FormNo.3401-829RevC

Groundsmaster

®

4500-Dand

4700-DTractionUnit

ModelNo.30881—SerialNo.315000001andUp

ModelNo.30881A—SerialNo.315000001andUp

ModelNo.30882—SerialNo.315000001andUp

ModelNo.30882A—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3401-829*C

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

GenuineT orosparkarrestersareapprovedbythe

USDAForestryService.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

ThissparkignitionsystemcomplieswithCanadian

ICES-002

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontherightfrontframememberoftheproduct.Write

thenumbersinthespaceprovided.

g009699

Figure1

1.Modelandserialnumberlocation

TheenclosedEngineOwner'sManualis

suppliedforinformationregardingtheUS

EnvironmentalProtectionAgency(EPA)and

theCaliforniaEmissionControlRegulationof

emissionsystems,maintenance,andwarranty.

Replacementsmaybeorderedthroughtheengine

manufacturer.

Introduction

Thismachineisaride-on,rotary-bladelawnmower

intendedtobeusedbyprofessional,hiredoperators

incommercialapplications.Itisprimarilydesignedfor

cuttinggrassonwell-maintainedlawnsinparks,golf

courses,sportselds,andoncommercialgrounds.It

isnotdesignedforcuttingbrush,mowinggrassand

othergrowthalongsidehighways,orforagricultural

uses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SoundPowerLevel............................................4

SoundPressureLevel........................................4

VibrationLevel...................................................4

EngineEmissionCertication.............................4

SafetyandInstructionalDecals..........................5

Setup......................................................................10

1InstallingtheHoodLatch(CEOnly).................11

2AdjustingtheRollerScraper

(Optional)......................................................12

3InstallingtheMulchingBafe

(Optional)......................................................12

4PreparingtheMachine...................................13

ProductOverview...................................................13

Controls...........................................................13

Specications..................................................20

Attachments/Accessories.................................20

BeforeOperation.................................................21

BeforeOperationSafety...................................21

CheckingtheEngine-OilLevel..........................22

CheckingtheCoolingSystem...........................22

CheckingtheHydraulicSystem........................22

FillingtheFuelTank..........................................22

CheckingtheTirePressure...............................23

CheckingtheTorqueoftheWheel

Nuts..............................................................23

AdjustingtheHeightofCut...............................24

CheckingtheInterlockSwitches.......................24

CheckingtheBlade-StoppingTime...................25

SelectingaBlade..............................................25

ChoosingAccessories......................................26

DuringOperation.................................................27

DuringOperationSafety...................................27

StartingandStoppingtheEngine......................28

CuttingGrasswiththeMachine........................28

DieselParticulateFilterRegeneration...............29

UnderstandingtheOperatingCharacteristics

oftheMachine..............................................37

OperatingtheEngine-CoolingFan....................37

OperatingTips.................................................37

AfterOperation....................................................39

AfterOperationSafety......................................39

JackingPoints..................................................39

TieDowns.........................................................39

PushingorT owingtheMachine........................39

HaulingtheMachine.........................................40

Maintenance...........................................................41

RecommendedMaintenanceSchedule(s)...........41

DailyMaintenanceChecklist.............................42

ServiceIntervalChart.......................................43

Pre-MaintenanceProcedures..............................44

RemovingtheHood..........................................44

Lubrication..........................................................44

GreasingtheBearingsandBushings................44

EngineMaintenance...........................................46

EngineSafety...................................................46

ServicingtheAirCleaner..................................46

ServicingtheEngineOil....................................47

ServicingtheDiesel-OxidationCatalyst

(DOC)andtheSootFilter..............................48

FuelSystemMaintenance...................................49

DrainingtheFuelT ank......................................49

InspectingtheFuelLinesand

Connections..................................................49

ServicingtheWaterSeparator..........................49

ServicingtheFuelFilter....................................50

ServicingtheFuel-PickupTube........................50

ElectricalSystemMaintenance...........................50

ChargingandConnectingtheBattery...............50

ServicingtheBattery.........................................52

Fuses................................................................52

DriveSystemMaintenance..................................53

CheckingforEnd-PlayinthePlanetary

Drives............................................................53

CheckingthePlanetaryGearDrive

Oil.................................................................53

ChangingthePlanetaryGearDrive

Oil.................................................................53

CheckingtheRearAxleLubricant.....................54

ChangingtheRearAxleLubricant....................54

CheckingtheRearAxleGearBox

Lubricant.......................................................55

CheckingtheRearWheelT oe-In......................55

CoolingSystemMaintenance..............................56

CoolingSystemSafety.....................................56

CheckingtheCoolingSystem...........................56

CleaningtheCoolingSystem............................56

BrakeMaintenance.............................................58

AdjustingtheServiceBrakes............................58

BeltMaintenance................................................58

ServicingtheAlternatorBelt.............................58

HydraulicSystemMaintenance...........................59

HydraulicSystemSafety...................................59

CheckingtheHydraulic-FluidLevel...................59

ChangingtheHydraulicFluid............................60

ReplacingtheHydraulicFilters.........................61

CheckingtheHydraulicLinesand

Hoses............................................................61

CuttingDeckMaintenance...................................62

SeparatingtheCuttingDecksfromthe

TractionUnit..................................................62

MountingtheCuttingDeckstotheTraction

Unit...............................................................62

ServicingtheBladePlane.................................62

ServicingtheCutterBlade................................63

ServicingtheFrontRoller.................................65

Storage...................................................................66

PreparingtheTractionUnit...............................66

PreparingtheEngine........................................66

CuttingDeck.....................................................66

3

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395:2013andANSIB71.4-2012.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

Ensurethateveryoneusingthisproductknows

howtouseitandunderstandsthewarnings.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof105

dBA,whichincludesanUncertaintyValue(K)of0.7

dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’s

earof90dBA,whichincludesanUncertaintyV alue

(K)of0.7dBA.

Soundpressurelevelwasdeterminedaccordingto

theproceduresoutlinedinENISO5395:2013.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersasafedistancefromthemachine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachineandshutofftheenginebefore

servicing,fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalitemsofsafetyinformationin

theirrespectivesectionsthroughoutthismanual.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=0.6m/s

Measuredvibrationlevelforlefthand=0.7m/s

UncertaintyValue(K)=0.3m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

WholeBody

Measuredvibrationlevel=0.2m/s

UncertaintyValue(K)=0.1m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

2

2

2

EngineEmission

Certication

TheengineinthismachineisEPATier4Finaland

stage3bcompliant.

2

2

4

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedorlost.

93-6681

1.Cutting/dismemberment—hazard,fan-stayawayfrom

movingparts.

93-7272

1.Cutting/dismembermenthazard;fan—stayawayfrom

movingparts.

decal93-6681

decal106-6754

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

decal93-7272

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto1 15to149N-m(85to110

ft-lb).

98-4387

1.Warning—wearhearingprotection.

decal93-7818

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

106-6755

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

decal106-6755

decal112-5019

112-5019

decal98-4387

5

112-5297

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Warning—readtheOperator'sManualbeforetowingthe

machine.

3.Tippinghazard—slowmachinebeforeturning,donotturn

athighspeeds;lowerthecuttingunitwhendrivingdown

slopes;usearolloverprotectionsystemandweartheseat

belt

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingunits,shutofftheengine,

andremovetheignitionkeybeforeleavingthemachine.

5.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

6.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

decal117-2718

117-2718

decal112-5297

decal117-4763

117-4763

1.Toengagetheparking

brake,securethebrake

pedalswiththelockingpin,

presstheparkingbrake

pedalsandengagethetoe

pedal.

2.Todisengagetheparking

brake,disengagethe

lockingpinandreleasethe

pedals.

decal112-5298

112-5298

(PlaceoverPartNo.1 12-5297forCE*)

*Thissafetydecalincludesaslopewarningrequiredonthemachinefor

compliancetotheEuropeanLawnMowerSafetyStandardEN836:1997.The

conservativemaximumslopeanglesindicatedforoperationofthismachineare

prescribedbyandrequiredbythisstandard.

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Warning—readtheOperator'sManualbeforetowingthe

machine.

3.Tippinghazard—donotoperateonslopesgreaterthan15°;

lowerthecuttingunitswhenoperatingonslopes;wearthe

safetybelt.

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingunits,shutofftheengine,

andremovetheignitionkeybeforeleavingthemachine.

5.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

6.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

decal117-4764

117-4764

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cuttinghazardofhand,mowerblade—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

3.Cuttinghazardoffoot,mowerblade—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

6

117-4765

1.ReadtheOperator'sManual.

2.Donotusestartingaids.

117-4766

1.Cutting/dismembermenthazard;fan—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

decal117-4765

decal121-3884

decal117-4766

121-3884

1.Engine—stop3.Engine—start

2.Engine—preheat

120-4159

Groundsmaster4700Shown

1.Off

2.Lights9.Tractiondrive

3.On

4.Lightswitchlocation

5.Fast

6.Variablespeedadjustment13.Lowercenterdeck

7.Slow

8.High

10.Low

11.Powertakeoff(PTO)

12.Lowerleftdeck

14.Lowerrightdeck

decal121-3887

121-3887

1.ReadtheOperator’sManual.

decal120-4159

decal125-4604

125-4604

Groundsmaster4700Shown

1.Raiseleftdeck

2.Raisecenterdeck

3.Raiserightdeck

7

decal125-4605

125-4605

1.Powerseat—10A6.Powersupplied—10A

2.Worklight—10A

7.TEC-5001—2A

3.Engine—10A8.Powersupplied—7.5A

4.Cigarettelighter—10A9.TEC-5002—2A

5.Infocenter—2A10.Cab—60A

decalbatterysymbols

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

1.Explosionhazard

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard

decal125-4606

125-4606

1.ReadtheOperator’sManualforinformationon

maintenance.

8

1.Heightofcut

decal104-1086

104-1086

9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Lockbracket1

Rivet2

1

2

3

4

Washer1

Screw(1/4x2inches)

Locknut(1/4inch)

Nopartsrequired

Nopartsrequired

Nopartsrequired

MediaandAdditionalParts

Description

WarningDecal6

Operator'sManual

EngineOperator'sManual

Qty.

Qty.

Installthehoodlatch(CE).

1

1

–

–

–

AfxtheCEwarningdecalsoverthecorresponding

Englishwarningdecals.

1

1

Readbeforeoperatingmachine

Readbeforeoperatingengine

Adjusttherollerscraper(optional).

Installthemulchingbafe(optional).

Preparethemachine.

Use

Use

PartsCatalog

OperatorTrainingMaterial

1

1

Usetoreferencepartnumbers

Viewbeforeoperatingmachine

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

10

1

G012628

1

2

G012629

1

2

G012630

1

InstallingtheHoodLatch (CEOnly)

Partsneededforthisprocedure:

1Lockbracket

2Rivet

1Washer

1

Screw(1/4x2inches)

1

Locknut(1/4inch)

Procedure

1.Unhookthehoodlatchfromthehood-latch

bracket.

2.Removethe2rivetssecuringthehood-latch

brackettothehood(Figure3).Removethe

hood-latchbracketfromthehood.

Figure4

1.CElockbracket

4.Alignthewasherswiththeholesontheinsideof

thehood.

5.Rivetthebracketsandthewasherstothehood

(Figure4).

6.Hookthelatchontothehood-latchbracket

(Figure5).

2.Boltandnutassembly

g012629

g012630

Figure5

1.Hoodlatch

Figure3

1.Hoodlatchbracket2.Rivets

3.Whilealigningthemountingholes,positionthe

CE-lockbracketandthehood-latchbracketonto

thehood.Thelockbracketmustbeagainstthe

hood(Figure4).Donotremovetheboltandnut

assemblyfromthelock-bracketarm.

g012628

7.Screwtheboltintotheotherarmofthehood-lock

brackettolockthelatchinposition(Figure6).

Tightentheboltbutdonottightenthenut.

11

G012631

1

2

3

1.Bolt

G011346

1

2

3

G011347

1

2.Nut

2

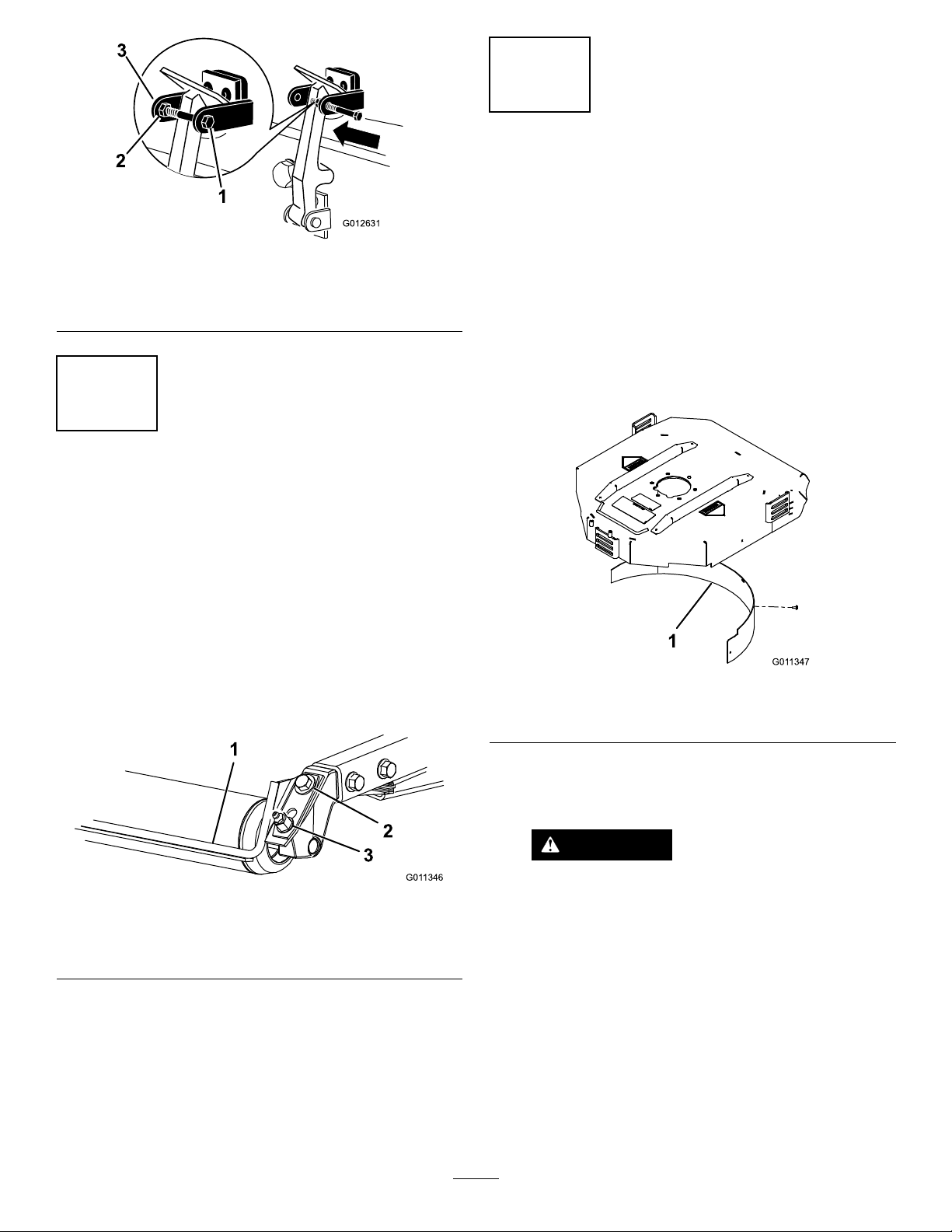

AdjustingtheRoller Scraper(Optional)

NoPartsRequired

Figure6

3.Armofhood-lockbracket

3

InstallingtheMulching

Bafe(Optional)

NoPartsRequired

g012631

Procedure

1.Thoroughlycleandebrisfromthemounting

holesontherearwallandleftsidewallofthe

chamber.

2.Installthemulchingbafeintherearopening

andsecureitwith5ange-headbolts(Figure8).

Procedure

Theoptionalrearrollerscraperisdesignedtowork

bestwhenthereisanevengapof0.5to1mm(0.020

to0.040inch)betweenthescraperandroller.

1.Loosenthegreasettingandthemounting

screw(Figure7).

1.Mulchingbafe

3.Verifythatmulchingbafedoesnotinterferewith

thetipofthebladeanddoesnotprotrudeinside

thesurfaceoftherearchamberwall.

Figure8

DANGER

g011346

Figure7

1.Rollerscraper

2.Mountingscrew

2.Slidethescraperupordownuntilagapof0.5to

1mm(0.020to0.040inch)isachievedbetween

therodandtheroller.

3.Securethegreasettingandscrewto41N-m

(30ft-lb)inanalternatingsequence.

3.Greasetting

Usingthehigh-liftbladewiththe

mulchingbafecouldcausetheblade

tobreak,resultinginpersonalinjuryor

death.

Donotusethehigh-liftbladewiththe

mulchingbafe.

g011347

12

ProductOverview

4

PreparingtheMachine

NoPartsRequired

CheckingtheTirePressure

Checkthetirepressurebeforeuse;refertoChecking

theTirePressure(page23).

Important:Maintainpressureinalltiresto

ensureagoodquality-of-cutandpropermachine

performance.Donotunderinatethetires.

CheckingtheFluidLevels

1.Checktherear-axlelubricantlevelbeforethe

engineisrststarted,refertoCheckingtheRear

AxleGearBoxLubricant(page55).

2.Checktheengine-oillevelbeforestartingthe

engine;refertoCheckingtheEngine-OilLevel

(page47).

Controls

BrakePedals

2footpedals(Figure9)operateindividualwheel

brakesforturningassistanceandtoaidinobtaining

bettersidehilltraction.

Pedal-LockingLatch

Thepedal-lockinglatch(Figure9)connectsthebrake

pedals.Usethelatchtoconnectthepedalstoengage

theparkingbrakeandwhileoperatingthemachine

intransportmode.

Parking-BrakePedal

Toengagetheparkingbrake,(Figure9)connectthe

pedalstogetherwiththepedal-lockinglatchandpush

downontherightbrakepedalwhileengagingthetoe

pedal.Toreleasetheparkingbrake,press1ofthe

brakepedalsuntiltheparkingbrakelatchretracts.

3.Checkthehydraulic-uidlevelbeforestarting

theengine;refertoCheckingtheHydraulic-Fluid

Level(page59).

4.Checkthecoolingsystembeforestartingthe

engine;refertoCheckingtheCoolingSystem

(page56).

GreasingtheMachine

Greasethemachinebeforeuse;refertoGreasingthe

BearingsandBushings(page44).Failuretoproperly

greasethemachineresultsinprematurefailureof

criticalparts.

g009979

Figure9

1.Brakepedal4.Tractionpedal

2.Pedal-lockinglatch5.Tilt-steeringpedal

3.Parking-brakepedal

TractionPedal

Thetractionpedal(Figure9)controlsforwardand

reverseoperation.Pressthetopofthepedaltomove

forwardandthebottomtomovebackward.

Tostopthemachine,useoneofthefollowing

procedures:

•Reduceyourfootpressureonthetractionpedal

andallowittoreturntothecenterposition.The

machinewilldynamicallybraketoasmoothstop.

•Taporholdthereversepedalbriey.Thisstops

themachinefasterthandynamicbraking.

13

Note:Inemergencybrakingsituations,pressthe

g020512

servicebrakepedalsinadditiontousingthereverse

pedalasstatedabove.Thisisthequickestmethod

tostopthemachine.

engagethecuttingunitblades.Pushinthebuttonto

disengagethecuttingunitblades.

Engine-SpeedSwitch

Tilt-SteeringPedal

Totiltthesteeringwheeltowardyou,pressthefoot

pedal(Figure9)down,andpullthesteeringtower

towardyoutothemostcomfortablepositionandthen

releasethepedal.

High-LowSpeedControl

Theswitch(Figure10)allowsthespeedrangeto

increasefortransportingthemachine.Toswitch

betweentheHighandLowspeedranges,raisethe

decks,disengagethePTO,putthetractionpedal

intotheNEUTRALposition,andmovethemachineat

aslowspeed.

Note:Thecuttingdecksdonotoperateand/or

cannotbeloweredfromthetransportpositionwhen

theswitchisinthehighrange.

Theengine-speedswitch(Figure10)has2modesto

changetheenginespeed.T aptheswitchtoincrease

ordecreasetheenginespeedin100rpmincrements.

HolddowntheswitchtoautomaticallymovetoHigh

orLowidle,dependingonwhichendoftheswitchis

depressed.

LiftSwitches

Theliftswitches(Figure10)raiseandlowerthe

cuttingunits.Presstheswitchesforwardtolowerthe

cuttingunitsandbackwardtoraisethecuttingunits.

Whenstartingthemachine,withthecuttingunitsin

thedownposition,presstheliftswitchdowntoallow

thecuttingunitstooat,andmow.

Note:ThedecksdonotlowerwhileintheHispeed

rangeandtheydonotraiseorloweriftheoperatoris

outoftheseatwhentheengineisrunning.Tolower

thedecksforservice,rotatethekeyintheignition

switchtotheONpositionwhilesittingintheseat.

LightSwitch

Presstheloweredgeoftheswitch(Figure10)toturn

onthelights.Presstheupperedgeoftheswitchto

turnoffthelights.

Figure10

1.Liftswitches

(Groundsmaster4700

only)

2.Liftswitch(Groundsmaster

4500and4700)

3.PTOswitch

4.Keyswitch

5.InfoCenter

6.Hi-Lospeedcontrol

7.Engine-speedswitch

8.Lightswitch

9.Cruisecontrol

KeySwitch

Thekeyswitch(Figure10)has3positions:Off,

On/Preheat,andStart.

PTOSwitch

ThePTOswitch(Figure10)has2positions:Out

(start)andIn(stop).PullthePTObuttonoutto

PowerPoint

Usethepowerpoint(Figure11)topoweroptional12

Velectricalaccessories.

g020433

g020512

Figure11

1.Powerpoint2.Bagholder

14

BagHolder

1

g020650

2

3

4

TORO

UsingtheInfoCenterLCDDisplay

Usethebagholder(Figure1 1)forstorage.

SeatAdjustments

SeatAdjustingLever

Pulloutonthelevertoslidetheseatforwardor

rearward(Figure12).

SeatArmRestAdjustingKnob

Rotatetheknobtoadjusttheseatarmrestangle.

SeatBackAdjustingLever

Movethelevertoadjusttheseatbackangle(Figure

12).

Weightgauge

Indicateswhentheseatisadjustedtotheweightof

theoperator(Figure12).Heightadjustmentismade

bypositioningthesuspensionwithintherangeofthe

greenregion.

TheInfoCenterLCDdisplayshowsinformationabout

yourmachine,suchastheoperatingstatus,various

diagnosticsandotherinformationaboutthemachine

(Figure13).Thereisasplashscreenandmain

informationscreenoftheInfoCenter.Youcanswitch

betweenthesplashscreenandmaininformation

screenatanytimebypressinganyoftheInfoCenter

buttonsandthenselectingtheappropriatedirectional

arrow.

g020650

Figure13

1.Indicatorlight3.Middlebutton

2.Rightbutton

4.Leftbutton

•LeftButton,MenuAccess/BackButton—pressthis

buttontoaccesstheInfoCentermenus.Youcan

useittoexitanymenuthatyouarecurrentlyusing.

•MiddleButton—usethisbuttontoscrolldown

menus.

•RightButton—usethisbuttontoopenamenu

wherearightarrowindicatesadditionalcontent.

•Beeper—activatedwhenloweringthedecksorfor

advisoriesandfaults.

Note:Thepurposeofeachbuttonmaychange

g008837

Figure12

1.Weightgauge

2.Weight-adjustinglever5.Armrestadjustingknob

3.Seatadjustinglever

4.Seatbackadjustinglever

(notshown-locatedunder

armrest)

dependingonwhatisrequiredatthetime.Each

buttonislabeledwithanicondisplayingitscurrent

function.

Weight-AdjustingLever

Adjustforyourweight(Figure12).Pulluptheleverto

increasetheairpressureandpushdowntodecrease

theairpressure.Youattaintheproperadjustment

whentheweightgaugeisinthegreenregion.

15

InfoCenterIconDescription

SERVICEDUE

Indicateswhenscheduledservice

shouldbeperformed

Thestatusoftheenginerpm.

InfoCenterIconDescription(cont'd.)

Thecruisecontrolison.

Infoicon

Maximumtractionspeedsetting

Fast

Slow

Thefanisreversed.

Stationaryregenerationisrequired.

Theair-intakeheaterisactive

Raisetheleftdeck.

Raisethecenterdeck

Raisetherightdeck

Theoperatormustsitintheseat.

Theparkingbrakeison.

Therangeishigh.

Neutral

IdentiestherangeasLow

Coolanttemperature(°Cor°F)

Temperature(hot)

TractionorTractionPedal

Notallowed

Starttheengine.

Stoptheengine.

Engine

Keyswitch

Cuttingunitsarelowering.

Cuttingunitsareraising.

PINcode

Hydraulicuidtemperature

CANbus

InfoCenter

Badorfailed

Center

Right

Left

Bulb

OutputofTECcontrollerorcontrol

wireinharness

Overtheallowedrange

Undertheallowedrange

Outofrange

/

Switch

Operatormustreleaseswitch.

Operatorshouldchangetoindicated

state.

ThePTOison.

16

InfoCenterIconDescription(cont'd.)

Symbolsareoften

combinedtoform

sentences.Some

examplesareshown

below

Operatorshouldputmachinein

neutral.

Enginestartisdenied.

Service

MenuItemDescription

Hours

CountsListsthenumberofstarts,

Liststhetotalnumberofhours

thatthemachine,engineand

fanhavebeenon,aswell

asthenumberofhoursthe

machinehasbeentransported

andoverheated.

deckPTOcycles,andfan

reversalsthemachinehas

experienced.

Engineshutdown.

Enginecoolantistoohot.

Hydraulicuidistoohot.

DPFashaccumulationnotication.

RefertoServicingtheDiesel

ParticulateFilter(DPF)inthe

maintenancesectionfordetails.

Sitdownorsetparkingbrake.

UsingtheMenus

ToaccesstheInfoCentermenusystem,pressthe

menuaccessbuttonwhileatthemainscreen.This

bringsyoutothemainmenu.Refertothefollowing

tablesforasynopsisoftheoptionsavailablefrom

themenus:

MainMenu

MenuItemDescription

Faults

ServiceContainsinformationonthe

DiagnosticsListsvariousstatesthatthe

Settings

AboutListsthemodelnumber,serial

Containsalistoftherecent

machinefaults.Referto

theServiceManualoryour

ToroDistributorformore

informationontheFaults

menuandtheinformation

containedthere.

machinesuchashoursofuse

andothersimilarnumbers.

machinecurrentlyhas.You

canusethistotroubleshoot

certainissuesasitquicklytells

youwhichmachinecontrols

areonandwhichareoff.

Allowsyoutocustomizeand

modifycongurationvariables

ontheInfoCenterdisplay.

number,andsoftwareversion

ofyourmachine.

Diagnostics

MenuItemDescription

LeftDeck

CenterDeck

RightDeck

TractionPedal

Traction

HI/LORange

PTO

EngineRun

Settings

MenuItemDescription

Units

Language

LCDBacklightControlsthebrightnessofthe

LCDContrastControlsthecontrastofthe

ProtectedMenusAllowsapersonauthorized

ProtectSettings

AutoIdle

MowSpeedControlsthemaximumspeed

Trans.SpeedControlsthemaximumspeed

CounterbalanceControlstheamountof

RefertotheServiceManualor

yourToroDistributorformore

informationontheEngine

Runmenuandtheinformation

containedthere.

Controlstheunitsusedonthe

InfoCenter(EnglishorMetric).

Controlsthelanguageused

ontheInfoCenter*.

LCDdisplay.

LCDdisplay.

byyourcompanywiththe

PINcodetoaccessprotected

menus.

Allowstheabilitytochange

thesettingsintheprotected

settings.

Controlstheamountoftime

allowedbeforeidlingthe

enginewhenthemachineis

notinuse.

whileinmow(lowrange).

whileintransport(highrange).

counterbalanceappliedbythe

decks.

*Only"operator-faced"textistranslated.Faults,

Service,andDiagnosticsscreensare"service-faced.”

Titlesareintheselectedlanguage,butmenuitems

areinEnglish.

17

About

MenuItemDescription

Model

SNListstheserialnumberofthe

S/WRevListsthesoftwarerevisionof

Liststhemodelnumberofthe

machine.

machine.

themastercontroller .

ProtectedMenus

Thereare5operatingcongurationsettingsthatare

adjustablewithintheSettingsMenuoftheInfoCenter:

autoidle,maximummowinggroundspeed,maximum

transportgroundspeed,SmartPower,anddeck

counterbalance.ThesesettingsareintheProtected

Menu.

AccessingProtectedMenus

Note:ThefactorydefaultPINcodeforyoumachine

iseither0000or1234.

IfyouchangedthePINcodeandforgotthe

code,contactyourAuthorizedToroDistributorfor

assistance.

1.FromtheMAINMENU,usethecenterbuttonto

scrolldowntotheSETTINGSMENUandpressthe

rightbutton(Figure14).

Figure14

2.IntheSETTINGSMENU,usethecenterbuttonto

scrolldowntothePROTECTEDMENUandpress

therightbutton(Figure15A).

g028522

Figure15

3.T oenterthePINcode,pressthecenterbutton

untilthecorrectrstdigitappears,thenpress

therightbuttontomoveontothenextdigit

(Figure15BandFigure15C).Repeatthisstep

untilthelastdigitisenteredandpresstheright

buttononcemore.

4.PressthemiddlebuttontoenterthePINcode

(Figure15D).

WaituntiltheredindicatorlightoftheInfoCenter

illuminates.

Note:IftheInfoCenteracceptsthePINcode

andtheprotectedmenuisunlocked,theword

“PIN”displaysintheupperrightcornerofthe

screen.

g028523

Note:RotatethekeyswitchtotheOFFpositionand

thentotheONpositionlockstheprotectedmenu.

Youhavetheabilitytoviewandchangethesettingsin

theProtectedMenu.OnceyouaccesstheProtected

Menu,scrolldowntoProtectSettingsoption.Usethe

rightbuttontochangethesetting.SettingtheProtect

SettingstoOFFallowsyoutoviewandchangethe

settingsintheProtectedMenuwithoutenteringthe

PINcode.SettingtheProtectSettingstoONhidesthe

protectedoptionsandrequiresyoutoenterthePIN

codetochangethesettingintheProtectedMenu.

AfteryousetthePINcode,rotatethekeyswitchOFF

andbacktotheONpositiontoenableandsavethis

feature.

18

ViewingandChangingthe

SettingtheCounterbalance

ProtectedMenuSettings

1.IntheProtectedMenu,scrolldowntoProtect

Settings.

2.T oviewandchangethesettingswithoutentering

apasscode,usetherightbuttontochangethe

ProtectSettingstoOFF.

3.T oviewandchangethesettingswitha

passcode,usetheleftbuttontoselectON,set

thepasscode,andturnthekeyintheignition

switchtotheOFFpositionandthentotheON

position.

SettingtheAutoIdle

1.IntheSettingsMenu,scrolldowntoAutoIdle.

2.Presstherightbuttontochangetheauto-idle

timebetweenOFF,8S,10S,15S,20S,and30S.

SettingtheMaximumAllowed

MowSpeed

1.IntheSettingsMenu,scrolldowntoMowSpeed

andpresstherightbutton.

1.IntheSettingsMenu,scrolldowntoCounter

Balanceandpresstherightbutton.

2.PresstherightbuttontoswitchbetweenLow,

Med,andHigh.

WhennishedwiththeProtectedMenu,presstheleft

buttontoexittotheMainMenu,thenpresstheleft

buttontoexittotheRunMenu.

2.Usetherightbuttontoincreasethemaxfull

mowspeed(50%,75%,or100%).

3.Usethecenterbuttontodecreasethemaxfull

mowspeed(50%,75%,or100%).

4.Presstheleftbuttontoexit.

SettingtheMaximumAllowed

TransportSpeed

1.IntheSettingsMenu,scrolldowntoTransport

Speedandpresstherightbutton.

2.Usetherightbuttontoincreasethemax

transportspeed(50%,75%,or100%).

3.Usethecenterbuttontodecreasethemax

transportspeed(50%,75%,or100%).

4.Presstheleftbuttontoexit.

TurningtheSmartPowerON/OFF

1.Inthesettingsmenu,scrolldowntoSmart

Power.

2.PresstherightbuttontoswitchbetweenONand

OFF.

3.Presstheleftbuttontoexit.

19

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

4500-D4700-D

Widthofcut2.8m(109inches)3.8m(150inches)

Overallwidth,

cuttingunitsdown

Overallwidth,

cuttingunitsup

(transport)

Overalllength370cm(145.8inches)370cm(145.8inches)

HeightwithROPS216cm(85inches)216cm(85inches)

Groundclearance15cm(6inches)15cm(6inches)

TrackWidth,front224cm(88.3inches)224cm(88.3inches)

TrackWidth,rear

Wheelbase

NetWeight(with

cuttingunitsand

nouids)

CuttingDeck

Length

Width

Height

Weight

286cm(1 12.8inches)391cm(153.8inches)

224cm(88.25inches)224cm(88.25inches)

141cm(55.5inches)141cm(55.5inches)

171cm(67-1/2inches)171cm(67-1/2inches)

1894kg(4175lb)2,234kg(4,925lb)

24.4cm(9.6inches)tocarriermount

26.7cm(10–1/2inches)at3/4inchheightofcut

34.9cm(13–3/4inches)at4inchheightofcut

86.4cm(34inches)

86.4cm(34inches)

88kg(195lb)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhance

andexpanditscapabilities.ContactyourAuthorizedServiceDealerorDistributororgotowww.Toro.comfora

listofallapprovedattachmentsandaccessories.

TobestprotectyourinvestmentandmaintainoptimalperformanceofyourToroequipment,countonT oro

genuineparts.Whenitcomestoreliability,Torodeliversreplacementpartsdesignedtotheexactengineering

specicationofourequipment.Forpeaceofmind,insistonTorogenuineparts.

20

Operation

FuelSafety

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

Knowhowtostopthemachineandenginequickly.

•Checkthatallsafetydevicesareattachedand

functioningproperly.Thisincludes,butisnot

limitedto,operator-presencecontrols;safety

switchesandshields;therolloverprotection

system(ROPS);attachments;andbrakes.Do

notoperatethemachineunlessallsafetydevices

areinpositionandfunctioningasintendedbythe

manufacturer.

•Alwaysinspectthemachinetoensurethatthe

blades,bladebolts,andcuttingassemblyarenot

wornordamaged.Replacewornordamaged

bladesandboltsinsetstopreservebalance.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

potentiallythrow.

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessories

requiredtooperatethemachineproperlyand

safely.

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana180-daysupplyoffuel.

•Donotoperatethemachinewithoutthe

entireexhaustsysteminplaceandin

properworkingcondition.

WARNING

Fuelisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepyourhandsandfaceawayfromthe

nozzleandthefuel-tankopening.

•Keepfuelawayfromyoureyesandskin.

•Useonlyanapprovedfuelcontainer.

•Neverremovethefuelcaporaddfueltothefuel

tankwhiletheengineisrunning.

•Neverllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

containersonthegroundandawayfromyour

vehiclebeforelling.

•Removetheequipmentfromthetruckortrailer

andaddfueltoitwhileitisontheground.Ifthis

isnotpossible,thenaddfuelusingaportable

containerratherthanfromafuel-dispensernozzle.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.

•Fillthefueltankuntilthefuellevelis25mm(1

inch)belowthebottomofthellerneck.Donot

21

overllthefueltank.Replacethefuel-tankcap

andtightenitsecurely.

CheckingtheEngine-Oil Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngine-OilLevel(page47).

CheckingtheCooling System

Beforeyoustarttheengineandusethemachine,

checkthecoolingsystem;refertoCheckingthe

CoolingSystem(page56).

CheckingtheHydraulic System

Beforeyoustarttheengineandusethemachine,

checkthehydraulicsystem;refertoCheckingthe

HydraulicLinesandHoses(page61).

FuelTable

Dieselfuelspecication

ASTMD975

No.1-DS15

No.2-DS15

EN590EuropeanUnion

ISO8217DMX

JISK2204GradeNo.2

KSM-2610

Location

USA

International

Japan

Korea

•Useonlyclean,freshdieselfuelorbiodieselfuels.

•Purchasefuelinquantitiesthatcanbeusedwithin

180daystoensurefuelfreshness.

Usesummer-gradedieselfuel(No.2-D)at

temperaturesabove-7°C(20°F)andwinter-grade

fuel(No.1-DorNo.1-D/2-Dblend)belowthat

temperature.

Note:Useofwinter-gradefuelatlowertemperatures

provideslowerashpointandcoldowcharacteristics

whicheasesstartingandreducesfuellterplugging.

Usingsummer-gradefuelabove-7°C(20°F)

contributestowardlongerfuelpumplifeandincreased

powercomparedtowinter-gradefuel.

FillingtheFuelTank

FuelTankCapacity

Fueltankcapacity:83L(22USgallons)

FuelSpecication

Important:Useonlyultra-lowsulphurdiesel

fuel.Fuelwithhigherratesofsulfurdegrades

thedieseloxidationcatalyst(DOC),whichcauses

operationalproblemsandshortenstheservicelife

ofenginecomponents.

Failuretoobservethefollowingcautionsmay

damagetheengine.

•Neverusekeroseneorgasolineinsteadofdiesel

fuel.

•Nevermixkeroseneorusedengineoilwiththe

dieselfuel.

•Neverkeepfuelincontainerswithzincplatingon

theinside.

•Donotusefueladditives.

PetroleumDiesel

Biodiesel

Thismachinecanalsouseabiodieselblendedfuelof

uptoB20(20%biodiesel,80%petroleumdiesel).

Sulfurcontent:Ultra-lowsulfur(<15ppm)

Biodieselfuelspecication:ASTMD6751or

EN14214

Blendedfuelspecication:ASTMD975,EN590,

orJISK2204

Important:Thepetroleumdieselportionmust

beultra-lowsulfur.

Observethefollowingprecautions:

•Biodieselblendsmaydamagepaintedsurfaces.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuel

astheymaybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatime

afterconvertingtobiodieselblends.

•ContactyourAuthorizedT oroDistributorifyou

wishformoreinformationonbiodiesel.

Cetanerating:45orhigher

Sulfurcontent:Ultra-lowsulfur(<15ppm)

22

AddingFuel

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Thecorrectairpressureinthetiresis138kPa(20psi).

Important:Maintaintherecommendedpressure

inalltirestoensureagoodqualityofcutand

propermachineperformance.Donotunder-inate

g031874

thetires.

Checktheairpressureinallthetiresbefore

operatingthemachine.

g001055

Figure17

Figure16

Fillthetankwithdieselfueluntilthelevelreachesthe

bottomofthellerneck.

Note:Ifpossible,llthefueltankaftereachuse;this

willminimizepossiblebuildupofcondensationinside

thefueltank.

CheckingtheTorqueofthe WheelNuts

ServiceInterval:Aftertherst8hours

Every200hours

g031869

WARNING

Failuretomaintainpropertorqueofthewheel

nutscouldresultinfailureorlossofwheel

andmayresultinpersonalinjury.

Torquethefrontandrearwheelnutsto115to

136N-m(85to100ft-lb)after1to4hoursof

operationandagainafter8hoursofoperation.

Torqueevery200hoursthereafter.

Note:Frontwheelnutsare1/2-20UNF.Rearwheel

nutsareM12x1.6-6H(Metric).

23

AdjustingtheHeightofCut

Important:Thiscuttingdeckoftencuts

approximately6mm(1/4inch)lowerthanareel

cuttingunitwiththesamebenchsetting.Itmay

benecessarytohavetheserotarycuttingdeck’s

benchset6mm(1/4inch)abovethatofreels

cuttinginthesamearea.

Important:Accesstotherearcuttingunitsis

greatlyimprovedbyremovingthecuttingunit

fromthetractor.

1.Lowerthecuttingdecktotheground,shutoff

theengine,andremovethekeyfromtheignition

switch.

2.Loosentheboltsecuringeachheight-of-cut

brackettotheheight-of-cutplate(frontandeach

side);refertoFigure18.

7.Installtheboltnger-tight.

8.Repeatsteps4through7foreachside

adjustment.

9.T orqueall3boltsto41N∙m(30ft-lb).Always

tightenthefrontboltrst.

Note:Adjustmentsofmorethan3.8cm(1-1/2

inches)mayrequiretemporaryassemblytoan

intermediateheighttopreventbinding(e.g.,

changingfrom3.1to7cm(1.25to2.75inches)

heightofcut).

CheckingtheInterlock Switches

ServiceInterval:Beforeeachuseordaily

3.Beginningwithfrontadjustment,removethe

bolt.

Figure18

1.Height-of-cutbracket3.Spacer

2.Height-of-cutplate

4.Whilesupportingthechamber,removethe

spacer(Figure18).

5.Movethechambertothedesiredheightof

cutandinstallaspacerintothedesignated

height-of-cutholeandslot(Figure19).

CAUTION

Ifsafetyinterlockswitchesaredisconnected

ordamaged,themachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Theinterlockswitchesaredesignedtostopthe

machinewhentheoperatorgetsofftheseatwhenthe

tractionpedalisdepressed.However,theoperator

maygetofftheseatwhiletheengineisrunningand

thetractionpedalisintheNEUTRALposition.Although

g011344

theenginecontinuestorunifthePTOswitchis

disengagedandthetractionpedalisreleased,itis

stronglyrecommendedthattheenginebestopped

beforerisingfromtheseat.

1.Parkthemachineonalevelsurface,lowerthe

cuttingunit,turnthekeyintheignitionswitchto

theOFFposition,andengagetheparkingbrake.

2.Pressthetractionpedal.Turnthekeyinthe

ignitionswitchtotheONposition.

Note:Iftheenginecranks,thereisa

malfunctionintheinterlocksystem.Correctthis

malfunctionbeforeoperatingthemachine.

3.TurnthekeyintheignitionswitchtotheON

position,risefromtheseat,andmovethePTO

switchtoON.

g026184

Figure19

6.Positionthetappedplatein-linewiththespacer.

Note:ThePTOshouldnotengage.Ifthe

PTOengages,thereisamalfunctioninthe

interlocksystem.Correctthismalfunctionbefore

operatingthemachine.

4.Engagetheparkingbrake,turnthekeyinthe

ignitionswitchtotheONposition,andmovethe

tractionpedaloutofNEUTRAL.

24

Note:TheInfoCenterdisplays"tractiondenied"

andthemachineshouldnotmove.Ifthe

machinedoesmove,thereisamalfunctionin

theinterlocksystem.Correctthismalfunction

beforeoperatingthemachine.

Checkingthe Blade-StoppingTime

ServiceInterval:Beforeeachuseordaily

Thebladesofthecuttingdeckshouldcometoa

completestopinapproximately5secondsafteryou

shutdownthecuttingdeckengagementswitch.

Note:Makesurethatthedecksareloweredontoa

cleansectionofturforhardsurfacetoavoidthrown

dustanddebris.

Toverifythisstoppingtime,haveasecondperson

standbackfromthedeckatleast6m(20ft)and

watchthebladeson1ofthecuttingdecks.Havethe

operatorshutthecuttingdecksdownandrecordthe

timeittakesforthebladestocometoacomplete

stop.Ifthistimeisgreaterthan7seconds,thebraking

valveneedsadjustment.CallyourT oroDistributorfor

assistanceinmakingthisadjustment.

Attributes:

•Moreliftandhigherdischargevelocity.

•Sparseorlimpturfispickedupsignicantlyat

higherheightsofcut.

•Wetorstickyclippingsaredischargedmore

efcientlyreducingcongestioninthedeck.

•Requiresmorehorsepowertorun.

•Tendstodischargefurtherleftandcantendto

windrowatlowerheightsofcut.

DANGER

Usingthehigh-liftbladewiththemulching

bafecouldcausethebladetobreak,

resultinginpersonalinjuryordeath.

Donotusethehigh-liftbladewiththebafe.

AtomicBlade

Thisbladewasdesignedtoprovideexcellentleaf

mulching.

Attributes:Excellentleafmulching

SelectingaBlade

StandardCombinationSail

Thisbladewasdesignedtoprovideexcellentliftand

dispersioninalmostanycondition.Ifmoreorlesslift

anddischargevelocityisrequired,consideradifferent

blade.

Attributes:Excellentliftanddispersioninmost

conditions.

AngledSail

Thebladegenerallyperformsbestinlowerheightsof

cut—1.9to6.4cm(3/4to2-1/2inches).

Attributes:

•Dischargeremainsmoreevenatlowerheightsof

cut.

•Dischargehaslesstendencytothrowleftandthus

acleanerlookaroundbunkersandfairways.

•Lowerpowerrequirementatlowerheightsand

denseturf.

High-Lift,ParallelSail

Thebladegenerallyperformsbetterinthehigher

heightsofcut—7to10cm(2to4inches).

25

ChoosingAccessories

OptionalEquipmentCongurations

AngleSailBladeHigh-Lift,Parallel-Sail

GrassCutting:1.9to4.4

cm(0.75to1.75inch)

heightofcut

GrassCutting:5to6.4

cm(2.00to2.50inch)

heightofcut

GrassCutting:7to10

cm(2.75to4.00inch)

heightofcut

LeafMulchingRecommendedforuse

ProsEvendischargeatlower

ConsDoesnotliftthegrass

Recommendedinmost

applications

Recommendedforthick

orlushturf

Mayworkwellinlushturf

withthemulchingbafe

heightofcutCleaner

lookaroundbunkersand

fairwaysLowerpower

requirements

wellinhighheightof

cutapplicationsWet

orstickygrasshasa

tendencytobuildupin

thechamber,leading

topoorqualityofcut

andhigherpower

requirements

Blade(Donotusewith

themulchingbafe)

Mayworkwellinlightor

sparseturf

Recommendedforlight

orsparseturf

Recommendedinmost

applications

NotAllowedUsewithcombination

Moreliftandhigher

dischargevelocity

Sparseorlimpturfis

pickedupathighheight

ofcutWetorsticky

clippingsaredischarged

efciently

Requiresmorepowerto

runinsomeapplications

Tendstowindrowat

lowerheightofcutin

lushgrassDonotuse

withthemulchingbafe

MulchingBafeRollerScraper

Hasbeenshownto

improvedispersionand

aftercutperformance

onnortherngrassesthat

arecutatleast3times

perweekandlessthan

1/3ofthegrassblade

isremoved.Donot

usewiththehigh-lift,

parallel-sailblade

sailoranglesailblade

only

Mayimprovedispersion

andappearancein

certaingrasscutting

applicationsVerygood

forleafmulching

Grasswillbuildupinthe

chamberifattemptingto

removetoomuchgrass

withbafeinplace

Canbeusedanytime

thatrollersbuildupwith

grassorlargeatgrass

clumpsofgrassare

seen.Thescrapers

mayactuallyincrease

clumpingincertain

applications.

Reducesrollerbuildup

incertainapplications

26

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/usercanpreventandisresponsible

foraccidentsthatmaycauseinjuriestopeople,

ordamagetoproperty.

•Wearappropriateclothing,includingeye

protection;substantial,slip-resistantfootwear;and

hearingprotection.Tiebacklonghair.Donot

wearjewelry.

•EnsurethatalldrivesareintheNEUTRALposition,

theparkingbrakeisengaged,andyouareinthe

operatingpositionbeforeyoustarttheengine.

•Keepallbodyparts,includinghandsandfeet,

awayfromallmovingparts.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Keepthedirectionofthemowerdischargeaway

frompeopleandpets.

•Donotmowinreverseunlessitisabsolutely

necessary.Ifyoumustmowinreverse,look

behindanddownforsmallchildrenbeforeand

whilemovingthemachineinreverse.Stayalert

andstopthemachineifachildentersthearea.

•Useextremecarewhenapproachingblind

corners,shrubs,trees,orotherobjectsthatmay

blockyourview.

•Donotmowneardrop-offs,ditches,or

embankments.Themachinecouldsuddenly

rolloverifawheelgoesovertheedgeorifthe

edgecavesin.

•Nevercarrypassengersonthemachine.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflighting.

•Donotmowonwetgrass.Reducedtractioncould

causethemachinetoslide.

•Neverraisethemowerdeckwiththeblades

running.

•Stopthemachineandinspectthebladesafter

strikinganobjectorifthereisanabnormal

vibrationinthemachine.Makeallnecessary

repairsbeforeresumingoperation.

•Stopthebladeswheneveryouarenotmowing,

especiallywhilecrossinglooseterrainsuchas

gravel.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Turnontheashingwarninglightsonthemachine

wheneveryoutravelonapublicroad,except

wheresuchuseisprohibitedbylaw.

•Disengagethedrivetotheattachmentandshutoff

theenginebeforeaddingfuelandadjustingthe

heightofcut.

•Reducethethrottlesettingbeforestoppingthe

engineand,iftheenginehasafuel-shutoffvalve,

shutoffthefuelwhenyouhavenishedoperating

themachine.

•Neverrunanengineinanareawhereexhaust

gasesareenclosed.

•Neverleavearunningengineunattended.

•Beforeleavingtheoperatingposition,dothe

following:

–Stopthemachineonlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Settheparkingbrake.

–Shutofftheengineandremovethekey .

–Waitforallmovingpartstostop.

•Donotchangethegovernorsettingsonor

overspeedtheengine.Operatingtheengineat

excessivespeedmayincreasethepotentialfor

personalinjury.

•Donotusethemachineasatowingvehicle.

•Useaccessoriesandattachmentsapprovedby

TheT oro®Companyonly.

RolloverProtectionSystem

(ROPS)Safety

•DonotremovetheROPSfromthemachine.

•Ensurethattheseatbeltisattachedandthatyou

canreleaseitquicklyintheeventofanemergency.

•Alwayswearyourseatbelt.

•Checkcarefullyforoverheadclearances,suchas

branches,doorways,andelectricalwires,before

drivingthemachineunderthem.Donotcontact

them.

•KeeptheROPSinsafeoperatingconditionby

thoroughlyinspectingitperiodicallyfordamage

andkeepingallthemountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorrevise

it.

•AnyalterationstoaROPSmustbeapprovedby

TheT oro®Company.

SlopeSafety

•Slowdownthemachineanduseextracareon

hillsides.Travelintherecommendeddirectionon

hillsides.Turfconditionscanaffectthestabilityof

themachine.

27

•Avoidstarting,stopping,orturningthemachine

onaslope.Ifthetireslosetraction,disengage

theblade(s)andproceedslowlystraightdownthe

slope.

•Donotturnthemachinesharply.Usecarewhen

reversingthemachine.

•Whenoperatingthemachineonaslope,always

keepallcuttingunitslowered.

•Avoidturningthemachineonslopes.Ifyoumust

turn,turnslowlyandgraduallydownhill,ifpossible.

•Useextracarewhileoperatingthemachinewith

attachments;theycanaffectthestabilityofthe

machine.Followtherecommendationsforusing

themachineonaslopeinthisOperator’sManual.

StartingandStoppingthe Engine

Important:Bleedthefuelsystembeforestarting

theengineiftheenginehasstoppedduetolack

offuel,oryouhaveperformedmaintenanceon

thefuelsystem.

StartingtheEngine

1.Sitontheseat,keepyourfootoffthetraction

pedalsothatitisinNEUTRAL,andengagethe

parkingbrake.

2.TurnthekeyintheignitionswitchtotheRUN

position.Theglowindicatorwilllight.

3.Whentheglowindicatordims,turnthekeyinthe

ignitionswitchtotheSTARTposition.Release

thekeyimmediatelywhentheenginestartsand

allowittoreturntotheRUNposition.Adjustthe

enginespeed.

Important:Donotrunthestartermotor

morethan30secondsatatimeorpremature

starterfailuremayresult.Iftheengine

failstostartafter30seconds,turnthekey

intheignitionswitchtotheOFFposition,

recheckthecontrolsandprocedures,wait30

additionalseconds,andrepeatthestarting

procedure.

Whenthetemperatureislessthan-7°C(20°F),

thestartermotorcanberunfor30secondson

then60secondsofffor2attempts.

CAUTION

Checkingthemachineforoilleaks,loose

parts,andothermalfunctionswhilethe

engineisrunningmaybringyouinclose

contactwithhotormovingpartsofthe

machine,causinginjury .

Shuttheengineoffandwaitforall

movingpartstostopbeforechecking

foroilleaks,looseparts,andother

malfunctions.

StoppingtheEngine

Important:Allowtheenginetoidlefor5minutes

beforeshuttingitoffafterafullloadoperation.

Thisallowstheturbochargertocooldownbefore

shuttingtheengineoff.

Note:Lowerthecuttingunitstothegroundwhenever

machineisparked.Thisrelievesthehydraulicload

fromthesystem,preventswearonsystempartsand

alsopreventsaccidentalloweringofthecuttingunits.

1.MovethePTOswitchtotheOFFposition.

2.Settheparkingbrake.

3.Returntheenginelowidle.

4.TurnthekeyintheignitionswitchtotheOFF

positionandremovethekey.

CuttingGrasswiththe Machine

Note:Cuttinggrassataratethatloadstheengine

promotesDPFregeneration.

1.Movethemachinetothejobsite.

2.Wheneverpossible,settheengine-speedswitch

tohighidle.

3.EngagethePTOswitch.

4.Graduallymovethetractionpedalforwardand

slowlydrivethemachineoverthemowingarea.

5.Oncethefrontofthecuttingunitsareoverthe

mowingarea,lowerthecuttingunits.

6.Cutgrasssothatthebladescancutand

dischargeclippingsatahighratewhile

producingagoodqualityofcut.

Note:Ifthecuttingrateistoohigh,thequality

ofcutmaydeteriorate.Reducetheground

speedofthemachineorreducethewidthofcut

toregainhighidleenginespeed.

7.Whenthecuttingunitsareoverthefaredgeof

themowingarea,liftthecuttingunits.

8.Performatear-shapedturntoquicklylineupfor

yournextpass.

28

DieselParticulateFilter Regeneration

Thedieselparticulatelter(DPF)ispartoftheexhaust

system.Thediesel-oxidationcatalystoftheDPF

reducesharmfulgassesandthesootlterremoves

sootfromtheengineexhaust.

TheDPFregenerationprocessusesheatfromthe

engineexhausttoincineratethesootaccumulatedon

thesootlter,convertingthesoottoash,andclears

thechannelsofthesootltersothatlteredengine

exhaustowsouttheDPF .

Theenginecomputermonitorstheaccumulationof

sootbymeasuringthebackpressureintheDPF .If

thebackpressureistoohigh,sootisnotincinerating

inthesootlterthroughnormalengineoperation.T o

keeptheDPFclearofsoot,rememberthefollowing:

•Passiveregenerationoccurscontinuouslywhile

theengineisrunning—runtheengineatfull

enginespeedwhenpossibletopromoteDPF

regeneration.

•Ifthebackpressureistoohigh,theengine

computersignalsyouthroughtheInfoCenter

whenadditionalprocesses(assistandreset

regeneration)arerunning.

•Allowtheassistandresetregenerationprocessto

completebeforeshuttingofftheengine.

Operateandmaintainyourmachinewiththefunction

oftheDPFinmind.Engineloadathighidle

enginespeedgenerallyproduceadequateexhaust

temperatureforDPFregeneration.

Important:Minimizetheamountoftimethatyou

idletheengineoroperatetheengineatlow-engine

speedtohelpreducetheaccumulationofsootin

thesootlter.

CAUTION

Theexhausttemperatureishot(approximately

600°C(1112°F)duringDPFparked

regenerationorrecoveryregeneration.Hot

exhaustgascanharmyouorotherpeople.

•Neveroperatetheengineinanenclosed

area.

•Makesurethattherearenoammable

materialsaroundtheexhaustsystem.

•Nevertouchahotexhaustsystem

component.

•Neverstandnearoraroundtheexhaust

pipeofthemachine.

DPFSootAccumulation

•Overtime,theDPFaccumulatessootinthesoot

lter.Thecomputerfortheenginemonitorsthe

sootlevelintheDPF .

•Whenenoughsootaccumulates,thecomputer

informsyouthatitistimetoregeneratethediesel

particulatelter.

•DPFregenerationisaprocessthatheatstheDPF

toconvertthesoottoash.

•Inadditiontothewarningmessages,thecomputer

reducesthepowerproducedbytheengineat

differentsoot-accumulationlevels.

EngineWarningMessages—SootAccumulation

IndicationLevel

Level1:Engine

Warning

Level2:Engine

Warning

FaultCode

g213866

Figure20

CheckEngine

SPN3719,FMI16

g213867

Figure21

CheckEngine

SPN3719,FMI0

EnginePowerRatingRecommendedAction

Thecomputerde-ratesthe

enginepowerto85%

Thecomputerde-ratesthe

enginepowerto50%

Performaparkedregeneration

assoonaspossible;referto

ParkedRegeneration(page33).

Performarecoveryregeneration

assoonaspossible;referto

RecoveryRegeneration

(page36).

29

DPFAshAccumulation

•Thelighterashisdischargedthroughtheexhaust

system;theheavierashcollectsinthesootlter.

•Ashisaresidueoftheregenerationprocess.Over

time,thedieselparticulatelteraccumulatesash

thatdoesnotdischargewiththeengineexhaust.

•Thecomputerfortheenginecalculatestheamount

ofashaccumulatedintheDPF.

InfoCenterAdvisoryandEngineWarningMessages—AshAccumulation

•Whenenoughashaccumulates,theengine

computersendsinformationtotheInfoCenterin

theformofasystemadvisoryoranenginefaultto

indicatetheaccumulationofashintheDPF .

•Theadvisoryandfaultsareindicationsthatitis

timetoservicetheDPF .

•Inadditiontothewarnings,thecomputerreduces

thepowerproducedbytheengineatdifferent

ash-accumulationlevels.

Indication

Level1:

System

Advisory

Level2:

Engine

Warning

Level3:

Engine

Warning

Level

AdvisoryorFaultCode

g213865

EngineSpeed

Reduction

None

EnginePowerRatingRecommendedAction

Notifyyourservice

100%

departmentthatadvisory

#179displaysinthe

InfoCenter.

Figure22

Advisory#179

ServicetheDPF;

refertoServicingthe

Diesel-OxidationCatalyst

(DOC)andtheSoot

Filter(page48)

g213863

Figure23

None

Thecomputer

de-ratestheengine

powerto85%

CheckEngine

SPN3720,FMI16

ServicetheDPF;

refertoServicingthe

Diesel-OxidationCatalyst

(DOC)andtheSoot

Filter(page48)

g213864

Figure24

None

Thecomputer

de-ratestheengine

powerto50%

CheckEngine

SPN3720,FMI0

Level4:

Engine

Warning

g214715

Figure25

CheckEngine

SPN3251,FMI0

Enginespeedatmax

torque+200rpm

30

Thecomputer

de-ratestheengine

powerto50%

ServicetheDPF;

refertoServicingthe

Diesel-OxidationCatalyst

(DOC)andtheSoot

Filter(page48)

TypesofDieselParticulateFilterRegeneration

Typesofdieselparticulatelterregenerationthatareperformedwhilethemachineisoperating:

TypeofRegenerationConditionsforDPFregenerationDPFdescriptionofoperation

Passive

Assist

Reset

Occursduringnormaloperationofthemachineat

high-enginespeedorhigh-engineload

Occursasaresultoflow-enginespeed,low-engine

load,orafterthecomputerdetectsbackpressure

intheDPF

Occursafterassistregenerationonlyifthe

computerdetectsthatassistregenerationdidnot

sufcientlyreducethesootlevel

Alsooccursevery100hourstoresetbaseline

sensorreadings

TheInfoCenterdoesnotdisplayaniconindicating

passiveregeneration.

Duringpassiveregeneration,theDPFprocesses

high-heatexhaustgasses;oxidizingharmful

emissionsandburningsoottoash.

RefertoPassiveDPFRegeneration(page32).

Whentheassist/reset-regenerationicon

isdisplayedintheInfoCenter,anassist

regenerationisinprogress.

Duringassistregeneration,thecomputercontrols

theintakethrottletoincreasetheexhaust

temperature,enablingassistregenerationtooccur.

RefertoAssistDPFRegeneration(page32).

Whentheassist/reset-regenerationicon

isdisplayedintheInfoCenter,aregenerationisin

progress.

Duringresetregeneration,thecomputercontrols

theintakethrottleandfuelinjectorstoincreasethe

exhausttemperatureduringregeneration.

RefertoResetRegeneration(page33).

Typesofdieselparticulatelterregenerationthatrequireyoutoparkthemachine:

TypeofRegenerationConditionsforDPFregenerationDPFdescriptionofoperation

Parked

Sootbuildupoccursasaresultofprolonged

operationatlow-enginespeedorlow-engineload.

Mayalsooccurasaresultofusingincorrectfuel

oroil

Thecomputerdetectsbackpressureduetosoot

buildupandrequestsaparkedregeneration

Whentheparked-regenerationicon

isdisplayedintheInfoCenter ,aregenerationis

requested.

•Performtheparkedregenerationassoonas

possibletoavoidneedingarecoveryregeneration.

•Aparkedregenerationrequires30to60minutes

tocomplete.

•Youmusthaveatleasta1/4tankoffuelinthe

tank.

•Youmustparkthemachinetoperformarecovery

regeneration.

RefertoParkedRegeneration(page33).

31

Typesofdieselparticulatelterregenerationthatrequireyoutoparkthemachine:(cont'd.)

TypeofRegenerationConditionsforDPFregenerationDPFdescriptionofoperation

Recovery

Occursasaresultofignoringparkedregeneration

requestsandcontinuingoperation,addingmore

sootwhentheDPFisalreadyinneedofaparked

regeneration

Whentherecovery-regenerationiconis

displayedintheInfoCenter ,arecoveryregeneration

isrequested.

ContactyourAuthorizedToroDistributorto

haveaservicetechnicianperformtherecovery

regeneration.

•Arecoveryregenerationrequiresupto4hours

tocomplete.

•Youmusthaveatleasta1/2tankoffuelinthe

machine.

•Youmustparkthemachinetoperformarecovery

regeneration.

RefertoRecoveryRegeneration(page36).

PassiveDPFRegeneration

•Passiveregenerationoccursaspartofnormal

engineoperation.

•Whileoperatingthemachine,runtheengineat

full-enginespeedwhenpossibletopromoteDPF

regeneration.

AssistDPFRegeneration

•Whileoperatingthemachine,runtheengineat

fullenginespeedwhenpossibletopromoteDPF

regeneration.

•The

icondisplaysintheInfoCenterwhile

theassistregenerationisprocessing.

•Wheneverpossible,donotshutofftheengineor

reduceenginespeedwhiletheassistregeneration

isprocessing.

Important:Allowthemachinetocompletethe

assistregenerationprocessbeforeshutting

offtheengine.

Note:Theassistregenerationisnished

processingwhenthe

theInfoCenter.

icondisappearsfrom

Figure26

Assist/reset-regenerationicon

•Theassist/reset-regenerationicondisplaysinthe

InfoCenter(Figure26).

•Thecomputertakescontroloftheintakethrottleto

increasethetemperatureoftheengineexhaust.

g214711

32

ResetRegeneration

ParkedRegeneration

Figure27

Assist/reset-regenerationicon

•Theassist/reset-regenerationicondisplaysinthe

InfoCenter(Figure27).

•Thecomputertakescontroloftheintakethrottle

andchangesthefuelinjectionoperationto

increasethetemperatureoftheengineexhaust.

Important:Theassist/reset-regeneration

iconindicatesthattheexhausttemperature

dischargedfromofyourmachinemaybe

hotterthanduringregularoperation.

•Whileoperatingthemachine,runtheengineat

fullenginespeedwhenpossibletopromoteDPF

regeneration.

•TheicondisplaysintheInfoCenterwhile

theresetregenerationisprocessing.

•Wheneverpossible,donotshutofftheengineor

reduceenginespeedwhiletheresetregeneration

isprocessing.

Important:Allowthemachinetocompletethe

resetregenerationprocessbeforeshuttingoff

theengine.

Note:Theresetregenerationisnished

processingwhenthe

theInfoCenter.

icondisappearsfrom

g214711

g214713

Figure28

Parked-regenerationrequesticon

•Theparked-regenerationrequestedicondisplays

intheInfoCenter(Figure28).

•Ifaparkedregenerationisneeded,theInfoCenter

displaysenginewarningSPN3719,FMI16

(Figure29)andtheenginecomputerderates

enginepowerto85%.

g213866

Figure29

Important:Ifyoudonotcompleteaparked

regenerationwithin2hours,theengine

computerderatesenginepowerto50%.

•Aparkedregenerationrequires30to60minutes

tocomplete.

•Ifyouareauthorizedbyyourcompany,youneed

thePINcodetoperformtheparked-regeneration

process.

PreparingtoPerformaParkedorRecovery

Regeneration

1.Ensurethatthemachinehasatleast1/4tank

offuel.

2.Movethemachineoutsidetoanareaawayfrom

combustiblematerials.

3.Parkthemachineonalevelsurface.

4.Ensurethatthetractioncontrolormotion-control

leversareintheNEUTRALposition.

5.Ifapplicable,lowerthecuttingunitsandshut

themoff.

33

6.Engagetheparkingbrake.

7.SetthethrottletothelowIDLEposition.

PerformingaParkedRegeneration

Note:Forinstructionsonunlockingprotectedmenus,

refertoAccessingProtectedMenus(page18).

1.Accesstheprotectedmenuandunlockthe

protectedsettingssubmenu(Figure30);referto

AccessingProtectedMenus(page18).

Figure30

g212138

Figure32

4.Whenthe“InitiateDPFRegen.Areyousure?”

messagedisplays,pressthecenterbutton

(Figure33).

g028523

2.NavigatetotheMAINMENU,pressthecenter

buttontoscrolldowntotheSERVICEMENU,and

presstherightbuttontoselecttheSERVICE

option(Figure31).

Note:TheInfoCentershoulddisplaythePIN

indicatorintheupperrightcornerofthedisplay .

Figure31

3.IntheSERVICEMENU,pressthemiddlebutton

untiltheDPFREGENERA TIONoptionsdisplays,

andpresstherightbuttontoselecttheDPF

REGENERATIONoption(Figure32).

g212125

Figure33

5.Ifthecoolanttemperatureisbelow60°C(140°F)

the“Insure

isrunningandabove60C/140F”

messagedisplays.(Figure34).

Observethetemperatureinthedisplay,andrun

themachineatfullthrottleuntilthetemperature

reaches60°C(140°F),thenpressthecenter

g212371

button.

Note:Ifthecoolanttemperatureisabove60°C

(140°F)thisscreenisskipped.

34

Figure34

g211986

g212405

Figure36

6.MovethethrottlecontroltoLOWIDLEandpress

thecenterbutton(Figure35).

Figure35

7.Thefollowingmessagesdisplayastheparked

regenerationprocessbegins:

A.The“InitiatingDPFRegen.”message

displays(Figure36).

B.The“Waitingon”messagedisplays

(Figure37).

g212372

Figure37

g212406

C.Thecomputerdetermineswhetherthe

regenerationruns.Oneofthefollowing

messagesdisplaysintheInfoCenter:

•Iftheregenerationisallowed,the

“RegenInitiated.Allowupto30minutes

forcompletion”messagedisplaysin

theInfoCenter,waitforthemachine

tocompletetheparkedregeneration

process(Figure38).

35

Figure38

•Iftheregenerationprocessisnot

allowedbytheenginecomputer,the

“DPFRegenNotAllowed”message

displaysintheInfoCenter(Figure39).

Presstheleftbuttontoexittothehome

screen

Important:Ifyoudidnotmeetallthe

requirementsforregenerationorif

lessthan50hourshavepassedsince

thelastregeneration,the“DPFRegen

NotAllowed”messageappears.

Theengineiscold—wait.

Theengineiswarm—wait.

Theenginehot—regenerationinprogress

(percentcomplete).

9.Theparkedregenerationiscompletewhenthe

“RegenComplete”messagedisplaysinthe

InfoCenter.Presstheleftbuttontoexittothe

g213424

homescreen(Figure40).

Figure39

8.Whiletheregenerationisrunning,theInfoCenter

returnstothehomescreenandshowsthe

followingicons:

g212404

Figure40

RecoveryRegeneration

•Ifyouignoretherequestforaparkedregeneration

(displayedintheInfoCenter)andcontinueto

operatethemachine,acriticalamountofsoot

buildsupintheDPF .

•Ifarecoveryregenerationisneeded,the

InfoCenterdisplaysenginewarningSPN3719,

FMI16(Figure41)andtheenginecomputer

g212410

deratesenginepowerto85%.

g213867

Figure41

Important:Ifyoudonotcompletearecovery

regenerationwithin15minutes,theengine

computerderatesenginepowerto50%.

36

•Performarecovery-regenerationwhenever

thereisalossofenginepowerandaparked

regenerationcannoteffectivelycleantheDPFof

soot.

•Arecoveryregenerationrequiresupto4hours

tocomplete.

•Youneedadistributortechniciantoperformthe

recoveryregenerationprocess;contactyour

AuthorizedT oroDistributor.

Understandingthe OperatingCharacteristics oftheMachine

Practicedrivingthemachinebecauseithasa

hydrostatictransmissionanditscharacteristicsare

differentthanmanyturfmaintenancemachines.

Somepointstoconsiderwhenoperatingthetraction

unitandcuttingunitsarethetransmission,engine

speed,loadonthecuttingbladesandtheimportance

ofthebrakes.

WithT oroSmartPower™,theoperatordoesnothave

tolistentotheenginespeedinheavyconditions.

SmartPowerpreventsboggingdowninheavyturf

byautomaticallycontrollingthemachinespeedand

optimizingcuttingperformance.

Operatingthe Engine-CoolingFan

Theengine-cooling-fanswitchhas2positionsfor

controllingtheoperationofthefan.The2positions

areRandAUTO.Thefanhastheabilitytoreverse

toblowdebrisofftherearscreen.Undernormal

operatingconditions,theswitchshouldbeintheAUTO

position.InAuto,thefanspeedwillbecontrolled

bythecoolantorhydraulic-oiltemperatureandwill

automaticallyreversetoblowdebrisofftherear

screen.Areversecycleisautomaticallyinitiatedwhen

eitherthecoolantorhydraulic-oiltemperaturereaches

acertainpoint.Bypressingthefanswitchforward

intotheRposition,thefanwillcompleteamanually

initiatedreversecycle.Itisrecommendedtoreverse

thefanwhentherearscreeniscloggedorpriorto

enteringtheshoporthestoragearea.

OperatingTips

MowingWhenGrassIsDry

Moweitherinthelatemorningtoavoidthedew,which

causesgrassclumping,orinlateafternoontoavoid

thedamagecausedbydirectsunlightonthesensitive,

freshlymowedgrass.

Anothercharacteristictoconsideristheoperation

ofthepedalsthatareconnectedtothebrakes.The

brakescanbeusedtoassistinturningthemachine.

However,usethemcarefully ,especiallyonsoftor

wetgrassbecausetheturfmaybetornaccidentally.

Anotherbenetofthebrakesistomaintaintraction.

Forexample,insomeslopeconditions,theuphill

wheelslipsandlosestraction.Ifthissituation

occurs,depresstheuphillturnpedalgraduallyand

intermittentlyuntiltheuphillwheelstopsslipping,thus,

increasingtractiononthedownhillwheel.

Useextracarewhenoperatingthemachineon

slopes.Makesurethattheseatlatchisproperly

securedandtheseatbeltisbuckled.Driveslowly

andavoidsharpturnsonslopestopreventrollovers.

Forsteeringcontrol,thecuttingunitmustbelowered

whengoingdownhill.

Important:Allowenginetoidlefor5minutes

beforeshuttingitoffafterafullloadoperation.

Thisallowstheturbochargertocooldownbefore

shuttingtheengineoff.Failuretodosomaylead

toturbo-chargertrouble.

Beforestoppingtheengine,disengageallcontrols

andsettheenginespeedtoSlow.Settingtheengine