Page 1

FormNo.3379-421RevA

Groundsmaster

®

4300-DTraction

Unit

ModelNo.30859—SerialNo.310000001andUp

ModelNo.30861—SerialNo.310000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3379-421*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

Figure1

WARNING

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Thismachineisaride-on,rotary-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrass

onwell-maintainedlawnsinparks,sportselds,andon

commercialgrounds.Itisnotdesignedforcuttingbrush,

mowinggrassandothergrowthalongsidehighways,orfor

agriculturaluses.

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Themodelandserialnumbersareona

platemountedontheleftsideoftheframeunderthefoot

rest.Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................5

SoundPowerLevel..................................................6

SoundPressureLevel...............................................6

VibrationLevel......................................................6

SafetyandInstructionalDecals.................................7

Setup...........................................................................11

1AdjustingtheTirePressure....................................11

2AdjustingtheStepHeight.....................................11

3AdjustingtheControlArmPosition........................12

4RemovetheShippingBlocksandPins.....................12

5InstallingRearW eights.........................................13

6InstallingtheHoodLatchforCE

Compliance........................................................14

7InstallingtheThrottleStopforCE

Compliance........................................................15

ProductOverview.........................................................16

Controls...............................................................16

Specications........................................................19

Attachments/Accessories........................................19

Operation....................................................................19

CheckingtheEngineOilLevel.................................19

CheckingtheCoolingSystem...................................20

AddingFuel...........................................................20

CheckingtheHydraulicFluid...................................22

ChecktheTorqueoftheWheelNuts.........................23

BleedingtheFuelSystem.........................................23

StartingandStoppingtheEngine..............................23

PushingorTowingtheMachine................................24

JackingPoints........................................................24

TieDowns............................................................24

UnderstandingtheDiagnosticLight..........................25

DiagnosticAceDisplay...........................................25

CheckingtheInterlockSwitches...............................26

HydraulicValveSolenoidFunctions..........................27

OperatingTips......................................................27

Maintenance.................................................................29

RecommendedMaintenanceSchedule(s)......................29

DailyMaintenanceChecklist....................................30

ServiceIntervalChart.............................................31

Lubrication...............................................................31

GreasingtheBearingsandBushings..........................31

EngineMaintenance..................................................33

ServicingtheAirCleaner.........................................33

ServicingtheEngineOilandFilter............................33

AdjustingtheThrottle.............................................34

FuelSystemMaintenance...........................................35

DrainingtheFuelTank...........................................35

CheckingtheFuelLinesandConnections..................35

ServicingtheWaterSeparator..................................35

FuelPick-upTubeScreen........................................35

BleedingAirfromtheFuelInjectors..........................35

ElectricalSystemMaintenance....................................36

ServicingtheBattery...............................................36

Fuses....................................................................36

DriveSystemMaintenance.........................................37

AdjustingtheTractionDriveforNeutral....................37

AdjustingtheRearWheelToe-in..............................38

CoolingSystemMaintenance......................................38

RemovingDebrisfromtheCoolingSystem................38

BrakeMaintenance....................................................39

AdjustingtheServiceBrakes....................................39

AdjustingtheParkingBrake....................................39

BeltMaintenance......................................................40

TensioningtheAlternatorBelt.................................40

HydraulicSystemMaintenance....................................41

ChangingtheHydraulicFluid...................................41

ReplacingtheHydraulicFilters.................................41

CheckingtheHydraulicLinesandHoses....................42

ChangingtheCounterbalanceSettings.......................42

HydraulicSystemTestPorts.....................................43

Storage........................................................................43

PreparingtheTractionUnit.....................................43

PreparingtheEngine..............................................43

Schematics...................................................................44

3

Page 4

Safety

ThismachinemeetsorexceedsCENstandardEN

836:1997,ISOstandard5395:1990,andANSIB71.4-2004

specicationsineffectattimeofproduction,when

equippedwithrearweight.Refertothesectioninthis

manualonInstallingRearWeight.

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandardEN

836:1997,ISOstandard5395:1990,andANSIB71.4-2004.

Training

•Readtheoperator'smanualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,orproperty.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,long

trousers,hardhat,safetyglasses,andearprotection.Long

hair,looseclothing,orjewelrymaygettangledinmoving

parts.Donotoperatetheequipmentwhenbarefootor

wearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Warning—Fuelishighlyammable.Takethefollowing

precautions:

–Storefuelincontainersspecicallydesignedforthis

purpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

–Addfuelbeforestartingtheengine.Neverremove

thecapofthefueltankoraddfuelwhiletheengineis

runningorwhentheengineishot.

–Iffuelisspilled,donotattempttostarttheengine

butmovethemachineawayfromtheareaofspillage

andavoidcreatinganysourceofignitionuntilfuel

vaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely.

•Replacefaultysilencers/mufers.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Checkthattheoperator'spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutches,shiftintoneutral,andengagethe

parkingbrake.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.Toguardagainst

overturning:

–donotstoporstartsuddenlywhengoingupor

downhill;

–machinespeedsshouldbekeptlowonslopesand

duringtightturns;

–stayalertforhumpsandhollowsandotherhidden

hazards;

–Donotturnsharply.Usecarewhenreversing.

–Usecounterweight(s)orwheelweightsasidentied

intheoperator'smanual.

•Stayalertforholesintheterrainandotherhiddenhazards.

4

Page 5

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfacesother

thangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besureall

interlocksareattached,adjustedproperly,andfunctioning

properly.

•Donotchangetheenginegovernorsettingsorover-speed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

–stoponlevelground;

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachmentswhentransportingornot

inuse.

•Stoptheengineanddisengagedrivetoattachment:

–beforerefuelling;

–beforeremovingthegrasscatcher/catchers;

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator'sposition.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthemower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperatingthe

equipment.

•Reducethethrottlesettingduringenginerun-outand,if

theengineisprovidedwithashut-offvalve,turnthefuel

offattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingdecks.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuelstorage

areafreeofgrass,leaves,orexcessivegrease.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

•Disengagedrives,lowerthecuttingdecks,setparking

brake,stopengineandremovekeyfromignition.Wait

forallmovementtostopbeforeadjusting,cleaningor

repairing.

•Cleangrassanddebrisfromcuttingdecks,drives,

silencers/mufers,andenginetohelppreventres.Clean

upoilorfuelspillage.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.Wearprotectiveclothing

anduseinsulatedtools.

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCEN,ISO,orANSIstandard.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

•Knowhowtostoptheenginequickly.

5

Page 6

•Donotoperatethemachinewhilewearingtennisshoes

orsneakers.

•Checkallfuellinesfortightnessandwearonaregular

basis.Tightenorrepairthemasneeded.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,or

otherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrolof

themachine.

•Raisethecuttingdeckswhendrivingfromoneworkarea

toanother.

•Donottouchtheengine,silencer/mufer,orexhaust

pipewhiletheengineisrunningorsoonafterithas

stoppedbecausetheseareascouldbehotenoughtocause

burns.

•Iftheenginestallsorlosesheadwayandcannotmakeit

tothetopofaslope,donotturnthemachinearound.

Alwaysbackslowly,straightdowntheslope.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingdecks,attachments,and

anymovingparts.Keepeveryoneaway.

•Toensuresafetyandaccuracy,haveanAuthorizedToro

Distributorcheckthemaximumenginespeedwitha

tachometer.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•UseonlyToro-approvedattachmentsandreplacement

parts.Thewarrantymaybevoidedifusedwith

unapprovedattachments.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof105dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinEN11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof92

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

VibrationLevel

•Whenapersonorpetappearsunexpectedlyinornearthe

mowingarea,stopmowing.Carelessoperation,combined

withterrainangles,ricochets,orimproperlypositioned

guardscanleadtothrownobjectinjuries.Donotresume

mowinguntiltheareaiscleared.

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightandall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Seekimmediatemedicalattentionifuidis

injectedintoskin.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

decksandattachmentstotheground.

Hand-Arm

Measuredvibrationlevelforrighthand=0.34m/s

Measuredvibrationlevelforlefthand=0.43m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

WholeBody

Measuredvibrationlevel=0.33m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

2

2

2

2

2

6

Page 7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

108-5278

1.ReadtheOperator'sManual.

93-7272

1.Cutting/dismembermenthazard;fan—stayawayfrom

movingparts.

110-8973

(Afxoverpartno.1 10–8869forCE*)

slopewarningrequiredonthemachineforcompliancetotheEuropeanLawnMower

SafetyStandardEN836:1997.Theconservativemaximumslopeanglesindicatedfor

operationofthismachineareprescribedbyandrequiredbythisstandard.

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

3.Tippinghazard—donotoperateonslopesgreaterthan15°;

lowerthecuttingdeckswhenoperatingonslopes;wear

thesafetybelt.

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingdecks,stoptheengineand

removetheignitionkeybeforeleavingthemachine

5.Warning—readtheOperator'sManualbeforetowingthe

machine.

*Thissafetydecalincludesa

110-8869

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

3.Tippinghazard—slowmachinebeforeturning,donotturn

athighspeeds;lowerthecuttingunitwhendrivingdown

slopes;usearolloverprotectionsystemandweartheseat

belt.AlwayswearaseatbeltwhenaROPSisinplace.

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingdecks,stoptheengineand

removetheignitionkeybeforeleavingthemachine.

5.Warning—readtheOperator'sManual,donottowthe

machine.

110-8921

1.Tractionunitspeed

2.Slow

3.Fast

117–2718

7

Page 8

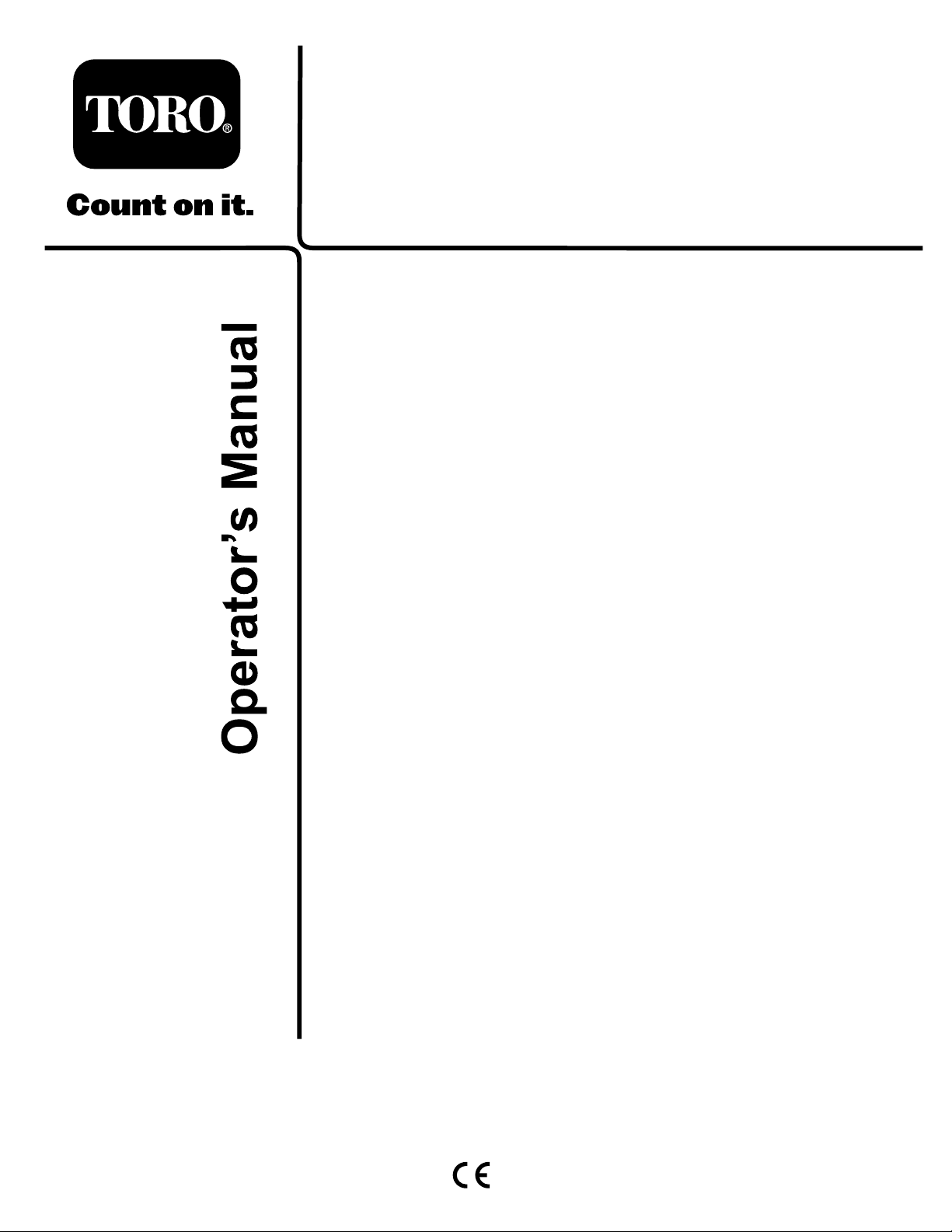

117–0169

1.ReadtheOperator'sManual.

2.Powerpoint—10amp

3.Headlights—10amp

4.Power—10amp

5.Enginestart—15amp

6.Optionalairrideseatsuspension—20amp

7.EnginecomputermanagementC—7.5amp

8.EnginecomputermanagementB—7.5amp

9.EnginecomputermanagementA—7.5amp

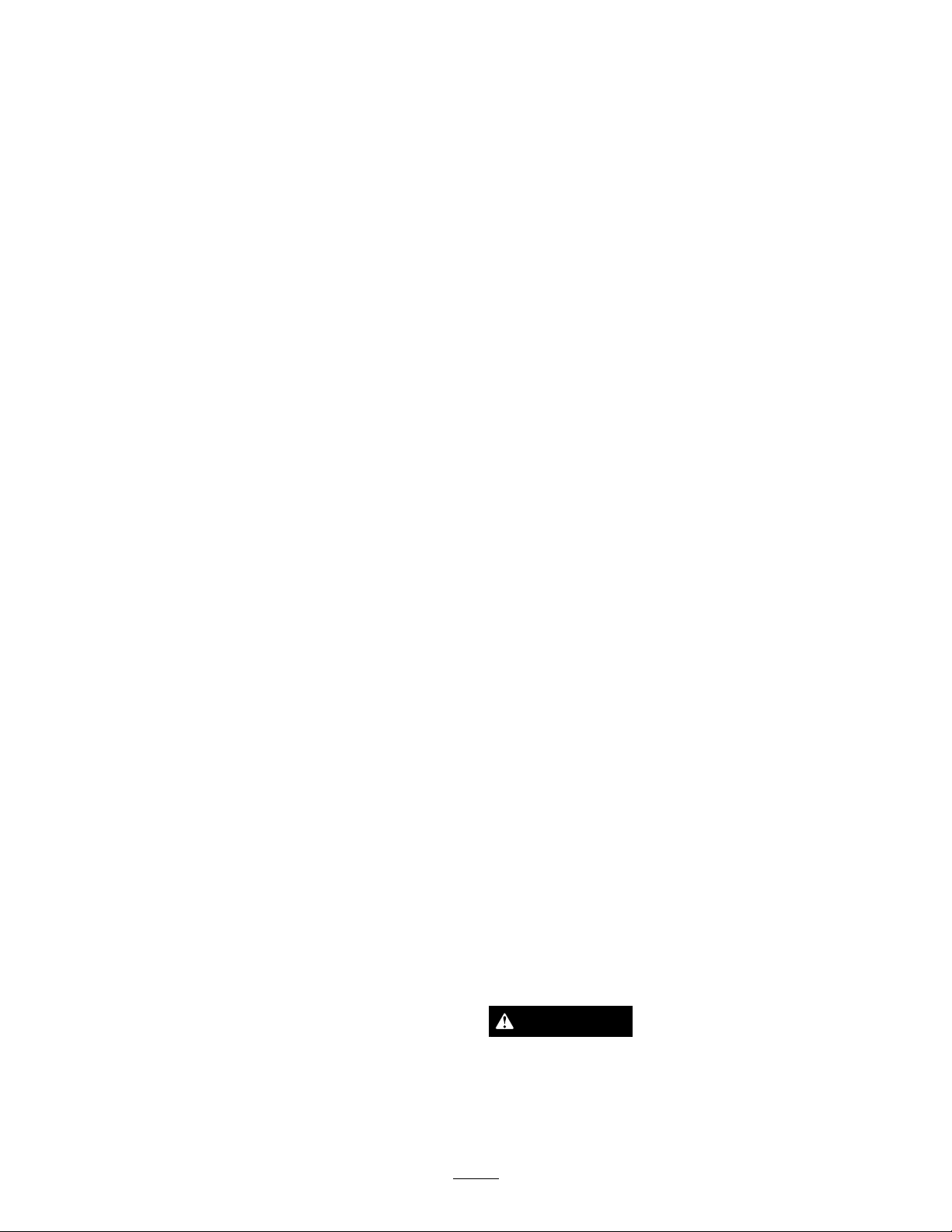

117–2385

117–0170

1.Headlights

2.Engage

3.Powertake-off(PTO)

4.Disengage9.Raisecuttingunits

5.Fast

6.Continuousvariable

throttlesetting

7.Slow

8.Lowercuttingunits

10.ReadtheOperator's

Manual.

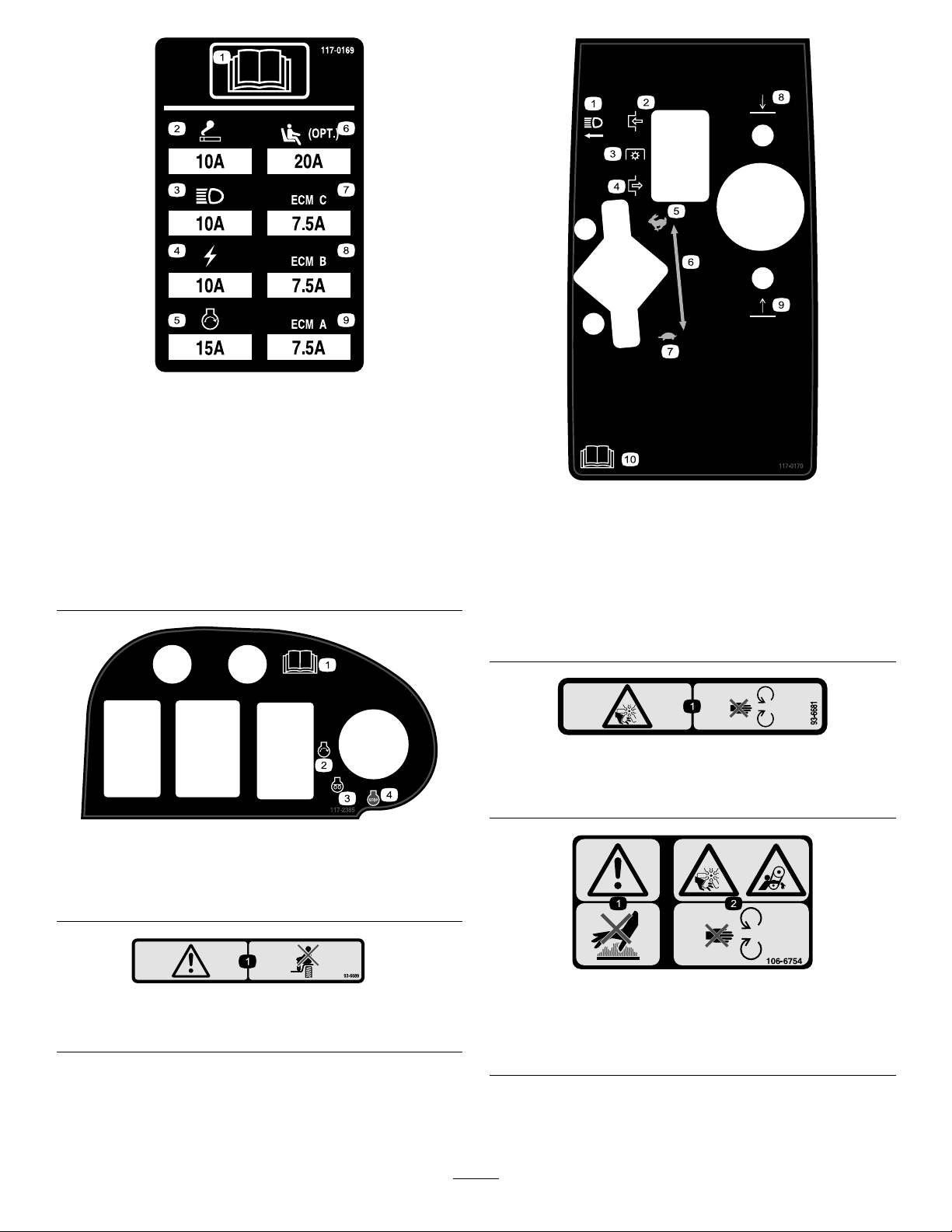

93-6681

1.Cutting/dismemberment—hazard,fan-stayawayfrom

movingparts.

1.ReadtheOperators

Manual.

2.Engine—start4.Engine—stop

93–6689

1.Danger—donotsitontheplasticshroud.

3.Engine—preheat

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

8

Page 9

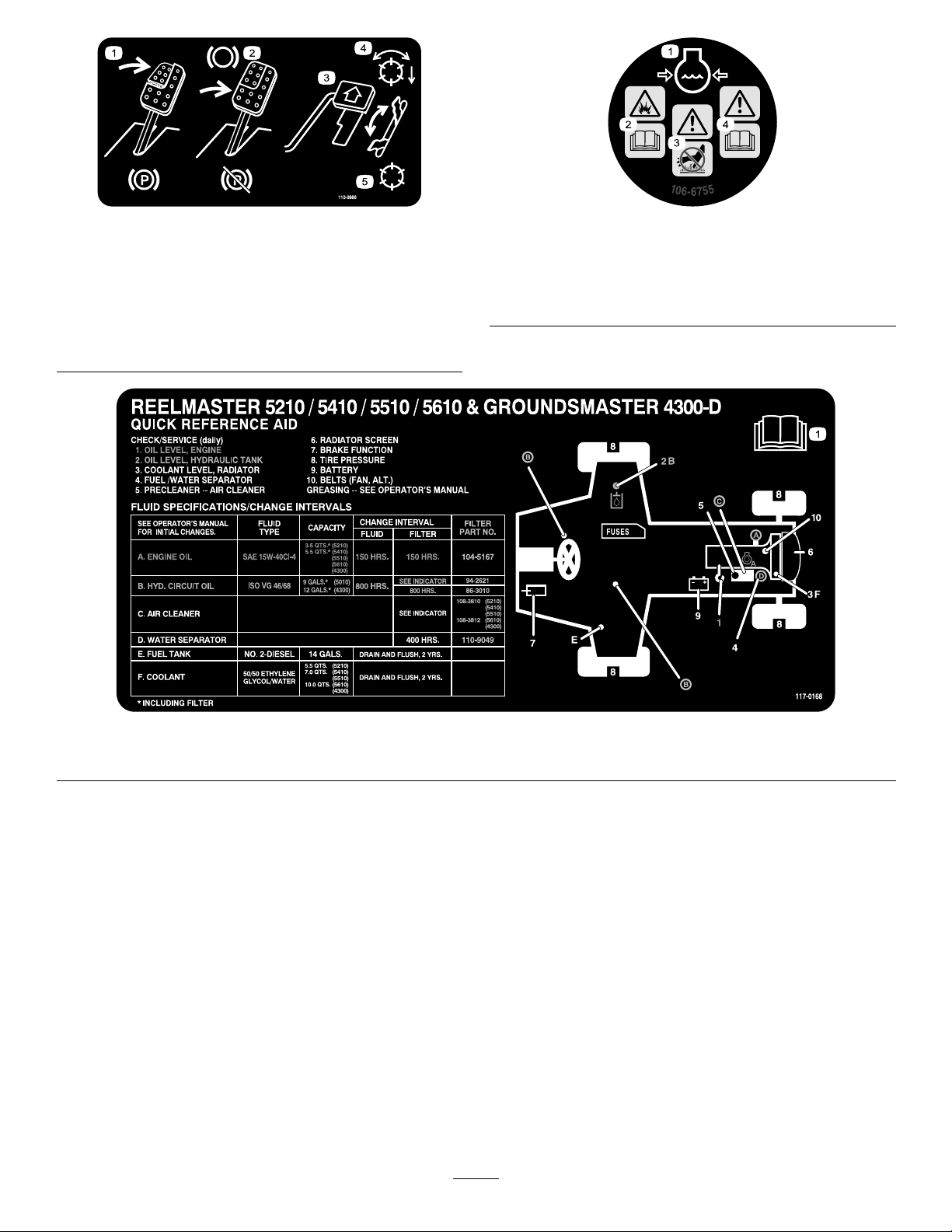

110-0986

106-6755

1.Pressthebrakepedalandparkingbrakepedaltosetthe

parkingbrake.

2.Pressthebrakepedaltoapplythebrake.

3.Pressthetractionpedaltomovethemachineforward.

4.Reelenabledmode

5.Transportmode

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

1.ReadtheOperator'sManual.

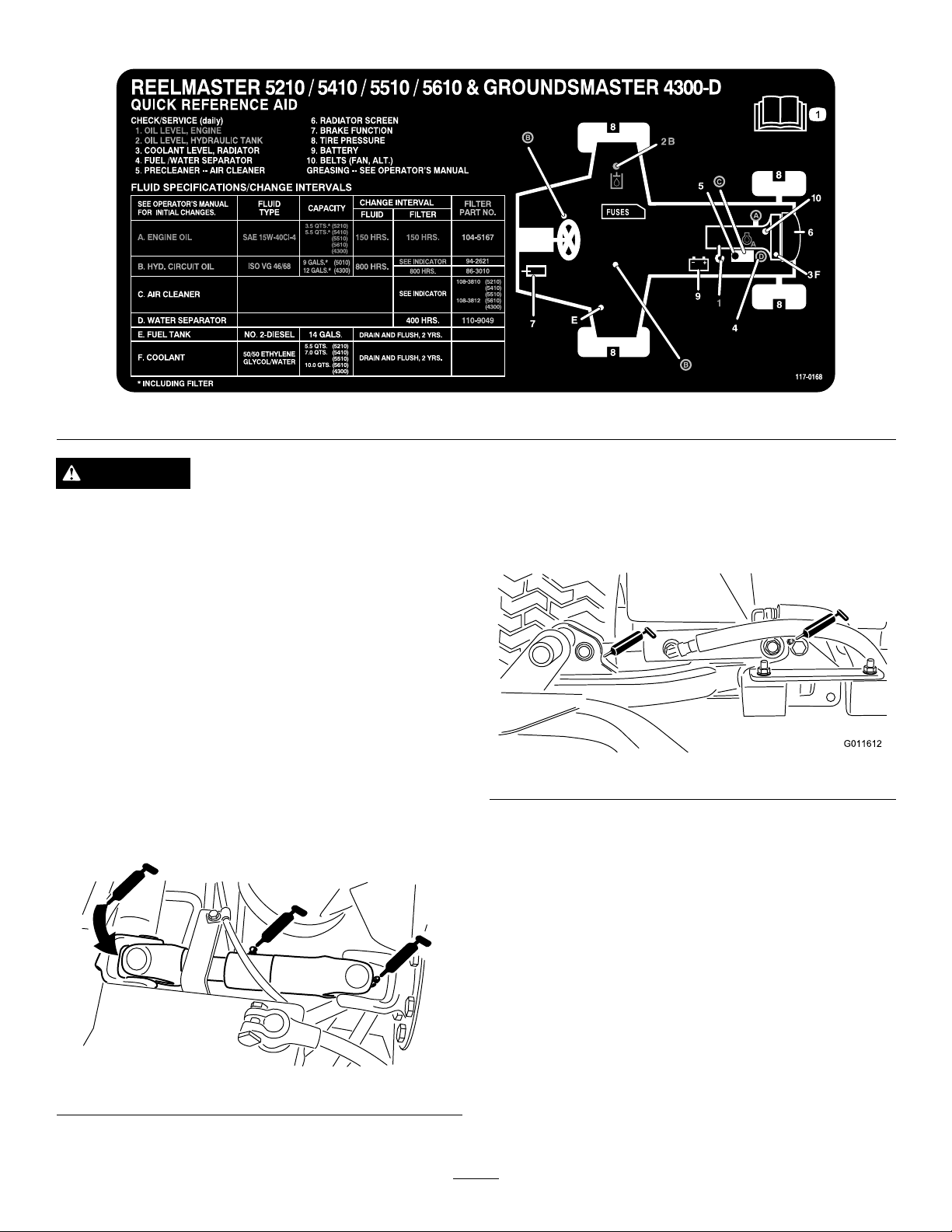

117-0168

9

Page 10

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery .

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

10

Page 11

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

MediaandAdditionalParts

Description

Operator'sManual

EngineOperator'sManual

PartsCatalog

CECerticate

OperatorTrainingMaterial

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Rearweights(quantityvarieswith

conguration).

Hoodlatchassembly1

Washer1

Throttlestop1

Setscrew

Qty.

1

1

1

1

1

Reviewbeforeoperatingmachine

Varies

Qty.

Use

–

–

–

–

1

Adjustthetirepressure.

Adjustthestepheight.

Adjustthecontrolarmposition.

Removeshippingblocksandpins

Installrearweights(orderfromyour

ToroDistributor).

InstallthehoodlatchforCEcompliance

InstallthethrottlestopforCEcompliance

Use

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

AdjustingtheTirePressure

NoPartsRequired

Procedure

Thetiresareover-inatedforshipping.Therefore,release

someoftheairtoreducethepressure.Correctairpressurein

thefrontandreartiresis12to15psi(83to103kPa).

Important:Maintainevenpressureinalltirestoensure

uniformcontactwiththeturf.

2

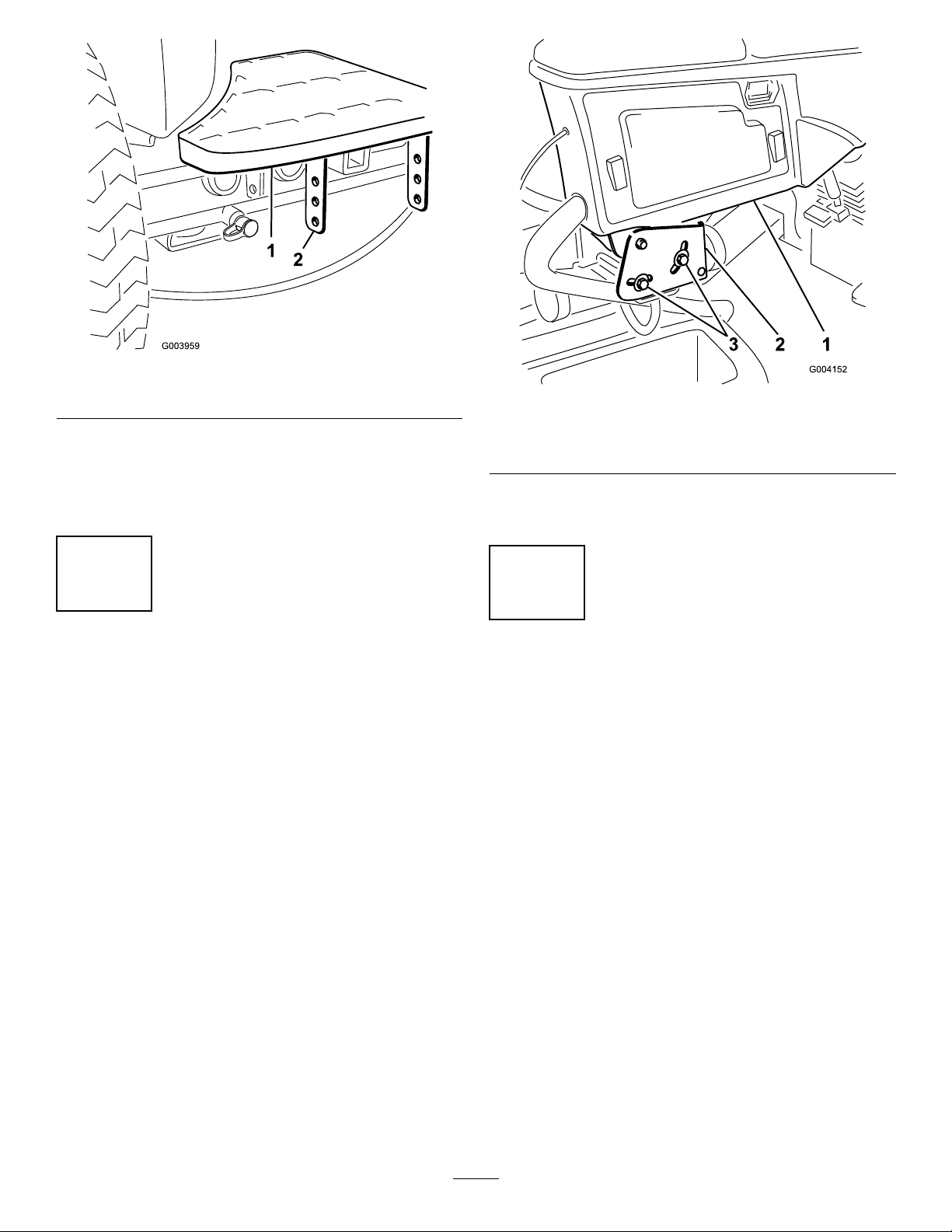

AdjustingtheStepHeight

NoPartsRequired

Procedure

Theheightofthestepscanbeadjustedfortheoperators

comfort.

1.Removethe2boltsandnutssecuringthestepbrackets

tothetractionunitframe(

Figure2)

11

Page 12

Figure2

1.Step2.Stepbrackets

2.Raiseorlowerthesteptothedesiredheightand

re-securethebracketstotheframewiththe2bolts

andnuts.

3.Repeattheprocedureontheotherstep.

3

AdjustingtheControlArm Position

NoPartsRequired

Procedure

Thecontrolarmpositioncanbeadjustedfortheoperators

comfort.

1.Loosenthe2boltssecuringthecontrolarmtothe

retainingbracket(Figure3).

Figure3

1.Controlarm3.Bolts(2)

2.Retainingbrackets

2.Rotatethecontrolarmtothedesiredpositionand

tightenthe2bolts.

4

RemovetheShippingBlocks andPins

NoPartsRequired

Procedure

1.Removeanddiscardtheshippingblocksfromthe

cuttingdecks.

2.Removeanddiscardtheshippingpinsfromthecutting

decksuspensionarms.Theshippingpinsstabilizethe

cuttingdecksduringshippingandmustberemoved

beforeoperation.

12

Page 13

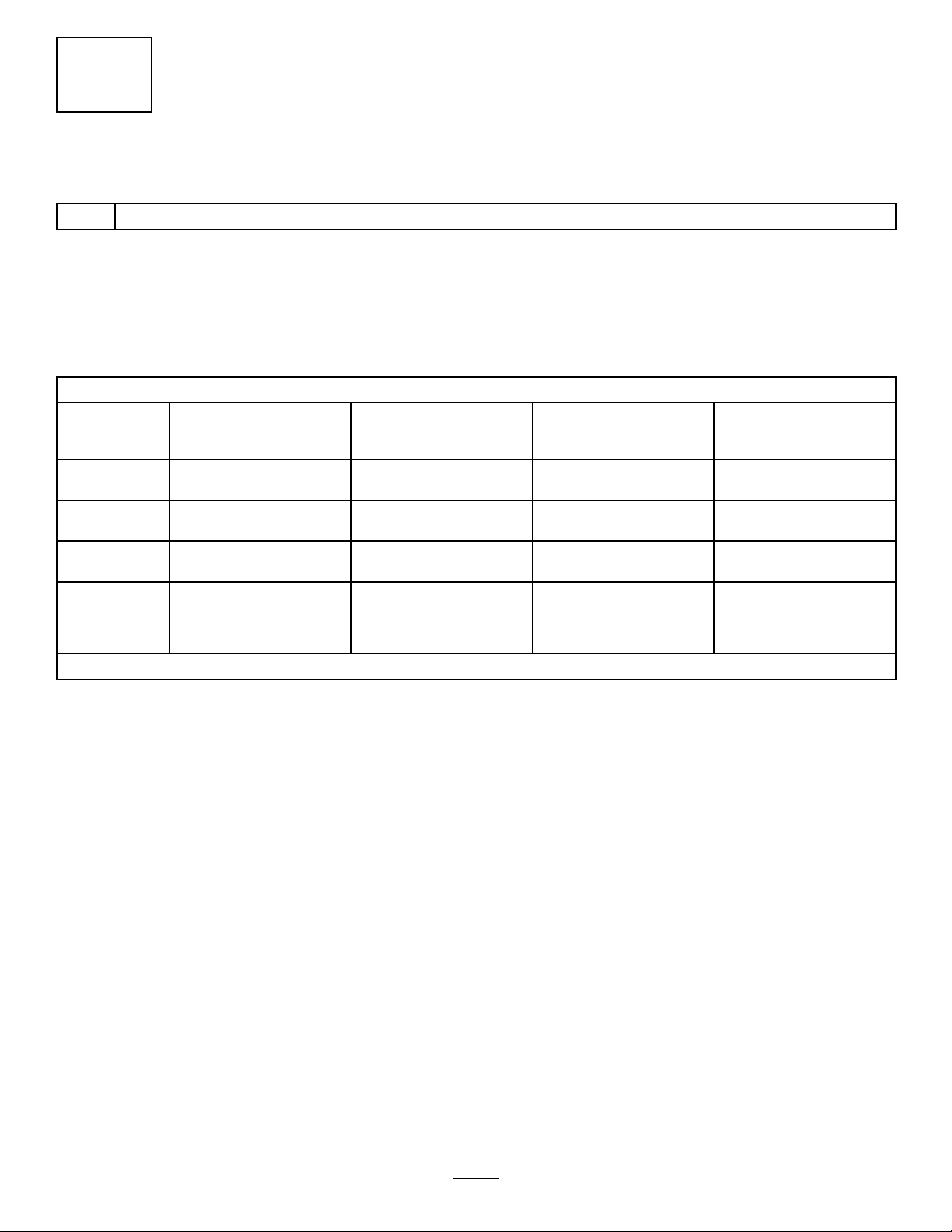

5

InstallingRearWeights

Partsneededforthisprocedure:

Varies

Rearweights(quantityvarieswithconguration).

Procedure

TheGroundsmaster4300–DTractionUnitcomplieswithCENstandardEN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004Standardswhenequippedwithrearweightsand/or90lbofcalciumchlorideballastisaddedtorearwheels.Use

thefollowingchartstodeterminethecombinationsofweightsrequiredforyourconguration.Orderpartsfromyour

localAuthorizedToroDistributor.

WeightP/N110-8985-03

Conguration

BaseUnit60

WithRecycler

Kit

WithSunshade

orCooltops

With4Post

ROPS&

Sunshadeor

Cooltops

Numberofweightsto

meetANSI(US)standards

90lbcalciumchloride*

90lbcalciumchloride*

90lbcalciumchloride*

*Installtubesinsidethereartiresbeforeaddingcalciumchloride.

Numberofweightsto

meetCE(European)

standards

0

4

4

Fasteners(2each

required)forweights

3231–34CarriageBolt

104–8301Nut

N/AN/A

3231–7Carriage

Bolt104–8301Nut

3231–7Carriage

Bolt104–8301Nut

WeightLocation

3ontopofbumperand

3underbumper

1ontopofbumperand

3underbumper

1ontopofbumperand

3underbumper

Important:Alwaysinstalltubesinsidethereartiresbeforecalciumchlorideisinstalled.Ifapunctureoccursina

tirewithcalciumchloride,removethemachinefromtheturfareaasquicklyaspossible.Topreventpossibledamage

totheturf,immediatelysoaktheaffectedareawithwater.

Usethefollowingproceduretomounttheappropriateamountofweight(seeweightcharts)tothetoporbottomofthe

rearbumperasshowninFigure4.

13

Page 14

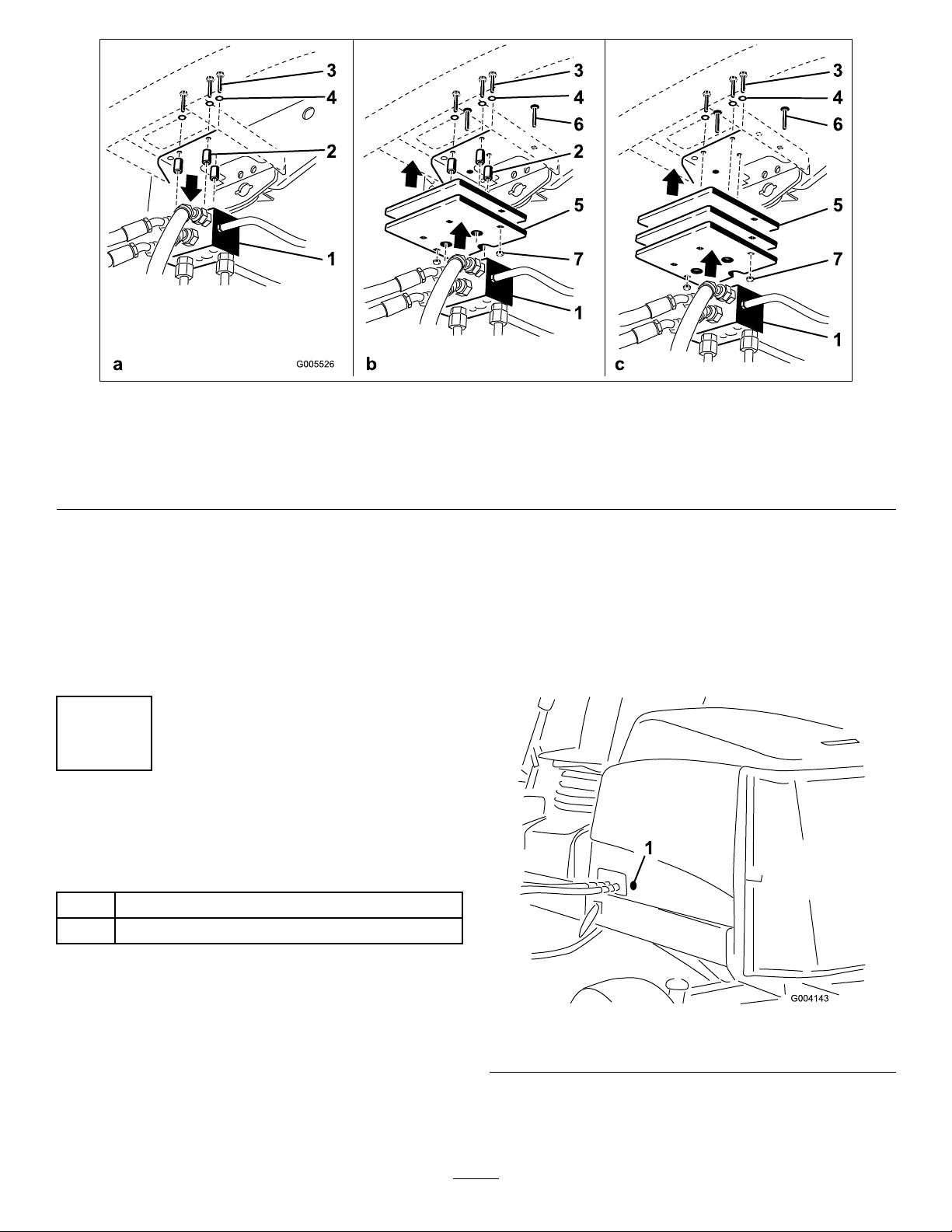

Figure4

1.Tractionmanifold5.Weight(s)

2.Spacers6.Carriagebolt

3.Bolts7.Nut

4.Washers

•Removethe3bolts,washers,andspacerssecuringthetractionmanifoldtothebottomoftherearbumper(Figure4a).

•Positiontheappropriateamountofweightonthetopand/orbottomoftherearbumper.

•Mounttheweight(s)andthetractionmanifoldtothebumperwiththe3bolts,washersandspacerspreviouslyremoved

(Figure4b).

Note:Donotusethespacerswheninstallingmorethantwoweightsunderthebumper(Figure4c).

•Securetheouteredgesoftheweight(s)tothebumperwith2carriageboltsandnuts(Figure4c).

6

InstallingtheHoodLatchfor CECompliance

Partsneededforthisprocedure:

1Hoodlatchassembly

1Washer

Procedure

1.Unlatchandraisethehood.

2.Removetherubbergrommetfromtheholeintheleft

sideofthehood(Figure5).

Figure5

1.Rubbergrommet

3.Removethenutfromthehoodlatchassembly(Figure

6).

14

Page 15

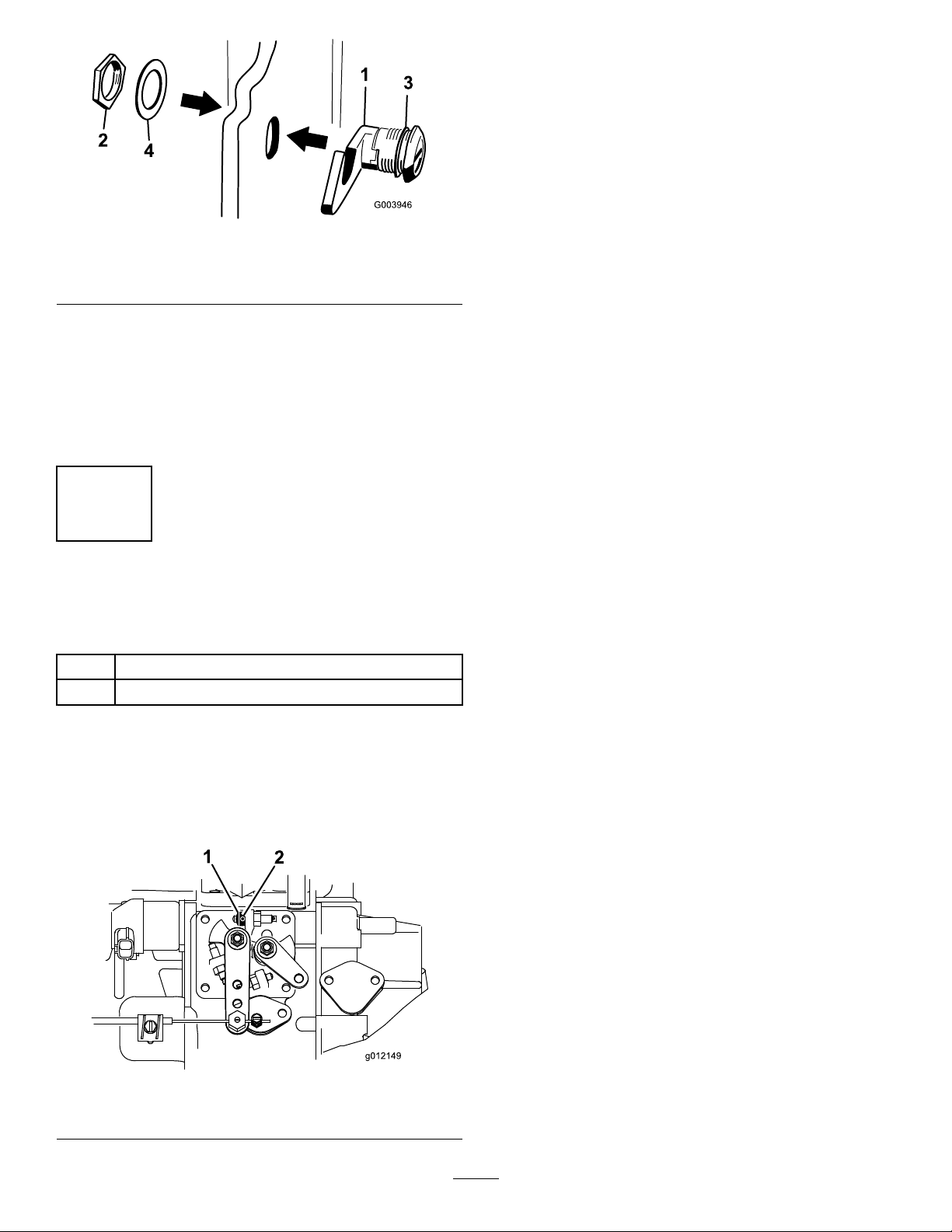

Figure6

1.Hoodlatch3.Rubberwasher

2.Nut4.Metalwasher

4.Outsidethehood,insertthehookendofthelatch

throughtheholeinthehood.Makesuretherubber

sealingwasherremainstotheoutersideofthehood.

5.Insidethehood,insertthemetalwasherontothelatch

andsecurewiththenut.Makesurethelatchengages

theframecatchwhenitislocked.Usetheenclosed

hoodlatchkeytooperatethehoodlatch.

3.Starttheengineandallowittorunfor5to10minutes.

4.Adjustthehighidleto2860rpmwiththecuttingdecks

disengaged.

5.Tightenthesetscrew.

6.Applyadhesiveintothesetscrewtopreventtampering.

7

InstallingtheThrottleStopfor CECompliance

Partsneededforthisprocedure:

1Throttlestop

1

Setscrew

Procedure

1.Loosenthesetscrewonthethrottlestop(Figure7).

2.Slidethethrottlestopontothehighidlestopscrew

(Figure7).Thechamferedendofthethrottlestopis

tobepositionedoutward.

1.Throttlestop

Figure7

2.Setscrew

15

Page 16

ProductOverview

Controls

SeatAdjustingKnobs

Theseatadjustinglever(Figure8)allowsyoutoadjustthe

seatforeandaft.Theweightadjustingknobadjuststheseat

fortheoperator'sweight.Theweightgaugeindicateswhen

theseatisadjustedtotheweightoftheoperator.Theheight

adjustingknobadjuststheseatfortheoperator'sheight.

Figure9

1.Tractionpedal4.Brakepedal

2.Mowspeedlimiter5.Parkingbrake

3.Spacers

6.Tiltsteeringpedal

Figure8

1.Weightgauge3.Heightadjustingknob

2.Weightadjustingknob

4.Adjustinglever(foreand

aft)

TractionPedal

Thetractionpedal(Figure9)controlstheforwardandreverse

operation.Pressthetopofthepedaltomoveforwardandthe

bottomtomoverearward.Groundspeeddependsonhow

faryoupressthepedal.Fornoload,maximumgroundspeed,

fullypressthepedalwhilethethrottleisintheFastposition.

Tostop,reducefootpressureonthetractionpedalandallow

ittoreturntothecenterposition.

MowSpeedLimiter

Whenthemowspeedlimiter(Figure9)isippedupitwill

controlthemowspeedandallowthecuttingdeckstobe

engaged.Eachspaceradjuststhemowingspeedby½mile

perhour.Themorespacersyouhave,onthetopofthebolt

thesloweryouwillgo.Fortransport,ipbackthemowspeed

limiterandyouwillhavemaximumtransportspeed.

BrakePedal

Pressthebrakepedal(Figure9)tostopthemachine.

ParkingBrake

Toengagetheparkingbrake,(Figure9)pushdownonthe

brakepedalandpressthetopforwardtolatch.Toreleasethe

parkingbrake,pressthebrakepedaluntiltheparkingbrake

latchretracts.

TiltSteeringPedal

Totiltthesteeringwheeltowardsyou,pressthefootpedal

(Figure9)down,andpullthesteeringtowertowardyouto

themostcomfortablepositionandthenreleasethepedal.

ThrottleControl

Movethethrottlecontrol(Figure10)forwardtoincreasethe

enginespeedandrearwardtodecreasespeed.

16

Page 17

G003956

1

2

3

4

5

6

7

8

9

10

Figure10

enabledinthemowmode.Whenstartingthedecksinthe

downposition,thisleverwillturnthedecksonifthePTO

andthemowspeedlimiterareengaged.

GlowPlugIndicatorLight

Thislight(Figure10)illuminateswhentheglowplugsare

preheating.

EngineOilPressureWarningLight

Thislight(Figure10)indicatesdangerouslylowengineoil

pressure.

ChargeIndicator

Thechargeindicator(Figure10)illuminateswhenthesystem

chargingcircuitmalfunctions.

1.Throttlecontrol6.Enginecoolant

2.Enable/disableswitch

3.Glowplugindicatorlight8.Chargeindicator

4.Enginecoolant

temperaturewarning

light

5.Diagnosticlight

temperaturegauge

7.Engineoilpressure

warninglight

9.Keyswitch

10.Lowermow/raisecontrol

lever

KeySwitch

Thekeyswitch(Figure10)hasthreepositions:Off,

On/Preheat,andStart.

EngineCoolantTemperatureWarning

Light

Thislight(Figure10)illuminatesandthemowersshutdown

whentheenginecoolantreachesahightemperature.Ifthe

enginetemperaturecontinuestorise,theenginewillshut

down.

Enable/DisableSwitch

Usetheenable/disableswitch(Figure10)inconjunctionwith

thelowermow/raisecontrollevertooperatethemowers.

Themowerscannotbeloweredwhenthemow/transport

leverisinthetransportposition.

HourMeter

Thehourmeter(Figure11)showsthetotalhoursthatthe

machinehasbeenoperated.

EngineCoolantTemperatureGauge

Duringnormaloperatingconditionsthegauge(Figure10)

shouldbeinthegreenrange.Checkthecoolingsystemifthe

gaugegoestotheyelloworredrange.

Figure11

1.Hourmeter

DiagnosticLight

Itwillilluminateshouldasystemfaultberecognized.

LowerMow/RaiseControlLever

Thislever(Figure10)raisesandlowersthecuttingdecks

andalsostartsandstopsthemowerswhenthemowersare

HydraulicFilterRestrictionIndicator

Withtheenginerunningatnormaloperatingtemperature,

viewtheindicator(Figure12),itshouldbeintheGreenzone.

WhentheindicatorisintheRedzone,changethehydraulic

lters.

17

Page 18

1.Hydrauliclterrestrictionindicator

Figure12

FuelGauge

Thefuelgauge(Figure13)showstheamountoffuelinthe

tank.

Figure13

Figure14

1.Headlightswitch

PowerPoint

Thepowerpointisa12voltpowersupplyforelectronic

devices(Figure15).

1.Fueltankcap

2.Fuelgauge

HeadlightSwitch

Pivottheswitchdownwardtoturnontheheadlights

(Figure14).

Figure15

1.Powerpoint

18

Page 19

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

TransportWidth

Widthofcut90inches(229cm)

Length

Height

Netweight*3,114lb(1,412kg)

Fueltankcapacity

Transportspeed

Mowingspeed

*Withcuttingdecksanduids

89inches(226cm)

126inches(320cm)

86inches(218cm)

13.5USgallons(51l)

0–10mph(0–16kph)

0–8mph(0–13kph)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .T oro.comforalistofallapproved

attachmentsandaccessories.

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CAUTION

Ifyouleavethekeyintheignitionswitch,someone

couldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Lowerthecuttingdeckstotheground,setthe

parkingbrakeandremovethekeyfromtheignition

switchbeforeservicingormakingadjustmentsto

themachine.

CheckingtheEngineOilLevel

Theengineisshippedwithoilinthecrankcase;however,the

oillevelmustbecheckedbeforeandaftertheengineisrst

started.

Crankcasecapacityisapproximately5.5qt.(5.2l)withthe

lter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4orhigher

•Preferredoil:SAE15W-40(above0degreesF)

•Alternateoil:SAE10W-30or5W-30(alltemperatures)

ToroPremiumEngineoilisavailablefromyourdistributorin

either15W-40or10W -30viscosity .

1.Parkthemachineonalevelsurface,stoptheengine,

settheparkingbrakeandremovethekeyfromthe

ignitionswitch.

2.Openthehood.

3.Removethedipstick,wipeitclean,andinstallit(Figure

16).

19

Page 20

CheckingtheCoolingSystem

Cleandebrisoffofthescreen,oilcooler,andfrontofthe

radiatordailyandmoreoftenifconditionsareextremely

dustyanddirty.RefertothesectiononRemovingDebris

fromtheCoolingSysteminMaintenance.

Thecoolingsystemislledwitha50/50solutionofwater

andpermanentethyleneglycolantifreeze.Checkthelevel

ofcoolantintheexpansiontankatthebeginningofeach

daybeforestartingtheengine.Thecapacityofthecooling

systemis10.0quarts(9.5l).

CAUTION

Iftheenginehasbeenrunning,thepressurized,hot

coolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhentheengine

Figure16

1.Dipstick

isrunning.

•Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

4.Removedipstickandcheckoillevelondipstick.

TheoillevelshouldbeuptotheFullmark.

5.IftheoillevelisbelowtheFullmark,removethell

cap(

Figure17)andaddoiluntillevelreachestheFull

markondipstick.

1.Checkthelevelofcoolantintheexpansiontank

(Figure18).

Thecoolantlevelshouldbebetweenthemarksonthe

sideofthetank.

Figure18

Figure17

1.Oilllcap

Donotoverll.

Important:Besuretokeeptheengineoillevel

betweentheupperandlowerlimitsontheoil

gauge.Enginefailuremayoccurasaresultofover

llingorunderllingtheengineoil.

6.Installtheoilllcapandclosethehood.

1.Expansiontank

2.Ifthecoolantlevelislow ,removetheexpansiontank

capandreplenishthesystem.Donotoverll.

3.Installtheexpansiontankcap.

AddingFuel

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchasefuelin

20

Page 21

quantitiesthatcanbeusedwithin180daystoensurefuel

freshness.

Fueltankcapacity:13.5gallons(51l)

Usesummergradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Useofwintergrade

fuelatlowertemperaturesprovideslowerashpointand

coldowcharacteristicswhichwilleasestartingandreduce

fuellterplugging.

Useofsummergradefuelabove20°F(-7°C)willcontribute

towardlongerfuelpumplifeandincreasedpowercompared

towintergradefuel.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepfuelawayfromeyesandskin.

BiodieselReady

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana180-daysupplyoffuel.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultralowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather.

•Monitorseals,hoses,gasketsincontactwithfuelasthey

maybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblended.

•Contactyourdistributorifyouwishformoreinformation

onbiodiesel.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipmentwithits

wheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromafueldispenser

nozzle.

•Ifafueldispensernozzlemustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

1.Parkthemachineonalevelsurface.

2.Usingacleanrag,cleanareaaroundfueltankcap.

3.Removecapfromthefueltank(

Figure19).

21

Page 22

Figure19

1.Fueltankcap2.Fuelgauge

4.Fillthetankuntilthelevelistothebottomoftheller

neckwithdieselfuel.

5.Installfueltankcaptightlyafterllingtank.

Note:Ifpossible,llthefueltankaftereachuse.This

willminimizepossiblebuildupofcondensationinside

thefueltank.

CheckingtheHydraulicFluid

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0

Note:Manyhydraulicuidsarealmostcolorless,makingit

difculttospotleaks.Areddyeadditiveforthehydraulic

systemoilisavailablein2/3oz.(20ml)bottles.Onebottleis

sufcientfor4-6gal(15-221)ofhydraulicoil.Orderpartno.

44-2500fromyourauthorizedTorodistributor.

BiodegradableHydraulicFluid-Mobil224H

ToroBiodegradableHydraulicFluid(Availablein5

gallonpailsor55gallondrums.SeepartscatalogorT oro

distributorforpartnumbers.)

Alternateuid:MobilEAL224H

Note:Thisisvegetable-oilbasedbiodegradableoiltested

andapprovedbyToroforthismodel.Thisuidisnotas

resistanttohightemperaturesasstandarduid,sobesure

tofollowtherecommendeduidchangeintervalswiththis

uid.Contaminationbymineral-basedhydraulicuidswill

changethebiodegradabilityandtoxicityofthisoil.When

changingfromstandarduidtothebiodegradabletype,be

certaintofollowtheapprovedushingprocedure.Contact

yourlocalToroDistributorfordetails.

1.Positionmachineonalevelsurface,lowerthecutting

decksandstoptheengine.

2.Cleanareaaroundllerneckandcapofhydraulictank

(Figure20).

Themachinesreservoirislledatthefactorywith

approximately10U .S.gallons(37.8l)ofhighqualityhydraulic

uid.Checkthelevelofthehydraulicuidbeforethe

engineisrststartedanddailythereafter.Therecommended

replacementuidisasfollows:

ToroPremiumAllSeasonHydraulicFluid(Availablein5

gallonpailsor55gallondrums.SeepartscatalogorT oro

distributorforpartnumbers.)

Alternateuids:IftheT orouidisnotavailable,other

uidsmaybeusedprovidedtheymeetallthefollowing

materialpropertiesandindustryspecications.W edonot

recommendtheuseofsyntheticuid.Consultwithyour

lubricantdistributortoidentifyasatisfactoryproductNote:

Torowillnotassumeresponsibilityfordamagecausedby

impropersubstitutions,souseonlyproductsfromreputable

manufacturerswhowillstandbehindtheirrecommendation.

HighViscosityIndex/LowPourPointAnti-wearHydraulic

Fluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48cSt

ViscosityIndexASTM

D2270

@100°C7.9to8.5

140to160

Figure20

1.Hydraulictankcap

3.Removecap/dipstickfromllerneckandwipeitwith

acleanrag.Insertdipstickintollerneck;thenremove

itandchecklevelofuid.Fluidlevelshouldbewithin

operatingrangeondipstick.Donotoverll.

4.Iflevelislow ,addappropriateuidtoraiselevelto

fullmark.

5.Installcap/dipstickontollerneck.

22

Page 23

ChecktheTorqueoftheWheel Nuts

Torquethewheelnutsto70to90ft-lb(94to122N⋅m).after

1-4hoursofoperationandagainafter10hoursofoperation.

Torqueevery250hoursthereafter.

WARNING

Failuretomaintainpropertorqueofthewheelnuts

couldresultinpersonalinjury.

BleedingtheFuelSystem

Youmustbleedthefuelsystembeforestartingtheengineif

anyofthefollowingsituationshaveoccurred:

•Initialstartupofanewmachine.

•Enginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponfuelsystem

components;i.e.,lterreplaced,separatorserviced,etc.

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1/4to1/2

in.(6to13mm)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsthe

fueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

1.Parkthemachineonalevelsurfaceandensurethatthe

fueltankisatleasthalffull.

2.Openthehood.

3.Opentheairbleedscrewonthefuelinjectionpump

(

Figure21)witha12mmwrench.

Figure21

1.Bleedscrew

4.TurnthekeyintheignitionswitchtotheOnposition.

Theelectricfuelpumpwillbeginoperation,thereby

forcingairoutaroundtheairbleedscrew .Leavethe

keyintheOnpositionuntilasolidstreamoffuelows

outaroundthescrew .

5.TightenthescrewandturnthekeytotheOffposition.

Note:Normally,theengineshouldstartaftertheabove

bleedingproceduresarefollowed.However,ifenginedoes

notstart,airmaybetrappedbetweeninjectionpumpand

injectors;refertoBleedingAirfromtheInjectors.

StartingandStoppingthe Engine

Important:Y oumustbleedthefuelsystembefore

startingtheengineifyouarestartingtheengineforthe

rsttime,theenginehasstoppedduetolackoffuel,or

youhaveperformedmaintenanceonthefuelsystem;

refertoBleedingtheFuelSystem.

StartingtheEngine

1.Sitontheseat,keepyourfootoffofthetractionpedal

sothatitisinNeutral,engagetheparkingbrake,set

thethrottletotheFastposition,andensurethatthe

Enable/DisableswitchisintheDisableposition.

2.TurntheignitionswitchtotheOn/Preheatposition.

Anautomatictimerwillcontroltheglowplugpreheat

for6seconds.

3.Afterpreheatingtheglowplugs,turnkeytotheStart

position.

Cranktheenginefornolongerthan15seconds.

Releasethekeywhentheenginestarts.Ifadditional

23

Page 24

preheatingisrequired,turnkeytotheOffpositionand

thentotheOn/Preheatposition.Repeatthisprocess

asrequired.

4.Runtheengineatlowidlespeeduntilitwarmsup.

StoppingtheEngine

1.MoveallcontrolstoNeutral,settheparkingbrake,

movethethrottletothelowidlepositionandallowthe

enginetoreachlowidlespeed.

Important:Allowtheenginetoidlefor5

minutesbeforeshuttingitoffafterafullload

operation.Failuretodosomayleadtotroubleon

aturbo-chargedengine.

2.TurnthekeytotheOffpositionandremoveitfrom

theswitch.

PushingorTowingthe Machine

Inanemergency,themachinecanbemovedbyactuatingthe

bypassvalveinthevariabledisplacementhydraulicpumpand

pushingortowingthemachine.

Important:Donotpushortowthemachinefasterthan

2-3mph(3-4.8km/h)becauseinternaltransmission

damagemayoccur.Thebypassvalvemustbeopen

wheneverthemachineispushedortowed.

1.Thebypassvalveislocatedontheleftsideofthe

hydrostat(

openandallowoiltobypassinternally.Becauseuid

isbypassed,themachinecanbemovedslowlywithout

damagingthetransmission.

Figure22).Rotatethebolt1–1/2turnsto

JackingPoints

Note:Usejackstandstosupportthemachinewhenrequired.

•Front—rectangularpad,undertheaxletube,insideeach

fronttire(Figure23).

Figure23

1.Frontjackingpoint

•Rear—rectangularaxletubeontherearaxle.

TieDowns

•Front—theholeintherectangularpad,undertheaxle

tube,insideeachfronttire(

Figure24).

Figure22

1.Bypassvalve

2.Closethebypassvalvebeforestartingtheengine.

However,donotexceed5-8ft.-lb.(7-11N·m)torque

toclosethevalve.

Important:Runningtheenginewiththebypass

valveopenwillcausethetransmissiontooverheat.

Figure24

1.Fronttiedown

•Rear—eachsideofthemachineontherearframe(Figure

25).

24

Page 25

1.Reartiedown

Figure25

Figure26

1.Diagnosticlight

UnderstandingtheDiagnostic Light

Themachineisequippedwithadiagnosticlightwhich

indicatesiftheelectroniccontrollersensesanelectronic

malfunction.Thediagnosticlightislocatedonthecontrol

arm(Figure26).Whentheelectroniccontrollerisfunctioning

correctlyandthekeyswitchismovedtotheOnposition,

thecontrollerdiagnosticlightwillturnONfor3seconds

andturnOFFtoindicatethelightisworkingproperly .If

themachinekillsthelightwillturnonsteadyuntilthekey

positionischanged.Thelightwillblinkifthecontroller

detectsamalfunctionintheelectricalsystem.Thelightwill

stopblinkingandautomaticallyresetwhenthekeyswitchis

turnedtotheOffpositiononcethefaulthasbeenresolved.

Whenthecontrollerdiagnosticlightblinks,oneofthe

followingproblemshasbeendetectedbythecontroller:

•Oneoftheoutputshasbeenshorted.

•Oneoftheoutputsisopencircuited.

Usingthediagnosticdisplay,determinewhichoutputis

malfunctioning;refertoCheckingtheInterlockSwitches.

Ifthediagnosticlightisnotilluminatedwhenthekeyswitchis

intheOnposition,thisindicatesthattheelectroniccontroller

isnotoperating.Possiblecausesareasfollows:

•Loop-backisnotconnected.

•Thelightisburnedout.

•Fusesareblown.

•Itisnotfunctioningcorrectly.

Checktheelectricalconnections,inputfuses,anddiagnostic

lightbulbtodeterminethemalfunction.Ensurethatthe

loop-backconnectorissecuredtothewireharnessconnector.

DiagnosticAceDisplay

Themachineisequippedwithanelectroniccontrollerwhich

controlsmostmachinefunctions.Thecontrollerdetermines

whatfunctionisrequiredforvariousinputswitches(i.e.seat

switch,keyswitch,etc.)andturnsontheoutputstoactuate

solenoidsorrelaysfortherequestedmachinefunction.

Fortheelectroniccontrollertocontrolthemachineas

desired,eachoftheinputswitches,outputsolenoids,and

relaysmustbeconnectedandfunctioningproperly .

UsetheDiagnosticACEdisplaytohelpverifyandcorrect

electricalfunctionsofthemachine.

25

Page 26

CheckingtheInterlock Switches

Thepurposeoftheinterlockswitchesistopreventthe

enginefromcrankingorstartingunlessthetractionpedalis

intheNeutralposition,theEnable/Disableswitchisinthe

Disableposition,andtheLowerMow/Raisecontrolisinthe

Neutralposition.Inaddition,theengineshouldstopwhen

thetractionpedalispressedwithoperatoroffoftheseatorif

theparkingbrakeisleftengaged.

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

VerifyingtheInterlockSwitchFunction

1.Parkthemachineonalevelsurface,lowerthecutting

decks,stoptheengine,andengagetheparkingbrake.

2.Removetheaccesspanelfromthesideofthecontrol

arm.

3.Locatethewireharnessandconnectorsnearthe

controller(Figure27).

Figure28

1.DiagnosticACE

6.TurnthekeyswitchtotheOnposition,butdonot

startthemachine.

Note:Theredtextontheoverlaydecalreferstoinput

switchesandthegreentextreferstooutputs.

7.The“inputsdisplayed”LED,onthelowerright

columnoftheDiagnosticACE,shouldbeilluminated.

Ifthe“outputsdisplayed”LEDisilluminated,press

thetogglebutton,onDiagnosticACE,tochangeLED

to“inputsdisplayed”.

TheDiagnosticACEwillilluminatetheLEDassociated

witheachoftheinputswhenthatinputswitchisclosed.

8.Individually,changeeachoftheswitchesfromopen

toclosed(i.e.,sitonseat,engagetractionpedal,etc.),

andnotethattheappropriateLEDonDiagnosticACE

willblinkonandoffwhencorrespondingswitchis

closed.Repeatthisforallswitchesthatyoucanchange

byhand.

9.IfaswitchisclosedandtheappropriateLEDdoesnot

turnon,checkallwiringandconnectionstotheswitch

and/orchecktheswitcheswithanohmmeter.Replace

anydefectiveswitchesandrepairanydefectivewiring.

Figure27

1.Wireharnessandconnectors

4.Carefullyunplugloopbackconnectorfromharness

connector.

5.ConnecttheDiagnosticACEdisplayconnectortothe

harnessconnector(Figure28).

Note:Makesurecorrectoverlaydecalispositioned

onDiagnosticACEdisplay .

Note:TheDiagnosticACEalsohastheabilitytodetect

whichoutputsolenoidsorrelaysareturnedon.Thisisa

quickwaytodetermineifamachinemalfunctioniselectrical

orhydraulic.

VerifyingOutputFunction

1.Parkthemachineonalevelsurface,lowerthecutting

decks,stoptheengine,andengagetheparkingbrake.

2.Removetheaccesspanelfromthesideofthecontrol

arm.

3.Locatewireharnessandconnectorsnearcontroller.

4.Carefullyunplugloopbackconnectorfromharness

connector.

5.ConnecttheDiagnosticACEconnectortotheharness

connector.

26

Page 27

Note:Makesurecorrectoverlaydecalispositioned

onDiagnosticACE.

6.TurnthekeyswitchtotheONposition,butdonot

startmachine.

Note:Theredtextontheoverlaydecalreferstoinput

switchesandthegreentextreferstooutputs.

7.The“outputsdisplayed”LED ,onlowerrightcolumn

ofDiagnosticACE,shouldbeilluminated.Ifthe

“inputsdisplayed”LEDisilluminated,pressthetoggle

button,ontheDiagnosticACE,tochangetheLEDto

“outputsdisplayed”.

Note:Itmaybenecessarytotogglebetween“inputs

displayed”and“outputsdisplayed”severaltimestodo

thefollowingstep.Totogglebackandforth,press

thetogglebuttononce.Thismaybedoneasoftenas

required.Donotholdthebutton.

HydraulicValveSolenoid Functions

Usethelistbelowtoidentifyanddescribethedifferent

functionsofthesolenoidsinthehydraulicmanifold.Each

solenoidmustbeenergizedtoallowfunctiontooccur.

Solenoid

PRV2Frontmowercircuit

PRV1Rearmowercircuit

PRV

S1

S2

Lift/lowercuttingdecks

Lowercuttingdecks

Lowercuttingdecks

Function

OperatingTips

8.Sitontheseatandattempttooperatethedesired

functionofthemachine.Theappropriateoutput

LEDsshouldilluminatetoindicatethattheECMis

turningonthatfunction.

Note:IfthecorrectoutputLEDsdonotilluminate,verify

thattherequiredinputswitchesareinthenecessarypositions

toallowthatfunctiontooccur.Verifycorrectswitchfunction.

IftheoutputLEDsareonasspecied,butthemachinedoes

notfunctionproperly,thisindicatesanon-electricalproblem.

Repairasnecessary.

Note:Ifeachoutputswitchisinthecorrectpositionand

functioningcorrectly,buttheoutputLEDsarenotcorrectly

illuminated,thisindicatesanECMproblem.Ifthisoccurs,

contactyourToroDistributorforassistance.

Important:TheDiagnosticACEdisplaymustnotbe

leftconnectedtothemachine.Itisnotdesignedto

withstandtheenvironmentofthemachine'severyday

use.WhendoneusingtheDiagnosticACE,disconnect

itfromthemachineandconnectloop-backconnector

toharnessconnector.Themachinewillnotoperate

withoutloopbackconnectorinstalledontheharness.

StoretheDiagnosticACEindry,securelocationinthe

shop,notonthemachine.

Familiarization

Beforemowinggrass,practiceoperatingthemachineinan

openarea.Startandstoptheengine.Operateinforward

andreverse.Lowerandraisethecuttingdecksandengage

anddisengagethemowers.Whenyoufeelfamiliarwiththe

machine,practiceoperatingupanddownslopesatdifferent

speeds.

WarningSystem

Ifawarninglightcomesonduringoperation,stopthe

machineimmediatelyandcorrecttheproblembefore

continuingoperation.Seriousdamagecouldoccurifyou

operatethemachinewithamalfunction.

Mowing

StarttheengineandmovethethrottletotheFastposition.

MovetheEnable/DisableswitchtotheEnablepositionand

usetheLowerMow/Raiselevertocontrolthecuttingdecks.

Tomoveforwardandcutgrass,pressthetractionpedal

forward.

Note:Allowtheenginetoidlefor5minutesbeforeshutting

itoffafterafullloadoperation.Failuretodosomayleadto

turbo-chargertrouble.

MowwhentheGrassisDry

Moweitherinthelatemorningtoavoidthedew ,whichcauses

grassclumping,orinlateafternoontoavoidthedamage

thatcanbecausedbydirectsunlightonthesensitive,freshly

mowedgrass.

SelecttheProperHeight-of-CutSetting

toSuitConditions

Removeapproximatelyoneinchornomorethan1/3ofthe

grassbladewhencutting.Inexceptionallylushanddense

grassyoumayhavetoraisetheheight–of–cutsetting.

27

Page 28

AlwaysStartMowingwithSharpBlades

Asharpbladecutscleanlyandwithouttearingorshredding

thegrassbladeslikeadullblade.Tearingandshredding

causesthegrasstoturnbrownattheedgeswhichimpairs

growthandincreasessusceptibilitytodiseases.Makesure

bladeisingoodconditionandafullsailispresent.

CheckConditionofDeck

Makesurethatthecuttingchambersareingoodcondition.

Straightenanybendsinthechambercomponentstoensure

thecorrectbladetip/chamberclearance.

AfterOperating

Toensureoptimumperformance,cleantheundersideof

mowerhousing.Ifyouallowresiduetobuildupinmower

housing,cuttingperformancewilldecrease.

Transport

MovetheEnable/DisableswitchtotheDisablepositionand

raisethecuttingdeckstothetransportposition.Movethe

Mow/Transportlevertothetransportposition.Becareful

whendrivingbetweenobjectssoyoudonotaccidentally

damagethemachineorcuttingdecks.Useextracarewhen

operatingthemachineonslopes.Driveslowlyandavoid

sharpturnsonslopestopreventrollovers.Lowerthecutting

deckswhengoingdownhillforsteeringcontrol.

28

Page 29

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

Aftertherst8hours

Aftertherst10hours

Aftertherst50hours

Beforeeachuseordaily

Every50hours

Every100hours

Every150hours

MaintenanceProcedure

•T orquethewheellugnutsto70to90ft-lb(94to122N⋅m).

•Checktheconditionandtensionofthealternatorbelt.

•T orquethewheellugnutsto70to90ft-lb(94to122N⋅m).

•Changetheengineoilandlter.

•ChecktheengineRPM(idleandfullthrottle).

•Checktheengineoillevel.

•Checkthecoolingsystem.

•Checkthehydraulicuidlevel.

•Checktheoperationoftheinterlockswitches.

•Removedebrisfromthescreen,oilcoolers,andradiator(morefrequentlyindirty

operatingconditions).

•Checkthehydrauliclinesandhosesforleaks,kinkedlines,loosemountingsupports,

wear,loosettings,weatherdeterioration,andchemicaldeterioration.

•Greasethebearingsandbushings.(Greasethemimmediatelyaftereverywashing

regardlessoftheintervallisted.)

•Checktheconditionofandcleanthebattery.

•Checkthebatterycableconnections.

•Inspectthecoolingsystemhoses.

•Checktheconditionandtensionofthealternatorbelt.

•Changetheengineoilandlter.

Every200hours

Every250hours

Every400hours

Every800hours

Beforestorage

Every2years

•Drainmoisturefromthefuelandhydraulicuidtanks.

•T orquethewheellugnutsto70to90ft-lb(94to122N⋅m).

•Servicetheaircleaner.(Servicetheaircleanerearlieriftheaircleanerindicator

showsred.Serviceitmorefrequentlyinextremelydirtyordustyconditions.)

•Checkthefuellinesandconnectionsfordeterioration,damage,orlooseconnections.

•Replacethefuelltercanister.

•ChecktheengineRPM(idleandfullthrottle).

•Drainandcleanthefueltank

•Checktherearwheeltoe-in.

•Changethehydraulicuid.

•Changethehydrauliclters(sooneriftheserviceintervalindicatorisintheRed

zone).

•Packtherearwheelbearings

•Adjusttheenginevalves(refertotheengineOperator'sManual)

•Drainandcleanthefueltank

•Flushandreplacethecoolingsystemuid.

•Drainandushthehydraulictank.

•Replaceallmovinghoses.

29

Page 30

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

Checkthesafetyinterlockoperation.

Checkthebrakeoperation.

Checktheengineoilandfuellevel.

Drainthewater/fuelseparator.

Checktheairlterrestrictionindicator.

Checktheradiatorandscreenfordebris.

Checkunusualenginenoises.

Checkunusualoperatingnoises.

Checkthehydraulicsystemoillevel.

Checkthehydrauliclterindicator.

Checkhydraulichosesfordamage.

Checkforuidleaks.

Checkthetirepressure.

Checktheinstrumentoperation.

ChecktheHeightofCutadjustment

CheckConditionofBlades

Checkallgreasettingsforlubrication.

Touch-updamagedpaint.

1.Checktheglowplugandinjectornozzlesifhardstarting,excesssmoke,orroughrunningisnoted.

1

2

3

Sat.Sun.

2.Checkwiththeenginerunningandtheoilatoperatingtemperature

3.Immediatelyaftereverywashing,regardlessoftheintervallisted

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

1

2

3

4

5

6

7

8

Important:Refertoyour

Information

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

30

Page 31

ServiceIntervalChart

Figure29

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

Lubrication

GreasingtheBearingsand Bushings

Ifyouoperatethemachineundernormalconditions,lubricate

allgreasettingsforthebearingsandbushingsafterevery

50hoursofoperationwithNo.2GeneralPurposeLithium

BaseGrease.Lubricatebearingsandbushingsimmediately

aftereverywashing,regardlessoftheintervallisted.

Thegreasettinglocationsandquantitiesareasfollows:

•PumpdriveshaftU-joint(3)(

Figure30)

Figure31

•Liftarmpivots(1each)(Figure31)

•Cuttingunitcarrierframepivot(1each)(

Figure32)

Figure30

•Cuttingunitliftarmcylinders(2each)(Figure31)

31

Page 32

Figure35

G011614

G011615

Figure32

•Liftarmpivotshaft(1each)(Figure33)

Figure33

•Rearaxletierod(2)(Figure34)

•Steeringcylinderballjoints(2)andrearaxle(1)(Figure36)

Figure36

•Brakepedal(1)(Figure37)

Figure34

•Axlesteeringpivot(1)(Figure35)

Figure37

32

Page 33

EngineMaintenance

ServicingtheAirCleaner

Checktheaircleanerbodyfordamagewhichcouldcausean

airleak.Replaceifdamaged.Checkthewholeintakesystem

forleaks,damageorloosehoseclamps.

Servicetheaircleanerlteronlywhentheserviceindicator

(Figure38)requiresit.Changingtheairlterbeforeitis

necessaryonlyincreasesthechanceofdirtenteringtheengine

whenthelterisremoved.

Important:Besurethecoverisseatedcorrectlyand

sealswiththeaircleanerbody .

1.Releasethelatchessecuringtheaircleanercovertothe

aircleanerbody(Figure38).

Figure38

1.Aircleanercover3.Aircleanerservice

indicator

2.Aircleanercoverlatch

2.Removethecoverfromtheaircleanerbody.Before

removingthelter,uselowpressureair(40psi,clean

anddry)tohelpremovelargeaccumulationsofdebris

packedbetweenoutsideofthelterandthecanister.

Avoidusinghighpressureairwhichcouldforce

dirtthroughthelterintotheintaketract.

Figure39

1.Aircleanercover

2.Aircleanerlter

3.Aircleanerindicator

4.Cleanthedirtejectionportlocatedintheremovable

cover.Removetherubberoutletvalvefromthecover,

cleanthecavityandreplacetheoutletvalve.

5.Installthecoverorientingtherubberoutletvalveina

downwardposition—betweenapproximately5:00to

7:00whenviewedfromtheend.

6.Securethelatches.

ServicingtheEngineOiland Filter

Changetheengineoilandlterinitiallyaftertherst50hours

ofoperationandevery150hoursthereafter.

1.Removethedrainplug(Figure40)andlettheoilow

intoadrainpan.

Thiscleaningprocesspreventsdebrisfrommigrating

intotheintakewhenthelterisremoved.

3.Removeandreplacethelter(Figure39).

Cleaningoftheusedelementisnotrecommendeddue

tothepossibilityofdamagetotheltermedia.Inspect

thenewlterforshippingdamage,checkingthesealing

endofthelterandthebody.Donotuseadamaged

element.Insertthenewlterbyapplyingpressureto

theouterrimoftheelementtoseatitinthecanister.

Donotapplypressuretotheexiblecenterofthe

lter.

Figure40

1.Oildrainplug

2.Whentheoilstops,installthedrainplug.

33

Page 34

3.Removetheoillter(Figure41).

Figure41

1.Oillter

3.Holdtheinjectionpumpleverarmagainstthehigh

idlestop(Figure42).

4.Whilepullingthethrottlecable,toremoveanyslack,

tightenthethrottlecableconnector.

Note:Whentightened,thecablepivotmustbefreeto

swivelontheinjectionpumpleverarm.

5.Ifthethrottledoesnotstayinpositionduring

operation,increasethetorqueonthelocknut,usedto

setthefrictiondeviceonthethrottlelever.

4.Applyalightcoatofcleanoiltothenewlterseal.

5.Installthereplacementoilltertothelteradapter.

Turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional1/2turn.

Important:Donotover-tightenthelter.

6.Addoiltothecrankcase;refertoCheckingtheEngine

Oil.

AdjustingtheThrottle

1.Positionthethrottleleverforwardsoitisapproximately

1/8inchfromthefrontofthecontrolarmslot.

2.Loosenthethrottlecableconnector,onthethrottle

cable,nexttotheinjectionpumplever(Figure42).

Figure42

1.Throttlecablepivot3.Highidlestop

2.Injectionpumpleverarm4.Throttlecableconnector

34

Page 35

FuelSystem

Maintenance

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1/4to1/2

in.(6to13mm)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsthe

fueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

DrainingtheFuelTank

ServiceInterval:Every800hours

Beforestorage

Drainandcleanthefueltankifthefuelsystembecomes

contaminatedorifthemachineistobestoredforanextended

period.Usecleanfueltoushoutthetank.

Figure43

1.Waterseparatorltercanister

3.Cleantheareawheretheltercanistermounts.

4.Removetheltercanisterandcleanthemounting

surface.

5.Lubricatethegasketontheltercanisterwithcleanoil.

6.Installtheltercanisterbyhanduntilthegasket

contactsmountingsurface,thenrotateitanadditional

1/2turn.

7.Tightenthedrainplugonthebottomofthelter

canister.

FuelPick-upTubeScreen

Thefuelpick-uptube,locatedinsidethefueltank,isequipped

withascreentohelppreventdebrisfromenteringthefuel

system.Removethefuelpick-uptubeandcleanscreenas

required.

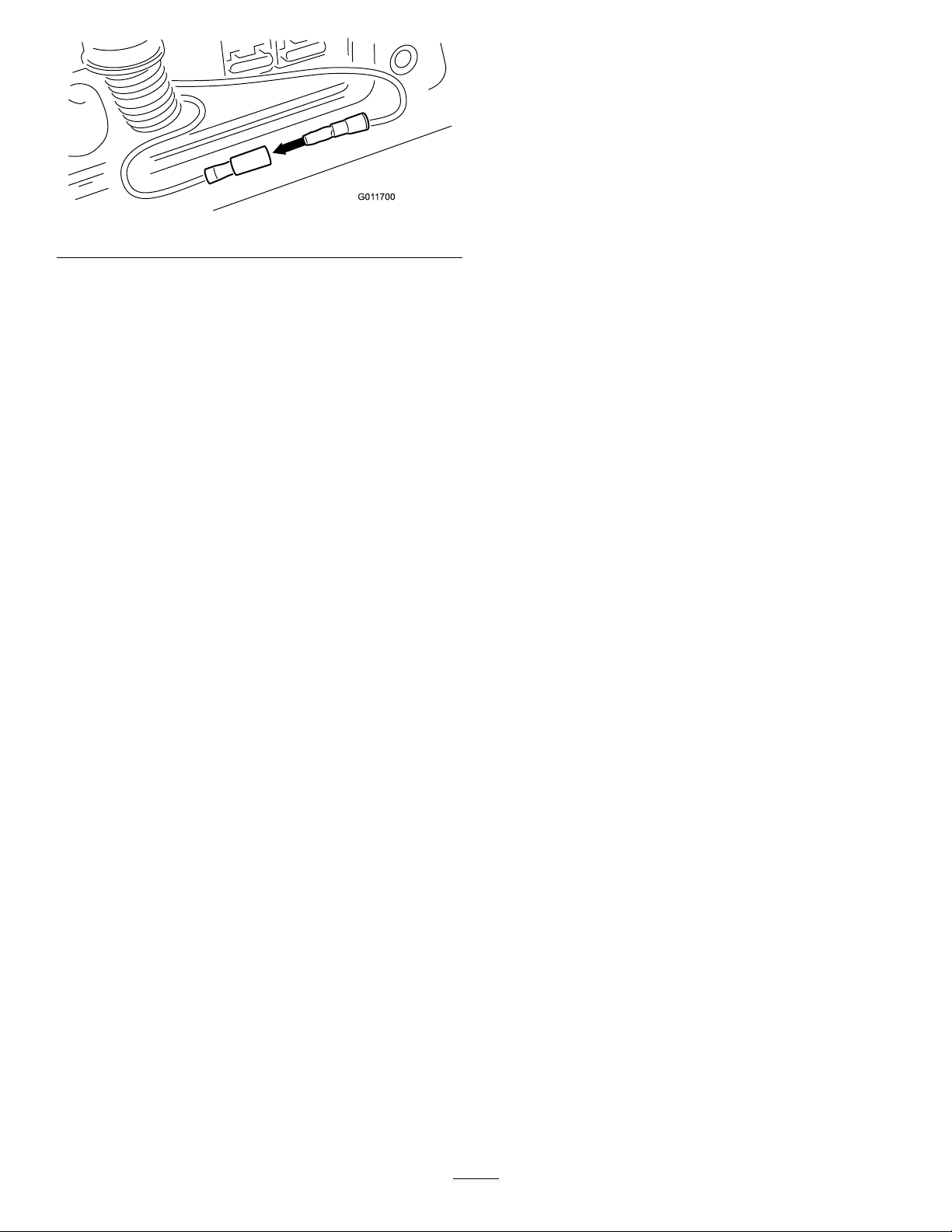

BleedingAirfromtheFuel

CheckingtheFuelLinesand

Connections

Checkthefuellinesandconnectionsevery400hoursor

yearly,whichevercomesrst.Inspectthemfordeterioration,

damage,orlooseconnections.

ServicingtheWaterSeparator

ServiceInterval:Every400hours

Drainwaterorothercontaminantsfromwaterseparator

(Figure43)daily.Replaceltercanisterafterevery400hours

ofoperation.

1.Placeacleancontainerunderthefuellter.

2.Loosenthedrainplugonthebottomofthelter

canister.

Injectors

Note:Thisprocedureshouldbeusedonlyifthefuelsystem

hasbeenpurgedofairthroughnormalprimingprocedures

andtheenginewillnotstart;refertoBleedingtheFuel

System.

1.LoosenthepipeconnectiontotheNo.1nozzleand

holderassembly(Figure44).

35

Page 36

ElectricalSystem

Maintenance

Important:Beforeweldingonthemachine,disconnect

bothcablesfromthebattery,bothwireharnessplugs

fromtheelectroniccontrolmodule,andtheterminal

connectorfromthealternatortopreventdamagetothe

electricalsystem.

ServicingtheBattery

Figure44

1.Fuelinjectors

2.TurnthekeyinthekeyswitchtotheOnpositionand

watchthefuelowaroundtheconnector.Whenyou

observeasolidowoffuel,turnthekeytotheOff

position.

3.Tightenthepipeconnectorsecurely.

4.Repeatsteps1through3ontheremainingnozzles.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyes,orclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfromit.

Checkthebatteryconditionweeklyorafterevery50hours

ofoperation.Keeptheterminalsandtheentirebatterycase

cleanbecauseadirtybatterywilldischargeslowly.Toclean

thebattery,washtheentirecasewithasolutionofbaking

sodaandwater.Rinseitwithclearwater.

Fuses

Thereare8fusesintheelectricalsystem.Thefuseblock

(Figure45)islocatedbehindthecontrolarmaccesspanel.

36

Page 37

1.Fuseblock

Figure45

DriveSystem

Maintenance

AdjustingtheTractionDrive forNeutral

Themachinemustnotcreepwhenthetractionpedalis

released.Ifitdoescreep,adjustasfollows:

1.Parkthemachineonalevelsurface,stoptheengine,

andlowerthecuttingdeckstotheoor.

2.Jackupthemachineuntilallthetiresareofftheshop

oor.Supportthemachinewithjackstandstoprevent

itfromfallingaccidentally .

3.Ontherightsideofthehydrostat,loosenthelocknut

onthetractionadjustmentcam(

Figure47).

Figure46

Figure47

1.Locknut2.Tractionadjustmentcam

WARNING

Theenginemustberunningsothenal

adjustmentofthetractionadjustmentcam

canbeperformed.Thiscouldcausepersonal

injury.

Keephands,feet,face,andotherbodyparts

awayfromthemufer,otherhotpartsofthe

engine,andanyrotatingparts.

4.Starttheengineandrotatethecamhexineither

directionuntilthewheelsceaserotation.

5.Tightenthelocknuttosecuretheadjustment.

6.Stoptheengine.Removethejackstandsandlowerthe

machinetotheshopoor.

37

Page 38

7.Testdrivethemachinetomakesureitdoesnotcreep.

CoolingSystem

AdjustingtheRearWheel Toe-in

1.Rotatethesteeringwheelsothattherearwheelsare

straightahead.

2.Loosenthejamnutoneachendofthetierod(

48).

Note:Theendofthetierodwiththeexternalgroove

isalefthandthread.

Maintenance

RemovingDebrisfromthe CoolingSystem

Figure

Removedebrisfromthescreen,oilcoolers,andradiatordaily

(cleanmorefrequentlyindirtyconditions).

1.Turntheengineoffandremovethekeyfromthe

ignitionswitch.

2.Thoroughlycleanalldebrisoutoftheenginearea.

3.Unlatchtheclampandpivotopentherearscreen

(Figure49).

Figure48

1.Jamnut3.Wrenchslot

2.Tierod

3.Usingthewrenchslot,rotatethetierod

4.Measurethedistanceatthefrontandrearoftherear

wheelsataxleheight.Thedistanceatthefrontofthe

rearwheelsshouldbelessthan1/4inch(6mm)ofthe

distancemeasuredattherearofthewheels.

5.Repeatprocedureasrequired.

Figure49

1.Rearscreenlatch2.Rearscreen

4.Cleanthescreenthoroughlywithcompressedair.

5.Pivotthelatchesinwardtoreleasetheoilcooler(Figure

50).

38

Page 39

Figure50

1

2

1.Oilcooler2.Oilcoolerlatches

6.Thoroughlycleanbothsidesoftheoilcoolerandthe

radiator(Figure51)withcompressedair.

BrakeMaintenance

AdjustingtheServiceBrakes

Adjusttheservicebrakeswhenthereismorethan1inchof

freetravelofthebrakepedal,orwhenthebrakesdonotwork

effectively.Freetravelisthedistancethebrakepedalmoves

beforeyoufeelbrakingresistance.

Note:Usethewheelmotorbacklashtorockthedrums

backandforthtoensurethatthedrumsarefreepriortoand

afteradjustment.

1.Toreducefreetravelofthebrakepedals,tightenthe

brakesbylooseningthefrontnutonthethreadedend

ofthebrakecable(Figure52).

Figure51

1.Radiator

7.Pivottheoilcoolerbackintopositionandsecurethe

latches.

8.Closethescreenandsecurethelatch.

Figure52

1.Brakecables2.Frontnuts

2.Tightentherearnuttomovethecablebackwarduntil

brakepedalshave1/2to3/4inch(1.27to1.9cm)of

freetravel,beforewheellockupisachieved.

3.Tightenthefrontnuts,ensuringthatbothcables

actuatethebrakessimultaneously .

AdjustingtheParkingBrake

Iftheparkingbrakefailstoengage,anadjustmenttothe

brakepawlisrequired.

1.Loosenthe2screwssecuringtheparkingbrakepawl

totheframe(Figure53).

39

Page 40

1

4

3

2

Figure53

1.Brakecables3.Parkingbrakepawl

2.Screws(2)

2.Presstheparkingbrakepedalforwarduntilthebrake

detentcompletelyengagesonthebrakepawl(Figure

53).

3.Tightenthe2screwslockingtheadjustment.

4.Brakedetent

BeltMaintenance

Checktheconditionandtensionofthealternatorbeltafter

therstdayofoperationandevery100operatinghours

thereafter.

TensioningtheAlternatorBelt

1.Openthehood.

2.Checkthetensionofthealternatorbeltbydepressing

it(Figure54)midwaybetweenthealternatorandthe

crankshaftpulleyswith22lb(10kg)offorce.

4.Pressthebrakepedaltoreleasetheparkingbrake.

5.Checktheadjustmentandreadjustasrequired.

Figure54

1.Brace3.Pivotbolt

2.Alternatorbelt

Thebeltshoulddeect7/16inch(11mm).Ifthe

deectionisincorrect,proceedtostep3.Ifcorrect,

continueoperation.

3.Loosentheboltsecuringthebracetotheengine

(Figure54),theboltsecuringthealternatortothebrace

andthepivotbolt.

4.Insertaprybarbetweenthealternatorandtheengine

andpryoutonthealternator.

5.Whenyouachievethepropertension,tighten

thealternator,braceandpivotboltstosecurethe

adjustment.

40

Page 41

HydraulicSystem

Maintenance

ChangingtheHydraulicFluid

Changehydraulicuidafterevery800operatinghours,in

normalconditions.Ifuidbecomescontaminated,contact

yourlocalTorodistributorbecausethesystemmustbe

ushed.Contaminateduidlooksmilkyorblackwhen

comparedtocleanoil.

1.Stoptheengineandraisethehood.

2.Placealargedrainpanunderthettingsecuredtothe

bottomofthehydraulicuidreservoir(Figure55).

ReplacingtheHydraulicFilters

Thehydraulicsystemisequippedwithaserviceinterval

indicator(Figure56).Withtheenginerunning,viewthe

indicator,itshouldbeintheGreenzone.Whentheindicator

isintheRedzone,changethehydrauliclters.

Figure56

1.Hydrauliclterrestrictionindicator

Important:Useofanyotherltersmayvoidthe

warrantyonsomecomponents.

Figure55

1.Hose

3.Disconnectthehosefromthebottomofthettingand

letthehydraulicuidowintothedrainpan.

4.Installthehosewhenhydraulicuidstopsdraining.

5.Fillthereservoirwithapproximately12U.S.gallons

(45l)ofhydraulicuid;refertoCheckingtheHydraulic

Fluid..

Important:Useonlyhydraulicuidsspecied.

Otheruidscouldcausesystemdamage.

6.Installthereservoircap.

7.Starttheengineanduseallofthehydrauliccontrolsto