Page 1

FormNo.3401-829RevA

Groundsmaster

®

4500-Dand

4700-DTractionUnit

ModelNo.30881—SerialNo.315000001andUp

ModelNo.30881A—SerialNo.315000001andUp

ModelNo.30882—SerialNo.315000001andUp

ModelNo.30882A—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3401-829*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontherightfrontframemember

oftheproduct.Writethenumbersinthespaceprovided.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

ThissparkignitionsystemcomplieswithCanadianICES-002

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Thismachineisaride-on,rotary-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrasson

well-maintainedlawnsinparks,golfcourses,sportselds,

andoncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongsidehighways,

orforagriculturaluses.

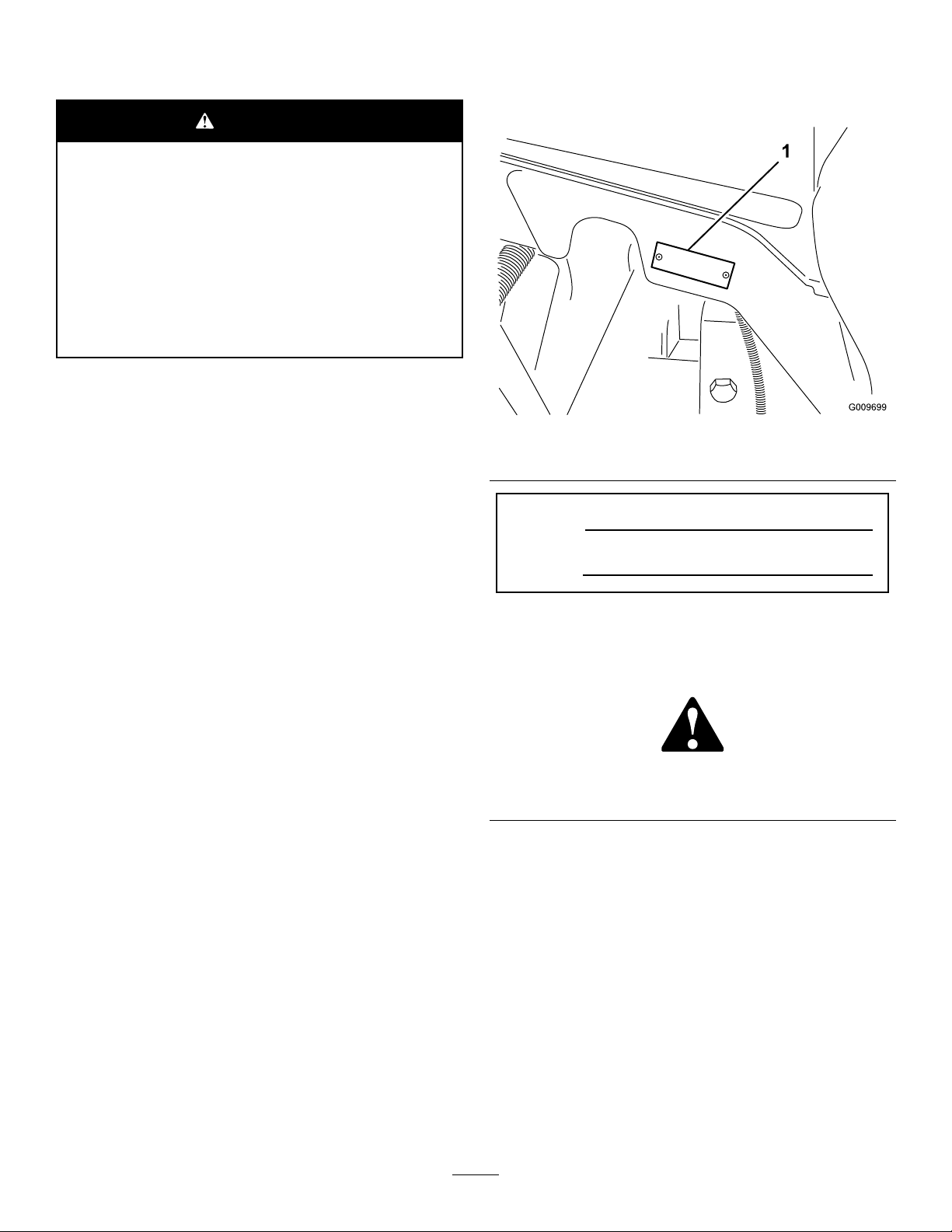

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

GeneralSafety.........................................................4

SoundPowerLevel..................................................4

SoundPressureLevel...............................................4

VibrationLevel......................................................4

EngineEmissionCertication...................................4

SafetyandInstructionalDecals.................................5

Setup...........................................................................10

1InstallingtheHoodLatch(CEOnly).......................11

2AdjustingtheRollerScraper(Optional)...................11

3InstallingtheMulchingBafe(Optional).................12

4PreparingtheMachine..........................................13

ProductOverview.........................................................13

Controls...............................................................13

Specications........................................................20

Attachments/Accessories........................................20

BeforeOperation......................................................21

BeforeOperationSafety..........................................21

CheckingtheEngine-OilLevel.................................22

CheckingtheCoolingSystem...................................22

CheckingtheHydraulicSystem................................22

FillingtheFuelTank...............................................22

CheckingtheTirePressure......................................23

CheckingtheTorqueoftheWheelNuts.....................23

AdjustingtheHeightofCut.....................................23

CheckingtheInterlockSwitches...............................24

CheckingtheBlade-StoppingTime...........................24

SelectingaBlade.....................................................24

ChoosingAccessories.............................................25

DuringOperation.....................................................26

DuringOperationSafety.........................................26

StartingandStoppingtheEngine..............................27

UnderstandingtheOperatingCharacteristicsofthe

Machine............................................................27

OperatingtheEngine-CoolingFan...........................27

OperatingTips......................................................28

AfterOperation........................................................29

AfterOperationSafety............................................29

JackingPoints........................................................29

TieDowns............................................................29

PushingorTowingtheMachine................................29

HaulingtheMachine...............................................29

Maintenance.................................................................30

RecommendedMaintenanceSchedule(s)......................30

DailyMaintenanceChecklist....................................31

ServiceIntervalChart.............................................32

PremaintenanceProcedures........................................33

RemovingtheHood...............................................33

Lubrication...............................................................33

GreasingtheBearingsandBushings..........................33

EngineMaintenance..................................................35

EngineSafety.........................................................35

ServicingtheAirCleaner.........................................35

ServicingtheEngineOil..........................................36

ServicingtheDieselParticulateFilter(DPF)...............37

ServicingtheDieselOxidationCatalyst

(DOC)..............................................................37

FuelSystemMaintenance...........................................38

DrainingtheFuelTank...........................................38

InspectingtheFuelLinesandConnections.................38

ServicingtheWaterSeparator...................................38

ServicingtheFuelFilter...........................................39

ServicingtheFuel-PickupTube................................39

ElectricalSystemMaintenance....................................39

ChargingandConnectingtheBattery........................39

ServicingtheBattery...............................................41

Fuses....................................................................41

DriveSystemMaintenance.........................................42

CheckingforEnd-PlayinthePlanetary

Drives...............................................................42

CheckingthePlanetaryGearDriveOil......................42

ChangingthePlanetaryGearDriveOil......................42

CheckingtheRearAxleLubricant.............................43

ChangingtheRearAxleLubricant.............................43

CheckingtheRearAxleGearBoxLubricant...............44

CheckingtheRearWheelT oe-In..............................44

CoolingSystemMaintenance......................................45

CoolingSystemSafety.............................................45

CheckingtheCoolingSystem...................................45

CleaningtheCoolingSystem....................................45

BrakeMaintenance....................................................46

AdjustingtheServiceBrakes....................................46

BeltMaintenance......................................................47

ServicingtheAlternatorBelt....................................47

HydraulicSystemMaintenance....................................47

HydraulicSystemSafety..........................................47

CheckingtheHydraulic-FluidLevel..........................47

ChangingtheHydraulicFluid...................................49

ReplacingtheHydraulicFilters.................................49

CheckingtheHydraulicLinesandHoses....................50

CuttingDeckMaintenance..........................................50

SeparatingtheCuttingDecksfromtheTraction

Unit..................................................................50

MountingtheCuttingDeckstotheTraction

Unit..................................................................51

ServicingtheBladePlane.........................................51

ServicingtheCutterBlade.......................................52

ServicingtheFrontRoller........................................53

Storage........................................................................54

PreparingtheTractionUnit.....................................54

PreparingtheEngine..............................................54

CuttingDeck.........................................................54

3

Page 4

Safety

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013andANSIB71.4-2012.

GeneralSafety

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof105dBA,

whichincludesanUncertaintyValue(K)of0.7dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

Thisproductiscapableofamputatinghandsandfeetand

ofthrowingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustoyouandbystanders.

•ReadandunderstandthecontentsofthisOperator’ sManual

beforeyoustarttheengine.Ensurethateveryoneusing

thisproductknowshowtouseitandunderstandsthe

warnings.

•Donotputyourhandsorfeetnearmovingcomponents

ofthemachine.

•Donotoperatethemachinewithoutallguardsandother

safetyprotectivedevicesinplaceandworkingonthe

machine.

•Keepclearofanydischargeopening.Keepbystandersa

safedistancefromthemachine.

•Keepchildrenoutoftheoperatingarea.Neverallow

childrentooperatethemachine.

•Stopthemachineandshutofftheenginebeforeservicing,

fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theseinstructionsmayresultinpersonalinjuryordeath.

Youcanndadditionalitemsofsafetyinformationintheir

respectivesectionsthroughoutthismanual.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof90

dBA,whichincludesanUncertaintyValue(K)of0.7dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=0.6m/s

Measuredvibrationlevelforlefthand=0.7m/s

UncertaintyValue(K)=0.3m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

WholeBody

Measuredvibrationlevel=0.2m/s

UncertaintyValue(K)=0.1m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

2

2

2

2

2

EngineEmissionCertication

TheengineinthismachineisEPATier4Finalandstage3b

compliant.

4

Page 5

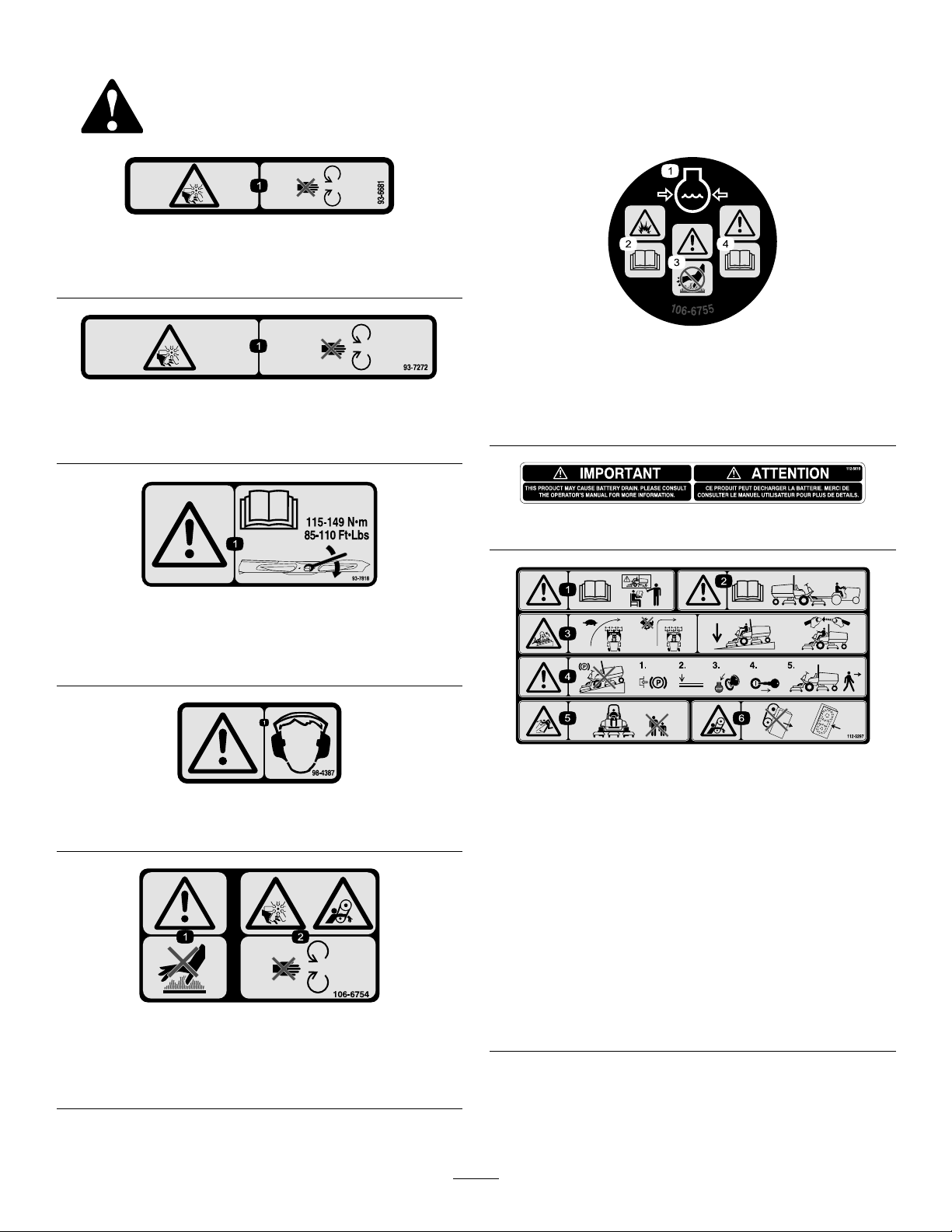

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-6681

1.Cutting/dismemberment—hazard,fan-stayawayfrom

movingparts.

106-6755

93-7272

1.Cutting/dismembermenthazard;fan—stayawayfrom

movingparts.

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto1 15to149N-m(85to110

ft-lb).

98-4387

1.Warning—wearhearingprotection.

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

112-5019

112-5297

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Warning—readtheOperator'sManualbeforetowingthe

machine.

3.Tippinghazard—slowmachinebeforeturning,donotturn

athighspeeds;lowerthecuttingunitwhendrivingdown

slopes;usearolloverprotectionsystemandweartheseat

belt

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingunits,shutofftheengine,

andremovetheignitionkeybeforeleavingthemachine.

5.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

6.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

5

Page 6

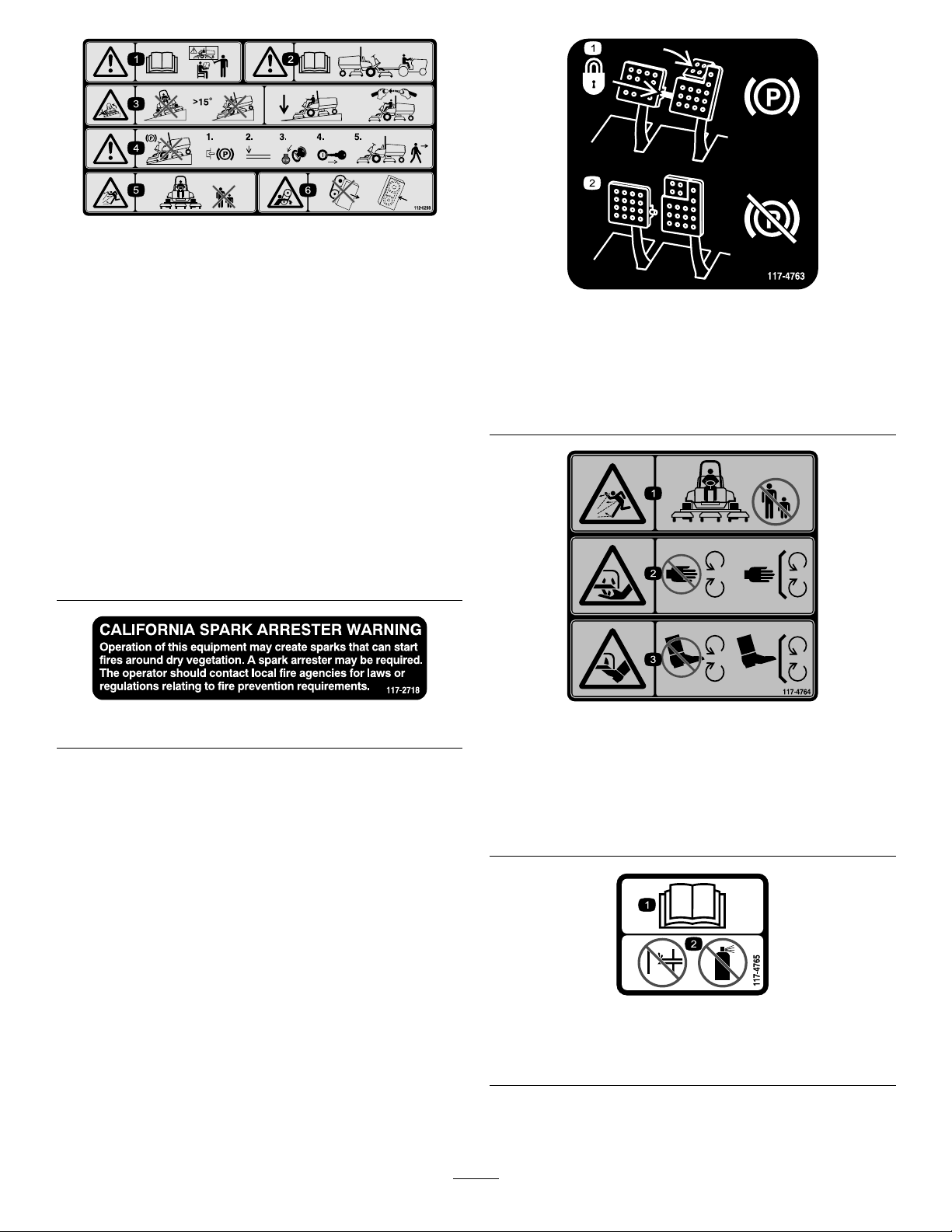

112-5298

(PlaceoverPartNo.112-5297forCE*)

*Thissafetydecalincludesaslopewarningrequiredonthemachinefor

compliancetotheEuropeanLawnMowerSafetyStandardEN836:1997.The

conservativemaximumslopeanglesindicatedforoperationofthismachineare

prescribedbyandrequiredbythisstandard.

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Warning—readtheOperator'sManualbeforetowingthe

machine.

3.Tippinghazard—donotoperateonslopesgreaterthan15°;

lowerthecuttingunitswhenoperatingonslopes;wearthe

safetybelt.

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingunits,shutofftheengine,

andremovetheignitionkeybeforeleavingthemachine.

5.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

6.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

1.Toengagetheparking

brake,securethebrake

pedalswiththelockingpin,

presstheparkingbrake

pedalsandengagethetoe

pedal.

117-4763

2.Todisengagetheparking

brake,disengagethe

lockingpinandreleasethe

pedals.

117-2718

117-4764

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cuttinghazardofhand,mowerblade—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

3.Cuttinghazardoffoot,mowerblade—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

117-4765

1.ReadtheOperator'sManual.

2.Donotusestartingaids.

6

Page 7

117-4766

1.Cutting/dismembermenthazard;fan—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

121-3884

1.Engine—stop3.Engine—start

2.Engine—preheat

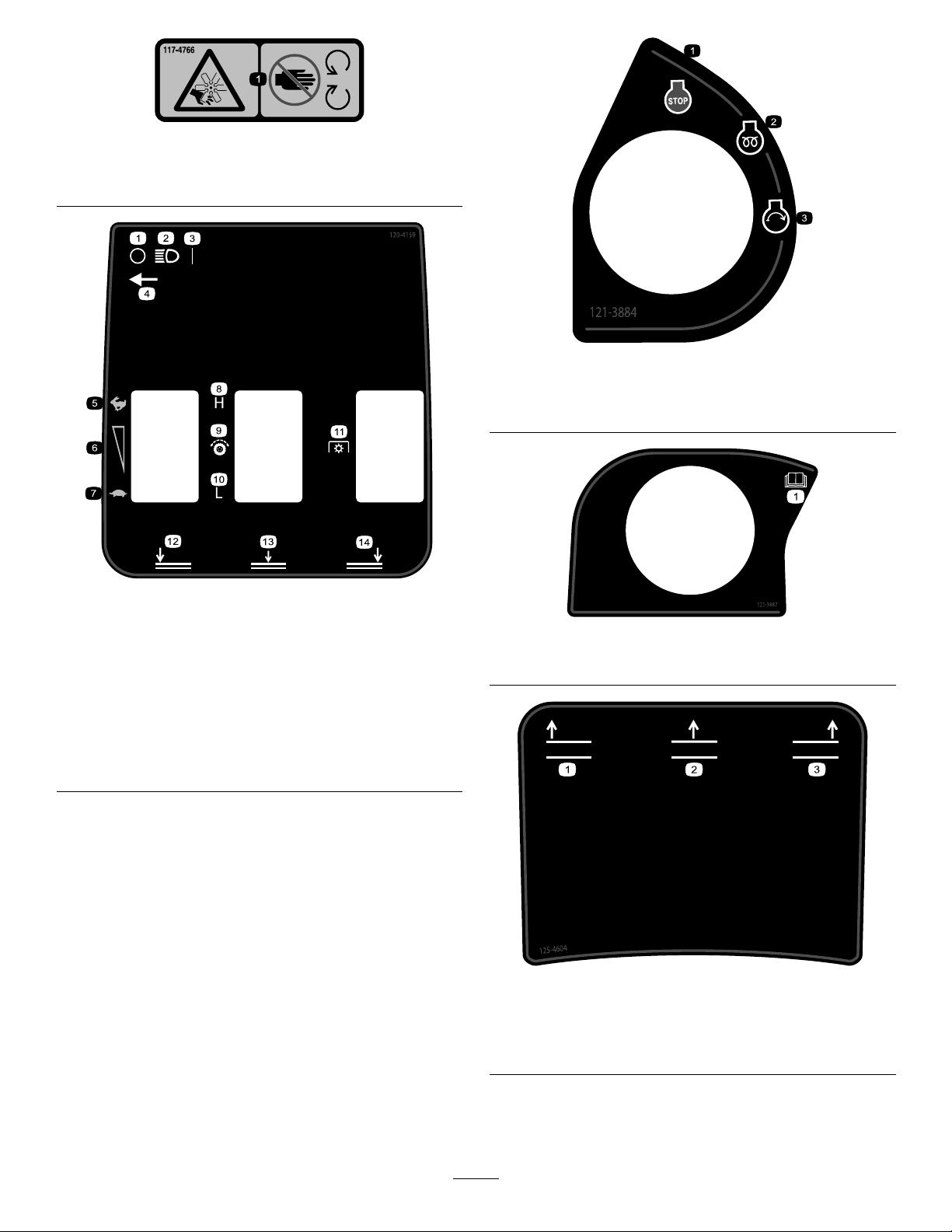

120-4159

Groundsmaster4700Shown

1.Off

2.Lights9.Tractiondrive

3.On

4.Lightswitchlocation

5.Fast

6.Variablespeedadjustment13.Lowercenterdeck

7.Slow

8.High

10.Low

11.Powertakeoff(PTO)

12.Lowerleftdeck

14.Lowerrightdeck

121-3887

1.ReadtheOperator’sManual.

125-4604

Groundsmaster4700Shown

1.Raiseleftdeck

2.Raisecenterdeck

3.Raiserightdeck

7

Page 8

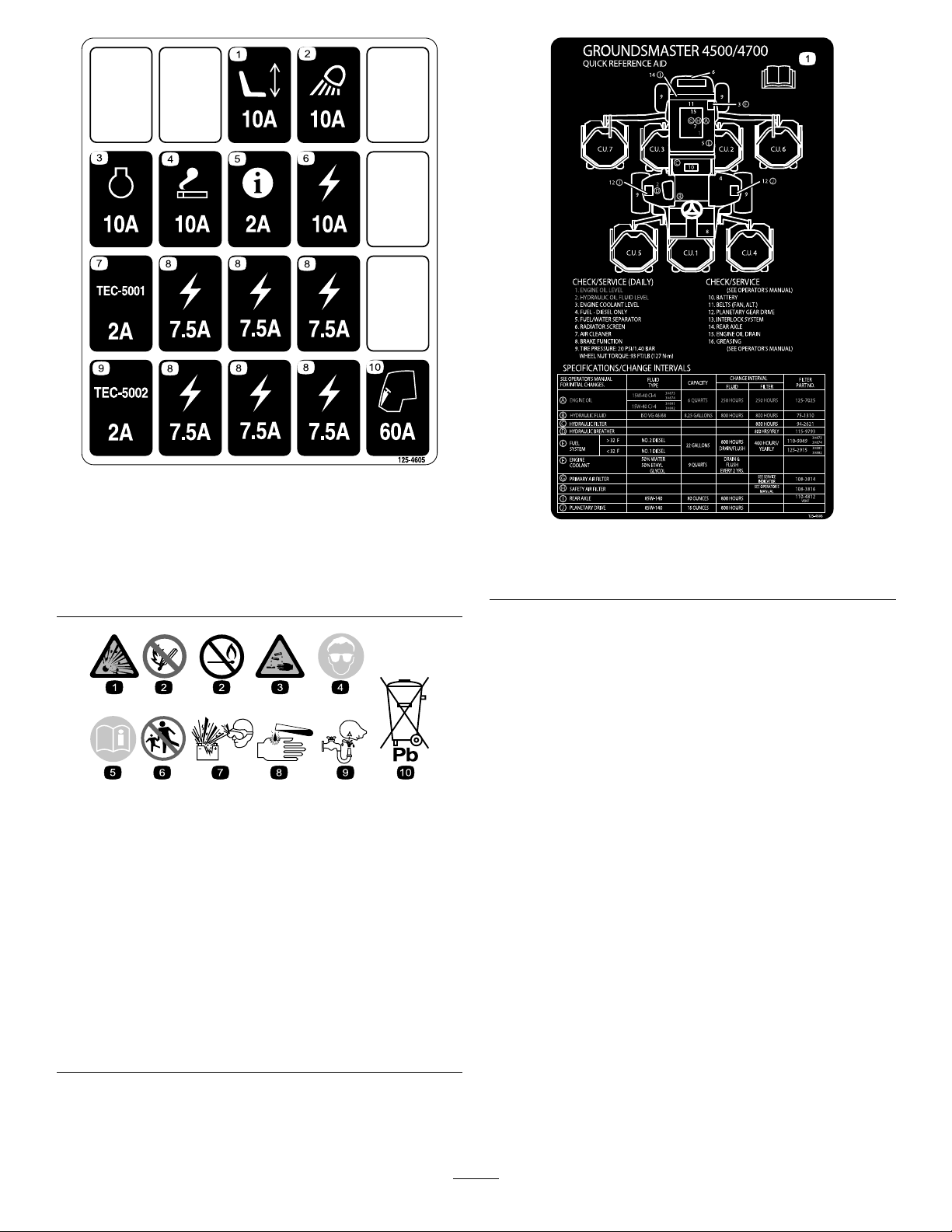

125-4605

1.Powerseat—10A6.Powersupplied—10A

2.Worklight—10A

3.Engine—10A8.Powersupplied—7.5A

4.Cigarettelighter—10A9.TEC-5002—2A

5.Infocenter—2A10.Cab—60A

7.TEC-5001—2A

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

125-4606

1.ReadtheOperator’sManualforinformationon

maintenance.

1.Explosionhazard

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries.

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard

8

Page 9

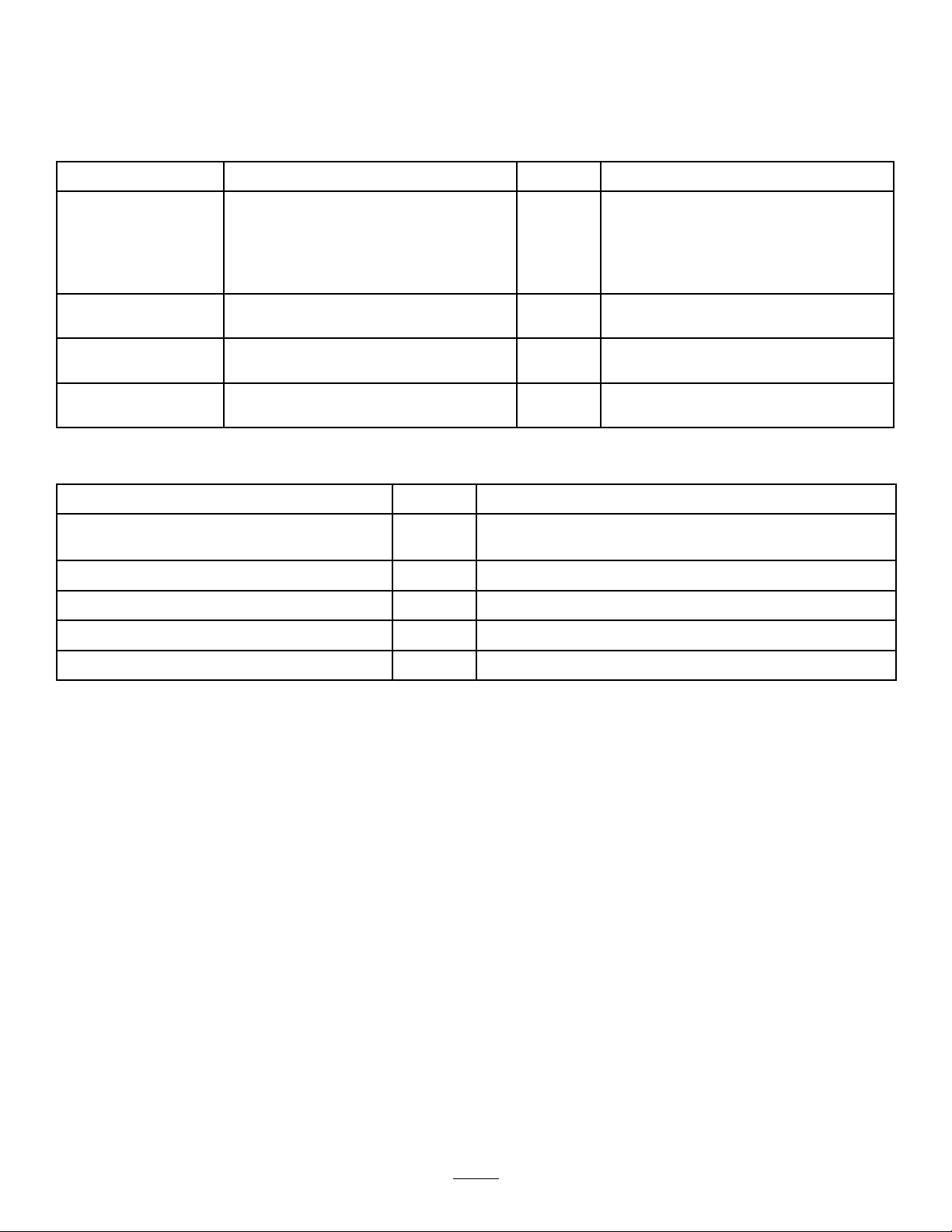

1.Heightofcut

104-1086

9

Page 10

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Lockbracket1

Rivet2

1

2

3

4

Washer1

Screw(1/4x2inches)

Locknut(1/4inch)

Nopartsrequired

Nopartsrequired

Nopartsrequired

MediaandAdditionalParts

Description

WarningDecal6

Operator'sManual

EngineOperator'sManual

Qty.

Qty.

Installthehoodlatch(CE).

1

1

–

–

–

AfxtheCEwarningdecalsoverthecorresponding

Englishwarningdecals.

1

1

Readbeforeoperatingmachine

Readbeforeoperatingengine

Adjusttherollerscraper(optional).

Installthemulchingbafe(optional).

Preparethemachine.

Use

Use

PartsCatalog

OperatorTrainingMaterial

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

1

1

Usetoreferencepartnumbers

Viewbeforeoperatingmachine

10

Page 11

1

G012628

1

2

G012629

1

2

G012630

1

G012631

1

2

3

InstallingtheHoodLatch(CE Only)

Partsneededforthisprocedure:

1Lockbracket

2Rivet

1Washer

1

Screw(1/4x2inches)

1

Locknut(1/4inch)

Procedure

1.Unhookthehoodlatchfromthehood-latchbracket.

2.Removethe2rivetssecuringthehood-latchbracketto

thehood(Figure3).Removethehood-latchbracket

fromthehood.

Figure4

1.CElockbracket

4.Alignthewasherswiththeholesontheinsideofthe

hood.

5.Rivetthebracketsandthewasherstothehood(Figure

4).

6.Hookthelatchontothehood-latchbracket(Figure5).

2.Boltandnutassembly

Figure5

1.Hoodlatch

Figure3

1.Hoodlatchbracket2.Rivets

3.Whilealigningthemountingholes,positionthe

CE-lockbracketandthehood-latchbracketontothe

hood.Thelockbracketmustbeagainstthehood

(Figure4).Donotremovetheboltandnutassembly

fromthelock-bracketarm.

7.Screwtheboltintotheotherarmofthehood-lock

brackettolockthelatchinposition(Figure6).Tighten

theboltbutdonottightenthenut.

Figure6

1.Bolt

2.Nut

3.Armofhood-lockbracket

11

Page 12

2

G011346

1

2

3

G011347

1

3

AdjustingtheRollerScraper

(Optional)

NoPartsRequired

Procedure

Theoptionalrearrollerscraperisdesignedtoworkbestwhen

thereisanevengapof0.5to1mm(0.020to0.040inch)

betweenthescraperandroller.

1.Loosenthegreasettingandthemountingscrew

(Figure7).

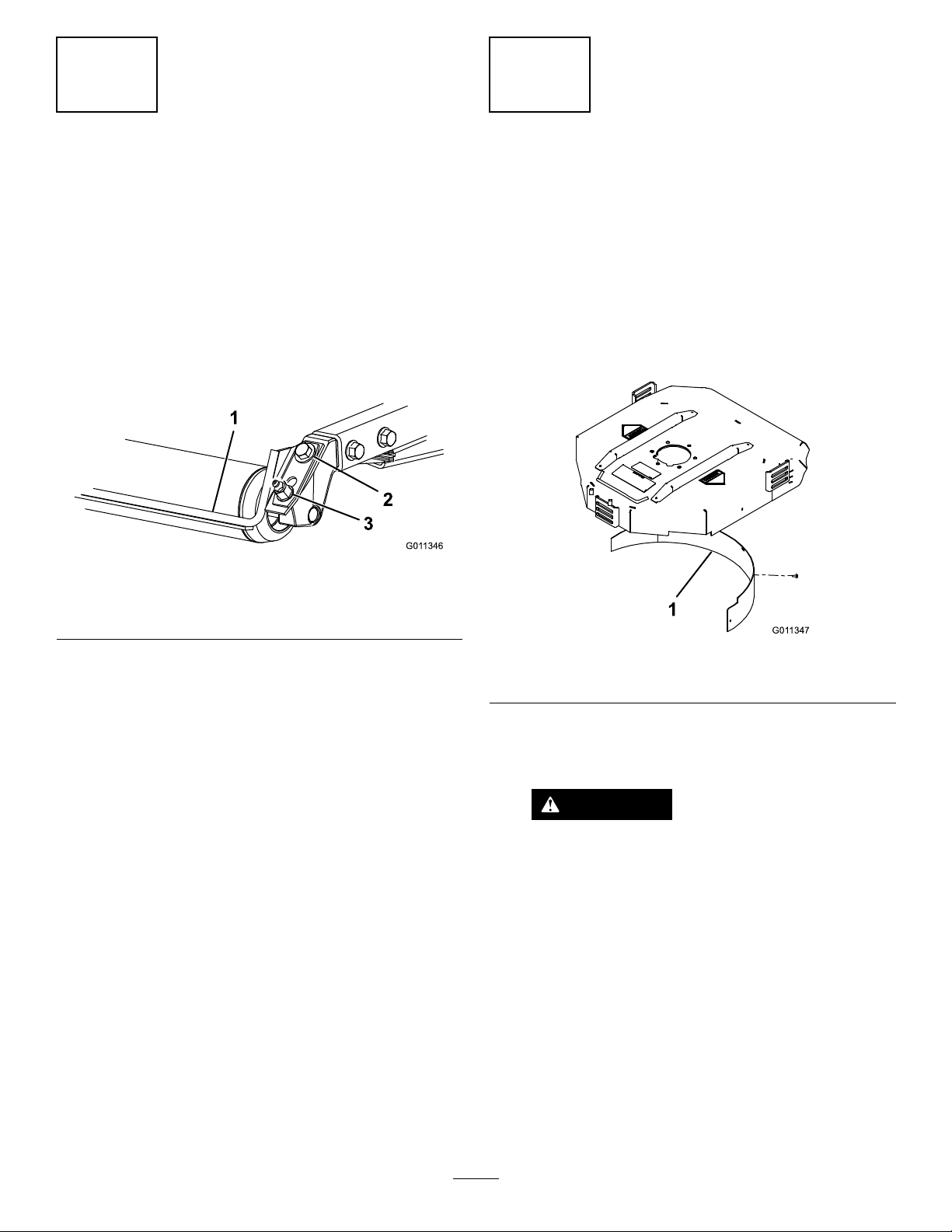

Figure7

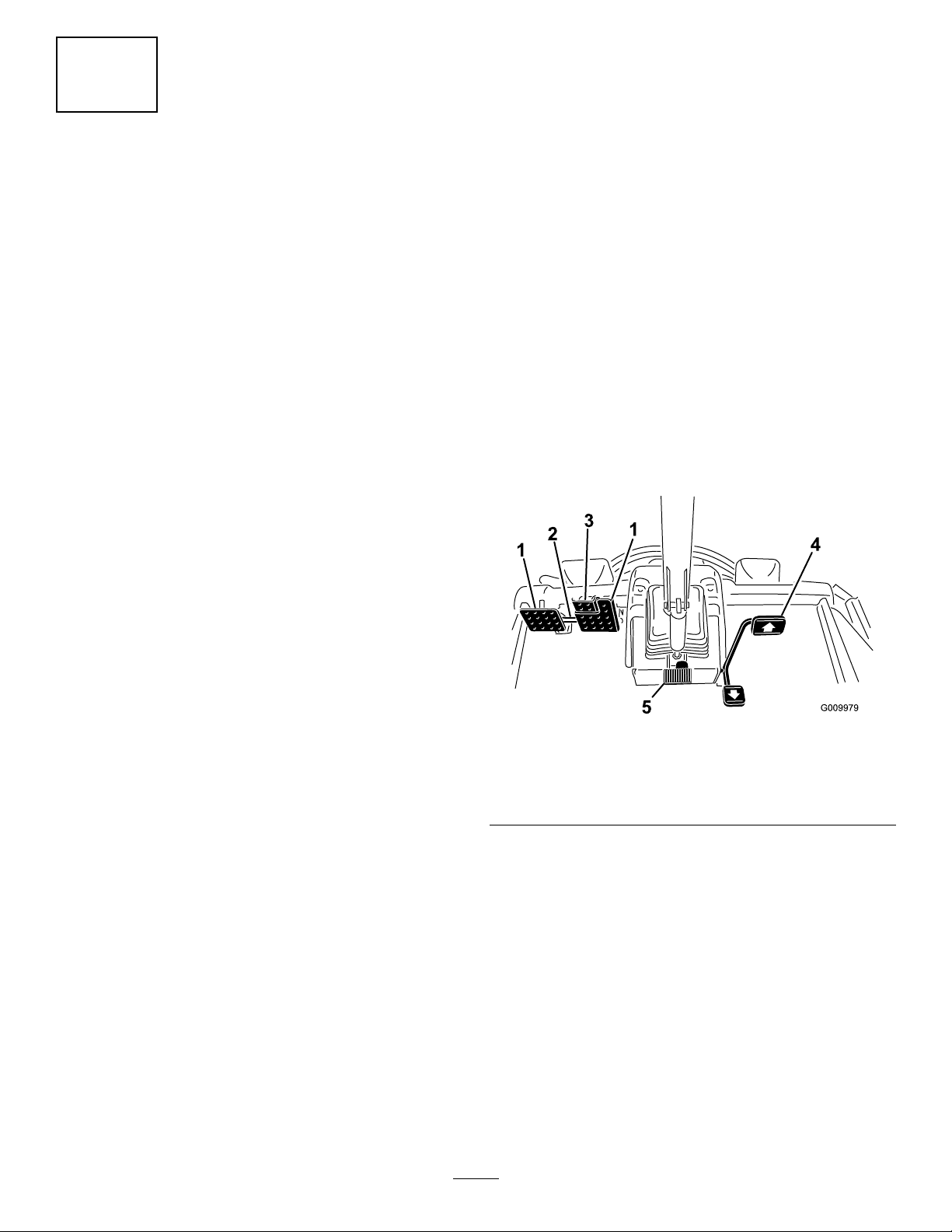

InstallingtheMulchingBafe

(Optional)

NoPartsRequired

Procedure

1.Thoroughlycleandebrisfromthemountingholeson

therearwallandleftsidewallofthechamber.

2.Installthemulchingbafeintherearopeningand

secureitwith5ange-headbolts(Figure8).

1.Rollerscraper

2.Mountingscrew

2.Slidethescraperupordownuntilagapof0.5to1

mm(0.020to0.040inch)isachievedbetweentherod

andtheroller.

3.Securethegreasettingandscrewto41N-m(30ft-lb)

inanalternatingsequence.

3.Greasetting

Figure8

1.Mulchingbafe

3.Verifythatmulchingbafedoesnotinterferewith

thetipofthebladeanddoesnotprotrudeinsidethe

surfaceoftherearchamberwall.

DANGER

Usingthehigh-liftbladewiththemulching

bafecouldcausethebladetobreak,resulting

inpersonalinjuryordeath.

Donotusethehigh-liftbladewiththe

mulchingbafe.

12

Page 13

ProductOverview

4

PreparingtheMachine

NoPartsRequired

CheckingtheTirePressure

Checkthetirepressurebeforeuse;refertoCheckingtheTire

Pressure(page23).

Important:Maintainpressureinalltirestoensurea

goodquality-of-cutandpropermachineperformance.

Do not underinate the tir es.

CheckingtheFluidLevels

1.Checktherear-axlelubricantlevelbeforetheengineis

rststarted,refertoCheckingtheRearAxleGearBox

Lubricant(page44).

2.Checktheengine-oillevelbeforestartingtheengine;

refertoCheckingtheEngine-OilLevel(page36).

3.Checkthehydraulic-uidlevelbeforestartingthe

engine;refertoCheckingtheHydraulic-FluidLevel

(page47).

Controls

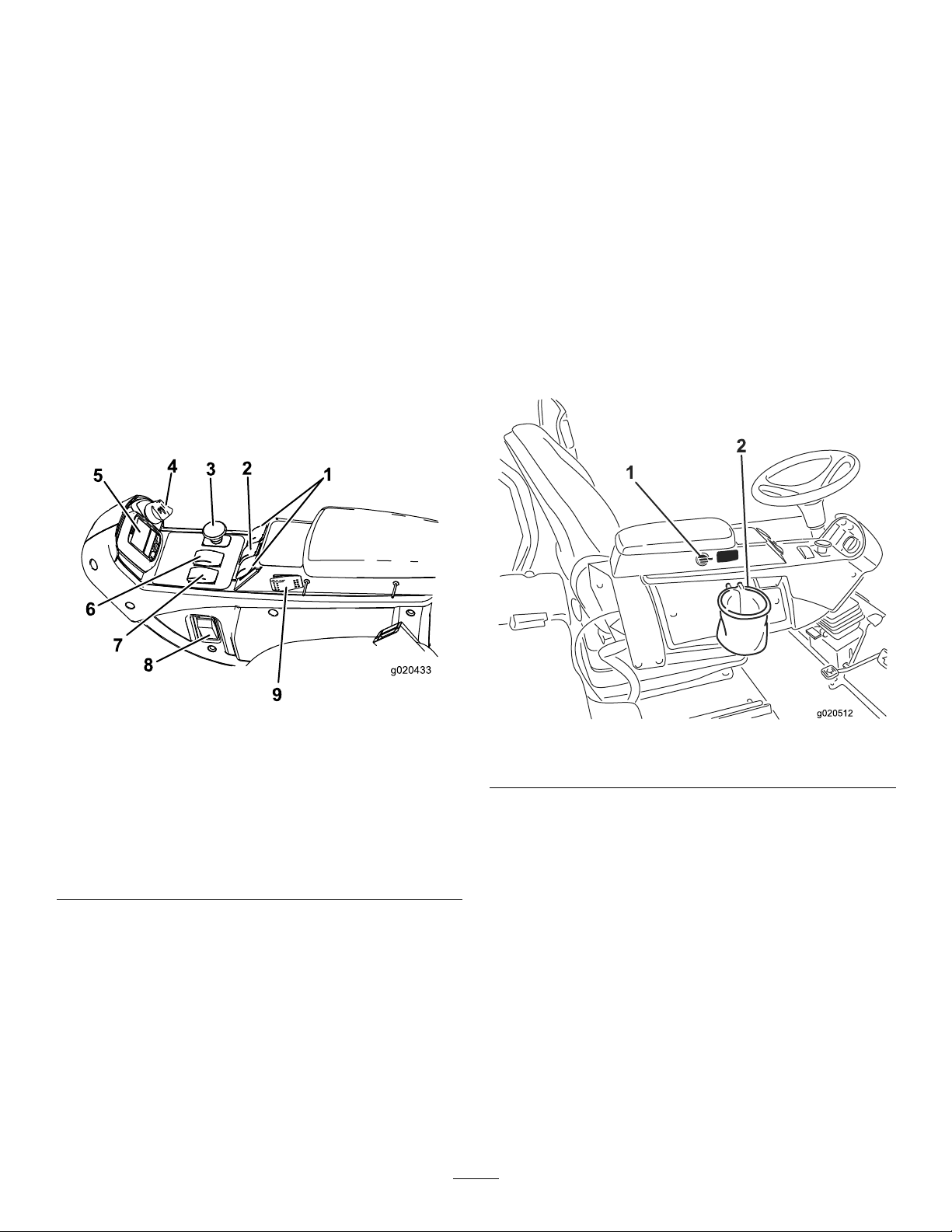

BrakePedals

2footpedals(Figure9)operateindividualwheelbrakesfor

turningassistanceandtoaidinobtainingbettersidehill

traction.

Pedal-LockingLatch

Thepedal-lockinglatch(Figure9)connectsthepedals

togethertoengagetheparkingbrake.

Parking-BrakePedal

Toengagetheparkingbrake,(Figure9)connectthepedals

togetherwiththepedal-lockinglatchandpushdownonthe

rightbrakepedalwhileengagingthetoepedal.T oreleasethe

parkingbrake,press1ofthebrakepedalsuntiltheparking

brakelatchretracts.

4.Checkthecoolingsystembeforestartingtheengine;

refertoCheckingtheCoolingSystem(page45).

GreasingtheMachine

Greasethemachinebeforeuse;refertoGreasingtheBearings

andBushings(page33).Failuretoproperlygreasethe

machineresultsinprematurefailureofcriticalparts.

Figure9

1.Brakepedal4.Tractionpedal

2.Pedal-lockinglatch5.Tilt-steeringpedal

3.Parking-brakepedal

TractionPedal

Thetractionpedal(Figure9)controlsforwardandreverse

operation.Pressthetopofthepedaltomoveforwardand

thebottomtomovebackward.

Tostop,reduceyourfootpressureonthetractionpedaland

allowittoreturntothecenterposition.

Tilt-SteeringPedal

Totiltthesteeringwheeltowardyou,pressthefootpedal

(Figure9)down,andpullthesteeringtowertowardyouto

themostcomfortablepositionandthenreleasethepedal.

13

Page 14

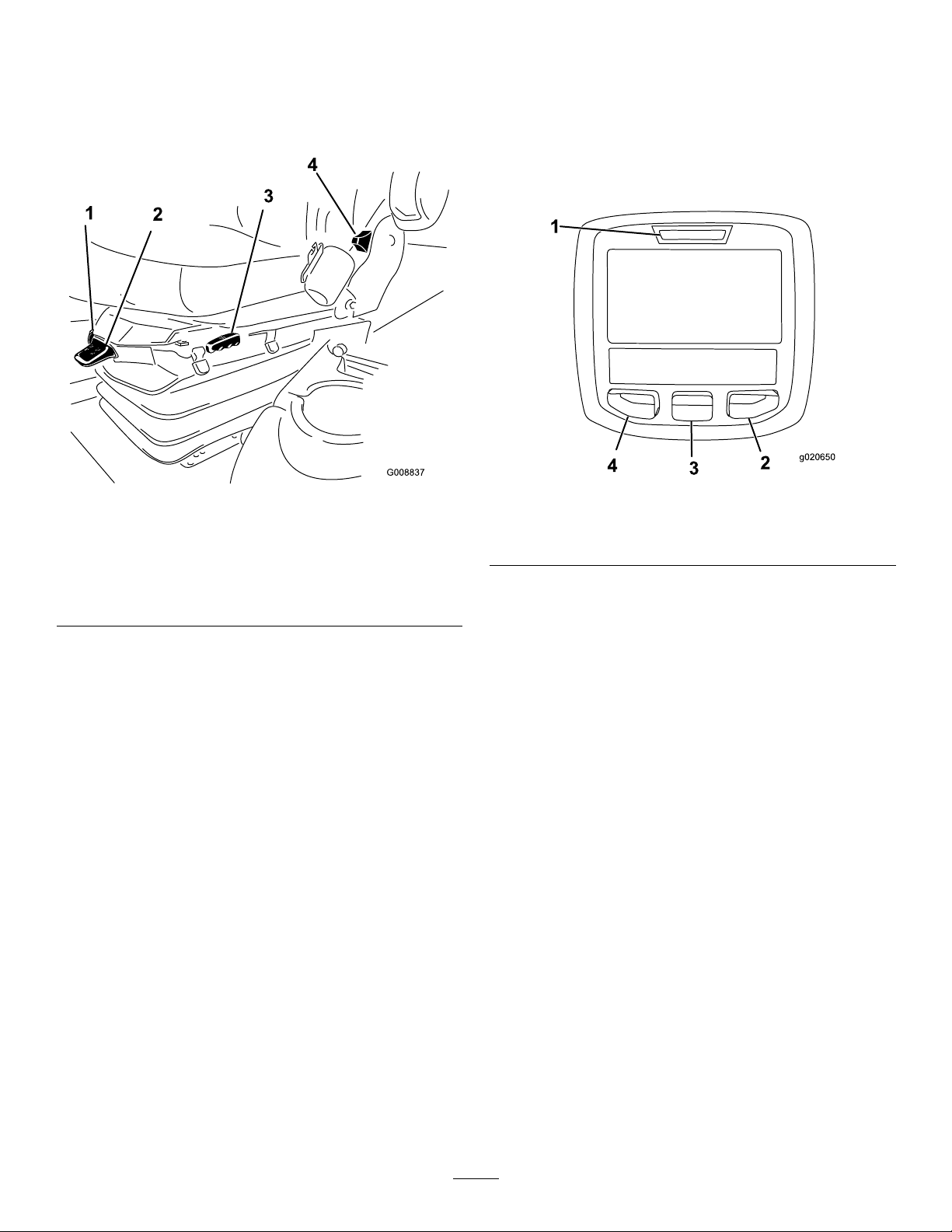

KeySwitch

g020512

Thekeyswitch(Figure10)has3positions:Off,On/Preheat,

andStart.

PTOSwitch

ThePTOswitch(Figure10)has2positions:Out(start)and

In(stop).PullthePTObuttonouttoengagethecutting

unitblades.Pushinthebuttontodisengagethecuttingunit

blades.

andbackwardtoraisethecuttingunits.Whenstartingthe

machine,withthecuttingunitsinthedownposition,pressthe

liftswitchdowntoallowthecuttingunitstooat,andmow .

Note:ThedecksdonotlowerwhileintheHispeedrange

andtheydonotraiseorloweriftheoperatorisoutoftheseat

whentheengineisrunning.Tolowerthedecksforservice,

rotatethekeyintheignitionswitchtotheONpositionwhile

sittingintheseat.

LightSwitch

High-LowSpeedControl

Theswitch(Figure10)allowsthespeedrangetoincrease

fortransportingthemachine.T oswitchbetweentheHigh

andLowspeedranges,raisethedecks,disengagethePTO ,

putthetractionpedalintotheNEUTRALposition,andmove

themachineataslowspeed.

Note:Thecuttingdecksdonotoperateand/orcannotbe

loweredfromthetransportpositionwhentheswitchisin

thehighrange.

Figure10

1.Liftswitches

(Groundsmaster4700

only)

2.Liftswitch(Groundsmaster

4500and4700)

3.PTOswitch

4.Keyswitch

5.InfoCenter

6.Hi-Lospeedcontrol

7.Engine-speedswitch

8.Lightswitch

9.Cruisecontrol

Presstheloweredgeoftheswitch(Figure10)toturnonthe

lights.Presstheupperedgeoftheswitchtoturnoffthelights.

PowerPoint

Usethepowerpoint(Figure11)topoweroptional12V

electricalaccessories.

Figure11

1.Powerpoint2.Bagholder

BagHolder

Usethebagholder(Figure11)forstorage.

Engine-SpeedSwitch

Theengine-speedswitch(Figure10)has2modestochange

theenginespeed.Taptheswitchtoincreaseordecreasethe

enginespeedin100rpmincrements.Holddowntheswitch

toautomaticallymovetoHighorLowidle,dependingon

whichendoftheswitchisdepressed.

LiftSwitches

Theliftswitches(Figure10)raiseandlowerthecutting

units.Presstheswitchesforwardtolowerthecuttingunits

SeatAdjustments

SeatAdjustingLever

Pulloutonthelevertoslidetheseatforwardorrearward

(Figure12).

SeatArmRestAdjustingKnob

Rotatetheknobtoadjusttheseatarmrestangle.

SeatBackAdjustingLever

Movethelevertoadjusttheseatbackangle(Figure12).

14

Page 15

Weightgauge

1

g020650

2

3

4

TORO

UsingtheInfoCenterLCDDisplay

Indicateswhentheseatisadjustedtotheweightofthe

operator(Figure12).Heightadjustmentismadeby

positioningthesuspensionwithintherangeofthegreen

region.

Figure12

1.Weightgauge

2.Weight-adjustinglever5.Armrestadjustingknob

3.Seatadjustinglever

4.Seatbackadjustinglever

(notshown-locatedunder

armrest)

TheInfoCenterLCDdisplayshowsinformationaboutyour

machinesuchastheoperatingstatus,variousdiagnosticsand

otherinformationaboutthemachine(Figure13).Thereisa

splashscreenandmaininformationscreenoftheInfoCenter.

PressanyoftheInfoCenterbuttonsandthenselectthe

appropriatedirectionalarrowtoswitchbetweenthesplash

screenandthemaininformationscreen.

Figure13

1.Indicatorlight3.Middlebutton

2.Rightbutton

4.Leftbutton

•LeftButton,MenuAccess/BackButton—presstoaccess

theInfoCentermenus.Youcanuseittobackoutofany

menuyouarecurrentlyusing.

Weight-AdjustingLever

Adjustforyourweight(Figure12).Pulluptheleverto

increasetheairpressureandpushdowntodecreasetheair

pressure.Y ouattaintheproperadjustmentwhentheweight

gaugeisinthegreenregion.

•MiddleButton—presstoscrolldownmenus.

•RightButton—presstoopenamenuwherearightarrow

indicatesadditionalcontent.

•Beeper—activatedwhenloweringthedecksorfor

advisoriesandfaults.

Note:Thepurposeofeachbuttonmaychange

dependingonwhatisrequiredatthetime.Eachbuttonis

labeledwithanicondisplayingitscurrentfunction.

15

Page 16

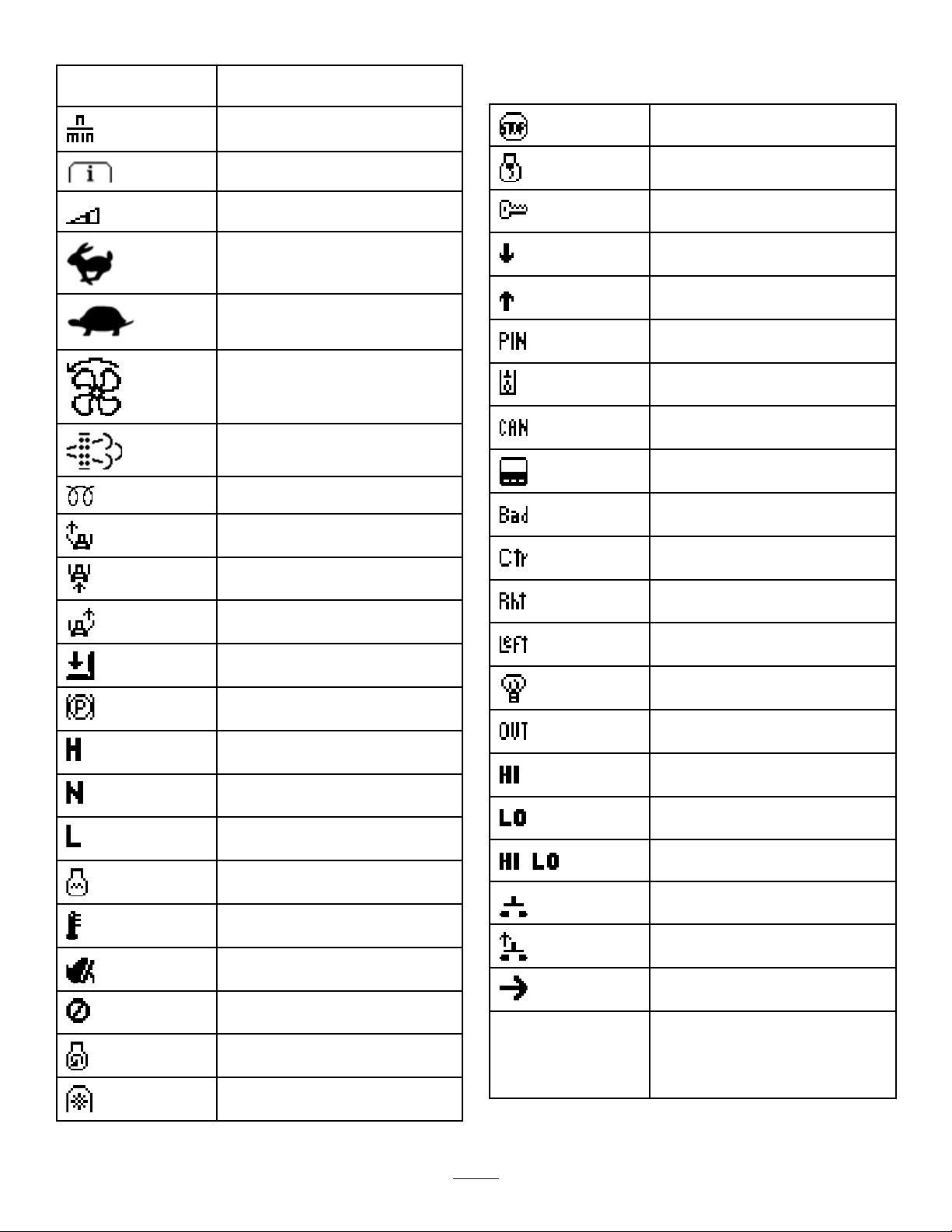

InfoCenterIconDescription

SERVICEDUE

Indicateswhenscheduledservice

shouldbeperformed

Thestatusoftheenginerpm.

InfoCenterIconDescription(cont'd.)

Stoptheengine.

Infoicon

Maximumtractionspeedsetting

Fast

Slow

Thefanisreversed.

Stationaryregenerationisrequired.

Theair-intakeheaterisactive

Raisetheleftdeck.

Raisethecenterdeck

Raisetherightdeck

Theoperatormustsitintheseat.

Theparkingbrakeison.

Therangeishigh.

Neutral

IdentiestherangeasLow

Coolanttemperature(°Cor°F)

Temperature(hot)

TractionorTractionPedal

Notallowed

Starttheengine.

ThePTOison.

Engine

Keyswitch

Cuttingunitsarelowering.

Cuttingunitsareraising.

PINpasscode

Hydraulicuidtemperature

CANbus

InfoCenter

Badorfailed

Center

Right

Left

Bulb

OutputofTECcontrollerorcontrol

wireinharness

Overtheallowedrange

Undertheallowedrange

Outofrange

/

Switch

Operatormustreleaseswitch.

Operatorshouldchangetoindicated

state.

Symbolsareoften

combinedtoform

sentences.Some

examplesareshown

below

16

Page 17

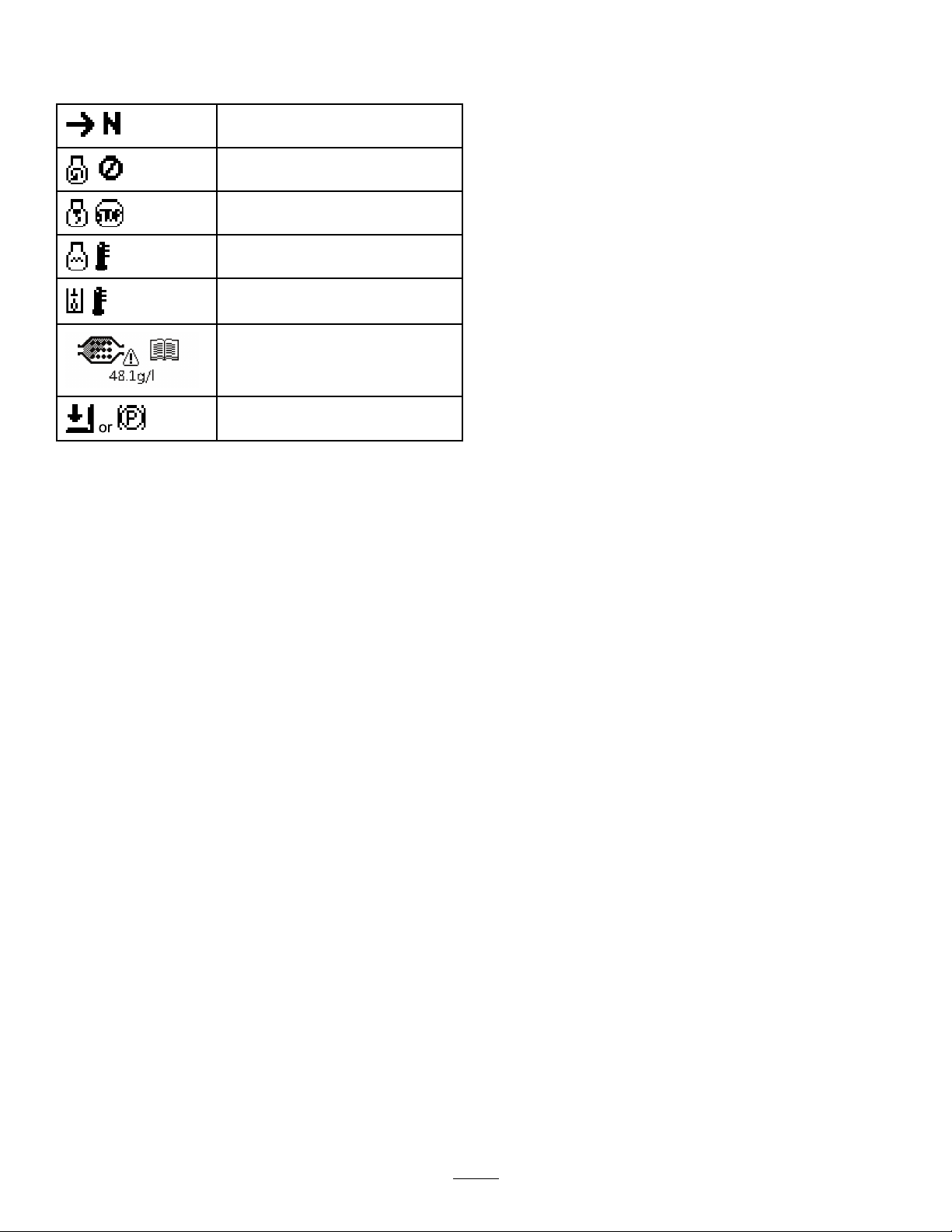

InfoCenterIconDescription(cont'd.)

Operatorshouldputmachinein

neutral.

Enginestartisdenied.

Engineshutdown.

Enginecoolantistoohot.

Hydraulicuidistoohot.

DPFashaccumulationnotication.

RefertoServicingtheDiesel

ParticulateFilter(DPF)inthe

maintenancesectionfordetails.

Sitdownorsetparkingbrake.

17

Page 18

UsingtheMenus

ToaccesstheInfoCentermenusystem,pressthemenuaccess

buttonwhileatthemainscreen.Thisbringsyoutothemain

menu.Refertothefollowingtablesforasynopsisofthe

optionsavailablefromthemenus:

MainMenu

MenuItemDescription

Faults

ServiceContainsinformationonthe

DiagnosticsListsvariousstatesthatthe

Settings

AboutListsthemodelnumber,serial

Service

MenuItemDescription

Hours

CountsListsthenumberofstarts,

Containsalistoftherecent

machinefaults.Referto

theServiceManualoryour

ToroDistributorformore

informationontheFaults

menuandtheinformation

containedthere.

machinesuchashoursofuse

andothersimilarnumbers.

machinecurrentlyhas.You

canusethistotroubleshoot

certainissuesasitquicklytells

youwhichmachinecontrols

areonandwhichareoff.

Allowsyoutocustomizeand

modifycongurationvariables

ontheInfoCenterdisplay.

number,andsoftwareversion

ofyourmachine.

Liststhetotalnumberofhours

thatthemachine,engineand

fanhavebeenon,aswell

asthenumberofhoursthe

machinehasbeentransported

andoverheated.

deckPTOcycles,andfan

reversalsthemachinehas

experienced.

Language

LCDBacklightControlsthebrightnessofthe

LCDContrastControlsthecontrastofthe

ProtectedMenusAllowsthemaintenance

ProtectSettings

AutoIdle

MowSpeedControlsthemaximumspeed

Trans.SpeedControlsthemaximumspeed

CounterbalanceControlstheamountof

Controlsthelanguageused

ontheInfoCenter*.

LCDdisplay.

LCDdisplay.

directortoaccessprotected

menusbyinputtinga

passcode.

Allowstheabilitytochange

thesettingsintheprotected

settings.

Controlstheamountoftime

allowedbeforeidlingthe

enginewhenthemachineis

notinuse.

whileinmow(lowrange).

whileintransport(highrange).

counterbalanceappliedbythe

decks.

*Only"operator-faced"textistranslated.Faults,Service,

andDiagnosticsscreensare"service-faced.”Titlesareinthe

selectedlanguage,butmenuitemsareinEnglish.

About

MenuItemDescription

Model

SNListstheserialnumberofthe

S/WRevListsthesoftwarerevisionof

Liststhemodelnumberofthe

machine.

machine.

themastercontroller .

Diagnostics

MenuItemDescription

LeftDeck

CenterDeck

RightDeck

TractionPedal

Traction

HI/LORange

PTO

EngineRun

Settings

MenuItemDescription

Units

RefertotheServiceManualor

yourToroDistributorformore

informationontheEngine

Runmenuandtheinformation

containedthere.

Controlstheunitsusedonthe

InfoCenter(EnglishorMetric).

18

Page 19

ProtectedMenus

Thereare5operatingcongurationsettingsthatare

adjustablewithintheSettingsMenuoftheInfoCenter:auto

idle,maximummowinggroundspeed,maximumtransport

groundspeed,SmartPower,anddeckcounterbalance.These

settingsareintheProtectedMenu.

2.Usetherightbuttontoincreasethemaxfullmow

speed(50%,75%,or100%).

3.Usethecenterbuttontodecreasethemaxfullmow

speed(50%,75%,or100%).

4.Presstheleftbuttontoexit.

AccessingtheProtectedMenuSettings

1.FromtheMainMenu,scrolldowntotheSettings

Menuandpresstherightbutton.

2.IntheSettingsMenu,scrolldowntotheProtected

Menuandpresstherightbutton.

3.Toenterthepasscode,usethecenterbuttontoset

therstdigitthenpresstherightbuttontomoveon

tothenextdigit.

4.Usethecenterbuttontosettheseconddigitthenpress

therightbuttontomoveontothenextdigit.

5.Usethecenterbuttontosetthethirddigitthenpress

therightbuttontomoveontothenextdigit.

6.Usethecenterbuttontosetthefourthdigitthenpress

therightbutton.

7.Pressthemiddlebuttontoenterthecode.

TheabilitytoviewandchangethesettingsintheProtected

Menucanbechanged.OncetheProtectedMenuhasbeen

accessed,scrolldowntoProtectSettings.Usingtheright

button,changingProtectSettingstoOFFwillallowthe

abilitytoviewandchangethesettingsintheProtectedMenu

withoutenteringthepasscode.ChangingProtectSettingsto

ONwillhidetheprotectedoptionsandwillrequireenteringa

passcodetochangethesettingintheProtectedMenu.After

thepasscodehasbeenset,thekeyswitchmustbeturnedoff

andbackontoenableandsavethisfeature.

SettingtheMaximumAllowedTransportSpeed

1.IntheSettingsMenu,scrolldowntoTransportSpeed

andpresstherightbutton.

2.Usetherightbuttontoincreasethemaxtransport

speed(50%,75%,or100%).

3.Usethecenterbuttontodecreasethemaxtransport

speed(50%,75%,or100%).

4.Presstheleftbuttontoexit.

TurningtheSmartPowerON/OFF

1.Inthesettingsmenu,scrolldowntoSmartPower.

2.PresstherightbuttontoswitchbetweenONandOFF.

3.Presstheleftbuttontoexit.

SettingtheCounterbalance

1.IntheSettingsMenu,scrolldowntoCounterBalance

andpresstherightbutton.

2.PresstherightbuttontoswitchbetweenLow,Med,

andHigh.

WhennishedwiththeProtectedMenu,presstheleftbutton

toexittotheMainMenu,thenpresstheleftbuttontoexit

totheRunMenu.

StationaryRegeneration

ViewingandChangingtheProtectedMenuSettings

1.IntheProtectedMenu,scrolldowntoProtectSettings.

2.Toviewandchangethesettingswithoutenteringa

passcode,usetherightbuttontochangetheProtect

SettingstoOFF.

3.Toviewandchangethesettingswithapasscode,use

theleftbuttontoselectON,setthepasscode,andturn

thekeyintheignitionswitchtotheOFFpositionand

thentotheONposition.

SettingtheAutoIdle

1.IntheSettingsMenu,scrolldowntoAutoIdle.

2.Presstherightbuttontochangetheauto-idletime

betweenOFF,8S,10S,15S,20S,and30S.

SettingtheMaximumAllowedMowSpeed

1.IntheSettingsMenu,scrolldowntoMowSpeedand

presstherightbutton.

IftheStationaryRegenerationiconappearsontheInfoCenter,

refertotheServiceManualorcontactyourToroDistributor

forthemaintenanceprocedure.

DPFAshLevel

TheDPFashlevelmaybecheckedbyenteringthePINas

describedinAccessingtheProtectedMenuSettings(page19)

andnavigatingtotheservicesection.

19

Page 20

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

4500-D4700-D

Widthofcut2.8m(109inches)3.8m(150inches)

Overallwidth,

cuttingunitsdown

Overallwidth,

cuttingunitsup

(transport)

Overalllength370cm(145.8inches)370cm(145.8inches)

HeightwithROPS216cm(85inches)216cm(85inches)

Groundclearance15cm(6inches)15cm(6inches)

TrackWidth,front224cm(88.3inches)224cm(88.3inches)

TrackWidth,rear

Wheelbase

NetWeight(with

cuttingunitsand

nouids)

286cm(112.8inches)391cm(153.8inches)

224cm(88.25inches)224cm(88.25inches)

141cm(55.5inches)141cm(55.5inches)

171cm(67-1/2inches)171cm(67-1/2inches)

1894kg(4175lb)2,234kg(4,925lb)

CuttingDeck

Length

Width

Height

26.7cm(10–1/2inches)at3/4inchheightofcut

Weight

24.4cm(9.6inches)tocarriermount

34.9cm(13–3/4inches)at4inchheightofcut

86.4cm(34inches)

86.4cm(34inches)

88kg(195lb)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealerorDistributororgotowww.Toro.comforalistofallapproved

attachmentsandaccessories.

TobestprotectyourinvestmentandmaintainoptimalperformanceofyourToroequipment,countonTorogenuineparts.

Whenitcomestoreliability,Torodeliversreplacementpartsdesignedtotheexactengineeringspecicationofourequipment.

Forpeaceofmind,insistonT orogenuineparts.

20

Page 21

Operation

FuelSafety

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopletooperateor

servicethemachine.Localregulationsmayrestrictthe

ageoftheoperator.Theownerisresponsiblefortraining

alloperatorsandmechanics.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.Knowhowtostop

themachineandenginequickly.

•Checkthatallsafetydevicesareattachedand

functioningproperly.Thisincludes,butisnotlimitedto,

operator-presencecontrols;safetyswitchesandshields;

therolloverprotectionsystem(ROPS);attachments;and

brakes.Donotoperatethemachineunlessallsafety

devicesareinpositionandfunctioningasintendedby

themanufacturer.

•Alwaysinspectthemachinetoensurethattheblades,

bladebolts,andcuttingassemblyarenotwornor

damaged.Replacewornordamagedbladesandboltsin

setstopreservebalance.

•Inspecttheareawhereyouwillusethemachineand

removeallobjectsthatthemachinecouldpotentially

throw .

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessoriesrequiredto

operatethemachineproperlyandsafely.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana180-daysupplyoffuel.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepyourhandsandfaceawayfromthenozzle

andthefuel-tankopening.

•Keepfuelawayfromyoureyesandskin.

•Useonlyanapprovedfuelcontainer.

•Neverremovethefuelcaporaddfueltothefueltank

whiletheengineisrunning.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundandawayfromyourvehiclebeforelling.

•Removetheequipmentfromthetruckortrailerandadd

fueltoitwhileitisontheground.Ifthisisnotpossible,

thenaddfuelusingaportablecontainerratherthanfrom

afuel-dispensernozzle.

•Keepthefuel-dispensernozzleincontactwiththerimof

thefueltankorcontaineropeningatalltimesuntilfueling

iscomplete.Donotuseanozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyourclothing

immediately.

•Fillthefueltankuntilthefuellevelis25mm(1inch)

belowthebottomofthellerneck.Donotoverllthe

fueltank.Replacethefuel-tankcapandtightenitsecurely .

21

Page 22

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page36).

CheckingtheCoolingSystem

Beforeyoustarttheengineandusethemachine,checkthe

coolingsystem;refertoCheckingtheCoolingSystem(page

45).

CheckingtheHydraulic System

Beforeyoustarttheengineandusethemachine,checkthe

hydraulicsystem;refertoCheckingtheHydraulicLinesand

Hoses(page50).

FillingtheFuelTank

RecommendedFuel

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather.

•Monitorseals,hoses,andgasketsincontactwithfuelas

theymaybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

•Contactyourdistributorifyouwishformoreinformation

onbiodiesel.

Useonlyclean,freshdieselfuelwithultralow(<15

ppm)sulfurcontentmeetingASTMD975orEN590

specications.Theminimumcetaneratingshouldbe40.

Purchasefuelinquantitiesthatcanbeusedwithin180days

toensurefuelfreshness.

Fueltankcapacity:83L(22USgallons).

Usesummer-gradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwinter-gradedieselfuel(No.1-Dor

No.1-D/2-Dblend)below-7°C(20°F).Usingwintergrade

fuelatlowertemperaturesprovideslowerashpointand

coldowcharacteristics,whicheasesstartingandreduces

fuellterplugging.

Usingsummergradefuelabove-7°C(20°F)contributes

towardlongerfuelpumplifeandincreasedpowercompared

towintergradefuel.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionmustbeultralowsulfur.Observethefollowing

precautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

Figure14

Fillthetankwithdieselfueluntilthelevelreachesthebottom

ofthellerneck.

Note:Ifpossible,llthefueltankaftereachuse;thiswill

minimizepossiblebuildupofcondensationinsidethefuel

tank.

22

Page 23

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Thecorrectairpressureinthetiresis138kPa(20psi).

Important:Maintaintherecommendedpressureinall

tirestoensureagoodqualityofcutandpropermachine

performance.Donotunder-inatethetires.

Checktheairpressureinallthetiresbeforeoperating

themachine.

Figure15

1.Lowerthecuttingdecktotheground,shutoffthe

engine,andremovethekeyfromtheignitionswitch.

2.Loosentheboltsecuringeachheight-of-cutbracket

totheheight-of-cutplate(frontandeachside);refer

toFigure16.

3.Beginningwithfrontadjustment,removethebolt.

Figure16

1.Height-of-cutbracket3.Spacer

2.Height-of-cutplate

CheckingtheTorqueofthe WheelNuts

ServiceInterval:Aftertherst8hours

Every200hours

WARNING

Failuretomaintainpropertorqueofthewheelnuts

couldresultinfailureorlossofwheelandmay

resultinpersonalinjury.

Torquethefrontandrearwheelnutsto115to136

N-m(85to100ft-lb)after1to4hoursofoperation

andagainafter8hoursofoperation.Torqueevery

200hoursthereafter.

Note:Frontwheelnutsare1/2-20UNF.Rearwheelnuts

areM12x1.6-6H(Metric).

AdjustingtheHeightofCut

Important:Thiscuttingdeckoftencutsapproximately

6mm(1/4inch)lowerthanareelcuttingunitwiththe

samebenchsetting.Itmaybenecessarytohavethese

rotarycuttingdeck’sbenchset6mm(1/4inch)above

thatofreelscuttinginthesamearea.

4.Whilesupportingthechamber,removethespacer

(Figure16).

5.Movethechambertothedesiredheightofcutand

installaspacerintothedesignatedheight-of-cuthole

andslot(Figure17).

Figure17

6.Positionthetappedplatein-linewiththespacer.

7.Installtheboltnger-tight.

8.Repeatsteps4through7foreachsideadjustment.

9.Torqueall3boltsto41N∙m(30ft-lb).Alwaystighten

thefrontboltrst.

Note:Adjustmentsofmorethan3.8cm(1-1/2

inches)mayrequiretemporaryassemblytoan

intermediateheighttopreventbinding(e.g.,changing

from3.1to7cm(1.25to2.75inches)heightofcut).

Important:Accesstotherearcuttingunitsisgreatly

improvedbyremovingthecuttingunitfromthetractor.

23

Page 24

CheckingtheInterlock Switches

Note:Makesurethatthedecksareloweredontoaclean

sectionofturforhardsurfacetoavoidthrowndustand

debris.

ServiceInterval:Beforeeachuseordaily

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Theinterlockswitchesaredesignedtostopthemachine

whentheoperatorgetsofftheseatwhenthetractionpedal

isdepressed.However,theoperatormaygetofftheseat

whiletheengineisrunningandthetractionpedalisin

theNEUTRALposition.Althoughtheenginecontinuesto

runifthePTOswitchisdisengagedandthetractionpedal

isreleased,itisstronglyrecommendedthattheenginebe

stoppedbeforerisingfromtheseat.

1.Parkthemachineonalevelsurface,lowerthecutting

unit,turnthekeyintheignitionswitchtotheOFF

position,andengagetheparkingbrake.

2.Pressthetractionpedal.Turnthekeyintheignition

switchtotheONposition.

Note:Iftheenginecranks,thereisamalfunctionin

theinterlocksystem.Correctthismalfunctionbefore

operatingthemachine.

Toverifythisstoppingtime,haveasecondpersonstandback

fromthedeckatleast6m(20ft)andwatchthebladeson1

ofthecuttingdecks.Havetheoperatorshutthecuttingdecks

downandrecordthetimeittakesforthebladestocometo

acompletestop.Ifthistimeisgreaterthan7seconds,the

brakingvalveneedsadjustment.CallyourToroDistributor

forassistanceinmakingthisadjustment.

SelectingaBlade

StandardCombinationSail

Thisbladewasdesignedtoprovideexcellentliftand

dispersioninalmostanycondition.Ifmoreorlessliftand

dischargevelocityisrequired,consideradifferentblade.

Attributes:Excellentliftanddispersioninmostconditions.

AngledSail

Thebladegenerallyperformsbestinlowerheightsof

cut—1.9to6.4cm(3/4to2-1/2inches).

Attributes:

•Dischargeremainsmoreevenatlowerheightsofcut.

•Dischargehaslesstendencytothrowleftandthusa

cleanerlookaroundbunkersandfairways.

•Lowerpowerrequirementatlowerheightsanddenseturf.

3.TurnthekeyintheignitionswitchtotheONposition,

risefromtheseat,andmovethePTOswitchtoON.

Note:ThePTOshouldnotengage.IfthePTO

engages,thereisamalfunctionintheinterlocksystem.

Correctthismalfunctionbeforeoperatingthemachine.

4.Engagetheparkingbrake,turnthekeyintheignition

switchtotheONposition,andmovethetractionpedal

outofNEUTRAL.

Note:TheInfoCenterdisplays"tractiondenied"and

themachineshouldnotmove.Ifthemachinedoes

move,thereisamalfunctionintheinterlocksystem.

Correctthismalfunctionbeforeoperatingthemachine.

CheckingtheBlade-Stopping Time

ServiceInterval:Beforeeachuseordaily

Thebladesofthecuttingdeckshouldcometoacomplete

stopinapproximately5secondsafteryoushutdownthe

cuttingdeckengagementswitch.

High-Lift,ParallelSail

Thebladegenerallyperformsbetterinthehigherheightsof

cut—7to10cm(2to4inches).

Attributes:

•Moreliftandhigherdischargevelocity.

•Sparseorlimpturfispickedupsignicantlyathigher

heightsofcut.

•Wetorstickyclippingsaredischargedmoreefciently

reducingcongestioninthedeck.

•Requiresmorehorsepowertorun.

•Tendstodischargefurtherleftandcantendtowindrow

atlowerheightsofcut.

DANGER

Usingthehigh-liftbladewiththemulchingbafe

couldcausethebladetobreak,resultinginpersonal

injuryordeath.

Donotusethehigh-liftbladewiththebafe.

24

Page 25

AtomicBlade

Thisbladewasdesignedtoprovideexcellentleafmulching.

Attributes:Excellentleafmulching

ChoosingAccessories

OptionalEquipmentCongurations

AngleSailBladeHigh-Lift,Parallel-Sail

GrassCutting:1.9to4.4

cm(0.75to1.75inch)

heightofcut

GrassCutting:5to6.4

cm(2.00to2.50inch)

heightofcut

GrassCutting:7to10

cm(2.75to4.00inch)

heightofcut

LeafMulchingRecommendedforuse

ProsEvendischargeatlower

ConsDoesnotliftthegrass

Recommendedinmost

applications

Recommendedforthick

orlushturf

Mayworkwellinlushturf

withthemulchingbafe

heightofcutCleaner

lookaroundbunkersand

fairwaysLowerpower

requirements

wellinhighheightof

cutapplicationsWet

orstickygrasshasa

tendencytobuildupin

thechamber,leading

topoorqualityofcut

andhigherpower

requirements

Blade(Donotusewith

themulchingbafe)

Mayworkwellinlightor

sparseturf

Recommendedforlight

orsparseturf

Recommendedinmost

applications

NotAllowedUsewithcombination

Moreliftandhigher

dischargevelocity

Sparseorlimpturfis

pickedupathighheight

ofcutWetorsticky

clippingsaredischarged

efciently

Requiresmorepowerto

runinsomeapplications

Tendstowindrowat

lowerheightofcutin

lushgrassDonotuse

withthemulchingbafe

MulchingBafeRollerScraper

Hasbeenshownto

improvedispersionand

aftercutperformance

onnortherngrassesthat

arecutatleast3times

perweekandlessthan

1/3ofthegrassblade

isremoved.Donot

usewiththehigh-lift,

parallel-sailblade

sailoranglesailblade

only

Mayimprovedispersion

andappearancein

certaingrasscutting

applicationsVerygood

forleafmulching

Grasswillbuildupinthe

chamberifattemptingto

removetoomuchgrass

withbafeinplace

Canbeusedanytime

thatrollersbuildupwith

grassorlargeatgrass

clumpsofgrassare

seen.Thescrapers

mayactuallyincrease

clumpingincertain

applications.

Reducesrollerbuildup

incertainapplications

25

Page 26

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/usercanpreventandisresponsiblefor

accidentsthatmaycauseinjuriestopeople,ordamage

toproperty.

•Wearappropriateclothing,includingeyeprotection;

substantial,slip-resistantfootwear;andhearing

protection.Tiebacklonghair.Donotwearjewelry.

•EnsurethatalldrivesareintheNEUTRALposition,the

parkingbrakeisengaged,andyouareintheoperating

positionbeforeyoustarttheengine.

•Keepallbodyparts,includinghandsandfeet,awayfrom

allmovingparts.

•Donotoperatethemachinewhileill,tired,orunderthe

inuenceofalcoholordrugs.

•Keepthedirectionofthemowerdischargeawayfrom

peopleandpets.

•Donotmowinreverseunlessitisabsolutelynecessary.If

youmustmowinreverse,lookbehindanddownforsmall

childrenbeforeandwhilemovingthemachineinreverse.

Stayalertandstopthemachineifachildentersthearea.

•Useextremecarewhenapproachingblindcorners,

shrubs,trees,orotherobjectsthatmayblockyourview.

•Donotmowneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyrolloverifawheelgoesover

theedgeoriftheedgecavesin.

•Nevercarrypassengersonthemachine.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperatethe

machinewhenthereistheriskoflighting.

•Donotmowonwetgrass.Reducedtractioncouldcause

themachinetoslide.

•Neverraisethemowerdeckwiththebladesrunning.

•Stopthemachineandinspectthebladesafterstrikingan

objectorifthereisanabnormalvibrationinthemachine.

Makeallnecessaryrepairsbeforeresumingoperation.

•Stopthebladeswheneveryouarenotmowing,especially

whilecrossinglooseterrainsuchasgravel.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalkswiththemachine.Always

yieldtheright-of-way.

•Turnontheashingwarninglightsonthemachine

wheneveryoutravelonapublicroad,exceptwheresuch

useisprohibitedbylaw.

•Disengagethedrivetotheattachmentandshutoffthe

enginebeforeaddingfuelandadjustingtheheightofcut.

•Reducethethrottlesettingbeforestoppingtheengine

and,iftheenginehasafuel-shutoffvalve,shutoffthe

fuelwhenyouhavenishedoperatingthemachine.

•Neverrunanengineinanareawhereexhaustgasesare

enclosed.

•Neverleavearunningengineunattended.

•Beforeleavingtheoperatingposition,dothefollowing:

–Stopthemachineonlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Settheparkingbrake.

–Shutofftheengineandremovethekey .

–Waitforallmovingpartstostop.

•Donotchangethegovernorsettingsonoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethepotentialforpersonalinjury.

•Donotusethemachineasatowingvehicle.

•UseaccessoriesandattachmentsapprovedbyTheToro®

Companyonly.

RolloverProtectionSystem(ROPS)

Safety

•DonotremovetheROPSfromthemachine.

•Ensurethattheseatbeltisattachedandthatyoucan

releaseitquicklyintheeventofanemergency.

•Alwayswearyourseatbelt.

•Checkcarefullyforoverheadclearances,suchasbranches,

doorways,andelectricalwires,beforedrivingthemachine

underthem.Donotcontactthem.

•KeeptheROPSinsafeoperatingconditionbythoroughly

inspectingitperiodicallyfordamageandkeepingallthe

mountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorreviseit.

•AnyalterationstoaROPSmustbeapprovedbyThe

Toro®Company.

SlopeSafety

•Slowdownthemachineanduseextracareonhillsides.

Travelintherecommendeddirectiononhillsides.Turf

conditionscanaffectthestabilityofthemachine.

•Avoidstarting,stopping,orturningthemachineona

slope.Ifthetireslosetraction,disengagetheblade(s)and

proceedslowlystraightdowntheslope.

•Donotturnthemachinesharply .Usecarewhenreversing

themachine.

•Whenoperatingthemachineonaslope,alwayskeepall

cuttingunitslowered.

•Avoidturningthemachineonslopes.Ifyoumustturn,

turnslowlyandgraduallydownhill,ifpossible.

•Useextracarewhileoperatingthemachinewith

attachments;theycanaffectthestabilityofthemachine.

Followtherecommendationsforusingthemachineona

slopeinthisOperator’ sManual.

26

Page 27

StartingandStoppingthe

UnderstandingtheOperating

Engine

Important:Bleedthefuelsystembeforestartingthe

engineiftheenginehasstoppedduetolackoffuel,or

youhaveperformedmaintenanceonthefuelsystem.

StartingtheEngine

1.Sitontheseat,keepyourfootoffthetractionpedalso

thatitisinNEUTRAL,andengagetheparkingbrake.

2.TurnthekeyintheignitionswitchtotheRUNposition.

Theglowindicatorwilllight.

3.Whentheglowindicatordims,turnthekeyinthe

ignitionswitchtotheSTARTposition.Releasethekey

immediatelywhentheenginestartsandallowitto

returntotheRUNposition.Adjusttheenginespeed.

Important:Donotrunthestartermotormore

than30secondsatatimeorprematurestarter

failuremayresult.Iftheenginefailstostartafter

30seconds,turnthekeyintheignitionswitch

totheOFFposition,recheckthecontrolsand

procedures,wait30additionalseconds,andrepeat

thestartingprocedure.

Whenthetemperatureislessthan-7°C(20°F),the

startermotorcanberunfor30secondsonthen60

secondsofffor2attempts.

CAUTION

Checkingthemachineforoilleaks,loose

parts,andothermalfunctionswhiletheengine

isrunningmaybringyouinclosecontactwith

hotormovingpartsofthemachine,causing

injury.

Shuttheengineoffandwaitforallmoving

partstostopbeforecheckingforoilleaks,

looseparts,andothermalfunctions.

CharacteristicsoftheMachine

Practicedrivingthemachinebecauseithasahydrostatic

transmissionanditscharacteristicsaredifferentthanmany

turfmaintenancemachines.Somepointstoconsider

whenoperatingthetractionunitandcuttingunitsarethe

transmission,enginespeed,loadonthecuttingbladesand

theimportanceofthebrakes.

WithToroSmartPower™,theoperatordoesnothave

tolistentotheenginespeedinheavyconditions.Smart

Powerpreventsboggingdowninheavyturfbyautomatically

controllingthemachinespeedandoptimizingcutting

performance.

Anothercharacteristictoconsideristheoperationofthe

pedalsthatareconnectedtothebrakes.Thebrakescanbe

usedtoassistinturningthemachine.However,usethem

carefully,especiallyonsoftorwetgrassbecausetheturf

maybetornaccidentally.Anotherbenetofthebrakesisto

maintaintraction.Forexample,insomeslopeconditions,the

uphillwheelslipsandlosestraction.Ifthissituationoccurs,

depresstheuphillturnpedalgraduallyandintermittentlyuntil

theuphillwheelstopsslipping,thus,increasingtractionon

thedownhillwheel.

Useextracarewhenoperatingthemachineonslopes.Make

surethattheseatlatchisproperlysecuredandtheseatbelt

isbuckled.Driveslowlyandavoidsharpturnsonslopesto

preventrollovers.Forsteeringcontrol,thecuttingunitmust

beloweredwhengoingdownhill.

Important:Allowenginetoidlefor5minutesbefore

shuttingitoffafterafullloadoperation.Thisallowsthe

turbochargertocooldownbeforeshuttingtheengine

off.Failuretodosomayleadtoturbo-chargertrouble.

Beforestoppingtheengine,disengageallcontrolsandset

theenginespeedtoSlow .SettingtheenginespeedtoSlow

reduceshighenginerpm,noise,andvibration.Turnthekeyin

theignitionswitchtotheOFFpositiontoshutofftheengine.

StoppingtheEngine

Important:Allowtheenginetoidlefor5minutesbefore

shuttingitoffafterafullloadoperation.Thisallowsthe

turbochargertocooldownbeforeshuttingtheengine

off.

Note:Lowerthecuttingunitstothegroundwhenever

machineisparked.Thisrelievesthehydraulicloadfromthe

system,preventswearonsystempartsandalsoprevents

accidentalloweringofthecuttingunits.

1.MovethePTOswitchtotheOFFposition.

2.Settheparkingbrake.

3.Returntheenginelowidle.

4.TurnthekeyintheignitionswitchtotheOFFposition

andremovethekey.

OperatingtheEngine-Cooling Fan

Theengine-cooling-fanswitchhas2positionsforcontrolling

theoperationofthefan.The2positionsareRandAUTO.

Thefanhastheabilitytoreversetoblowdebrisoffthe

rearscreen.Undernormaloperatingconditions,theswitch

shouldbeintheAUTOposition.InAuto,thefanspeedwill

becontrolledbythecoolantorhydraulic-oiltemperature

andwillautomaticallyreversetoblowdebrisofftherear

screen.Areversecycleisautomaticallyinitiatedwheneither

thecoolantorhydraulic-oiltemperaturereachesacertain

point.BypressingthefanswitchforwardintotheRposition,

thefanwillcompleteamanuallyinitiatedreversecycle.It

isrecommendedtoreversethefanwhentherearscreenis

cloggedorpriortoenteringtheshoporthestoragearea.

27

Page 28

OperatingTips

MowingWhenGrassIsDry

ResolvingAftercutAppearance

ReferenceAftercutAppearanceTroubleshootingGuide

availableatwww .Toro.com.

Moweitherinthelatemorningtoavoidthedew,which

causesgrassclumping,orinlateafternoontoavoidthe

damagecausedbydirectsunlightonthesensitive,freshly

mowedgrass.

SelectingtheProperHeightofCut

Removeapproximately25mm(1inch)ornomorethan1/3

ofthegrassbladewhencutting.Inexceptionallylushand

densegrass,youmayhavetoraisetheheightofcuttothe

nextsetting.

MowingatProperIntervals

Undermostnormalconditions,youwillneedtomow

approximatelyevery4to5days.Butremember,grassgrows

atdifferentratesatdifferenttimes.Thismeansthatinorder

tomaintainthesameheightofcut,whichisagoodpractice,

youwillneedtocutmorefrequentlyinearlyspring;asthe

grassgrowthrateslowsinmidsummer,cutonlyevery8to10

days.Ifyouareunabletomowforanextendedperioddue

toweatherconditionsorotherreasons,mowrstwiththe

heightofcutatahighlevel;thenmowagain2to3dayslater

withalower-heightsetting.

Transporting(Groundsmaster4700–D

Only)

Usethe2reartransportlatchesfortheoutercuttingunits

whentransportingoverlongdistances,roughterrain,orwhen

trailering.

CleaningandParkingtheMachineAfter

EachUse

Toensureoptimumperformance,cleantheundersideof

themowerhousingsaftereachuse.Ifresidueisallowedto

buildupinthemowerhousing,cuttingperformancewill

decline.

Note:Lowerthecuttingunitstothegroundwheneverthe

machineisparked.Thisrelievesthehydraulicloadfromthe

system,preventswearonsystemparts,andalsoprevents

accidentalloweringofthecuttingunits.

MowingwithSharpBlades

Asharpbladecutscleanlyandwithouttearingorshredding

thegrassbladeslikeadullblade.Tearingandshredding

causesthegrasstoturnbrownattheedgeswhichimpairs

growthandincreasessusceptibilitytodiseases.

ChangingMowingPatterns

Changemowingpatternsoftentominimizeafter-cut

appearanceissuesinducedbyrepetitiveoperationinonly1

direction.

AdjustingtheCounterbalance

Thecounterbalancesystemmaintainshydraulicbackpressure

onthedeckliftcylinders.Thiscounterbalancepressure

transferscuttingdeckweighttothemower'sdrivewheels

toimprovetraction.Thecounterbalancepressurehasbeen

factorysettoanoptimalbalanceofafter-cutappearanceand

tractioncapabilityinmostturfconditions.Decreasingthe

counterbalancesettingcanproduceamorestablecutting

deck,butcandecreasethetractioncapability.Increasingthe

counterbalancesettingcanincreasethetractioncapability,

butmayresultinafter-cutappearanceissues.Referencethe

ServiceManualforyourtractionunitforinstructionstoadjust

counterbalancepressure.

28

Page 29

AfterOperation

AfterOperationSafety

GeneralSafety

•Cleangrassanddebrisfromthecuttingunits,drives,

mufers,andenginetohelppreventres.Cleanupoil

orfuelspills.

•Shutoffthefuelwhilestoringortransportingthe

machine.

•Disengagethedrivetotheattachmentwheneveryouare

transportingornotusingthemachine.

•Allowtheenginetocoolbeforestoringthemachinein

anyenclosure.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlight,suchasonawater

heateroronotherappliances.

TowingSafety

•Towonlywithamachinethathasahitchdesignedfor

towing.Donotattachtowedequipmentexceptatthe

hitchpoint.

•Followthemanufacturer’ srecommendationforweight

limitsfortowedequipmentandtowingonslopes.On

slopes,theweightofthetowedequipmentmaycauseloss

oftractionandlossofcontrol.

•Neverallowchildrenorothersinorontowedequipment.

•Travelslowlyandallowextradistancetostopwhen

towing.

Important:Donotpushortowthemachinefasterthan

3to4.8km/h(2to3mph)becauseinternaltransmission

damagemayoccur.Thebypassvalvemustbeopen

wheneveryoupushortowthemachine.

Important:Ifyoumustpushortowthemachinein

reverse,thecheckvalveinthefour-wheeldrivemanifold

mustalsobebypassed.T obypassthecheckvalve,

connectahoseassembly(PartNo.95-8843),2coupler

ttings(PartNo.95-0985),and2hydraulicttings

(PartNo.340-77)tothereverse-traction,pressuretest

port,locatedonthehydrostat,andontheportlocated

in-betweenportsM8andP2onthereartractionmanifold

whichislocatedtotheinsideofthefrontreartire.

1.Openthehoodandlocatethebypassvalves(Figure18)

onthetopofpump,behindthebattery/storageboxes.

2.Rotateeachvalve3turnscounter-clockwisetoopen

andallowoiltobypassinternally.Donotopen

morethan3turns.Becauseuidisbypassed,the

machinecanbeslowlymovedwithoutdamagingthe

transmission.

JackingPoints

Note:Alwaysusejackstands.Donotrelyonajackorhoist

toholdthemachine.

•Front—frame,ontheinsideofeachdrivetire.

•Rear—centeroftheaxle.

TieDowns

•UseproperlyratedDOTapprovedstrapsinfourcorners

totiedownmachine.

•Oneachsideoftheframebytheoperator’sseat.

•Ontherearbumper.

PushingorTowingthe Machine

Inanemergency,themachinecanbemovedforwardby

actuatingthebypassvalveinthevariabledisplacement

hydraulicpumpandpushingortowingthemachine.

Figure18

1.Bypassvalve(2)

3.Closethebypassvalvesbeforestartingtheengine.

Torqueto70N-m(52ft-lb)toclosethevalve.

HaulingtheMachine

•Usecarewhenloadingorunloadingthemachineintoa

traileroratruck.

•Usefull-widthrampsforloadingthemachineintoa

traileroratruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

29

Page 30

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Note:Downloadafreecopyoftheelectricalorhydraulicschematicbyvisitingwww .Toro.comandsearchingforyour

machinefromtheManualslinkonthehomepage.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst200hours

Beforeeachuseordaily

Every50hours

Every100hours

Every200hours

Every250hours

MaintenanceProcedure

•Torquethewheelnuts.

•Changetheplanetarygeardriveoil.

•Changetherearaxlelubricant.

•Changethehydrauliclters.

•Checkthetirepressure.

•Checktheinterlockswitches.

•Checkthebladestoppingtime.

•Checktheengine-oillevel.

•Drainwaterorothercontaminantsfromthewaterseparator.

•Drainwaterorothercontaminantsfromthefuellter/waterseparator.

•Checkthecoolingsystem.

•Removedebrisfromtheenginearea,oilcooler,andradiator.

•Checkthehydraulic-uidlevel.

•Inspectthehydrauliclinesandhosesforleaks,kinkedlines,loosemounting

supports,wear,loosettings,weatherdeterioration,andchemicaldeterioration.

•Greasethebearingsandbushings(oraftereverywashing).

•Checkthebatterycondition.

•Checktheconditionandtensionofthealternatorbelt.

•Torquethewheelnuts.

•Changetheengineoilandlter.

Every400hours

Every800hours

Every6,000hours

Beforestorage

•Servicetheaircleaner(earlieriftheaircleanerindicatorshowsred,andmore

frequentlyinextremelydirtyordustyconditions).

•Inspectthefuellinesandconnections.

•Replacethefuel-ltercanister.

•Replacetheenginefuellter.

•Checkforend-playintheplanetarydrives.

•Checktheplanetarygeardriveoillevel(Also,checkifexternalleakageisobserved).

•Checktherearaxlelubricantlevel.

•Checktherearaxlegearboxlubricant.

•Drainandcleanthefueltank.

•Changetheplanetarygeardriveoil(oryearly,whichevercomesrst).

•Changetherearaxlelubricant.

•Checktherearwheeltoe-in.

•Changethehydraulicuid.

•Changethehydrauliclters.

•Servicethedieseloxidationcatalyst(DOC)(orasrequired).

•Drainandcleanthefueltank.

•Checkthetirepressure.

•Checkallfasteners.

•Greaseoroilallgreasettingsandpivotpoints.

•Paintchippedsurfaces.

Yearly

•Inspectthefuellinesandconnections.

30

Page 31

Important:Refertoyour

Engine Operator's Man ual

maintenanceprocedures.

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

and

Cutting Unit Operator's Man ual

foradditional

Maintenance

CheckItem

Checkthe

safetyinterlock

operation.

Checkthebrake

operation.

Checktheengine

oilandfuellevel.

Checkthe

coolingsystem

uidlevel.

Drainthe

water/fuel

separator.

Checktheair

lterrestriction

indicator.

Checkthe

radiator,oil

cooler,and

screenfordebris.

Checkunusual

enginenoises.

Checkunusual

operatingnoises.

Checkthe

hydraulicsystem

oillevel.

Checkhydraulic

hosesfor

damage.

Checkforuid

leaks.

Checkthetire

pressure.

Checkthe

instrument

operation.

Lubricateall

greasettings.

Checkthe

height-of-cut

adjustment.

Touch-up

damagedpaint.

1

2

Fortheweekof:

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

1.Checktheglowplugandinjectornozzlesifhardstarting,excesssmoke,orroughrunningisnoted.

2.Immediatelyaftereverywashing,regardlessoftheintervallisted.

31

Page 32

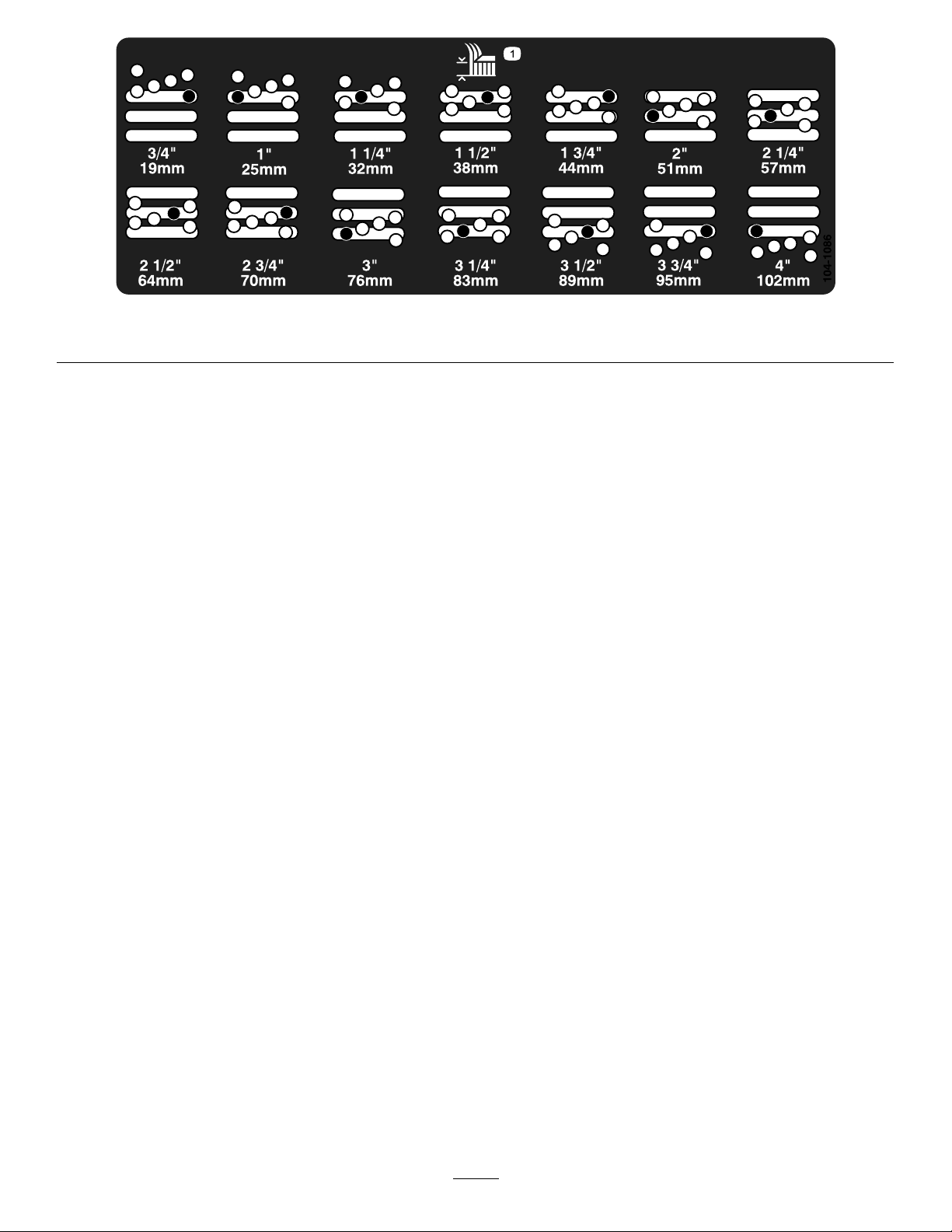

ServiceIntervalChart

Figure19

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionswitchbeforeyouperformanymaintenance.

32

Page 33

Premaintenance

Lubrication

Procedures

GreasingtheBearingsand

RemovingtheHood

1.Releasethehoodlatches(Figure20)andpivotopen

thehood.

Figure20

1.Hoodlatch(2)

Bushings

ServiceInterval:Every50hours(oraftereverywashing).

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2lithiumgrease.

Thegreasettinglocationsandquantitiesareasfollows:

•Brake-shaftpivotbearings(5)(Figure21)

Figure21

•Rearaxlepivotbushings(2)(Figure22)

2.Removethecotterpinssecuringtherearhoodbrackets

totheframepinsandliftoffthehood.

Figure22

33

Page 34

•Steeringcylinderballjoints(2)(Figure23)

•Cuttingunitspindle-shaftbearings(2percuttingunit)

(Figure25)

Note:Y oucanuseeithertting,whicheverismore

accessible.Pumpgreaseintothettinguntilasmall

amountappearsatbottomofthespindlehousing(under

thedeck).

Figure23

1.T opttingonkingpin

•Tie-rodballjoints(2)(Figure23)

•King-pinbushings(2)(Figure23).Thetopttingon

thekingpinshouldonlybelubricatedannually

(2pumps).

•Lift-armbushings(1perdeck)(Figure24)

Figure25

•Cuttingunitcarrier-armbushings(1percuttingunit)

(Figure25)

•Rearrollerbearings(2percuttingunit)(Figure26)

Figure26

Important:Makesurethatthegreasegroovein

eachrollermountalignswiththegreaseholeineach

endoftherollershaft.Tohelpalignthegrooveand

hole,thereisalsoanalignmentmarkon1endofthe

rollershaft.

Figure24

•Lift-cylinderbushings(2perdeck)(Figure24)

34

Page 35

EngineMaintenance

EngineSafety

Shutofftheenginebeforecheckingtheoiloraddingoilto

thecrankcase.

ServicingtheAirCleaner

ServiceInterval:Every400hours

Checktheair-cleanerbodyfordamagethatcouldcausean

airleak.Replaceitifitisdamaged.Checkthewholeintake

systemforleaks,damage,orloosehoseclamps.

Servicetheair-cleanerlteronlywhentheserviceindicator

(Figure27)requiresit.Changingtheairlterbeforeitis

necessaryonlyincreasesthechanceofdirtenteringtheengine

whenyouremovethelter.

Figure27

1.Air-cleanerindicator

Important:Besurethatthecoverisseatedcorrectly

andsealswiththeair-cleanerbody.

1.Replacetheaircleaner(Figure28).

Figure28

Note:Cleaningtheusedelementisnotrecommended

duetothepossibilityofdamagetotheltermedia.

Important:Neverattempttocleanthesafety

lter.Replacethesafetylterafterevery3primary

lterservices.

2.Resettheindicator(Figure27)ifitshowsred.

35

Page 36

ServicingtheEngineOil

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;however,the

oillevelmustbecheckedbeforeandaftertheengineisrst

started.

Thecrankcasecapacityisapproximately5.7L(6USqt)with

thelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CJ-4orhigher.

•Preferredoil:SAE15W -40(above-18°C[0°F])

•Alternateoil:SAE10W-30or5W-30(alltemperatures)

Important:UsingnonCJ-4orhigheroilwillcause

DPFplugginganddamagetheengine.

Note:ToroPremiumEngineoilisavailablefromyour

distributorineither15W-40or10W-30viscosity .Seethe

PartsCatalogforpartnumbers.

Thebesttimetochecktheengineoiliswhentheengine

iscoolbeforeithasbeenstartedfortheday.Ifithas

alreadybeenrun,allowtheoiltodrainbackdowntothe

sumpforatleast10minutesbeforechecking.Iftheoil

levelisatorbelowtheADDmarkonthedipstick,addoil

tobringtheoilleveltotheFULLmark.Donotoverll.

IftheoillevelisbetweentheFULLandADDmarks,no

oiladditionisrequired.

Figure29

1.Parkthemachineonalevelsurface.

2.Checktheengine-oillevel(Figure29).

Note:Whenusingdifferentoil,drainalloldoilfrom

thecrankcasebeforeaddingnewoil.

36

Page 37

ChangingtheEngineOilandFilter

ServicingtheDiesel

ServiceInterval:Every250hours

1.Starttheengineandletitrun5minutestoallowthe

oiltowarmup.

2.Withthemachineparkedonalevelsurface,shutoff

theengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Replacetheengineoilandlter(Figure30).

ParticulateFilter(DPF)

ServiceInterval:WheninstructedbytheInfocenter

TheDPFrequiresremovalandprofessionalcleaningafter

ithasaccumulatedover50g/Lofash.TheInfocenterwill

warmtheoperatorinphaseswhenthisDPFmaintenanceis

due.Therstwarningwilloccurwhentheashaccumulation

reaches48g/Landwillshowanadvisory(number179)on

theInfocenter.Thisadvisoryismeanttogiveyourservice

departmentnoticethatyourmachinewillsoonneedDPF

cleaningmaintenance.Ifyouwouldliketoknowthecurrent

levelofashinanyofyourToroTier4products,youcan

nditbygoingtotheServicemenuoftheInfocenterafter

enteringthePIN.Reference“UsingtheInfoCenterLCD

Display”formoreinformationonaccessingprotectedmenus.

Whentheashaccumulationreaches50g/L,youwillseea

enginefaultcomeupontheinfocenter(SPN3720,FMI16)

toalerttheoperatorthattheDPFneedscleaning.Alsoatthe

50g/Llevel,theenginewillde-rateitspowerto85%.Atthis

time,theDPFneedstoberemovedandreplacedwithaclean

DPF.AYanmardiagnostictoolwillneedtobeusedtoreset

theengineECUafteracleanDPFisinstalled.Talkwithyour

ToroDistributorandseeyourServiceManualformoredetails

ontheremovalandinstallationoftheDPF .

Figure30

4.Addoiltothecrankcase;refertoChangingtheEngine

OilandFilter(page37).

IftheDPFisnotcleanedatthe50g/Llevel,theenginewill

continuetorunatthede-rated85%powerleveluntiltheash

accumulationreaches60g/L.Whentheashlevelreaches60

g/L,theenginewillsendoutafault(SPN3720,FMI0)and

theenginewillde-rateto50%power.Atthistime,theDPF

isfullypluggedandneedstoberemovedandreplacedwitha

cleanDPF.AYanmardiagnostictoolwillneedtobeusedto

resettheengineECUafteracleanDPFisinstalled.

ForinformationonservicingtheDieselParticulateFilter

(DPF),refertotheServiceManualorcontactyourT oro

Distributor.

ServicingtheDieselOxidation Catalyst(DOC)

ServiceInterval:Every6,000hours(orasrequired).

ForinformationonservicingtheDieselParticulateFilter

(DPF),refertotheServiceManualorcontactyourT oro

Distributor.

37

Page 38

FuelSystem

ServicingtheWaterSeparator

Maintenance

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunneltollthefueltankoutdoors,inan

openarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis6to13mm

(1/4to1/2inch)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsthe

fueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

ServiceInterval:Beforeeachuseordaily—Drainwater

orothercontaminantsfromthefuel

lter/waterseparator.

Every400hours—Replacethefuel-ltercanister.

DrainingtheFuelTank

ServiceInterval:Every800hours—Drainandcleanthefuel

tank.

Beforestorage—Drainandcleanthefueltank.

Drainandcleanthetankiffuelsystembecomescontaminated

orifthemachinewillbestoredforanextendedperiodof

time.Usecleanfueltoushoutthetank.

InspectingtheFuelLinesand Connections

ServiceInterval:Every400hours

Yearly

Inspectthefuellinesandconnectionsfordeterioration,

damage,orlooseconnections.

Figure31

38

Page 39

ServicingtheFuelFilter

ElectricalSystem

ServiceInterval:Every400hours

1.Cleantheareaaroundthefuellterhead(Figure32).

Figure32

1.Fuel-lterhead

2.FuelFilter

Maintenance

ChargingandConnectingthe Battery

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

1.Unlatchandraisetheoperator'sconsolepanel(Figure

33).