Toro 31236, Groundsmaster 360, 31230 Operator's Manual

FormNo.3403-595RevA

Groundsmaster

®

3604-Wheel

DriveMulti-PurposeMachine

withCab

ModelNo.31236—SerialNo.316000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3403-595*A

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

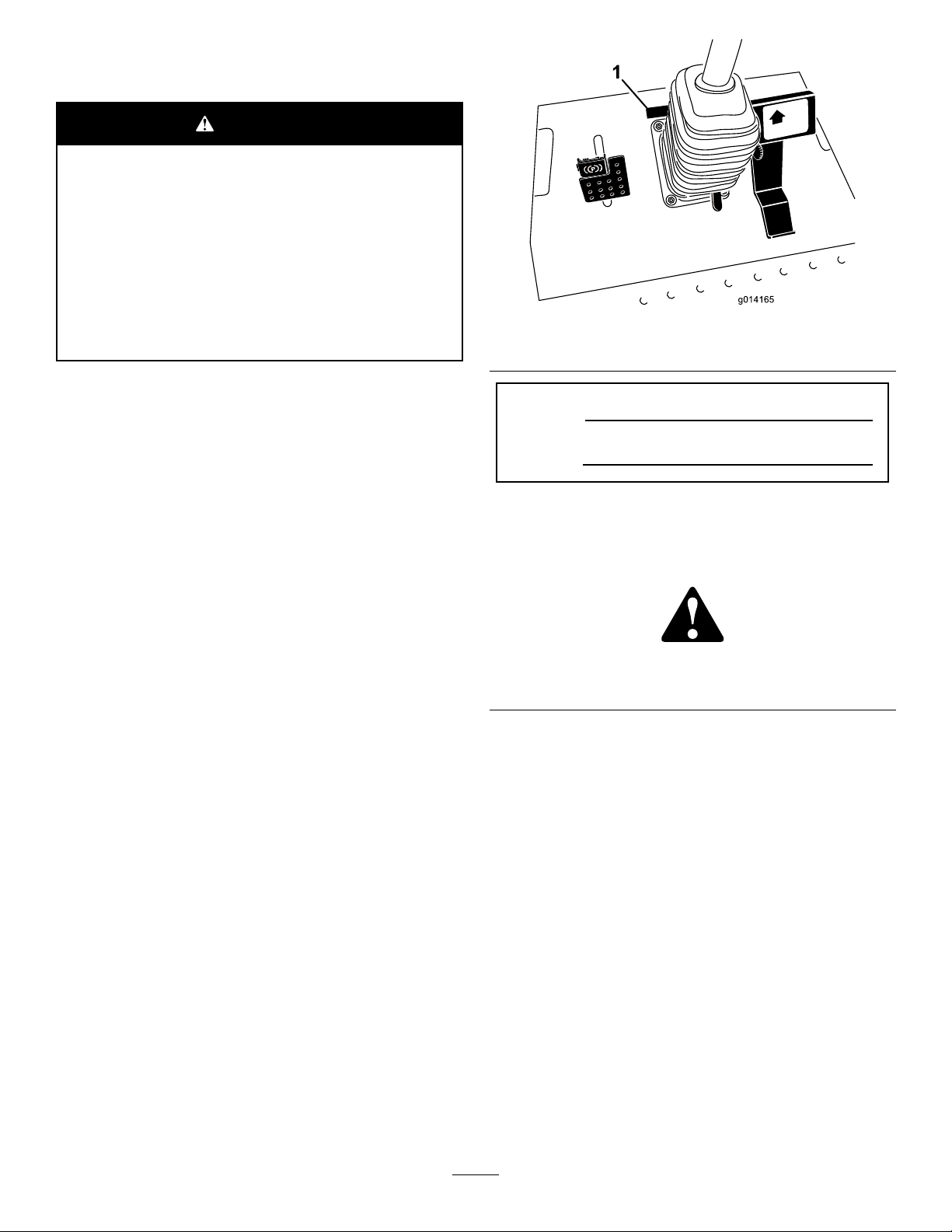

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Introduction

Thismachineisaride-on,multi-purposemachineintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedformaintaininggrass

onwell-maintainedlawnsinparks,sportselds,andon

commercialgrounds.Itisnotdesignedforcuttingbrush,

mowinggrassandothergrowthalongsidehighways,orfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety...........................................................................4

GeneralSafety.........................................................4

SoundPressure.......................................................4

SoundPower..........................................................4

VibrationLevel......................................................4

SafetyandInstructionalDecals.................................5

Setup...........................................................................10

1InstallingthePTODriveshafttoanOptional

MowerDeckorQAS...........................................10

2UsingtheOptionalMower-Deck-Mounting

Hardware...........................................................11

3CheckingtheTirePressure....................................11

4CheckingtheFluidLevels.....................................11

ProductOverview.........................................................12

Controls...............................................................12

CabControls......................................................14

Specications........................................................15

Attachments/Accessories........................................15

BeforeOperation......................................................15

BeforeOperationSafety..........................................15

FillingtheFuelTank...............................................16

PositioningtheStandardSeat...................................17

PositioningtheDeluxeSeat......................................18

RaisingandLoweringtheSeat..................................19

DuringOperation.....................................................19

DuringOperationSafety.........................................19

ThinkSafetyFirst...................................................20

UsingtheRollover-ProtectionSystem(ROPS)............20

StartingandShuttingofftheEngine..........................21

DrivingtheMachine...............................................22

StoppingtheMachine.............................................22

TheSafety-InterlockSystem....................................22

UnderstandingtheDiagnosticLight..........................23

DiagnosticAceDisplay...........................................23

CheckingtheInterlockSwitches...............................24

OperatingaMowerDeckorAttachment....................25

AdjustingtheHeight-of-Cut....................................26

SelectingTwo-orFour-WheelSteering......................26

OperatingTips......................................................27

AfterOperation........................................................27

AfterOperationSafety............................................27

PushingtheMachinebyHand..................................28

HaulingtheMachine...............................................28

Maintenance.................................................................29

RecommendedMaintenanceSchedule(s)......................29

DailyMaintenanceChecklist....................................30

PremaintenanceProcedures........................................31

Pre-MaintenanceSafety...........................................31

PreparingtheMachineforMaintenance.....................32

UsingtheHood-PropRod.......................................32

Lubrication...............................................................32

GreasingtheBearingsandBushings..........................32

EngineMaintenance..................................................35

EngineSafety.........................................................35

ServicingtheAirCleaner.........................................35

CheckingtheEngine-OilLevel.................................35

ChangingtheEngineOilandFilter...........................36

AdjustingtheThrottle.............................................36

FuelSystemMaintenance...........................................37

ServicingtheWaterSeparator..................................37

BleedingtheFuelSystem.........................................38

BleedingAirfromtheFuelInjectors..........................38

CleaningtheFuelTank............................................38

CheckingtheFuelLinesandConnections..................38

ElectricalSystemMaintenance....................................39

ElectricalSystemSafety...........................................39

CheckingtheFuses.................................................39

ServicingtheBattery...............................................39

StoringtheBattery..................................................40

DriveSystemMaintenance.........................................40

CheckingtheTirePressure......................................40

CorrectingtheSteeringMisalignment........................40

CoolingSystemMaintenance......................................41

CoolingSystemSafety.............................................41

CheckingtheCoolingSystem..................................41

CleaningtheRadiator..............................................41

BrakeMaintenance....................................................42

AdjustingtheServiceBrakes....................................42

AdjustingtheParkingBrake....................................42

BeltMaintenance......................................................43

CheckingtheAlternatorBelt...................................43

ControlsSystemMaintenance.....................................44

AdjustingtheTractionDriveforNeutral....................44

AdjustingtheMaximumGroundSpeed.....................44

HydraulicSystemMaintenance....................................45

HydraulicSystemSafety..........................................45

CheckingtheHydraulicSystem................................45

ChangingtheHydraulicFluidandFilter.....................46

CabMaintenance.......................................................47

FillingtheWasher-FluidBottle.................................47

CleaningtheCabAirFilters.....................................47

CleaningtheAir-ConditioningCoil..........................48

Cleaning...................................................................49

CleaningtheCab....................................................49

WasteDisposal.......................................................49

Storage........................................................................49

ServicingtheEngine...............................................49

ServicingtheMachine.............................................49

3

Safety

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013andANSIB71.4-2012.

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theinstructionmayresultinpersonalinjuryordeath.

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof87

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof103dBA,

whichincludesanUncertaintyValue(K)of1dBA.

GeneralSafety

Thisproductiscapableofamputatinghandsandfeetand

ofthrowingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustoyouandbystanders.

•ReadandunderstandthecontentsofthisOperator’ sManual

beforeyoustarttheengine.Ensurethateveryoneusing

thisproductknowshowtouseitandunderstandsthe

warnings.

•Donotputyourhandsorfeetnearmovingcomponents

ofthemachine.

•Donotoperatethemachinewithoutallguardsandother

safetyprotectivedevicesinplaceandworkingonthe

machine.

•Keepclearofanydischargeopening.Keepbystandersa

safedistancefromthemachine.

•Keepchildrenoutoftheoperatingarea.Neverallow

childrentooperatethemachine.

•Stopthemachineandshutofftheenginebeforeservicing,

fueling,oruncloggingthemachine.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=0.39m/s

Measuredvibrationlevelforlefthand=0.34m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

WholeBody

Measuredvibrationlevel=0.41m/s

UncertaintyValue(K)=0.5m/s

2

2

2

2

2

Improperlyusingormaintainingthismachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theseinstructionsmayresultinpersonalinjuryordeath.

Youcanndadditionalitemsofsafetyinformationintheir

respectivesectionsthroughoutthismanual.

4

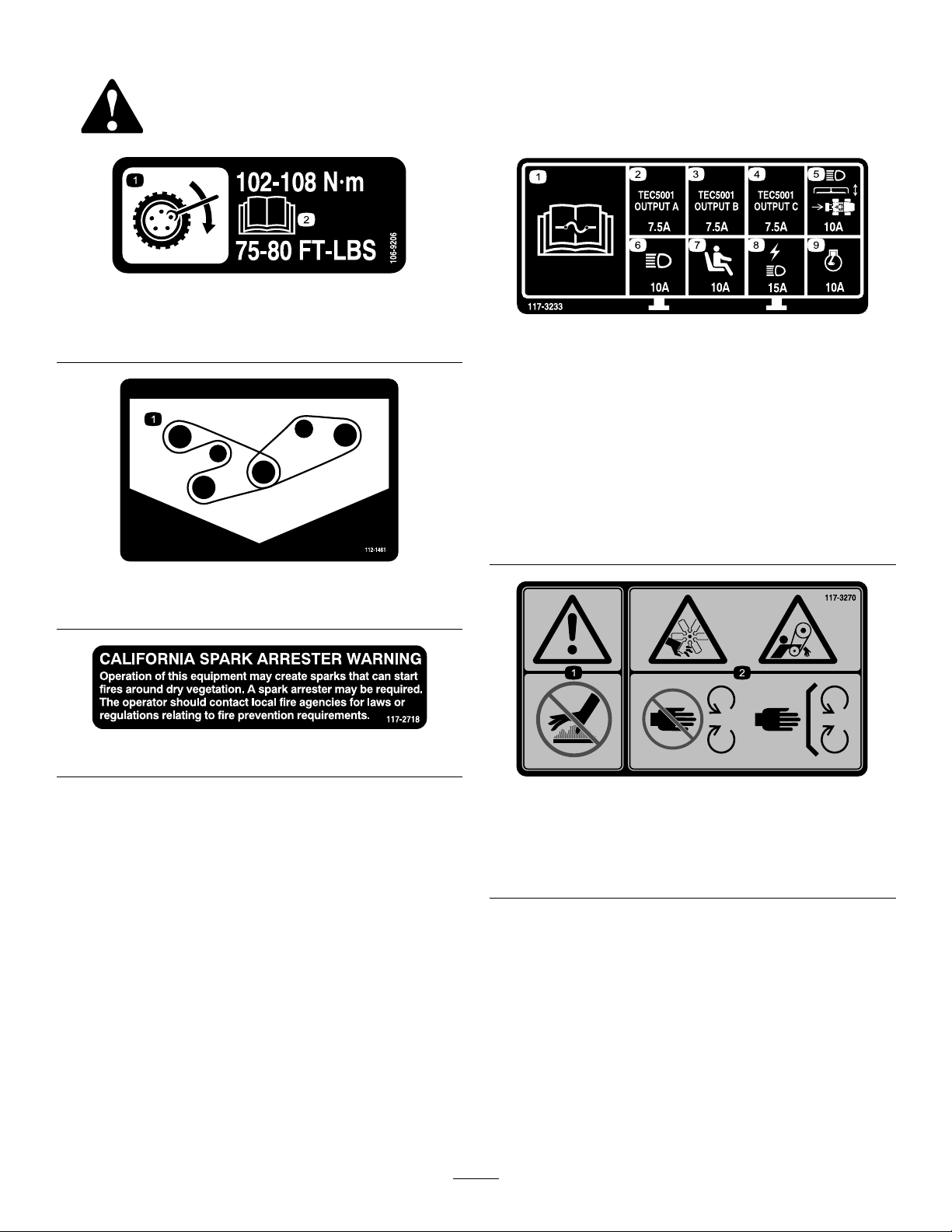

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

106-9206

1.Wheel-torquespecications

2.ReadtheOperator'sManual.

112-1461

1.Beltrouting

117-2718

117-3233

1.ReadtheOperator'sManualforinformationonfuses.

2.4-wheelsteersolenoid—7.5A

3.PTOenable,4-wheel-steerlamp,decklift,deckoat—7.5A

4.Glowindicator,fuel-runsolenoid,diagnosticlight,start—7.5

A

5.Headlights,deckactuator,powertakeoff—10A

6.Lights—15A

7.Operator-presenceswitch—10A

8.Powerpoint,lights—15A

9.Engine—10A

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,hand;entanglement

hazard,belt—stayawayfrommovingparts,keepallguards

andshieldsinplace.

5

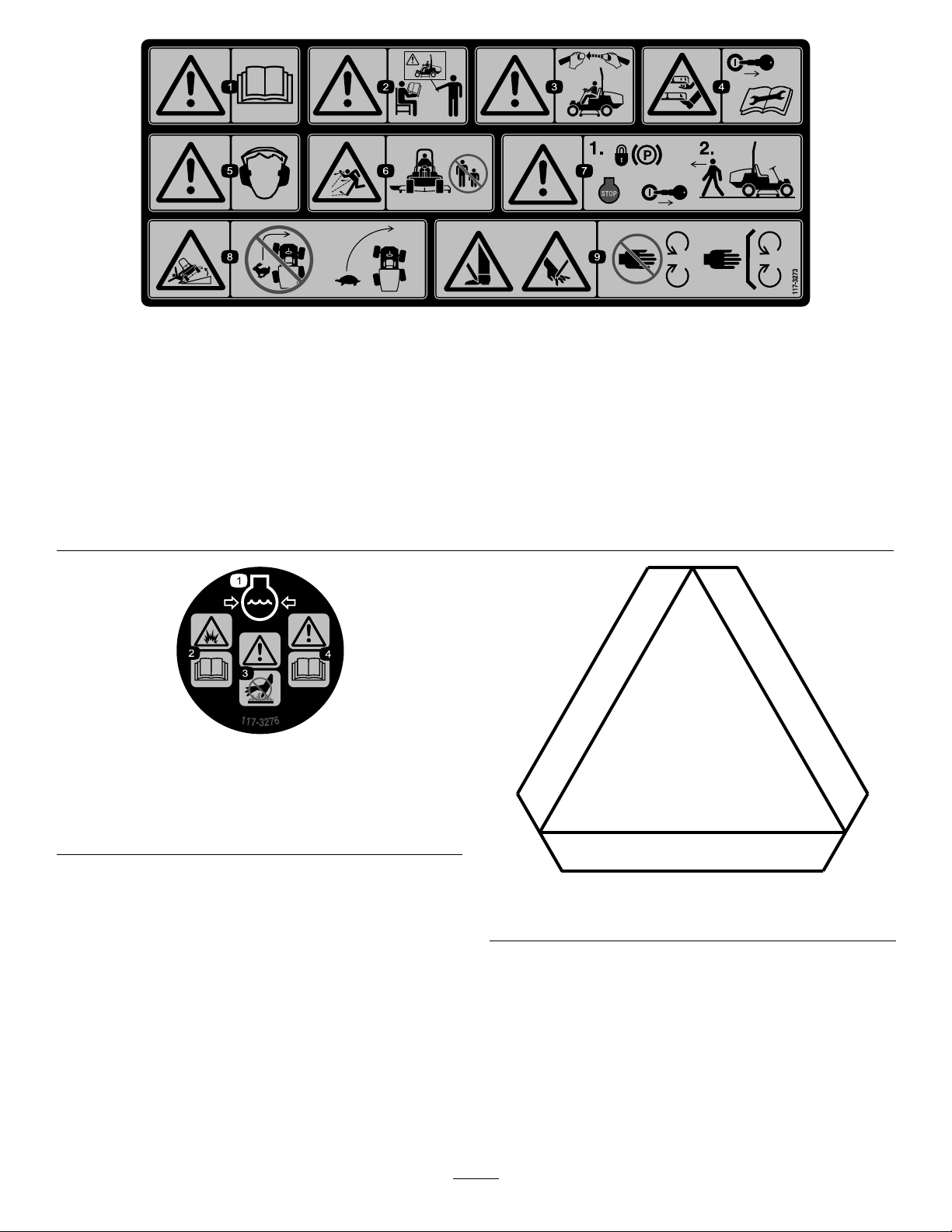

117-3270

117-3273

1.Warning—readtheOperator'sManual.6.Thrownobjecthazard—keepbystandersasafedistancefrom

2.Warning—donotoperatethismachineunlessyouaretrained.7.Warning—locktheparkingbrake,stoptheengine,and

3.Warning—weartheseatbeltwhenseatedintheoperator's

position.

4.Cutting/dismembermenthazardofhandorfoot—removethe

ignitionkeyandreadtheinstructionsbeforeservicingor

performingmaintenance.

5.Warning—wearhearingprotection.

themachine.

removetheignitionkeybeforeleavingthemachine.

8.Tippinghazard—lowerthecuttingunitwhendrivingdown

slopes;slowthemachinebeforeturning,donotturnathigh

speeds.

9.Cuttinghazardofhandorfoot—stayawayfrommovingparts;

keepallguardsinplace.

117-3276

1.Enginecoolantunder

pressure

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

6

120-0250

1.Slow-movingvehicle

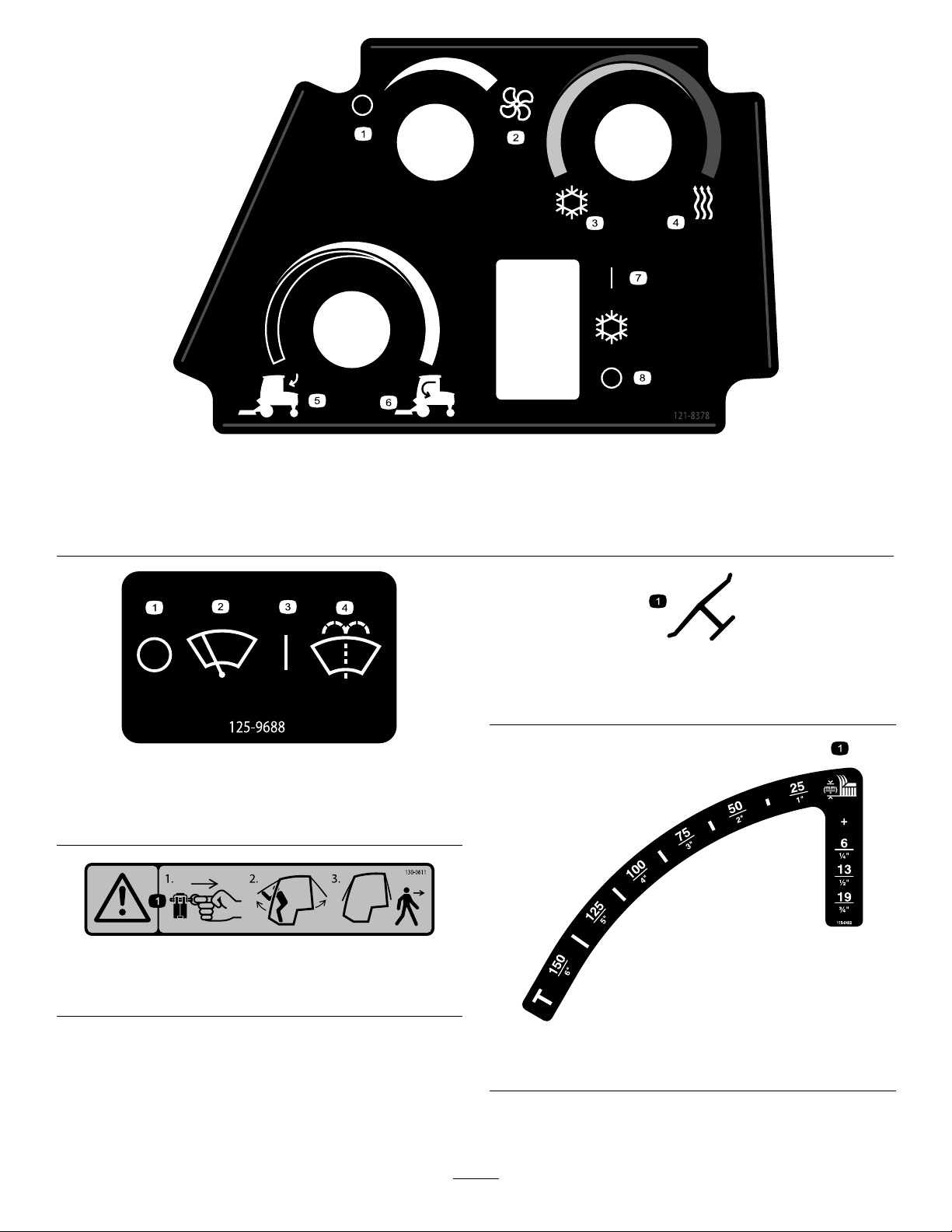

121-8378

1.Fan—off

2.Fan—onfull

3.Coldair7.Airconditioner—off

4.Hotair8.Airconditioner—on

5.Externalair

6.Internalair

1.Indicatesthatthebladeisidentiedasapartfromthe

originalmachinemanufacturer.

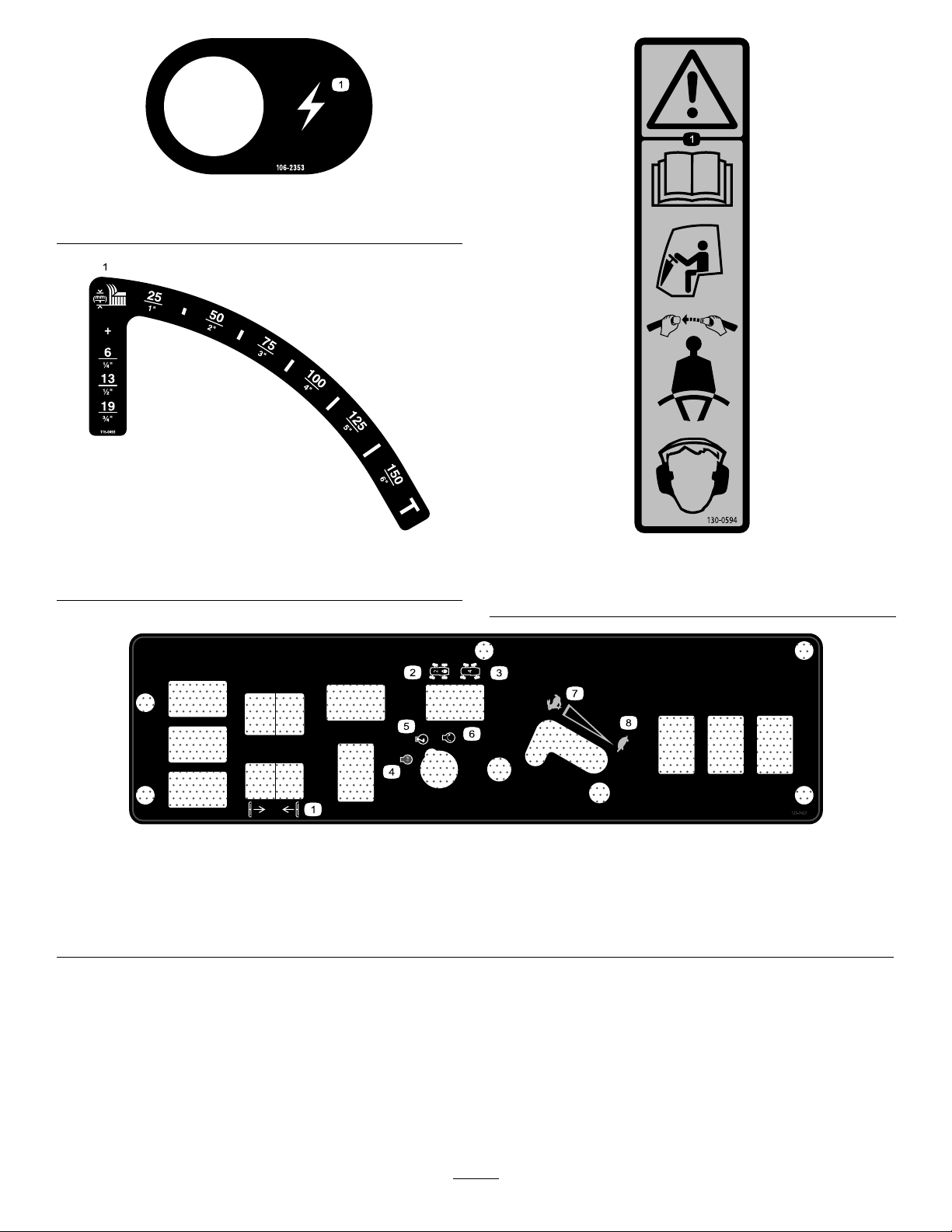

125-9688

1.Windshieldwipers—off

2.Windshieldwipers

3.Windshieldwipers—on

4.Spraywindshieldwasher

uid

Manufacturer'sMark

130-0611

1.Warning—1)Removethepin;2)Raisethedoors;3)Exit

thecab

115-0492

1.Heightofcut(mm)

7

1.Electricalpowerpoint

00

0

0

0

0

00

00

000

106-2353

115-0493

1.Heightofcut(mm)

125–7427

1.Raise/Lowerdecks

2.2-wheelsteering6.Engine—start

3.4-wheelsteering7.Fast

4.Engine—stop

130-0594

1.Warning—readtheOperator’sManual;whensittinginthe

cab,alwayswearaseatbelt;wearhearingprotection.

5.Engine—run

8.Slow

8

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

1.Explosionhazard

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries.

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard

9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

PTOdriveshaft

Bolt(5/16x1-3/4inches)

1

2

3

4

Locknut(5/16inch)

Rollpin(3/16x1-1/2inches)

Retainerpin2

Greasetting

Washerheadscrew(5/16x7/8inch)

Nopartsrequired

Nopartsrequired

MediaandAdditionalParts

Description

Operator'sManual

Engineoperator'smanual1

PartsCatalog

Operatortrainingmaterial

Qty.

Qty.

1

4

4

2

2

2

–

–

1

1

1

Readbeforeoperatingthemachine

Readbeforeoperatingthemachine

Usereferencepartnumbers

Viewthevideobeforeoperatingthemachine.

InstallthePTOdriveshafttoaoptional

deckorQAS.

Usethehardwaretoinstalltheoptional

mowerdeck.

Checkthetirepressure.

Checkthehydraulicuid,engineoil,

andcoolantlevels.

Use

Use

1

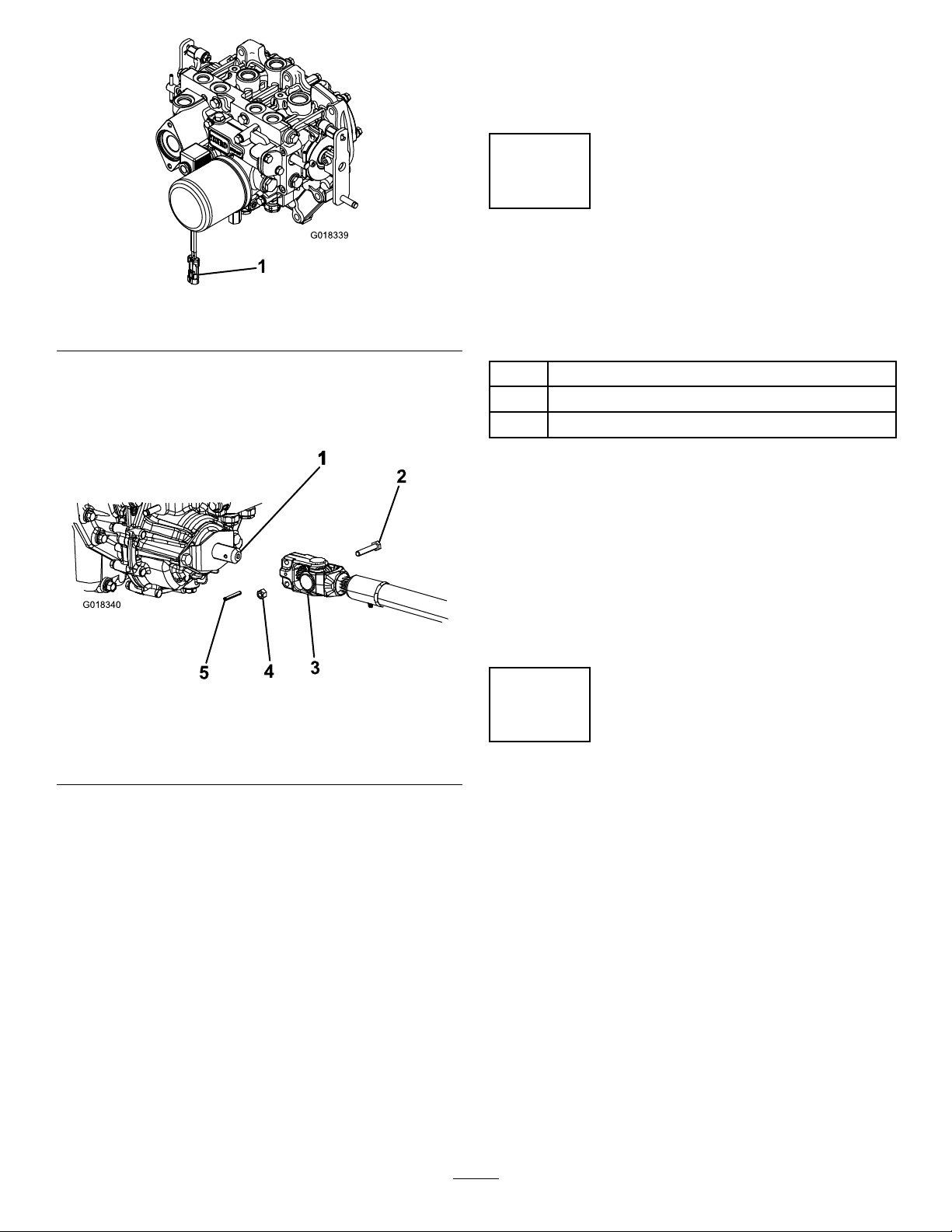

InstallingthePTODriveshaft toanOptionalMowerDeckor QAS

Partsneededforthisprocedure:

1

PTOdriveshaft

4

Bolt(5/16x1-3/4inches)

4

Locknut(5/16inch)

2

Rollpin(3/16x1-1/2inches)

Procedure

Note:InstallingthePTOdriveshaftiseasierifyouposition

themachineonahoist.

1.Parkmachineonalevelsurface,shutofftheengine,

engagetheparkingbrake,andremovekeyfromthe

ignitionswitch.

WARNING

Donotstarttheengineandengagethe

PTOswitchwhenthePTOdriveshaftis

disconnectedfromthecuttingdeck.Ifyou

starttheengineandthePTOshaftisallowed

torotate,seriouspersonalinjuryandmachine

damagecouldresult.BeforethePTO

driveshaftisdisconnectedfromthecutting

deck,disconnectthePTOsolenoid-valve-coil

connectorfromthewireharnesstoprevent

unintentionallyengagingthePTOclutch.

2.Disconnectthewire-harnessconnectorfromthePTO

solenoid-valve-coilconnector(Figure3).

10

G018339

1

G018340

1

2

3

4

5

8.Afteryouconnecttheotherendofthedriveshaftto

theattachmentgearboxshaft,connectthewire-harness

connectortothePTOsolenoid-valve-coilconnector

(Figure3).

2

UsingtheOptional

Mower-Deck-Mounting

Figure3

1.Wire-harnessconnector

3.PositionthePTOdriveshaftunderthefrontofthe

machine.Ensurethattheslip-shaftyokeofthe

driveshaftispositionedtowardthetransmission

driveshaft(Figure4).

Figure4

1.Transmissiondriveshaft

2.Bolt5.Rollpin

3.PTOdriveshaft

4.Locknut

Hardware

Partsneededforthisprocedure:

2Retainerpin

2

Greasetting

2

Washerheadscrew(5/16x7/8inch)

Procedure

Note:Thesecomponentsandprocedurearerequiredonly

ifamowerdeckthatrequiresretainerpinsismountedtothe

tractionunit.RefertothemowerdeckOperator’ sManualfor

theinstallationinstructions.

Note:Ifyouarenotinstallingamowerdeckonthetraction

unit,removeortieupthe4deck-liftchainsfromthelift

suspension.

3

CheckingtheTirePressure

4.Alignthesplineandroll-pinholeofthedriveshaftyoke

withthetransmissiondriveshaft.

5.SlidethePTOdriveshaftendyokeontothe

transmissiondriveshaft.

6.SecuretheendyokeofthePTOdriveshaftasfollows:

A.Installtherollpinintheendyokeandshaft.

B.Installtheboltsthroughthedriveshaftendyoke.

C.Installandtightenthelocknutstosecuretheend

yoketothePTOdriveshaft.

Note:Retaintheremainingbolts,locknuts,and

rollpintosecuretheotherendofthedriveshaft

totheattachmentgearboxshaft.

D.Torquethelocknutsto20to25N-m(175to225

in-lb).

7.LubricatethegreasettingsonthePTOdriveshaft.

NoPartsRequired

Procedure

Thetiresareoverinatedforshipping.Therefore,release

someoftheairtoreducethepressure.Alltiresshouldbe

inatedto172kPa(25psi).

11

ProductOverview

4

CheckingtheFluidLevels

NoPartsRequired

Procedure

1.Checkthehydraulic-uidlevelbeforestartingthe

engine,refertoCheckingtheHydraulicSystem(page

45).

2.Checktheengine-oillevelbeforestartingtheengine,

refertoCheckingtheEngine-OilLevel(page35).

3.Checkthecoolingsystembeforestartingtheengine;

refertoCheckingtheCoolingSystem(page41).

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine.

TractionPedal

Thetractionpedal(Figure5)controlstheforwardandreverse

operation.Pressthetopofthepedaltomoveforwardand

thebottomtomoverearward.Thegroundspeeddependson

howfaryoupressthepedal.Fornoload,maximumground

speed,fullypressthepedalwhilethethrottleisintheFAST

position.

Tostopthemachine,reducethefootpressureonthetraction

pedalandallowittoreturntothecenterposition.

Figure5

1.Parkingbrake4.Tractionpedal

2.Brakepedal

3.Tilt-steeringpedal

5.Thisfeaturenolonger

existsonthemachine.

BrakePedal

Usethebrakepedalwiththebrake-pedallatchtoengageand

disengagetheparkingbrake(Figure5).Tostopthemachine,

releasethetractionpedalandallowittoreturntothecenter

position.Youcanusethebraketoassistinstoppingthe

machineinanemergencysituation.

ParkingBrake

Toengagetheparkingbrake,pushdownonthebrakepedal

andpressthetopforwardtolatch(Figure5).T oreleasethe

parkingbrake,pressthebrakepedaluntiltheparkingbrake

latchretractswithoutcontactingthelockingmechanism.

12

TiltSteeringPedal

Totiltthesteeringwheeltowardyou,pressthefootpedal

down,pullthesteeringtowertowardyoutothemost

comfortableposition,andreleasethepedal(Figure5).To

movethesteeringwheelawayfromyou,pressthefootpedal

andreleaseitwhenthesteeringwheelreachesthedesired

operatingposition.

themachinewiththethrottleintheFASTpositionwhen

operatingattachments.

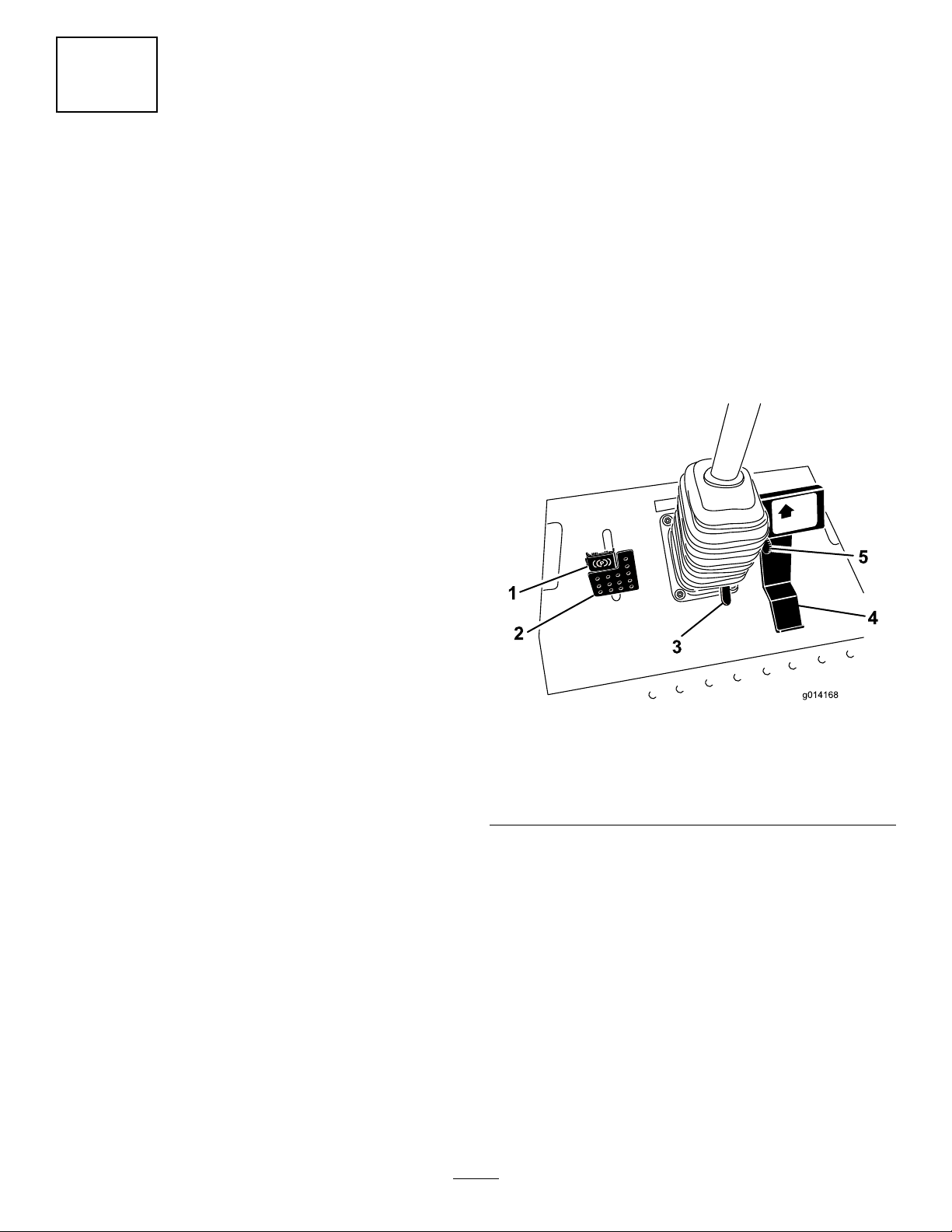

Power-Takeoff(PTO)Switch

Thepower-takeoff(PTO)switchstartsandstopsthe

attachment(Figure6).

IgnitionSwitch

Theignitionswitchhas3positions:OFF,ON/PREHEAT,and

START(Figure6).

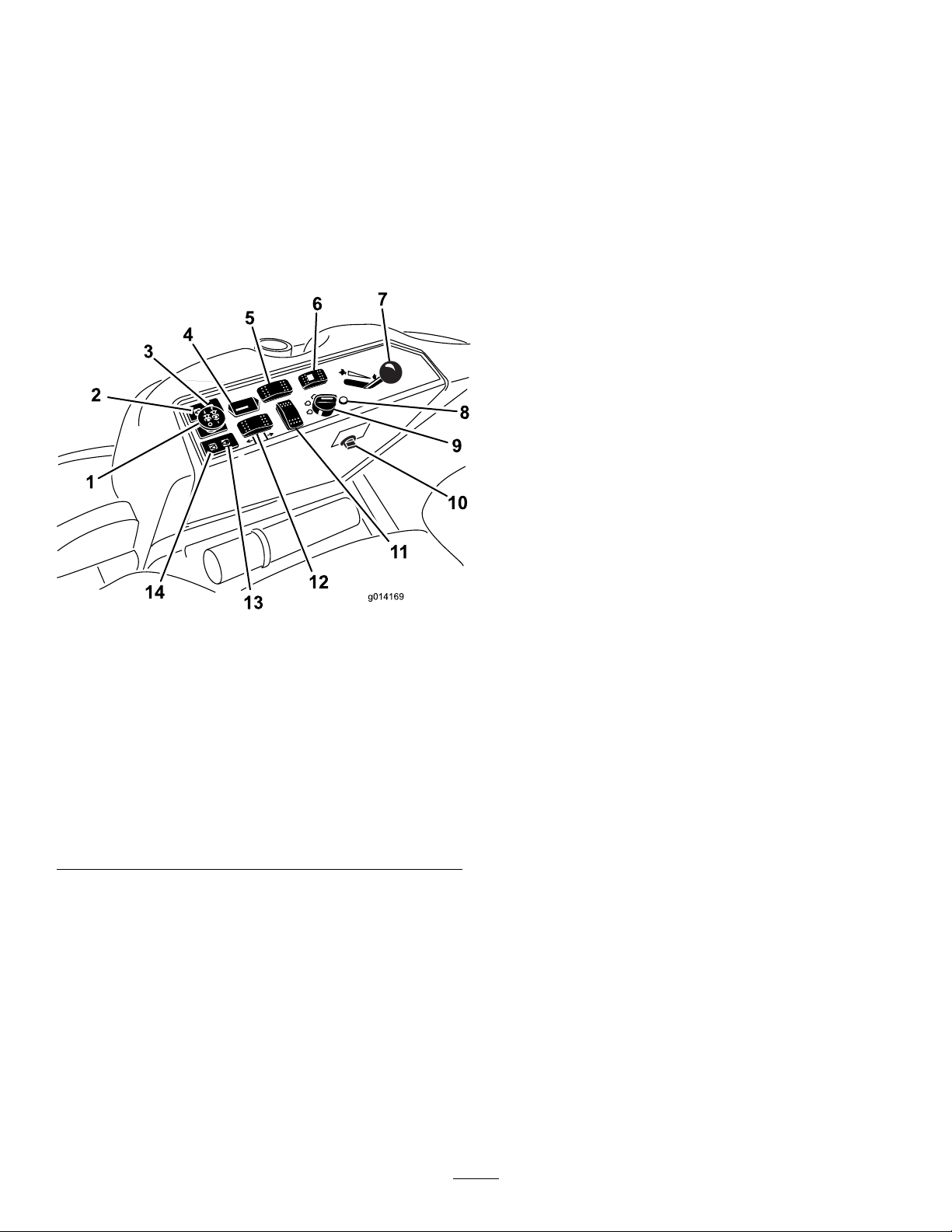

Figure6

1.Power-takeoff(PTO)

switch

2.Oil-pressure-warninglight

3.Charge-indicatorlight

4.Hourmeter

5.Differential-lockswitch

(2-wheel-driveonly)

6.Steering-selectorswitch

(4-wheel-driveonly)

7.Throttlelever

8.Diagnosticlight

(4-wheel-driveonly)

9.Ignitionswitch

10.Powerpoint

11.Optionalswitchlocation

12.Deck-liftswitch

13.Glow-pluglight

14.Coolant-temperature-warning

light

SteeringSelectorSwitch

Pressthesteeringselectorswitchtothereartoengage4-wheel

steeringandforwardtoreturnto2-wheelsteering(Figure6).

HourMeter

Thehourmeter(Figure6)recordsthenumberofhoursthat

theenginehasoperated.Itoperateswhenthekeyswitchis

intheRUNposition.Usethesetimesforschedulingregular

maintenance.

Glow-Plug-IndicatorLight(Orange

Light)

Theglow-plug-indicatorlight(Figure6)turnsonwhenyou

turntheignitionswitchtotheONposition.Itremainsonfor

6seconds.Whenthelightturnsoff,youcanstarttheengine.

Engine-Coolant-Temperature-Warning

Light

Thislightglowsandtheattachmentstopsifthetemperature

oftheenginecoolantishigh(Figure6).Ifyoudonotstop

themachineandthecoolanttemperaturerisesanother7°C

(20°F),theengineshutsoff.

Important:Iftheattachmentshutsdownandthe

temperaturewarninglightison,pushthePTOknob

down,drivethemachinetoasafe,atarea,movethe

throttlelevertotheSLOWposition,allowthetraction

pedaltomovetotheNEUTRALposition,andengage

theparkingbrake.Allowtheenginetoidleforseveral

minuteswhileitcoolstoasafelevel.Shutofftheengine

andcheckthecoolingsystem;refertoCheckingthe

CoolingSystem(page41).

DiagnosticLight

Thediagnosticlightilluminateswhenthesystemdetectsa

fault(Figure6).

ThrottleLever

Thethrottlelever(Figure6)controlstheenginespeed.

MovingthethrottleleverforwardtowardtheFASTposition

increasestheenginespeed.Movingitrearwardtowardthe

SLOWpositiondecreasestheenginespeed.Thethrottle

controlsthespeedofthePTOand,withthetractionpedal,

controlsthegroundspeedofthemachine.Alwaysrun

ChargeIndicator

Thechargeindicatorilluminateswhenthecharging-system

circuitmalfunctions(Figure6).

Oil-Pressure-WarningLight

Theoil-pressure-warninglight(Figure6)glowswhentheoil

pressureinenginedropsbelowasafelevel.Iflowoilpressure

everoccurs,shutofftheengineanddeterminethecause.

Repairthedamagebeforestartingtheengineagain.

13

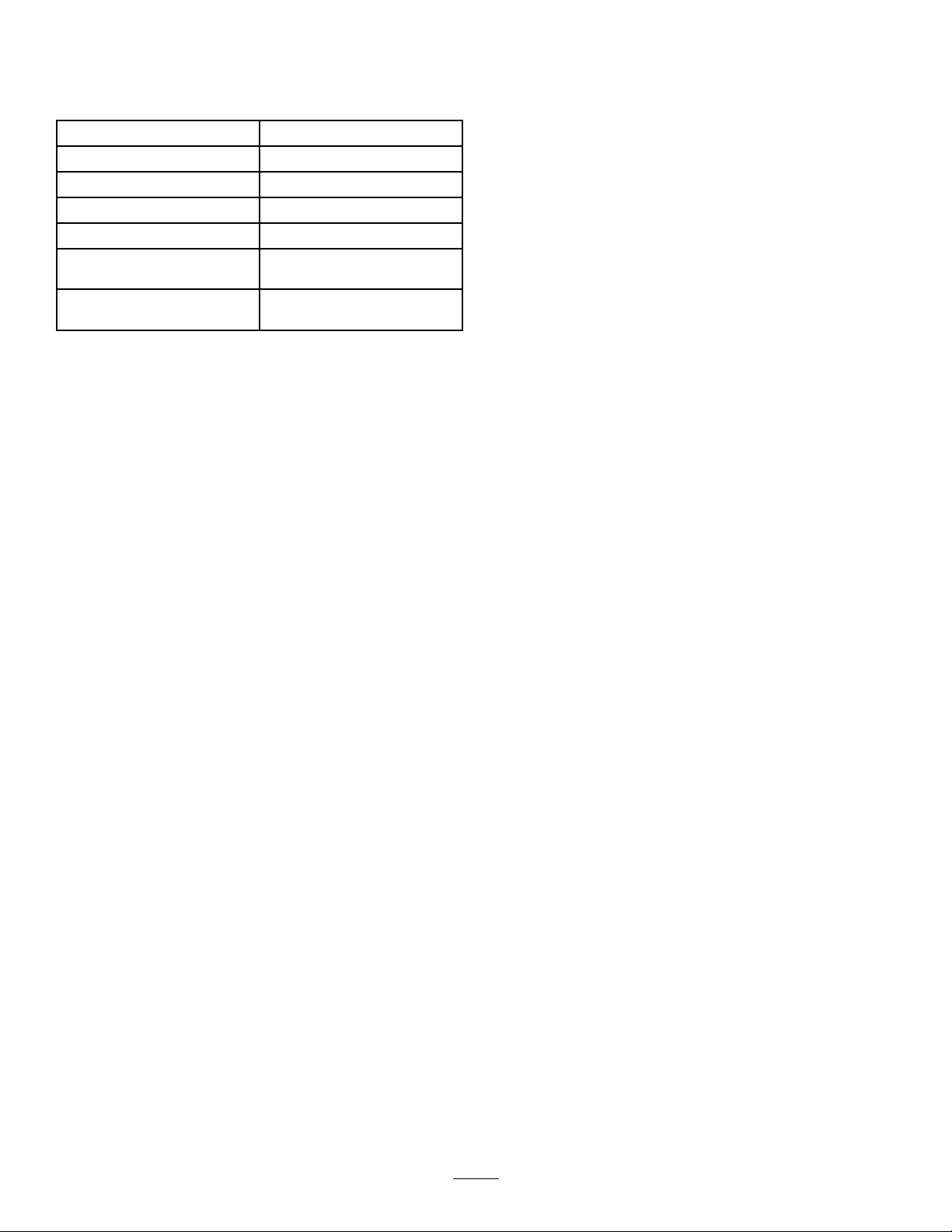

FuelGauge

1

2

3

4

5

6

7

8

g028431

9

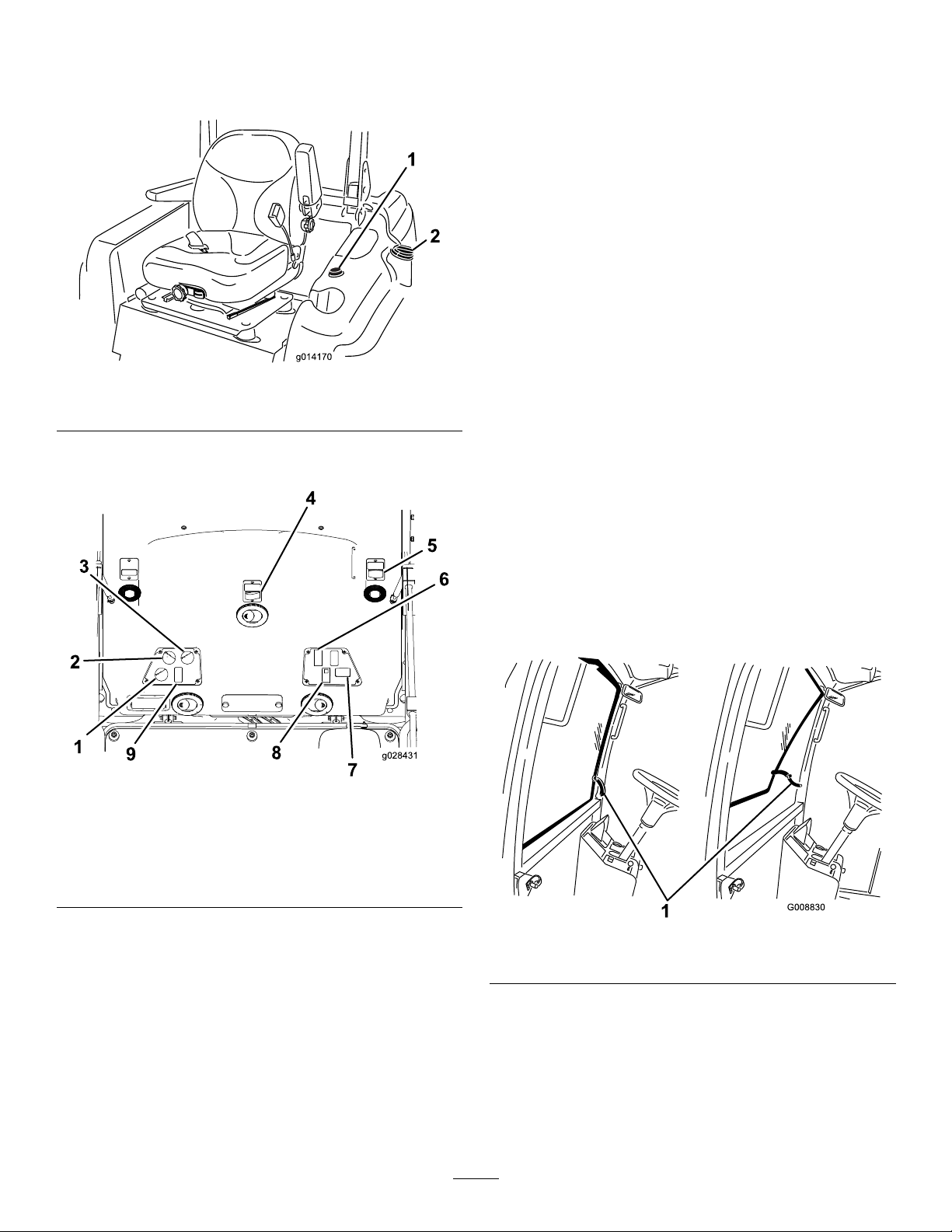

Temperature-Control-Knob

Thefuelgauge(Figure7)indicatestheamountoffuel

remaininginthefueltank.

Figure7

1.Fuelgauge2.Fuel-tankcap

CabControls

Rotatethetemperature-controlknobtoregulatetheair

temperatureinthecab(Figure8).

Windshield-WiperSwitch

Usethisswitchtoturnthewindshieldwipersonoroff

(Figure8).

PowerOutlet

Usethis15A,12VDCpoweroutlettopowercompatible

devices(Figure8).

LightsSwitch

Usethisswitchtoturntheheadlightsandtaillightonoroff

(Figure8).

FlashersSwitch

Usethisswitchtoturntheashers(hazardlights)onoroff

(Figure8).

Air-ConditioningSwitch

Usethisswitchtoturntheairconditioningonoroff(Figure

8).

Figure8

1.Air-recirculationcontrol5.Poweroutlet

2.Fancontrol6.Lightsswitch

3.Temperaturecontrol7.Flashersswitch

4.Windshield-wiperswitch8.Air-conditioningswitch

Air-RecirculationControl

Setsthecabtoeitherrecirculatetheairinthecabinortodraw

airintothecabinfromoutside(Figure8).

•Setittorecirculatetheairwhenusingtheair-conditioning.

•Setittodrawairinwhenusingtheheaterorfan.

Fan-ControlKnob

WindshieldLatch

Liftupthelatchestoopenthewindshield(Figure9).Pressin

thelatchtolockthewindshieldintheopenposition.Pullout

anddownonthelatchtocloseandsecurethewindshield.

Figure9

1.Windshieldlatch

RearWindowLatch

Liftupthelatchestoopentherearwindow .Pressinthelatch

tolockthewindowintheopenposition.Pulloutanddown

onthelatchtocloseandsecurethewindow(Figure9).

Rotatethefan-controlknobtoregulatethespeedofthefan

(Figure8).

Important:Y oumustclosetherearwindowbefore

openingthehood;otherwise,damagemayoccur.

14

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Length

Width(RearWheels)147.3cm(58inches)

Height

Weight

MachinewithoutaDeck

Machinewith72-inchBase

Deck

Machinewith72-inch

Side-DischargeDeck

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

241.3cm(95inches)

221cm(87inches)

1,361kg(3,000lb)

1,531kg(3,375lb)

1,571kg(3,464lb)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopletooperateor

servicethemachine.Localregulationsmayrestrictthe

ageoftheoperator.Theownerisresponsiblefortraining

alloperatorsandmechanics.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.Knowhowtostop

themachineandenginequickly.

•Checkthatallsafetydevicesareattachedand

functioningproperly.Thisincludes,butisnotlimitedto,

operator-presencecontrols;safetyswitchesandshields;

therolloverprotectionsystem(ROPS);attachments;and

brakes.Donotoperatethemachineunlessallsafety

devicesareinpositionandfunctioningasintendedby

themanufacturer.

•Alwaysinspectthemachinetoensurethattheblades,

bladebolts,andcuttingassemblyarenotwornor

damaged.Replacewornordamagedbladesandboltsin

setstopreservebalance.

•Inspecttheareawhereyouwillusethemachineand

removeallobjectsthatthemachinecouldpotentially

throw .

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessoriesrequiredto

operatethemachineproperlyandsafely.

15

FuelSafety

FillingtheFuelTank

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana180-daysupplyoffuel.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepyourhandsandfaceawayfromthenozzle

andthefuel-tankopening.

•Keepfuelawayfromyoureyesandskin.

•Useonlyanapprovedfuelcontainer.

•Neverremovethefuelcaporaddfueltothefueltank

whiletheengineisrunning.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundandawayfromyourvehiclebeforelling.

•Removetheequipmentfromthetruckortrailerandadd

fueltoitwhileitisontheground.Ifthisisnotpossible,

thenaddfuelusingaportablecontainerratherthanfrom

afuel-dispensernozzle.

RecommendedFuel

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchasefuelin

quantitiesthatyoucanusewithin180daystoensurethat

thefuelisfresh.

FuelT ankCapacity:51L(13.5USgallons)

Usesummer-gradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Usingwinter-grade

fuelatlowertemperaturesprovidealowerashpointand

cold-owcharacteristics,whicheasesstartingandreduces

pluggingofthefuellter.

Usingsummer-gradefuelabove-7°C(20°F)contributes

towardlongerlifeofthefuelpumpandincreasedpower

comparedtowinter-gradefuel.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failingtoobservethiscautionwilldamage

theengine.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeultra-lowsulfur.Observethefollowing

precautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Biodieselblendsmaydamagepaintedsurfaces.

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather.

•Checkallseals,hoses,andgasketsincontactwithfuelas

theymaydegradeovertime.

•Espectthefuelltertoplugupforatimeafterconverting

tobiodiesel-blendedfuel.

•Contactyourdistributorformoreinformationon

biodieselfuel.

•Keepthefuel-dispensernozzleincontactwiththerimof

thefueltankorcontaineropeningatalltimesuntilfueling

iscomplete.Donotuseanozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyourclothing

immediately.

•Fillthefueltankuntilthefuellevelis25mm(1inch)

belowthebottomofthellerneck.Donotoverllthe

fueltank.Replacethefuel-tankcapandtightenitsecurely .

Note:Ifpossible,llthefueltankaftereachuse.This

minimizespossiblebuildupofcondensationinsidethefuel

tank.

1.Parkthemachineonalevelsurface.

2.Shutofftheengineandsettheparkingbrake.

3.Cleanaroundthefuel-tankcapandremovethecap

(Figure10).

16

Loading...

Loading...