Page 1

FormNo.3383-175RevA

Groundsmaster

®

360

Multi-PurposeMachine

ModelNo.31222—SerialNo.314000001andUp

ModelNo.31223—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3383-175*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.

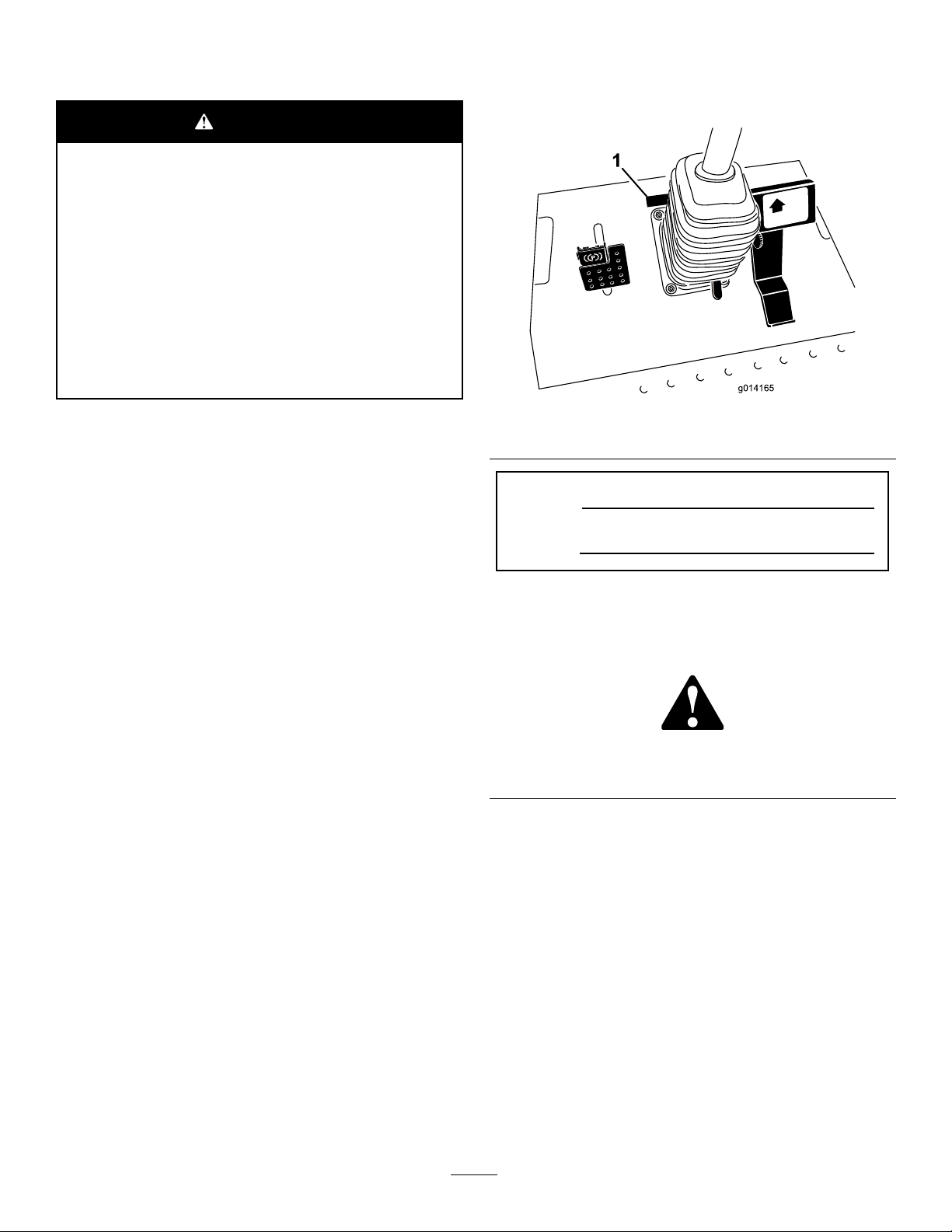

Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Introduction

Thismachineisaride-on,multi-purposemachineintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedformaintaininggrass

onwell-maintainedlawnsinparks,sportselds,andon

commercialgrounds.Itisnotdesignedforcuttingbrush,

mowinggrassandothergrowthalongsidehighways,orfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure2

1.Safetyalertsymbol

Thismanualalsouses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................5

SoundPowerLevel..................................................6

SoundPressureLevel...............................................6

SoundPressureLevel...............................................6

VibrationLevel......................................................6

SafetyandInstructionalDecals.................................7

Setup...........................................................................14

1InstallingtheDriveShafttoanOptionalMower

DeckorQAS.....................................................14

2OptionalMowerDeckMountingHardware.............15

3AdjustingtheROPS.............................................15

4CheckingtheTirePressure....................................16

5CheckingtheFluidLevels.....................................16

ProductOverview.........................................................16

Controls...............................................................16

Specications........................................................19

Attachments/Accessories........................................19

Operation....................................................................19

AddingFuel...........................................................19

FillingtheFuelTank...............................................20

UsingtheRolloverProtectionSystem(ROPS)

........................................................................20

ThinkSafetyFirst...................................................21

StartingandStoppingtheEngine..............................21

DrivingtheMachine...............................................22

SteeringSelection(4wheeldrivemodels

only).................................................................23

StoppingtheMachine.............................................23

OperatingaMowerDeckor

Attachment(Optional).........................................23

AdjustingtheHeight-of-Cut....................................24

TheSafetyInterlockSystem.....................................25

UnderstandingtheDiagnosticLight.........................25

DiagnosticAceDisplay...........................................26

CheckingtheInterlockSwitches..............................26

PositioningtheStandardSeat...................................28

PositioningtheDeluxeSeat......................................28

Raising/LoweringtheSeat.......................................29

PushingtheMachinebyHand..................................30

LoadingMachines..................................................30

TransportingMachines............................................31

Maintenance.................................................................33

RecommendedMaintenanceSchedule(s)......................33

DailyMaintenanceChecklist....................................34

PremaintenanceProcedures........................................35

UsingtheHoodPropRod.......................................35

Lubrication...............................................................35

GreasingtheBearingsandBushings..........................35

EngineMaintenance..................................................38

ServicingtheAirCleaner.........................................38

CheckingtheEngineOilLevel.................................38

ChangingtheEngineOilandFilter...........................39

AdjustingtheThrottle.............................................39

FuelSystemMaintenance...........................................40

ServicingtheWaterSeparator..................................40

BleedingtheFuelSystem.........................................40

BleedingAirfromtheFuelInjectors..........................40

CleaningtheFuelTank............................................41

FuelLinesandConnections.....................................41

ElectricalSystemMaintenance....................................42

CheckingtheFuses.................................................42

ServicingtheBattery...............................................42

StoringtheBattery..................................................43

DriveSystemMaintenance.........................................43

CheckingtheTirePressure......................................43

CorrectingSteeringMisalignment.............................43

CoolingSystemMaintenance......................................44

CheckingtheCoolingSystem..................................44

CleaningtheRadiator..............................................44

BrakeMaintenance....................................................45

AdjustingtheServiceBrakes....................................45

AdjustingtheParkingBrake....................................46

BeltMaintenance......................................................46

CheckingtheAlternatorBelt...................................46

ControlsSystemMaintenance.....................................47

AdjustingtheTractionDriveforNeutral....................47

AdjustingtheMaximumGroundSpeed.....................47

AdjustingtheSpeedLimiterLever............................48

HydraulicSystemMaintenance....................................49

CheckingtheHydraulicSystem................................49

ChangingtheHydraulicOilAndFilter.......................49

CabMaintenance.......................................................50

MaximizingAirConditionerPerformance..................50

CleaningtheCabAirFilters.....................................50

CleaningtheAirConditioningCoil...........................51

CleaningtheA/CCondenserScreen.........................52

Cleaning...................................................................52

CleaningtheCab....................................................52

WasteDisposal.......................................................52

Storage........................................................................53

Engine..................................................................53

Machine................................................................53

3

Page 4

Safety

ThismachinemeetsorexceedsCENstandardEN836:1997

andANSIB71.4-2012specicationsineffectatthetimeof

production,whentheoptionalmowerdeckisinstalled.

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theinstructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromtheCEN

standardEN836:1997andANSIB71.4-2012.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Training

•ReadtheOperator'sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethisequipment.Localregulationscan

restricttheageoftheoperator.

•Neveroperatewhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversshouldseekandobtainprofessionaland

practicalinstruction.Suchinstructionshouldemphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip,especiallyonwetgrass;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrectloaddistribution.

Preparation

•Whileoperatingthemachine,alwayswearsubstantial

footwearandlongtrousers.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Replacefaultysilencers/mufers.

•Ifamowerdeckisinstalledonthemachine,beforeusing

it,alwaysvisuallyinspecttoseethattheblades,blade

boltsandcutterassemblyarenotwornordamaged.

Replacewornordamagedbladesandboltsinsetsto

preservebalance.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

Operation

•Bealert,slowdownandusecautionwhenmakingturns.

Lookbehindandtothesidebeforechangingdirections.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Operateonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutchesandshiftintoneutral.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.T oguardagainst

overturning:

–donotstoporstartsuddenlywhenonaslope;

–useslowspeedsonslopesandduringtightturns;

4

Page 5

–stayalertforhumpsandhollowsandotherhidden

hazards;

•Watchoutfortrafcwhencrossingornearroadways.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

–disengagethepowertake-offandlowerthe

attachments;

–settheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachments,stoptheengine,and

removetheignitionkey:

–beforechecking,cleaningorworkingonthemachine;

–afterstrikingaforeignobject.Inspectthemachine

fordamageandmakerepairsbeforerestartingand

operatingtheequipment;

–ifthemachinestartstovibrateabnormally(check

immediately).

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Disengagedrivetoattachmentswhentransportingornot

inuse.

•Stoptheengineanddisengagedrivetoattachmentbefore

refueling.

•KeeptheROPSinsafeoperatingconditionby

periodicallythoroughlyinspectingfordamageand

keepingallmountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorrevise.

•DonotremovetheROPS.

•AnyalterationstoaROPSmustbeapprovedbythe

manufacturer.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuelstorage

areafreeofgrass,leaves,orexcessivegrease.

•Replacewornordamagedpartsforsafety.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Ifamowerdeckisinstalledonthemachine,takecareas

manuallyrotatingonebladecancauseotherbladesto

rotate.

•Whenmachineistobeparked,storedorleftunattended,

lowertheattachment.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine

RolloverProtectionSystem(ROPS)UseandMaintenance

•TheROPSisanintegralandeffectivesafetydevice.Keep

afoldingROPSintheraisedandlockedpositionanduse

theseatbeltwhenoperatingthemachine.

•LowerafoldingROPStemporarilyonlywhenabsolutely

necessary.Donotweartheseatbeltwhenfoldeddown.

•Beawarethereisnorolloverprotectionwhenafolded

ROPSisinthedownposition.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Checktheareatobemowedandneverfolddowna

foldingROPSinareaswherethereareslopes,dropoffs

orwater.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCENstandard.

•Engineexhaustcontainscarbonmonoxide,whichisan

odorless,deadlypoisonthatcankillyou.Donotrun

engineindoorsorinanenclosedarea.

•Keephands,feet,hairandlooseclothingawayfrom

attachmentdischargearea,undersideofmowerandany

movingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowtocoolbeforeattempting

tomaintain,adjust,orservice.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyesandclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

5

Page 6

•Thismachineisnotdesignedorequippedforon-road

useandisa“slow-movingvehicle.”Ifyoumustcross

ortravelonapublicroad,youshouldbeawareofand

complywithlocalregulations,suchasrequiredlights,

slowmovingvehiclesigns,andreectors.

•Batterygasescanexplode.Keepcigarettes,sparksand

amesawayfrombattery.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

•UseonlyToroapprovedattachments.Warrantymaybe

voidedifusedwithunapprovedattachments.

SoundPowerLevel

Note:Thedatacontainedinthissectiononlypertainsto

unitsmarkedwiththeCElogo.

Thisunithasaguaranteedsoundpowerlevelof101dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

SlopeOperation

•Donotoperateneardrop-offs,ditches,steepbanksor

water.Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,ordrowning.

•Donotoperateonslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcauseslidingand

lossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,etc.

fromtheoperatingarea.Tallgrasscanhideobstacles.

•Watchforditches,holes,rocks,dips,andrisesthatchange

theoperatingangle,asroughterraincouldoverturnthe

machine.

•Avoidsuddenstartswhenoperatinguphillbecausethe

machinemaytipbackwards.

•Alwaysavoidsuddenstartingorstoppingonaslope.If

tireslosetraction,disengagetheattachmentandproceed

slowlyofftheslope.

•Followthemanufacturer'srecommendationsforwheel

weightsorcounterweightstoimprovestability.

•Useextremecarewithallattachments.Thesecanchange

thestabilityofthemachineandcauselossofcontrol.

Model31222

Note:Thedatacontainedinthissectiononlypertainsto

unitsmarkedwiththeCElogo.

Theseunitshaveasoundpressurelevelattheoperator’sear

of85dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

SoundPressureLevel

Model31223

Note:Thedatacontainedinthissectiononlypertainsto

unitsmarkedwiththeCElogo.

Theseunitshaveasoundpressurelevelattheoperator’sear

of80dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

VibrationLevel

Note:Thedatacontainedinthissectiononlypertainsto

unitsmarkedwiththeCElogo.

UsingtheRolloverProtectionSystem

(ROPS)

•Keeptherollbarintheraisedandlockedpositionand

usetheseatbeltwhenoperatingthemachine.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Beawarethereisnorolloverprotectionwhentheroll

barisdown.

•ChecktheareaofoperationandneverfoldtheROPSin

areaswherethereareslopes,dropoffsorwater.

•Lowertherollbaronlywhenabsolutelynecessary.Do

notweartheseatbeltwiththerollbarfoldeddown.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

Hand-Arm

Measuredvibrationlevelforrighthand=0.39m/s

Measuredvibrationlevelforlefthand=0.34m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

WholeBody

Measuredvibrationlevel=0.41m/s

UncertaintyValue(K)=0.5m/s

6

2

2

2

2

2

Page 7

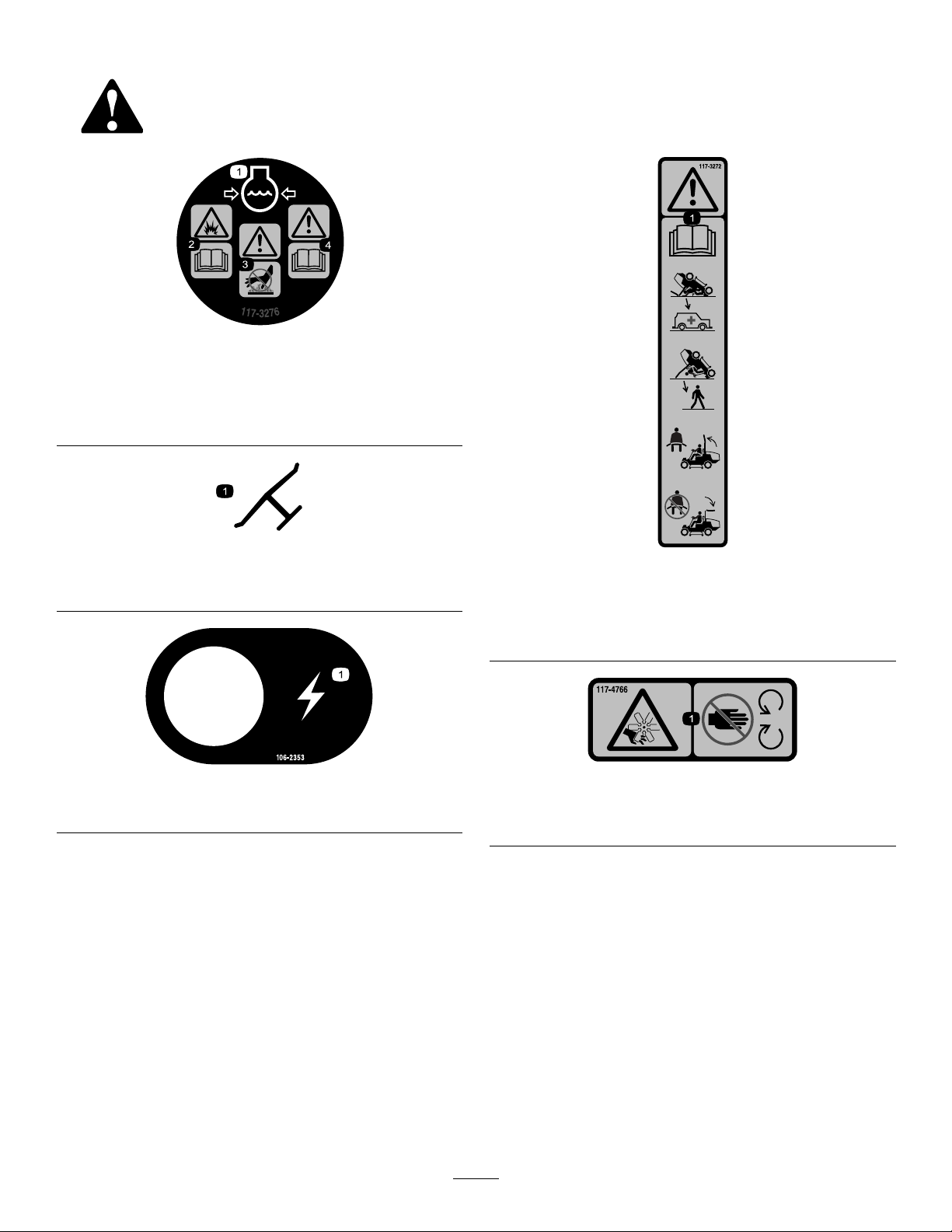

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

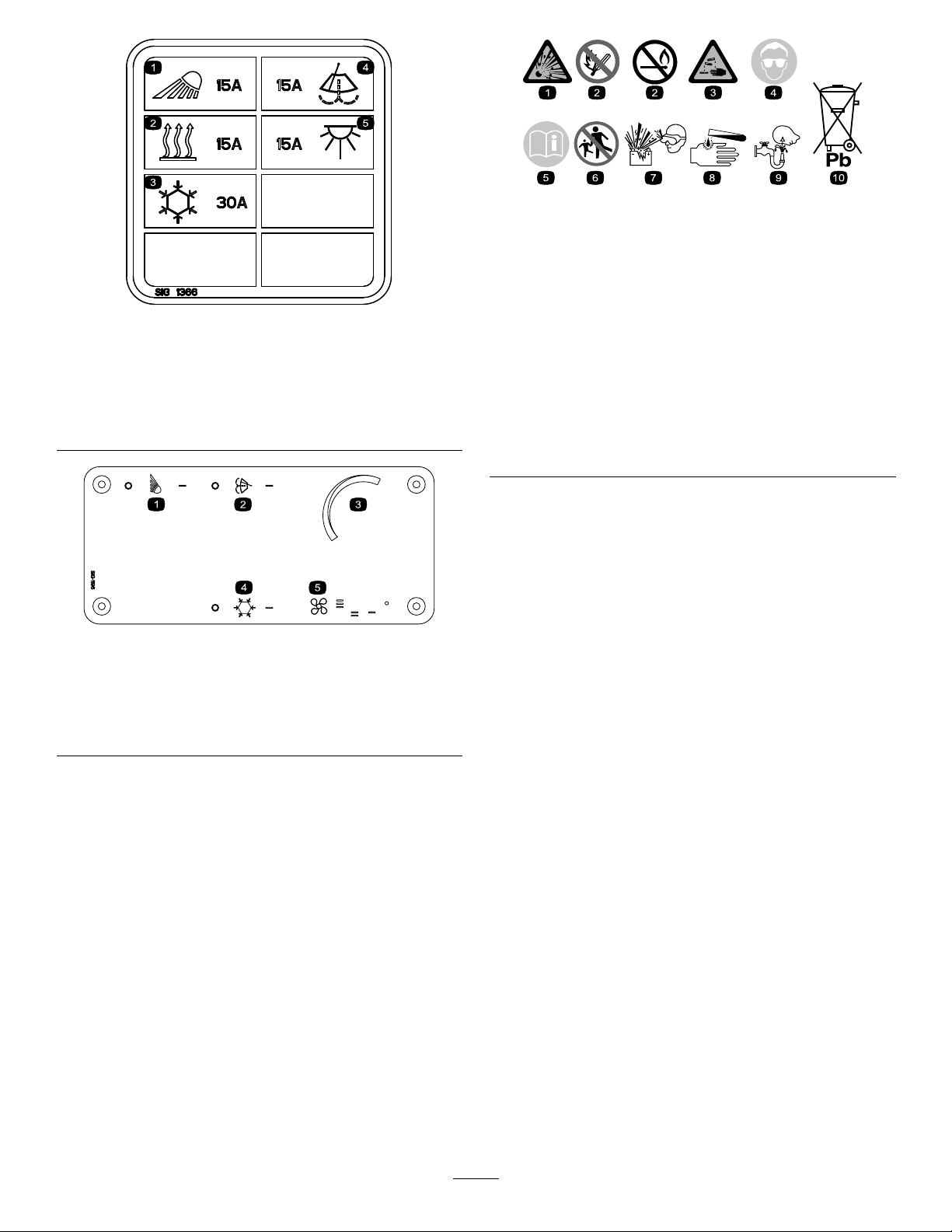

117-3276

1.Enginecoolantunder

pressure

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

106-2353

1.Electricalpowerpoint

117-3272

1.Warning—readtheOperator'sManual;failuretousthe

rolloverprotectionsystem(ROPS)canresultininjuryin

theeventofarollover;wearaseatbeltwhenaROPSisin

place,donotwearaseatbeltwhenROPSislowered.

117-4766

1.Cutting/dismembermenthazard;fan—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

7

Page 8

117-3270

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,hand;entanglement

hazard,belt—stayawayfrommovingparts,keepallguards

andshieldsinplace.

117–2718

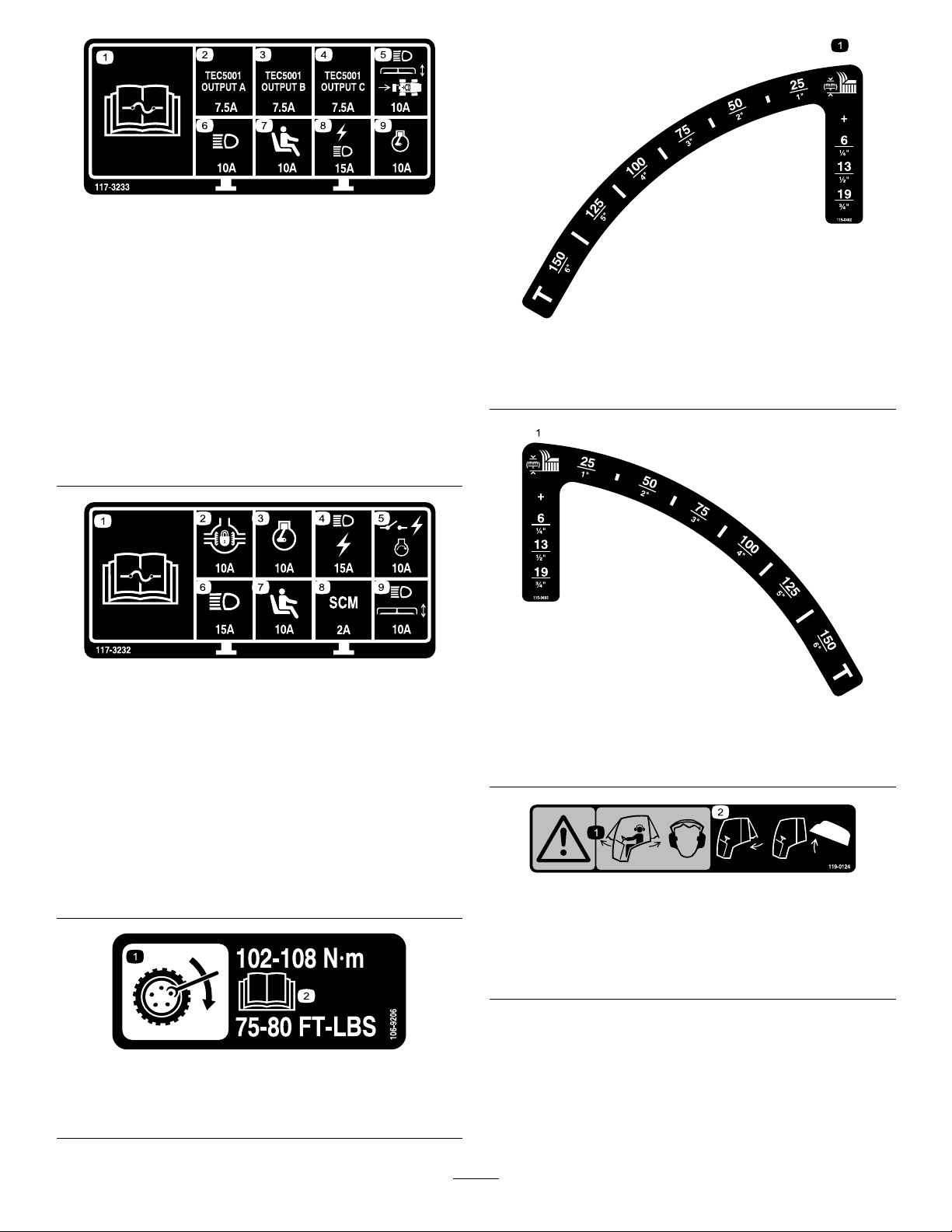

117-3273

1.Warning—readtheOperator'sManual.6.Thrownobjecthazard—keepbystandersasafedistancefrom

2.Warning—donotoperatethismachineunlessyouaretrained.7.Warning—locktheparkingbrake,stoptheengineandremove

3.Warning—weartheseatbeltwhenseatedintheoperator's

position.

4.Cutting/dismembermenthazardofhandorfoot—removethe

ignitionkeyandreadtheinstructionsbeforeservicingor

performingmaintenance.

5.Warning—wearhearingprotection.

themachine.

theignitionkeybeforeleavingthemachine.

8.Tippinghazard—lowerthecuttingunitwhendrivingdown

slopes;slowmachinebeforeturning,donotturnathigh

speeds

9.Cuttinghazardofhandorfoot—stayawayfrommovingparts;

keepallguardsinplace.

8

Page 9

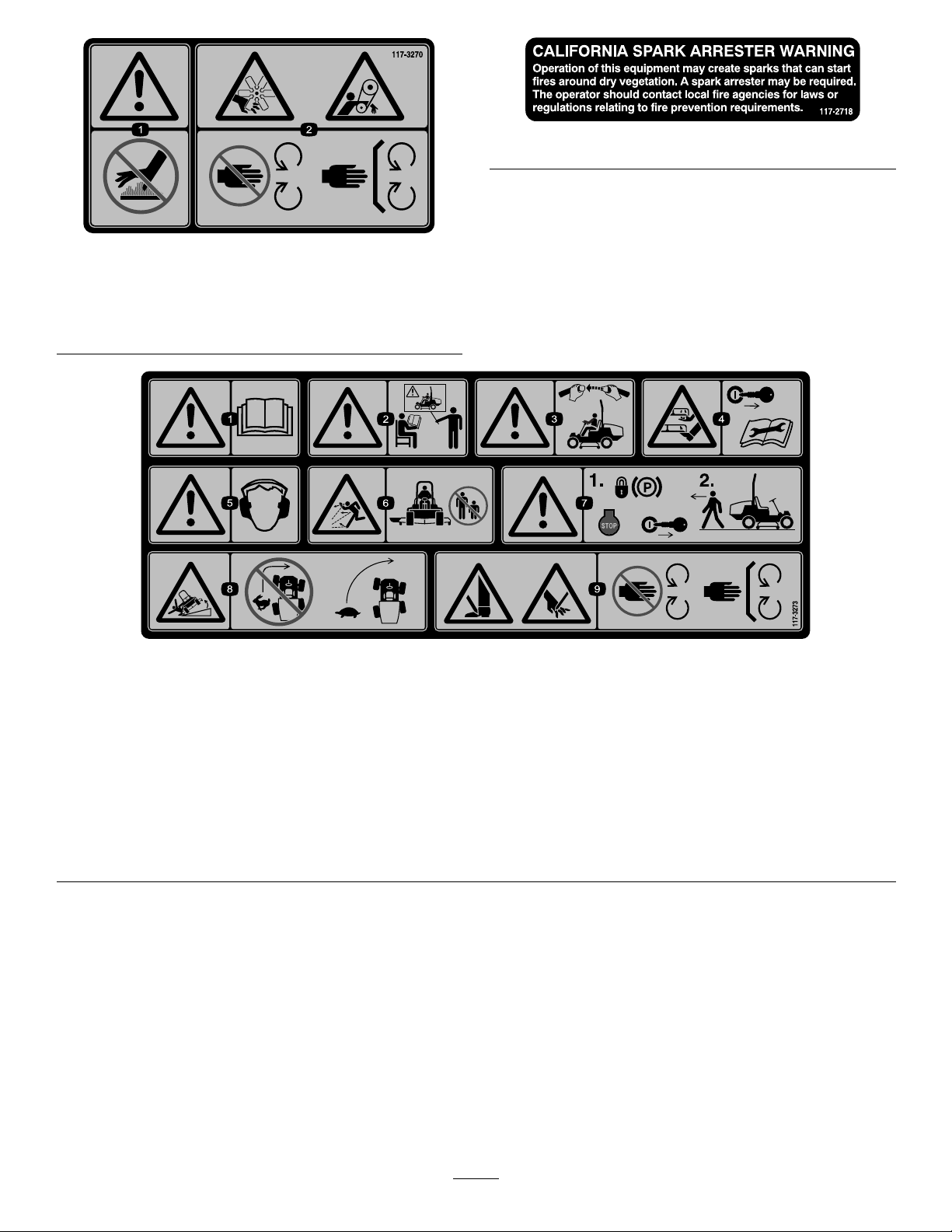

117-3233

4Wheeldrivemodels

1.ReadtheOperator'sManualforinformationonfuses.

2.4wheelsteersolenoid—7.5amp

3.PTOenable,4wheelsteerlamp,decklift,deckoat—7.5

amp

4.Glowindicator,fuelrunsolenoid,diagnosticlight,start—7.5

amp

5.Headlights,deckactuator,powertake–off—10amp

6.Lights—15amp

7.Operatorpresenceswitch—10amp

8.Powerpoint,lights—15amp

9.Engine—10amp

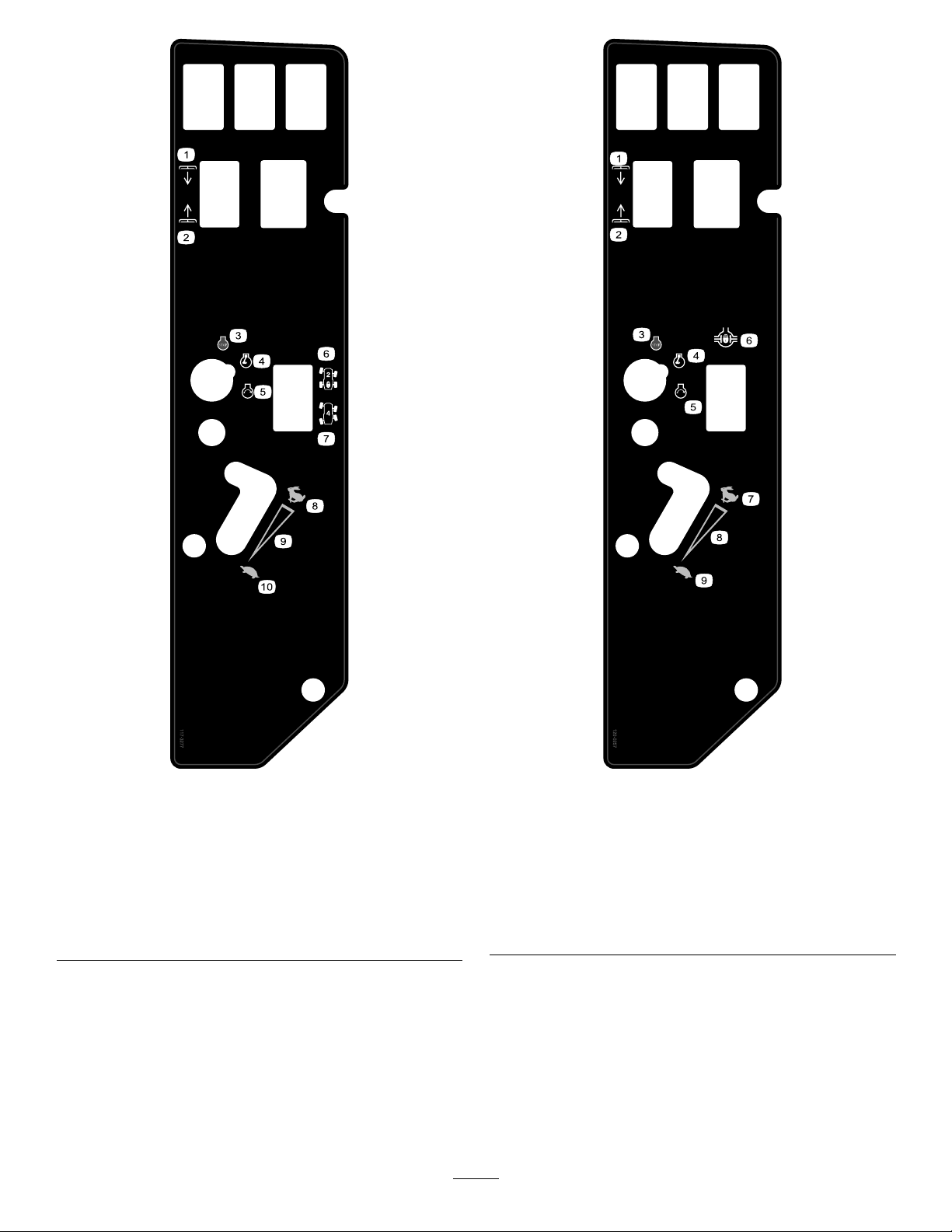

115-0492

Non-cabmodels

1.Heightofcut(mm)

117-3232

2Wheeldrivemodels

1.ReadtheOperator'sManualforinformationonfuses.

2.Differentiallockout—10amp

3.Engine—10amp

4.Lights,powerpoint—15amp

5.Powerswitch,engineignition—10amp

6.Lights—15amp

7.Operatorpresenceswitch—10amp

8.Computer—2amp

9.Headlights,deckactuator—10amp

106-9206

1.Wheeltorquespecications

2.ReadtheOperator'sManual.

115-0493

Cabmodels

1.Heightofcut(mm)

119–0124

(Cabmodels)

1.Warning—whenthecabwindowsareopenwearhearing

protection.

2.Closetherearwindowbeforeattemptingtoopenthehood.

9

Page 10

BatterySymbols

Someorallofthesesymbolsareonyourbattery

117–2787

(Cabmodels)

1.Headlights,15Afuse

2.Heater,15Afuse5.Domelight,15Afuse

3.Airconditioning,30Afuse

4.Windshieldwipers,15A

fuse

115–5501

(CabModels)

1.Lights4.Airconditioningswitch

2.Windshieldwiperswitch5.Fancontrol

3.Temperaturecontrol

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

10

Page 11

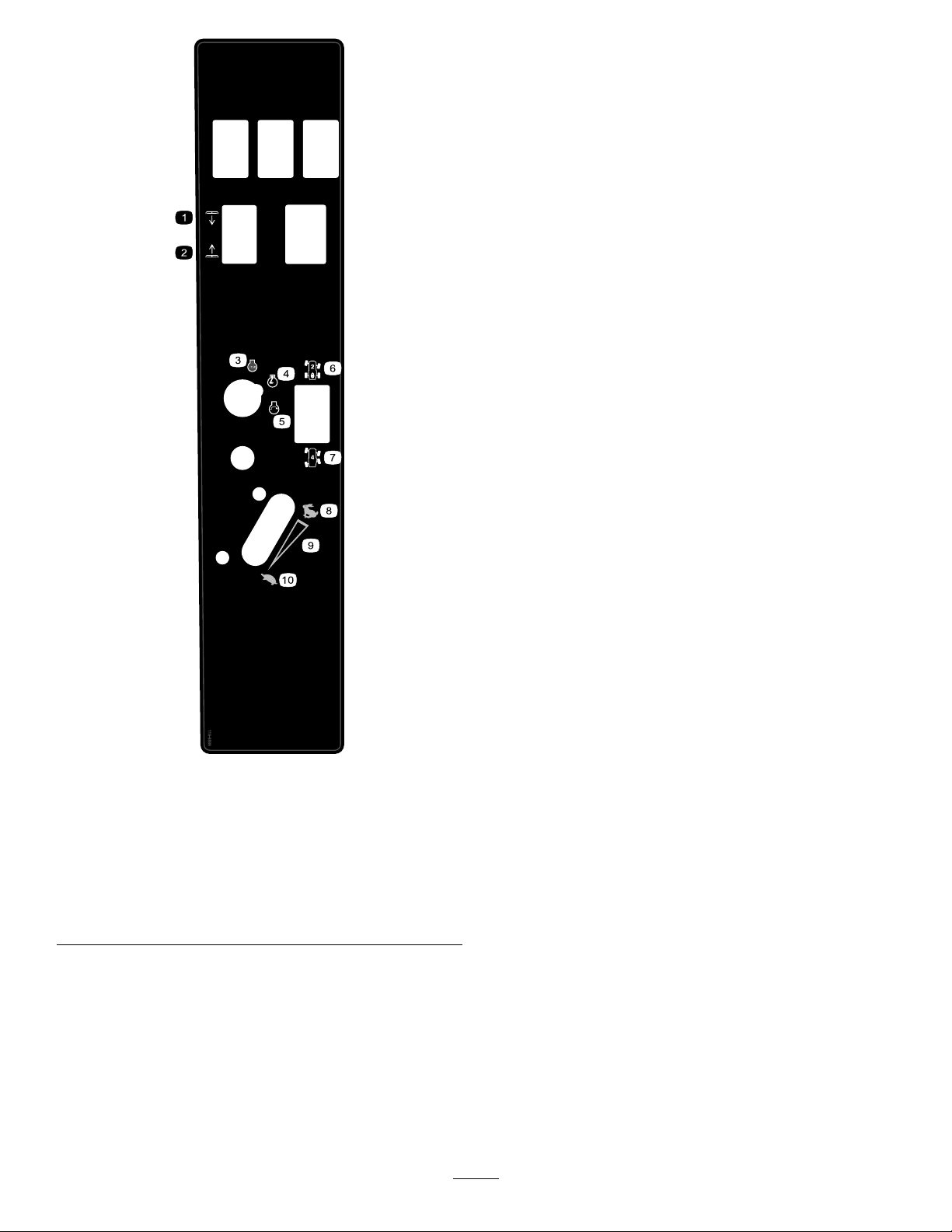

106-9290

Twowheeldrivemodelsonly

1.Inputs5.Inseat

2.Notactive

3.Hightemperatureshutdown

4.Hightemperaturewarning8.Neutral

6.PowerTake-off(PTO)10.PowerTakeOff(PTO)

7.ParkingbrakeOff11.Start

9.Outputs13.Start

14.Power

12.EnergizetoRun(ETR)

1.Removetheignitionkeyandreadthe

Operator'sManualbeforeservicingor

performingmaintenance.

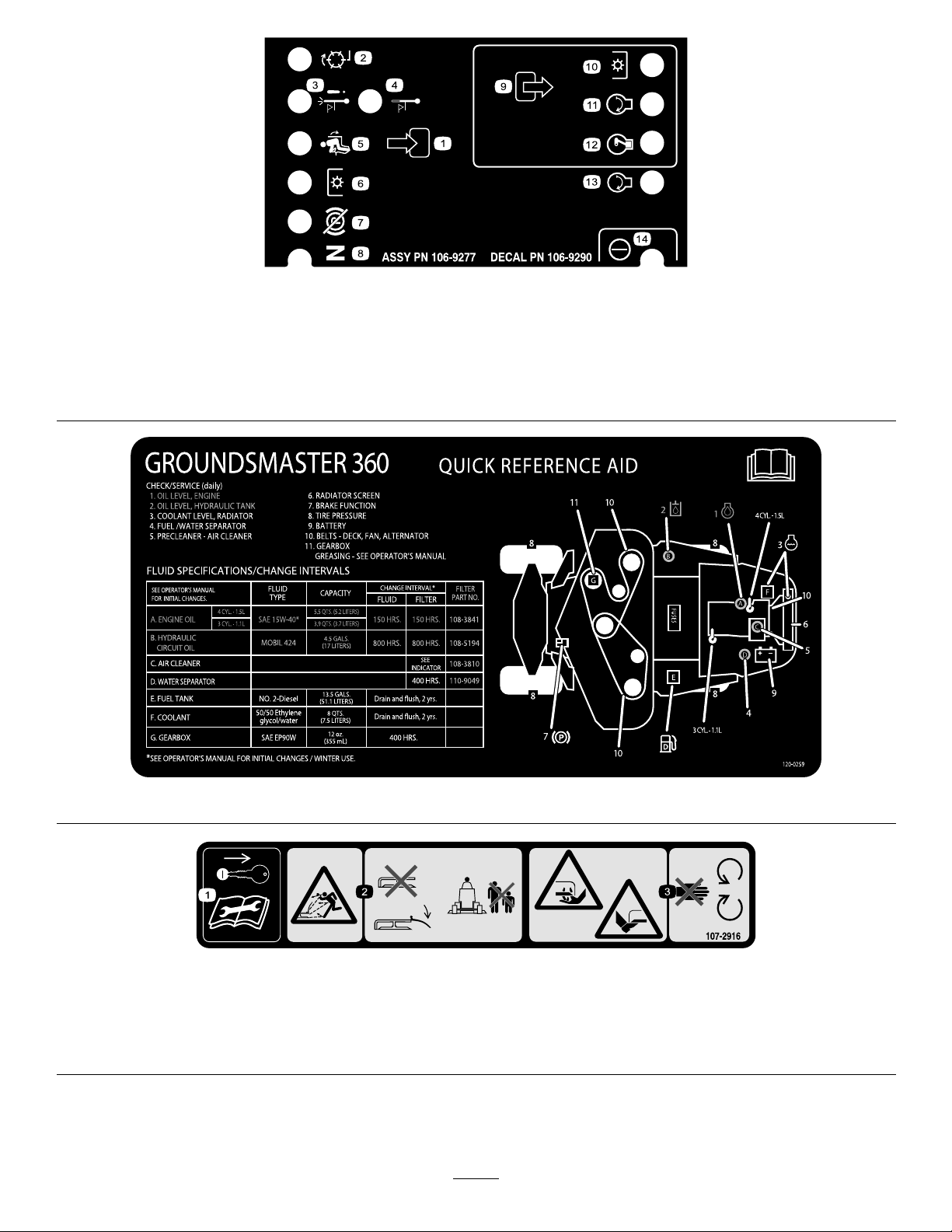

120-0259

107-2916

2.Thrownobjecthazard—donotoperate

themowerwiththedeectorupor

removed,keepthedeectorinplace;

keepbystandersasafedistancefrom

themachine.

11

3.Cutting/dismembermenthazardof

handorfoot,mowerblade—stayaway

frommovingparts.

Page 12

117-3277

Fourwheeldrive,non-cabmodels

120-0257

Twowheelsdrivemodels

1.Lowerdecks6.Two-wheelsteering

2.Raisedecks7.Four-wheelsteering

3.Engine—stop8.Fast

4.Engine—run

5.Engine—start

9.Continuousvariable

setting

10.Slow

1.Lowerdecks

2.Raisedecks7.Fast

3.Engine—stop

4.Engine—run

5.Engine—start

12

6.Differentiallock

8.Continuousvariable

setting

9.Slow

Page 13

119-9899

Modelswithcabsonly

1.Lowerdecks6.Two-wheelsteering

2.Raisedecks7.Four-wheelsteering

3.Engine—stop8.Fast

4.Engine—run

5.Engine—start

9.Continuousvariable

setting

10.Slow

13

Page 14

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

MediaandAdditionalParts

Description

Operator'sManual

EngineOperator'sManual

Driveshaft

Screw,5/16x1–3/4inch

Locknut,5/16inch

Rollpin,3/16x1–1/2inch

Retainerpin2

Greasetting

Washerheadscrew,5/16x7/8inch

Nopartsrequired

Nopartsrequired

Nopartsrequired

Qty.

1

1

Readbeforeoperatingthemachine

Readbeforeoperatingthemachine

Qty.

Use

1

4

4

2

2

2

–

–

–

Installthedriveshafttoaoptionaldeck

orQAS

Usetoinstalloptionalmowerdeck

AdjusttheROPS

Checkthetirepressure.

Checkthehydraulicuid,engineoil,

andcoolantlevels.

Use

PartsCatalog

OperatorTrainingMaterial

1

InstallingtheDriveShafttoan OptionalMowerDeckorQAS

Partsneededforthisprocedure:

1

Driveshaft

4

Screw,5/16x1–3/4inch

4

Locknut,5/16inch

2

Rollpin,3/16x1–1/2inch

Procedure

Note:PTOdriveshaftinstallationiseasierifthemachineis

positionedonahoist.

1

1

Usereferencepartnumbers

Viewthevideobeforeoperatingthemachine

WARNING

Donotstarttheengineandengagethe

PTOswitchwhenthePTOdriveshaftis

disconnectedfromthecuttingdeck.Ifthe

engineisstartedandthePTOshaftisallowed

torotate,seriouspersonalinjuryandmachine

damagecouldresult.BeforethePTOdrive

shaftisdisconnectedfromthecuttingdeck,

disconnectPTOsolenoidcoilconnector

fromwireharnesstopreventunintentional

engagementofthePTOclutch.

2.TopreventtheunintentionalengagementofthePTO

clutch,disconnectthewireharnesselectricalconnector

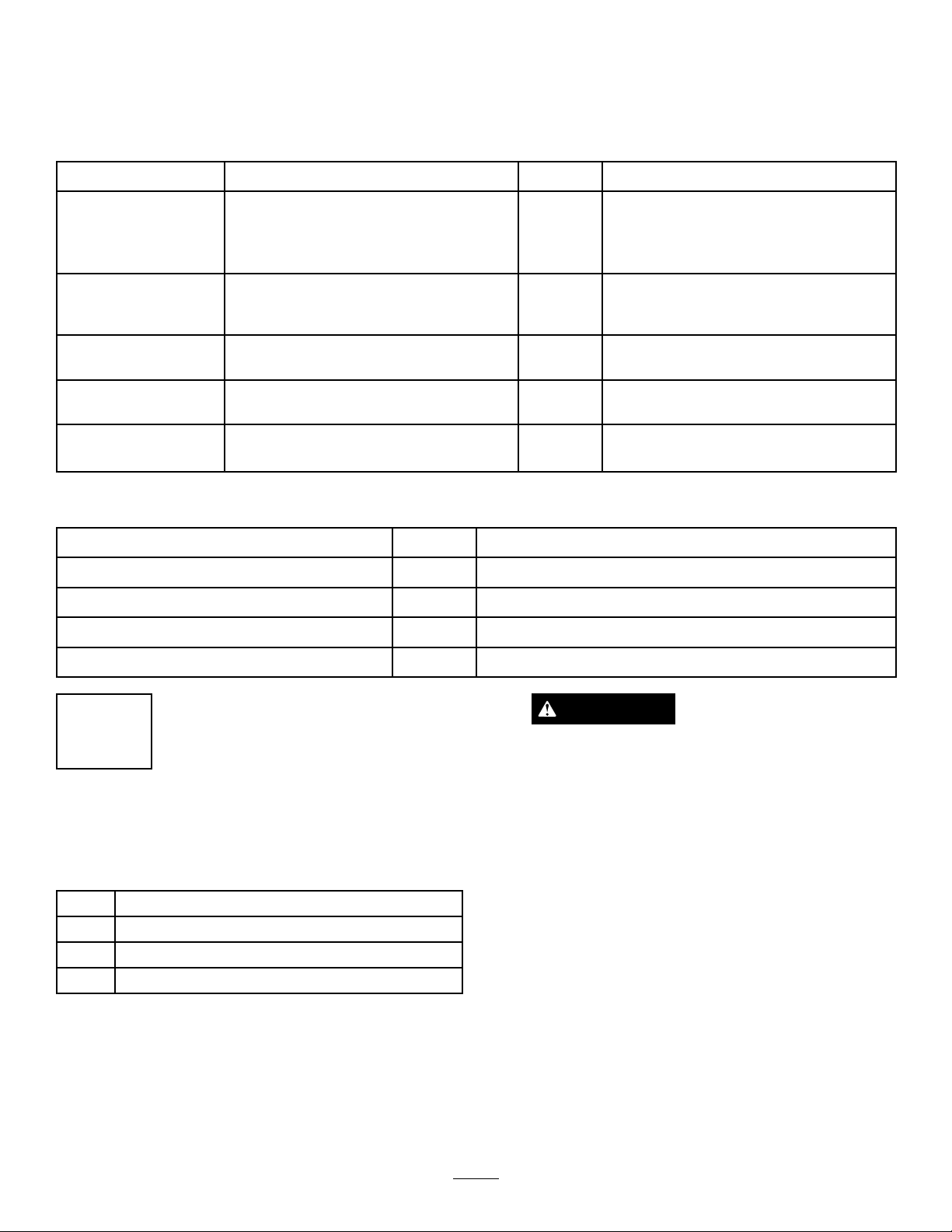

fromthePTOsolenoidvalvecoilconnector(Figure3).

1.Parkmachineonalevelsurface,stopengine,engage

parkingbrakeandremovekeyfromtheignitionswitch.

14

Page 15

G018339

1

Figure3

G018340

1

2

3

4

5

1.Wireharnesselectricalconnector

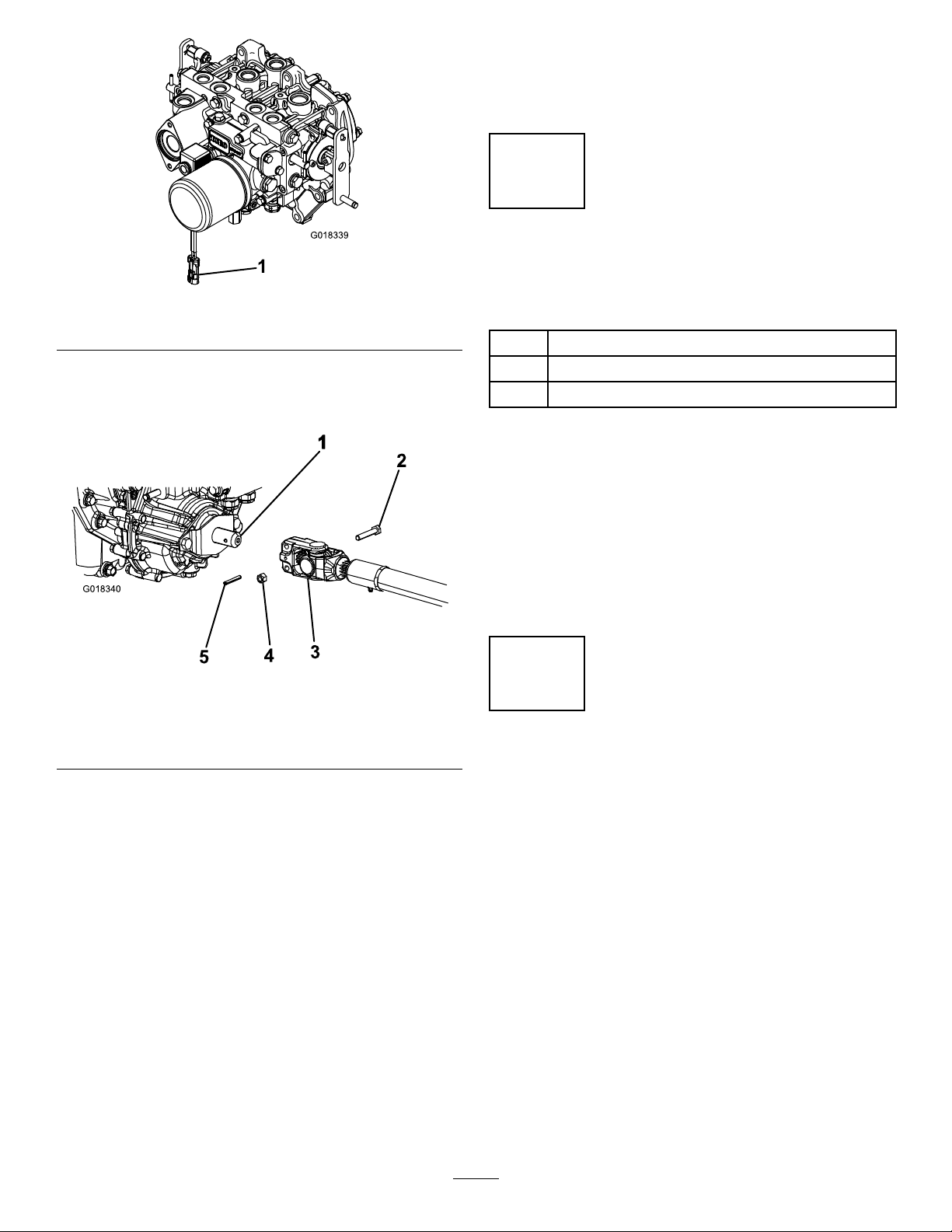

3.PositionthePTOdriveshaftunderthefrontofthe

machine.Makesurethatthedriveshaftslipshaftyoke

(Figure4)istowardthetransmissionPTOshaft.

8.Aftertheotherendofthedriveshaftisconnected

totheattachmentgearboxshaft,connectthewire

harnesselectricalconnectortothePTOsolenoidvalve

coilconnector(

Figure3).

2

OptionalMowerDeck MountingHardware

Partsneededforthisprocedure:

2Retainerpin

2

Greasetting

2

Washerheadscrew,5/16x7/8inch

Procedure

Note:Thesecomponentsandprocedureareonlyrequiredif

amowerdeck,thatrequiresretainerpins,ismountedtothe

tractionunit.RefertotheMowerDeckOperator’sManual

fortheinstallationinstructions

Figure4

1.Transmissiondriveshaft

2.Capscrew

3.PTOshaft

4.Alignthesplineandrollpinholeofdriveshaftyoke

withthetransmissionshaft.

5.SlidePTOdriveshaftendyokeontothetransmission

PTOshaft.

6.SecuretheendyokeofthePTOdriveshaftasfollows:

A.Installtherollpinintheendyokeandshaft.

B.Installthecapscrewsthruthedrivesshaftend

yoke.

C.Installandtightenthelocknutstosecuretheend

yoketothePTOshaft.Torquethelocknutsto20

to25N-m(175to225in-lb).

Note:Retaintheremainingcapscrews,locknuts

androllpintosecuretheotherendofthedrive

shafttotheattachmentgearboxshaft.

4.Locknut

5.Rollpin

Note:Ifamowerdeckisnottobeinstalledonthetraction

unit,removeortieupthe(4)deckliftchainsfromthelift

suspension.

3

AdjustingtheROPS

NoPartsRequired

Procedure

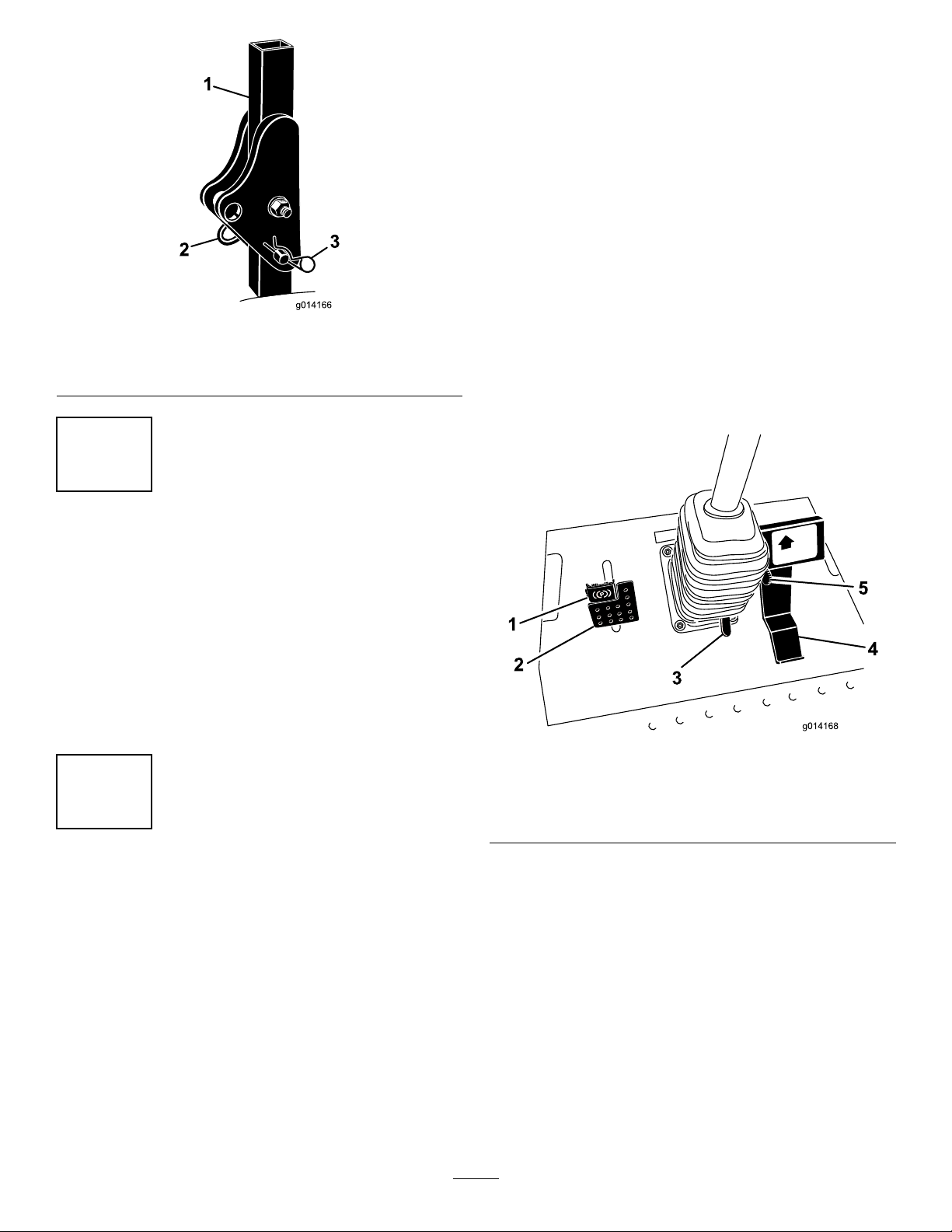

1.Removethehairpincotterpinsandthepinsfromthe

rollbar(Figure5).

2.Raisetherollbartotheuprightpositionandinstall

thetwopinsandsecurethemwiththehairpincotter

pins(Figure5).

Note:Ifyoumustlowertherollbar,pushthebar

forwardtorelievepressureonthepins,removethe

pins,lowerthebarslowly,andsecureitwiththepinsso

thatitdoesnotdamagethehood.

7.LubricatethePTOdriveshaftgreasettings.

15

Page 16

Figure5

1.Rollbar3.Hairpincotterpin

2.Pin

4

ProductOverview

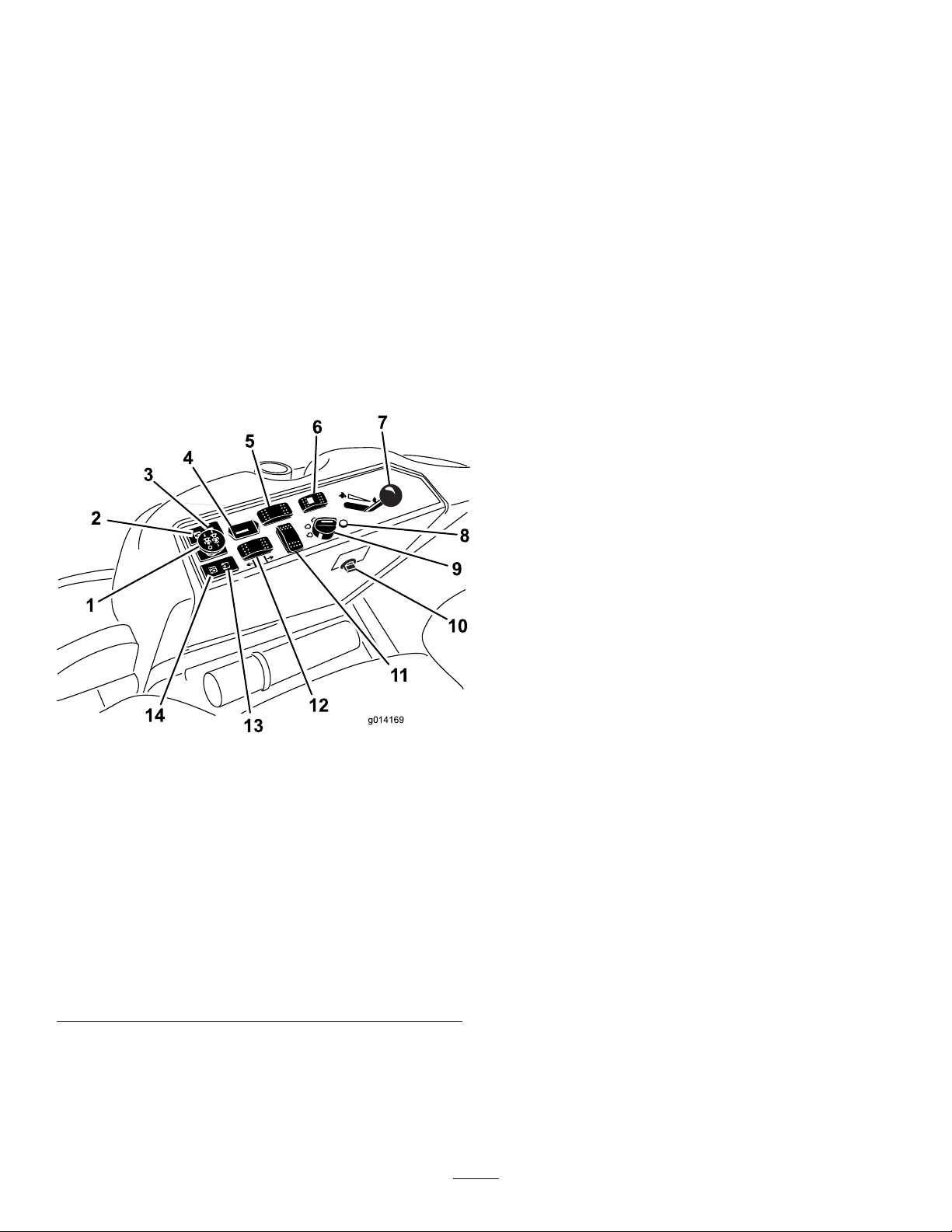

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine.

TractionPedal

Thetractionpedal(Figure6)controlstheforwardandreverse

operation.Pressthetopofthepedaltomoveforwardandthe

bottomtomoverearward.Groundspeeddependsonhow

faryoupressthepedal.Fornoload,maximumgroundspeed,

fullypressthepedalwhilethethrottleisintheFastposition.

Tostop,reducefootpressureonthetractionpedalandallow

ittoreturntothecenterposition.

Note:Foremergencystops,presstherearofthetraction

pedal(reverse)tostopthemachinequickly.

CheckingtheTirePressure

NoPartsRequired

Procedure

Thetiresareoverinatedforshipping.Therefore,release

someoftheairtoreducethepressure.Thecorrectair

pressurefornon-cabmodelsis103kPa(15psi)inthefront

tiresand172kPa(25psi)inthereartires.Ifacabisinstalled

onthemachine,thefrontandreartiresshouldbeinatedto

172kPa(25psi).

5

CheckingtheFluidLevels

NoPartsRequired

Procedure

1.Checkthehydraulicuidlevelbeforestartingthe

engine,refertoCheckingtheHydraulicFluidLevelin

theMaintenanceSection.

2.Checktheengineoillevelbeforestartingtheengine,

refertoCheckingtheEngineOilLevelinthe

MaintenanceSection.

3.Checkthecoolingsystembeforestartingthe

engine;refertoCheckingtheCoolingSysteminthe

MaintenanceSection.

Figure6

1.Parkingbrake4.Tractionpedal

2.Brakepedal

3.Tiltsteeringpedal

5.Speedlimiter

SpeedLimiter

Thespeedlimiterlever(Figure6)canbeippedforwardto

limitthetractionspeedwhileoperating.

BrakePedal

Thebrakepedalisusedinconjunctionwiththebrakepedal

latchtoengageanddisengagetheparkingbrake(Figure6)To

stopthemachine,releasethetractionpedalandallowitto

returntothecenterposition.Thebrakecanassistinstopping

inanemergencysituation.

16

Page 17

ParkingBrake

ThrottleLever

Toengagetheparkingbrake,pushdownonthebrakepedal

andpressthetopforwardtolatch(Figure6).T oreleasethe

parkingbrake,pressthebrakepedaluntiltheparkingbrake

latchretractswithoutcontactingthelockingmechanism.

TiltSteeringPedal

Totiltthesteeringwheeltowardsyou,pressthefootpedal

down,andpullthesteeringtowertowardyoutothemost

comfortablepositionandthenreleasethepedal(Figure6).T o

movethesteeringwheelawayfromyou,pressthefootpedal

andreleaseitwhenthesteeringwheelreachesthedesired

operatingposition.

IgnitionSwitch

Theignitionswitchhasthreepositions:Off,On/Preheat,

andStart(Figure7).

Thethrottlelever(Figure7)controlsthespeedoftheengine.

MovingthethrottleleverforwardtowardtheFastposition

increasestheenginespeed.Movingitrearwardtowardthe

Slowpositiondecreasestheenginespeed.Thethrottle

controlsthespeedofthePTOand,inconjunctionwiththe

tractionpedal,controlsgroundspeedofthemachine.Always

runthemachinewiththethrottleintheFastpositionwhen

operatingattachments.

PowerTakeOff(PTO)Switch

Thepowertakeoff(PTO)switchstartsandstopsthe

attachment(Figure7).

SteeringSelectorSwitch(4wheeldrive

modelsonly)

Pressthesteeringselectorswitchtothereartoengage4wheel

steeringandforwardtoreturnto2wheelsteering(Figure7).

HourMeter

Thehourmeter(Figure7)recordsthenumberofhoursthe

enginehasoperated.Itoperateswhenthekeyswitchisin

theRunposition.Usethesetimesforschedulingregular

maintenance.

Figure7

1.Powertakeoff(PTO)

Switch

2.Oilpressurewarninglight

3.Chargeindicatorlight

4.Hourmeter

5.Differentiallockswitch

(optional-2wheeldrive

only)

6.Steeringselectorswitch(4

wheeldriveonly)

7.Throttlelever14.Enginecoolant

8.Diagnosticlight(4wheel

driveonly)

9.Ignitionswitch

10.Powerpoint

11.Optionalswitchlocation

12.Deckliftswitch

13.Glowpluglight

temperaturewarning

light

DiagnosticLight(4wheeldrivemodels

only)

Itwillilluminateshouldasystemfaultberecognized(Figure

7).

DifferentialLockSwitch(optional-2

wheeldrivemodelsonly)

Pressthefrontoftheswitchandholditdowntoengagethe

differentiallock(Figure7).

GlowPlugLight(OrangeLight)

Theglowplugindicatorlight(Figure7)turnsonwhenthe

ignitionswitchisturnedtotheOnposition.Itremainslit

for6seconds.Whenthelightturnsoff,theengineisready

tobestarted.

EngineCoolantTemperatureWarning

Light

Thislightglowsandthecuttingbladesstopiftheengine

coolanttemperatureishigh(Figure7).Ifthemachineisnot

stoppedandthecoolanttemperaturerisesanother-7°C(20°

F),theenginewillstop.

Important:Iftheattachmentshutsdownandthe

temperaturewarninglightison,pushPTOknobdown,

drivetoasafeatarea,movethethrottlelevertothe

Slowposition,allowthetractionpedaltomovetothe

neutralposition,andengagetheparkingbrake.Allow

theenginetoidleforseveralminuteswhileitcoolstoa

safelevel.Stoptheengineandcheckthecoolingsystem;

refertoCheckingtheCoolingSystem.

17

Page 18

ChargeIndicator

Illuminateswhenthechargingsystemcircuitmalfunctions

(Figure7).

OilPressureWarningLight

Theoilpressurewarninglight(Figure7)glowswhentheoil

pressureinenginedropsbelowasafelevel.Iflowoilpressure

everoccurs,stoptheengineimmediatelyanddeterminethe

cause.Repairthedamagebeforestartingtheengineagain.

FuelGauge

Thefuelgauge(Figure8)indicatesthefuellevelremaining

inthefueltank.

Figure9

Figure8

1.Fuelgauge2.Fueltankcap

CabControls

Model31222only

WindShieldWiper/WasherSwitch

Presstherearoftheswitchtoactivatethewindshieldwipers

(Figure9)andthefrontofswitchtoactivatethewindshield

washer.Releasetheswitchtoturnoffthewasher.

1.Windshieldwiper/washer

switch

2.Airconditioningswitch4.Temperaturecontrol

FanControl

3.Fancontrol

Rotatethefancontrolknobtoregulatethespeedofthefan

(Figure9).

TemperatureControl

Rotatethetemperaturecontrolknobtoregulatetheair

temperatureinthecab(Figure9).

HeaterShut-offValve

Closingtheheatershut-offvalve,locatedinengine

compartment(

Figure10),willmaximizetheairconditioner

capacitytothecabduringthesummer.Duringthefall

conversion,fullyopenthevalve.

AirConditioningSwitch

Pressthefrontoftheswitchtoactivatetheairconditioning

(Figure9)andtherearoftheswitchtoturnofftheair

conditioning.

18

Page 19

Figure10

1.Heatershut-offvalve

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Length

Width(RearWheels)147.3cm(58inches)

Height,Model31223(withRoll

BarUp)

Height,Model31223(withRoll

BarDown)

Height,Model31222

Weight,Model31222

Weight,Model31223

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

241.3cm(95inches)

198cm(78inches)

137.2cm(54inches)

218.4cm(86inches)

1361kg(3000lb)

1134kg(2500lb)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CAUTION

Thismachineproducessoundlevelsinexcessof80

dBAattheoperatorsearandcancausehearingloss

throughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

AddingFuel

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchasefuelin

quantitiesthatcanbeusedwithin180daystoensurefuel

freshness.

Fueltankcapacity:51.1liters(13.5USgallons)

Usesummergradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Useofwintergrade

fuelatlowertemperaturesprovideslowerashpointand

coldowcharacteristicswhichwilleasestartingandreduce

fuellterplugging.

Useofsummergradefuelabove-7°C(20°F)willcontribute

towardlongerfuelpumplifeandincreasedpowercompared

towintergradefuel.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandfueltankor

conditioneropening.

•Keepfuelawayfromeyesandskin.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultralowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

19

Page 20

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather.

•Monitorseals,hoses,gasketsincontactwithfuelasthey

maybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblended.

•Contactyourdistributorifyouwishformoreinformation

onbiodiesel.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

FillingtheFuelTank

1.Parkthemachineonalevelsurface.

2.Shuttheengineoffandsettheparkingbrake.

3.Cleanaroundthefueltankcapandremovethecap

(Figure11).

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipmentwithits

wheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromafueldispenser

nozzle.

•Ifafueldispensernozzlemustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

Figure11

1.Fuelgauge

2.Fueltankcap

Important:Donotopenthefueltankwhen

parkedonahill.Thefuelcouldspillout.

4.Addfueltothefueltank,untilthelevelisevenwith

thebottomofthellerneck.Donotoverllthefuel

tank.

5.Installthefueltankcapandsecure.Wipeupanyfuel

thatmayhavespilled.

Note:Ifpossible,llthefueltankaftereachuse.Thiswill

minimizepossiblebuildupofcondensationinsidethefuel

tank.

UsingtheRolloverProtection System(ROPS)

•Keeptherollbarintheraisedandlockedpositionand

usetheseatbeltwhenoperatingthemachine.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Beawarethereisnorolloverprotectionwhentheroll

barisdown.

•ChecktheareaofoperationandneverfoldtheROPSin

areaswherethereareslopes,dropoffsorwater.

•Lowertherollbaronlywhenabsolutelynecessary.Do

notweartheseatbeltwiththerollbarfoldeddown.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

20

Page 21

WARNING

Toavoidinjuryordeathfromrollover:keepthe

rollbarintheraisedlockedpositionandusethe

seatbelt.

Ensurethattheseatplateissecuredwiththeseat

latch.

WARNING

Thereisnorolloverprotectionwhentherollbaris

inthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbaris

inthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearancepermits.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

1.Tolowertherollbar,removethehairpincotters,push

therollbarforwardagainstthesprings,andremove

thetwopins(Figure12).

Important:Ensurethattheseatissecuredwith

theseatlatch.

4.Toraisetherollbar,removethehairpincotterpinsand

removethetwopins(Figure12).

5.Raisetherollbartotheuprightpositionandinstallthe

twopinsandsecurethemwiththehairpincotterpins

(Figure12).

Important:Alwaysusetheseatbeltwhentherollbar

isintheraisedandlockedposition.Donotusetheseat

beltwhentherollbarisintheloweredposition.

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthesafety

section.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

DANGER

Operatingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Thereisnorolloverprotectionwhentherollbaris

down.

Alwayskeeptherollbarintheraisedandlocked

positionandusetheseatbelt.

Figure12

1.Pin3.Rollbar,raisedposition

2.Hairpincotter4.Rollbar,loweredposition

2.Lowertherollbartothedownposition(Figure12).

3.Installthetwopinsandsecurethemwiththehairpin

cotterpins(Figure12).

Readandfollowtherolloverprotectioninstructions

andwarnings.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotoperateneardrop-offsornearwater.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

CAUTION

Thismachineproducessoundlevelsinexcessof

80dBAattheoperatorsearandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

StartingandStoppingthe Engine

StartingtheEngine

1.Raisetherollbarupandlockitintoplace,sitonthe

seat,andfastentheseatbelt.

21

Page 22

2.Makesurethetractionpedalisintheneutralposition.

3.Settheparkingbrake.

4.MovethePTO(powertakeoff)switchtotheoff

position(Figure13).

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeencompletelydrained.

8.LeavethethrottlemidwaybetweentheSlowandFast

positionsuntiltheengineandhydraulicsystemwarm

up.

Important:Whenengineisstartedfortherst

time,orafteranengineoilchange,oranoverhaul

oftheengine,transmission,orwheelmotor,

operatethemachinewiththethrottleleverinthe

Slowpositioninboththeforwardandreverse

directionsforonetotwominutes.Alsooperatethe

liftleverandPTOlevertoensureproperoperation

ofallparts.Thenshuttheengineoffandcheck

uidlevels,checkforoilleaks,looseparts,and

anyothernoticeablemalfunctions.

Figure13

1.Powertakeoffswitch

(PTO)

2.Ignitionswitch4.Throttlelever

5.MovethethrottlelevermidwaybetweentheFastand

Slowpositions(Figure13).

6.TurntheignitionkeyclockwisetotheRunposition

(Figure14).

Theglowpluglightwillturnonfor6seconds.

3.Glowpluglight

CAUTION

Shuttheengineoffandwaitforallmoving

partstostopbeforecheckingforoilleaks,

looseparts,orothermalfunctions.

StoppingtheEngine

1.DisengagethePTO,makesurethetractionpedalisin

theneutralposition,settheparkingbrake,andmove

thethrottlelevertotheSlowposition.

2.Lettheengineidlefor60seconds.

3.TurntheignitionkeytotheOffposition(Figure14).

Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

4.Removethekeybeforetransportingorstoringmachine.

Important:Makesuretoremovethekeyasthe

fuelpumporaccessoriesmayrunandcausethe

batterytolosecharge.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhile

itisunattended.

Figure14

1.Start3.Off

2.Run/glowplug4.Glowplugindicatorlight

7.Aftertheglowplugindicatorlightgoesout,turnthe

keytotheStartposition.Whentheenginestarts

releasethekey.

Important:Usestartingcyclesofnomorethan

15secondsperminutetoavoidoverheatingthe

startermotor.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

DrivingtheMachine

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

theFastpositionforbestperformance.Alwaysoperateinthe

Fastthrottlepositionwhenoperatingattachments.

22

Page 23

SteeringSelection(4wheel

StoppingtheMachine

drivemodelsonly)

Formaximumtrimmingandminimumturfdamagethe

machineshouldalwaysbeoperatedin4wheelsteering.

However,whenitisdesiredtotransportthemachineonroads

ortrails,themachinecanbeswitchedinto2wheelsteering.

Figure15

1.Steeringselectorswitch

Switchingfrom4wheelsteeringto2

wheelsteering

Tostopthemachine,releasethetractionpedaltotheneutral

position.

Settheparkingbrakewheneveryouleavethemachine.

Remembertoremovethekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

attempttomoveoroperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

OperatingaMower DeckorAttachment (Optional)

RaisingandLoweringthe

Mower/Attachment

Thedeckliftswitchraisesandlowersthemower

deck/attachment(Figure16).Theenginemustberunning

foryoutousethisswitch.

Pressthesteeringselectorswitch(Figure15)totheforward

position.Ifthewheelsarenotalignedintheforwardposition,

thegreenlightwillashandthemachinewillremainin

4wheelsteeringuntilthefourtiresaredirectedstraight

ahead.Theoperatorshouldturnthesteeringwheelslowlyto

straightenoutthewheelsuntilthegreenlightceasestoash

andremainsON.Whentheswitchlightissolidgreen,the

machineisin2wheelsteering.

Note:Ifthesteeringwheelisturnedtoobriskly,steering

misalignmentmayoccur.

Switchingfrom2wheelsteeringto4

wheelsteering

Pressthesteeringselectorswitch(Figure15)totherearward

position.Ifthefrontwheelsarenotalignedintheforward

position,thegreenlightwillashandthemachinewillremain

in2wheelsteeringuntilthefourtiresaredirectedstraight

ahead.Theoperatorshouldturnthesteeringwheelslowlyto

straightenoutthewheelsuntilthegreenlightceasestoash

andremainsOFF .Ifthesteeringwheelisturnedtoobriskly,

steeringmisalignmentmayoccur.Whentheswitchlightis

continuouslyOFF,themachineisin4wheelsteering.

Figure16

1.Deckliftswitch

•Tolowerthemowerdeck/attachment,pushtheswitch

forward.

•Toraisethemoverdeck/attachment,pushtheswitch

rearward.

Important:Donotcontinuetoholdtheswitchback

afterthemower/attachmenthasfullyraised.Doingso

willdamagethehydraulicsystem.

Note:Ifthesteeringsystemismisalignedafterrepeated

2wheelsteeringto4wheelsteeringengagements,referto

CorrectingSteeringMisalignmentintheMaintenanceSection.

Note:Tolockthemowerdeck/attachmentinaraised

position,raisethedeckpastthe15cm(6inch)position,

removetheheightofcutstoppin(refertoAdjustingthe

23

Page 24

Height-of-Cut),andplacethepininthe15cm(6inch)

height-of-cutposition(Figure18).

EngagingthePowerTakeOff(PTO)

Thepowertakeoff(PTO)switchstartsandstopsthemower

bladesandsomepoweredattachments.

1.Iftheengineiscold,allowtheenginetowarmup5to

10minutesbeforeengagingthePTO .

2.Whileseatedintheseat,makesurethetractionpedalis

intheneutralpositionandtheengineisatfullthrottle.

3.PulluponthePTOswitchtoengageit(

Figure17).

AdjustingtheHeight-of-Cut

Theheight-of-cutisadjustedfrom2.5to15.8cm(1to

6inches)in6mm(1/4inch)incrementsbyrelocatingthe

stoppinintodifferentholelocations.

1.Withtheenginerunning,pushbackonthedecklift

switchuntilthemowerdeckisfullyraisedandrelease

theswitchimmediately(

2.Toadjust,rotatethestoppinuntilthenubonitlines

upwiththeslotsintheholesintheheight-of-cut

bracketandremoveit(Figure18).

3.Selectaholeintheheight-of-cutbracketcorresponding

totheheight-of-cutdesired,insertthepin,androtateit

downtolockitinplace(Figure18).

Note:Therearefourrowsofholepositions(Figure

18).Thetoprowgivesyoutheheightofcutlisted

abovethepin.Thesecondrowdowngivesyouthe

heightlistedplus6mm(1/4inch).Thethirdrow

downgivesyoutheheightlistedplus12mm(1/2inch).

Thebottomrowgivesyoutheheightlistedplus18mm

(3/4inch).Forthe15.8cm(6inch)positionthereis

onlyonehole,locatedinthesecondrow .Thisdoesnot

add6mm(1/4inch)tothe15.8cm(6inch)position.

Figure18).

Figure17

1.PTOswitch

DisengagingthePTO

Todisengage,pushthePTOswitchtotheoffposition.

Figure18

1.Stoppin

4.Adjusttheanti-scalprollersandskidsasrequired.

24

Page 25

TheSafetyInterlockSystem

CAUTION

Ifthesafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

5.Withoutanoperatorontheseat,disengagetheparking

brake,movethePTOswitchtooff,andallowthe

tractionpedaltoreturntotheneutralposition.Try

startingtheengine;theengineshouldnotcrank.

UsingtheSCMtoDiagnoseSystem

Problems

2wheeldrivemodelsonly

Themachineisequippedwithastandardcontrolmodule

(SCM)monitoringsystemthattracksthefunctionofvarious

keysystems.TheSCMislocatedundertheseat.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Youaresittingontheseatortheparkingbrakeisengaged.

•Thepowertakeoff(PTO)isdisengaged.

•Thetractionpedalisintheneutralposition

•Theenginetemperatureisbelowthemaximumoperating

temperature.

Thesafetyinterlocksystemalsoisdesignedtostoptheengine

whenthetractionpedalismovedfromtheneutralposition

withtheparkingbrakeengaged.Ifyourisefromtheseat

whenthePTOisengagedthereisa1seconddelayandthen

theenginestops.

TestingtheSafetyInterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafetyinterlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Sittingontheseat,engagetheparkingbrakeandmove

thePTOtoon.Trystartingtheengine;theengine

shouldnotcrank.

2.Sittingontheseat,engagetheparkingbrakeandmove

thePTOtooff.Engagethetractionpedal.Trystarting

theengine;theengineshouldnotcrank.

3.Sittingontheseat,engagetheparkingbrake,move

thePTOswitchtooffandallowthetractionpedalto

returntotheneutralposition.Nowstarttheengine.

Whiletheengineisrunning,releasetheparkingbrake,

engagethePTOandriseslightlyfromtheseat.Ontwo

wheeldrivemachines,theengineshouldstopwithin2

seconds.Onfourwheeldrivemachines,themower

deckwillshutoff.Theenginewillcontinuetorun.

4.Withoutanoperatorontheseat,engagetheparking

brake,movethePTOswitchtooffandmovethe

tractionpedaltotheneutralposition.Nowstartthe

engine.Whiletheengineisrunning,engagethetraction

pedal;theengineshouldstopwithin2seconds.

OnthefaceoftheSCMare11LEDsthatilluminateto

indicatevarioussystemconditions.Sevenoftheselightscan

beusedbytheoperatorforsystemdiagnosis.Referto

19foradescriptionofwhateachlightmeans.Fordetails

onusingtherestoftheSCMfunctions,refertotheService

Manual,availablethroughyourAuthorizedToroDistributor.

Figure19

1.Hightemperatureshutdown—theenginetemperaturehas

exceededsafelevelsandtheenginehasbeenshutdown.

Checkthecoolingsystem.

2.Hightemperaturewarning—theenginetemperatureis

approachingunsafelevelsandthePTOhasbeenshut

down.Checkthecoolingsystem.

3.Operatorisintheseat

4.ThePTOisOn

5.Theparkingbrakeisnotengaged

6.ControlsareinNeutral

7.TheSCMisreceivingpowerandisoperational

Figure

UnderstandingtheDiagnostic Light

(4WheelDriveonly)

Themachineisequippedwithadiagnosticlightwhich

indicatesiftheelectroniccontrollersensesanelectronic

malfunction.Thediagnosticlightislocatedonthecontrol

panel(

Figure20).Whentheelectroniccontrolleris

functioningcorrectlyandthekeyswitchismovedtothe

Onposition,thecontrollerdiagnosticlightwillturnON

for3secondsandturnOFFtoindicatethelightisworking

25

Page 26

properly.Ifthemachinekillsthelightwillturnonsteady

untilthekeypositionischanged.Thelightwillblinkifthe

controllerdetectsamalfunctionintheelectricalsystem.The

lightwillstopblinkingandautomaticallyresetwhenthekey

switchisturnedtotheOffpositiononcethefaulthasbeen

resolved.

UsetheDiagnosticACEdisplaytoolandoverlaytohelp

verifyandcorrectelectricalfunctionsofthemachine.Contact

yourTorodistributorforassistance.

CheckingtheInterlock Switches

4WheelDriveonly

Thepurposeoftheinterlockswitchesistopreventtheengine

fromcrankingorstartingunlessthetractionpedalisinthe

NeutralpositionandthePTOisdisengaged.Inaddition,the

engineshouldstopwhenthetractionpedalispressedwith

operatoroffoftheseatoriftheparkingbrakeisleftengaged.

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

Figure20

1.Diagnosticlight

Whenthecontrollerdiagnosticlightblinks,oneofthe

followingproblemshasbeendetectedbythecontroller:

•Oneoftheoutputshasbeenshorted.

•Oneoftheoutputsisopencircuited.

Usingthediagnosticdisplay,determinewhichoutputis

malfunctioning;refertoCheckingtheInterlockSwitches.

Ifthediagnosticlightisnotilluminatedwhenthekeyswitchis

intheOnposition,thisindicatesthattheelectroniccontroller

isnotoperating.Possiblecausesareasfollows:

•Thelightisburnedout.

•Fusesareblown.

•Itisnotfunctioningcorrectly.

Checktheelectricalconnections,inputfuses,anddiagnostic

lightbulbtodeterminethemalfunction.Ensurethatthe

loop-backconnectorissecuredtothewireharnessconnector.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

VerifyingtheInterlockSwitchFunction

1.Parkthemachineonalevelsurface,lowerthe

attachment,stoptheengine,andengagetheparking

brake.

2.Raisetheseat.

3.Locatethewireharnessandconnectorsnearthe

controller(Figure21).

DiagnosticAceDisplay

4WheelDriveonly

Themachineisequippedwithanelectroniccontrollerwhich

controlsmostmachinefunctions.Thecontrollerdetermines

whatfunctionisrequiredforvariousinputswitches(i.e.seat

switch,keyswitch,etc.)andturnsontheoutputstoactuate

solenoidsorrelaysfortherequestedmachinefunction.

Fortheelectroniccontrollertocontrolthemachineas

desired,eachoftheinputswitches,outputsolenoids,and

relaysmustbeconnectedandfunctioningproperly.

26

Page 27

g018321

Figure21

1.Wireharnessandconnectors

4.ConnecttheDiagnosticACEdisplaytoolconnectorto

thediagnosticconnector(

Figure22).

TheDiagnosticACEwillilluminatetheLEDassociated

witheachoftheinputswhenthatinputswitchisclosed.

7.Individually,changeeachoftheswitchesfromopen

toclosed(i.e.,sitonseat,engagetractionpedal,etc.),

andnotethattheappropriateLEDonDiagnosticACE

willblinkonandoffwhencorrespondingswitchis

closed.Repeatthisforallswitchesthatyoucanchange

byhand.

8.IfaswitchisclosedandtheappropriateLEDdoesnot

turnon,checkallwiringandconnectionstotheswitch

and/orchecktheswitchwithanohmmeter.Replace

anydefectiveswitchandrepairanydefectivewiring.

Note:TheDiagnosticACEalsohastheabilitytodetect

whichoutputsolenoidsorrelaysareturnedon.Thisisaquick

waytodeterminethesourceofthemachine’smalfunction.

VerifyingOutputFunction

1.Parkthemachineonalevelsurface,lowerthe

attachment,stoptheengine,andengagetheparking

brake.

2.Raisetheseat.

3.Locatewireharnessandconnectorsnearcontroller.

4.Carefullyunplugloopbackconnectorfromharness

connector.

Note:Makesurecorrectoverlaydecalispositioned

onDiagnosticACEdisplay.

Figure22

1.DiagnosticACE

5.TurnthekeyswitchtotheOnposition,butdonot

startthemachine.

Note:Theredtextontheoverlaydecalreferstoinput

switchesandthegreentextreferstooutputs.

6.The“inputsdisplayed”LED ,onthelowerright

columnoftheDiagnosticACE,shouldbeilluminated.

Ifthe“outputsdisplayed”LEDisilluminated,press

thetogglebutton,onDiagnosticACE,tochangeLED

to“inputsdisplayed”.

5.ConnecttheDiagnosticACEconnectortothe

appropriateharnessconnector.Ifthemachineis

equippedwithafrontattachment,itwillhavetwo

controllers.

Note:Makesurecorrectoverlaydecalispositioned

onDiagnosticACE.

6.TurnthekeyswitchtotheONposition,butdonot

startmachine.

Note:Theredtextontheoverlaydecalreferstoinput

switchesandthegreentextreferstooutputs.

7.The“outputsdisplayed”LED,onlowerrightcolumn

ofDiagnosticACE,shouldbeilluminated.Ifthe

“inputsdisplayed”LEDisilluminated,pressthetoggle

button,ontheDiagnosticACE,tochangetheLEDto

“outputsdisplayed”.

Note:Itmaybenecessarytotogglebetween“inputs

displayed”and“outputsdisplayed”severaltimestodo

thefollowingstep.Totogglebackandforth,press

thetogglebuttononce.Thismaybedoneasoftenas

required.Donotholdthebutton.

8.Sitontheseatandattempttooperatethedesired

functionofthemachine.Theappropriateoutput

LEDsshouldilluminatetoindicatethattheECMis

turningonthatfunction.

Note:IfthecorrectoutputLEDsdonotilluminate,verify

thattherequiredinputswitchesareinthenecessarypositions

toallowthatfunctiontooccur.V erifycorrectswitchfunction.

27

Page 28

IftheoutputLEDsareonasspecied,butthemachinedoes

notfunctionproperly,thisindicatesanon-electricalproblem.

Repairasnecessary.

Note:Ifeachoutputswitchisinthecorrectpositionand

functioningcorrectly,buttheoutputLEDsarenotcorrectly

illuminated,thisindicatesanECMproblem.Ifthisoccurs,

contactyourToroDistributorforassistance.

Important:TheDiagnosticACEdisplaymustnotbe

leftconnectedtothemachine.Itisnotdesignedto

withstandtheenvironmentofthemachine'severyday

use.WhendoneusingtheDiagnosticACE,disconnect

itfromthemachineandconnectloop-backconnector

toharnessconnector.Themachinewillnotoperate

withoutloopbackconnectorinstalledontheharness.

StoretheDiagnosticACEindry,securelocationinthe

shop,notonthemachine.

PositioningtheStandardSeat

ChangingtheSeatSuspension

Theseatcanbeadjustedtoprovideasmoothandcomfortable

ride.Positiontheseatwhereyouaremostcomfortable.

Withoutsittingontheseat,turntheknobinfronteither

directiontoprovidethebestcomfort(Figure23).

Figure24

1.Seatsuspensionknob2.Operatorweightsetting

ChangingtheSeatPosition

Theseatcanmoveforwardandbackward.Positiontheseat

whereyouhavethebestcontrolofthemachineandaremost

comfortable.

1.Toadjust,movetheleversidewaystounlocktheseat

(Figure23).

ChangingtheBackPosition

Thebackoftheseatcanbeadjustedtoprovideacomfortable

ride.Positionthebackoftheseatwhereitismost

comfortable.

Toadjustit,turntheknob,undertheright-sidearmrest,in

eitherdirectiontoprovidethebestcomfort(Figure23).

ChangingtheLumbarSupport

Thebackoftheseatcanbeadjustedtoprovideacustomized

lumbarsupportforyourlowerback.

Toadjustit,turntheknob,undertheleft-sidearmrest,in

eitherdirectiontoprovidethebestcomfort(Figure23).

PositioningtheDeluxeSeat

Figure23

1.Backrestknob3.Lumbarsupport

adjustmentknob

2.Seatsuspensionknob4.Seatpositionadjustment

lever

2.Slidetheseattothedesiredpositionandreleaselever

tolockinposition.

3.Verifythattheseathaslockedintoplacebyattempting

tomoveitbackandforth.

Figure25

1.Fore/Aftadjustmentlever

2.Weightadjustmentlever5.Lumbarsupportadjusting

3.Backrestlockinglever

28

4.Armrestadjustmentknob

knob

Page 29

ChangingtheWeightAdjustment

AdjustingtheArmrests

Theseatcanbeadjustedtoprovideasmoothandcomfortable

ride.

Important:Toadjusttheseatforthedriversweightthe

drivermustbeseatedandtheignitionkeymovedtothe

Onposition.

Theseatisadjustedforthedriver’sweightbypullingor

pressingtheweightadjustmentlever(Figure25).

Thedriver’sweightisadjustedcorrectlywhenthearrowisin

themiddleclearareaoftheviewingwindow .

Withinthisviewingarea,theseatcanbeadjustedtoa

minimumspringmovement.

Whentheminimum/maximumweightadjustmenthasbeen

reached,youcanhearitreachingtheupperorlowerendstop.

Important:Topreventinjurytotheoperatorand/or

damagetothemachine,thesettingforthedriver’s

weightandtheseatmustbecheckedandadjusted

beforethemachineisoperated.

Note:T oavoidcompressordamageduringweight

adjustment,thecompressormustbeoperatednolongerthan

1minute.

Thearmrestscanbefoldedbackifrequiredandtheheight

individuallyadjusted.

Toadjustthearmrestsforheight,separatetheroundcap

(Figure25)fromthecover,loosenthehexagonnut(13mm)

behinditandadjustthearmreststothedesiredpositionand

tightenthenut.Replacethecapontothenut.

WARNING

Donotinstallthearmrestinthelowestpositionas

theseatbeltrollermightnotfunctionproperly.

ChangingtheArmrestAngle

Theangleofthearmrestscanbeadjustedforoperator

comfort.

Toadjusttheangleofthearmrests,turntheadjustmentknob

(Figure25).

Whenturningtheknobtotheoutside(+)thefrontpartof

thearmrestwillbelifted,whenturningtheknobtoinside(-)

itwillbelowered.

ChangingtheBackrestPosition

ChangingtheSeatPosition

Theseatcanmoveforwardandbackward.Positiontheseat

whereyouhavethebestcontrolofthemachineandaremost

comfortable.

1.Toadjust,liftthelevertounlocktheseat(Figure25).

2.Slidetheseattothedesiredpositionandreleaselever

tolockinposition.

3.Verifythattheseathaslockedintoplacebyattempting

tomoveitbackandforth.

Note:Donotoperatethelockingleverwhile

operatingthemachine.

ChangingtheLumbarSupport

Thelumbarsupportincreasesboththeseatingcomfortand

theperformanceofthedriver.

Thebackoftheseatcanbeadjustedtoprovideacustomized

lumbarsupportforyourlowerback.

Byturningtheadjustmentknobupwards,thecurvaturein

theupperpartofthebackrestcushioncanbeadjusted.By

turningtheknobdownwards,thecurvatureinthelowerpart

ofthebackrestcushioncanbeadjusted(

Figure25).

Thebackoftheseatcanbeadjustedtoprovideamore

comfortableride.Positionthebackoftheseatwhereitis

mostcomfortable.

Pullupthelockinglevertoreleasethebackrestcatch(Figure

25).Whenreleasingthebackrestcatch,donotapplyloadto

thebackrestbypressingagainstit.

Byexertingpressureonoroffthefrontorrearoftheseatit

canbemovedtothedesiredposition.Releasethelocking

levertolockthebackrest.

Note:Thebackrestshouldnotbeabletomovetheinto

anotherpositionafterithasbeenlocked.

Raising/LoweringtheSeat

Toaccessthehydraulicandothersystemsundertheseat,you

needtounlatchtheseatandswingitforward.

1.Movetheseatlatch,locatedontheleftsideoftheseat,

rearwardtounlatchtheseatandpullforwardonthe

topoftheseat(Figure26).

0=Nocurvature

1=Maximumcurvatureatthetop

2=Maximumcurvatureatthebottom

29

Page 30

Figure26

4.Rotateeachby-passvalvecounterclockwise1turn

(Figure28).

Thisallowshydraulicuidtoby-passthepump

enablingthewheelstoturn.

Important:Donotrotatetheby-passvalvesmore

than1turn.Thispreventsvalvesfromcomingout

ofthebodyandcausinguidtorunout.

5.Disengagetheparkingbrakebeforepushing.

ChangingtoMachineOperation

Rotateeachby-passvalveclockwise1turnandhandtighten

them(torqueofapproximately8N-m(71in-lb)(Figure28).

1.Seatlatch

2.Tolowertheseat,pullupontheseatlatchreleasebar

andlowertheseatintothelockedposition.

Figure27

1.Seatlatchreleasebar

Note:Donotovertightentheby-passvalves.

Themachinewillnotdriveproperlyunlesstheby-passvalves

areturnedin.

Figure28

1.By-passvalves

PushingtheMachinebyHand

Ifthemachinestalls,runsoutoffuel,etc.youmayneedto

pushit.Todoso,yourstneedtoopenbothofthehydraulic

by-passvalves.

Important:Alwayspushthemachinebyhandand

neveralongdistance.Nevertowthemachinebecause

hydraulicdamagemayoccur.

PushingtheMachine

1.Disengagethepowertakeoff(PTO),turntheignition

keytooffandapplytheparkingbrake.

2.Removethekeyfromtheignitionswitch.Both

by-passvalvesmustbeopened.

3.Lifttheseat.

LoadingMachines

Useextremecautionwhenloadingunitsontrailersortrucks.

Onefullwidthrampthatiswideenoughtoextendbeyond

thereartiresisrecommendedinsteadofindividualrampsfor

eachsideoftheunit(Figure29).Thelowerrearsectionof

thetractorframeextendsbackbetweentherearwheelsand

servesasastopfortippingbackward.Havingafullwidth

rampprovidesasurfacefortheframememberstocontactif

theunitstartstotipbackward.Ifitisnotpossibletouseone

fullwidthramp,useenoughindividualrampstosimulatea

fullwidthcontinuousramp.

Therampshouldbelongenoughsothattheanglesdonot

exceed15degrees(

machinecomponentstogetcaughtastheunitmovesfrom

ramptotrailerortruck.Steeperanglesmayalsocausethe

unittotipbackward.Ifloadingonornearaslope,position

thetrailerortrucksoitisonthedownsideoftheslopeand

30

Figure29).Asteeperanglemaycause

Page 31

therampextendsuptheslope.Thiswillminimizetheramp

angle.Thetrailerortruckshouldbeaslevelaspossible.

TransportingMachines

Important:Donotattempttoturntheunitwhileonthe

ramp;youmaylosecontrolanddriveofftheside.

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausetheunittotipbackward.

WARNING

Loadingaunitontoatrailerortruckincreasesthe

possibilityofbackwardtip-overandcouldcause

seriousinjuryordeath.

•Useextremecautionwhenoperatingauniton

aramp.

•Useonlyasingle,fullwidthramp;Donotuse

individualrampsforeachsideoftheunit.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurfacewider

thantheunit.

•Donotexceeda15degreeanglebetweenramp

andgroundorbetweenrampandtrailerortruck.

•Avoidsuddenaccelerationwhiledrivingunitup

aramptoavoidtippingbackward.

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow

movingvehicleemblemisdangerousandcanlead

toaccidentscausingpersonalinjury.

Donotdrivemachineonapublicstreetorroadway

withoutsigns,lights,and/ormarkingsrequiredby

localregulations.

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarylightingand

markingasrequiredbylaw.Pleasecarefullyreadallthesafety

instructions.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

Totransportthemachine:

•Ensurethatyourvehicle,hitch,safetychains,andtrailer

areadequatefortheloadyouarepullingandthatthey

meetalllocaltrafcregulationsforyourarea.

•Lockthebrakeandblockthewheels.

•Securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropesasrequiredbylocaltrafc

regulationsinyourarea(Figure30).

•Avoidsuddendecelerationwhilebackingunit

downaramptoavoidtippingbackward.

Figure29

1.Trailer3.Notgreaterthan

2.Fullwidthramp4.Fullwidthramp—sideview

15degrees

31

Page 32

Figure30

1.Fronttie-down2.Reartie-downs

32

Page 33

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst10hours

Aftertherst50hours

Aftertherst200hours

Beforeeachuseordaily

Every50hours

Every100hours

Every150hours

MaintenanceProcedure

•Checkthealternatorbelttension.

•Checktheairconditioningcompressorbelttension(cabmodels)

•T orquewheellugnuts.

•Changetheengineoilandlter.

•Changethehydraulicoilandlter.

•T estthesafetysystem.

•Checktheoperationoftheinterlockswitches.

•Checktheengineoillevel.

•Checktheenginecoolantlevel.

•Cleantheradiatorwithcompressedair(donotusewater)

•Checkthehydraulicuidlevel.

•Cleantheattachment

•Greasethebearingandbushinggreasettings.

•Checkbatterycableconnections.

•Checkthetirepressure.

•Cleantheairconditioningscreen.(Cleanmorefrequentlyinextremelydustyor

dirtyconditions)

•Checkthealternatorbelttension.

•Checktheairconditioningcompressorbelttension(cabmodels)

•Changetheengineoilandlter.

Every200hours

Every250hours

Every400hours

Every800hours

Every1,500hours

Every2years

Important:Refertoyour

•Inspectcoolingsystemhosesandseals.Replacethemifcrackedortorn.

•T orquewheellugnuts.

•Cleanthecabairlters.(Replacethemiftheyaretornorexcessivelydirty.)

•Cleantheairconditioningcoil.(Cleanmorefrequentlyinextremelydustyordirty

conditions)

•Servicetheaircleaner.(Servicetheaircleanerearlieriftheaircleanerindicator

showsred.Serviceitmorefrequentlyinextremelydirtyordustyconditions.)

•Replacethefuelltercanister.

•Checkthefuellinesandconnections.

•Changethehydraulicoilandlter.

•Inspectenginevalveclearance.RefertoyourEngineOperator'sManual.

•Replacemovinghoses

•Drainandcleanthefueltank.

•Flushandreplacecoolingsystemuid.

Engine Operator's Man ual

foradditionalmaintenanceprocedures.AdetailedService

ManualisalsoavailableforpurchasefromyourAuthorizedToroDistributor.

33

Page 34

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

CheckSafetyInterlock

Operation

CheckParkingBrake

Operation

CheckFuelLevel

CheckHydraulicOilLevel

CheckEngineOilLevel

CheckCoolingSystemFluid

Level

CheckDrainWater/Fuel

Separator

CheckAirFilterRestriction

Indicator

CheckRadiator&Screenfor

Debris

CheckUnusualEngine

Noises

CheckUnusualOperating

Noises

CheckHydraulicHosesfor

Damage

CheckFluidLeaks

CheckTirePressure

CheckInstrumentOperation

LubricateAllGreaseFittings

Touch-upDamagedPaint

1.Checkglowplugandinjectornozzles,ifhardstarting,excesssmokeorroughrunningisnoted.

3

1

2

Sat.Sun.

2.Immediatelyaftereverywashing,regardlessoftheintervallisted.

3.Ifindicatorshowsred

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

34

Page 35

Figure31

1

G015806

ServiceIntervalChart

Premaintenance

Procedures

UsingtheHoodPropRod

1.Releasethehoodlatches.

2.Liftuponthehooduntiltheproprodcanbe

positionedbehindtheframetube(Figure32).

3.Lowerthehooduntiltherodisinfrontofandresting

againsttheframetube.

4.Tolowerthehood,raisethehooduntiltheproprod

canberaisedabovetheframetube,thenlowerthe

hood.

5.Securethehoodlatches

Lubrication

GreasingtheBearingsand Bushings

ServiceInterval:Every50hours

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBaseGrease.

Ifthemachineisoperatedundernormalconditions,lubricate

allbearingsandbushingsafterevery50hoursofoperation.

Bearingsandbushingsmustbelubricateddailywhen

operatingconditionsareextremelydustyanddirty.Dusty

anddirtyoperatingconditionscouldcausedirttogetinto

thebearingsandbushings,resultinginacceleratedwear.

Lubricatethegreasettingsimmediatelyaftereverywashing,

regardlessofintervalspecied.

1.Wipethegreasettingscleansoforeignmattercannot

beforcedintothebearingorbushing.

2.Pumpgreaseintothettings.

3.Wipeoffexcessgrease.

1.Proprod

Figure32

35

Page 36

Figure33

(Shownwithmowerdeckinstalled)

36

Page 37

Note:Toaccesstherearsteeringlinkagegreasettings,the

storagecompartmentneedstoberemoved.