Toro 30859, 30864 Specifications

Groundsmaster® 4300-D

The Groundsmaster 4300-D provides superior hill climbing ability, a lightweight footprint and ample power with its

44 hp turbo diesel engine. Its five Contour Plus cutting units closely follow contours for an even cut on undulating

terrain and heavy-duty rear rollers provide a beautiful striping pattern for spectacular results.

2015 Toro Commercial Equipment Guide 15-003-T Rev. 2/15

24

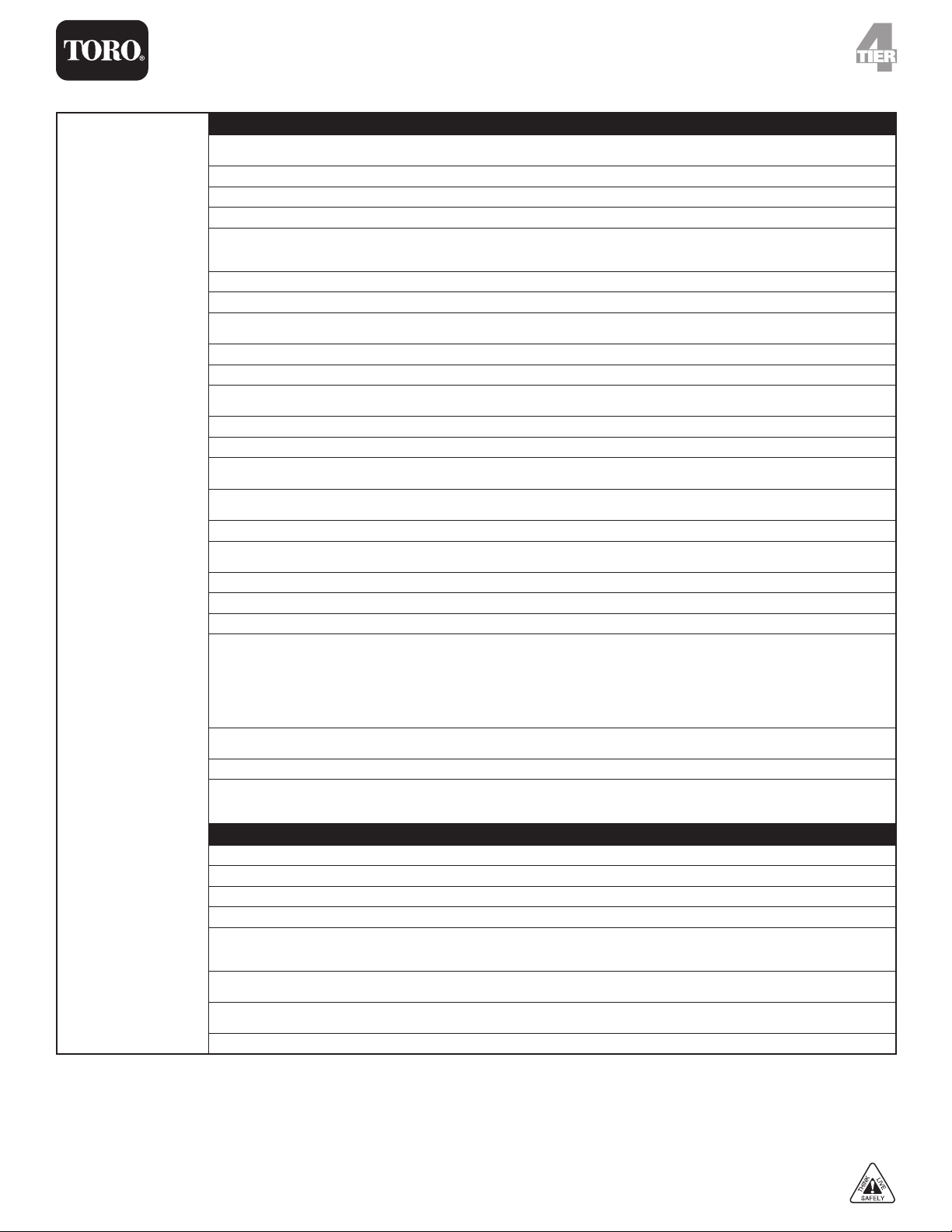

ENGINE

AIR CLEANER

RADIATOR

FUEL CAPACITY

TRACTION DRIVE

HYDRAULICS/COOLING

DIAGNOSTICS

GROUND SPEED

TIRES

MAIN FRAME

BRAKES

SEAT

STEERING

INSTRUMENTATION

CONTROLS

ELECTRICAL

INTERLOCKS

OPERATOR AREA

WORK LIGHTS

ROLL-OVER PROTECTION

DIMENSIONS

W/ CUTTING UNITS

& WEIGHT

SAFETY

WARRANTY

ACCESSORIES

TYPE

WIDTH OF CUT

HEIGHT OF CUT

DECK DRIVE

CONSTRUCTION

SPINDLE ASSEMBLY

GROUND FOLLOWING

BLADES

Groundsmaster® 4300-D Specifications

*

GROUNDSMASTER 4300-D, TIER 4 DIESEL, MODEL 30864 (A)

Yanmar® 3-cylinder, 88.5 ft.-lbs. of torque, liquid-cooled, turbo-charged diesel, 43.4 hp (32.4 kW) 91.4 cu. in. (1.5 liter) displacement. 5.5 quart (4.7 liter) oil capacity.

EPA Tier IV Final Compliant.

Dry, replaceable primary and optional safety element.

Rear-mount, cross flow, 7-row, 6.3 fins per inch, 5.5 quart (5.2 liter) capacity.

13.5 gallons (51.1 liters) diesel fuel. Biodiesel-ready for use up to B20 (20% biodiesel 80% diesel blend).

Front drive wheels powered by a hydrostatic pump with individual wheel motors. Parallel - Series Hydrostatic, closed loop 4 wheel drive, forward direction only.

Variable displacement piston pump with direct displacement control, Standard all-wheel drive with CrossTrax

front wheels to the opposite rear wheels via independent rear wheel motors.

14 gallon (53 liter) capacity with two remote spin-on filters; main system, and traction charge, Oil cooler is a double row single pass (11 fin/in) that tilts out for cleaning.

Diagnostics pressure test ports: forward and reverse traction, deck circuit 1 & 2, change 4WD, and lift.

Transport: 0-10 mph (0-16.7 km/h) forward, 0-3.5 mph (0-5.6 km/h) reverse.

Mow: 0-7 mph (0-11.3 km/h) forward, 0-3.5 mph (0-5.6 km/h) reverse.

Front: 26.5 x 14-12, 6-ply turf tread. Rear: 20 x 12-10, 6-ply turf tread.

All welded formed-steel frame with integral tie-down anchors.

8”mechanical drum-type front wheel brakes. Brakes may be actuated for service braking via left foot pedal. Integrated foot pedal lock provides parking brake.

Dynamic braking through hydrostatic traction drive system.

Mechanical suspension seat standard with pivoting LH armrest, pivoting RH control arm and retractable seat belt, Air-Ride seat suspension optional.

Rear wheel, power steering with an independent hydraulic pump circuit.

InfoCenter™: Onboard LCD display shows gauges, alerts/faults, service reminders, electrical system diagnostics. Indicates fuel level, coolant temp, low oil pressure,

alternator, engine hours, engine rpm, voltage, counterbalance settings, glow indicator, lift/lower indicator.

Ignition switch, foot-operated traction pedal, engine speed control, mow/transport selector switch, service brake with parking brake latch, joystick control for raising

and lowering cutting units, mow/transport lever.

12-volt battery with 540 cold cranking amps, 55 amp alternator. Overload protection with automotive-type fuses.

Prevents engine from starting unless traction pedal is in neutral and deck is disengaged. If operator leaves seat with deck engaged, decks stop. If operator leaves the

seat with the unit out of neutral, engine stops. Mowing only permitted in low range. Engine stops if parking brake engaged and traction pedal not in neutral.

Beverage holder, radio holder / mobile phone holder, 12-volt power outlet, open compartment for tools, jackets, golf balls, etc. under control arm.

Standard.

2-post standard.

Overall length w/decks down: 126” (320 cm) Traction Unit Weight: 3,205 lbs (1454 kg) - with full fluids and 5 cutting units.

Overall width: 96.3” (245 cm) (outside of decks) Cutting Unit Weight: 140 lbs (64 kg) – single cutting unit assembly only.

Overall transport width: 88.3” (224 cm) (outside of front tires)

Height w/2-post ROPS: 86” (215 cm)

Wheelbase: 60” (152.4 cm)

Track Width, front/rear: 88.3” (224 cm)/54” (137 cm)

Ground clearance: 5” (12.7 cm)

Complies with American National Standards Institute (ANSI B71.4-2004) and applicable ISO EN 5395 (CE) standards (machine directive 89/392, 91/368, 93/44, 84/538,

89/336) requirements.

Two-year limited.

Air ride seat suspension (03667), leaf mulching kit (108-7409-01), combination blade (108-7395-03), angle sail blade (117-0209-03) atomic mulching blade (114-

0435), parallel sail blade (114-0434-03), white sunshade (30349), red sunshade (30552), rear roller scraper kit,(117-0149), operator fan kit (110-8804), 22” rotary

replacement cutting unit (30845), diagnostic display box (85-4750).

®

All-Wheel Drive system, which transfers power from the

CUTTING UNITS

Five Contour™ Plus 22” (55.9 cm), rear-discharge rotary cutting units w/rear rollers.

90” (229 cm), overlap 5” (12.7 cm), overhang 1” (2.5 cm).

.75”-4” (1.9-10.2 cm) in .25” (.6 cm) increments.

Hydraulic, direct coupled to spindle

Cutting chamber is 10-gauge steel constructed chambers with 12-gauge welded reinforcements. Spindle support is 3/16” (.48 cm) high-strength steel and 10-gauge

exterior channels. Cutting unit frame is welded 1.5” (3.8 cm) square x .25” (.6 cm) wall tube with 7-gauge side supports. Spindle support 3/16” (.48 cm) high-strength

steel and 10-gauge exterior channels.

Ductile cast iron spindle housing. Dual greaseable tapered roller bearings. 1.25” (3.2 cm) diameter solid cold finished steel spindle shaft. Splined connection between

spindle shaft and pulley. Welded blade retainer plus anti-scalp cups.

6” (15.3 cm) anti-scalp cups on each blade. On each deck: two 5” (12.7 cm) diameter front rollers with sealed stainless steel bearings, one 3” (7.6 cm) diameter rear

roller with greaseable stainless steel bearings.

22” (55.9 cm) long, 2.5” (6.4 cm) wide, .25” (.64 cm) thick. Standard: combo blade (108-7395-03)

* Specifications and design subject to change without notice. Products depicted in this literature are for demonstration purposes

only. Actual products offered for sale may vary in use, design, required attachments and safety features. See distributor for details

on all warranties.

**Dependent on operator and turf conditions.

2015 Toro Commercial Equipment Guide 15-003-T Rev. 2/15

25

The Groundsmaster 4300-D is manufactured

in Tomah, WI ISO 9002 Certified Plant.

Loading...

Loading...