Toro 30864, Groundsmaster 4300-D, 30864A Operator's Manual

FormNo.3376-508RevA

Groundsmaster

®

4300-DTraction

Unit

ModelNo.30864—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3376-508*A

WARNING

rest.Writethenumbersinthespaceprovided.

platemountedontheleftsideoftheframeunderthefoot

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisincorporatedwith

themuferassembly.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:Thisengineisequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure1

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Introduction

Thismachineisaride-on,rotary-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawnsinparks,sportselds,andon

commercialgrounds.Itisnotdesignedforcuttingbrush,

mowinggrassandothergrowthalongsidehighways,orfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Themodelandserialnumbersareona

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................5

SoundPowerLevel..................................................6

SoundPressureLevel...............................................6

VibrationLevel......................................................6

SafetyandInstructionalDecals.................................7

Setup...........................................................................10

1AdjustingtheTirePressure....................................10

2AdjustingtheStepHeight.....................................10

3AdjustingtheControlArmPosition........................11

4RemovetheShippingBlocksandPins.....................11

ProductOverview.........................................................12

Controls...............................................................12

Specications........................................................16

Operation....................................................................17

CheckingtheEngineOil..........................................17

CheckingtheCoolingSystem...................................17

AddingFuel...........................................................18

CheckingtheHydraulicFluid...................................19

ChecktheTorqueoftheWheelNuts.........................20

StartingandStoppingtheEngine..............................20

PushingorTowingtheMachine................................20

JackingPoints........................................................21

TieDowns............................................................21

UnderstandingtheDiagnosticLight..........................22

ChangingtheCounterbalanceSettings.......................22

CheckingtheInterlockSwitches...............................22

HydraulicValveSolenoidFunctions..........................23

OperatingTips......................................................23

Maintenance.................................................................24

RecommendedMaintenanceSchedule(s)......................24

DailyMaintenanceChecklist....................................25

ServiceIntervalChart.............................................26

Lubrication...............................................................26

GreasingtheBearingsandBushings..........................26

EngineMaintenance..................................................28

ServicingtheAirCleaner.........................................28

ServicingtheEngineOilandFilter............................28

ServicingtheDieselParticulateFilter(DPF)...............29

ServicingtheDieselOxidationCatalyst

(DOC)..............................................................29

FuelSystemMaintenance...........................................29

DrainingtheFuelTank...........................................29

CheckingtheFuelLinesandConnections..................29

ServicingtheWaterSeparator..................................29

ServicingtheEngineFuelFilter................................30

FuelPick-upTubeScreen........................................30

ElectricalSystemMaintenance....................................31

ServicingtheBattery...............................................31

Fuses....................................................................31

DriveSystemMaintenance.........................................32

AdjustingtheTractionDriveforNeutral....................32

AdjustingtheRearWheelToe-in..............................32

CoolingSystemMaintenance......................................33

RemovingDebrisfromtheCoolingSystem................33

BrakeMaintenance....................................................34

AdjustingtheServiceBrakes....................................34

AdjustingtheParkingBrake....................................34

BeltMaintenance......................................................35

ServicingtheAlternatorBelt....................................35

HydraulicSystemMaintenance....................................35

ChangingtheHydraulicFluid...................................35

ReplacingtheHydraulicFilters.................................36

CheckingtheHydraulicLinesandHoses....................36

HydraulicSystemTestPorts.....................................37

Storage........................................................................37

PreparingtheTractionUnit.....................................37

PreparingtheEngine..............................................37

Schematics...................................................................38

3

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandardEN

836:1997,ISOstandard5395:1990,andANSIB71.4-2012.

Training

•Readtheoperator'smanualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,orproperty.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,long

trousers,hardhat,safetyglasses,andearprotection.Long

hair,looseclothing,orjewelrymaygettangledinmoving

parts.Donotoperatetheequipmentwhenbarefootor

wearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Warning—Fuelishighlyammable.Takethefollowing

precautions:

–Storefuelincontainersspecicallydesignedforthis

purpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

–Addfuelbeforestartingtheengine.Neverremove

thecapofthefueltankoraddfuelwhiletheengineis

runningorwhentheengineishot.

–Iffuelisspilled,donotattempttostarttheengine

butmovethemachineawayfromtheareaofspillage

andavoidcreatinganysourceofignitionuntilfuel

vaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely.

•Replacefaultysilencers/mufers.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Checkthattheoperator'spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutches,shiftintoneutral,andengagethe

parkingbrake.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.Toguardagainst

overturning:

–donotstoporstartsuddenlywhengoingupor

downhill;

–machinespeedsshouldbekeptlowonslopesand

duringtightturns;

–stayalertforhumpsandhollowsandotherhidden

hazards;

–Donotturnsharply.Usecarewhenreversing.

–Usecounterweight(s)orwheelweightsasidentied

intheoperator'smanual.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Watchoutfortrafcwhencrossingornearroadways.

4

•Stopthebladesrotatingbeforecrossingsurfacesother

thangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besureall

interlocksareattached,adjustedproperly,andfunctioning

properly.

•Donotchangetheenginegovernorsettingsorover-speed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

–stoponlevelground;

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachmentswhentransportingornot

inuse.

•Stoptheengineanddisengagedrivetoattachment:

–beforerefuelling;

–beforeremovingthegrasscatcher/catchers;

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator'sposition.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthemower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperatingthe

equipment.

•Reducethethrottlesettingduringenginerun-outand,if

theengineisprovidedwithashut-offvalve,turnthefuel

offattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingdecks.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuelstorage

areafreeofgrass,leaves,orexcessivegrease.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

•Disengagedrives,lowerthecuttingdecks,setparking

brake,stopengineandremovekeyfromignition.Wait

forallmovementtostopbeforeadjusting,cleaningor

repairing.

•Cleangrassanddebrisfromcuttingdecks,drives,

silencers/mufers,andenginetohelppreventres.Clean

upoilorfuelspillage.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.Wearprotectiveclothing

anduseinsulatedtools.

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCEN,ISO,orANSIstandard.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennisshoes

orsneakers.

5

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,or

otherhazards.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingdecks,attachments,and

anymovingparts.Keepeveryoneaway.

•Toensuresafetyandaccuracy,haveanAuthorizedToro

Distributorcheckthemaximumenginespeedwitha

tachometer.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•UseonlyToro-approvedattachmentsandreplacement

parts.Thewarrantymaybevoidedifusedwith

unapprovedattachments.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrolof

themachine.

•Raisethecuttingdeckswhendrivingfromoneworkarea

toanother.

•Donottouchtheengine,silencer/mufer,orexhaust

pipewhiletheengineisrunningorsoonafterithas

stoppedbecausetheseareascouldbehotenoughtocause

burns.

•Iftheenginestallsorlosesheadwayandcannotmakeit

tothetopofaslope,donotturnthemachinearound.

Alwaysbackslowly,straightdowntheslope.

•Whenapersonorpetappearsunexpectedlyinornearthe

mowingarea,stopmowing.Carelessoperation,combined

withterrainangles,ricochets,orimproperlypositioned

guardscanleadtothrownobjectinjuries.Donotresume

mowinguntiltheareaiscleared.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof105dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinEN11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof93

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=2.4m/s

Measuredvibrationlevelforlefthand=2.1m/s

UncertaintyValue(K)=1.18m/s

2

2

2

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightandall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Seekimmediatemedicalattentionifuidis

injectedintoskin.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

decksandattachmentstotheground.

•Checkallfuellinesfortightnessandwearonaregular

basis.Tightenorrepairthemasneeded.

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

WholeBody

Measuredvibrationlevel=0.9m/s

UncertaintyValue(K)=0.45m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

6

2

2

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

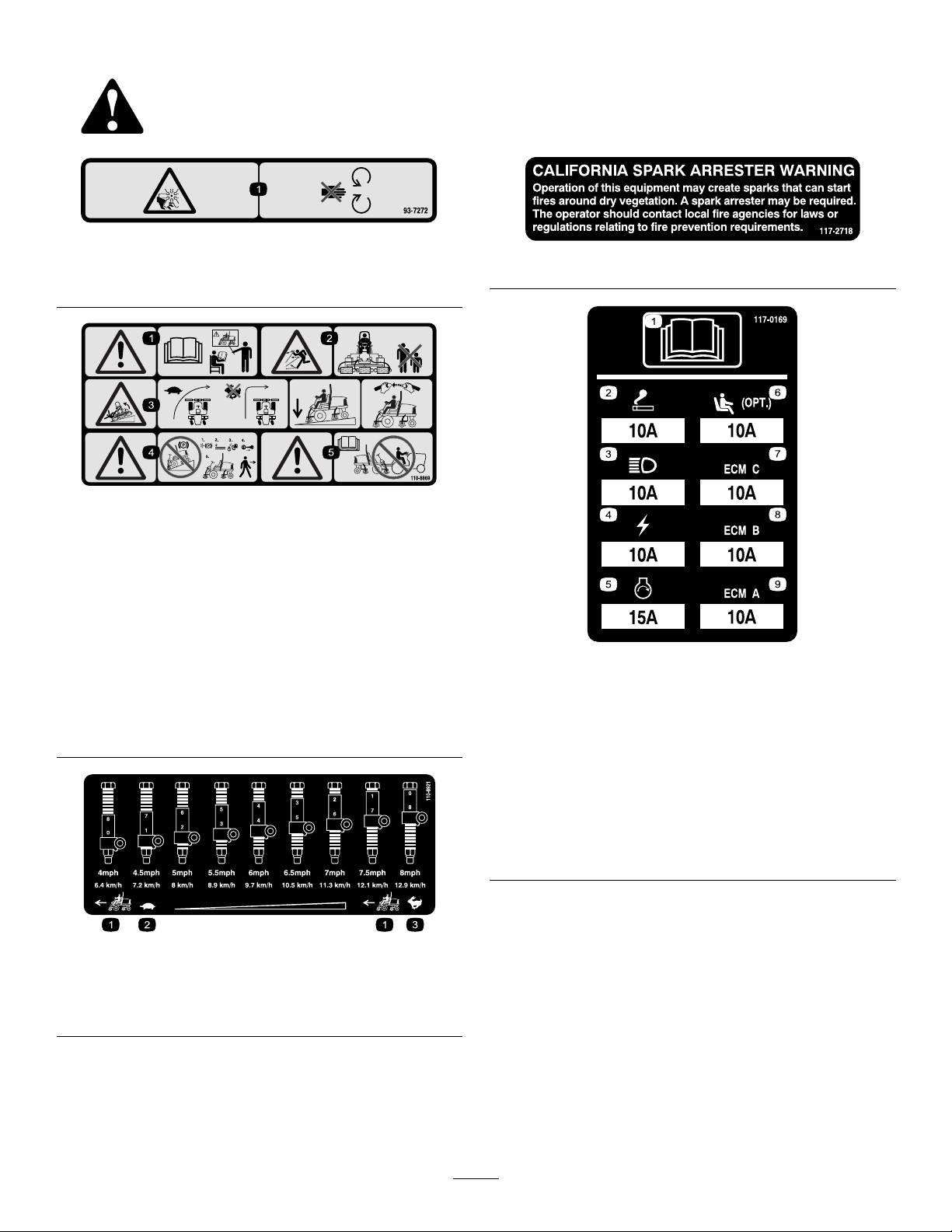

93-7272

1.Cutting/dismembermenthazard;fan—stayawayfrom

movingparts.

110-8869

117–2718

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

3.Tippinghazard—slowmachinebeforeturning,donotturn

athighspeeds;lowerthecuttingunitwhendrivingdown

slopes;usearolloverprotectionsystemandweartheseat

belt.AlwayswearaseatbeltwhenaROPSisinplace.

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingdecks,stoptheengineand

removetheignitionkeybeforeleavingthemachine.

5.Warning—readtheOperator'sManual,donottowthe

machine.

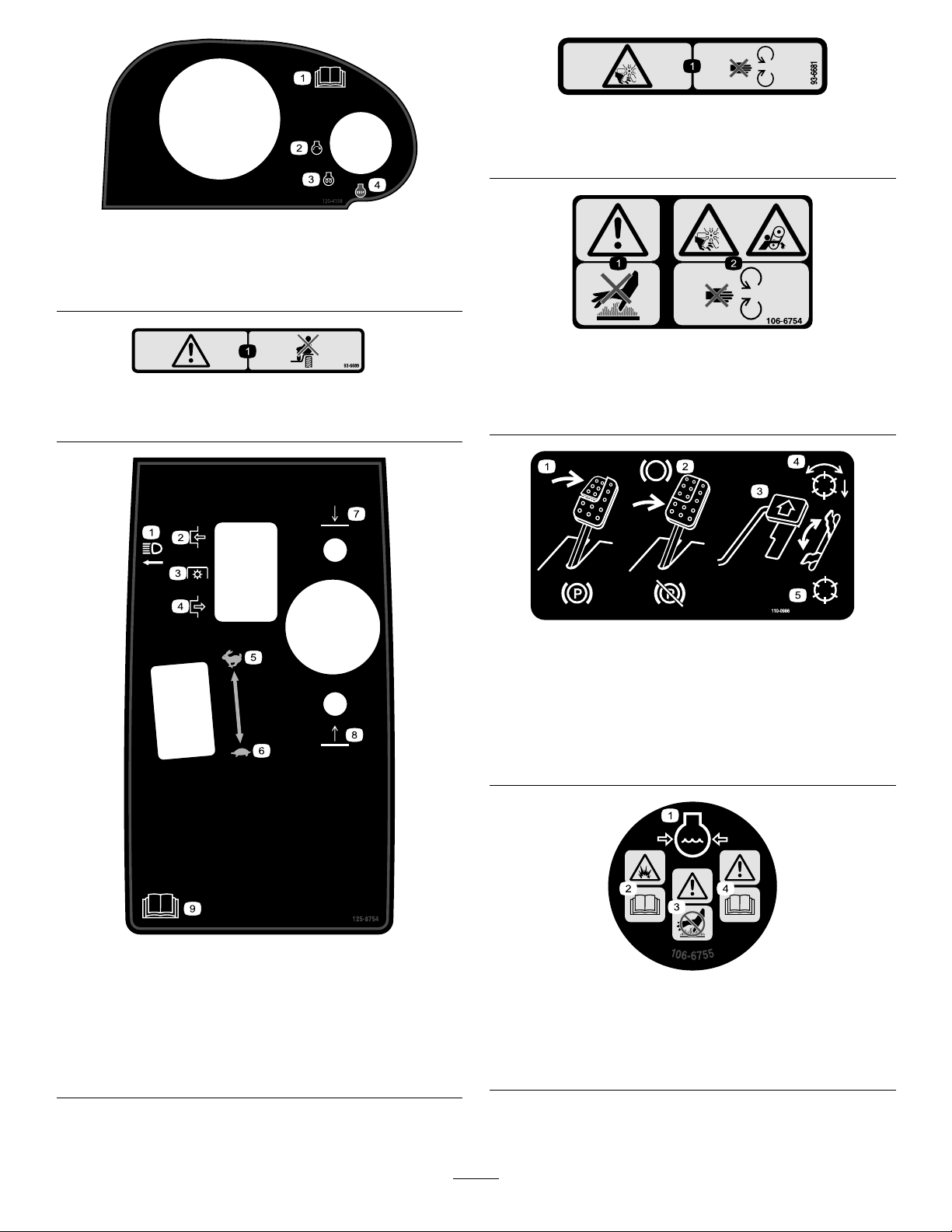

110-8921

1.Tractionunitspeed

2.Slow

3.Fast

117–0169

1.ReadtheOperator'sManual.

2.Powerpoint—10amp

3.Headlights—10amp

4.Power—10amp

5.Enginestart—15amp

6.Optionalairrideseatsuspension—20amp

7.EnginecomputermanagementC—7.5amp

8.EnginecomputermanagementB—7.5amp

9.EnginecomputermanagementA—7.5amp

7

93-6681

1.Cutting/dismemberment—hazard,fan-stayawayfrom

movingparts.

120–4158

1.ReadtheOperator’s

Manual.

2.Engine—start4.Engine—stop

1.Warning—donotcarrypassengers.

3.Engine—preheat

106-6754

93-6689

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

110-0986

1.Pressthebrakepedalandparkingbrakepedaltosetthe

parkingbrake.

2.Pressthebrakepedaltoapplythebrake.

3.Pressthetractionpedaltomovethemachineforward.

4.PTOenabledmode

5.Transportmode(NoPTO)

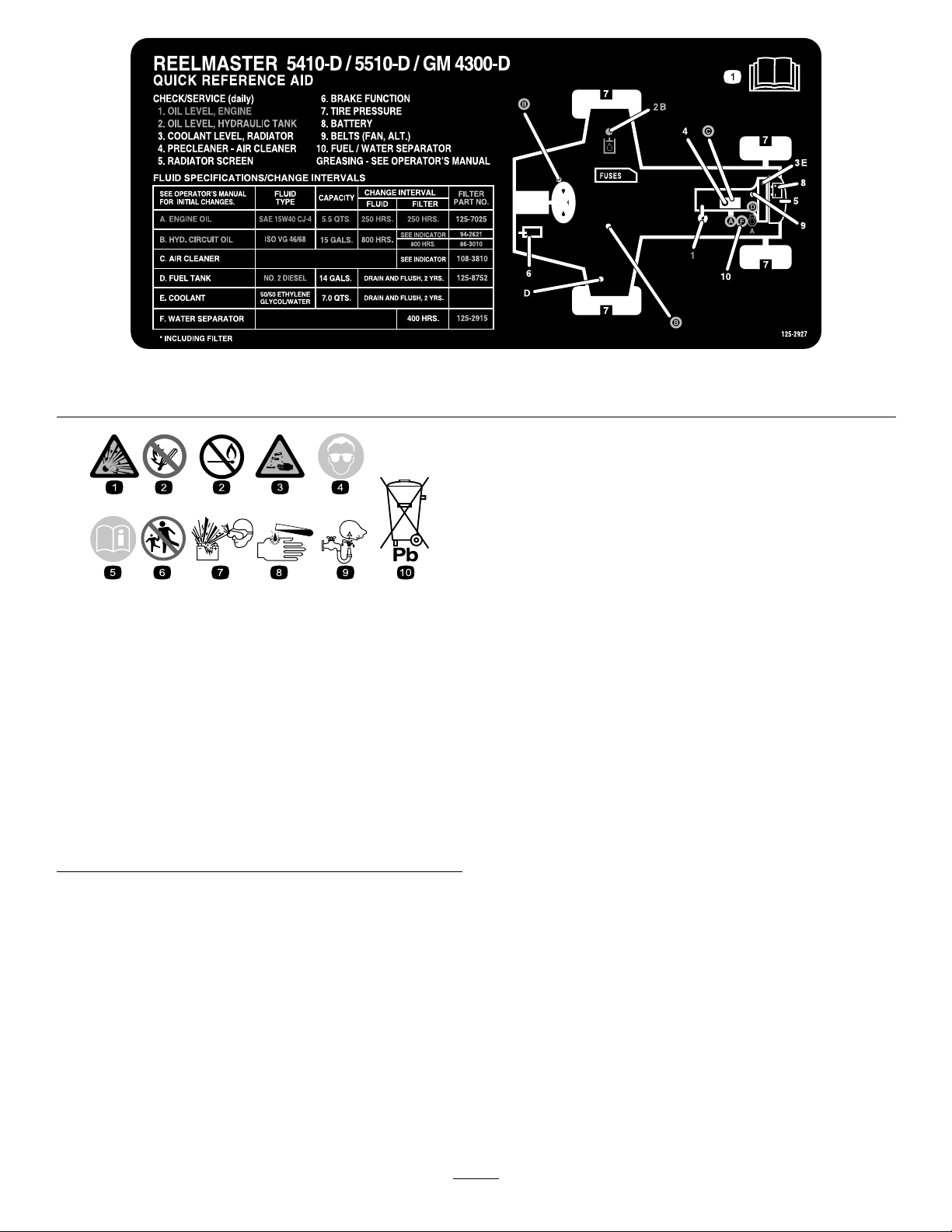

125–8754

1.Headlights

2.Engage7.Lowerthecuttingunits

3.Powertake-off(PTO)

4.Disengage

5.Fast

6.Slow

8.Raisethecuttingunits

9.ReadtheOperator’s

Manual.

1.Enginecoolantunder

2.Explosionhazard—read

8

pressure.

theOperator'sManual.

106-6755

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

1.ReadtheOperator’sManualformaintenanceinformation.

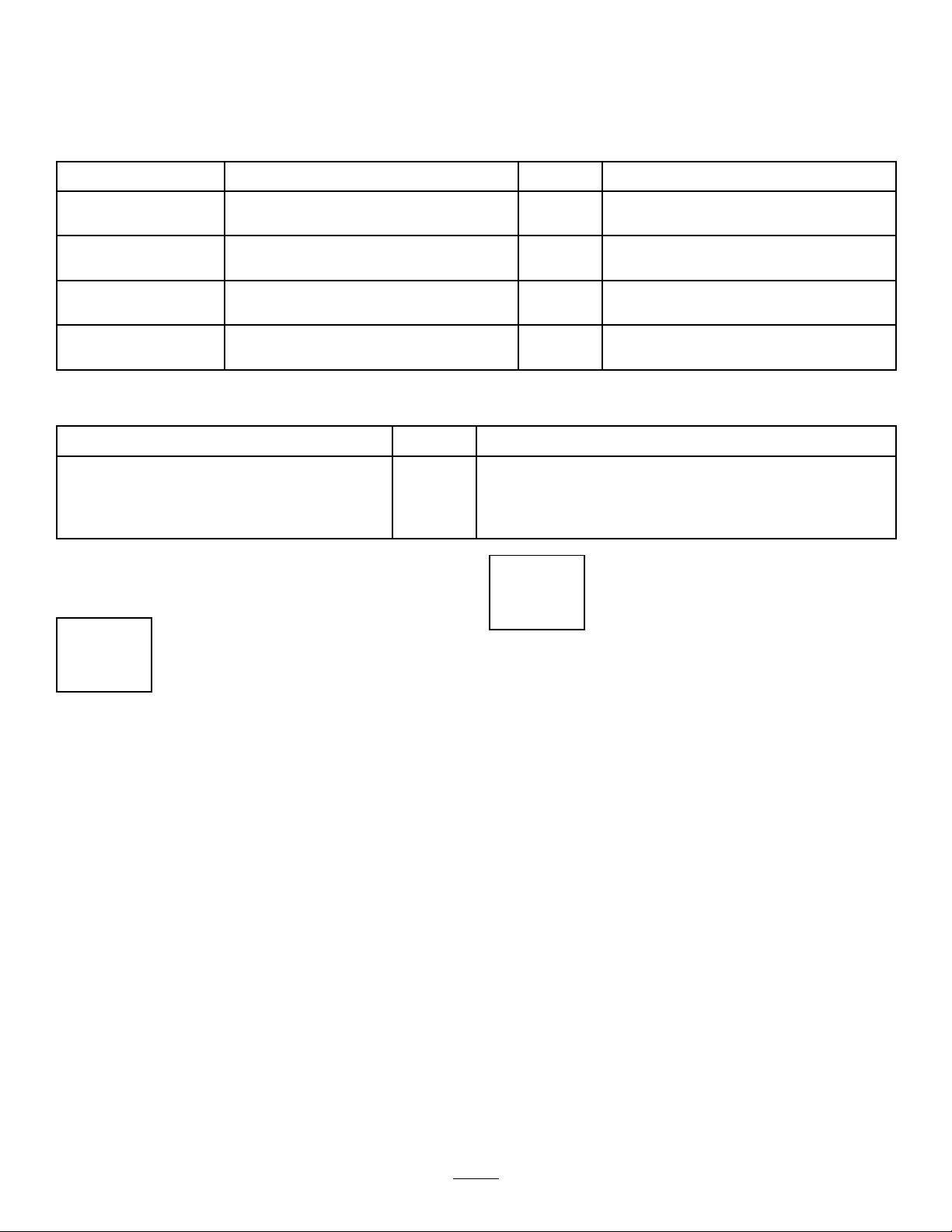

BatterySymbols

Someorallofthesesymbolsareonyourbattery

125–2927

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery .

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

MediaandAdditionalParts

Description

Operator'sManual

EngineOperator'sManual

PartsCatalog

OperatorTrainingMaterial

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Qty.

Qty.

–

–

–

–

1

1

1

1

Reviewbeforeoperatingmachine

Adjustthetirepressure.

Adjustthestepheight.

Adjustthecontrolarmposition.

Removeshippingblocksandpins

Use

Use

2

1

AdjustingtheTirePressure

NoPartsRequired

Procedure

Thetiresareover-inatedforshipping.Therefore,release

someoftheairtoreducethepressure.Correctairpressurein

thefrontandreartiresis83to103kPa(12to15psi).

Important:Maintainevenpressureinalltirestoensure

uniformcontactwiththeturf.

AdjustingtheStepHeight

NoPartsRequired

Procedure

Theheightofthestepscanbeadjustedfortheoperators

comfort.

1.Removethe2boltsandnutssecuringthestepbrackets

tothetractionunitframe(Figure2)

10

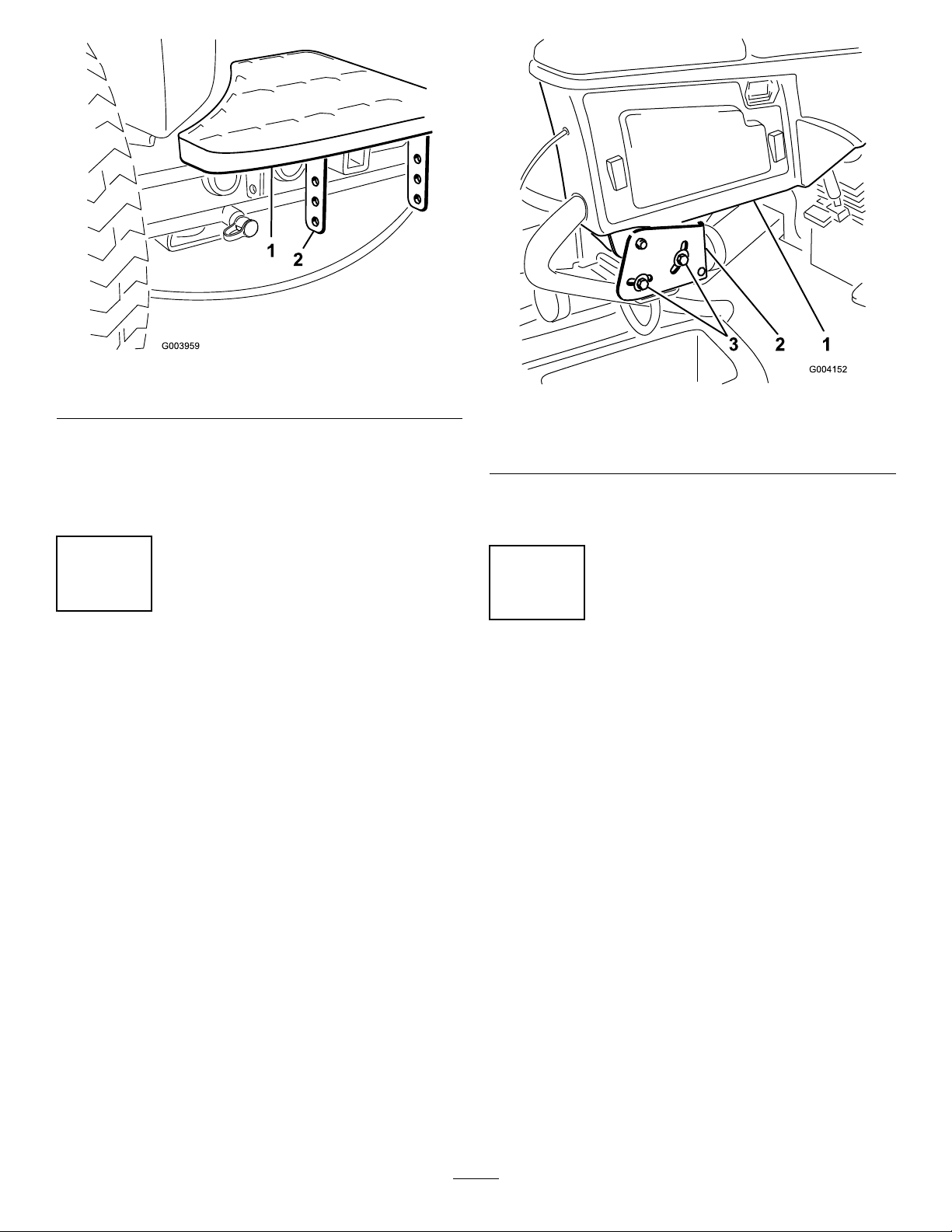

Figure2

1.Step2.Stepbrackets

2.Raiseorlowerthesteptothedesiredheightand

re-securethebracketstotheframewiththe2bolts

andnuts.

3.Repeattheprocedureontheotherstep.

3

AdjustingtheControlArm Position

NoPartsRequired

Procedure

Thecontrolarmpositioncanbeadjustedfortheoperators

comfort.

1.Loosenthe2boltssecuringthecontrolarmtothe

retainingbracket(Figure3).

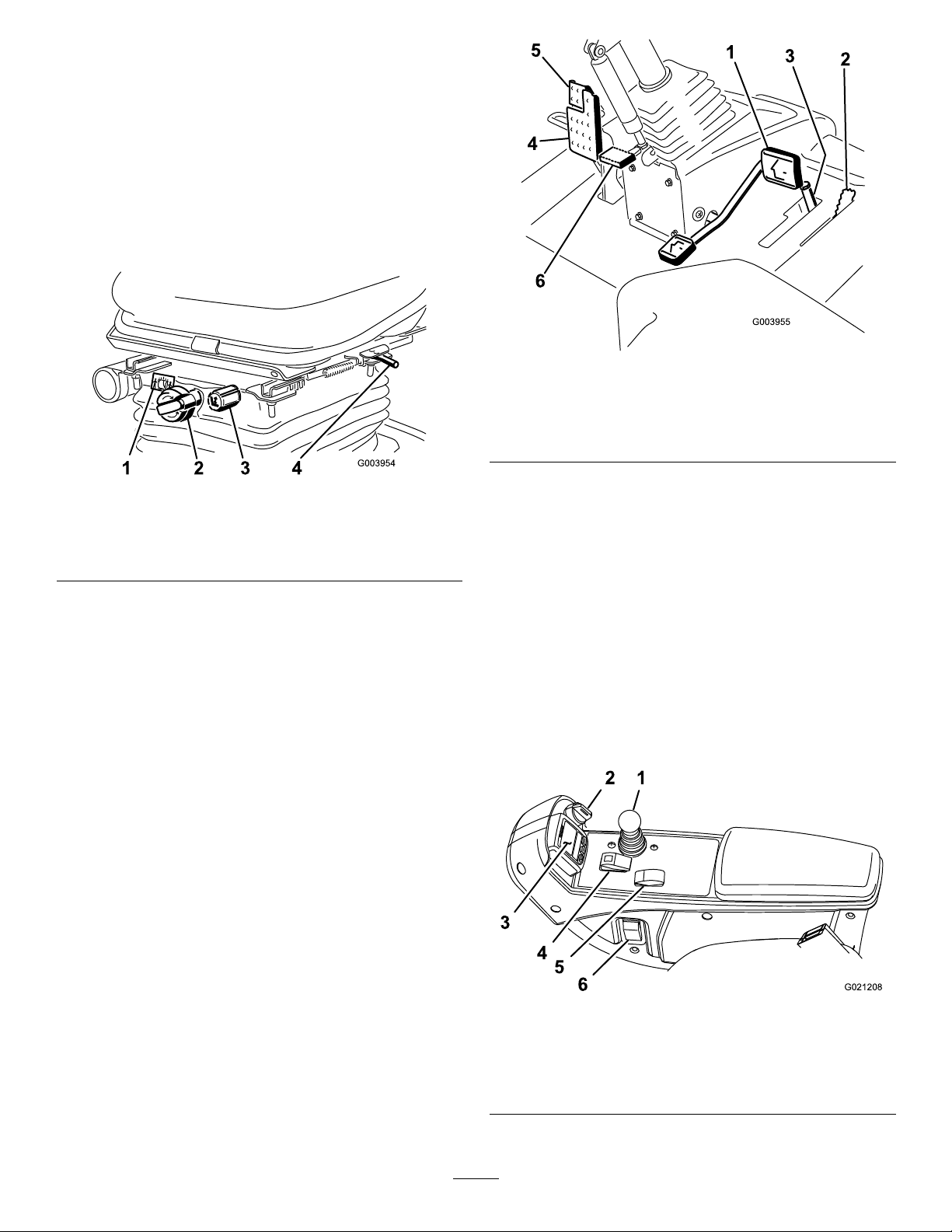

Figure3

1.Controlarm3.Bolts(2)

2.Retainingbrackets

2.Rotatethecontrolarmtothedesiredpositionand

tightenthe2bolts.

4

RemovetheShippingBlocks andPins

NoPartsRequired

Procedure

1.Removeanddiscardtheshippingblocksfromthe

cuttingdecks.

2.Removeanddiscardtheshippingpinsfromthecutting

decksuspensionarms.Theshippingpinsstabilizethe

cuttingdecksduringshippingandmustberemoved

beforeoperation.

11

ProductOverview

1

2

3

4

5

6

G021208

Controls

SeatAdjustingKnobs

Theseatadjustinglever(Figure4)allowsyoutoadjustthe

seatforeandaft.Theweightadjustingknobadjuststheseat

fortheoperator'sweight.Theweightgaugeindicateswhen

theseatisadjustedtotheweightoftheoperator.Theheight

adjustingknobadjuststheseatfortheoperator'sheight.

Figure4

1.Weightgauge3.Heightadjustingknob

2.Weightadjustingknob

4.Adjustinglever(foreand

aft)

Figure5

1.Tractionpedal4.Brakepedal

2.Mowspeedlimiter5.Parkingbrake

3.Spacers

6.Tiltsteeringpedal

TiltSteeringPedal

Totiltthesteeringwheeltowardsyou,pressthefootpedal

(Figure5)down,andpullthesteeringtowertowardyouto

themostcomfortablepositionandthenreleasethepedal.

TractionPedal

Thetractionpedal(Figure5)controlstheforwardandreverse

operation.Pressthetopofthepedaltomoveforwardandthe

bottomtomoverearward.Groundspeeddependsonhow

faryoupressthepedal.Fornoload,maximumgroundspeed,

fullypressthepedalwhilethethrottleisintheFastposition.

Tostop,reducefootpressureonthetractionpedalandallow

ittoreturntothecenterposition.

MowSpeedLimiter

Whenthemowspeedlimiter(Figure5)isippedupitwill

controlthemowspeedandallowthecuttingdeckstobe

engaged.Eachspaceradjuststhemowingspeedby½mile

perhour.Themorespacersyouhave,onthetopofthebolt

thesloweryouwillgo.Fortransport,ipbackthemowspeed

limiterandyouwillhavemaximumtransportspeed.

BrakePedal

Pressthebrakepedal(Figure5)tostopthemachine.

ParkingBrake

Toengagetheparkingbrake,(Figure5)pushdownonthe

brakepedalandpressthetopforwardtolatch.Toreleasethe

parkingbrake,pressthebrakepedaluntiltheparkingbrake

latchretracts.

EngineSpeedSwitch

Theenginespeedswitch(Figure6)hastwomodestochange

theenginespeed.Bymomentarilytappingtheswitch,the

enginespeedcanbeincreasedordecreasedin100rpm

increments.Byholdingtheswitchdowntheenginewill

automaticallymovetoHighorLowidle,dependingonwhich

endoftheswitchisdepressed.

Figure6

1.Lowermow/raisecontrol

lever

2.Keyswitch5.Enginespeedswitch

3.InfoCenter

4.Enable/disableswitch

6.Headlightswitch

12

Loading...

Loading...