FormNo.3424-443RevA

Groundsmaster

®

4300-DTraction

Unit

ModelNo.30864—SerialNo.403270001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3424-443*A

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

WARNING

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Themodel

andserialnumbersareonaplatemountedonthe

leftsideoftheframeunderthefootrest.Writethe

numbersinthespaceprovided.

ModelNo.

SerialNo.

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure1),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure1

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Introduction

Thismachineisaride-on,rotary-bladelawnmower

intendedtobeusedbyprofessional,hiredoperators

incommercialapplications.Itisprimarilydesigned

forcuttinggrassonwell-maintainedlawnsinparks,

sportselds,andoncommercialgrounds.

Important:Tomaximizethesafety ,performance,

andproperoperationofthismachine,carefully

readandfullyunderstandthecontentsofthis

Operator’sManual.Failingtofollowthese

operatinginstructionsortoreceiveproper

trainingmayresultininjury.Formoreinformation

onsafeoperatingpractices,includingsafetytips

andtrainingmaterials,gotowww.Toro.com.

YoumaycontactT orodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

Setup........................................................................9

1AdjustingtheControlArmPosition...................9

2RemovingtheShippingBlocksand

Pins.................................................................9

3AdjustingtheRollerScraper...........................10

4InstallingtheMulchingBafe...........................11

5PreparingtheMachine....................................11

ProductOverview...................................................12

Controls...........................................................12

Specications..................................................19

CuttingUnitSpecications................................20

Attachments/Accessories.................................20

BeforeOperation.................................................21

BeforeOperationSafety...................................21

FillingtheFuelTank..........................................21

CheckingtheEngine-OilLevel..........................23

CheckingtheCoolingSystem...........................23

CheckingtheHydraulicSystem........................23

DrainingtheWaterSeparator...........................23

CheckingtheTirePressure...............................23

CheckingtheT orqueoftheWheel-Lug

Nuts..............................................................23

AdjustingtheHeightofCut...............................24

CheckingtheSafety-InterlockSwitches............25

BurnishingtheBrakes.......................................25

SelectingaBlade..............................................25

UnderstandingtheDiagnosticLight..................26

ChangingtheCounterbalanceSettings............26

ChoosingAccessories......................................27

DuringOperation.................................................28

DuringOperationSafety...................................28

StartingtheEngine...........................................29

ShuttingOfftheEngine.....................................29

CuttingGrasswiththeMachine........................29

DieselParticulateFilterRegeneration...............30

OperatingTips.................................................42

AfterOperation....................................................43

AfterOperationSafety......................................43

IdentifyingtheTie-DownPoints........................43

HaulingtheMachine.........................................43

PushingorT owingtheMachine........................44

Maintenance...........................................................45

RecommendedMaintenanceSchedule(s)...........45

DailyMaintenanceChecklist.............................46

Pre-MaintenanceProcedures..............................47

MaintenanceSafety..........................................47

RaisingtheMachine.........................................47

Lubrication..........................................................48

GreasingtheBearingsandBushings................48

EngineMaintenance...........................................50

EngineSafety...................................................50

ServicingtheAirCleaner..................................50

ServicingtheEngineOil....................................51

ServicingtheDiesel-OxidationCatalyst

(DOC)andtheSootFilter..............................52

FuelSystemMaintenance...................................53

ServicingtheFuelFilter....................................53

ServicingtheFuelSystem................................53

ServicingtheWaterSeparator..........................54

ServicingtheFuel-PickupTube........................54

ElectricalSystemMaintenance...........................55

ElectricalSystemSafety...................................55

ServicingtheBattery.........................................55

LocatingtheFuses...........................................55

DriveSystemMaintenance..................................56

AdjustingtheTractionDriveforNeutral.............56

AdjustingtheRearWheelT oe-in.......................56

CoolingSystemMaintenance..............................57

CoolingSystemSafety.....................................57

CheckingtheCoolingSystem...........................57

RemovingDebrisfromtheCooling

System..........................................................57

BrakeMaintenance.............................................59

AdjustingtheParkingBrakes............................59

AdjustingtheParking-BrakeLatch....................59

BeltMaintenance................................................60

ServicingtheAlternatorBelt.............................60

HydraulicSystemMaintenance...........................60

HydraulicSystemSafety...................................60

CheckingtheHydraulic-FluidLevel...................60

ChangingtheHydraulicFluid............................62

ReplacingtheHydraulicFilters.........................62

CheckingtheHydraulicLinesand

Hoses............................................................63

TestingtheHydraulic-SystemPressure............63

HydraulicValveSolenoidFunctions..................63

CuttingUnitMaintenance.....................................64

SeparatingtheCuttingUnitfromtheTraction

Unit...............................................................64

MountingtheCuttingUnitstotheTraction

Unit...............................................................64

ServicingtheFrontRoller.................................64

BladeMaintenance..............................................65

BladeSafety.....................................................65

ServicingtheBladePlane.................................65

RemovingandInstallingaBlade.......................67

InspectingandSharpeningtheBlade................67

Storage...................................................................68

PreparingtheMachineforStorage...................68

StoringtheCuttingUnits...................................69

3

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395:2013andANSIB71.4-2017.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersandpetsasafedistanceawayfrom

themachine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachine,shutofftheengine,removethe

key,andwaitforallmovingpartstostopbefore

servicing,fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury .T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthisOperator’sManual.

,which

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

93-6681

1.Cutting/dismemberment—hazard,fan-stayawayfrom

movingparts.

93-6689

1.Warning—donotcarrypassengers.

decal93-6681

decal93-7818

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto1 15to149N∙m(85to1 10

ft-lb).

decal93-6689

93-7272

1.Cutting/dismembermenthazard;fan—stayawayfrom

movingparts.

decal93-7272

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

4

decal106-6754

decal106-6755

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

110-0986

1.Pressthebrakepedalandparking-brakepedaltoengage

theparkingbrake.

2.Pressthebrakepedaltoapplythebrake.

3.Pressthetractionpedaltomovethemachineforward.

4.PTOenabledmode

5.Transportmode(NoPTO)

decal117-0169

117-0169

1.ReadtheOperator'sManual.

2.Powerpoint(10A)

3.Headlights(10A)

4.Power(10A)

decal110-0986

5.Enginestart(15A)

6.Optionalairrideseatsuspension(20A)

7.EnginecomputermanagementC(7.5A)

8.EnginecomputermanagementB(7.5A)

9.EnginecomputermanagementA(7.5A)

1.Tractionunitspeed

2.Slow

3.Fast

decal110-8921

110-8921

decal117-4764

117-4764

1.Thrownobjecthazard—keepbystandersasafedistance

awayfromthemachine.

2.Cuttinghazardofhand,mowerblade—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

3.Cuttinghazardoffoot,mowerblade—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

5

decal120-4158

120-4158

1.ReadtheOperator’s

Manual.

2.Engine—start

133-8062

BatterySymbols

Someorallofthesesymbolsareonyourbattery

3.Engine—preheat

4.Engine—shutoff

decal133-8062

decal125-8754

125-8754

1.Headlights

2.Engage7.Lowerthecuttingunits

3.Powertake-off(PTO)

4.Disengage

decalbatterysymbols

5.Fast

6.Slow

8.Raisethecuttingunits

9.ReadtheOperator’s

Manual.

1.Explosionhazard

2.Nore,opename,or

6.Keepbystandersasafe

7.Weareyeprotection;

smoking

3.Causticliquid/chemical

8.Batteryacidcancause

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

10.Containslead;donot

Manual.

distanceawayfromthe

battery.

explosivegasescan

causeblindnessandother

injuries.

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard

6

1.ReadtheOperator’sManualformaintenanceinformation.

1.Heightofcut

decal125-2927

125-2927

decal104-1086

104-1086

7

decal133-2930

133-2930

1.Warning—readtheOperator'sManual;donotoperatethis

machineunlessyouaretrained.

4.Tippinghazard—slowthemachinebeforeturning;donotturn

athighspeeds;onlydriveonslopeswiththecuttingunits

lowered;alwayswearaseatbelt.

2.Warning—wearhearingprotection.5.Warning—donotparkonslopes;locktheparkingbrake,shut

offtheengineandremovetheignitionkeybeforeleavingthe

machine.

3.Thrownobjecthazard—keepbystandersasafedistance

awayfromthemachine.

6.Warning—readtheOperator'sManual;donottowthe

machine.

133-2931

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineintheconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

decal133-2931

1.Warning—readtheOperator'sManual;donotoperatethis

machineunlessyouaretrained.

4.Tippinghazard—donotdriveacrossordownslopesgreater

than15°;onlydriveonslopeswiththecuttingunitslowered;

alwayswearaseatbelt.

2.Warning—wearhearingprotection.5.Warning—donotparkonslopes;engagetheparkingbrake,

lowerthecuttingunits,shutofftheengine,andremovethe

ignitionkeybeforeleavingthemachine.

3.Thrownobjecthazard—keepbystandersaway .

6.Warning—readtheOperator'sManual;donottowthe

machine.

8

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

MediaandAdditionalParts

Description

Operator'sManual

Engineowner’smanual1

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Qty.

Qty.

–

–

–

–

–

1

Adjustthecontrolarmposition.

Removeshippingblocksandpins.

Adjusttherollerscraper(optional).

Installthemulchingbafe(optional).

Preparethemachine.

Use

Use

1

AdjustingtheControlArm Position

NoPartsRequired

Procedure

Thecontrolarmpositioncanbeadjustedforyour

comfort.

1.Loosenthe2boltssecuringthecontrolarmto

theretainingbracket(Figure2).

g031681

Figure2

1.Controlarm3.Bolts(2)

2.Retainingbrackets

2.Rotatethecontrolarmtothedesiredposition

andtightenthe2bolts.

9

2

3

RemovingtheShipping

BlocksandPins

NoPartsRequired

Procedure

1.Removeanddiscardtheshippingblocksfrom

thecuttingunits.

2.Removeanddiscardtheshippingpinsfromthe

cutting-unitsuspensionarms.

Note:Theshippingpinsstabilizethecutting

unitsduringshipping;removethembefore

operatingthemachine.

AdjustingtheRoller Scraper

Optional

NoPartsRequired

Procedure

Theoptionalrearrollerscraperfunctionsbestwhen

thereisanevengapof0.5to1mm(0.02to0.04inch)

betweenthescraperandtheroller.

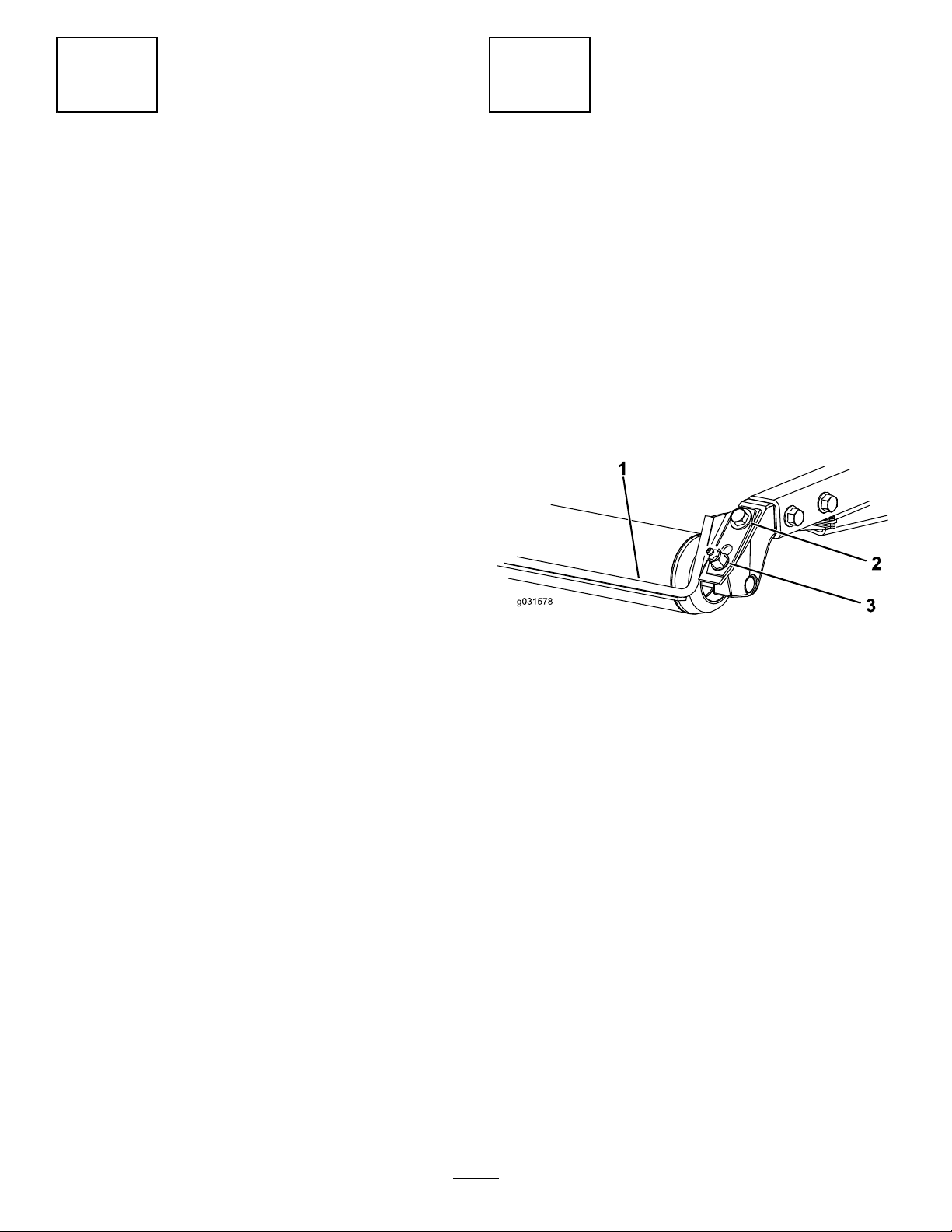

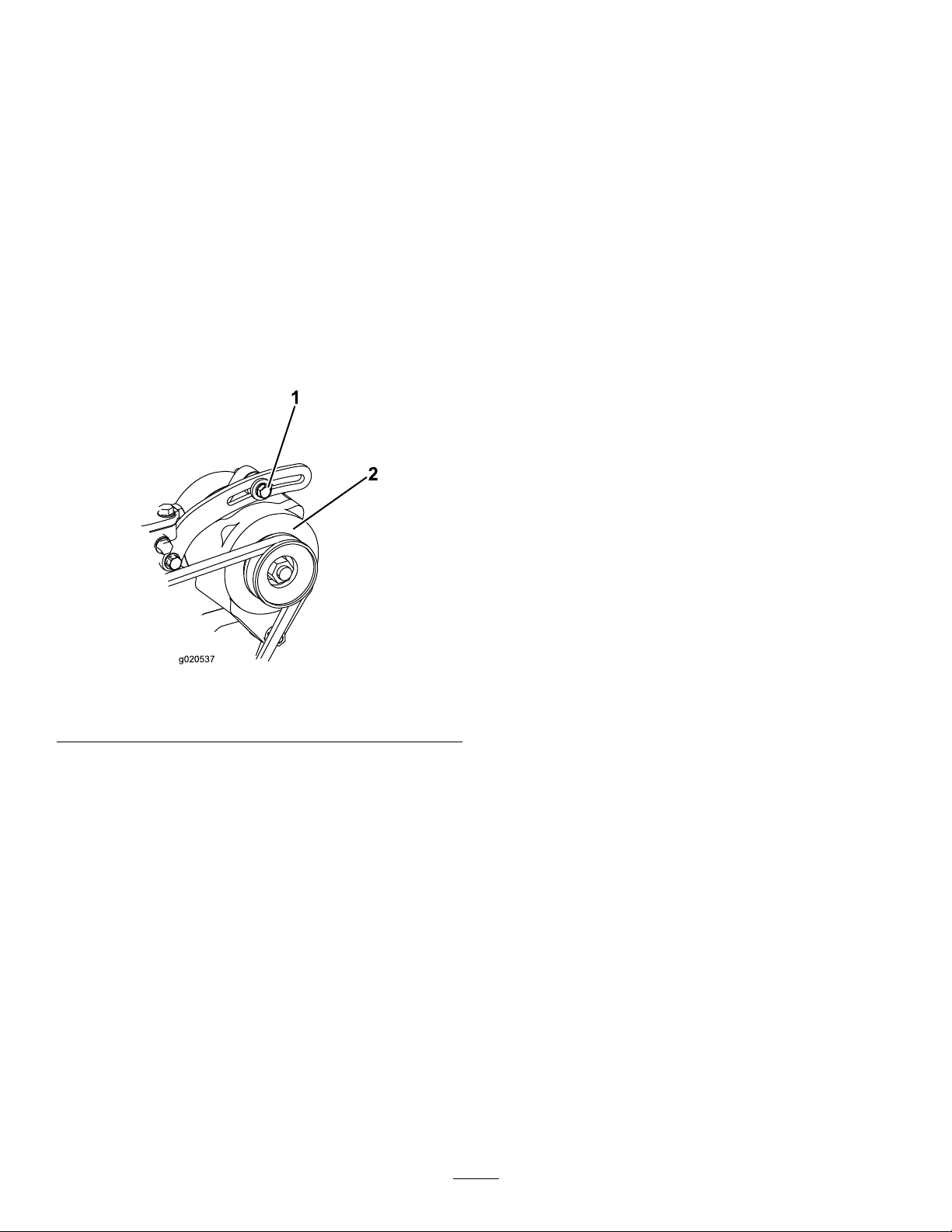

1.Loosenthegreasettingandthemounting

screw(Figure3).

Figure3

1.Rollerscraper

2.Mountingscrew

2.Slidethescraperupordownuntilyouobtaina

gapof0.5to1mm(0.02to0.04inch)between

therodandtheroller.

3.Tightenthegreasettingandscrewto41N∙m

(30ft-lb)inanalternatingsequence.

3.Greasetting

g031578

10

4

5

InstallingtheMulching

Bafe

Optional

NoPartsRequired

Procedure

1.Thoroughlycleandebrisfromthemountingholes

ontherearwallandleftwallofthechamber.

2.Installthemulchingbafeintherearopening

andsecureitwith5ange-headbolts(Figure4).

PreparingtheMachine

NoPartsRequired

CheckingtheTirePressure

Checkthetirepressurebeforeuse;refertoChecking

theTirePressure(page23).

Important:Maintainpressureinalltiresto

ensureagoodquality-of-cutandpropermachine

performance.Donotunderinatethetires.

CheckingtheFluidLevels

1.Checktheengine-oillevelbeforestartingthe

engine;refertoCheckingtheEngine-OilLevel

(page51).

2.Checkthehydraulic-uidlevelbeforestarting

theengine;refertoCheckingtheHydraulic-Fluid

Level(page60).

3.Checkthecoolingsystembeforestartingthe

engine;refertoCheckingtheCoolingSystem

(page57).

Figure4

1.Mulchingbafe

3.Verifythatthemulchingbafedoesnotinterfere

withthetipofthebladeanddoesnotprotrude

insidethesurfaceoftherearchamberwall.

2.Flange-headbolt

DANGER

Usingthehigh-liftbladewiththe

mulchingbafecouldcausetheblade

tobreak,resultinginpersonalinjuryor

death.

Donotusethehigh-liftbladewiththe

bafe.

GreasingtheMachine

g031579

Greasethemachinebeforeuse;refertoGreasingthe

BearingsandBushings(page48).Failuretoproperly

greasethemachineresultsinprematurefailureof

criticalparts.

11

ProductOverview

BrakePedal

Pressthebrakepedal(Figure5)tostopthemachine.

Controls

Tilt-SteeringPedal

TractionPedal

Thetractionpedal(Figure5)controlstheforwardand

reverseoperation.Pressthetopofthepedaltomove

forwardandthebottomtomoverearward.Ground

speeddependsonhowfaryoupressthepedal.For

noload,maximumgroundspeed,fullypressthepedal

whilethethrottleisintheFASTposition.

Tostop,reducefootpressureonthetractionpedal

andallowittoreturntothecenterposition.

Mow-SpeedLimiter

Whenthemow-speedlimiter(Figure5)isippedupit

willcontrolthemowspeedandallowthecuttingdecks

tobeengaged.Eachspaceradjuststhemowing

speedby0.8km/h(0.5mph).Themorespacers

youhaveonthetopofthebolt,thesloweryouwill

go.Fortransport,ipbackthemowspeedlimiterfor

maximum-transportspeed.

Totiltthesteeringwheeltowardyou,pressthefoot

pedaldown,pullthesteeringtowertowardyouto

themostcomfortableposition,andreleasethepedal

(Figure5).Tomovethesteeringwheelawayfrom

you,pressthefootpedalandreleaseitwhenthe

steeringwheelreachesthedesiredoperatingposition.

ParkingBrake

Toengagetheparkingbrake,(Figure5)pushdown

thebrakepedalandpressthetopforwardtolatch.To

disengagetheparkingbrake,pressthebrakepedal

untiltheparking-brakelatchretracts.

Figure5

1.Tractionpedal4.Brakepedal

2.Mow-speedlimiter5.Parkingbrake

3.Spacers

6.Tilt-steeringpedal

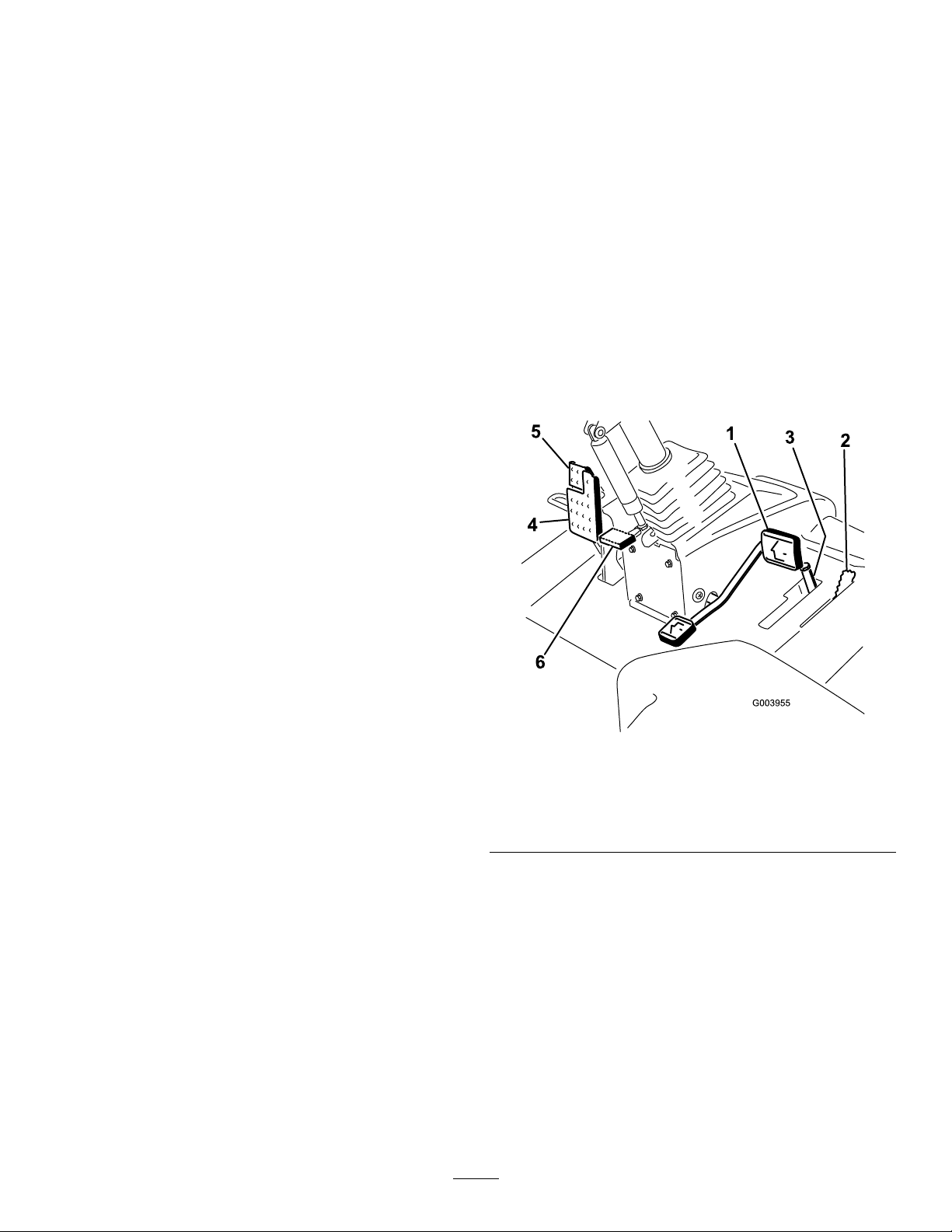

Engine-SpeedSwitch

Theengine-speedswitch(Figure6)has2modesto

changetheenginespeed.Taptheswitchtoincrease

ordecreasetheenginespeedin100rpmincrements.

Holdtheswitchdowntoautomaticallymovethe

enginetoHighorLowidle,dependingonwhichend

oftheswitchthatyoupress.

g003955

12

Figure6

1.Lowermow/raisecontrol

lever

2.Keyswitch5.Engine-speedswitch

3.InfoCenter

4.Enable/disableswitch

6.Headlightswitch

KeySwitch

Thekeyswitch(Figure6)has3positions:OFF,

ON/PREHEAT,andSTART.

LowerMow/RaiseControlLever

Thelowermow/raisecontrollever(Figure6)raises

andlowersthecuttingunitsandalsostartsandstops

themowerswhenthemowersareenabledinthemow

mode.Whenstartingthecuttingunitsinthedown

position,thisleverwillturnthecuttingunitsonifthe

PTOandthemowspeedlimiterareengaged.

g021208

Figure7

1.Hydraulic-lter-restrictionindicator

g031683

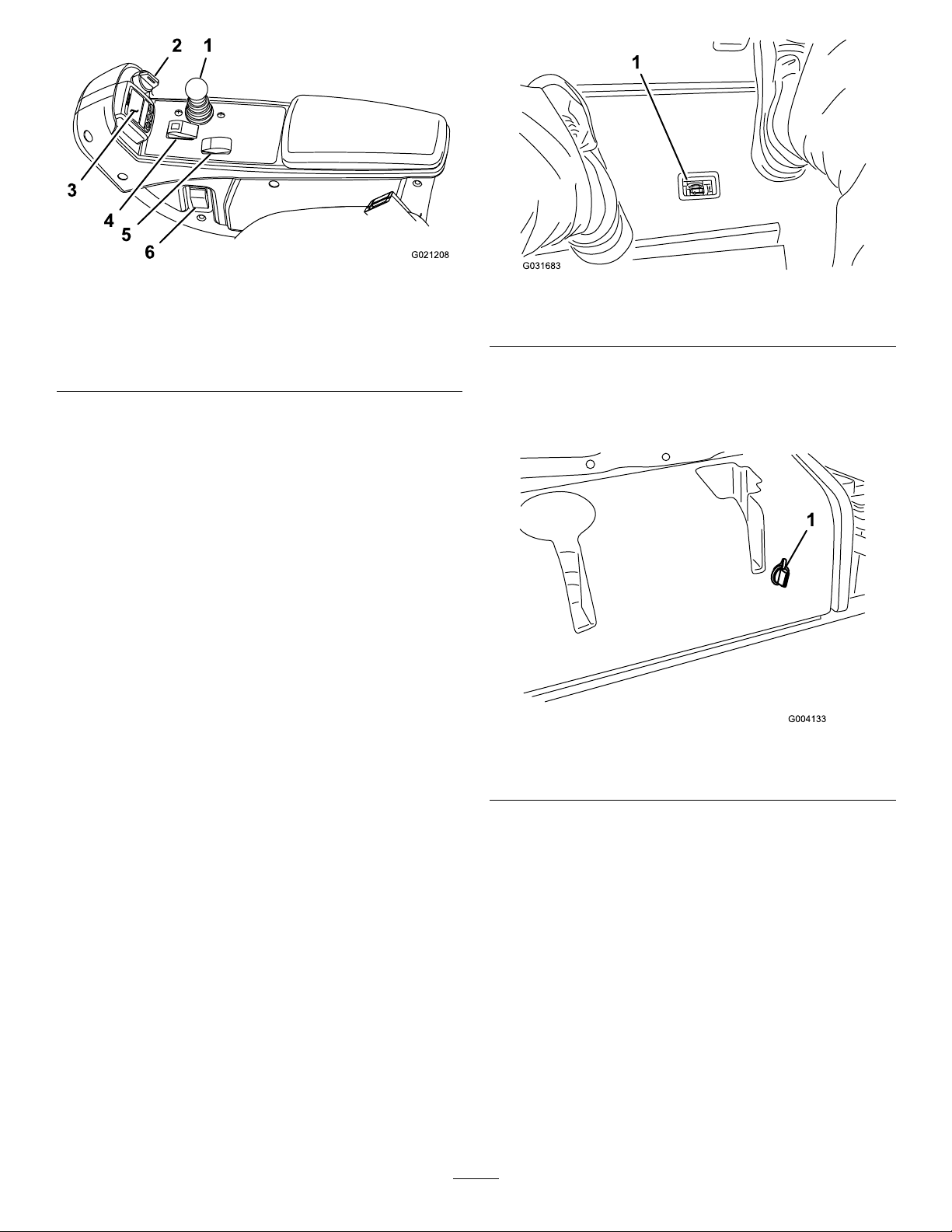

PowerPoint

Thepowerpoint(Figure8)isa12Vpowersupplyfor

electronicdevices.

HeadlightSwitch

Pivottheswitchdownwardtoturnontheheadlights

(Figure6).

Enable/DisableSwitch

Usetheenable/disableswitch(Figure6)inconjunction

withthelowermow/raisecontrollevertooperatethe

mowers.Themowerscannotbeloweredwhenthe

mow/transportleverisintheTRANSPORTposition.

Hydraulic-Filter-Restriction

Indicator

Thehydraulic-lter-restrictionindicatoralertsyou

whenthehydraulicltersmustbechanged;referto

ReplacingtheHydraulicFilters(page62).

g004133

Figure8

1.Powerpoint

InfoCenter

TheInfoCenterLCDdisplayshowstheoperating

status,variousdiagnostics,andotherinformation

aboutthemachine(Figure6).

UsingtheInfoCenterLCDDisplay

TheInfoCenterLCDdisplayshowsinformationabout

yourmachine,suchastheoperatingstatus,various

diagnosticsandotherinformationaboutthemachine

(Figure9).Thereisasplashscreenandmain

informationscreenoftheInfoCenter.Youcanswitch

betweenthesplashscreenandmaininformation

screenatanytimebypressinganyoftheInfoCenter

buttonsandthenselectingtheappropriatedirectional

arrow.

13

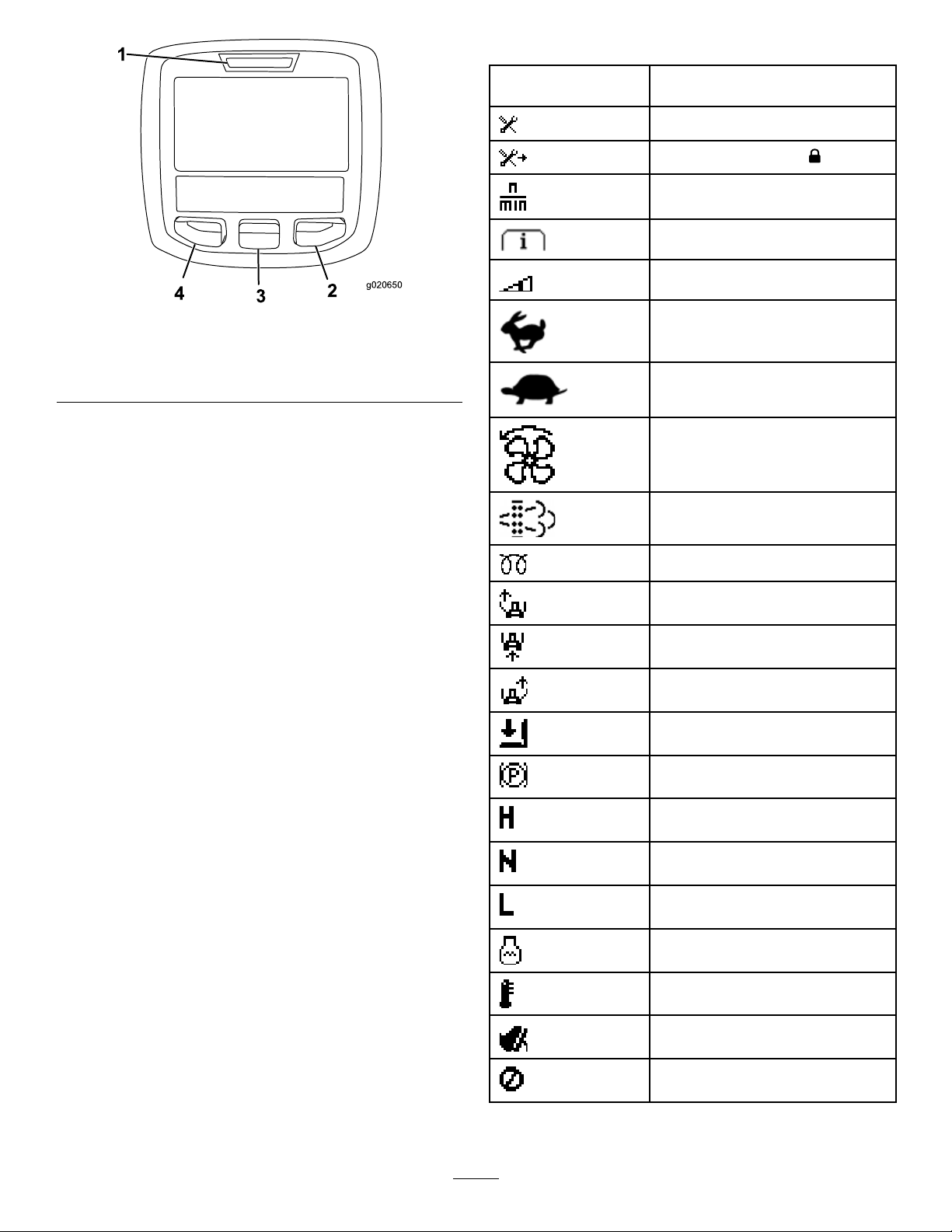

InfoCenterIconDescription

Figure9

1.Indicatorlight3.Middlebutton

2.Rightbutton

4.Leftbutton

•LeftButton,MenuAccess/BackButton—pressthis

buttontoaccesstheInfoCentermenus.Youcan

useittoexitanymenuthatyouarecurrentlyusing.

•MiddleButton—usethisbuttontoscrolldown

menus.

SERVICEDUE

g020650

Indicateswhenscheduledservice

shouldbeperformed

Hoursremaininguntilservice

Resettheservicehours

Thestatusoftheenginespeed(rpm)

Infoicon

Maximumtractionspeedsetting

Fast

Slow

Thefanisreversed.

Stationaryregenerationisrequired.

•RightButton—usethisbuttontoopenamenu

wherearightarrowindicatesadditionalcontent.

•Beeper—activatedwhenloweringthecuttingunits

orforadvisoriesandfaults.

Note:Thepurposeofeachbuttonmaychange

dependingonwhatisrequiredatthetime.Each

buttonislabeledwithanicondisplayingitscurrent

function.

Theair-intakeheaterisactive.

Raisetheleftcuttingunit.

Raisethecentercuttingunit.

Raisetherightcuttingunit.

Theoperatormustsitintheseat.

Theparkingbrakeisengaged.

Therangeishigh.

Neutral

IdentiestherangeasLow

Coolanttemperature(°Cor°F)

Temperature(hot)

TractionorTractionPedal

Notallowed

14

InfoCenterIconDescription(cont'd.)

InfoCenterIconDescription(cont'd.)

Starttheengine.

ThePTOison.

Thecruisecontrolison.

Shutofftheengine

Engine

Keyswitch

Cuttingunitsarelowering

Cuttingunitsareraising

PINcode

Hydraulicuidtemperature

CANbus

InfoCenter

Operatorshouldchangetoindicated

state

Symbolsareoftencombinedtoformsentences.Some

examplesareshownbelow.

Operatorshouldputmachinein

neutral

Enginestartisdenied

Engineshutdown

Enginecoolantistoohot

Hydraulicuidistoohot

DPFashaccumulationnotication.

RefertoServicingtheDiesel

ParticulateFilter(DPF)inthe

maintenancesectionfordetails

Reset-standbyregenerationrequest

Parkedorrecoveryregeneration

request

Aparkedorrecoveryregenerationis

processing.

Badorfailed

Center

Right

Left

Bulb

Highexhausttemperature

Thepowertake-offisdisabled.

Sitdownorengagetheparking

brake.

AccessibleonlybyenteringPIN

OutputofTECcontrollerorcontrol

wireinharness

Overtheallowedrange

Undertheallowedrange

Outofrange

/

Switch

Operatormustreleaseswitch

15

UsingtheMenus

ToaccesstheInfoCentermenusystem,pressthe

menuaccessbuttonwhileatthemainscreen.This

bringsyoutothemainmenu.Refertothefollowing

tablesforasynopsisoftheoptionsavailablefrom

themenus:

MainMenu—MenuItemDescription

Faults

ServiceContainsinformationonthe

Diagnostics

Settings

AboutListsthemodelnumber,serial

Service—MenuItem

Hours

Counts

DPFRegeneration

InhibitRegenUsetocontrolreset

ParkedRegenUsetoinitiateaparked

LastRegenListsthenumberhourssince

RecoverRegenUsetoinitiatearecovery

Containsalistoftherecent

machinefaults.Referto

theServiceManualoryour

authorizedTorodistributorfor

moreinformationontheFaults

menuandtheinformation

containedthere.

machinesuchashoursofuse,

counters,andothersimilar

numbers

Displaysthestateofeach

machineswitch,sensor,and

controloutput.Y oucanuse

thistotroubleshootcertain

issuesasitquicklytellsyou

whichmachinecontrolsare

ONandwhichareOFF.

Allowsyoutocustomizeand

modifycongurationvariables

ontheInfoCenterdisplay.

number,andsoftwareversion

ofyourmachine.

Description

Liststhetotalnumberofhours

thatthemachine,engine,and

PTOhavebeenon,aswell

asthenumberofhoursthe

machinehasbeentransported

andservicedue

Listsnumerouscountsthe

machinehasexperienced.

Thedieselparticulatelter

regenerationoptionandDPF

submenus

regeneration

regeneration

thelastreset,parked,or

recoveryregeneration

regeneration

Hi/LowRangeIndicatestheinputs,qualiers,

PTOIndicatestheinputs,qualiers,

EngineRun

Settings—MenuItem

Units

Language

LCDBacklightControlsthebrightnessofthe

LCDContrastControlsthecontrastofthe

ProtectedMenus

ProtectSettings

Counterbalance

andoutputsfordrivingin

transportmode

andoutputsforenablingthe

PTOcircuit

Indicatestheinputs,qualiers,

andoutputsforstartingthe

engine

Description

Controlstheunitsusedonthe

InfoCenter(EnglishorMetric)

Controlsthelanguageused

ontheInfoCenter*

LCDdisplay

LCDdisplay

Allowsapersonauthorized

byyourcompanywiththe

PINcodetoaccessprotected

menus

Allowstheabilitytochange

thesettingsintheprotected

settings

Controlstheamountof

counterbalanceappliedtothe

cuttingdecks

ProtectedunderProtectedMenus—accessibleonly

byenteringPIN

About—MenuItemDescription

Model

SNListstheserialnumberofthe

MachineControllerRevisionListsthesoftwarerevisionof

InfoCenterRevisionListsthesoftwarerevisionof

CANBus

Liststhemodelnumberofthe

machine

machine

themastercontroller

theInfoCenter

Liststhemachine

communicationbusstatus

Diagnostics—MenuItemDescription

CuttingUnitsIndicatestheinputs,qualiers,

andoutputsforraisingand

loweringthecuttingunits

16

ProtectedMenus

Thereare2operatingcongurationsettingsthatare

adjustablewithintheSettingsMenuoftheInfoCenter:

autoidletimedelayandcounterbalance.T olock

thesesettings,usetheProtectedMenu.

Note:Atthetimeofdelivery ,theinitialpassword

codeisprogrammedbyyourdistributor.

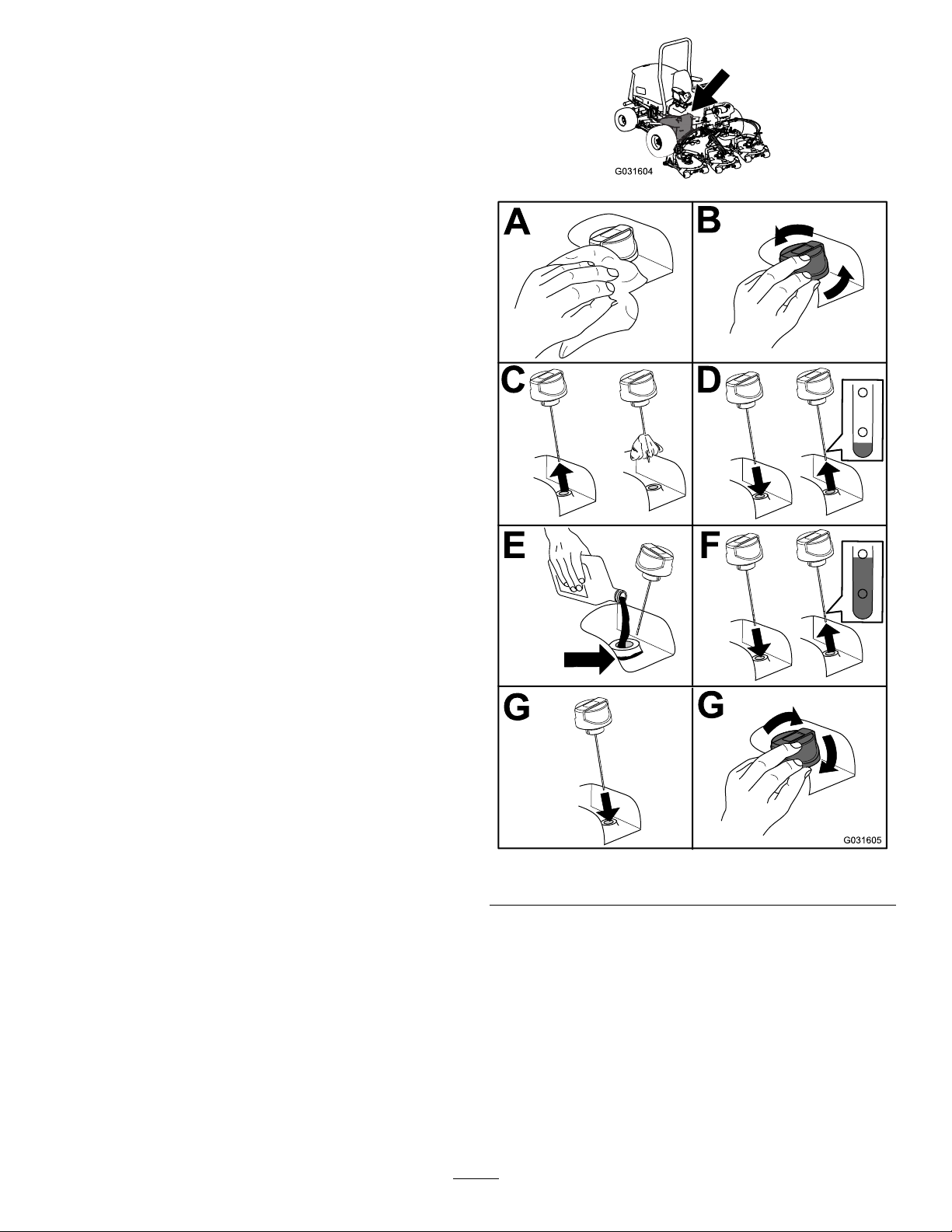

AccessingProtectedMenus

Note:ThefactorydefaultPINcodeforyoumachine

iseither0000or1234.

IfyouchangedthePINcodeandforgotthecode,

contactyourauthorizedT orodistributorforassistance.

1.FromtheMAINMENU,usethecenterbuttonto

scrolldowntotheSETTINGSMENUandpressthe

rightbutton(Figure10).

g028522

Figure11

Figure10

2.IntheSETTINGSMENU,usethecenterbuttonto

scrolldowntothePROTECTEDMENUandpress

therightbutton(Figure11A).

3.ToenterthePINcode,pressthecenterbutton

untilthecorrectrstdigitappears,thenpress

therightbuttontomoveontothenextdigit

(Figure11BandFigure11C).Repeatthisstep

g028523

untilthelastdigitisenteredandpresstheright

buttononcemore.

4.PressthemiddlebuttontoenterthePINcode

(Figure11D).

WaituntiltheredindicatorlightoftheInfoCenter

illuminates.

Note:IftheInfoCenteracceptsthePINcode

andtheprotectedmenuisunlocked,theword

“PIN”displaysintheupperrightcornerofthe

screen.

Note:RotatethekeyswitchtotheOFFpositionand

thentotheONpositionlockstheprotectedmenu.

YoucanviewandchangethesettingsintheProtected

Menu.OnceyouaccesstheProtectedMenu,scroll

downtoProtectSettingsoption.Usetherightbutton

tochangethesetting.SettingtheProtectSettingsto

OFFallowsyoutoviewandchangethesettingsin

theProtectedMenuwithoutenteringthePINcode.

SettingtheProtectSettingstoONhidestheprotected

optionsandrequiresyoutoenterthePINcodeto

changethesettingintheProtectedMenu.Afteryou

setthePINcode,rotatethekeyswitchOFFandback

totheONpositiontoenableandsavethisfeature.

17

ViewingandChangingthe

ProtectedMenuSettings

1.IntheProtectedMenu,scrolldowntoProtect

Settings.

2.Toviewandchangethesettingswithoutentering

aPINcode,usetherightbuttontochangethe

ProtectSettingstoOFF.

3.ToviewandchangethesettingswithaPIN

code,usetheleftbuttontochangetheProtect

SettingstoON,setthePINcode,andturnthe

keyintheignitionswitchtotheOFFpositionand

thentotheONposition.

SettingtheCounterbalance

1.IntheSettingsMenu,scrolldownto

Counterbalance.

2.Presstherightbuttontoselectcounterbalance

andchangebetweenthelow,medium,andhigh

settings.

SettingtheAutoIdle

1.IntheSettingsMenu,scrolldowntoAutoIdle.

2.Presstherightbuttontochangetheautoidle

timebetweenOFF,8S,10S,15S,20S,and30S.

18

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Figure12

g193881

19

DescriptionFigure12

Overallheight

Wheeltread(tirecentertocenter)rear

Overallwidth(transportposition)C231cm(91inches)

Overallwidth(mowingposition)

Wheelbase

reference

A

B

D

E

DimensionorWeight

217cm(85.5inches)

185cm(72.5inches)

247cm(97inches)

152cm(60inches)

Overalllength(transportposition)

Overalllength(mowingposition)G315cm(124inches)

Fuel-tankcapacity

Transportspeed

Mowingspeed

Netweight(withcuttingdecksanduids)1492kg(3,289lb)

F

315cm(124inches)

51L(13.5USgallons)

0to16km/h(0to10mph)

0to13km/h(0to8mph)

CuttingUnitSpecications

Length

Width

Height

Weight

86.4cm(34inches)

86.4cm(34inches)

24.4cm(9.6inches)tocarriermount

26.7cm(10–1/2inches)at3/4inchheightofcut

34.9cm(13–3/4inches)at4inchheightofcut

88kg(195lb)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhance

andexpanditscapabilities.ContactyourAuthorizedServiceDealerorauthorizedT orodistributororgoto

www.T oro.comforalistofallapprovedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafetycerticationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementpartsandaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty .

20

Operation

FillingtheFuelTank

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Checkthatoperator-presencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Beforemowing,alwaysinspectthemachineto

ensurethattheblades,bladebolts,andcutting

assembliesareingoodworkingcondition.

Replacewornordamagedbladesandboltsinsets

topreservebalance.

FuelTankCapacity

Fueltankcapacity:53L(14USgallons)

FuelSpecication

Important:Useonlyultra-lowsulphurdiesel

fuel.Fuelwithhigherratesofsulfurdegrades

thedieseloxidationcatalyst(DOC),whichcauses

operationalproblemsandshortenstheservicelife

ofenginecomponents.

Failuretoobservethefollowingcautionsmay

damagetheengine.

•Neverusekeroseneorgasolineinsteadofdiesel

fuel.

•Nevermixkeroseneorusedengineoilwiththe

dieselfuel.

•Neverkeepfuelincontainerswithzincplatingon

theinside.

•Donotusefueladditives.

PetroleumDiesel

Cetanerating:45orhigher

Sulfurcontent:Ultra-lowsulfur(<15ppm)

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

21

FuelTable

AddingFuel

Dieselfuelspecication

ASTMD975

No.1-DS15

No.2-DS15

EN590EuropeanUnion

ISO8217DMX

JISK2204GradeNo.2

KSM-2610

Location

USA

International

Japan

Korea

•Useonlyclean,freshdieselfuelorbiodieselfuels.

•Purchasefuelinquantitiesthatcanbeusedwithin

180daystoensurefuelfreshness.

Usesummer-gradedieselfuel(No.2-D)at

temperaturesabove-7°C(20°F)andwinter-grade

fuel(No.1-DorNo.1-D/2-Dblend)belowthat

temperature.

Note:Usingwinter-gradefuelatlowertemperatures

provideslowerashpointandcoldowcharacteristics

whicheasesstartingandreducesfuellterplugging.

Usingsummer-gradefuelabove-7°C(20°F)

contributestowardlongerfuelpumplifeandincreased

powercomparedtowinter-gradefuel.

g194207

UsingBiodiesel

Thismachinecanalsouseabiodiesel-blendedfuelof

uptoB20(20%biodiesel,80%petrodiesel).

Sulfurcontent:Ultra-lowsulfur(<15ppm)

Biodieselfuelspecication:ASTMD6751or

EN14214

Blendedfuelspecication:ASTMD975,EN590,

orJISK2204

Important:Thepetroleumdieselportionmust

beultra-lowsulfur.

Observethefollowingprecautions:

•Biodieselblendsmaydamagepaintedsurfaces.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuel

astheymaydegradeovertime.

•Fuellterpluggingmayoccurforatimeafteryou

converttobiodieselblends.

g031869

Figure13

Fillthetanktoabout6to13mm(1/4to1/2inch)

belowthetopofthetank,notthellerneck,with

Number2-Ddieselfuel.

Note:Ifpossible,llthefueltankaftereachuse;this

willminimizepossiblebuildupofcondensationinside

thefueltank.

•Formoreinformationonbiodiesel,contactyour

authorizedT orodistributor.

22

CheckingtheEngine-Oil Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngine-OilLevel(page51).

CheckingtheCooling System

Beforeyoustarttheengineandusethemachine,

checkthecoolingsystem;refertoCheckingthe

CoolingSystem(page23).

CheckingtheHydraulic System

Beforeyoustarttheengineandusethemachine,

checkthehydraulicsystem;refertoCheckingthe

HydraulicLinesandHoses(page63).

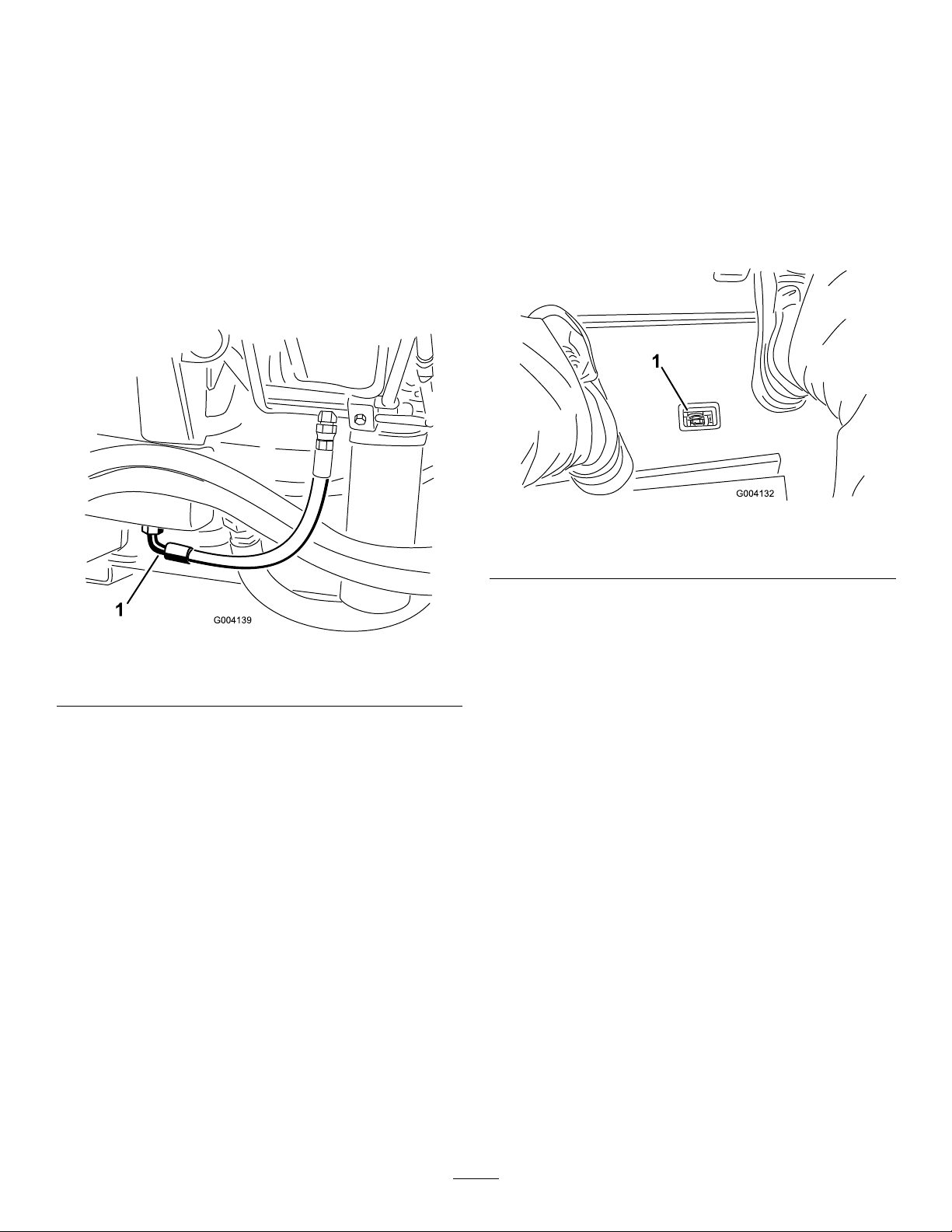

DrainingtheWater Separator

Drainwaterorothercontaminantsfromthewater

separator;refertoServicingtheWaterSeparator

(page54).

CheckingtheTirePressure

g001055

Figure14

CheckingtheTorqueofthe Wheel-LugNuts

ServiceInterval:Afterthersthour

Aftertherst10hours

Every250hours

WARNING

Failuretomaintainthepropertorqueofthe

wheelnutscouldresultinfailureorlossofa

wheel,andmayresultinpersonalinjury.

Torquethefrontandrear-wheelnutsto94to

122N·m(70to90ft-lb)attherecommended

serviceintervals.

ServiceInterval:Beforeeachuseordaily

Thecorrectairpressureinthefrontandreartiresis

83to103kPa(12to15psi).

Important:Maintainpressureinalltiresto

ensureagoodqualityofcutandpropermachine

performance.Donotunder-inatethetires.

Checktheairpressureinallthetiresbefore

operatingthemachine.

23

AdjustingtheHeightofCut

Important:Thiscuttingdeckoftencuts

approximately6mm(1/4inch)lowerthanareel

cuttingunitwiththesamebenchsetting.Itmay

benecessarytohavethebenchoftherotary

cuttingdeckset6mm(1/4inch)abovethatof

reelscuttinginthesamearea.

Important:Accesstotherearcuttingunitsis

greatlyimprovedbyremovingthecuttingunit

fromthetractor.Iftheunitisequippedwitha

Sidewinder®,sidewindthecuttingunitstothe

right,removetherearcuttingunit,andslideitout

totherightside.

g026184

Figure16

6.Positionthetappedplatein-linewiththespacer.

7.Installtheboltnger-tight.

8.Repeatstepsthroughforeachsideadjustment.

1.Lowerthecuttingdecktotheground,shutoff

theengine,andremovethekeyfromtheignition

switch.

2.Loosentheboltsecuringeachheight-of-cut

brackettotheheight-of-cutplate(frontandeach

side)asshowninFigure15.

3.Beginningwiththefrontadjustment,removethe

bolt.

Figure15

9.Torqueall3boltsto41N∙m(30ft-lb).Always

tightenthefrontboltrst.

Note:Adjustmentsofmorethan3.8cm(1-1/2

inches)mayrequiretemporaryassemblytoan

intermediateheighttopreventbinding(e.g.,

changingfrom3.1to7cm(1-1/4to2-3/4inches)

heightofcut).

g011344

1.Height-of-cutbracket3.Spacer

2.Height-of-cutplate

4.Whilesupportingthechamber,removethe

spacer(Figure15).

5.Movethechambertothedesiredheightof

cutandinstallaspacerintothedesignated

height-of-cutholeandslot(Figure16).

24

Checkingthe

BurnishingtheBrakes

Safety-InterlockSwitches

ServiceInterval:Beforeeachuseordaily

CAUTION

Ifthesafety-interlockswitchesare

disconnectedordamaged,themachinecould

operateunexpectedlyandcausepersonal

injury.

•Donottamperwiththesafety-interlock

switches.

•Checktheoperationofthesafety-interlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Themachinehasinterlockswitchesintheelectrical

system.Theseswitchesdisengageeitherthetraction

orthePTOwheneveryouleavetheseat.Although

theenginecontinuestorunifyoudisengagethePTO

switch,andyoureleasethetractionpedal,shutoffthe

enginebeforerisingfromtheseat.

1.Parkthemachineonalevelsurface,lowerthe

cuttingunit,shutofftheengine,andengagethe

parkingbrake.

Toensureoptimumperformanceoftheparking-brake

system,burnish(breakin)thebrakesbeforeuse.

Settheforwardtractionspeedto6.4km/h(4mph)

tomatchthereversetractionspeed(all8spacers

movedtothetopofthemow-speedcontrol).With

theengineathighidle,proceedforwardwiththe

mow-speed-controlstopengagedandridethebrake

for15seconds.Proceedbackwardatfullreverse

speedandridethebrakefor15seconds.Repeatthis

5times,waiting1minutebetweeneachforwardand

reversecycletoavoidoverheatingthebrakes;referto

AdjustingtheParkingBrakes(page59).

SelectingaBlade

UsingaStandardCombination Sail

Thisbladeprovidesexcellentliftanddispersionin

almostanycondition.Ifyourequiremoreorlesslift

anddischargevelocity,consideradifferentblade.

Attributes:Excellentliftanddispersioninmost

conditions.

2.Pressthetractionpedal.Turnthekeyinthe

ignitionswitchtotheONposition.

Note:Iftheenginecranks,thereisa

malfunctionintheinterlocksystem.Correctthis

malfunctionbeforeoperatingthemachine.

3.TurnthekeyintheignitionswitchtotheON

position,starttheengine,risefromtheseat,and

movethePTOswitchtotheONposition.

Note:ThePTOshouldnotengage.Ifthe

PTOengages,thereisamalfunctioninthe

interlocksystem.Correctthismalfunctionbefore

operatingthemachine.

4.Engagetheparkingbrake,turnthekeyinthe

ignitionswitchtotheONposition,startthe

engine,andmovethetractionpedaloutofthe

NEUTRALposition.

Note:TheInfoCenterdisplays"tractiondenied"

andthemachineshouldnotmove.Ifthe

machinedoesmove,thereisamalfunctionin

theinterlocksystem.Correctthismalfunction

beforeoperatingthemachine.

UsinganAngled-SailBlade

Thebladegenerallyperformsbestinlowerheightsof

cut—1.9to6.4cm(3/4to2-1/2inches).

Attributes:

•Thedischargeremainsmoreevenatlowerheights

ofcut.

•Thedischargehaslesstendencytothrowleftand

thusleavesacleanerlookaroundbunkersand

fairways.

•Thereisalowerpowerrequirementatlower

heightsofcutandindenseturf.

UsinganAtomicBlade

Attributes:Thisbladeprovidesexcellentleaf

mulching.

5.StarttheenginewiththePTOengaged.

Note:Iftheenginecranks,thereisa

malfunctionintheinterlocksystem.Correctthis

malfunctionbeforeoperatingthemachine.

25

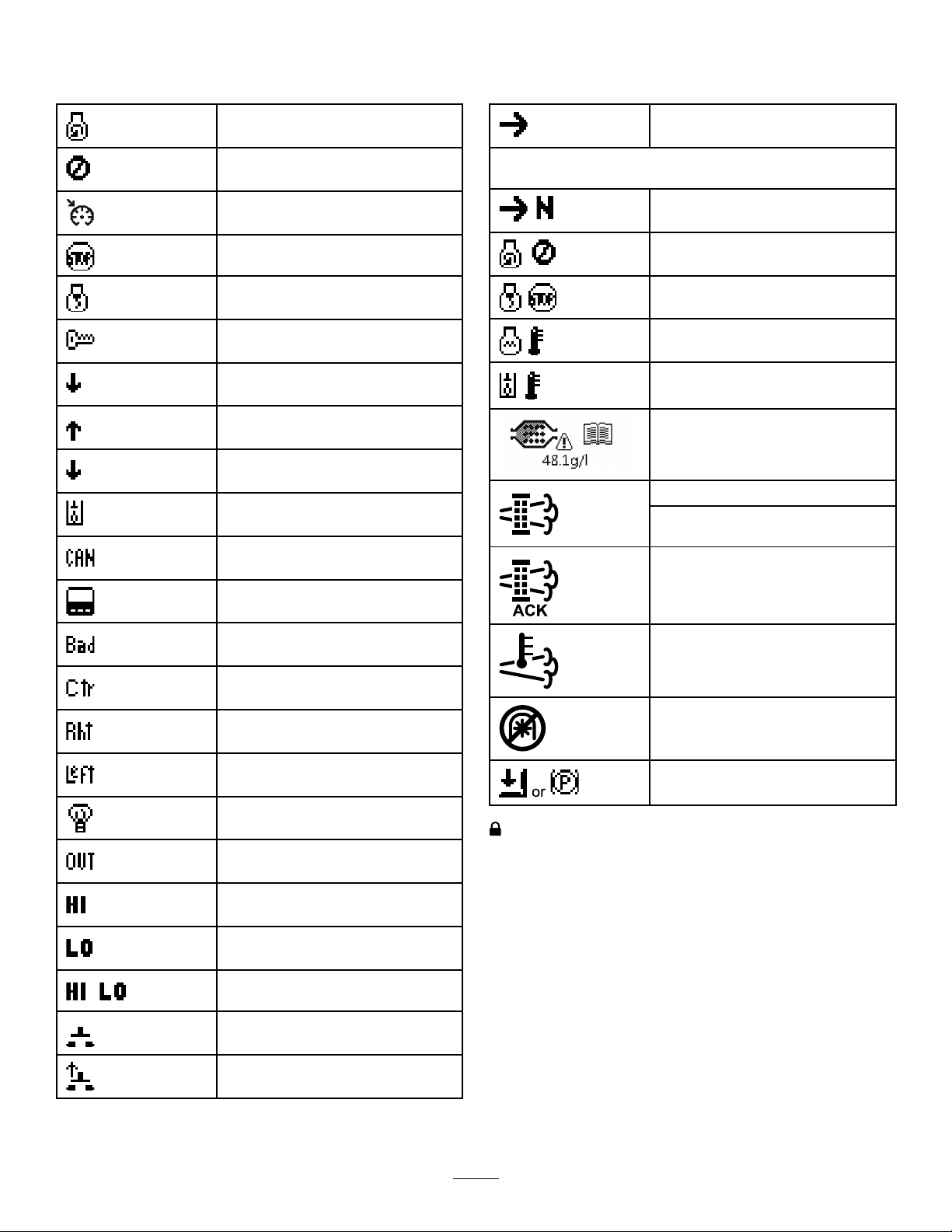

Understandingthe

Changingthe

DiagnosticLight

Themachineisequippedwithadiagnosticlight,which

indicatesifthemachinedetectsamalfunction.The

diagnosticlightislocatedontheInfoCenter,above

thedisplayscreen(Figure17).Whenthemachine

functionsproperlyandthekeyswitchismovedto

theON/RUNposition,thediagnosticlightturnson

brieytoindicatethatthelightisworkingproperly.

Whenamachineadvisorymessagedisplays,thelight

illuminateswhenthemessageispresent.Whena

faultmessageisdisplayed,thelightblinksuntilthe

faultisresolved.

CounterbalanceSettings

Youcanchangetheamountofrequiredcutting-unit

counterbalance(upwardlift)tomeetyourcurrent

mowingconditions.

1.Parkthemachineonalevelsurface,lowerthe

cuttingdecks,turnthekeyintheswitchtothe

OFFposition,andengagetheparkingbrake.

2.TurnthekeyintheswitchtotheRUNposition.

3.IntheInfoCenterSettingsMenu,scrolldownto

Counterbalance.

4.Presstherightbuttontoselectcounterbalance

andchangebetweenthelow,medium,andhigh

settings.

Note:Oncetheadjustmenthasbeen

completed,movethemachinetoatestareaand

operatethemachinewiththenewsetting.The

newcounterbalancedsettingmaychangethe

effectiveheightofcut.

1.Diagnosticlight

g021272

Figure17

26

ChoosingAccessories

OptionalEquipmentCongurations

AngleSailBladeHigh-Lift,Parallel-Sail

GrassCutting:1.9to4.4

cm(3/4to1-3/4inches)

heightofcut

GrassCutting:5to6.4

cm(2to2-1/2inches)

heightofcut

GrassCutting:7to10

cm(2-3/4to4inches)

heightofcut

LeafMulchingRecommendedforuse

ProsEvendischargeatlower

ConsDoesnotliftthegrass

Recommendedinmost

applications

Recommendedforthick

orlushturf

Mayworkwellinlushturf

withthemulchingbafe

heightofcut;cleaner

lookaroundbunkersand

fairways;lowerpower

requirements

wellinhighheight-of-cut

applications;wetor

stickygrasshasa

tendencytobuildupin

thechamber,leading

topoorqualityofcut

andhigherpower

requirements

Blade(Donotusewith

themulchingbafe)

Mayworkwellinlightor

sparseturf

Recommendedforlight

orsparseturf

Recommendedinmost

applications

NotAllowedUsewithcombination

Moreliftandhigher

dischargevelocity;

sparseorlimpturfis

pickedupathighheight

ofcut;wetorsticky

clippingsaredischarged

efciently

Requiresmorepowerto

runinsomeapplications;

tendstowindrowat

lowerheightofcutin

lushgrass;donotuse

withthemulchingbafe

MulchingBafeRollerScraper

Hasbeenshownto

improvedispersionand

after-cutperformance

onnortherngrassesthat

arecutatleast3times

perweekandlessthan

1/3ofthegrassblade

isremoved.Donot

usewiththehigh-lift,

parallel-sailblade

sailoranglesailblade

only

Mayimprovedispersion

andappearancein

certaingrasscutting

applications;verygood

forleafmulching

Grasswillbuildupinthe

chamberifyouattempt

toremovetoomuch

grasswiththebafein

place

Useitwheneverthe

rollersbuildupwith

grassorlarge,atgrass

clumpsofgrassare

seen.Thescrapersmay

increaseclumpingin

certainapplications.

Reducesrollerbuildup

incertainapplications

27

DuringOperation

•Beforeleavingtheoperatingposition(including

toemptythecatchersortounclogthechute),do

thefollowing:

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearloosejewelry .

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachine

duringoperation.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Beforeyoustarttheengine,ensurethatalldrives

areinneutral,theparkingbrakeisengaged,and

youareintheoperatingposition.

•Keepyourhandsandfeetawayfromrotating

parts.Keepclearofthedischargeopeningatall

times.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Stopthebladeswheneveryouarenotmowing.

•Stopthemachine,removethekey,andwaitfor

allmovingpartstostopbeforeinspectingthe

attachmentafterstrikinganobjectorifthereis

anabnormalvibrationinthemachine.Makeall

necessaryrepairsbeforeresumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Disengagethedrivetothecuttingunit,shut

offtheengine,removethekey,andwaitforall

movingpartstostopbeforeadjustingtheheightof

cut(unlessyoucanadjustitfromtheoperating

position).

•Neverrunanengineinanareawhereexhaust

gassesareenclosed.

•Neverleavearunningmachineunattended.

–Parkthemachineonlevelground.

–Disengagethepowertakeoffandlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

–Waitforallmovingpartstostop.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Donotusethemachineasatowingvehicle.

•Useaccessories,attachments,andreplacement

partsapprovedbyTheT oro®Companyonly.

RolloverProtectionSystem (ROPS)Safety

•DonotremovetheROPSfromthemachine.

•Ensurethattheseatbeltisattachedandthatyou

canreleaseitquicklyinanemergency.

•Checkcarefullyforoverheadobstructionsanddo

notcontactthem.

•KeeptheROPSinsafeoperatingconditionby

thoroughlyinspectingitperiodicallyfordamage

andkeepingallthemountingfastenerstight.

•ReplacedamagedROPScomponents.Donot

repairoralterthem.

MachineswithaFixedRollBar

•TheROPSisanintegralsafetydevice.

•Alwayswearyourseatbelt.

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Y ouareresponsibleforsafeslope

operation.Operatingthemachineonanyslope

requiresextracaution.

•Evaluatethesiteconditionstodetermineifthe

slopeissafeformachineoperation,including

surveyingthesite.Alwaysusecommonsense

andgoodjudgmentwhenperformingthissurvey .

•Reviewtheslopeinstructionslistedbelowfor

operatingthemachineonslopesandtodetermine

whetheryoucanoperatethemachineinthe

conditionsonthatdayandatthatsite.Changes

intheterraincanresultinachangeinslope

operationforthemachine.

28

•Avoidstarting,stopping,orturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction.Maketurnsslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steering,orstabilityisinquestion.

•Removeormarkobstructionssuchasditches,

holes,ruts,bumps,rocks,orotherhiddenhazards.

Tallgrasscanhideobstructions.Uneventerrain

couldoverturnthemachine.

•Beawarethatoperatingthemachineonwet

grass,acrossslopes,ordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.

•Useextremecautionwhenoperatingthemachine

neardrop-offs,ditches,embankments,water

hazards,orotherhazards.Themachinecould

suddenlyrolloverifawheelgoesovertheedge

ortheedgecavesin.Establishasafetyarea

betweenthemachineandanyhazard.

•Identifyhazardsatthebaseoftheslope.

Iftherearehazards,mowtheslopewitha

pedestrian-controlledmachine.

•Ifpossible,keepthecuttingunit(s)loweredtothe

groundwhileoperatingonslopes.Raisingthe

cuttingunit(s)whileoperatingonslopescancause

themachinetobecomeunstable.

•Useextremecautionwithgrass-collectionsystems

orotherattachments.Thesecanchangethe

stabilityofthemachineandcausealossofcontrol.

Alwayskeepthemachineingearwhengoing

downslopes.Donotcoastdownhill(applicable

onlytogear-driveunits).

StartingtheEngine

Important:Thefuelsystemautomaticallybleeds

itselfbeforestartingtheengineifyouarestarting

theengineforthersttime,theenginehasshut

offduetolackoffuel,oryouhaveperformed

maintenanceonthefuelsystem.

1.Sitontheseat,keepyourfootoffthetraction

pedalsothatitisinNEUTRAL,engagetheparking

brake,settheengine-speedswitchtotheMID

position,andensurethattheEnable/Disable

switchisintheDISABLEposition.

2.TurnthekeyintheswitchtotheRUNposition.

3.Whentheglowindicatordims,turnthekeyinthe

switchtotheST ARTposition.Releasethekey

immediatelywhentheenginestartsandallowit

toreturntotheRUNposition.

4.Runtheengineatlowidlespeeduntilitwarms

up.

ShuttingOfftheEngine

1.MoveallcontrolstoNEUTRAL,engagethe

parkingbrake,movetheengine-speedswitchto

theLOWIDLEpositionandallowtheengineto

reachlowidlespeed.

Important:Allowtheenginetoidlefor5

minutesbeforeshuttingitoffafterafull

loadoperation.Failuretodosomayleadto

troubleonaturbo-chargedengine.

2.TurnthekeyintheswitchtotheOFFposition

andremovethekey.

CuttingGrasswiththe Machine

Note:Cuttinggrassataratethatloadstheengine

promotesDPFregeneration.

1.Movethemachinetothejobsite.

2.Wheneverpossible,settheengine-speedswitch

tohighidle.

3.EngagethePTOswitch.

4.Graduallymovethetractionpedalforwardand

slowlydrivethemachineoverthemowingarea.

5.Oncethefrontofthecuttingunitsareoverthe

mowingarea,lowerthecuttingunits.

6.Cutgrasssothatthebladescancutand

dischargeclippingsatahighratewhile

producingagoodqualityofcut.

Note:Ifthecuttingrateistoohigh,thequality

ofcutmaydeteriorate.Reducetheground

speedofthemachineorreducethewidthofcut

toregainhighidleenginespeed.

29

7.Whenthecuttingunitsareoverthefaredgeof

themowingarea,liftthecuttingunits.

8.Performatear-shapedturntoquicklylineupfor

yournextpass.

DieselParticulateFilter Regeneration

Thedieselparticulatelter(DPF)ispartoftheexhaust

system.Thediesel-oxidationcatalystoftheDPF

reducesharmfulgassesandthesootlterremoves

sootfromtheengineexhaust.

TheDPFregenerationprocessusesheatfromthe

engineexhausttoincineratethesootaccumulatedon

thesootlter,convertingthesoottoash,andclears

thechannelsofthesootltersothatlteredengine

exhaustowsouttheDPF .

Theenginecomputermonitorstheaccumulationof

sootbymeasuringthebackpressureintheDPF.If

thebackpressureistoohigh,sootisnotincinerating

inthesootlterthroughnormalengineoperation.T o

keeptheDPFclearofsoot,rememberthefollowing:

•Passiveregenerationoccurscontinuouslywhile

theengineisrunning—runtheengineatfull

enginespeedwhenpossibletopromoteDPF

regeneration.

•IfthebackpressureintheDPFistoohighora

resetregenerationhasnotoccurredfor100hours,

theenginecomputersignalsyouthroughthe

InfoCenterwhenresetregenerationisrunning.

•Allowtheresetregenerationprocesstocomplete

beforeshuttingofftheengine.

Operateandmaintainyourmachinewiththefunction

oftheDPFinmind.Engineloadathighidle(full

throttle)enginespeedgenerallyproducesadequate

exhausttemperatureforDPFregeneration.

Important:Minimizetheamountoftimethatyou

idletheengineoroperatetheengineatlow-engine

speedtohelpreducetheaccumulationofsootin

thesootlter.

DPFSootAccumulation

•Overtime,thedieselparticulatelteraccumulates

sootinthesootlter.Thecomputerfortheengine

monitorsthesootlevelintheDPF .

•Whenenoughsootaccumulates,thecomputer

informsyouthatitistimetoregeneratetheDPF.

•DPFregenerationisaprocessthatheatstheDPF

toconvertthesoottoash.

•Inadditiontothewarningmessages,thecomputer

reducesthepowerproducedbytheengineat

differentsoot-accumulationlevels.

EngineWarningMessages—SootAccumulation

IndicationLevel

Level1:Engine

Warning

Level2:Engine

Warning

FaultCode

g213866

Figure18

CheckEngine

SPN3719,FMI16

g213867

Figure19

CheckEngine

SPN3719,FMI0

EnginePowerRatingRecommendedAction

Thecomputerde-ratesthe

enginepowerto85%.

Thecomputerde-ratesthe

enginepowerto50%.

Performaparkedregeneration

assoonaspossible;refer

toParkedorRecovery

Regeneration(page37).

Performarecoveryregeneration

assoonaspossible;refer

toParkedorRecovery

Regeneration(page37).

30

DPFAshAccumulation

•Thelighterashisdischargedthroughtheexhaust

system;theheavierashcollectsinthesootlter.

•Ashisaresidueoftheregenerationprocess.Over

time,thedieselparticulatelteraccumulatesash

thatdoesnotdischargewiththeengineexhaust.

•Thecomputerfortheenginecalculatestheamount

ofashaccumulatedintheDPF.

InfoCenterAdvisoryandEngineWarningMessages—AshAccumulation

•Whenenoughashaccumulates,theengine

computersendsinformationtotheInfoCenter

intheformofanenginefaulttoindicatethe

accumulationofashintheDPF.

•Thefaultmessagesindicatethatitistimeto

servicetheDPF.

•Inadditiontothewarnings,thecomputerreduces

thepowerproducedbytheengineatdifferent

ash-accumulationlevels.

Indication

Level1:

Engine

Warning

Level2:

Engine

Warning

Level3:

Engine

Warning

Level

FaultCode

g213863

EngineSpeed

Reduction

None

Figure20

EnginePowerRatingRecommendedAction

Thecomputer

de-ratestheengine

powerto85%.

ServicetheDPF;

refertoServicingthe

Diesel-OxidationCatalyst

(DOC)andtheSoot

Filter(page52)

CheckEngine

SPN3720,FMI16

ServicetheDPF;

refertoServicingthe

Diesel-OxidationCatalyst

(DOC)andtheSoot

Filter(page52)

g213863

Figure21

Thecomputer

None

de-ratestheengine

powerto50%.

CheckEngine

SPN3720,FMI16

ServicetheDPF;

refertoServicingthe

Diesel-OxidationCatalyst

(DOC)andtheSoot

Filter(page52)

g214715

Figure22

Enginespeedat

maximumtorque+

200rpm

Thecomputer

de-ratestheengine

powerto50%.

CheckEngine

SPN3251,FMI0

31

TypesofDieselParticulateFilterRegeneration

Typesofdieselparticulatelterregenerationthatareperformedwhilethemachineisoperating:

TypeofRegenerationConditionsthatcauseDPFregenerationDPFdescriptionofoperation

Passive

Assist

Reset

Occursduringnormaloperationofthemachineat

high-enginespeedorhigh-engineload

Occursbecauseoflow-enginespeed,low-engine

load,orafterthecomputerdetectstheDPFis

becomingobstructedwithsoot

Occursevery100hours

Alsooccursafterassistregenerationonlyifthe

computerdetectsthatassistregenerationdidnot

sufcientlyreducethesootlevel

•TheInfoCenterdoesnotdisplayaniconindicating

passiveregeneration.

•Duringpassiveregeneration,theDPFprocesses

high-heatexhaustgasses,oxidizingharmful

emissions,andburningsoottoash.

RefertoPassiveDPFRegeneration(page34).

•TheInfoCenterdoesnotdisplayaniconindicating

assistregeneration.

•Duringassistregeneration,theenginecomputer

adjuststheenginesettingstoraisetheexhaust

temperature.

RefertoAssistDPFRegeneration(page35).

•Whenthehighexhaust-temperatureicon

isdisplayedintheInfoCenter,aregenerationisin

progress.

•Duringresetregeneration,theenginecomputer

adjuststheenginesettingstoraisetheexhaust

temperature.

RefertoResetRegeneration(page35).

Typesofdieselparticulatelterregenerationthatrequireyoutoparkthemachine:

TypeofRegenerationConditionsthatcauseDPFregenerationDPFdescriptionofoperation

Parked

Occursbecausethecomputerdetectsback

pressureintheDPFduetosootbuildup

Alsooccursbecausetheoperatorinitiatesaparked

regeneration

MayoccurbecauseyousettheInfoCentertoinhibit

resetregenerationandcontinuedoperatingthe

machine,addingmoresootwhentheDPFalready

needsaresetregeneration

Mayresultfromusingtheincorrectfuelorengineoil

•Whenthereset-standby/parkedorrecovery

regenerationiconorADVISORY#188

displaysintheInfoCenter,aregenerationis

requested.

•Performtheparkedregenerationassoonas

possibletoavoidneedingarecoveryregeneration.

•Aparkedregenerationrequires30to60minutes

tocomplete.

•Youmusthaveatleasta1/4tankoffuelinthe

tank.

•Youmustparkthemachinetoperformaparked

regeneration.

RefertoParkedorRecoveryRegeneration(page

37).

32

Typesofdieselparticulatelterregenerationthatrequireyoutoparkthemachine:(cont'd.)

TypeofRegenerationConditionsthatcauseDPFregenerationDPFdescriptionofoperation

Recovery

Occursbecausetheoperatorignoredrequestsfor

aparkedregenerationandcontinuedoperatingthe

machine,addingmoresoottotheDPF

•Whenthereset-standby/parkedorrecovery

regenerationiconorADVISORY#190

displaysintheInfoCenter,arecoveryregeneration

isrequested.

•Arecoveryregenerationrequiresupto3hours

tocomplete.

•Youmusthaveatleasta1/2tankoffuelinthe

machine.

•Youmustparkthemachinetoperformarecovery

regeneration.

RefertoParkedorRecoveryRegeneration(page

37).

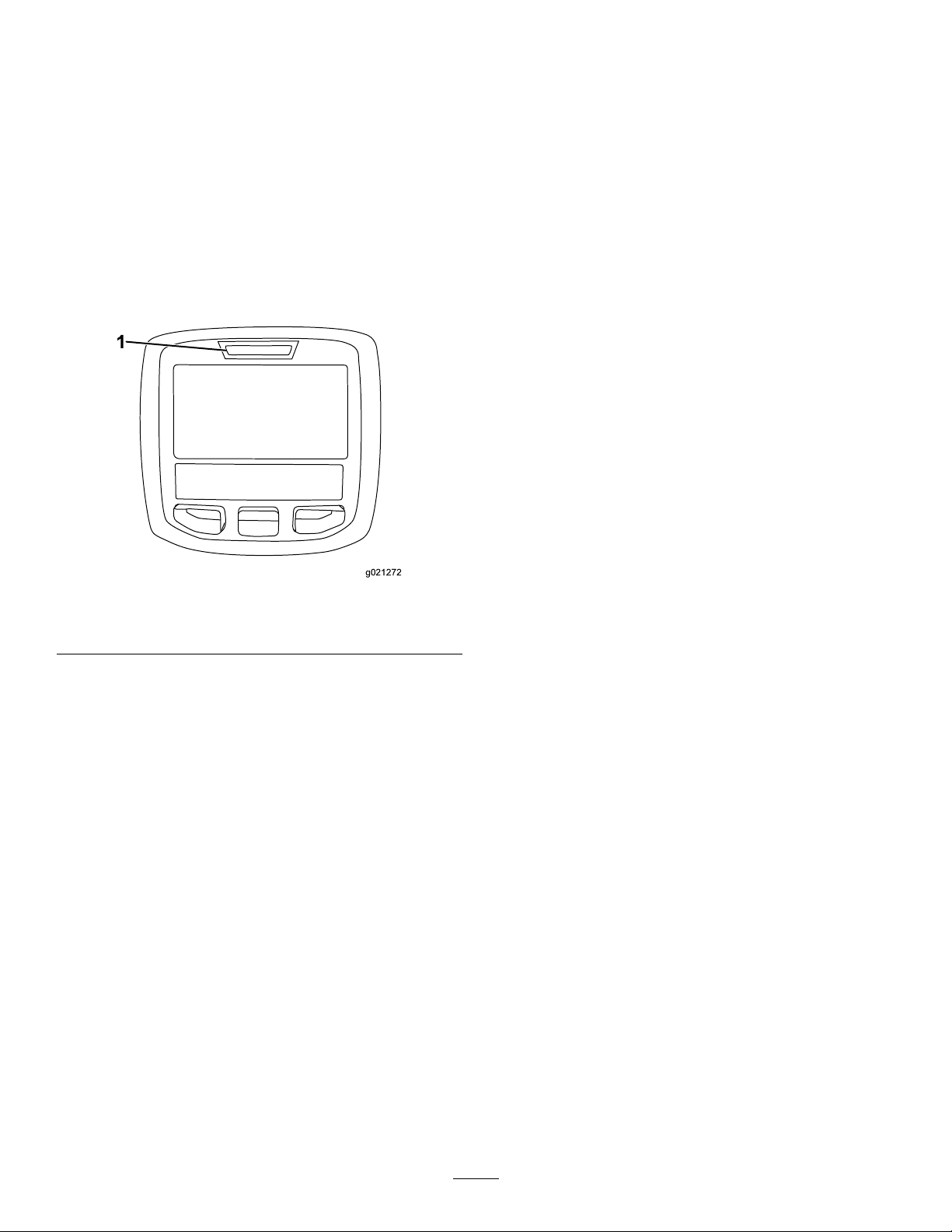

AccessingtheDPFRegeneration Menus

AccessingtheDPFRegenerationMenus

1.AccesstheServicemenu,pressthecenter

buttontoscrolldowntotheDPFREGENERATION

option(Figure23).

UsetheLASTREGENeldtodeterminehowmany

hoursyouhaveruntheenginesincethelastreset,

parked,orrecoveryregeneration.

g224693

Figure24

Figure23

2.PresstherightbuttontoselecttheDPF

Regenerationentry(Figure23).

TimeSinceLastRegeneration

AccesstheDPFRegenerationmenu,pressthecenter

buttontoscrolldowntotheLASTREGENeld(Figure

24).

g227667

TechnicianMenu

Important:Foroperatingconvenience,you

maydecidetoperformaparkedregeneration

beforethesootloadreaches100%,provided

theenginehasrunmorethan50hourssince

thelastsuccessfulreset,parked,orrecovery

regeneration.

Usethetechnicianmenutoviewthecurrentstateof

engineregenerationcontrolandviewthereported

sootlevel.

AccesstheDPFRegenerationmenu,pressthecenter

buttontoscrolldowntotheTECHNICIANoption,and

33

presstherightbuttontoselecttheT echnicianentry

(Figure25).

DPFOperationTable(cont'd.)

Figure25

•UsetheDPFoperationtabletounderstandthe

currentstateofDPFoperation(Figure26).

State

ResetRegenTheenginecomputerisrunningareset

ParkedStby

ParkedRegenYouinitiatedaparkedregeneration

Recov.Stby

Recov.RegenY ouinitiatedarecoveryregeneration

g227348

•Viewthesootloadwhichismeasuredasthe

percentageofsootintheDPF(Figure27);referto

Description

regeneration.

Theenginecomputerisrequestingthat

yourunaparkedregeneration.

requestandtheenginecomputeris

processingtheregeneration.

Theenginecomputerisrequestingthat

yourunarecoveryregeneration.

requestandtheenginecomputeris

processingtheregeneration.

thesoot-loadtable.

Note:Thesootloadvaluevariesasthemachine

isoperatedandDPFregenerationoccurs.

.

DPFOperationTable

State

NormalTheDPFisinnormal-operating

AssistRegen

ResetStby

Figure26

Description

mode—passiveregeneration.

Theenginecomputerisperformingan

assistregeneration.

Theengine

computeristrying

torunareset

regeneration,but

1ofthefollowing

conditionsprevents

regeneration:

Theregeninhibit

settingissettoON.

Theexhaust

temperature

istoolowfor

regeneration.

g227359

Figure27

Soot-LoadTable

ImportantSootLoadValuesRegenerationState

0%to5%

78%Theenginecomputerperforms

g227360

100%

122%

Minimumsootloadrange

anassistregeneration.

Theenginecomputer

automaticallyrequestsa

parkedregeneration.

Theenginecomputer

automaticallyrequestsa

recoveryregeneration.

PassiveDPFRegeneration

•Passiveregenerationoccursaspartofnormal

engineoperation.

•Whileoperatingthemachine,runtheengineat

full-enginespeedandhighloadwhenpossibleto

promoteDPFregeneration.

34

AssistDPFRegeneration

•Theenginecomputeradjustsenginesettingsto

raisetheexhausttemperature.

•Whileoperatingthemachine,runtheengineat

fullenginespeedandhighloadwhenpossibleto

promoteDPFregeneration.

ResetRegeneration

•TheicondisplaysintheInfoCenterwhilethereset

regenerationisprocessing.

•Wheneverpossible,donotshutofftheengineor

reduceenginespeedwhiletheresetregeneration

isprocessing.

Important:Wheneverpossible,allowthe

machinetocompletetheresetregeneration

processbeforeshuttingofftheengine.

CAUTION

Theexhausttemperatureishot(approximately

600°C(1,112°F)duringDPFregeneration.Hot

exhaustgascanharmyouorotherpeople.

•Neveroperatetheengineinanenclosed

area.

•Makesurethattherearenoammable

materialsaroundtheexhaustsystem.

•Nevertouchahotexhaustsystem

component.

•Neverstandnearoraroundtheexhaust

pipeofthemachine.

PeriodicResetRegeneration

IftheenginehasnotcompletedasuccessfulReset,

Parked,orRecoveryregenerationintheprevious100

hoursofengineoperation,theenginecomputerwill

attempttoperformaresetregeneration.

SettingtheInhibitRegen

ResetRegenerationOnly

Note:IfyousettheInfoCentertoinhibitregeneration,

theInfoCenterdisplaysADVISORY#185(Figure29)

every15minuteswhiletheenginerequestsareset

regeneration.

g224692

Figure29

Aresetregenerationproducestheelevatedengine

exhaust.Ifyouareoperatingthemachinearound

trees,brush,tallgrass,orothertemperature-sensitive

plantsormaterials,youcanusetheInhibitRegen

settingtopreventtheenginecomputerfrom

performingaresetregeneration.

Figure28

•Thehighexhaust-temperatureicondisplays

intheInfoCenter(Figure28).

•Theenginecomputeradjustsenginesettingsto

raisetheexhausttemperature.

Important:Thehighexhaust-temperature

iconindicatesthattheexhausttemperature

dischargedfromofyourmachinemaybe

hotterthanduringregularoperation.

•Whileoperatingthemachine,runtheengineat

fullenginespeedandhighloadwhenpossibleto

promoteDPFregeneration.

g224417

Important:Whenyoushutofftheengineand

startitagain,theinhibitregensettingdefaultsto

OFF.

1.AccesstheDPFRegenerationmenu,pressthe

centerbuttontoscrolldowntotheINHIBITREGEN

option,andpresstherightbuttontoselectthe

InhibitRegenentry(Figure30).

35

Figure30

g227304

Figure32

g224394

2.Presstherightbuttontochangetheinhibit

regenerationsettingfromOntoOff(Figure30)

orfromOfftoOn(Figure31).

Figure31

AllowingaResetRegeneration

TheInfoCenterdisplaysthehighexhaust-temperature

icon

whentheresetregenerationisinprocess.

Note:IfINHIBITREGENissettoON,theInfoCenter

displaysADVISORY#185(Figure32).Pressbutton3

tosetinhibitregenerationsettingtoOFFandcontinue

withtheresetregeneration.

Note:Iftheengineexhausttemperatureistoolow,

theInfoCenterdisplaysADVISORY#186(Figure33)to

informyoutosettheenginetofullthrottle(highidle).

g224691

g224395

Figure33

Note:Whentheresetregenerationcompletes,the

highexhaust-temperature

InfoCenterscreen.

disappearsfromthe

36

ParkedorRecoveryRegeneration

•Whentheenginecomputerrequestseithera

parkedregenerationorarecoveryregeneration,

theregenerationrequesticon(Figure34)displays

intheInfoCenter.

Figure34

•Themachinedoesnotautomaticallyperforma

parkedregenerationorarecoveryregeneration,

youmustruntheregenerationthroughthe

InfoCenter.

ParkedRegenerationMessages

regenerationrequired—powertakeoffdisabled

ADVISORY#189(Figure37).

g224398

Figure37

Important:Performaparkedregenerationto

restorethePTOfunction;refertoPreparingto

PerformaParkedorRecoveryRegeneration

(page38)andPerformingaParkedorRecovery

Regeneration(page38).

Note:TheHomescreendisplaysthePTO

disabledIcon(Figure38).

g224404

g224415

Figure38

Whenaparkedregenerationisrequestedbythe

enginecomputerthefollowingmessagesdisplayin

theInfoCenter:

•EnginewarningSPN3720,FMI16(Figure35)

Figure35

•ParkedregenerationrequiredADVISORY#188

(Figure36)

Note:Advisory#188displaysevery15minutes.

Figure36

RecoveryRegenerationMessages

Whenarecoveryregenerationisrequestedbythe

enginecomputer,thefollowingmessagesdisplayin

theInfoCenter:

•EnginewarningSPN3719,FMI:0(Figure39)

g213863

g213867

Figure39

•Recoveryregenerationrequired—powertakeoff

disabledADVISORY#190(Figure40)

g224397

•Ifyoudonotperformaparkedregeneration

within2hours,theInfoCenterdisplaysparked

g224399

Figure40

37

Important:Performarecoveryregeneration

torestorethePTOfunction;refertoPreparing

toPerformaParkedorRecoveryRegeneration

(page38)andPerformingaParkedorRecovery

Regeneration(page38).

Note:TheHomescreendisplaysthePTOdisabled

Icon;refertoFigure38inParkedRegeneration

Messages(page37).

DPFStatus-Limitation

•Iftheenginecomputerrequestsarecovery

regenerationorisprocessingarecovery

regenerationandyouscrolldowntothePARKED

REGENoption,parkedregenerationlocksandthe

lockicon(Figure41)appearsinthelowerright

corneroftheInfoCenter.

2.Movethemachineoutsidetoanareaawayfrom

combustiblematerials.

3.Parkthemachineonalevelsurface.

4.Ensurethatthetractioncontrolormotion-control

leversareintheNEUTRALposition.

5.Ifapplicable,shutoffthePTO,andlowerthe

cuttingunitsoraccessories.

6.Engagetheparkingbrake.

7.SetthethrottletothelowIDLEposition.

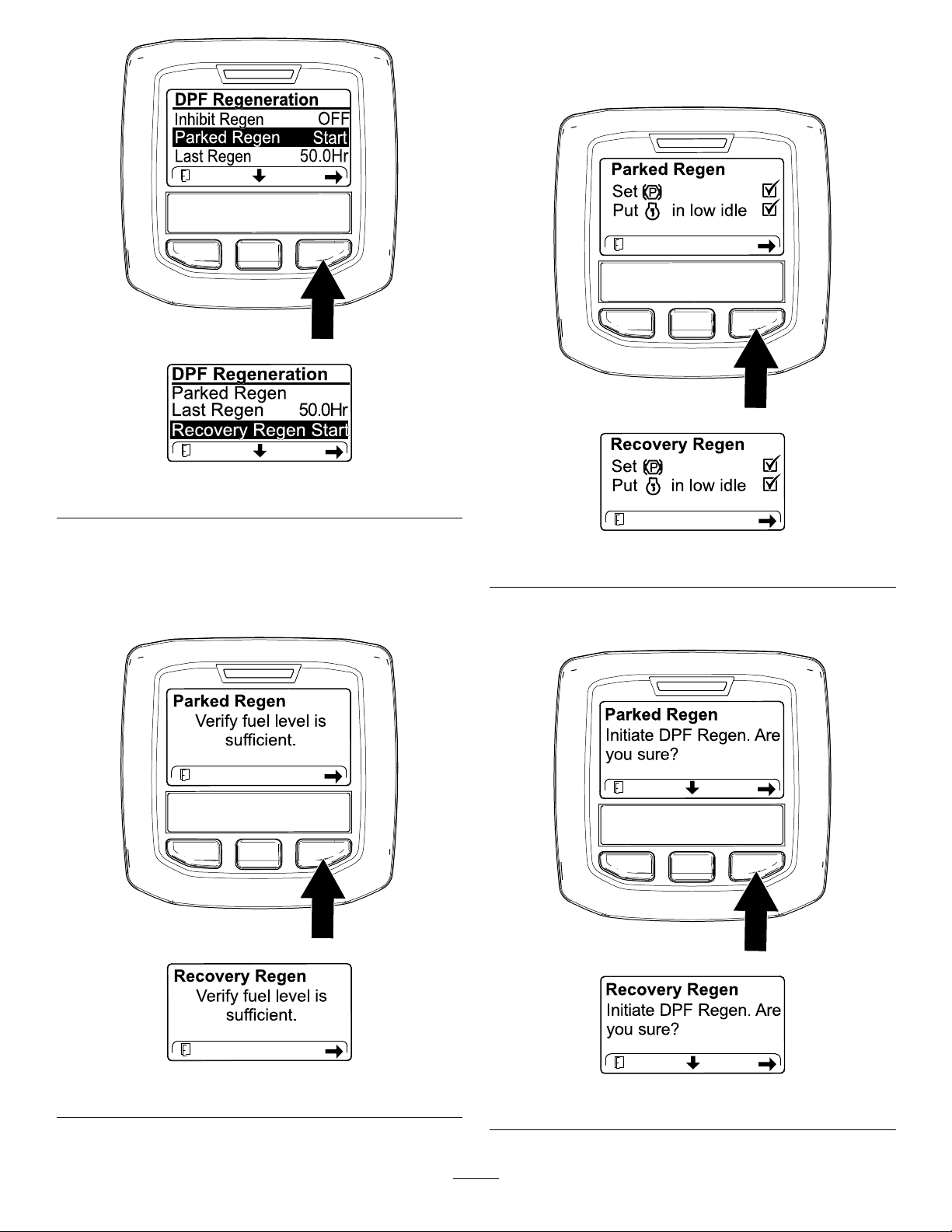

PerformingaParkedorRecovery

Regeneration

CAUTION

Theexhausttemperatureishot(approximately

600°C(1,112°F)duringDPFregeneration.Hot

exhaustgascanharmyouorotherpeople.

•Neveroperatetheengineinanenclosed

area.

Figure41

•Iftheenginecomputerhasnotrequesteda

recoveryregenerationandyouscrolldown

totheRECOVERYREGENoption,therecovery

regenerationlocksandthelockicon(Figure42)

appearsinthelowerrightcorneroftheInfoCenter.

Figure42

PreparingtoPerformaParkedorRecovery

Regeneration

•Makesurethattherearenoammable

g224625

materialsaroundtheexhaustsystem.

•Nevertouchahotexhaustsystem

component.

•Neverstandnearoraroundtheexhaust

pipeofthemachine.

Important:Thecomputerofthemachinecancels

DPFregenerationifyouincreasetheenginespeed

fromlowidleorreleasetheparkingbrake.

1.AccesstheDPFRegenerationmenu,press

thecenterbuttontoscrolldowntoeitherthe

PARKEDREGENST ARToptionortheRECOVERY

REGENSTARToption(Figure43),andpressthe

rightbuttontoselectthestarttheregeneration

(Figure43).

g224628

1.Ensurethatthemachinehasfuelinthetankfor

thetypeofregenerationyouareperforming:

•ParkedRegeneration:Ensurethatyou

have1/4tankoffuelbeforeperformingthe

parkedregeneration.

•RecoveryRegeneration:Ensurethatyou

have1/2tankoffuelbeforeperformingthe

recoveryregeneration.

38

Figure43

3.AttheDPFchecklistscreen,verifythatthe

parkingbrakeisengagedandthattheengine

speedissettolowidle(Figure45).

g224402

g224407

g224629

2.AttheVERIFYFUELLEVELscreen,verifythatyou

have1/4tankoffuelifyouareperformingthe

parkedregenerationor1/2tankoffuelifyouare

performingtherecoveryregeneration,andpress

therightbuttontocontinue(Figure44).

g227679

Figure45

4.AttheINITIATEDPFREGENscreen,pressthe

rightbuttontocontinue(Figure46).

g224414

g224626

Figure44

g227678

g224630

Figure46

39

5.TheInfoCenterdisplaystheINITIA TINGDPF

REGENmessage(Figure47).

Figure47

6.TheInfoCenterdisplaysthetimetocomplete

message(Figure48).

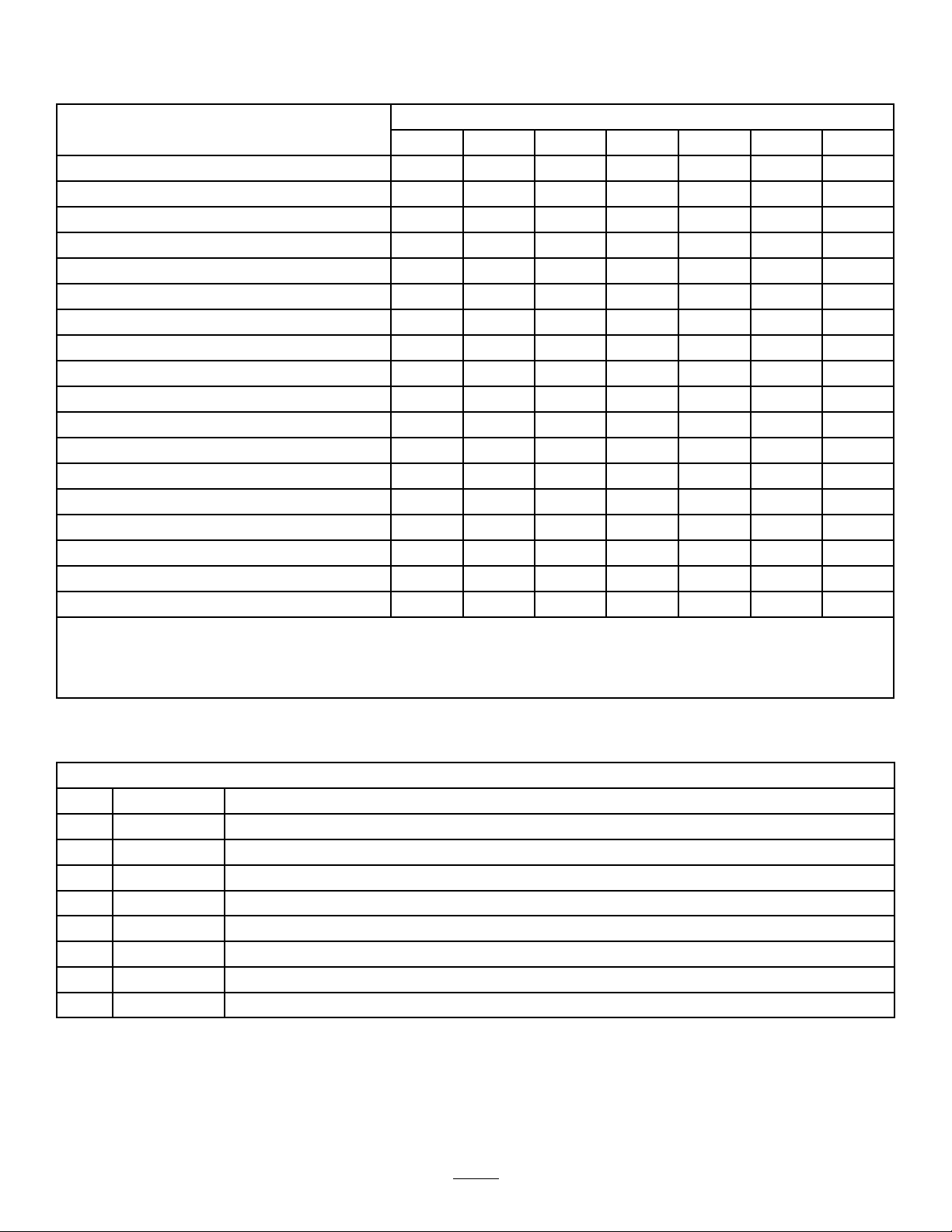

CheckMessageandCorrectiveActionTable

(cont'd.)

g224411

CorrectiveAction:Startandruntheengine.

g227681

CorrectiveAction:Runtheenginetowarmthecoolant

temperatureto60°C(140°F).

Figure48

7.Theenginecomputercheckstheenginestate

andfaultinformation.TheInfoCentermay

displaythefollowingmessagesfoundinthe

tablethatfollows:

CheckMessageandCorrectiveActionT able

CorrectiveAction:Exittheregenerationmenuandrunthe

machineuntilthetimesincelastregenerationisgreaterthan

50hours;refertoTimeSinceLastRegeneration(page33).

g224406

g224406

CorrectiveAction:Changetheenginespeedtolowidle.

CorrectiveAction:Troubleshoottheenginecomputer

conditionandretryDPFregeneration.

8.TheInfoCenterdisplaysthehomescreenand

theregenerationacknowledgeicon(Figure49)

appearsinthelowerrightcornerofthescreen

astheregenerationprocesses.

g224403

Figure49

CorrectiveAction:Troubleshoottheenginefaultandretry

DPFregeneration.

Note:WhiletheDPFregeneration

runs,theInfoCenterdisplaysthehigh

exhaust-temperatureicon.

9.Whentheenginecomputercompletesa

parkedorrecoveryregeneration,theInfoCenter

40

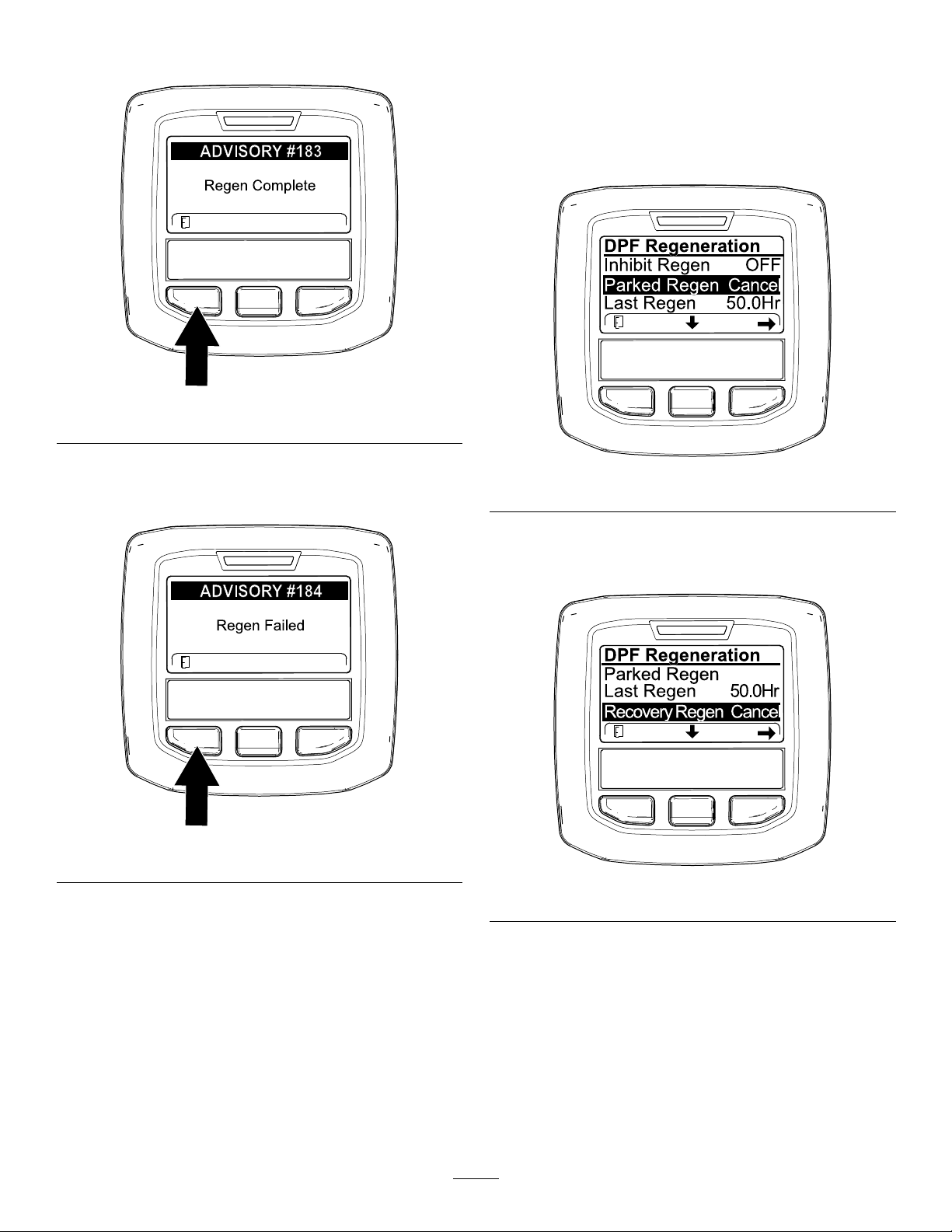

displaysADVISORY#183(Figure50).Pressthe

leftbuttontoexittothehomescreen.

Figure50

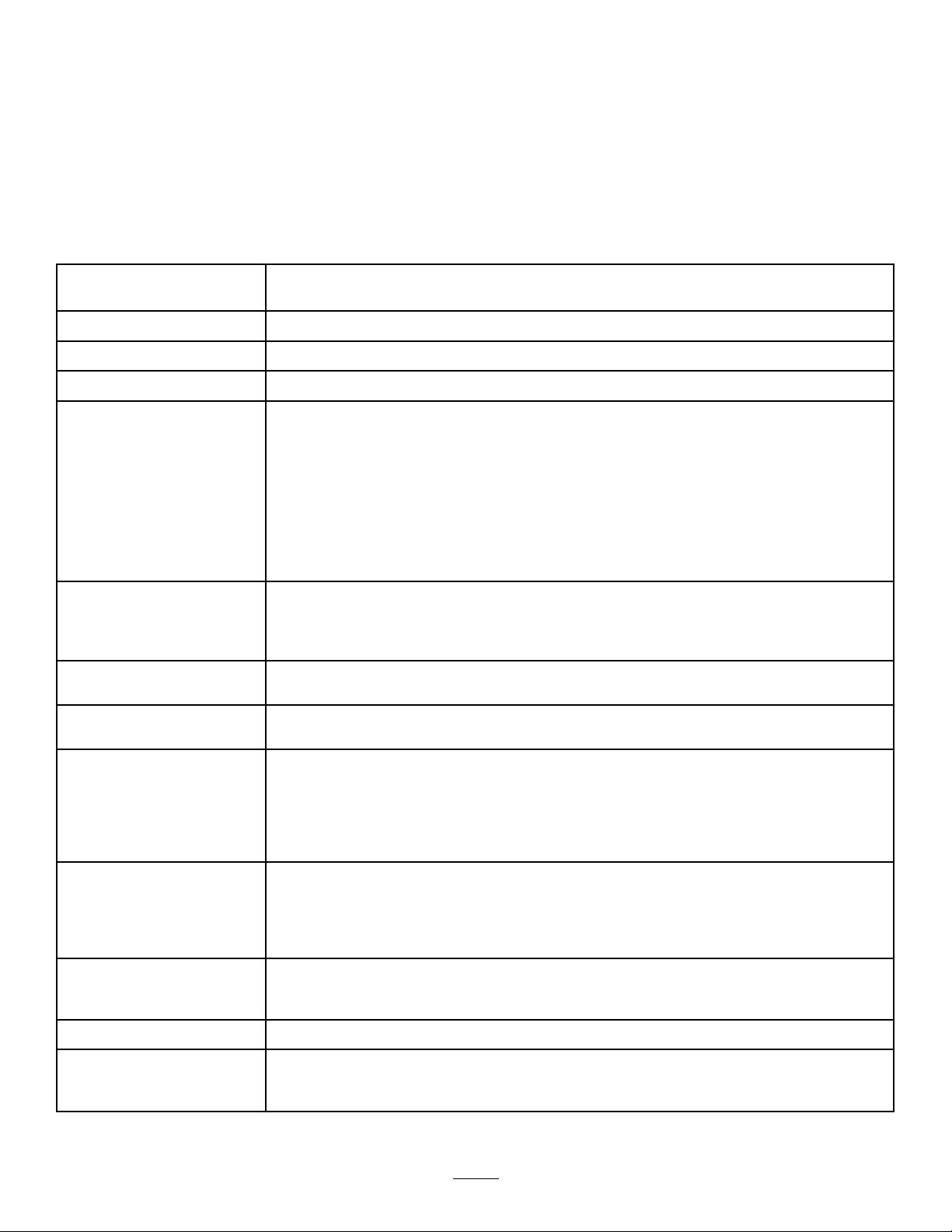

CancelingaParkedorRecoveryRegeneration

UsetheParkedRegenCancelorRecoveryRegen

Cancelsettingtocancelarunningparkedorrecovery

regenerationprocess.

1.AccesstheDPFRegenerationmenu(Figure

52).

g224392

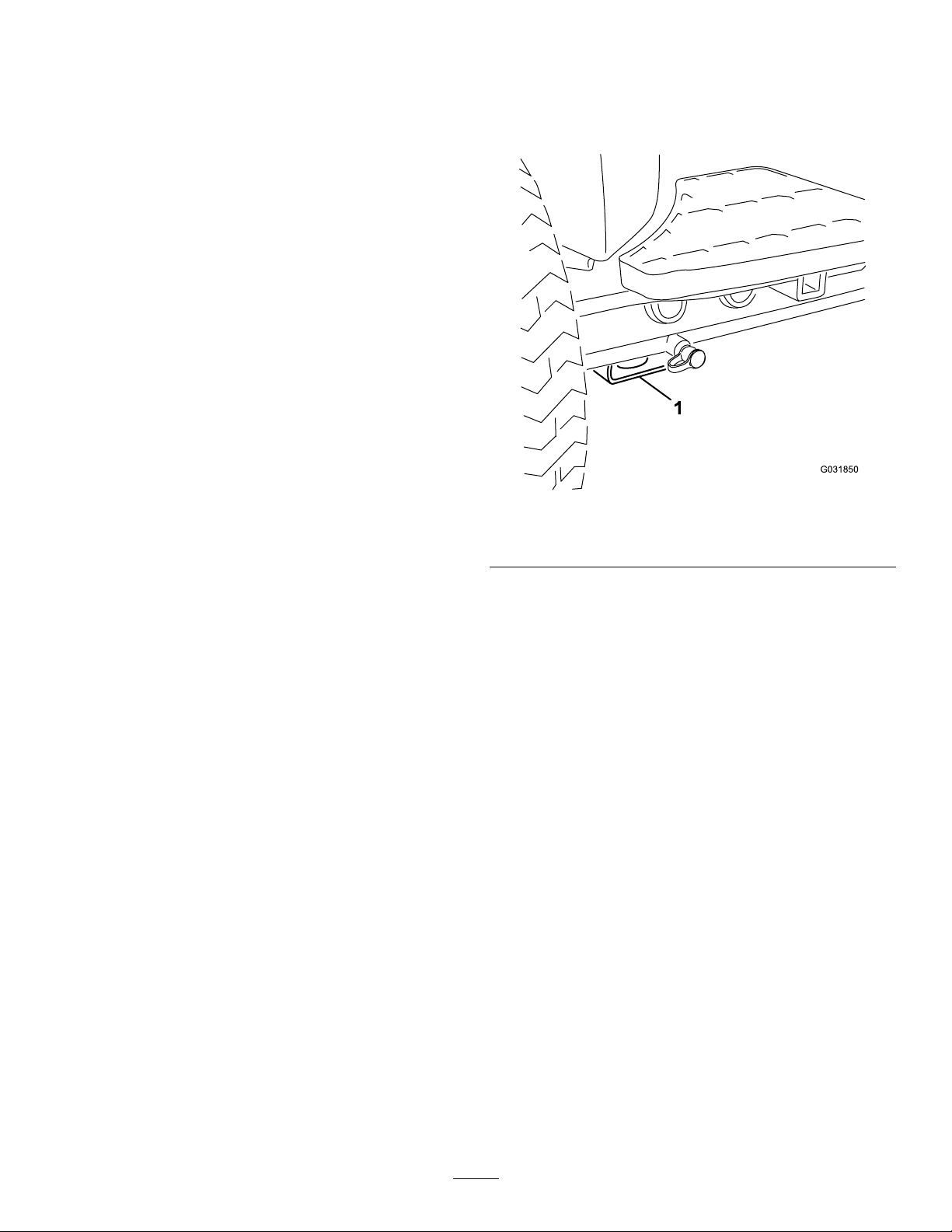

Note:Iftheregenerationfailstocomplete,the

InfoCenterdisplaysAdvisory#184(Figure50).

Presstheleftbuttontoexittothehomescreen.

Figure51

g227305

Figure52

2.Pressthecenterbuttontoscrolldowntothe

PARKEDREGENCANCEL(Figure52)orthe

RECOVERYREGENCANCELoption(Figure53).

g224393

g227306

Figure53

3.PresstherightbuttontoselecttheRegen

Cancelentry(Figure52orFigure53).

41

OperatingTips

buildupinmowerhousing,cuttingperformancewill

decrease.

BecomingFamiliarizedwiththe

Machine

Beforemowinggrass,practiceoperatingthemachine

inanopenarea.Startandshutofftheengine.

Operateinforwardandreverse.Lowerandraisethe

cuttingdecksandengageanddisengagethemowers.

Whenyoufeelfamiliarwiththemachine,practice

operatingupanddownslopesatdifferentspeeds.

SelectingtheProperHeight-of-Cut

SettingtoSuitConditions

Removenomorethanapproximately25mm(1inch),

or1/3ofthegrassbladewhencutting.Inexceptionally

lushanddensegrass,youmayneedtoraiseyour

height-of-cutsetting.

Mowing

TurnthekeyintheignitionswitchtotheONposition,

starttheengine,andmovethethrottletotheFAST

position.MovetheEnable/Disableswitchtothe

ENABLEpositionandusetheLowerMow/Raiselever

tocontrolthecuttingdecks.T omoveforwardandcut

grass,pressthetractionpedalforward.

TransportingtheMachine

MovetheEnable/DisableswitchtotheDISABLE

positionandraisethecuttingunitstotheTRANSPORT

position.MovetheMow/Transportlevertothe

TRANSPORTposition.Becarefulwhendrivingbetween

objectssoyoudonotaccidentallydamagethe

machineorcuttingunits.Useextracarewhen

operatingthemachineonslopes;refertoSlope

Safety(page28).

Note:Allowtheenginetoidlefor5minutesbefore

shuttingitoffafterafullloadoperation.Failuretodo

somayleadtoturbo-chargertrouble.

MowingwithSharpBlades

Asharpbladecutscleanlyandwithouttearingor

shreddingthegrassblades.Adullblade,whichtears

andshredsgrass,causesgrasstoturnbrownat

theedges.Thisimpairsgrassgrowthandincreases

susceptibilitytodiseases.Ensurethatthebladeisin

goodconditionandthatthereisafullsail.

CheckingtheCutting-Unit

Condition

Ensurethatthechambersofeachcuttingunitarein

goodcondition.Straightenanychamber-component

bendstoensurethecorrectbladetip/chamber

clearance.

CheckingtheMowerHousing

AfterOperating

Toensurethatoptimumperformanceismet,cleanthe

undersideofmowerhousing.Ifyouallowresidueto

42

AfterOperation

AfterOperationSafety