Page 1

FormNo.3385-829RevA

Groundsmaster

®

4500-Dand

4700-DRotaryMower

ModelNo.30857N—SerialNo.314000001andUp

ModelNo.30858N—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3385-829*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisincorporatedwith

themuferassembly.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontherightfrontframemember

oftheproduct.Writethenumbersinthespaceprovided.

Important:Thisengineisequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Thismachineisaride-on,rotary-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrasson

well-maintainedlawnsinparks,golfcourses,sportselds,

andoncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongsidehighways,

orforagriculturaluses.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactT orodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................6

SafetyandInstructionalDecals.................................8

Setup...........................................................................12

AdjustingtheHeight-of-Cut....................................12

AdjustingtheRollerScraper(Optional).....................12

InstallingtheMulchingBafe(Optional)...................13

GreasingtheMachine.............................................13

CheckingFluidLevels.............................................13

ProductOverview.........................................................14

Controls...............................................................14

Specications........................................................17

TractionUnitSpecications.....................................17

CuttingUnitSpecications......................................17

Attachments/Accessories........................................17

Operation....................................................................18

CheckingtheEngine-oilLevel..................................18

CheckingtheCoolingSystem...................................19

FillingtheFuelTank...............................................19

CheckingtheHydraulic-uidLevel...........................20

CheckingtheTirePressure......................................21

StartingandStoppingtheEngine..............................21

CheckingtheInterlockSwitches...............................22

PushingorTowingtheMachine................................22

LocatingtheJackingPoints......................................23

LocatingtheTieDowns..........................................23

OperatingtheEngineCoolingFan............................23

SelectingaBlade.....................................................23

ChoosingAccessories.............................................24

OperatingTips......................................................24

Maintenance.................................................................26

RecommendedMaintenanceSchedule(s)......................26

DailyMaintenanceChecklist....................................27

ServiceIntervalChart.............................................28

PremaintenanceProcedures........................................29

RemovingtheHood...............................................29

Lubrication...............................................................29

GreasingtheBearingsandBushings..........................29

EngineMaintenance..................................................31

ServicingtheAirCleaner.........................................31

ServicingtheEngineOilandFilter............................32

AdjustingtheThrottle.............................................32

FuelSystemMaintenance...........................................33

ServicingtheFuelTank...........................................33

CheckingtheFuelLinesandConnections..................33

ServicingtheWaterSeparator..................................33

ServicingtheFuelPickupTubeScreen.......................33

BleedingAirfromtheInjectors................................34

ElectricalSystemMaintenance....................................34

ChargingandConnectingtheBattery........................34

ServicingtheBattery...............................................36

ServicingtheFuses.................................................36

DriveSystemMaintenance.........................................37

CheckingtheTorqueoftheWheelNuts.....................37

CheckingthePlanetaryGearDriveOil......................37

ChangingthePlanetaryGearDriveOil......................37

CheckingtheRearAxleLubricant.............................38

ChangingtheRearAxleLubricant.............................38

AdjustingtheTractionDriveforNeutral....................38

CheckingtheRearWheelToe-in...............................39

CoolingSystemMaintenance......................................40

ServicingtheEngineCoolingSystem........................40

BrakeMaintenance....................................................41

AdjustingtheServiceBrakes....................................41

BeltMaintenance......................................................41

ServicingtheAlternatorBelt....................................41

HydraulicSystemMaintenance....................................42

ChangingtheHydraulicFluid...................................42

ReplacingtheHydraulicFilters.................................42

CheckingtheHydraulicLinesandHoses....................43

ChangingtheCounterbalanceSettings.......................43

CuttingDeckMaintenance..........................................44

SeparatingtheCuttingDecksfromtheTraction

Unit..................................................................44

MountingtheCuttingDeckstotheTraction

Unit..................................................................45

ServicingtheBladePlane.........................................45

ServicingtheCutterBlade.......................................46

ServicingtheFrontRoller........................................47

Cleaning...................................................................48

ServicingtheSparkArresterMufer.........................48

Storage........................................................................48

PreparingtheTractionUnit.....................................48

PreparingtheEngine..............................................48

CuttingDeck.........................................................48

3

Page 4

Safety

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentionto

thesafetyalertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theinstructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromtheENISO

5395:2013andANSIB71.4-2012.

Training

•Readtheoperator'smanualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Iftheoperatorormechaniccannotreadthelanguageof

thismanual,itistheowner'sresponsibilitytoexplainthis

materialtothem.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforthetask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleordamageto

property.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,long

trousers,ahardhat,safetyglasses,andhearingprotection.

Longhair,looseclothing,orjewelrymaygettangled

inmovingparts.Donotoperatetheequipmentwhen

barefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Replacewornordamagedsilencers.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Checkthatoperator'spresencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutches,shiftintoneutral,andengagethe

parkingbrake.

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.Toguardagainst

overturning:

–donotstoporstartsuddenlywhengoingupor

downhill;

–machinespeedsshouldbekeptlowonslopesand

duringtightturns;

–stayalertforhumpsandhollowsandotherhidden

hazards;

–nevermowacrossthefaceoftheslope,unlessthe

mowerisdesignedforthispurpose.

–Usecounterweight(s)orwheelweightswhen

suggestedintheoperator'smanual.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesfromrotatingbeforecrossingsurfaces

otherthangrass.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besure

thatallinterlocksareattached,adjustedproperly,and

functioningproperly.

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

–stoponlevelground;

–disengagethepowertake-offandlowerthe

attachments;

–settheparkingbrake;

4

Page 5

–stoptheengineandremovethekey.

Important:Allowtheenginetoidlefor5minutes

beforeshuttingitoffafterafull-loadoperation.

Failuretodosomayleadtoturbochargertrouble.

•Stoptheengineinthefollowingconditions:

–beforefuelling;

–beforemakingheightadjustment.

–beforeclearingblockages;

–beforechecking,cleaning,orworkingonthemower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforestartingandoperatingthe

equipmentagain.

•Reducethethrottlesettingduringenginerun-out.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesfromrotating.

•Beawareofthemowerdischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineinto

atrailerortruck

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•DonotremovetheROPS.

•AnyalterationstoaROPSmustbeapprovedbythe

manufacturer.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

•Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

RolloverProtectionSystem

(ROPS)—UseandMaintenance

•TheROPSisanintegralandeffectivesafetydevice.Keep

afoldingROPSintheraisedandlockedpositionanduse

theseatbeltwhenoperatingthemachine.

•LowerafoldingROPStemporarilyonlywhenabsolutely

necessary.Donotweartheseatbeltwhenfoldeddown.

•Beawarethereisnorolloverprotectionwhenafolded

ROPSisinthedownposition.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Checktheareatobemowedandneverfolddowna

foldingROPSinareaswherethereareslopes,drop-offs,

orwater.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•KeeptheROPSinsafeoperatingconditionby

periodicallythoroughlyinspectingfordamageand

keepingallmountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorrevise.

MaintenanceandStorage

•Keepallnuts,bolts,andscrewstighttobesurethatthe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartment,andfuel-storage

areafreeofgrass,leaves,orexcessivegrease.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

•Onmulti-spindlemowers,takecareasrotatingoneblade

cancauseotherbladestorotate.

•Disengagedrives,lowerthecuttingunits,settheparking

brake,stoptheengine,andremovetheignitionkey.Wait

5

Page 6

forallmovementtostopbeforeadjusting,cleaning,or

repairing.

•Cleangrassanddebrisfromcuttingunits,drives,

silencers/mufers,andenginetohelppreventres.Clean

upoilorfuelspillage.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthepositive

last.Connectthepositiverstandnegativelast.

•Usecarewhencheckingtheblades.Wearglovesanduse

cautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopen,well-ventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.Wear

protectiveclothinganduseinsulatedtools.

•Storethemachinewiththecuttingunitsinthelowered

positionorsecurethewingdeckswiththestoragelatches

topreventthemfromunintentionallylowering.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCEN,ISO,orANSIstandard.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

•Knowhowtostoptheenginequickly .

•Donotoperatethemachinewhilewearingtennisshoes

orsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,

embankments,orotherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrolof

themachine.

•WhenoperatingamachinewithROPS(roll-over

protectionsystem)neverremovetheROPSandalways

usetheseatbelt.

•Raisethecuttingunitswhendrivingfromoneworkarea

toanother.

•Donottouchtheengine,silencer/mufer,orexhaust

pipewhiletheengineisrunningorsoonafterithas

stopped,becausetheseareascouldbehotenoughto

causeburns.

•Onanyhill,thereisthepossibilityoftippingorrolling

over,buttheriskincreasesastheslopeangleincreases.

Steephillsshouldbeavoided.

•Thecuttingunitsmustbeloweredwhengoingdown

slopes,tomaintainsteeringcontrol.

•Engagethetractiondriveslowly,alwayskeepyourfoot

onthetractionpedal,especiallywhentravelingdownhill.

•Usereverseonthetractionpedalforbraking.

•Ifthemachinestallswhenclimbingaslope,donotturn

themachinearound.Alwaysbackslowly,straightdown

theslope.

•Whenapersonorpetappearsunexpectedlyinornearthe

mowingarea,stopmowing.Carelessoperation,combined

withterrainangles,ricochets,orimproperlypositioned

guardscanleadtothrownobjectinjuries.Donotresume

mowinguntiltheareaiscleared.

MaintenanceandStorage

•Makesurethatallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

6

Page 7

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Seekimmediatemedicalattentionifuidis

injectedintoskin.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

unitsandattachmentstotheground.

•Checkallfuellinesfortightnessandwearonaregular

basis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts.

•Toensuresafetyandaccuracy,haveanAuthorizedToro

Distributorcheckthemaximumenginespeedwitha

tachometer.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•UseonlyToro-approvedattachmentsandreplacement

parts.Thewarrantymaybevoidedifusedwith

unapprovedattachments.

7

Page 8

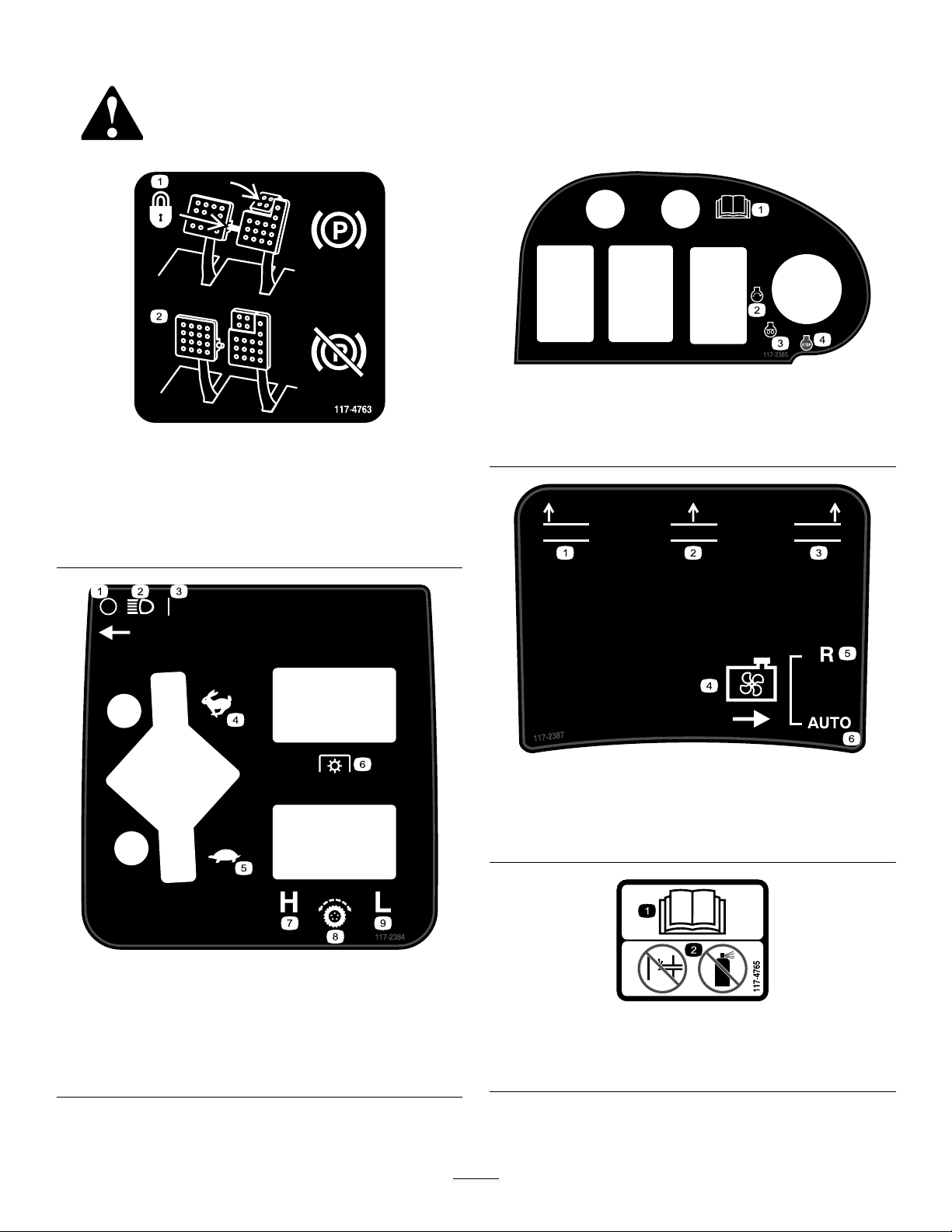

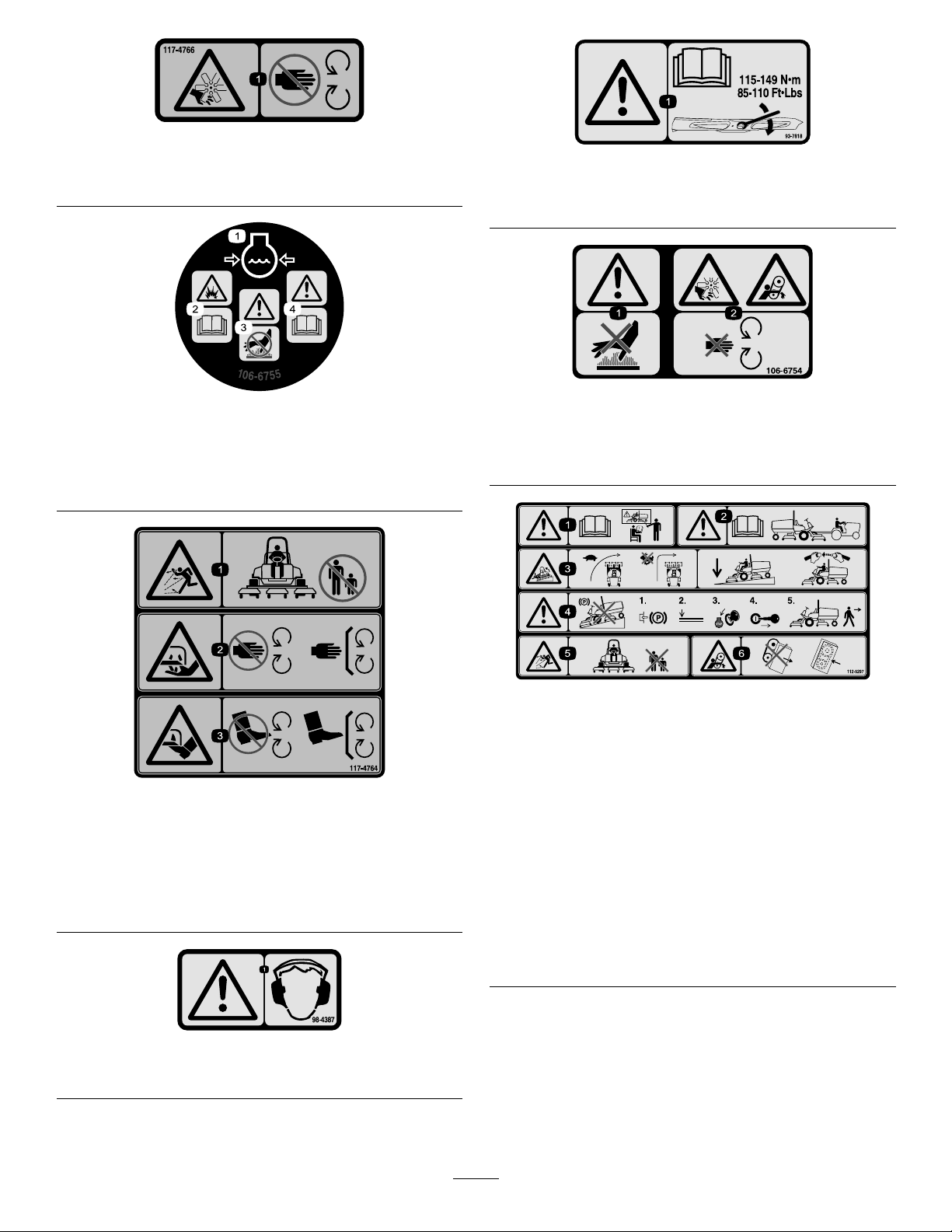

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

117–2385

1.Toengagetheparking

brake,securethebrake

pedalswiththelockingpin,

presstheparkingbrake

pedalsandengagethetoe

pedal.

117-4763

2.Todisengagetheparking

brake,disengagethe

lockingpinandreleasethe

pedals.

1.ReadtheOperator’s

Manual.

2.Engine—start4.Engine—stop

3.Engine—preheat

117–2387

1.Raiseleftdeck4.Coolingfan

2.Raisecenterdeck5.Reverse

3.Raiserightdeck6.Automatic

117–2384

1.Off6.PowerT ake-off(PTO)

2.Headlights7.High

3.On

4.Fast9.Low

5.Slow

8.Tractioncontrol

117-4765

1.ReadtheOperator'sManual.

2.Donotusestartingaids.

8

Page 9

117-4766

1.Cutting/dismembermenthazard;fan—stayawayfrom

movingparts.

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N-m(85-110ft-lb).

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

117-4764

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cuttinghazardofhand,mowerblade—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

3.Cuttinghazardoffoot,mowerblade—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

112-5297

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Warning—readtheOperator'sManualbeforetowingthe

machine.

3.Tippinghazard—slowmachinebeforeturning,donotturn

athighspeeds;lowerthecuttingunitwhendrivingdown

slopes;usearolloverprotectionsystemandweartheseat

belt

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingunits,stoptheengineand

removetheignitionkeybeforeleavingthemachine.

5.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

6.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

1.Warning—wearhearingprotection.

98-4387

9

Page 10

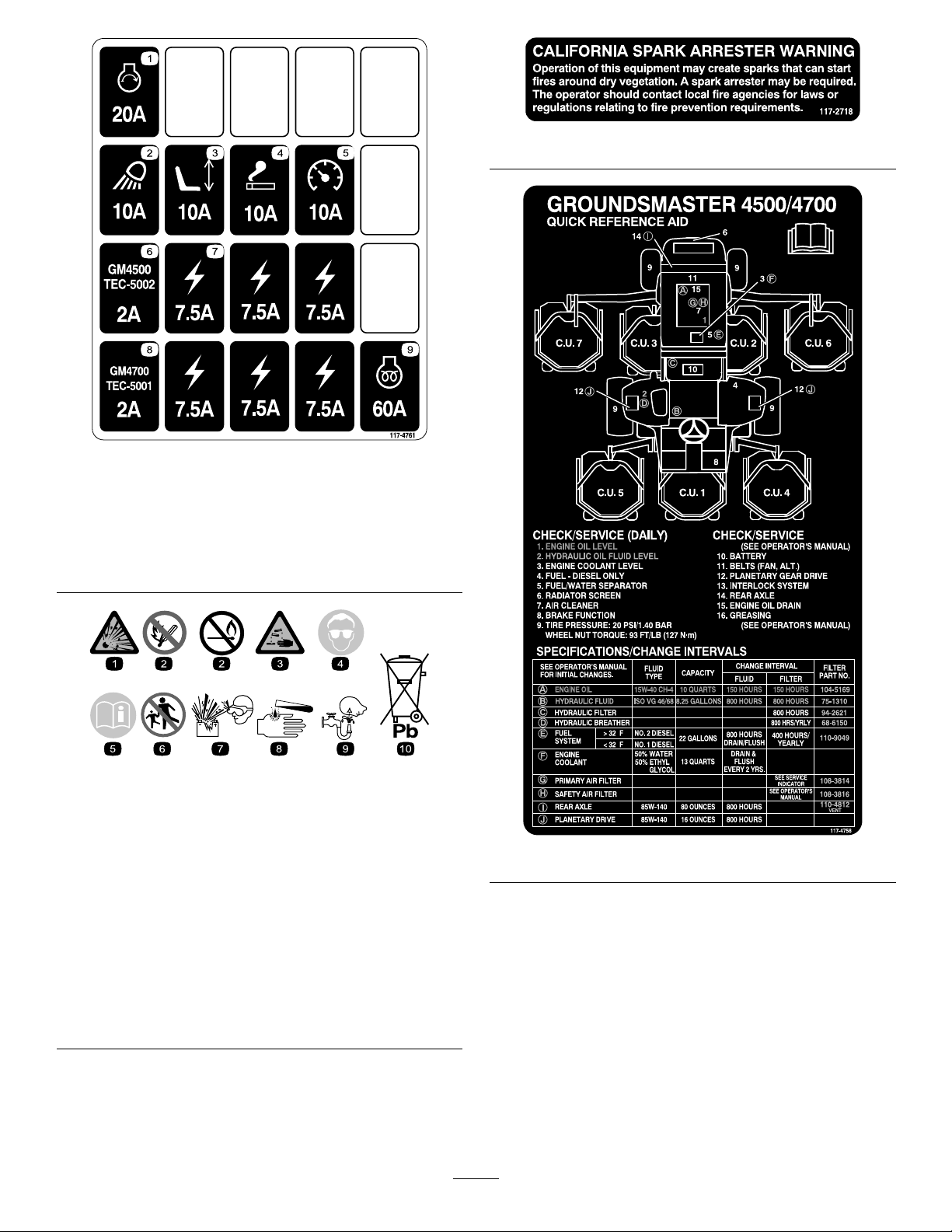

117-4761

1.Starter,20A6.GM4500controller,2A

2.Worklight,10A7.Powersupplied,7.5A

3.Seat,10A8.GM4700controller,2A

4.Powerpoint,10A9.Enginepreheat,60A

5.Gauges,10A

117–2718

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

117-4758

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

10

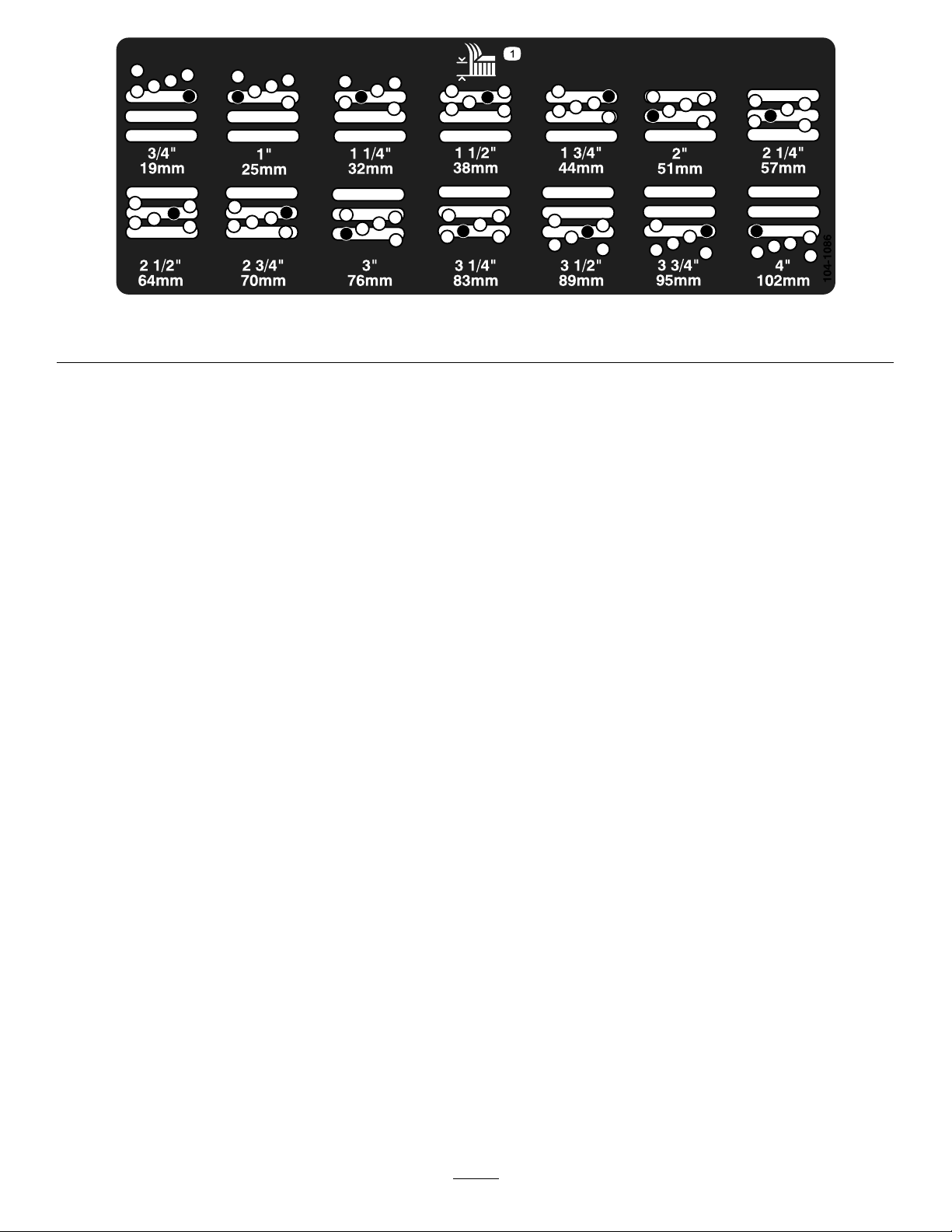

Page 11

1.Heightofcut

104-1086

11

Page 12

Setup

MediaandAdditionalParts

Description

Operator'sManual

EngineOperator'sManual

PartsCatalog

OperatorTrainingMaterial

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

AdjustingtheHeight-of-Cut

Important:Thiscuttingdeckoftencutsapproximately

6mm(1/4inch)lowerthanareelcuttingunitwiththe

samebenchsetting.Itmaybenecessarytohavethese

rotarycuttingdeck’sbenchset6mm(1/4inch)above

thatofreelscuttinginthesamearea.

Important:Accesstotherearcuttingunitsisgreatly

improvedbyremovingthecuttingunitfromthetractor.

IftheunitisequippedwithaSidewinder®,sidewindthe

cuttingunitstotheright,removetherearcuttingunit,

andslideitouttotherightside.

Qty.

1

1

1

1

Readbeforeoperatingmachine

Readbeforeoperatingengine

Usetoreferencepartnumbers

Viewbeforeoperatingmachine

5.Movethechambertothedesiredheight-of-cutand

installaspacerintothedesignatedheight-of-cuthole

andslot(Figure4).

Use

Figure4

1.Lowerthecuttingdecktotheground,stoptheengine,

andremovethekeyfromignitionswitch.

2.Loosentheboltsecuringeachheight-of-cutbracketto

theheight-of-cutplate(frontandeachside)(Figure3).

3.Beginningwithfrontadjustment,removethebolt.

Figure3

1.Heightofcutbracket3.Spacer

2.Heightofcutplate

6.Positionthetappedplateinlinewiththespacer.

7.Installtheboltngertight.

8.Repeatsteps4-7foreachsideadjustment.

9.Tightenallthreeboltsto41N-m(30ft-lb).Always

tightenthefrontboltrst.

Note:Adjustmentsofmorethan3.8cm(1-1/2

inches)mayrequiretemporaryassemblytoan

intermediateheighttopreventbinding(e.g.changing

from3.1to7cm(1.25to2.75inch)height-of-cut).

AdjustingtheRollerScraper

(Optional)

Theoptionalrearrollerscraperisdesignedtoworkbest

whenthereisanevengapof0.5to1mm(0.020–0.040inch)

betweenthescraperandroller.

1.Loosenthegreasettingandthemountingscrew

(Figure5).

4.Whilesupportingthechamber,removethespacer

(Figure3).

12

Page 13

G011346

1

2

3

1.Rollerscraper

G011347

1

2.Mountingscrew

Figure5

3.Greasetting

GreasingtheMachine

Beforethemachineisoperated,itmustbegreasedtoensure

properlubrication.Failuretoproperlygreasethemachine

willresultinprematurefailureofcriticalparts.

CheckingFluidLevels

1.Checktherear-axlelubricantlevelbeforetheengineis

rststarted,refertoCheckingtheRearAxleLubricant.

2.Checkthehydraulic-uidlevelbeforetheengineisrst

started,refertoCheckingtheHydraulicFluidLevel.

2.Slidethescraperupordownuntilagapof0.5to1

mm(0.020to0.040inch)isachievedbetweentherod

andtheroller.

3.Securethegreasettingandscrewto41N-m(30ft-lb)

inanalternatingsequence.

InstallingtheMulchingBafe

(Optional)

1.Thoroughlycleandebrisfromthemountingholeson

therearwallandleftsidewallofthechamber.

2.Installthemulchingbafeintherearopeningand

secureitwith5angeheadbolts(Figure6).

3.Checktheengine-oillevelbeforeandaftertheengine

isrststarted,refertoCheckingtheEngineOilLevel.

Figure6

1.Mulchingbafe

3.Verifythatmulchingbafedoesnotinterferewith

thetipofthebladeanddoesnotprotrudeinsidethe

surfaceoftherearchamberwall.

WARNING

Donotusethehighliftbladewiththe

mulchingbafe.Thebladecouldbreak,

resultinginpersonalinjuryordeath.

13

Page 14

ProductOverview

Controls

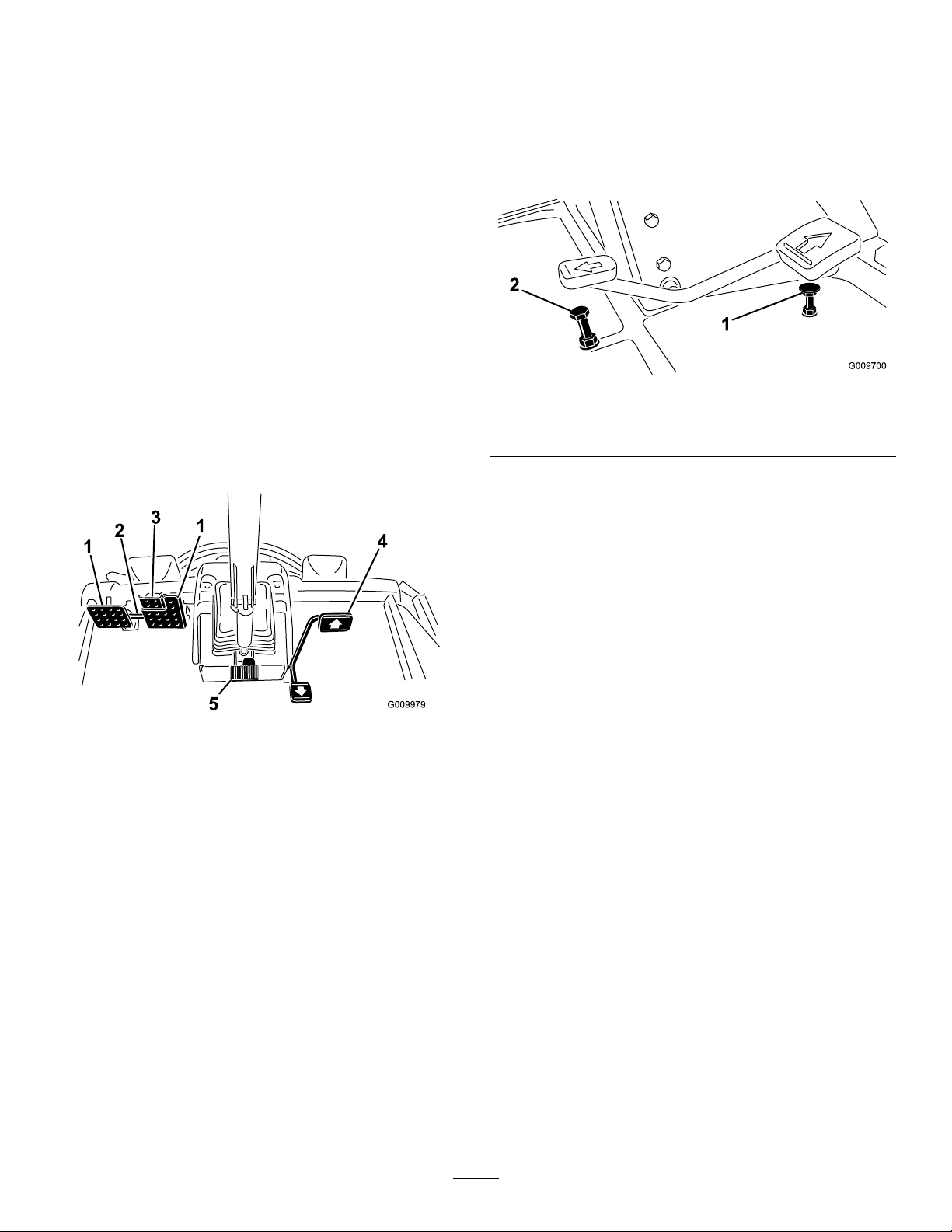

Speed-limiterScrews

Adjustthescrew(s)(Figure8)tolimittheextenttowhich

youcanpressthetractionpedalintheforwardorreverse

directiontolimitspeed.

BrakePedals

2footpedals(Figure7)operateindividualwheelbrakesfor

turningassistanceandtoaidinobtainingbetterside-hill

traction.

Pedal-lockingLatch

Thepedal-lockinglatch(Figure7)connectsthepedals

togethertoengagetheparkingbrake.

Parking-brakePedal

Toengagetheparkingbrake,(Figure7)connectthepedals

togetherwiththepedal-lockinglatch,pushdownonthe

rightbrakepedalwhileengagingthetoepedal.Torelease

theparkingbrake,press1ofthebrakepedalsuntilthe

parking-brakelatchretracts.

Important:Thespeed-limiterscrewmuststopthe

tractionpedalbeforethepumpreachesfullstroke,or

damagetothepumpmayoccur.

Figure8

1.Forwardspeed-limiter

screw

2.Reversespeed-limiter

screw

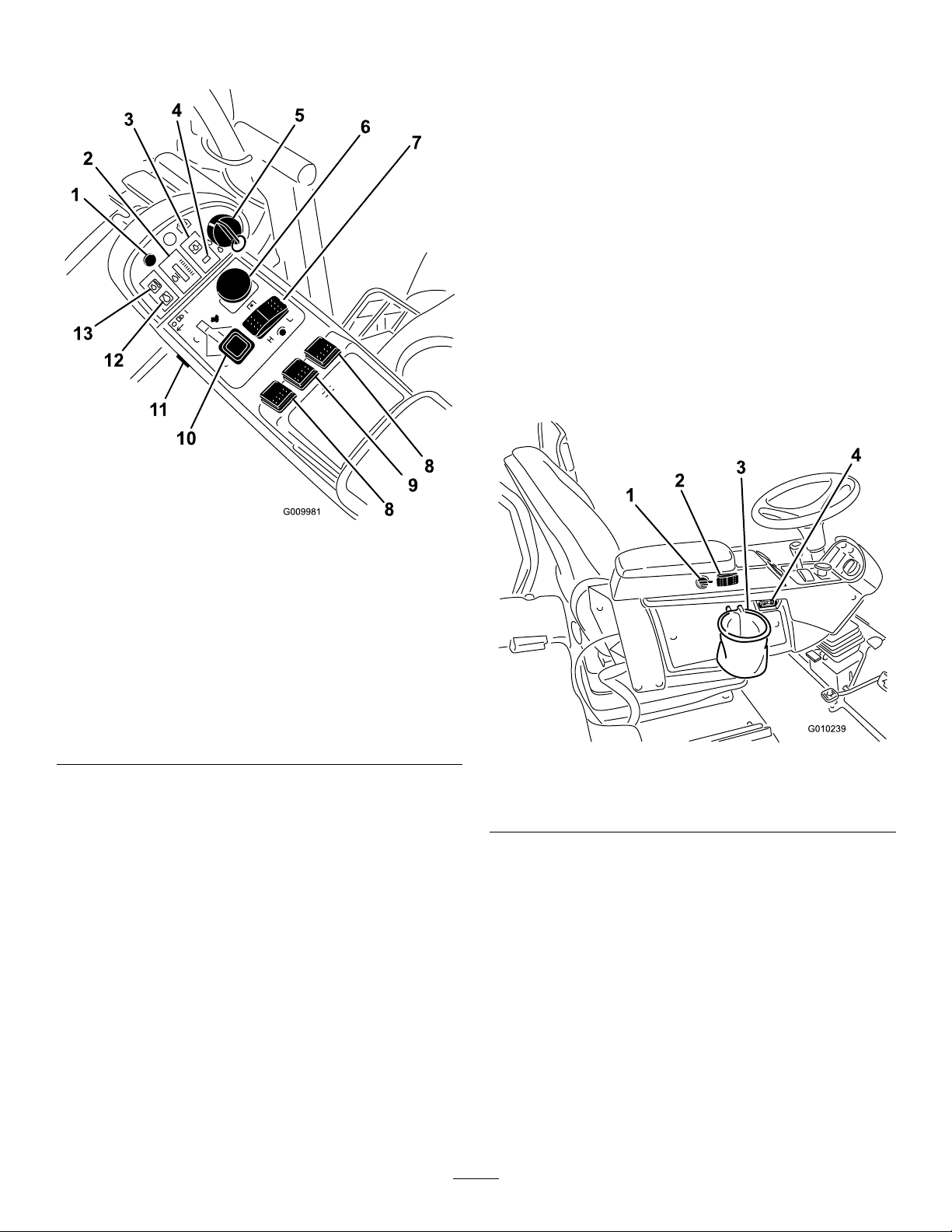

DiagnosticLight

Thediagnosticlight(Figure9)willilluminateshouldasystem

faultberecognized.

Coolant-temperatureGauge

Figure7

1.Brakepedal4.Tractionpedal

2.Pedal-lockinglatch5.Tilt-steeringpedal

3.Parking-brakepedal

TractionPedal

Thetractionpedal(Figure7)controlsforwardandreverse

operation.Pressthetopofthepedaltomoveforwardandthe

bottomtomovebackward.Groundspeeddependsonhow

faryoupressthepedal.Forno-load,maximumgroundspeed,

fullypressthepedalwhilethethrottleisintheFastposition.

Tostop,reduceyourfootpressureonthetractionpedaland

allowittoreturntothecenterposition.

Tilt-steeringPedal

Totiltthesteeringwheeltowardsyou,pressthefootpedal

(Figure7)down,andpullthesteeringtowertowardyouto

themostcomfortablepositionandthenreleasethepedal.

Duringnormaloperatingconditionsthegauge(Figure9)

shouldbeinthegreenrange.Checkthecoolingsystemifthe

gaugegoestotheyelloworredrange.

Oil-pressureWarningLight

Thelight(Figure9)illuminateswhentheengineoilpressure

isdangerouslylow.

ChargeIndicator

Thechargeindicator(Figure9)illuminateswhenthesystem

chargingcircuitmalfunctions.

KeySwitch

Thekeyswitch(Figure9)has3positions:Off,On/Preheat,

andStart.

PTOSwitch

ThePTOswitch(Figure9)has2positions:Out(start)and

In(stop).PullthePTObuttonouttoengagethecutting

unitblades.Pushinthebuttontodisengagethecuttingunit

blades.

High-lowSpeedControl

Theswitch(Figure9)allowsthespeedrangetoincreasefor

transportofthemachine.Cuttingdeckswillnotoperatein

14

Page 15

thehighrange.Also,thedeckscannotbeloweredfromthe

transportpositionwhentheswitchisinthehighrange.

LightSwitch

Presstheloweredgeoftheswitch(Figure9)toturnonthe

lights.Presstheupperedgeoftheswitchtoturnoffthelights.

Glow-plugIndicatorLight

Whenlit,theglow-plugindicatorlight(Figure9)indicates

thattheglowplugsareon.

Coolant-temperatureWarningLight

Thelight(Figure9)illuminatesandthecuttingunitsshut

down(PTOdisengages).Ifthetemperaturecontinuestorise

theenginewillshutdown.

PowerPoint

Thepowerpoint(Figure10)isusedtopoweroptional12-volt

electricalaccessories.

Figure9

1.Diagnosticlight

2.Coolant-temperature

gauge

3.Oil-pressurewarninglight

4.Chargeindicator

5.Keyswitch

6.PTOswitch13.Coolant-temperature

7.High-lowspeedcontrol

8.Liftswitches(GM4700

only)

9.Liftswitch(GM4500and

GM4700)

10.Throttlecontrol

11.Lightswitch

12.Glow-plugindicatorlight

warninglight

LiftSwitches

Theliftswitches(Figure9)raiseandlowerthecutting

units.Presstheswitchesforwardtolowerthecuttingunits

andbackwardtoraisethecuttingunits.Whenstartingthe

machine,withthecuttingunitsinthedownposition,pressthe

liftswitchdowntoallowthecuttingunitstooatandmow .

Note:Thedeckswillnotlowerwhileinthehigh-speed

range,andtheywillnotraiseorloweriftheoperatorisout

oftheseatwhentheengineisrunning.

ThrottleControl

Movethecontrol(Figure9)forwardtoincreasetheengine

speedandrearwardtodecreasethespeed.

Figure10

1.Powerpoint3.Bagholder

2.Engine-cooling-fanswitch

4.Hourmeter

Engine-cooling-fanSwitch

Themachineisequippedwithahydraulicallydriven

auto-reversingengine-coolingfan.Thefanswitch(Figure10)

has2positions:R(manualreverse)andAuto(normal).Refer

toOperatingtheEngineCoolingFan(page23).

BagHolder

Usethebagholder(Figure10)forstorage.

HourMeter

Thehourmeter(Figure10)showsthetotalhoursthatthe

machinehasbeenoperated.

15

Page 16

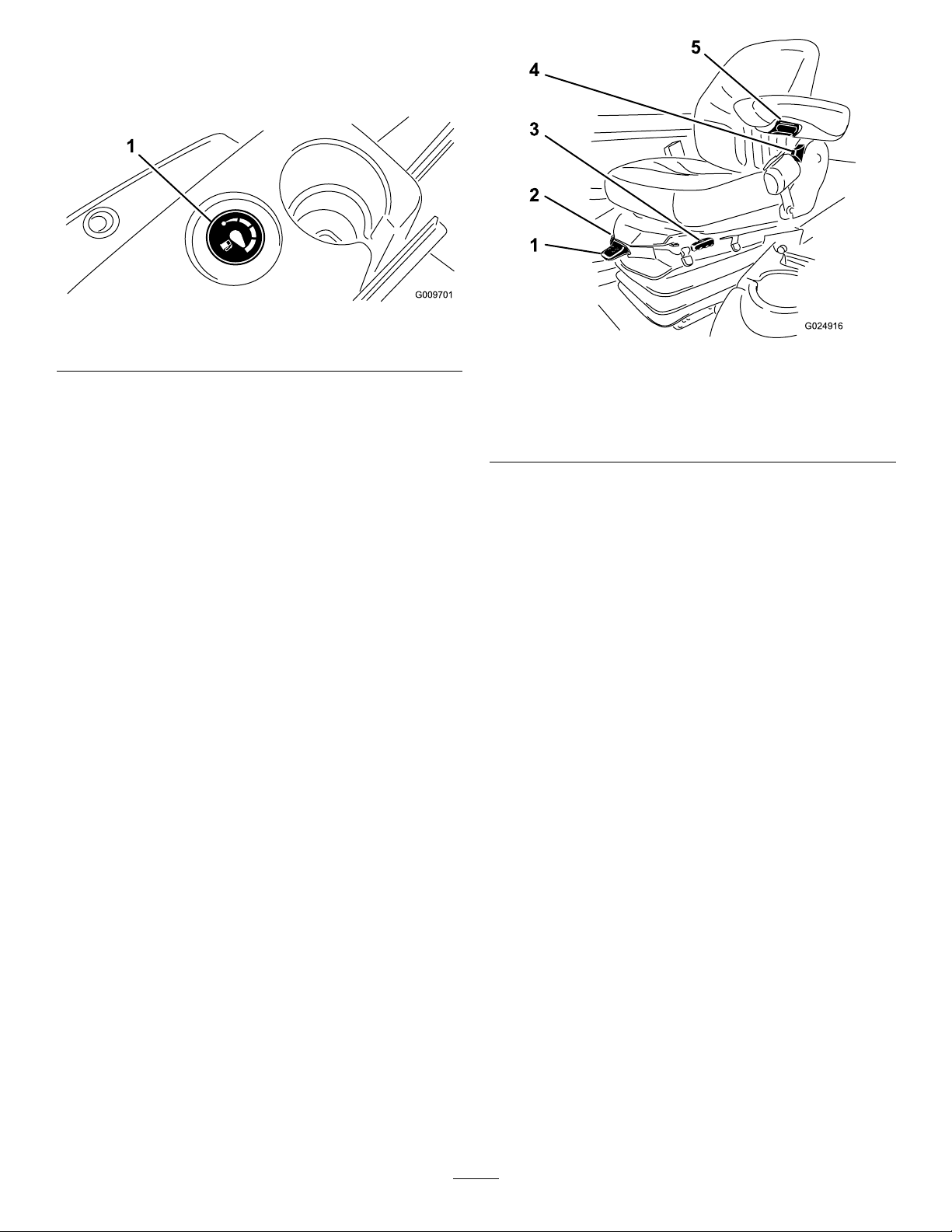

FuelGauge

1

2

3

4

5

G024916

Thefuelgauge(Figure11)indicatestheleveloffuelinthe

tank.

Figure11

1.Fuelgauge

SeatAdjustments

ForeandAftAdjustingLever

Pulloutonthelevertoslidetheseatforeoraft(Figure12).

SeatArmrestAdjustingKnob

Rotatetheknobtoadjusttheseatarmrestangle(Figure12).

Seat-backAdjustingLever

Movethelevertoadjusttheseat-backangle(Figure12).

Weightgauge

Theweightgaugeindicateswhentheseatisadjustedtothe

weightoftheoperator(Figure12).Youcanmakeheight

adjustmentsbypositioningthesuspensionwithintherange

ofthegreenregion.

Figure12

1.Weight-adjustinglever

2.Weightgauge5.Armrestadjustingknob

3.Foreandaftadjusting

lever

Weight-adjustingLever

4.Seat-backadjustinglever

Adjustforoperatorweight(Figure12).Pulluponthelever

toincreasetheairpressureandpushdowntodecreasetheair

pressure.Theproperadjustmentisattainedwhentheweight

gaugeisinthegreenregion.

16

Page 17

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

TractionUnitSpecications

4500-D4700-D

Widthofcut2.8m(109inches)3.8m(150inches)

Overallwidth,

cuttingunits

down

Overallwidth,

cuttingunitsup

(transport)

Overalllength370cm(145.8inches)370cm(145.8inches)

Heightwith

ROPS

Ground

clearance

Trackwidth,

front

Trackwidth,

rear

Wheelbase

Netweight(with

cuttingunits

andnouids)

286cm(1 12.8inches)391cm(153.8inches)

224cm(88.25inches)224cm(88.25inches)

216cm(85inches)216cm(85inches)

15cm(6inches)15cm(6inches)

224cm(88.25inches)224cm(88.25inches)

141cm(55.5inches)141cm(55.5inches)

171cm(67.5inches)171cm(67.5inches)

1995kg(4400lb)2245kg(4950lb)

CuttingUnitSpecications

Length

Width

Height

Weight

86.4cm(34inches)

86.4cm(34inches)

24.4cm(9.6inches)

tocarriermount

26.7cm(10–1/2inches)

at3/4inchheightofcut

34.9cm(13–3/4inches)at

4inchheightofcut

88kg(195pounds)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealerorDistributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

17

Page 18

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator'searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theoillevelshouldbeinthesaferange(Figure13).

CAUTION

Ifyouleavethekeyintheignitionswitch,someone

couldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoany

maintenance.

CheckingtheEngine-oilLevel

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;however,the

oillevelmustbecheckedbeforeandaftertheengineisrst

started.

Thecrankcasecapacityisapproximately9.5L(10USqt)with

thelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4,orhigher.

•Preferredoil:SAE15W-40(above-18°C[0°F])

•Alternateoil:SAE10W-30or5W-30(alltemperatures)

Note:ToroPremiumEngineoilisavailablefromyour

distributorineither15W-40or10W-30viscosity.Seethe

partscatalogforpartnumbers.

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscoolbeforeithasbeenstartedfortheday.Ifit

hasalreadybeenrun,allowtheoiltodrainbackdownto

thesumpforatleast10minutesbeforechecking.Ifthe

oillevelisatorbelowtheAddmarkonthedipstick,add

oiltobringtheoilleveltotheFullmark.Donotoverll.

IftheoillevelisbetweentheFullandAddmarks,nooil

additionisrequired.

Figure13

1.Dipstick

4.Iftheoilisbelowthesaferange,removethellcap

(Figure14)andaddoiluntilthelevelreachestheFull

mark.Donotoverll.

Figure14

1.Oil-llcap

Note:Whenusingdifferentoil,drainalloldoilfrom

thecrankcasebeforeaddingnewoil.

5.Installtheoilllcapanddipstick.

6.Closetheenginecoverandsecureitwiththelatches.

1.Parkthemachineonalevelsurface.

2.Unlocktheenginecoverlatchesandopentheengine

cover.

3.Removethedipstick,wipeitclean,installthedipstick

intothetube,andpullitoutagain.

18

Page 19

CheckingtheCoolingSystem

FillingtheFuelTank

ServiceInterval:Beforeeachuseordaily

Checkthecoolantlevelatthebeginningofeachday .The

capacityofthesystemis12.3L(13USqt).

1.Carefullyremovetheradiatorcap.

CAUTION

Iftheenginehasbeenrunning,the

pressurized,hotcoolantcanescapeandcause

burns.

•Donotopentheradiatorcapwhenthe

engineisrunning.

•Usearagwhenopeningtheradiatorcap,

andopenthecapslowlytoallowsteamto

escape.

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultra-low(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchasefuelin

quantitiesthatcanbeusedwithin180daystoensurefuel

freshness.

Fueltankcapacity:83L(22USgallons)

Usesummer-gradedieselfuel(Number2-D)attemperatures

above-7°C(20°F)andwinter-gradedieselfuel(Number1-D

orNumber1-D/2-Dblend)below-7°C(20°F).Useof

winter-gradefuelatlowertemperaturesprovidesalowerash

pointandcold-owcharacteristicswhichwilleasestarting

andreducefuel-lterplugging.

Useofsummer-gradefuelabove-7°C(20°F)willcontribute

towardlongerfuel-pumplifeandincreasedpowercompared

towinter-gradefuel.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

Figure15

1.Expansiontank

2.Checkthecoolantlevelintheradiator.

Note:Theradiatorshouldbelledtothetopofthe

llerneckandtheexpansiontanklledtotheFull

mark(Figure15).

3.Ifthecoolantislow ,adda50/50mixtureofwaterand

ethyleneglycolantifreeze.

Important:Donotusewateronlyor

alcohol/methanol-basedcoolants.

4.Installtheradiatorcapandtheexpansion-tankcap.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepfuelawayfromeyesandskin.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultra-lowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather.

•Monitorseals,hoses,andgasketsincontactwithfuelas

theymaybedegradedovertime.

•Fuel-lterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

•Contactyourdistributorifyouwishformoreinformation

onbiodiesel.

19

Page 20

DANGER

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineiscold.Wipeup

anyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Addfuel

tothefueltankuntilthelevelis6to13mm(1/4

to1/2inch)belowthetopofthetank,notthe

llerneck.Thisemptyspaceinthetankallows

thefueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana180-daysupplyoffuel.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworkingcondition.

Incertainconditionsduringfueling,static

electricitycanbereleased,causingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailer,andfueltheequipmentwiththe

wheelsontheground.

•Ifthisisnotpossible,thenfuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromafuel-dispensernozzle.

•Ifafuel-dispensernozzlemustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

1.Removethefuel-tankcap(Figure16).

Figure16

1.Fuel-tankcap

2.Fillthetanktoabout6to13mm(1/4to1/2inch)

belowthetopofthetank,notthellerneck,with

Number2-Ddieselfuel.Theninstallthecap.

CheckingtheHydraulic-uid

Level

ServiceInterval:Beforeeachuseordaily

Thereservoirislledatthefactorywithapproximately

28.4L(7.5USgallons)ofhigh-qualityhydraulicuid.Check

thelevelofthehydraulicuidbeforetheengineisrststarted

anddailythereafter.Therecommendedreplacementuid

isasfollows:

ToroPremiumAllSeasonHydraulicFluid(Availablein

19L(5USgallon)pailsor208L(55gallon)drums.Seethe

partscatalogorTorodistributorforpartnumbers)

Alternativeuids:IftheTorouidisnotavailable,other

conventional,petroleum-baseduidsmaybeused,

providedtheymeetallofthefollowingmaterialproperties

andindustryspecications.Checkwithyouroilsupplier

toseewhethertheoilmeetsthesespecications.Note:

Torowillnotassumeresponsibilityfordamagecausedby

impropersubstitutions,souseonlyproductsfromreputable

manufacturerswhowillstandbehindtheirrecommendation.

Note:Ifpossible,llthefueltankaftereachuse;this

willminimizepossiblebuildupofcondensationinside

thefueltank.

20

Page 21

HighViscosityIndex/LowPourPointAnti-wearHydraulic

Fluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C(104°F)44to48

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-37°Cto-45°C(-34°Fto-49°F)

FZG,Failstage

Watercontent(new

uid):

IndustrySpecications:

VickersI-286-S,VickersM-2950-S,DenisonHF-0,Vickers

35VQ25(EatonATS373-C)

cSt@100°C(212°F)7.9to9.1

140orhigher

11orbetter

500ppm(maximum)

Theproperhydraulicuidsmustbespeciedformobile

machinery(asopposedtoindustrialplantusage),multi-weight

type,withZnDTPorZDDPanti-wearadditivepackage(not

anashless-typeuid).

ToroSyntheticBiodegradableHydraulicFluid(Available

in19L(5USgallon)pailsor208L(55USgallon)drums.See

partsdocumentationorTorodistributorforpartnumbers)

Thishighqualitysynthetic,biodegradableuidhasbeen

testedandfoundcompatibleforthisToromodel.Other

brandsofsyntheticuidmayhavesealcompatibilityproblems

andTorocannotassumeresponsibilityforunauthorized

substitutions.

Important:Thissyntheticuidisnotcompatiblewith

theT oroBiodegradableFluidpreviouslysold.Seeyour

AuthorizedToroDistributorformoreinformation.

Alternativebiodegradableuids:

MobilEALEnvirosynH46(US)

Figure17

1.Hydraulic-tankcap

3.Removethecapfromthellerneck.

4.Removethedipstickfromthellerneckandwipeit

withacleanrag.

5.Insertthedipstickintothellerneck;thenremoveit

andchecktheuidlevel.

Note:Theuidlevelshouldbebetweenthe2marks

onthedipstick.

6.Ifthelevelislow ,addtheappropriateuidtoraisethe

leveltotheuppermark.

7.Installthedipstickandcapontothellerneck.

MobilEALHydraulicOil46(International)

Important:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein20ml(2/3oz)

bottles.Onebottleissufcientfor15to22L(4to6US

gallons)ofhydraulicoil.Orderpart44-2500fromyour

authorizedT orodistributor.

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,andremovethekey.

2.Cleantheareaaroundthellerneckandthecapofthe

hydraulictank(Figure17).

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Thetiresareover-inatedforshipping.Therefore,release

someoftheairtoreducethepressure.Thecorrectair

pressureinthetiresis138kPa(20psi).Checkthetire

pressuredaily.

Important:Maintaintherecommendedpressureinall

tirestoensureagoodqualityofcutandpropermachine

performance.Donotunder-inatethetires.

StartingandStoppingthe Engine

StartingtheEngine

Important:Thefuelsystemmustbebledifanyofthe

followingsituationshaveoccurred:

•Theenginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponthefuelsystem

components.

1.Removeyourfootfromthetractionpedalandensure

thatitisinneutral.Ensurethattheparkingbrakeisset.

21

Page 22

2.Movethethrottlecontroltothelowidleposition.

3.TurntheignitionkeytotheRunposition.Theglow

indicatorwilllight.

4.Whentheglowindicatordims,turntheignitionkey

totheStartposition.

Important:Donotrunthestartermotormore

than15secondsatatimeorprematurestarter

failuremayresult.Iftheenginefailstostartafter

15seconds,turnthekeytotheOffposition,check

thecontrolsandprocedures,wait15additional

seconds,andrepeatthestartingprocedure.

5.Releasethekeyimmediatelywhentheenginestartsand

allowittoreturntotheRunposition.

CheckingtheInterlock Switches

ServiceInterval:Beforeeachuseordaily

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

6.Movethethrottlecontroltothedesiredposition.

Whenthetemperatureislessthan-7°C(20°F),the

startermotorcanberunfor30secondsonthen60

secondsofffor2attempts.

CAUTION

Shuttheengineoffandwaitforallmoving

partstostopbeforecheckingforoilleaks,

looseparts,andothermalfunctions.

StoppingtheEngine

Important:Allowtheenginetoidlefor5minutesbefore

shuttingitoffafterafull-loadoperation.Thisallowsthe

turbochargertocooldownbeforeshuttingtheengine

off.Failuretodosomayleadtoturbochargertrouble.

Note:Lowercuttingunitstothegroundwhenevermachine

isparked.Thisrelievesthehydraulicloadfromthesystem,

preventswearonsystemparts,andalsopreventsaccidental

loweringofthecuttingunits.

1.MovethethrottlecontrolbackwardtotheSlow

position.

2.MovethePTOswitchtotheOffposition.

3.Settheparkingbrake.

4.RotatetheignitionkeytotheOffposition.

5.Removethekeyfromtheswitchtopreventaccidental

starting.

Themachinehasinterlockswitchesintheelectricalsystem.

Theseswitchesaredesignedtostoptheenginewhenoperator

risesfromtheseatwhilepressingthetractionpedal.However,

theoperatormayrisefromtheseatwhiletheengineis

runningandthetractionpedalisinneutral.Althoughthe

enginewillcontinuetorunifthePTOswitchisdisengaged

andthetractionpedalisreleased,stoptheenginebefore

risingfromtheseat.

Tochecktheoperationoftheinterlockswitches,perform

thefollowingprocedure:

1.Drivethemachineslowlytoalarge,relativelyopen

area.Lowerthecuttingunit,stoptheengine,andapply

theparkingbrake.

2.Sitontheseatanddepressthetractionpedal.Tryto

starttheengine.Theengineshouldnotcrank.Ifthe

enginecranks,thereisamalfunctionintheinterlock

systemthatshouldbecorrectedbeforebeginning

operation.

3.Sitontheseatandstarttheengine.Risefromtheseat

andmovethePTOswitchtoOn.ThePTOshould

notengage.IfthePTOengages,thereisamalfunction

intheinterlocksystemthatshouldbecorrectedbefore

beginningoperation.

4.Sitontheseat,engagetheparkingbrakeandstartthe

engine.Movethetractionpedaloutoftheneutral

position.Theengineshouldkill.Iftheenginedoesnot

kill,thereisamalfunctionintheinterlocksystemthat

shouldbecorrectedbeforebeginningoperation.

PushingorTowingthe Machine

Inanemergency,youcanmovethemachineforwardby

actuatingthebypassvalveinthevariabledisplacement

hydraulicpumpandpushingortowingthemachine.Donot

pushortowthemachineformorethan0.4km(1/4mile).

Important:Donotpushortowthemachinefaster

than3to4.8km/h(2to3mph),becauseinternal

transmissiondamagemayoccur.Thebypassvalvemust

beopenwheneverthemachineispushedortowed.

22

Page 23

Important:Ifthemachinemusttobepushedortowed

inreverse,thecheckvalveinthe4-wheel-drivemanifold

mustalsobebypassed.Tobypassthecheckvalve,

connectahoseassembly(hosepart95-8843,coupler

tting95-0985[qty2],andhydraulictting340-77

[qty2])tothereversetractionpressuretestportandthe

reverse4-wheel-drivepressureport.

1.Openthehoodandremovethecentershroud

2.Rotatethebypassvalve90°(1/4turn)ineither

directiontoopenandallowoiltobypassinternally

(Figure18).

Note:Becauseuidisbypassed,themachinecan

beslowlymovedwithoutdamagingthetransmission.

Notethepositionofthevalvewhenopeningorclosing.

andwillautomaticallyreversetoblowdebrisofftherear

screen.Areversecycleisautomaticallyinitiatedwheneither

thecoolantorhydraulic-oiltemperaturereachesacertain

point.BypressingthefanswitchforwardintotheRposition,

thefanwillcompleteamanuallyinitiatedreversecycle.It

isrecommendedtoreversethefanwhentherearscreenis

cloggedorpriortoenteringtheshoporthestoragearea.

SelectingaBlade

StandardCombinationSail

Thisbladewasdesignedtoprovideexcellentliftand

dispersioninalmostanycondition.Ifmoreorlessliftand

dischargevelocityisrequired,consideradifferentblade.

Attributes:Excellentliftanddispersioninmostconditions.

AngledSail

Thebladegenerallyperformsbestinlowerheightsofcut-

1.9to6.4cm(3/4to2–1/2inch).

Attributes:

Figure18

1.Bypassvalve

3.Rotatethebypassvalve90°(1/4turn)backbefore

startingtheengine.Donotexceed7to11N-m(5to

8ft-lb)torquetoclosethevalve.

LocatingtheJackingPoints

•Onthefrontofthemachineontheframeontheinside

ofeachdrivetire

•Ontherearofthemachineatthecenteroftheaxle

LocatingtheTieDowns

•Oneachsideoftheframeunderthefrontsteps

•Therearbumper

OperatingtheEngineCooling Fan

Theenginecoolingfanswitchhas2positionsforcontrolling

theoperationofthefan.The2positionsareRandAuto.

Thefanhastheabilitytoreversetoblowdebrisoffthe

rearscreen.Undernormaloperatingconditions,theswitch

shouldbeintheAutoposition.InAuto,thefanspeedwill

becontrolledbythecoolantorhydraulic-oiltemperature

•Dischargeremainsmoreevenatlowerheightsofcut.

•Dischargehaslesstendencytothrowleftandthusa

cleanerlookaroundbunkersandfairways.

•Lowerpowerrequirementatlowerheightsanddenseturf.

HighLiftParallelSail

Thebladegenerallyperformsbetterinthehigherheightsof

cut-7to10cm(2to4inch).

Attributes:

•Moreliftandhigherdischargevelocity.

•Sparseorlimpturfispickedupsignicantlyathigher

heightsofcut.

•Wetorstickyclippingsaredischargedmoreefciently

reducingcongestioninthedeck.

•Requiresmorehorsepowertorun.

•Tendstodischargefurtherleftandcantendtowindrow

atlowerheightsofcut.

WARNING

Donotusethehighliftbladewiththemulching

bafe.Thebladecouldbreak,resultinginpersonal

injuryordeath.

AtomicBlade

Thisbladewasdesignedtoprovideexcellentleafmulching.

Attributes:Excellentleafmulching

23

Page 24

ChoosingAccessories

OptionalEquipmentCongurations

AngleSailBladeHighLiftParallelSail

GrassCutting:1.9to4.4

cm(0.75to1.75inch)

Height-of-Cut

GrassCutting:5to6.4

cm(2.00to2.50inch)

Height-of-Cut

GrassCutting:7to10

cm(2.75to4.00inch)

Height-of-Cut

LeafMulchingRecommendedforuse

ProsEvendischargeatlower

ConsDoesnotliftthegrass

Recommendedinmost

applications

Recommendedforthick

orlushturf

Mayworkwellinlushturf

withthemulchingbafe

heightofcutCleaner

lookaroundbunkersand

fairwaysLowerpower

requirements

wellinhighheightof

cutapplicationsWet

orstickygrasshas

atendencytobuild

upinthechamber,

leadingtopoorquality

ofcutandhigherpower

requirements

Blade(Donotusewith

themulchingbafe)

Mayworkwellinlightor

sparseturf

Recommendedforlight

orsparseturf

Recommendedinmost

applications

NotAllowedUsewithcombination

Moreliftandhigher

dischargevelocity

Sparseorlimpturfis

pickedupathighheight

ofcutWetorsticky

clippingsaredischarged

efciently

Requiresmorepowerto

runinsomeapplications

Tendstowindrowat

lowerheightofcutin

lushgrassDonotuse

withthemulchingbafe

MulchingBafeRollerScraper

Hasbeenshownto

improvedispersionand

aftercutperformance

onnortherngrassesthat

arecutatleastthree

timesperweekandless

than1/3ofthegrass

bladeisremoved.Do

notusewiththehigh

liftparallelsailblade

sailoranglesailblade

only

Mayimprovedispersion

andappearancein

certaingrasscutting

applicationsVerygood

forleafmulching

Grasswillbuildupinthe

chamberifattemptingto

removetoomuchgrass

withbafeinplace

Canbeusedanytime

thatrollersbuildup

withgrassorlargeat

grassclumpsofgrass

areseen.Thescrapers

mayactuallyincrease

clumpingincertain

applications.

Reducesrollerbuildup

incertainapplications

OperatingTips

UnderstandingtheOperating

CharacteristicsoftheMachine

Practicedrivingthemachine,becauseithasahydrostatic

transmissionanditscharacteristicsaredifferentthanmany

turfmaintenancemachines.Somepointstoconsider

whenoperatingthetractionunitandcuttingunitsarethe

transmission,enginespeed,loadonthecuttingblades,and

theimportanceofthebrakes.

Tomaintainenoughpowerforthetractionunitwhile

operating,regulatethetractionpedaltokeeptheenginespeed

highandsomewhatconstant.Agoodruletofollowisto

decreasethegroundspeedastheloadonthecuttingunits

increases,andincreasethegroundspeedastheloaddecreases.

Therefore,allowthetractionpedaltomovebackwardasthe

enginespeeddecreases,andpressthepedalslowlyasthe

enginespeedincreases.Bycomparison,whendrivingfrom

oneworkareatoanother,withnoloadandthecuttingunits

raised,havethethrottleintheFastpositionandpressthe

tractionpedalslowlybutfullytoattainmaximumground

speed.

Anothercharacteristictoconsideristheoperationofthe

pedalsthatareconnectedtothebrakes.Youcanusethe

brakestoassistinturningthemachine.However,usethem

carefully,especiallyonsoftorwetgrass,becausetheturf

maybetornaccidentally.Anotherbenetofthebrakesisto

maintaintraction.Forexample,insomeslopeconditions,the

uphillwheelslipsandlosestraction.Ifthissituationoccurs,

depresstheuphillturnpedalgraduallyandintermittentlyuntil

theuphillwheelstopsslipping,thus,increasingtractionon

thedownhillwheel.

Useextracarewhenoperatingthemachineonslopes.Make

surethattheseatlatchisproperlysecuredandtheseatbelt

isbuckled.Driveslowlyandavoidsharpturnsonslopesto

preventrollovers.Forsteeringcontrol,thecuttingunitmust

beloweredwhengoingdownhill.

24

Page 25

WARNING

Thisproductisdesignedtodriveobjectsintothe

groundwheretheyloseenergyquicklyingrass

areas.However,carelessoperation,combinedwith

terrainangle,ricochets,orimproperlypositioned

safetyguardcanleadtothrownobjectinjuries.

•Whenapersonorpetappearssuddenlyinor

nearthemowingarea,stopmowing.

•Donotresumemowinguntiltheareaiscleared.

Important:Allowtheenginetoidlefor5minutesbefore

shuttingitoffafterafull-loadoperation.Thisallowsthe

turbochargertocooldownbeforeshuttingtheengine

off.Failuretodosomayleadtoturbochargertrouble.

Beforestoppingtheengine,disengageallcontrolsandmove

thethrottletoSlow .MovingthethrottletoSlowreduces

enginespeed,noise,andvibration.TurnthekeytotheOff

positiontostoptheengine.

MowingWhenGrassisDry

Moweitherinthelatemorningtoavoidthedew ,whichcauses

grassclumping,orinlateafternoontoavoidthedamage

thatcanbecausedbydirectsunlightonthesensitive,freshly

mowedgrass.

AdjustingtheCounterbalance

Thecounterbalancesystemmaintainshydraulicbackpressure

onthedeckliftcylinders.Thiscounterbalancepressure

transferscuttingdeckweighttothemower'sdrivewheels

toimprovetraction.Thecounterbalancepressurehasbeen

factorysettoanoptimalbalanceofafter-cutappearanceand

tractioncapabilityinmostturfconditions.Decreasingthe

counterbalancesettingcanproduceamorestablecutting

deck,butcandecreasethetractioncapability.Increasingthe

counterbalancesettingcanincreasethetractioncapability,

butmayresultinafter-cutappearanceissues.Referencethe

servicemanualforyourtractionunitforinstructionstoadjust

counterbalancepressure.

ResolvingAftercutAppearance

ReferencetheAftercutAppearanceTroubleshootingGuide

availableatwww .Toro.com.

Transporting(Groundsmaster4700-D

Only)

Usethe2reartransportlatchesfortheoutercuttingunits

whentransportingoverlongdistances,roughterrain,orwhen

trailering.

SelectingtheProperHeightofCut

Removeapproximately25mm(1inch)ornomorethan1/3

ofthegrassbladewhencutting.Inexceptionallylushand

densegrass,youmayhavetoraisetheheightofcuttothe

nextsetting.

MowingatProperIntervals

Undermostnormalconditionsyouwillneedtomow

approximatelyevery4to5days.Butremember,grassgrows

atdifferentratesatdifferenttimes.Thismeansthatinorder

tomaintainthesameheightofcut,whichisagoodpractice,

youwillneedtocutmorefrequentlyinearlyspring;asthe

grassgrowthrateslowsinmidsummer,cutonlyevery8to10

days.Ifyouareunabletomowforanextendedperioddue

toweatherconditionsorotherreasons,mowrstwiththe

heightofcutatahighlevel;thenmowagain2to3dayslater

withalowerheightsetting.

MowingwithSharpBlades

Asharpbladecutscleanlyandwithouttearingorshredding

thegrassbladeslikeadullblade.Tearingandshredding

causesthegrasstoturnbrownattheedgeswhichimpairs

growthandincreasessusceptibilitytodiseases.

CleaningandParkingtheMachineafter

EachUse

Toensureoptimumperformance,cleantheundersideofthe

mowerhousingsaftereachuse.Ifresidueisallowedtobuild

upinthemowerhousing,cuttingperformancewilldecline.

Note:Lowerthecuttingunitstothegroundwheneverthe

machineisparked.Thisrelievesthehydraulicloadfromthe

system,preventswearonsystemparts,andalsoprevents

accidentalloweringofthecuttingunits.

ChangingMowingPatterns

Changemowingpatternsoftentominimizeafter-cut

appearanceissuesinducedbyrepetitiveoperationinonlyone

direction.

25

Page 26

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Aftertherst200hours

Beforeeachuseordaily

Every50hours

Every100hours

Every150hours

MaintenanceProcedure

•Torquethewheelnuts.

•Changetheengineoilandlter.

•Changetheplanetarygeardriveoil.

•Changetherearaxlelubricant.

•Changethehydrauliclters.

•Checktheengine-oillevel.

•Checkthecoolantlevel.

•Checkthehydraulic-uidlevel.

•Checkthetirepressure.

•Checktheinterlockswitches.

•Drainwaterorothercontaminantsfromthewaterseparator.

•Drainwaterorothercontaminantsfromthefuellter/waterseparator.

•Removedebrisfromtheenginearea,oilcooler,andradiator.

•Inspectthehydrauliclinesandhosesforleaks,kinkedlines,loosemounting

supports,wear,loosettings,weatherdeterioration,andchemicaldeterioration.

•Checkthebladestoppingtime

•Greasethebearingsandbushings.

•Checkthebatterycondition.

•Checktheconditionandtensionofthealternatorbelt.

•Changetheengineoilandlter.

Every200hours

Every400hours

Every800hours

Beforestorage

Yearly

Important:Refertoyourengine

procedures.

•Torquethewheelnuts.

•Cleanthesparkarrestermufer.

•Servicetheaircleaner(earlieriftheaircleanerindicatorshowsred,andmore

frequentlyinextremelydirtyordustyconditions).

•Checkthefuellinesandconnections.

•Replacethefuel-ltercanister.

•Checktheplanetarygeardriveoillevel(alsocheckifexternalleakageisobserved).

•Checktherearaxlelubricantlevel.

•Drainandcleanthefueltank.

•Changetheplanetarygeardriveoil.

•Changetherearaxlelubricant.

•Checktherearwheeltoe-in.

•Changethehydraulicuid.

•Changethehydrauliclters.

•Drainandcleanthefueltank.

•Checkthetirepressure.

•Checkallfasteners.

•Greaseoroilallgreasettingsandpivotpoints.

•Paintchippedsurfaces.

•Checkthefuellinesandconnections.

Operator's Man ual

andcuttingunit

Operator's Man ual

foradditionalmaintenance

Note:LookingforanElectricalSchematicorHydraulicSchematicforyourmachine?Downloadafreecopyoftheschematicby

visitingwww .T oro.comandsearchingforyourmachinefromtheManualslinkonthehomepage.

26

Page 27

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Maintenance

CheckItem

Checkthe

safetyinterlock

operation.

Checkthebrake

operation.

Checktheengine

oilandfuellevel.

Checkthe

coolingsystem

uidlevel.

Drainthe

water/fuel

separator.

Checktheair

lterrestriction

indicator.

Checkthe

radiator,oil

cooler,and

screenfordebris.

Checkunusual

enginenoises.

Checkunusual

operatingnoises.

Checkthe

hydraulicsystem

oillevel.

Checkhydraulic

hosesfor

damage.

Checkforuid

leaks.

Checkthetire

pressure.

Checkthe

instrument

operation.

Checkthe

height-of-cut

adjustment.

Lubricateall

greasettings.

Touch-up

damagedpaint.

1

2

Fortheweekof:

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

1.Checktheglowplugandinjectornozzlesifhardstarting,excesssmoke,orroughrunningisnoted.

2.Immediatelyaftereverywashing,regardlessoftheintervallisted.

27

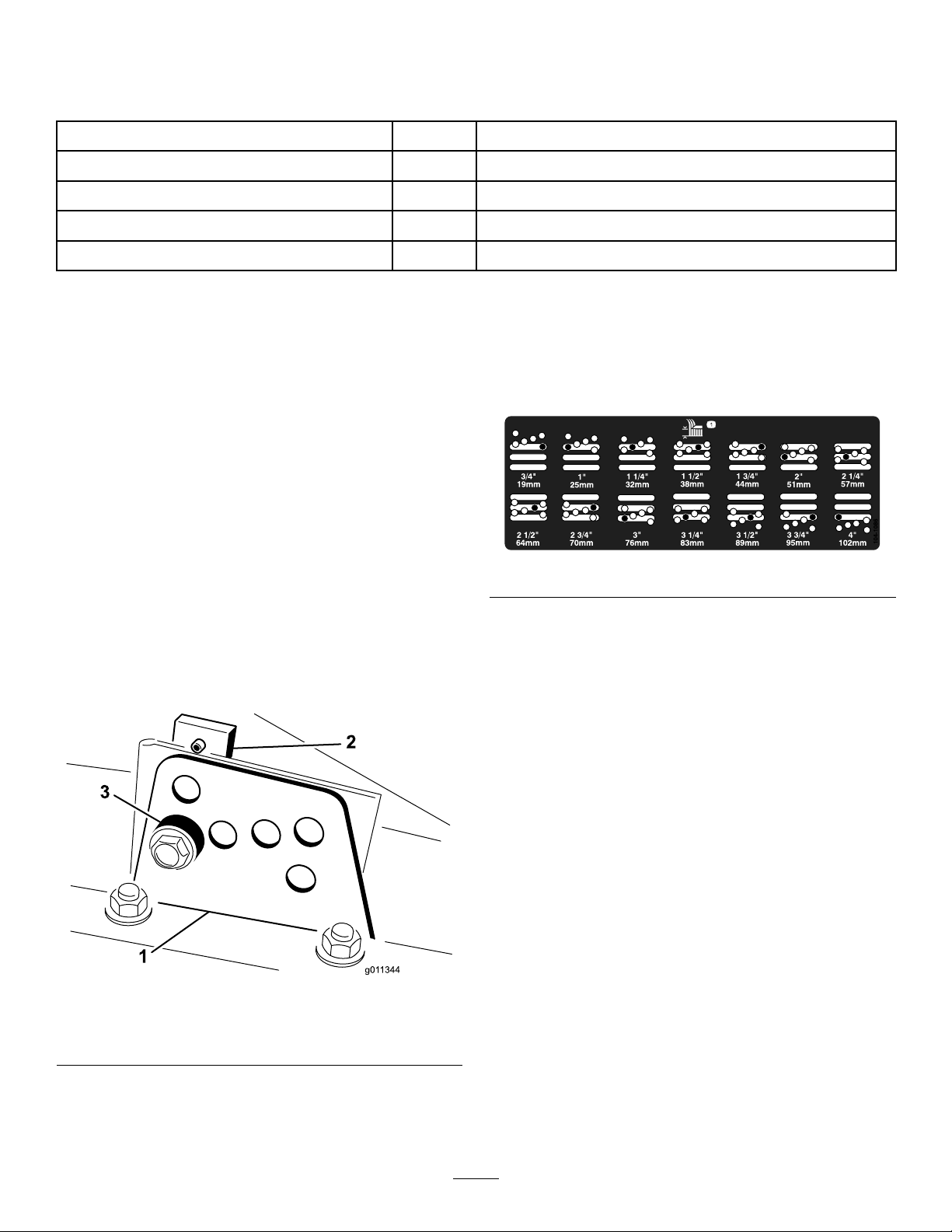

Page 28

ServiceIntervalChart

Figure19

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

28

Page 29

Premaintenance

Lubrication

Procedures

GreasingtheBearingsand

RemovingtheHood

1.Releasehoodlatches(Figure20)andpivotopenthe

hood.

Figure20

1.Hoodlatch(2)

Bushings

ServiceInterval:Every50hours

Themachinehasgreasettingsthatmustbelubricated

regularlywith#2general-purposelithium-basedgrease.If

themachineisoperatedundernormalconditions,lubricateall

bearingsandbushingsafterevery50hoursofoperationor

immediatelyaftereverywashing.

Thegreasettinglocationsandquantitiesareasfollows:

•Brake-shaftpivotbearings(5)(Figure21)

Figure21

2.Removethecotterpinssecuringtherearhoodbrackets

totheframepinsandliftoffthehood.

•Rearaxlepivotbushings(2)(Figure22)

Figure22

29

Page 30

•Steering-cylinderballjoints(2)(Figure23)

•Cutting-unitspindle-shaftbearings(2percuttingunit)

(Figure25)

Note:Eitherttingcanbeused,whicheverismore

accessible.Pumpgreaseintothettinguntilasmall

amountappearsatbottomofthespindlehousing(under

thedeck).

Figure23

1.T opttingonkingpin

•Tie-rodballjoints(2)(Figure23)

•Kingpinbushings(2)(Figure23).Thetopttingon

thekingpinshouldonlybelubricatedannually

(2pumps).

•Lift-armbushings(1perdeck)(Figure24)

Figure25

•Cutting-unitcarrier-armbushings(1percuttingunit)

(Figure25)

•Rearrollerbearings(2percuttingunit)(Figure26)

Figure26

Important:Makesurethatthegreasegroovein

eachrollermountalignswiththegreaseholeineach

endoftherollershaft.Tohelpalignthegrooveand

thehole,thereisalsoanalignmentmarkon1endof

therollershaft.

Figure24

•Lift-cylinderbushings(2perdeck)(Figure24)

30

Page 31

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Every400hours

Checktheair-cleanerbodyfordamagewhichcouldcausean

airleak.Replaceitifitisdamaged.Checkthewholeintake

systemforleaks,damage,orloosehoseclamps.

Servicetheair-cleanerlteronlywhentheserviceindicator

(Figure27)requiresit.Changingtheairlterbeforeitis

necessaryonlyincreasesthechanceofdirtenteringtheengine

whenthelterisremoved.

largeaccumulationsofdebrispackedbetweenoutside

ofprimarylterandthecanister.Avoidusing

high-pressureairwhichcouldforcedirtthrough

thelterintotheintaketract.

Thiscleaningprocesspreventsdebrisfrommigrating

intotheintakewhentheprimarylterisremoved.

3.Removeandreplacetheprimarylter(Figure29).

Note:Cleaningtheusedelementisnotrecommended

duetothepossibilityofdamagetotheltermedia.

Figure27

1.Air-cleanerindicator

Important:Besurethecoverisseatedcorrectlyand

sealswiththeair-cleanerbody.

1.Pullthelatchoutwardandrotatetheair-cleanercover

counterclockwise(Figure28).

Figure29

1.Air-cleanerprimarylter

4.Inspectthenewlterforshippingdamage,checking

thesealingendofthelterandthebody.

Note:Donotuseadamagedelement.Insertthe

newlterbyapplyingpressuretotheouterrimof

theelementtoseatitinthecanister.Donotapply

pressuretotheexiblecenterofthelter.

Important:Neverattempttocleanthesafetylter

(Figure30).Replacethesafetylterwithanew

oneafterevery3primarylterservices.

Figure28

1.Air-cleanerlatch2.Air-cleanercover

2.Removethecoverfromtheair-cleanerbody.

Note:Beforeremovingthelter,uselow-pressure

air(276kPa[40psi],cleananddry)tohelpremove

31

Page 32

Figure30

1.Air-cleanersafetylter

5.Cleanthedirt-ejectionportlocatedintheremovable

cover.

6.Removetherubberoutletvalvefromthecover,clean

thecavity,andinstalltheoutletvalve.

2.Removetheoillter(Figure32).

Note:Applyalightcoatofcleanoiltothenewlter

sealbeforescrewingiton.Donotovertightenthelter.

Figure32

1.Engineoillter

7.Installthecover,orientingtherubberoutletvalveina

downwardposition—betweenapproximately5:00to

7:00whenviewedfromtheend.

8.Resettheindicator(Figure27)ifitshowsred.

ServicingtheEngineOiland Filter

ServiceInterval:Aftertherst50hours

Every150hours

1.Removethereardrainplug(Figure31)andlettheoil

owintoadrainpan.Whentheoilstops,installthe

drainplug.

3.Addoiltothecrankcase;refertoCheckingthe

Engine-oilLevel(page18).

AdjustingtheThrottle

Adjustthethrottlecable(Figure33)sothatthegovernor

leverontheenginecontactsthehighspeedsetboltatthe

samepointthatthethrottlecablecontactstheendoftheslot

inthecontrolarm.

1.Engineoildrainplug

Figure33

1.Throttlecable

Figure31

32

Page 33

FuelSystem

ServicingtheWaterSeparator

Maintenance

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis6to13mm

(1/4to1/2inch)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsthe

fueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

ServiceInterval:Beforeeachuseordaily—Drainwater

orothercontaminantsfromthefuel

lter/waterseparator.

Every400hours—Replacethefuel-ltercanister.

Drainwaterorothercontaminantsfromwaterseparatordaily.

Replaceltercanisterafterevery400hoursofoperation.

1.Placeacleancontainerunderthefuellter(Figure34).

2.Loosenthedrainplugonthebottomofthelter

canister.

Figure34

ServicingtheFuelTank

Every800hours—Drainandcleanthefueltank.

Beforestorage—Drainandcleanthefueltank.

Drainandcleanthefueltankevery800hours.Also,drainand

cleanthetankiffuelsystembecomescontaminatedorifthe

machinewillbestoredforanextendedperiodoftime.Use

cleanfueltoushoutthetank.

CheckingtheFuelLinesand Connections

ServiceInterval:Every400hours—Checkthefuellinesand

connections.

Yearly—Checkthefuellinesandconnections.

Checkthefuellinesandconnectionsevery400hoursor

yearly,whichevercomesrst.Inspectthemfordeterioration,

damage,orlooseconnections.

1.Water-separatorltercanister

3.Cleantheareawherethelter-canistermounts.

4.Removetheltercanisterandcleanthemounting

surface.

5.Lubricatethegasketontheltercanisterwithcleanoil.

6.Installtheltercanisterbyhanduntilthegasket

contactsmountingsurface,thenrotateitanadditional

1/2turn.

7.Tightenthedrainplugonthebottomofthelter

canister.

ServicingtheFuelPickupTube Screen

Thefuelpickuptube,locatedinsidethefueltank,isequipped

withascreentohelppreventdebrisfromenteringthefuel

system.Removethefuelpickuptubeandcleanscreenas

required.

33

Page 34

BleedingAirfromtheInjectors

ElectricalSystem

Note:Thisprocedureshouldbeusedonlyifthefuelsystem

hasbeenpurgedofairthroughnormalprimingprocedures

andtheenginewillnotstart.

1.Loosenthepipeconnectiontothe#1injectornozzle

andholderassemblyattheinjectionpump(Figure35).

Figure35

1.#1injectornozzle

Maintenance

ChargingandConnectingthe Battery

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling .

1.Unlatchandraisetheoperator'sconsolepanel(Figure

36).

2.MovethethrottletotheFastposition.

3.TurnthekeyintheignitionswitchtotheStartposition

andwatchthefuelowaroundtheconnector.

4.TurnthekeytotheOffpositionwhenyouobserve

solidow .

5.Tightenthepipeconnectorsecurely.

6.Repeattheprocedureontheremainingnozzles.

Figure36

1.Operator'sconsolepanel

2.Latch

DANGER

Batteryelectrolytecontainssulfuricacid

whichisadeadlypoisonandcausessevere

burns.

•Donotdrinkelectrolyteandavoidcontact

withskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubber

glovestoprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

34

Page 35

2.Connecta3to4amperebatterychargertothebattery

posts.

3.Chargethebatteryatarateof3to4amperesfor4

to8hours.

4.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

7.CoatbothbatteryconnectionswithGrafo112X

(skin-over)grease,Toropart505-47,petroleumjelly,or

lightgreasetopreventcorrosion.

8.Slidetherubberbootoverthepositiveterminal.

9.Closetheconsolepanelandsecurethelatch.

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

5.Installthepositivecable(red)tothepositive(+)

terminalandthenegativecable(black)tothenegative

(-)terminalofthebattery(Figure37).

Note:Securethecablestothepostswithcapscrews

andnuts.Makesurethatthepositive(+)terminalisall

ofthewayontothepostandthecableispositioned

snugtothebattery.Thecablemustnotcontactthe

batterycover.

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalcomponentscausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsof

themachine.

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

Figure37

1.Positivebatterycable2.Negativebatterycable

6.Slidetherubberbootoverthepositiveterminalto

preventapossibleshortfromoccurring.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling .

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

35

Page 36

ServicingtheBattery

ServiceInterval:Every50hours

Important:Beforeweldingonthemachine,disconnect

thenegativecablefromthebatterytopreventdamageto

theelectricalsystem.

Note:Checkthebatteryconditionweeklyorafterevery50

hoursofoperation.Keeptheterminalsandtheentirebattery

casecleanbecauseadirtybatterywilldischargeslowly .To

cleanthebattery,removeitfromthemachineandwashthe

entirecasewithasolutionofbakingsodaandwater.Rinseit

withclearwater.Coatthebatterypostsandcableconnectors

withGrafo112X(skin-over)grease(Toropart505-47)or

petroleumjellytopreventcorrosion.