Page 1

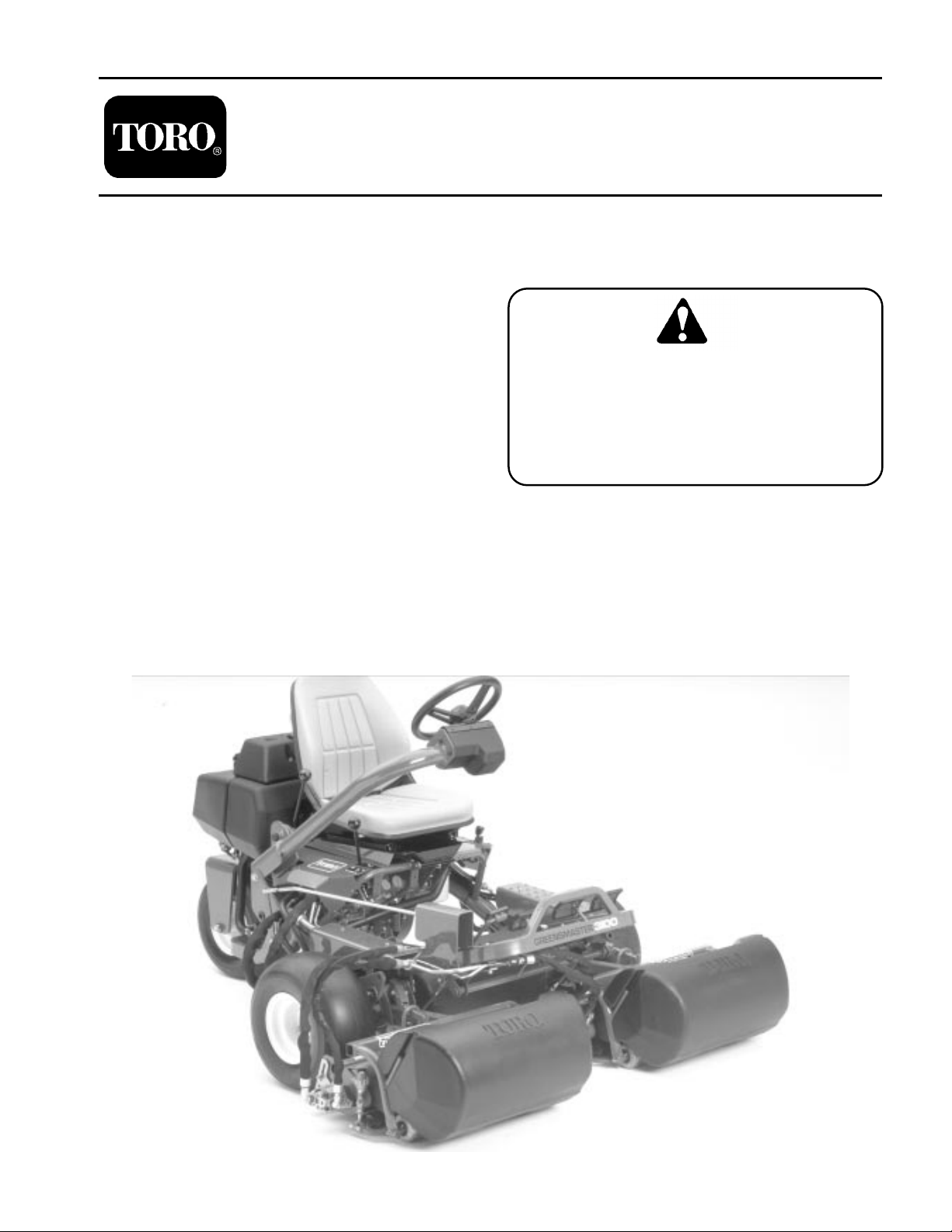

Greensmaster ® 3100/3050

Preface

This publication provides the service technician with

information for troubleshooting, testing, and repair of

major systems and components on the

Greensmaster 3100 and 3050.

REFER TO THE TRACTION UNIT, CUTTING UNIT

AND ACCESSORY OPERATOR’S MANUALS FOR

OPERATING, MAINTENANCE AND ADJUSTMENT

INSTRUCTIONS. Space is provided at the end

of Chapter 2 in this publication to insert the Operator’s

Manuals and Parts Catalogs for your machine. Replacement Operator’s Manuals are available by sending complete Model and Serial Number of traction unit and

cutting unit to:

The Toro Company

8111 Lyndale Avenue South

Minneapolis, MN 55420

The Toro Company reserves the right to change product

specifications or this publication without notice.

Part No. 92784SL, Rev. E

Service Manual

This safety symbol means DANGER, WARNING, or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol,

carefully read the instructions that follow.

Failure to obey the instructions may result in

personal injury.

NOTE: A NOTE will give general information about the

correct operation, maintenance, service, testing or repair of the machine.

IMPORTANT: The IMPORTANT notice will give important instructions which must be followed to prevent damage to systems or components on the

machine.

© The Toro Company - 1991, 1998, 2002, 2004, 2005

Page 2

This page is intentionally blank.

Page 3

Table Of Contents

Chapter 1 - Safety

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Chapter 2 - Product Records and Manuals

Product Records. . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Equivalents and Conversions. . . . . . . . . . . . . . . . 2 - 2

Torque Specifications . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Maintenance Interval Charts. . . . . . . . . . . . . . . . . 2 - 4

Equipment Operational and

Service Historical Report Record

Chapter 3 - Engine

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 5

BRIGGS & STRATTON VANGUARD V-TWIN OHV

SERVICE & REPAIR INSTRUCTIONS

Chapter 4 - Hydraulic System

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

General Information . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Hydraulic Flow Diagrams . . . . . . . . . . . . . . . . . . . 4 - 5

Hydraulic Schematic. . . . . . . . . . . . . . . . . . . . . . 4 - 12

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 13

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 16

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 27

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 36

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 39

Chapter 5 - Electrical System

Wiring Schematic . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

Turf Guardian Leak Detection System . . . . . . . . . 5 - 3

Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 9

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 13

Chapter 6 - Wheels, Steering and Brakes

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

Chapter 7 - 4 Bolt Adjust Cutting Units

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 2

Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 5

Set Up and Adjustments . . . . . . . . . . . . . . . . . . . . 7 - 7

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 15

Chapter 8 - Single Point Adjust Cutting Units

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 3

Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 4

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 6

Set Up and Adjustments . . . . . . . . . . . . . . . . . . . . 8 - 6

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 19

Chapter 9 - Grooming Reel Cutting Units

Greensmaster

®

3100

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 3

Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 4

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 6

Set Up and Adjustments . . . . . . . . . . . . . . . . . . . 9 - 10

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 21

Chapter 10 - Dual Point Adjust Cutting Units

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 5

Setup and Adjustments . . . . . . . . . . . . . . . . . . . .10 - 7

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 8

Rev. D

Page 4

This page is intentionally blank.

Page 5

Table of Contents

Chapter 1

Safety

SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . 1

Before Operating. . . . . . . . . . . . . . . . . . . . . . . . . 1

While Operating. . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Instructions

The Greensmaster 3100 has been tested and certified

for compliance with the B71.4-1984 specifications of the

American National Standards Institute (ANSI) for riding

mowers when 40 lbs. of ballast is added to rear wheel.

Hazard control and accident prevention are dependent

upon the awareness, concern, and proper training of the

personnel involved in the operation, transport, maintenance and storage of the machine. Improper use or

maintenance of the machine can result in personal injury or death. To reduce the potential for injury or death,

comply with the following safety instructions.

Before Operating

While Doing Maintenance, Troubleshooting,

Testing, Adjustments or Repairs . . . . . . . . . . . . . 3

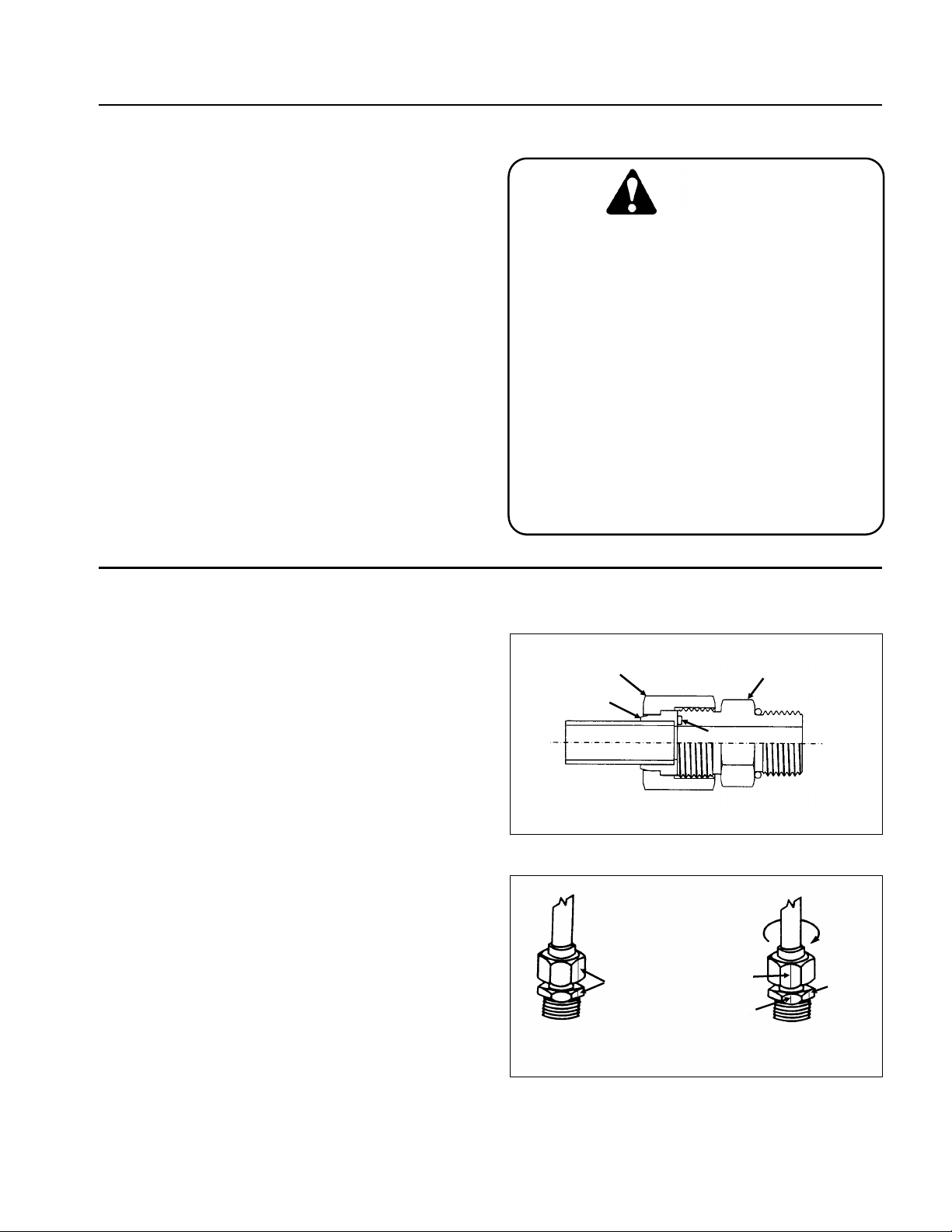

CAUTION

Obey the following safety instructions. Read

and understand these instructions before operating the Greensmaster 3100 or doing maintenance, troubleshooting, testing,

adjustments or repairs. Failure to comply with

the safety instructions may result in personal injury.

1. Read and understand the Operator’s Manual before

starting, operating, maintaining or repairing the machine. Replacement Operator’s Manuals are available

by sending complete Model and Serial Number of traction unit and cutting units to:

The Toro Company

8111 Lyndale Avenue South

Minneapolis, MN 55420

Use the Model and Serial Number when referring to your

machine. If you have questions about this Service Information, please contact:

The Toro Company

Commercial Service Department

8111 Lyndale Avenue South

Minneapolis, MN 55420

2. Never allow children to operate the machine or adults

to operate it without proper instruction.

Greensmaster®3100 Page 1 - 1 Safety Instructions

3. Become familiar with the controls and know how to

stop the machine and engine quickly.

4. Keep all shields, safety devices and decals in place.

If a shield, safety device or decal is defective or damaged, repair or replace it before operating the machine.

5. Always wear substantial shoes. Do not operate machine wearing sandals, tennis shoes, sneakers or when

barefoot. Do not wear loose fitting clothing that could get

caught in moving parts and possibly cause personal

injury.

6. Wearing safety glasses, safety shoes, long pants and

a helmet is advisable and required by some local ordinances and insurance regulations.

7. Make sure the work area is clear of objects which

might be picked up and thrown by the reels.

Page 6

8. Do not carry passengers on the machine. Keep

everyone, especially children and pets, away from the

areas of operation.

9. Since gasoline is highly flammable, handle it

carefully:

A. Use an approved fuel container.

While Operating

B. Do not remove fuel tank cap while engine is hot

or running.

C. Do not smoke while handling fuel.

D. Fill fuel tank outdoors and only to within an inch

(25 mm) from the top of the tank, not the filler neck.

Do not overfill.

E. Wipe up any spilled fuel.

10. Do not run engine in a confined area without adequate ventilation. Exhaust is hazardous and could be

deadly.

11. Sit on the seat when starting and operating the

machine.

12. Check interlock switches daily for proper operation.

If a switch fails, replace it before operating the machine.

The interlock system is for your protection, so do not

bypass it. Replace all interlock switches every two

years.

13. To start the engine:

A. Sit on the seat, depress lift pedal and release it to

disengage cutting units.

B. Verify that traction system is in neutral.

C. Verify that parking brake is set.

D. Proceed to start the engine.

14. Using the machine demands attention. To prevent

loss of control:

A. Mow only in daylight or when there is good artificial light.

B. Watch for holes or other hidden hazards.

C. Be extremely careful when operating close to

sand traps, ditches, creeks, steep hillsides or other

hazards.

D. Reduce speed when making sharp turns. Avoid

sudden stops and starts.

E. Look to the rear to assure no one is behind the

machine before backing up.

F. Watch for traffic when near or crossing roads.

Always yield the right-of-way.

G. Apply the service brakes when going down hill to

keep forward speed slow and to maintain control of

the machine.

15. Keep hands, feet and clothing away from moving

parts and the reels. The grass baskets must be in place

during operation of the reels or thatchers for maximum

safety. Shut the engine off before emptying the baskets.

16. Raise cutting units when driving from one work area

to another.

17. Do not touch engine, muffler or exhaust pipe while

engine is running or soon after it is stopped. These areas

could be hot enough to cause burns.

18. Stay clear of rotating screen at side of engine to

prevent direct contact with body or clothing.

19. If cutting unit strikes a solid object or vibrates abnormally, stop immediately, turn engine off, set parking

brake and wait for all motion to stop. Inspect for damage.

If reel or bedknife is damaged, repair or replace it before

operating.

20. Before getting off the seat:

A. Move shift selector to N (neutral).

B. Depress the lift pedal to raise the cutting units,

wait for the reels to stop spinning and release

lift pedal.

C. Set the parking brake.

E. Stop engine and remove key from switch.

21. Traverse slopes carefully. Do not start or stop suddenly when traveling uphill or downhill.

22. Operator must be skilled and trained in how to drive

on hillsides. Failure to use caution on slopes or hills may

cause loss of control and vehicle to tip or roll, possibly

resulting in personal injury or death.

23. If engine stalls or loses headway and cannot make

it to the top of a slope, do not turn machine around.

Always back slowly straight down the slope.

24. DO NOT TAKE AN INJURY RISK! When a person

or pet appears unexpectedly in or near the mowing area,

STOP MOWING. Careless operation, combined with

terrain angles, ricochets, or improperly positioned

guards can lead to thrown object injuries. Do not resume

mowing until area is cleared.

25. Whenever machine is left unattended, make sure

cutting units are fully raised and reels are not spinning,

key is removed from ignition switch and parking brake

is set.

Safety Instructions Page 1 - 2 Greensmaster

®

3100

Page 7

While Doing Maintenance, Troubleshooting, Testing, Adjustments or Repairs

26. Before servicing or making adjustments to the machine, stop the engine, remove key from ignition switch

and pull wires off spark plugs to prevent accidental

starting of the engine.

27. Make sure the entire machine is properly maintained

and in good operating condition. Frequently tighten all

nuts bolts. and screws.

28. Make sure all hydraulic line connectors are tight and

all hydraulic hoses and lines are in good condition

before applying pressure to the system.

29. Keep body and hands away from pin hole leaks or

nozzles that eject high pressure hydraulic fluid. Use

cardboard or paper to find hydraulic leaks. Hydraulic

fluid escaping under pressure can penetrate the skin

and cause injury. Fluid accidentally injected into the skin

must be surgically removed within a few hours by a

doctor or gangrene may occur.

30. Before disconnecting or performing any work on the

hydraulic system, all pressure in system must be relieved by stopping engine and lowering cutting units and

attachments to the ground.

31. To reduce potential fire hazard, keep engine area

free of excessive grease, grass, leaves and dirt. Do not

use flammable solvents for cleaning parts. Do not use

diesel fuel, kerosene or gasoline.

32. If the engine must be running to perform an inspection or procedure, use extreme caution. Always use two

people, with the operator at the controls able to see the

person doing the inspection or procedure. Keep hands,

feet, clothing, and body away from cutting units and

other moving parts.

33. Do not overspeed the engine by changing governor

settings. Maximum governed engine speed should be

2850 rpm.

34. Shut engine off before checking or adding oil to the

engine crankcase.

35. Be sure you understand a service procedure before

working on the machine. Unauthorized modifications to

the machine may impair the function, safety and life of

the machine. If major repairs are ever needed, or assistance is desired, contact your TORO Distributor.

36. Wear safety glasses, goggles or a face shield to

prevent possible eye injury when using compressed air

for cleaning or drying components.

37. When changing attachments or performing other

service, use the correct blocks and hoists. Always use

jackstands to safely support the machine when it is

raised by a jack or hoist.

38. Do not use your hand to prevent cutting unit reel

from turning while servicing; this can result in personal

injury. Use a 1/2 in. thick x 3 in. wide x 8 in. long piece

of hardwood inserted into front of cutting unit between

reel blades.

39. For optimum performance and safety, use genuine

Toro replacement parts and accessories. Replacement

parts and accessories made by other manufacturers

could be dangerous and my void the product warranty

of The Toro Company.

Greensmaster

®

3100 Page 1 - 3 Safety Instructions

Page 8

Safety Instructions Page 1 - 4 Greensmaster®3100

Page 9

Table of Contents

Rev. D

Chapter 2

Product Records and Manuals

PRODUCT RECORD FORM . . . . . . . . . . . . . . . . . . 1

EQUIVALENTS AND CONVERSIONS . . . . . . . . . . 2

Decimal and Millimeter Equivalents . . . . . . . . . . 2

U.S. to Metric Conversions . . . . . . . . . . . . . . . . . 2

Product Records

Insert Operator's Manual and Parts Catalog for your

Greensmaster 3100 or 3050 at the end of this chapter.

Refer to Operator's Manual for recommended

maintenance intervals. Additionally, insert Installation

Instructions, Operator's Manuals and Parts Catalogs for

any accessories that have been installed on your

Greensmaster 3100 or 3050 at the end of this section.

TORQUE SPECIFICATIONS . . . . . . . . . . . . . . . . . . 3

Capscrew Markings and Torque Values - U.S. . . 3

Capscrew Markings and Torque Values - Metric . 3

Greensmaster®3100 Page 2 - 1 Product Records

Rev. B

Page 10

Equivalents and Conversions

Decimal and Millimeter Equivalents

_________________________________________________________ __________________________________________

Fractions Decimals mm Fractions Decimals mm

_________________________________________________________ __________________________________________

1/64 0.015625 — 0.397 33/64 0.515625 — 13.097

1/32 ––––– 0.03125 — 0.794 17/32 –––– 0.53125 — 13.494

3/64 0.046875 — 1.191 35/64 0.546875 — 13.891

1/16 –––––––––––– 0.0625 — 1.588 9/16 –––––––––––– 0.5625 — 14.288

5/64 0.078125 — 1.984 37/64 0.578125 — 14.684

3/32 ––––– 0.9375 — 2.381 19/32 –––– 0.59375 — 15.081

7/64 0.109275 — 2.778 39/64 0.609375 — 15.478

1/8 ––––––––––––– 0.1250 — 3.175 5/8 ––––––––––––– 0.6250 — 15.875

9/64 0.140625 — 3.572 41/64 0.640625 — 16.272

5/32 ––––– 0.15625 — 3.969 21/32 –––– 0.65625 — 16.669

11/64 0.171875 — 4.366 43/64 0.671875 — 17.066

3/16 –––––––––––– 0.1875 — 4.762 11/16 ––––––––––– 0.6875 — 17.462

13/64 0.203125 — 5.159 45/64 0.703125 — 17.859

7/32 ––––– 0.21875 — 5.556 23/32 –––– 0.71875 — 18.256

15/64 0.234375 — 5.953 47/64 0.734375 — 18.653

1/4 ––––––––––––– 0.2500 — 6.350 3/4 ––––––––––––– 0.7500 — 19.050

17/64 0.265625 — 6.747 49/64 0.765625 — 19.447

9/32 ––––– 0.28125 — 7.144 25/32 –––– 0.78125 — 19.844

19/64 0.296875 — 7.541 51/64 0.796875 — 20.241

5/16 –––––––––––– 0.3125 — 7.541 13/16 ––––––––––– 0.8125 — 20.638

21/64 0.328125 — 8.334 53/64 0.828125 — 21.034

11/32 –––– 0.34375 — 8.731 27/32 –––– 0.84375 — 21.431

23/64 0.359375 — 9.128 55/64 0.859375 — 21.828

3/8 ––––––––––––– 0.3750 — 9.525 7/8 ––––––––––––– 0.8750 — 22.225

25/64 0.390625 — 9.922 57/64 0.890625 — 22.622

13/32 –––– 0.40625 — 10.319 29/32 –––– 0.90625 — 23.019

27/64 0.421875 — 10.716 59/64 0.921875 — 23.416

7/16 –––––––––––– 0.4375 — 11.112 15/16 ––––––––––– 0.9375 — 23.812

29/64 0.453125 — 11.509 61/64 0.953125 — 24.209

15/32 –––– 0.46875 — 11.906 31/32 –––– 0.96875 — 24.606

31/64 0.484375 — 12.303 63/64 0.984375 — 25.003

1/2 ––––––––––––– 0.5000 — 12.700 1 –––––––––––––– 1.000 — 25.400

1 mm = 0.03937 in. 0.001 in. = 0.0254 mm

_________________________________________________________ __________________________________________

U.S to Metric Conversions

_________________________________________________________ __________________________________________

_________________________________________________________ __________________________________________

Linear Miles Kilometers 1.609

Measurement Yards Meters 0.9144

_________________________________________________________ __________________________________________

Area Square Miles Square Kilometers 2.59

_________________________________________________________ __________________________________________

Volume Cubic Yards Cubic Meters 0.7646

_________________________________________________________ __________________________________________

Weight Tons (Short) Metric Tons 0.9078

_________________________________________________________ __________________________________________

Pressure Pounds/Sq. In. Kilopascal 6.895

_________________________________________________________ __________________________________________

Work Foot-pounds Newton-Meters 1.356

_________________________________________________________ __________________________________________

Liquid Volume Quarts Liters 0.9463

_________________________________________________________ __________________________________________

Liquid Flow Gallons/Minute Liters/Minute 3.785

_________________________________________________________ __________________________________________

Temperature Fahrenheit Celsius 1. Subract 32

_________________________________________________________ __________________________________________

To Convert Into Multiply By

Feet Meters 0.3048

Feet Centimeters 30.48

Inches Meters 0.0254

Inches Centimeters 2.54

Inches Millimeters 25.4

Square Feet Square Meters 0.0929

Square Inches Square Centimeters 6.452

Acre Hectare 0.4047

Cubic Feet Cubic Meters 0.02832

Cubic Inches Cubic Centimeters 16.39

Pounds Kilograms 0.4536

Ounces (Avdp.) Grams 28.3495

Foot-pounds Kilogram-Meters 0.1383

Inch-pounds Kilogram-Centimeters 1.152144

Gallons Liters 3.785

o

2. Multiply by 5/9

Equivalents and Conversions Page 2 - 2 Greensmaster®3100

Page 11

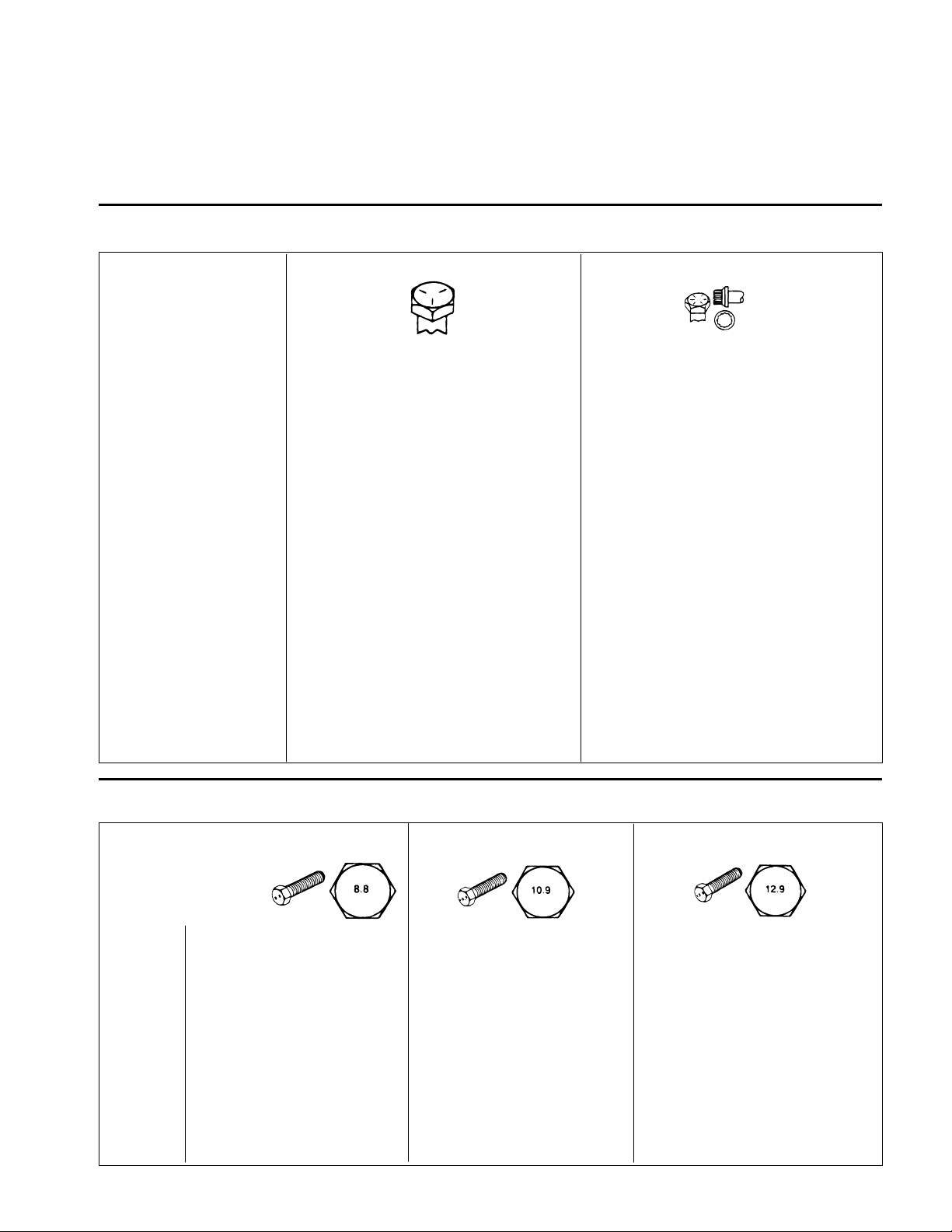

Torque Specifications

Use these torque values when specific torque values

are not given. DO NOT use these values in place of

The torque values listed below are for lubricated

threads. Plated threads are considered to be lubricated.

specified values.

Capscrew Markings and Torque Values - U.S. Customary

SAE Grade Number 5 8

_______________________________________________________ _________________________________________________________________________________________________

Capscrew Head Markings

_______________________________________________________ _________________________________________________________________________________________________

Capscrew Body Size Cast Iron Aluminum Cast Iron Aluminum

_______________________________________________________ _________________________________________________________________________________________________

1/4-20 79681115912

_______________________________________________________ _________________________________________________________________________________________________

_______________________________________________________ _________________________________________________________________________________________________

_______________________________________________________ _________________________________________________________________________________________________

_______________________________________________________ _________________________________________________________________________________________________

_______________________________________________________ _________________________________________________________________________________________________

_______________________________________________________ _________________________________________________________________________________________________

_______________________________________________________ _________________________________________________________________________________________________

_______________________________________________________ _________________________________________________________________________________________________

-28 9 12 7 9 13 18 10 14

5/16-18 1520121622301824

-24 1723141924331925

3/8-16 3040202540553040

-24 3040253545603545

7/16-14 4560354565905065

-20 5065405570955575

1/2-13 709555759513075100

-20 75 100 60 80 110 150 90 120

9/16-12 100 135 80 110 140 190 110 150

-18 110 150 85 115 155 210 125 170

5/8-11 135 180 110 150 190 255 150 205

-18 155 210 120 160 215 290 170 230

3/4-10 240 325 190 255 340 460 270 365

-16 270 365 210 285 380 515 300 410

7/8-9 360 490 280 380 550 745 440 600

_______________________________________________________ _________________________________________________________________________________________________

-14 390 530 310 420 610 825 490 660

1-8 530 720 420 570 820 1100 660 890

-14 590 800 480 650 890 1200 710 960

Capscrew Torque - Grade 5 Capscrew Torque - Grade 8

ft-lb Nm ft-lb Nm ft-lb Nm ft-lb Nm

Capscrew Markings and Torque Values – Metric

Commercial Steel Class 8.8 10.9 12.9

_______________________________________________________ _________________________________________________________________________________________________

Capscrew Head Markings

_______________________________________________________ _________________________________________________________________________________________________

Thread Capscrew Torque - Class 8.8 Capscrew Torque - Class 10.9 Capscrew Torque - Class 12.9

Diameter Cast Iron Aluminum Cast Iron Aluminum Cast Iron Aluminum

mm ft-lb Nm ft-lb Nm ft-lb Nm ft-lb Nm ft-lb Nm ft-lb Nm

_______________________________________________________ _________________________________________________________________________________________________

_______________________________________________________ _________________________________________________________________________________________________

_______________________________________________________ _________________________________________________________________________________________________

_______________________________________________________ _________________________________________________________________________________________________

_______________________________________________________ _________________________________________________________________________________________________

_______________________________________________________ _________________________________________________________________________________________________

_______________________________________________________ _________________________________________________________________________________________________

_______________________________________________________ _________________________________________________________________________________________________

Greensmaster®3100 Page 2 - 3 Torque Specifications

65947914711914711

7 914 7111418 111418231418

8182514182332182527362128

10 30 40 25 30 45 60 35 45 50 70 40 55

12 55 70 40 55 75 105 60 80 95 125 75 100

14 85 115 65 90 120 160 95 125 145 195 110 150

16 130 180 100 140 175 240 135 190 210 290 165 220

18 170 230 135 180 240 320 185 250 290 400 230 310

Page 12

This page is intentionally blank.

Page 13

Table of Contents

Rev. D

Chapter 3

Engine

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 1

ADJUSTMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Throttle Control Adjustment. . . . . . . . . . . . . . . . . 2

Choke Control Adjustment . . . . . . . . . . . . . . . . . 2

Governor Adjustment. . . . . . . . . . . . . . . . . . . . . . 3

ENGINE REMOVAL AND INSTALLATION . . . . . . . . 5

Removing the Engine . . . . . . . . . . . . . . . . . . . . . 5

Installing the Engine . . . . . . . . . . . . . . . . . . . . . . 5

BRIGGS & STRATTON VANGUARD V-TWIN OHV

SERVICE & REPAIR INSTRUCTIONS

Carburetor and Speed Control Adjustment . . . . . 4

Specifications

Item Specification

___________________________________________________________________________________________

Make/Designation Briggs & Stratton Vanguard ® V-Twin OHV,

_______________________________________________________ _________________________________________________________________________________________________

Crankcase Oil Capacity See Operator's Manual

_______________________________________________________ _________________________________________________________________________________________________

Oil See Operator's Manual

_______________________________________________________ _________________________________________________________________________________________________

Fuel Unleaded Regular Gasoline

_______________________________________________________ _________________________________________________________________________________________________

High Idle Speed (no load) 2800

_______________________________________________________ _________________________________________________________________________________________________

Low Idle Speed (no load) 1400 ± 50 RPM

air cooled, gas engine with cast iron cylinder sleeves

+50

/

RPM

–100

Greensmaster®3100 Page 3 - 1 Specifications

Page 14

Adjustments

Throttle Control Adjustment (Fig. 1)

Before adjusting carburetor, make sure throttle control

is operating properly.

1. Loosen cable clamp screw securing cable to engine.

2. Move remote throttle control lever forward to FAST

position.

3. Pull firmly on throttle cable until back of swivel contacts stop.

4. Tighten cable clamp screw.

2

6

5

7

1

4

3

Figure 1

1. Throttle casing clamp screw

2. Throttle cable

3. Swivel

4. Stop

5. Choke casing clamp screw

6. Choke cable

7. Choke butterfly

Choke Control Adjustment (Fig. 1)

1. Loosen cable clamp screw securing cable to engine.

2. Move remote choke control lever forward to CLOSED

position.

3. Pull firmly on choke cable until choke butterfly is

completely closed, then tighten cable clamp screw.

Adjustments Page 3 - 2 Greensmaster®3100

Page 15

Governor Adjustment (Before starting engine)

IMPORTANT: If carburetor has been removed or

governor linkage disassembled, the governor lever,

throttle restrictor and secondary governor spring

must be adjusted before the engine is started.

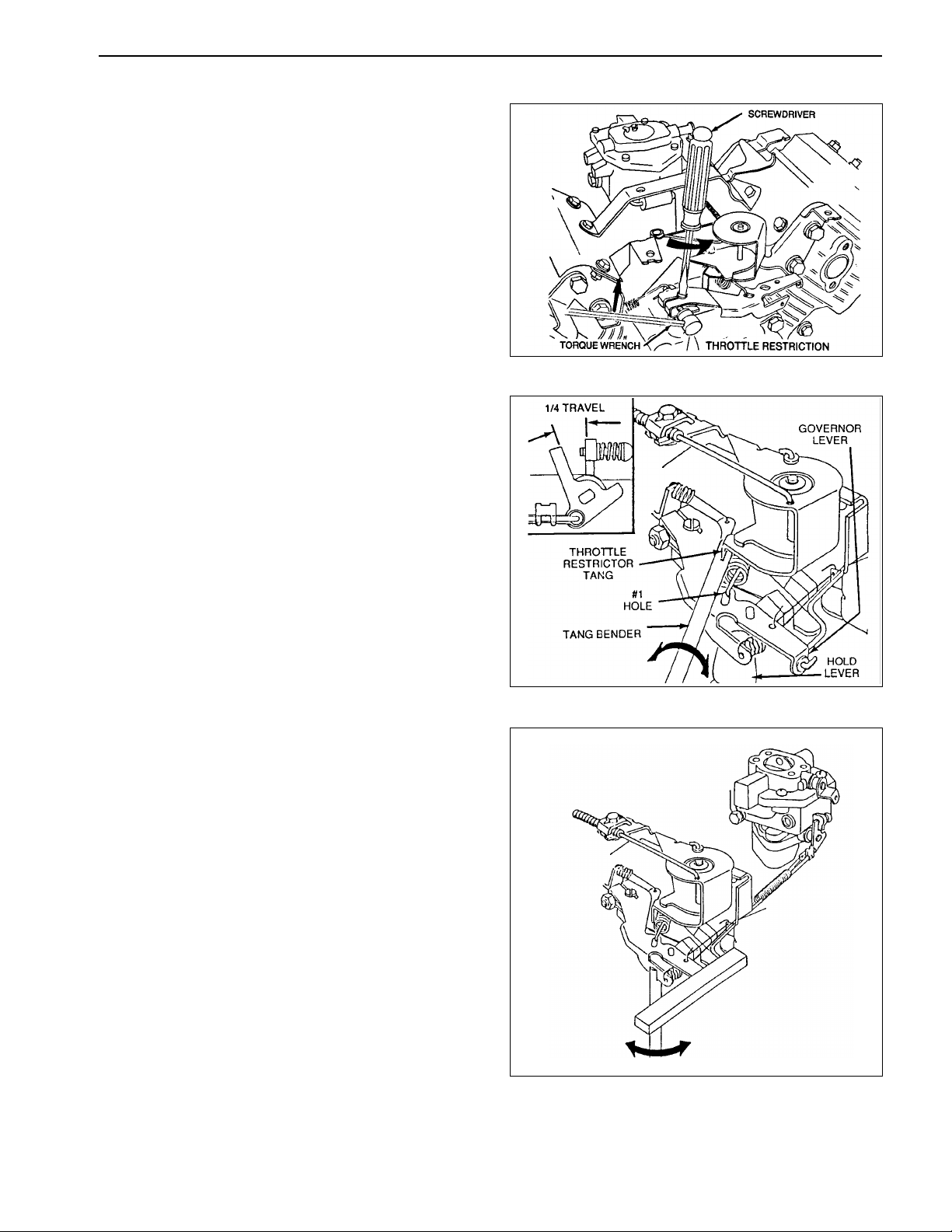

Governor Lever Adjustment (Fig. 2)

All linkage must be installed to make adjustment.

Loosen governor lever bolt and nut. Push on governor

lever until throttle is wide open. DO NOT bend governor

link. Hold lever in this position and rotate governor shaft

counterclockwise as far as it will go. Hold lever and shaft

in position and torque governor lever bolt and nut to

70 in-lb.

Throttle Restrictor Adjustment (Fig. 3)

Move throttle control lever to SLOW position. Hold

governor lever so that throttle lever touches idle speed

adjustment screw. Use tang bender (Briggs & Stratton

Tool #19352) and bend throttle restrictor tang so throttle

opening is limited to 1/4 in. travel when governor lever

is released.

Figure 2

Secondary Spring Adjustments (Fig. 4)

With throttle control lever in SLOW position, install

adjustment gauge (Brigss & Stratton Tool #19385) over

end of governor lever as shown. Holding gauge in

position, bend tab so that all slack is removed from

secondary governor spring between its two anchor

points. DO NOT STRETCH SPRING. Remove adjustment gauge.

Figure 3

Figure 4

Greensmaster®3100 Page 3 - 3 Adjustments

Page 16

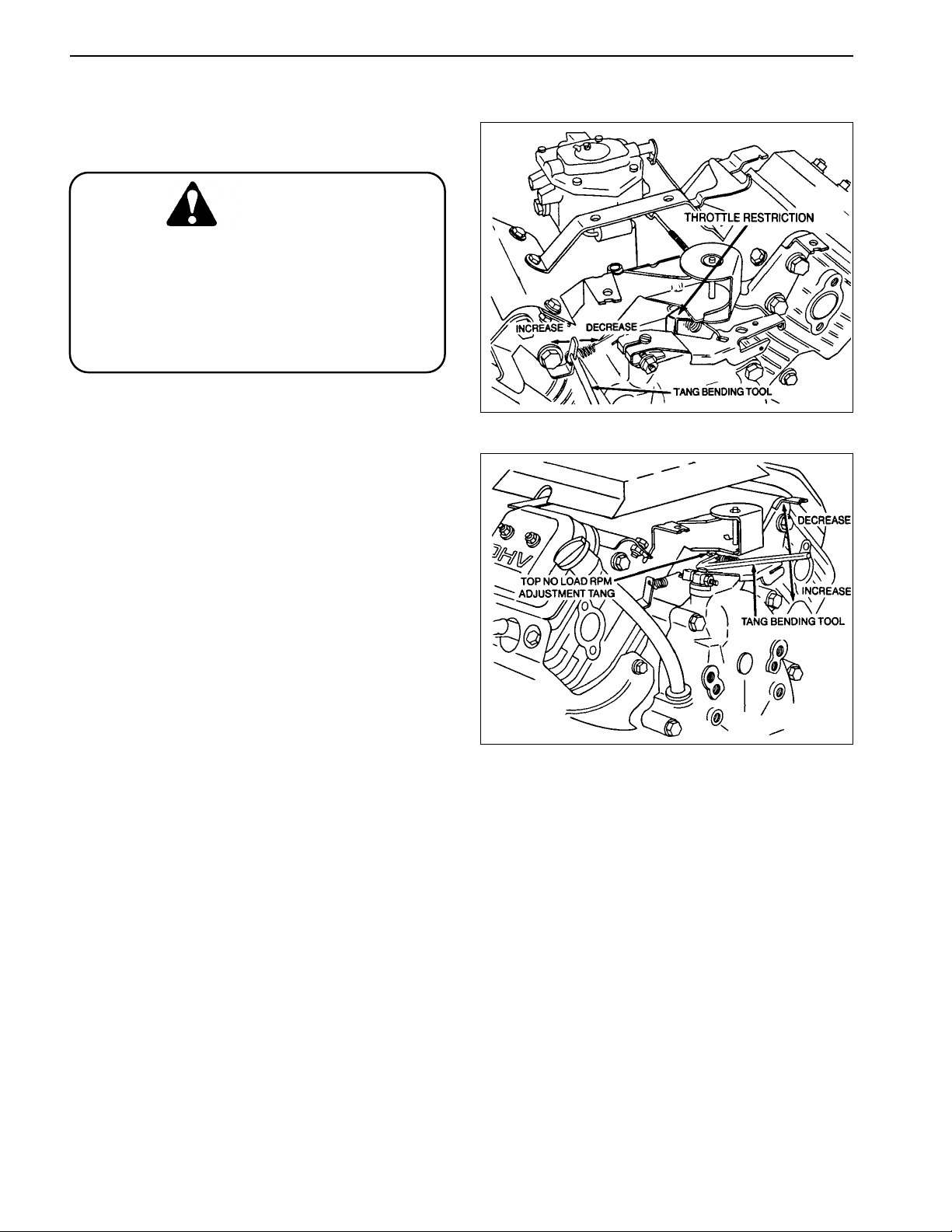

Carburetor and Speed Control Adjustment (Fig. 5, 6)

IMPORTANT: Before carburetor and speed control

are adjusted, the throttle and choke controls must

be adjusted properly.

WARNIN G

Engine must be running during adjustment of

carburetor and speed control. To guard

against possible personal injury, shift into

neutral and engage parking brake. Keep

hands, feet, face and other parts of the body

away from the cutter blades and any rotating

engine parts.

1. Start engine and let it run at half throttle for approximately five (5) minutes to warm up.

2. Move throttle control to SLOW position. Hold governor lever so throttle lever is in the idle position (against

idle stop screw) and turn idle stop screw in or out to get

1400 ± 50 RPM. Check speed with a tachometer.

Figure 5

3. Adjust idle mixture screw:

A. Turn idle mixture screw slowly clockwise (lean

mixture) until engine speed just starts to decrease.

Note position of screw.

B. Now turn idle mixture screw slowly counterclockwise (rich mixture) until engine speed just starts to

decrease. Note position of screw.

C. Set the idle mixture screw half way between the

rich and lean settings.

4. After idle mixture has been adjusted, hold governor

lever so throttle lever is in idle position (against idle stop

screw) and adjust idle stop screw to bring engine speed

to 1200 ± RPM.

5. With governor control lever in governed idle position

(no tension on high speed spring) bend governed idle

spring anchor tang to get a governed idle speed of

1400 ± RPM (Fig. 5).

6. Move throttle control to FAST position. Bend high

speed spring anchor tang to bring engine speed to

2800 +50/–100 RPM (Fig. 6).

Figure 6

Adjustments Page 3 - 4 Greensmaster®3100

Page 17

Engine Removal and Installation

Removing the Engine

1. Disconnect the negative (–) and positive (+) battery

cables from the battery.

2. Close the fuel shut-off valve and disconnect the fuel

line.

WARNIN G

Gasoline is highly flammable. Use caution

while handling it. Do not smoke cigarettes,

cigars or pipes. Dispose of the gasoline in a

safe place immediately after draining.

Installing the Engine

1. Support the engine, align it with the engine mounts,

and instal the pump hub over the engine shaft and key.

Be sure that the key is properly positioned and aligned

with the keyway.

2. Install the engine mount bolts, washers and nuts.

3. Remove the starter cable, throttle and choke cable

and ground wire from engine.

4. Disconnect the wiring harness connector.

5. Loosen the two (2) set screws securing the pump hub

onto the engine shaft. Remove the two (2) capscrews

securing the pump to the pump mount. DO NOT disconnect the hydraulic hoses from the pump.

6. Support the engine and remove the engine mount

bolts, nuts and washers to remove the engine.

4. Re-connect the fuel line, wire connectors and the

cables to the engine and battery.

5. Make sure the crankcase is filled the correct oil. Open

the fuel shut-off valve. Fill the fuel tank. Start the engine

and check for proper operation.

3. Mount the pump to the pump housing and tighten the

set screws to secure the hub to the shaft.

Greensmaster®3100 Page 3 - 5 Engine Removal and Installation

Page 18

Engine Removal and Installation Page 3 - 6 Greensmaster®3100

Page 19

Table of Contents

Chapter 4

Hydraulic System

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 2

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . 3

Hydraulic Hoses . . . . . . . . . . . . . . . . . . . . . . . . . 3

Hydraulic Fitting Installation . . . . . . . . . . . . . . . . 3

HYDRAULIC FLOW DIAGRAMS . . . . . . . . . . . . . . . 5

Traction, No. 1 Position . . . . . . . . . . . . . . . . . . . . 5

Traction, No. 2 Position . . . . . . . . . . . . . . . . . . . . 6

Traction, Reverse Position . . . . . . . . . . . . . . . . . 7

Reel Drive, Mowing Operation . . . . . . . . . . . . . . 8

Reel Drive, Lower Cutting Units . . . . . . . . . . . . . 9

Reel Drive, Raising Cutting Units . . . . . . . . . . . 10

Power Steering, R.H. Turn . . . . . . . . . . . . . . . . . 11

HYDRAULIC SCHEMATIC. . . . . . . . . . . . . . . . . . . 12

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . 13

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . 16

Slow Groundspeed in All Traction Selections . . 17

Slow or No Ground Speed in No. 1

and Reverse, No. 2 Appears Normal . . . . . . . . 18

No Increase in Speed From No. 1 to No. 2 . . . . 19

One or More Cutting Units Slow

or No Reel Drive Action. . . . . . . . . . . . . . . . . . . 20

All Reels Slow or Will Not Turn . . . . . . . . . . . . . 21

Mow Pedal Won’t Stay Engaged -

Reels Slow Down or Stop . . . . . . . . . . . . . . . . . 22

Cutting Unit(s) Drop During Transport. . . . . . . . 23

Cutting Units Lift Too Slowly or Not At All . . . . . 24

Lift Pedal Binding . . . . . . . . . . . . . . . . . . . . . . . 25

Center (#1) Cutting Unit

Operates In Raised Position . . . . . . . . . . . . . . . 25

Center (#1) Cutting Unit Drops Before

Front Cutting Units or Drops Too Fast. . . . . . . . 25

Steering Loss, Steering Wander or Free Play. . 26

TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Test Hook Up No. 1, Traction Pump

Flow and Traction Relief Setting . . . . . . . . . . . . 28

Test Hook Up No. 2, Traction

Motors Mechanical Drag, Valve

Bank Leakage,Traction Motors Efficiency . . . . . 28

Test Hook Up No. 3,

Reel Drive Pump Efficiency . . . . . . . . . . . . . . . . 32

Test Hook Up No. 4, Reel Drive Motor Flow,

Reel Drive Relief Setting, Reel Motor Efficiency 33

Test Hook Up No. 5, Steering Pump

Flow and Steering Pump Relief Setting. . . . . . . 35

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Lift and Mow Pedal Height Adjustment . . . . . . . 36

Traction Pedal Adjustment. . . . . . . . . . . . . . . . . 37

Rear Camshaft Adjustment . . . . . . . . . . . . . . . . 38

REPAIRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Reel Motor Removal and Installation. . . . . . . . . 39

Reel Motor Shaft Seal Replacement . . . . . . . . . 39

Reel Motor Repair . . . . . . . . . . . . . . . . . . . . . . . 40

Pump Removal and Installation. . . . . . . . . . . . . 42

Pump Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Control Valve Removal and Installation. . . . . . . 44

Relief Valve Removal and Installation . . . . . . . . 45

Control Valve Spool Seal Replacement. . . . . . . 46

Control Valve Internal Seal Replacement . . . . . 47

Control Valve No. 1 Spool Detent Replacement 48

Control Valve No. 4 Spool Detent Replacement 49

Lift Cylinder Removal and Installation . . . . . . . . 50

Lift Cylinder Repair . . . . . . . . . . . . . . . . . . . . . . 52

Wheel Motor Removal and Installation . . . . . . . 54

Wheel Motor Repair. . . . . . . . . . . . . . . . . . . . . . 55

Steering Cylinder Removal and Installation. . . . 58

Steering Cylinder Repair . . . . . . . . . . . . . . . . . . 59

Steering Control Unit Removal and Installation. 60

Steering Control Unit Repair . . . . . . . . . . . . . . . 61

Greensmaster®3100 Page 4 - 1 Table of Contents

Page 20

Specifications

Item Description

__________________________________________________________________________________________

Hydraulic Pump External gear type

Steering relief pressure (Greensmaster 3100) 850 psi

_________________________________________________________________ _______________________________________________________________________________________

Wheel Motor (2) Orbit rotor type

_________________________________________________________________ _______________________________________________________________________________________

Reel Motor (3) External gear type

_________________________________________________________________ _______________________________________________________________________________________

Control Valve 5 section spool type

Main and No. 1 section port relief pressure 2000 psi

No. 2 and 3 section port relief pressure 2000 psi

No. 4 (traction) section port relief pressure 1850 psi

_________________________________________________________________ _______________________________________________________________________________________

Power Steering Control Gerotor type steering control unit

_________________________________________________________________ _______________________________________________________________________________________

Hydraulic Oil See Operator's Manual

_________________________________________________________________ _______________________________________________________________________________________

Reservoir Capacity See Operator's Manual

_________________________________________________________________ _______________________________________________________________________________________

Oil filter Screw-on cartridge type, 10 micron

5 section (Greensmaster 3100)

4 section (Greensmaster 3050)

Specifications Page 4 - 2

Figure 1a

(Greensmaster 3050)

1. Hydraulic reservoir 2. Screen

Rev. D

Greensmaster

®

3100

Page 21

General Information

Hydraulic Hoses

Hydraulic hoses are subject to extreme conditions such

as, pressure differentials during operation and exposure

to weather, sun, chemicals, very warm storage conditions or mishandling during operation or maintenance.

These conditions can cause damage or premature deterioration. Some hoses, such as reel motor hoses, are

more susceptible to these conditions than others. Inspect the hoses frequently for signs of deterioration or

damage. To prevent possible problems it is recommended that hoses are replaced periodically, regardless

of condition.

When replacing a hydraulic hose, be sure that the hose

is straight (not twisted) before tightening the fittings. This

can be done by observing the imprint on the hose. Use

two wrenches; one to hold the hose straight and one to

tighten the hose swivel nut onto the fitting.

WARNING

Before disconnecting or performing any work

on the hydraulic system, all pressure in the

system must be relieved by stopping the engine and lowering the cutting units to the

ground.

Keep body and hands away from pin hole

leaks or nozzles that eject hydraulic fluid under high pressure. Use paper or cardboard,

not hands, to search for leaks. Hydraulic fluid

escaping under pressure can have sufficient

force to penetrate the skin and do serious

damage. If fluid is injected into the skin, it

must be surgically removed within a few

hours by a doctor familiar with this type of

injury or gangrene may result.

Hydraulic Fitting Installation

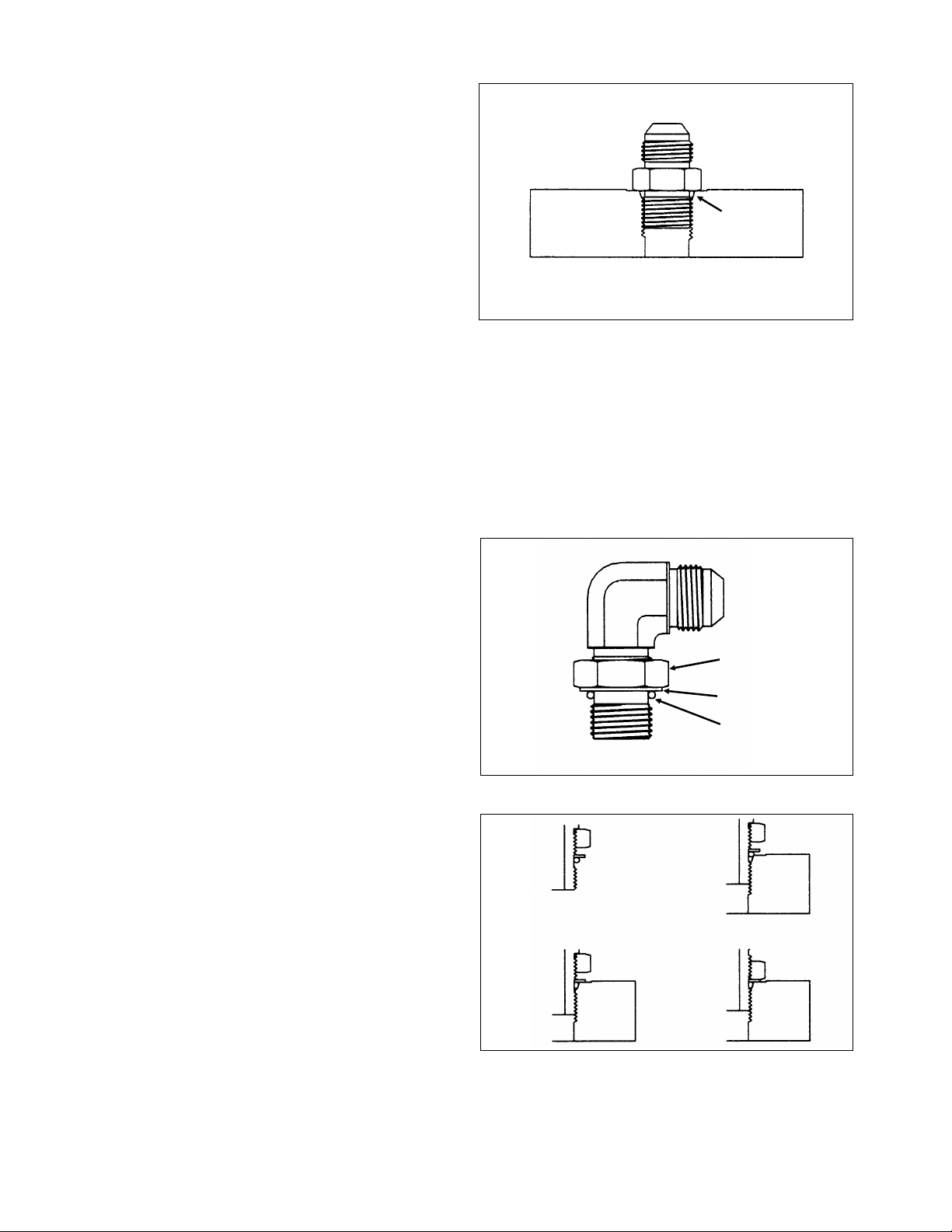

O-Ring Face Seal (Fig. 1, 2)

1. Make sure both threads and sealing surfaces are free

of burrs, nicks, scratches, or any foreign material.

2. Make sure the O-ring is installed and properly seated

in the groove. It is recommended that the O-ring be

replaced any time the connection is opened.

3. Lubricate the O-ring with a light coating of oil.

4. Put the tube and nut squarely into position on the face

seal end of the fitting and tighten the nut until finger tight.

5. Mark the nut and fitting body. Hold the body with a

wrench. Use another wrench to tighten the nut to the

correct flats from finger tight (F.F.F.T.). The markings on

the nut and fitting body will verify that the connection has

been tightened.

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) .75 ± .25

6 (3/8 in.) .75 ± .25

8 (1/2 in.) .75 ± .25

10 (5/8 in.) 1.00 ± .25

12 (3/4 in.) .75 ± .25

16 (1 in.) .75 ± .25

Nut

Sleeve

Seal

Body

Figure 1

Mark Nut

and Body

Finger Tight After Proper Tightening

Final

Position

Extend Line

Initial

Position

Figure 2

Greensmaster®3100 Page 4 - 3 General Information

Page 22

SAE Straight Thread O-Ring Port (Non-adjustable)

(Fig. 3)

1. Make sure both threads and sealing surfaces are free

of burrs, nicks, scratches, or any foreign material.

2. Always replace the O-ring seal when this type of fitting

shows signs of leakage.

3. Lubricate the O-ring with a light coating of oil.

4. Install the fitting into the port and tighten it down full

length until finger tight.

5. Tighten the fitting to the correct flats from finger tight

(F.F.F.T.).

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00 ± .25

6 (3/8 in.) 1.50 ± .25

8 (1/2 in.) 1.50 ± .25

10 (5/8 in.) 1.50 ± .25

12 (3/4 in.) 1.50 ± .25

16 (1 in.) 1.50 ± .25

O-Ring

Figure 3

SAE Straight Thread O-Ring Port (Adjustable)

(Fig. 4, 5)

1. Make sure both threads and sealing surfaces are free

of burrs, nicks, scratches, or any foreign material.

2. Always replace the O-ring seal when this type of fitting

shows signs of leakage.

3. Lubricate the O-ring with a light coating of oil.

4. Turn back the jam nut as far as possible. Make sure

the back up washer is not loose and is pushed up as far

as possible (Step 1).

5. Install the fitting into the port and tighten finger tight

until the washer contacts the face of the port (Step 2).

6. To put the fitting in the desired position, unscrew it by

the required amount, but no more than one full turn

(Step 3).

7. Hold the fitting in the desired position with a wrench

and turn the jam nut with another wrench to the correct

flats from finger tight (F.F.F.T.) (Step 4)

Step 1

Lock Nut

Back-Up Washer

O-Ring

Figure 4

Step 3

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00 ± .25

6 (3/8 in.) 1.50 ± .25

8 (1/2 in.) 1.50 ± .25

10 (5/8 in.) 1.50 ± .25

12 (3/4 in.) 1.50 ± .25

16 (1 in.) 1.50 ± .25

Step 2

Step 4

Figure 5

General Information Page 4 - 4 Greensmaster®3100

Page 23

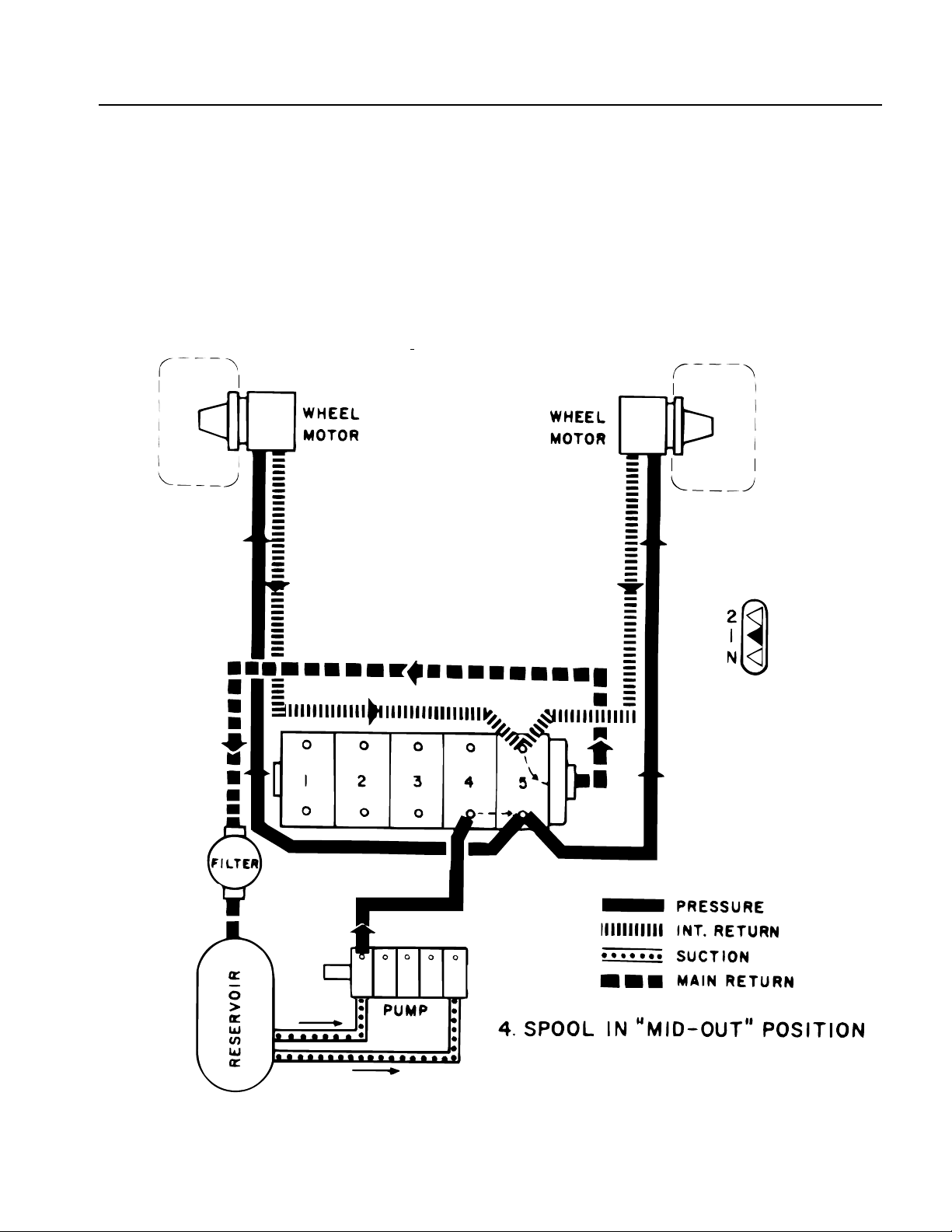

Hydraulic Flow Diagrams

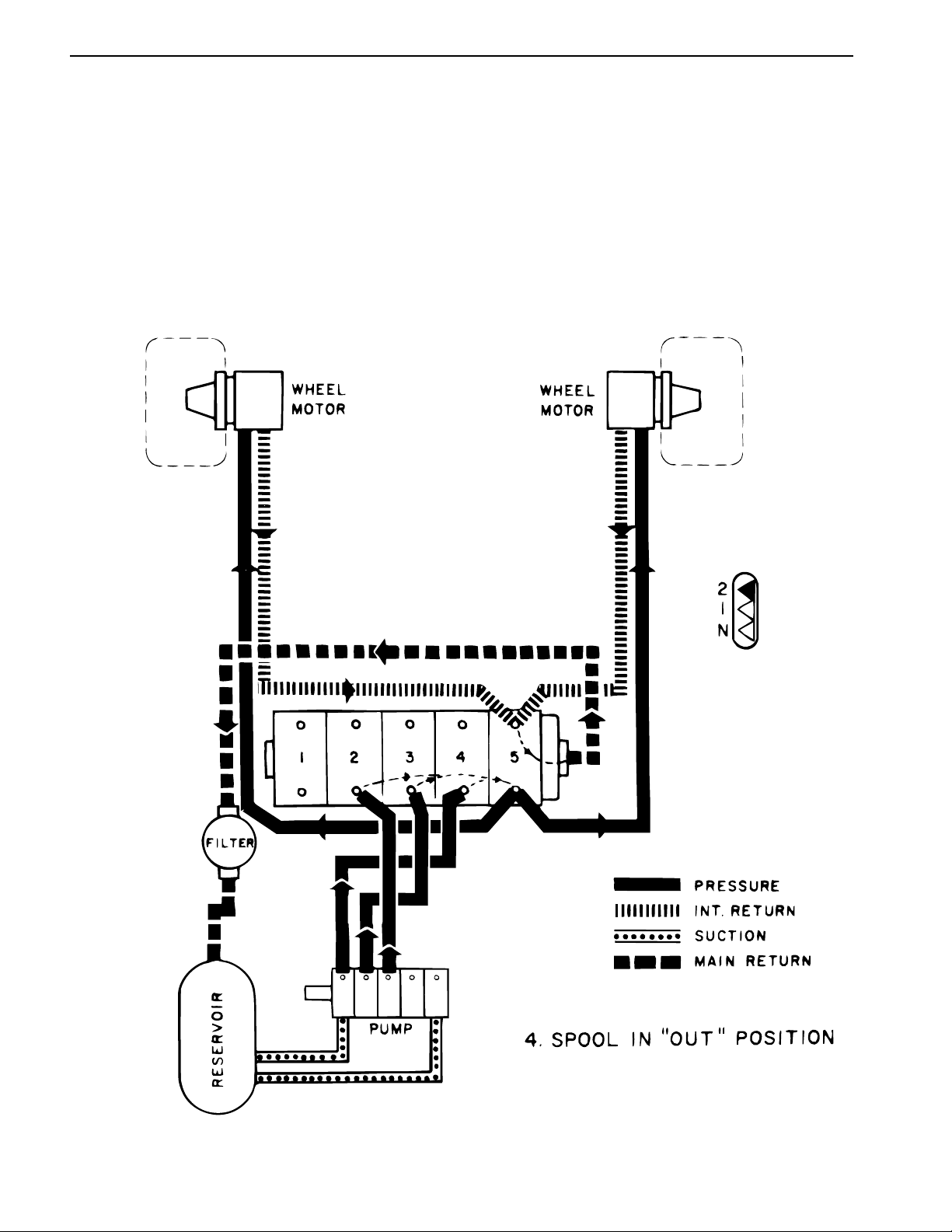

Traction, No. 1 Position

When engine is started, pump draws oil from reservoir

through two suction lines. Oil from one section of pump

passes through fitting in No. 4 spool valve into valve.

Traction lever, when located in No. 1, positions spool so

oil is directed to flow into the No. 5 metering valve

section. When the traction pedal is pushed forward oil

flows out lines at rear of metering valve section to each

motor to drive the motors. Low pressure oil returns to

valve through valve and main return line, through filter

to reservoir.

Greensmaster®3100 Page 4 - 5 Hydraulic Flow Diagrams

Page 24

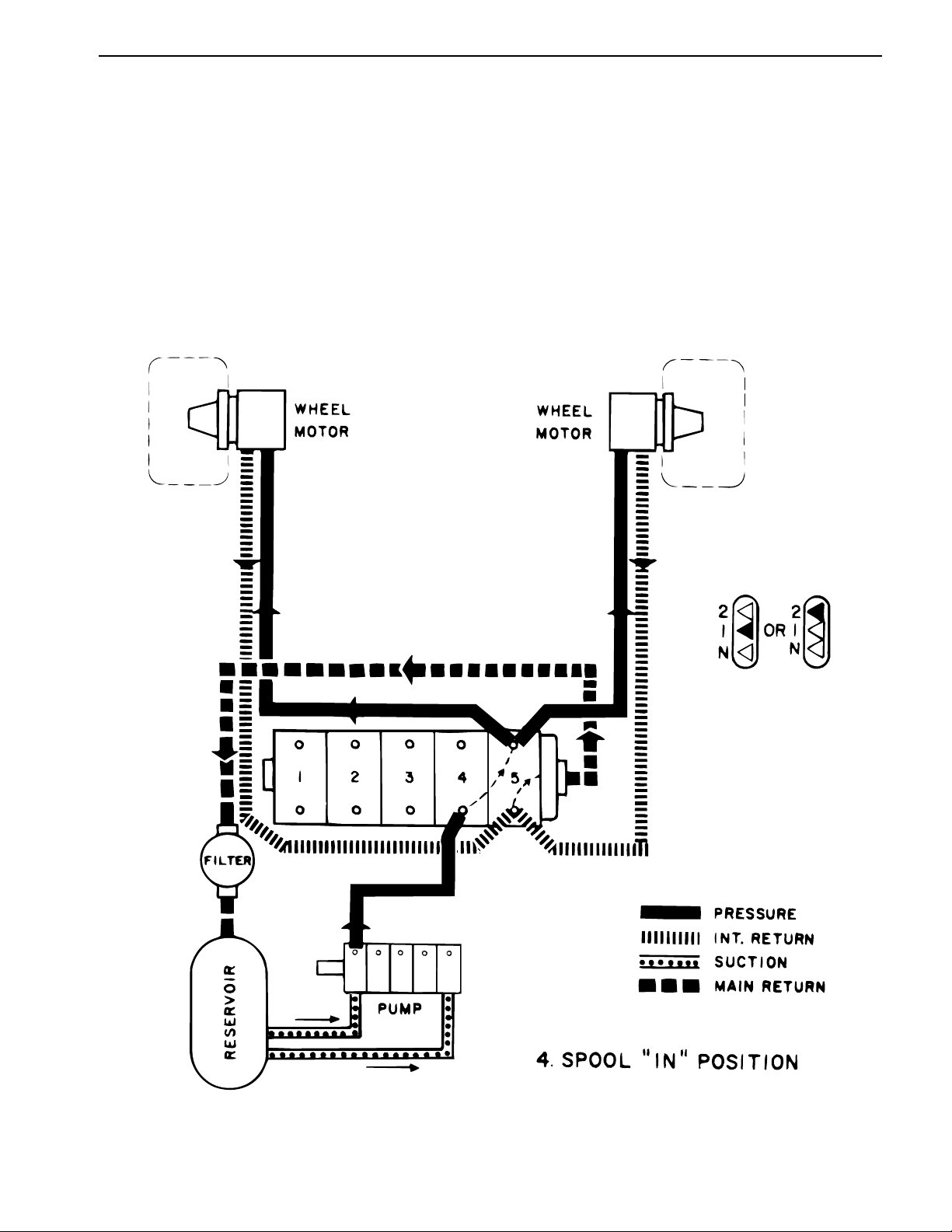

Traction, No. 2 Position

When the traction lever is positioned in No. 2, flow from

one pump section passes through same lines as for No.

1 traction position. This flow is joined by additional flow

from two other pump sections. The additional flow increases the RPM of the wheel motors to increase ground

speed.

Hydraulic Flow Diagrams Page 4 - 6 Greensmaster®3100

Page 25

Traction, Reverse Position

Traction lever is positioned in No. 1 or No. 2. When

traction pedal is pushed rearward, flow from one pump

section goes through No. 4 selector valve section into

No. 5 metering section and out the lines at the front of

the valve to the traction motors, which drive the traction

wheels, to operate in reverse.

Greensmaster®3100 Page 4 - 7 Hydraulic Flow Diagrams

Page 26

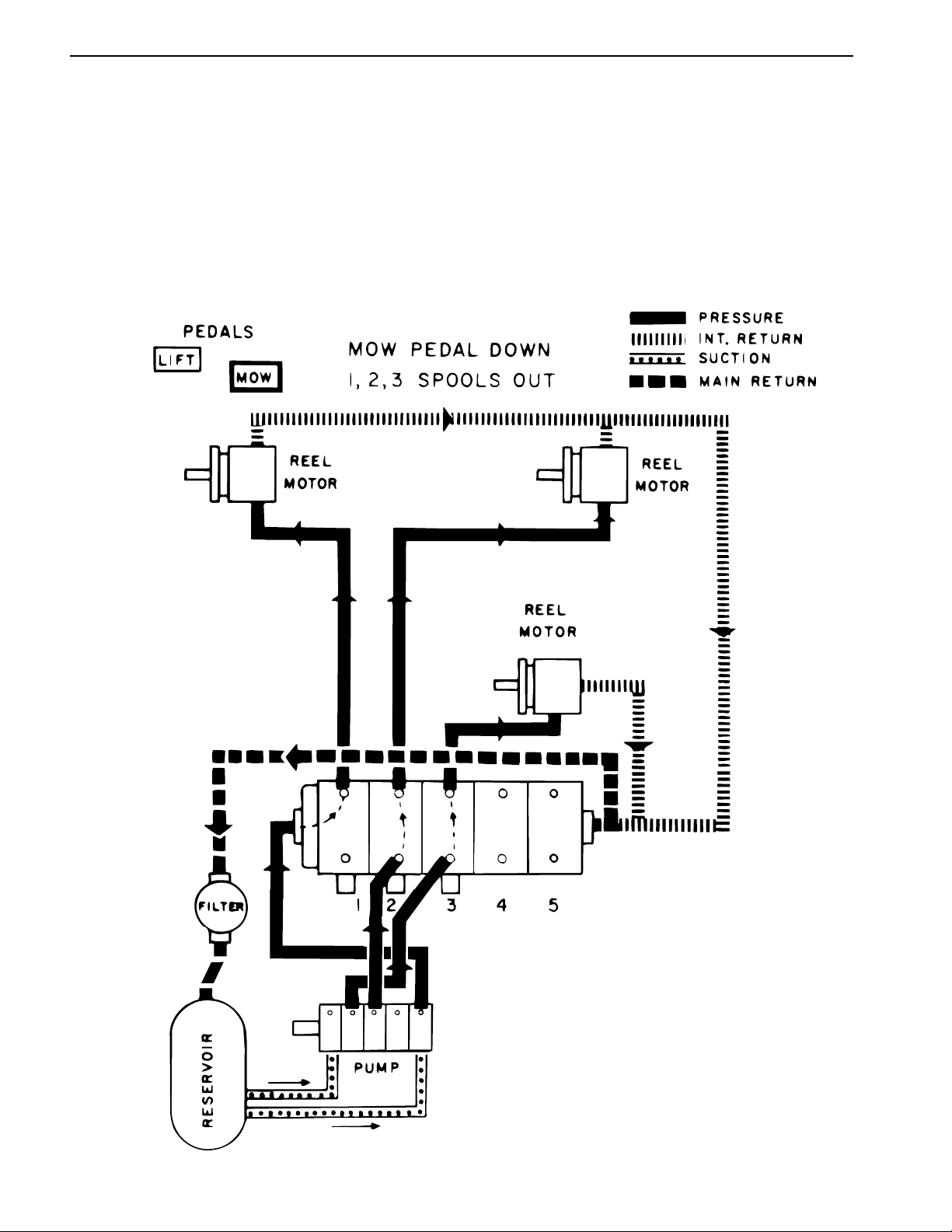

Reel Drive, Mowing Operation

GR3100 WITH DANFOSS PUMP SHOWN.

MACHINES WITH PARKER PUMP USE

CENTER 3 PUMP SECTIONS FOR REEL

DRIVE CIRCUITS.

Rev. E

The MOW pedal is depressed, which causes the No. 1,

2 and 3 spools to be positioned fully out of valve bank.

This directs flow from one pump section to pass through

left end cover and out line lead ing to left front cutting unit

drive motor. Flow causes motor to turn, driving reel.

Flow from separate pump section passes through No. 2

valve section and out a line to right front cutting unit

motor. Return oil from two front cutting units joins together and returns to right end of valve section, where

is passes into the main return line and flows back to

reservoir.

Flow from another separate pump section passes

through No. 3 spool section and out through a line to the

rear cutting unit drive motor. Return oil from the motor

passes through a line leading to the right hand end of

the valve bank, where it also joins with the main return

line back to the reservoir.

Hydraulic Flow Diagram s Page 4 - 8 Greensmaster® 3100

Page 27

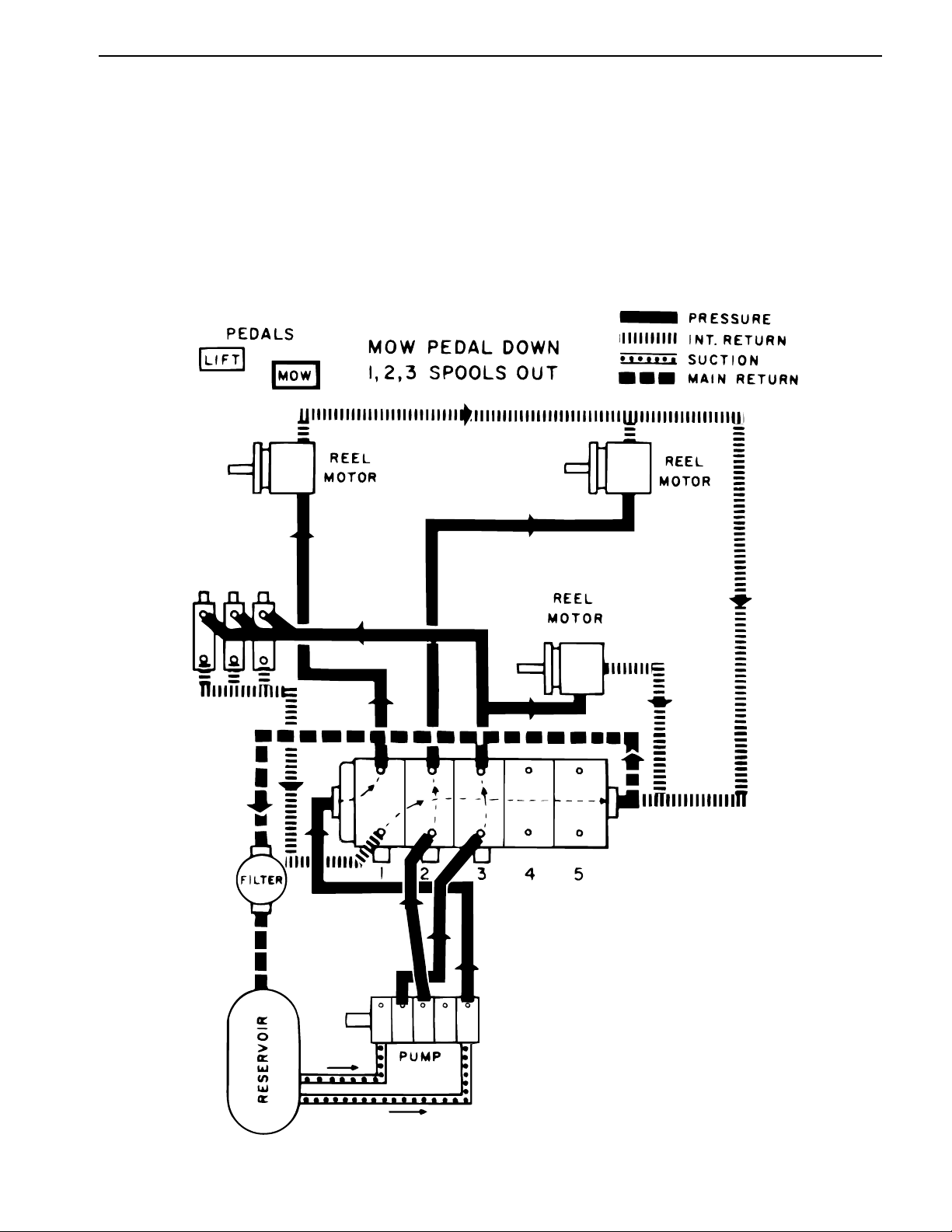

Reel Drive, Lower Cutting Units

GR3100 WITH DANFOSS PUMP SHOWN.

MACHINES WITH PARKER PUMP USE

CENTER 3 PUMP SECTIONS FOR REEL

DRIVE CIRCUITS.

Rev. E

The MOW pedal is depressed to start reel drive operation, flow from one pump section passes throu gh No. 3

spool section and out three lines, each leading to a lift

cylinder. This actuates the lift cylinders and lowers the

cutting units. Oil is returned to a three -way fit ting on the

No. 1 spool section through lines on the top end of each

cylinder, where it passes through the valve section and

returns to the reservoir through the main return line.

When the cylinders complete their travel, oil flow from

the No. 3 spool section is then directed to the rear cut ting

unit drive motor.

Greensmaster® 3100 Page 4 - 9 Hydraulic Flow Diagrams

Page 28

Reel Drive, Raising Cutting Units

GR3100 WITH DANFOSS PUMP SHOWN.

MACHINES WITH PARKER PUMP USE

FOURTH PUMP SECTION FOR LIFT.

Rev. E

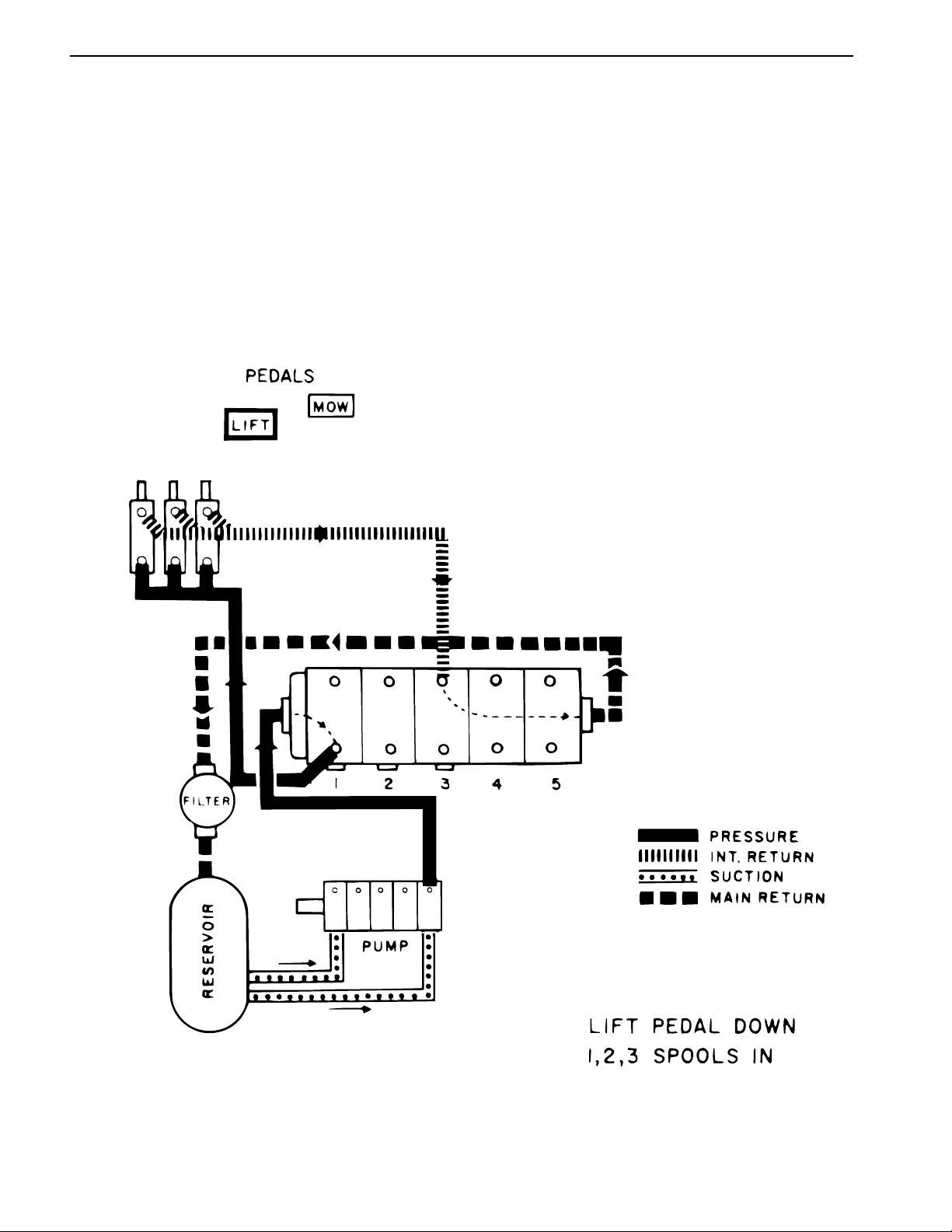

When the LIFT pedal is depressed, No. 1, 2 and 3 spools

are pushed inward. When spools pass neutral, cutting

units stop operation. Holding pedal depressed keeps

spools fully in. This directs flow from one pump section

to pass through end cover and No. 1 spool valve, out

three lines leading to lift cylinders, causing cylinders to

raise the cutting units. Oil forced out of c ylinders travels

through lines leading to No. 3 spool section, th rough the

valve bank and back to reservoir through main return line.

Hydraulic Flow Diagrams Page 4 - 10 Greensmaster® 3100

Page 29

Power Steering, R.H. Turn (Greensmaster 3100)

GR3100 WITH DANFOSS PUMP SHOWN.

MACHINES WITH PARKER PUMP USE

LAST PUMP SECTION FOR STEERING

CIRCUIT.

Rev. E

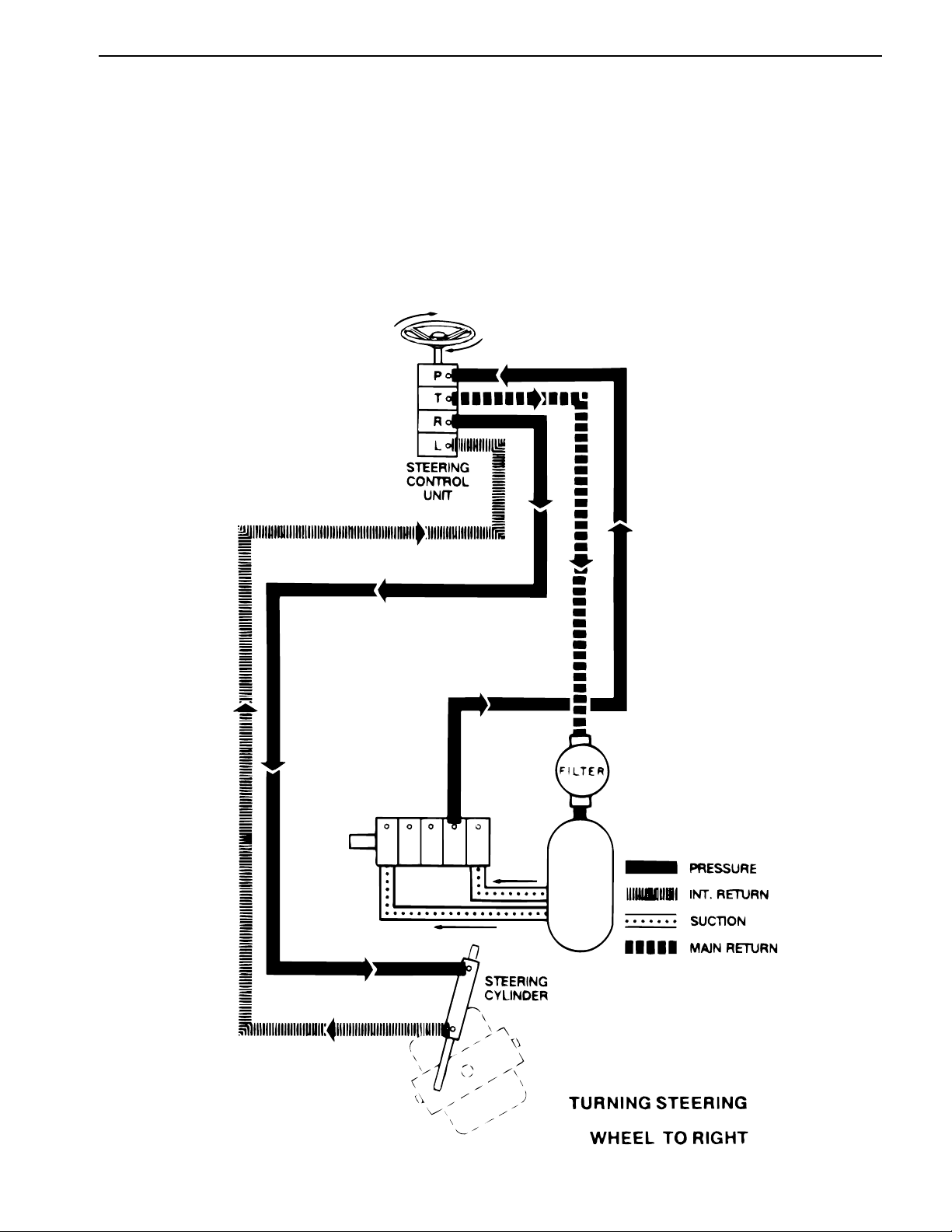

Oil is supplied to port “P” of the steering control unit from

the pump steering section. When the steering wheel is

turned to the right, the control se ction within the steering

valve shifts to direct oil supplied by the pump to the

metering section of the steering valve. As the steering

wheel turns, system oil is metered out port “R” to the

steering cylinder. Oil displaced by the other end of the

steering cylinder returns to the steering valve through

port “L” which directs it out port “T” back to reservoir.

When the steering wheel stops turning , th e cont rol s ection within the steering valve shifts back to neutral

allowing all oil from the pump to flow through the s teering

valve out port “T” back to reservoir. Oil in the rest of the

steering circuit is then trapped.

Greensmaster® 3100 Page 4 - 11 Hydraulic Flow Diagrams

Page 30

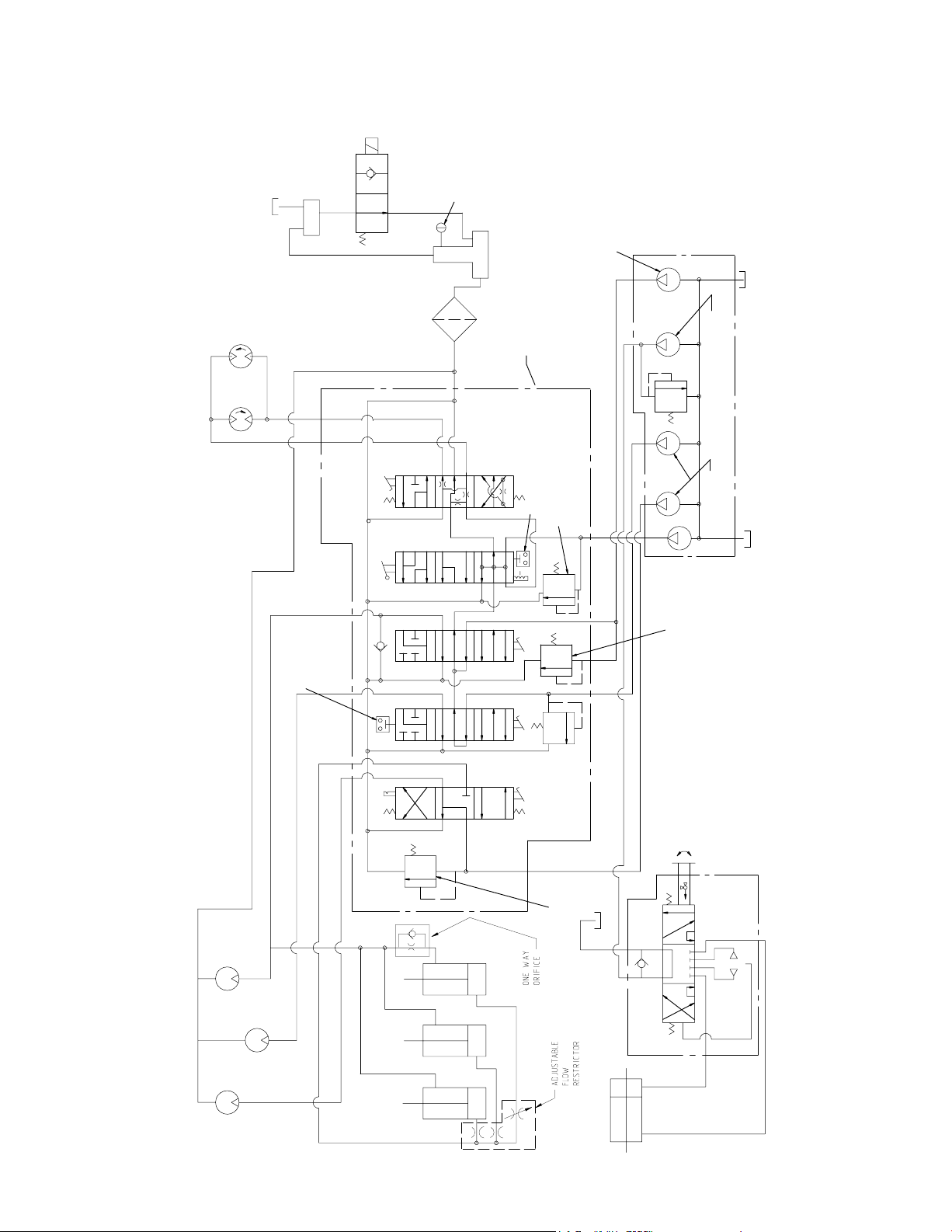

Hydraulic Schematic

(Greensmaster 3100 2WD Serial Number Below 230000000)

LEVEL

SENSOR

HYDRAULIC

TANK

40 MICRON

TANK BREATHER

AUXILIARY

HYDRAULIC

TANK

NORMALLY OPEN

SOLENOID VALVE

3

.33 IN /REV

(5.4 CU CM/REV)

2850 RPM MAX

PUMP (DANFOSS)

10.3 CU. IN/REV.

(169 CU. CM/REV)

WHEEL DRIVE MOTORS

RH

OIL FILTER

10 MICRON

LH

N

FWD

2ND

1ST

SAFETY

INTERLOCK

SWITCH

VALVE BANK

REV

SWITCH

SAFETY INTERLOCK

1850 PSI

(130 KG/SQ CM)

N

2000 PSI

3

.18 IN /REV

850 PSI

(60 KG/SQ CM)

3

.33 IN /REV

3

.58 IN /REV

2000 PSI

(141 KG/SQ CM)

(2.9 CU CM/REV)

(5.4 CU CM/REV)

(9.5 CU CM/REV)

REEL MOTORS

.43 CU. IN/REV.

(7 CU. CM/REV.)

Hydraulic Schematics

CENTER

LH

RH

CENTER

RH

LH

Page 4 – 12

LIFT CYLINDERS

Rev. E

(141 KG/SQ CM)

2000 PSI

(141 KG/SQ CM)

STEERING CYLINDER

TP

LR

STEERING CONTROL VALVE

4.5 CU. IN/REV.

(75 CU. CM/REV)

Greensmaster 3100

Page 31

Hydraulic Schematic

(Greensmaster 3100 2WD Serial Number Above 230000000)

LEVEL

SENSOR

HYDRAULIC

TANK

40 MICRON

TANK BREATHER

AUXILIARY

HYDRAULIC

TANK

NORMALLY OPEN

SOLENOID VALVE

3

.18 IN /REV

(2.9 CU CM/REV)

PUMP (PARKER)

2850 RPM MAX

10.3 CU. IN/REV.

(169 CU. CM/REV)

WHEEL DRIVE MOTORS

RH

OIL FILTER

10 MICRON

LH

N

FWD

2ND

1ST

SAFETY

INTERLOCK

SWITCH

VALVE BANK

REV

SWITCH

SAFETY INTERLOCK

1850 PSI

(130 KG/SQ CM)

N

2000 PSI

850 PSI

(60 KG/SQ CM)

3

.32 IN /REV

3

.57 IN /REV

2000 PSI

(141 KG/SQ CM)

(5.2 CU CM/REV)

(9.3 CU CM/REV)

REEL MOTORS

CENTER

RH

.43 CU. IN/REV.

(7 CU. CM/REV.)

LH

RH

LH

CENTER

LIFT CYLINDERS

Greensmaster 3100 Page 4 – 12.1 Hydraulic SchematicsRev. E

(141 KG/SQ CM)

2000 PSI

(141 KG/SQ CM)

STEERING CYLINDER

TP

LR

STEERING CONTROL VALVE

4.5 CU. IN/REV.

(75 CU. CM/REV)

Page 32

Hydraulic Schematic (Greensmaster 3100 3WD)

TANK

AUXILIARY

RH

40 MICRON

TANK BREATHER

WHEEL DRIVE MOTOR

20 CU IN/REV

(328 CU CM/REV)

HYDRAULIC

OIL FILTER

10 MICRON

LEVEL

SENSOR

TANK

HYDRAULIC

VALVE

BANK

3

.33 IN /REV

(5.4 CU CM/REV)

2850 RPM MAX.

PUMP (DANFOSS)

3

.18 IN /REV

(2.9 CU CM/REV)

10.3 CU IN/REV

(169 CU CM/REV)

WHEEL DRIVE MOTORS

REAR

LH

SAFETY

SWITCH

INTERLOCK

FWD

2ND

1ST

N

REV

SAFETY

SWITCH

INTERLOCK

1850 PSI

(130 KG/SQ.CM)

N

3

.58 IN /REV

2000 PSI

(141 KG/SQ CM)

2000 PSI

(141 KG/SQ CM)

850 PSI

3

.33 IN /REV

(9.5 CU CM/REV)

(60 KG/SQ. CM)

(5.4 CU CM/REV)

4.5 CU IN/REV

(75 CU CM/REV)

STEERING CONTROL VALVE

.43 CU IN/REV

(7 CU CM/REV)

REEL MOTORS

CENTER

LH

RH

CENTER

RH

LH

2000 PSI

(141 KG/SQ CM)

LIFT CYLINDERS

PT

R

L

STEERING CYLINDER

Greensmaster 3100Page 4 – 12.2Hydraulic Schematics Rev. E

Page 33

Hydraulic Schematic (Greensmaster 3050)

HYDRAULIC

OIL FILTER

10.3 CU. IN/REV.

(169 CU. CM/REV)

WHEEL DRIVE MOTORS

LH RH

TANK

VALVE BANK

3

.33 IN /REV

(5.4 CU CM/REV)

PUMP

2850 RPM MAX

SAFETY

INTERLOCK

SWITCH

2ND

FWD

1ST

N

REV

SWITCH

SAFETY INTERLOCK

1850 PSI

(130 KG/SQ CM)

N

2000 PSI

(141 KG/SQ CM)

2000 PSI

(141 KG/SQ CM)

3

.33 IN /REV

(5.4 CU CM/REV)

3

.58 IN /REV

(9.5 CU CM/REV)

REEL MOTORS

CENTER

RH

.43 CU. IN/REV.

(7 CU. CM/REV.)

LH

RH

LH

CENTER

LIFT CYLINDERS

Greensmaster 3100 Page 4 – 12.3 Hydraulic SchematicsRev. E

2000 PSI

(141 KG/SQ CM)

Page 34

This page is blank.

Greensmaster 3100Page 4 – 12.4Hydraulic Schematics Rev. E

Page 35

Special Tools

NOTE: Order special tools from the TORO SPECIAL

TOOLS AND APPLICATIONS GUIDE (COMMERCIAL

PRODUCTS). Some tools may be listed in the

Greensmaster 3100 Parts Catalog. Some tools may

also be available from a local supplier.

Hydraulic Tester (Fig. 6)

Low Pressure

Gauge

Load Valve

Outlet

Hose

Gauge

Protector Valve

Inlet Hose

You must have o-ring face seal (ORFS) adapter fittings

for this tester to use it on the Greensmaster 3100.

1. INLET HOSE: Hose connected from the system

circuit to the inlet side of the hydraulic tester.

2. LOAD VALVE: If required, upon turning the valve to

restrict flow, a simulated working load is created in the

circuit.

3. LOW PRESSURE GAUGE: Low range gauge to

provide accurate reading at low pressure, 0 - 1000 psi

(0 - 6895 kPa).

Flow Meter

High Pressure

Gauge

Figure 6

4. HIGH PRESSURE GAUGE: High range gauge to

accommodate pressure beyond the capacity of the low

pressure gauge, 0 - 5000 (0 - 34475 kPa).

5. FLOW METER: This meter measures actual oil flow

in the operation circuit. The reading is given in gallons

per minute (GPM) and liters per minute (LPM) with a

gauge rated at 15 GPM (57 LPM).

6. OUTLET HOSE: Hose from the outlet side of the

hydraulic tester to be connected to the hydraulic system

circuit.

This gauge has a protector valve which cuts out

when pressure is about to exceed the normal range

for the gauge. The cutout pressure is adjustable.

Greensmaster®3100 Page 4 - 13 Special Tools

Page 36

Seal Protector (Fig. 7)

Slide the protector (Item 1) over the reel motor shaft

before installing the shaft seal to protect the seal from

damage. Apply a light coating of clean oil to the seal

protector to ease movement of the seal over the tools.

Use the installer (Item 2) and a small hammer to drive

the reel motor shaft seal into position in the bore of the

reel motor body.

Detent Installation Tool (Fig. 8)

Use this tool with a 3/8 in. drive torque wrench to tighten

the detent stud in the No. 1 spool of the control valve.

Apply Loctite 222 or equivalent to the threads of the

detent stud. Tighten the stud to a torque of 10 - 14 ft-lb.

Figure 7

Figure 8

Special Tools Page 4 - 14 Greensmaster®3100

Page 37

Seal Installation Tool (Fig. 9)

Use to assure proper fit and positioning of lip seals used

in the TRW Torqmotor hydraulic wheel motor. Put the

seal inside the ring (Item 2) with the seal lip toward the

motor. Slide the main tube (Item 1) of the tool into the

ring. Put the tool into position in the bore of the motor

housing. Tap against the main tube of the tool to seat

the seal.

Assembly Studs (Fig. 10)

Use for proper alignment of internal parts during disassembly and repair of the TRW Torqmotor hydraulic

wheel motor.

Figure 9

IMPORTANT: The wheel motor geroters are indexed

and must be kept in their original position.

Control Valve Spool Seal Installation Tools (Fig. 11)

This tool can be made to the dimensions shown.

Soak new seal in clean hydraulic fluid before installing.

Install seal into end of large diameter tool with open side

of seal facing out. Install small diameter tool into large

diameter tool against flat (closed) side of seal. Carefully

install seal and tools over valve spool, hold large tool

against valve body and push seal into bore with small

diameter tool.

Figure 10

0.75

DIA

2.5

NOTE: REMOVE SHARP EDGES.

0.991/

0.994

DIA

0.997/

1.000

DIA

1.5

Dimensions shown in inches.

1.25

DIA

Figure 11

Greensmaster®3100 Page 4 - 15 Special Tools

Page 38

Troubleshooting

The cause of an improperly functioning hydraulic system is best diagnosed with the use of proper testing

equipment and a thorough understanding of the complete hydraulic system.

A hydraulic system with an excessive increase in heat

or noise is a potential failure. Should either of these

conditions be noticed, immediately stop the machine,

turn off the engine, locate the cause of the trouble, and

correct it before allowing the machine to be used again.

Continued use of an improperly functioning hydraulic

system could lead to extensive internal component

damage.

The charts that follow contain detailed information to

assist in troubleshooting. There may possibly be more

than one cause for a machine malfunction. All causes

should be checked in the order in which they are listed

on the charts; do not deviate from this procedure.

Refer to the Testing section of this Chapter for precautions and specific test procedures.

Troubleshooting Page 4 - 16 Greensmaster

®

3100

Page 39

Slow Groundspeed in All Traction Selections

* Check

engine

RPM

OK

* Check

hydraulic

oil level

OK

Check

hydraulic

oil filter

OK

* Check shift

lever bracket

and rear

camshaft

OK

Improper

Improper

Clogged

Misadjusted

or damaged

Adjust –

use

tachometer

* Reels also affected.

Fill to

proper

level

Replace

filter

Adjust

Check brakes and

brake linkage

for binding

OK

Check traction

pump flow.

Test hook up

No. 1 Test A

OK

Check traction

relief. Test

hook up

No. 1 Test B

OK

Check traction mo-

tors for mech.

drag. Test hook up

No. 2 Test A

OK

Binding

Low

Defective

Drag

Free linkage

and adjust

brakes

Check for

restriction in

pump intake line

Repair

or replace

traction relief

valve

Remove brake

drum and

repeat test

OK

Drag

Repair

or replace

pump

Repair or

replace

defective motor

Check traction mo-

tor efficiency.

Test hook up

No. 2 Test C

Inefficient

Repair or

replace

defective motor

Greensmaster®3100 Page 4 - 17 Troubleshooting

Page 40

Slow or No Ground Speed in No. 1 and Reverse

No. 2 Appears Normal

Check

control

linkage

OK

Check traction

pump flow.

Test hook up

No. 1 Test A

OK

Check for internal

valve bank leakage.

Test hook up

No. 2 Test B

Misadjusted

or damaged

Low

Leaking

Adjust

or

repair

Check for

restriction in

pump intake line

Check disk seal

between #3 and

#4 valve sections

OK

Defective

Repair or

replace

traction pump

Remove valve bank

and replace

disk seal

Troubleshooting Page 4 - 18 Greensmaster®3100

Page 41

No Increase in Speed from No. 1 to No. 2

Check

hydraulic

oil level

OK

Check traction

Check traction

lever

lever

OK

Check rear

camshaft

OK

Check #2 and #3

pump section flow.

Test hook up No. 3

Test A

OK

Low

Misadjuste

or damaged

Misadjusted

or damaged

Fill to

proper

level

Adjust or

repair

Adjust or

Adjust or

repair

repair

Check for

restriction in

pump intake line

OKLow

Repair or

replace

pump

Check #2 and #3

valve section re-

liefs. Test hook up

No. 4 Test B

Defective

Repair or

replace

relief valve

Greensmaster®3100 Page 4 - 19 Troubleshooting

Page 42

One or More Cutting Units Slow or

No Reel Drive Action

Check

Pedal

Linkage

OK

Check rear-

ward valve

spool trave

OK

Check

bedknife

adjustment

OK

Check for

tight

reel bearings

OK

Misadjusted

or Damaged

Insufficient

Tight

Tight

Adjust or repair

and

lubricate

Adjust or repair

rear camshaft

Adjust

bedknife

Adjust

bearings. Replace

if necessary.

Check reel pump

flow. Test hook up

No. 3 Test A

OK

Check reel motor

flow. Test hook up

No. 4 Test A

OK

Check reel drive

relief. Test hook

up No. 4 Test B

OK

Check reel motor

efficiency. Test

hook up No. 4

Test B

Low

Low

Defective

Defective

Check for

restriction in pump

intake line(s).

Check for flow re-

striction.

Repair or replace

reel drive

relief valve

Repair or replace

reel drive motor

OK

Repair or

replace pump

Troubleshooting Page 4 - 20 Greensmaster®3100

Page 43

All Reels Slow or Will Not Turn

Check

engine

RPM

OK

Check

hydraulic

oil level

OK

Check

hydraulic

oil filter

OK

Check linkage

and roll pin

on end of mow

pedal shaft

OK

Low

Low

Clogged

Worn or

broken

Adjust –

use tachometer

Fill to proper

level

Replace

filter

Repair

linkage

Check reel pump

flow. Test hook up

No. 3 Test A

Low

Repair or

replace pump

Greensmaster®3100 Page 4 - 21 Troubleshooting

Page 44

Mow Pedal Won’t Stay Engaged –

Reels Slow Down or Stop

Check linkage

from pedal

to valve bank

OK

Check roll pin in

end of mow pedal

shaft

OK

Check rearward

valve spool

travel

OK

Check the

spool detent

Misadjusted

or damaged

Worn

or broken

Insufficient

Defective

Adjust, repair and

lubricate linkage

Replace

pin

Adjust rear

camshaft

Lubricate or

repair valve spool

detent

Troubleshooting Page 4 - 22 Greensmaster®3100

Page 45

Cutting Unit(s) Drop During Transport

Check that valve

spool returns to

neutral

OK

Check for internal

lift cylinder leakage

OK

Check lift check

plug o-rings in #1

valve section

OK

Check valve

spool detent for

binding

Binding

Leaking

Leaking

Binding

Lubricate and

adjust camshaft

Repair or replace

cylinder(s)

Replace

o-ring

Lubricate or repair

valve spool detent

Greensmaster®3100 Page 4 - 23 Troubleshooting

Page 46

Cutting Units Lift Too Slowly or Not At All

Check for binding

lift assemblies

OK

Check forward

valve spool travel

OK

Check for

restriction in

lines to or from

cylinders

OK

Check for

leaking cylinder

OK

Binding

Insufficient

Restricted

Leaking

Loosen and

lubricate lift

assemblies

Adjust rear

camshaft

Replace restricted

line or fitting

Repair or

replace cylinder

Check lift section

of pump. Test

hook up No. 3

Test A

Defective

Repair or replace

pump

Troubleshooting Page 4 - 24 Greensmaster®3100

Page 47

Lift Pedal Binding

Check pedal

linkage

OK

Check valve spool

detent assembly

Misadjusted

or Damaged

Binding or

Damaged

Adjust or repair link-

age and

lubricate

Lubricate and repair

detent

Center (#1) Cutting Unit Operates in Raised Position

shaft for #3 spool

too far out of body

OK

Check for restric-

tion in brazed tube

assembly on #3

valve section

Misadjusted

Restricted

Adjust camshaftCheck rear cam-

Remove

restriction

OK

Check for restriction

in valve return port

between #3 section

and R.H. cover

Defective

Remove valve bank

and disassemle to

remove restriction

Center (#1) Cutting Unit Drops

Before Front Cutting Units or Drops Too Fast

Check for missing

orifce reducer in cylin-

der line attached to

center fitting on crows-

foot

OK

Check for

incorrect crows

foot fitting

Missing

Incorrect

Install orifice re-

ducer in cylinder line

Replace crows foot

fitting with correct fit-

ting

Greensmaster®3100 Page 4 - 25 Troubleshooting

Page 48

Steering Loss, Steering Wander or Free Play

Check steering cyl-

inder

ball joints

OK

Disconnect cylin-

der and check cas-

tor fork movement

OK

Check steering cyl-

inder for

internal leakage

OK

Check for

restriction in hy-

draulic hose or fit-

ting

OK

Loose

Binding

Leakage

Restriction

Tighten castle nuts

and jam nut

Repair and

lubricate castor fork

and bushings

Repair or replace

steering cylinder

Replace restricted

line or fitting

OK

Replace ball

joint(s)

Check steering

pump flow. Test

hook up No. 5

Test A

OK

Check for dam-

aged steering

wheel or shaft

OK

Worn or damaged

steering control

unit. *Thermal

shock

Defective OK

Defective

Defective

Check for

restriction in pump

intake line

Replace steering

wheel or shaft

Repair or replace

steering

control unit

Repair or replace

pump

* Thermal shock - A condition caused when the hydraulic system is operated for some time without turning

the steering wheel so that fluid in the reservoir and system is hot and the steering control unit is relatively

cool (more than 50

o

F temperature differential). This can also happen when washing the machine. When the

steering wheel is turned quickly the result is temporary seizure and possible damage to internal parts of the

steering control unit. The temporary seizure may be followed by total free wheeling.

Troubleshooting Page 4 - 26 Greensmaster

®

3100

Page 49

Testing

The most effective method for isolating troubles in the

hydraulic system is by using hydraulic test equipment

such as pressure gauges and flow meters in the circuits

during various operational checks. (See the Special

Tools section in this Chapter.)

Hydraulic testers may vary significantly in size, construction, accuracy, and cost. The decision as to which

tester to purchase should be influenced by what type of

tests will be performed on all of the hydraulically-powered equipment in the shop.

All obvious areas such as oil supply, filter, binding

linkage, loose fasteners, or improper adjustments must

be checked before assuming that a hydraulic component is the source of the problem being experienced.

WARNING

Before disconnecting or performing any work

on the hydraulic system, all pressure in the

system must be relieved by stopping the engine and lowering the implement to the

ground.

Keep body and hands away from pin hole

leaks or nozzles that eject hydraulic fluid under high pressure. Use paper or cardboard,

not hands, to search for leaks. Hydraulic fluid

escaping under pressure can have sufficient

force to penetrate skin and do serious damage. If fluid is injected into the skin, it must be

surgically removed within a few hours by a

doctor familiar with this type of injury or gangrene may result.

Before Performing Hydraulic Tests

2. Put caps or plugs on any hydraulic lines left open or

exposed during testing or removal of components.

3. The engine must be in good operating condition.

ALWAYS use a tachometer when making a hydraulic

test. Engine speed will affect the accuracy of the tester

readings.

4. To prevent damage to the tester or components, the

inlet and the outlet hoses must be properly connected,

and not reversed (tester with pressure and flow capabilities).

5. To minimize the possibility of damaging the components, completely open the load valve by turning it

counterclockwise (tester with pressure and flow capabilities).

IMPORTANT: The pump used on the Greensmaster

3100 is a positive displacement type. If its output

flow is completely restricted or stopped, damage to

the pump or other components could occur.

6. Install fittings finger tight, far enough to insure that

they are not cross-threaded, before tightening with a

wrench.

7. Position the tester hoses so that rotating machine

parts will not make contact with them and result in hose

or tester damage.

8. Check the oil level in the reservoir.

9. Check the control linkage for improper adjustment,

binding or broken parts.

10. All hydraulic tests should be made with the hydraulic

oil at normal operating temperature (hoses warm to the

touch).

1. Thorough clean the machine before disconnecting or

disassembling any hydraulic components. Always keep

in mind the need for cleanliness when working on hydraulic equipment.

Greensmaster®3100 Page 4 - 27 Testing

Page 50

TEST HOOK UP NO. 1

Traction Pump Flow

Traction Relief Setting

TESTER CONNECTION:

Tester in series between traction pump outlet line and valve bank port on No. 4 section of

valve bank.

(Tester Flow Control Valve Open)

CAUTION: Keep everyone away from the front of the machine during traction

system tests. Operator must be on seat or the safety interlock will stop the

engine when the traction lever is engaged.

TESTER

TEST A: TRACTION PUMP FLOW

PROCEDURE

Traction lever in neutral.

Engine RPM 2800 RPM.

Hydraulic oil at operating temperature.

While watching flow and pressure gauges, slowly close flow control valve until 1000 PSI

is obtained.

TESTER READINGS

Flow not lower than 5 GPM at 1000 PSI.

Record pressure and flow readings.

If flow is lower than 5 GPM or a pressure of 1000 PSI cannot be obtained, check for

restriction in pump intake line. If not restricted, remove pump and repair as necessary.

Testing Page 4 - 28 Greensmaster

®

3100

Page 51

TEST HOOK UP NO. 1 (continued)

TEST B: RELIEF VALVE SETTING

PROCEDURE

Tester flow control valve open.

Block up traction wheels off floor.

Apply brakes and engage park lock.

Engine RPM 2800.

Hydraulic oil at normal operating temperature.

Engage transmission lever to No. 1 position.

Push traction pedal to forward position.

TESTER READINGS

Pressure: 1850 to 1950 PSI.

If pressure is not in listed range, remove traction relief cartridge and examine for

contamination or damage.

Greensmaster

®

3100 Page 4 - 29 Testing

Page 52

TEST HOOK UP NO.2

Traction Motors Mechanical Drag

Valve Bank Leakage

Traction Motors Efficiency

TESTER CONNECTION:

Disconnect hydraulic hose that leads to front right wheel motor from T fitting on rear outlet port of valve bank section

No. 5. Connect tester in series between fitting and disconnected hose.

(Tester Flow Control Valve Open)

Note: On machines that have a “U” tube between the elbow fitting on rear outlet port of valve bank section No. 5 and

hydraulic tube leading to front wheel motors, remove “U” tube and install tester in series between the two exposed

fittings.