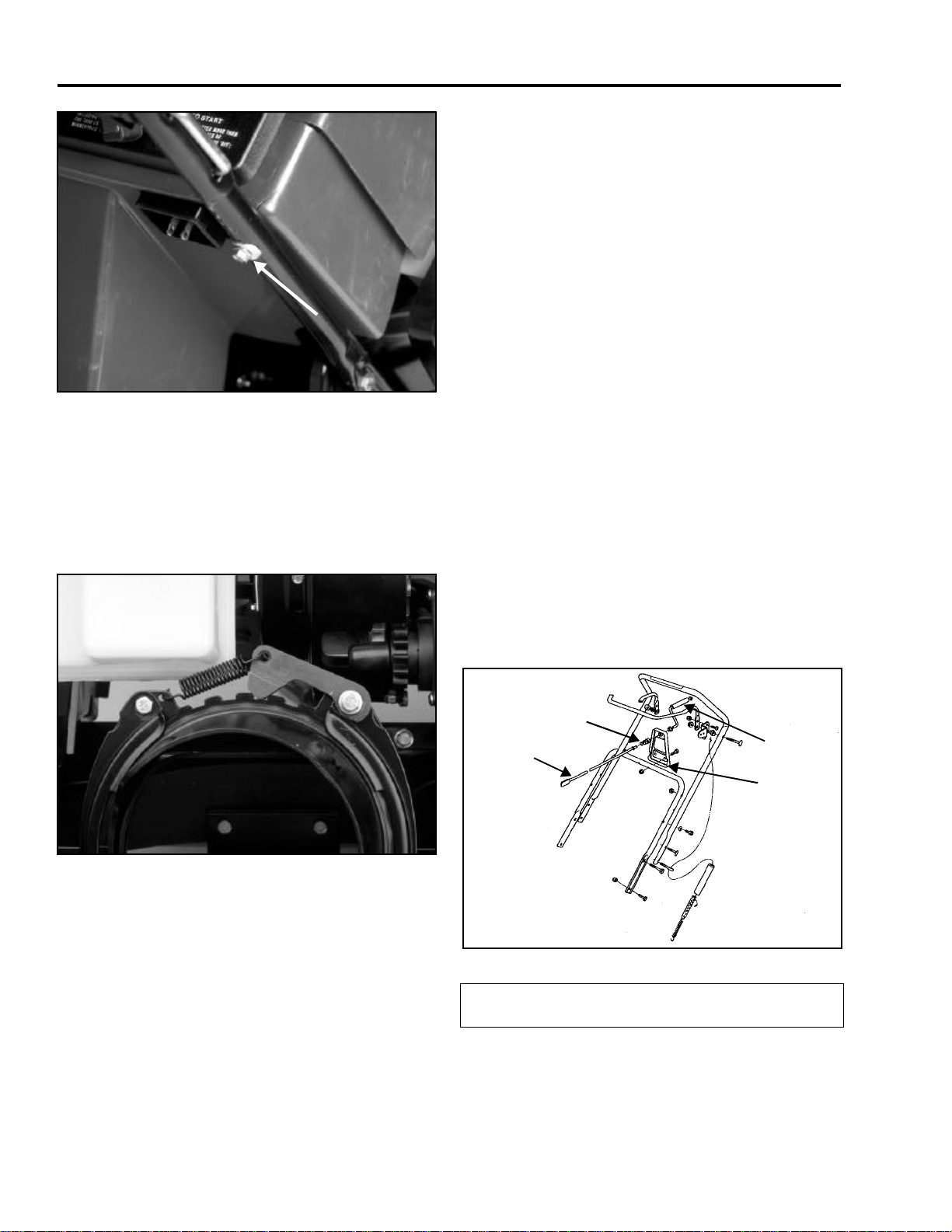

Remove the 2 screws holding the nameplate to the

chassis. Allow the nameplate to hang loose from the

starter rope (the nameplate has 3 tabs that engage the

upper shroud). Remove the two bolts and locknuts,

one in each front corner of the shroud and 2 screws,

one in each rear corner of the shroud (Figure 27 and

Figure 28).

Reassembly is accomplished by installing the springs

on the chute detent and installing the chute detent into

the rotor housing. The chute assembly can be slid into

place and the chute retainer installed (Figure 24).

20” CCR Manual Chute System

Some 20” CCR models were equipped with a manual

chute system. As with the others, the component parts

are all plastic to eliminate the need for lubrication and

reduce icing.

On this version, the discharge chute attaches to the

handle and chute ring. Three carriage head bolts and

washers connect the parts. Below the upper shroud is

the balance of the chute components.

To access the balance of the chute parts, remove the 3

carriage bolts and nuts at the base of the discharge

chute (Figure 26). Remove the chute, deflector and

handle. The upper shroud must now be removed.

Remove the bolt in each front corner.

Figure 27 1352-03

Single Stage Snowthrower Service Manual 3 - 7

Page 28

CONTROLS/LOCATION AND OPERATION

Reassembly is the reverse of disassembly.

Note: The rounded heads of the carriage bolts must

be on the inside of the chute. The smooth head

prevents snow from building up on the bolt head.

20” CCR Crank System

The third system, used on CCR2000 as well as the

2400, 2500 and 3600 series uses a crank that is

mounted to the handle.

Rotating the handle turns a set of gears that engage a

ring gear that the chute is mounted to. The gears are

contained in a bracket located under the upper shroud.

Figure 28 1352-08

The chute ring gear rests on a support and is held in

Remove the gas cap and lift the upper shroud off the

machine. Replace the gas cap to prevent fuel spillage

or dirt from entering the fuel system. Now you see the

chute ring, the two chute ring retainers, and the detent

arm and spring (Figure 29). To remove the chute ring,

remove the 4 bolts and nuts that retain the left and right

chute ring retainers.

place by two retainers. The chute retainers allow the

ring gear to rotate only.

To access the chute ring and gears:

1. Remove the 3 carriage head bolts and locknuts at

the base of the chute and lift off the chute

assembly.

Figure 29 1854-40

Note: The rear bolt in the left hand chute ring retainer

is also the pivot for the detent arm. This arm engages

the notches in the chute ring to prevent unwanted

rotation of the chute. With the four bolts removed, the

retainers and chute ring will then lift off.

These parts are all plastic to eliminate the need for

lubrication and resist icing.

2. Remove the 2 bolts and nuts that hold the chute

crank rod bracket to the lower handle and draw

the rod out of the upper shroud (Figure 30).

D

C

Figure 30 0309-22

(A) Crank Handle Grip

(B) Chute Crank Support

(C) Chute Crank Rod

(D) Spring

A

B

3 - 8 Single Stage Snowthrower Service Manual

Page 29

CONTROLS/LOCATION AND OPERATION

3. To remove the upper shroud, remove the two

bolts and locknuts in the front corners of the

shroud (Figure 31).

H

G

F

E

D

Figure 31

(A) Nameplate

(B) Control Panel

(C) Lower Shroud

(D) Push Nut

A

B

C

(E) Chute Seal Retainer

(F) Chute Seal

(G) Upper Shroud

(H) Gas Cap

6. The gears are held in the bracket by a shaft with a

push nut on either end (Figure 32). To remove the

shaft, remove one of the push nuts and pull the

shaft out.

A

Figure 32 1854-19

(A) Shaft and Push Nut

7. To reassemble, reverse the process.

4. Remove 3 screws that hold the face plate to the

control panel and let the face plate hang from the

starter rope.

5. Remove the gas cap and lift the upper shroud,

replace the gas cap. The chute ring and gears are

now all exposed.

Note: When installing the chute, the rounded

heads of the carriage bolts must be on the inside

of the chute. The smooth head prevents snow

from building up on the bolt head.

Single Stage Snowthrower Service Manual 3 - 9

Page 30

CONTROLS/LOCATION AND OPERATION

Chute Seal

This system has a seal incorporated into the upper

shroud (Figure 33). This is to prevent melted snow

from seeping into the engine compartment. To replace

the seal, remove the upper shroud in the same manner

as accessing the chute gears. Turn the shroud over

and remove the 8 pushnuts. (Cutting them with a side

cutter is the best way to remove them.) Slide the seal

and retainer off the mounting pegs and replace the seal

and retainer. Install new pushnuts, using a socket to

push them into place.

A

(A) Seal

A

Figure 33 1854-38

3 - 10 Single Stage Snowthrower Service Manual

Page 31

ENGINE REMOVAL AND INSTALLATION

1965 - 1985 MODELS, ENGINE REMOVAL

Certain engine servicing procedures will require

removing the engine from your snowthrower. The

following procedures are required for engine removal:

1. Drain the gasoline from the fuel tank. Refer to

“Draining The Fuel Tank” on page 2 - 5.

2. Remove all the mounting screws retaining the

upper shroud on 20” units. On all 14” and 21”

snowthrowers, remove both the upper and lower

shrouds. Be certain to install the gas cap after the

upper shroud is removed.

3. Disconnect the spark plug wire.

4. Pull the rope from the starter and tie a small knot

in the starter rope before the starter housing

(Figure 34). Allow the starter rope to retract until

the knot stops the starter rope at the starter

housing. Next, remove the knot in the starter

handle and slide the handle off the starter rope.

Chain Drive Units:

A. Remove the left side plate, chain guard and

chain. To remove the chain, refer to "Chain

Replacement" on page 5 - 25. Consult step 2.

B. Remove the crankshaft sprocket. Refer to

"Crankshaft Sprocket Replacement (all

models)" on page 5 - 21. Consult step 3.

6. Remove the switch terminal from the key switch if

your unit is so equipped. Some 1980 model

S-200’s may have a terminal connection slightly

below the key switch. It will be necessary to

separate the two terminals.

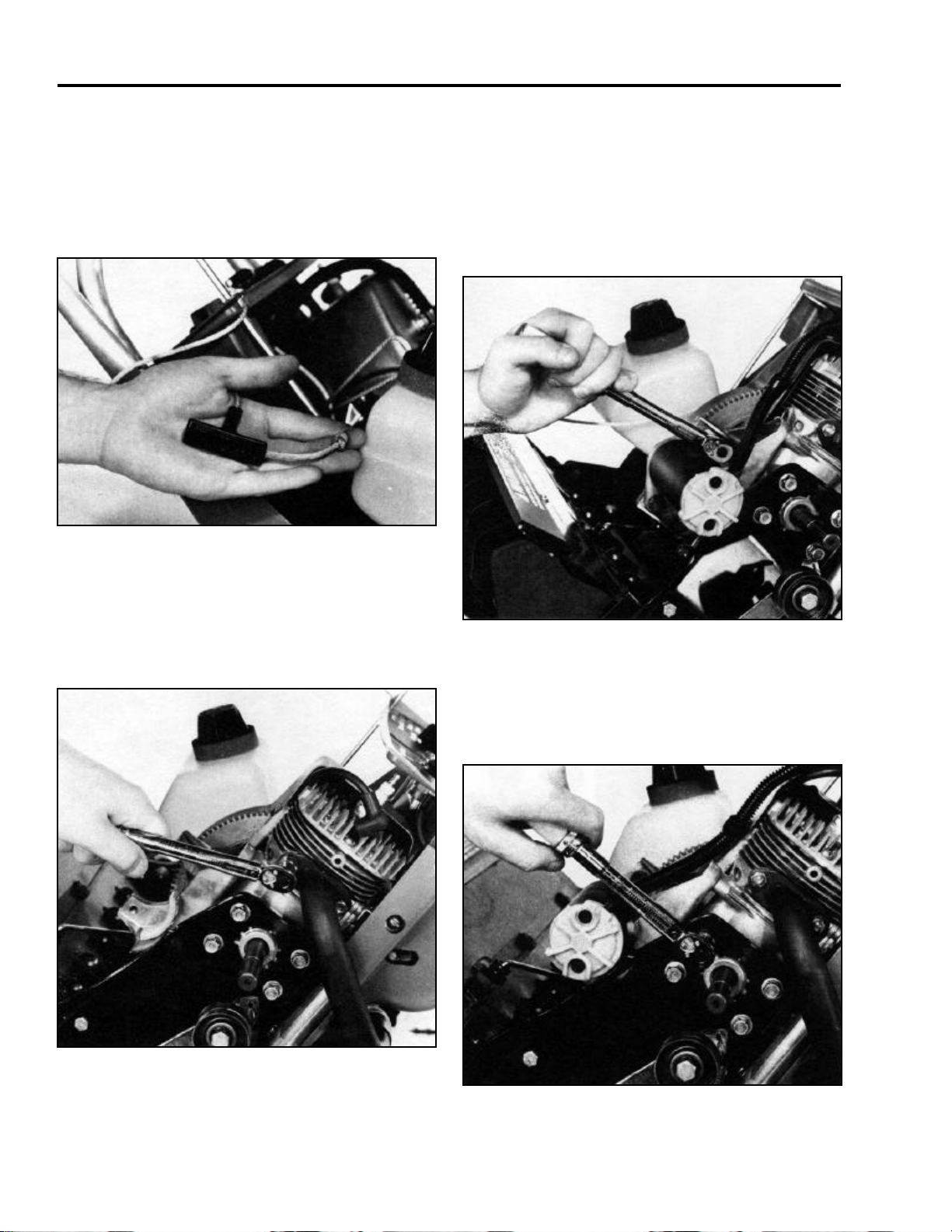

7. Slide the primer hose off the primer bulb fitting.

8. Remove the choke control. Note: Do not bend or

misform the carburetor choke control linkage.

9. Remove the mounting screws retaining the lower

shroud on all 20” units. On electric start 20” units,

remove screws retaining the switch and plug

assembly to the lower shroud.

Figure 34 0217-017

5. Belt Drive Units:

A. Remove the left side plate and belt. Refer to

"Replacing Drive Belt" on page 5 - 1.

Complete steps 1 through 4.

10. Using a hose clamp pliers or a needle nose pliers,

compress the fuel line clamp at the carburetor

fitting and slide the clamp down the fuel line hose

(Figure 35). Remove the fuel line from the

carburetor.

Figure 35 0217-018

B. Remove the crankshaft pulley. Refer to

"Replacing Drive Belt" on page 5 - 1.

Complete step 2.

Single Stage Snowthrower Service Manual 4 - 1

Page 32

ENGINE REMOVAL AND INSTALLATION

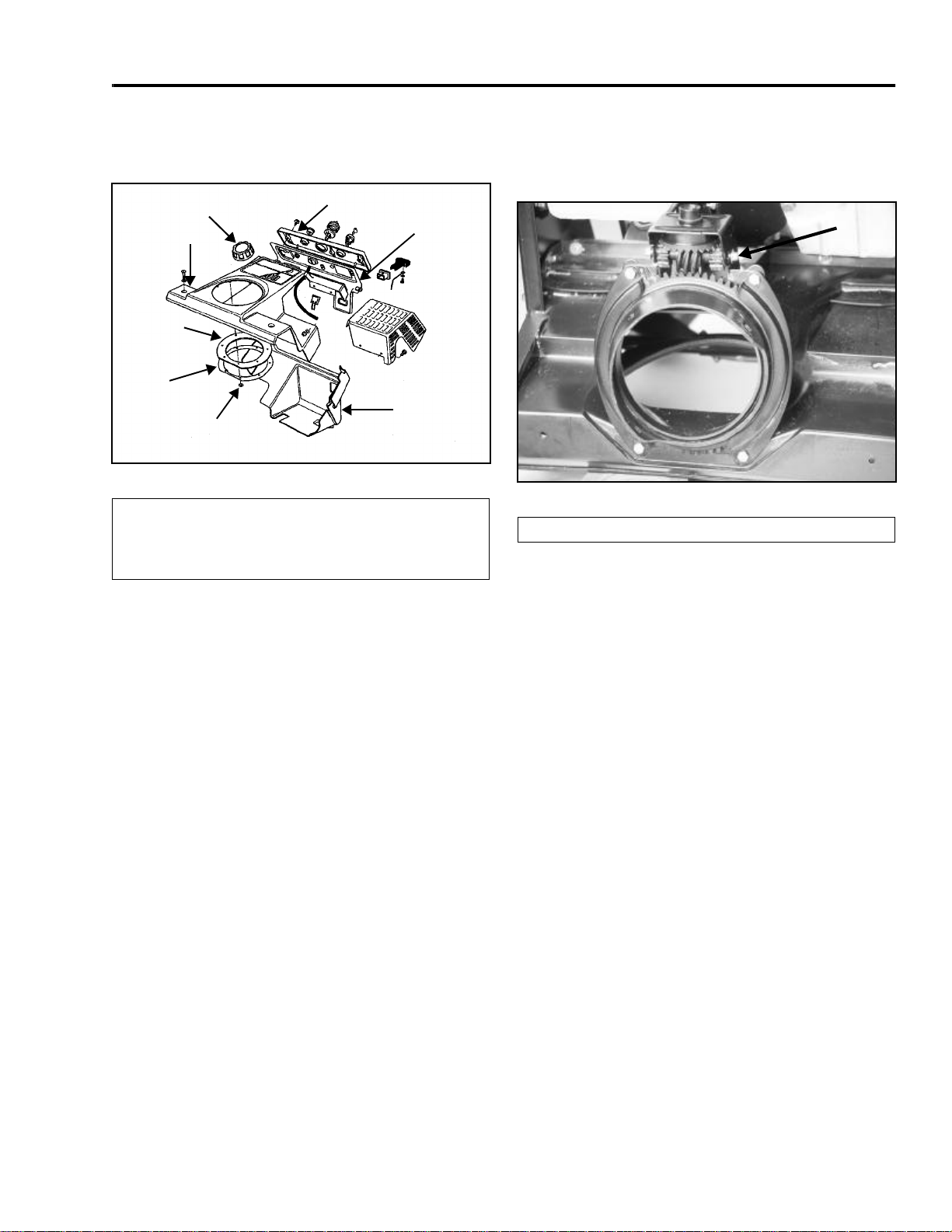

11. If your 20” Snowthrower is equipped with an

electric starter, remove the bolts retaining the

electric starter to the engine mounting bracket

(Figure 36). Also, remove the bolt and cable

clamp retaining the wire harness to the engine.

Finally, remove the motor tie down strap.

Figure 38 – 14” and 21” Models 0217-021

Note: On the 20” models, it will be necessary to

remove the small self-tapping screw retaining the vane

control rod to the vane control bracket and remove the

muffler mounting nuts.

13. Lastly, remove the four mounting nuts retaining

the engine to the engine mounting bracket on the

crankshaft side (Figure 39).

Figure 36 0217-019

12. Remove the engine mounting bracket that

supports the engine on the starter housing side

(Figure 37 and Figure 38).

The engine can now be removed from the unit for

servicing.

Figure 39 0217-022

Figure 37 – 20” Model 0217-020

4 - 2 Single Stage Snowthrower Service Manual

Page 33

ENGINE REMOVAL AND INSTALLATION

1965 - 1985 MODELS, ENGINE

INSTALLATION

After performing the necessary servicing procedures to

your engine, install the engine back into the unit.

Proceed with the following:

1. Slide the engine into the engine mounting bracket.

Loosely install the four mounting nuts to retain the

engine to the mounting bracket (Figure 40).

Figure 41 0217-024

3. Slide the fuel line or hose onto the carburetor

fitting. Compress the fuel line clamp and slide into

position.

Figure 40 0217-023

2. Install the engine mounting bracket that supports

the engine on the starter housing side. Loosely

install the starter housing nut (Figure 41). Tighten

the engine mounting bracket to the frame.

Note: On all 20” snowthrowers, install the small

self-tapping screw retaining the vane control rod

to the vane bracket. Refer to your parts manual if

additional guidance is necessary.

4. On 20” models, install the lower shroud.

5. Install the switch terminal back onto the switch if

your unit is so equipped. (On some 1980 S-200

models, the key switch has pig tail leads running

to a receptable. This receptable should be

connected to the terminal.)

6. Install the choke linkage and choke control. Take

care not to bend or misform the choke control

linkage.

7. Slide the primer hose onto the primer fitting.

Single Stage Snowthrower Service Manual 4 - 3

Page 34

ENGINE REMOVAL AND INSTALLATION

8. Pull the recoil starter rope through the hole in the

control panel (Figure 42). Next, slide the rope

onto and through the starter handle and make a

small knot. Slide the starter rope back into the

starter handle. Remove the knot in the starter

rope at the starter housing and allow the starter

rope to retract into the starter.

Figure 42 0217-025

9. On 20” models, slide the muffler into place on the

engine. Torque the muffler nuts to 90 - 120 in·lbs.

(Figure 43).

Note: Do not over torque the nuts, you may crack

the engine block.

10. If your snowthrower is equipped with an electric

starter, install the starter to the engine mounting

bracket (Figure 44). Torque the starter mounting

bolts at the mounting bracket to 120 - 180 in·lbs.

Install the wire harness with the cable clamp to the

engine. Replace the starter motor tie down strap.

Finally, mount the switch and plug assembly to the

lower shroud.

Figure 44 0217-027

11. Belt Drive Units:

Figure 43 0217-026

A. Torque the crankshaft engine mounting nut to

170 - 220 in·lbs. Then tighten the starter nut to

70 - 120 in·lbs (Figure 45).

Figure 45 0217-028

4 - 4 Single Stage Snowthrower Service Manual

Page 35

ENGINE REMOVAL AND INSTALLATION

B. Install the crankshaft pulley. Refer to

"Crankshaft Pulley Replacement" on page 5 -

3.

C. Connect the spark plug lead wire.

D. Install the belt and side plate. Refer to

"Replacing Drive Belt" on page 5 - 1.

Complete Steps 5 through 7.

Chain Drive Units:

A. Install the crankshaft sprocket. Be certain to

align the keyway (slot) of the crankshaft

sprocket with the location key on the

crankshaft. Should the locating key on the

crankshaft show signs of wear, replace.

B. Install the chain. Refer to "Chain

Replacement" on page 5 - 25. Do Step 3.

Align and adjust the chain. Refer to

"Crankshaft Sprocket Replacement (all

models)" on page 5 - 21. Consult Steps 5

through 8.

C. Install left side plate and chainguard.

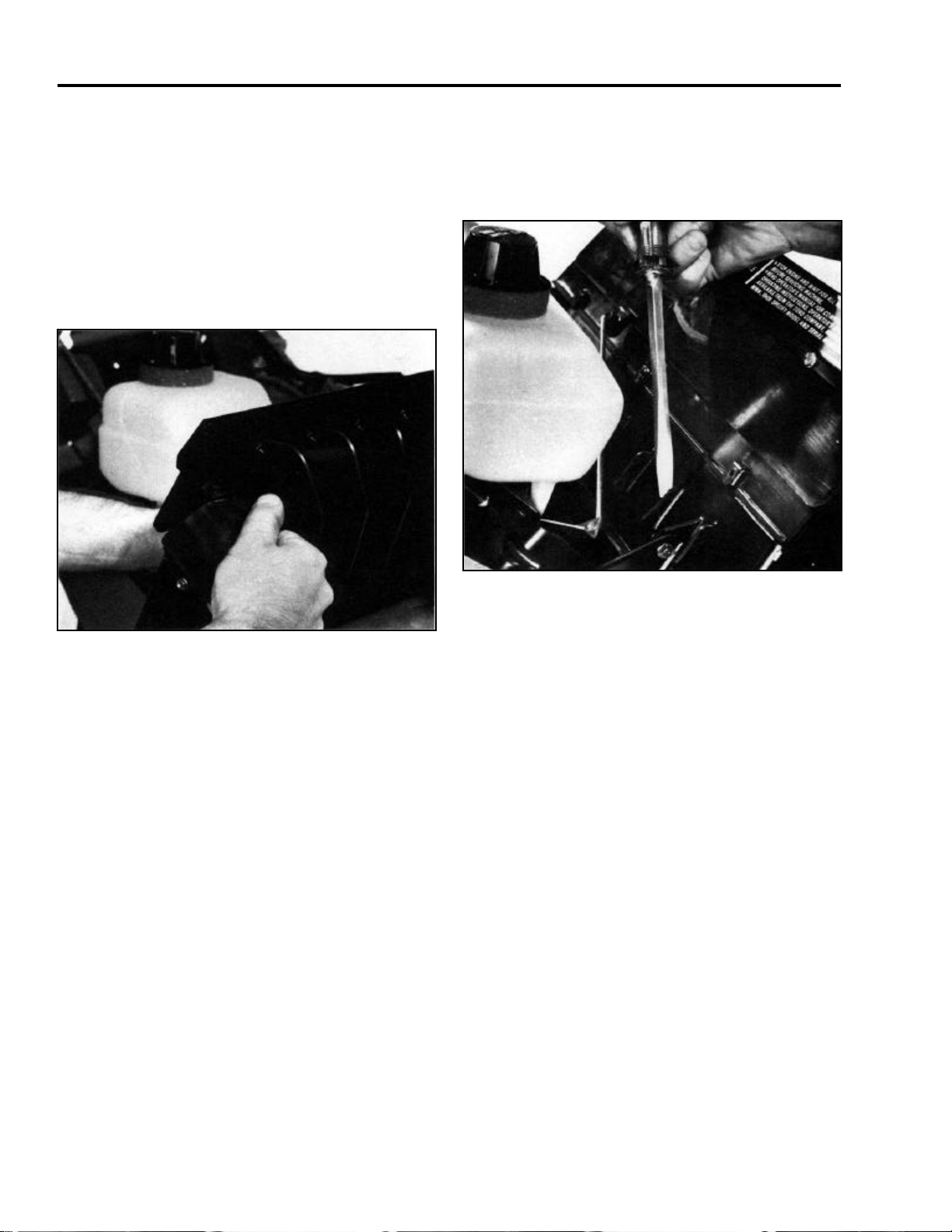

3. Remove the belt from the engine pulley and

remove the engine pulley and key if so equipped

(Figure 47).

Figure 47 1854-35-2

4. Remove the two screws at the bottom of the

control panel and remove the control panel cover

(Figure 48).

D. Connect the spark plug lead wire.

POWERLITE, ENGINE REMOVAL

1. Use a pump type siphon to remove the fuel from

the fuel tank.

2. Remove the belt cover from the left side (Figure

46).

A

Figure 48 1854-42

(A) Screws

Figure 46 1854-35

Single Stage Snowthrower Service Manual 4 - 5

Page 36

ENGINE REMOVAL AND INSTALLATION

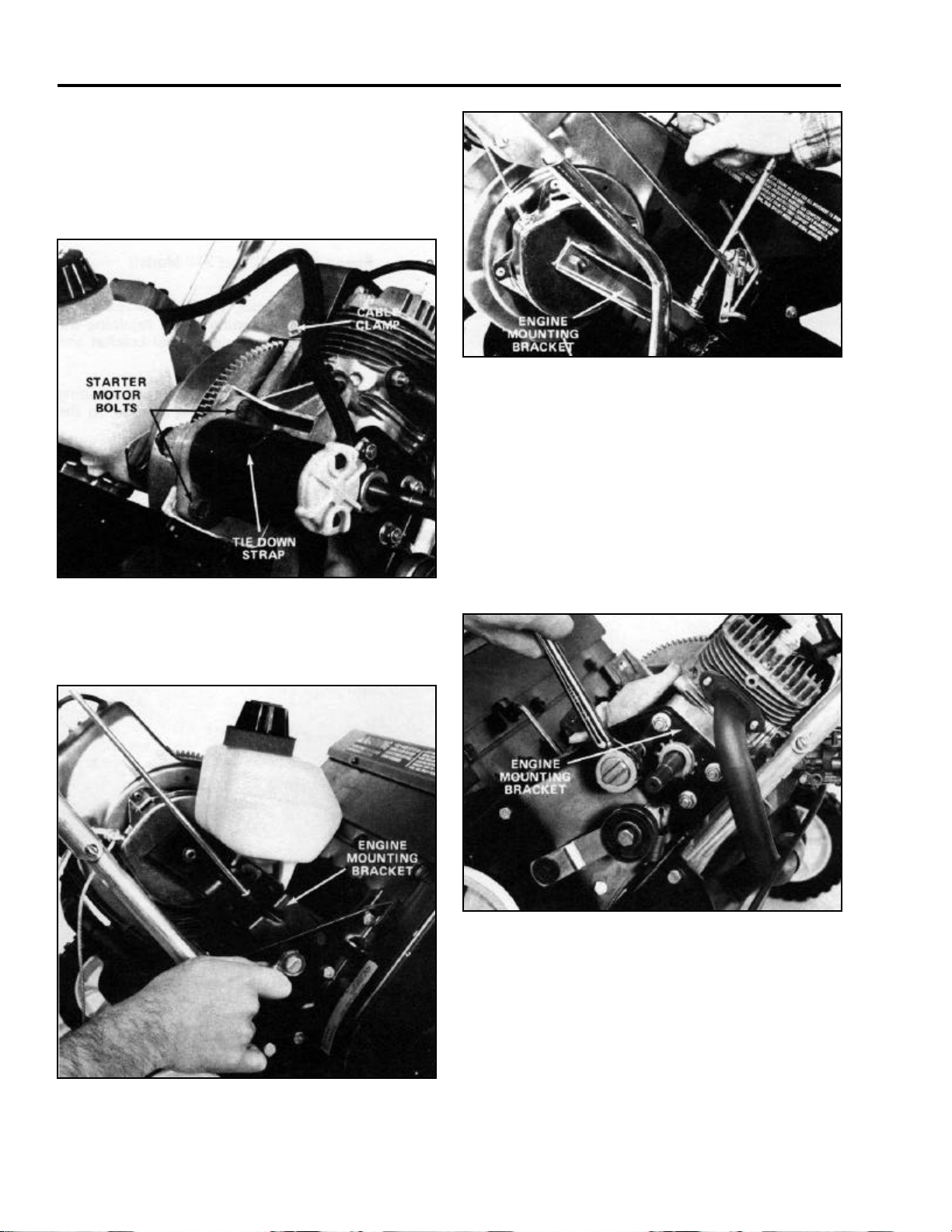

5. The upper shroud/fuel tank is retained by one

screw in each corner. On electric start models

only, remove the three screws surrounding the

starter button (Figure 52). These screws hold the

switch box to the upper shroud. Unless they are

removed the wire harness between the switch box

and the starter motor will prevent complete shroud

removal (Figure 49). Once they are removed the

upper shroud and tank can be lifted enough to

remove the primer line, unplug the wiring from the

switch and the fuel line from the fitting on the

bottom of the tank. Note: There might be a small

amount of fuel in the fuel line. Be prepared with a

shop towel to catch any remaining fuel.

Depending on what work is to be done, the shroud

could hang from the starter rope. If the engine is

to be removed, tie a knot in the starter rope

between the recoil starter and the shroud. The

knot in the starter handle can now be untied and

the rope pulled through the shroud.

A

B

(A) Bracket

(B) Locknut

7. The engine can now be moved to the right until

the 4 mounting studs clear the side plate and the

engine can be lifted out. (Caution: The choke

arm protrudes through a slot in the lower shroud,

do not damage it when lifting the engine out of the

chassis.) (Figure 51). You may prefer to remove

the lower shroud as there are only two screws

holding it on. Note: There is a second engine

plate on the inside of the side plate, this may fall

off when the engine is lifted out of the chassis.

A

B

C

Figure 50 1854-17-2

(C) Stud

Figure 49 1854-06

(A) Switch Box (B) Wire Harness

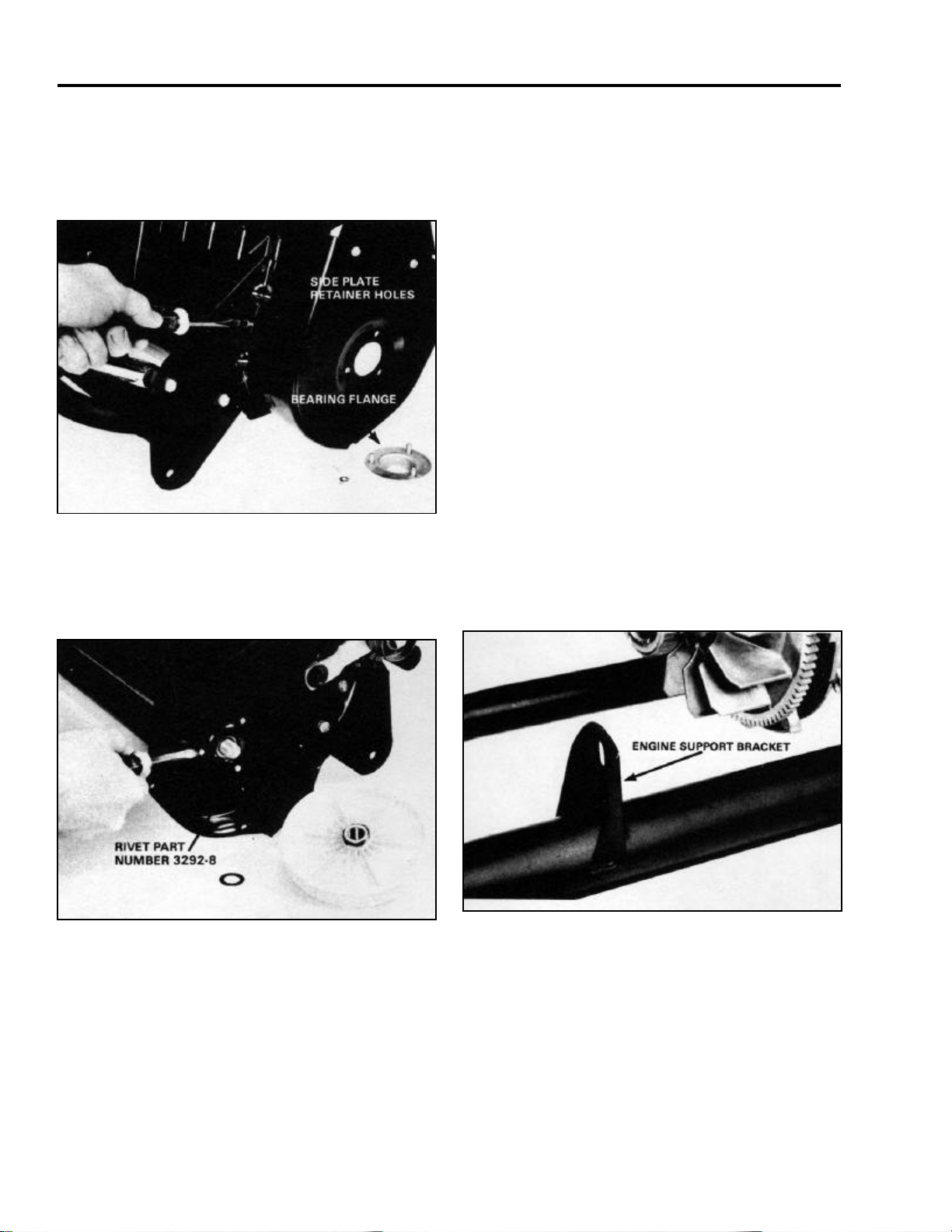

6. The recoil side of the engine is supported by a

bracket. Remove the bracket or remove the

locknut holding the bracket to the recoil (it may be

necessary to loosen the bracket to disengage it

from the stud on the recoil) (Figure 50). Remove

the 4 nuts around the crankshaft and slide the

plate off the crankshaft.

4 - 6 Single Stage Snowthrower Service Manual

Figure 51 1854-36

Page 37

ENGINE REMOVAL AND INSTALLATION

Alternate Method

1. Remove the fuel with a pump type siphon. Tilt the

machine forward so it rests on the rotor housing

and the chute.

2. Remove the belt cover, belt, and engine pulley.

3. Remove the two screws holding the control panel

and let the control panel hang from the starter

rope.

4. Remove the two hex head capscrews holding the

lower shroud to the handles.

5. As you lift the lower shroud up, you will need to

reach in and unhook the primer line and the wiring

to the switch. Pull the starter rope out and tie it to

the handle so it doesn’t restrict the removal of the

lower shroud. Caution: The choke lever goes

through a slot in the lower shroud. Do not

damage the lever while removing the shroud.

6. The balance of engine removal is the same as the

previous process.

POWERLITE, ENGINE INSTALLATION

Installation is the reverse of removal. There are some

things worthy of mentioning.

1. One engine side plate must be installed over the

engine mounting studs before the engine is placed

in the chassis.

20” CCR, ALL MODELS, ENGINE

REMOVAL

The engine can be removed from the top or bottom.

We will cover the steps for both.

1. Remove the 3 bolts on the chute and 2 more

where the chute crank attaches to the handle (on

models so equipped). Some models use a chute

handle to rotate the chute; this will come off when

the chute is removed.

2. Drain the fuel tank using a pump type siphon.

3. Remove the 3 screws securing the control panel.

Let the panel hang from the starter rope.

4. The upper shroud is retained with a bolt and

locknut in each front corner and some have a

screw in each rear corner. On some models, the

rear of the shroud is retained by the control panel.

Electric Start models only - The electric start

switch box is attached to the upper shroud or the

control panel (Figure 52). There are 3 screws

next to the electric start button that must be

removed or the wire harness between the switch

box and starter motor will prevent removal of the

shroud (on some models) and engine removal on

all models. Remove the gas cap and the shroud

will lift off.

2. When installing the engine, be sure to feed the

choke lever through the slot in the lower shroud.

3. After the engine is located in the chassis, install

the second engine plate and the 4 mounting nuts.

4. Install the stabilizer bracket to the recoil side of the

engine and torque the nut to 30 in·lbs. Tighten the

4 engine mounting nuts to 170 - 220 in·lbs.

(A) 3 Screws

Single Stage Snowthrower Service Manual 4 - 7

A

Figure 52 1854-11

Page 38

ENGINE REMOVAL AND INSTALLATION

5. On most models, the fuel tank is mounted at 3

points with capscrews and locknuts on two of the

points, the third point is a pin on the chassis that

goes through a rubber grommet (Figure 53) on the

bottom of the tank. CCR1000’s use a tongue and

groove system and one (Figure 54) mounting

screw. Remove them and lift the tank out. Now

disconnect the fuel line. Caution: If the tank had

fuel in it, there will be some remaining in the fuel

line. Be prepared to clamp the end of the fuel line

or drain it. Note: Do not use a screw or bolt to

plug the end of the fuel line. The threads can

damage the inside of the fuel line and prevent it

from sealing.

(A) Screw (B) Fuel Tank

D

6. Disconnect the wiring to the switch and the primer

line.

A

B

Figure 54 1854-14

C

(A) Stabilizer Bracket

(B) Recoil Starter

A

B

Figure 53 1854-18

(C) Rubber Grommet

(D) Pin

7. Tie a knot in the starter rope BETWEEN the

control panel and the engine. The knot in the

starter handle can now be untied and the rope

pulled through the control panel. (A slip knot is

recommended, it can be untied, at any time, by

merely pulling on the rope.)

8. Remove the locknut connecting the engine

stabilizer bracket to the recoil starter. You may

wish to loosen the bracket at the other end to pivot

it away from the engine.

9. Remove the belt cover and roll the belt off the

engine pulley. Loosen the 2 set screws, remove

the engine pulley and key (Figure 55).

4 - 8 Single Stage Snowthrower Service Manual

Page 39

ENGINE REMOVAL AND INSTALLATION

1

2

A

Figure 55 1854-02

(A) Set Screws

10. Remove the screw securing the choke knob to the

choke rod. Note how the choke rod is connected

to the engine, then remove the choke rod.

11. Remove the 4 bolts or locknuts (depending on the

model) around the crankshaft (Figure 56). These

are the last fasteners retaining the engine. Lift the

engine out of the chassis.

4

3

Figure 56 1854-03

1-4 engine mounting bolts or locknuts (depending on

model)

20” CCR, ALL MODELS, ENGINE

ASSEMBLY

Assembly is the reverse of the removal procedure.

Torque the 4 engine mounting nuts to 170 - 220 in·lbs.

and the nut on the engine stabilizer bracket to 30 in·lbs.

Single Stage Snowthrower Service Manual 4 - 9

Page 40

THIS PAGE INTENTIONALLY LEFT BLANK

4 - 10 Single Stage Snowthrower Service Manual

Page 41

DRIVE SYSTEMS

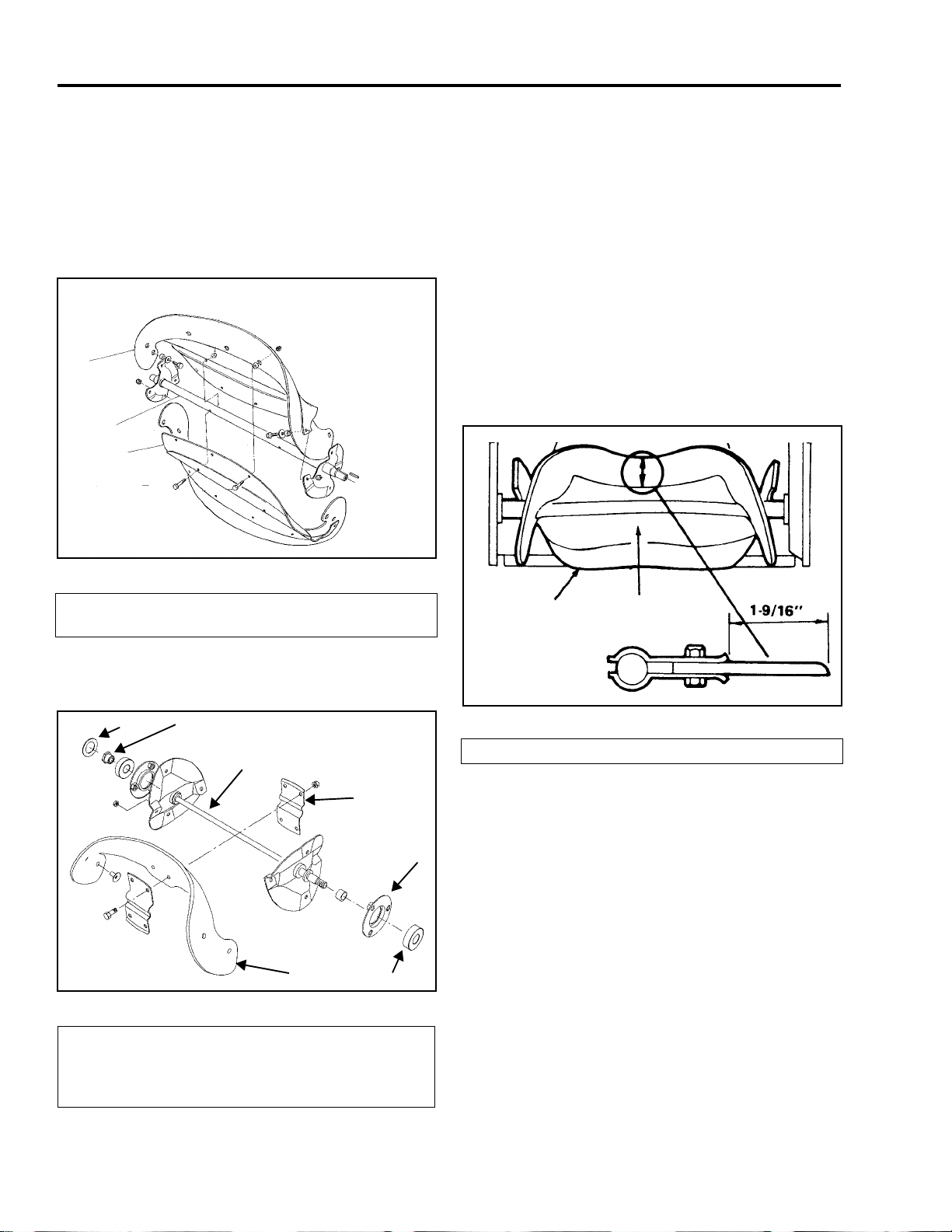

DRIVE SYSTEM (BELT) SNOWMASTER S-200, S-620

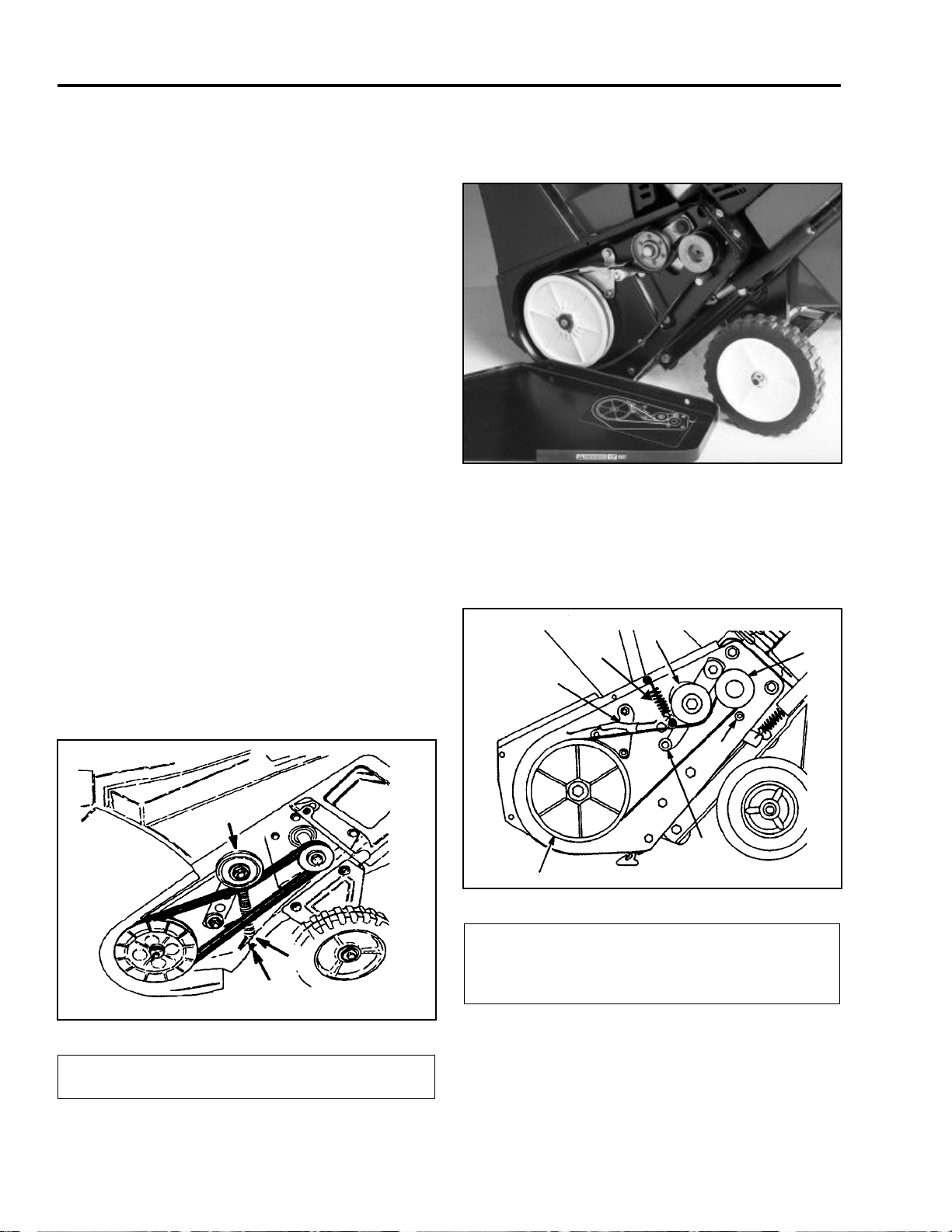

The Toro belt drive system, which is utilized on all 20”

Snowmasters and S-200’s, consists of a crankshaft

pulley, a rotor pulley, a spring loaded idler and a

multigrooved V-belt (Figure 57.). The power from the

engine is transferred from the crankshaft pulley to a

rotor pulley by the multigrooved V-belt. A constant

tension is supplied to the V-belt from the spring loaded

idler.

3. Move the idler pulley up and away from the V-belt

and pull the belt out so it is free; then allow the

spring loaded idler to release (Figure 59).

Note: Do not allow the idler to snap when

released as damage to components may occur.

4. Remove the drive belt from the impeller pulley and

engine pulley.

Figure 57 0217-029

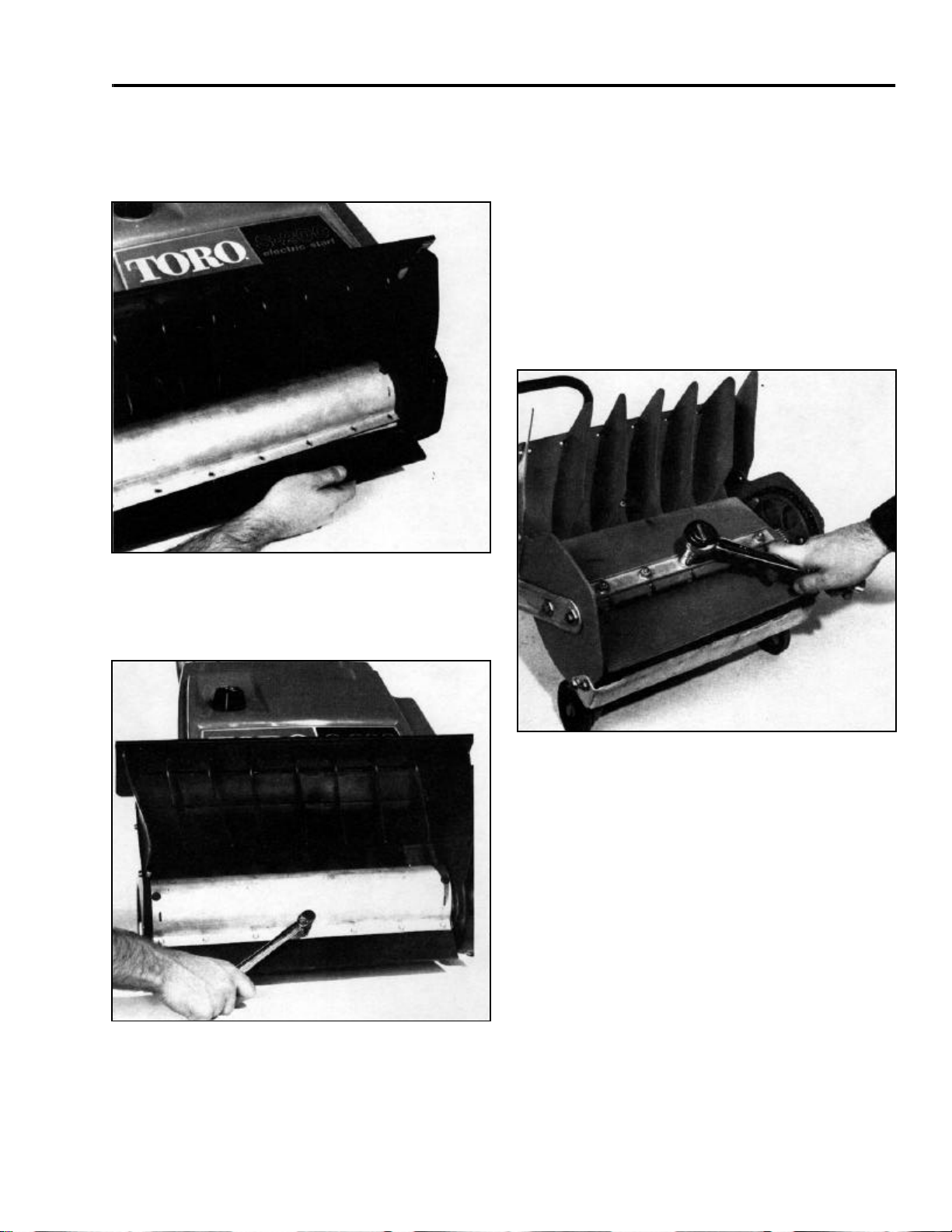

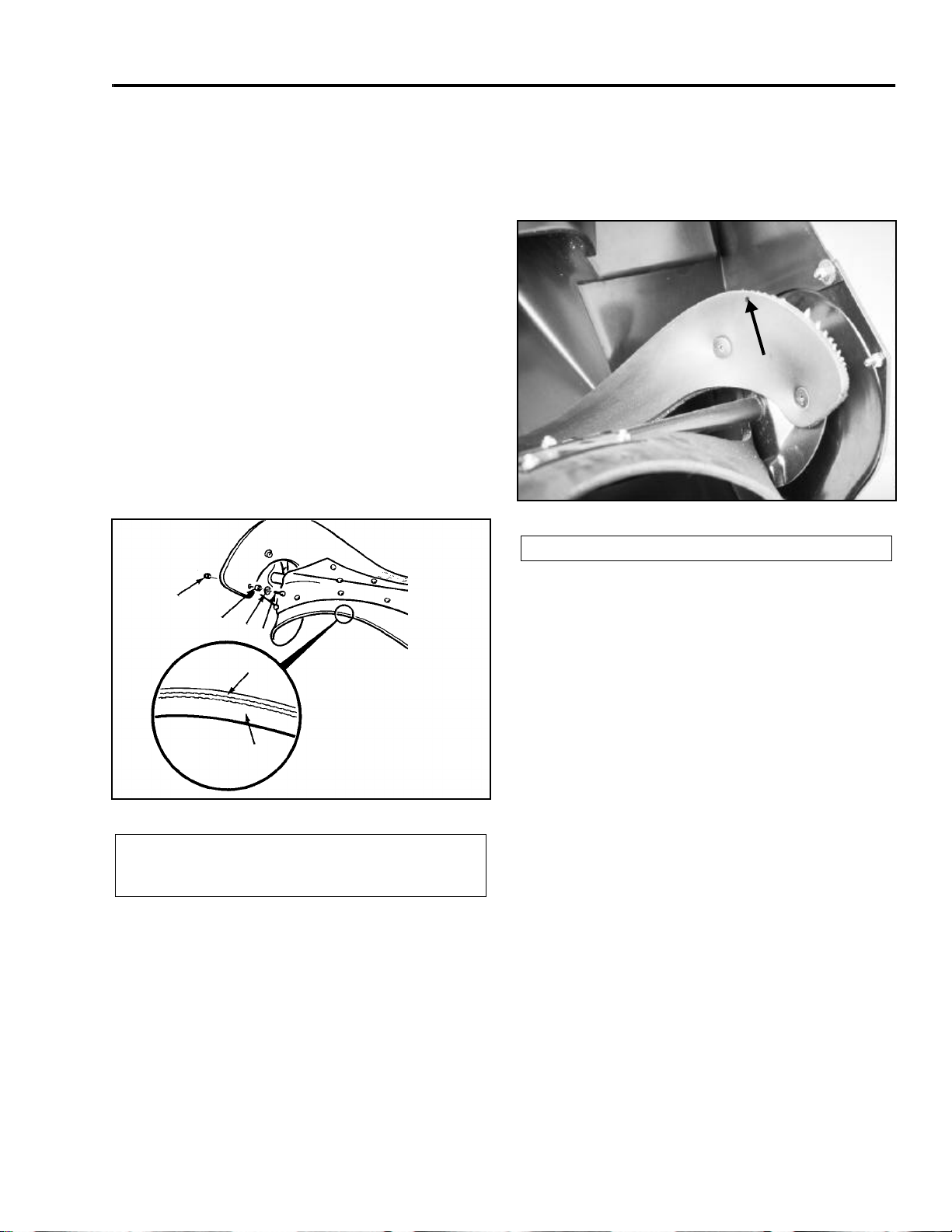

Replacing Drive Belt

The belt that drives the impeller may become worn

after many hours of use. This wear will cause the

impeller to slip. If the impeller slips, the V-belt should

be replaced.

To Replace The Belt

1. Turn the key to the “OFF” position.

2. Remove the washer faced cap screw. On the

1975 Snowmaster, the cap screw is located at the

top of the drive cover. Next, remove the four

screws and locknuts holding the drive cover in

place (Figure 58). Remove the cover.

Figure 58 0217-030

Figure 59 0217-031

Single Stage Snowthrower Service Manual 5 - 1

Page 42

DRIVE SYSTEMS

5. When installing the replacement belt, loop the belt

around the engine pulley and under the idler

pulley. Now start the belt around the impeller

pulley (Figure 60).

Figure 60 0217-032

6. After the belt is started around the impeller pulley,

pull the idler up and rotate the impeller pulley

forward allowing the belt to roll on (Figure 61).

7. Finally, install the drive cover with the washerfaced cap screw, four screws, and locknuts.

Belt Alignment

Whenever a pulley is removed, or if belt jumping is

experienced, belt alignment will be necessary. To align

the crankshaft pulley and rotor pulley perform the

following procedures. They are:

1. Refer to "Replacing Drive Belt" on page 5 - 1.

Complete steps 1 and 2.

2. Loosen the two allen head screws on the

crankshaft pulley (Figure 62).

Figure 62 0217-034

Figure 61 0217-033

5 - 2 Single Stage Snowthrower Service Manual

Page 43

DRIVE SYSTEMS

3. Align the crankshaft pulley and rotor pulley with a

straight edge (ie. ruler, piece of wood, etc...)

(Figure 63).

Figure 63 0217-035

Crankshaft Pulley Replacement

1. Refer to "Replacing Drive Belt" on page 5 - 1.

Complete steps 1 through 4.

2. Loosen the two allen head screws on crankshaft

pulley. Slide pulley off crankshaft (Figure 62).

3. Slide replacement crankshaft pulley on the

crankshaft. Be certain to align the keyway (slot) in

the crankshaft pulley with the location key on the

crankshaft. Should the location key on the

crankshaft show signs of wear, replace (Figure

64).

4. When both pulleys are aligned with respect to the

straight edge, tighten the allen head screws on the

crankshaft pulley.

5. If the idler pulley is not centered with respect to

the V-belt, adjust by bending the idler arm.

6. Refer to "Replacing Drive Belt" on page 5 - 1.

Complete step 7.

Figure 64 0217-036

4. Refer to "Belt Alignment" on page 5 - 2 (Figure

63). Perform steps 3 through 5.

5. Refer to "Replacing Drive Belt" on page 5 - 1.

Complete steps 5 through 7.

Single Stage Snowthrower Service Manual 5 - 3

Page 44

DRIVE SYSTEMS

Idler Spring Replacement

1. Refer to "Replacing Drive Belt" on page 5 - 1.

Complete steps 1 through 4.

2. Using a needle nose pliers, remove the idler

spring from the idler arm then from the left side

plate (Figure 65). Pay close attention to the shape

of the ends of the idler spring. The ends have

different shapes; the more closed end of the

spring rides in a small hole in the idler arm, while

the more open end is fastened to a small hole in

the left side plate.

4. Refer to "Replacing Drive Belt" on page 5 - 1.

Complete the idler spring replacement with steps

5 through 7.

Figure 66 0217-038

Idler Arm And Pulley Replacement

Figure 65 0217-037

3. When installing the replacement spring, slide the

more opened end of spring into the left side plate

first (Figure 66). Next, slip the more closed end of

the spring into the small hole in the idler arm.

1. Refer to "Replacing Drive Belt" on page 5 - 1.

Begin with steps 1 through 4.

2. Remove all the self-tapping screws retaining the

upper shroud to the snowthrower. Remove the

upper shroud. Also, remove the idler spring.

Refer to "Idler Spring Replacement" on page 5 - 4.

Complete step 2.

IMPORTANT: When servicing the idler assembly,

pay special attention as it is disassembled. When

you reassemble the idler assembly, you may wish

to consult the parts manual for your unit.

5 - 4 Single Stage Snowthrower Service Manual

Page 45

DRIVE SYSTEMS

3. Using a 5/8” open end wrench and a 1/2” socket

wrench, remove the shoulder bolt, washers, and

nut, retaining the idler assembly to the left side

plate (Figure 67). At this point, inspect the entire

assembly. If the idler arm is misformed, replace.

Also, inspect the washers for excessive wear.

Replace if necessary.

5. Reassemble the idler assembly and attach it to

the left side plate with shoulder bolt, washers, and

nut (Figure 69). Tighten the nut firmly.

Figure 69 0217-041

Figure 67 0217-039

4. By removing the capscrew and locknut that retains

the idler pulley to the idler arm, the idler pulley can

be removed and the bearings can be inspected

(Figure 68). Should the bearing have unusual